Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

904 results about "Countersink" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A countersink (symbol: ⌵) is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. A common use is to allow the head of a countersunk bolt, screw or rivet, when placed in the hole, to sit flush with or below the surface of the surrounding material (by comparison, a counterbore makes a flat-bottomed hole that might be used with a socket-head capscrew). A countersink may also be used to remove the burr left from a drilling or tapping operation thereby improving the finish of the product and removing any hazardous sharp edges.

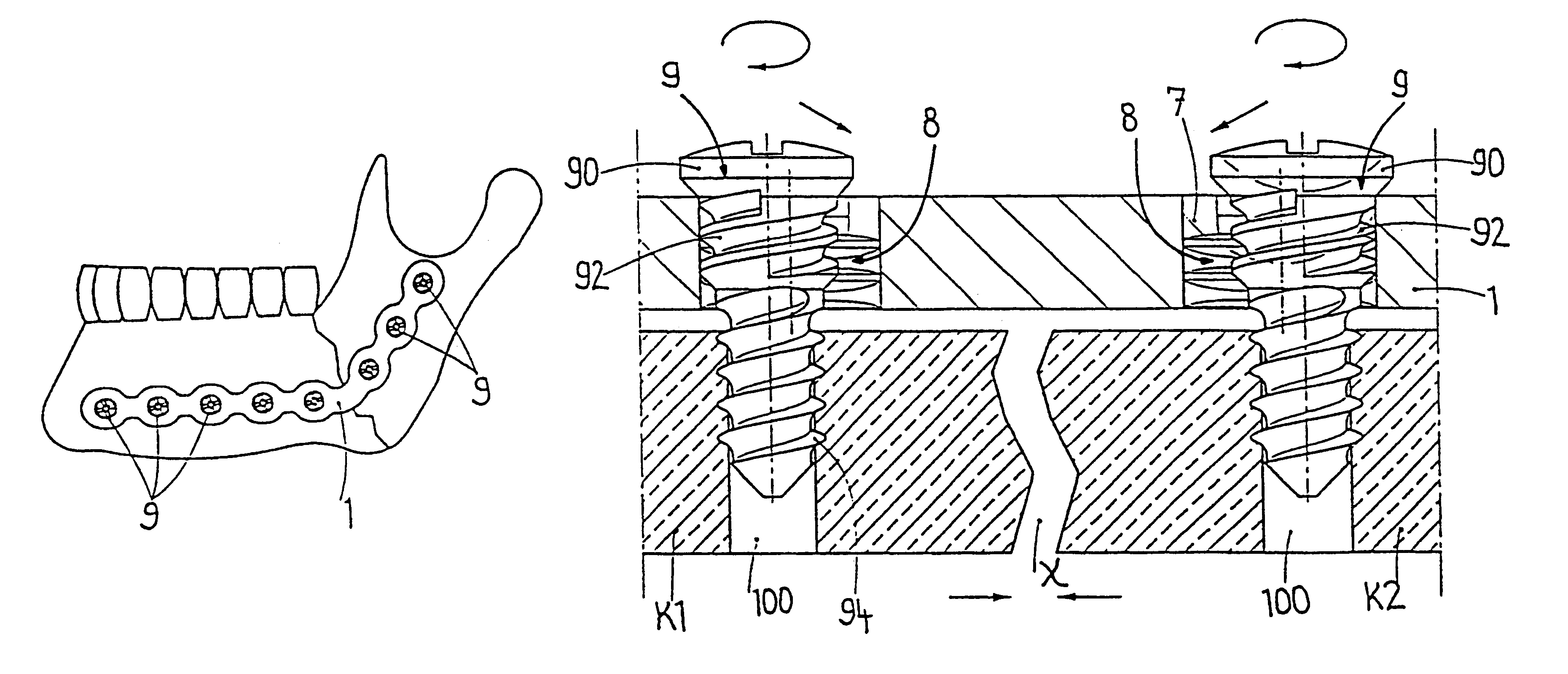

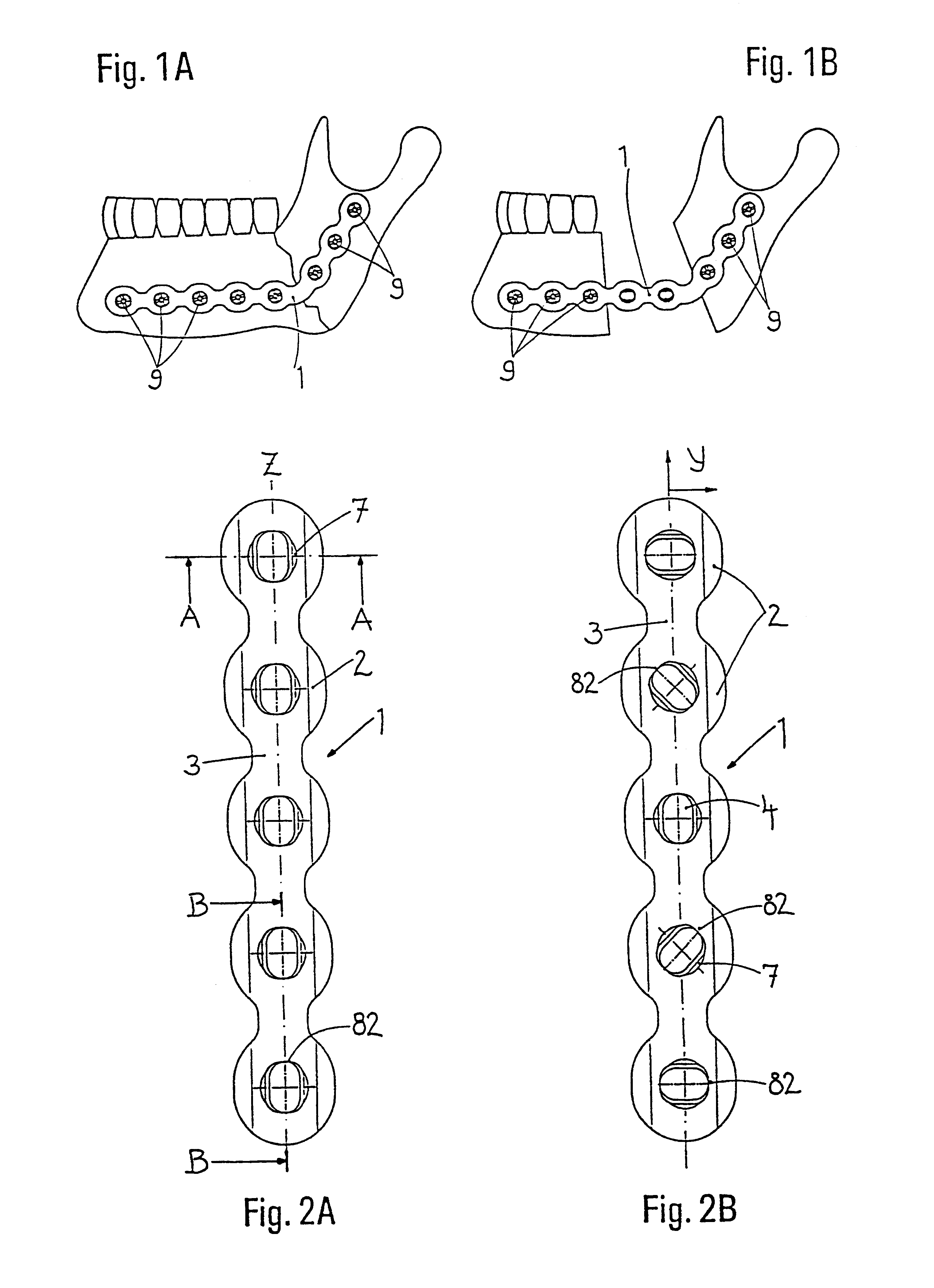

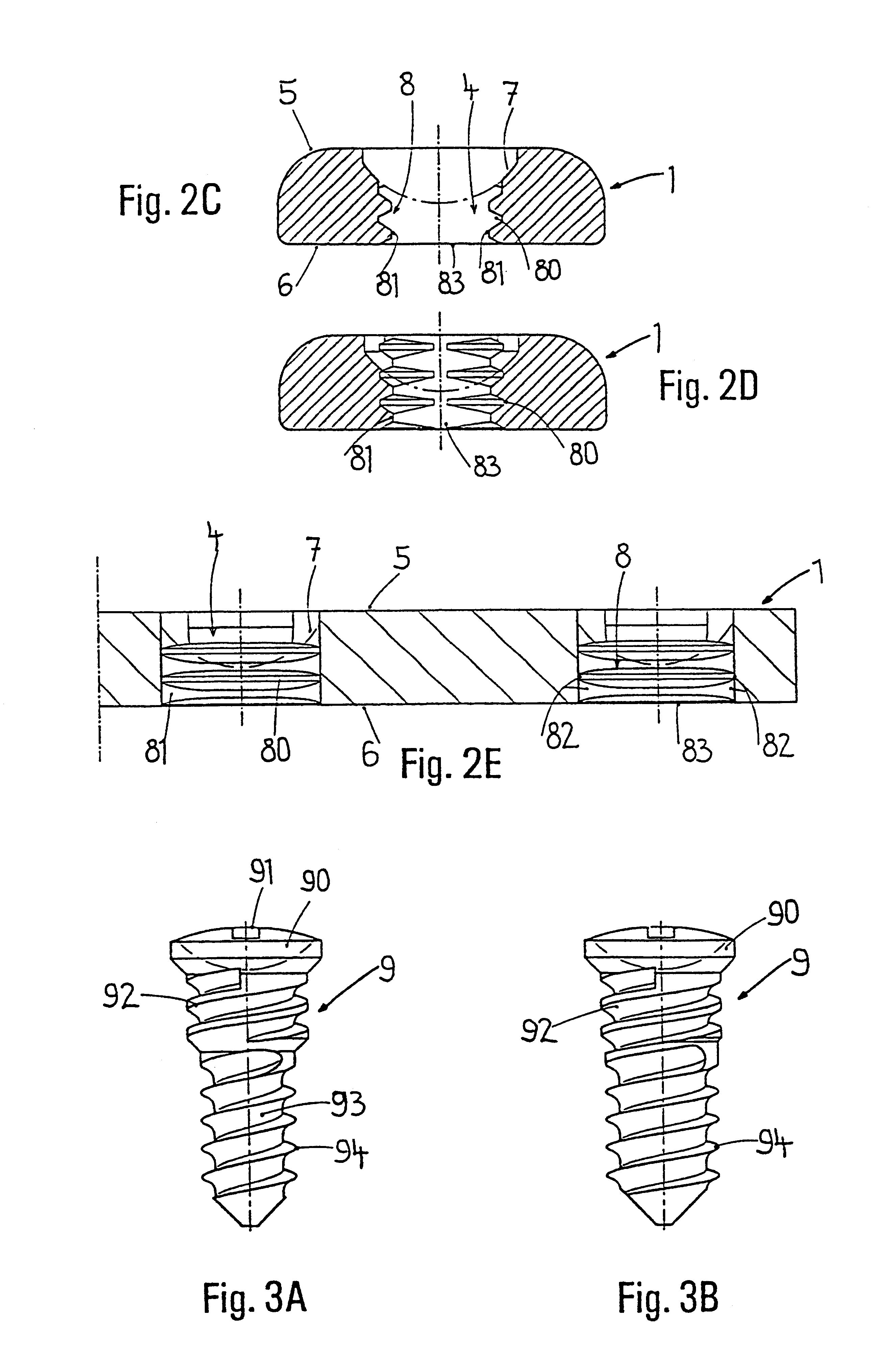

Blockable bone plate

InactiveUS6730091B1Cost effective productionLow costSuture equipmentsInternal osteosythesisEngineeringIliac screw

The blockable bone plate consists of a plurality of plate members which are connected to each other via webs. A screw hole is provided in at least some plate members, preferably in each plate member. The screw hole is surrounded by a spherical countersink on the upper surface of the plate. Provided internally in the screw hole there is an engagement contour which consists of contour valleys and contour peaks partially running in a horizontal and radial peripheral direction on the wall of the screw hole. The engagement contour is preferably produced by milling and has for example a pointed, round, trapezoidal or serrated configuration. A blocking thread is provided under the screw head of the screw intended for blocking. As the screw is screwed in, the blocking thread engages in the engagement contour. The particular advantages lie in increased security against the screw coming loose and in the possibility of also inserting the screw through the plate at an inclination. Furthermore, a bone plate is proposed which has the shape of an arc of a circle in the longitudinal axis of the plate and which requires less bending, particularly on the human lower jaw, and adapts to the bone in a more ideal manner.

Owner:MEDARTIS AG

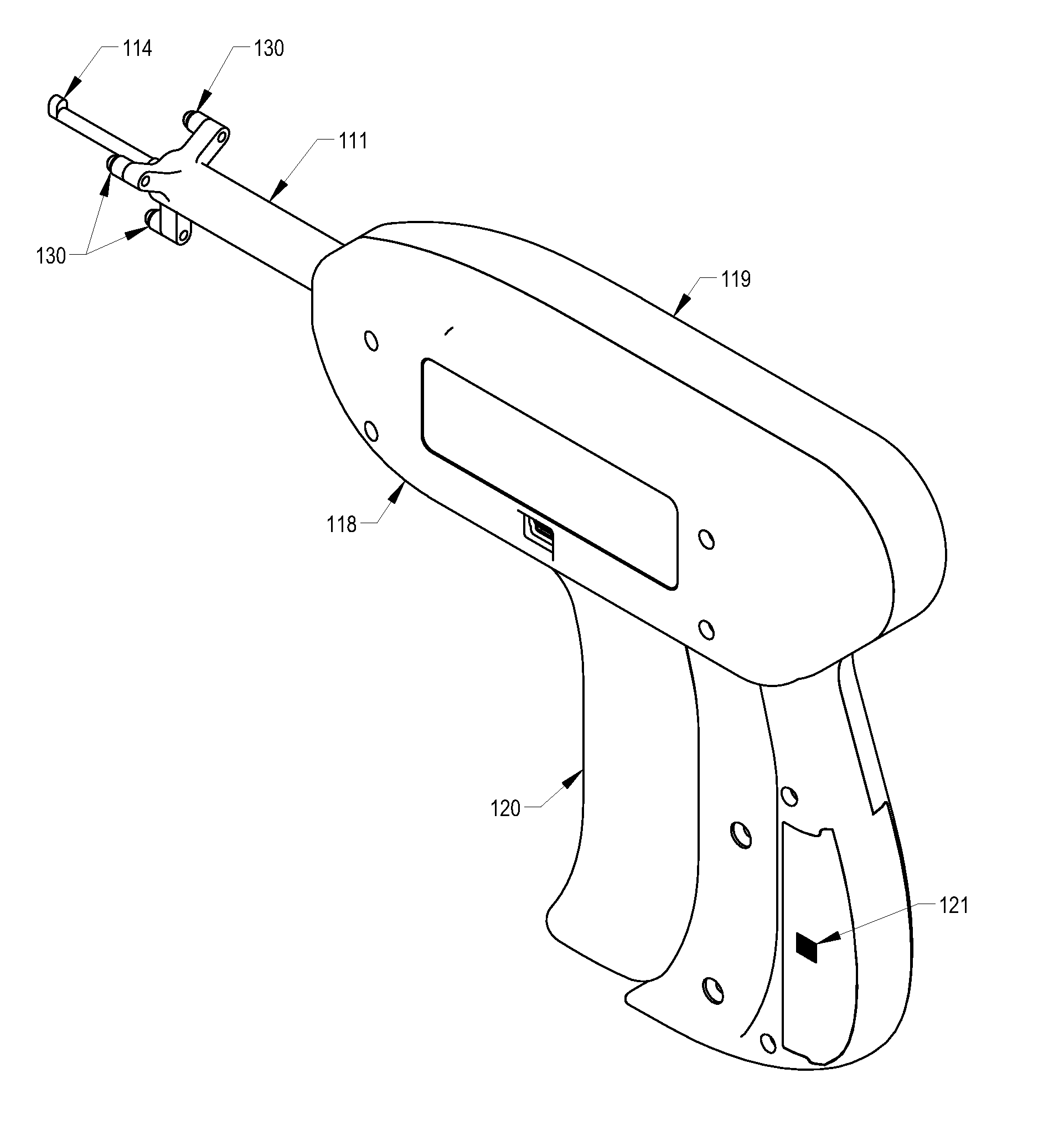

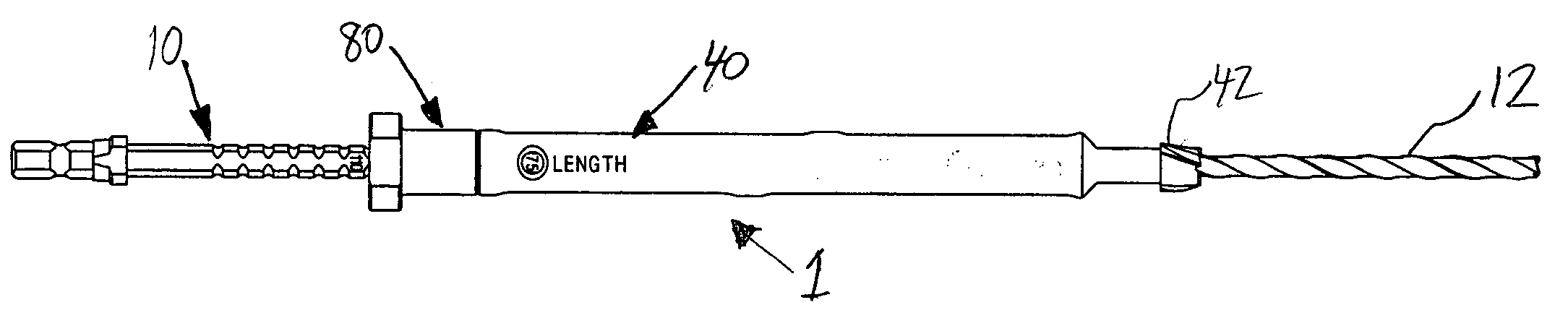

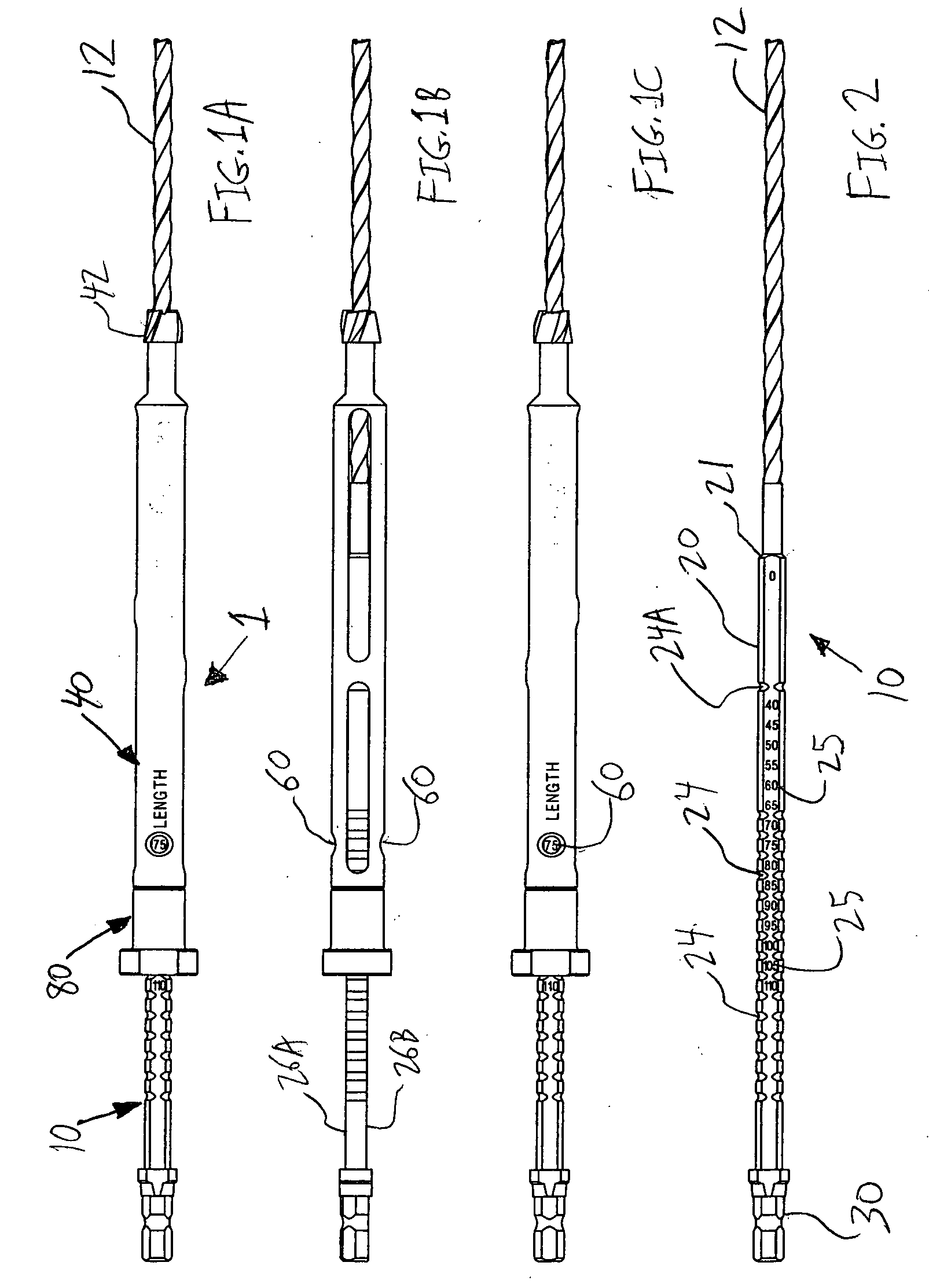

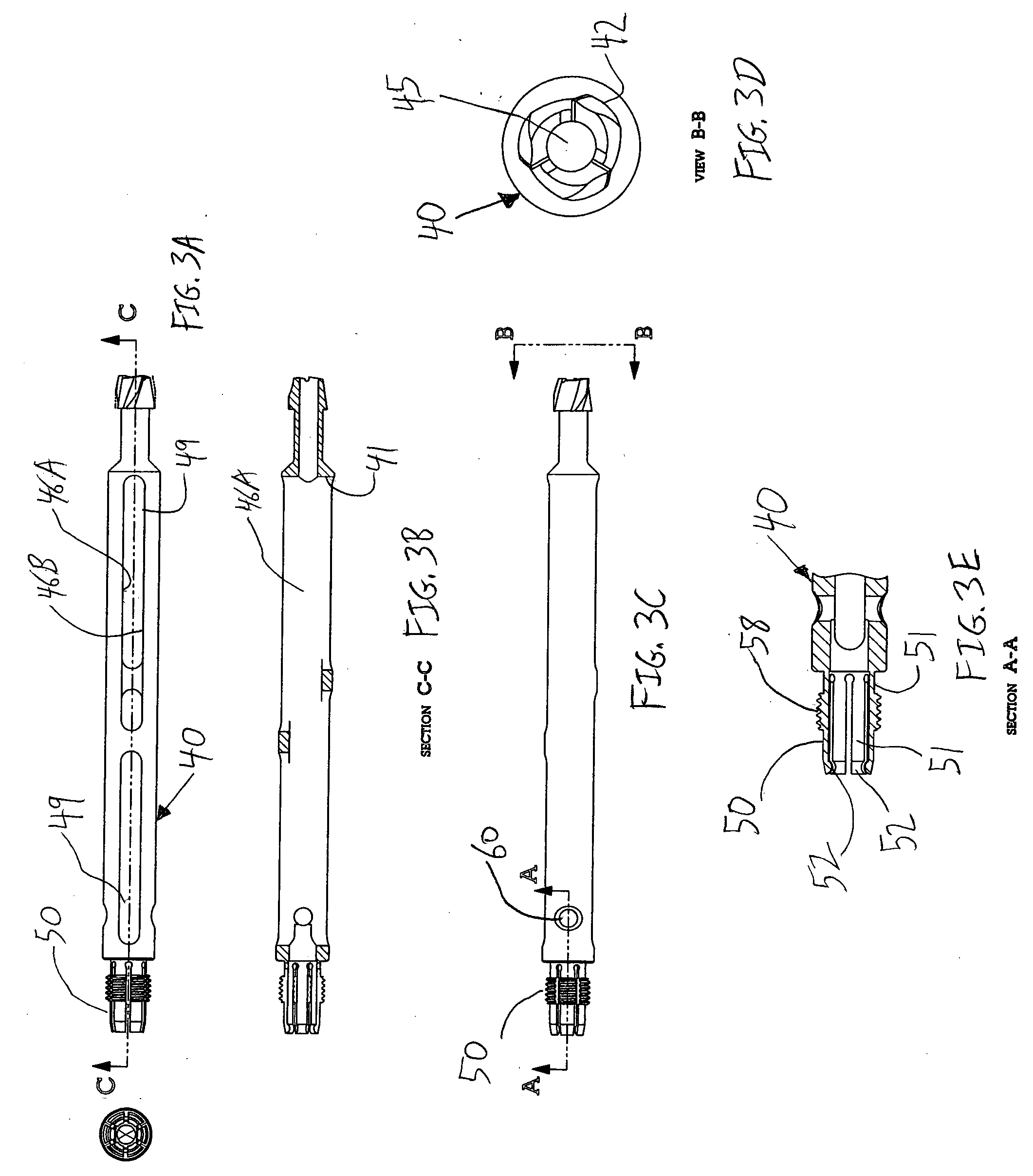

Hole Measurement Apparatuses

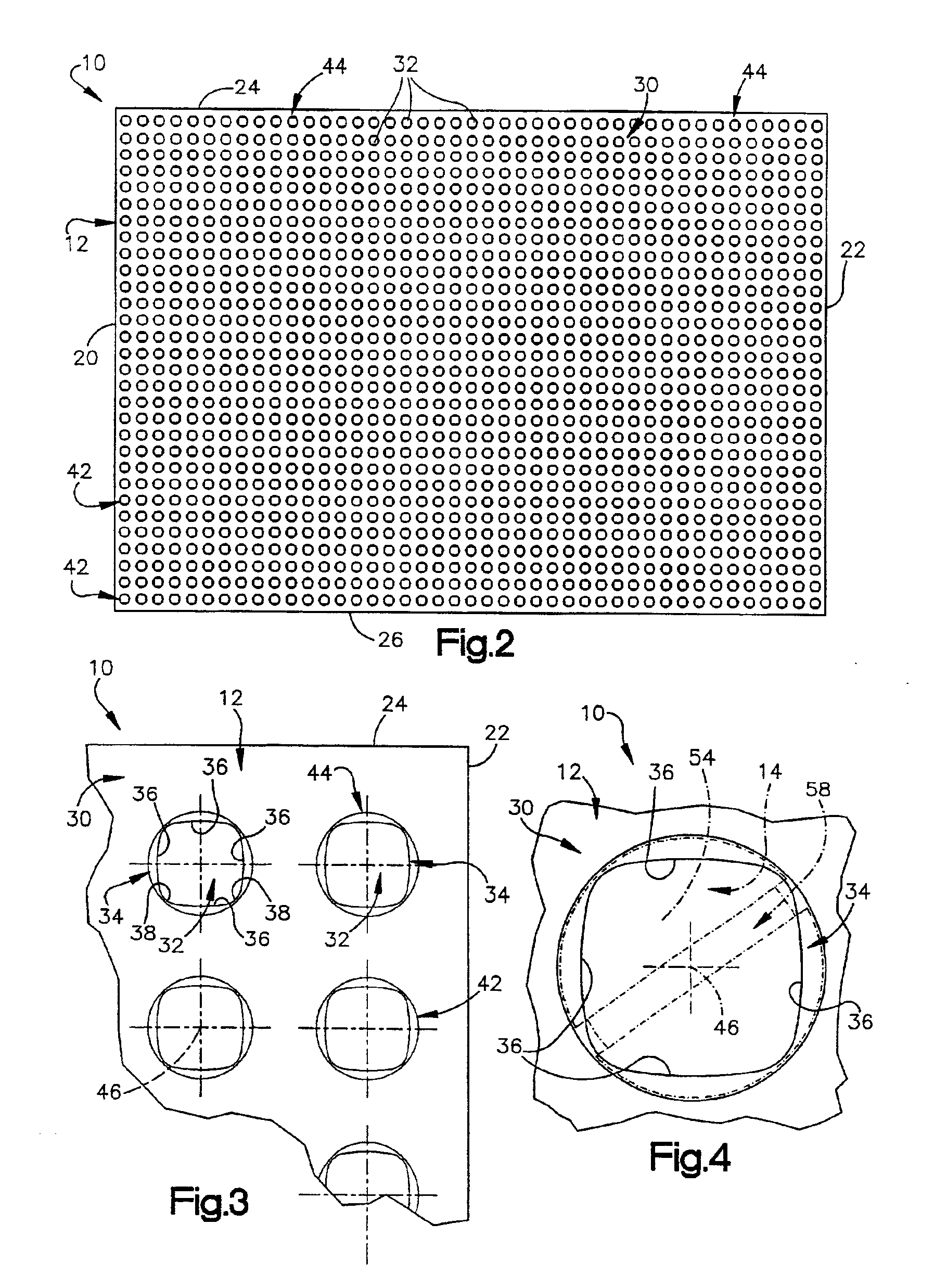

ActiveUS20110166824A1Increase productionIncrease workforceElectric/magnetic depth measurementElectrical/magnetic diameter measurementsEngineeringDiameter measurement

The present invention is directed to automated apparatuses and methods for measuring fastener hole depth, fastener length, countersink depth and / or hole diameters in a workpiece (or other object) in an automated and extremely rapid, efficient and accurate manner. The apparatuses may be operably connected with a power source and with one or a plurality of computers or other data collection devices to transmit fastener hole depth, countersink depth and / or hole diameter measurement data and / or information to them each time that a fastener hole is measured, while the apparatus is continuously measuring fastener holes (i.e., with no interruptions). Extremely advantageously, using only one hand, and by only squeezing a trigger only one time, an operator of such an apparatus may successfully and very rapidly and accurately perform more than one, or all three, of the following functions: (i) normalize the apparatus relative to one or a plurality of fastener holes and / or workpiece surfaces; (ii) make one or a plurality of accurate measurements; and (iii) transmit the one or more measurements from the apparatus to one or a plurality of computers and / or other data collection devices for, for example, recordation, storage, manipulation, other use and / or the like.

