Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3921 results about "Observational error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Observational error (or measurement error) is the difference between a measured value of a quantity and its true value. In statistics, an error is not a "mistake". Variability is an inherent part of the results of measurements and of the measurement process.

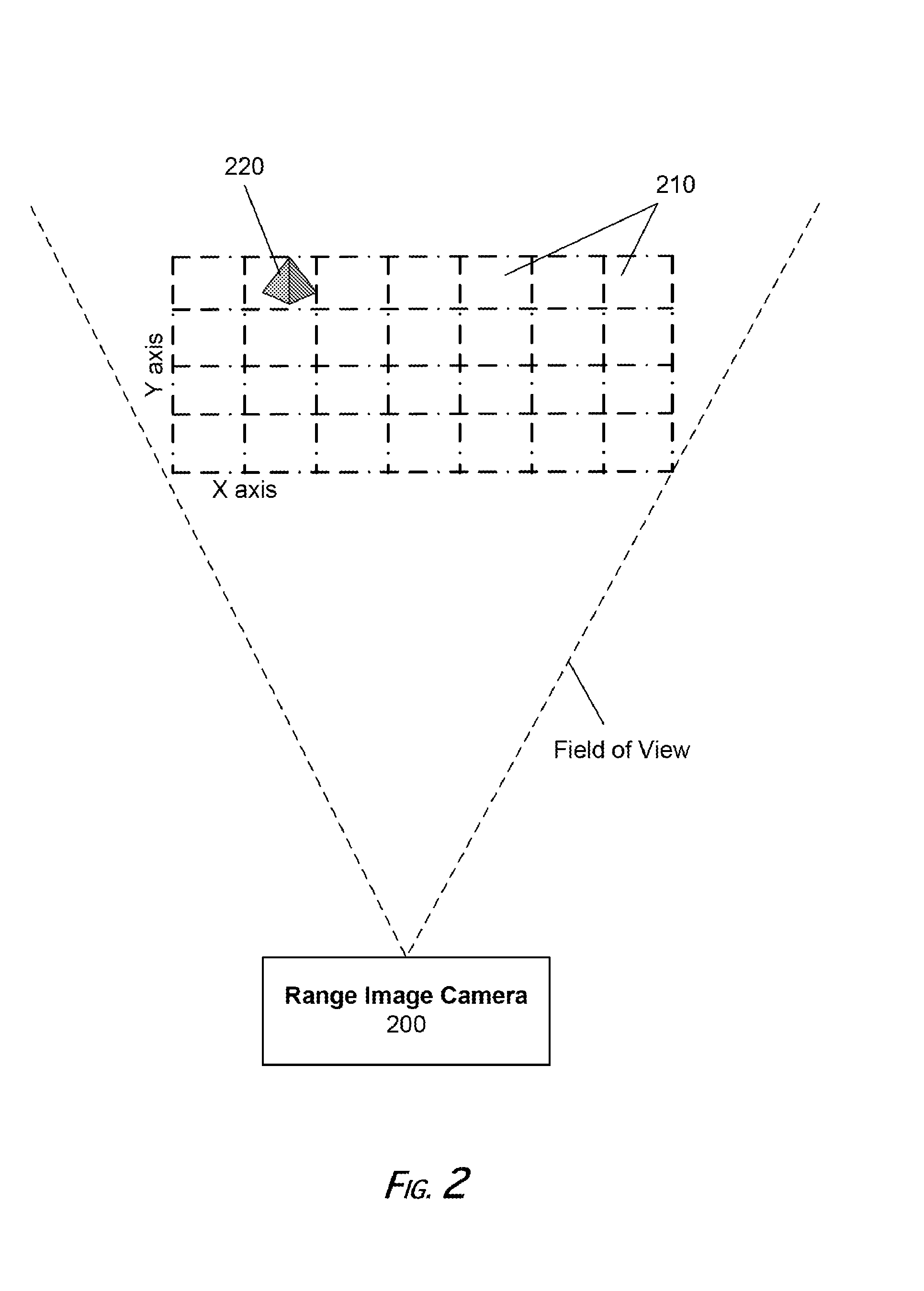

Method of Error Correction for 3D Imaging Device

A method is presented for correcting errors in a 3D scanner. Measurement errors in the 3D scanner are determined by scanning each of a plurality of calibration objects in each of a plurality of sectors in the 3D scanner's field of view. The calibration objects have a known height, a known width, and a known length. The measurements taken by the 3D scanner are compared to the known dimensions to derive a measurement error for each dimension in each sector. An estimated measurement error is calculated based on scans of each of the plurality of calibration objects. When scanning target objects in a given sector, the estimated measurement error for that sector is used to correct measurements obtained by the 3D scanner.

Owner:HAND HELD PRODS

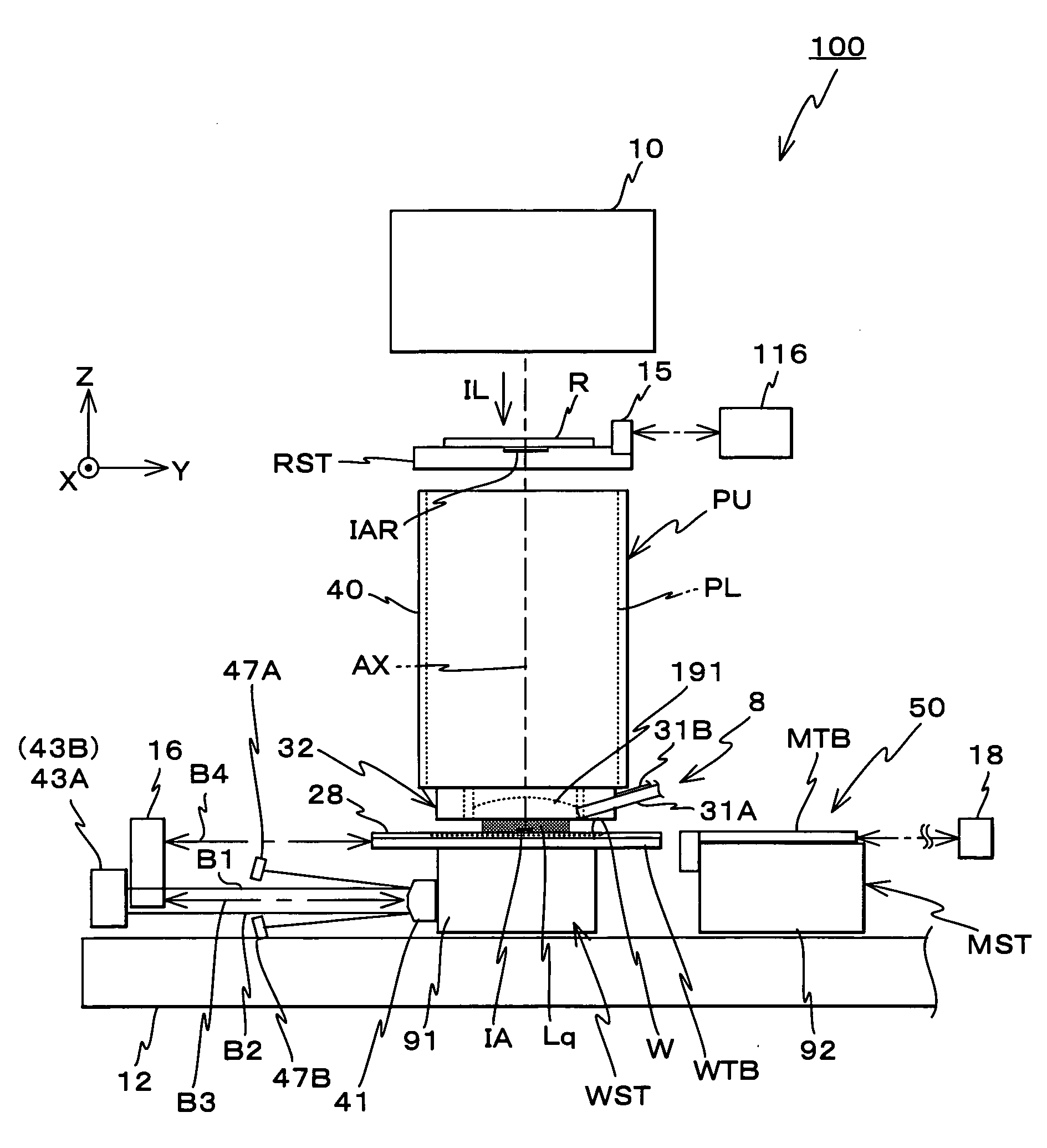

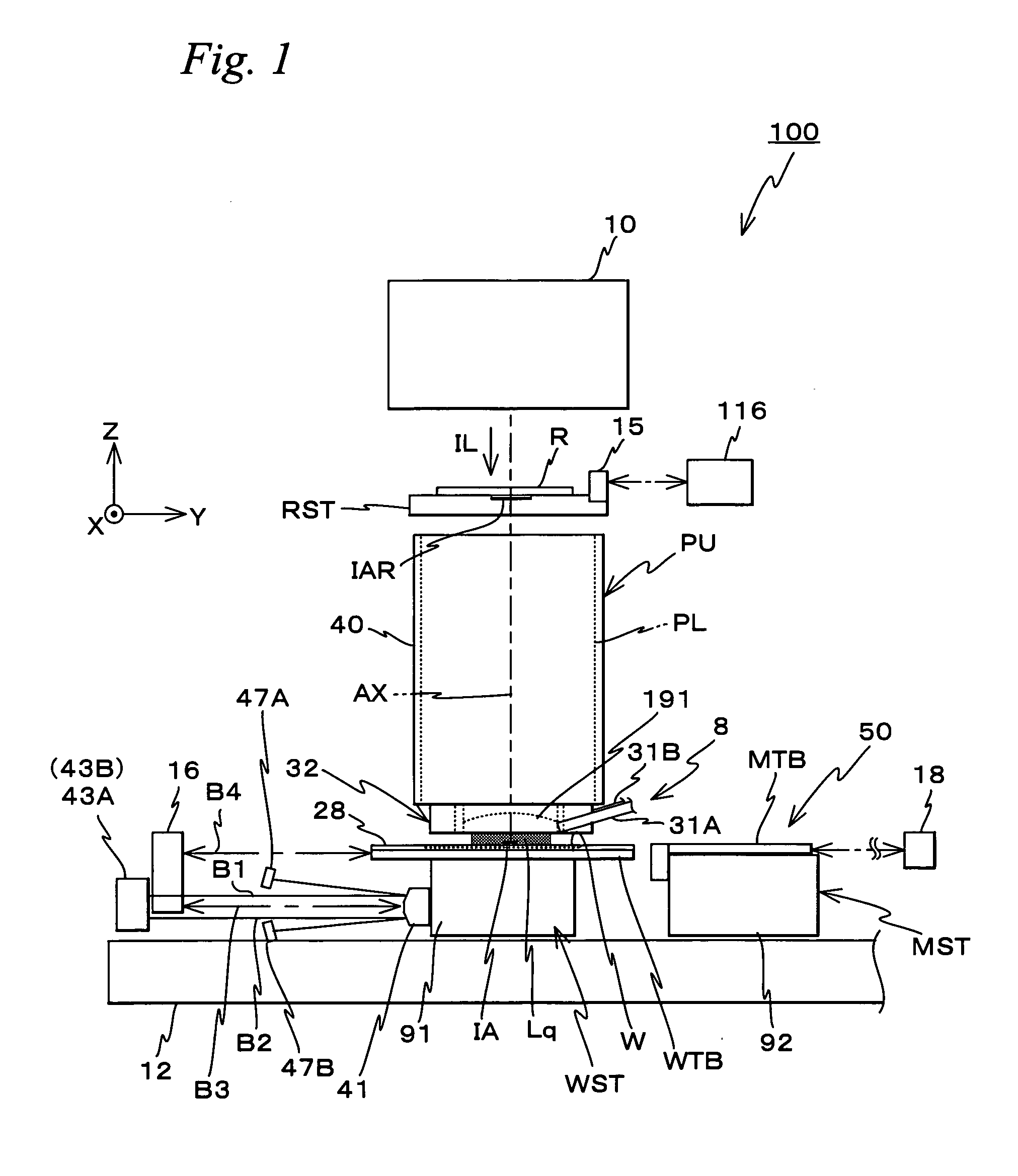

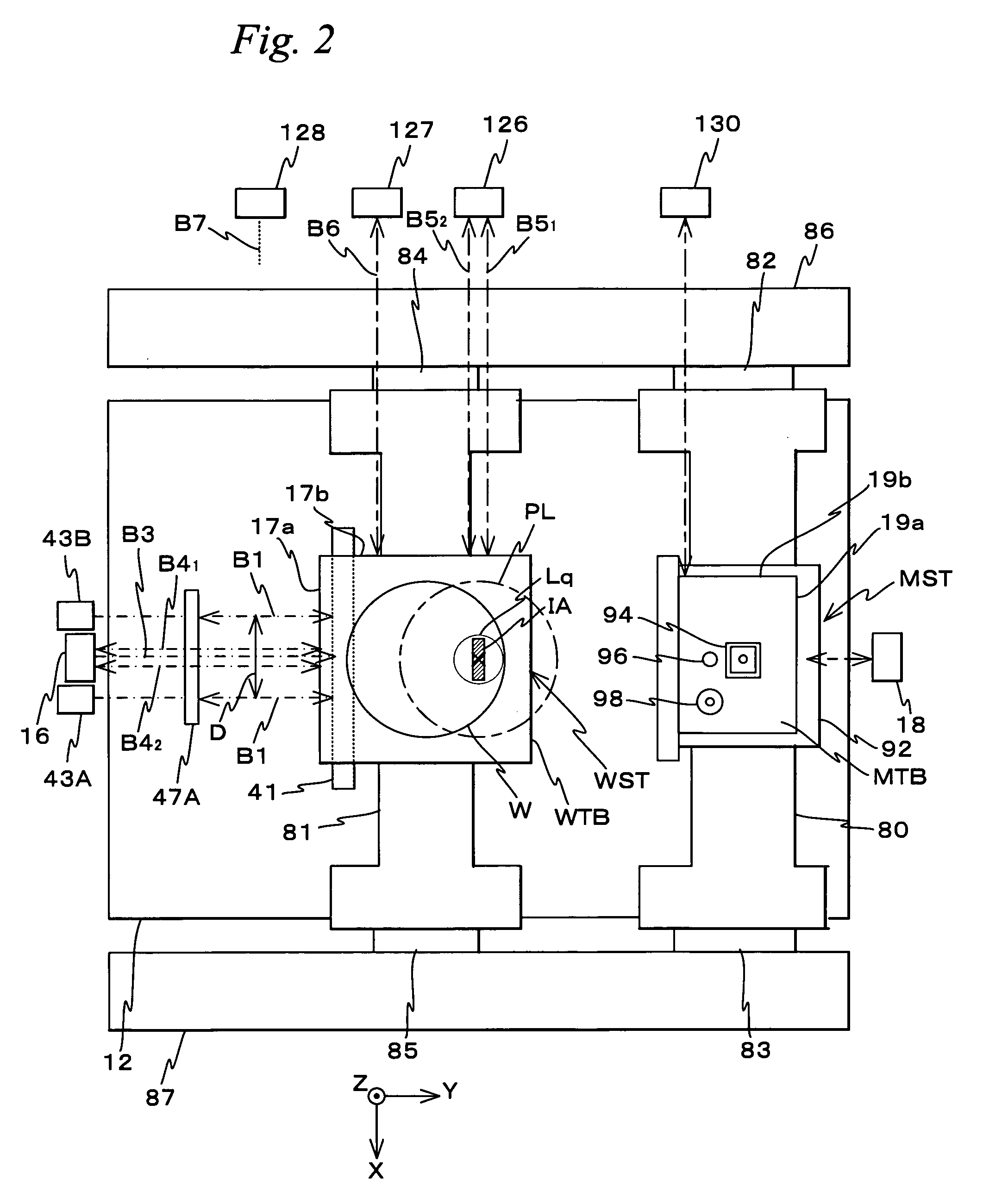

Exposure apparatus and method of manufacturing device

InactiveUS7884918B2Improve accuracyIncrease productivityPhotomechanical apparatusSemiconductor/solid-state device manufacturingObservational errorMeasurement device

Owner:CANON KK

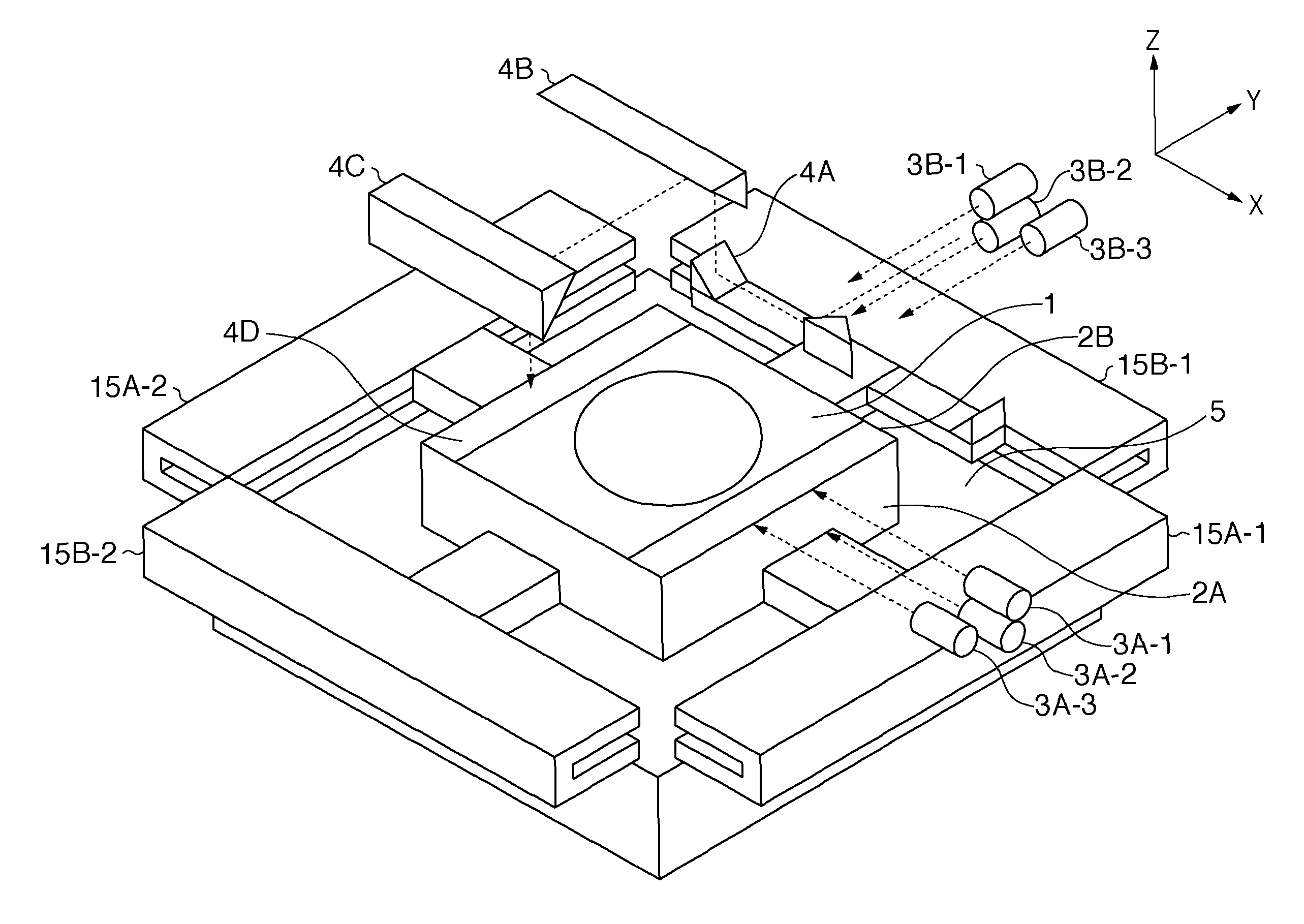

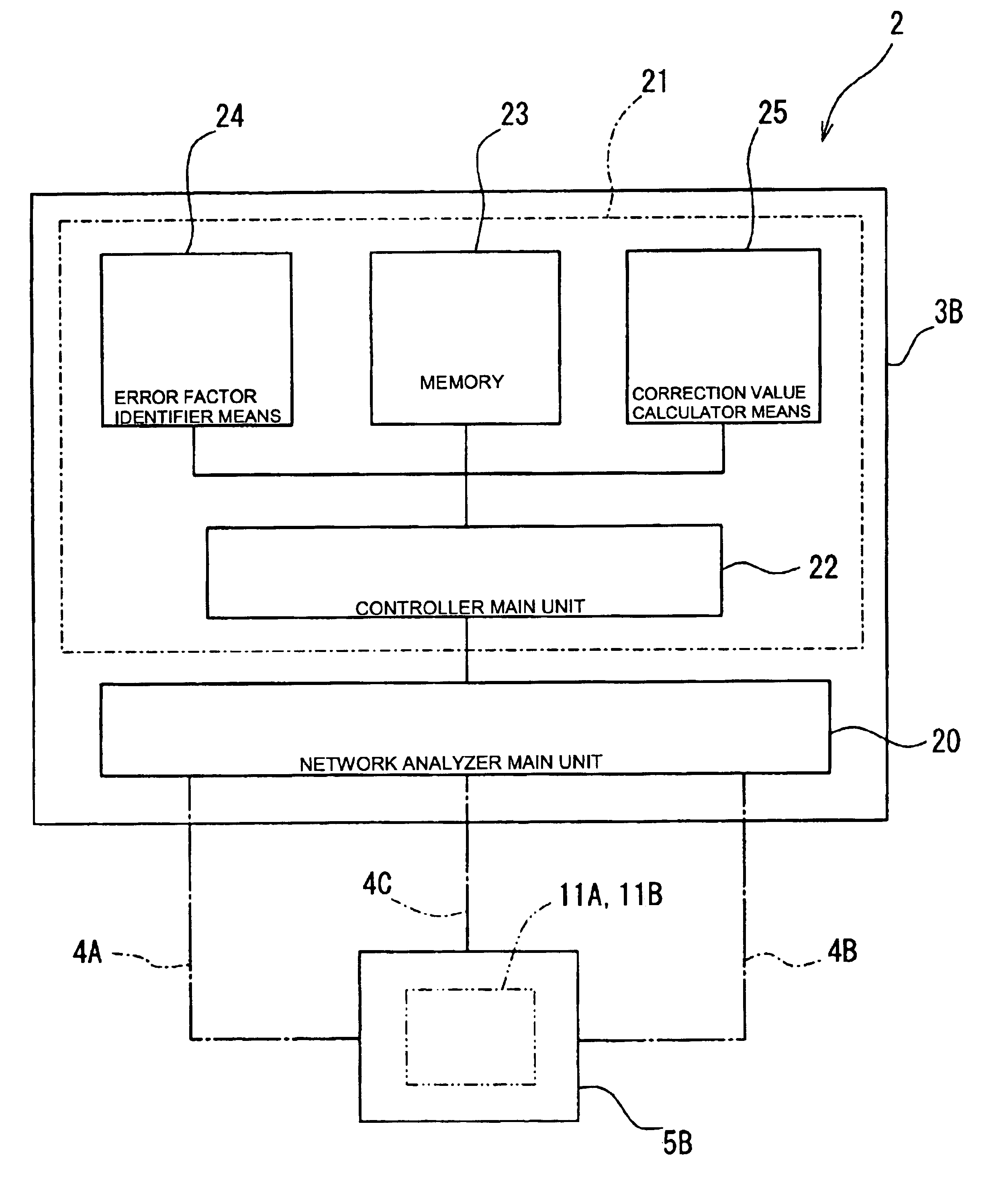

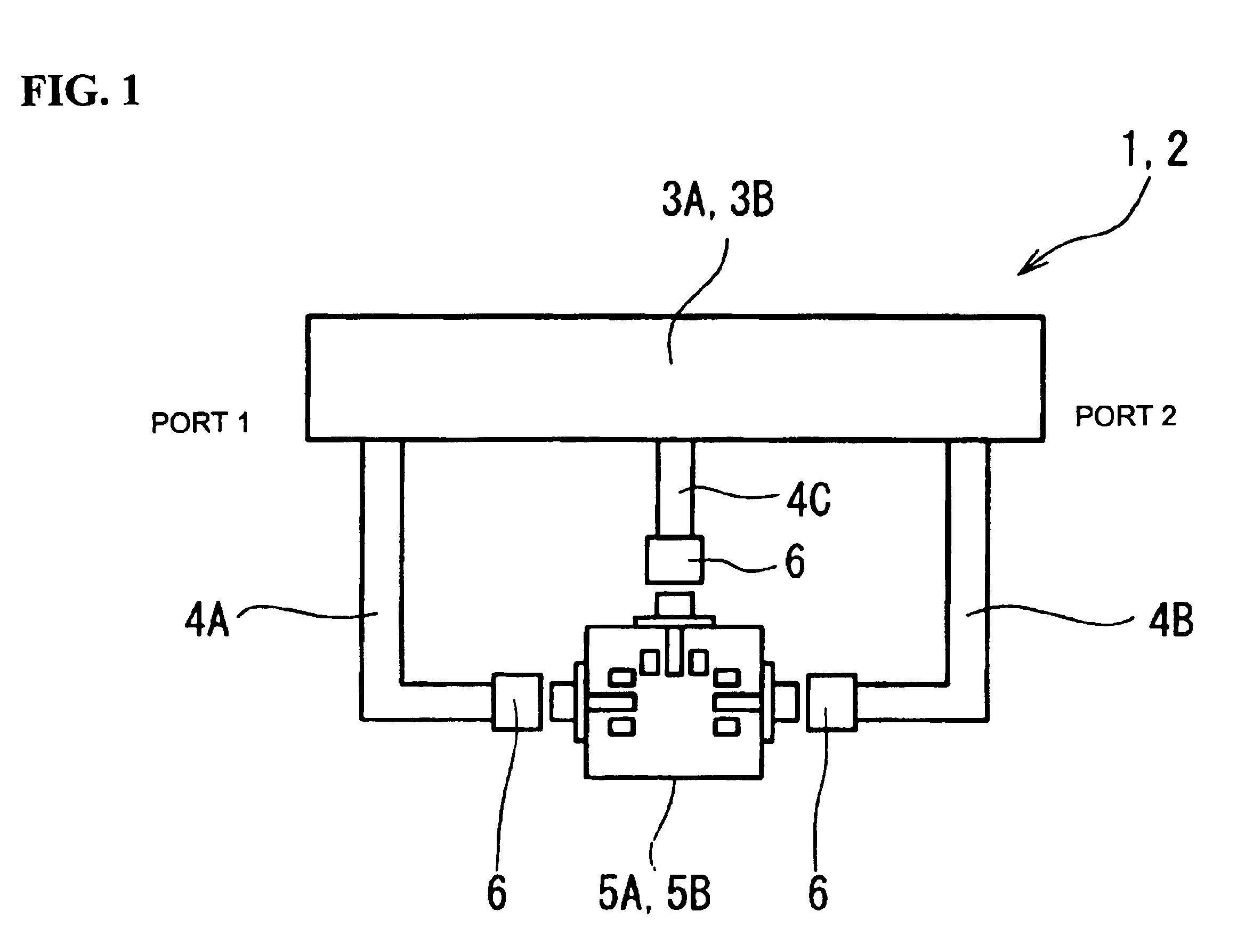

Method of correcting measurement error and electronic component characteristic measurement apparatus

ActiveUS6838885B2Easily and automatically expressedSuppress mutationResistance/reactance/impedenceElectrical testingObservational errorMeasurement device

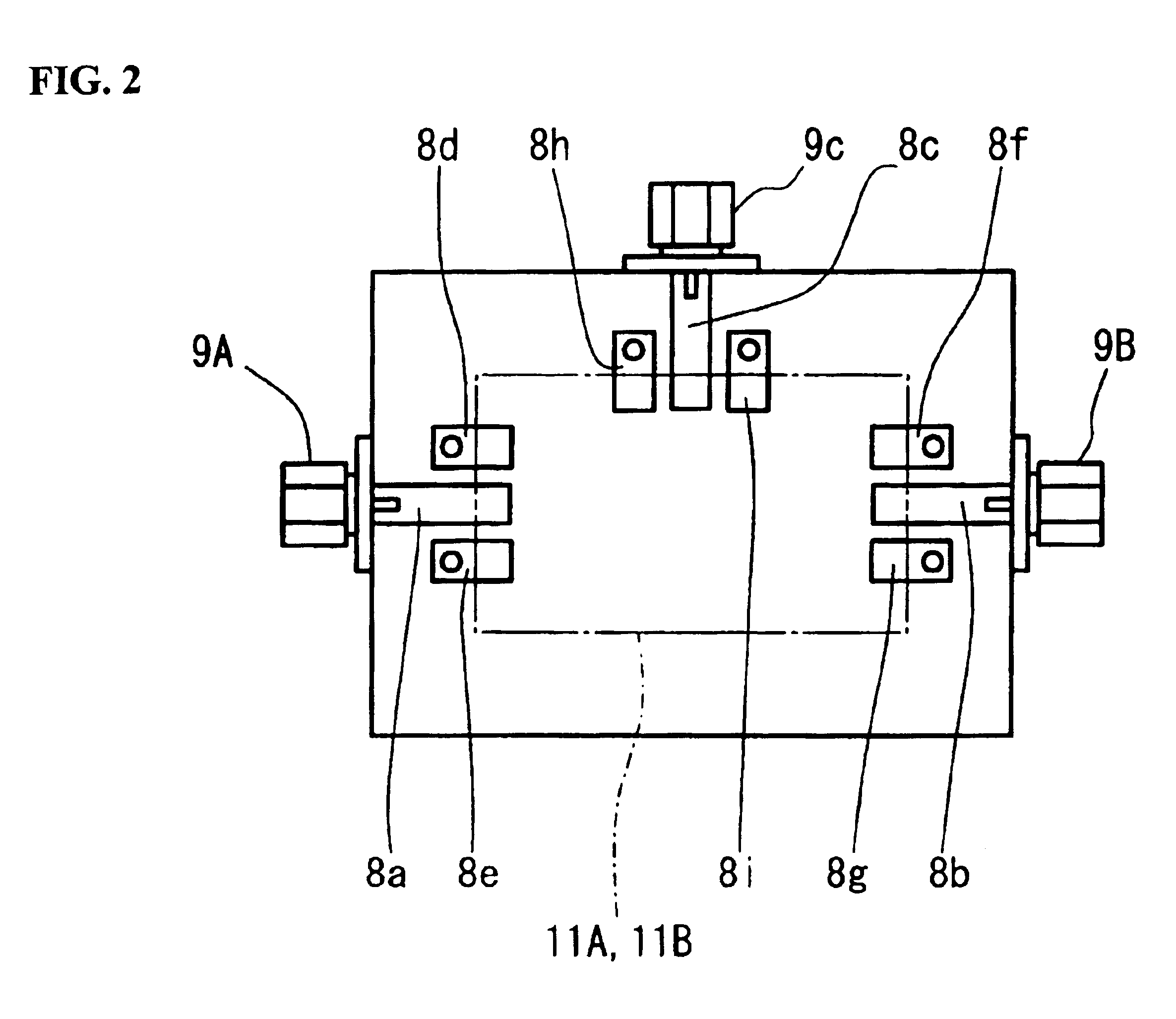

A high-precision, multi-port compatible, relative correction method and apparatus for correcting measurement errors covering an increase in the number of ports of a non-coaxial electronic component, in which a relative correction adapter 31 is provided that is formed of a two-port network connected to each port of a production test fixture 5B adjacent to a measurement apparatus. The relative correction adapter has a characteristic that modifies the electrical characteristics generated by the production test fixture 5B having an electronic component under test mounted thereon into electrical characteristics generated by a standard test fixture 5A having the electronic component under test mounted thereon. An error factor of the relative correction adapter 31 is identified from a standard test fixture measurement value and a production test fixture measurement value of a correction data acquisition specimen 11B. A production test fixture measurement value of the electronic component under test 11A is corrected with the error factor of the relative correction adapter 31 to thereby obtain the standard test fixture measurement value of the electronic component under test 11A which is assumed to be obtained when the electronic component under test 11A.

