Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

389 results about "Shoulder surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

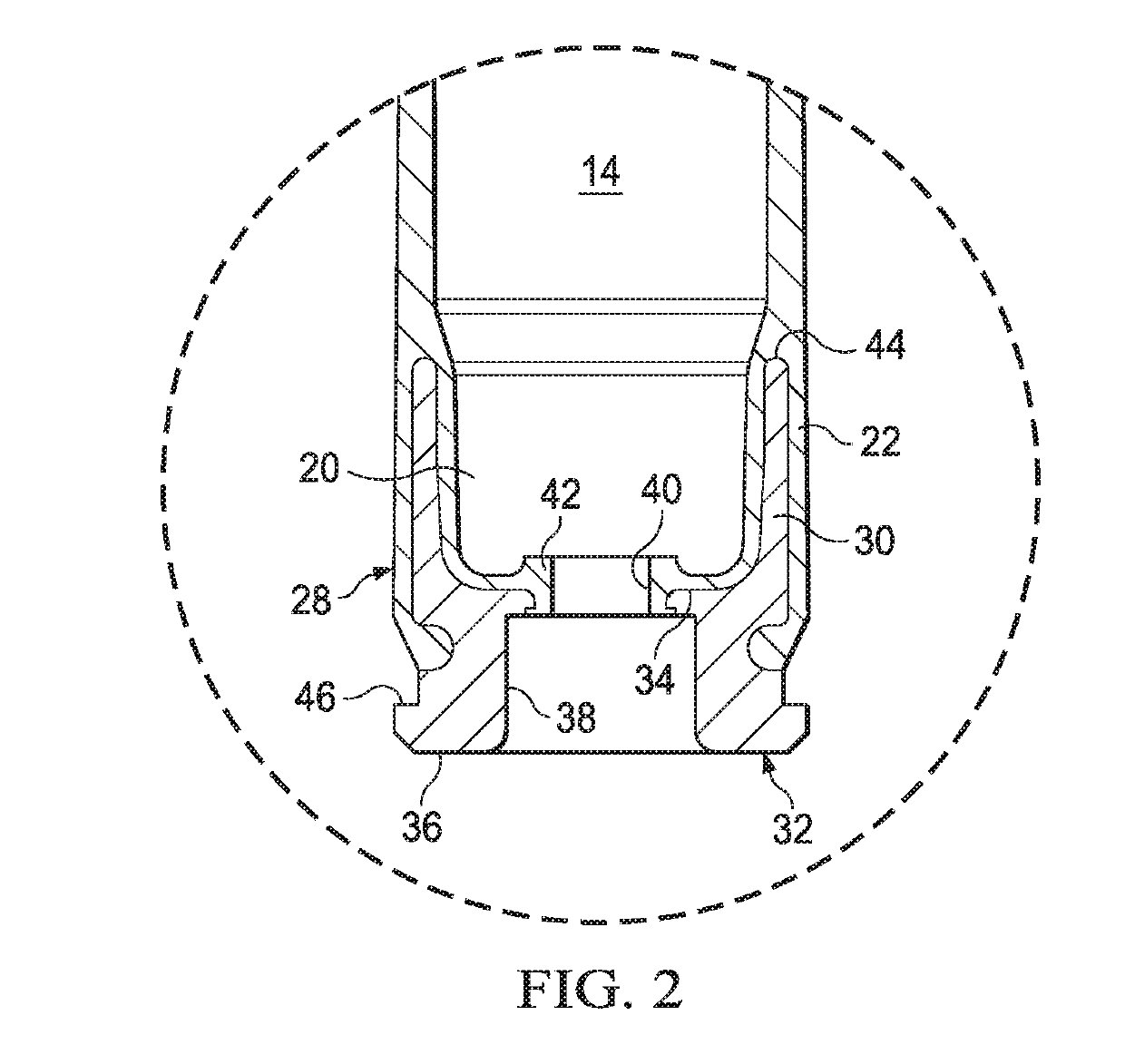

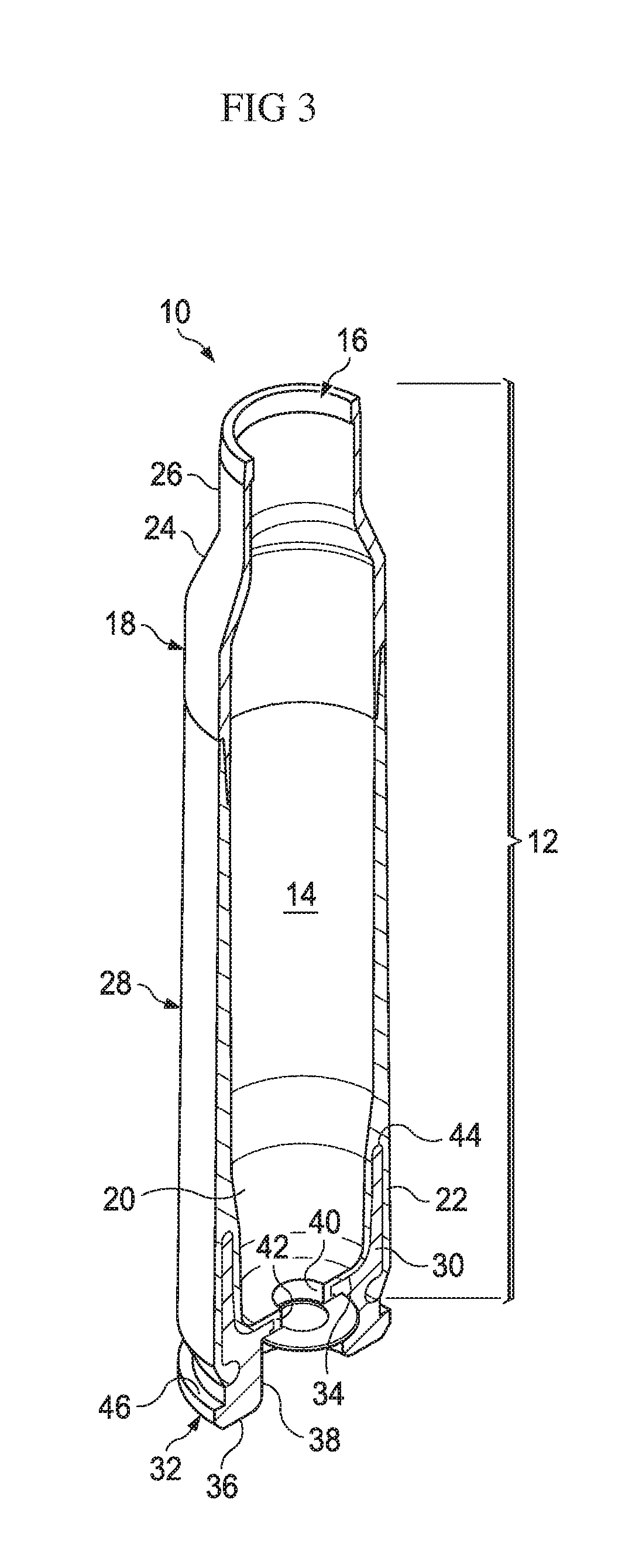

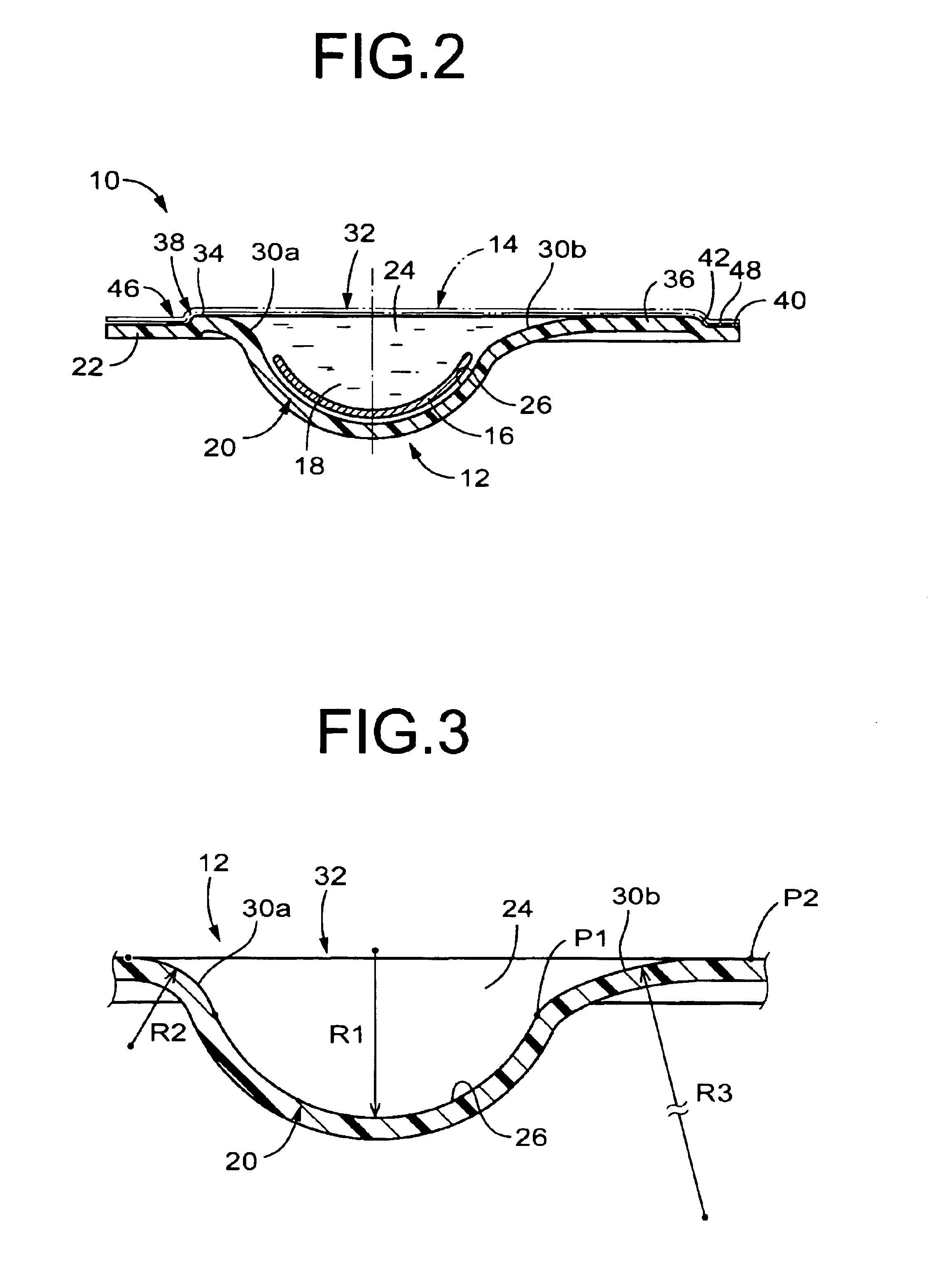

Uveoscleral drainage device

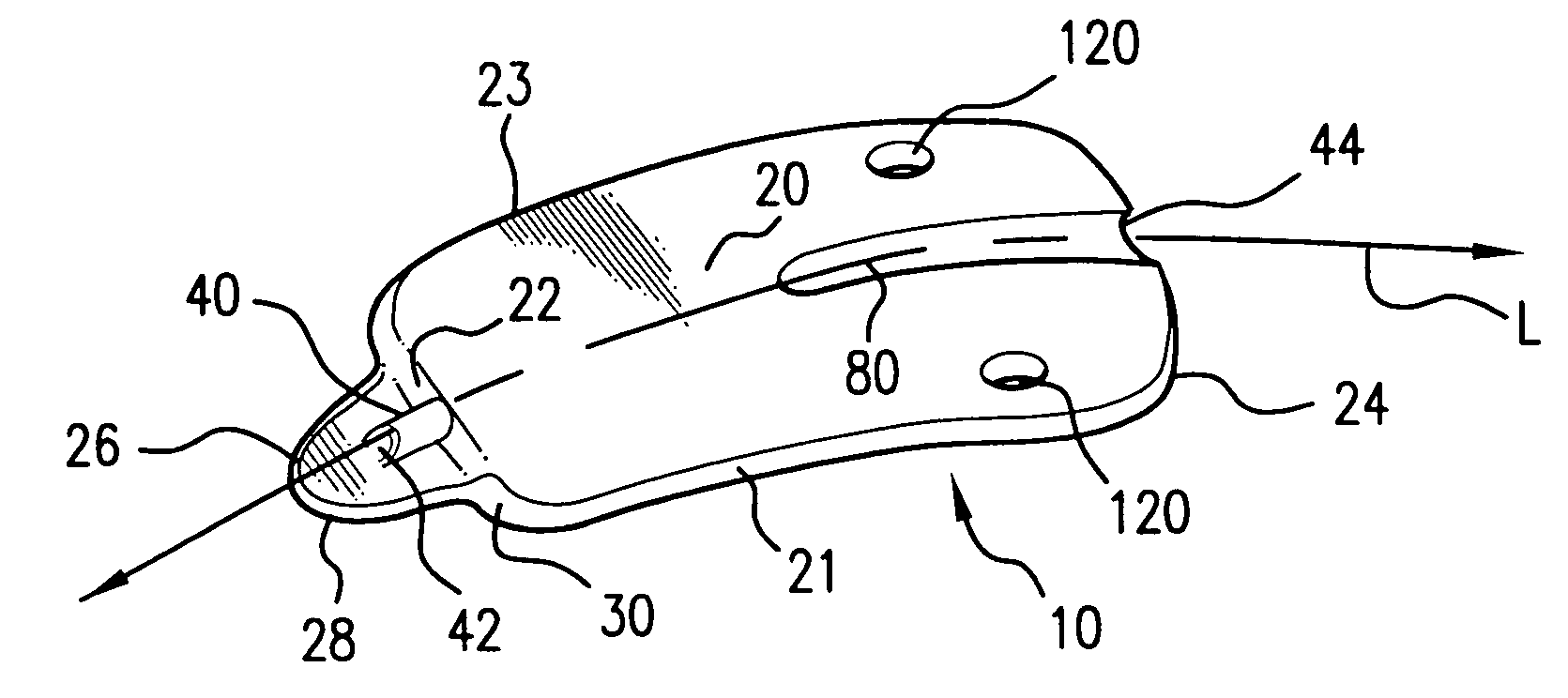

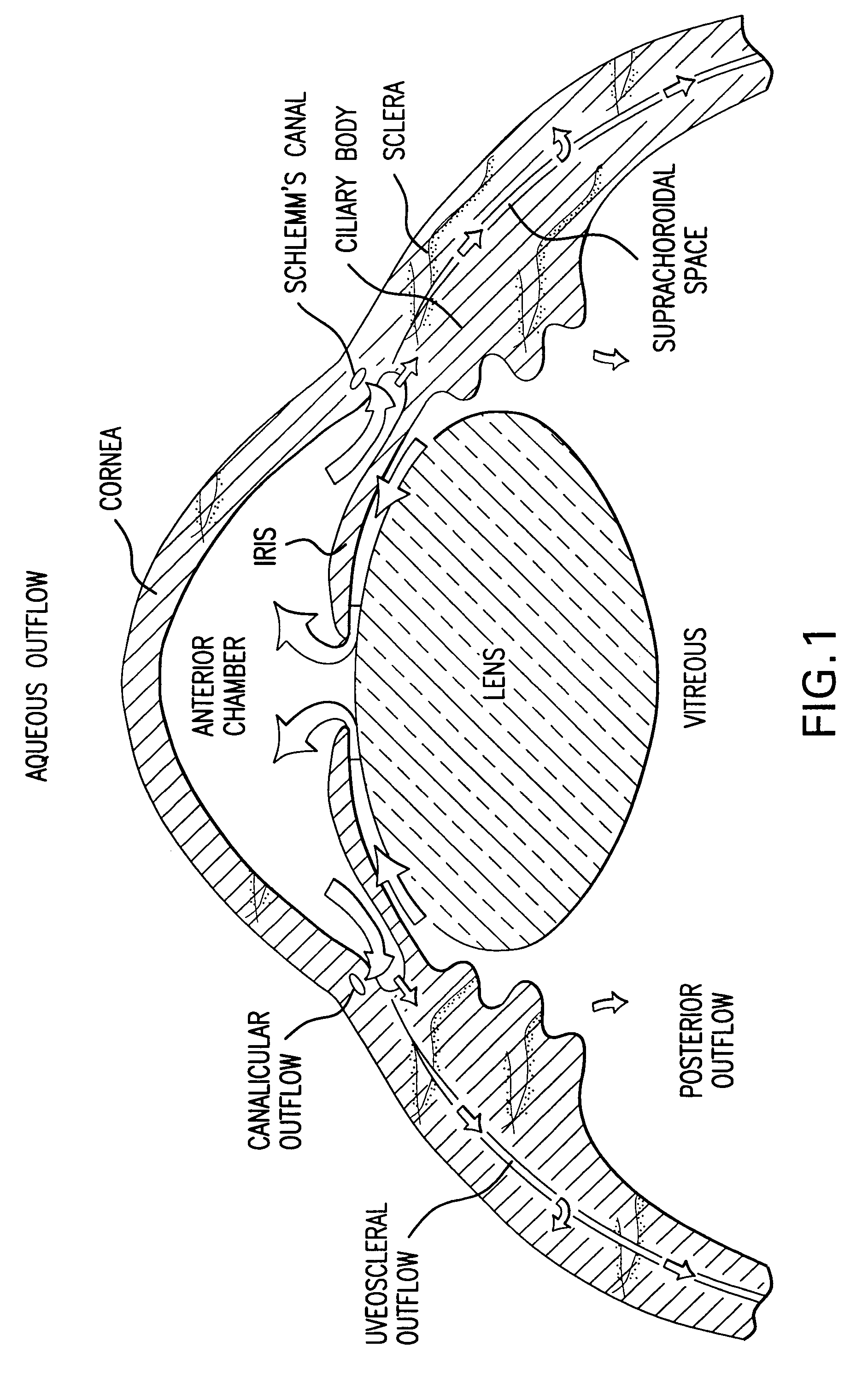

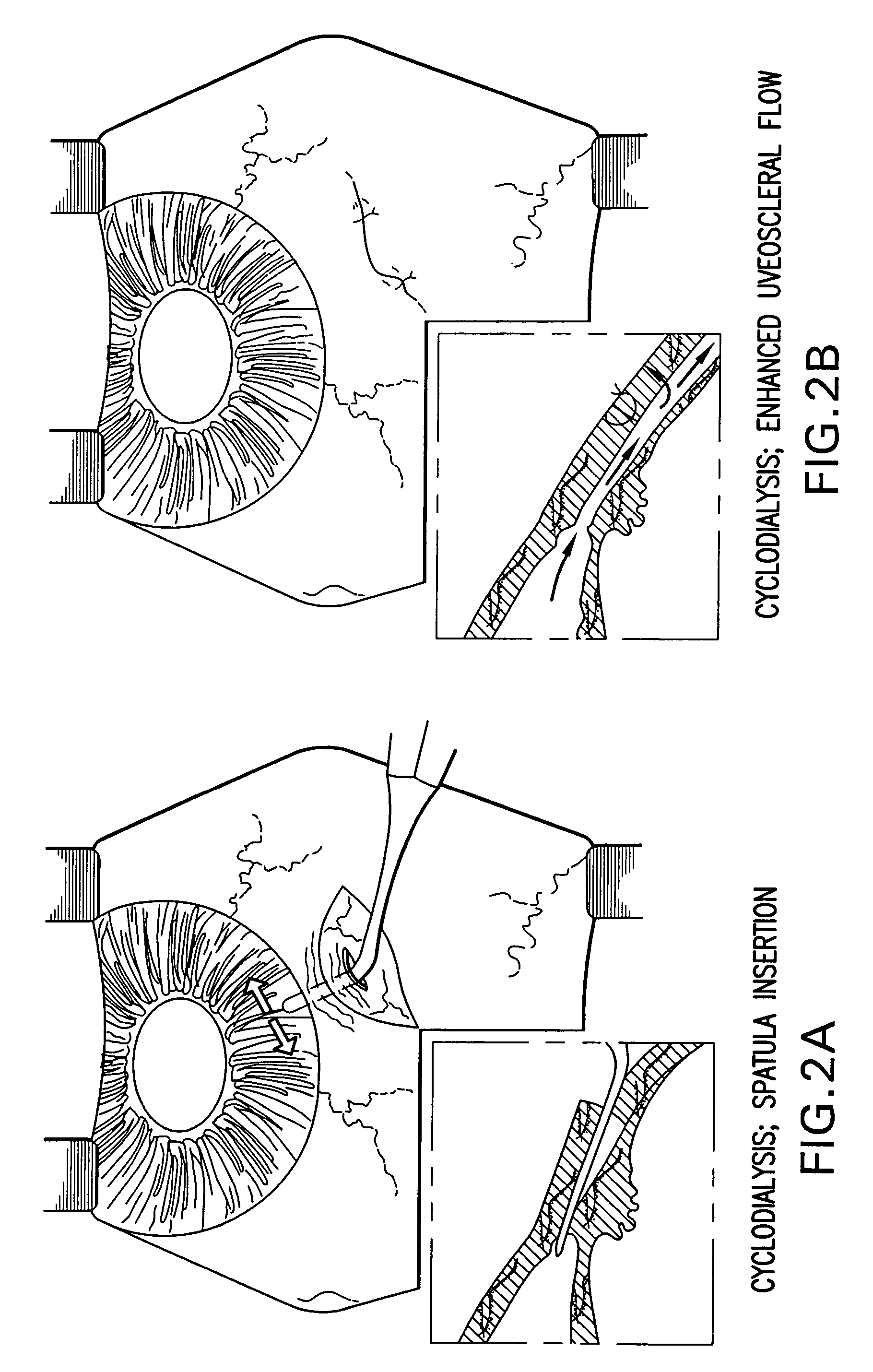

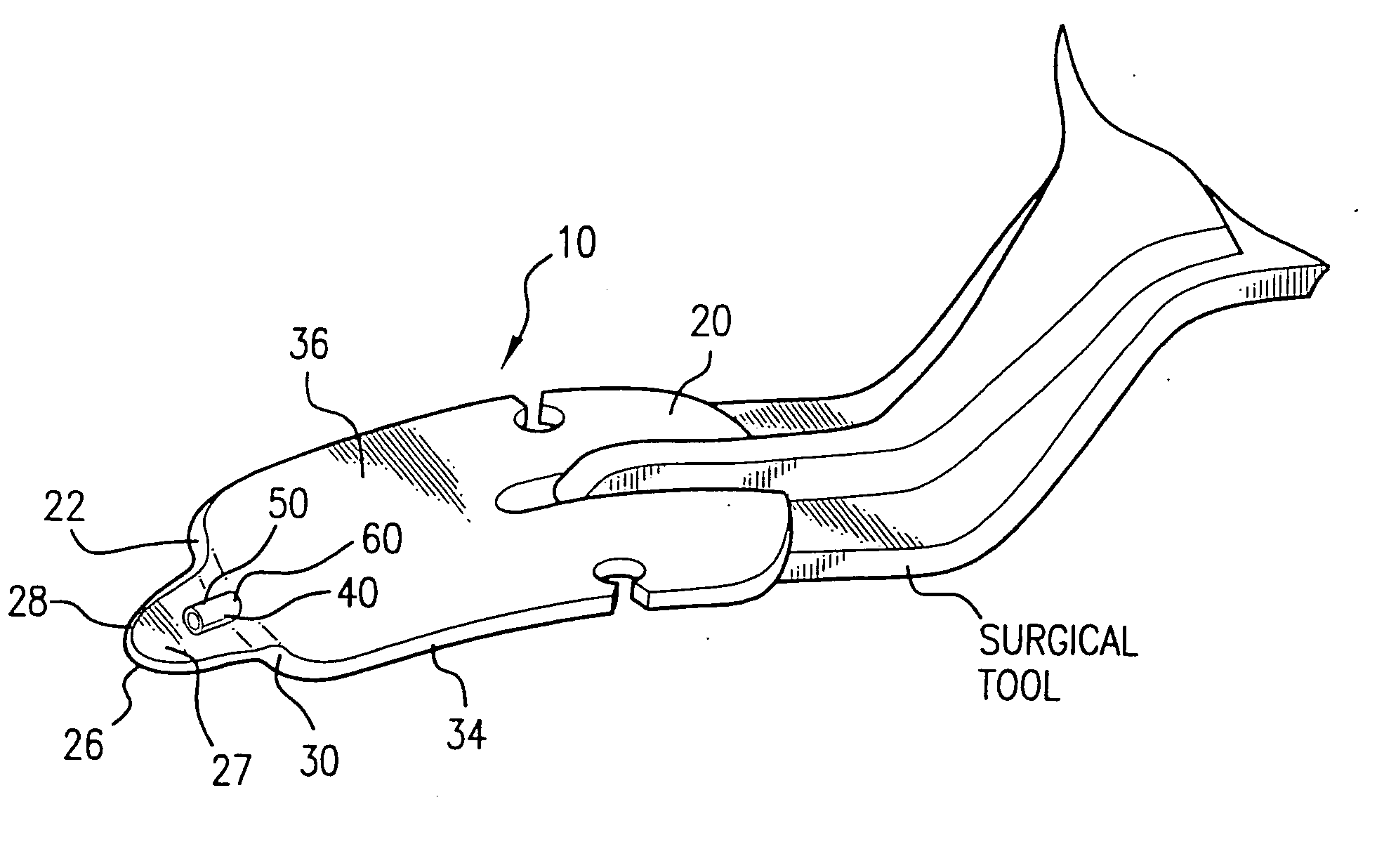

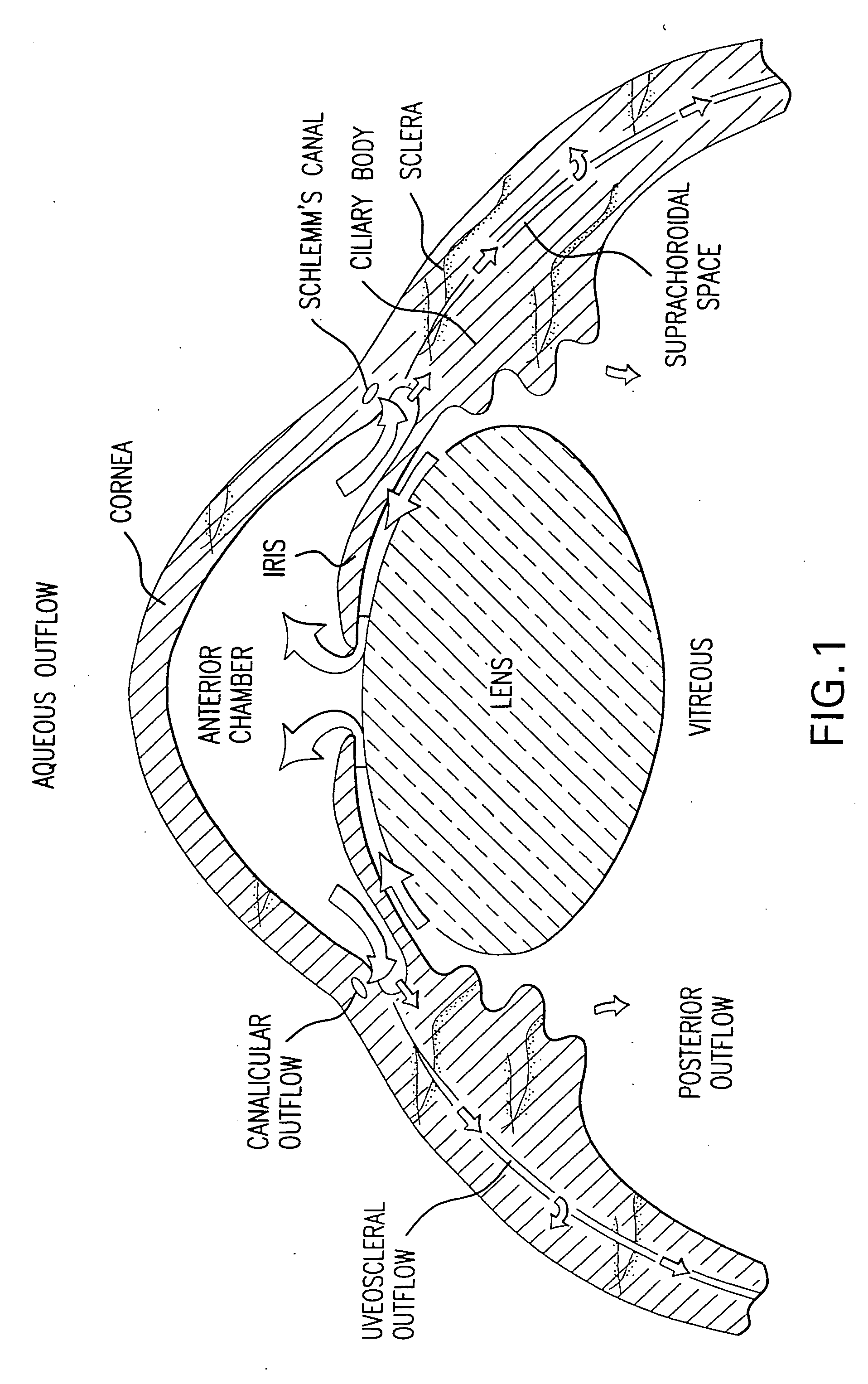

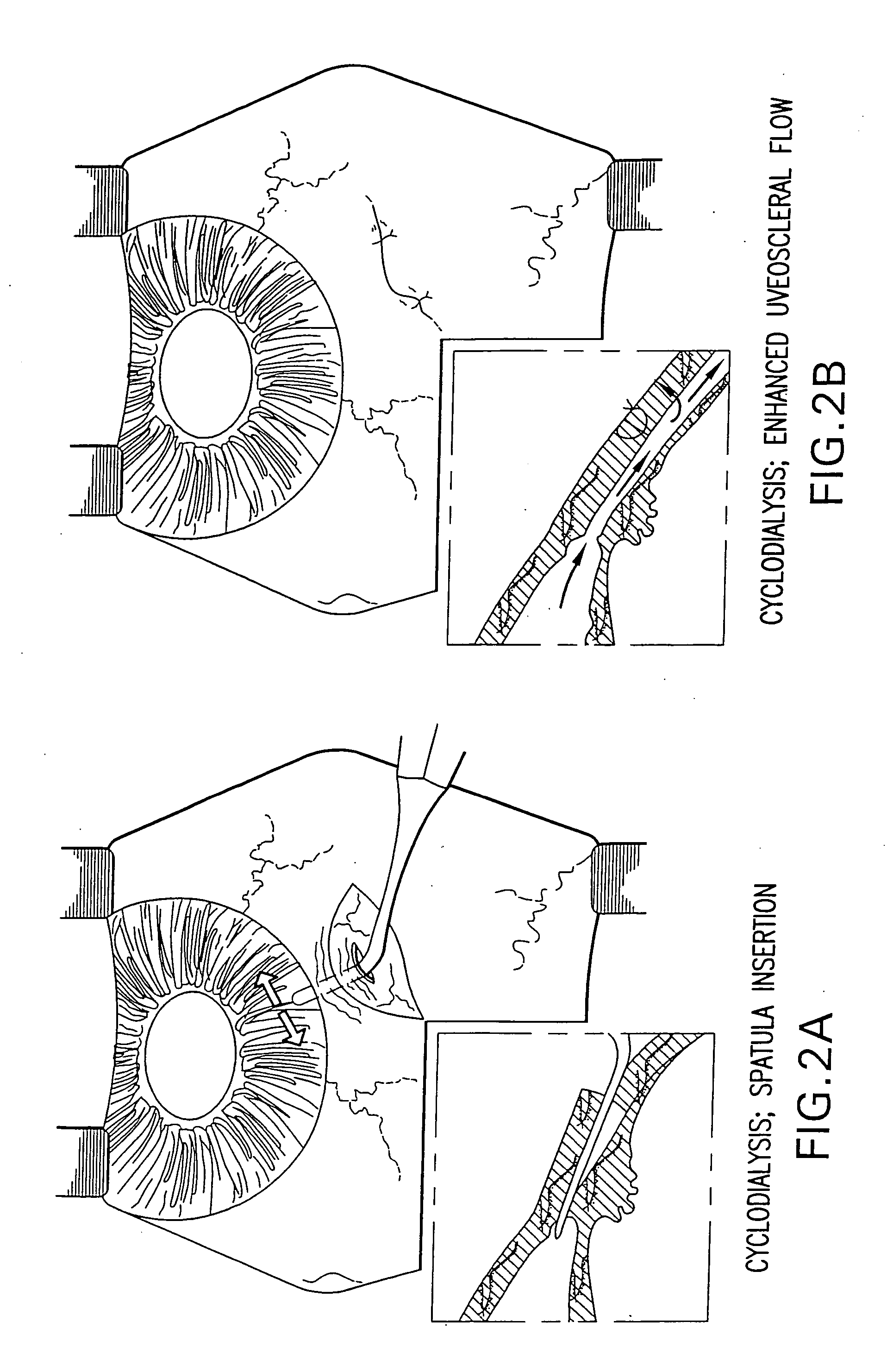

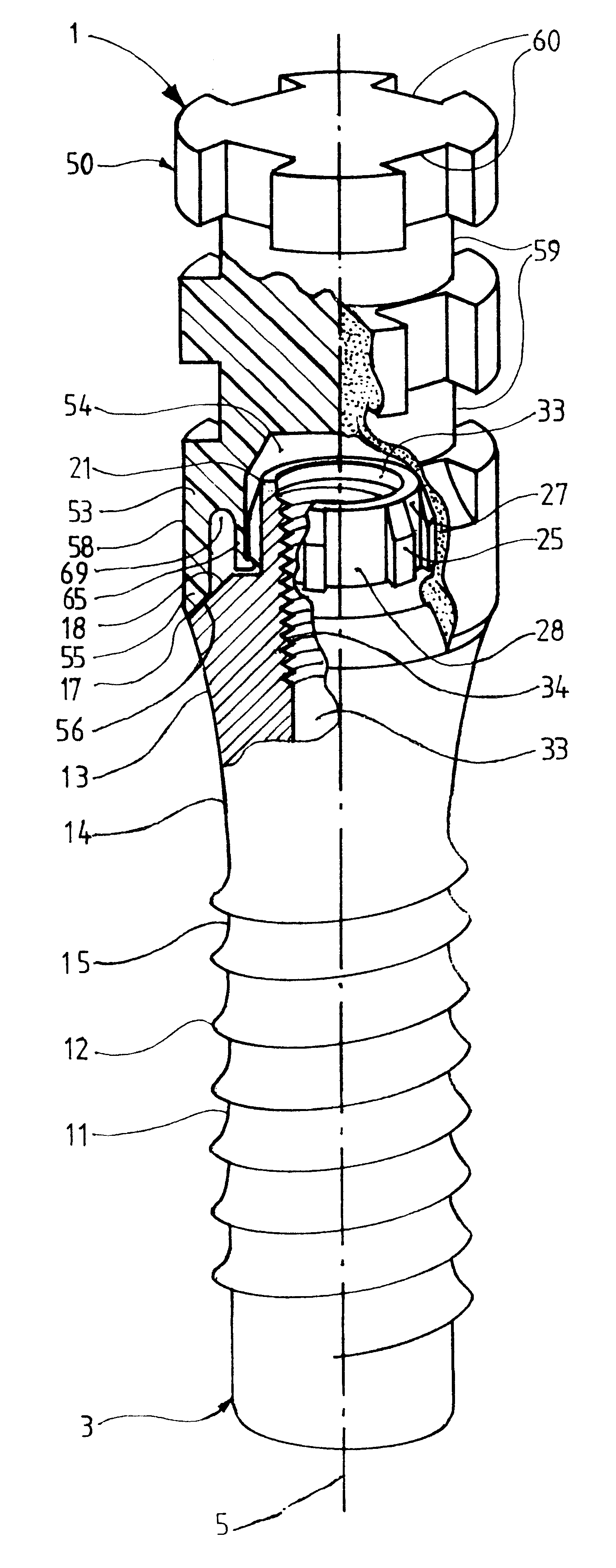

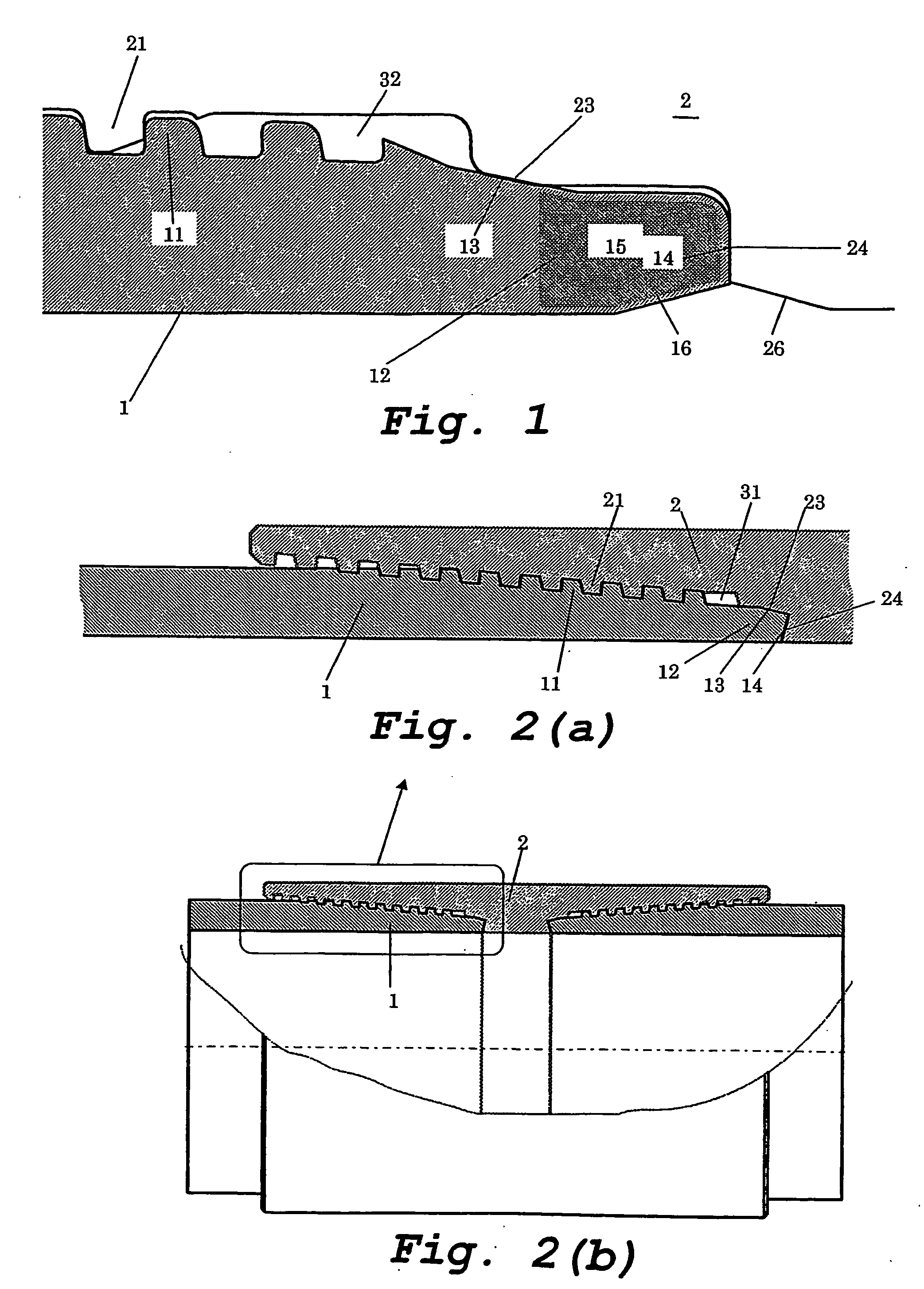

An ophthalmic shunt implantable in an eye having an elongate body and a conduit for conducting aqueous humor from an anterior chamber of the eye to the suprachoroidal space of the eye. The elongate body has a forward end and an insertion head that extends from the forward end. The insertion head defines a shearing edge suitable for cutting eye tissue engage thereby. The forward end and the insertion head of the body define a shoulder surface. The conduit has a first end defined on a portion of a top surface of the insertion head. The conduit also extends through the body from the forward end to a back end thereof. The first end of the conduit is spaced from the shearing edge and, in one example, from the shoulder of the body.

Owner:YALE UNIV

Uveoscleral drainage device

InactiveUS20060155238A1Easy to implantLower eye pressureEye surgeryIntravenous devicesAqueous humorCatheter

An ophthalmic shunt implantable in an eye having an elongate body and a conduit for conducting aqueous humor from an anterior chamber of the eye to the suprachoroidal space of the eye. The elongate body has a forward end and an insertion head that extends from the forward end. The insertion head defines a shearing edge suitable for cutting eye tissue engage thereby. The forward end and the insertion head of the body define a shoulder surface. The conduit has a first end defined on a portion of a top surface of the insertion head. The conduit also extends through the body from the forward end to a back end thereof. The first end of the conduit is spaced from the shearing edge and, in one example, from the shoulder of the body.

