Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

191results about How to "Short molding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Curing composition for forming a heat-conductive sheet, heat-conductive sheet, production thereof and heat sink structure

InactiveUS6517744B1High heat conductivityImprove adhesionNon-metal conductorsConductive materialFiberCarbon fibers

A heat-conductive sheet comprising a cured or semi-cured binder wherein a carbon fiber is orientated in the direction of the thickness of the heat-conductive sheet. This heat-conductive sheet exhibits a high anisotropic heat conductivity along the direction of the thickness thereof to thereby enable efficiently releasing heat from a heating element such as a semiconductor element or semiconductor package. Moreover, the heat-conductive sheet is excellent in not only heat resistance, durability and mechanical strength but also adherence to the heating element.

Owner:JSR CORPORATIOON

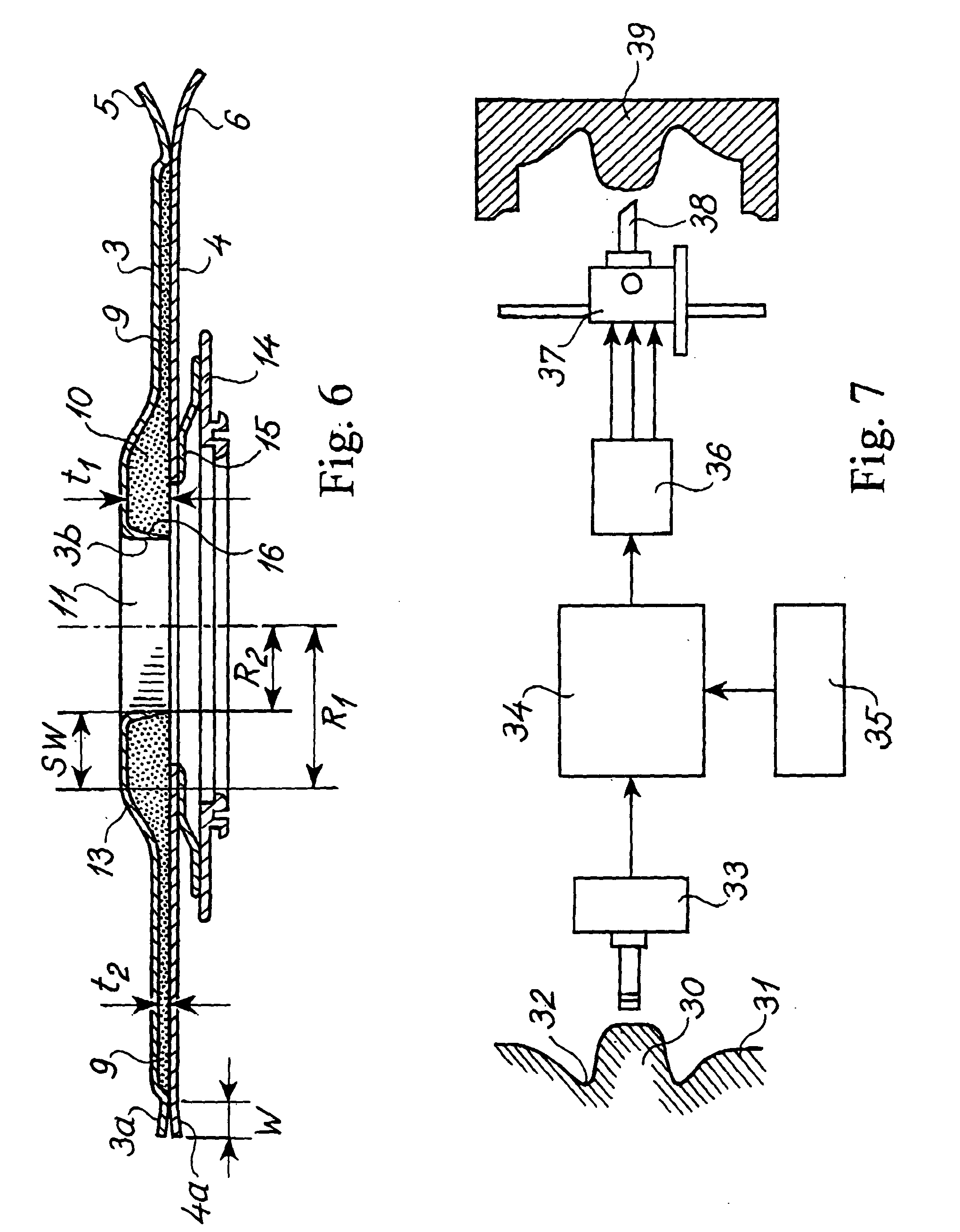

Method of manufacturing soft convex adhesive wafer

InactiveUS20040106908A1Improve sealingShort molding timeNon-surgical orthopedic devicesColostomyCounter pressurePeristomal Skin

