Method for preparing porous meta-aramid diaphragm through non-solvent induced phase separation method

A phase separation method and non-solvent technology, which is used in the field of preparing porous meta-aramid fiber membranes and preparing meta-aramid fiber membranes, which can solve the problems of increased battery resistance, shrinkage, and poor wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

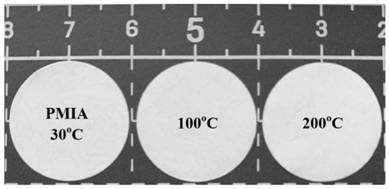

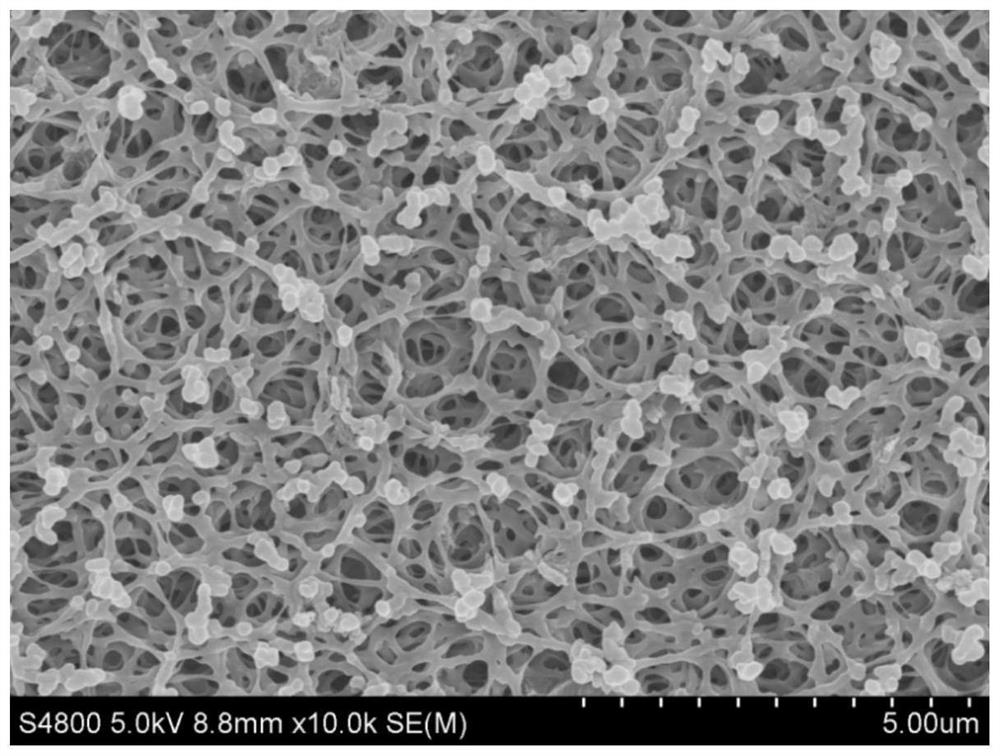

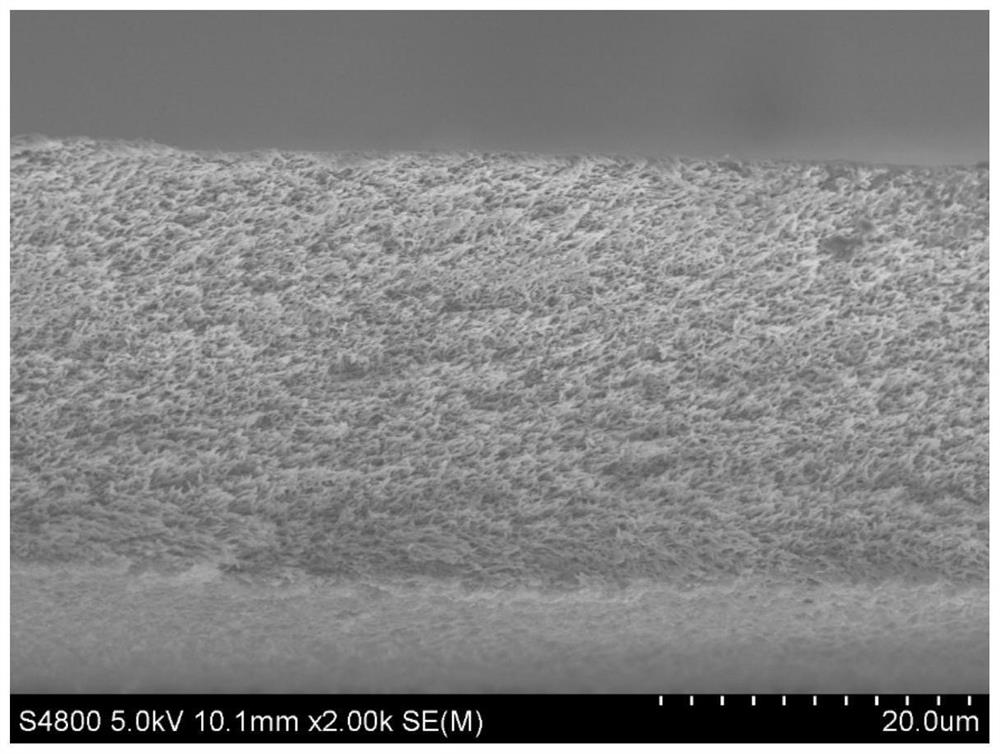

Embodiment 1

[0031]Prepare the casting solution: blend 3% lithium bromide, 1% water and dimethylacetamide relative to the entire casting solution system, then slowly add it dropwise to the PMIA stock solution, stir, and add 0.5% glycerol , stirred for 12 hours until a uniform solution was obtained; then it was subjected to centrifugal degassing at 6000r / min to obtain a homogeneous transparent casting solution. Preparation of coagulation bath: use V (dimethylacetamide): V (glycerol) = 7: 3 to prepare coagulation bath solution C1; use V (dimethylacetamide): V (water) = 3: 7 to prepare coagulation bath solution C2; pour the prepared film casting solution on the forming substrate, and use a 100 μm scraper to scrape it into a film, and then put it in the coagulation bath C1 for 30 seconds; in the coagulation bath C2 for 30 seconds; finally put it into pure 12h in water. After the residual solvent was removed, the PMIA separator was rinsed with deionized water three times, and then dried in a v...

Embodiment 2

