Three-dimensional bending, twisting and forming die based on multi-point control

A forming die, multi-point control technology, applied in forming tools, manufacturing tools, metal processing equipment and other directions, can solve the problems of high testing cost, long design and production cycle, high manufacturing cost of bending and twisting parts, etc. The effect of reducing manufacturing costs and simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

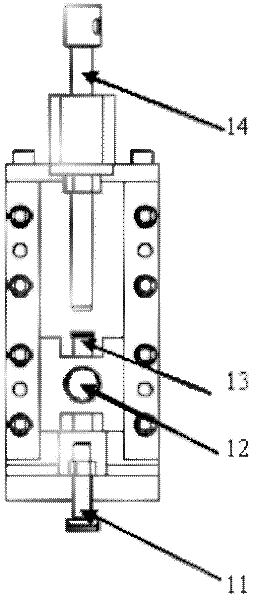

[0014] The present invention adopts the finite element method to divide the forming surface of the stretch bending torsion mold into several sections, and each section is used as a control unit 2 of the forming mold. The main forming parameters such as profile thickness and profile thickness are determined. Each control unit 2 is installed on a standard independent bracket 4, and the control unit 2 is composed of a forming surface slider 9, a guide slider 8, a vertical guide rail 10, a limiting element (pad 6, screw rod 14, horizontal pin 12 , vertical pin 13) and other components. The mold base 1 is provided with several mold base T-shaped slots 3 precisely at equal distances in the longitudinal direction, and the two ends of the bottom plate of the bracket 4 are connected in the T-shaped slots 3 of the mold base by bolts, and guide keys 5 are provided on the bottom plate of the bracket, and the control unit 2 The bracket 4 can move forward and backward along the T-shaped gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com