Owner:YALE UNIV

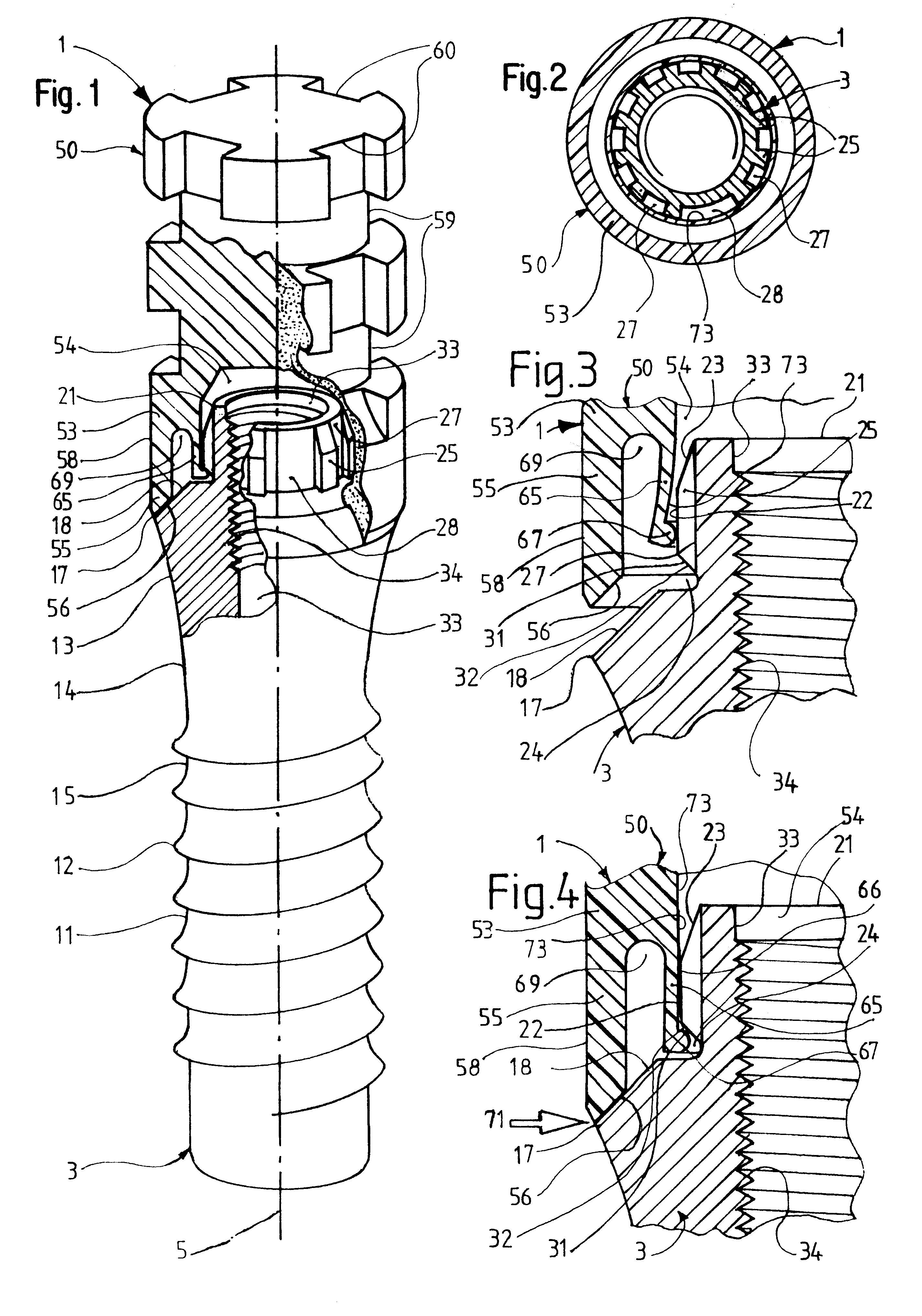

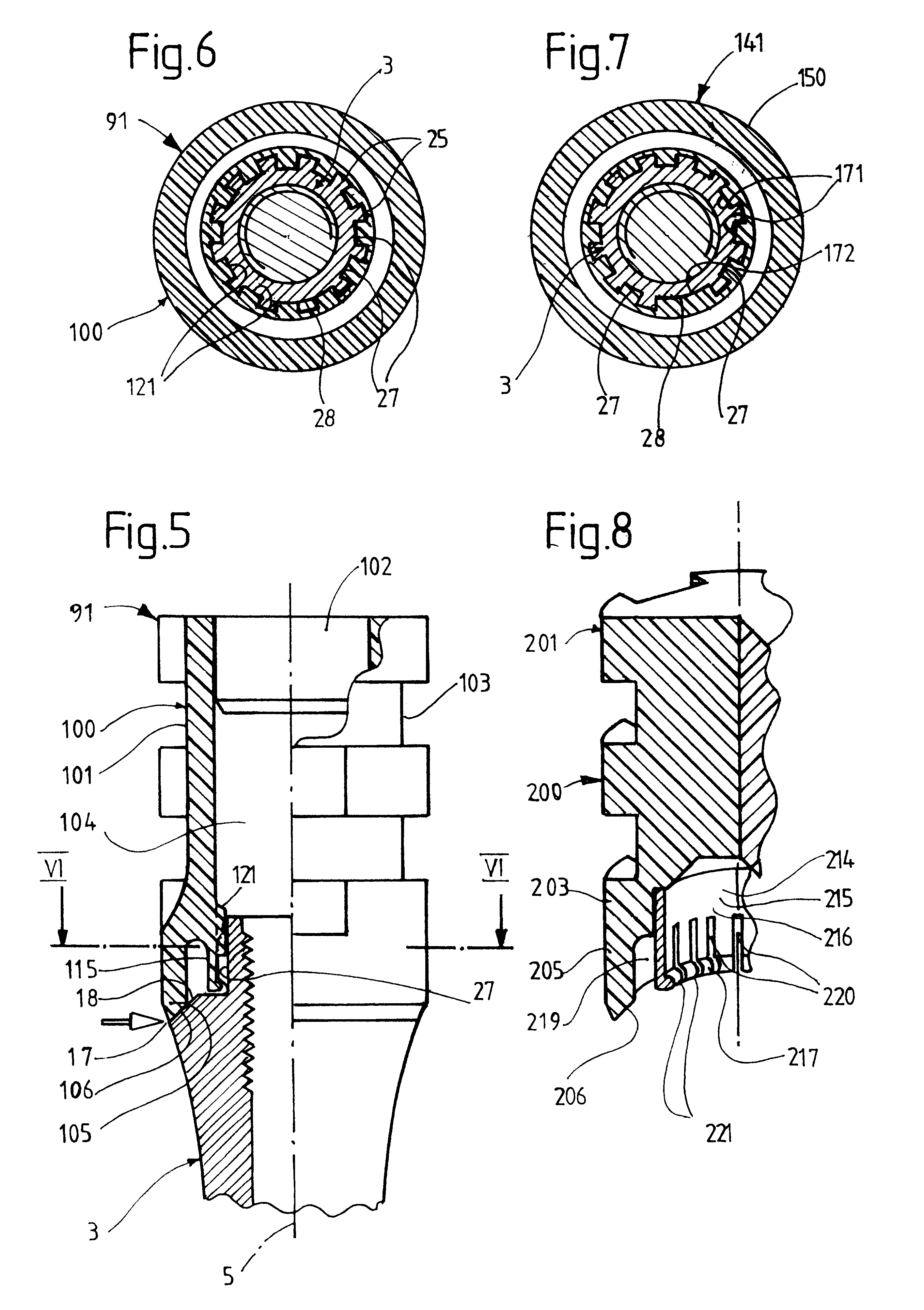

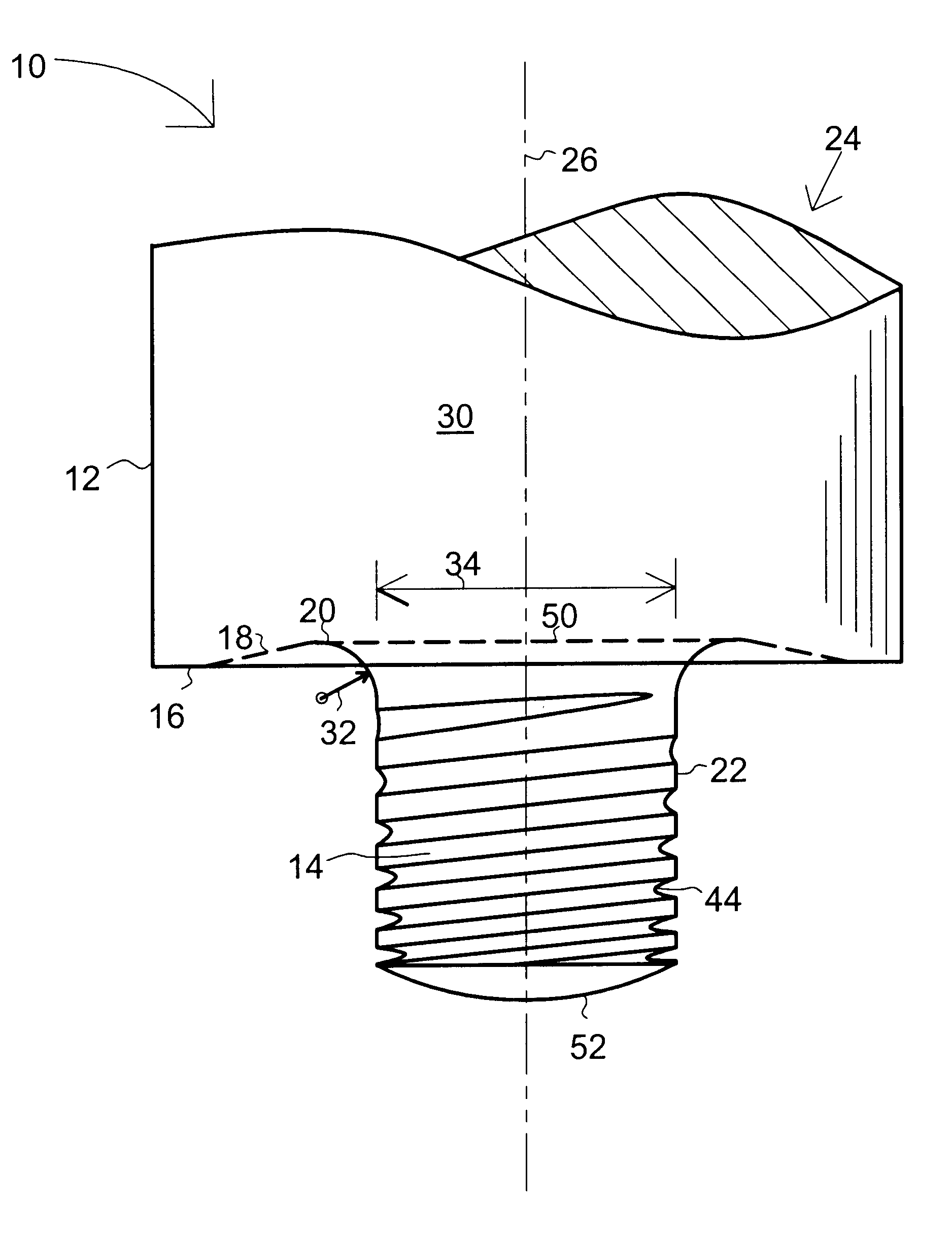

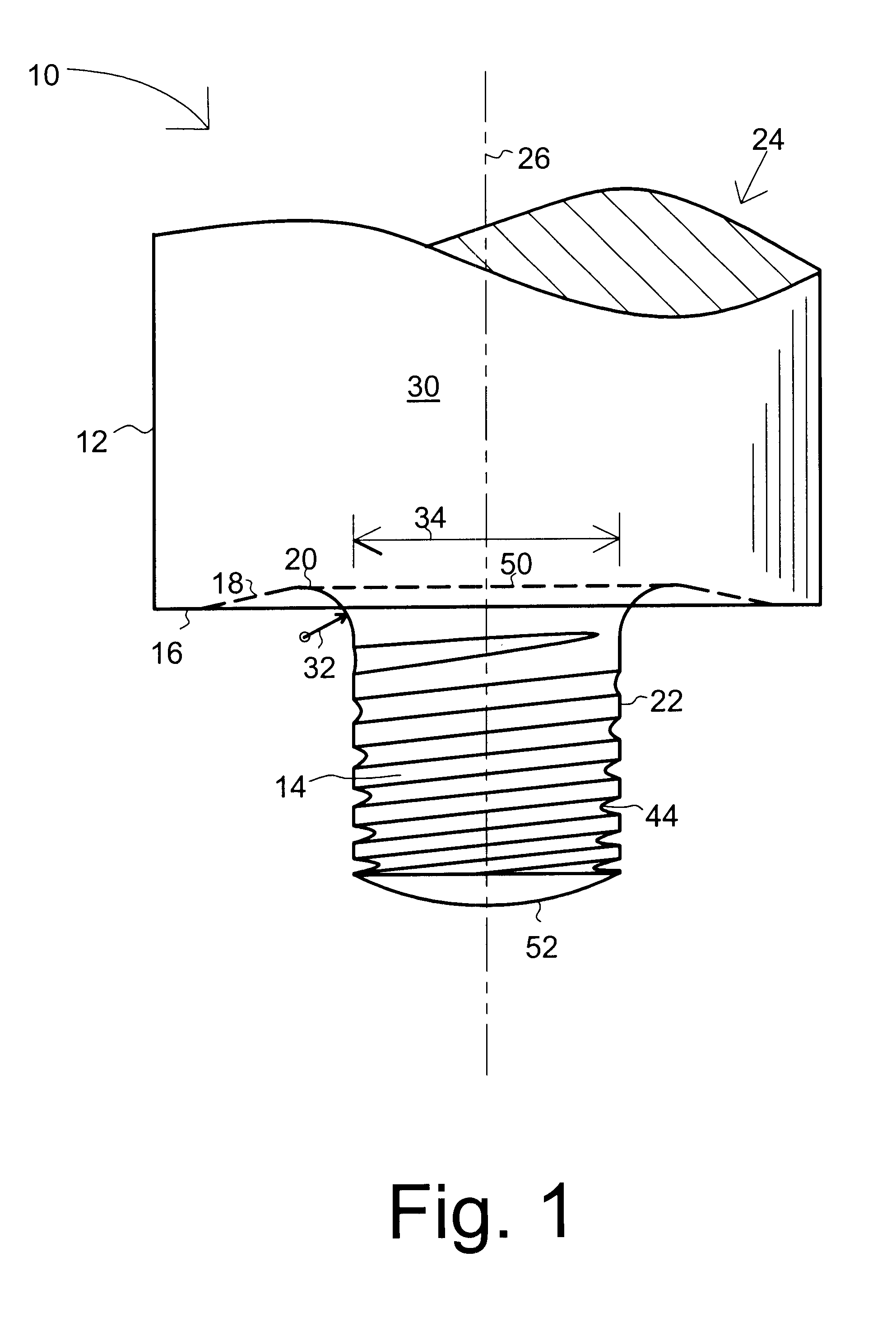

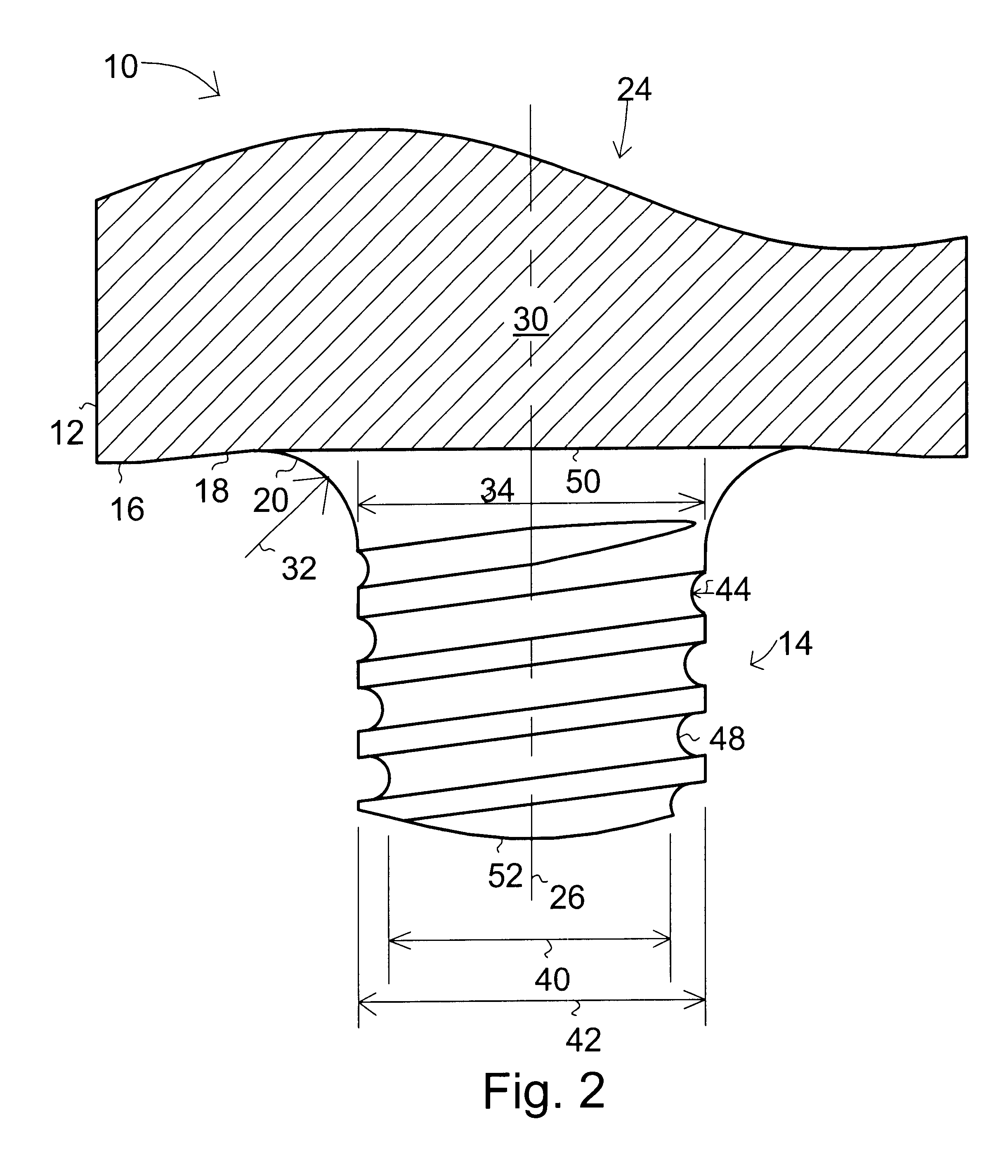

Device for forming a dental prosthesis

InactiveUS6332777B1Quick releaseOvercome the influence of errorDental implantsImpression capsEngineeringShoulder surface

A device for forming a dental prosthesis includes a support and an element which can be attached thereto, such as an impression element. The support has an anchoring part for anchoring in a bone or a master model, a shoulder with an annular shoulder surface, and a head. The impression element has an elastically deformable fixing agent. When the device is assembled, the fixing agent jams and / or latches with the support, either externally on the support, on the side of the shoulder facing the anchoring part, or in an axial hole of the support. The element can be quickly detachably connected to the support by placing it on top of the support, and can be quickly separated from the support by moving the support away. When the device is assembled, the support and the element can lay on top of each other with annular surfaces. The annular surfaces have fully circular outer edges which are visible from the outside in an approximately radial viewing direction.

Owner:STRAUMANN HLDG AG +1

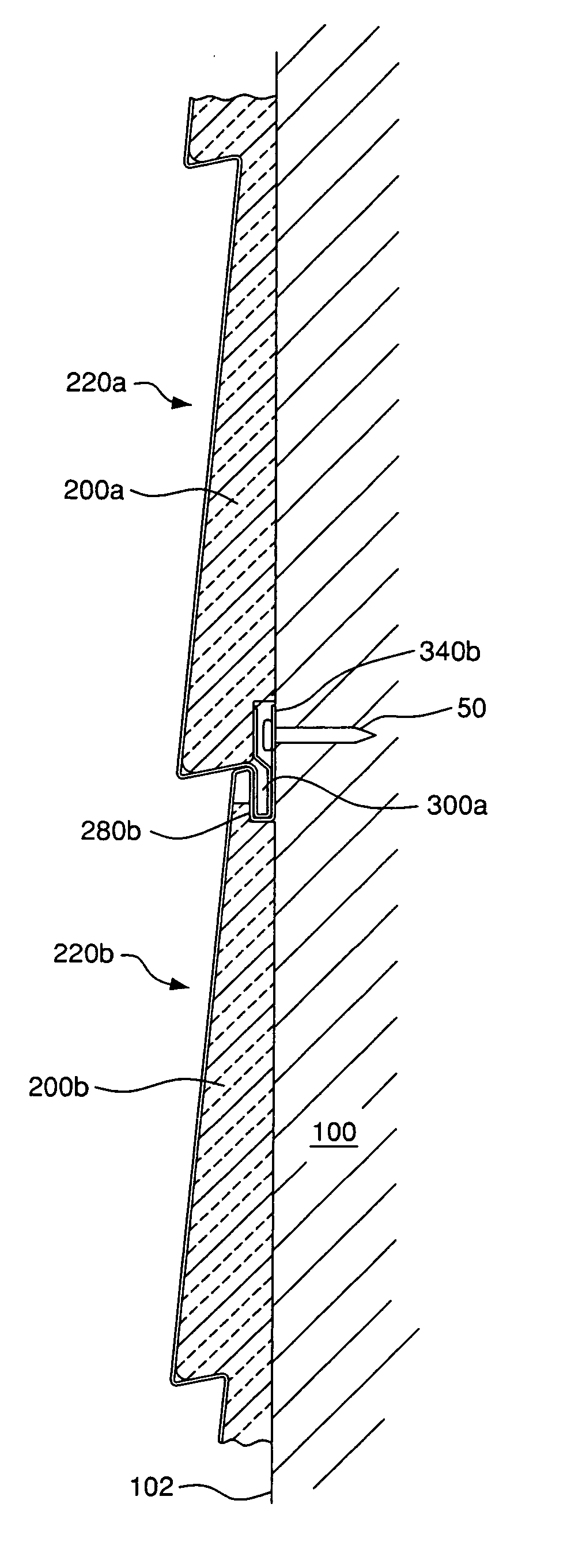

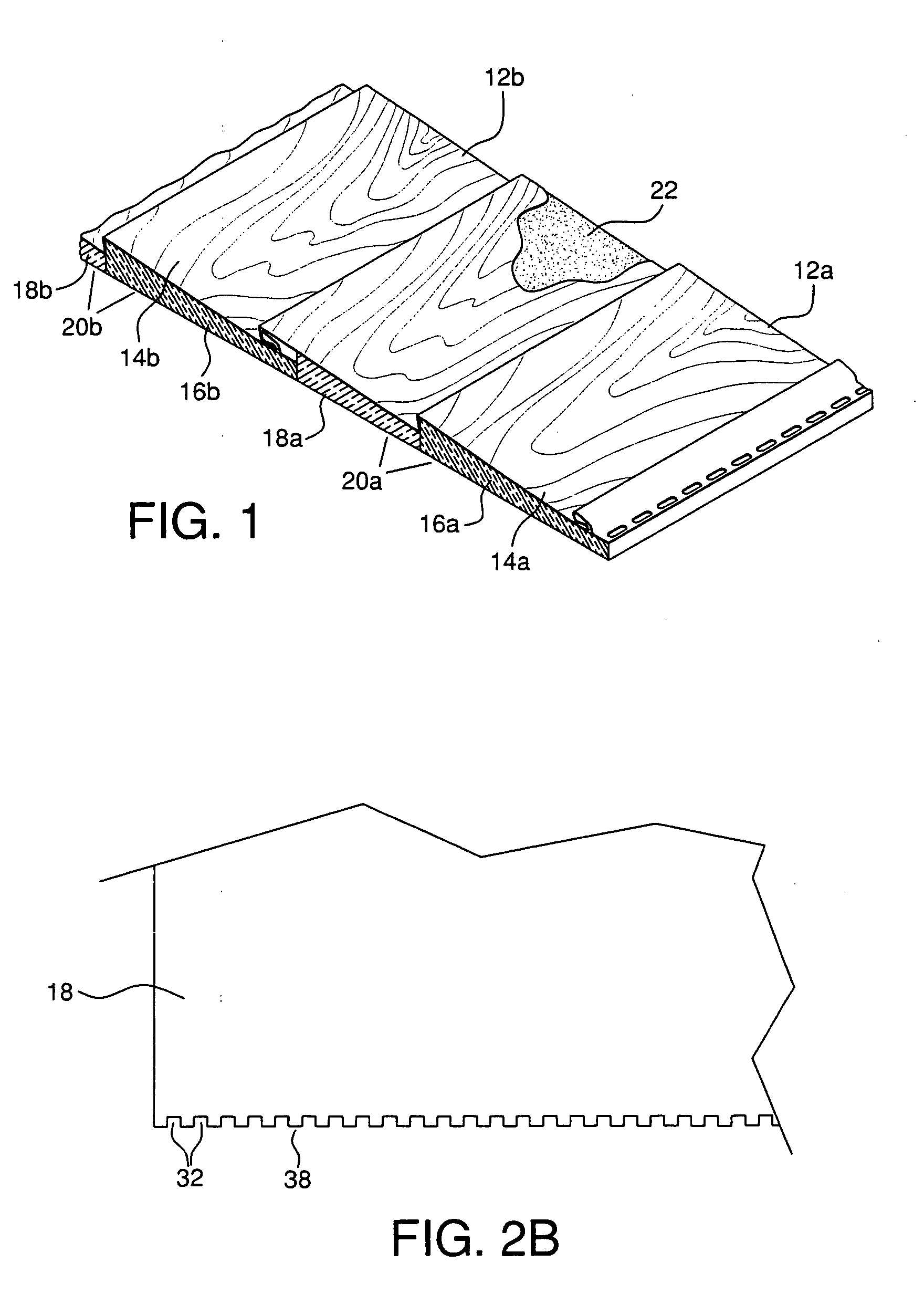

Moisture diverting insulated siding panel

InactiveUS20060075712A1Reducing thermal and acoustic insulation performanceReduce wasteRoof covering using tiles/slatesCovering/liningsEngineeringMoisture

A siding panel product is provided comprising a first polymeric siding panel having a butt end and a top end, a front surface comprising a plurality of front faces defined between the top and butt ends and separated by at least one shoulder surface to define a stepped contour, and a rear surface. An insulation backing is coupled to the rear surface of the siding panel. The insulation backing comprises at least first and second insulation members coupled to the rear surface of said siding panel. The first insulation member has a bottom edge thereof coupled proximate to the stepped contour and the second insulation member has a top edge thereof coupled proximate to the stepped contour.

Owner:CERTAINTEED CORP

Tool for friction stir welding

InactiveUS6676004B1Low costImprove joint efficiencyWelding/cutting auxillary devicesAuxillary welding devicesUltimate tensile strengthScrew thread

A friction stir welding tool for welding high-strength materials with one or more of the following features: 1) a curved transition geometry structure at the shoulder face and probe interface; 2) a tool material selected on the basis of an ultimate tensile strength determined at or above the temperature of the tool processing temperature; 3) a compressive stress at the point of crack fatigue introduced by mechanical or chemical means; and 4) a threaded probe with a) a major to minor thread diameter ratio that increases toward the distal end of the probe and / or b) with a curved thread root.

Owner:EDISON WELDING INSTITUTE INC

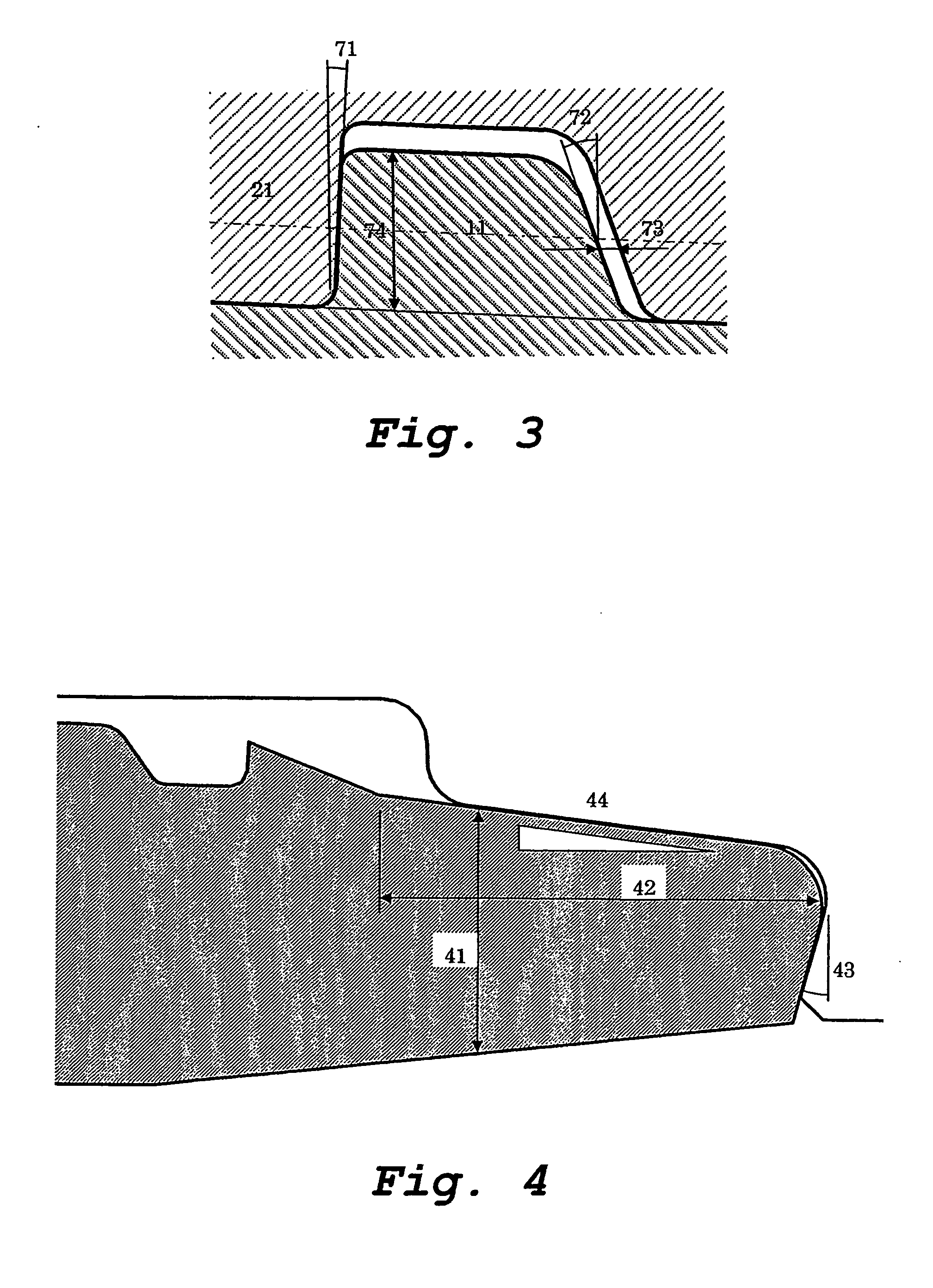

Multi-piece polymer ammunition cartridge

The present invention provides polymeric ammunition cartridge having a generally cylindrical neck having a projectile aperture at a first end, an outer shoulder surface that extends from the generally cylindrical neck, an outer shoulder angle defined by the outer shoulder surface, an inner shoulder surface on the inside of the polymer nose opposite the outer shoulder surface, an inner shoulder angle defined by the outer shoulder surface, a skirt surface extending from the inner shoulder surface, a skirt angle defined by the skirt surface, and a nose junction that extends from the outer shoulder surface to the skirt surface, wherein the nose junction is adapted to mate to a polymer cartridge.

Owner:TRUE VELOCITY IP HLDG LLC

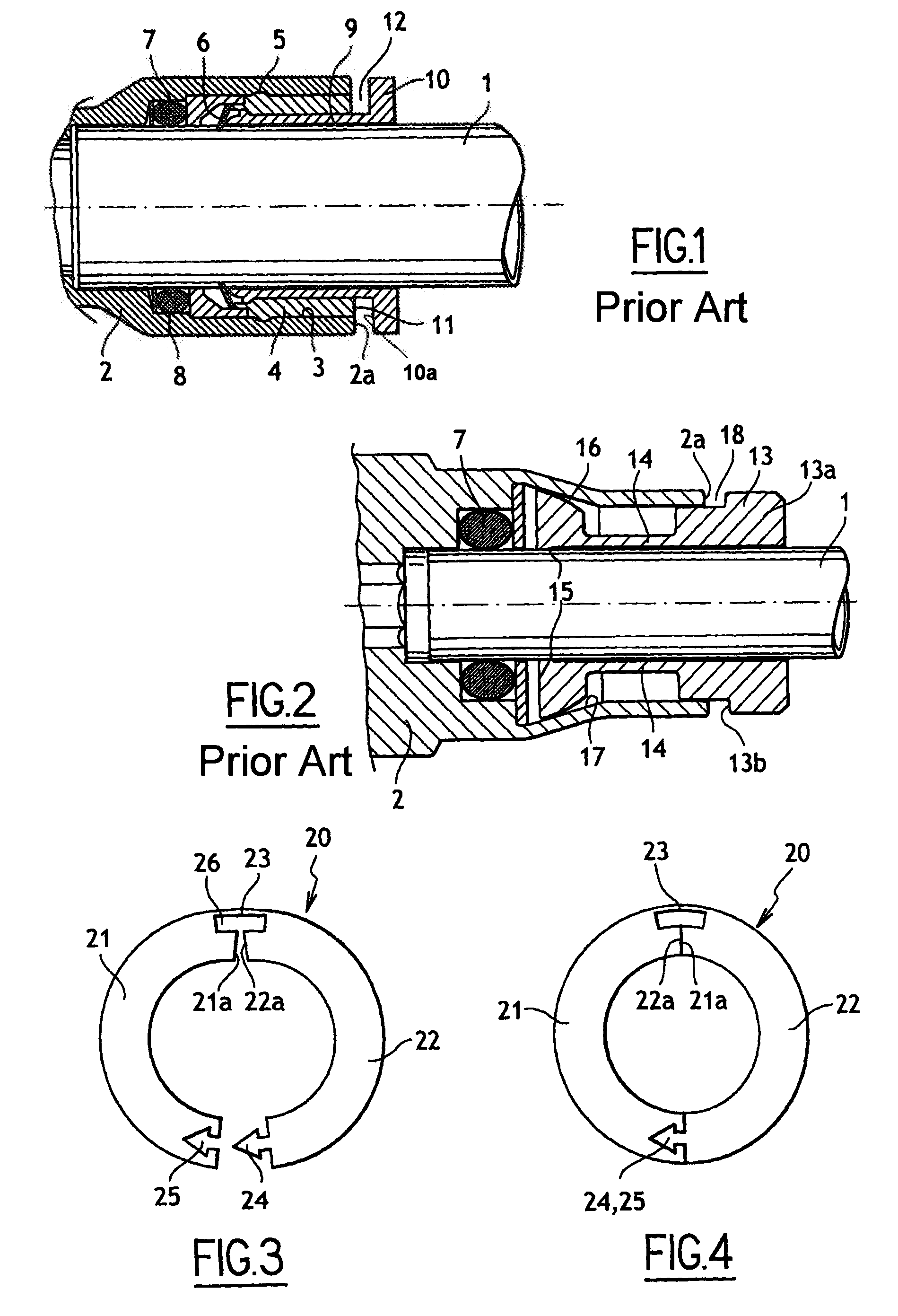

Device for fast connection of a tube to a rigid element with anti-extraction ring and safety seal

InactiveUS6145887AImprove securitySleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

Owner:LEGRIS

Multi-Piece Polymer Ammunition Cartridge

The present invention provides polymeric ammunition cartridge having a generally cylindrical neck having a projectile aperture at a first end, an outer shoulder surface that extends from the generally cylindrical neck, an outer shoulder angle defined by the outer shoulder surface, an inner shoulder surface on the inside of the polymer nose opposite the outer shoulder surface, an inner shoulder angle defined by the outer shoulder surface, a skirt surface extending from the inner shoulder surface, a skirt angle defined by the skirt surface and a nose junction that extends from the outer shoulder surface to the skirt surface, wherein the nose junction is adapted to mate to a polymer cartridge.

