Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2593 results about "Collet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A collet /ˈkɒlɪt/ is a subtype of chuck that forms a collar around an object to be held and exerts a strong clamping force on the object when it is tightened, usually by means of a tapered outer collar. It may be used to hold a workpiece or a tool.

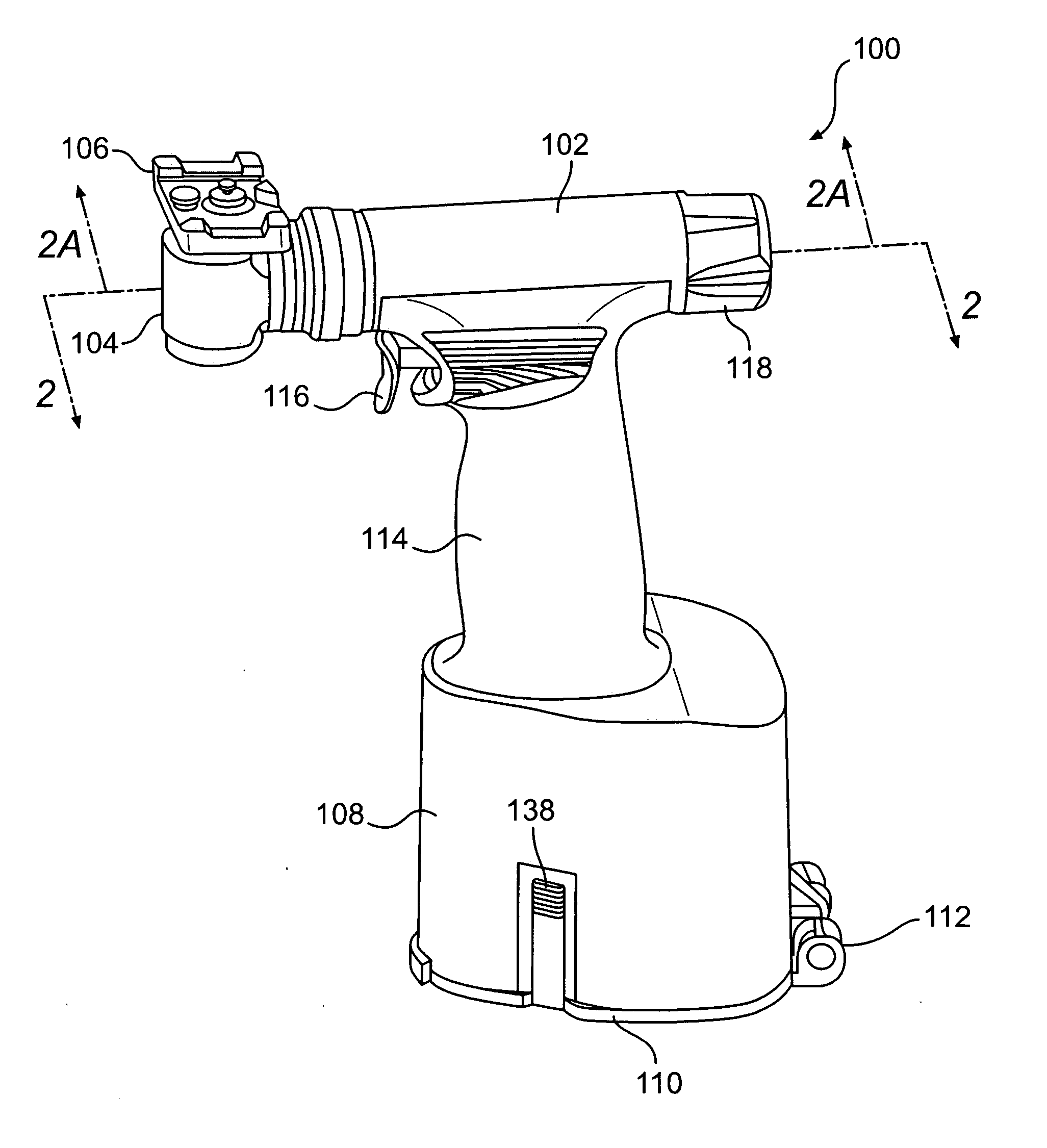

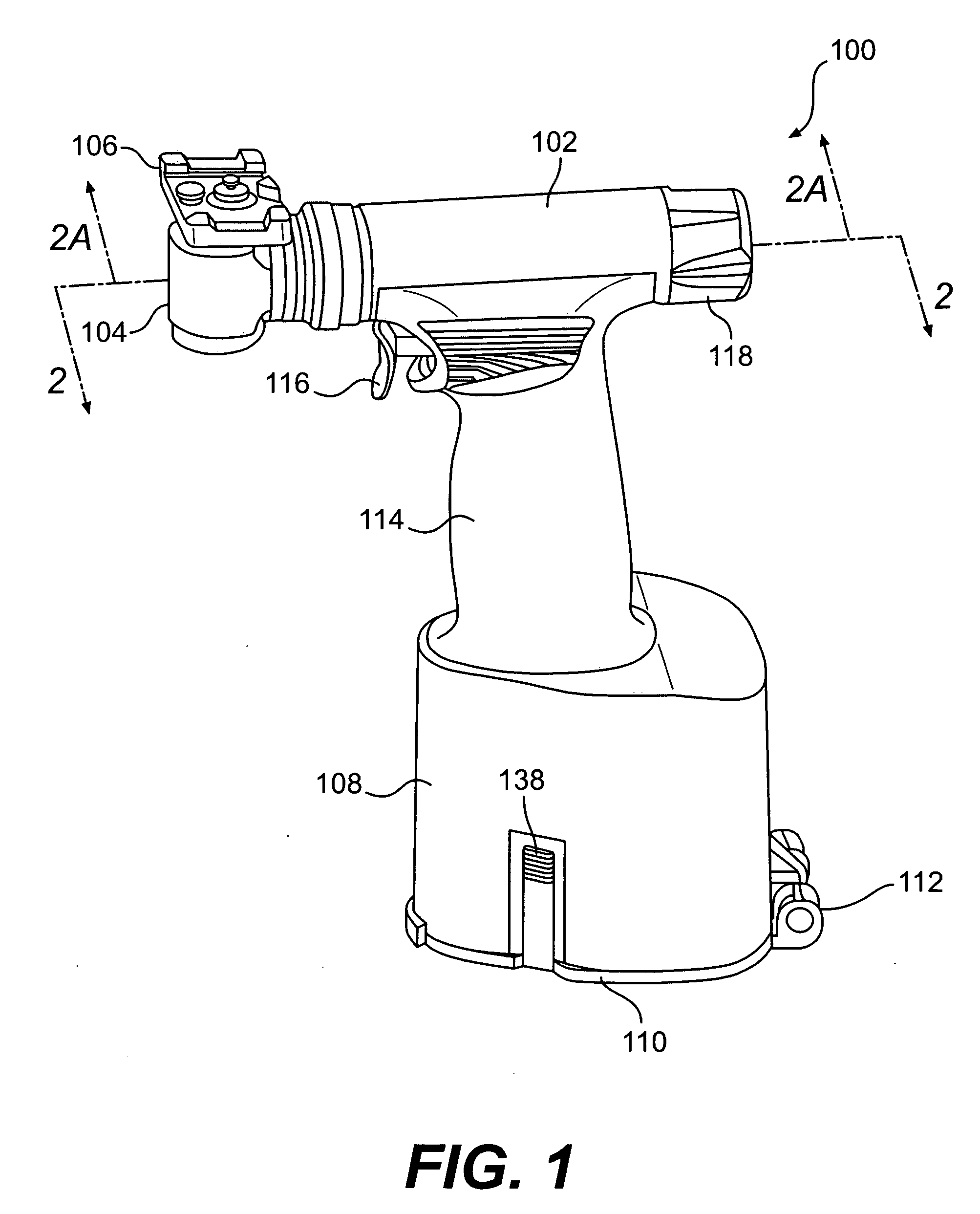

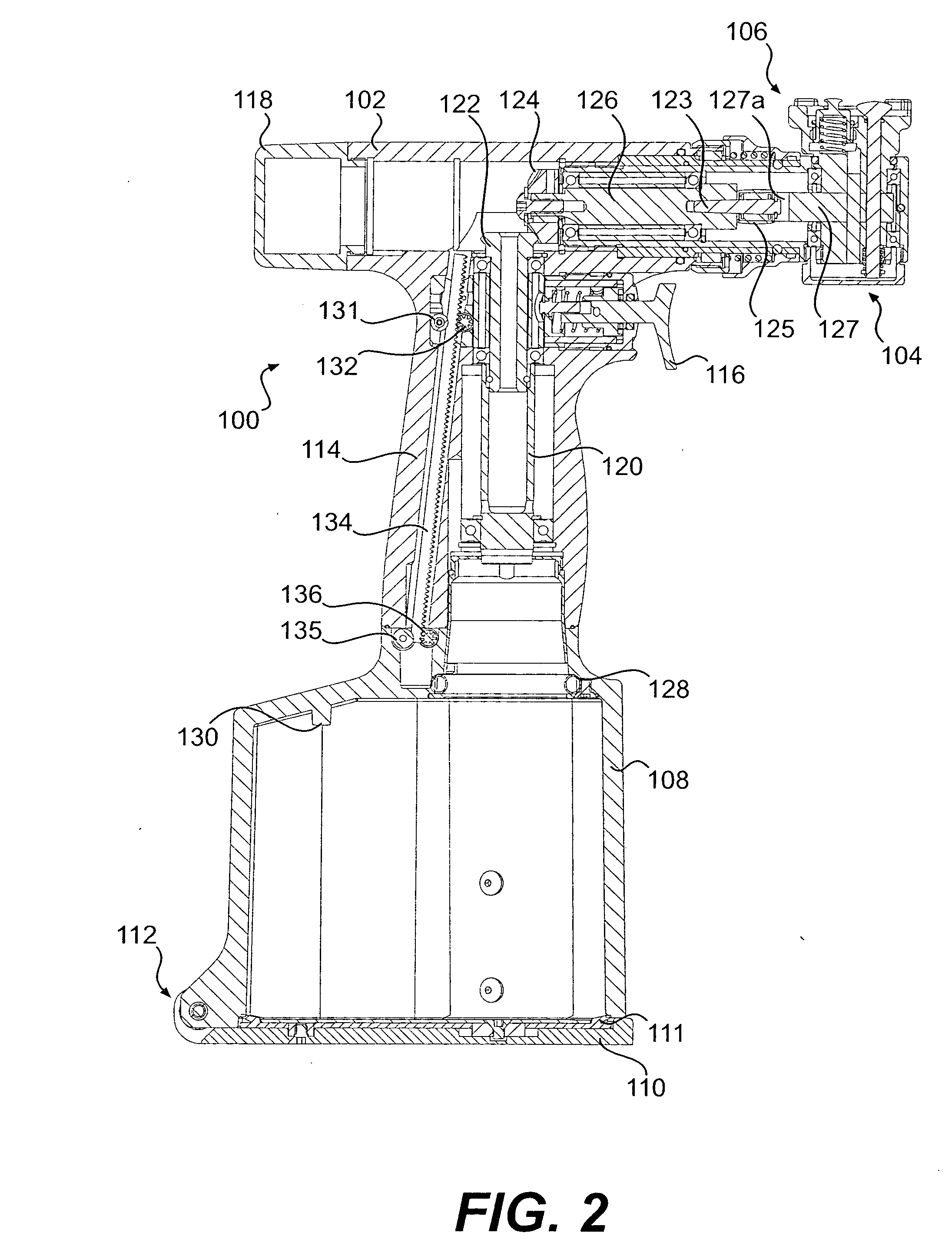

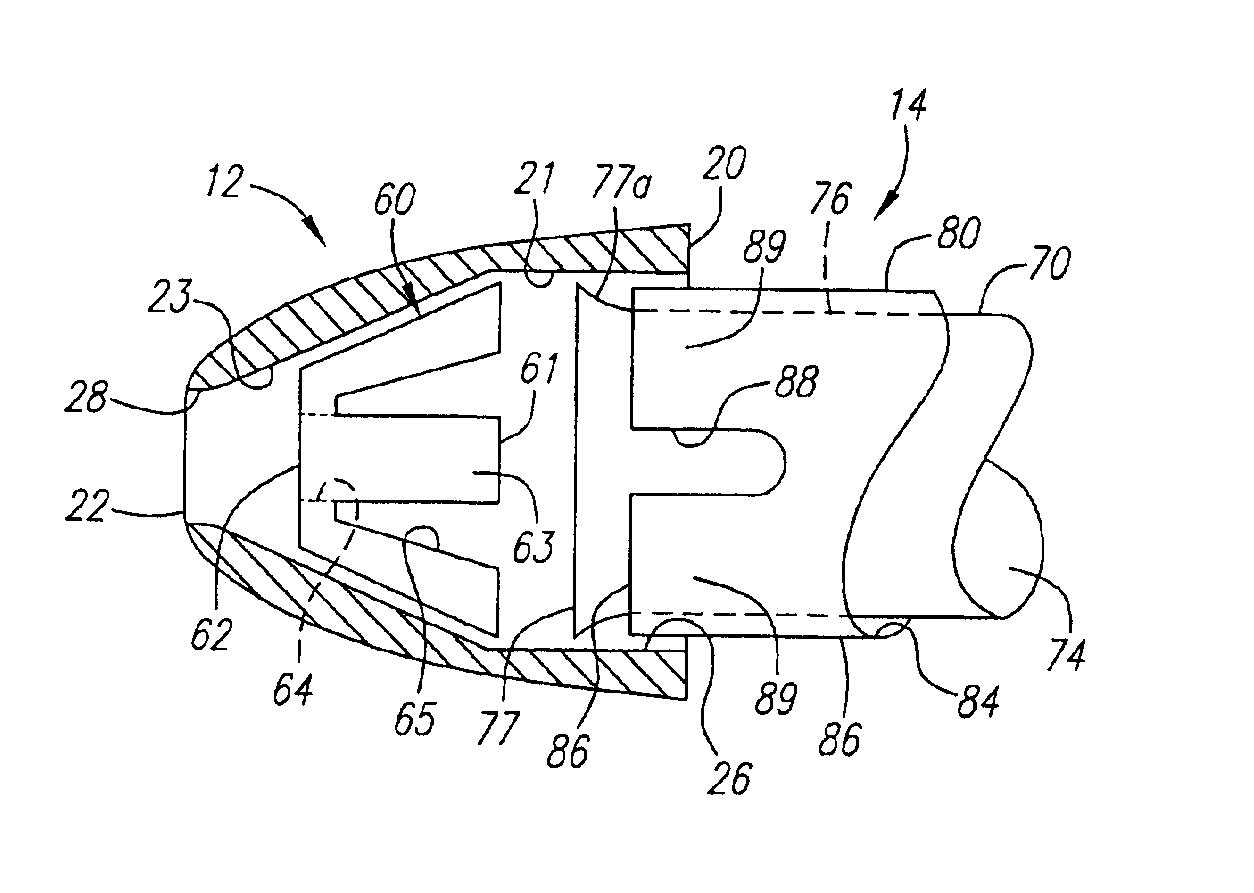

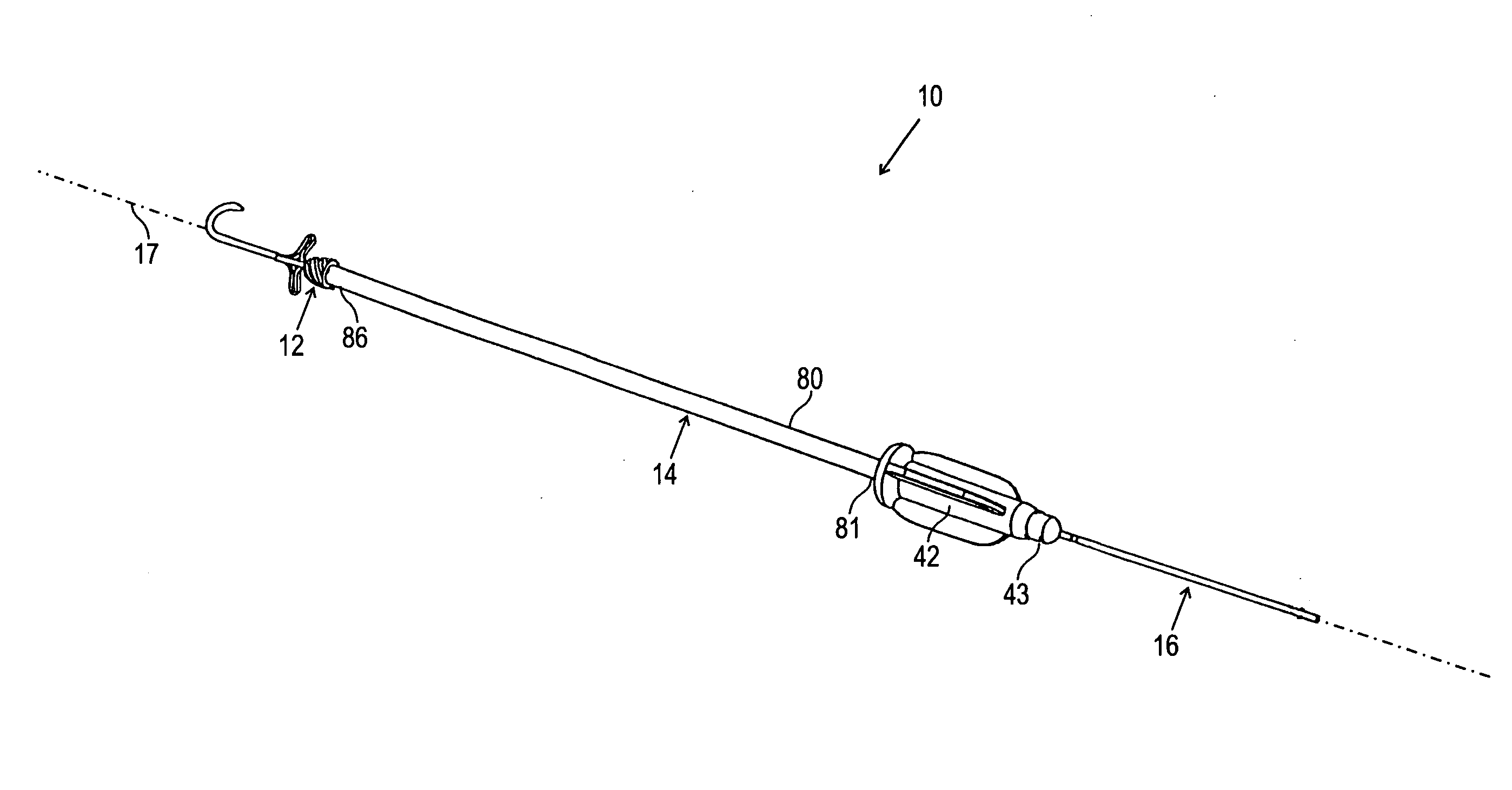

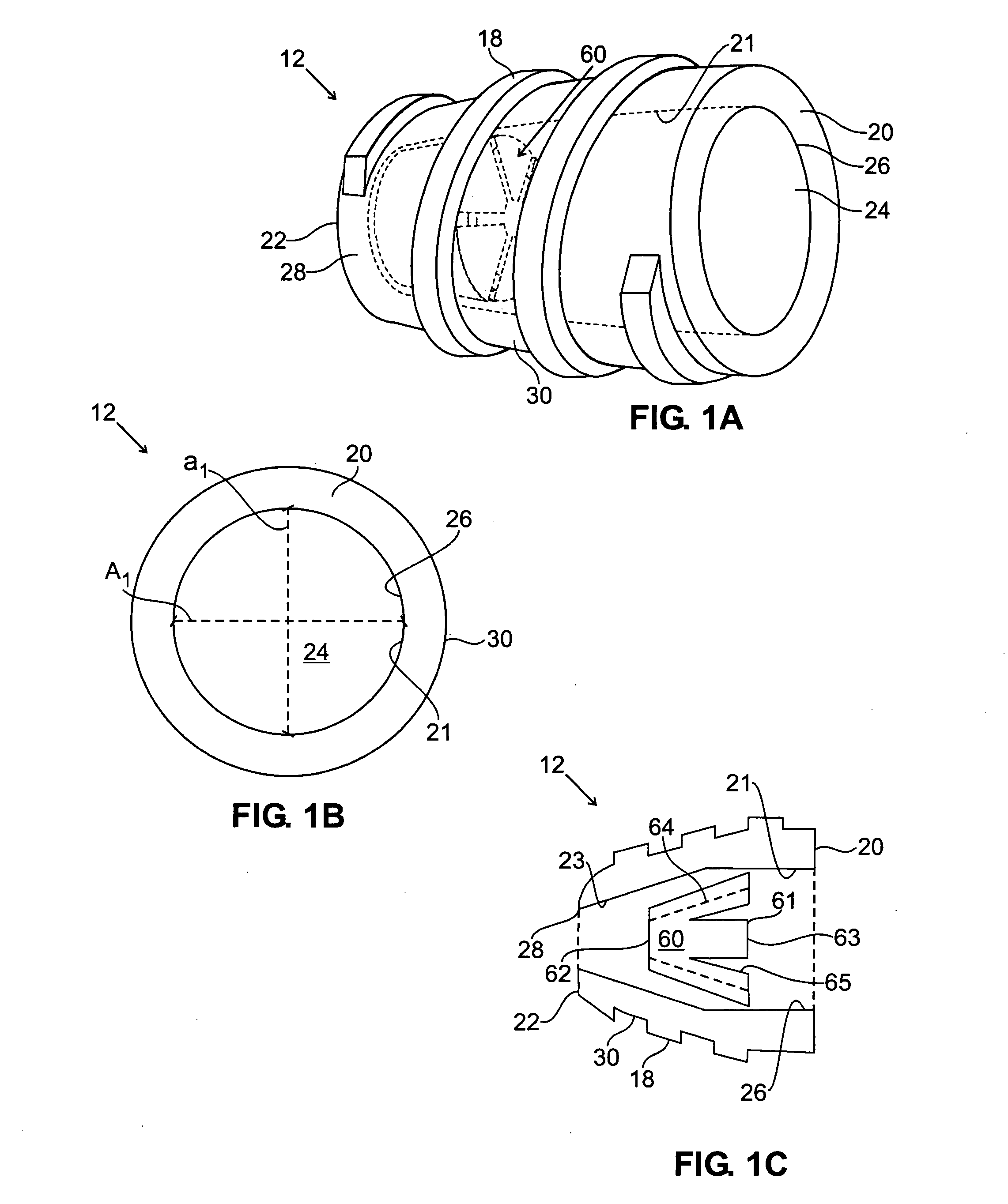

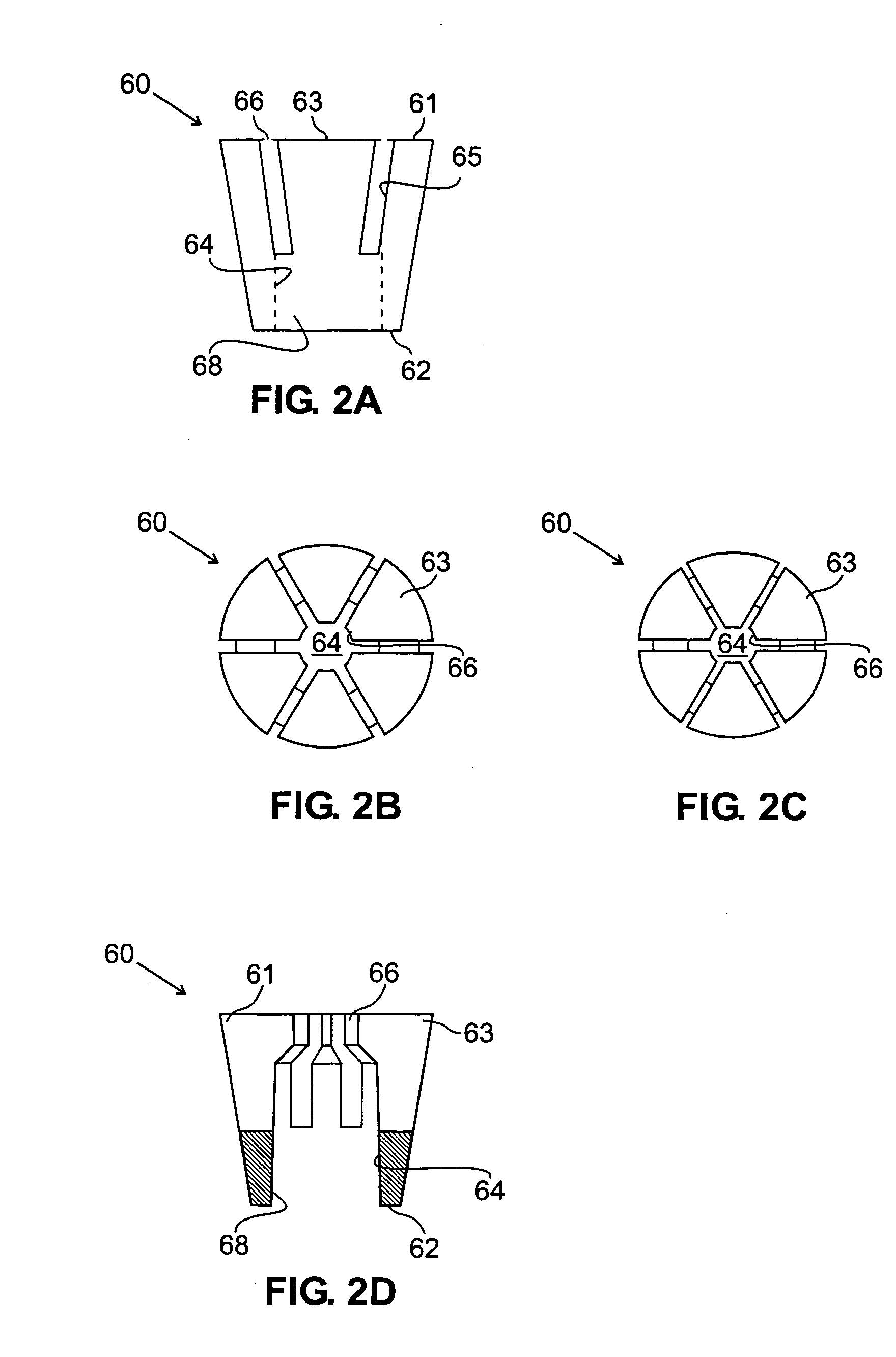

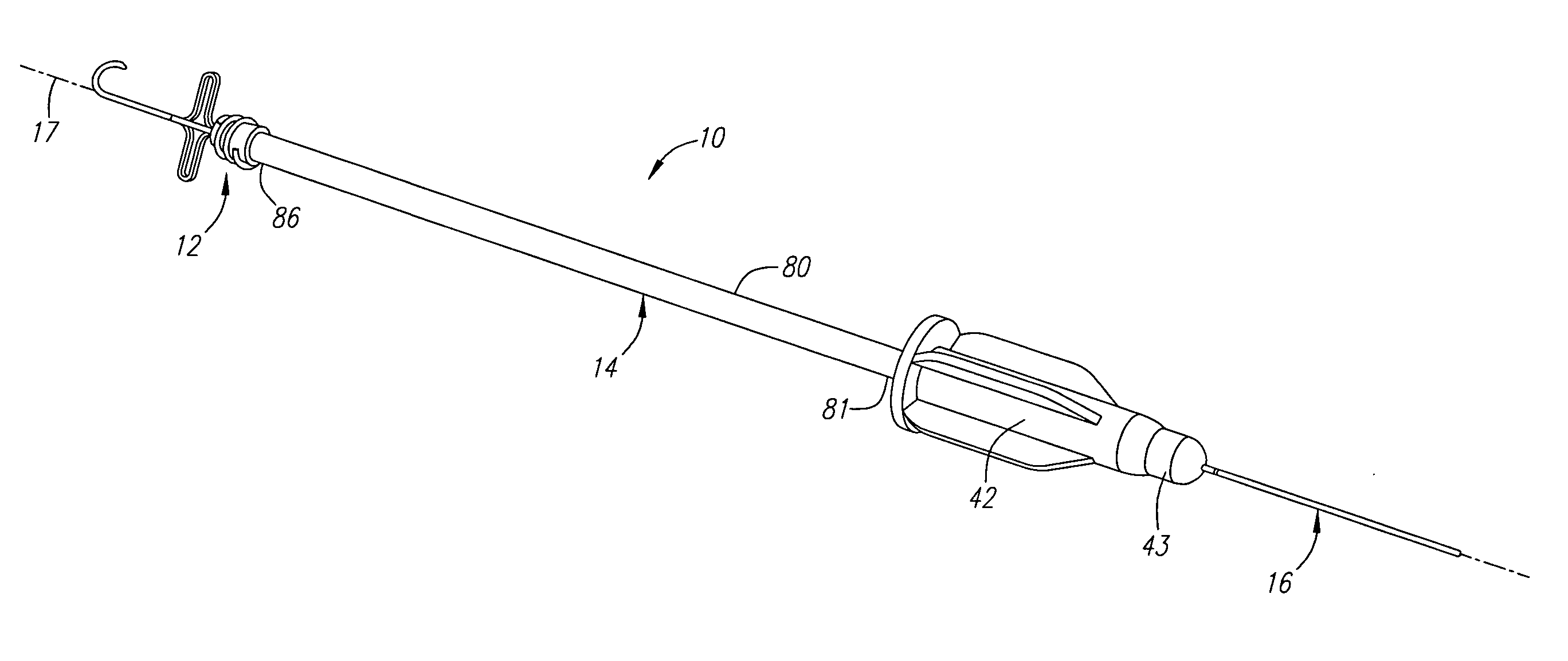

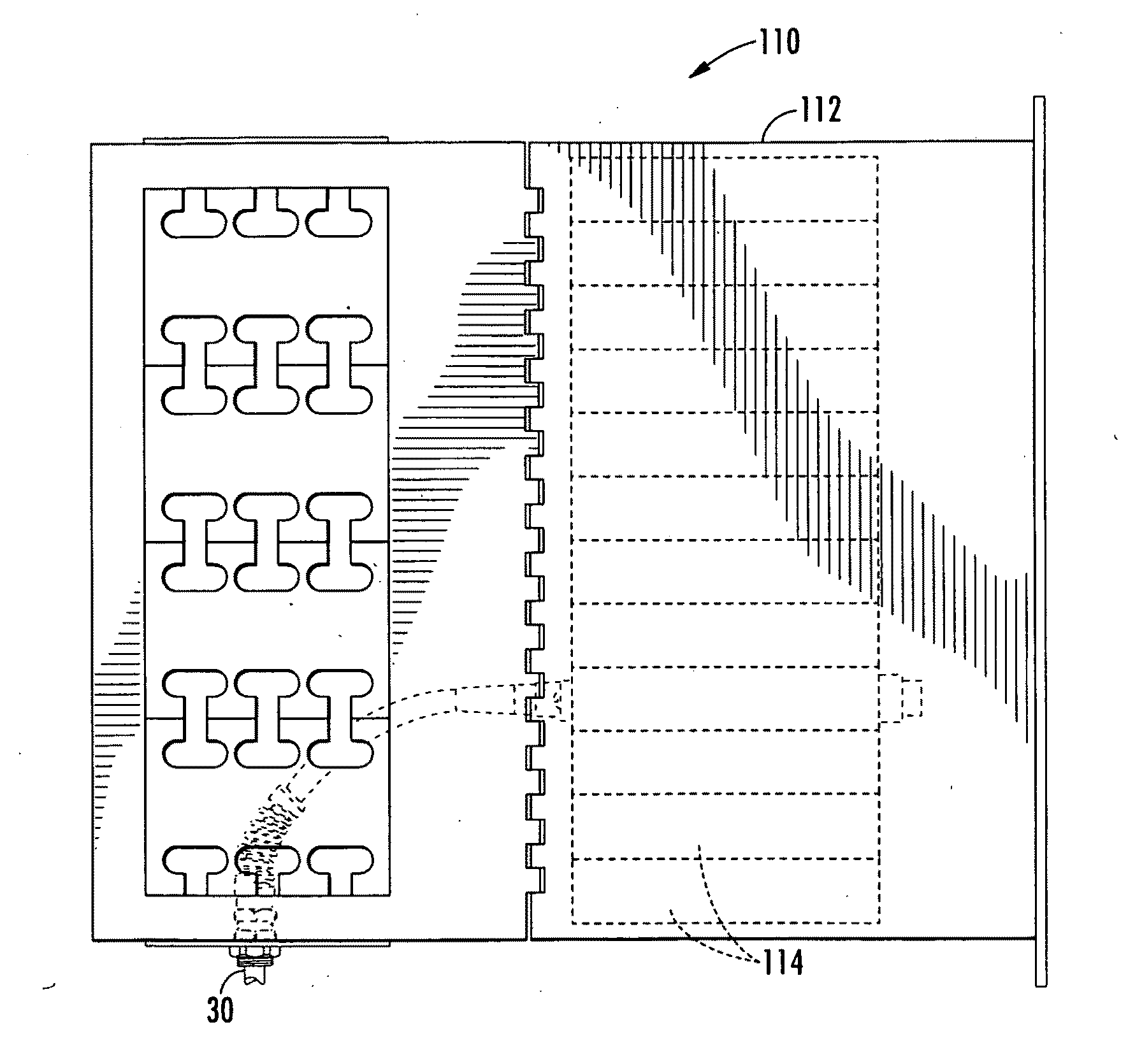

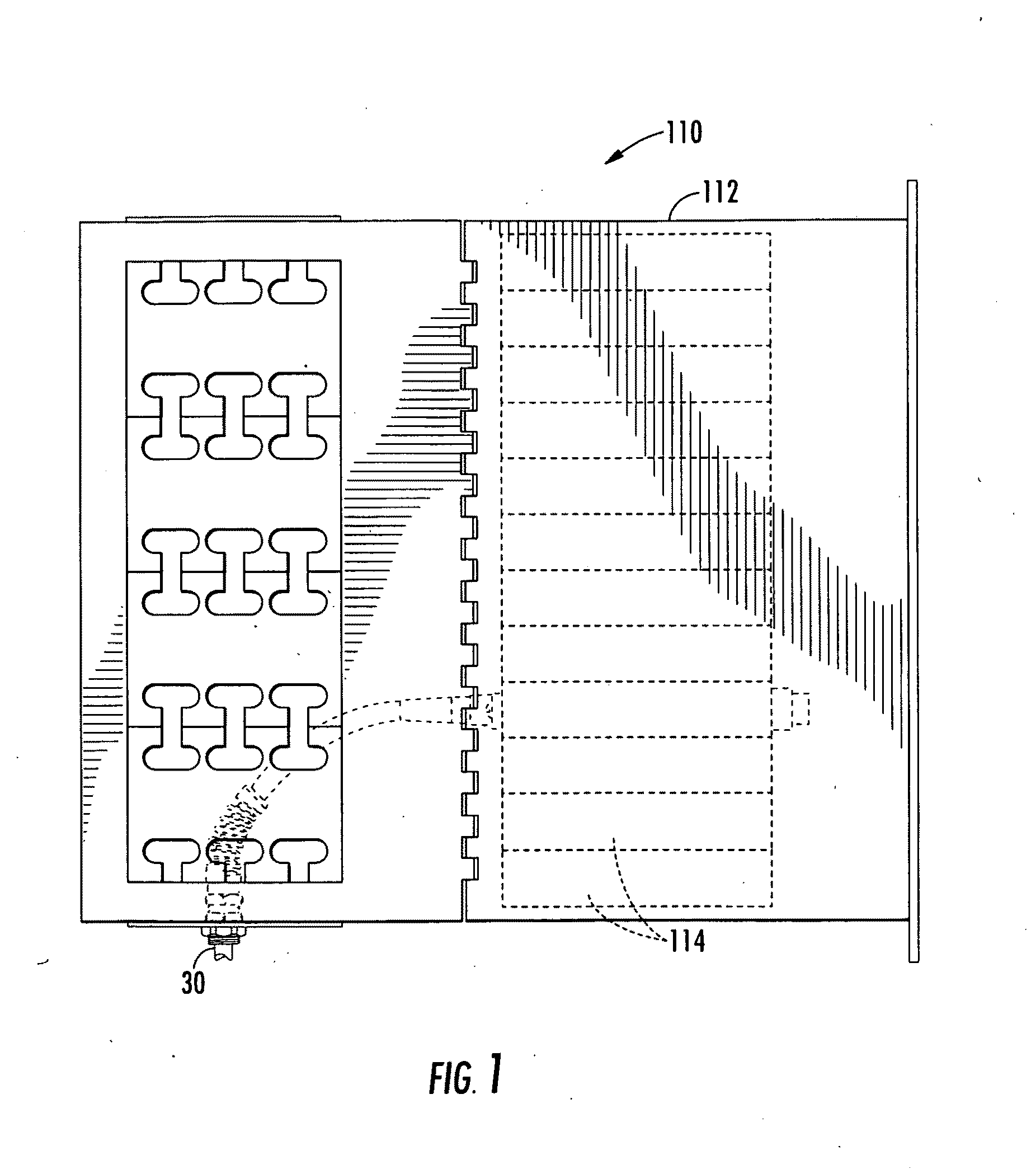

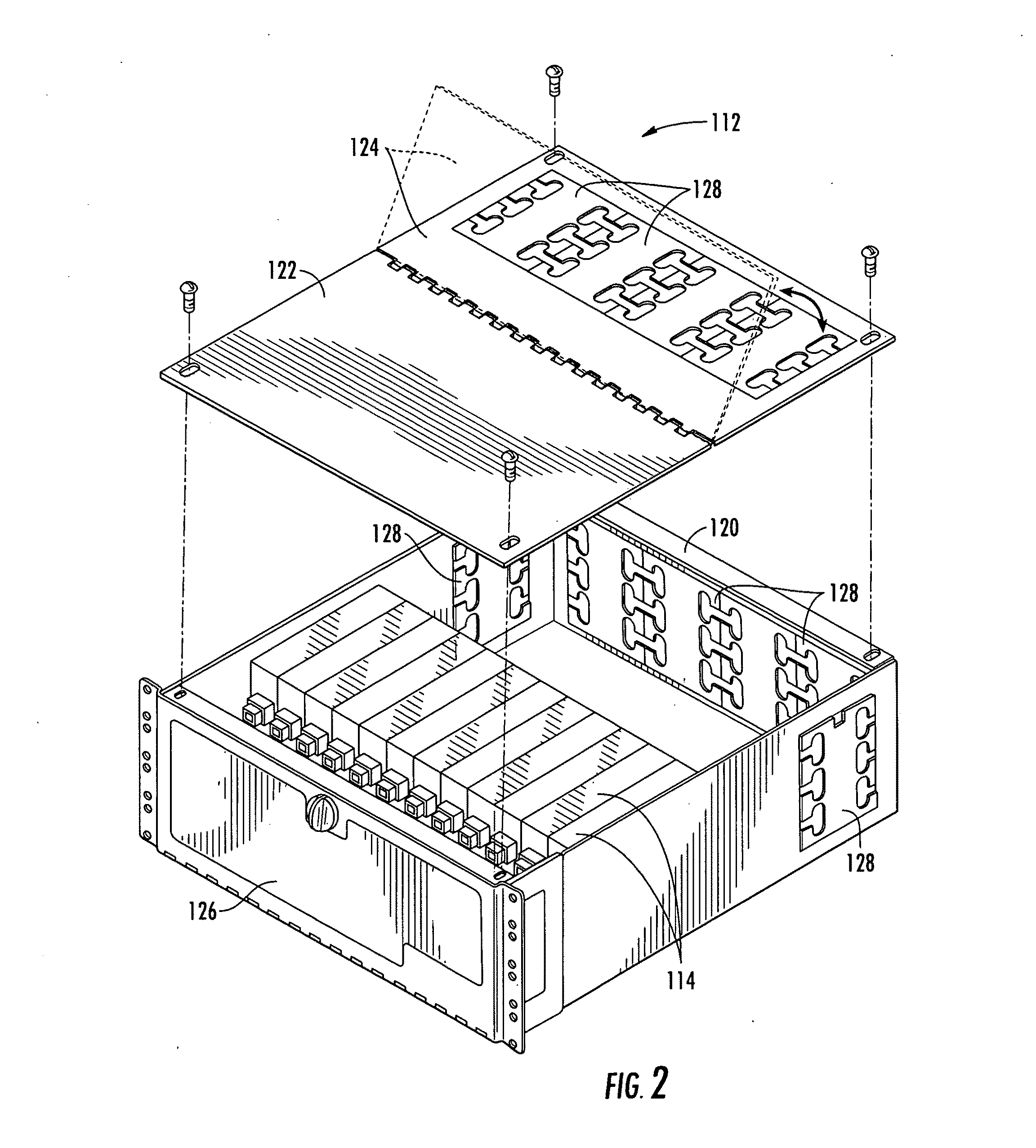

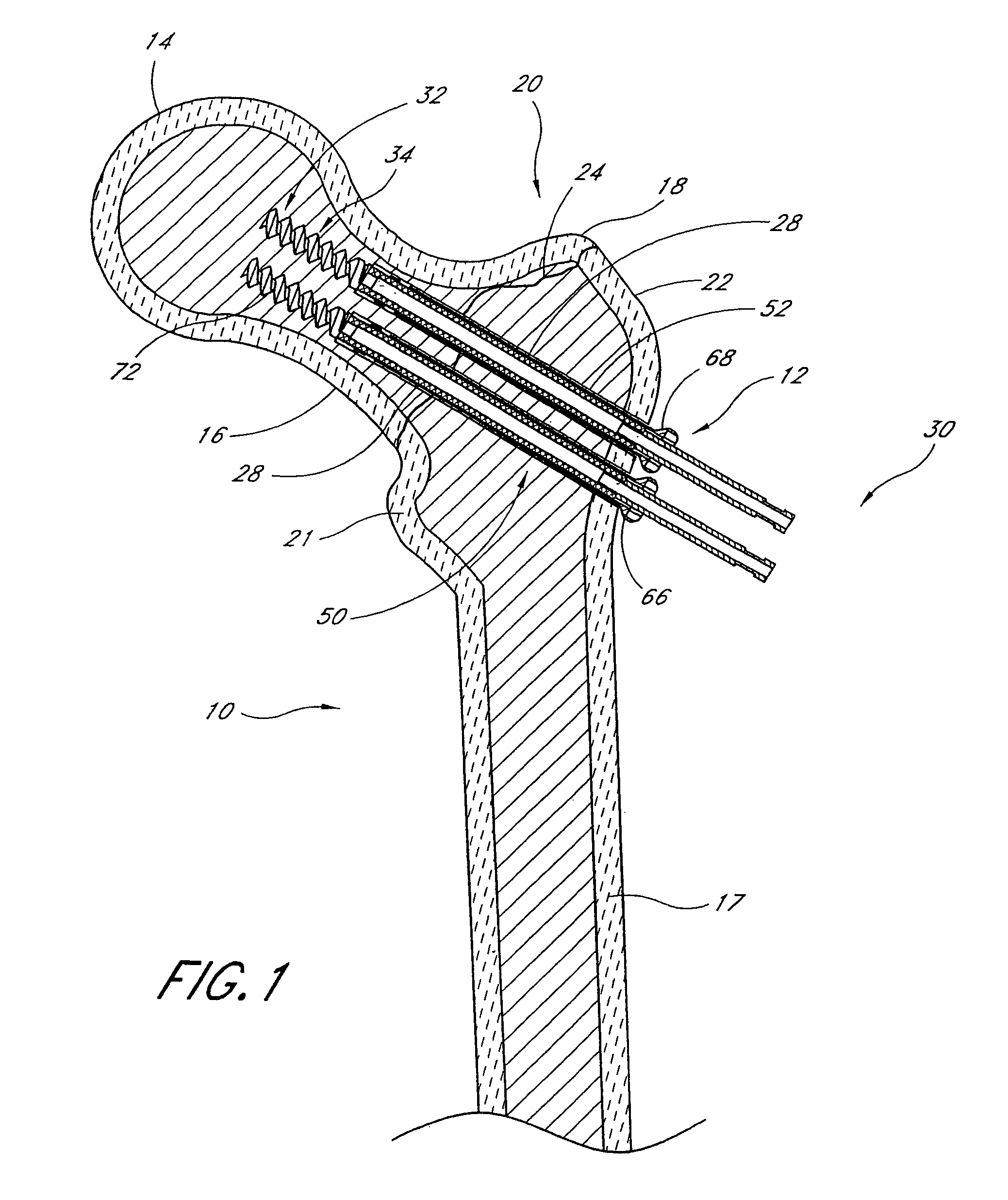

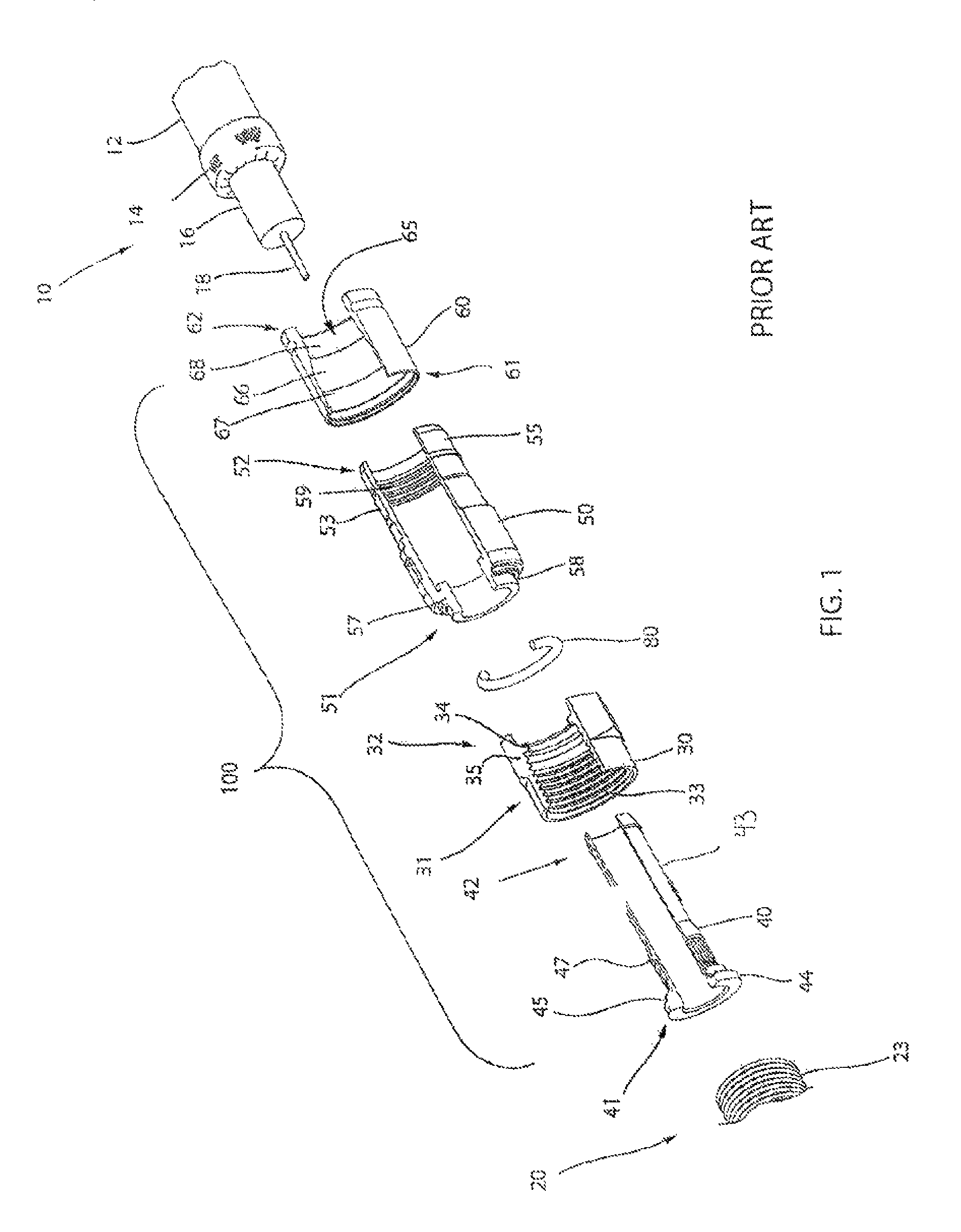

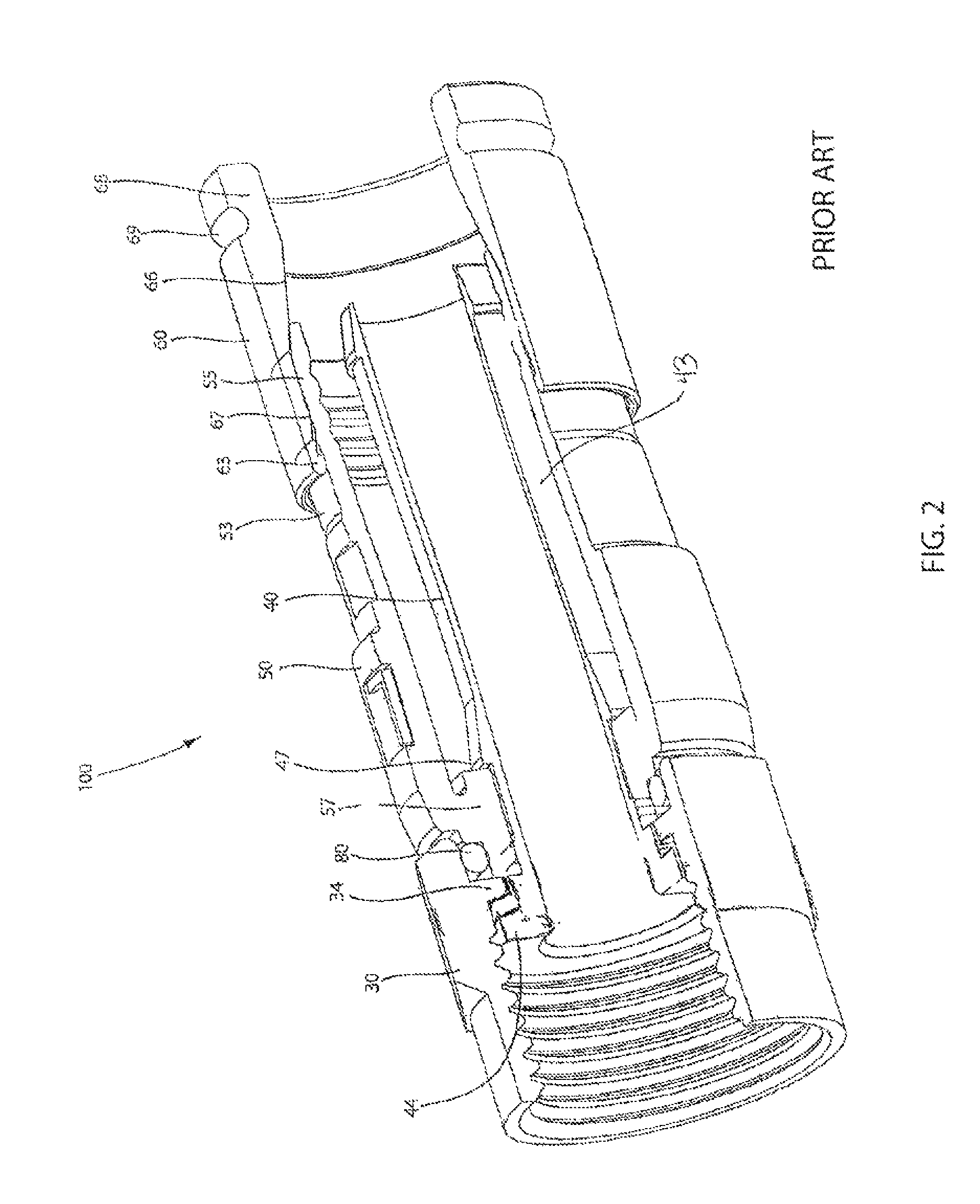

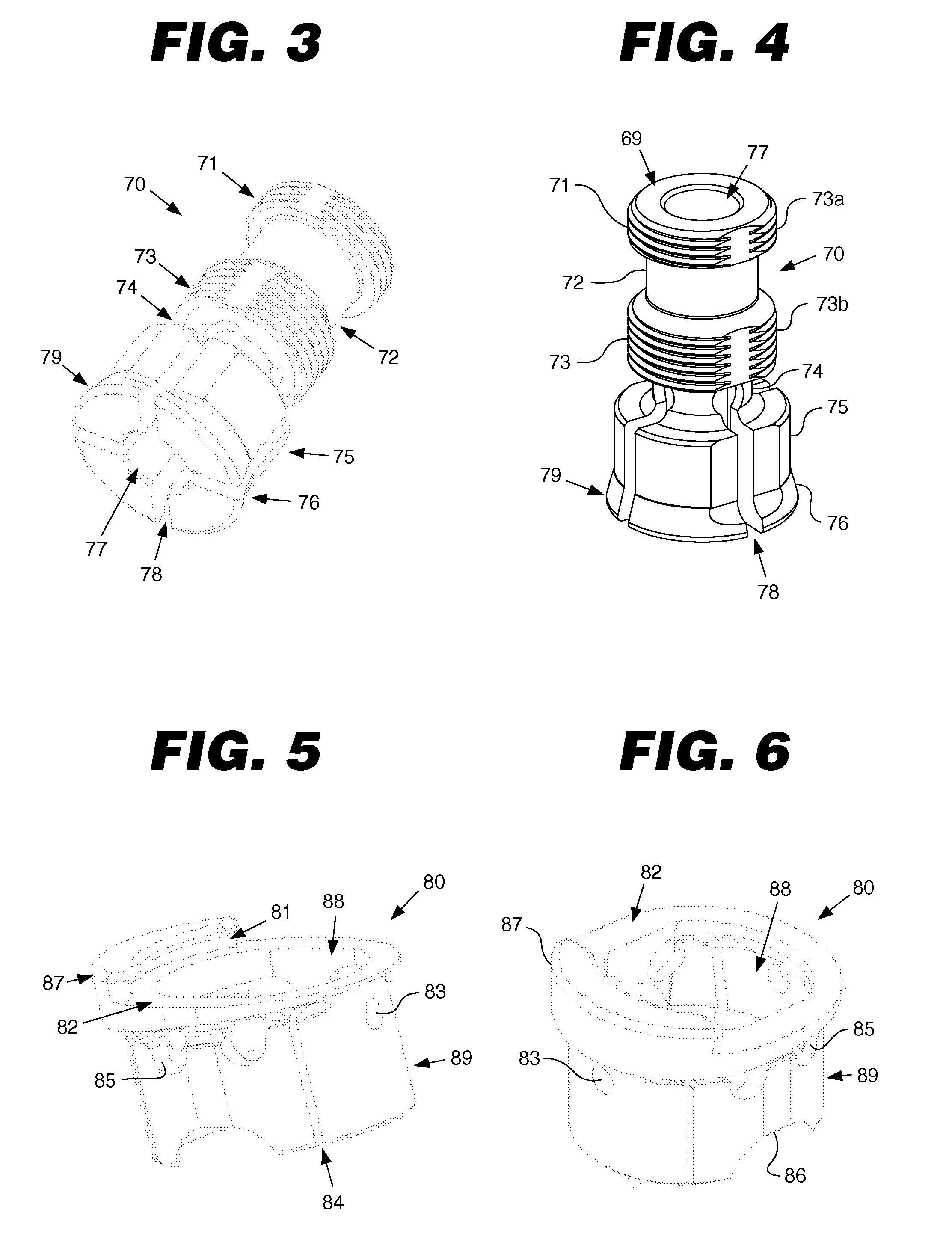

Surgical apparatus and tools for same

InactiveUS20060217729A1Easy to useNot easy to damageDiagnosticsSmall-sized cells cases/jacketsEngineeringPower tool