Owner:DELTA SIGMA

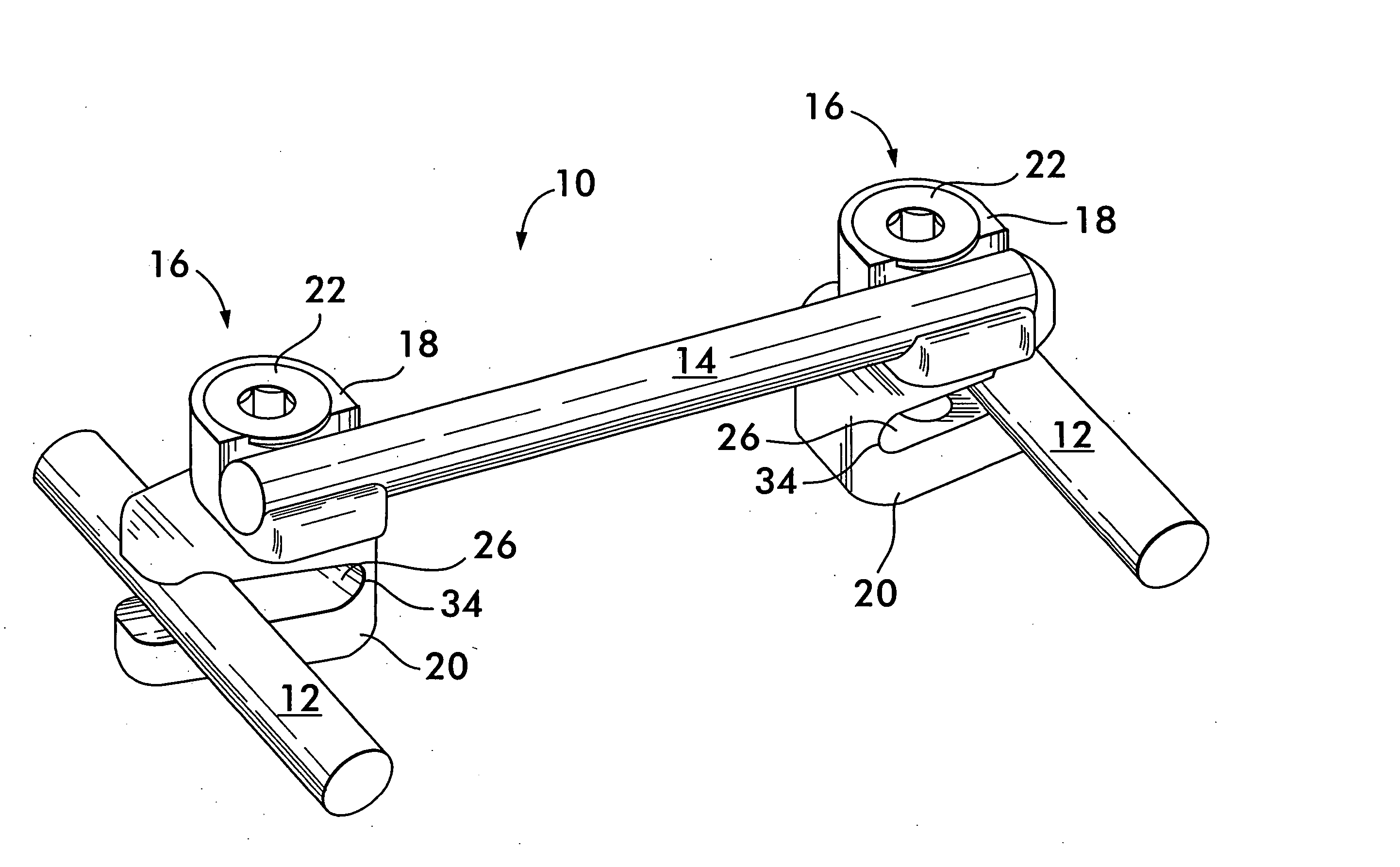

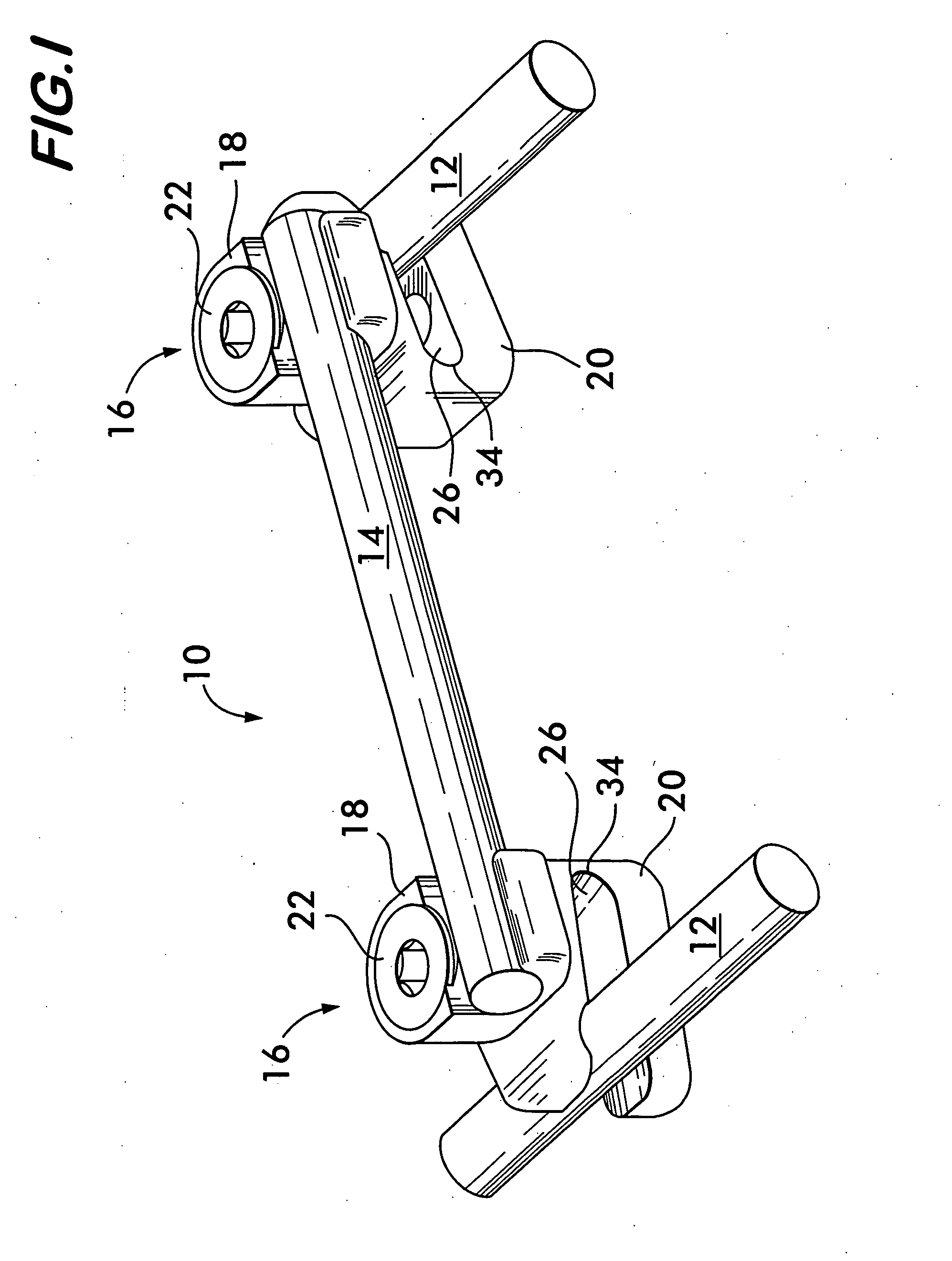

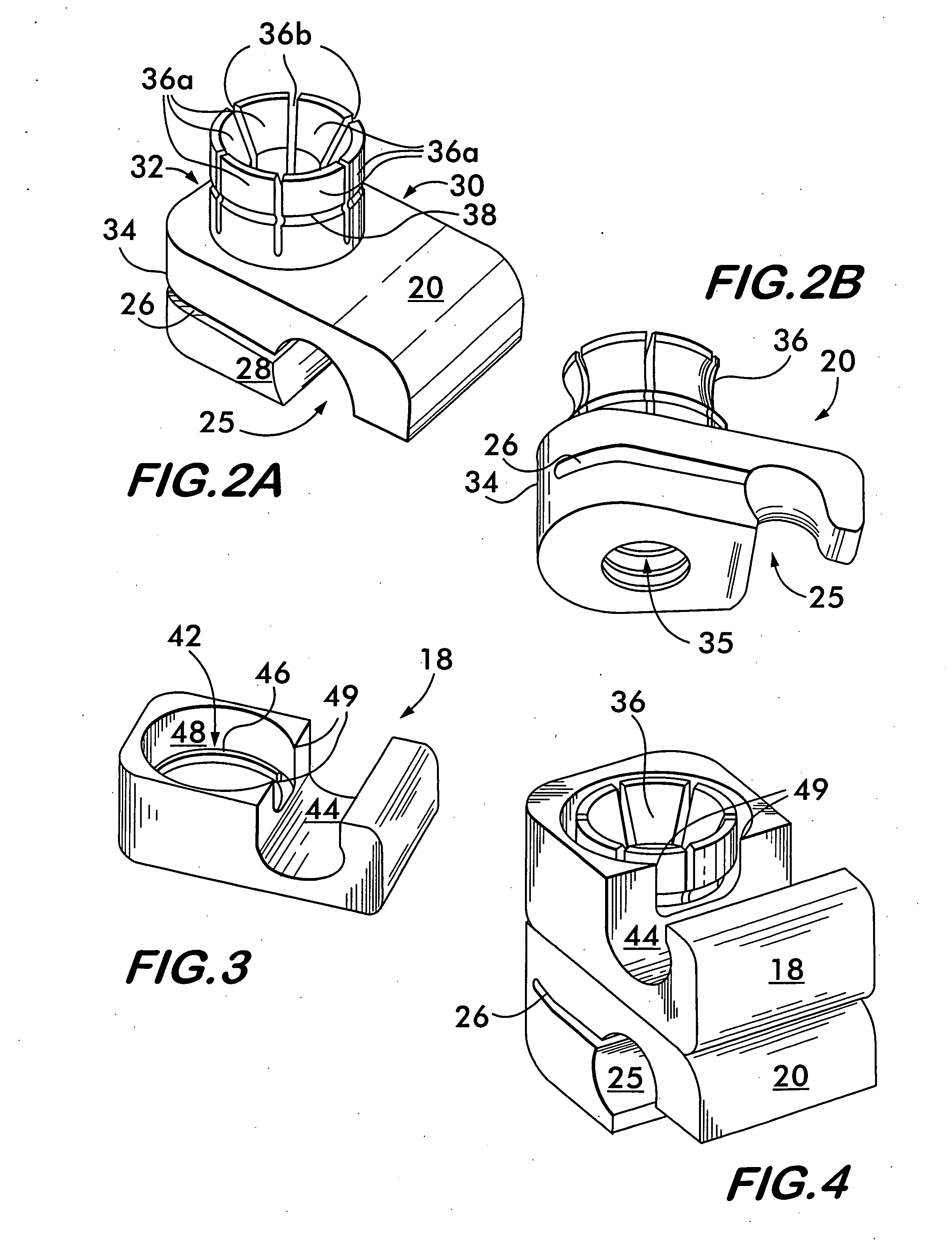

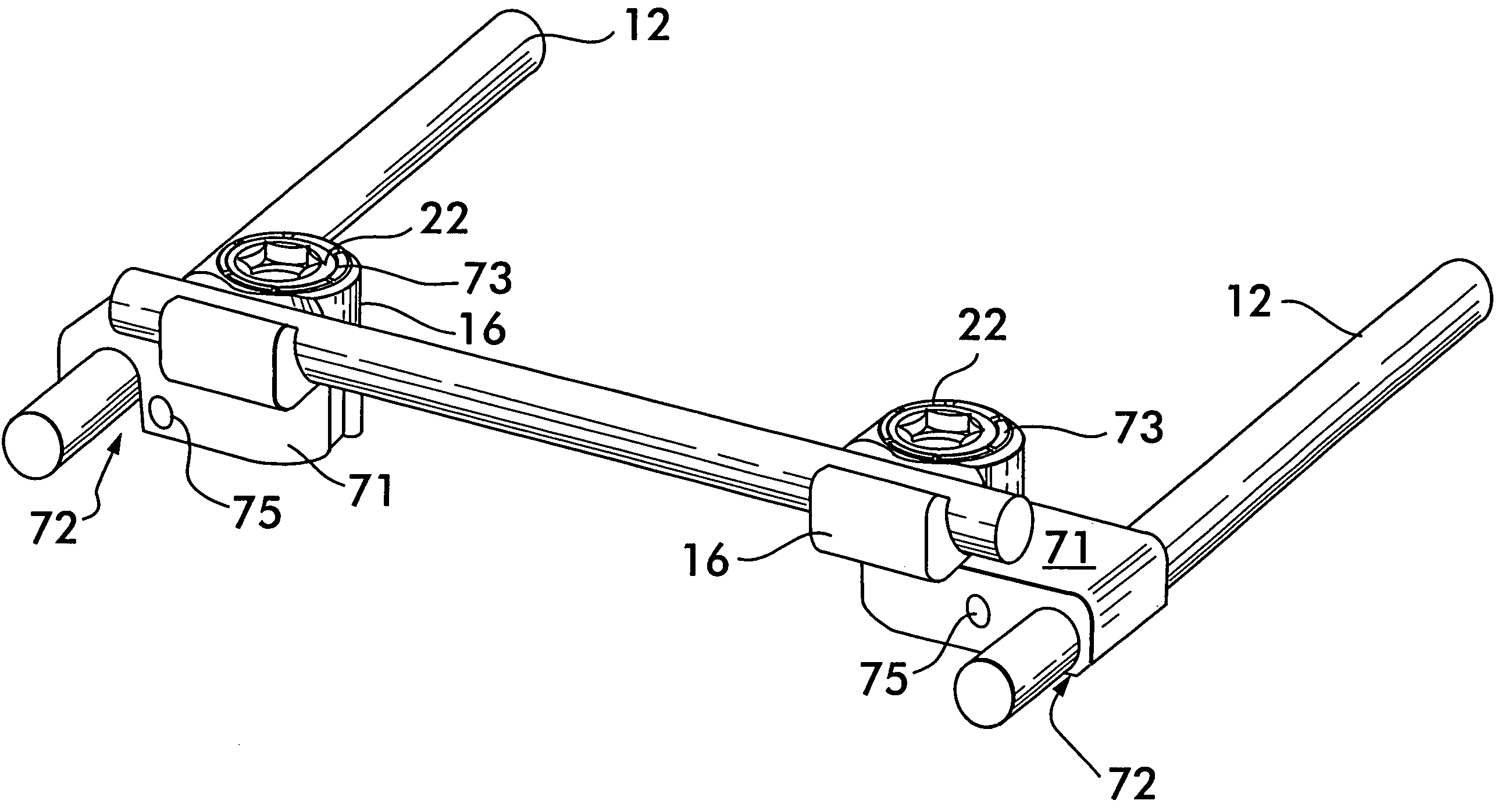

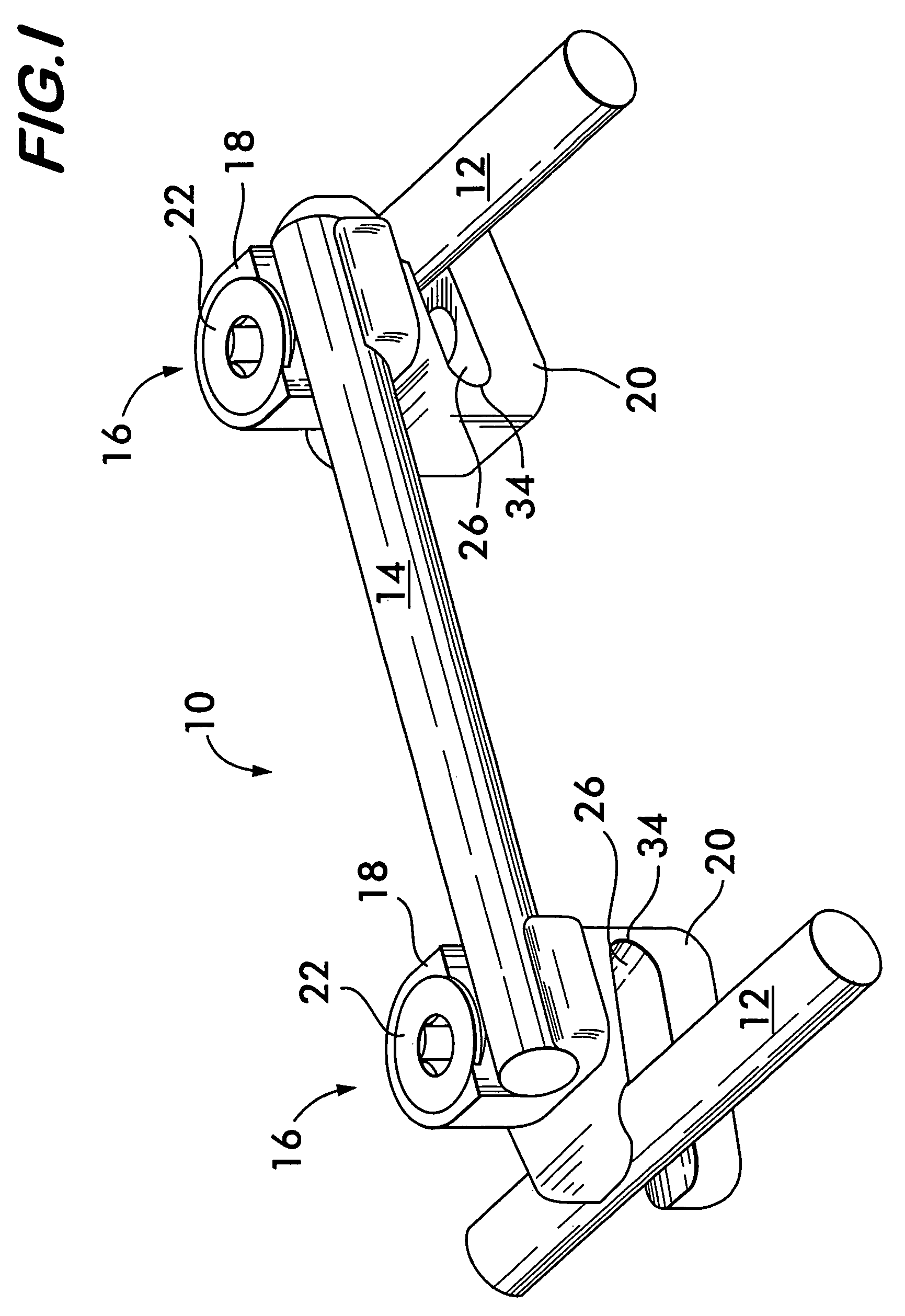

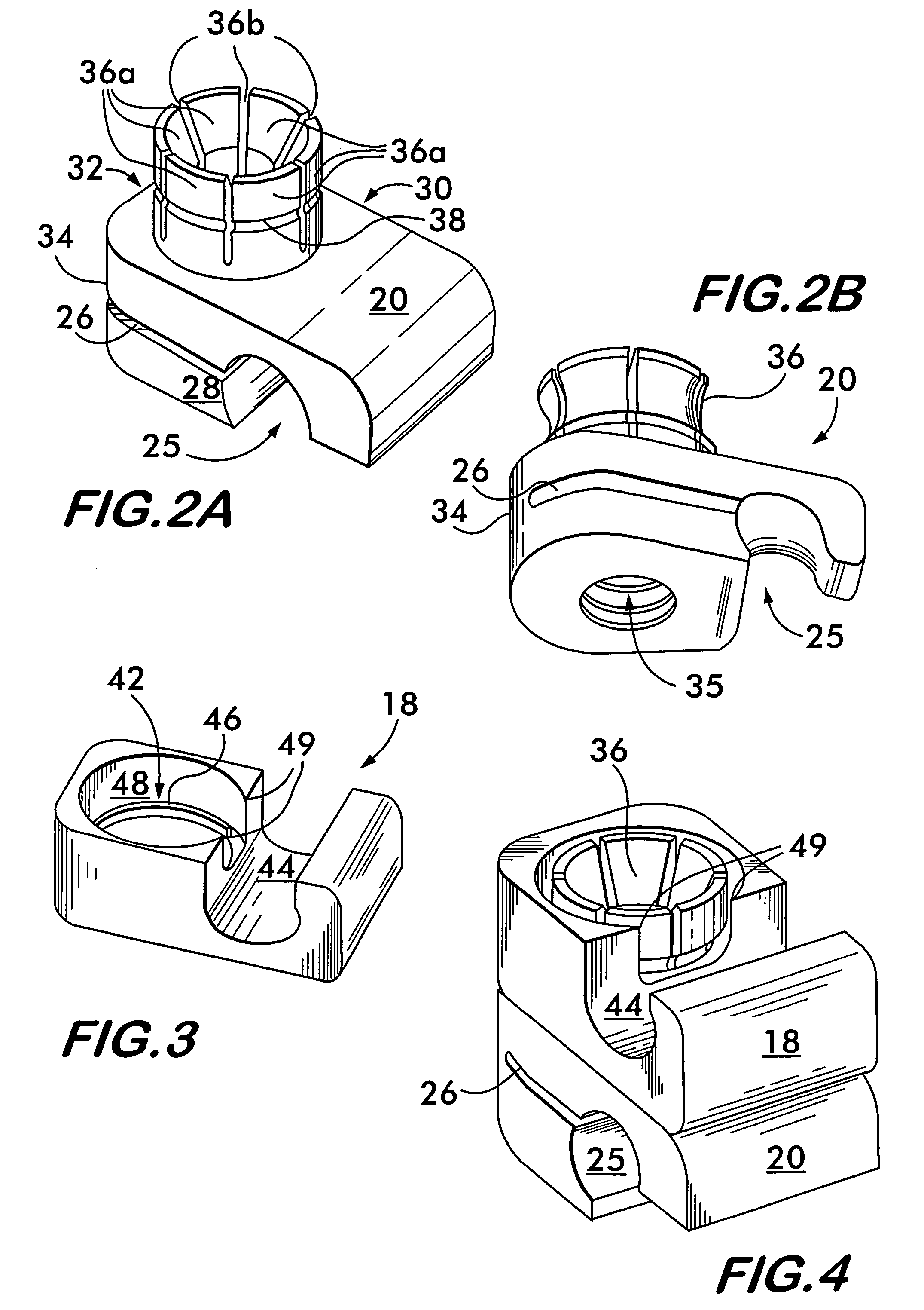

Rod to rod connector

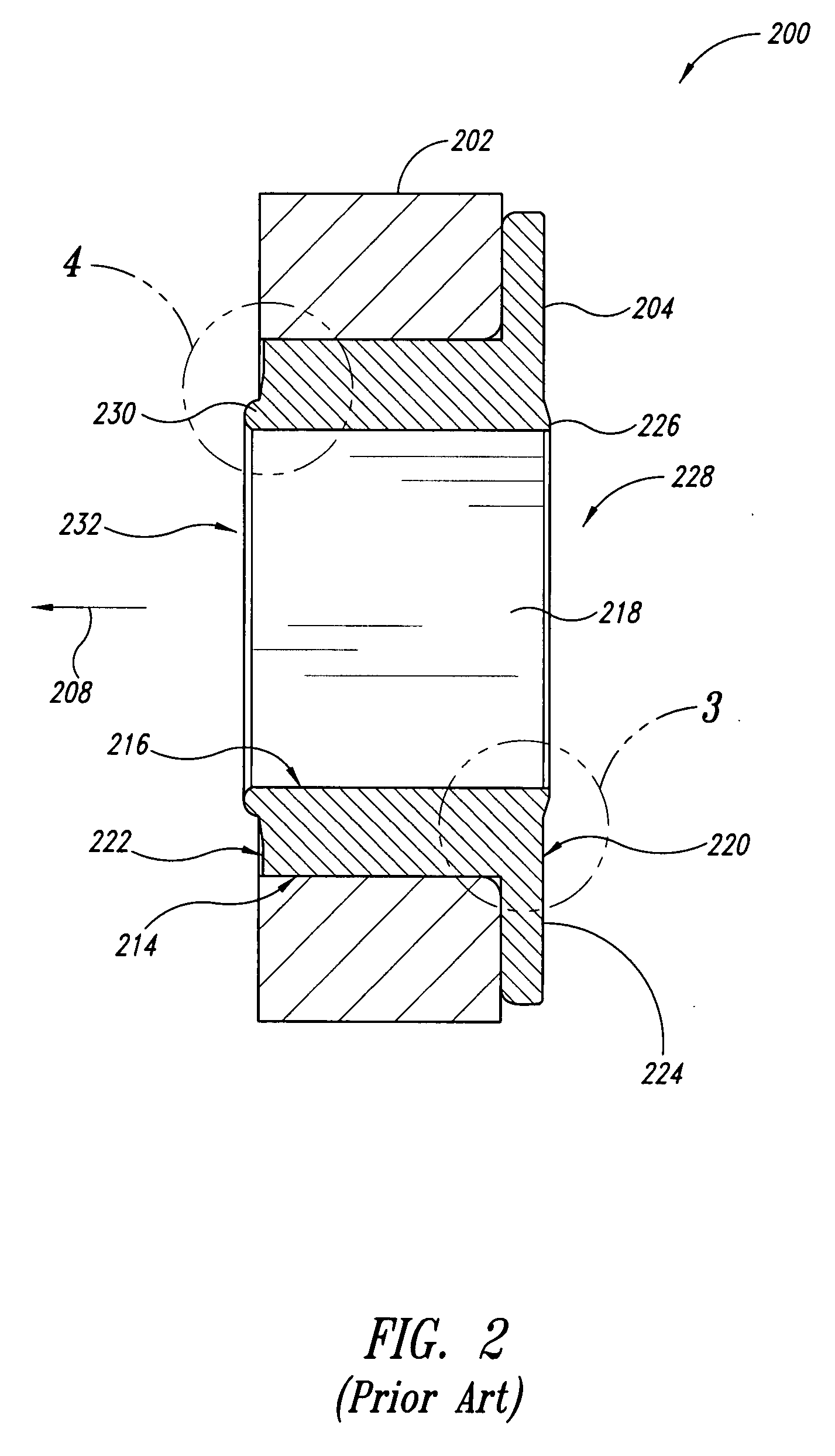

InactiveUS20070049932A1Improve the immunityInternal osteosythesisJoint implantsBearing downEngineering

The invention is a rod to rod connector that can be used to interconnect two generally parallel spinal rods of a spinal rod and anchor system. The connector comprises a transverse rod and two pairs of clamping bodies, one for each spinal rod. Each pair connects one of the longitudinal spinal rods to the transverse rod in infinitely adjustable angular relationship. One of the two clamping bodies of each pair comprises a C-shaped channel for accepting the spinal rod. The channel is in communication with a slot that defines a hinge. A threaded screw hole passes transversely through the slot and permits a screw to squeeze the hinge, thereby causing the C-shaped channel to close around and clamp the rod. The second clamping body is similar to the first except that there is no slot or hinge and the screw hole preferably is not threaded, but includes a countersink for seating a chamfered screw head. Also, an angular portion of the screw hole intersects the C-shaped channel. The two clamping bodies are aligned with each other so that their screw holes are coaxial so that a single screw can pass through both holes thereby clamping both rods in the C-shaped channels and fixing the angle between the two clamping bodies and, hence, the two rods. The first clamp clamps the spinal rod by squeezing the hinge to cause the C-shaped channel to squeeze around the rod. The second clamp clamps the transverse rod by virtue of the bottom of the screw head bearing down on the transverse rod over the portion of the screw hole that intersects the C-shaped channel.

Owner:AESCULAP AG

Hole measurement apparatuses

ActiveUS8606540B2Fast, efficient and accurate measurementEasy transferElectric/magnetic depth measurementElectrical/magnetic diameter measurementsDiameter measurementBiomedical engineering

The present invention is directed to automated apparatuses and methods for measuring fastener hole depth, fastener length, countersink depth and / or hole diameters in a workpiece (or other object) in an automated and extremely rapid, efficient and accurate manner. The apparatuses may be operably connected with a power source and with one or a plurality of computers or other data collection devices to transmit fastener hole depth, countersink depth and / or hole diameter measurement data and / or information to them each time that a fastener hole is measured, while the apparatus is continuously measuring fastener holes (i.e., with no interruptions). Extremely advantageously, using only one hand, and by only squeezing a trigger only one time, an operator of such an apparatus may successfully and very rapidly and accurately perform more than one, or all three, of the following functions: (i) normalize the apparatus relative to one or a plurality of fastener holes and / or workpiece surfaces; (ii) make one or a plurality of accurate measurements; and (iii) transmit the one or more measurements from the apparatus to one or a plurality of computers and / or other data collection devices for, for example, recordation, storage, manipulation, other use and / or the like.

Owner:DELTA SIGMA

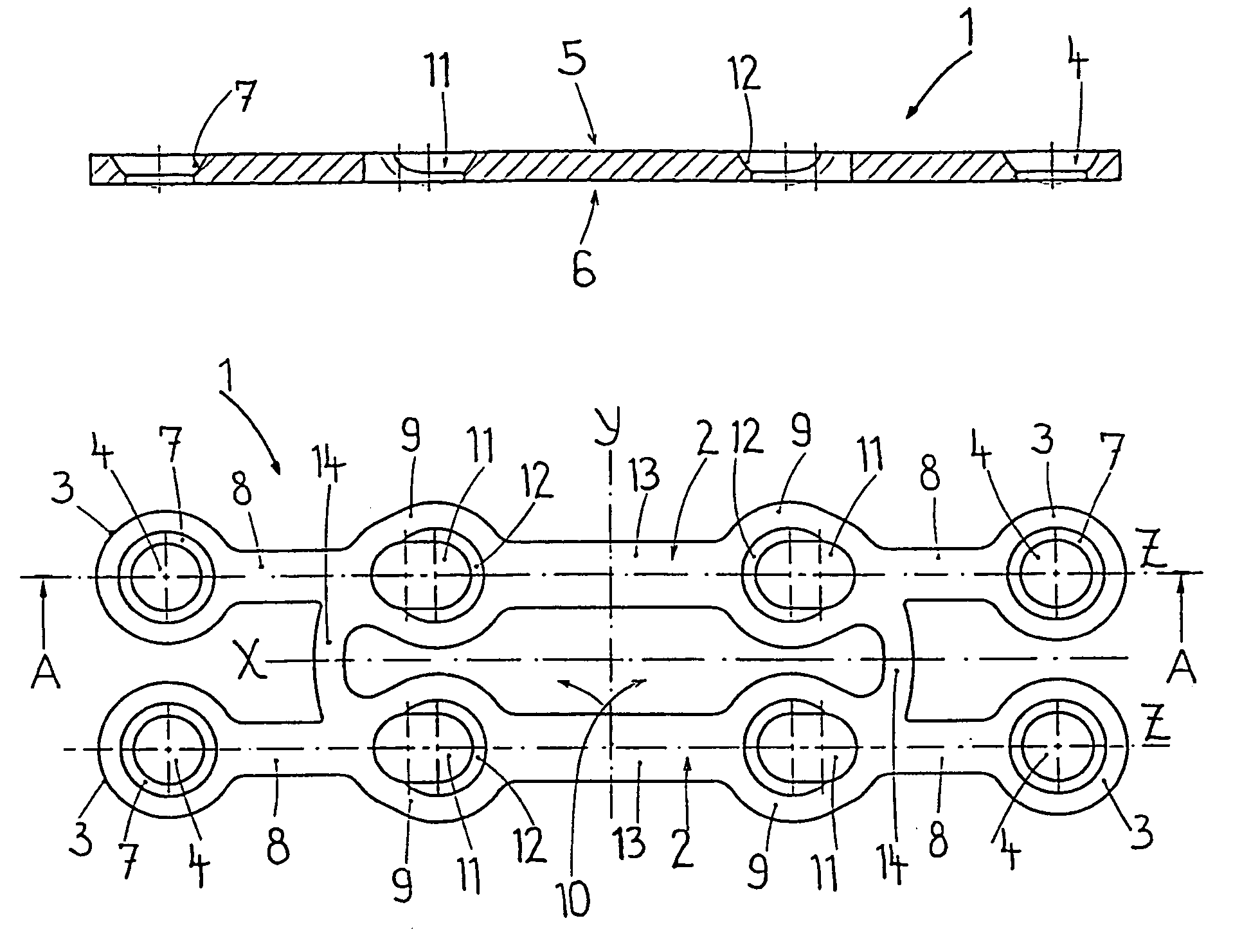

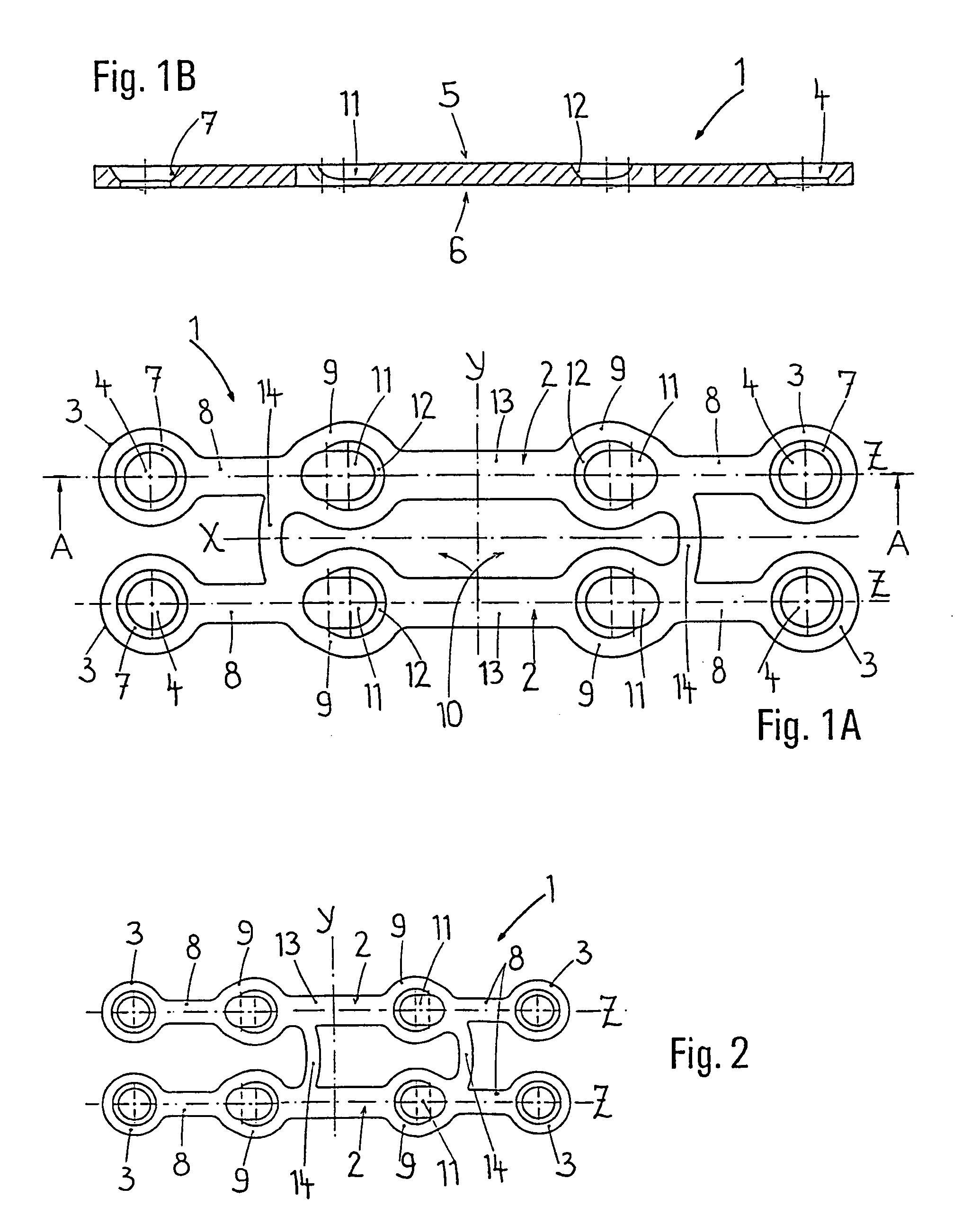

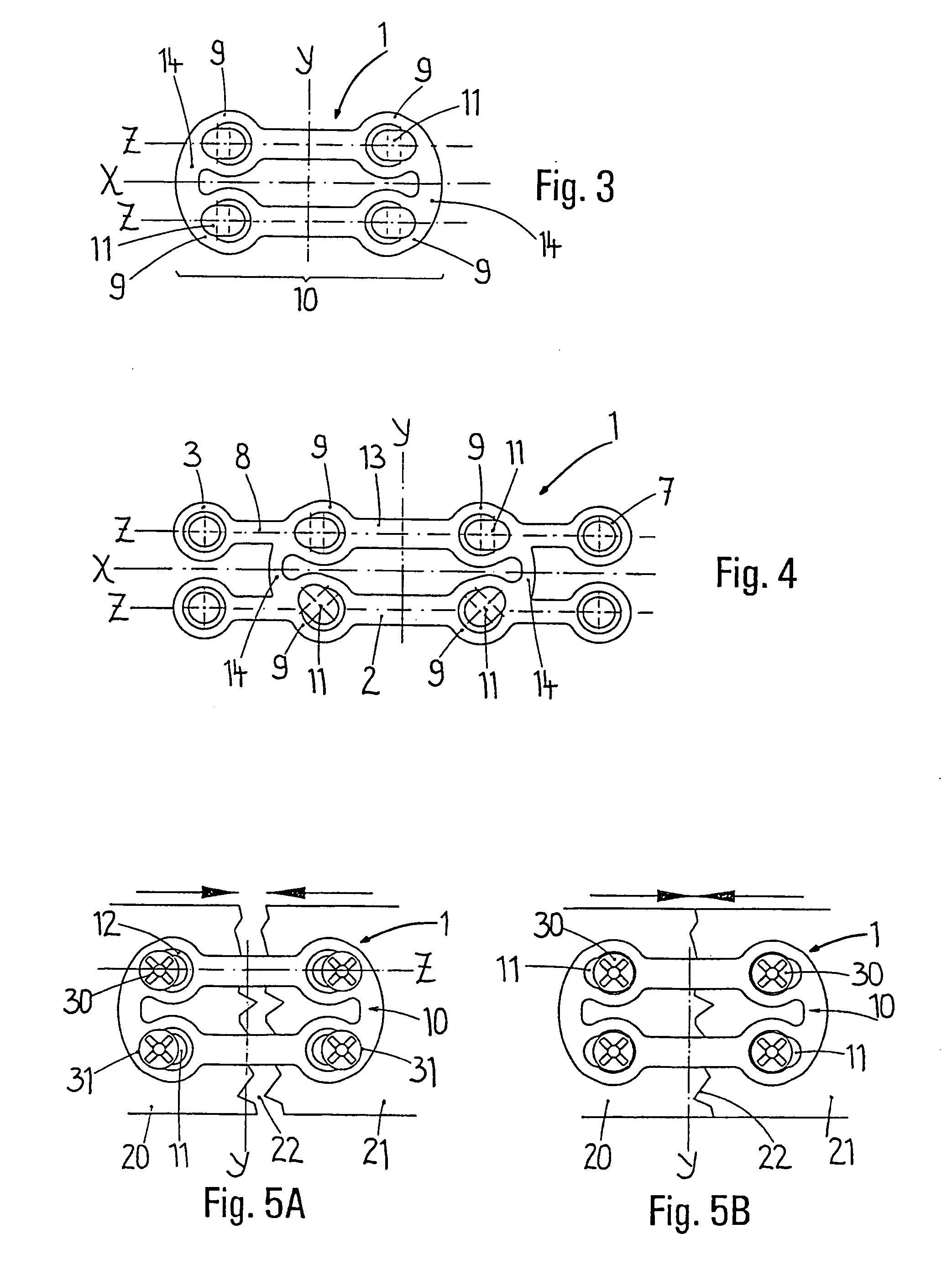

Osteosynthetic bone plate

An osteosynthetic bone plate has elongated compression cavities containing eccentric countersinks. The plate includes a longitudinal axis, a transverse axis, a plate upper side, and a plate lower side for facing bone fragments. The bone plate also includes a compression element with two plate braces which run substantially parallel to the longitudinal axis. Both plate braces are linked together by bridging struts which intersect the longitudinal axis. A plate brace has an eyelet on at least one of the outer sides of the compression element. Additional eyelets can be positioned in front of this eyelet. A compression cavity is situated in each of said eyelets and a connecting strut, which intersects the transverse axis, extends between the eyelets which are located on each plate brace.

