Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Accurate tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

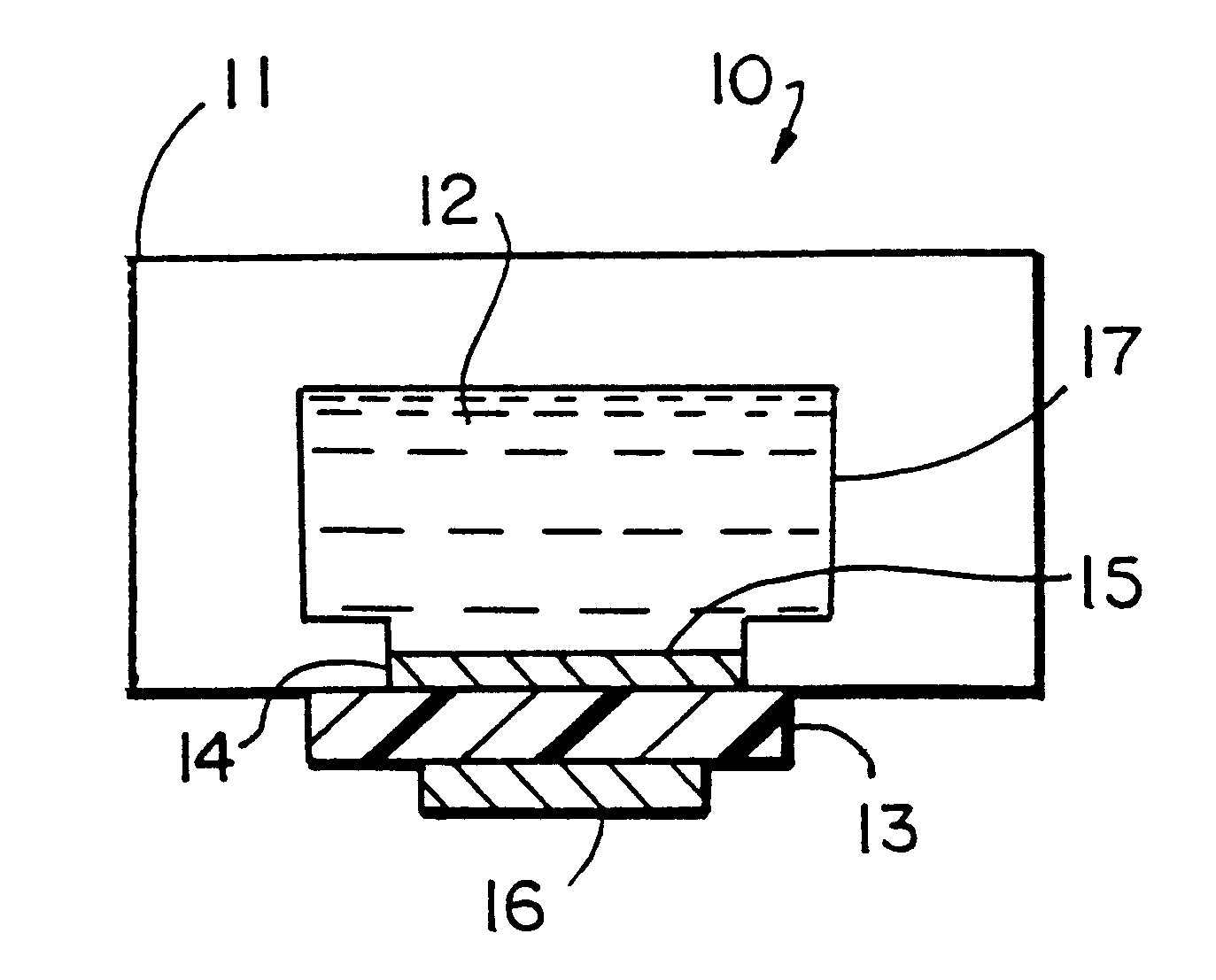

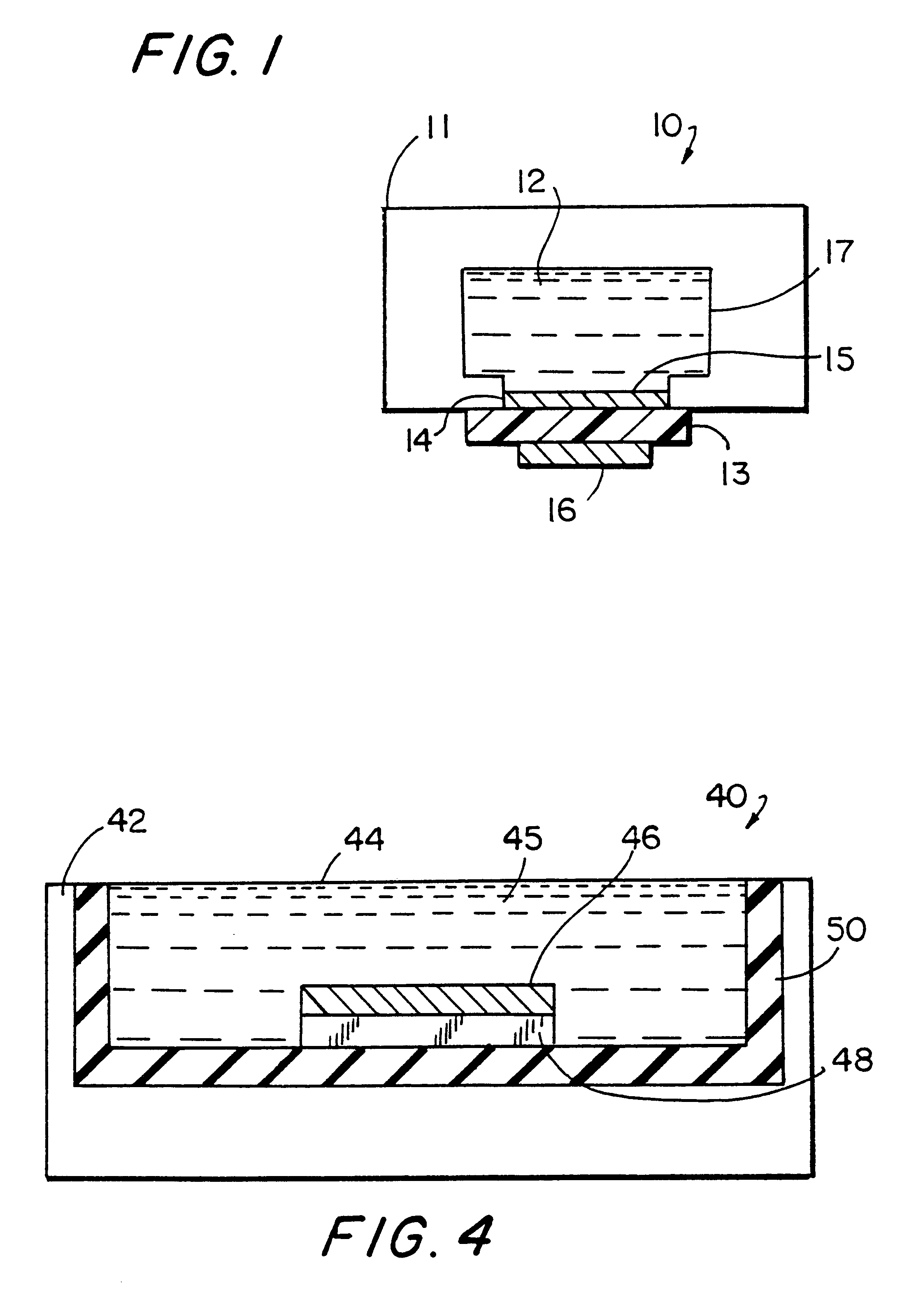

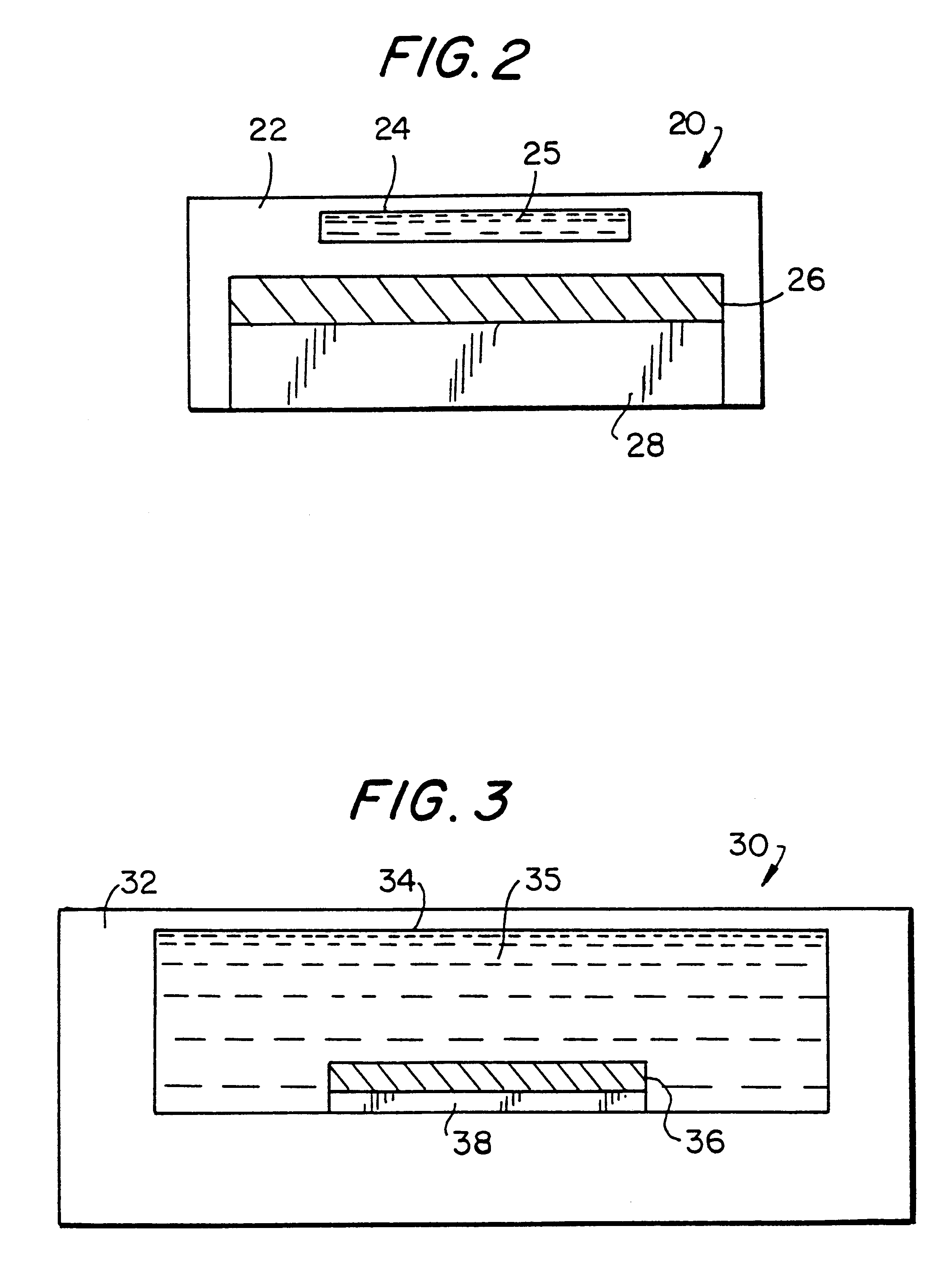

Assay sonication apparatus and methodology

InactiveUS6413783B1Accurate toleranceEasy to explainImmobilised enzymesBioreactor/fermenter combinationsAssayCell biology

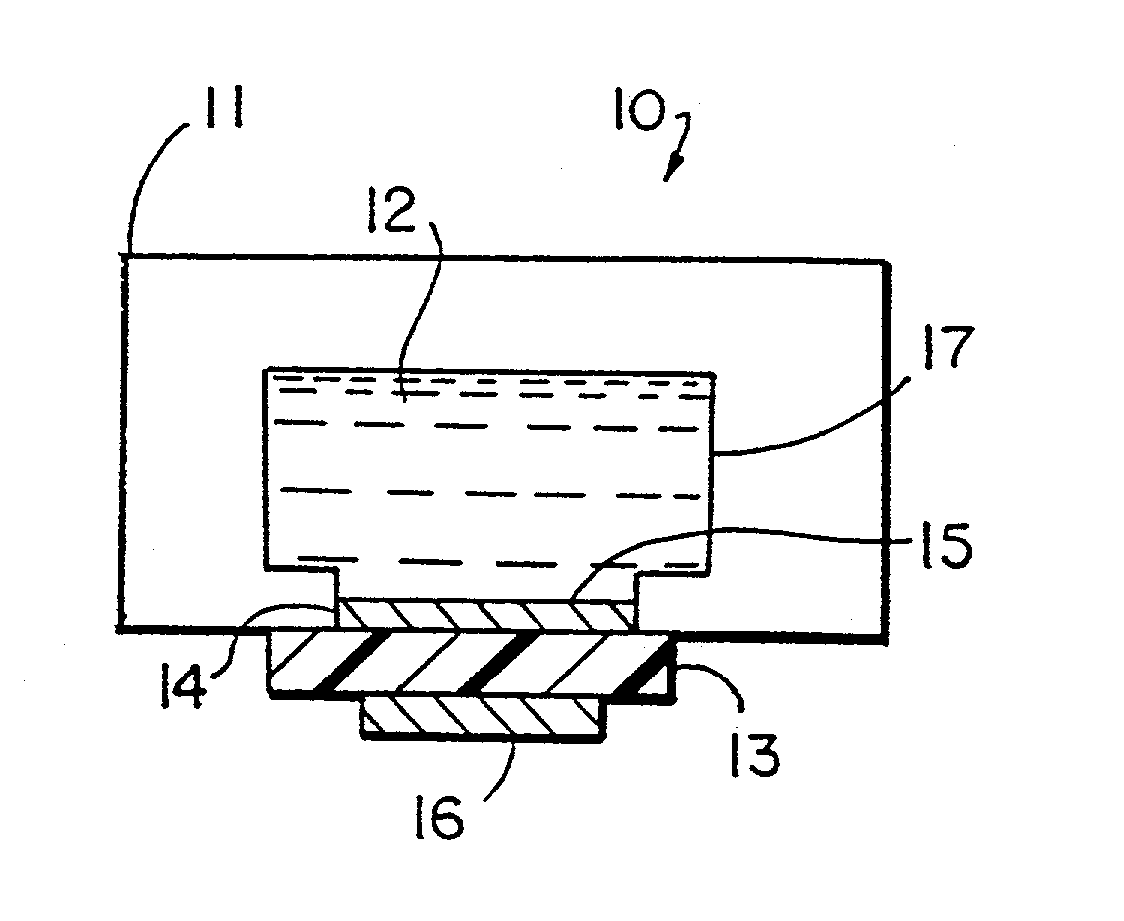

An assay apparatus includes a cell with a working electrode and a sonicating device structurally coupled to the cell for sonication the contents of the cell.