Owner:TRUE VELOCITY IP HLDG LLC

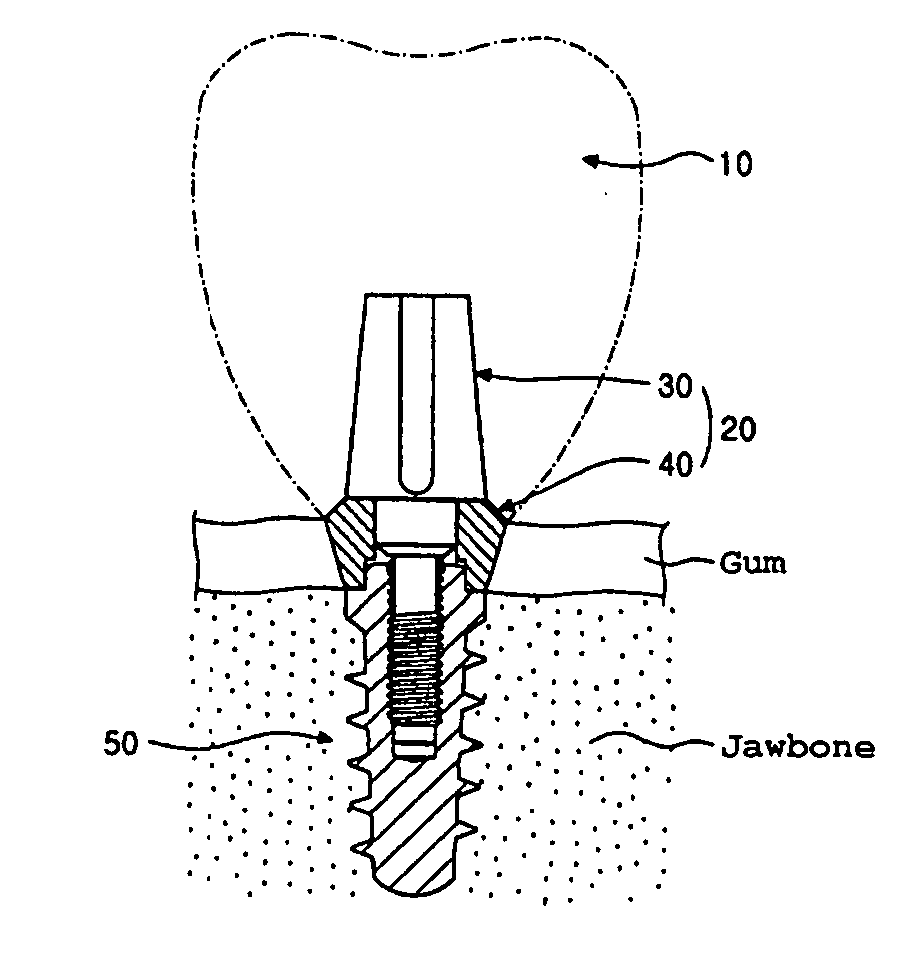

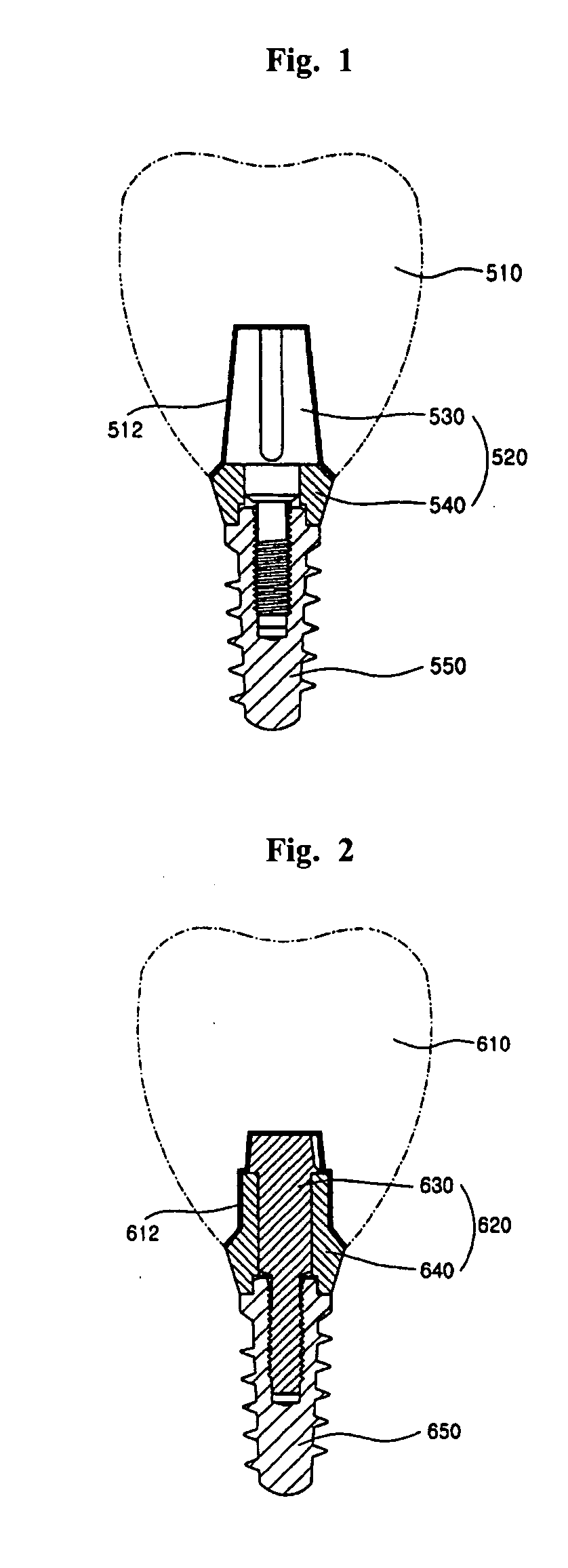

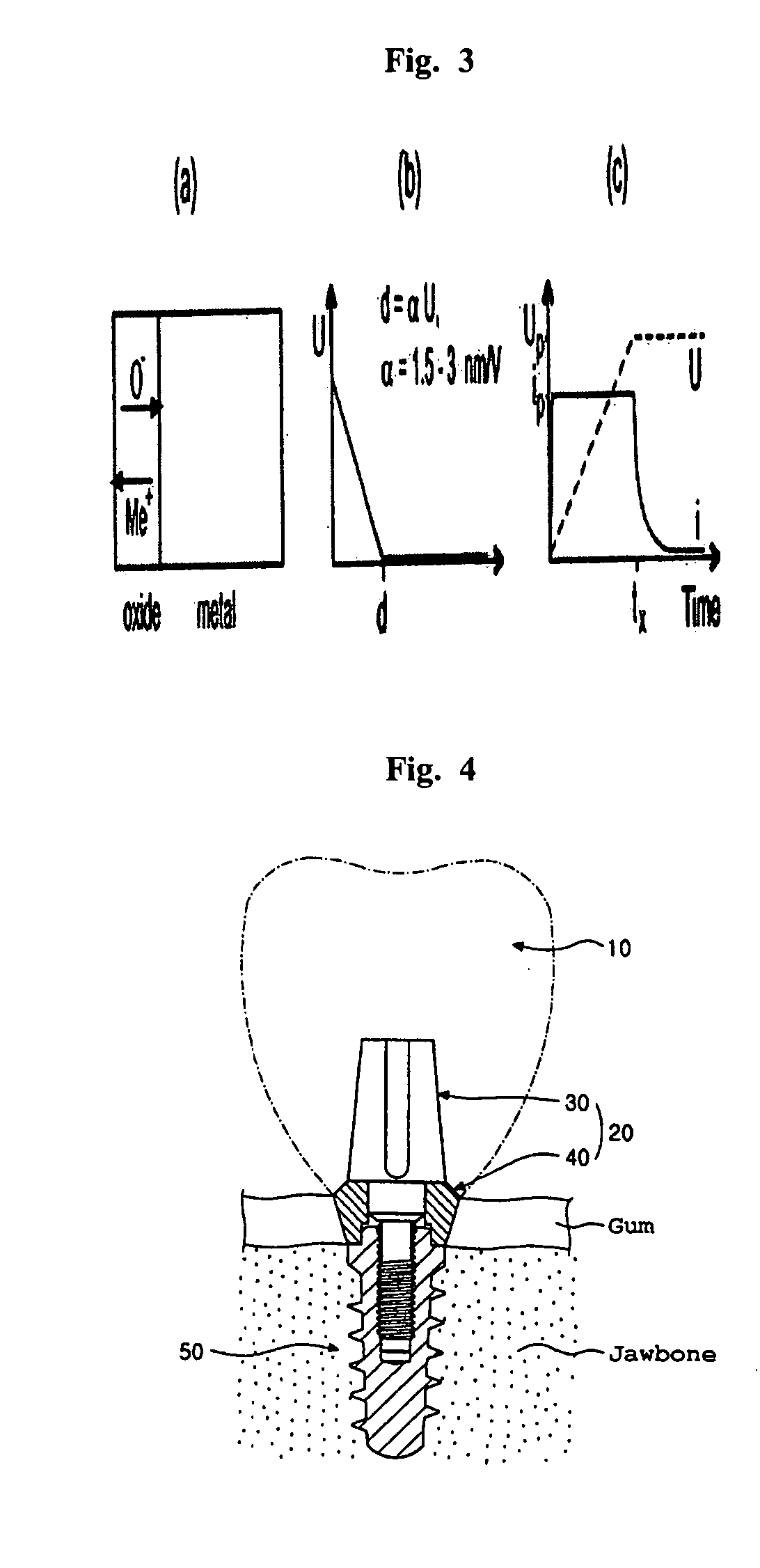

Abutment of dental implant and aesthetic surface treatment method of the same

InactiveUS20050181330A1Improve adaptabilityGood bio-compatibility with human bodyDental implantsSwitch operated by excess voltageTooth Supporting StructuresTitanium alloy

The present invention discloses an abutment of a dental implant consisting of an abutment screw and a shoulder surface. The upper structure of a crown or bridge abutment, i.e., the abutment screw is made of titanium alloy, and surface-treated in brown color by an anodizing process, and the connecting structure thereof, i.e., the shoulder surface is made of ceramic material containing zirconia of a white color, thereby providing an adequate mechanical strength, while maintaining the natural color of human teeth and light permeability. Further, the present invention discloses a method of aesthetically surface-treating the abutment screw of a dental implant abutment by using the anodizing process, and a method of fabricating the shoulder surface of a dental implant abutment.

Owner:COWELL MEDI CO LTD

Multi-Piece Polymer Ammunition Cartridge

The present invention provides polymeric ammunition having a generally cylindrical neck having a projectile aperture at a first end, an outer shoulder surface that extends from the generally cylindrical neck, an outer shoulder angle defined by the outer shoulder surface, an inner shoulder surface on the inside of the polymer nose opposite the outer shoulder surface, an inner shoulder angle defined by the outer shoulder surface, a skirt surface extending from the inner shoulder surface, a skirt angle defined by the skirt surface, and a nose junction that extends from the outer shoulder surface to the skirt surface, wherein the nose junction is adapted to mate to a polymer cartridge.

Owner:TRUE VELOCITY IP HLDG LLC

Multi-Piece Polymer Ammunition Cartridge Nose

The present invention provides a polymer nose for a polymeric ammunition cartridge having a generally cylindrical neck having a projectile aperture at a first end, an outer shoulder surface that extends from the generally cylindrical neck, an outer shoulder angle defined by the outer shoulder surface, an inner shoulder surface on the inside of the polymer nose opposite the outer shoulder surface, an inner shoulder angle defined by the outer shoulder surface, a skirt surface extending from the inner shoulder surface, a skirt angle defined by the skirt surface and a nose junction that extends from the outer shoulder surface to the skirt surface, wherein the nose junction is adapted to mate to a polymer cartridge.

Owner:TRUE VELOCITY IP HLDG LLC

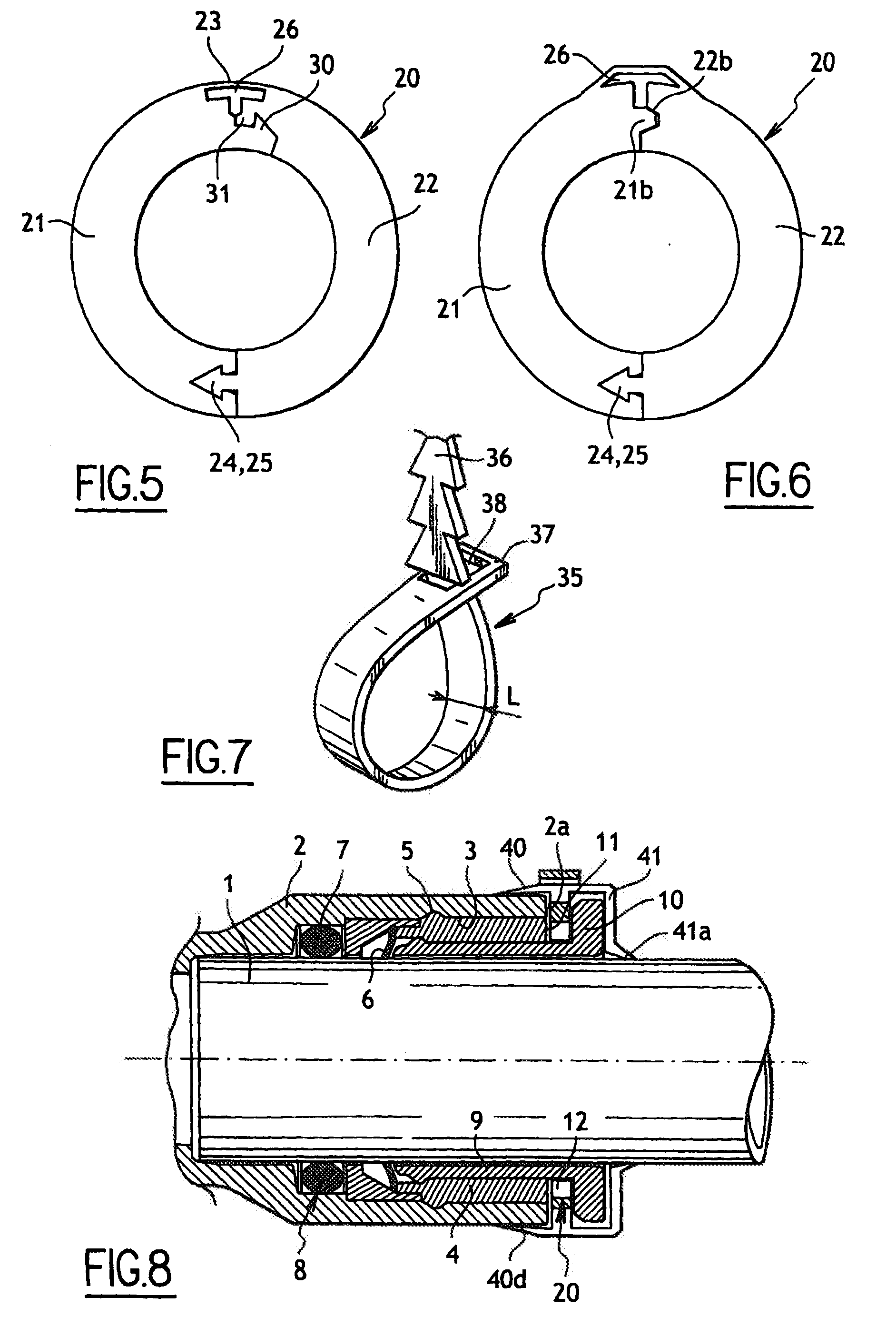

Tool for chip removing machining, and a basic body and a lock member therefor

A tool for chip removing machining, including a basic body and a replaceable cutting insert that has a center axis and is detachably mounted in an insert seat formed in the basic body. The seat is delimited by a bottom surface and at least one side support surface. The cutting insert includes an out of round engagement surface that is pressed against an out of round shoulder surface to rotationally secure the cutting insert. The shoulder surface is included in a separate lock member that is partially inserted in a space formed in the basic body, the space opening towards the insert seat and located between the side support surface and the bottom surface of the insert seat such that the lock member rotationally secures a lower part of the cutting insert, while an upper part of the cutting insert is supported by the side support surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

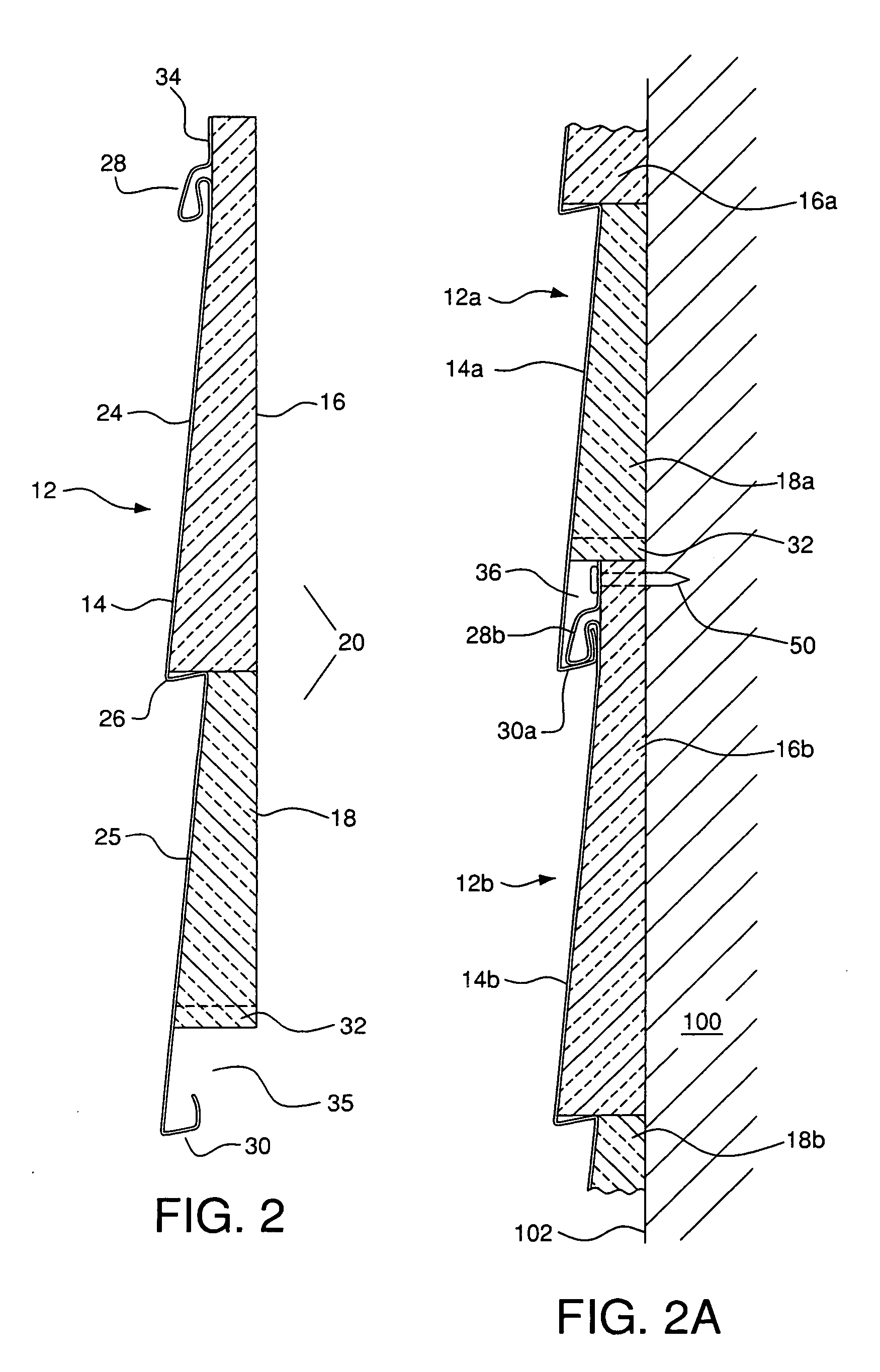

Keyed system for connection of filter cartridge to filter holder

InactiveUS6977006B2Carefully controlledIncentive to provide cheap, low quality copies will be minimizedCombination devicesDispersed particle filtrationFiltrationFilter holder

Embodiments of a key system for filters and their connecting heads / holders are shown. The filter cartridge and its holder each have a keyed surface, one being a protruding “key” and one being a recessed “lock”. Cooperation of these keyed surfaces is required in order for the filter cartridge to be installed in the holder, so that mismatched cartridges cannot be installed into the holder, for example, to prevent a particular type of cartridge from being placed in a filtration or other process where it would be inappropriate, or undesired. The keyed surfaces are selectively locate-able preferably at different circumferential locations on a perimeter of the filter and a corresponding location on a perimeter of the head / holder. The perimeter may be, for example, on an outer shoulder surface of a filter and an inner surface of a valve head, or on outer and inner surfaces of connectors that provide a liquid seal between the filter and the head / holder.

Owner:OMNIPURE FILTER CO INC

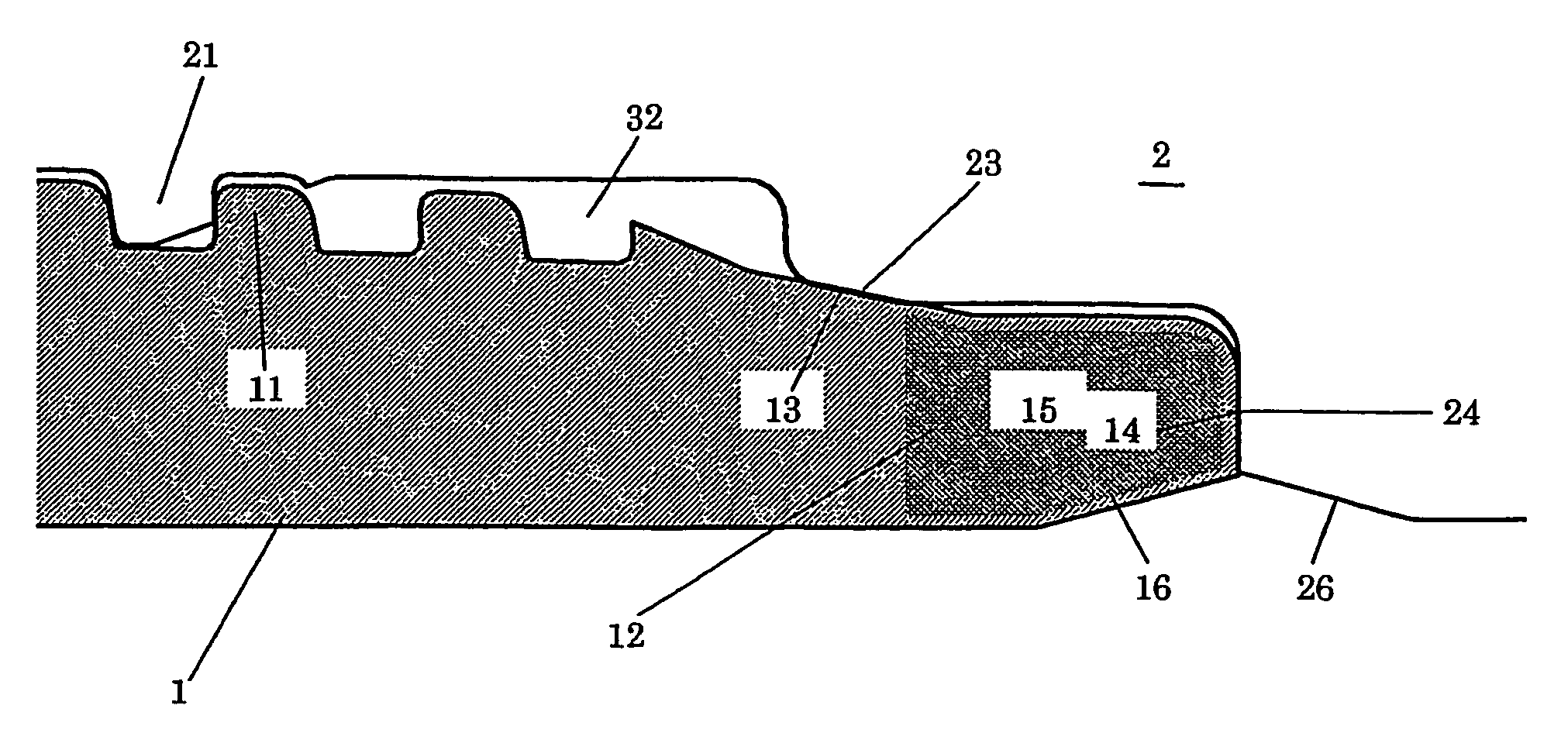

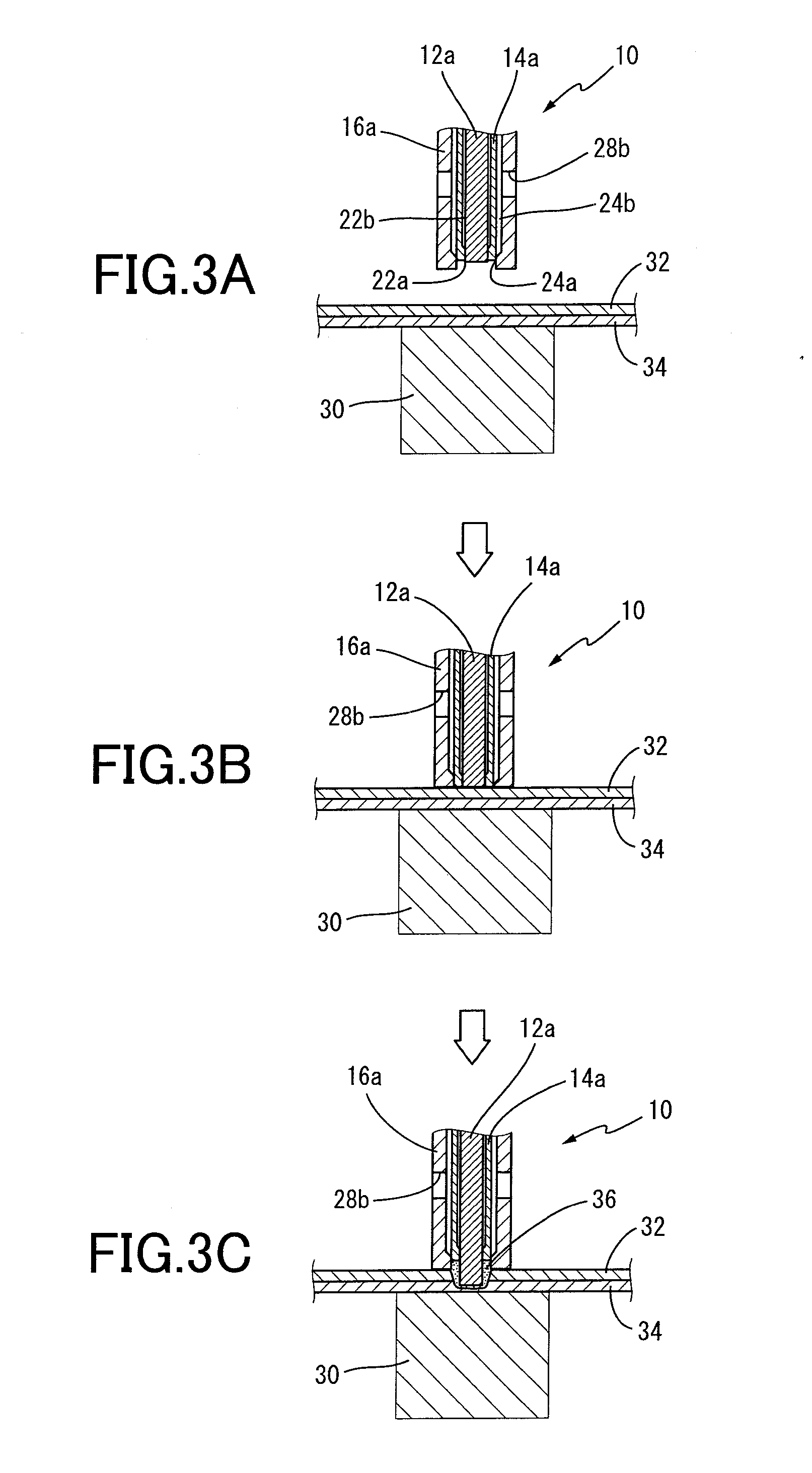

Threaded joint for steel pipes

ActiveUS20050248153A1Increase wall thicknessImprove sealingDrilling rodsHose connectionsEngineeringScrew thread

A threaded joint for steel pipes comprises a pin (1) and a box (2). The pin has male thread (11), a sealing surface (13), and a shoulder surface (14) located on the end face of the pin. Correspondingly, the box has female thread (21), a sealing surface (23), and a shoulder surface (24) which can mate or contact with the corresponding portions of the pin. The shoulder surface (14) of the pin (1) is provided at an end face of the pin. The sealing surface (13) of the pin (1) is located on a pipe end side near the male thread (11). A a nose portion (15) is provided on the pin (1) between the sealing surface (13) and the shoulder surface (14), the nose portion (15) being not in contact with a corresponding portion of the box (2).

