Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

379results about "Workpiece holders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

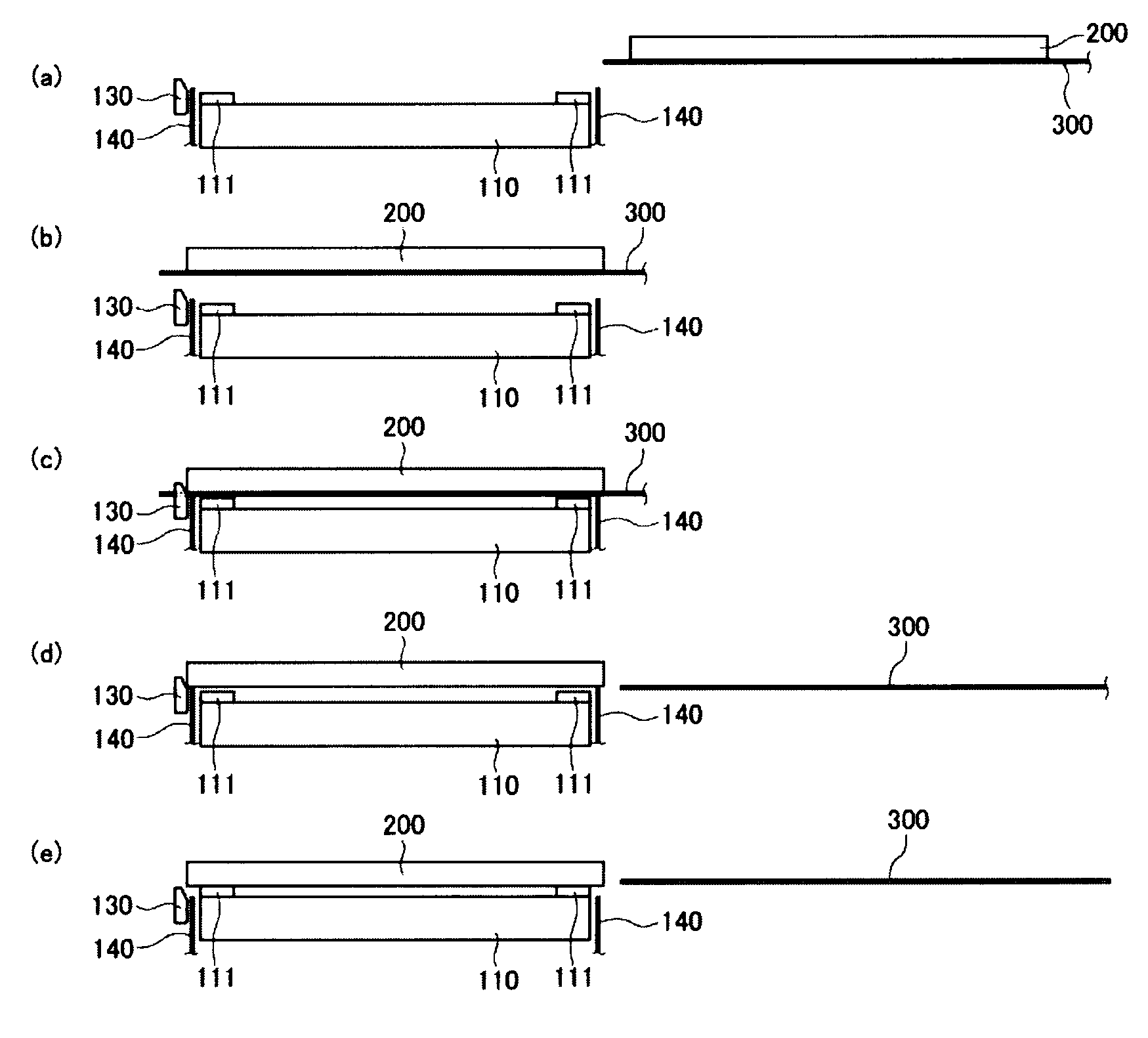

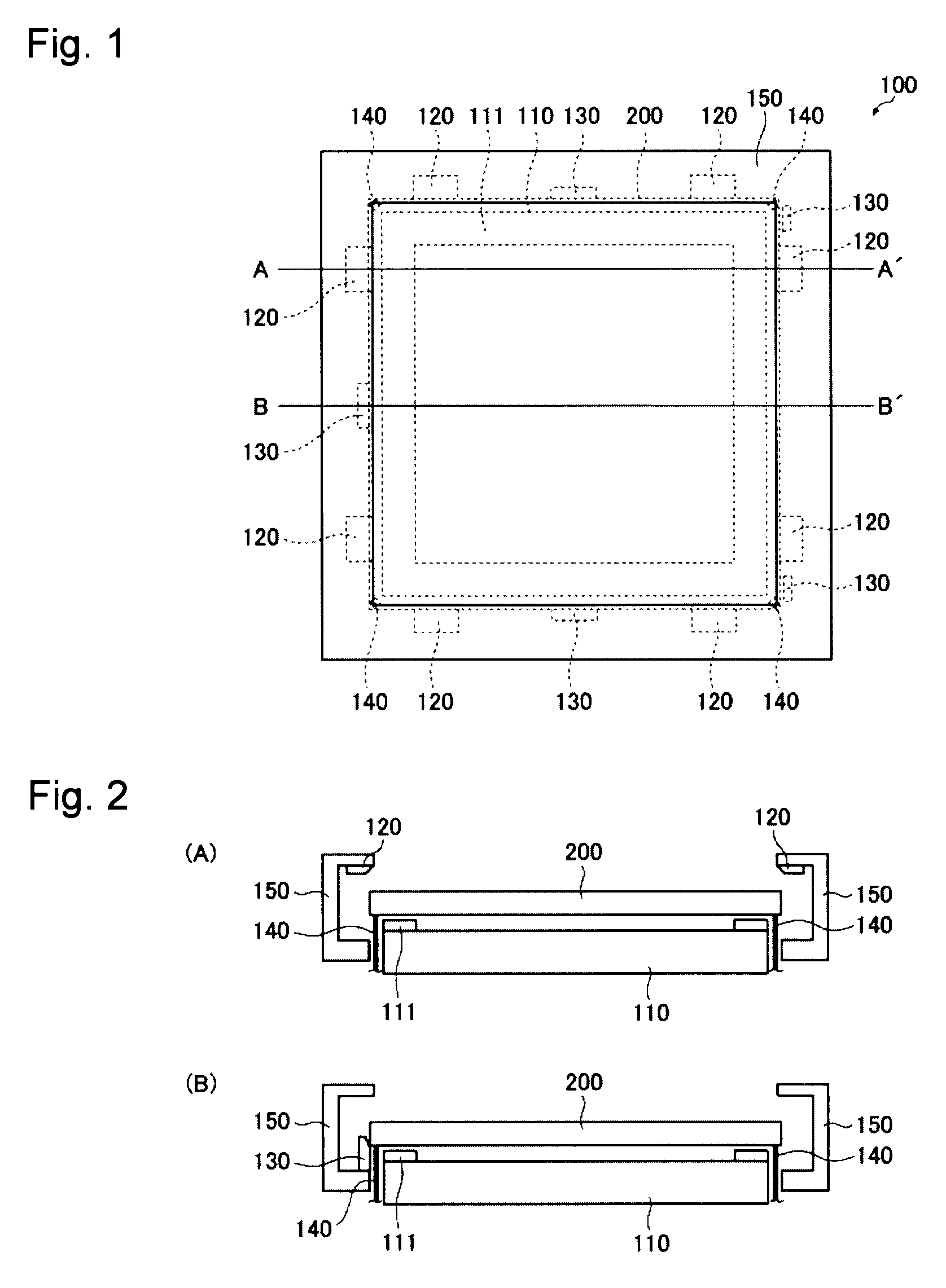

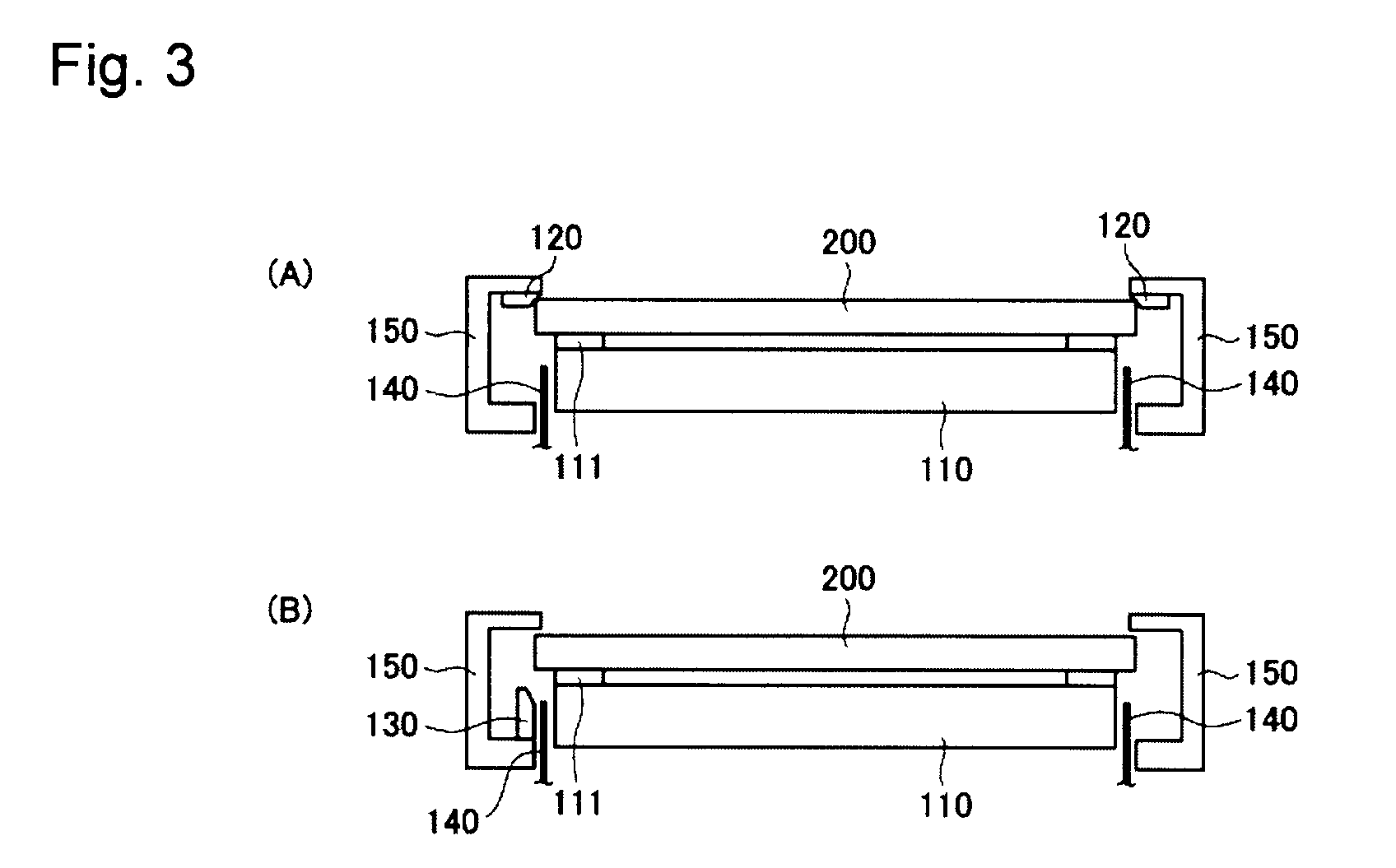

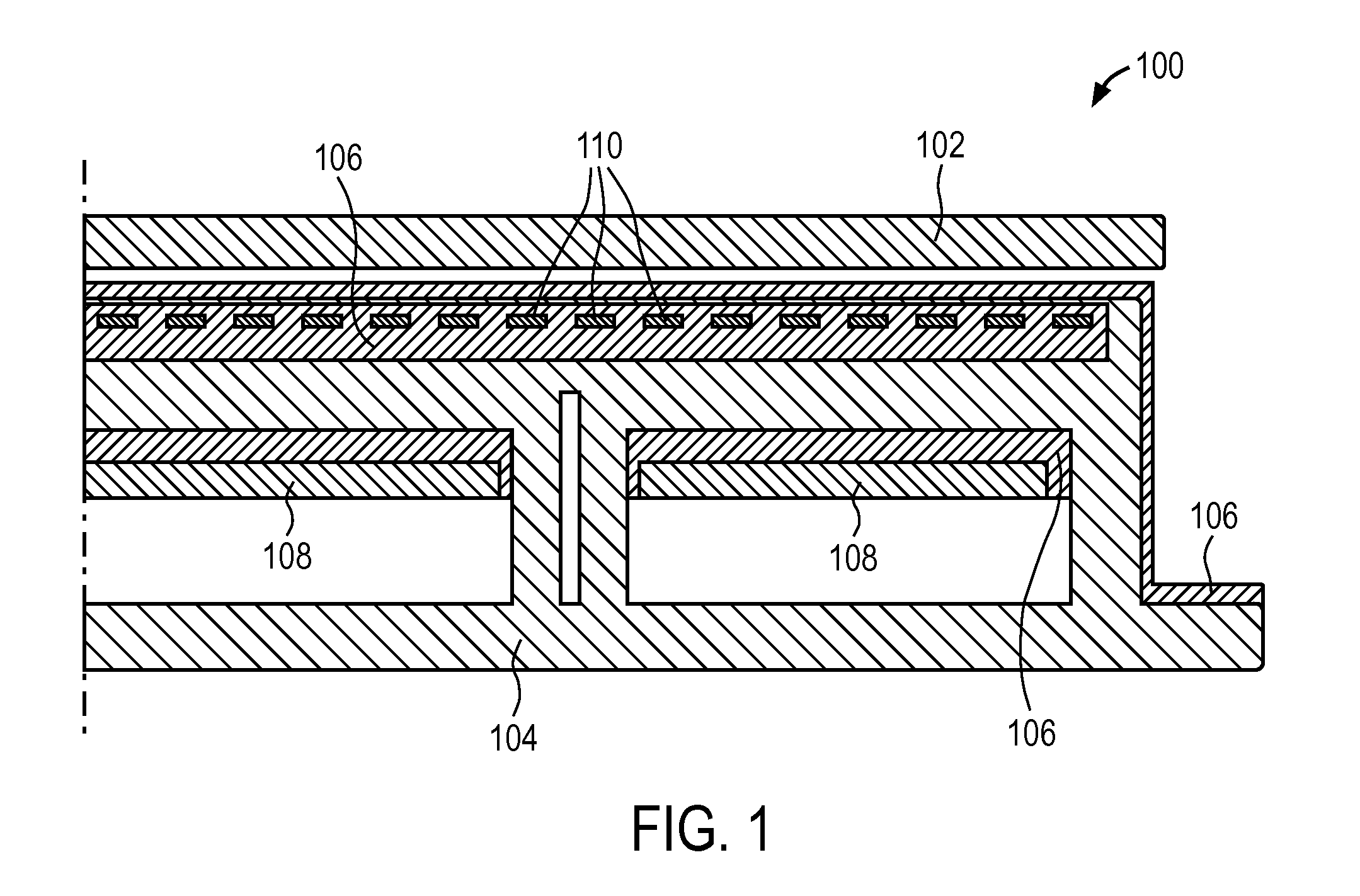

Glass substrate-holding tool and method for producing an EUV mask blank by employing the same

InactiveUS8967608B2InhibitionAccurate placementWorkpiece holdersVacuum evaporation coatingLithographic artistMaterials science

A glass substrate-holding tool employed during the production of a reflective mask blank for EUV lithography includes an electrostatic chuck and a mechanical chuck. A caught and held portion of a glass substrate caught and held by the electrostatic chuck, and pressed portions of the glass substrate pressed by the mechanical chuck are located outside a quality-guaranteed region on each of a film deposition surface and a rear surface of the glass substrate. The sum of a catching and holding force applied to the glass substrate by the electrostatic chuck and a holding force applied to the glass substrate by the mechanical chuck is at least 200 kgf. A pressing force per unit area applied to the glass substrate by the mechanical chuck is at most 25 kgf / mm2.

Owner:ASAHI GLASS CO LTD

Apparatus and method for aligning a substrate on a support member

InactiveUS6146463AWorkpiece holdersSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:APPLIED MATERIALS INC

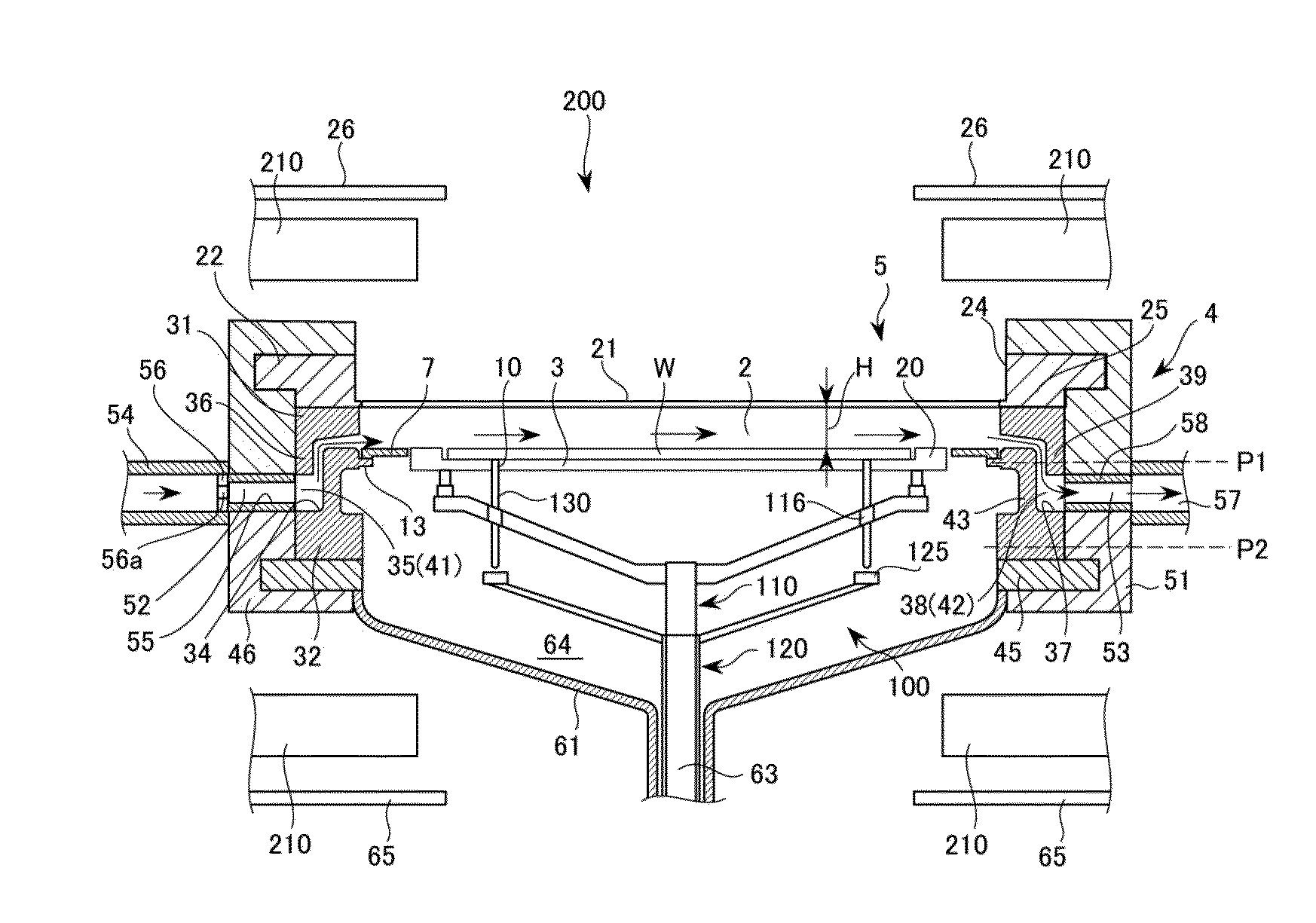

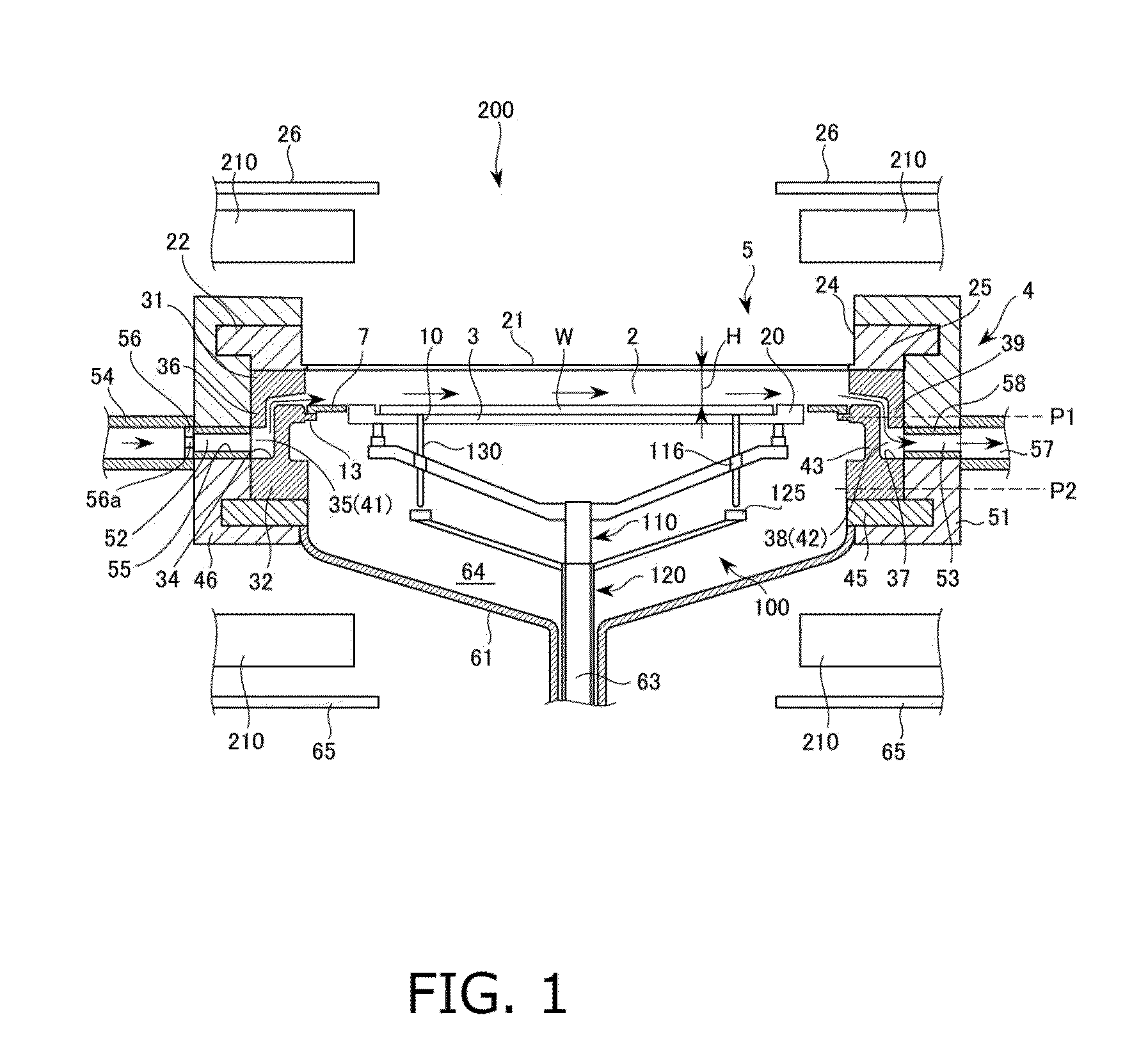

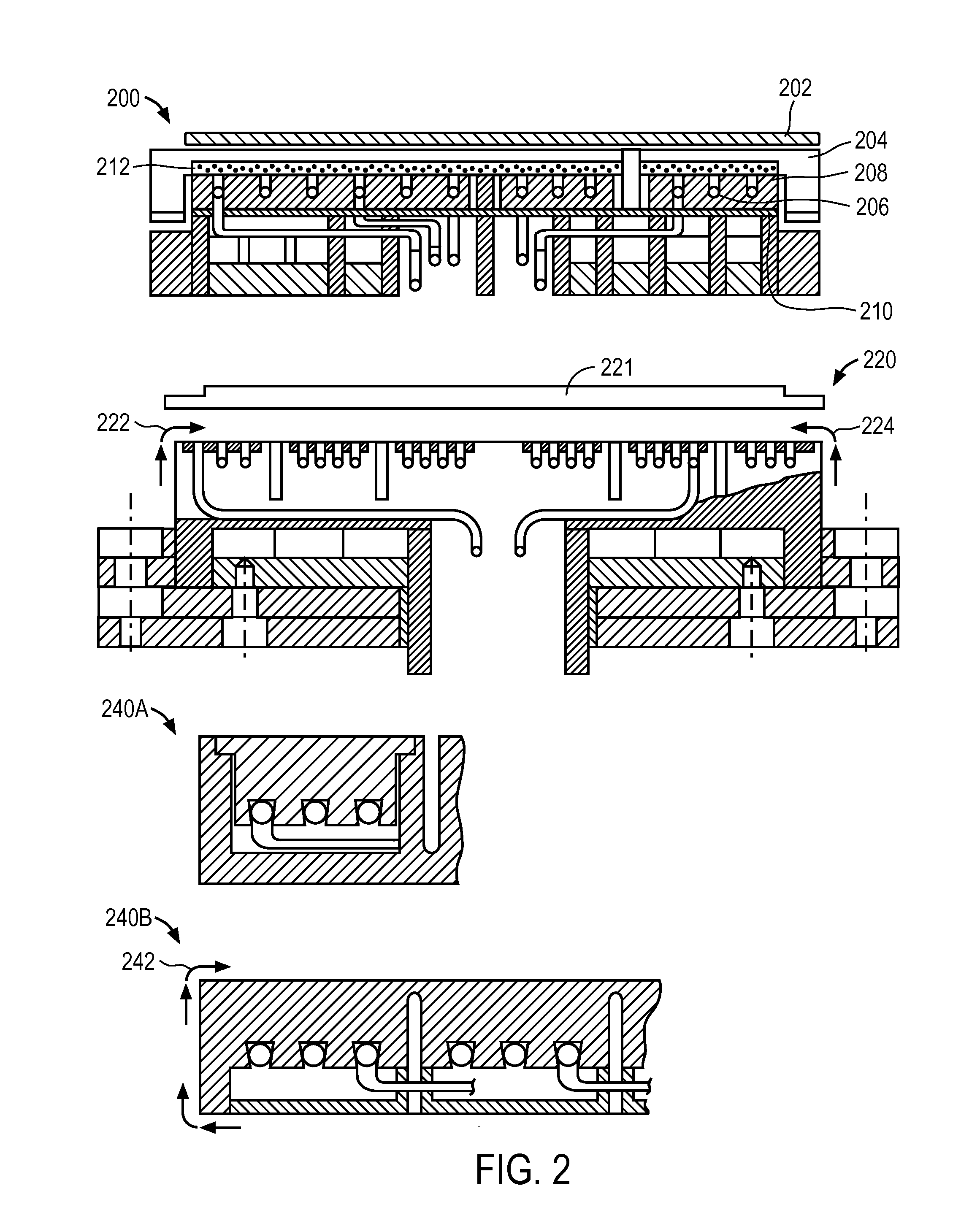

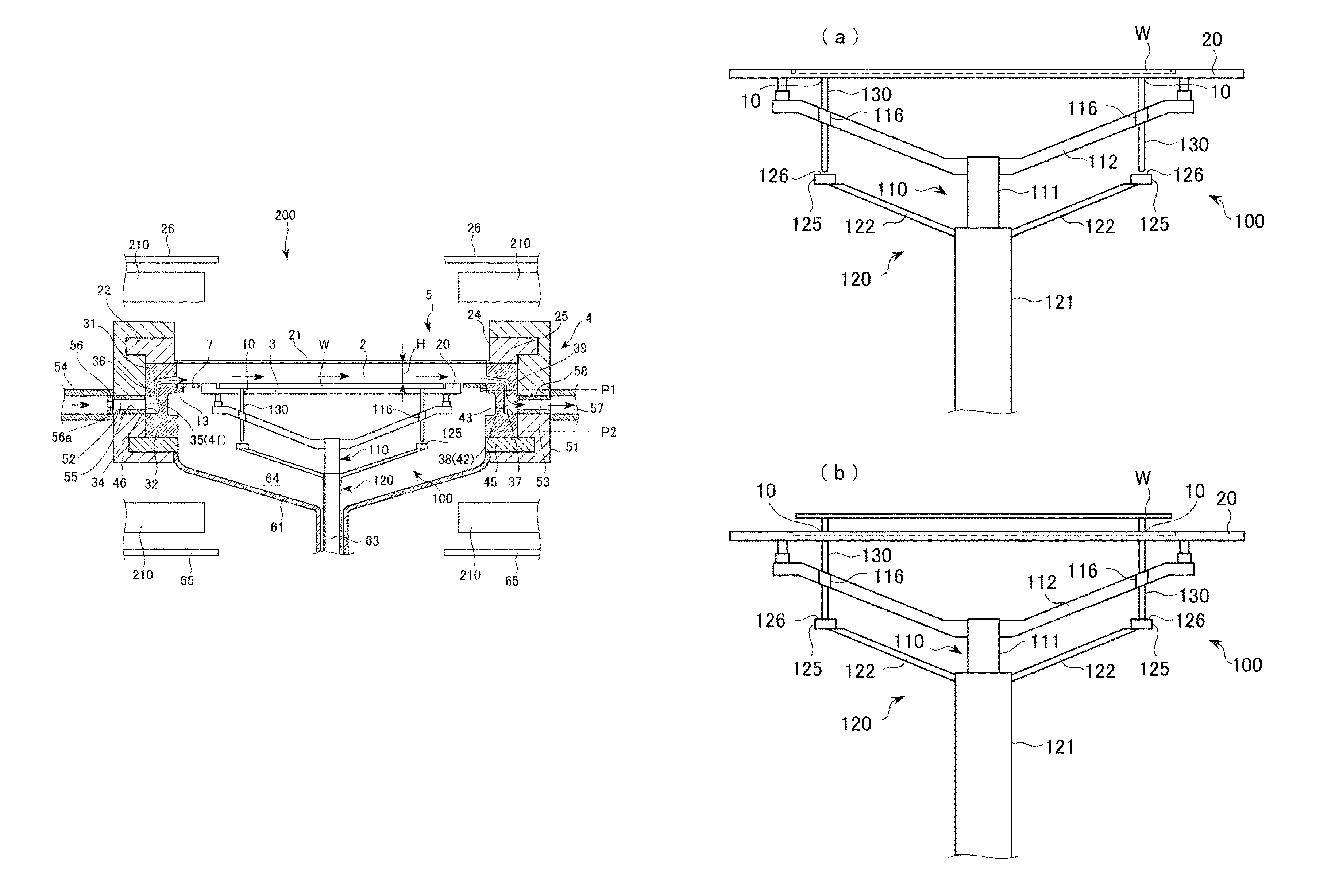

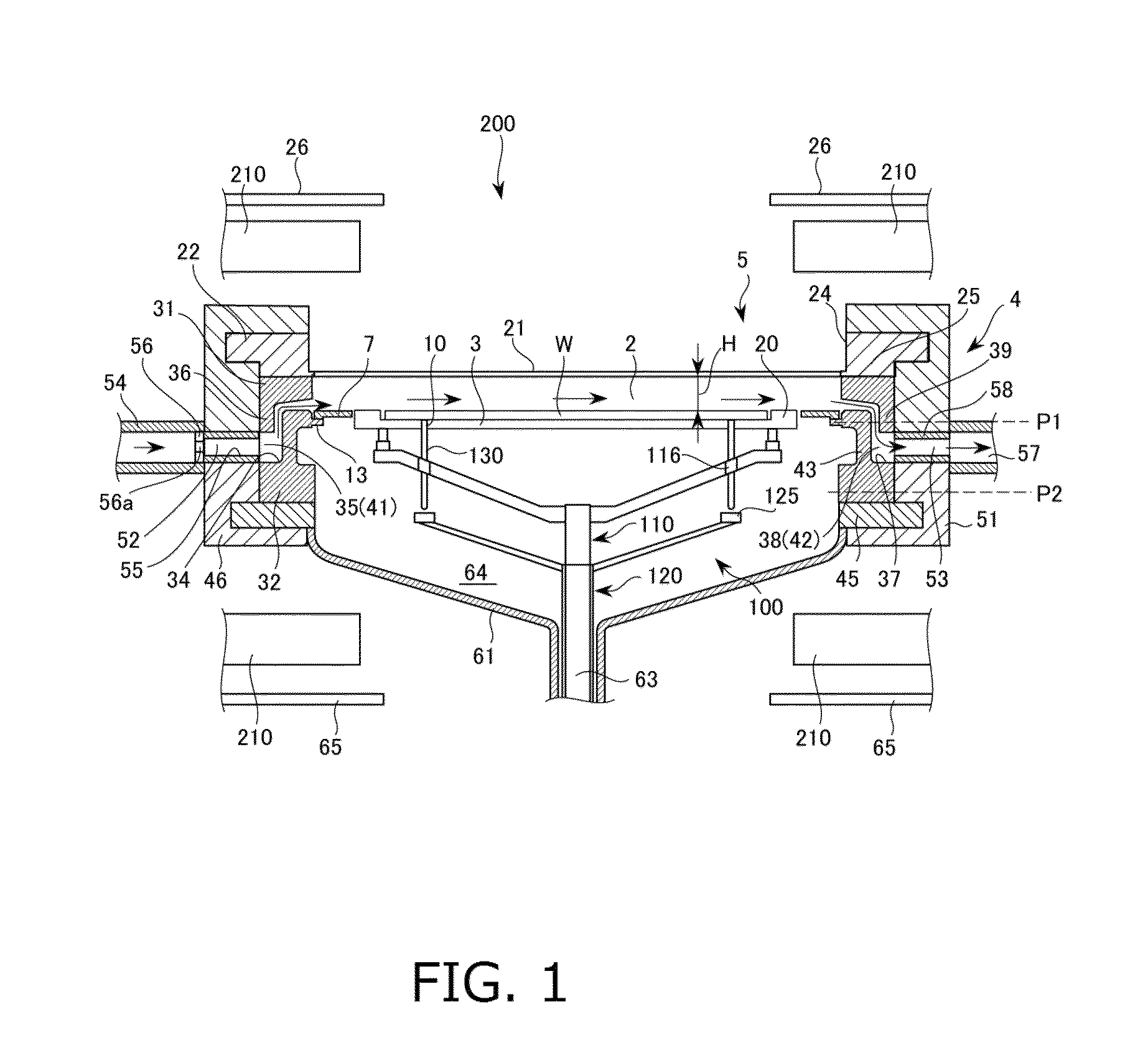

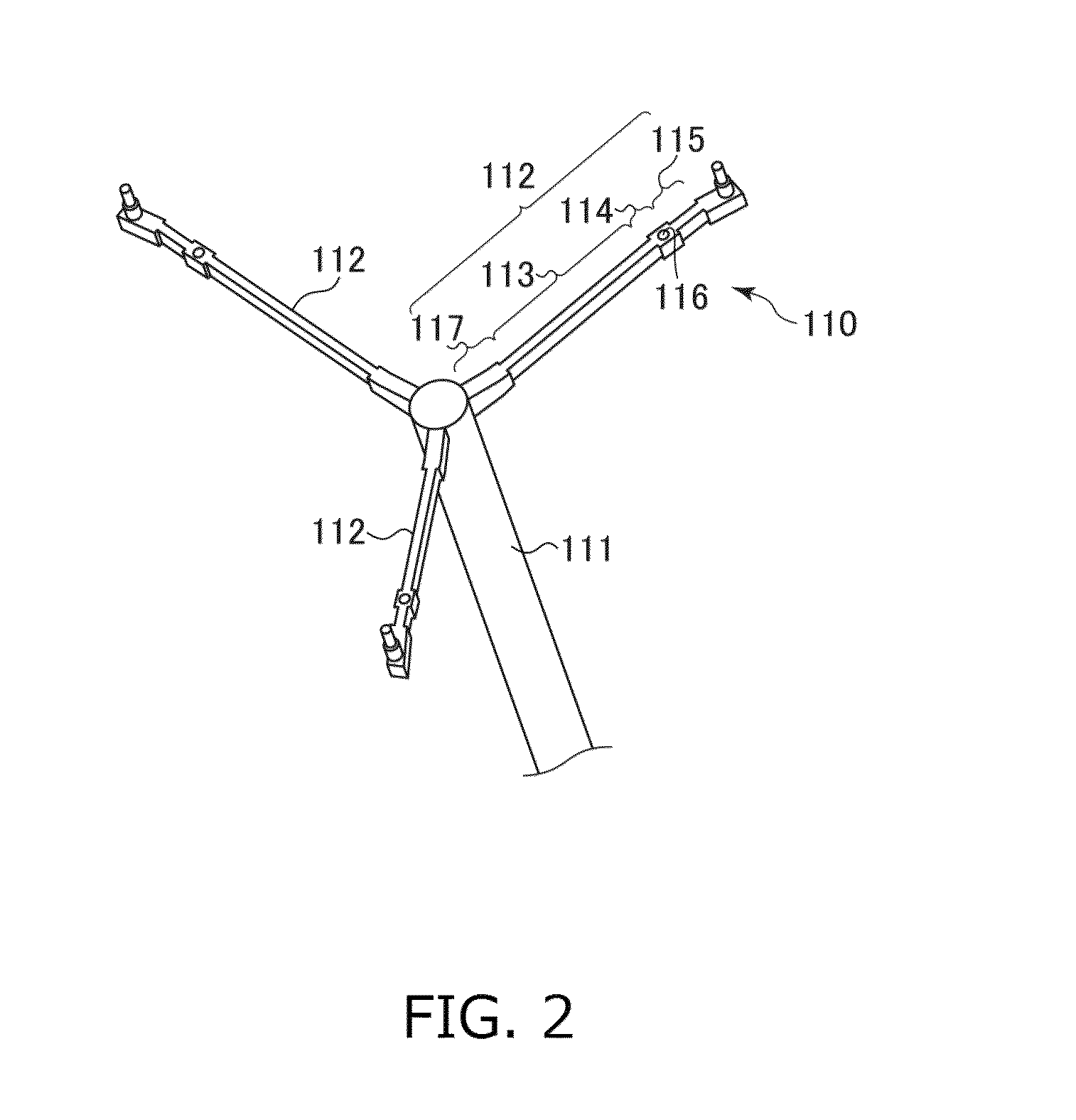

Susceptor Support Portion and Epitaxial Growth Apparatus Including Susceptor Support Portion

ActiveUS20140290573A1Reduce the impactSupport susceptorWorkpiece holdersLiquid surface applicatorsSusceptorEngineering

A susceptor support portion of the present invention includes a susceptor shaft and a substrate lift portion. The susceptor shaft includes a support column and a plurality of arms that extend radially from the support column, the substrate lift portion includes a support column and a plurality of arms that extend radially from the support column, the arm of the susceptor shaft includes a first arm, a second arm coupled to the first arm, and a third arm coupled to the second arm, from the support column side of the susceptor shaft, the second arm being provided with a through hole which passes through the second arm in a vertical direction, and a width of the first arm of the susceptor shaft is smaller than a width of the second arm of the susceptor shaft.

