High-speed detection system and method of tunnel defects

A detection system and tunnel technology, applied in the field of high-speed detection systems for tunnel defects, can solve problems such as many blind spots, large errors, and cannot effectively reduce vehicle vibration measurement errors, and achieve the effect of avoiding measurement errors and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

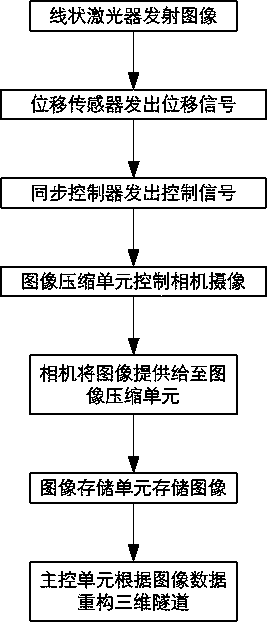

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

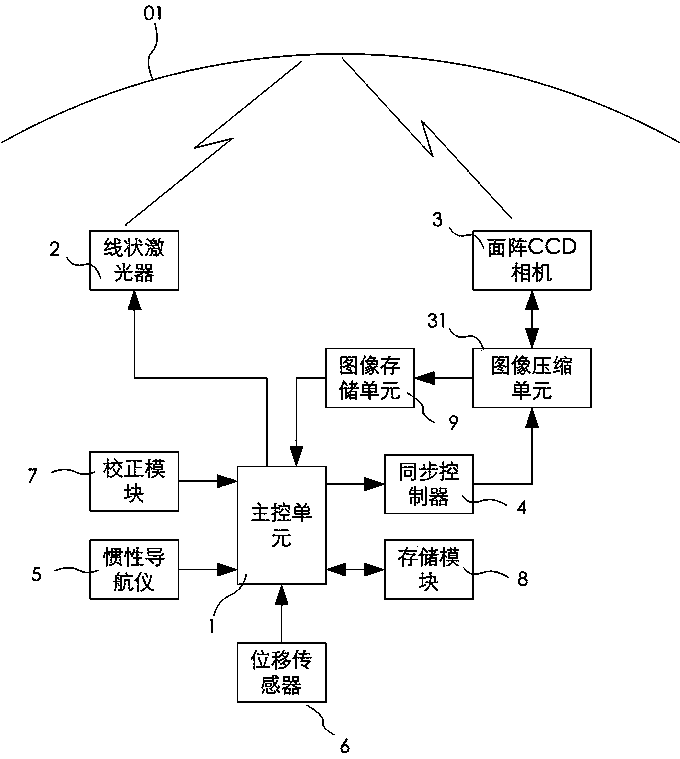

[0040] Such as Figures 1 to 2 The high-speed detection system for tunnel defects of the present invention shown at least includes a movable detection platform, a main control unit 1, a linear laser 2, an area array CCD camera 3, a displacement sensor 6, a synchronous controller 4, a high-speed storage module 9, Storage module 8, correction module 7 and inertial navigator 5.

[0041] The detection platform is the carrying device of the system, which can be a tunnel trolley. When the tunnel trolley is walking on the track, the system acquires image information of the inner side of the tunnel in real time to obtain a panoramic image.

[0042] The main control unit 1 is the central processing device of the present invention, which mainly controls the data transmission of each eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com