Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

617results about "Electrical/magnetic diameter measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

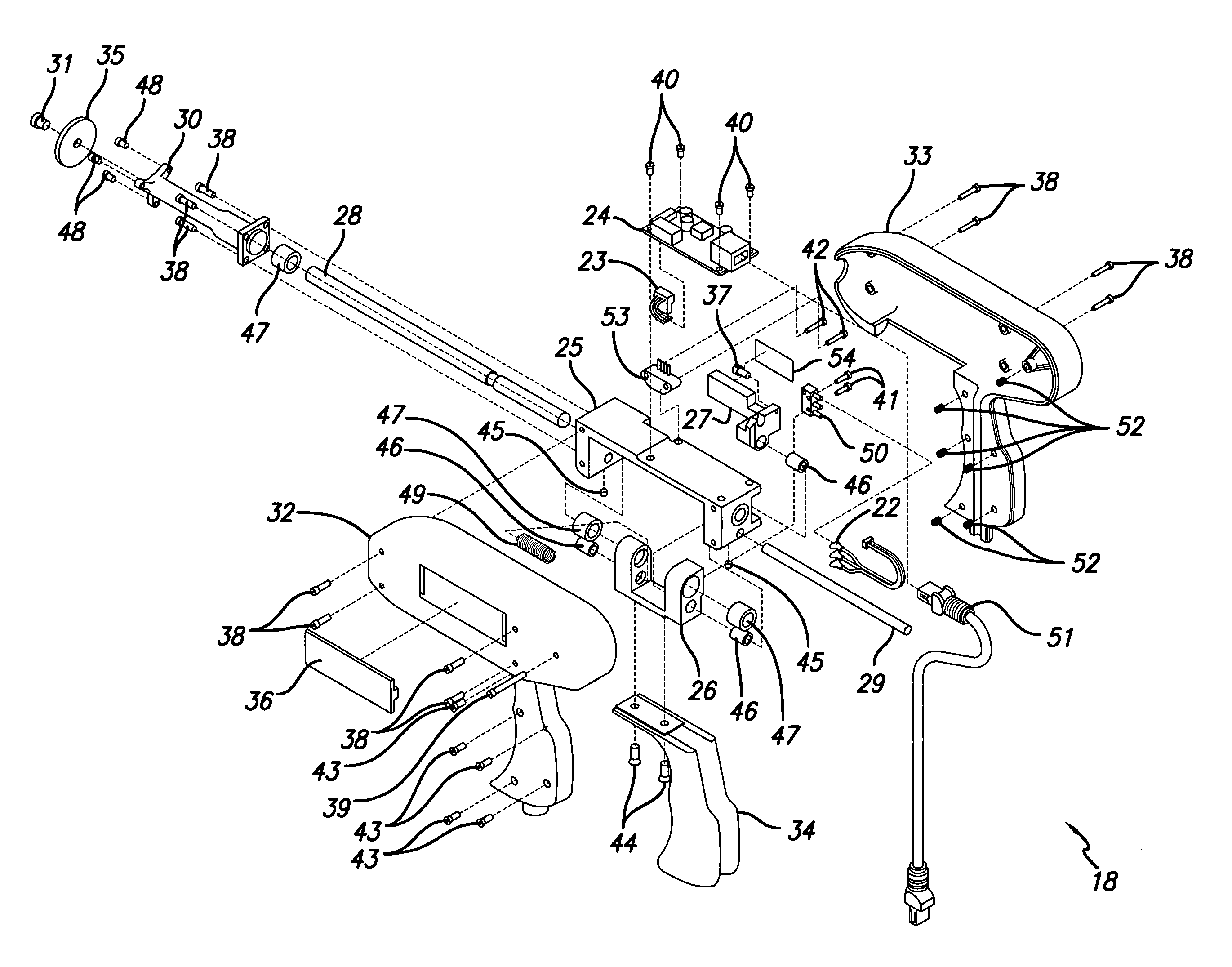

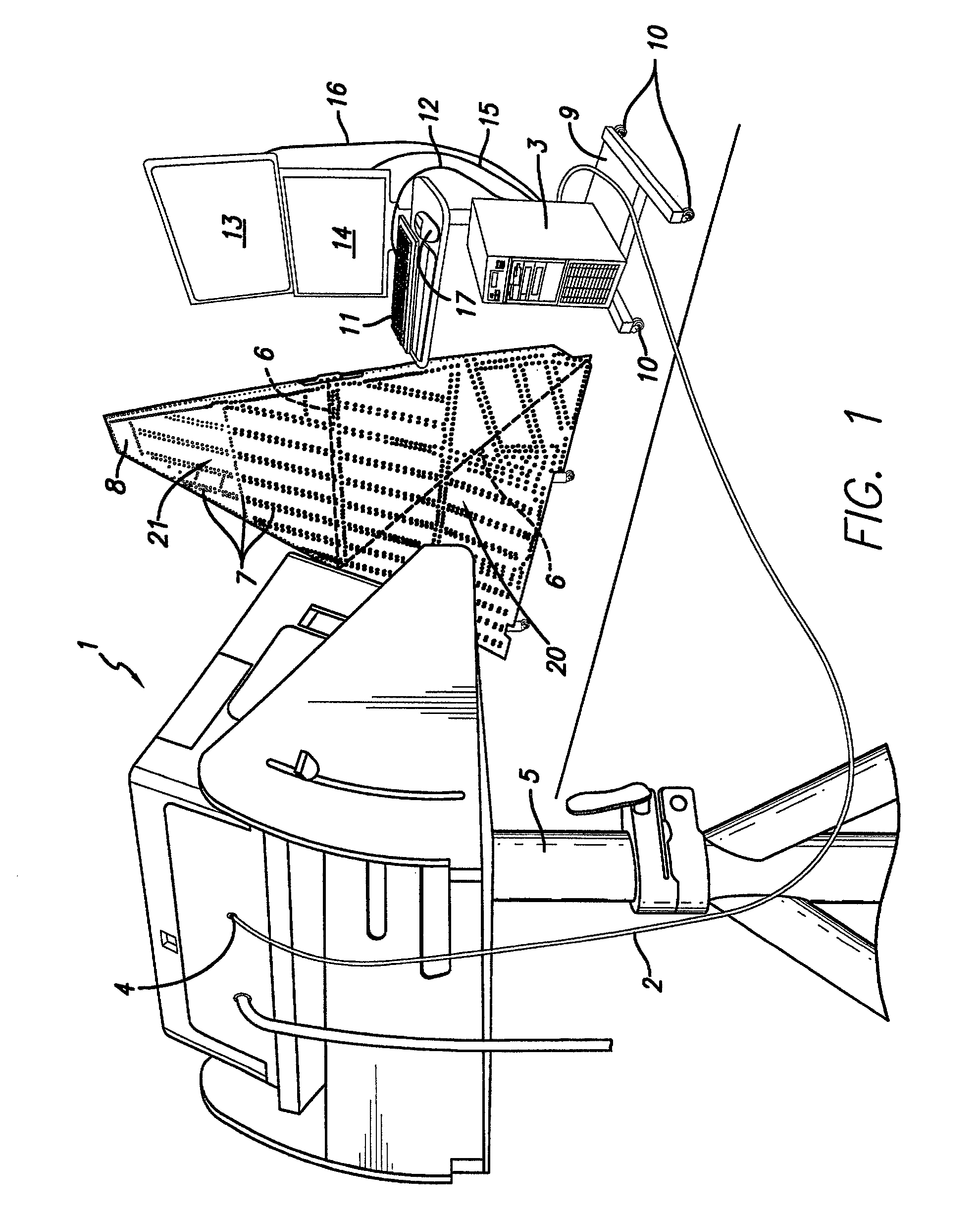

Hole Measurement Apparatuses

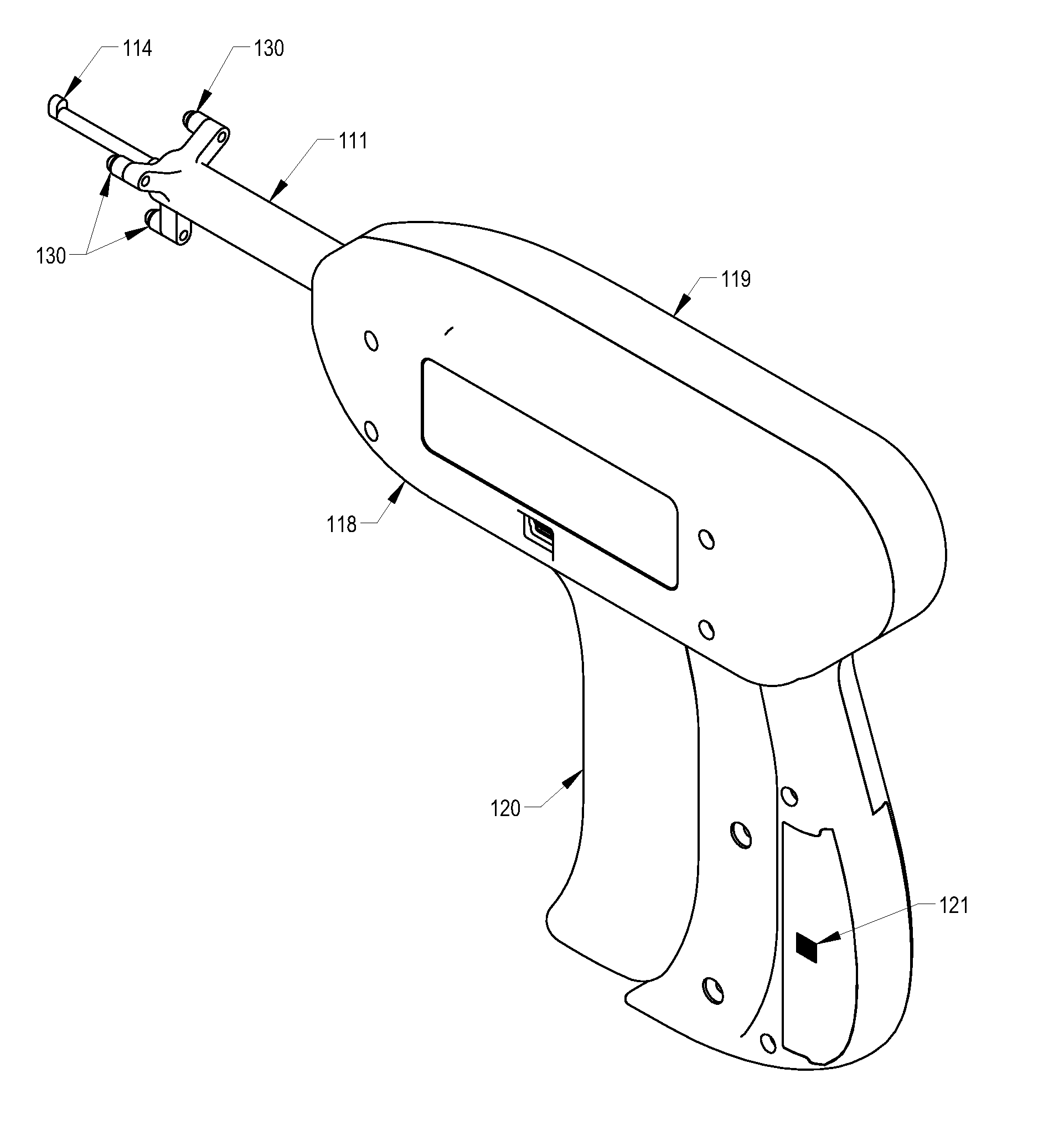

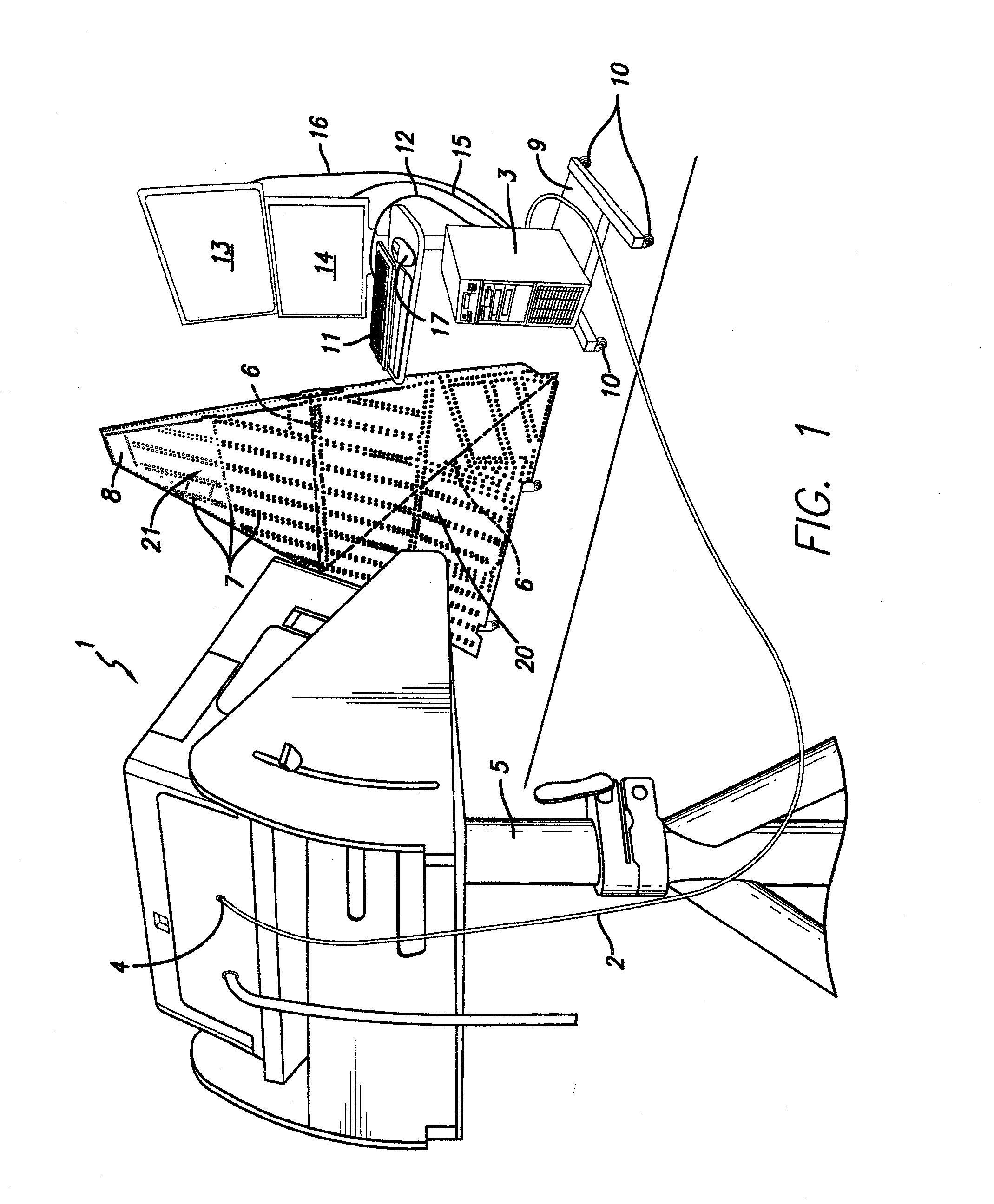

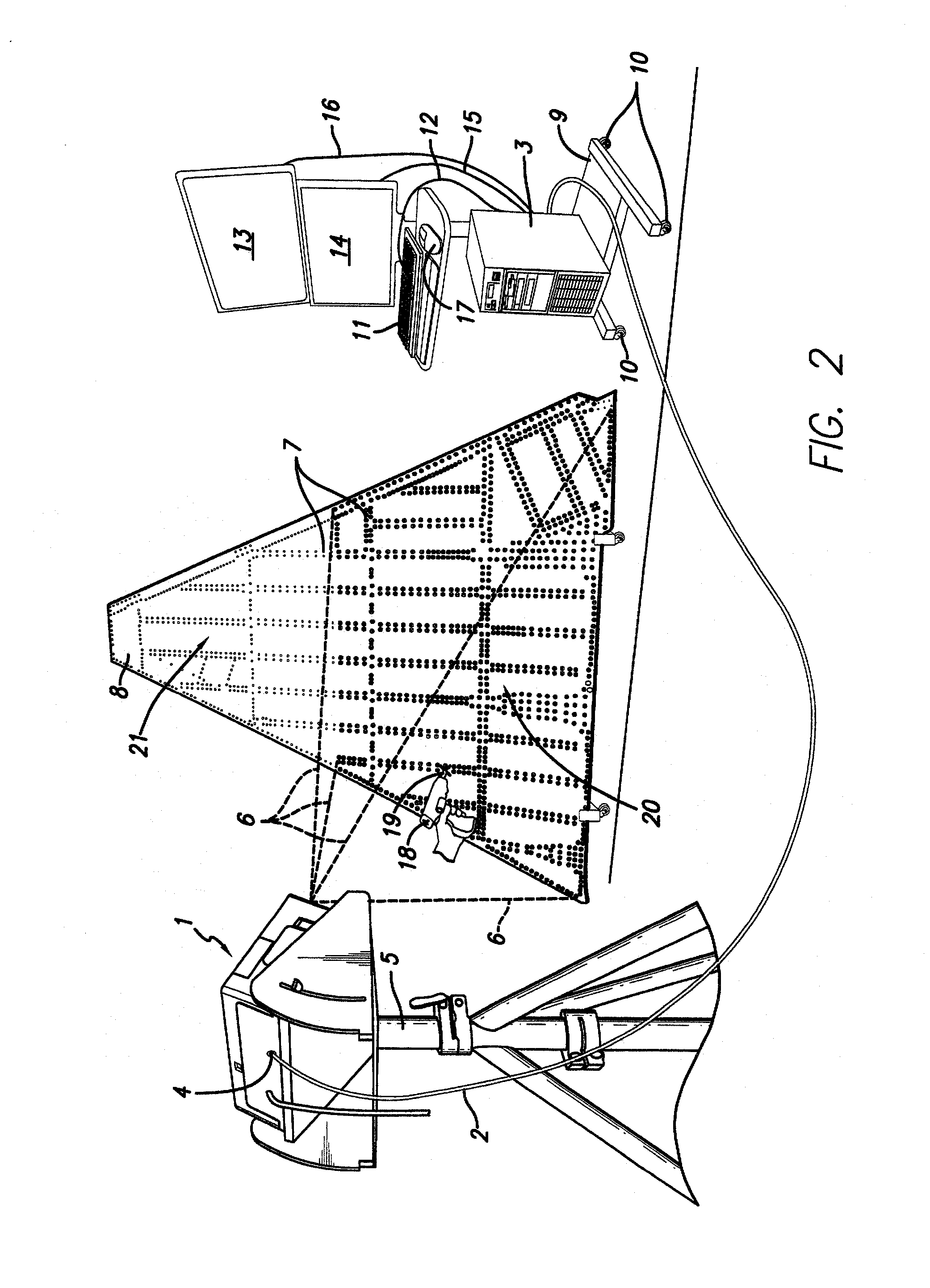

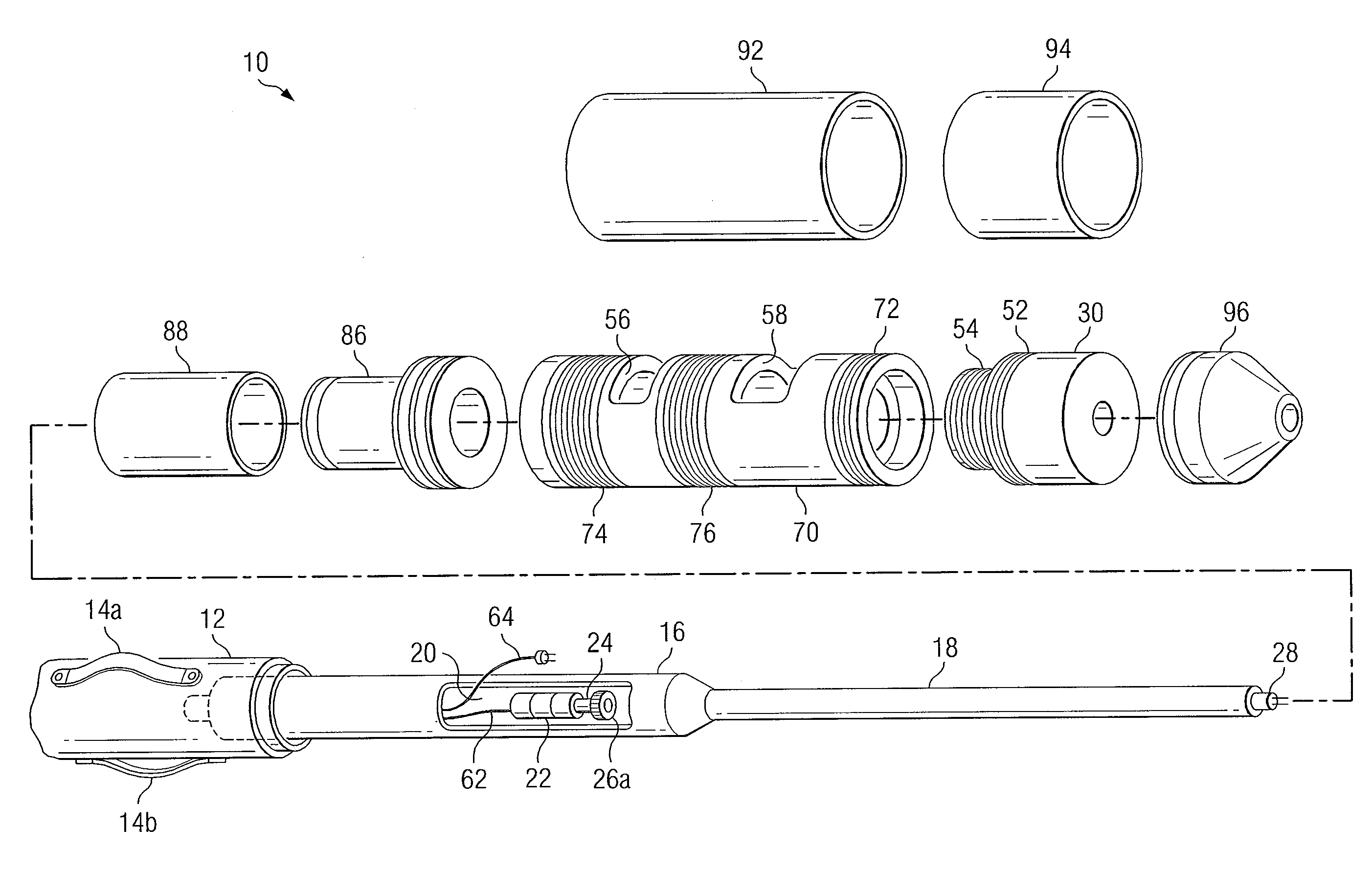

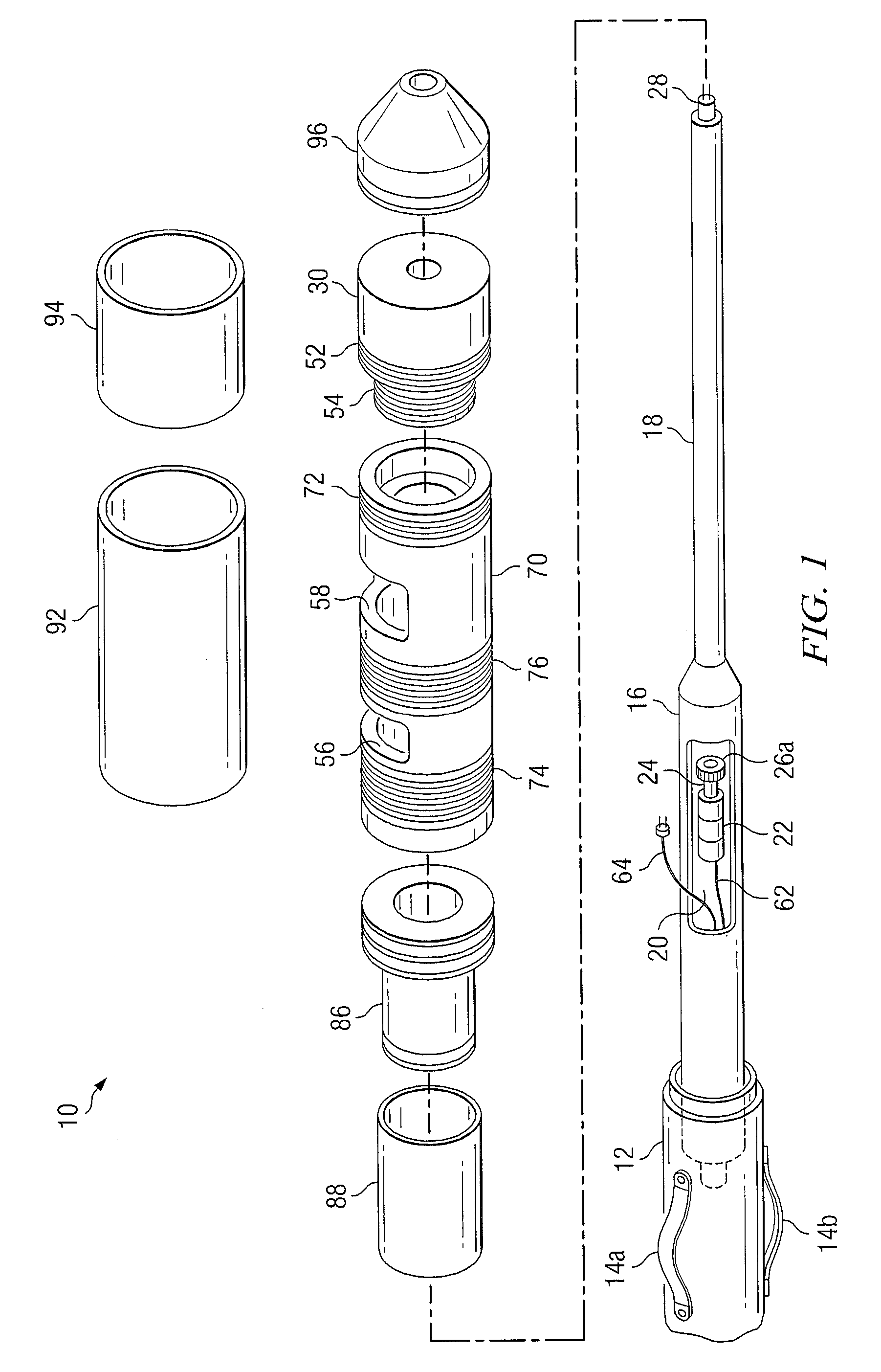

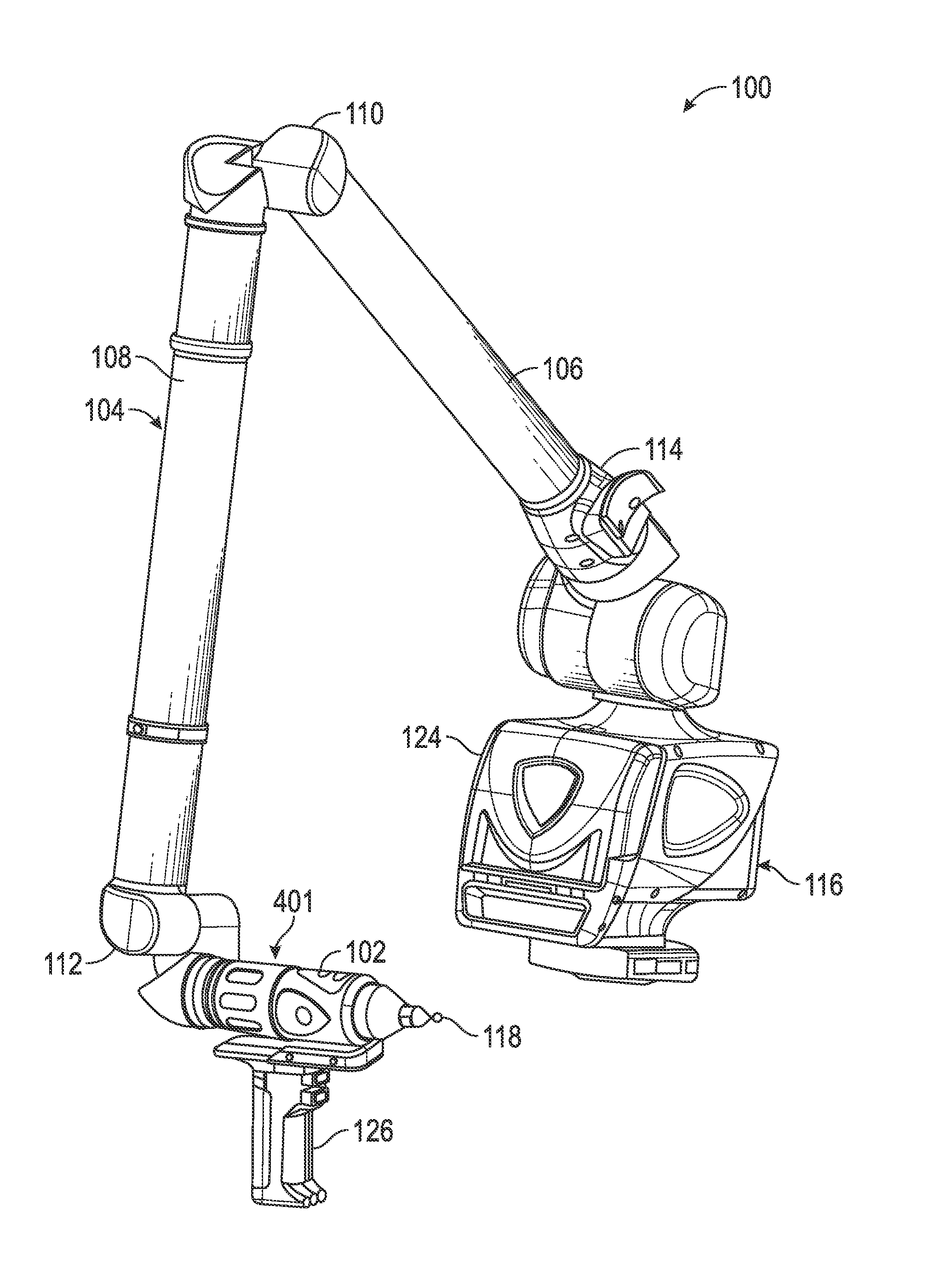

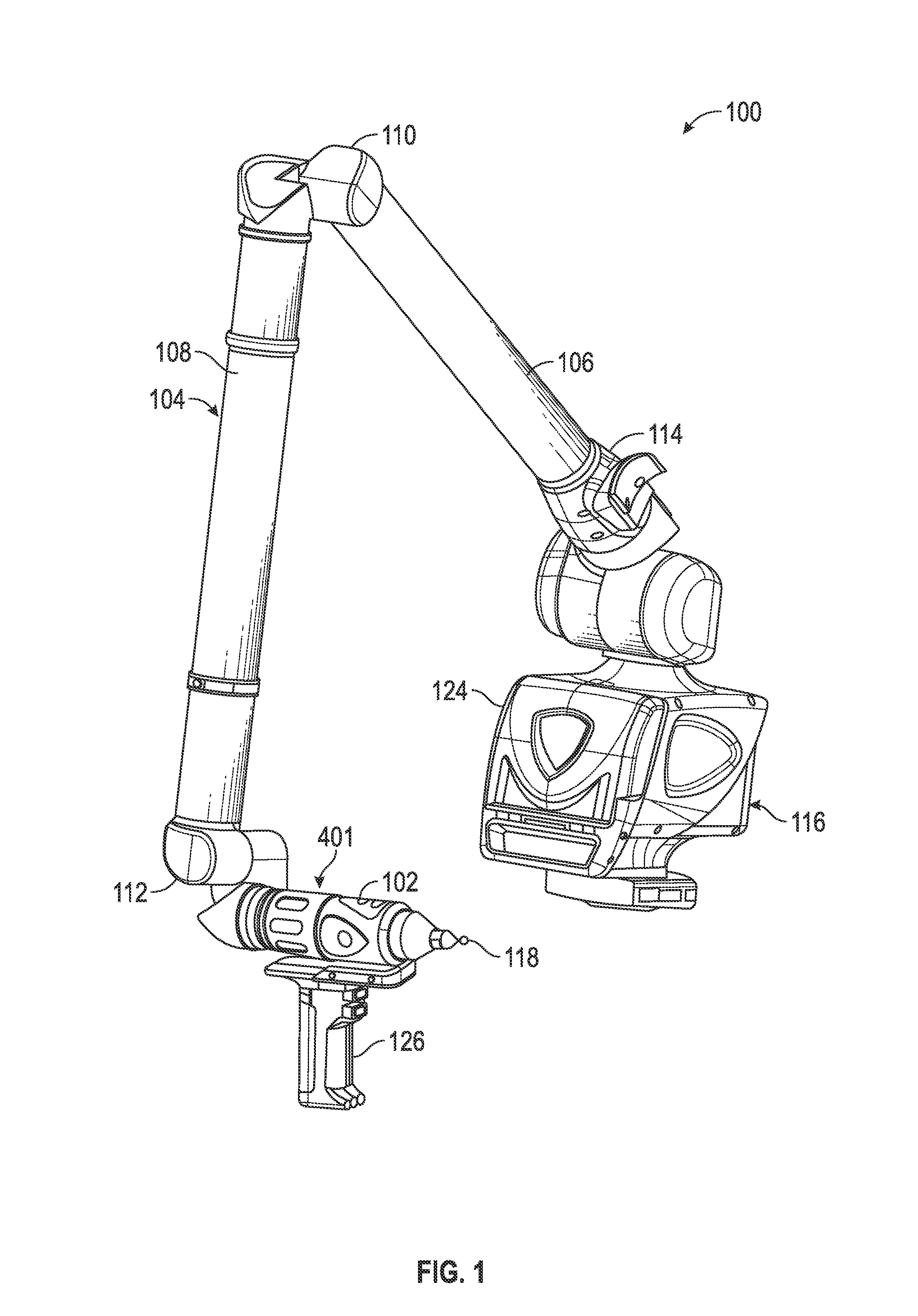

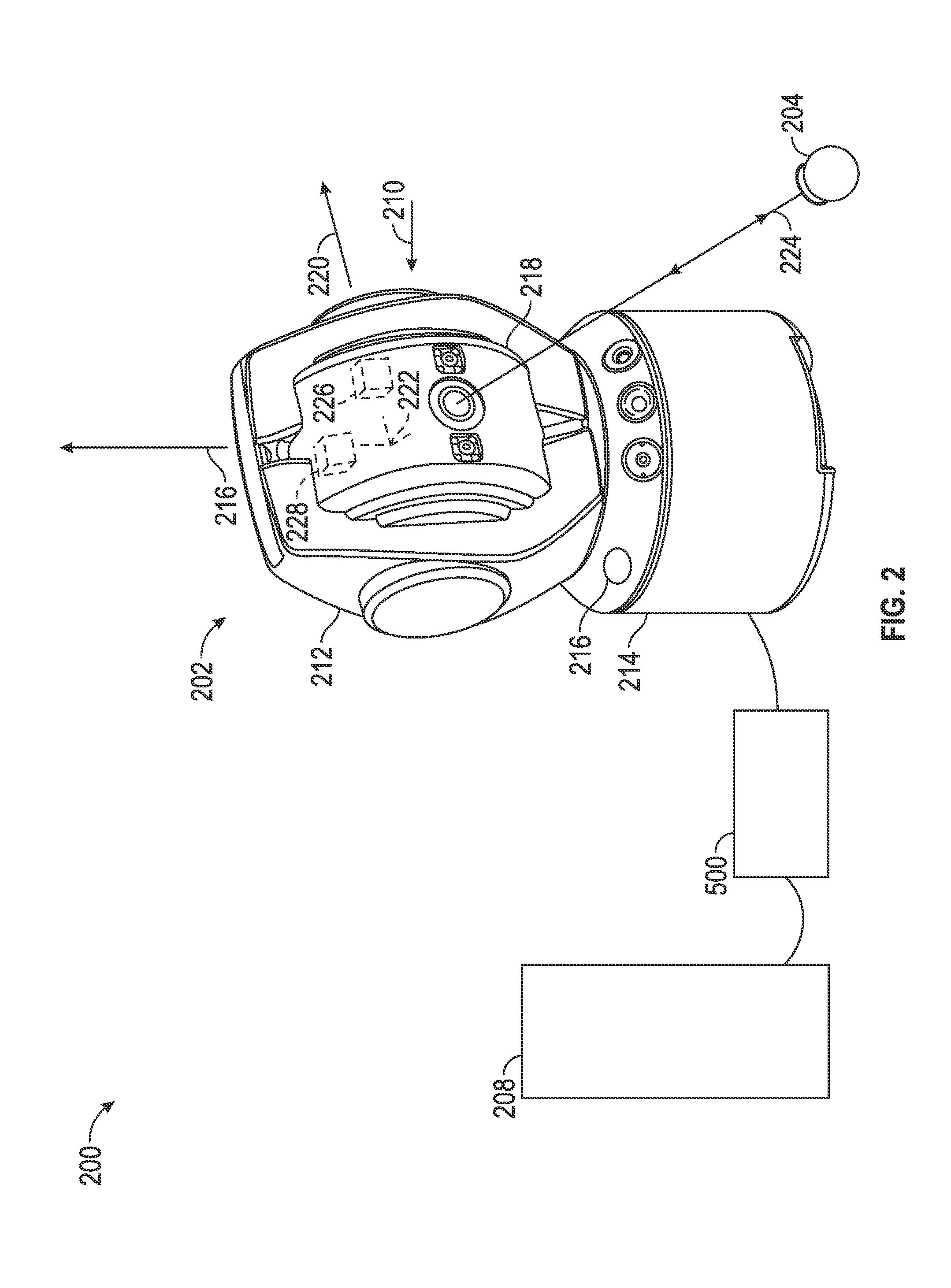

ActiveUS20110166824A1Increase productionIncrease workforceElectric/magnetic depth measurementElectrical/magnetic diameter measurementsEngineeringDiameter measurement

