Manufacturing method for glass fiber reinforced plastic pressing mould

A technology of pressing mold and production method, applied in the field of glass fiber reinforced plastic pressing mold production, can solve problems such as the inability of steel mold to meet, and achieve the effects of heat insulation performance surface technology, light quality and good surface technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

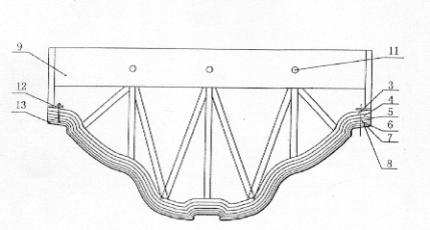

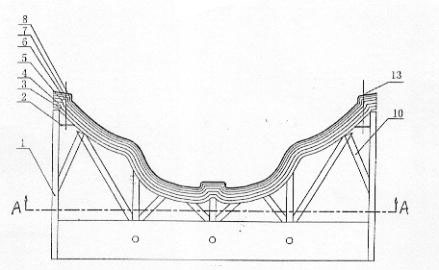

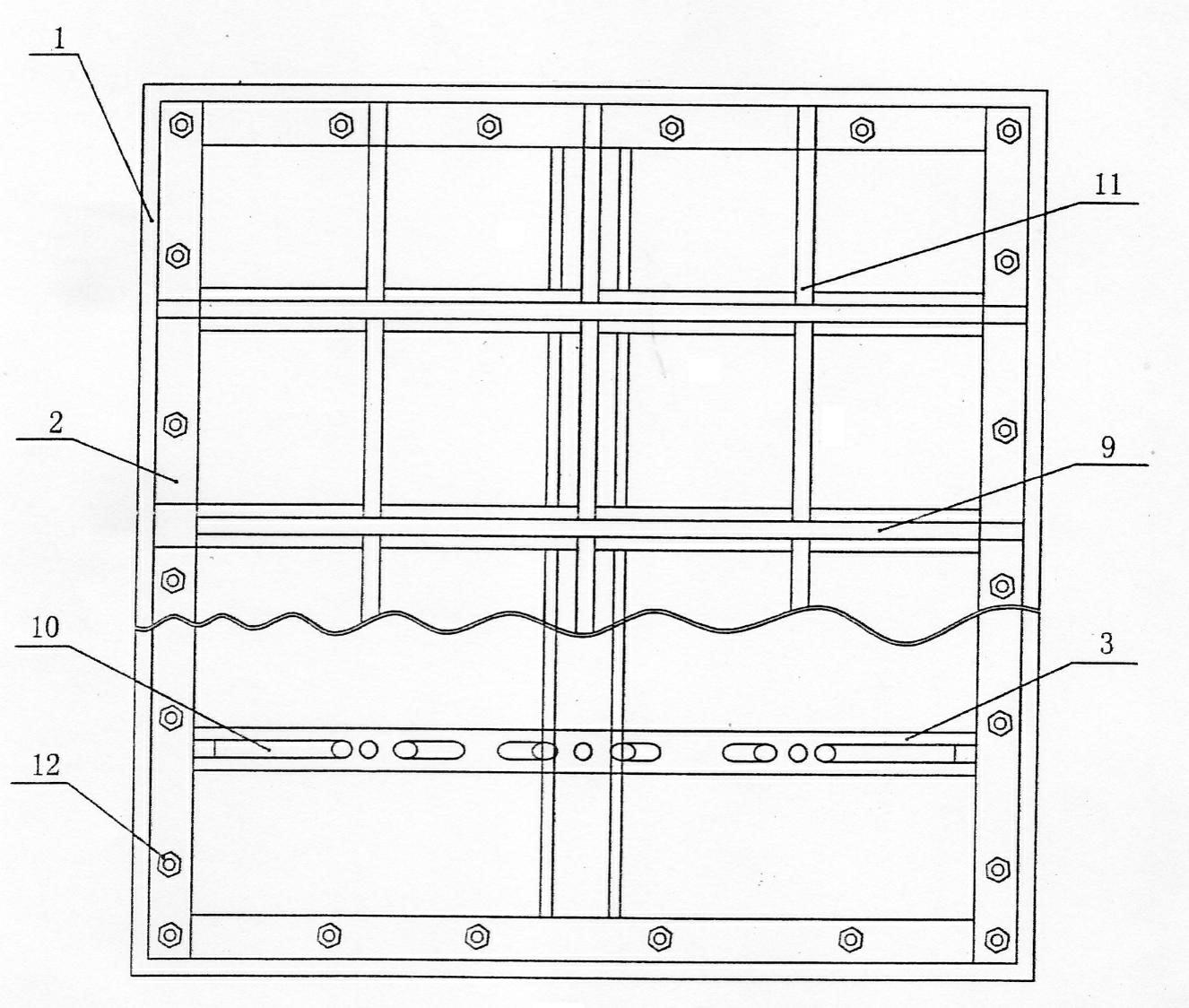

[0030] Such as Figure 1-3 Shown, a kind of glass fiber reinforced plastics pressing mold manufacturing method, this mold is by unsaturated polyester resin and glass fiber as the main material of mold, adopts steel as frame fixed mould, and its manufacturing method is:

[0031] 1. Make a wooden or plaster mold (female or male mold) according to the design requirements of the product, and evenly apply the release wax.

[0032] 2. Manually paint the gel coat layer on the waxed mold product. The thickness of the gel coat layer is generally 0.3-0.4mm.

[0033] The gel coat layer needs to be painted twice. The thickness of the first painting is 0.4-0.6mm. After the first layer is cured, the second painting is carried out. The second painting is mainly to make up the gel coat evenly. The thickness of the layer is more uniform, and the thickness is 0.5-0.8mm. Then polish and grind to make the thickness 0.3-0.4mm. The gel coat layer mainly plays the role of beautification and an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com