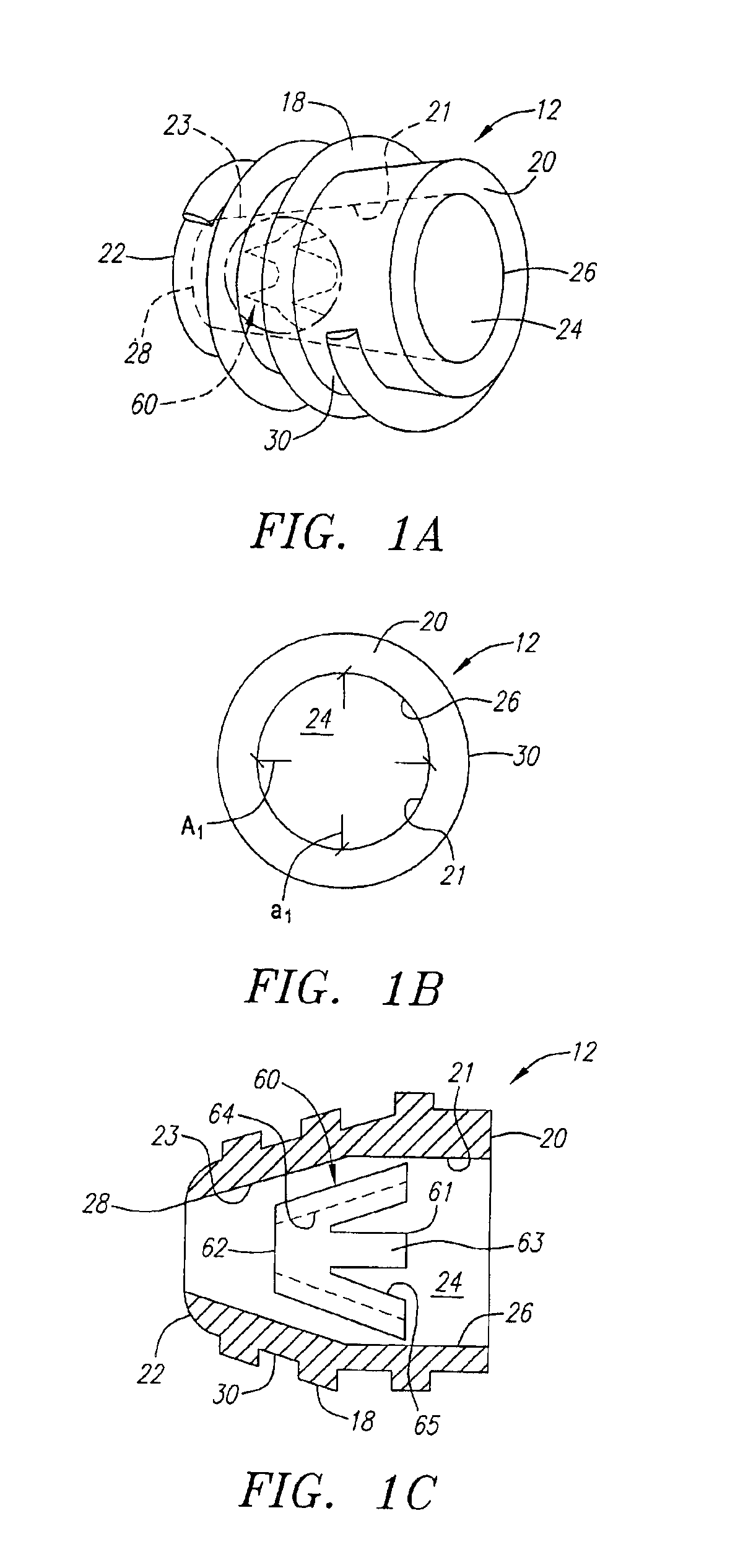

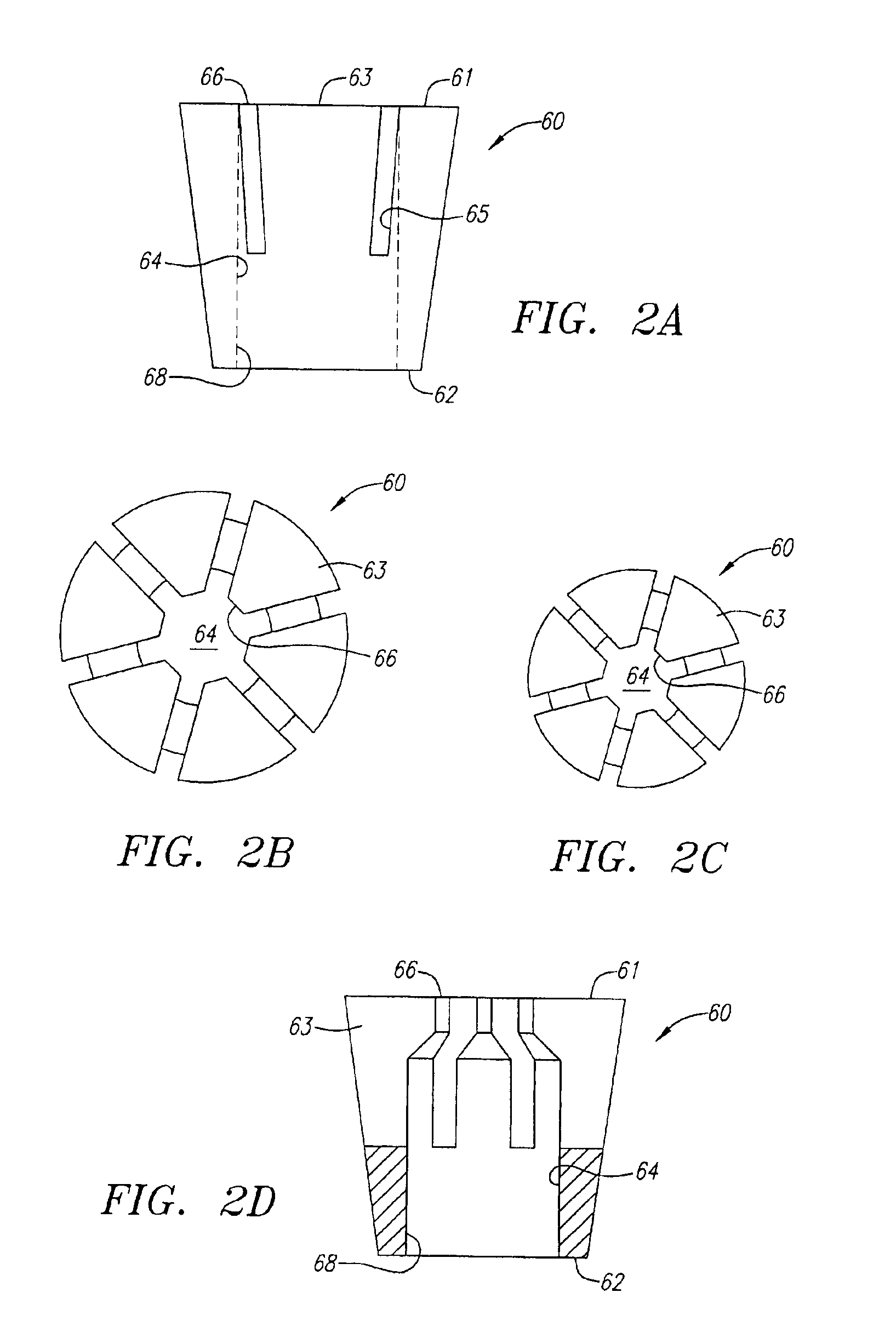

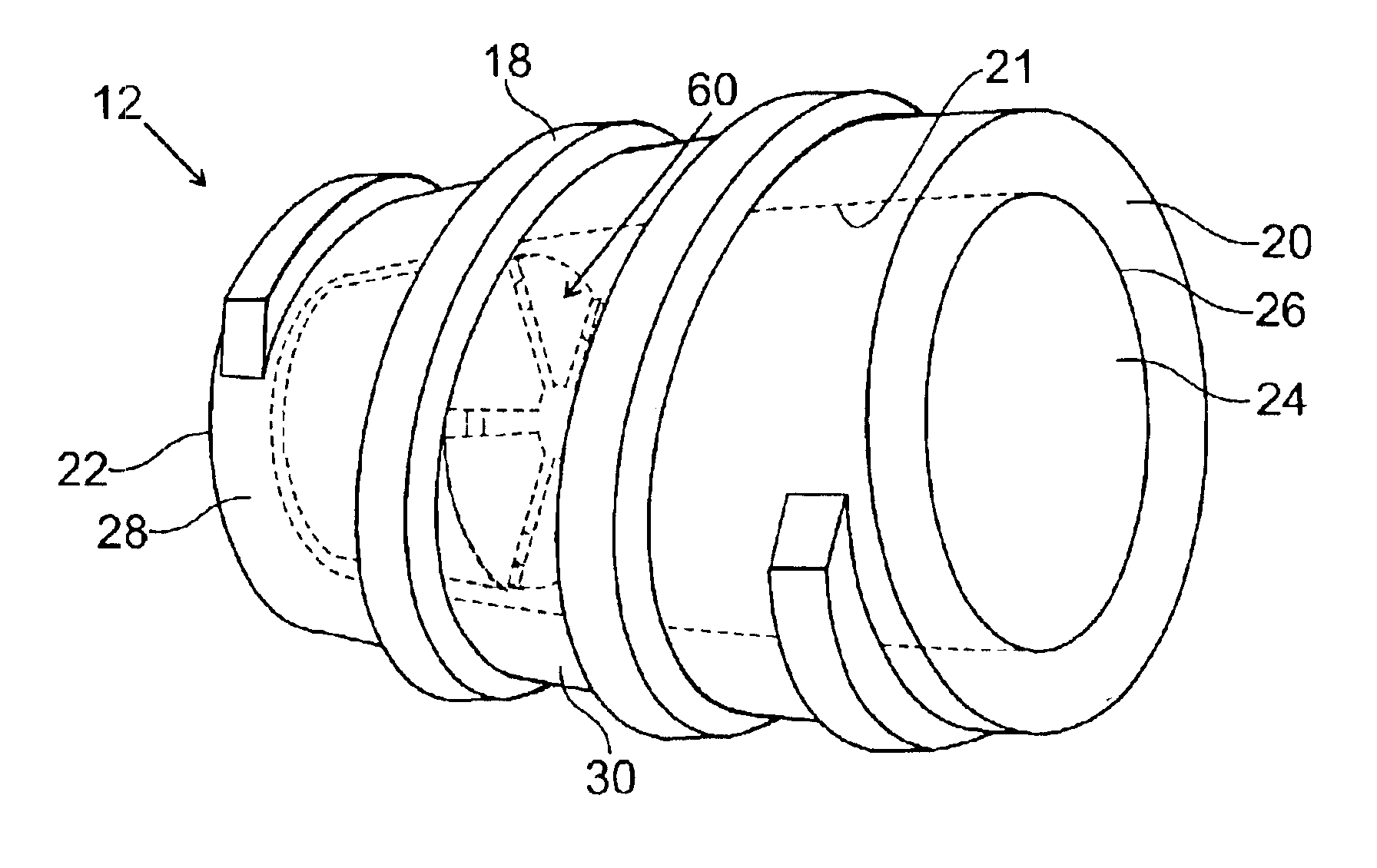

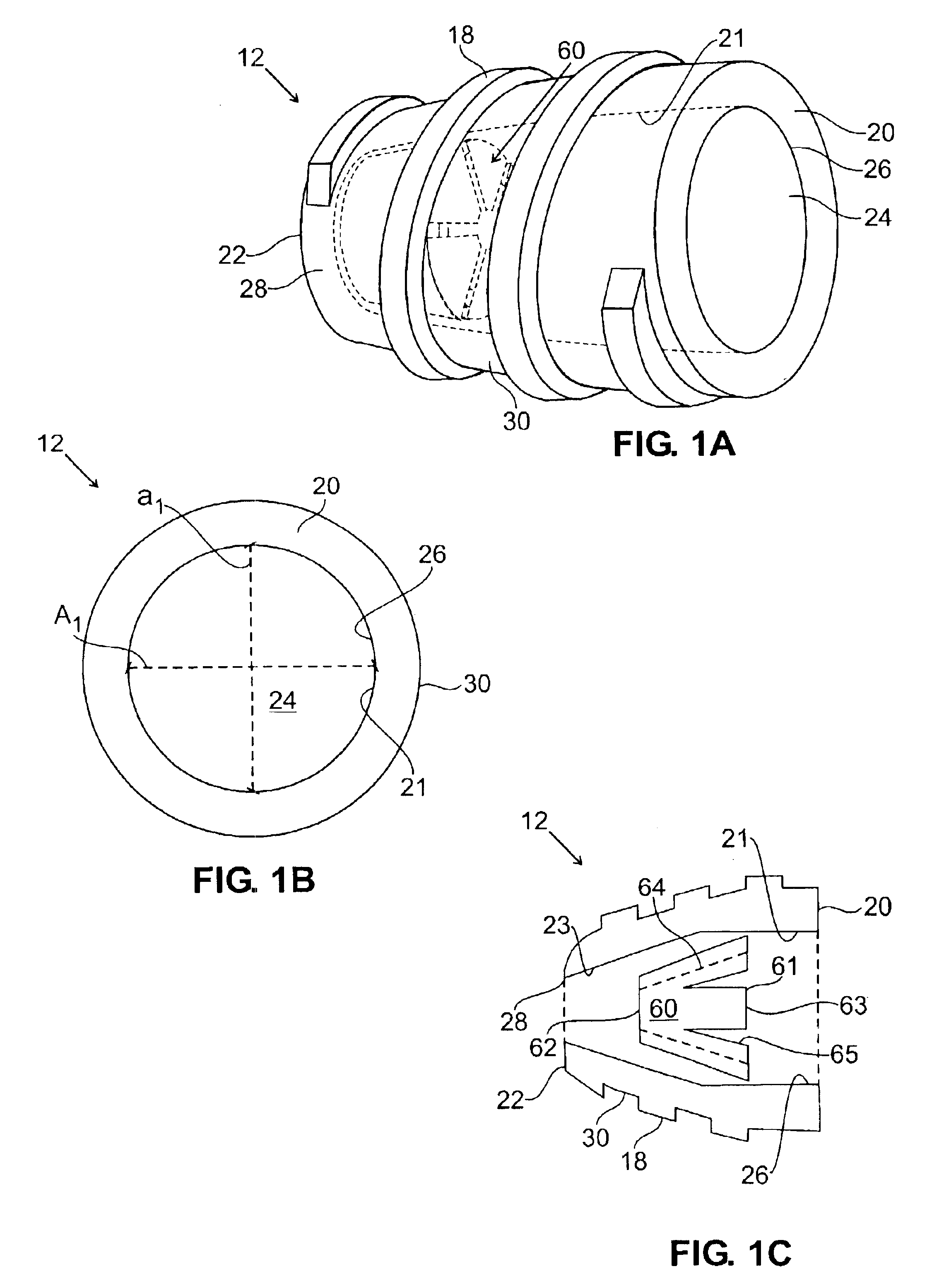

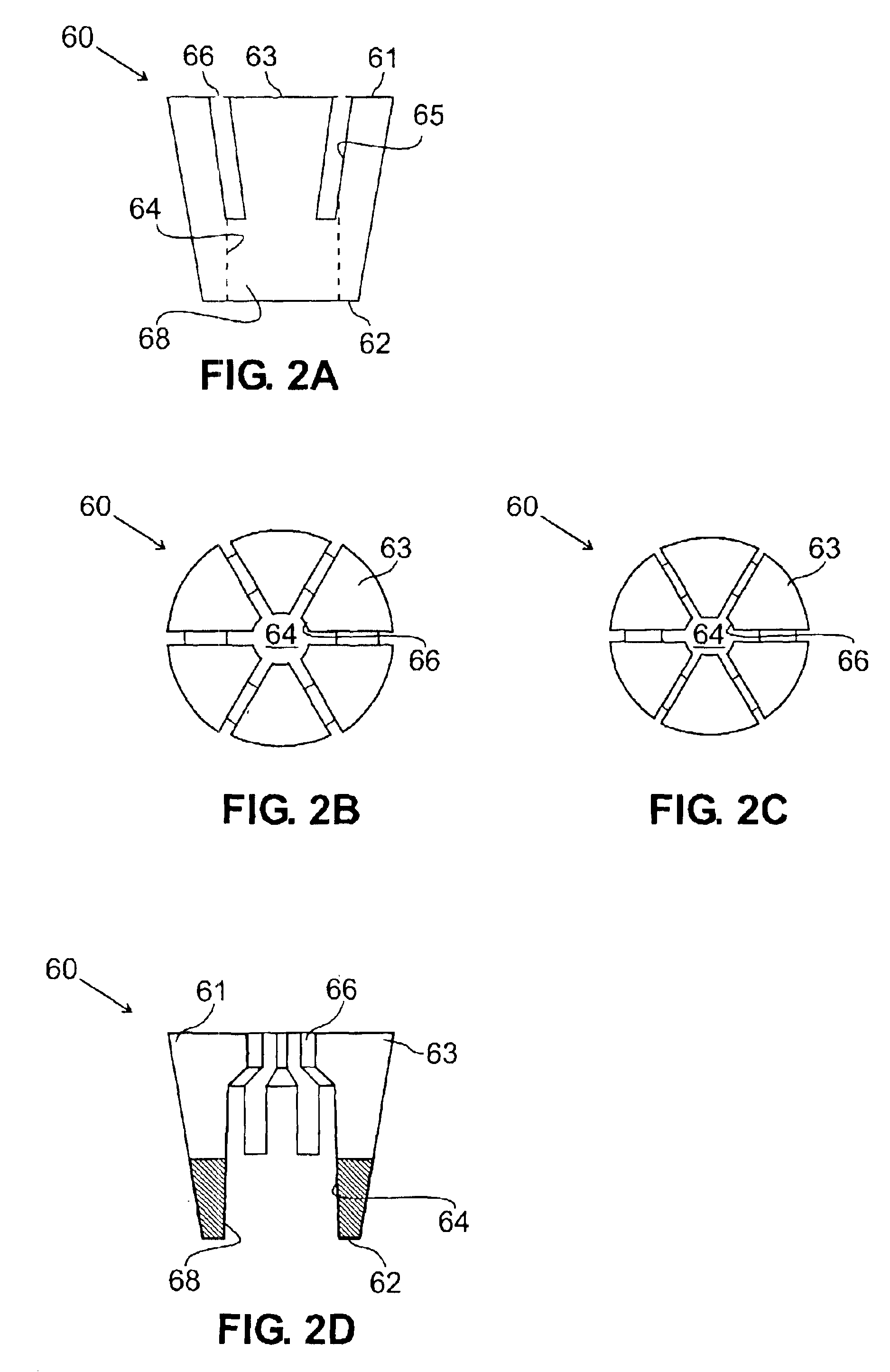

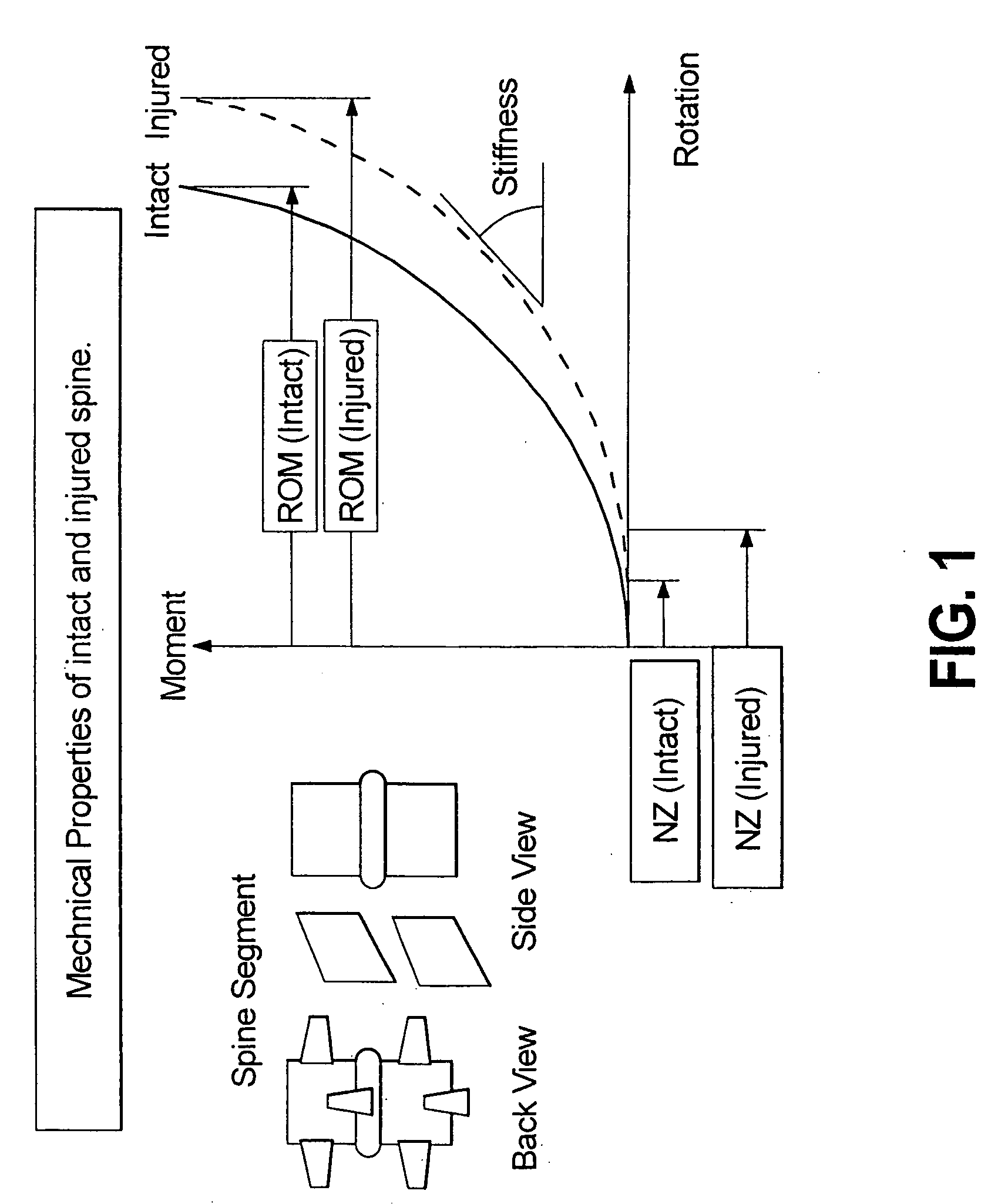

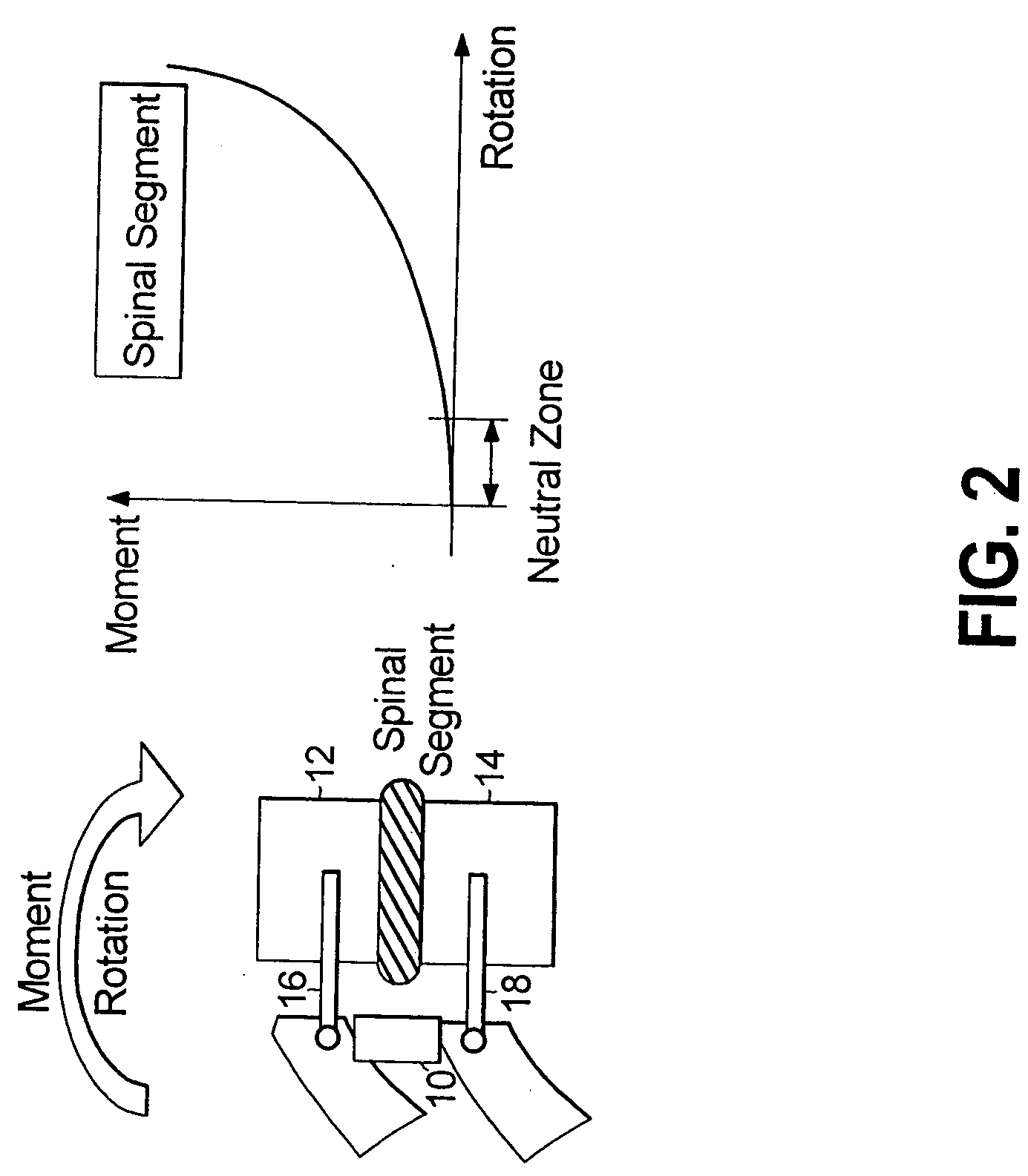

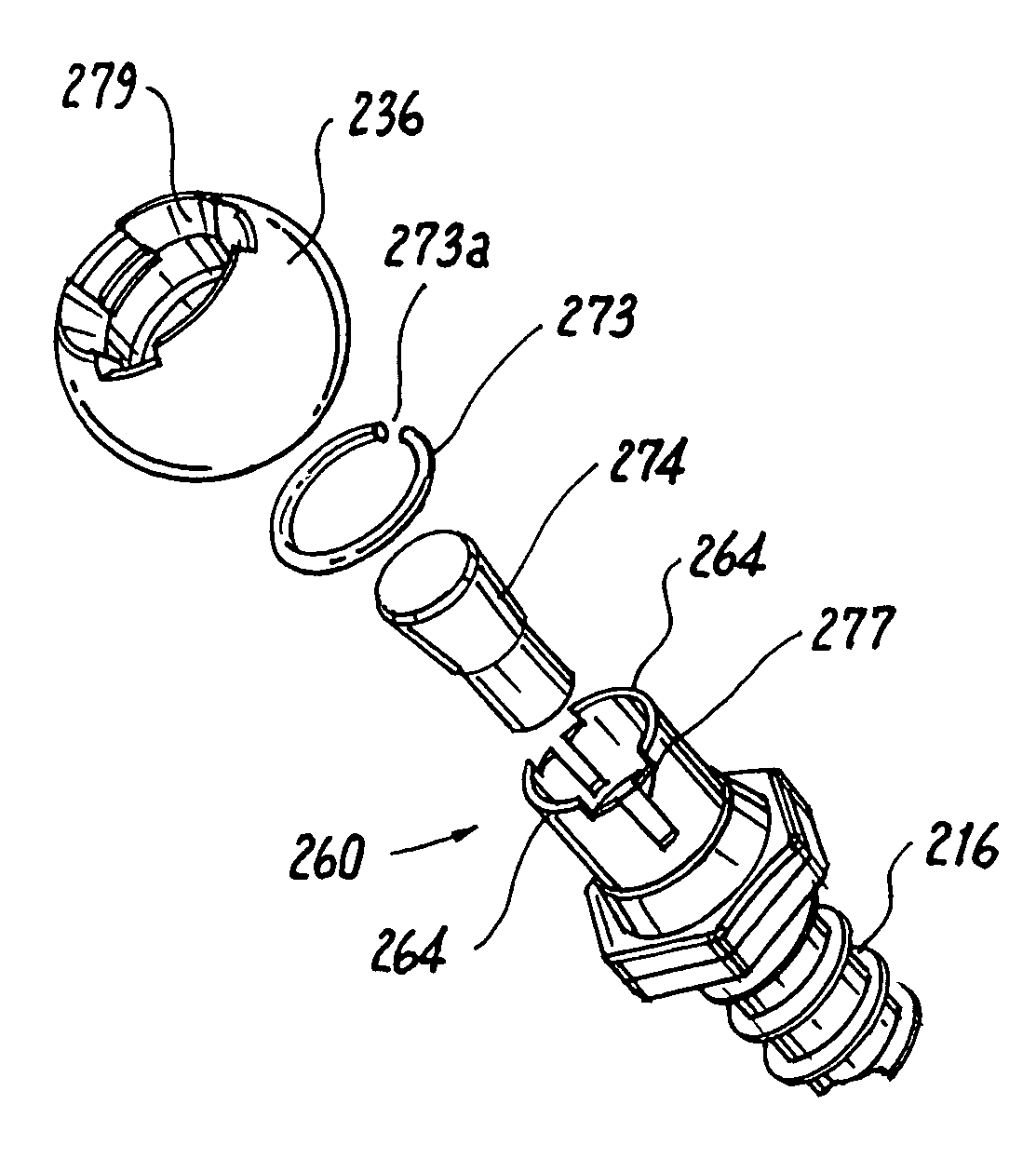

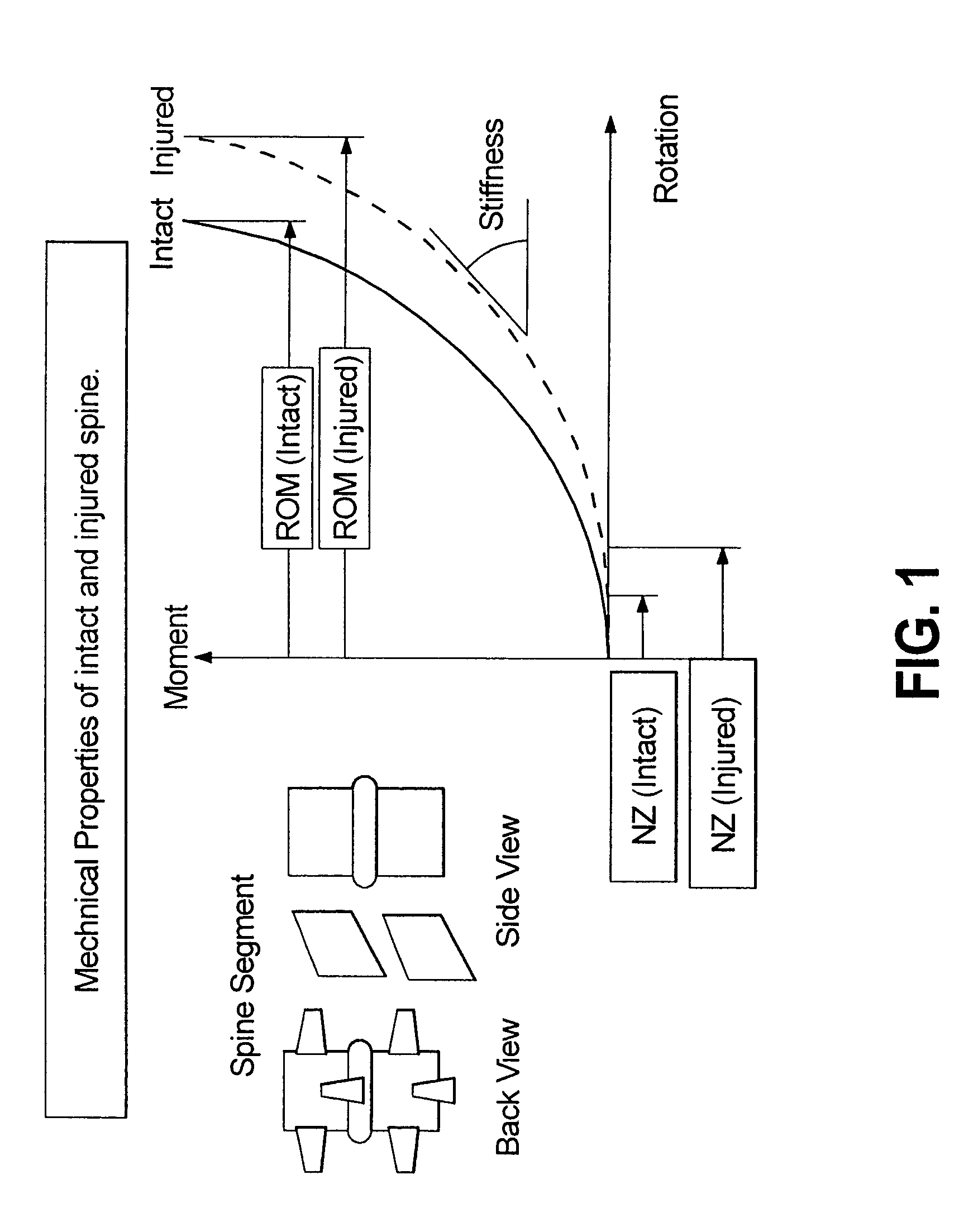

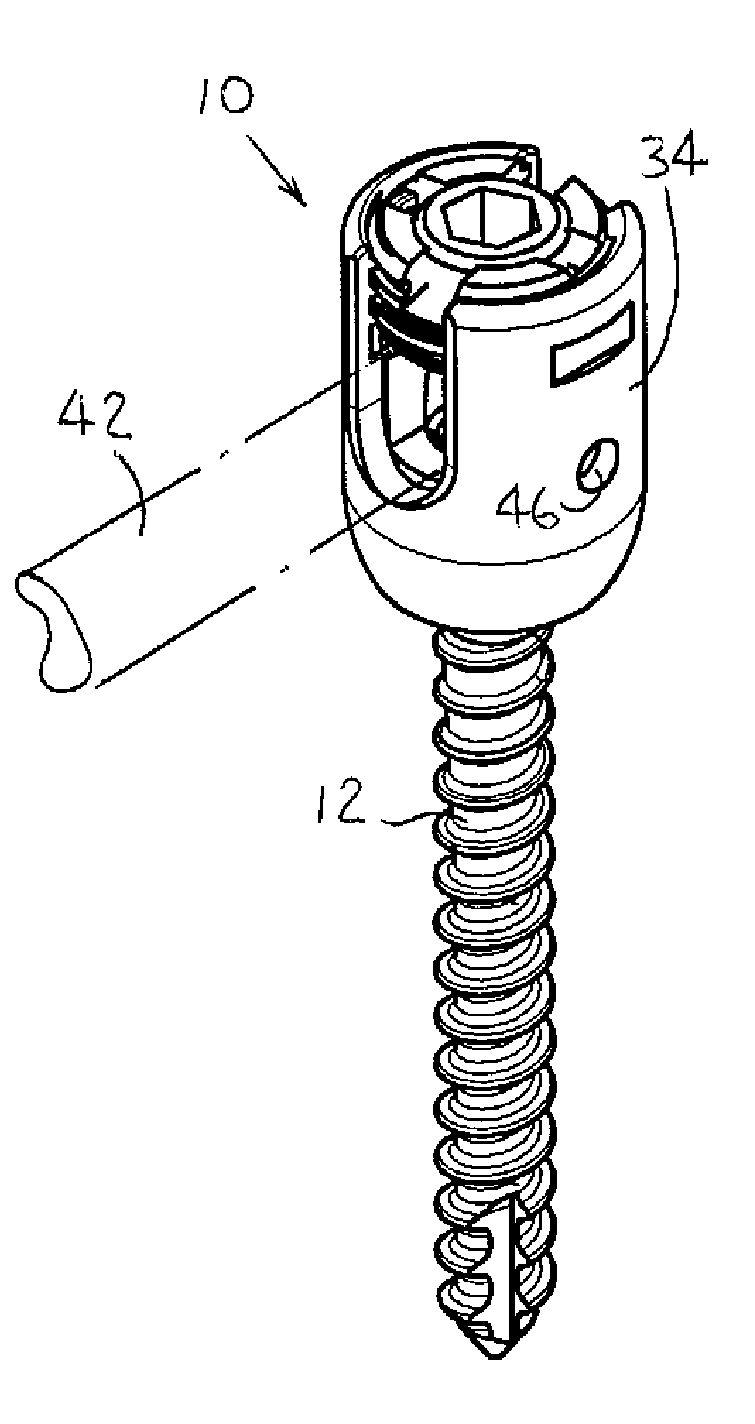

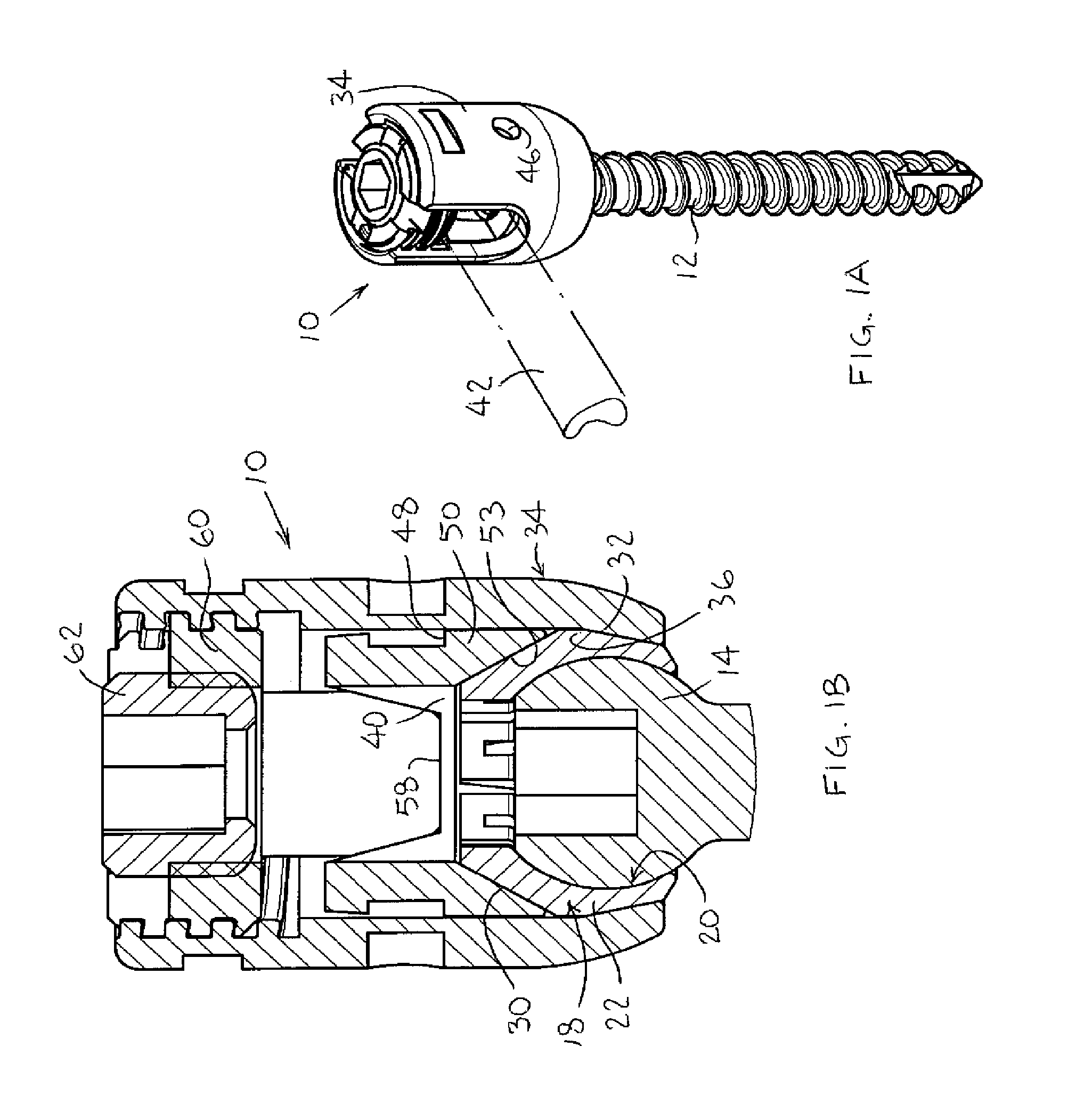

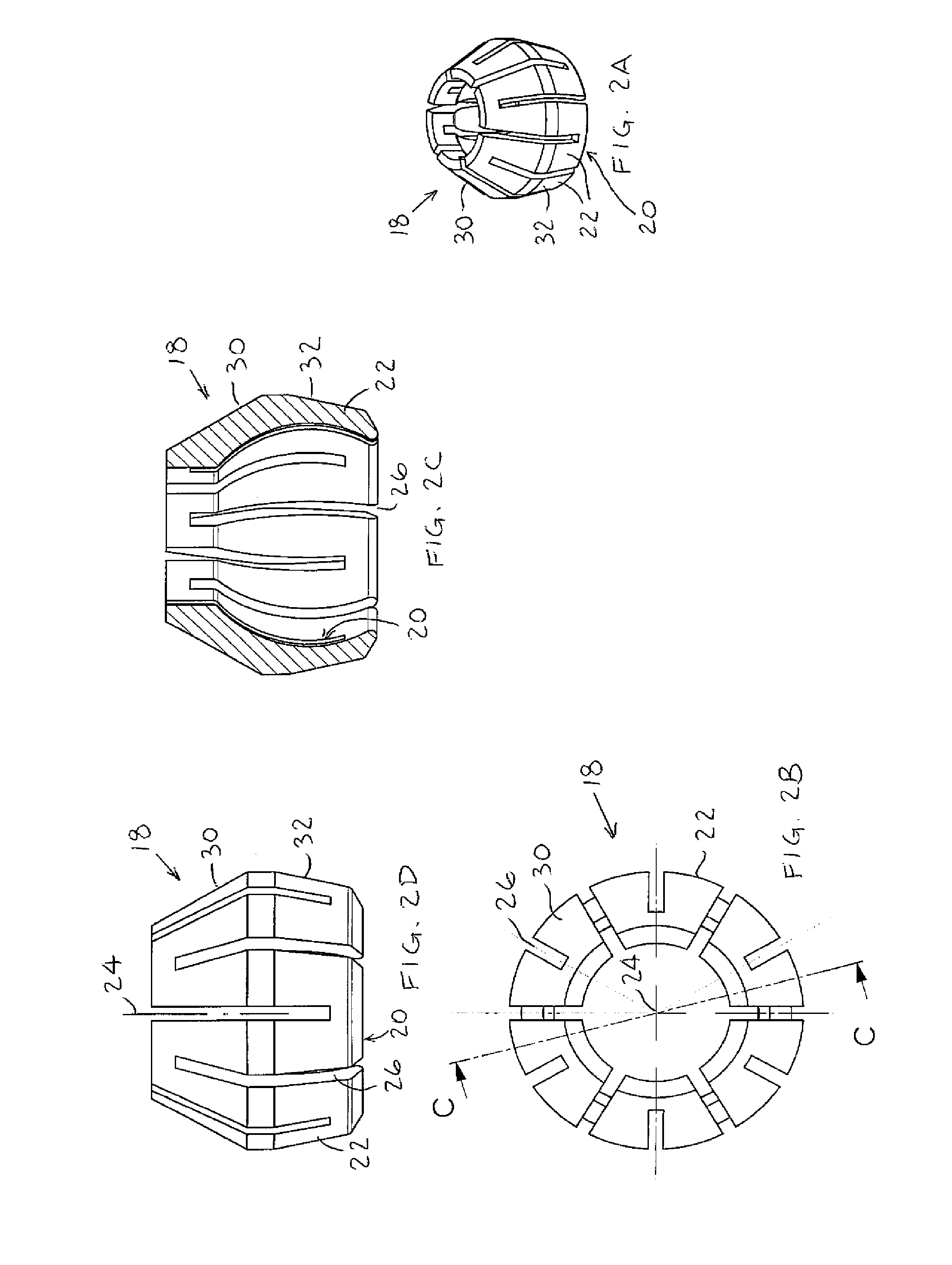

A surgical power tool includes a hand unit and a tool holder. The tool holder engages a hub of a tool to hold the tool during use. One tool holder includes a substantially planar support surface, a pair of spaced-apart sidewalls protruding from the support surface, each sidewall having at least one tab extending from the sidewall toward the other of the sidewalls. A tool clamp, including a post protrudes from the support surface with an enlarged head at a distal end thereof. A lock button protrudes from the support surface, the lock button being depressible toward the support surface. Another tool holder includes an output shaft having a driven end and a free end, the free end of the output shaft having a slot formed therein. A collet is disposed coaxially with the output shaft and is rotatable relative thereto. The collet has a collet wall extending between the first and second ends of the collet. The collet has a plurality of slots in the first end of the collet, a plurality of grooves in an inner surface of the collet wall, and a plurality of internal ridges protruding from the inner surface of the collet wall.