Owner:MEDARTIS AG

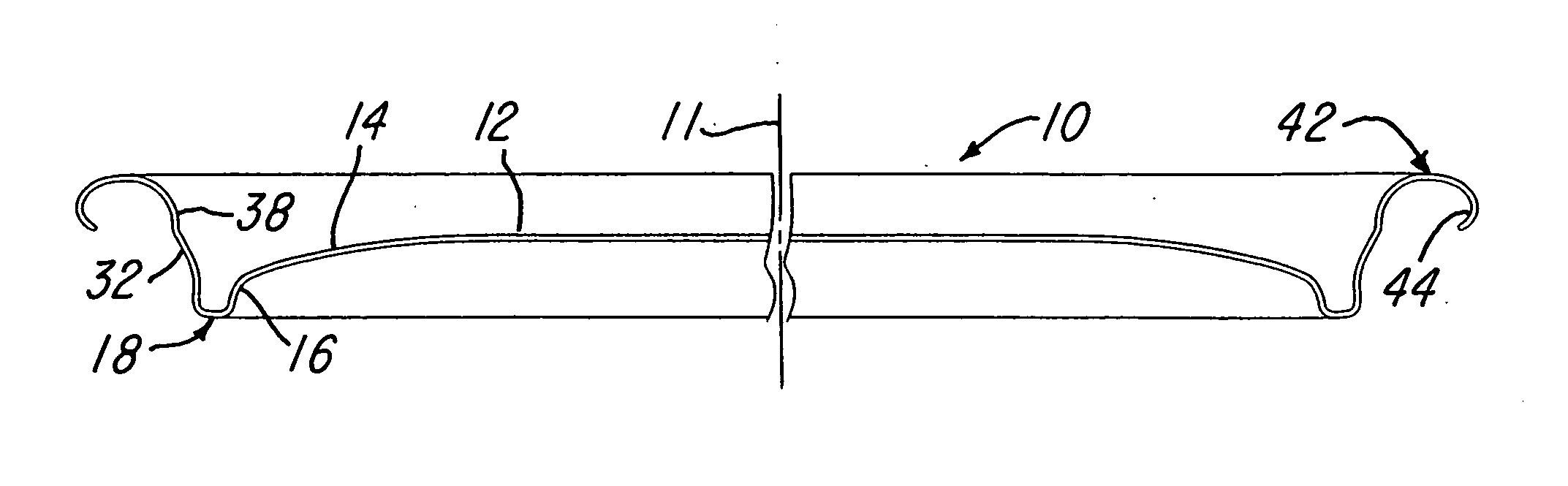

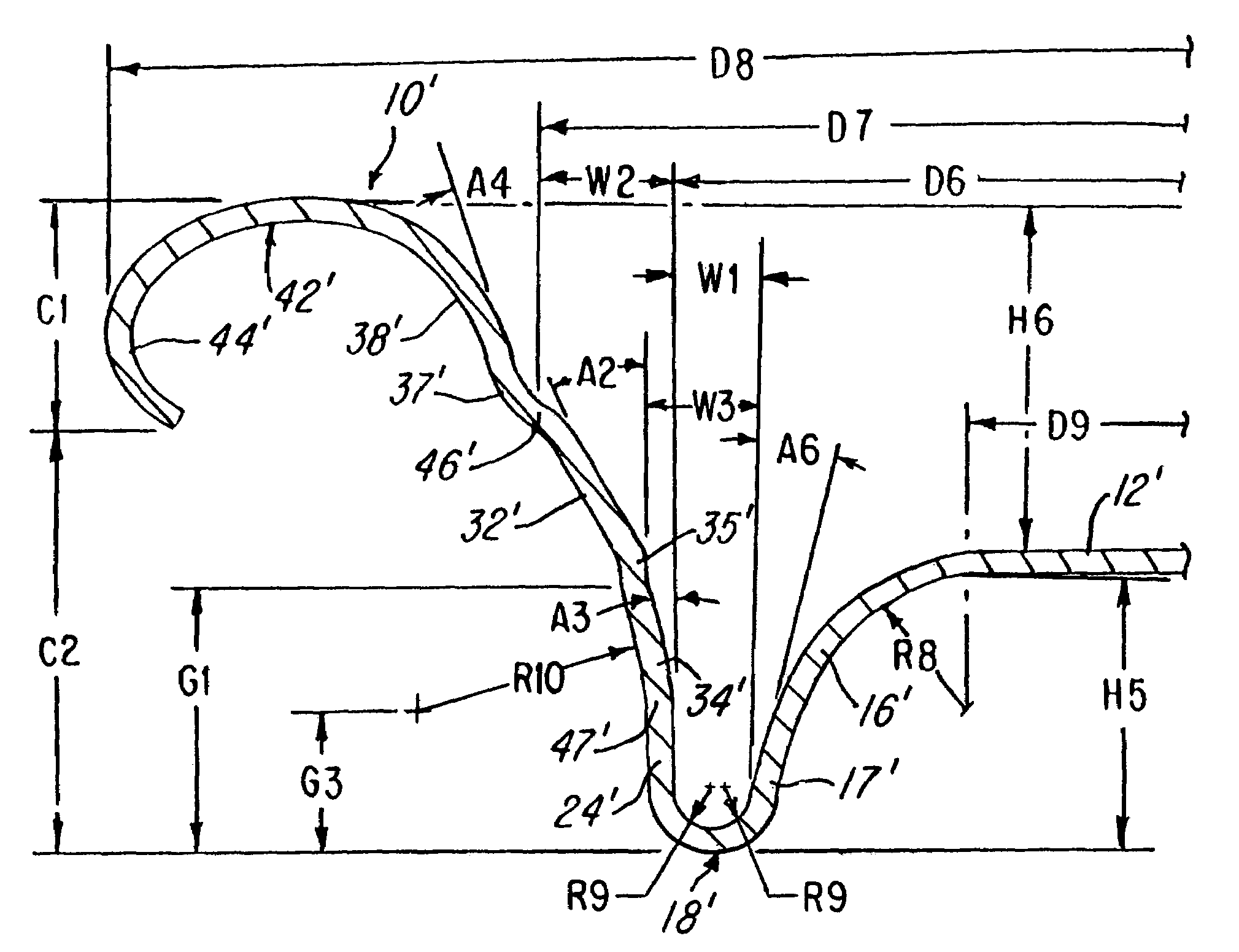

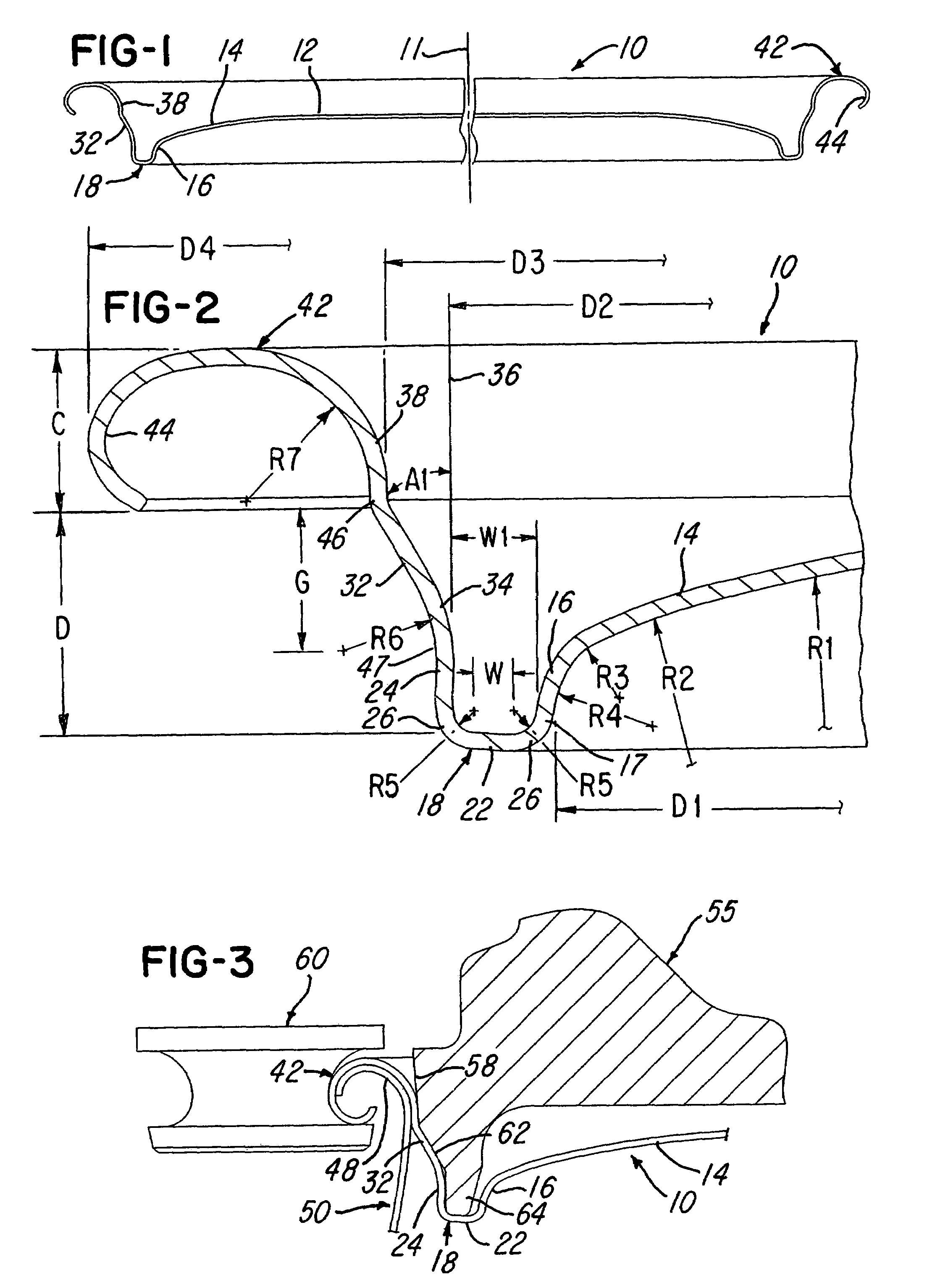

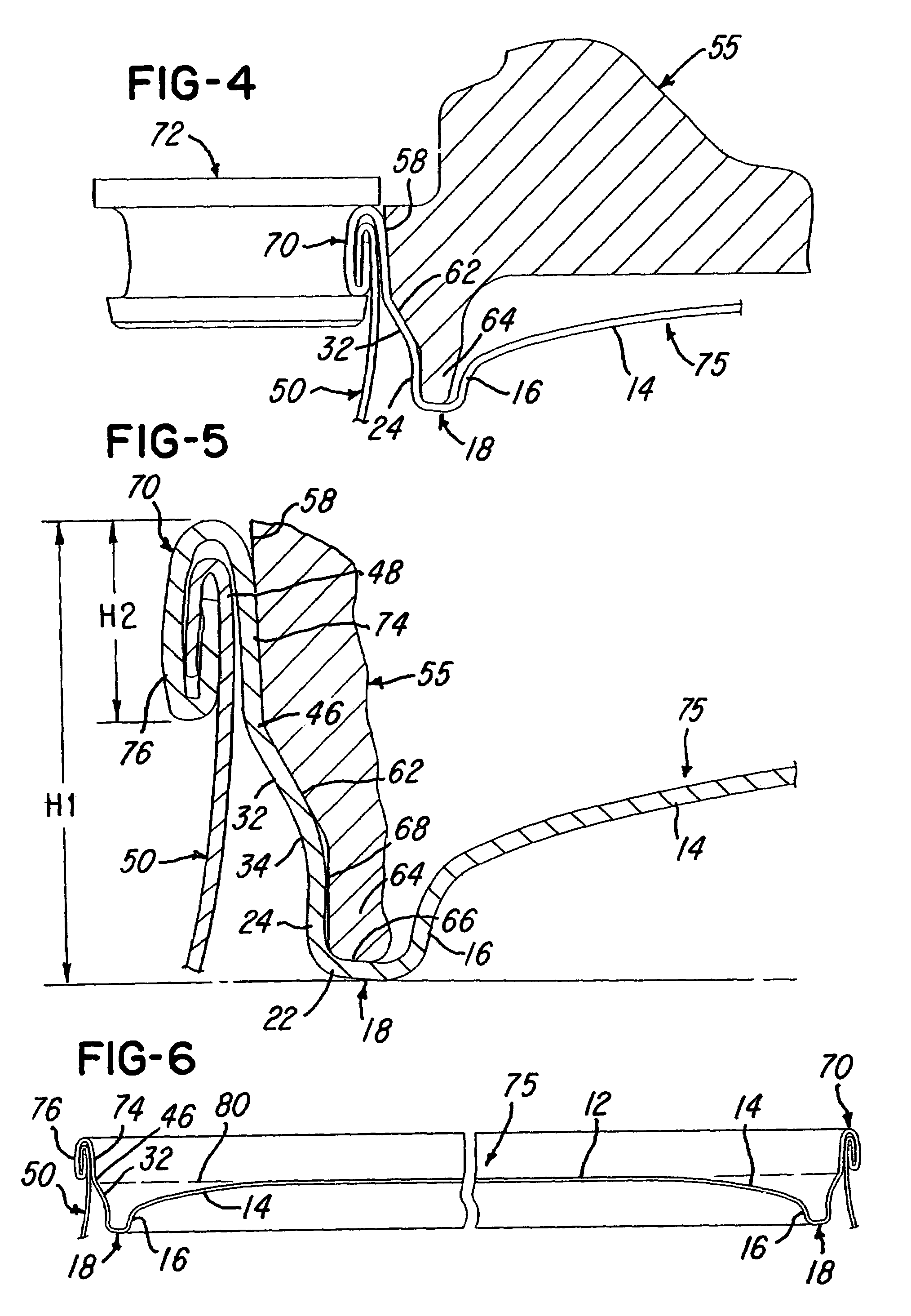

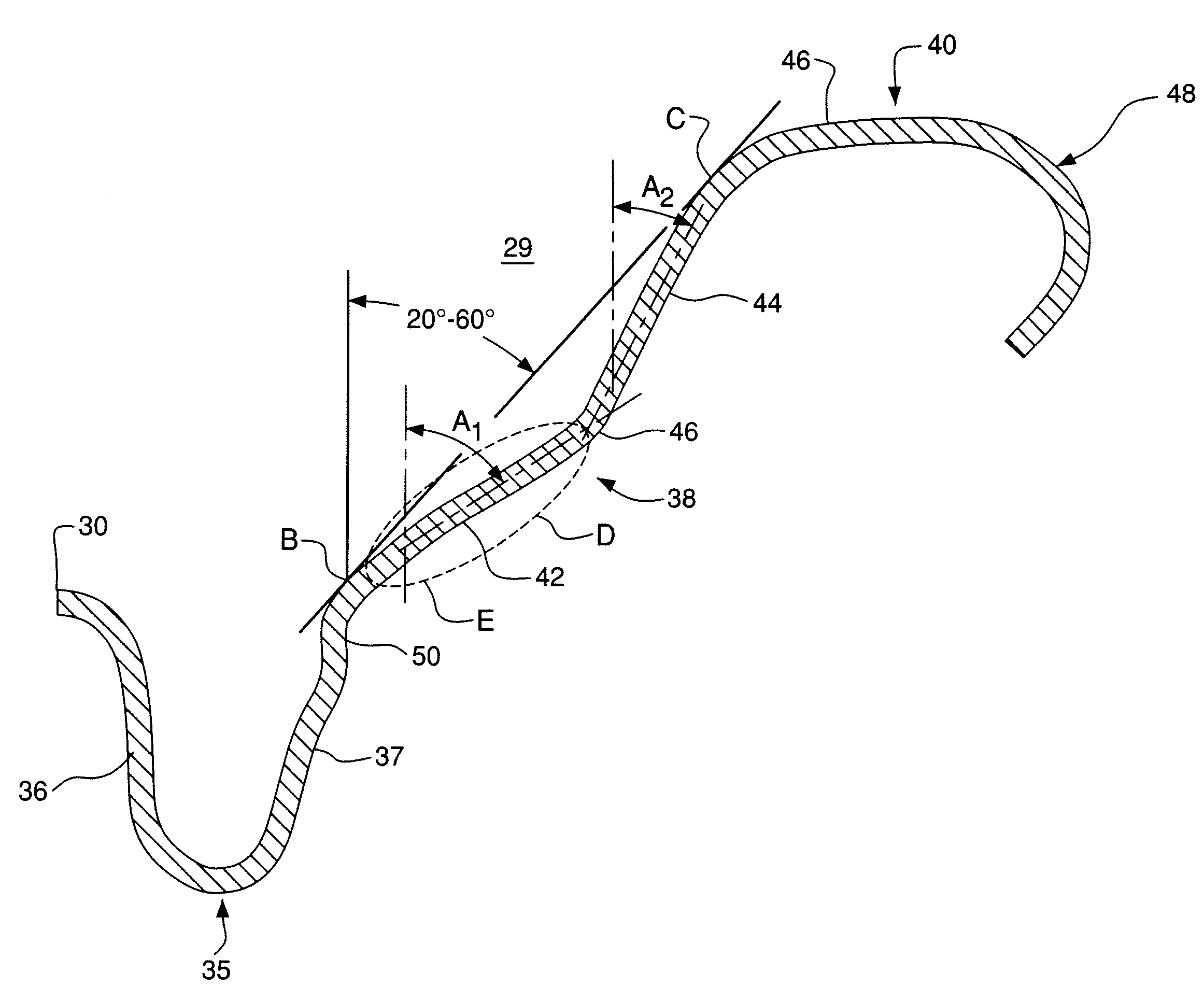

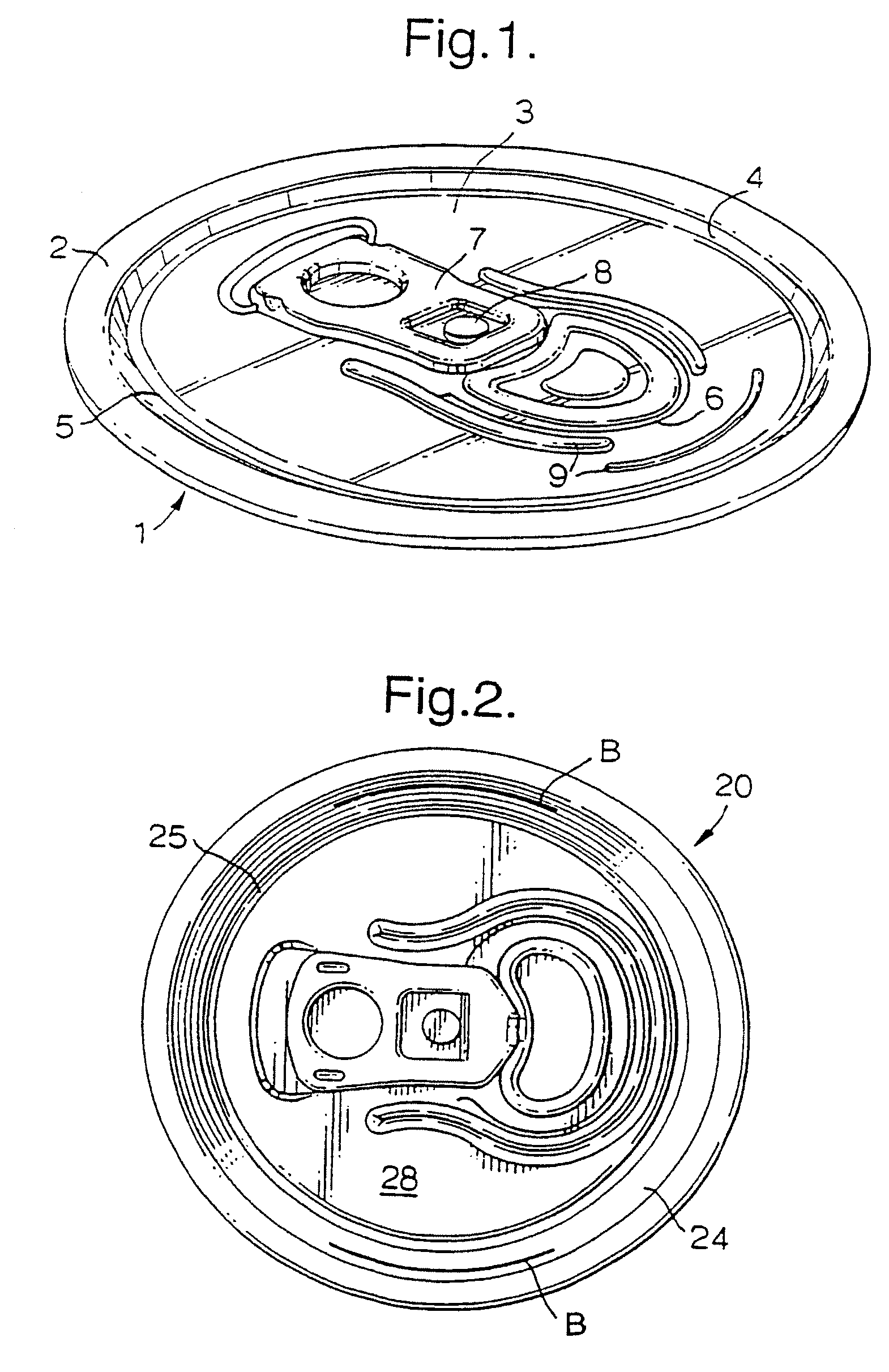

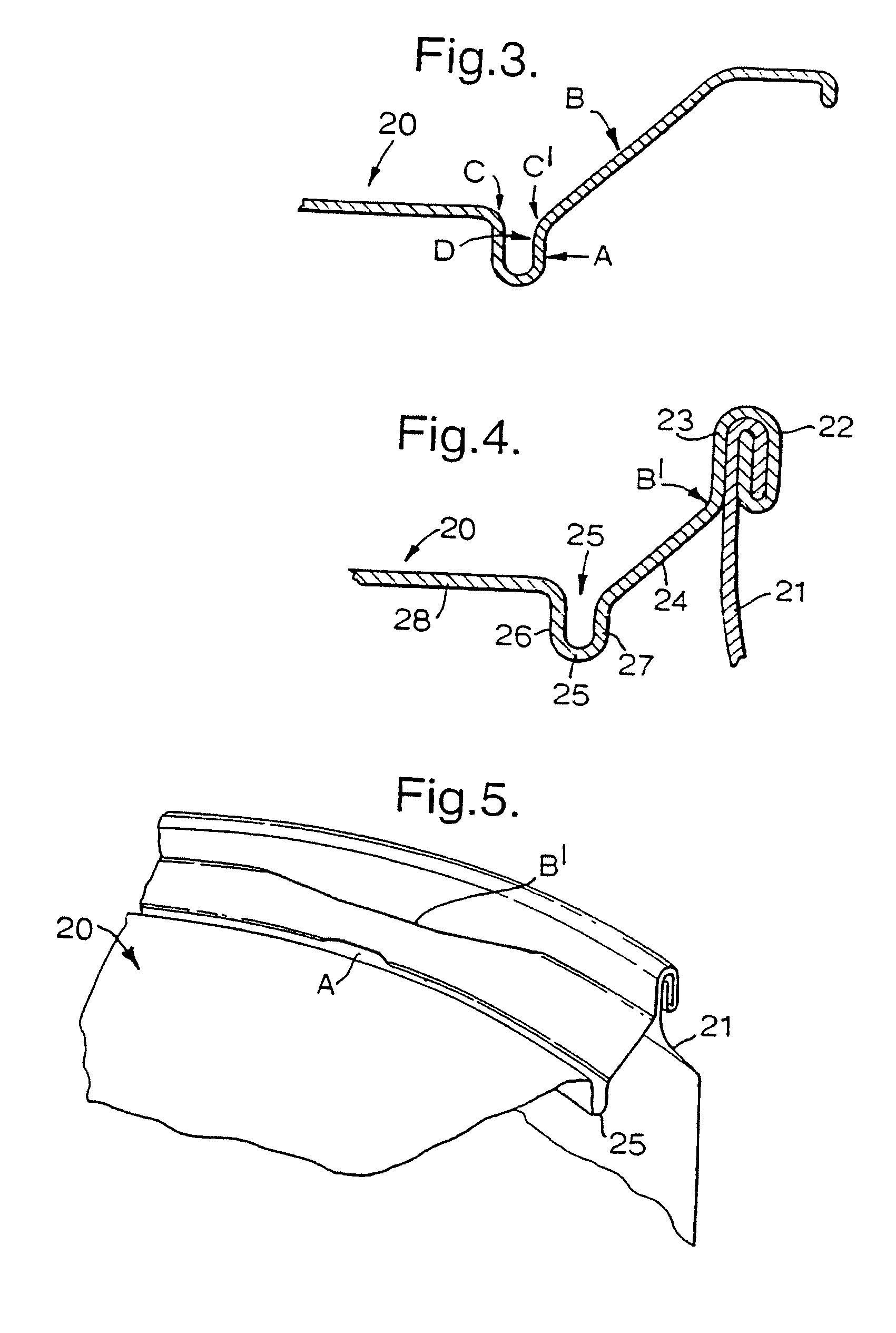

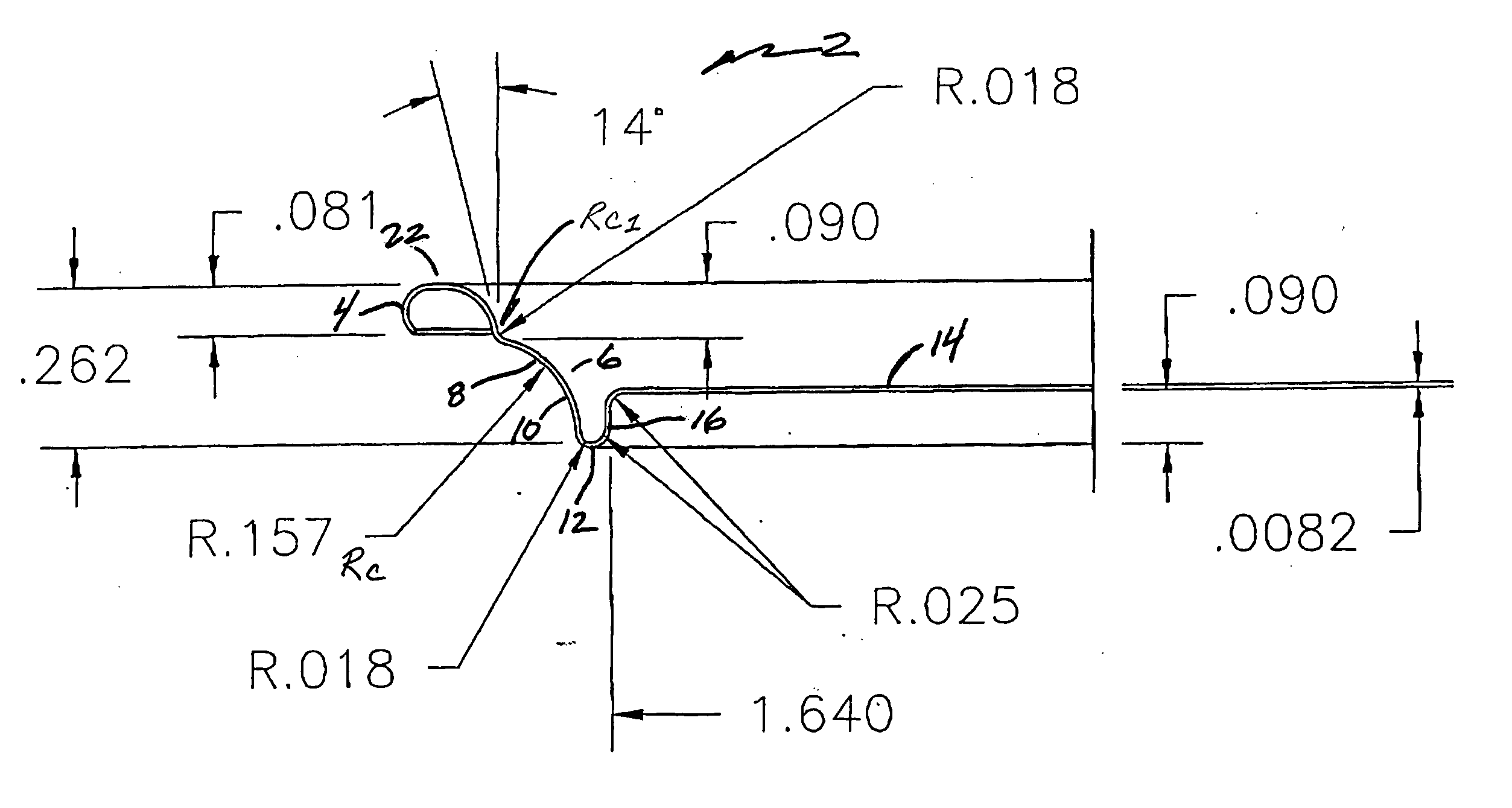

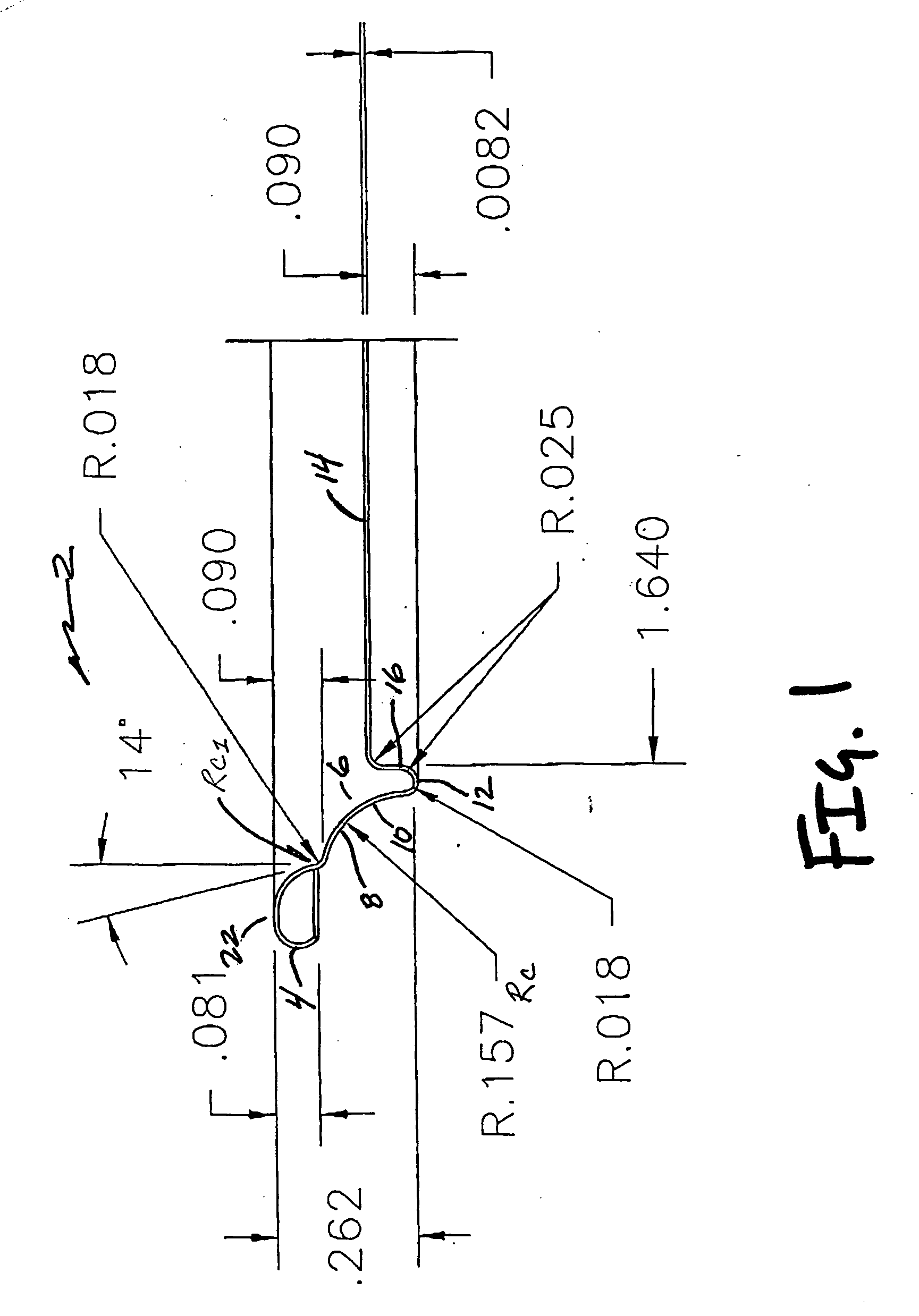

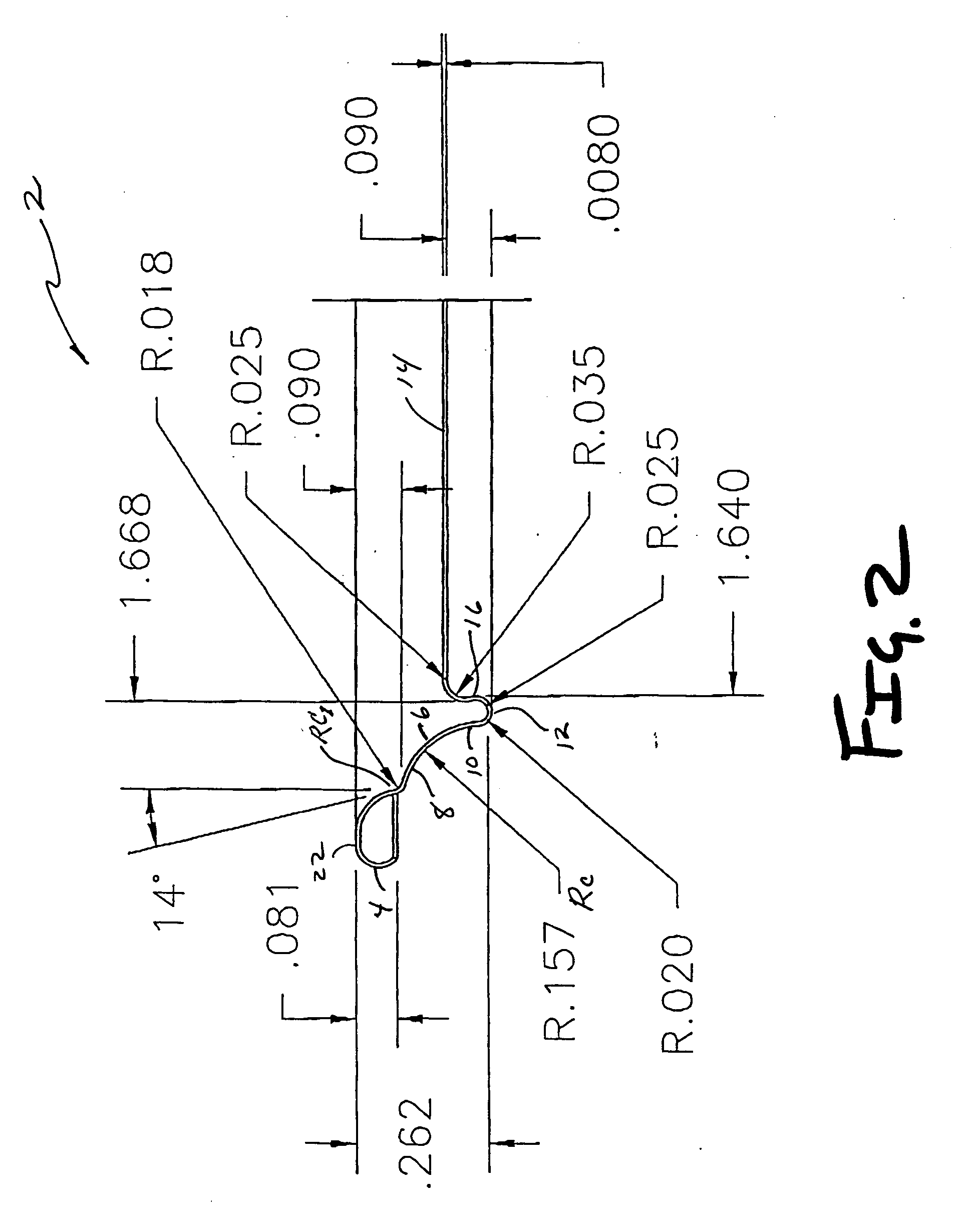

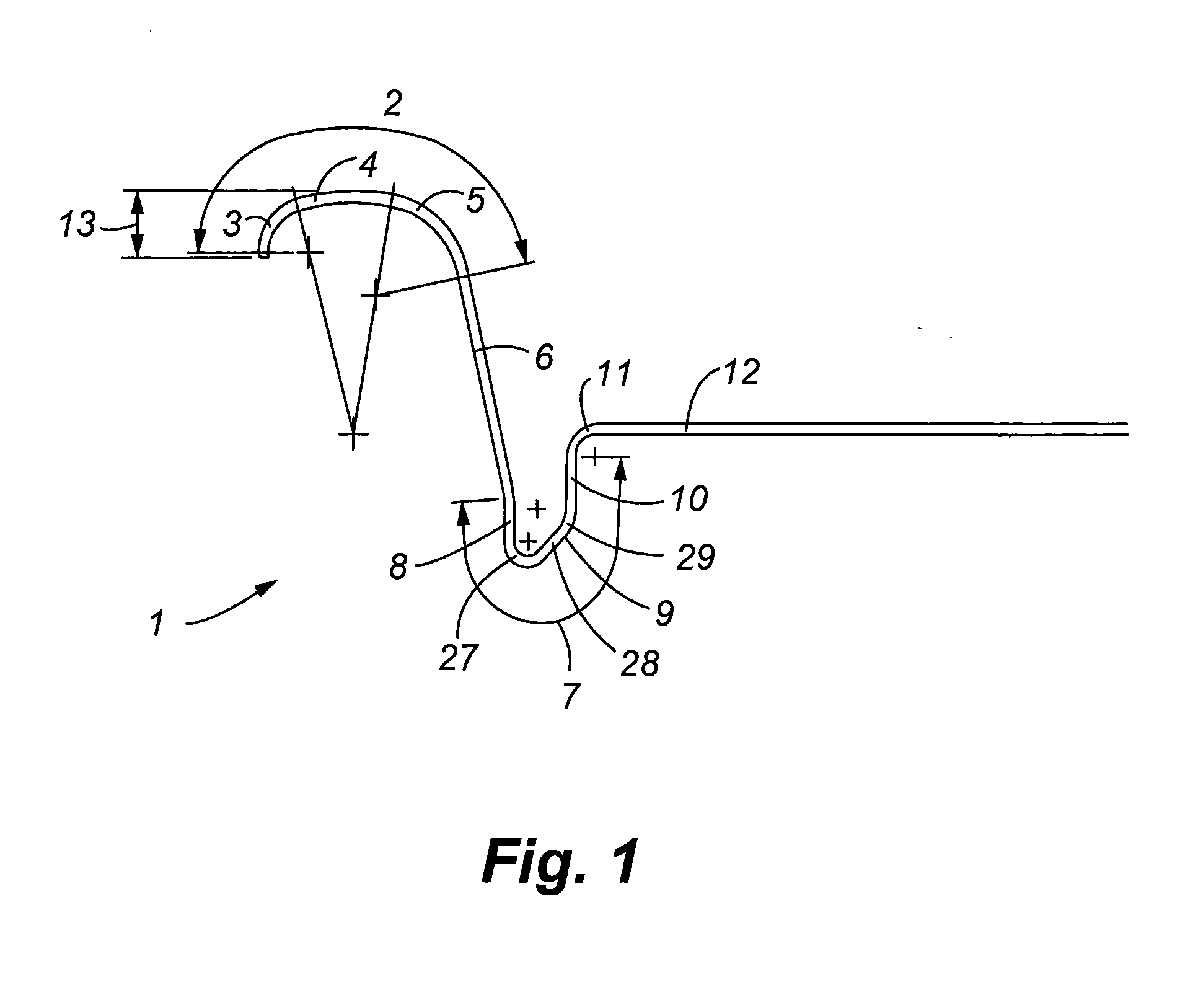

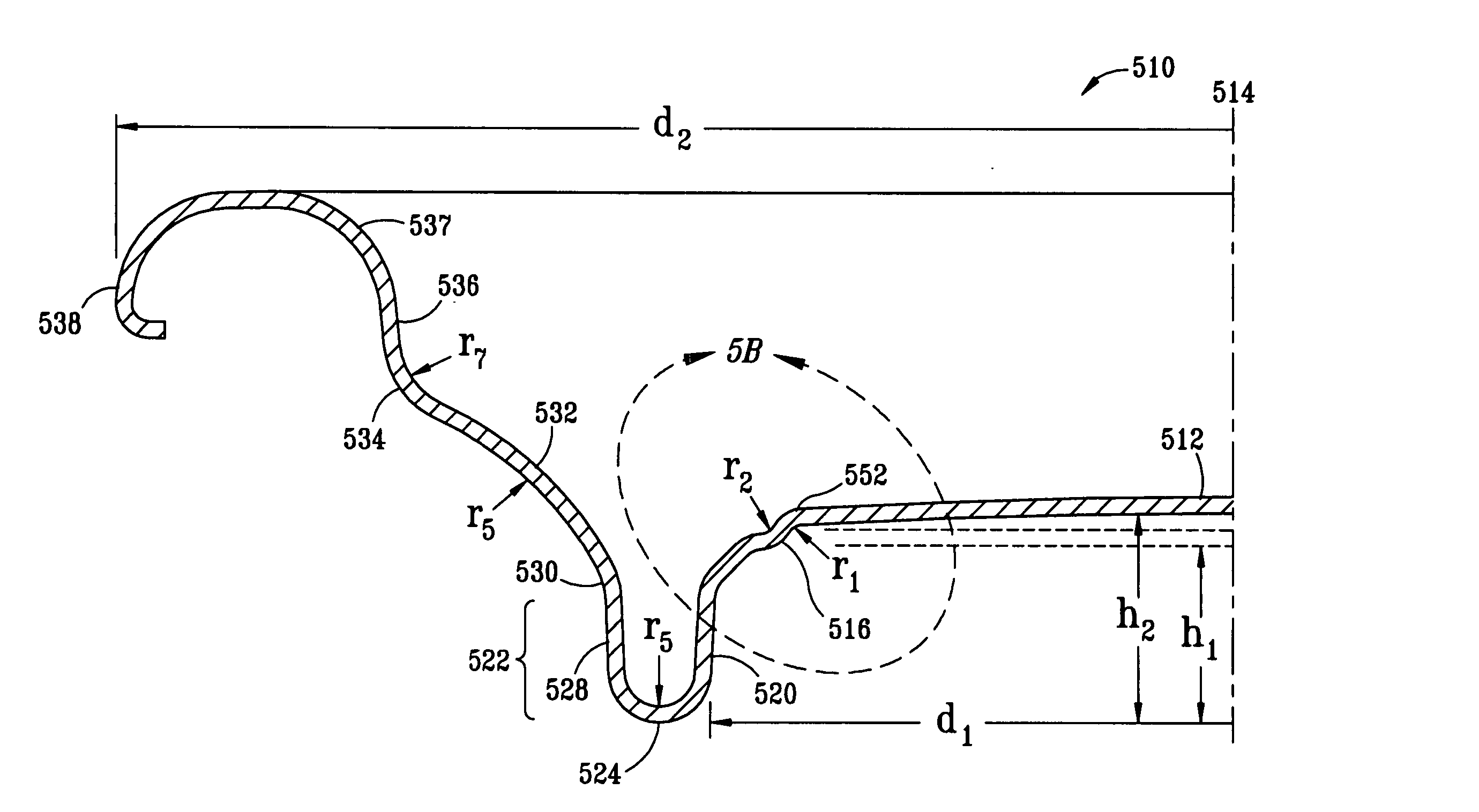

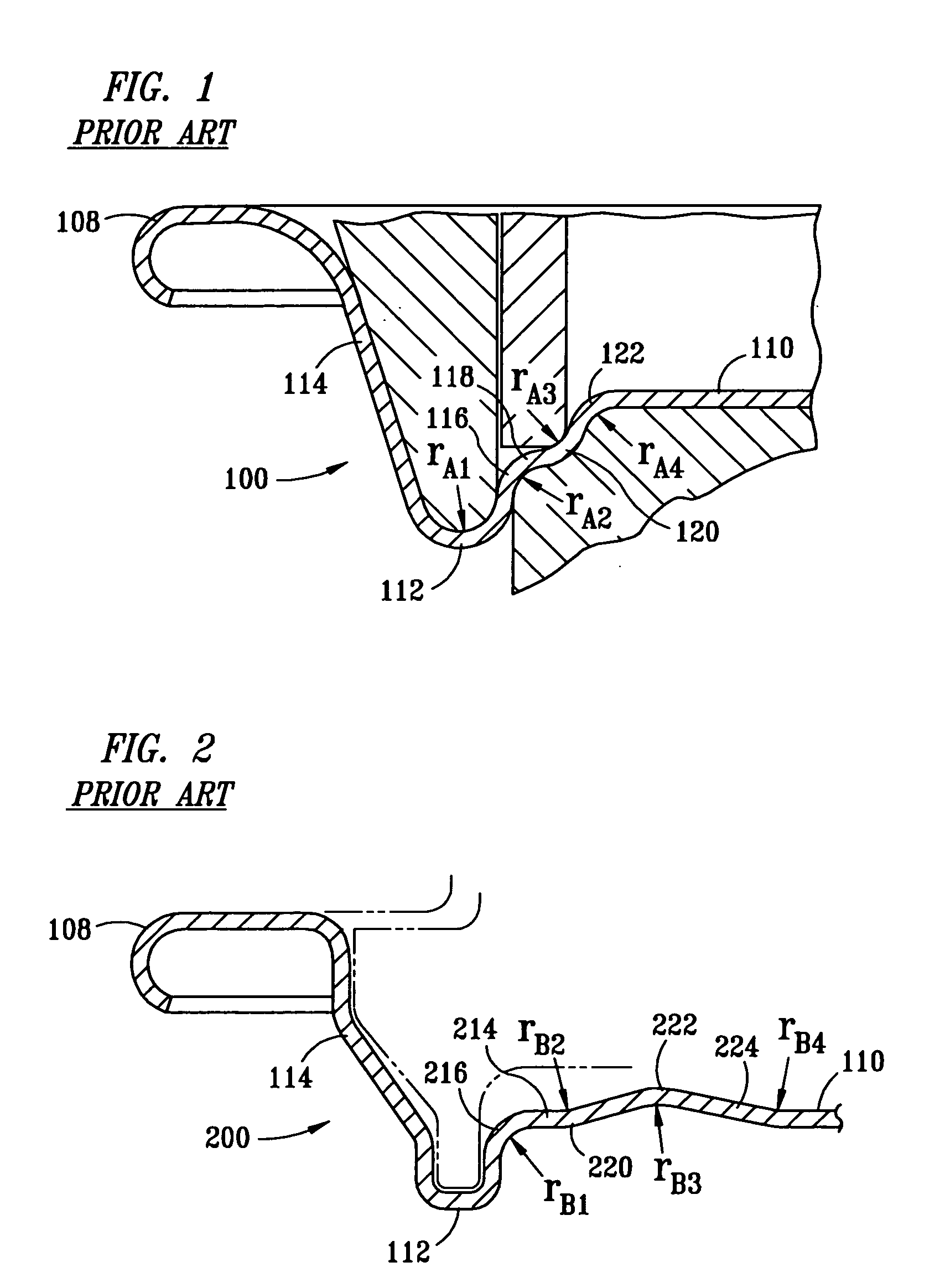

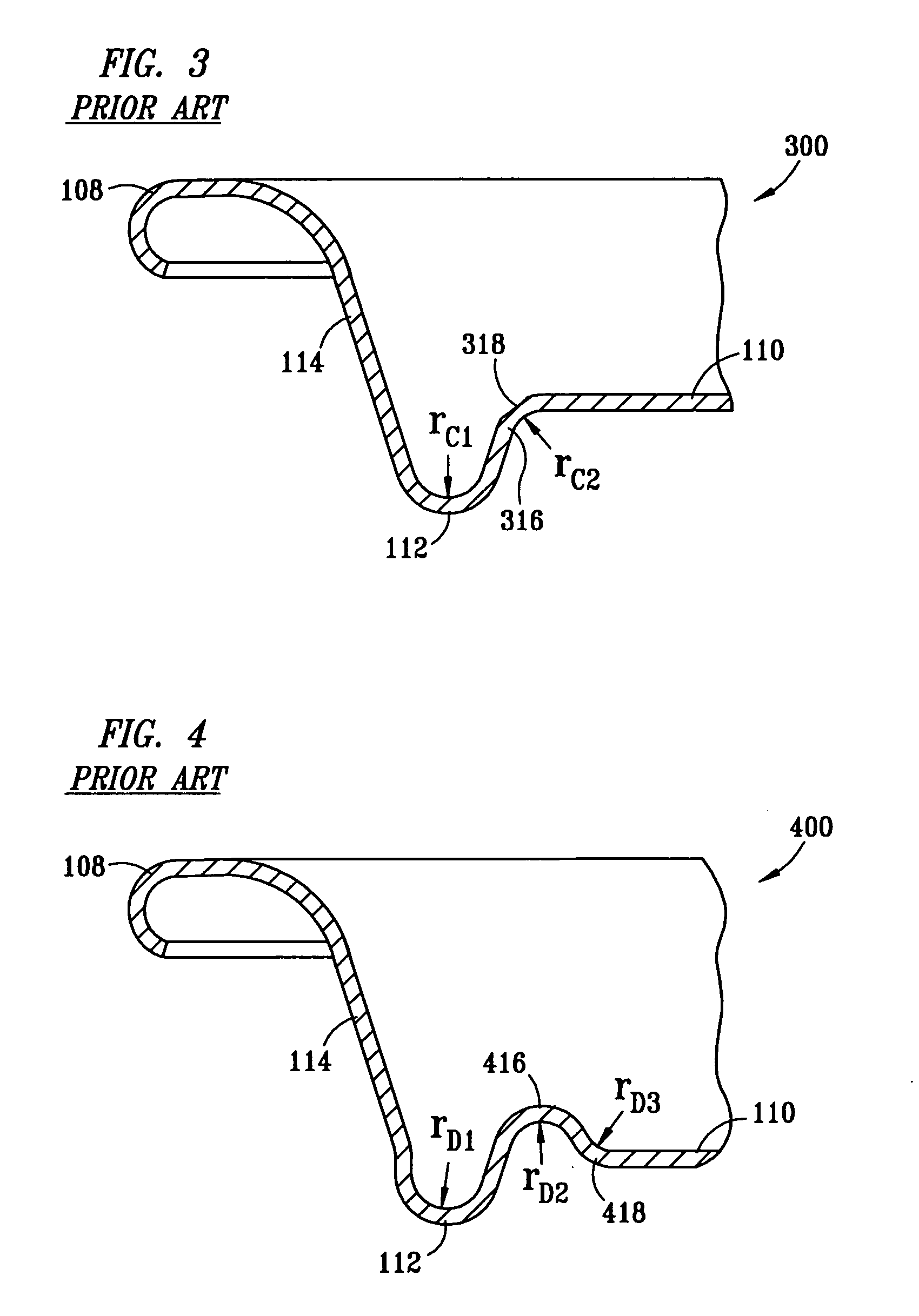

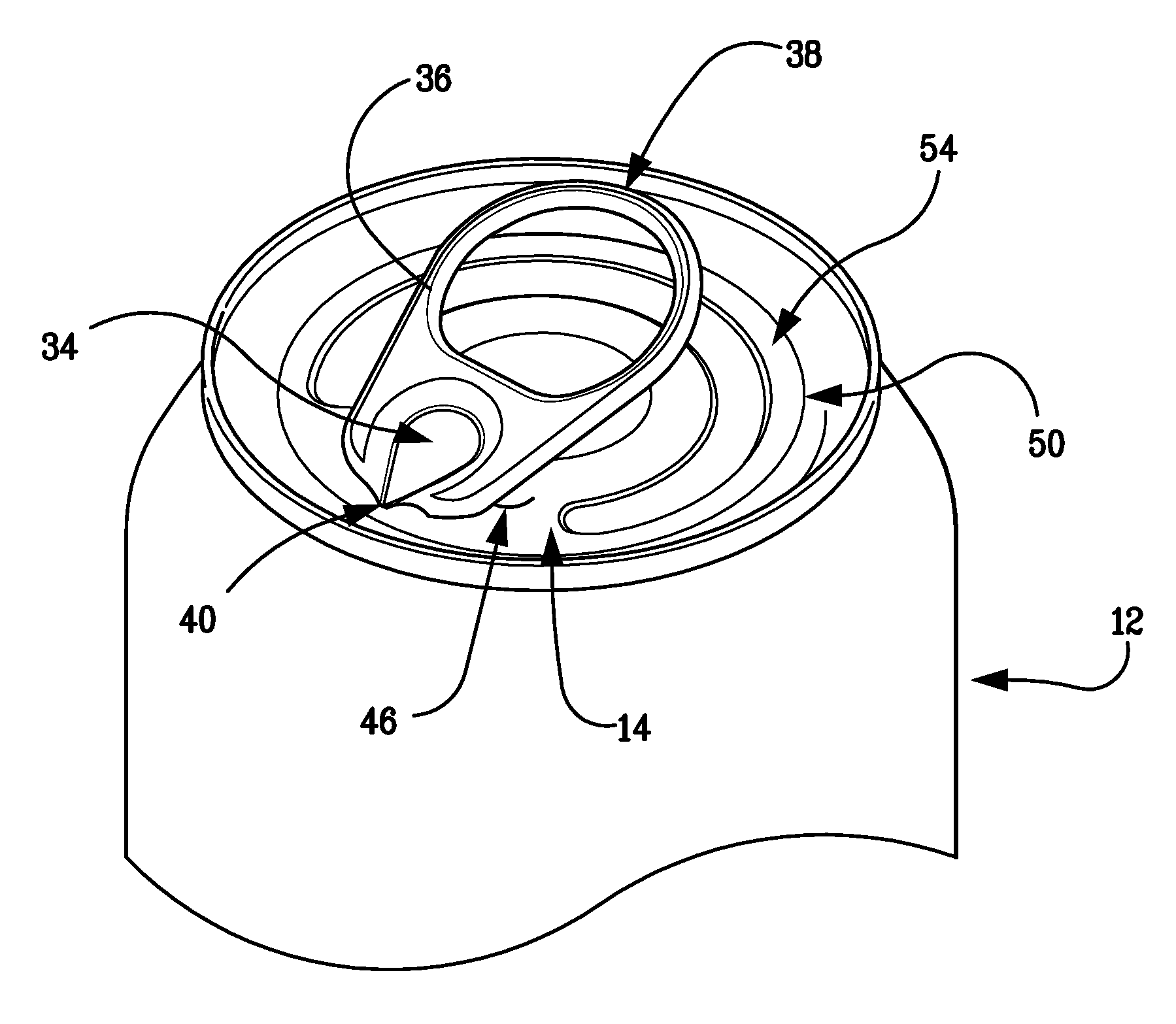

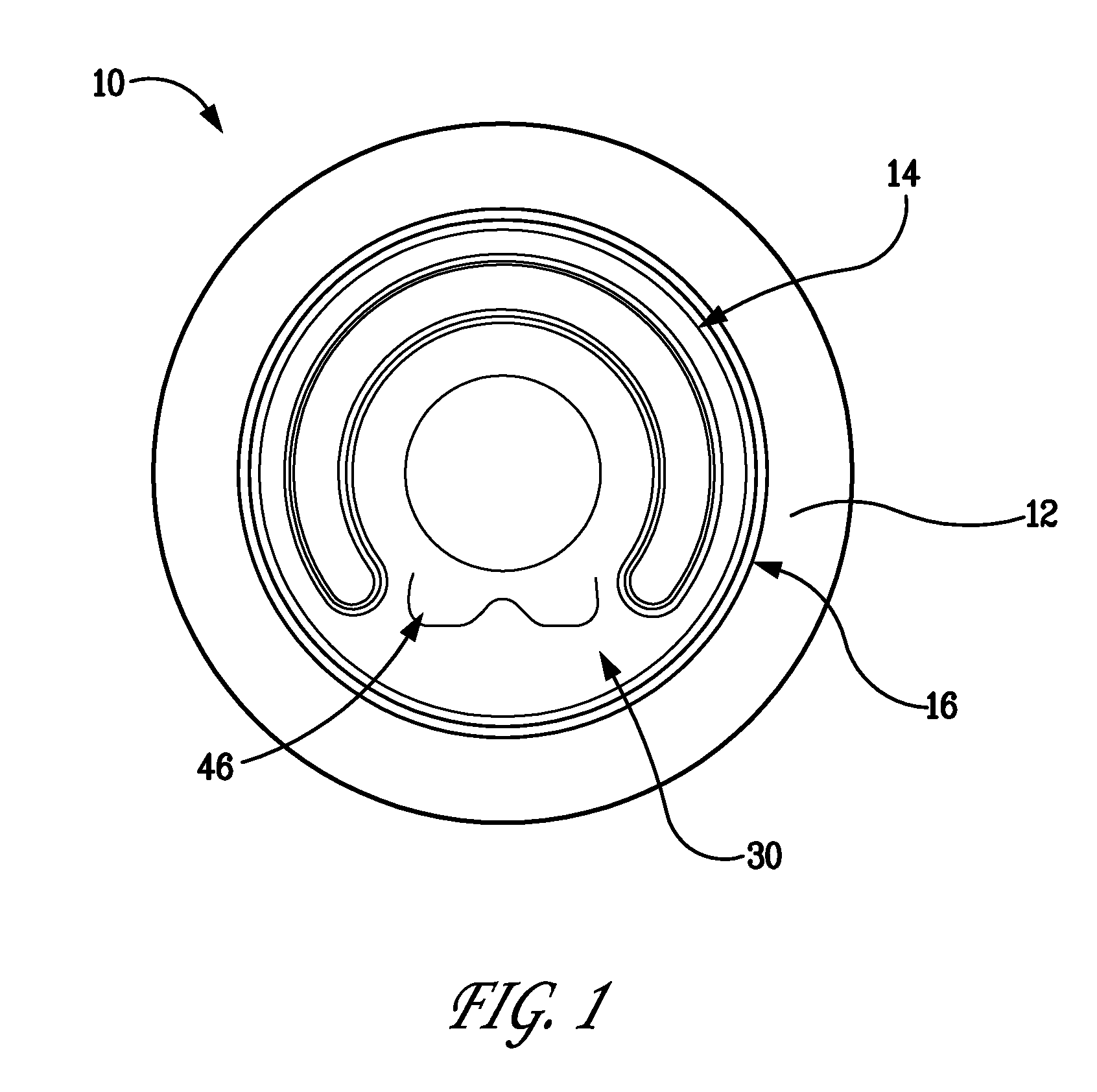

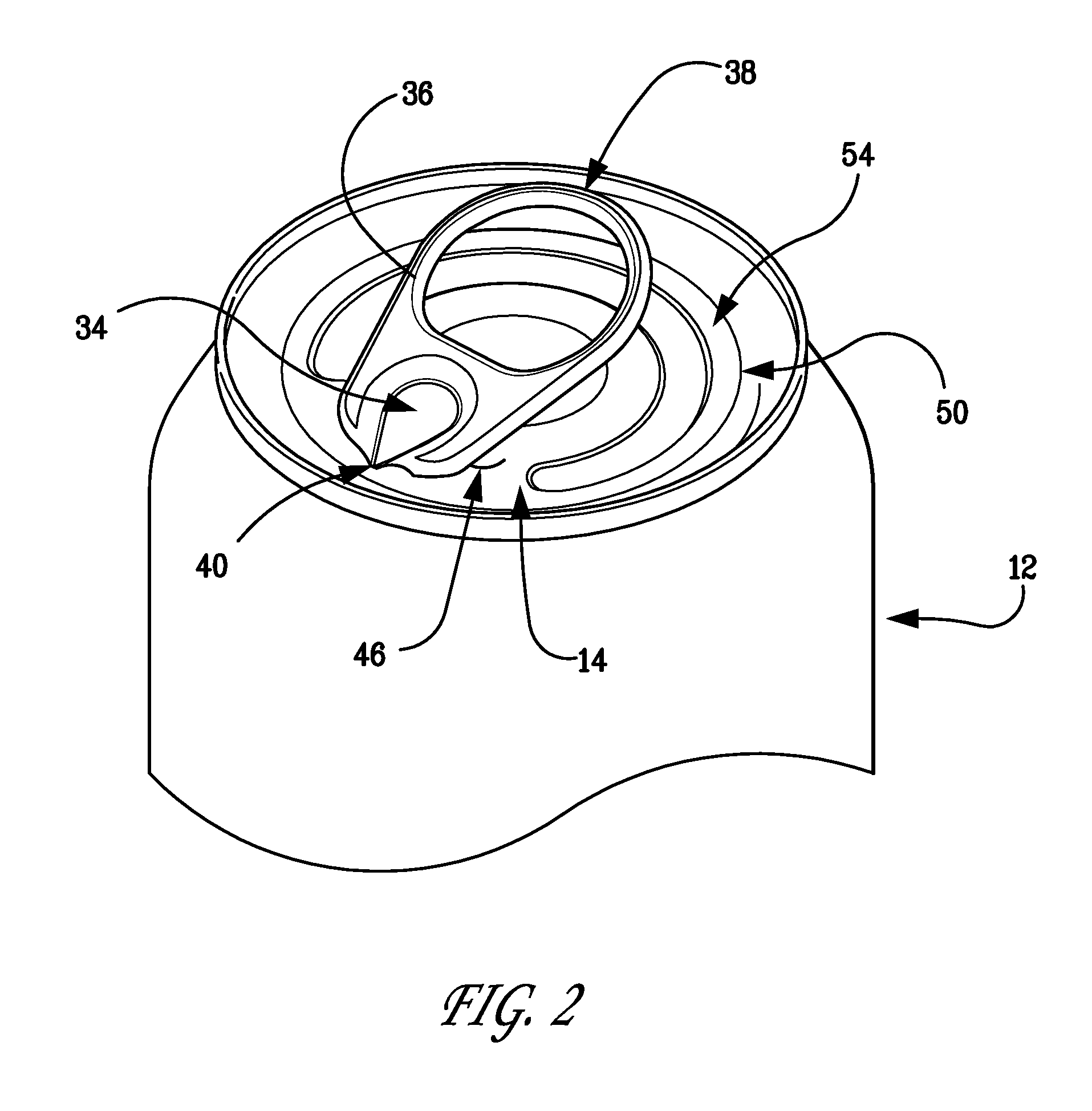

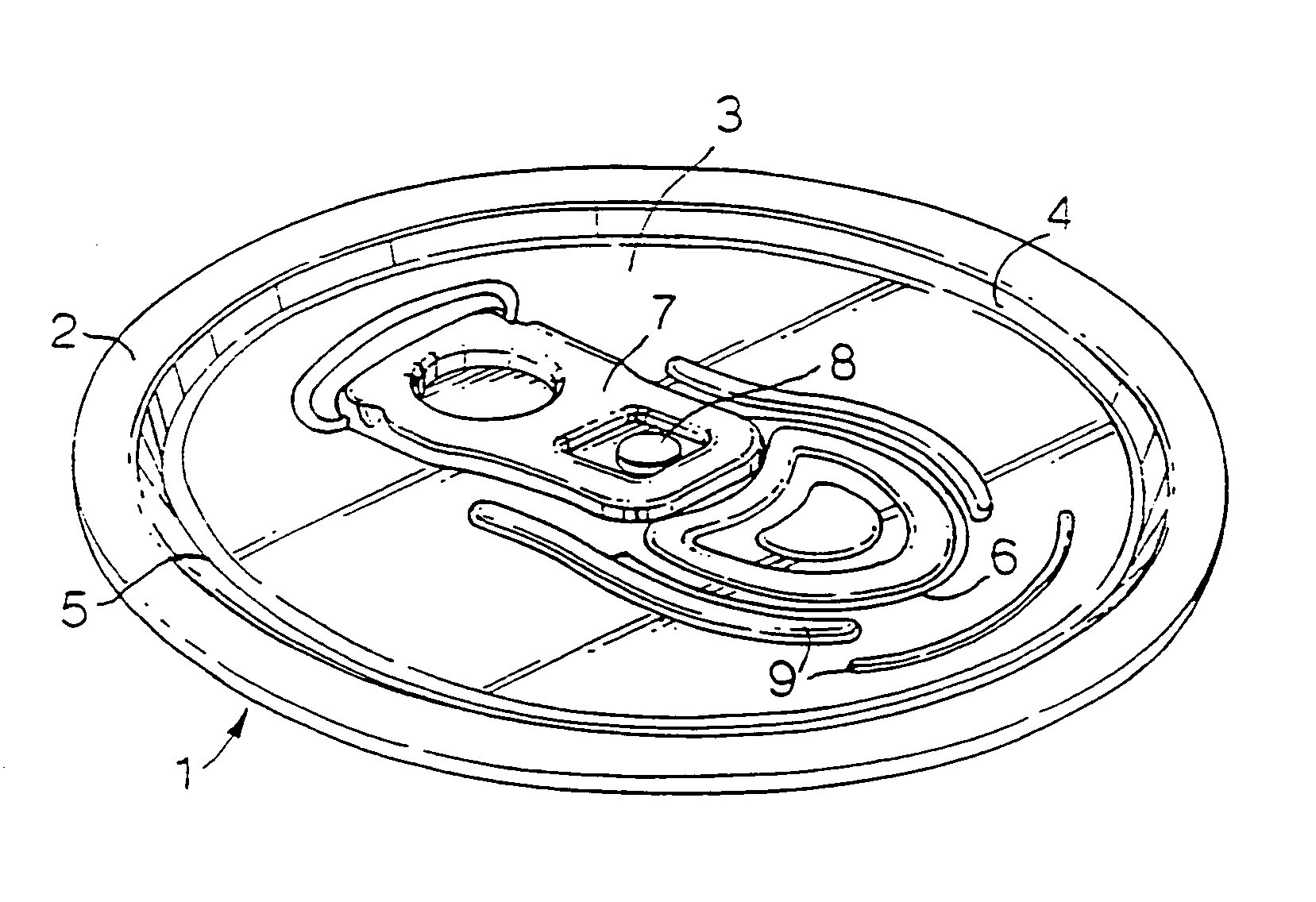

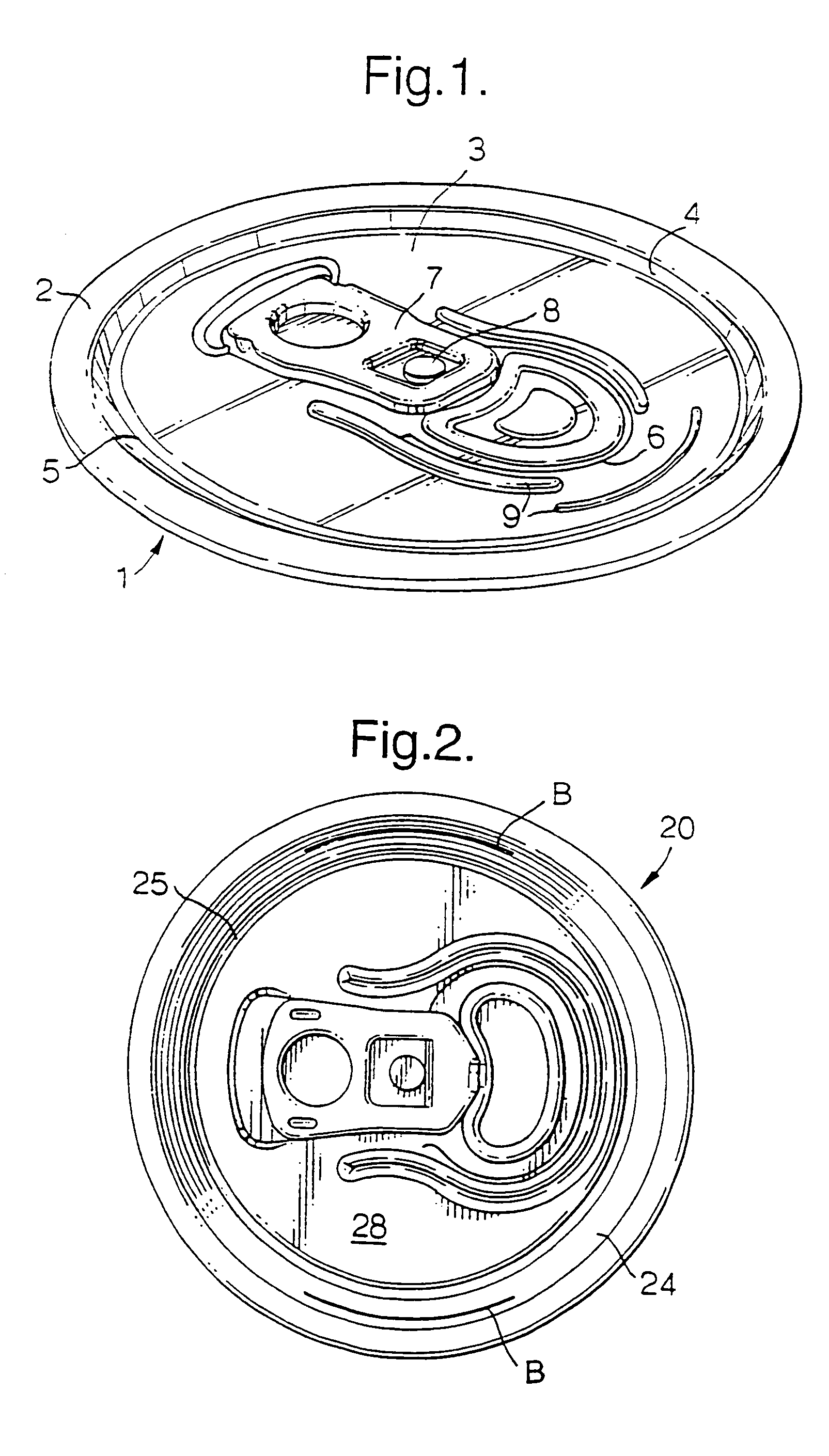

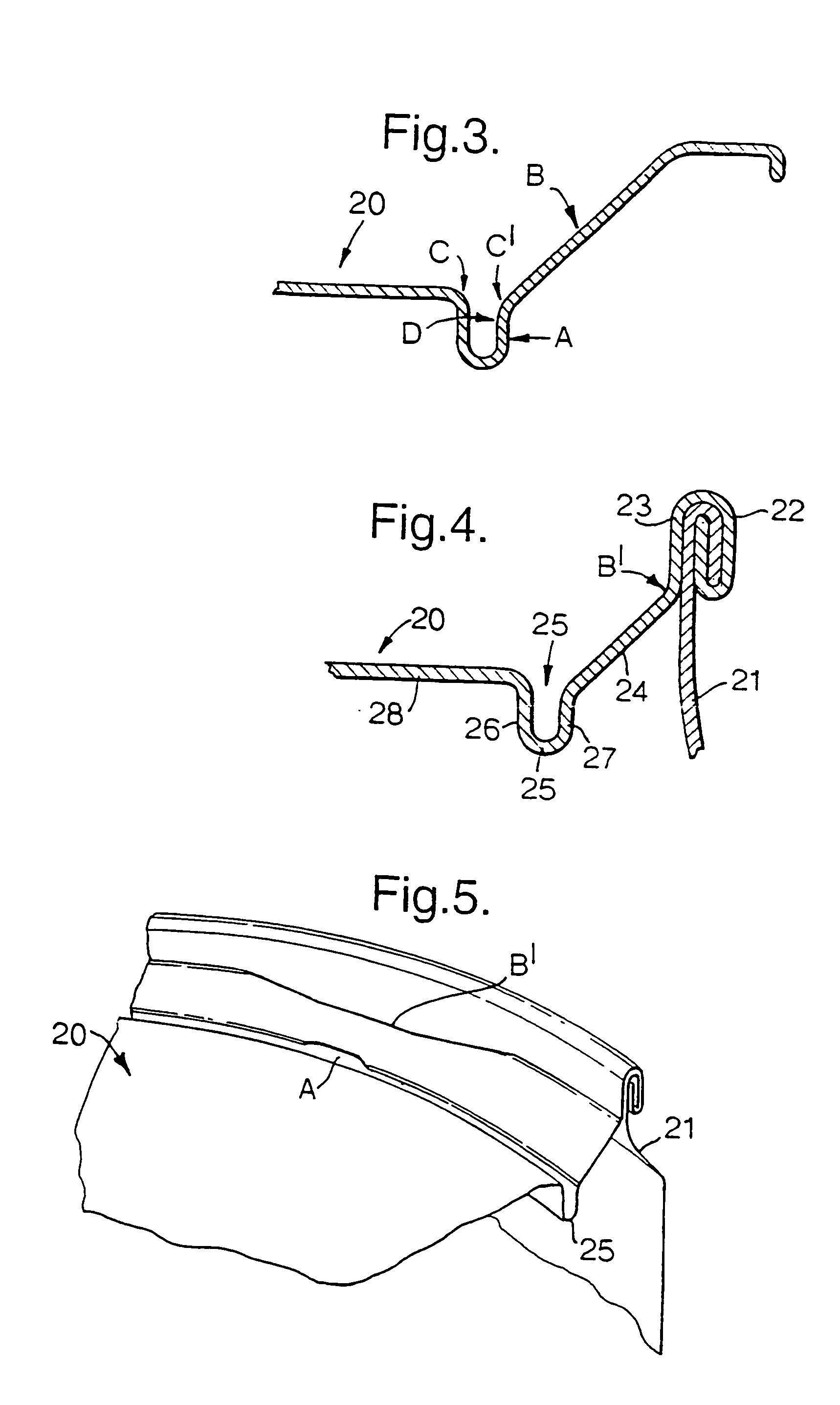

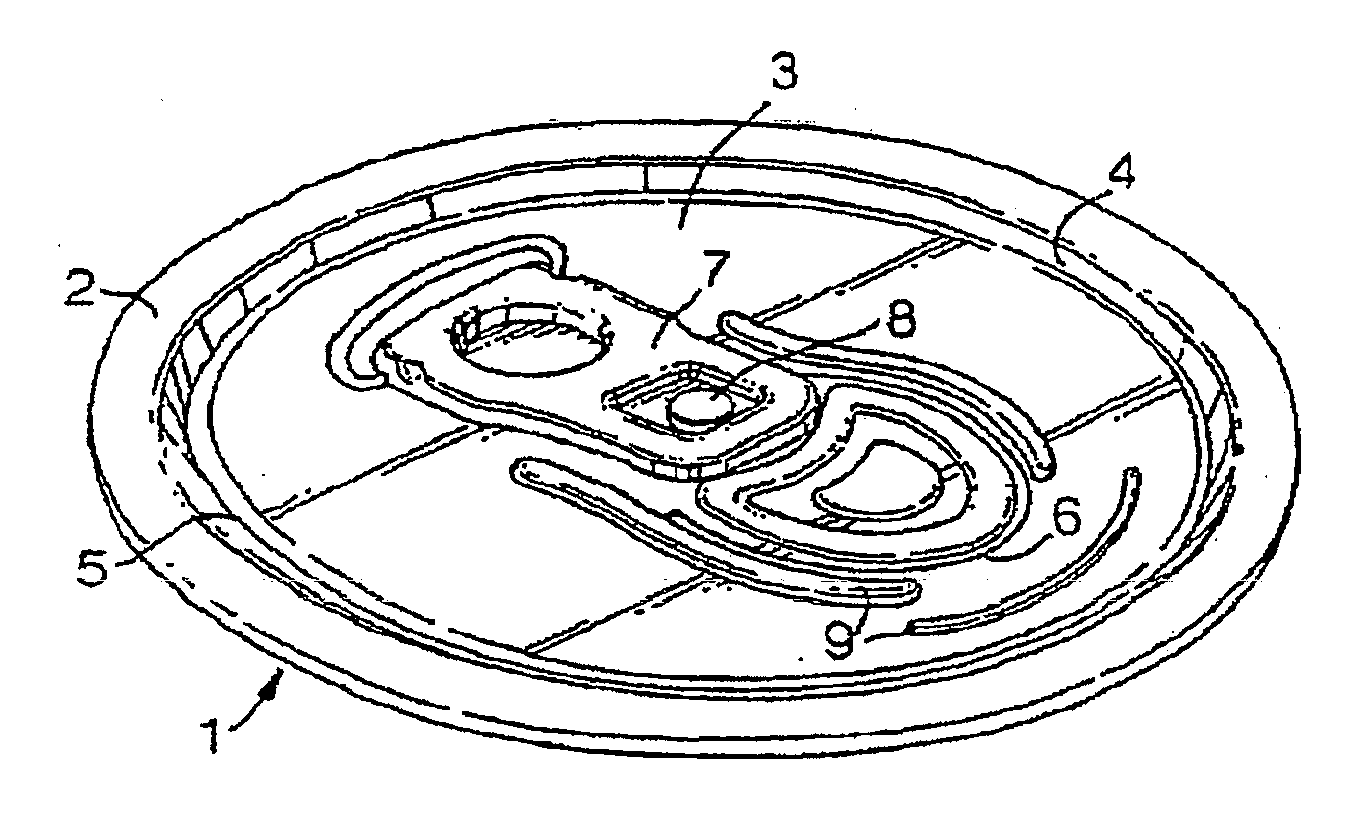

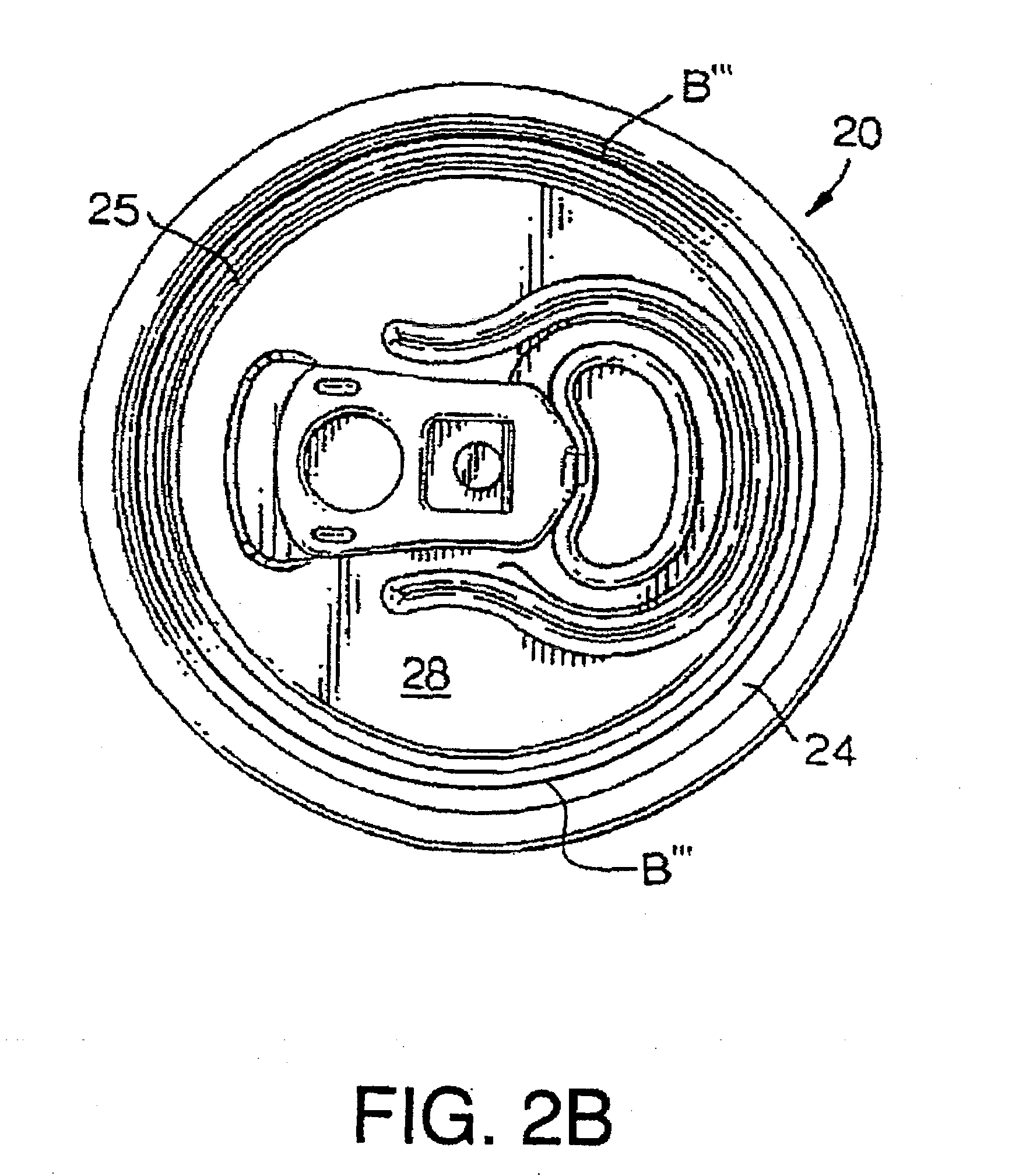

Can shell and double-seamed can end

