Screw head formation

a screw head and head technology, applied in the direction of screws, geometric arrangements, bolts, etc., can solve the problems of increasing costs, not being able to form in a single strike, and not being able to form deep recesses without, so as to reduce the tendency for tips and achieve the effect of considerable skill and patien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

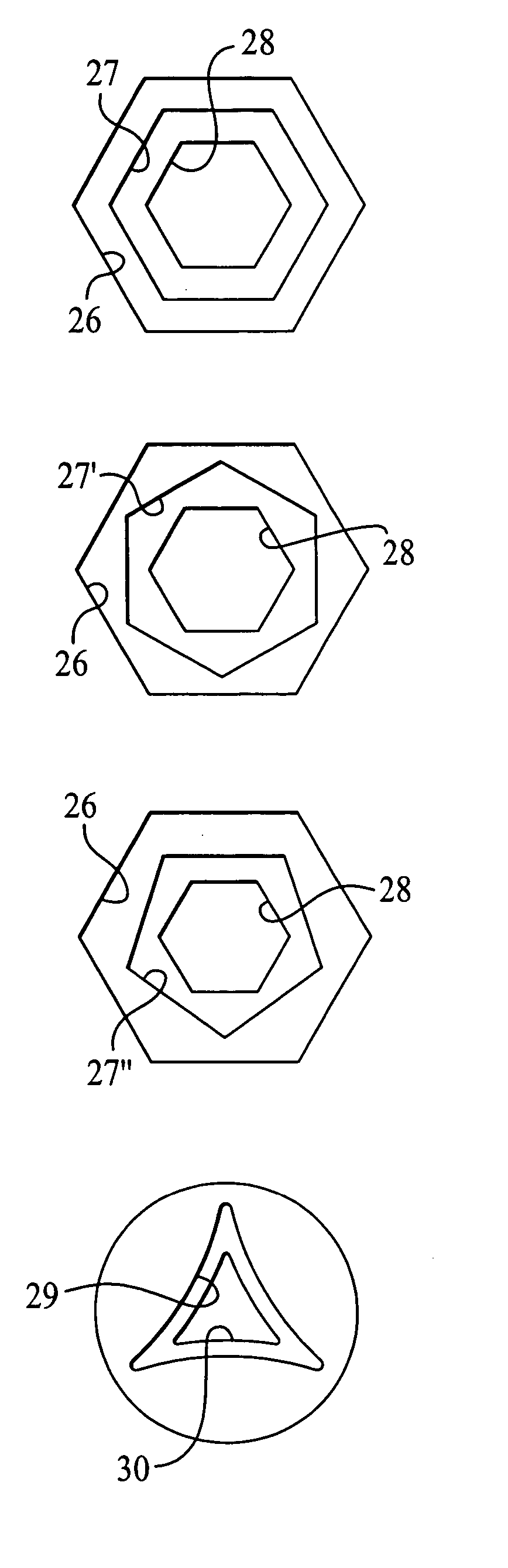

[0050] With reference to FIG. 1, each drawing illustrates a punch 10a,b,c,d having respectively one, two, three and four tiers 12,14,16,18. Each tier has a height of approximately 1 mm. Each tier has a fillet 20 at its base serving to support it. The fillet has a radius of approximately 0.05 mm. The punch 10 is made by cutting the profile of the head from a bar stock 22,23 using a profilating CNC machine described further below. As well as cutting the profile 11, the CNC machine will also cut a locating slot 24 and part the formed punch 10b from the remaining bar stock 23.