Owner:MURATA MFG CO LTD

Biosensor, measuring instrument for biosensor, and method of quantifying substrate

InactiveUS7232510B2Immobilised enzymesBioreactor/fermenter combinationsObservational errorMeasuring instrument

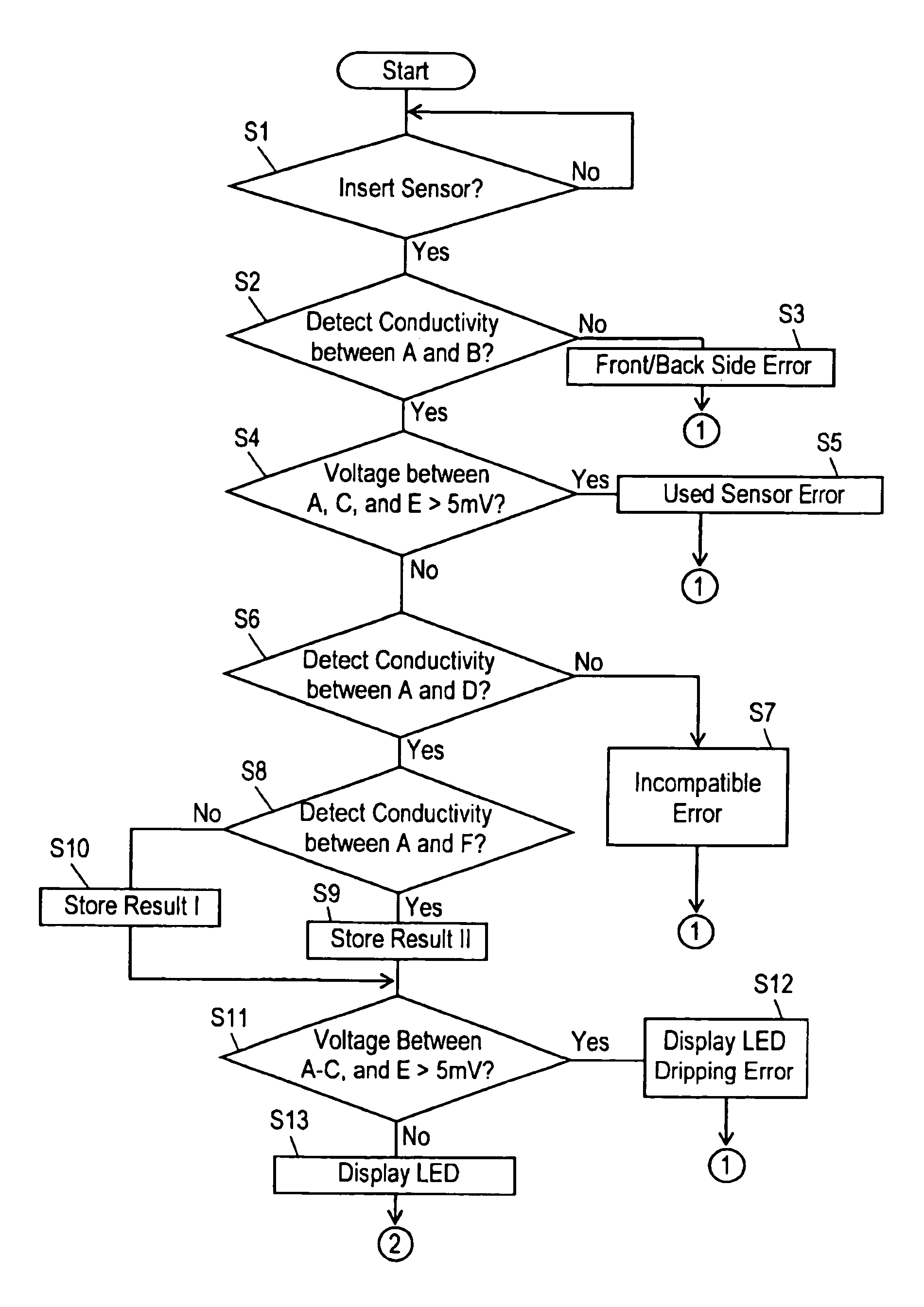

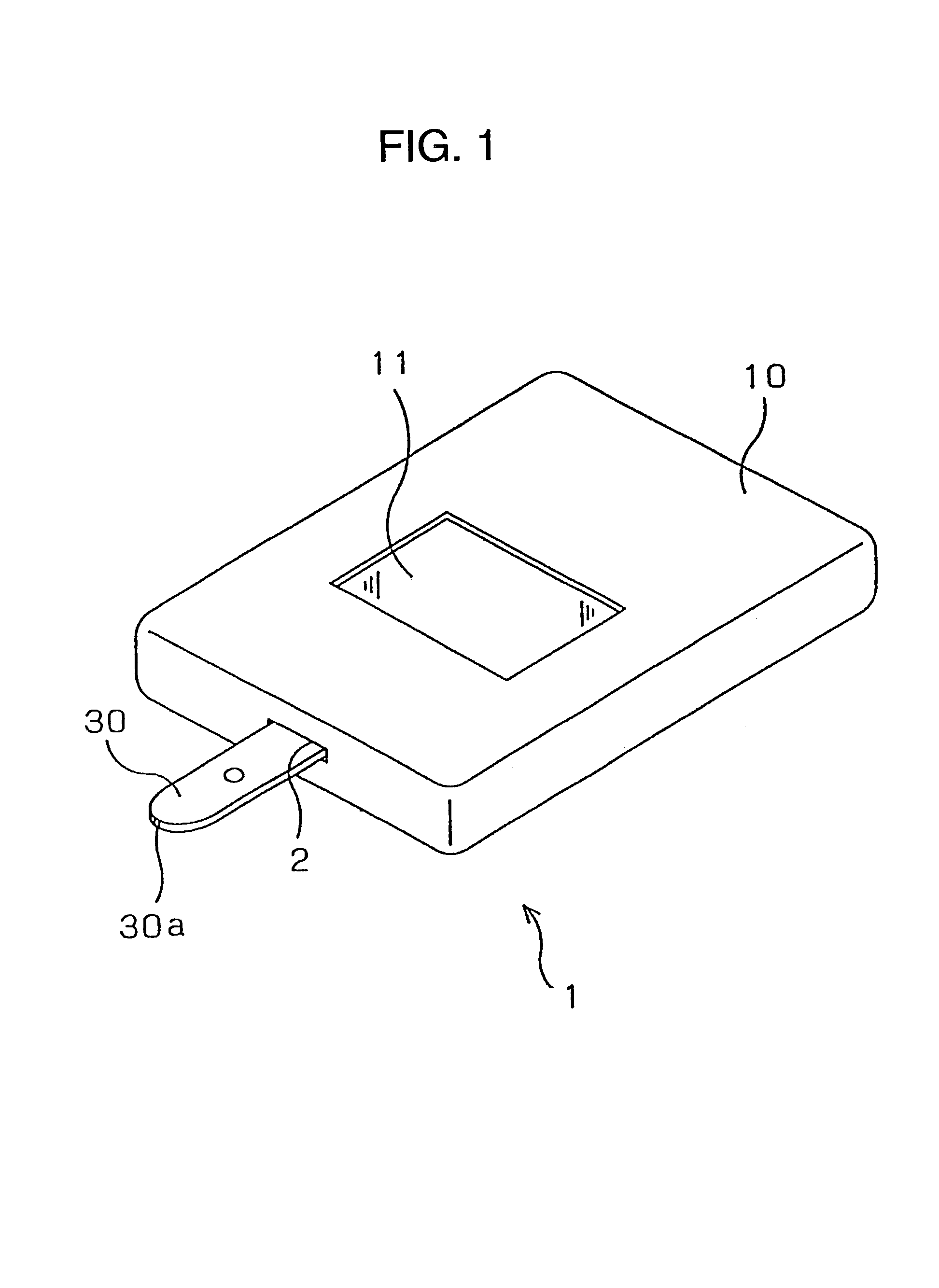

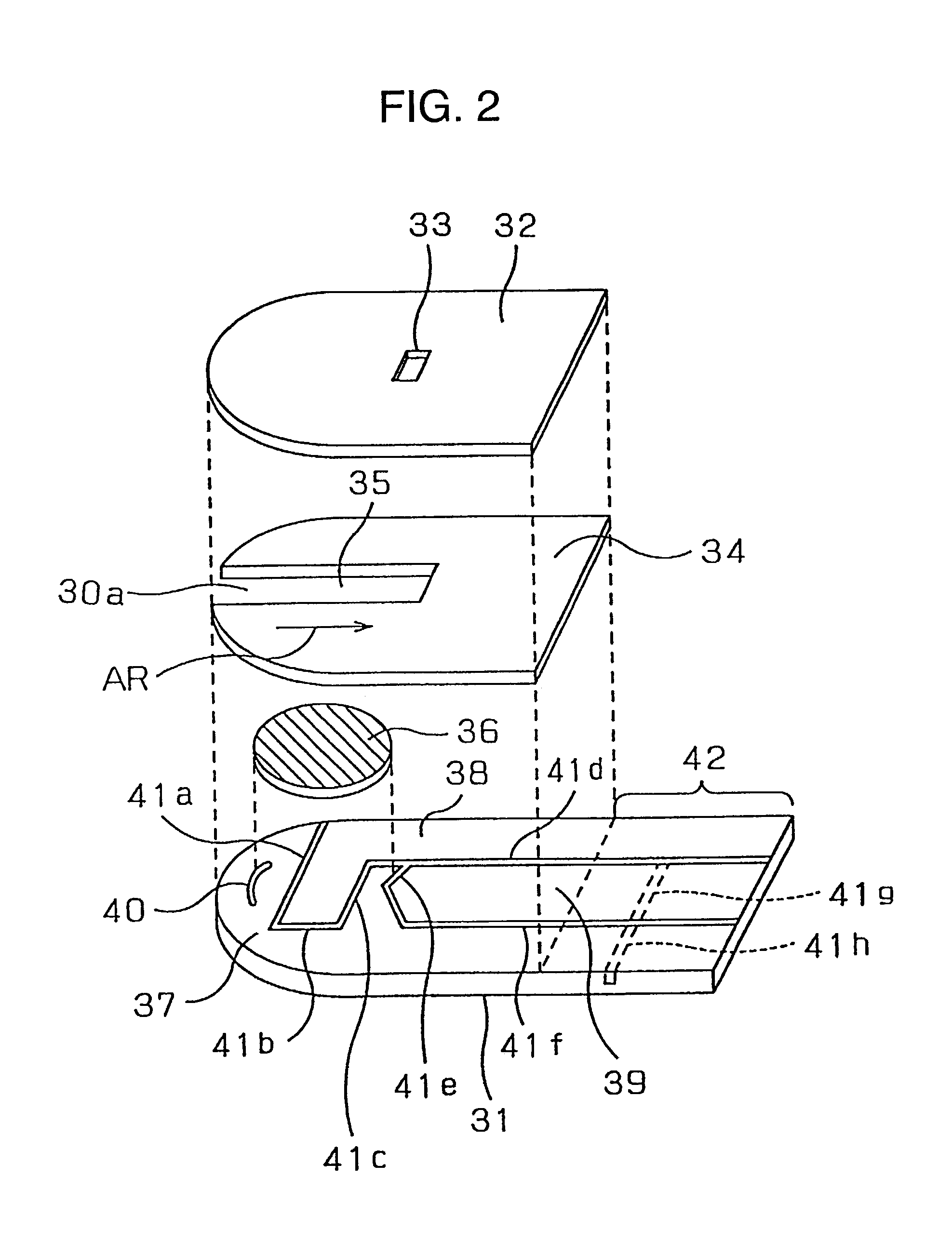

A biosensor, a measuring instrument for biosensor, and a method of quantifying a substrate contained in specimen liquid to reduce a measurement error by the biosensor; a biosensor, comprising at least a pair of electrodes formed on an insulation substrate; a measuring instrument, comprising a supporting part for detachably supporting the biosensor, a plurality of connection terminals electrically connected to the electrodes, and a drive power supply for applying a voltage to the electrodes through the connection terminals; wherein the biosensor is inserted into the measuring instrument, either one of the electrodes of the biosensor is connected to first and second connection terminals fined to the measuring instrument only when the biosensor is inserted into the support part of the measuring instrument in a specified direction and has an electrode structure to allow the first connection terminal to conduct with the second connection terminal when a voltage is applied by the drive power supply.

Owner:PHC HLDG CORP

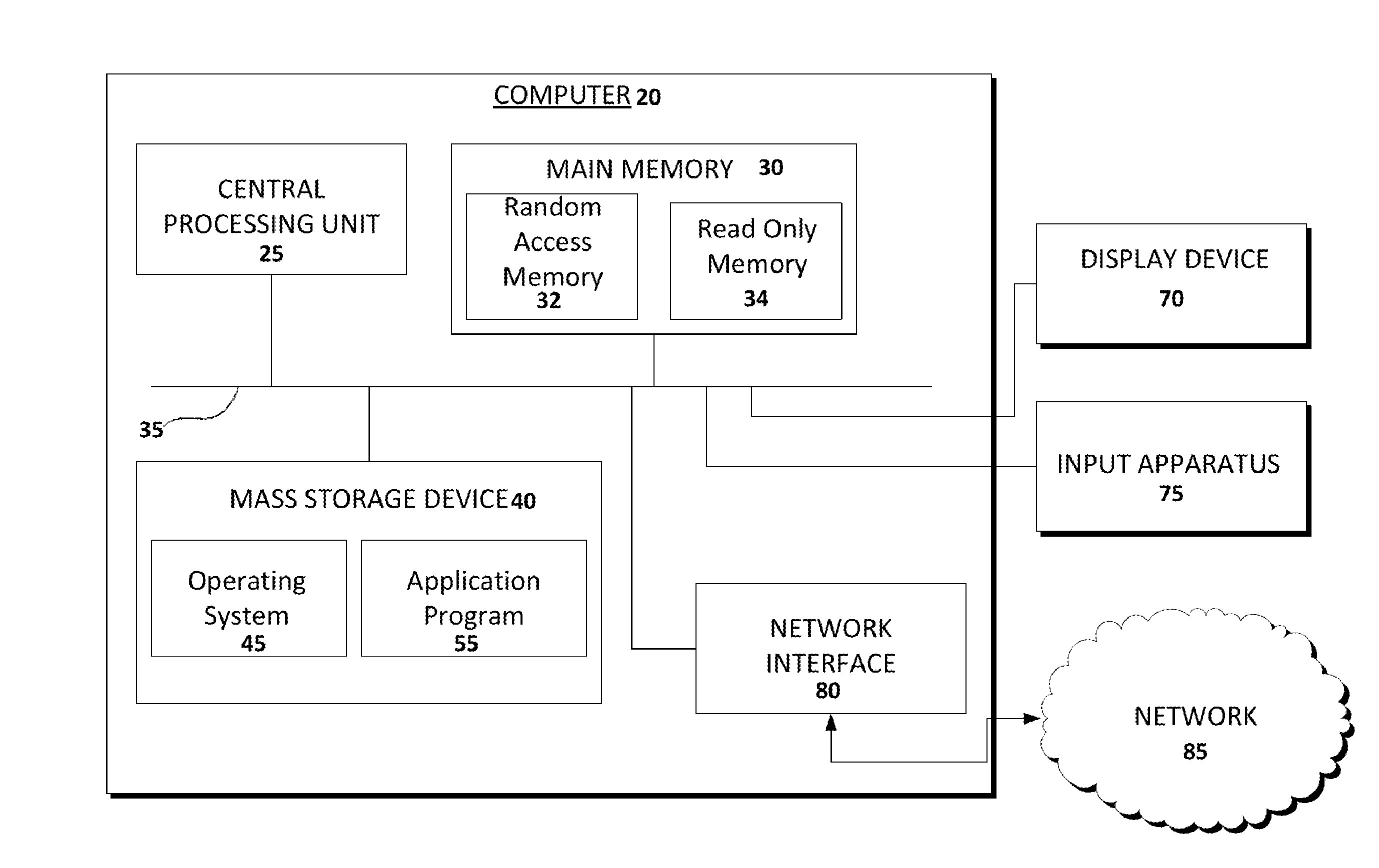

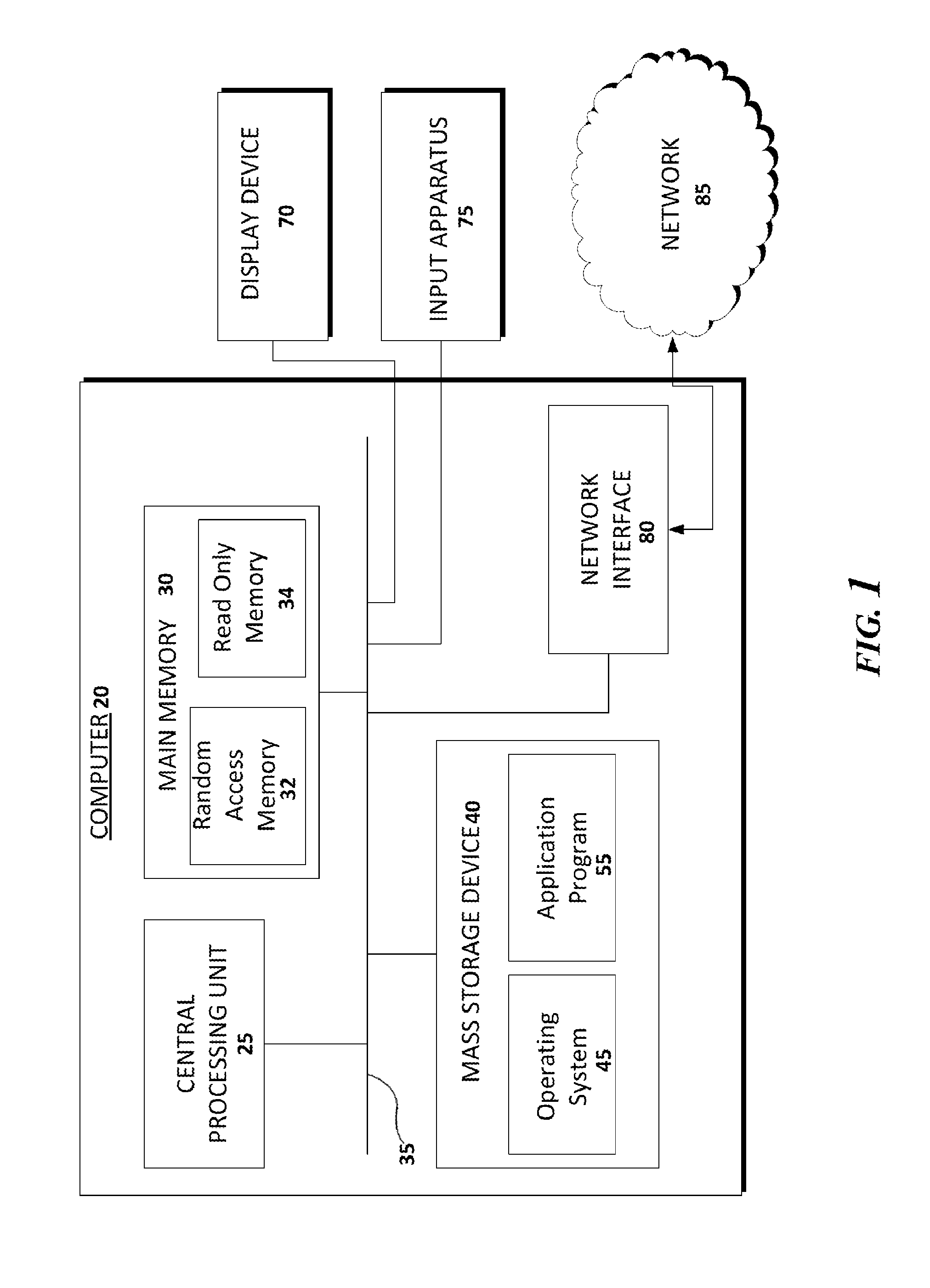

3-d imaging and processing system including at least one 3-d or depth sensor which is continually calibrated during use

InactiveUS20130329012A1Low costSimplify useImage enhancementImage analysis3d sensorObservational error

3D imaging and processing method and system including at least one 3D or depth sensor which is continuously calibrated during use are provided. In one embodiment, a calibration apparatus or object is continuously visible in the field of view of each 3D sensor. In another embodiment, such as a calibration apparatus is not needed. Continuously calibrated 3D sensors improve the accuracy and reliability of depth measurements. The calibration system and method can be used to ensure the accuracy of measurements using any of a variety of 3D sensor technologies. To reduce the cost of implementation, the invention can be used with inexpensive, consumer-grade 3D sensors to correct measurement errors and other measurement deviations from the true location and orientation of an object in 3D space.

Owner:LIBERTY REACH

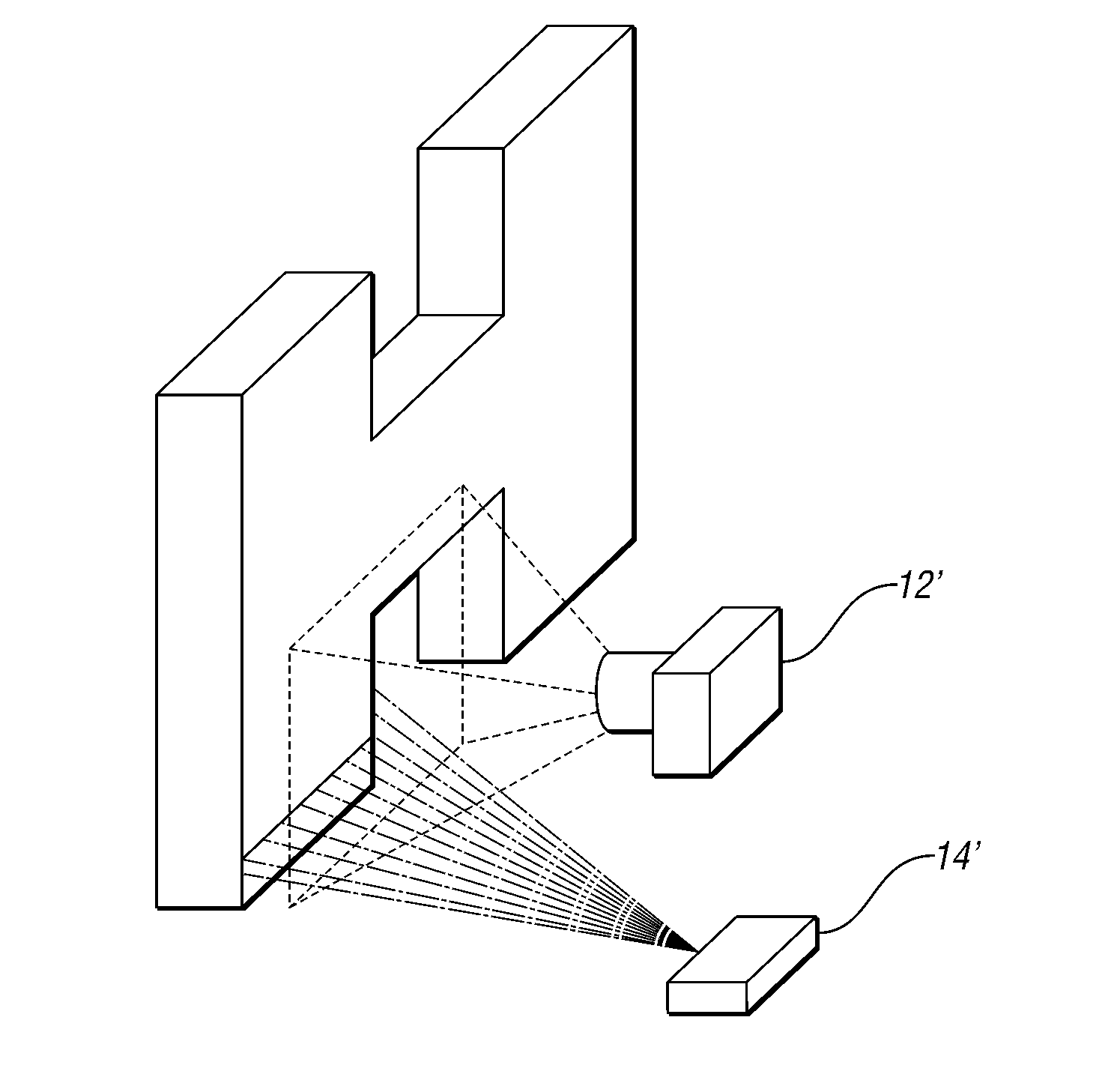

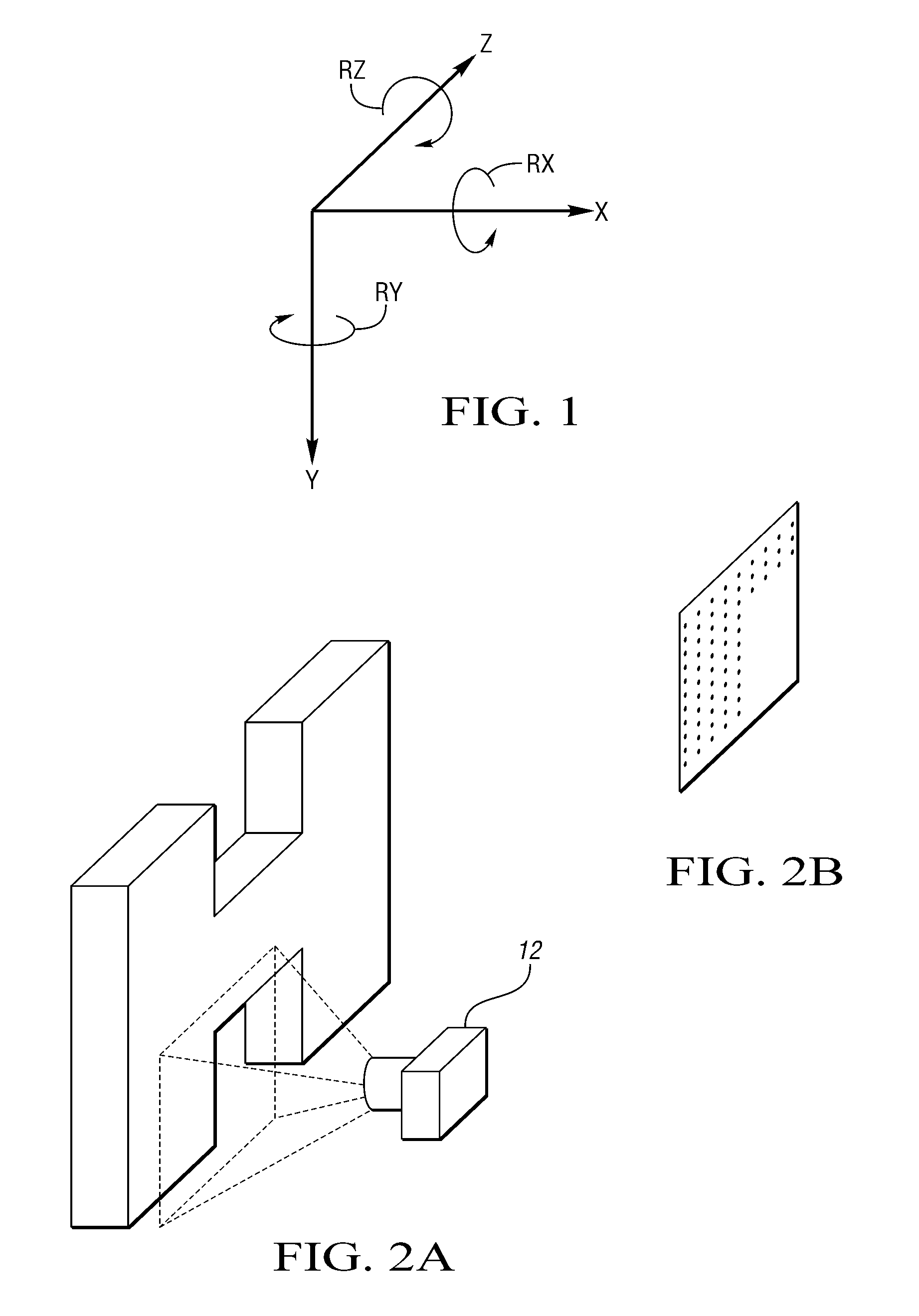

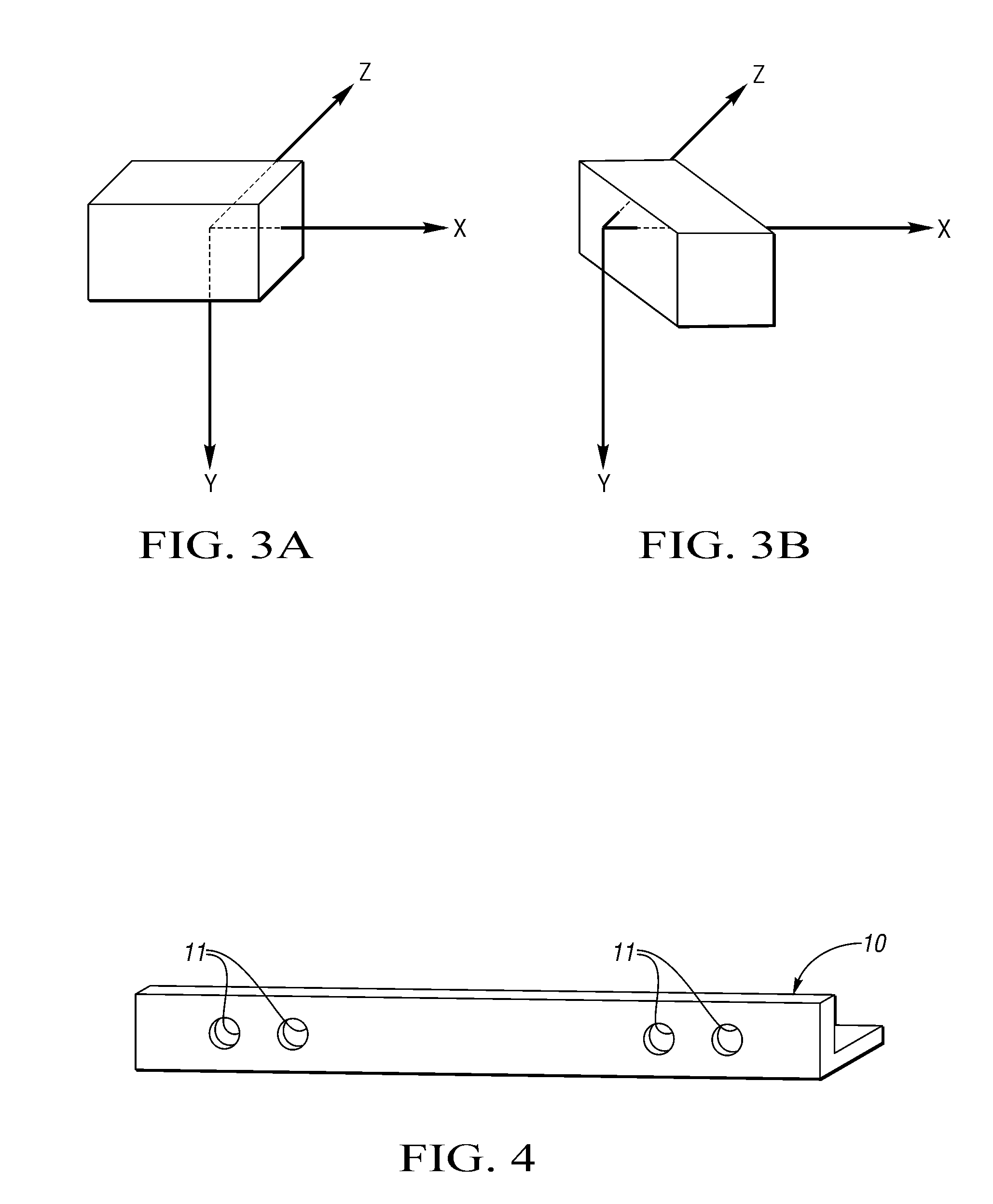

Movable body drive method and movable body drive system, pattern formation method and apparatus, exposure method and apparatus, and device manufacturing method

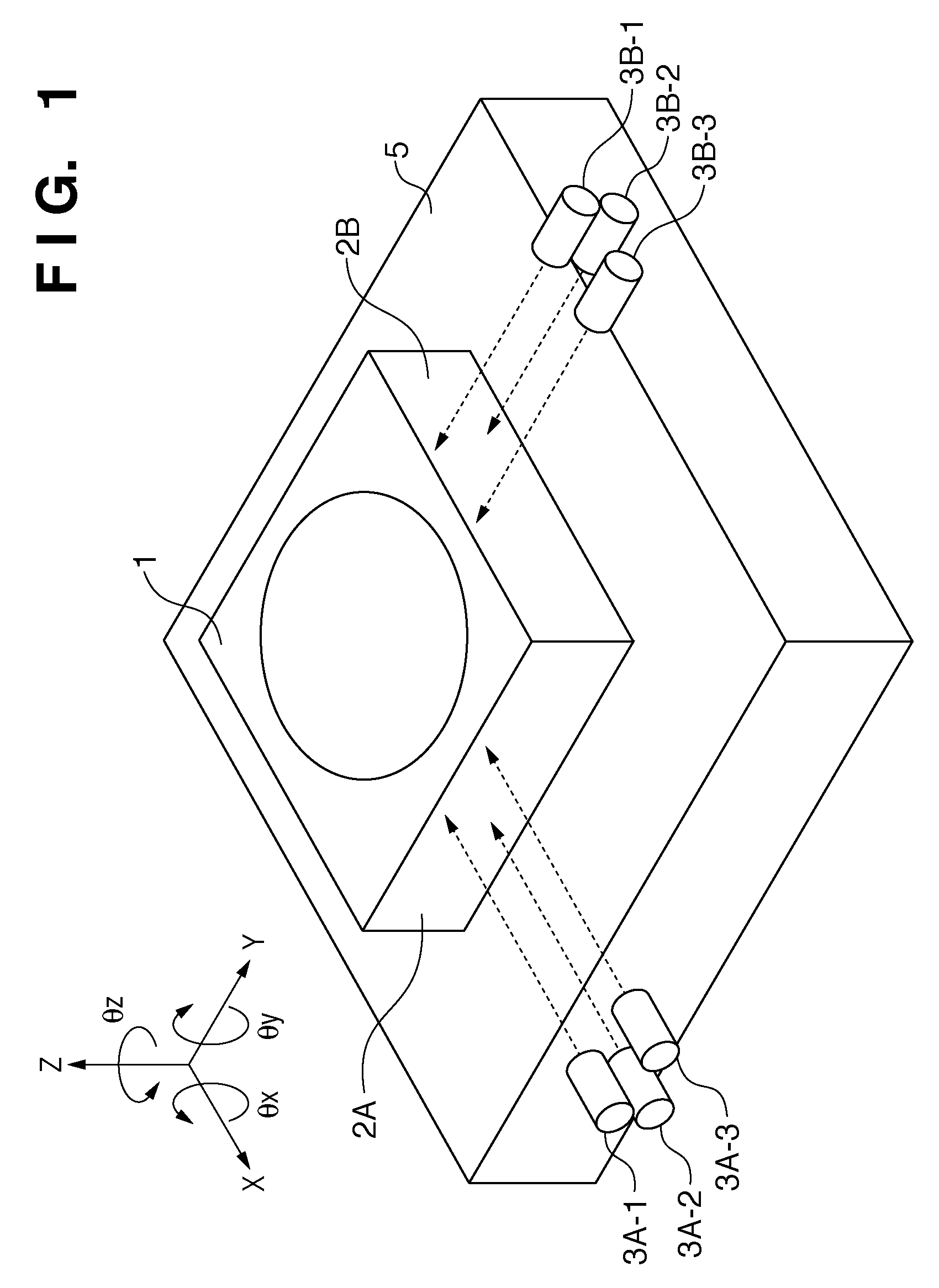

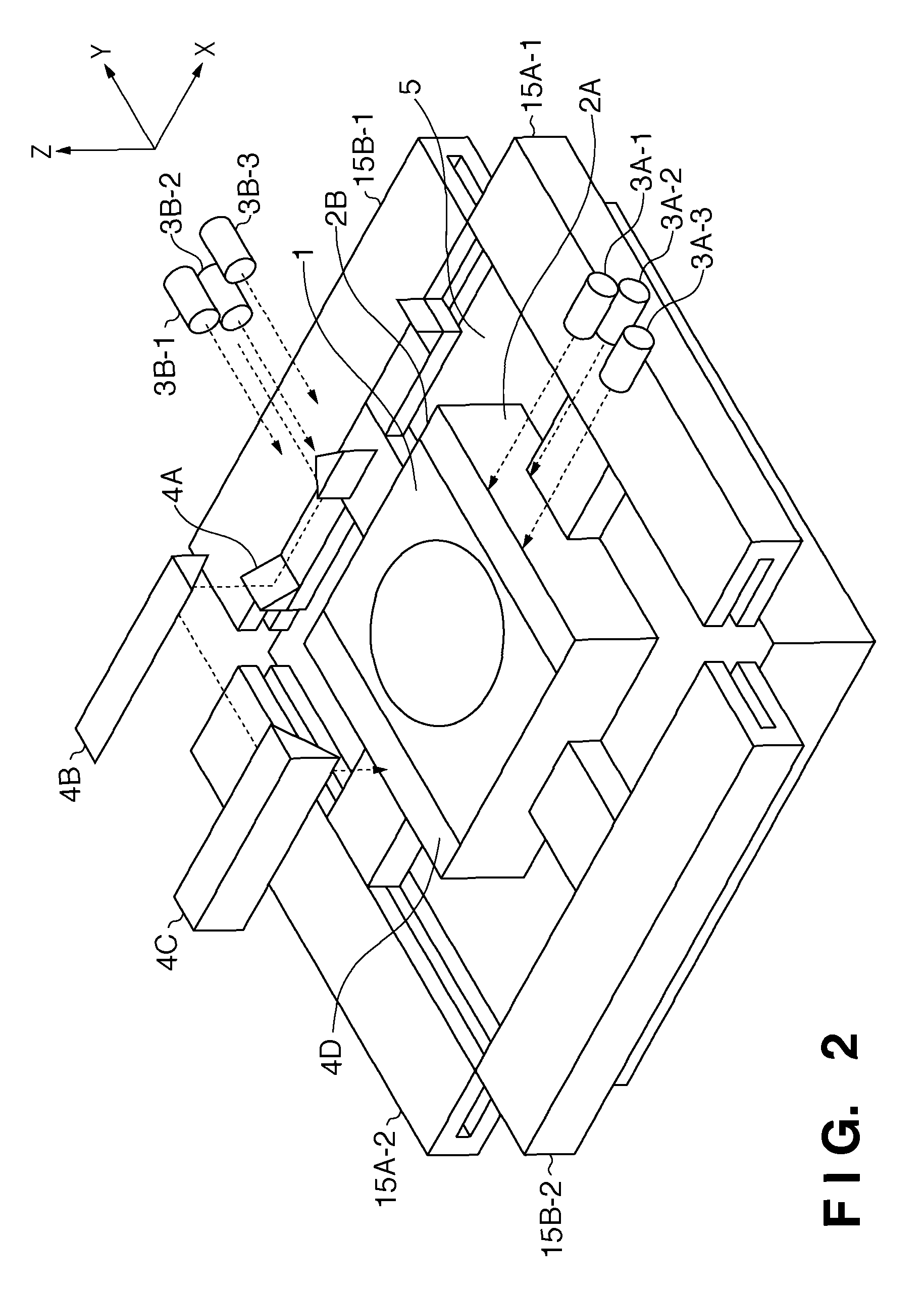

InactiveUS20080218713A1Improve accuracyEasy to controlPhotomechanical apparatusSemiconductor/solid-state device manufacturingObservational errorEngineering

A drive unit drives a wafer stage in a Y-axis direction based on a measurement value of an encoder that measures position information of the wafer stage in the Y-axis direction and based on information on the flatness of a scale that is measured by the encoder. In this case, the drive unit can drive the wafer stage in a predetermined direction based on a measurement value after correction in which a measurement error caused by the flatness of the scale included in the measurement value of the encoder is corrected based on the information on the flatness of the scale. Accordingly, the wafer stage can be driven with high accuracy in a predetermined direction using the encoder, without being affected by the unevenness of the scale.