[0033] Prepare the casting solution: blend 1% lithium bromide, 3% water and dimethylformamide relative to the entire casting solution system, then slowly add it dropwise to the PMIA stock solution, and stir for 10 hours until a uniform solution is obtained; then It was subjected to centrifugal defoaming at 8000r / min to obtain a homogeneous transparent casting solution. Prepare coagulation bath: use V (dimethylformamide): V (glycerol) = 5:5 to prepare coagulation bath solution C1; use V (dimethylformamide): V (water) = 2:8 to prepare coagulation bath solution C2; pour the prepared film casting solution on the forming substrate, and use a 150 μm scraper to scrape it into a film, and then put it in the coagulation bath C1 for 120s; in the coagulation bath C2 for 120s; 12h in water. After the residual solvent was removed, the PMIA separator was rinsed with deionized water three times, and then dried in a vacuum oven at 60° C. for 12 hours to obtain a PMIA separator that can be us...

Embodiment 3

[0035] Prepare the casting solution: blend 4.5% calcium chloride and dimethyl sulfoxide relative to the entire casting solution system, then slowly add it dropwise to the PMIA stock solution, stir, add 1% glycerol, and stir for 6h Until a uniform solution is obtained; then it is subjected to centrifugal defoaming at 6000r / min to obtain a homogeneous transparent casting solution. Preparation of coagulation bath: use V (dimethyl sulfoxide): V (water) = 6: 4 to prepare coagulation bath solution C1; use pure water as coagulation bath solution C2; pour the prepared casting solution on the molding substrate, and use Scrape it with an 80 μm doctor blade to form a film, and then put it in the coagulation bath C1 for 30 seconds; in the coagulation bath C2 for 12 hours. After the residual solvent was removed, the PMIA separator was rinsed with deionized water three times, and then dried in a vacuum oven at 60° C. for 12 hours to obtain a PMIA separator that can be used in lithium-ion ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com