Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

432 results about "Counter pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Counter Pressure. Counter pressure is an effective labor pain management strategy for back labor or other area-specific discomfort. It is performed by applying pressure, usually significant pressure, to an area of discomfort, such as the small of the back. Back labor can also be a sign of an occiput-posterior baby,...

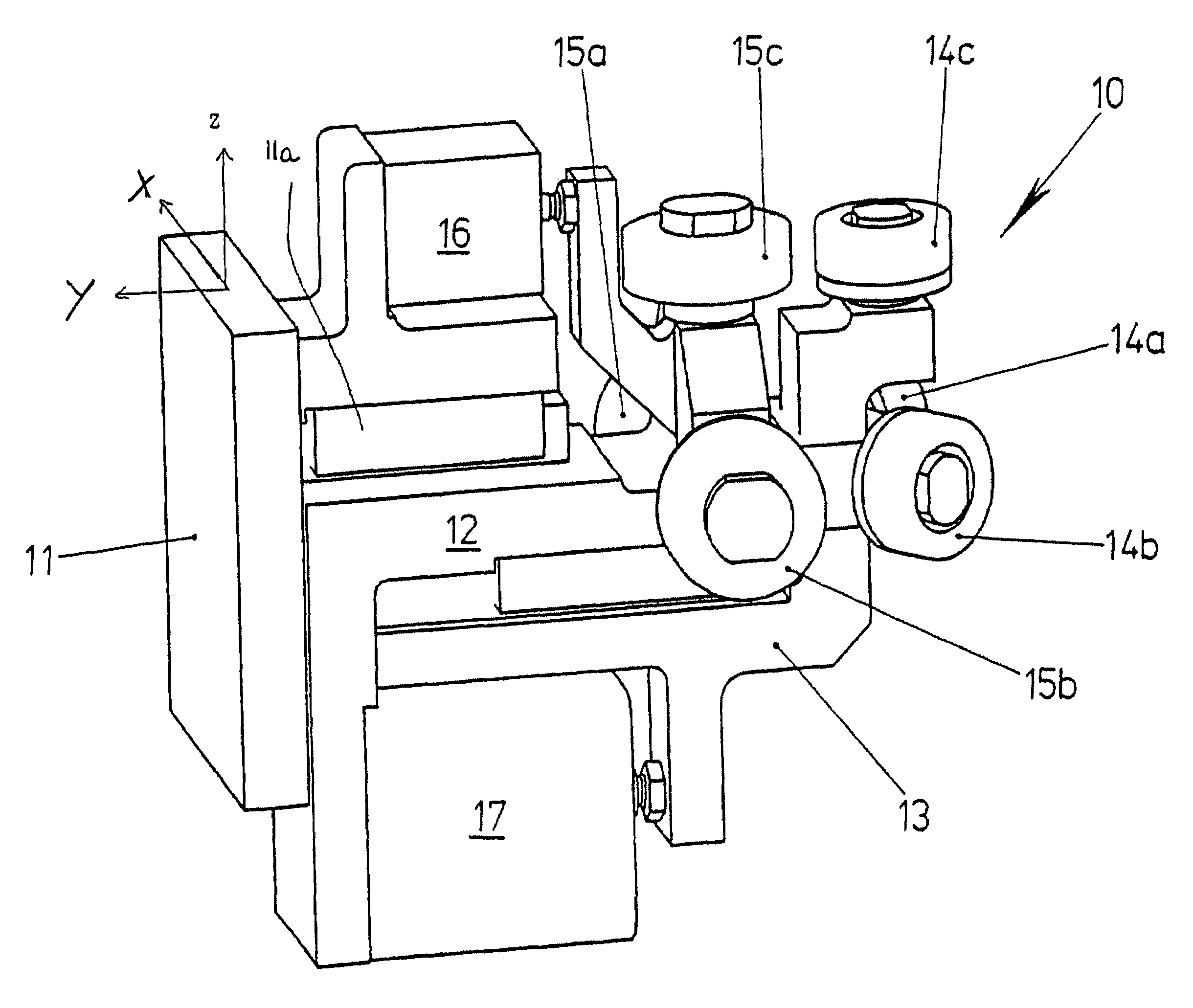

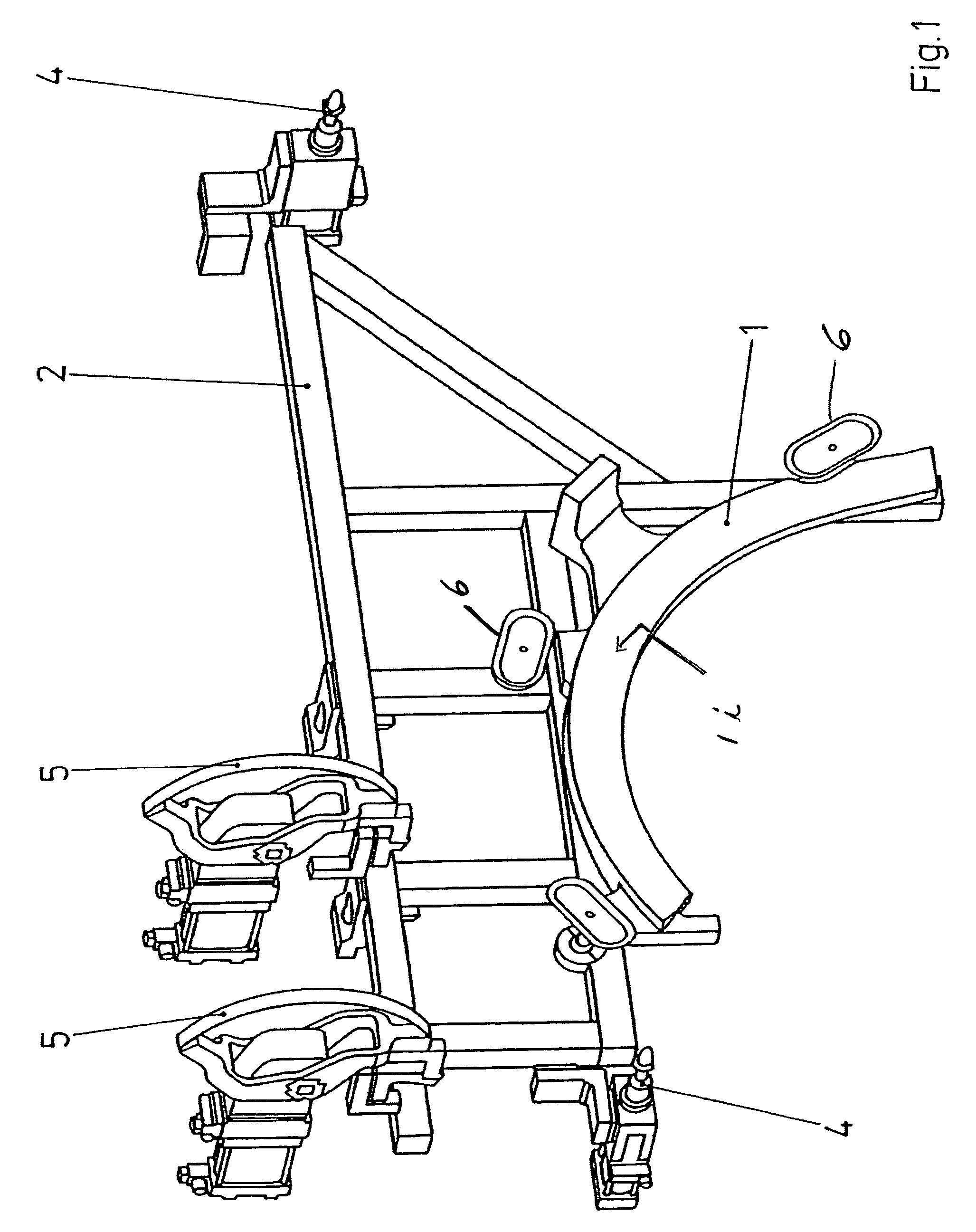

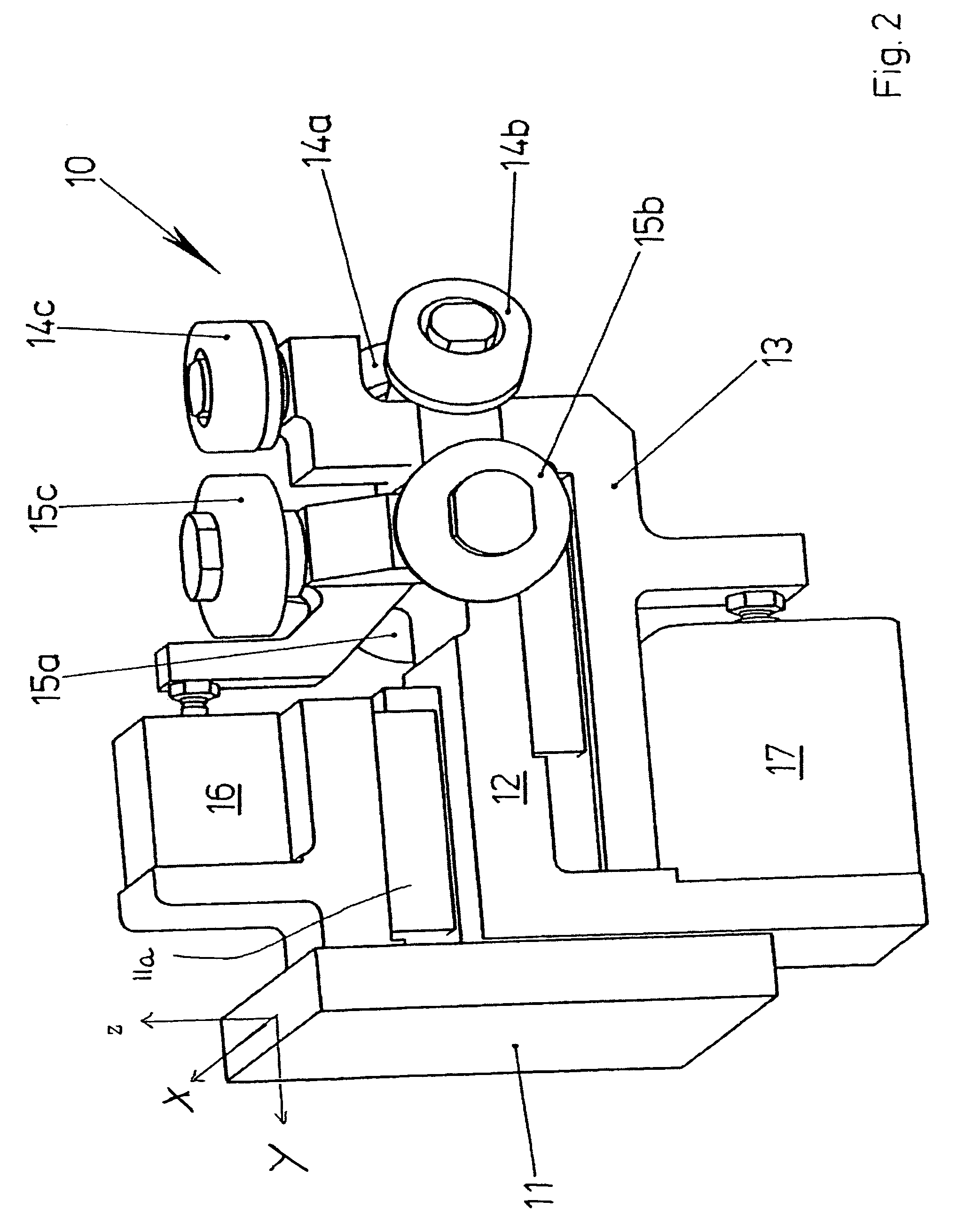

Flanging device and flanging method with component protection

ActiveUS7500373B2Adapt quicklyVehicle design optimisationMetal working apparatusCounter pressureEngineering

Owner:FFT PRODIONSSYST

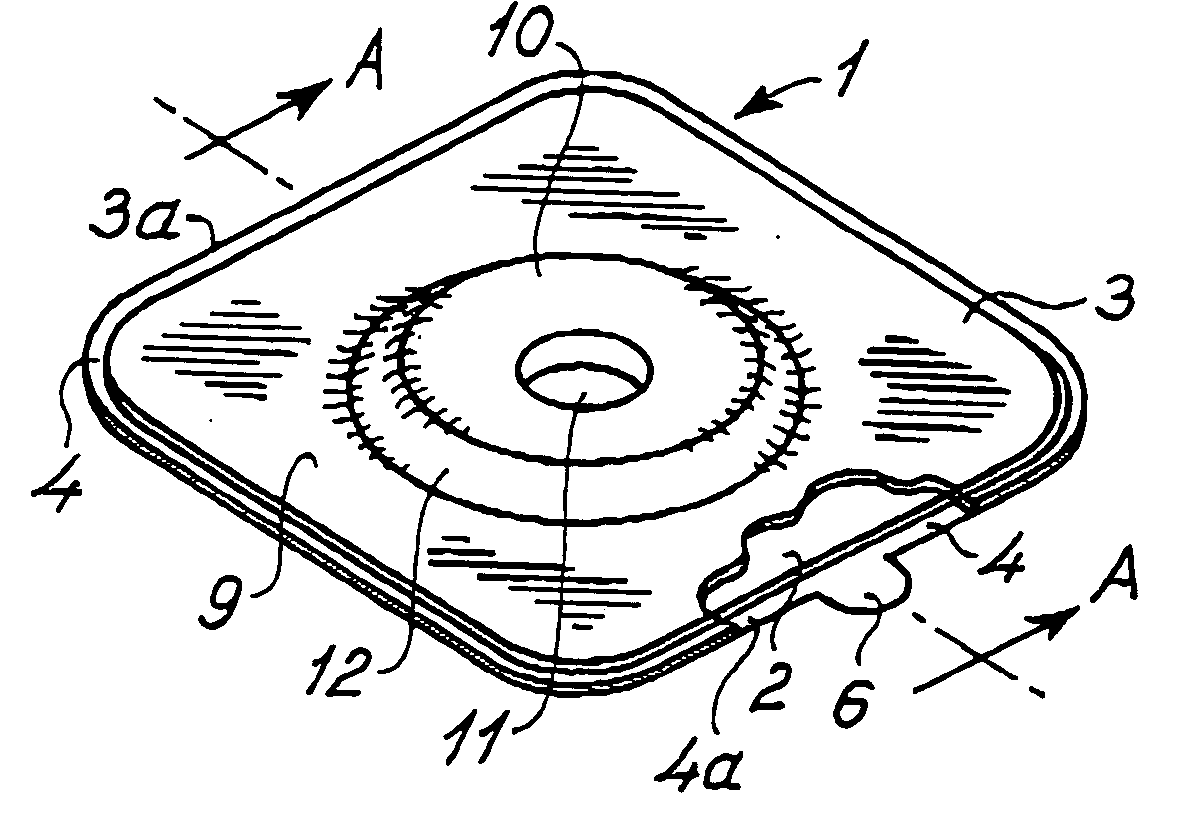

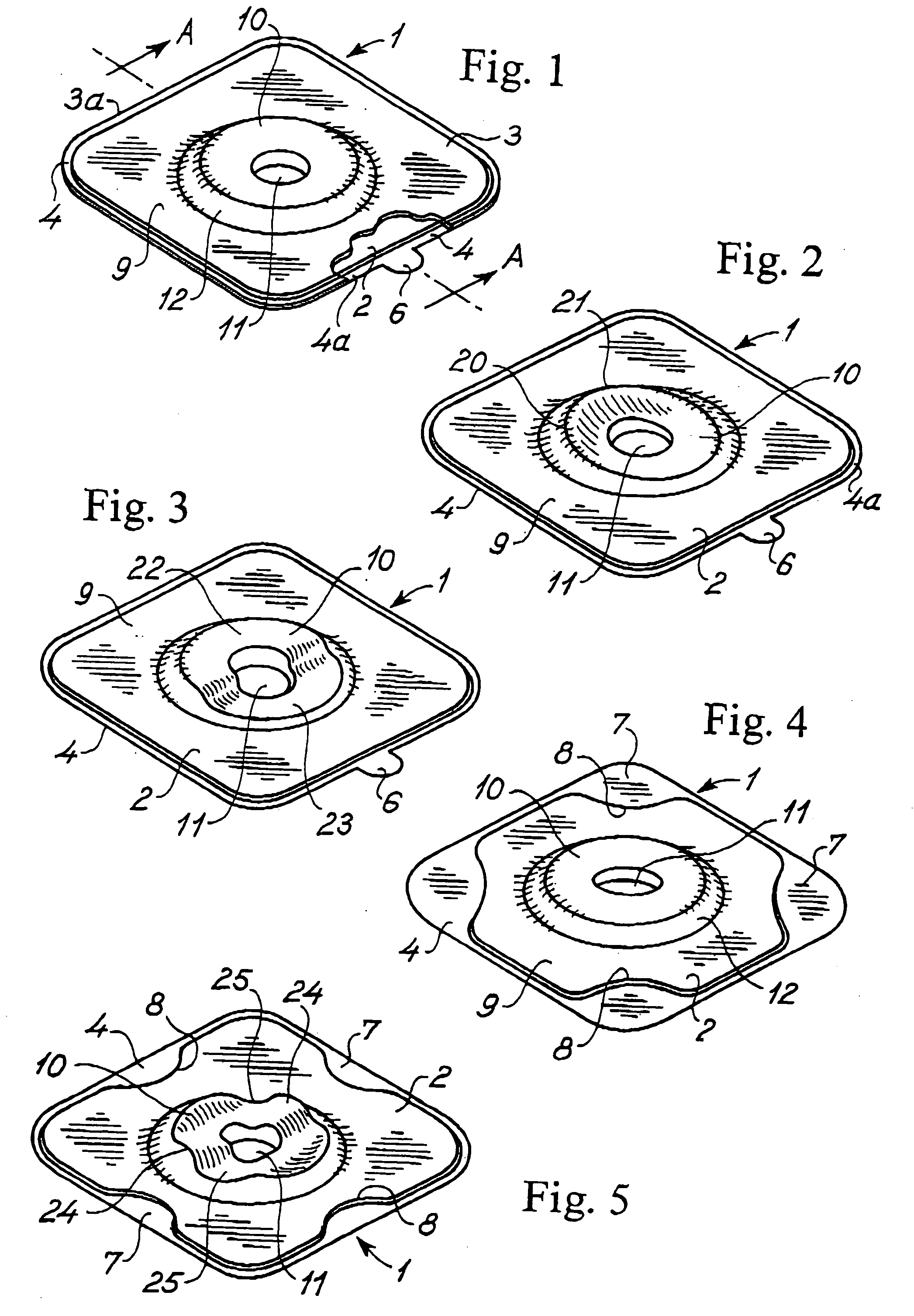

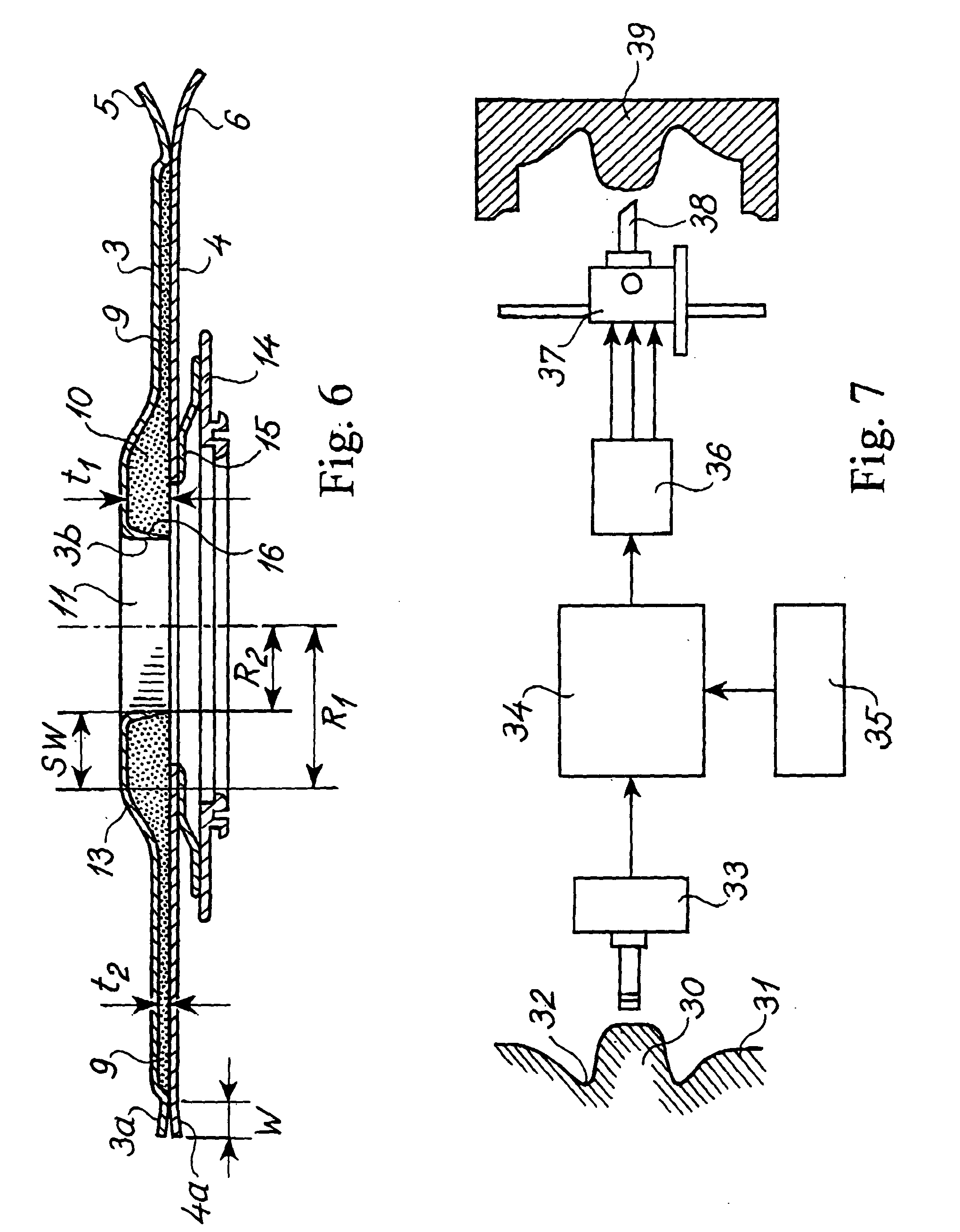

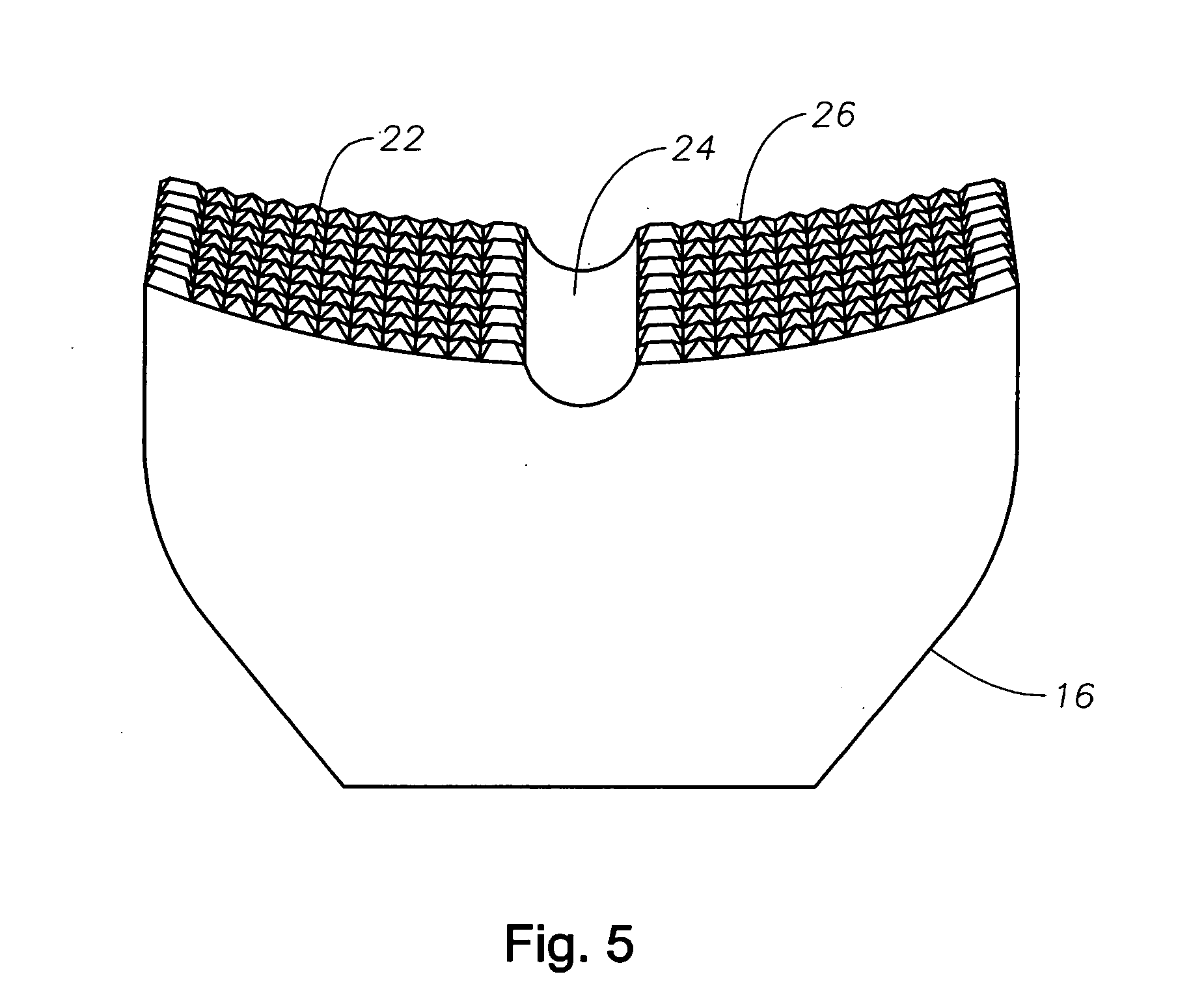

Method of manufacturing soft convex adhesive wafer

InactiveUS20040106908A1Improve sealingShort molding timeNon-surgical orthopedic devicesColostomyCounter pressurePeristomal Skin

