Process for rolling taper pipe thread on thin-wall metal pipe fitting

A technology of metal pipe fittings and tapered pipe threads, which is applied in the field of forming rollers to process external threads, to achieve the effects of easy removal, convenient operation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

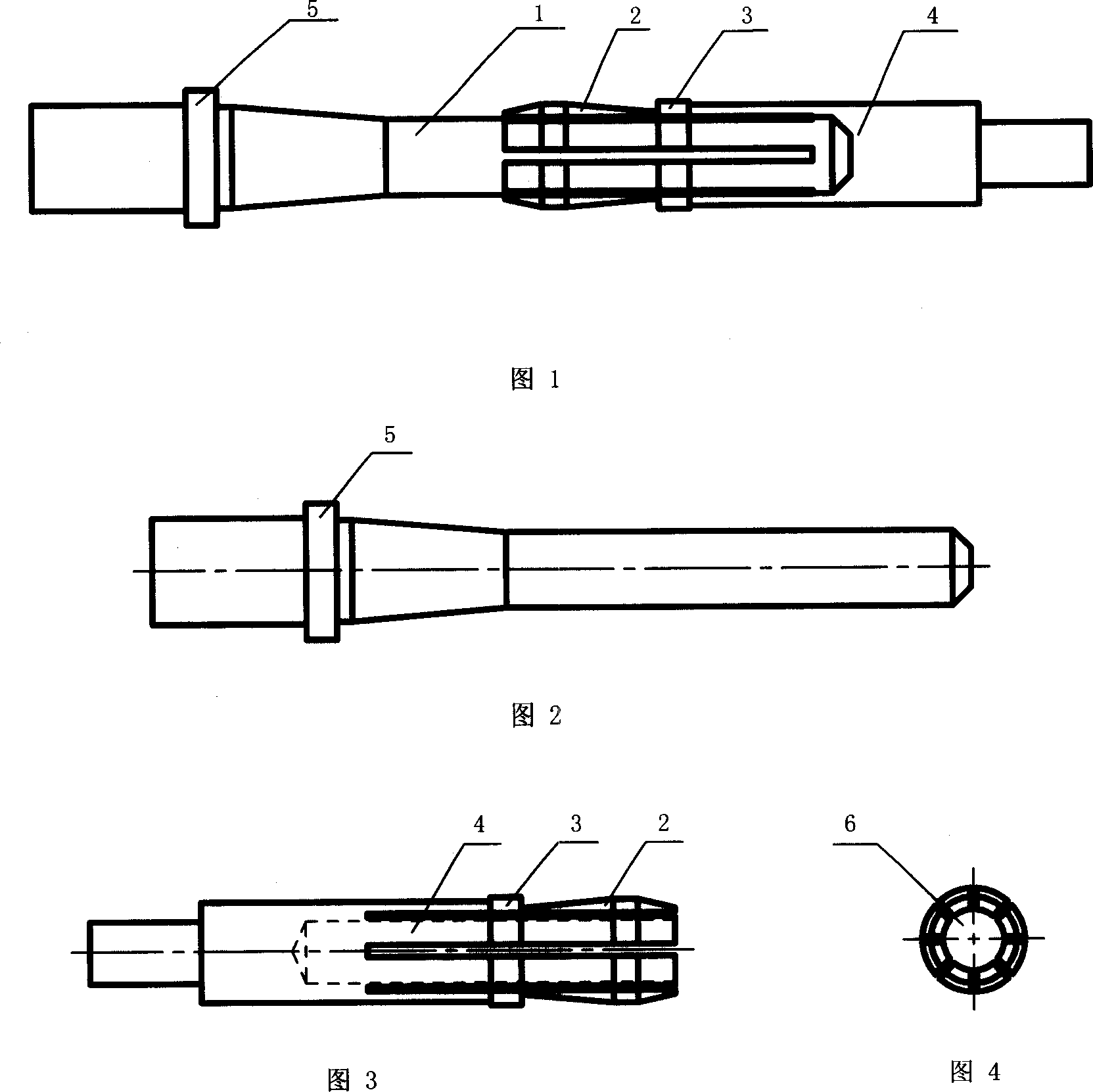

[0018] As shown in Figures 1 to 4. A process method for rolling tapered pipe threads on thin-walled metal pipe fittings. The main process is to use a combined tooling to complete on a well-known thread rolling machine, and it is characterized by comprising the following steps:

[0019] (1) Put the tensioning sleeve 4 into the clamping body of the machine tool, and then set the pipe to be processed on the end of the tensioning sleeve with the tapered head (2),

[0020] (2) Load the mandrel 1 into the workpiece to be processed, and at the same time into the middle hole 6 of the tensioning sleeve, clamp it,

[0021] (3) Process taper pipe threads according to process requirements.

[0022] The tensioning sleeve 4 and the mandrel 1 constitute a combined tooling. The tensioning sleeve 4 is a back pressure mechanism, which is characterized in that the rebound force increases with the increase of the rolling force, so as to keep the pipe fittings from being deformed. When the rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com