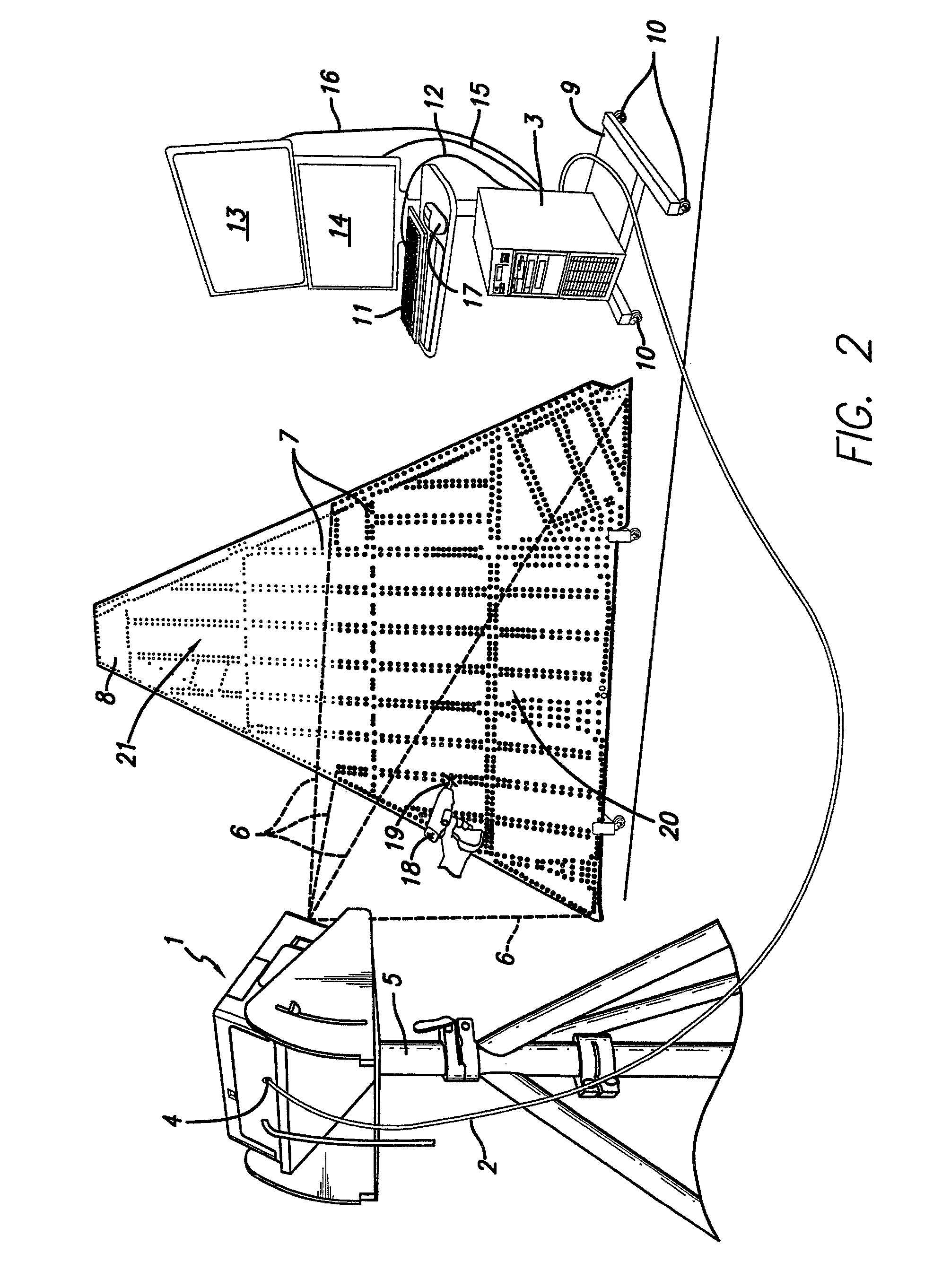

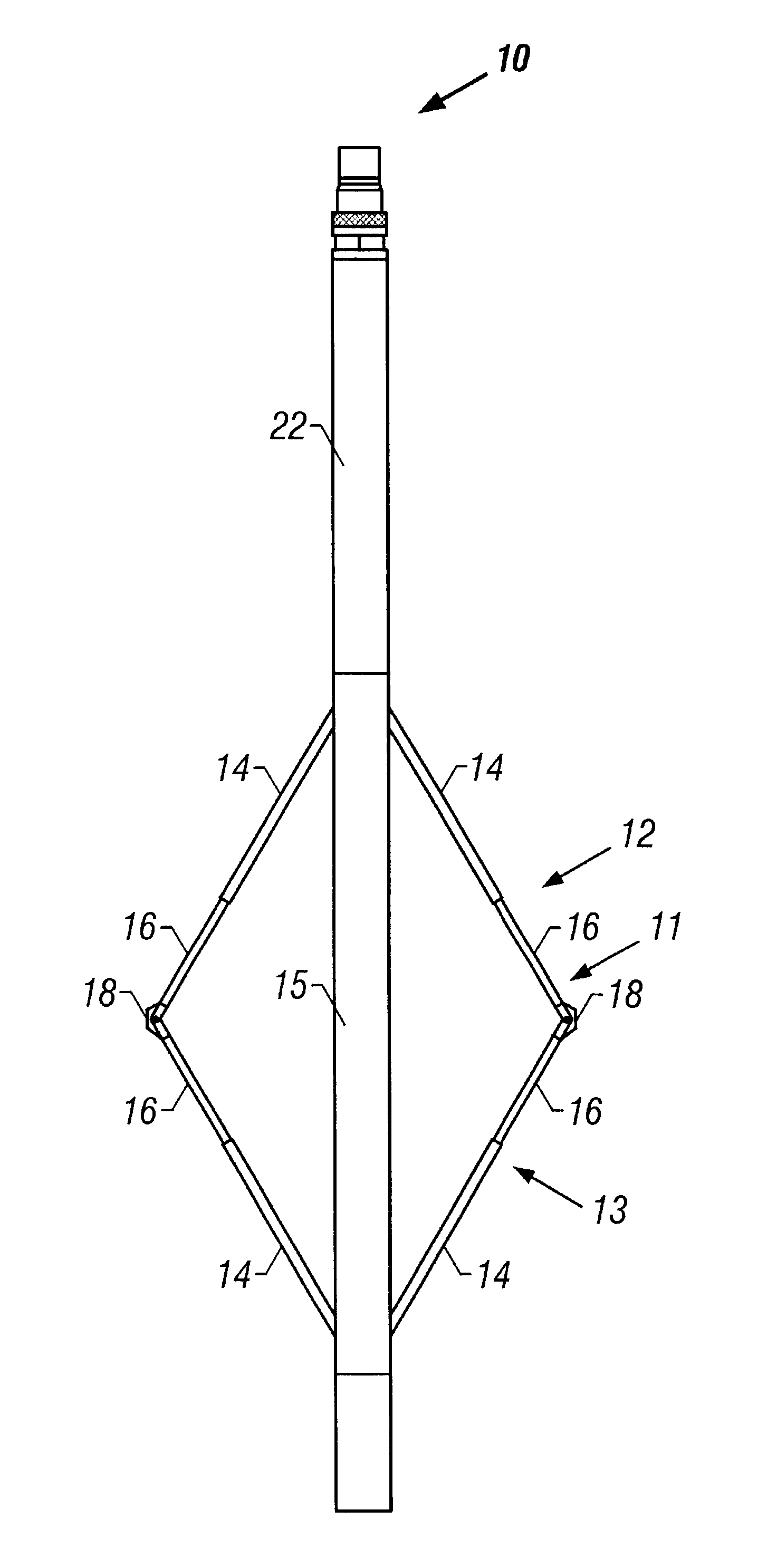

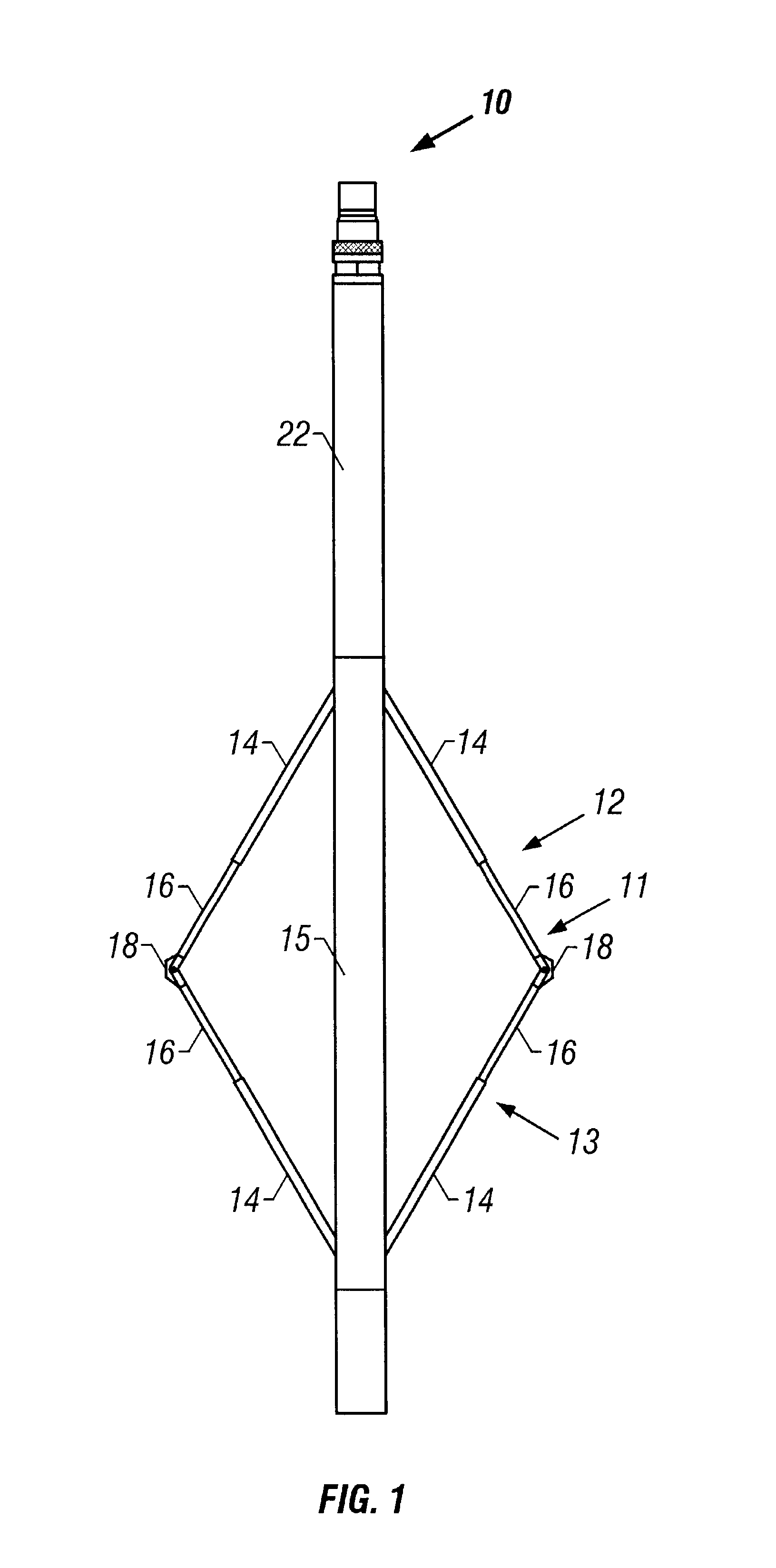

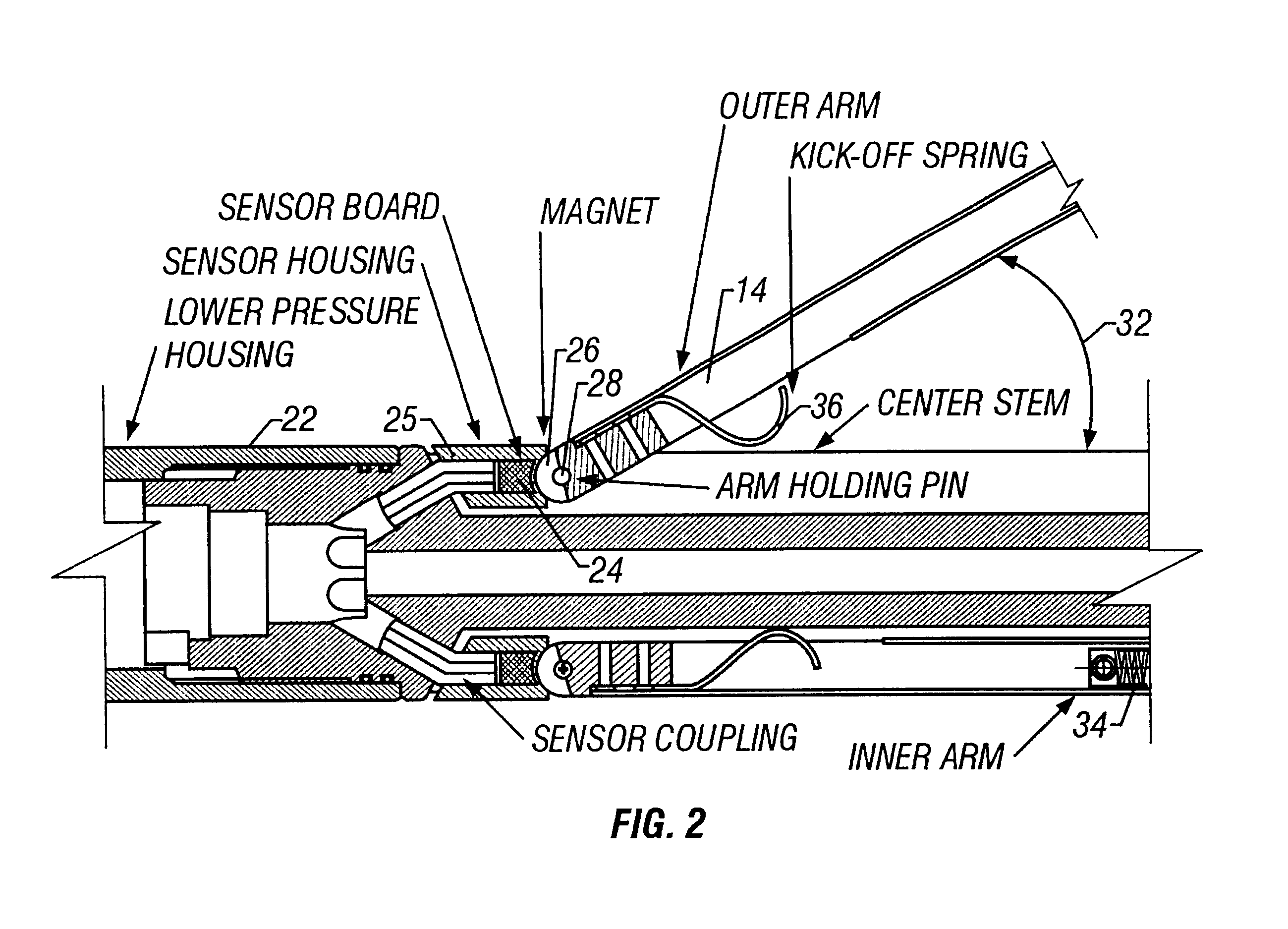

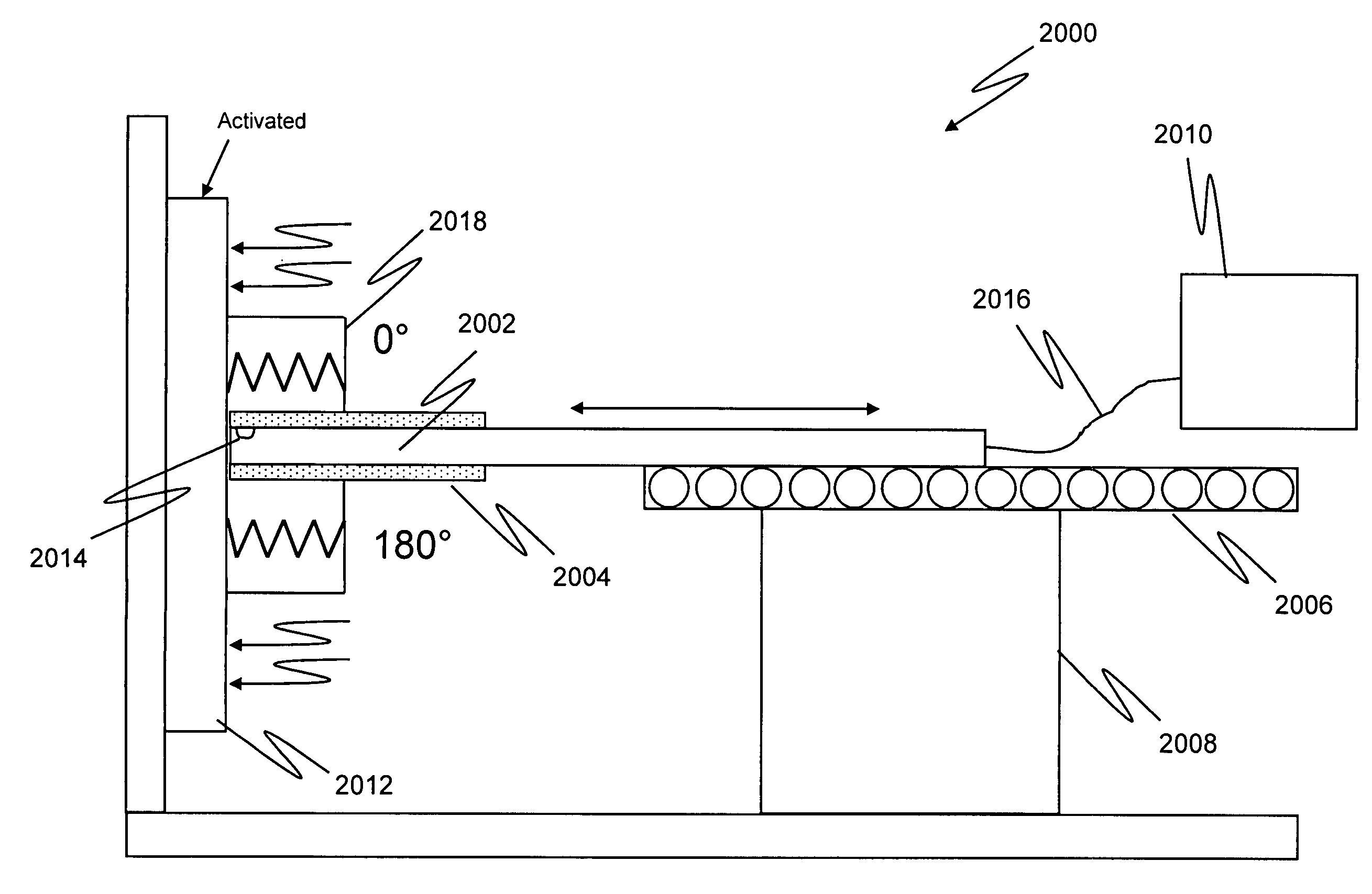

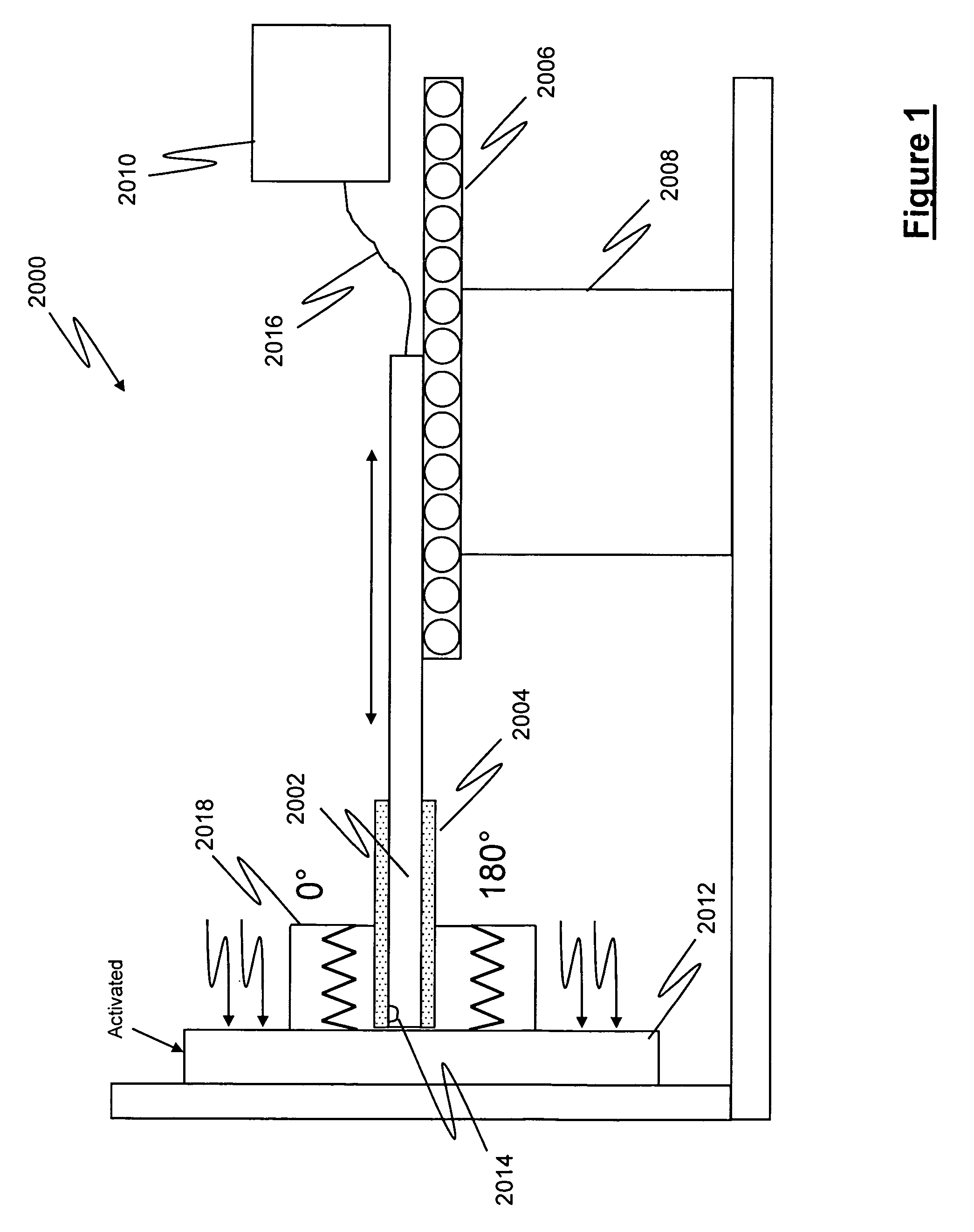

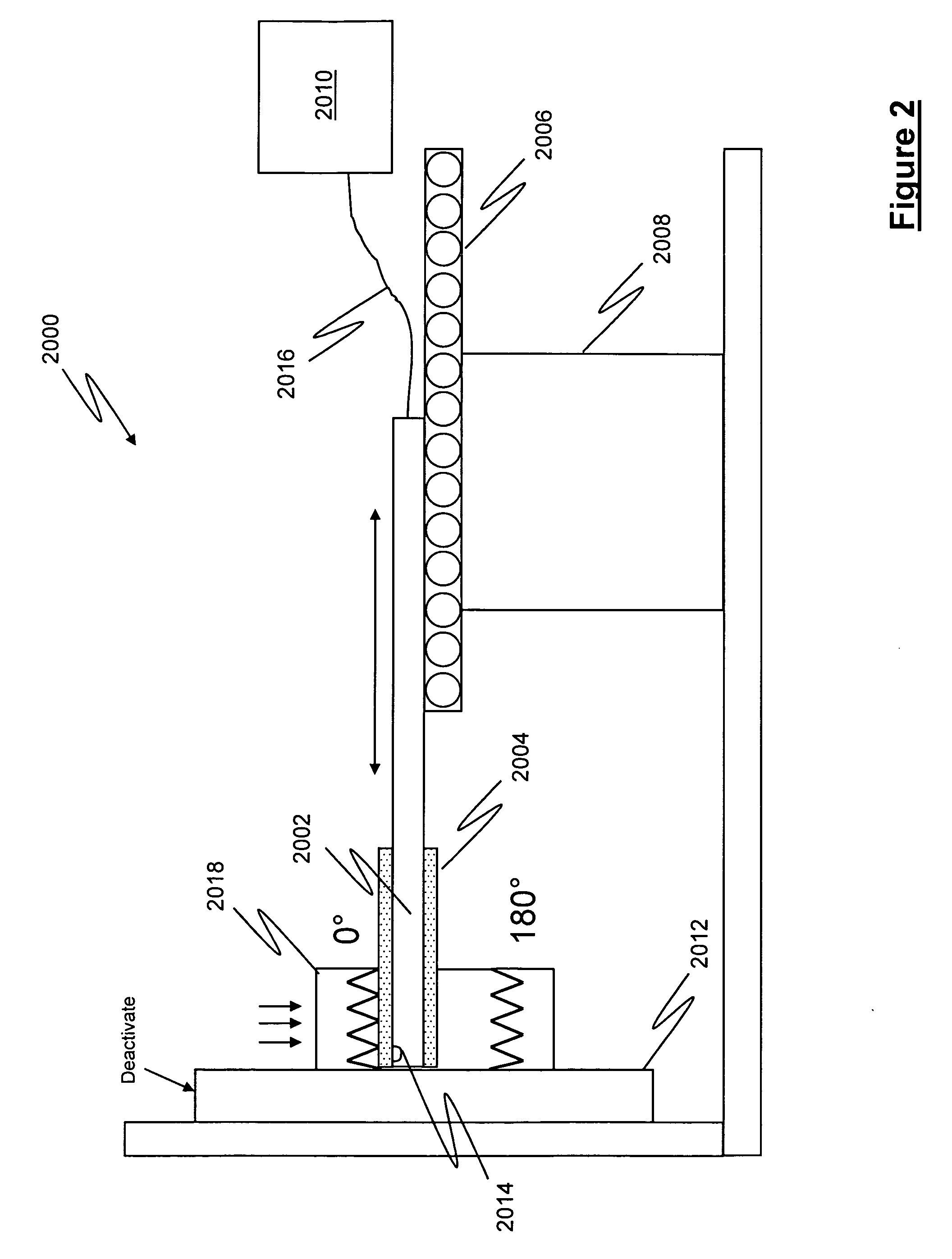

The present invention is directed to automated apparatuses and methods for measuring fastener hole depth, fastener length, countersink depth and / or hole diameters in a workpiece (or other object) in an automated and extremely rapid, efficient and accurate manner. The apparatuses may be operably connected with a power source and with one or a plurality of computers or other data collection devices to transmit fastener hole depth, countersink depth and / or hole diameter measurement data and / or information to them each time that a fastener hole is measured, while the apparatus is continuously measuring fastener holes (i.e., with no interruptions). Extremely advantageously, using only one hand, and by only squeezing a trigger only one time, an operator of such an apparatus may successfully and very rapidly and accurately perform more than one, or all three, of the following functions: (i) normalize the apparatus relative to one or a plurality of fastener holes and / or workpiece surfaces; (ii) make one or a plurality of accurate measurements; and (iii) transmit the one or more measurements from the apparatus to one or a plurality of computers and / or other data collection devices for, for example, recordation, storage, manipulation, other use and / or the like.

Owner:DELTA SIGMA

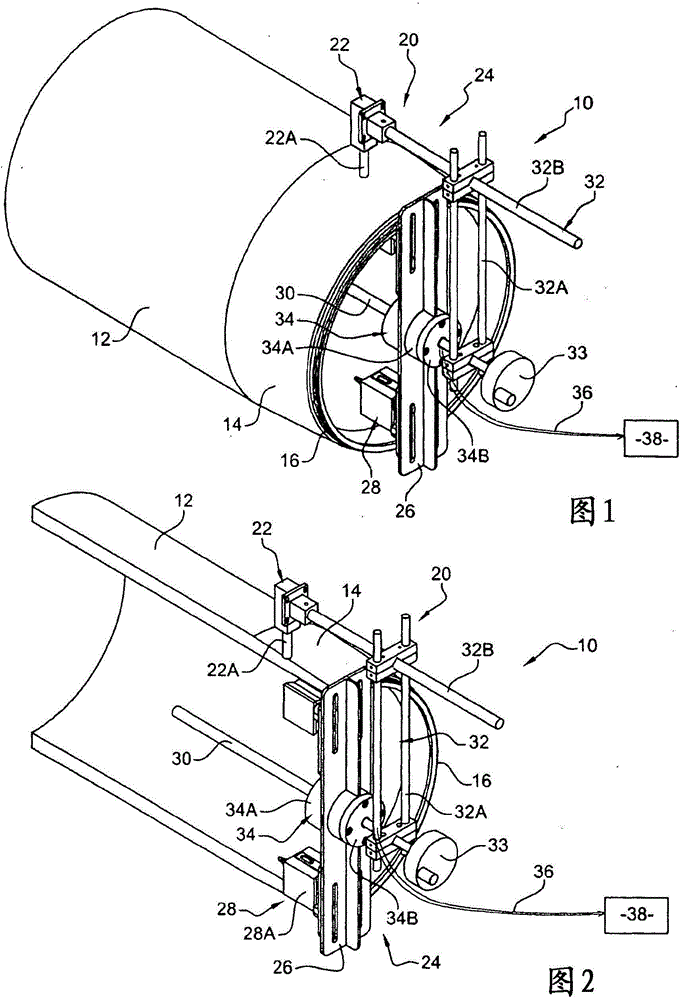

Integrated coiled tubing defect detection device

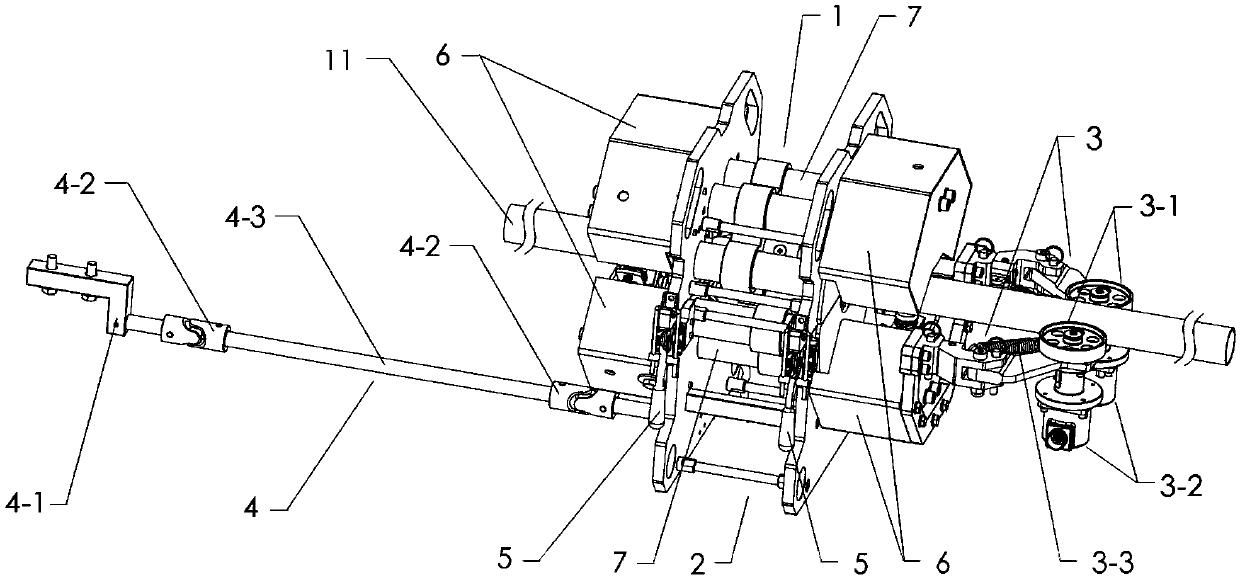

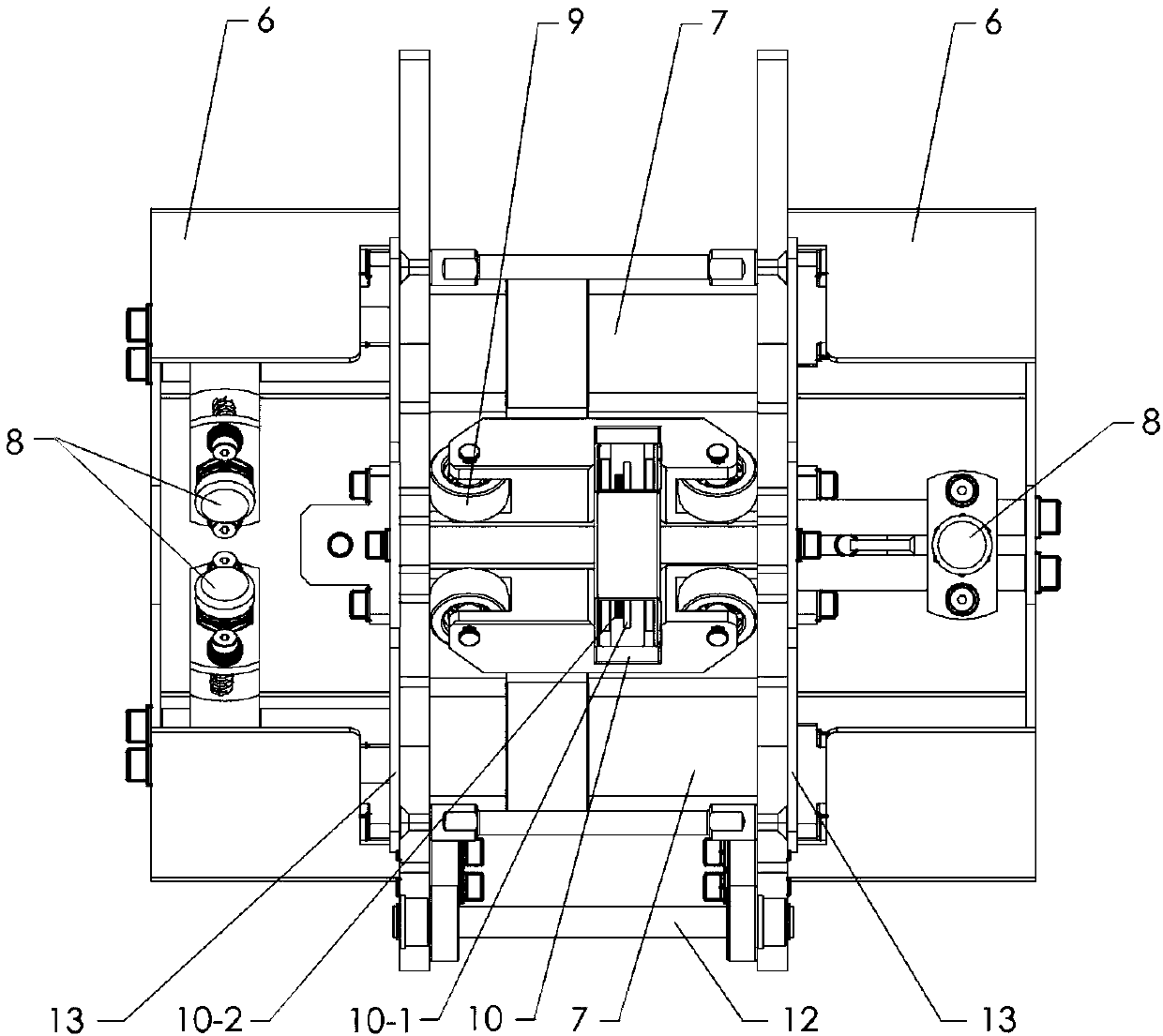

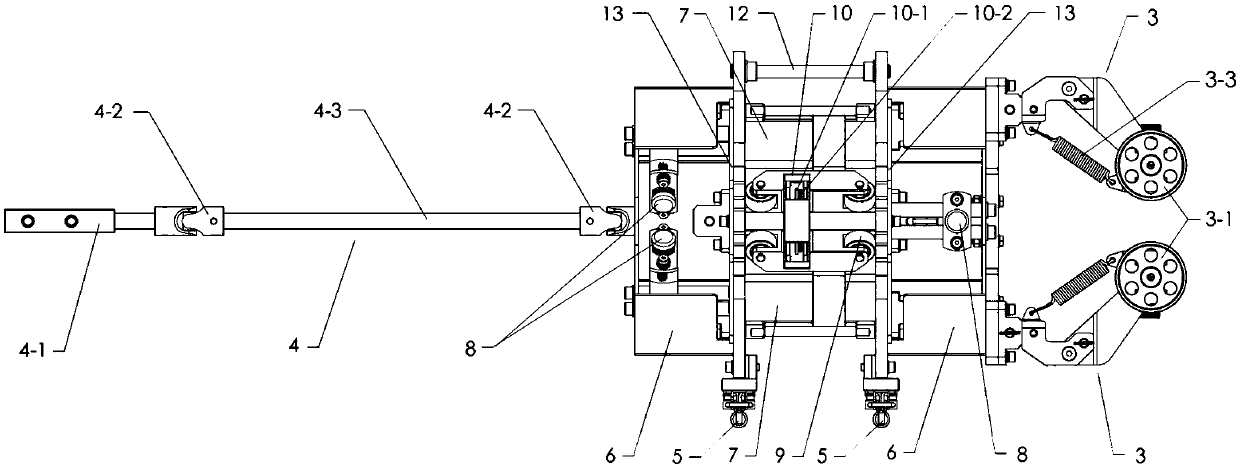

PendingCN109682881AAccurate defect detectionAccurate detection of wall thicknessElectric/magnetic contours/curvatures measurementsUsing electrical meansCoiled tubingEngineering

The invention provides an integrated coiled tubing defect detection device. The coiled tubing defect detection device comprises an upper half detection unit and a lower half detection unit, and a passage for coiled tubing to pass through is formed between the two detection units after the two detection units are matched and assembled with each other, and internally provided with a magnetism generating device, a magnetism leakage detection probe, an ellipticity detection probe and a guide device which are arranged on the two detection units; a measuring arm assembly kit for guiding the two detection units in moving along the coiled tubing is connected to the outsides of the detection units. The device can achieve real-time and precise detection of the wall thickness, outer diameter, ovalityand various physical defects such as corrosion, cracks, mechanical damage and pitting corrosion of coiled tubing columns.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

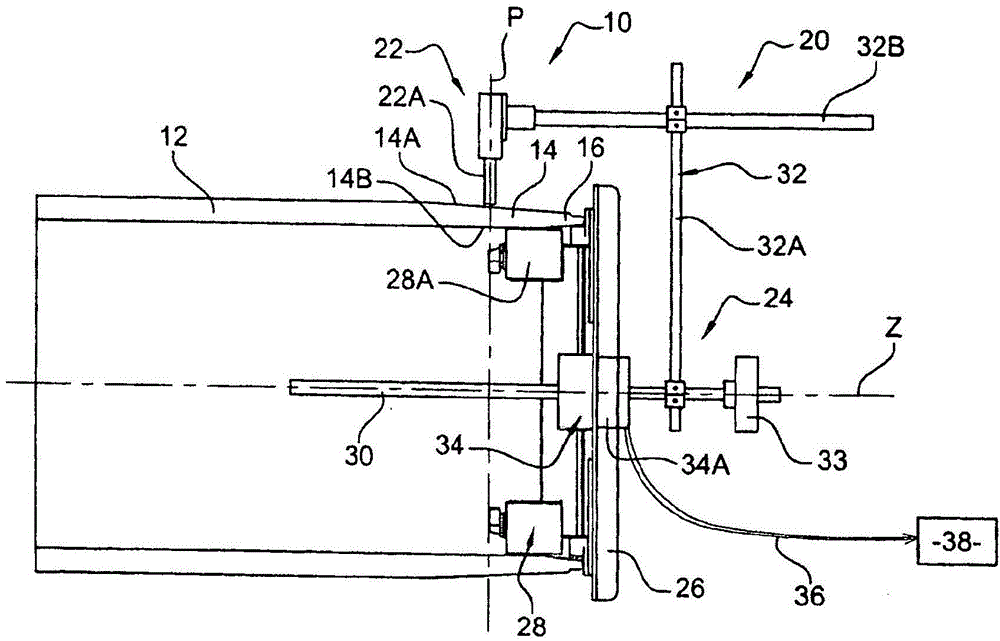

Hole measurement apparatuses

ActiveUS8606540B2Fast, efficient and accurate measurementEasy transferElectric/magnetic depth measurementElectrical/magnetic diameter measurementsDiameter measurementBiomedical engineering

The present invention is directed to automated apparatuses and methods for measuring fastener hole depth, fastener length, countersink depth and / or hole diameters in a workpiece (or other object) in an automated and extremely rapid, efficient and accurate manner. The apparatuses may be operably connected with a power source and with one or a plurality of computers or other data collection devices to transmit fastener hole depth, countersink depth and / or hole diameter measurement data and / or information to them each time that a fastener hole is measured, while the apparatus is continuously measuring fastener holes (i.e., with no interruptions). Extremely advantageously, using only one hand, and by only squeezing a trigger only one time, an operator of such an apparatus may successfully and very rapidly and accurately perform more than one, or all three, of the following functions: (i) normalize the apparatus relative to one or a plurality of fastener holes and / or workpiece surfaces; (ii) make one or a plurality of accurate measurements; and (iii) transmit the one or more measurements from the apparatus to one or a plurality of computers and / or other data collection devices for, for example, recordation, storage, manipulation, other use and / or the like.