Owner:HOLLISTER INCORPORAED

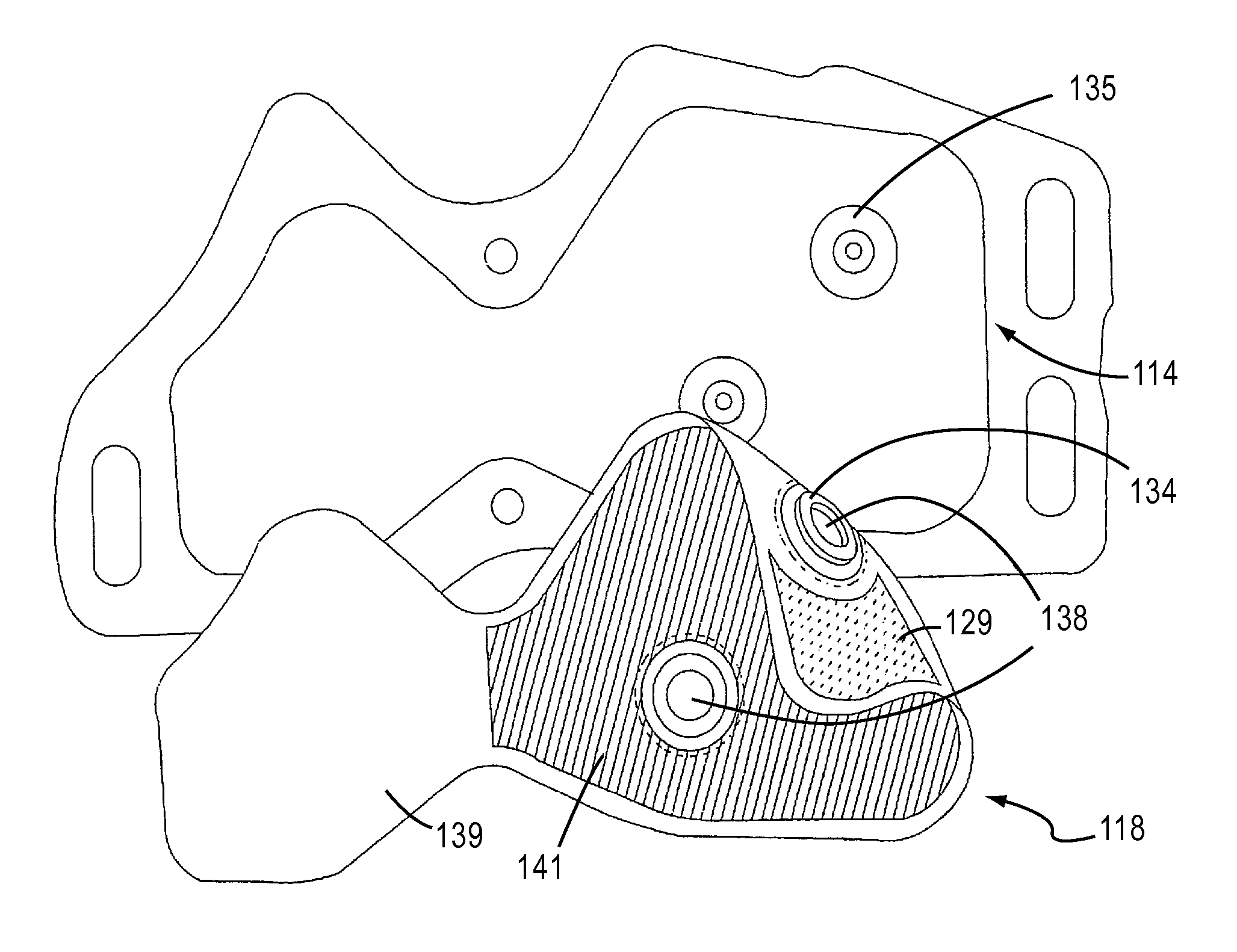

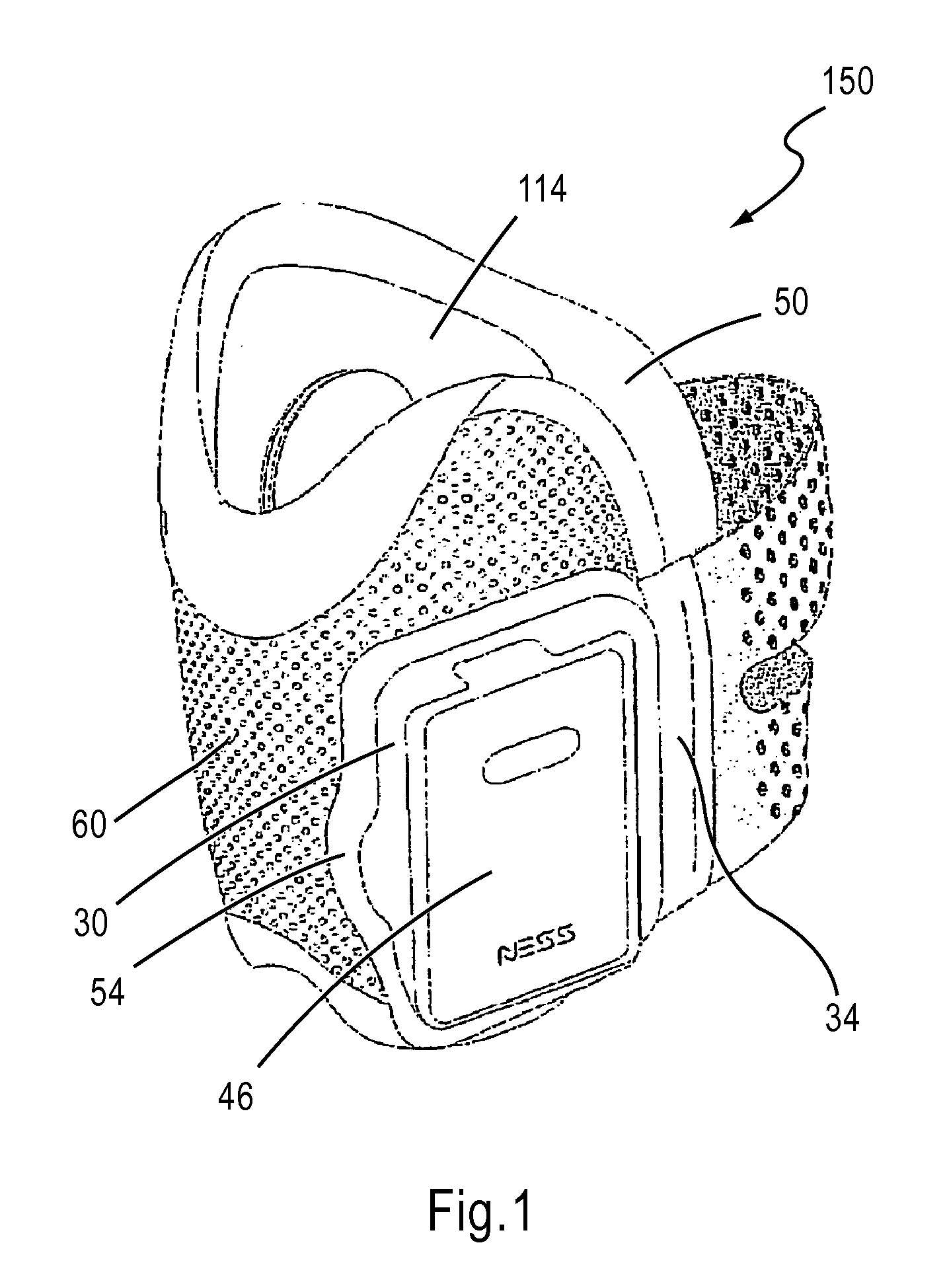

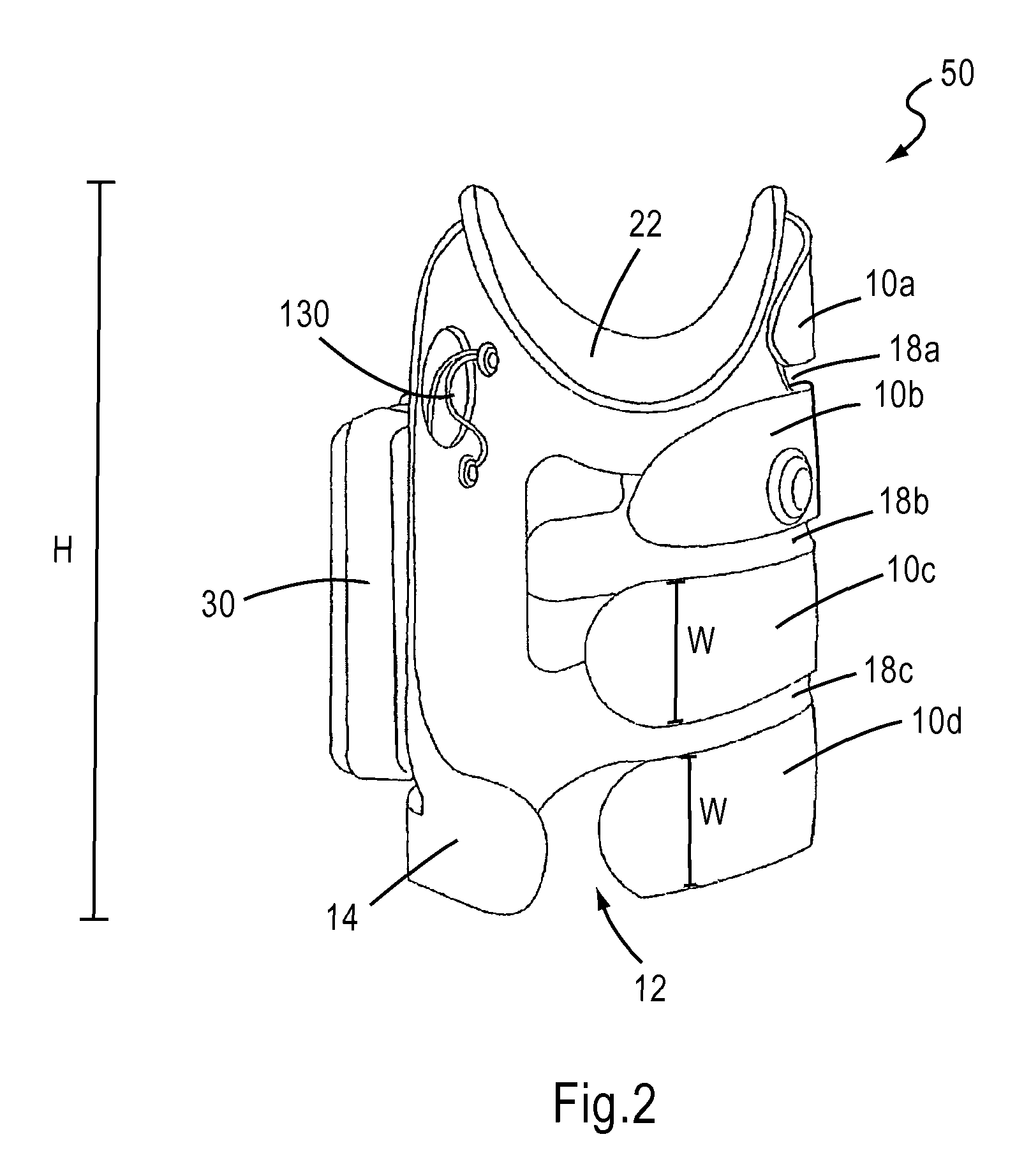

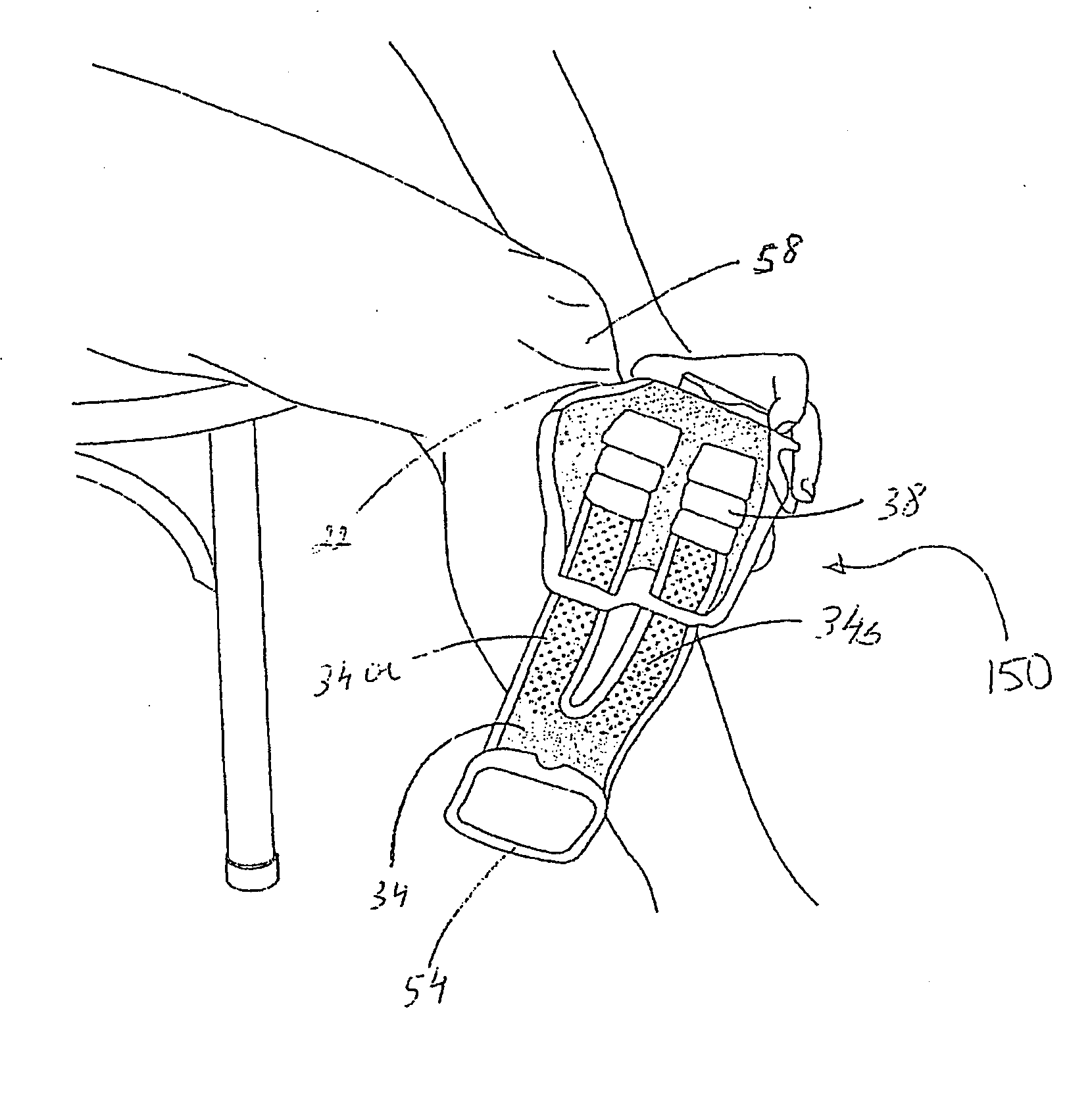

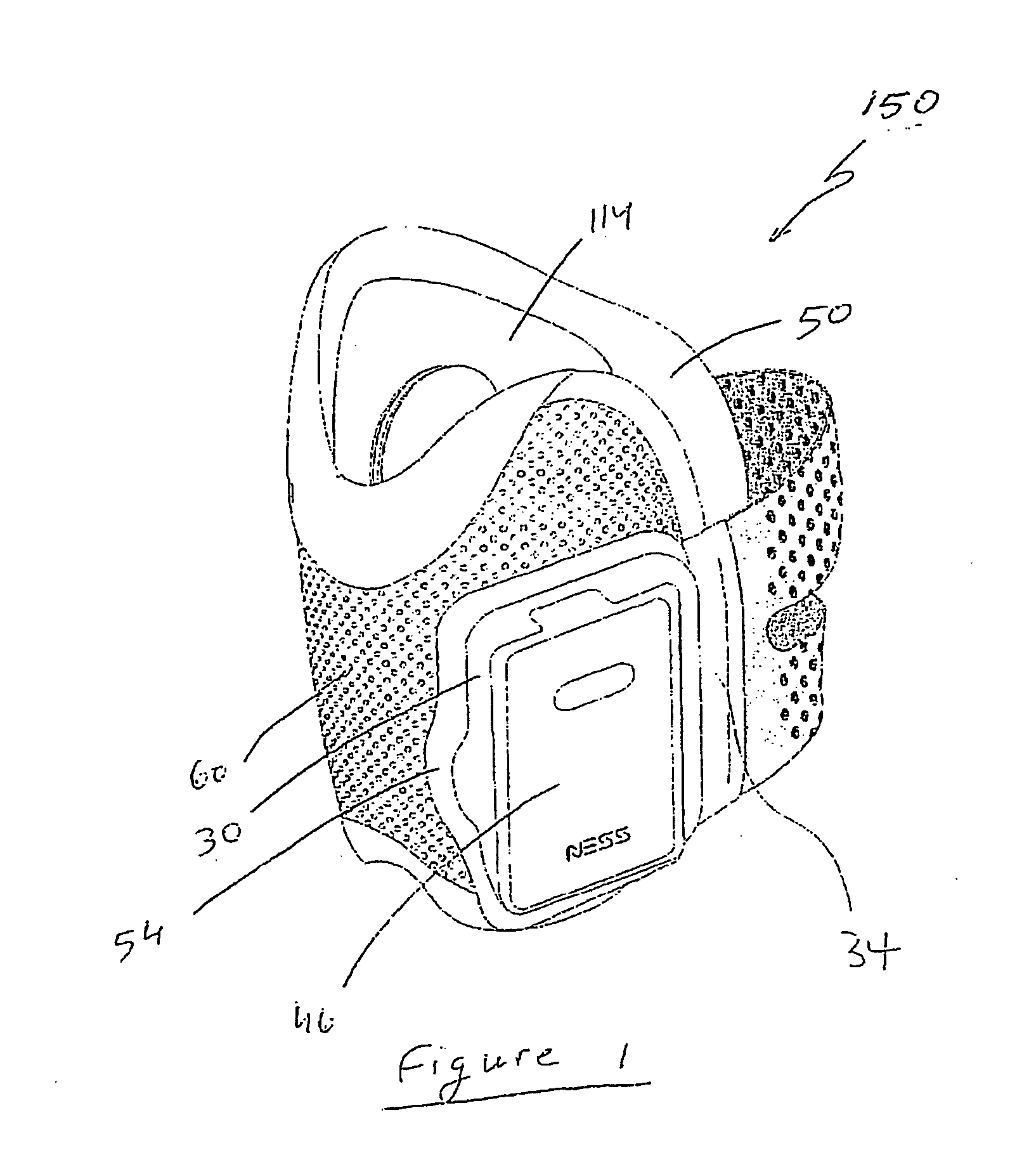

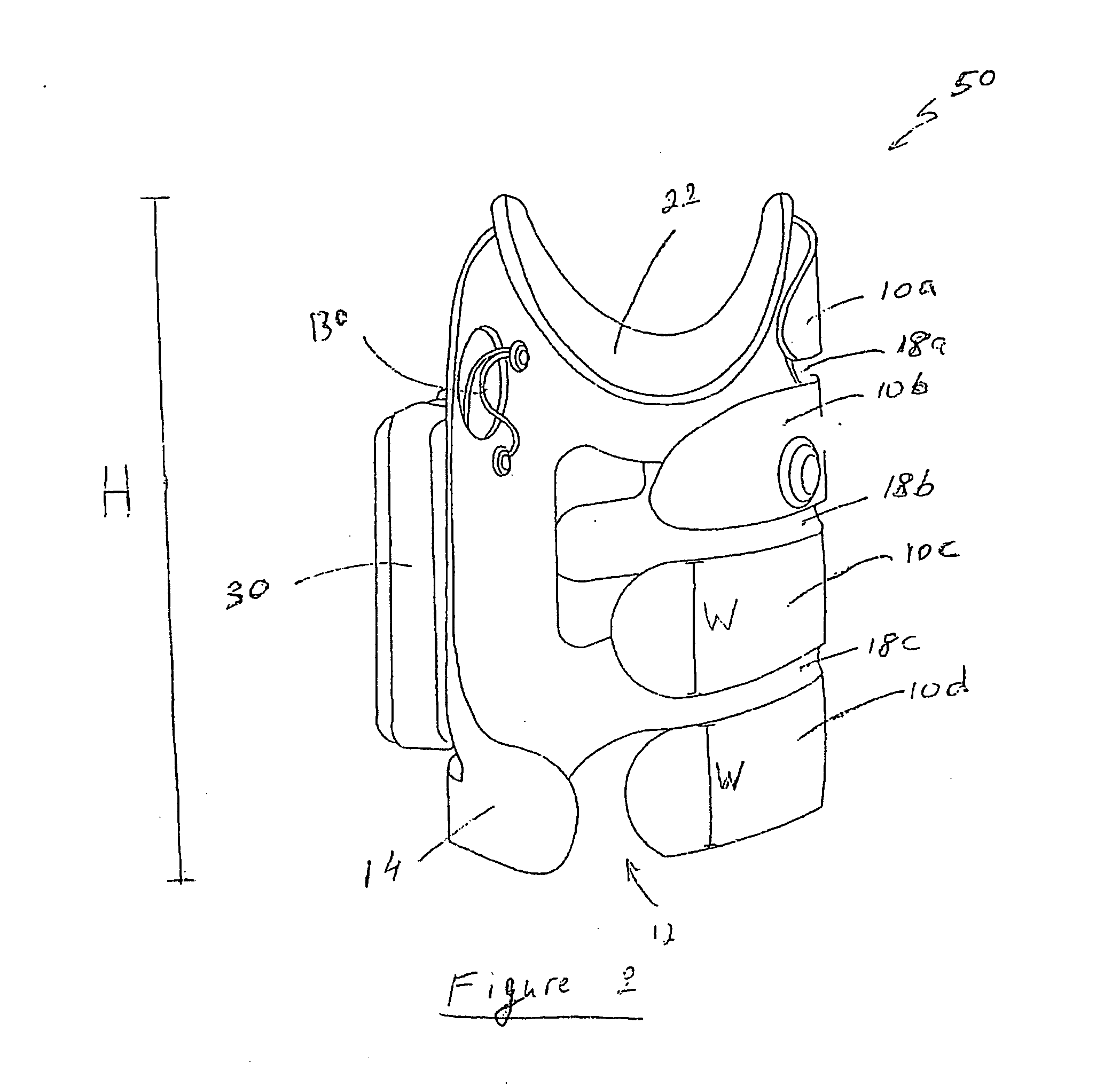

Orthosis for a gait modulation system

A functional electrical stimulation (FES) orthosis for FES to a limb segment, including: (a) a semi-rigid, self-retaining C-shaped frame, the frame configured to substantially envelop the limb segment, the frame including a first flexible and elongated circumferentially retaining element and at least a first and a second opposing flexible and elongated circumferentially retaining elements disposed on the circumferentially opposite side of the frame, the first retaining element and the first opposing retaining element forming a pair of opposing retaining elements, and (b) a surface electrical stimulation electrode for contacting at least one stimulation point on a surface of the limb segment, associated with, and supported by, the frame, the surface electrode for electrically associating, via the frame, with a neuroprosthetic stimulator unit, so as to provide FES, wherein the opposing retaining elements are configured to be radially spring-loaded towards a center of the frame, such that in donning the orthosis around the limb segment, the limb segment applies a counter-pressure from within the frame, against the opposing retaining elements, such that the orthosis is firmly and fixedly self-retained in a pre-determined position on the surface.

Owner:VIDACARE +1

Orthosis for a gait modulation system

A functional electrical stimulation (FES) orthosis for FES to a limb segment, including: (a) a semi-rigid, self-retaining C-shaped frame, the frame configured to substantially envelop the limb segment, the frame including a first flexible and elongated circumferentially retaining element and at least a first and a second opposing flexible and elongated circumferentially retaining elements disposed on the circumferentially opposite side of the frame, the first retaining element and the first opposing retaining element forming a pair of opposing retaining elements, and (b) a surface electrical stimulation electrode for contacting at least one stimulation point on a surface of the limb segment, associated with, and supported by, the frame, the surface electrode for electrically associating, via the frame, with a neuroprosthetic stimulator unit, so as to provide FES, wherein the opposing retaining elements are configured to be radially spring-loaded towards a center of the frame, such that in donning the orthosis around the limb segment, the limb segment applies a counter-pressure from within the frame, against the opposing retaining elements, such that the orthosis is firmly and fixedly self-retained in a pre-determined position on the surface.

Owner:VIDACARE +1

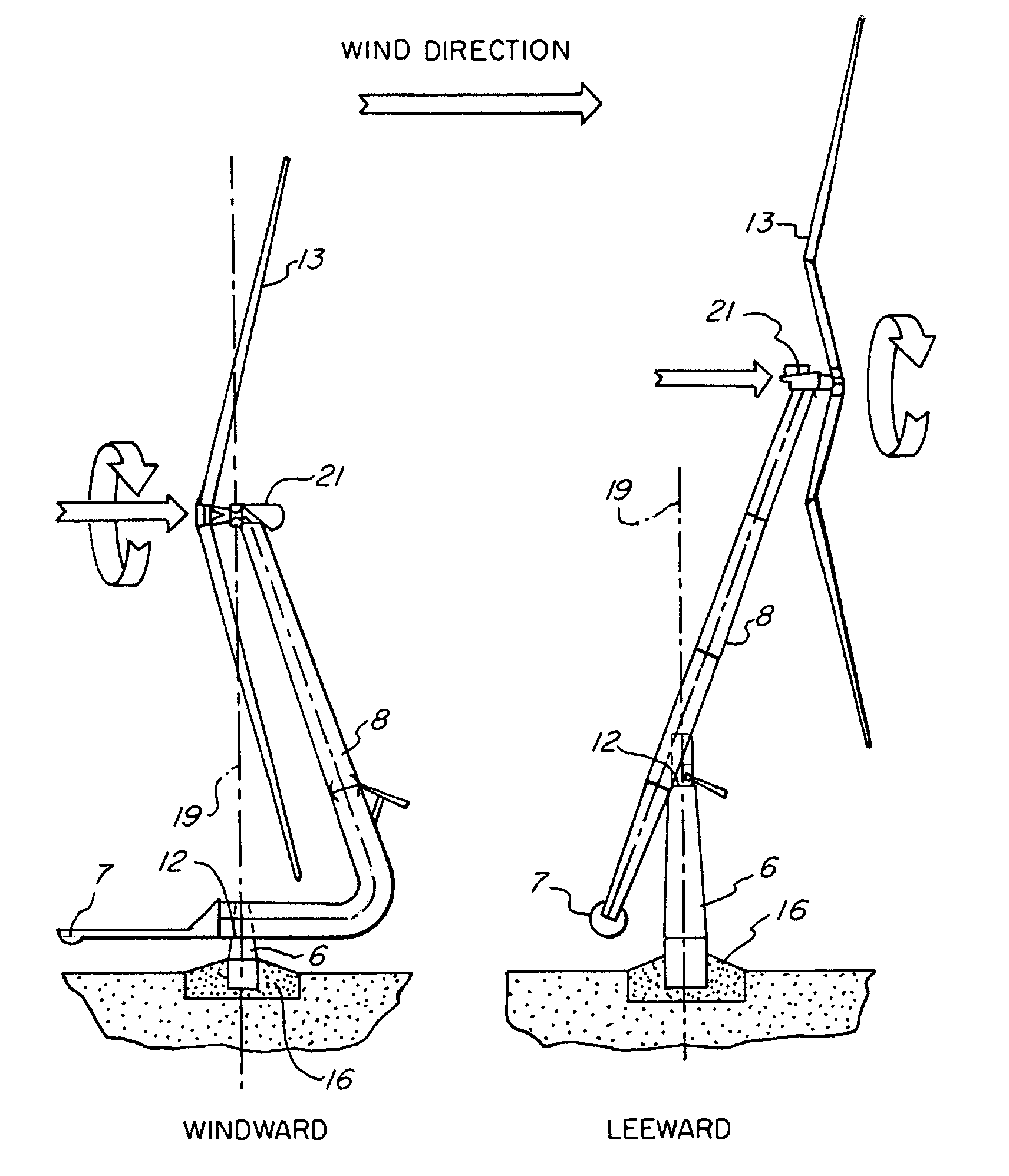

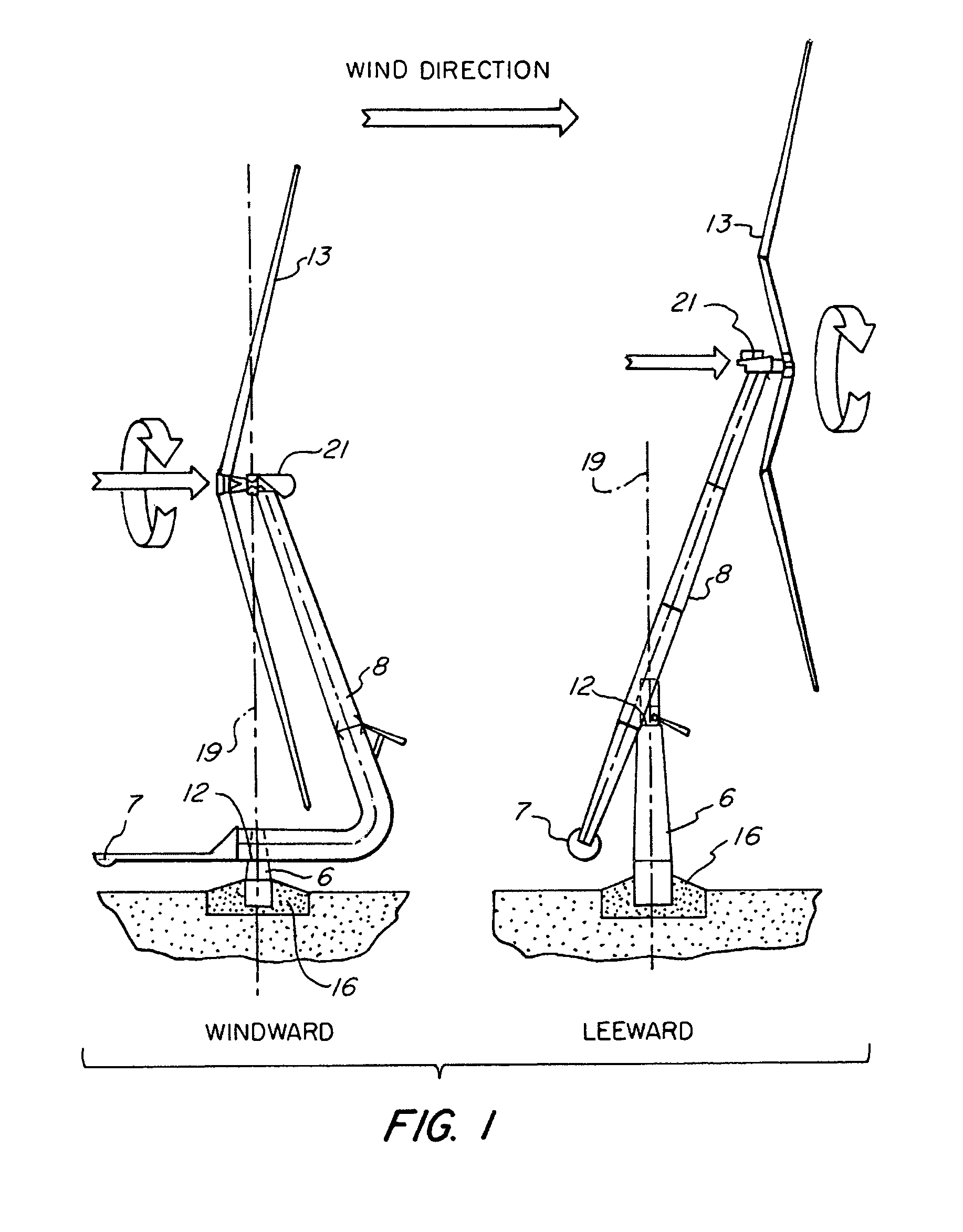

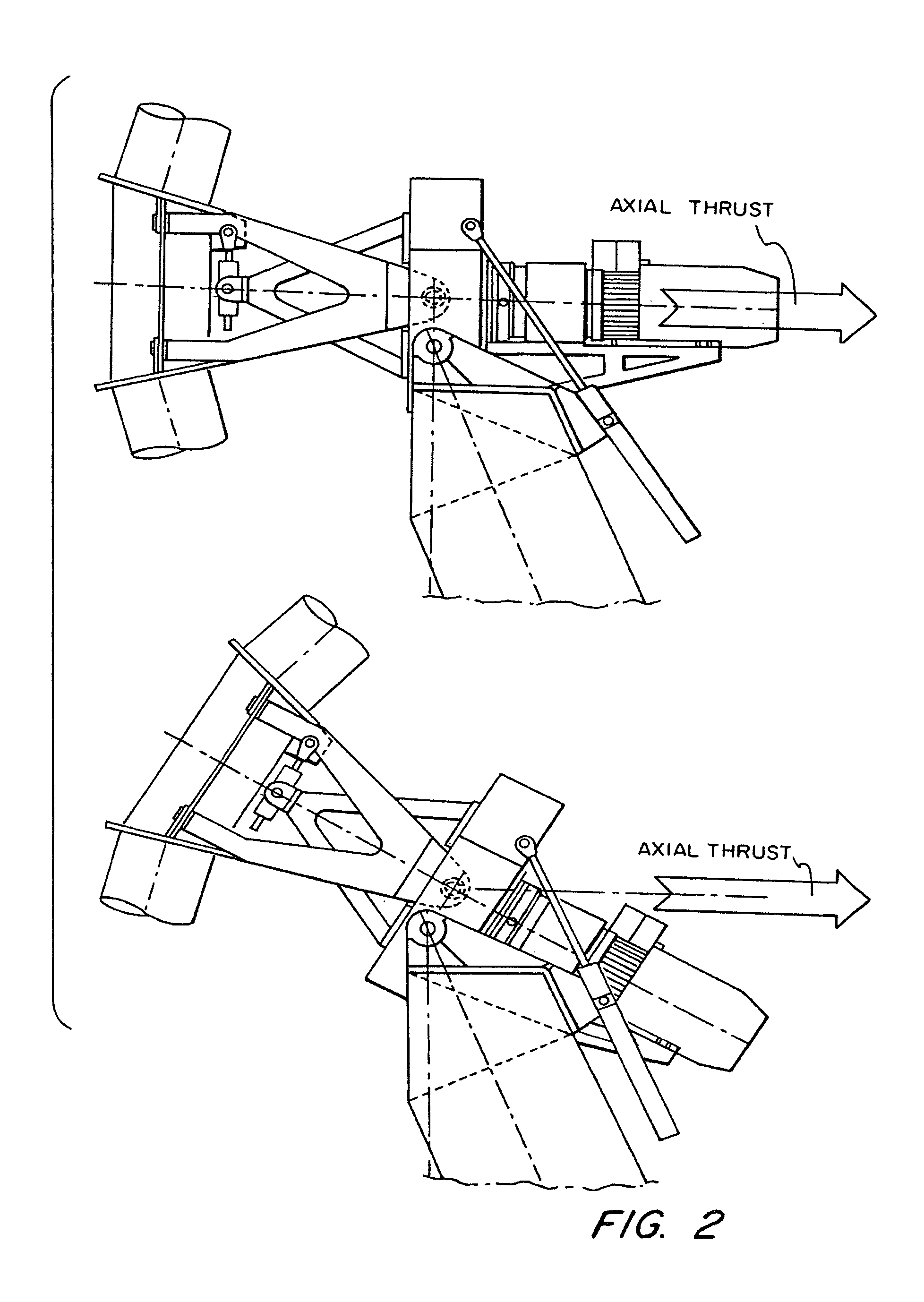

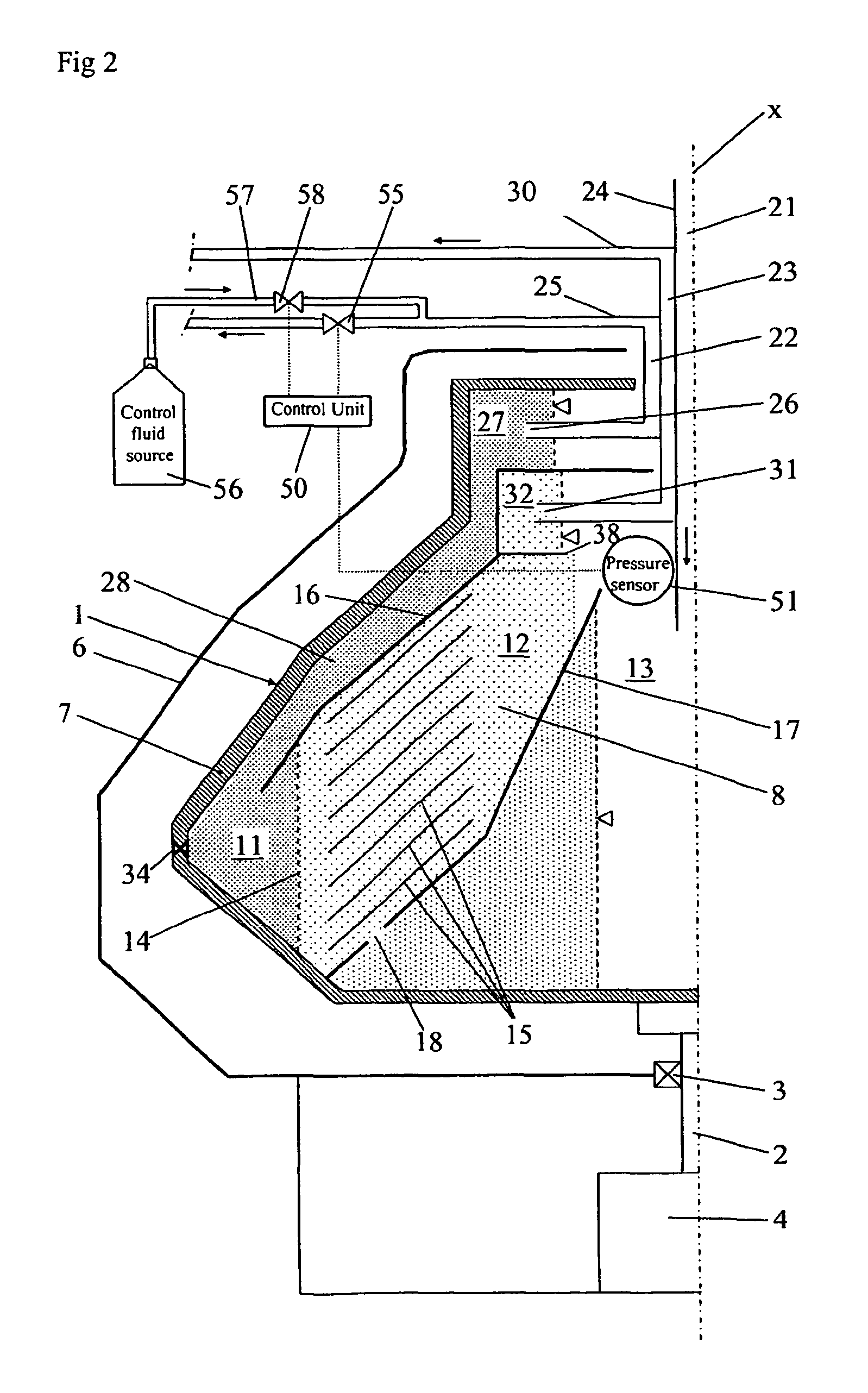

Self-guiding wind turbine

A self-guiding wind turbine made of two reinforced parallel girders whose side center of thrust is displaced from the column axis where it is supported and turns. Its dihedral-shaped two-bladed rotor is self-stabilizing since its center of thrust is behind its center of gravity and the guiding axis of the turbine, thus improving self-guiding whilst in motion. The axial thrust is controlled, whilst the head and rotor are tilting, hydraulically by counter-pressure, ensuring they do not surpass the power collected and the moments on the structure, shoe and ground. The self-guiding structure can tilt hydraulically lowering its head and rotor and facilitating its assembly and maintenance, and can remain “asleep” when not in use, thus reducing the visual impact on the environment. This turbine makes use of the force of the wind to control itself, simplifying the manufacture of large turbines connected to the network or in isolated applications.

Owner:ANTOUNE IVAN LAHUERTA

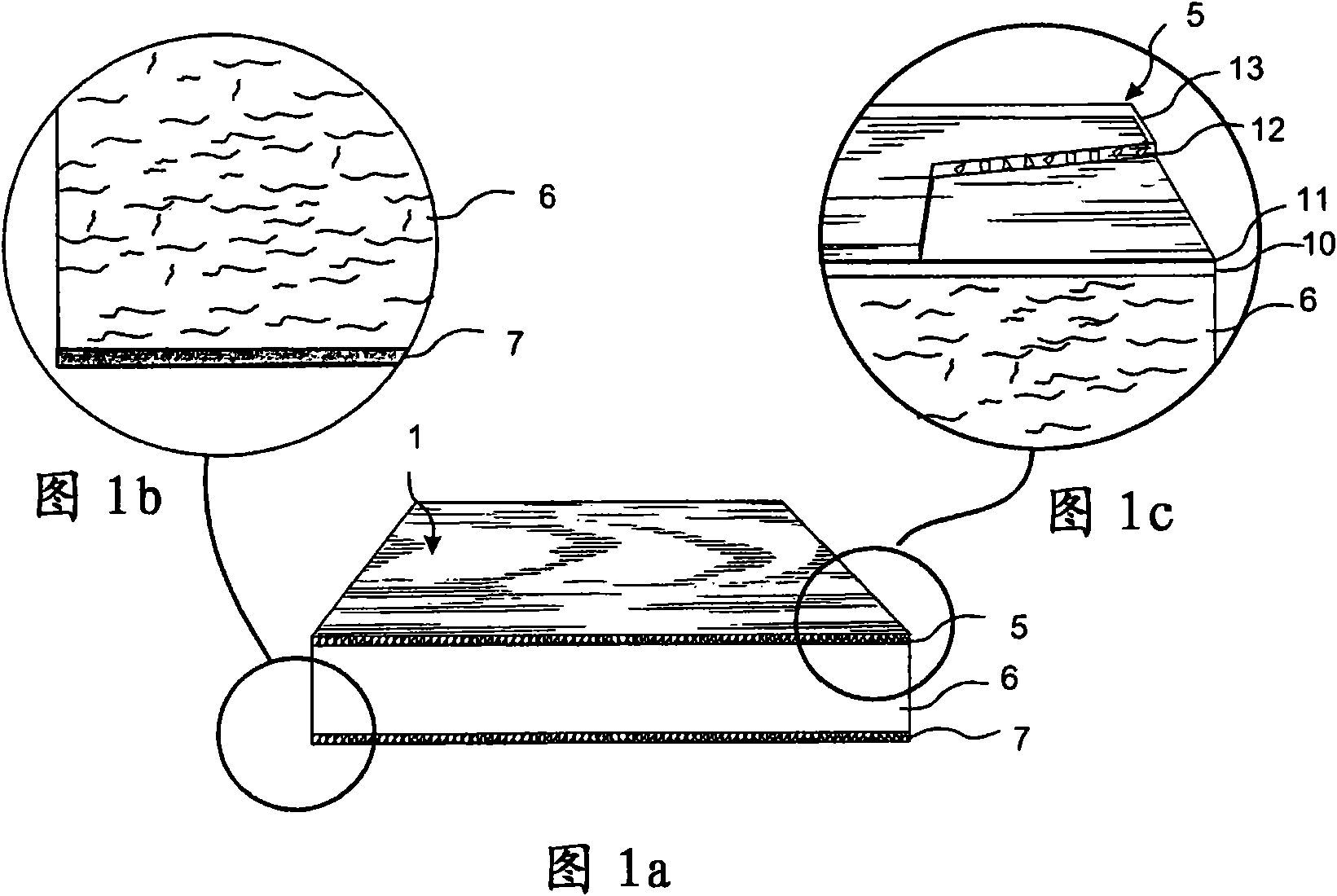

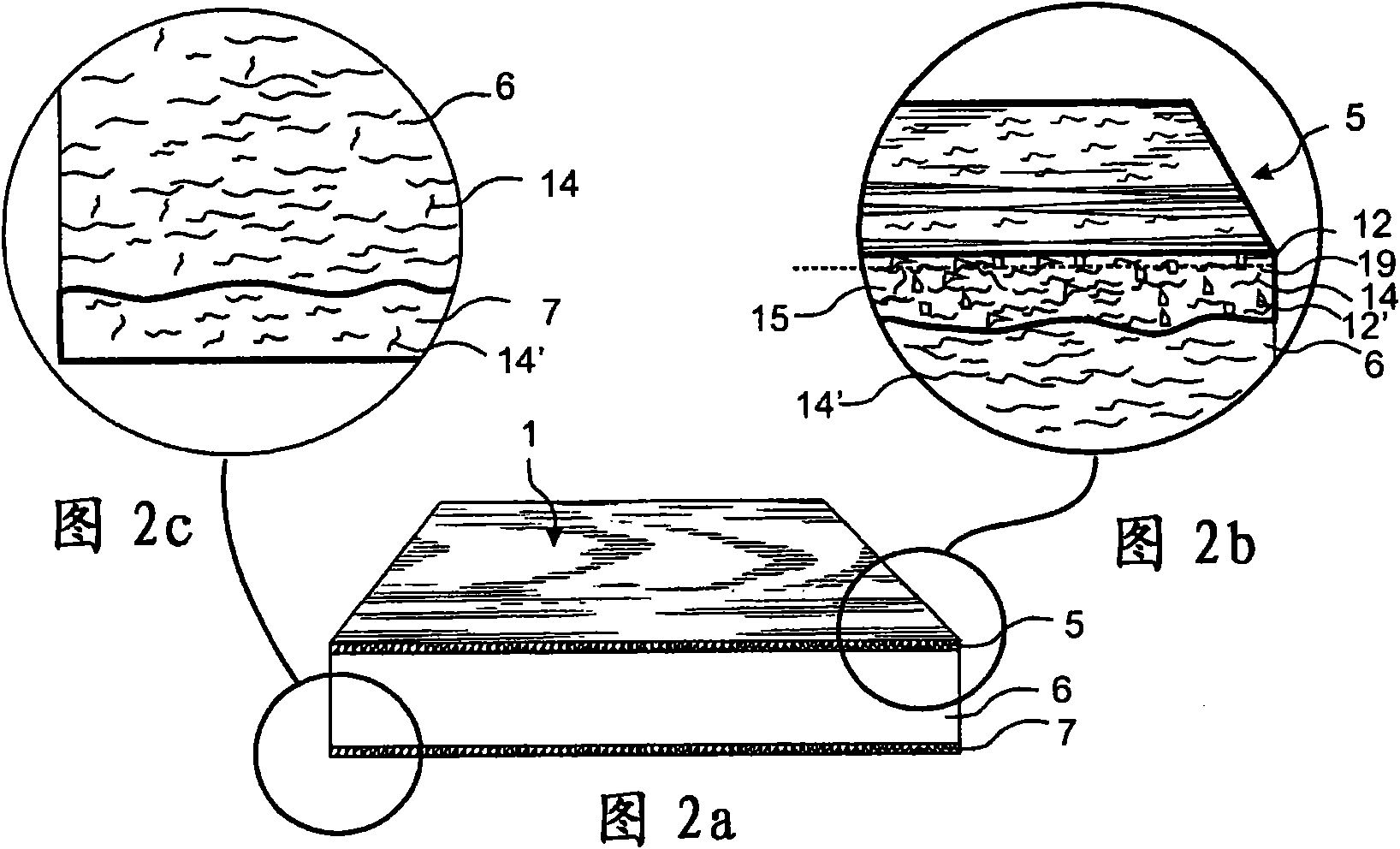

Fibre based panels with a wear resistance surface

ActiveCN101998896AImprove impact resistanceEasy to moveLiquid surface applicatorsLamination ancillary operationsWood veneerSurface layer

Floor board (1) comprising a wood fibre based core (6) such as HDF, a thin surface layer (5) such as wood veneer, and a sub layer (6a) between the surface layer (5) and the core (6). The sub layer (6a) comprises wood fibres (14) and an uncured binder (19) and is applied on the core (6) as a powder. The layers (5, 6a) are connected to the core (6) and embossed in register by heating and pressing, the uncured sub layer (6a) behaving similar to a paste or a liquid substance and creating a uniform counter pressure under the thin surface layer (5), thus providing an easier forming of deep and sharp embossing without damaging the surface layer (5).