Owner:MESO SCALE TECH LLC

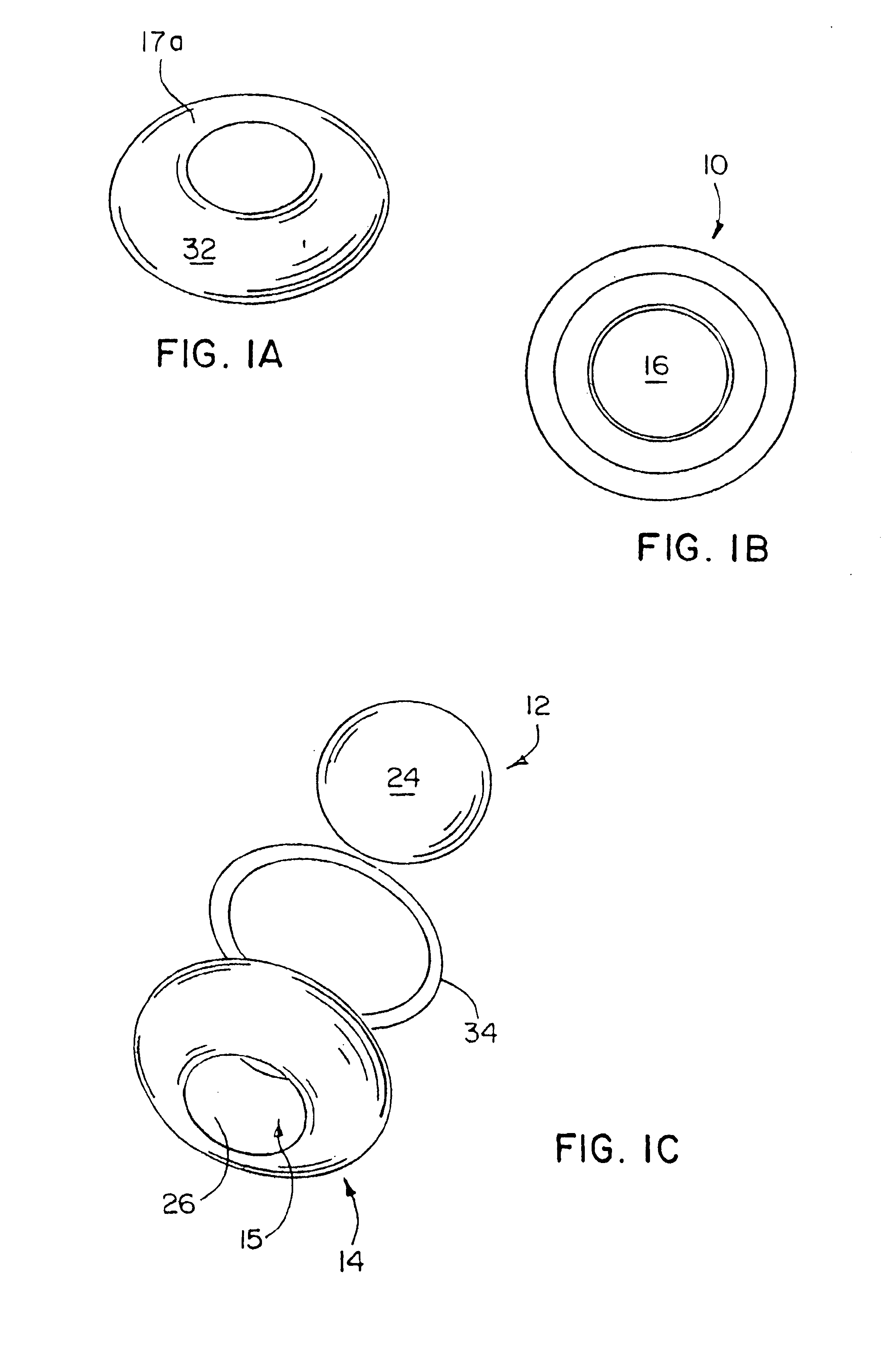

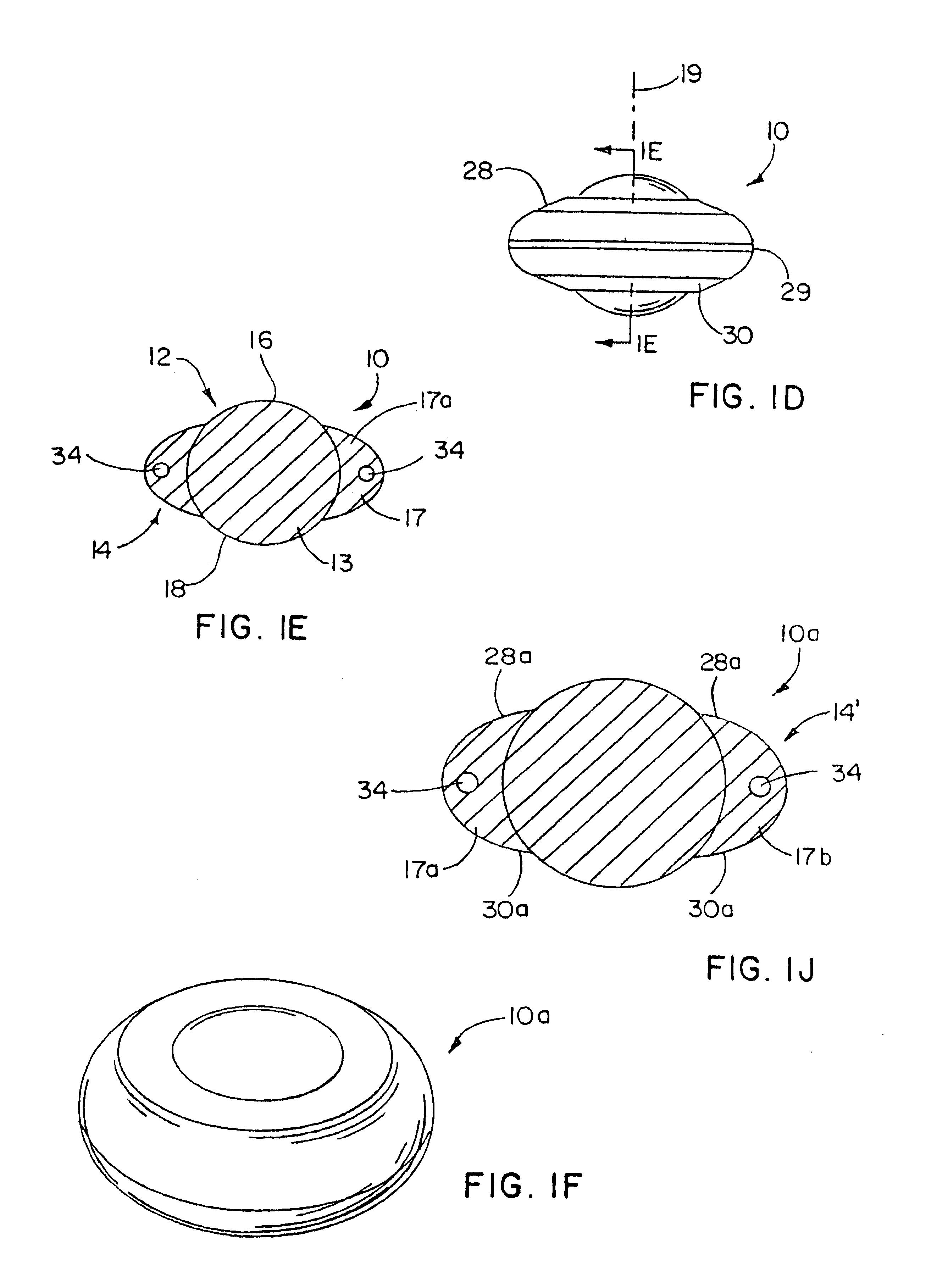

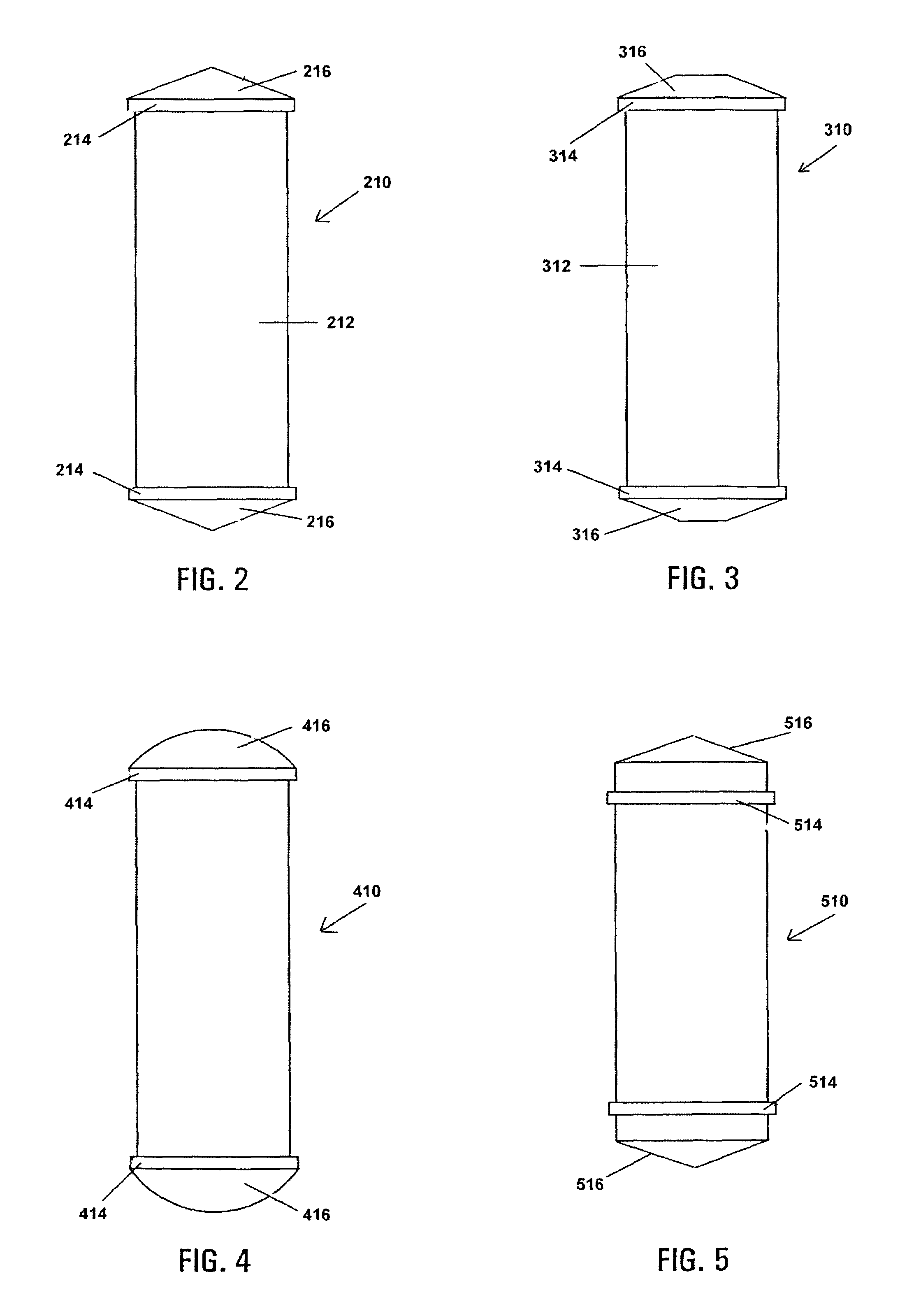

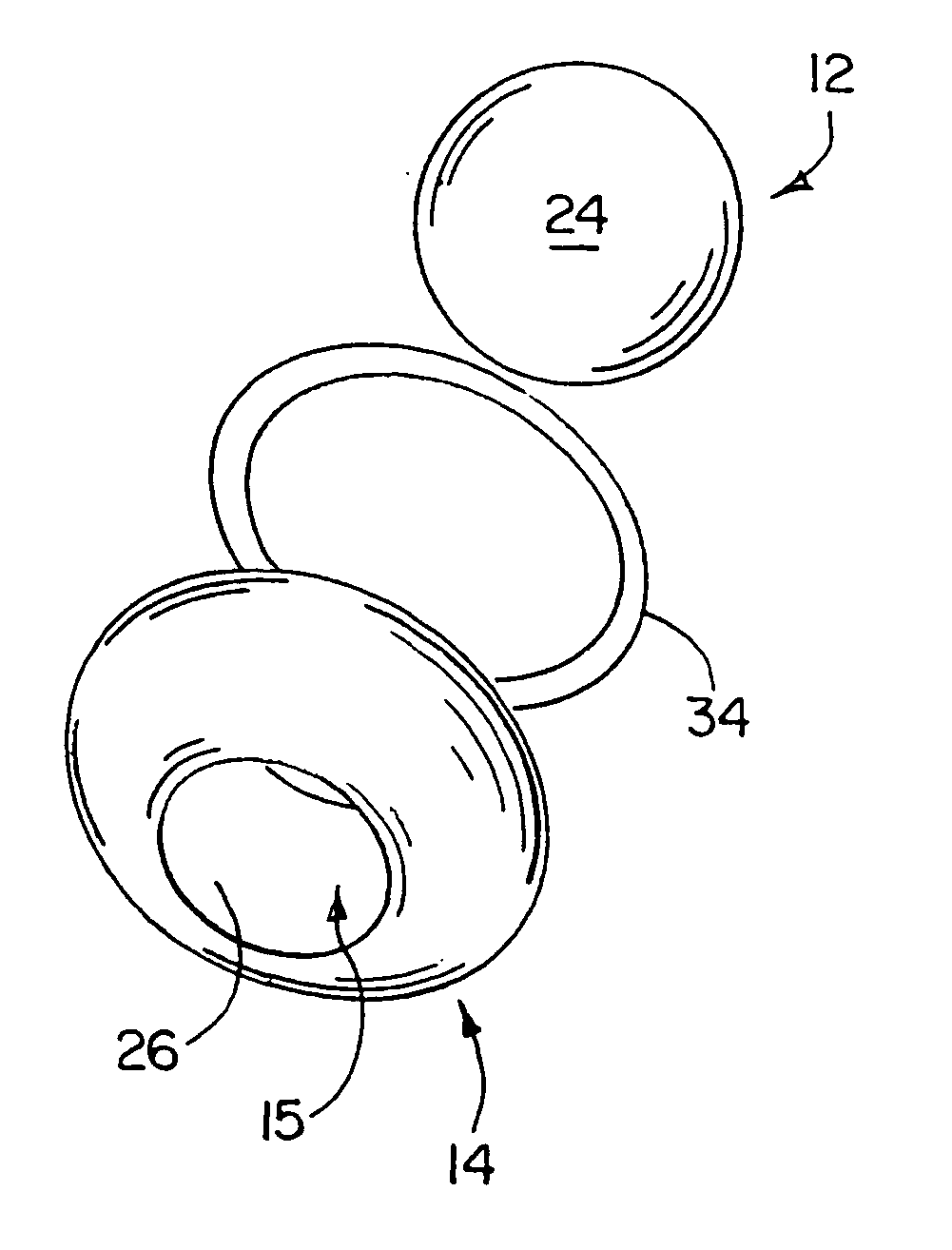

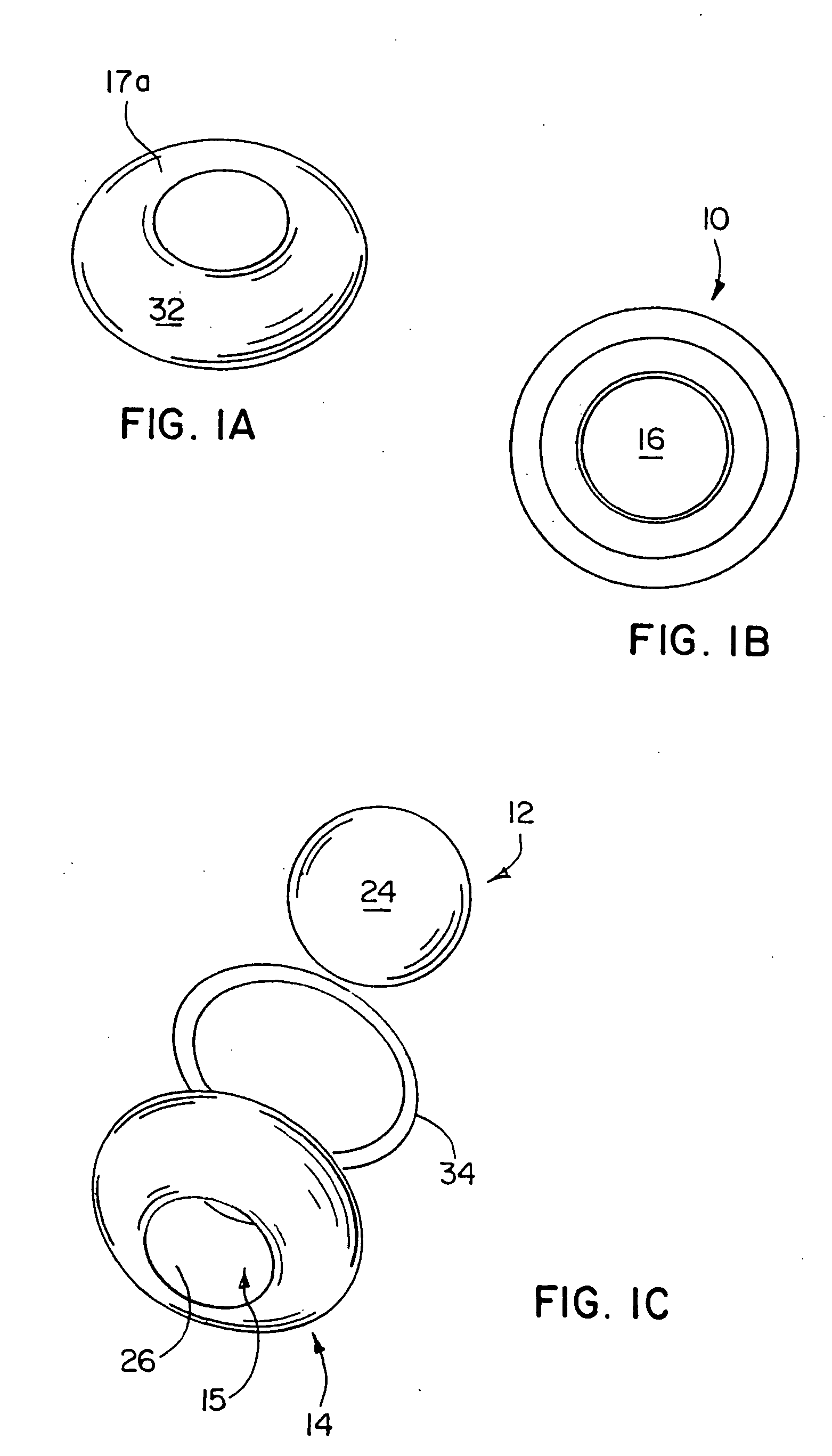

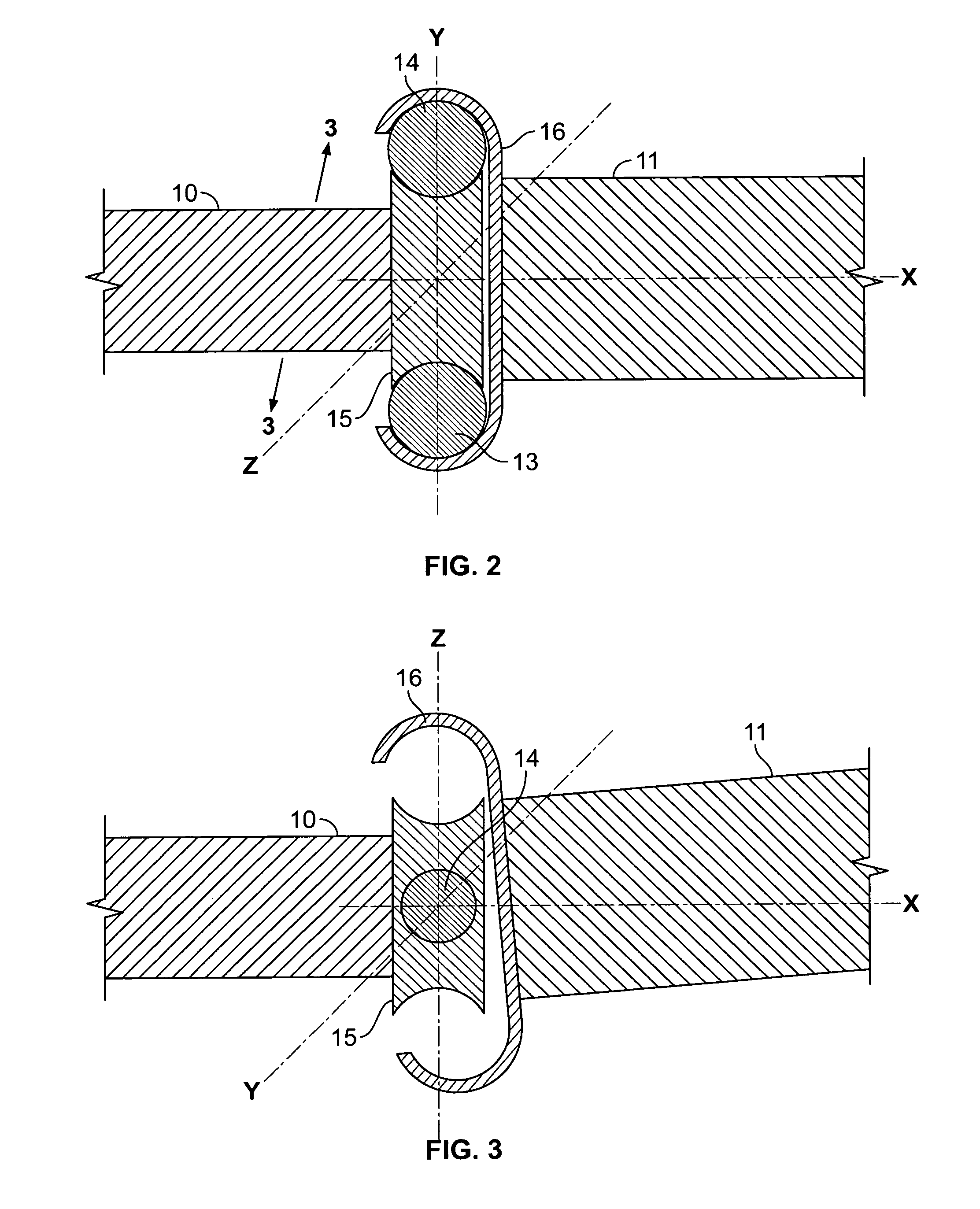

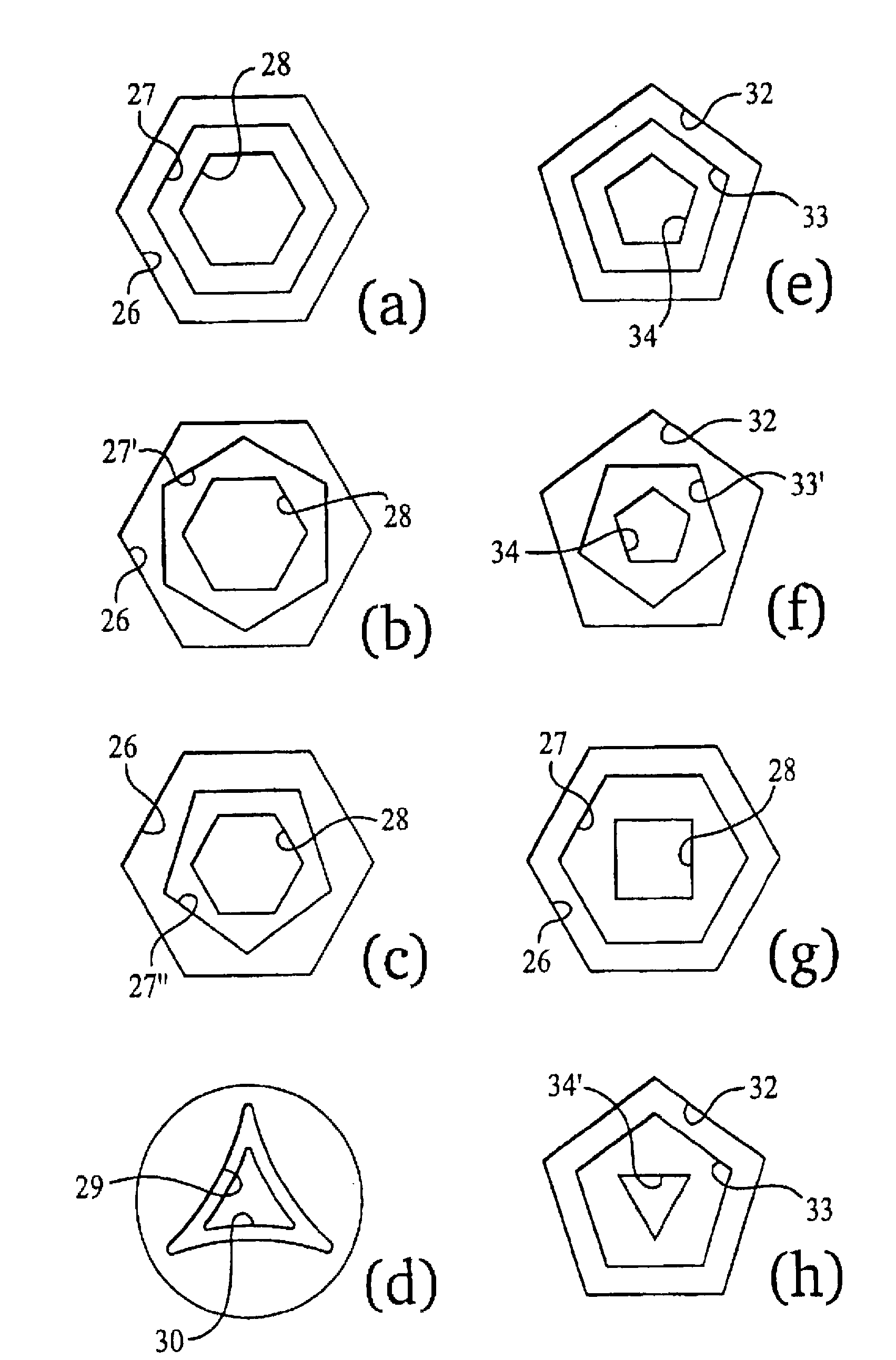

Artificial intervertebral disc device

InactiveUS7001433B2Improve distributionImprove shock absorptionInternal osteosythesisJoint implantsBall bearingBiomechanics