Owner:DELTA SIGMA

Use of magneto-resistive sensors for borehole logging

Owner:BAKER HUGHES INC

Internal inspection system and method

ActiveUS20100110448A1Feeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansOffset distanceEngineering

A system and method for measuring the threaded surface of an internally threaded component is provided, where the inspection system includes at least one measuring probe, wherein the at least one measuring probe includes an emitter and a receiver and is sized and shaped to be positionable adjacent at least a portion of the threaded surface at an offset distance, wherein the emitter is configured to emit electromagnetic energy that is incident upon the threaded surface to generate reflected electromagnetic energy responsive to the threaded surface and wherein the receiver is configured to receive at least a portion of the reflected electromagnetic energy and generate threaded surface data. A processing device is also provided, wherein the processing device is in signal communication with the measuring probe to receive the threaded surface data and process the threaded surface data to determine physical characteristics of the threaded surface.

Owner:QUEST INTEGRATED LLC

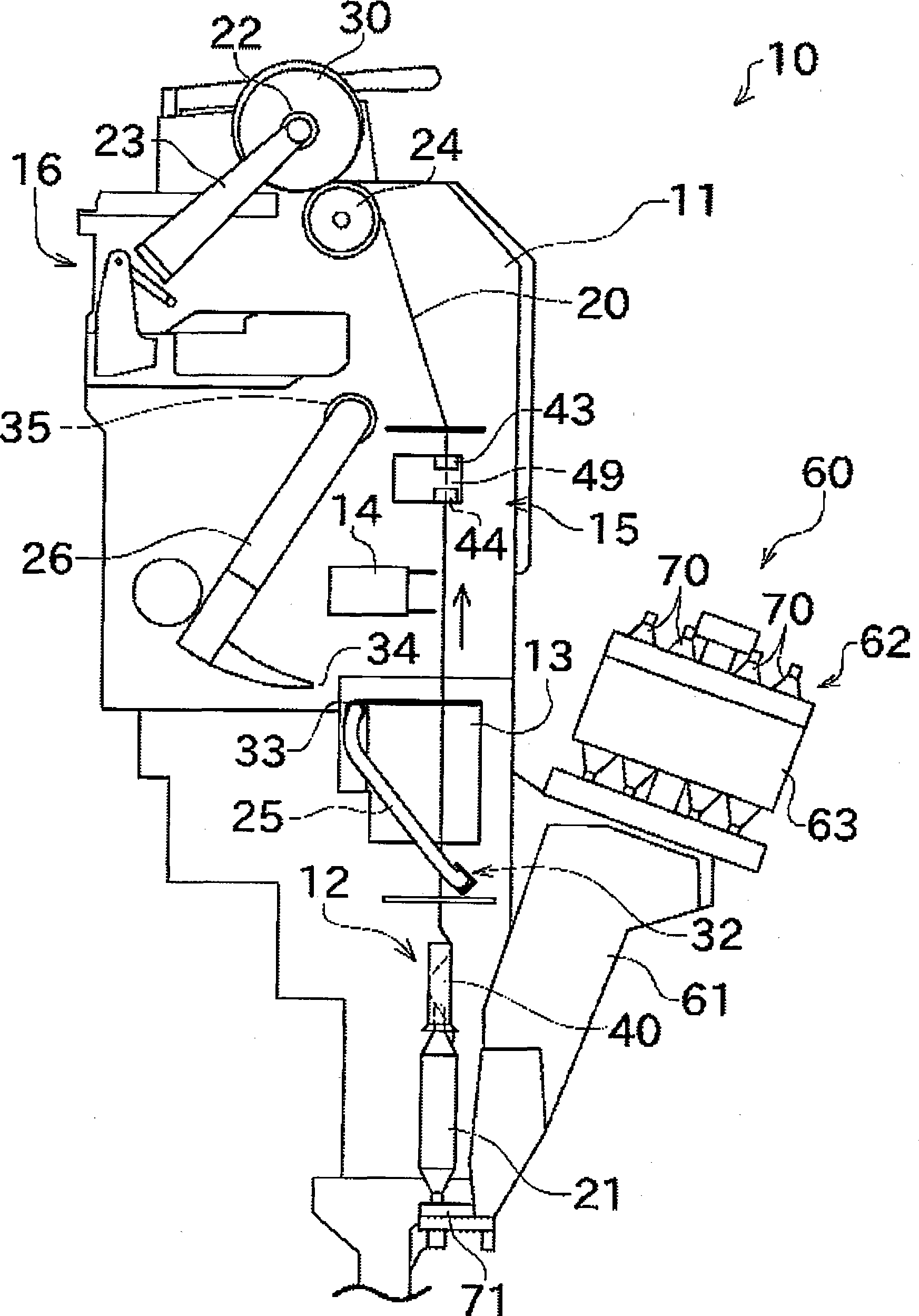

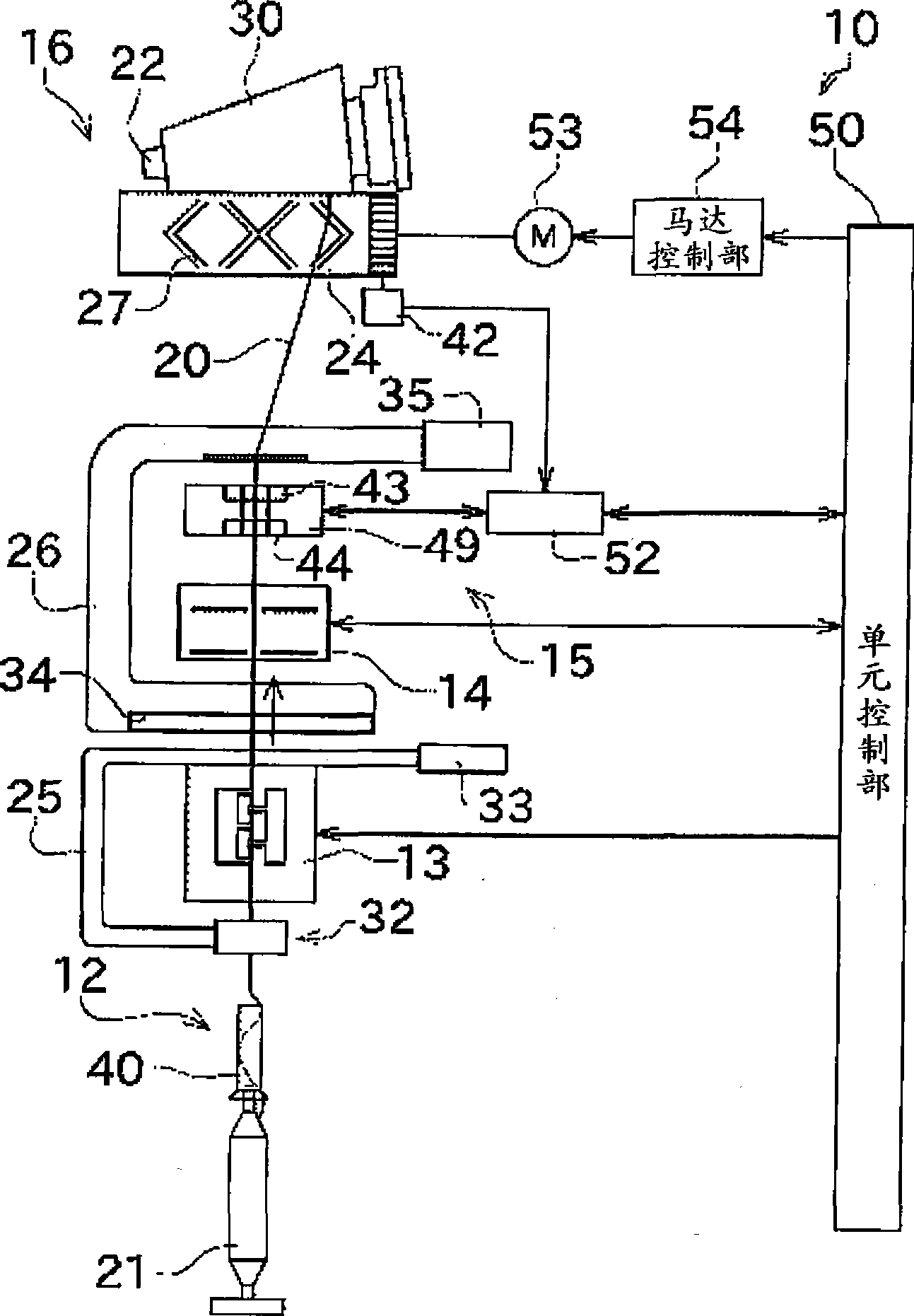

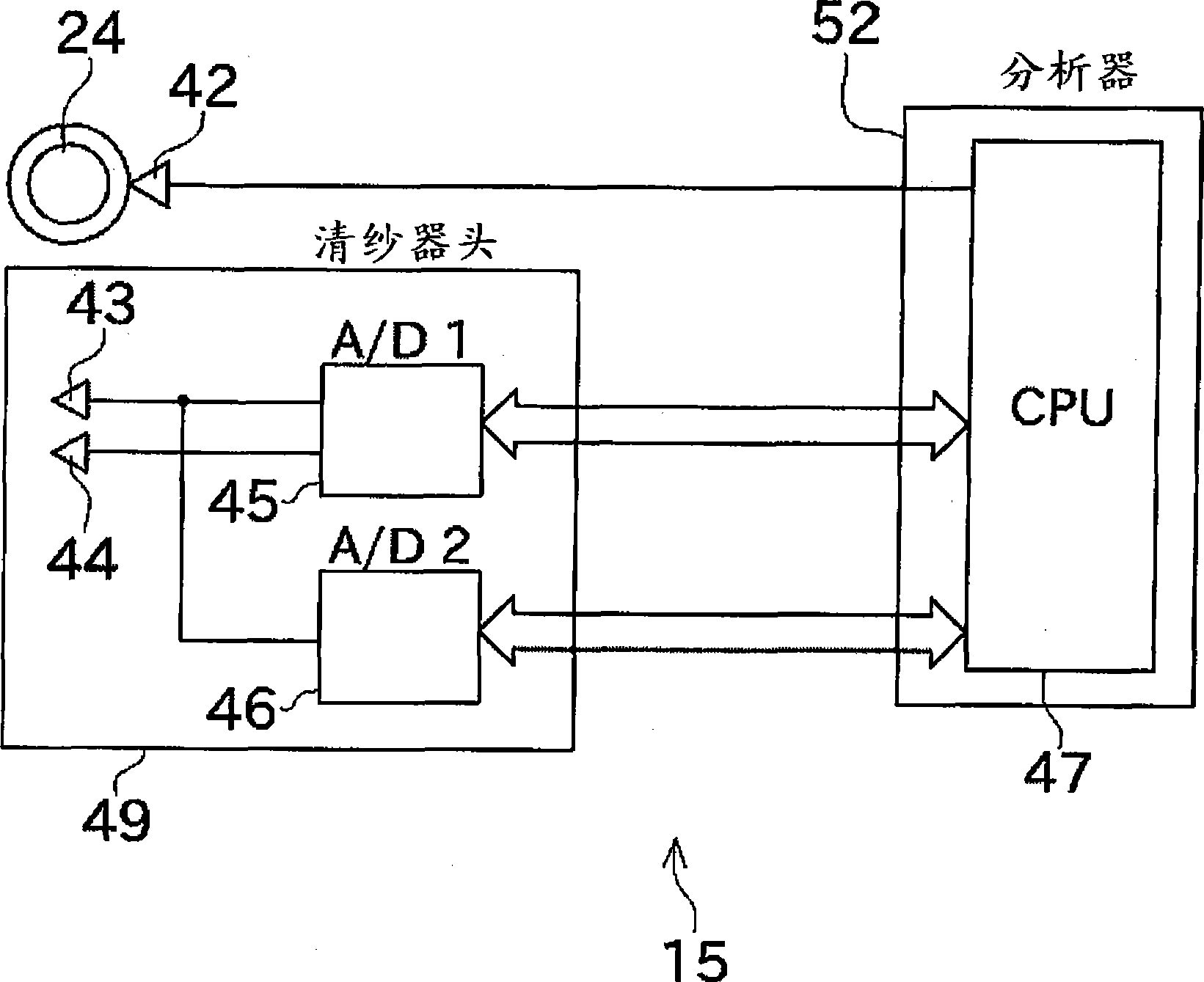

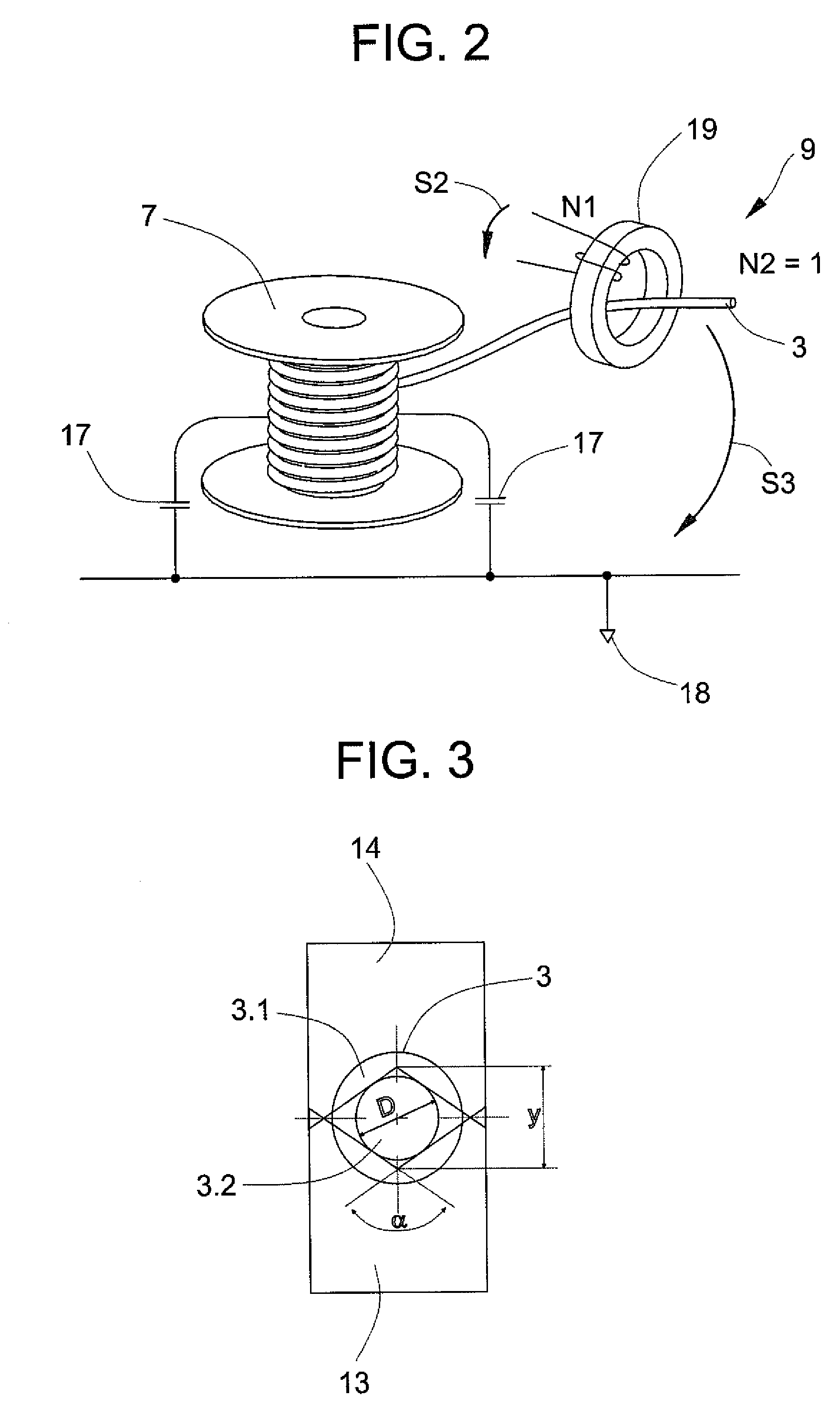

Yarn quality measuring instrument and yarn winding machine

ActiveCN101509756AStrict quality inspectionImprove qualityFilament handlingDevices using time traversedWinding machineYarn

An object of the present invention is to provide a yarn quality measuring instrument and a yarn winding machine which can accurately evaluate the length of a yarn defect and detect periodic unevenness. A winder unit 10 constituting an automatic winder includes a clearer (yarn quality measuring instrument) 15. The clearer 15 detects thickness unevenness in a spun yarn 20 traveling with a speed thereof varied, to detect the thickness unevenness in the yarn. The clearer 15 includes a first yarn unevenness sensor 43 detecting the thickness of the traveling yarn, and a CPU 47. The CPU 47 receives a yarn speed signal obtained from an external rotation sensor 42 to sample signals from the first yarn unevenness sensor 43 at a sampling frequency according to the yarn speed signal.

Owner:MURATA MASCH LTD

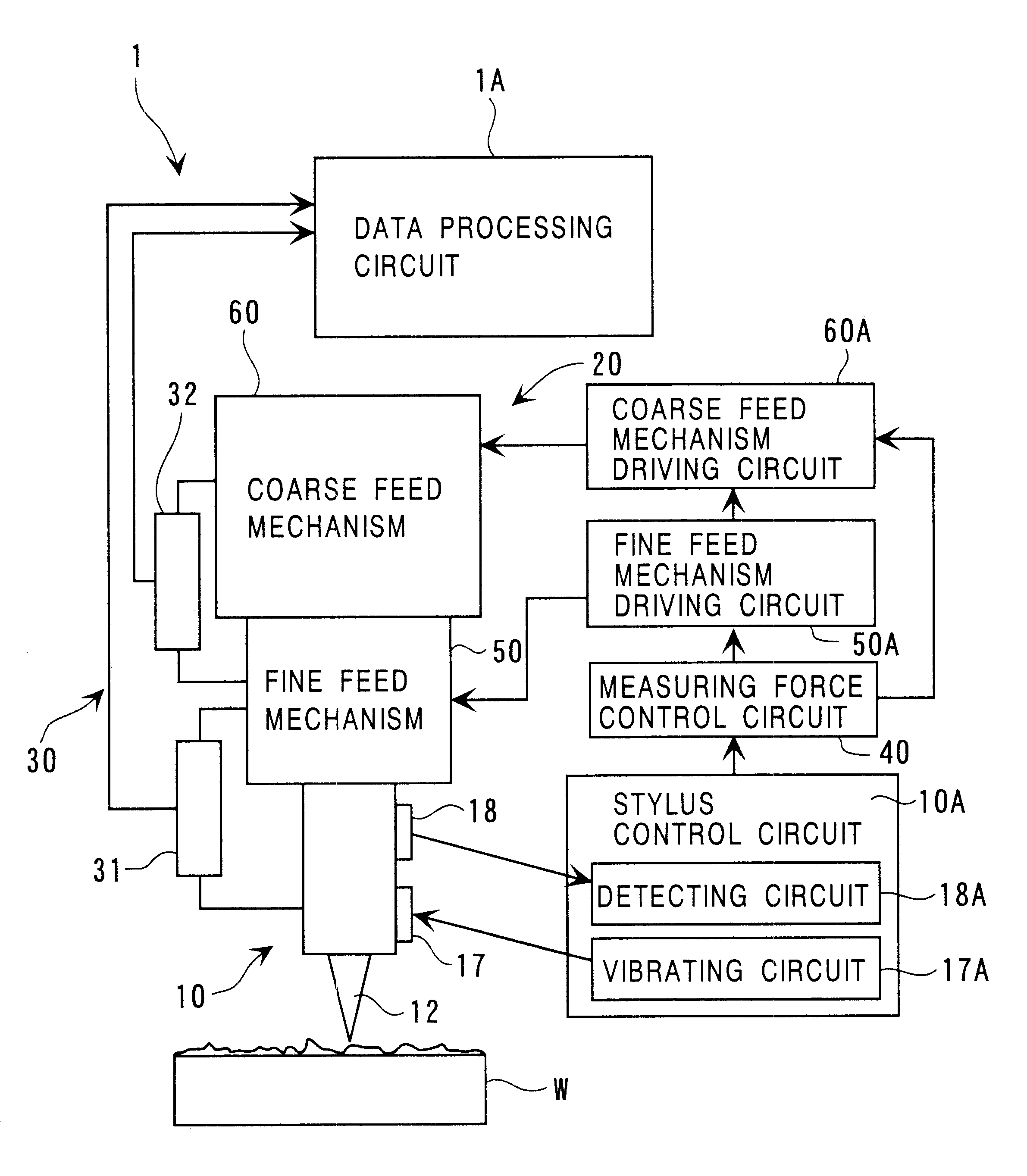

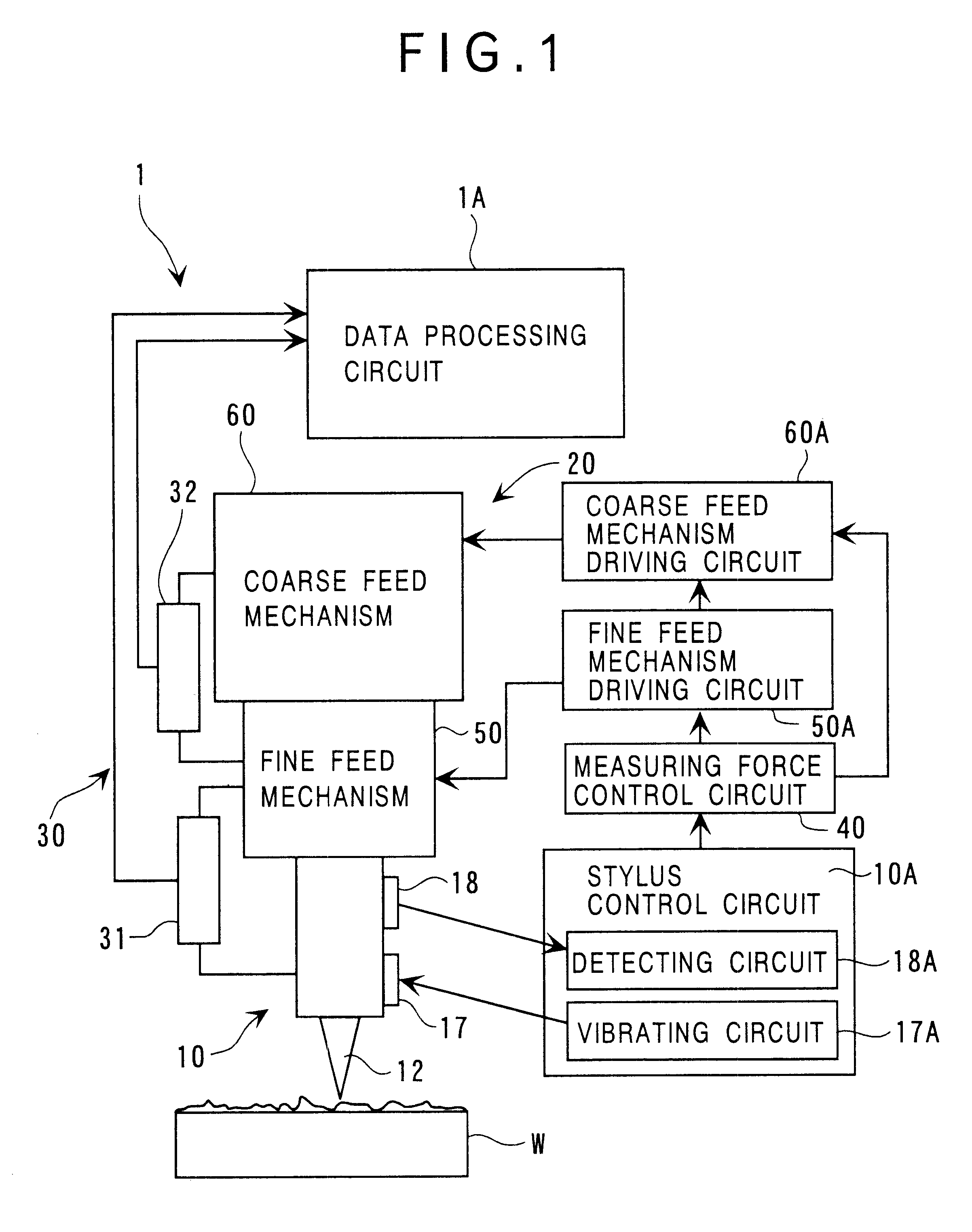

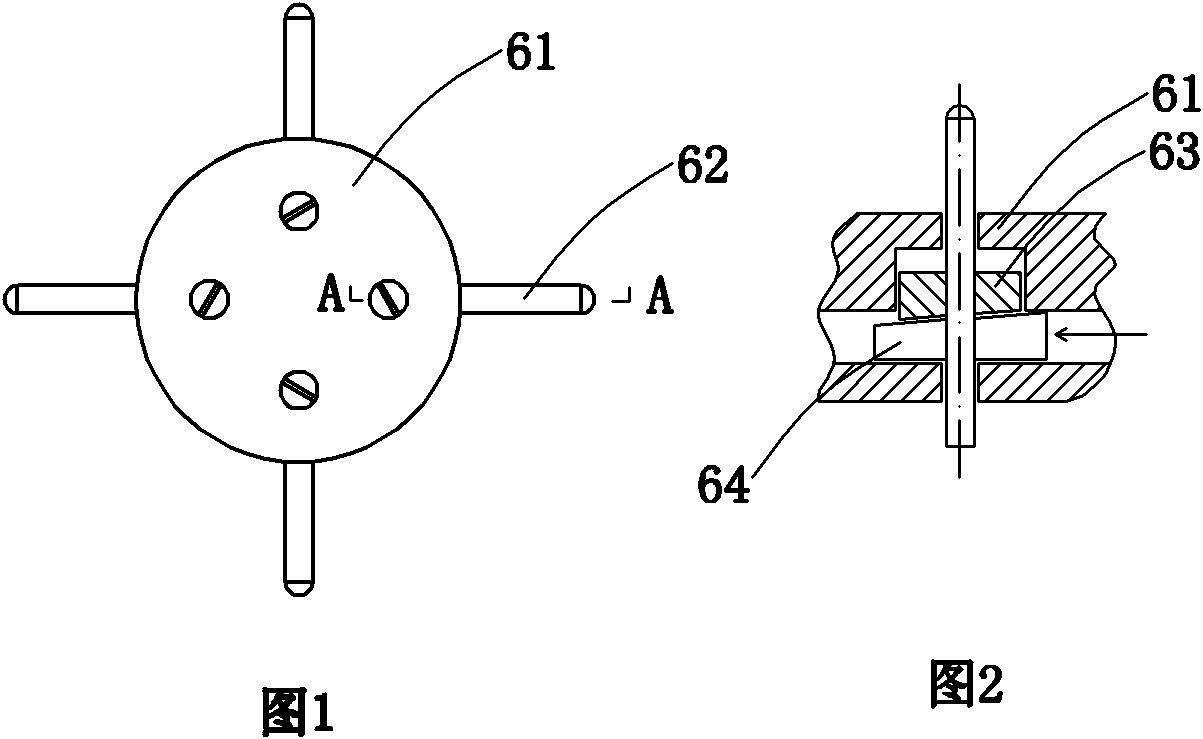

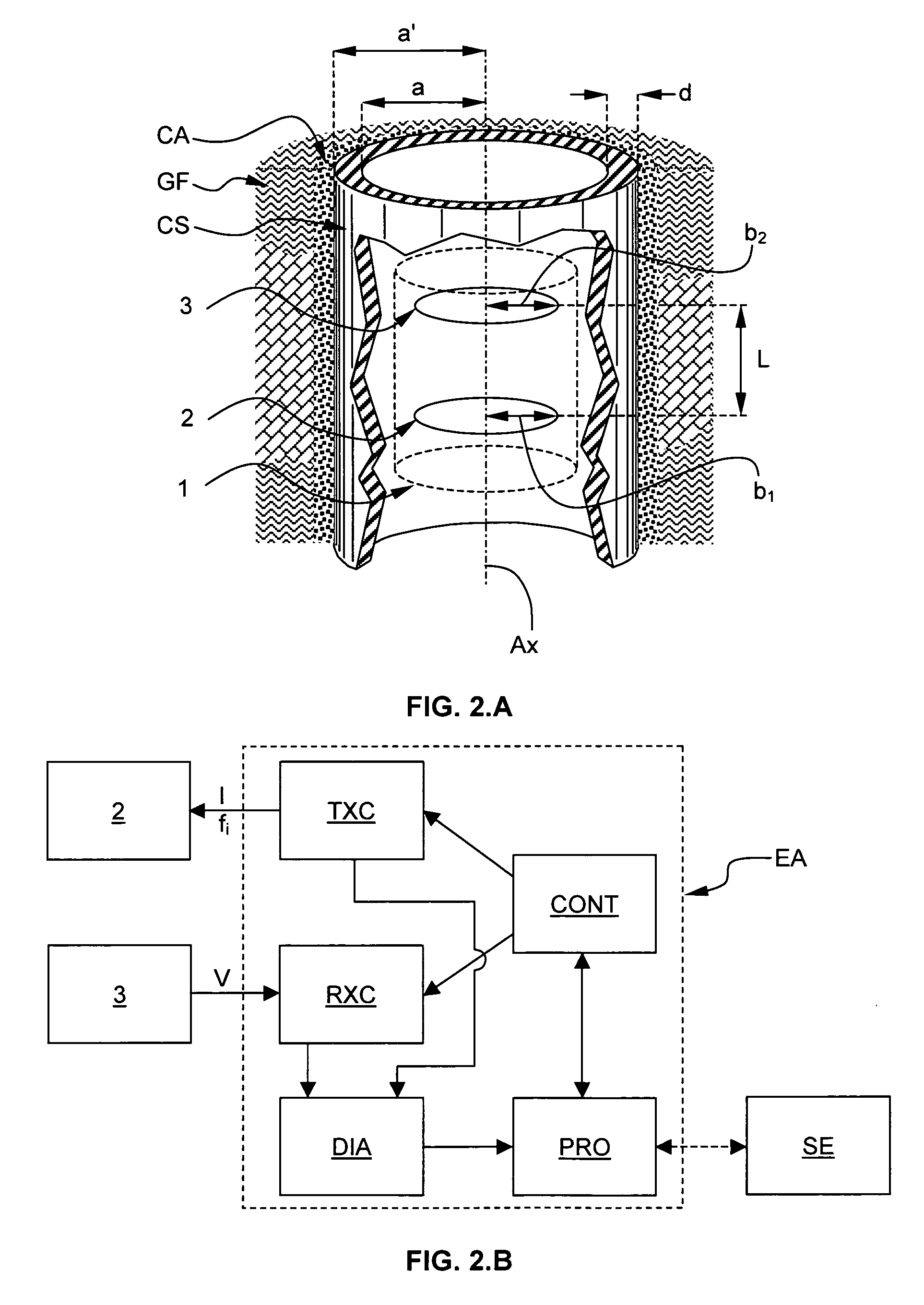

Microscopic geometry measuring device

InactiveUS6604295B2Eliminate mechanical interferenceDegradation in responsivityMechanical counters/curvatures measurementsNanotechnologyMeasurement deviceEngineering

A fine feed mechanism (50) and a coarse feed mechanism (60) respectively for minutely and greatly displacing a stylus (12) is provided to a microscopic geometry measuring device (1), so that the respective mechanisms (50, 60) are combinedly actuated for easily controlling the movement of the stylus (12) in a wide range at a short time. Further, a movable balancing portion (53) moving in a direction opposite to a movable driving portion (52) is provided to the fine feed mechanism (50). Since a reaction force caused by the movement of the movable driving portion (52) is cancelled by another reaction force caused by the movement of the movable balancing portion (53) at a fixed portion (51), no mechanical interference is caused between the respective mechanisms (50, 60), thus accurately controlling the movement of the stylus (12).