Owner:HOLLISTER INCORPORAED

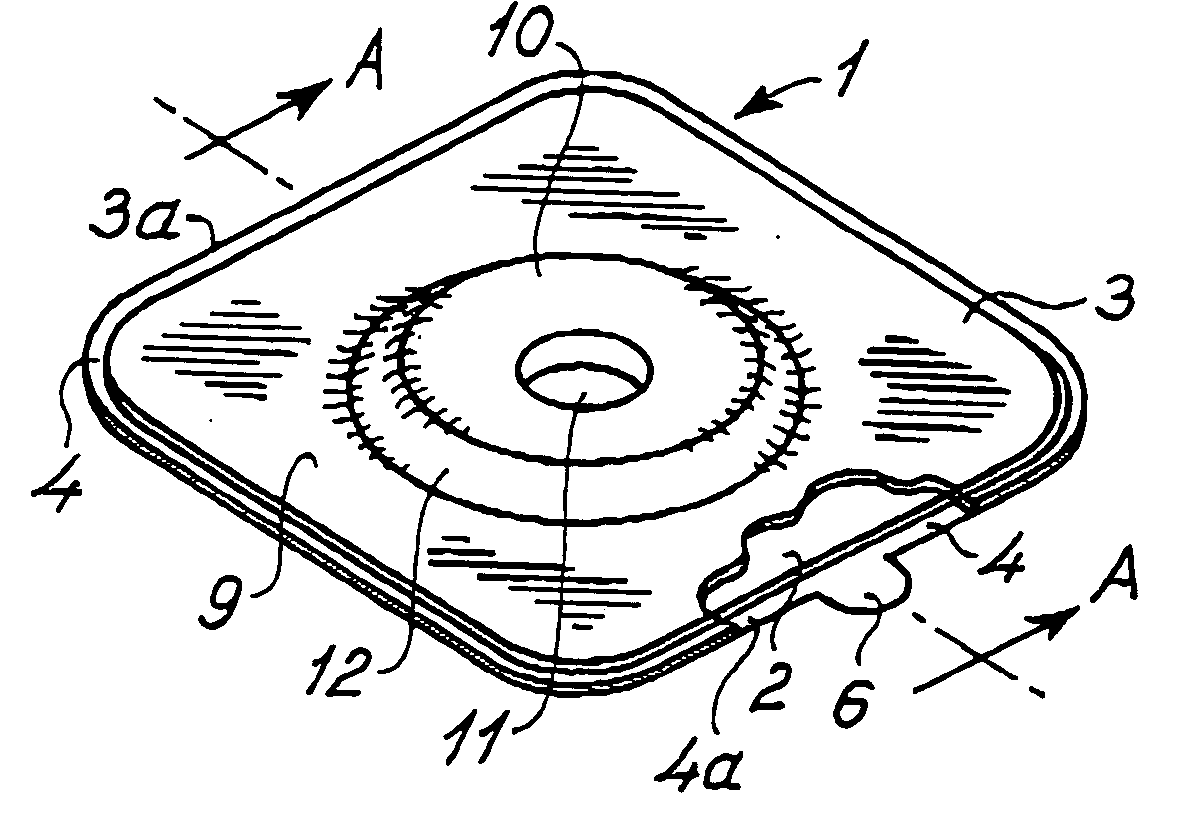

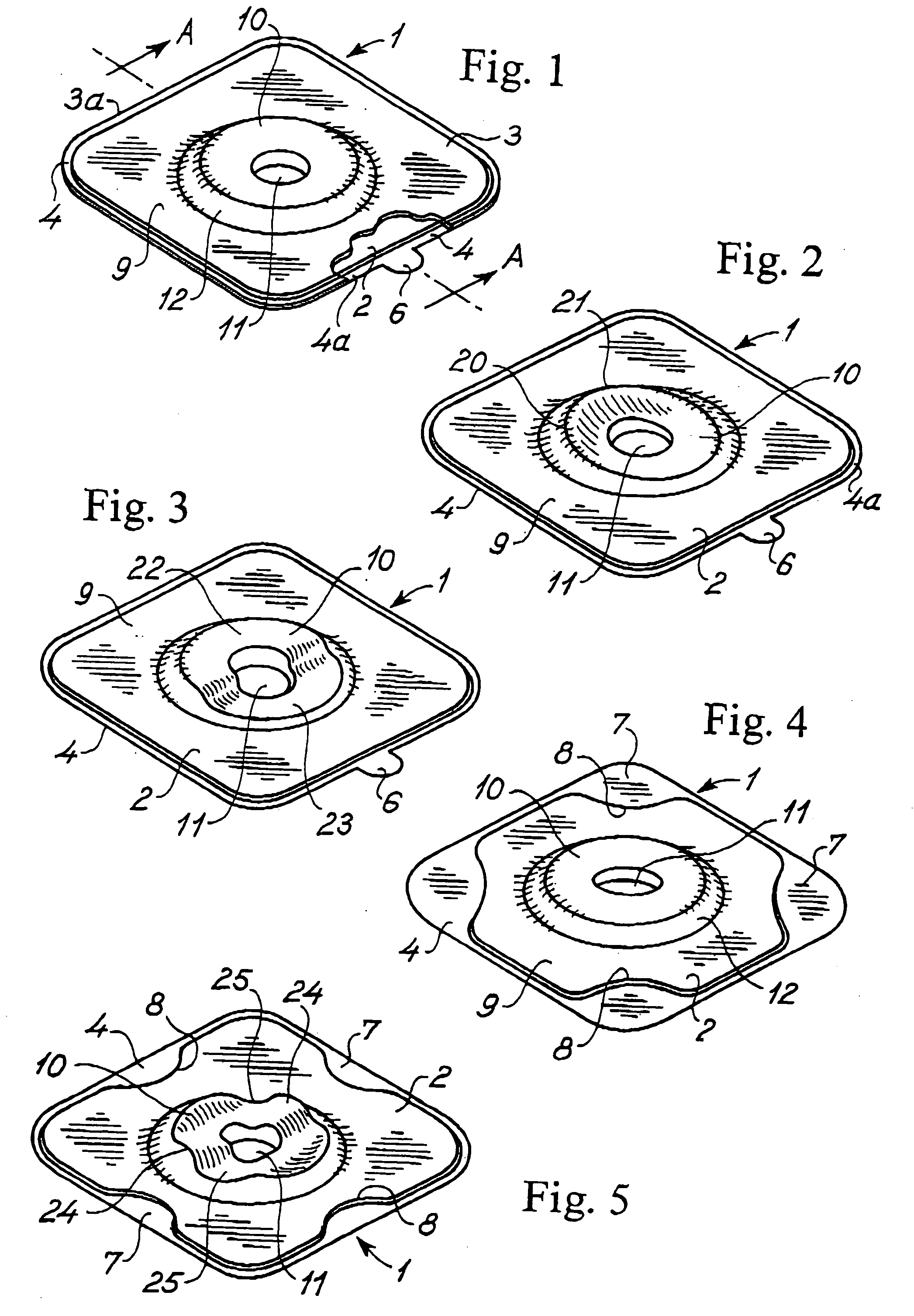

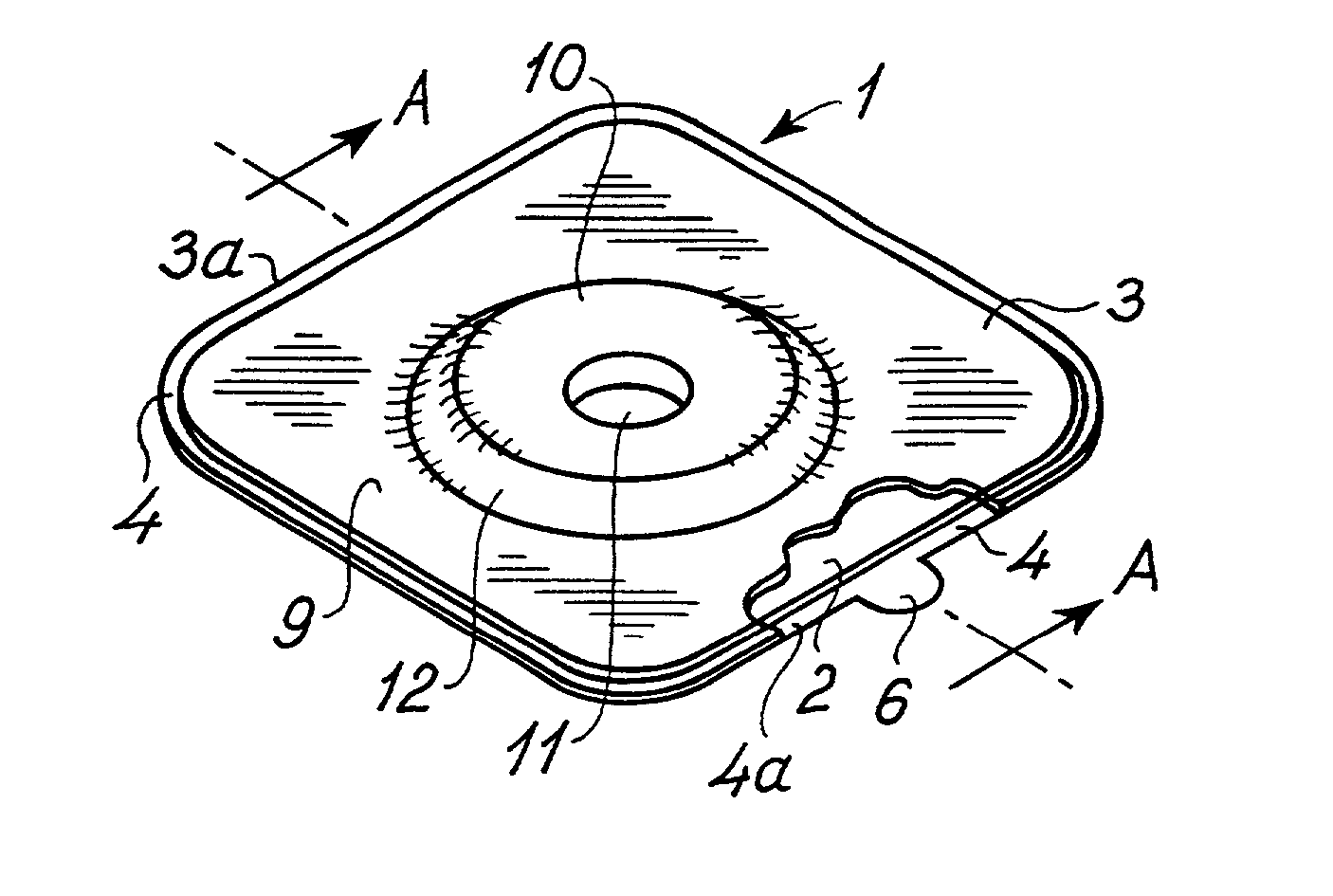

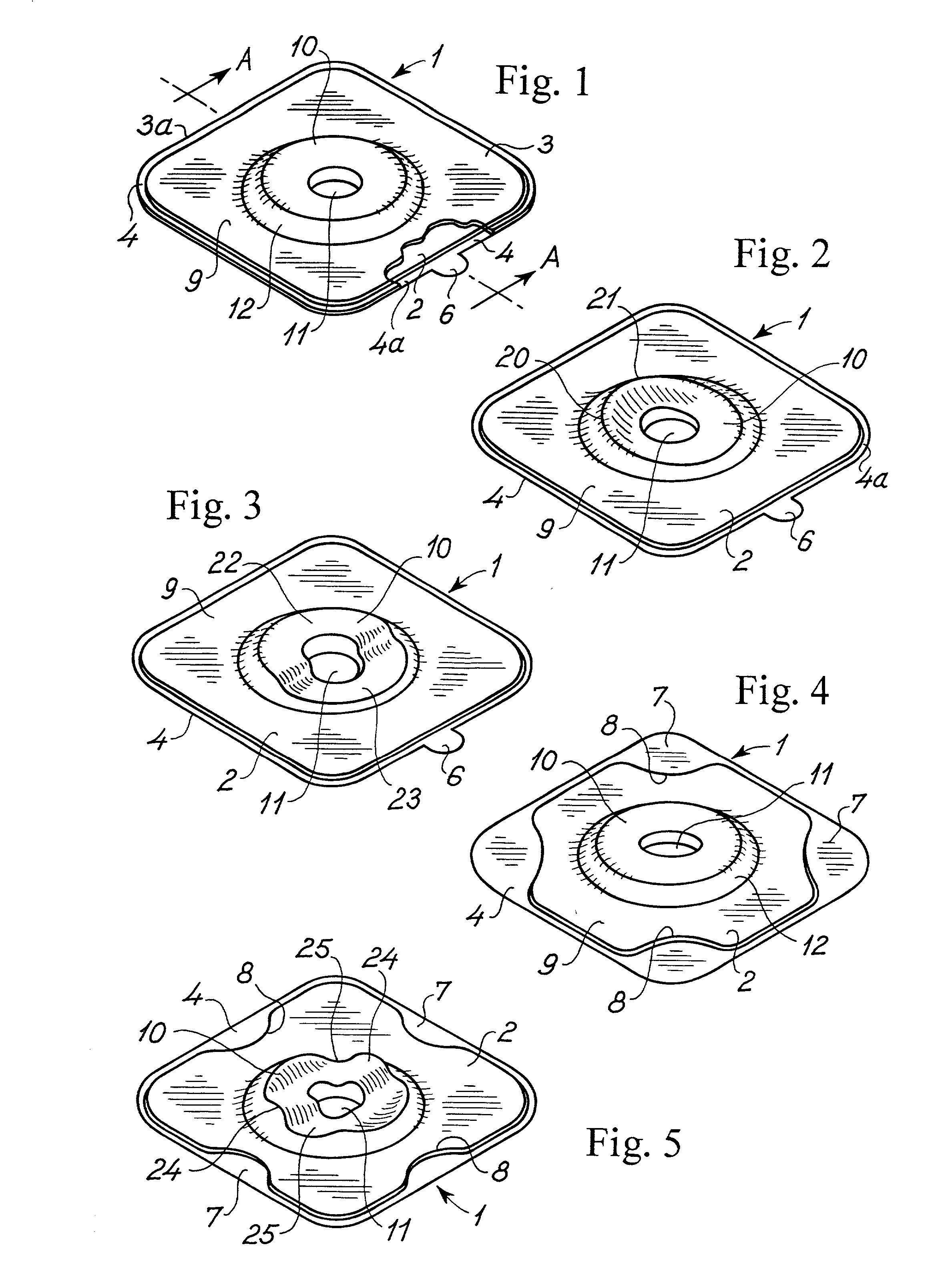

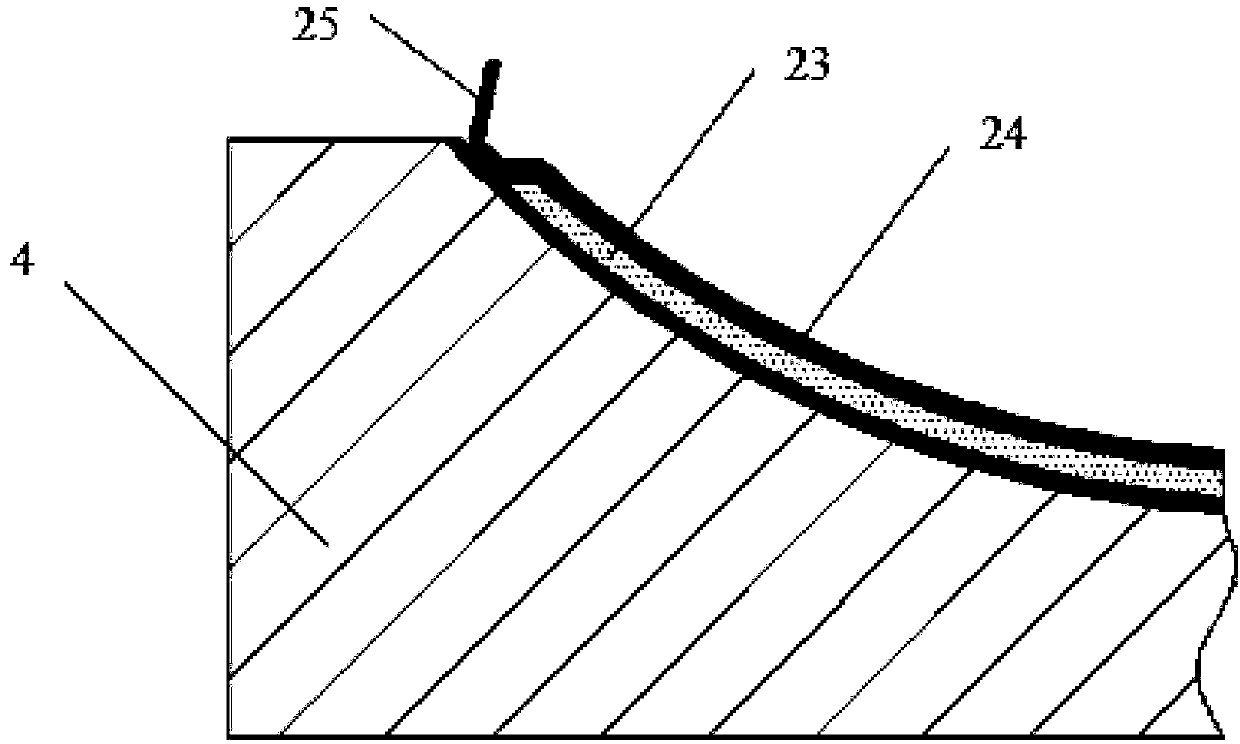

Soft convex adhesive wafer

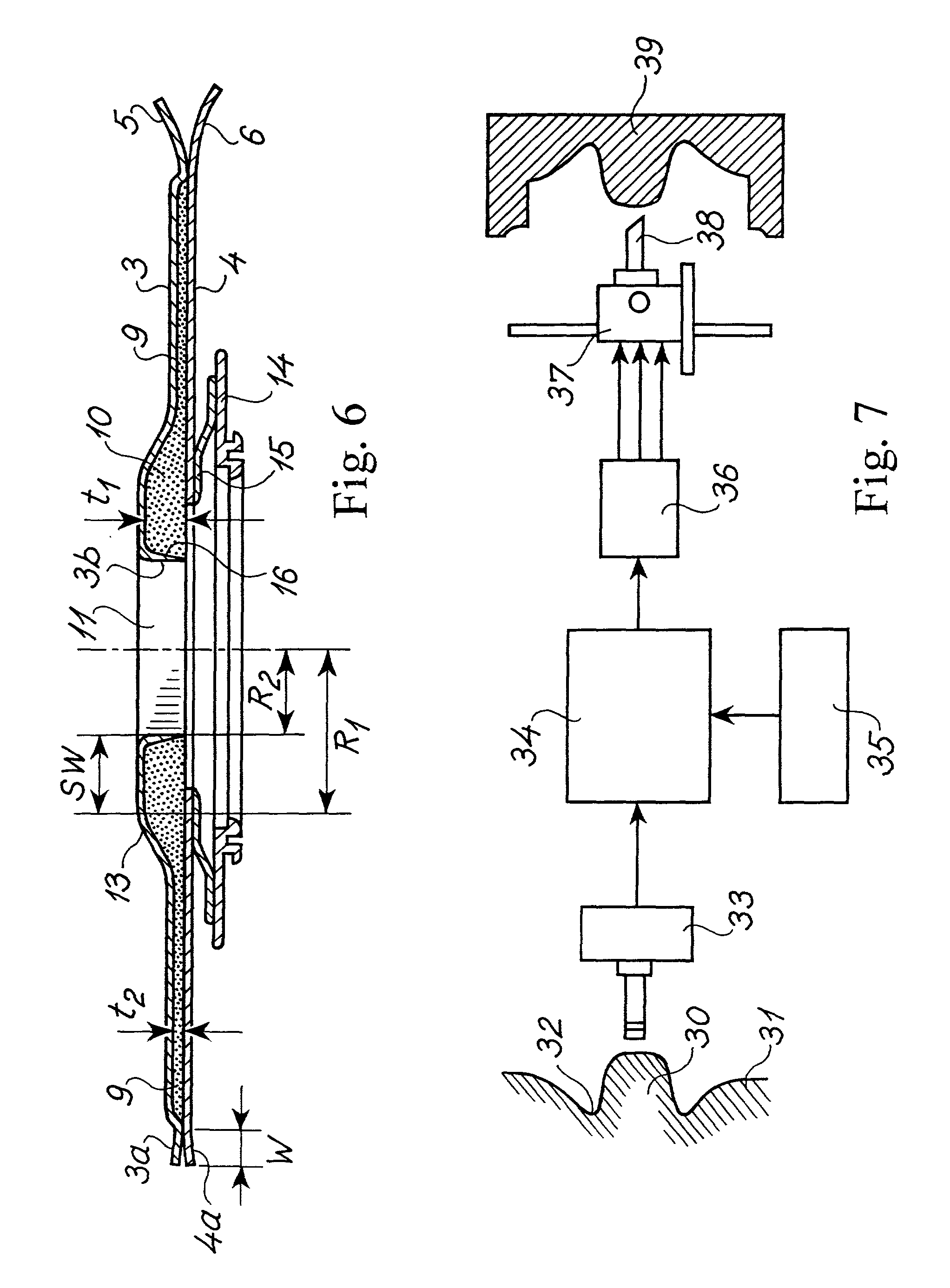

InactiveUS20030171737A1Improve sealingShort molding timeLayered productsNon-surgical orthopedic devicesOstomy appliancesEngineering

An adhesive wafer for attaching an ostomy appliance to a peristomal skin surface surrounding a stoma has an integrally molded adhesive layer made of a skin barrier material, a distal surface covered by a flexible backing layer, and a proximal bodyside surface contoured so the adhesive layer has a thin peripheral portion and thick central portion surrounding a stoma-receiving aperture. A set of at least two wafers is provided in one embodiment, wherein individual wafers have differing central portion surface topography, and different stoma receiving apertures. To produce a closely fitting wafer for a given stoma, a method of producing wafers includes providing a representation of the topography of the peristomal surface and the stoma, and, using the representation, manufacturing a mold having a surface configuration substantially matching the topography of the peristomal surface and stoma.

Owner:HOLLISTER INCORPORAED

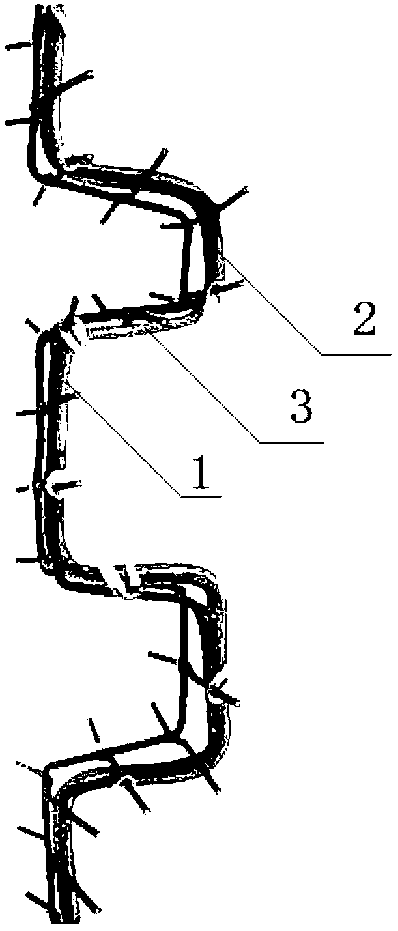

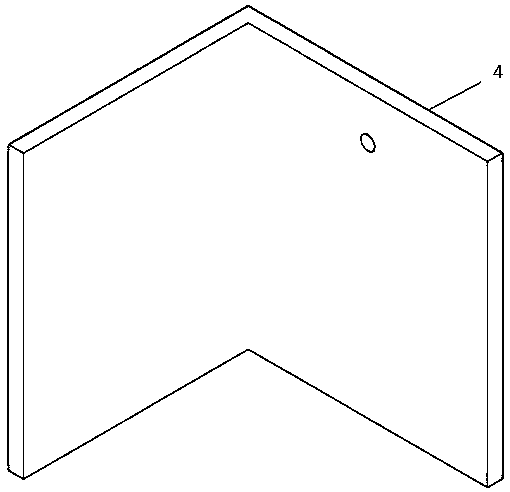

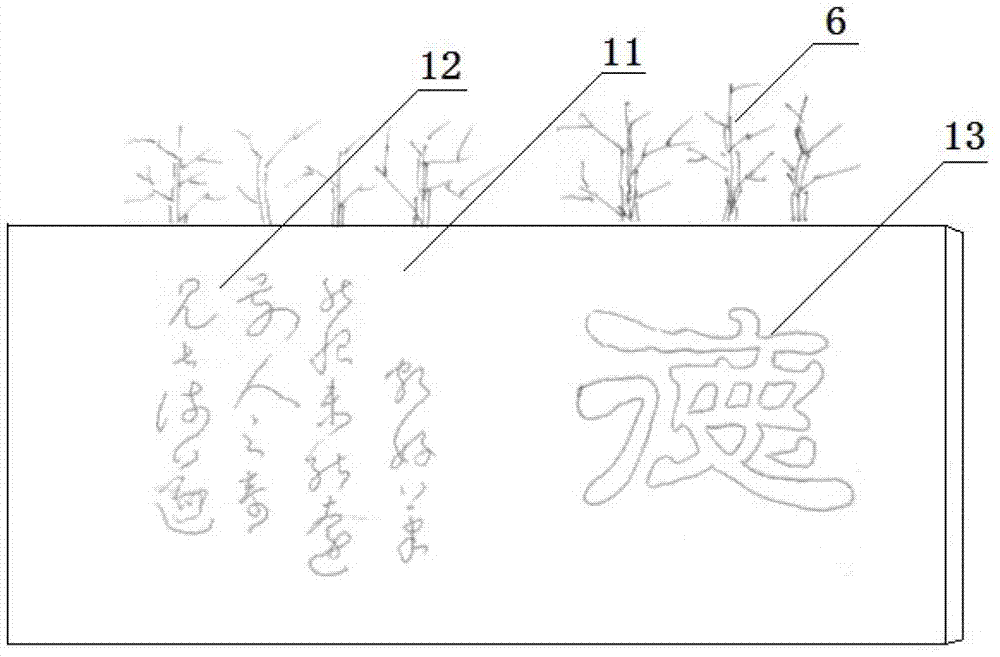

Bow-type cultivation trunk molding method of lythraceae lagerstroemia trunks

The invention discloses a bow-type cultivation trunk molding method of lythraceae lagerstroemia trunks. The method mainly includes the following steps: (1) designing trunk molds, deconstructing the molds into single-plant technical atlases, and selecting a planting bed for cultivating nursery-grown plants; (2) manufacturing and installing a supporting net frame in the planting bed; (3) manufacturing and installing a bow-shaped cultivation trunk molding ladder frame on the supporting frame; (4) carrying out bud fixing and bud picking on the nursery-grown plants; (5) binding and fixing twigs on the bow-shaped cultivation trunk molding ladder frame; (6) unbinding and exchanging binding objects which are not beneficial for trunk growth; (7) carrying out multi-point nurse grafts on the bow-shaped trunks according to molding design; and (8) cultivating in a healing mode, constructing crowns, the trunks and branches, and forming the target molds. The bow-type cultivation trunk molding method of the lythraceae lagerstroemia trunks is creative. Moreover, the nurse grafts can be carried out on single plants of the certain number to obtain the molded trunks, molding time is shortened, and characters, patterns or three-dimensional bodies can also be molded on planes or curved surfaces of the trunks.

Owner:TONGREN MANTANGHONG AGRI TECH

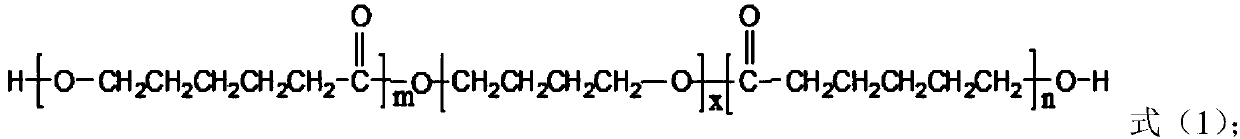

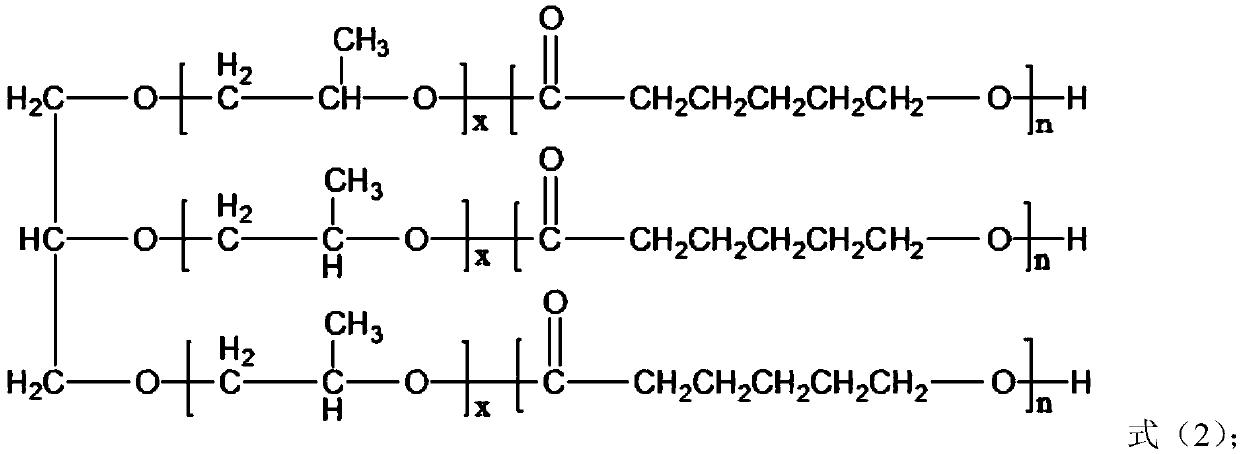

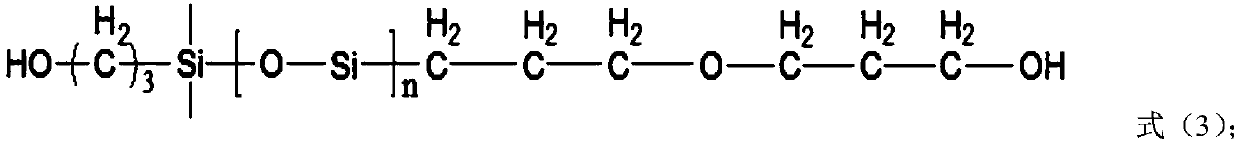

Polyurethane damping cushion with high cold resistance and preparation method thereof

ActiveCN107602817ADisruption of regularityImprove low temperature performanceSide reactionCaprolactone

The invention provides a polyurethane damping cushion with high cold resistance and a preparation method thereof. The polyurethane damping cushion is prepared in the manner of crosslinking a componentA with a component B; the component A is a polyalcohol composition and comprises the following raw materials: caprolactone modified polyether polyol, polyether polyol, hydroxyl terminated polybutadiene, primary hydroxyl terminated siloxane, a chain extender, a catalyst, a foam stabilizer and a foaming agent; the component B is NCO-terminated isocyanate prepolymer and comprises the following raw materials: caprolactone modified polyether polyol, 4,4-diphenylmethane diisocyanate and a side reaction inhibitor. The polyurethane damping cushion with high cold resistance prepared according to the invention has excellent damping property, excellent dynamic fatigue resistance and obviously improved low-temperature performance and can be applied to the field of construction of the Moscow-Kazan high-speed rails and the rails in cold areas, such as, Northern Europe and Siberia and the field of automobile damping in extreme cold areas.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

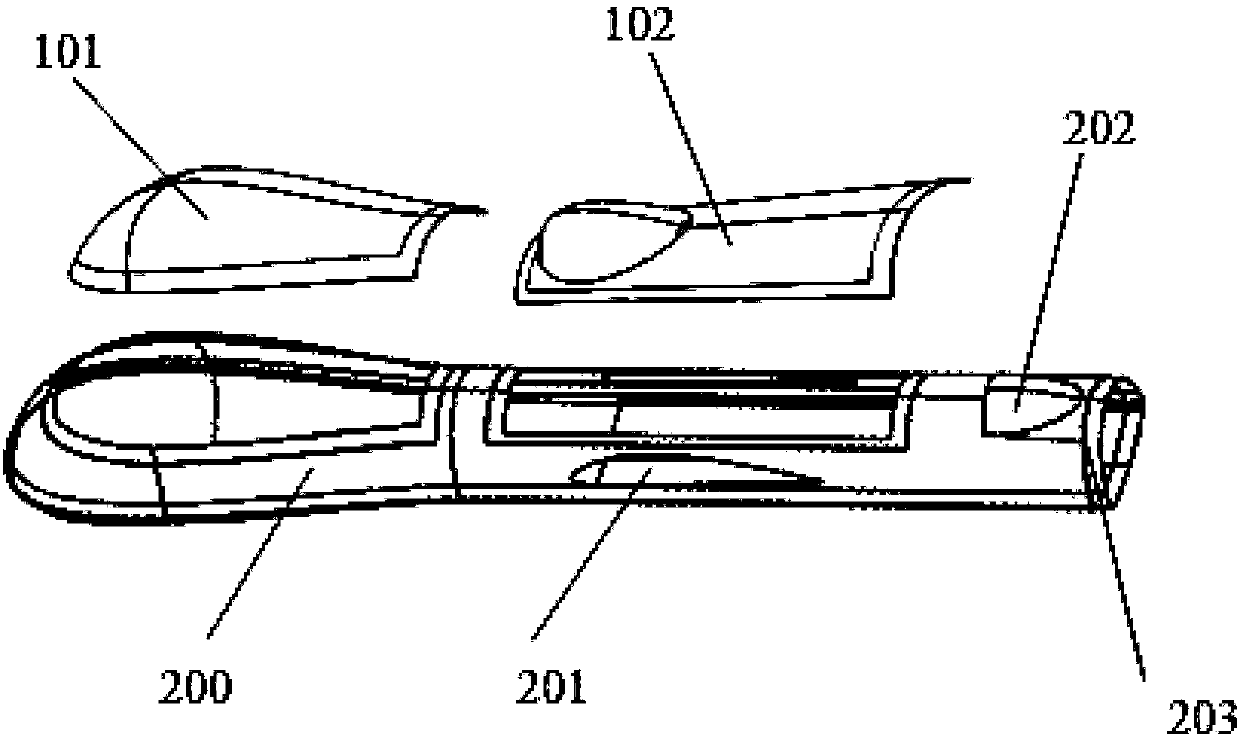

Unmanned aerial vehicle body integrated molding technology

InactiveCN107738457AImprove performanceImprove mobilityFuselage framesWeight reductionFiberCarbon fibers

The invention discloses an unmanned aerial vehicle body integrated molding technology. Carbon fiber prepreg and lightweight foam are used as raw materials, are paved on the inner wall of a double-female mold combination mold by adopting a prepreg lapping joint integral layering technology, and then are integrally solidified and molded by adopting an autoclave molding technology. The unmanned aerial vehicle body integrated molding technology has the beneficial effects that the technology is simple and is easy to operate; the molding time is short; the product size is accurate and controllable;and a manufactured unmanned aerial vehicle body has high strength, good rigidity, light dead weight and a smooth and fat surface, is easy to maintain routinely and is suitable for large batch production.

