Sandwich panel with interior barrier

a sandwich panel and interior barrier technology, applied in the field of sandwich panel with interior barrier, can solve the problems of reducing the overall strength of the sandwich panel, reducing the amount of voids and other imperfections of certain types of skins and adhesives, and increasing the mold pressure generally has little effect, so as to reduce the effect of substantially reducing the amount of voids and other imperfections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

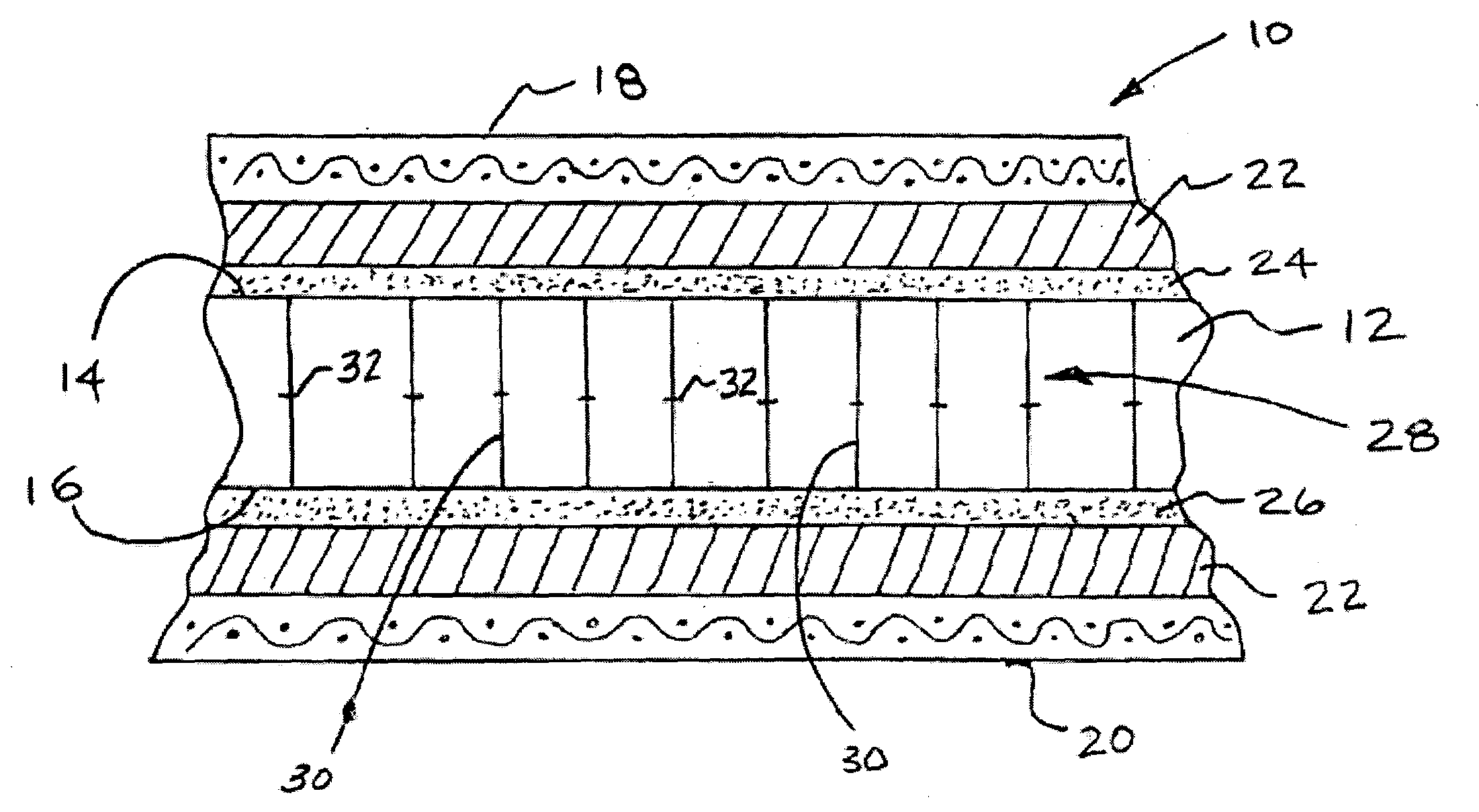

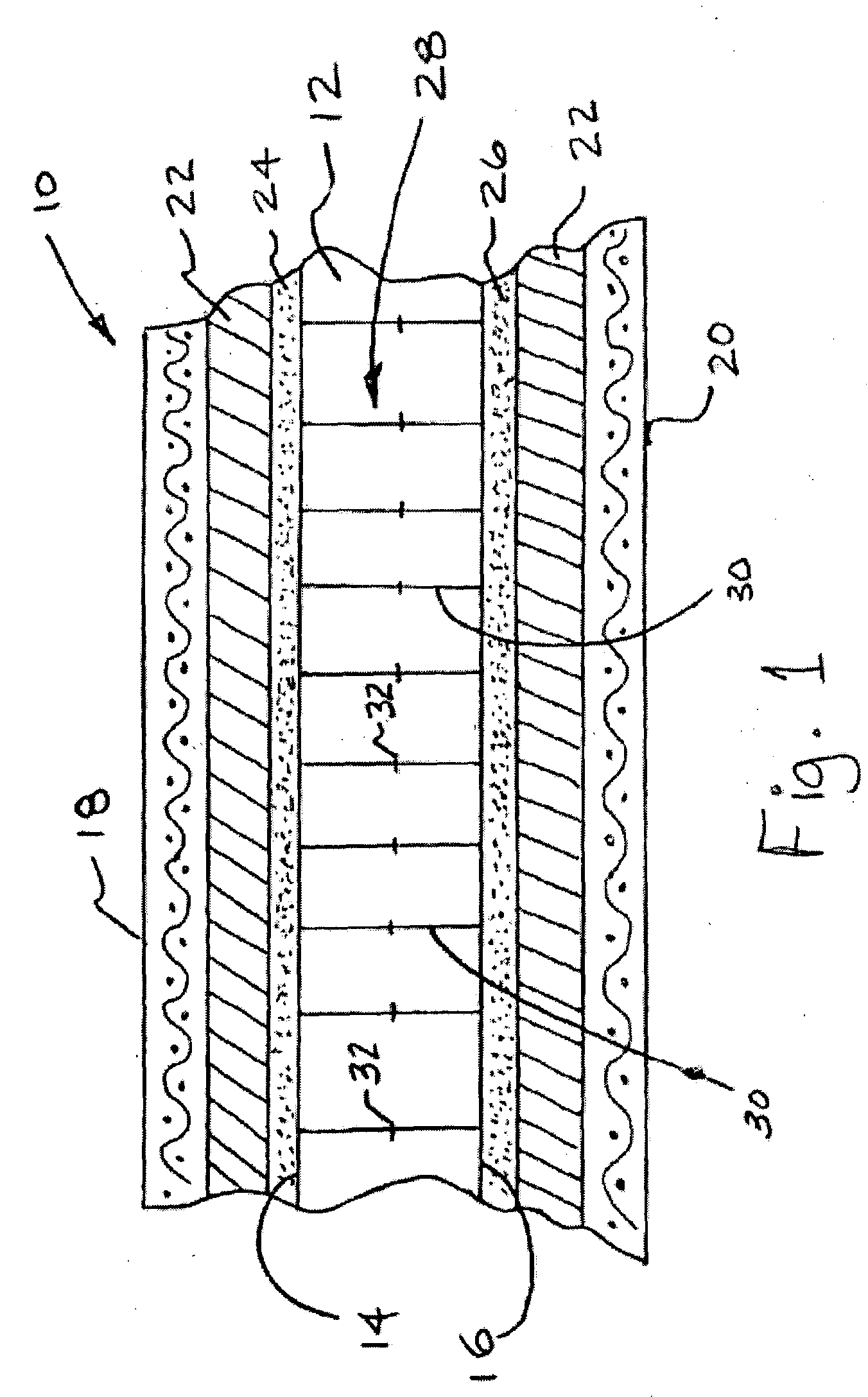

All Thermosetting Materials where Extra Adhesives are Used—FIGS. 1 and 4

[0038] A sandwich panel in accordance with the present invention was prepared using aluminum honeycomb as the core material. The honeycomb was perforated for internal ventilation and had a cell size of {fraction (1 / 2)} inch. The core was 11.5 inches long, 11.5 inches wide and 1.00 inch thick. The honeycomb was placed between two sheets of CAPRAN 526 Nylon 6 / 6 film that was 0.003 inch thick. This particular Nylon film is available from Honeywell Corp. (Buffalo, N.Y.). Each of the Nylon films was 15 inches wide and 15 inches long so that they overlapped the edges of