Owner:APPLIED MATERIALS INC

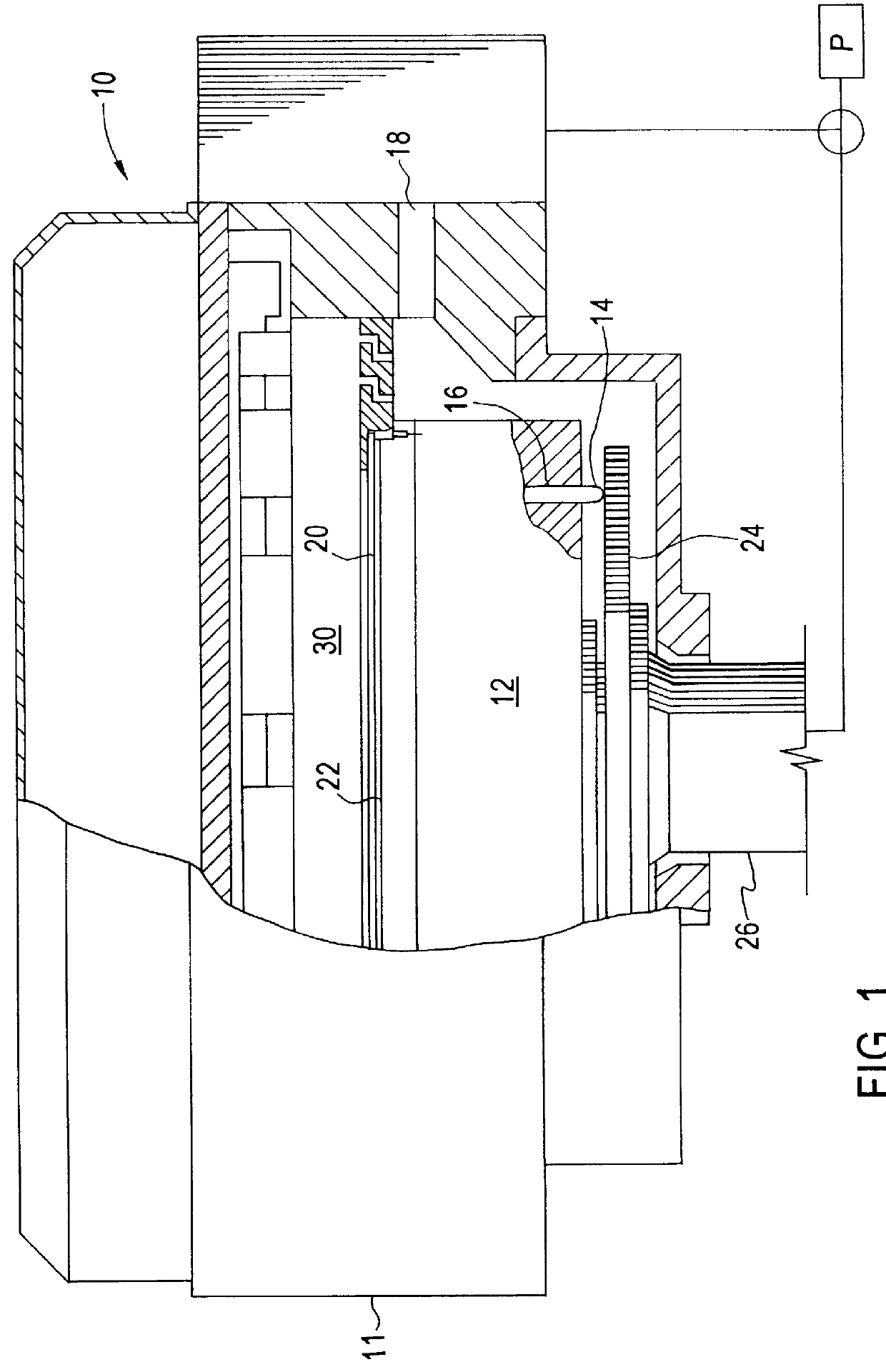

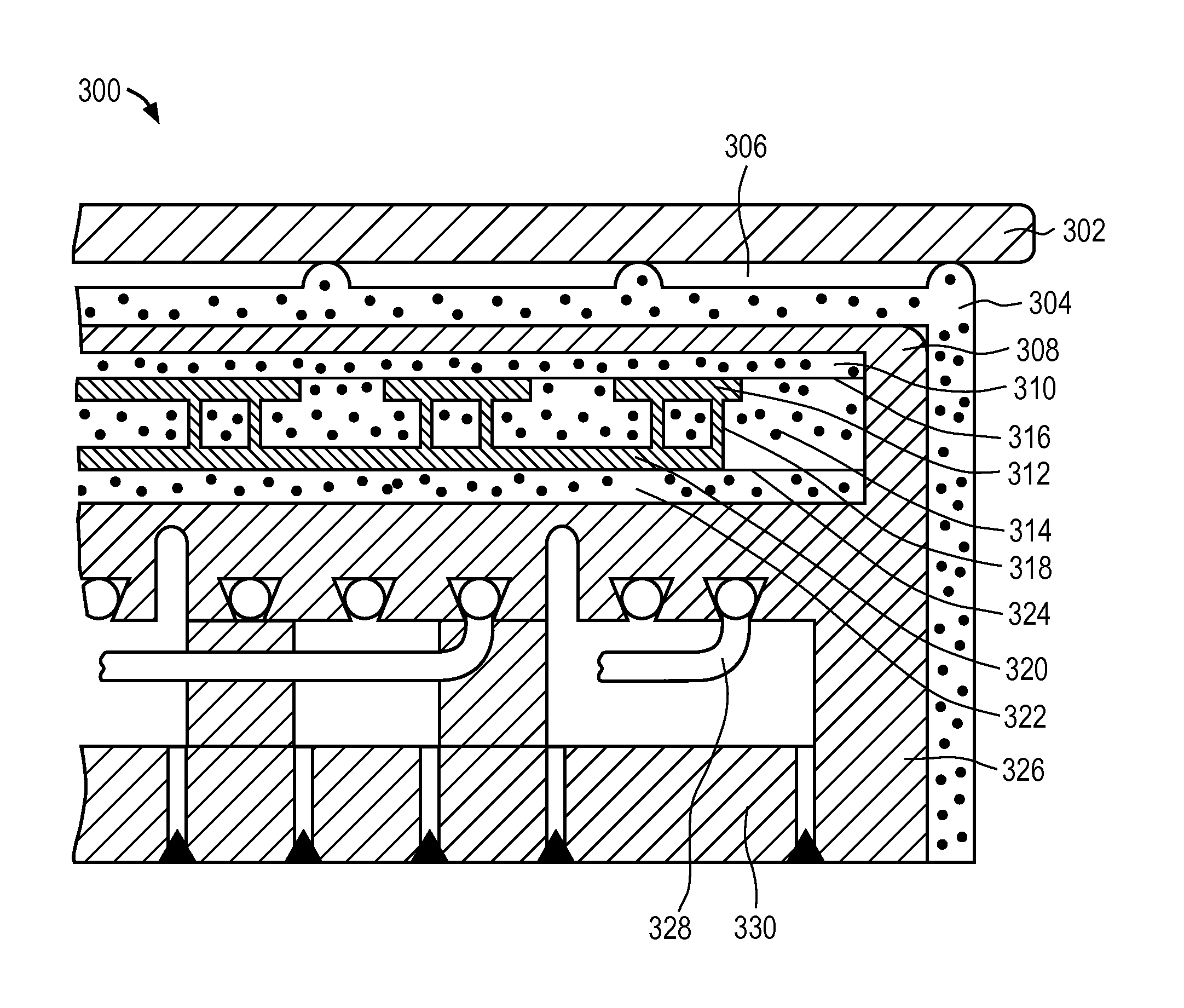

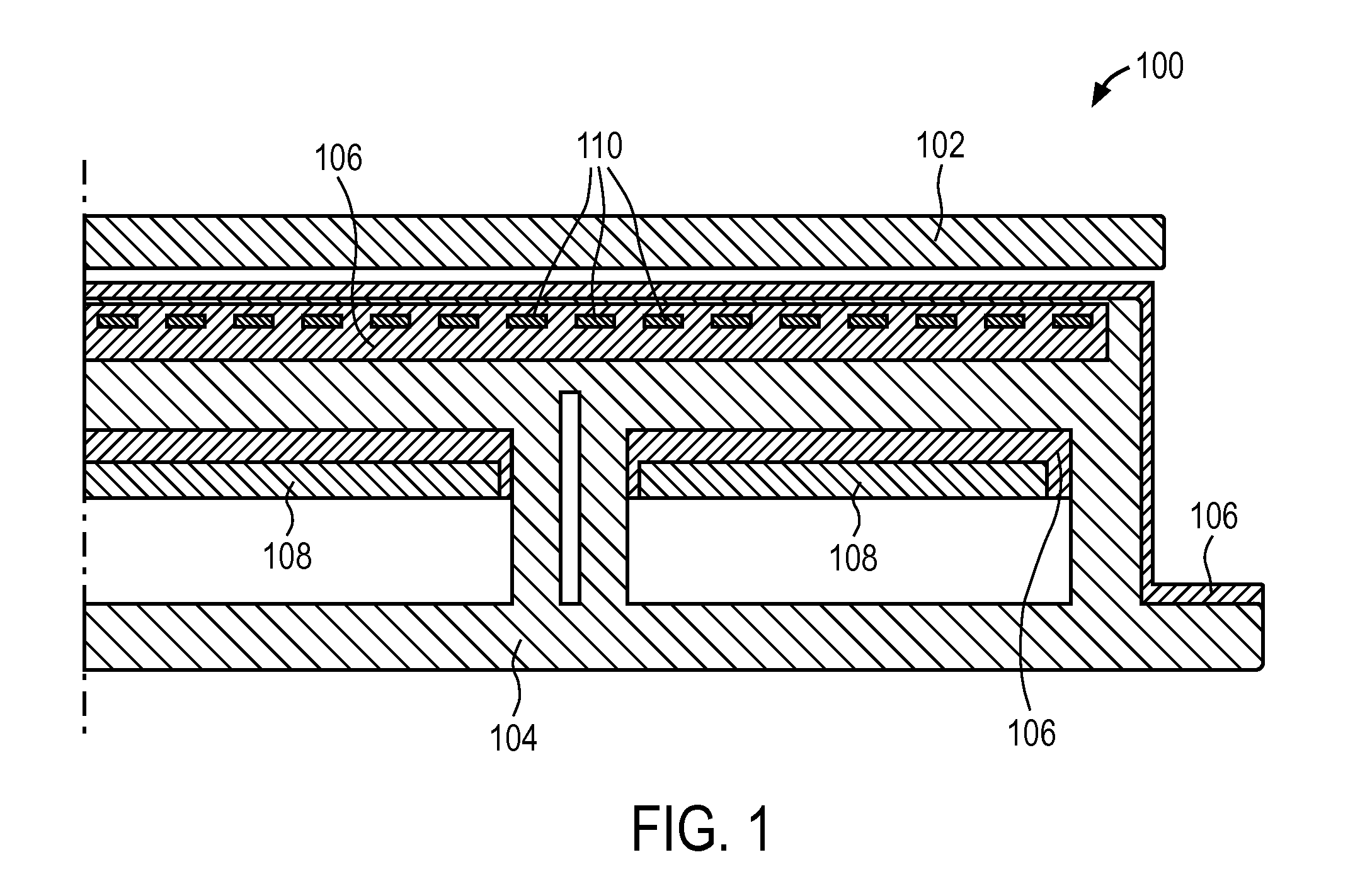

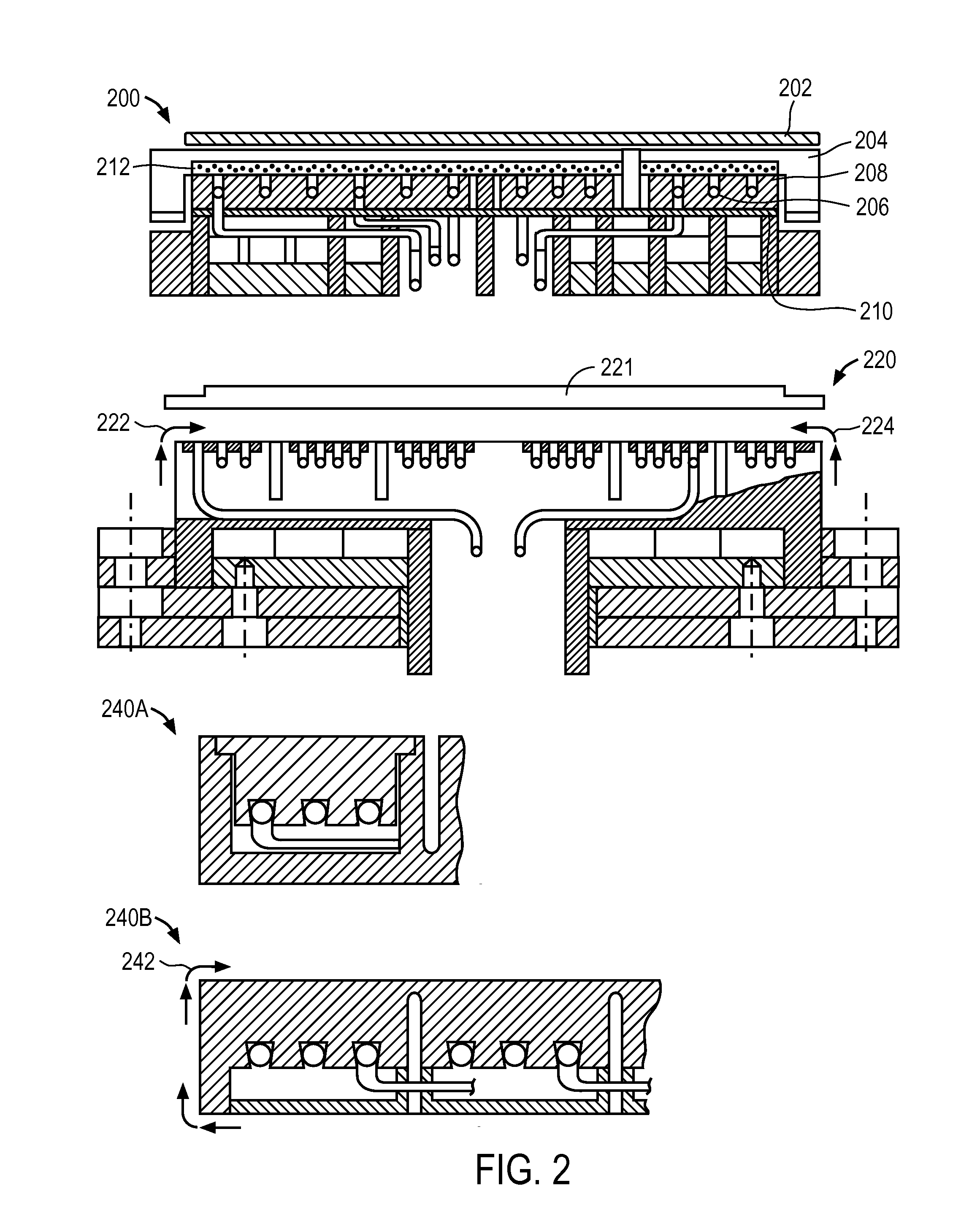

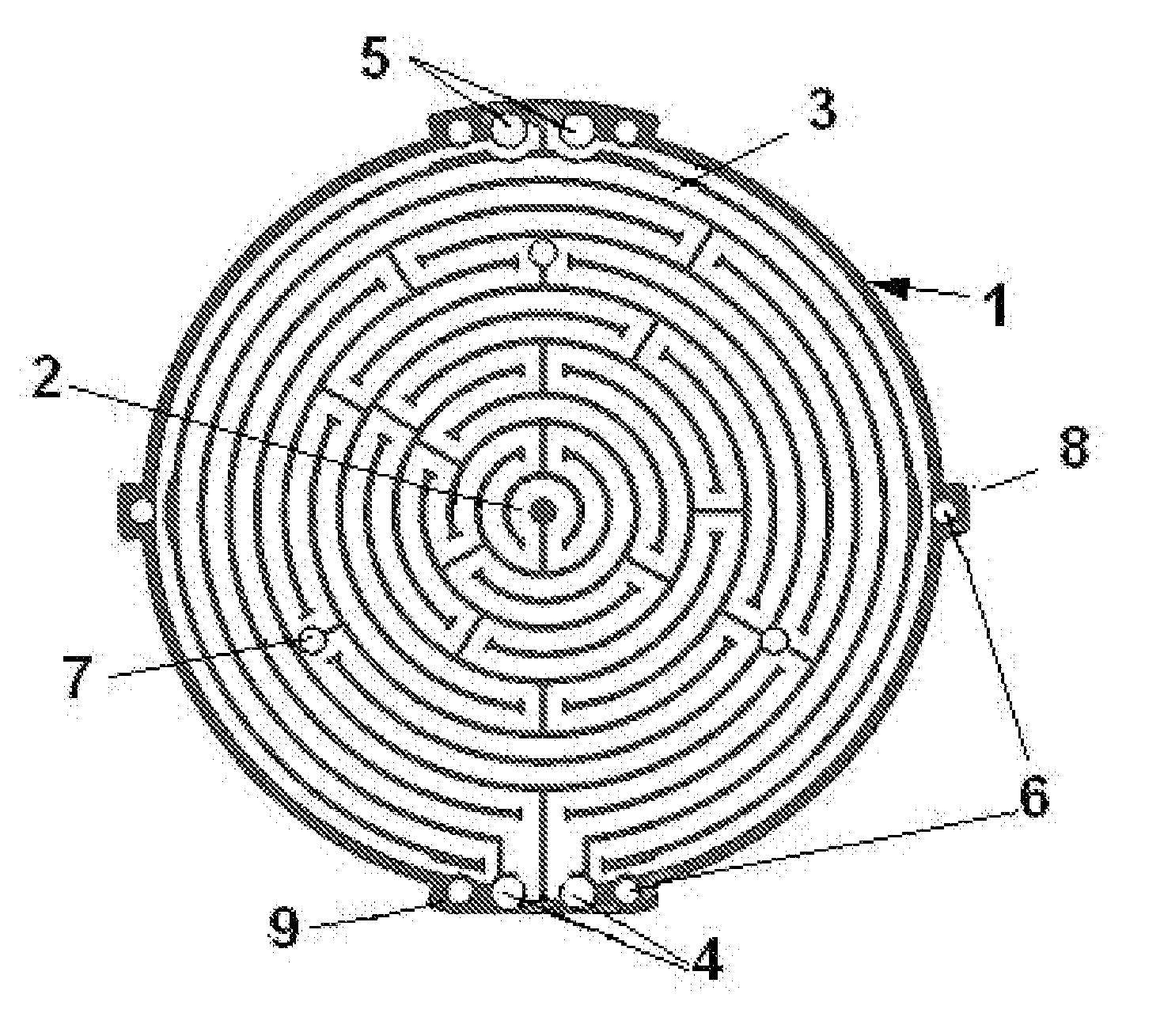

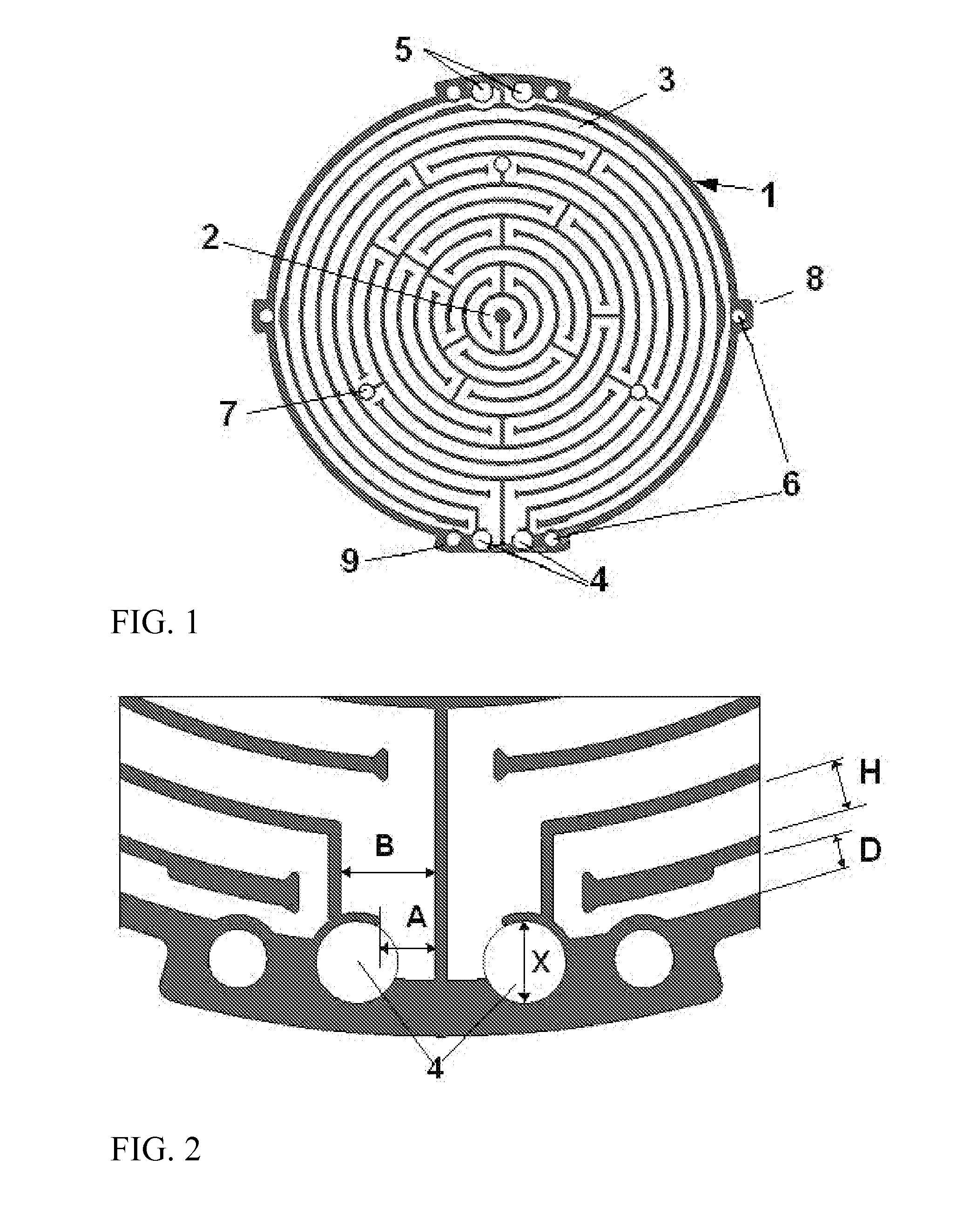

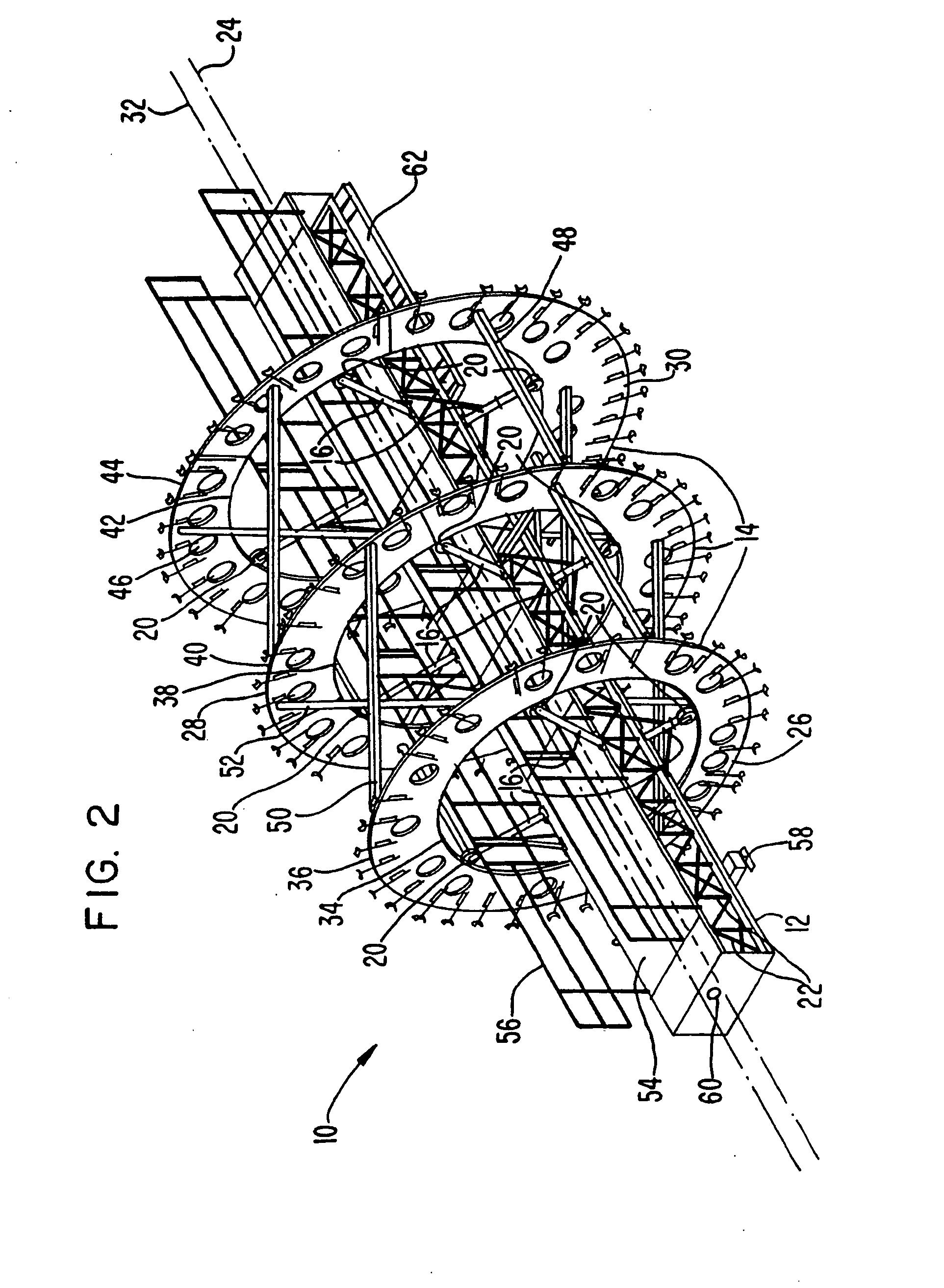

Electrostatic chuck with advanced RF and temperature uniformity

ActiveUS8937800B2Improve the level ofIncrease the diameterWorkpiece holdersSemiconductor/solid-state device manufacturingEngineeringRadio frequency

Owner:APPLIED MATERIALS INC

Electrostatic chuck with advanced RF and temperature uniformity

ActiveUS20130279066A1Improve the level ofIncrease the diameterWorkpiece holdersSemiconductor/solid-state device manufacturingEngineeringRadio frequency

Electrostatic chucks (ESCs) with RF and temperature uniformity are described. For example, an ESC includes a top dielectric layer. An upper metal portion is disposed below the top dielectric layer. A second dielectric layer is disposed above a plurality of pixilated resistive heaters and surrounded in part by the upper metal portion. A third dielectric layer is disposed below the second dielectric layer, with a boundary between the third dielectric layer and the second dielectric layer. A plurality of vias is disposed in the third dielectric layer. A bus power bar distribution layer is disposed below and coupled to the plurality of vias. A fourth dielectric layer is disposed below the bus bar power distribution layer, with a boundary between the fourth dielectric layer and the third dielectric layer. A metal base is disposed below the fourth dielectric layer. The metal base includes a plurality of high power heater elements housed therein.

Owner:APPLIED MATERIALS INC

Susceptor support portion and epitaxial growth apparatus including susceptor support portion

ActiveUS8888087B2Reduce impactHigh-quality epitaxial waferWorkpiece holdersSemiconductor/solid-state device manufacturingSusceptorEngineering

A susceptor support portion of the present invention includes a susceptor shaft and a substrate lift portion. The susceptor shaft includes a support column and a plurality of arms that extend radially from the support column, the substrate lift portion includes a support column and a plurality of arms that extend radially from the support column, the arm of the susceptor shaft includes a first arm, a second arm coupled to the first arm, and a third arm coupled to the second arm, from the support column side of the susceptor shaft, the second arm being provided with a through hole which passes through the second arm in a vertical direction, and a width of the first arm of the susceptor shaft is smaller than a width of the second arm of the susceptor shaft.