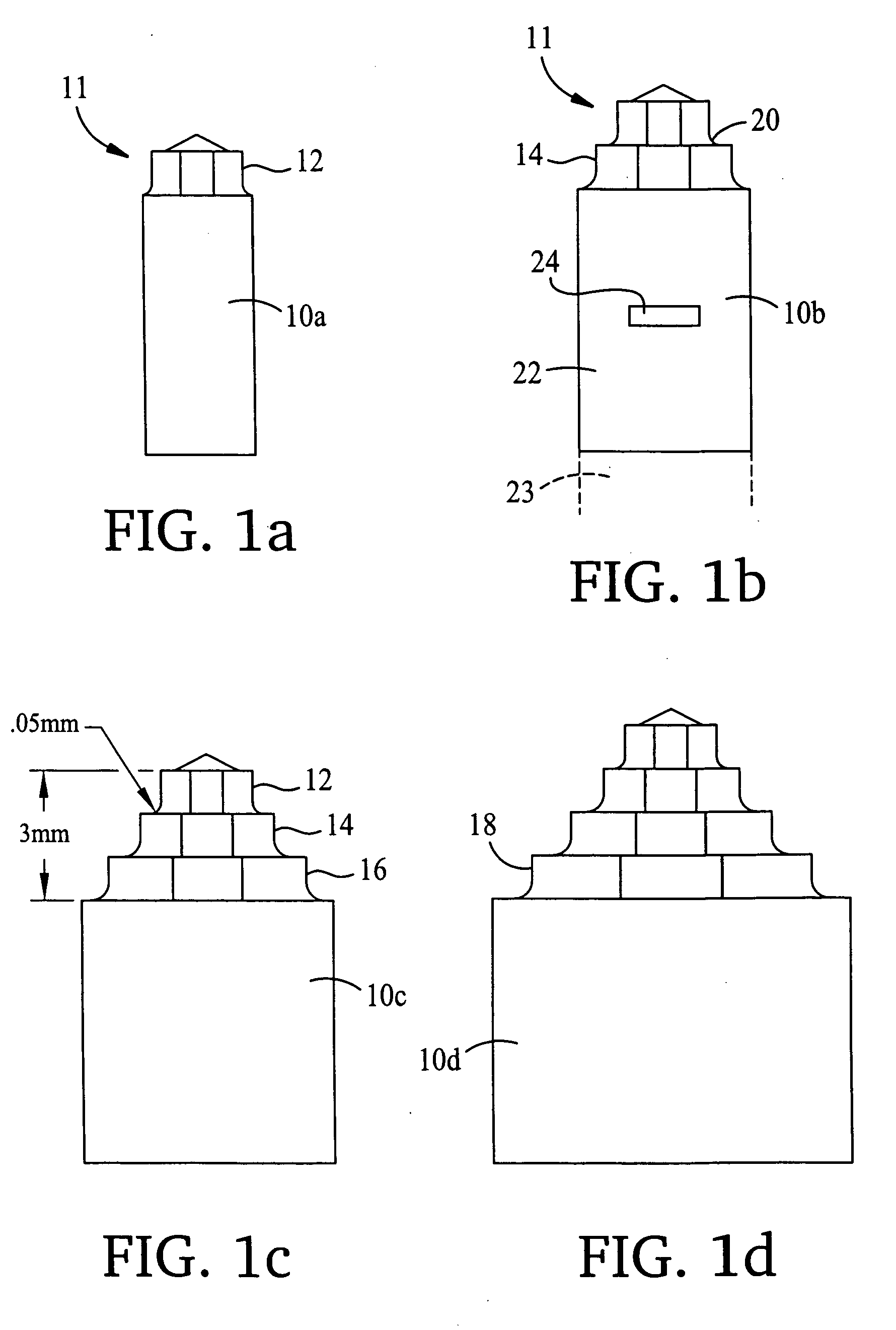

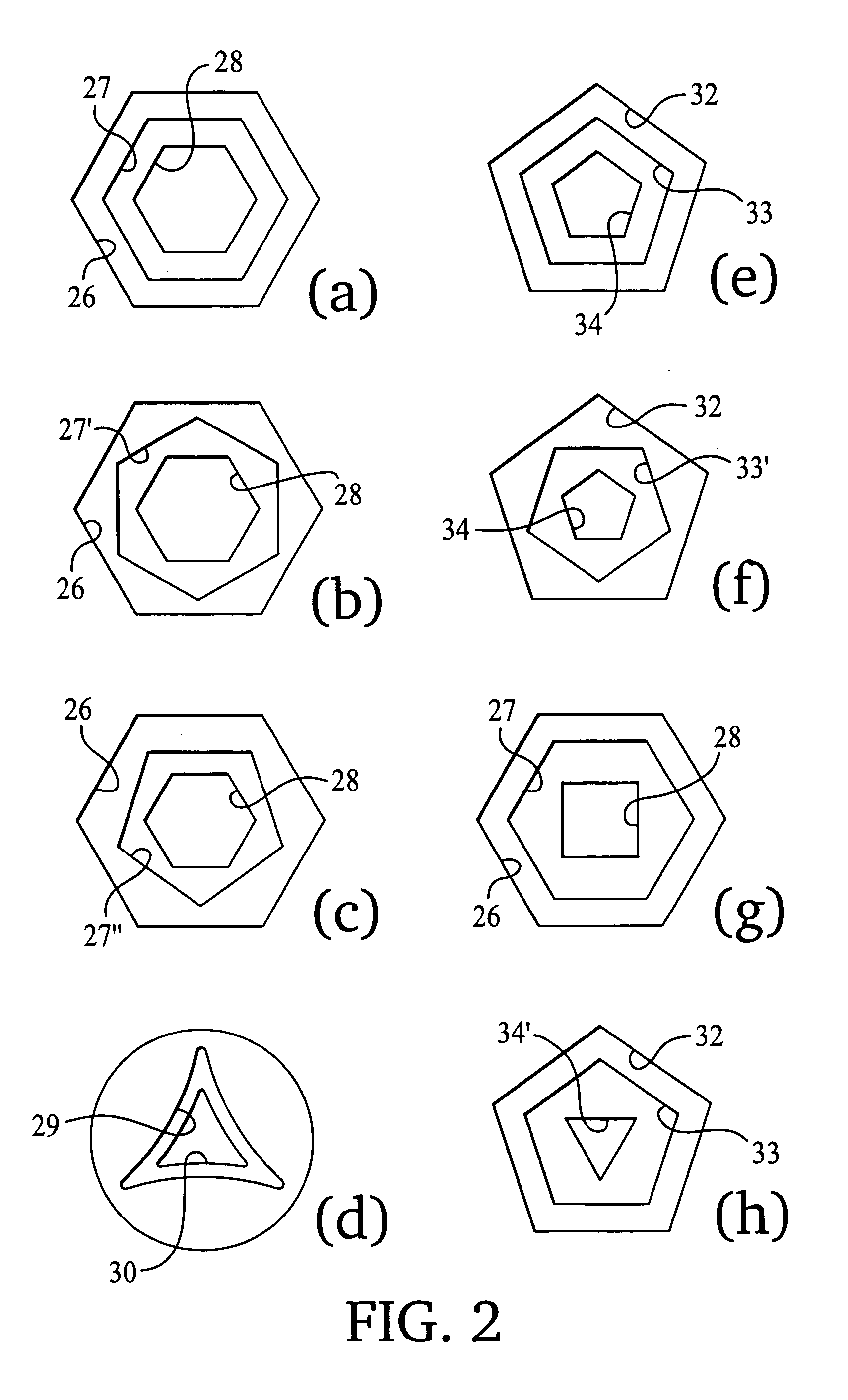

[0051] When the punch 10 is fitted in a cold heading device, and driven into the head of a screw in an axial direction, recesses having the profiles of the sort illustrated in FIG. 2 are formed.

[0052]FIG. 2a is a three-recess design with concentric and aligned hexagons 26,27,28. FIG. 2b is similar to FIG. 2a, except that the middle recess 27′ is rotationally offset with respect to recesses 26,28 by 30°.

[0053]FIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com