Owner:VÄLINGE INNOVATION AB

Indoor grouting testing device under simulation of complex stress effect and testing method thereof

InactiveCN103018152ASolve drainage problemsDoes not affect the drainage effectPermeability/surface area analysisRubber membranePressure system

Owner:HUNAN UNIV OF SCI & TECH

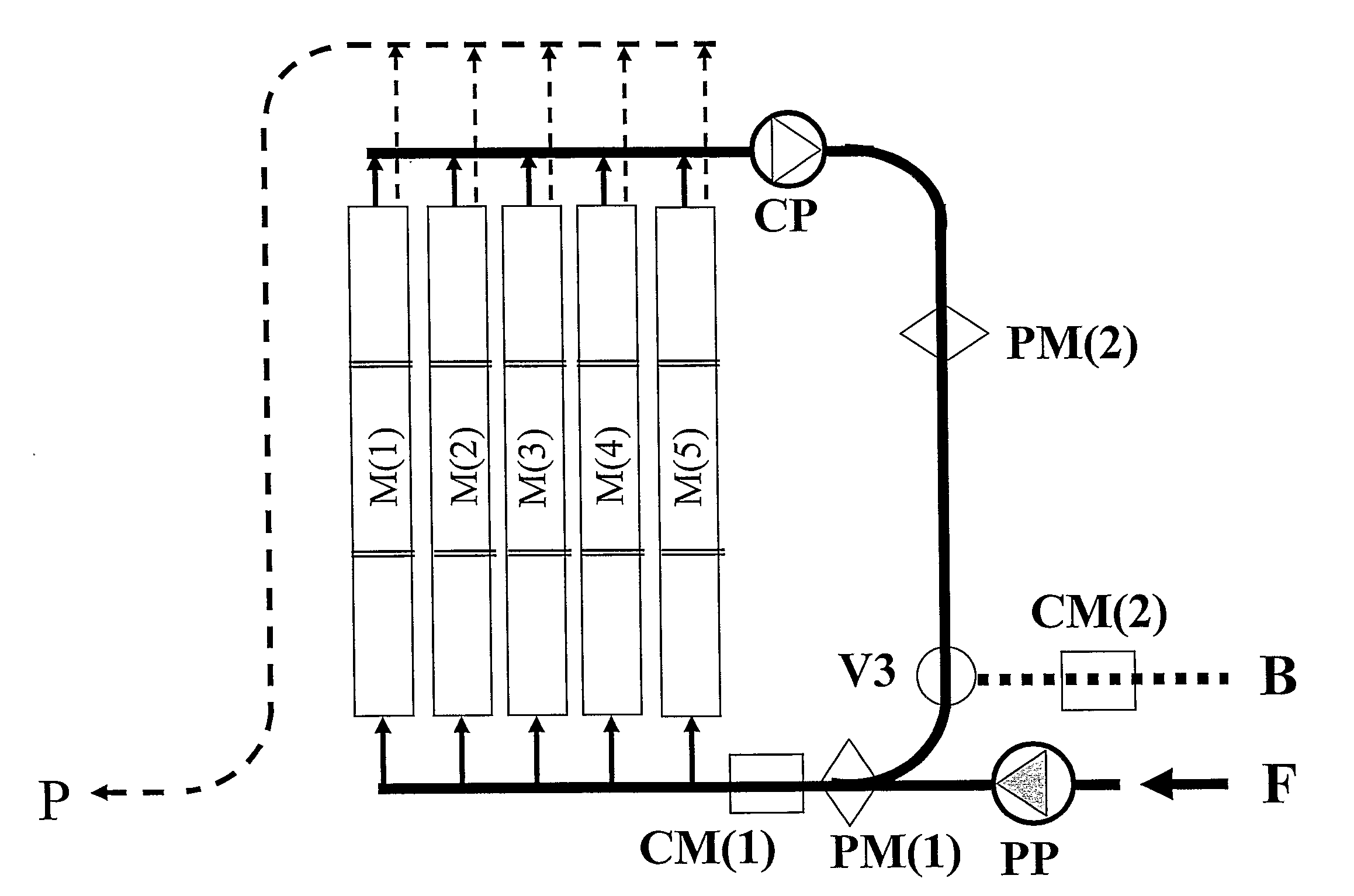

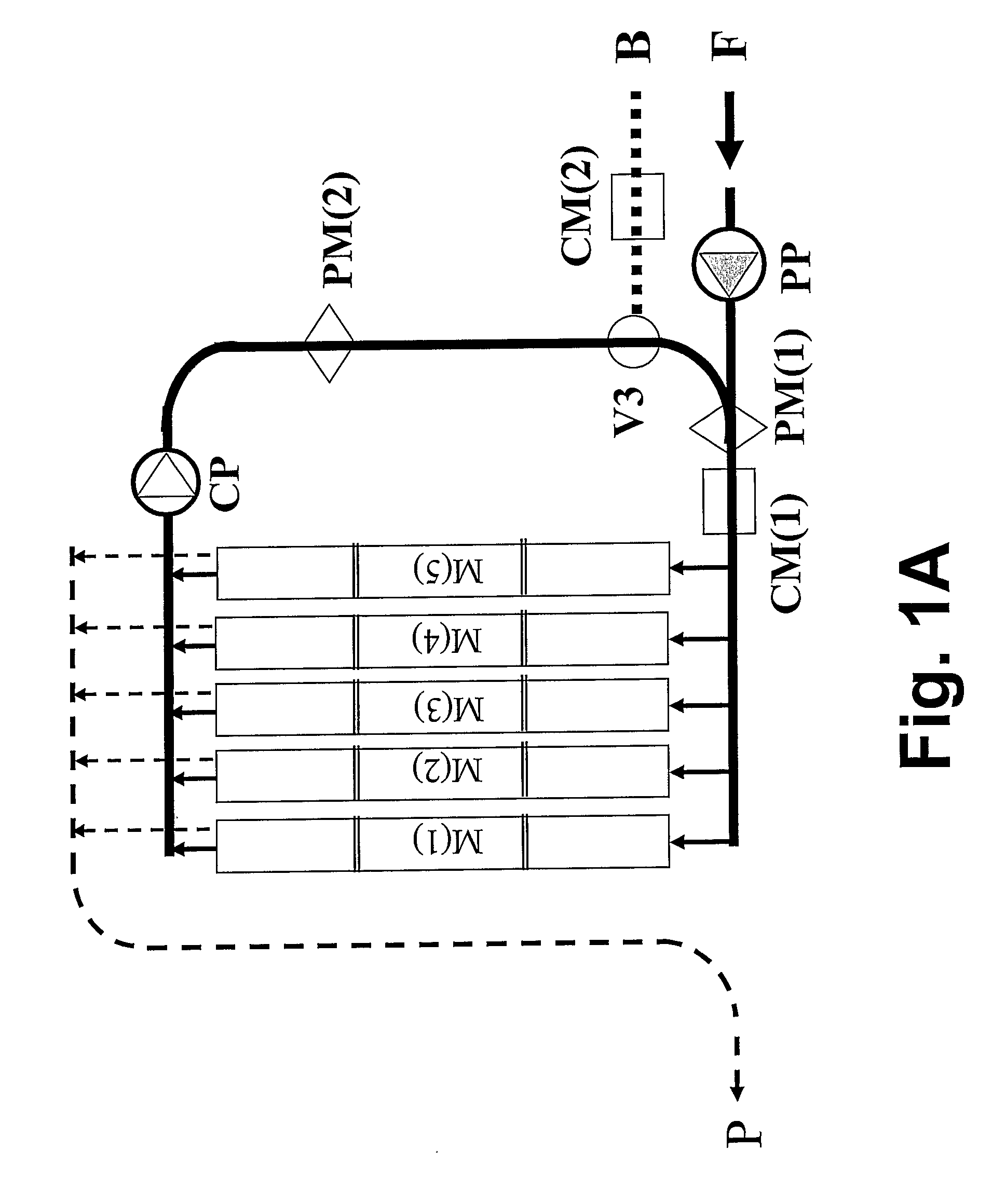

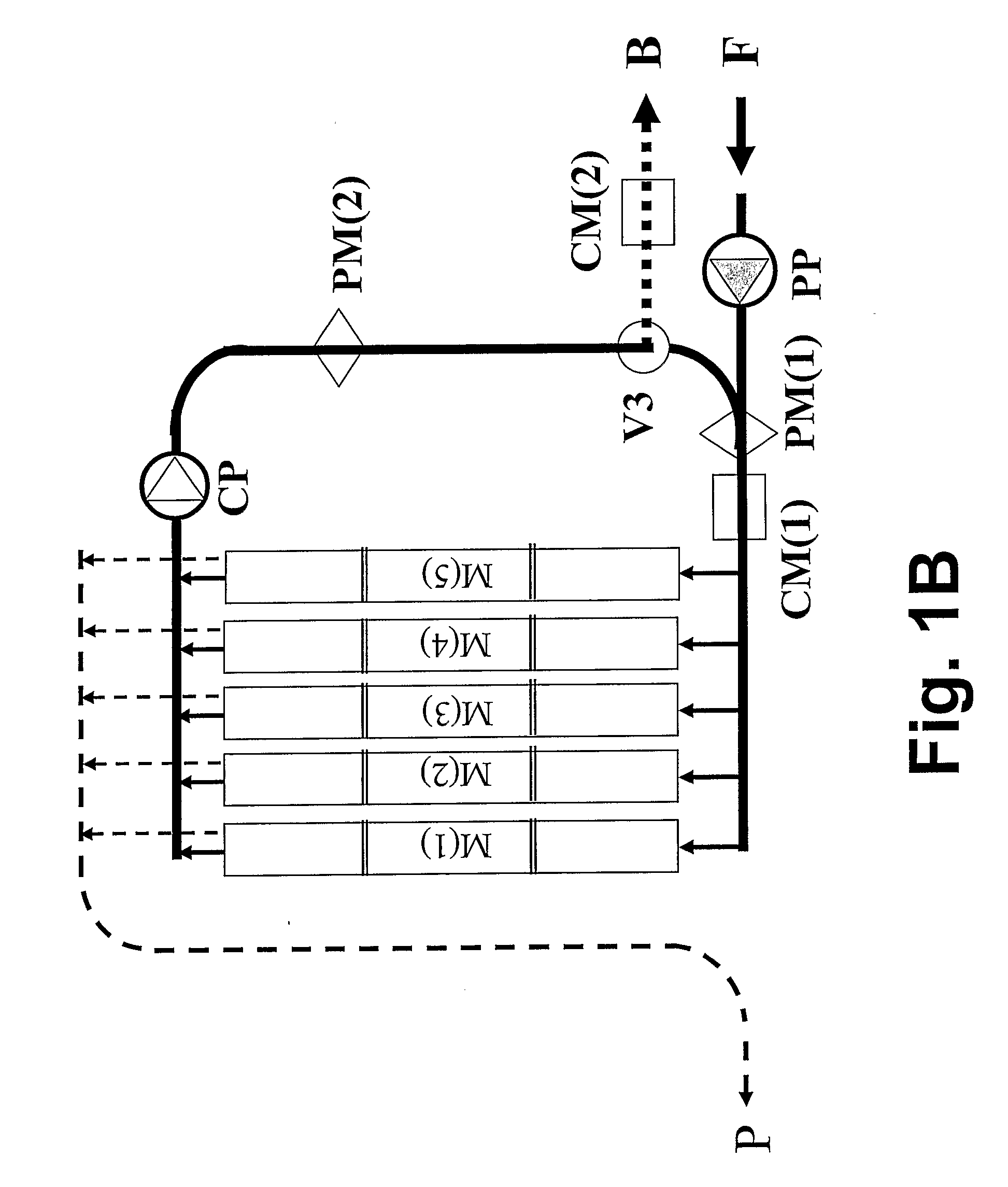

Continuous Closed-Circuit Desalination Apparatus Without Containers

ActiveUS20080023410A1Simple inexpensive designFewer power componentsGeneral water supply conservationSeawater treatmentSaline waterControl system

An apparatus for continuous closed-circuit consecutive sequential desalination of a salt water solution by reverse osmosis that comprises a closed circuit system comprising one or more desalination modules having their respective inlets and outlets connected in parallel by conducing lines, each of desalination modules comprising of one or more membrane elements, a pressurizing device for creating counter pressure to enable reverse osmosis desalination and replacement of released permeate by fresh, a circulation system for recycling the desalinated solution through the desalination modules, a conducting line systems for permeate collection from the desalination modules, a conducting line system for removing brine effluent a valve system to enable periodic discharge of brine from the closed circuit without stopping desalination, and monitoring and control systems to enable continuous closed circuit desalination of desired recovery proceed in consecutive sequential steps under variable or constant pressure conditions.

Owner:DESALITECH

Clear view cannula

Owner:LYON THOMAS R

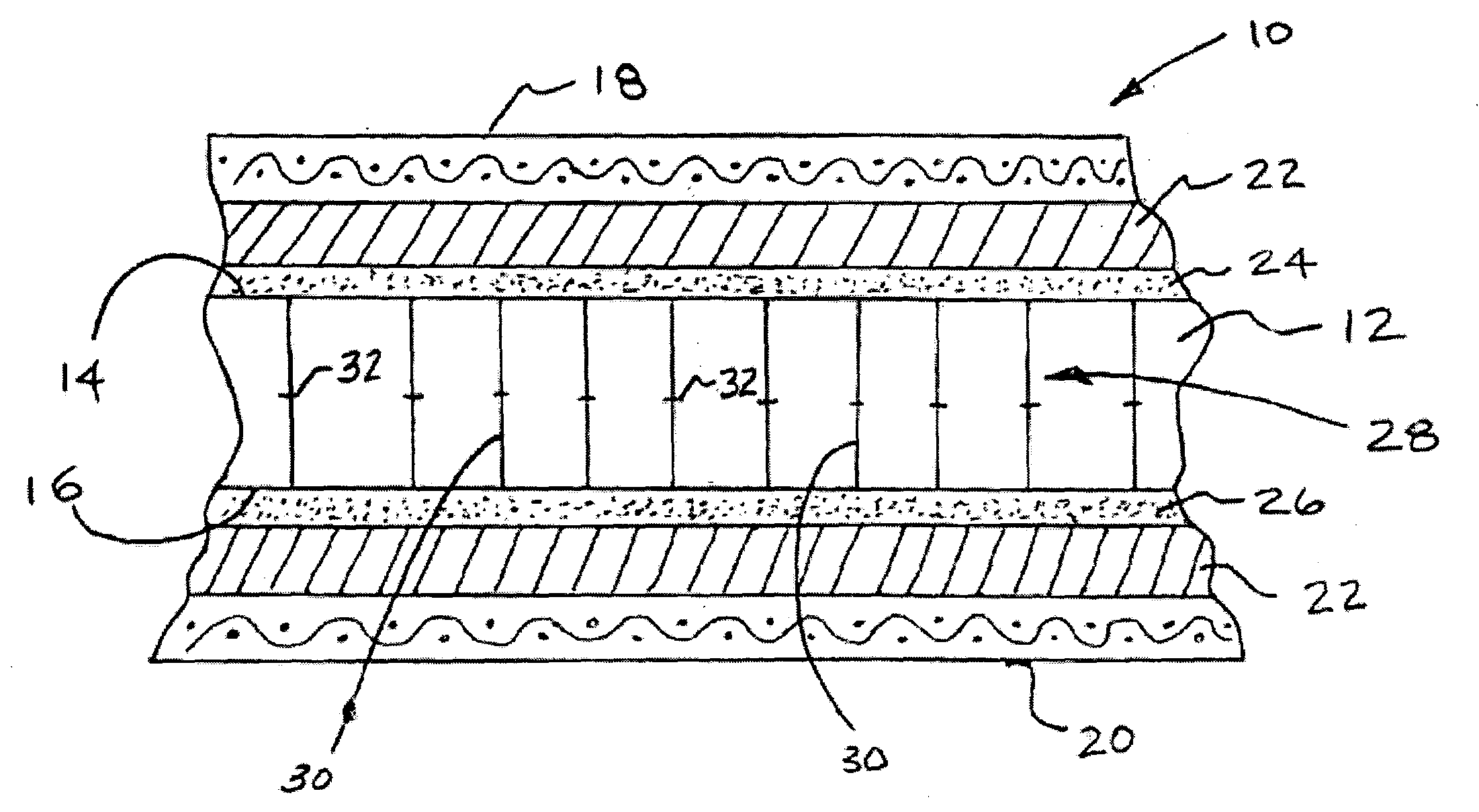

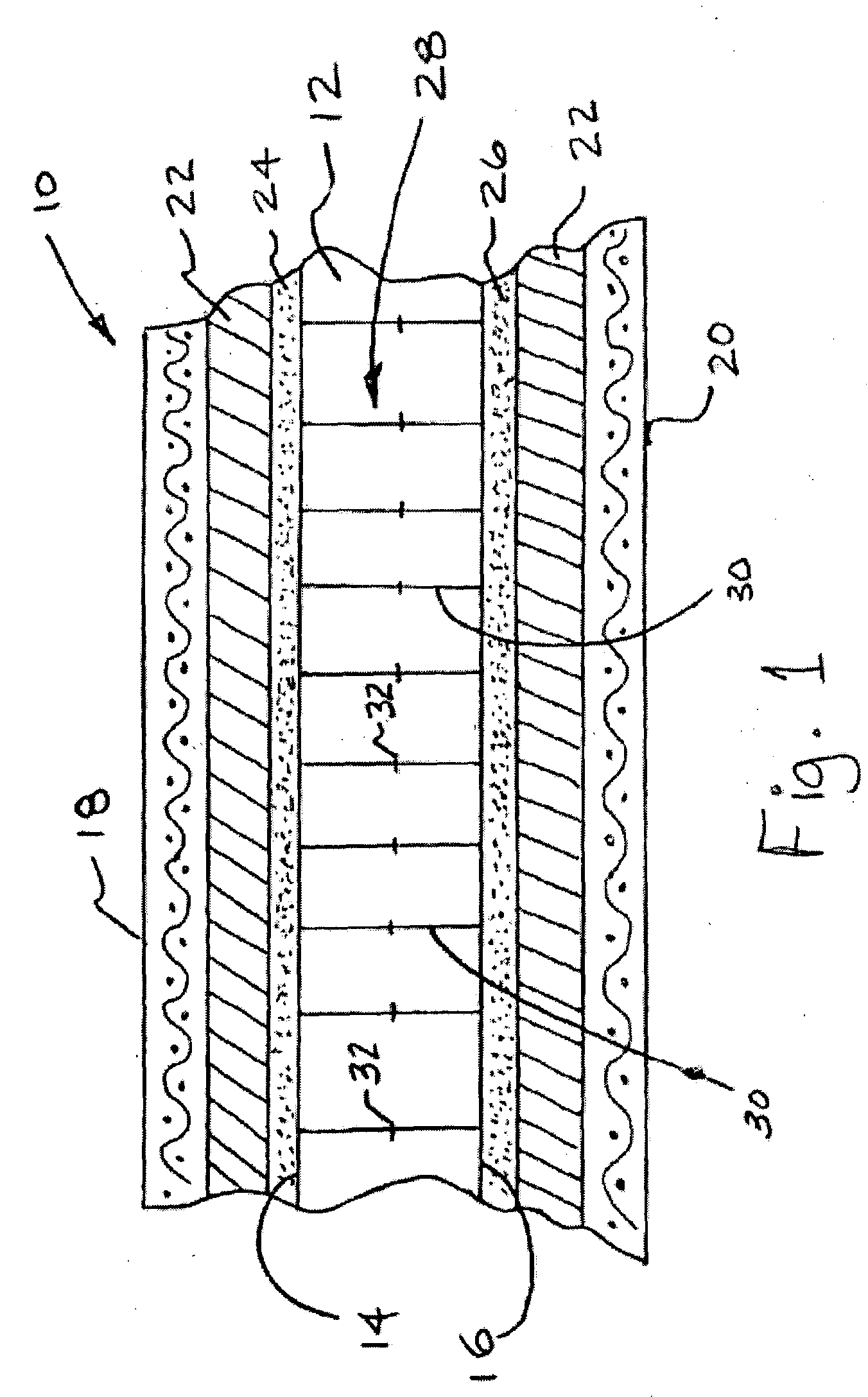

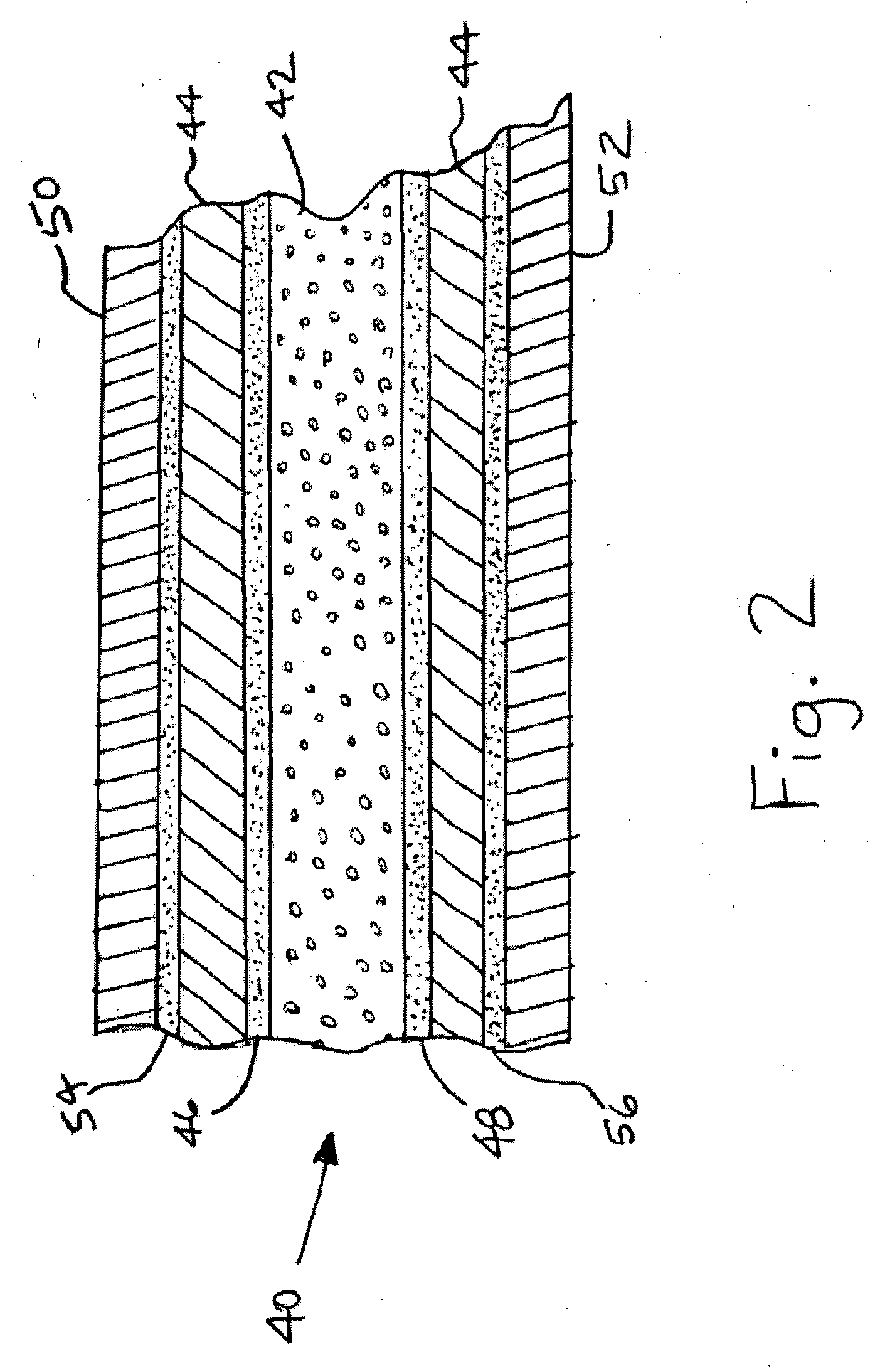

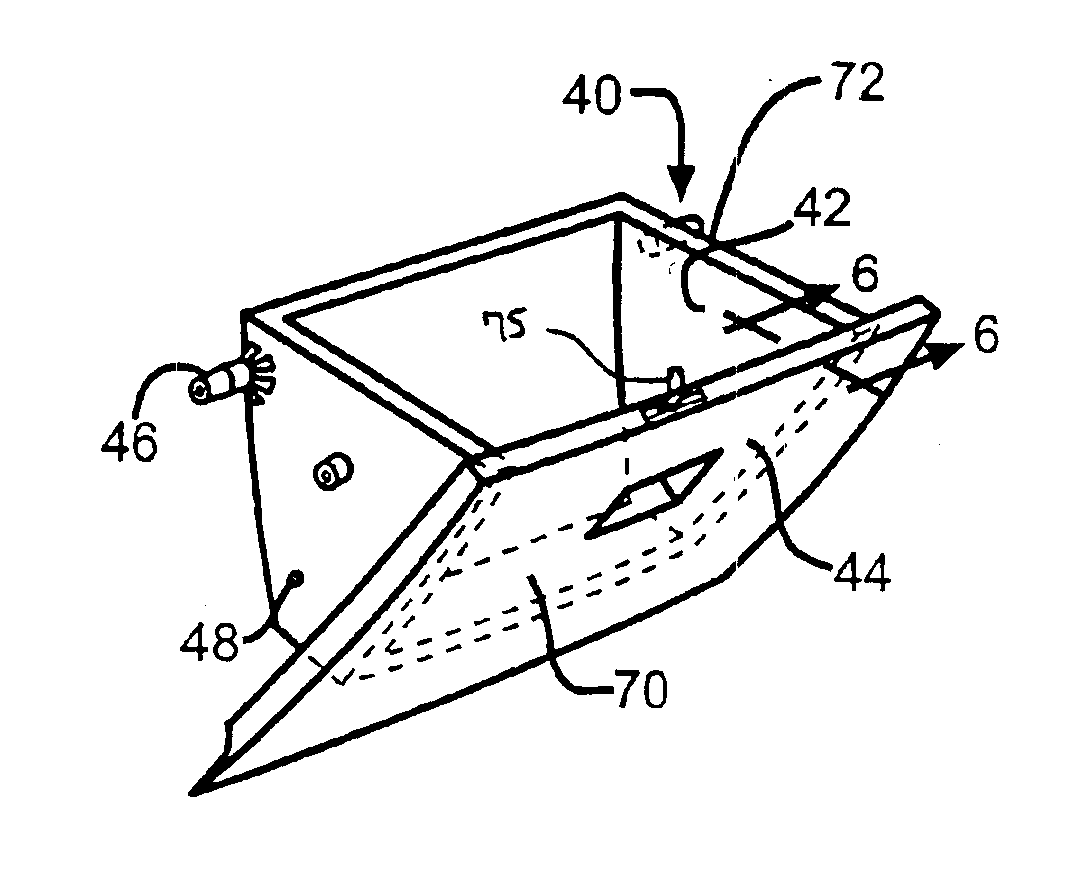

Sandwich panel with interior barrier

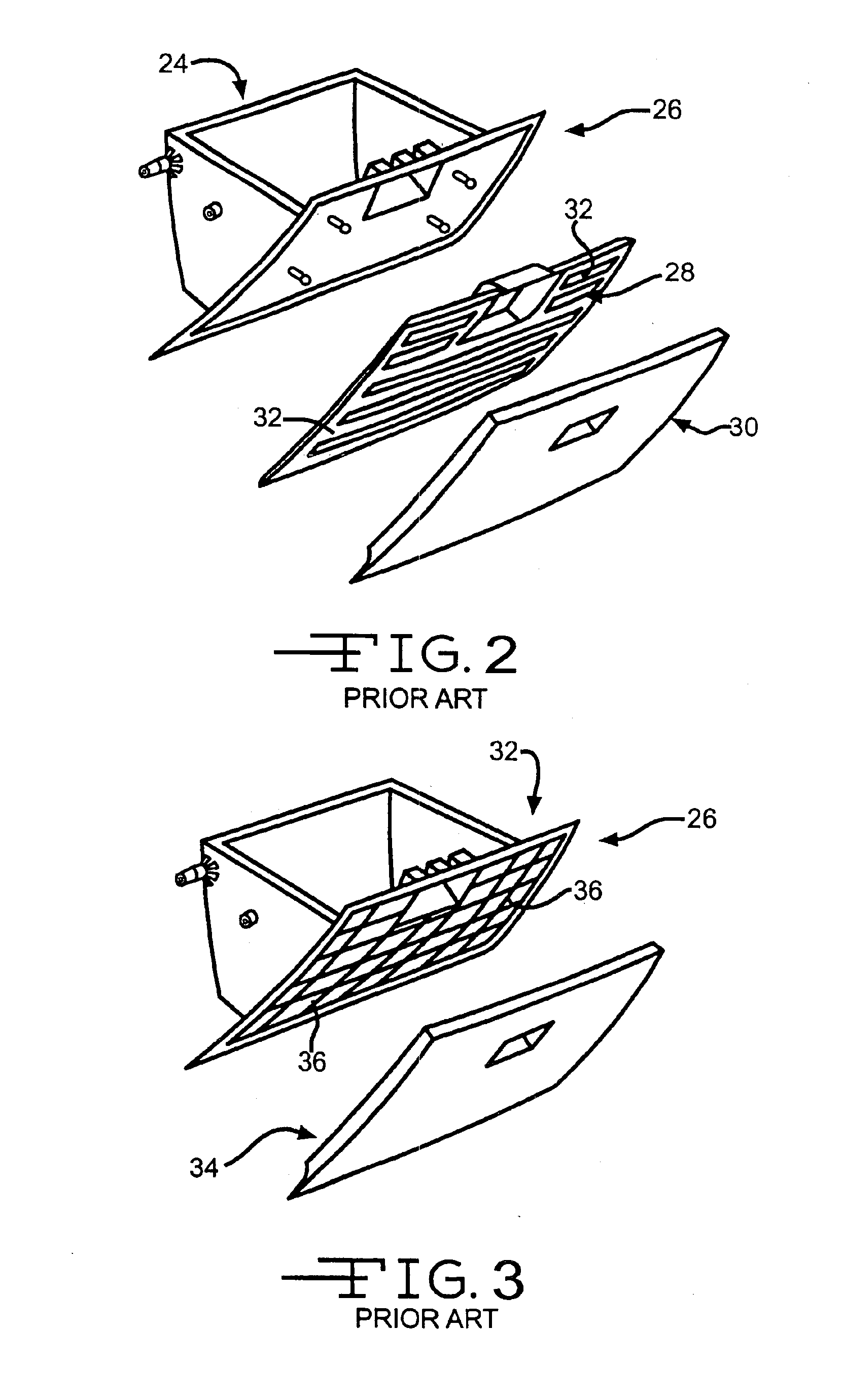

InactiveUS20050025929A1Reducing of other imperfectionReducing amount of void and other imperfectionLabelling non-rigid containersLaminationSurface finishCounter pressure

Composite sandwich panels that include a core having a permeable body that is sandwiched between two skins. An internal barrier is located between the skins and the core to provide an impermeable chamber surrounding the permeable core. The chamber is pressurized during formation of the panel to provide an interior counter pressure against the mold / press used to form the panel. The counter pressure applied by the chamber reduces the amount of voids in the skins and improves the surface finish of the skins. In addition, the impermeable material remains within the finished panel to provide an internal barrier surrounding the core.