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

Keyed system for connection of filter cartridge to filter holder

InactiveUS20060162305A1Carefully controlledIncentive to provide cheap, low quality copies will be minimizedDispersed particle filtrationMembrane filtersFiltrationEngineering

Embodiments of a key system for filters and their connecting heads, brackets, or other holders are shown. The filter cartridge and its holder each have a keyed surface, one being a protruding “key” and one being a recessed “lock”. Cooperation of these keyed surfaces is required in order for the filter cartridge to be installed in the holder, so that mis-matched cartridges cannot be installed into the holder, for example, to prevent a particular type of cartridge from being placed in a filtration or other process where it would be inappropriate, or undesired. The keyed surfaces are selectively locate-able preferably at different circumferential locations on a perimeter of the filter and a corresponding location on a perimeter of the head / holder. The perimeter may be, for example, on an outer shoulder surface of a filter and an inner surface of a valve head, or on outer and inner surfaces of connectors that provide a liquid seal between the filter and the head / holder.

Owner:OMNIPURE FILTER CO INC

Quick-connect tube fitting connection including a safety ring

A quick-coupling tube fitting for coupling a tube to a body having a bore. The fitting includes a retaining member received within the bore for retaining the tube, and a release member received within the bore to be slidably moveable to release the retaining member when pushed. The release member has a rear portion that projects outwardly from the body. The rear portion has a shoulder surface which faces a stationary surface of the body to define a groove therebetween in which a safety member is disposed to delimit the sliding of the release member. The safety member is provided in the form of an elongate member which is closable to form a ring in the groove.

Owner:LEGRIS

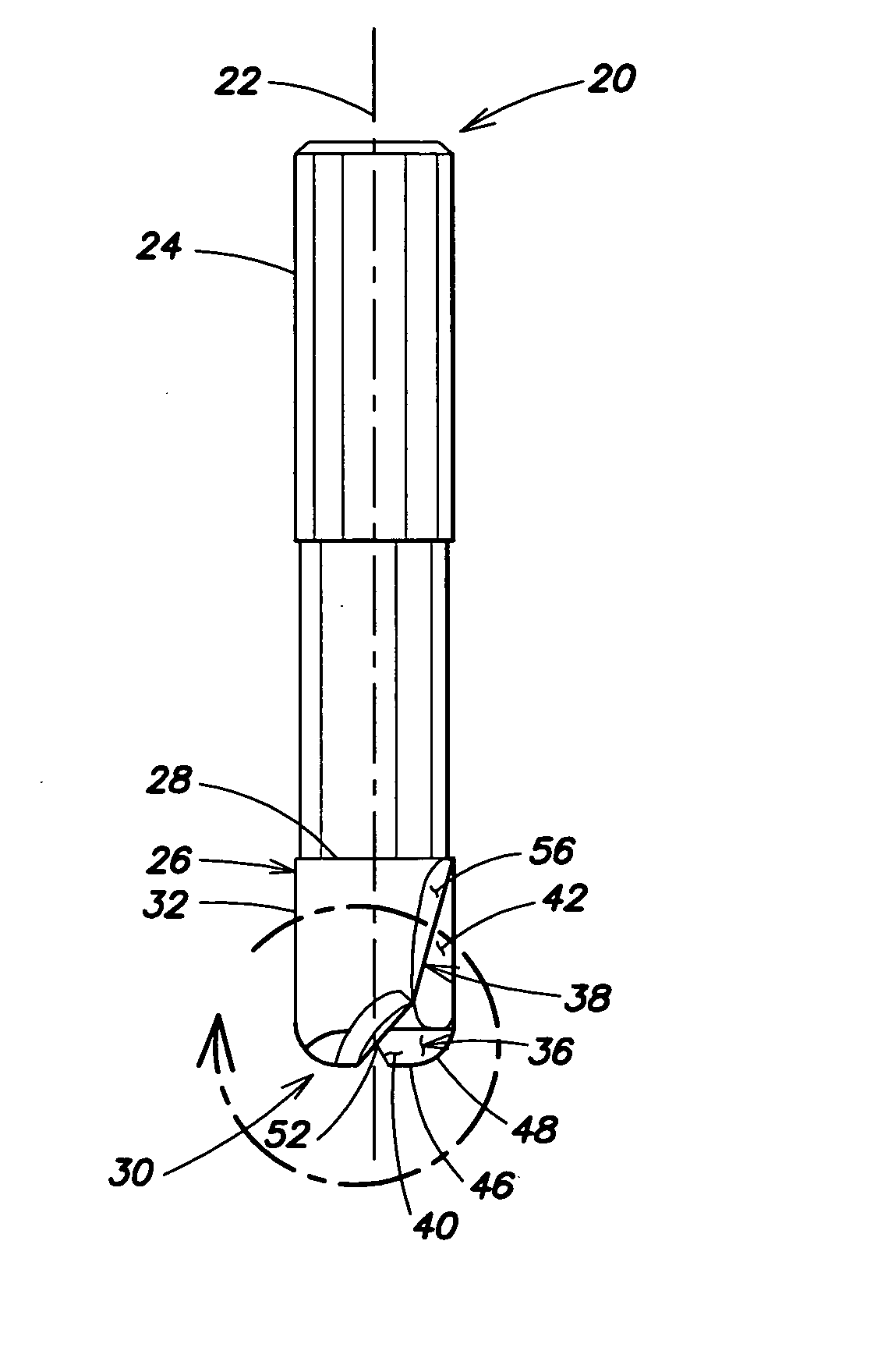

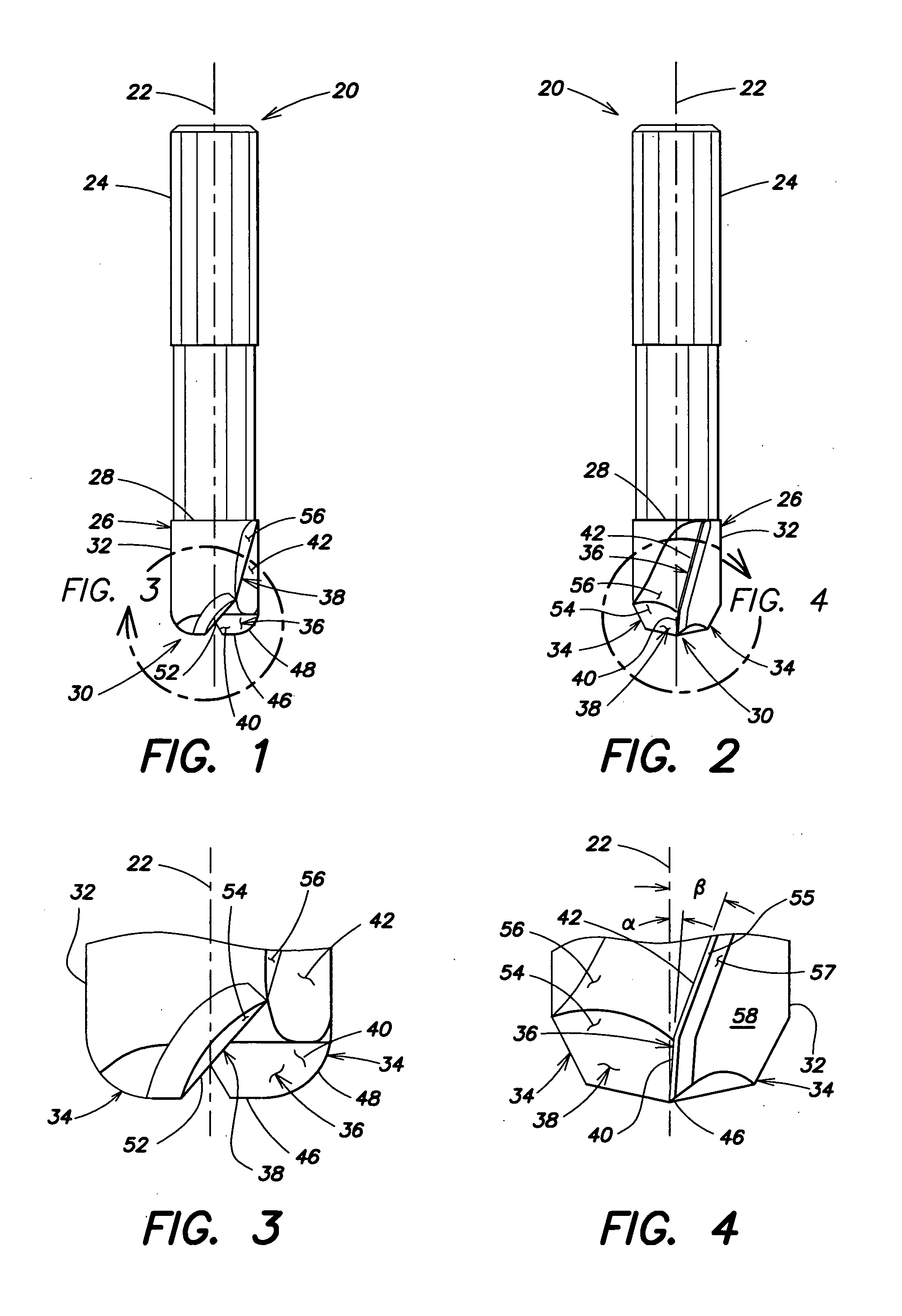

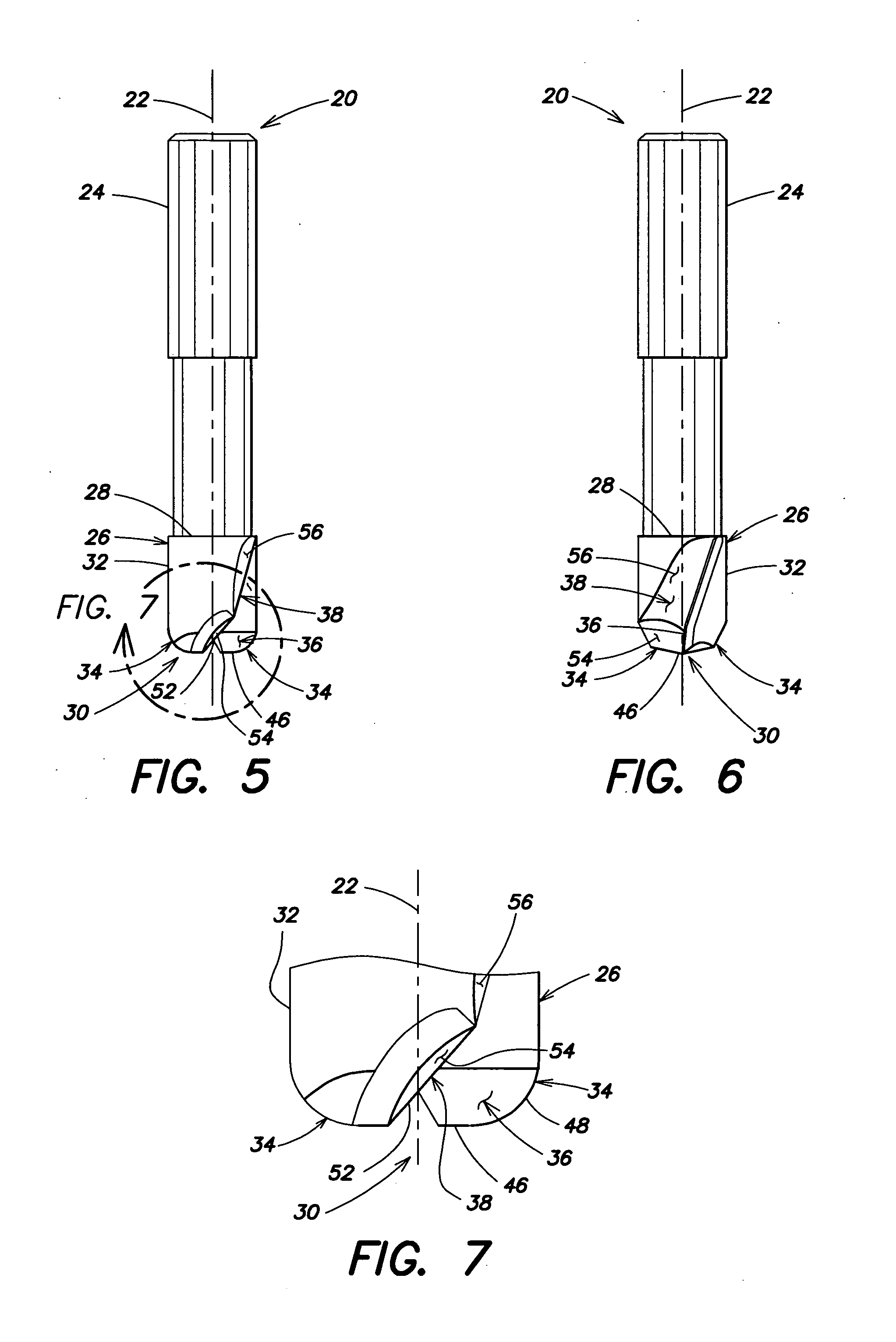

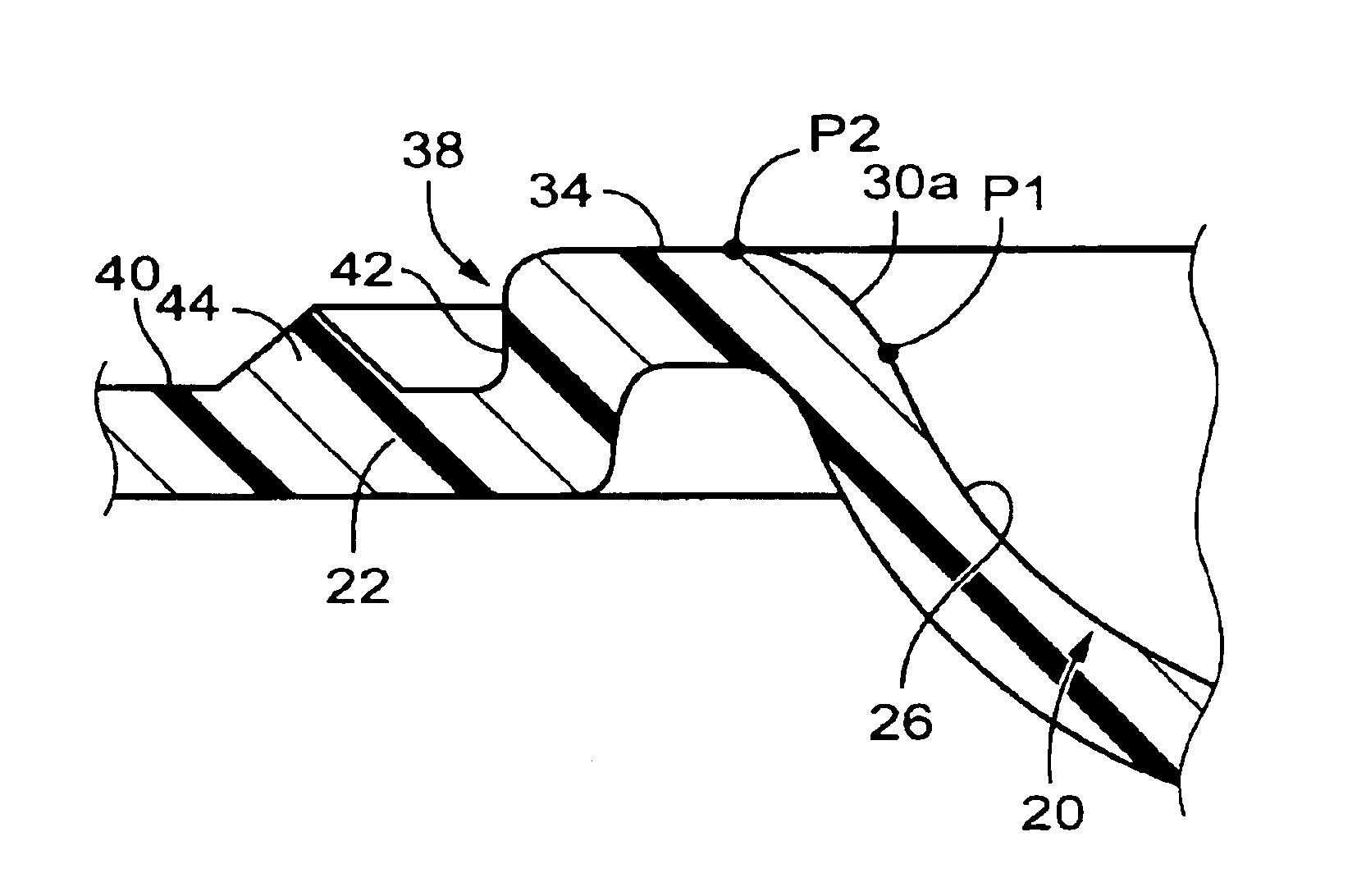

Multiple-axis cutting toroidal end mill

InactiveUS20060045639A1Increases effective machining of machineLower capability requirementsMilling cuttersShaping cuttersRotational axisMilling cutter

A one-piece toroidal end mill having an axis of rotation is provided. The end mill includes a shank section and a fluted section. The shank section extends along the axis of rotation. The fluted section extends along the axis of rotation, and has a first end, an outer surface, and a plurality of teeth. The first end is integrally attached to the shank section. Each of the plurality of teeth has a cutting surface and a shoulder surface. The cutting surface includes a cutting edge. The shoulder surfaces intersect with one another to form a center void disposed between the cutting surfaces.

Owner:BERKSHIRE PRECISION TOOL

Ophthalmic lens storage container

Disclosed is an ophthalmic lens storage container comprising: a container body including a lens storage portion having a cavity for storing a lens and a preserving solution, and a flange surrounding the cavity; and a cover sheet stripably sealed to the flange in a sealing zone that extends around the cavity to thereby fluid-tightly seal the lens storage portion. The flange of said container body includes an insulating portion located radially outward of an open-end peripheral portion of the cavity, extending circumferentially and includes a shoulder surface that extends in a first direction opposite to a second direction along which the cavity is exposed, and the sealing zone is located radially outward of the insulating portion of the flange.