Owner:CGN JUNER NEW MATERIALS +1

Rigid pure gold ornamental article processing technology

The invention relates to a processing technology of hard gold ornaments with the purity of 99.999 percent, the processing technology consists of the following steps of: wax plate carving, wax mold opening, wax connecting, wax repairing, oiling, gold plating, wax removing and quality inspection. The technique differs from the prior art of gold plating in that: LJJAS auxiliary agent is added into an electrolyte; the electroforming temperature is 50 to 60 DEG C, the electroforming speed is 0.05g / h, the pH value of the plating solution is between 7.0 and 70.5. Therefore, the gilt produced by the technology has the advantages of uniform distribution, strong covering capability, thin plating layer, short molding time, large volume, small weight, and high hardness, and is especially applicable for the gold ornament processing industry.

Owner:SHANDONG ZHAOJIN WANZUJIN BIJOU

Method for preparing carbon fiber reinforced thermoplastic composite material

The invention discloses a method for preparing a carbon fiber reinforced thermoplastic composite material, which comprises the following steps: 1)alternatively paving carbon fiber and thermoplastic resin in a die, wherein a bottom layer and a top layer of the die are thermoplastic resin, closing the die and applying pressure; 2)accessing power supply to a carbon fiber layer, rapidly heating under current effect, when the temperature is higher than the melting point of thermoplastic resin, fusing thermoplastic resin, dipping carbon fiber under pressure; and 3)breaking power, cooling the die, and then opening the die to obtain the carbon fiber reinforced thermoplastic composite material. The method takes carbon fiber as a heat-generating body, the electrothermal conversion efficiency can reach as high as more than 90%, and the energy saving effect is obvious; simultaneously, carbon fiber is capable of melting thermoplastic resin and completing dipping, and has the advantages of short moulding time and good dipping effect, formation of good cross section of thermoplastic resin and fiber can be realized, composite material performance is increased, and processing of product with large thickness can be realized in short time.

Owner:蓝星纤维(北京)有限公司

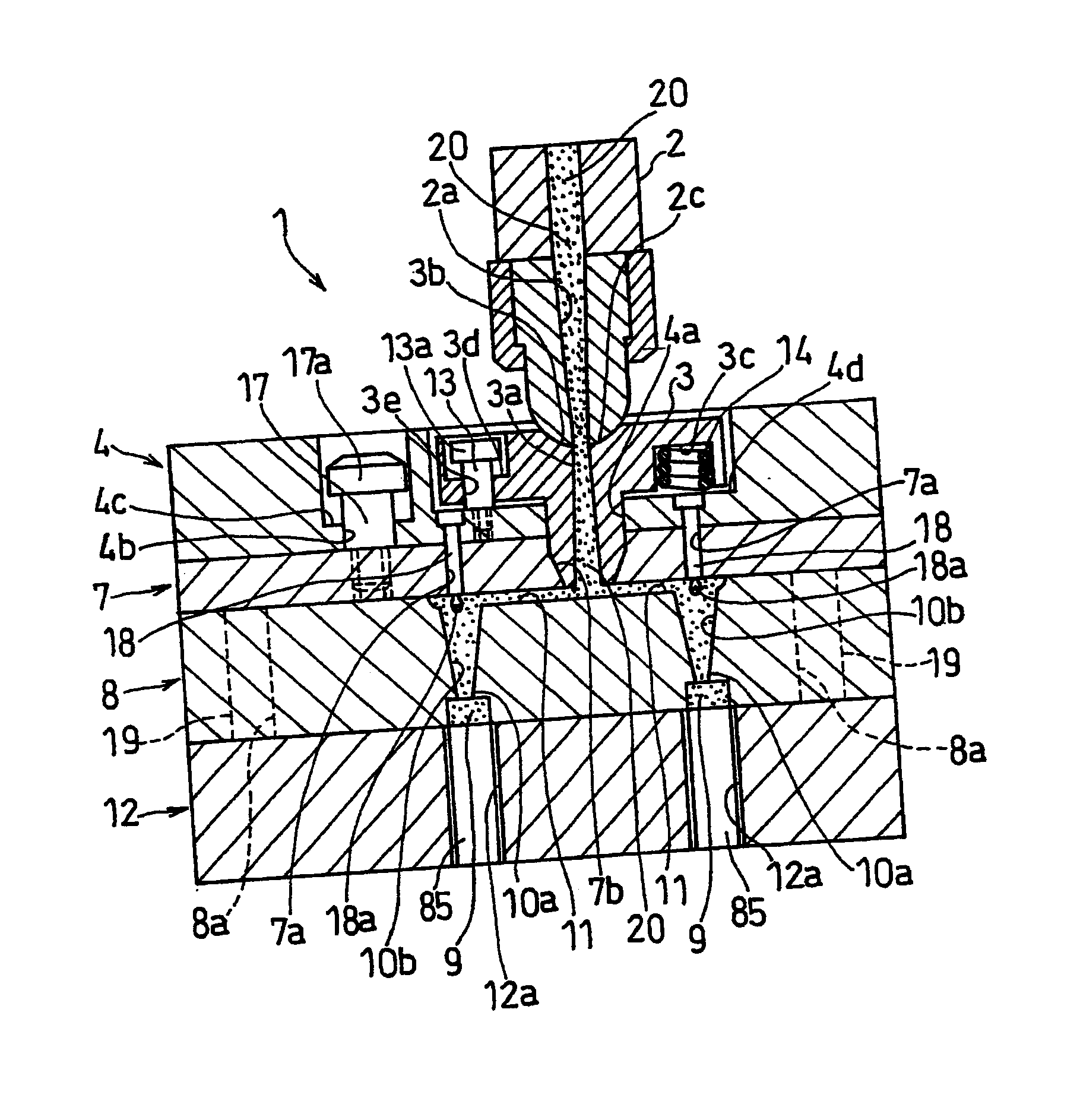

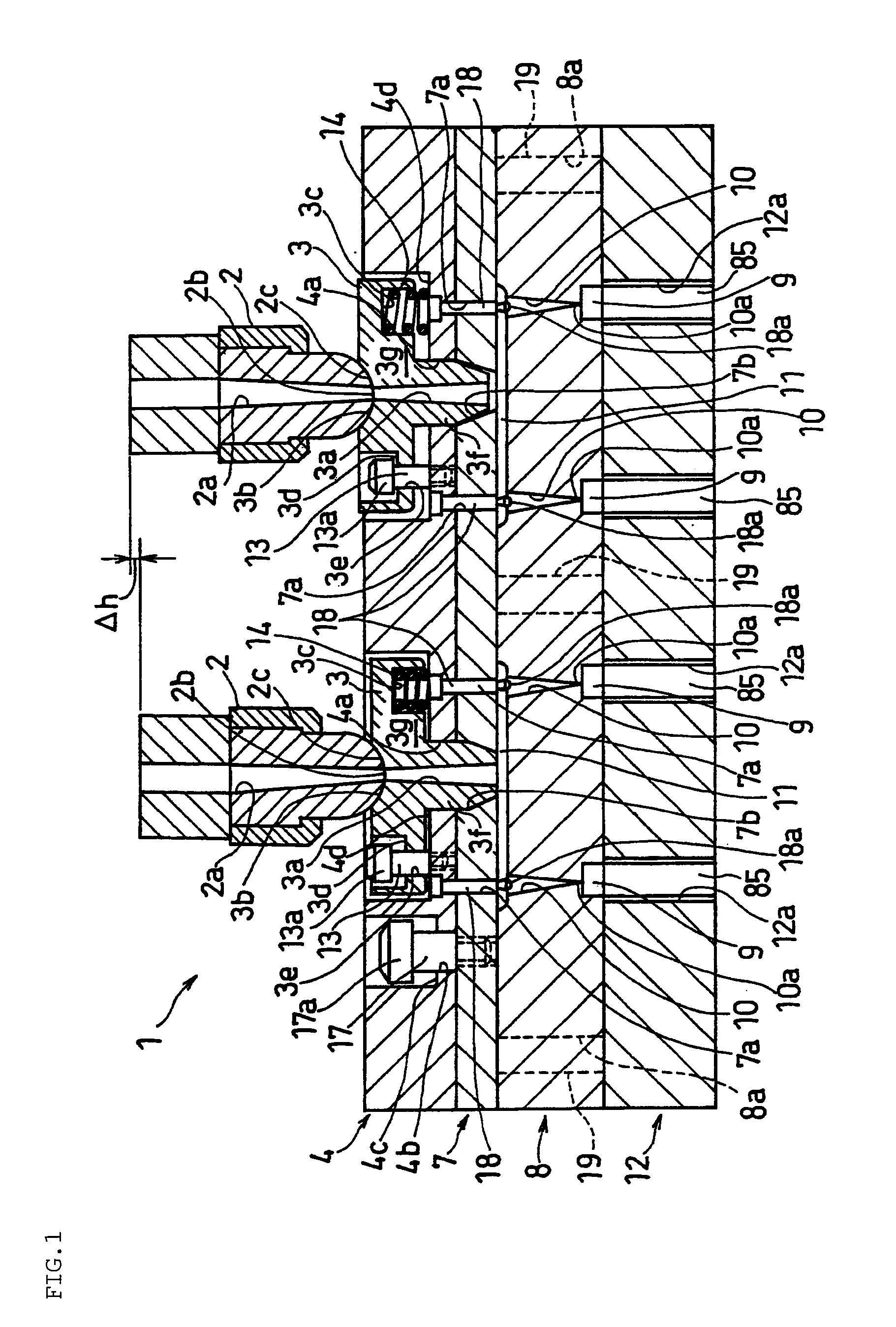

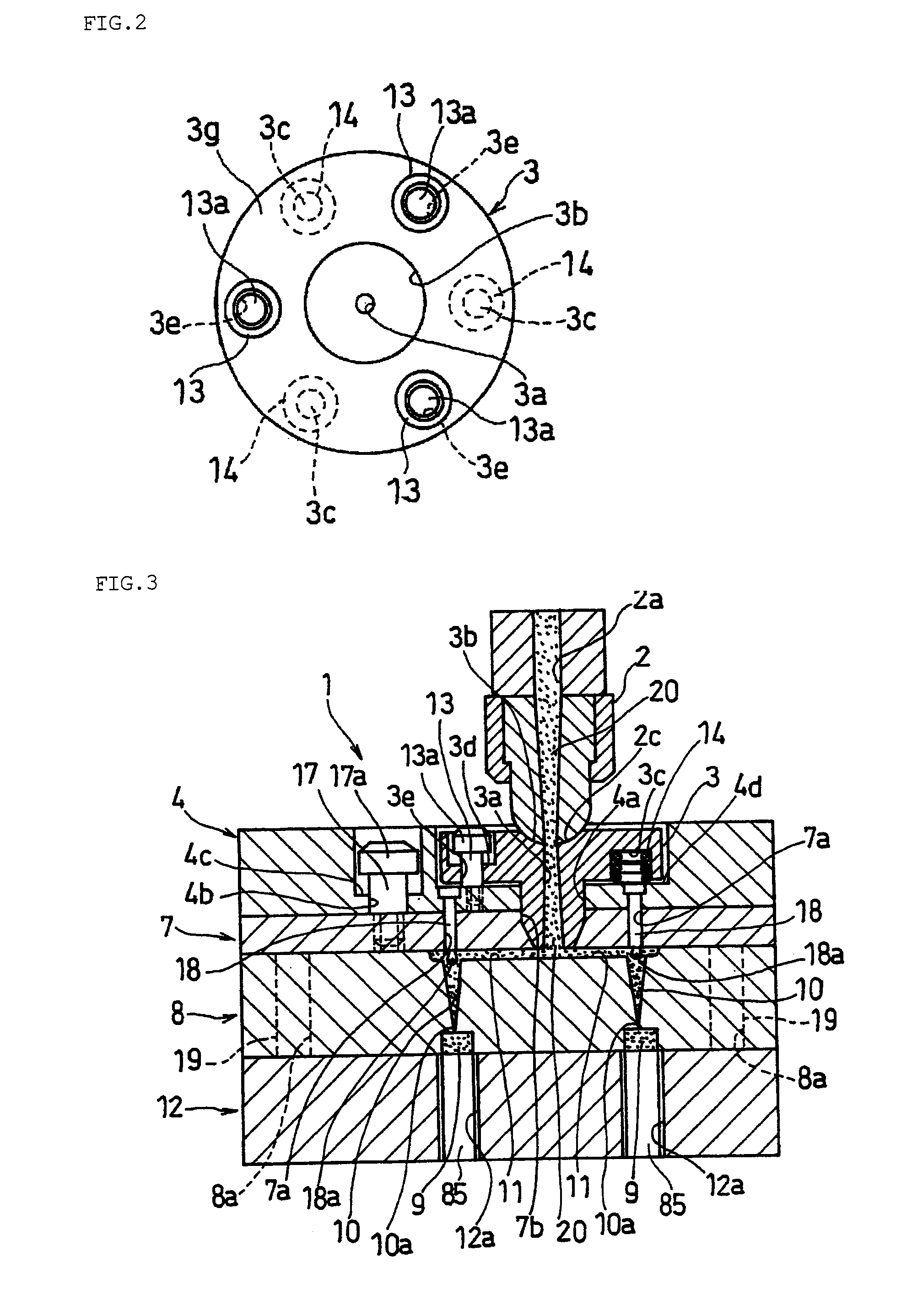

Method and apparatus for producing battery pack

InactiveUS20100258975A1Improve productivityCross-sectional shape thereof decreaseFood shapingCell component detailsShell moldingBattery pack

A tensile stress is applied to solidified resin. The tensile stress is so small that the solidified resin formed in the sprue by solidification of molding material does not break and is so large that the solidified resin formed in the sprue is separated from the inner surface of the sprue due to a reduction in the diameter of the cross sectional area thereof. For the application of such a tensile stress, the runner stripper plate holding the solidified resin is moved away from the nozzle and sprue bushing. This state is maintained for a predetermined time to separate the solidified resin from the inner surface of the sprue.

Owner:GK BRIDGE 1

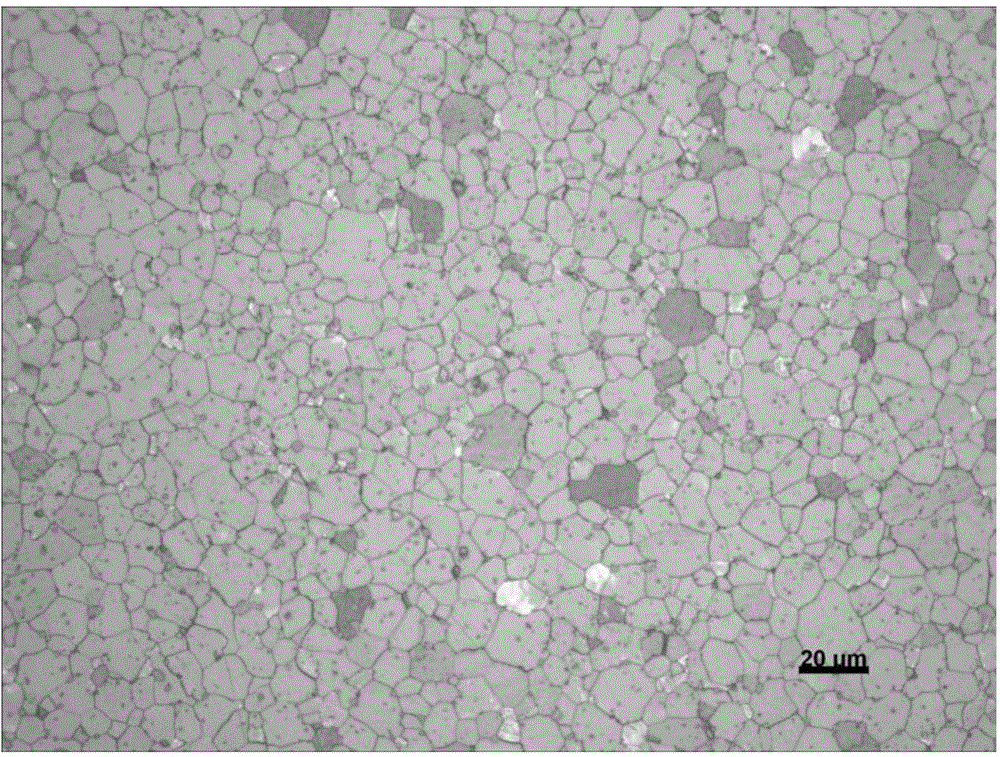

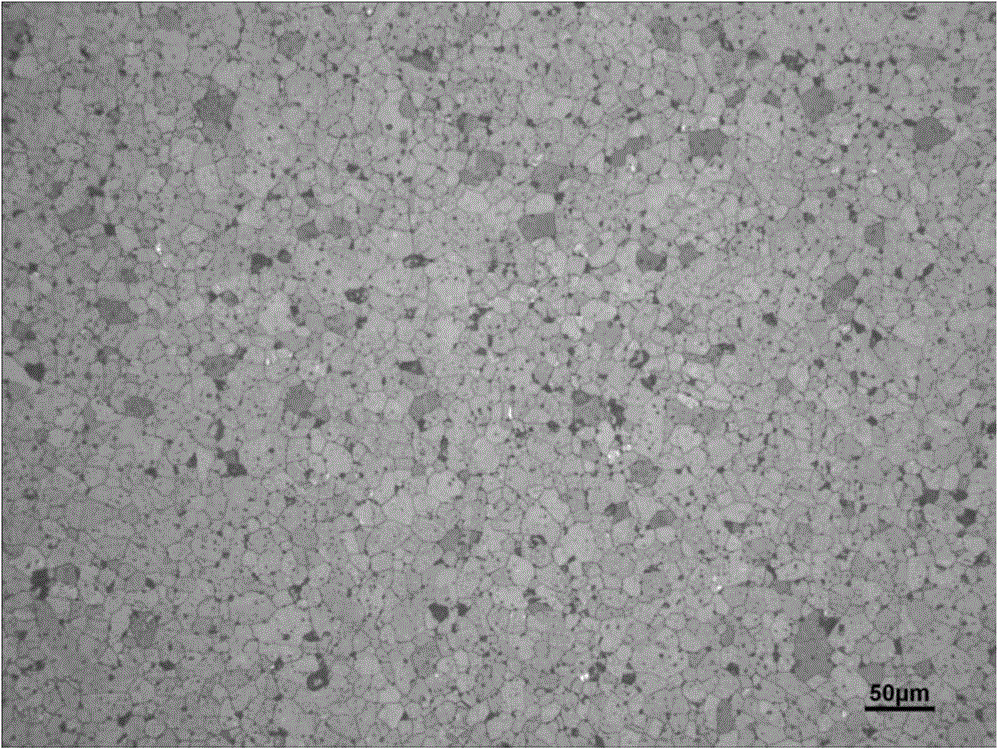

High-density zinc oxide based target and preparation method thereof

The invention discloses a high-density zinc oxide based target and a preparation method thereof. The method sequentially comprises the following steps: mixing materials: adding a binder and water into raw materials, mixing uniformly, so as to obtain uniform slurry, and carrying out drying and powdering on the slurry, so as to obtain dry powder particles with uniform particle size distribution; carrying out binder removal and degassing: loading the dry powder particles into a package of a corresponding size, and carrying out binder removal and degassing treatment; carrying out hot isostatic pressing: soldering and sealing the package which is subjected to binder removal and degassing, and then, carrying out hot isostatic pressing treatment; annealing: carrying out annealing treatment on package removed ingot blank. The zinc oxide based target obtained by adopting the method has the advantages that the relative density is not lower than 99% of theoretical density, the density is uniform, the average crystal grain size is not greater than 30 microns, and the zinc oxide based target is free from air pores and loosening.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

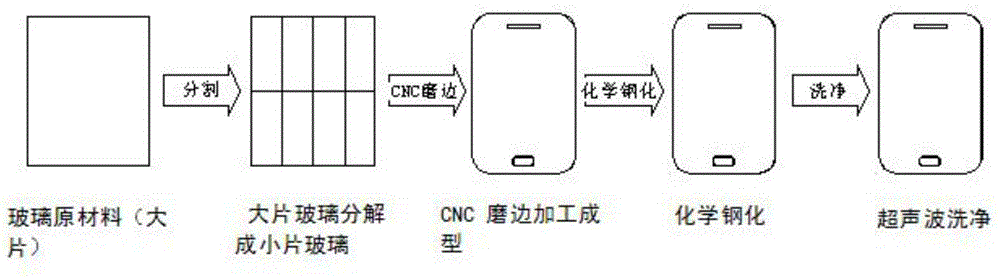

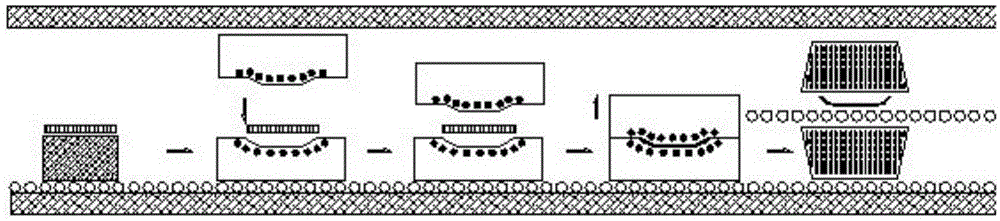

Production technology for hot bending of bent glass

ActiveCN104860514AShort molding timeHigh forming precisionGlass reforming apparatusGlass tempering apparatusEngineeringSlow cooling

A production technology for hot bending of bent glass comprises two specific steps, namely, glass sheet preprocessing and quick hot bending of glass; the specific glass sheet preprocessing technology comprises steps as follows: a large sheet of raw glass material is cut into small glass sheets, chemical tempering is performed after CNC (computer numerical control) edge polishing molding, and then ultrasonic cleaning is performed; in the step of quick hot bending of the glass, small cleaned and tempered sheets are sent into a preheating device by a conveying device for preheating, then upper and lower modules are heated, the small tempered sheets are sent into a mold cavity, then the upper and lower modules are combined and perform continuous pressurization for a preset time, finally, slow cooling is performed in the mold cavity, the upper and lower modules are separated after water cooling, and the molded bent glass is taken out. The production technology has the advantages of short molding time, high molding precision, low energy consumption, high yield, low cost and diversified appearance.