Owner:BRASSELER USA MEDICAL

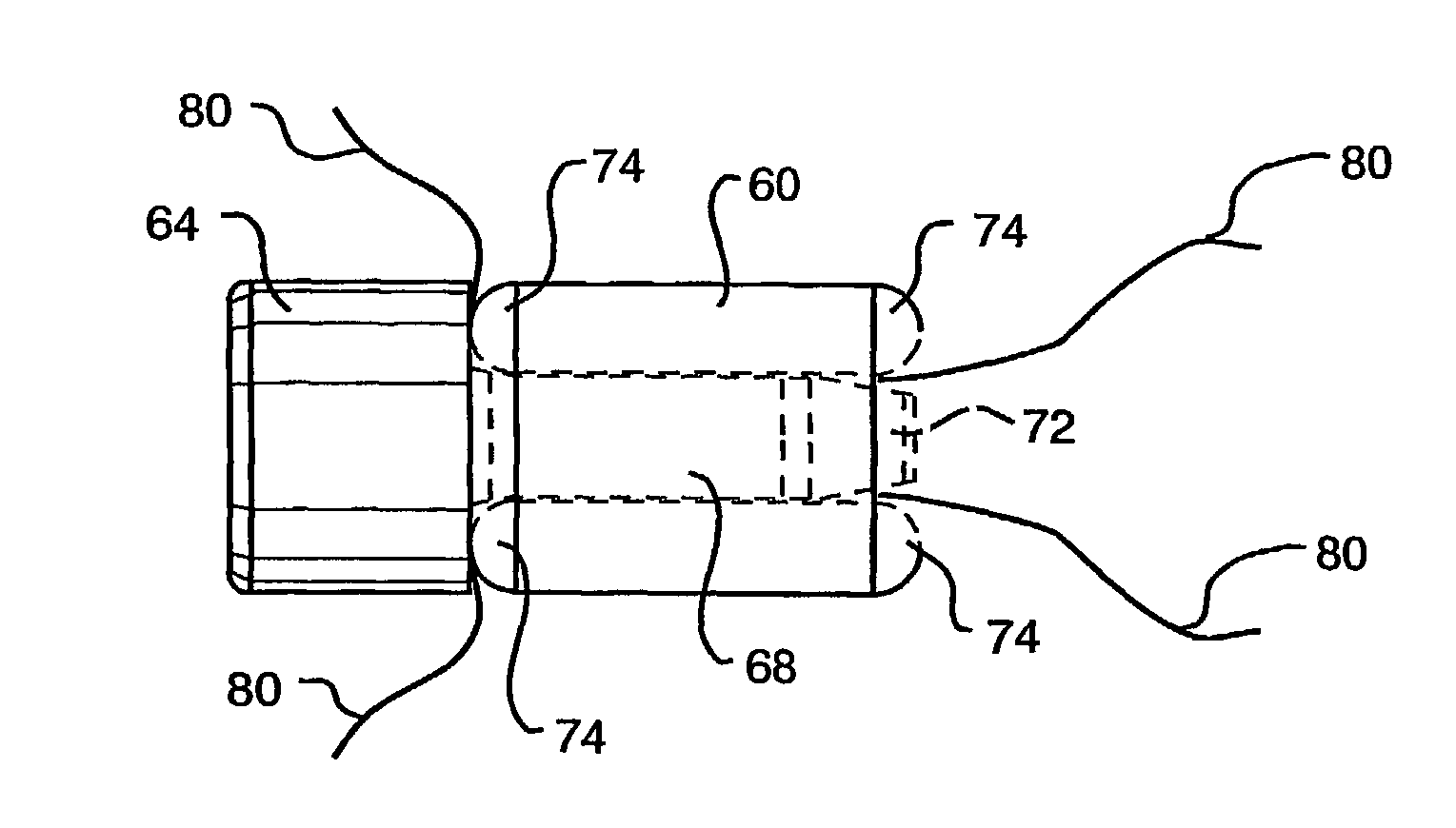

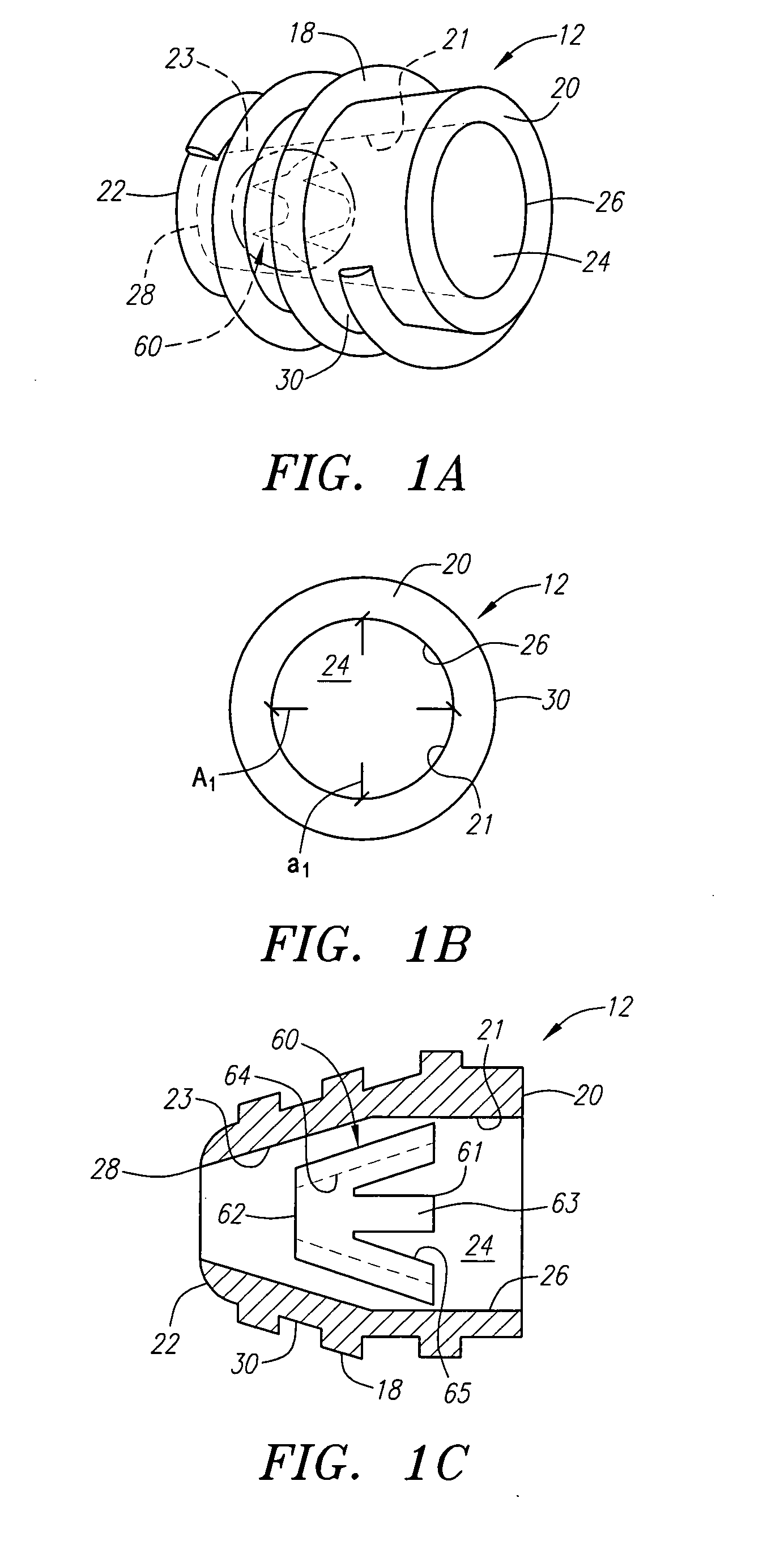

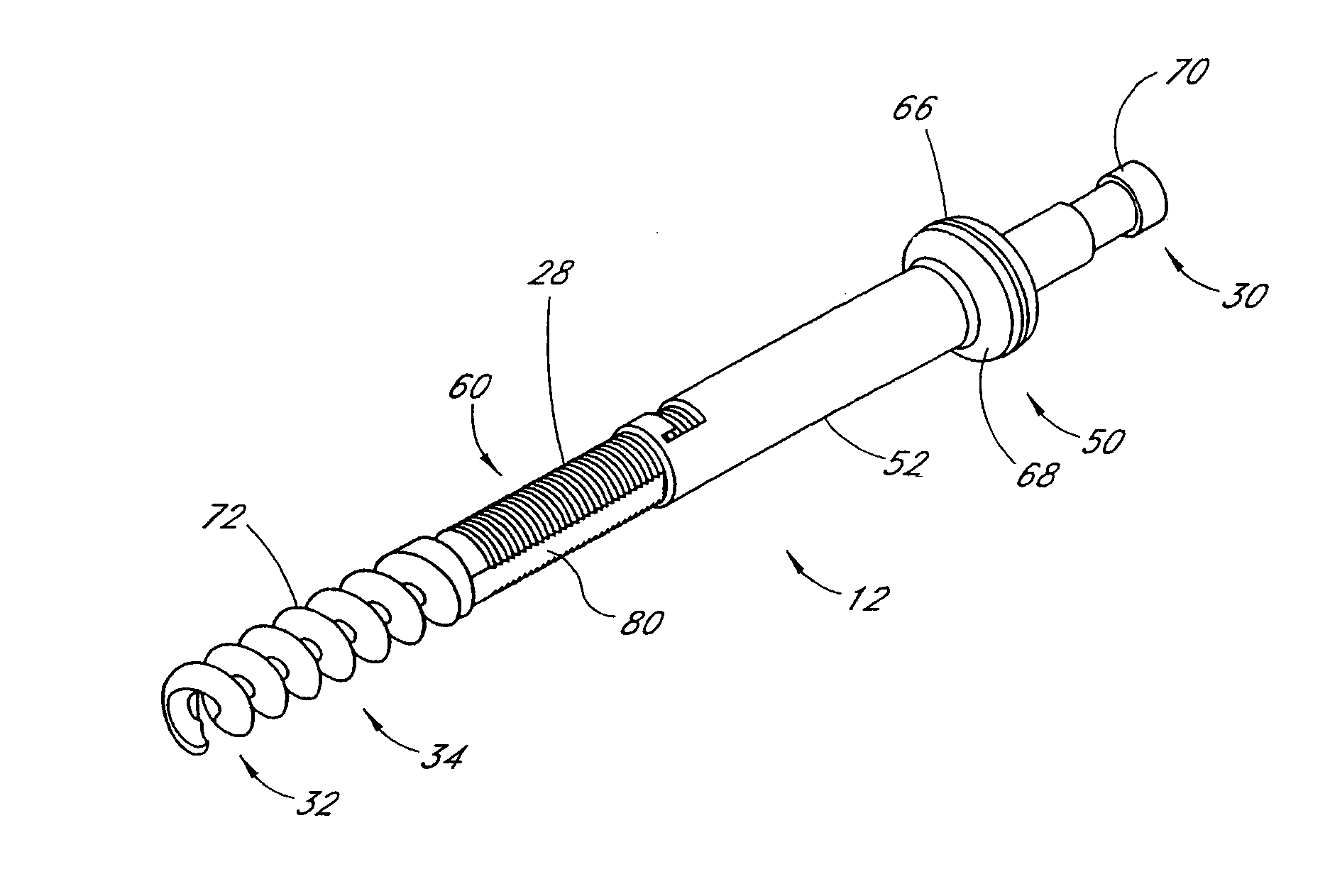

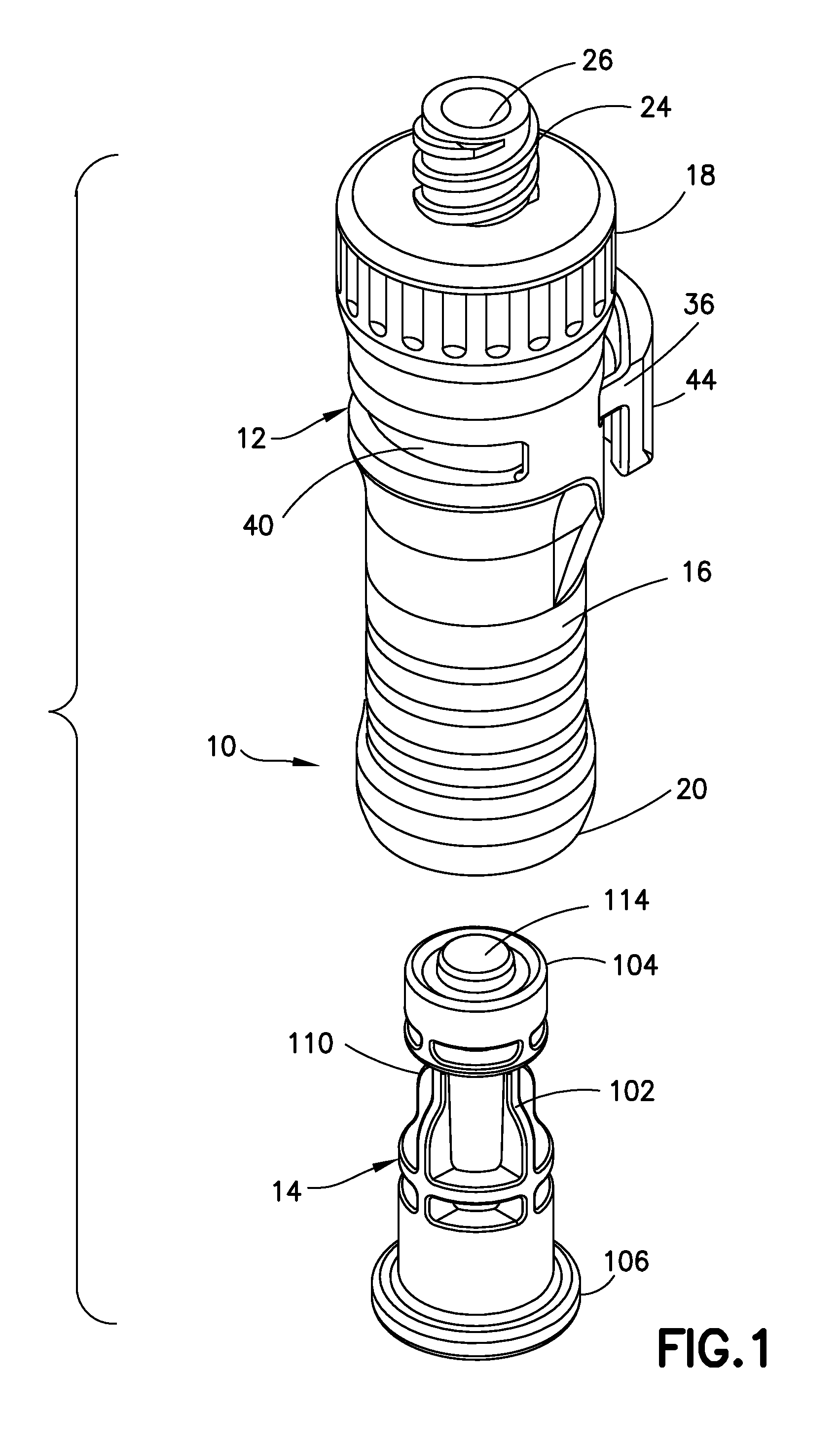

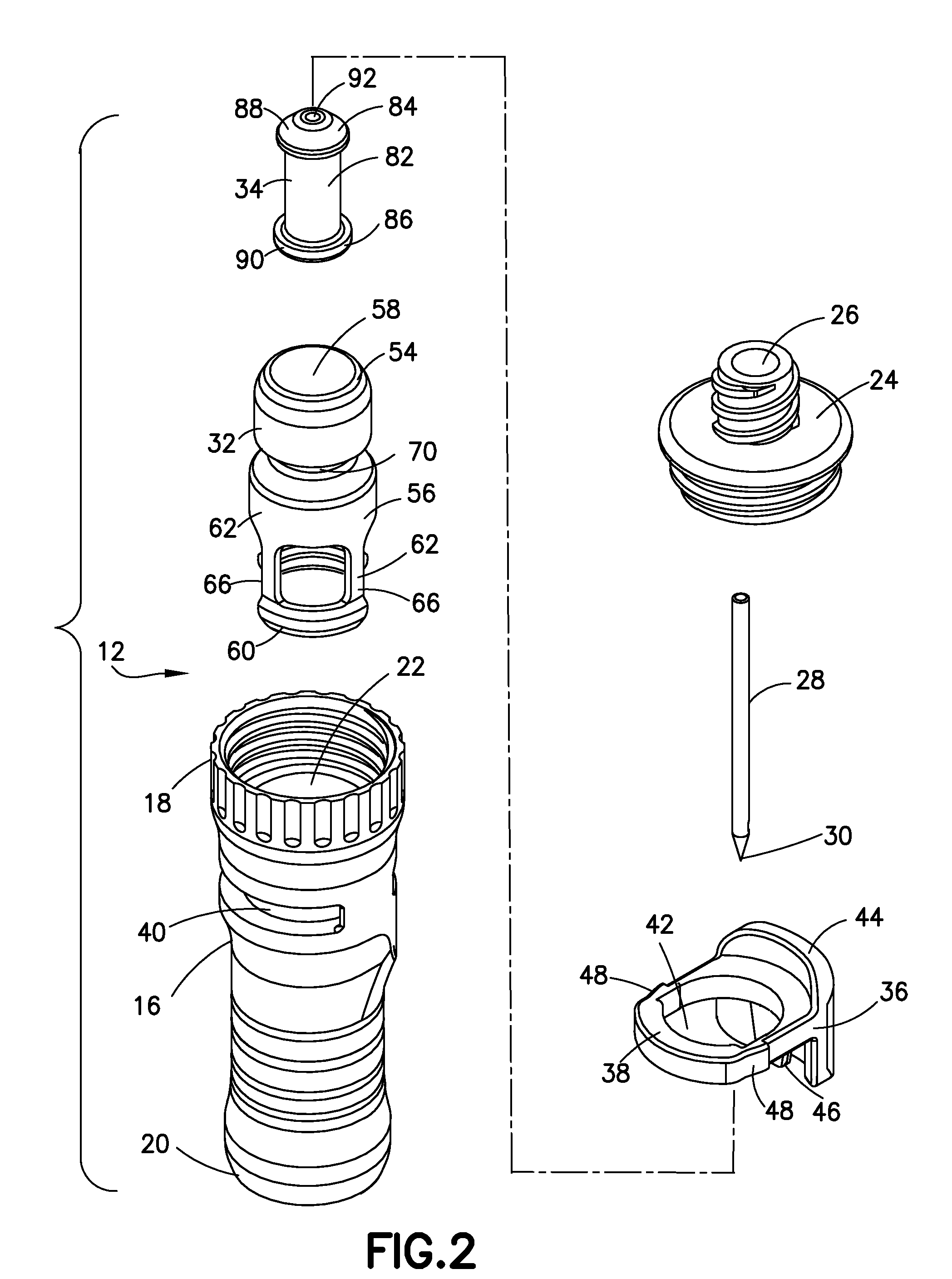

Plug with collet and apparatus and method for delivering such plugs

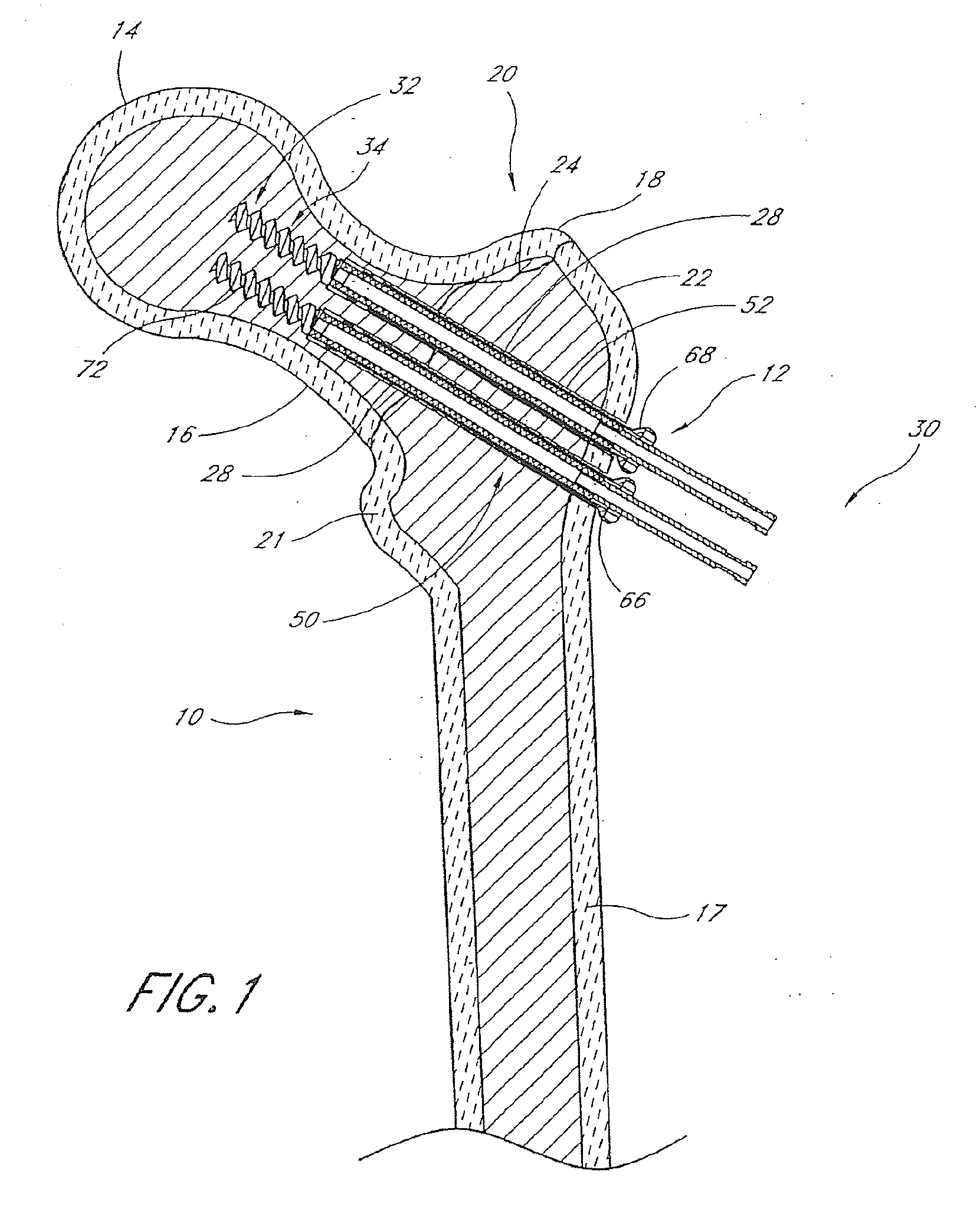

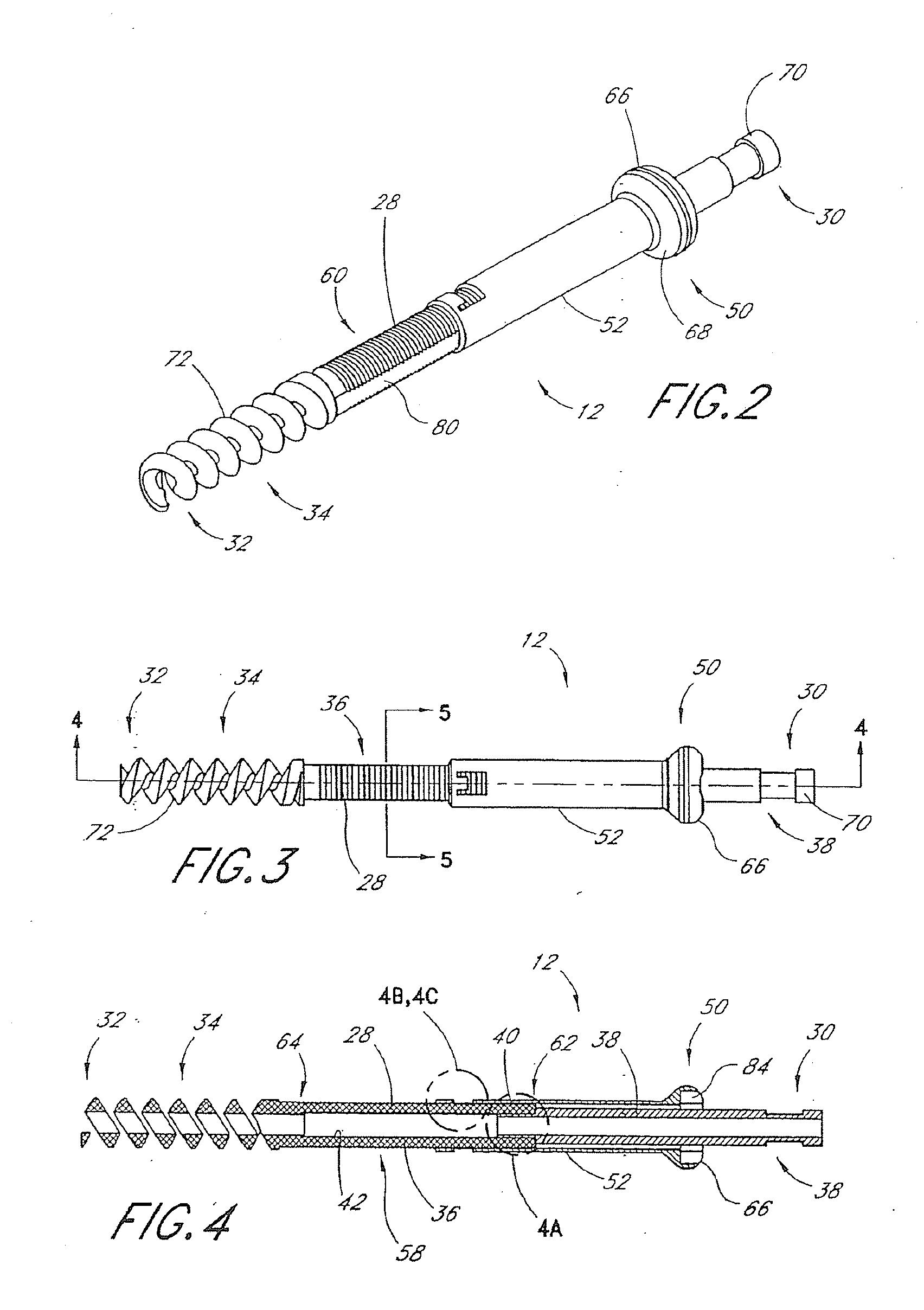

InactiveUS6896692B2Low profilePromote progressVaccination/ovulation diagnosticsTubular organ implantsEngineeringGuide wires

An apparatus for sealing a passage through tissue includes a plug including external threads, a lumen extending between its proximal and distal ends, and an annular collet slidably disposed within the lumen. The plug is carried on a distal end of a handle device that includes an inner member with a distal end that is slidable axially within the lumen of the body for moving the collet into a reduced cross-sectional region of the lumen, thereby compressing the collet to seal the lumen, and for deploying the plug from the handle device. During use, the plug is threaded into a passage through tissue over a guide wire. Once