Owner:APPLIED MATERIALS INC

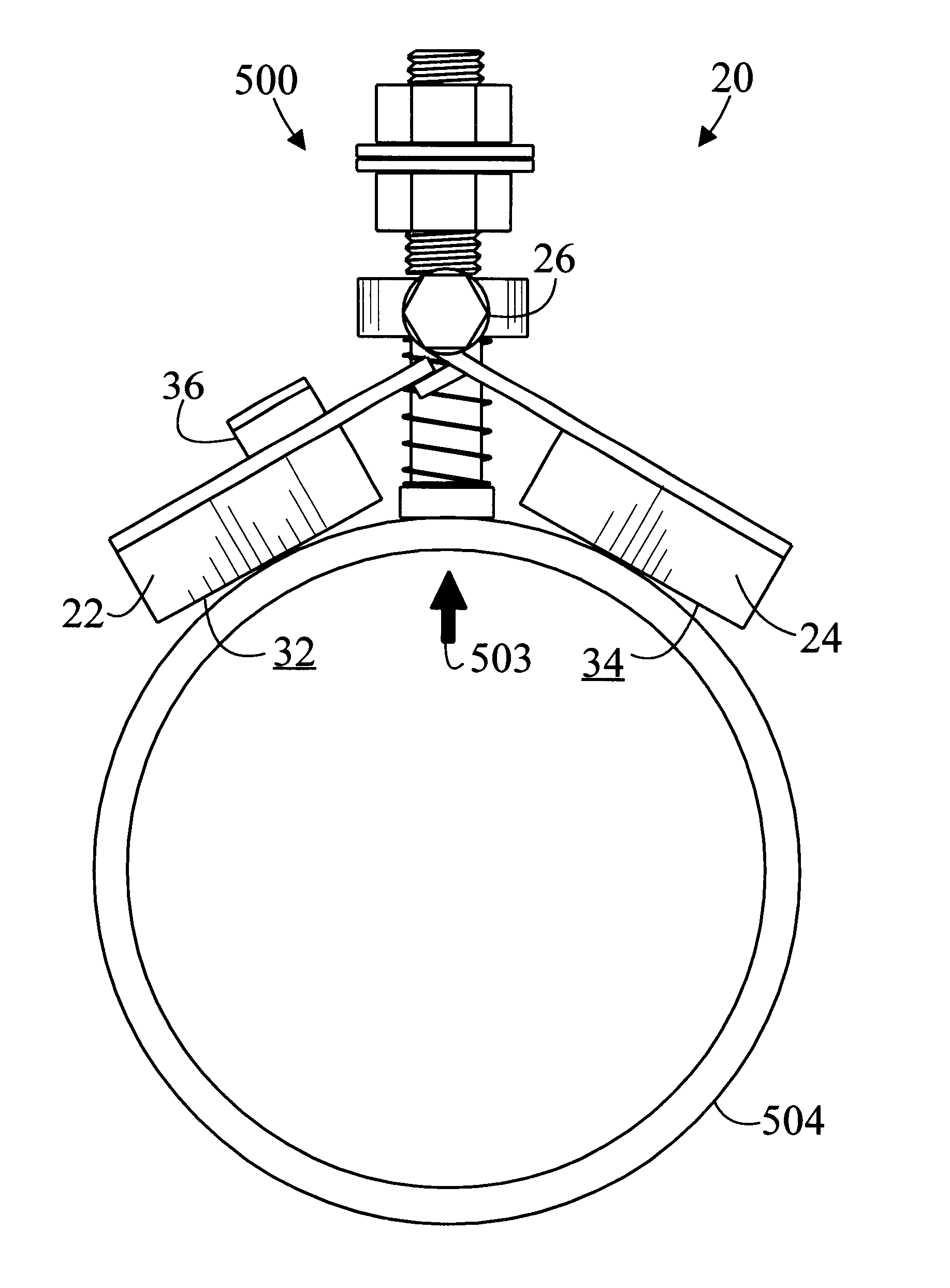

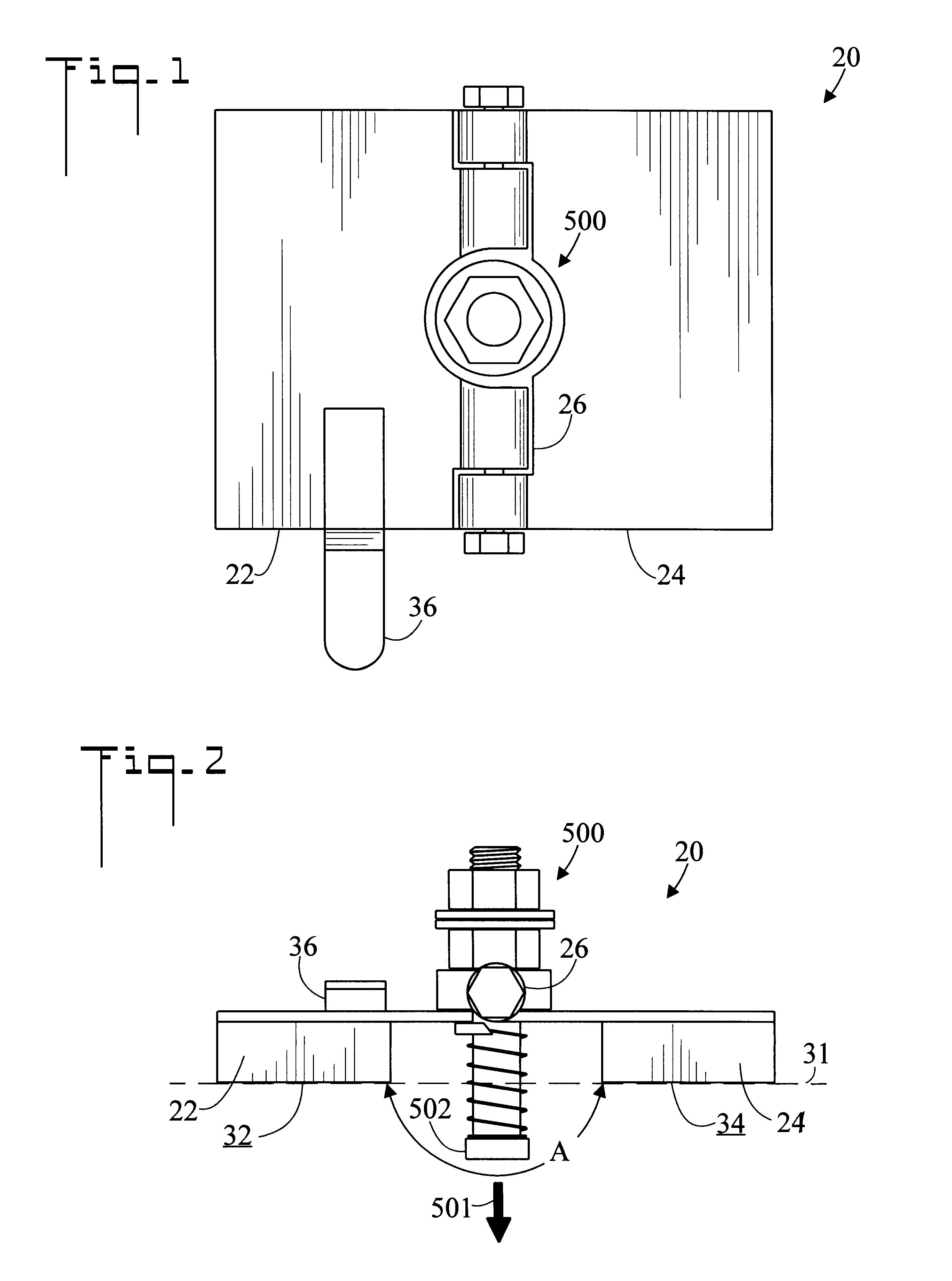

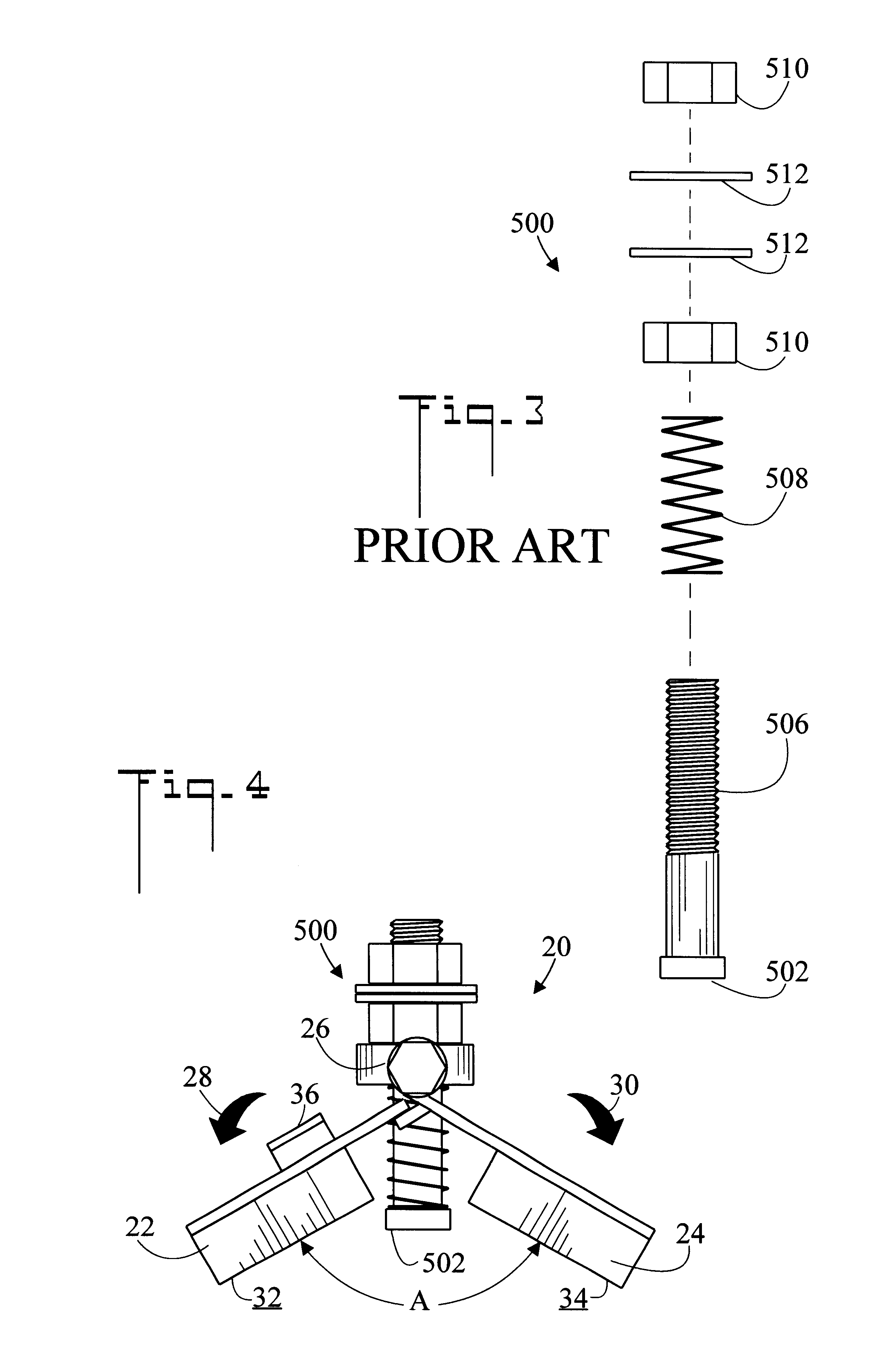

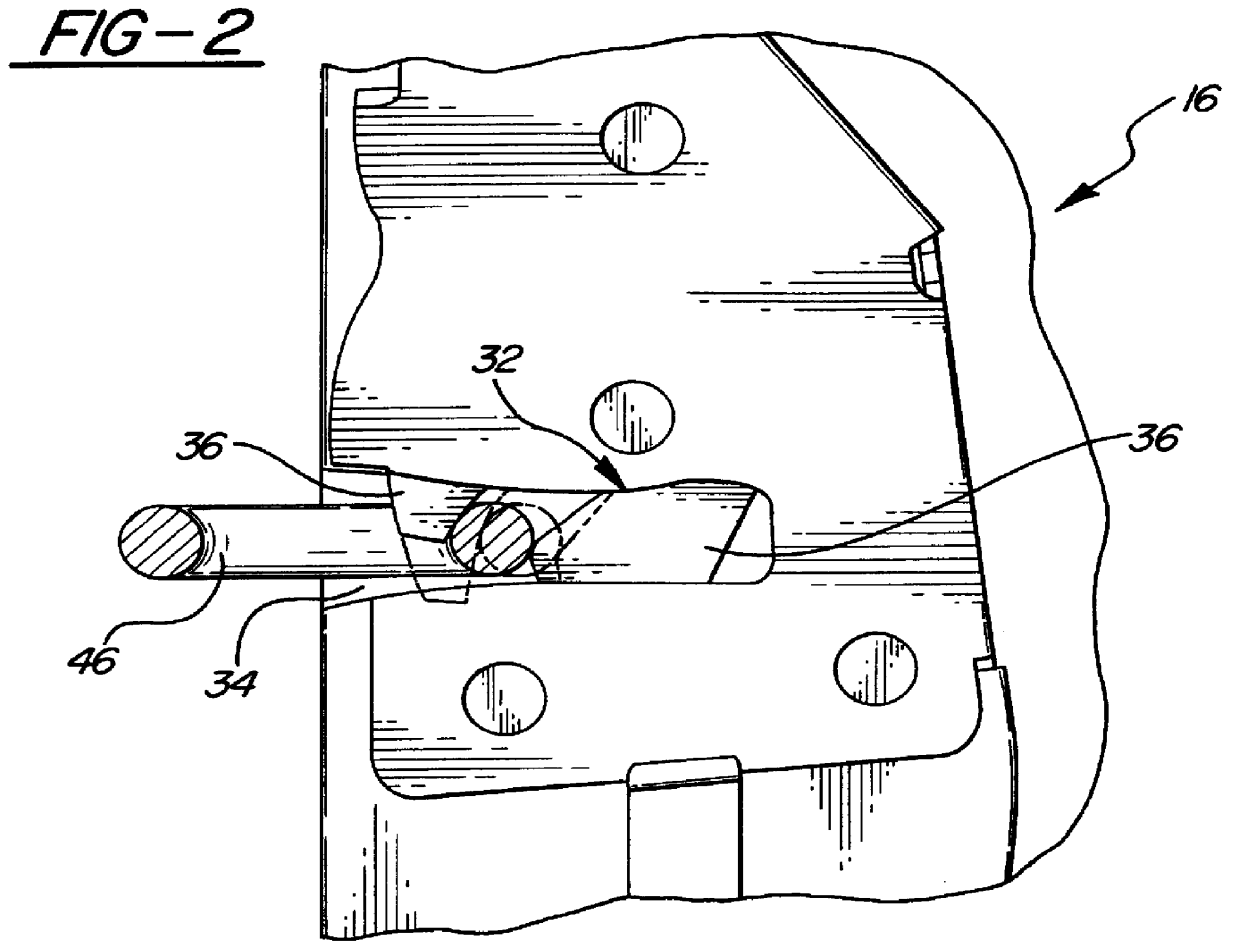

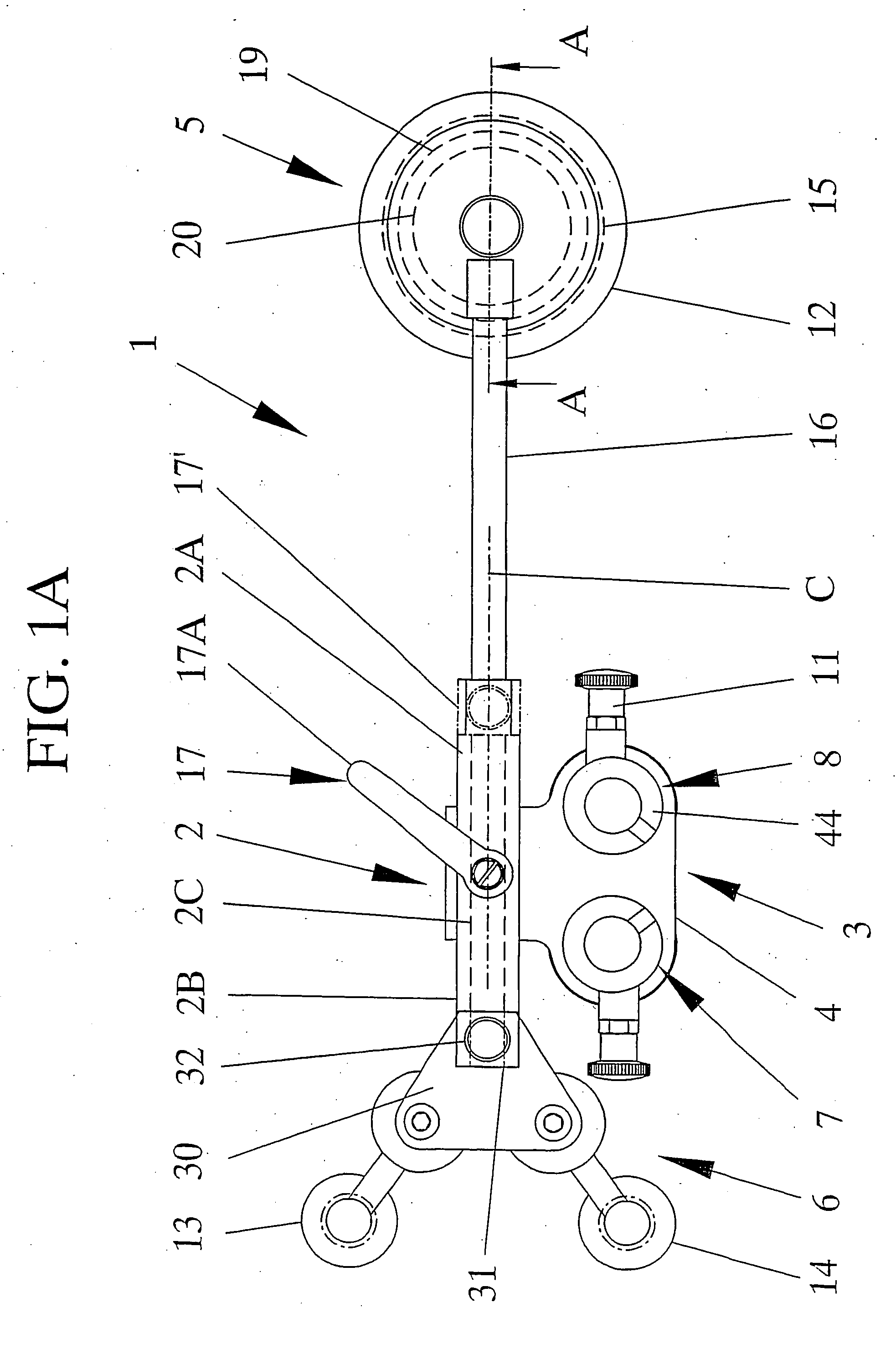

Magnetic clamp for welding magnetic objects

InactiveUS6279885B1Easily be twisted off of pipeImprove gripWorkpiece holdersWelding/cutting auxillary devicesEngineeringHinge angle

A magnetic clamp (20) for welding a magnetic object (504), includes a first magnetic member (22) and a second magnetic member (24). A hinge (26) connects magnetic members (22) and (24) so that an angle formed by magnetic members (22) and (24) may be changed. A spring loaded terminal (500) having a contact end (502) is disposed between first magnetic member (22) and second magnetic member (24). Magnetic clamp (20) may be attached to magnetic object (504) so that first magnetic member (22), second magnetic member (24), and contact end (502) all abut magnetic object (504). In a preferred embodiment, a removal tab (36) is connected to magnetic clamp (20) to assist in removing magnetic clamp (20) from magnetic object (504).

Owner:LEON JR RAYMOND

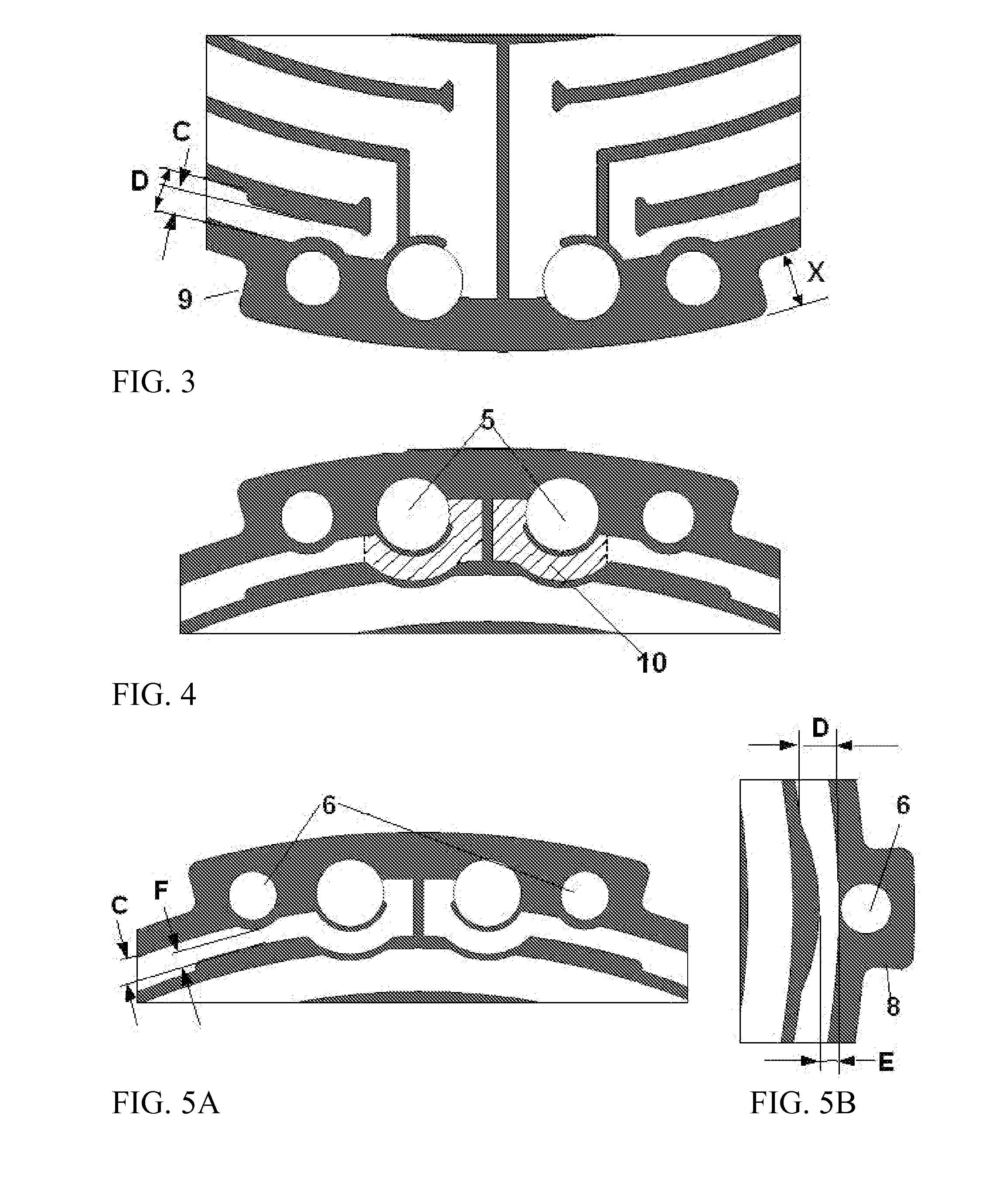

Electrode Pattern For Resistance Heating Element and Wafer processing Apparatus

ActiveUS20080029195A1Uniform temperature distributionImprove heat lossWorkpiece holdersCellsElectrical resistance and conductanceElectrical connection

There is disclosed a wafer processing apparatus having optimized electrode patterns for its resistive heating element. The optimized electrode pattern is designed to compensate for the heat loss around contact areas, electrical connections, and through-holes, etc., by generating more heat near or around those areas, providing maximum temperature uniformity. In another embodiment of the optimized design of the invention, the resistance of heating element closely matches the impedance of the power supply for higher efficiency, especially when higher operating temperature or higher electrical power is required.

Owner:GENERAL ELECTRIC CO

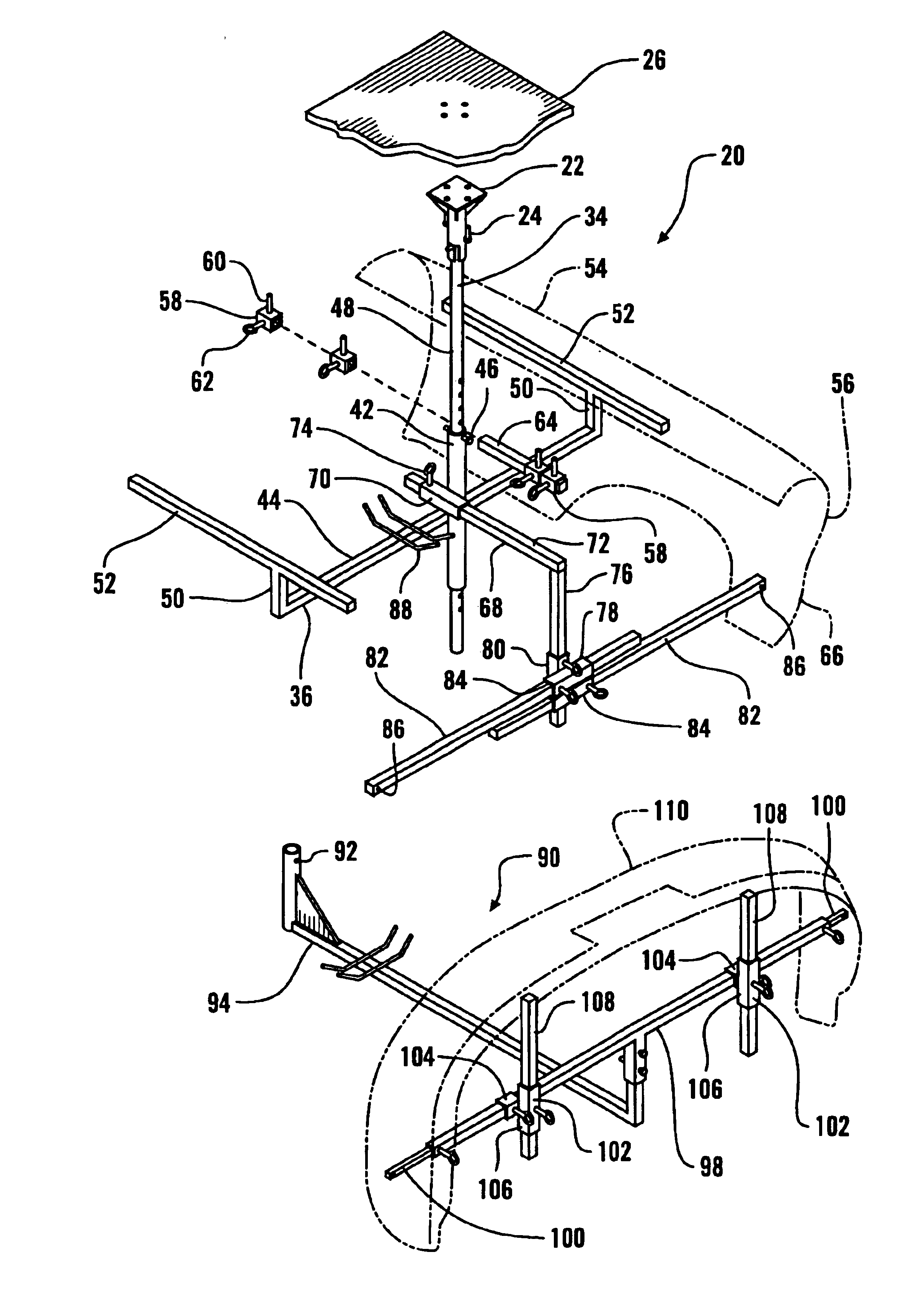

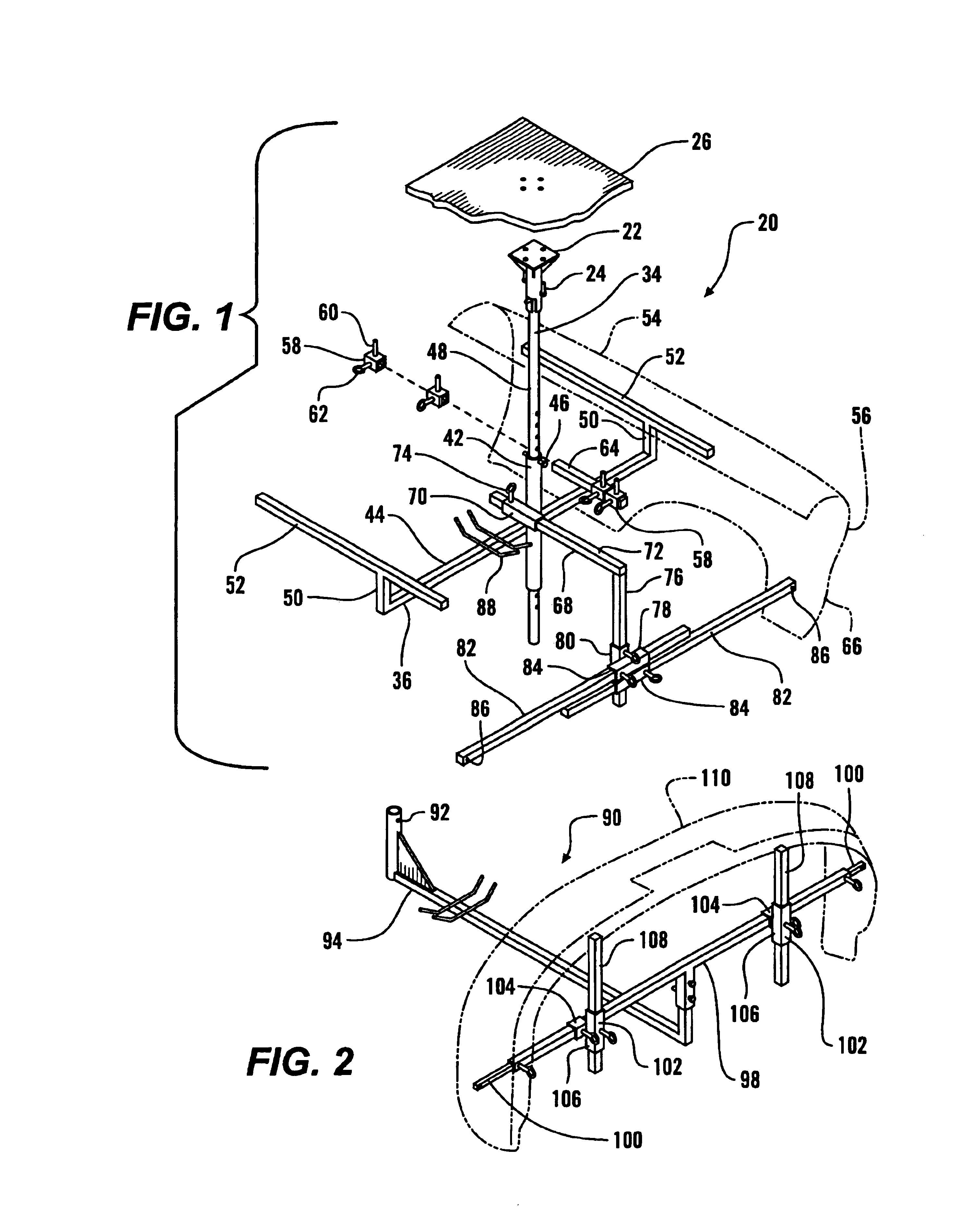

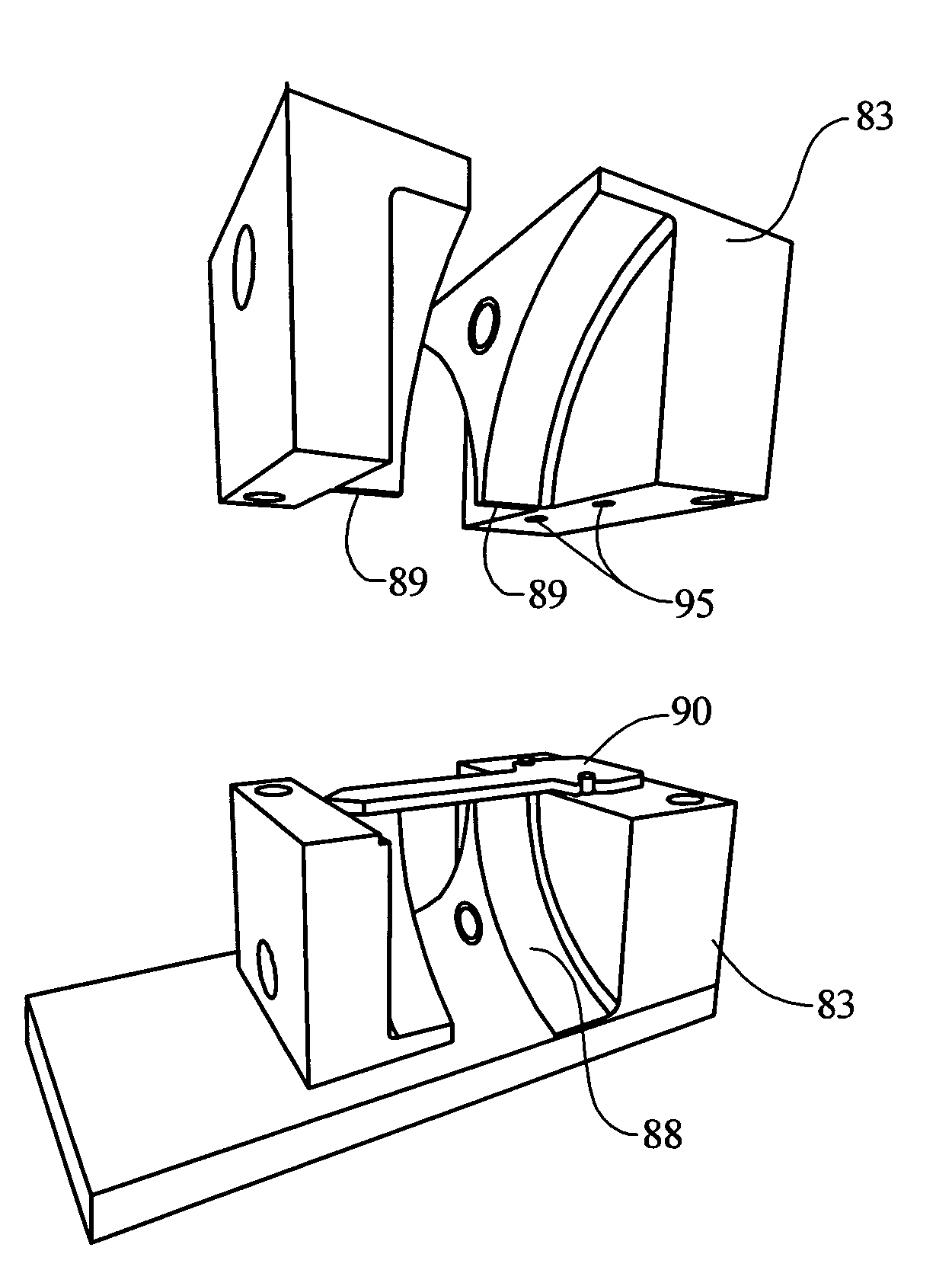

Racking system

A support rack, such as for supporting automobile body parts during painting, may be supported entirely from overhead by a single vertical support tube received within an overhead mounting bracket. A central frame has a sidewardly projecting cross member, which supports side members which extend front to back. A front frame projects frontwardly of the cross member, and has adjustable side support arms. When a fender is supported on one of the side members by an upper edge, one of the side support arms can be adjusted to properly engage the fender. Alternatively, the rack's vertical mount tube can be supported from below on a wheeled support frame. Adjustable pin collars can be moved along the side arm to support parts which have mounting holes.