Owner:HEXCEL

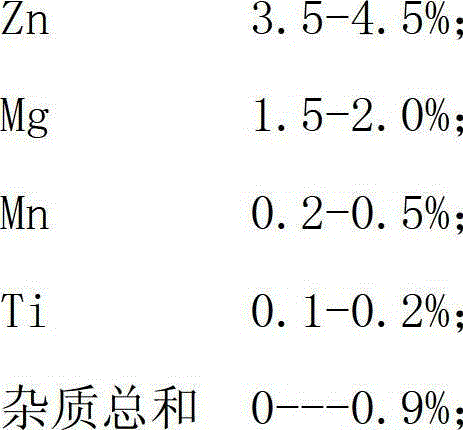

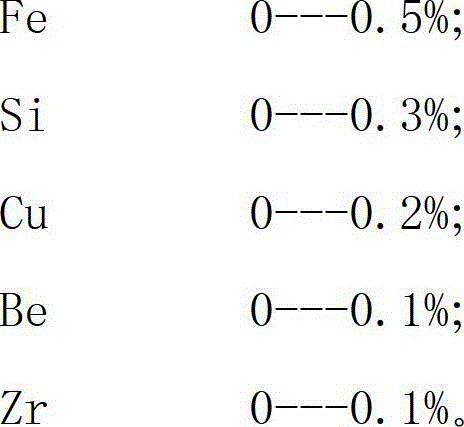

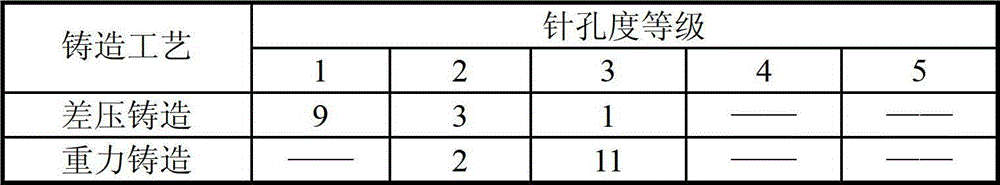

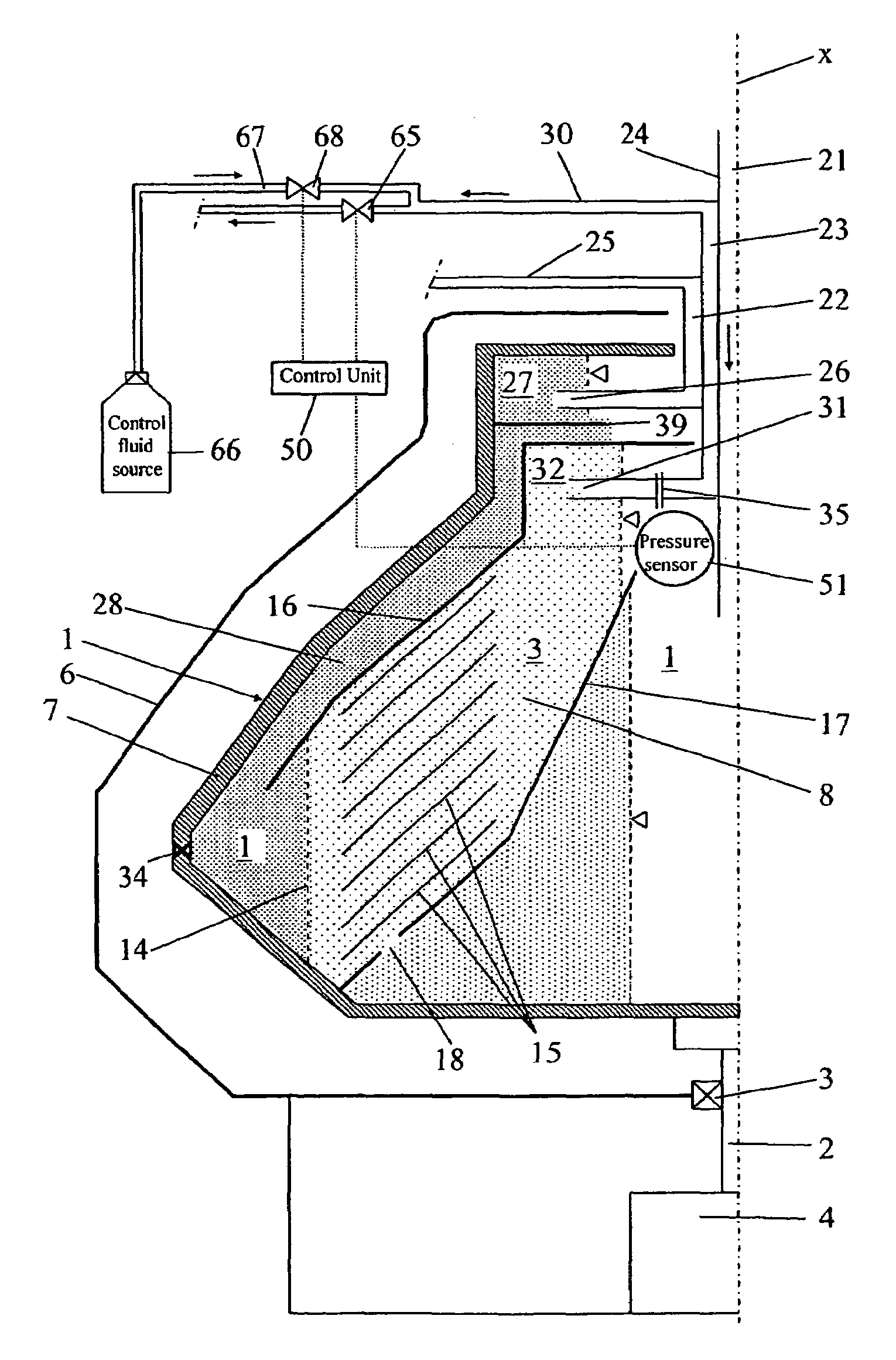

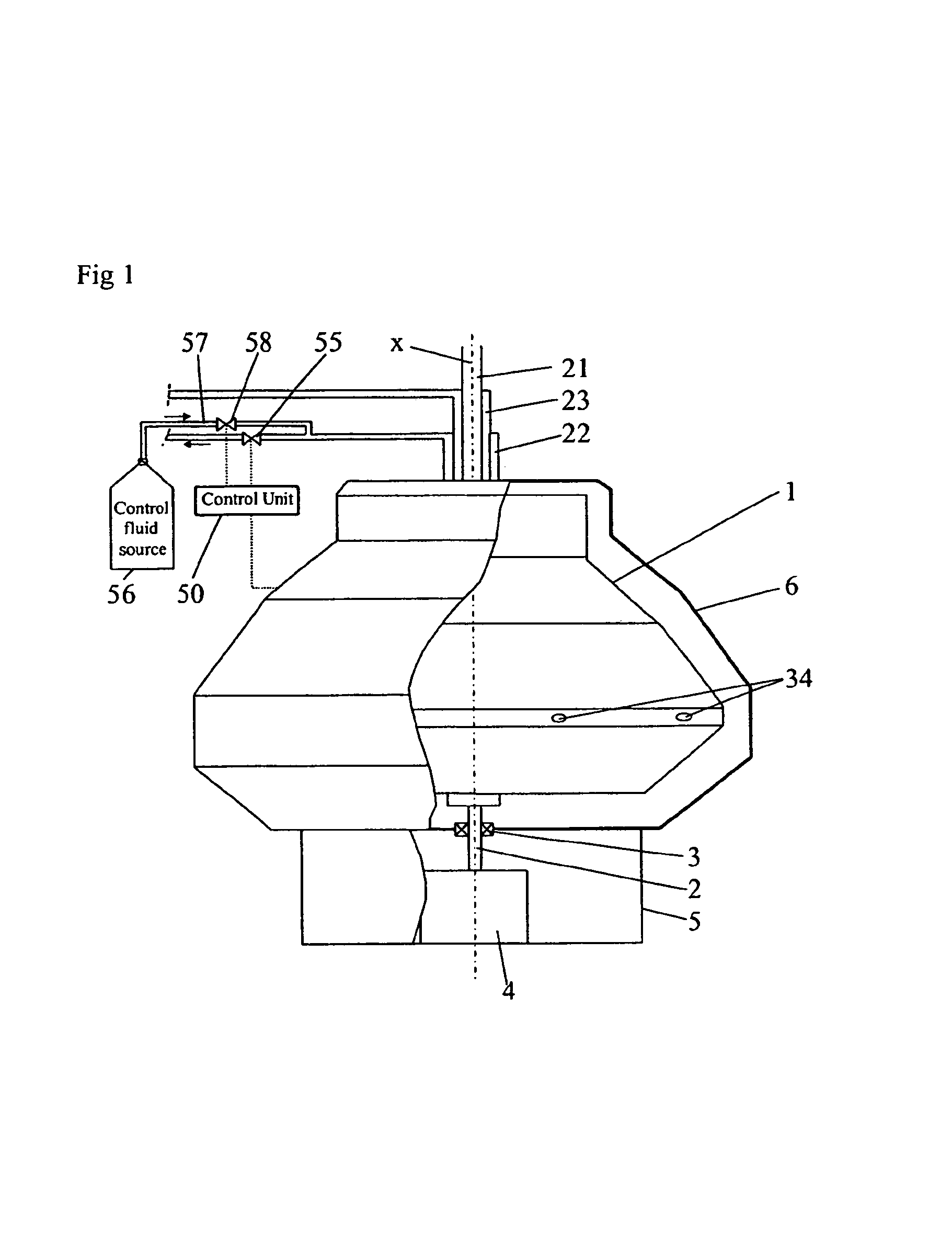

Counter-pressure casting process for ZL424 aluminum alloy castings

ActiveCN102873301AIncrease the speed of solidificationNot easy to precipitateCounter pressureShrinkage porosity

The invention relates to a counter-pressure casting process for ZL424 aluminum alloy castings. The process includes the steps: (1) alloy burdening; (2) using secondary refining and intermediate purifying for smelting alloy; (3) using a counter-pressure casting method for preparing ZL424 aluminum alloy castings; (4) cleaning the ZL424 aluminum alloy blank castings prepared at the step (3) before heat treatment; (5) checking the ZL424 aluminum alloy blank castings subjected to heat treatment. Blank castings prepared by the counter-pressure casting process overcome defects of ZL424 aluminum alloy castings obtained by traditional gravity casting methods, internal pinholes, microscopic shrinkage porosity and microcracks of castings are eliminated, and chemical component acceptability, mechanical performance and compactness of the castings are improved. In addition, the process has the advantages of high efficiency, high casting yield, low manufacturing cost and the like.

Owner:TIANJIN NAVIGATION INSTR RES INST

Method for preparing dried fowls egg

InactiveCN101243887ARealize industrial productionCater to dietary habitsFood preparationFowlCounter pressure

The invention relates to the preparation method of a dried poultry egg which is characterized in that 2 to 5 portions weight of agar powder and 0.1 to 1 portions weight of konjak gum are dissolved in 10 to 20 portions weight of the distilled water and stir the mixture to mix well; then, the stirred and mixed poultry egg plup of 80 to 100 portions weight is poured into the mixture and the stirring is made under the temperature of 70 to 80 DEG C; the stirred and mixed liquid is poured into the anti-viscous mould and is steamed. The sopping is made according to the preparation method and is heated to 80 to 90 DEG C. After being taken out from the mould, the steamed material is put into the sopping, steeped under the temperature of 80 to 90 DEG C in 1 to 2 hours. Then the dried poultry egg is taken out and is dried under the temperature of 55 to 65 DEG C in 20 to 60 minutes. After being dried, the poultry egg is cut into different shapes and sizes according to different needs; then the vacuum packaging is made. The packaged product is made counter-pressure sterilization under the high temperature of 100 to 121 DEG C in 10 to 60 minutes. After being made stepped cooling, wiping water on the surface, further air-drying, sticking label, printing code and packaging, the product is produced finally.

Owner:SICHUAN UNIV

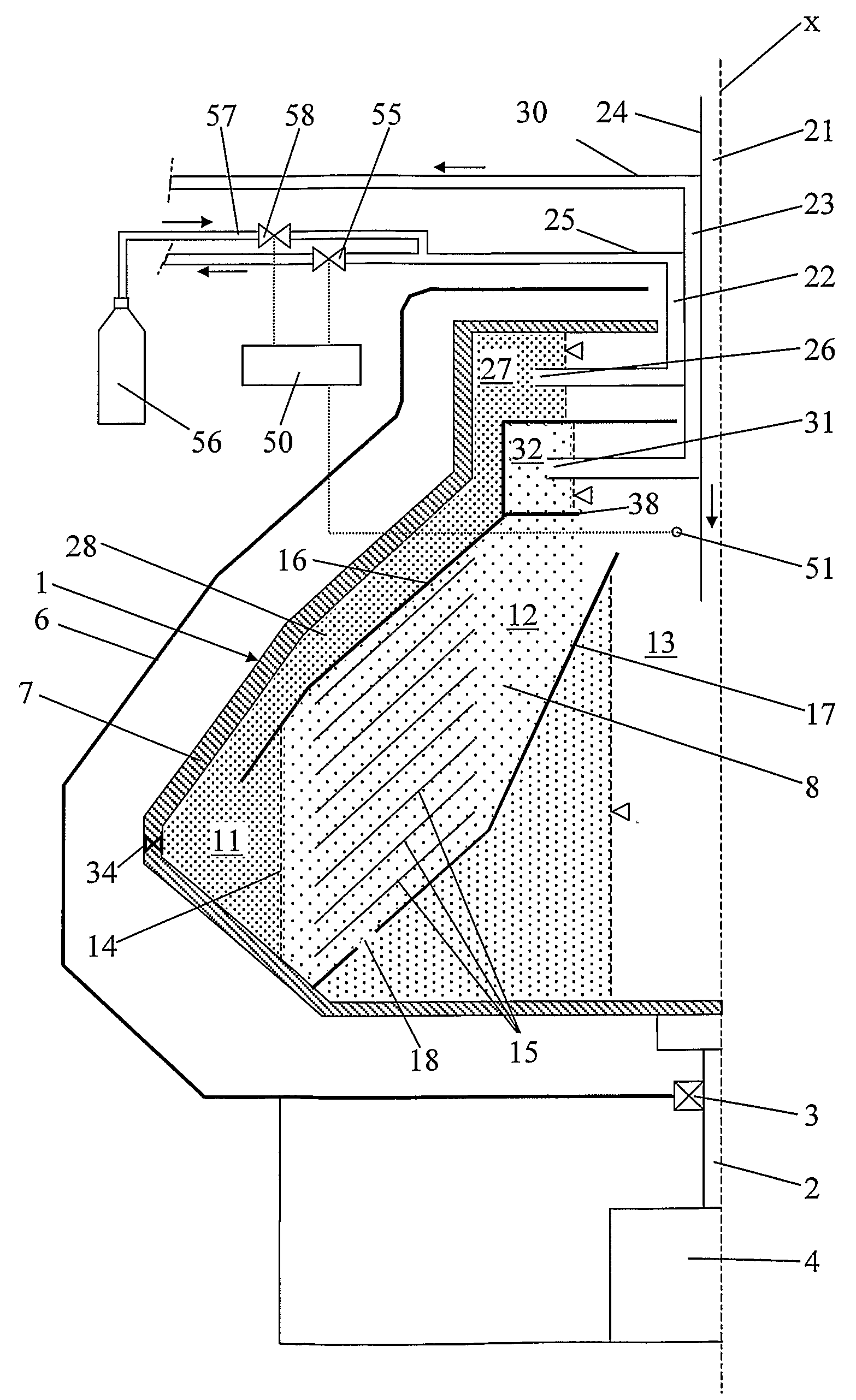

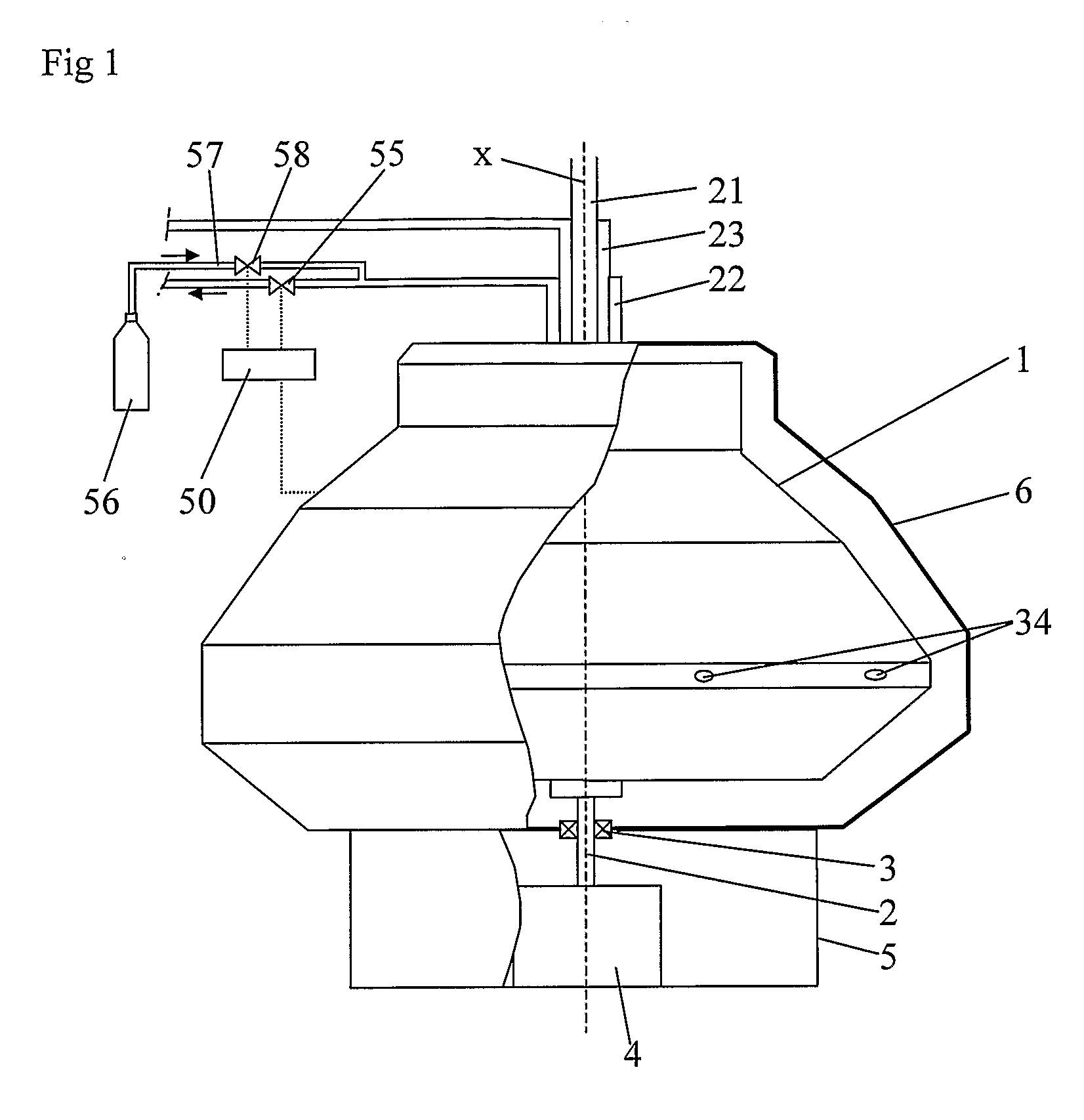

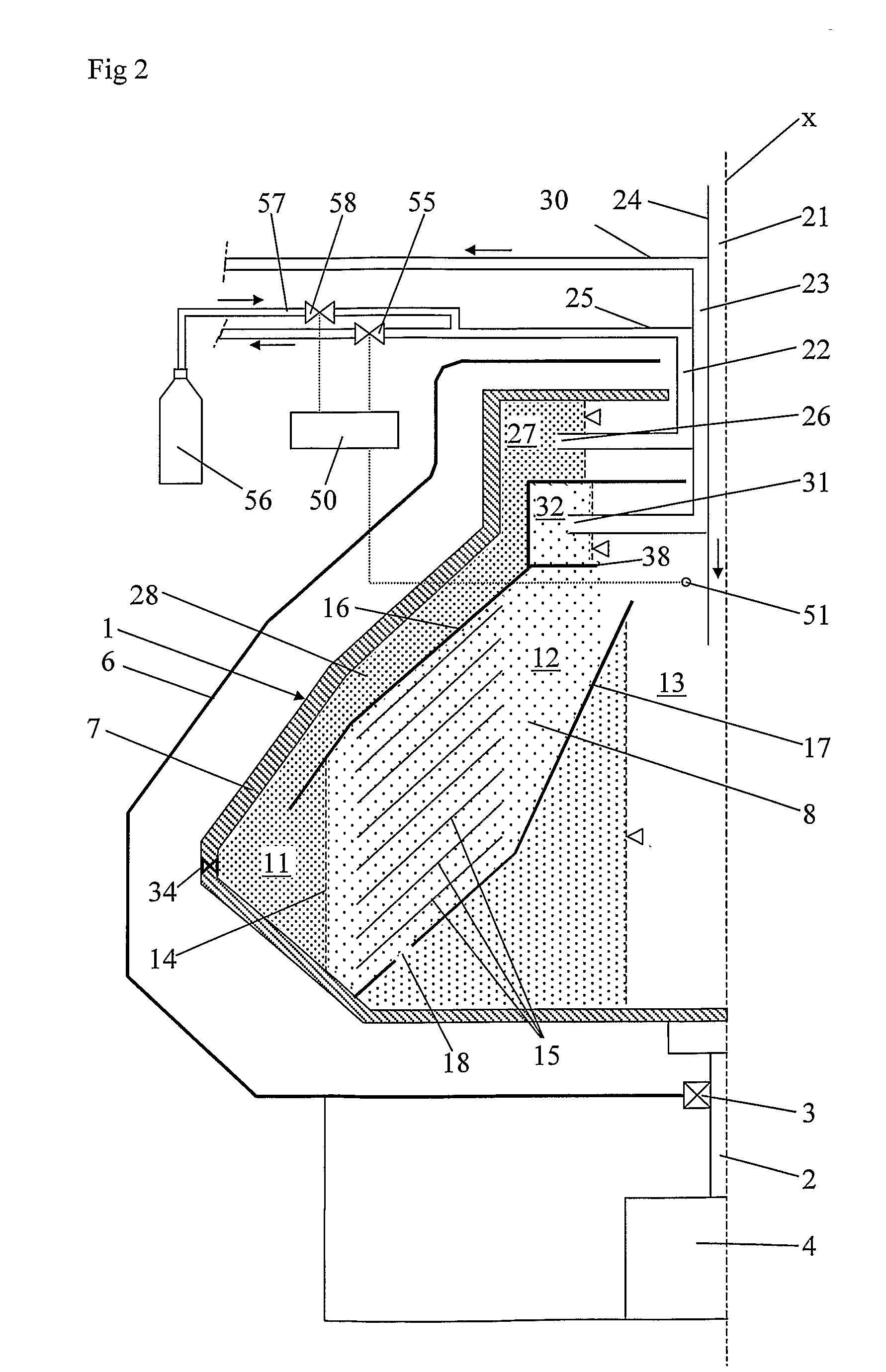

Apparatus and method for controlling the radial level of an interface in a centrifugal separator

ActiveUS7485084B2OptimalEasily realizedDispersed particle separationRotary centrifugesCentrifuge rotorRadial position

The invention refers to a centrifugal separator and a method of separating a product to a heavy phase and light phase. A centrifuge rotor encloses a closed separation space, which has a radially outer part for the heavy phase, a radially inner part for the light phase and a central gas-filled space. The radially outer part is separated from the radially inner part by a interface layer level. An inlet extends into the separation space for feeding the product. A first outlet extend from the radially outer part for discharge of the heavy phase. A second outlet extends from the radially inner part for discharge of the light phase. A control equipment permits control of the interface layer level to a desired radial position. A sensor senses a parameter related to the gas pressure in the central space. The control equipment controls the counter pressure in the first outlet in response to the sensed parameter for controlling the interface layer level to the desired radial position.