Owner:MENICON CO LTD

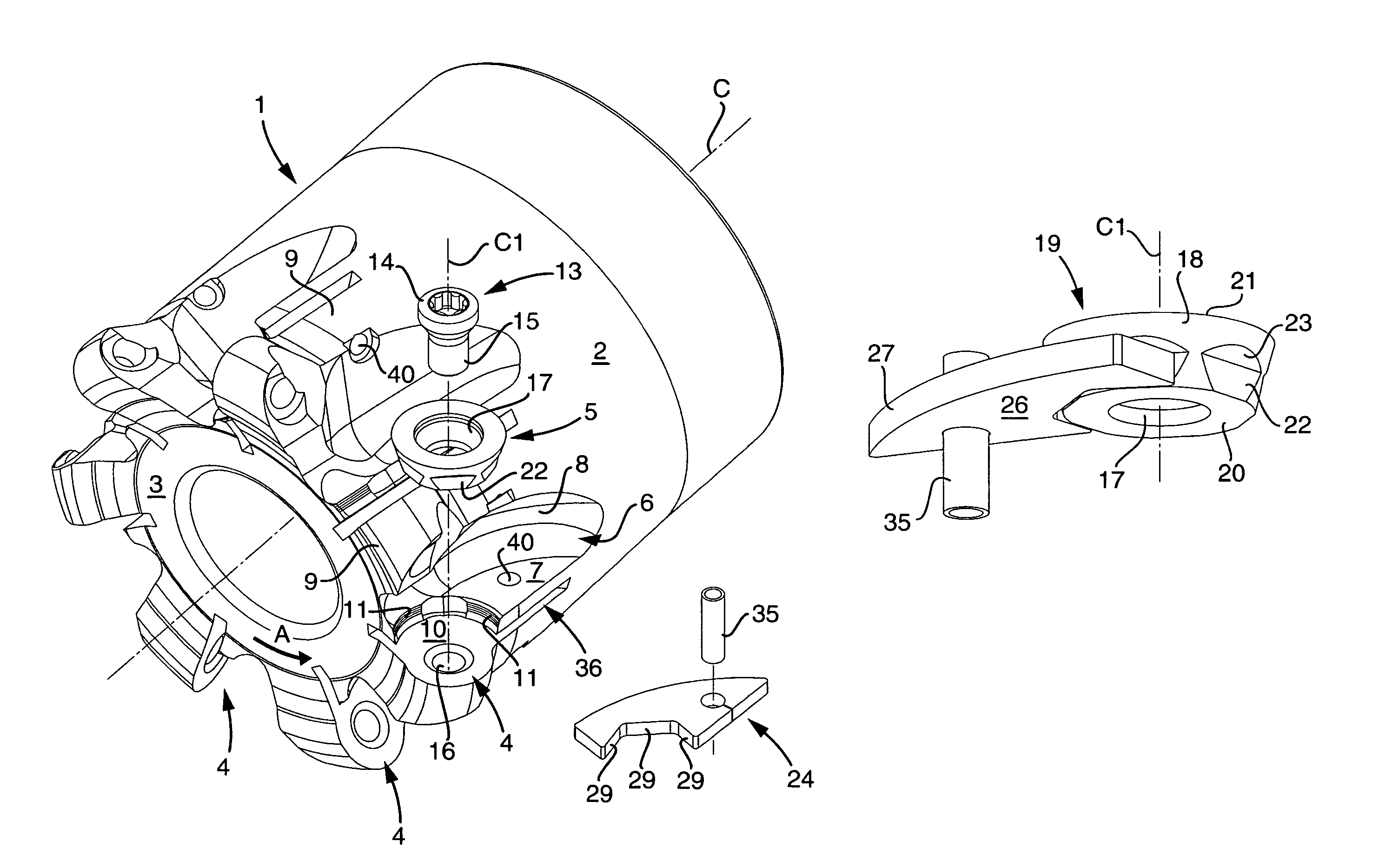

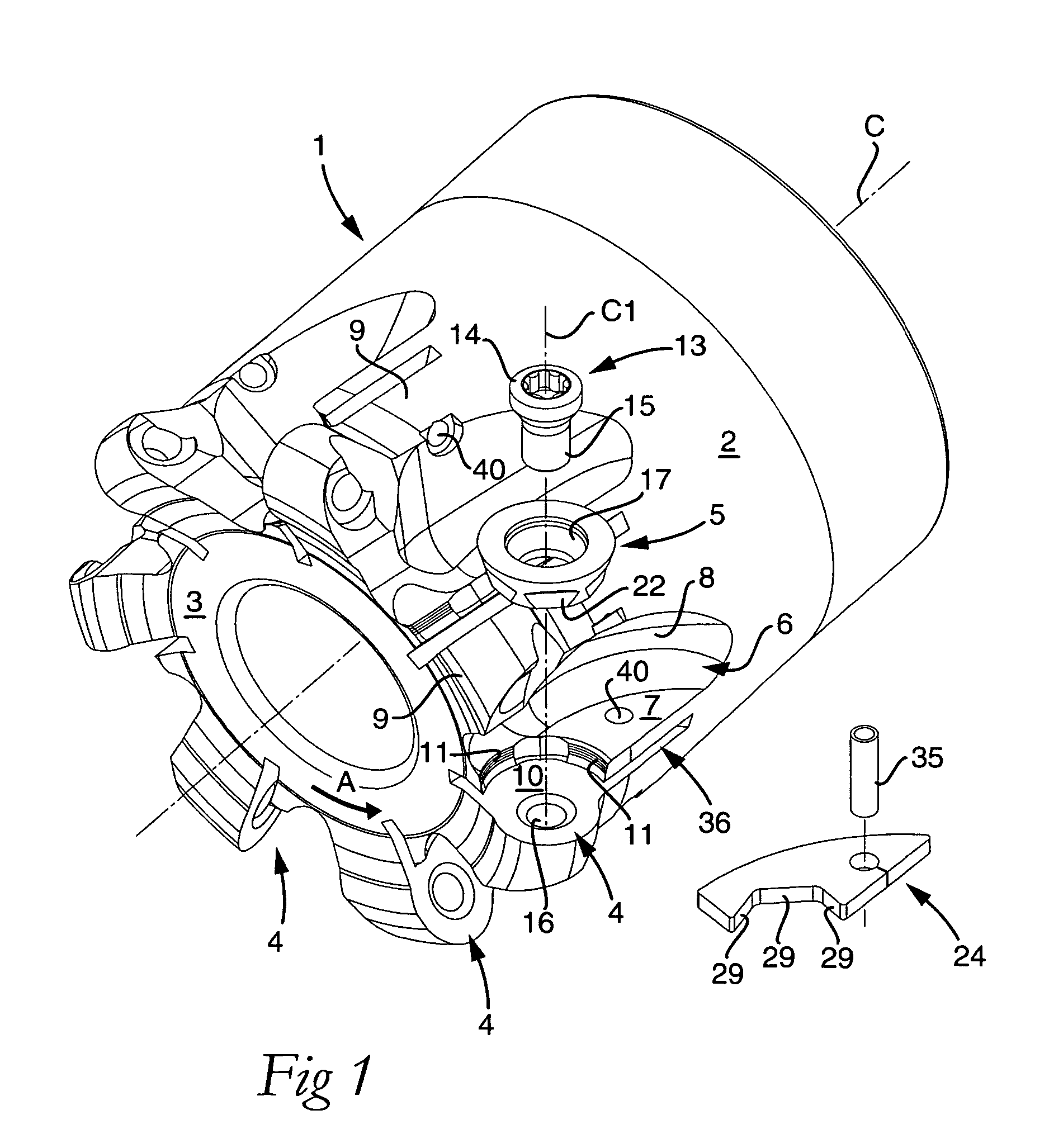

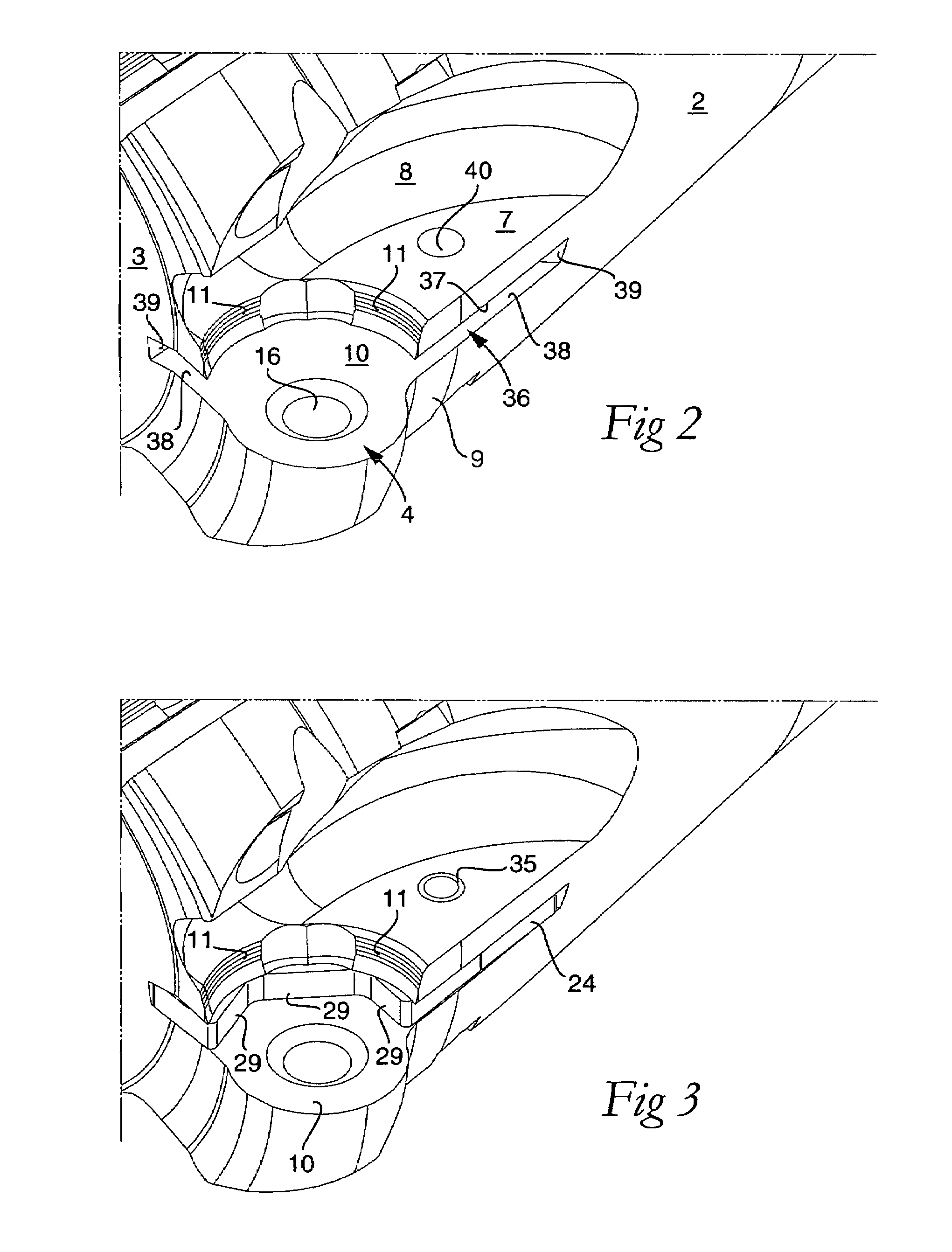

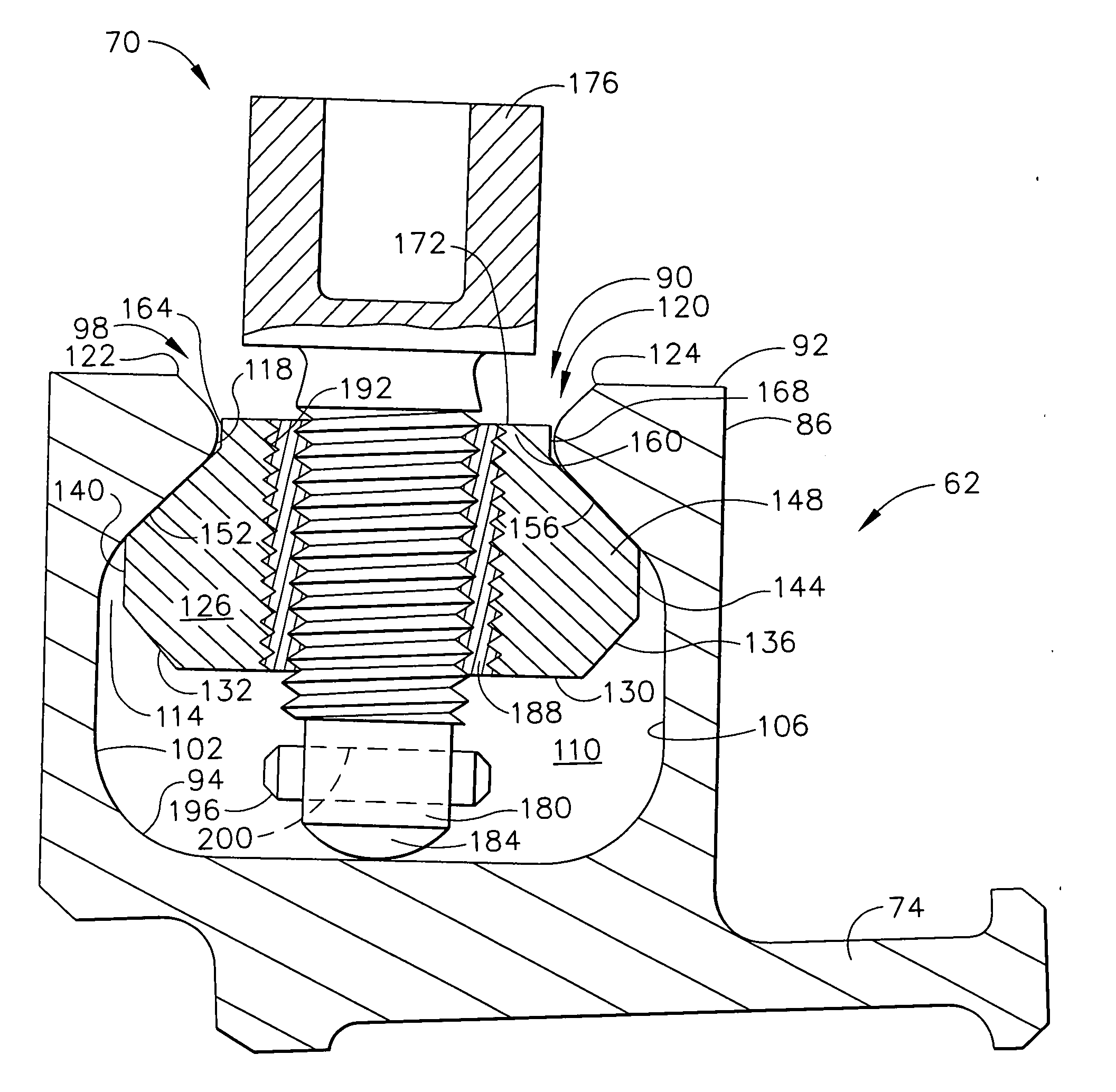

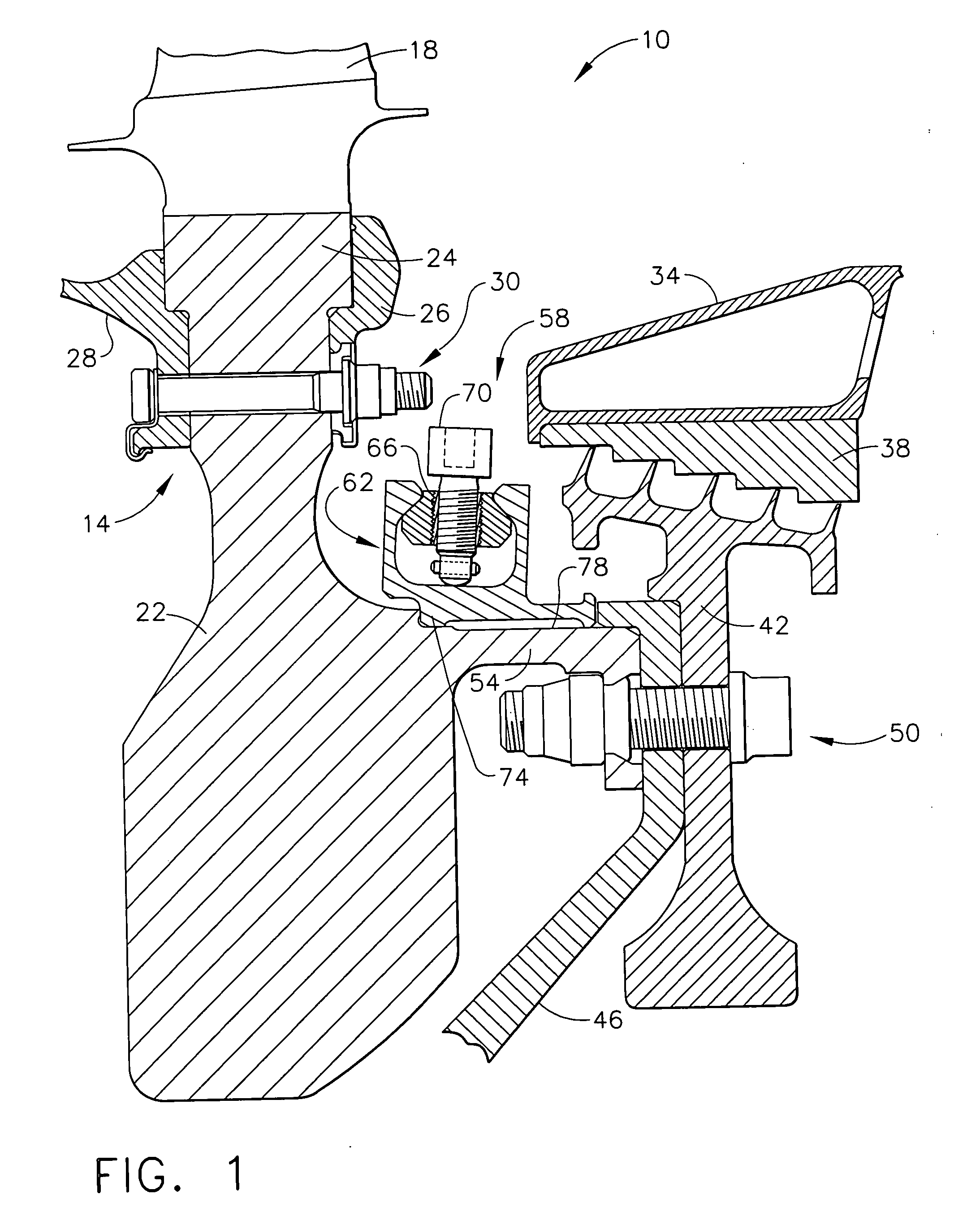

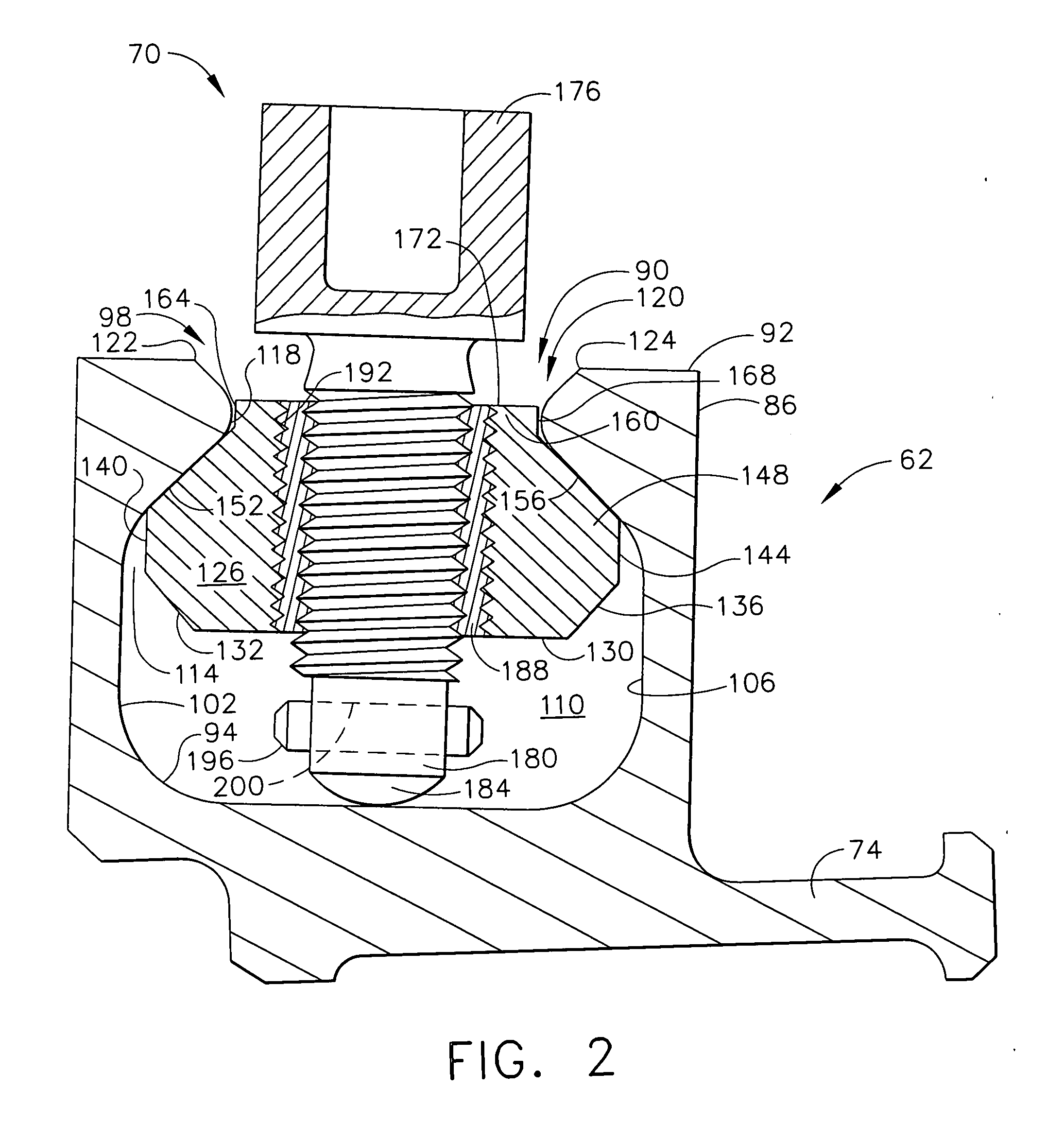

Balance assembly for rotary turbine component and method for installing and/or adjusting balance weight

A balance assembly for turbine rotating components, such as turbine rotors, as well as method for installing and / or adjusting at least one balance weight in the balance assembly and turbine section having this balance assembly and a radially extending access pathway for accessing this balance assembly. The balance assembly comprises; (a) a balance weight retention member having a circumferential periphery and a slot formed therein along at least a portion thereof, the slot having: (1) a bottom surface; (2) an opening; and (3) a pair of spaced apart and opposed side walls connecting the bottom surface and the opening, the side walls sloping inwardly between the bottom surface and the opening to define a balance weight engaging section; (b) at least one balance weight configured and sized to be insertable through the opening of the slot and to be positionable for movement within the slot and having a pair of spaced apart generally inwardly sloping shoulder surfaces capable of engaging the side walls of the slot at the balance weight engaging section; and (c) a balance weight securing member associated with the at least one balance weight that can be actuated to: (1) move the at least one balance weight away from the bottom surface so that the shoulder surfaces engage the side walls at the balance weight engaging section such that the at least one balance weight is in a secured position within the slot; or (2) move the at least one balance weight towards the bottom surface so that the shoulder surfaces do not engage the side walls at the balance weight engaging section such that the at least one balance weight is in a unsecured position within the slot.

Owner:GENERAL ELECTRIC CO

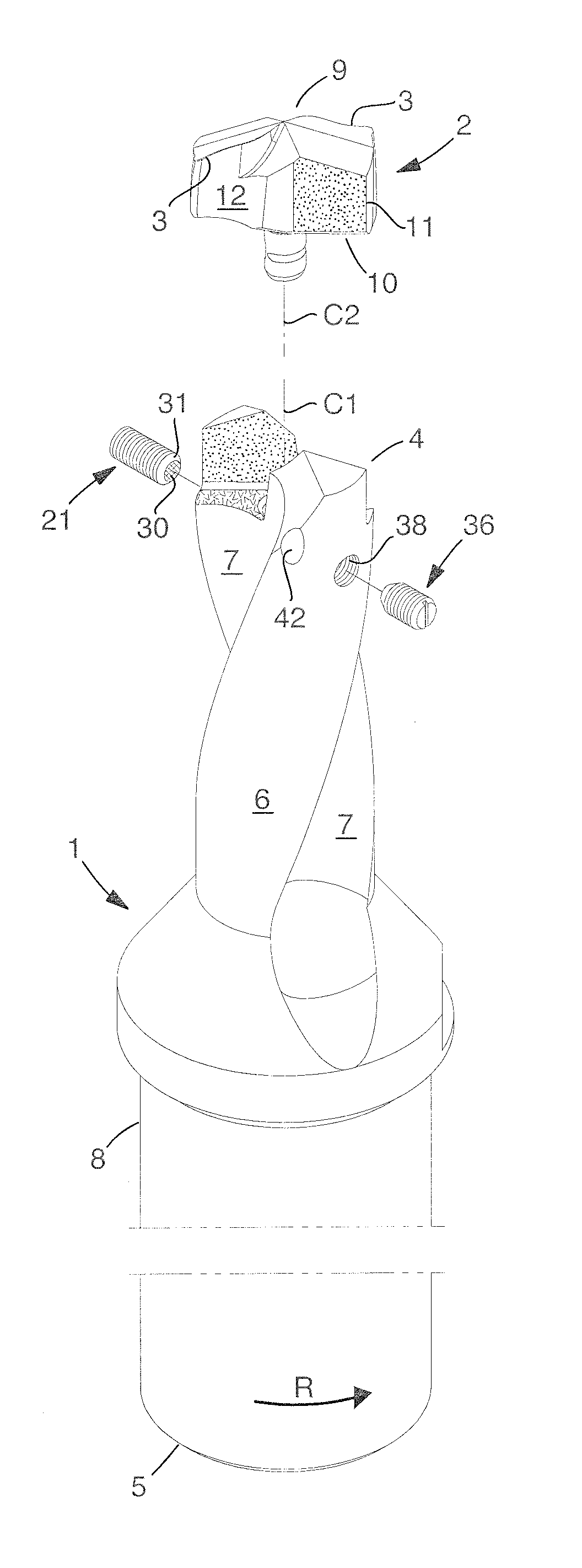

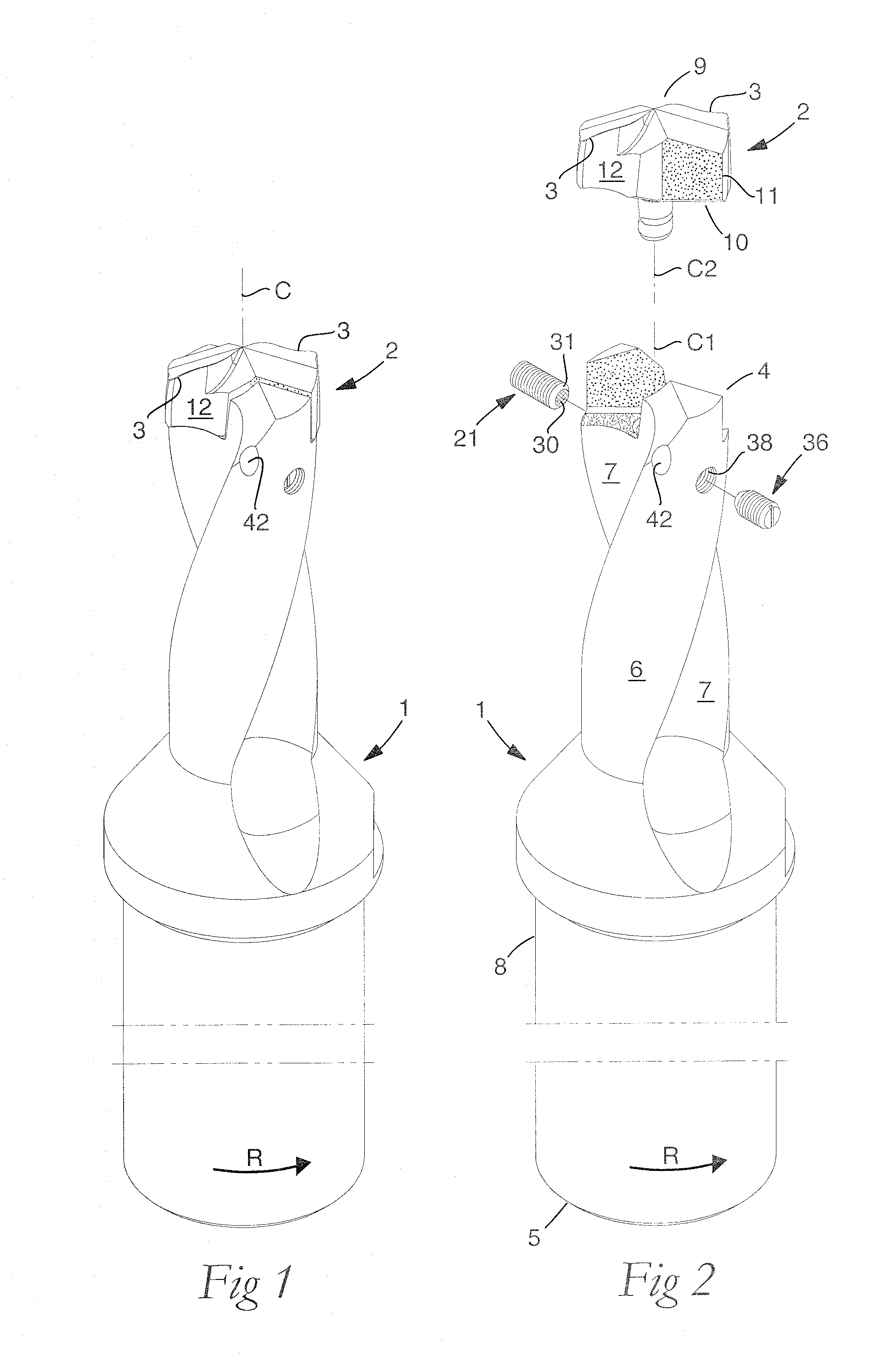

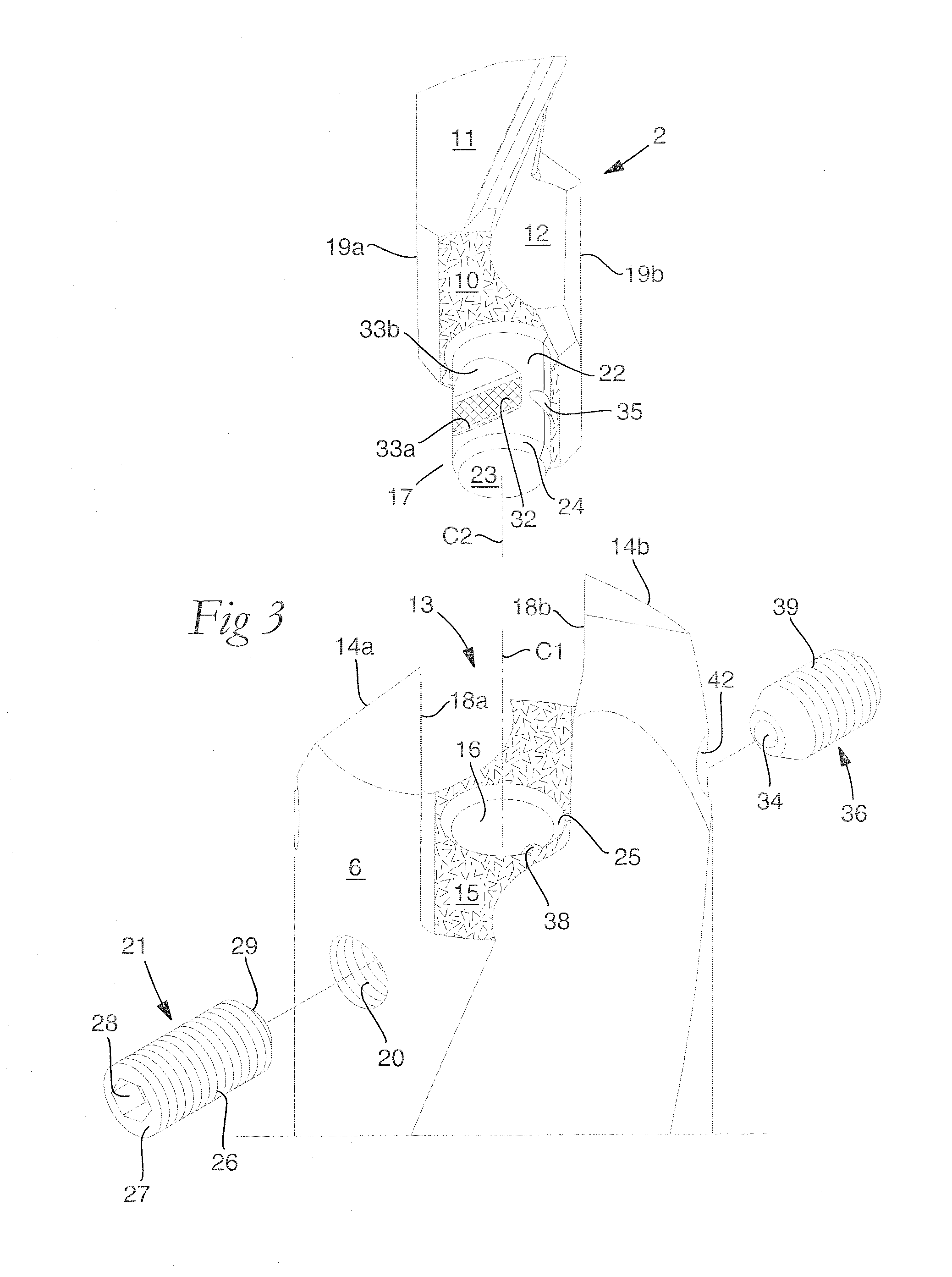

Rotatable tool for chip removing machining as well as a loose top and a basic body therefor

InactiveUS20110110739A1Convenient and quick and reliable wayThread cutting toolsWood turning toolsEngineeringFront and back ends

A rotatable tool for chip removing machining, including a basic body having front and rear ends between which a first center axis extends with which an envelope surface is concentric, the front end including a jaw delimited by two torque-transferring drivers and an intermediate bottom in which a center hole extending axially inside the basic body mouths, and a bore for a locking screw extending radially between the center hole and the envelope surface. A loose top has front and rear ends between which a second center axis extends, in the extension of which a pin protruding from the rear end extends that is delimited by a free end surface and an envelope surface in which a shoulder surface is included for the locking screw arranged in the radial bore. A countersink axially spaced apart from the end surface is formed in the envelope surface of the pin of the loose top for the receipt of a snap-in member arranged along the inside of the center hole to provisionally clamp the pin in the center hole when the locking screw is not tightened.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Rotary tool for friction stir spot welding and method of friction stir spot welding using the same

ActiveUS20080006677A1Suppress entryGood introductionCooking-vessel materialsWelding/cutting auxillary devicesEngineeringSpot welding

A rotary tool for friction stir spot welding including: a rod-like probe to be inserted into one side of stacked planar portions of plural metal members to be joined while being rotated; and a cylindrical shoulder member which is disposed coaxially outwardly of the probe and which has a shoulder surface to be abutted against the one side of the stacked portions while being rotated, wherein the probe and the shoulder member are individual components and are disposed so as to have a double-acting structure which enable them to move independently in their axial direction, and in which a gap between an inner surface of the shoulder member and an outer surface of the probe is formed to have a small gap on a tip side of the rotary tool and to have an enlarged gap having larger clearance than the small gap on a base portion side thereof.