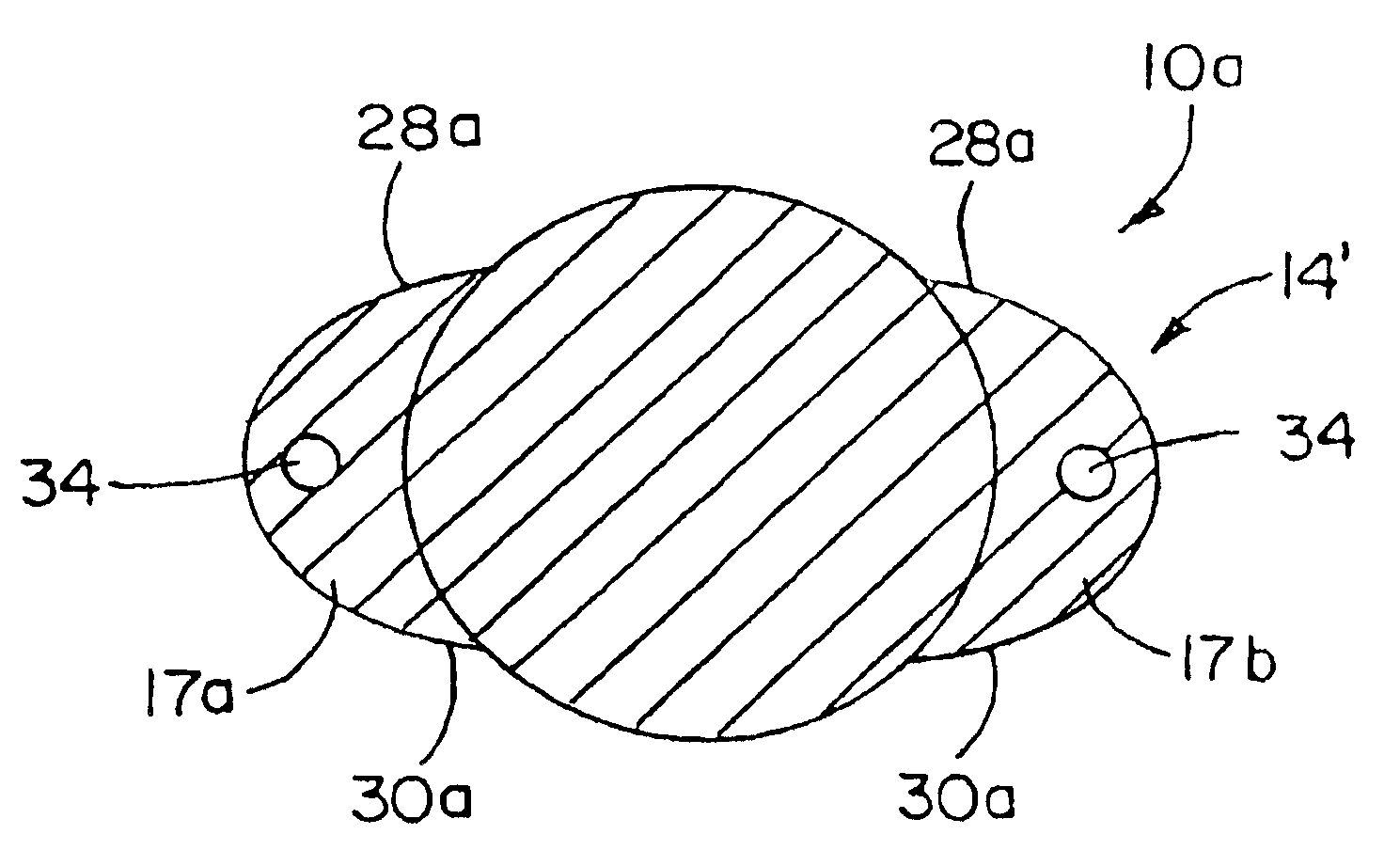

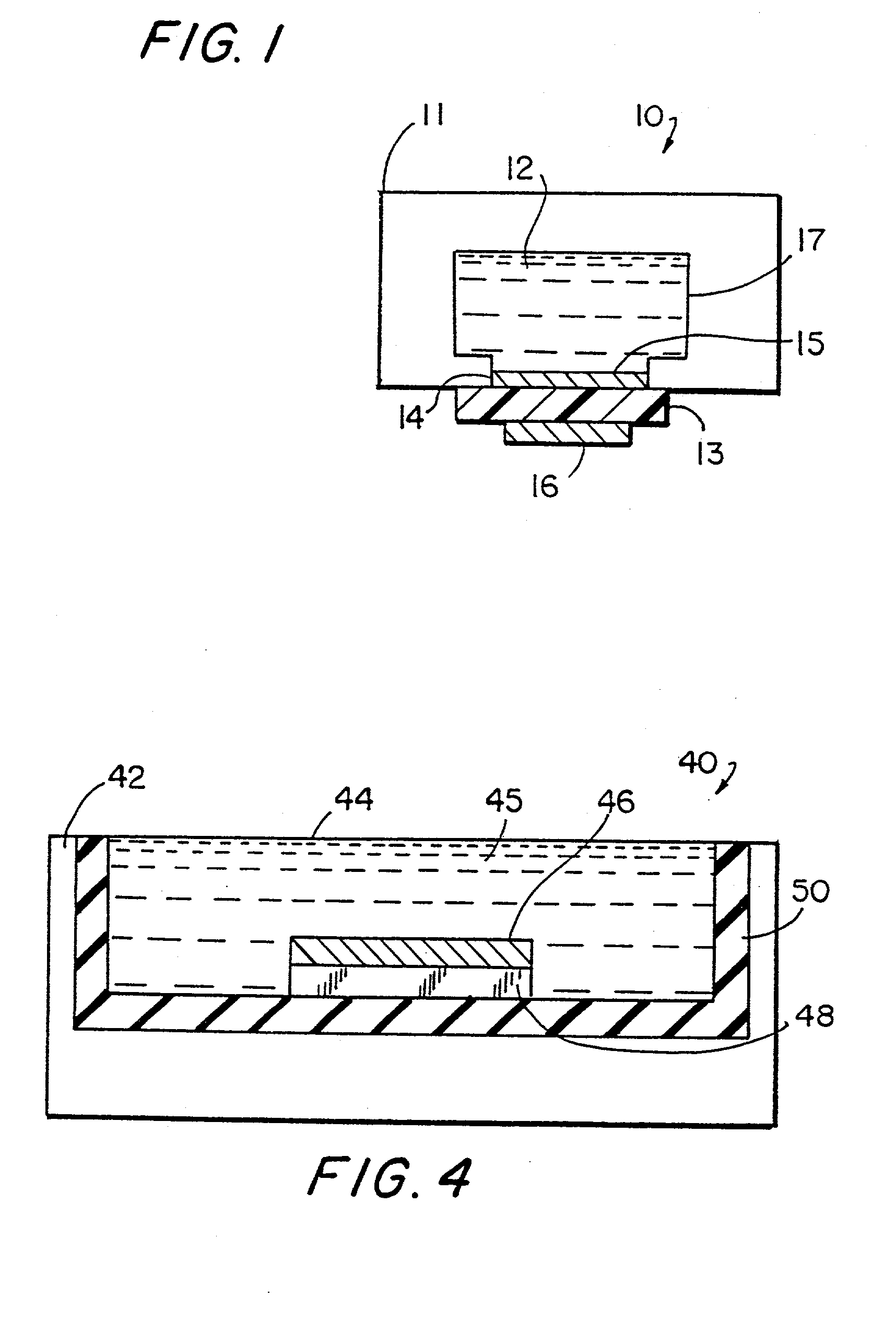

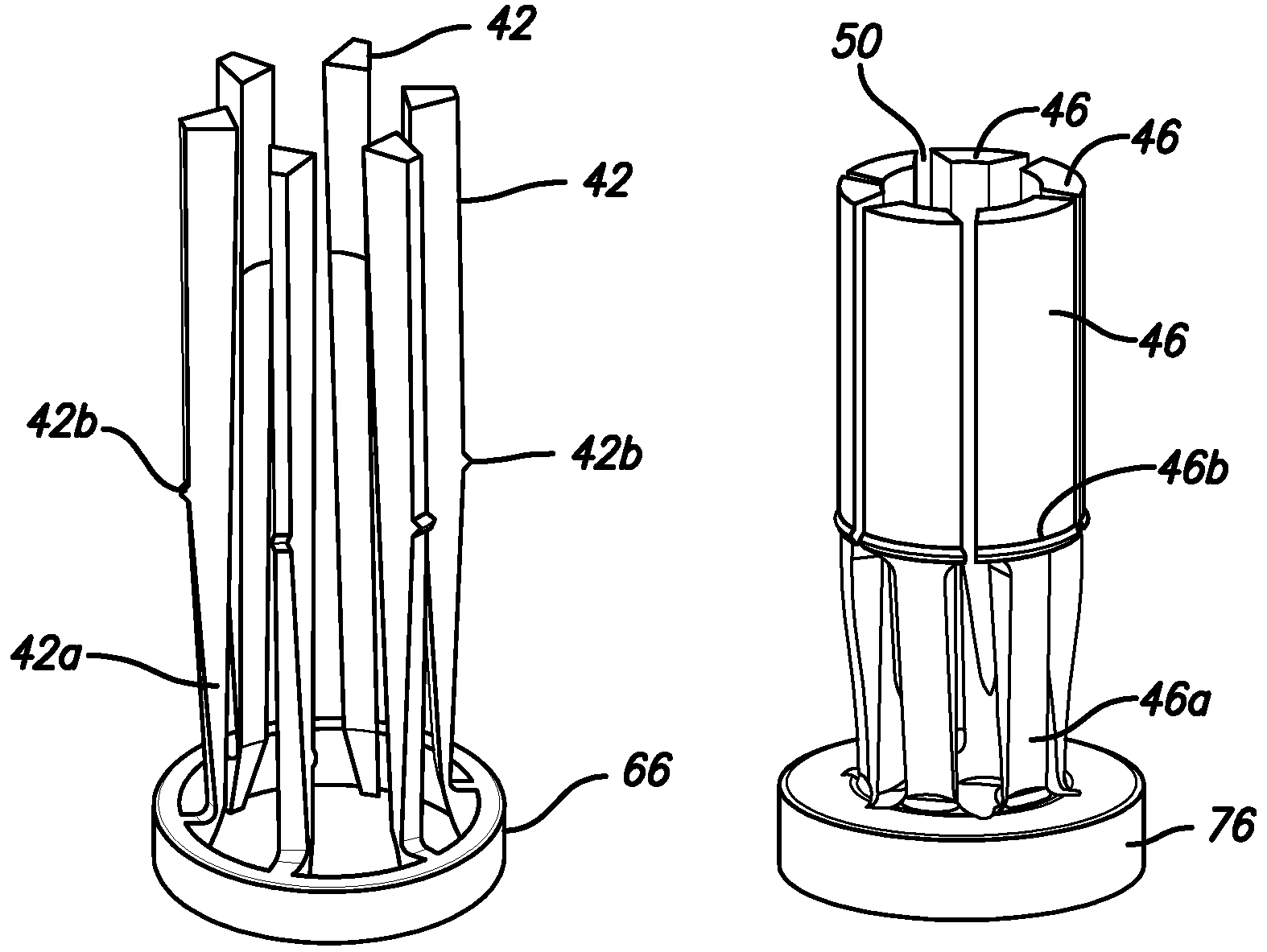

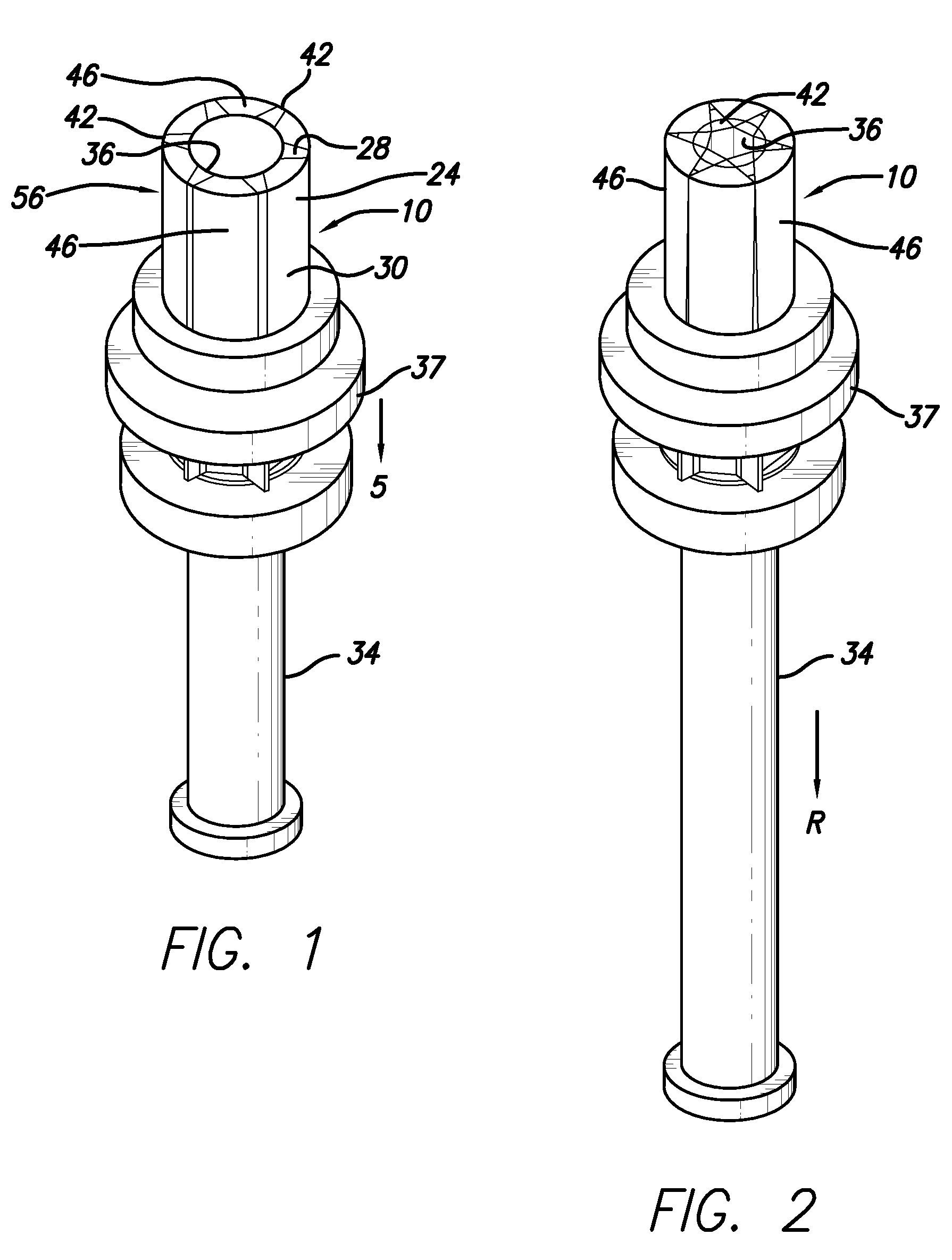

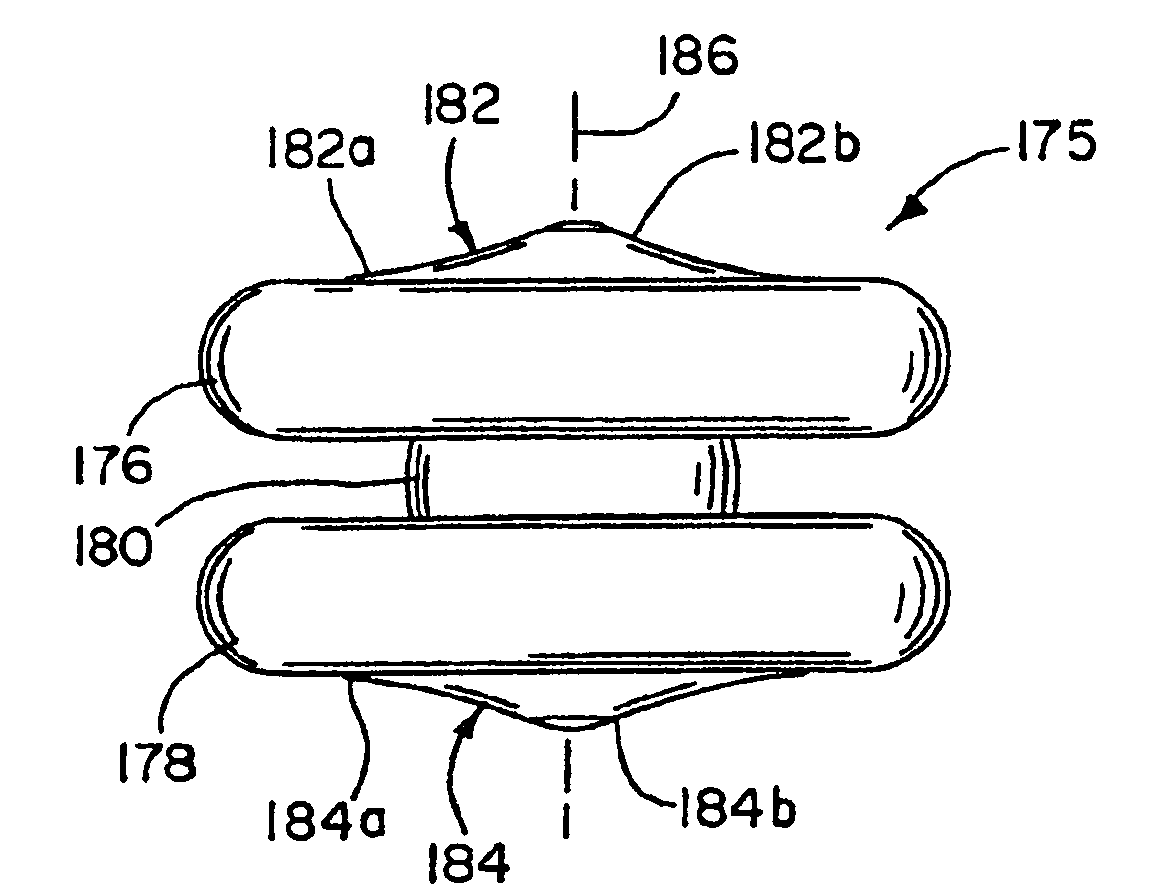

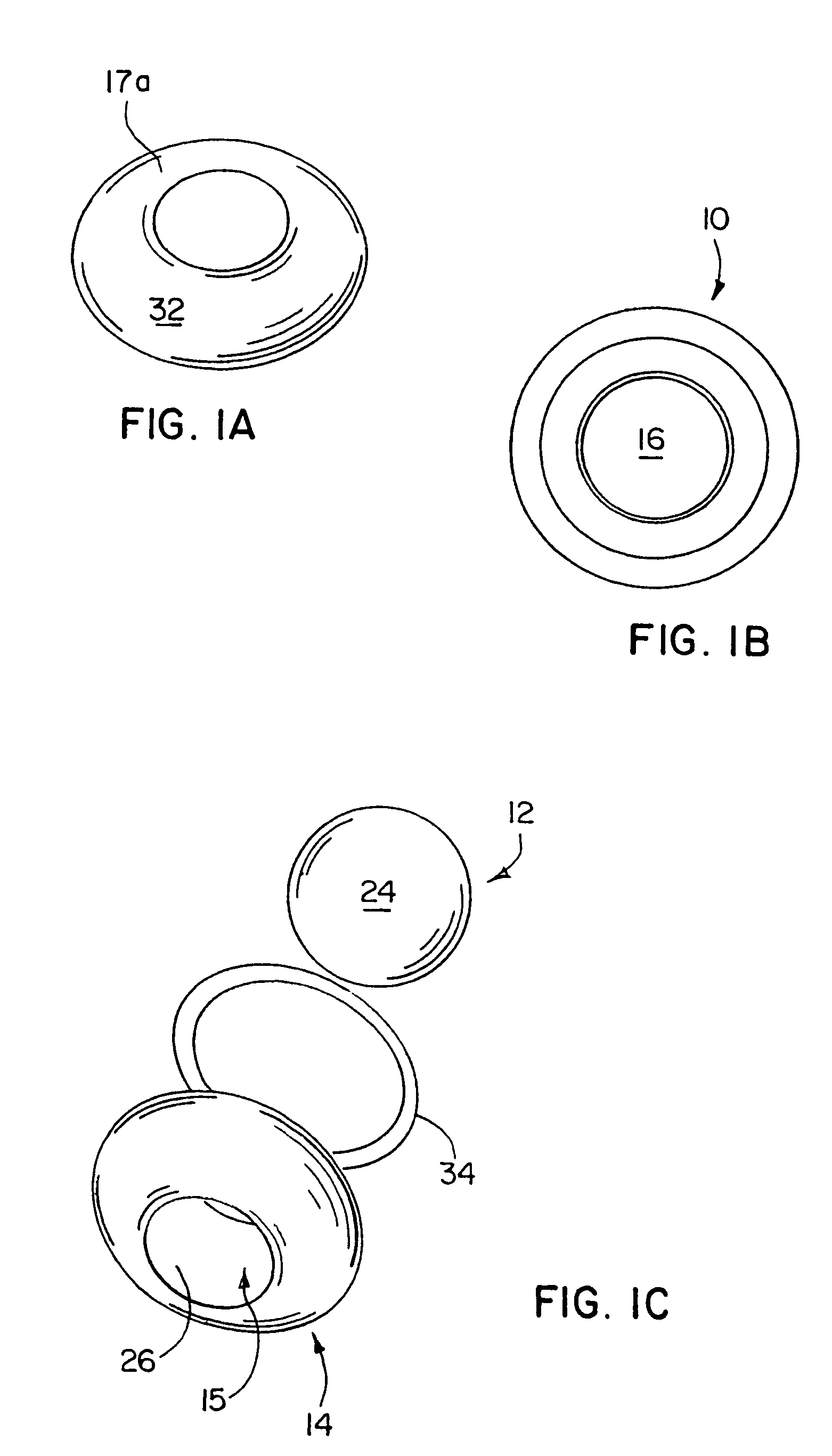

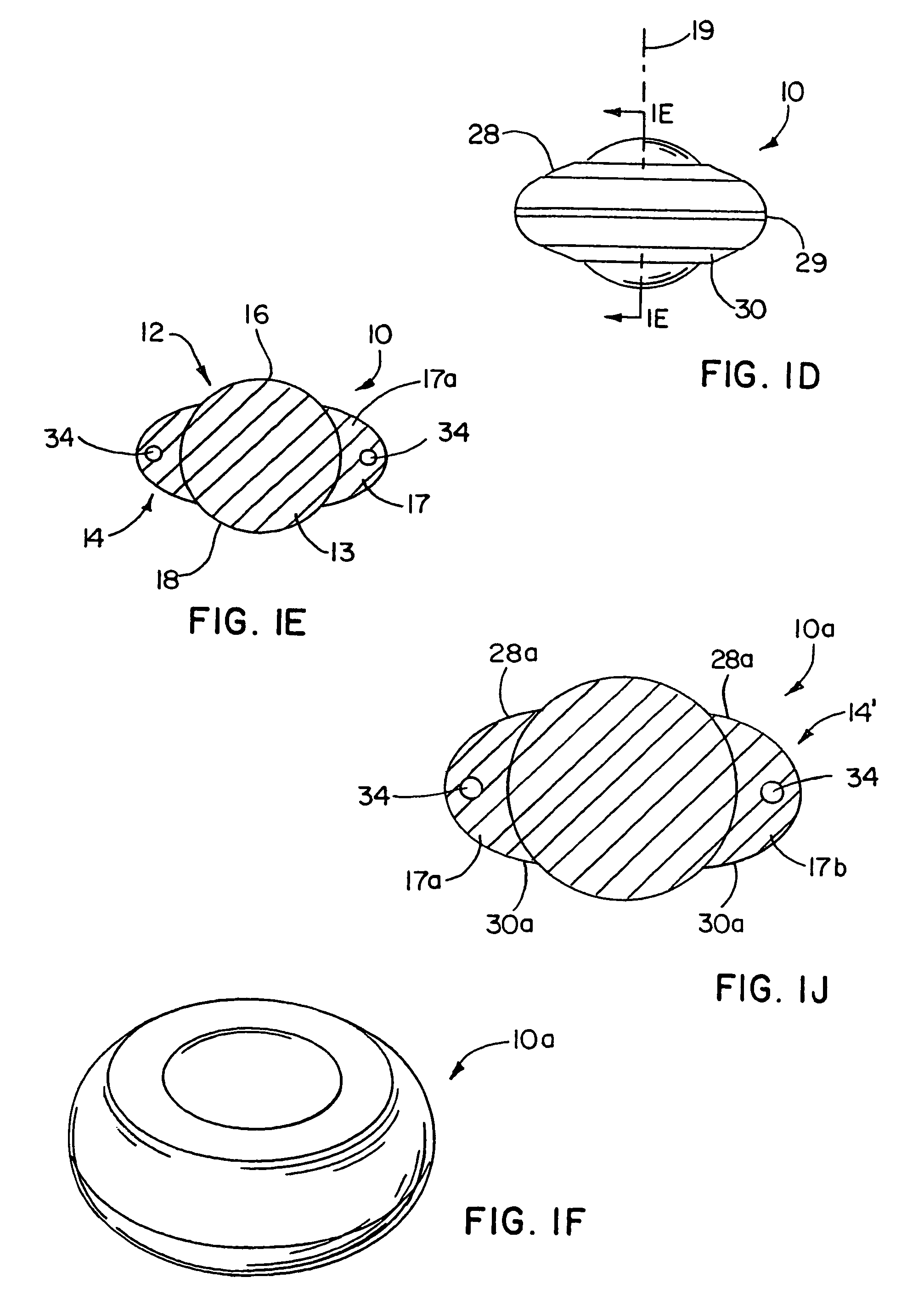

Artificial disc devices are disclosed that restore correct anatomical intervertebral spacing for damaged discs while maintaining a substantially normal range of biomechanical movement for the vertebrae between which they are implanted. The disc devices include center bearing and outer or annular bearing portions with the center bearing portion including generally axially extending locating surfaces which cooperate with the facing vertebral surfaces to resist migration. The outer bearing portion is for load bearing or load sharing with the center bearing portion and includes surfaces that extend radially toward the periphery of the vertebrae so that subsidence about the center bearing portion is minimized. Alternate forms of the disc devices include one with an axially enlarged center ball bearing having an annular ring bearing extending thereabout and another having upper and lower plate members with a central bumper member and a surrounding resilient annular member therebetween.

Owner:PIONEER SURGICAL TECH INC

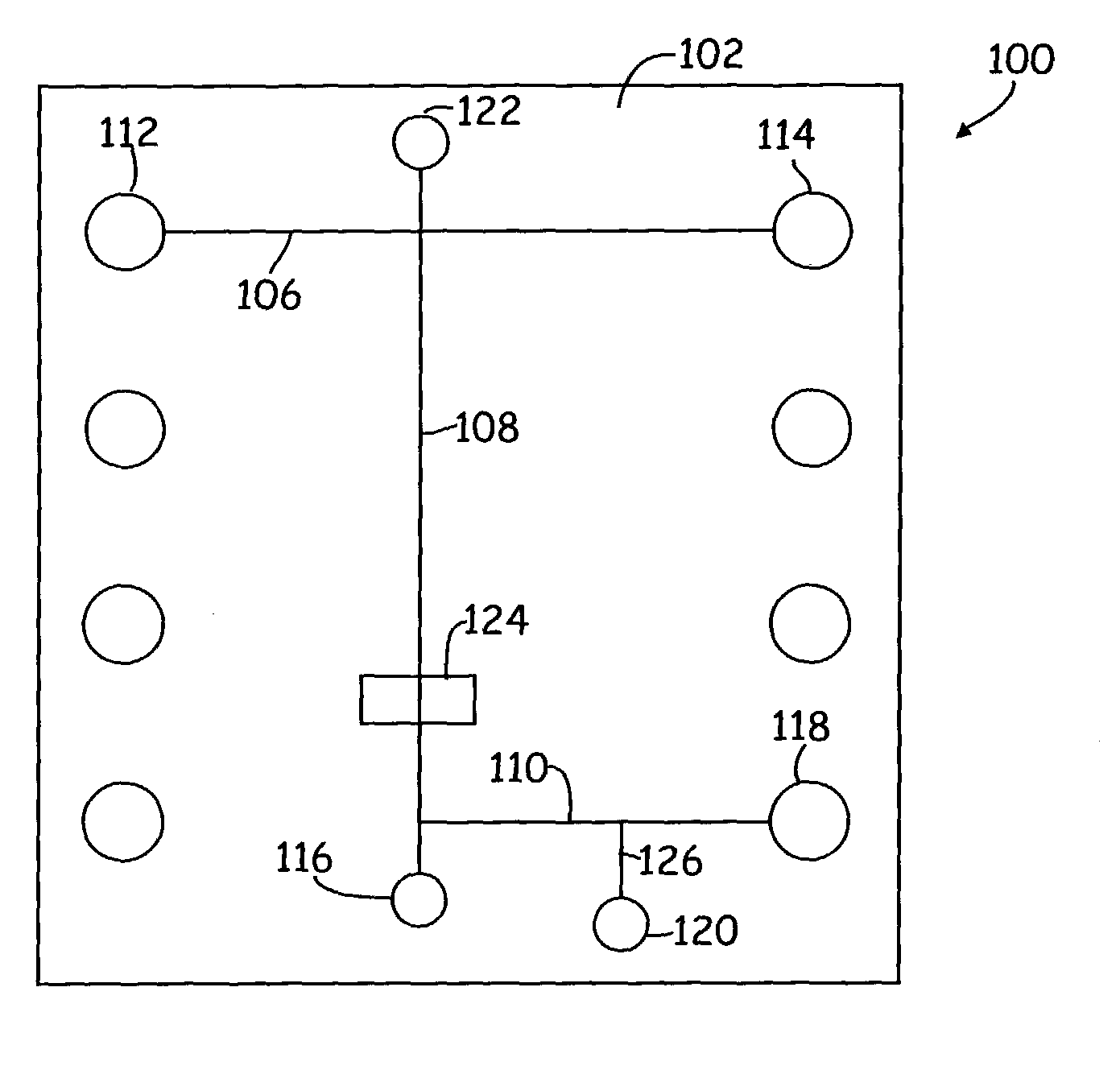

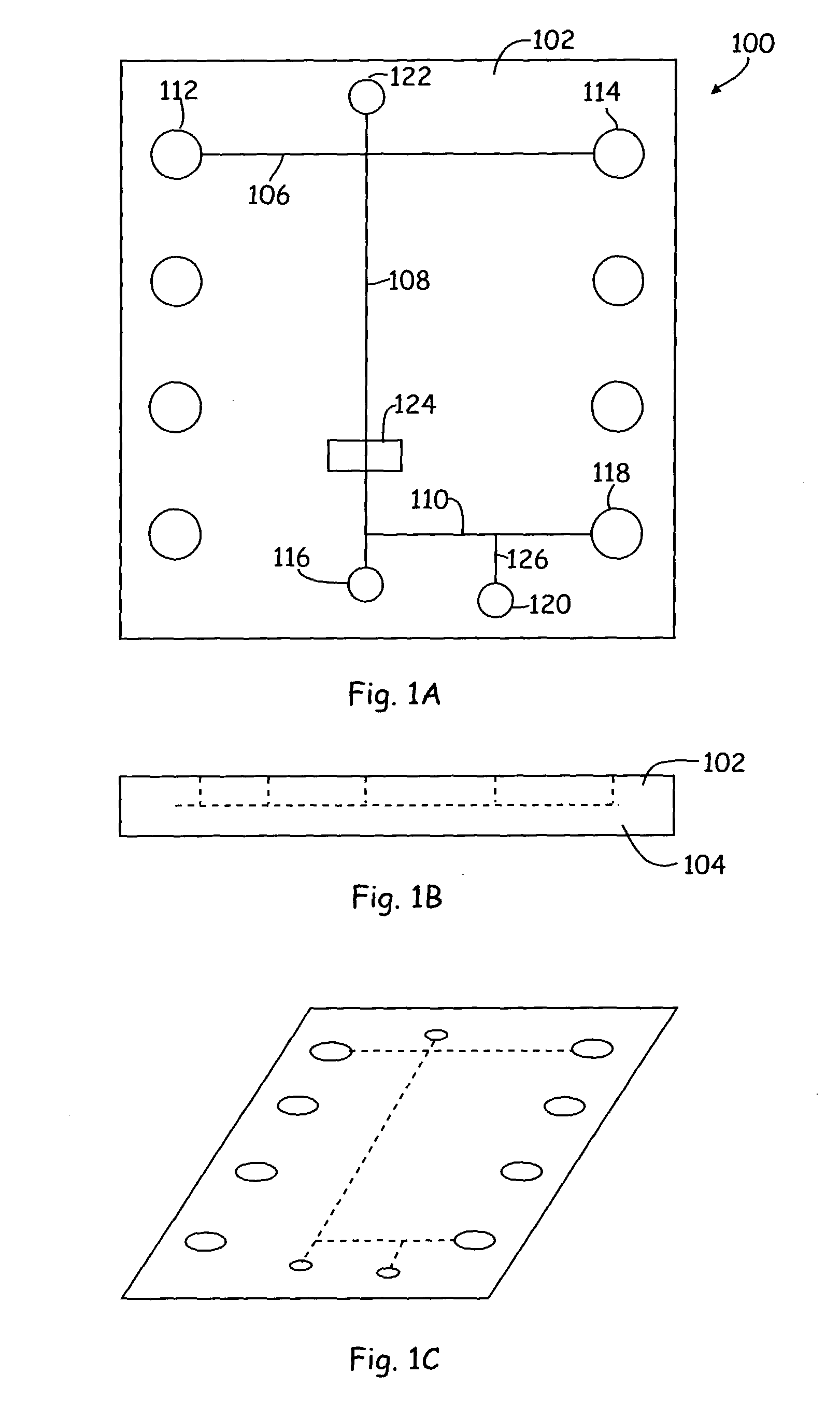

Methods, systems and apparatus for separation and isolation of one or more sample components of a sample biological material

ActiveUS20030215855A1AccuracyAccurate toleranceBioreactor/fermenter combinationsBiological substance pretreatmentsElectrophoresisBiological materials

Devices, systems and methods for use in separating sample materials into different sample components and then isolating one or more of the sample components for further processing or analysis are disclosed. Devices employ configurations that optionally allow a sample material to be electrophoretically separated into sample components in a separation matrix within a separation conduit. The sample components may then be detected in a detection zone in the separation conduit, and then selected components shunted to a component collection conduit within the device downstream of the detection zone for further processing or analysis based on information received at the detection zone. Methods of using these devices, and systems that incorporate these devices are also envisioned.