Owner:NIKON CORP

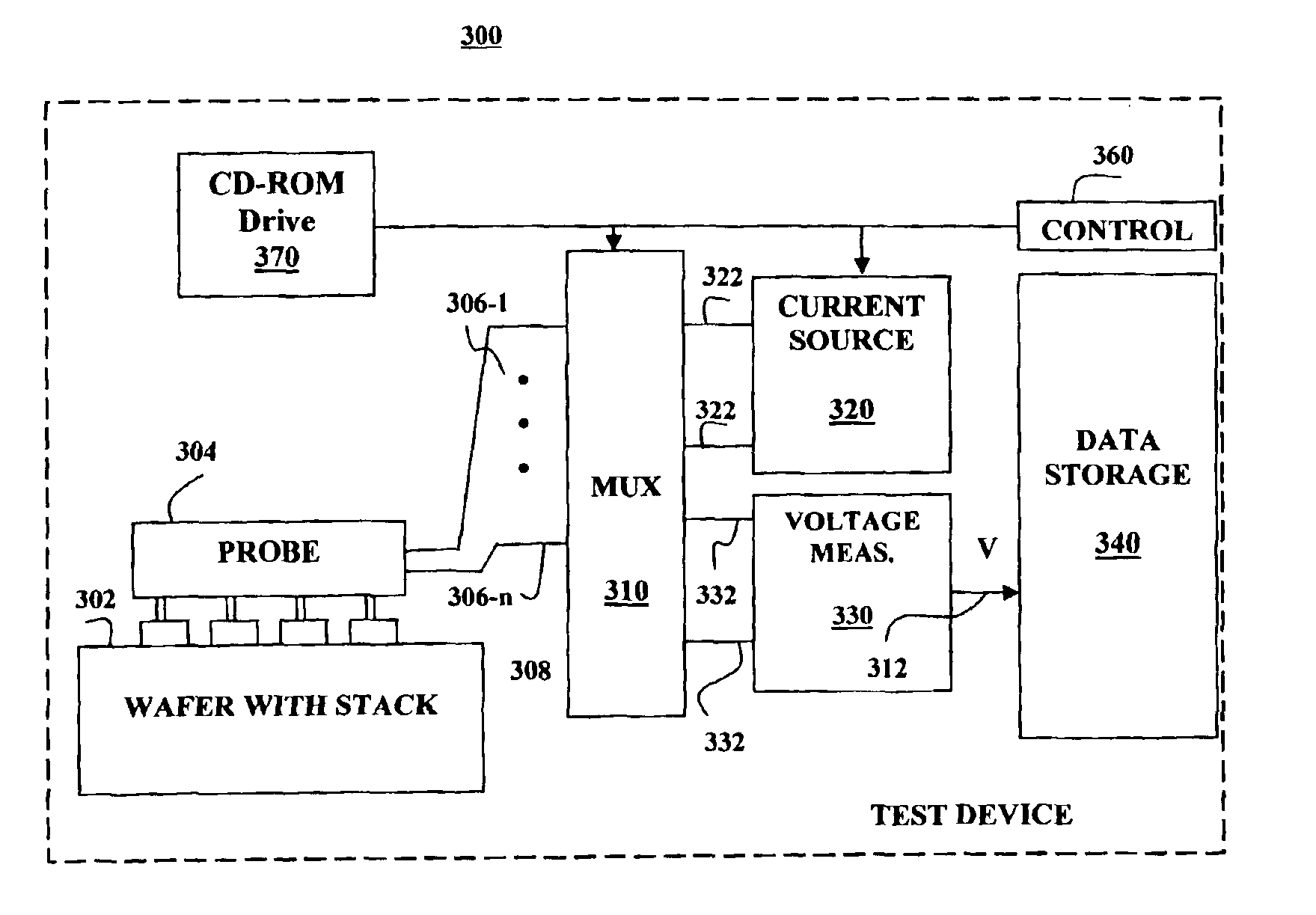

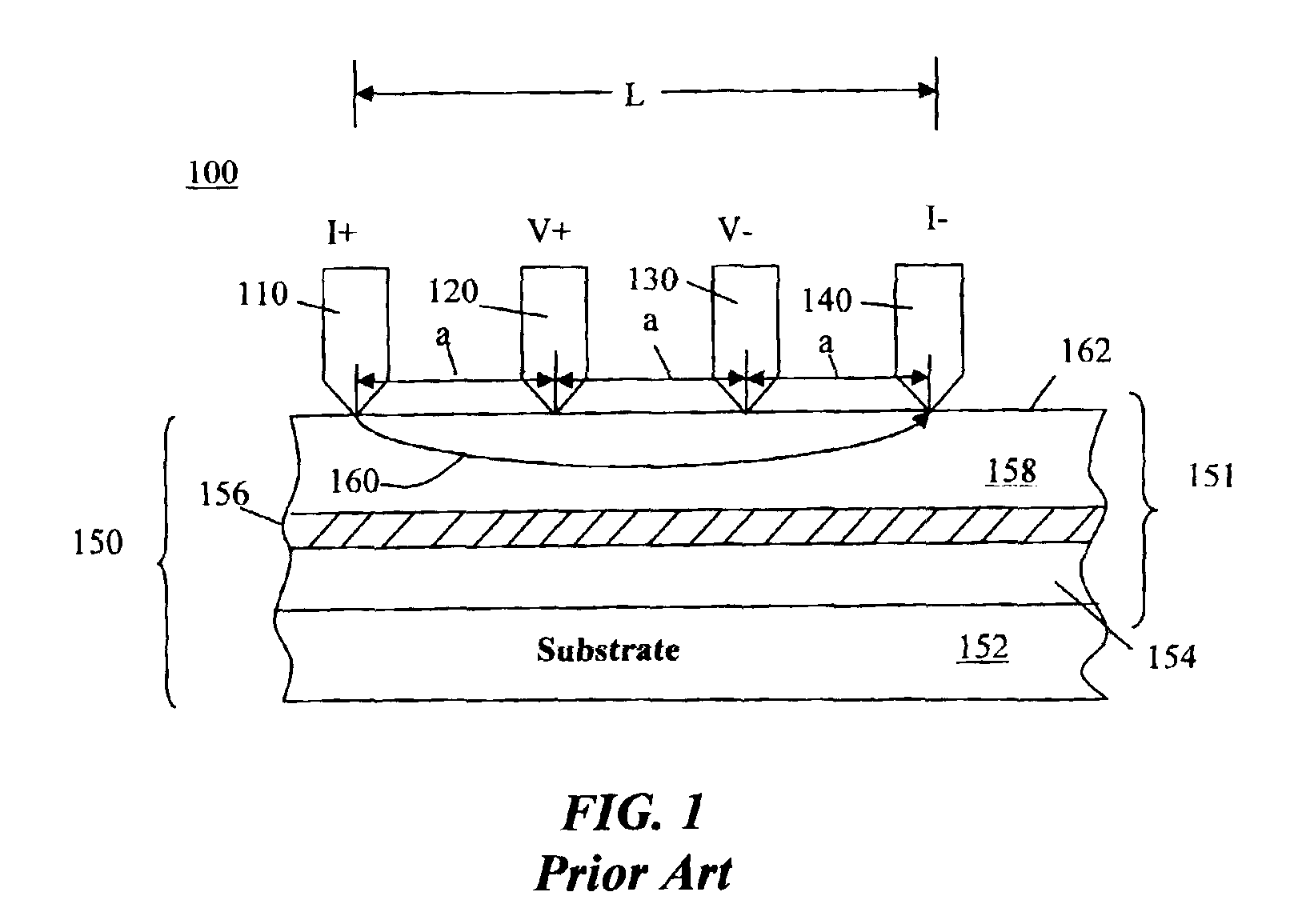

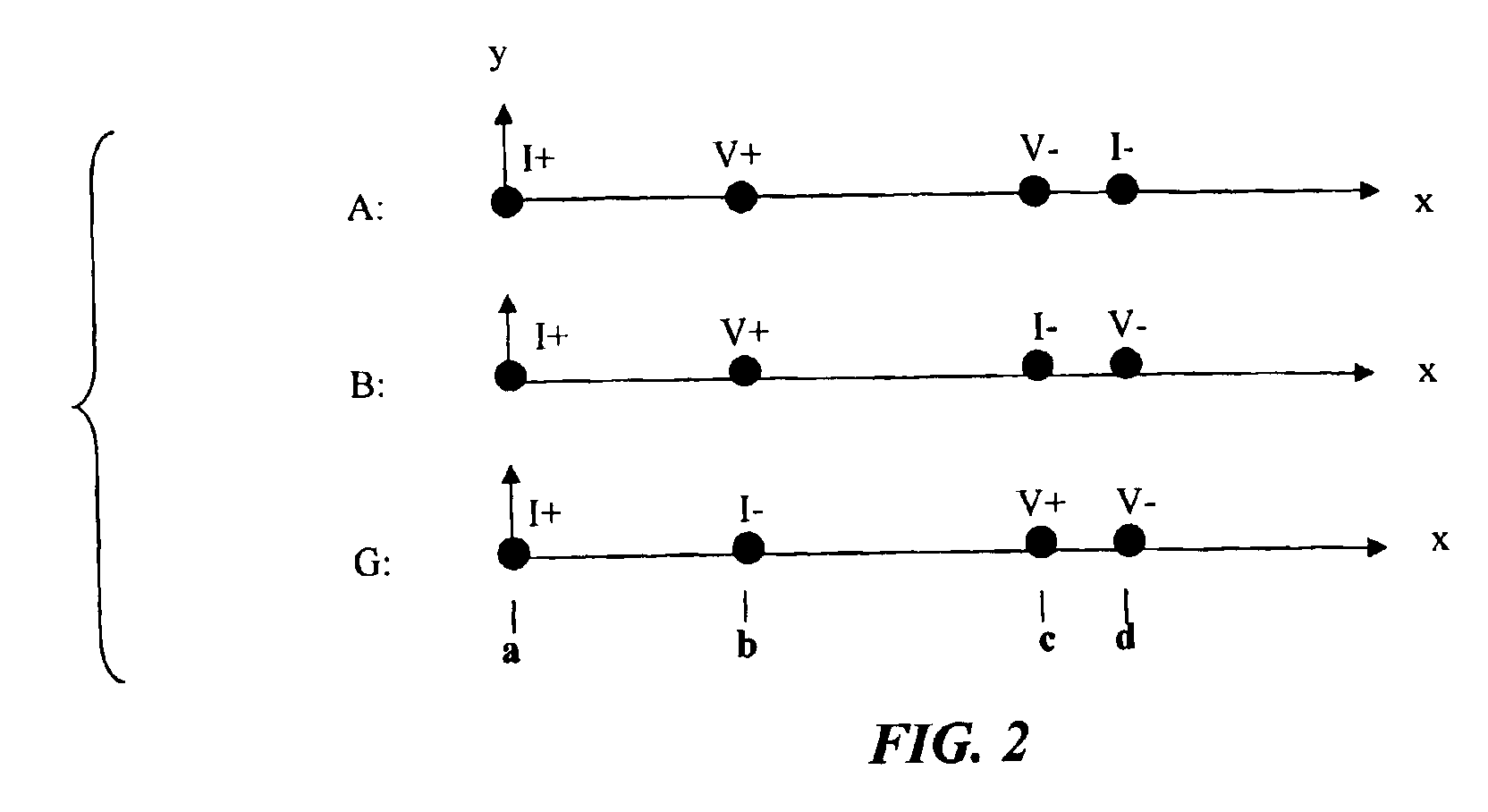

Reduction of positional errors in a four point probe resistance measurement

ActiveUS6943571B2Reduce measurement errorResistance/reactance/impedenceSemiconductor characterisationObservational errorElectrical resistance and conductance

A system and method for measuring a resistance or a resistance per square, Rsq, of a material having a surface using a multi-point probe including four or more collinear contact points placed in the interior of the sample, the method including: making a first measurement using a first set of probe electrodes for inducing a current and a second set of probe electrodes for measuring the voltage difference when the current is induced; making a second measurement using a set of probe electrodes different from the first set for inducing a current and a set of probe electrodes different from the second set for measuring the voltage difference when the current is induced; and using a known relationship among the currents induced, the voltages measured, the nominal probe positions and the resistance per square to determine the resistance per square such that measurement errors resulting from positioning of the probes are reduced.

Owner:IBM CORP

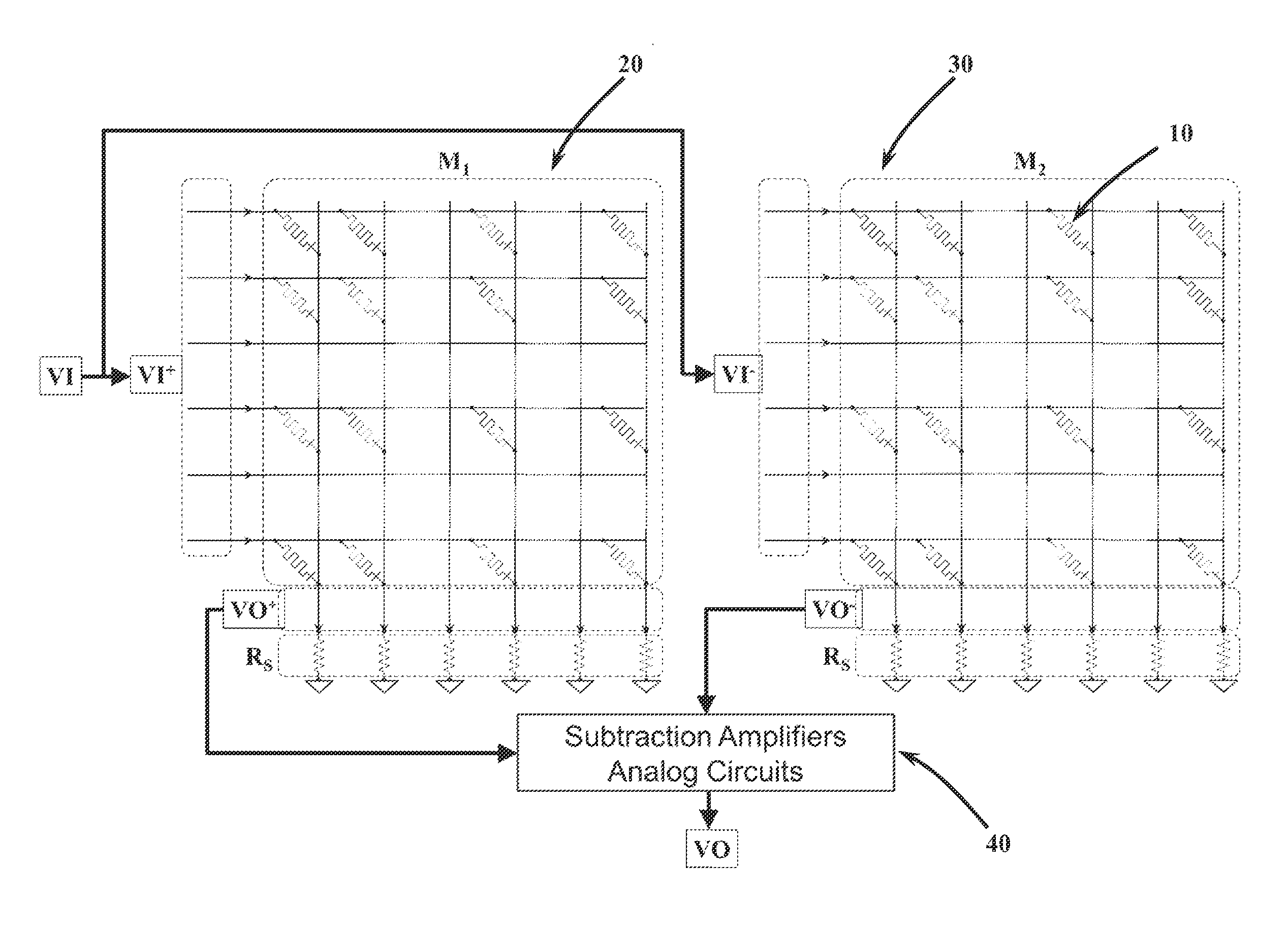

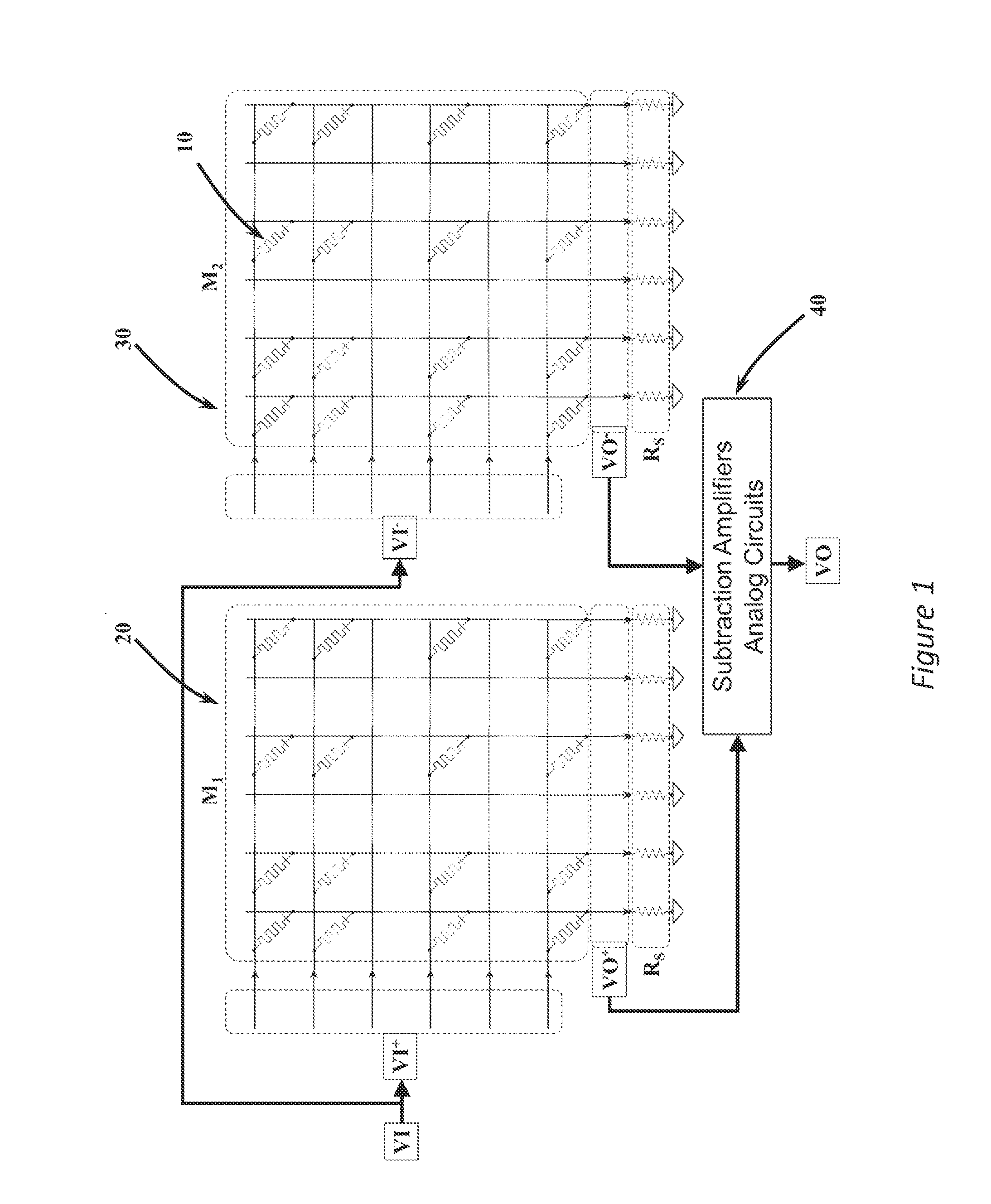

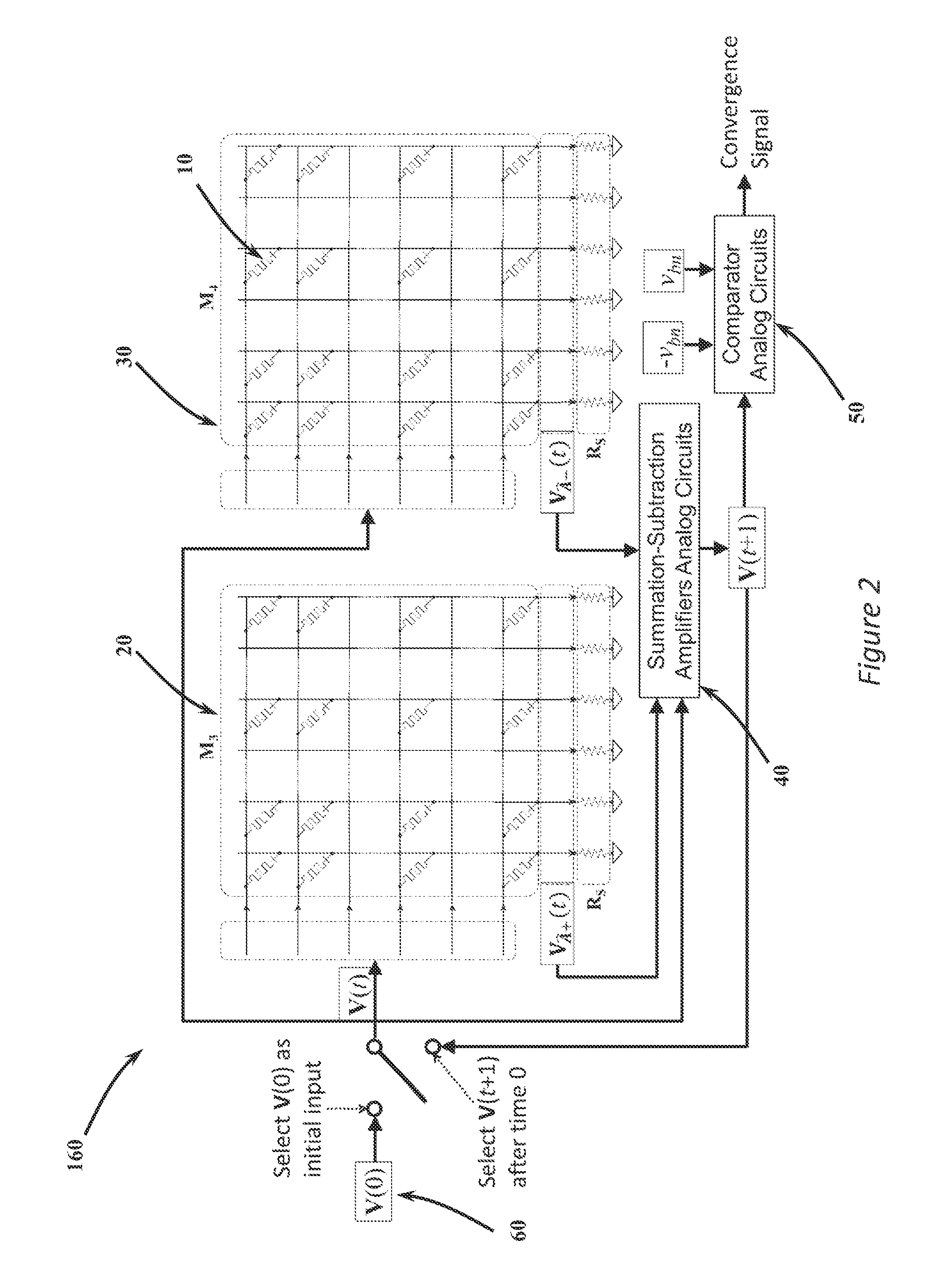

Method and apparatus for performing close-loop programming of resistive memory devices in crossbar array based hardware circuits and systems

ActiveUS20150170025A1Reduce Design ComplexityConvenient and accurateDigital computer detailsDigital storageObservational errorElectrical resistance and conductance

Method and apparatus for performing close-loop programming of resistive memory devices in crossbar array based hardware circuits and systems. Invention provides iterative training of memristor crossbar arrays for neural networks by applying voltages corresponding to selected training patterns. Error is detected and measured as a function of the actual response to the training patterns versus the expected response to the training pattern.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

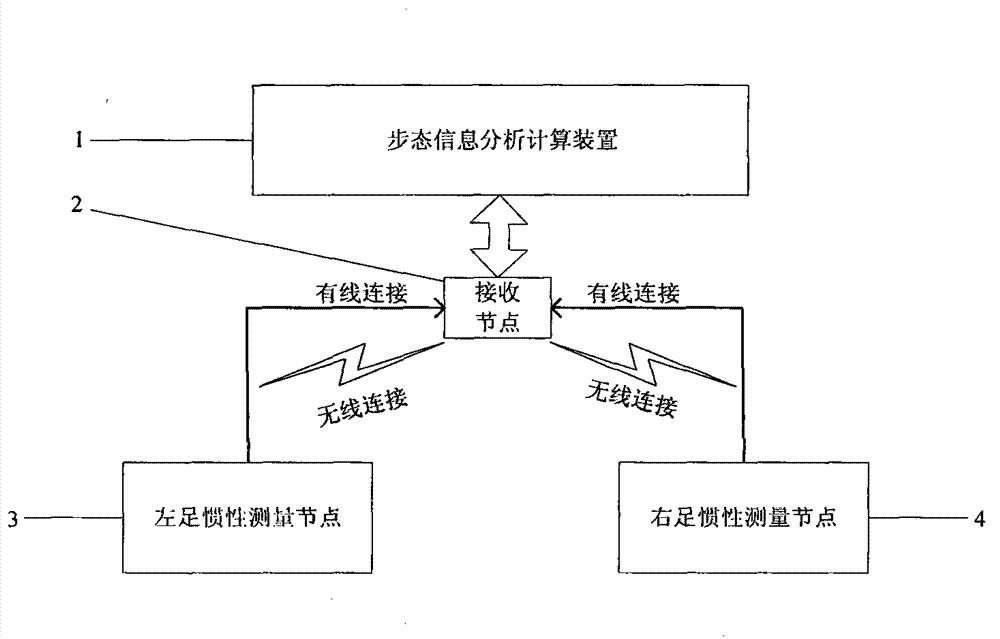

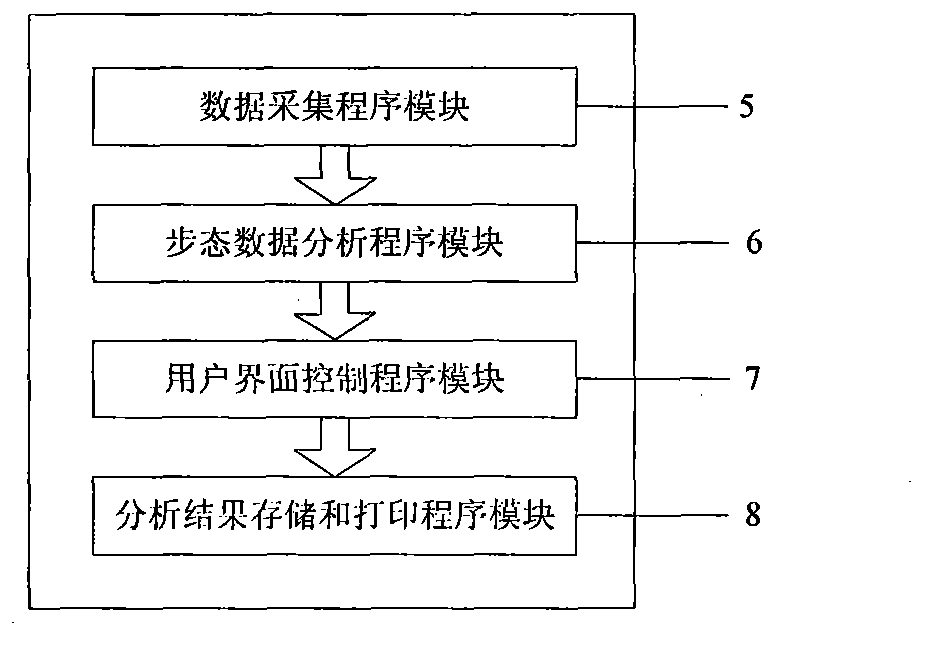

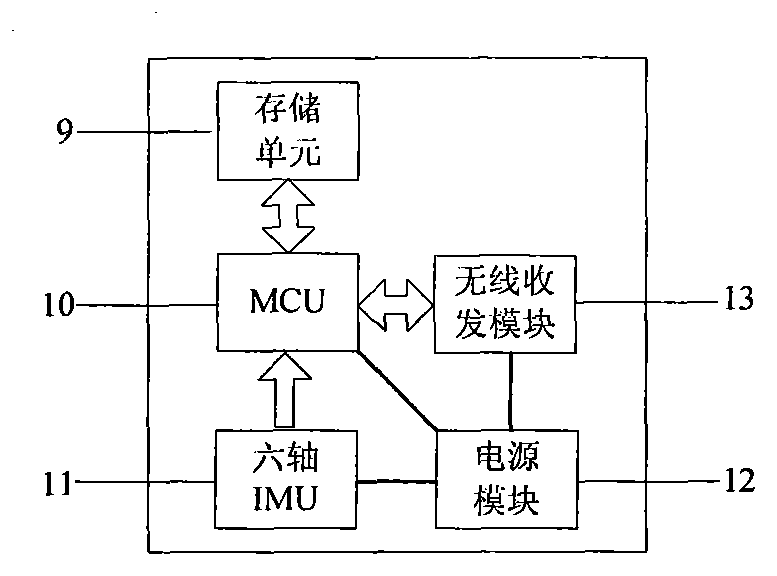

Three-dimensional human body gait quantitative analysis system and method

ActiveCN102824177AAccurate collectionHigh speed acquisitionDiagnostic recording/measuringSensorsNODALObservational error

The invention discloses a three-dimensional human body gait quantitative analysis system and method. The method comprises the following steps of: simultaneously using two inertia measurement nodes on feet, carrying out analyses fusion on the data of the two inertia measurement nodes, measuring a more accurate gait parameter, and obtaining information which can not be measured in a single-foot manner; and firstly storing the collected data in storage units of the measurement nodes in a walking process, and finally transmitting the collected data to an analytical calculation device in a wired or wireless manner after the walking process is ended. The high-speed acquisition of all gait information in the walking process can be realized and no characteristic gait information point is omitted. A foot part binding device of the designed inertia measurement node is adopted, a measuring error brought by fixed position shift of the measurement nodes in the walking process is eliminated, and the identity of fixed positions of the measurement nodes in a walking process is guaranteed through repeated measurement; and a gait analytical calculation program module adopts a moving window searching value method to definition a characteristic point of gait information, and can more exactly extract the gait diagnostic information.