Owner:江苏瑞慕科技有限公司

Firework cylinder material and preparation method thereof

The invention discloses a firework cylinder material which is prepared from the following components in percentage by mass: 20-55% of plant fiber, 0-15% of reinforcing fiber, 1-5% of fiber finishing agent, 25-39% of air hardening material, 0.1-2% of catalyst, 5-25% of filler, 0-2% of lubricant, 0-2% of water-condensing agent, 5-15% of toughener and 0-5% of foaming agent, wherein stabilizer accounts for 2-15% of the total mass of the formula. The invention also discloses a preparation method of the firework cylinder material. The technical scheme can completely replace the traditional firework cylinder production mode, and is high in processing operability, high in molding speed and easy to realize large-scale stable production; and meanwhile, the raw materials are abundant, easy to acquire and low in cost. Besides, the produced firework cylinder can achieve qualified mechanical strength and favorable physical / chemical stability, causes no environmental pollution and can be degraded naturally.

Owner:汤华荣 +1

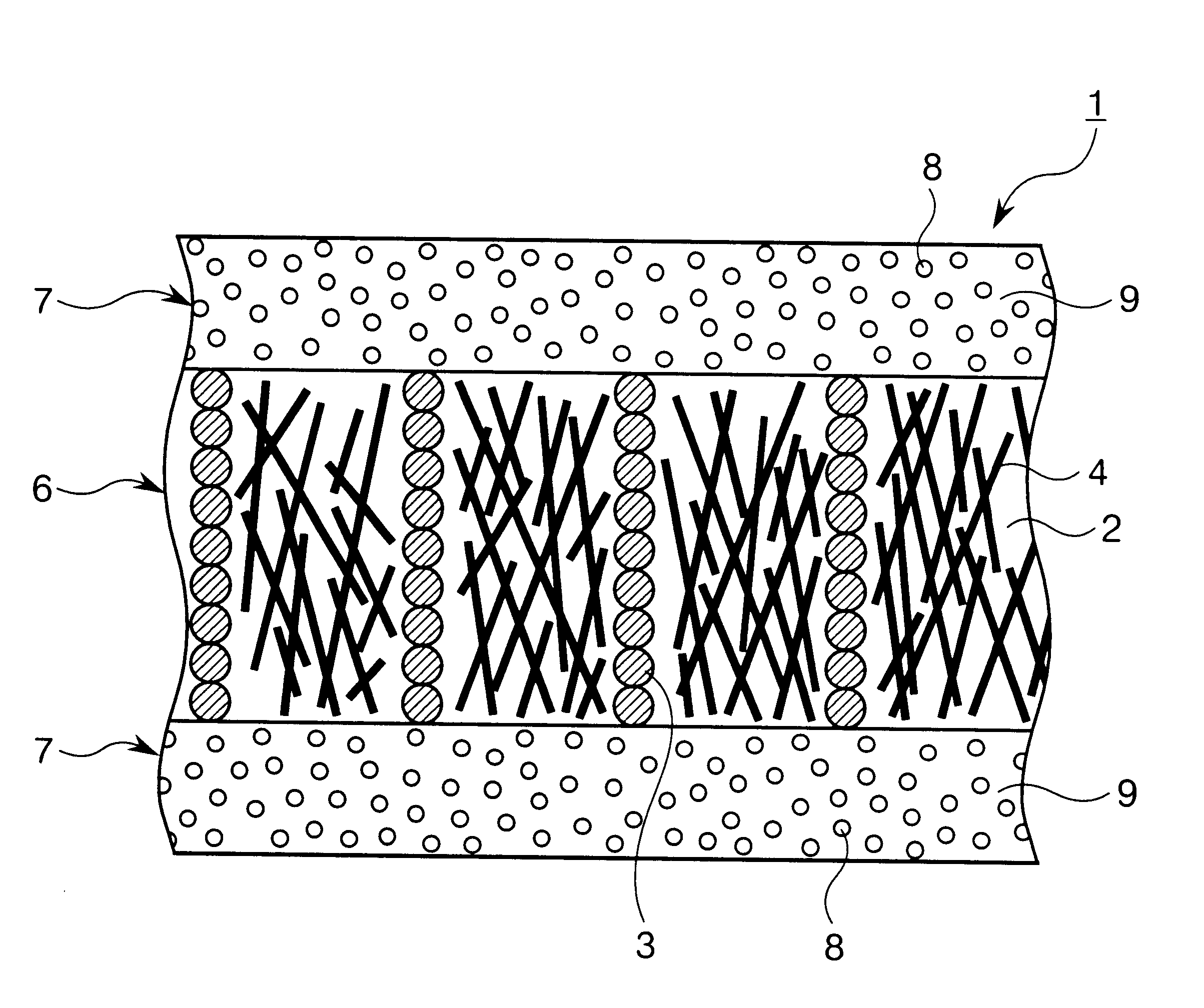

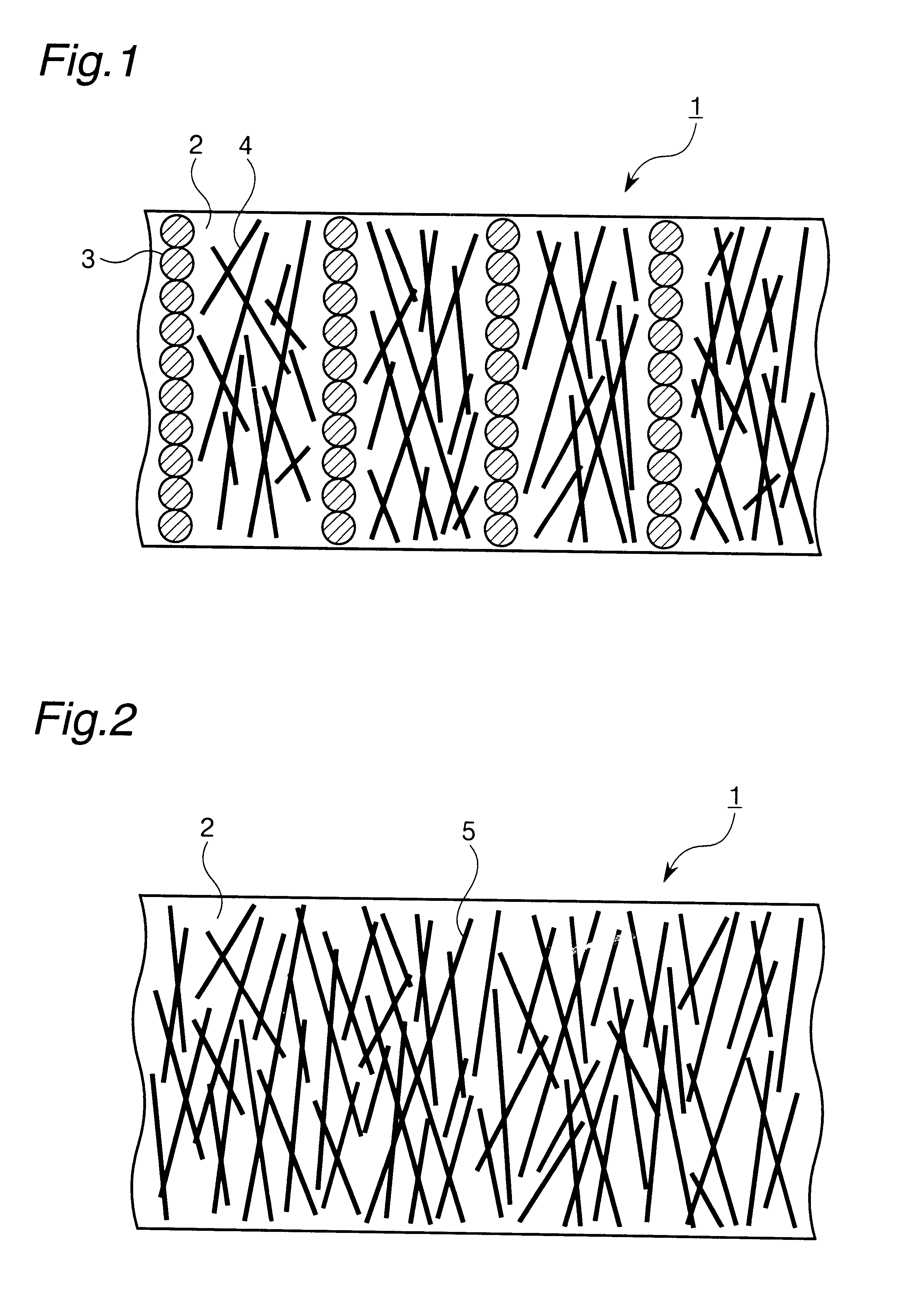

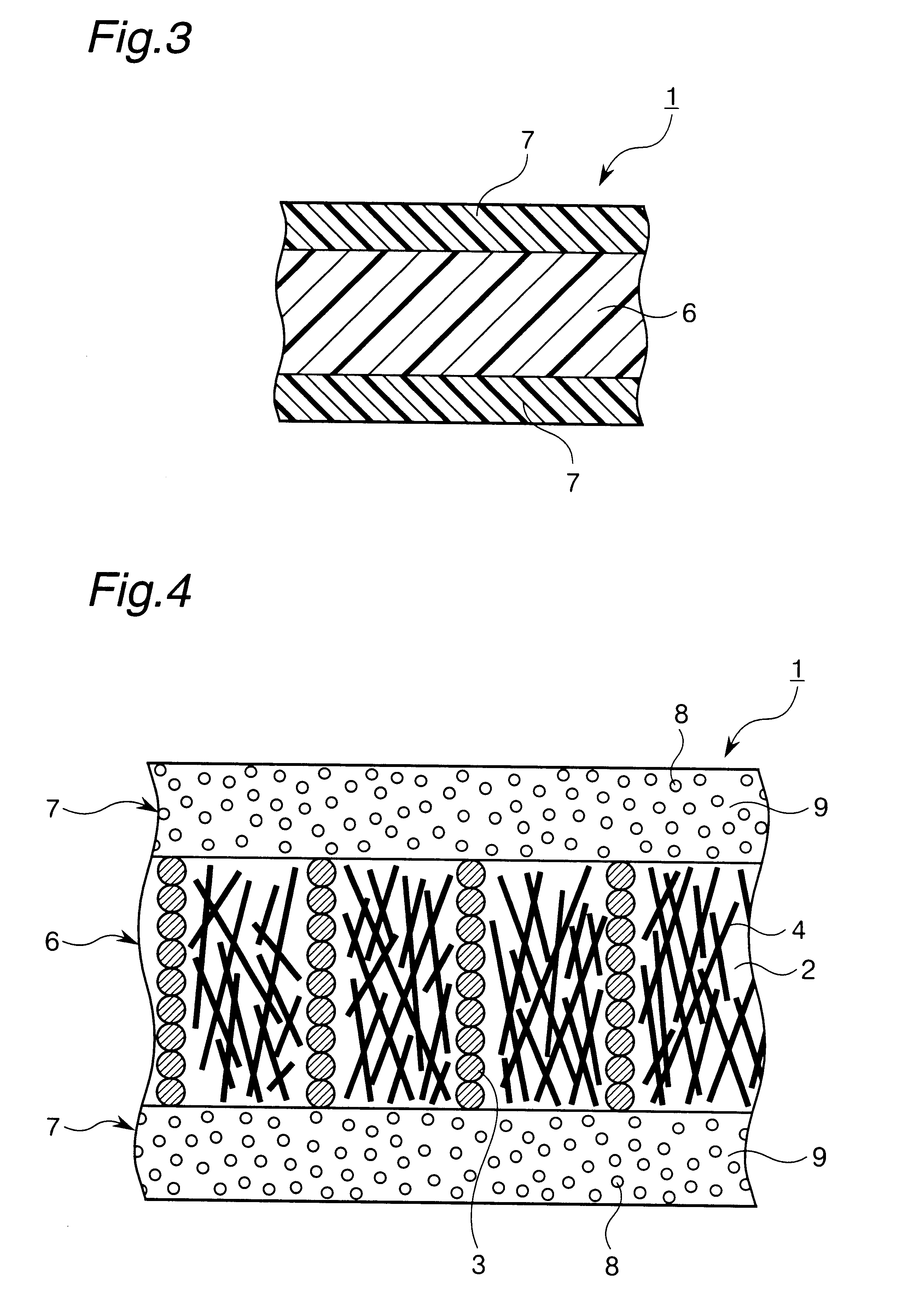

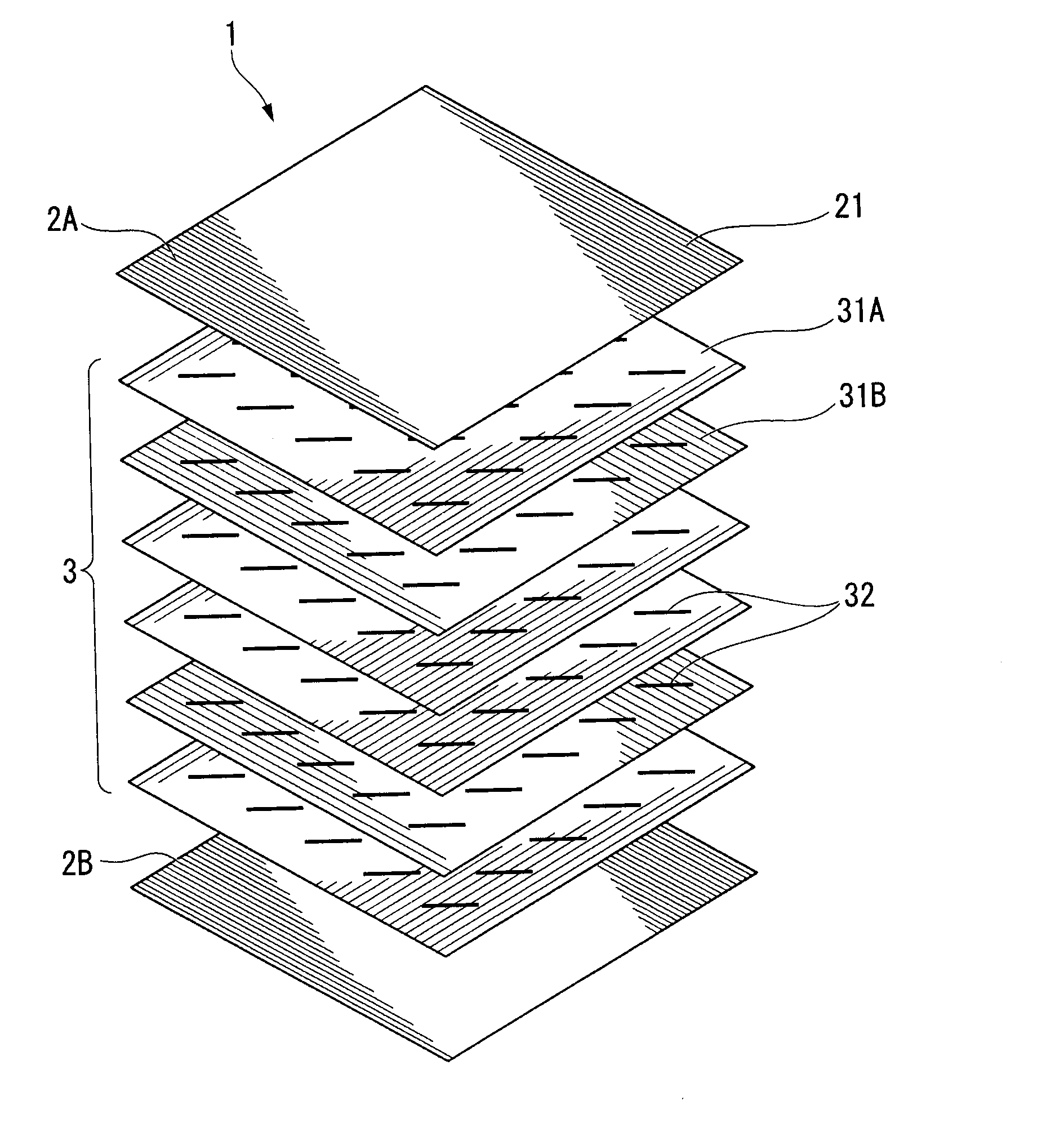

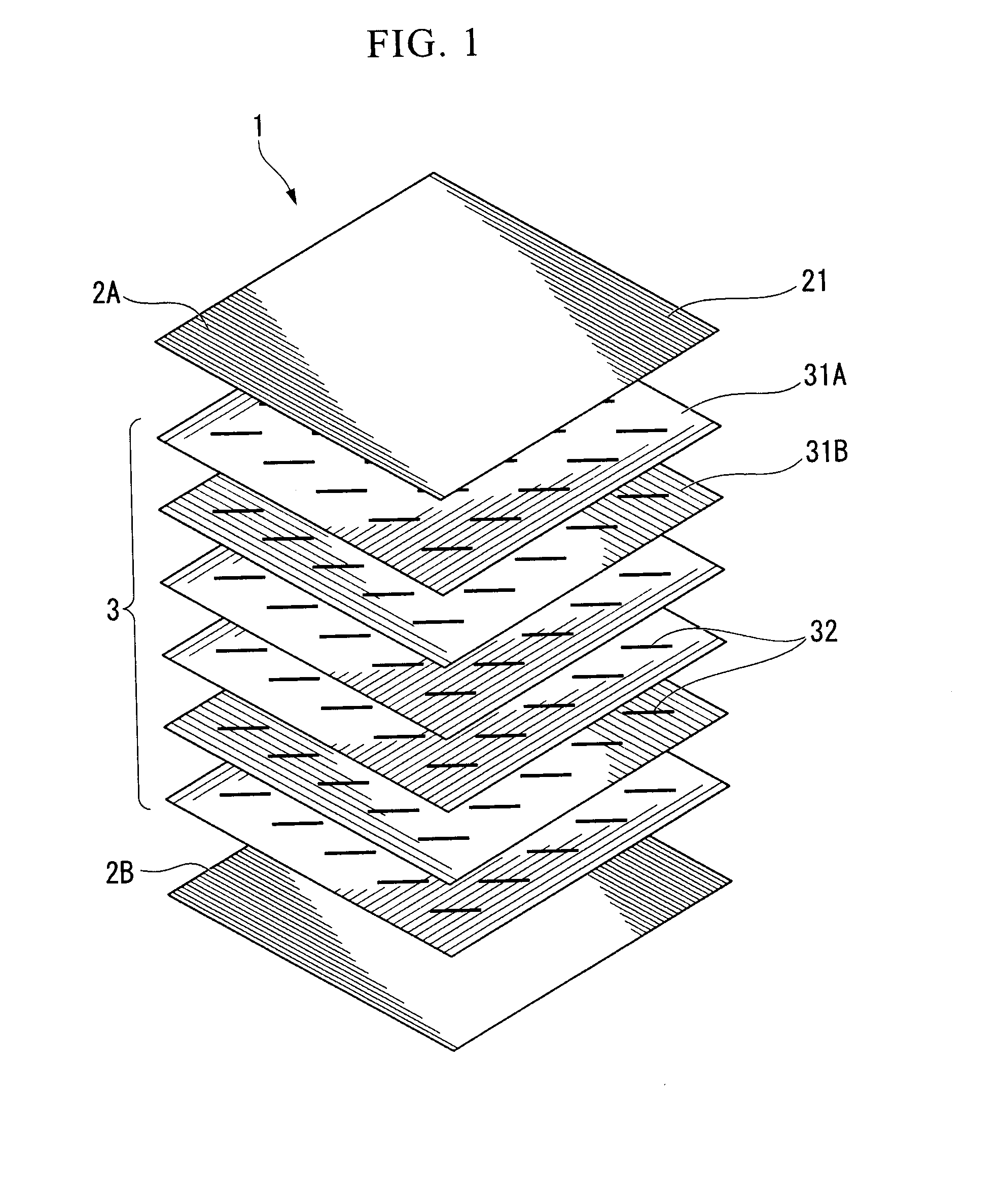

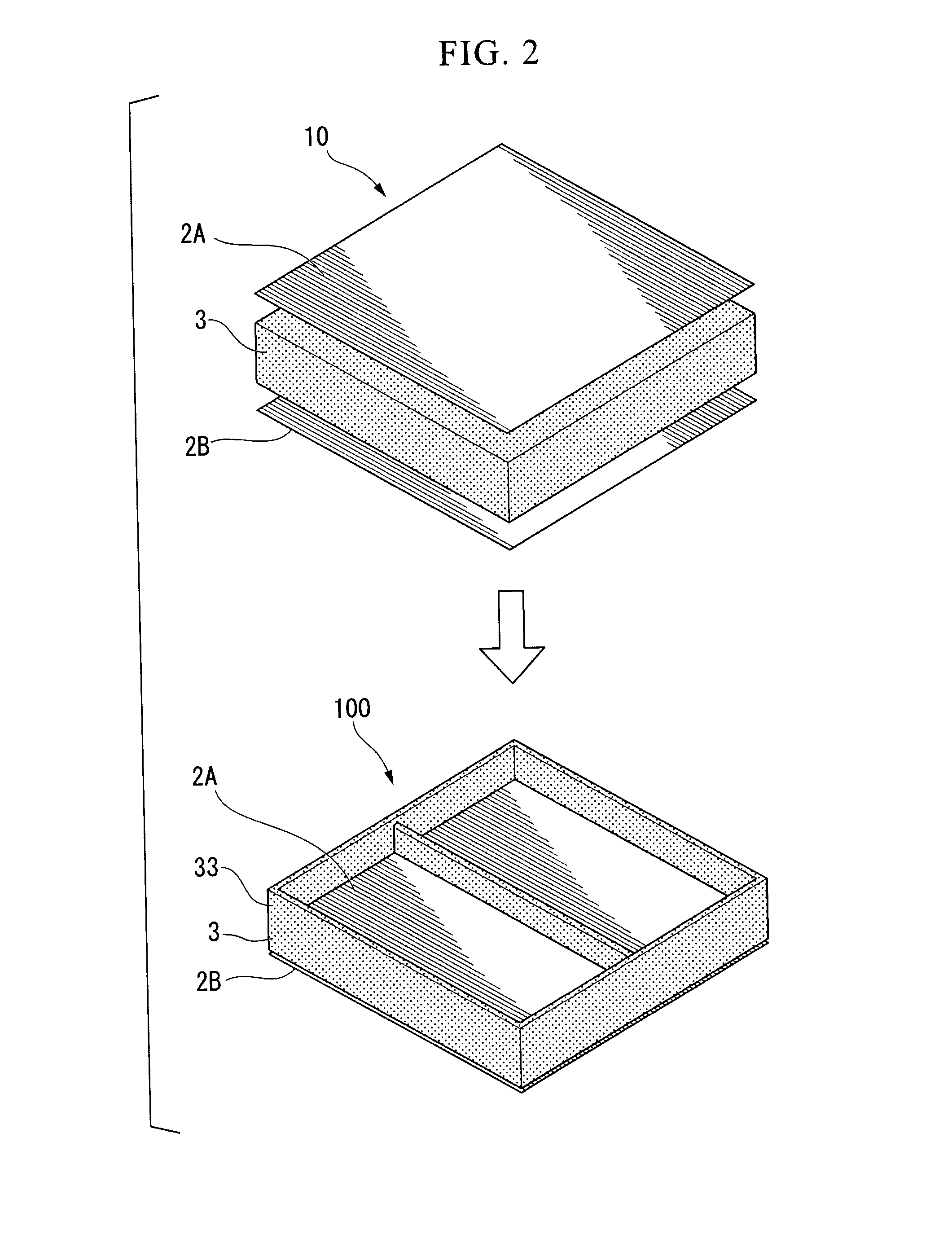

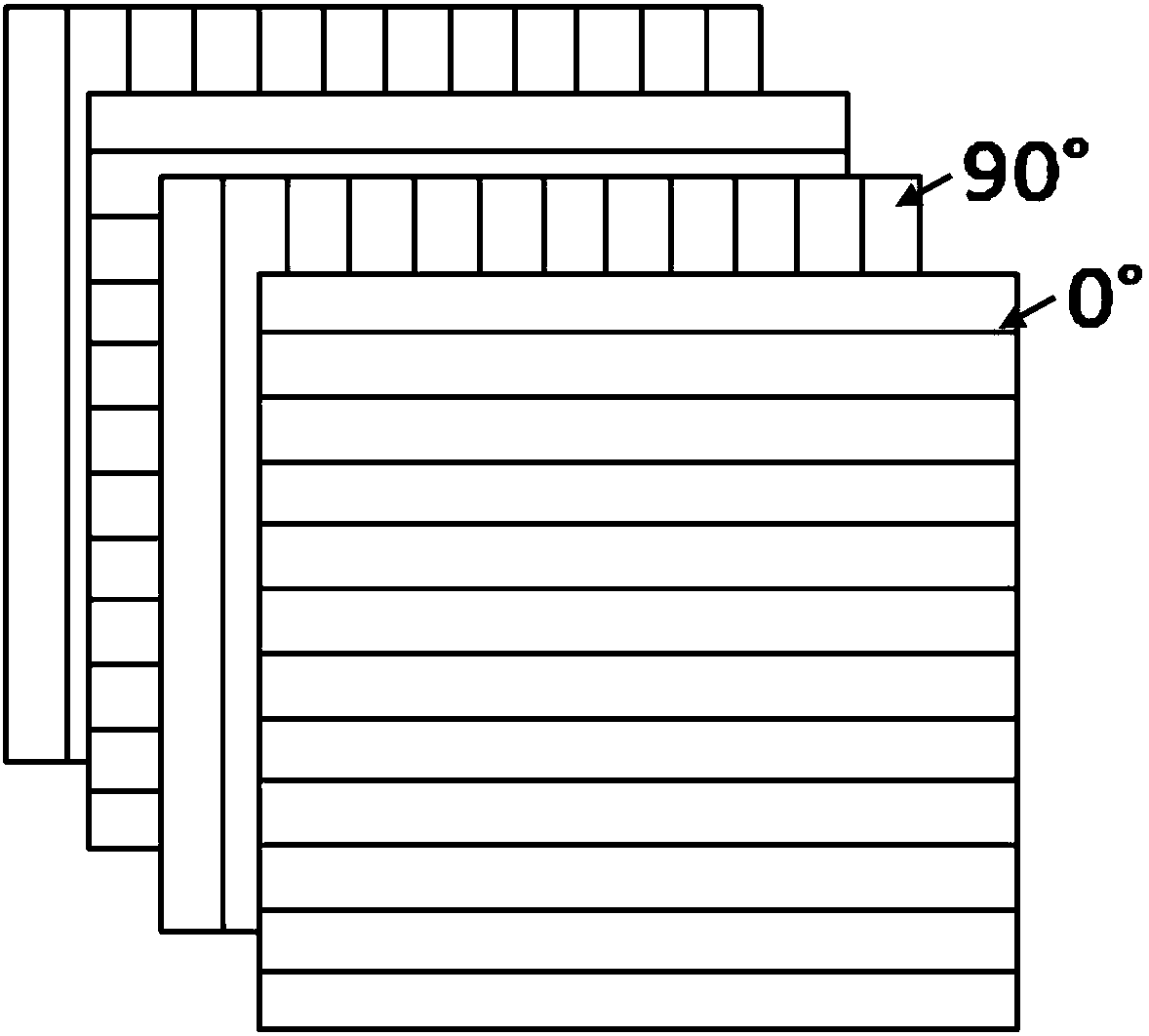

Carbon-fiber-reinforced thermoplastic-resin composite material and molded body using the same

ActiveUS20160009054A1Excellent in balance among stiffness and strength and thermal conductivityShort molding timeSynthetic resin layered productsCeramic layered productsFiberCarbon fibers

The invention is intended to obtain a composite material suitable for mass production or the like by shortening the molding time while obtaining the advantages of the composite materials described above, and intended to provide a composite material which has a short molding time by the use of a thermoplastic resin as a matrix and is excellent in balance among stiffness, strength, and thermal conductivity. A carbon-fiber-reinforced thermoplastic-resin composite material comprising: a layer (I) containing a carbon fiber (A) aligned in one direction and a thermoplastic resin (C-1); and a layer (II) containing a carbon fiber (B) aligned in one direction and a thermoplastic resin (C-2), wherein the carbon fiber (A) has a higher elastic modulus than the carbon fiber (B).

Owner:MITSUBISHI CHEM CORP

Solid silica gel

The present invention belongs to the field of polymer technology. The solid silica gel consists of: base polymer 50-70 wt%, crosslinking agent 0.8-3 wt%, stuffing 25-45 wt%, catalyst 2-4 wt%, processing agent 4-12 wt%, demolding agent 0.01-0.3 wt%, yellow resisting agent 0.01-0.3 wt% and diluent 0-30 wt%. The solid silica gel is formed in once sulfurizing at low temperature and has simplified mold manufacture, low cost, no low molecular matter exhaust during sulfurizing, less shrinkage, high chemical stability and excellent acid and alkali resistance.

Owner:刘淑芬

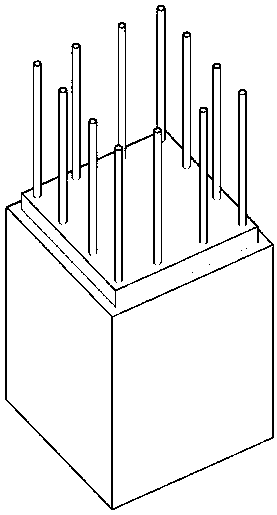

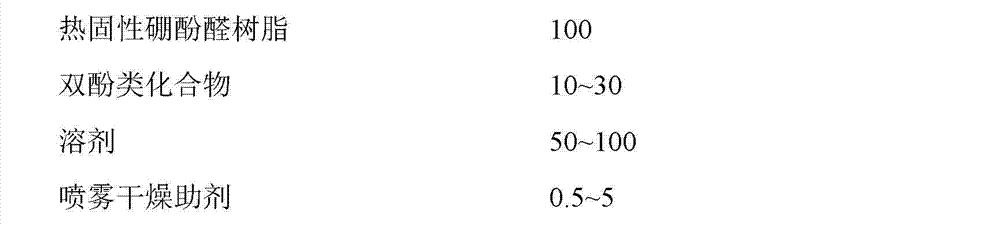

Quick concrete assembly type joint and method for constructing same

InactiveCN108035439AImprove compactnessHigh strengthBuilding constructionsEngineeringUltimate tensile strength

