Quick concrete assembly type joint and method for constructing same

A construction method and assembly technology, which is applied in the direction of construction and building construction, can solve the problems of slow assembly speed, low shear and bending resistance, poor bonding performance, etc., and achieve the effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings and examples.

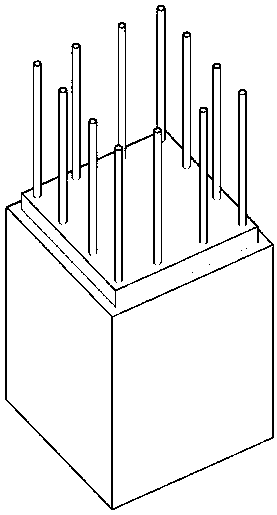

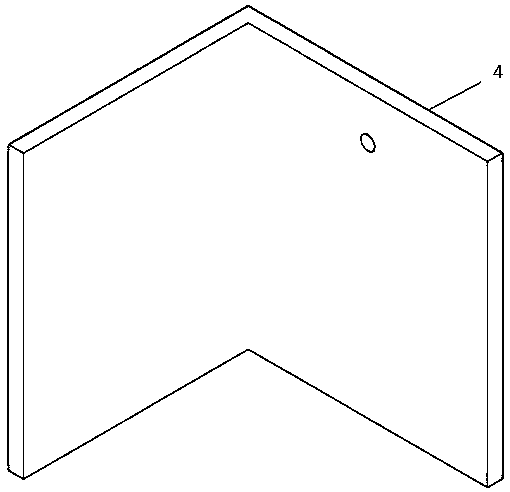

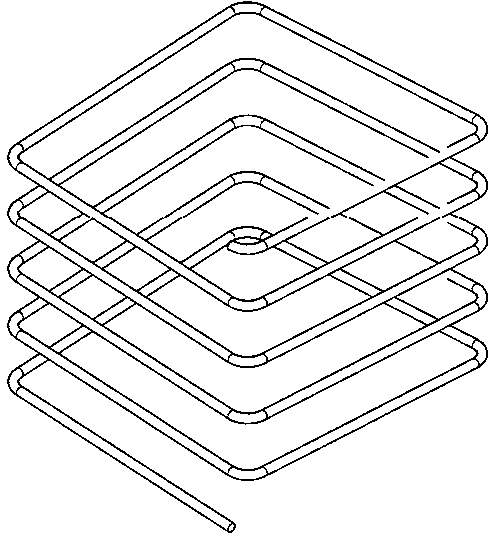

[0041] Figure 1 to Figure 3 It is a detailed drawing of each component that forms the invention.

[0042] Such as figure 1 As shown, it is a prefabricated assembled column, and a piece of steel bar is reserved at the end of the prefabricated column (the length of the steel bar should not be less than 40 times the diameter of the steel bar or the length of the longitudinal bar is not less than 500mm), and the reserved steel bar is the longitudinal bar of the column. The end of the prefabricated column is made into a stepped shape. The prefabricated column is poured with ordinary Portland concrete and cured for more than 28 days under standard curing conditions. The end face of the column has a certain roughness.

[0043] Such as figure 2 As shown, in order to support the L-shaped st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com