Owner:SUMITOMO LIGHT METAL INDS LTD

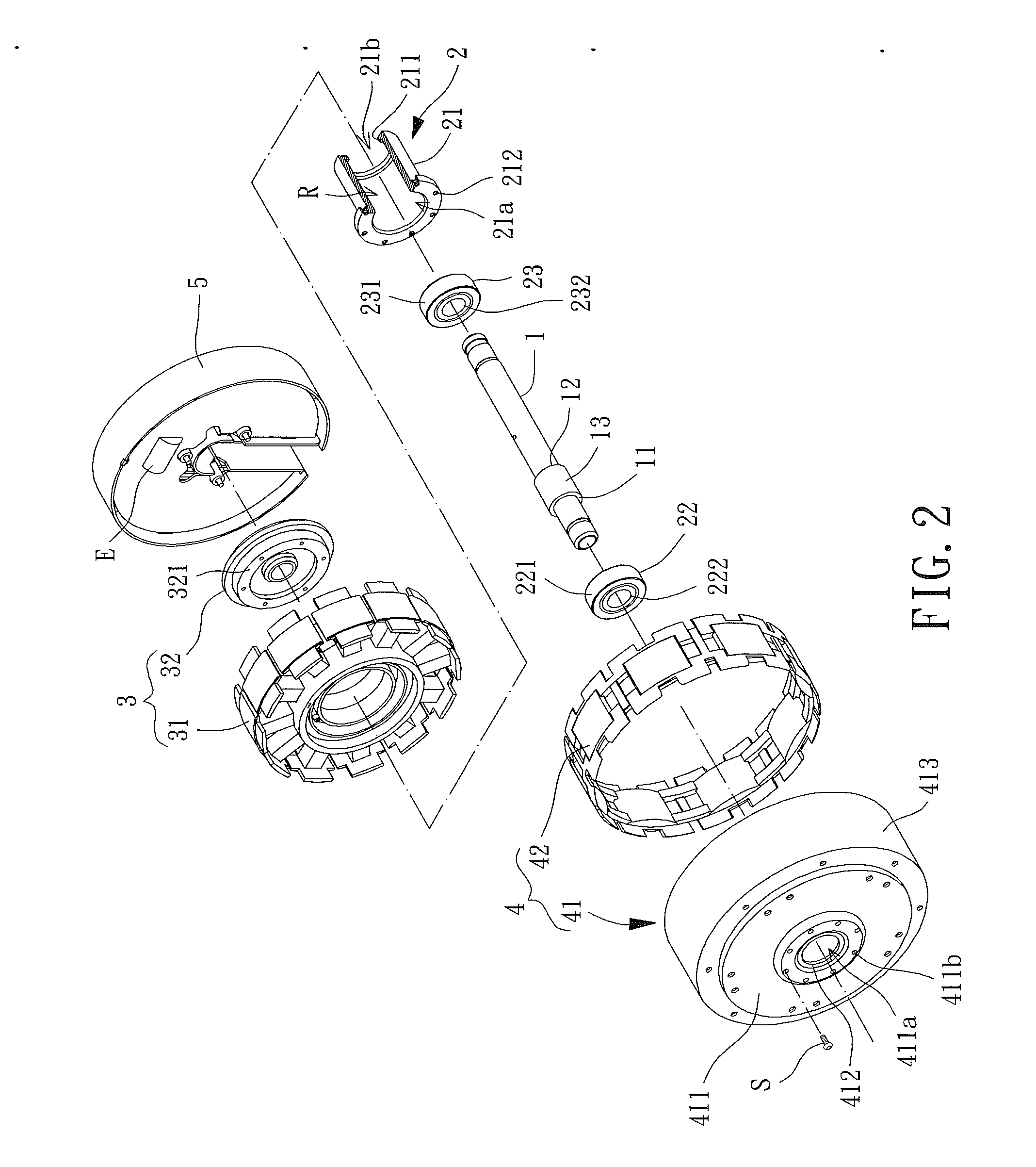

Motor of a Ceiling Fan

ActiveUS20150333592A1Simplified assembly stepsAvoid damageRolling contact bearingsPump componentsCeiling fanEngineering

A motor of a ceiling fan includes: a shaft having two shoulder surfaces facing in opposite axial directions of the shaft, with the shaft coupling with a stator; a bearing sleeve receiving two bearings for supporting the shaft, with an annular flange formed at an end of the bearing sleeve, wherein the annular flange and one of the shoulder surfaces of the shaft clamp and position one of the bearings; and a rotor having a housing coupling with the bearing sleeve, with the housing having a connecting portion, wherein the connecting portion and the other one of the shoulder surfaces of the shaft clamp and position the other one of the bearings.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Endoscope and endoscope system

An endoscope having an insertion portion to be inserted into an object to be observed, includes: a substantially tubular holder member mounted to the insertion portion and having an open front end portion including a shoulder surface surrounded by an axial wall; a lens barrel holding an objective lens system and received in the holder member; and a light-transmissive closure member fitted into a front opening defined by the axial wall, and fixed to the front opening by a bonding agent interposed between an outer circumferential surface of the closure member and an opposing inner circumferential surface of the open front end portion of the holder member, wherein a space axially adjoining the shoulder surface is defined between an outer circumferential surface of a front end portion of the lens barrel and an opposing inner circumferential surface of the holder member.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Cable retention system

A cable retention device includes a conduit that is joined to an end plate forming a continuous passage through the conduit. Cable shielding is clamped to the conduit to establish a pathway to ground. The end plate presents a shoulder face that is inserted into a guide rail clamp. The shoulder face includes a pair of arches that function as fulcrums to flex the guide rail bracket, which secures the cable retention device to a chassis under compressive force.

Owner:HEWLETT PACKARD DEV CO LP

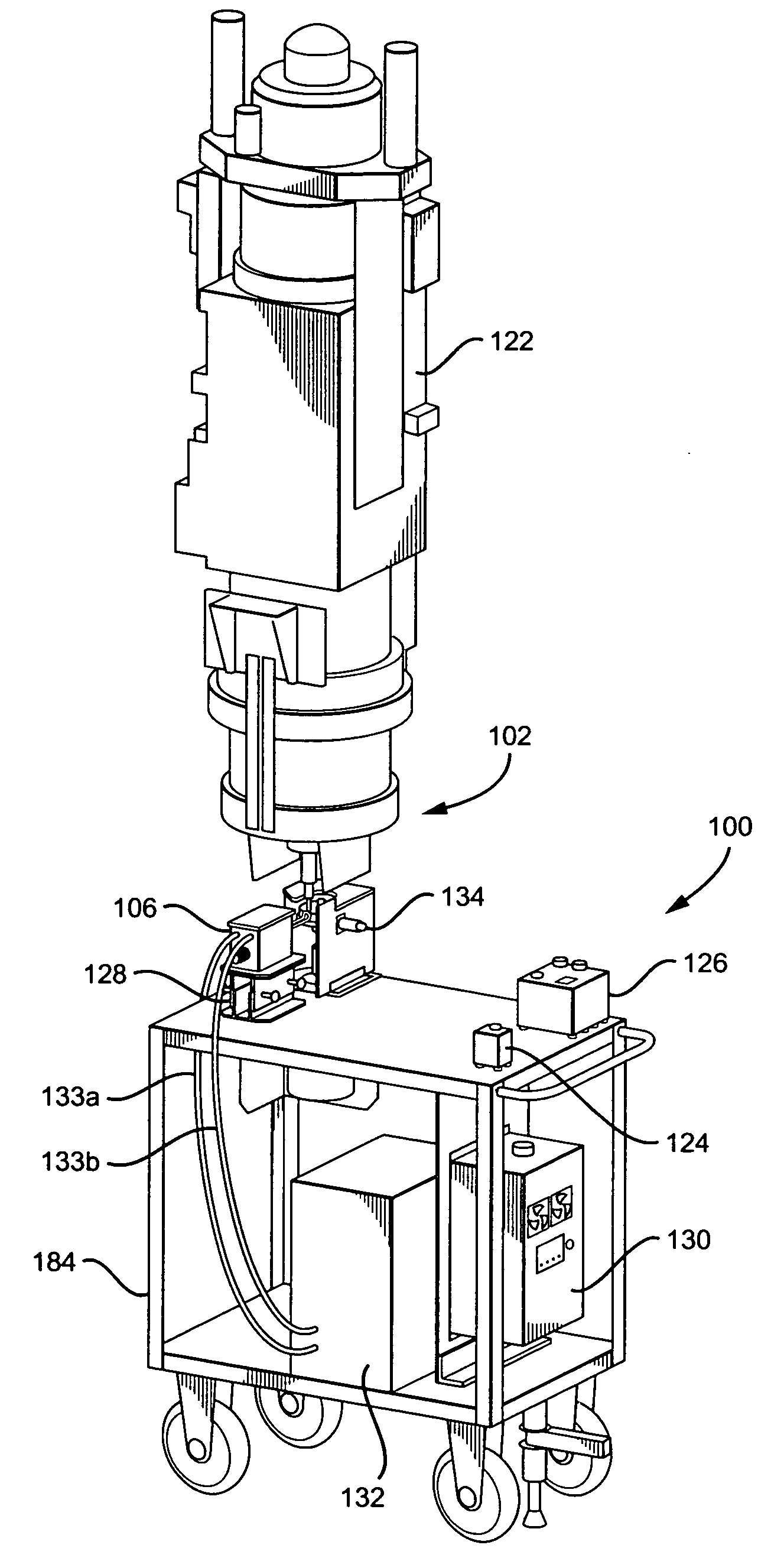

Friction stir welding tool cleaning method and apparatus

ActiveUS20070284419A1Easy to useReduce inspectionWelding/cutting auxillary devicesElectrostatic cleaningEngineeringCleaning methods

The invention is directed to a friction stir welding tool cleaning method and apparatus for fixed and retractable pin tools. The method and apparatus use a heating component, a temperature indicator component, a controller component, and a rotatable tool cleaner component for cleaning fixed pin tools. An additional bore cleaner component is used for cleaning retractable pin tools. Heat is applied to a friction stir welding tool having a surface with weld process residue material until the process residue material is sufficiently plasticized, and then the tool cleaner component is applied to the heated tool to remove the plasticized residue on the pin and shoulder surfaces of the tool, and for retractable pin tools, the bore cleaner component is applied to the heated tool to remove the plasticized residue in the tool bore.

Owner:THE BOEING CO

Keyed system for connection of filter cartridge to filter holder

InactiveUS7476314B2Carefully controlledIncentive to provide cheap, low quality copies will be minimizedDispersed particle filtrationMembrane filtersFiltrationEngineering

Embodiments of a key system for filters and their connecting heads, brackets, or other holders are shown. The filter cartridge and its holder each have a keyed surface, one being a protruding “key” and one being a recessed “lock”. Cooperation of these keyed surfaces is required in order for the filter cartridge to be installed in the holder, so that mis-matched cartridges cannot be installed into the holder, for example, to prevent a particular type of cartridge from being placed in a filtration or other process where it would be inappropriate, or undesired. The keyed surfaces are selectively locate-able preferably at different circumferential locations on a perimeter of the filter and a corresponding location on a perimeter of the head / holder. The perimeter may be, for example, on an outer shoulder surface of a filter and an inner surface of a valve head, or on outer and inner surfaces of connectors that provide a liquid seal between the filter and the head / holder.