Owner:PATRYKUS JOEL A

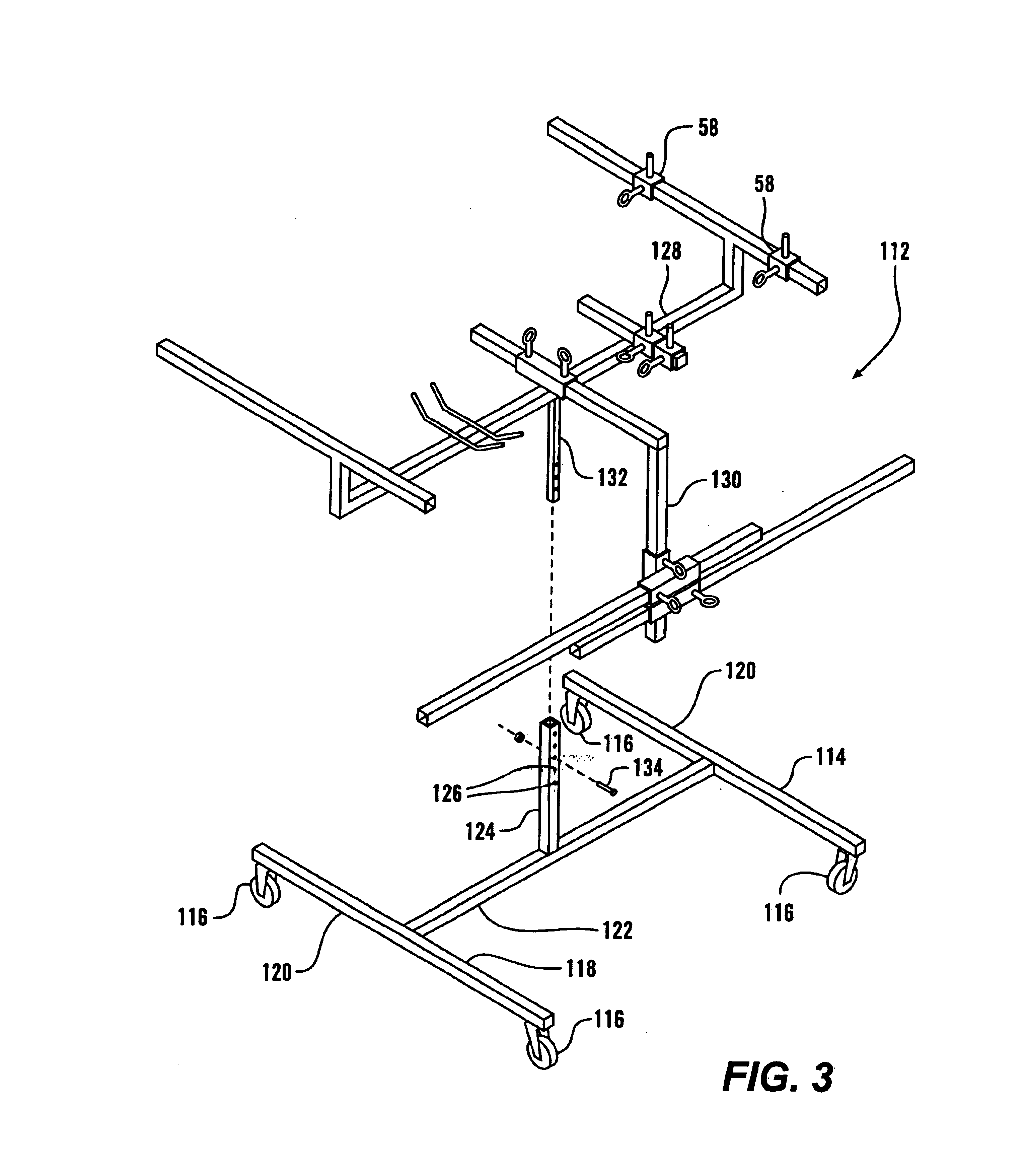

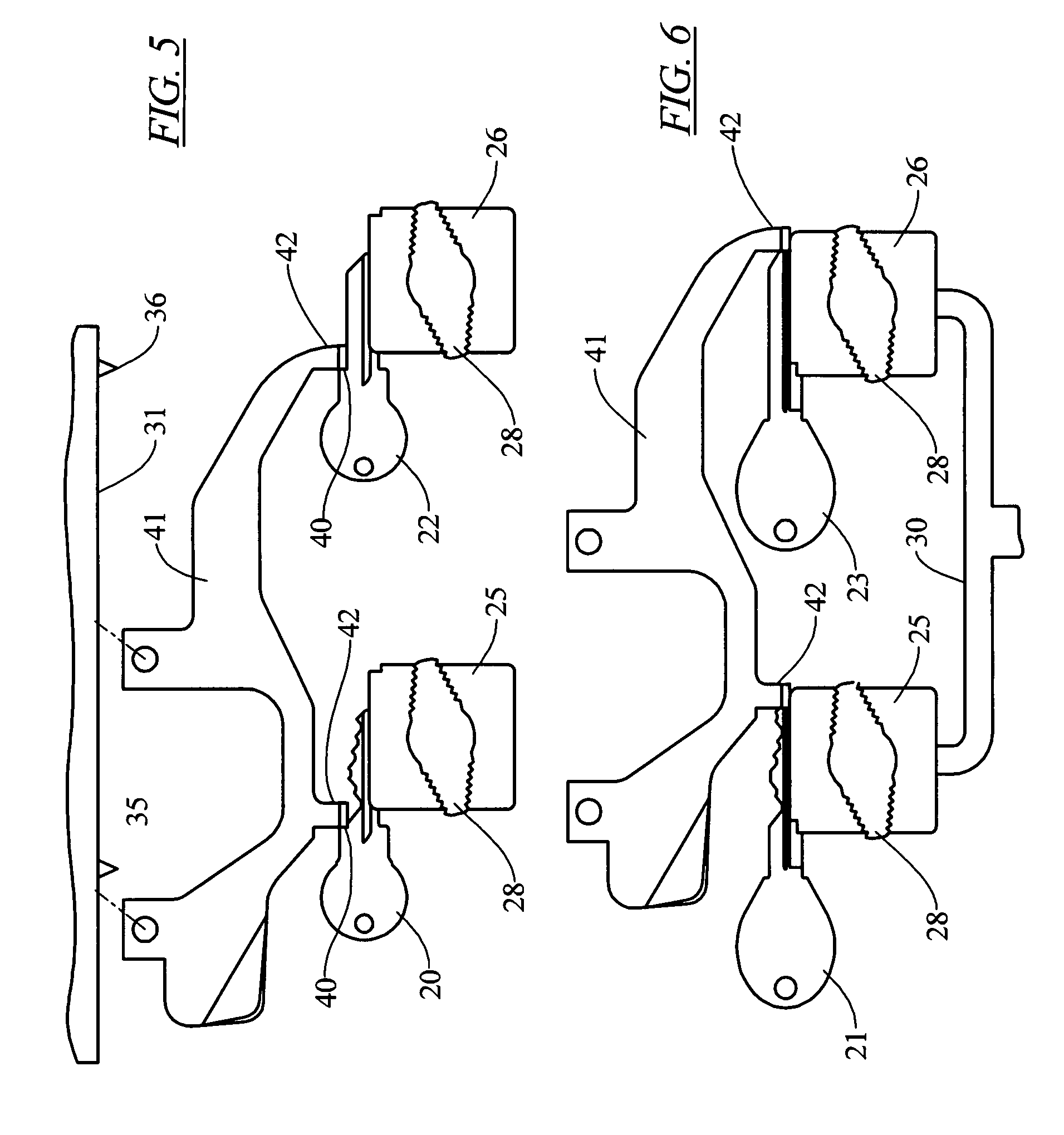

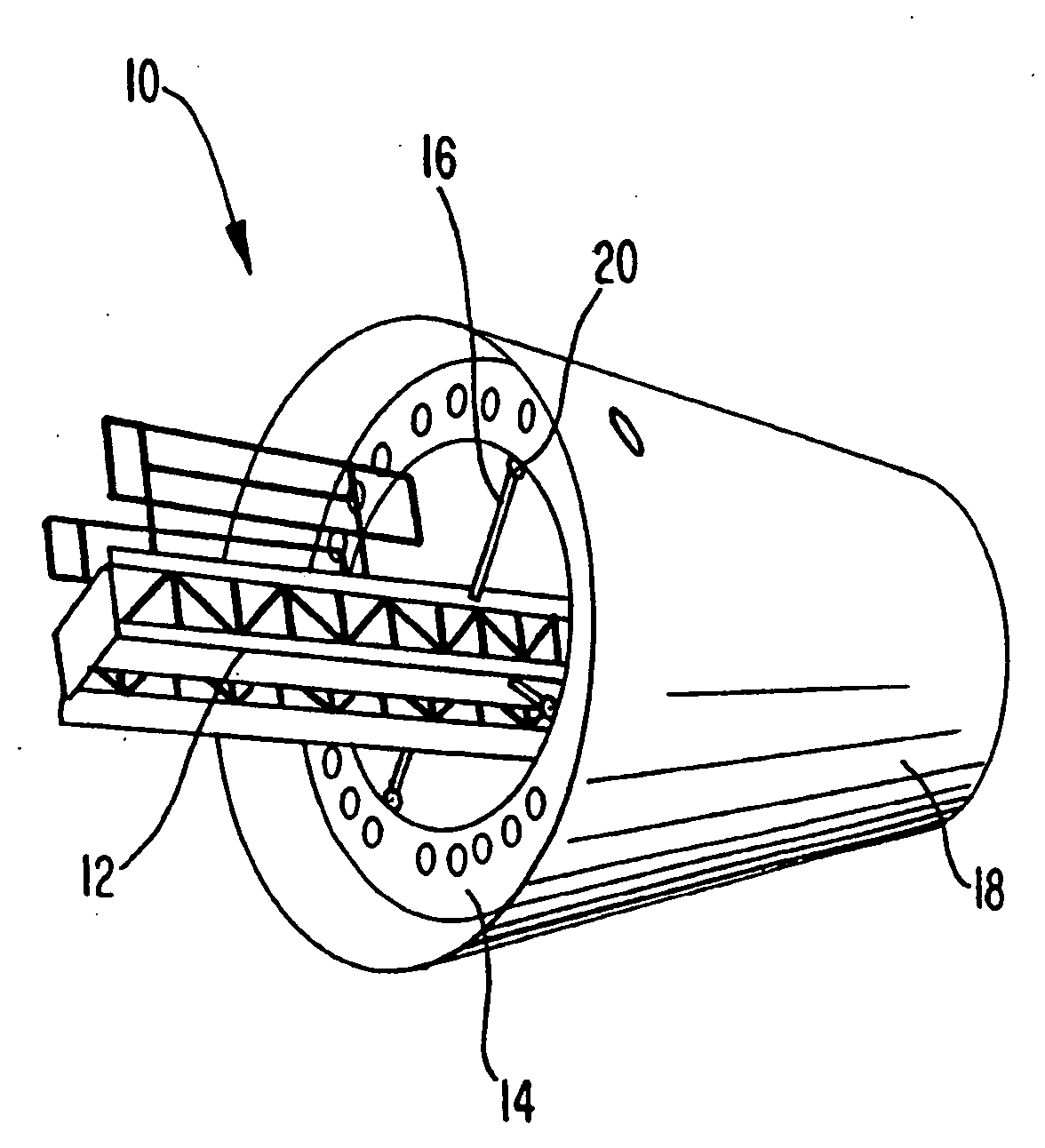

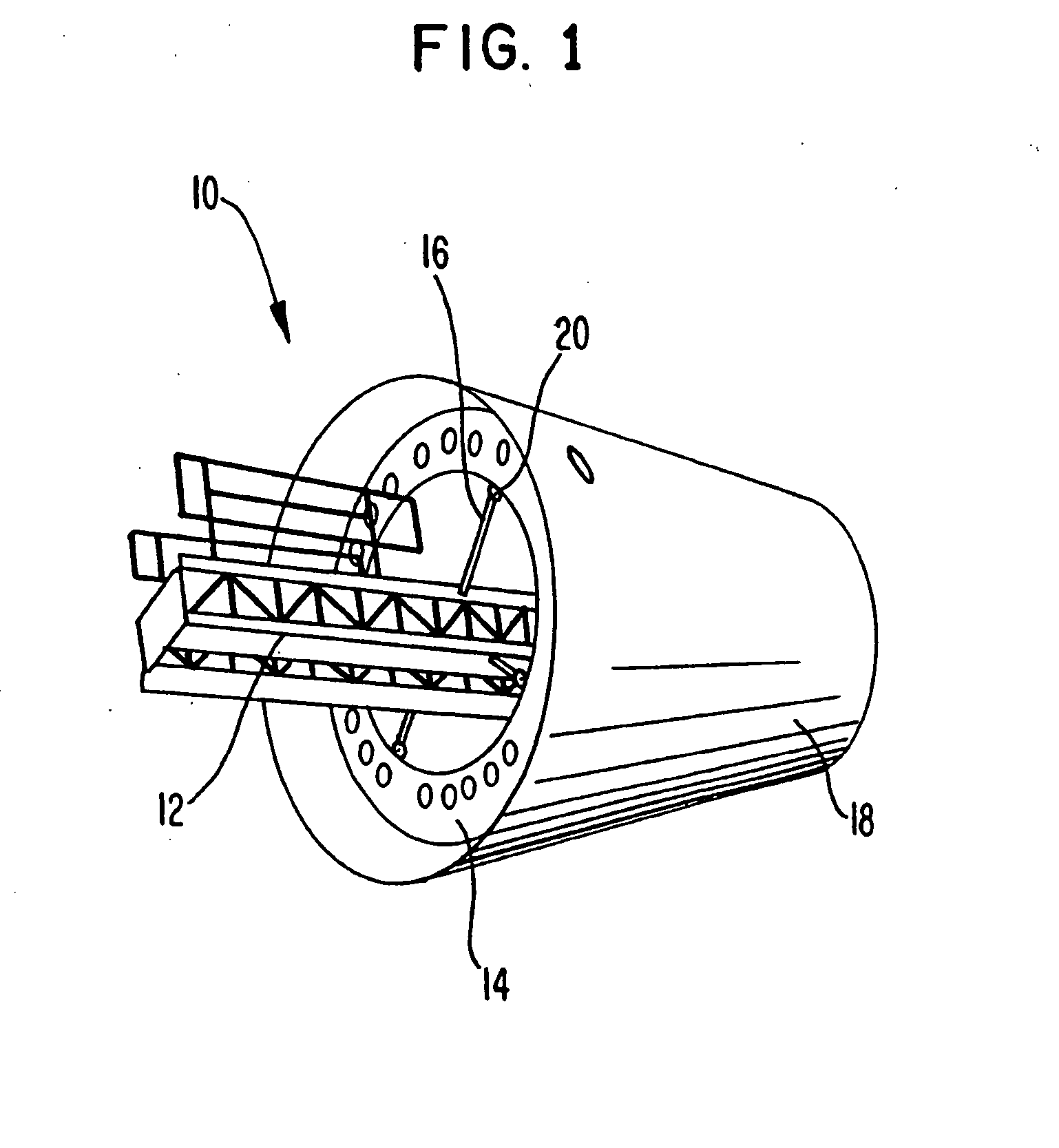

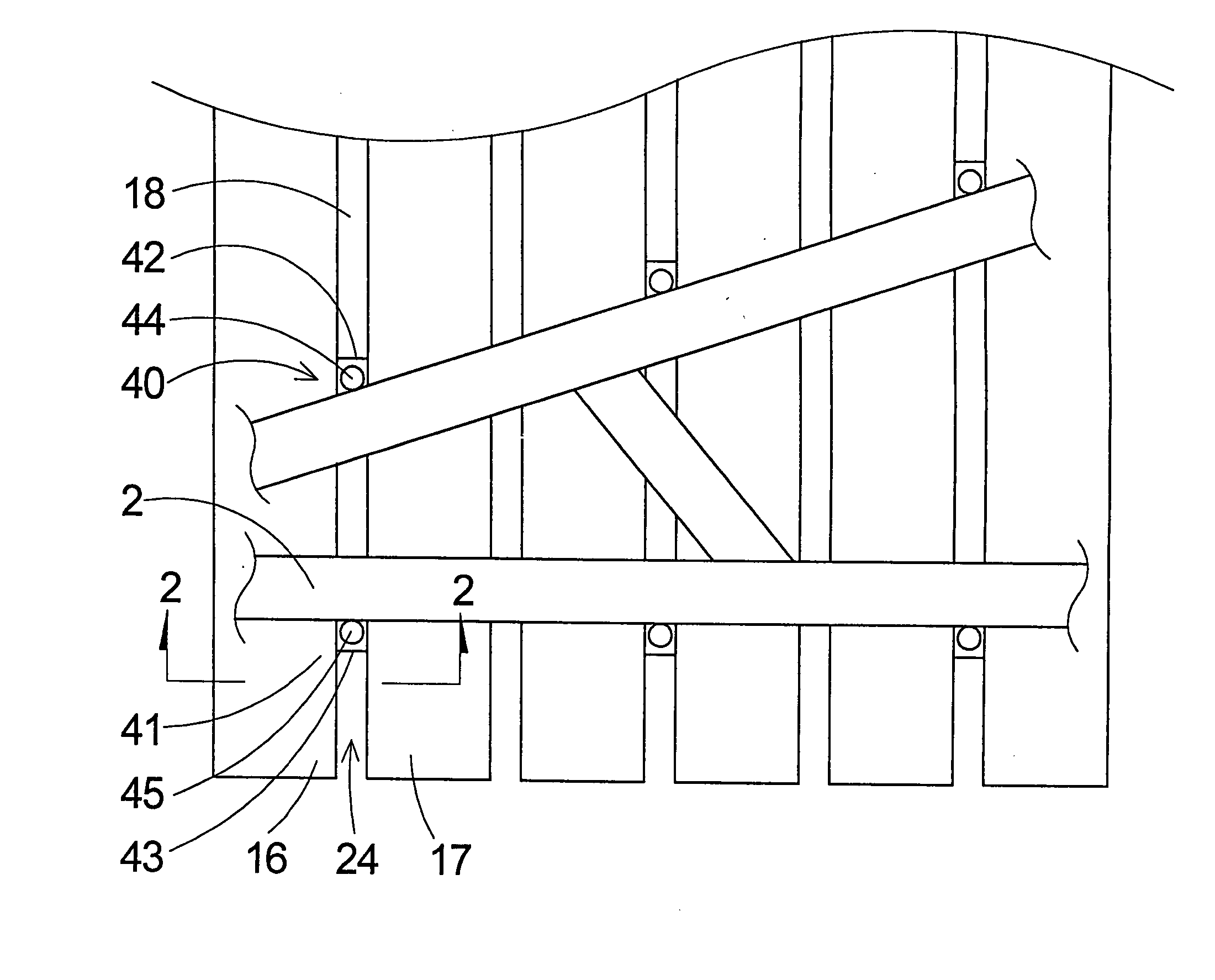

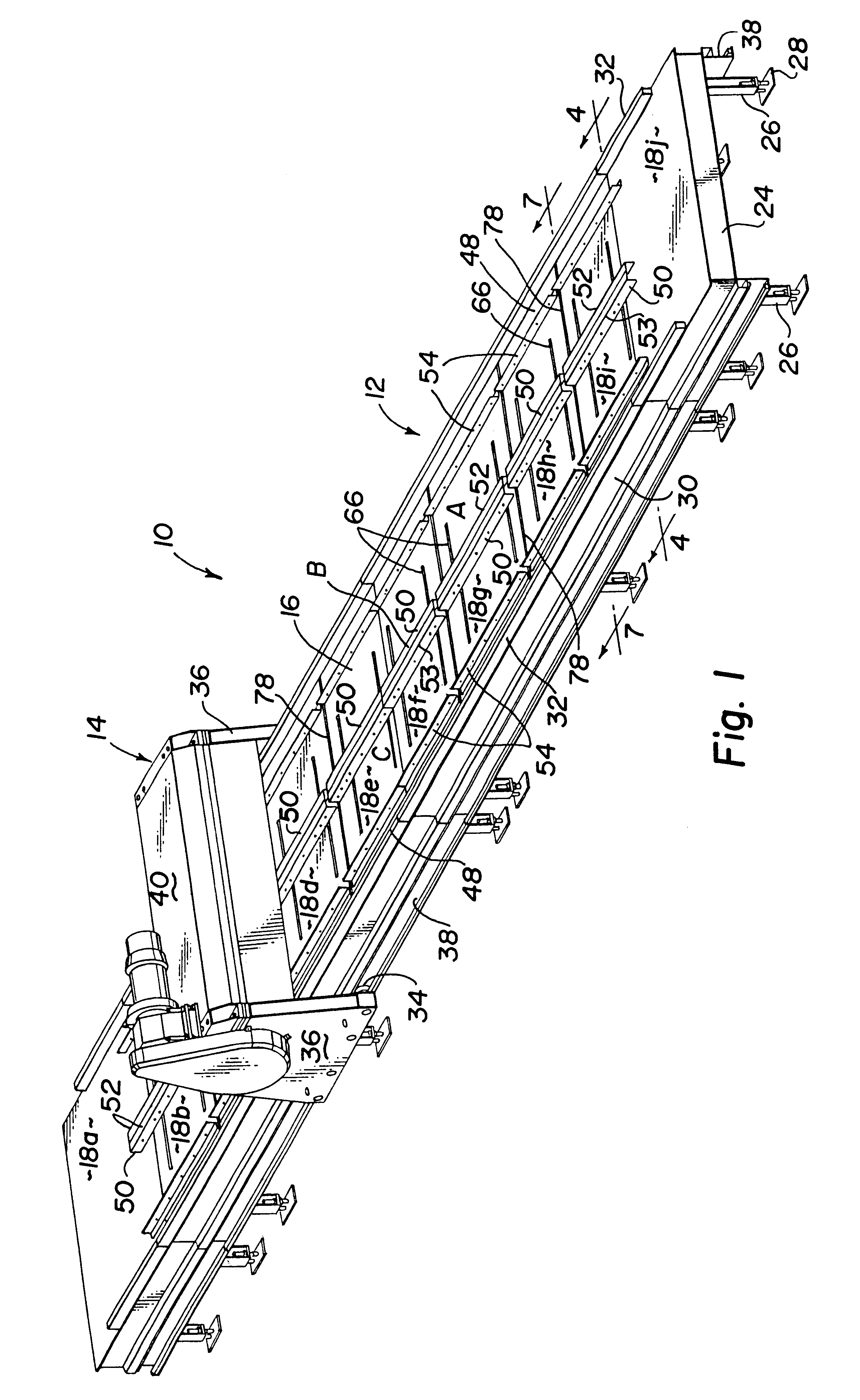

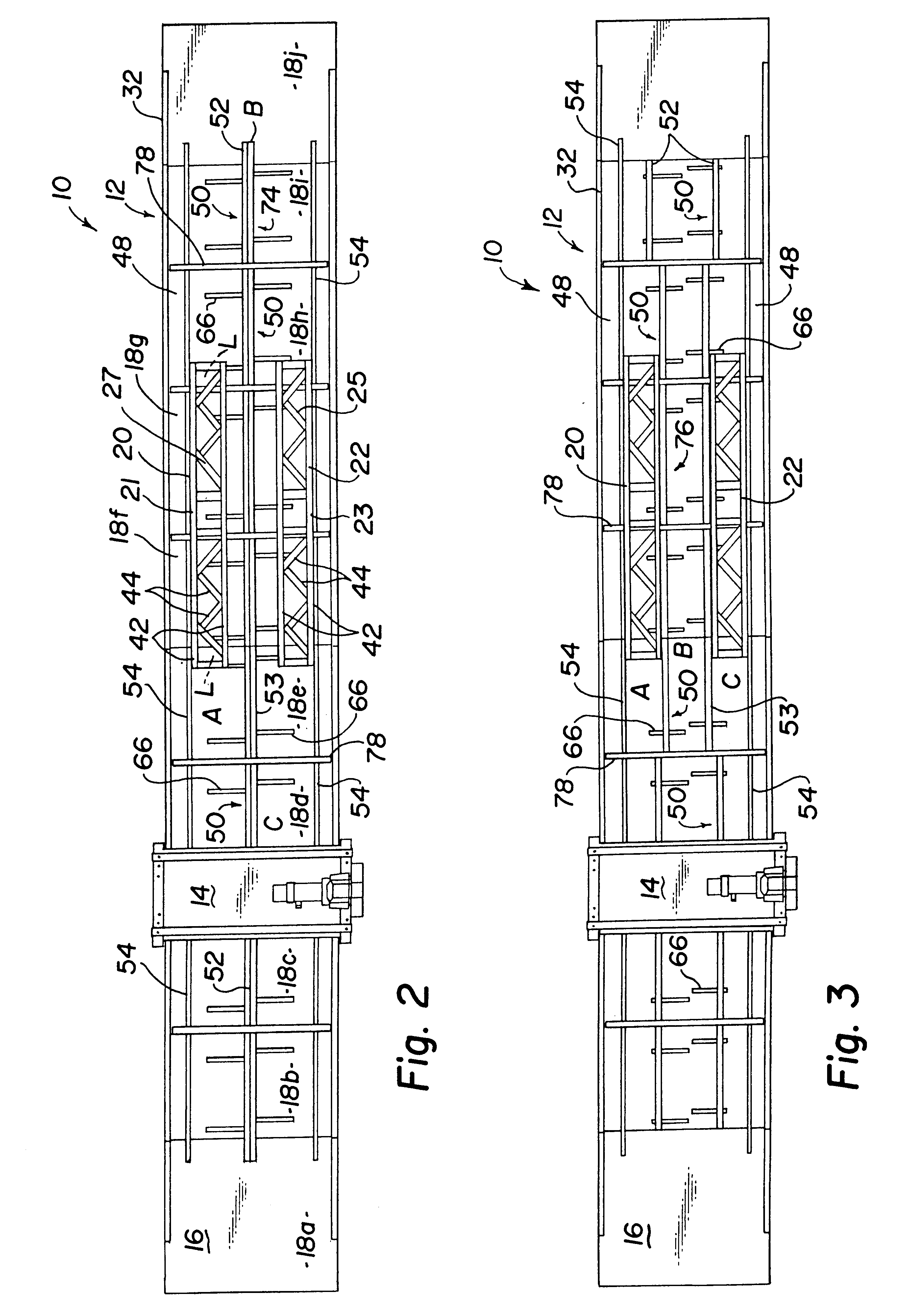

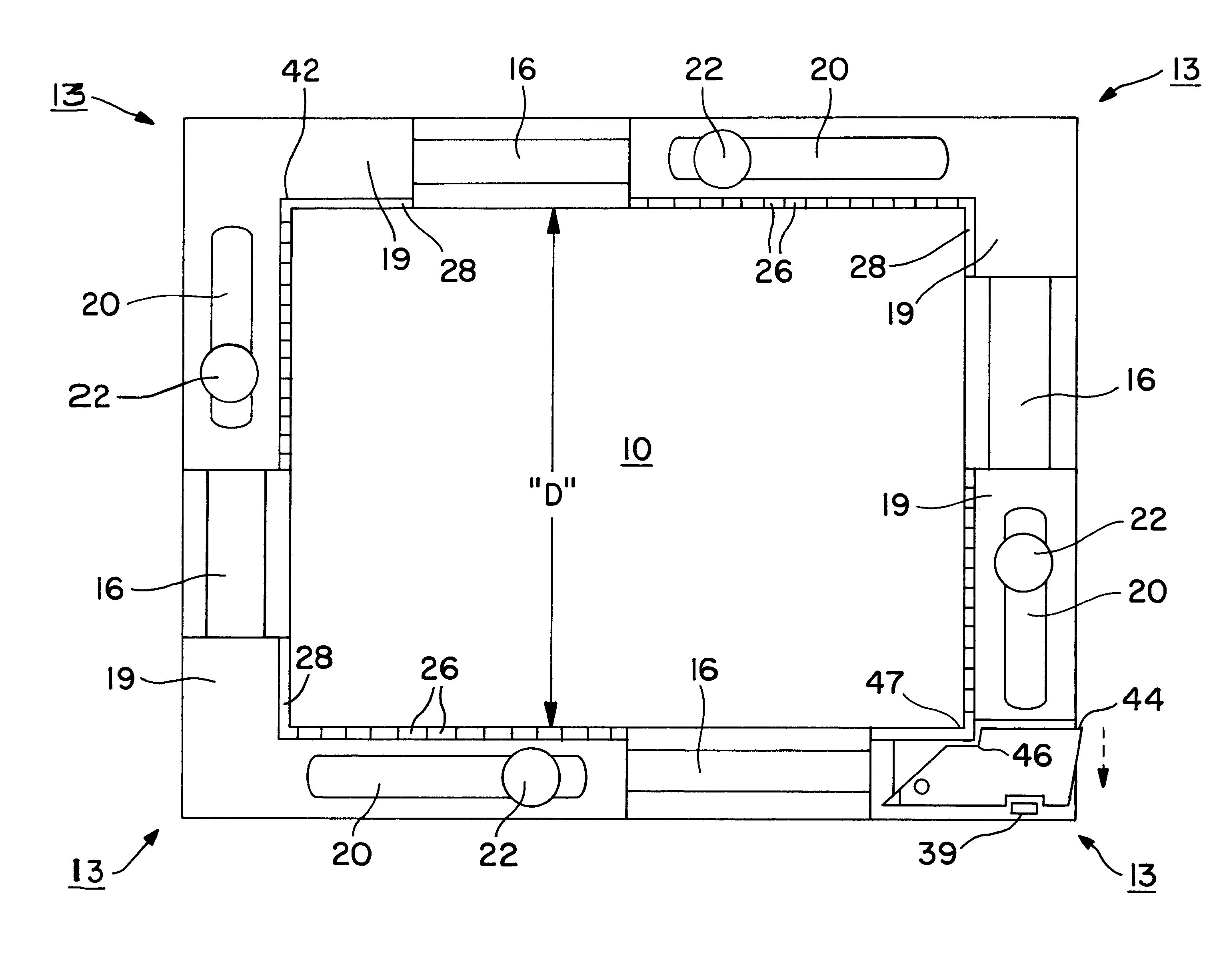

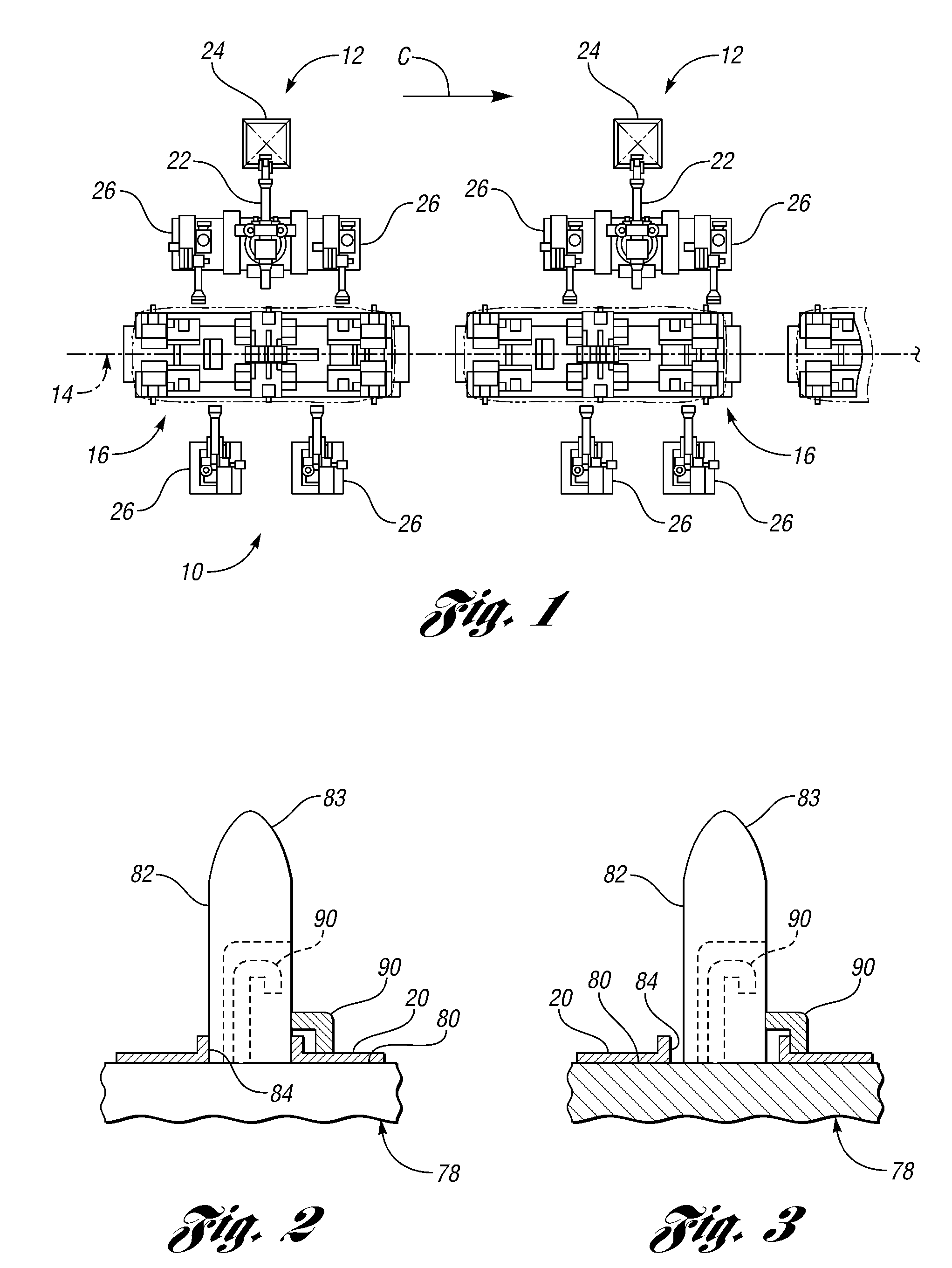

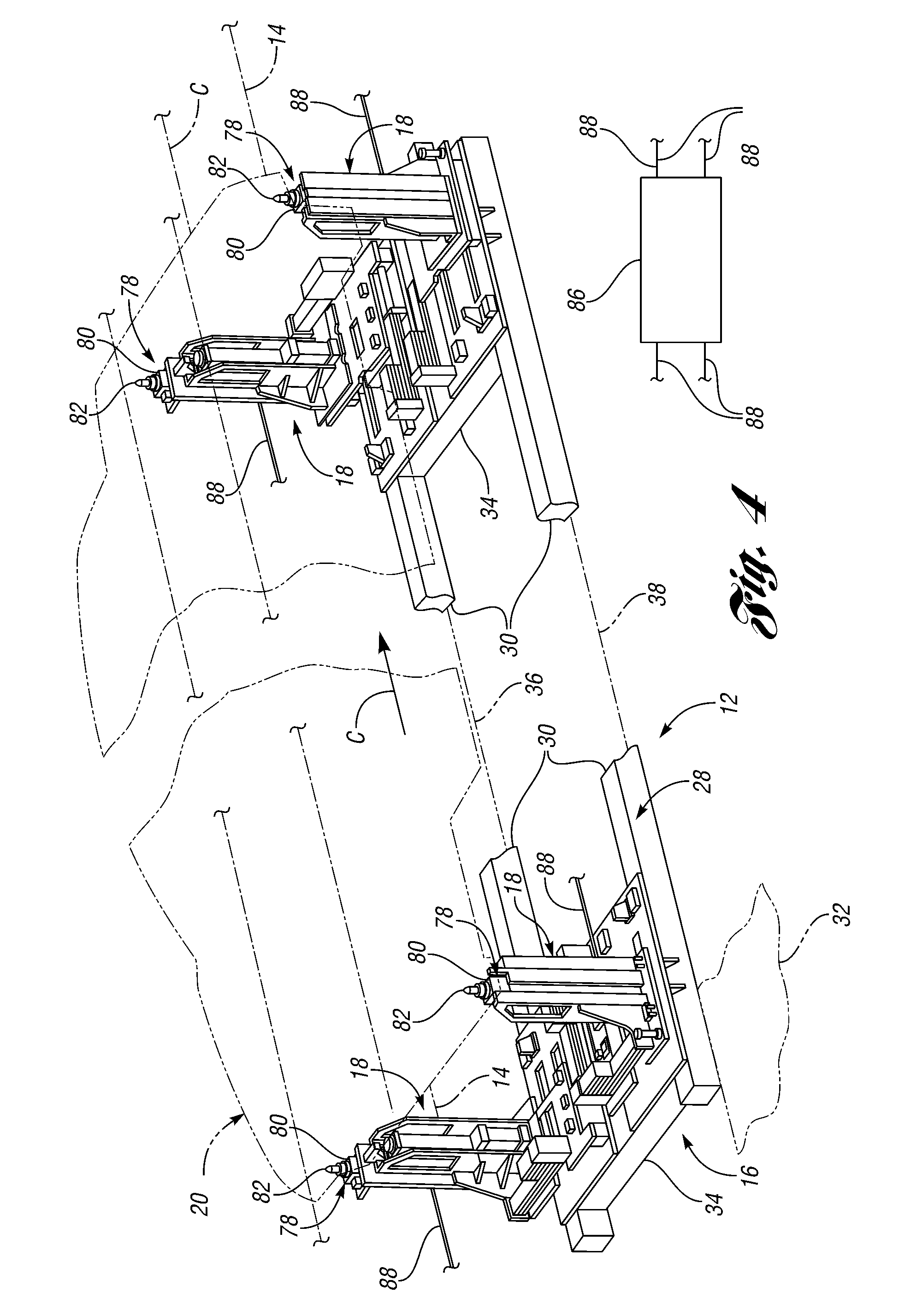

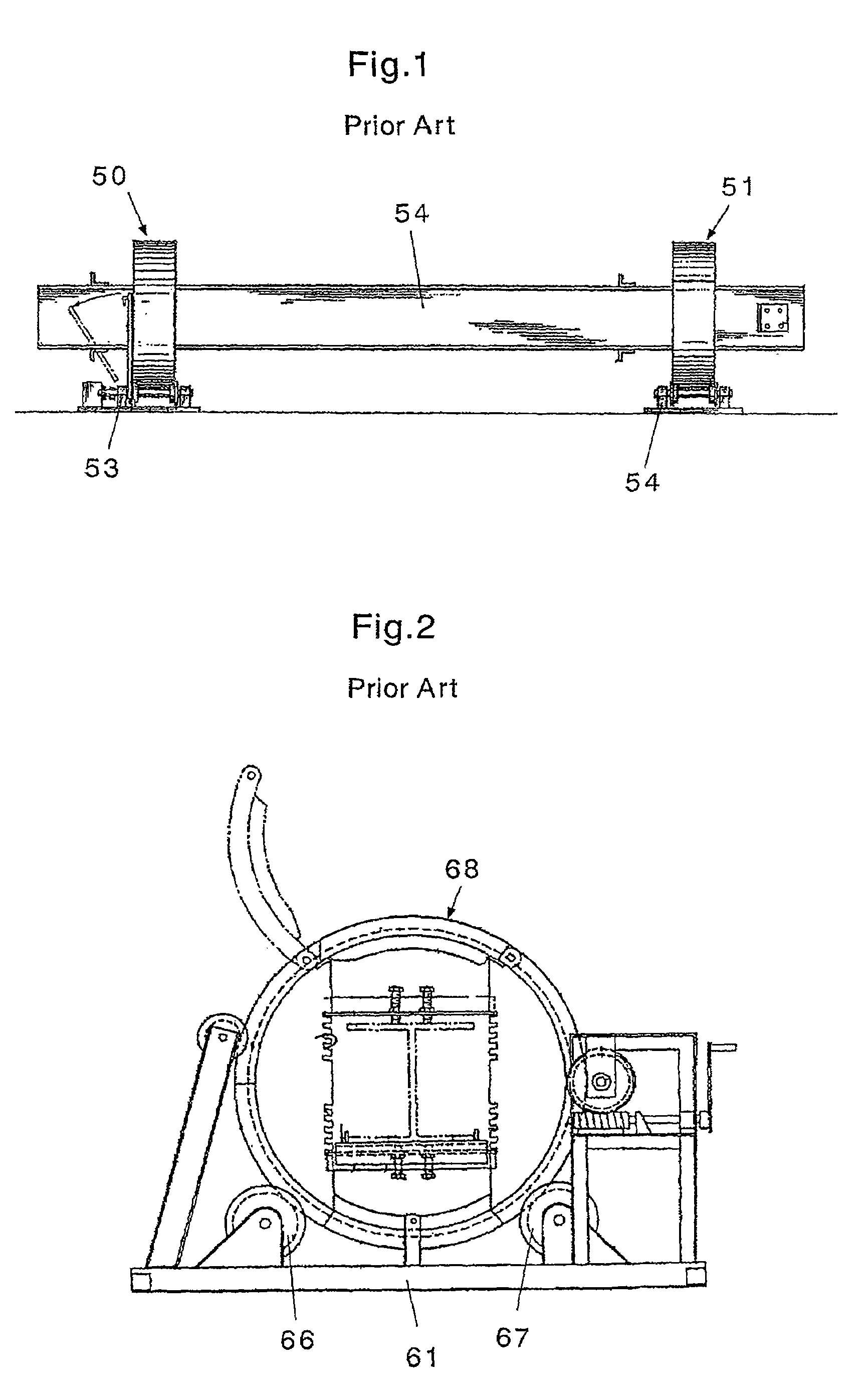

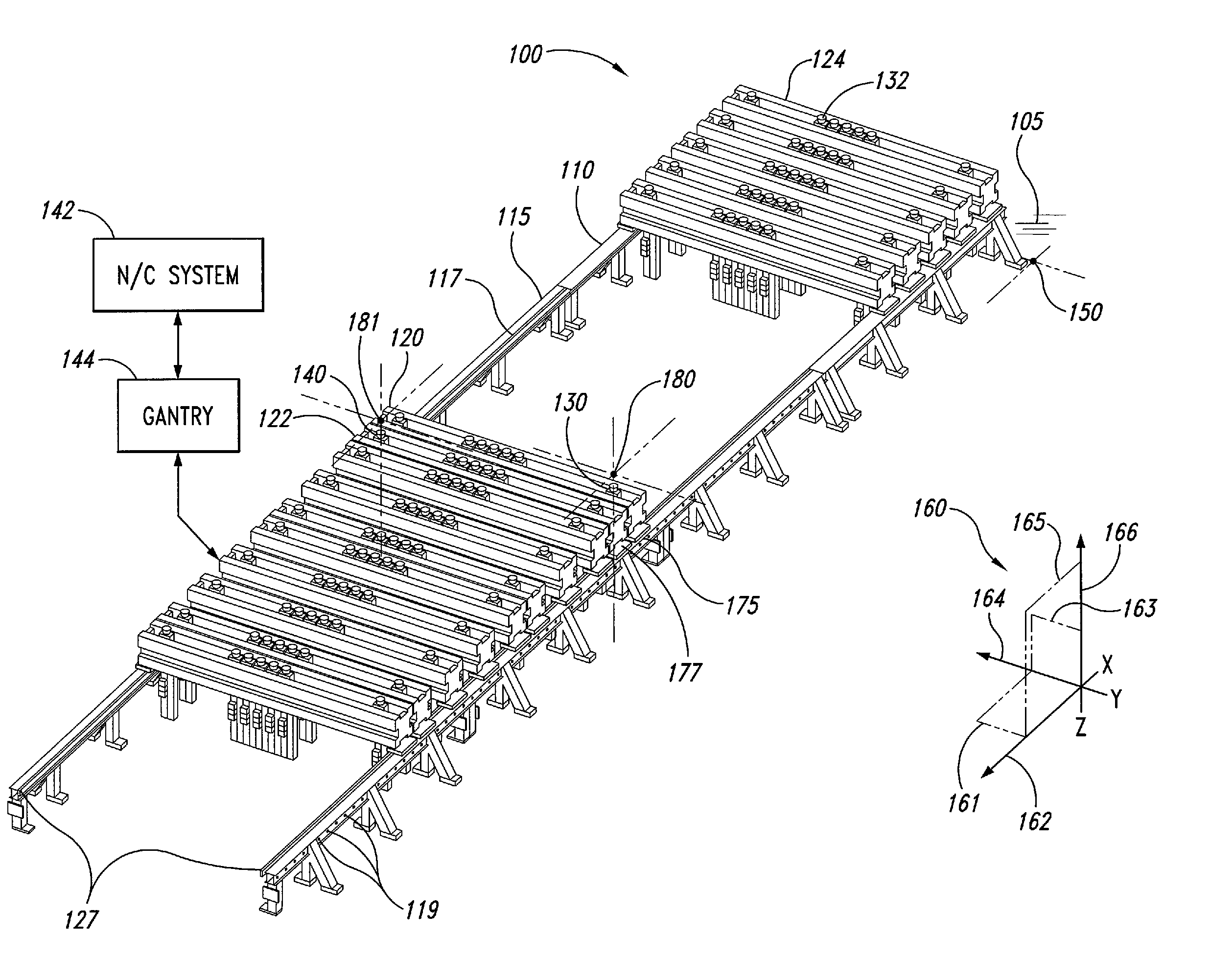

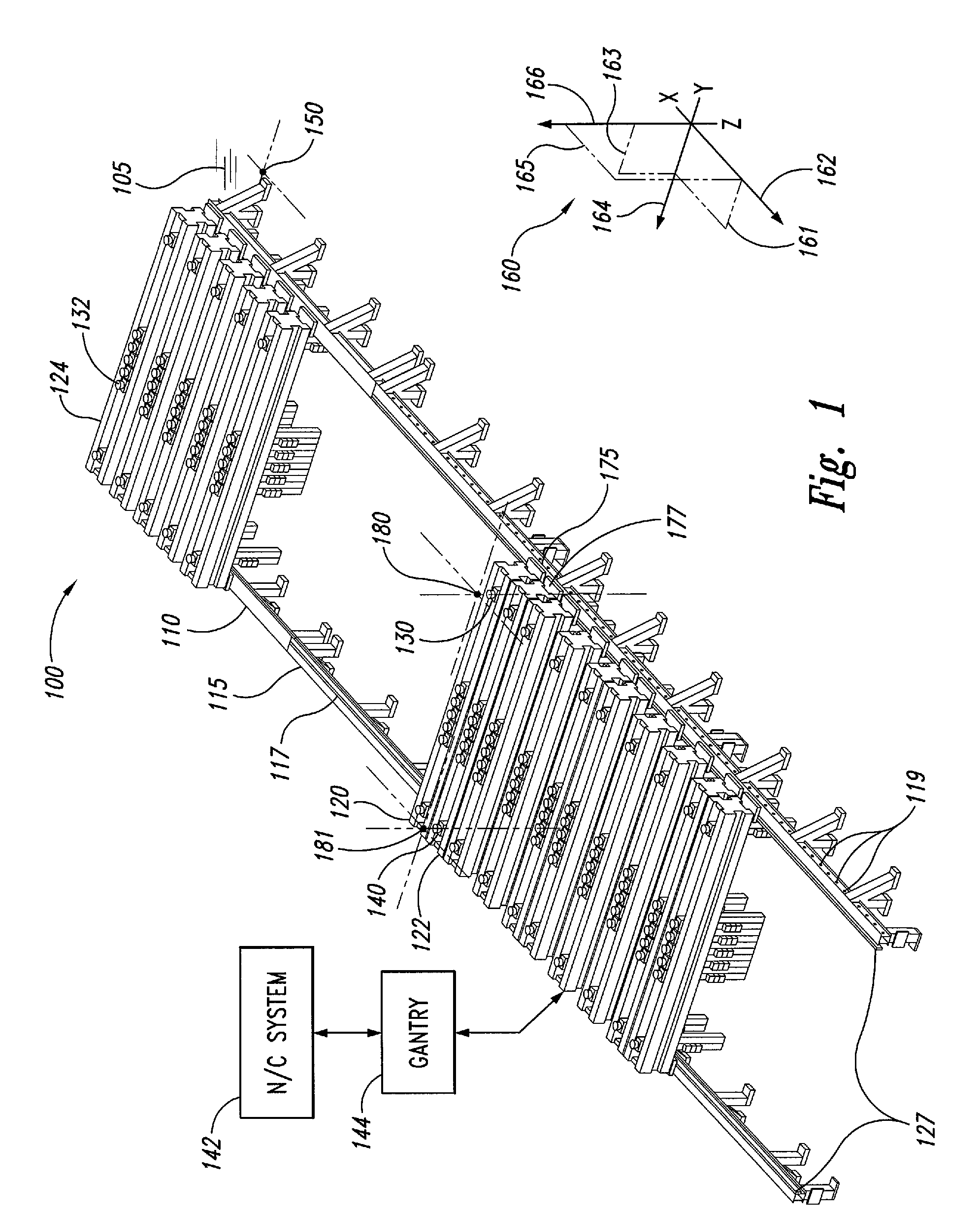

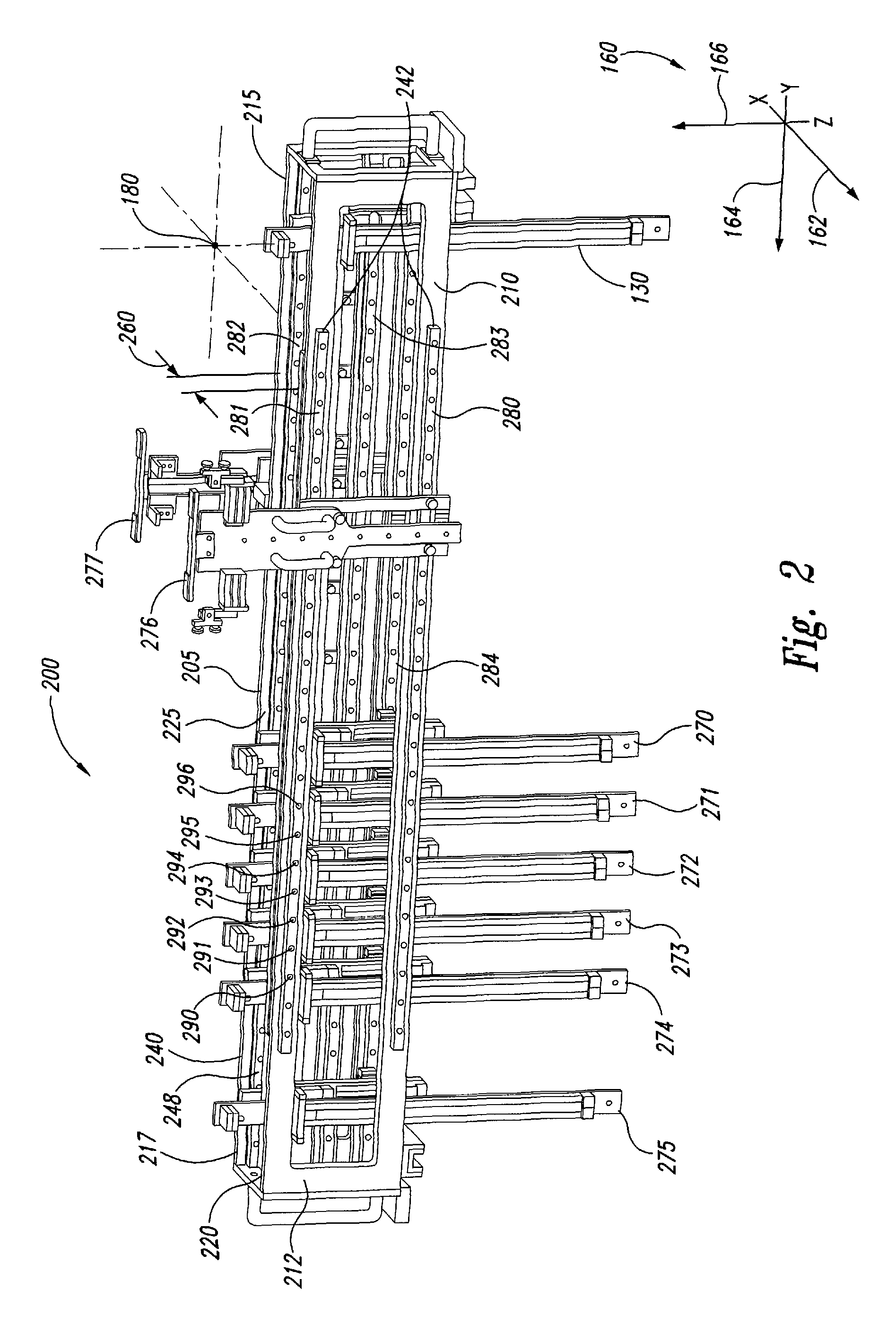

Automatic truss jig setting system

A automatic truss jig setting system is disclosed that includes a table including a plurality of segments with a side edge of adjacent segments defining a slot. At least one pin assembly, and optionally a pair of pin assemblies, is movable independently of each other along the slot. Movement apparatus is provided for independently moving the pin assemblies along the slot. Each of the side edges of the segments associated with the slot defines a substantially vertical plane with a zone being defined between the substantially vertical planes of the side edges, and the movement apparatus is located substantially outside of the zone of the slot. The invention may optionally include a system for handling the obstruction of pin assembly movement, and a system for keeping track of the position of the pin assembly when the pin assembly has encountered an obstruction.