Owner:王哲龙

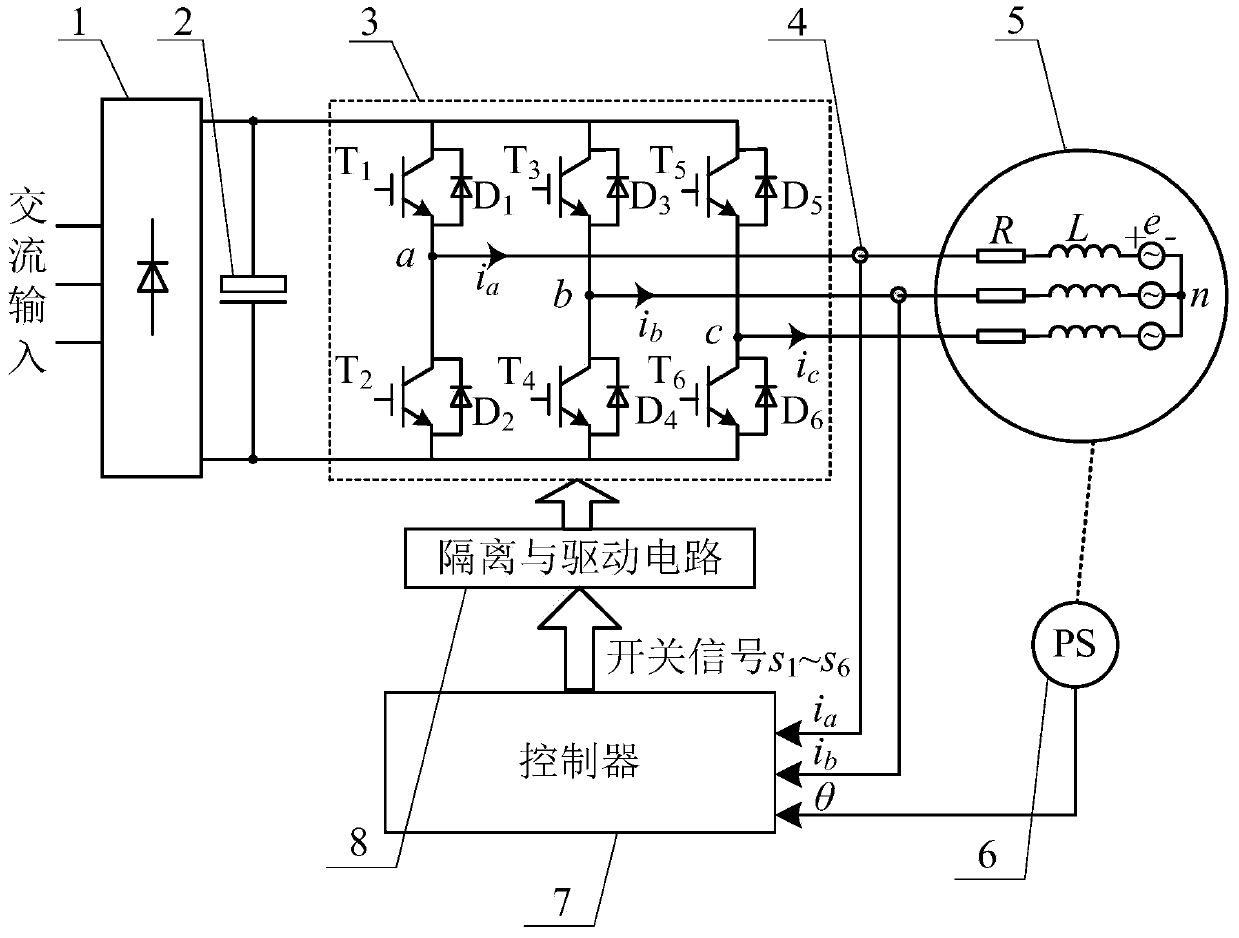

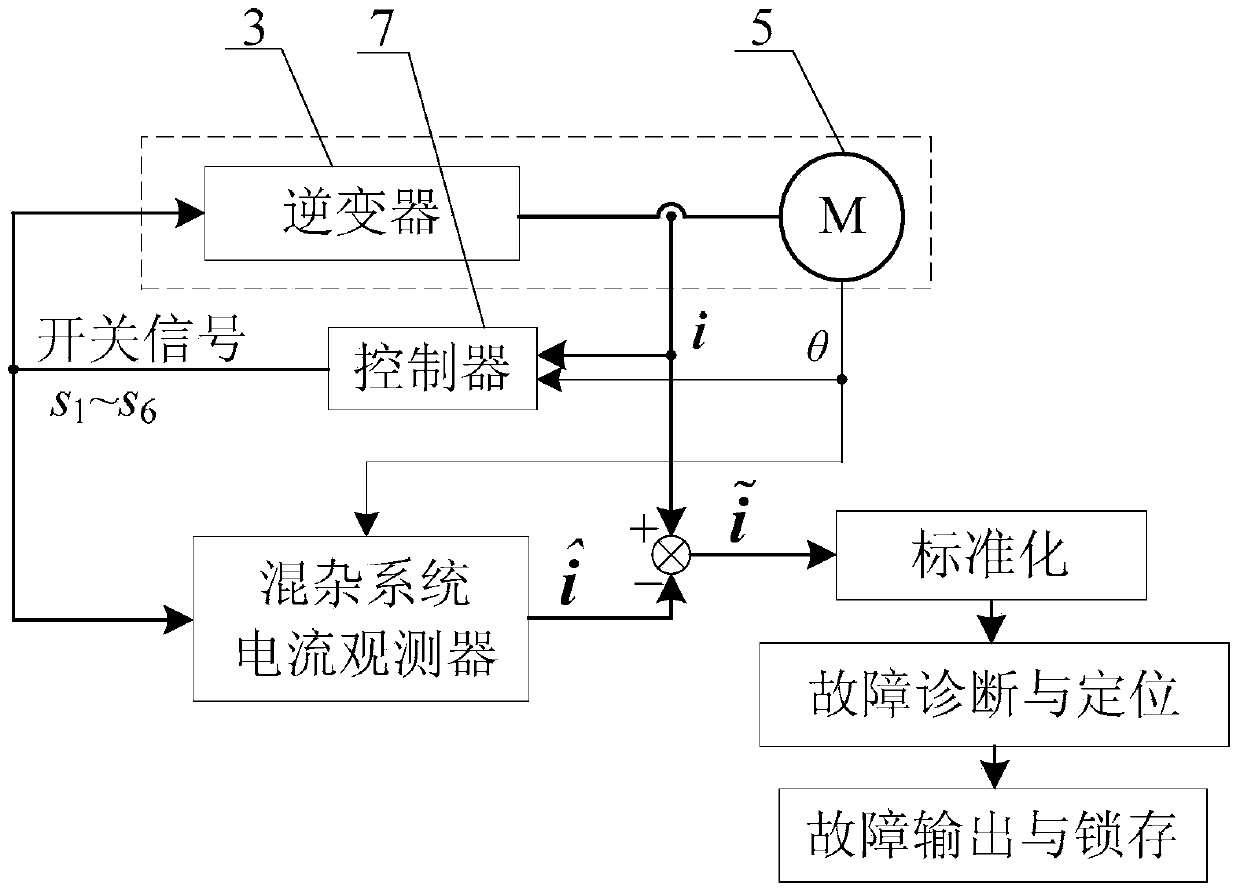

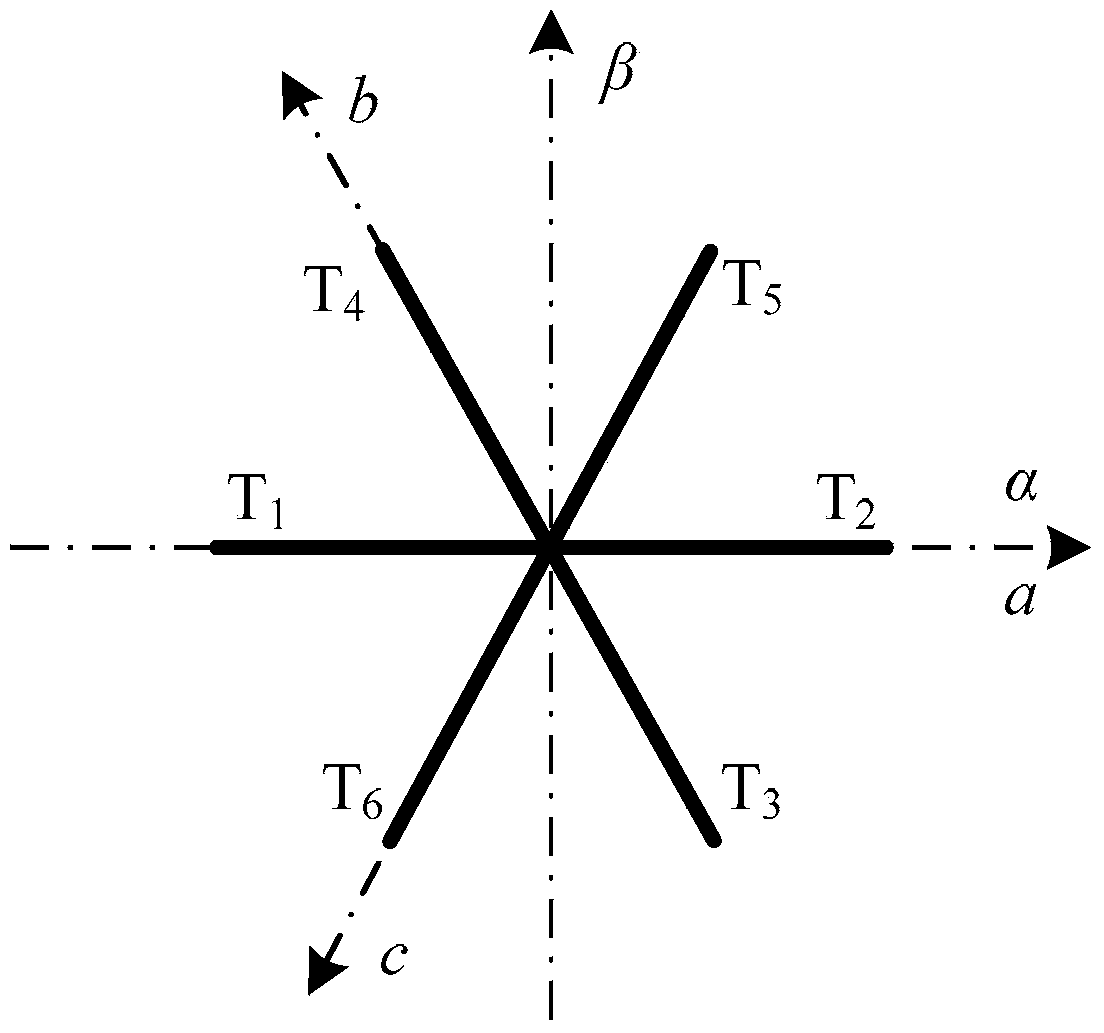

Current-magnitude-based open-circuit failure online-diagnosis method for power tube of inverter

InactiveCN103701394AImprove robustnessElectronic commutation motor controlVector control systemsObservational errorLoop control

The invention discloses a current-magnitude-based open-circuit failure online-diagnosis method for a power tube of an inverter, belongs to the field of motor control, and aims to solve the problem of poor robustness of a current-magnitude-based open-circuit failure diagnosis technology for the power tube of the inverter. The method comprises the following steps of establishing a current observer model of a permanent magnet synchronous motor driving system in a failure-free state, comparing an observed current value with detection current to obtain a three-phase current residual, converting the three-phase current residual to a two-phase coordinate system in a coordinate conversion way to obtain a current residual vector, standardizing the current residual vector, and diagnosing and positioning an open-circuit failure of the power tube of the inverter according to the amplitude and the phase of the standardized current residual vector. The current-magnitude-based open-circuit failure online-diagnosis method for the power tube of the inverter is free of influence of a system closed-loop control algorithm and insensitive to loads, and has higher robustness to parameter errors, measurement errors, system disturbance and the like.

Owner:HARBIN INST OF TECH

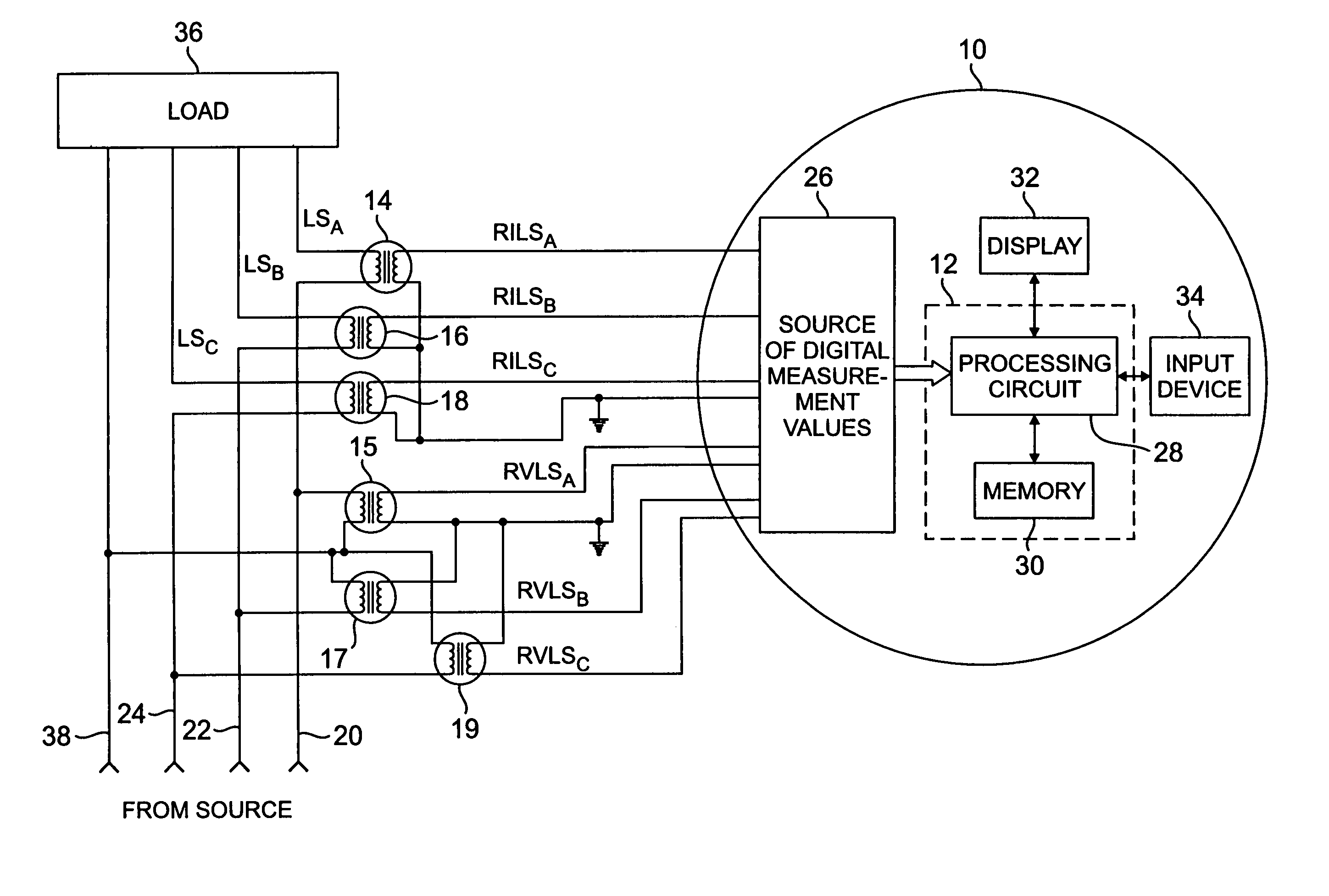

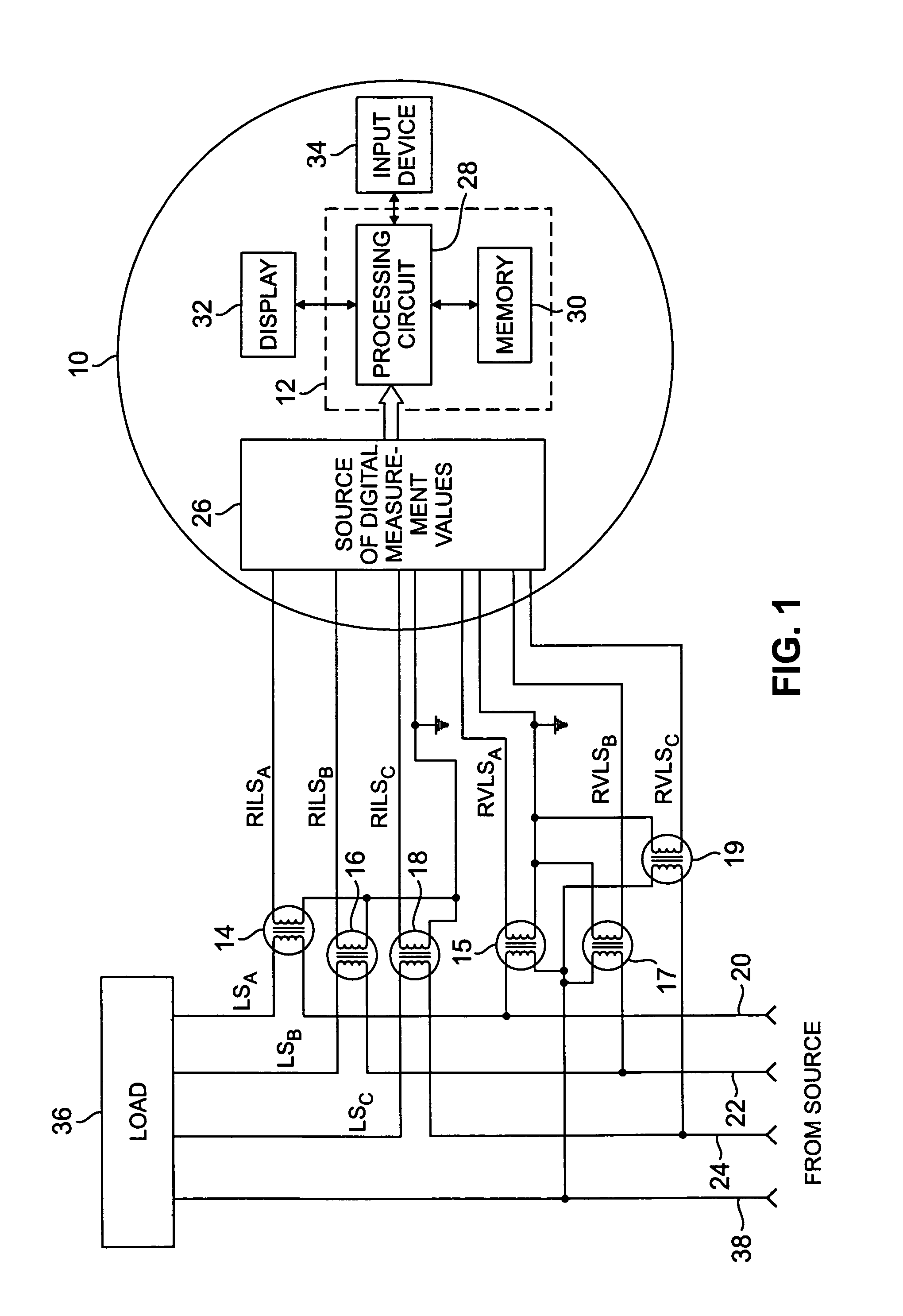

External transformer correction in an electricity meter

InactiveUS6988043B1High measurement accuracyCompensating for such errorElectric signal transmission systemsElectric devicesObservational errorElectricity

A method compensates for measurement errors of an external transformer coupled between an electricity meter and one or more power lines. The method includes a first step of obtaining at least one error rating for the external transformer. The method also includes the step of storing data representative of the at least one error rating in a memory within the meter. At some point the electricity meter is coupled to the external transformer. The method further includes the step of employing the meter to obtain at least one electricity consumption measurement value, the at least one electricity consumption value including either a sampled current value or a sampled voltage value. Finally, the method includes the step of causing the meter to adjust the at least one electricity consumption measurement value using at least a portion of the stored data.

Owner:LANDIS GYR LLC

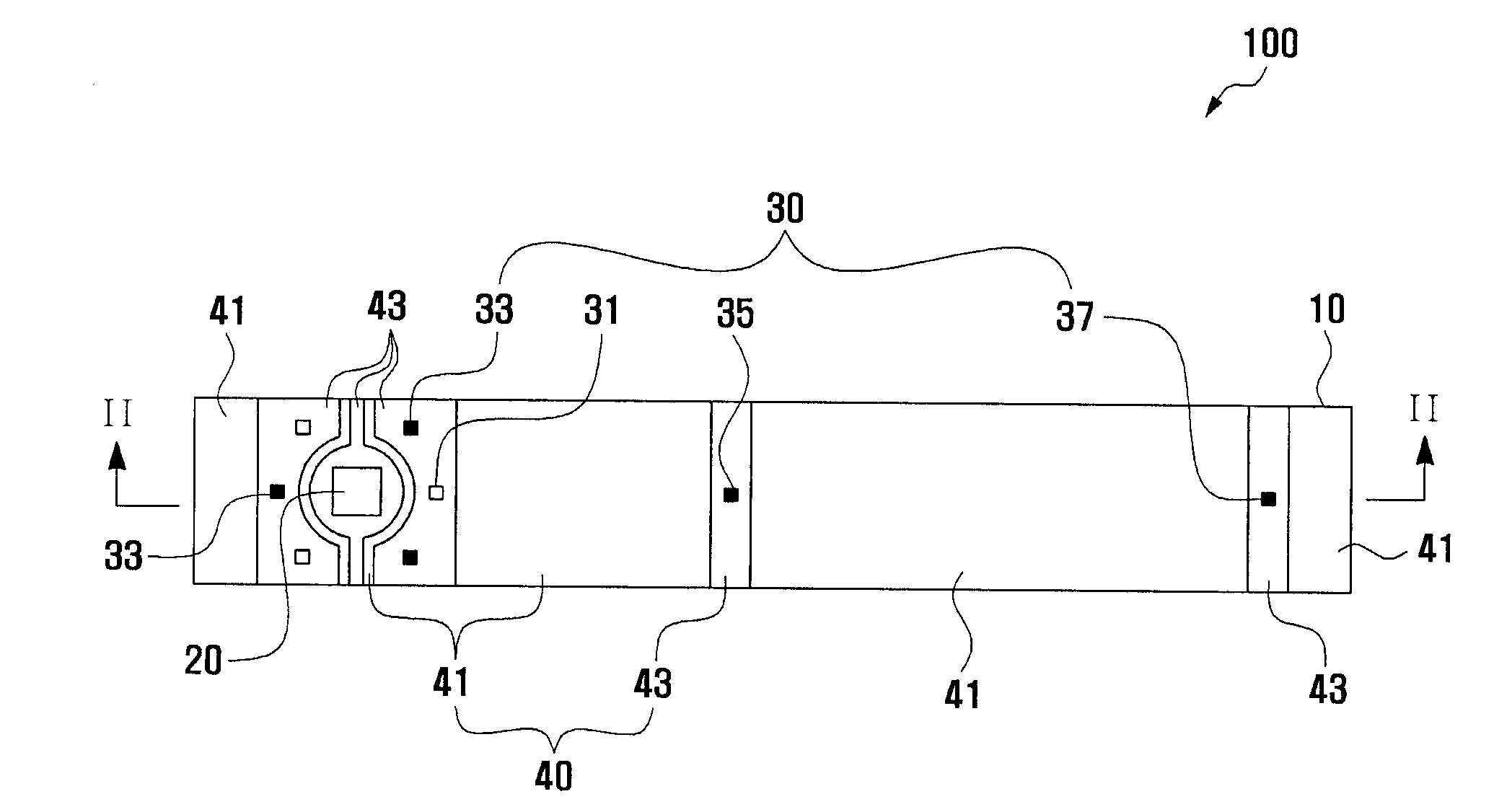

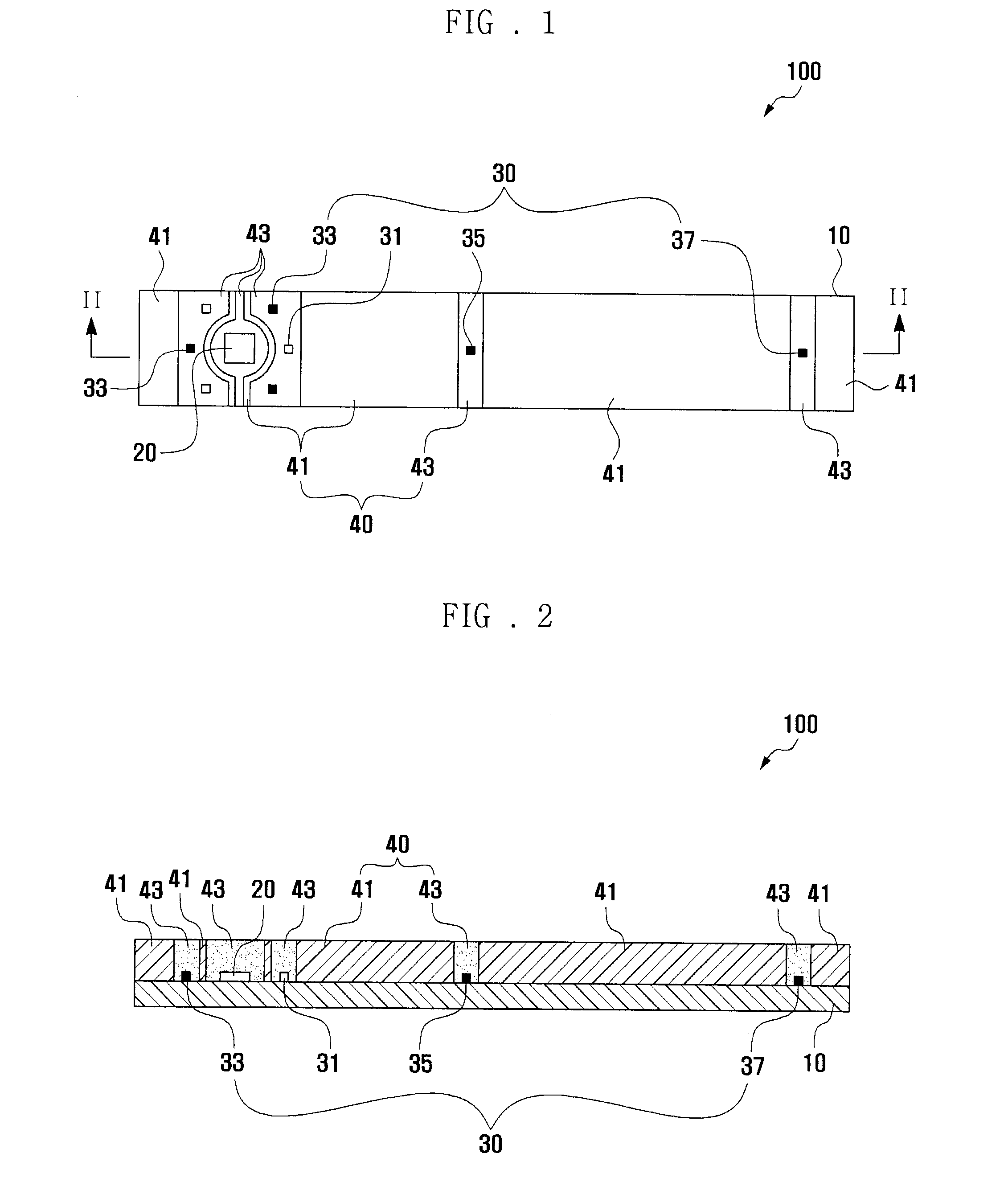

Physiological signal measuring sensor and manufacturing method for the same

InactiveUS20090182208A1Minimize measurement errorMaintain measurement accuracyDiagnostics using lightWave amplification devicesObservational errorPrinted circuit board

A physiological signal measuring sensor that minimizes the measurement error due to a soldering tolerance during the manufacturing process, and a manufacturing method for the same is disclosed. The physiological signal measuring sensor includes a printed circuit board, a light receiving chip mounted to the upper surface of the printed circuit board, light emitting chips mounted to the upper surface of the printed circuit board adjacent to the light receiving chip and resin sealing portions sealing the light receiving chip and the light emitting chips mounted to the upper surface of the printed circuit board wherein a first resin is selected to have opaque optical characteristics and a second resin is selected to have transparent characteristics.