Owner:MITUTOYO CORP

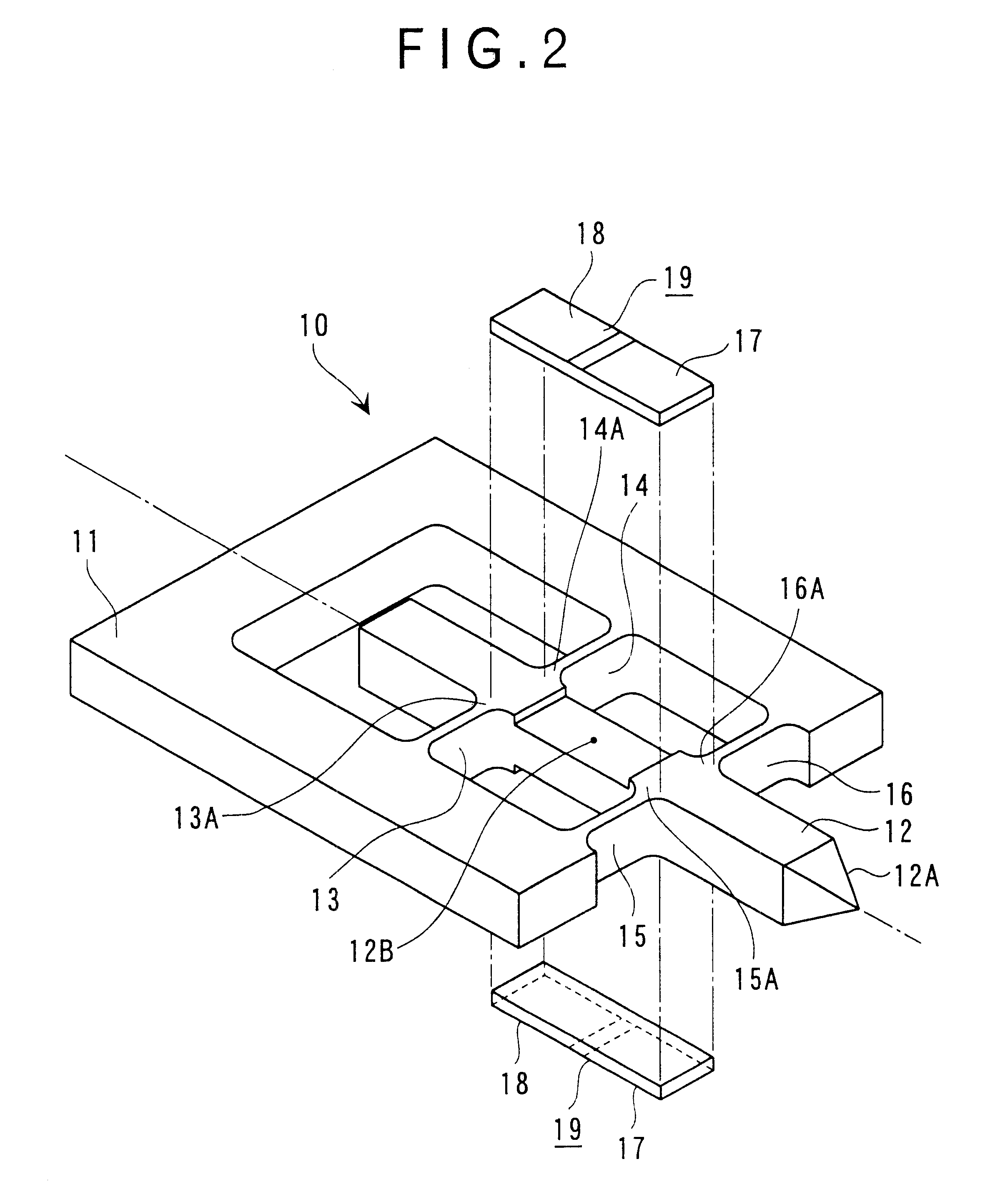

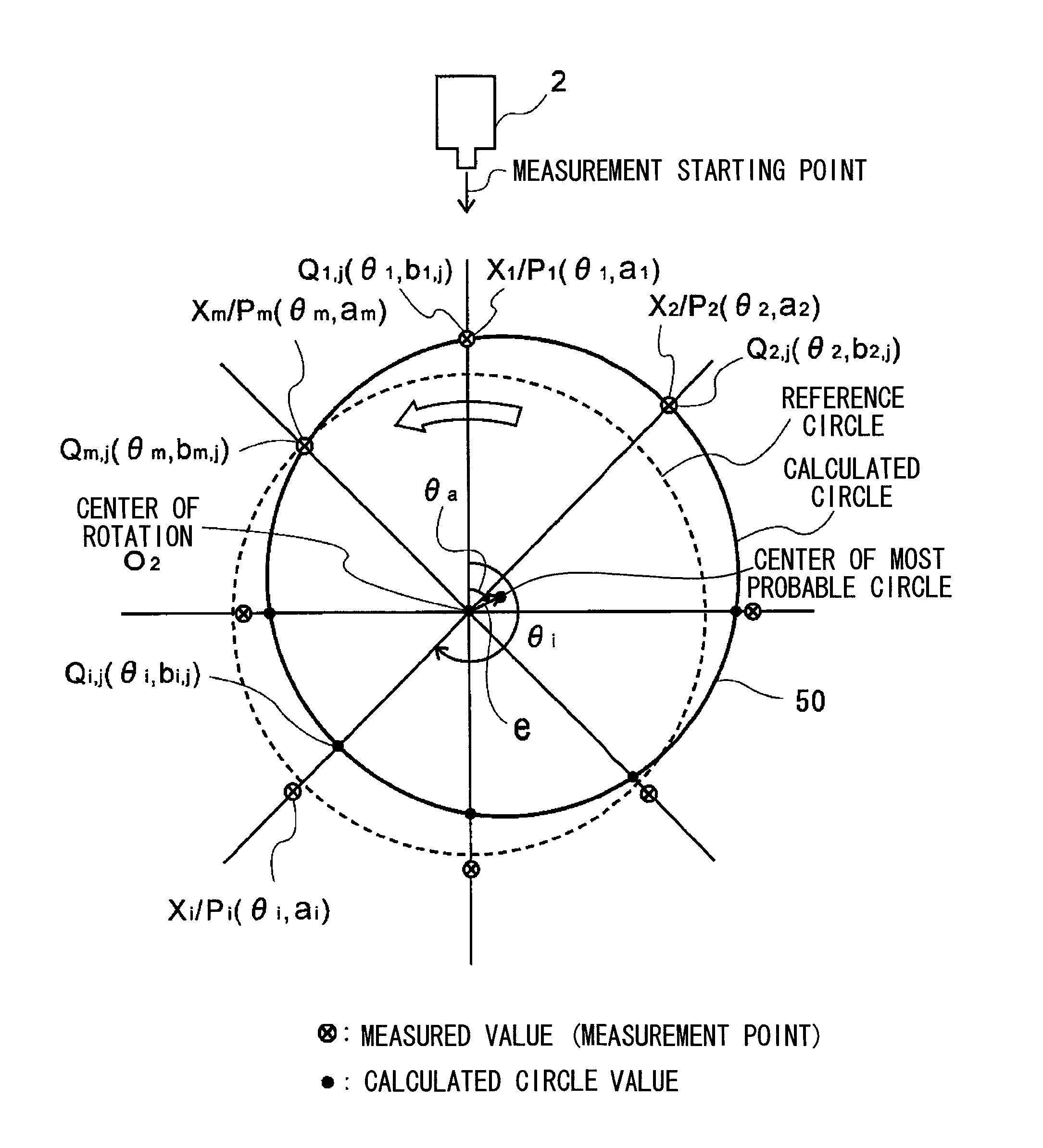

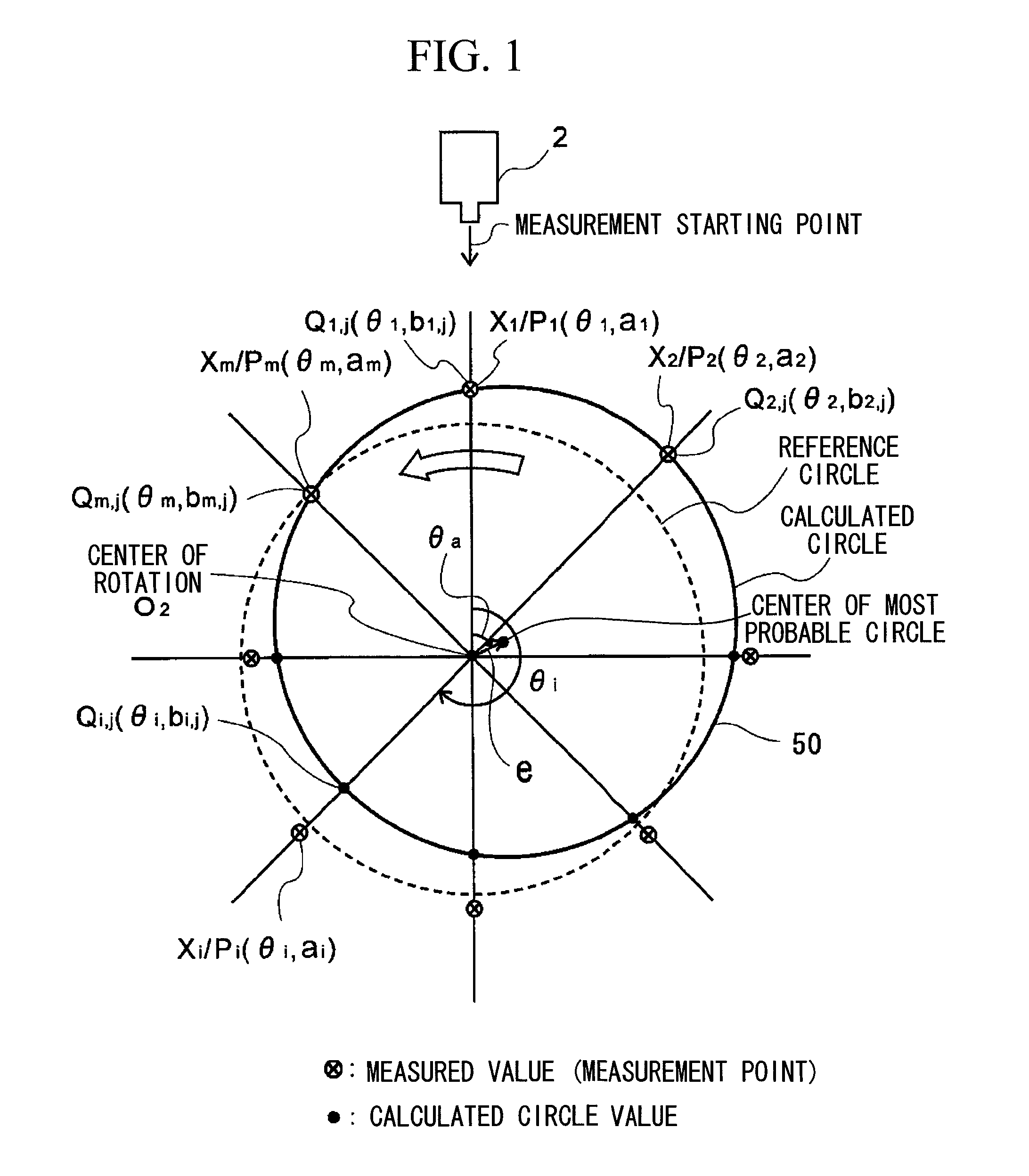

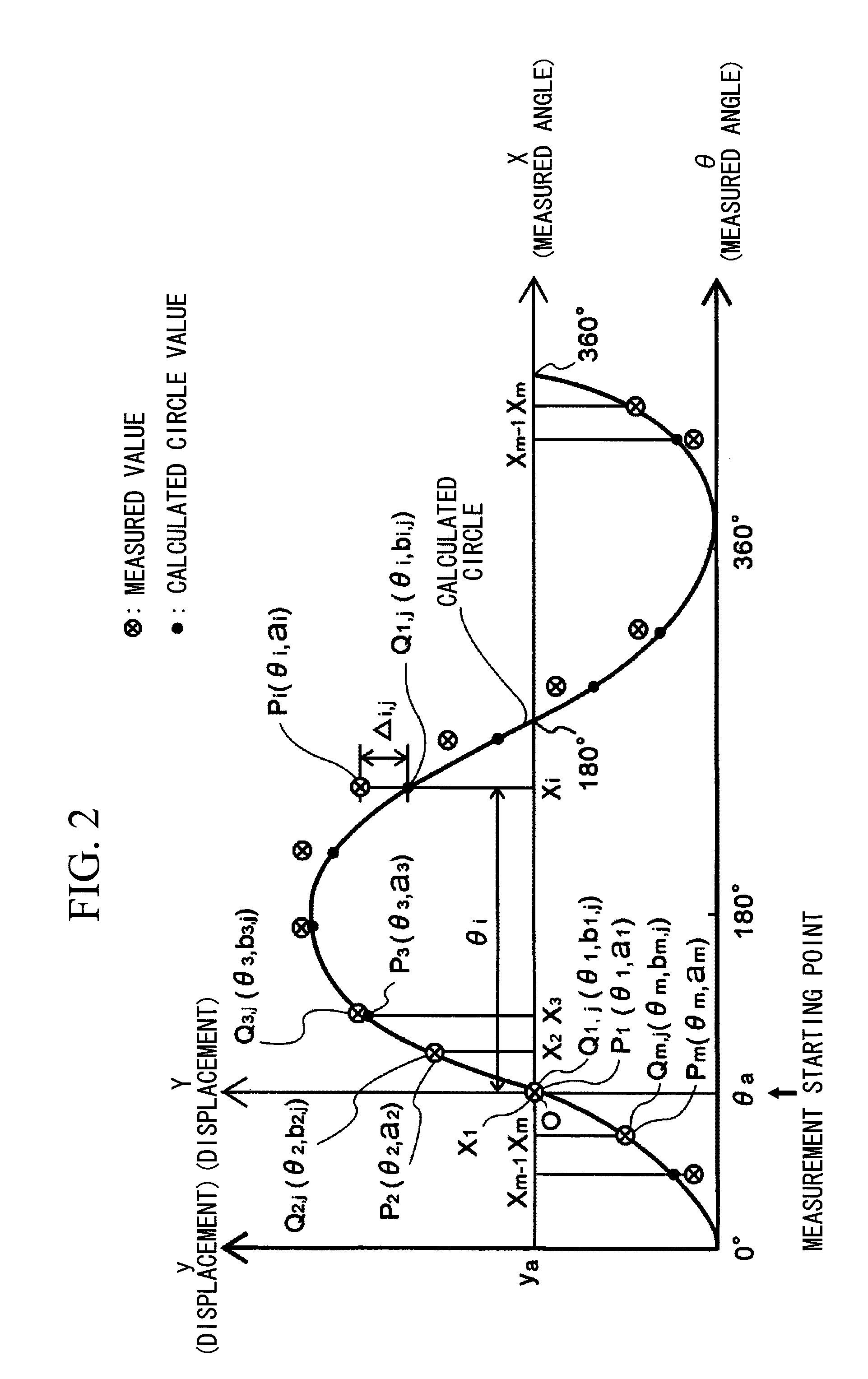

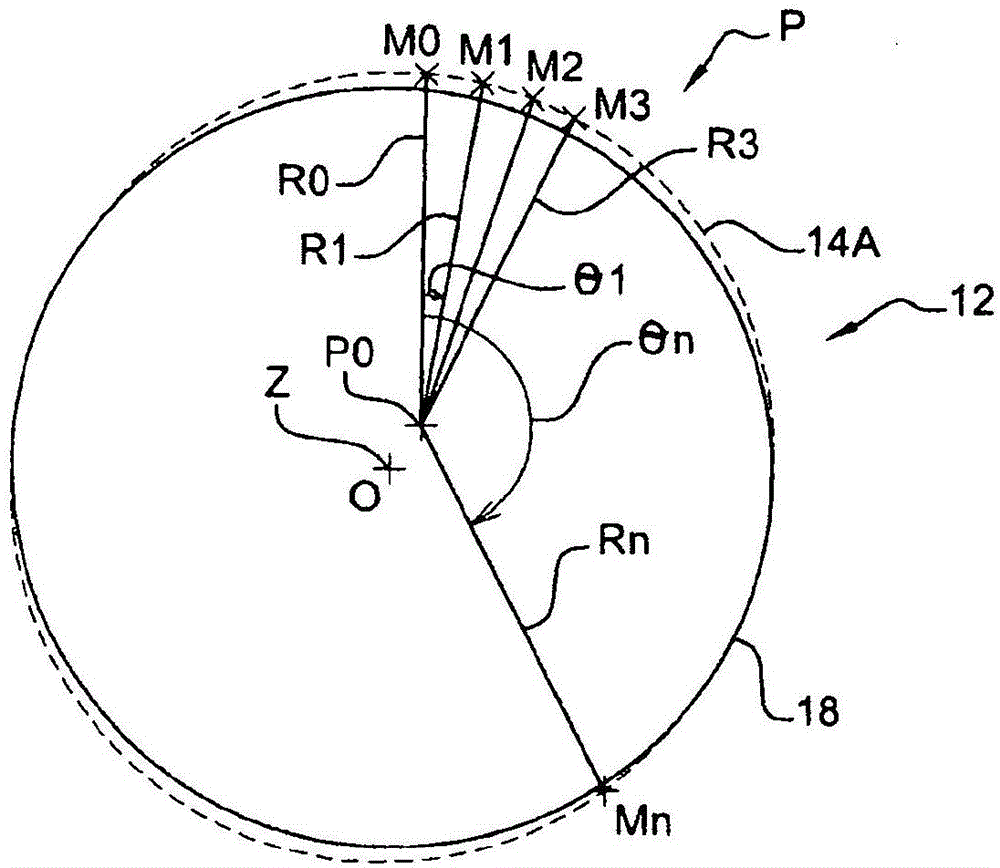

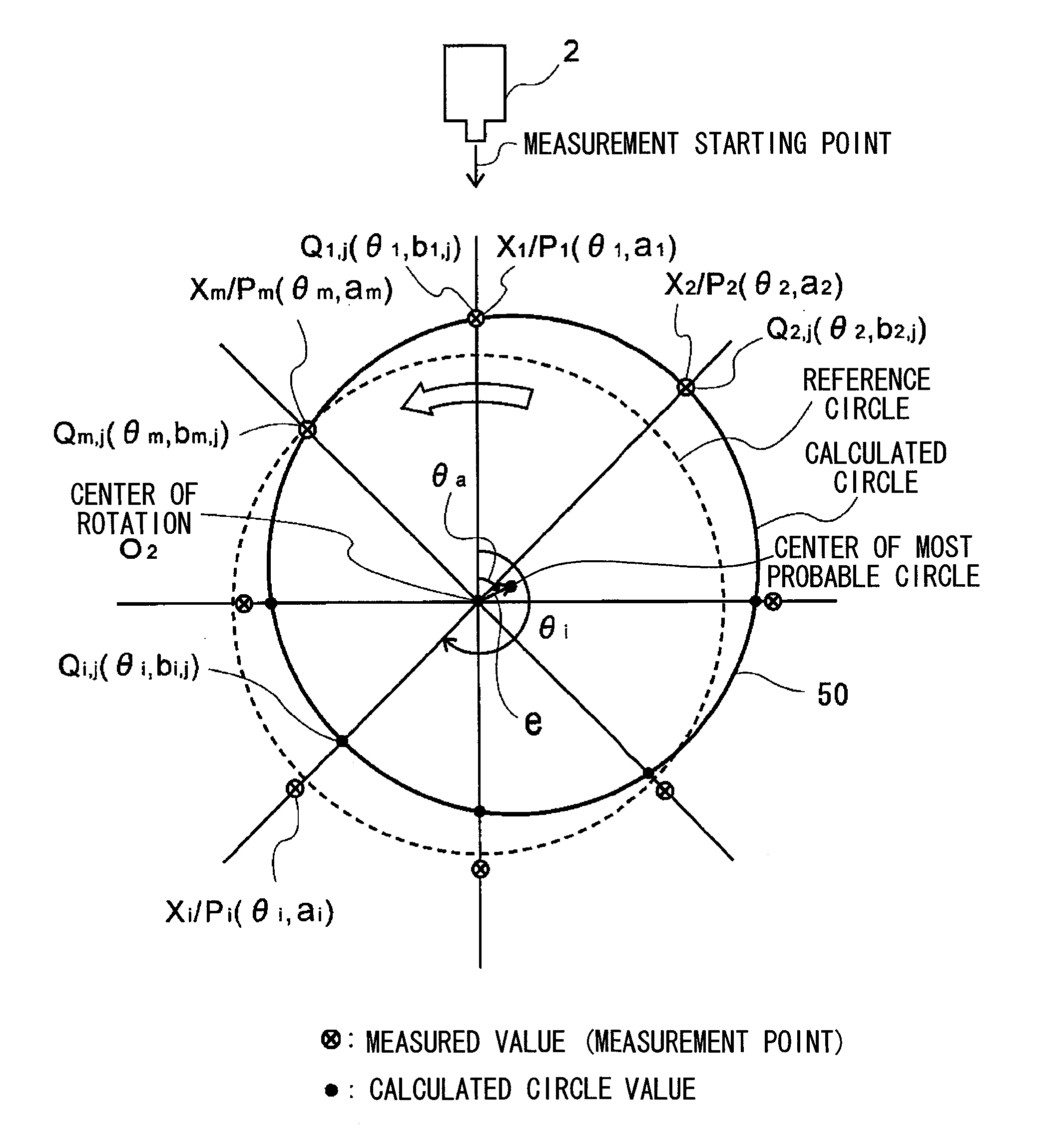

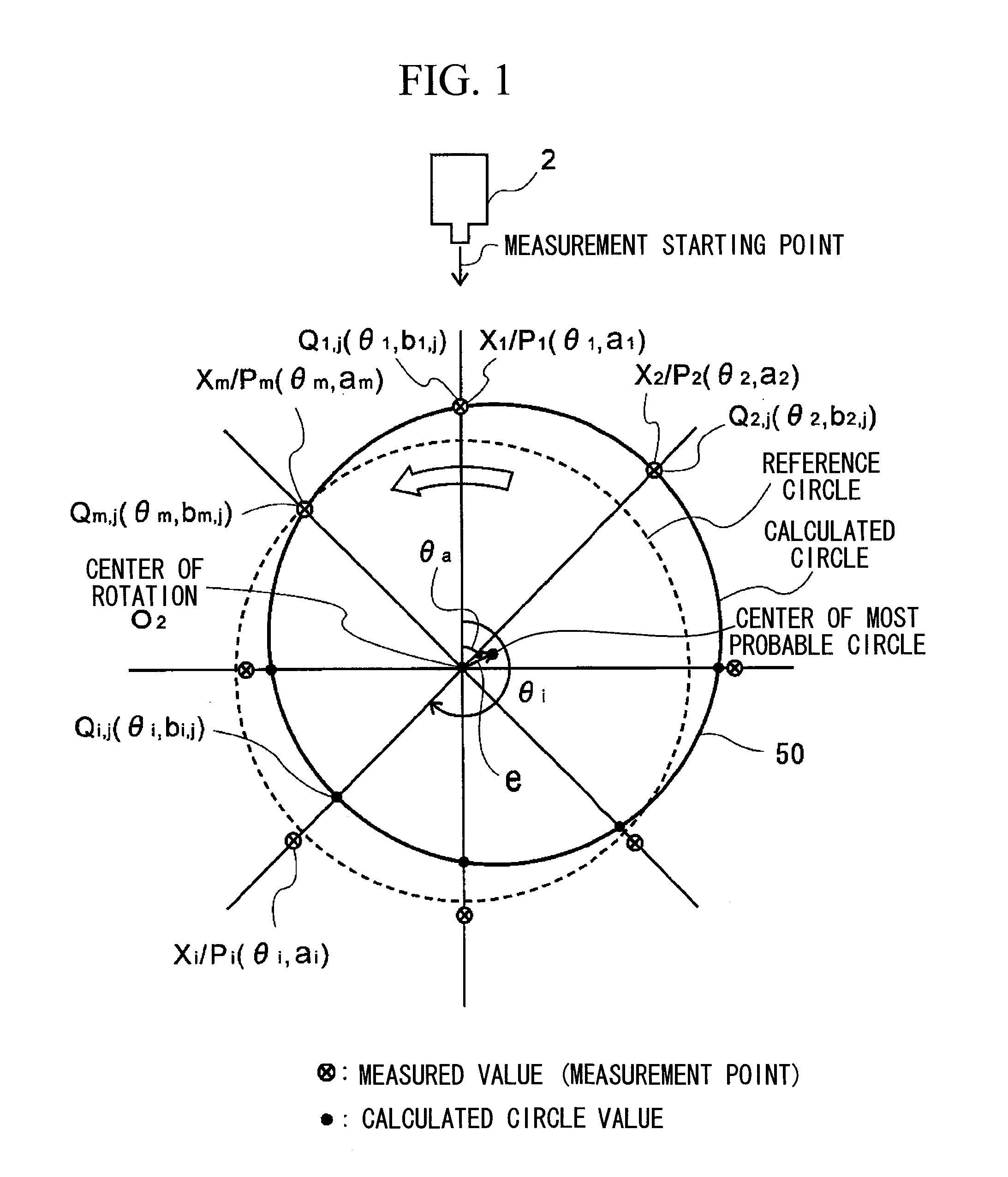

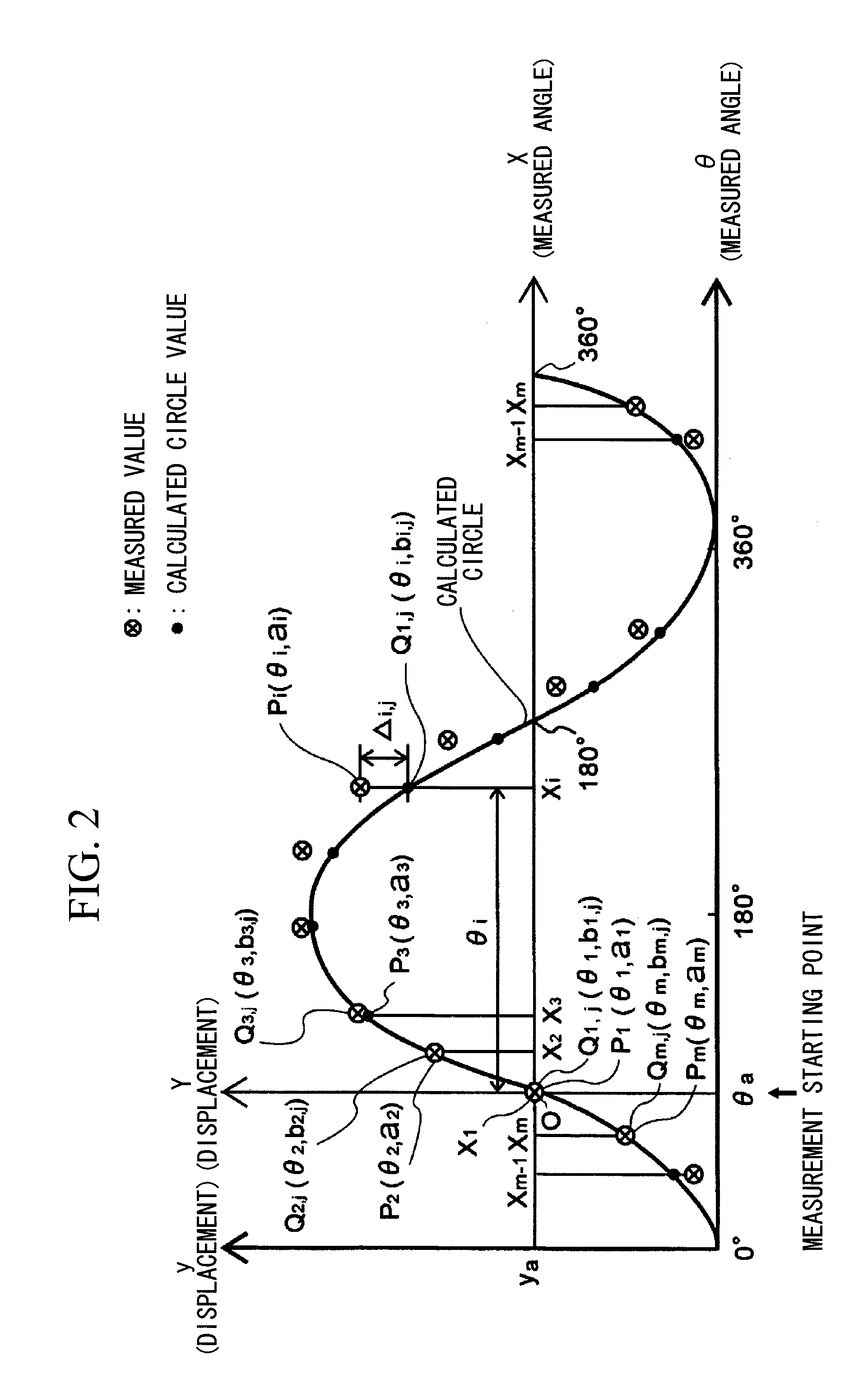

Method and system for calculating misalignment of rotational body

ActiveUS8306776B2Quick and reliable maintenanceElectrical/magnetic diameter measurementsIncline measurementMeasurement pointRepeating circle

In a method of calculating misalignment of a rotational body, radial displacement values are measured using a displacement gauge. A calculation part performs the steps of deriving radial displacement amounts of the rotational body for at least four or more measurement points along an outer surface while rotating the rotational body, selecting three arbitrary points to calculate a circle, calculating circle values for all the measurement points, calculating differences between the calculated circle values and the radial displacement amounts as error amounts, summing the error amounts to derive a total error amount, repeating circle calculation for different combinations and calculating a total error amount for each calculated circle, selecting a circle with a minimum total error amount as a most probable circle, and calculating deviation between the center of the most probable circle and the center of rotation of the rotational body.

Owner:MITSUBISHI POWER LTD

Casing Inspection Logging Tool

An instrument assembly for a well casing inspection tool, comprising a main shaft having an extension shaft extending therefrom. An instrument head is supported on bearings proximate one end of the main shaft. The rotating instrument head, which includes sensors for measuring wall thickness and caliper of the well casing, provides continuous 360 degree scanning of the interior of the well casing to obtain detailed measurements of the well casing. A motor drives the rotating instrument head through a gear train. A mandrel supported by the main shaft includes exciter coils for wall thickness, caliper, and permeability measurements. A capacitive slip ring couples signals between the rotating instrument head and stationary circuits in the instrument assembly.