Owner:MITEK USA

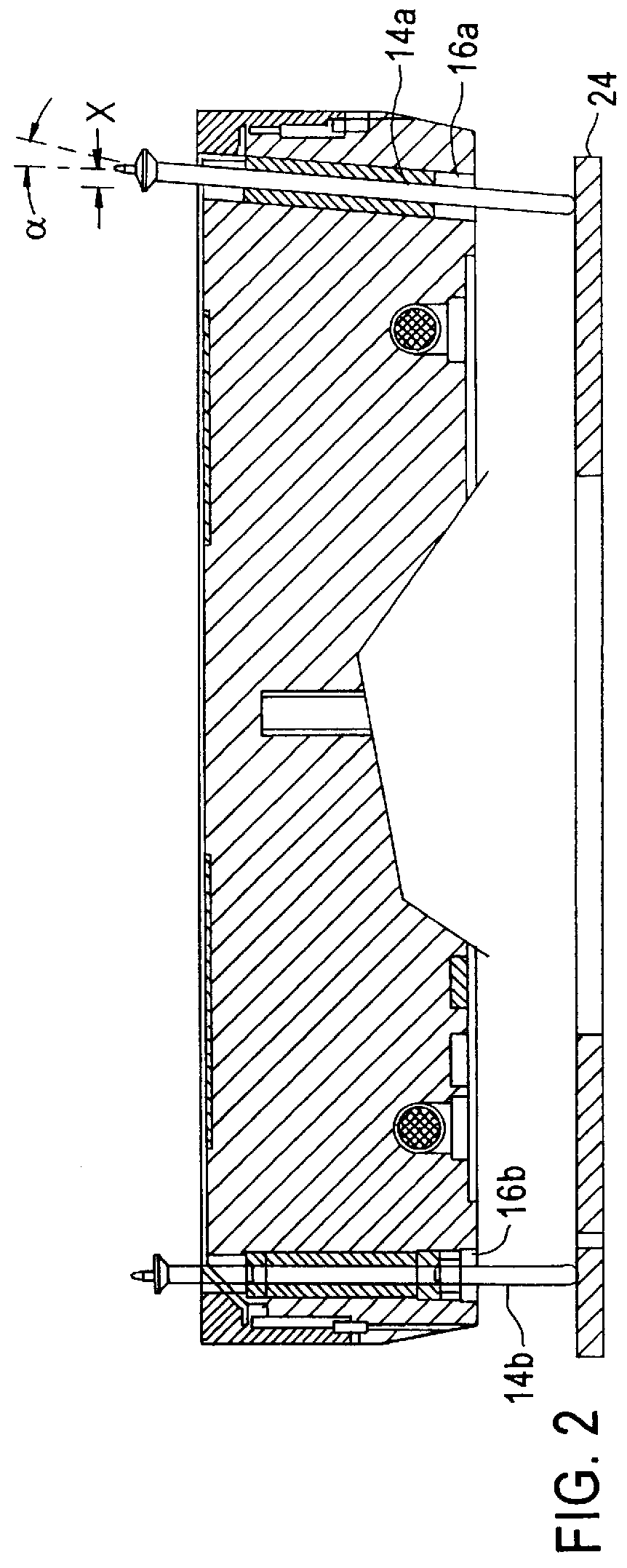

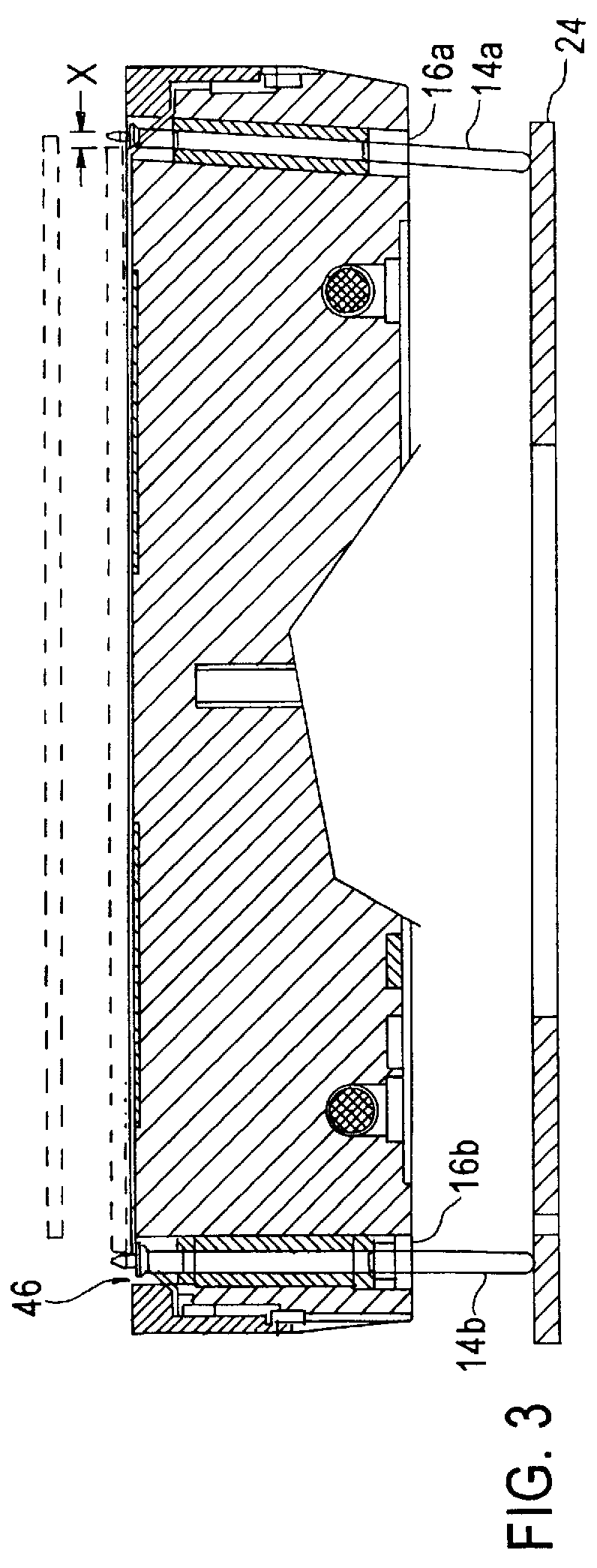

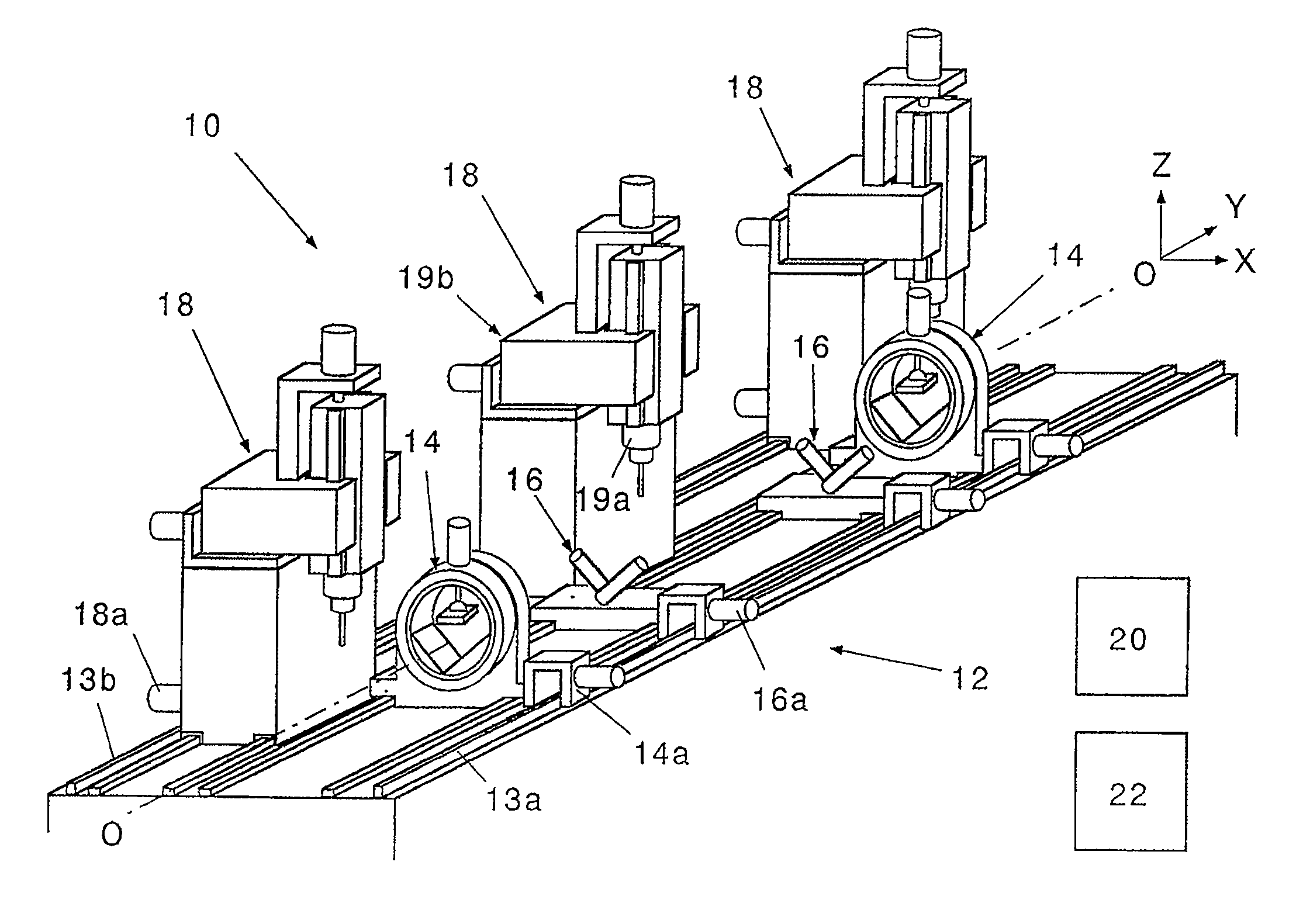

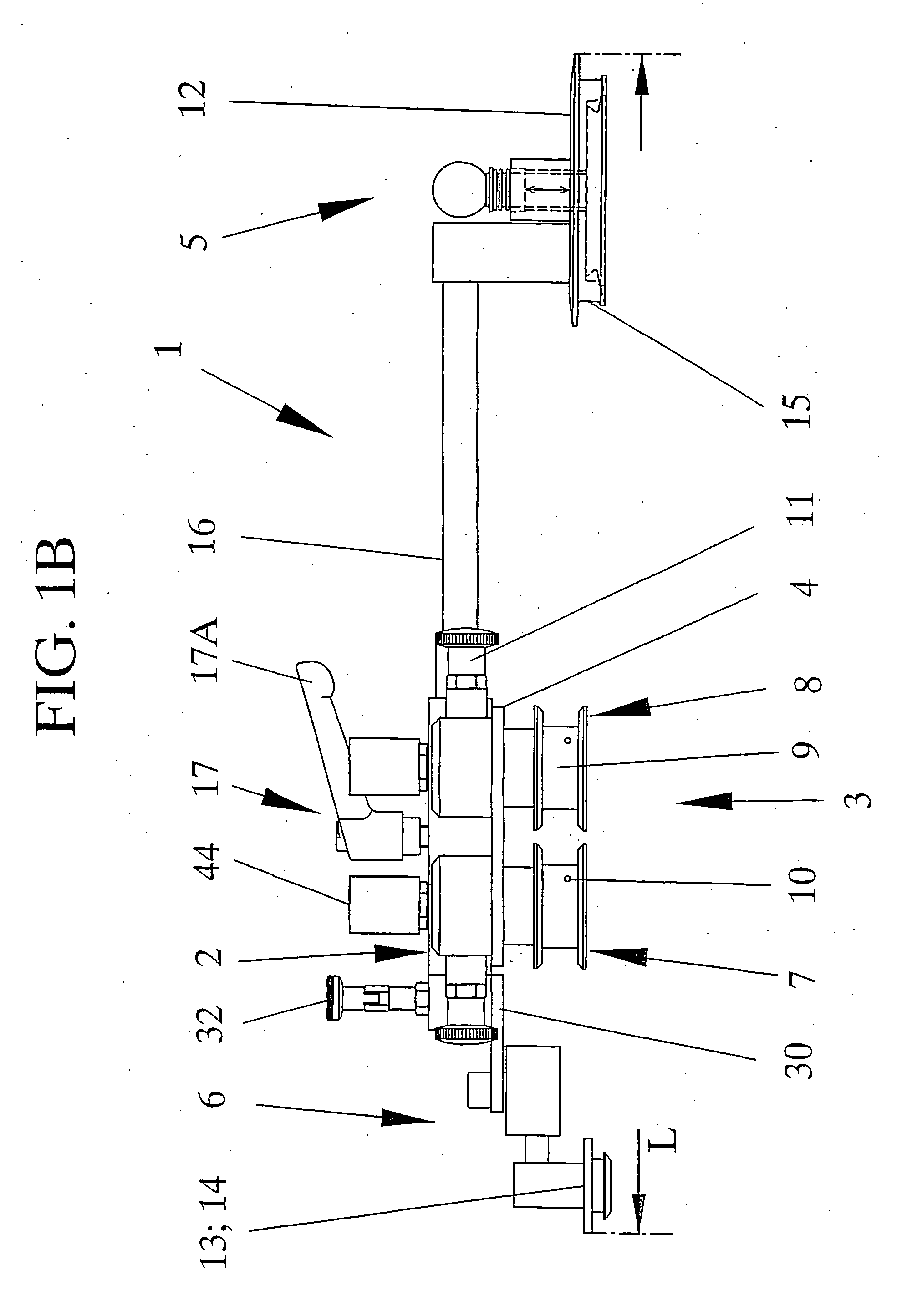

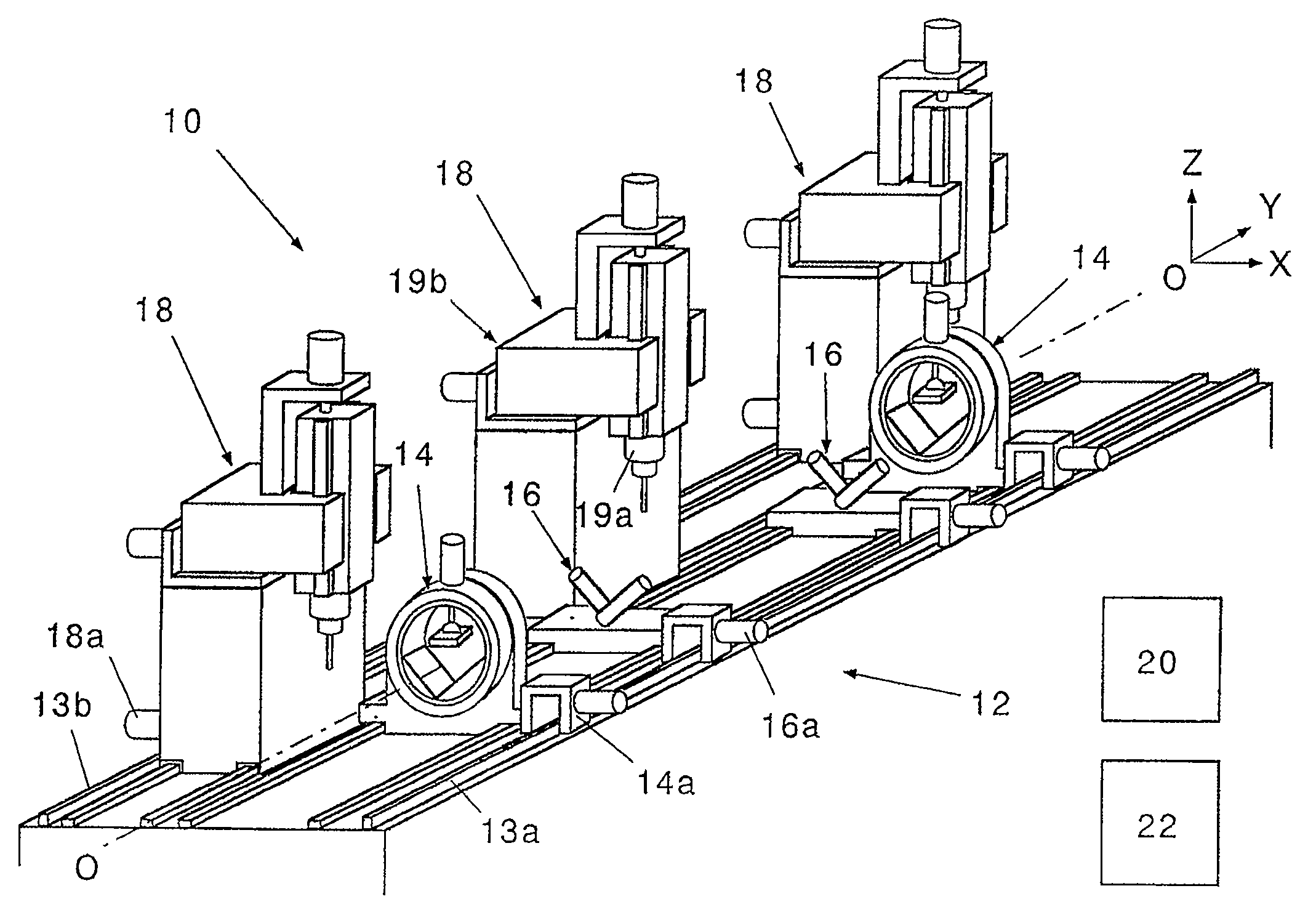

Apparatus and method for machining long workpiece

There are provided a base frame 12 positioned below a horizontal axis O; a pair of clamp units 14 positioned at the two ends above the base frame; a pair of support units 16 that horizontally support the long workpiece in two locations, and that are capable of moving vertically; and machining units 18 that are capable of machining the long workpiece. The two clamp units 14 are capable of moving from the outside toward the inside, which support the long workpiece in two locations, and rotate around the horizontal axis O in synchronization with each other.

Owner:IMAX CO LTD

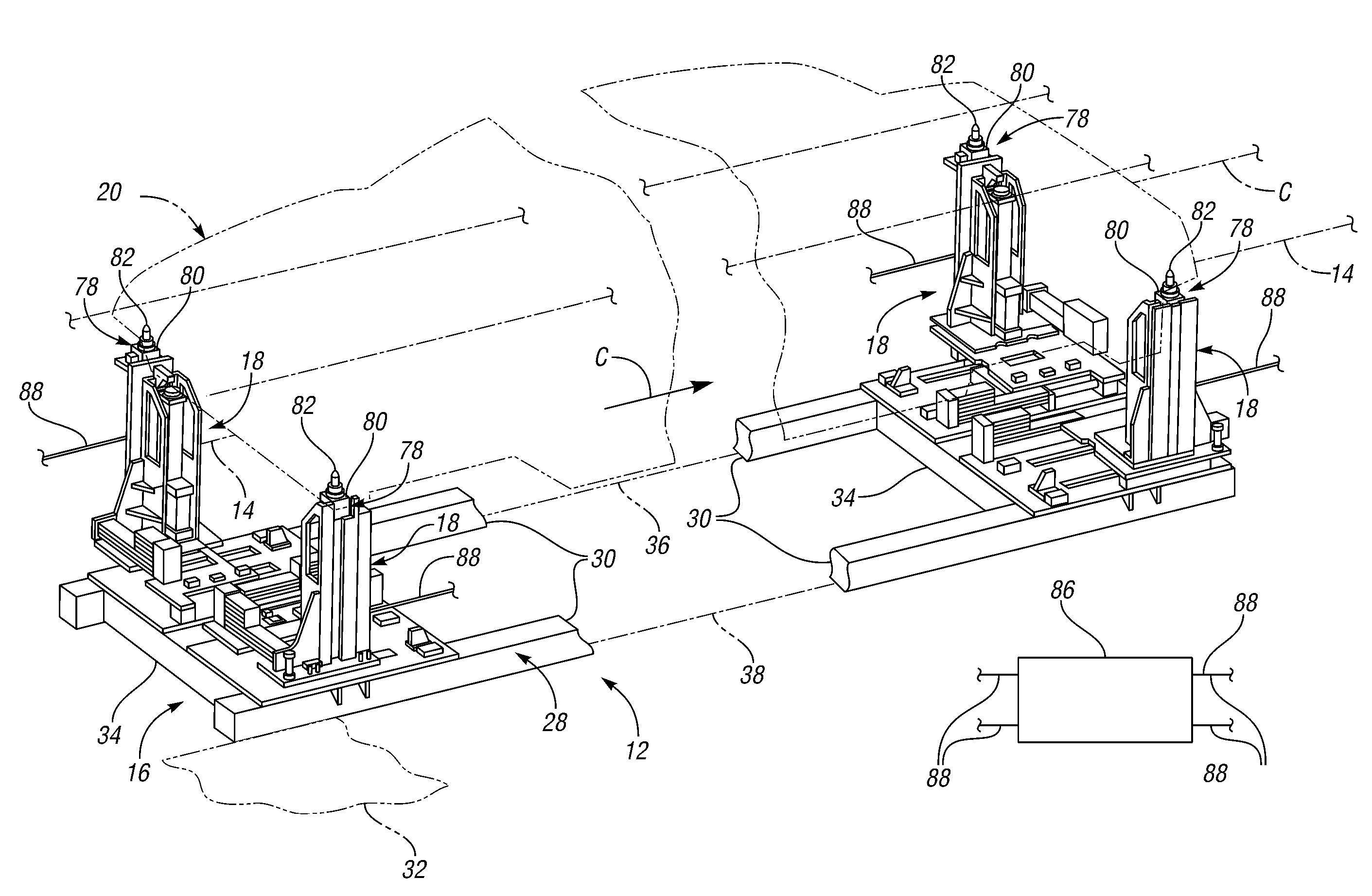

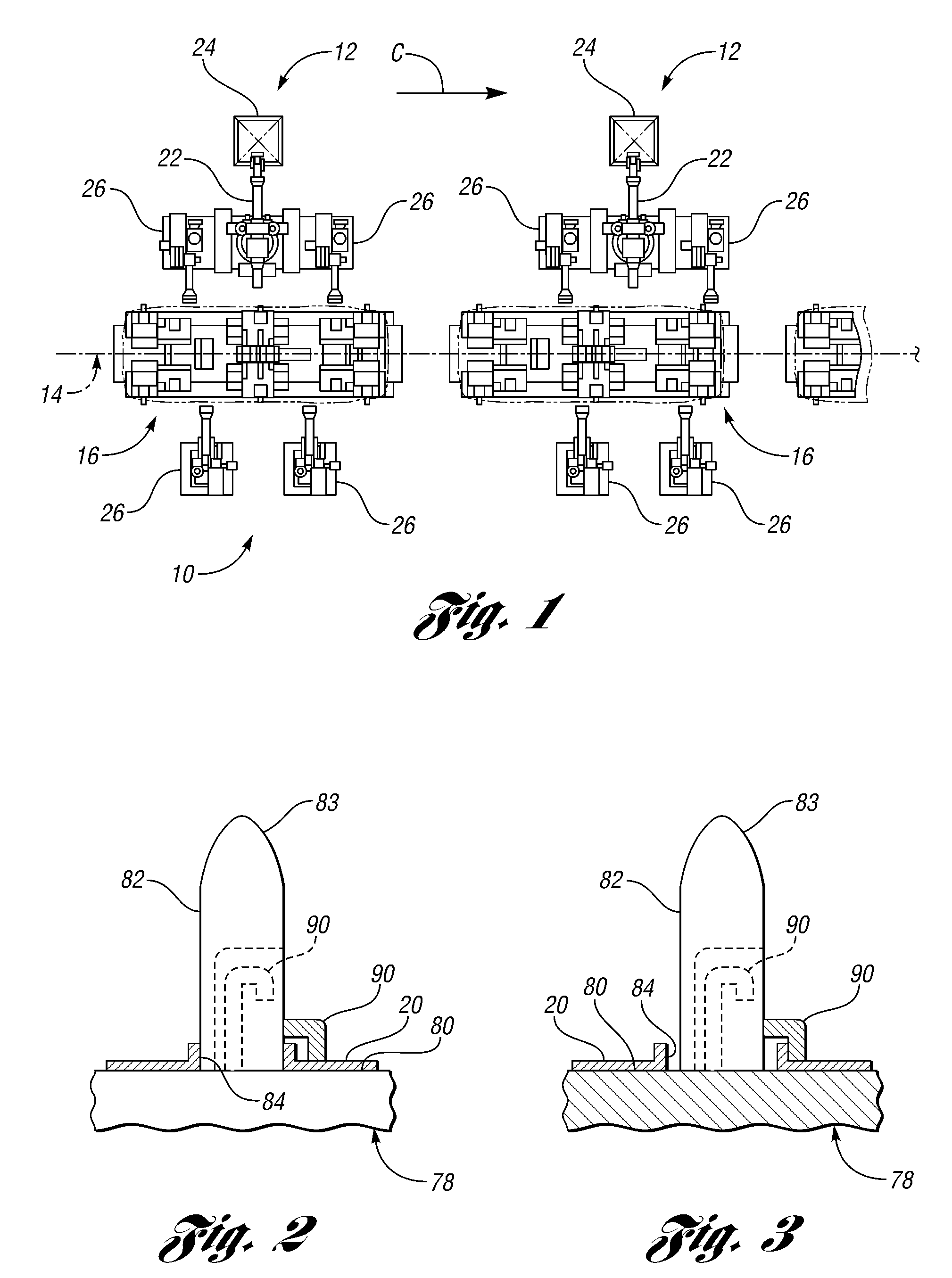

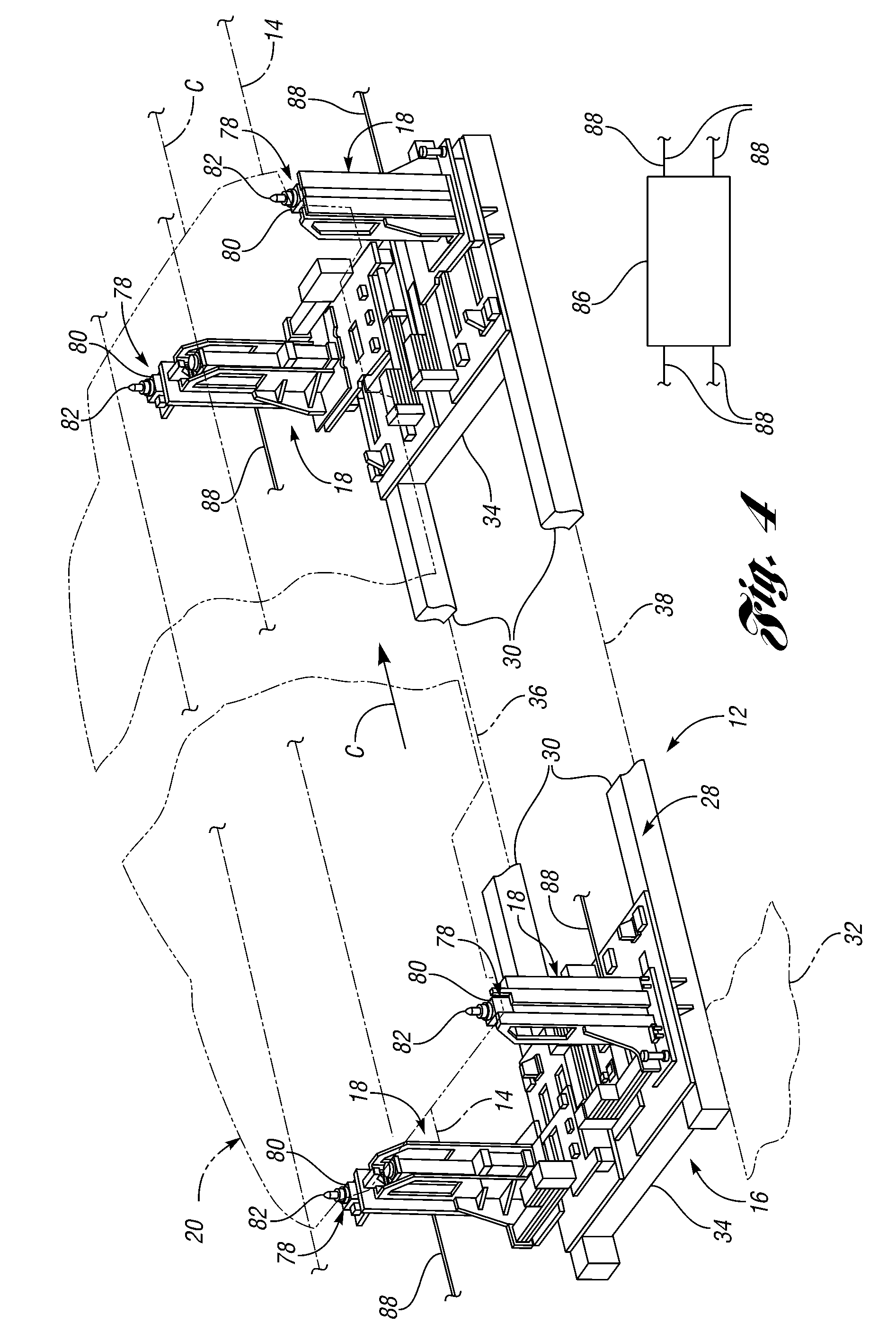

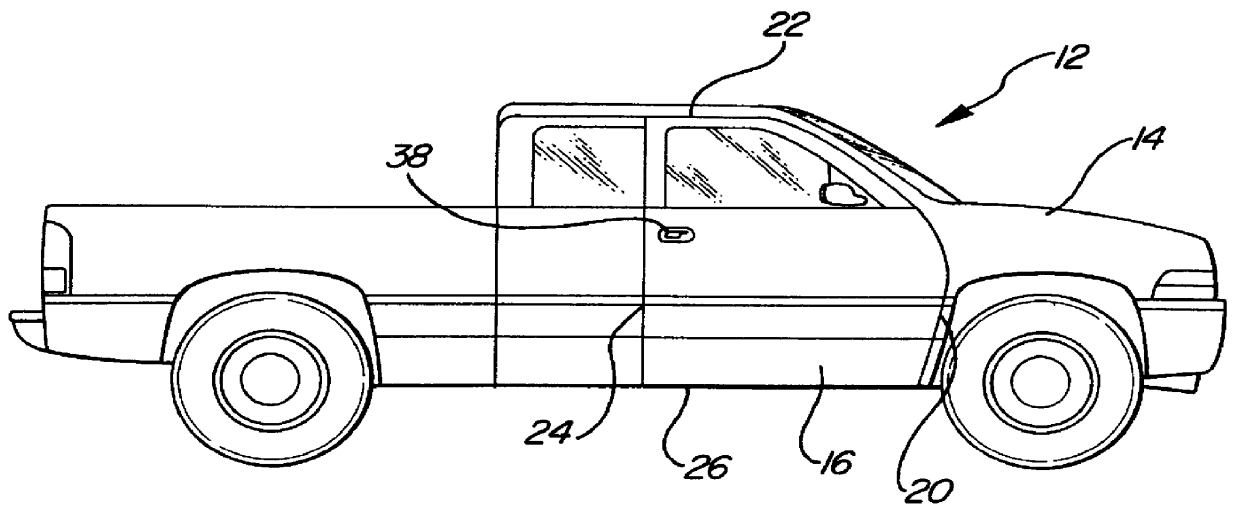

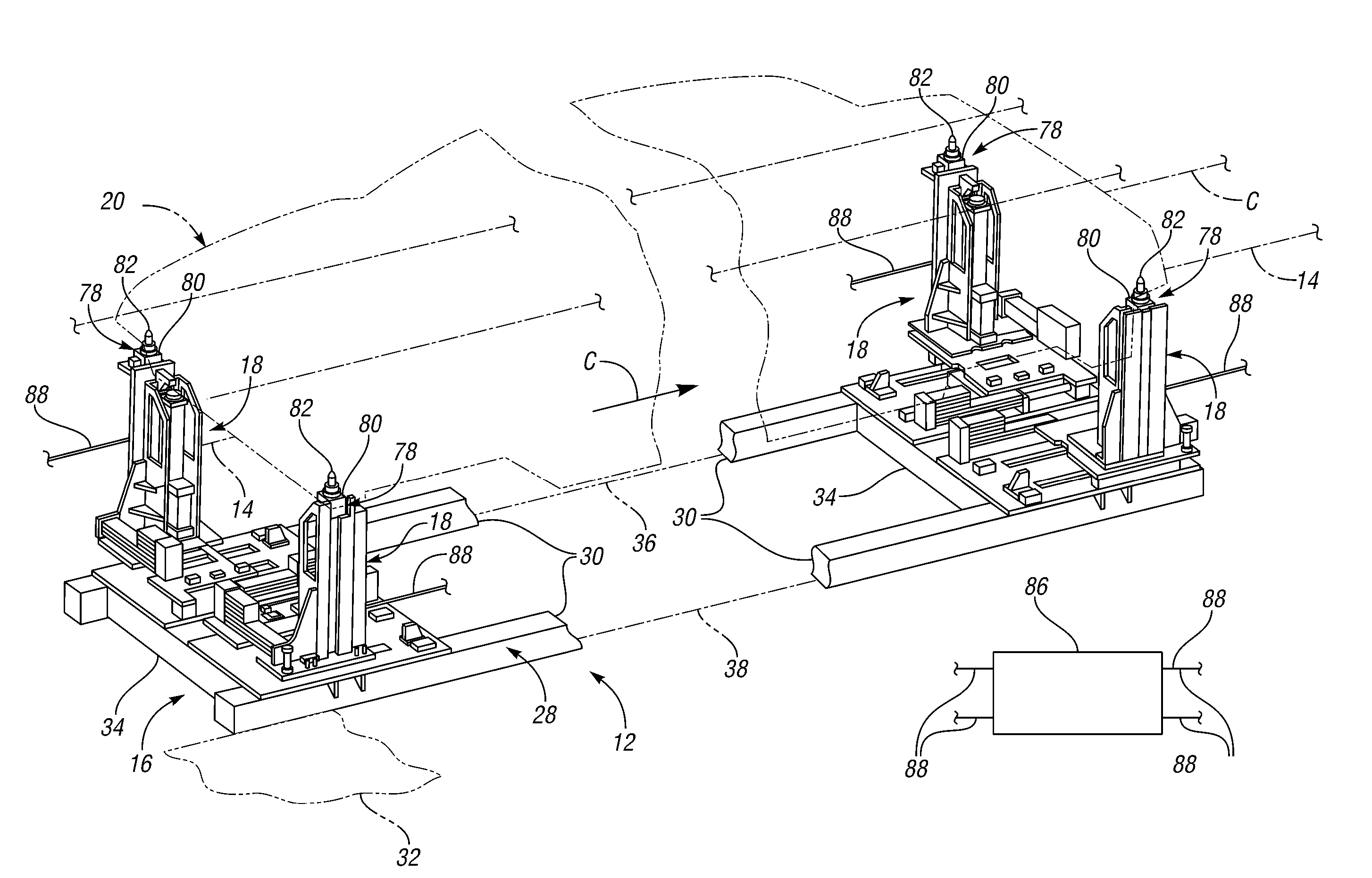

Assembly line vehicle body positioning

A vehicle body assembly line locator assembly (16) includes locators (18) driven by horizontal longitudinal X, horizontal sideways Y and vertical Z power operated actuators (50. 58. 72) and having locator pins (82) received by vehicle body positioning holes (84) upon upward movement to provide accurate positioning. As the locator pins (82) are moved upwardly and initially move into the vehicle body positioning holes (84 ), the horizontal power operated actuators (50,58) are back driven. The upward movement is continued so that vertical rest surfaces (80) of locator heads (78) contact the vehicle body (20) and provide lifting thereof upwardly off a system conveyor, and the power operated actuators then move the vehicle body to the proper positioning for further assembly.