Owner:SAMSUNG ELECTRONICS CO LTD

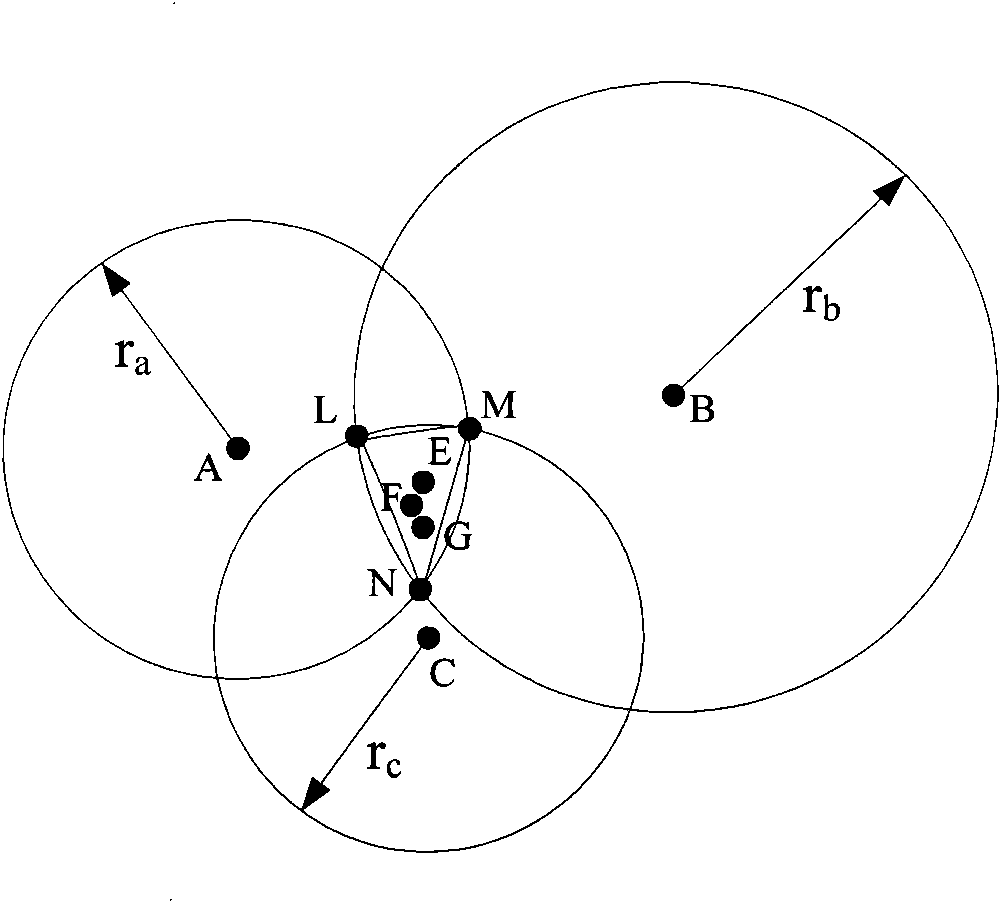

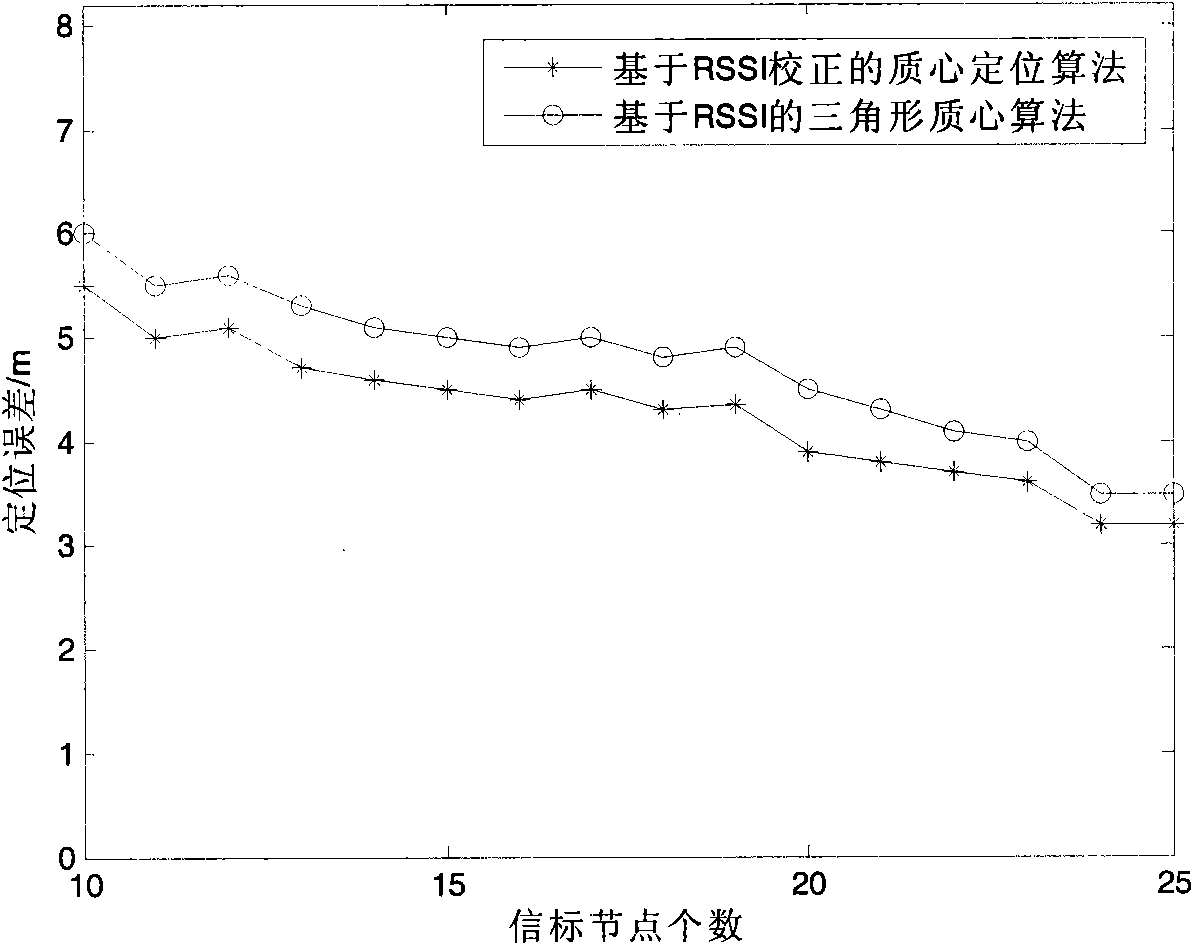

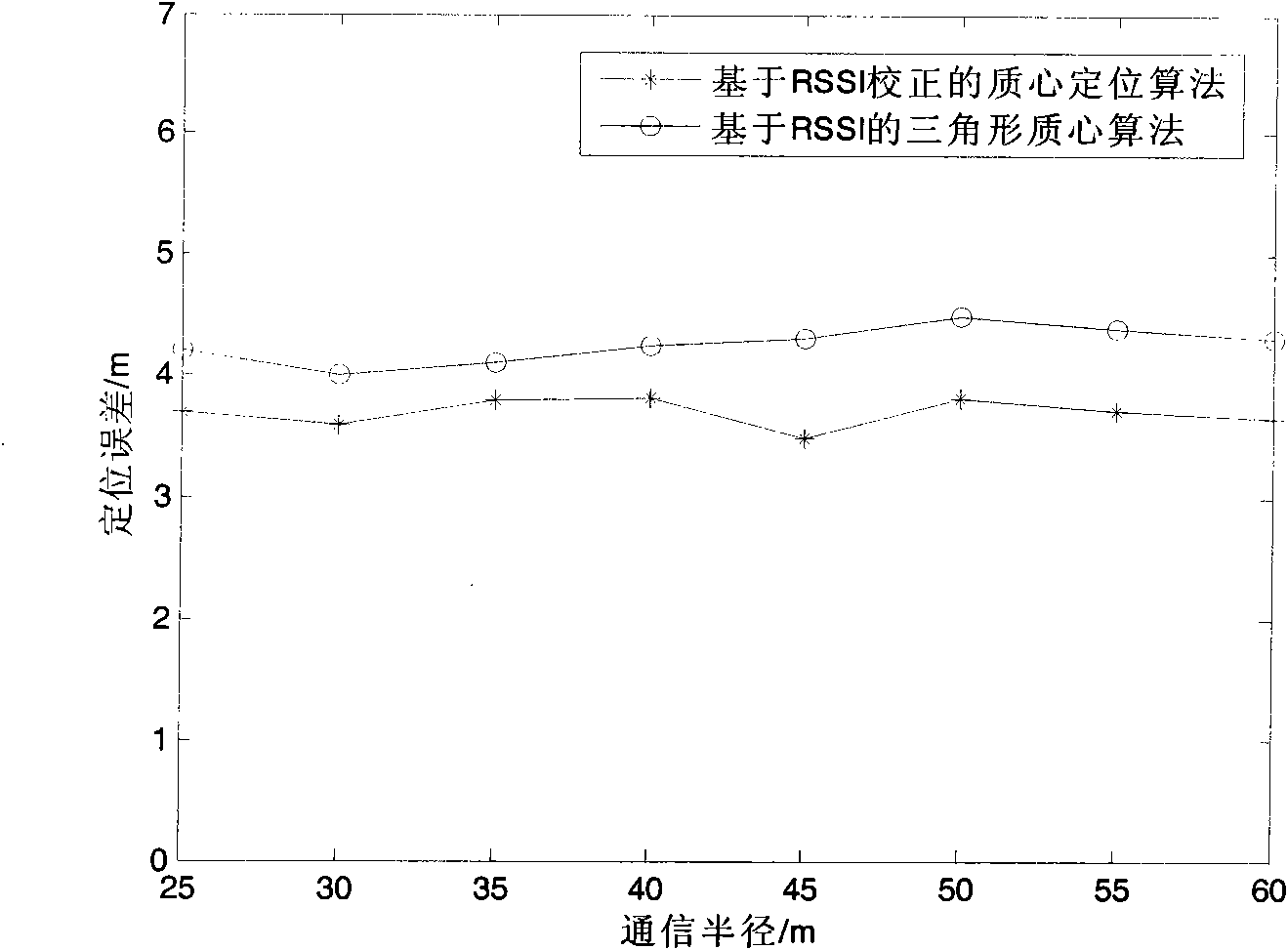

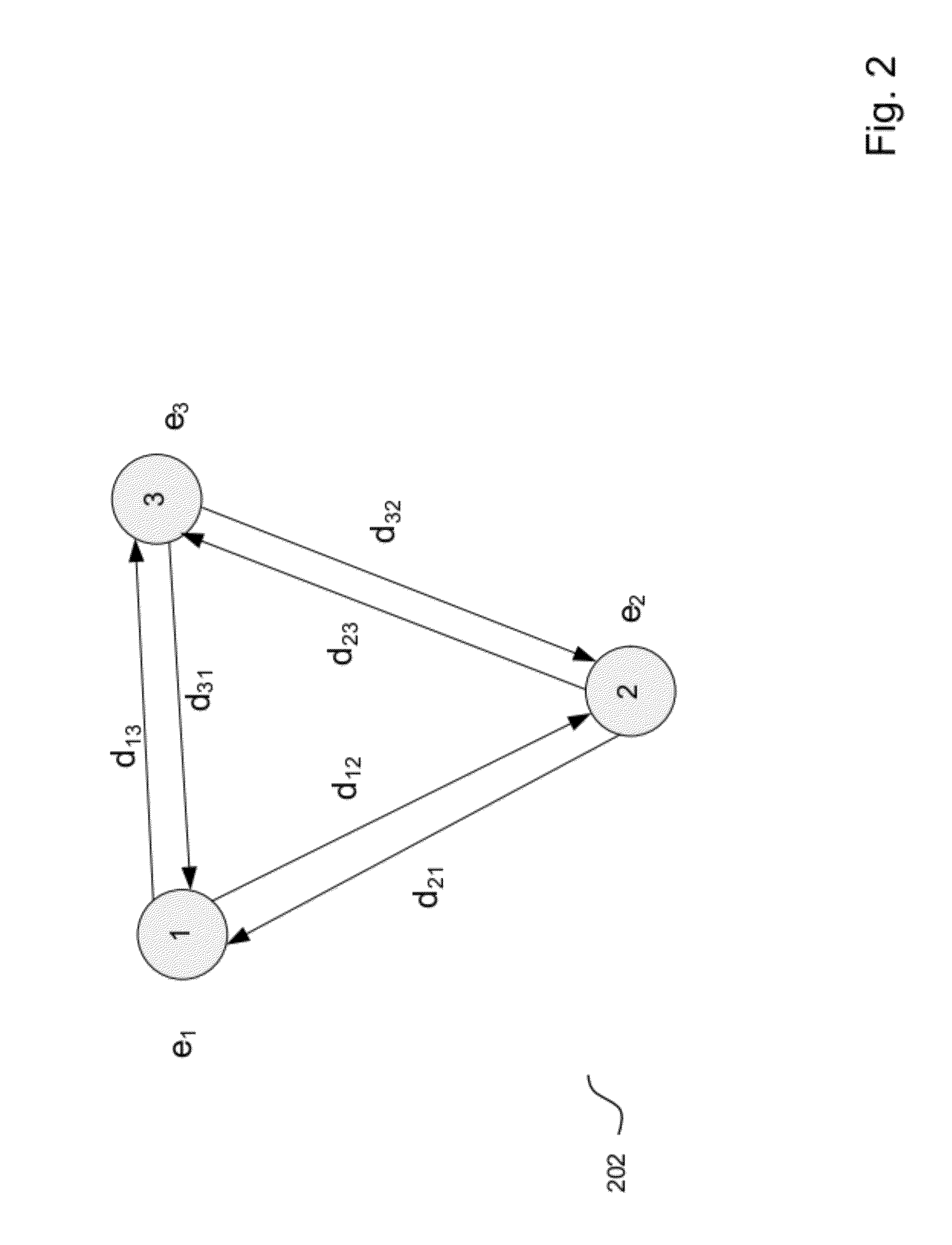

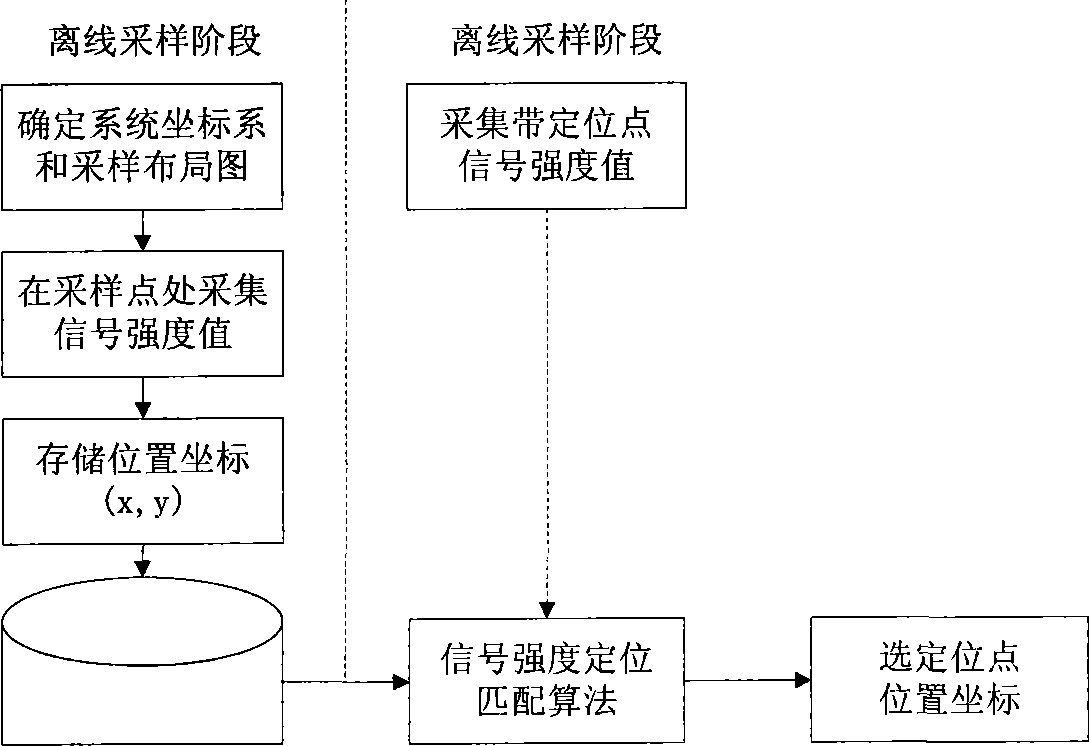

Centroid location algorithm based on RSSI (Received Signal Strength Indication) correction for wireless sensor network

InactiveCN102123495AReduce measurement errorHigh positioning accuracyTransmission monitoringWireless communicationObservational errorWireless mesh network

The invention discloses a centroid location algorithm based on RSSI (Received Signal Strength Indication) correction for a wireless sensor network, and the centroid location algorithm comprises: (1) anchor nodes periodically broadcast information around, wherein the information contains respective node ID (identity) and coordinates; and ordinary nodes average the RSSI of the same anchor node after receiving the information; (2) the ordinary nodes do not receive new information any more after collecting the information of n anchor nodes, wherein n is greater than 3 and less than or equal to 100; the ordinary nodes sort the anchor nodes according to the RSSI from strong to weak and establish mapping of the RSSI value and the distance from the nodes to the anchor nodes; (3) the anchor nodes with the RSSI value greater than or equal to minus 93dbm and less than or equal to minus 113dbm is selected for self-location calculation; and (4) the calculated unknown node coordinate set is aggregated and averaged to obtain the unknown node coordinates. In the invention, the point-to-point distance between the nodes is measured by correcting an RSSI ranging technology, and a triangle centroid location algorithm is adopted for location, thus the measurement error of the RSSI is reduced. Compared with the triangle centroid location algorithm based on the RSSI, the centroid location algorithm provided by the invention has the advantage that the location accuracy is greatly improved.

Owner:SHANDONG UNIV

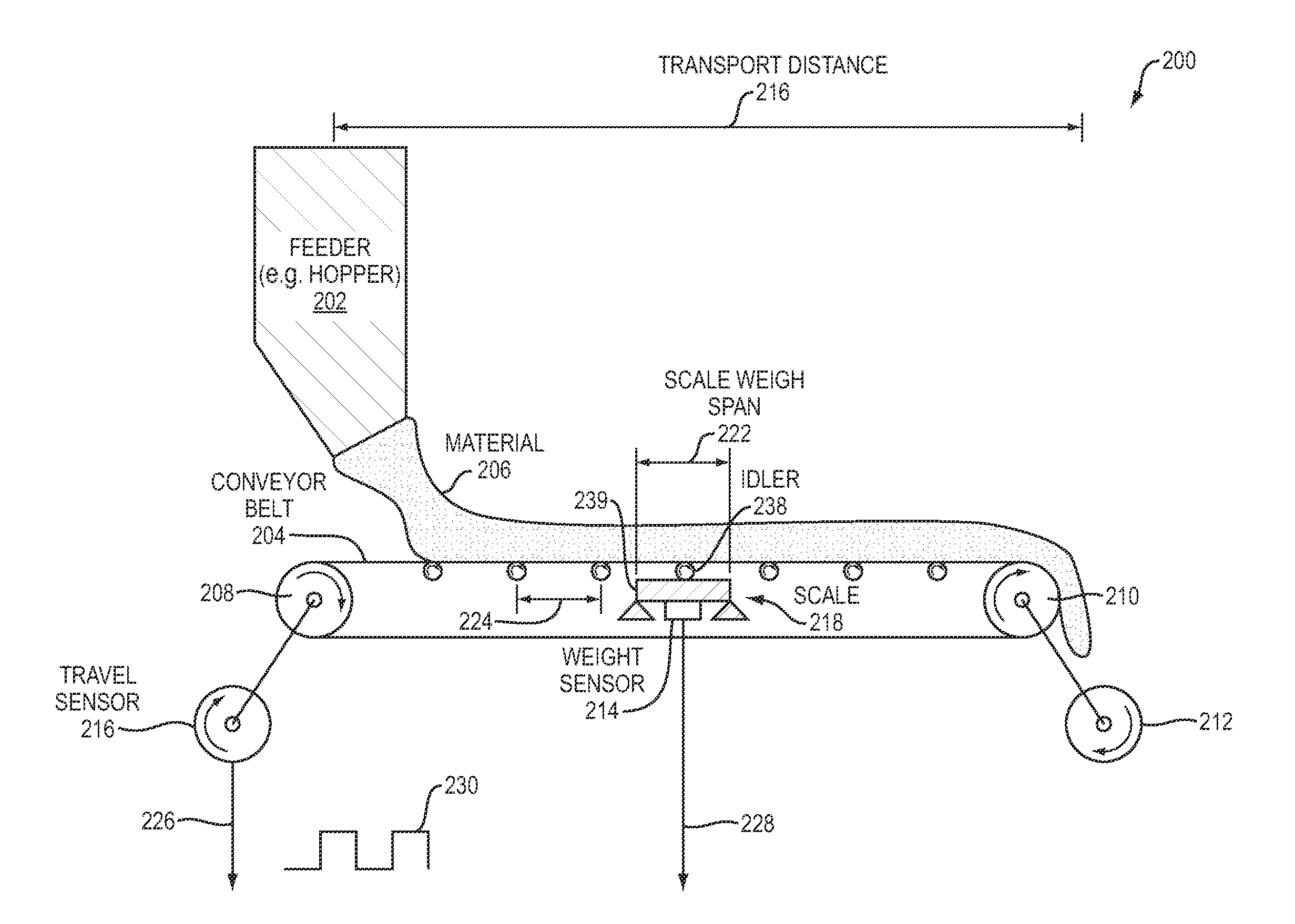

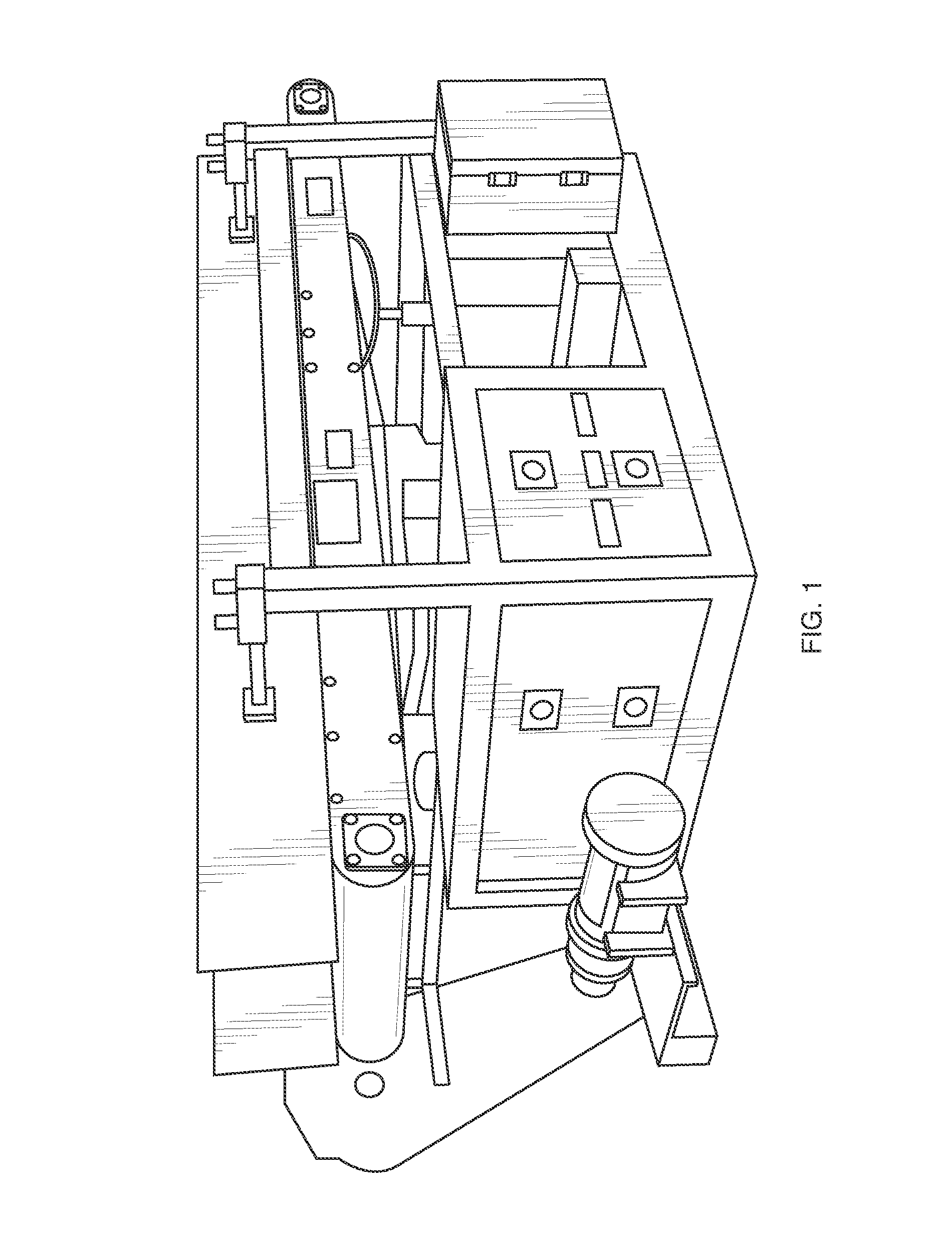

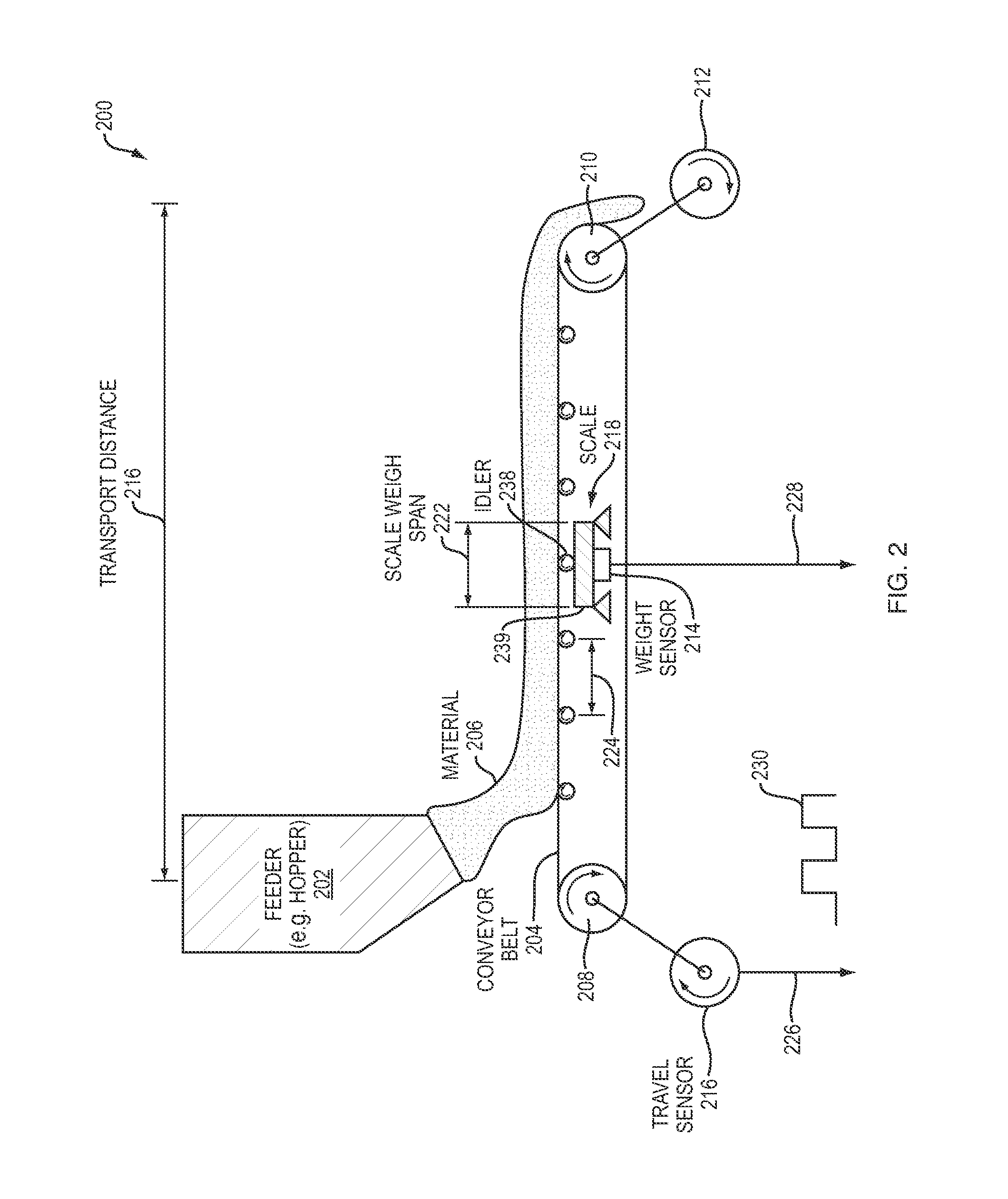

System and methods for belt conveyor weighing

ActiveUS20140062709A1Mass flow measurement devicesWeighing apparatus for materials with special property/formObservational errorSnack food

Imperfections in conveyor belting and its supporting elements can adversely affect weighing accuracy of belt scales, particularly when weighing and / or metering low density materials, such as those encountered in the snack food industry. A system and methods for a belt conveyor according to an embodiment of the present invention provide simultaneous benefits of both short and long weigh spans. According to an embodiment of the present invention, a virtual weigh span may be programmably set to adjust for variations in the belt conveyor weighing system. Advantages include, higher degrees of accuracy and calibration to account for changes in the belt or belting system over time using non-mechanical adjustments. In addition, weight measurement error producing effects, some that may not be particularly known, may be reduced.

Owner:HYER IND

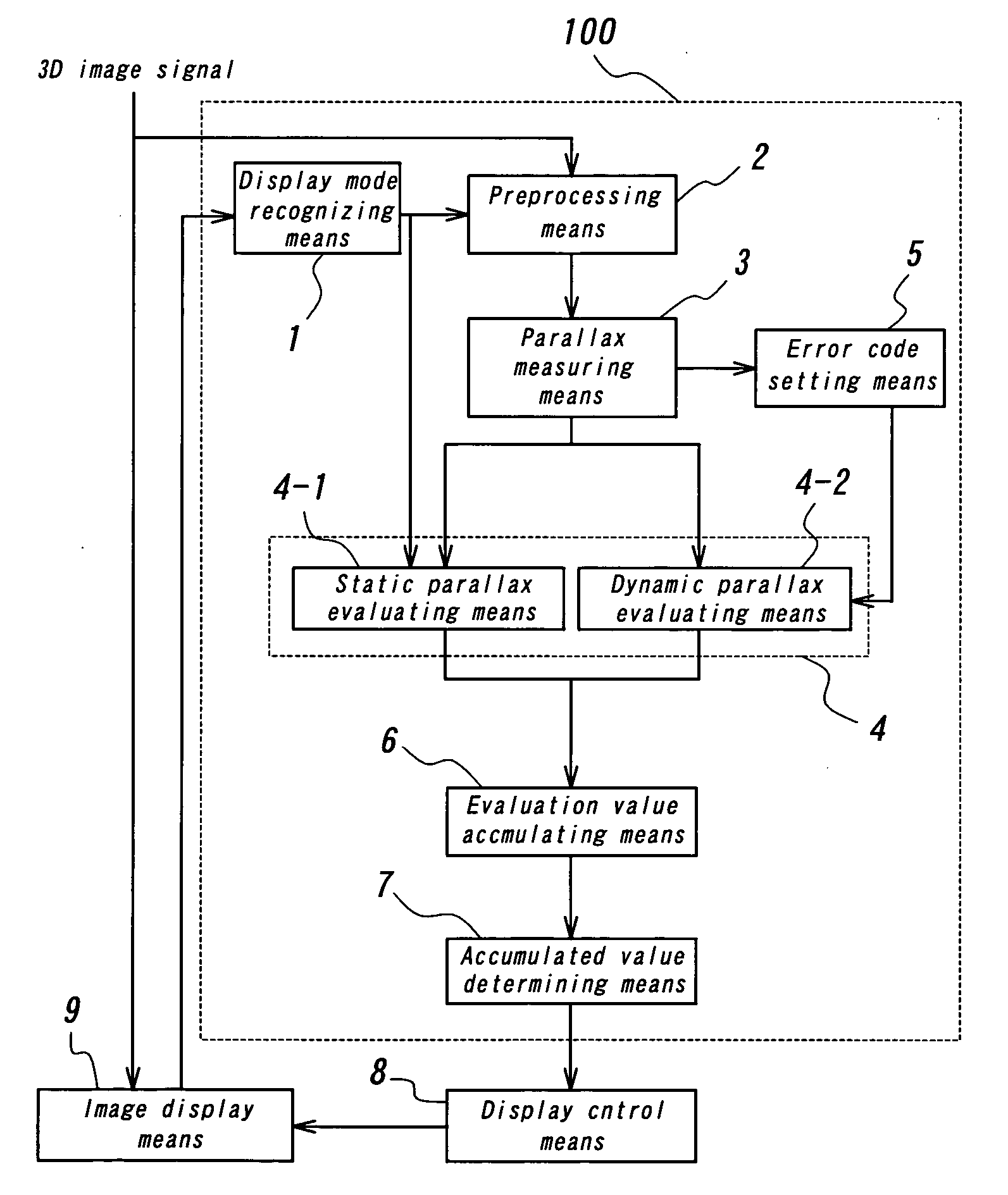

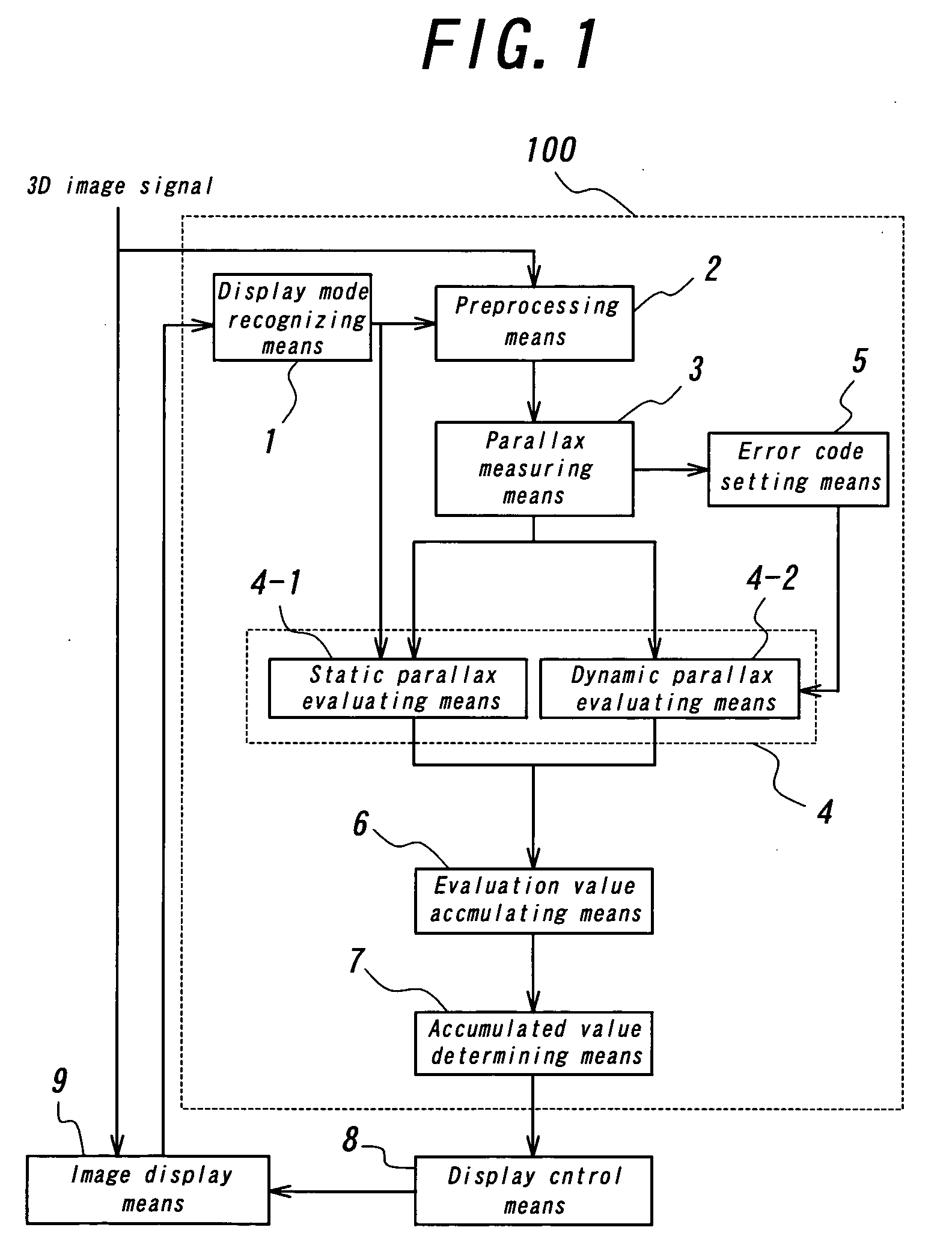

Three-dimensional image evaluation unit and display device using the unit

InactiveUS20040208357A1Quick changeKeep for a long timeImage enhancementImage analysisObservational errorParallax

A three-dimensional image evaluation unit (100) for evaluating an input image. The parallax statistic is calculated by measuring the parallax included in the input image by a parallax measuring means (3), the static parallax evaluation value for the calculated parallax statistic and / or a dynamic parallax evaluation value for a temporal change in the parallax statistic is determined by a static parallax evaluating means (4-1) and / or a dynamic parallax evaluating means (4-2) of an evaluating means (4) to evaluate parallax information on the image. An abrupt change in the parallax can be evaluated thereby, and countermeasures against errors in measurement and noise of the image can be taken, so that parallax information on the image can be suitably evaluated.

Owner:OLYMPUS CORP

Vision measuring method for spaced round geometrical parameters

InactiveCN1566900AHigh measurement accuracyHigh degree of automationTelevision system detailsColor television detailsObservational errorThree-dimensional space

This invention belongs to measuring technique field and relates to improvement for space round geometry parameters non-contact measuring method. This invention can calculate eh real three dimensional coordinates of round fringe by use of polar line restriction and calculate space round geometry parameters based on space round optimal fit. This invention reduces the measuring error caused by shape distortion of space round perspective projecting and increases the measuring accuracy of round geometry parameters based on the optical method. When the surface of space round to be measured is angle more than fifty degrees, the repeatability accuracy 3sigma of space round geometry center is superior to minus or plus 0.01 mm.

Owner:HUANGSHI BANGKE TECH CO LTD

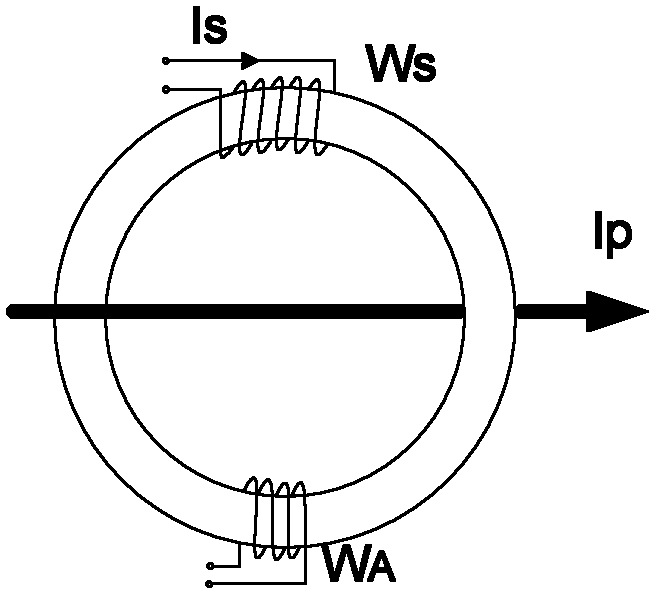

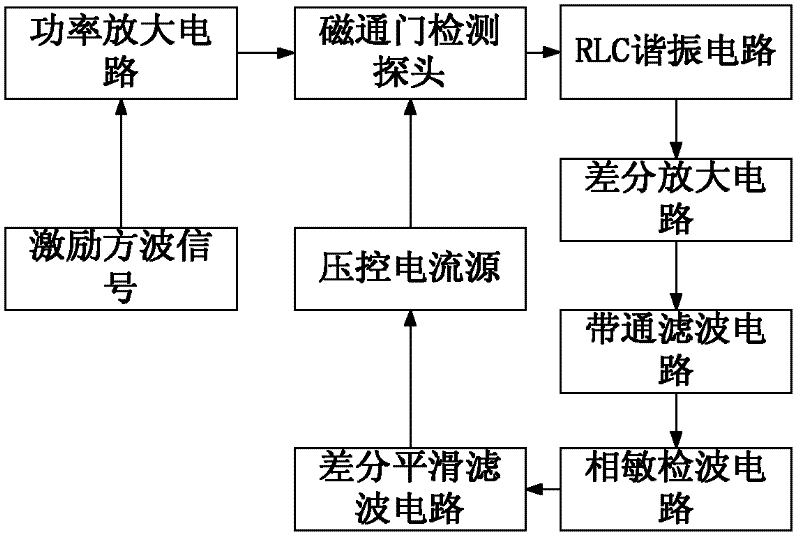

Double-shaft fluxgate current sensor

InactiveCN102401853AHighlight substantive featuresReduce nonlinear errorCurrent/voltage measurementVoltage/current isolationBandpass filteringObservational error

The invention discloses a double-shaft fluxgate current sensor of the invention, relating to a device for measuring the current, comprising a fluxgate detecting probe, a zero flux current transformer and a signal processing circuit, wherein the fluxgate detecting probe is composed of two inner annular magnetic cores a and b, an excitation winding and an induction winding, wherein the fluxgate detecting probe is composed of an outer annular magnetic core and a secondary side winding; two inner annular magnetic cores a and b and the outer annular magnetic core are wound via a feedback winding; the signal processing circuit includes an exciting circuit and a detecting circuit, wherein the exciting circuit includes an exciting signal generating circuit, a voltage comparer and a power amplifying circuit; the detecting circuit includes an RLC resonant circuit, a differential amplifier circuit, a bandpass filtering circuit, a phase sensitive detecting circuit, a differential smooth filteringcircuit, a feedback circuit, a voltage controlled current source and a sampling resistor. The invention eliminates the measurement error of the current fluxgate current sensor by means of a closed loop formed by the feedback winding.