The invention discloses a quick concrete assembly type joint and a method for constructing the same. The quick concrete assembly type joint comprises a first prefabricated column and a second prefabricated column. The ends of the first prefabricated column and the second prefabricated column are integrally connected with each other, a connection zone is arranged between the ends of the first prefabricated column and the second prefabricated column, two longitudinal bars which are positioned in the connection zone are reserved at the ends of the first prefabricated column and the second prefabricated column, and the reserved longitudinal bar positioned on the first prefabricated column and the reserved longitudinal bar positioned on the second prefabricated column are staggered from each other and are overlapped on each other in the connection zone; stirrups are arranged on the reserved longitudinal bars, form frames are arranged on the outer side of the connection zone, and grouting openings and exhaust openings are formed in the form frames; concrete connection sections which are integrated with formworks are poured in the form frames. The quick concrete assembly type joint and the method have the advantages of short forming time, high strength, good toughness, zero maintenance and simple and convenient construction processes. Besides, the quick concrete assembly type joint ismainly applied to connecting prefabricated assembly type concrete columns.

Owner:XIANGTAN UNIV

Rapid construction highway repair material and preparation method and application method thereof

InactiveCN103979890AWith compressive strengthWith flexural strengthRoads maintainenceEpoxyRoad surface

The invention relates to the technical field of pavement repair material, and provides a rapid construction highway repair material and a preparation method and application method thereof. The rapid construction highway repair material is obtained according to the following steps: adding a required amount of dibutyl phthalate, acetone, a filling material and ethene diamine in order into heated to epoxy resin, and mixing evenly to obtain the rapid construction highway repair material. The rapid construction highway repair material provided by the invention not only has the compressive strength and flexural strength of an ordinary cement concrete, but also has the advantages of short forming time and low spreading temperature, so as to reduce the construction temperature requirement and simplify the construction process. Therefore, the rapid construction highway repair material provided by the invention has higher practicability, allows usage of the highway as soon as possible, realizes full performance of usage efficiency of the highway, and shows wide application prospect.

Owner:新疆交通科学研究院有限责任公司

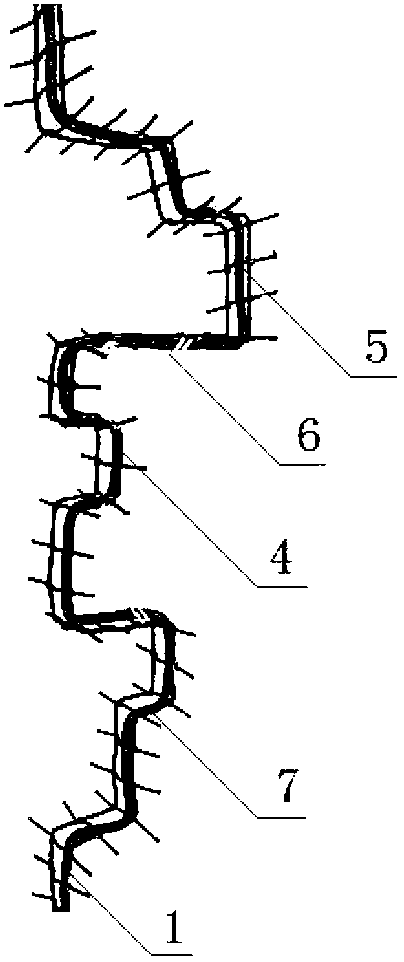

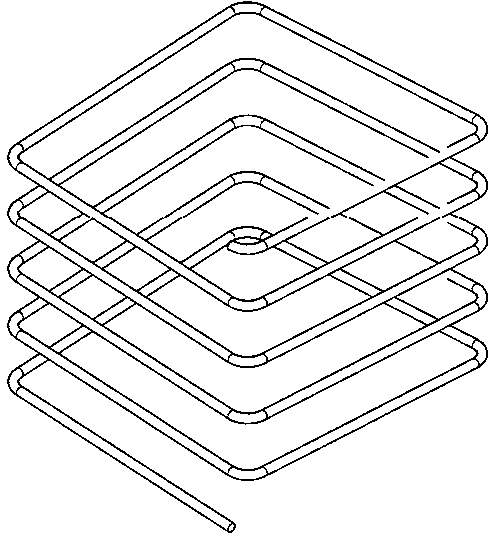

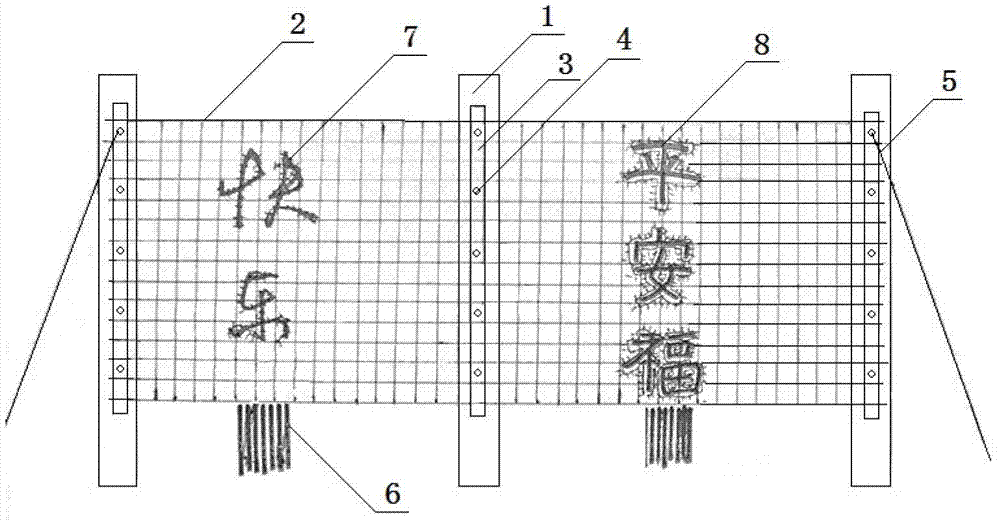

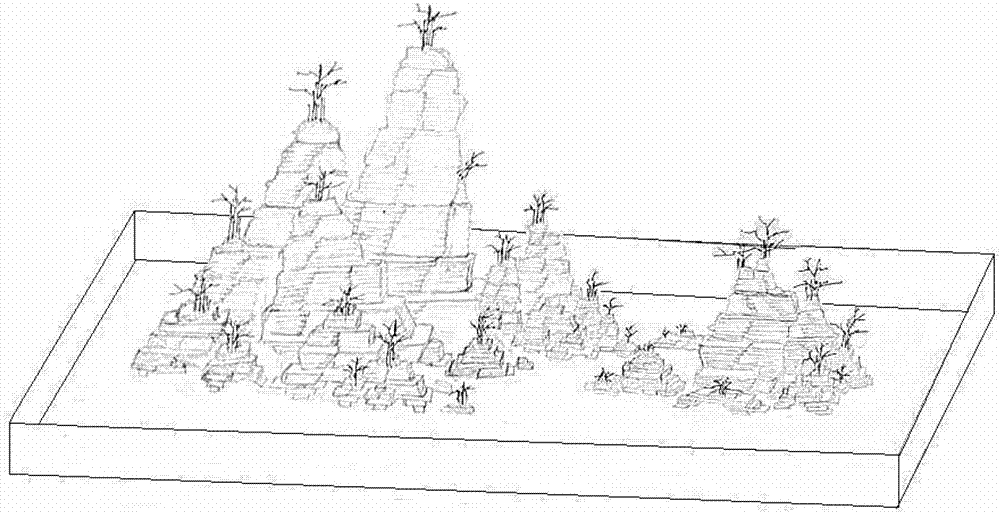

Wall calligraphy artistic-forming method for Lagerstroemia plants in Lythraceae

ActiveCN103109685AEasy to viewIncrease valueSpecial ornamental structuresCultivating equipmentsArtistic renderingLythraceae

The invention discloses a wall calligraphy artistic-forming method for Lagerstroemia plants in Lythraceae. The method mainly includes the steps of firstly, designing wall calligraphy artistic-form maps; secondly, raising seedlings and making a culture bed; thirdly, making and erecting a support net frame; fourthly, making and erecting an aerial-ladder dipped metal net frame; fifthly, planting for the first time, and performing trunk growth and text formation to twigs; sixthly, trimming seedlings and tying the twigs; seventhly, planting for the second time, and erecting a text wall control support frame and a trunk fixation and support frame; and eighthly, creating wall calligraphy artistic forms. Calligraphic and artistic forms of trunks are expressed on walls, so that ornamentality of the trunks is improved and seedling value is increased. The forming ladder system is continuously available for many years, requires short forming time and is long in service life. Complete forms are available for enjoyment all year round for many years. Standard and large-scale production is realized. The forms have artistic effect of wall calligraphy, and ornamentality and commodity value of the seedlings are increased.