Owner:OMNIPURE FILTER CO INC

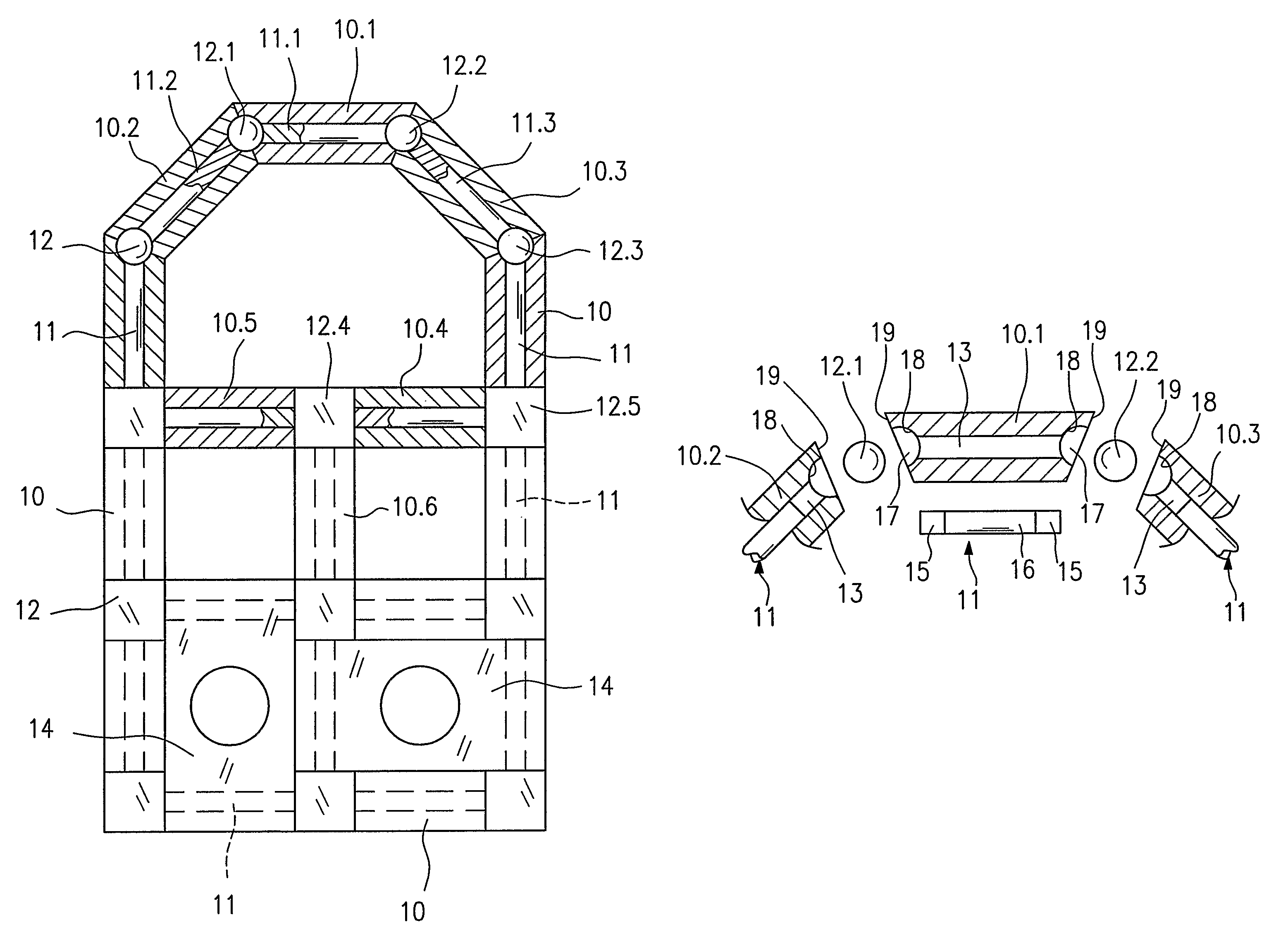

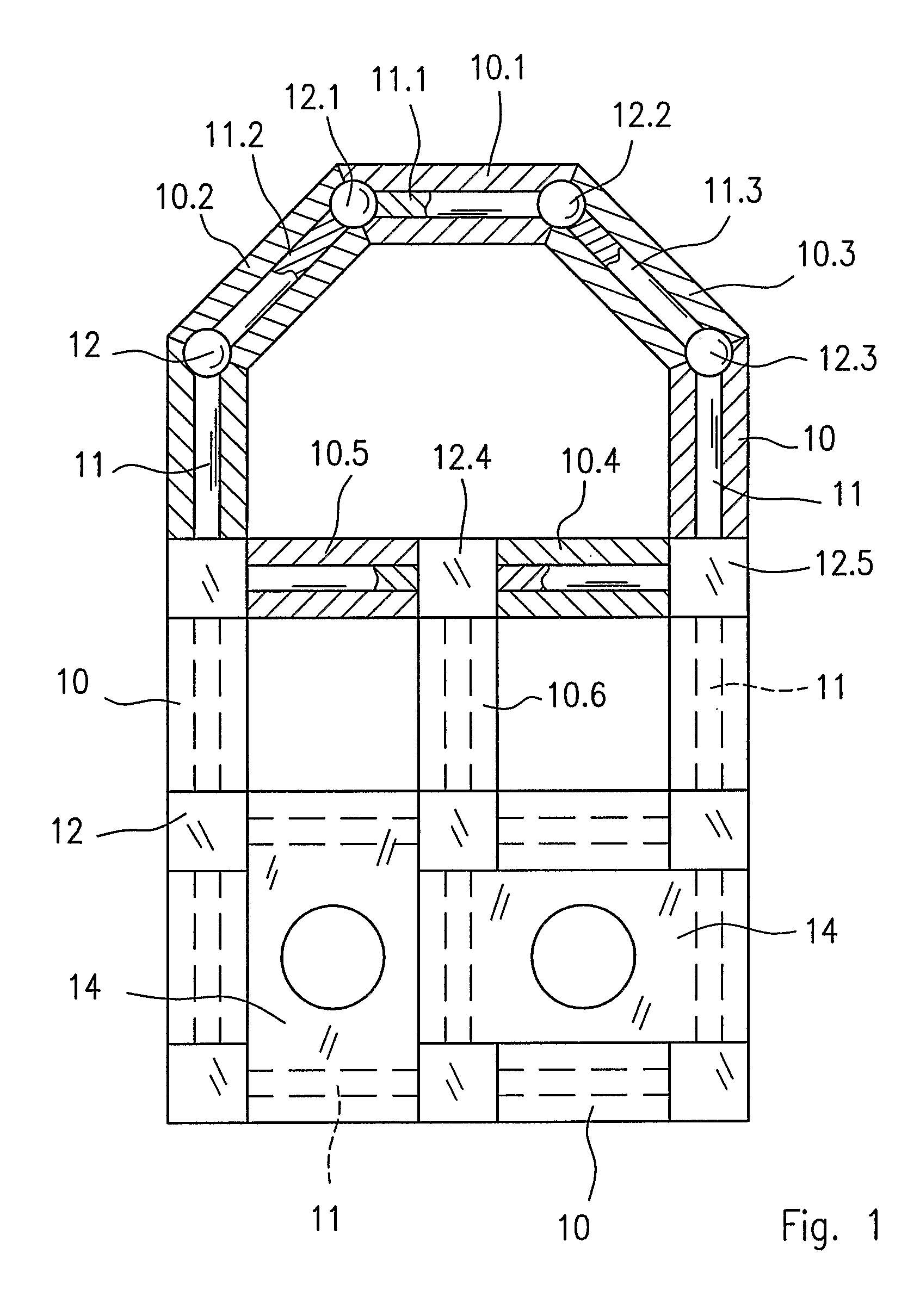

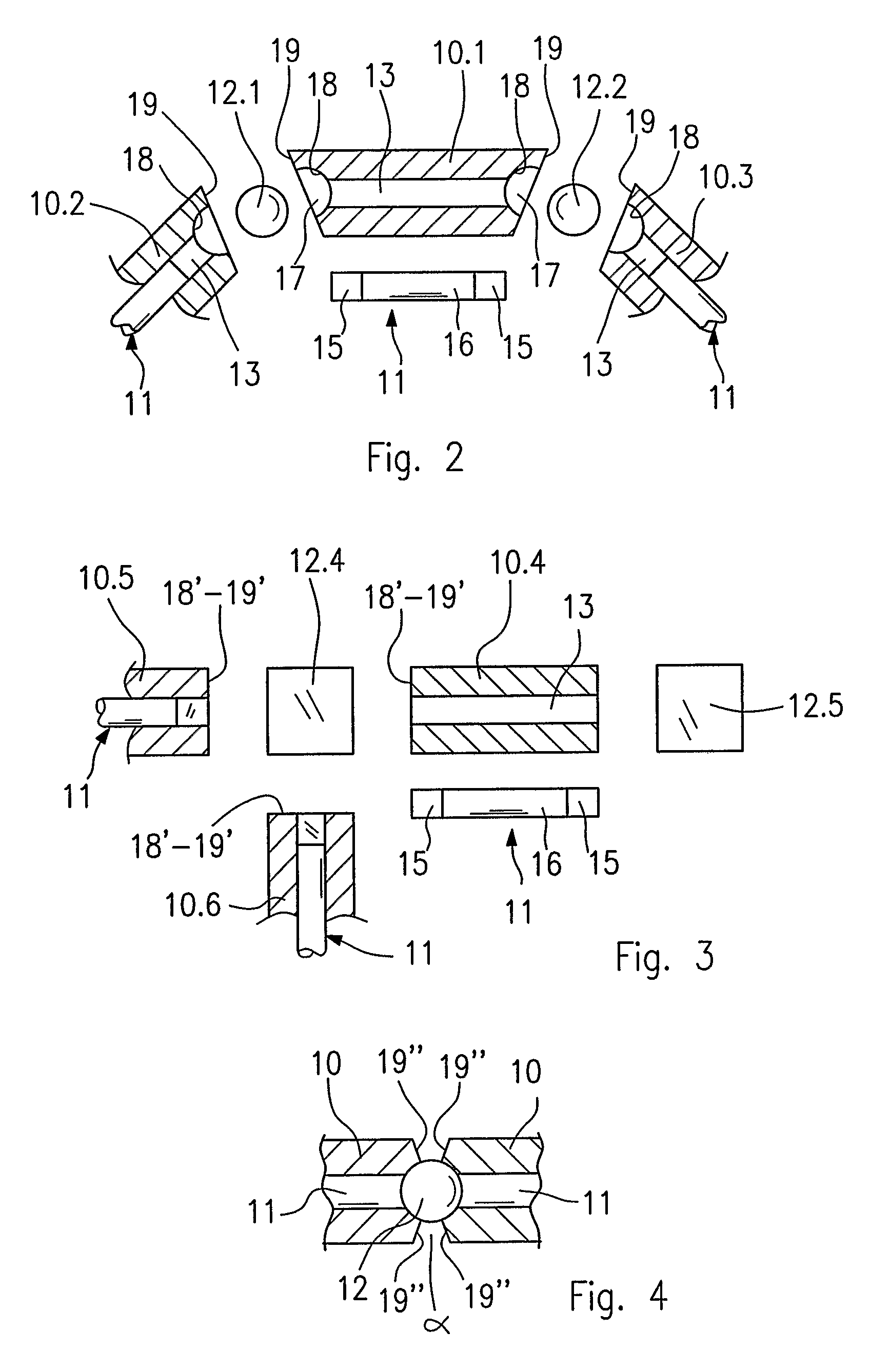

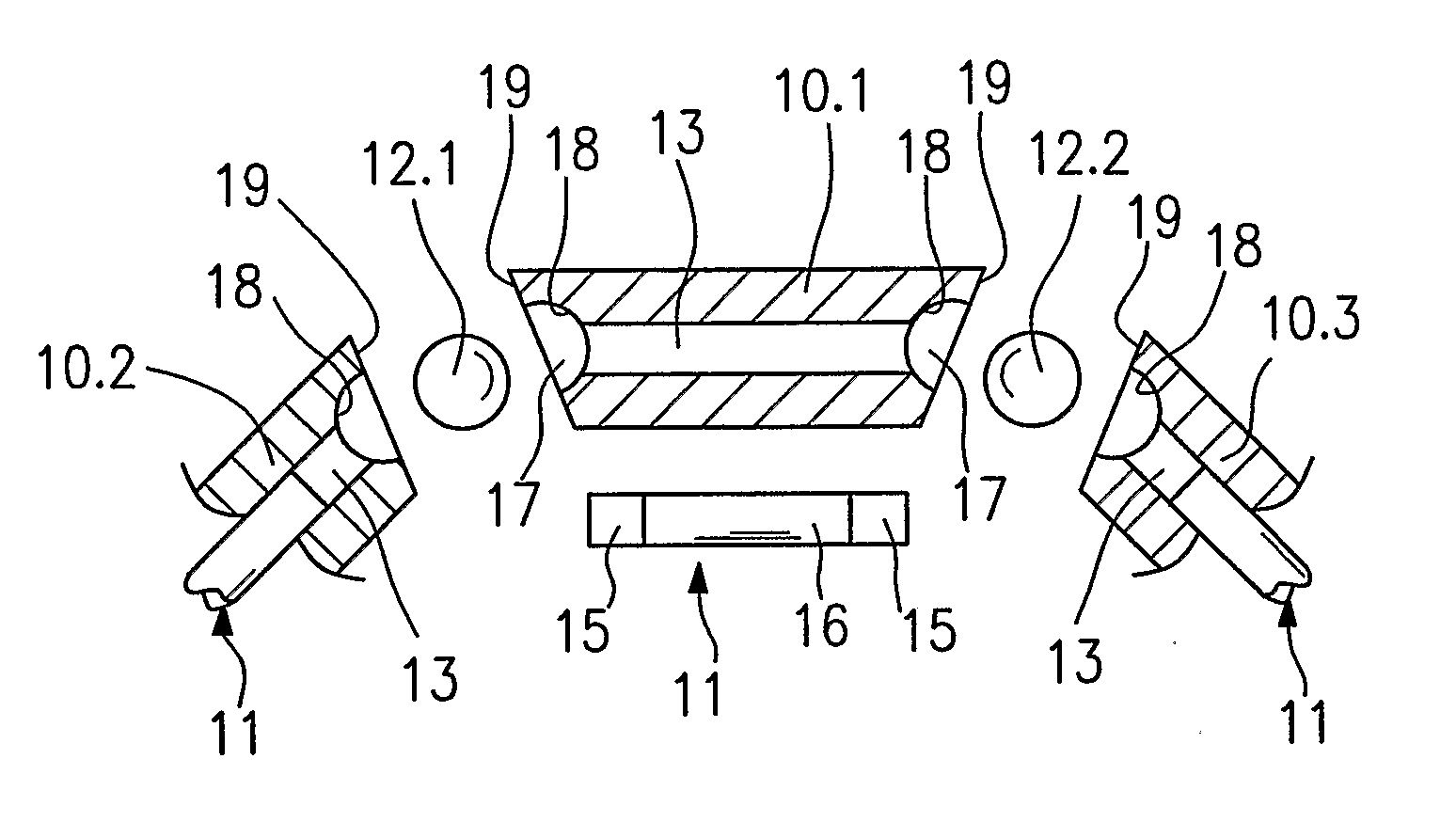

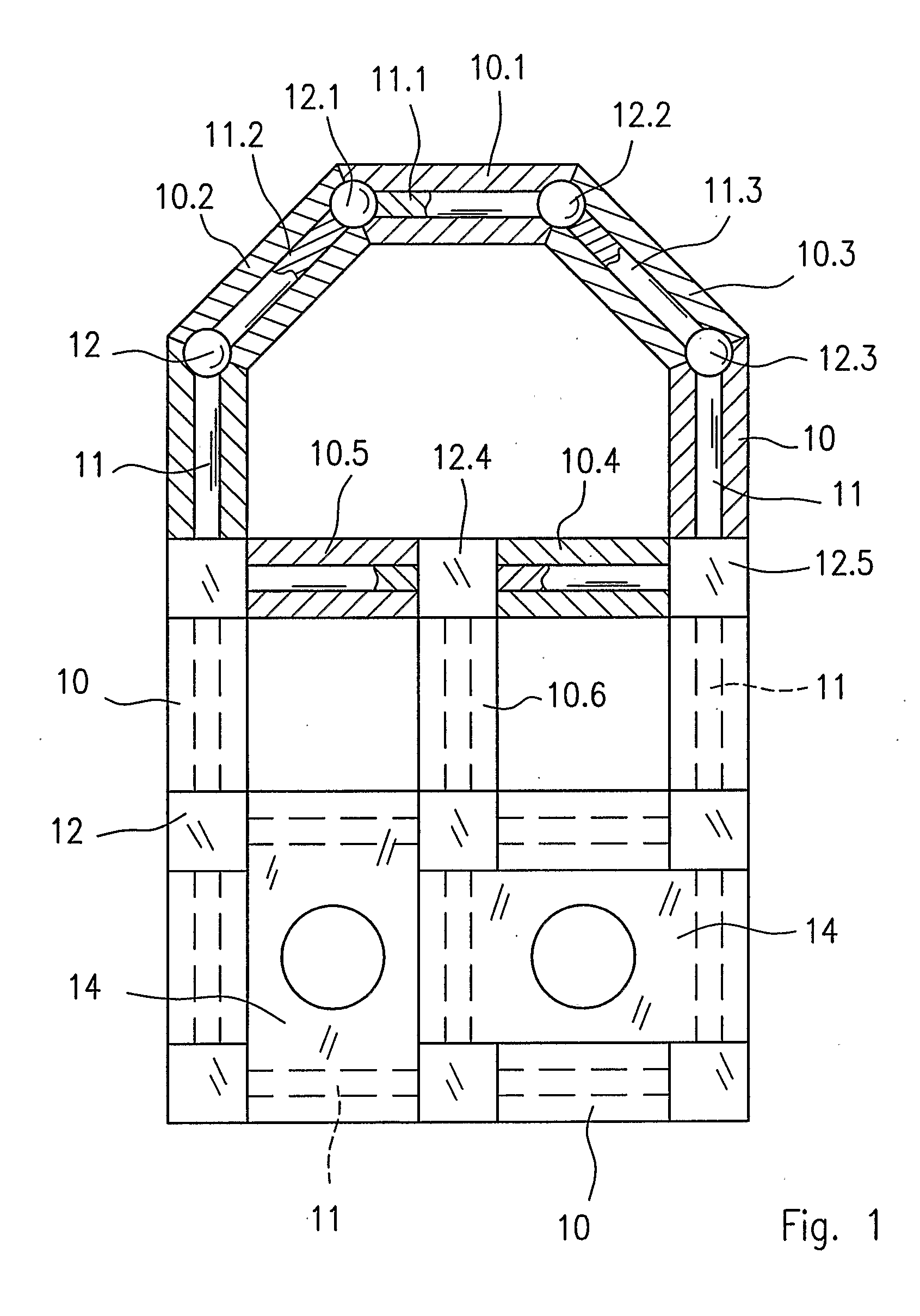

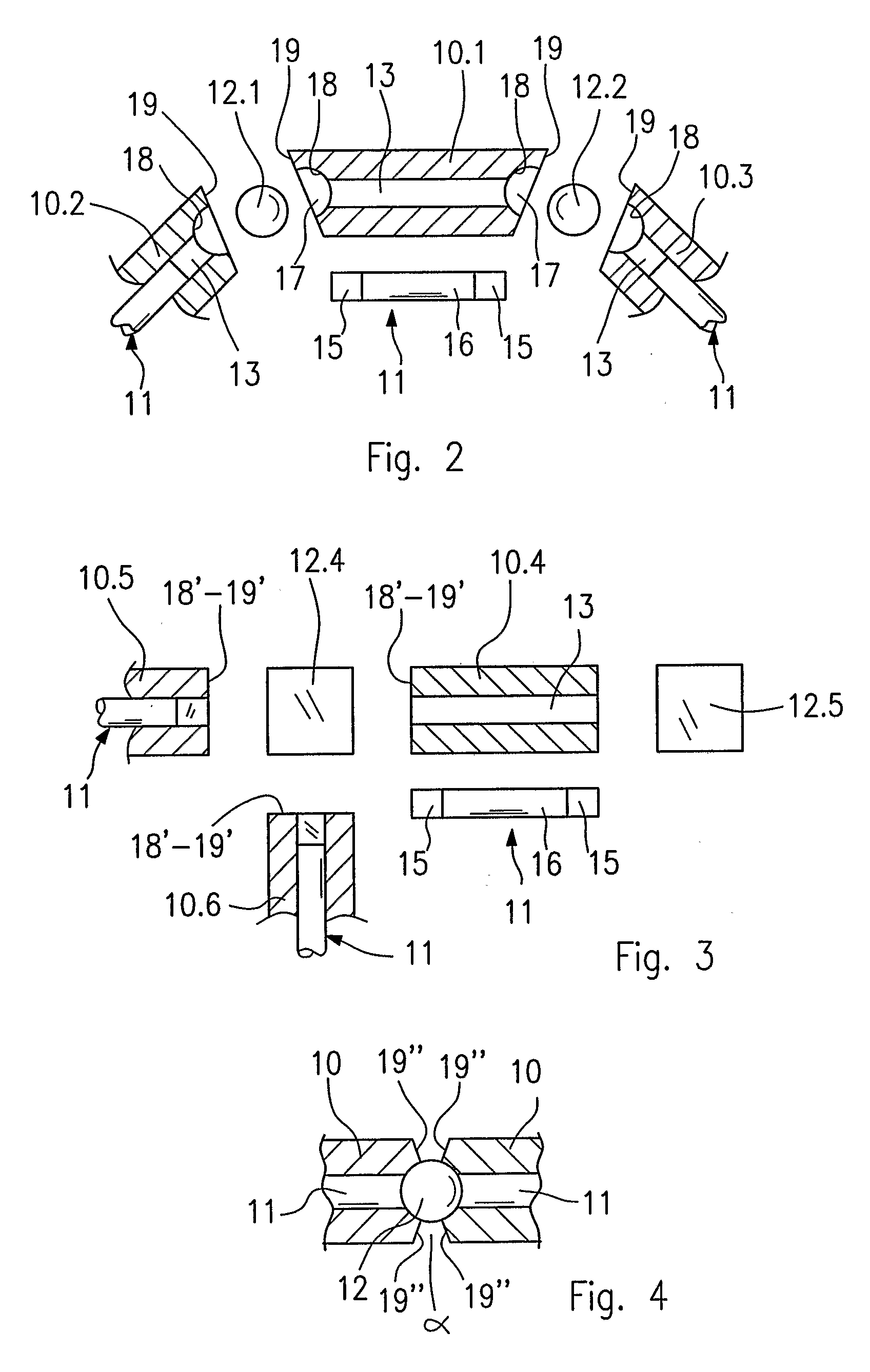

Constructional modular system with removable magnetic framework

InactiveUS7892065B2Considerable flexibility of useHigh degreeToysAnimal drawn vehicleShoulder surface

The system comprises a plurality of modular blocks (10, 14) of nonmagnetic material, to be assembled to create compositions imitating, for example, a building, a doll, an animal, a vehicle or any other fancying assembly; a framework for connecting the blocks, comprises a plurality of magnetic frame members (11, 12) removably disposable into corresponding seatings (13, 17) in each modular block (10, 14), or between adjacent blocks of the composition. The modular blocks (11, 12) and the magnetic frame members of framework have shoulder surfaces (18, 19) mutually engageable in the assembled condition of the assembly.

Owner:VICENTELLI CLAUDIO

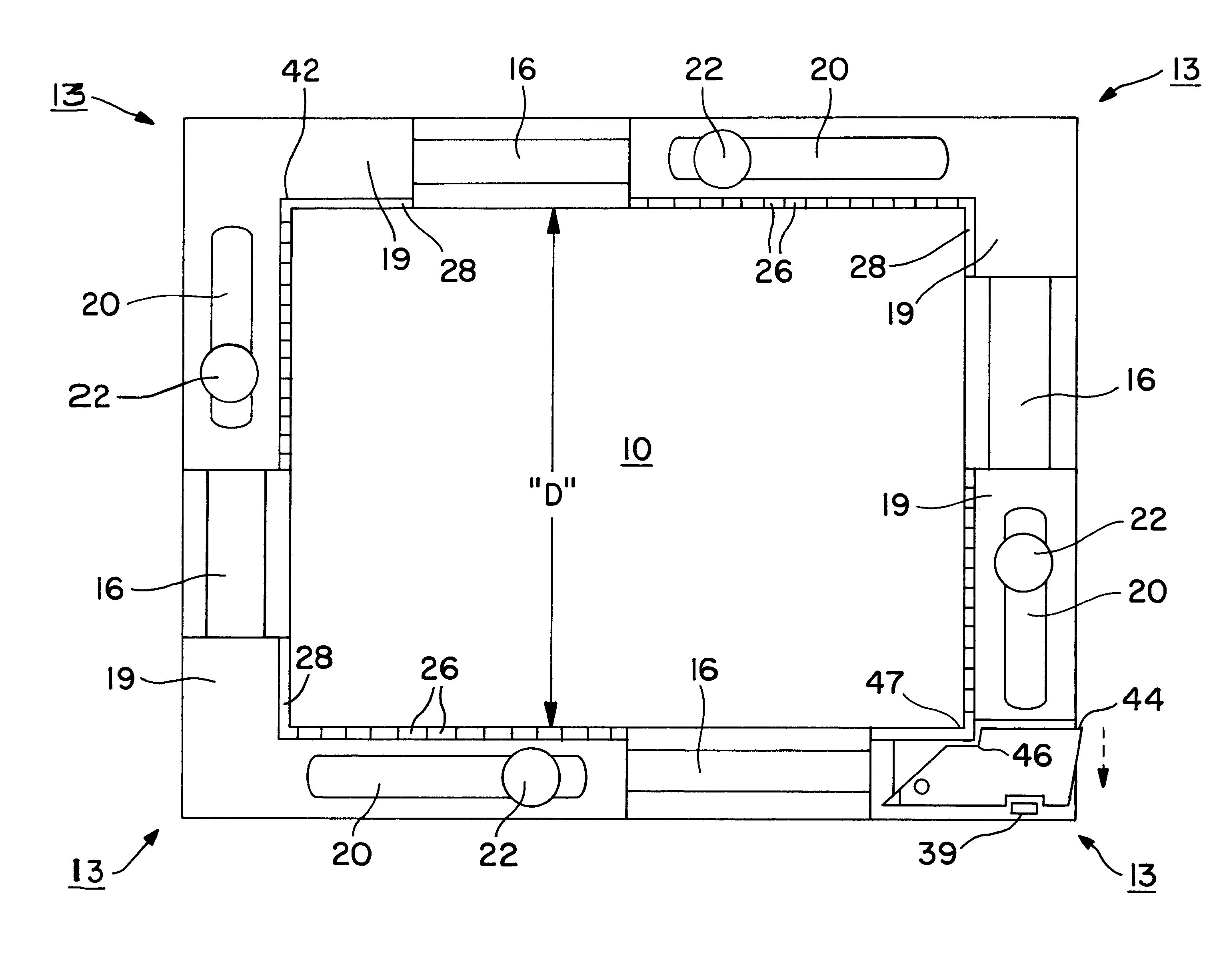

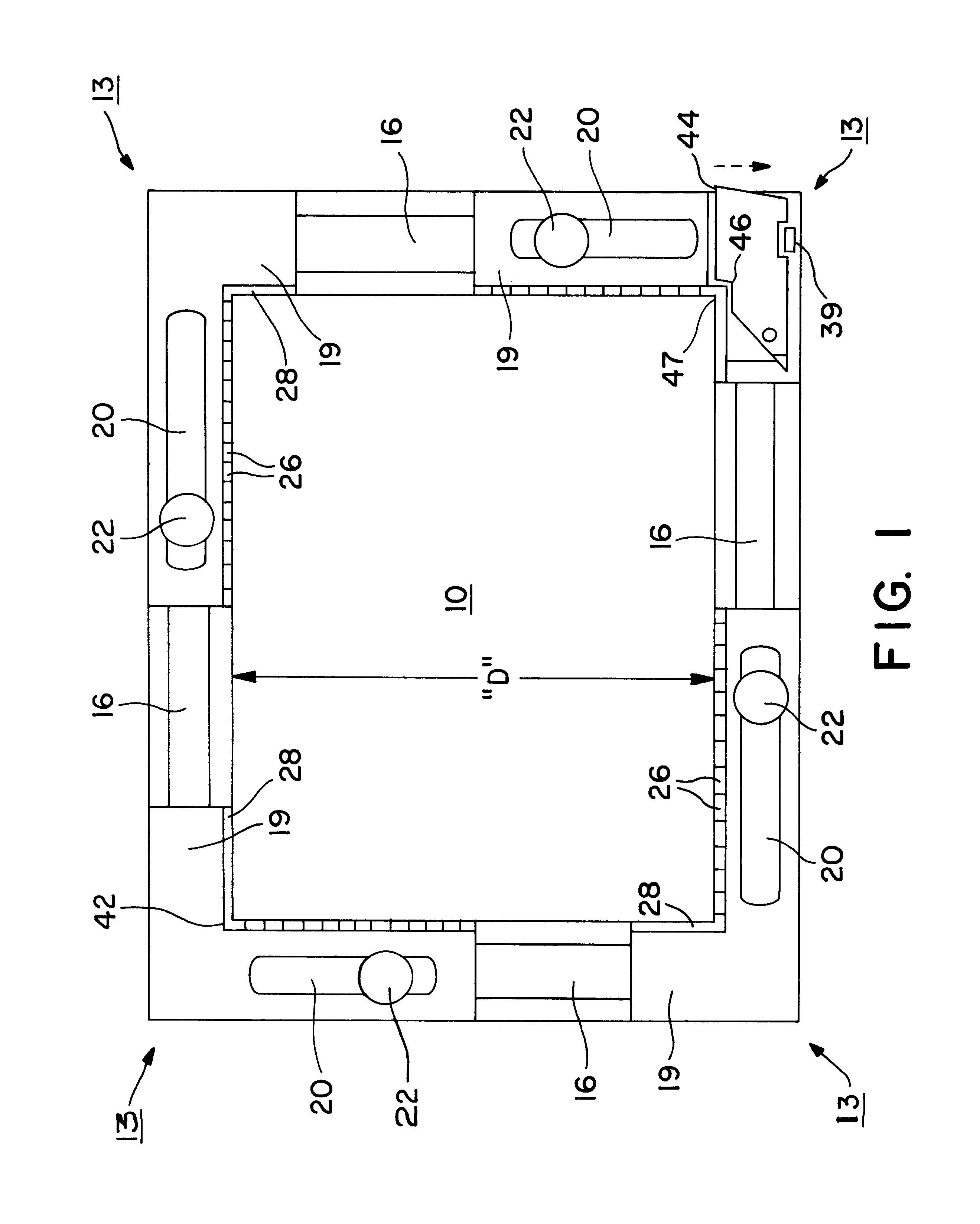

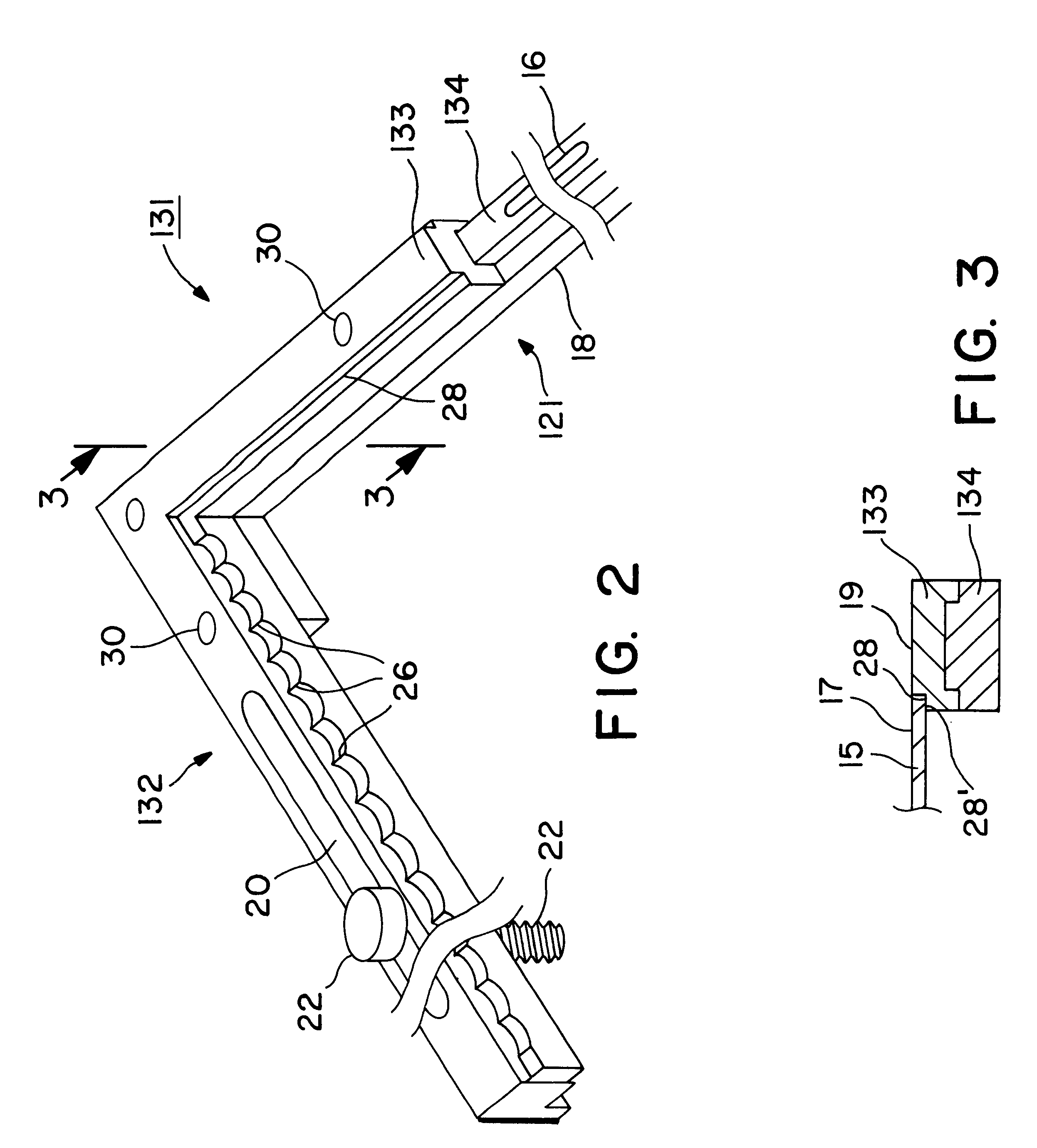

Universal reflow fixture

InactiveUS6209859B1Reduce heat lossMinimizing amount of stretchWorkpiece holdersPrinted circuitsSurface mountingEngineering

A frame comprising four angles each angle having two legs, each leg connected to a a leg of a neighboring angle wherein locations of attachment of the legs are adjustable so as to accommodate a range of sizes of boards for a surface mount manufacturing process. One leg of each angle has a tongue and the other leg has a groove so that tongue of one leg slideably engages the groove of the leg of a neighboring angle to enable adjustment in size of the frame opening. The board is supported on a shoulder around the frame opening with the surface of the board opposite the supporting shoulder surface coplanar with the plane surface of the frame. A flat spring loaded rotatable finger on the plan surface in one corner of the board urges the board toward the opposite corner of the frame.

Owner:CHUNG HENRY

Constructional Modular System With Removable Magnetic Framework

The system comprises a plurality of modular blocks (10, 14) of nonmagnetic material, to be assembled to create compositions imitating, for example, a building, a doll, an animal, a vehicle or any other fancying assembly; a framework for connecting the blocks, comprises a plurality of magnetic frame members (11, 12) removably disposable into corresponding seatings (13, 17) in each modular block (10, 14), or between adjacent blocks of the composition. The modular blocks (11, 12) and the magnetic frame members of framework have shoulder surfaces (18, 19) mutually engageable in the assembled condition of the assembly.

Owner:VICENTELLI CLAUDIO

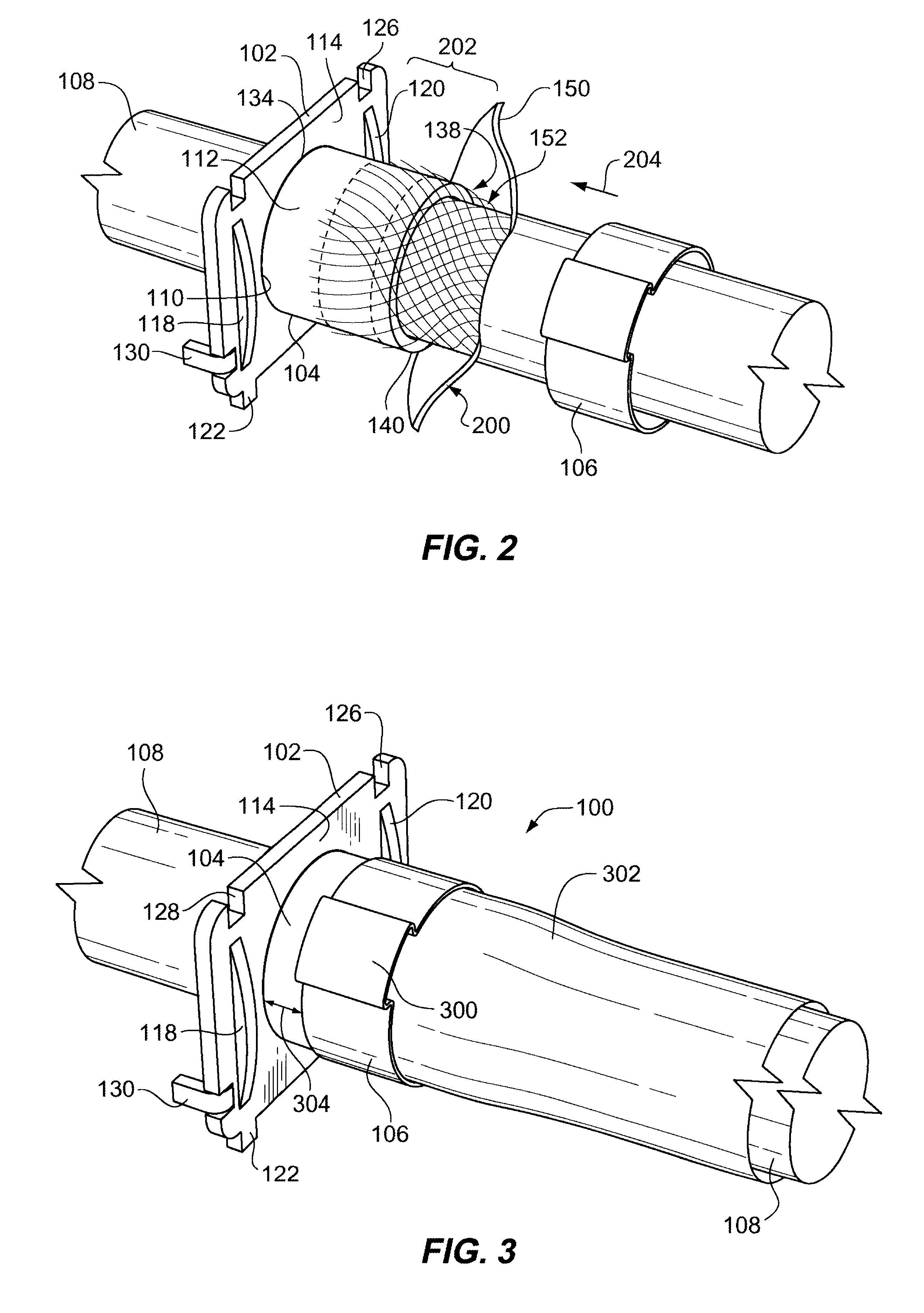

Repeatably releasable cable connector

InactiveUS20060276071A1Large separation forceFree from damageCoupling device detailsShoulder surface

A cable connector has male and female connector portions that slide together in a mating direction. The housing of one connector portion has a shoulder with a surface roughly perpendicular to the mating direction. The other connector portion has a resilient retainer spring attached thereto which extends parallel to the mating direction. When the connector portions are mated, the retainer spring has a finger which slips over the shoulder surface and is held in position by the resilience of the spring to provide a retention force that resists a separation of the male and female connector portions. However, the finger is shaped and resilience of the retainer spring is such that the finger will slip off the shoulder surface upon application of a sufficiently large separation force so that separation of the connector portions may occur without damage.

Owner:SCULLY SIGNAL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com