Owner:ALFA LAVAL CORP AB

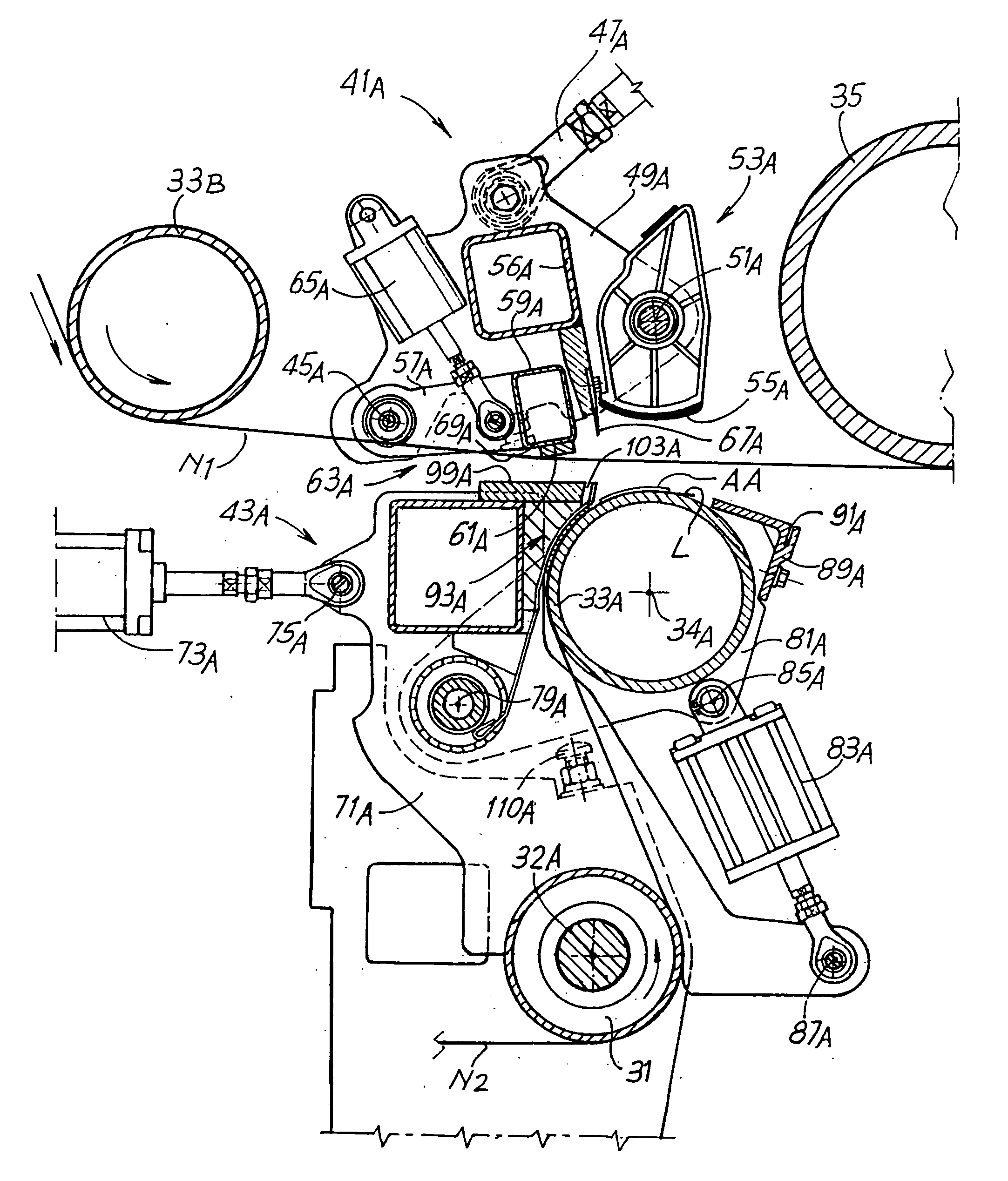

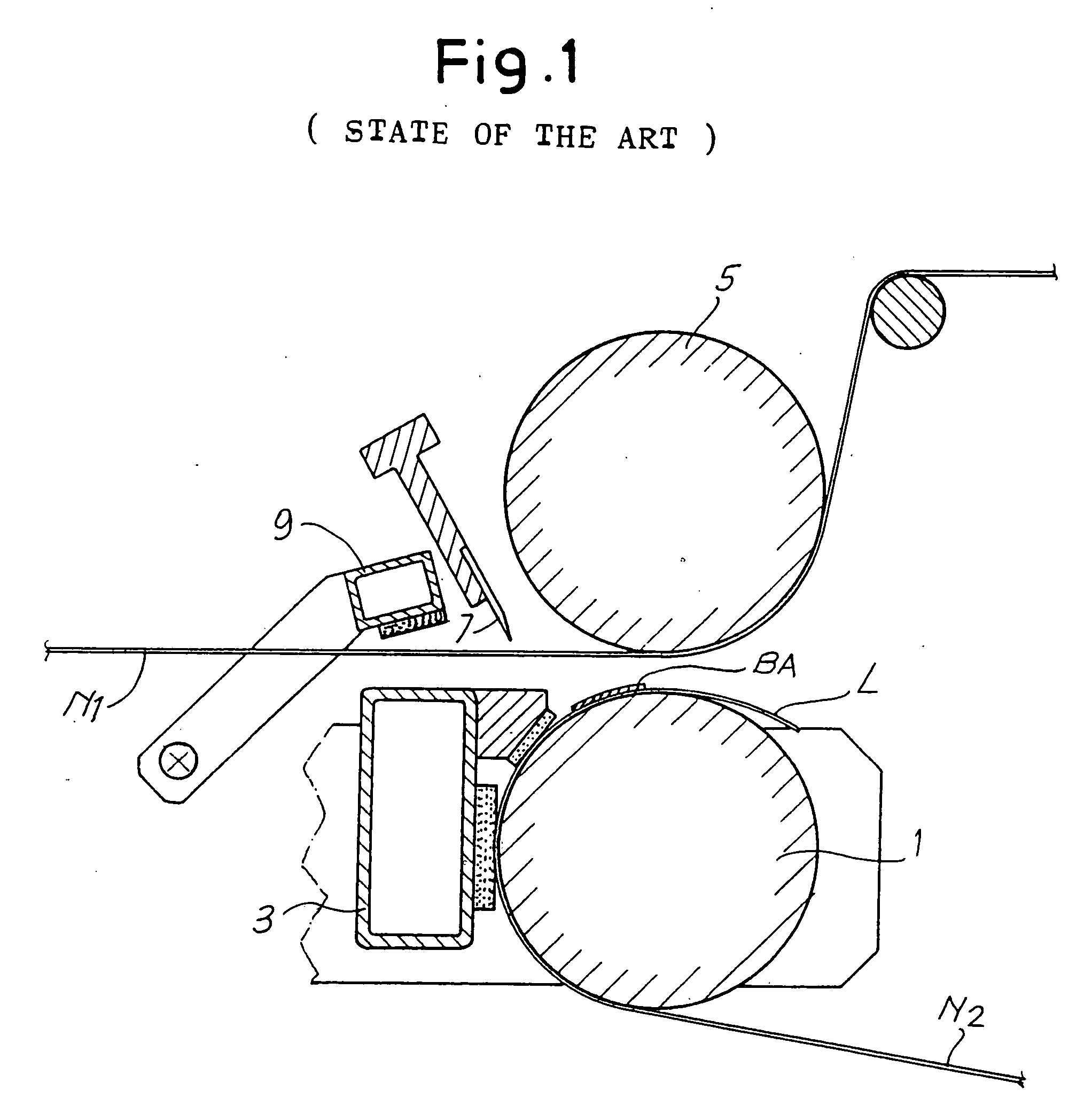

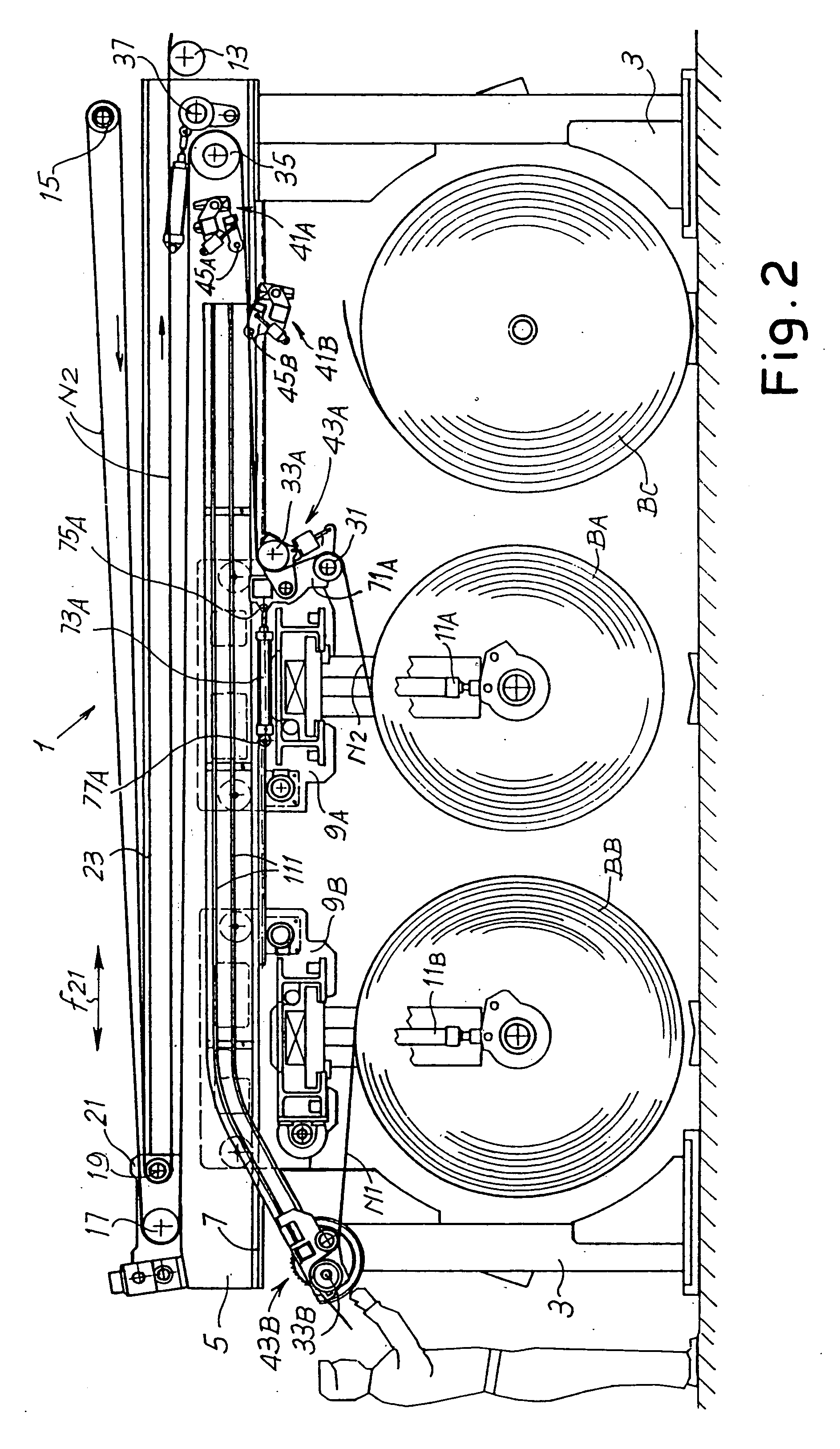

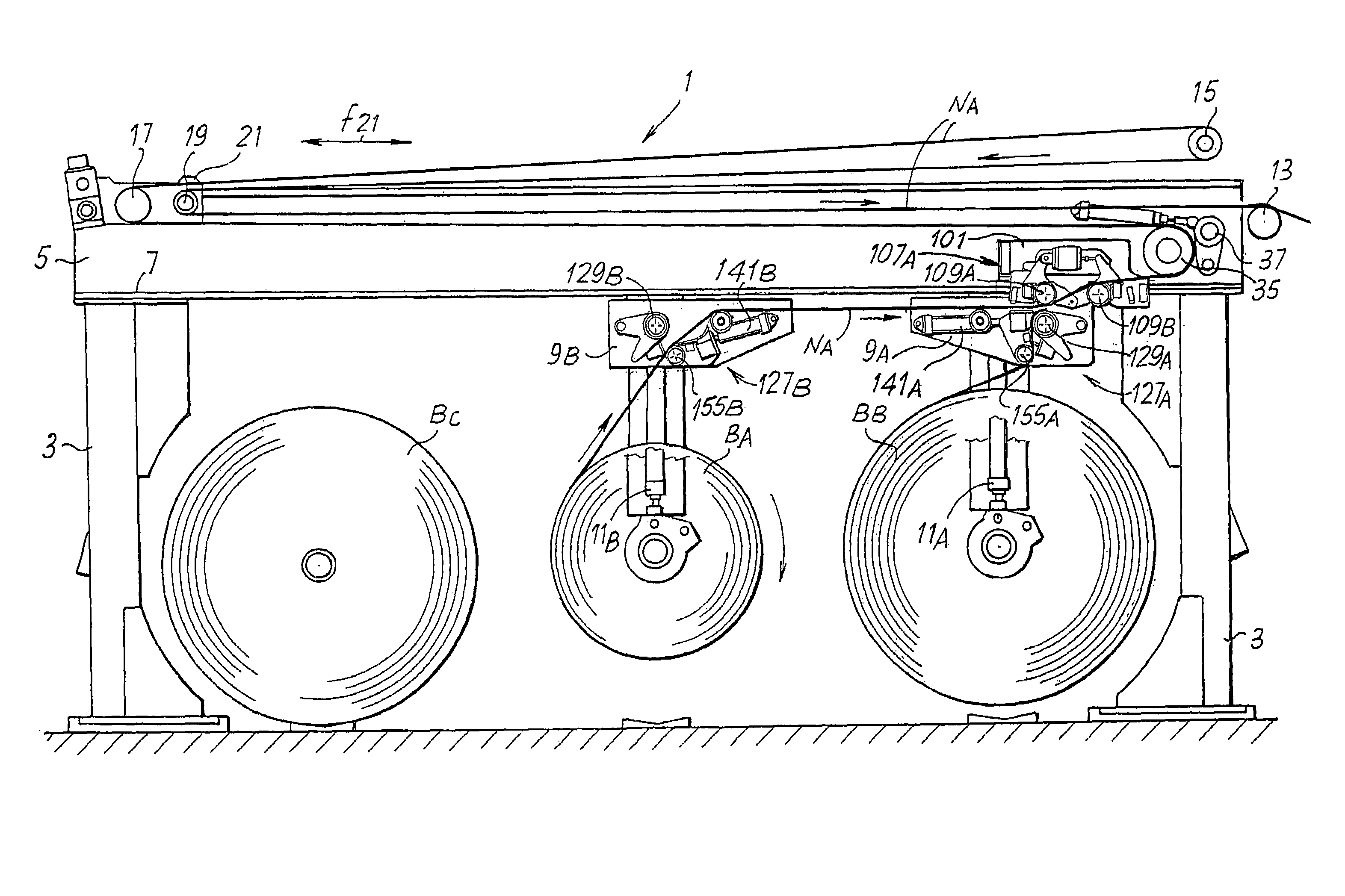

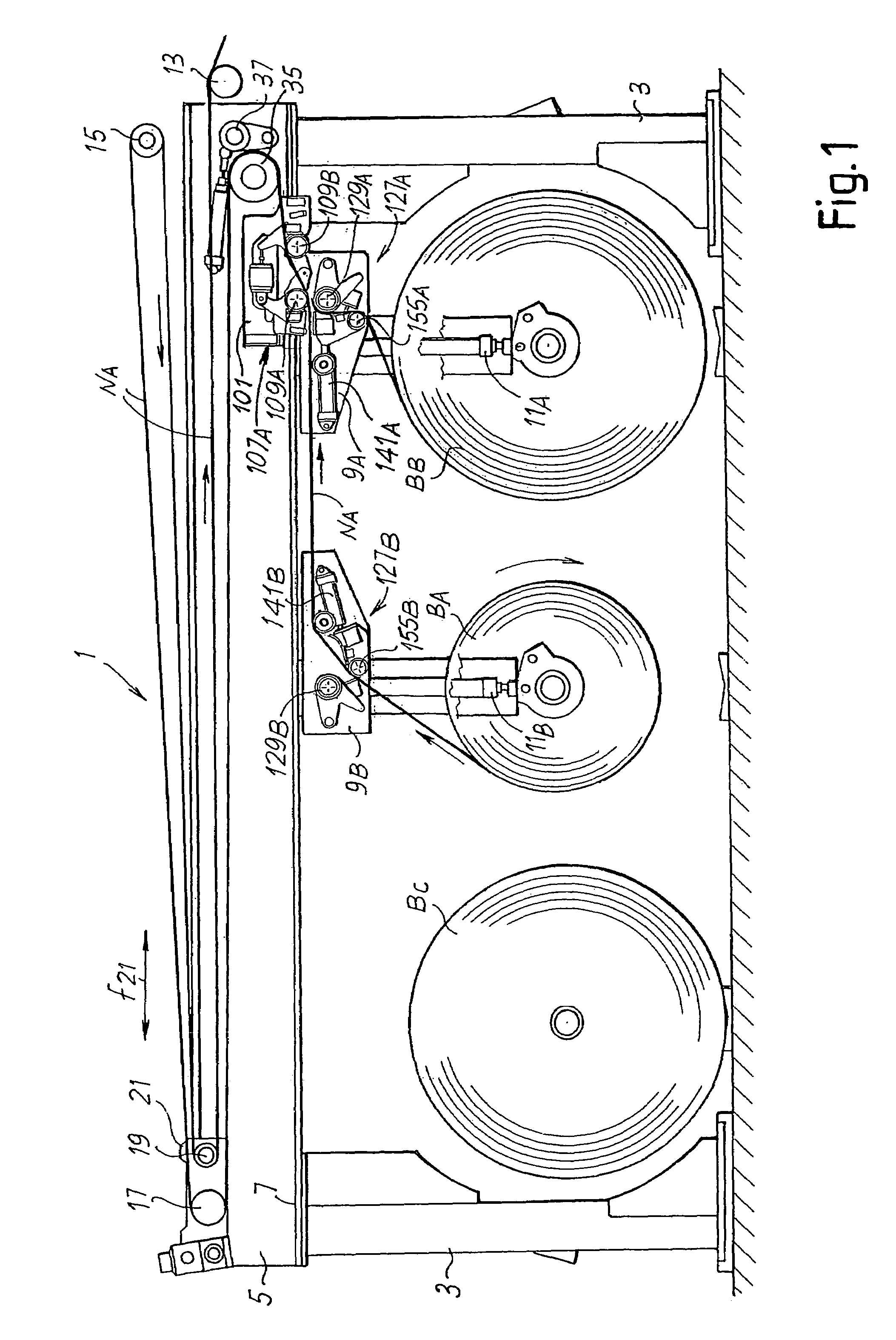

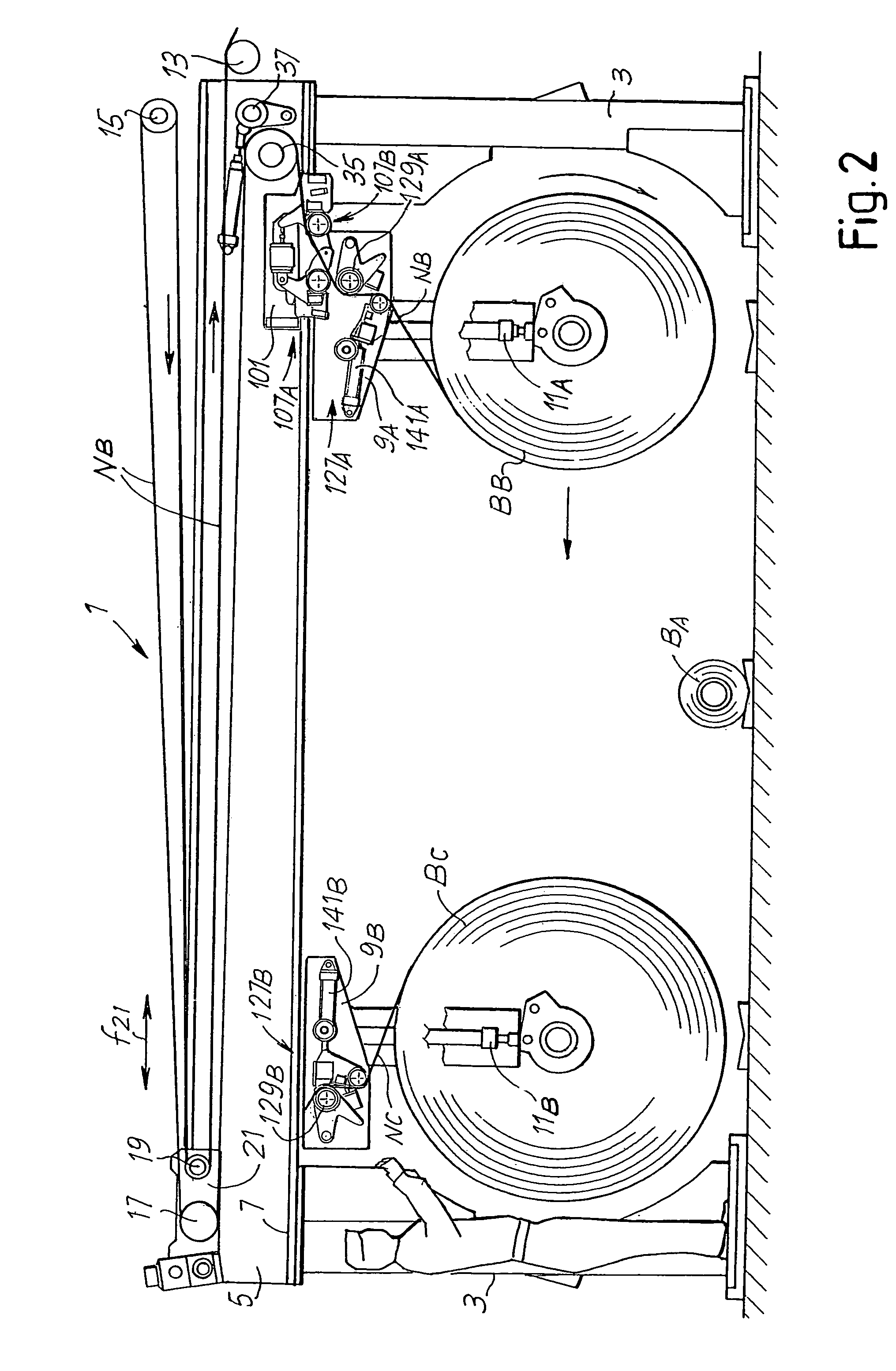

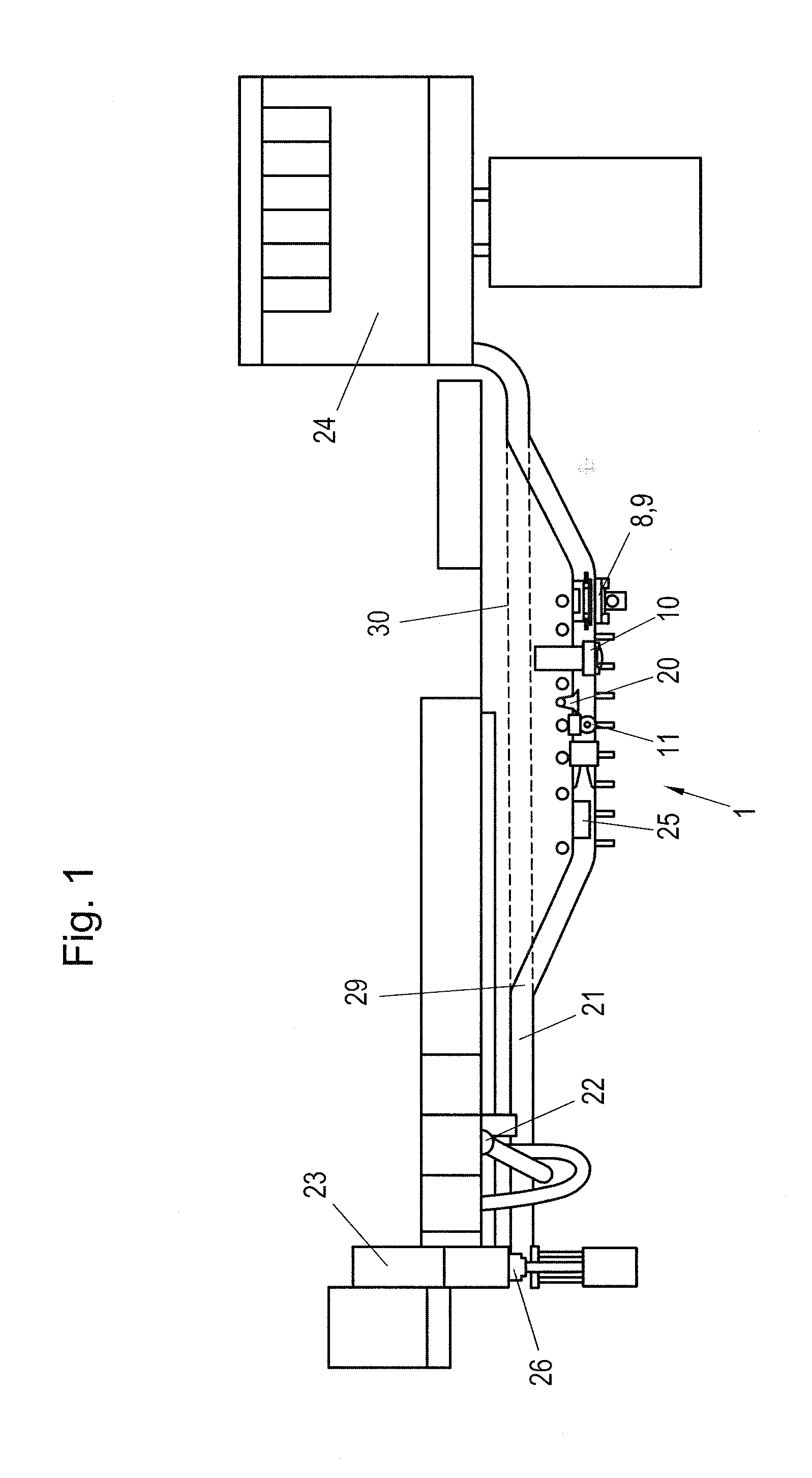

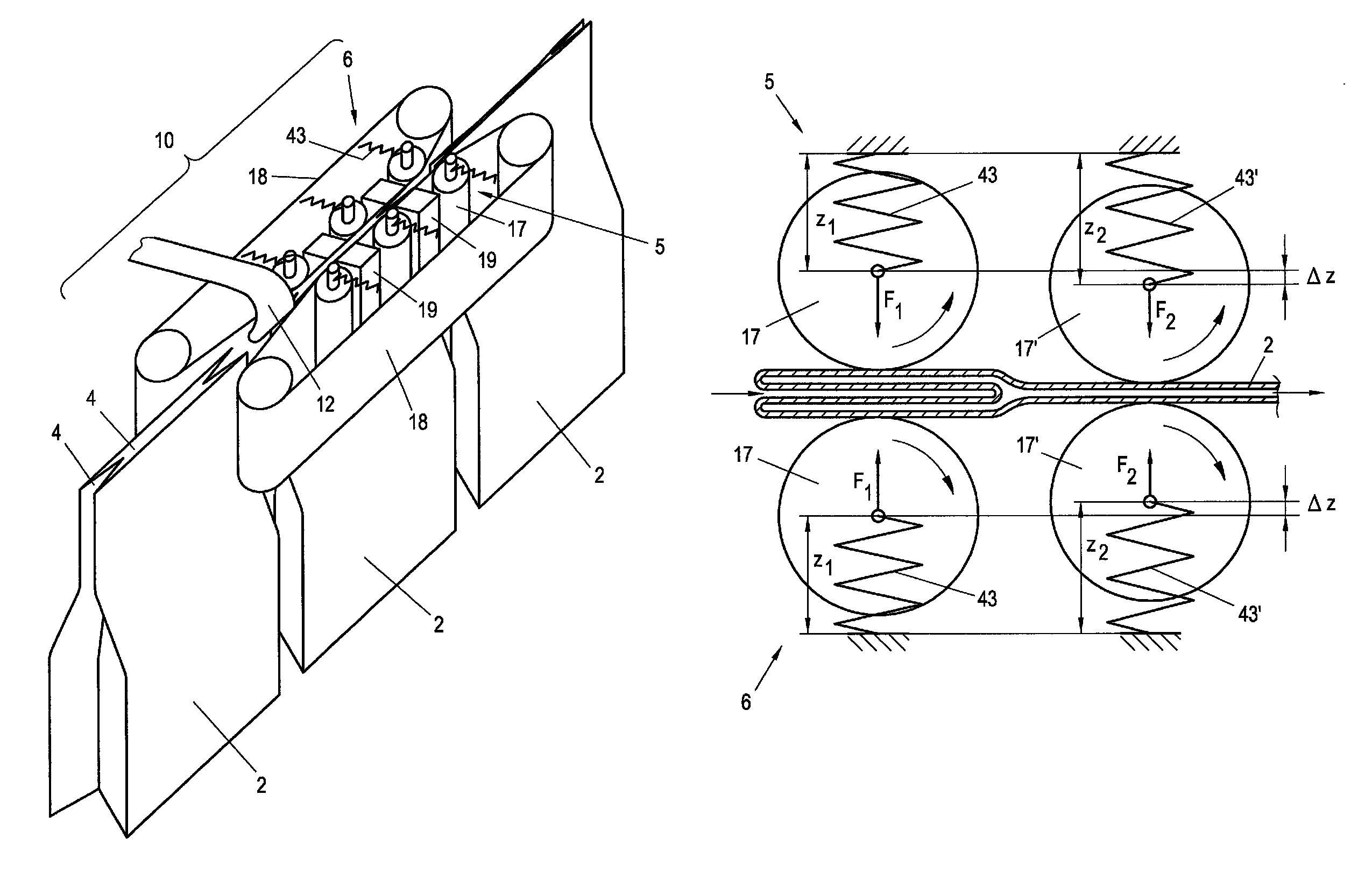

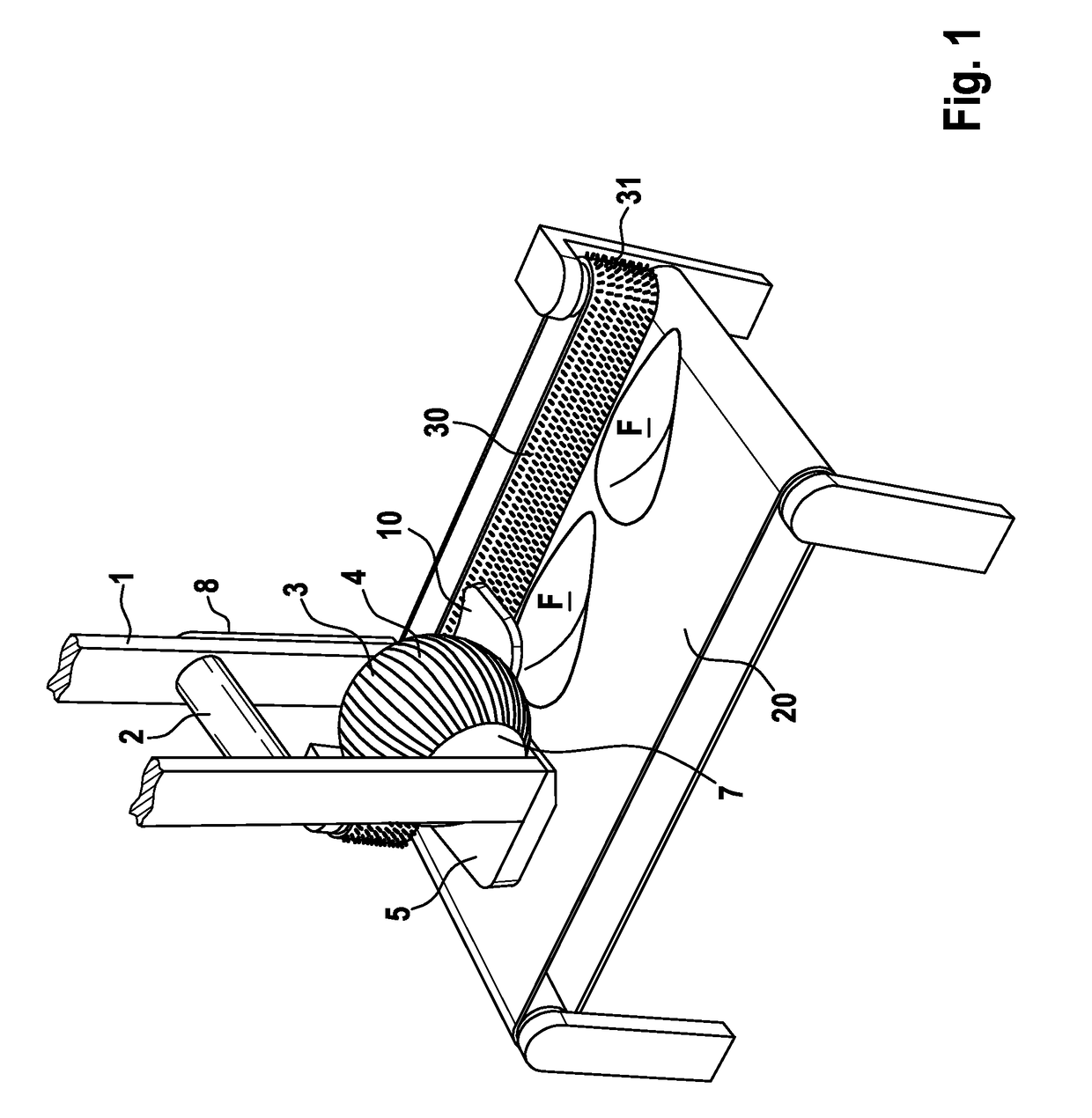

Splicing device for splicing two web materials together, unwinder comprising said slicing device and relative method

InactiveUS20040084133A1Easy constructionFast and reliableMechanical working/deformationFilament handlingCounter pressureEngineering

The splicing device comprises two heads (41A, 43A; 41B, 43B), each of which has: a roller (33A; 33B) associated with a clamping bar (93A; 93B) to hold between said roller and said clamping bar an initial edge (L) of the second web material; a counter-pressure member (53A; 53B) cooperating with said roller to press said first and second web materials against each other; and a cutting member (67A; 67B).

Owner:FOSBER

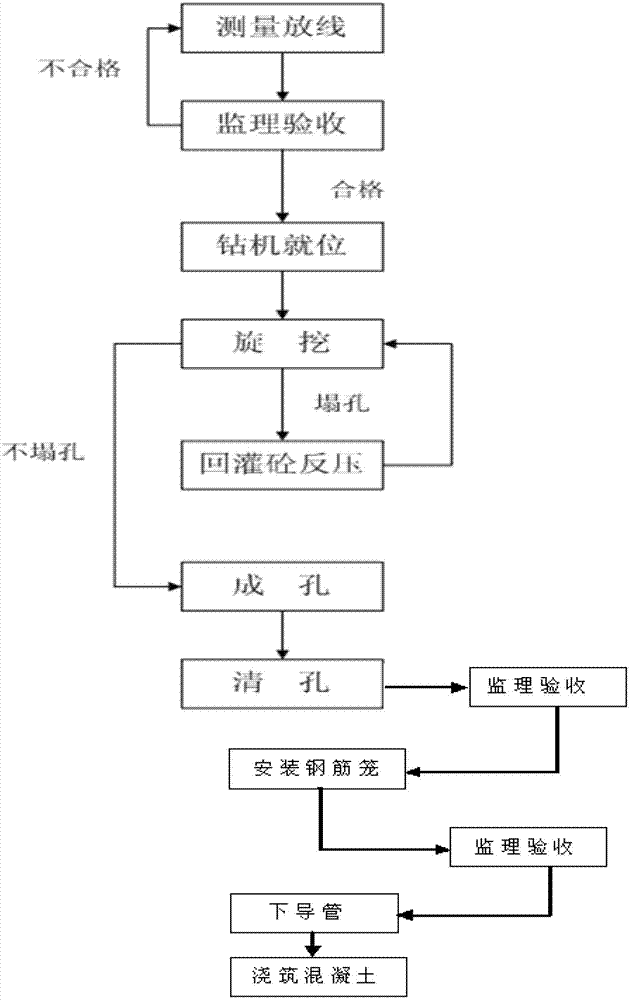

Large-diameter rotary digging pile construction technology for ultra-deep dumped unconsolidated soil bodies

ActiveCN102758430ASolve the pile problemSimple structureDirectional drillingBulkheads/pilesCounter pressureLower grade

The invention discloses a large-diameter rotary digging pile construction technology for ultra-deep dumped unconsolidated soil bodies, wherein low grade concrete is reinjected in a hole collapse section for countering pressure in the rotary digging pile construction process, so that the collapse of soil bodies around a pile hole is prevented; after the concrete is finally solidified and reaches a certain strength, the peripheral soil bodies are solidified, and a rotary digging operation is carried out in site for excavating soil, so that the reinjected concrete forms a protective wall; and the operations are carried out in circles till the hole is formed. The large-diameter rotary digging pile construction technology disclosed by the invention is a construction technology capable of carrying out large-diameter rotary digging pile construction on the unconsolidated soil bodies.

Owner:中建五局第三建设有限公司 +1

Centrifugal Separator

ActiveUS20080171645A1OptimalEasily realizedDispersed particle separationRotary centrifugesCentrifuge rotorRadial position

The invention refers to a centrifugal separator and a method of separating a product to a heavy phase and light phase. A centrifuge rotor encloses a closed separation space, which has a radially outer part for the heavy phase, a radially inner part for the light phase and a central gas-filled space. The radially outer part is separated from the radially inner part by a interface layer level. An inlet extends into the separation space for feeding the product. A first outlet extend from the radially outer part for discharge of the heavy phase. A second outlet extends from the radially inner part for discharge of the light phase. A control equipment permits control of the interface layer level to a desired radial position. A sensor senses a parameter related to the gas pressure in the central space. The control equipment controls the counter pressure in the first outlet in response to the sensed parameter for controlling the interface layer level to the desired radial position.

Owner:ALFA LAVAL CORP AB

Splicing device to join together two web materials, unwinding device comprising said splicing device

Owner:FOSBER

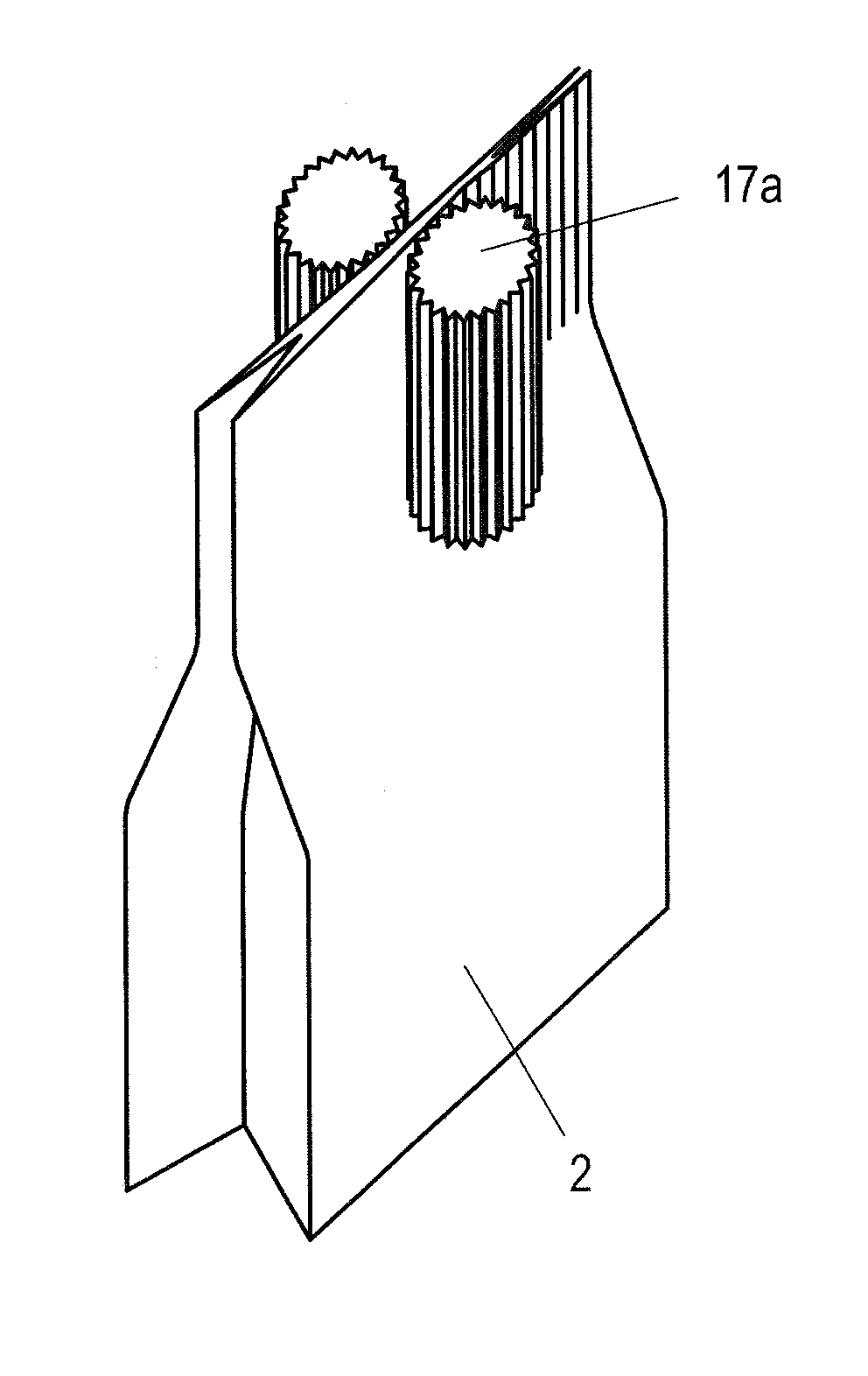

Closing apparatus for closing preferably bag-type packaging units

ActiveUS20110167763A1Uniform and reliable sealingWrapper twisting/gatheringDomestic articlesCounter pressurePaperboard

A closing apparatus for closing preferably bag-type packaging units by compression, which units have regions of differing thickness along the package opening to be closed, such as square bottom bags for instance, in particular made of coated or uncoated paper, paperboard, plastic, film, and / or woven material, which packaging units have at least one suitable sealing surface that is integrated in or applied to the material for permanent bonding to a surface that is adjacent to or opposite and pressed against the material, wherein the closing apparatus has a pressing device with at least one pressure device and at least one counter-pressure device between which the packaging units can be compressed, preferably with the application of heat, in the region of their sealing surface(s). In order to achieve a uniformly durable closure, the pressure device and the counter-pressure device have zones of different pressure and / or different temperature along the package opening to be closed.

Owner:WESTWIND VERPACKUNGEN

High strength corrosion resistant rare earth cast magnesium alloy and preparation method thereof

The invention discloses a high strength corrosion resistant rare earth cast magnesium alloy and a preparation method thereof, which is characterized in that: the magnesium alloy comprises the following components according to the weight percentage: 1.8 to 4.0 percent of Nd, 1.0 to 2.0 percent of Gd, 0.2 to 0.8 percent of Zn, 0.4 to 1.0 percent of Zr, 0.0 to 0.8 of Ca, not more than 0.02 percent of total content of impurity elements of Fe, Cu and Ni, and the balance of Mg complemented to 100 percent; and the preparation method comprises the following steps of: melting pure magnesium, adding Mg-Nd intermediate alloy, Mg-Gd intermediate alloy, Mg-Ca intermediate alloy and commercial pure Zn in sequence, heating up to 760 DEG C to 785 DEG C after the mixture is totally melted, adding Mg-Zr intermediate alloy, stirring fully and evenly after the Mg-Zr intermediate alloy is melted, standing for 10 to 20 minutes, removing dross, and then casting ingots or casting the cast products at the temperature of 720 DEG C to 750 DEG C. The cast magnesium alloy has the advantages of controllable melting process, appropriate cost, excellent mechanical property, corrosivity, good casting process property and the like; and the cast magnesium alloy can be used to manufacture various non-die casting magnesium alloy parts by adopting the processes of sand mold casting, low-pressure casting, counter-pressure casting or squeezing casting, etc.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