Owner:TONGREN MANTANGHONG AGRI TECH

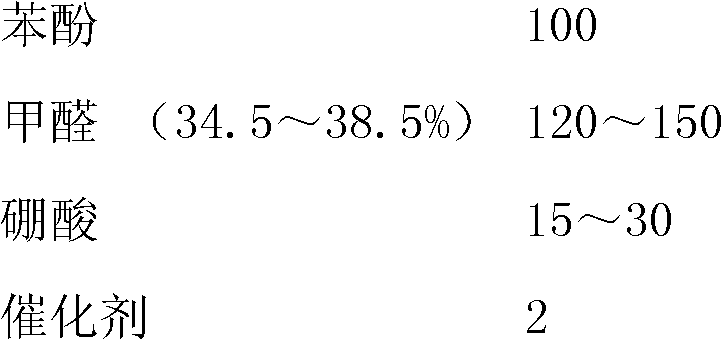

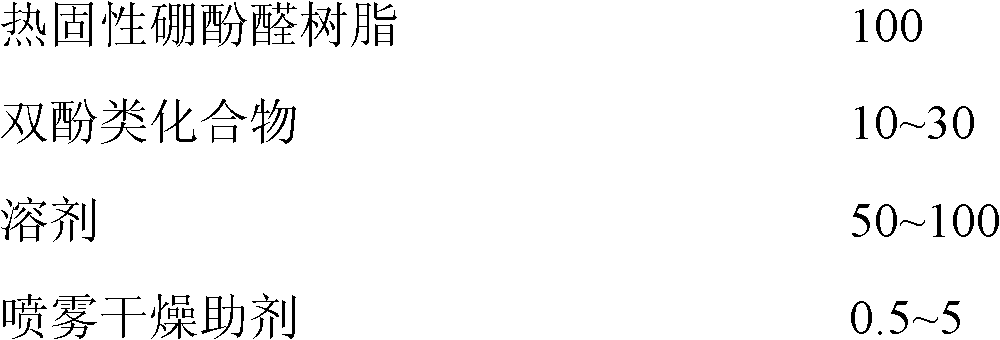

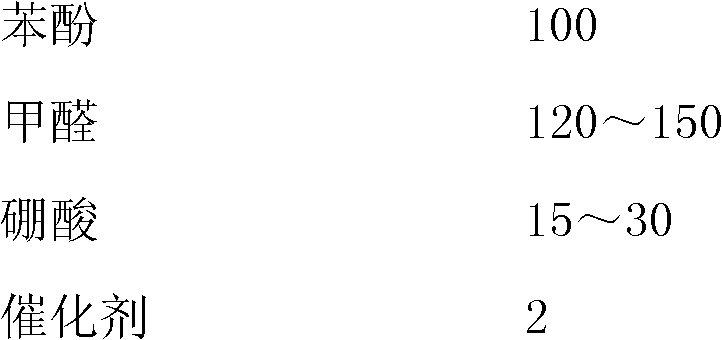

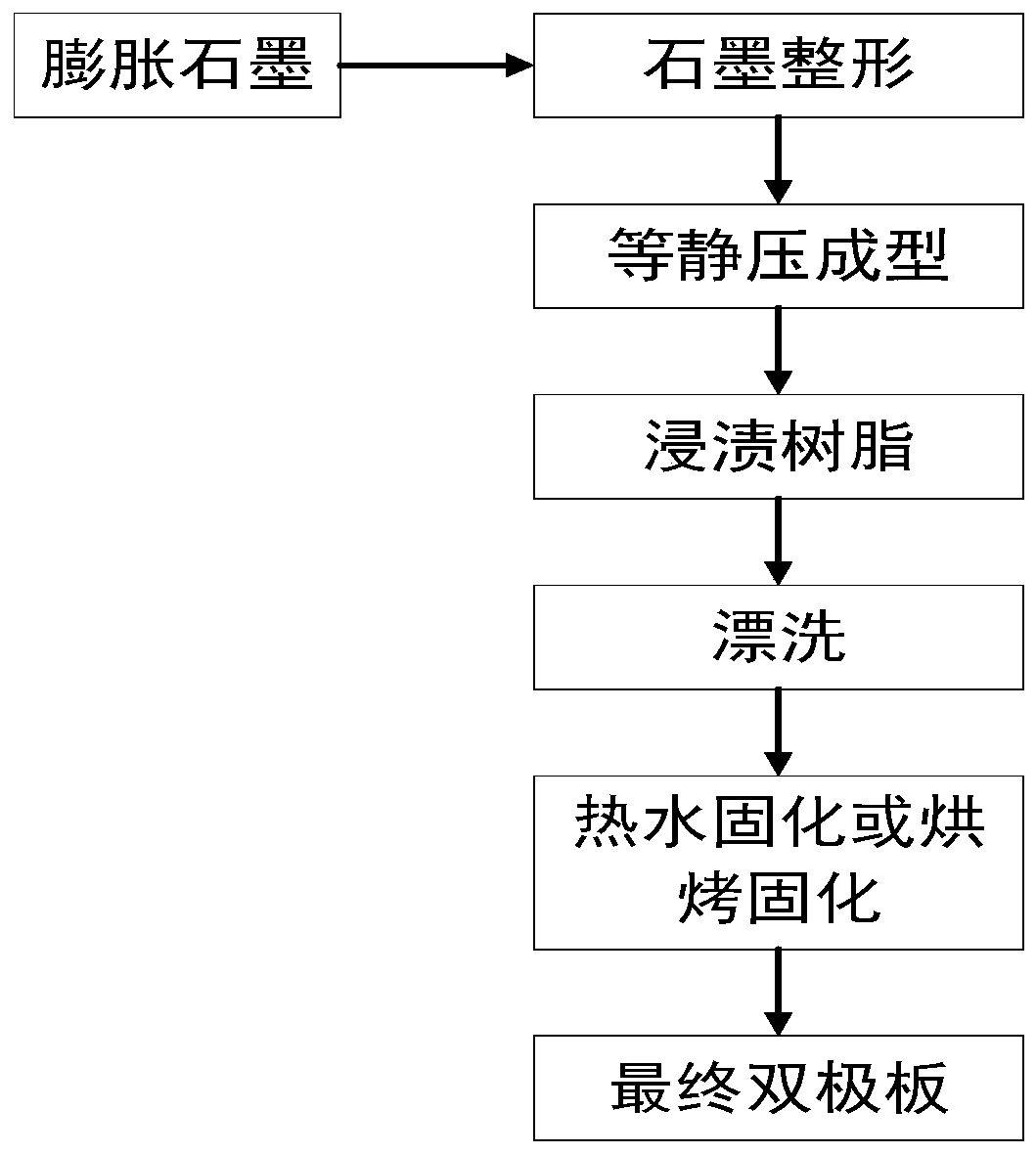

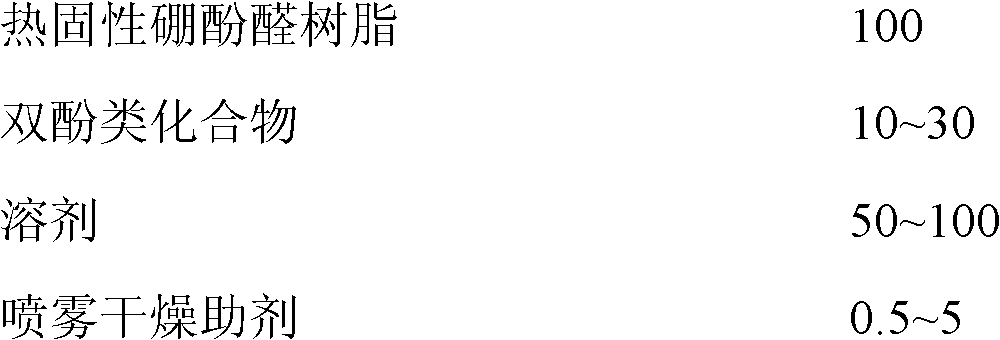

Method for preparing thermosetting boron-containing phenolic resin powder

The invention discloses a method for preparing thermosetting boron-containing phenolic resin powder, comprising the following steps: (1) preparing a thermosetting boron-containing phenolic resin; (2) preparing a spray drying composition; and (3) preparing the spray drying composition into the thermosetting boron-containing phenolic resin powder by using a spray drying method. The prepared thermosetting boron-containing phenolic resin powder has good fluidity under the conditions of heating and pressure, and has excellent storage stability.

Owner:太仓力达莱特精密工业有限公司

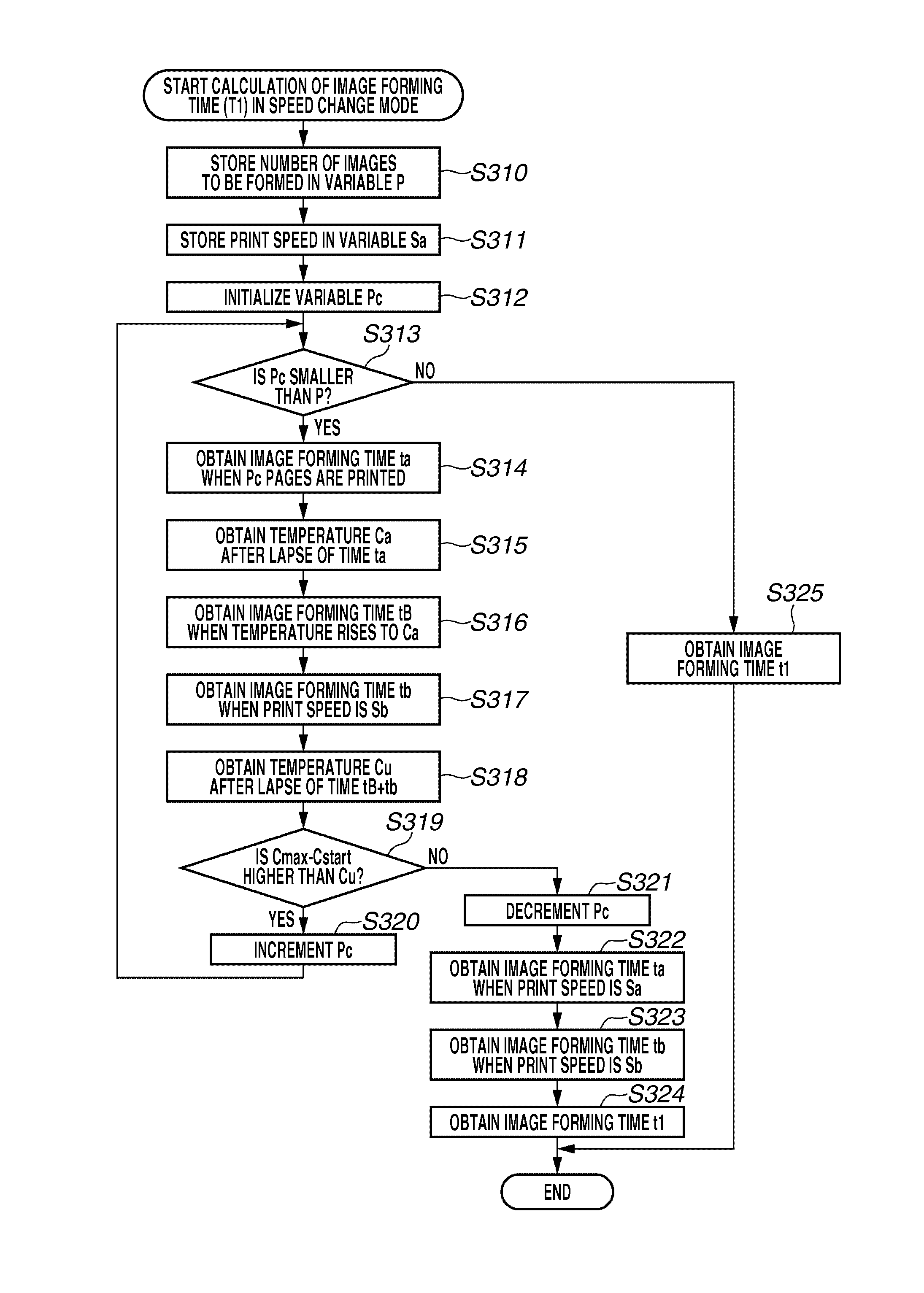

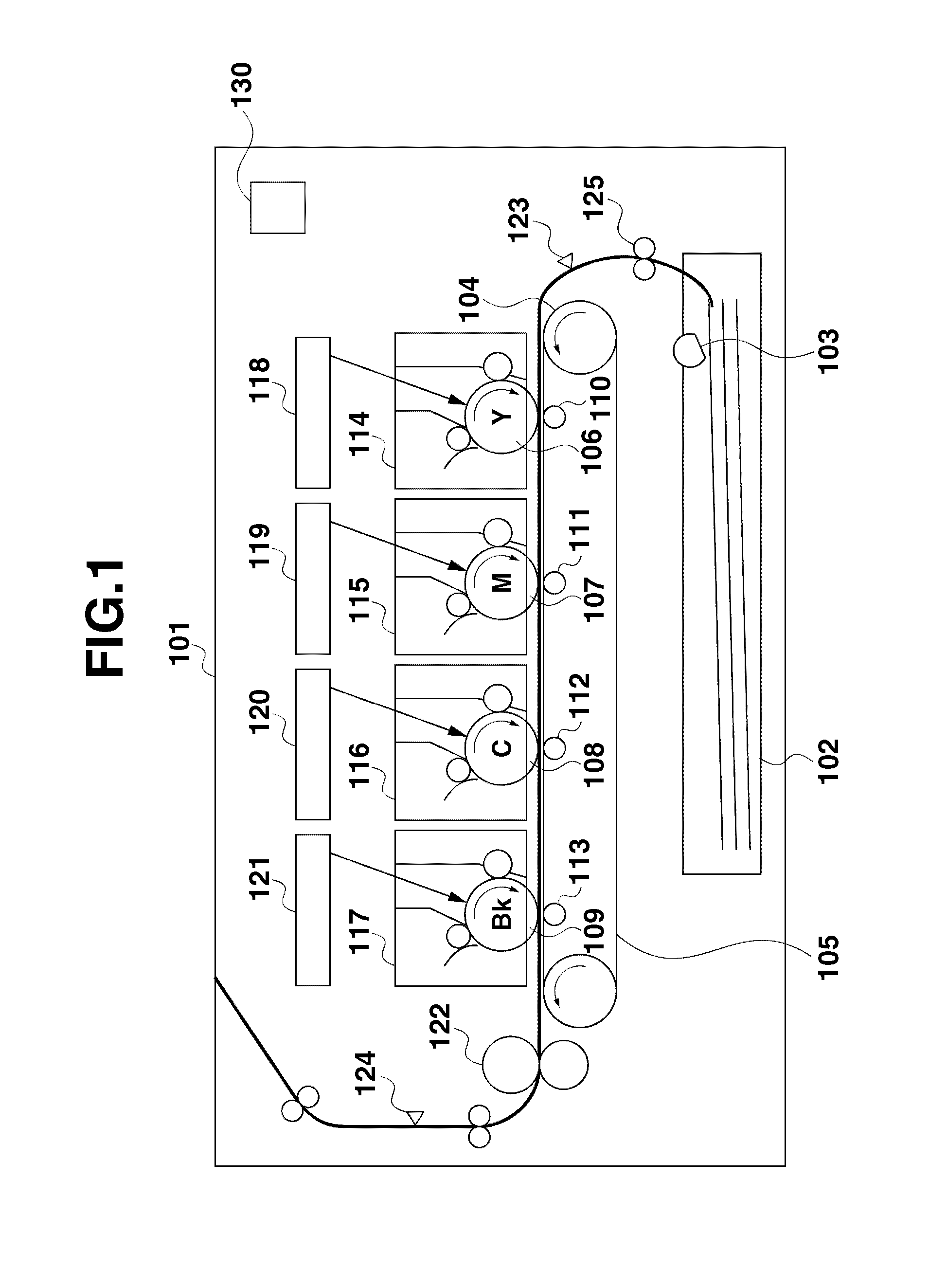

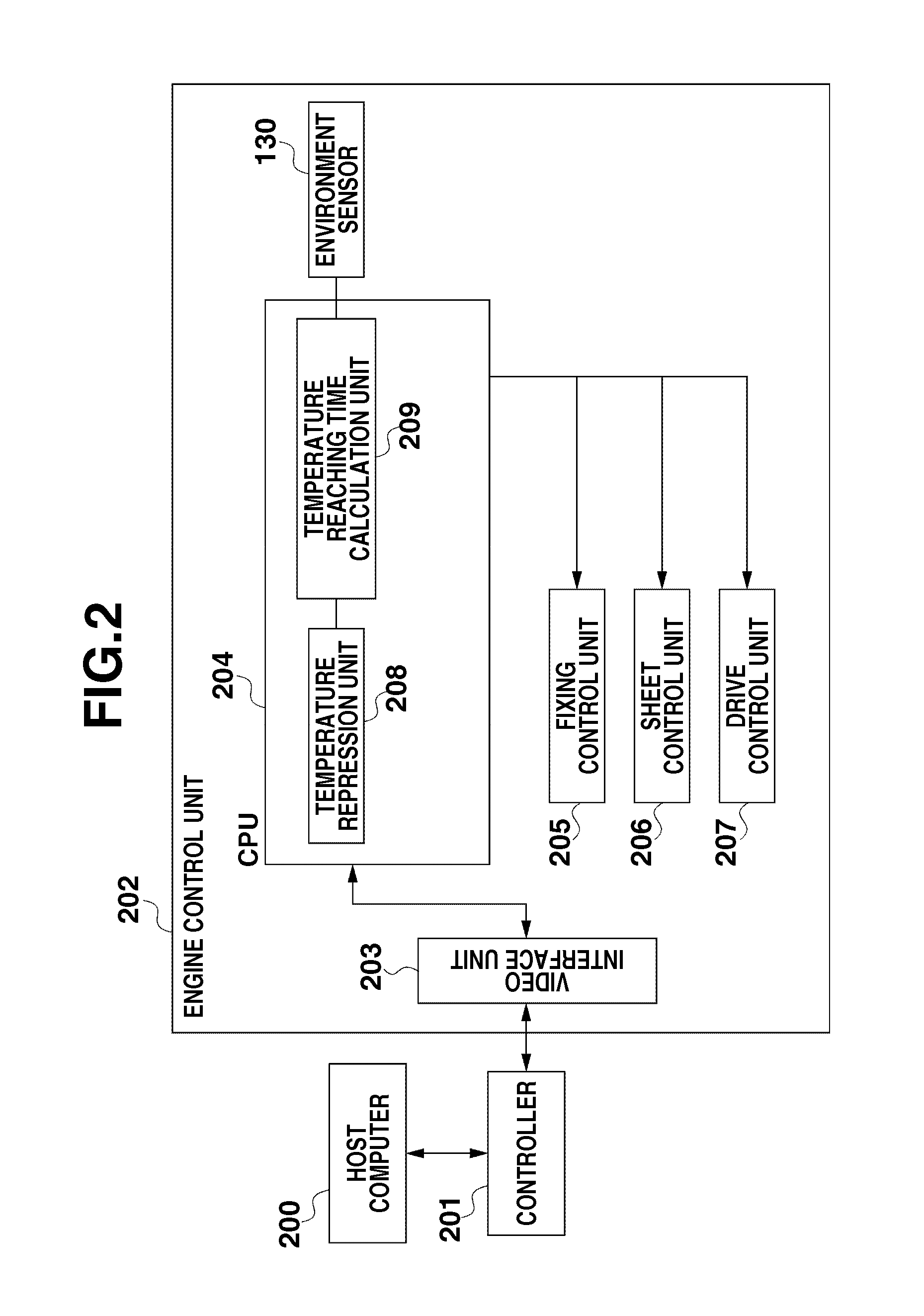

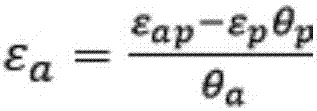

Temperature control in image forming apparatus

InactiveUS20110142460A1Reduce drop in throughputShort molding timeElectrographic process apparatusImage basedTime based

An image forming apparatus includes a reception unit, an image forming unit, a drive unit, a detection unit, a prediction unit, and a control unit. The image forming unit forms an image based on image information received by the reception unit. The drive unit controls an imaging forming unit drive. The detection unit detects temperature within the image forming apparatus. The prediction unit predicts a transition of temperature within the image forming apparatus and an image formation time based on the image information and the temperature within the image formation unit. The control unit is responsive to detected temperature and predicted image forming time. The control unit switches between image forming modes and controls the image forming apparatus to form an image in a short image forming time.