Owner:UTICA ENTERPRISES

Ez key registration assembly

InactiveUS7918629B2Precise positioningReduce cutting vibrationWorkpiece holdersMilling machinesEngineeringMechanical engineering

A locating system and method for accurately positioning key blanks with respect to a key cutter where the key head is clamped between opposing jaws with the key blade working edges projecting therefrom, the key head is provided with shaped recesses having at least a partially specifically shaped edge wall and wherein at least one jaw member is provided with a projection having a correspondingly shaped sidewall, the pin being positioned with respect to the clamp such that when the key blank head is abutted against the pin with the key blank edge configuration mating to the pin sidewall configuration, the key blade will project from the jaw in a proper position for engagement by either the bitting follower or bitting cutter respectively.

Owner:KABA ILCO CORP

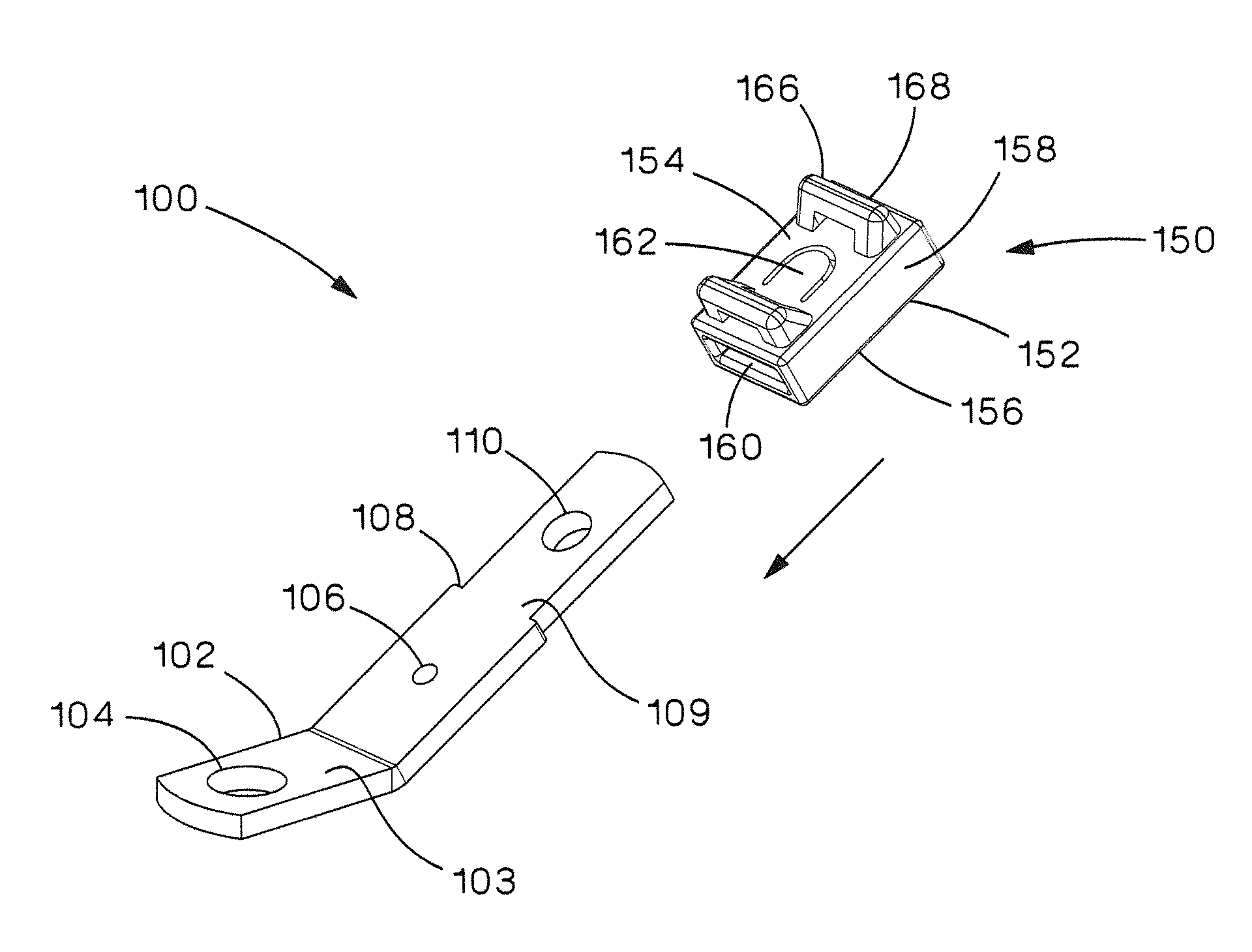

Cable Tray Mount

The present invention is directed towards a cable tie mount. The cable tie mount includes a body and a mount. The mount includes a top, a bottom, sides, and a channel therethrough. The body has a base member with a mounting hole and a receiving member with a locking hole. The receiving member extends at an angle from the base member. The mount is installed on the receiving member of the body such that the receiving member is positioned within the channel of the mount.

Owner:PANDUIT

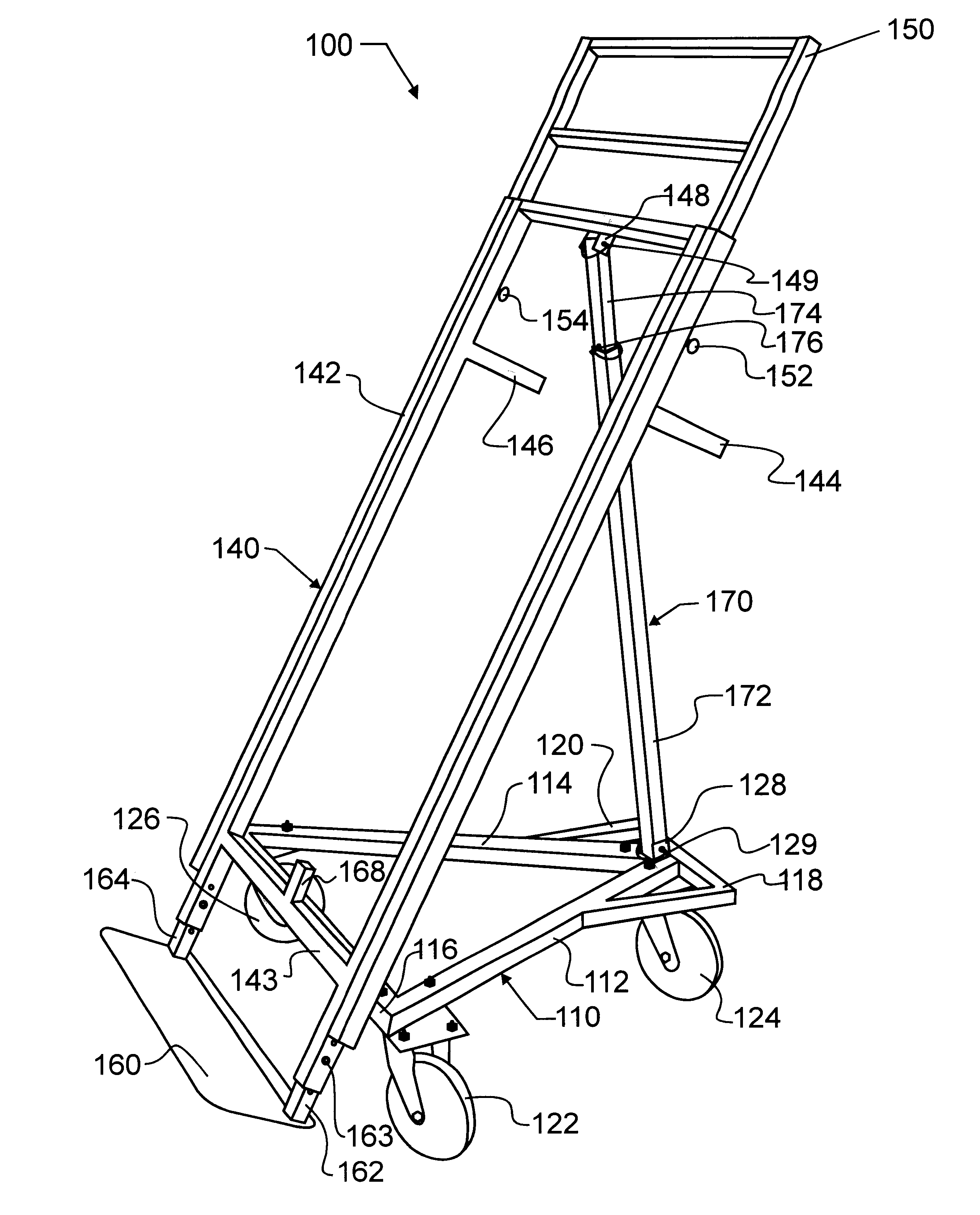

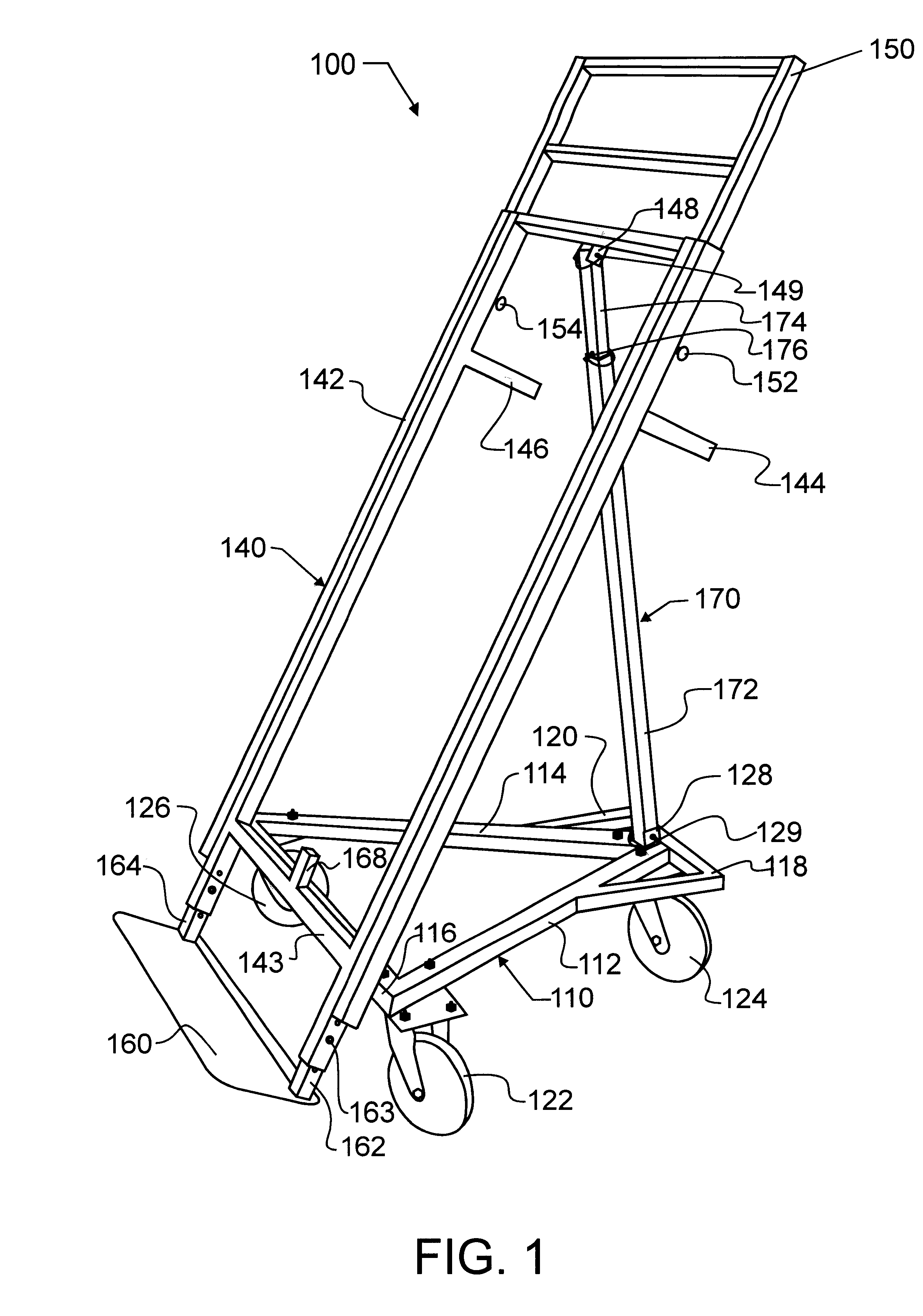

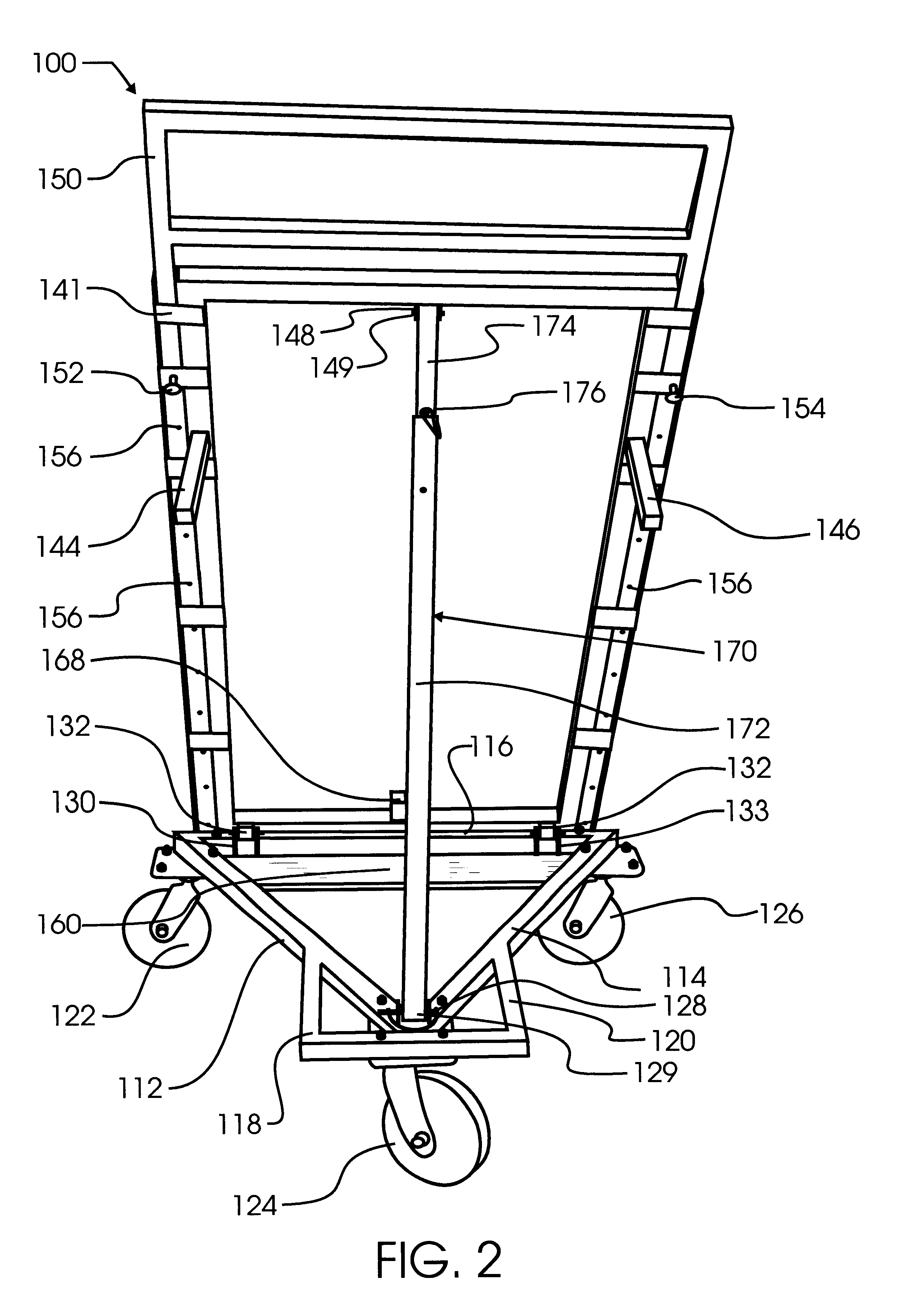

Wheeled transports

Owner:KELLER WILLIAM A

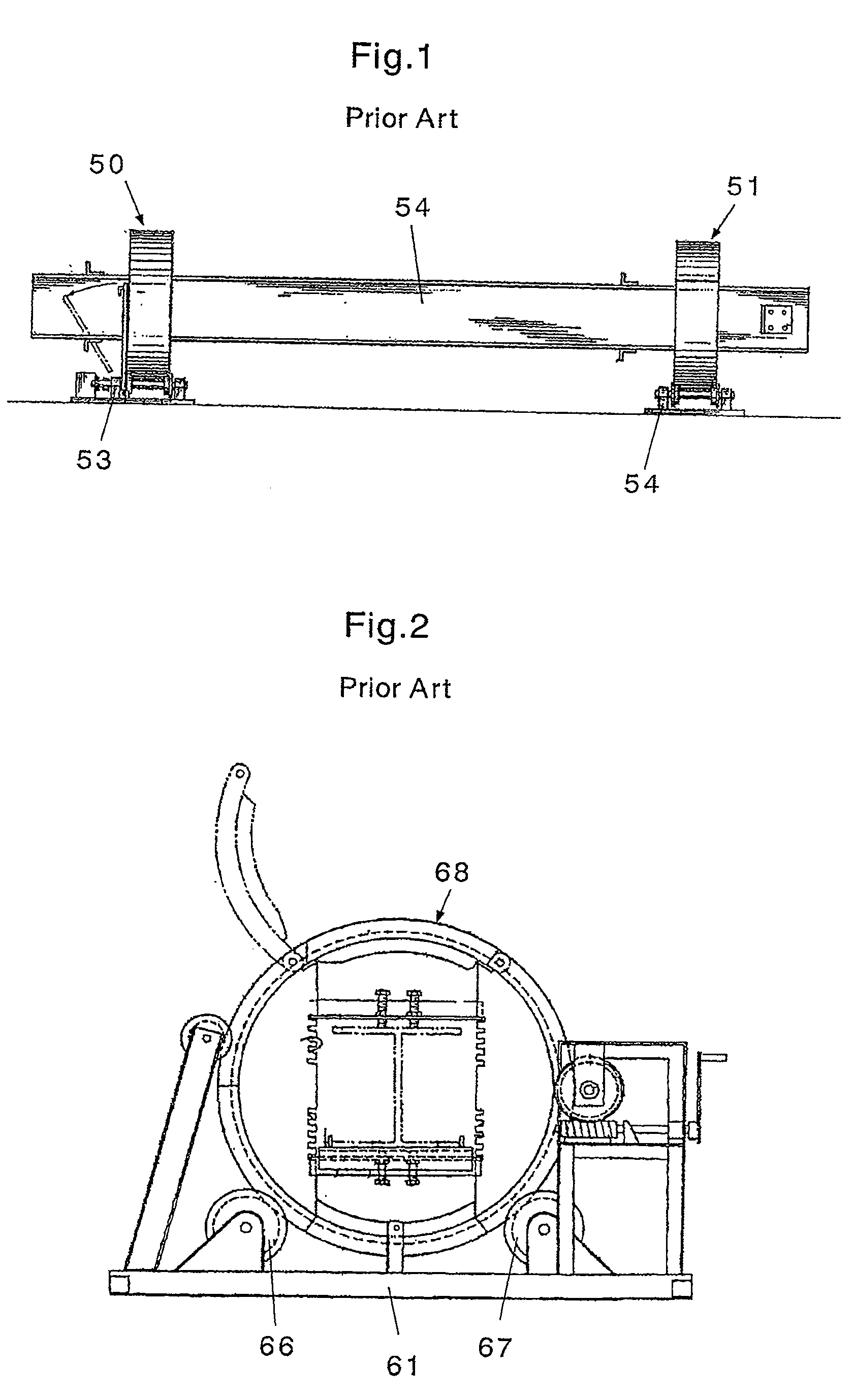

Rotating internal support apparatus and method for large hollow structures

Owner:THE BOEING CO

Etch resistant wafer processing apparatus and method for producing the same

InactiveUS20070138601A1Liquid surface applicatorsSemiconductor/solid-state device detailsThin film electrodeHard metal

A wafer processing apparatus is fabricated by depositing a film electrode onto the surface of a base substrate, the structure is then overcoated with a protective coating film layer comprising at least one of a nitride, carbide, carbonitride or oxynitride of elements selected from a group consisting of B, Al, Si, Ga, refractory hard metals, transition metals, and combinations thereof. The film electrode has a coefficient of thermal expansion (CTE) that closely matches the CTE of the underlying base substrate layer as well as the CTE of the protective coating layer.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

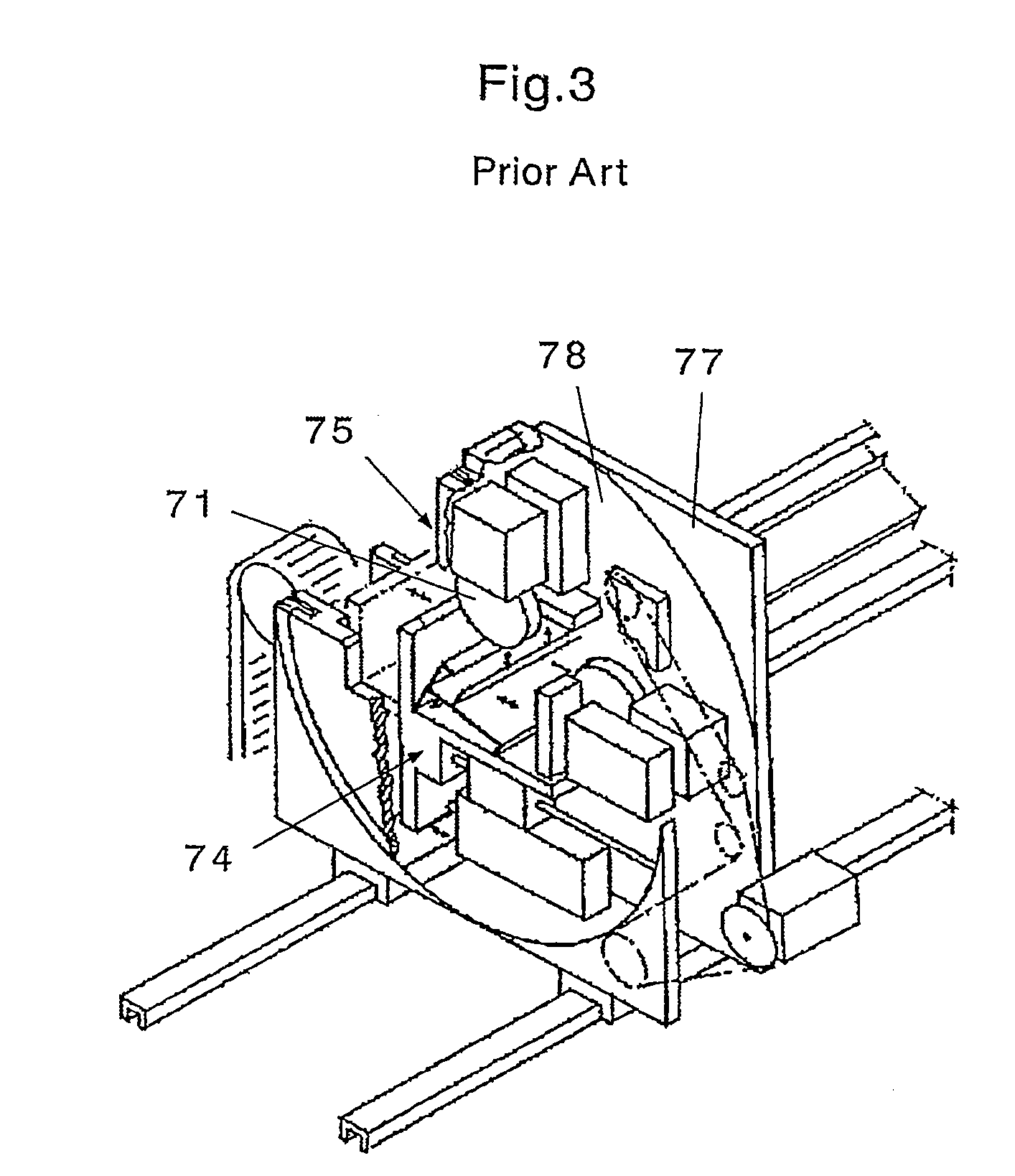

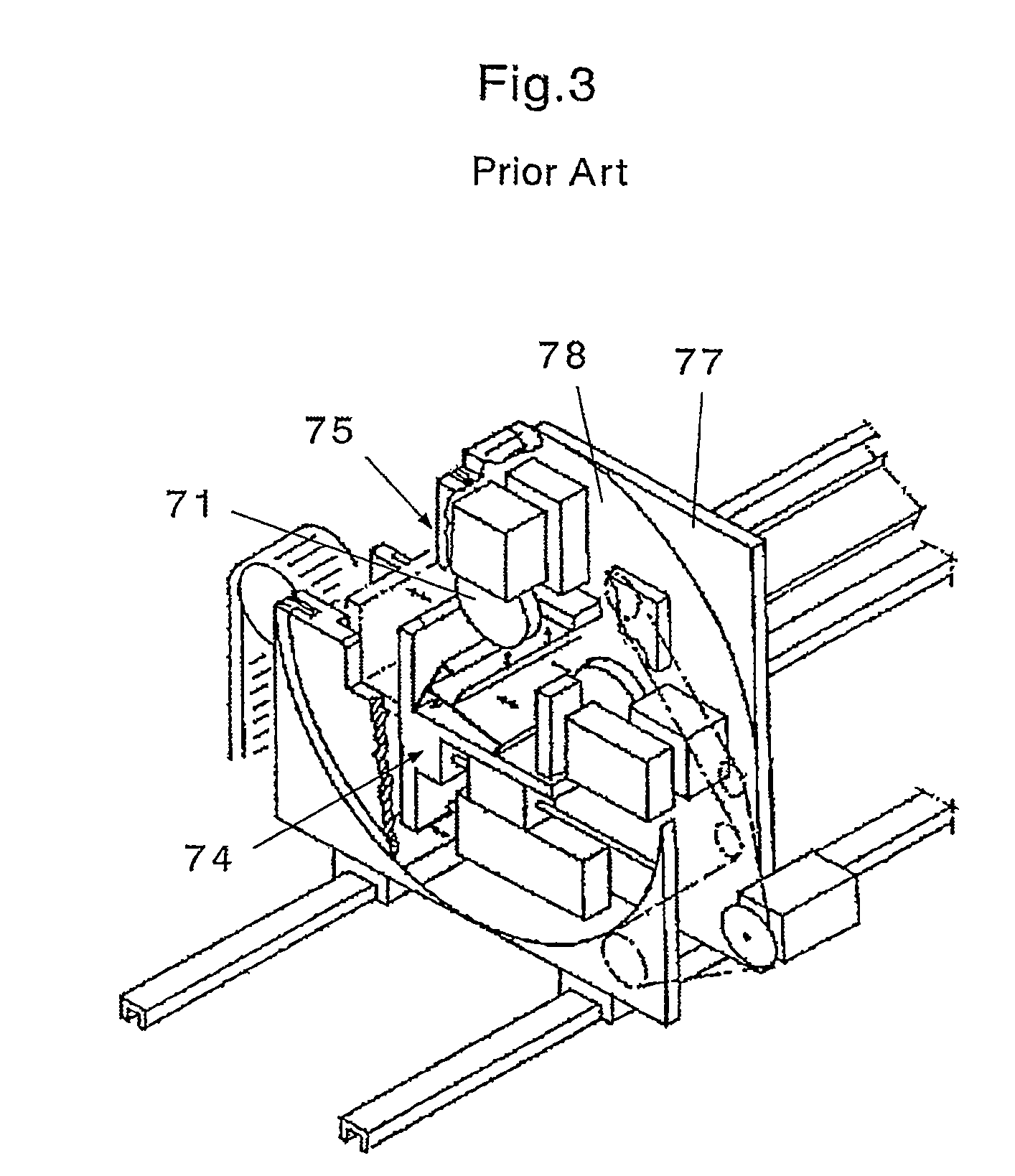

Automatic truss jig setting system

InactiveUS20050121844A1Avoid Debris BuildupAvoid cleaningWorkpiece holdersStapling toolsVertical planeEngineering

A automatic truss jig setting system is disclosed that includes a table including a plurality of segments with a side edge of adjacent segments defining a slot. At least one pin assembly, and optionally a pair of pin assemblies, is movable independently of each other along the slot. Movement apparatus is provided for independently moving the pin assemblies along the slot. Each of the side edges of the segments associated with the slot defines a substantially vertical plane with a zone being defined between the substantially vertical planes of the side edges, and the movement apparatus is located substantially outside of the zone of the slot. The invention may optionally include a system for handling the obstruction of pin assembly movement, and a system for keeping track of the position of the pin assembly when the pin assembly has encountered an obstruction.