a desired location is reached, the plug is deployed from the handle device, thereby compressing the collet and sealing the lumen. The guide wire and handle device are removed, leaving the plug to seal the passage.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

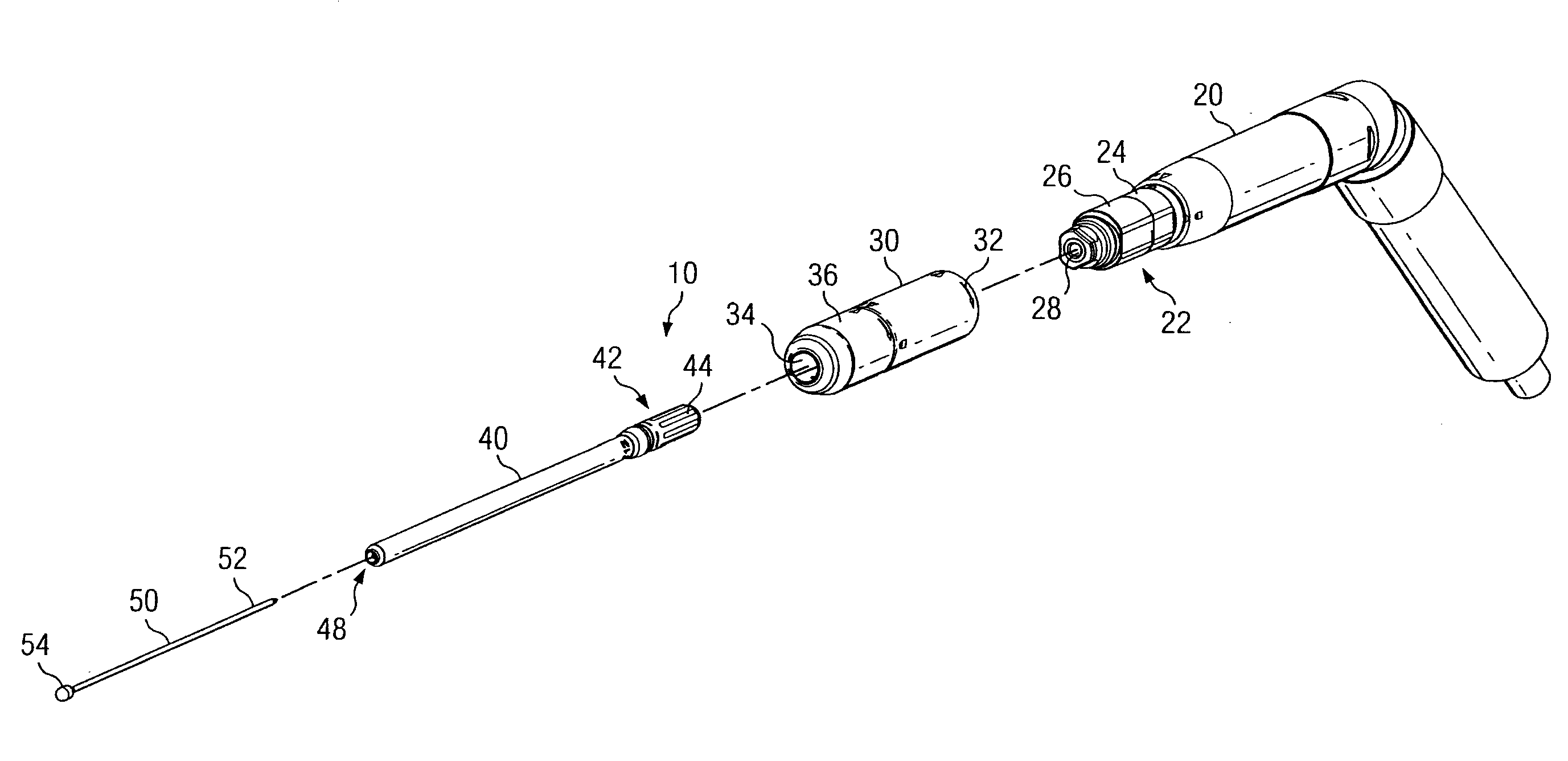

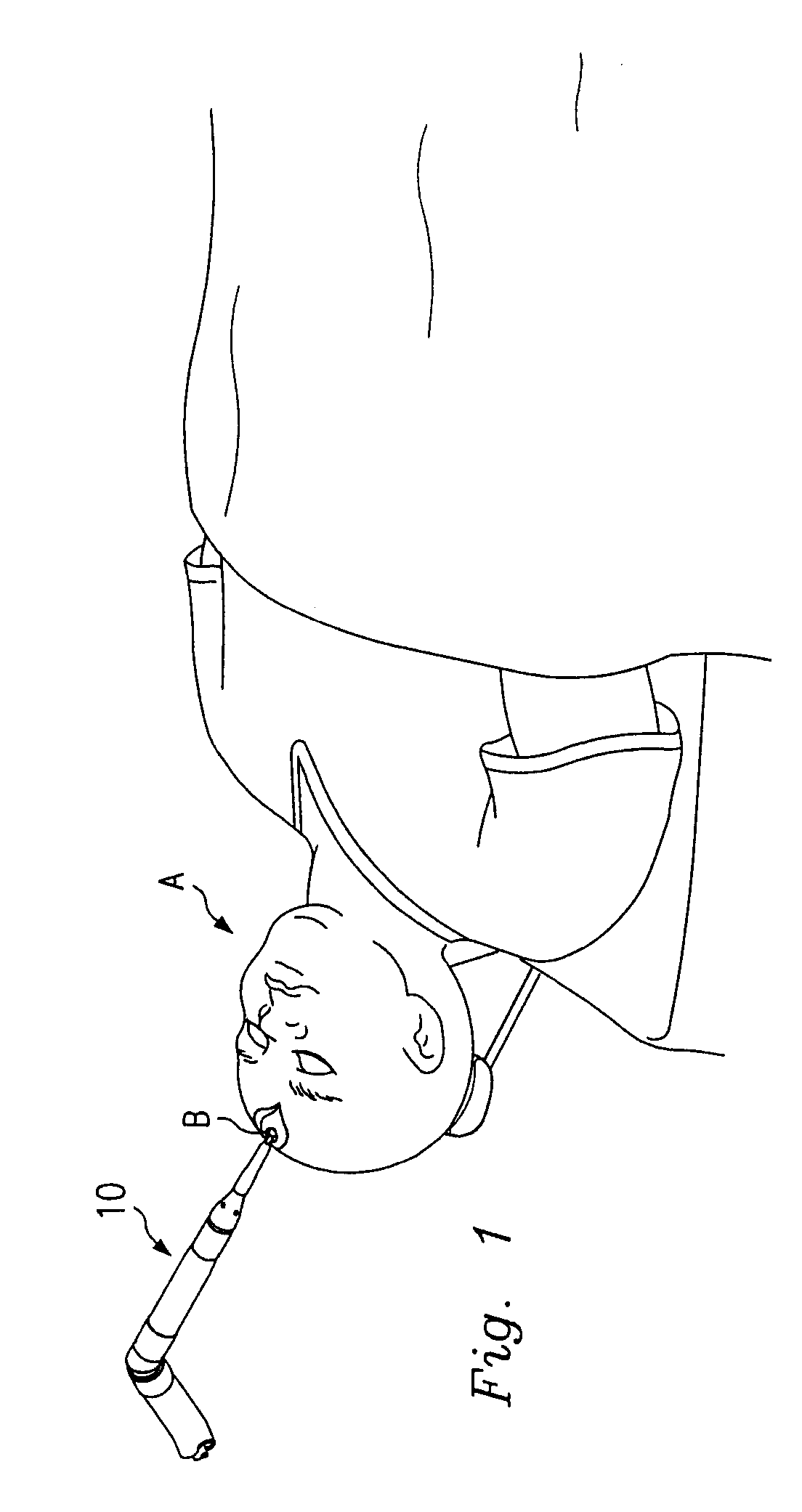

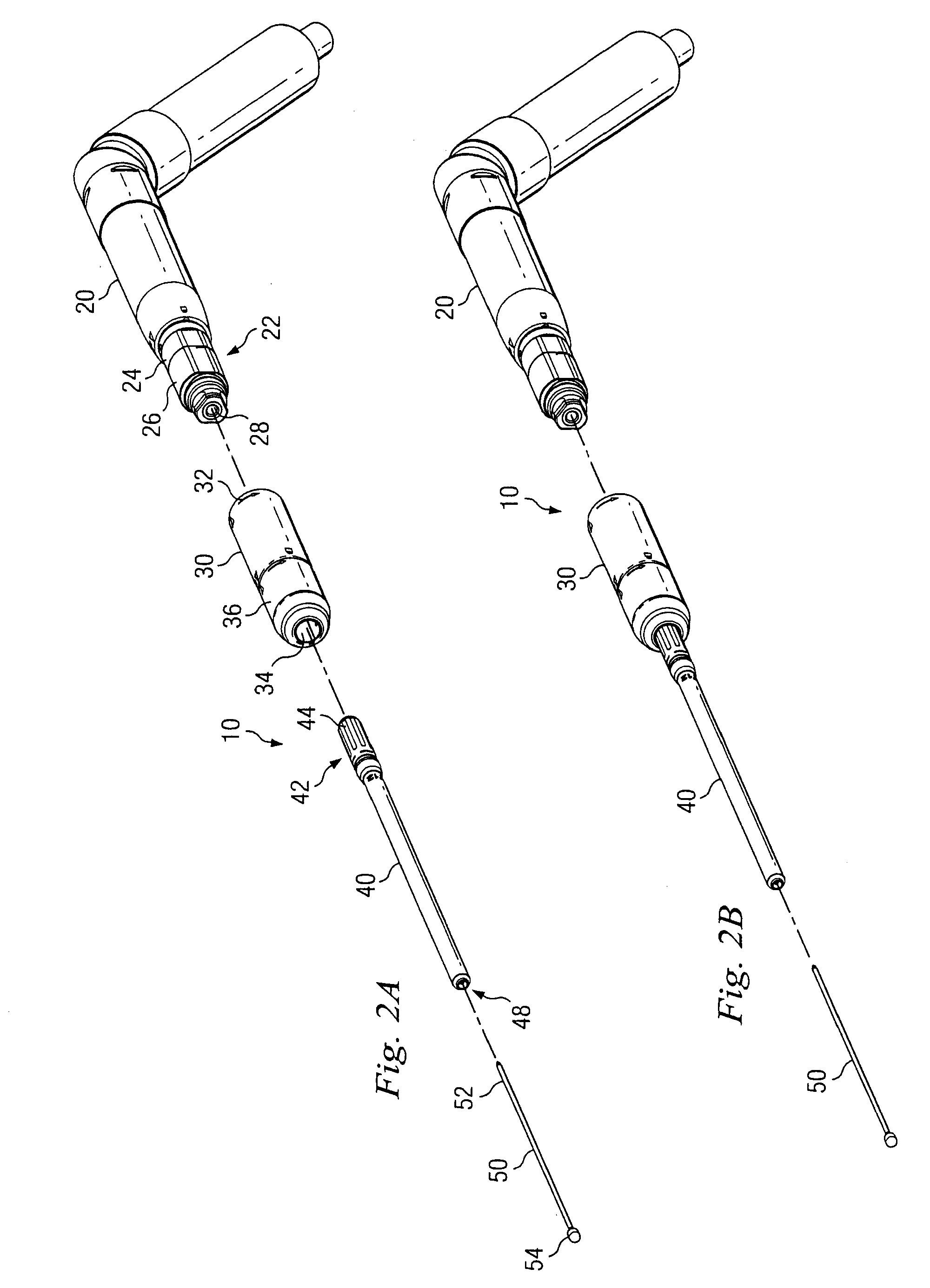

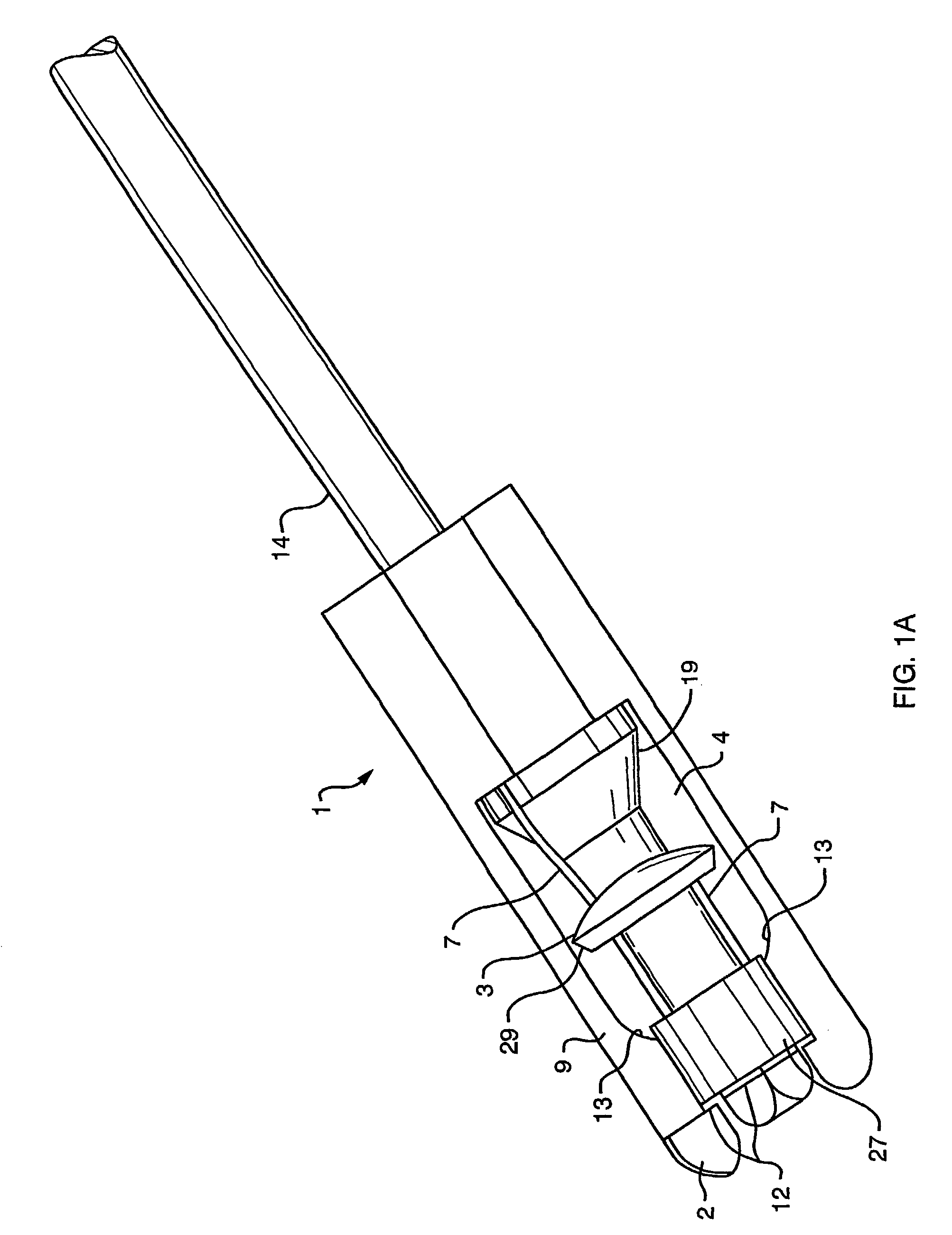

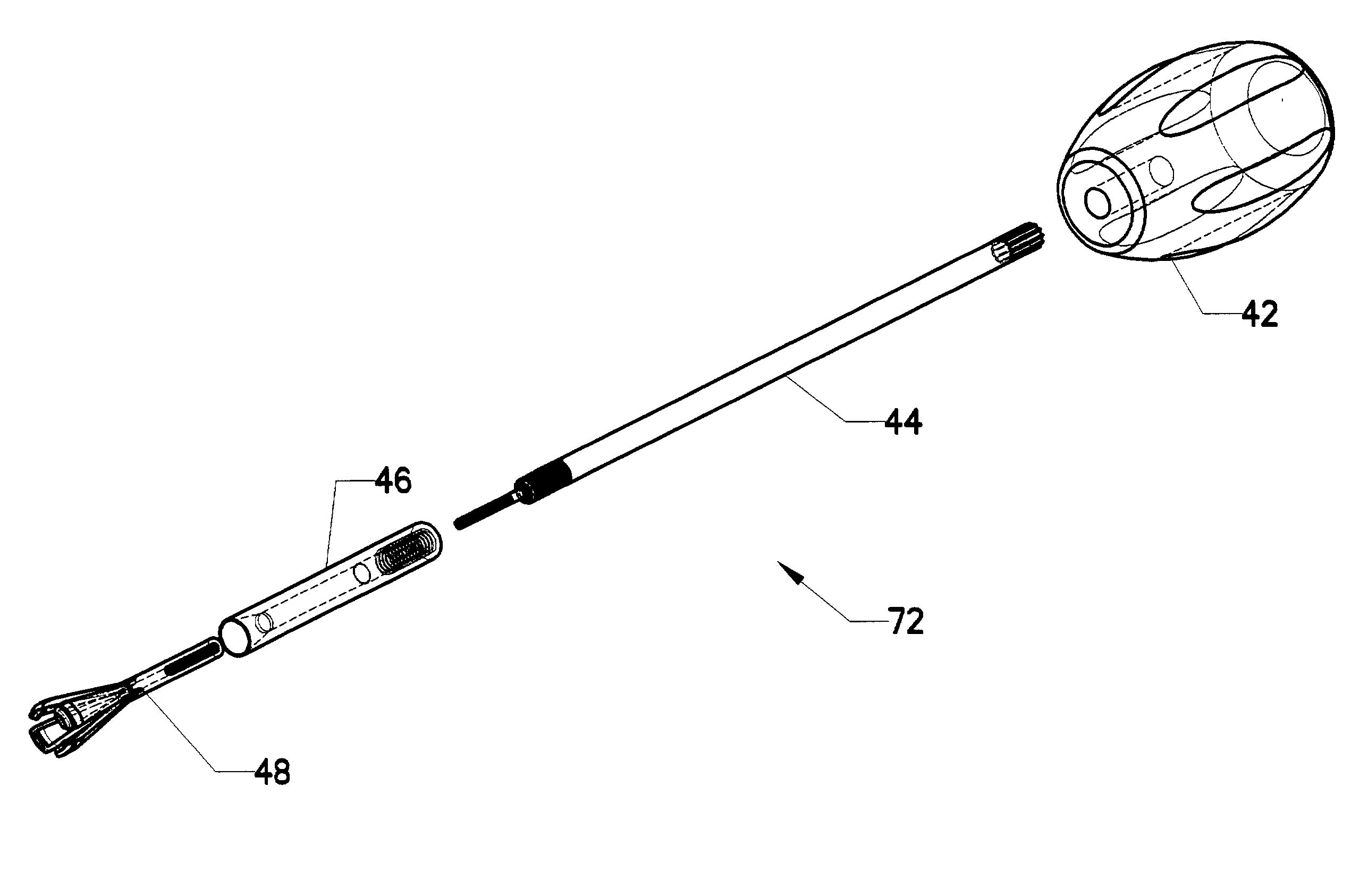

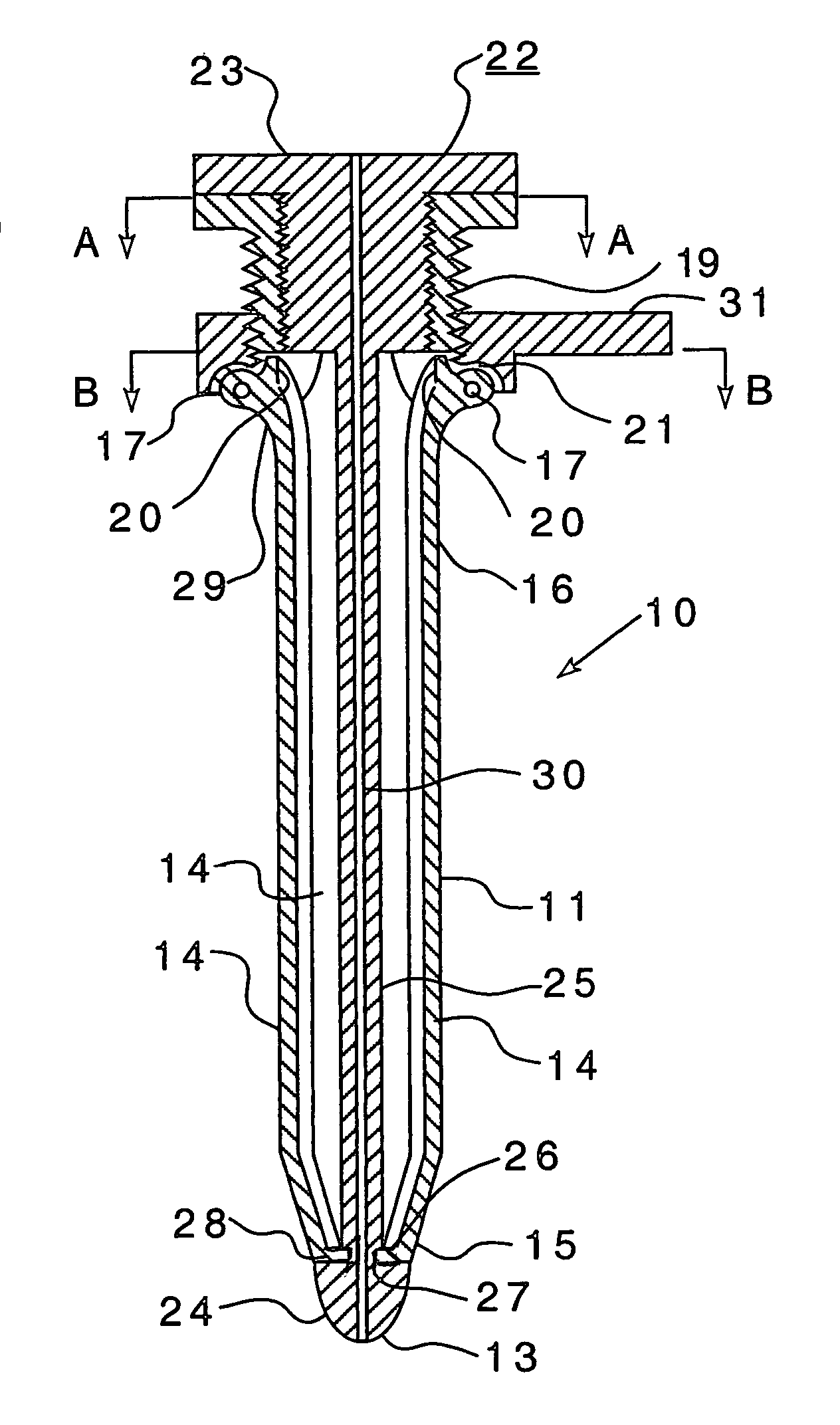

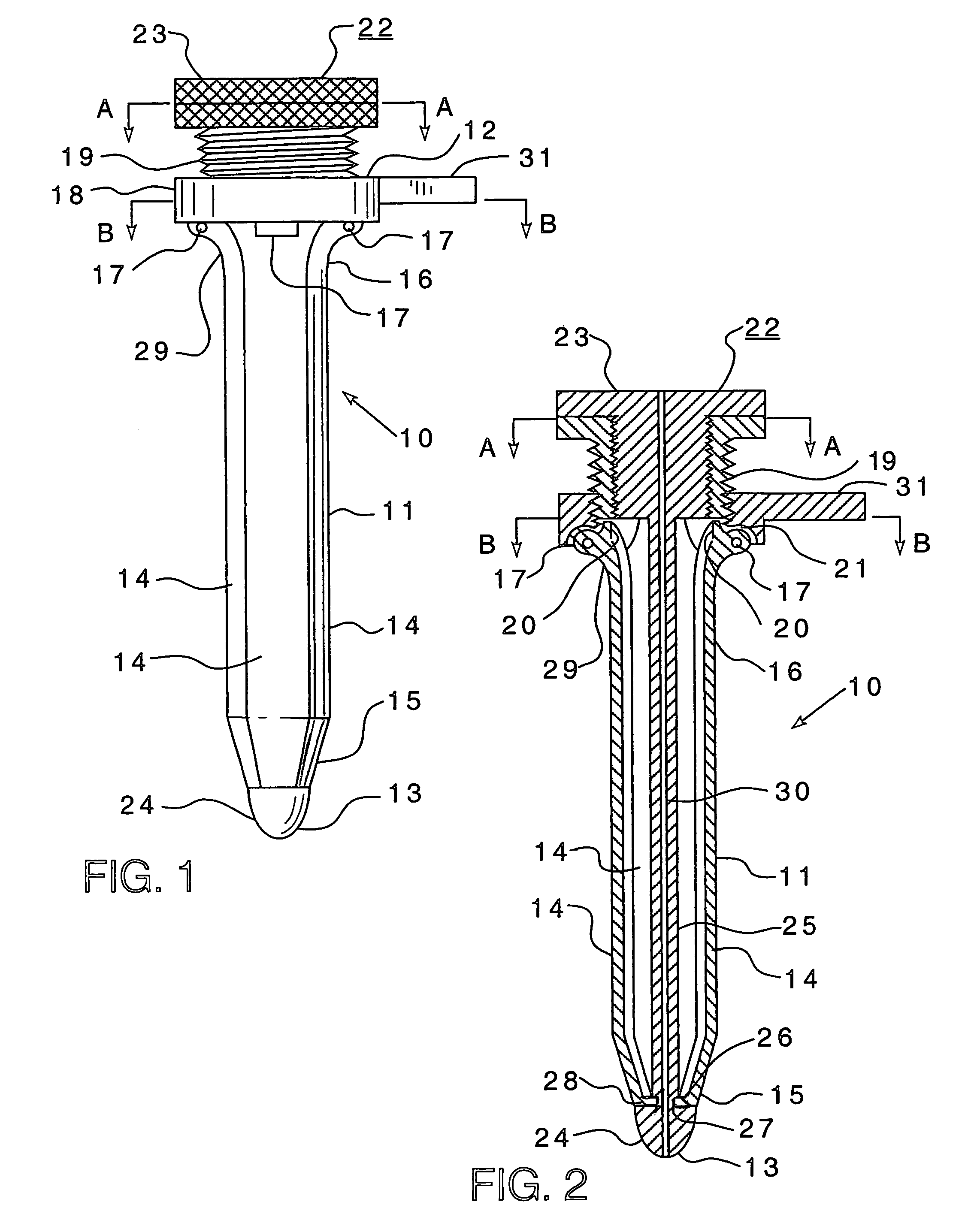

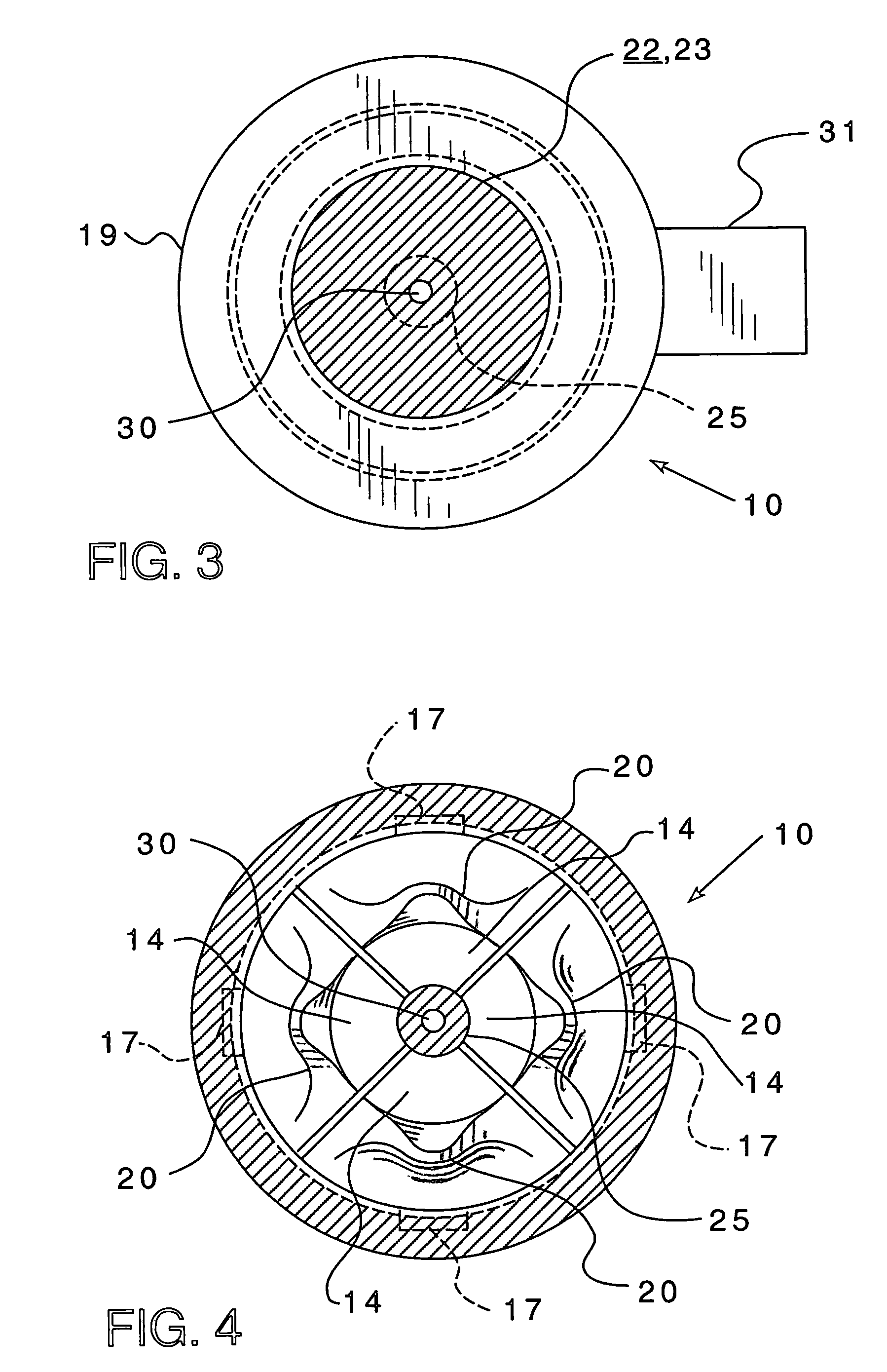

Surgical Instrument With Telescoping Attachment

A surgical instrument for the dissection of bone and other tissue includes a spindle, a dissection tool and an coupler disposed between the spindle and the dissection tool. The coupler includes a tool collet and an attachment locking mechanism operable to permit tool collet operation and telescoping movement of an attachment tube with respect to the dissection tool. A method is also provided for convenient coupling of the dissection tool and adjustment of the attachment tube length.