Owner:HUNTING TITAN +1

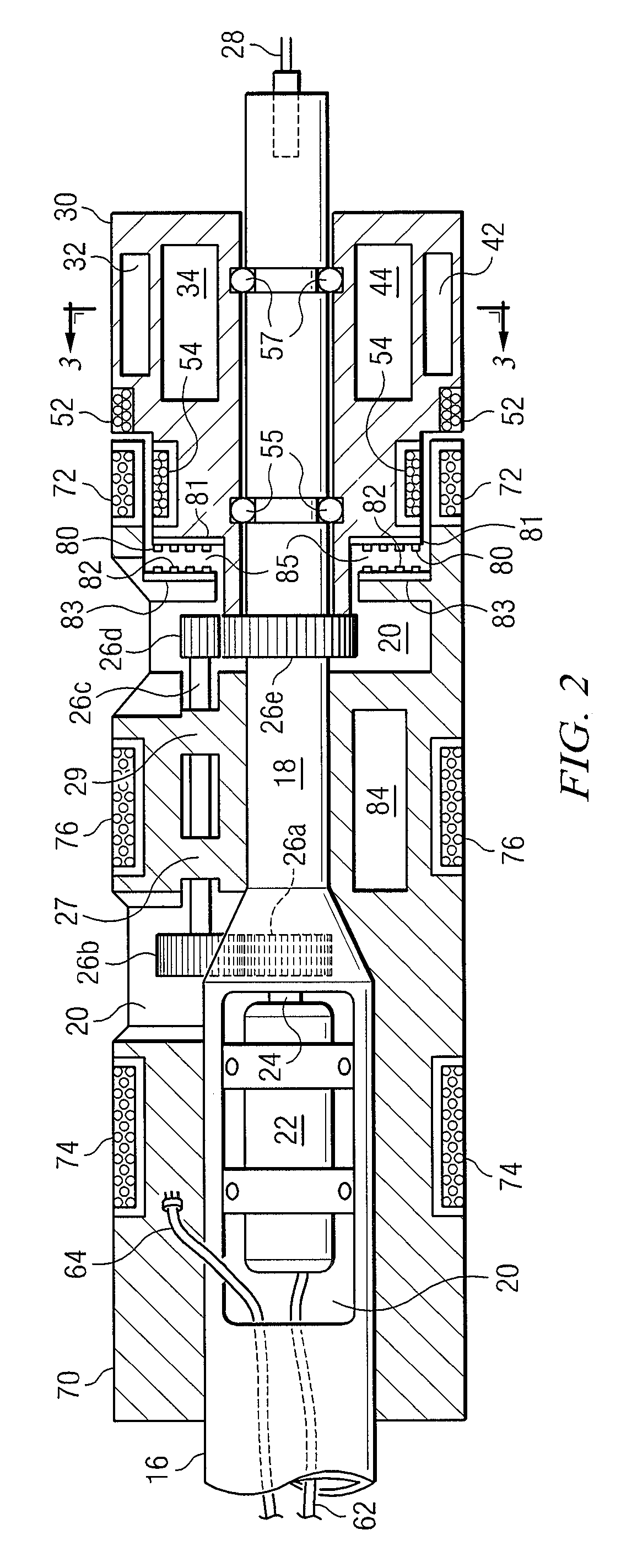

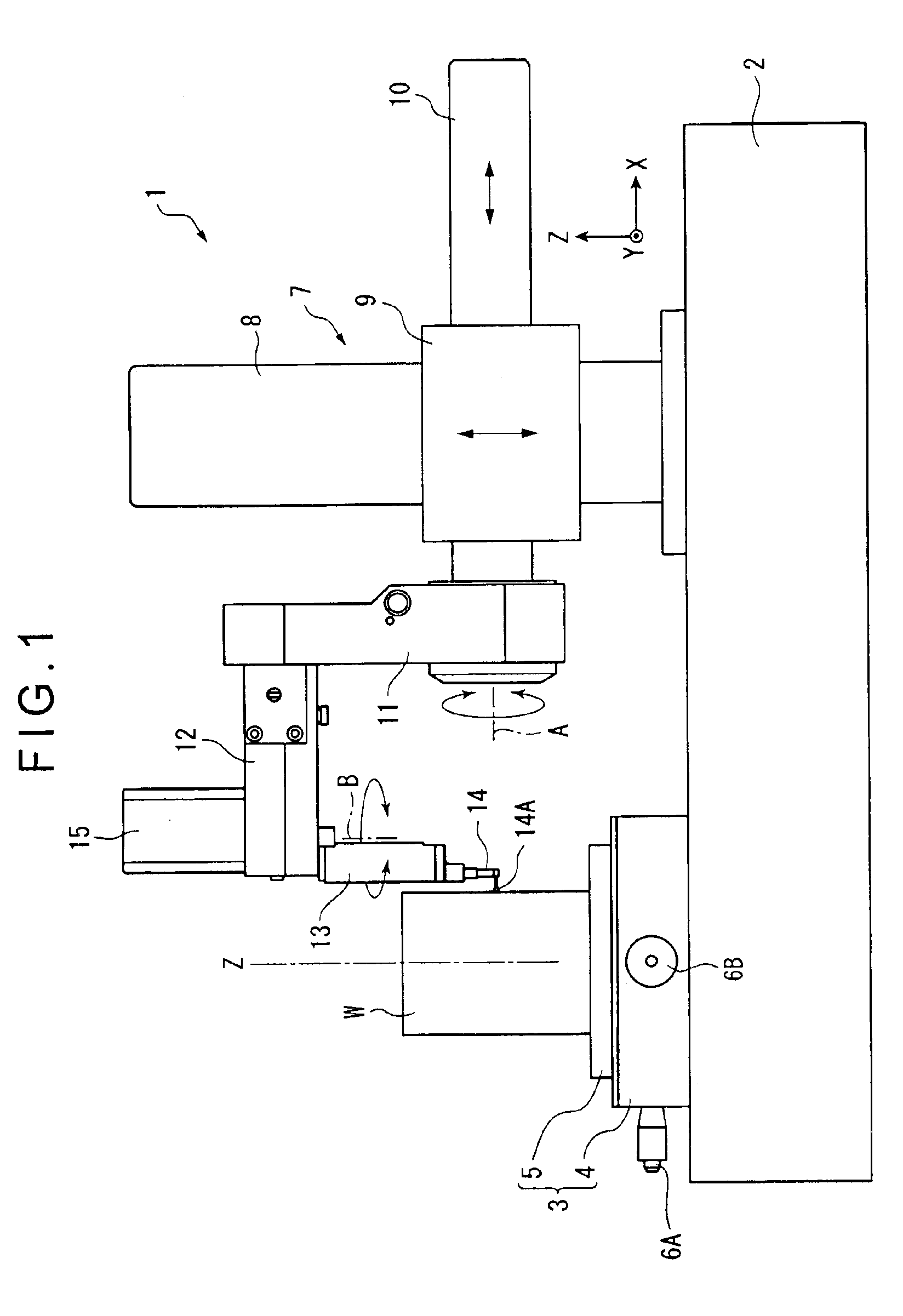

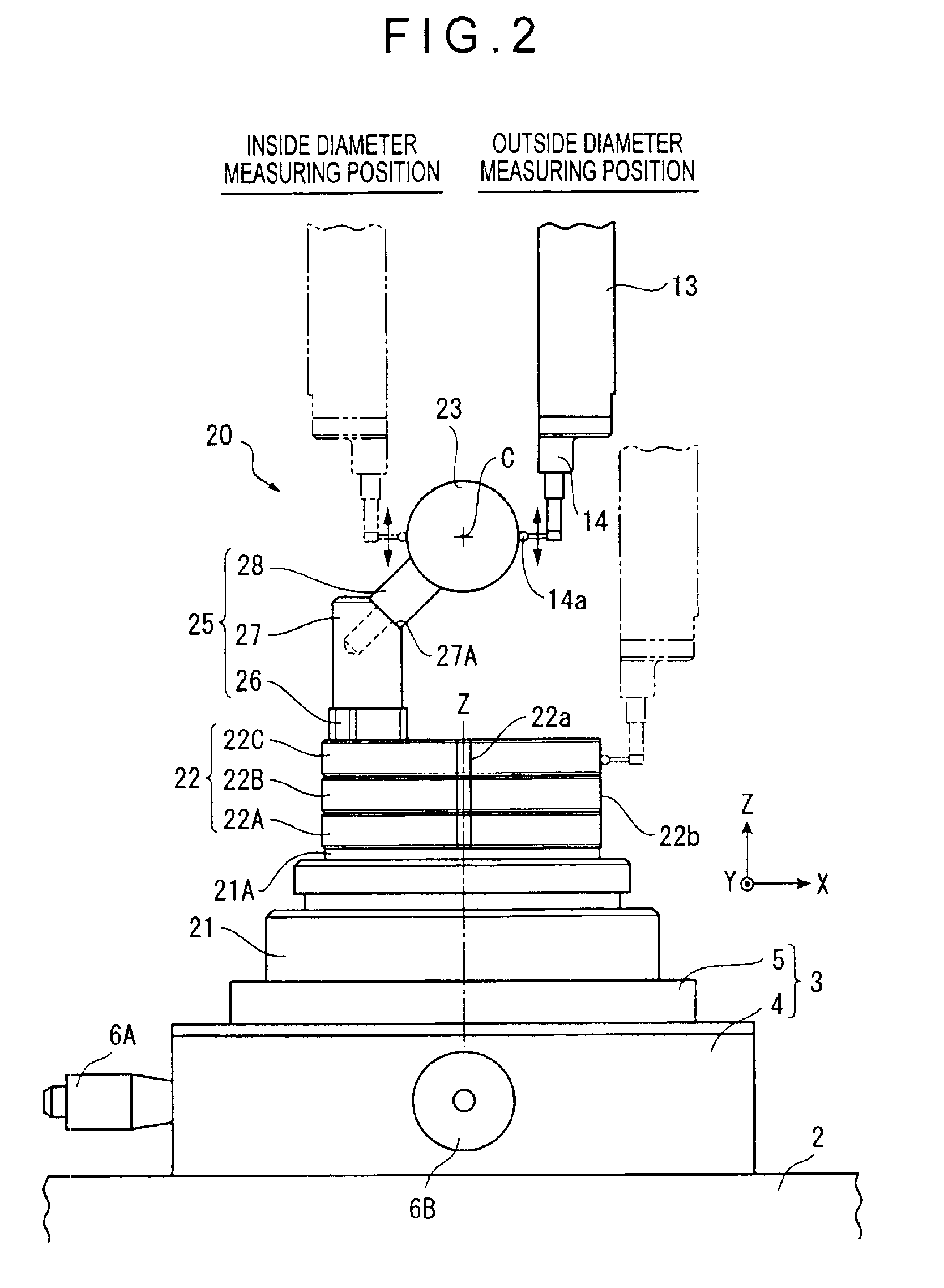

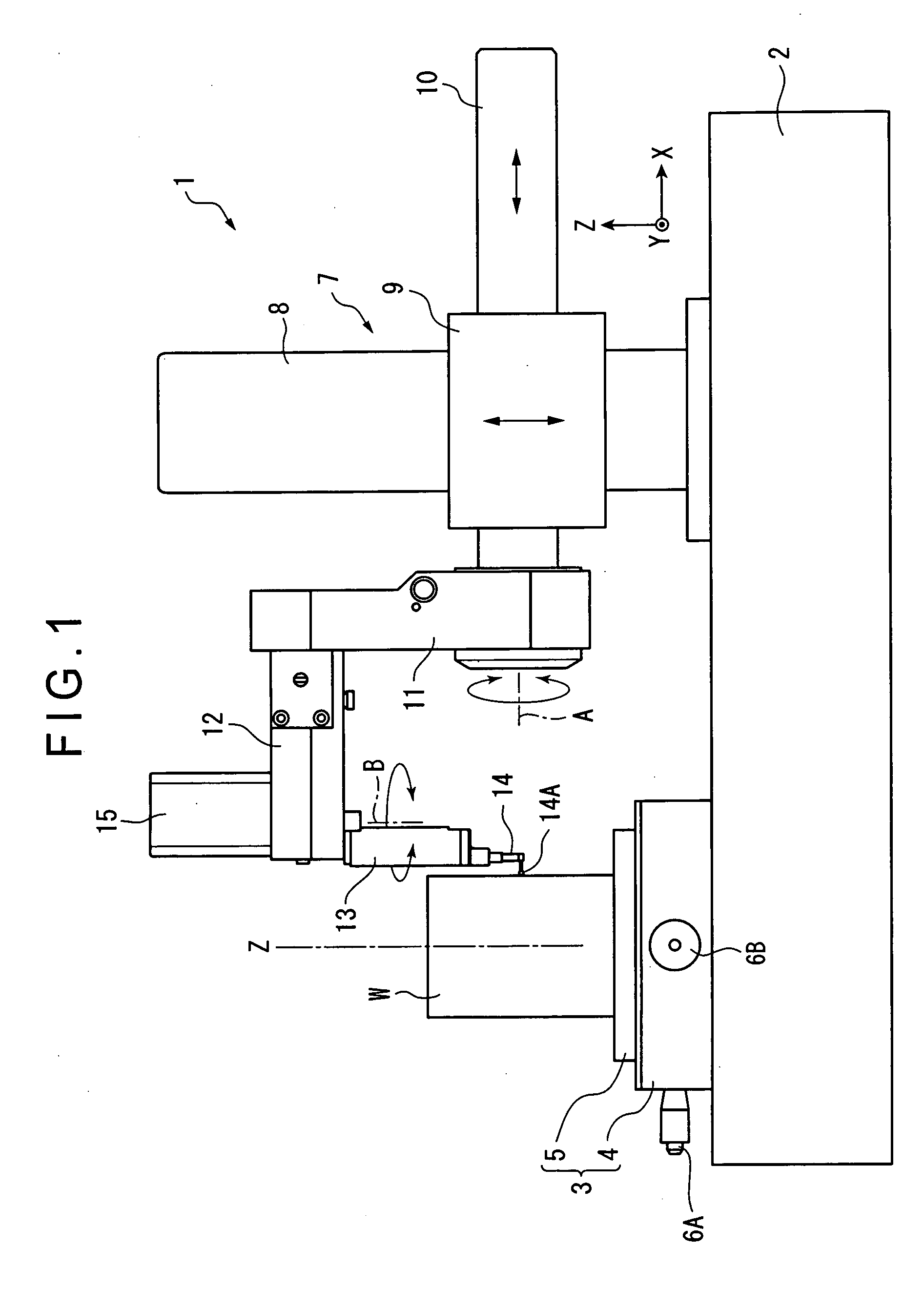

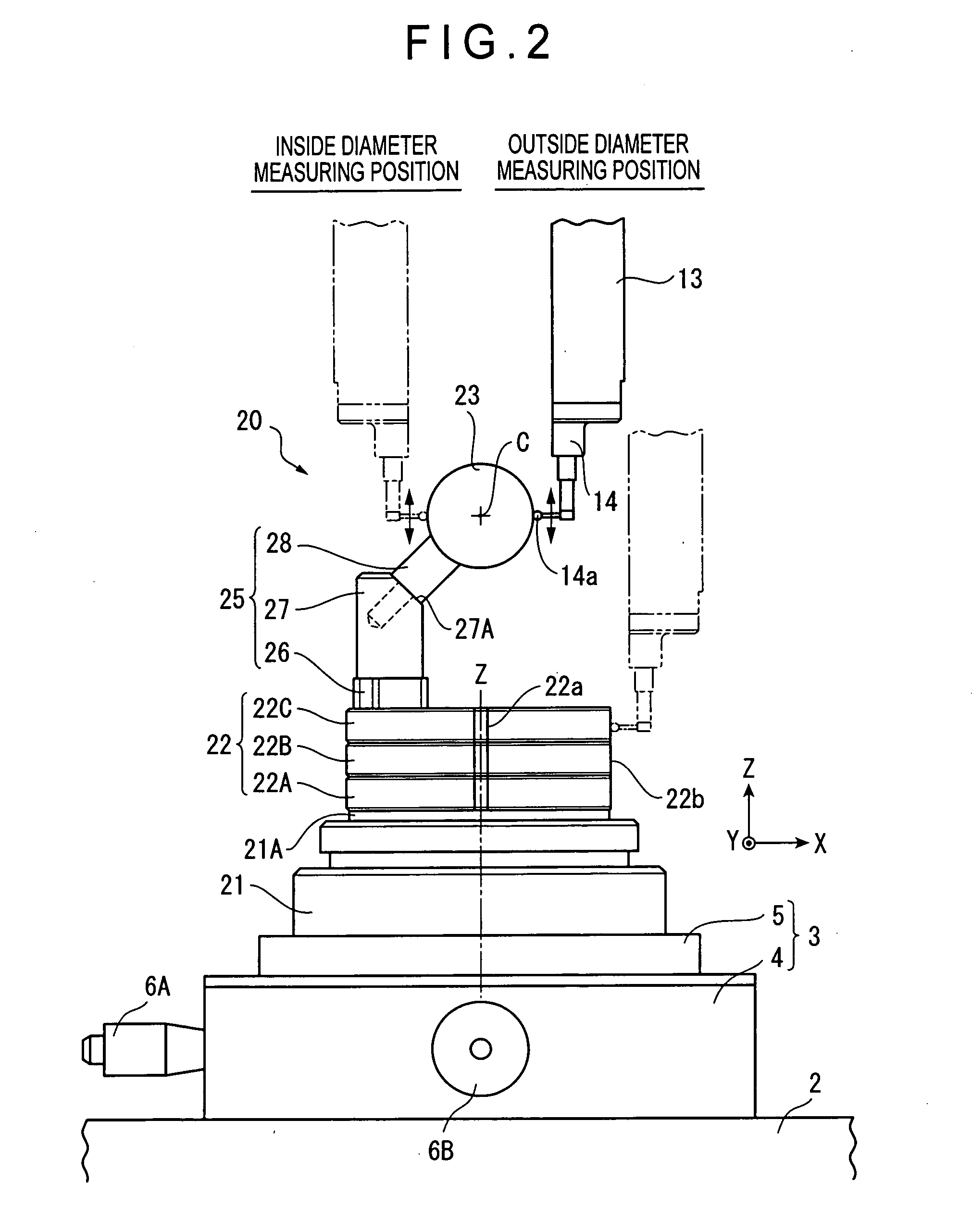

Reference fixture for roundness measuring instrument

ActiveUS6886264B2Improve accuracyImprove efficiencyMechanical counters/curvatures measurementsElectric/magnetic contours/curvatures measurementsMeasuring instrumentEngineering

A reference fixture (20) for a roundness measuring instrument performs acquisition of origin information of a roundness measuring instrument (1) including a workpiece rotary mechanism (3) on which a workpiece is set and a probe (14) provided with a stylus (14a) and also performs calibration of the probe (14). The reference fixture (20) includes a mount (21), a calibration master (22) provided on a top face of the mount (21) for calibrating the sensitivity of the probe (14), an origin ball (23) disposed above the calibration master (22) for providing the origin information of the roundness measuring instrument (1) by the stylus (14a) of the probe (14), and a holder (25) that holds the origin ball (23).

Owner:MITUTOYO CORP

Metrology device and method of servicing

A system is provided for communicating between a 3D metrology instrument and a portable computing device via near field communications. In one embodiment, the metrology device is an articulated coordinate measurement machine (AACMM), a laser tracker, a laser scanner or a triangulation scanner, and the portable communications device is a cellular phone or a tablet. The portable device may use the NFC to determine the configuration of and to configure the metrology instrument.

Owner:FARO TECH INC

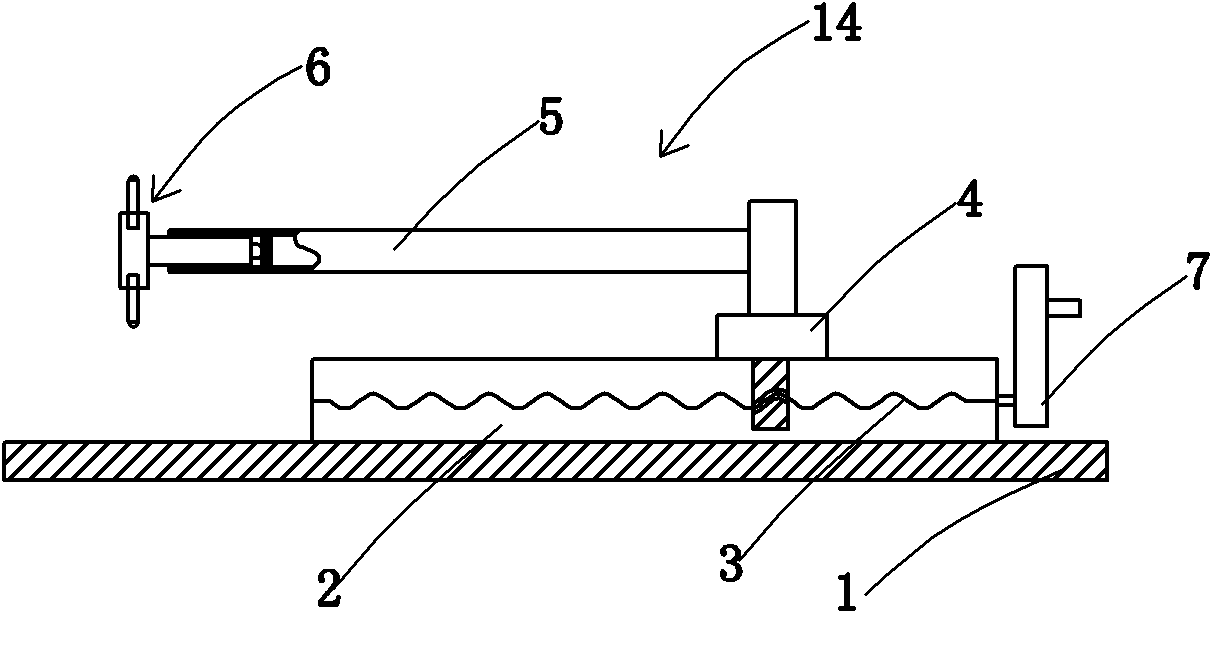

Inner diameter multiparameter measuring device for large length-to-diameter ratio pipe and measuring method thereof

ActiveCN102032861AIncrease contactReasonable measurement structure designUsing electrical meansElectric/magnetic contours/curvatures measurementsDiameter ratioEngineering

The invention discloses an inner diameter multiparameter measuring device for a large length-to-diameter ratio pipe which is characterized by comprising a measuring table, wherein both ends of the measuring table are respectively provided with a clamping device and a measuring mechanism for the pipe; the measuring mechanism comprises a guide rail arranged on one end of the measuring table; the inside of the guide rail is horizontally provided with a handwheel-driven screw; the guide rail is matched with a screw-driven slide block which can horizontally slide along the guide rail; the slide block is detachably connected with a clamping lever which extends towards the clamping device; the end part of the clamping lever is provided with a sensor; the pipe is horizontally fixed and clamped by the clamping device; and the axial line of the pipe is perpendicular to the axial line of the sensor. The inner diameter multiparameter measuring device for a large length-to-diameter ratio pipe in the invention can be used for simultaneously measuring the inner diameter, circular degree and straightness of the measured pipe. The measuring head of the sensor can reach any cross section in the measured space to carry out the measurement without dead points for measurement.

Owner:HEFEI LIHENG HYDRAULIC SYST

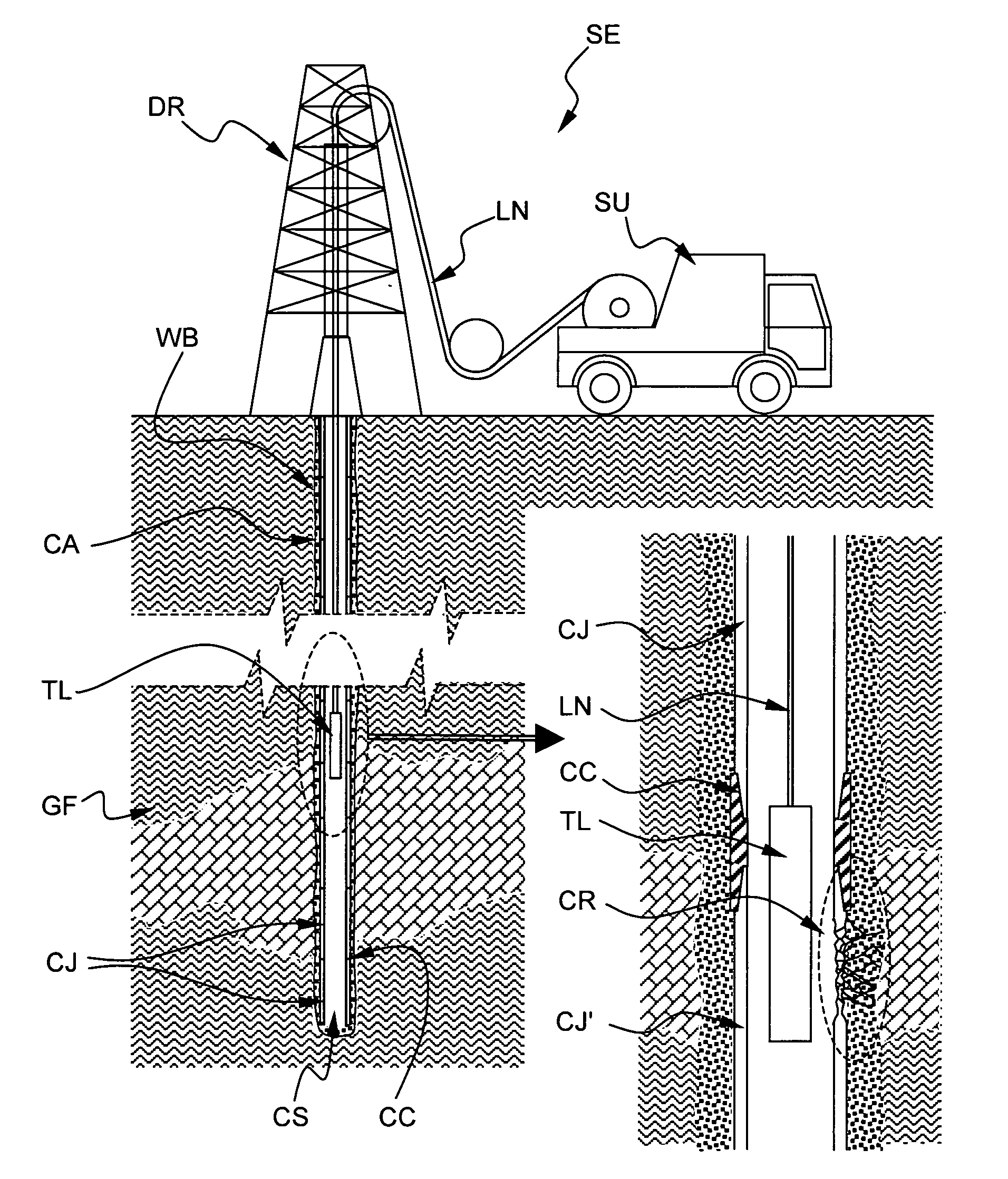

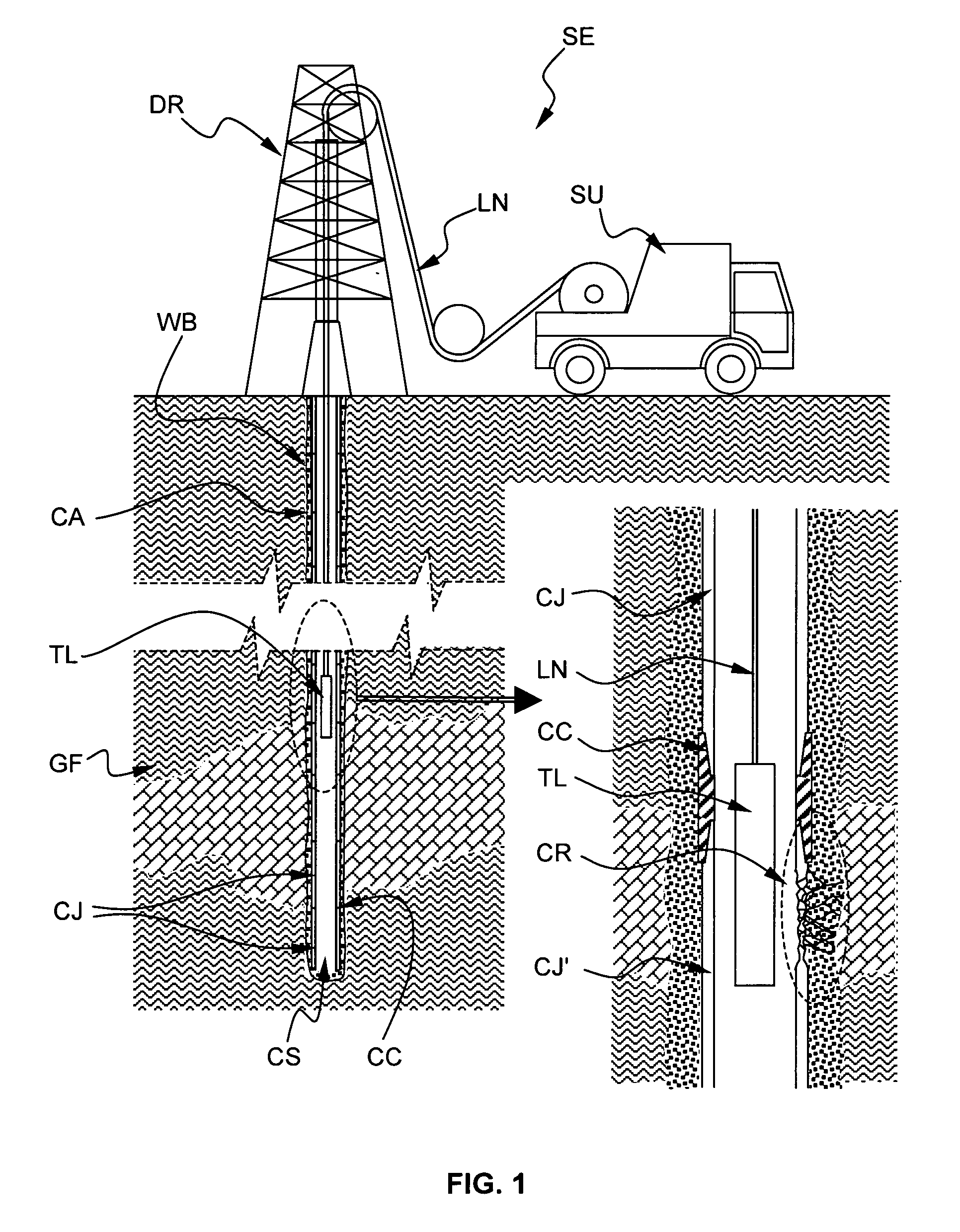

Method for electromagnetically measuring physical parameters of a pipe

ActiveUS20100017137A1Improve accuracyPlug gaugesElectric/magnetic detection for well-loggingTransmitter coilPower flow

The method electromagnetically measures a pipe inner diameter ID and a pipe ratio of magnetic permeability to electrical conductivity μ2 / σ2 by means of a measuring arrangement 1 comprising a transmitter coil 2 and a receiver coil 3, both coils being coaxial to and longitudinally spaced from each other, the measuring arrangement 1 being adapted to be positioned into the pipe CS and displaced through the pipe. The method comprises the steps of:a1) exciting the transmitter coil 2 by means of a transmitter current Ii, the transmitter current having a first excitation frequency f1,a2) measuring a receiver voltage Vi at the receiver coil 3, a3) determining a transimpedance Vi / Ii between the transmitter coil 2 and the receiver coil 3 based on the transmitter current Ii and the receiver voltage Vi, and determining a measurement ratio Mi based on said transimpedance,b) repeating the excitation step a1), the measuring step a2), the transimpedance and the measurement ratio determination step a3) for at least a second excitation frequency f2 so as to define a measurement ratio vector [M1, M2, . . . Mn],c) calculating a prediction function vector [G1, G2, . . . Gn] based on the first and at least the second excitation frequency, a plurality of potential pipe ratio of magnetic permeability to electrical conductivity and a plurality of potential pipe inner diameter ID, andd) applying a minimizing algorithm onto the measurement ratio vector [M1, M2, . . . Mn] and the prediction function vector [G1, G2, . . . Gn] and determining the pipe inner diameter and the pipe ratio of magnetic permeability to electrical conductivity corresponding to a maximum solution of the algorithm.

Owner:SCHLUMBERGER TECH CORP

Reference fixture for roundness measuring instrument

ActiveUS20040200085A1Easy to getImprove accuracyMechanical counters/curvatures measurementsUsing electrical meansMeasuring instrumentEngineering

A reference fixture (20) for a roundness measuring instrument performs acquisition of origin information of a roundness measuring instrument (1) including a workpiece rotary mechanism (3) on which a workpiece is set and a probe (14) provided with a stylus (14a) and also performs calibration of the probe (14). The reference fixture (20) includes a mount (21), a calibration master (22) provided on a top face of the mount (21) for calibrating the sensitivity of the probe (14), an origin ball (23) disposed above the calibration master (22) for providing the origin information of the roundness measuring instrument (1) by the stylus (14a) of the probe (14), and a holder (25) that holds the origin ball (23).

Owner:MITUTOYO CORP

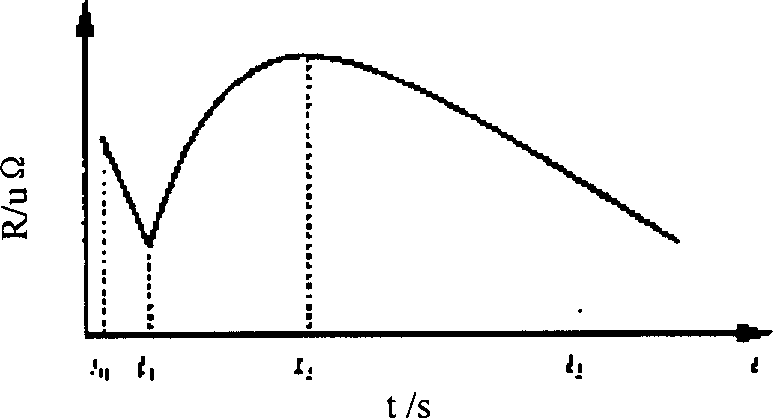

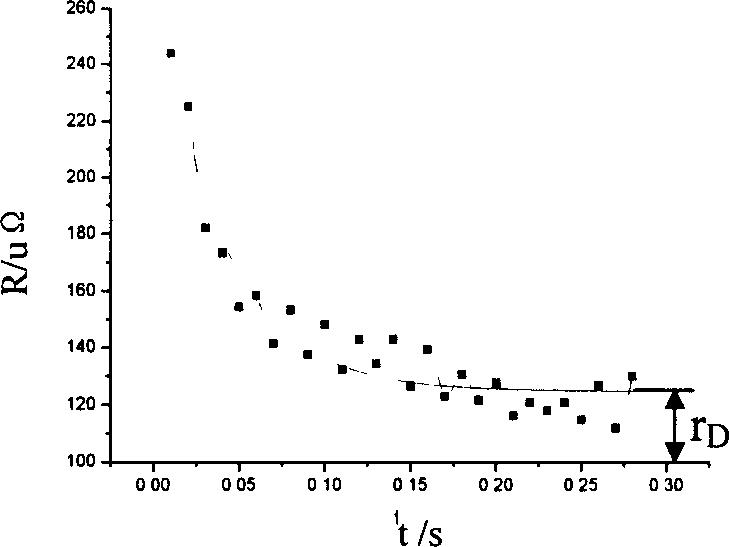

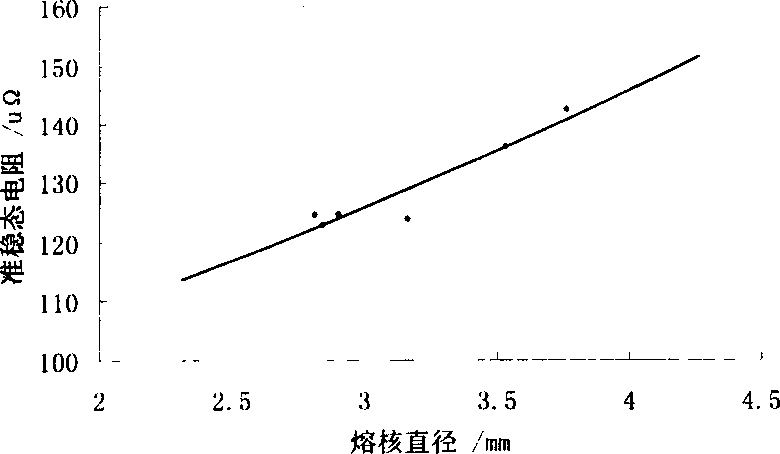

Real-time detection method for spot welding nugget diameter

InactiveCN1609622ACan be judged qualified or notElectrical testingElectrical/magnetic diameter measurementsElectrical resistance and conductanceStable state