Owner:HEBEI UNIV OF TECH

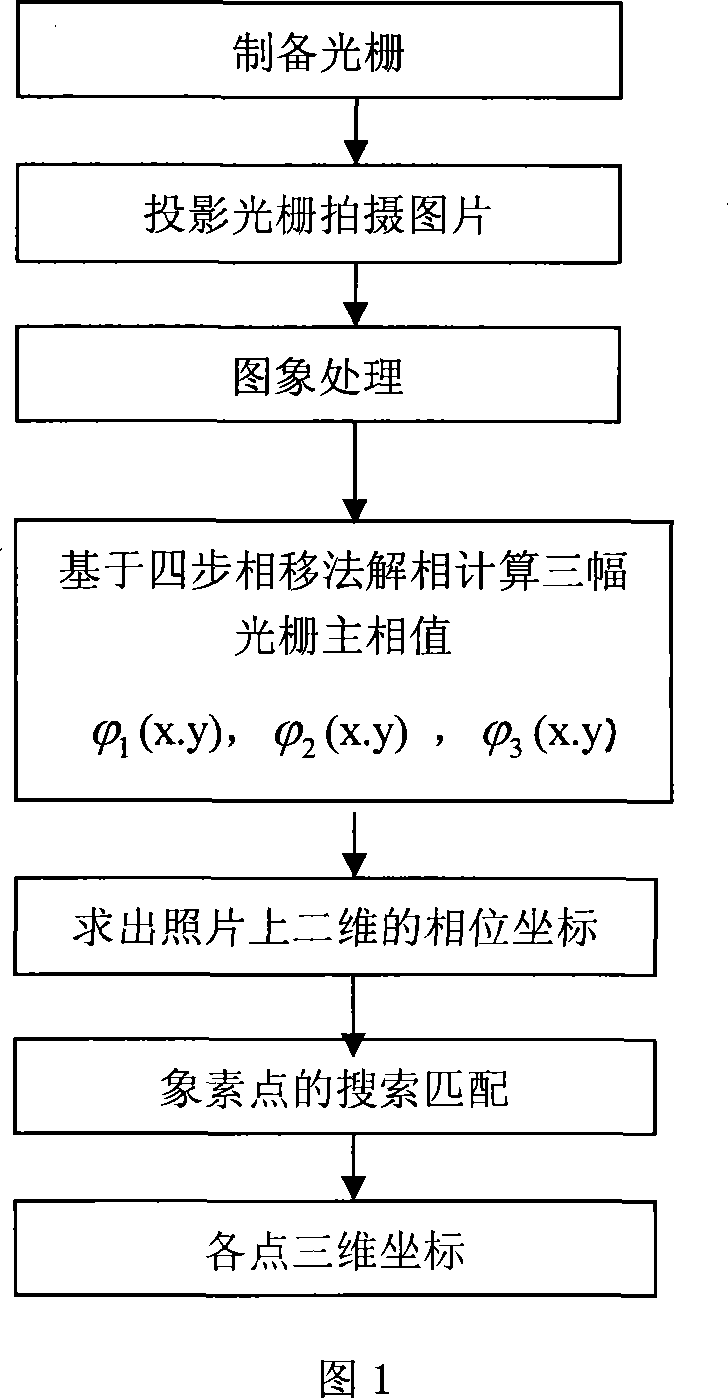

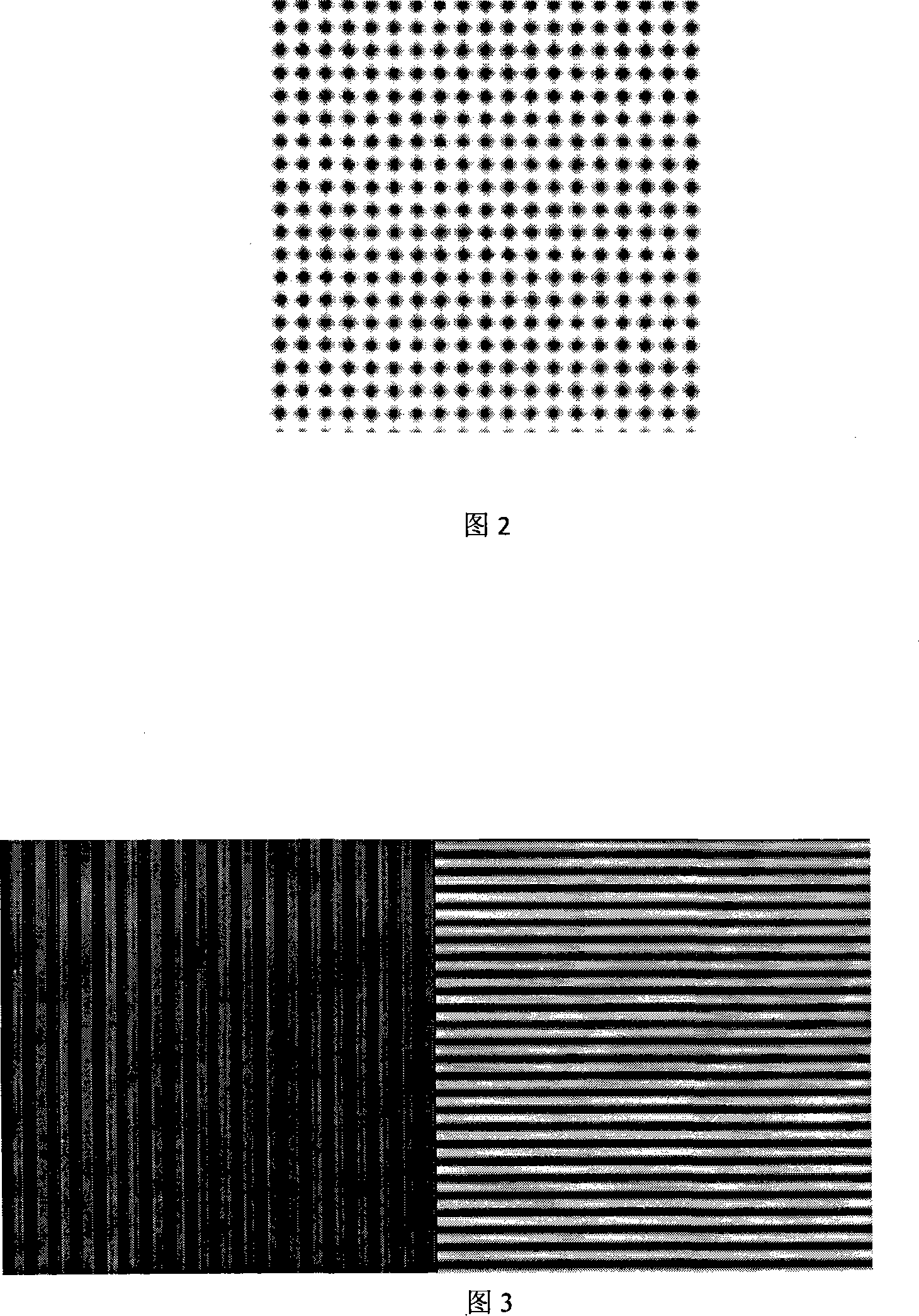

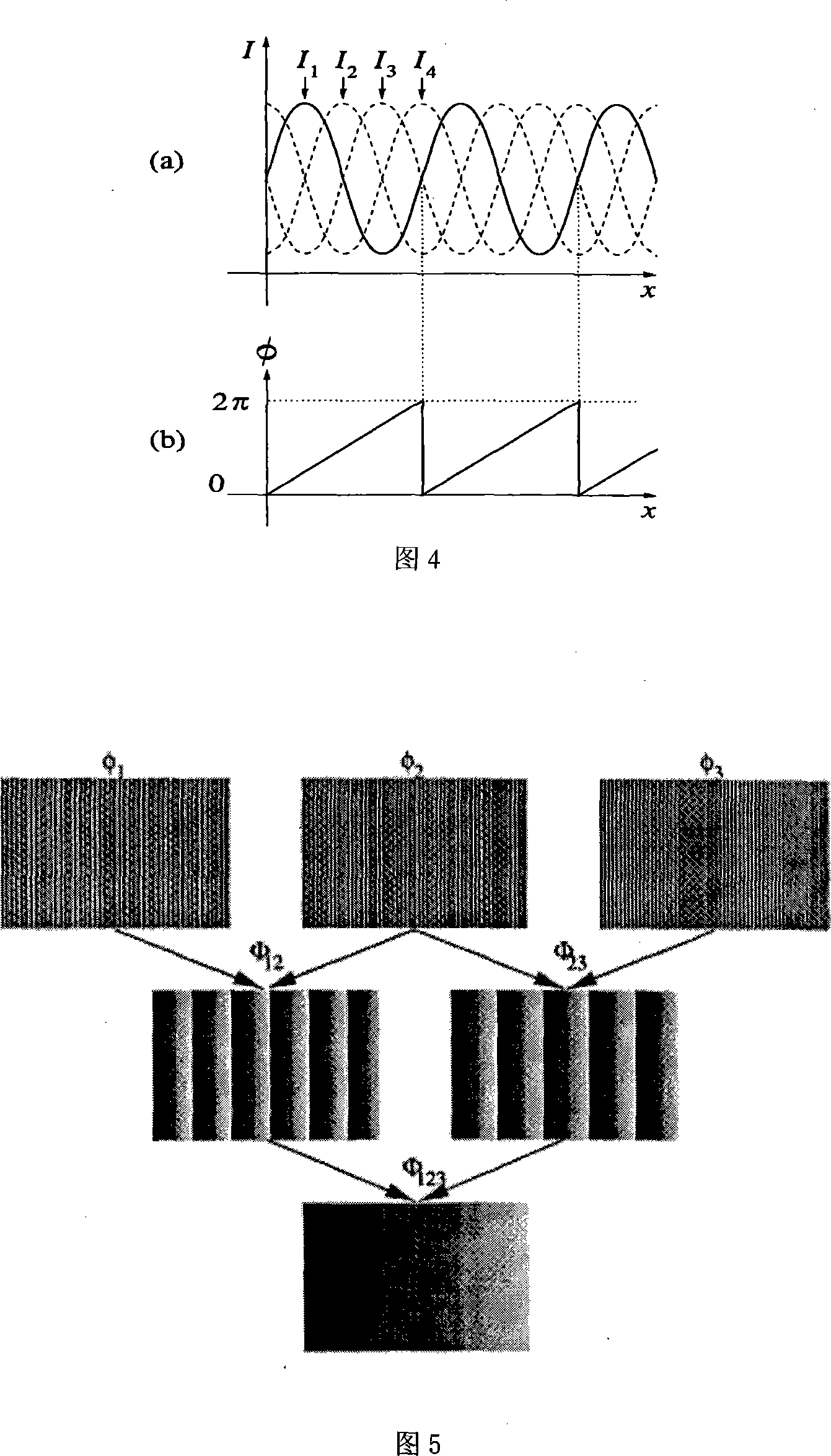

Two-diensional three-frequency dephase measuring method base on color structural light

InactiveCN101089547AAvoid measurement errorsOvercoming Coding FlawsUsing optical meansPicture interpretationObservational errorGrating

A 2-D three-frequency diphase measuring method based on colored- structure light includes preparing three gratings by complexing different three primary color sine light with three the same frequencies, projecting said gratings on object to be measured, utilizing two the same CCD vide cameras to make shooting for obtaining 24 pieces of pictures, dephasing said pictures to obtain phase values at X and Y direction on each pixel pf each picture and matching two phase values for calculating out 3-D coordinate of each point.

Owner:HUAZHONG UNIV OF SCI & TECH

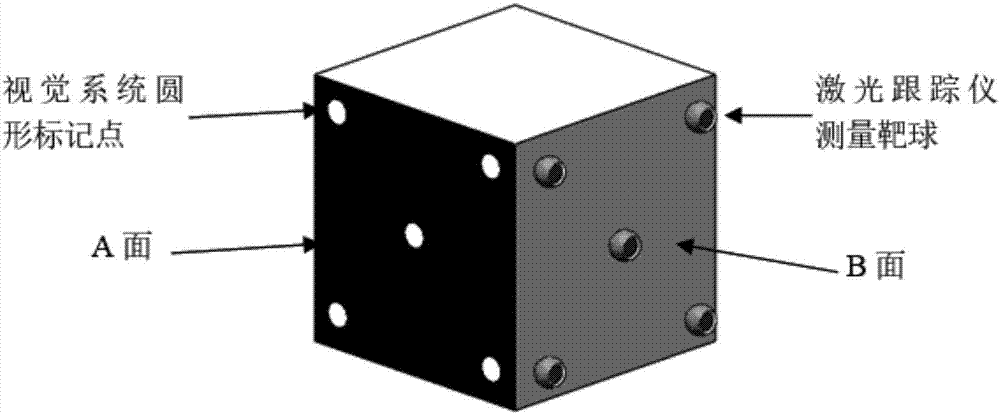

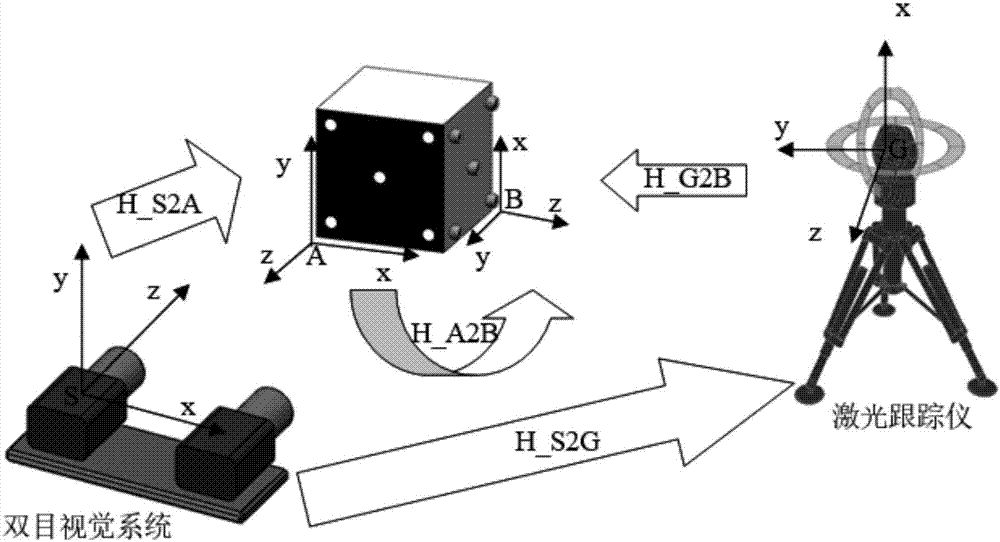

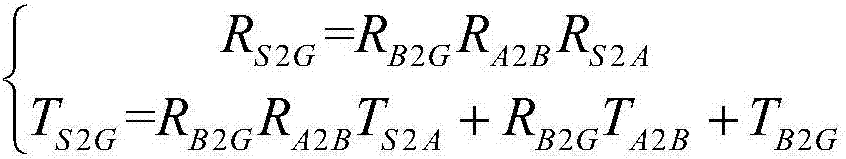

Global calibration method based on binocular visual system and laser tracker measurement system

ActiveCN107883870AReduce difficultyAvoid measurement errorsUsing optical meansObservational errorCalibration result

The invention discloses a global calibration method based on a binocular visual system and a laser tracker measurement system. Firstly a rigid stereoscopic target of which the A side is provided withbinocular visual system circular mark points and the B side is provided with laser tracker measurement target balls is manufactured; then the A side coordinate system and the B side coordinate systemof the stereoscopic target are established; the transformation relation between the A side coordinate system of the stereoscopic target and the left camera coordinate system of the binocular visual system and the transformation relation between the B side coordinate system of the stereoscopic target and the laser tracker world coordinate system are solved; the transformation relation between the Aside coordinate system and the B side coordinate system is solved according to the transformation relation solved in the last step; and finally the transformation relation between the left camera coordinate system of the global calibration binocular visual system and the laser tracker world coordinate system is solved. The difficulty of directly processing and maintaining the high-precision stereoscopic target can be reduced so that the measurement error caused by direct measurement can be solved and the more accurate calibration result can be acquired.

Owner:四川雷得兴业信息科技有限公司

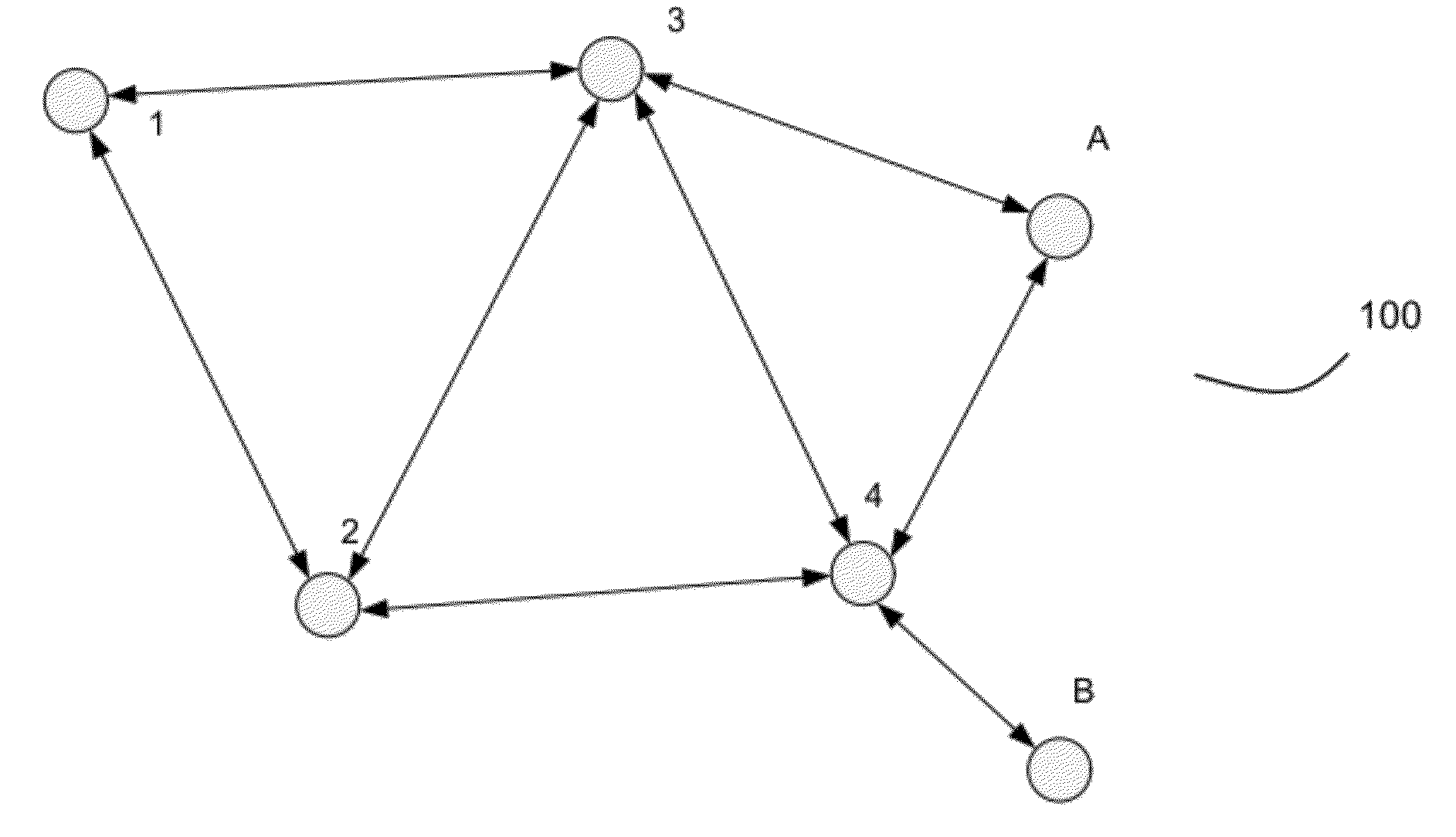

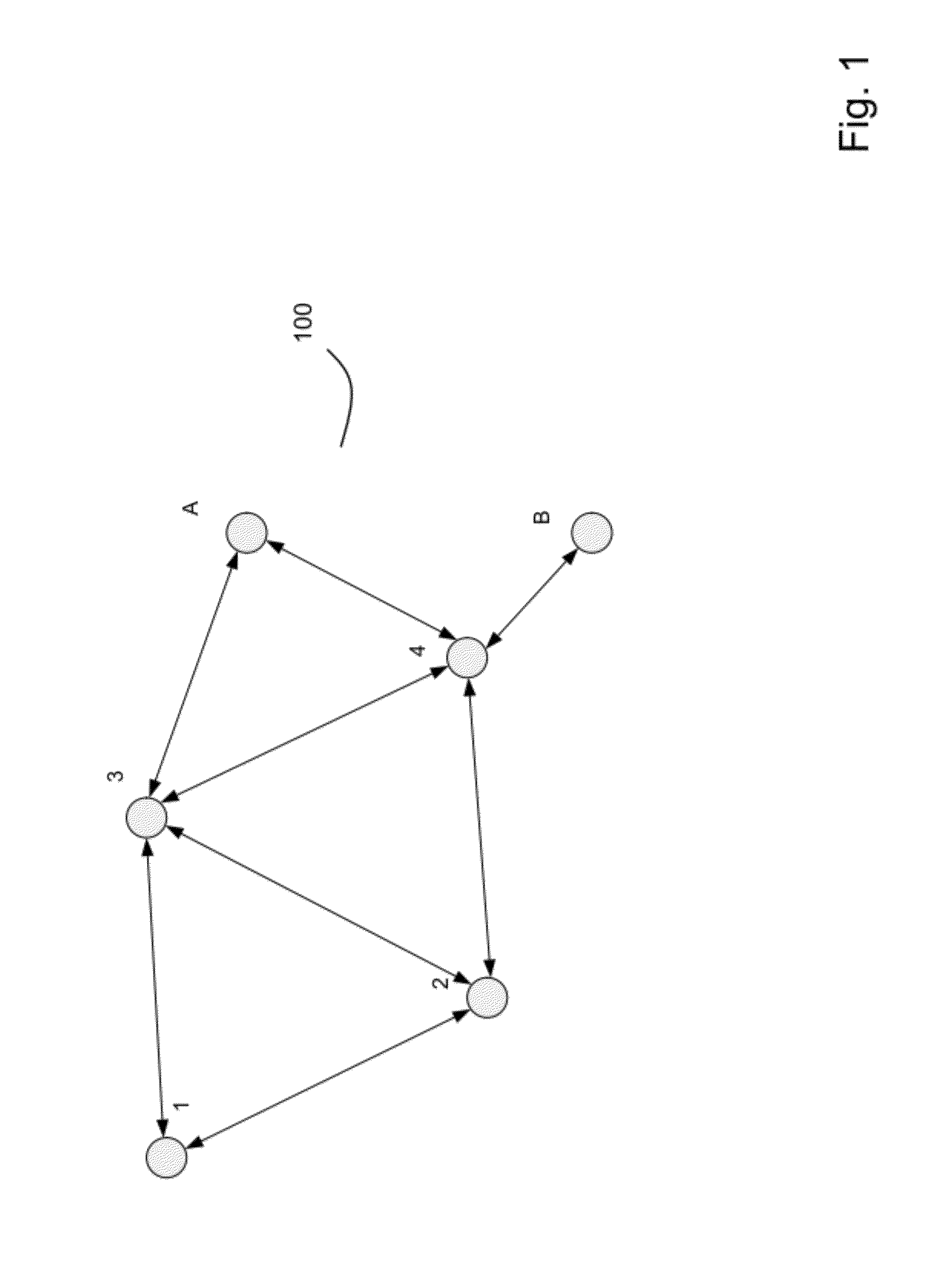

Synchronization of time in a mobile ad-hoc network

ActiveUS20120127977A1Reduce overheadEfficient communicationSynchronisation arrangementNetwork topologiesObservational errorSynchronous network

Methods and systems are disclosed herein for synchronizing network time in a mobile ad-hoc network (MANET). Each node in the MANET may be synchronized with all of its neighbors for effective communications. More specifically, a local timing reference may be adjusted according to measured errors in incoming control packets so that time slotted transmissions can be scheduled without collisions with other nodes. The method and system is a low overhead protocol that only requires a small amount of data attached to each scheduled transmission avoiding the requirement for separate messaging. This may reduce the overhead of maintaining the MANET providing additional efficiency and robustness.

Owner:POWERWAVE COGNITION INC

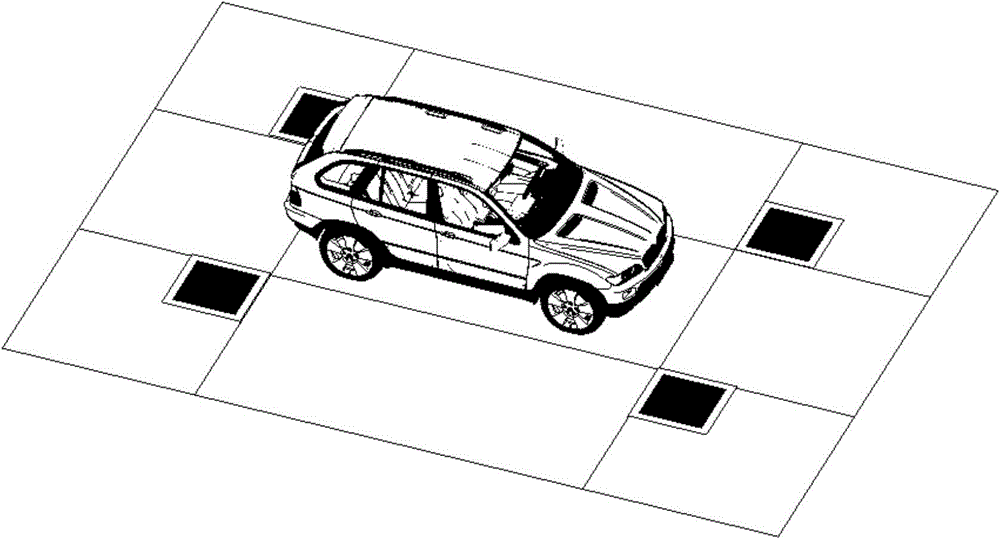

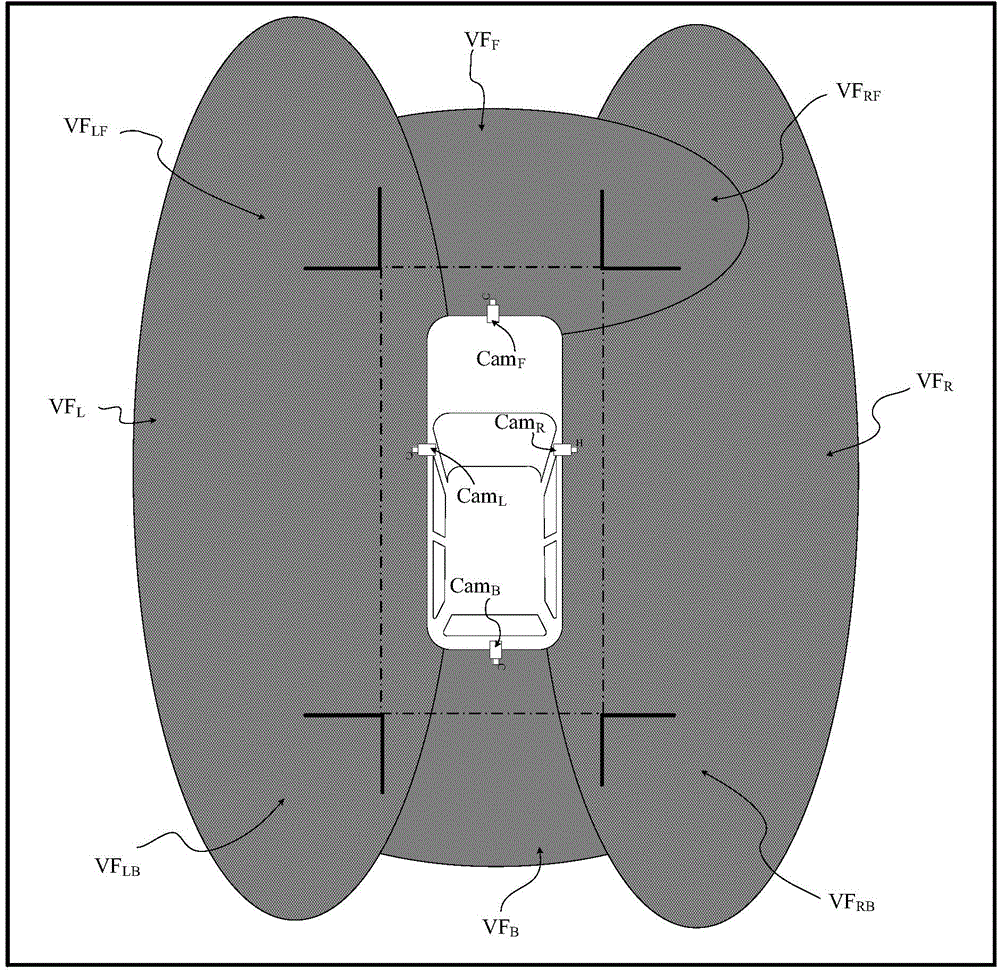

Parameter calibration method for cameras of vehicle-mounted all-round view system

Provided is a parameter calibration method for cameras of a vehicle-mounted all-round view system. When internal parameters and external parameters of the cameras of the vehicle-mounted all-round view system are calibrated, a set of three-dimensional calibration markers are adopted and comprise a plurality of characteristic points which can be recognized easily from images and are provided with given three-dimensional coordinates; when a vehicle to be calibrated is parked in a calibration area, automatic image data collection is carried out through manual work or through external trigger signals, characteristic point extraction is carried out on the collected images, each camera is calibrated corresponding to the three-dimensional coordinate of each characteristic point, and errors of locating are lowered through the processes such as parameter optimization. According to the parameter calibration method for the cameras of the vehicle-mounted all-round view system, through the three-dimensional calibration markers, all areas of the cameras can be covered as much as possible, and the influence of camera distortion on the measuring errors in the calibration process is small; compared with a previous plane two-dimensional calibration board, a three-dimensional calibration board is accurate in selected characteristic point position, clear in imaging and low in error value, and image stitching precision is greatly improved.