the honeycomb. The resulting flashing of Nylon film surrounding the honeycomb was compression sealed by the clamp tonnage, to provide a chamber or bag surrounding the honeycomb. Prior to “bagging”, an epoxy adhesive was applied to the interior surface of the Nylon film. The epoxy adhesive was a 250° F. supported film adhesive such as Redux 382H or Redu...

example 2

Mismatch Thermoplastic / Thermosetting Materials, Some Adhesive Necessary—FIGS. 1 and 4

[0041] A sandwich panel in accordance with the present invention was prepared using HEXWEB prime cure aramid honeycomb as the core material. The honeycomb was not perforated for internal ventilation, as it is somewhat porous and had a cell size of {fraction (3 / 16)} inch. The core was 11.5 inches long, 11.5 inches wide and 1.00″ inch thick. The honeycomb was placed between two sheets of CAPRAN 980 Nylon 6 Film 0.003 inches thick, available from Honeywell Corp, that acts as an adhesive. CAPRAN 526 Nylon 6 / 6 film that was 0.003 inch thick by 15 inches wide and 15 inches long overlapping the edges of the honeycomb and adhesive films forms the barrier. The resulting flashing of Nylon film surrounding the honeycomb is sealed by the clamp tonnage, to provide a chamber or bag surrounding the honeycomb.