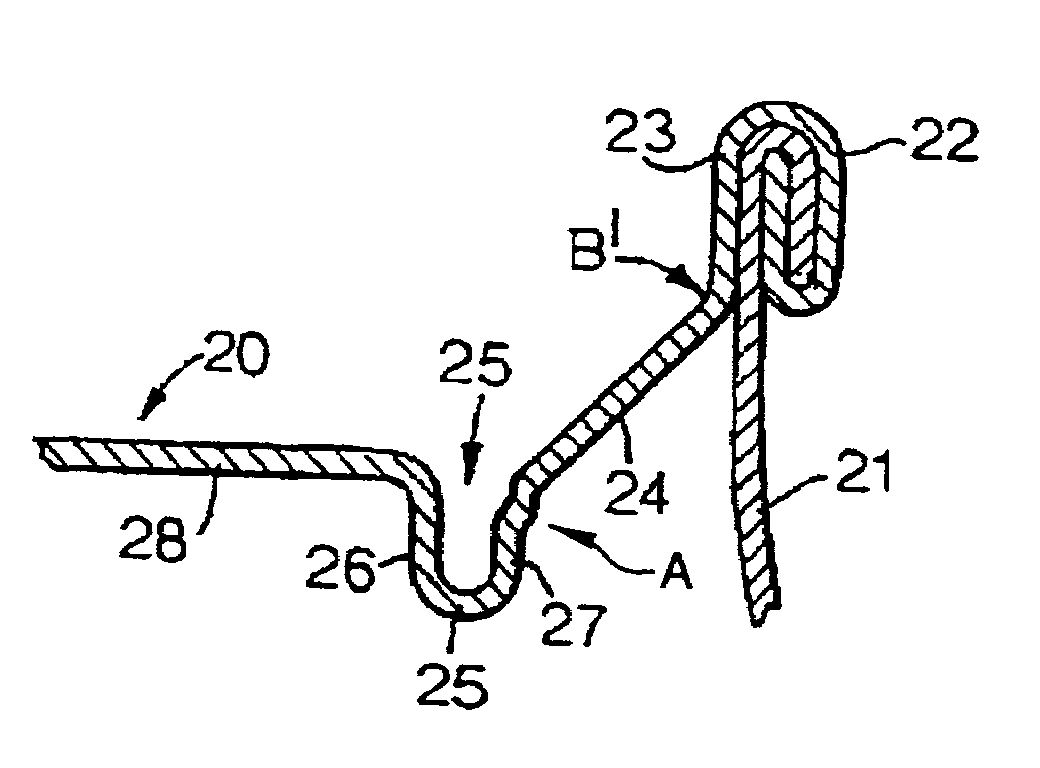

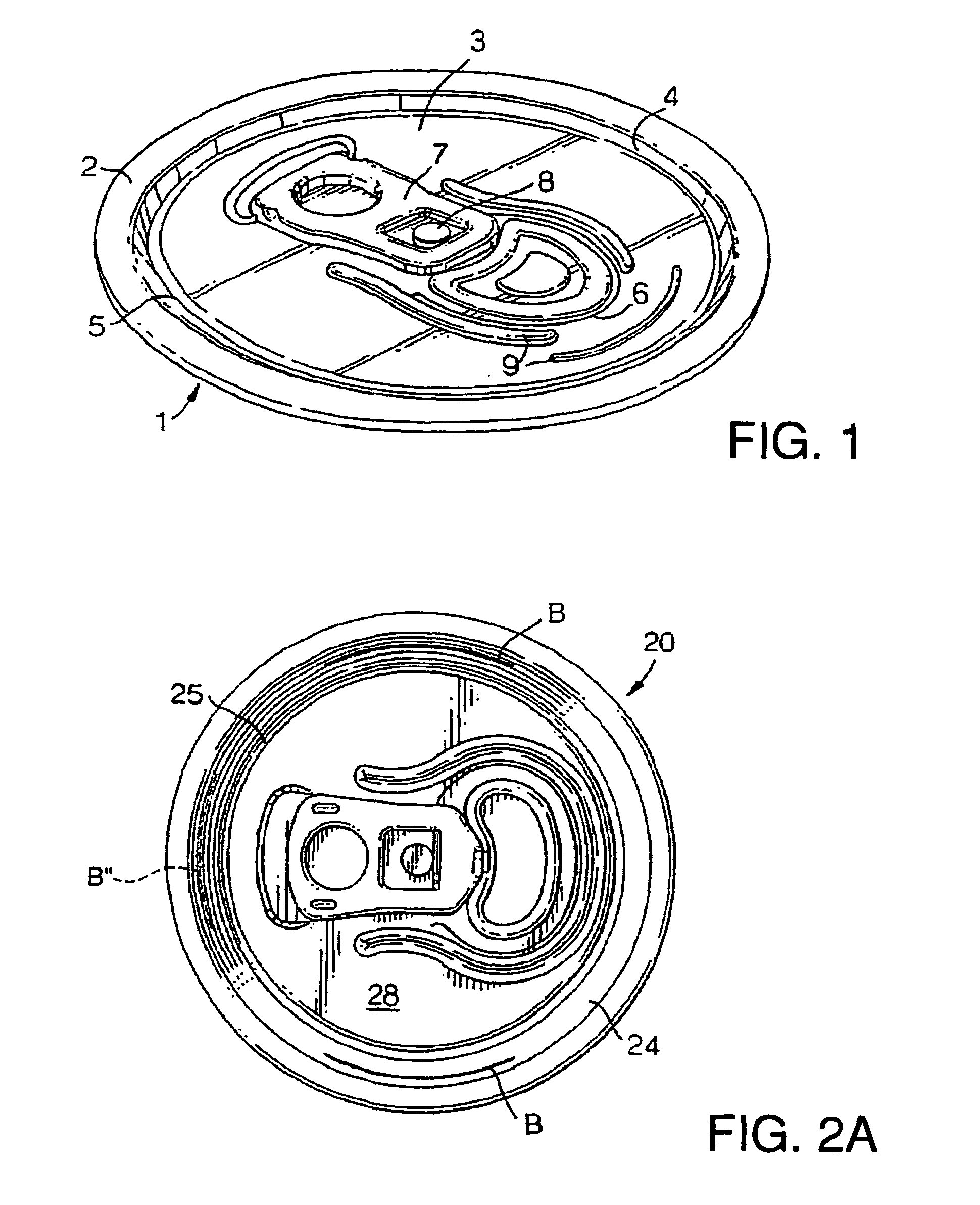

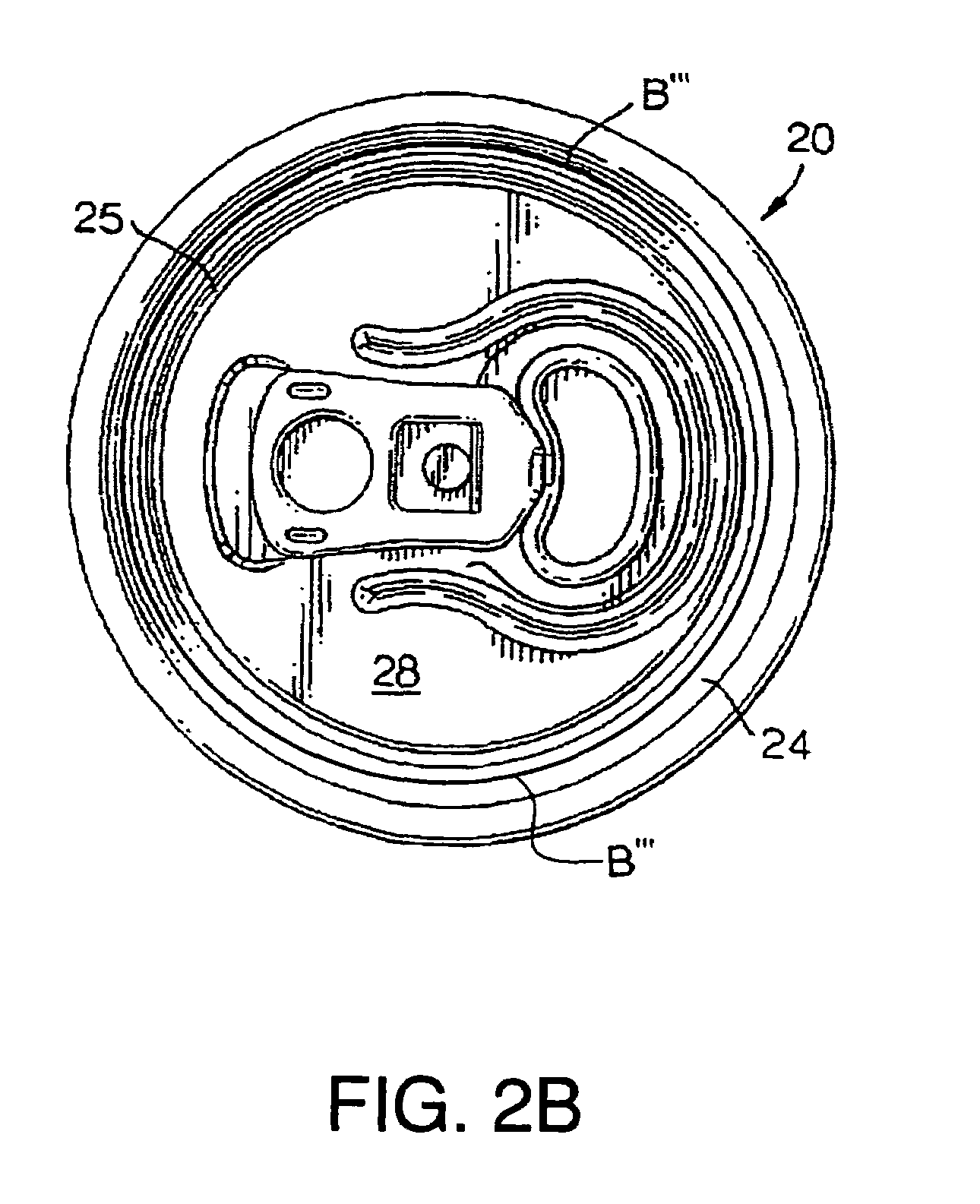

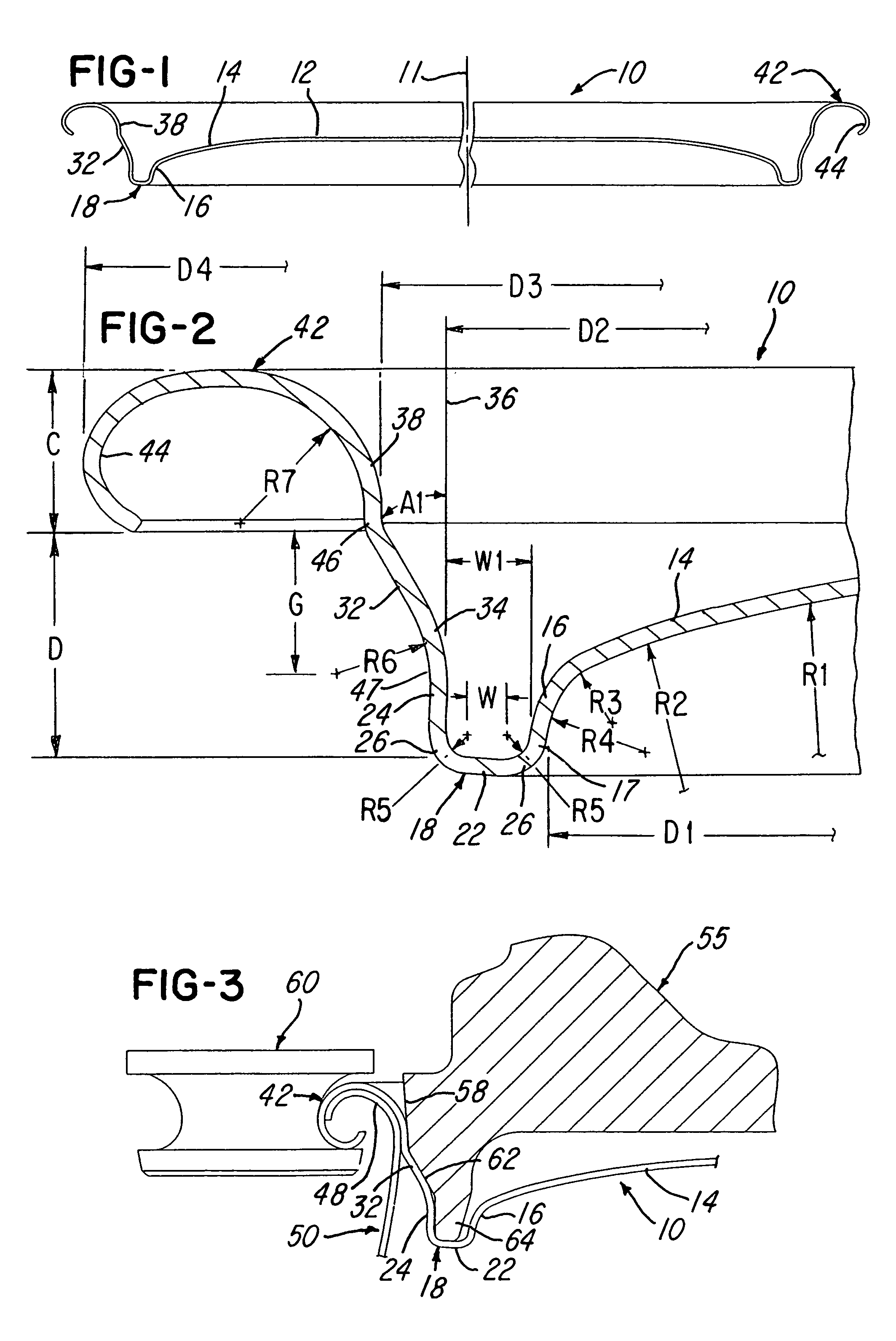

InactiveUS20050029269A1Reduction in blank diameterIncrease strength/weight ratioRigid containersHollow articlesCountersinkAluminum can

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by an inclined curved or straight panel wall to an inclined inner wall of an annular U-shaped countersink. The countersink has an outer wall which connects with an inclined lower wall portion of a chuckwall at a junction below the center panel, and the chuckwall has a curved or inclined upper wall portion which connects with an inner wall of the crown. The chuckwall also has an intermediate wall portion forming a break, and the inner bottom width of the countersink is less than the radial width of the panel wall. The inclined upper wall portion of the chuckwall extends at an angle greater than the angle of the inclined lower wall portion of the chuckwall.