Owner:CAPLIPER LIFE SCI INC

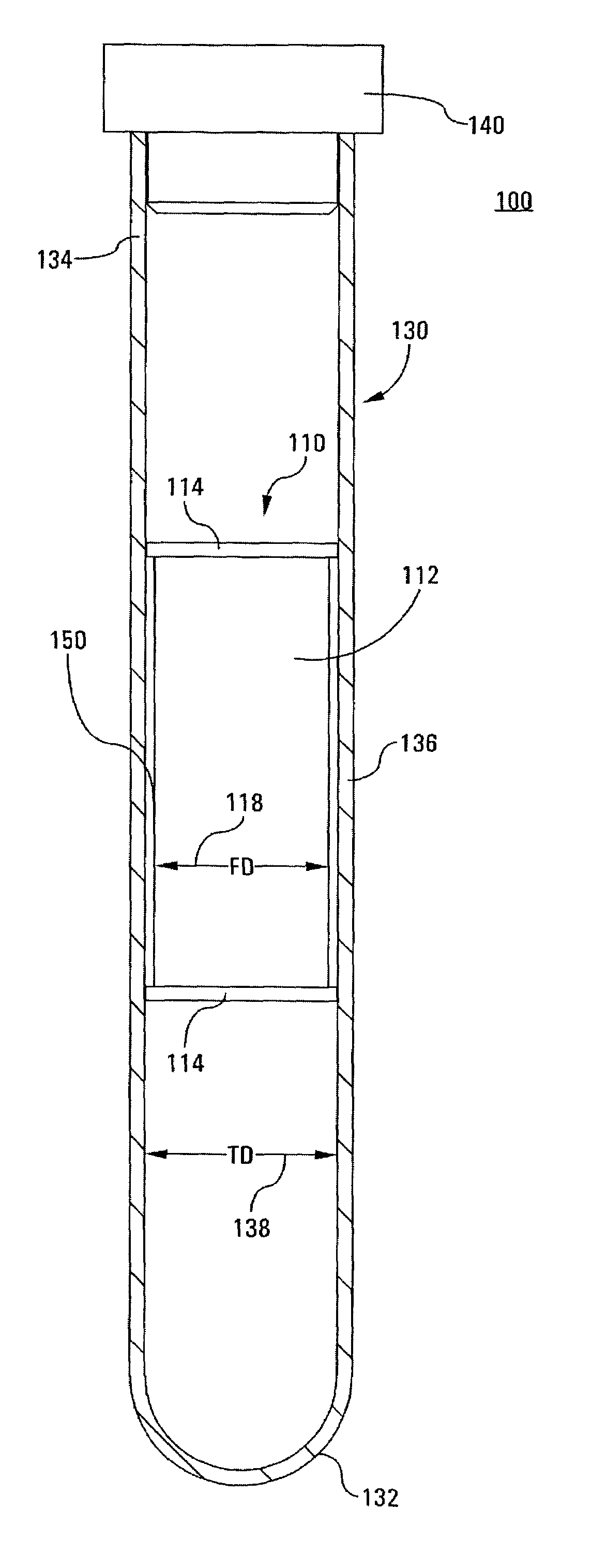

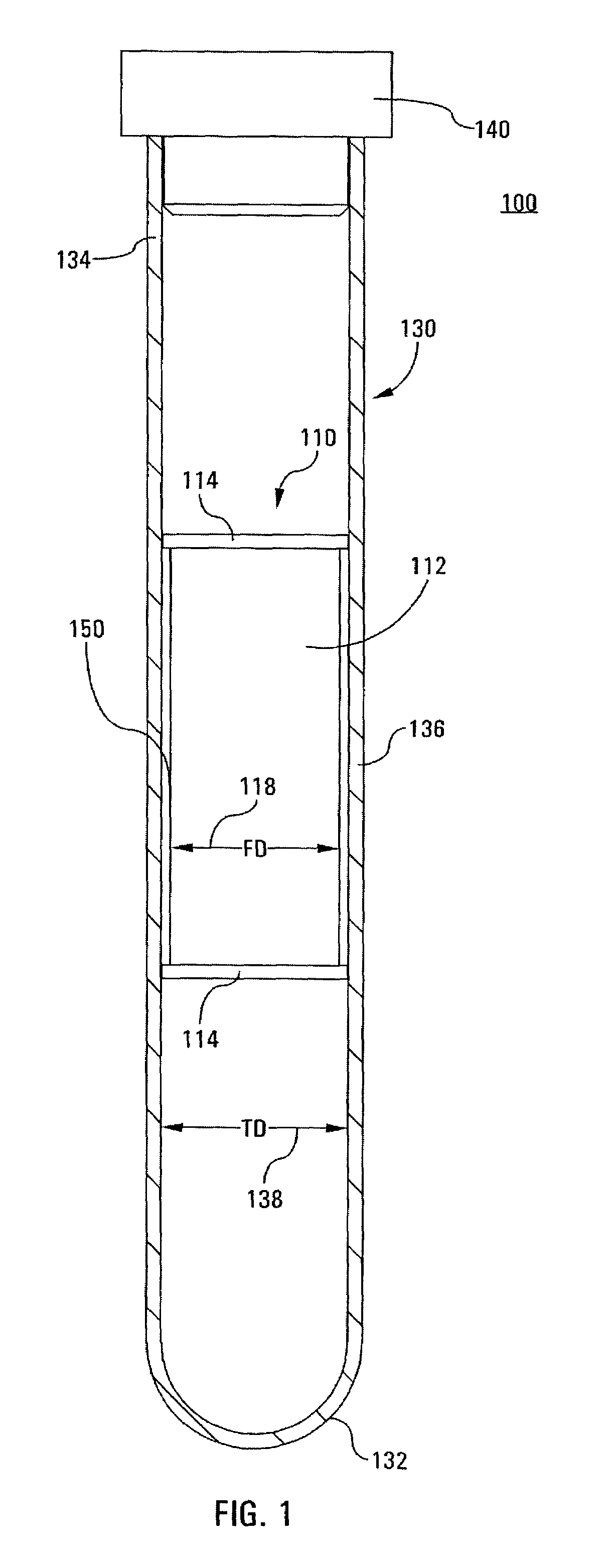

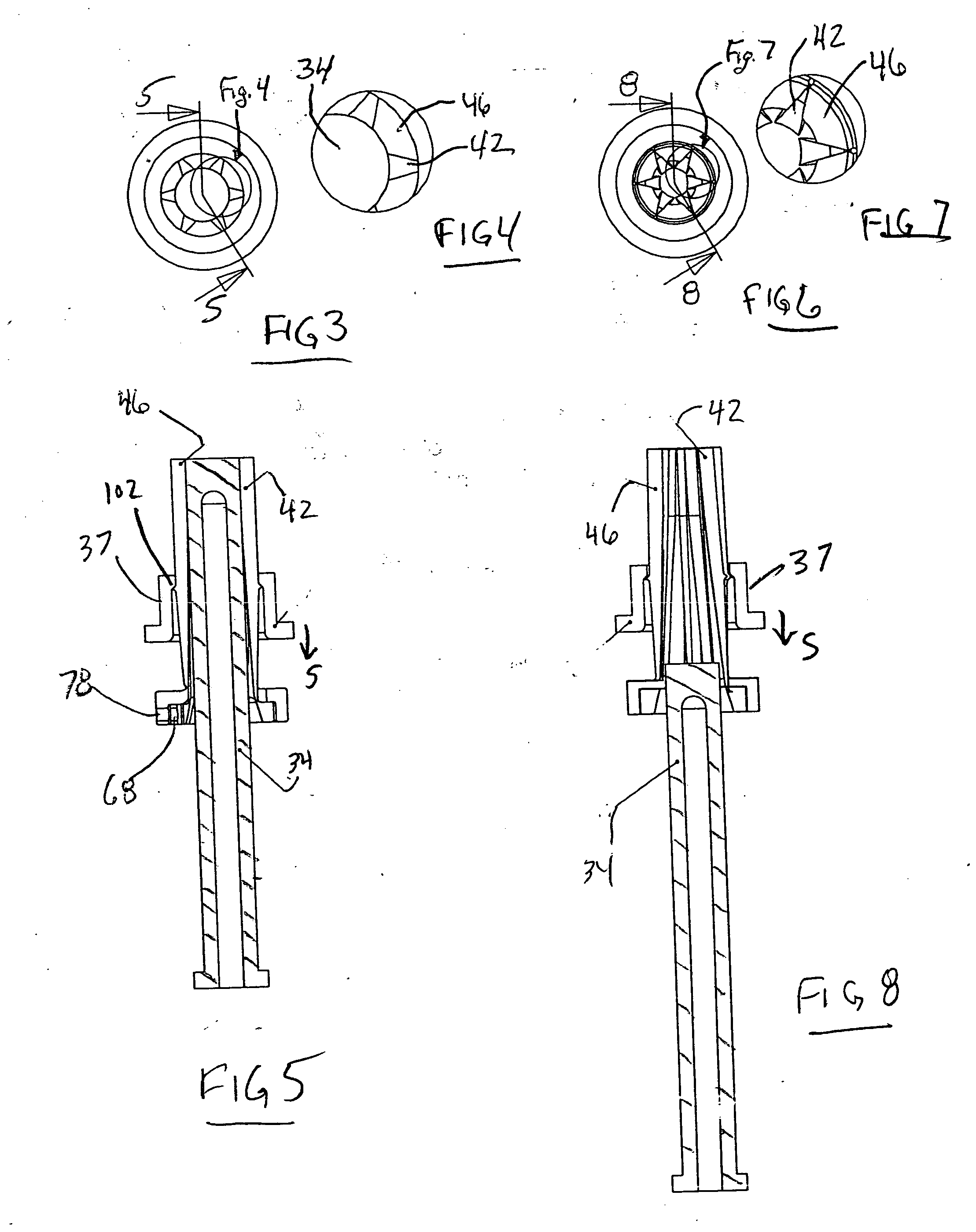

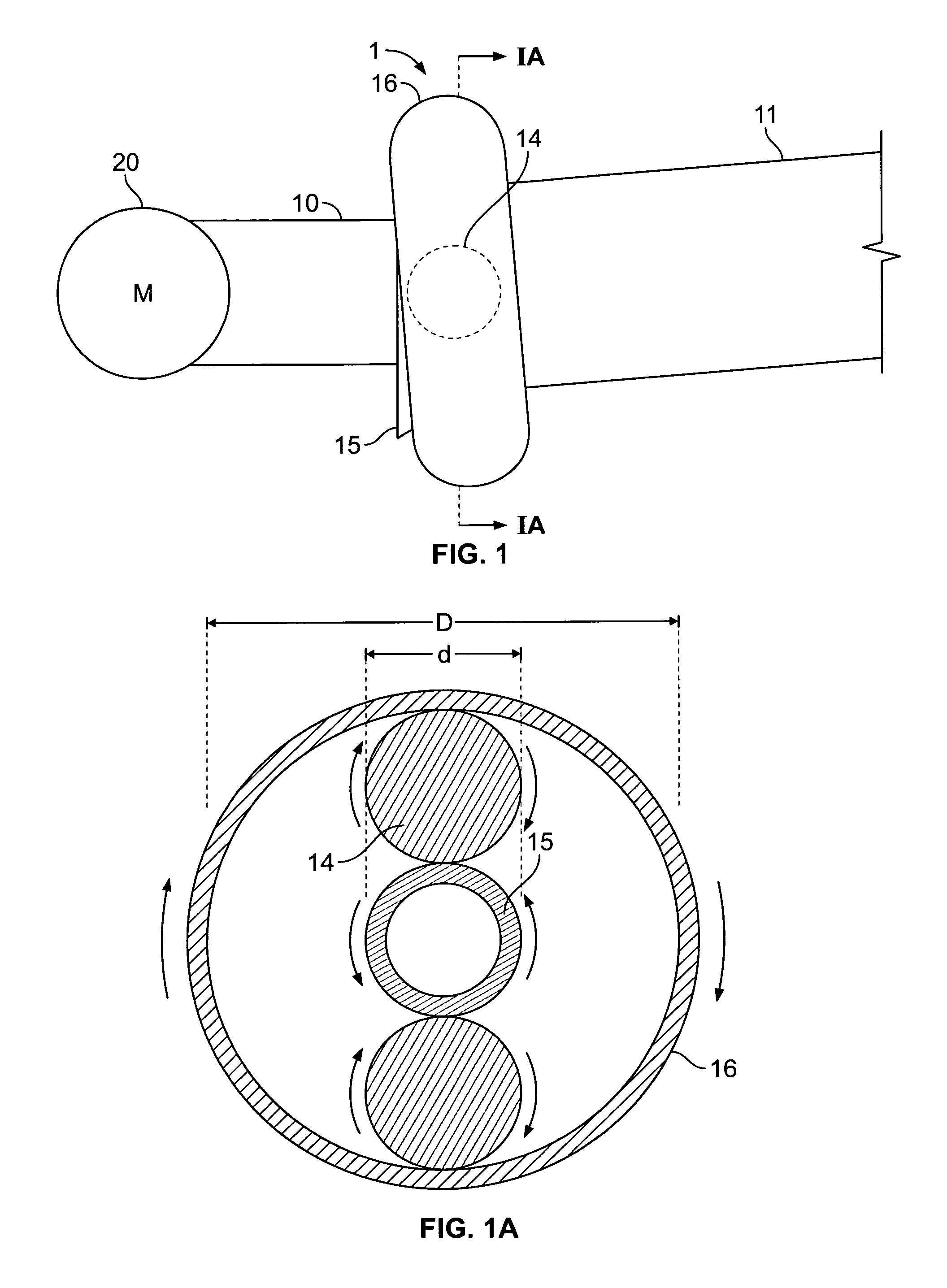

Buffy coat tube and float system and method

ActiveUS7074577B2Easy to separateReducing necessary cost of componentBioreactor/fermenter combinationsBiological substance pretreatmentsCentrifugationRed blood cell

A tube and float system for use in separation and axial expansion of the buffy coat is provided. The system includes a transparent, or semi-transparent, flexible sample tube and a rigid separator float having a specific gravity intermediate that of red blood cells and plasma. The sample tube has an elongated sidewall having a first cross-sectional inner diameter. The float consists of a main body portion and one or more support members protruding from the main body portion to engage and support the sidewall of the sample tube. The main body portion and the support members of the float have a cross-sectional diameter less than that of the first cross-sectional inner diameter of the tube when the sample tube is expanded, such as by centrifugation. The main body portion of the float together with an axially aligned portion of the sidewall define an annular volume therebetween. The support members protruding from the main body portion of the float traverse said annular volume to produce one or more analysis areas. During centrifugation, the centrifugal force enlarges the diameter of the tube to permit density-based axial movement of the float in the tube. Thereafter, the centrifugal force is reduced to cause the tube sidewall to return to its first diameter, thereby capturing the float and trapping the buffy coat constituents in the analysis area. The buffy coat constituents can then be evaluated or measured.

Owner:BATTELLE MEMORIAL INST

Assay sonication apparatus and methodology

InactiveUS20020137234A1Accurate toleranceImprove reaction speedBioreactor/fermenter combinationsBiological substance pretreatmentsAssayCell biology

An assay apparatus includes a cell with a working electrode and a sonicating device structurally coupled to the cell for sonication the contents of the cell.

Owner:MESO SCALE TECH LLC

Collapsible core assembly for a molding apparatus

ActiveUS7293341B2Improve manufacturabilityImproves manufactureMouldsConfectioneryShell moldingBiomedical engineering

Owner:ZYDRON GARRY

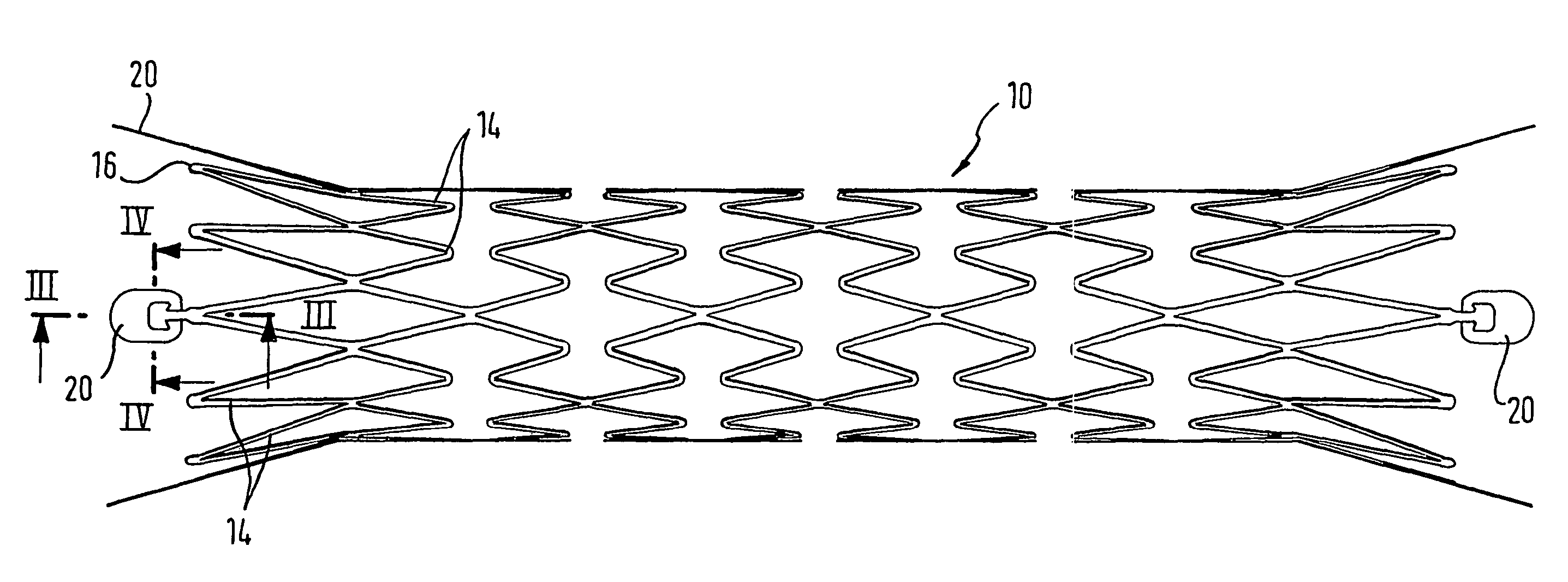

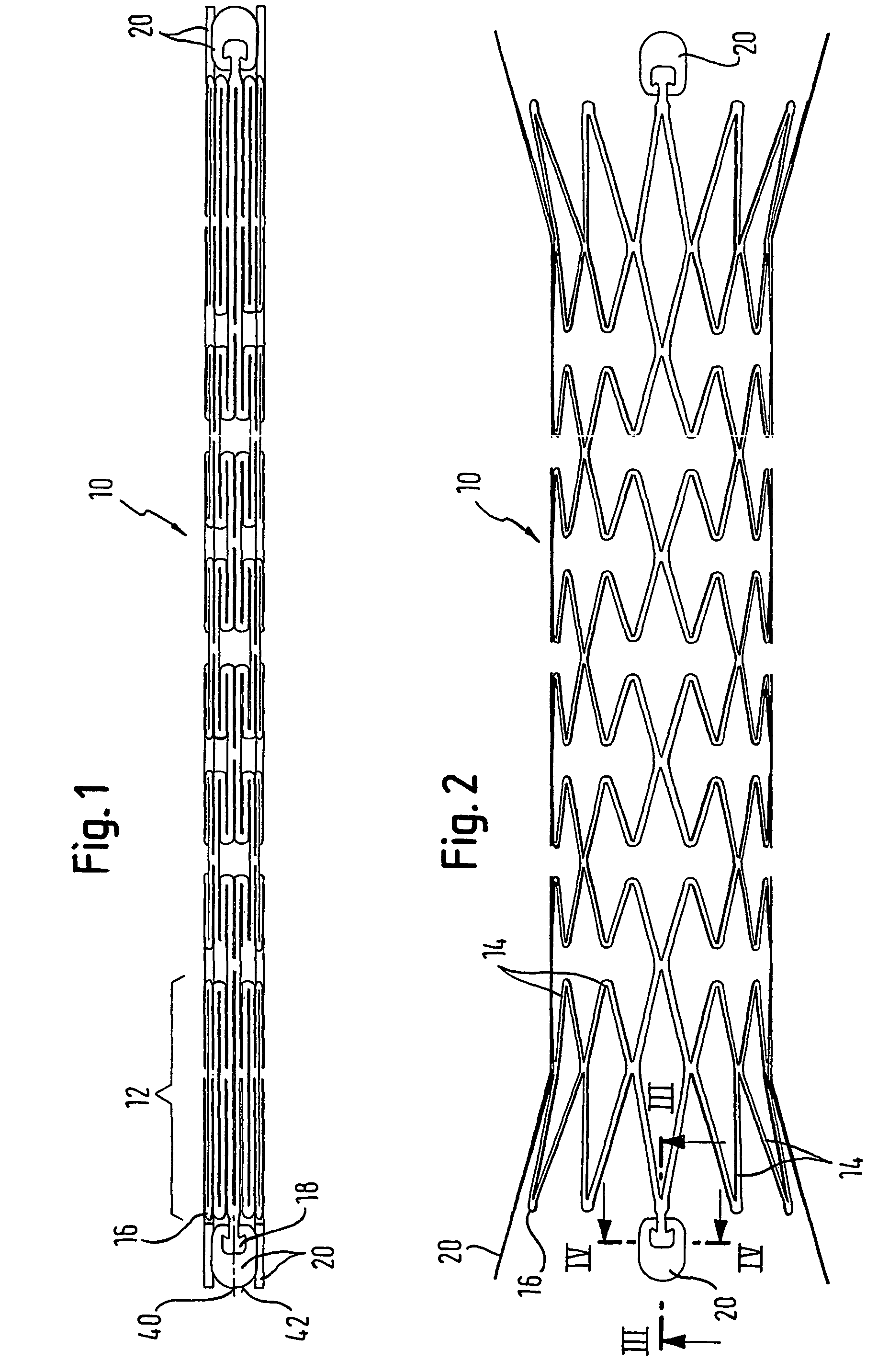

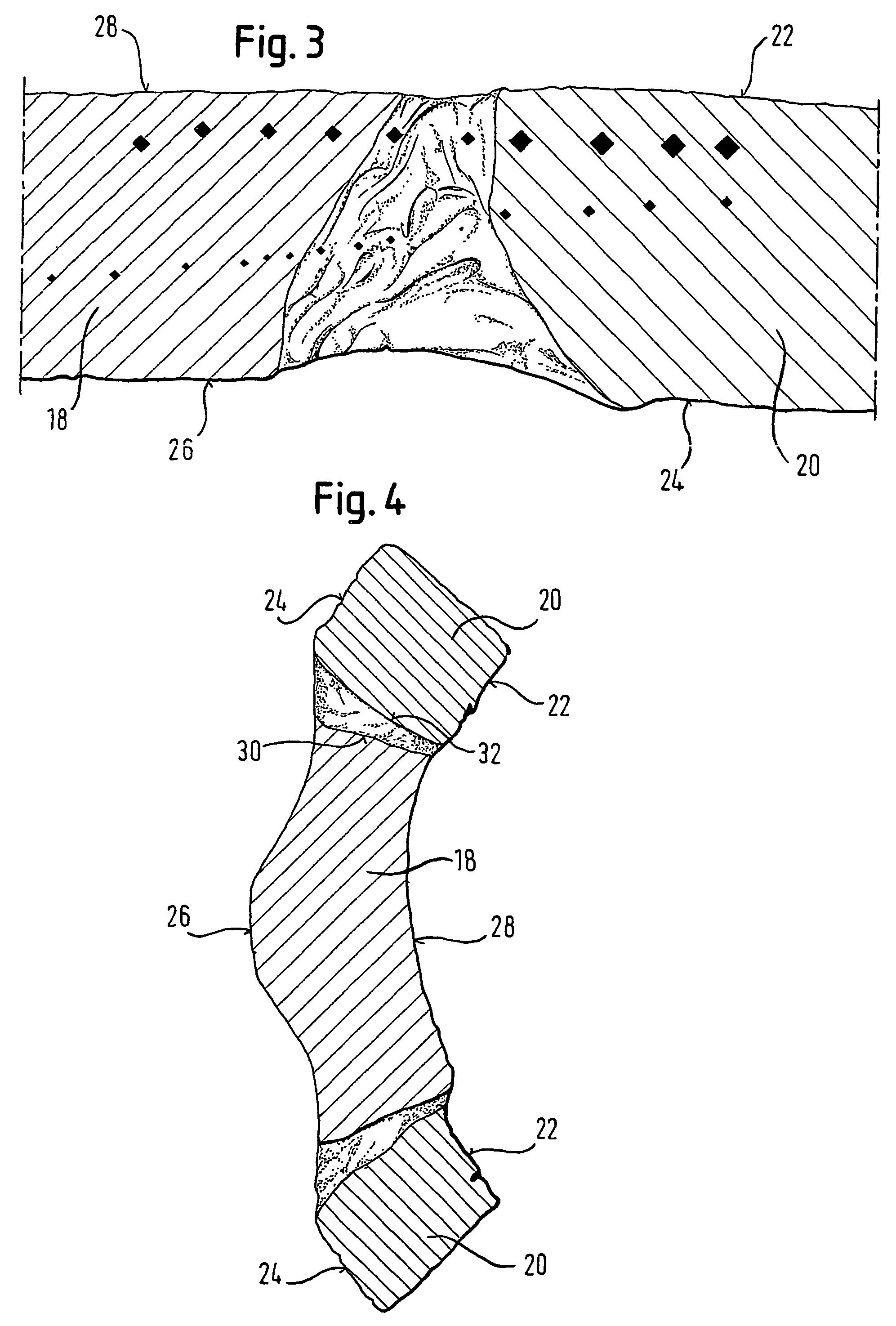

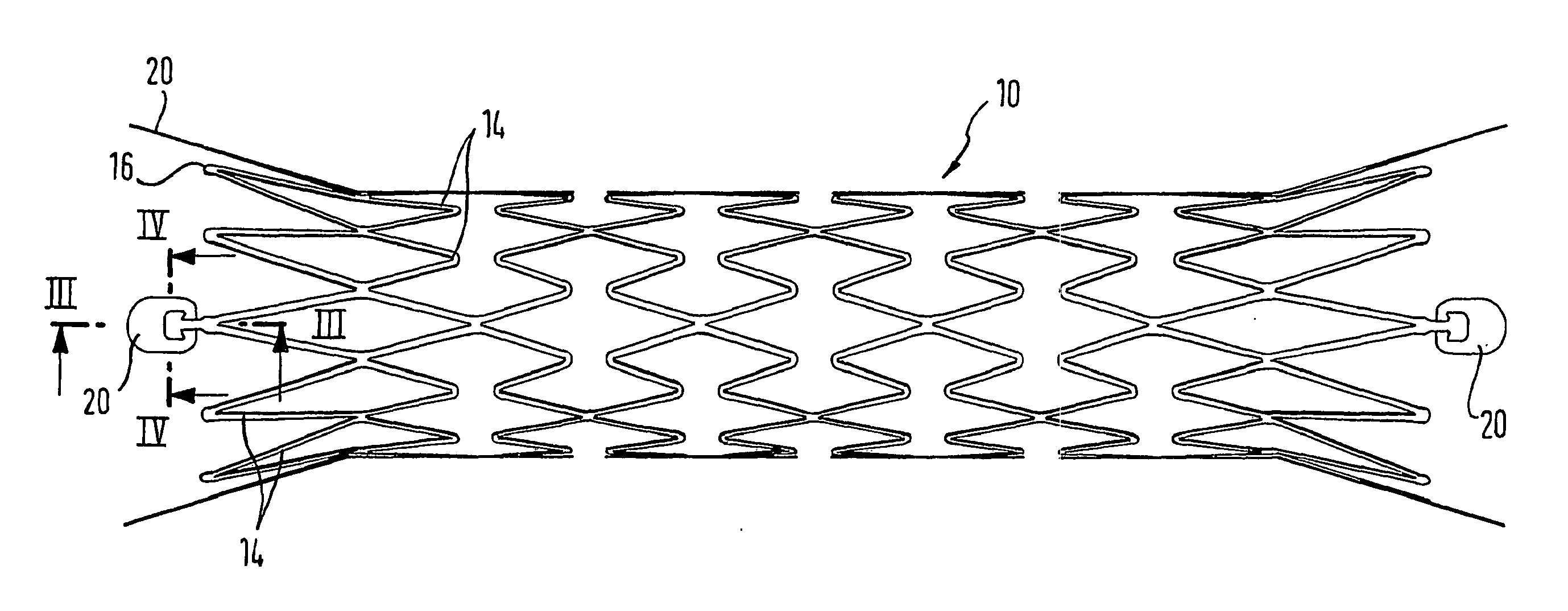

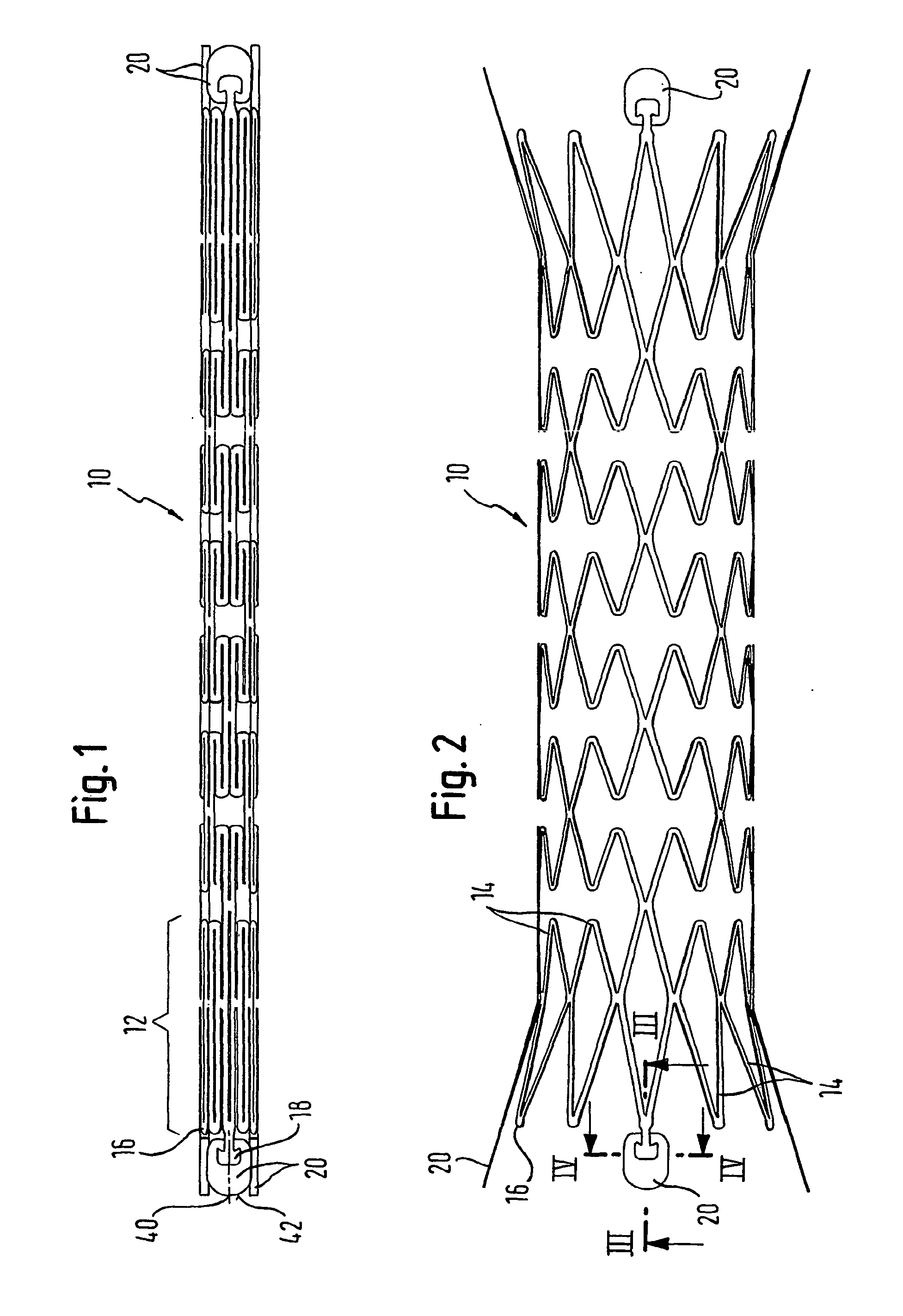

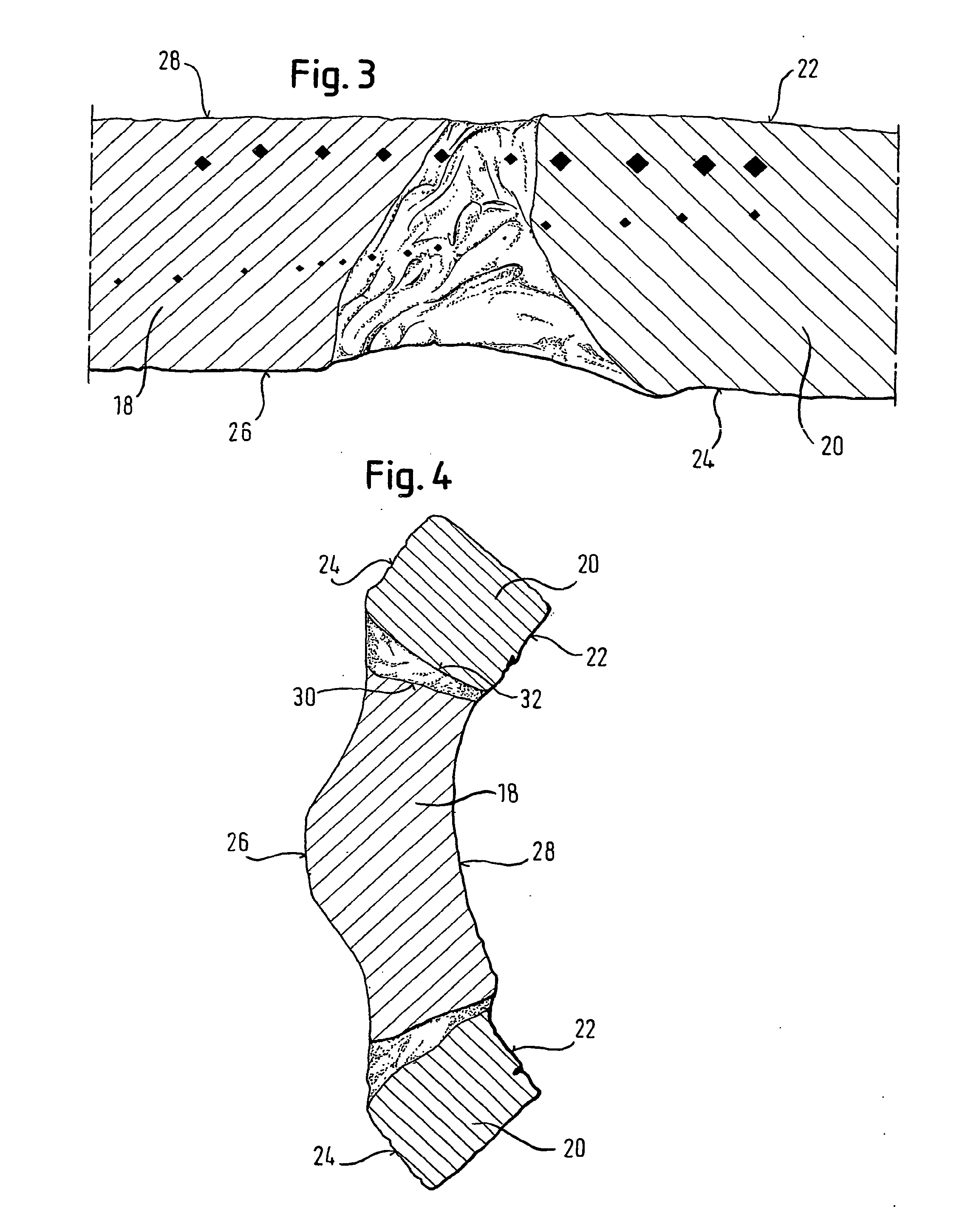

Implant with attached element and method of making such an implant

A tubular implant having an axial end to which is attached a ring of spoons of a material different from that of the implant. In another aspect, the invention provides a method of attaching elements to an axial end of a tubular implant comprising the steps of providing said elements on one end of a support tube having a radius substantially that of the implant in its unexpanded configuration, abutting the implant and elements end-to-end, fixing the elements to the implant; and parting the elements from the support tube. In a third aspect, the invention provides an implant carrying an element of another material, the element and implant having complementary tapered mating surfaces for achieving a taper form fit of the element onto the implant.