Owner:COLUMBIA INSURANCE CO

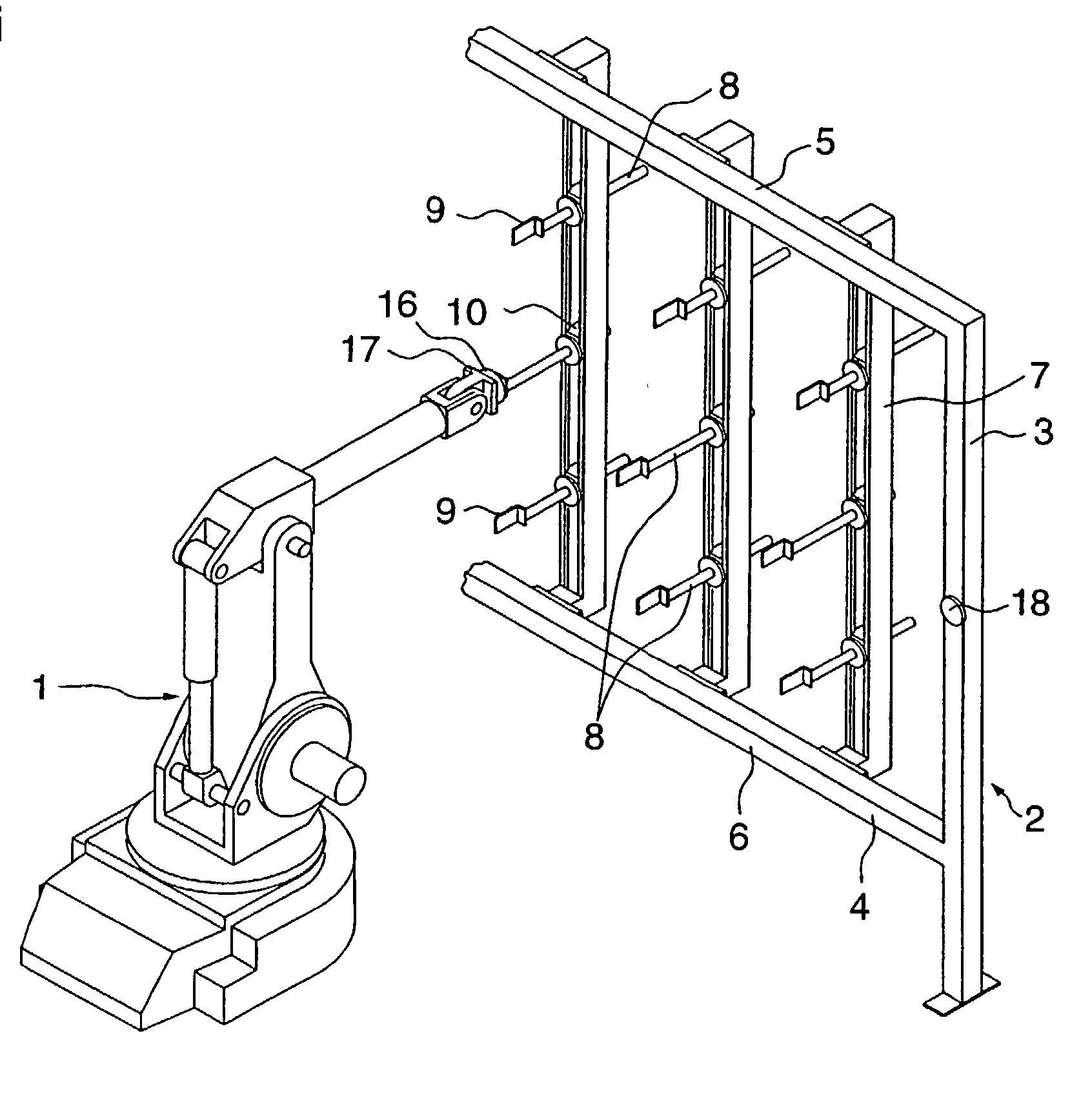

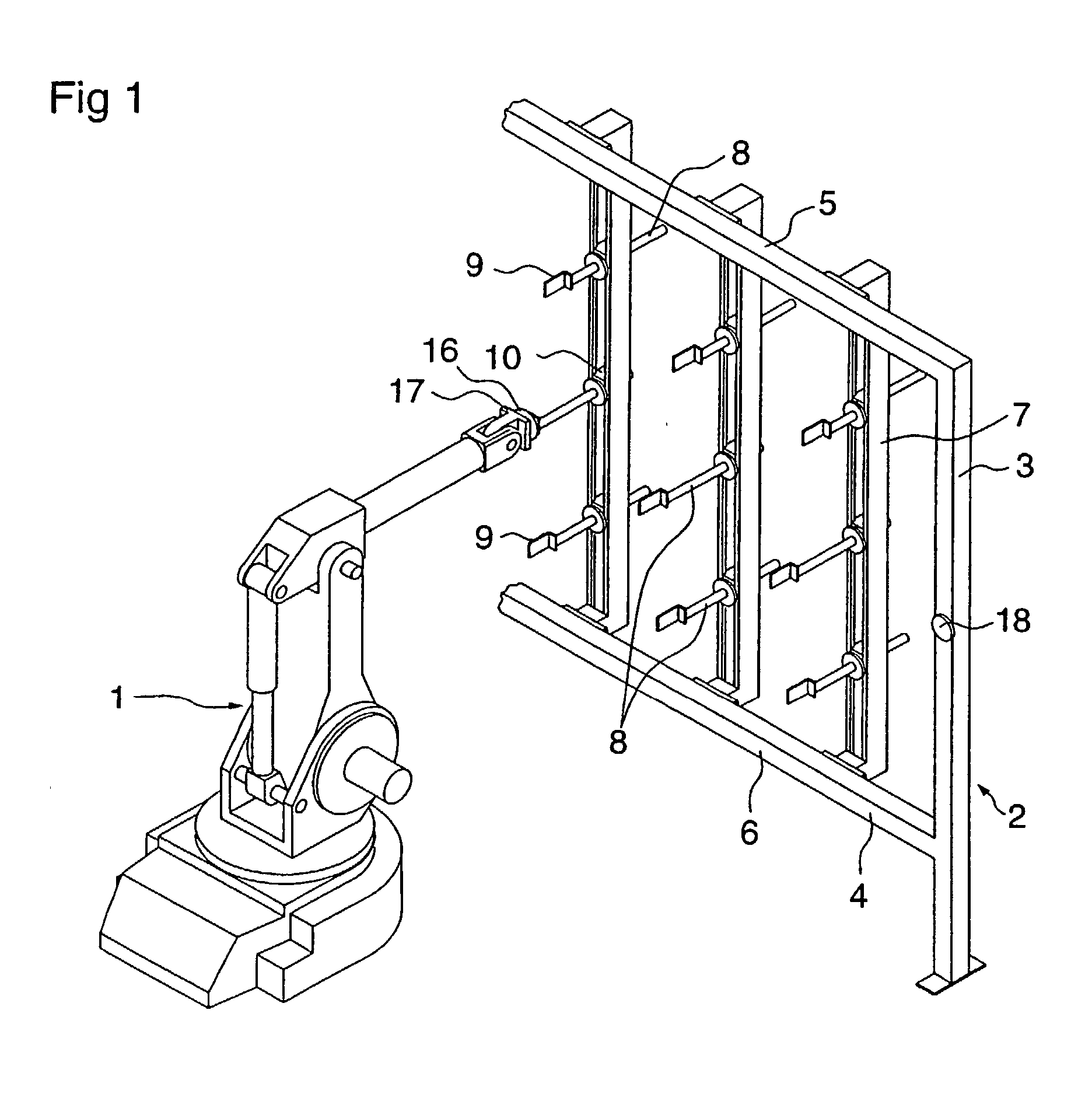

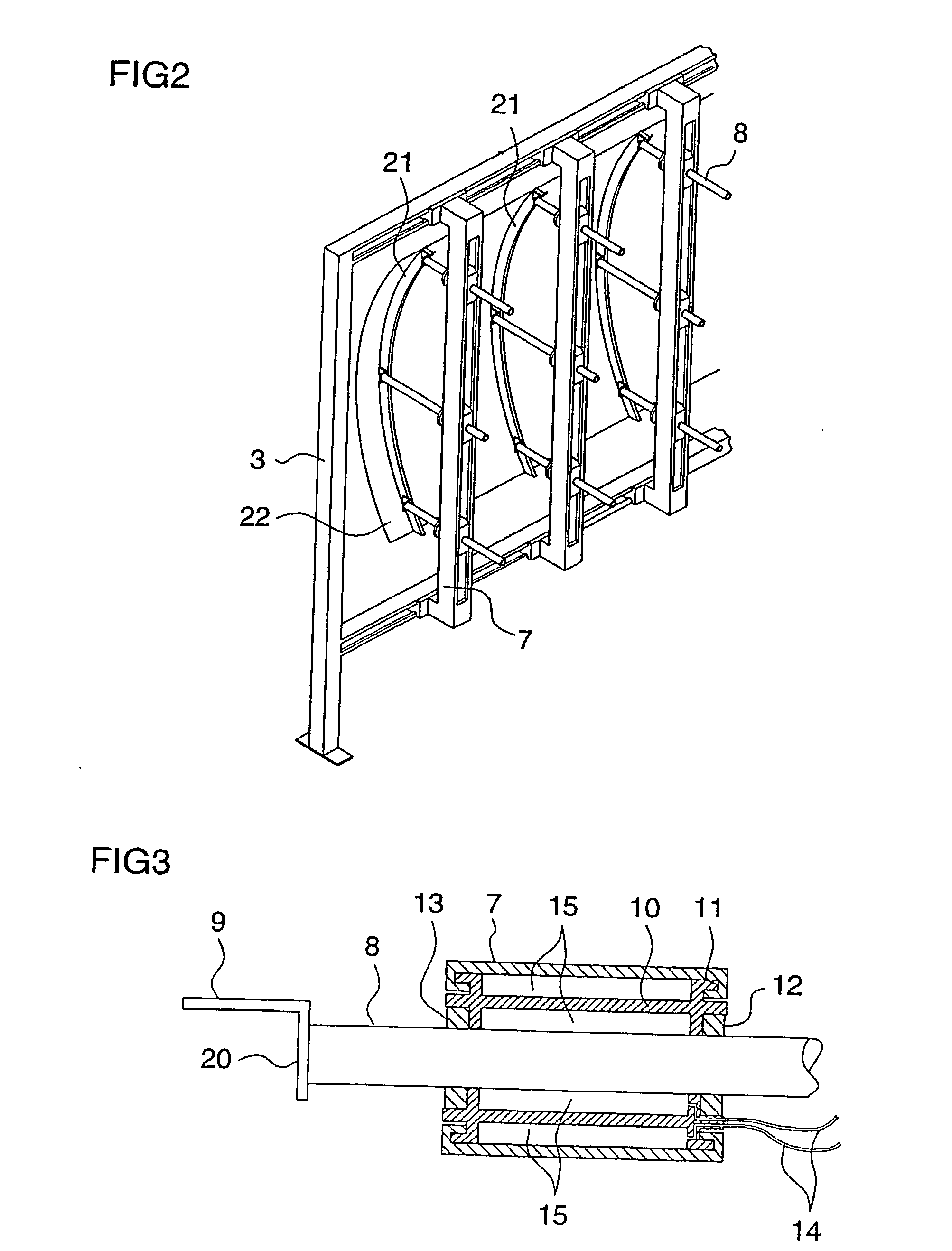

Device and method for fixation of airframe pieces

A method for regulating a device (2) used for fixing aircraft airframe pieces in connection with assembly of airframe parts (21, 22), where the device consists of a rig (3) comprising a matrix of rails (7, 8) that can slide in such a way that a number of fixing elements (9) attached to the rails (7, 8) can be positioned freely along three co-ordinates x, y, z in space within a given volume, where a manipulator (1) grasps a fixing element (9) after which the fixing element (9) is moved by the manipulator (1) to the given co-ordinate, and where the rails on which a fixing element (9) is arranged is locked in relation to the rig (3) by an automatic locking function initiated by the manipulator, thereby fixing the fixing element's (9) position in space and the setting procedure is repeated for a predetermined number of fixing elements (9) on the rig.

Owner:SAAB AB

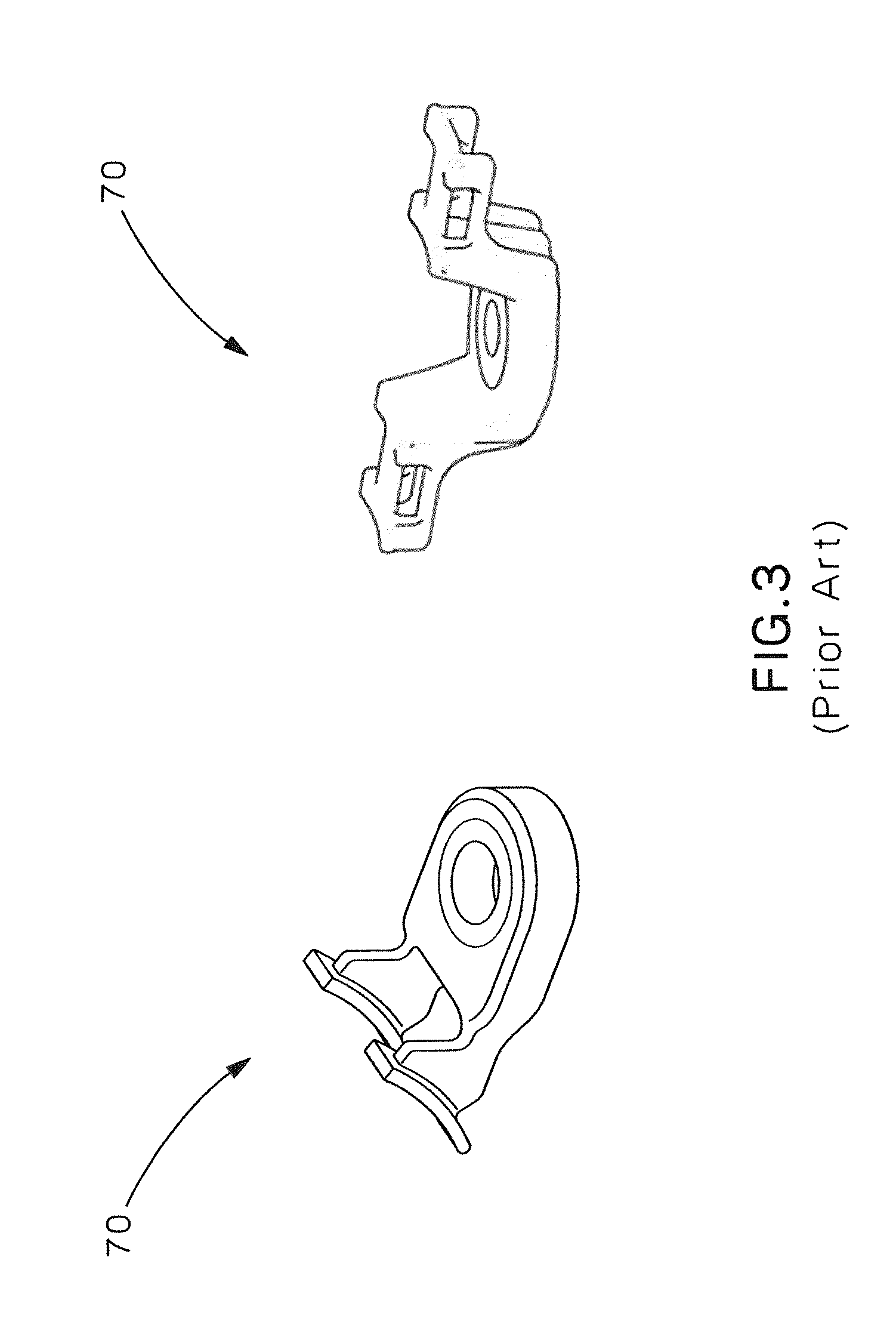

Method and tool for aligning a striker with a latch

Owner:CHRYSLER MOTORS CORP

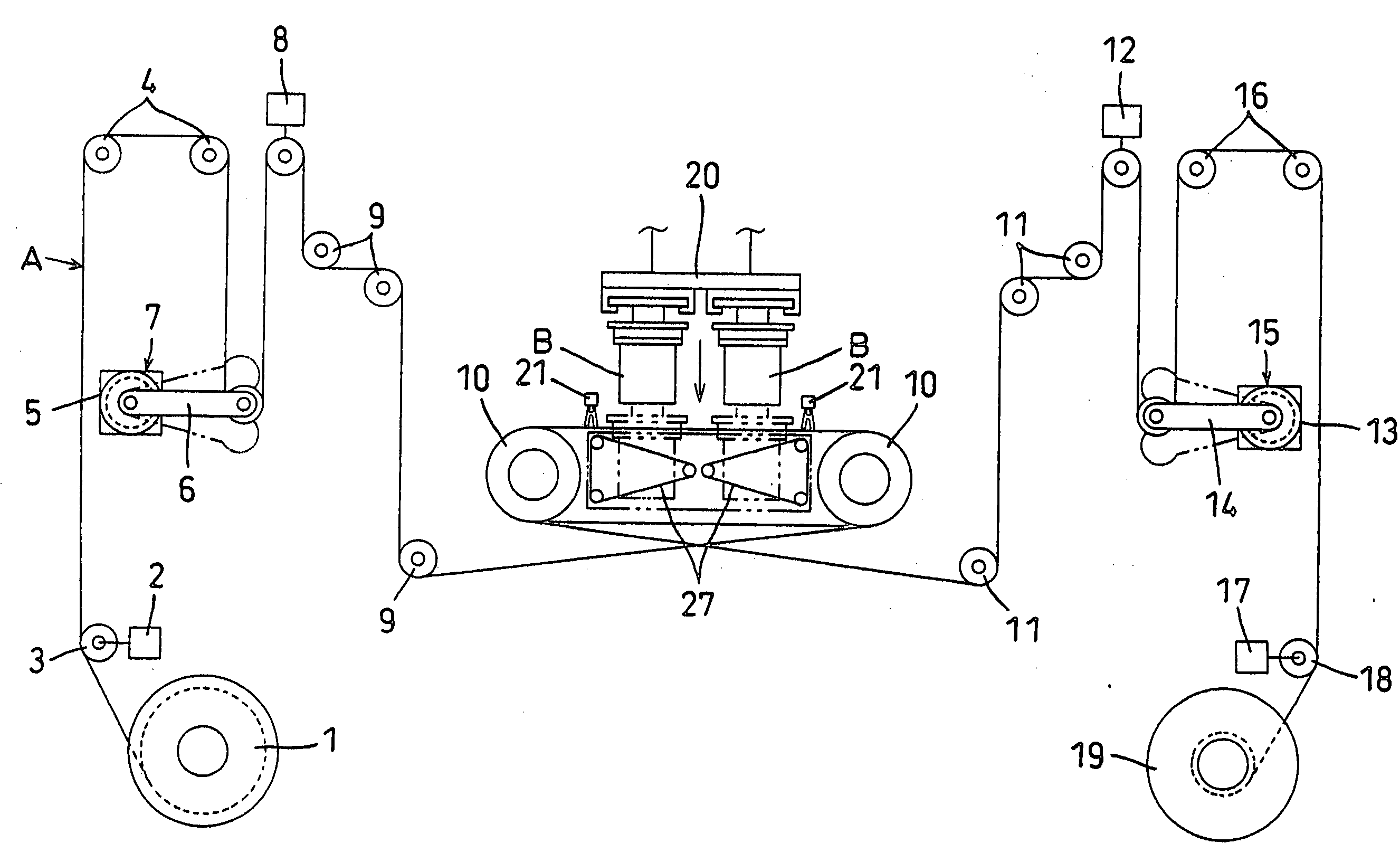

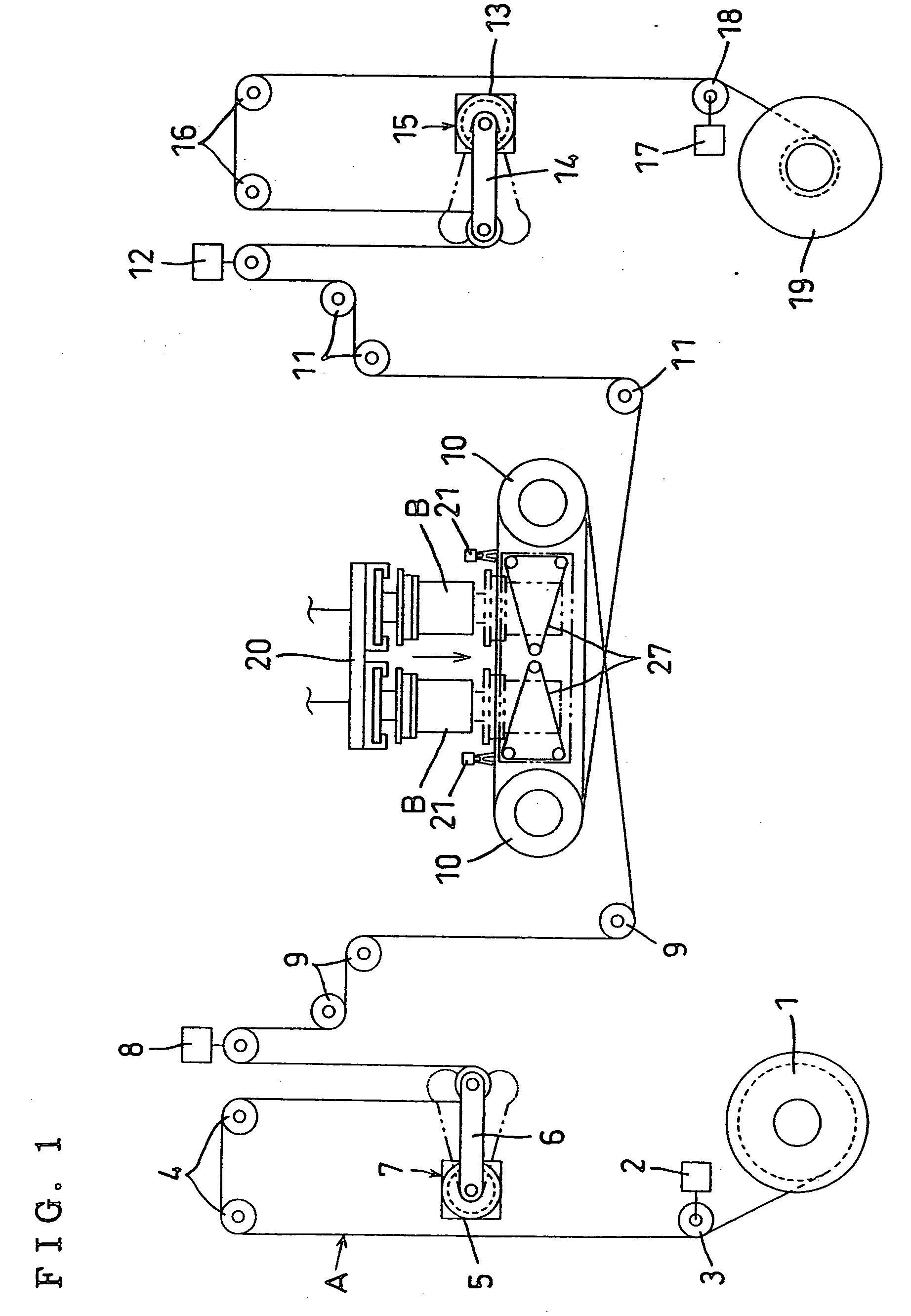

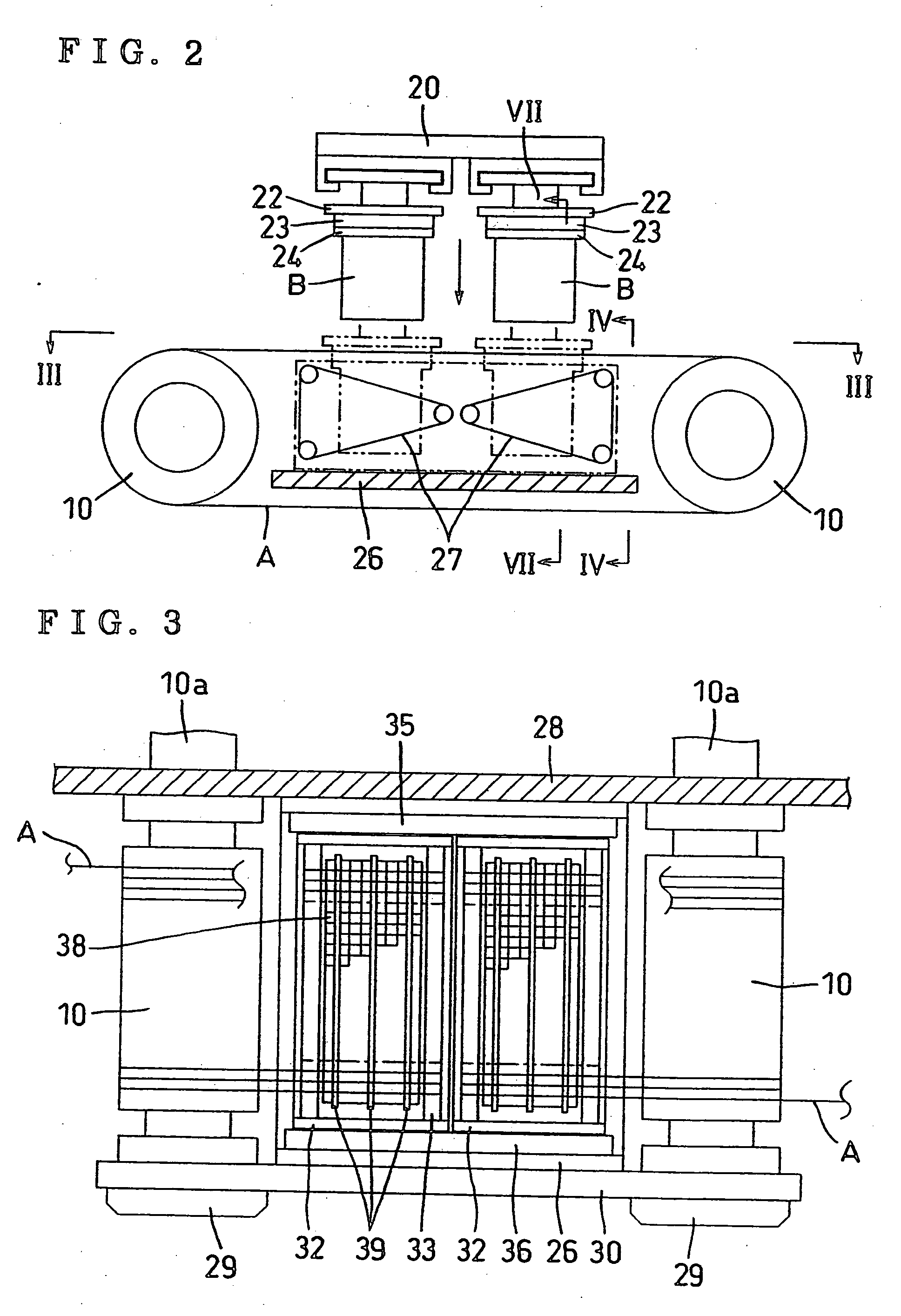

Cutting method by wire saw and cut workpiece receiving member in wire saw

InactiveUS20070131213A1Accurately cut outEnhance wafer cleansing performanceWorkpiece holdersBelt grinding machinesEngineeringAbutment

In a cutting method by a wire saw, in which a wire A at a wire array wound around work rollers 10 is made to reciprocate or travel in one direction at a high speed and numerous pieces of wafers are cut out in abutment of a workpiece B against the wire array, a receiving member 27 of a cassette type having numerous support wires 34 arranged at the same pitch as that of the wire at the wire array is disposed at a position immediately under the wire array for cutting the workpiece B; and wafers b cut out of the workpiece B by the wire A are contained in separation one from another between the support wires 34 in the receiving member 27. Thus, the wafers can be prevented from adhering to each other during a cutting operation, thus to be accurately cut, and further, the wafers can be prevented from being cracked during the cutting operation, thus to be efficiently separated one from another, so as to enhance wafer cleansing performance.

Owner:TAKATORI

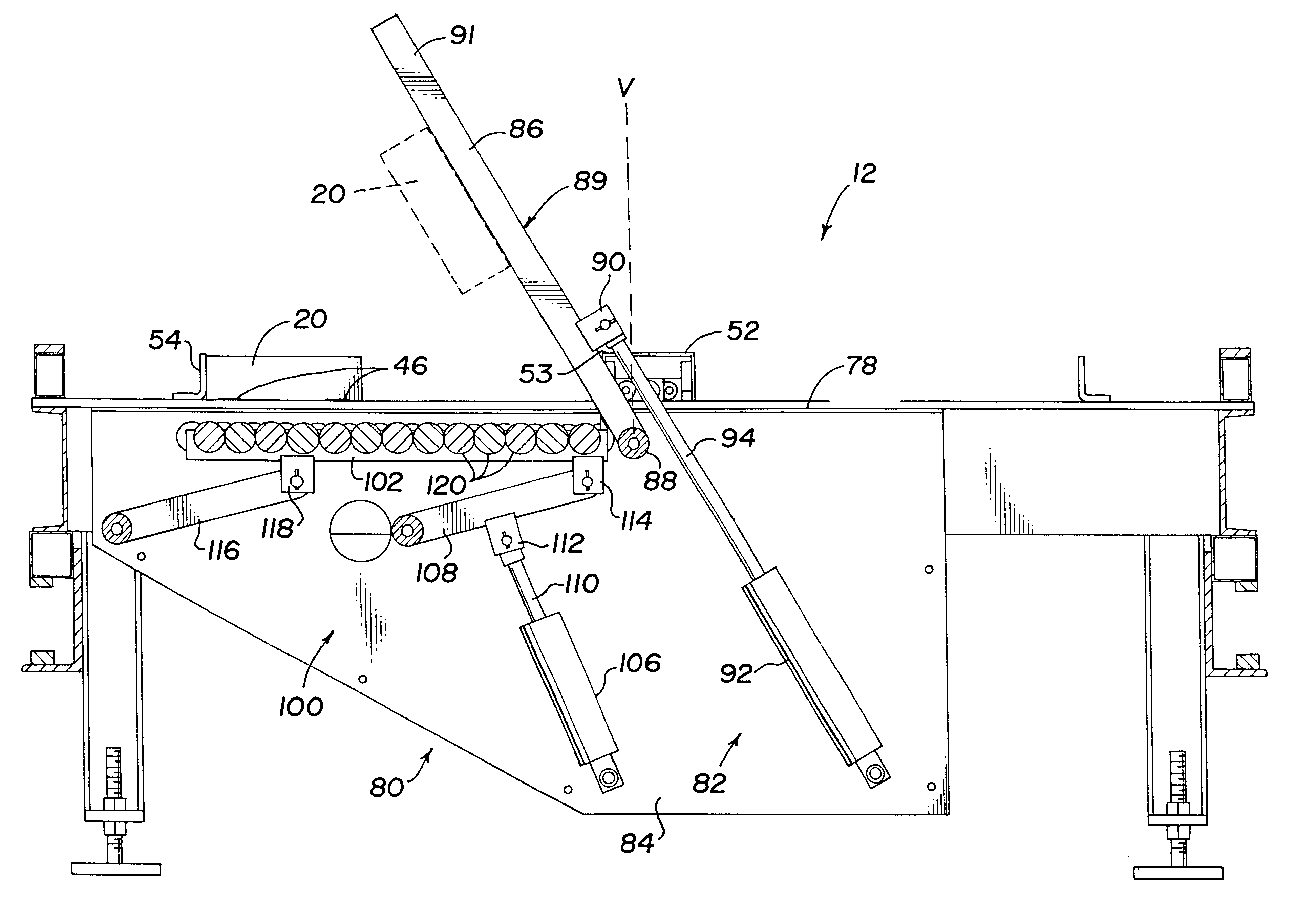

Truss table apparatus with automatic truss movement assembly and method

A truss assembly apparatus and method for assembling a truss utilizing the apparatus are presented, the apparatus comprising a truss table having a work surface with a first and second assembly zone. A first clamping assembly has a movable first clamp rail for clamping the truss in the first assembly zone, the first clamp rail having at least one flip-arm recess therein. A flip-over assembly has at least one flip-over arm movable relative to the work surface for moving the truss from a first truss position-in the first assembly zone to a second truss position in the second assembly zone, the flip-over arm movable into the flip-arm recess of the first clamp rail. The apparatus may have a plurality of such recesses and flip arms. The truss assembly apparatus may further comprise a second clamping assembly having a movable second clamp rail for clamping the truss in the second assembly zone, the second clamp rail having a flip-arm recess therein movable into the flip-arm recess of the second clamp rail.

Owner:ILLINOIS TOOL WORKS INC

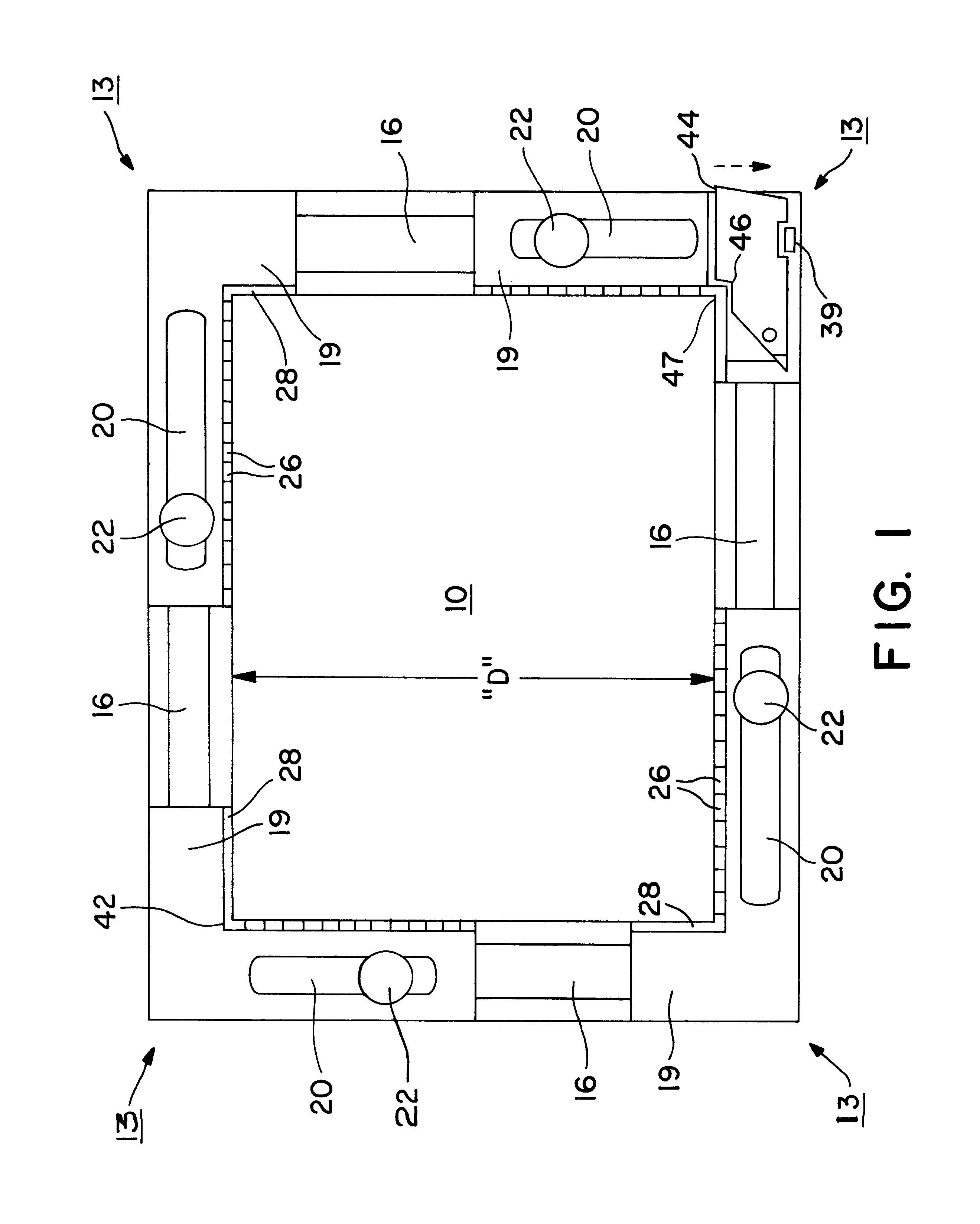

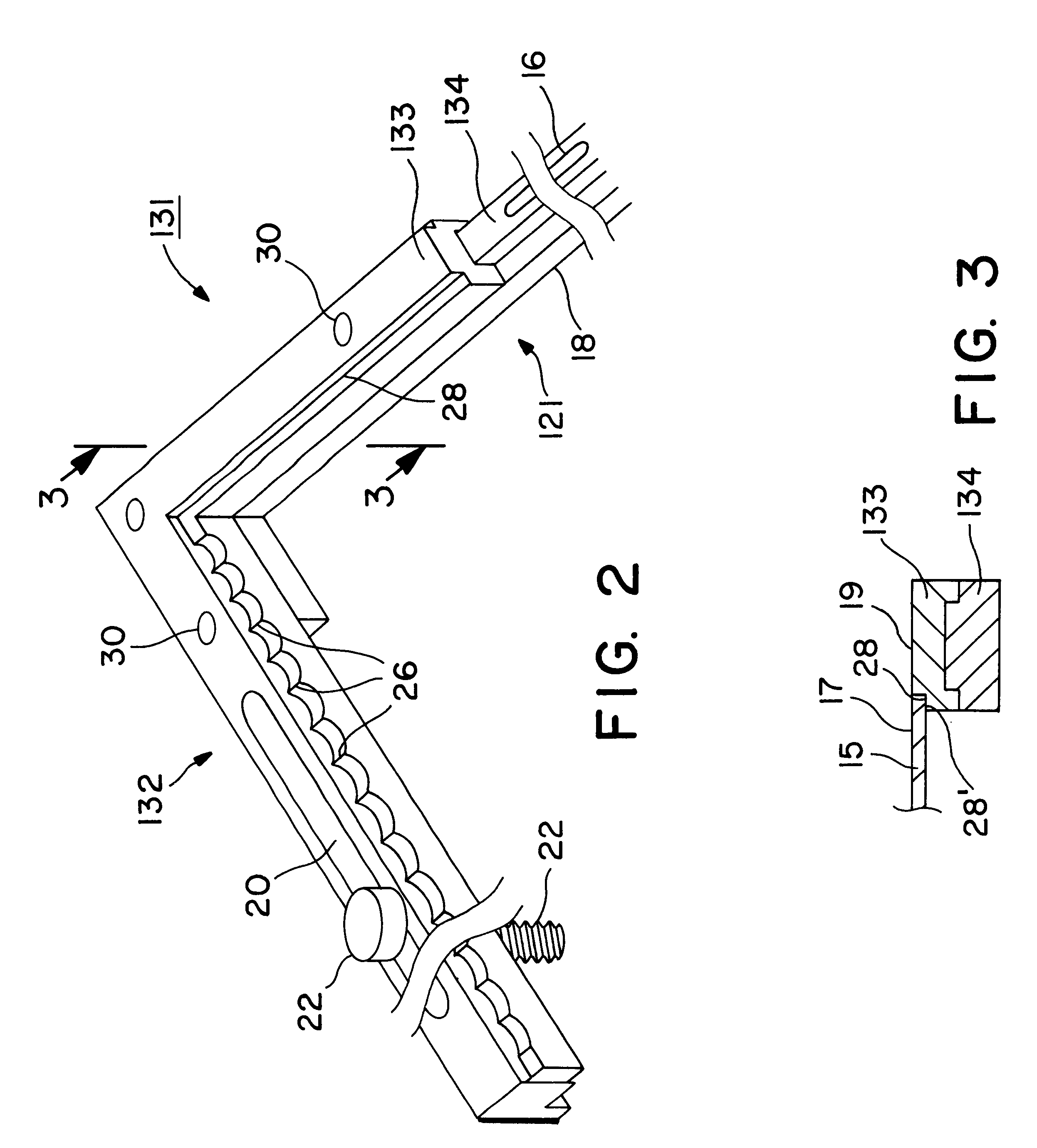

Universal reflow fixture

InactiveUS6209859B1Reduce heat lossMinimizing amount of stretchWorkpiece holdersPrinted circuitsSurface mountingEngineering

A frame comprising four angles each angle having two legs, each leg connected to a a leg of a neighboring angle wherein locations of attachment of the legs are adjustable so as to accommodate a range of sizes of boards for a surface mount manufacturing process. One leg of each angle has a tongue and the other leg has a groove so that tongue of one leg slideably engages the groove of the leg of a neighboring angle to enable adjustment in size of the frame opening. The board is supported on a shoulder around the frame opening with the surface of the board opposite the supporting shoulder surface coplanar with the plane surface of the frame. A flat spring loaded rotatable finger on the plan surface in one corner of the board urges the board toward the opposite corner of the frame.