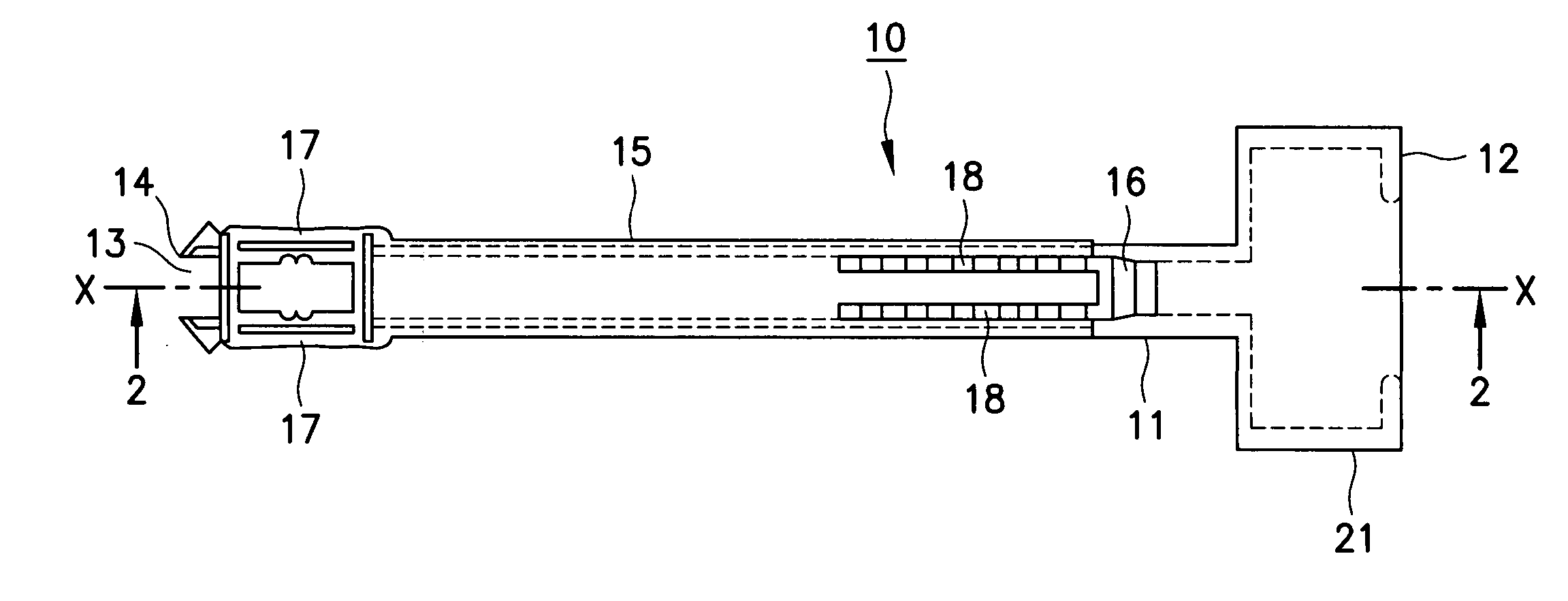

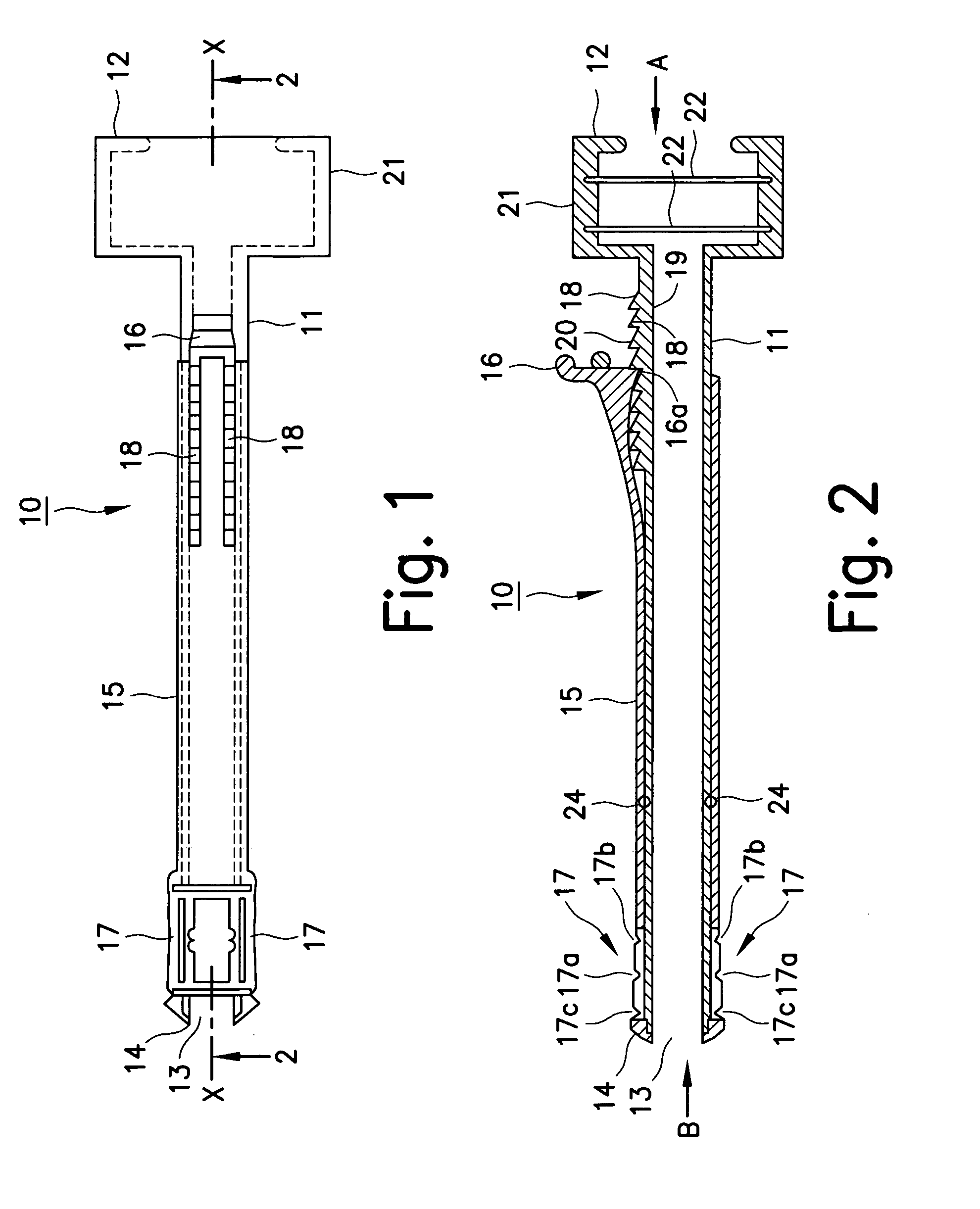

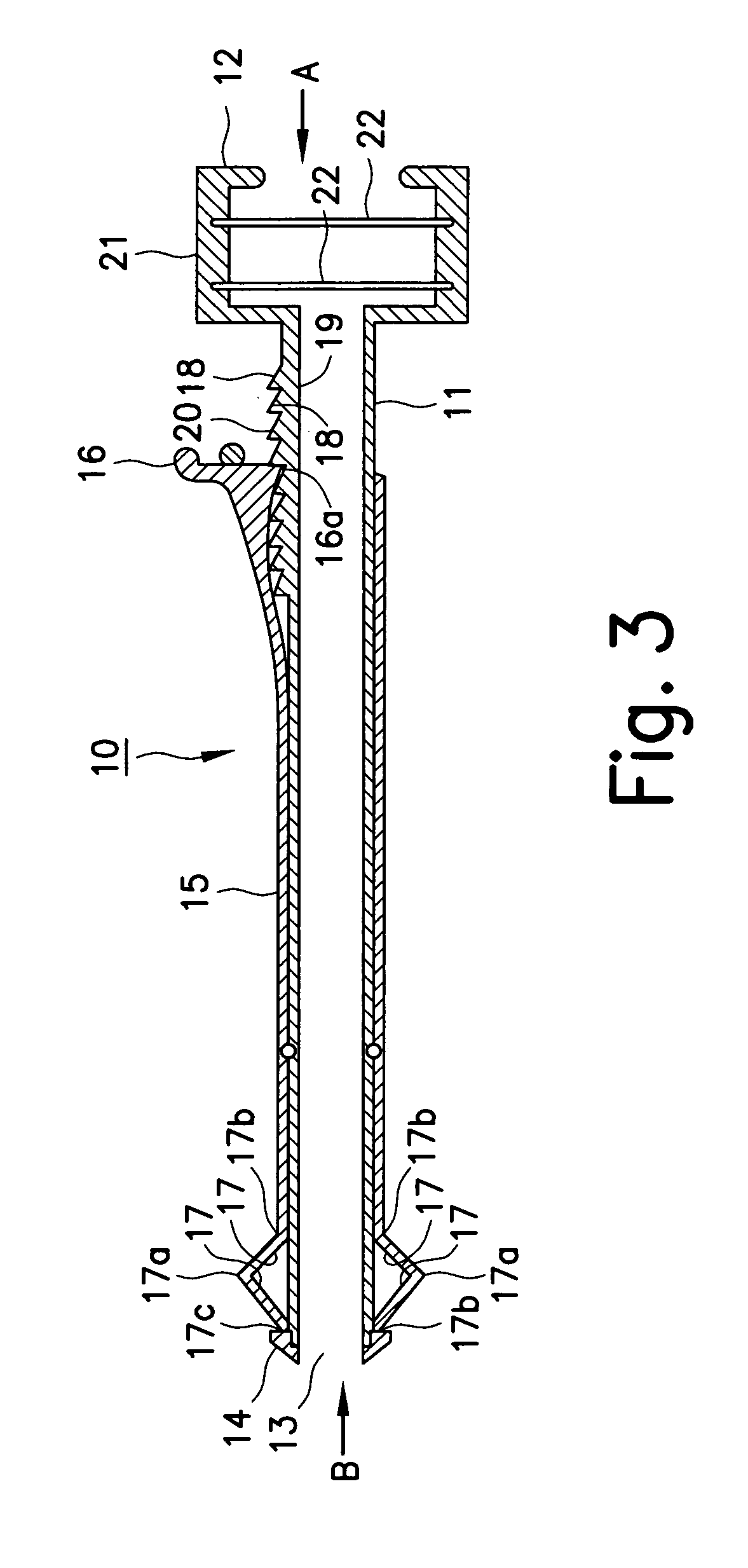

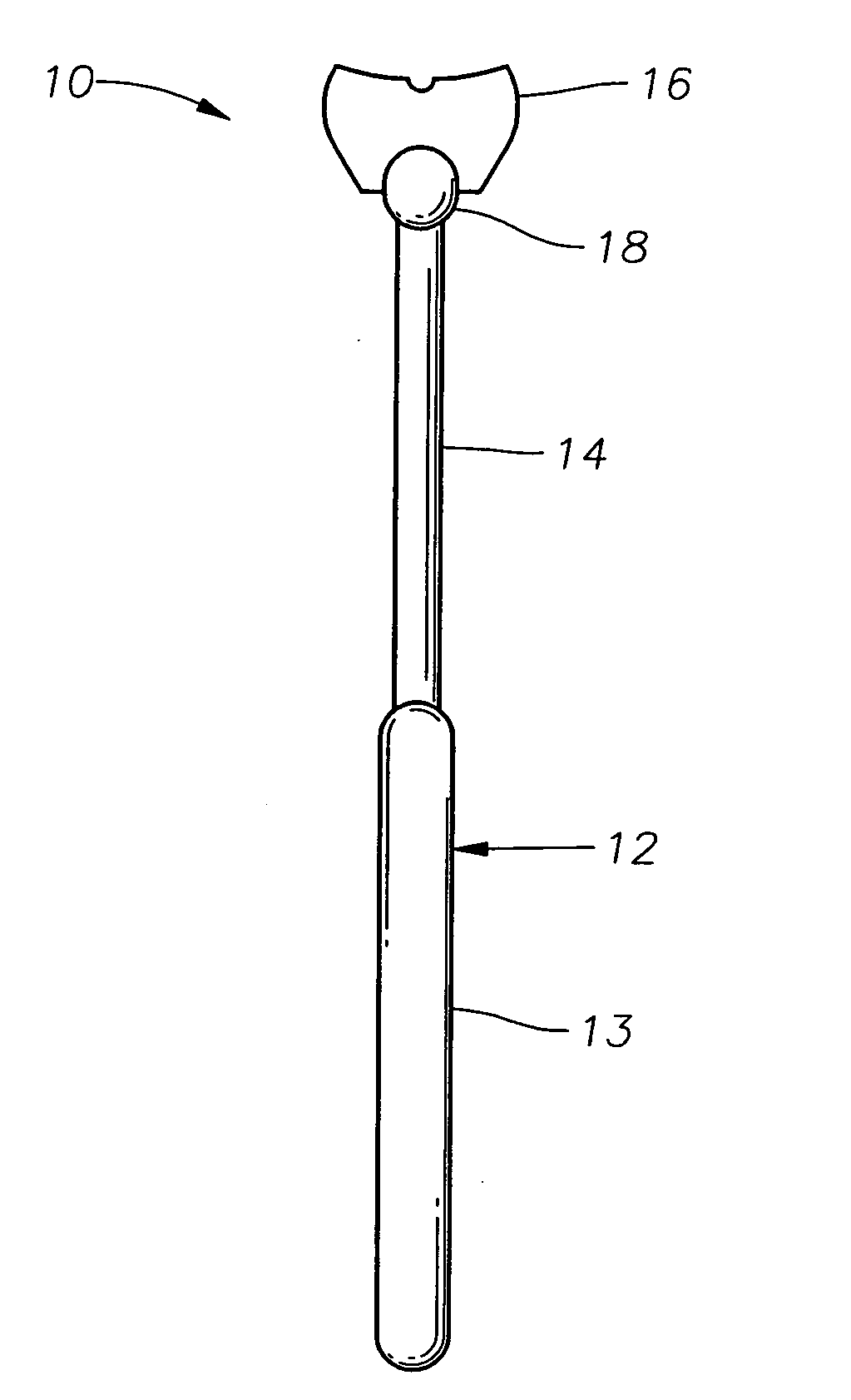

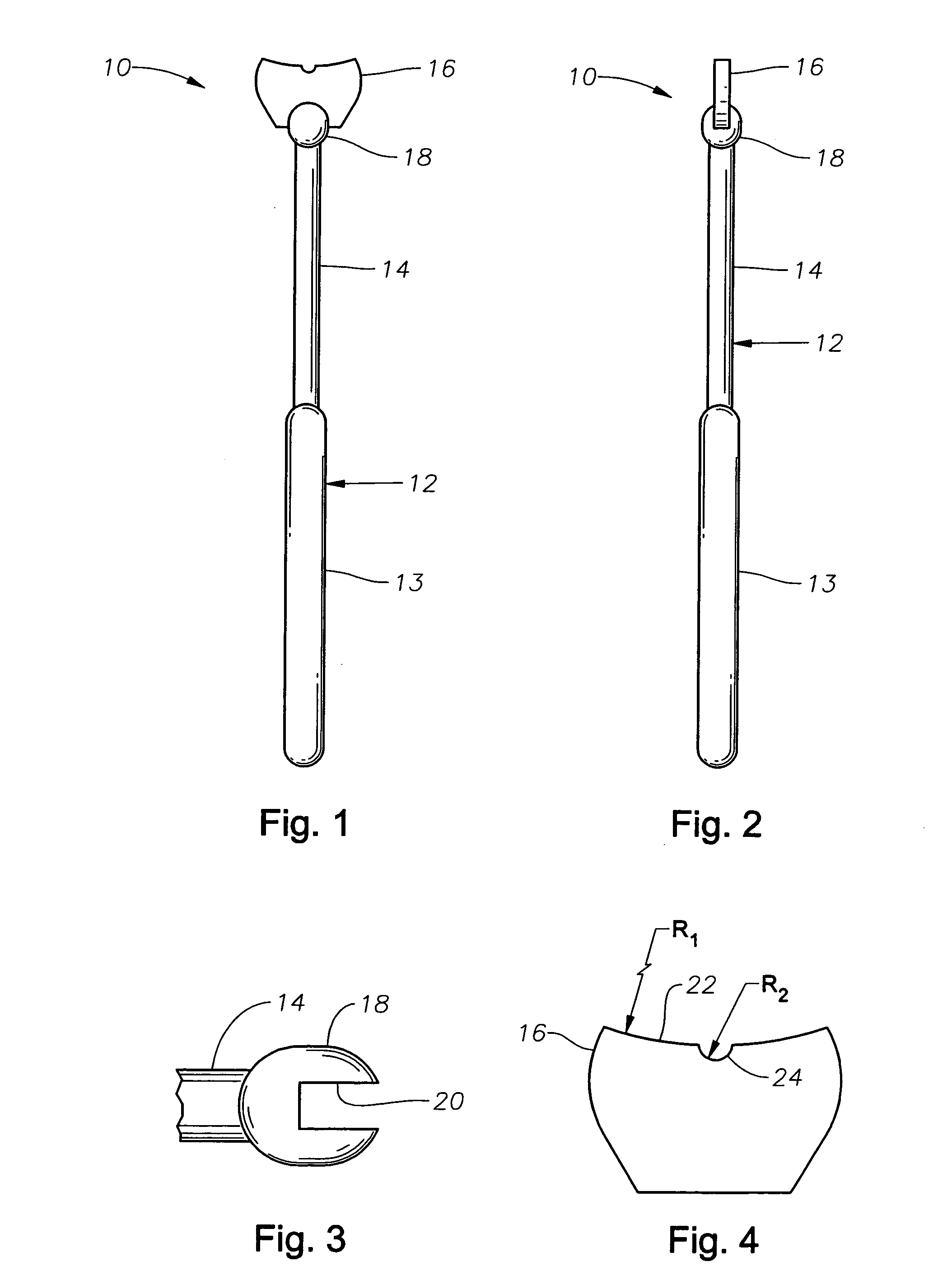

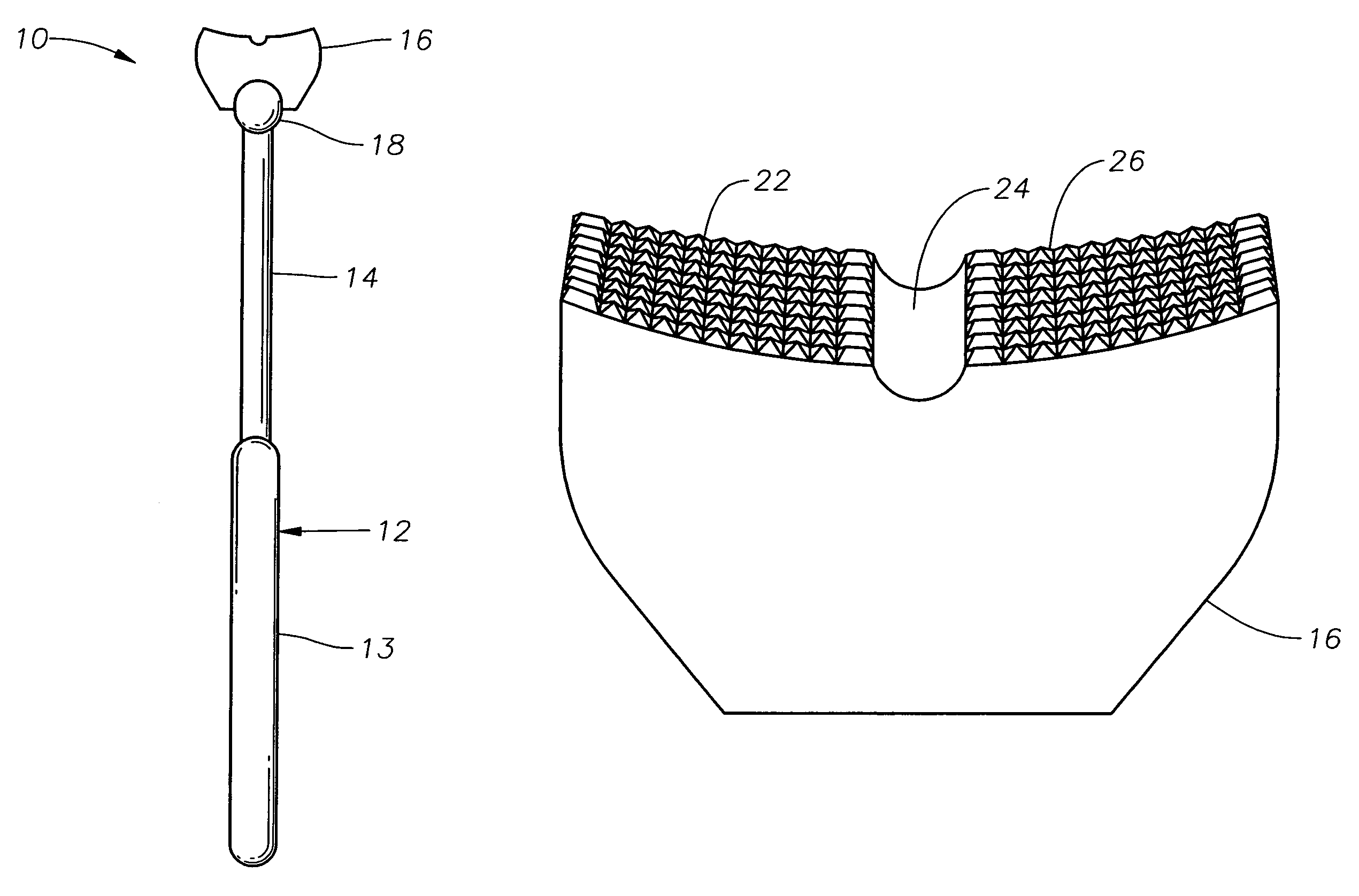

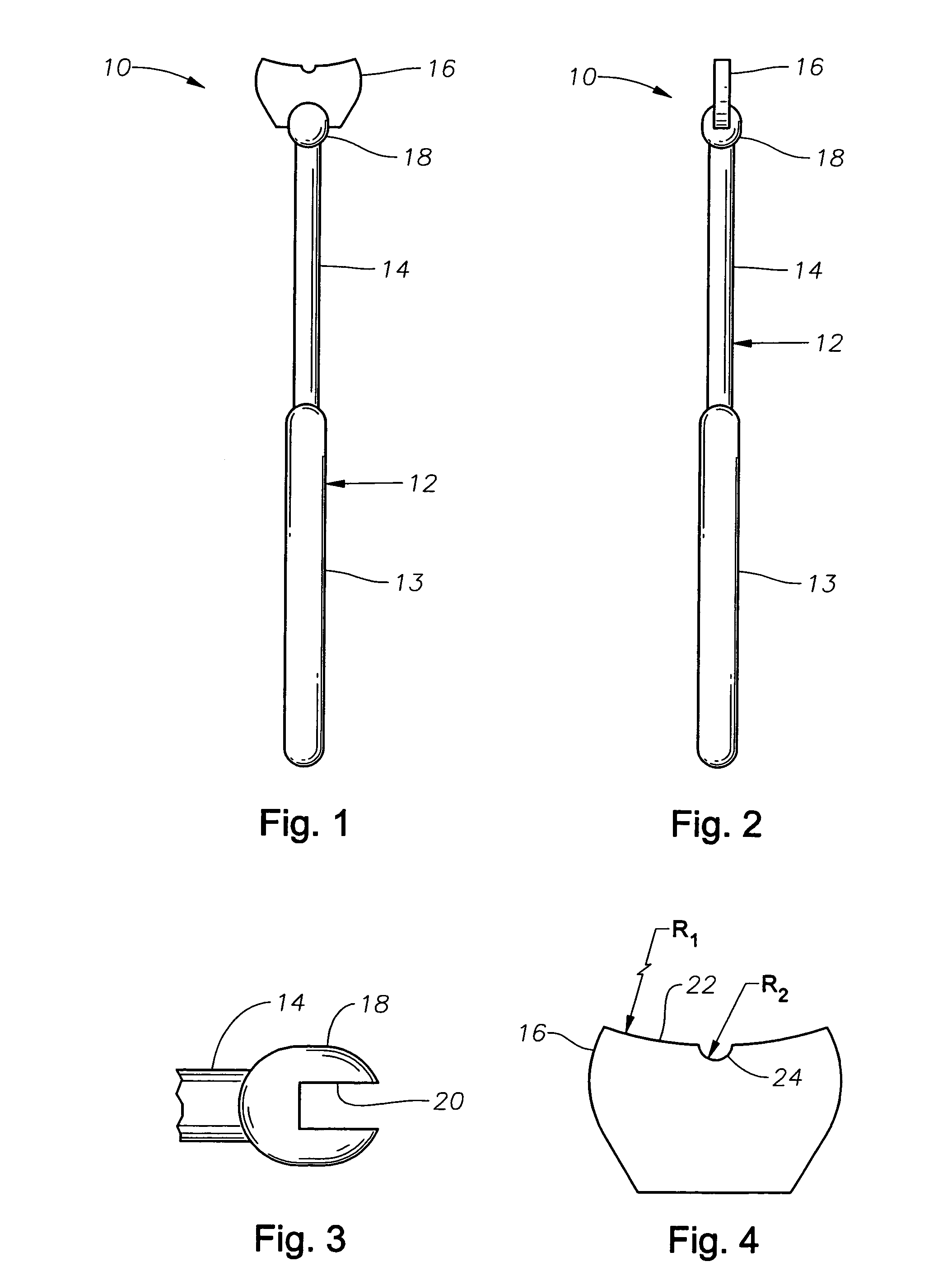

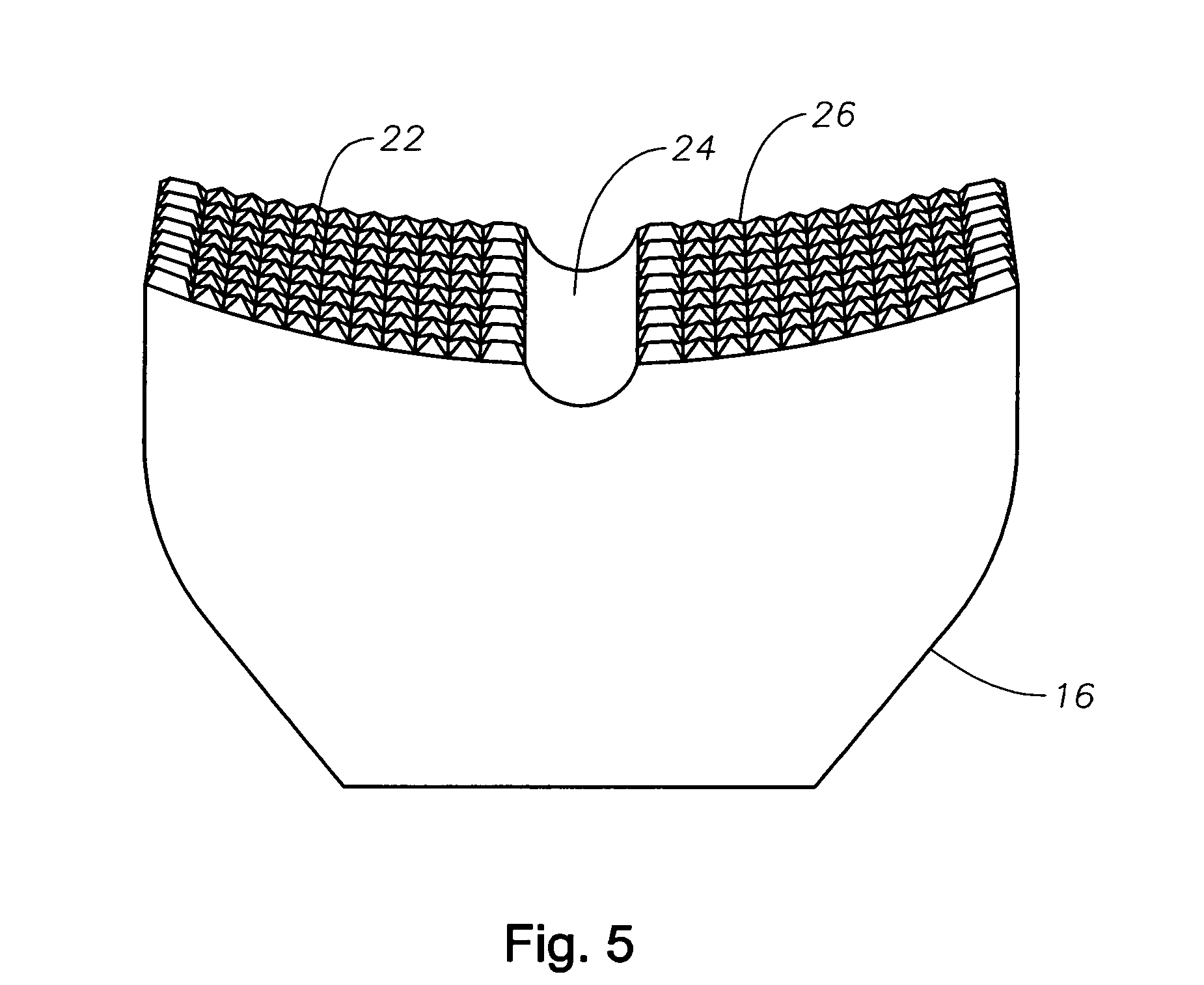

Counter pressure device for ophthalmic drug delivery

InactiveUS20060047255A1Facilitates drug placementPreventing and minimizingSurgical instrument detailsMedical applicatorsRefluxConjunctiva

A counter pressure device for ophthalmic drug delivery. The device includes a handle and a head coupled to a distal end of the handle. The head comprises a curved, concave surface for contacting the conjunctiva and having a notch for removably receiving a cannula. The device minimizes or prevents drug reflux and facilitates drug placement during ophthalmic drug delivery.

Owner:NOVARTIS AG

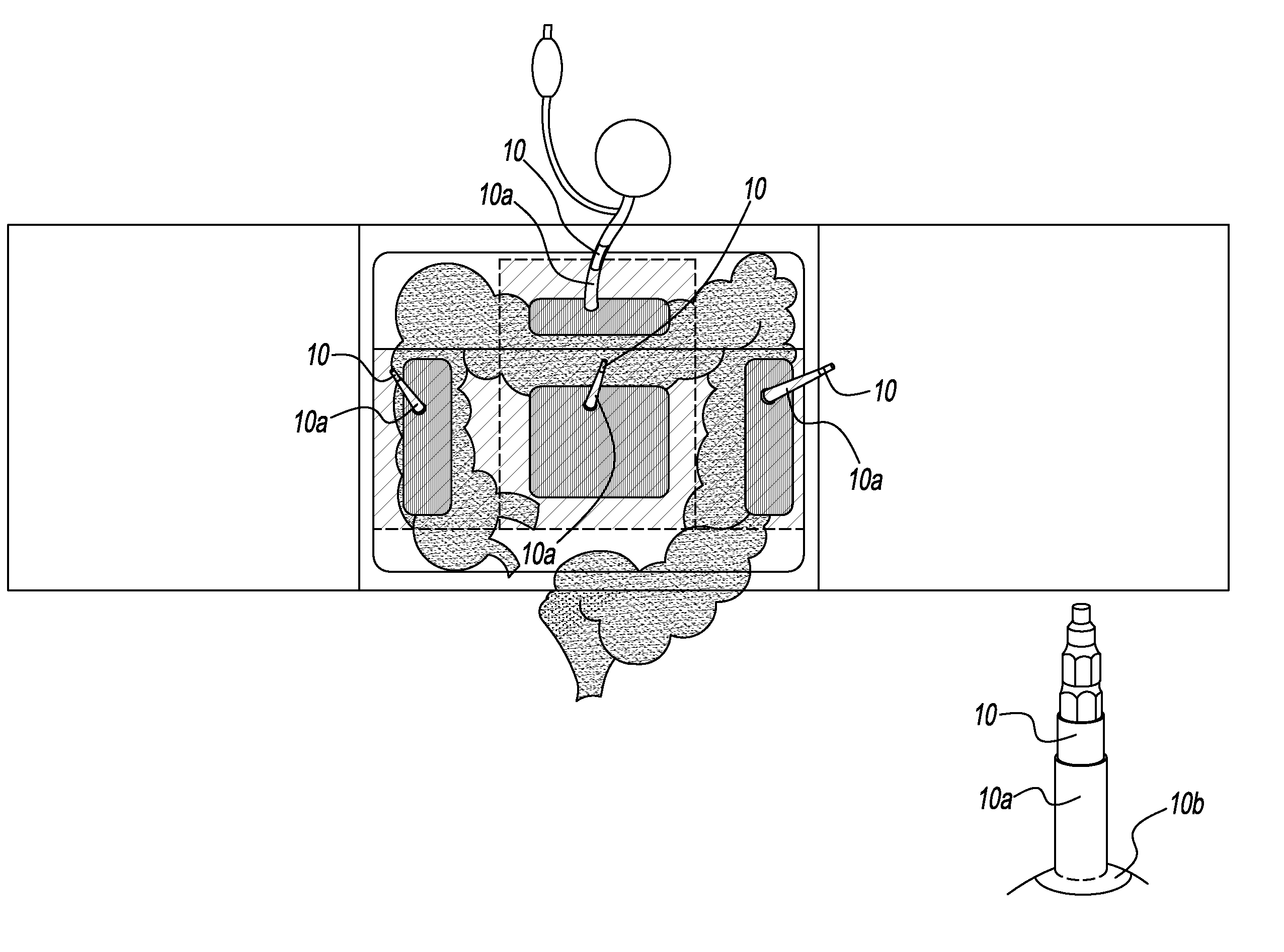

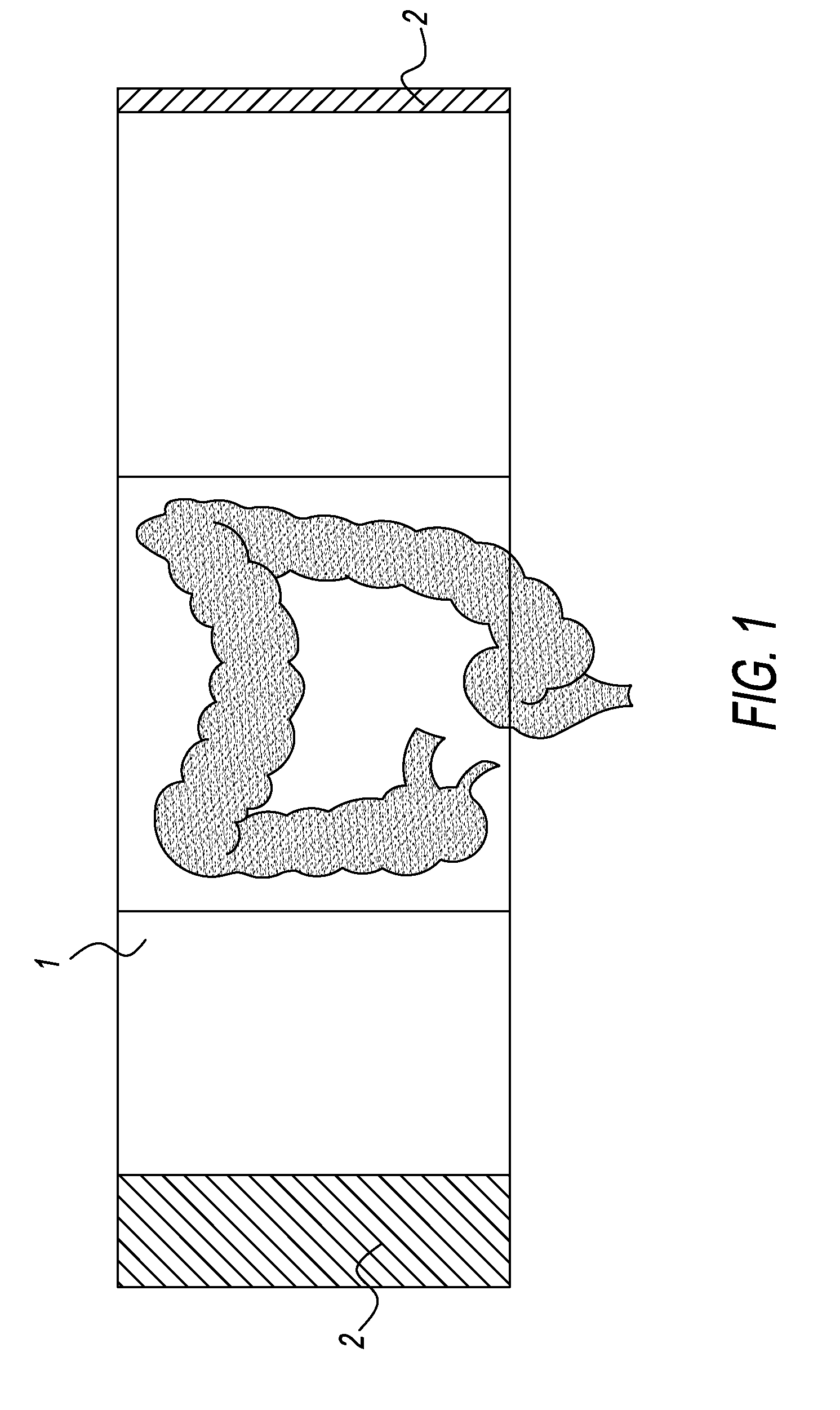

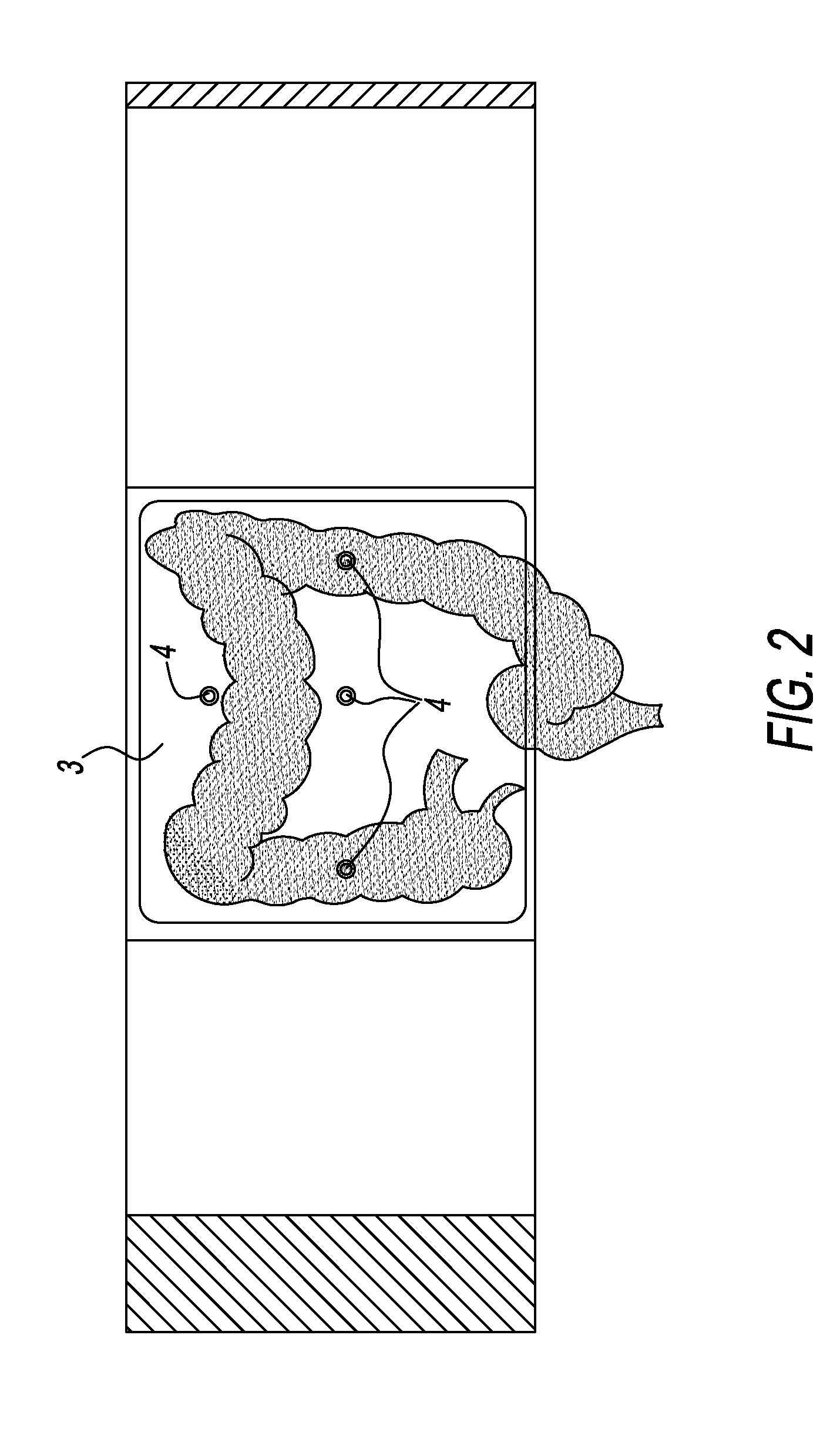

External Pneumatic Compression Device

InactiveUS20110087263A1Passage is slowedReduce circulationTourniquetsCompression deviceLarge intestine

The present invention relates to a device for facilitating a colonoscopy, and more particularly to a non-invasive external pneumatic compression device that applies pressure to the abdomen of a patient in order to decrease looping of the colon during a colonoscopy and thus effectively splint a looping colon without the need for human intervention. This external pneumatic compression device comprises a flexible and breathable elastic abdominal binder for surrounding the abdomen of a patient undergoing a colonoscopy, a counter pressure plate that is secured to the middle inside of the binder for providing a counter pressure during and while the bladder or bladders are inflated, a means for supplying air and regulating the pressure in the bladders, and a plurality of inflatable bladders for applying downward pressure to specific anatomical areas of the large intestines of a patient when inflated. When the binder is secured to the abdomen of a patient, the inflatable bladders will be placed over four noted regions of the abdomen corresponding to the ascending colon, the mid-umbilical colon, the transverse colon, and the sigmoid bladder.

Owner:ARBER PATRICK THOMAS

Closing apparatus for closing preferably bag-type packaging units

ActiveUS8225583B2Uniform and reliable sealingWrapper twisting/gatheringDomestic articlesCardboardCounter pressure

A closing apparatus for closing preferably bag-type packaging units by compression, which units have regions of differing thickness along the package opening to be closed, such as square bottom bags for instance, in particular made of coated or uncoated paper, paperboard, plastic, film, and / or woven material, which packaging units have at least one suitable sealing surface that is integrated in or applied to the material for permanent bonding to a surface that is adjacent to or opposite and pressed against the material, wherein the closing apparatus has a pressing device with at least one pressure device and at least one counter-pressure device between which the packaging units can be compressed, preferably with the application of heat, in the region of their sealing surface(s). In order to achieve a uniformly durable closure, the pressure device and the counter-pressure device have zones of different pressure and / or different temperature along the package opening to be closed.