Owner:ANGIOMED GMBH & CO MEDIZINTECHNIK KG

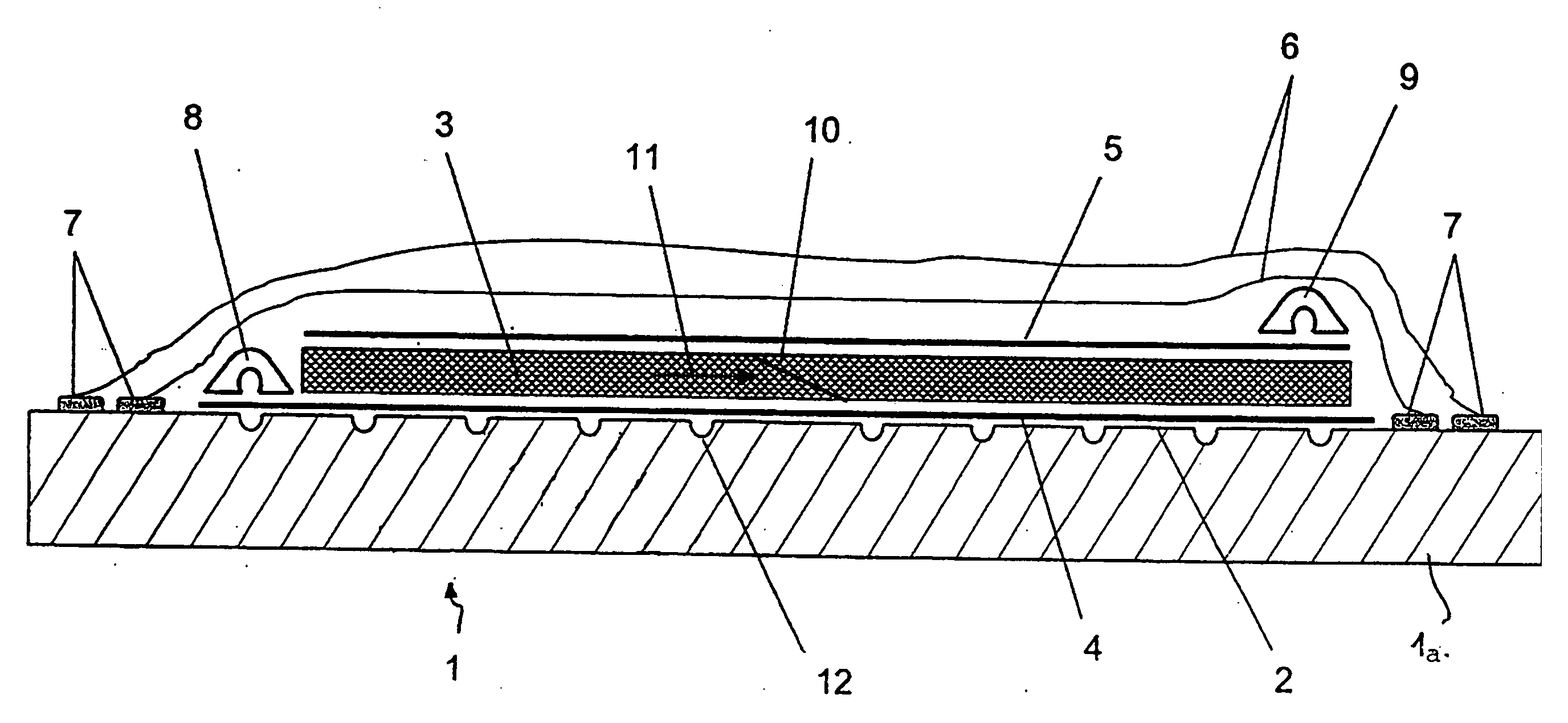

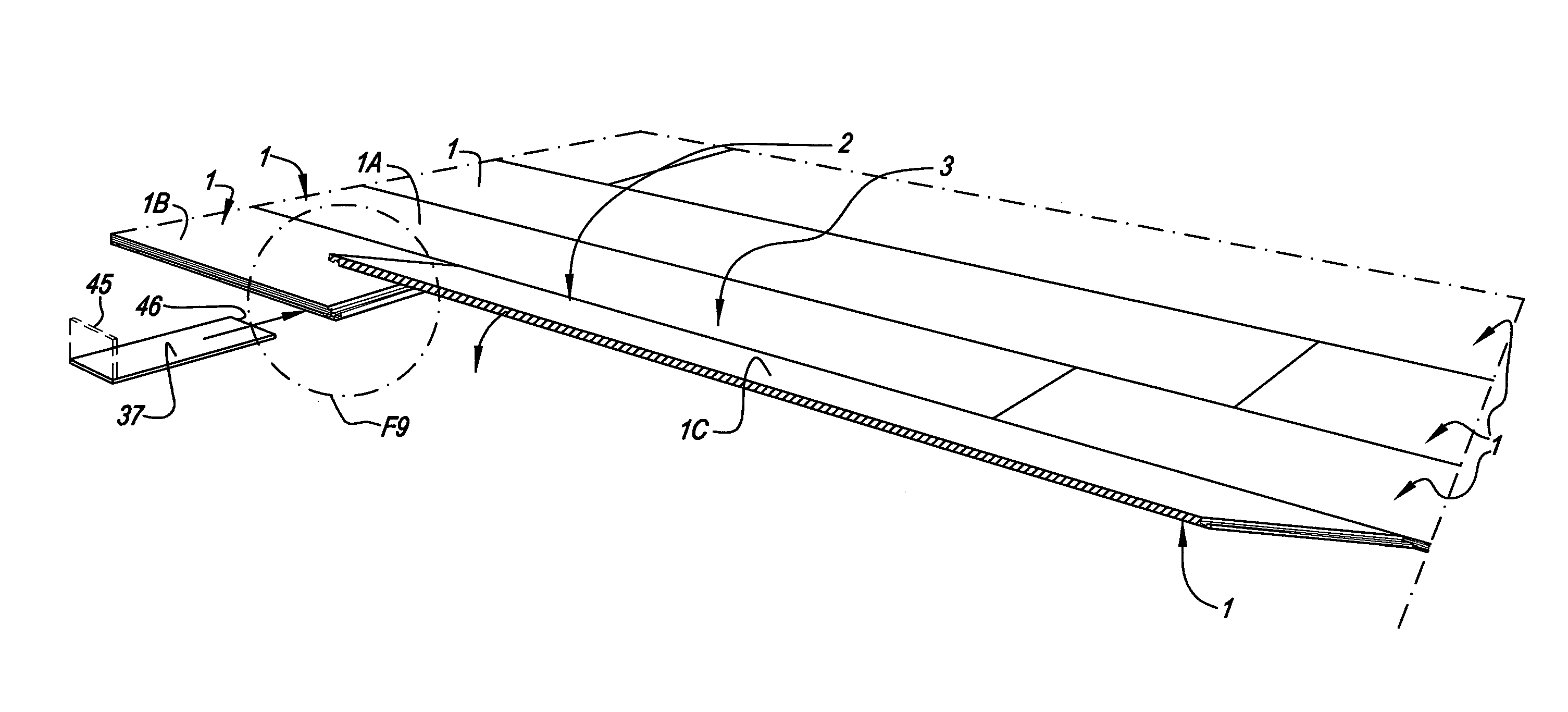

Tool for the production of fiber composite components

InactiveUS20080044506A1Excellent impregnationShort timeConfectionerySweetmeatsWork in processFibrous composites

The present invention provides a tool for the production of fiber composite components. The tool has a surface for depositing semifinished fiber products on the surface, the surface having a number of openings for feeding a matrix to the deposited semifinished fiber products. It is consequently possible to dispense entirely or partly with a conventional flow promoter and possible to achieve a high quality of fiber composite component.

Owner:AIRBUS OPERATIONS GMBH

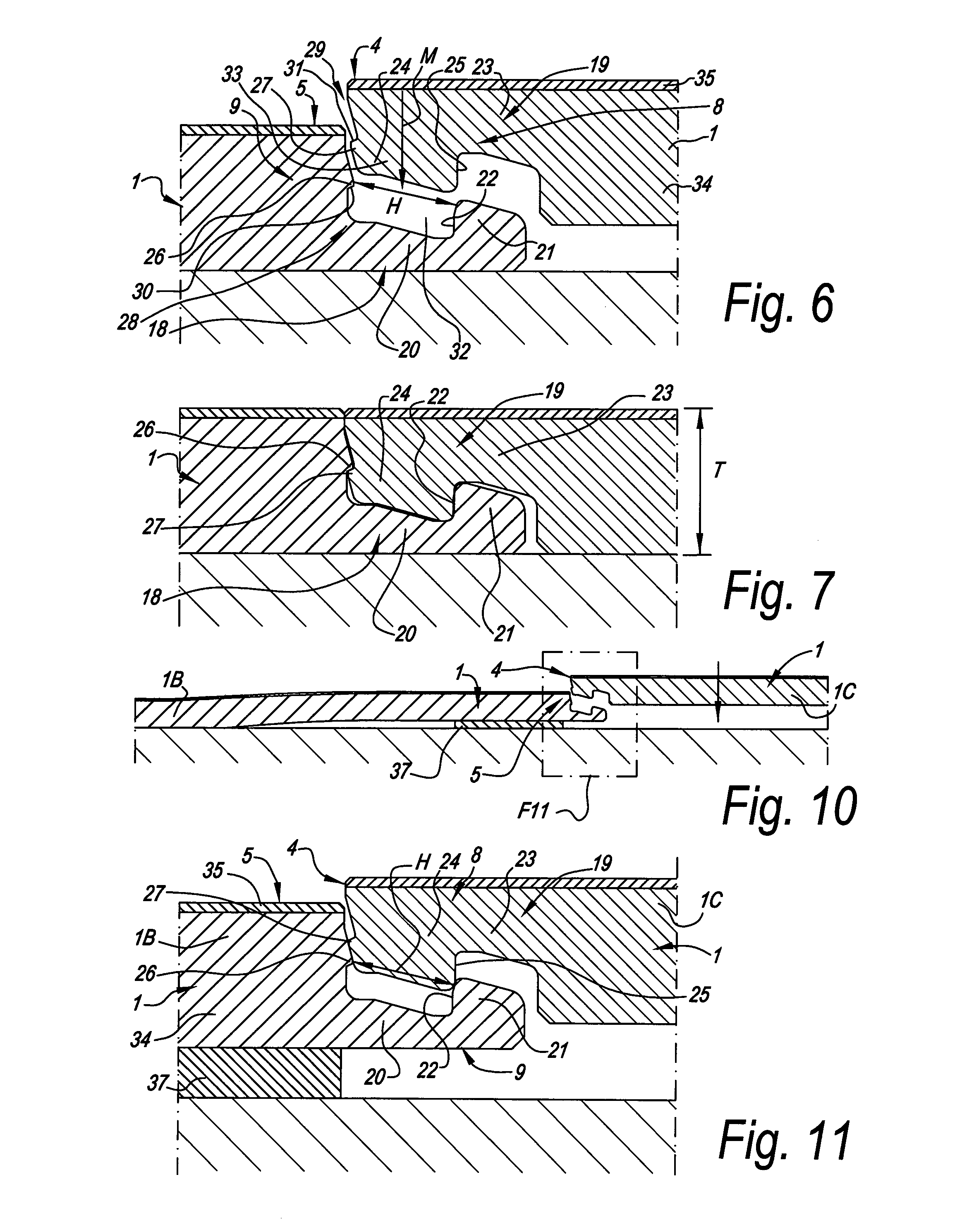

Artificial disc device

InactiveUS20050256581A1Improve distributionImprove shock absorptionSurgeryJoint implantsBall bearingEngineering

Artificial disc devices are disclosed that restore correct anatomical intervertebral spacing for damaged discs while maintaining a substantially normal range of biomechanical movement for the vertebrae between which they are implanted. The disc devices include center bearing and outer or annular bearing portions with the center bearing portion including generally axially extending locating surfaces which cooperate with the facing vertebral surfaces to resist migration. The outer bearing portion is for load bearing or load sharing with the center bearing portion and includes surfaces that extend radially toward the periphery of the vertebrae so that subsidence about the center bearing portion is minimized. Alternate forms of the disc devices include one with an axially enlarged center ball bearing having an annular ring bearing extending thereabout and another having upper and lower plate members with a central bumper member and a surrounding resilient annular member therebetween.

Owner:PIONEER SURGICAL TECH INC

Peep sight and related method of manufacture

A peep sight for an archery bow. The peep sight can define a peep aperture bounded by a curvilinear bulge optionally constructed from magnesium or a magnesium alloy. The peep sight bulge can circumferentiate the peep aperture, and can form an apex about midway between a forward surface and a rearward surface of the peep sight. The peep sight can define a serving slot and two or more angled bowstring strand slots for receiving portions of the bowstring strands to mount the peep sight to a bowstring. The peep sight can be blue in color. A method is provided including: machining a magnesium, magnesium alloy and / or other material blank into a peep body; and removing a portion of a peep body to define a peep aperture bound by a curvilinear bulge. Optionally, a strand slot and / or a serving slot can be machined into a surface of the body.

Owner:GRACE ENG

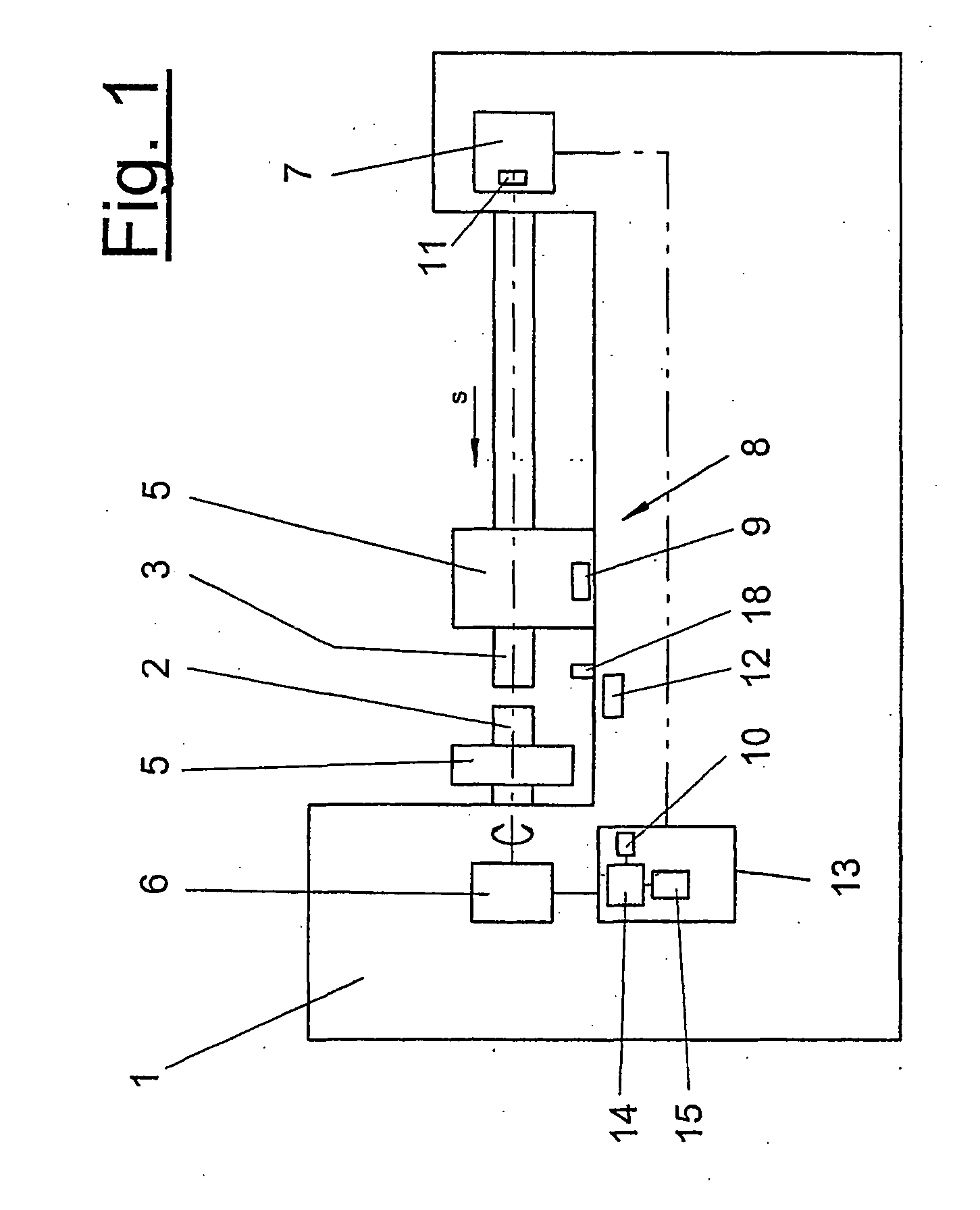

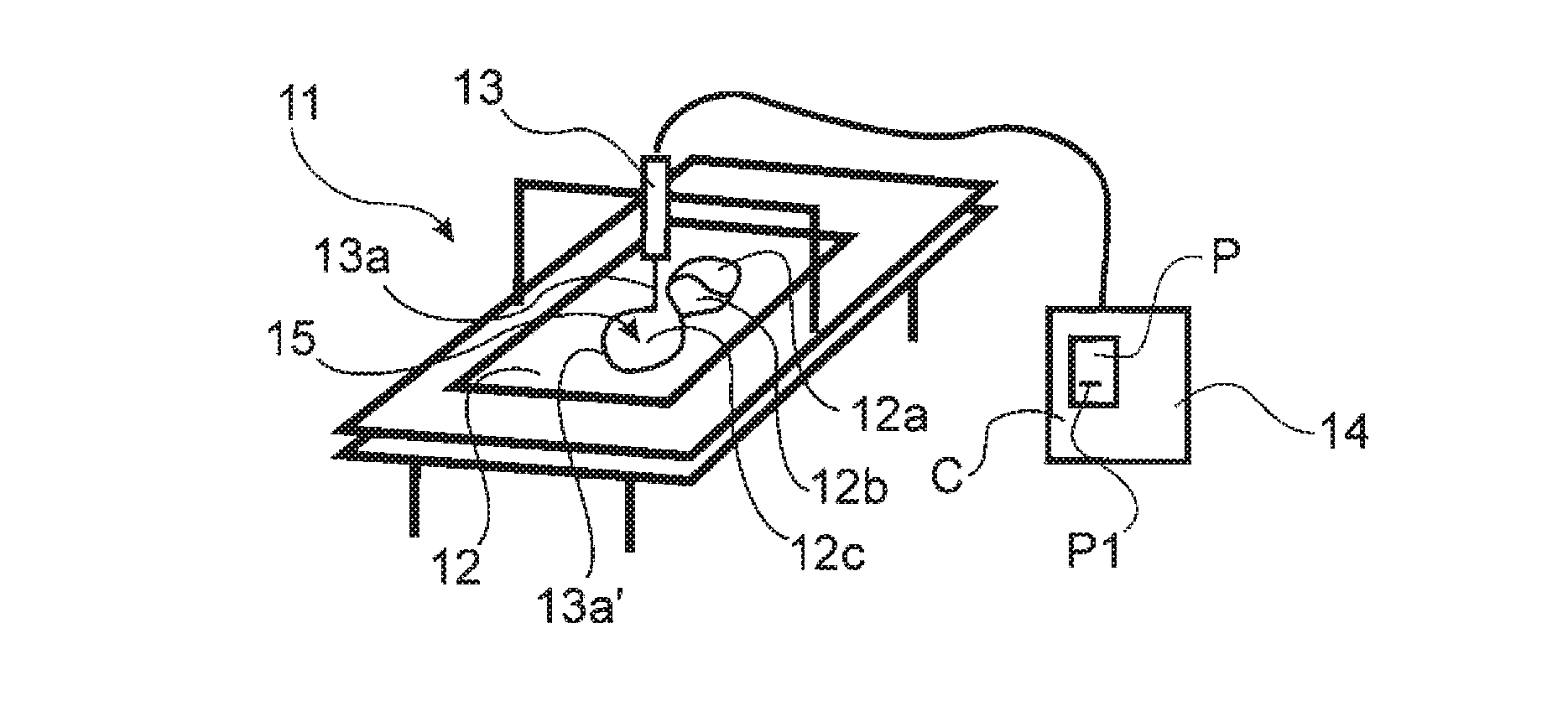

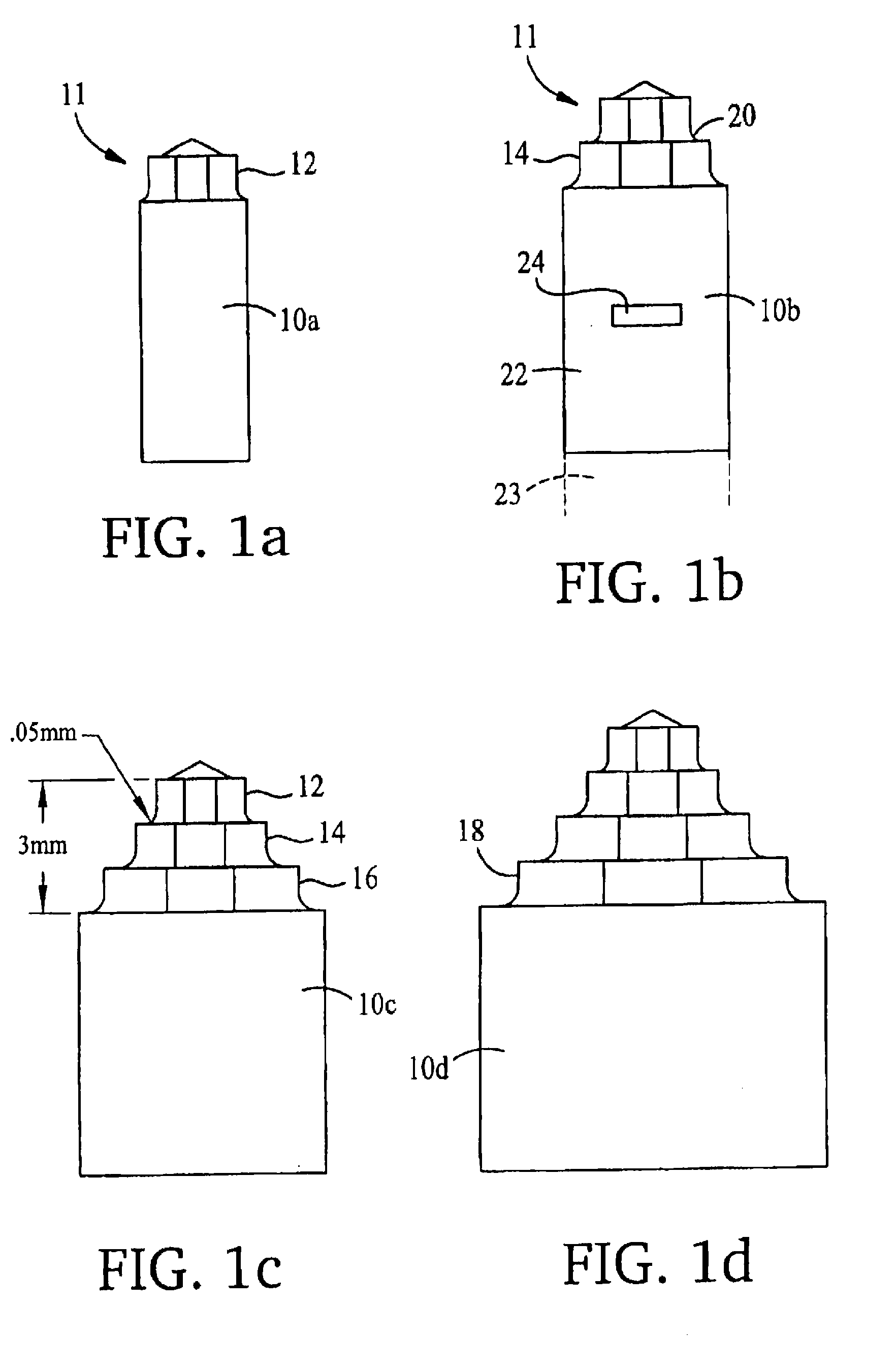

Method and device for pressure welding, which takes into account deviations in the length of workpieces

InactiveUS20060196916A1Suitable for processingChangeArc welding apparatusNon-electric welding apparatusFriction weldingUnits of measurement

A method and a device are provided for pressure welding, in particular for the friction welding or magnetic arc welding of workpieces (2, 3). The actual length of one or both workpieces (2, 3) and a potential length deviation (DELTA 1) from a target value is measured. If a length deviation exists, the target value of at least one parameter, in particular of the friction length, friction duration, arcing time or forge force is modified. A correction factor C, by which the length deviation (DELTA 1) is multiplied, is determined for this modification. The pressure welding device (1) includes a corresponding measuring unit (12) for determining workpiece lengths and length deviations. The controller (13) comprises an arithmetic unit (14) for setting and modifying target values, taking into account the correction factor C.

Owner:KUKA SYSTEMS

Implant with attached element and method of making such an implant

A tubular implant having an axial end to which is attached a ring of spoons of a material different from that of the implant. In another aspect, the invention provides a method of attaching elements to an axial end of a tubular implant comprising the steps of providing said elements on one end of a support tube having a radius substantially that of the implant in its unexpanded configuration, abutting the implant and elements end-to-end, fixing the elements to the implant, and parting the elements from the support tube. In a third aspect, the invention provides an implant carrying an element of another material, the element and implant having complementary tapered mating surfaces for achieving a taper form-fit of the element onto the implant.