Owner:CHUNG HENRY

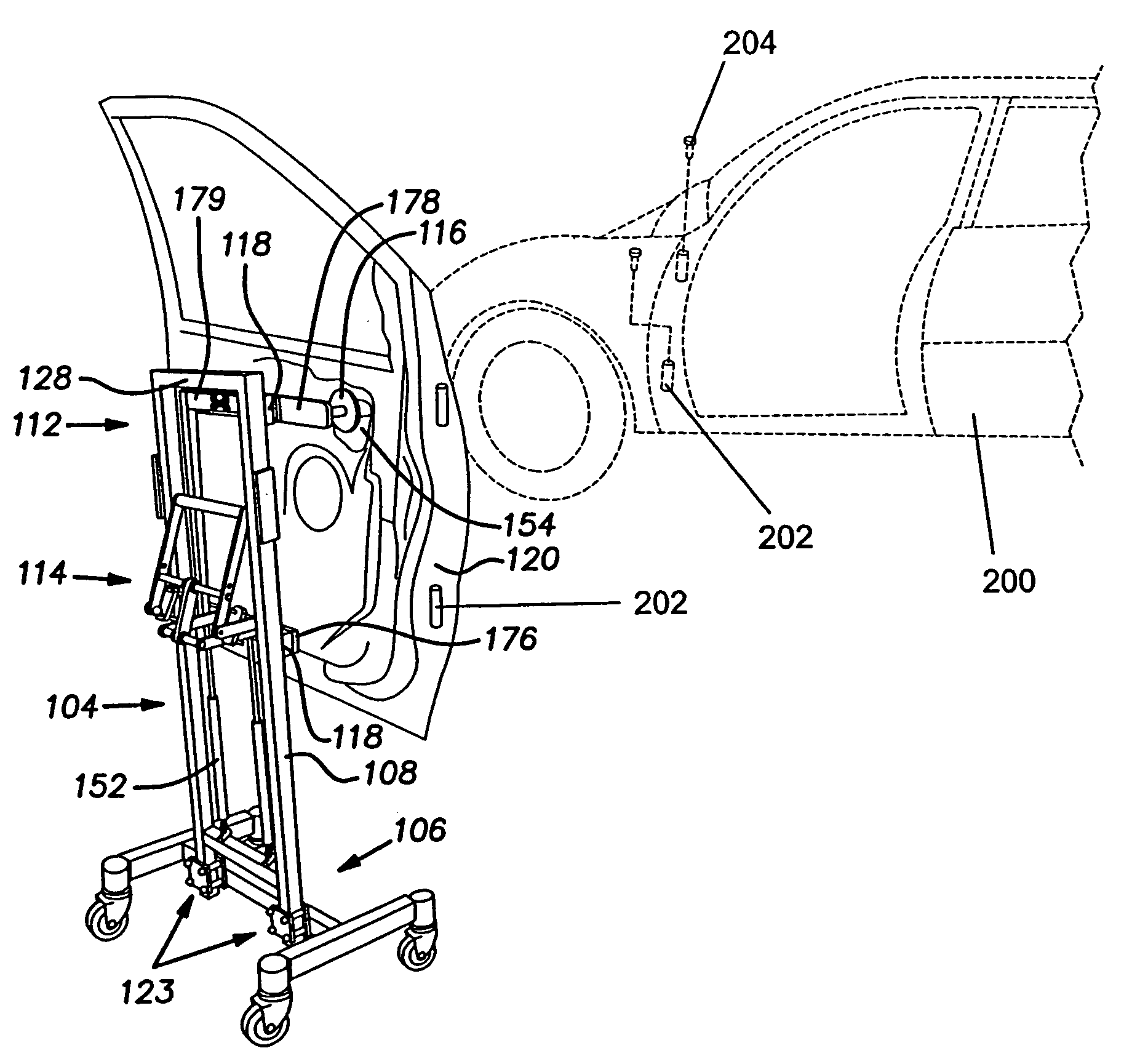

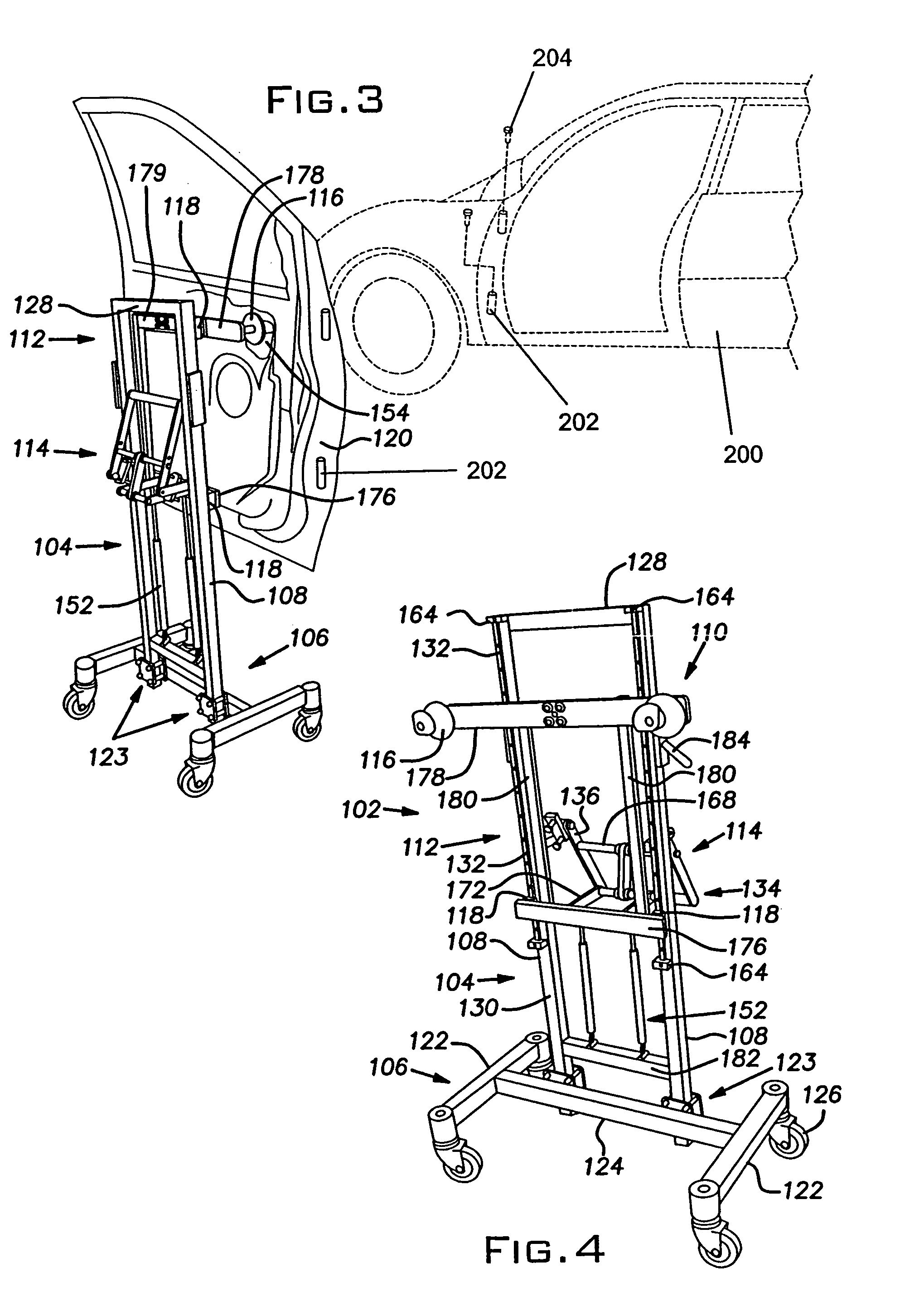

Door lifting apparatus and method

InactiveUS7008166B1Lifting and lowering doorWorkpiece holdersLifting devicesEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

Assembly line vehicle body positioning

InactiveUS20080000069A1Optimize locationWorkpiece holdersAssembly machinesAssembly lineBody positions

A vehicle body assembly line locator assembly (16) includes locators (18) having locator pins (82) received by vehicle body positioning holes (84) upon upward movement to provide accurate positioning. As the locator pins (82) are moved upwardly and initially move into the vehicle body positioning holes (84), horizontal power actuators (50,58) are deactuated to permit back driving of the locator pins to permit full insertion. The upward movement is continued so that vertical rest surfaces (80) of locator heads (78) contact the vehicle body (20) and provide lifting thereof upwardly off a system conveyor, and the power actuators then move the vehicle body to the proper positioning for further assembly.

Owner:UTICA ENTERPRISES

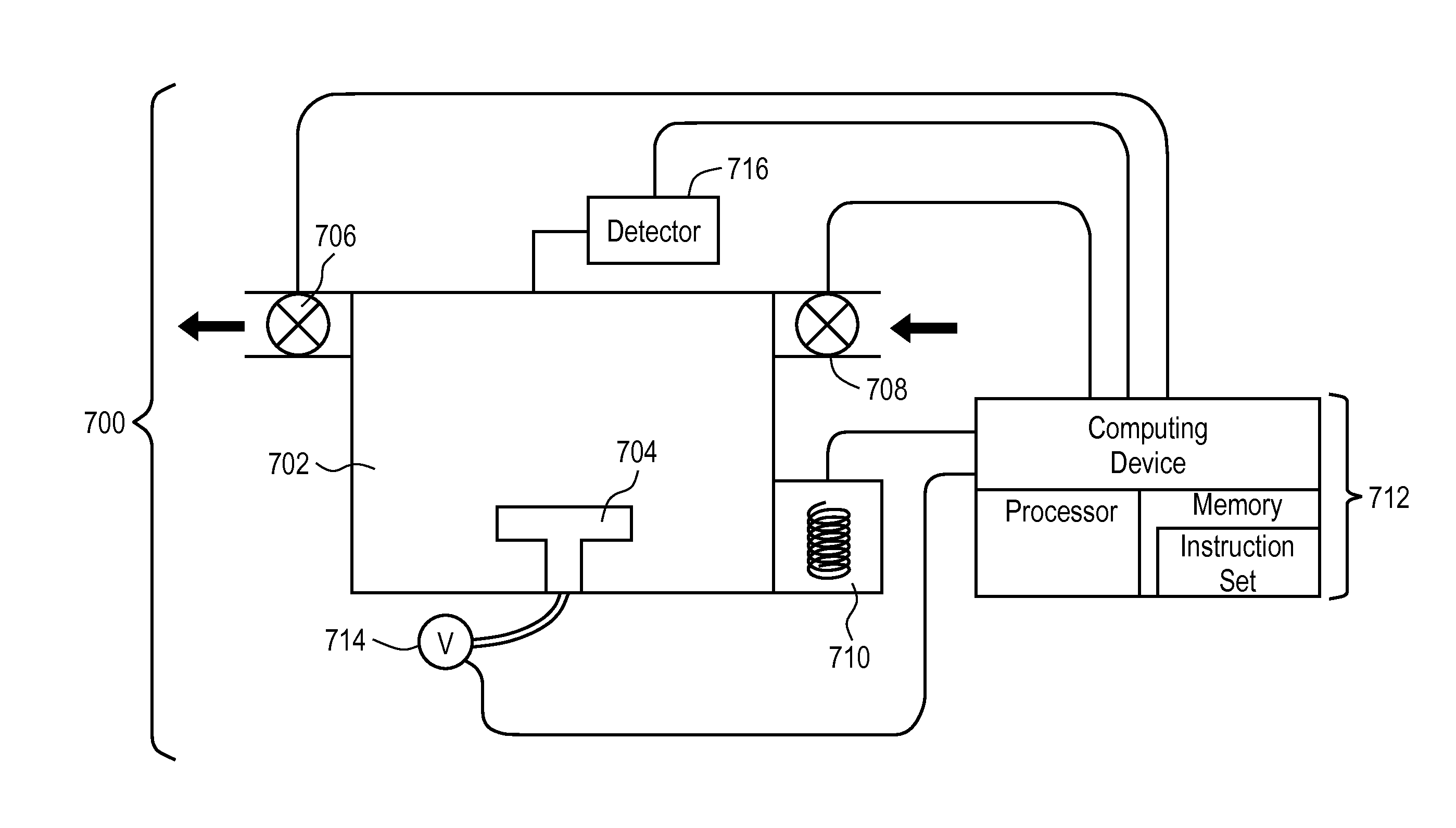

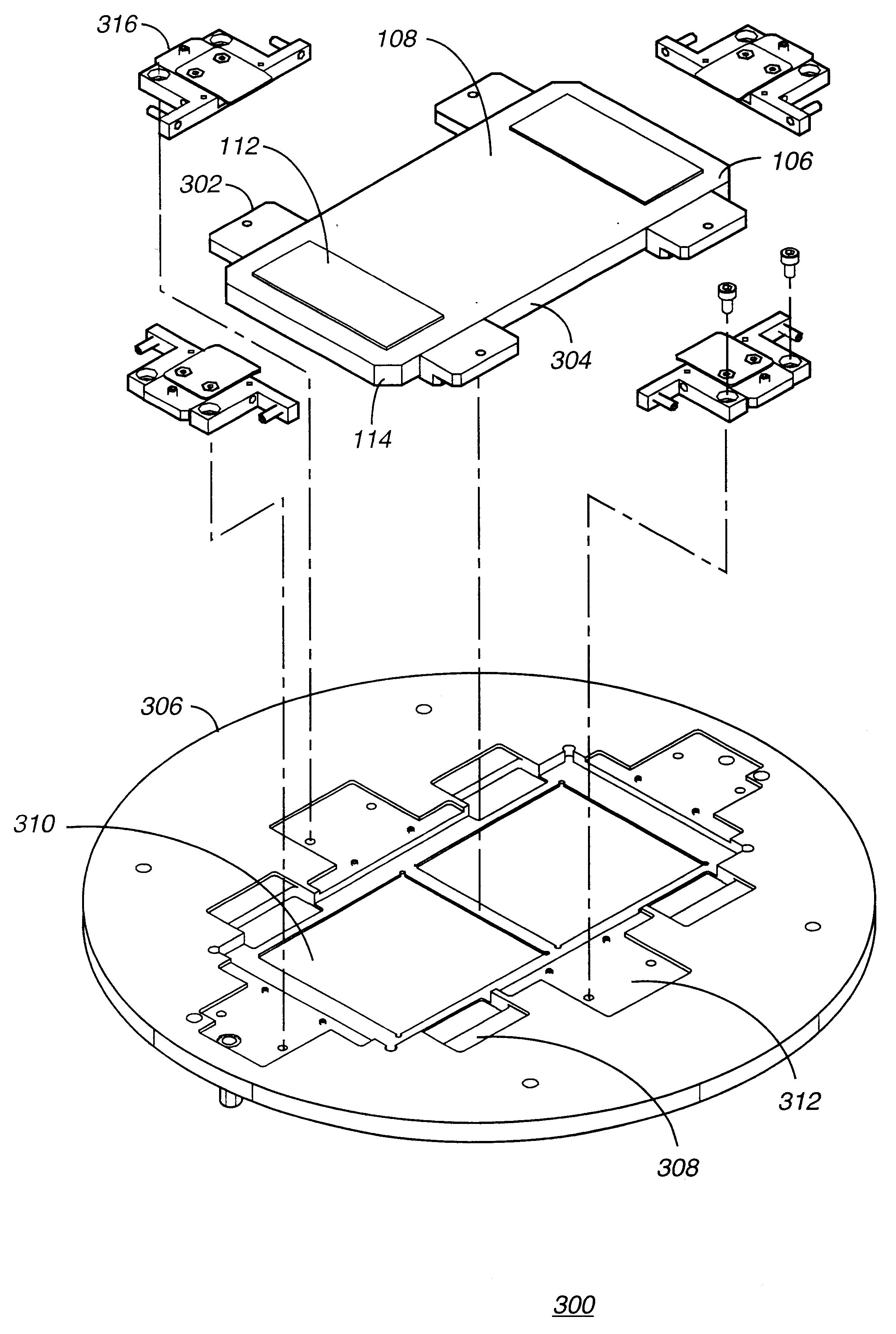

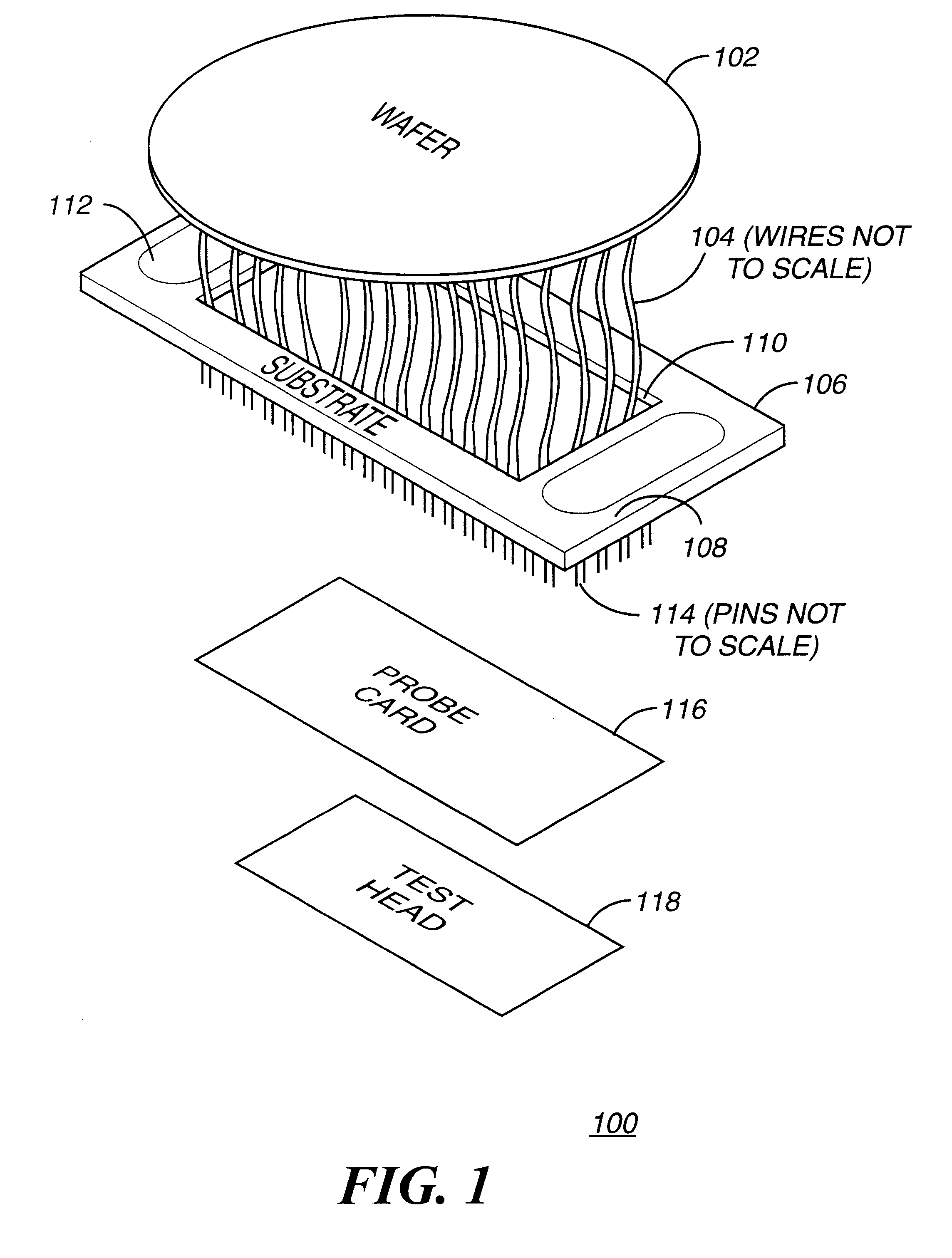

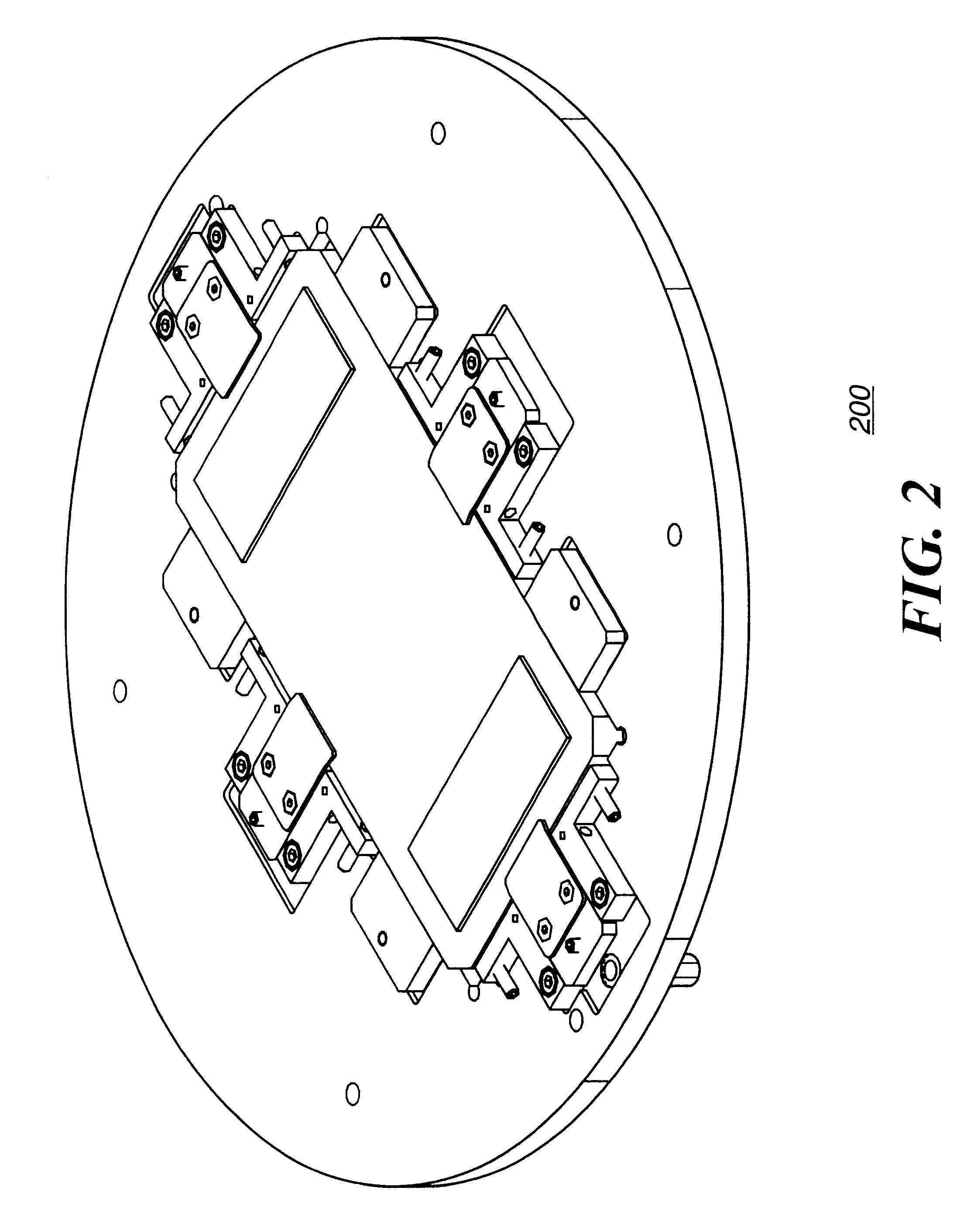

Mechanical fixture for holding electronic devices under test showing adjustments in multiple degrees of freedom

A fixture to hold an electronic substrate having probe areas on a top surface. The top surface of the electronic substrate is left open to provide a maximum area to couple interconnect wires for a device under test. In addition, a bottom surface of the substrate is left open to provide a maximum area to couple with a probe card in one embodiment, or a test head in another embodiment. This open bottom and open top minimize the mechanical interference with electrical connections. The substrate is planarized to a frame by one or more clamps that are attached to the frame. The clamps provide adjustment of the pressure down on the substrate in a Z-axis direction which is normal to the top surface of the substrate for providing a good connection with a planar card. In addition, the clamps provide adjustment in the an X-Y plane parallel to the frame and rotational correction about the Z-axis.

Owner:IBM CORP

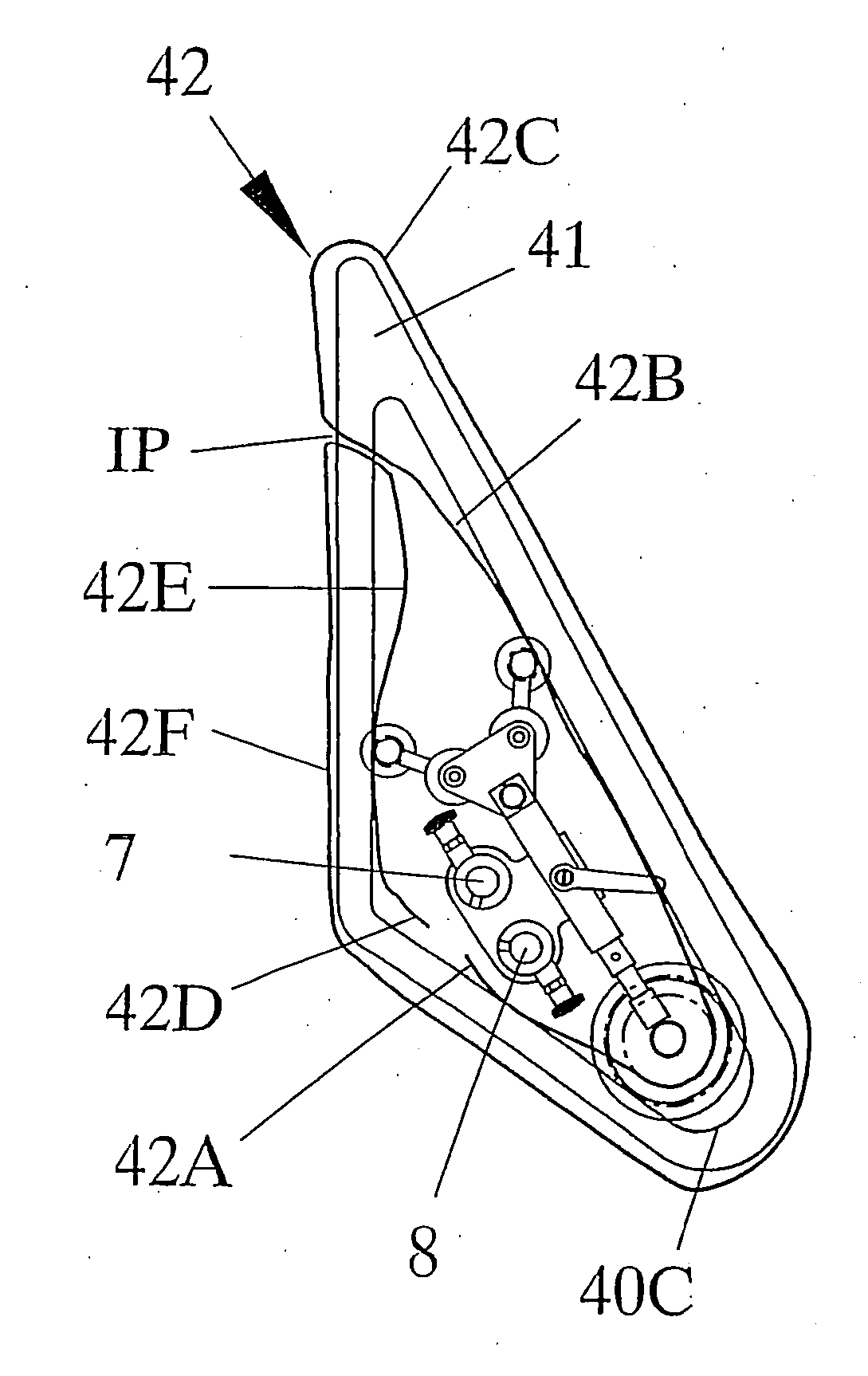

Method and a device for removing vehicle windows

InactiveUS20070000361A1Secure and effective non-destructiveEffective non-destructive removalWorkpiece holdersVehicle dissasembly recoveryNon destructiveEngineering

A method for the non-destructive removal of very small fixed window elements (40) from vehicles uses a cutting wire that is threaded through the adhesive bonding a window element to a vehicle, that is placed in a loop around the perimeter of the window element and that is pulled by wire wind-up elements (3) of a window element removal device. The device (1) is fitted to a window element frame (41), is expanded into firm clamping engagement with the window element frame (41) and is locked in the position firmly engaging the window element frame (41). The wire wind-up elements (3) are then operated until the wire cuts through the adhesive at the edge of the side window element around the entire perimeter thereof.

Owner:RAMHUSET DALA SPEGLAR

Apparatus and method for machining long workpiece

There are provided a base frame 12 positioned below a horizontal axis O; a pair of clamp units 14 positioned at the two ends above the base frame; a pair of support units 16 that horizontally support the long workpiece in two locations, and that are capable of moving vertically; and machining units 18 that are capable of machining the long workpiece. The two clamp units 14 are capable of moving from the outside toward the inside, which support the long workpiece in two locations, and rotate around the horizontal axis O in synchronization with each other.

Owner:IMAX CO LTD

Modular universal holding fixture

ActiveUS7866642B2Less-costly toolingWorkpiece holdersMachine tool componentsModularityLinear actuator

Owner:THE BOEING CO

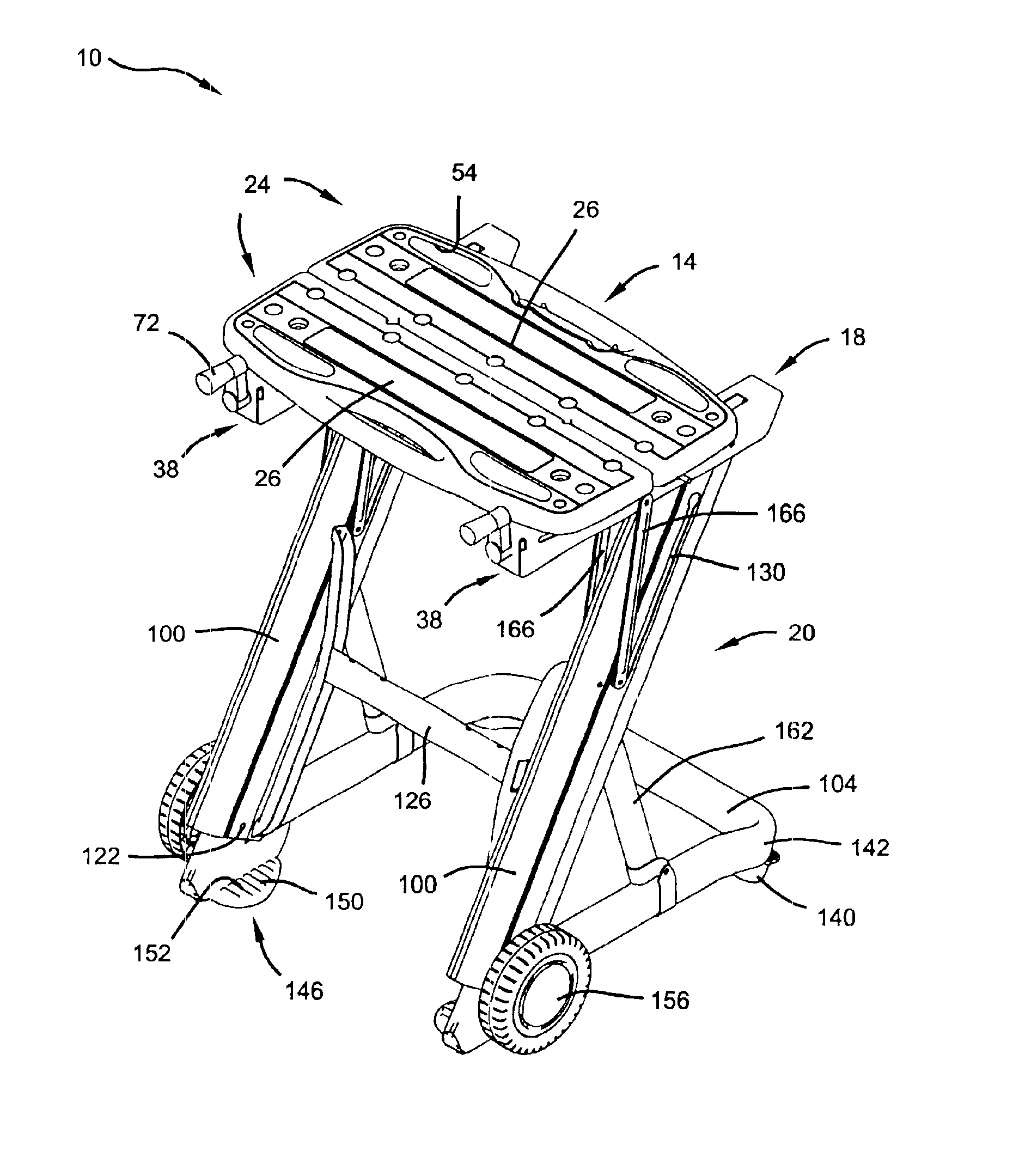

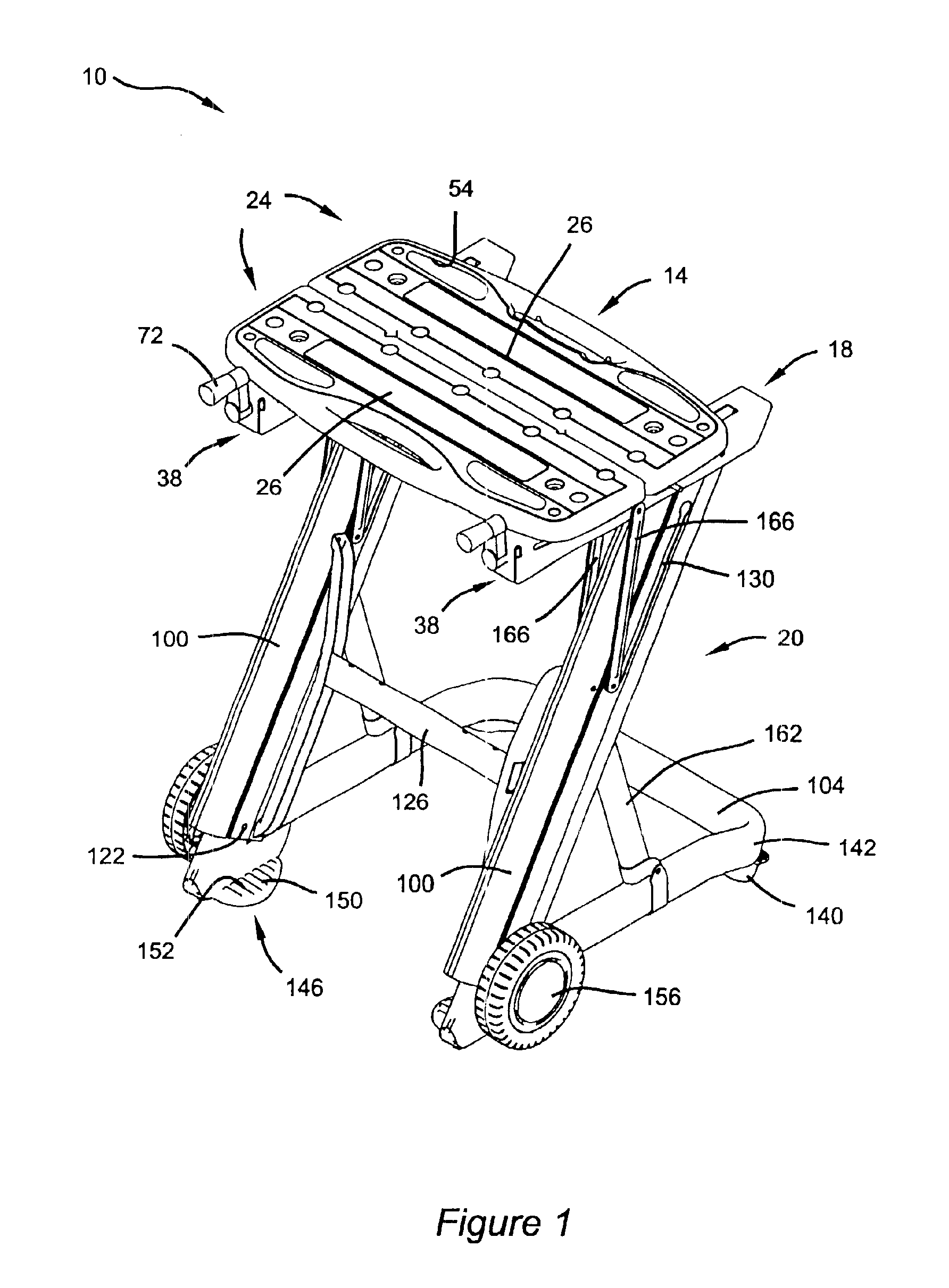

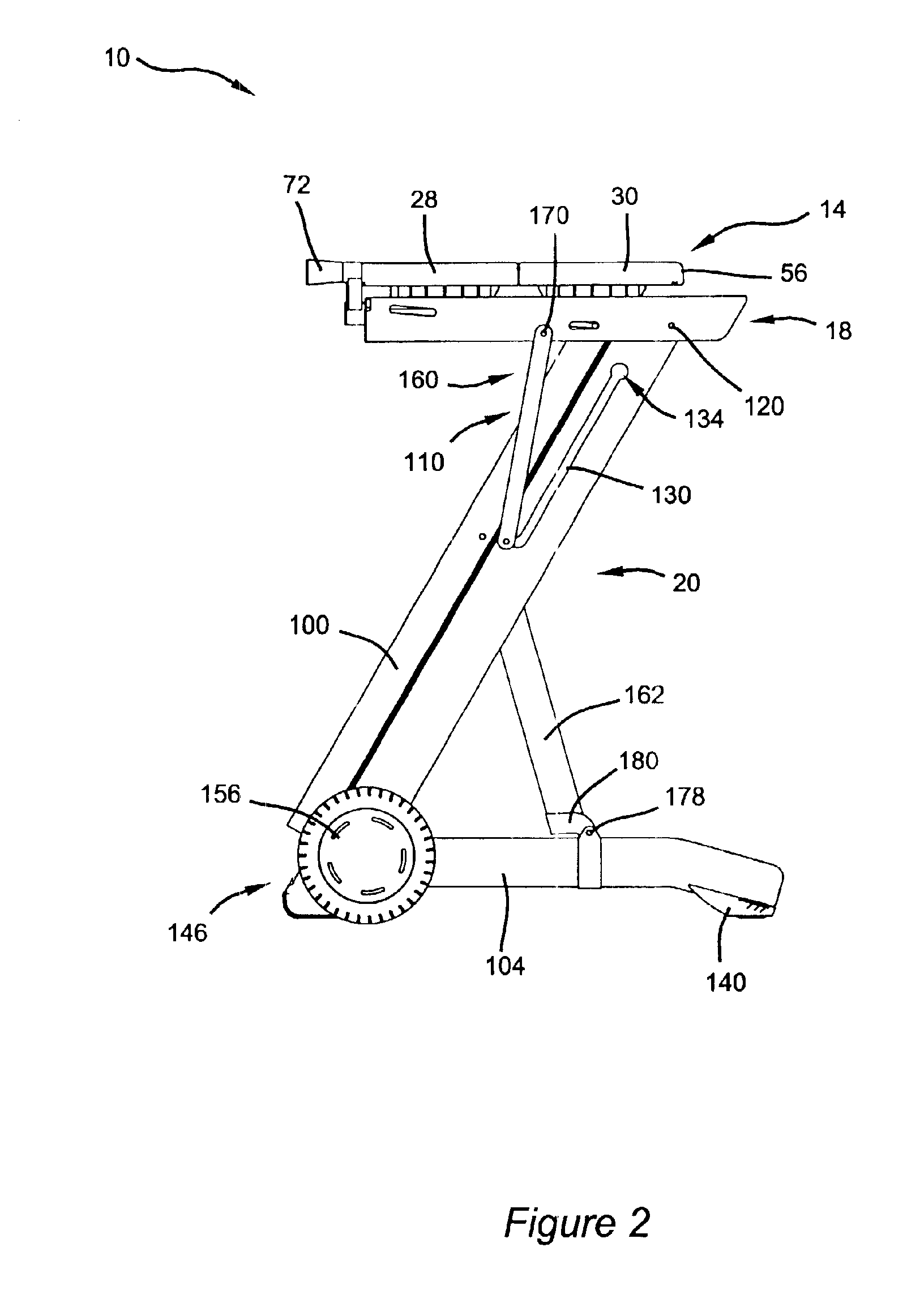

Workbench having plastic clamping work surface

A portable workbench includes a top structure, a support structure and a collapsible frame. The top structure includes top members lying in a common plane. The top members include upper working surfaces and lower supporting surfaces. The lower supporting surfaces include a plurality of rib portions formed thereon. The top members further include longitudinally extending opposed side portions defining clamping surfaces. A linkage mechanism cooperates with the frame to actuate the workbench between an expanded working position and a collapsed transport position. A lever releasably cooperates with the frame to maintain the workbench in a locked expanded position.

Owner:BLACK & DECKER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com