Owner:WESTWIND VERPACKUNGEN

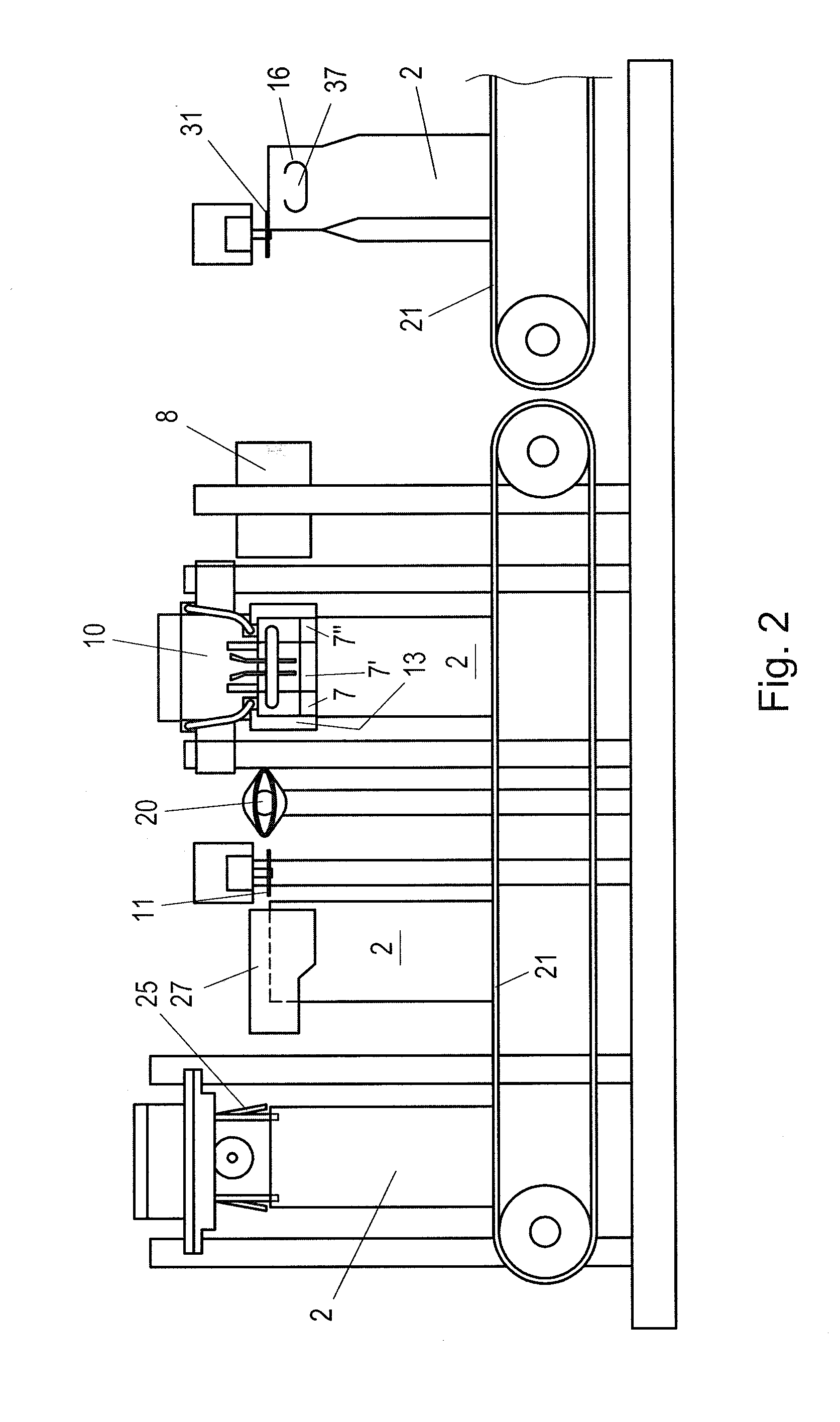

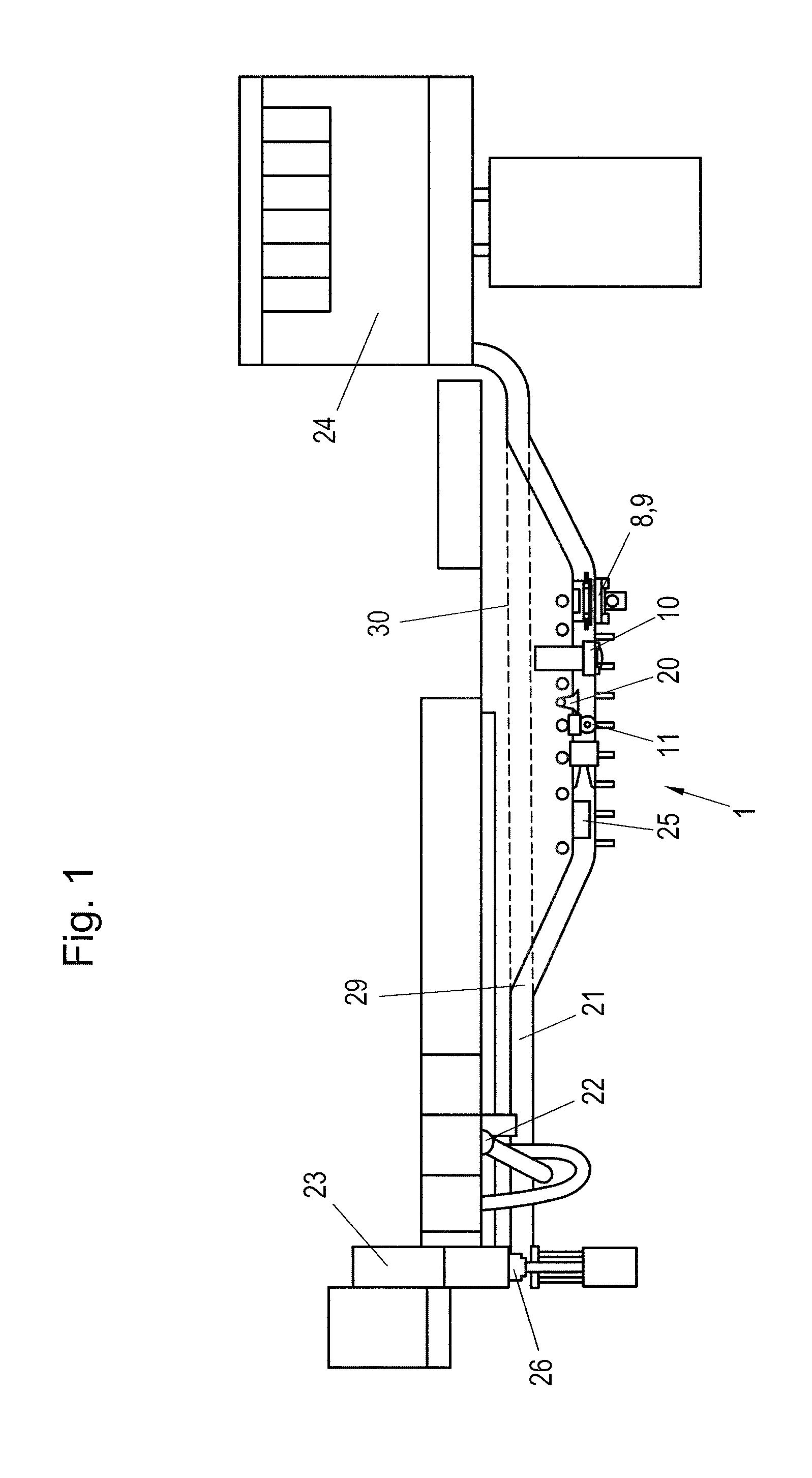

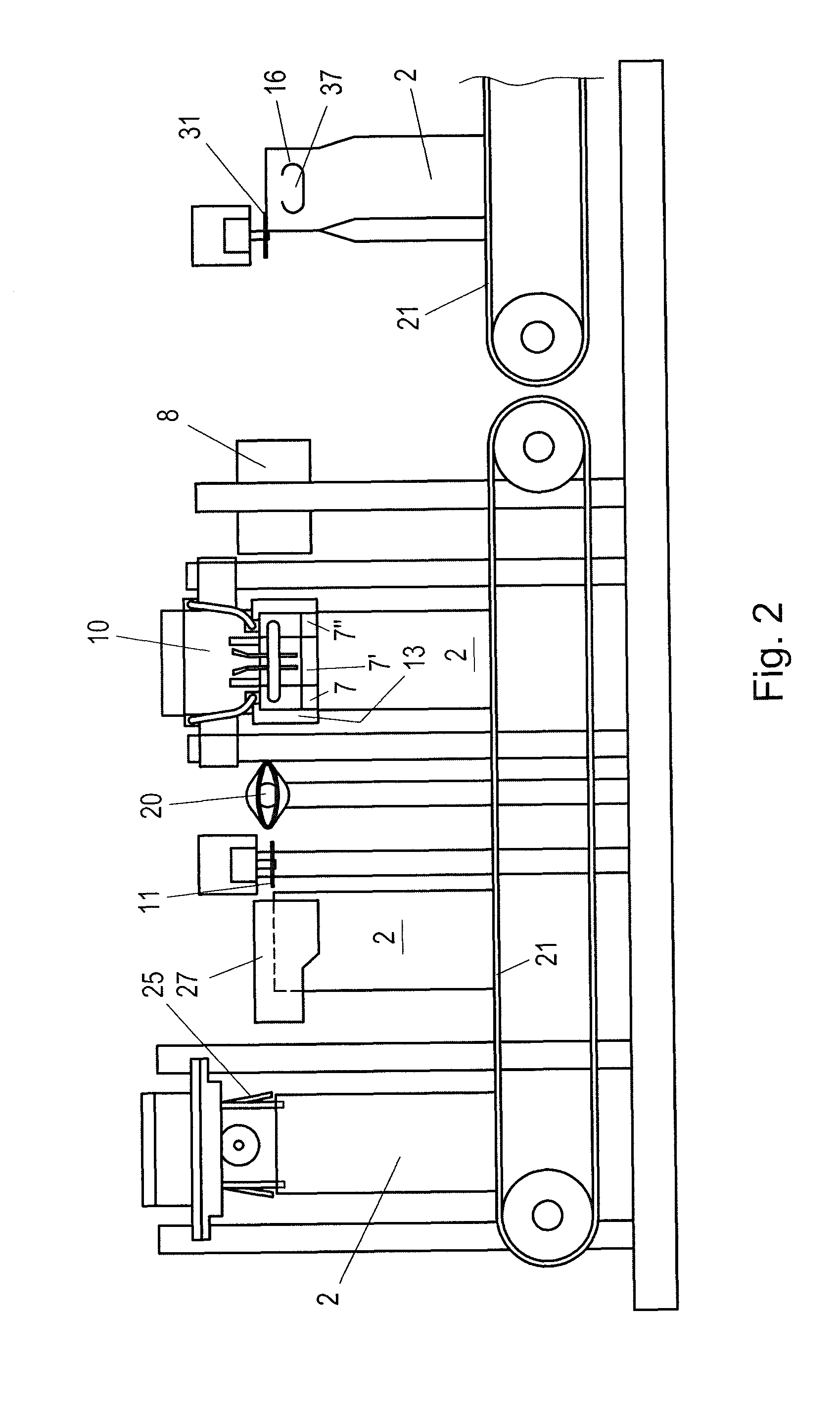

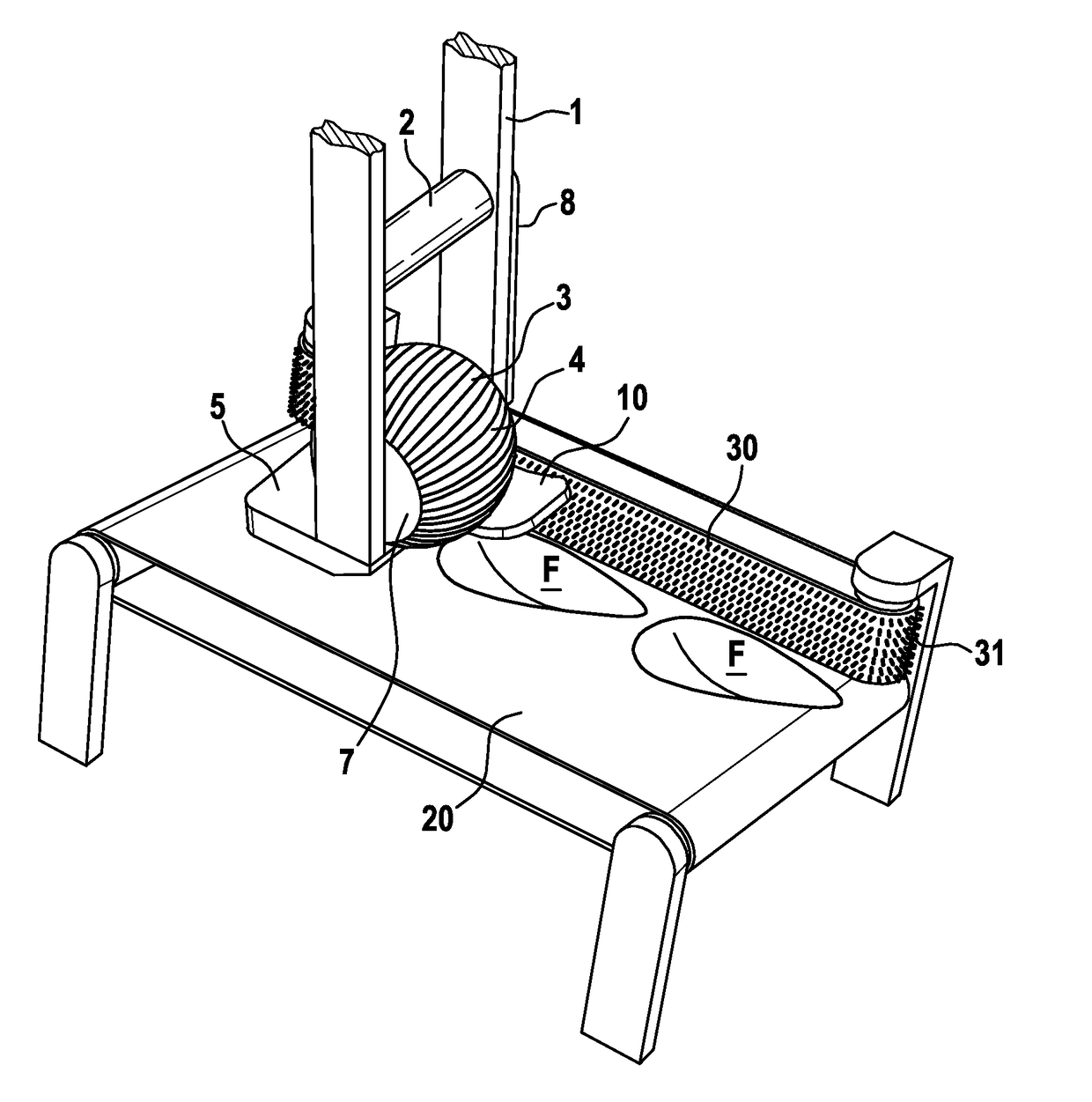

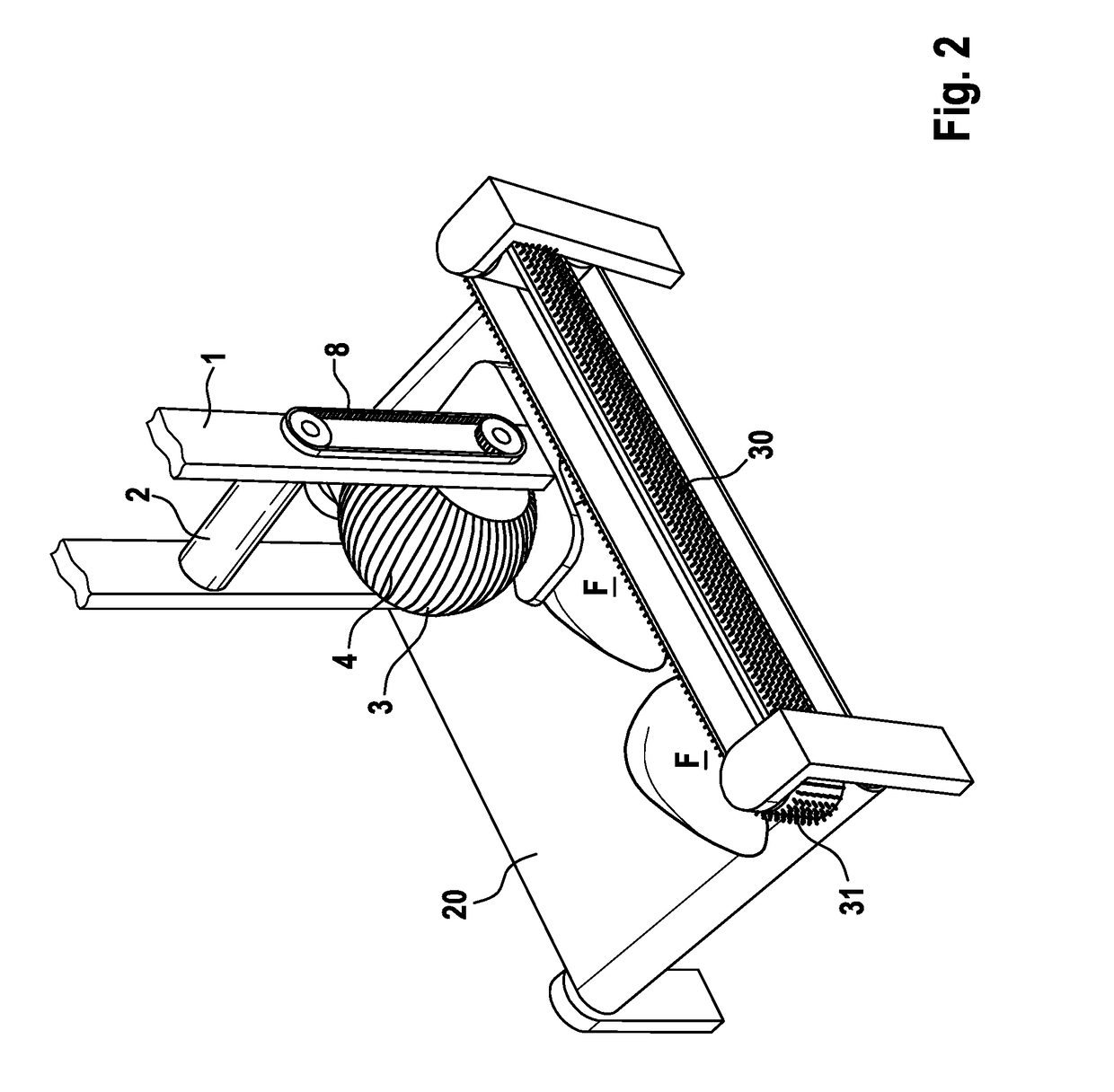

Apparatus for removing bones from fish meat

The invention relates to an apparatus for removal of pin bones from fish meat, preferably from a fillet of white fish, comprising a frame for supporting a drive device and a rotatably driven member driven by drive device, the rotatably driven member being provided with engagement means, and a counter pressure element for providing a clamping function between the counter pressure element and the rotatably driven element. The rotatably driven member has a curved convex engagement surface directed towards the fillet and adapted to match the shape of said fillet where the pin bones are located when the fillet is lying on a flat surface.

Owner:NORDISCHER MASCHINENBAU RUD BAADER GMBH CO KG

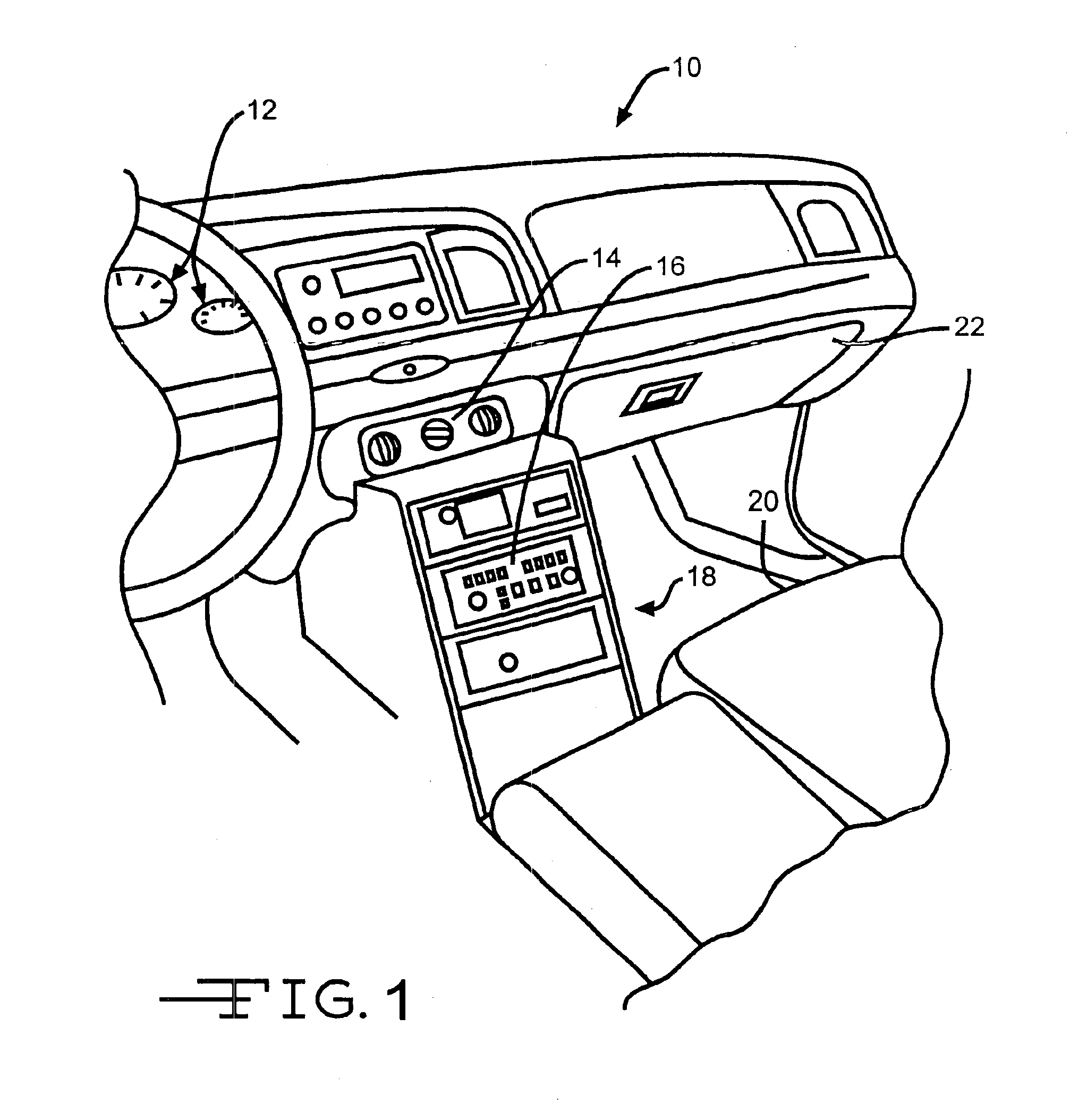

One piece vehicle storage compartment

A vehicle storage compartment includes a door with an interior face and exterior face. The exterior face of the door faces the interior of a vehicle. The vehicle storage compartment also includes a panel connected to the door, wherein the panel and the interior face of the door define a bin for the storage of goods. The panel is integrally formed with the door in a molding operation to form a single component. The vehicle storage compartment door and bin wherein are integrally formed by a counter-pressure molding process such that cell structures are formed in an interior of walls forming the door and the panel.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

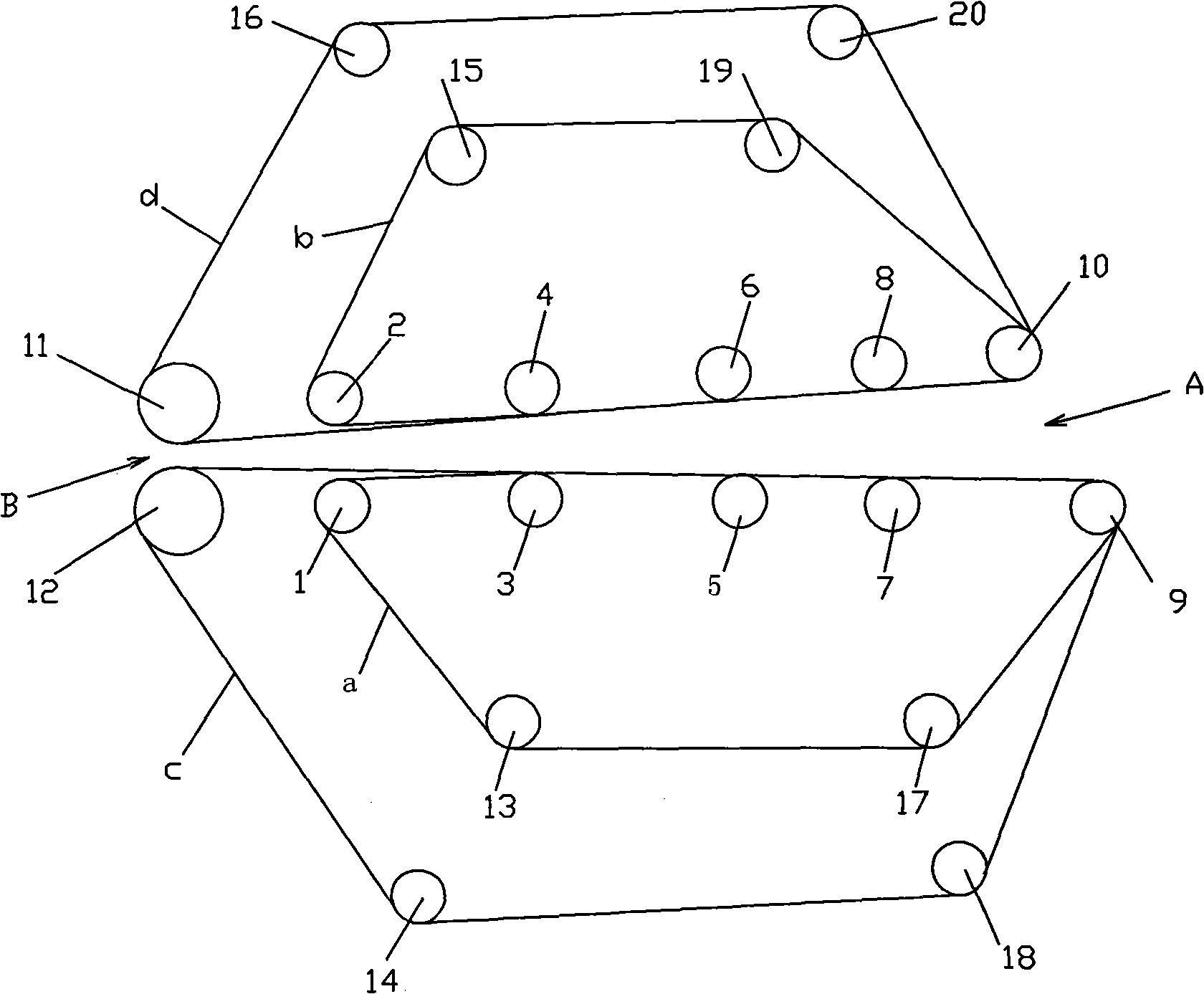

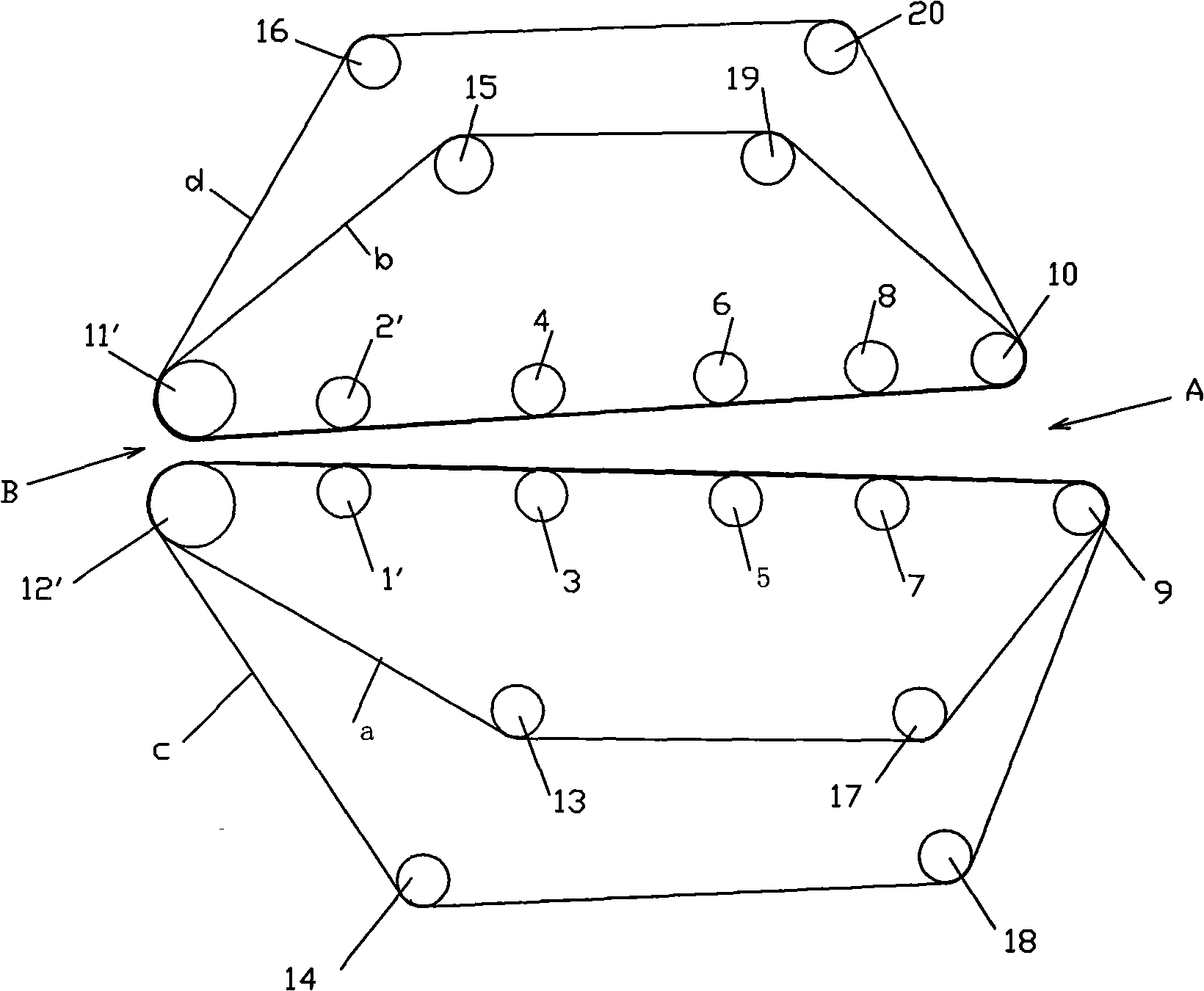

Triangular belt type filter press

InactiveCN101279163AReasonable structureDesign sciencePressesMoving filtering element filtersCounter pressureEngineering

The invention discloses a wedge-shaped draper-type press filter which consists essentially of a chassis, a pressing area, a driving device, a feeding device, a scrapper assembly, a deviation-rectifying device, a rinsing device and a water receiving device. The structure of the wedge-shaped draper-type press filter is characterized in that the pressing area is a wedge-shaped pressing area with an included angle more than zero degree but less than 15 degrees between an upper filter strip and a lower filter strip; the wedge-shaped pressing area is divided into an upper press area and a lower press area; respective tension band and filter strip of the upper press area and the lower press area are stacked and wrapped outside respective press roll in parallel; the tension band is stuck to the press roll and the filter strip is firmly stuck outside the tension band; the press rolls of two press areas are arranged in a counter pressure way. The draper-type press filter of the invention adopts a single wedge-shaped press area, changes press dehydration technique of the prior art that adopts a plurality of press rolls to enwind and operate in snaking way, realizes that the press roll operates press dehydration in a counter pressure and liner way, greatly reduces the abrasion of the filter strips caused by tension, effectively prolongs the service life of the filter strips and can reduce operation energy consumption of the press filter.