Owner:ANGIOMED GMBH & CO MEDIZINTECHNIK KG

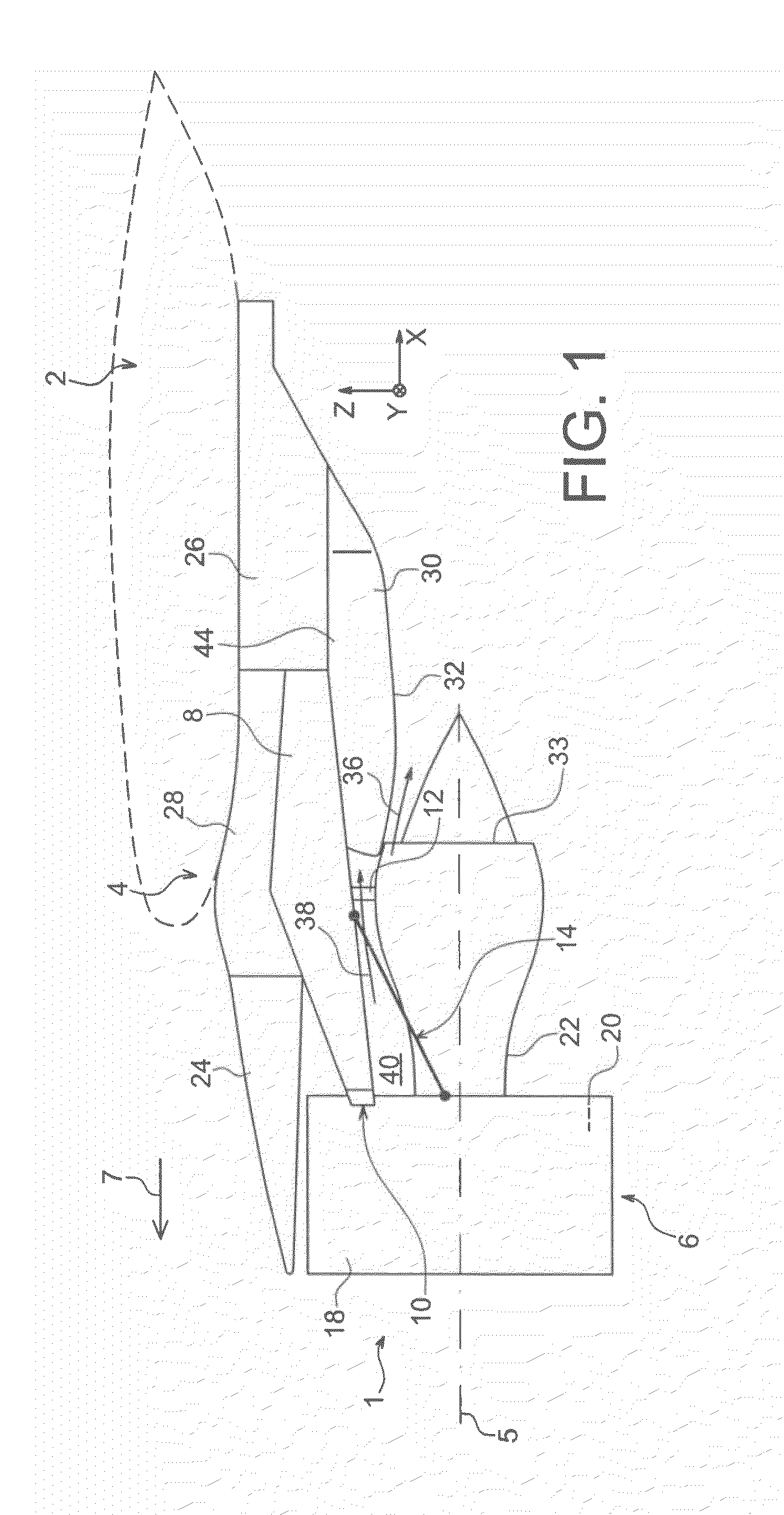

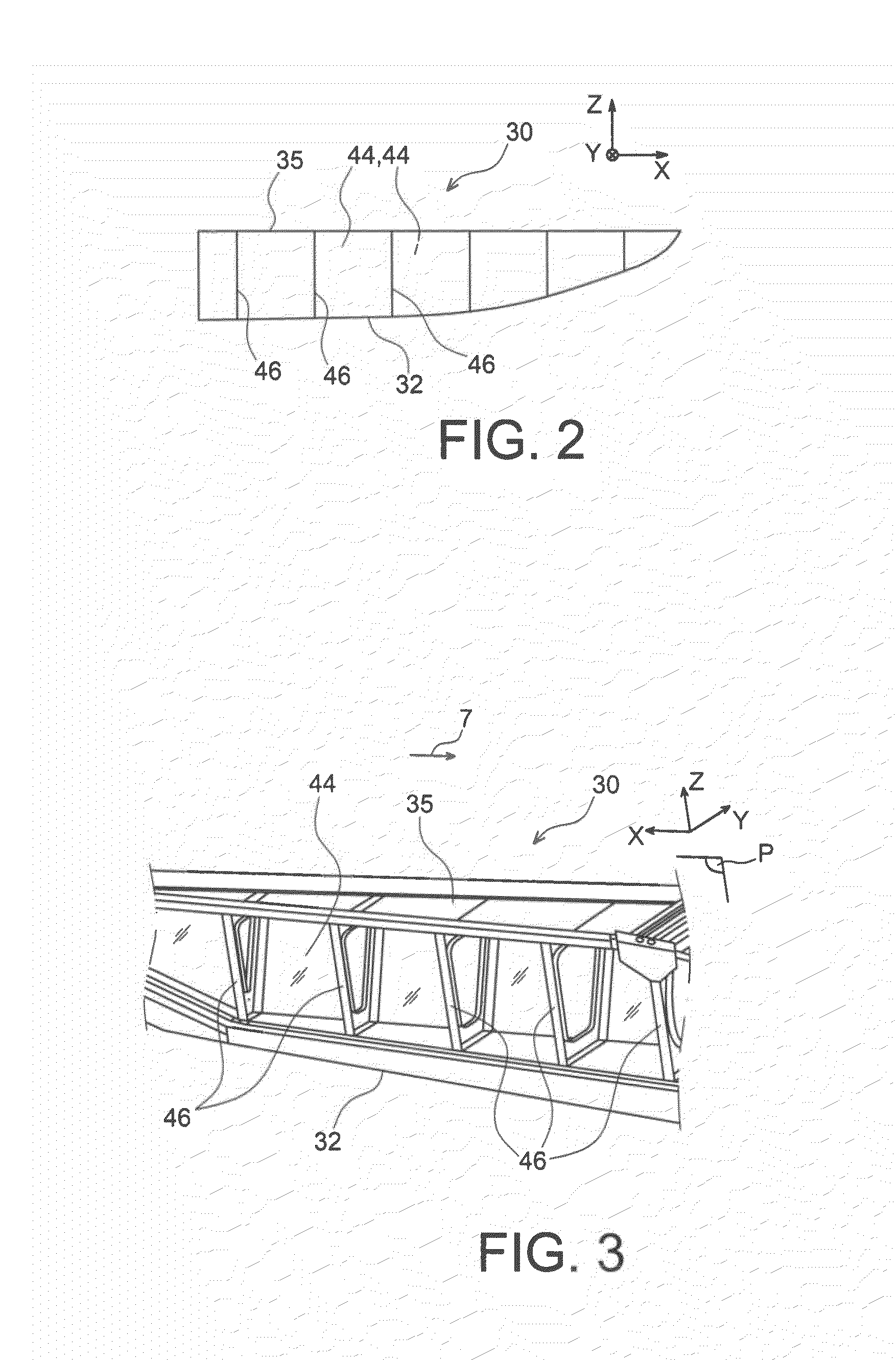

Method of manufacture by superplastic forming and by fishplating of a rib for an aerodynamic fairing of an aircraft engine mounting pylon

InactiveUS20110290935A1Accurate toleranceSimple and inexpensiveFuselage framesPower plant exhaust arrangementsLine segmentAirplane

The present invention relates to a method of manufacture of a stiffening transverse internal rib for an aerodynamic fairing of an engine mounting device, including:the production of a rib preform by superplastic forming having an outline of a broadly quadrilateral shape, and a central opening (52) traversing this preform;the division of the preform into two parallel straight-line segments (56, 60), which are diagonally opposed, causing the separation into two half-parts (46a′, 46a″) of the rib preform; andfishplating of the two rib preform half-parts (46a′, 46a″) by bolting.

Owner:AIRBUS OPERATIONS SAS

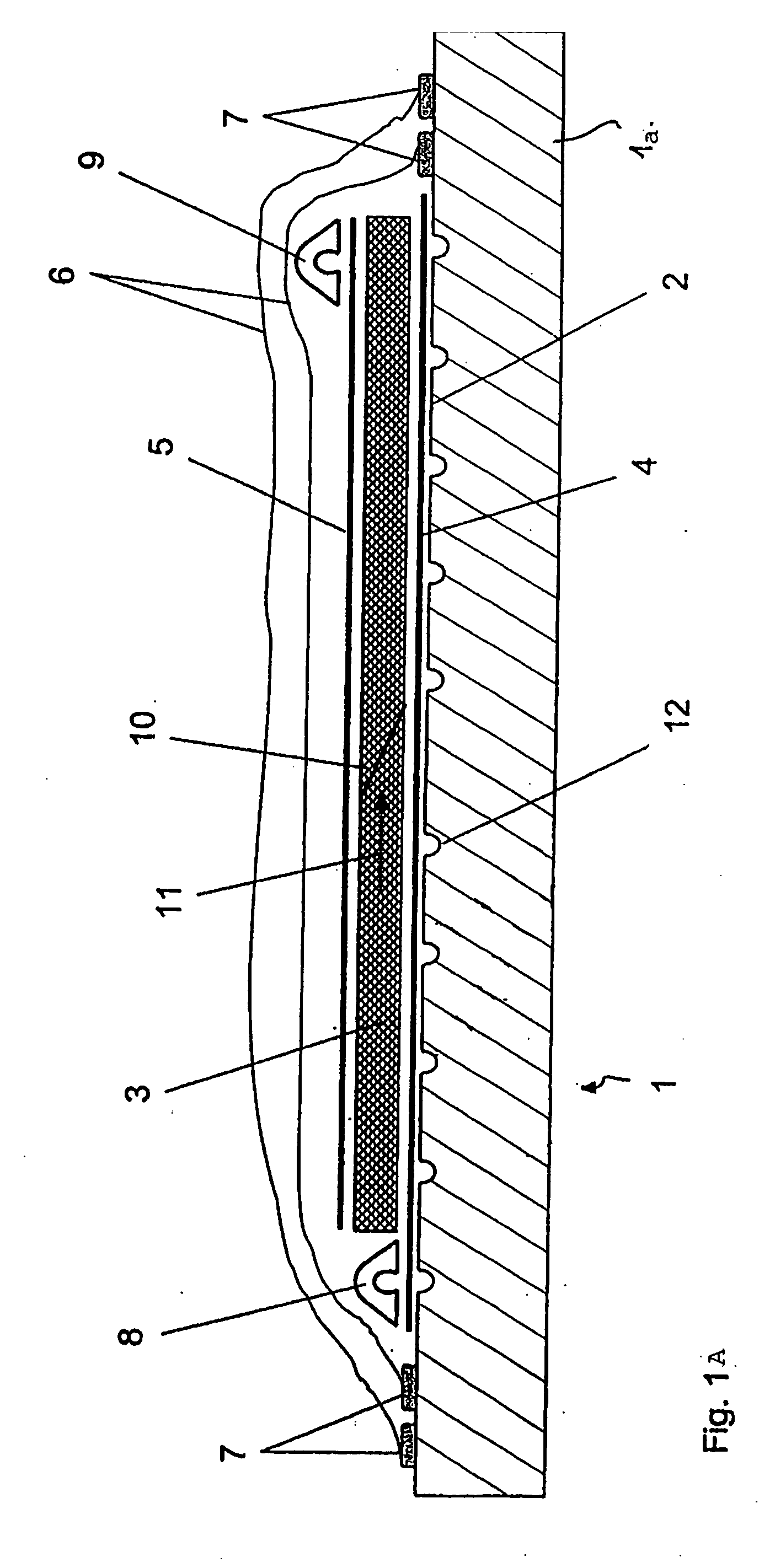

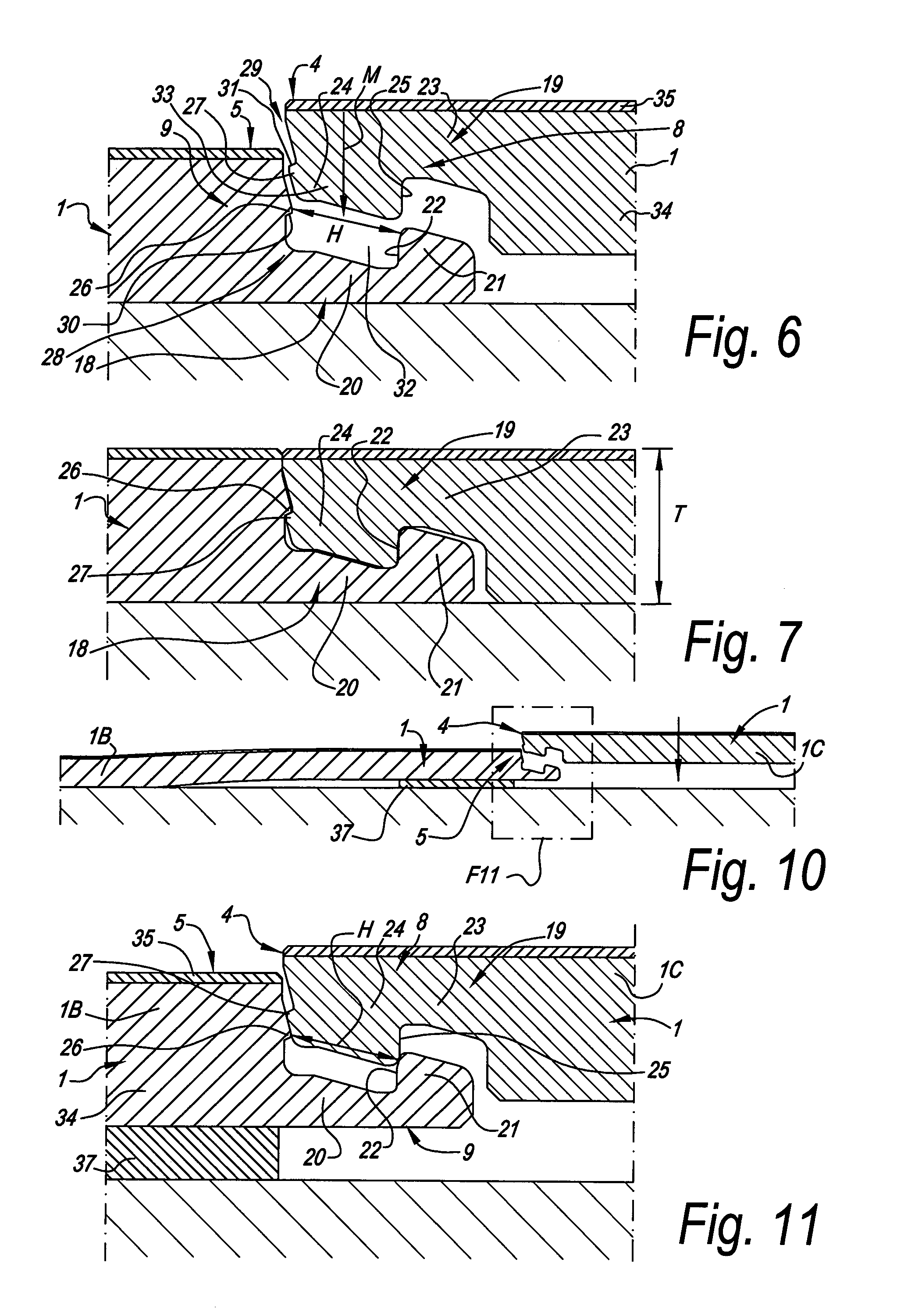

Panel, covering and method for installing such panels

ActiveUS20160369516A1Accurate toleranceControllable elastic propertiesSynthetic resin layered productsFloor coveringsPolyvinyl chlorideMechanical engineering

Owner:FLOORING IND LTD

Control arm, and method of making a control arm

InactiveUS6913273B2Reduce weightEliminates working stepSteering linkagesFluid steeringFriction weldingMaterial removal

A control arm includes a connection tube and two mounting eyes respectively attached to opposite ends of the tube. Each mounting eye has a sleeve and a rubber-metal element vulcanized into the sleeve. In a method of making such a control arm, an elongate tubular member is sized to a sleeve blank of a length commensurate with the tube. Parallel thereto, an extruded profile is made with a cross sectional configuration of the sleeve and subsequently sized to the axial height of the sleeve. Rubber-metal elements are vulcanized into the sleeve blanks which together with the tube are then clamped, axially shiftable, in a friction welding machine for subsequently fabricating protruding collars on the sleeves through material removal and joining the end surfaces of the protruding collars with the end surfaces of the tube. While still clamped, the tube and the mounting eyes are calibrated through cold upsetting and the joints are smoothed.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

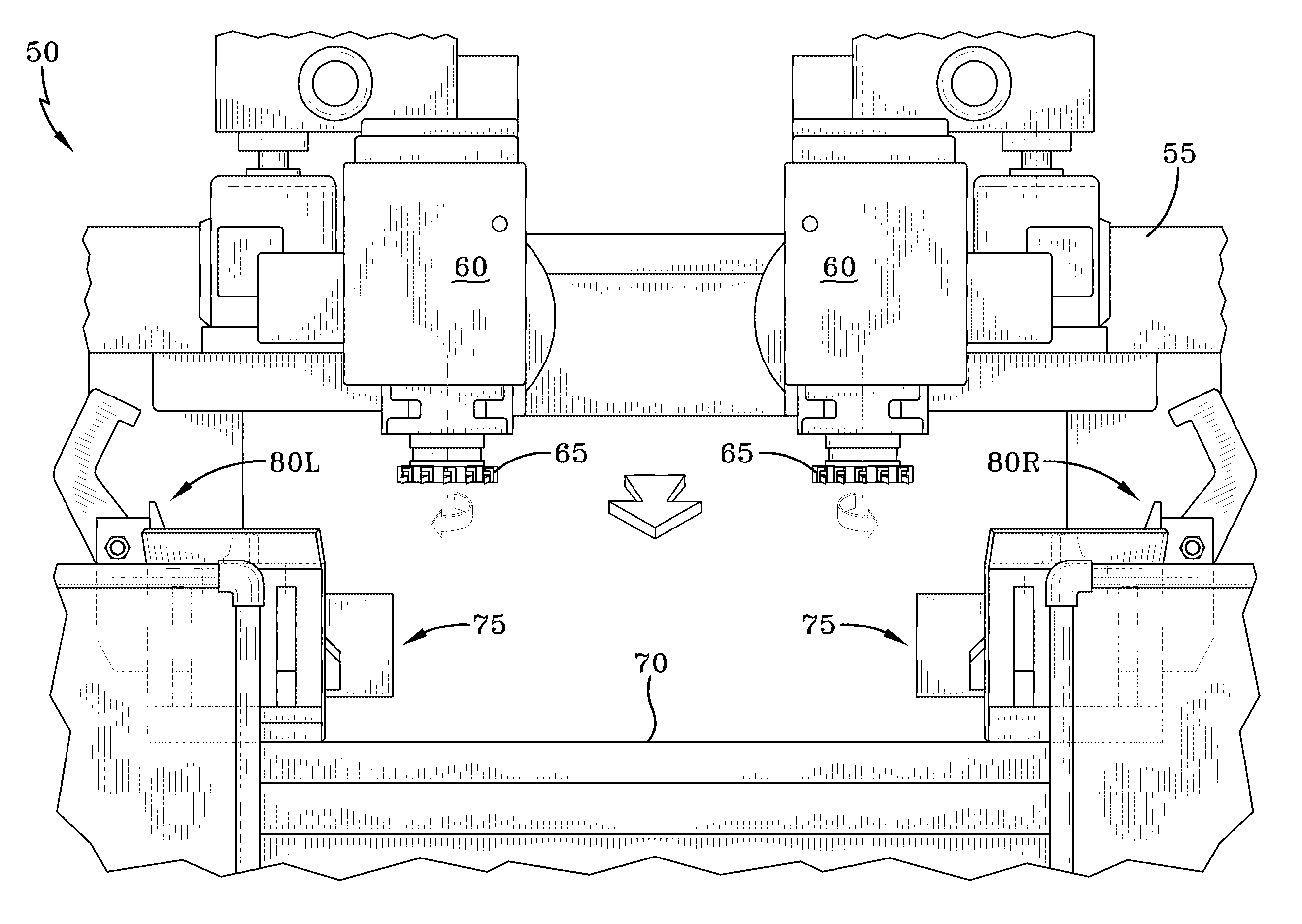

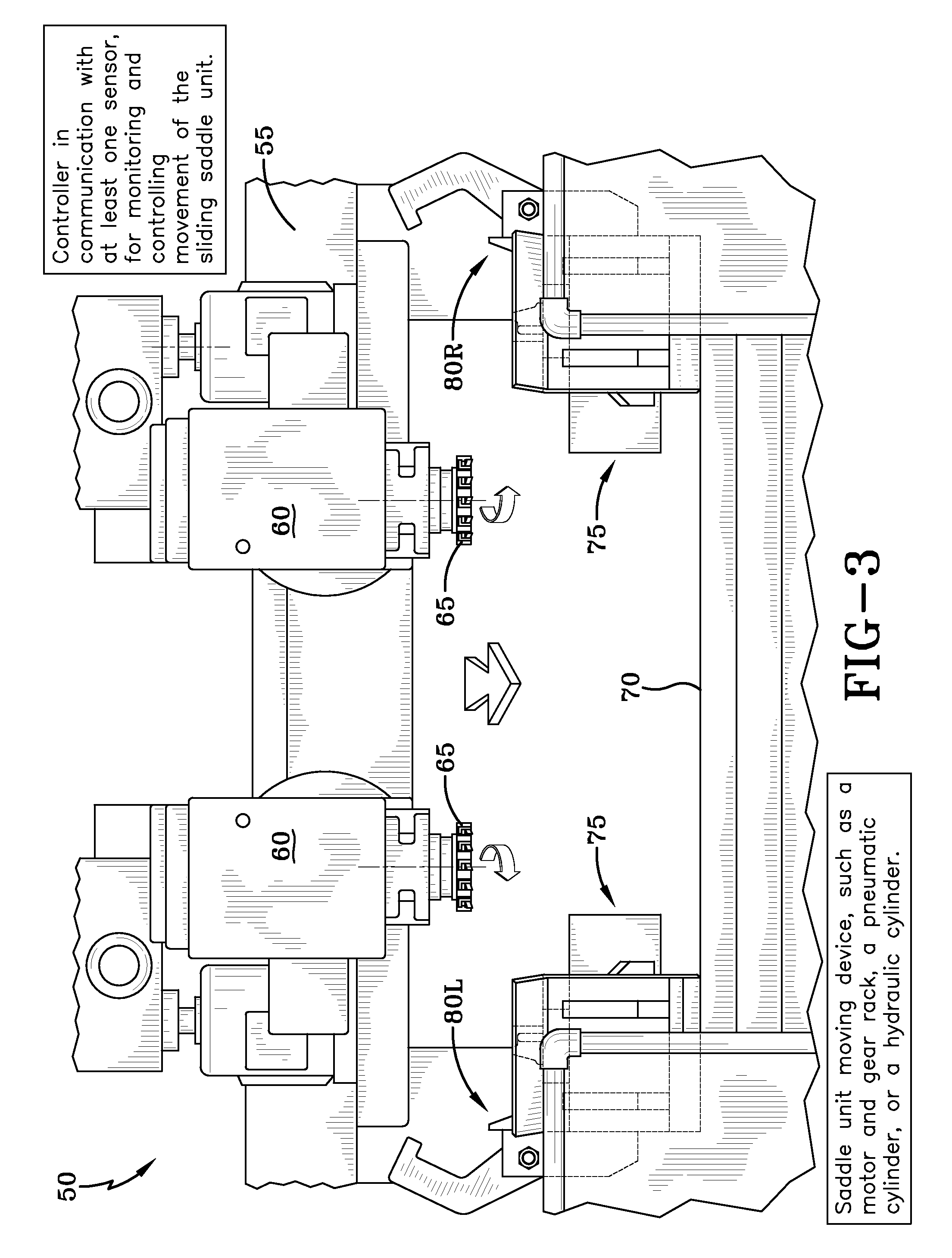

Railcar truck bolster side bearing mounting pad milling machine and method

InactiveUS7523535B2Repeat positioning is accuratePrecise and repeatable locatingPlaning/slotting machinesMilling machinesEngineeringTruck

A railcar truck bolster side bearing mounting pad milling machine and method. A milling machine of the present invention includes a pair of milling heads and associated cutters suspended from an overhead frame member. A sliding saddle unit is provided for transporting the bolster into and out of a work envelope of the milling machine. At least one fixturing assembly is attached to the sliding saddle unit to support and fix the position of the bolster in three directions. The bolster is rigidly supported from its underside, thereby eliminating the risk that the bolster may move downward during machining. Since the vertical position of the bolster when presented to the cutters is fixed, thereby the need to raise the bolster into a working position is also eliminated.

Owner:COLUMBUS STEEL CASTINGS

High speed differential encoder and interleaver

ActiveUS20080112507A1Small gate delayPrecise processFrequency-modulated carrier systemsPhase-modulated carrier systemsCommunications systemData stream

A plurality of differential encoders encodes a plurality of parallel data bit streams. XOR gates interleave the outputs of the differential encoders forming a single high speed differentially encoded bit stream with a data rate that is the sum of the data rate of the parallel data bit streams. The high speed data stream provides a single differentially encoded input to a differential phase shift keying modulator that generates symbols for a high speed optical communication system.

Owner:NORTHROP GRUMMAN SYST CORP

Artificial disc device

InactiveUS8262731B2Improve distributionImprove shock absorptionSurgeryJoint implantsBall bearingEngineering

Artificial disc devices are disclosed that restore correct anatomical intervertebral spacing for damaged discs while maintaining a substantially normal range of biomechanical movement for the vertebrae between which they are implanted. The disc devices include center bearing and outer or annular bearing portions with the center bearing portion including generally axially extending locating surfaces which cooperate with the facing vertebral surfaces to resist migration. The outer bearing portion is for load bearing or load sharing with the center bearing portion and includes surfaces that extend radially toward the periphery of the vertebrae so that subsidence about the center bearing portion is minimized. Alternate forms of the disc devices include one with an axially enlarged center ball bearing having an annular ring bearing extending thereabout and another having upper and lower plate members with a central bumper member and a surrounding resilient annular member therebetween.

Owner:PIONEER SURGICAL TECH INC

Panel, covering and method for installing such panels

ActiveUS20160356047A1Easy alignmentPrecise positioningSynthetic resin layered productsFloor coveringsPolyvinyl chlorideEngineering

A panel for forming a covering, more particularly a floor panel for forming a floor covering, which at least at two opposite edges, comprises coupling parts arranged to couple two of such panels to each other by means of a downward movement of one panel in respect to the other. The coupling parts form a first locking system arranged to lock in the plane of the panels and perpendicularly to the edges, as well as form a second locking system, which effects a locking perpendicularly to the plane of the panels. At least one of the coupling parts is formed at least partially in soft PVC (polyvinyl chloride), as well as at least partially formed from a milled profiled part of this soft PVC.

Owner:FLOORING IND LTD

Construction element form and method of fabricating same

InactiveUS20070276526A1Assembled quickly and efficientlyAccurate toleranceBuilding material handlingSpecial data processing applicationsUnderlayBuilding material

A portable and re-usable form for molding construction panels, and a method for fabricating such a form, including, but not limited to, exterior and interior wall panels, columns, and roof panels is provided. The form includes a frame made from frame members which are precision fitted together utilizing corresponding tabs and slots machined into the frame members and held together with bolts or pins. Additional frame members may be positioned inside of the form to provide spaces for window or door frame installation and electrical conduits. A patterned liner may be placed into the form to produce a pattern on the surface of the construction panel. The form may be assembled at a job site and filled with light weight concrete, cellular concrete, concrete or other pourable construction material. When cured, the form is dis-assembled by removing the bolts or pins, freeing the construction panel which can be then placed into position and used to form a section of a structure.

Owner:SWANSON THOR

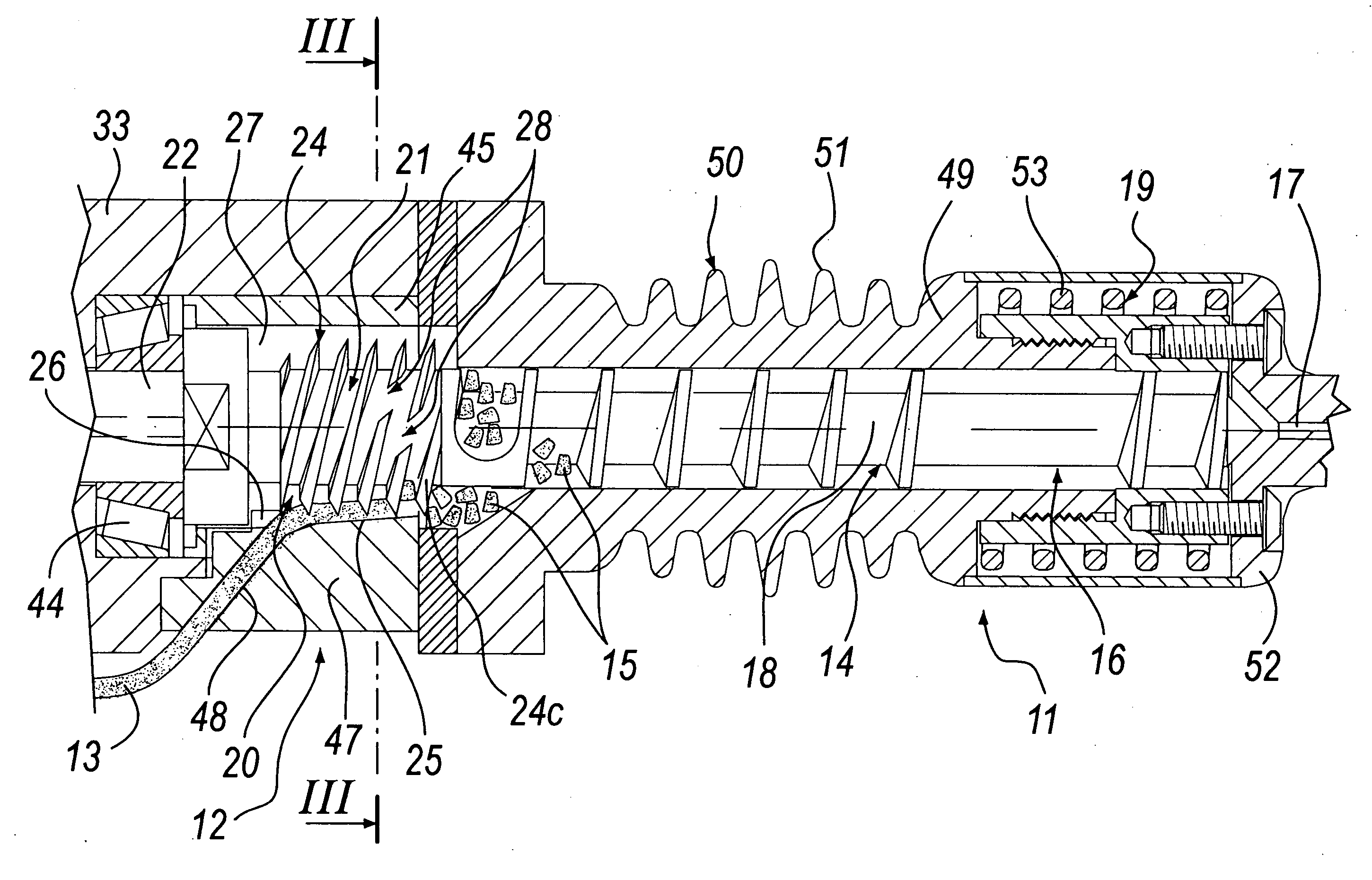

Extruder for welding plastic components

InactiveUS20050129796A1Drawback can be solvedAccurate toleranceLiquid surface applicatorsRotary stirring mixersPlastic materialsEngineering

An extruder for welding plastic components, comprising a front part for plasticizing and ejecting additional plastic welding material, and a rear part, for feeding and breaking up a continuous filament made of the additional plastic material. The rear part comprises a feed channel that cooperates with a worm screw for the advancement of the filament. The feed channel is delimited by the thread of the worm screw on one side and by a sliding surface for the filament on the opposite side. The distance between the sliding surface and the crest of the thread decreases in the direction in which the filament is fed, in order to provide scoring of increasing depth on the filament. The thread comprises at least one discontinuity of the worm that has a sharp discontinuity end for cropping the filament at the scoring.