Owner:CANON KK

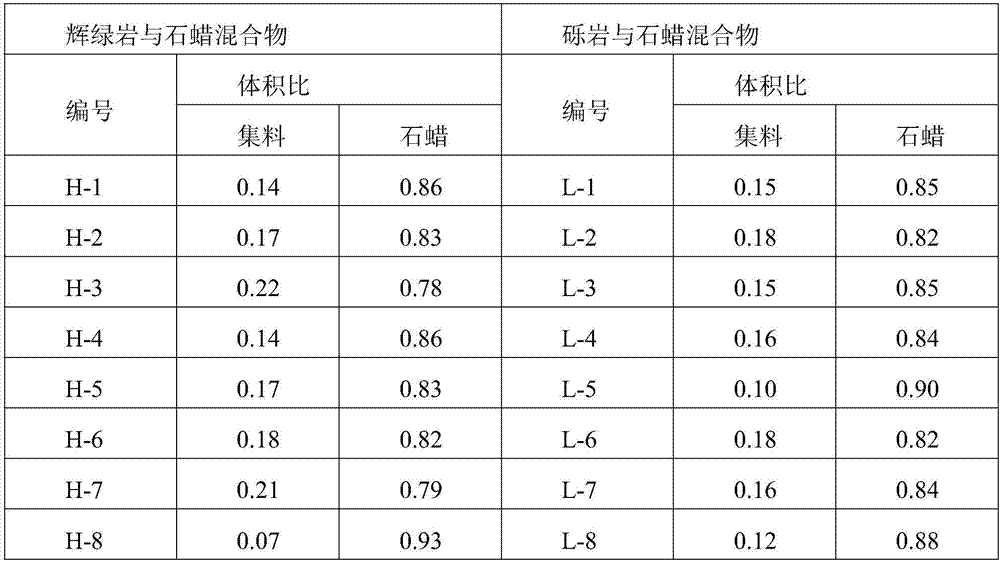

Method for detecting dielectric constant of irregularly-shaped aggregate

InactiveCN106932651AImprove detection accuracyGood application effectDielectric property measurementsDielectricParaffin oils

The present invention discloses a method for detecting the dielectric constant of an irregularly-shaped aggregate. The method comprises the following steps that: after being weighed, the irregularly-shaped aggregate is mixed with liquid paraffin, and the mixture of the irregularly-shaped aggregate and the liquid paraffin is poured into a mold, after the mixture is cooled, so that a regularly-shaped paraffin and aggregate two-phase mixture can be obtained; a pure paraffin sample is prepared with the same mold; the sample is weighed, and the volume of the sample is calculated, so that the density of solid paraffin is obtained, and the volume ratio of the paraffin to the aggregate in the paraffin and aggregate two-phase mixture is obtained; the dielectric constants of the pure paraffin sample and the two-phase mixture are measured through a dielectric constant test system; and a composite material linear model is inferred, so that the dielectric constant calculation formula of the aggregate can be obtained. The test method used in the invention is simple and convenient, can measure the dielectric constant of the irregularly-shaped aggregate and is of great significance for the research of the dielectric properties of asphalt mixtures and the improvement of the detection precision and applicability of ground penetrating radars. The test method can meet actual requirements from the aspects of the rationality of test schemes and the convenience of test operation.

Owner:WUHAN UNIV OF TECH

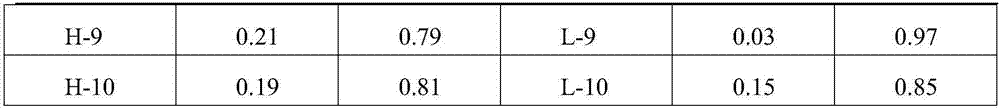

Molding preparation method of fuel cell bipolar plate

ActiveCN109950569AReduce unevennessImprove uniformityFinal product manufactureFuel cellsHigh volume manufacturingFuel cells

The invention discloses a molding preparation method of a fuel cell bipolar plate, and the method belongs to the technical field of fuel cell component manufacturing. The method comprises the following steps of selecting expanded graphite, shaping the expanded graphite, placing the shaped expanded graphite into a mold of an isostatic pressing device to press the expanded graphite to obtain a bipolar plate with a flow field, and performing dipping in resin, rinsing and hot water curing or dry curing to obtain the bipolar plate. According to the method, the uniformity of a gap of the bipolar plate after molding and the uniformity of the density of a molded plate are improved, the density uniformity is within + / -1%, and the bipolar plate can be as thin as 0.5 mm. Furthermore, the uniformity of the resistance of different regions of the bipolar plate is improved. At the same time, the bipolar plate is prepared by isostatic pressing at room temperature, no additional release agent is needed, the molding time is short, and the bipolar plate is suitable for mass production.

Owner:TSINGHUA UNIV

Modeling method of waxberry landscape tree

ActiveCN104396602APromote accumulationIncrease concentrationCultivating equipmentsHorticulture methodsMyrica rubraTransplantation

The invention discloses a modeling method of a waxberry landscape tree. In the method, the viewing value of the strawberry tree and the transplanting survival rate thereof are improved through selection, transplantation, planting, modeling and containerization cultivation of the strawberry tree, at the same time, the method can ensure that waxberry landscape tree is shaped in three years.

Owner:CHENGDU MIAOFU MODERN NURSERY STOCK SCI & TECH

Method for preparing thermosetting boron-containing phenolic resin powder

The invention discloses a method for preparing thermosetting boron-containing phenolic resin powder, comprising the following steps: (1) preparing a thermosetting boron-containing phenolic resin; (2) preparing a spray drying composition; and (3) preparing the spray drying composition into the thermosetting boron-containing phenolic resin powder by using a spray drying method. The prepared thermosetting boron-containing phenolic resin powder has good fluidity under the conditions of heating and pressure, and has excellent storage stability.

Owner:太仓力达莱特精密工业有限公司

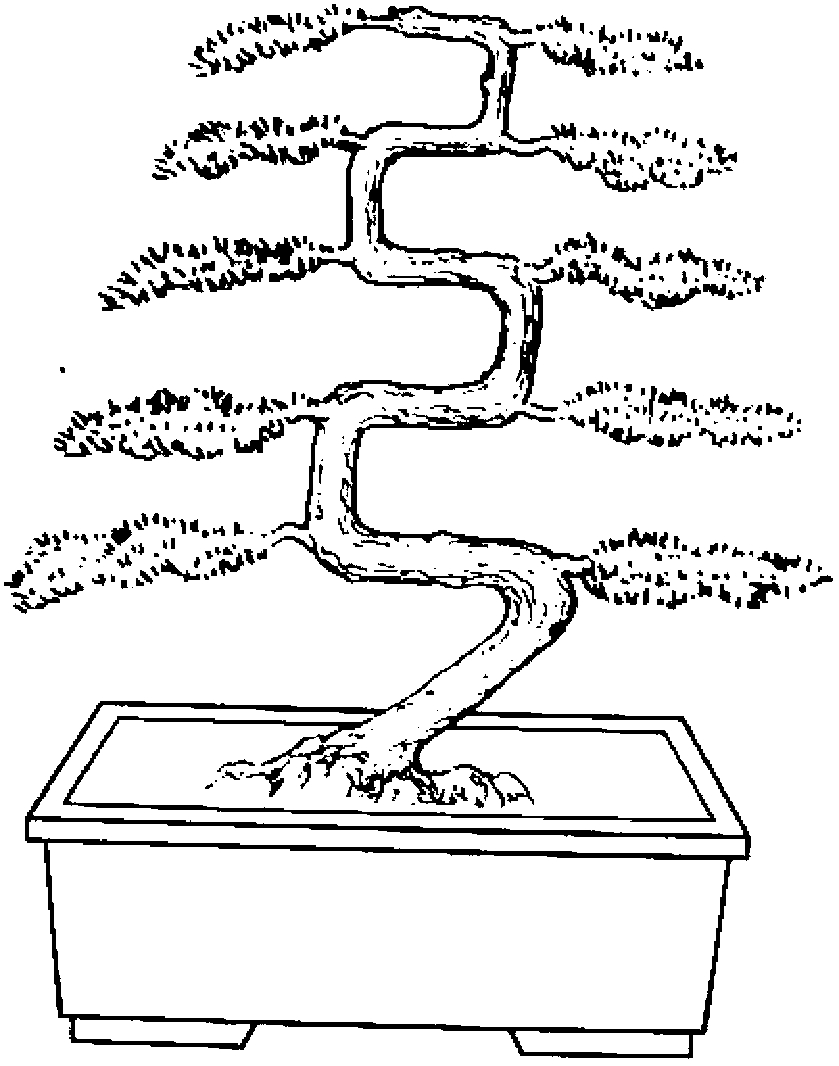

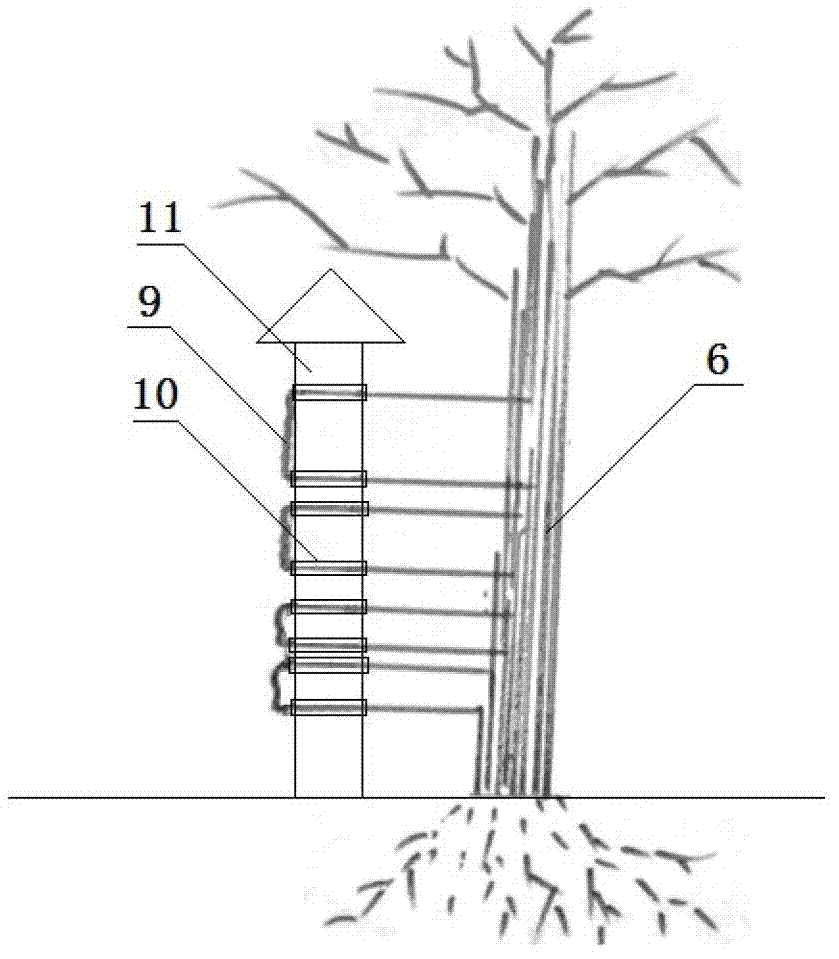

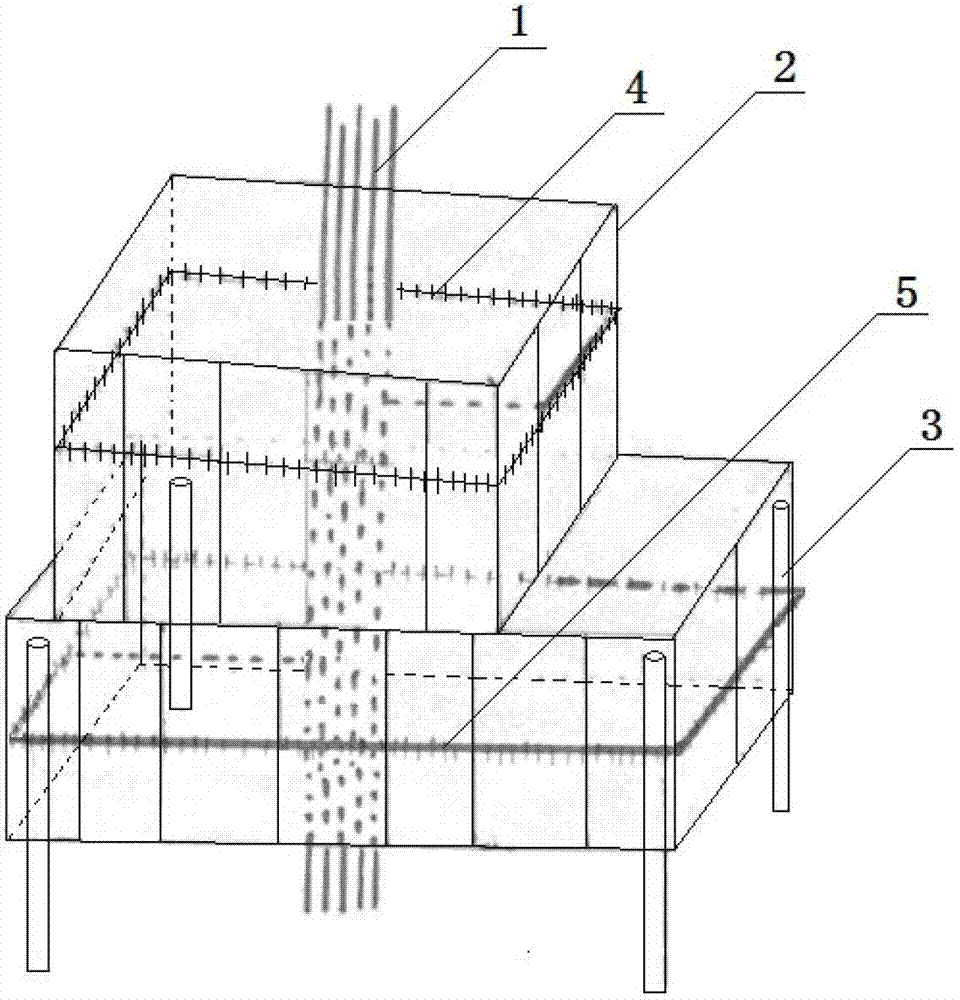

Potted-landscape artistic forming method for Lagerstroemia trees in Lythraceae

ActiveCN103109696AEasy to viewIncrease valueSpecial ornamental structuresHorticulture methodsLythraceaeLagerstroemia

The invention discloses a potted-landscape artistic forming method for Lagerstroemia trees in Lythraceae. The method mainly includes the steps of firstly, designing potted-landscape form maps; secondly, selecting, planting and cutting seedlings; thirdly, making and erecting a support frame; fourthly, making and erecting a trunk growth forming ladder; fifthly, rearing seedlings; sixthly, tying twigs to the trunk growth forming ladder; seventhly, transplanting the seedlings and inarching rectangular trunks; eighthly, configuring other devices; and ninthly, maintaining the seedlings. Trunk forming is performed according to the designed maps, so that standard and large-scale production can be realized. The rectangular trunk forms are created by the seedlings of different heights, and forming time is short. The trunks are grown into different blocks having the features of landscape stones on Mount Fanjing, the corresponding trunks are selected and subjected to form inarching or transplanting according to layout of potted landscapes, and accordingly the trunks are imparted with implication or artistic conception of the potted landscapes, ornamentality of the trunks is improved, and seedling value is increased.