Owner:宁波舜宇智行传感技术有限公司

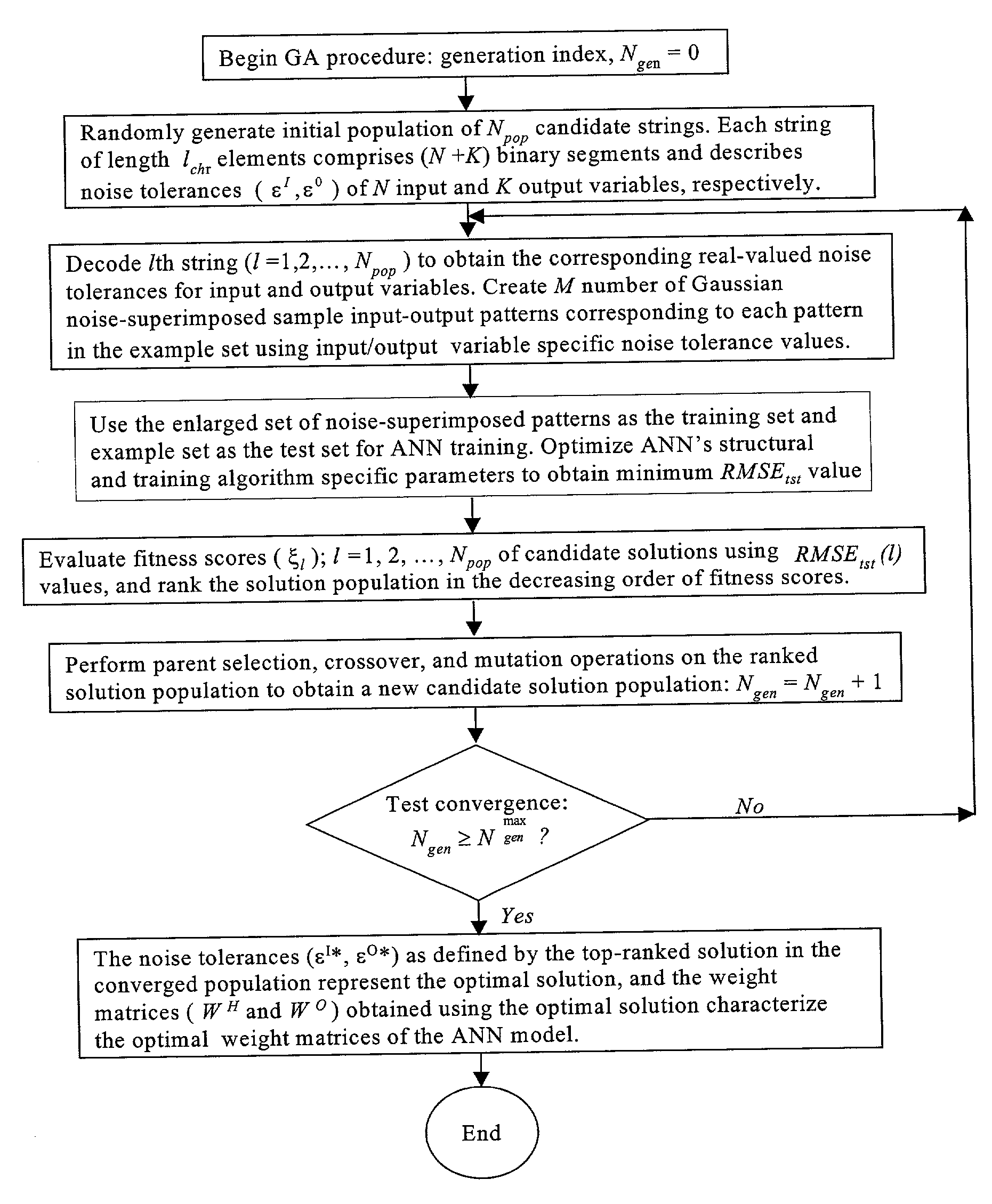

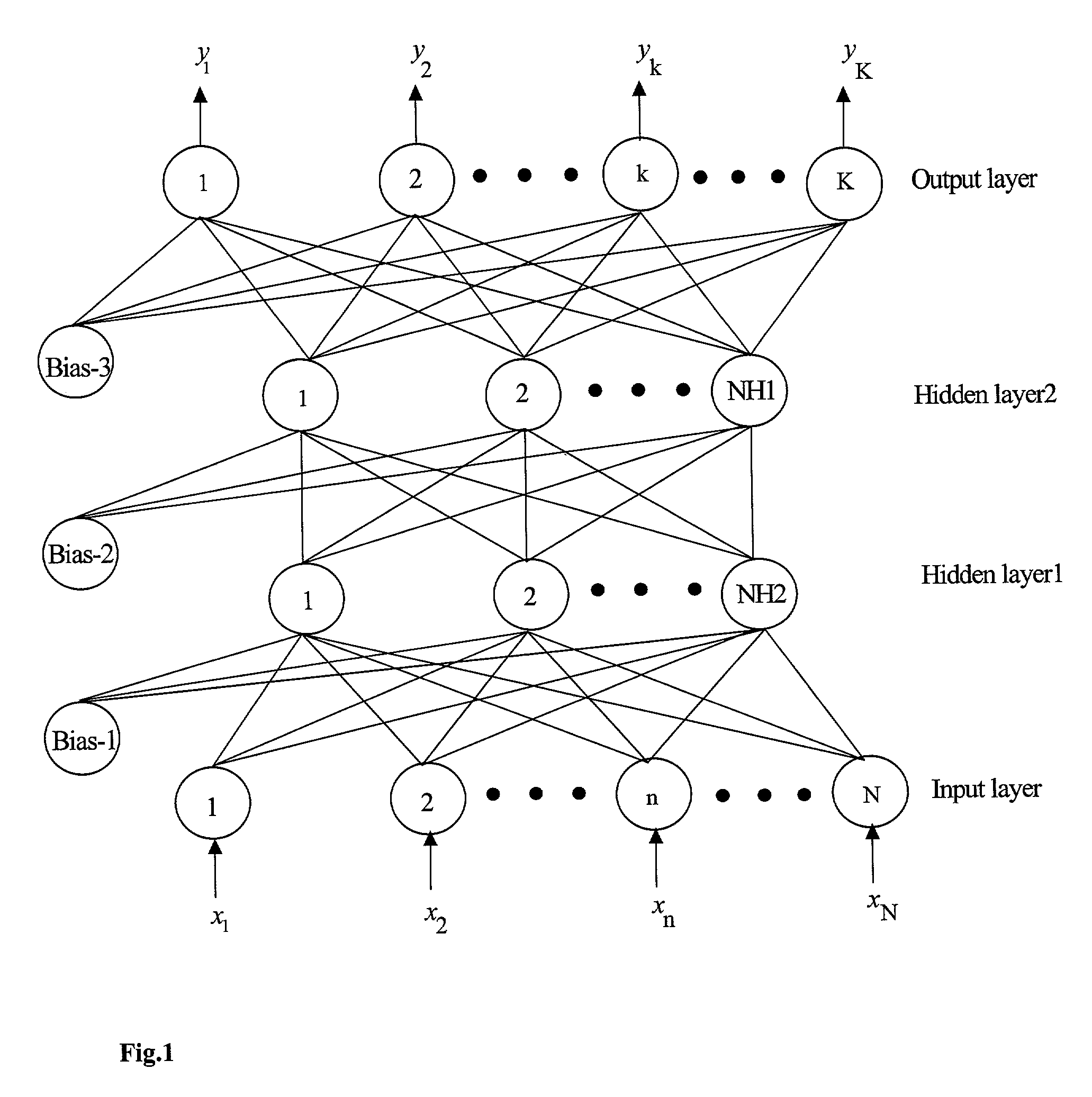

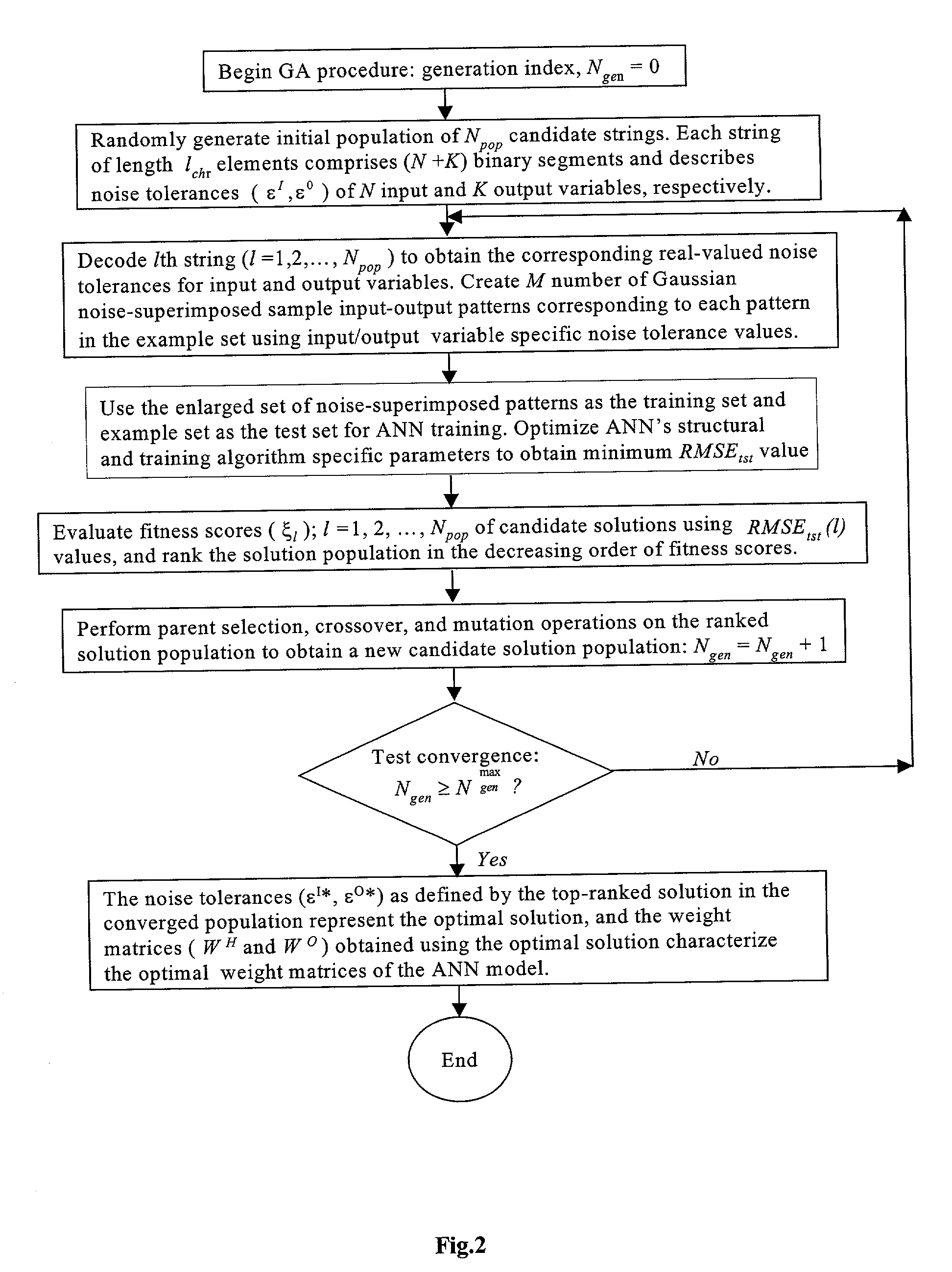

Performance of artificial neural network models in the presence of instrumental noise and measurement errors

ActiveUS20030191728A1Improve accuracy performanceImprove generalization performanceGenetic modelsDigital computer detailsObservational errorData set

A method is described for improving the prediction accuracy and generalization performance of artificial neural network models in presence of input-output example data containing instrumental noise and / or measurement errors, the presence of noise and / or errors in the input-output example data used for training the network models create difficulties in learning accurately the nonlinear relationships existing between the inputs and the outputs, to effectively learn the noisy relationships, the methodology envisages creation of a large-sized noise-superimposed sample input-output dataset using computer simulations, here, a specific amount of Gaussian noise is added to each input / output variable in the example set and the enlarged sample data set created thereby is used as the training set for constructing the artificial neural network model, the amount of noise to be added is specific to an input / output variable and its optimal value is determined using a stochastic search and optimization technique, namely, genetic algorithms, the network trained on the noise-superimposed enlarged training set shows significant improvements in its prediction accuracy and generalization performance, the invented methodology is illustrated by its successful application to the example data comprising instrumental errors and / or measurement noise from an industrial polymerization reactor and a continuous stirred tank reactor (CSTR).

Owner:COUNCIL OF SCI & IND RES

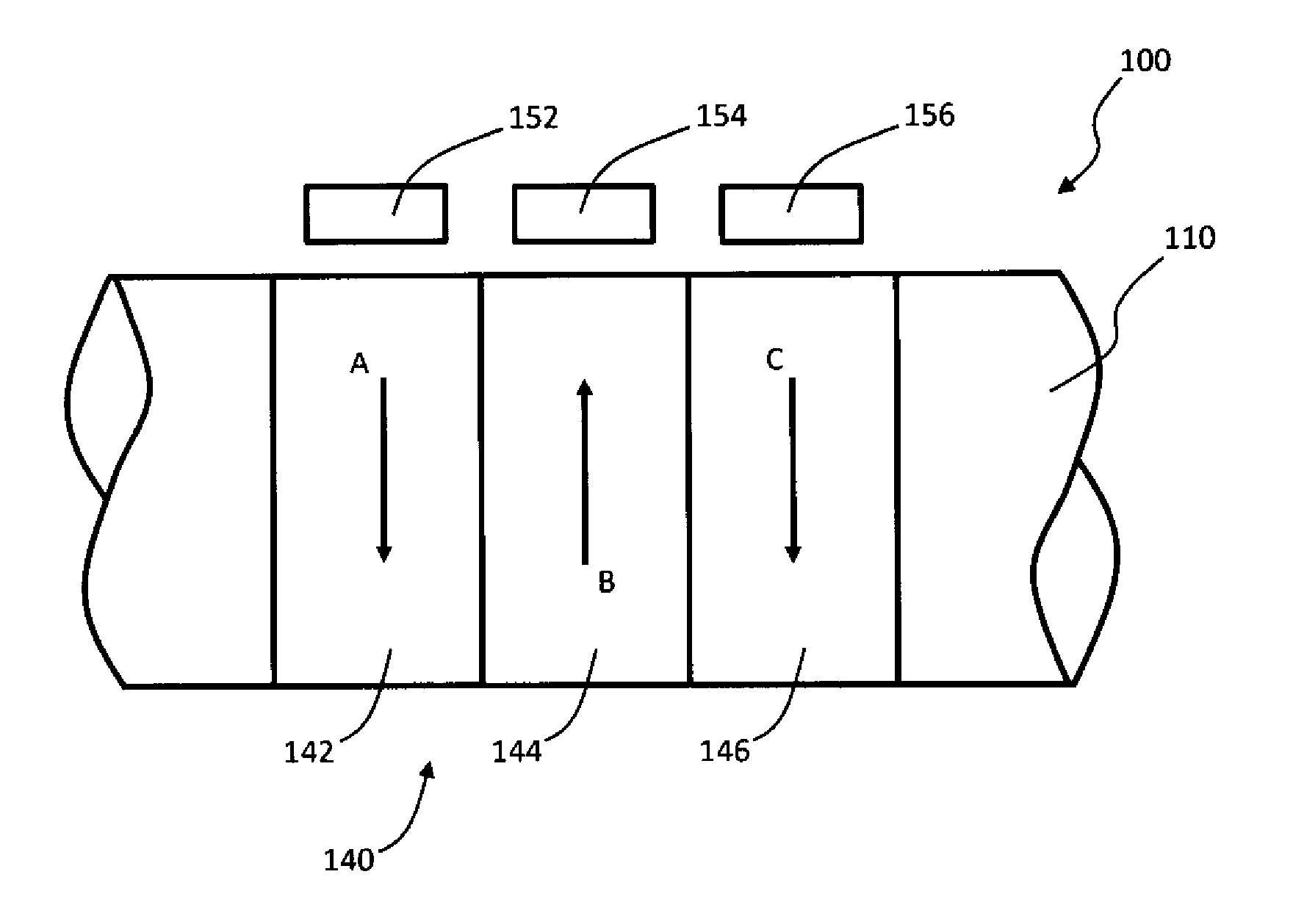

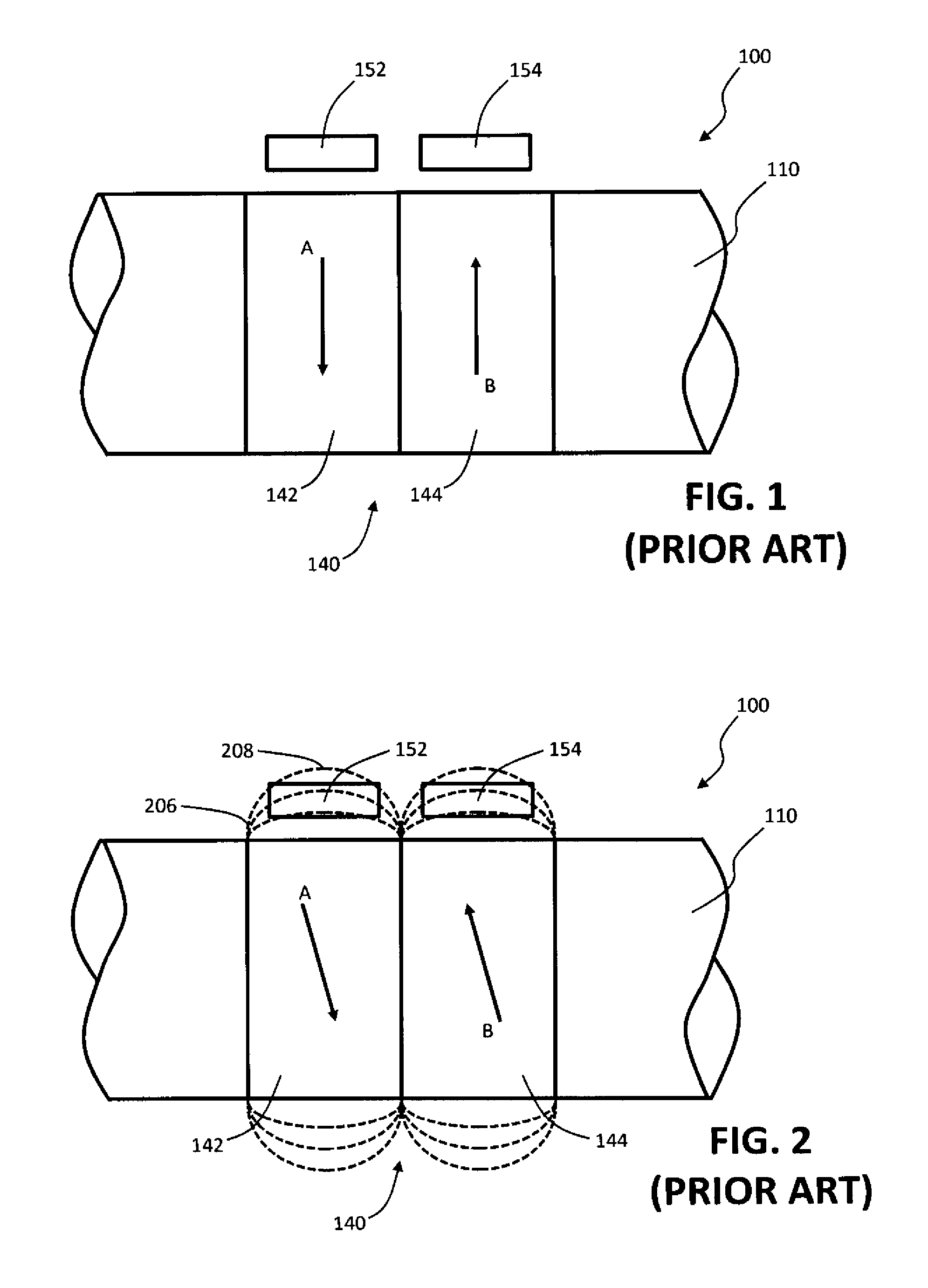

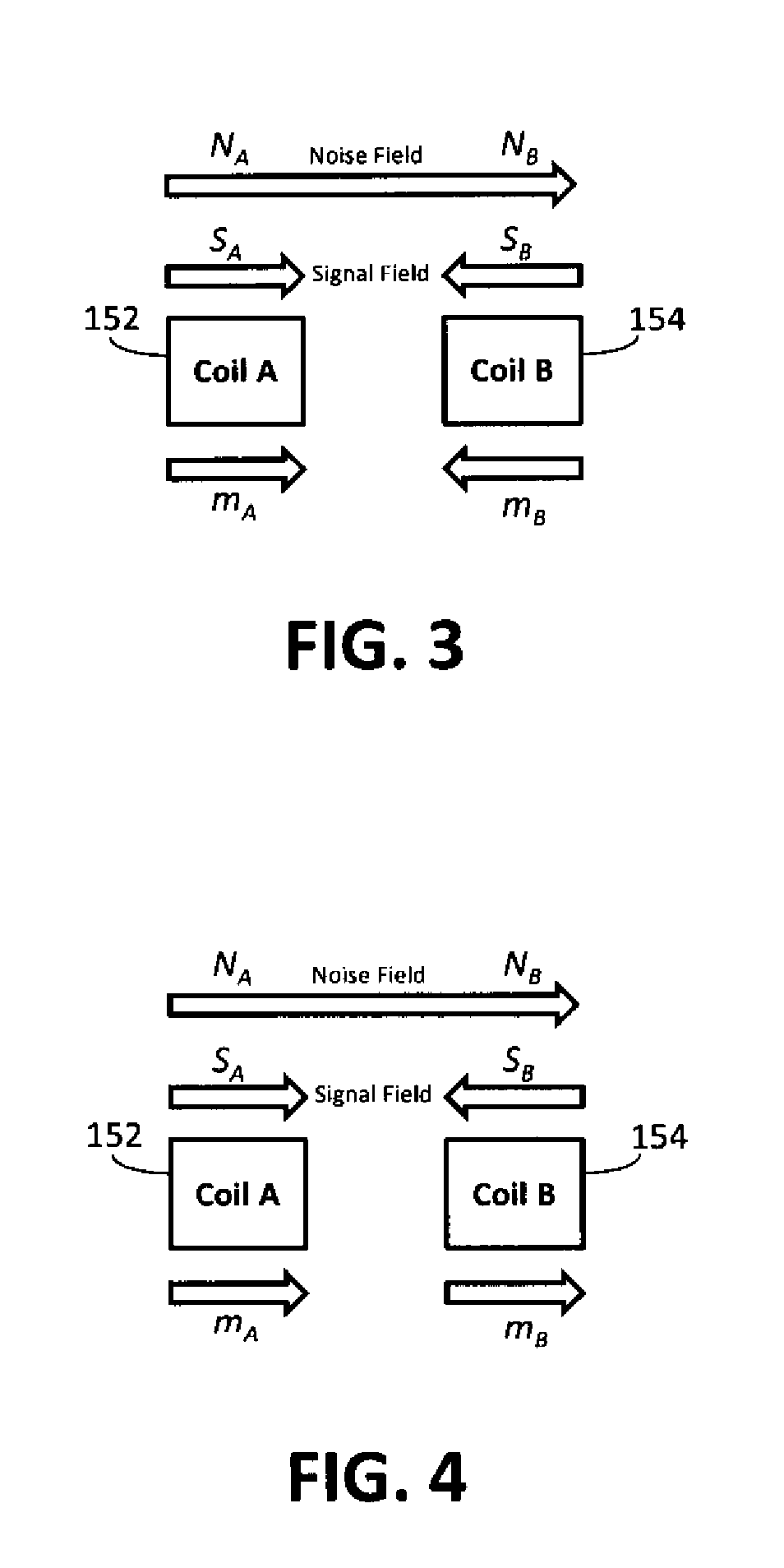

System and method for detecting magnetic noise by applying a switching function to magnetic field sensing coils

ActiveUS8893562B2Accurate measurementReduce spacingForce measurementWork measurementObservational errorNoise detection

A torque sensing device for measuring the torque applied to a rotatable shaft, and also measuring the magnetic field noise affecting the device. The device incorporates a switching function thereby enabling the device to operate in a common signal detection mode and a differential noise detection mode. The device is capable of determining the torque applied to the rotatable shaft based upon output signals obtained from magnetic field sensors operating in both the common signal detection mode and the differential noise detection mode. The device is capable of accurately measuring a torque induced magnetic field and is capable of canceling measurement error resulting from noise induced magnetic fields.

Owner:METHODE ELETRONICS INC

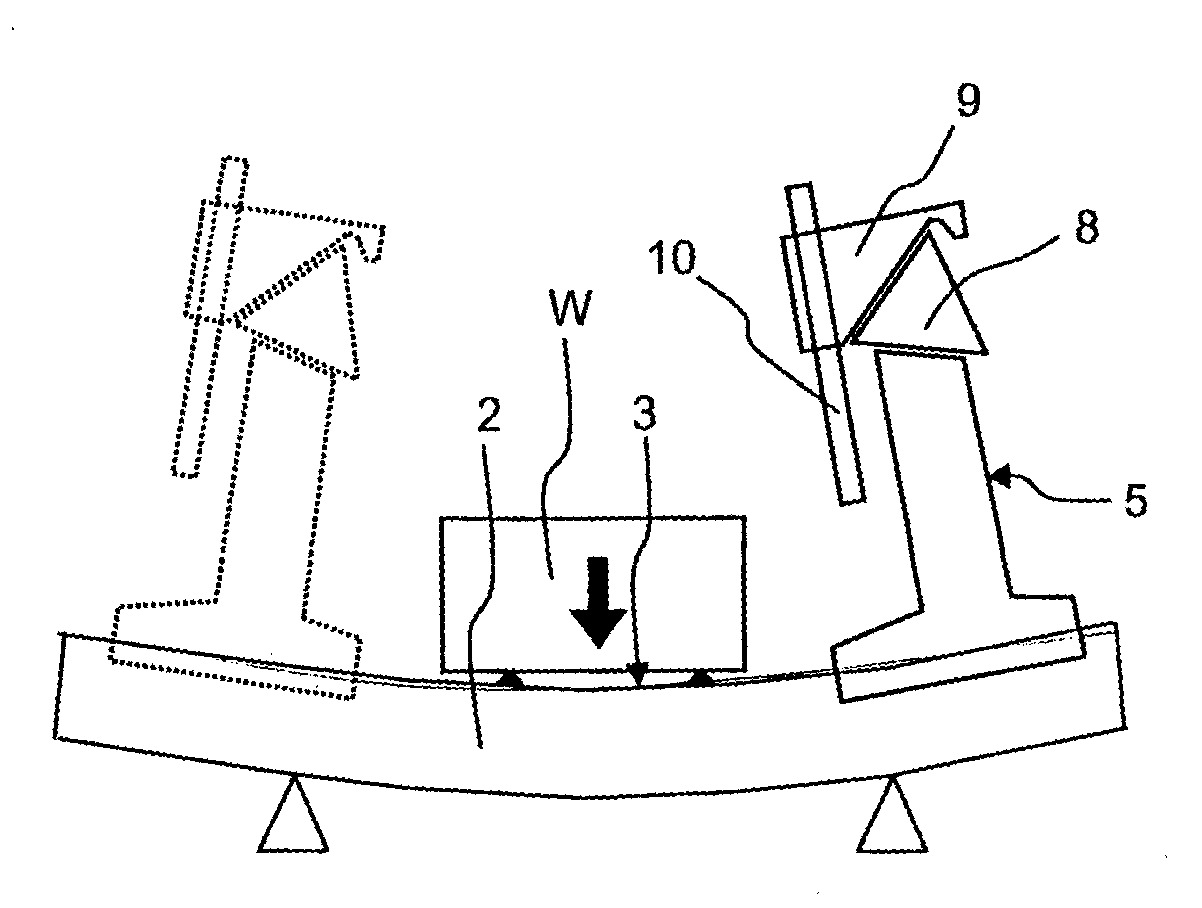

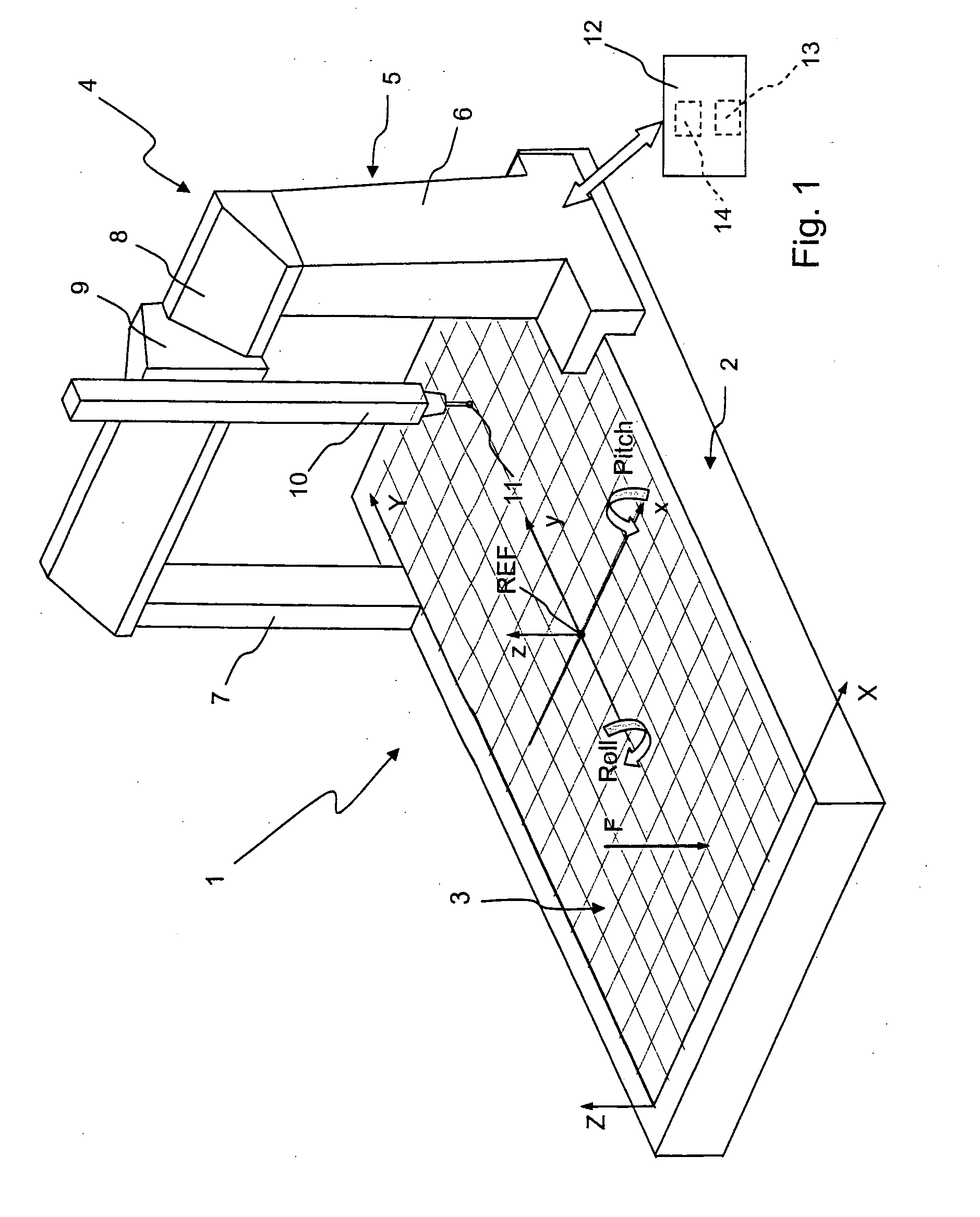

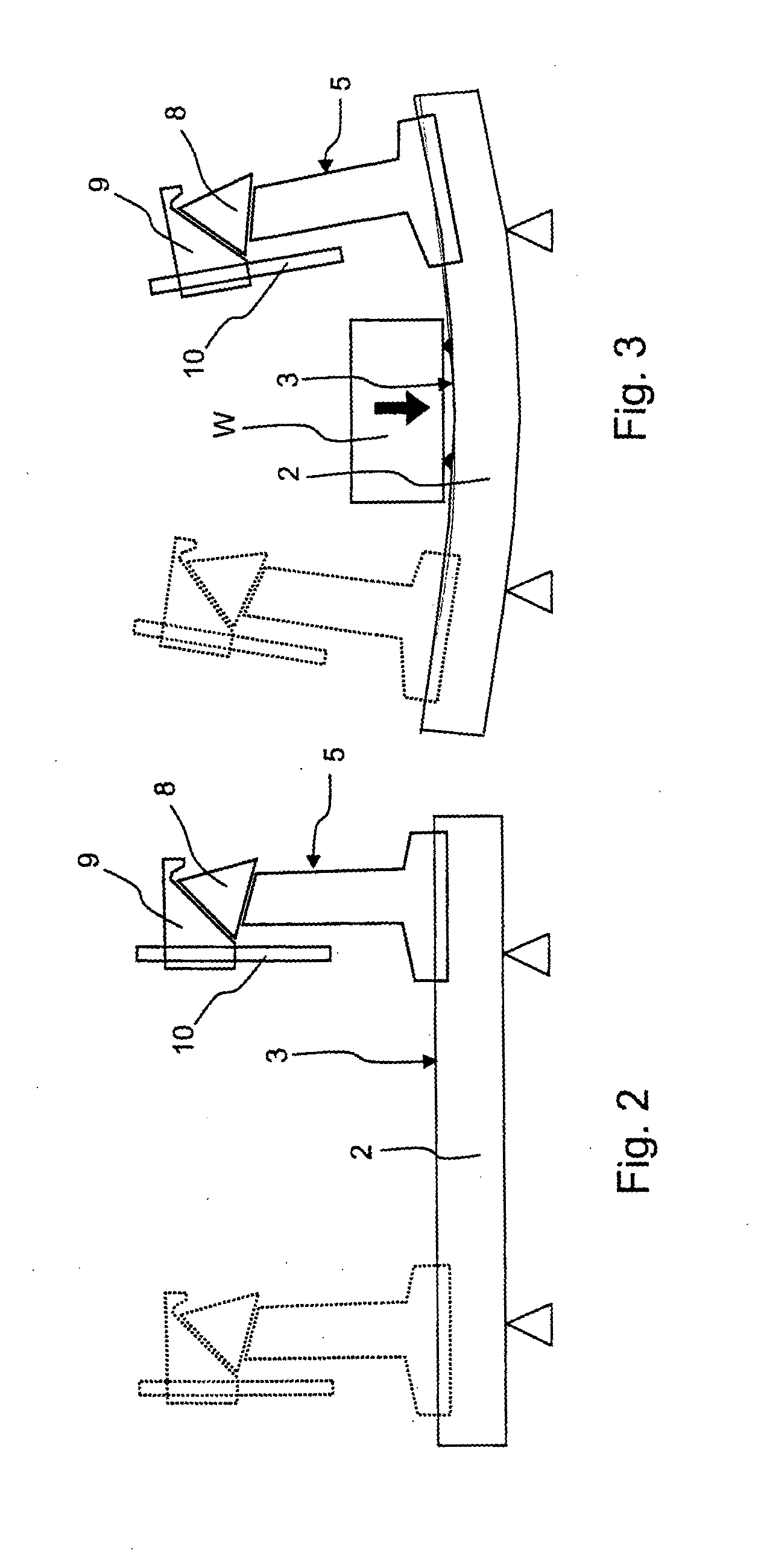

Method for compensating measurement errors caused by deformations of a measuring machine bed under the load of a workpiece and measuring machine operating according to said method

ActiveUS20100286941A1Testing/calibration of speed/acceleration/shock measurement devicesSpecial data processing applicationsObservational errorEngineering

A method of compensating the measurement errors of a measuring machine that derive from the deformations of the machine bed caused by the load exerted by the workpiece to be measured on the machine bed, comprising a first acquisition step in which data regarding the weight of the workpiece and the modes of resting of the workpiece on the machine bed are acquired, and a second calculation step in which correction values depending upon said data are calculated.

Owner:HEXAGON METROLOGY SPA

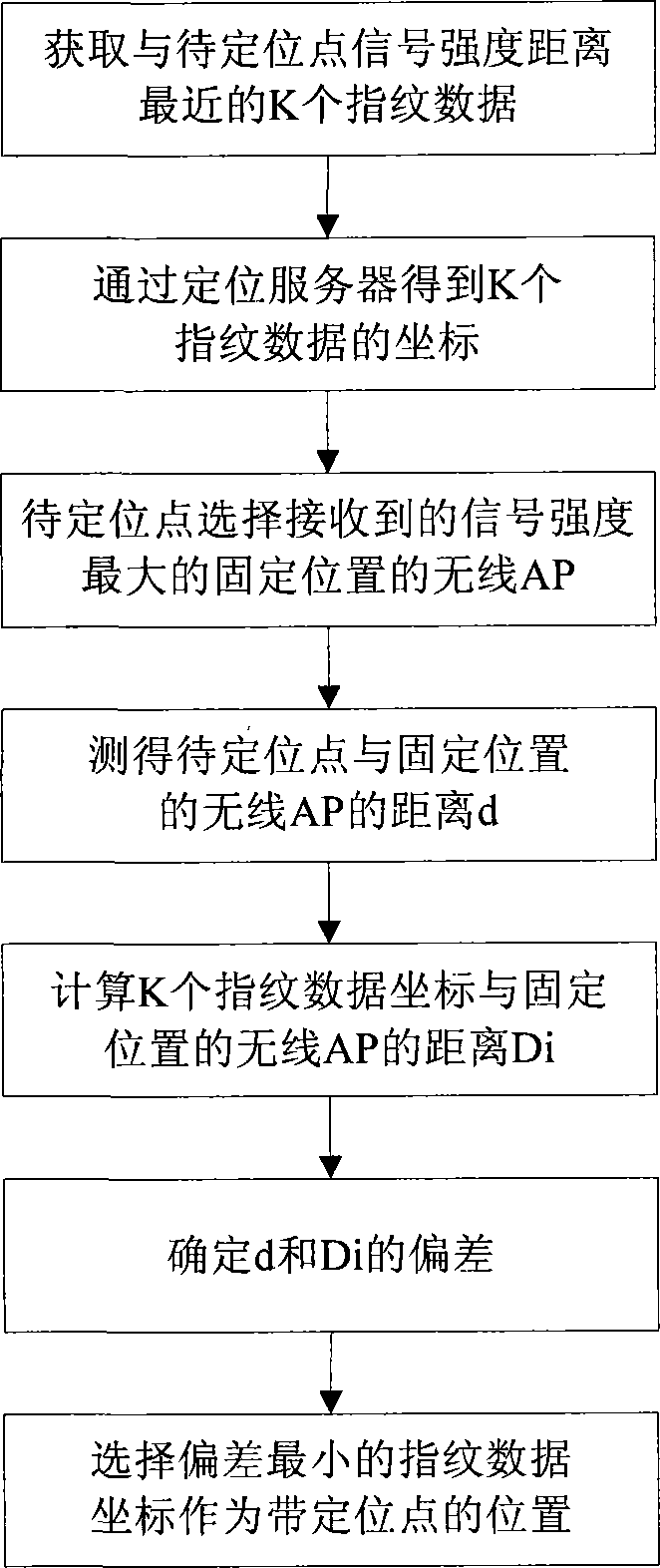

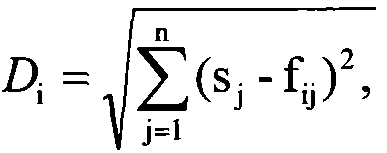

Wi-Fi (Wireless Fidelity)-based indoor positioning system and method

The invention discloses a Wi-Fi (Wireless Fidelity)-based indoor positioning system and a Wi-Fi (Wireless Fidelity)-based indoor positioning method. The positioning system comprises a positioning server, a local area network, a plurality of first wireless APs (Access Points), a plurality of known-position second wireless APs and a mobile terminal to be positioned. According to the system, the first wireless APs are adopted to position the mobile terminal, and the second wireless APs are used for amending a positioned result; according to an amending method, the existing K nearest neighbor (KNN) points obtained by a KNN method are subjected to selection, distances from the mobile terminal to be positioned to the wireless APs of fixed positions are obtained by adopting an RSSI (Received Signal Strength Indicator) ranging manner, and the KNN points are selected by using the distances. The system and the method have the advantages that the adopted APs of the fixed positions have the maximum received signal strength and are less affected by environmental factors, such as wall bodies, so that the measurement error is reduced, and the positioning is more accurate.