[0042] TOWFLEX TFFEG 682 2×2 N6:30% Nylon 6 / E Glass prepreg skins (available from Hexcel Corp.) were appli...

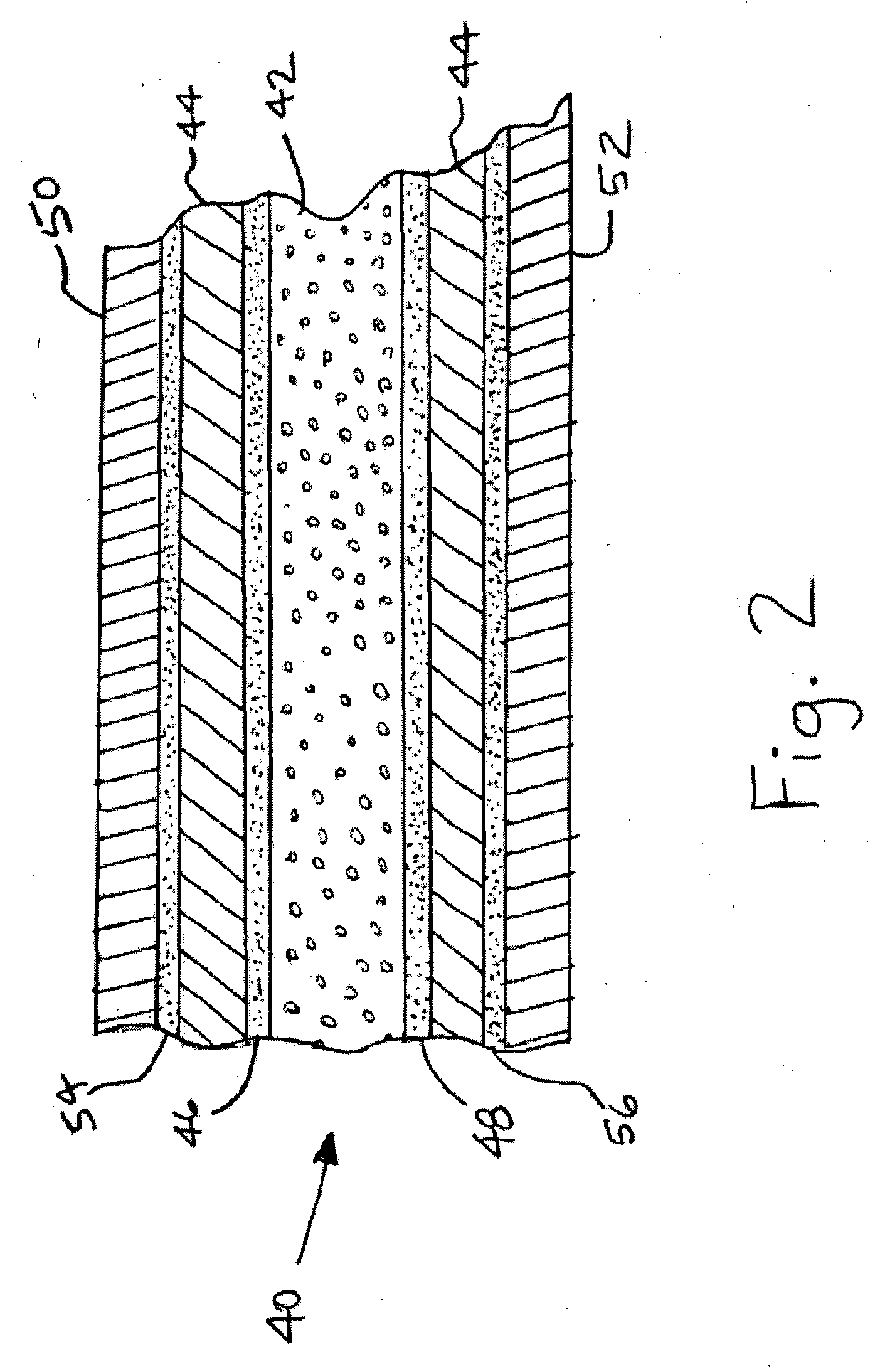

example 3

All Mismatched Thermoplastics where Adhesives are Necessary and Surfacing Film—FIG. 6

[0044] A sandwich panel in accordance with the present invention was prepared using HEXWEB EM polyester / nylon honeycomb as the core material. The honeycomb is porous and had a cell size of {fraction (3 / 8)} inch. The core was 11.5 inches long, 11.5 inches wide and 1.00″ inch thick. The honeycomb was placed between two sheets of 0.002 inches thick Polyolefin Film that acts as an adhesive (available from Bemis, Shirley, Mass.). CAPRAN 526 Nylon 6 / 6 film that was 0.003 inch thick by 15 inches wide and 15 inches long overlapping the edges of the honeycomb and adhesive films forms the barrier. The resulting flashing of Nylon film surrounding the honeycomb is sealed by the clamp tonnage, to provide a chamber or bag surrounding the honeycomb. Again two layers of Polyolefin film acting as adhesive are placed on either side of the assembly. These adhesive layers may be necessary when the various polymeric com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| external pressure | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com