Owner:BALL CORP +1

Rod to rod connector

The invention is a rod to rod connector that can be used to interconnect two generally parallel spinal rods of a spinal rod and anchor system. The connector comprises a transverse rod and two pairs of clamping bodies, one for each spinal rod. Each pair connects one of the longitudinal spinal rods to the transverse rod in infinitely adjustable angular relationship. One of the two clamping bodies of each pair comprises a C-shaped channel for accepting the spinal rod. The channel is in communication with a slot that defines a hinge. A threaded screw hole passes transversely through the slot and permits a screw to squeeze the hinge, thereby causing the C-shaped channel to close around and clamp the rod. The second clamping body is similar to the first except that there is no slot or hinge and the screw hole preferably is not threaded, but includes a countersink for seating a chamfered screw head. Also, an angular portion of the screw hole intersects the C-shaped channel. The two clamping bodies are aligned with each other so that their screw holes are coaxial so that a single screw can pass through both holes thereby clamping both rods in the C-shaped channels and fixing the angle between the two clamping bodies and, hence, the two rods. The first clamp clamps the spinal rod by squeezing the hinge to cause the C-shaped channel to squeeze around the rod. The second clamp clamps the transverse rod by virtue of the bottom of the screw head bearing down on the transverse rod over the portion of the screw hole that intersects the C-shaped channel.

Owner:AESCULAP AG

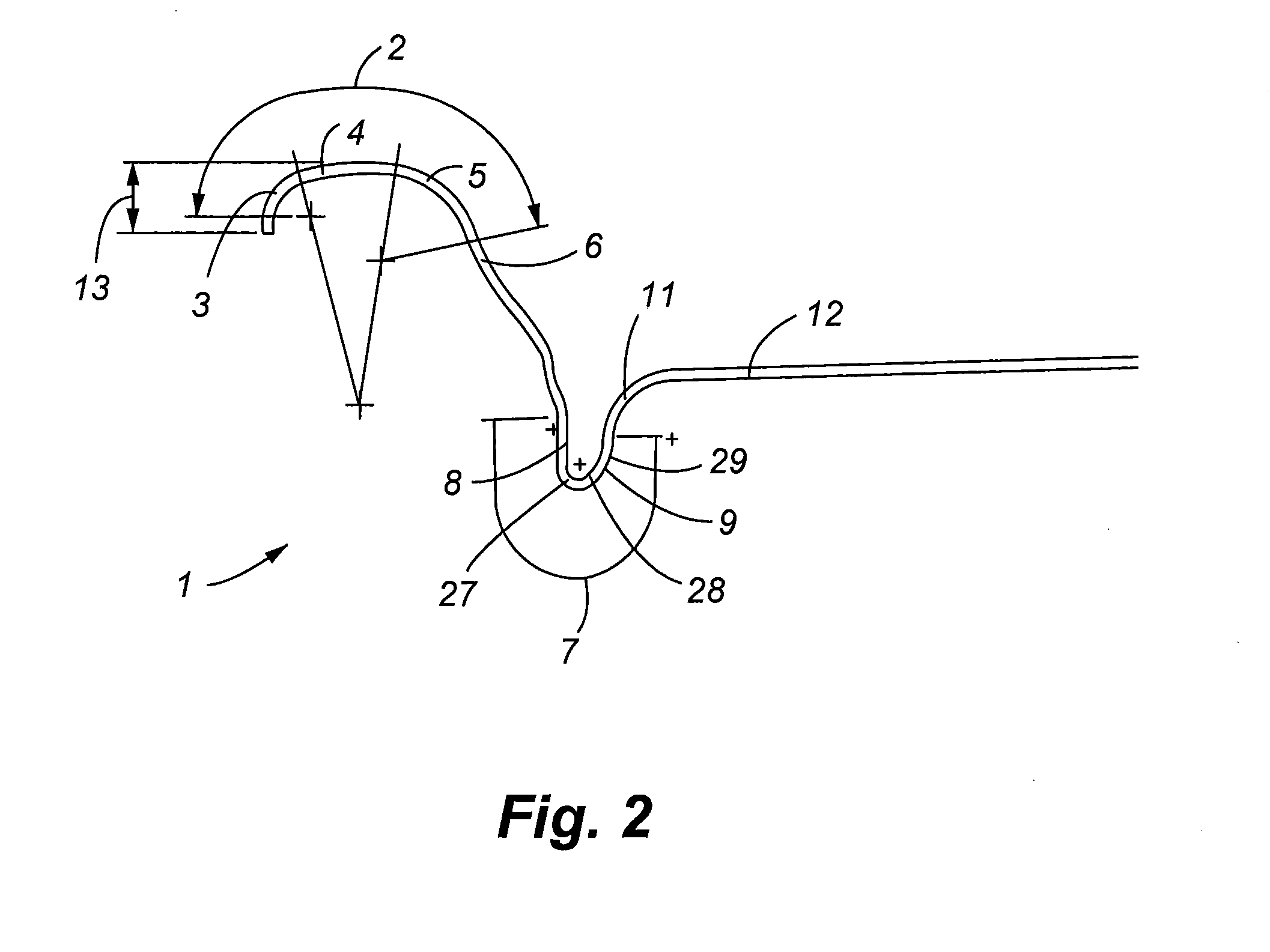

Can shell and double-seamed can end

InactiveUS7341163B2Reduction in blank diameterIncrease strength/weight ratioRigid containersHollow articlesAcute angleAluminum can

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by a curved panel wall to an inner wall of an annular U-shaped countersink. The countersink has a generally cylindrical outer wall and an inner width less than the radius of the panel wall. The outer wall of the countersink connects with a frusto-conical chuckwall at a junction below the center panel, and the chuckwall extends to an inner wall of the crown at an angle of at least 16° with the center axis. The chuckwall has an S-curved intermediate configuration, the inner width of the countersink is less than the radius of the panel wall, and the inner wall of the countersink extends at an acute angle relative to the outer wall.

Owner:CONTAINER DEVELOPMENT LTD

Full core biopsy device

ActiveUS20110208089A1Readily apparentSurgical needlesVaccination/ovulation diagnosticsCore biopsyCountersink

A biopsy device includes coaxially disposed inner and outer needles in which the outer needle tip is configured for obtaining a tissue sample. The inner surface of the outer needle includes a tissue retention feature which may include a countersink and / or a feature formed in the inner surface. The device may be configured such that the inner needle does not extend past a certain point within the outer needle.

Owner:PAVE LLC

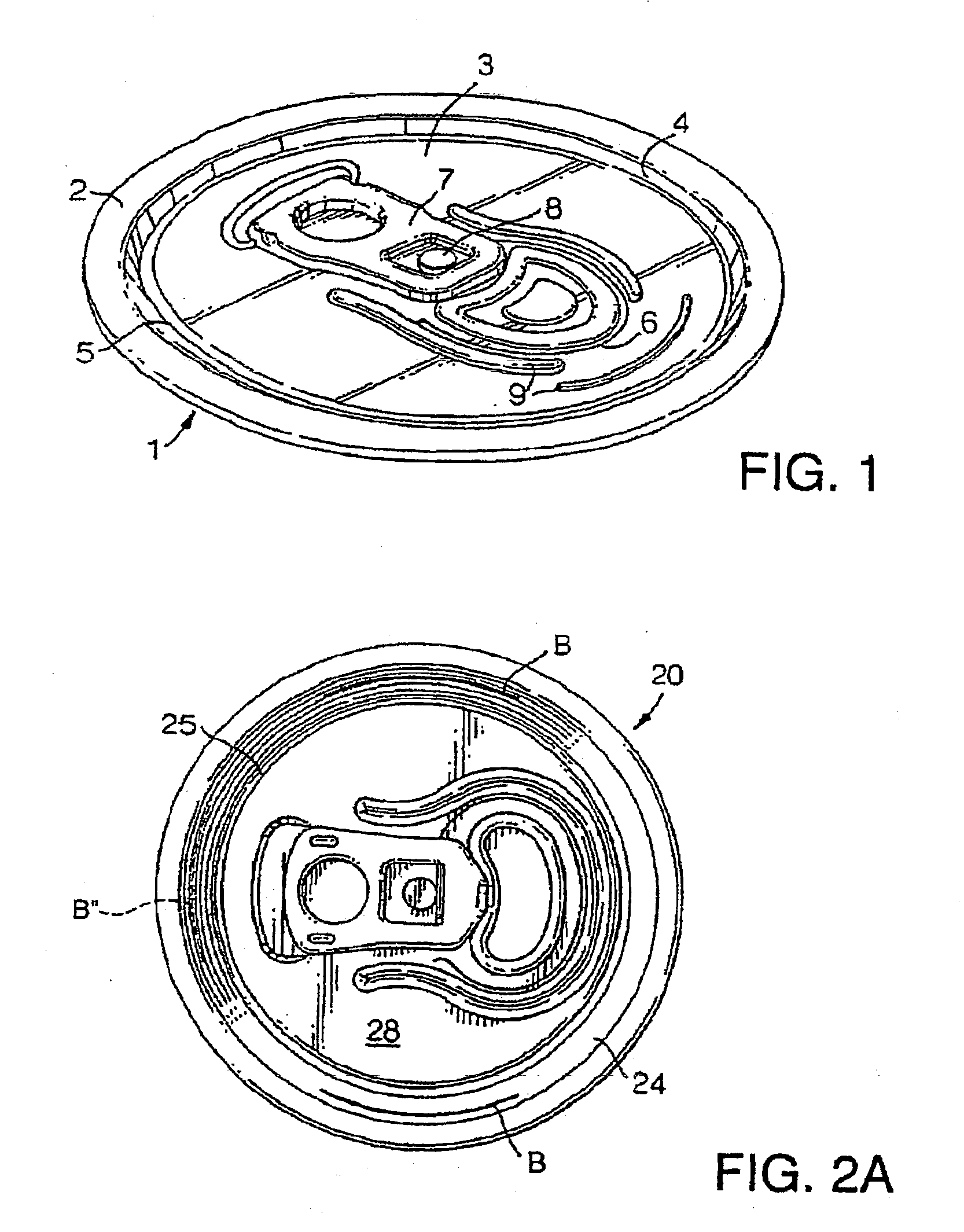

Can end

A can end having a countersink bead, an inclined chuck wall and a strong seam, resists distortion from its circular profile when subjected to thermal processing or when packaging carbonated beverages. This high hoop strength affects the manner in which the can end ultimately fails when placed under extreme abuse conditions, even if buckle pressure performance is within industry specified standards. The can end of the invention has control features introduced which control the failure mode whilst maintaining specified buckle pressure performance. In one embodiment, the control feature comprises expansion of the countersink bead to act as a trigger for local peaking, together with a groove in the chuck wall which prevents the peaking force from being concentrated at a single point which could result in leaking by the production of a pin hole.

Owner:CROWN CORK & SEAL TECH CORP

Instruments for bone screws

An adjustable drill for use in implanting orthopedic screws, such as adjustable compression screws having a separate adjustable head. The adjustable drill comprises a primary drill bit and a countersink drill bit encircling the primary drill bit. The countersink drill bit is configured to selectively slide along the primary drill bit for use in selecting a drill depth. The countersink drill bit is associated with a stop member that is configured to selectively lock the countersink drill bit at one of a plurality of selected positions along the primary drill bit to thereby establish a drill depth. The drill depth corresponds to the size of a selected screw implant, allowing the drill to be used as a trial. The adjustable drill forms a bore having a primary bore and a countersunk entry.

Owner:WRIGHT MEDICAL TECH

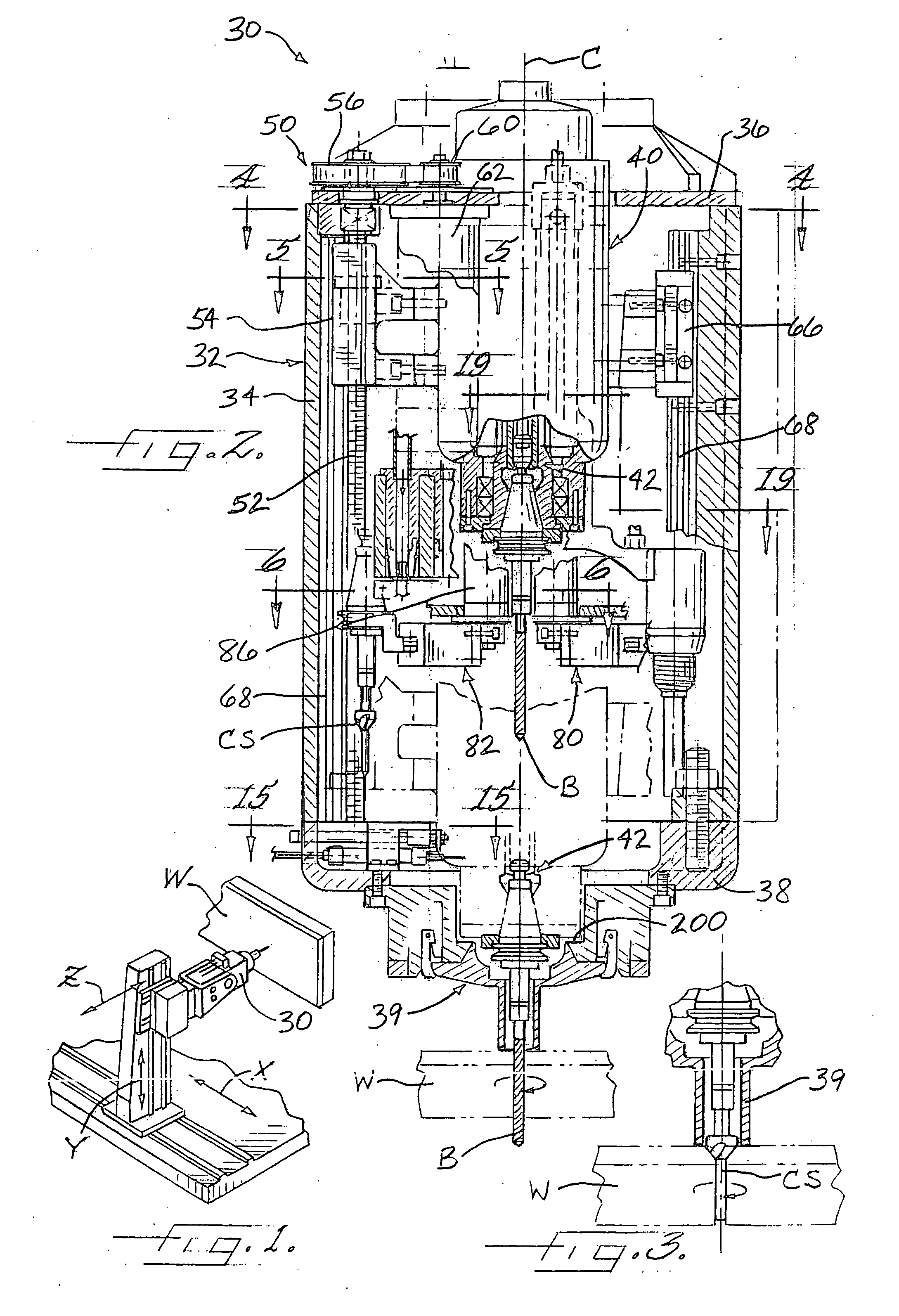

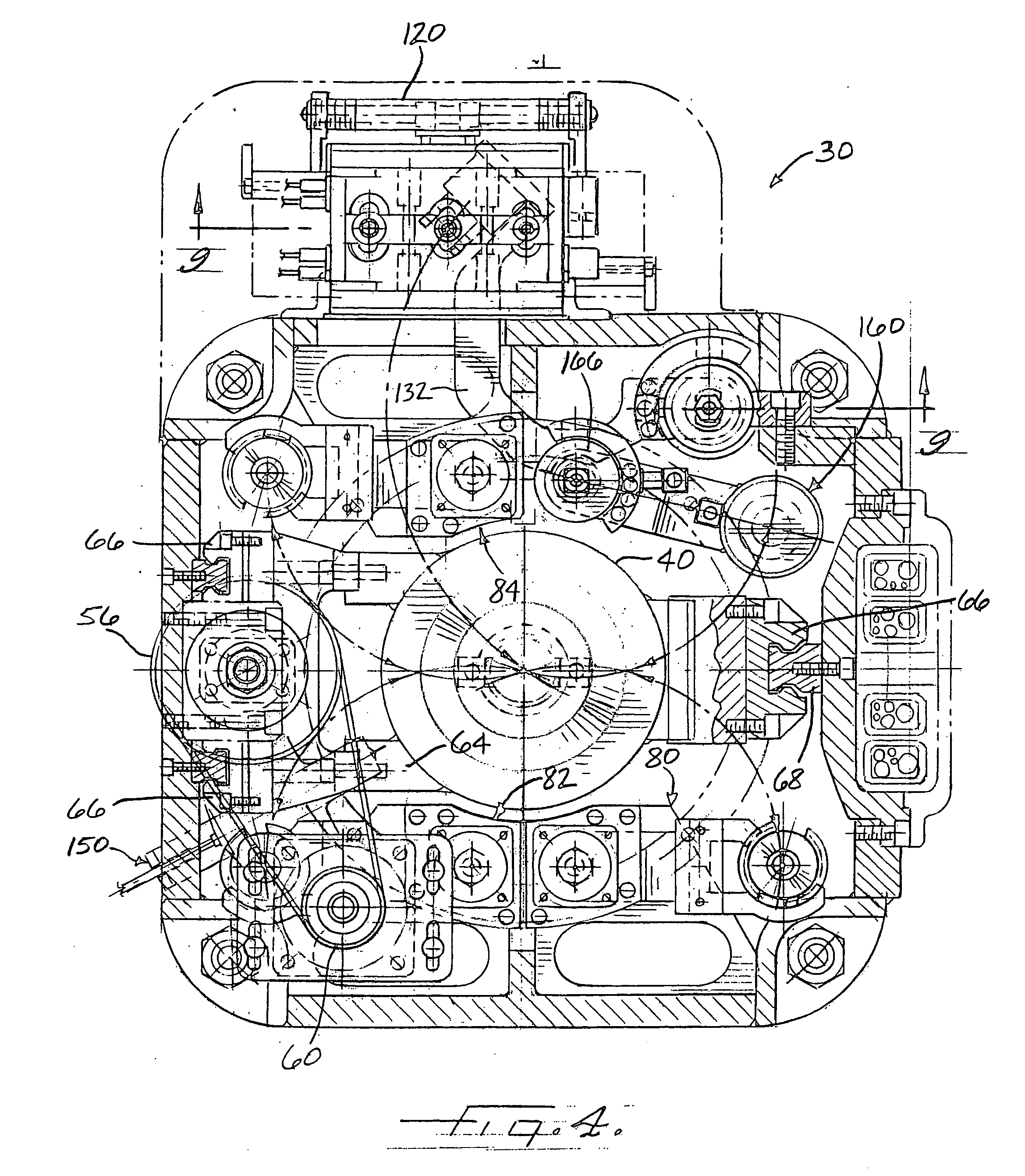

Multi-function end effector

A multi-function end effector includes a plurality of tool change mechanisms in a housing in which a spindle is also mounted for translation along an axis of the spindle. Each tool change mechanism has a gripper that releasably grips a tool holder in which a tool is mounted. The gripper of each tool change mechanism is movable between a stowed position to a tool-change position in which the gripper is coaxially aligned with the axis of the spindle for placing a tool holder held in the gripper in a position to be received by the spindle and for positioning the gripper to receive a tool holder from the spindle. The tools mounted in the tool holders include a drill bit, a countersink tool, and a fastener insertion tool. The end effector also includes a fastener feed system, a hammer device, and a sealant applicator.

Owner:THE BOEING CO

Can end

A can end having a countersink bead, an inclined chuck wall and a strong seam, resists distortion from its circular profile when subjected to thermal processing or when packaging carbonated beverages. This high hoop strength affects the manner in which the can end ultimately fails when placed under extreme abuse conditions, even if buckle pressure performance is within industry specified standards. The can end of the invention has control features introduced which control the failure mode while maintaining specified buckle pressure performance. In one embodiment, the can end has a two part wall and a control feature that comprises expansion of the countersink bead to act as a trigger for local peaking, together with a groove in the chuck wall which prevents the peaking force from being concentrated at a single point which could result in leaking by the production of a pin hole.

Owner:CROWN PACKAGING TECH

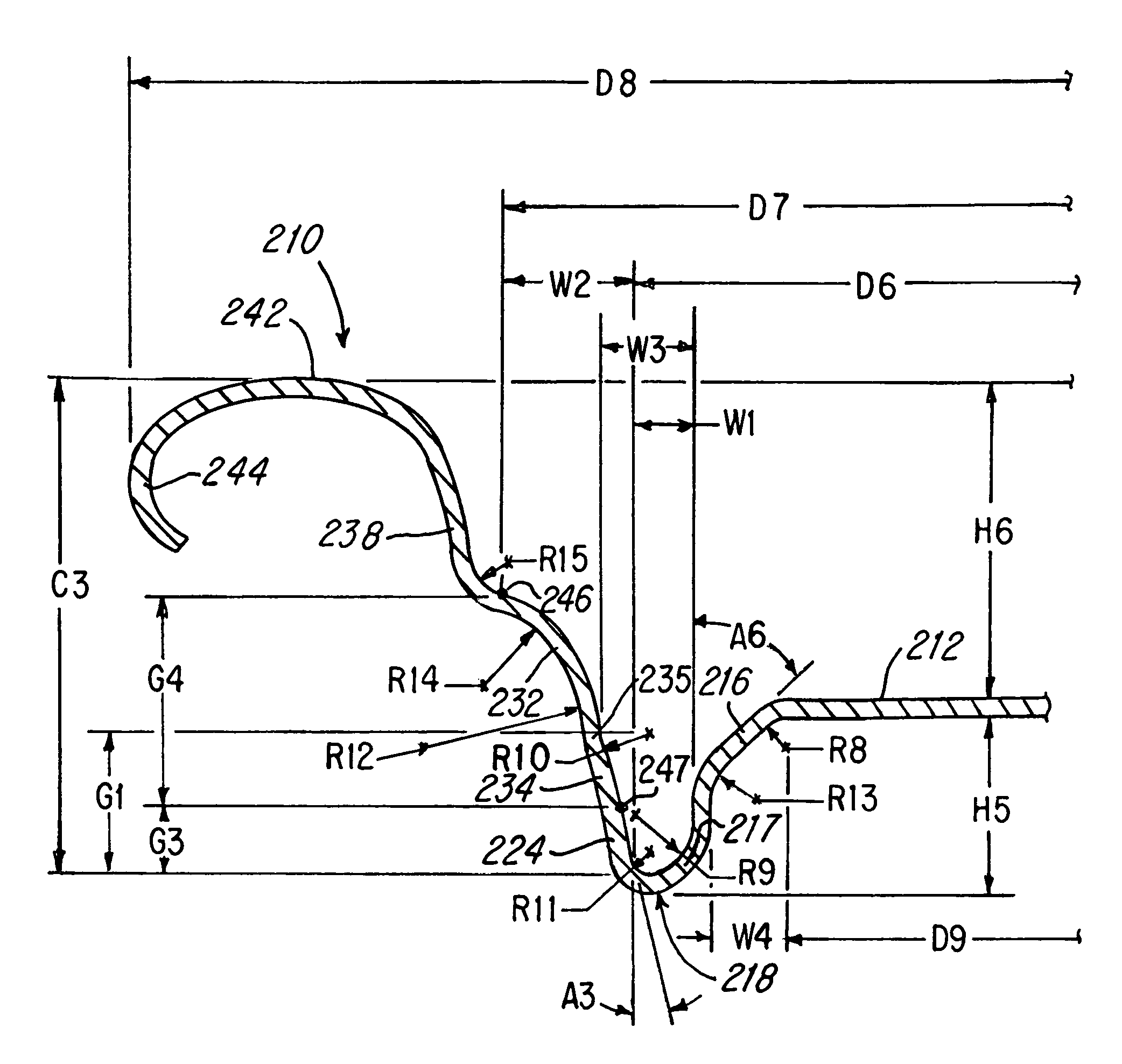

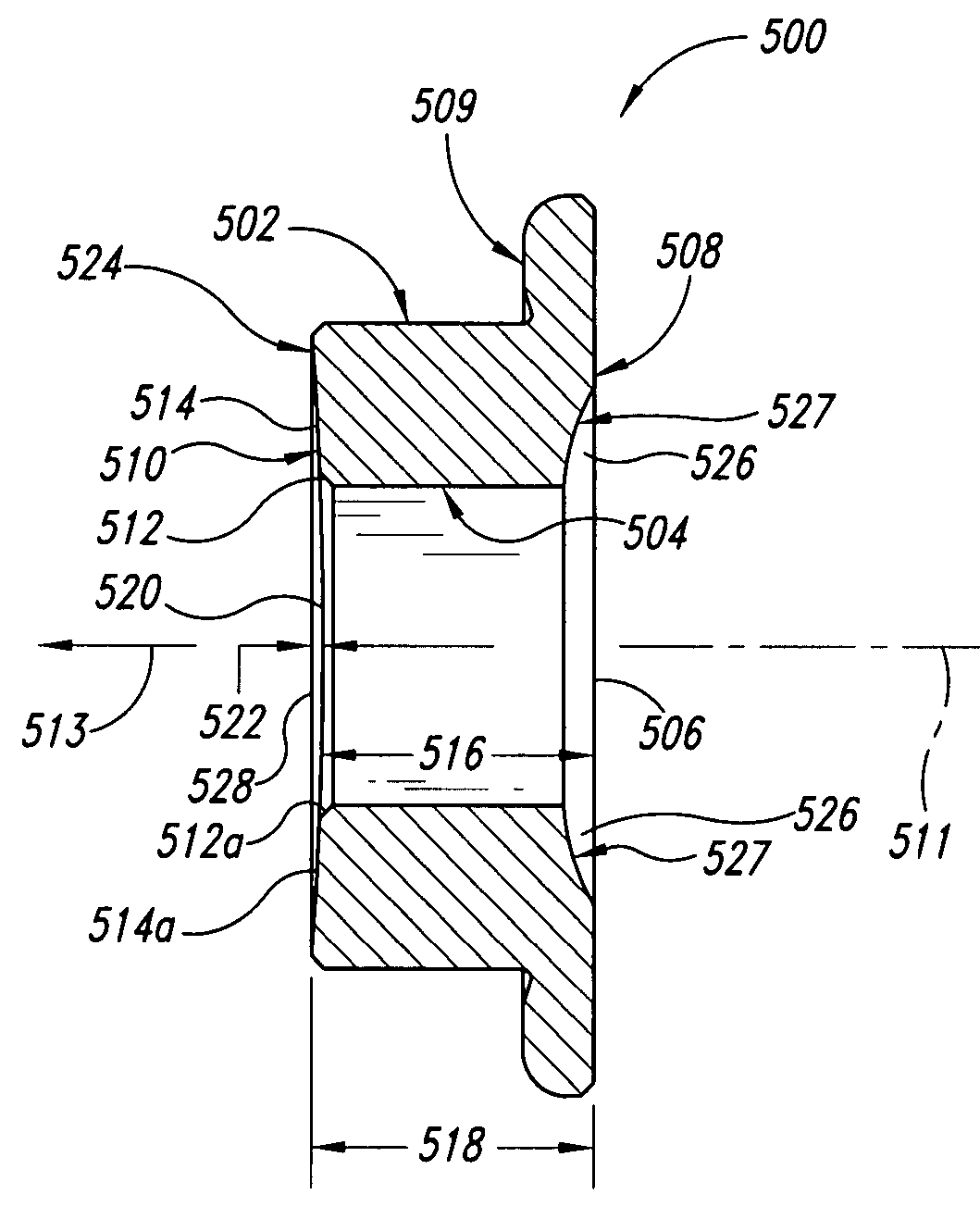

Container end closure with improved chuck wall and countersink

InactiveUS20060071005A1High strengthReduce material costsRefuse receptaclesRigid containersArcuate shapeStrengths based

The present invention describes a beverage can end which utilizes less material and has an improved internal buckle strength based on the geometric configuration of a chuck wall, inner panel wall and central panel, and which, in one embodiment utilizes an arcuate shaped chuck wall with a radius of curvature between about 0.150 inches and 0.250 inches with at least one transition zone positioned between an upper and lower end of the chuck wall.

Owner:BALL CORP

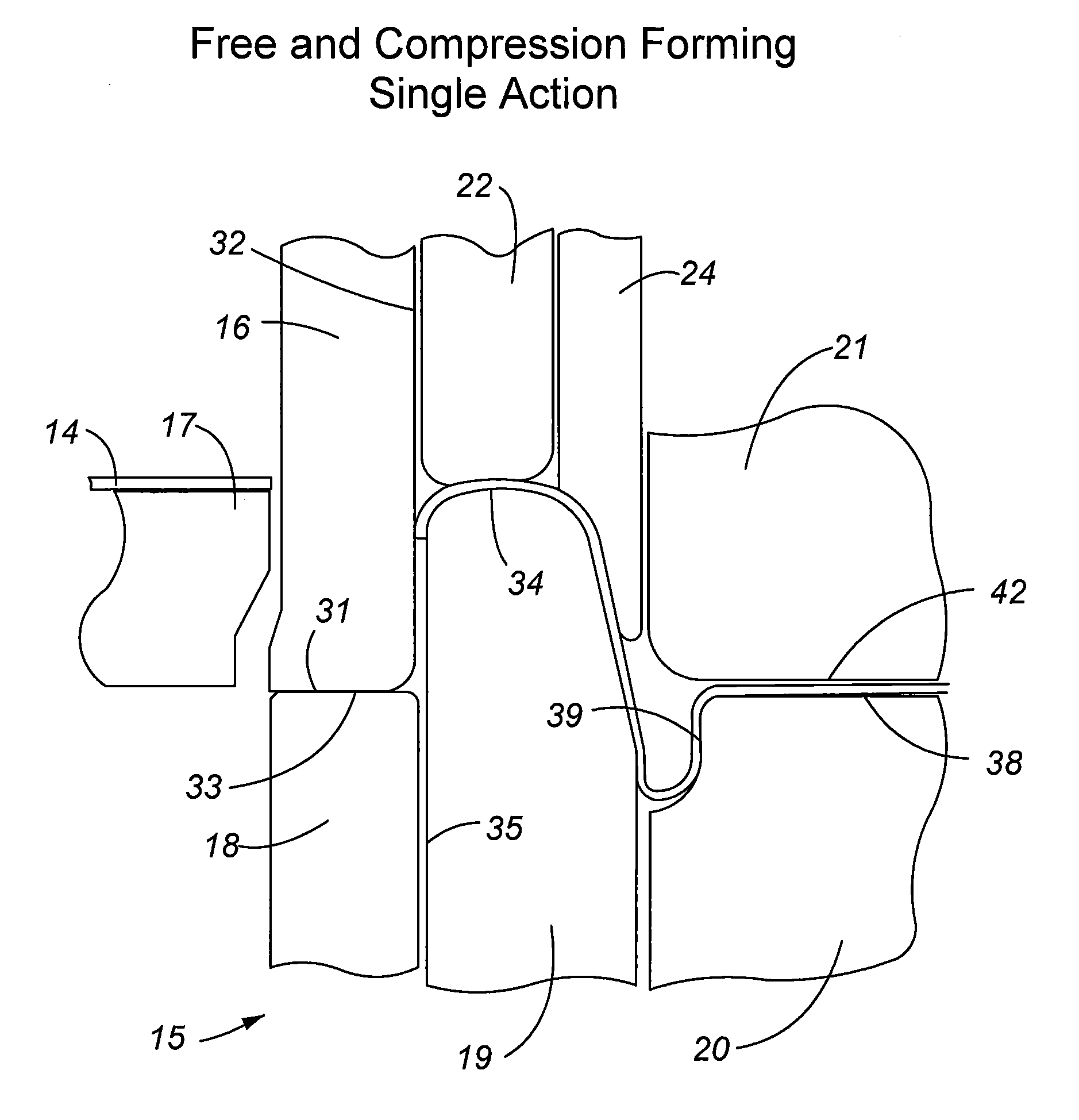

Method and apparatus for shaping a metallic container end closure

ActiveUS7500376B2Excellent characteristicsImprove propertiesHollow articlesEngineeringUltimate tensile strength

The present invention describes an apparatus and forming process to manufacture container end closures with improved internal buckle strength. The present invention provides greater material and dimensional control during the forming process by utilizing a pressure sleeve to provide support to at least a portion of an end closure chuck wall and seaming panel radius while placing an end closure countersink in compression during the forming process.

Owner:BALL CORP

Can shell and double-seamed can end

InactiveUS7819275B2Reduce the overall diameterRaise the ratioRigid containersHollow articlesAluminum canEngineering

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by an inclined curved or straight panel wall to an inclined inner wall of an annular U-shaped countersink. The countersink has an outer wall which connects with an inclined lower wall portion of a chuckwall at a junction below the center panel, and the chuckwall has a curved or inclined upper wall portion which connects with an inner wall of the crown. The chuckwall also has an intermediate wall portion forming a break, and the inner bottom width of the countersink is less than the radial width of the panel wall. The inclined upper wall portion of the chuckwall extends at an angle greater than the angle of the inclined lower wall portion of the chuckwall.