Owner:RITMO SRL

Collapsible core assembly for a molding apparatus

ActiveUS20060188602A1Quality improvementImprove reliabilityMouldsConfectioneryEngineeringMechanical engineering

Owner:ZYDRON GARRY

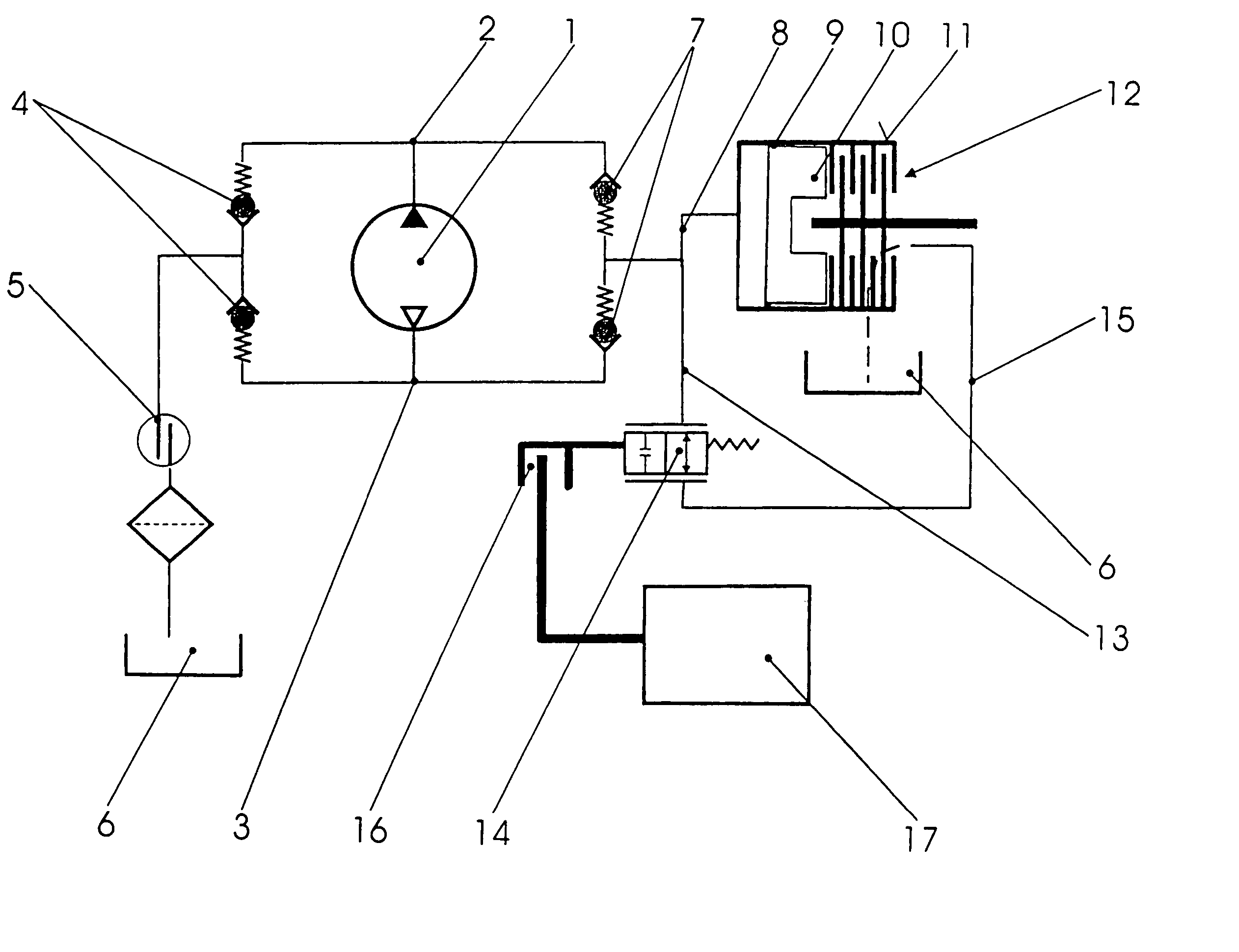

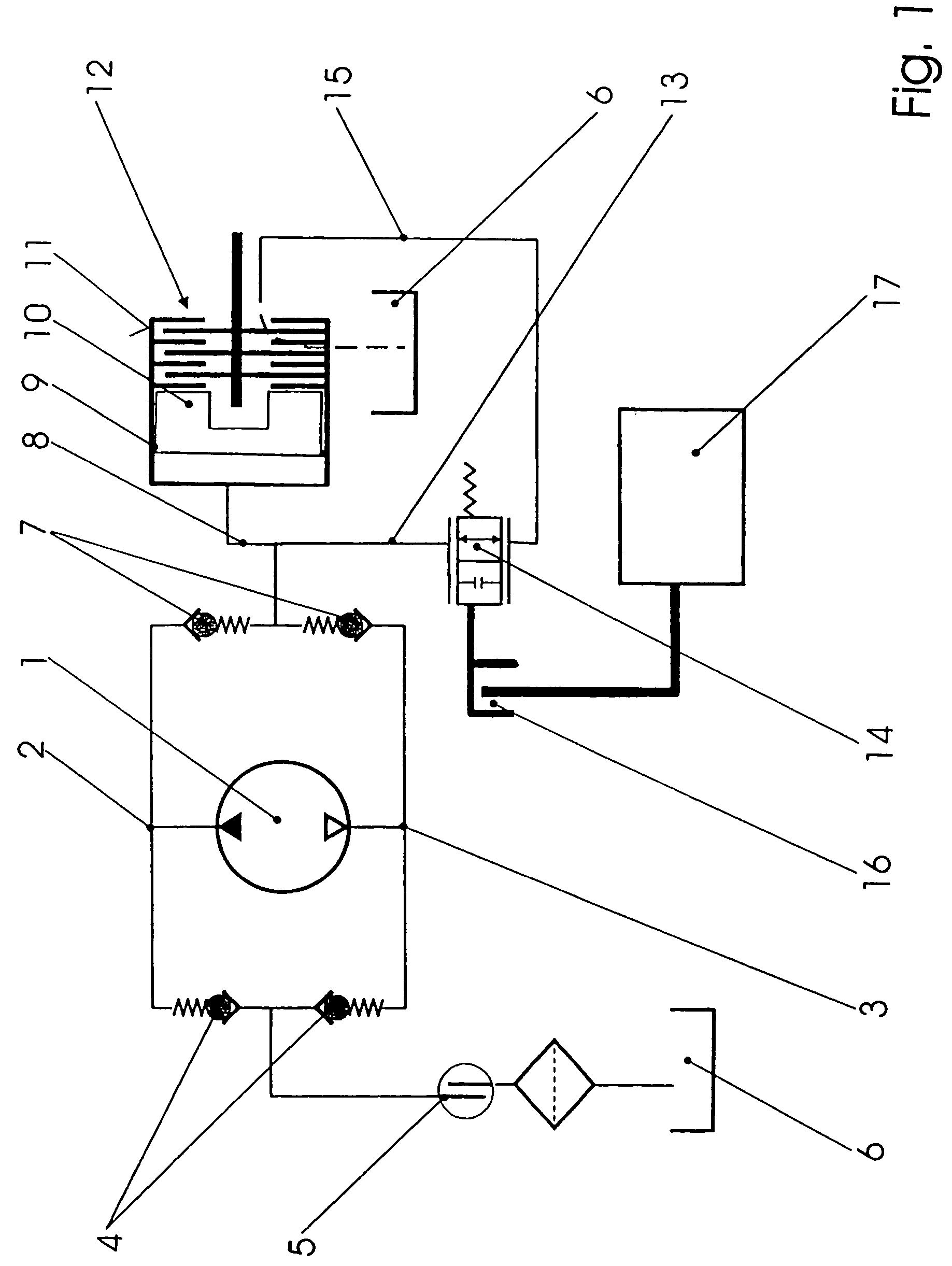

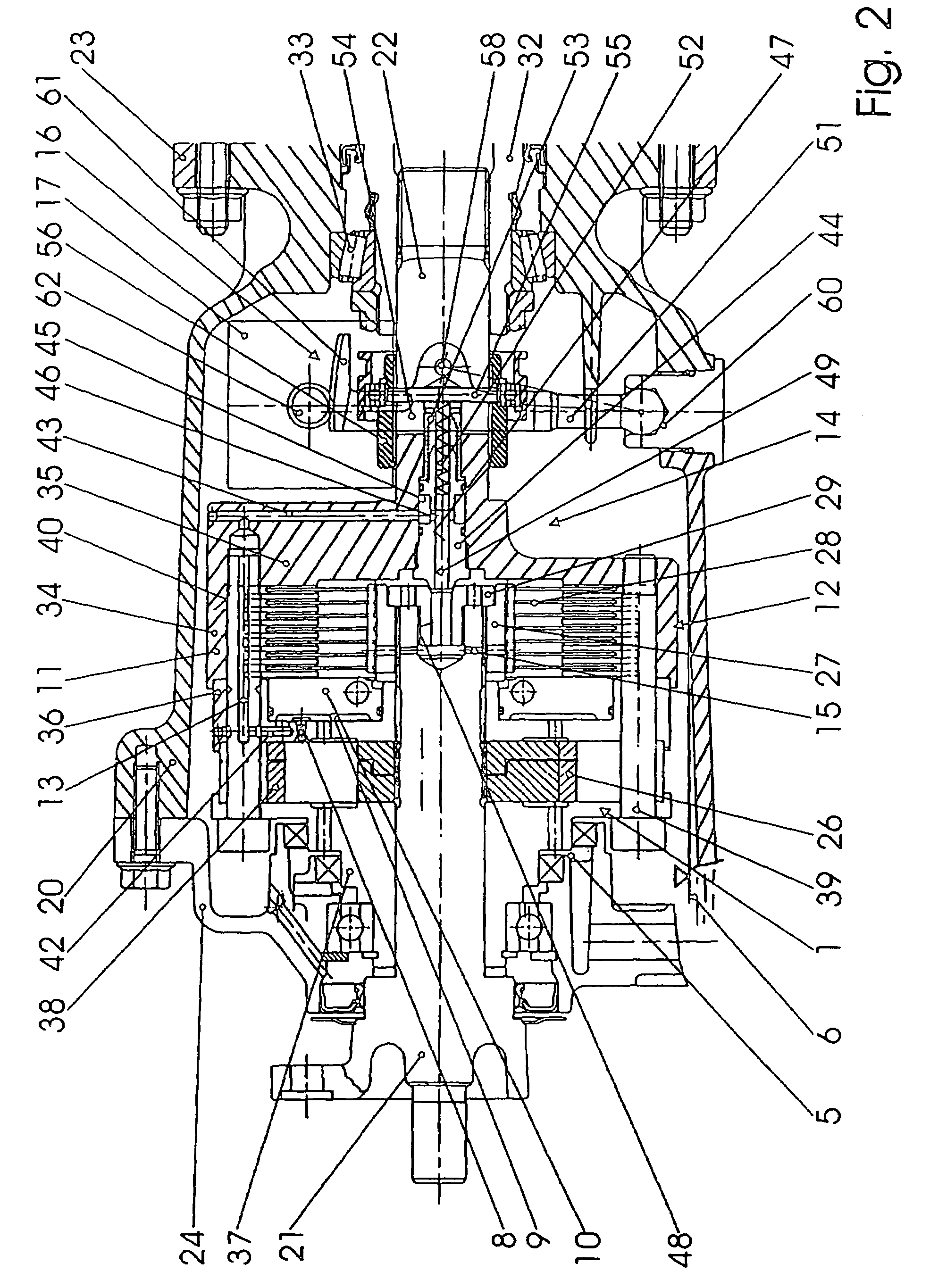

Speed differential-dependent hydraulic clutch with a control valve

InactiveUS7077256B2Small diameterAccurate guideFluid actuated clutchesEngine controllersControl mannerControl valves

A speed-difference-dependent hydraulic clutch comprises a drive housing (11), which rotates in a housing (20), a first shaft (21) which can be connected in a rotationally fixed manner to the drive housing, a second shaft (22) which is connected in a rotationally fixed manner to the drive housing, and furthermore a hydrostatic displacement machine (1), a friction clutch (12) for connecting the first shaft (21) to the drive housing (11), and a piston (10) for acting on the friction clutch (12), the drive housing (11) having a pressure space (9) and where a pressure is produced in the pressure space (9) when a difference in speed occurs in the pressure space (9), this pressure giving rise to action upon the friction clutch (12), and a passage (13) leading from the pressure space to a control valve which opens up the route to a space of lower pressure in a controlled manner.

Owner:MAGNA STEYR POWERTRAIN

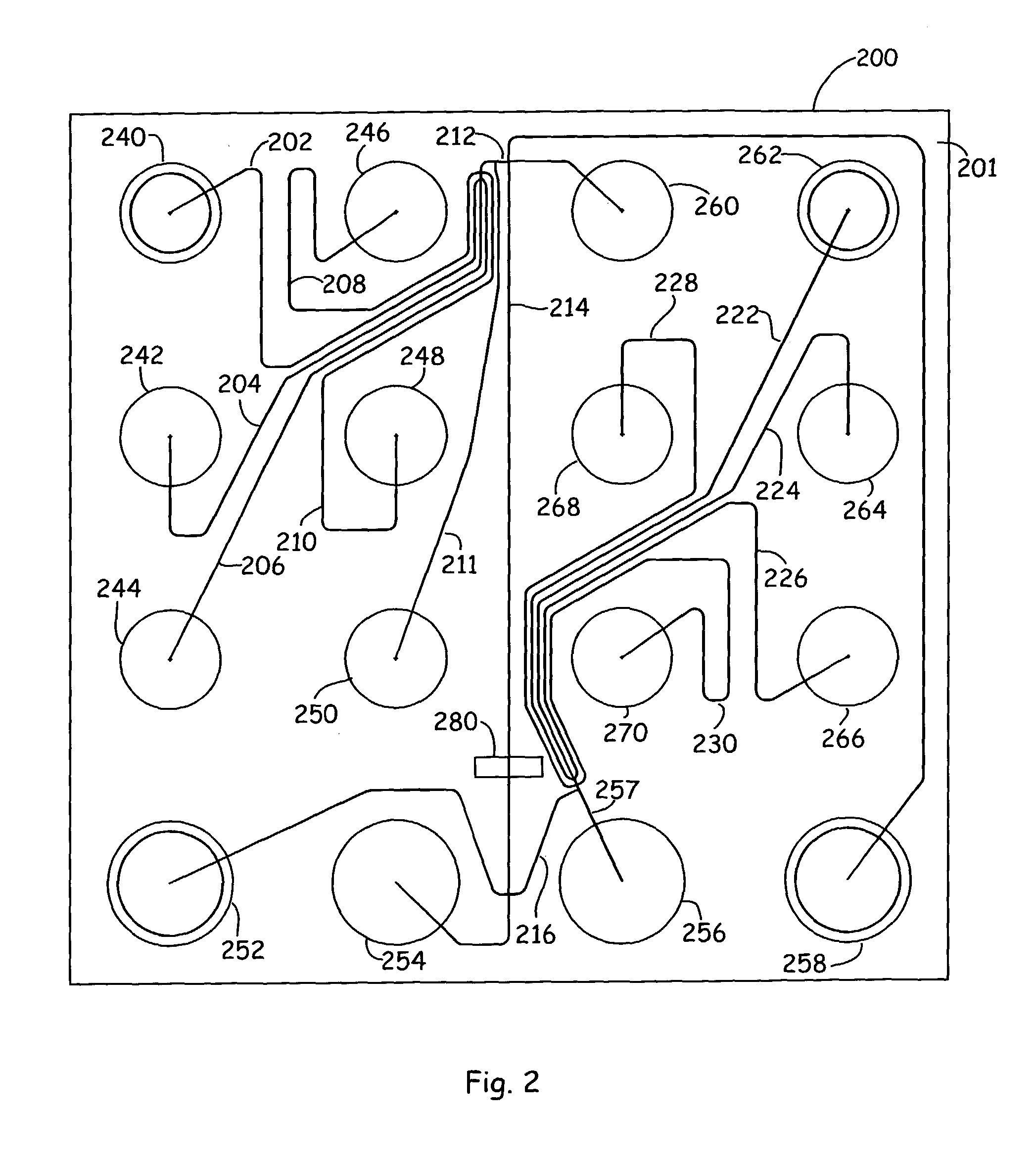

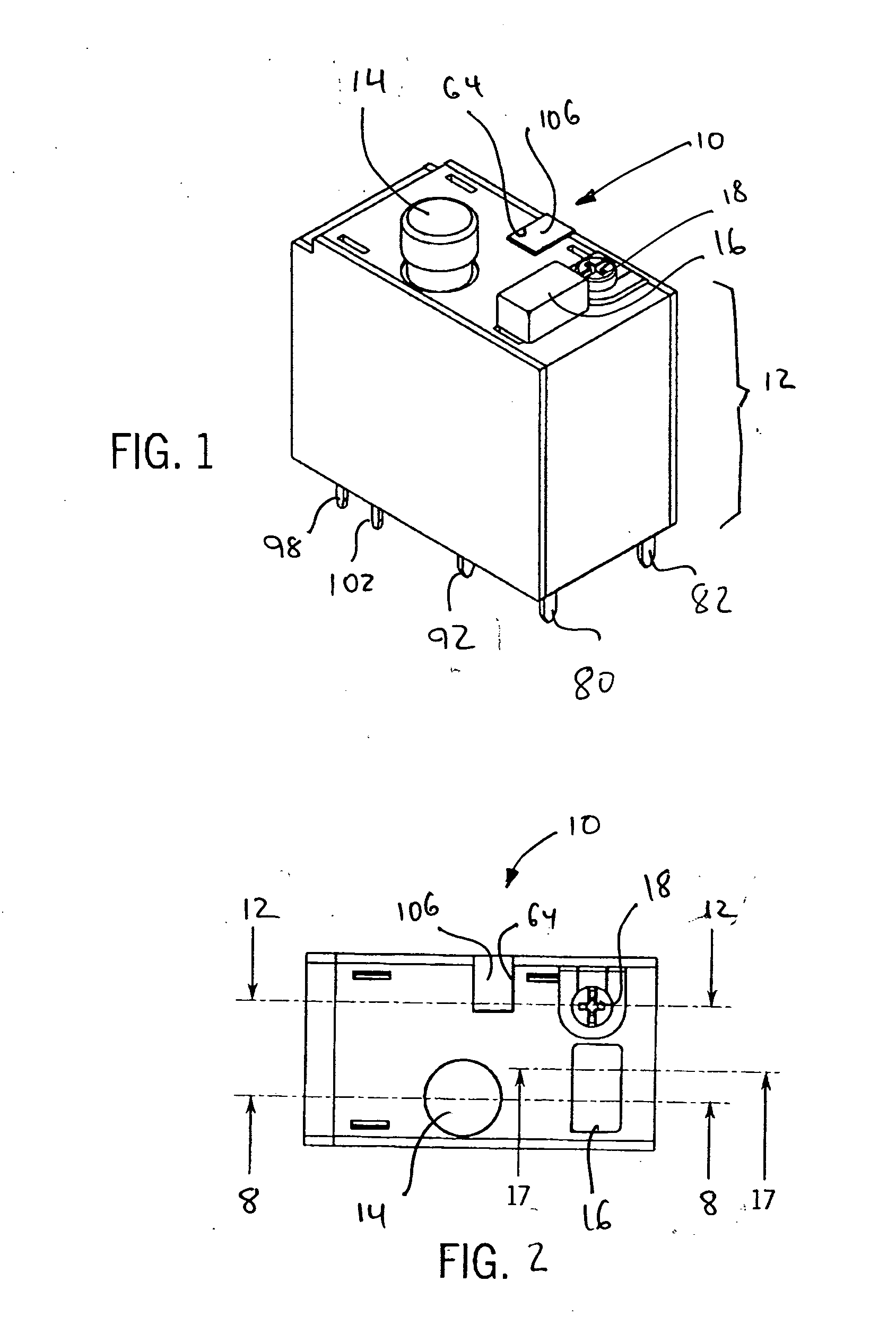

Trip-free PCB mountable relay configuration and method

ActiveUS20050067267A1Reduced case sizeReduced dimensionSwitches with electromagnetic releaseSelector switchesEngineeringPrinted circuit board

A method and assembly for use with a printed circuit board (PCB), the assembly comprising a relay assembly including a relay housing and a trip free reset assembly mounted within the housing and linked to other relay components mounted within the housing for manually resetting the relay after the relay is tripped and at least one pin linked to at least one of the relay components and including a distal end extending from the housing and suitable for direct connection to the PCB.

Owner:ROCKWELL AUTOMATION TECH

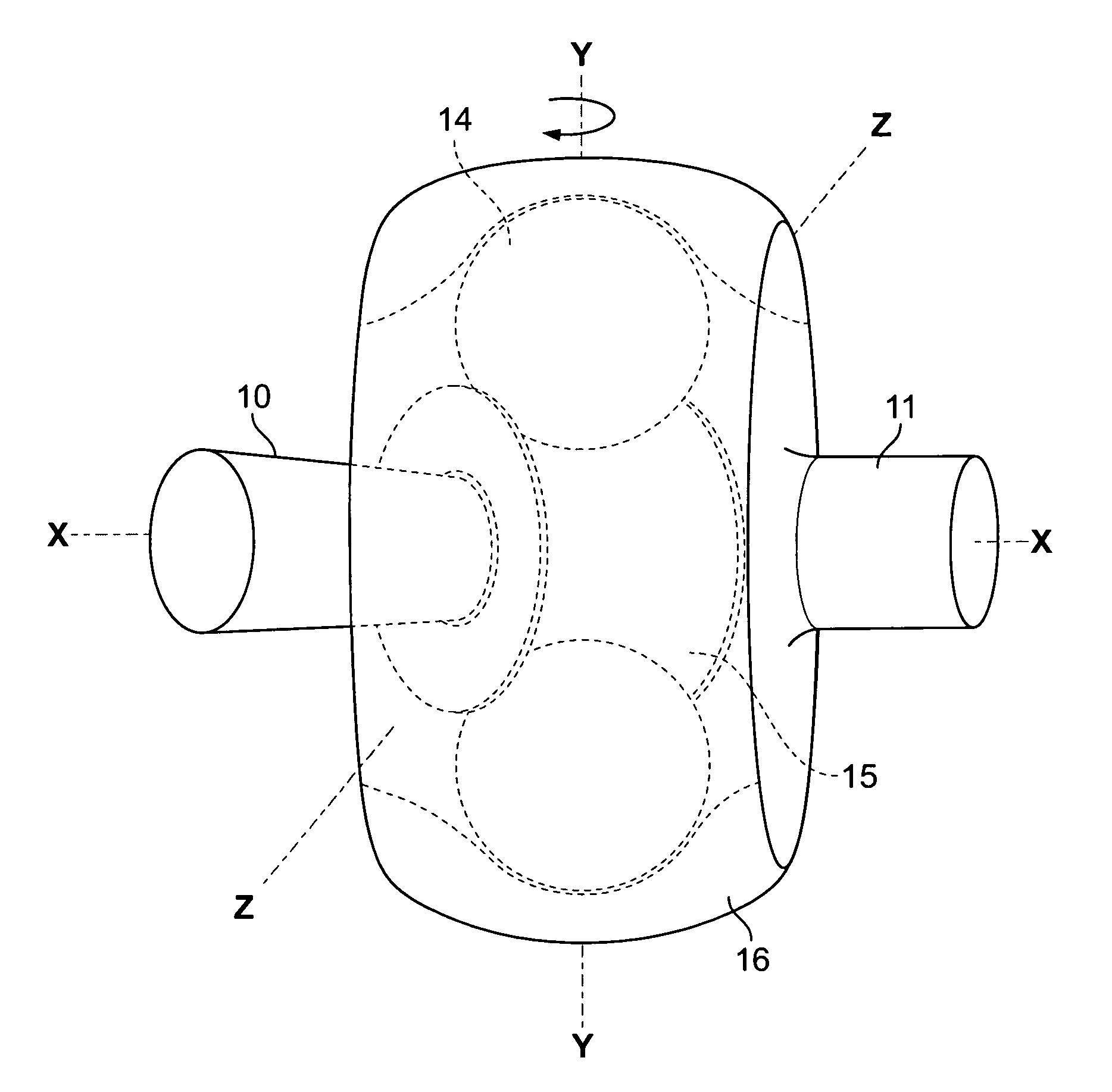

Gearless speed reducer or increaser

ActiveUS8033953B2Easy to manufactureAccurate toleranceYielding couplingFriction gearingsBall bearingReduction drive

A gearless speed reducer or increaser consists of an input shaft, an output shaft, and a motor connected to the input shaft. There is an external race connected to one of the shafts, and an internal race attached to the other shaft. Two ball bearings are disposed between the races. After the ball bearings have been inserted, the shafts are tilted relative to each other so that the balls become fixed in pockets created between the races and cannot slide within the races. Rotating one of the shafts thus rotates the other shaft, since the balls do not slip but only rotate between the races. The system acts as a speed reducer or increaser due to the different diameters of the inner and outer races. The system can be uncoupled by pivoting the shafts back into alignment so that the balls can slide freely within the races.