Owner:NORTHWESTERN POLYTECHNICAL UNIV

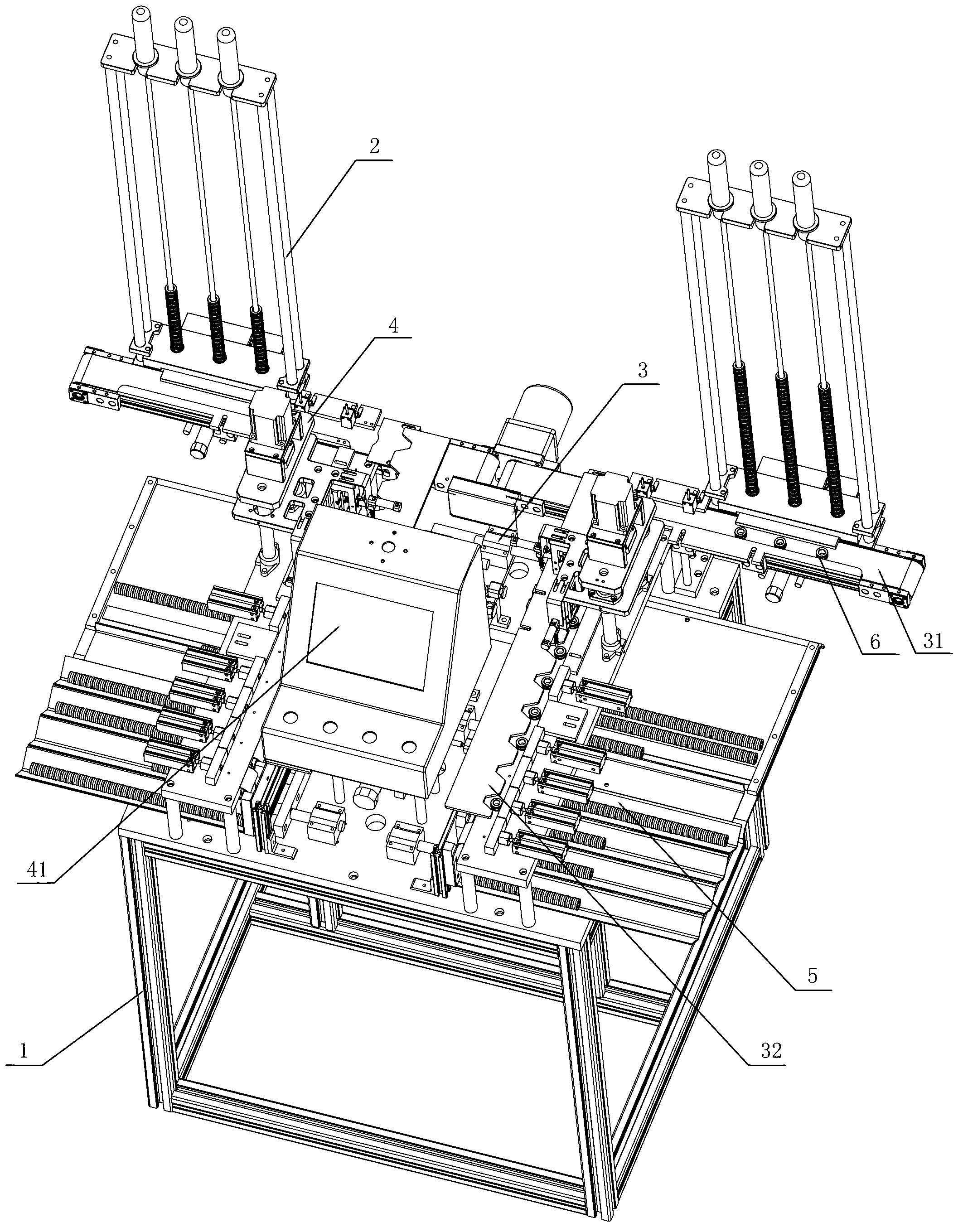

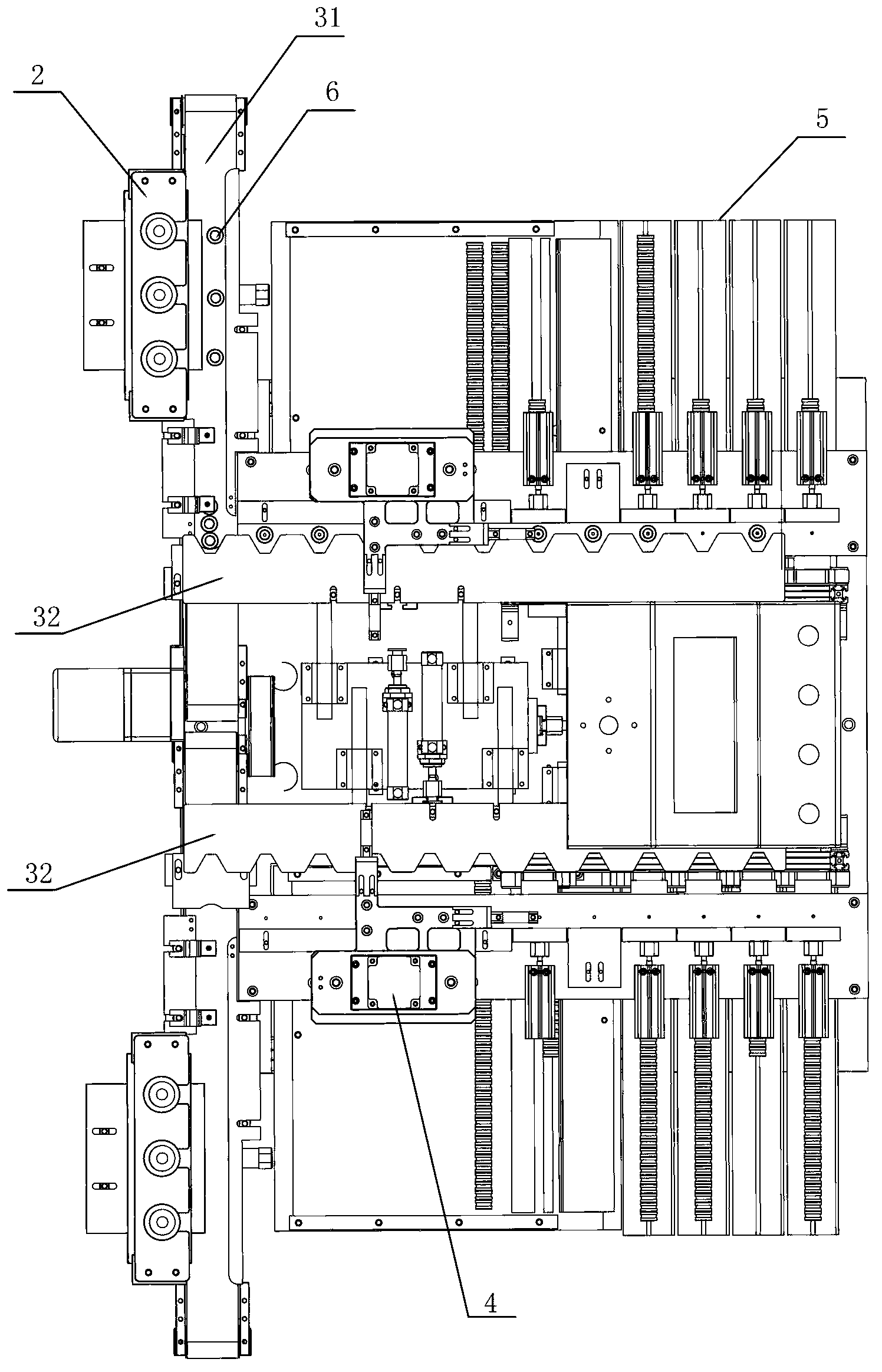

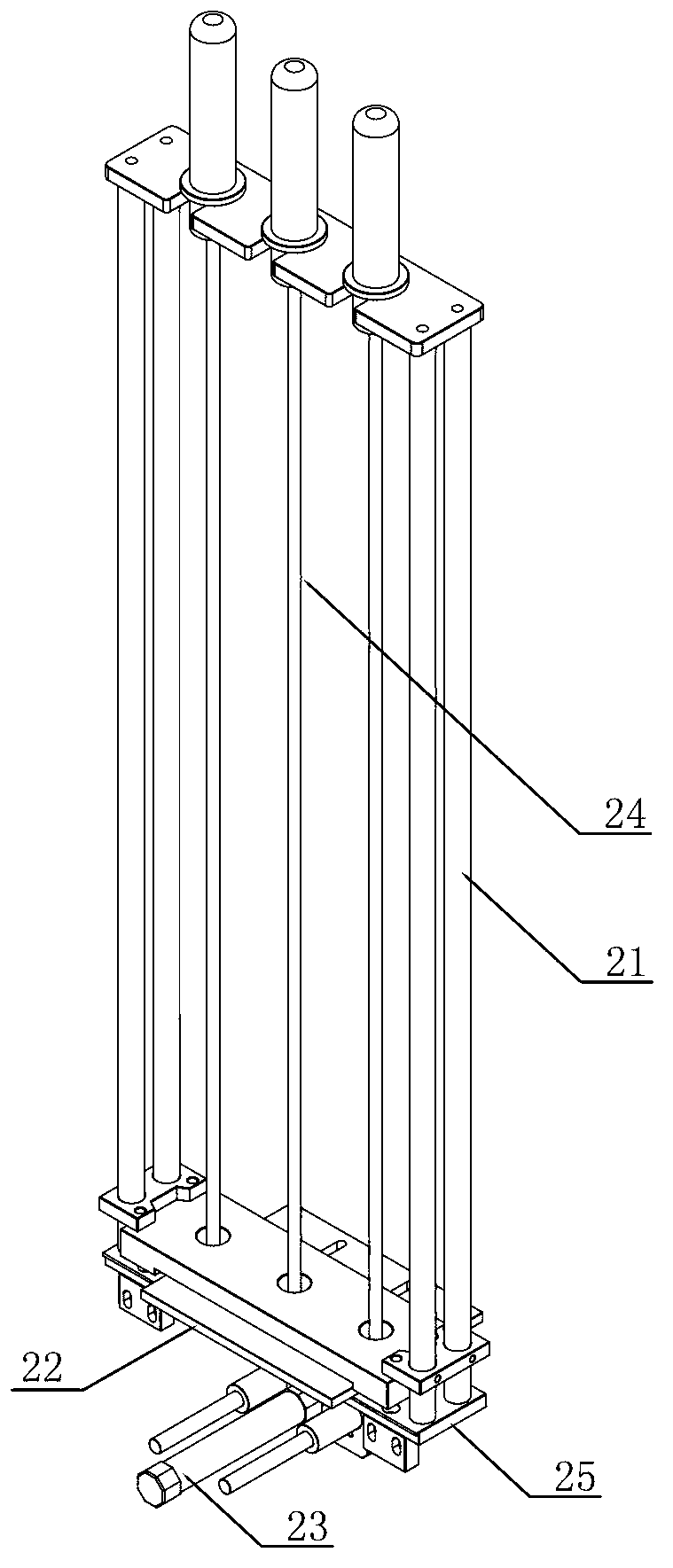

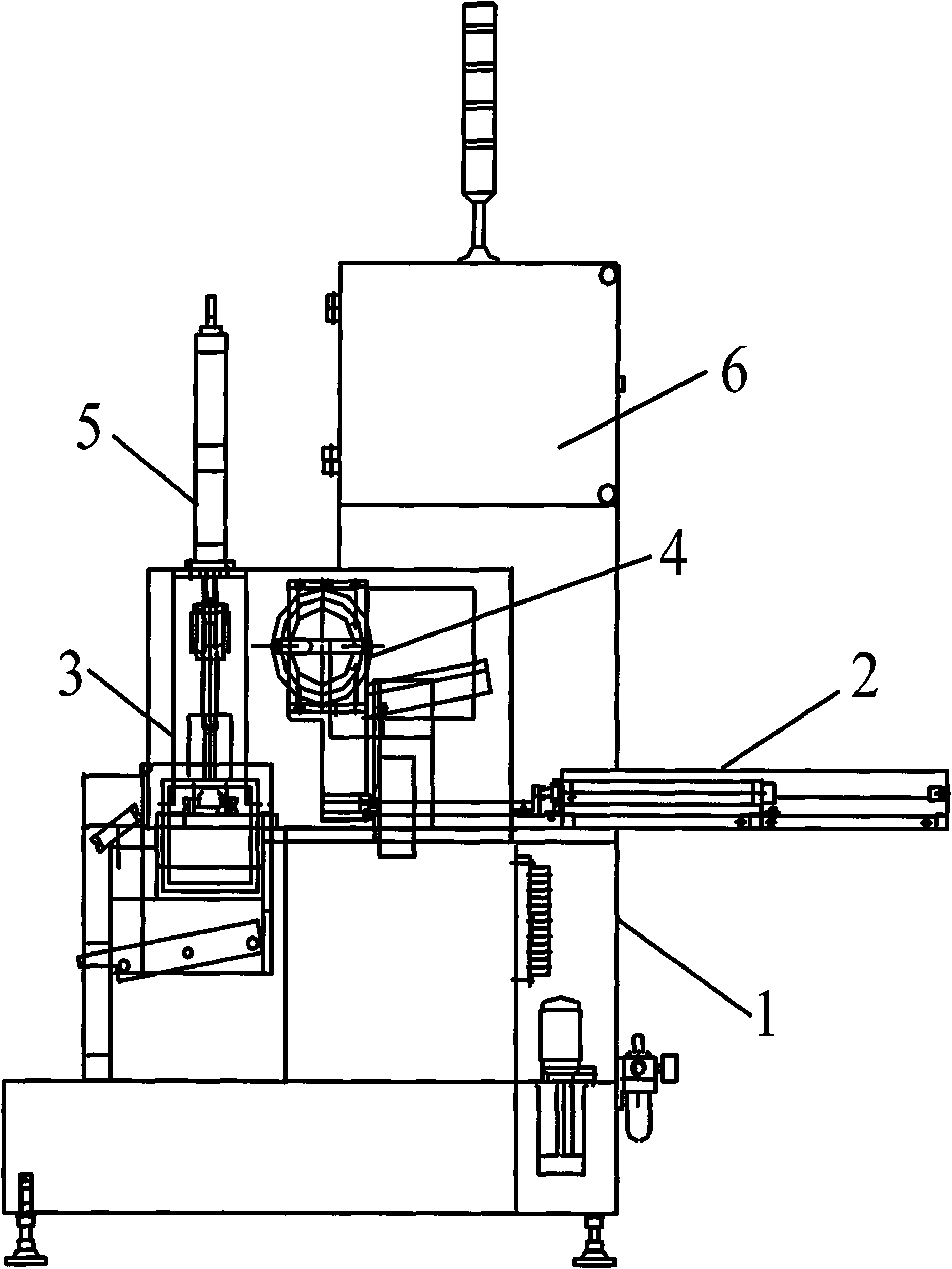

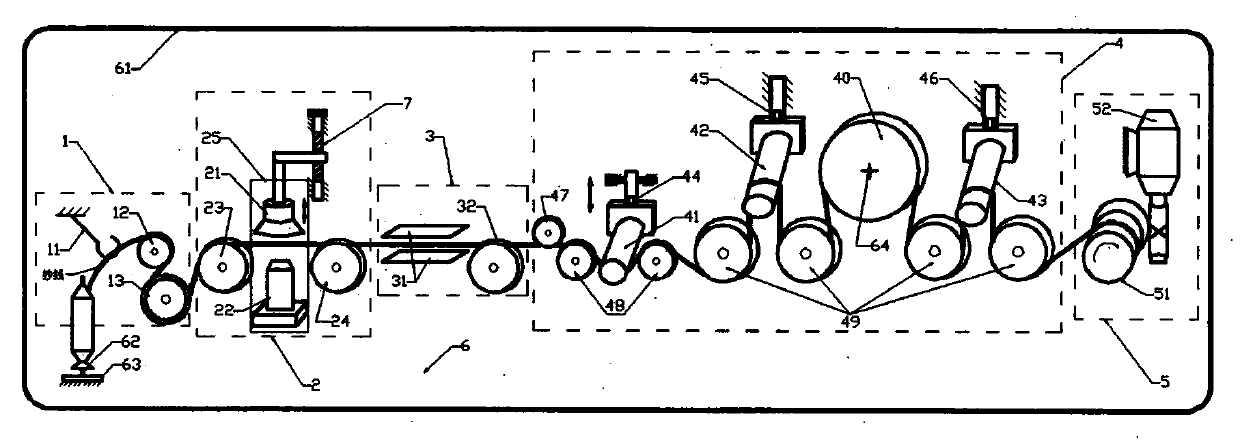

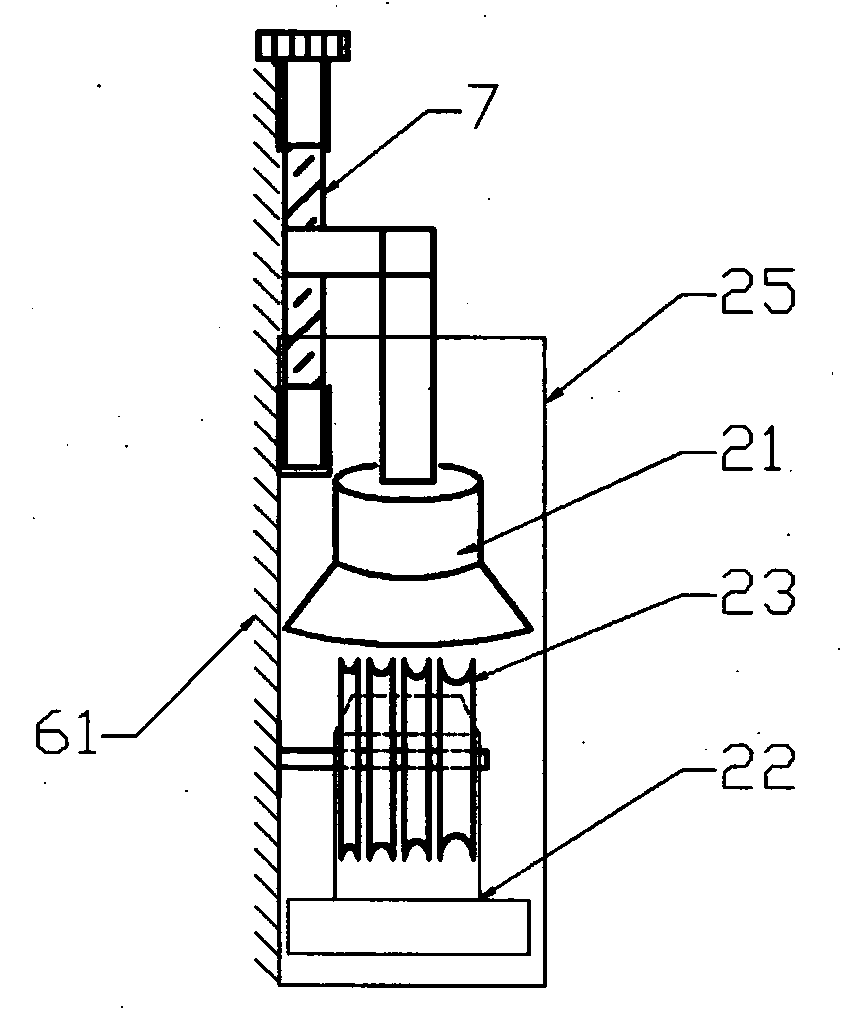

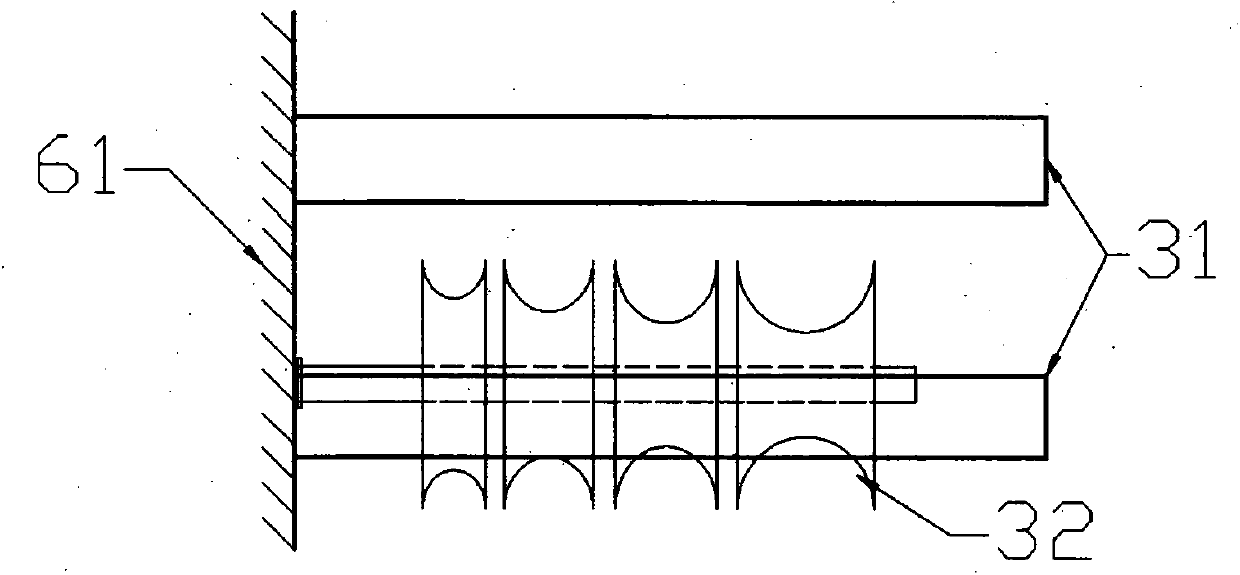

Bearing inner ring diameter detection device and detection method thereof

ActiveCN103225998AImprove stabilityImprove work efficiencyUsing electrical meansElectric/magnetic contours/curvatures measurementsTransmission beltControl cell

The invention discloses a bearing inner ring diameter detection device and a detection method thereof, and belongs to the technical field of bearing inner ring detection. The bearing inner ring diameter detection device comprises a base, and feed mechanisms, transfer mechanisms, detection mechanisms and discharge mechanisms which are mounted on the base, as well as a control unit, wherein the feed mechanisms are mounted on the side edges of transfer mechanism conveying belts; the detection mechanisms are mounted on the side edges of transfer mechanism displacement sheets; the discharge mechanisms are located below the displacement sheets; to-be-detected bearing inner rings on the feed mechanisms are conveyed to the detection mechanisms by the conveying belts and the displacement sheets, and displaced to the discharge mechanisms by the displacement sheets after detection; the displacement sheets are displaced by expansion of piston rods of station clamping air cylinders and station pushing air cylinders which are connected with the displacement sheets; and the control unit is connected with the feed mechanisms, the transfer mechanisms, the detection mechanisms and the discharge mechanisms respectively by signal lines.

Owner:绍兴中轴自动化设备有限公司

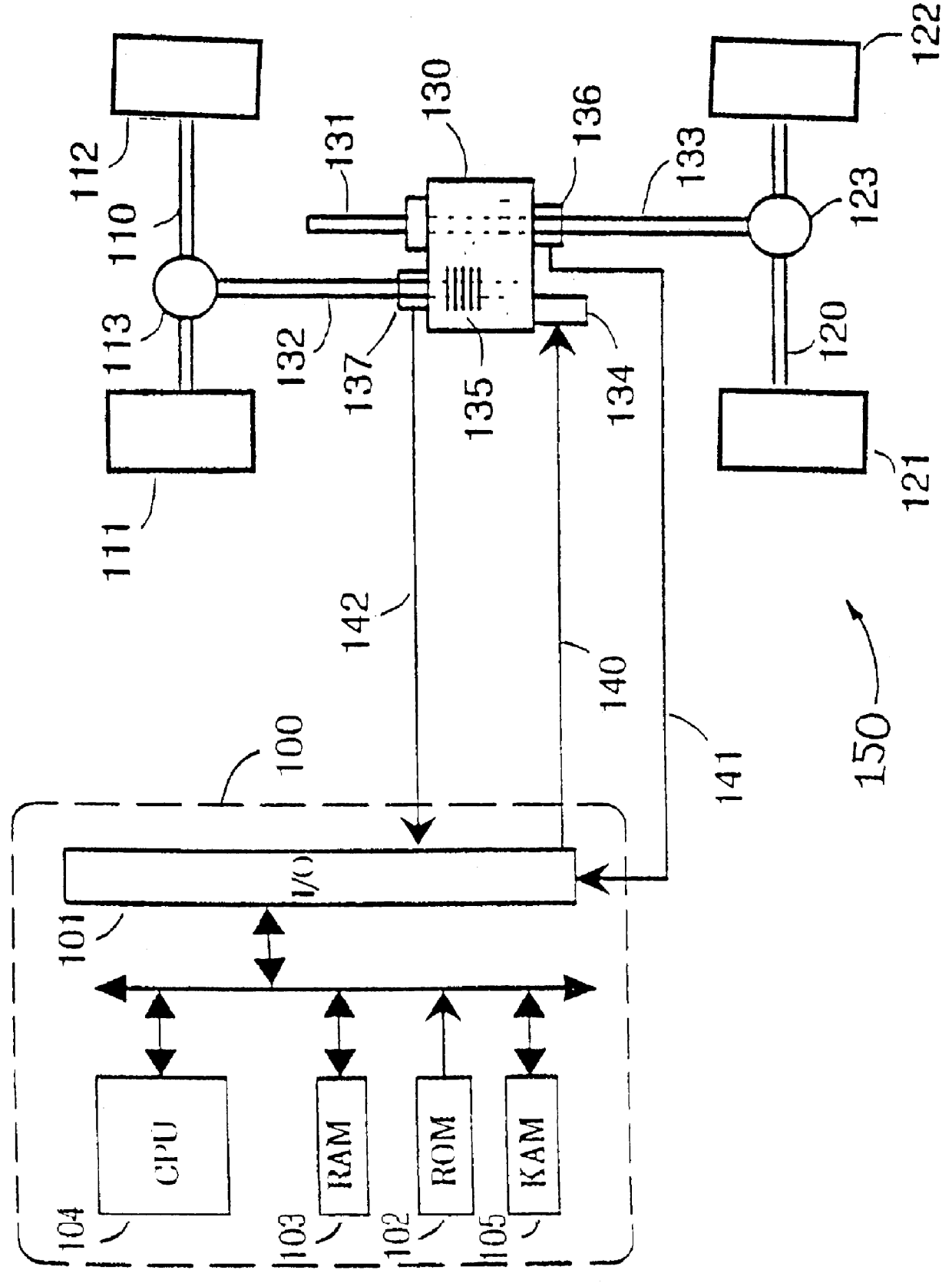

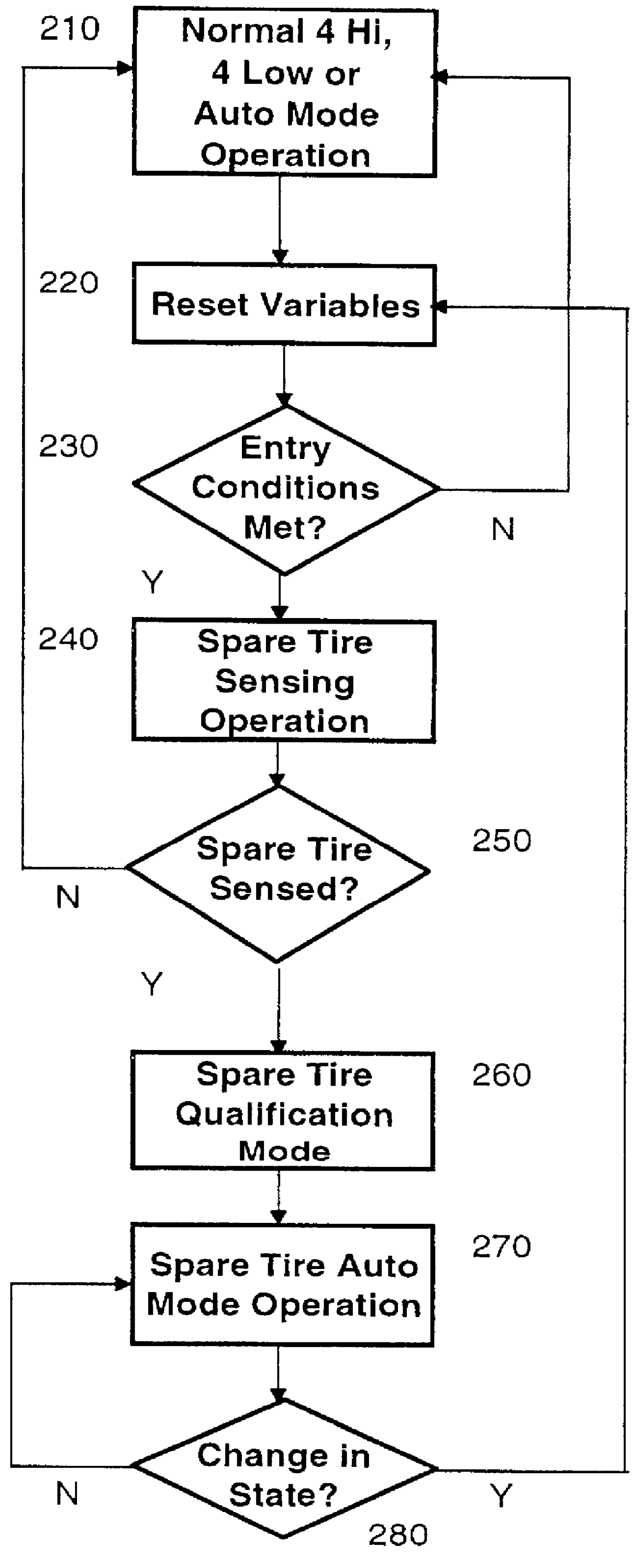

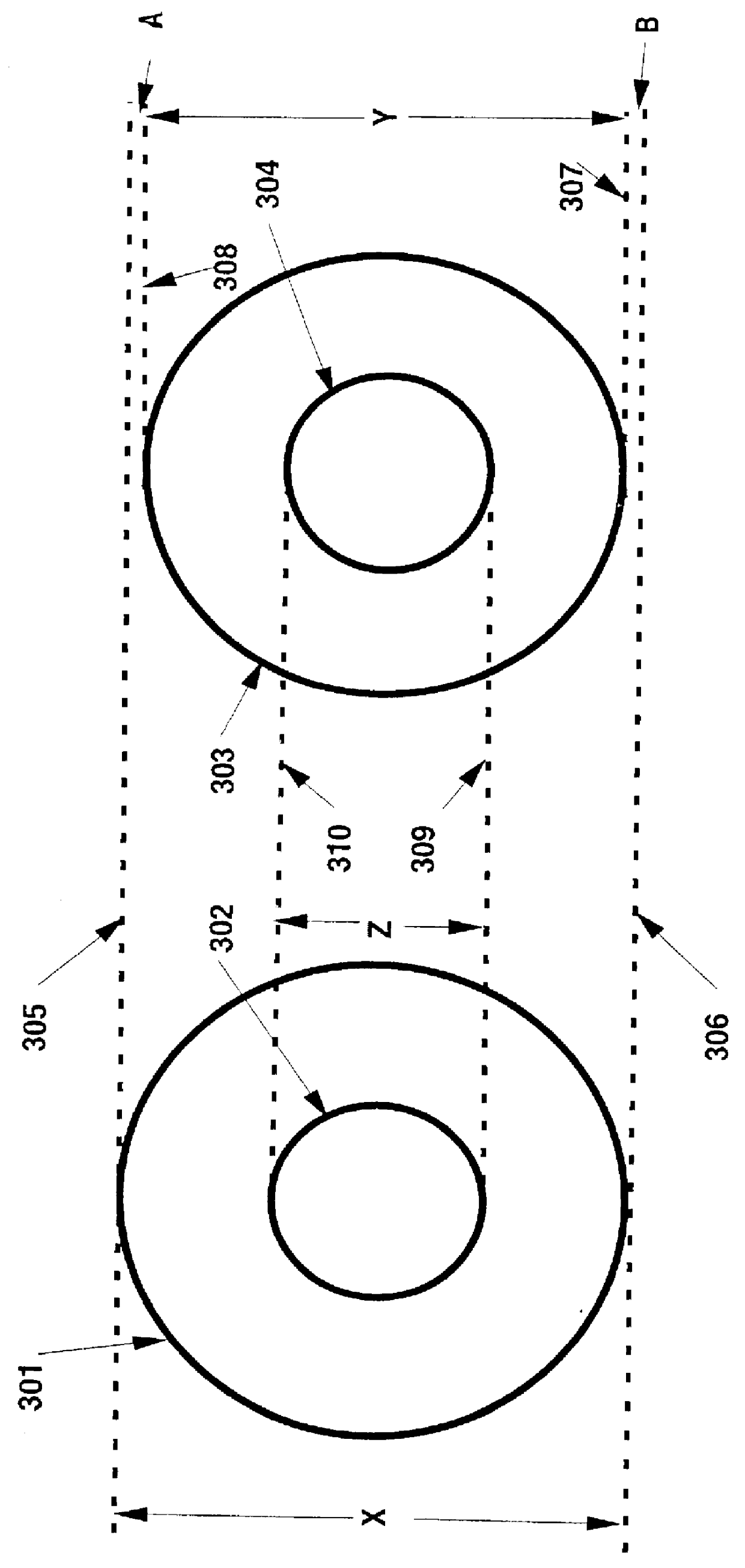

Four wheel drive transfer case controller compatible with a spare tire

A method of monitoring the relative effective diameters of the tires and compensating therefor in a vehicle which includes a front driveshaft for transferring motive power to a front set of wheels and a rear driveshaft for transferring motive power to a rear set of wheels, each of the wheels having an effective diameter. Front and rear driveshaft values indicative of the rotational speed of each driveshaft are generated. A difference value indicative of a difference between said front and rear driveshaft values is then generated. A low pass filtered value is generated according to the relationship of Y1p=(1- beta )*U(k)+ beta *Y1p(k-1). The low pass filtered value is monitored for a predetermined period of time to determine if one of the wheels has a smaller effective diameter than the other wheels.

Owner:FORD GLOBAL TECH LLC

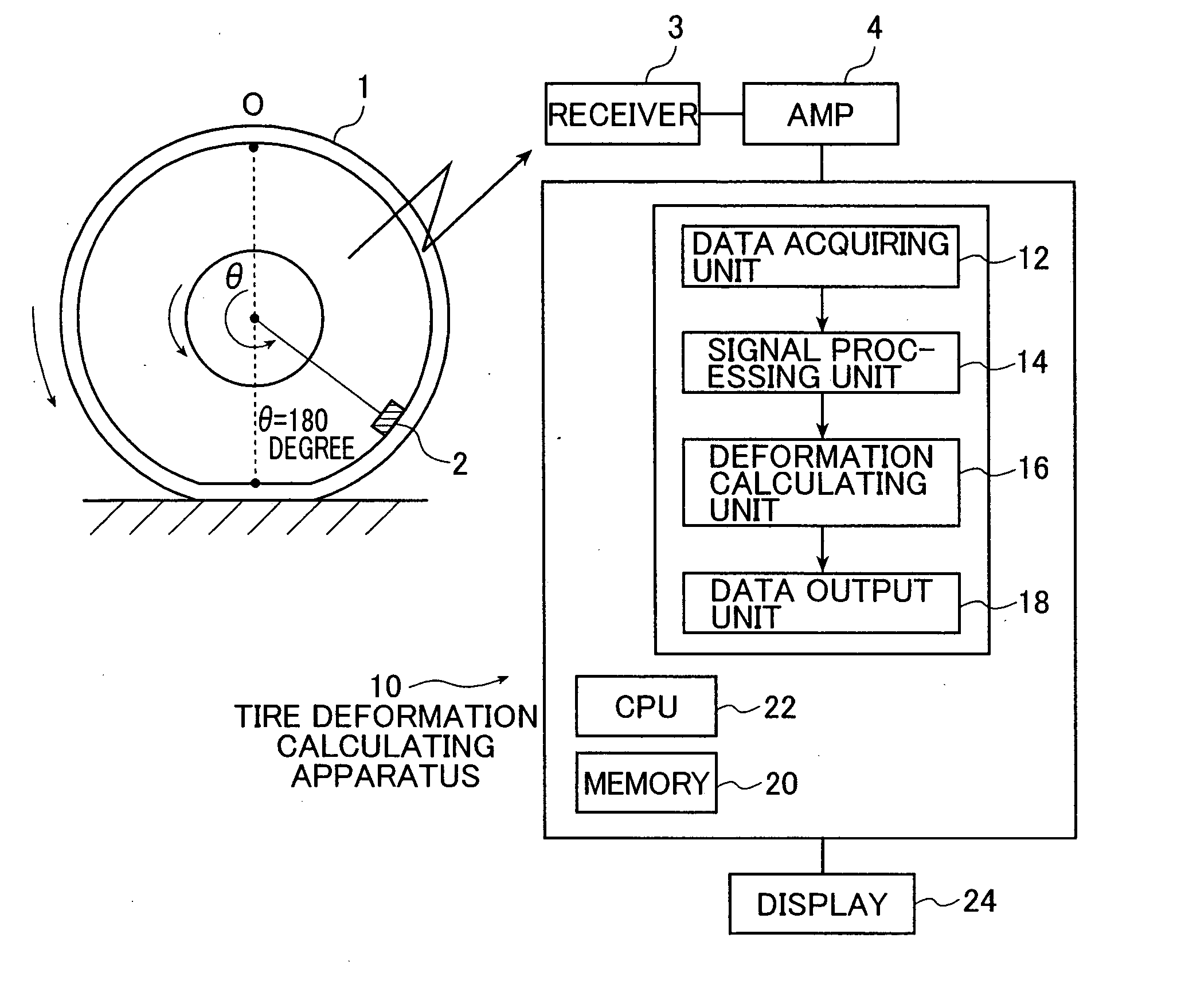

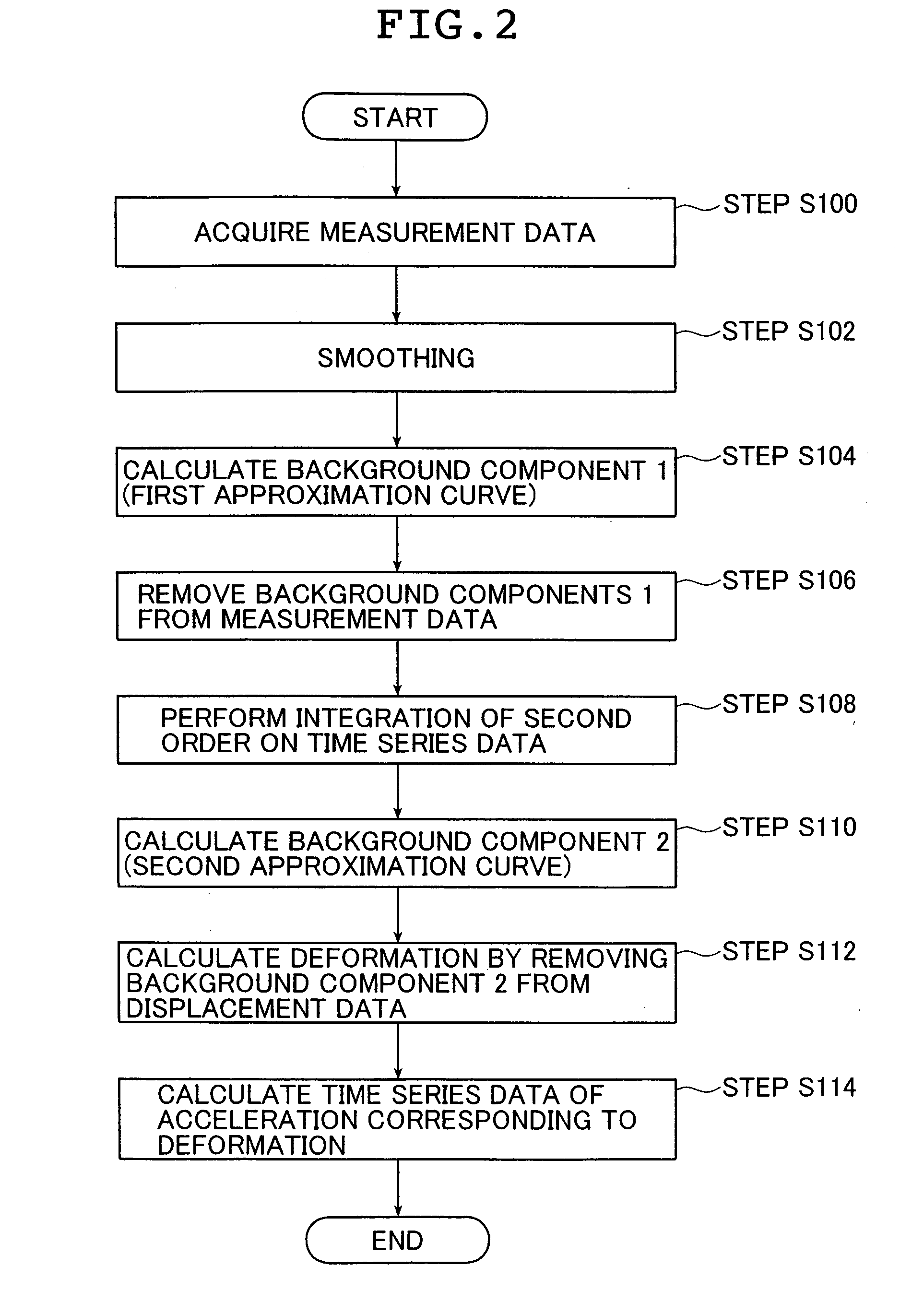

Tire Deformation Calculating Method And Tire Deformation Calculating Apparatus

InactiveUS20070213953A1Good coefficientImprove accuracyMeasurement arrangements for variableOptical signallingEngineeringRoad surface

A deformation of a rotating tire on a road surface is calculated the following. At first, time series data of acceleration extracted from measurement data of acceleration corresponding to one round of tire rotation is subjected to a time integration of second order to obtain displacement data so as to calculate the deformation at the tread portion. The time series data of acceleration and the displacement data in the non-contact region excluding a road surface contact region on the tire circumference at the tread portion are respectively approximated to calculate a first and a second approximation curves. The two approximation curves are subtracted respectively from the time series data of acceleration and the calculated displacement data, thereby extracting time series data of acceleration due to tire deformation and obtaining the deformation at the tread portion.

Owner:THE YOKOHAMA RUBBER CO LTD

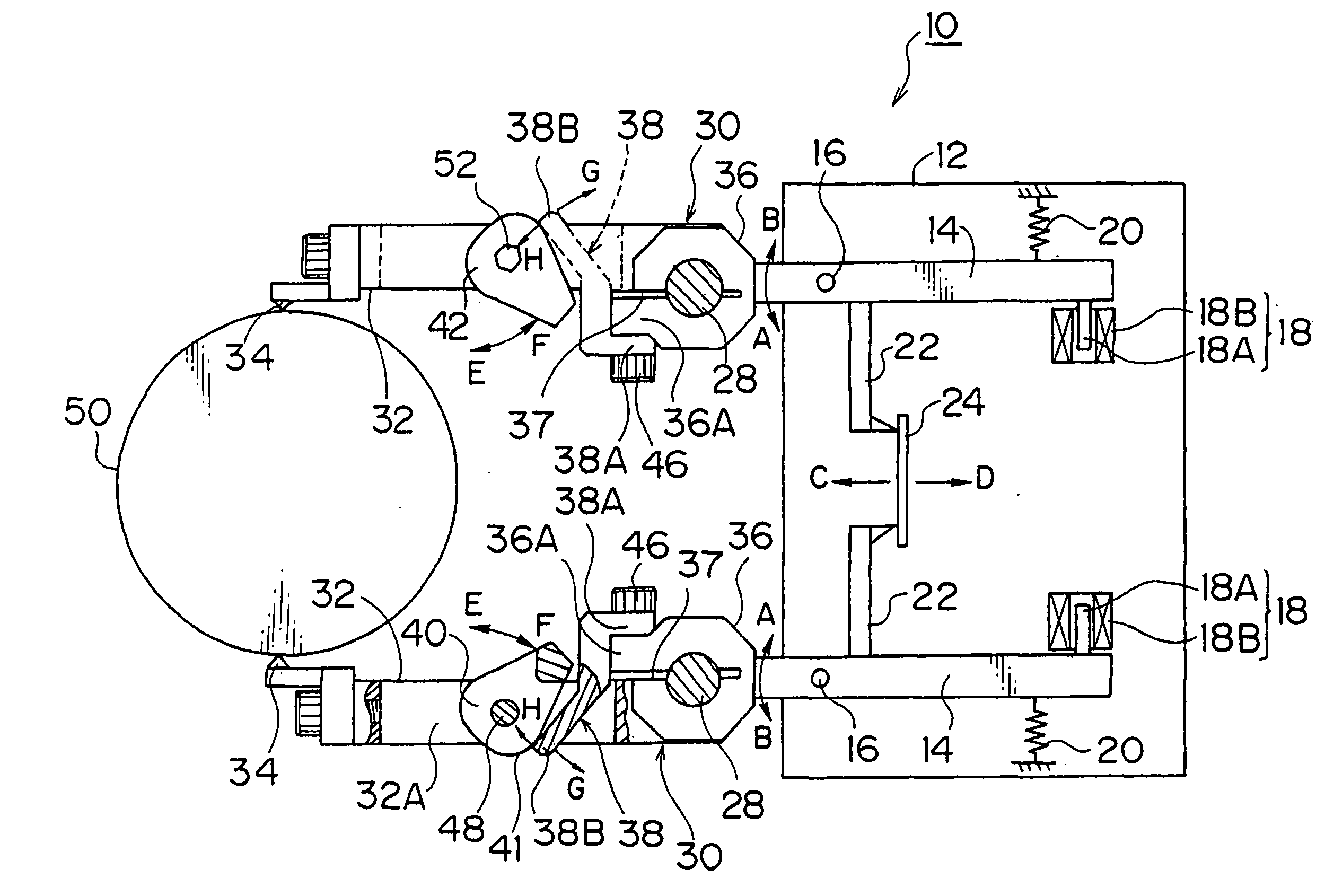

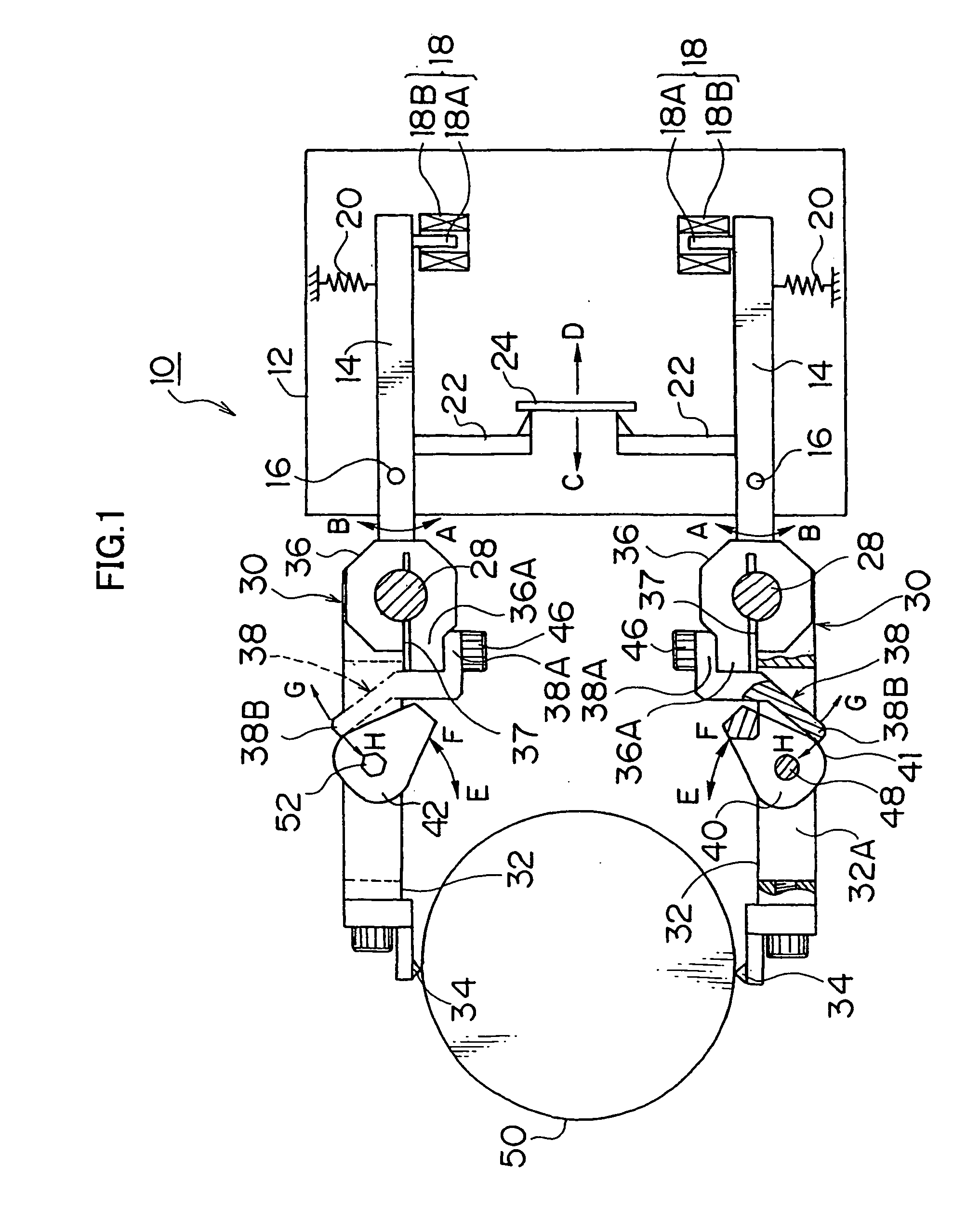

Measuring head

InactiveUS20060042109A1Increase flexibilityProlong lifeMechanical diameter measurementsElectrical/magnetic diameter measurementsEngineeringRestoring force

According to the measuring head, the zero point and the amount of front travel settings are facilitated. Firstly, the amount of front travel is set by allowing contacts 34, 34 to abut a master 50. Then, rotating the lever 42 in a direction indicated by an arrow E, or a close position, causes the bearing member 36 to be fastened to the swinging support shaft 28. At this time, a restoring force, or a force caused by reaction, of the bearing member 36 transferred from the bearing member 36 through the arm 38, cam plate 40 and shaft 48 to the measurement lever 32 causes the measurement lever 32 to deflect by an amount that equals to the amount of front travel, and therefore from the position where the amount of front travel is set to the zero point position. This automatically sets the zero point position.