Owner:BALL CORP +1

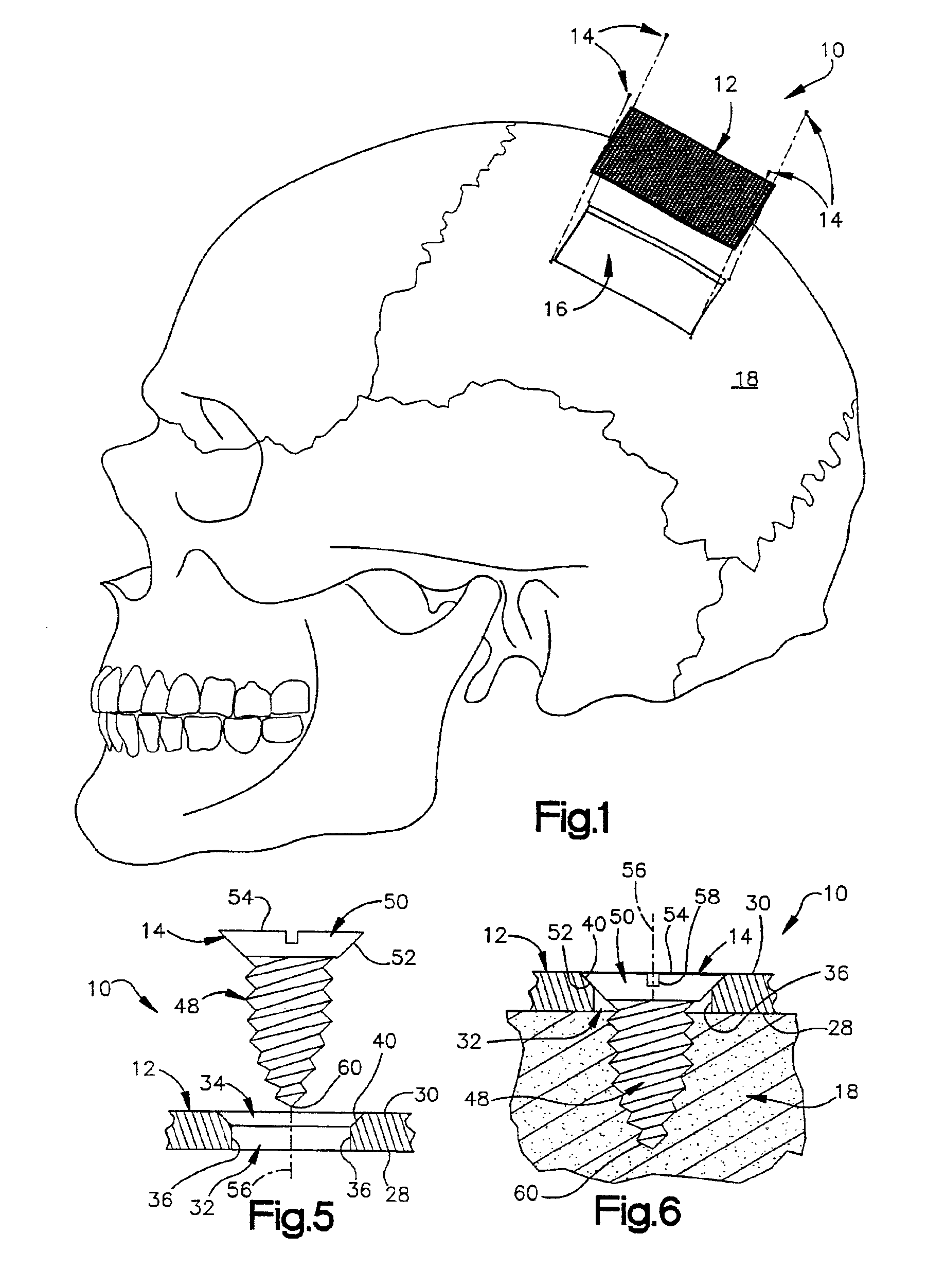

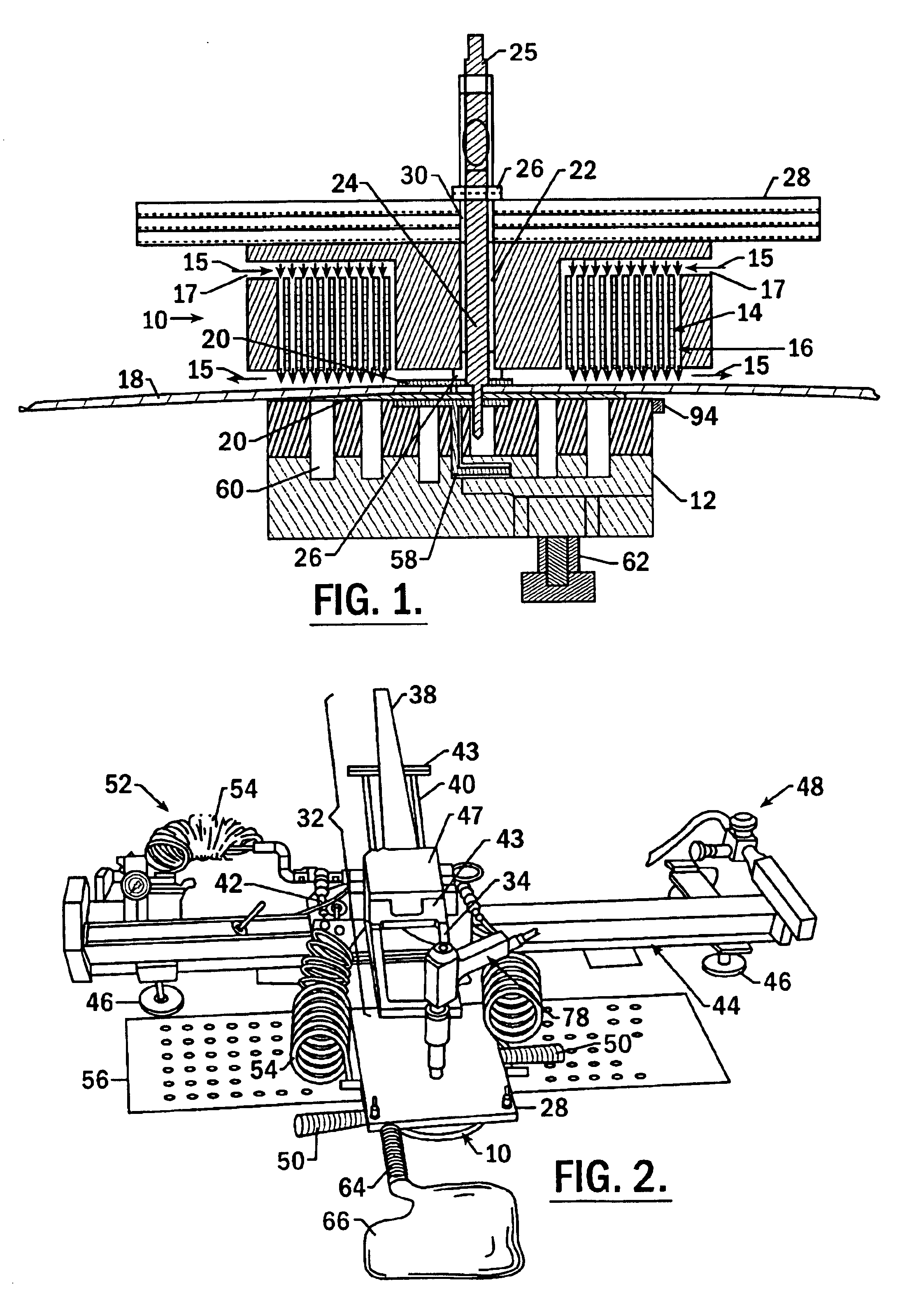

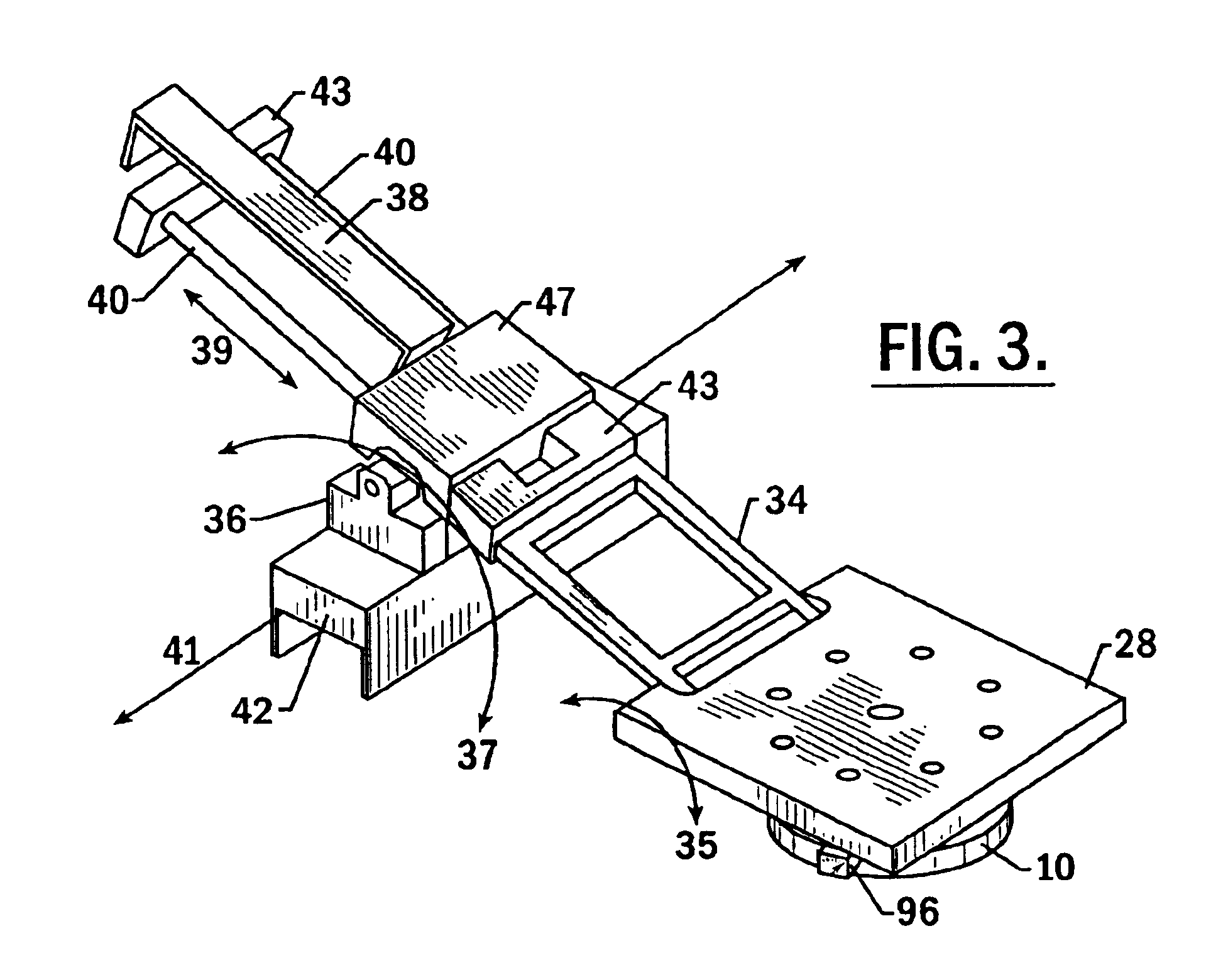

Implantable device for covering and opening in a cranium

An apparatus (10) for attachment to bone (18) comprises a plate (12) having a lower surface (28) for abutting against the bone (18) and an upper surface (30) opposite the lower surface (28). The plate (12) further includes a plurality of through-holes (32) extending between the lower and upper surfaces (28 and 30). Each through-hole (32) has an associated countersink (34). Each through-hole (32) defines a substantially square opening in the lower surface (28) of the plate (12) and each associated countersink (34) defines a circular opening in the upper surface (30) of the plate (12).