Owner:MEDTRONIC INC

Plug with detachable guidewire element and methods for use

InactiveUS6890343B2Low profilePromote progressVaccination/ovulation diagnosticsSurgical veterinaryDistal portionGuide wires

An apparatus for sealing a passage through tissue includes a bioabsorbable, threaded plug carried by a delivery device. A guide wire is receivable through lumens in the plug and delivery device that includes wings on a bioabsorbable distal portion. With the wings collapsed, the guide wire is advanced through the passage into a blood vessel, the wings expanding once located within the vessel, and the guide wire is withdrawn until the wings contact the vessel wall. The plug is threaded into the passage over the guide wire until the plug is disposed adjacent the wings. The distal portion of the guide wire is secured to the plug, e.g., by compressing a collet within the plug lumen that seals the lumen, and is severed from a proximal portion thereof. Thus, the plug and distal portion are deployed with the plug sealing the passage.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

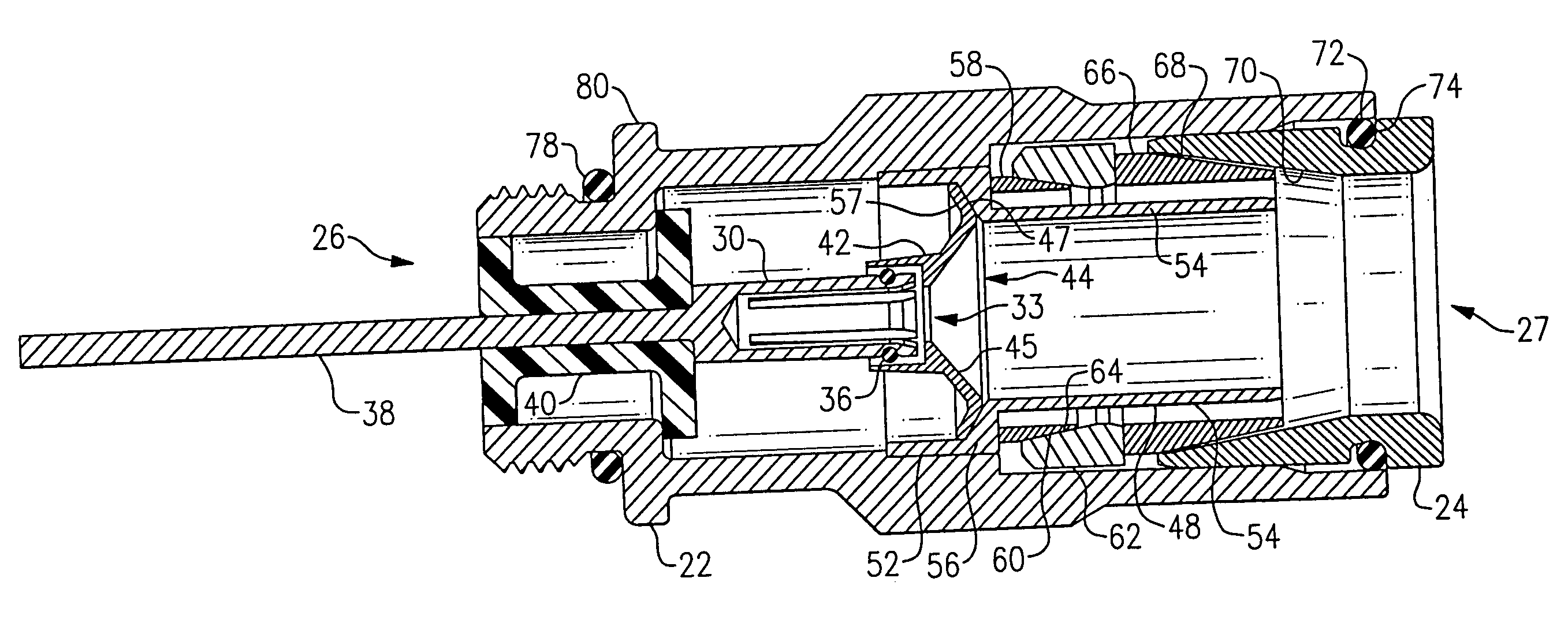

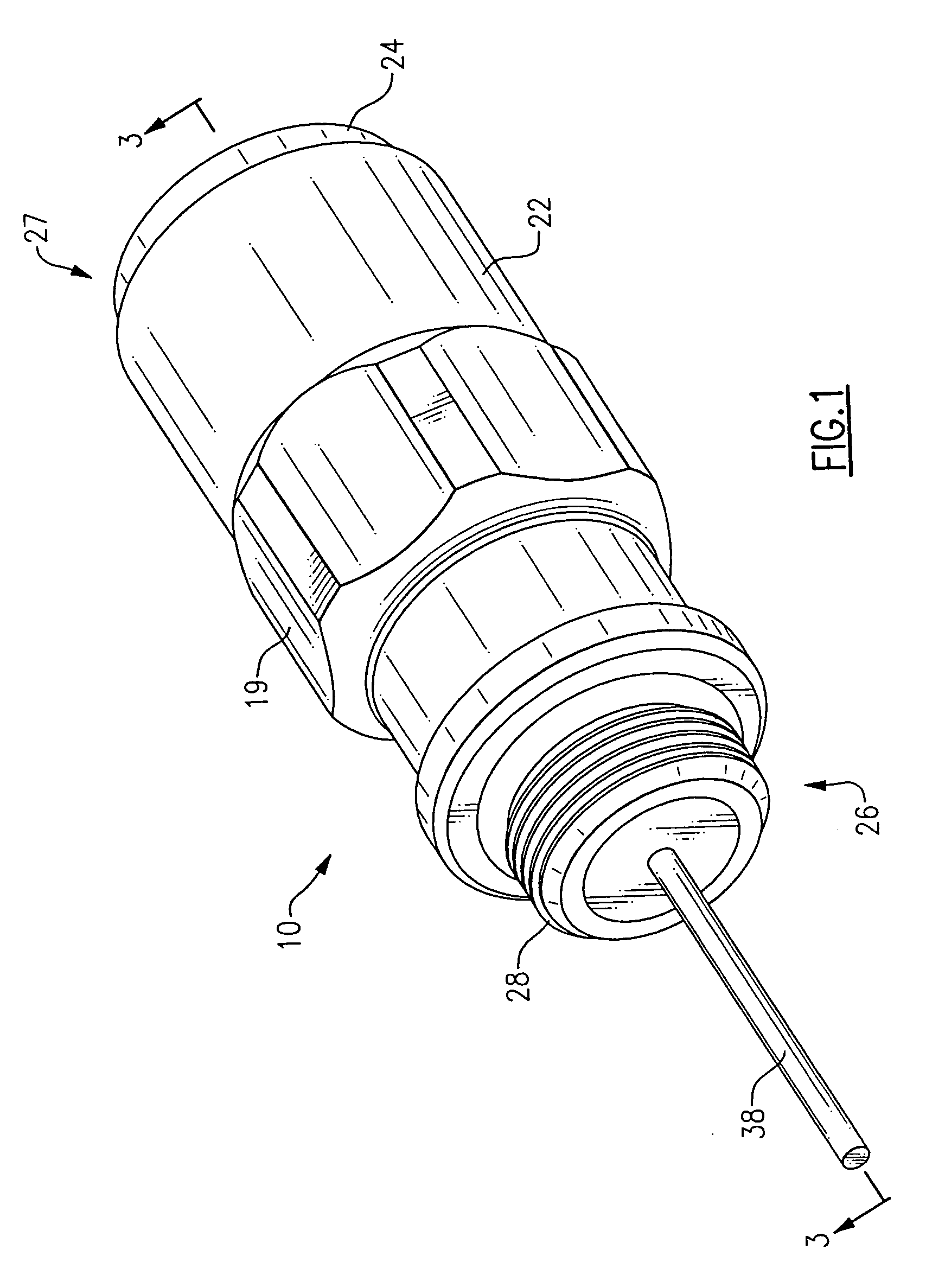

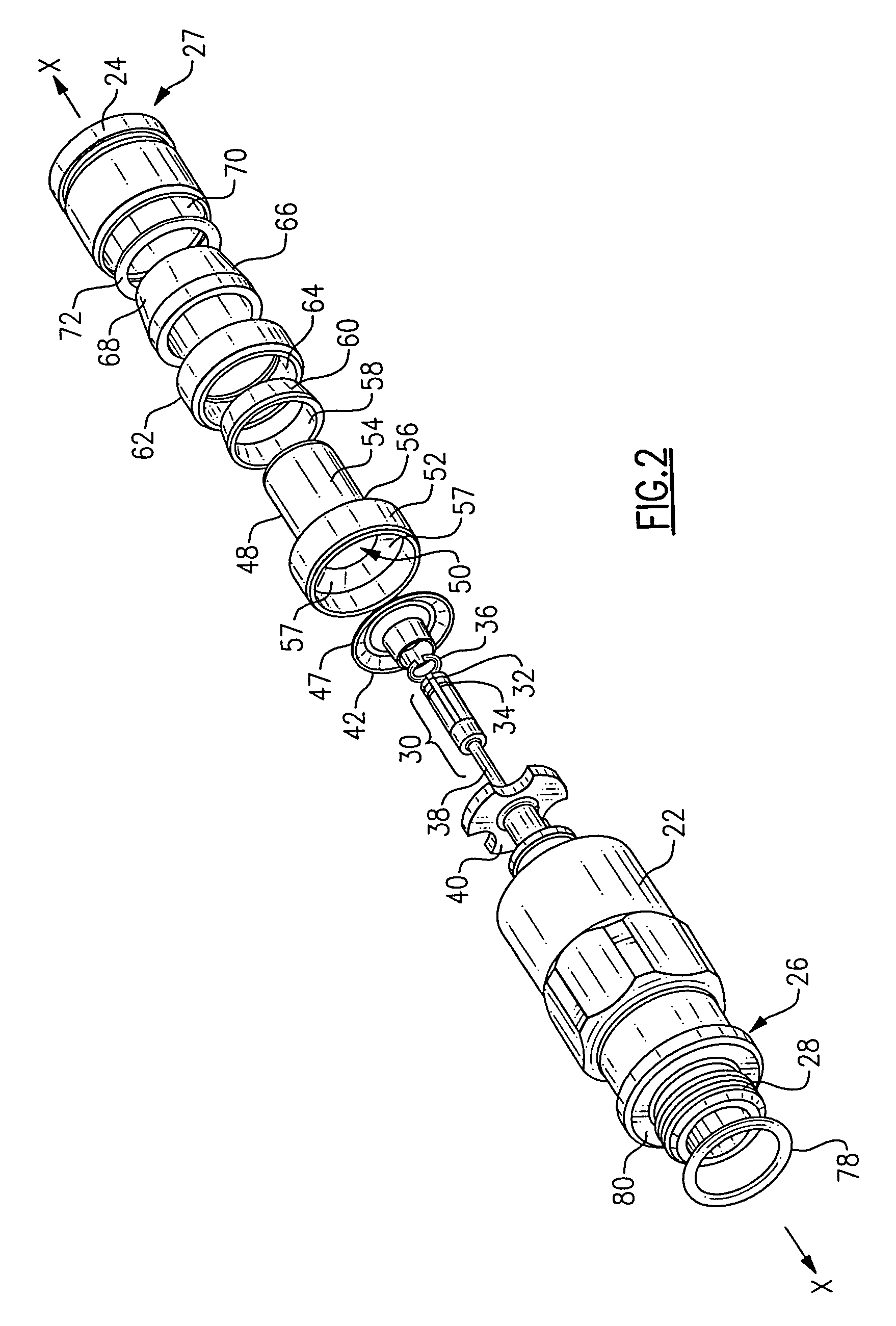

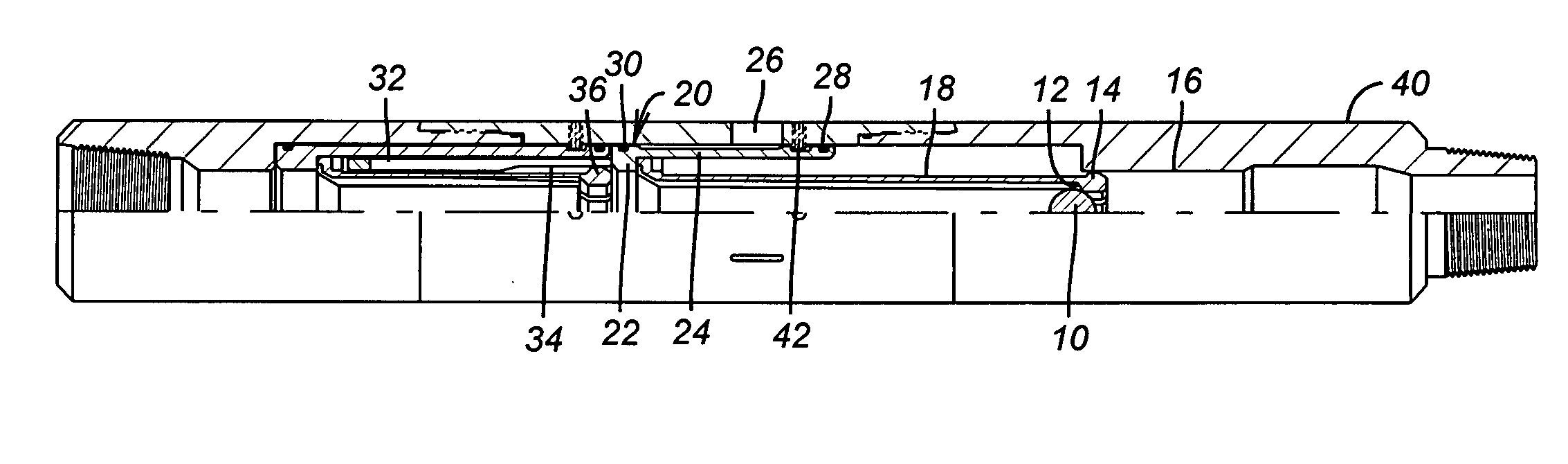

Apparatus for making permanent hardline connection

InactiveUS6884113B1Electrically conductive connectionsTwo pole connectionsCoaxial cableElectrical conductor

A permanent connector interconnects a hard-line coaxial cable to a connection housing. A contact is interconnected with and extends coaxially through a connector body. A collet one-piece with the contact receives a central conductor of the coaxial cable, while a sealing member and mandrel receive an outer conductor of the coaxial cable between them. A compression body positioned radially adjacent a portion of the connector body moves axially between first and second positions, wherein when the compression body is in its first position, the coaxial cable is removable from within the connector, and when the compression body is in its second position, the coaxial cable is not removable from within the connector. The compression body acts indirectly upon the sealing member so that an electrical connection is made between the sealing member and the outer conductor of the cable when the compression body is in its second position.

Owner:PPC BROADBAND INC

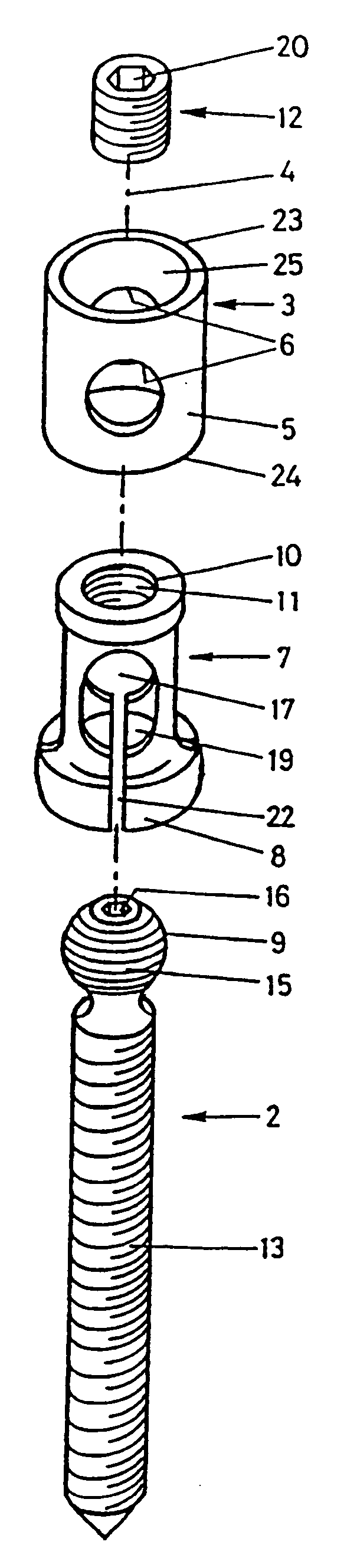

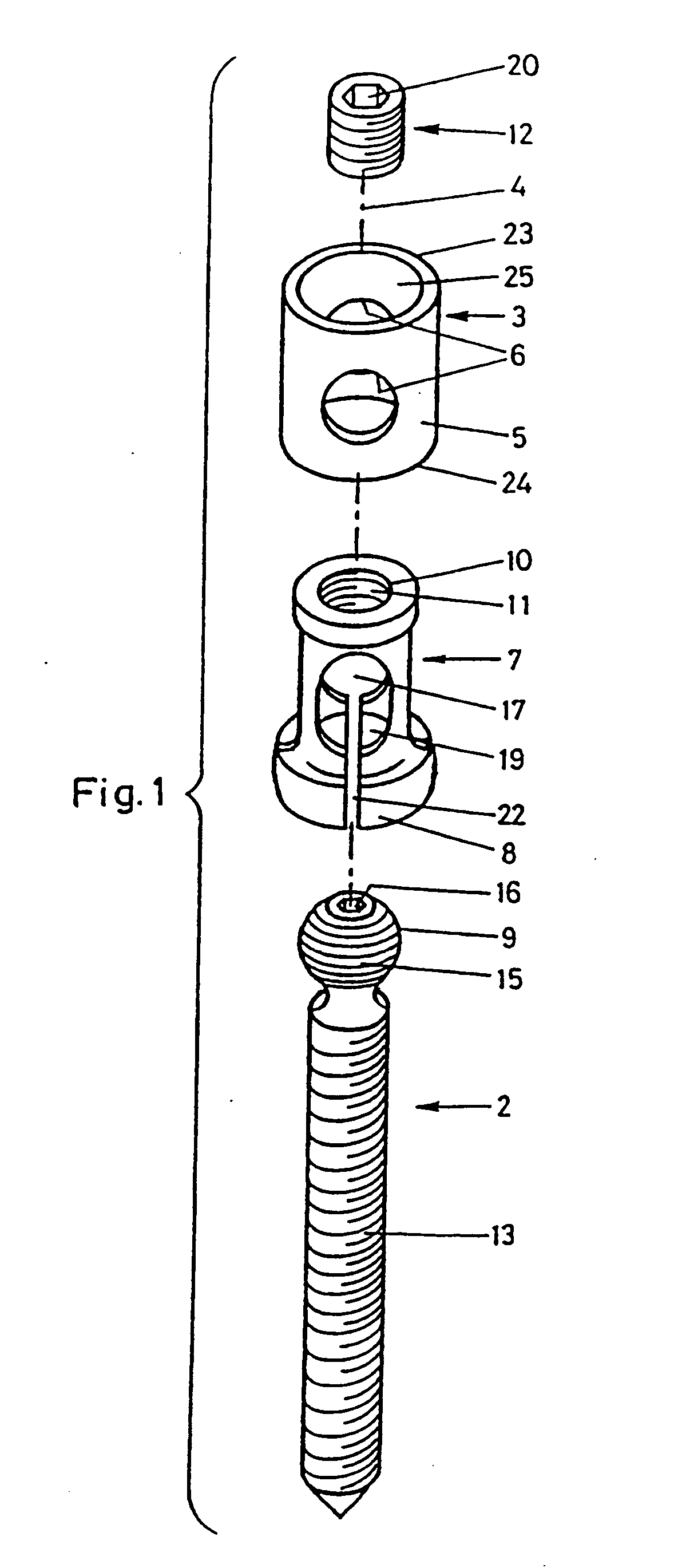

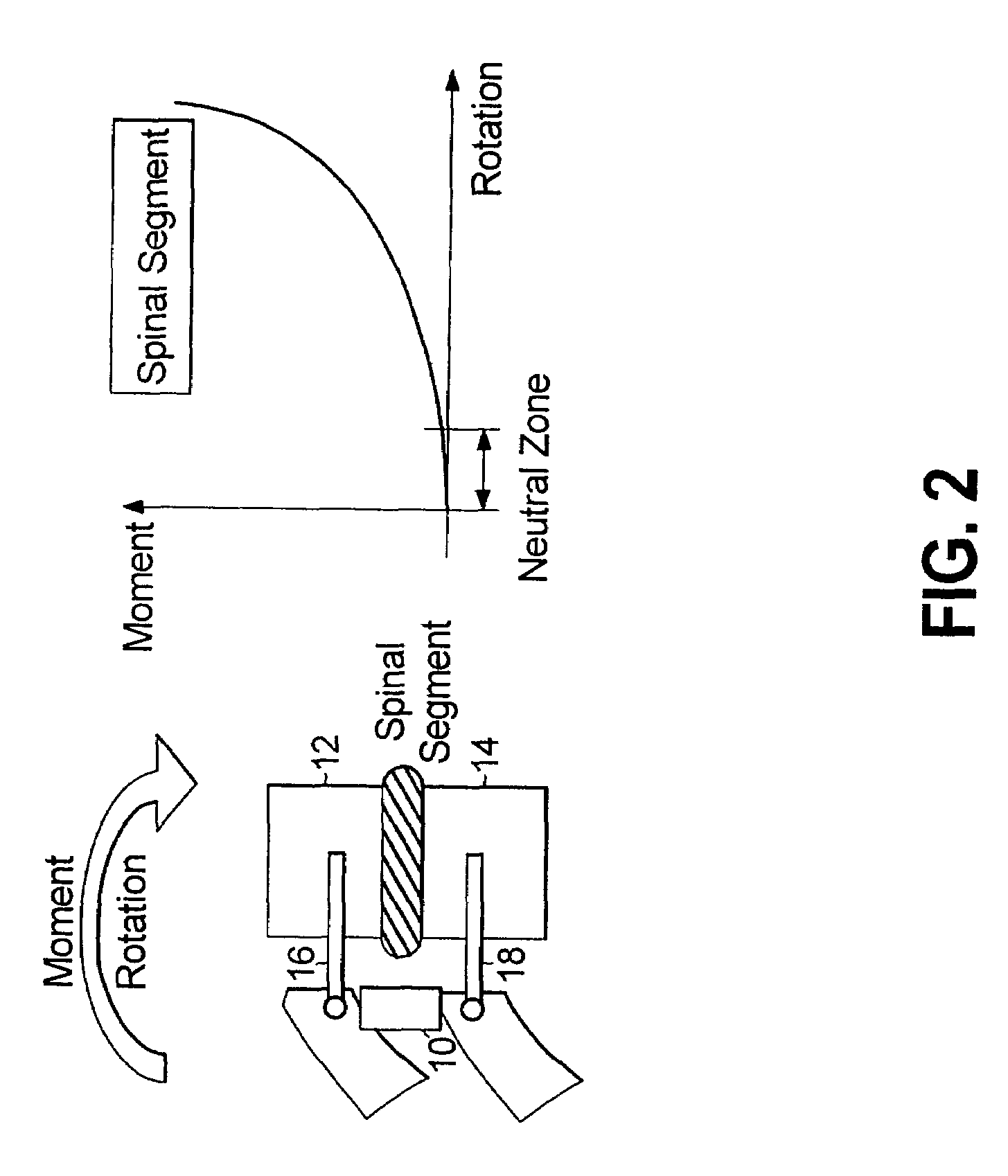

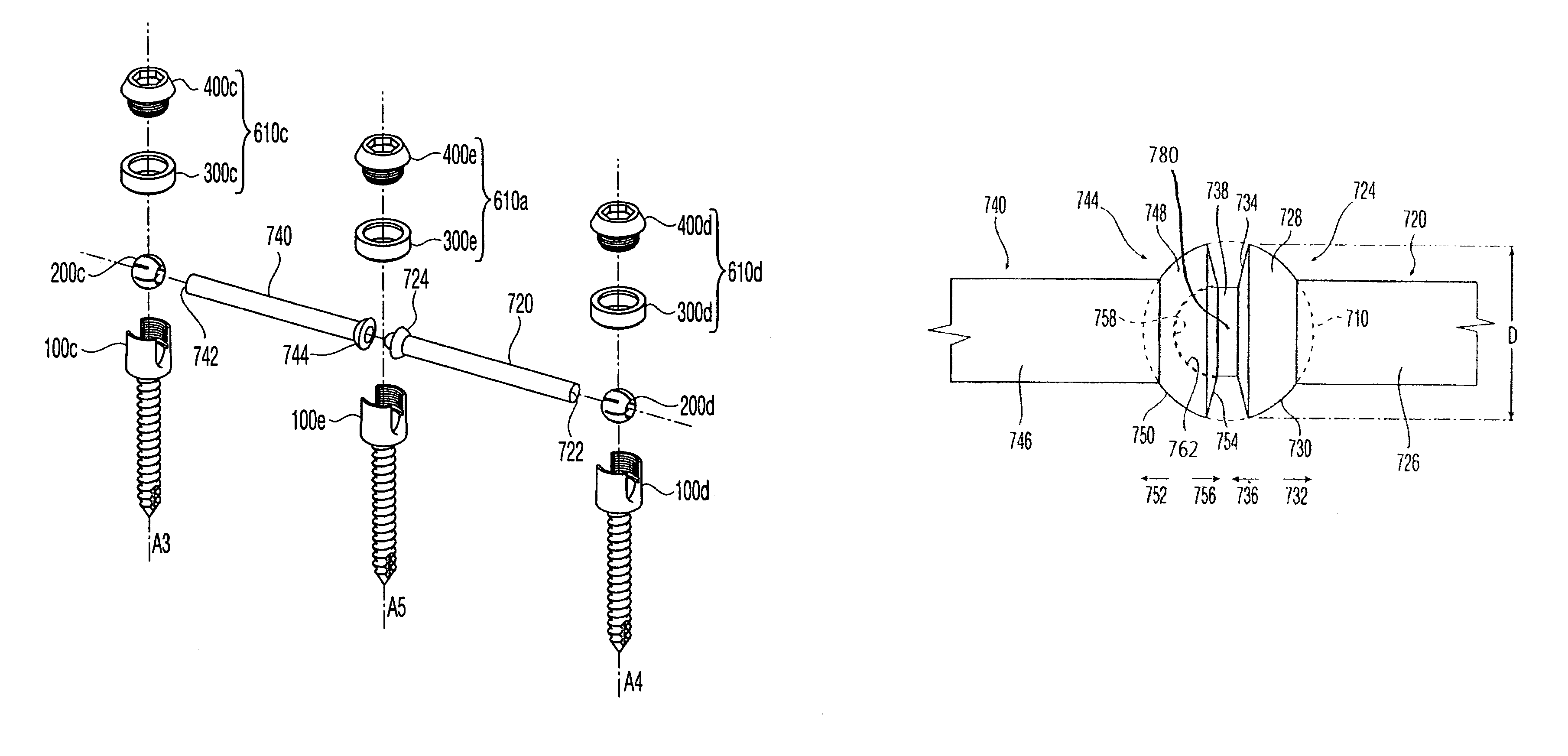

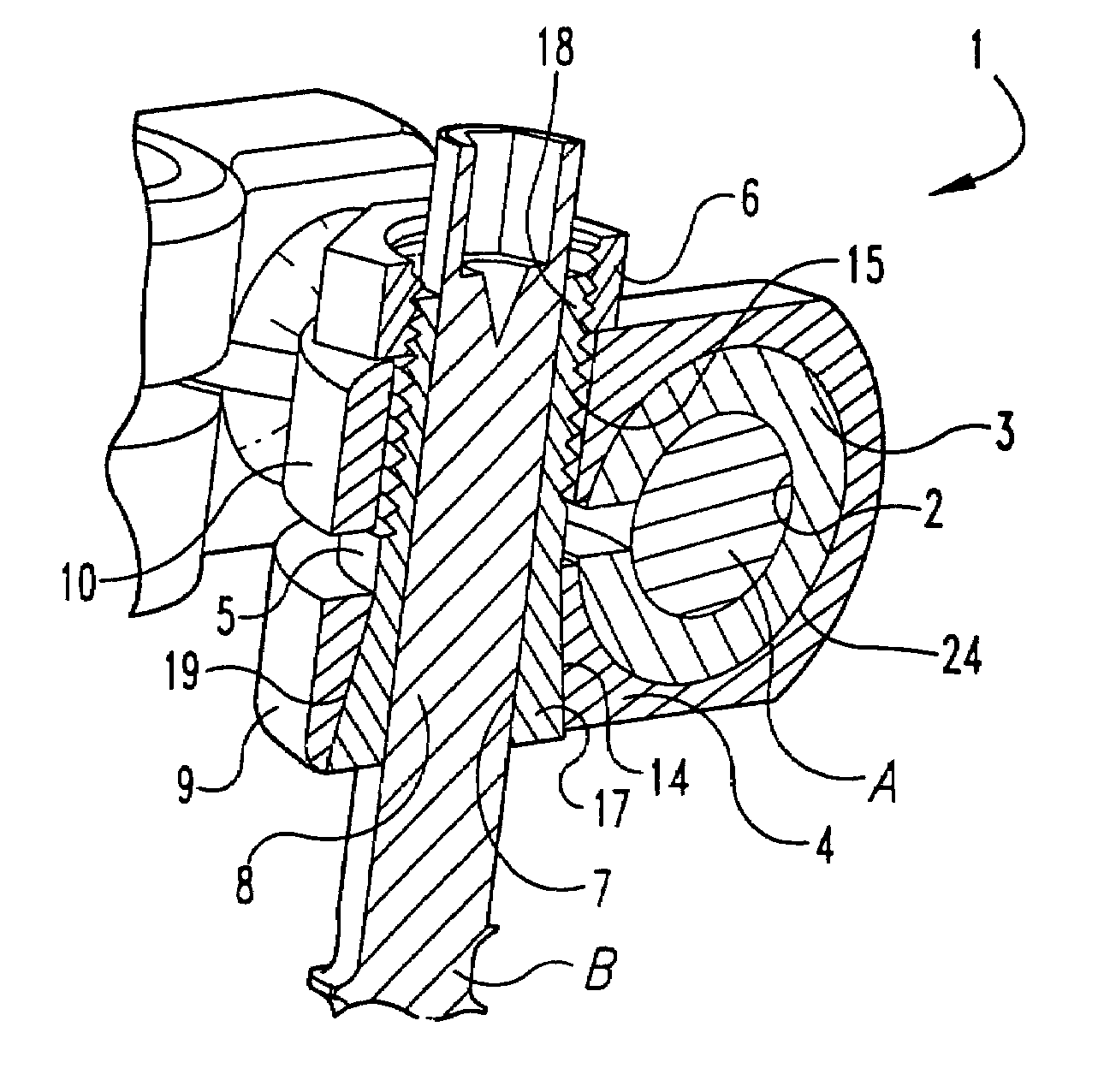

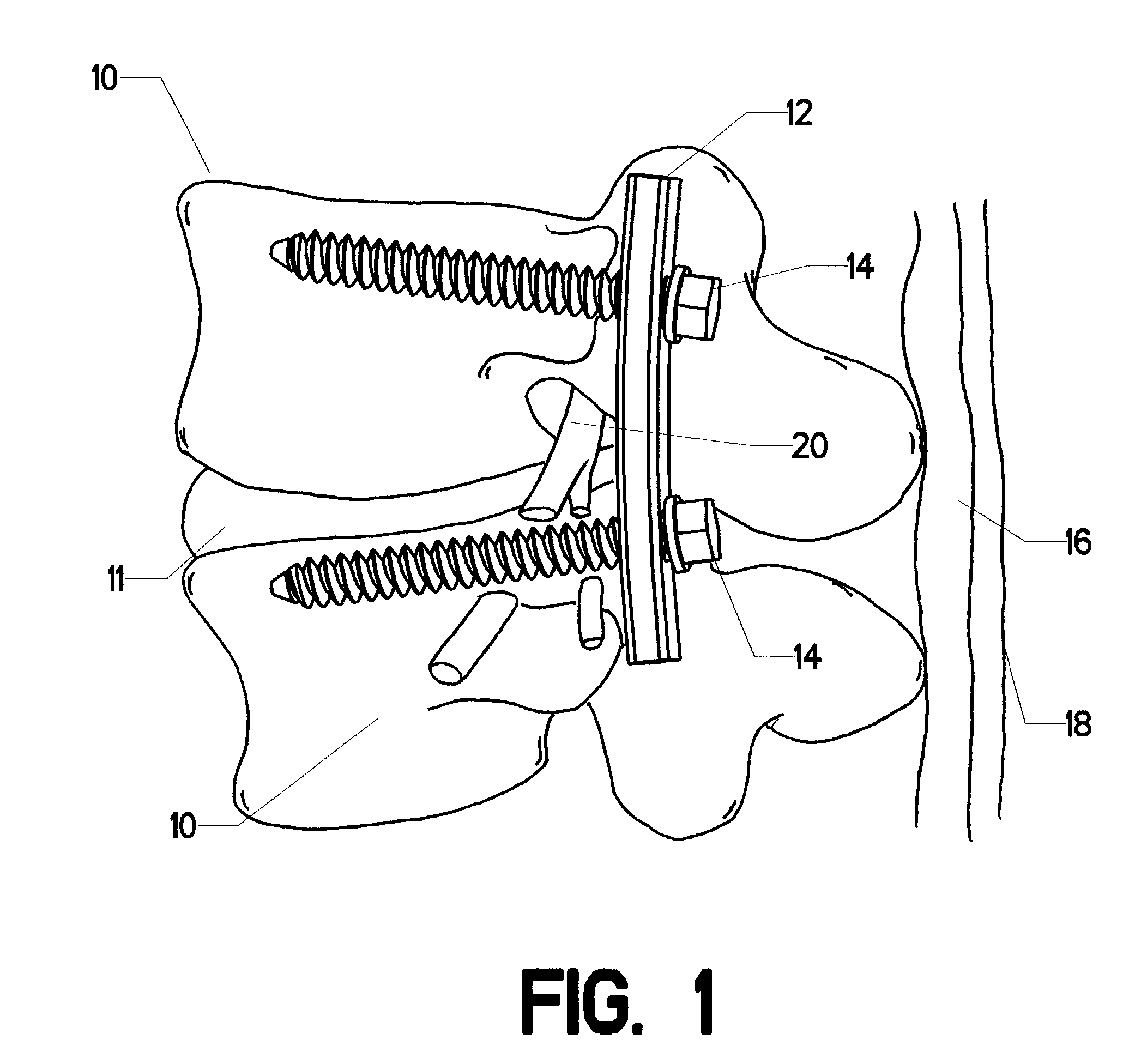

Device for connecting a longitudinal bar to a pedicle screw

A device for connecting a longitudinal bar to a pedicle screw for fixation of the spine includes a body having an axis, an upper end, a lower end, a hole coaxial with the axis, and a through hole positioned perpendicular to the axis. The device also includes a collet chuck slidably disposed within the hole. The collet chuck includes a through hole substantially aligned with the through hole of the body for receiving the longitudinal bar. The collet chuck also includes a chamber defined by elastic tongues for receiving the head of the pedicle screw.