Owner:ZHEJIANG HUAZHANG TECH

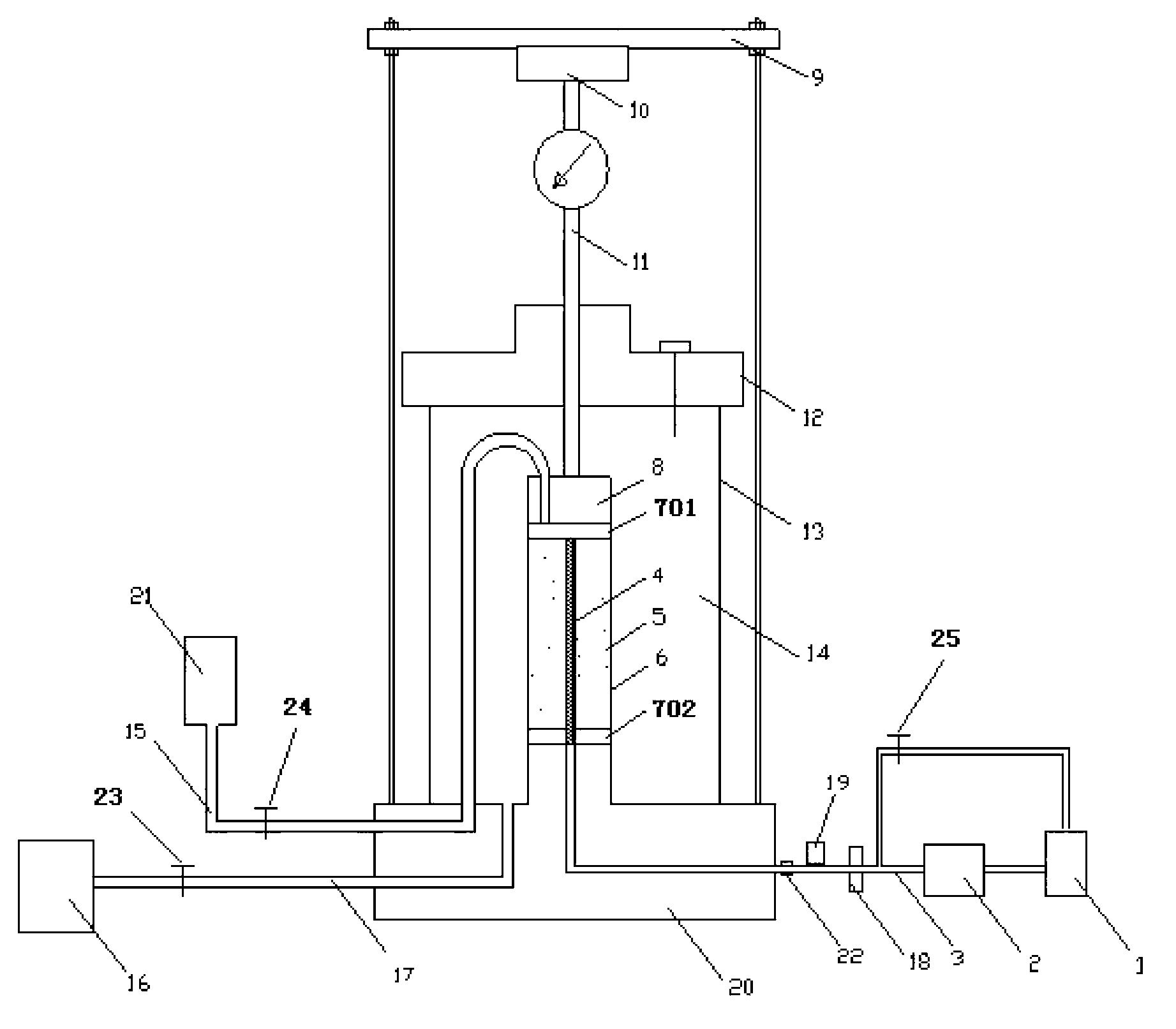

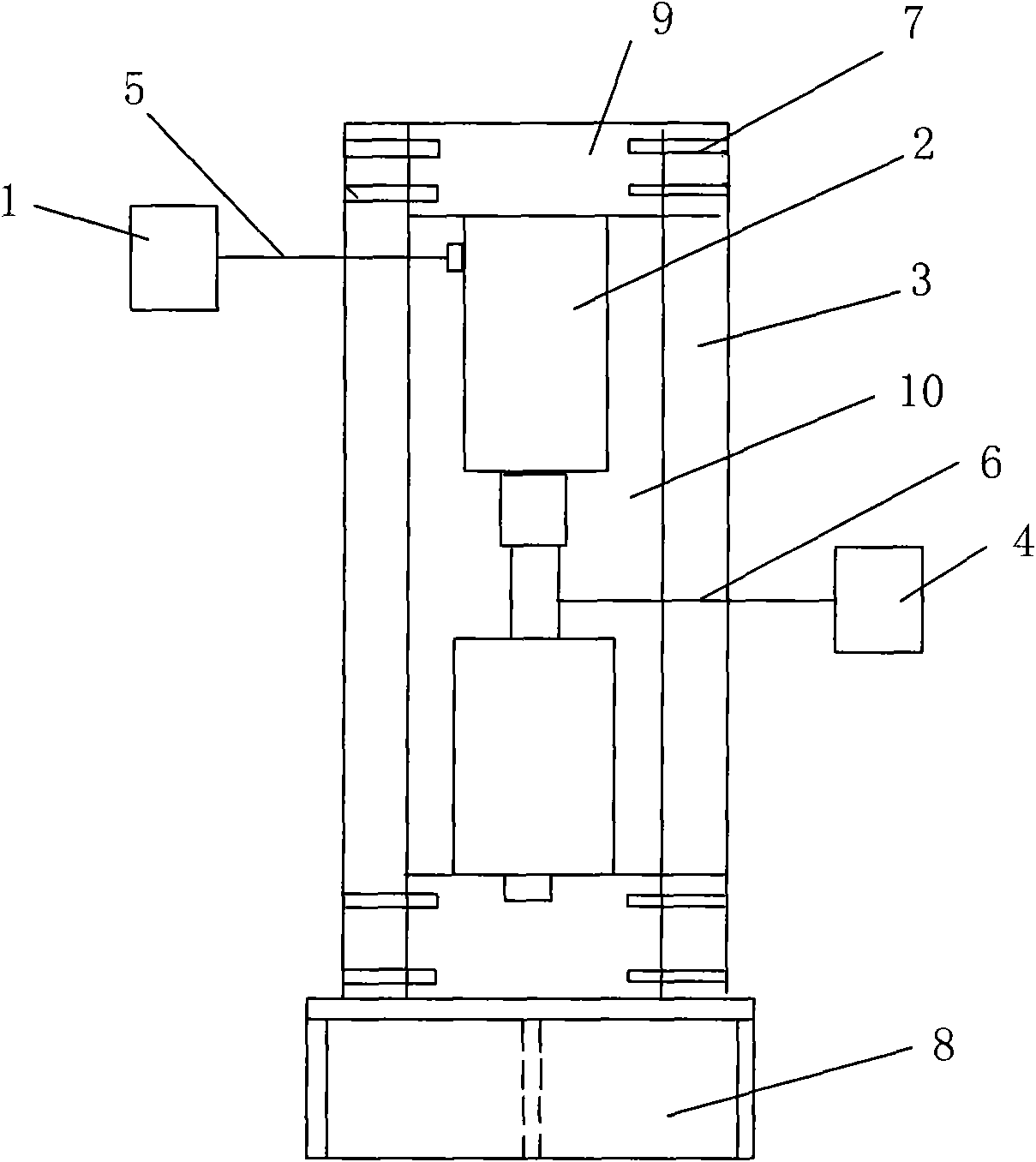

Simple creep test device of rocks and test method thereof

InactiveCN101620055AThe testing process is simpleSimple structureInvestigating material ductilityPresent methodAxial pressure

The invention relates to a simple creep test device of rocks and a test method thereof, which effectively overcome the defects of complex systems, high cost, complicated test processes and high test cost of the test device and effectively solve the problem of obtaining a stress-strain curve in uniaxial and triaxial tests of rocks. The device has the structural characteristics that a reaction frame of a test platform comprises a base and a counter-pressure strut on the base, wherein the upper part of the counter-pressure strut is provided with a top beam; the lower part of the top beam is provided with an axial pressure actuating system of specimens; the axial pressure actuating system of specimens is connected with an external hydraulic control system through an oil conveying pipe; the lower part of the axial pressure actuating system of specimens is provided with a pressure sensor; the pressure sensor is connected with an external automatic data collecting system; and the inside of the counter-pressure strut is a triaxial pressure chamber of a pressure-confined actuating system of specimens. The invention has the advantages of simple structure, novelty, peculiarity, easy operation, low cost and simple test processes, can be effectively used in uniaxial and triaxial creep tests of rocks to obtain the stress-strain curve, provides a scientific basis for engineering construction, and has significant economic and social benefits.

Owner:HENAN POLYTECHNIC UNIV

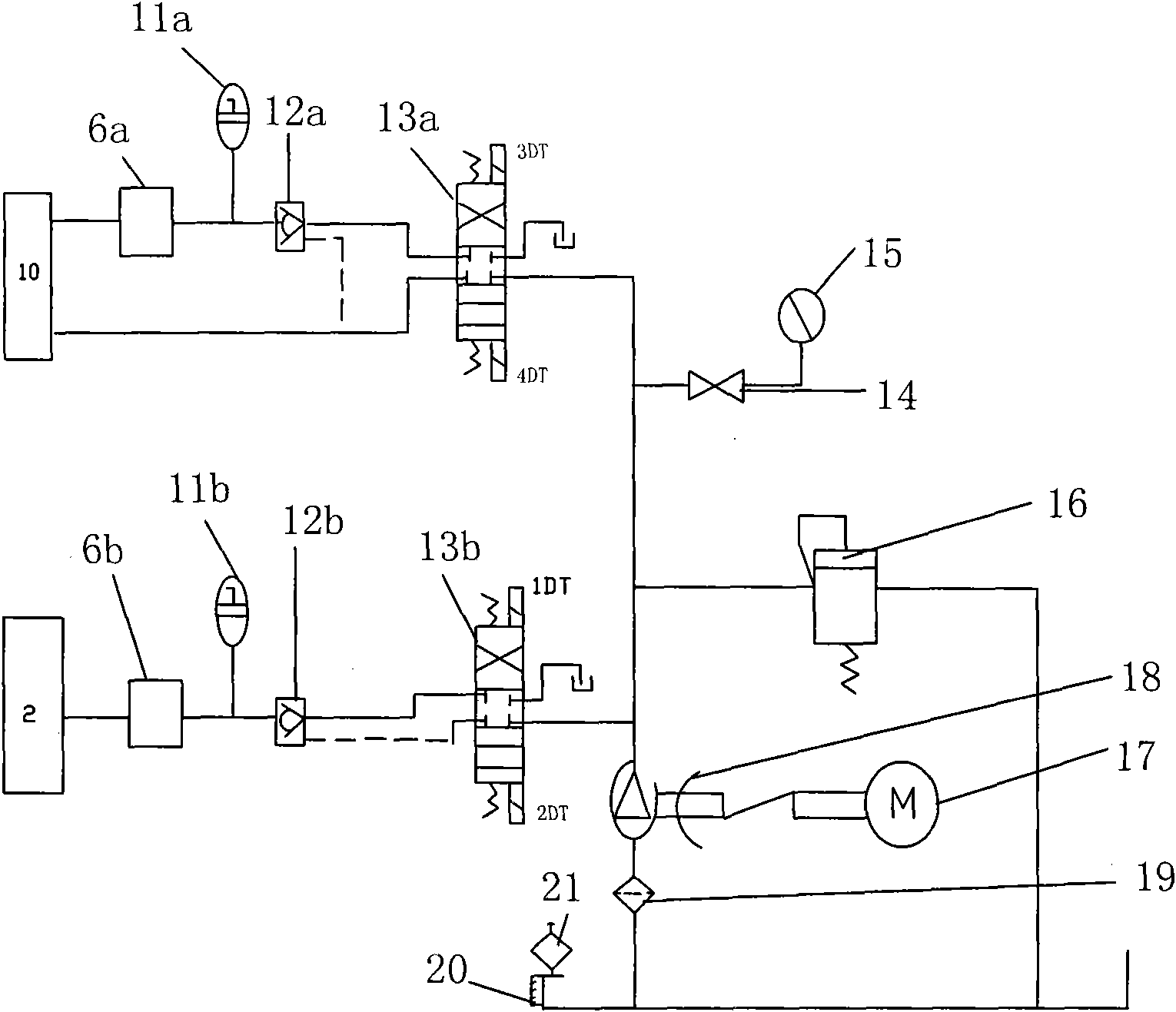

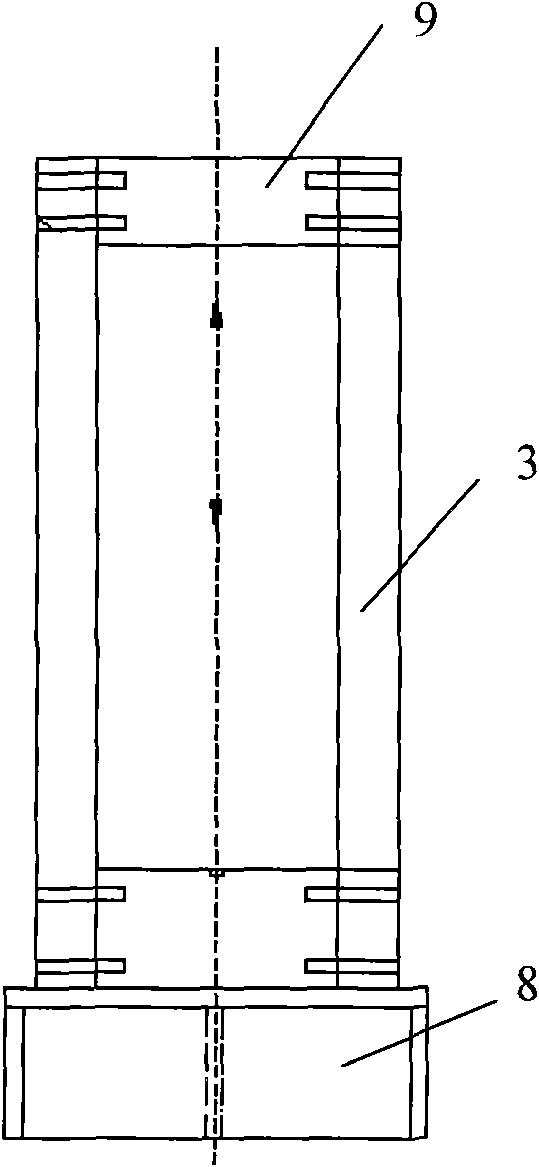

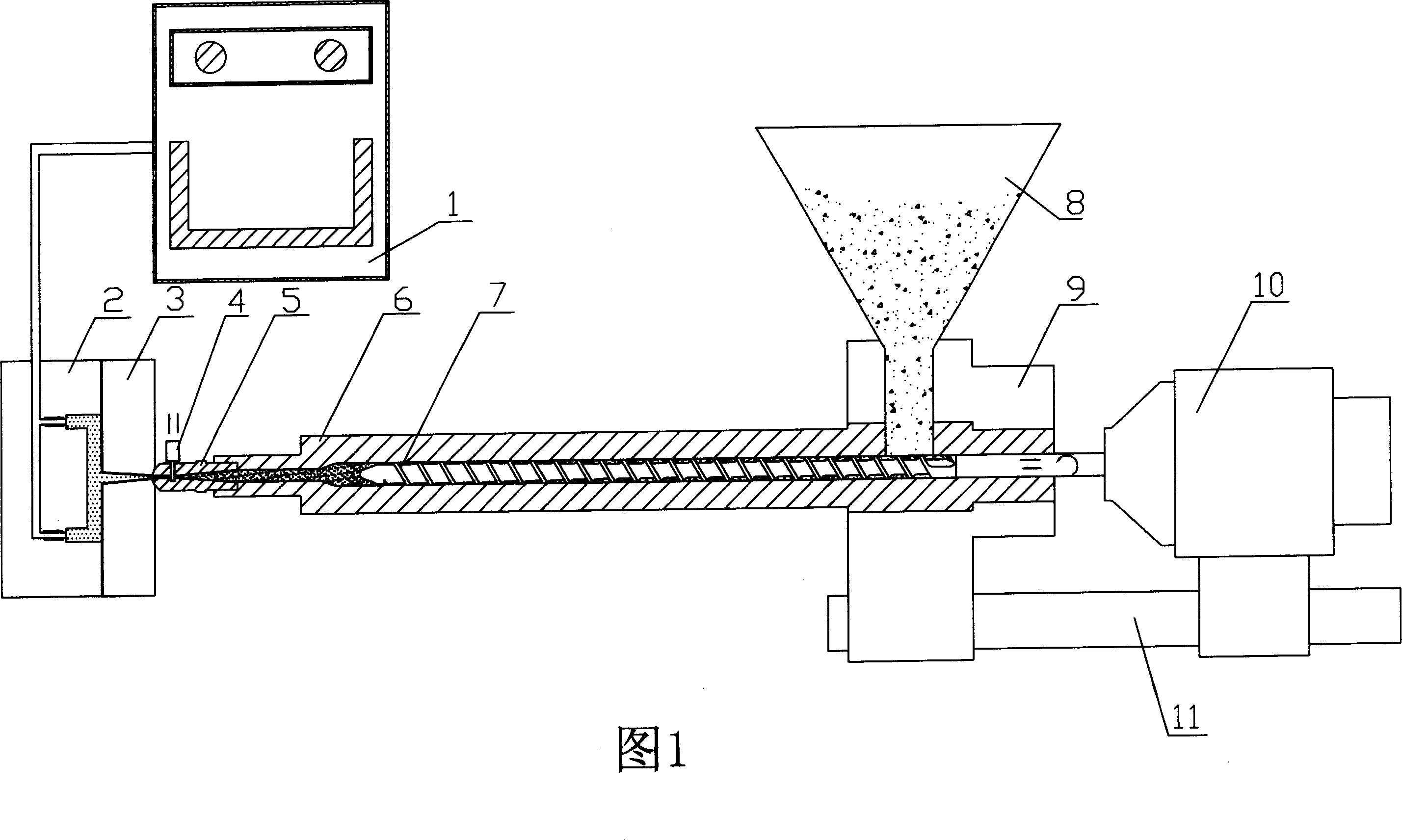

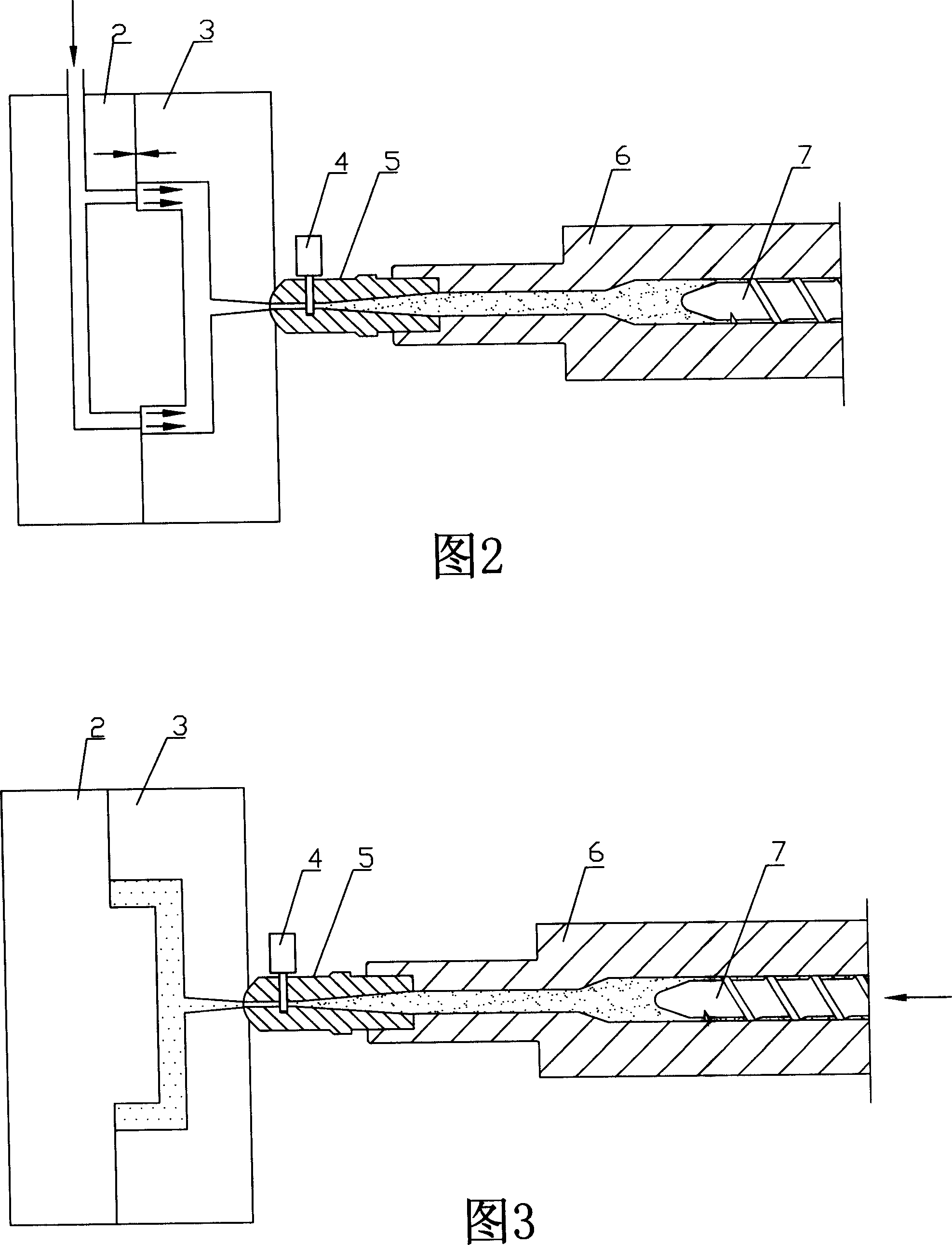

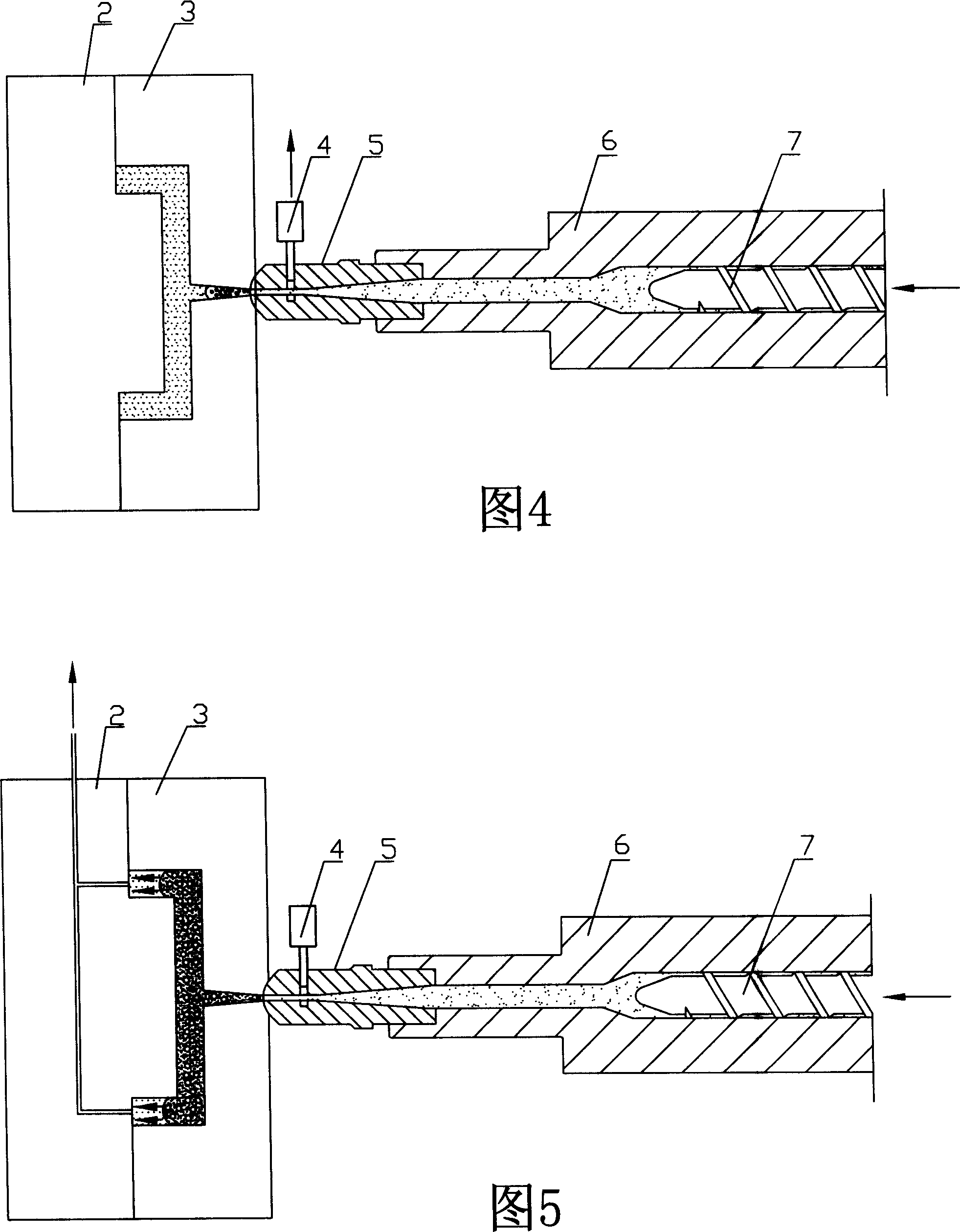

High speed injecting molding method by counter pressure method and chemical foaming method

The invention involves a counter-pressure chemical foaming high speed injection moulding shaping method. The invention provides a method which utilizes injection moulding shaping machine equipment, and dies, general gas energy, plastic raw materials and other system resources comprehensively, produces thick-wall plastic-foam product high speed and high effectively. The invention first closes the die and injects gas into die cavity, then injects molten material into die cavity, the welding fluid is full of die cavity after inner foaming, the molten material surface is closed to the metal wall-surface of die cavity, the molten material in die cavity is solidified and shaped after cooled, then opens the moving mold and static mold, the plastic products are prepared which surface is smooth and dense and inner is distributed with uniform foam. The invention can eliminate or reduce the converging cave and warping deformation of product surface, reduces injection moulding pressure, thereby reduces the lock-mode pressure of injection machine; reduces equipment operating costs, thereby improves the size accuracy and strength of products, can reduces 15% ~ 35% raw material consumption effectively, products have higher mechanical property and weight proportion.

Owner:DONGHUA MACHINERY

Counter pressure device for ophthalmic drug delivery

InactiveUS7402156B2Facilitates drug placementPreventing and minimizingSurgical instrument detailsMedical applicatorsConjunctivaReflux

A counter pressure device for ophthalmic drug delivery. The device includes a handle and a head coupled to a distal end of the handle. The head comprises a curved, concave surface for contacting the conjunctiva and having a notch for removably receiving a cannula. The device minimizes or prevents drug reflux and facilitates drug placement during ophthalmic drug delivery.

Owner:NOVARTIS AG

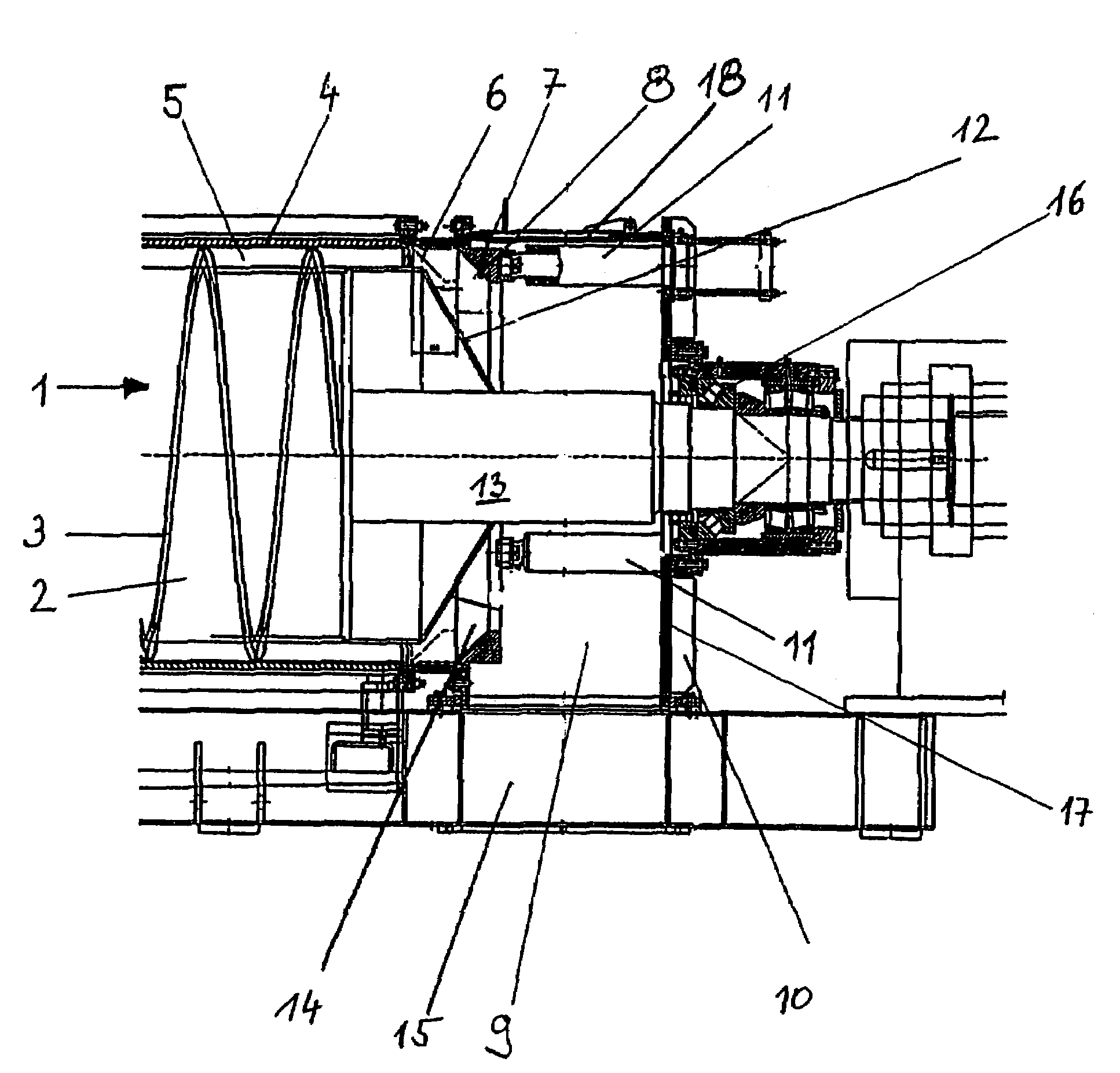

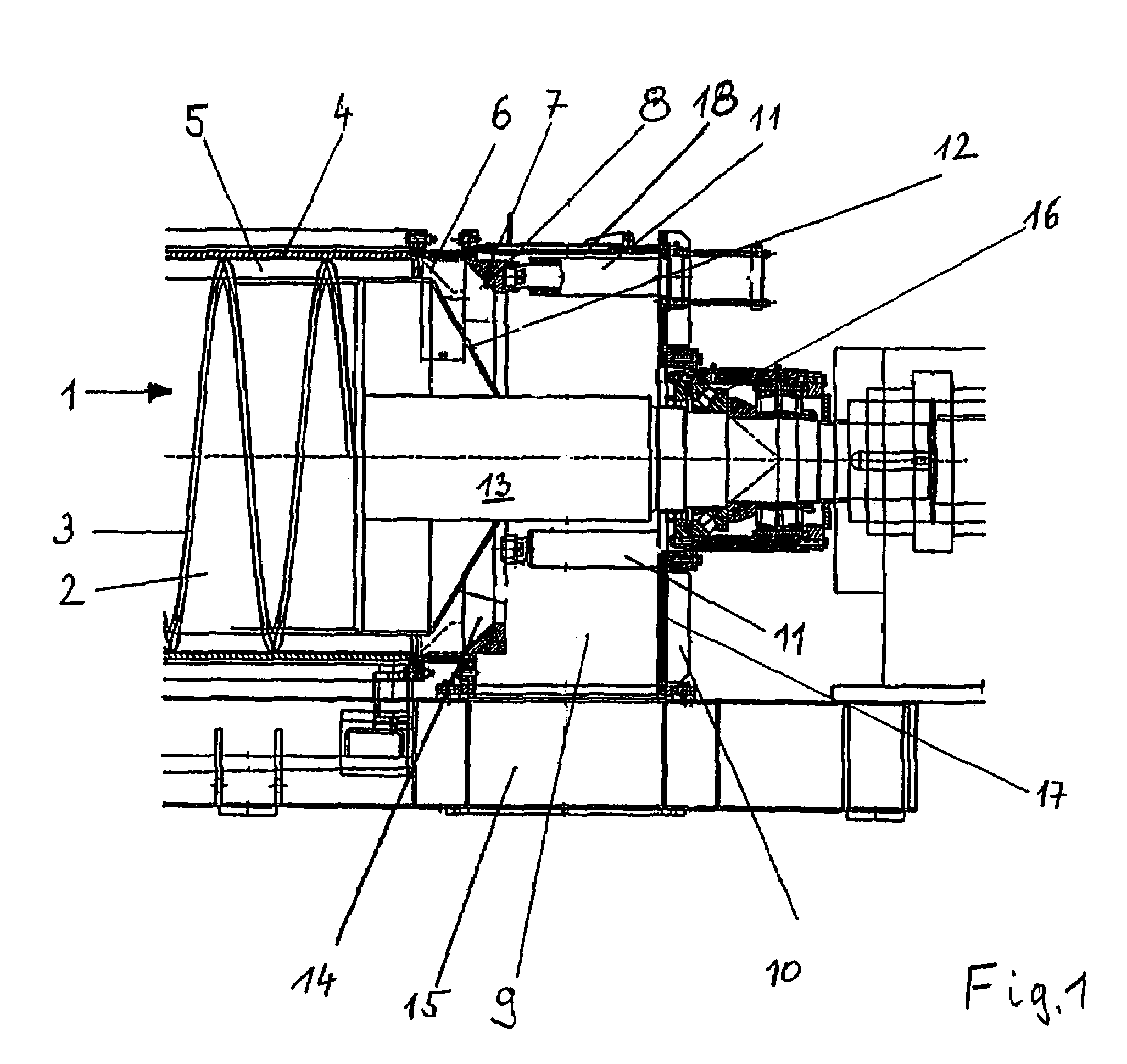

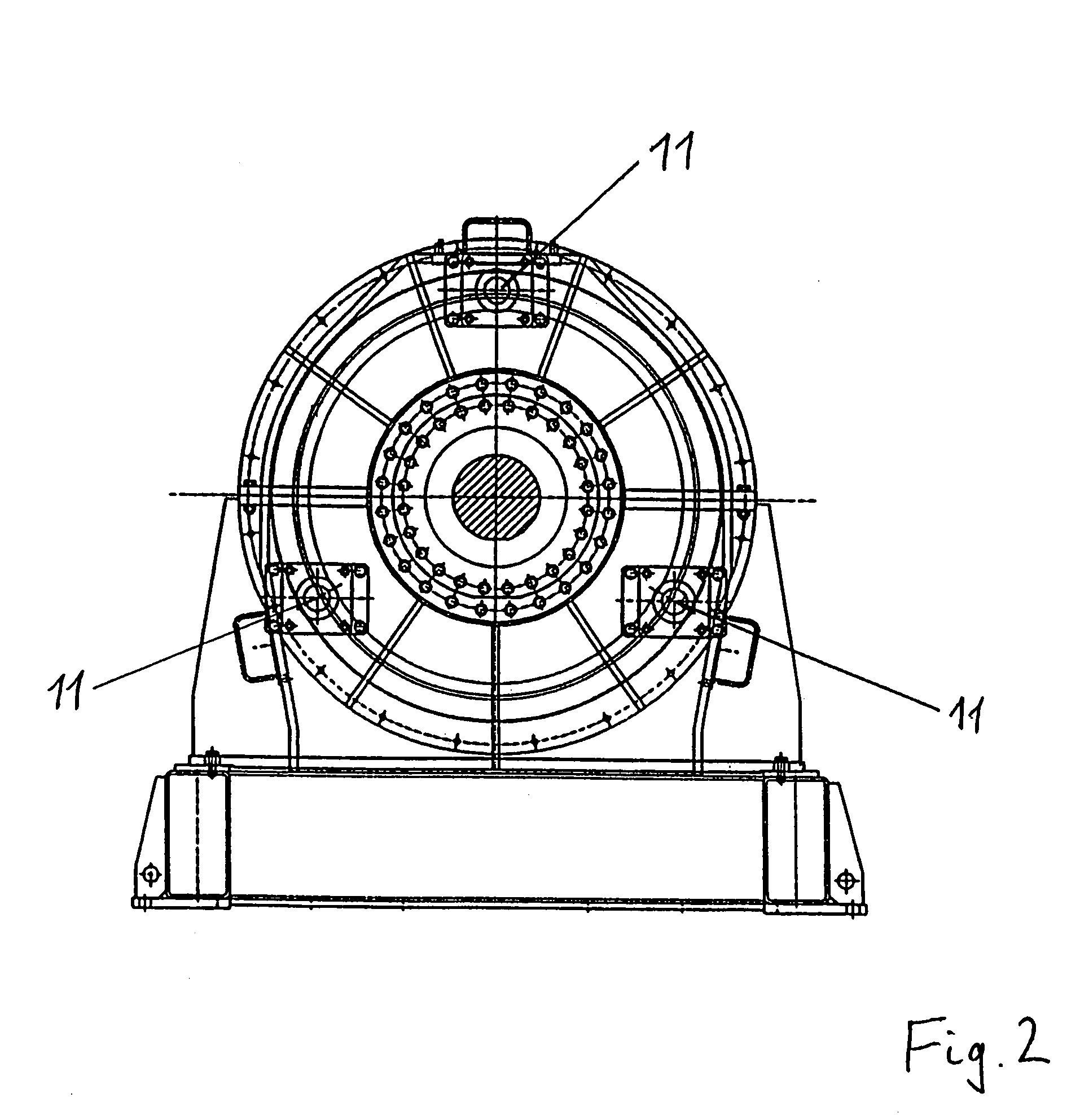

Screw press for separation of liquid from solid-liquid mixtures especially pulp suspensions

Screw press for separation of liquid from solid liquid mixtures, especially pulp suspensions, with a casing with perforations for liquid and a screw shaft provided in it between which a circular gap is formed through which the solid liquid mixture is pressed. Furthermore, a counter pressure device in the area of the discharge end of the circular gap is provided. To reduce the space requirement in the discharge area at the discharge end of the circular gap, which makes it possible to reduce the size of the discharge casing and cut costs due to a less complicated design, the counter pressure device has a counter pressure surface, the radius of which is decreasing in the conveying direction of the solid liquid mixture. In this way the solid liquid mixture with the liquid largely extracted will be redirected radially inwards and outside of the counter pressure device no additional space is needed to discharge the solid liquid mixture with the liquid largely extracted, so that the discharge casing may be reduced in size correspondingly.

Owner:ANDRITZ AG

Oversized high-strength heatproof magnesium alloy ingot blank semicontinuous casting technique

The invention relates to an oversized high-strength heatproof magnesium alloy ingot blank semicontinuous casting technique. The alloy comprises the following components by weight percent: 6-13% of Gd, 2-6% of Y, 0.3-0.8% of Zr and the balance of Mg and irremovable impurity elements. The technique comprises the steps of melting magnesium ingots, adding solvents, adding alloy elements, refining, degassing, removing impurities, preserving heat and standing, and semicontinuously casting under the low casting speed by using a counter-pressure gas fluid-guiding method at low temperature and under low cooling speed. In the invention, technique parameters such as the casting temperature, the cooling speed, the ingot pulling speed, the inner liquid level height of a crystallizer, and the like are controlled to obtain the oversized high-strength magnesium alloy ingot blank with flat and smooth surface, refining and uniform tissue and no solute segregation, and the diameter of the ingot blank is from 220 mm to 505 mm. The length of the ingot is 1000-5000 mm. The invention meets the requirements for the oversized ingot blank required by high-strength heatproof magnesium alloy materials in the fields of aerospace, information electronics, communications and transportation, and the like.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com