Owner:INTEGRA SIGNATURE TECH +1

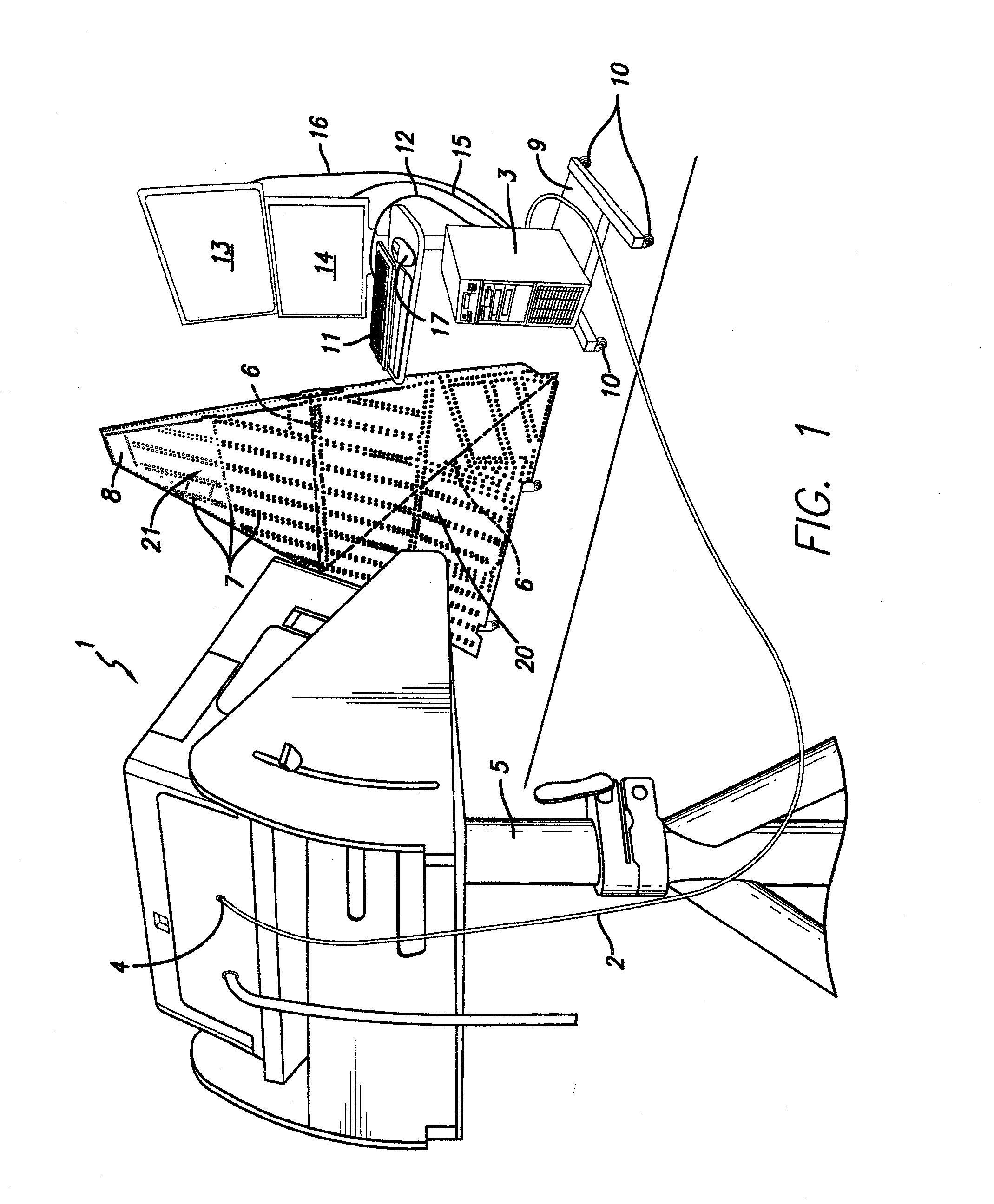

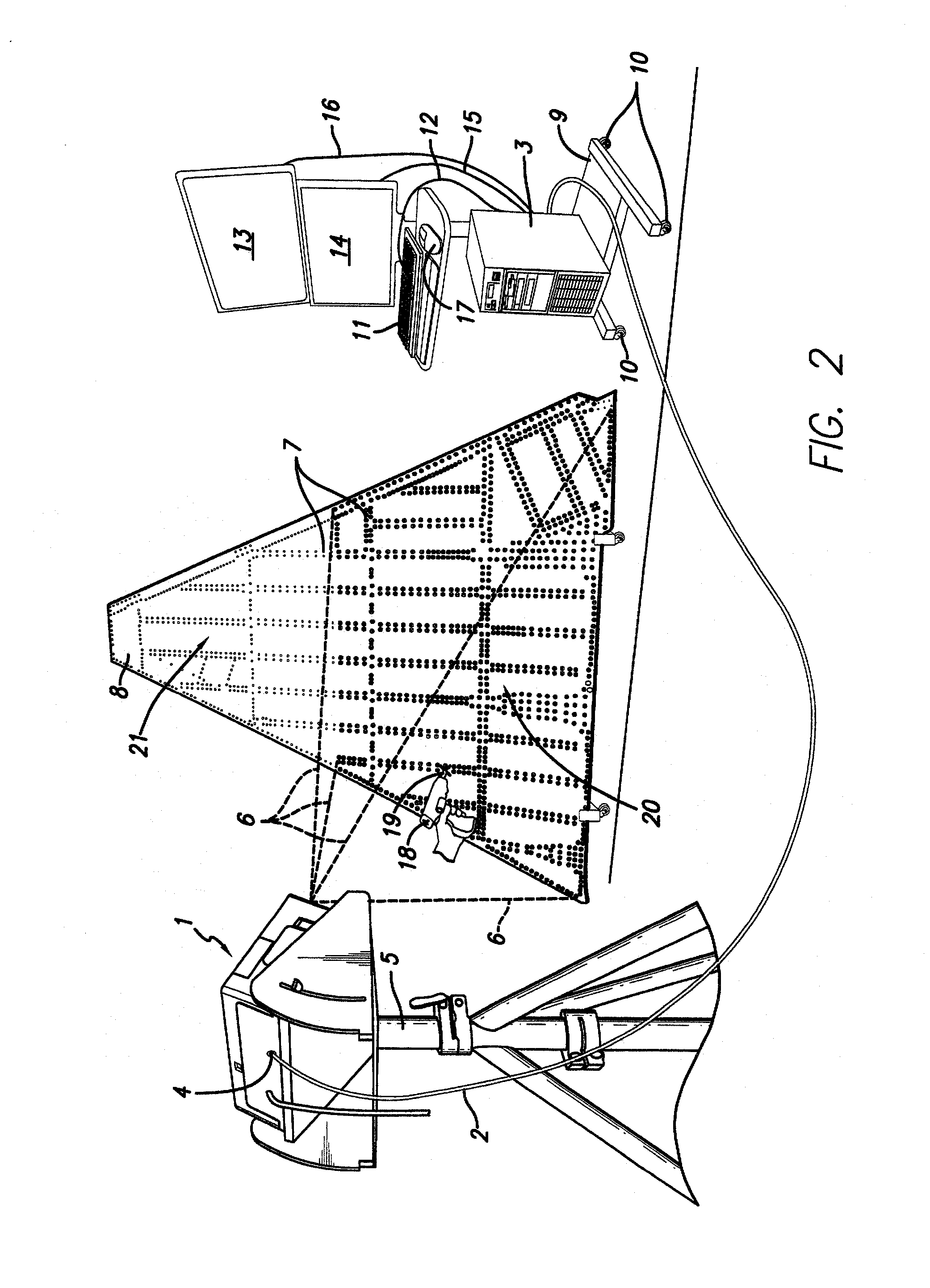

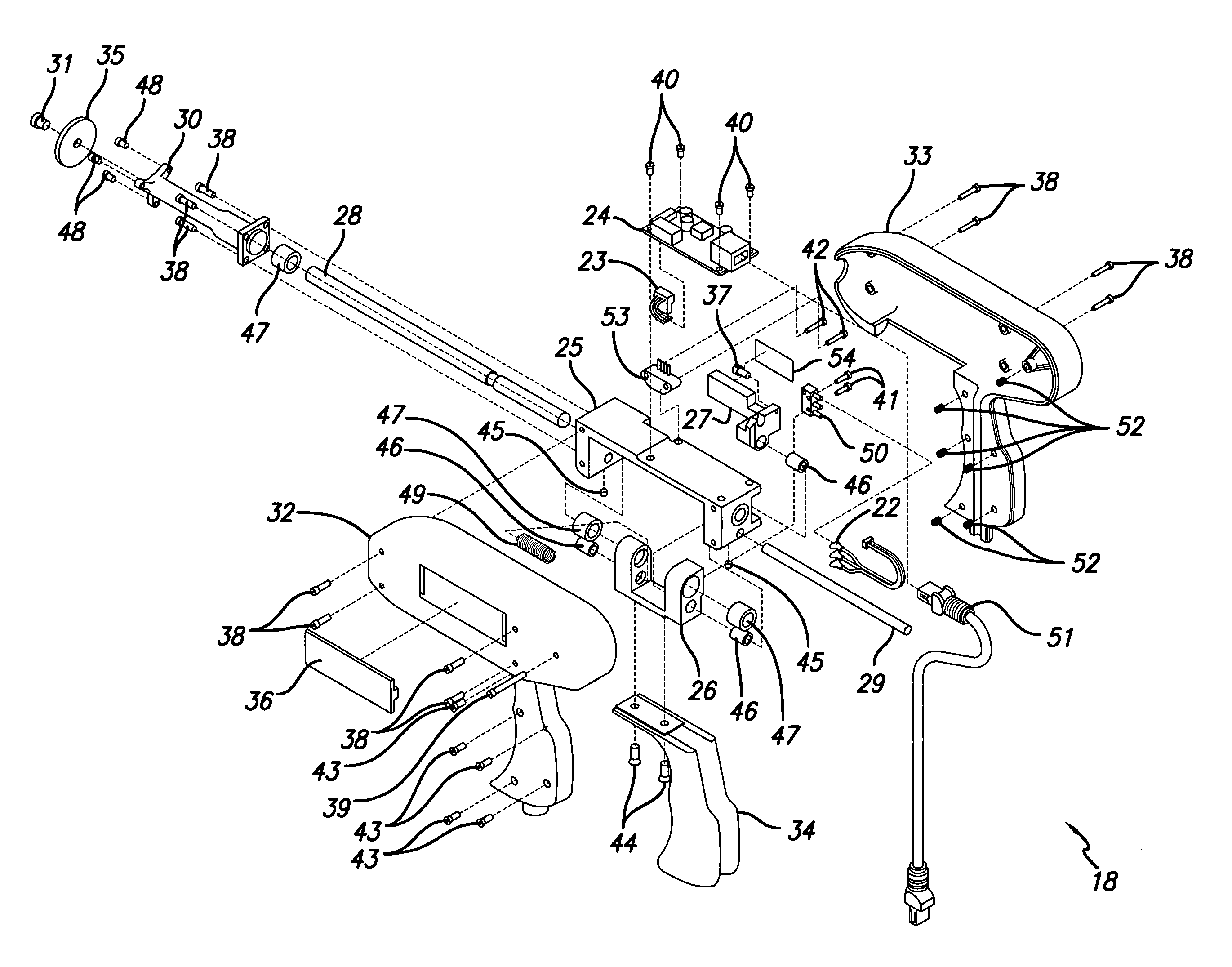

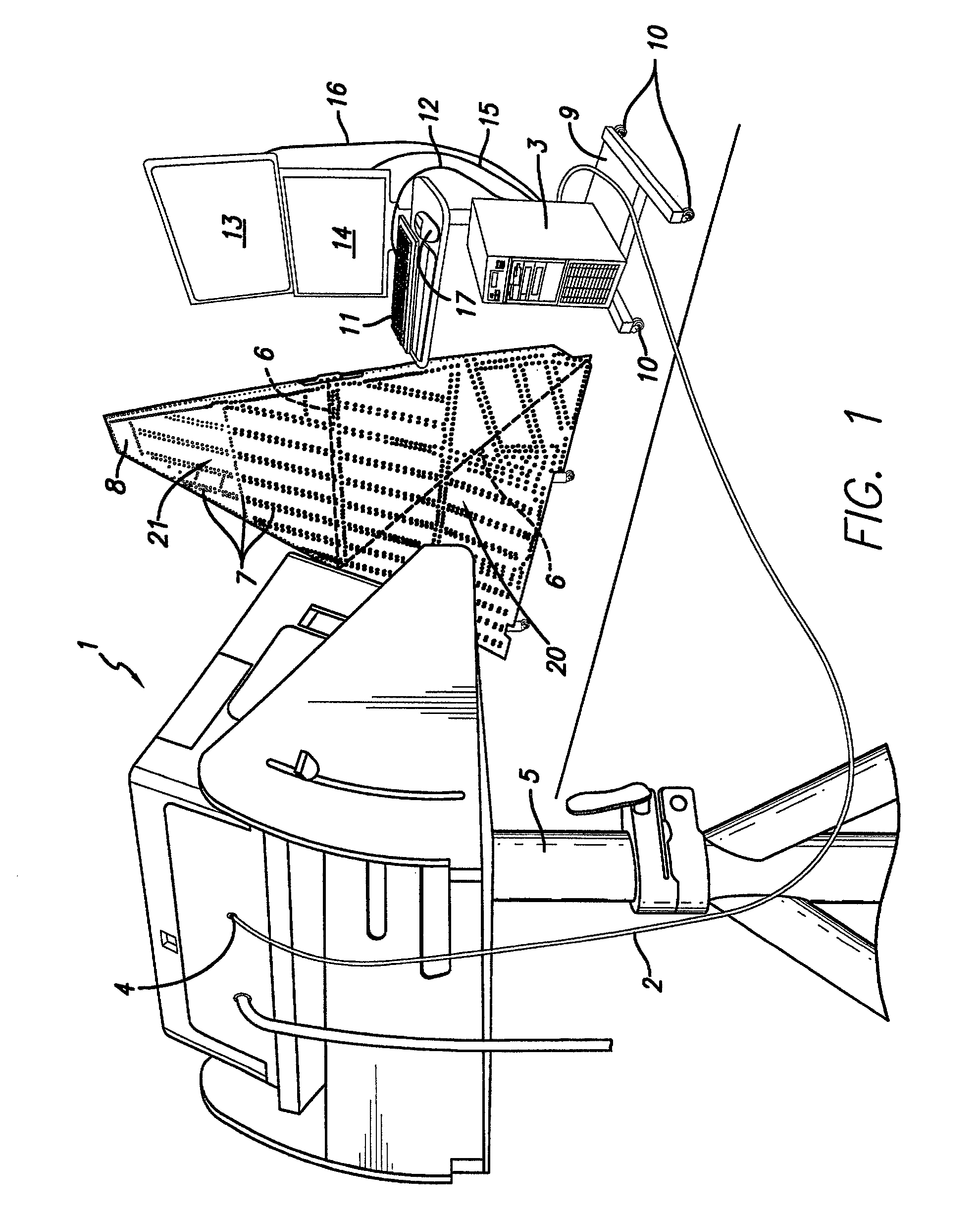

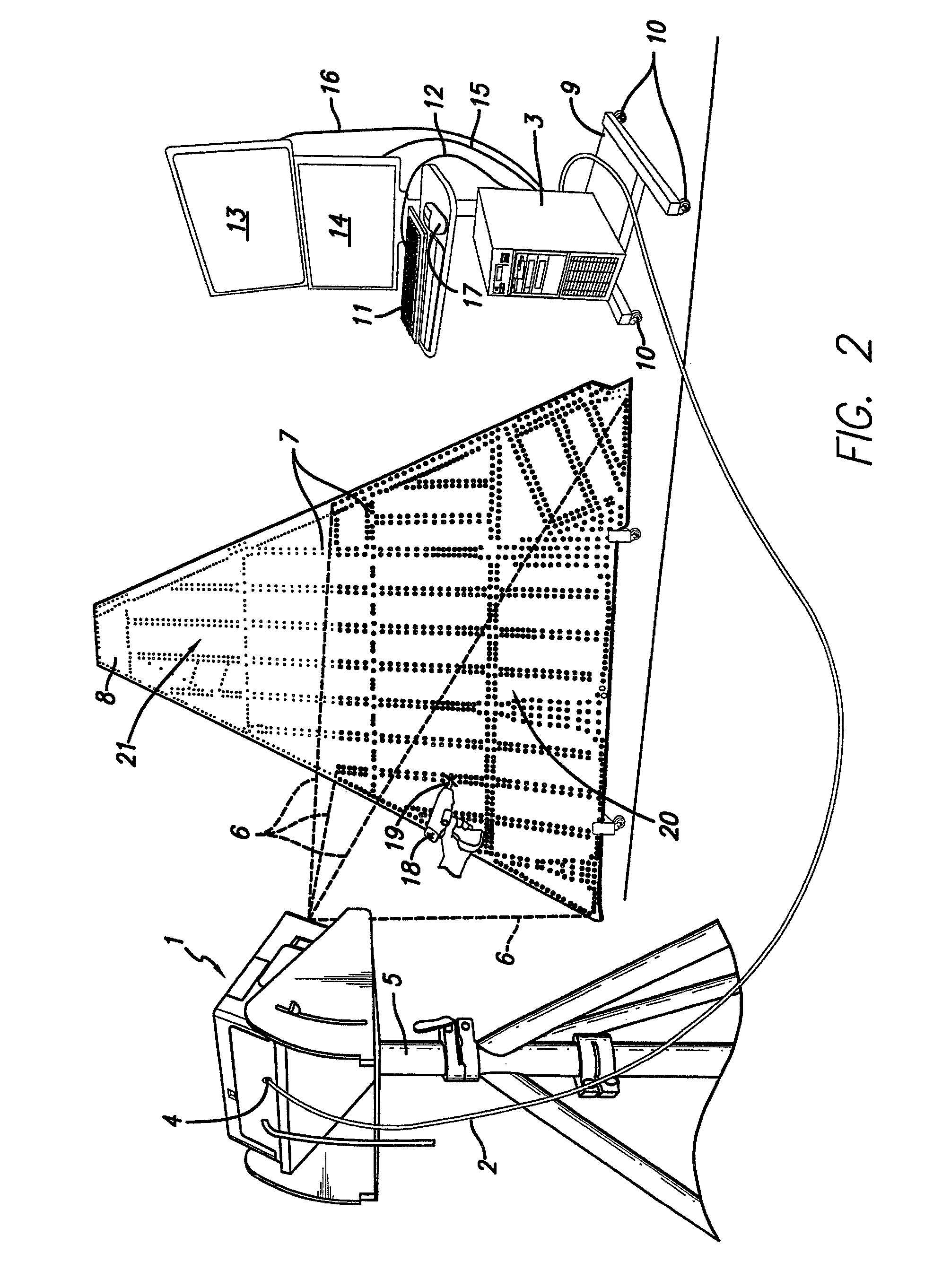

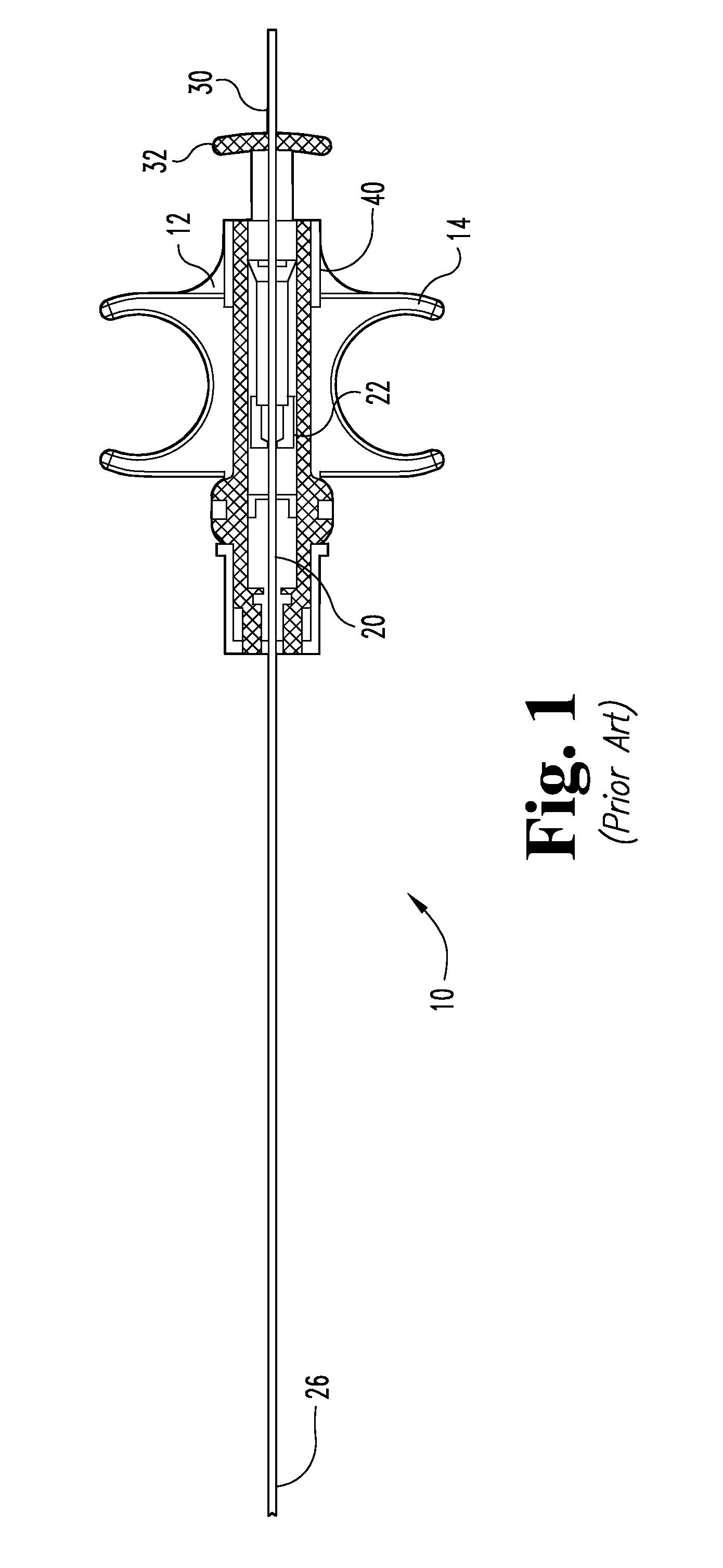

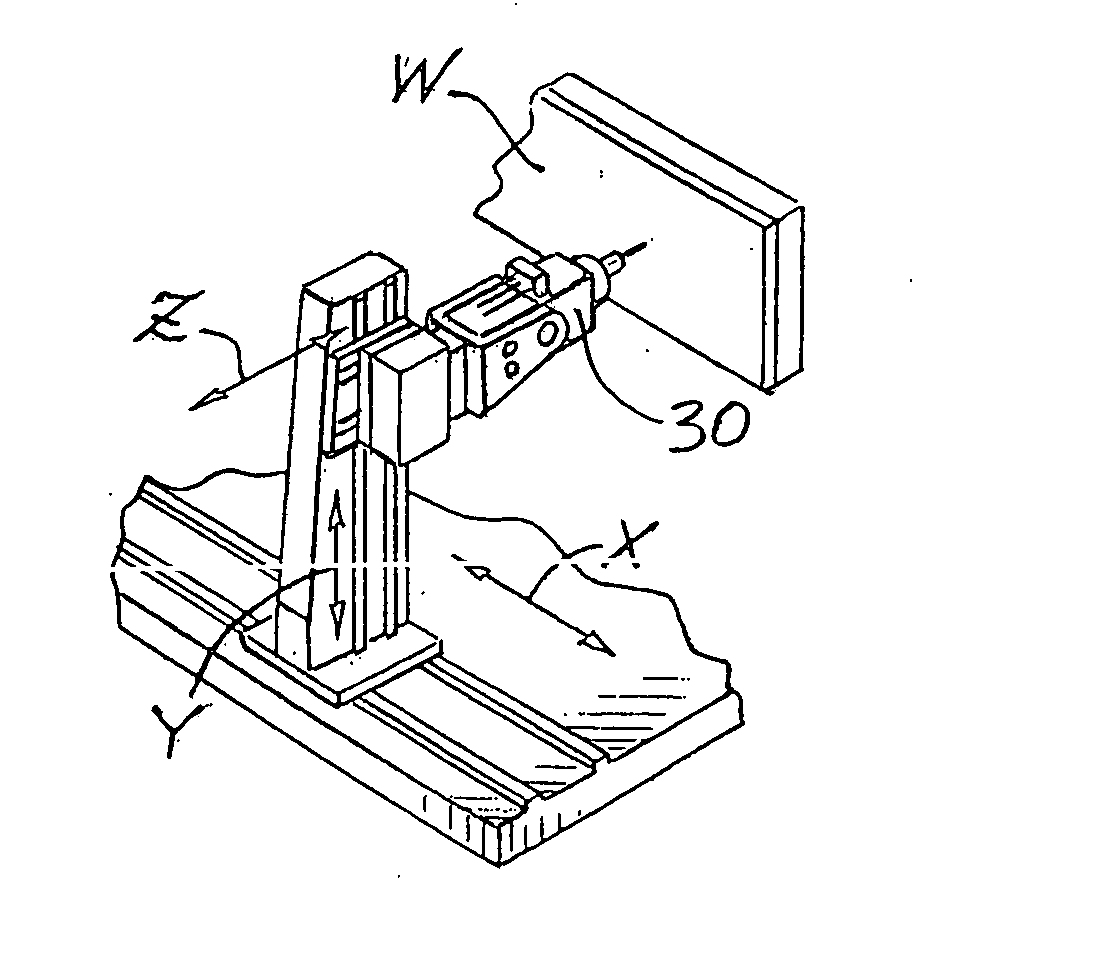

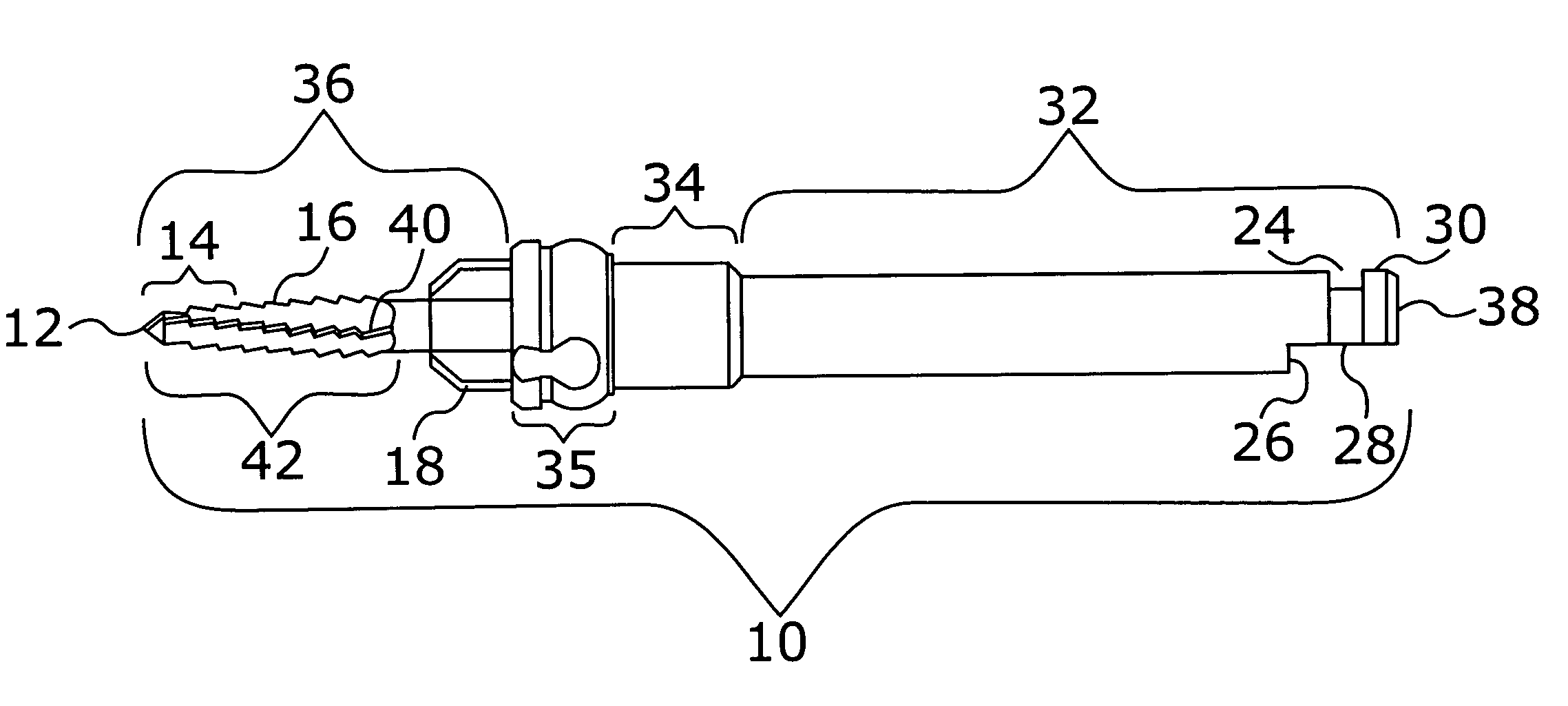

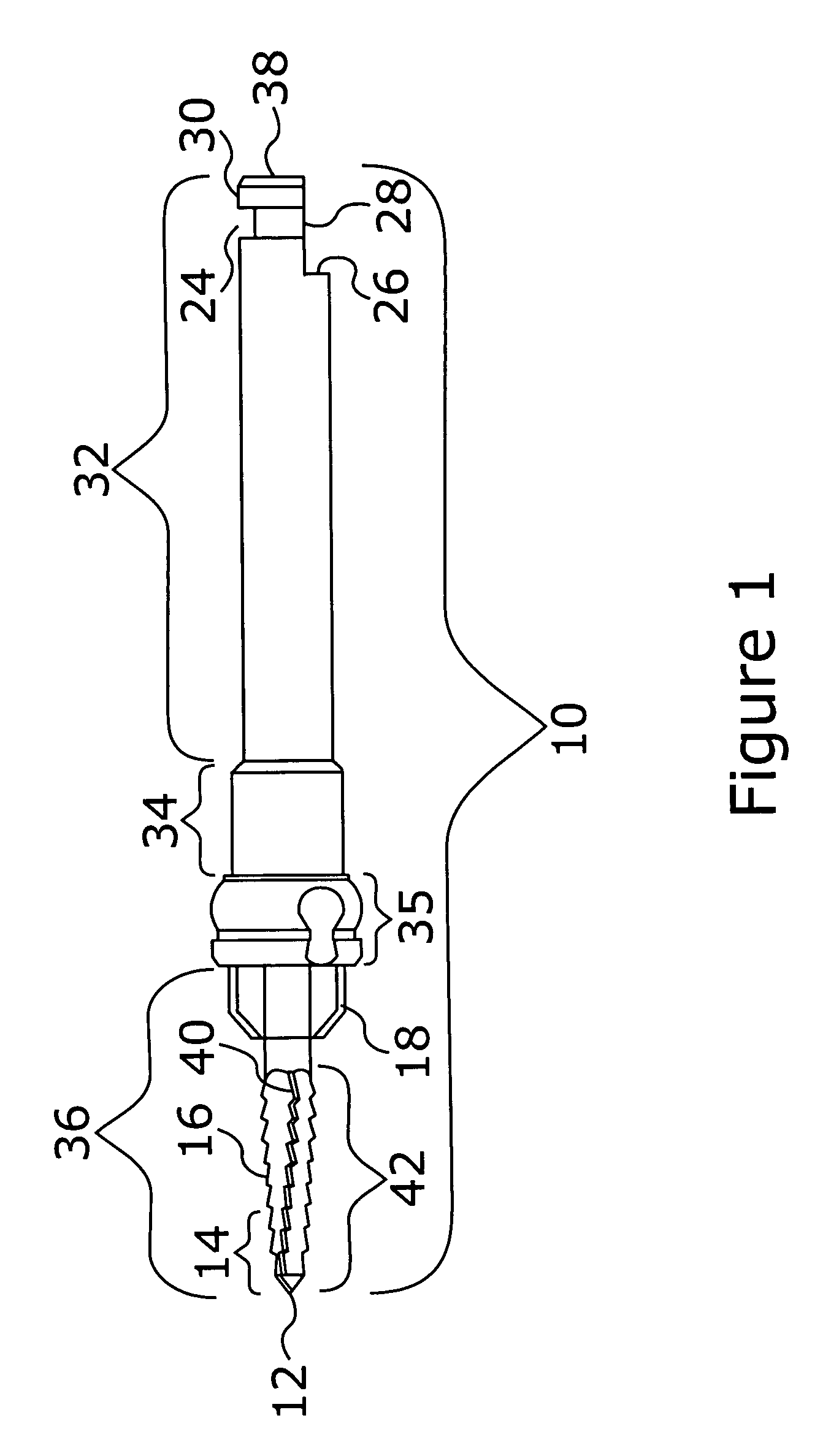

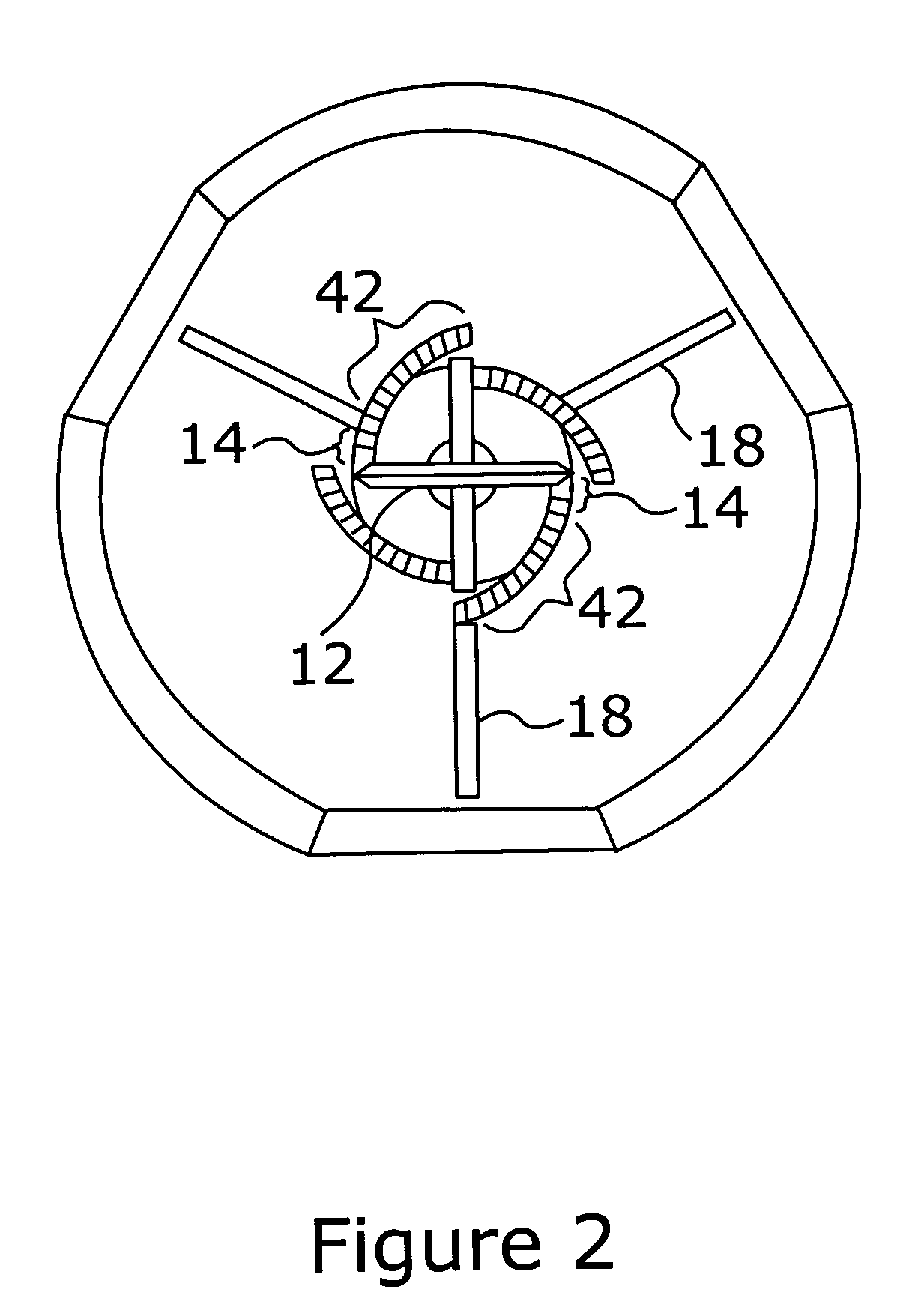

Apparatus and method for drilling holes and optionally inserting fasteners

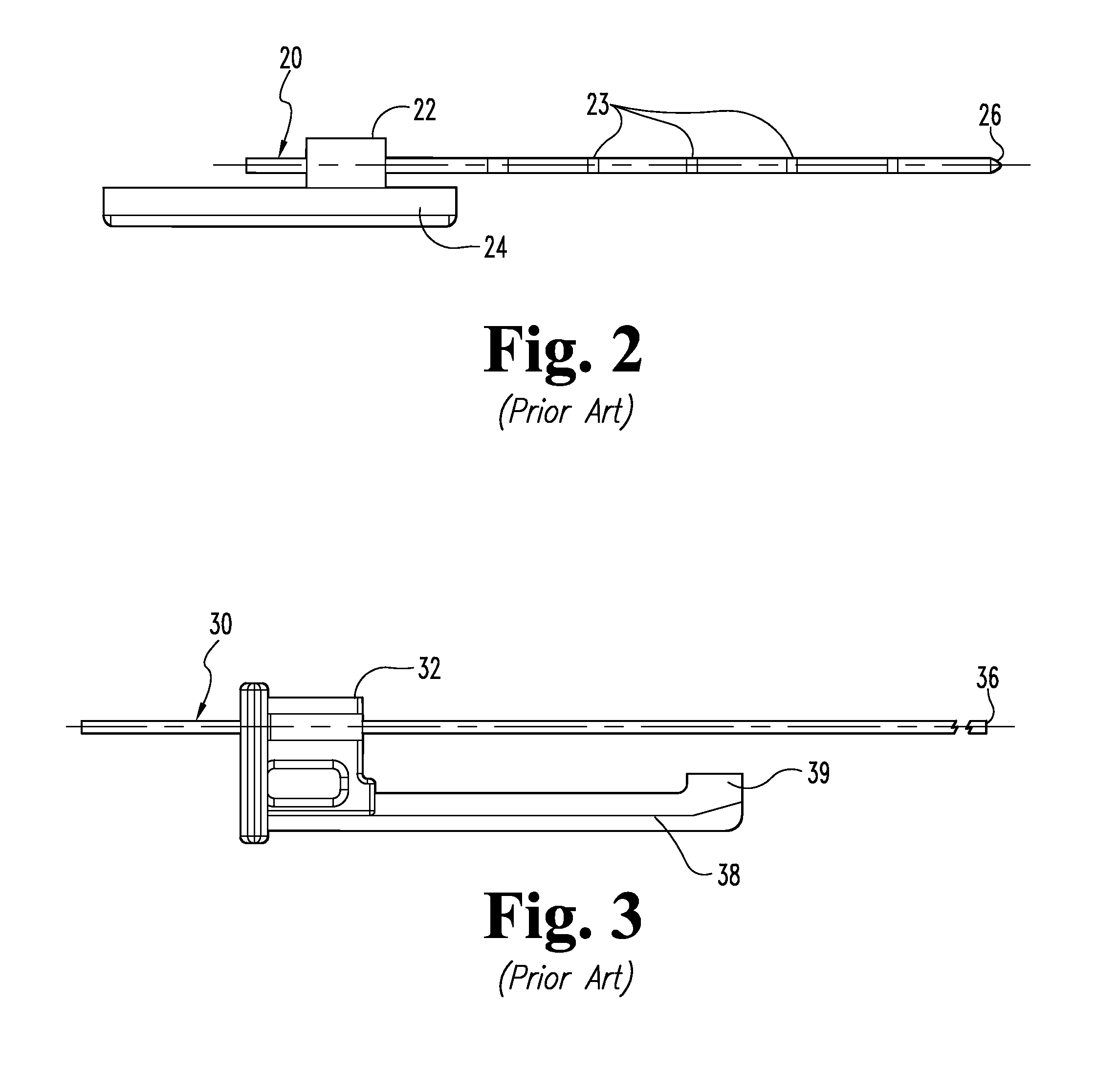

InactiveUS6905291B2Shorten the timeReduce expensesAircraft componentsDrilling/boring measurement devicesEngineeringSealant

The method and apparatus for drilling holes and optionally inserting fasteners of the present invention provide for efficiently drilling holes through a multiple-layer structure because the layers are securely held together during the drilling by an electromagnet and a clamp, each on opposite sides of the structure. The electromagnet and clamp hold the layers together so tightly that burrs do not form within the holes and debris does not accumulate between the layers and, therefore the layers do not have to be disassembled after drilling. In addition, the apparatus and method of the present invention provide for initially drilling the hole with a countersink and for inserting a fastener into the hole, through the electromagnet, immediately after drilling the hole, such that the hole does not have to be revisited after reassembly and drying of the sealant in order to drill a countersink and / or insert a fastener.

Owner:THE BOEING CO

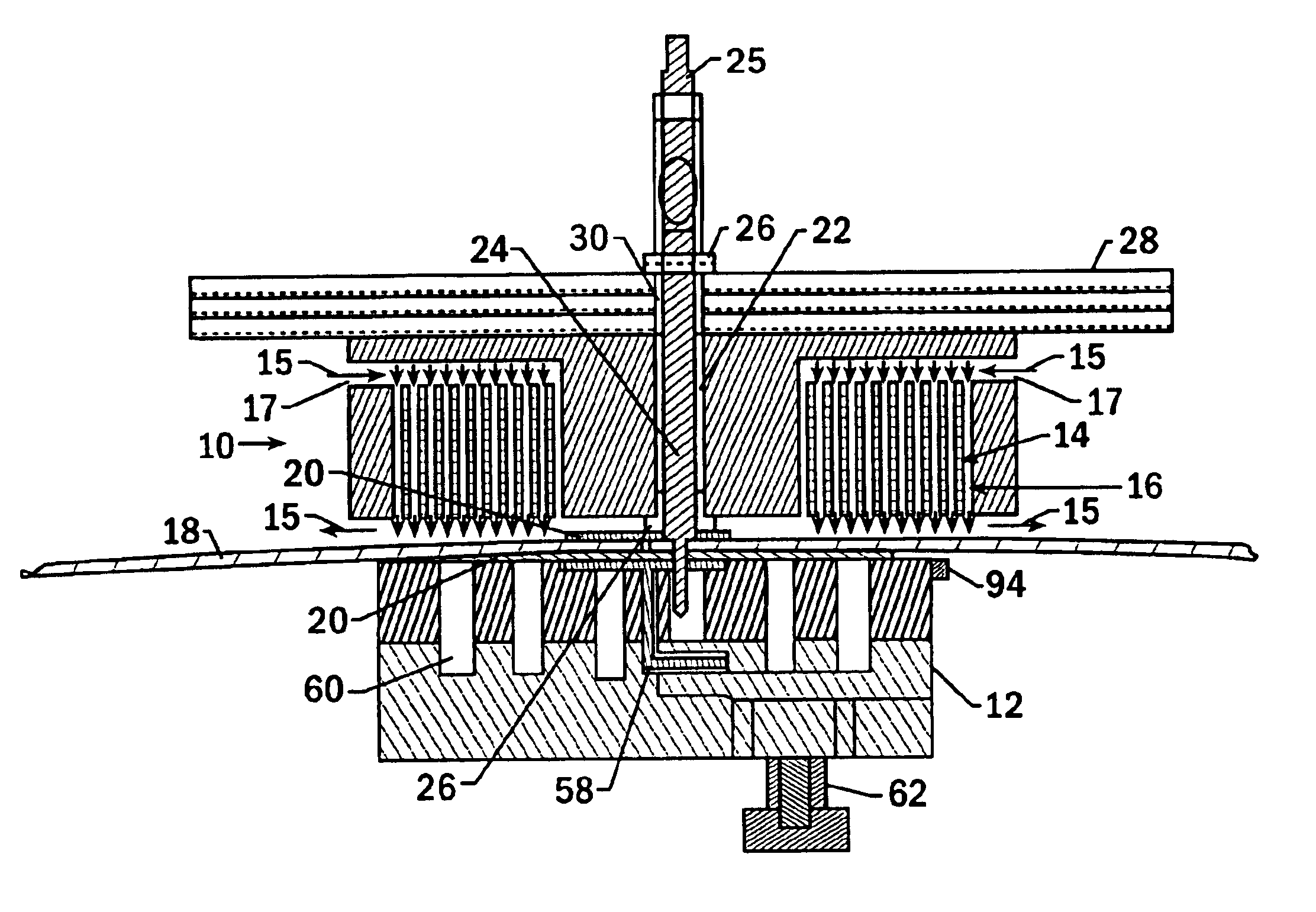

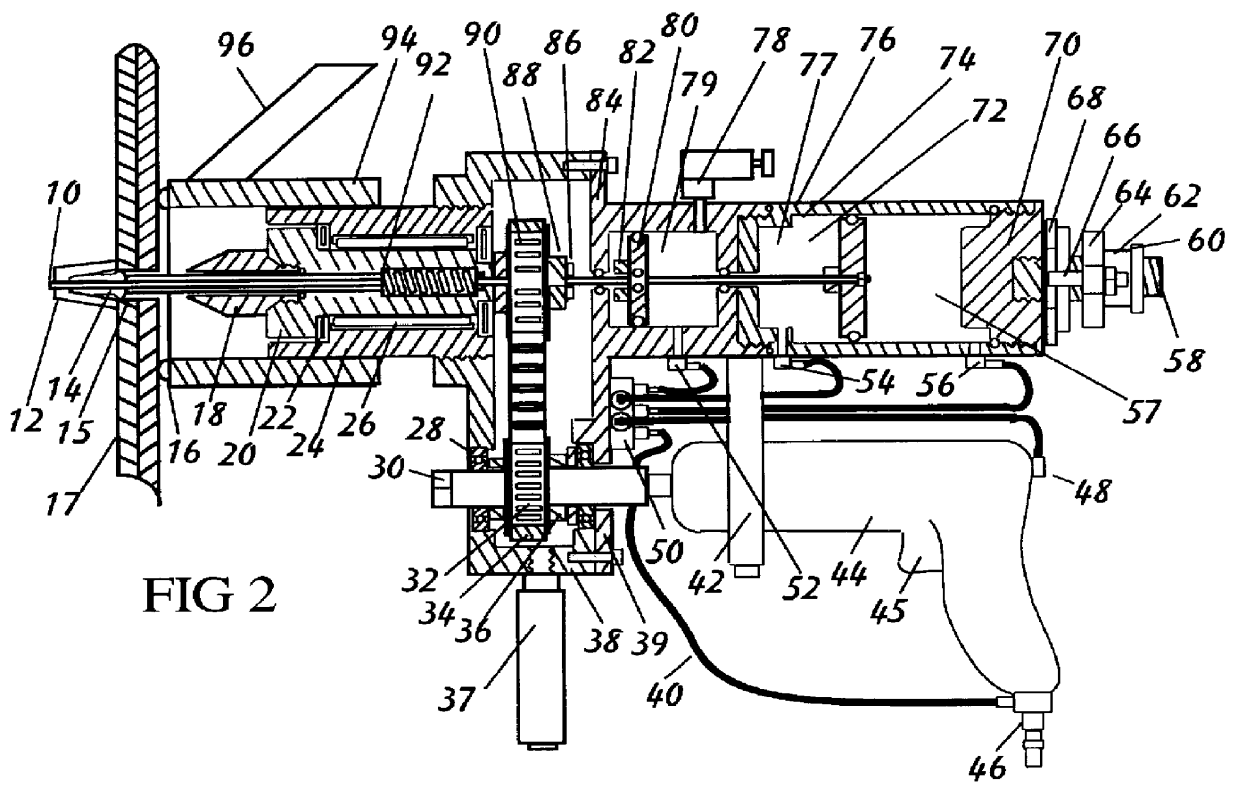

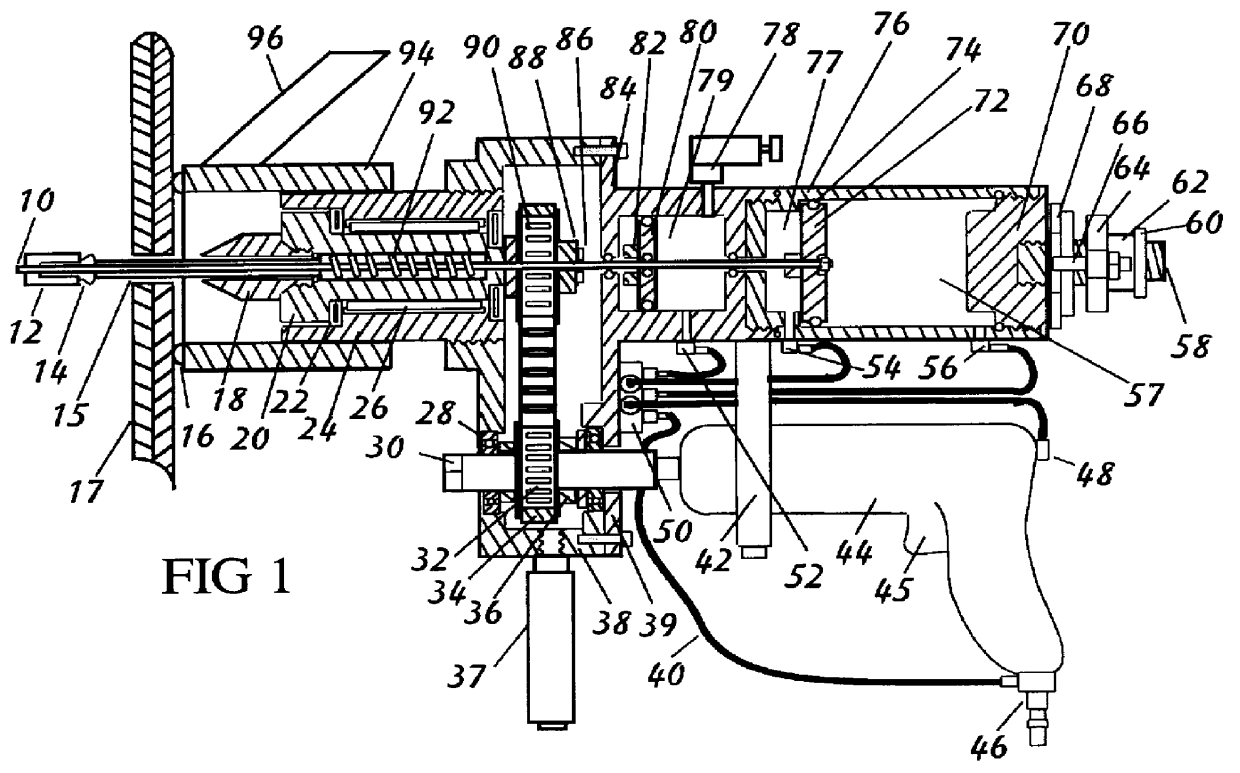

Blind hole self-collet countersink

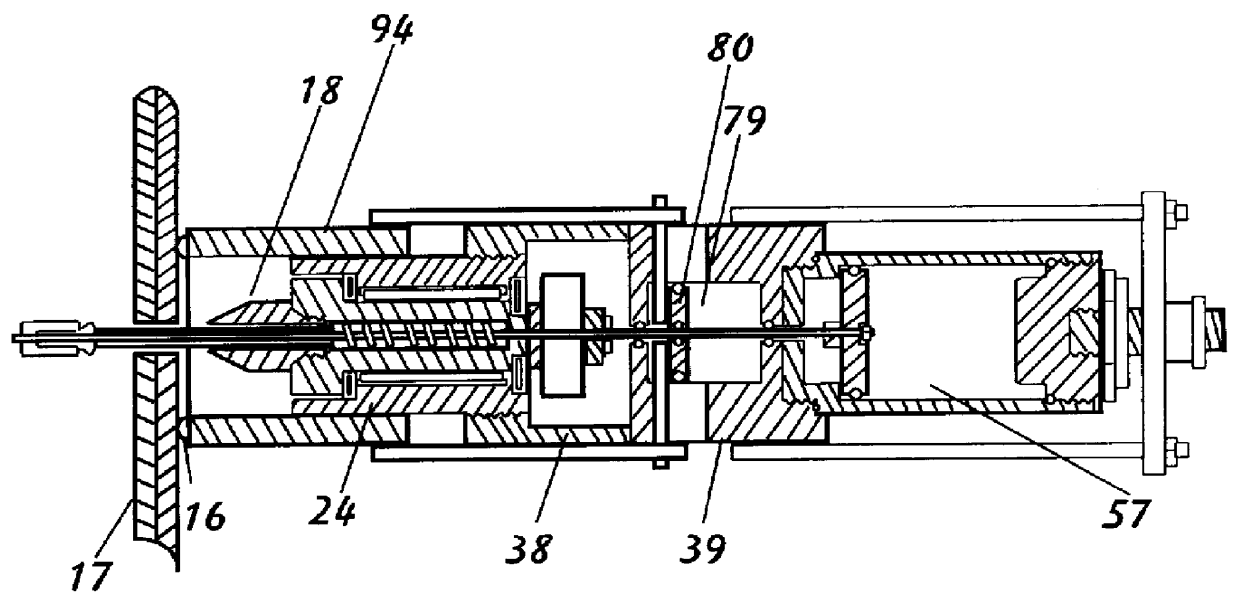

This invention is a portable pneumatic cutter tool for cutting countersinks into a workpiece 17 having pre-drilled holes 15. When pressure is applied, a piston return cylinder 57 and a feed rate cylinder 79 are also pressurized, which sets a body piston 72 and spindle piston 80 reacts against a spindle bar 82 which holds nose 94 in its outer-most limit position. A pistol grip drill 44 drives a geared belt 34 to cut the countersink after actuation by trigger 45. A flare tube shaft 14 expands a multiple finger and pad arrangement of a collet 12 to provide clamp-up on the back side of workpiece 17. Clamp-up on the front side of workpiece 17 is provided by pneumnatic pressure and solid mechanical stops 16. The countersink cutter 18 advances into workpiece 17, reaching its depth, and returns automatically to its start position.

Owner:THE BOEING CO

Can lid closure and method of joining a can lid closure to a can body

Over the years there have been numerous attempts to improve the can lid oftentimes found on aluminum beverage can lids. The aims have traditionally been to reduce costs and improve performance. These aims have been accomplished through a variety of means, such as creating different formations within the can lid to reduce the amount of metal used while maintaining performance levels. Here, step portions are utilized between the annular countersink and the center panel of the can lid that cause a curvature of the center panel or to simply provide an angled inside wall. These formations, thus, reduce the amount of metal used while maintaining quality and yielding the desired performace.

Owner:METAL CONTAINERS

Full aperture beverage end

InactiveUS20110056945A1Content becomes visibleOpening closed containersBottle/container closureDifferential pressureEngineering

A full aperture beverage end has a center panel, a countersink surrounding the centre panel, a main score arranged in proximity to the countersink to define a removable aperture panel and a vent score. The beverage end is adapted for use with products that are pressurized to over 30 psi (200 kPa) when opened, and during opening the vent score is adapted to sever first, controlling the pressure differential between the external surface and internal surface of the centre panel, thereby allowing the main score to tear in a controlled and reliable manner.

Owner:CROWN PACKAGING TECH

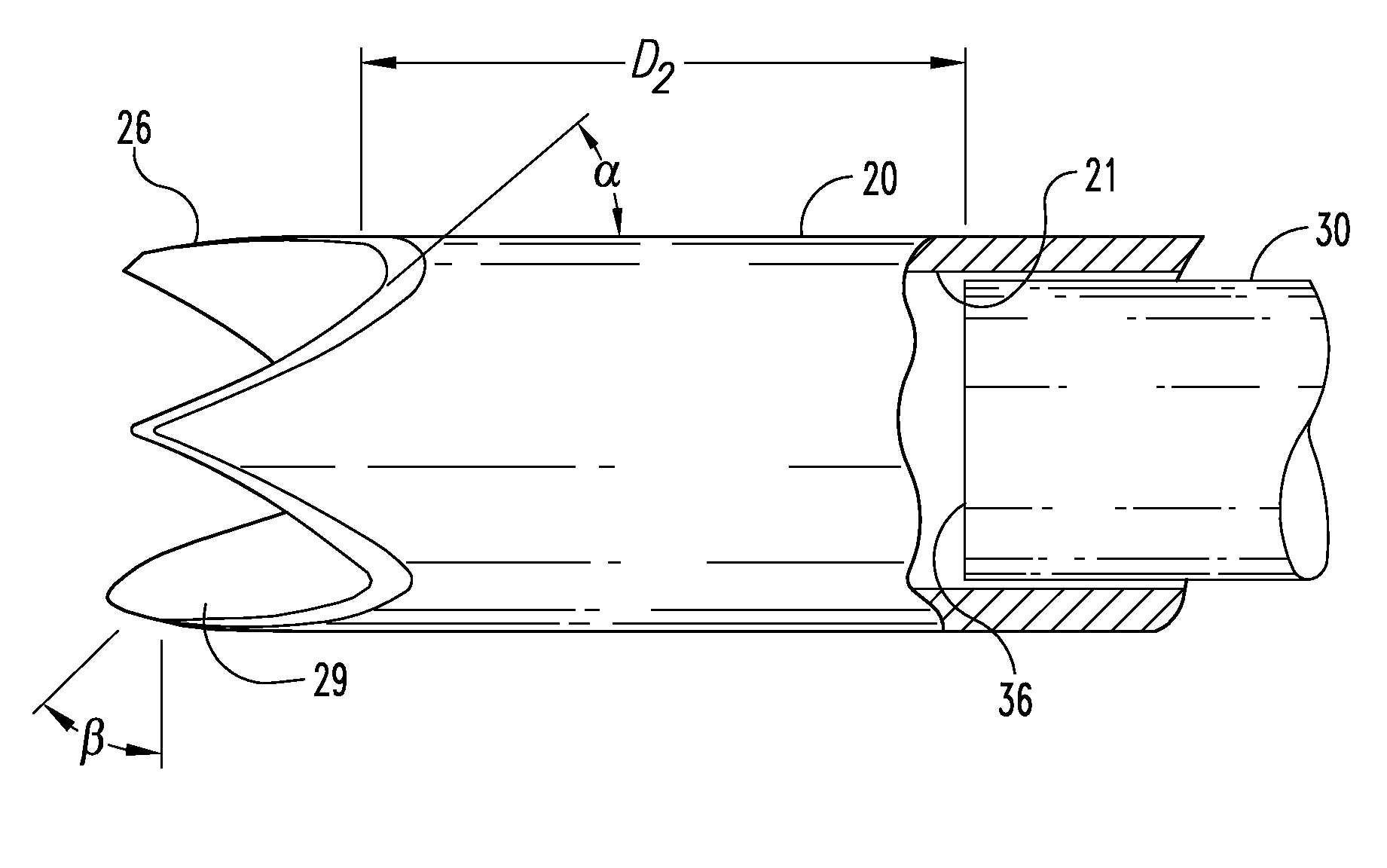

Wave relieving geometric features in structural members that are radially expandable into workpieces

A bushing with wave relieving geometric features includes a unique geometric end feature such as a countersink or arcuate surface, which creates a pocket, volume, and / or reservoir, to receive an amount of material that is extruded in a longitudinal direction during radial expansion of the bushing. At the mandrel exit side of the bushing, the extruded material may be accumulated from a propagating wave of material preceding a radial-expansion mandrel. At the mandrel entry side of the bushing, the extruded material may be caused by the radial force of the expansion mandrel near the unrestrained end surface at the entry side of the bushing. The unique geometric end features of the bushing may also include a high portion on the end surface of the bushing to direct the fastener clamp-up loads through the radial flange of the bushing and into the workpiece.

Owner:FATIGUE TECH

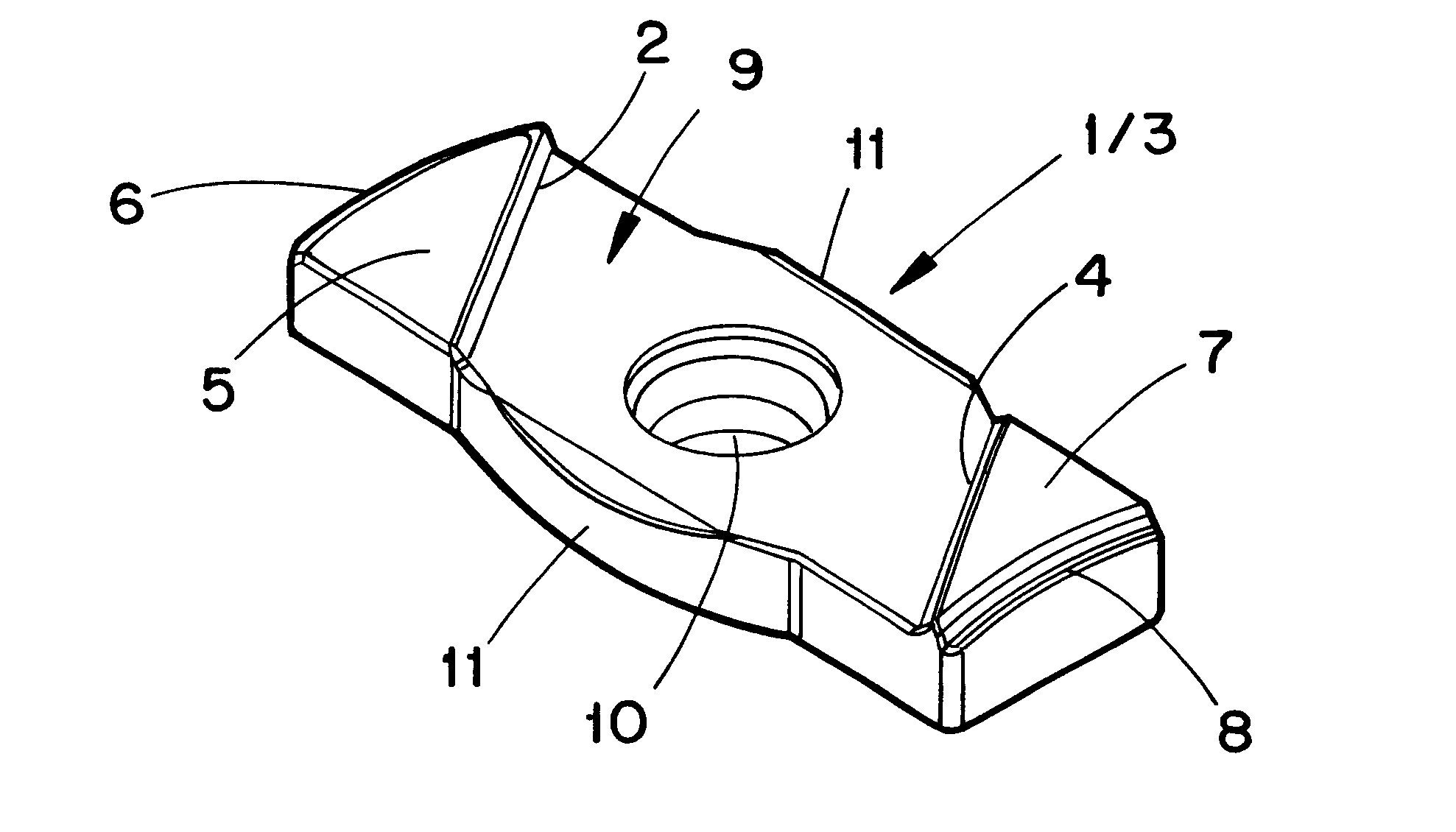

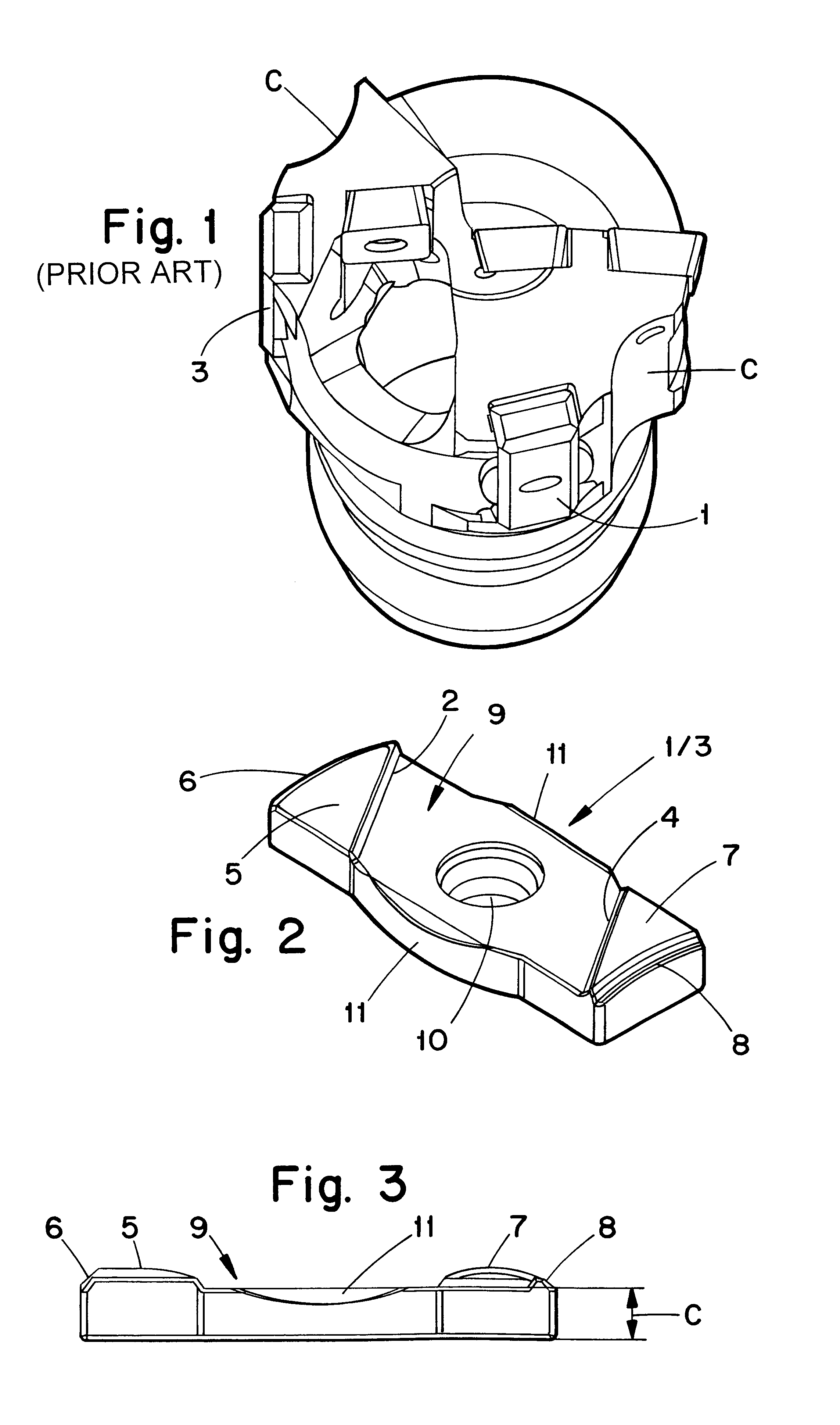

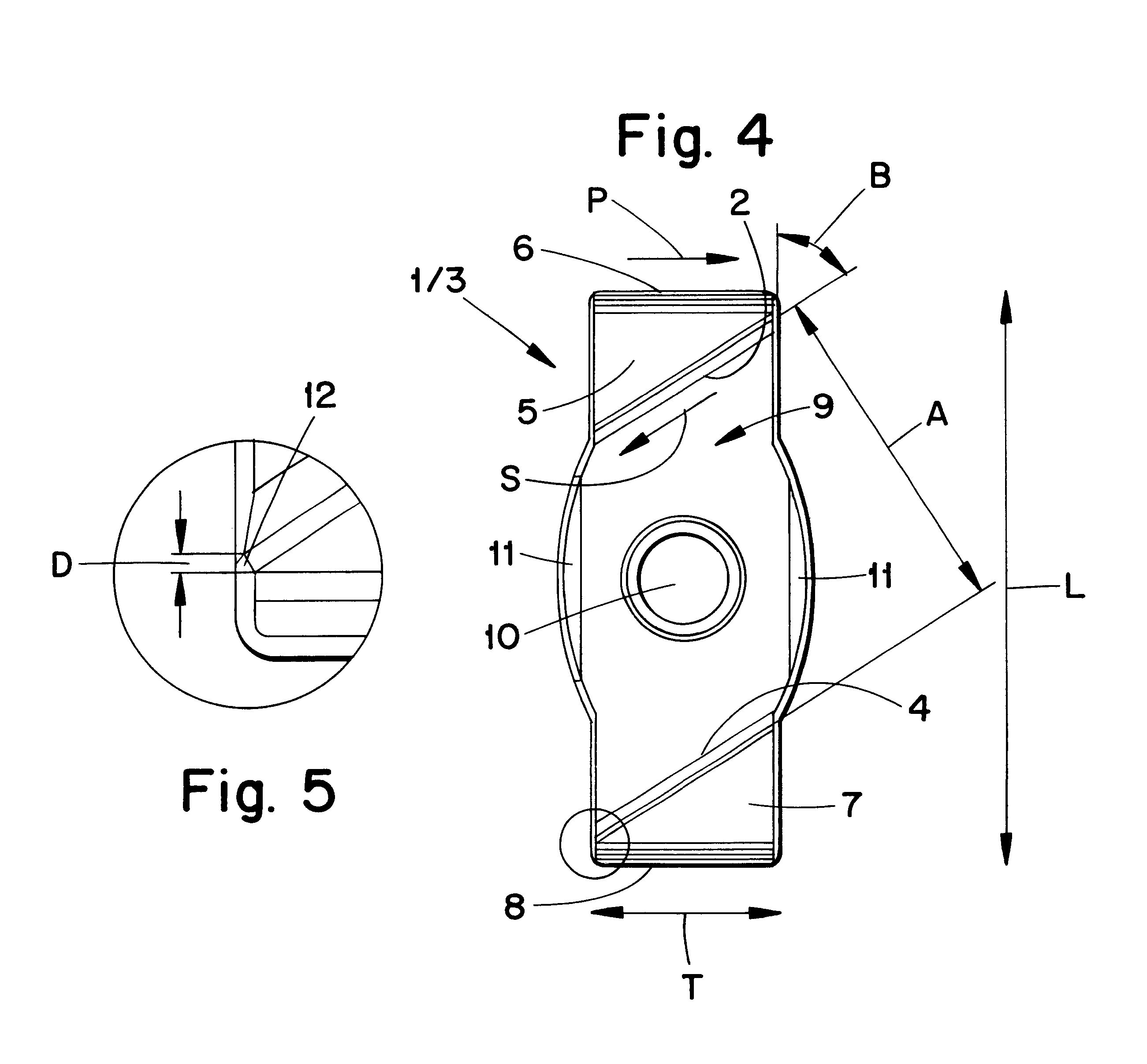

Support pad for a deep hole drill

An element which defines a support pad and / or a guide bar adapted to be mounted in a seat of a cutter head of a deep hole drill comprises a body which defines a longitudinal direction and a cross-direction. The body includes an inner mounting side and an opposing outer side. The outer side includes a contact surface which is adapted to engage a wall of a hole being drilled. The outer side also includes a countersink extending across the outer side in a direction transversely of the longitudinal direction. An edge of the contact surface facing toward a center of the body forms an angle with the longitudinal direction in the range of 55°±10°.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