Owner:TONGREN MANTANGHONG AGRI TECH

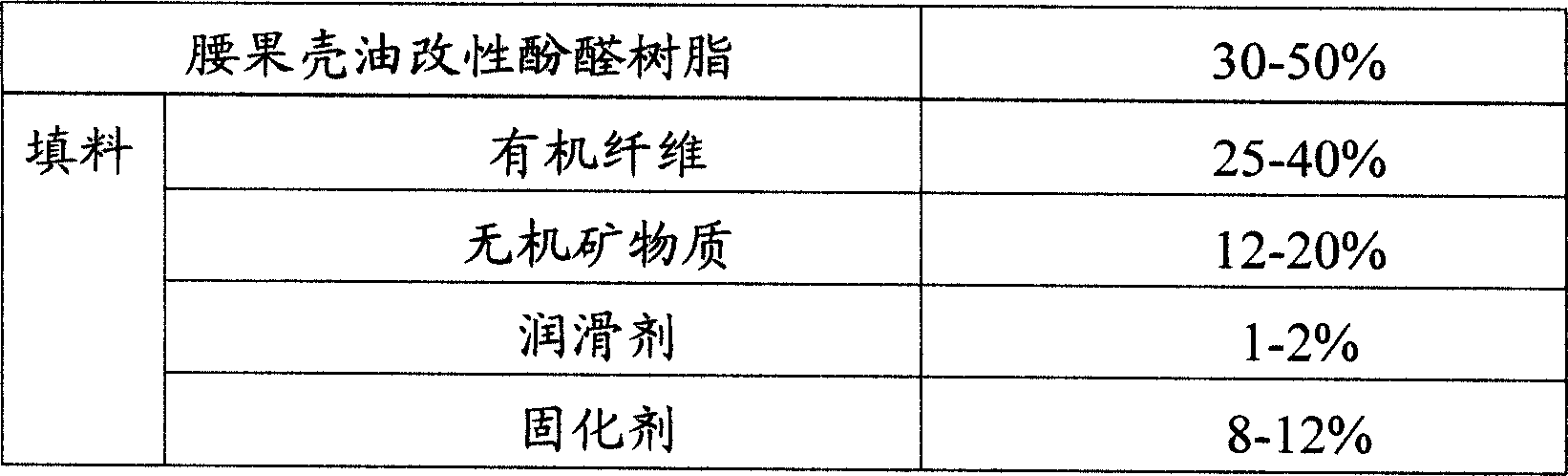

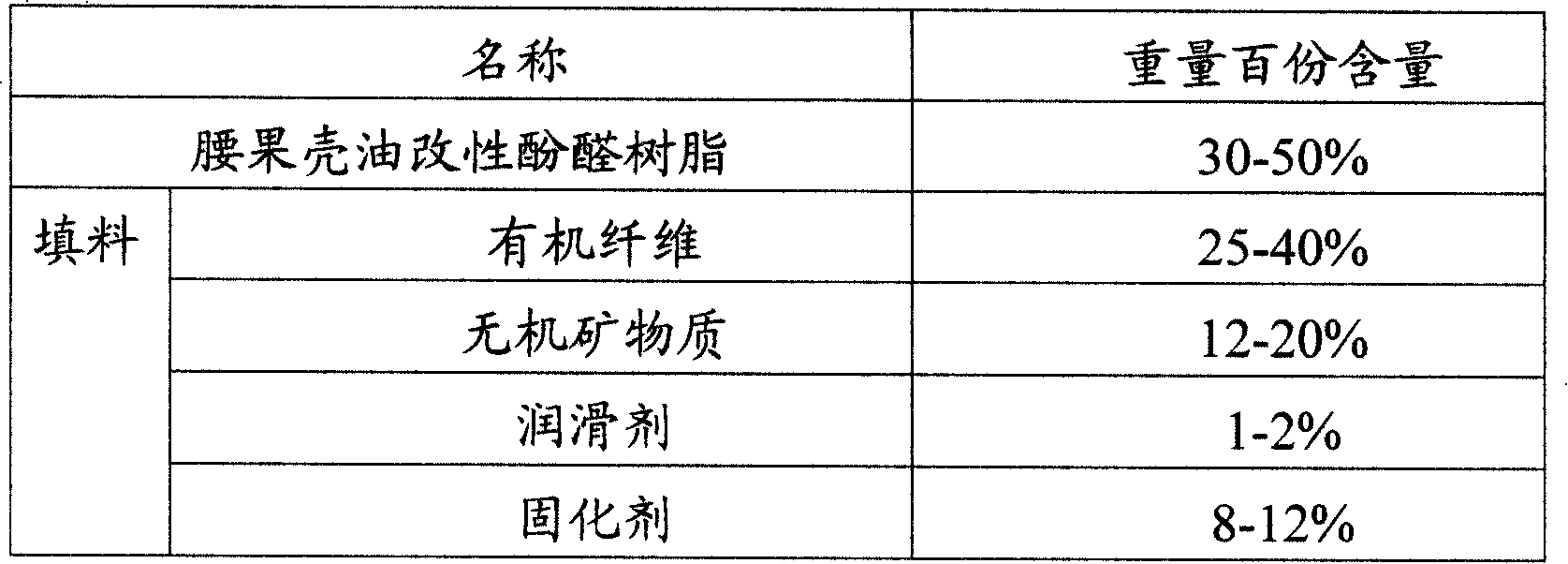

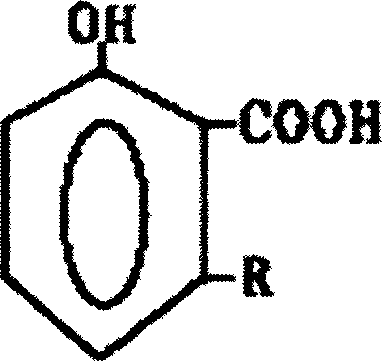

Cashew nut oil modified alkyd resin moulding material and preparation method thereof

The invention provides a modified phenolic resin moulding material of cashew nut shell oil and a preparation method thereof. The modified phenolic resin moulding material of cashew nut shell oil is made by mixing, milling and synthesizing following components including a. an adhesive of the modified phenolic resin of cashew nut shell oil; b. a curing agent of hexamine; c. organic and inorganic fillers; d. a lubricant of stearic acid and homologs under the temperature of 100 DEG C to 120 DEG C. Then a moulding material of the improved temperature resistance, the impact resistance, the electrical insulation resistance and the increased toughness can be produced.

Owner:浙江南方塑胶制造有限公司

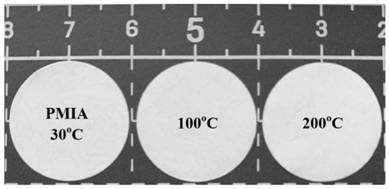

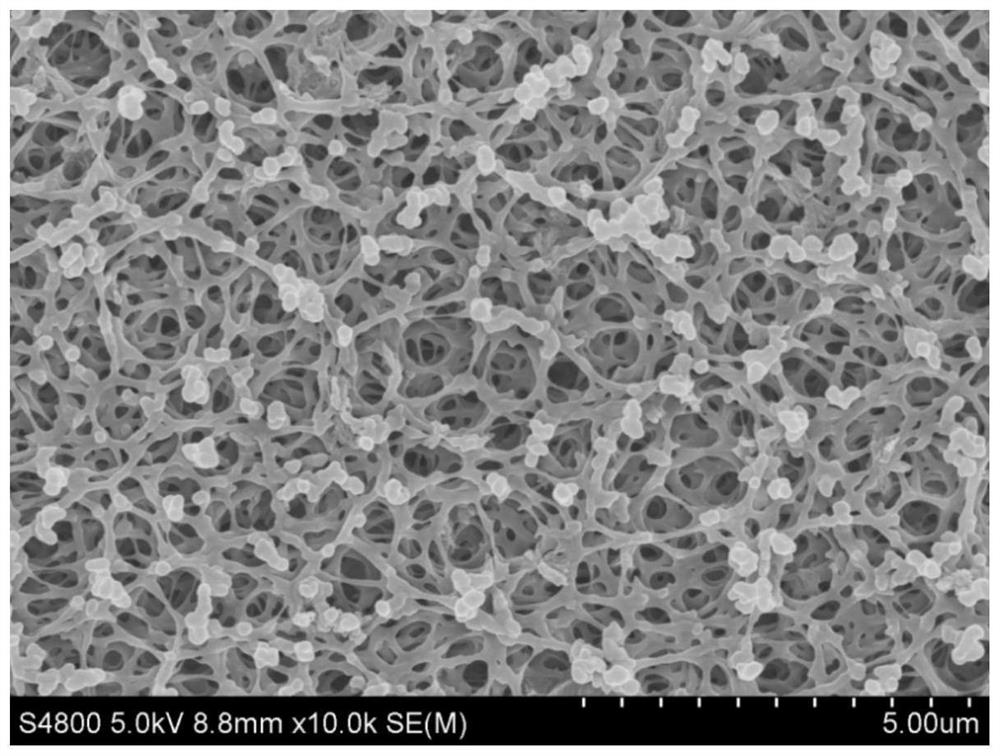

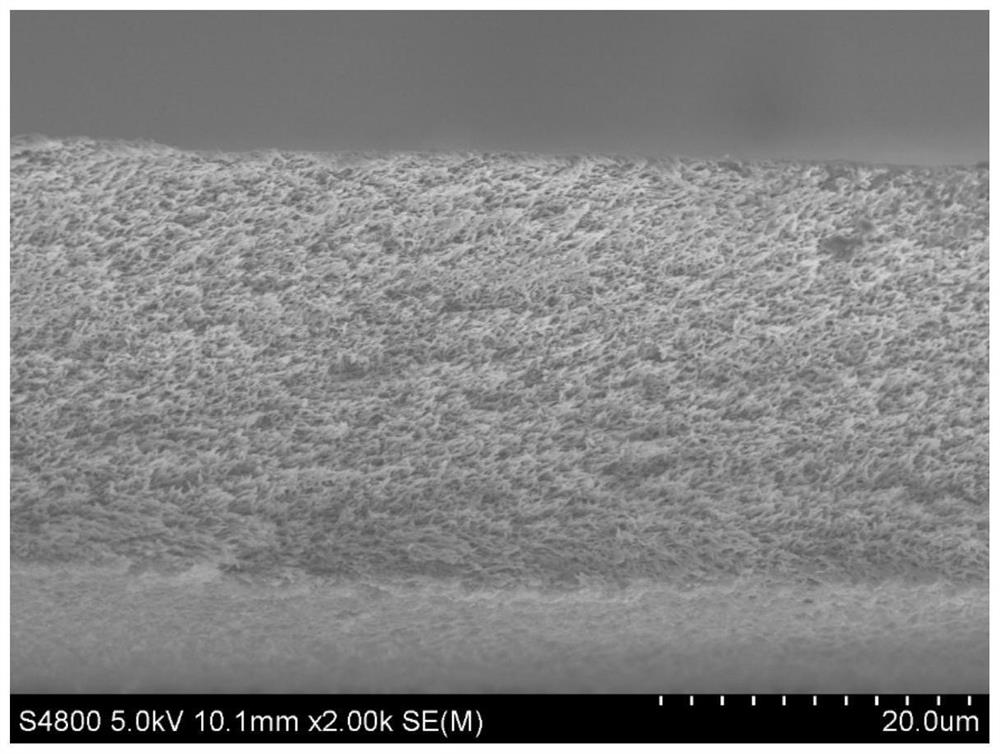

Method for preparing porous meta-aramid diaphragm through non-solvent induced phase separation method

InactiveCN113381122AImprove electrochemical performanceImprove wettabilitySecondary cellsCell component detailsNon solventElectrolytic agent

The invention discloses a method for preparing a porous meta-aramid diaphragm through a non-solvent induced phase separation method and an application of the porous meta-aramid diaphragm in a lithium ion battery diaphragm. According to the method disclosed by the invention, the porous meta-aramid diaphragm with an excellent epidermal pore structure and an excellent internal pore structure is prepared by adjusting the composition of a membrane casting solution, the composition of a coagulating bath and forming conditions and adopting a stepped coagulating bath. The porous meta-aramid diaphragm is high in porosity and uniform in structure, and the high-temperature-resistant diaphragm has excellent mechanical performance and wettability to an electrolyte so that reduction of a lithium ion transmission internal resistance is facilitated, and the electrochemical performance of a battery is improved; and the preparation process is simple, the forming time is short, the preparation process is easy to adjust, the energy consumption is low, and the method is suitable for large-scale industrial production.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST

Integrated forming device for acrylic material bathtub and bathtub forming method

The invention discloses an integrated forming device for an acrylic material bathtub and a bathtub forming method. The integrated forming device for the acrylic material bathtub comprises a mold base provided with a mold cavity; a through hole is formed in the bottom of a cavity body of the mold cavity; the position below the through hole is communicated with a vacuum pump located outside the mold base; the position above the through hole is connected with an upper cover through a hinge; a male mold matched with the mold cavity is installed on the lower surface of the upper cover and is located over the mold cavity; an empty cavity is formed in the male mold and is internally provided with a heating pipe for heating the male mold; and the mold base and the upper cover are each provided with a clamping device pressing the edge of an acrylic plate in a matched manner. The integrated forming device for the acrylic material bathtub integrates blister with mold pressing, the problem that the blister forming time is long is solved, the mold pressing plays a role of pre-forming, it can be guaranteed that the machined acrylic plate is in a state capable of being subjected to blister in the mold pressing process, and the blister forming time is shortened.

Owner:什邡市中天洁具有限责任公司

Method for extracting, processing and reconstructing point cloud data of dental crown by adopting digital laminar shear

InactiveCN106923853AHigh precisionConducive to remedial programsOthrodonticsComputerised tomographsAnalysis dataPoint cloud

The invention provides a method for extracting, processing and reconstructing point cloud data of the dental crown by adopting digital laminar shear, aiming at converting point cloud data into a gray level image with the topological structure. The method comprises the following steps: first, cutting a dental model into a plurality of pieces of three-dimensional stratified data with the same thickness, then, carrying out two dimensionalization on the three-dimensional stratified data, extracting the cross-section data such as the outer contour of the dental crown on the basis, and carrying out data analysis treatment, thus obtaining the gray level image with the topological structure, which is convenient for further generating of data capable of realizing 3D printing. In match with the correcting scheme of an orthodontic doctor, the moving methods including the inclined movement, root control movement, translation movement, rotation movement, vertical movement and the like for the teeth are realized in the digital dental model, and in addition, the method closely combines the dynamic mask imaging technology realizing DLP (facial exposure) 3D printing formation, and the purpose of rapid formation is realized.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

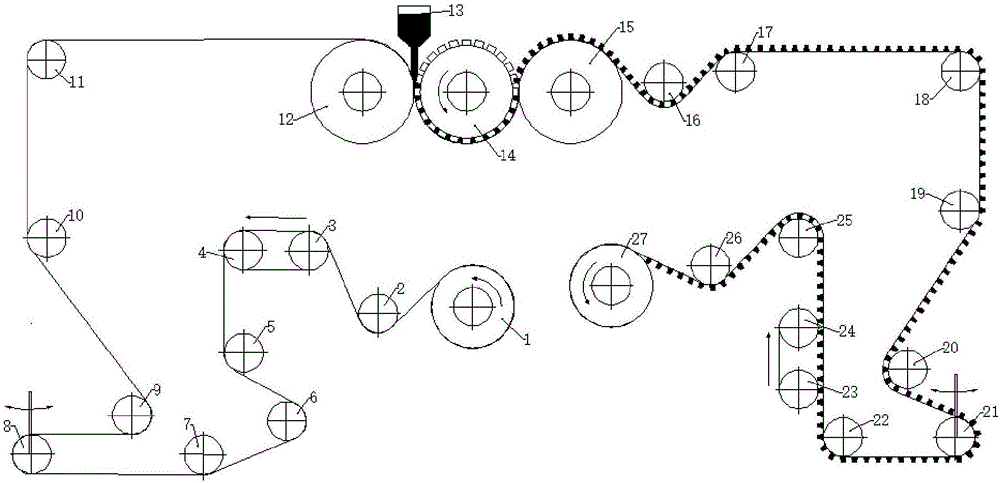

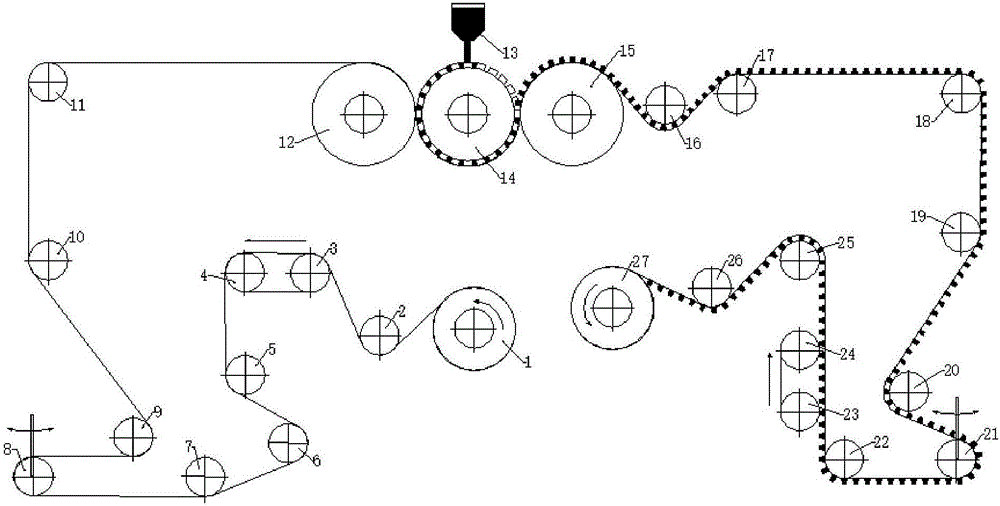

Roll-to-roll hot rolling powder forming method and system for thin polymer film surface microstructure

The invention relates to a roll-to-roll hot rolling powder forming method and system for a thin polymer film surface microstructure. The method includes the steps that a base material is sent out through an unwinding roller, and then is evenly wrapped with polymer powder through a powder feeding device; heating, forming, cooling and tensile force adjusting are carried out; and finally, winding is performed through a winding roller. The system comprises the unwinding roller, driving rollers, transfer rollers, tensioning rollers, deviation rectifying devices, a pressure roller, a mold roller, a cooling roller, the powder feeding device and the winding roller, wherein the driving rollers, the transfer rollers, the tensioning rollers and the deviation rectifying devices are arranged in the conveying process; the pressure roller, the mold roller and the cooling roller are arranged in the conveying process and are connected with one another; and the powder feeding device is arranged between the pressure roller and the mold roller or above the mold roller. By the adoption of the method and system, good mobility of the polymer powder is adopted, mold filling time is shortened, and the rolling speed is greatly increased; moreover, material deformation is small, the microstructure resilience is small after demolding, and structural precision is high; and meanwhile, ingredients of the powder can be composed of various materials, raw materials of the powder can be allocated according to the application requirements, and thus a thin polymer film with different optical characteristics can be prepared.

Owner:SHANGHAI JIAO TONG UNIV

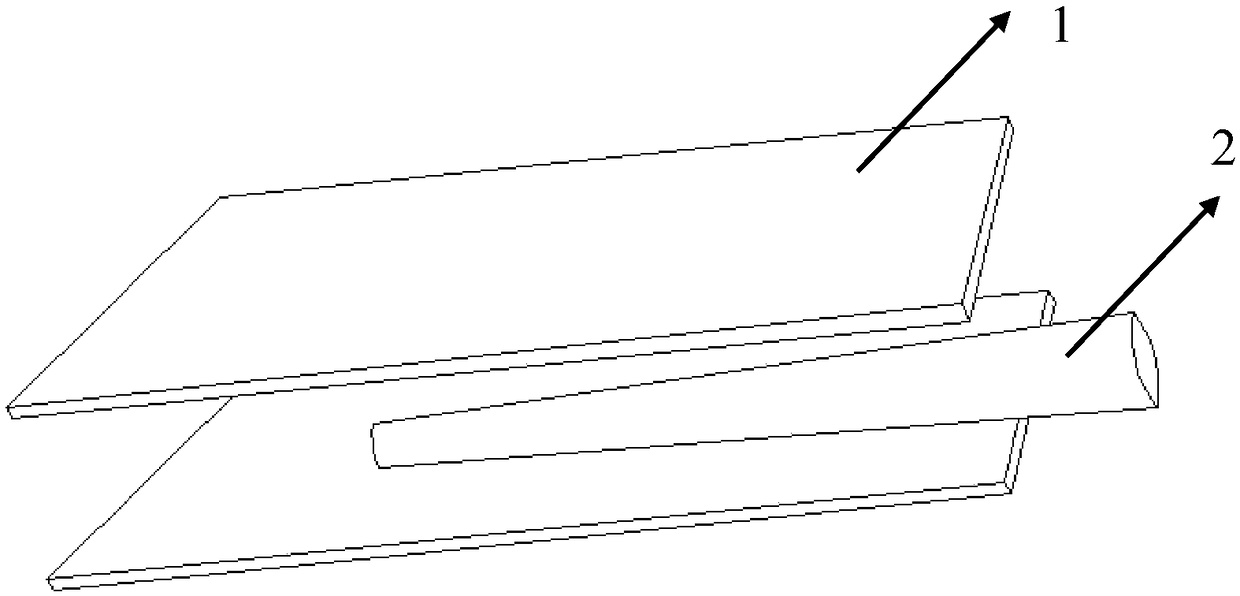

Continuous fiber enhanced thermoplastic resin composite paddle and preparation method thereof

ActiveCN108192201AIn line with the development trend of green environmental protectionHigh strengthDomestic articlesCoatingsMechanical propertyCorrosion resistant

The invention discloses a preparation method of a continuous fiber enhanced thermoplastic resin composite paddle. The method comprises the following steps: preparing a continuous fiber enhanced thermoplastic resin unidirectional prepreg tape; clipping the unidirectional prepreg tape into two types of master slices along a 0-degree direction and a 90-degree direction, alternately stacking master slice groups formed by the two types of master slices in an orthometric manner, laying a core model in the middle of the master slice groups, transferring the master slice groups into a paddle die, performing hot press molding, and then performing machining trimming treatment, so as to obtain the paddle. The preparation method adopts hot-pressing technology, realizes one-step molding, is short in molding time, and ensures that product size is accurate and controllable; the formed paddle is excellent in mechanical property, anti-fatigue performance and corrosion-resistant performance, is light inweight and recyclable, and can be machined repeatedly.

Owner:CGN JUNER NEW MATERIALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com