Owner:MARMALADE TECH LLC

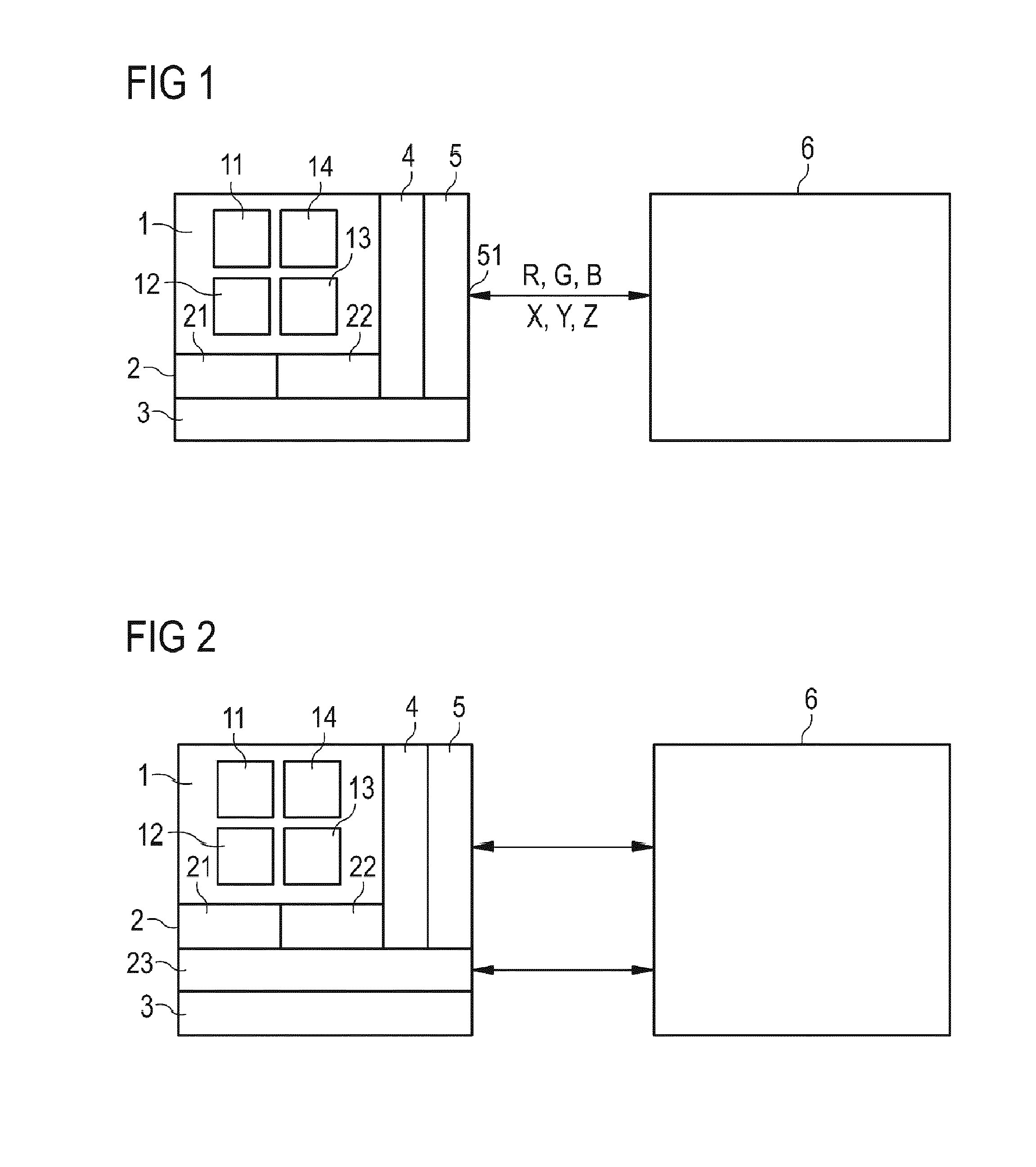

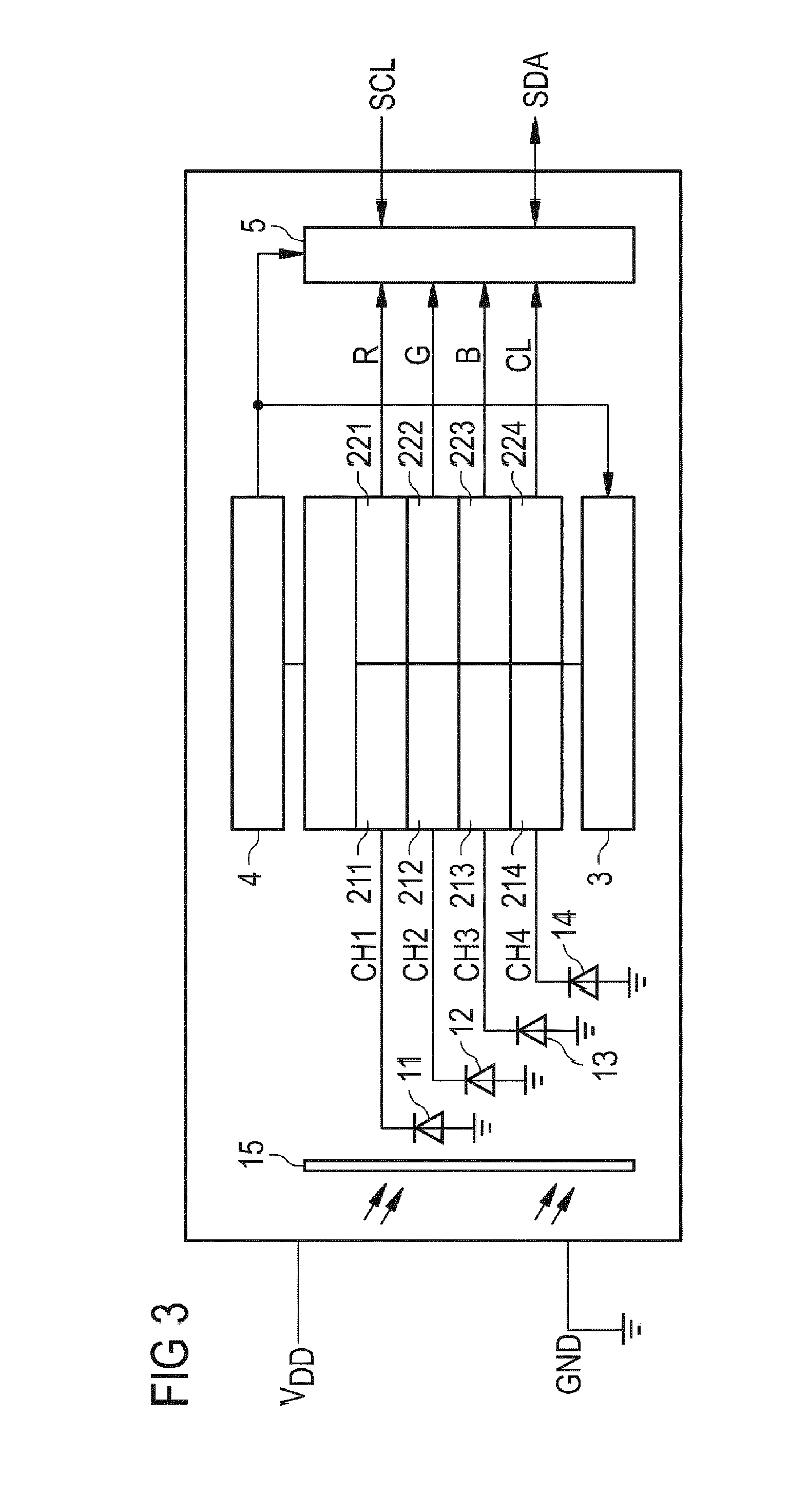

Colour sensor arrangement and method for colour sensor calibration

ActiveUS20160245695A1Precise processHigh device-to-device toleranceRadiation pyrometryColor measuring using electric radiation detectorsComputer terminalColor signal

A colour sensor arrangement comprises a colour sensor arranged to generate at least a first channel signal being indicative of a colour of light incident on the colour sensor. A processing unit is connected to the colour sensor and arranged to generate a tuple of colour signals by processing the at least first channel signal. A memory is connected to the processing unit and a control unit is connected to the processing unit and to the memory. Furthermore, the control unit is arranged to receive calibration data relating the tuple of colour signals to a calibrated tuple of colour signals and arranged to store said calibration data (M) by means of the memory. An interface is connected to the processing unit and comprises an interface terminal.

Owner:AMS AG

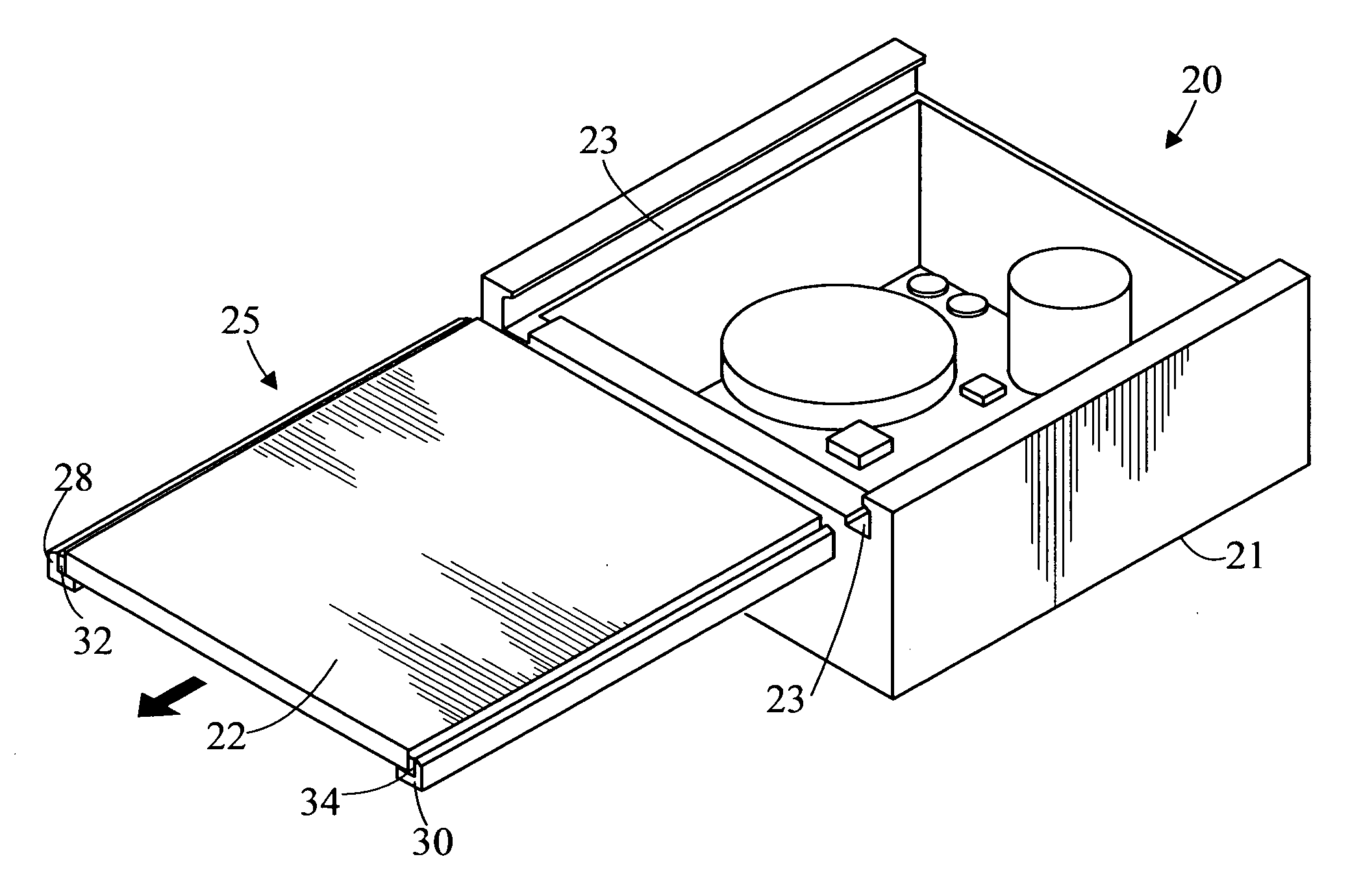

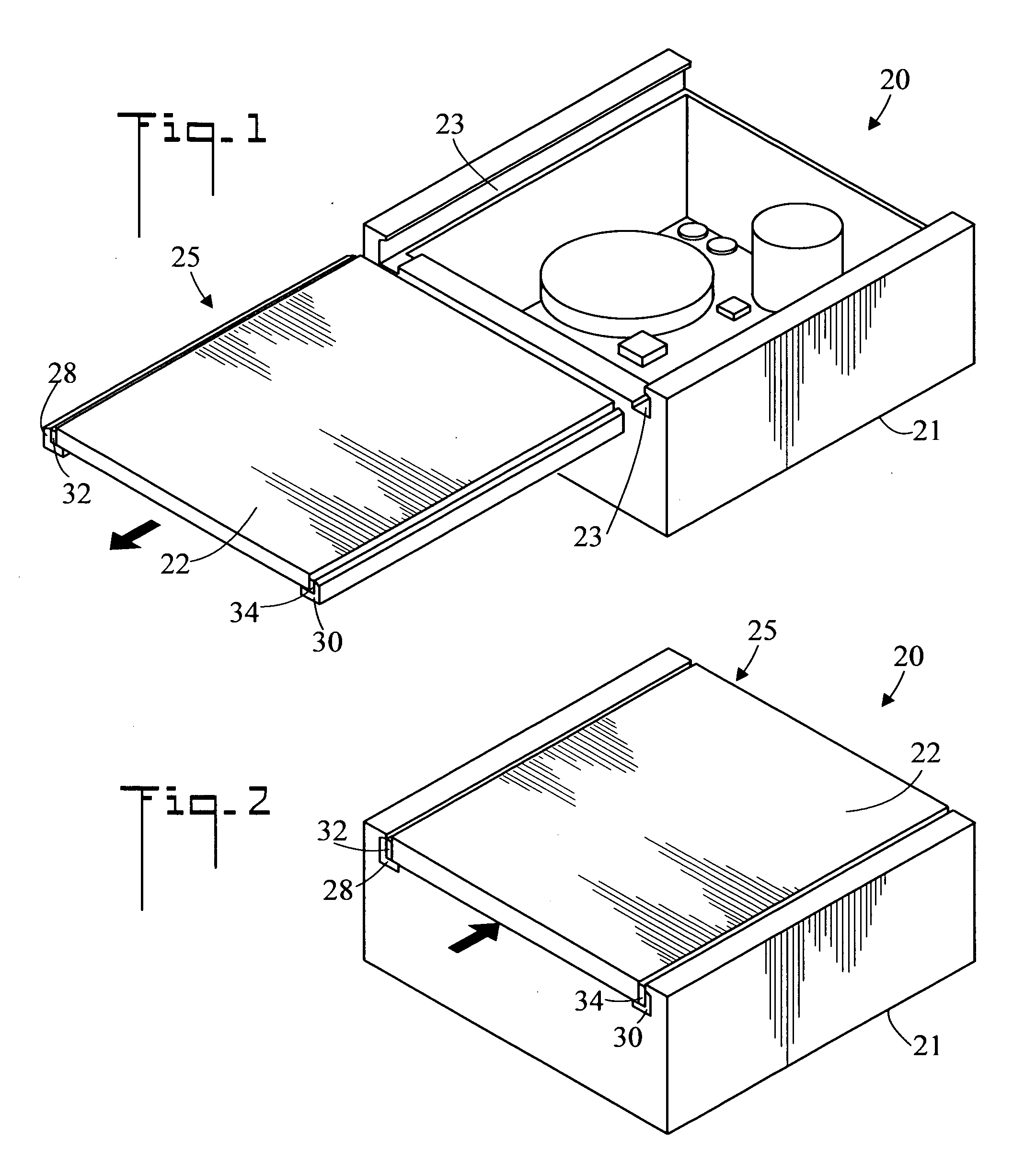

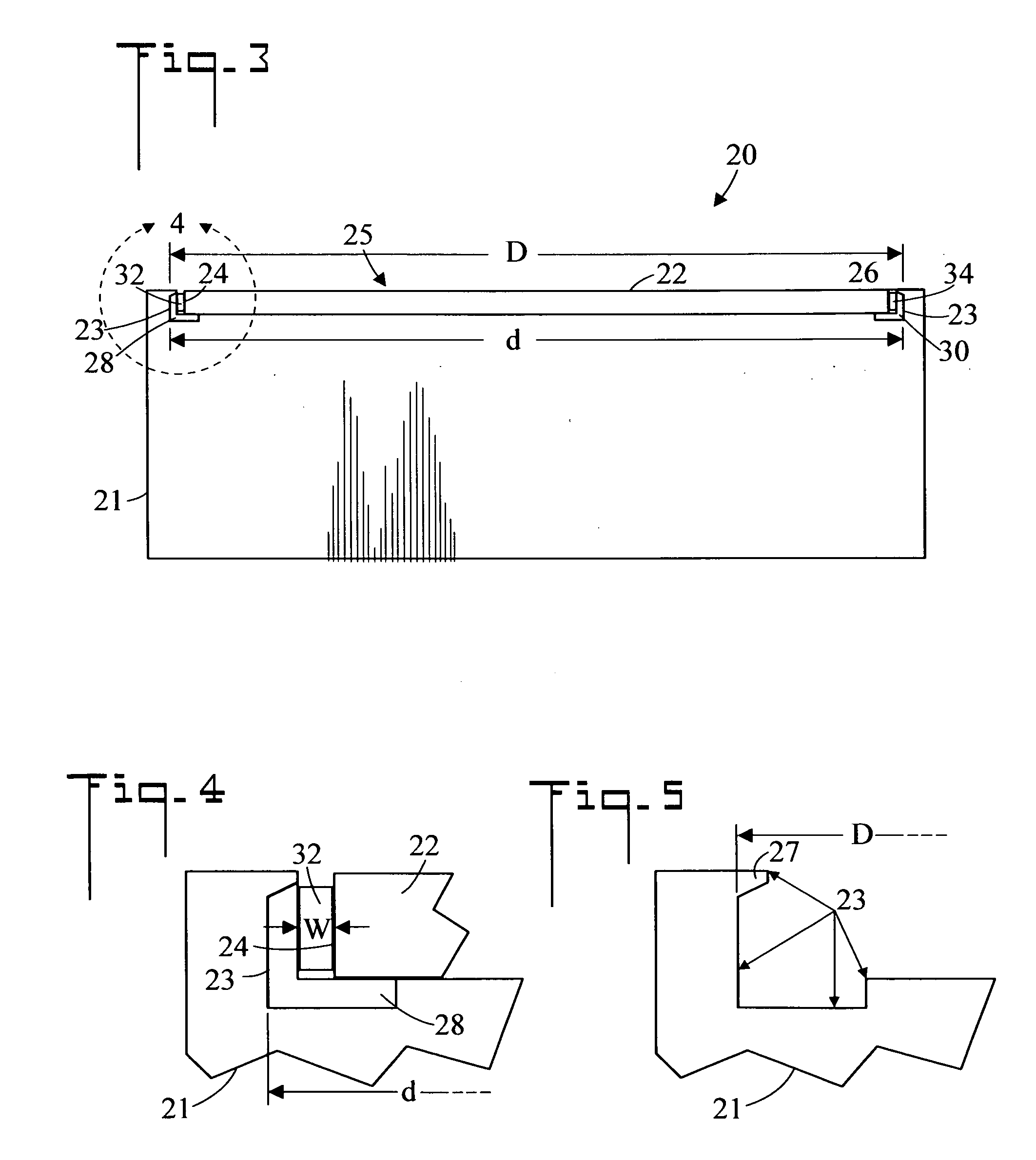

Enclosure system and method of use

InactiveUS20080303393A1Appearance can be easily and rapidlyEasy to disassembleDigital data processing detailsMetal working apparatusElectrical and Electronics engineeringSurface plate

An enclosure system and method for customizing the appearance of an enclosure includes an enclosure which has two spaced apart receiving rails. A panel assembly having two spaced apart rails is fabricated so that the rails of the panel assembly will precisely engage and slide along the receiving rails of the enclosure. Spacers ensure that the width of the panel assembly is slightly less than the width of the receiving rails of the enclosure. In a second embodiment, the panel assembly rails are spaced apart the desired distance by at least one connecting member.

Owner:KRINSLY ANTHONY S

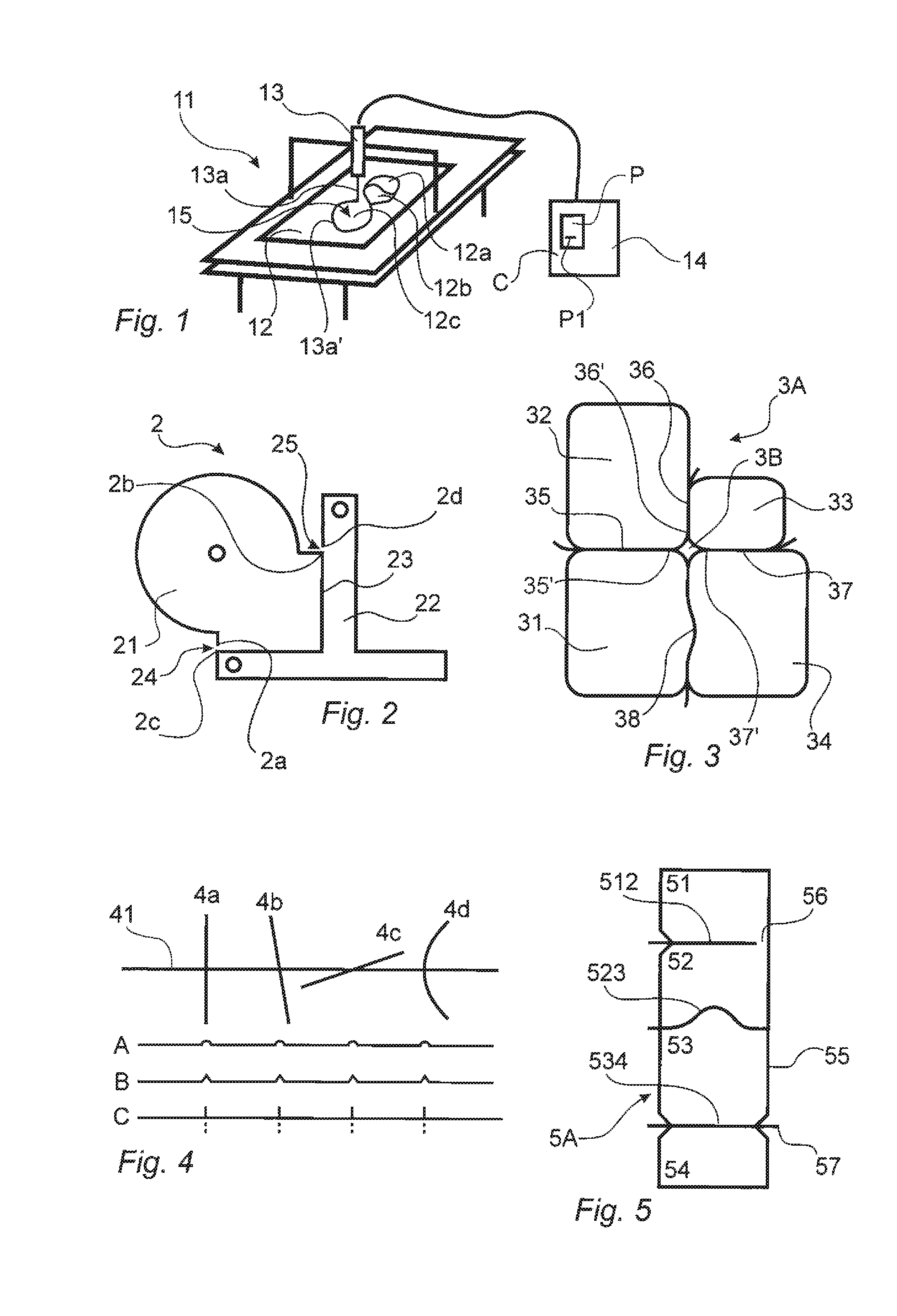

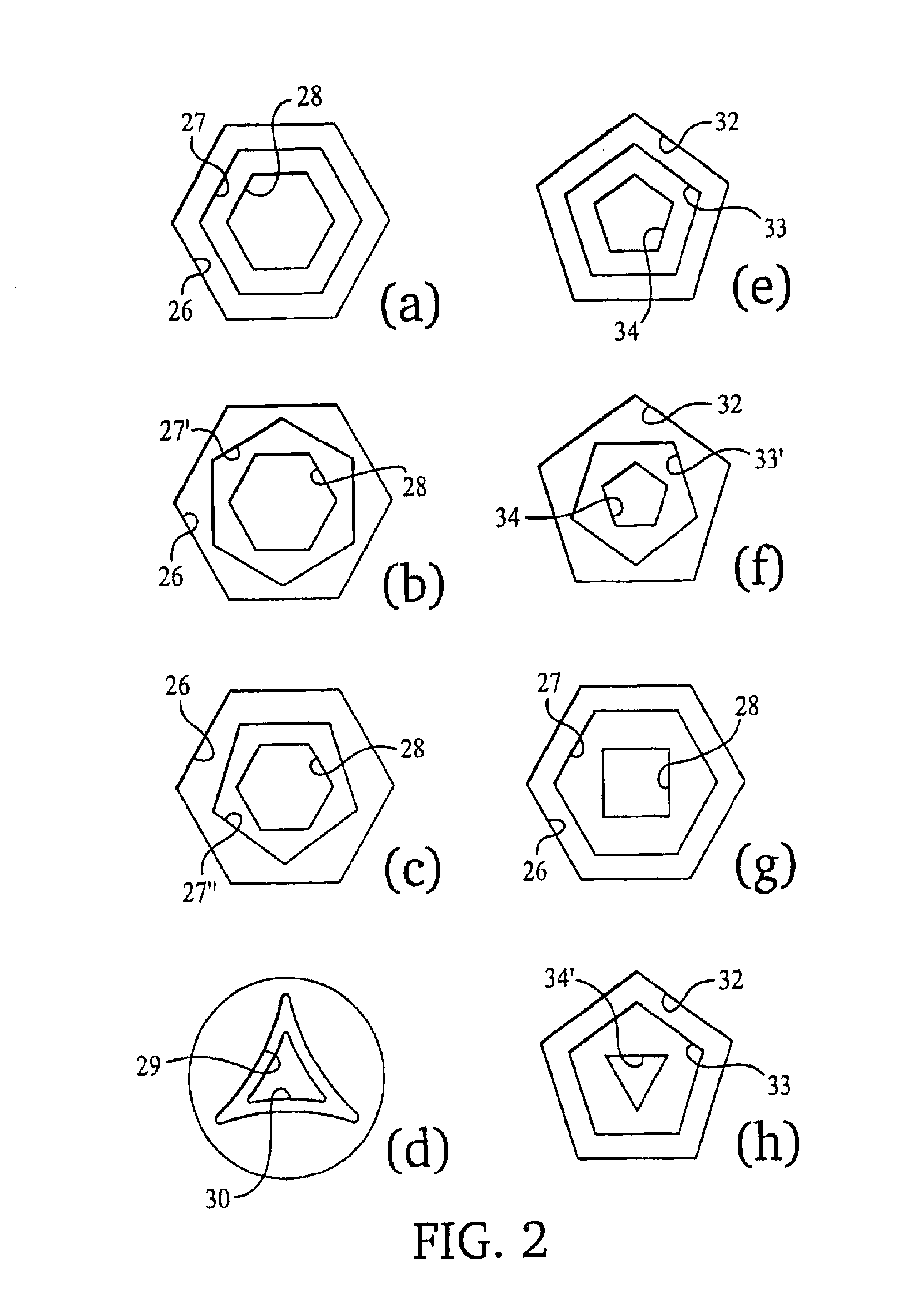

Controlling Rules and Variables for Cutting

ActiveUS20120192690A1Reduce material wasteCost optimizationMetal working apparatusLaser beam welding apparatusFree form shapesMechanical engineering

The present invention relates to a method and a system for machine cutting several parts (31, 32, 33, 34) out of a piece of material using a beam cutting technology. The invention provides a set of controlling rules and variables for cutting two dimensional shapes or patterns. One rule or a combination of several rules are used for the cutting operation depending on the shape or pattern to be cut, the shape or pattern forming the parts (31, 32, 33, 34) out of the piece of material. The present invention specifically teaches that the set of controlling rules comprises rules for the forming of a duster (3A) of parts with free form shapes, the parts being positioned so close to each other so that only the thickness of the cutting beam is found between adjacent parts whenever the shape of the parts allows it.

Owner:TOMOLOGIC

Method of manufacturing optical crystal element of laser

InactiveUS20050232320A1Accurate toleranceDesire thicknessPolycrystalline material growthAfter-treatment detailsPhysicsEtching rate

A method of manufacturing an optical crystal element of a laser device includes measuring an initial thickness of a crystal substrate formed of YAG or YVO4; introducing a mixture of a fluorine gas and an Ar gas having a ratio of the fluorine gas to the Ar gas in a range of 1:10 to 1:2 into a process chamber holding the crystal substrate; and generating ion beams of the mixture in the process chamber for etching a surface of the crystal substrate for a period time determined from an etching rate depending on the ratio of the mixture and the initial thickness of the crystal substrate. Thickness of the optical crystal element is controlled to a desired thickness. In the method, it is possible to produce the optical crystal element of a microchip laser having functions as a laser medium, a resonator and an etalon.

Owner:SHIMADZU CORP

Screw head formation

InactiveUS20080279653A1Reduce the facing areaReduce manufacturing costCutting toolsMilling cuttersNumerical controlEngineering

A screw having in its head a recess that includes two or three non-circular superimposed recess-tiers. The depth of each recess-tier is less than 1.35 mm and there is less than 1° draw in each recess. The screw head recess is formed using a punch (10) in a cold heading process. The punch is formed in a profilating CNC machine, cutting the profiles of the punch to a tolerance of better than ±0.0025 mm.

Owner:UNI SCREW EURO BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com