Owner:北京可信金科信息技术有限公司

Calibration compensation method for triaxial vector sensor and biaxial vector sensor

InactiveCN101887068ACorrect measurement errorMeasurement Error CalibrationElectrical measurementsTesting/calibration of speed/acceleration/shock measurement devicesObservational errorMathematical model

The invention relates to error correction of a vector sensor, in particular to a calibration compensation method for a triaxial vector sensor and a biaxial vector sensor, and solves the problems that the calibration compensation method of the existing multi-axial vector sensor fails to take all factors causing measurement error into account and the like. In the method, an error correction mathematical model of the vector sensor is built according to the relation of actually measured output Sm and theoretical output Se of the vector sensor, i.e. Sm=KSe + S0 and according to an error coefficient matrix K=K1K2, wherein, K1 and K2 are respectively a sensitivity error coefficient matrix of the triaxial vector sensor and a non-orthogonal error coefficient matrix among three measured axes; and an effective method is utilized to obtain correct zero-offset S0 and a correction coefficient matrix K-1 in the error correction mathematical model, and finally the error correction mathematical model of the measured vector sensor is obtained to carry out calibration compensation on the measuring result of the vector sensor. The method achieves calibration compensation taking into account of all the factors causing the measurement error of the multi-axial sensor, thus improving the accuracy of measuring results; and the method has concise and convenient process and no excessively high requirements on hardware equipment, thus being suitable for various vector sensors.

Owner:ZHONGBEI UNIV

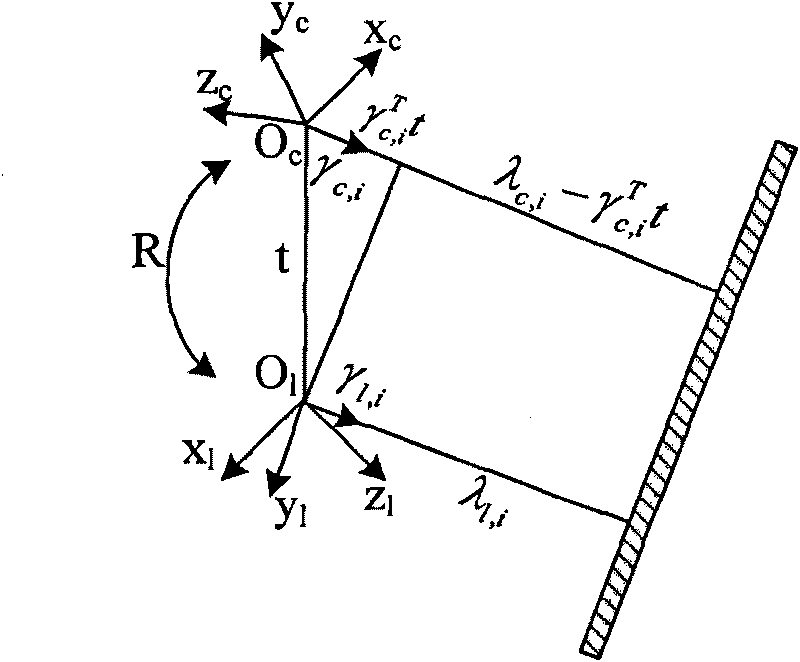

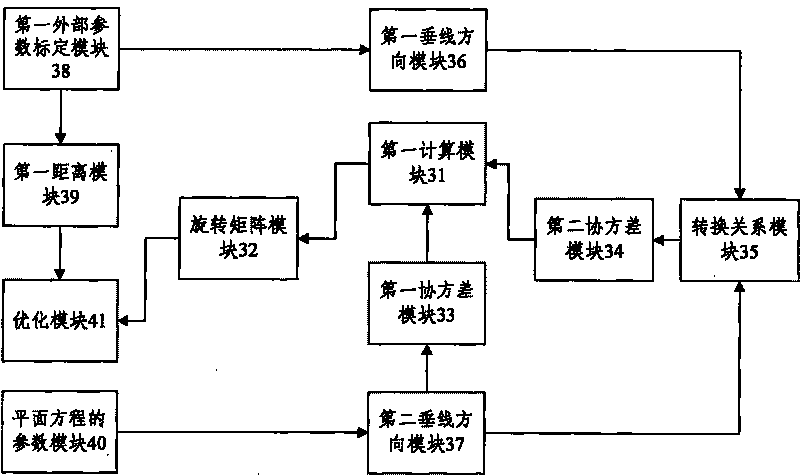

Method and system for calibrating external parameters based on camera and three-dimensional laser radar

InactiveCN101699313AImprove accuracyThe result is accurateImage analysisWave based measurement systemsObservational errorClassical mechanics

The invention discloses a method for calibrating external parameters based on a camera and a three-dimensional laser radar, which comprises the following steps: according to a covariance of measurement errors in the perpendicular line direction from a three-dimensional laser radar coordinate system origin to different position target planes and a covariance of measurement errors in a conversion relationship from a three-dimensional laser radar coordinate system to a camera coordinate system in the perpendicular line direction, acquiring an equation of a quadratic sum of the variance including the variance of the camera measurement noise and the variance of the three-dimensional laser radar measurement noise in the covariance of the measurement errors in the conversion relationship; and calibrating a rotation matrix with maximum likelihood estimate by using the reciprocal of the quadratic sum of the variances of all obtained measurement noise as a weighting coefficient. The invention also discloses a system for calibrating the external parameters based on the camera and the three-dimensional laser radar at the same time. The effect of the measurement errors on the rotation matrix to be calibrated is taken into consideration during calibrating, and the algorithm of the maximum likelihood estimate is adopted for the measurement errors in the calibrated result of the rotation matrix, so the calibrating result is more accurate.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

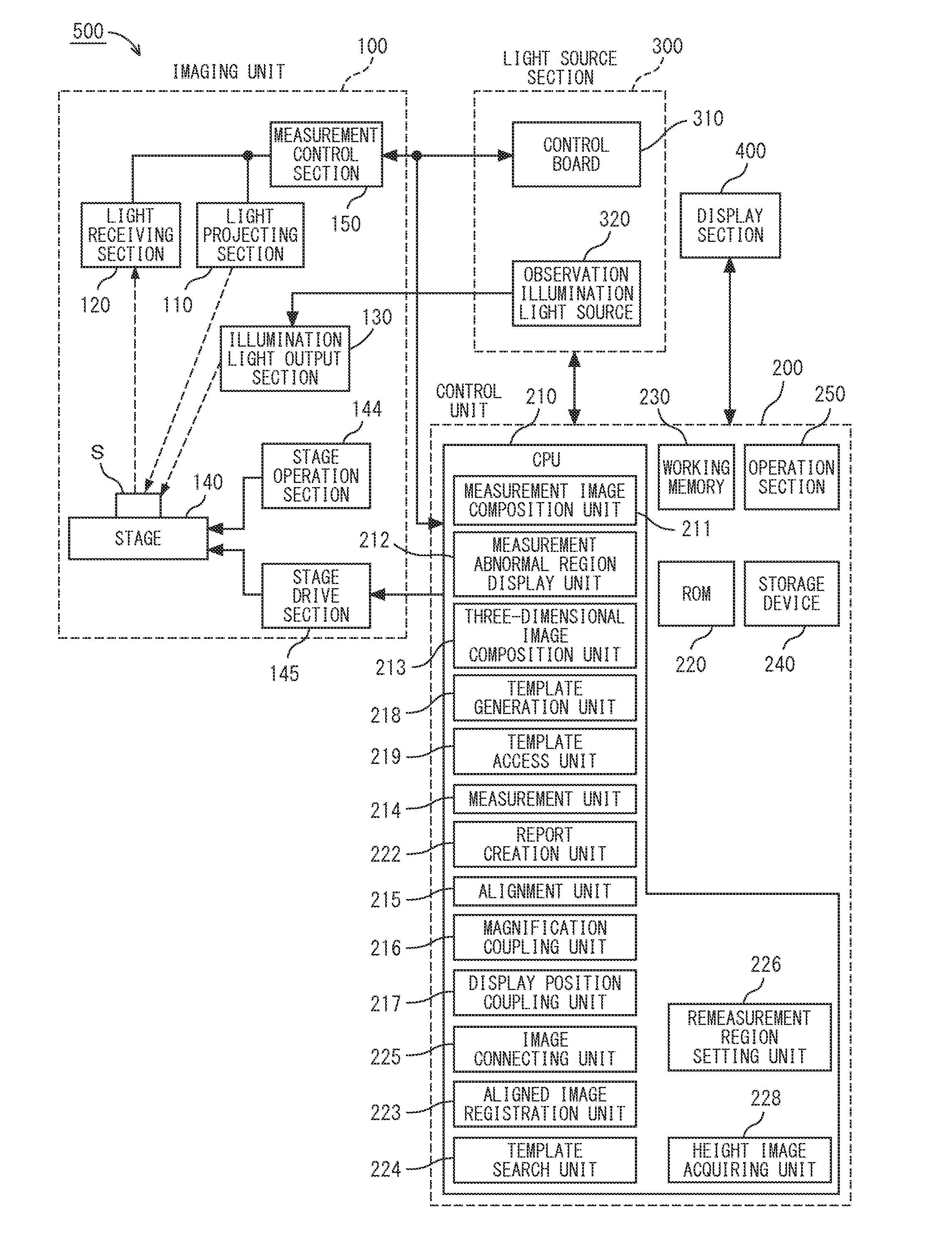

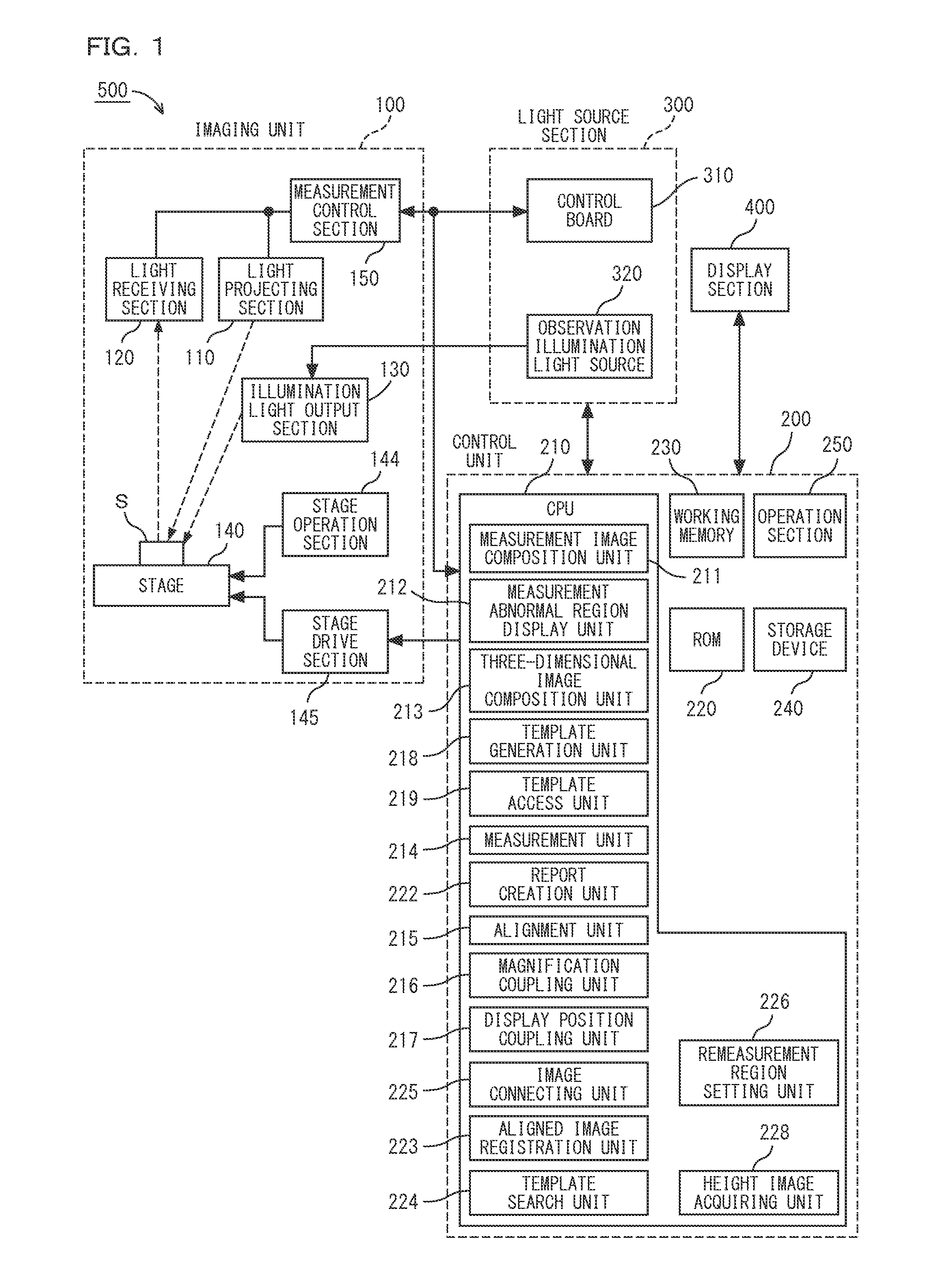

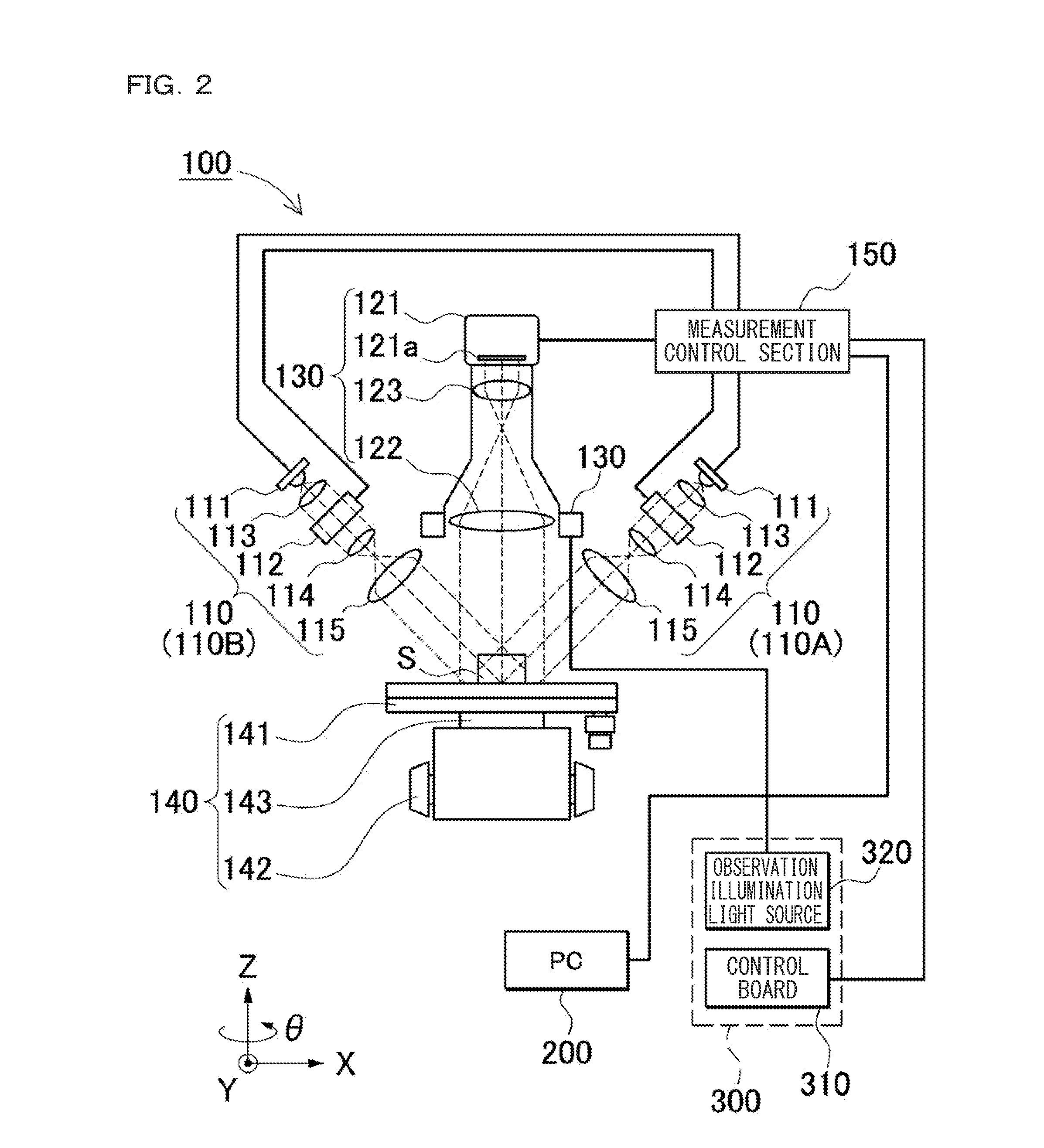

Measurement Microscope Device, Image Generating Method, Measurement Microscope Device Operation Program, And Computer-Readable Recording Medium

ActiveUS20140152794A1Wide visual field without causing deterioration in measurement accuracyImprove accuracyColor television detailsClosed circuit television systemsVisual field lossObservational error

An image with a wide visual field can be captured without causing deterioration in measurement accuracy. There are provided: a stage on which an object is placed; a display unit for displaying a height image or an observation image; a measurement unit for performing measurement on the height image; an image connecting unit configured to, by moving the stage and capturing a different region, acquire a plurality of height images, and connect the obtained plurality of height images and observation images to generate a connected image; a measurement error region display unit configured to superimpose and display a measurement error region, on an image of the object; and a measurement-image imaging condition setting unit for adjusting an imaging condition for a striped image required for generation of the height image to reduce the measurement error region.

Owner:KEYENCE

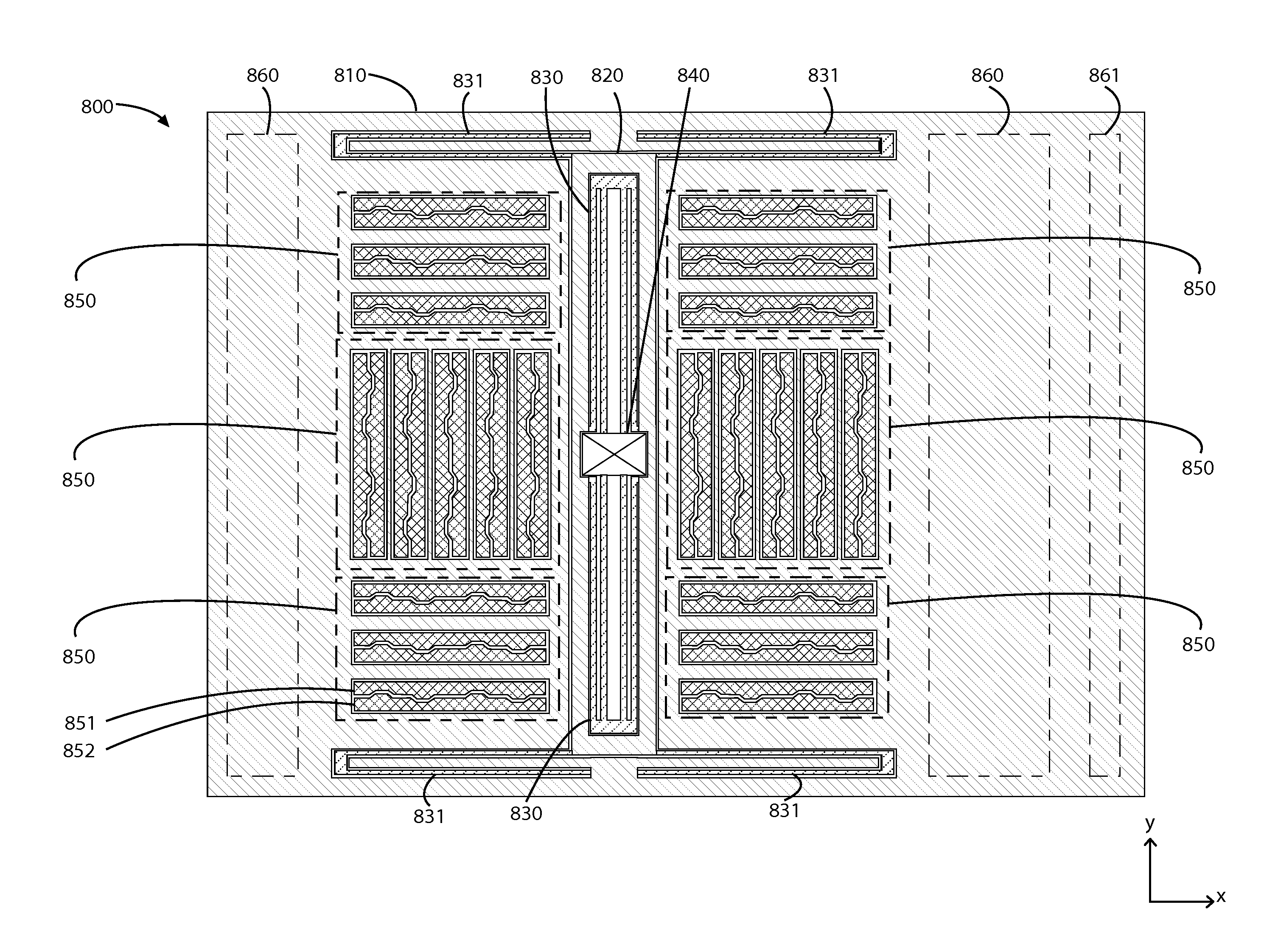

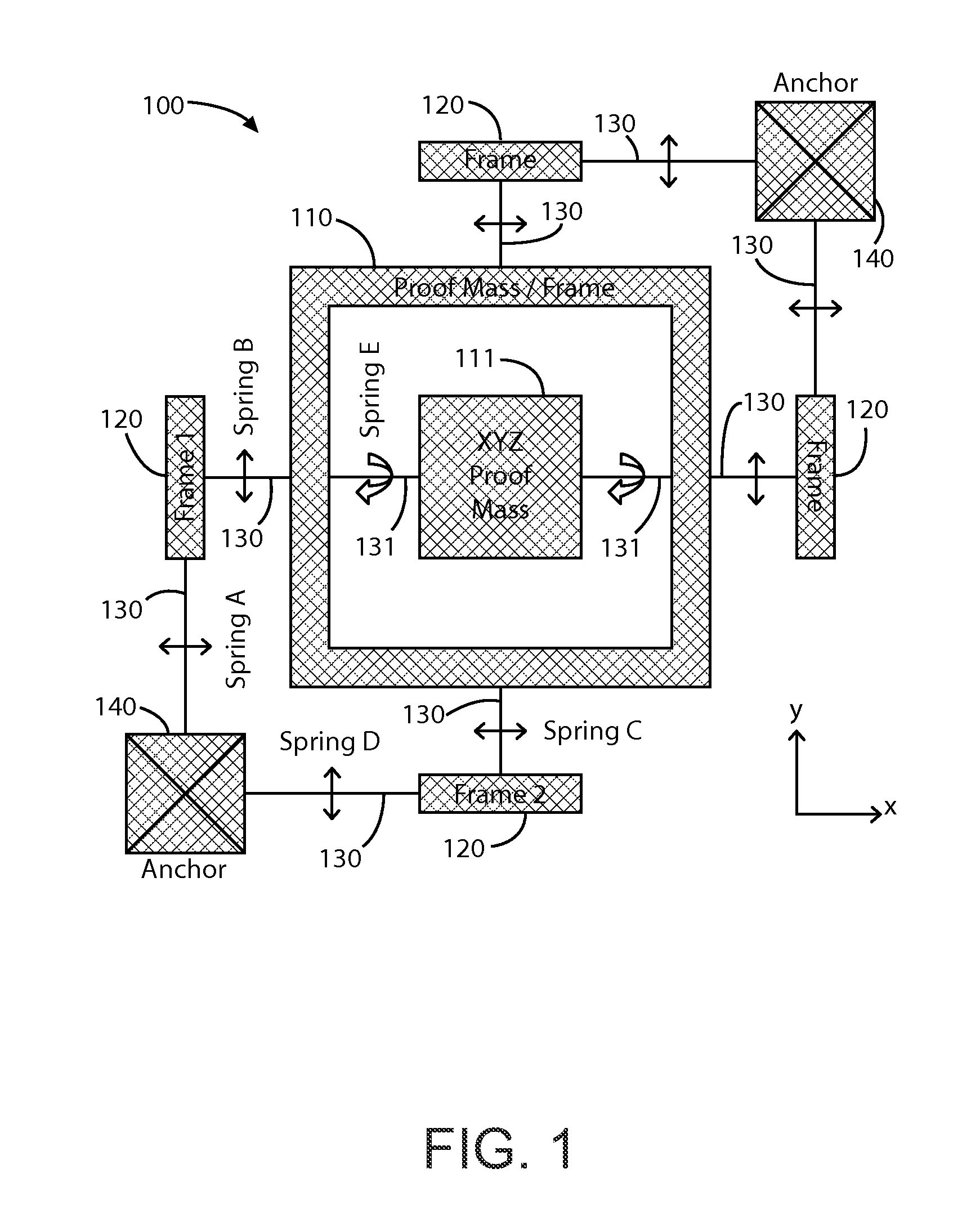

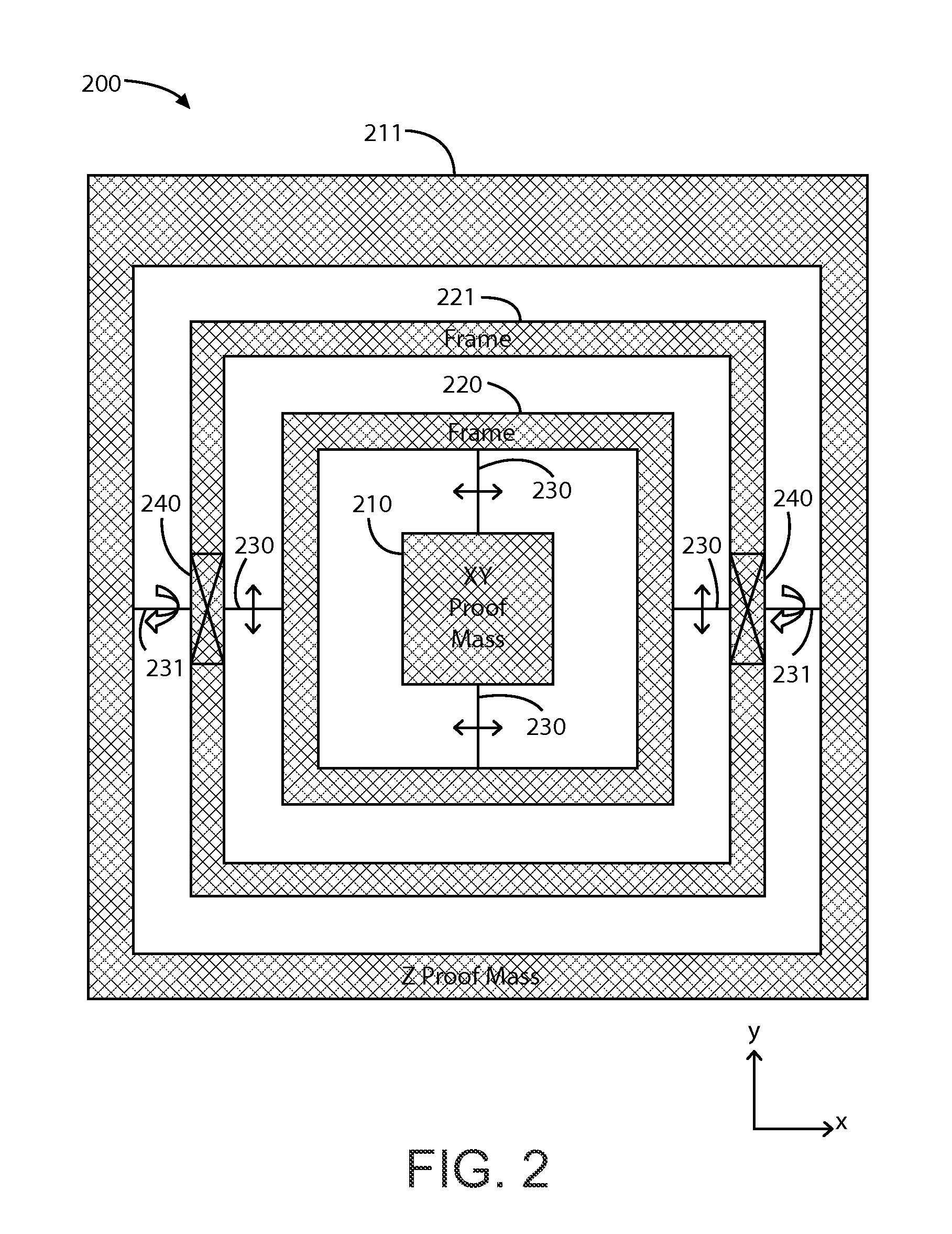

Mems-based dual and single proof-mass accelerometer methods and apparatus

ActiveUS20130214367A1Easy to measureMinimize, orAcceleration measurement using interia forcesSemiconductor devicesObservational errorEngineering

An integrated MEMS inertial sensor device includes one or more three-axis MEMS inertial sensor devices, such as accelerometers, with dual or single proof mass configurations. These designs can be compact and can decouple the motion of each axis to minimize the measurement errors due to cross-axis sensitivity. Some embodiments include a frame to decouple the motion of two axes and to provide geometric symmetry. Some embodiments also include double-folded springs. In a specific embodiment, the three axes of an integrated MEMS accelerometer device are entirely decoupled. Thus, the actuation of each axis, through a force due to acceleration, has little or substantially no effect on the other axes.

Owner:MOVELLA INC

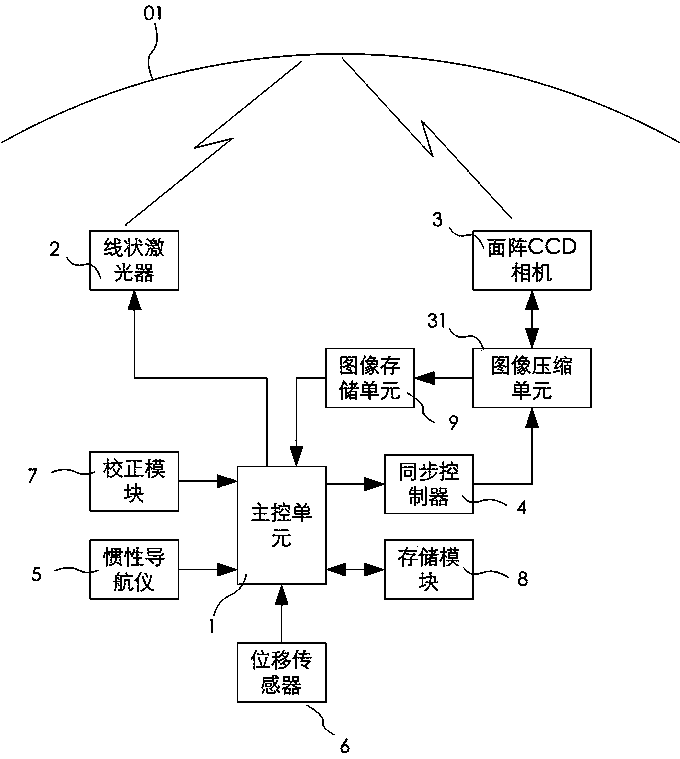

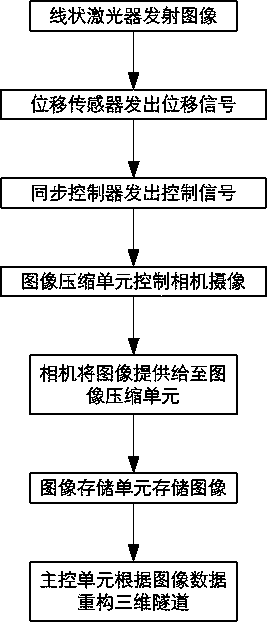

High-speed detection system and method of tunnel defects

ActiveCN104048970AMeasuring fast dynamicsHigh precisionOptically investigating flaws/contaminationUsing optical meansObservational errorImage compression

The invention provides a high-speed detection system and method of tunnel defects. The system comprises a master control unit, a linear laser, an area array charge coupled device (CCD) camera, an image compression unit, a displacement sensor, a synchronous controller, an image storage unit, a storage module, a correction module and an inertial navigator. A special measurement locomotive serves as a mobile monitoring platform for the design and is particularly suitable for subway tunnel monitoring, and subway and other tunnel space structures can be effectively, rapidly and dynamically measured; the actually measured data is compared with actual real distance, errors are analyzed, the parameter setting is adjusted, and the measurement accuracy is greatly improved; moreover, the XYZ axial vibration of the mobile monitoring platform is subjected to error correction through the inertial navigator, and a measurement error is prevented from being introduced into mobile measurement.

Owner:樊晓东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com