Owner:TOKYO SEIMITSU

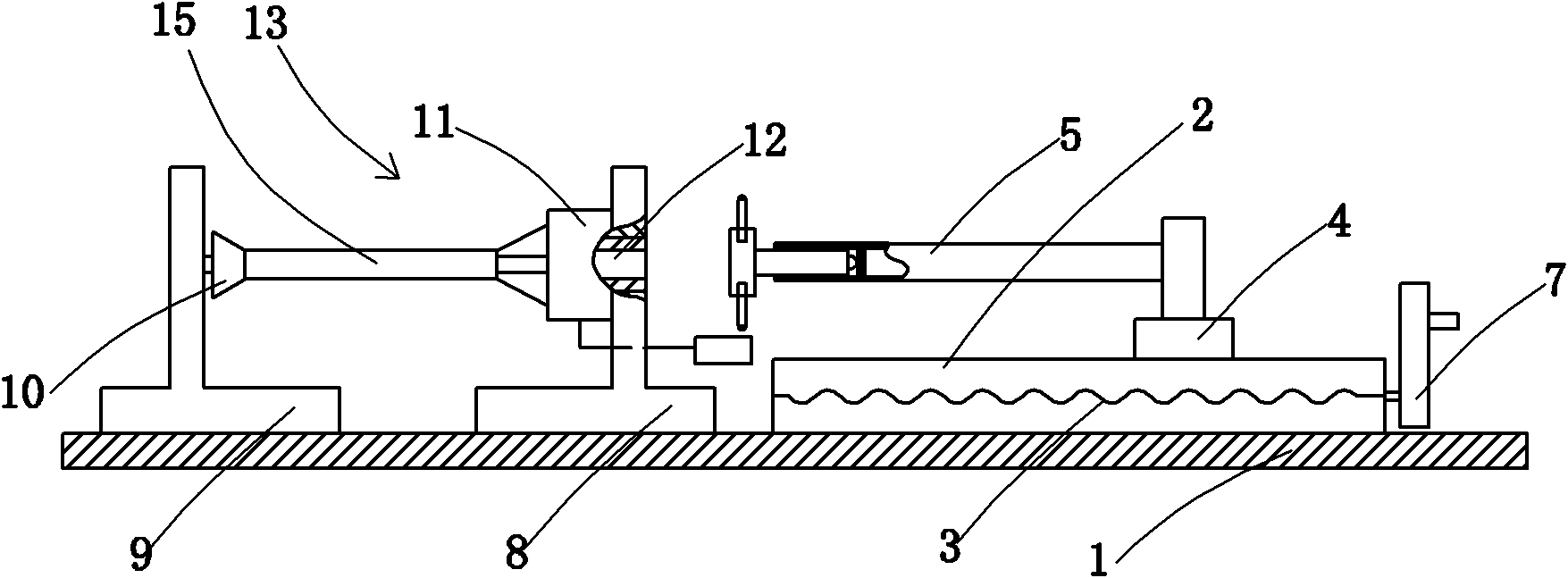

Error detection device for hourglass worm

ActiveCN101750006AConform to shape characteristicsEliminate the effects ofElectric/magnetic contours/curvatures measurementsUsing electrical meansRotary stageMotor drive

The invention discloses an error detection device for a hourglass worm, comprising a body, a spindle unit and a measuring unit, wherein the spindle unit comprises a spindle servo motor, a spindle, a workpiece fixture to be measured and a tailstock; the spindle servo motor drives the spindle to rotate; the workpiece fixture to be measured is fixedly matched with the spindle in the circumferential direction; the measuring unit comprises a base, a rotating table, a measuring contact, a data acquisition system and a computer; the rotating table is arranged on the base in the manner of rotating around a z-axis; and the measuring contact is arranged on the rotating table in the manner of adjustable position along an x-axis, a y-axis and the z-axis and can rotate around an axis parallel to the z-axis. The coordinate measurement can be carried out for the hourglass worm by adopting the arc measuring method, the line by line measurement can be carried out, the efficiency is higher than that of the point by point measurement in the prior art, the influences of subjectivity of human intervention and mechanical error of the standard worm on the detection results are avoided, as different types of measuring contacts are adopted, various errors of the worm can be accurately detected, and the universality is strong.

Owner:CHONGQING UNIV

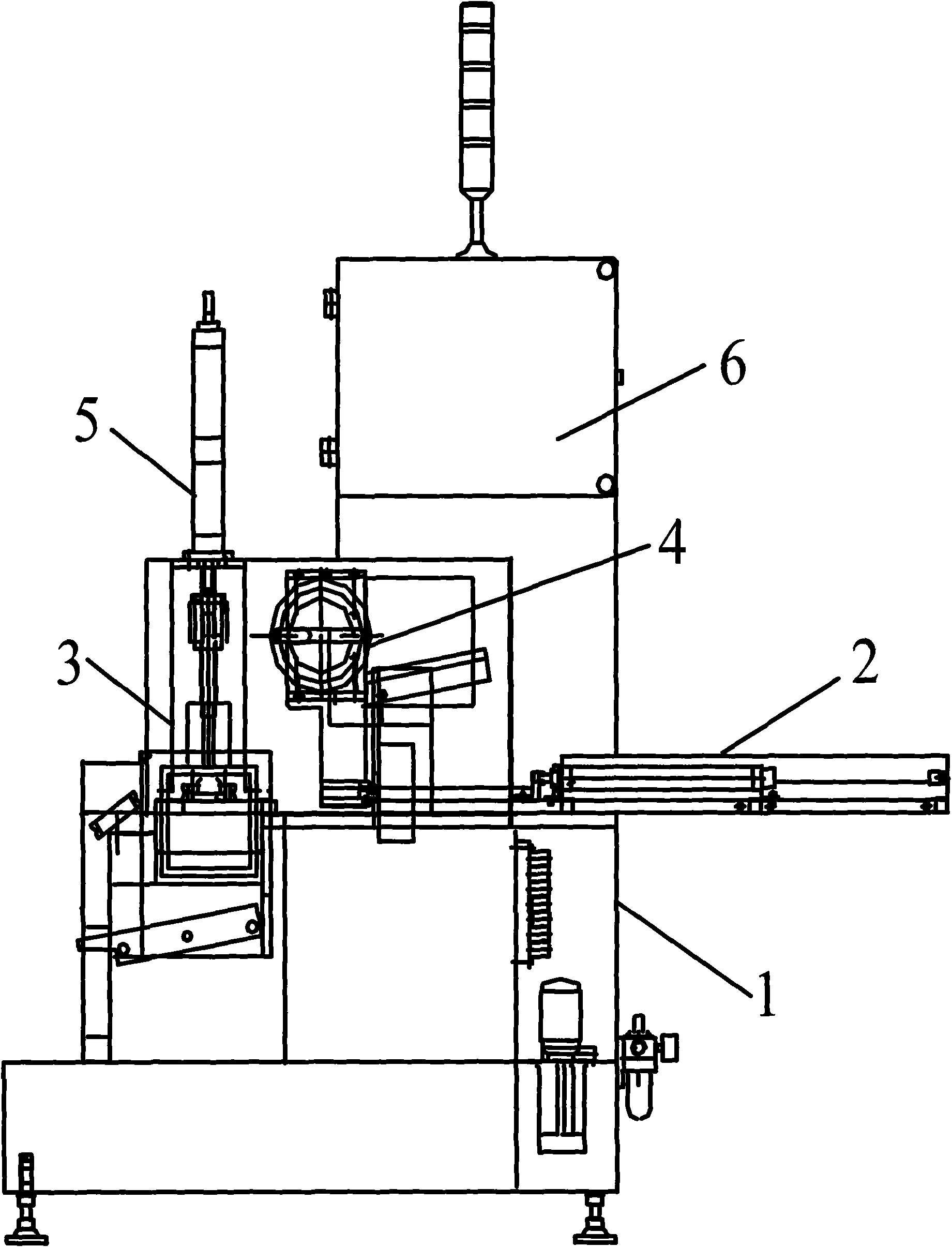

Full-automatic bearing outboard detector

InactiveCN101907435AEasy to adjustIntuitive displayGrinding feed controlUsing electrical meansBiochemical engineeringSystem stability

The invention discloses a full-automatic bearing outboard detector, which comprises a detector body, a feeding structure, a detecting mechanism, a loading mechanism, a baiting mechanism and an electrical cabinet, wherein the feeding mechanism and the detecting mechanism are respectively arranged at two sides of the body; the loading mechanism is arranged between the feeding mechanism and the detecting mechanism; the baiting mechanism is arranged right above the detecting mechanism; and the electrical cabinet is arranged above the loading mechanism. The invention adopts the flexibility design of the complete machine function, can meet the on line requirement of grinding machines from different manufacturers and with different sizes, is convenient to regulate and intuitive to display, and has strong adaptability, higher measurement accuracy, excellent system stability and reliable feedback function.

Owner:上海莱必泰精密机电有限公司

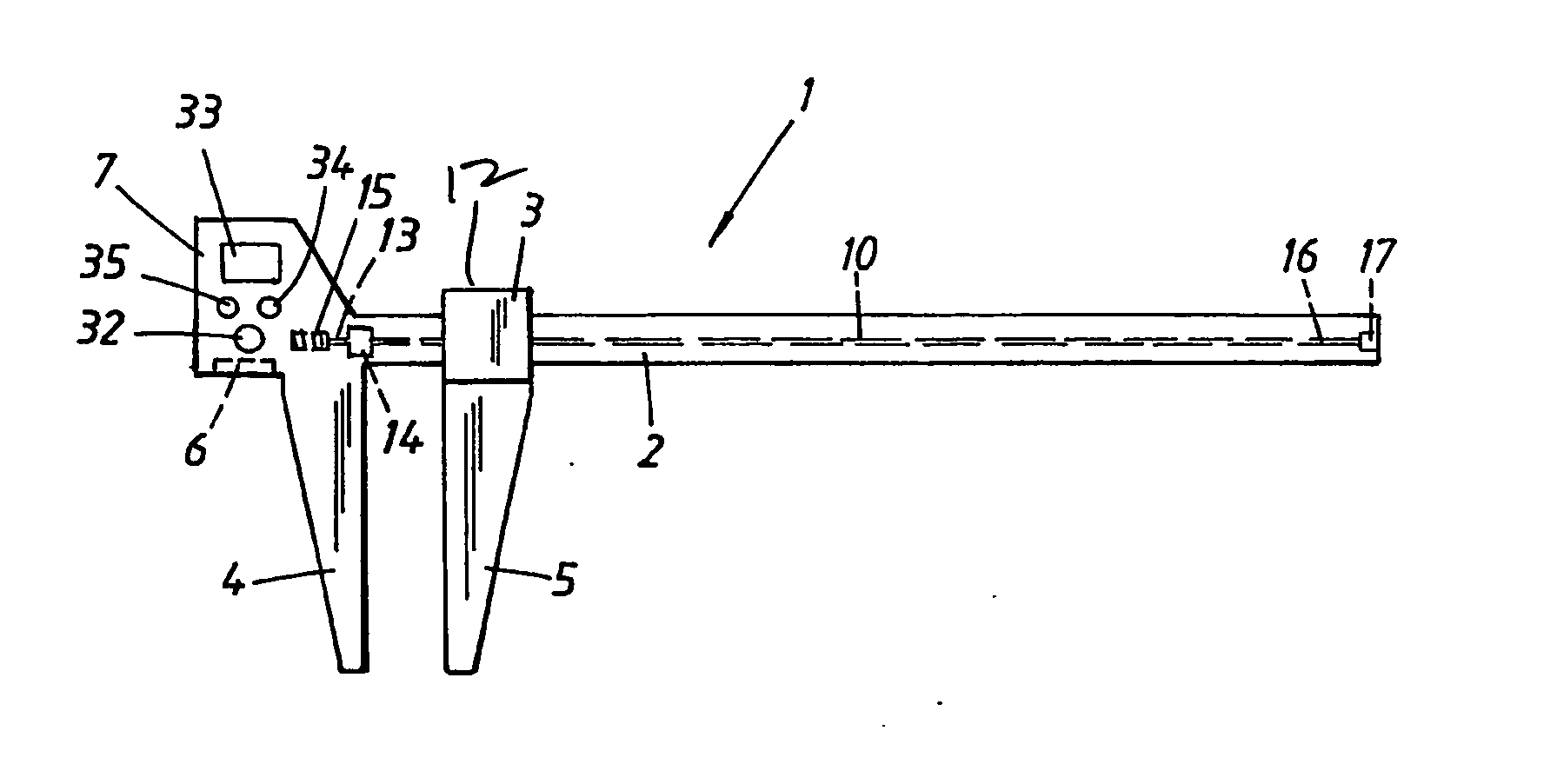

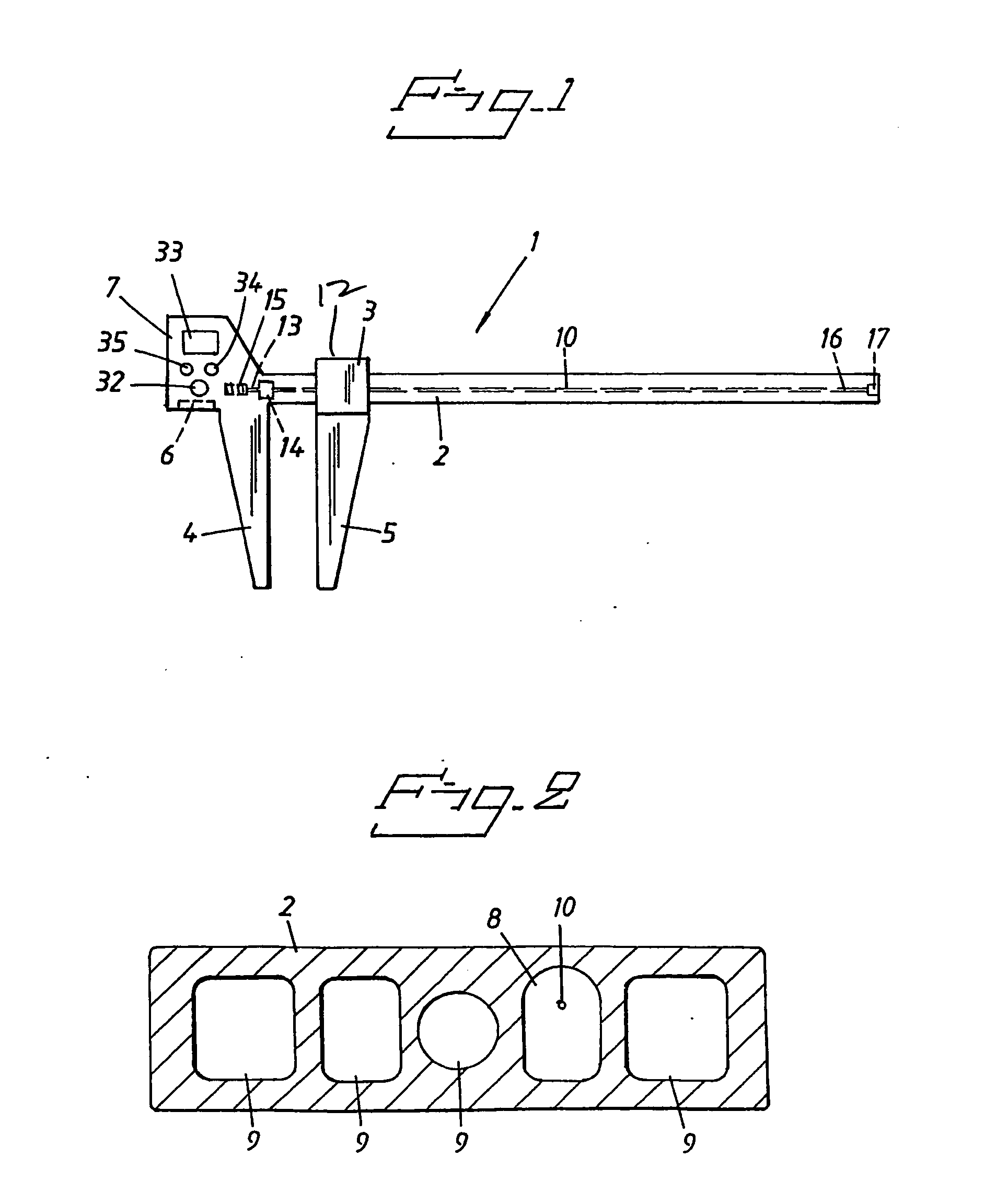

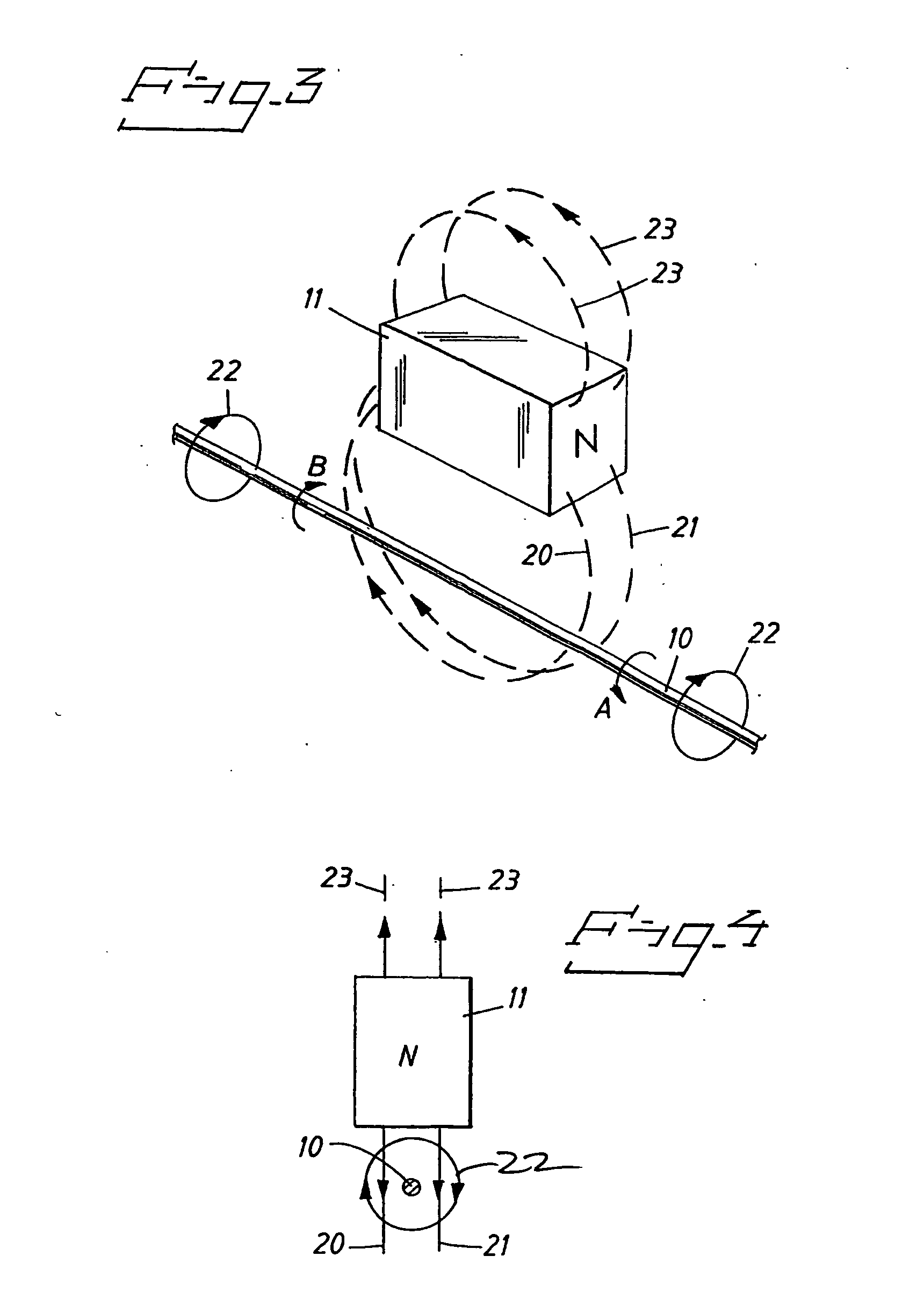

Calliper

InactiveUS20050028398A1Slide gaugesElectrical/magnetic diameter measurementsCalipersBiomedical engineering

The present invention relates to a calliper of the king used to measure tree diameters, comprising a fixed scale or a graduated rule (2) along which a slide (3) is movable, wherein the calliper includes a leg (4) attached to one end of said rule and a leg (5) attached to the slide (3), wherein measuring of said diameter is effected between said legs, and wherein said calliper includes an electronic unit for measuring the position of the slide (3) along the rule (2) and for storing measurement values and other desired data. The invention is characterised in that the graduated rule (2) includes a longitudinally extending internal cavity (8); in that a measuring element includes an electrically conductive wire (10) extending in said cavity (8) and attached to oth ends of the rule (2); in that the part of the slide (3) located at the rule (2) includes a permanent magnet (11); in that the wire (10) co-acts with a piezo crystal (19) in the close proximity of said one end (13); in that respective ends (13, 16) of said wire (10) are connected electrically to a pulse generator which functions to generate short electric pulses of predetermined duration; and in that the calliper includes detector means (18) which co-acts with the piezo crystal (19) and which is adapted to detect a geometric change in the wire (10), wherein said piezo crystal functions to emit an electric pulse in response to said geometric change.

Owner:HAGLOF SWEDEN

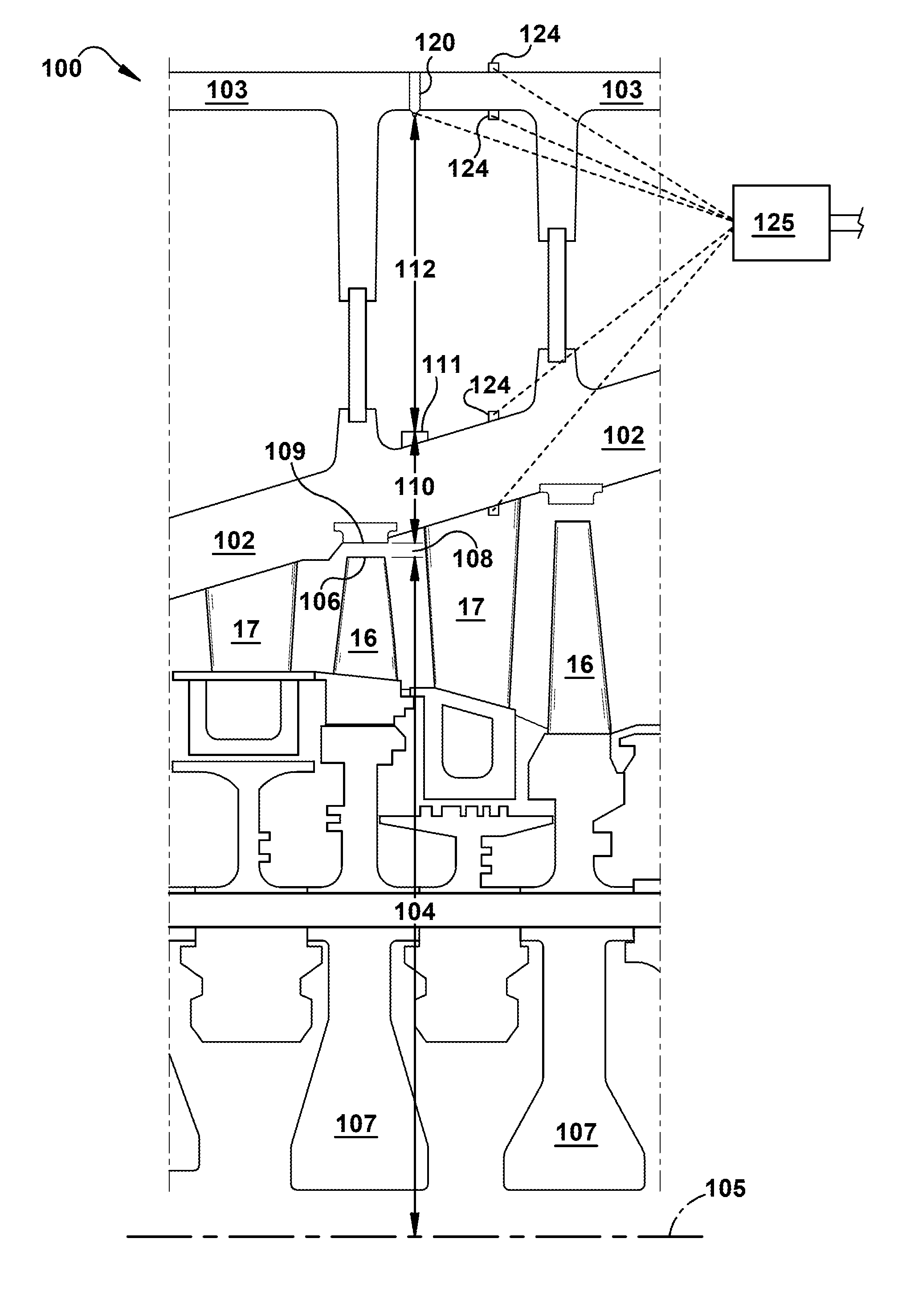

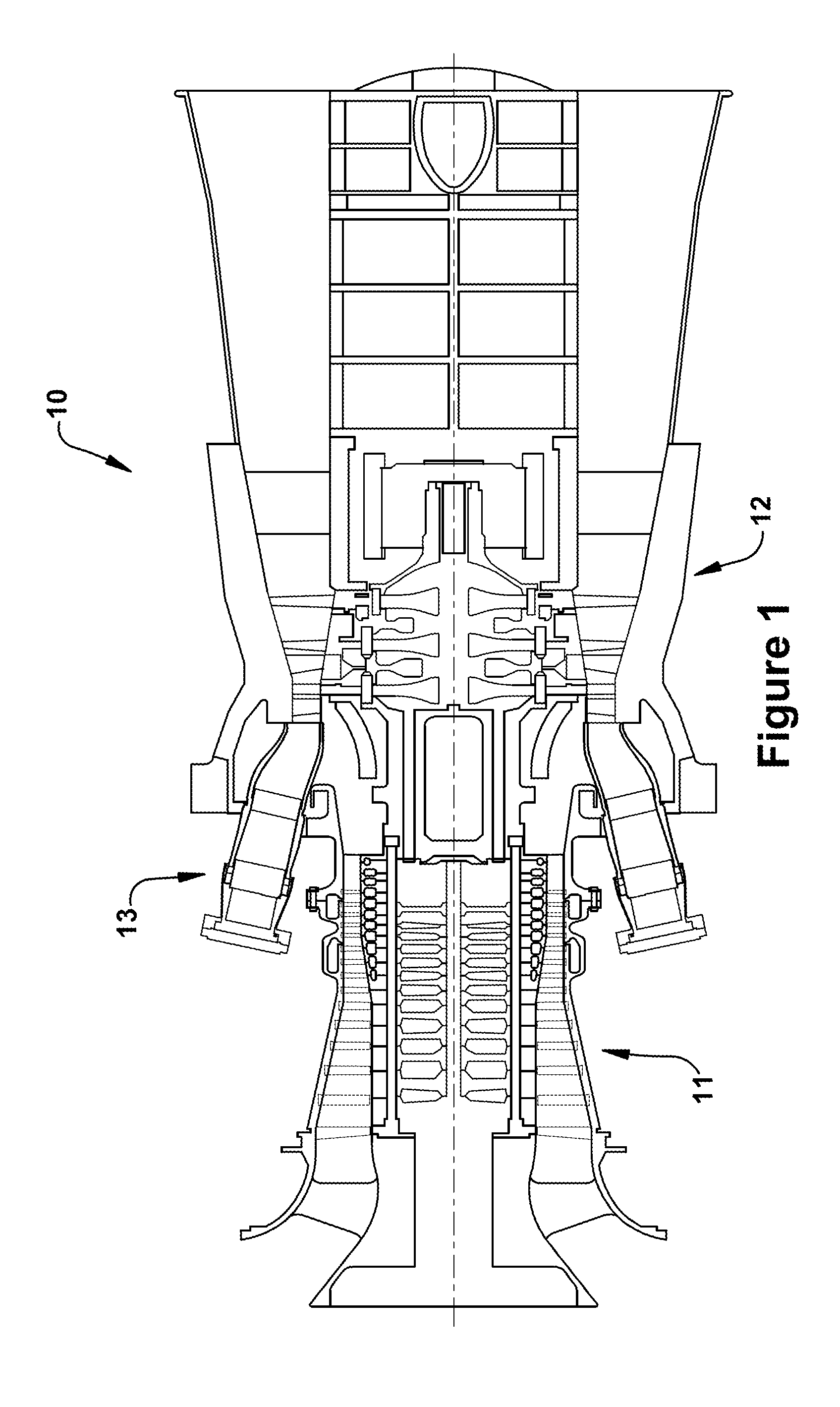

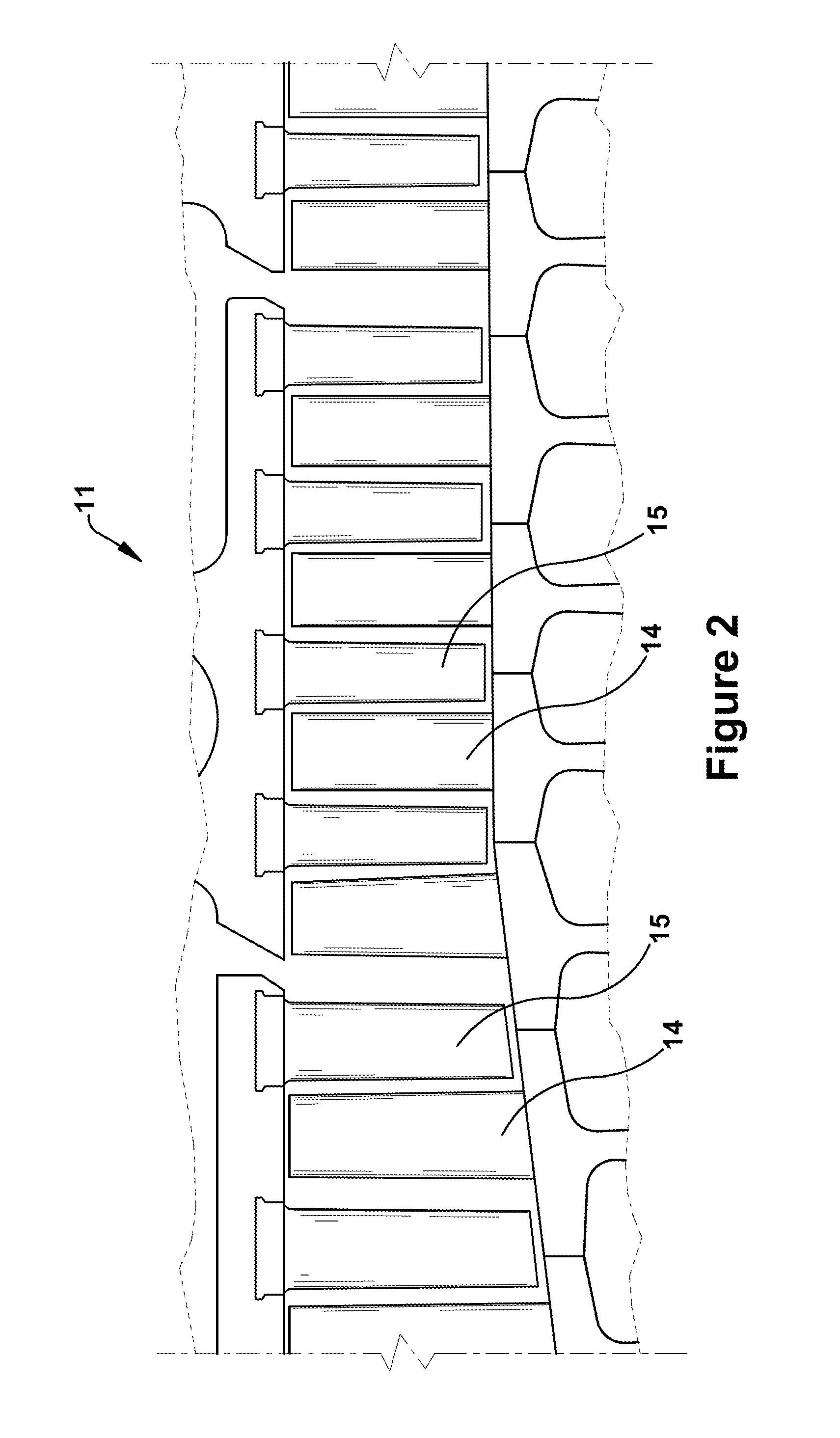

Methods, systems and apparatus relating to tip clearance calculations in turbine engines

A method of calculating the tip clearance during operation of a combustion turbine engine that includes the steps of: measuring a cold tip clearance and a cold shell-to-shell distance; while the combustion turbine engine is operating, measuring an operating parameter and measuring a shell-to-shell distance with a proximity sensor; calculating the tip clearance based on the cold tip clearance measurement and the operating parameter measurement; calculating the shell-to-shell distance based on the cold shell-to-shell distance measurement and the operating parameter measurement; comparing the shell-to-shell distance measurement of the proximity sensor with the shell-to-shell distance calculation; and calibrating the calculated tip clearance calculation based on the comparison.