Owner:DEPUY SYNTHES PROD INC

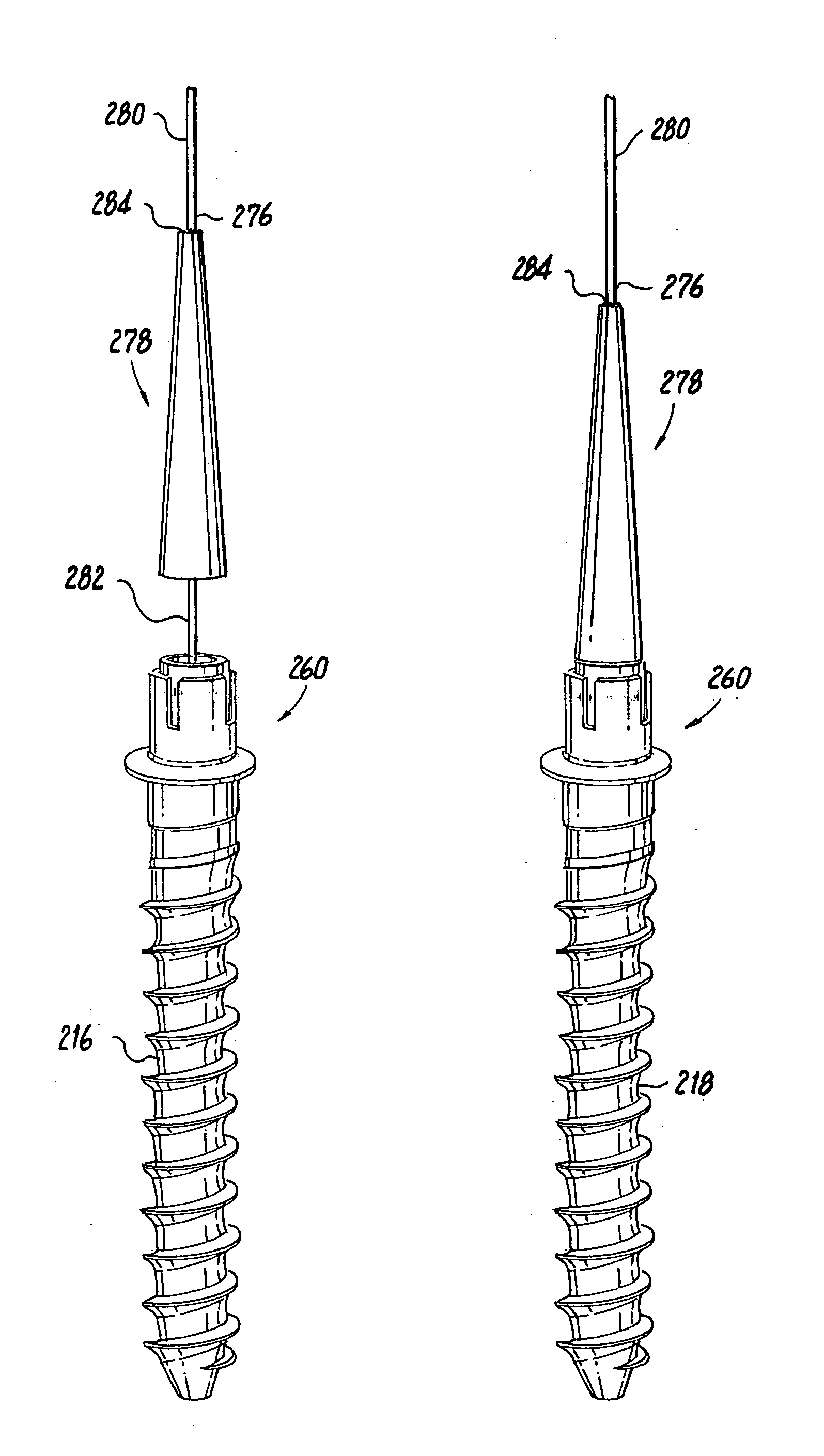

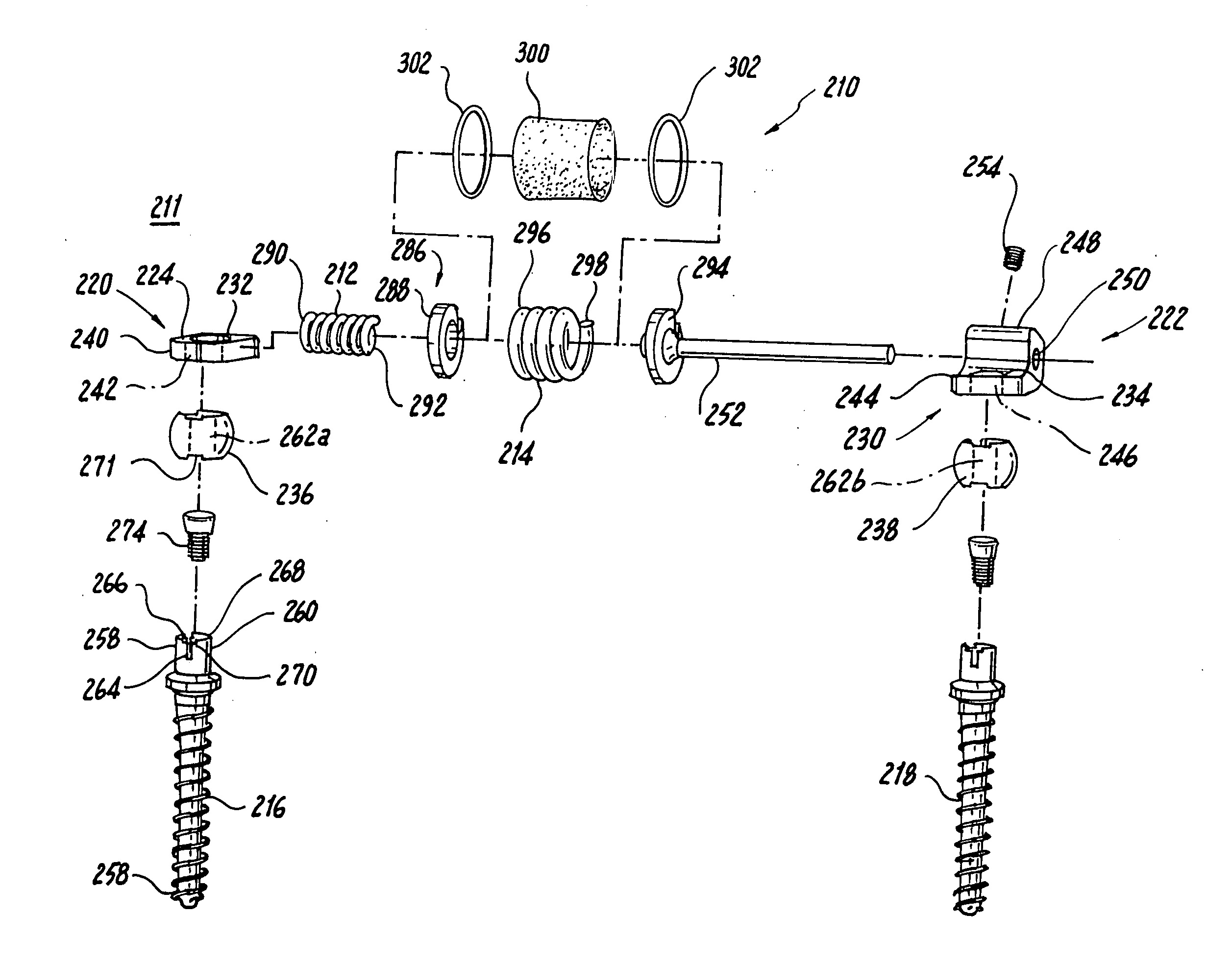

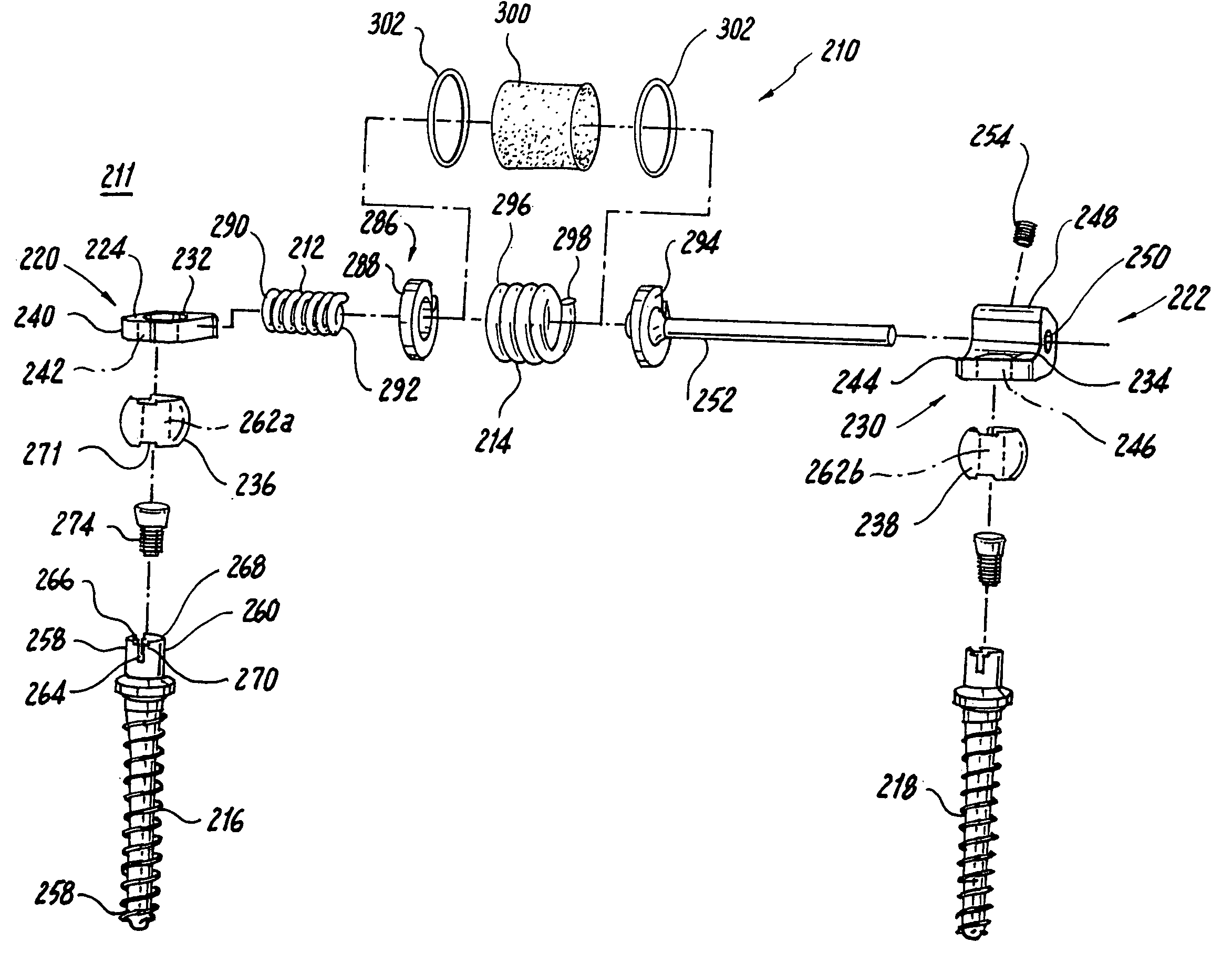

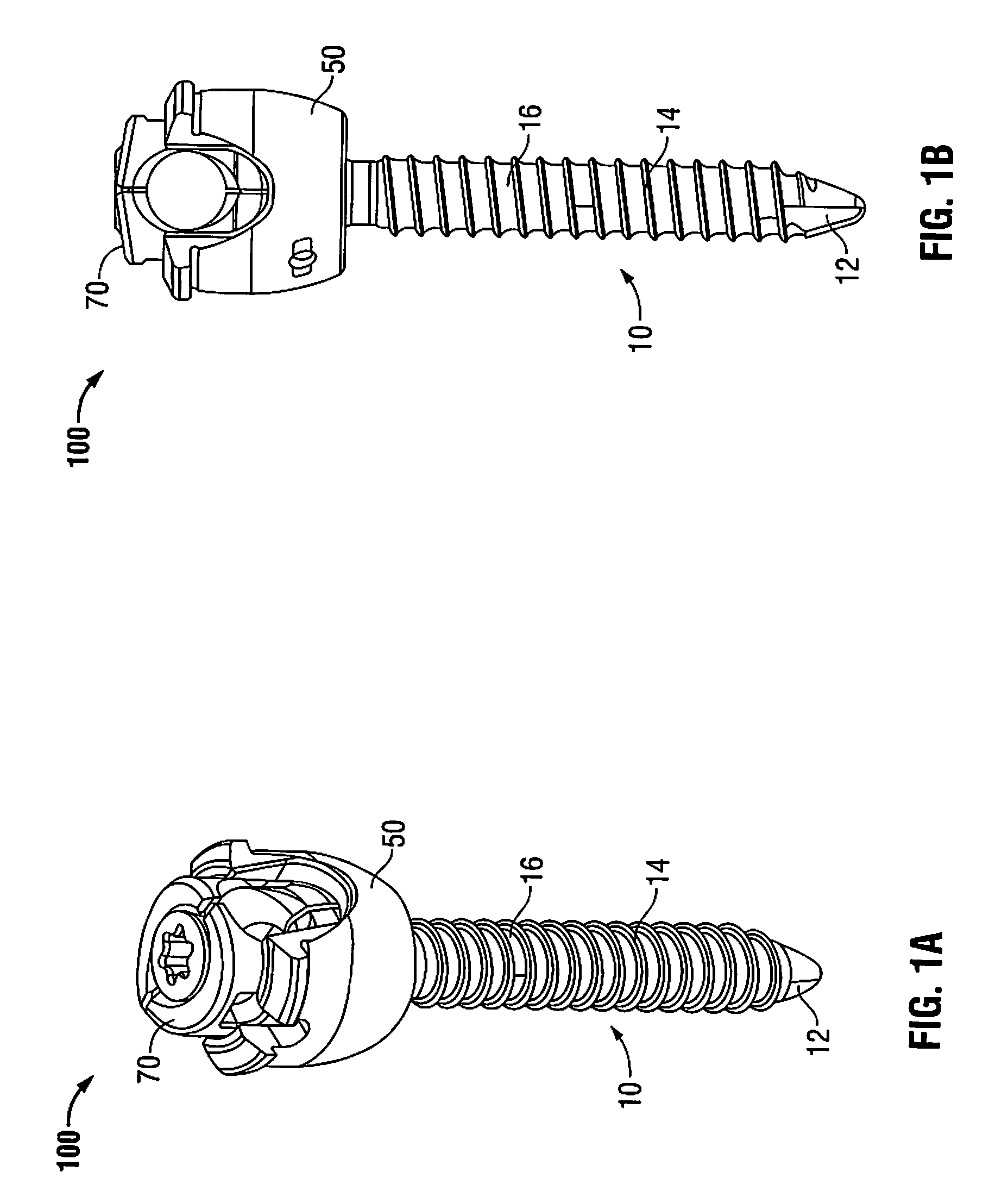

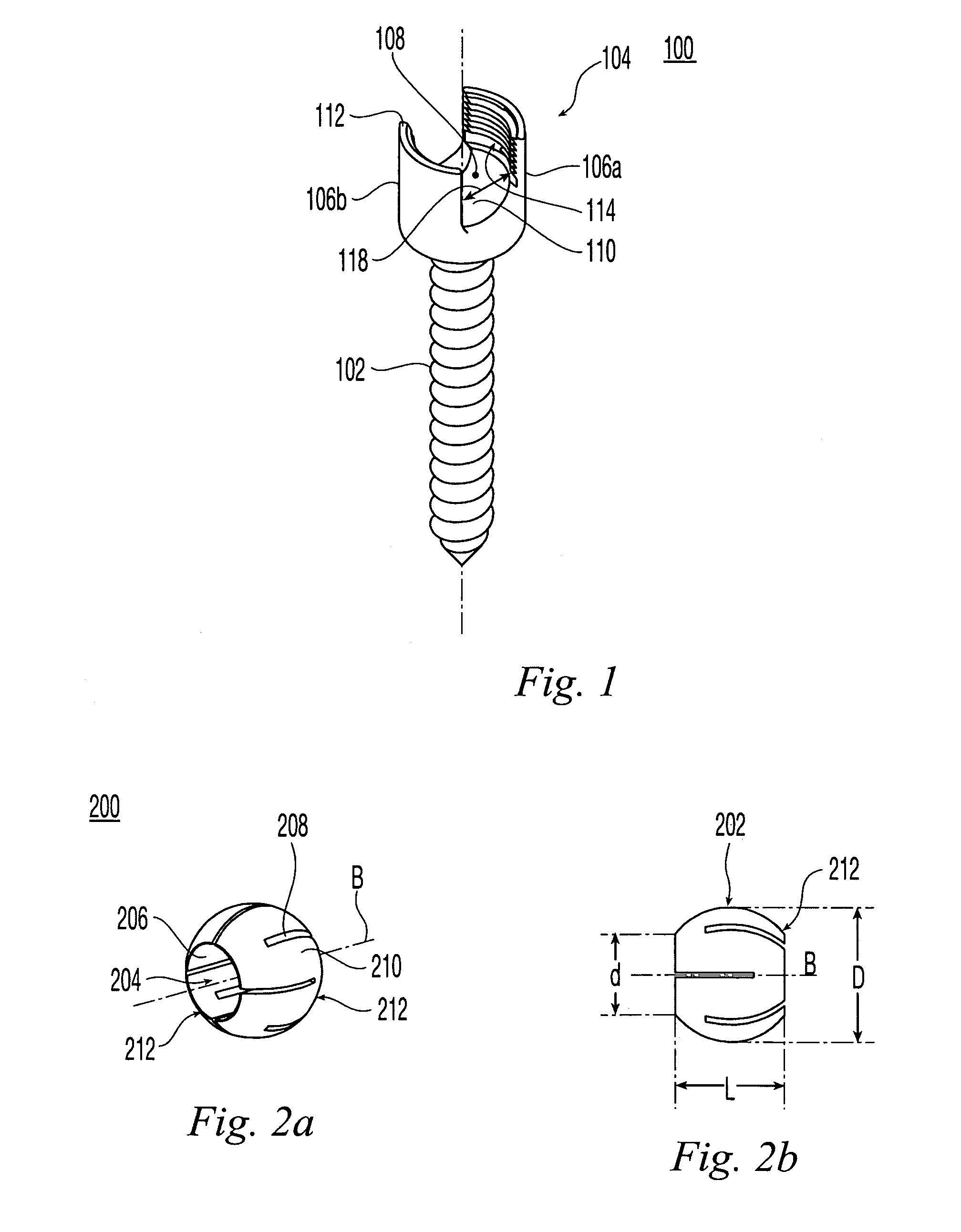

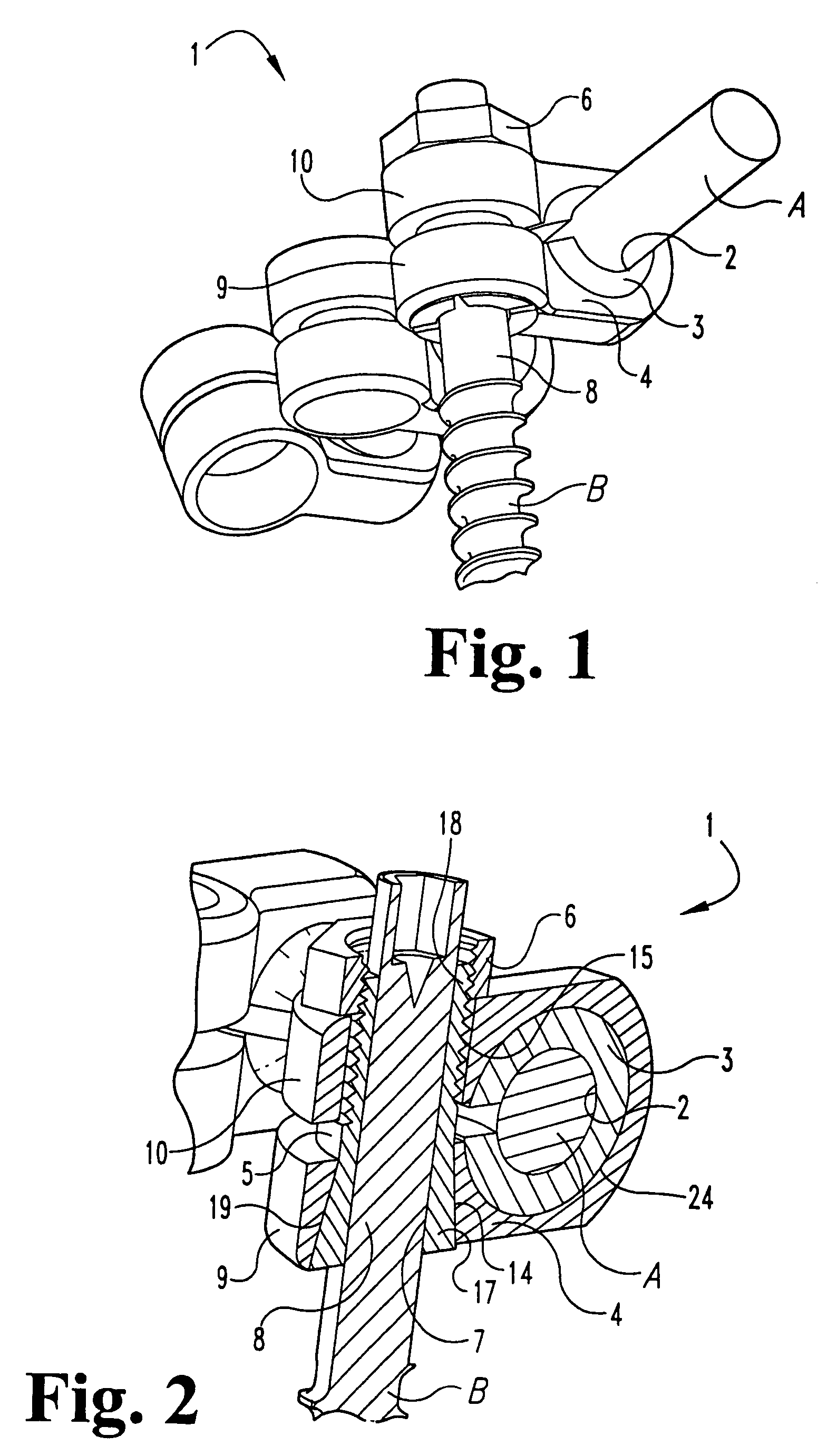

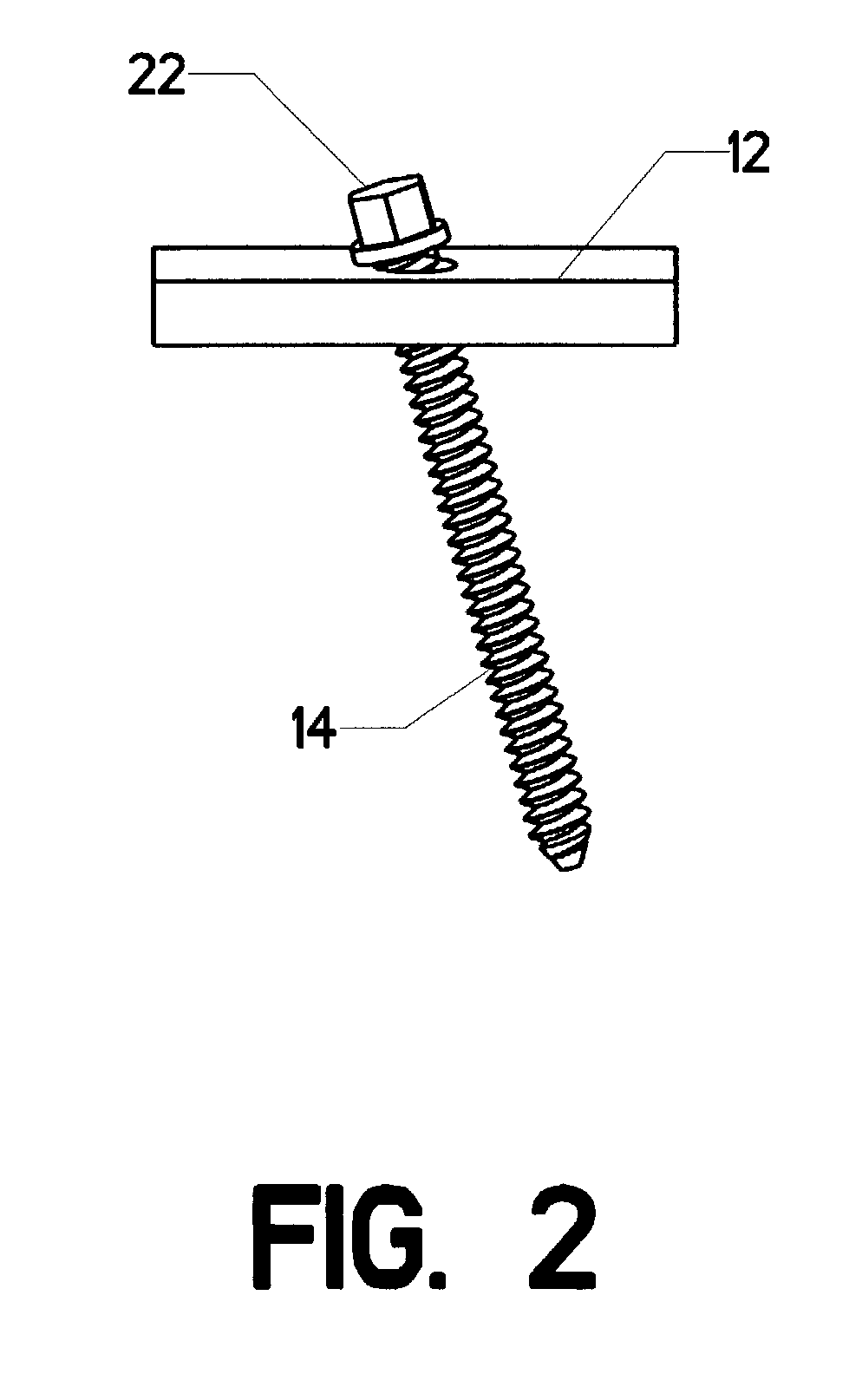

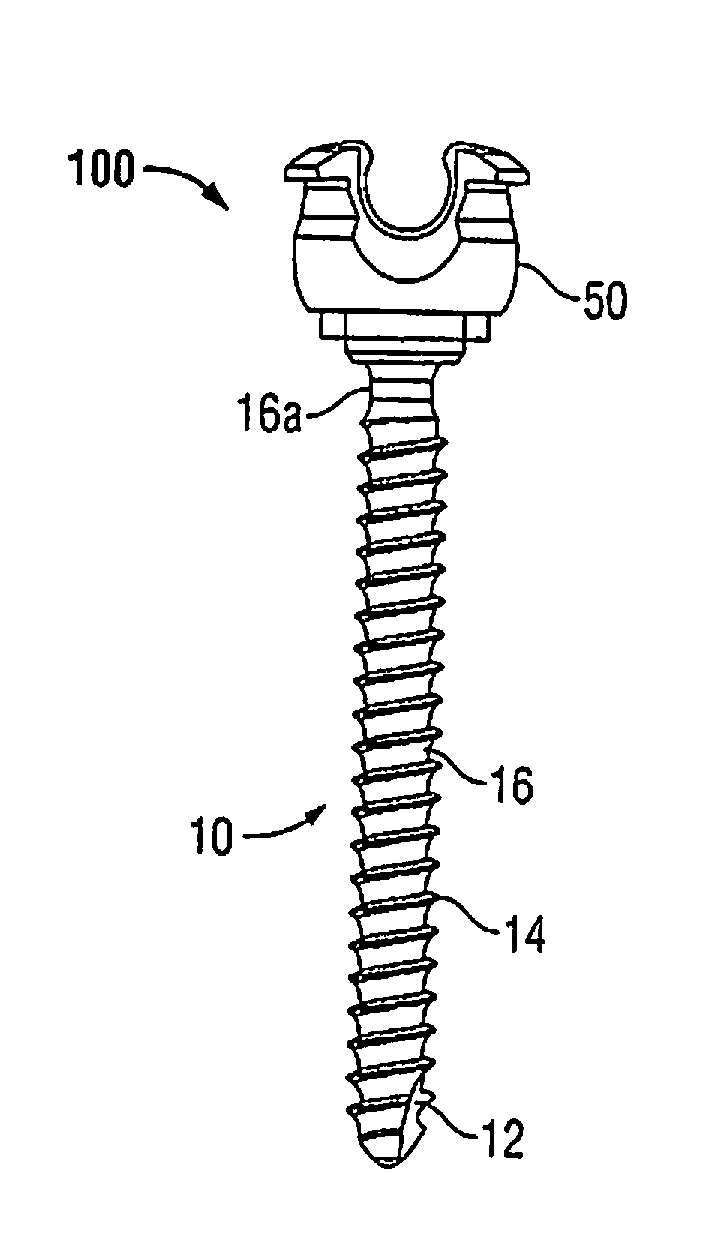

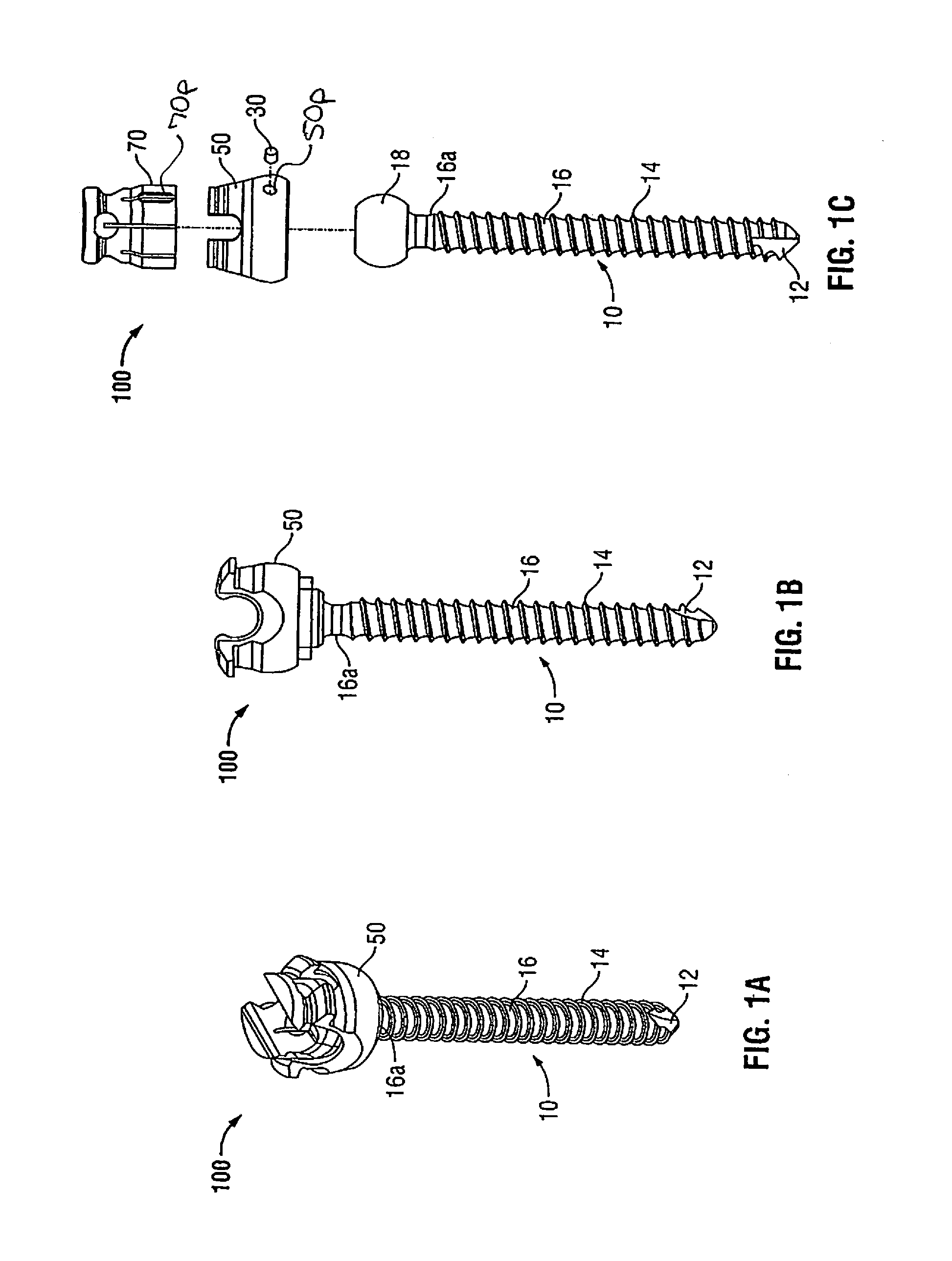

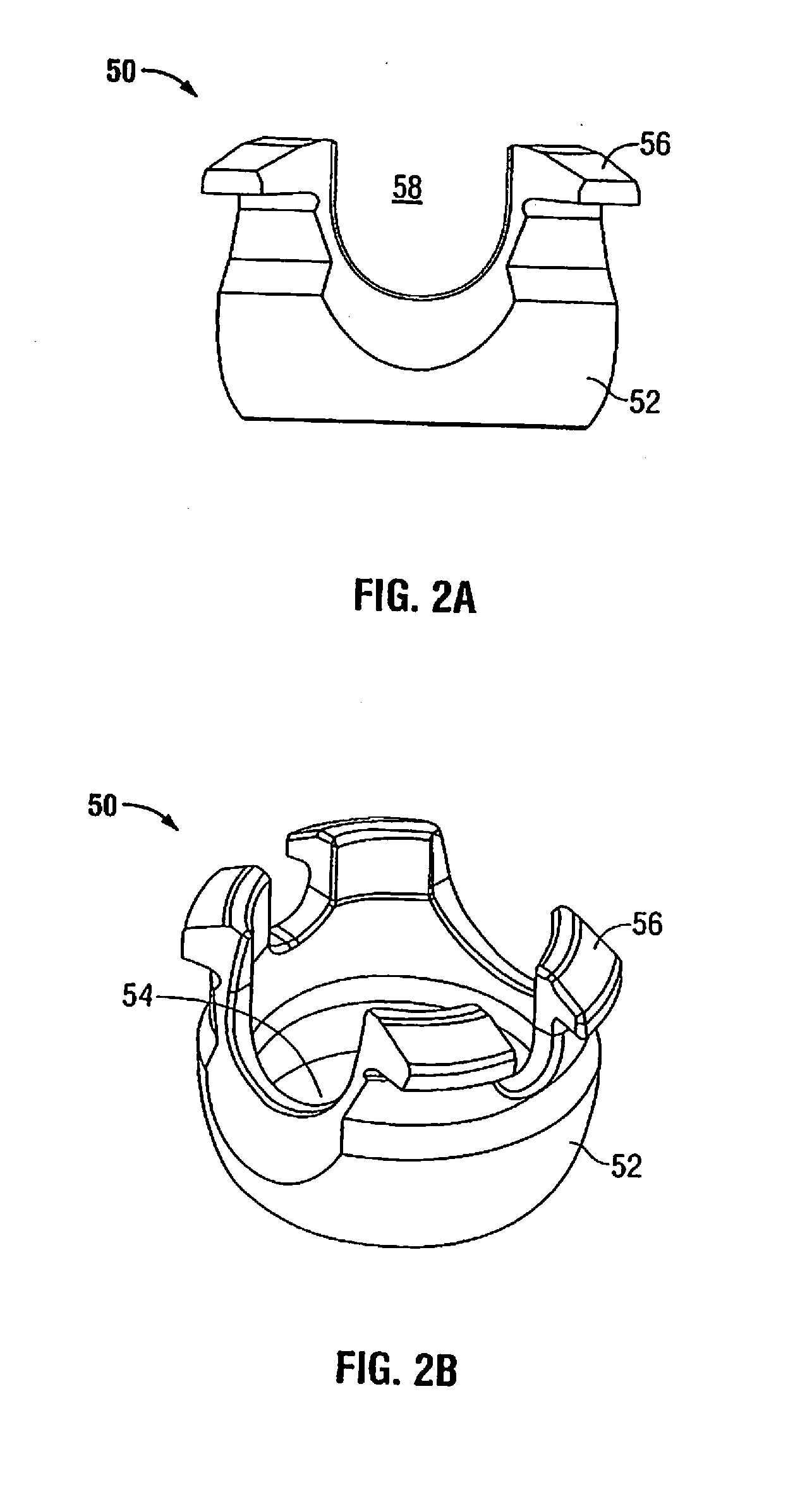

Mounting mechanisms for pedicle screws and related assemblies

ActiveUS20050177166A1Easy to installImprove clinical outcomesSuture equipmentsInternal osteosythesisSet screwEngineering

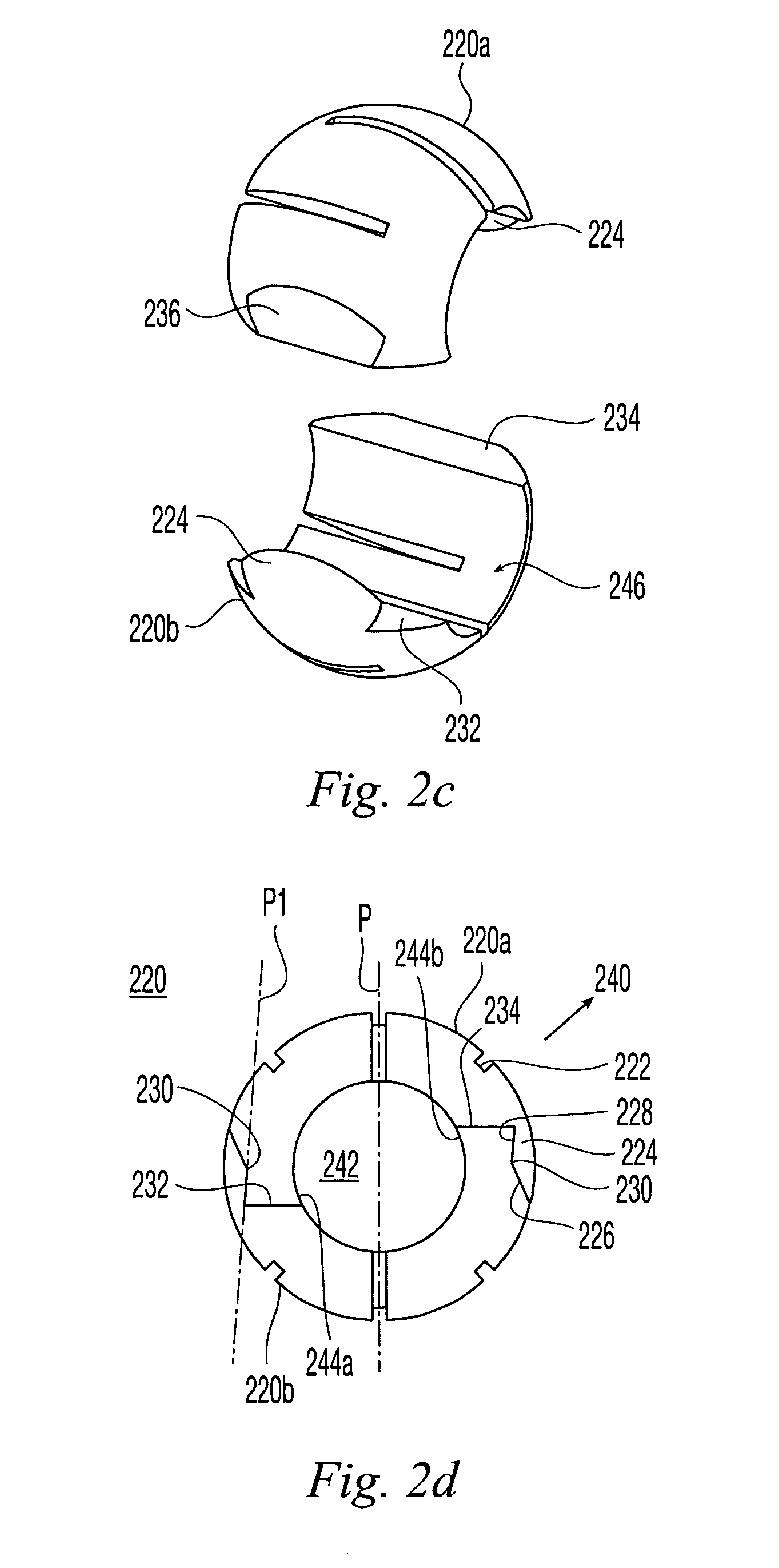

A pedicle screw is provided that includes an upwardly extending collet. The collet may include downwardly extending slots that define deflectable segments therebetween. When a spherical element or other structure, e.g., a non-dynamic stabilizing element, is positioned around the collet, introduction of a set screw causes outward deflection of the upstanding segments into engagement with the spherical element. A snap ring may be interposed between the collet and the spherical element to facilitate positioning therebetween. In an alternative embodiment, a non-slotted collet is employed. In such embodiment, the collet and the spherical element may be threadingly engaged and may include a snap ring therebetween. The pedicle screw subassemblies may be incorporated into a spinal stabilization system which may include a dynamic stabilizing member to provide clinically efficacious results.

Owner:RACHIOTEK

Pedicle screw devices, systems and methods having a preloaded set screw

InactiveUS20050177164A1The result is validEase of installation and in applicationSuture equipmentsInternal osteosythesisSet screwPedicle screw fixation

A pedicle screw assembly is provided that includes a pedicle screw and a preloaded set screw. The set screw is preloaded in a threaded, central aperture formed in the head region of the pedicle screw. An interference is advantageously formed on the set screw to prevent dislodgement of the set screw, e.g., during shipment and / or clinical placement of the pedicle screw. An upwardly extending collet is generally formed in the head region of the pedicle screw, the collet being sized to receive a spherical element therearound. Advancement of the set screw relative to the pedicle screw secures the spherical element relative to the pedicle screw. The spherical element typically includes a socket member that cooperates with a dynamic stabilizing member. The pedicle screw assembly and dynamic stabilizing member are advantageously used as part of a spinal stabilization system to provide clinically efficacious results.

Owner:APPLIED SPINE TECH

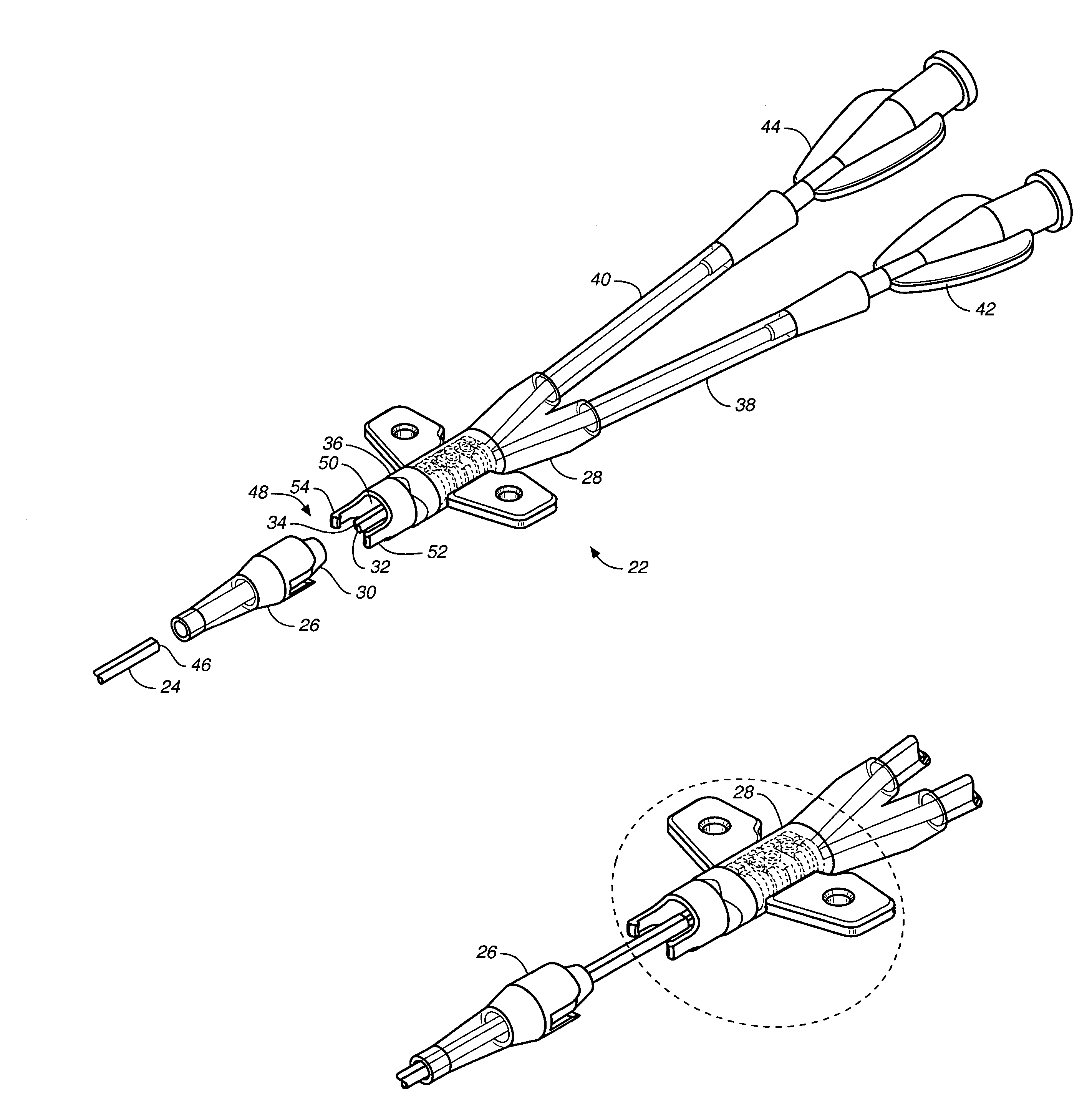

Suture clips, delivery devices and methods

InactiveUS7993368B2Removal from surfaceEliminate needSnap fastenersSuture equipmentsSuturing clipSuture clip

Provided herein are suture clips that include a plug, a ring, and a shaft. Also provided is a catheter that includes a collet cage with a plurality of flexible collet fingers that engage a suture clip ring and a suture clip plug for assembly with a suture. The catheter is designed to hold and assemble the suture clip in a first position and release the suture clip and sever the suture ends proximal to the suture clip in a second position.