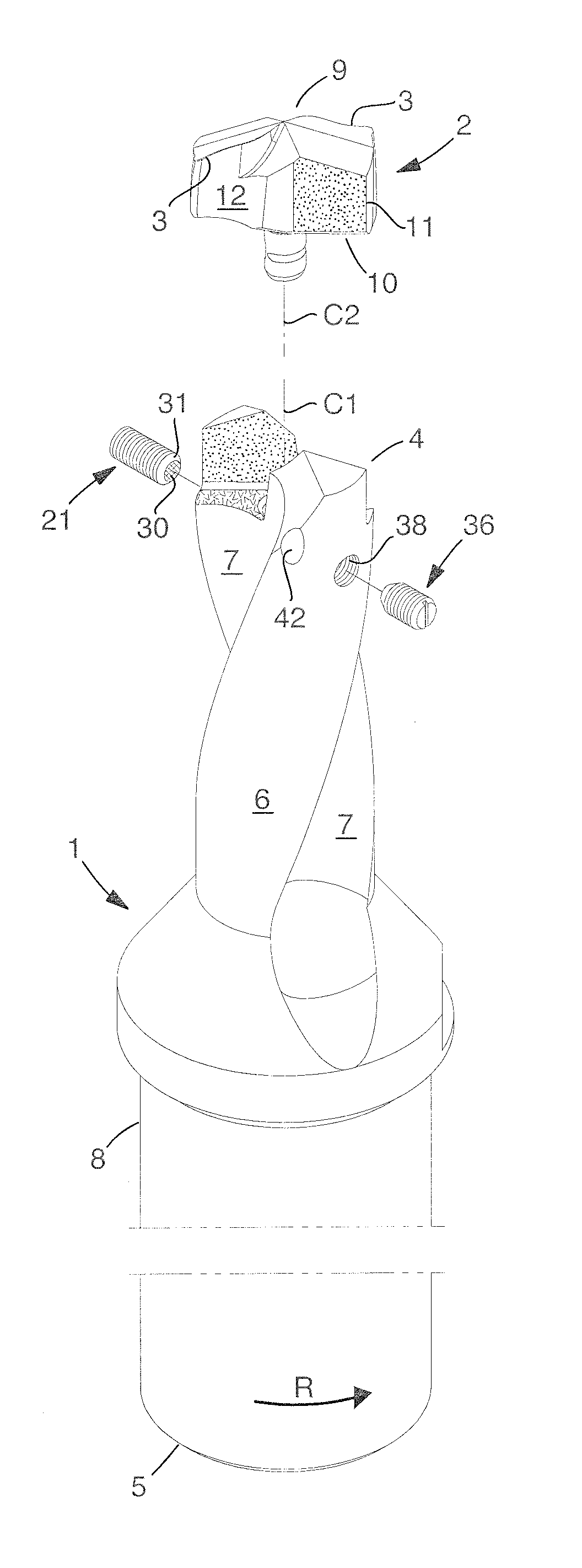

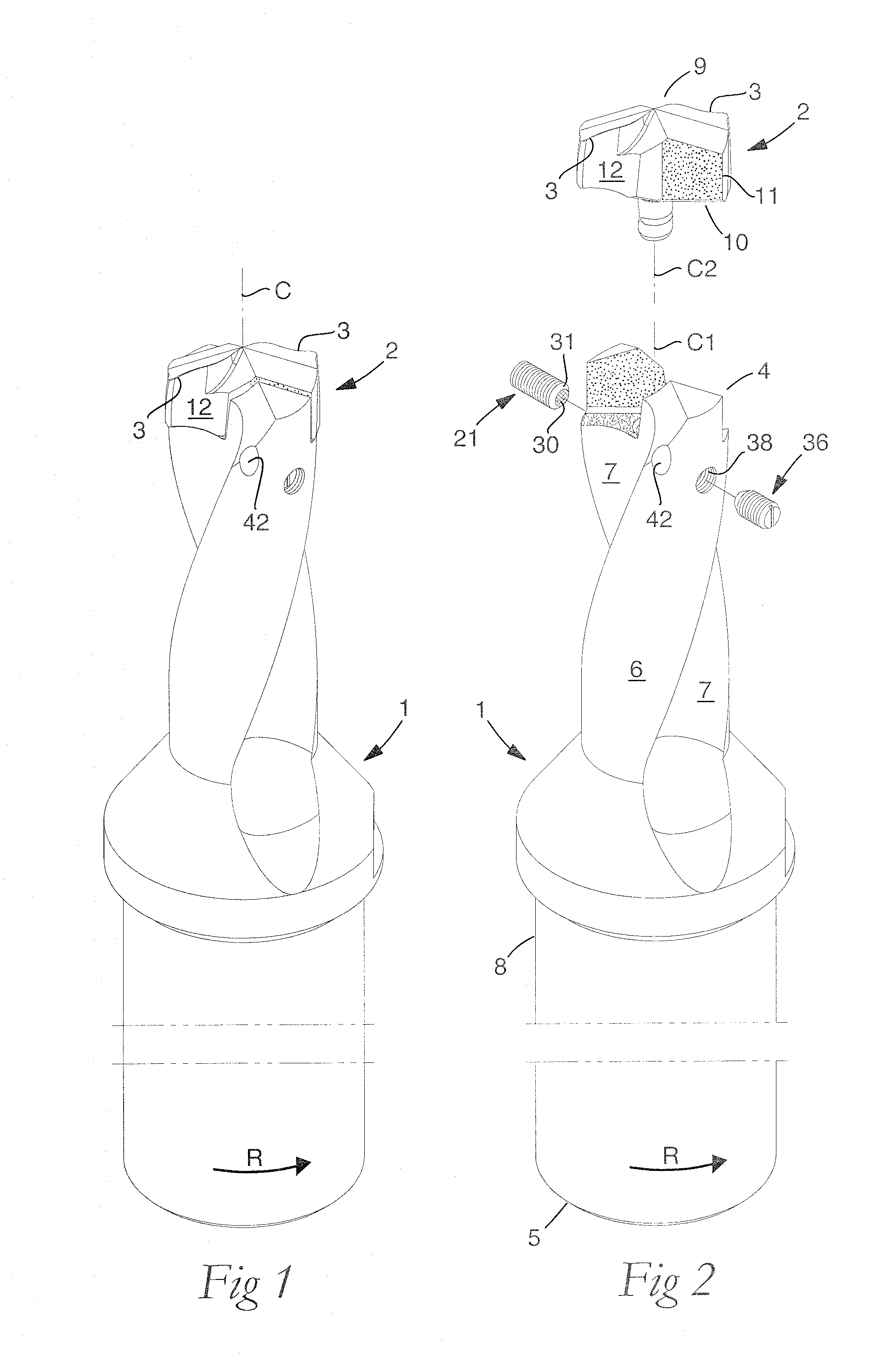

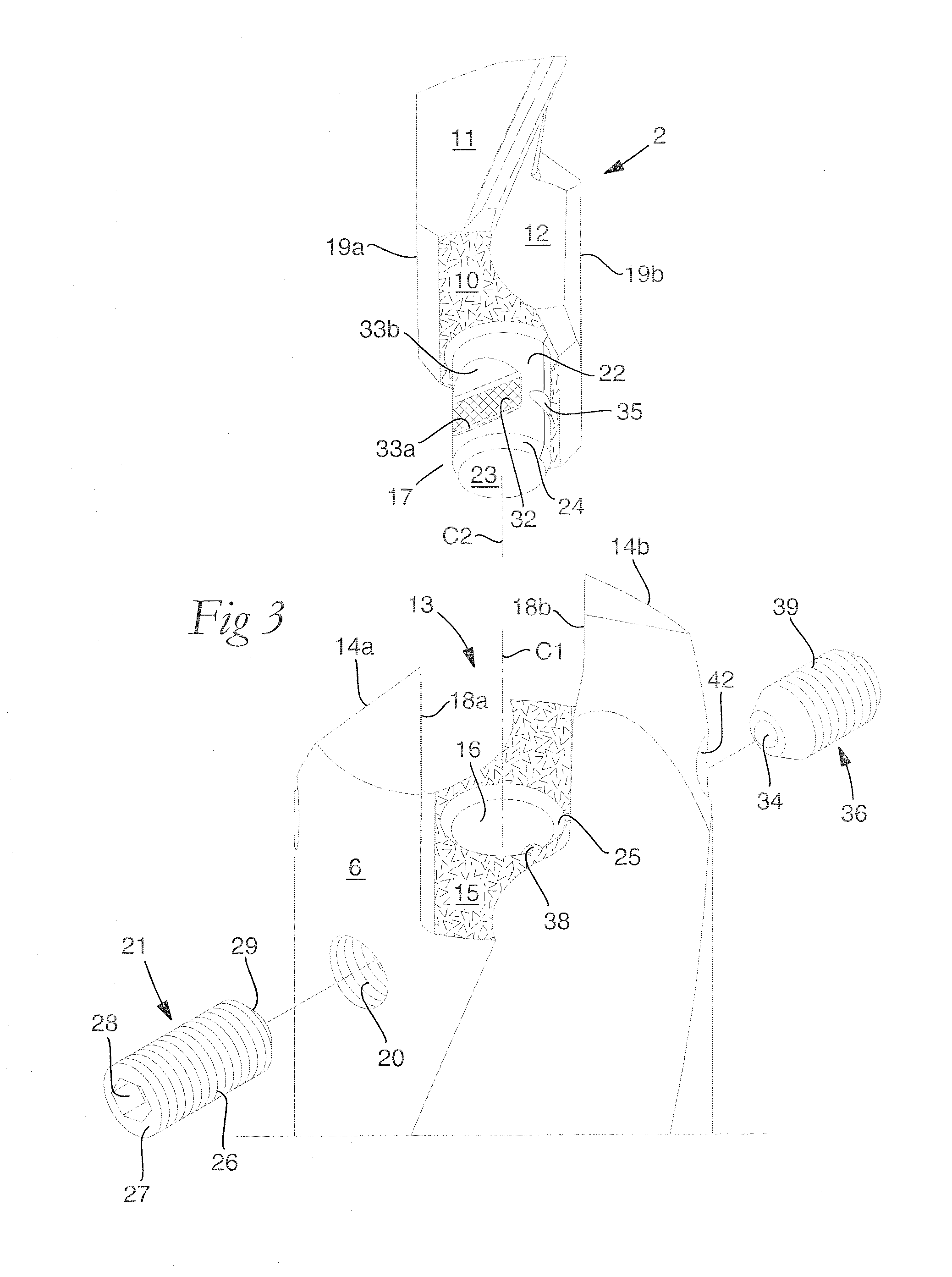

Rotatable tool for chip removing machining as well as a loose top and a basic body therefor

InactiveUS20110110739A1Convenient and quick and reliable wayThread cutting toolsWood turning toolsEngineeringFront and back ends

A rotatable tool for chip removing machining, including a basic body having front and rear ends between which a first center axis extends with which an envelope surface is concentric, the front end including a jaw delimited by two torque-transferring drivers and an intermediate bottom in which a center hole extending axially inside the basic body mouths, and a bore for a locking screw extending radially between the center hole and the envelope surface. A loose top has front and rear ends between which a second center axis extends, in the extension of which a pin protruding from the rear end extends that is delimited by a free end surface and an envelope surface in which a shoulder surface is included for the locking screw arranged in the radial bore. A countersink axially spaced apart from the end surface is formed in the envelope surface of the pin of the loose top for the receipt of a snap-in member arranged along the inside of the center hole to provisionally clamp the pin in the center hole when the locking screw is not tightened.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

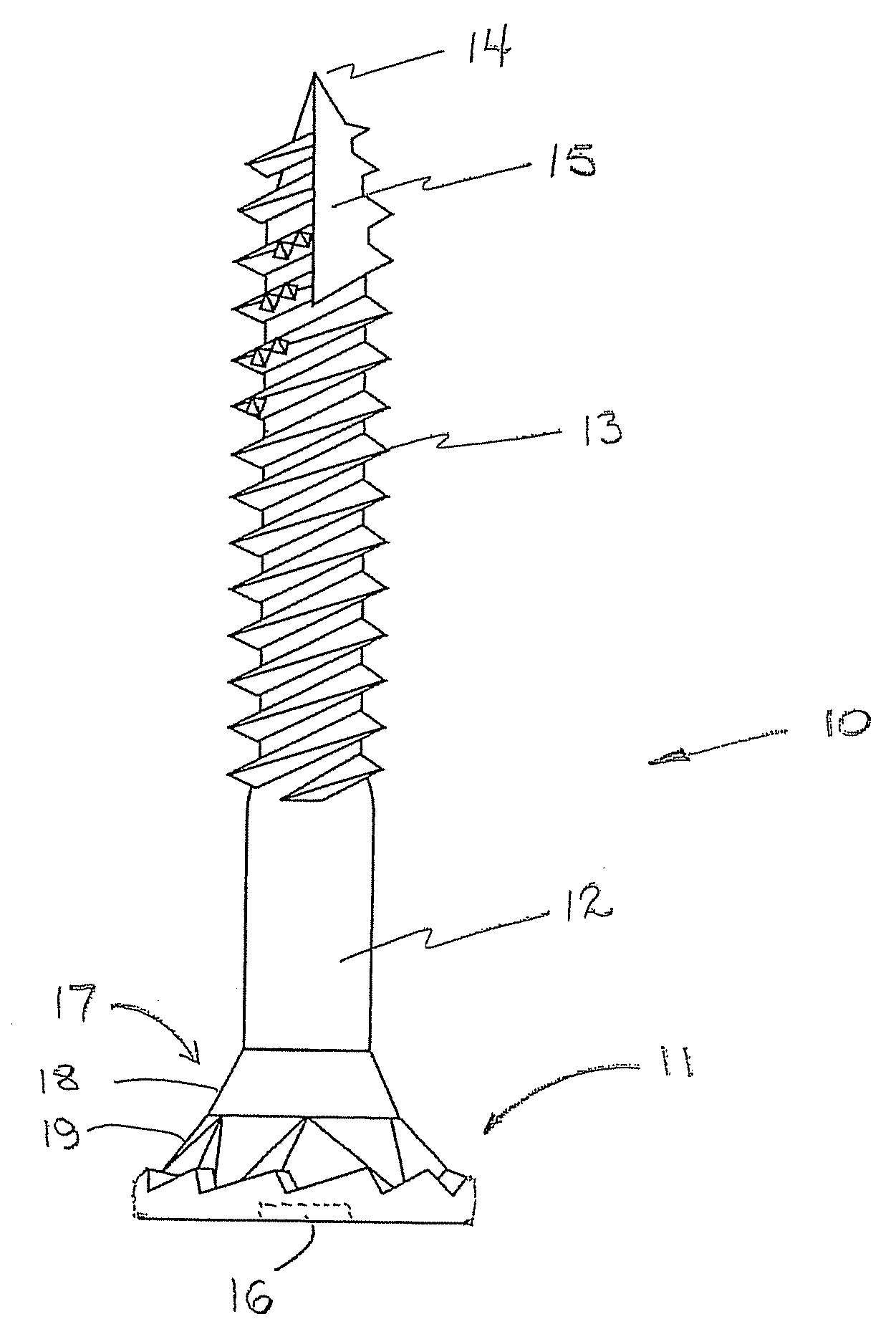

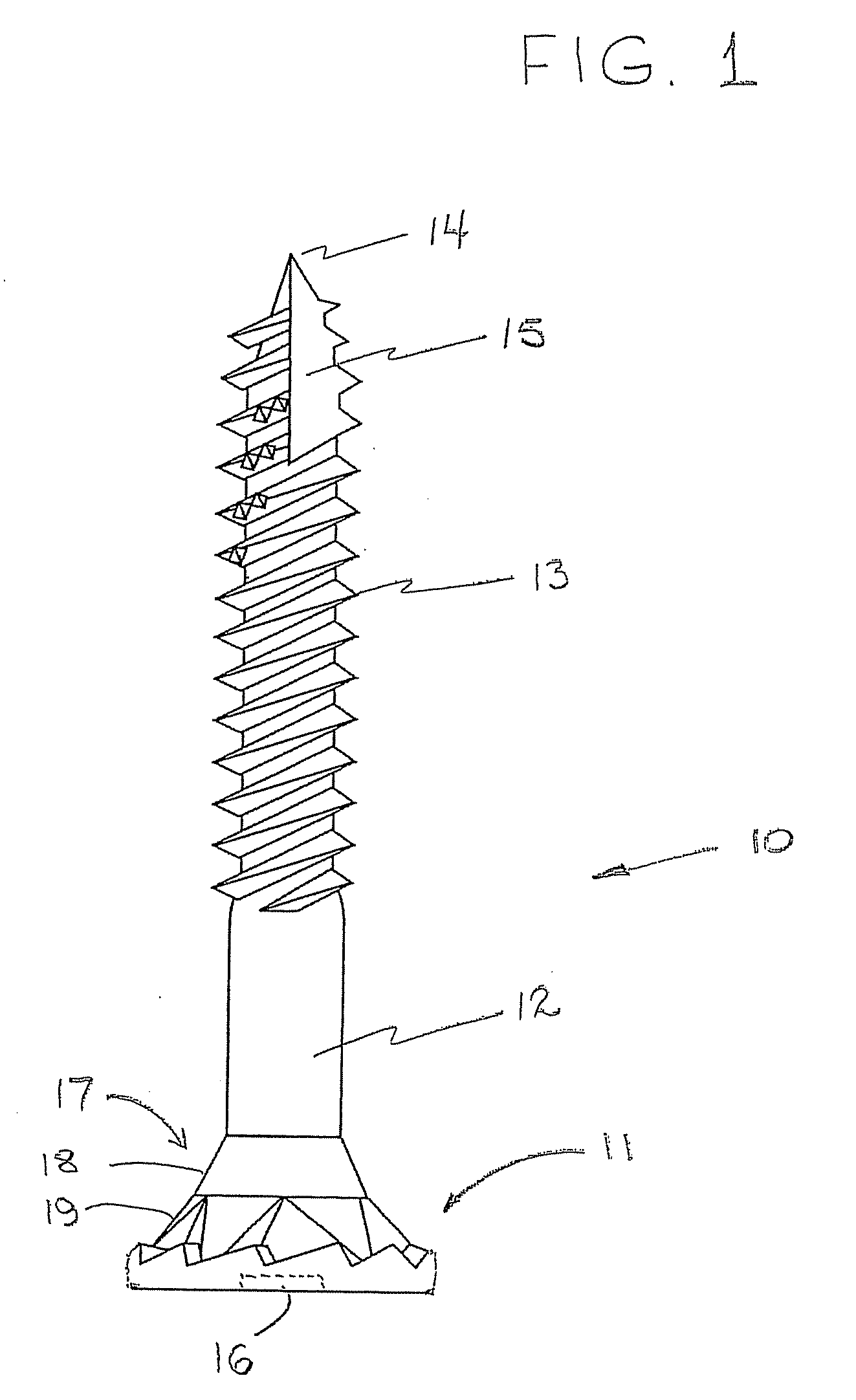

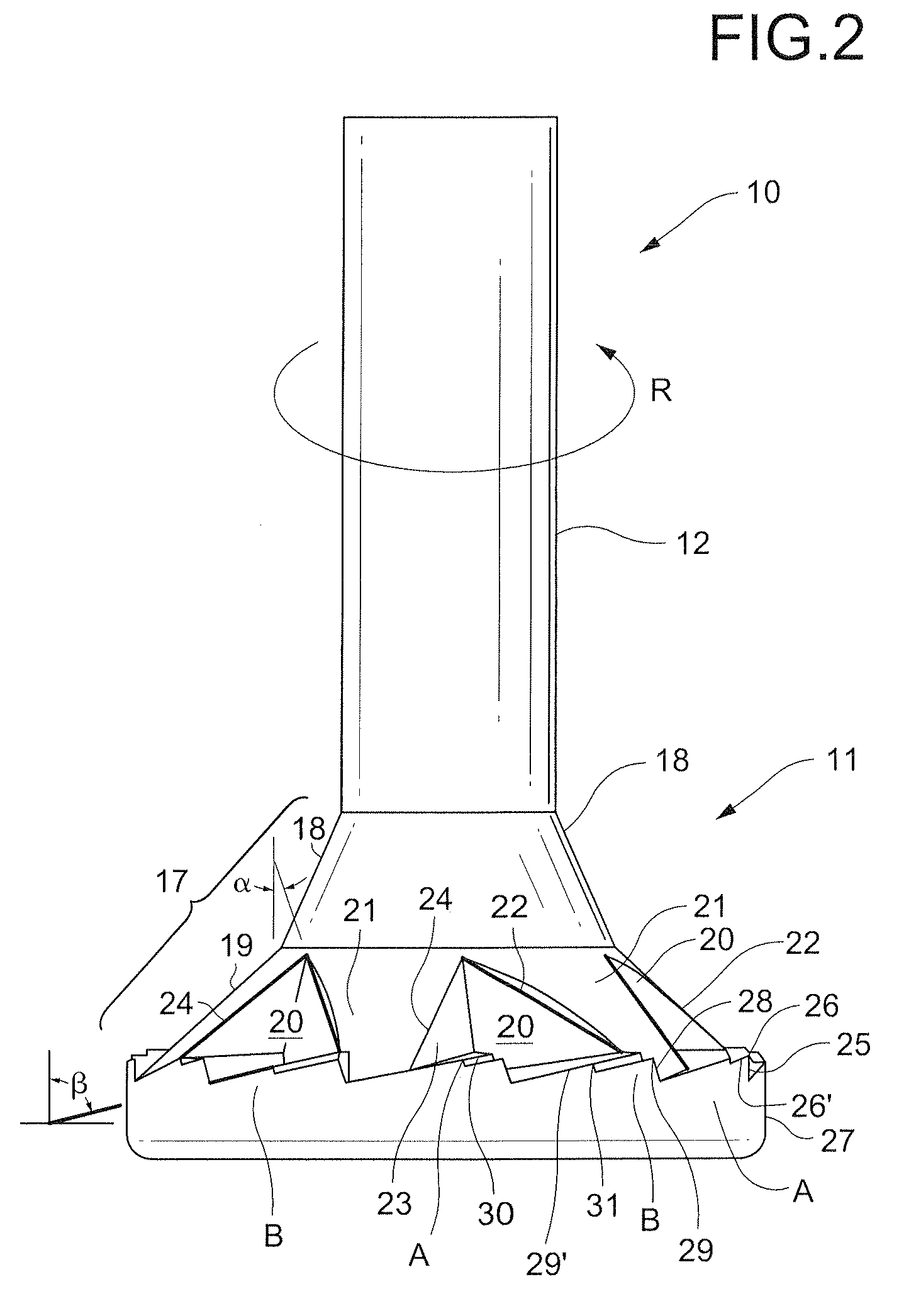

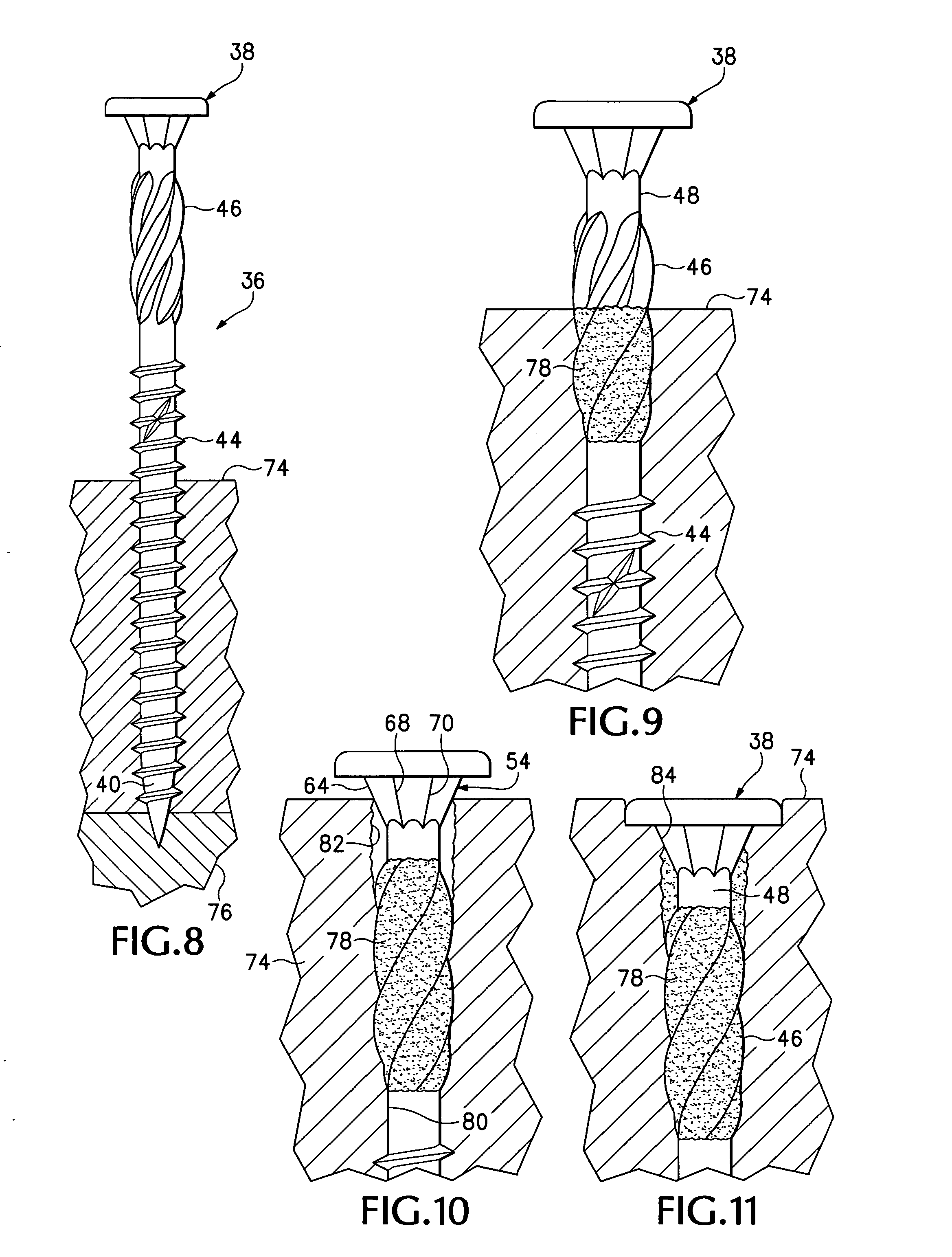

Self-Counter-Sinking Screw with Circumferential Cutters

Owner:ILLINOIS TOOL WORKS INC

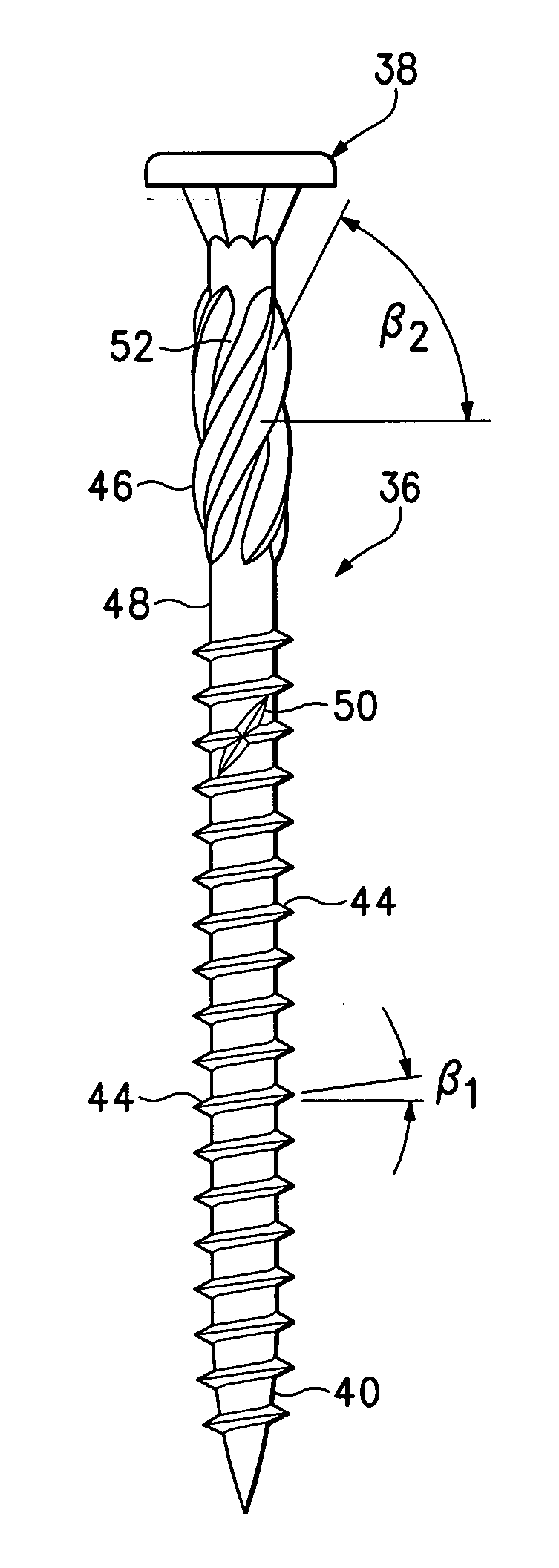

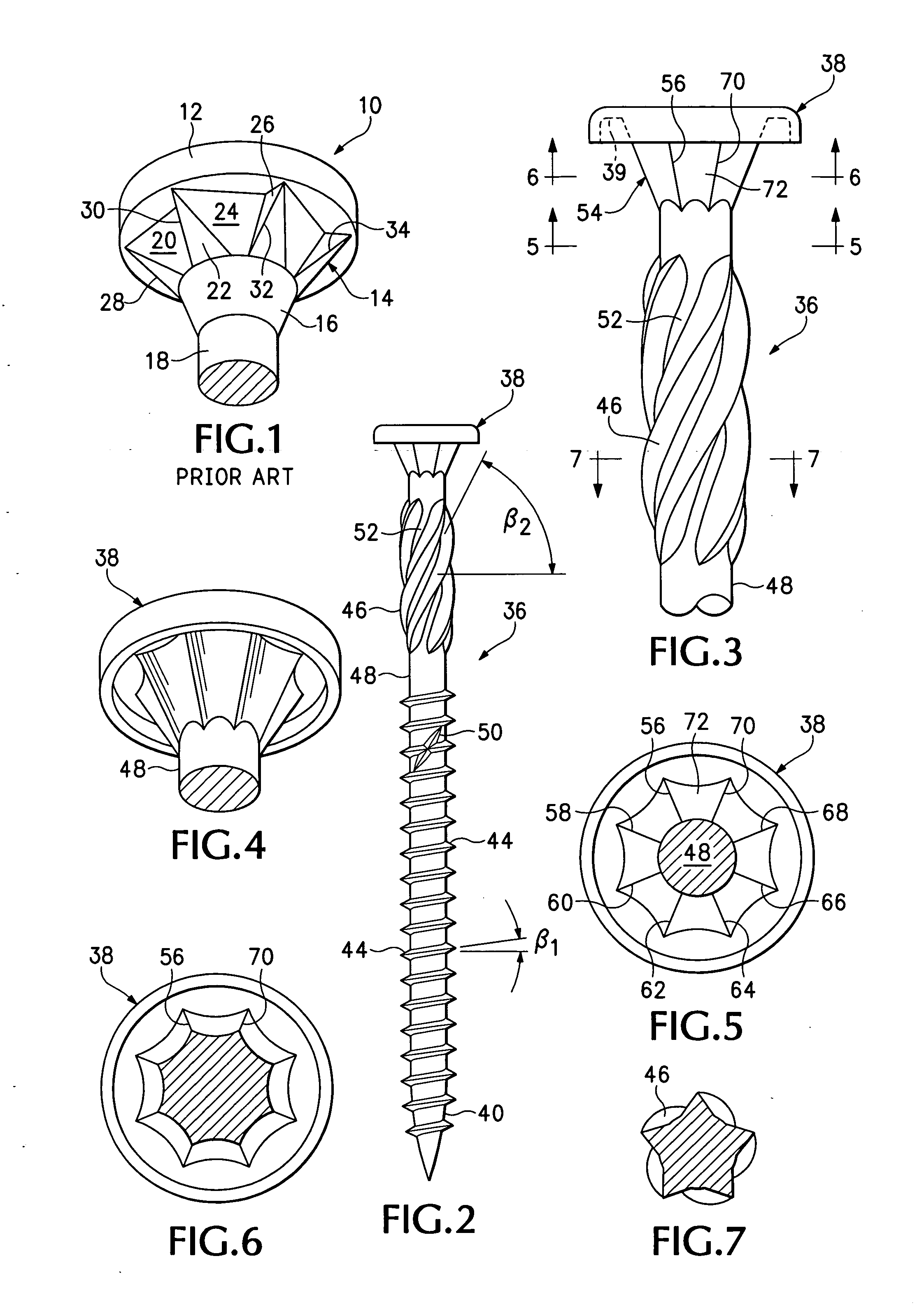

Screw for composite building materials

A screw includes a lower set of cutting threads and an upper set of storage threads, the latter having a larger diameter than the cutting threads. The underside of the head includes an annular groove formed thereabout. A countersink feature is disposed between the underside of the head and the shaft of the screw. It includes a plurality of cutting ribs and a curved surface disposed between each rib pair thereby defining a groove. When the screw is installed in a composite wood-plastic material, cuttings cut by the cutting threads move upwardly and are stored between adjacent storage threads. Material cut by the countersink feature is pushed down the grooves. A space between the countersink feature and the storage threads provides additional room for storing cuttings. As a result, cuttings are retained in the bore thus preventing bulging of the surface around the bore.

Owner:YAO SEIBYO

Can end

ActiveUS20050115976A1Refuse receptaclesContainer/bottle contructionEngineeringUltimate tensile strength

A can end having a countersink bead, an inclined chuck wall and a strong seam, resists distortion from its circular profile when subjected to thermal processing or when packaging carbonated beverages. This high hoop strength affects the manner in which the can end ultimately fails when placed under extreme abuse conditions, even if buckle pressure performance is within industry specified standards. The can end of the invention has control features introduced which control the failure mode whilst maintaining specified buckle pressure performance. In one embodiment, the can end has a two part wall and a control feature that comprises expansion of the countersink bead to act as a trigger for local peaking, together with a groove in the chuck wall which prevents the peaking force from being concentrated at a single point which could result in leaking by the production of a pin hole.

Owner:CROWN PACKAGING TECH

Universal, multifunctional, single unit, rotary osteotome

InactiveUS7547210B1Precise positioningReduce crestal bone heightDental implantsTeeth fillingSurgical dentistrySurgical department

A multifunctional surgical rotary instrument with a corrosion resistant wear reducing hard coating, to be used in a surgical dental motor driven handpiece for preparing an osteotomy for implant insertion, combining the functions of six surgical instruments is described. The multifunctional surgical rotary instrument has structural features that provide the functions of a crestal bone height reducer, an osteotomy locator, an osteotomy lateral redirector, osteotomy drill, tapered countersink, and an osteocompressor. These structural features include a dual-lobed single plane tip that remains where the drilling is initiated without wandering, and facilitates the precise location of the osseous implant site. Advantageously, the instrument can save time and cost in the implant procedure.

Owner:IMPLADENT

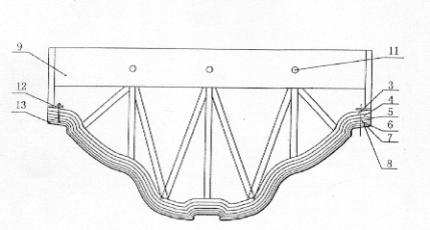

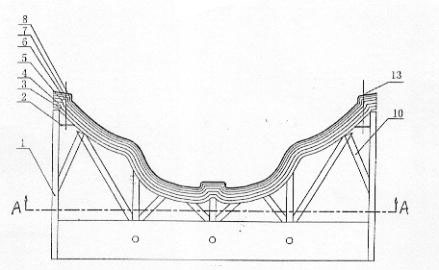

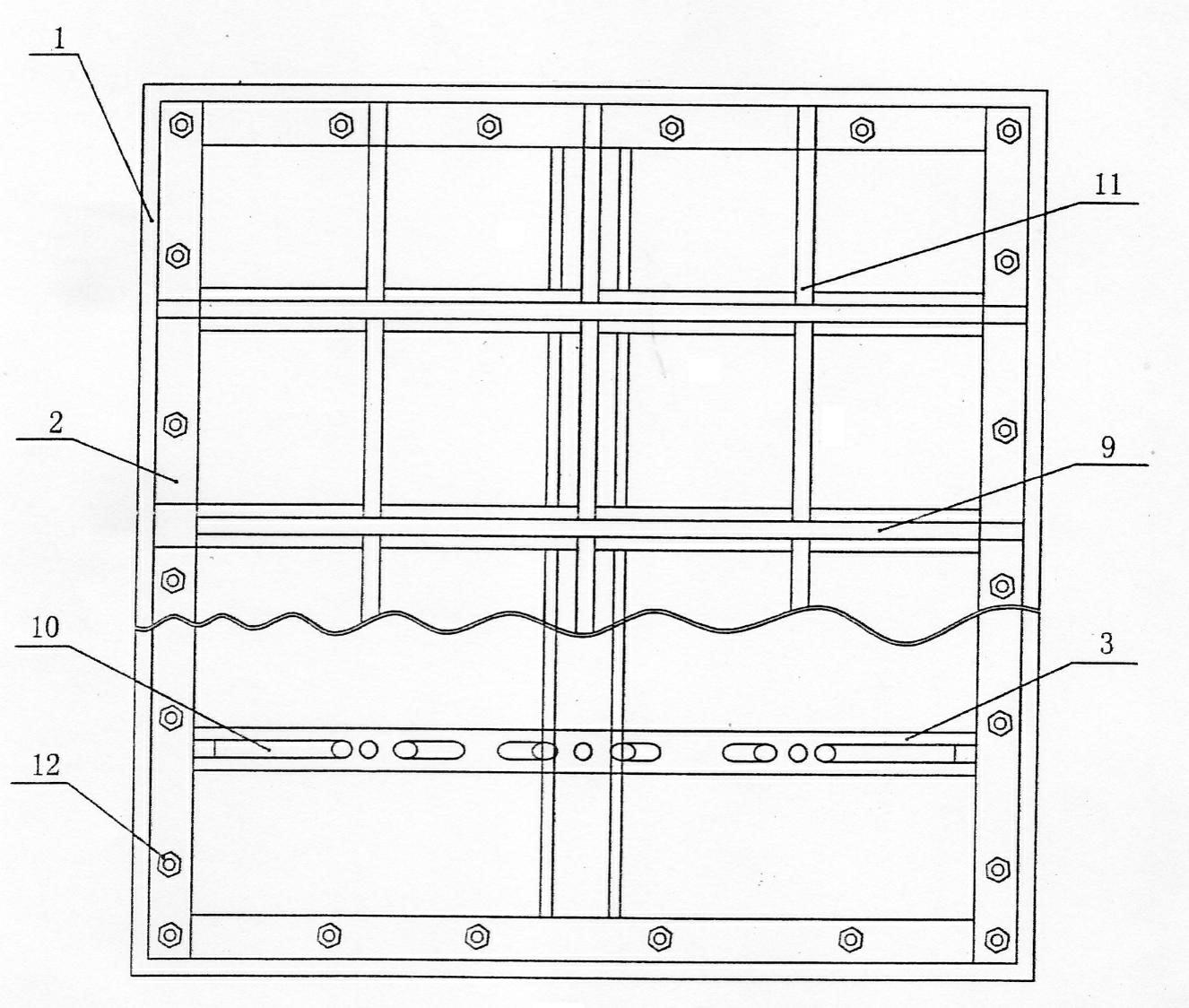

Manufacturing method for glass fiber reinforced plastic pressing mould

The invention provides a manufacturing method for a glass fiber reinforced plastic pressing mould. Unsaturated polyester resin and glass fibers are used as main materials for the pressing mould, and steel is used as a framework to fix the pressing mould. The manufacturing method comprises the following steps: fabricating a wood mould or a plaster mould according to product design requirements; brushing a gel coating on the waxed mould; pasting alkali-free surfacing mat, with an impregnating compound being an S-904 resin mixture; pasting alkali-free chopped strands of the glass fibers; pasting medium-alkali glass fiber plaid; pasting a plurality of layers of medium-alkali glass fiber plaid, with an impregnating compound being an S-685 resin mixture; pasting a plurality of layers of medium-alkali glass fiber plaid again, with an impregnating compound being an S-191 resin mixture, so as to finish fabrication of the glass fiber reinforced plastic pressing mould. According to needs of the mould, the framework for the mould is welded, flat steel and support are installed, and the glass fiber reinforced plastic pressing mould is fixed on the framework for the mould by using countersink bolts. According to the invention, manufacturing cost for the glass fiber reinforced plastic pressing mould is low, readjusting and remodification of the mould can be carried out, and products capable of satisfying current performance requirements for interior decorative parts for automobiles can be produced.

Owner:GUIZHOU HUAYUN AUTOMOBILE DECORATING PART MFG CO LTD

Can end

InactiveUS20100044383A1Refuse receptaclesContainer/bottle contructionUltimate tensile strengthDistortion

A can end having a countersink bead, an inclined chuck wall and a strong seam, resists distortion from its circular profile when subjected to thermal processing or when packaging carbonated beverages. This high hoop strength affects the manner in which the can end ultimately fails when placed under extreme abuse conditions, even if buckle pressure performance is within industry specified standards. The can end of the invention has control features introduced which control the failure mode whilst maintaining specified buckle pressure performance. In one embodiment, the can end has a two part wall and a control feature that comprises expansion of the countersink bead to act as a trigger for local peaking, together with a groove in the chuck wall which prevents the peaking force from being concentrated at a single point which could result in leaking by the production of a pin hole.

Owner:CROWN PACKAGING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com