Owner:GENERAL ELECTRIC CO

Device for measuring an internal or external profile of a tubular component

ActiveCN104024787AHigh precisionMechanical counters/curvatures measurementsMechanical diameter measurementsEngineering

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

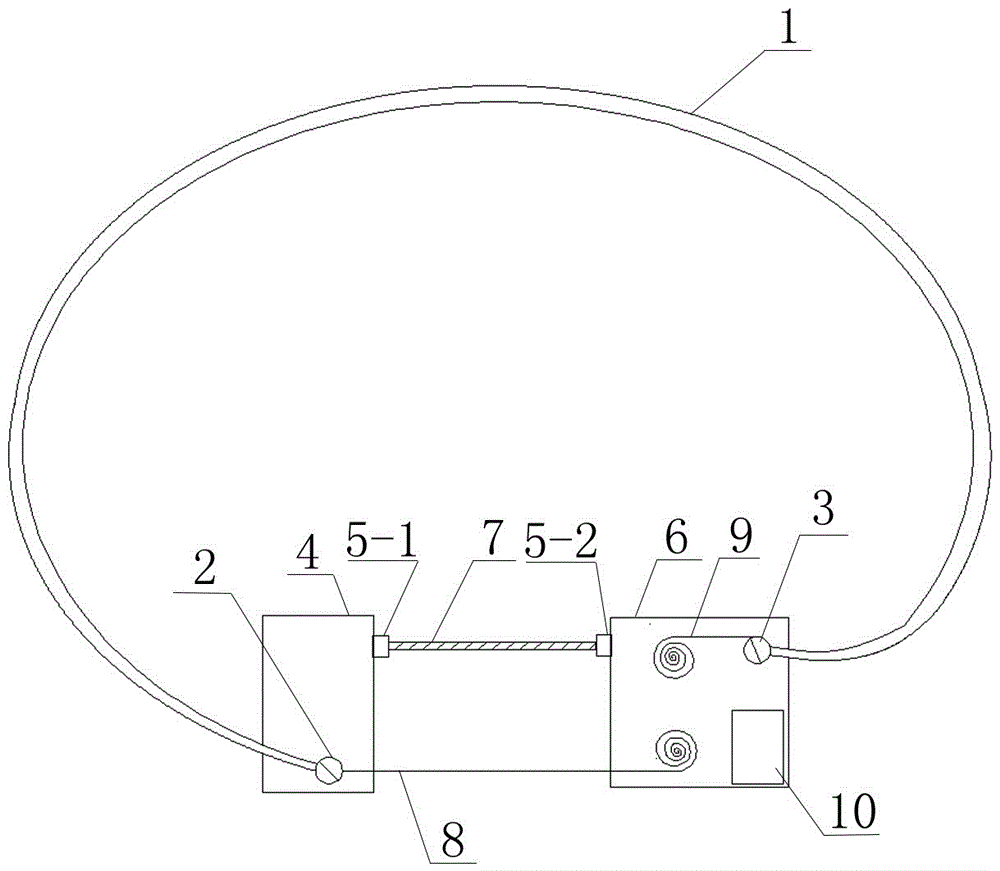

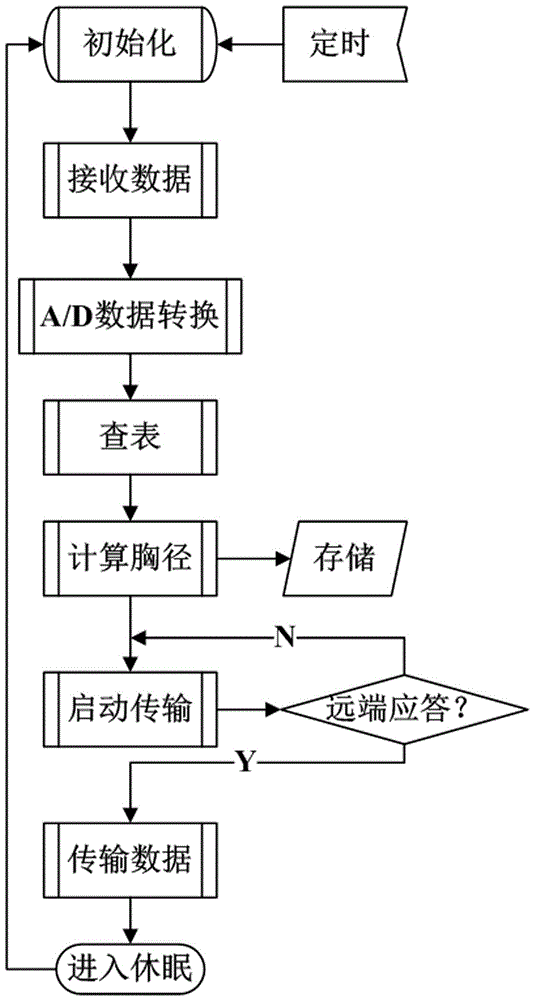

Tree diameter at breast height automatic measurer

ActiveCN105783694AImplement automatic detectionAccurate readingElectrical/magnetic diameter measurementsMeasurement deviceDiameter at breast height

The invention discloses a tree diameter at breast height automatic measurer, which relates to a measurement device, particularly relates to a wireless sensor network-based tree diameter at breast height automatic measurer and belongs to the technical field of tree measurement tools. The tree diameter at breast height automatic measurer comprises a binding band; the binding band is a resistance band; one end of the resistance band is provided with a fixed knot and the other end of the resistance band is provided with a mobile knot; the fixed knot is arranged in a fixed knot box, and a first buckle is arranged on the side surface of the fixed knot box; the mobile knot is arranged in a spring pressure box, a second buckle is arranged on the side surface of the spring pressure box, the first buckle and the second buckle are located in the same horizontal plane, and the first buckle and the second buckle are connected via a clamping band; a fixed knot wire and a mobile knot wire are respectively connected onto the fixed knot and the mobile knot, and tail ends of the fixed knot and the mobile knot are sealed in the spring pressure box; tail ends of the fixed knot wire and the mobile knot wire are bent; and the spring pressure box is internally provided with a measurement control unit. The measurement reading is accurate, the efficiency is high, and the safety is good.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

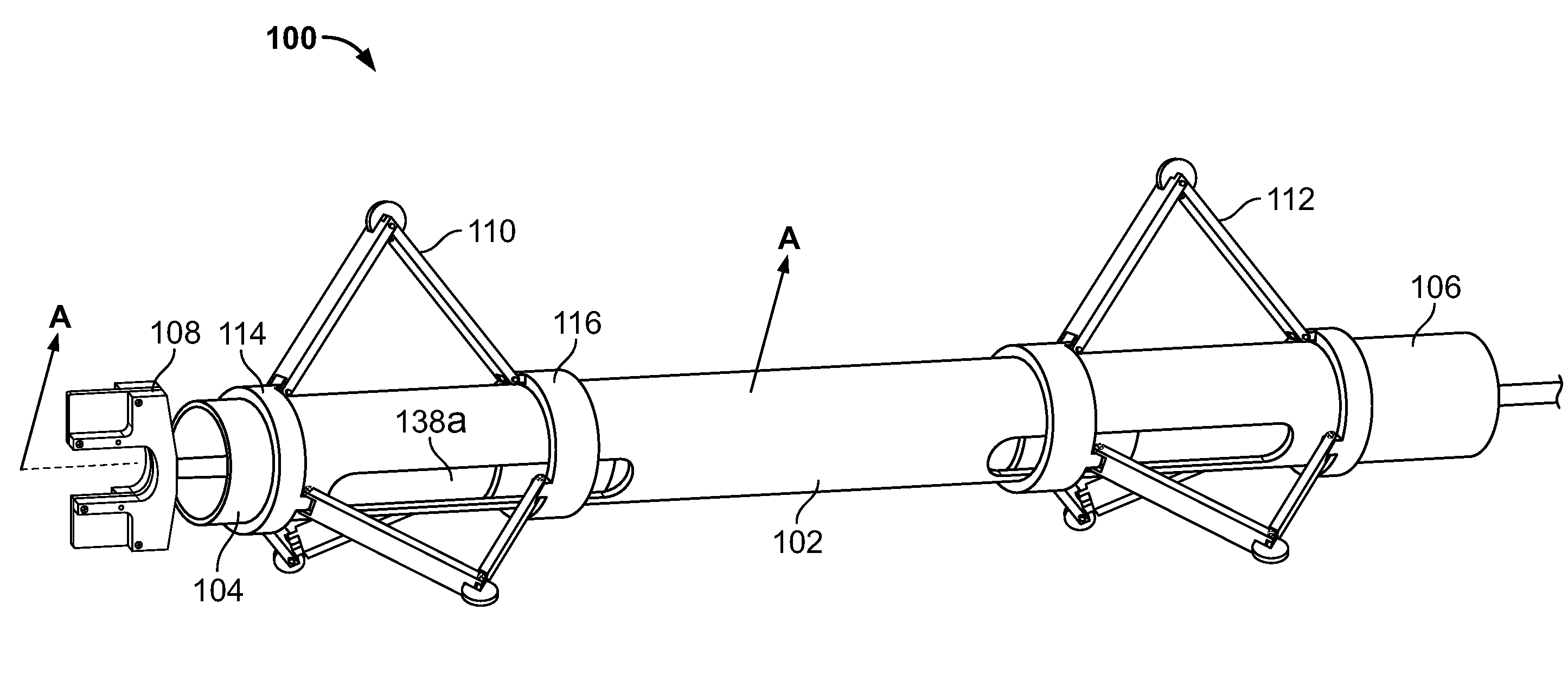

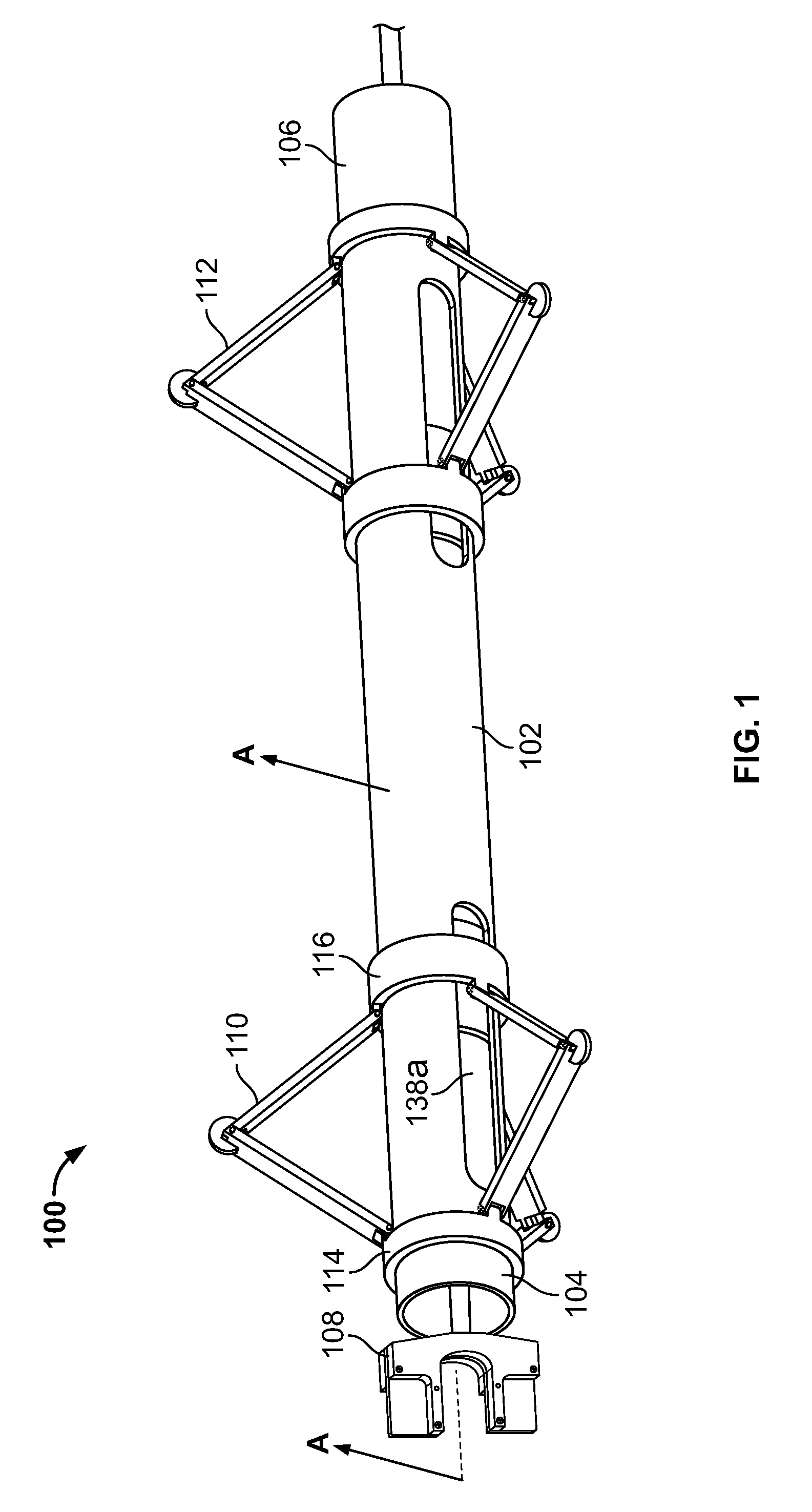

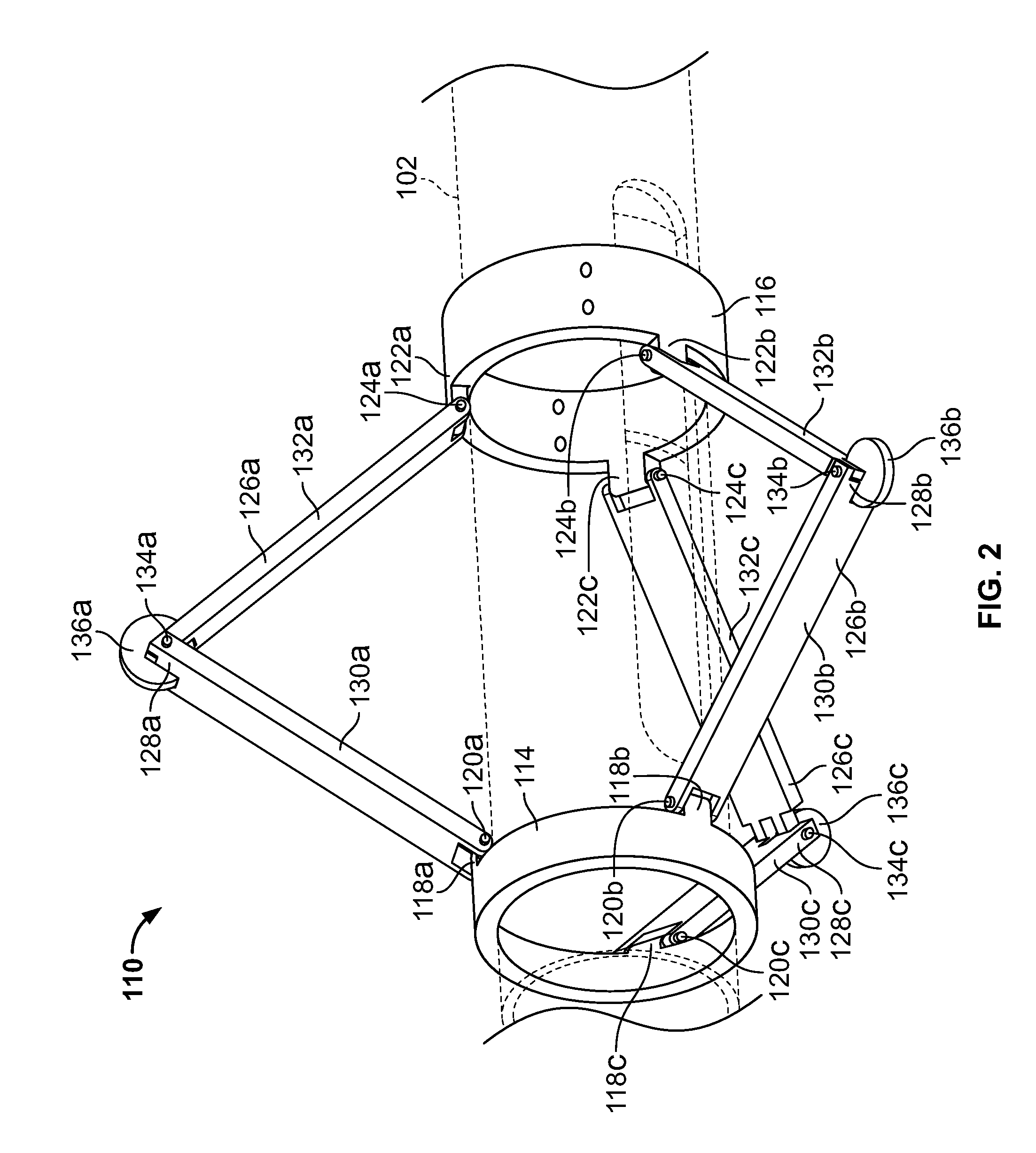

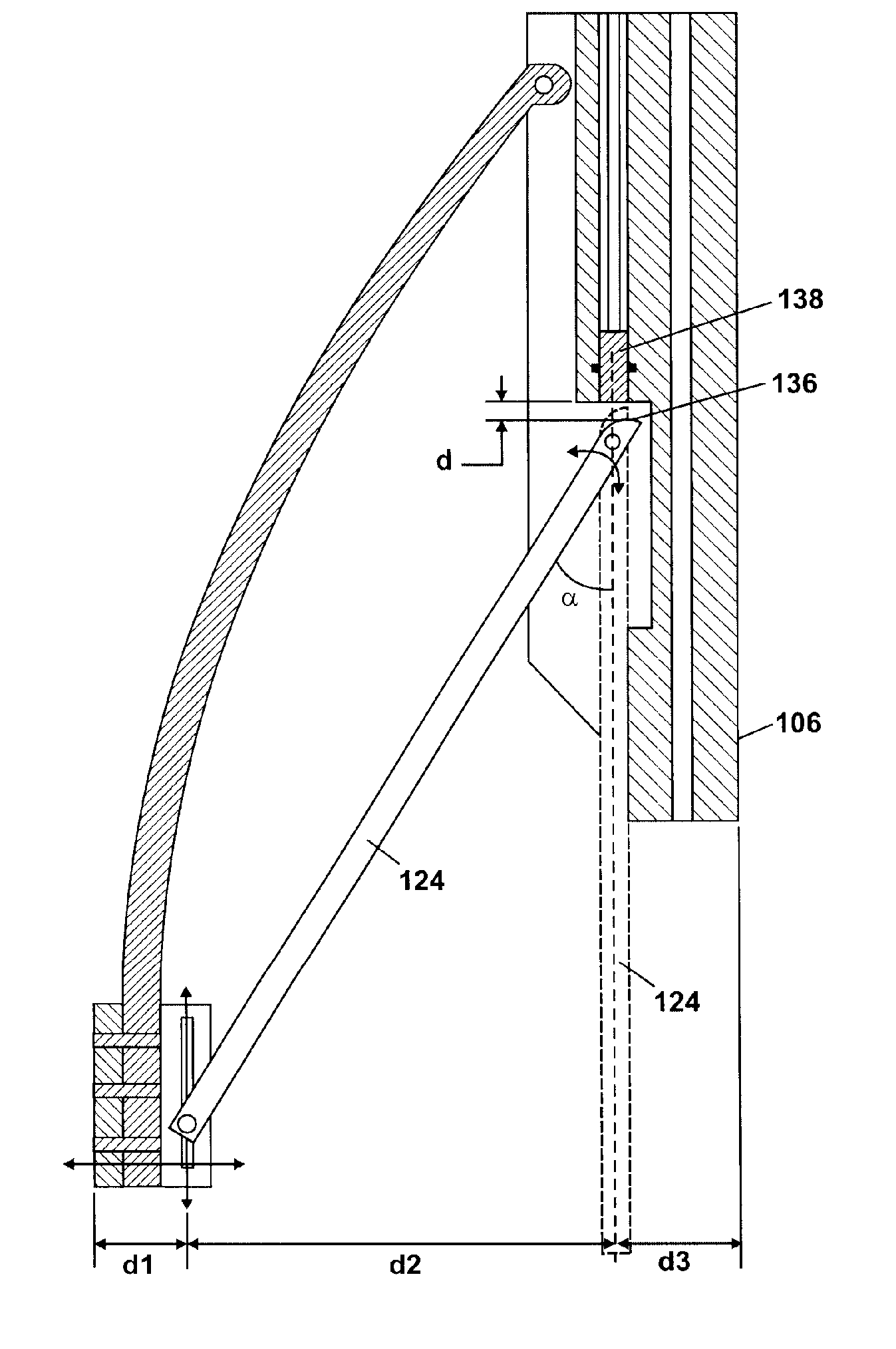

Self centering bore measurement unit

InactiveUS20120239345A1Accurate measurementAccurate “ best fit ” readingSurveyDrilling rodsEngineering

Disclosed is a bore measurement unit having an elongate main body with first and second ends. A first adjustment mechanism is disposed near the first end and a second adjustment mechanism is disposed near said second end. The adjustment mechanisms expand or contract, through triangulating arms, to relative diameters, such that when the unit is inserted into a hollow bore it may be centered therein. A measuring portion of the unit measures the internal diameter of the bore. The measuring unit includes at least one sensor and preferably takes more than three readings at each distance of insertion to formulate a best fit circle of the inner bore diameter.

Owner:SIEMENS ENERGY INC

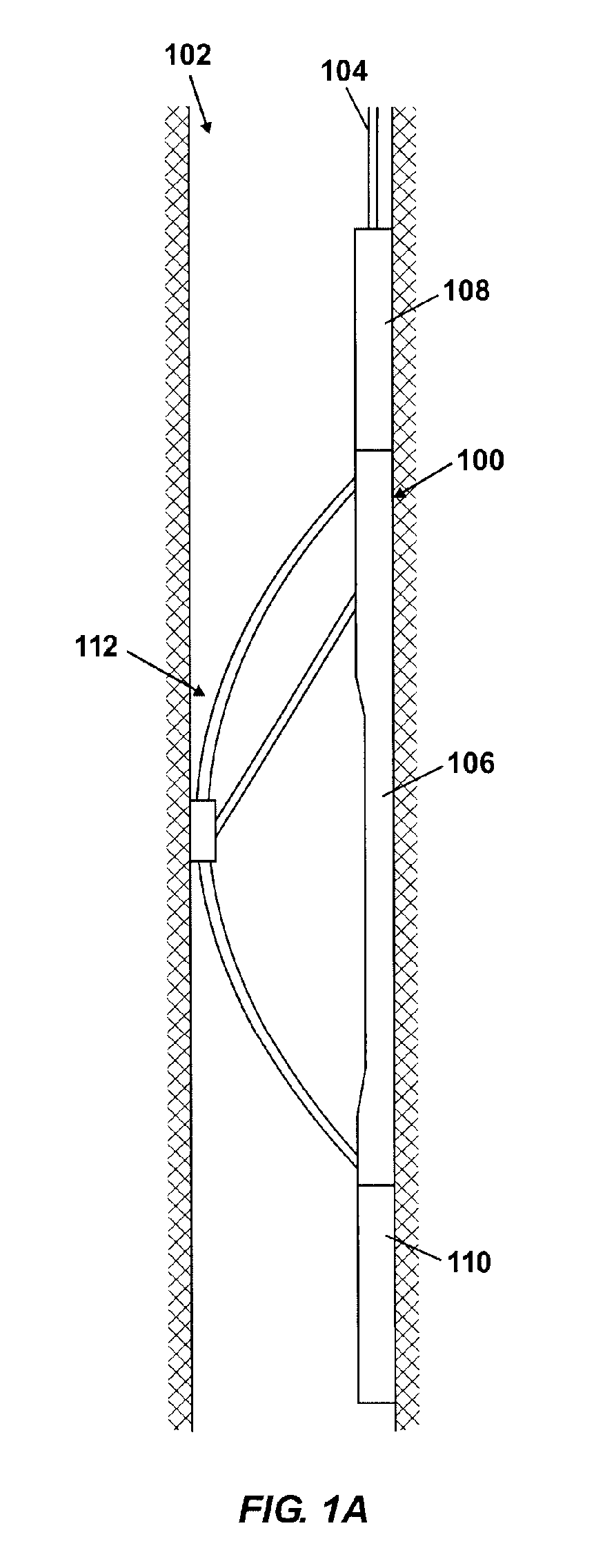

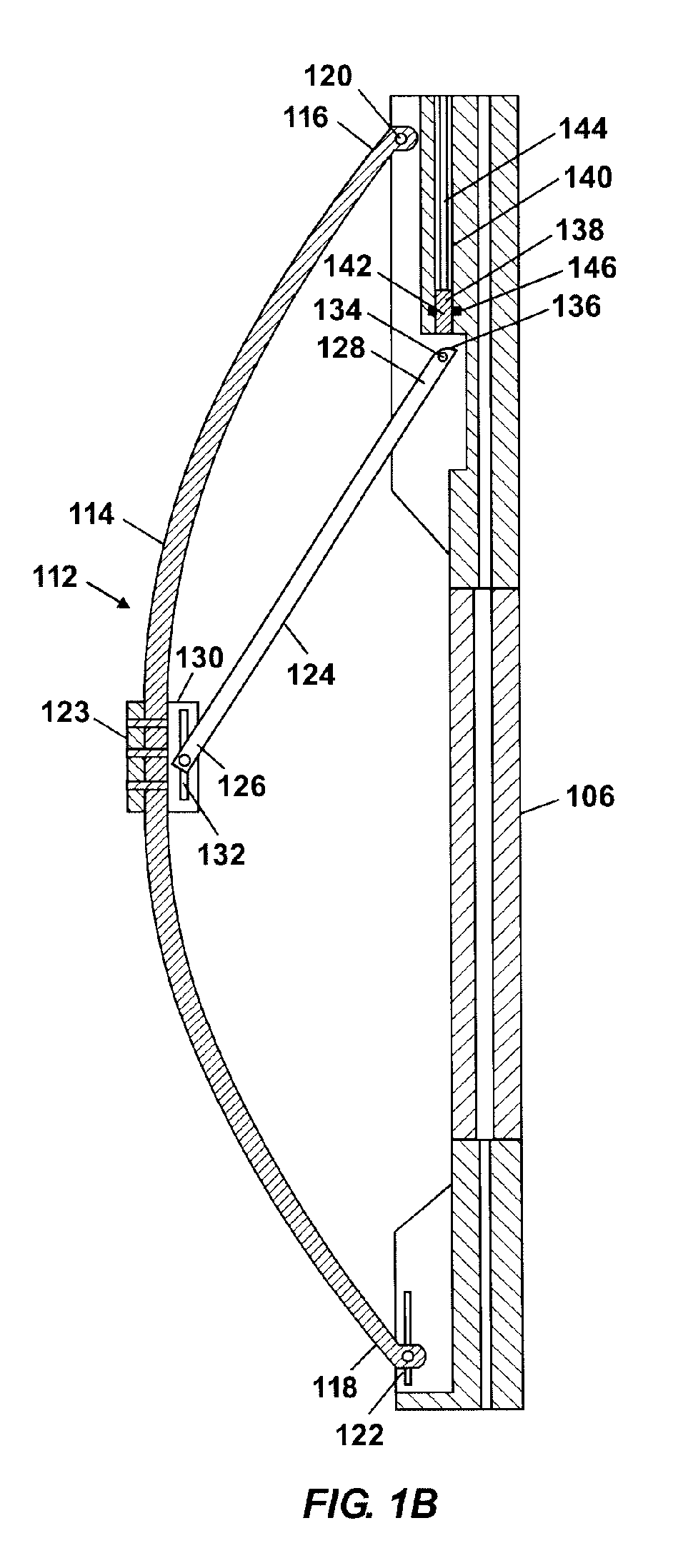

Borehole caliper tool

A borehole caliper tool includes a tool body and an arm coupled to the tool body. The arm is deflectable relative to the tool body. The caliper tool further includes a cam coupled to the arm such that a position of the cam changes as the arm deflects. The caliper tool further includes a proximity sensor for sensing the position of the cam, wherein the position of the cam provides an indication of the deflection of the arm relative to the tool body.

Owner:SCHLUMBERGER TECH CORP

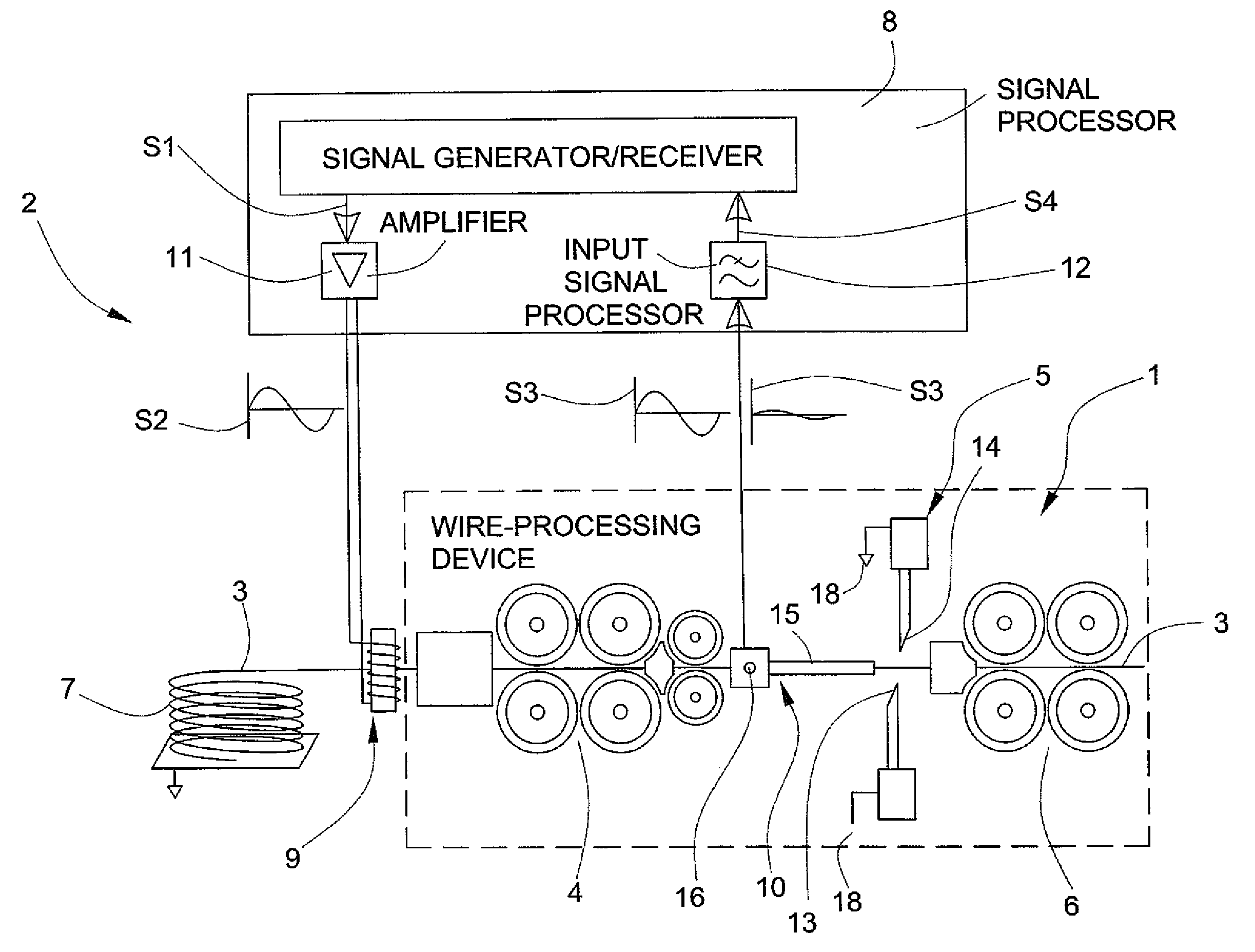

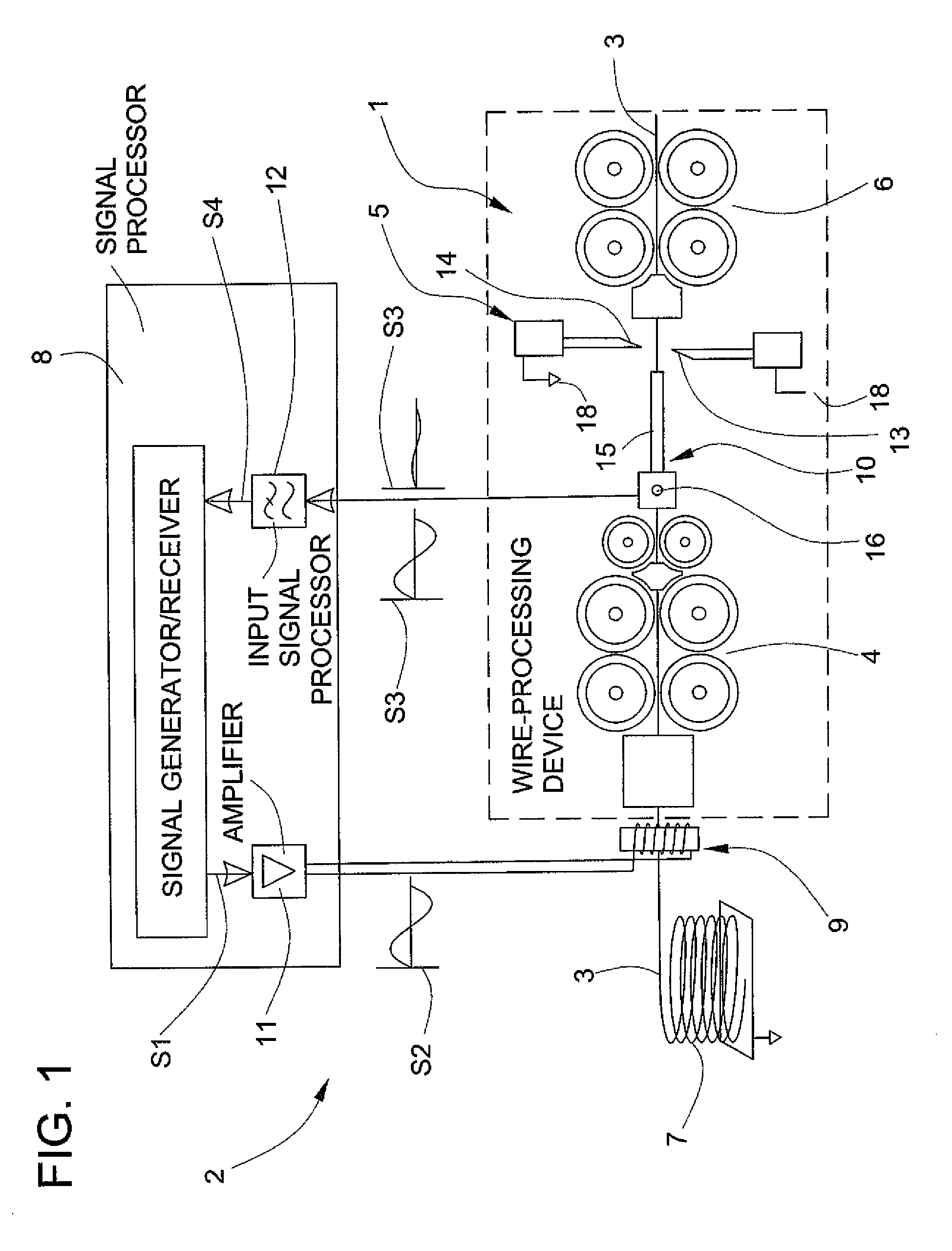

Device to Determine the Diameter of the Conductor of a Wire

ActiveUS20070121796A1Sure easyShorten the timeApparatus for cutting/splicing cablesSupervisory/monitoring/testing arrangementsElectrical conductorEngineering

A wire-processing device includes a first advancing device, a cutter head, and a second advancing device. The first advancing device pulls the wire out of a wire store and advances according to the desired length of wire to be cut. After the wire is cut through by the cutter head, the wire-ends of the wire-length are processed. The wire-processing device is provided with a device to determine the diameter of the conductor of the wire including an input coupler that applies to the wire an output signal that can be sensed as an input signal and interpreted by a signal processor, wherein the cutters of the cutter head touch the conductor and change the input signal when cutting into the wire.

Owner:KOMAX HOLDING

Method and system for calculating misalignment of rotational body

ActiveUS20100241394A1Sure easyEasy maintenanceElectrical/magnetic diameter measurementsIncline measurementMeasurement pointCentre of rotation

A system and method for calculating misalignment of a rotational body includes: deriving radial displacement amounts of the rotational body for at least four or more measurement points; selecting three arbitrary points among all the measurement points to calculate a circle; calculating circle values for all the measurement points from the calculated circle; calculating differences between the calculated circle values and the radial displacement amounts as error amounts at the measurement points; summing the error amounts to derive a total error amount value; repeating calculation for combinations of three measurement points to calculate each total error amount value; selecting a calculated circle with a minimum total error amount value as a most probable circle; and calculating deviation between the center of the most probable circle and the center of rotation of the rotational body as misalignment data of the most probable circle.

Owner:MITSUBISHI POWER LTD

Device and method for measuring curvature, friction, evenness and hairiness of yarn in combined mode

InactiveCN103727976ASmall footprintLow costMaterial analysis by optical meansMaterial strength using steady bending forcesYarnCapacitance

The invention relates to a device and method for measuring curvature, friction, evenness and hairiness of yarn in a combined mode. The device is composed of a yarn guiding mechanism, a hairiness measuring mechanism, an evenness measuring mechanism, a force measuring mechanism, a dragging and winding mechanism and a bottom plate assembly and is further composed of a corresponding form and force signal collecting, driving control and processing system and a computer. The method for achieving the device comprises the steps that yarn is guided through the yarn guiding mechanism, and the yarn is dragged through the dragging and winding mechanism; the hairiness measuring mechanism is used for horizontally supporting the yarn and extracting the surface hairiness of the yarn, and the hairiness index is obtained through the processing system; a capacitance plate of the evenness measuring mechanism is used for obtaining the evenness of the yarn; a bending mechanism, composed of a pressing needle and double carrier rollers, of the force measuring mechanism is used for bending the yarn, and then the yarn anti-bent strength is obtained; a friction roller of the force measuring mechanism rubs with the yarn, the tension of the yarn before being input into the friction roller and the tension of the yarn after being input into the friction roller are obtained, and then the yarn friction coefficient is obtained. The device and method have the advantage of combining optics, electrics and mechanics measurement.

Owner:DONGHUA UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com