Owner:CR BARD INC

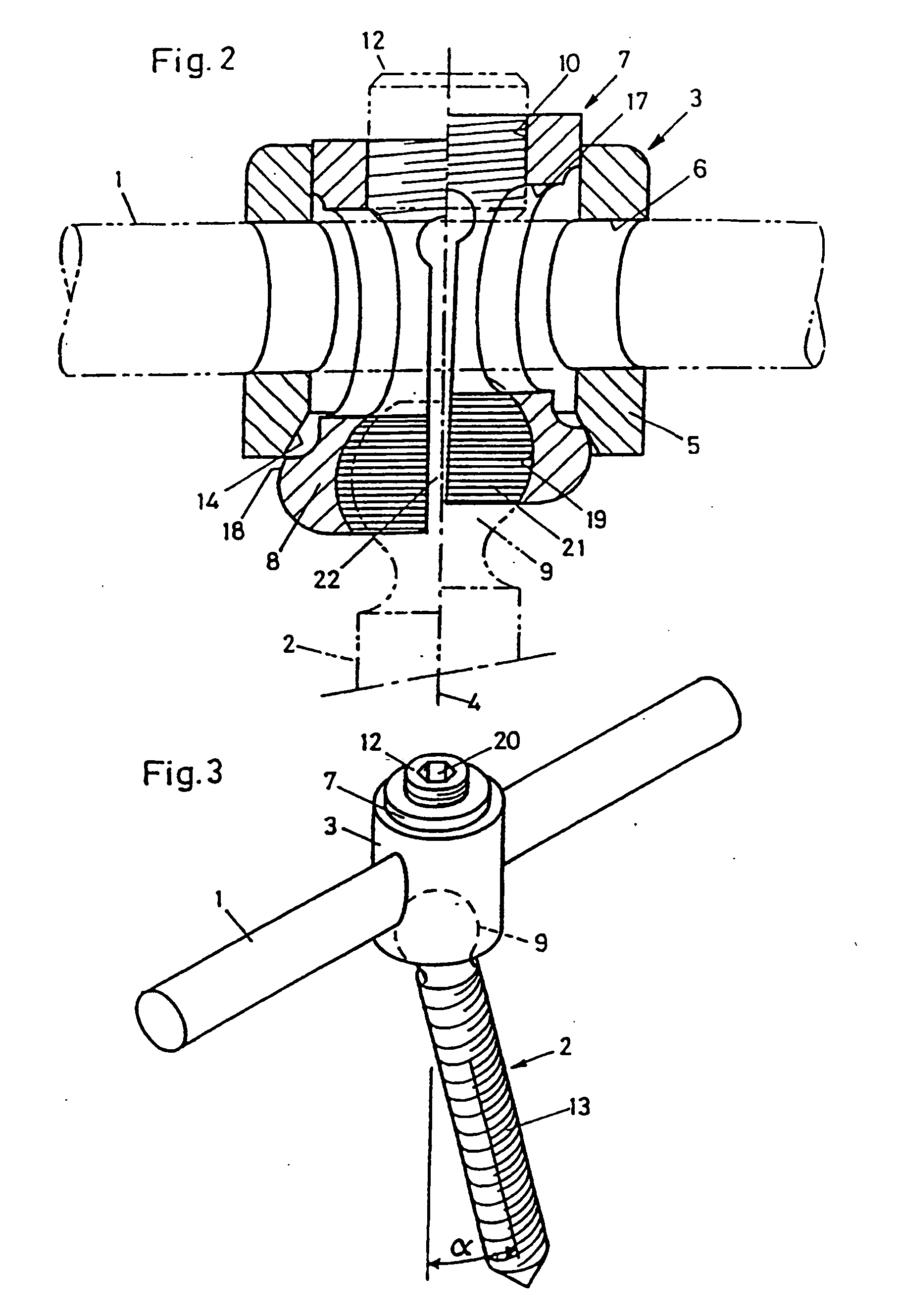

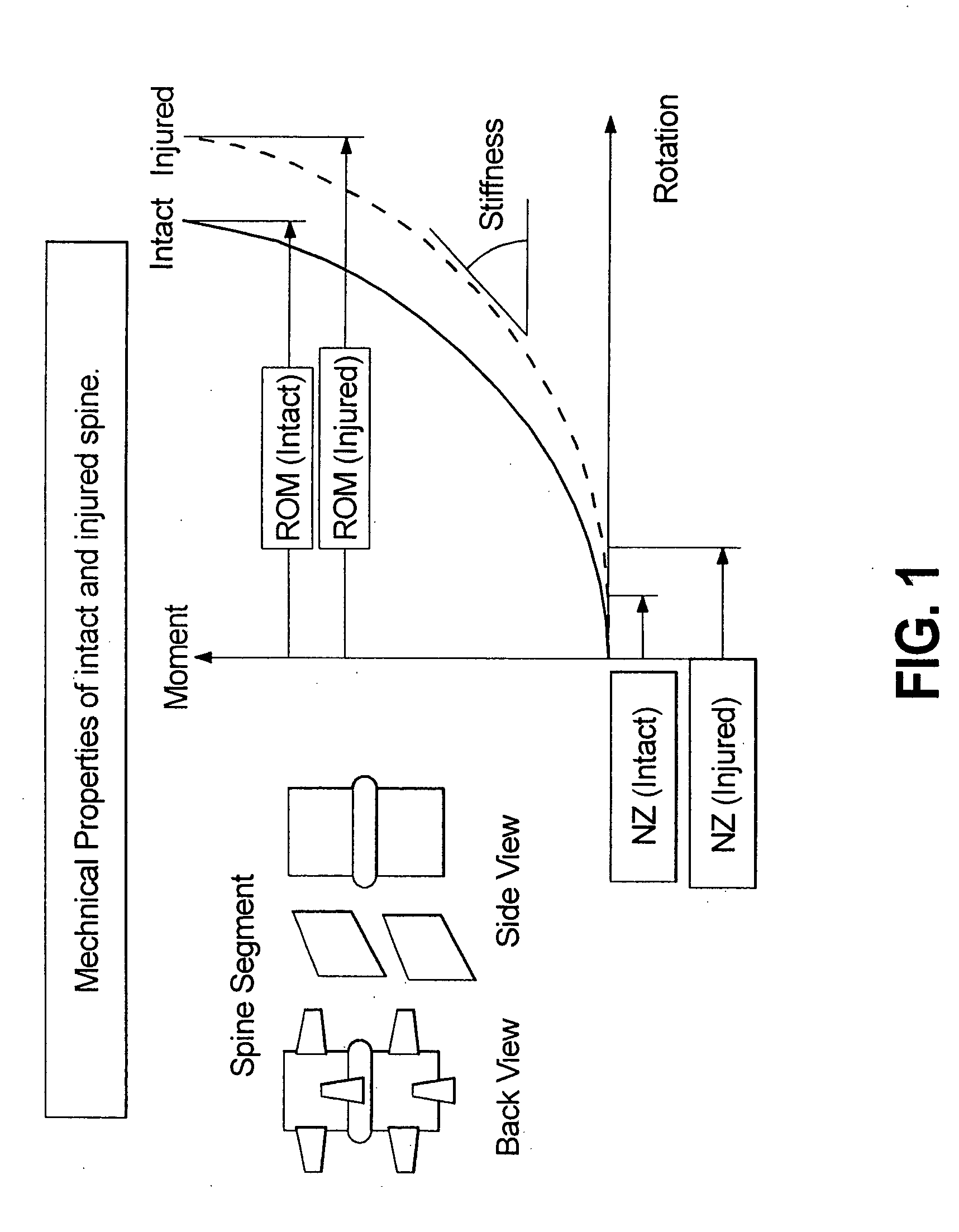

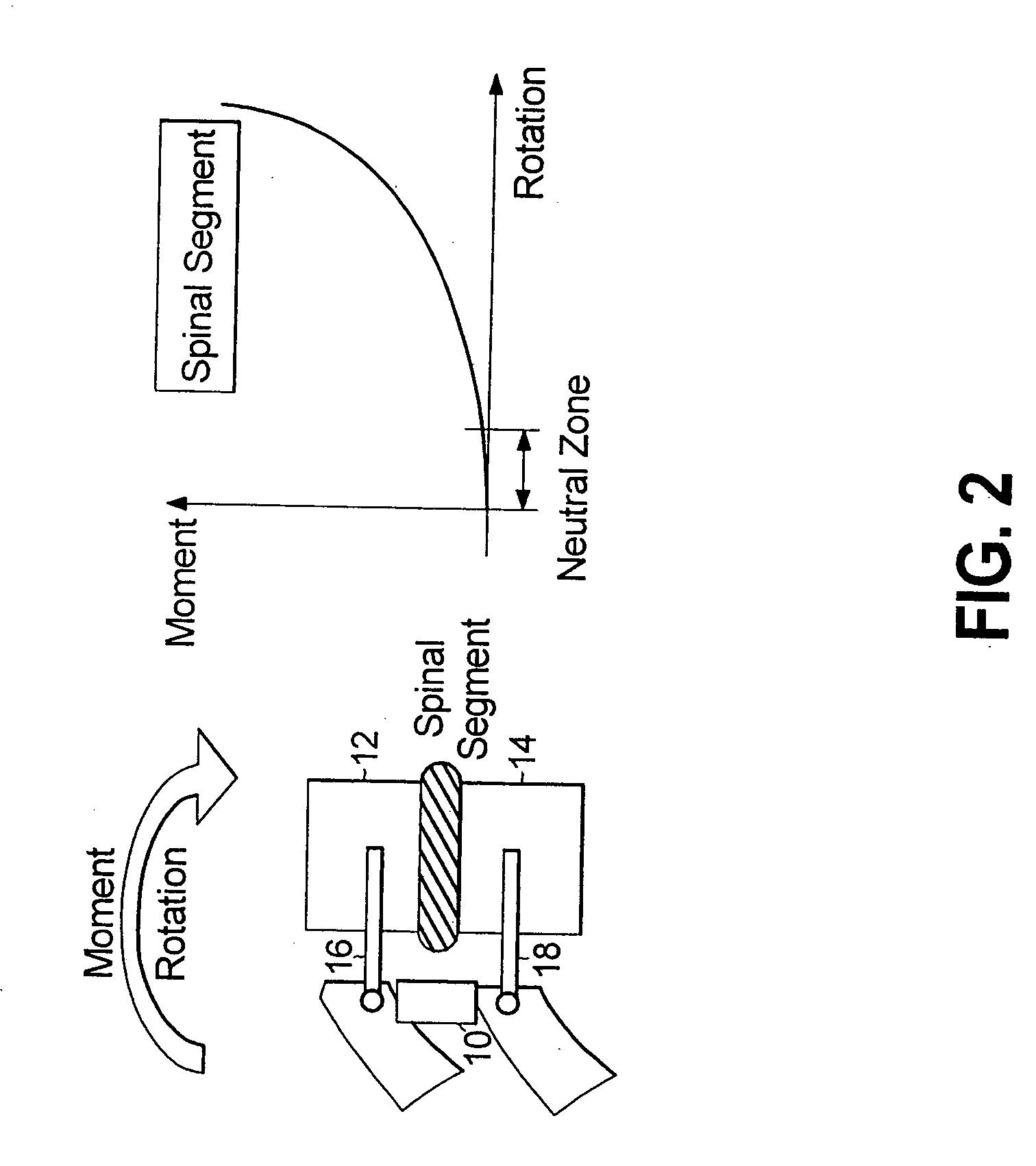

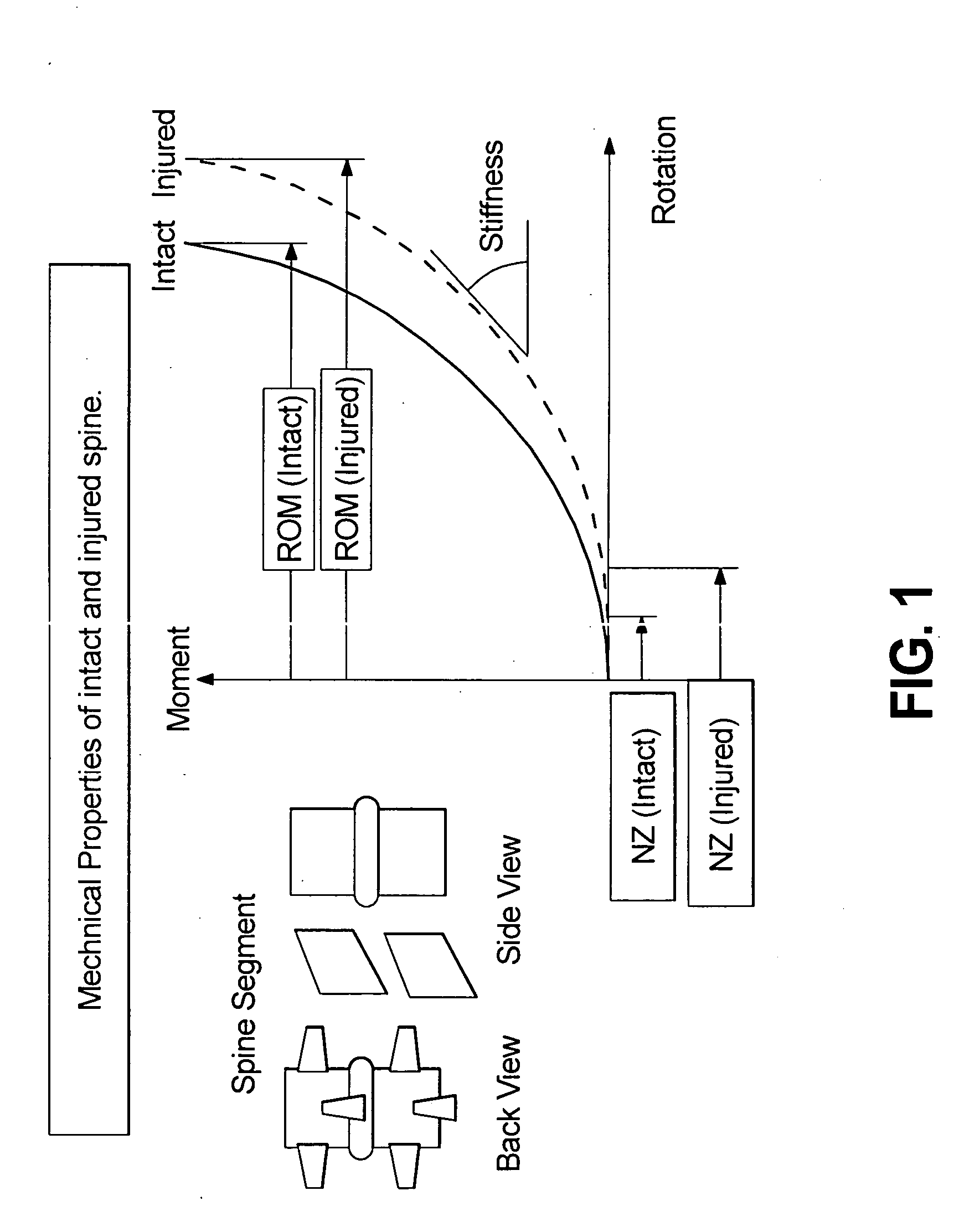

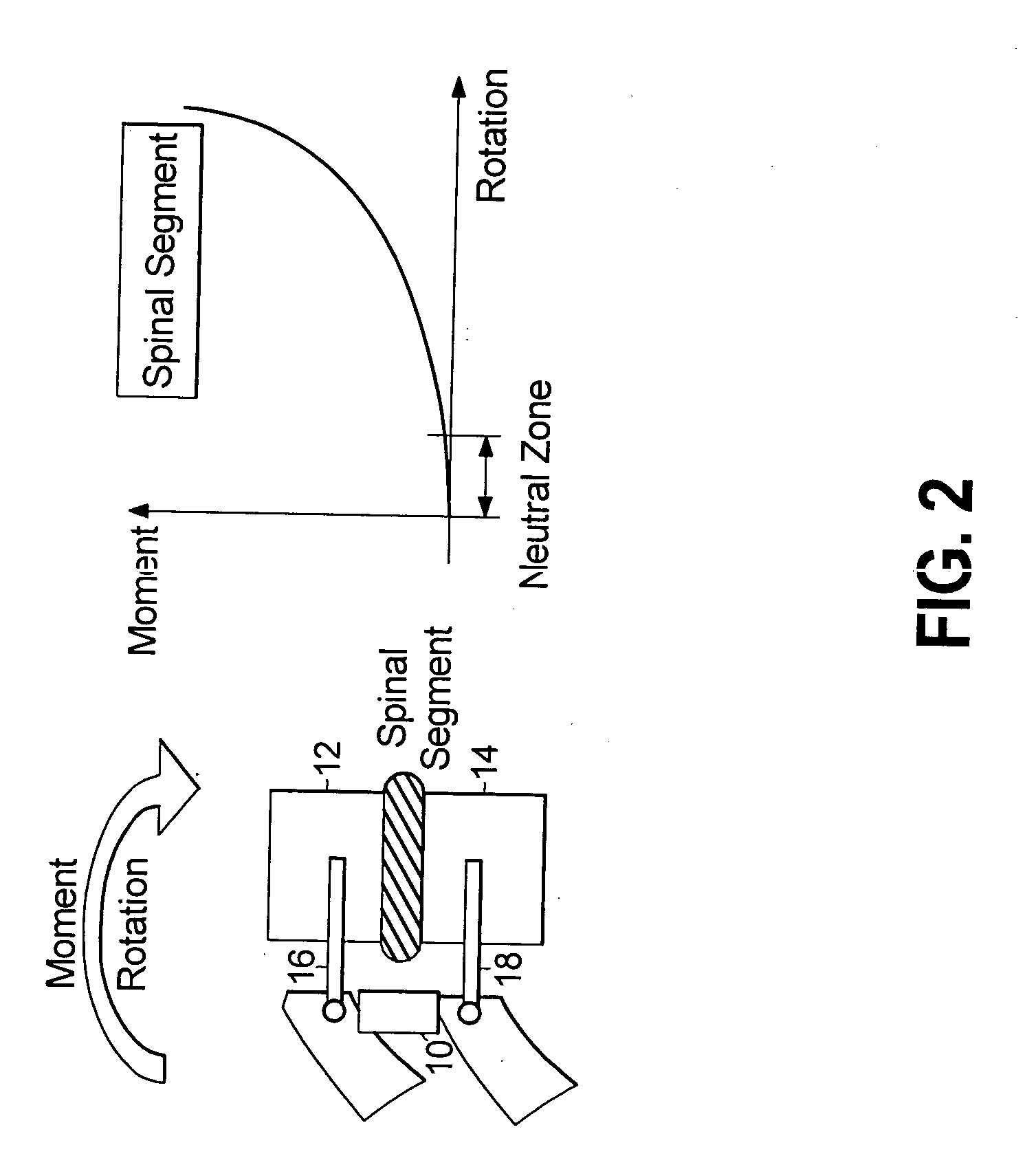

Spine stabilization systems, devices and methods

InactiveUS20050182400A1Easy to installImprove clinical outcomesInternal osteosythesisJoint implantsPedicle screwBiomedical engineering

A system and method for facilitating a spinal stabilization procedure is provided. A tapered guide member is positioned adjacent to or in juxtaposition with the head of a pedicle screw, and the associated components are thus guided into alignment therewith. A component, e.g., a spherical element, may be advanced onto a collet that extends upwardly from the head of the pedicle screw. A guidewire may also be employed to guide components to the pedicle screw and / or to guide the guidewire into position. Thus, a conical guide member may be slid down a guidewire into alignment with a pedicle screw, and subsequently advanced components may be guided into alignment with the pedicle screw. The tapered guide member may include registration feature(s) and may facilitate alignment with off-axis locations. The facilitating system may be employed with a dynamic spinal stabilization system that provides clinically efficacious results at least in part based upon inclusion of dynamic stabilizing member(s).

Owner:APPLIED SPINE TECH

Mounting mechanisms for pedicle screws and related assemblies

ActiveUS7615068B2The result is validEase of installation and in applicationSuture equipmentsInternal osteosythesisSet screwEngineering

A pedicle screw is provided that includes an upwardly extending collet. The collet may include downwardly extending slots that define deflectable segments therebetween. When a spherical element or other structure, e.g., a non-dynamic stabilizing element, is positioned around the collet, introduction of a set screw causes outward deflection of the upstanding segments into engagement with the spherical element. A snap ring may be interposed between the collet and the spherical element to facilitate positioning therebetween. In an alternative embodiment, a non-slotted collet is employed. In such embodiment, the collet and the spherical element may be threadingly engaged and may include a snap ring therebetween. The pedicle screw subassemblies may be incorporated into a spinal stabilization system which may include a dynamic stabilizing member to provide clinically efficacious results.

Owner:RACHIOTEK

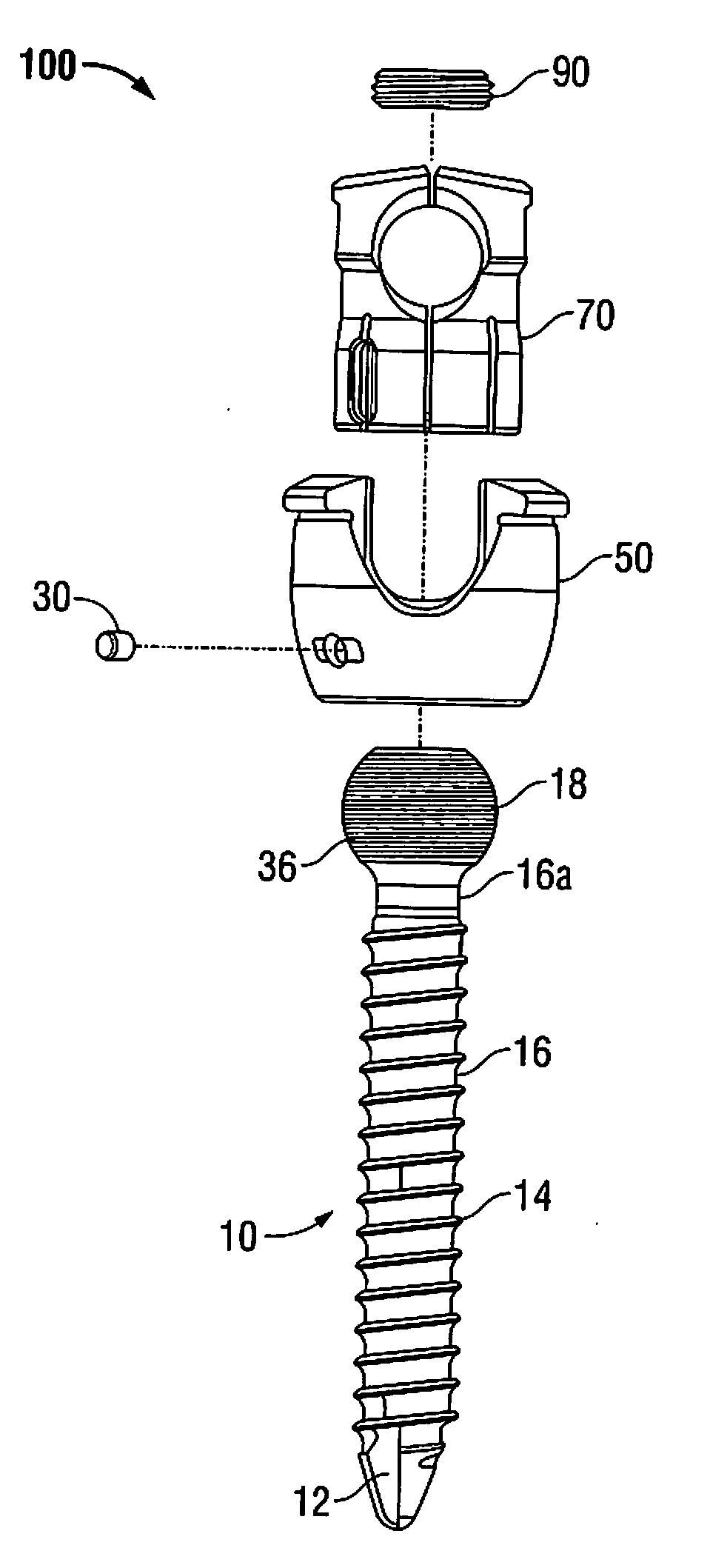

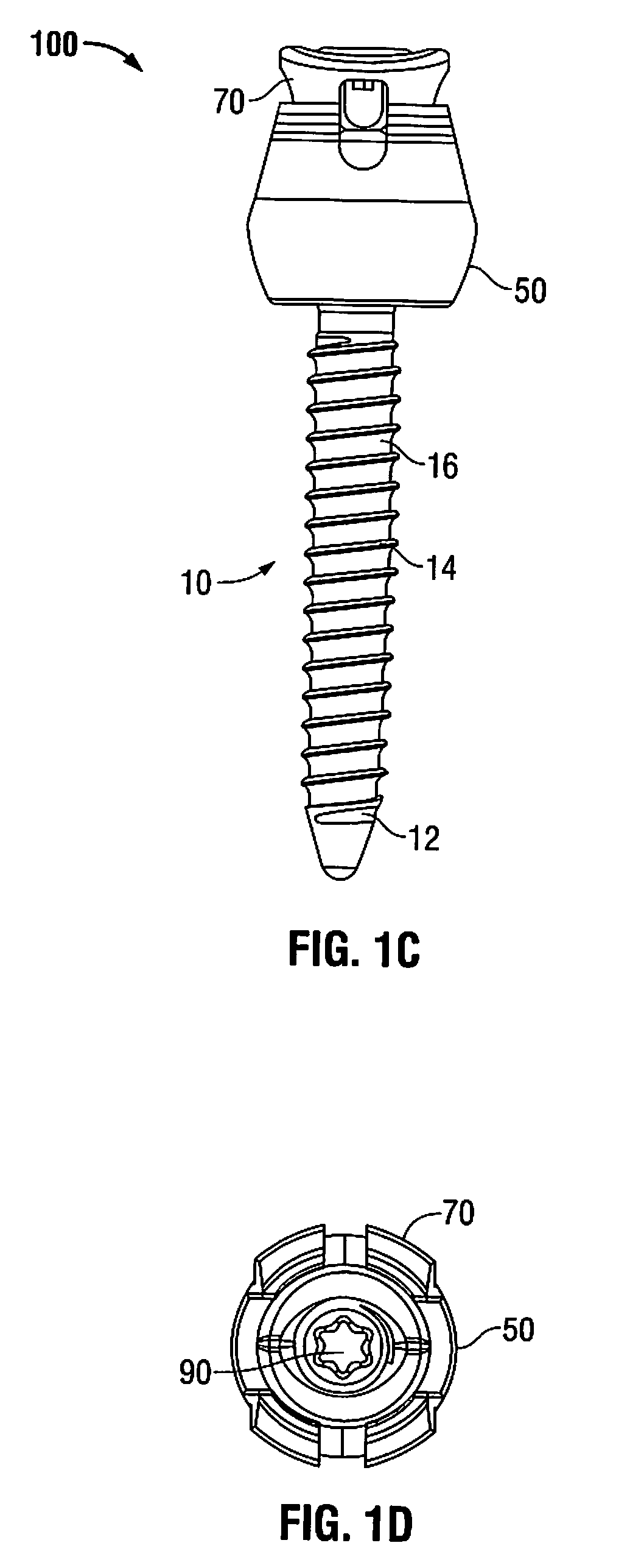

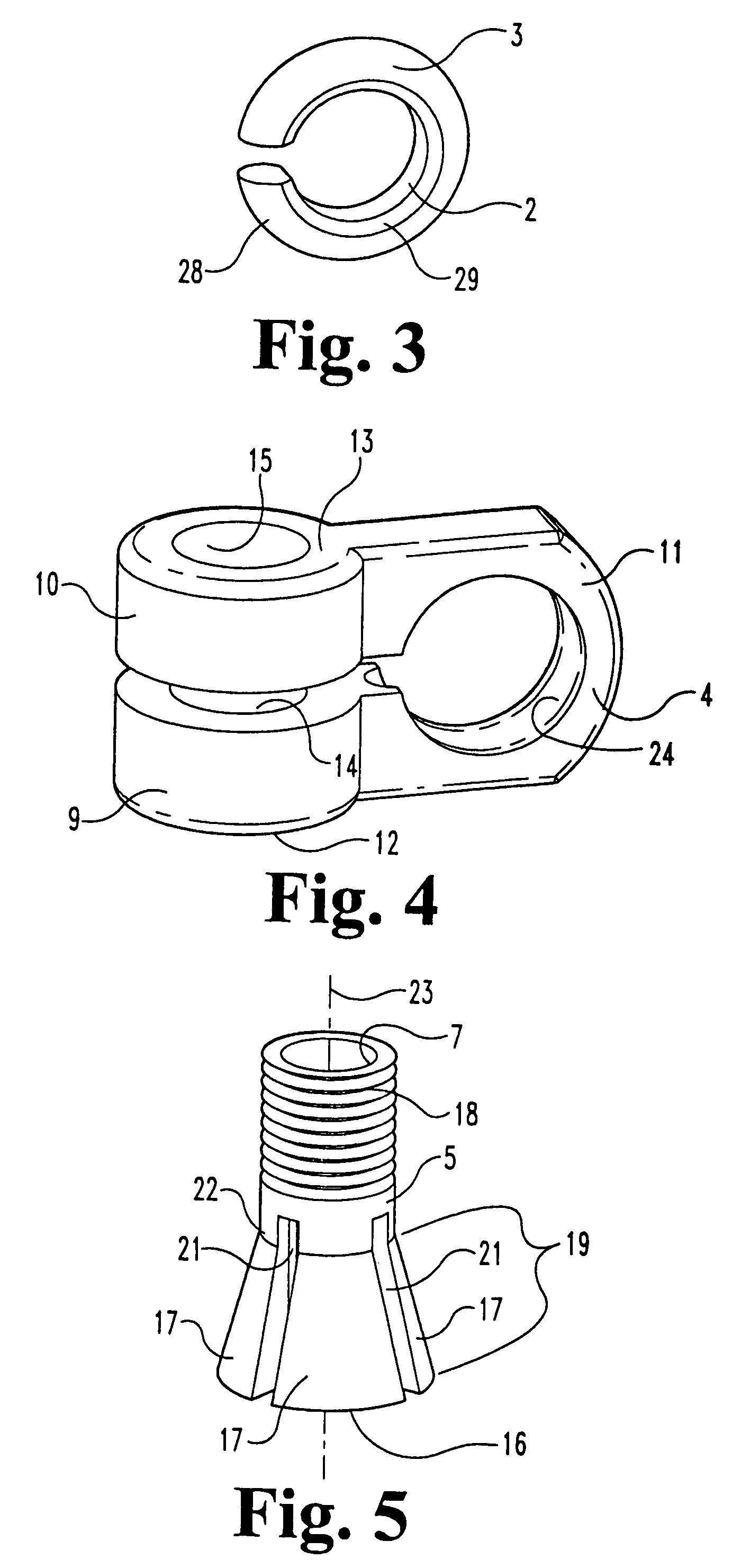

Multi-planar, taper lock screw with additional lock

A pedicle screw construct includes a pedicle screw, a coupling, a collet, and a set screw. The pedicle screw includes a shank having a helical thread formed thereon and a head at one end. The collet is positioned atop the head of the pedicle screw. The collet and pedicle screw are inserted into the coupling. The set screw is positioned in the collet such that the set screw contacts a portion of the rod and is releasably secured to the pedicle screw via a gripping tool. The pedicle screw is rotatable and pivotable relative to the collet and coupling assembly.

Owner:K2M

Plug with detachable guidewire element and methods for use

InactiveUS20050177189A1Reduce the cross-sectional areaEasy to optimizeVaccination/ovulation diagnosticsSurgical veterinaryDistal portionGuide wires

An apparatus for sealing a passage through tissue includes a bioabsorbable, threaded plug carried by a delivery device. A guide wire is receivable through lumens in the plug and delivery device that includes wings on a bioabsorbable distal portion. With the wings collapsed, the guide wire is advanced through the passage into a blood vessel, the wings expanding once located within the vessel, and the guide wire is withdrawn until the wings contact the vessel wall. The plug is threaded into the passage over the guide wire until the plug is disposed adjacent the wings. The distal portion of the guide wire is secured to the plug, e.g., by compressing a collet within the plug lumen that seals the lumen, and is severed from a proximal portion thereof. Thus, the plug and distal portion are deployed with the plug sealing the passage.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Plug with collet and apparatus and method for delivering such plugs

InactiveUS20050222614A1Reduce the cross-sectional areaEasy to optimizeVaccination/ovulation diagnosticsSurgical veterinaryEngineeringGuide wires

An apparatus for sealing a passage through tissue includes a plug including external threads, a lumen extending between its proximal and distal ends, and an annular collet slidably disposed within the lumen. The plug is carried on a distal end of a handle device that includes an inner member with a distal end that is slidable axially within the lumen of the body for moving the collet into a reduced cross-sectional region of the lumen, thereby compressing the collet to seal the lumen, and for deploying the plug from the handle device. During use, the plug is delivered into a passage through tissue over a guide wire. Once a desired location is reached, the plug is deployed from the handle device, thereby compressing the collet and sealing the lumen. The guide wire and handle device are removed, leaving the plug to seal the passage.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

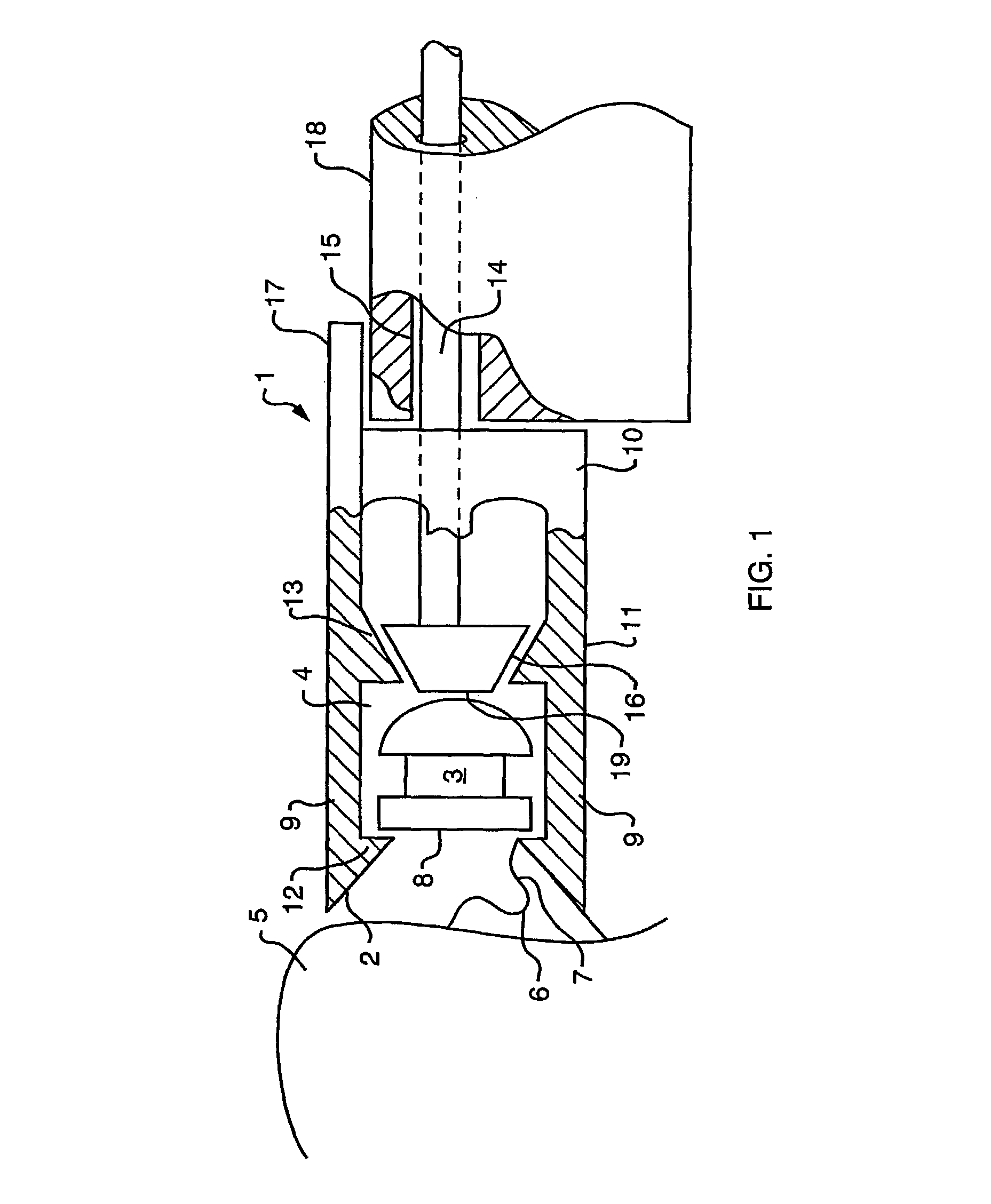

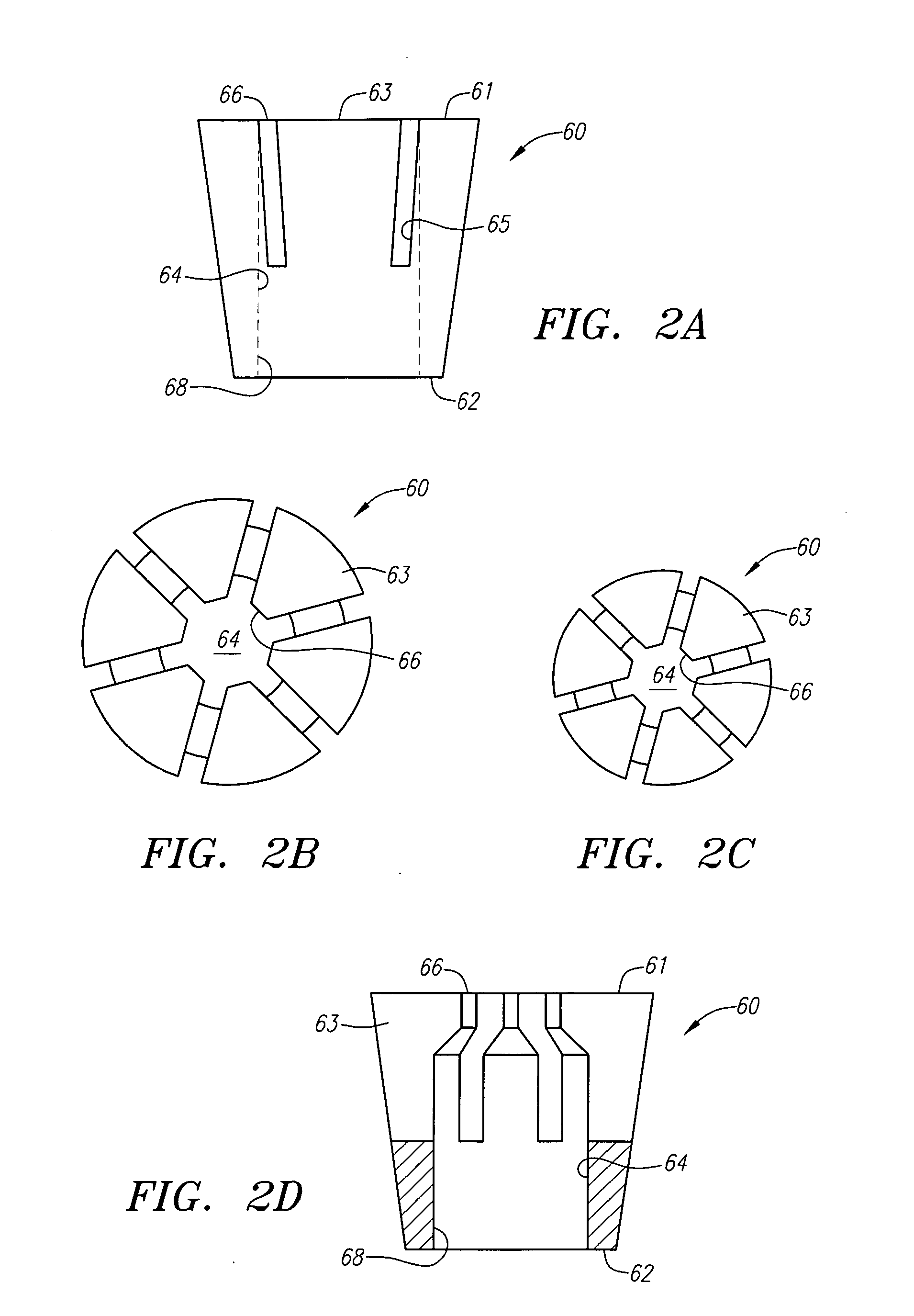

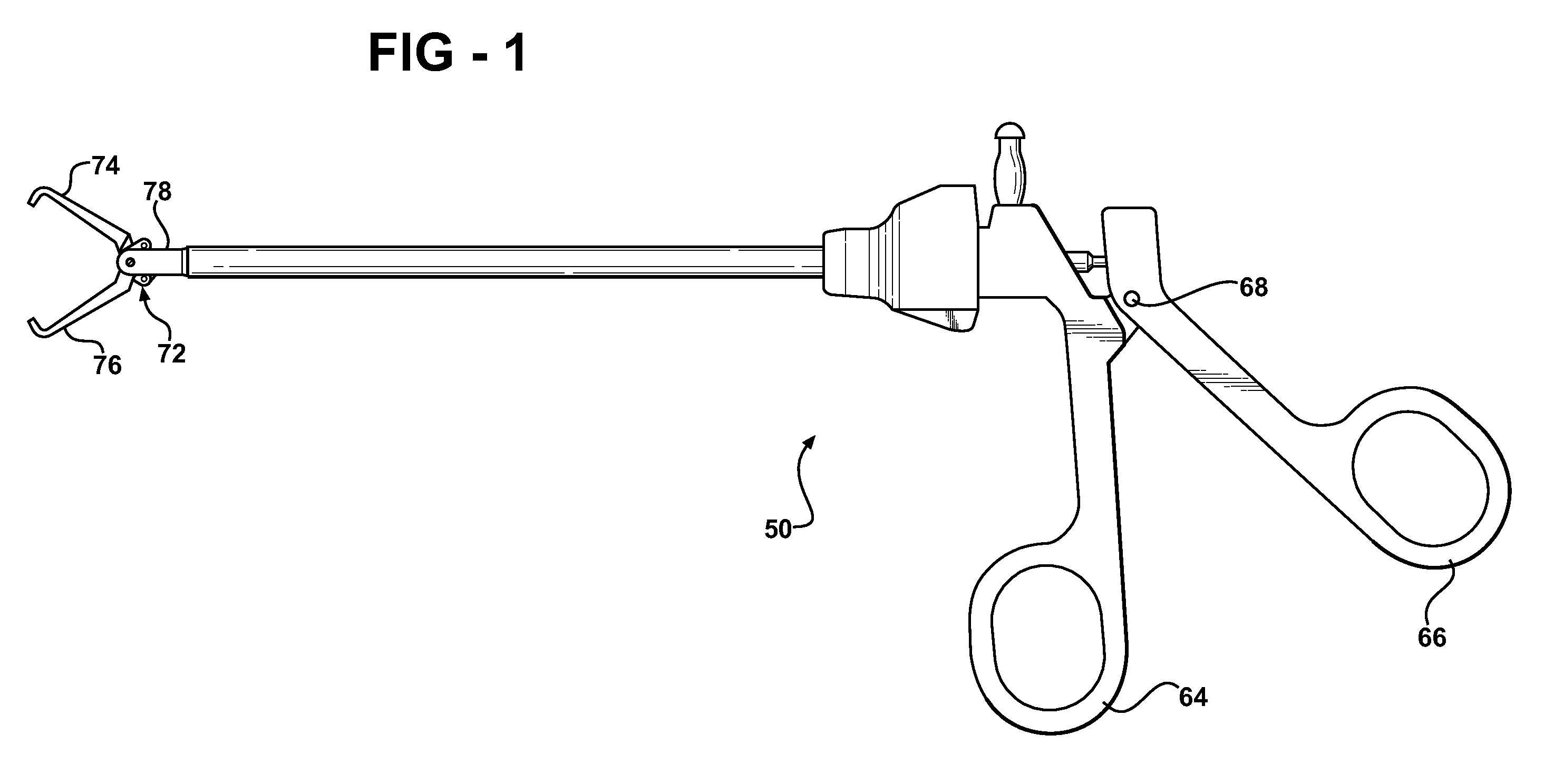

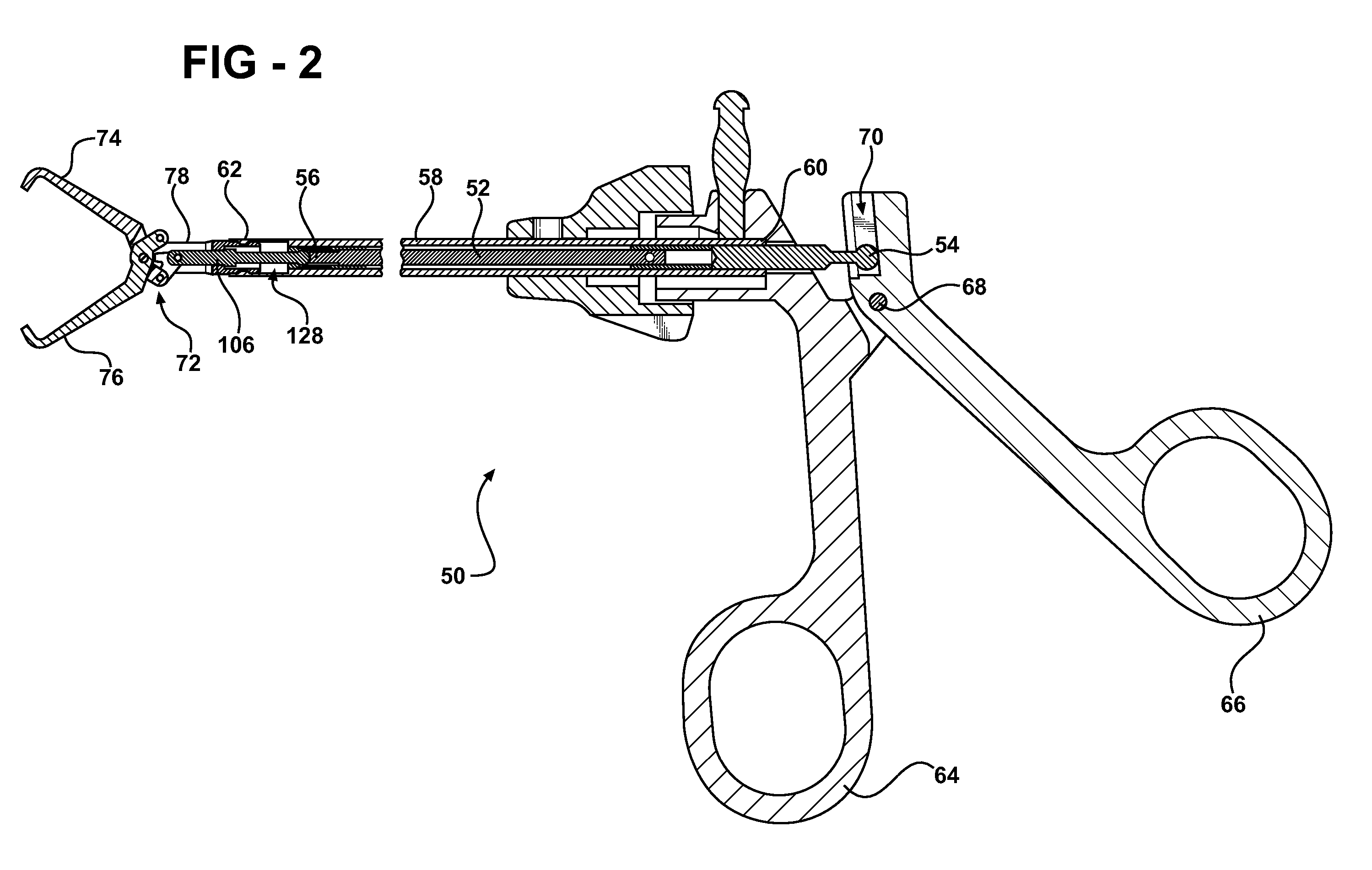

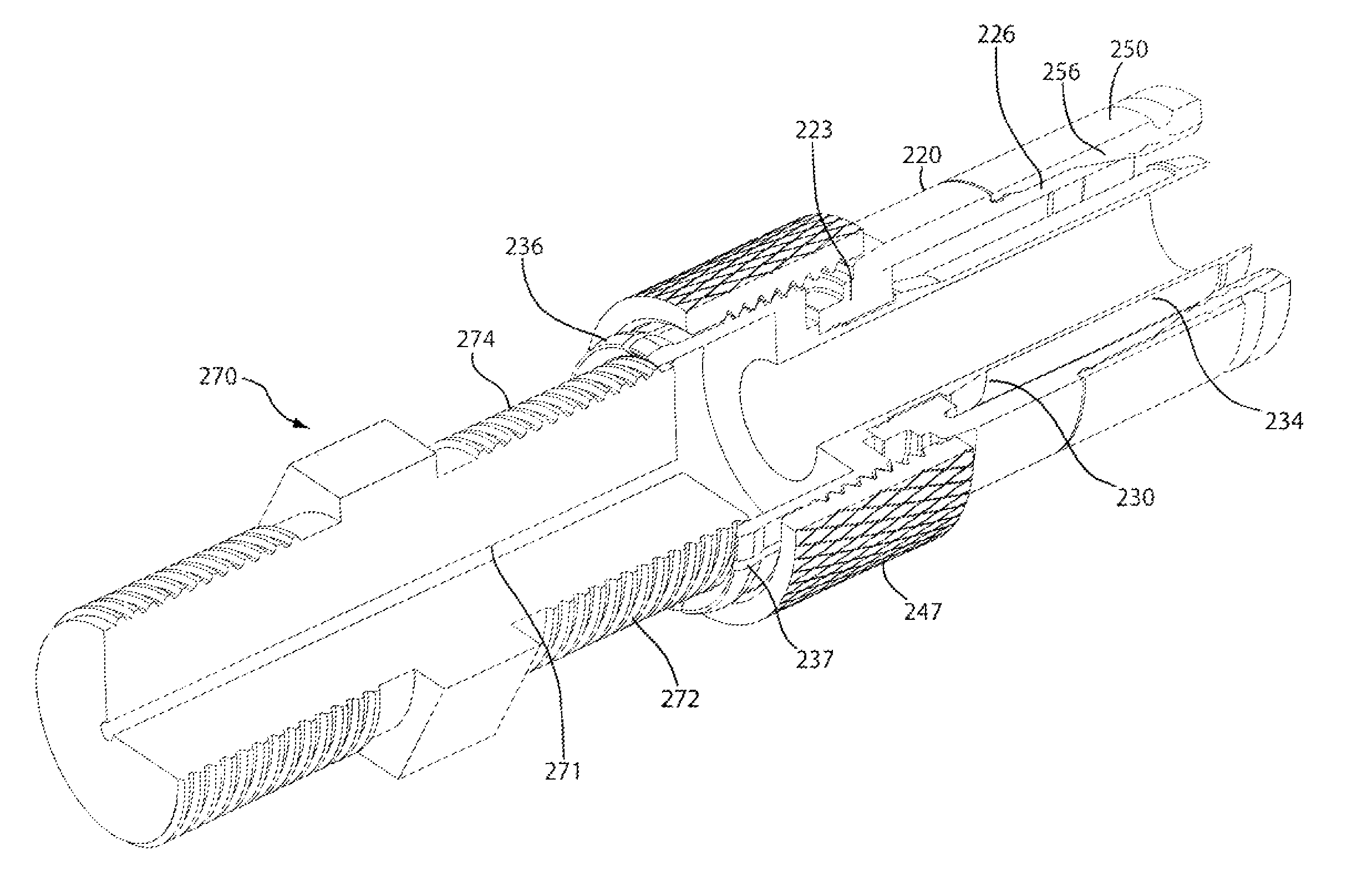

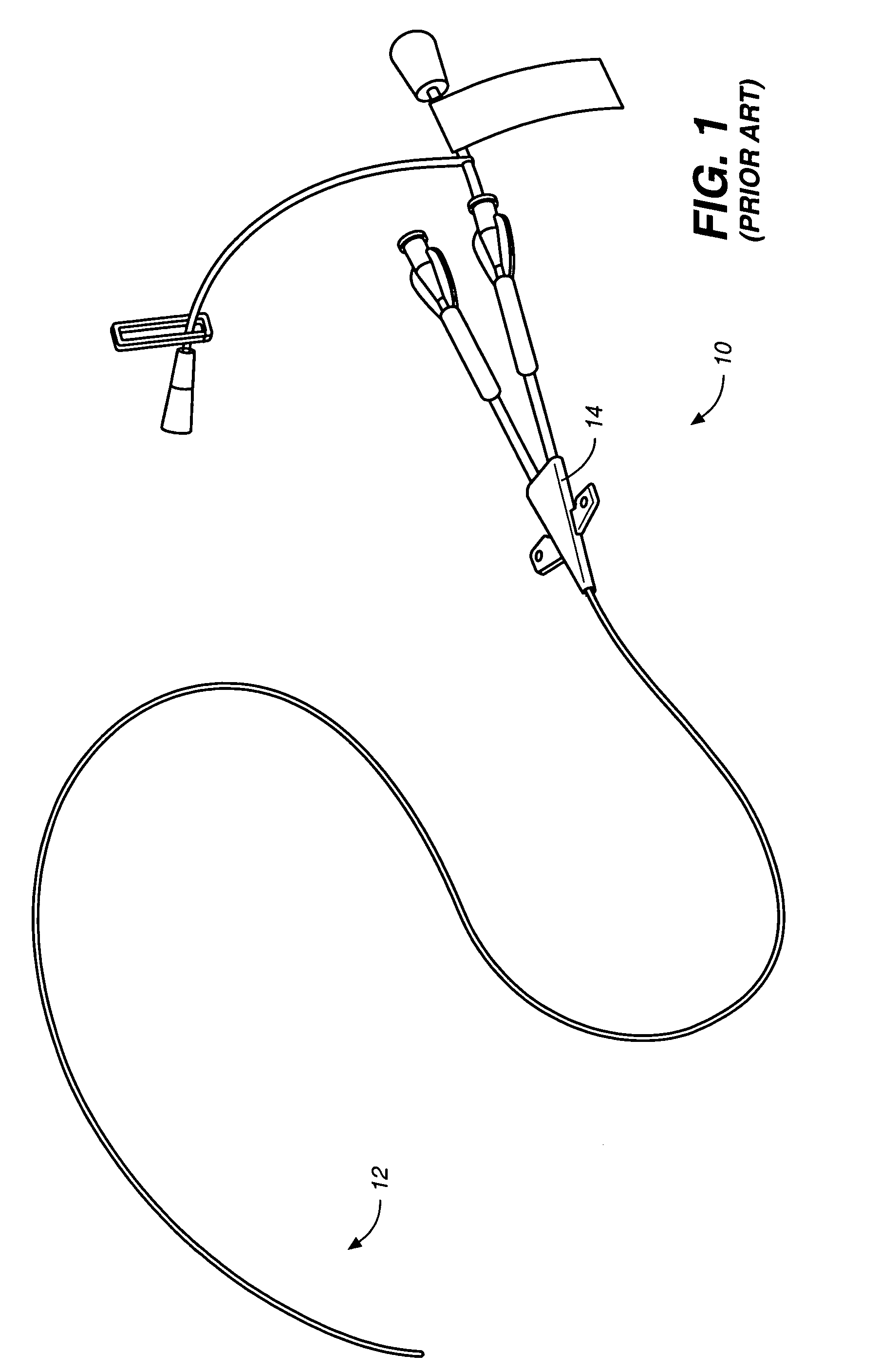

Surgical instrument with detachable tool assembly

InactiveUS20080004656A1Avoid Potential ContaminationEasy to separateSurgical instrument detailsSurgical forcepsCouplingEngineering

A surgical instrument includes a detachable tool assembly. The assembly includes a connection rod and a tool, such as a pair of jaws or an electrode. The instrument also includes a shaft operatively connected to a handle movable between operating positions and an ejected position. A tubular housing encloses the shaft and a collet. The collet is attached to the rod and movable between the positions. The fingers of the collet are flared apart in the ejected position but collapse to capture the connection rod in the operating positions. A tongue-and-groove arrangement provides a secondary coupling between the assembly and the housing when the handle is in the operating positions.

Owner:LIVNEH STEVE

Fiber optic communication system

Owner:MULLSTEFF DAVID M

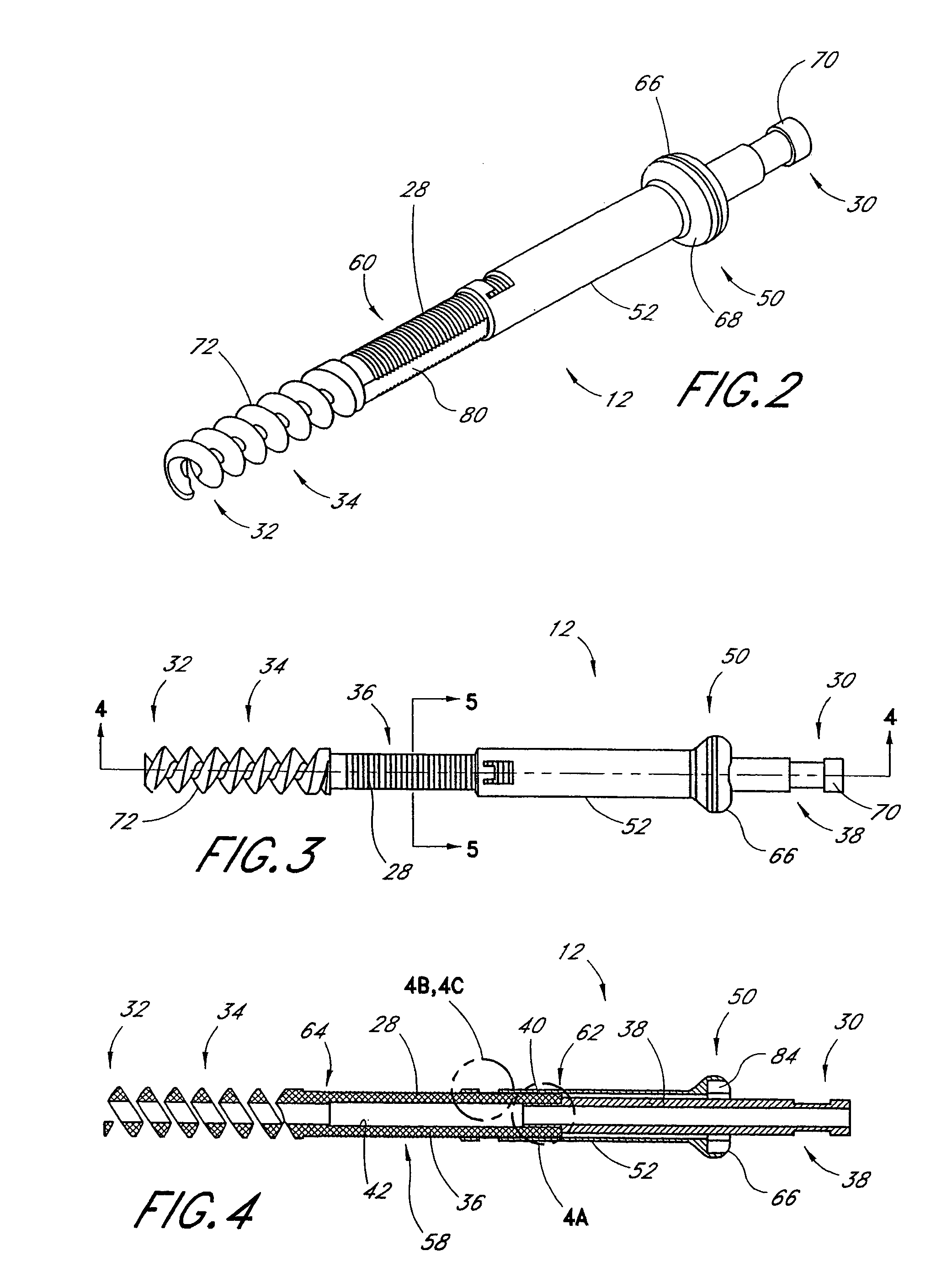

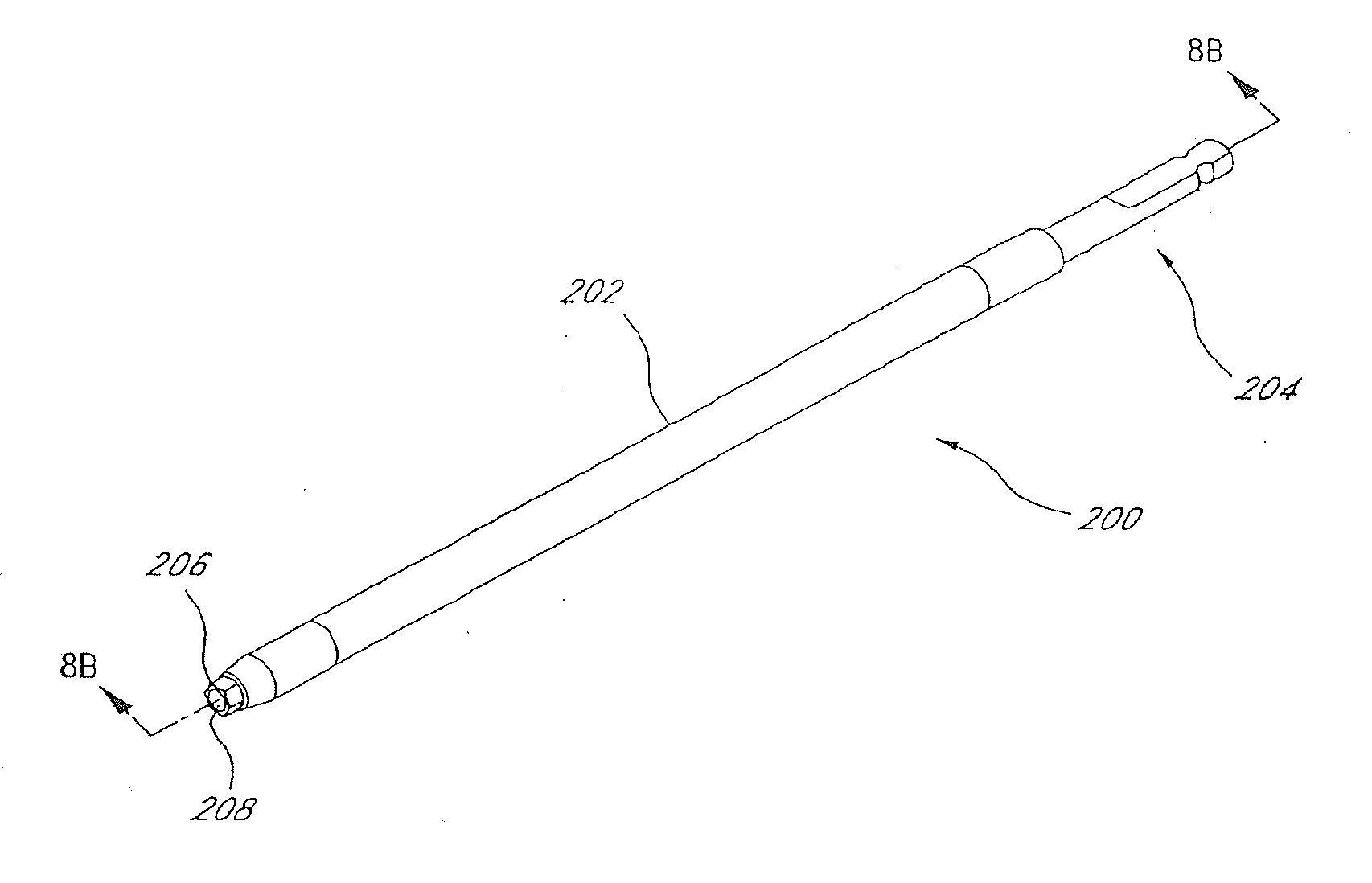

Deployment tool for distal bone anchors with secondary compression

The invention relates to a deployment systems for deploying a bone fixation device. One embodiment of a deployment system includes a syringe-shaped body configured to provide proximal traction to a bone fixation device in response to a compressive force between a finger grip and a plunger adapted to be engaged by the heel of a clinician's hand. The device may include a collet for gripping a proximal pin of a fixation device. The deployment device may also include a tool that includes an elongate body with a distal tip adapted to rotationally engage a bone fixation device in order to axially rotate the fixation device. A further deployment device embodiment includes a cauterizing tip for heat-cutting an excess portion of a pin of a bone fixation device.

Owner:DEPUY SYNTHES PROD INC

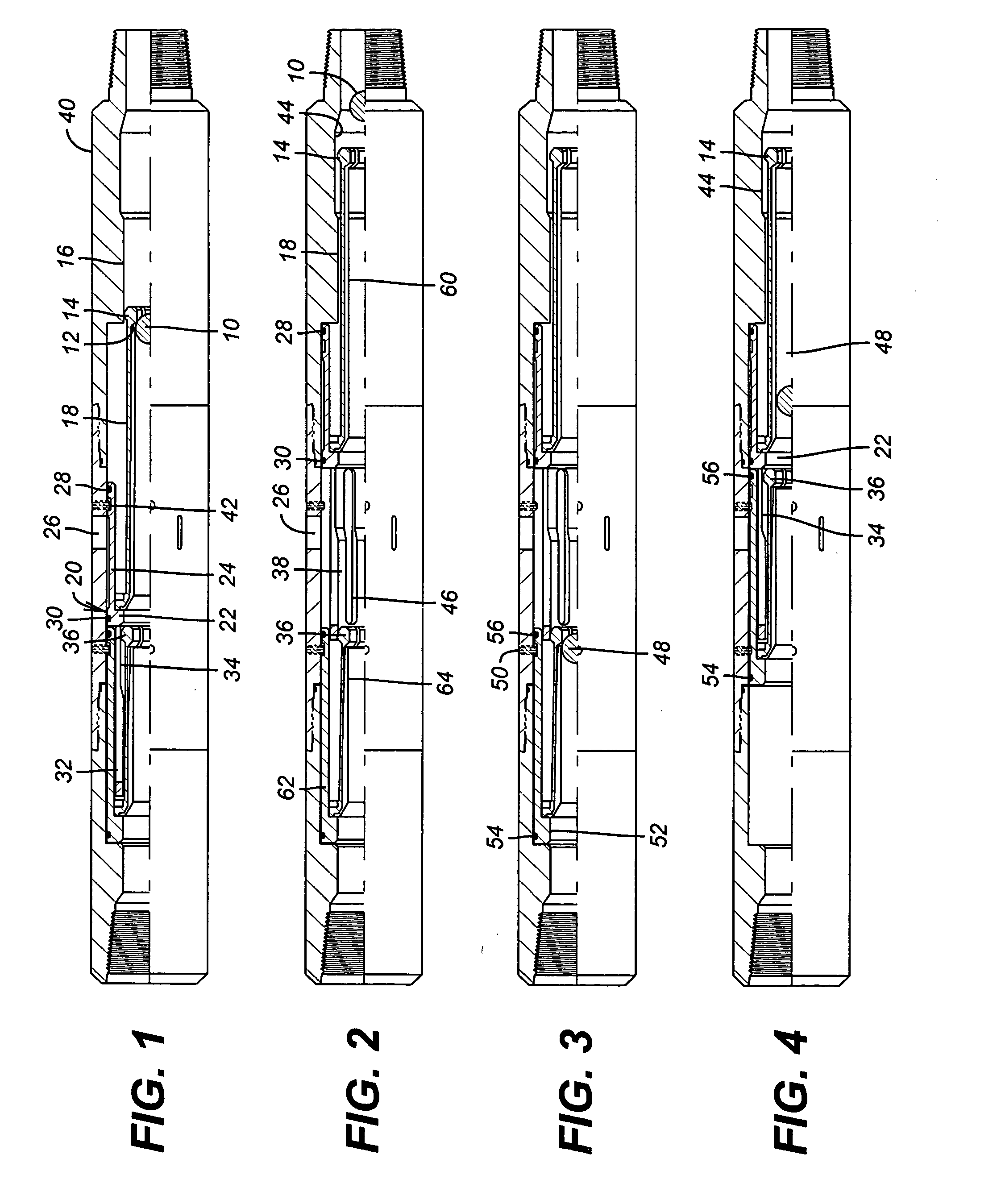

Ball drop circulation valve

A downhole tool can perform a series of operations with balls of the same size where movement caused by pressuring up on the first ball positions the next seat to accept another ball just like it. In a preferred embodiment a circulation sub is run in with a port closed and a first seat comprising of collets pushed together and preferably lined with a sleeve are in position to accept a first ball to perform a downhole operation and thereafter pass the ball and open the port. The act of opening the port gives support, by reducing their dimension, to the next assembly of collets also preferably lined with a sleeve so that they are energized to accept the same size ball. Pressuring up on the second ball can shift another sleeve to close the circulation port. The tool is modular and more than one module can be deployed in a given bottom hole assembly.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

Deployment tool for distal bone anchors with secondary compression

Deployment systems for deploying a bone fixation device are disclosed herein. One embodiment of a deployment system includes a syringe-shaped body configured to provide proximal traction to a bone fixation device in response to a compressive force between a finger grip and a plunger adapted to be engaged by the heel of a clinician's hand. The device may include a collet for gripping a proximal pin of a fixation device. The deployment device may also include a tool that includes an elongate body with a distal tip adapted to rotationally engage a bone fixation device in order to axially rotate the fixation device. A further deployment device embodiment includes a cauterizing tip for heat-cutting an excess portion of a pin of a bone fixation device.

Owner:INTERVENTIONAL SPINE

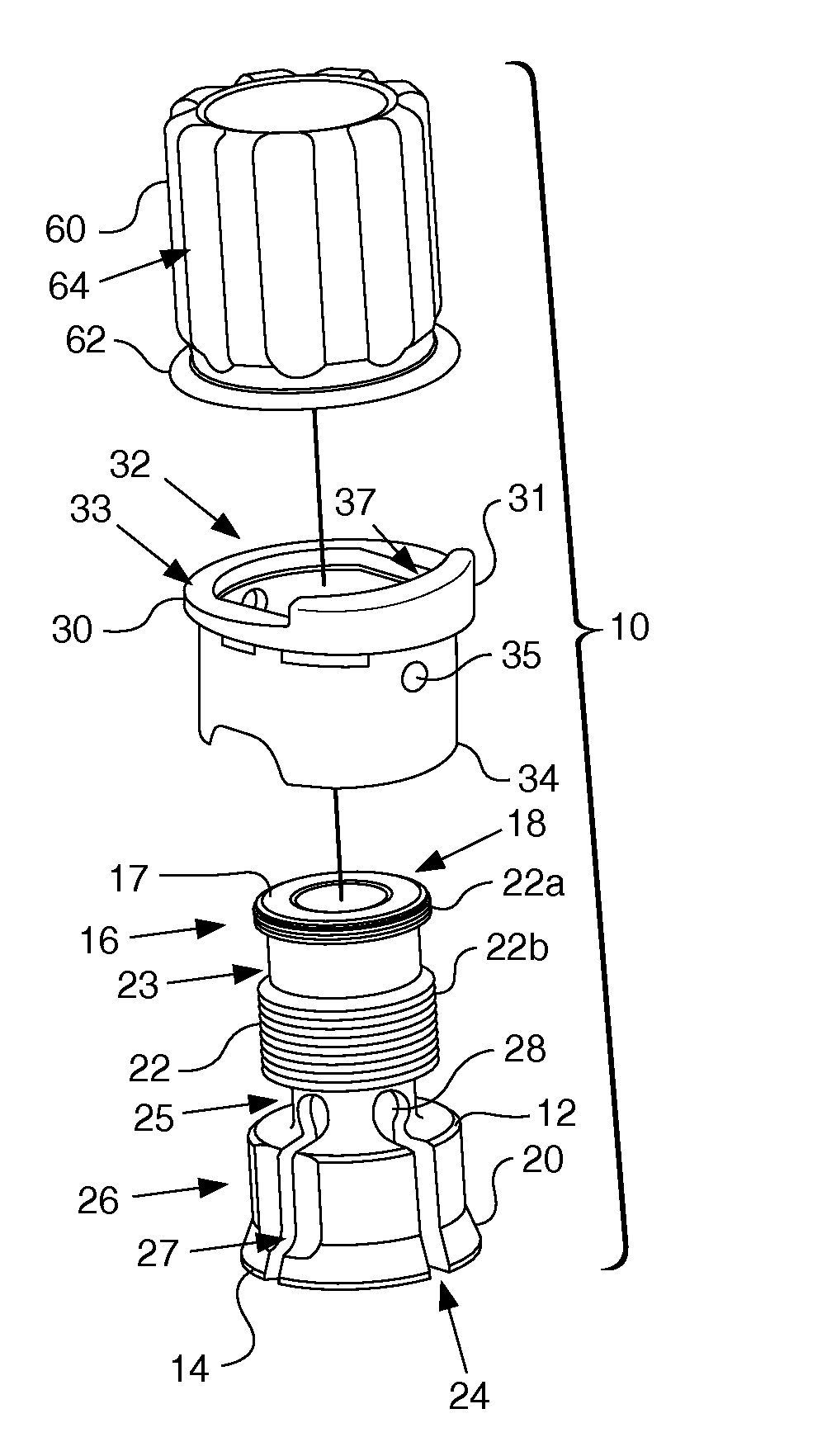

Cable connector having threaded locking collet and nut

ActiveUS8079860B1Precise maintenanceAvoid missed connectionsCoupling device detailsTwo-part coupling devicesCoaxial cableScrew thread

A connector for a coaxial cable includes a connector body and a post having a flanged end as well as a coupling nut rotatably attached to the flanged end of the post. The flanged end of the post is defined by an open-ended port retaining portion having an exterior threaded surface that is engaged by respective internal threads of the coupling nut. The port retaining portion defines a locking collet that enables exterior ports of varying diameters to be engaged with and secured to the connector.

Owner:PPC BROADBAND INC

Ball jointed pedicle screw and rod system

A pedicle screw assembly includes pedicle screw having a plurality of spaced-apart posts. A ball collet having a ball collet bore is seated on the pedicle screw between the posts and a rod is gripped by an inner surface of the ball collet bore. The assembly also includes a cap that is coupled to the posts, the cap applying a compressive force to the ball collet against a seat of said pedicle screw. A free end of the rod may be provided with various structures to enable such free end to be retained by another pedicle screw.

Owner:MUHANNA NABIL L

Double collet connector assembly for bone anchoring element

InactiveUS20090143827A1Increase forceSuture equipmentsInternal osteosythesisEngineeringBiomedical engineering

A connector assembly including a bone anchoring element including a spherical head, a double collet that includes an inner clamping portion formed by inner surfaces of a plurality of resilient fingers, the resilient fingers defining a first wedge surface and a second wedge surface, an outer closure element that includes an inner clamping portion that corresponds in shape to an outer contour of the double collet, the outer closure element including a pair of arms that define a channel shaped for receiving therein a connector element, and an interface ring that includes a base formed with an inner wedge surface and a pair of wing extensions that extend from the base.

Owner:EXPANDING ORTHOPEDICS

Multi-planar adjustable connector

Owner:WARSAW ORTHOPEDIC INC

Non-sheath based medical device delivery system

InactiveUS7092765B2Reduce the overall diameterEasy to disassembleEpicardial electrodesCannulasMedical deviceDelivery system

Owner:MEDTRONIC INC

Clamping screw extractor

InactiveUS20040068269A1Prevent rotationSleeve/socket jointsDispensing apparatusScrew extractorScrew thread

A tool for gripping and removing mechanical fasteners such as pedicle screws. With reference to FIG. 7, the device generally resembles a screwdriver, having a handle on one end, a long shaft in the middle, and fastener engaging means on the other end. The fastener engaging means comprises a set of two or more jaws having inward facing gripping surfaces positioned to grasp the external surfaces of a screw head. The jaws are formed as part of a collet slidably mounted within an outer thread sleeve. The thread sleeve is attached to the shaft. A tapered journal on the collet interacts with a tapered bore in the thread sleeve so that when the collet is pulled into the thread sleeve, the set of two or more jaws are squeezed together. The threaded engagements between the collet and the thread sleeve should be the reverse of the thread on the screw to be removed; i.e., if a right-hand screw is to be removed then the threaded engagement between the collet and the thread sleeve should be made with a left-hand thread. In operation, the jaws are placed over the screw head and the device is rotated in a counterclockwise direction (for removal of a screw with a right-hand thread). The inward facing surfaces on the jaws bear against the bolt head, thereby impeding the rotation of the collet relative to the thread sleeve. The left-hand threaded engagement between the collet and the thread sleeve therefore pulls the collet further into the thread sleeve, whereupon the tapered bore squeezes the jaws more tightly together. Thus, the reader will appreciate, applying torque to the device when it is in position on a screw head simultaneously torques the screw head and squeezes the jaws more tightly together. The inward facing surfaces are also provided with an undercut in order to accommodate axial misalignment between the jaws and the screw head.

Owner:MEDITRON DEVICES

System for Closed Transfer of Fluids

A syringe adapter includes a housing having a first end and a second end with the first end configured to be secured to a first container, a cannula having a first end and a second end with the second end positioned within the housing, and a collet having a first end and a second end with at least a portion of the collet received within the housing. The collet includes a body defining a passageway, a seal member received by the passageway, and an arcuate, resilient locking member connected to the body of the collet. The collet is movable from a first position where the locking member is open to receive a mating connector to a second position where radially outward movement of the locking member is restricted.

Owner:BECTON DICKINSON & CO

Multi-planar taper lock screw with increased rod friction

A spinal fixation device includes a coupling, a pedicle screw, and a collet. The coupling has an opening extending therethrough. The pedicle screw has a head mounted to a shank that is positionable within a first vertebral body. The collet is receivable in the opening of the coupling and engagable with the head of the pedicle screw. The collet is selectively positionable between a first position and a second position where the collet engages a spinal rod and prevents one or both of axial and rotational movement of the spinal rod. The collet is adapted to facilitate the connection of the spinal rod to a second vertebral body. The collet defines a saddle having one or more locking features for engaging the spinal rod.

Owner:K2M

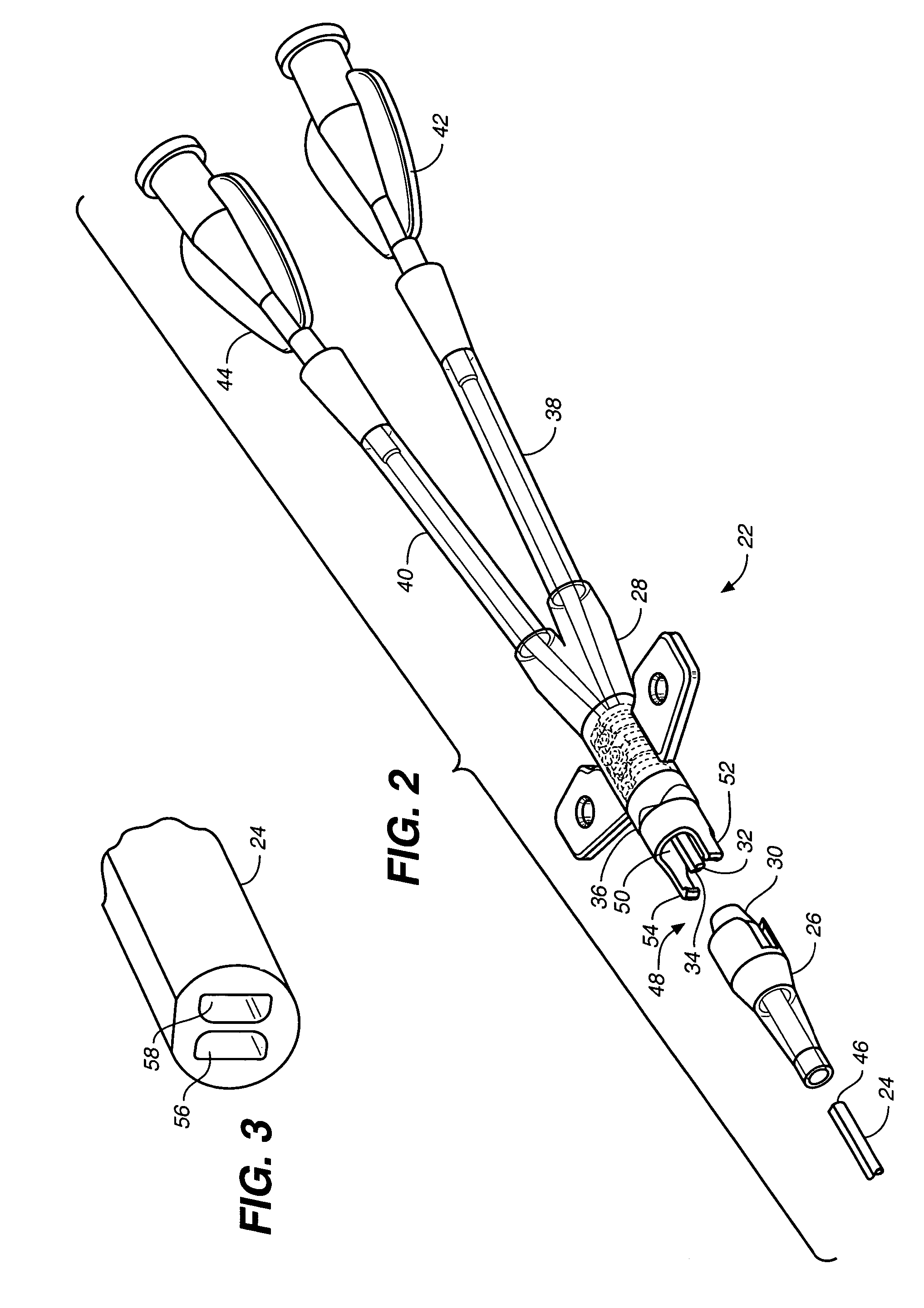

Catheter connector system

ActiveUS7377915B2Shorten assembly timeSafely and effectively connects a proximal endCatheterTube connectorsCatheter deviceCollet

Owner:CR BARD INC

Locking instrument assembly

ActiveUS20090204115A1Reducing and eliminating needSleeve/socket jointsJoint implantsEngineeringFastener

A locking instrument assembly for use in conjunction with an intramedullary device is disclosed. The locking instrument assembly includes an inner collet, an outer body, and a knob. The inner collet has a collar and a fastener member. The knob engages the fastener member to press the outer body against the collar. As the knob mates with the fastener member, the collar applies a clamping force to the intramedullary device.

Owner:SMITH & NEPHEW INC

Retractor and method for percutaneous tissue retraction and surgery

A retractor for percutaneous surgery in a patient which includes an elongate retractor tube composed of circumferentially arranged elongate independent tube segments with proximal ends of the tube segments respectively hinged to a unitary collar whereby the distal ends of the tube segments may be outwardly expanded in umbrella fashion by outwardly pivoting the segments about their respective hinges for thereby retracting surrounding tissue. The distal end of the retractor tube is provided with a tapered distal end suitably dimensioned for insertion into a stab incision. An internally open expansion collet is coaxially received in the collar for adjustable coaxial advancement downwardly into the collar toward the retractor tube segments and fulcrum tabs protrude inwardly and upwardly towards the expansion collet from each tube segment adjacent a respective hinge. The fulcrum tabs are sized for engaging a bottom end of the collet for thereby progressively pivoting the segments outward about their hinges as the collet advances downwardly into the collar.

Owner:DALTON BRIAN E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com