Method for preparing thermosetting boron-containing phenolic resin powder

A boron phenolic resin and thermosetting technology, which is applied in the field of synthetic resin powder preparation, can solve the problems of poor fluidity of phenolic resin, easy bonding and agglomeration of phenolic resin powder, etc., and achieves fast curing speed, excellent storage stability and good fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

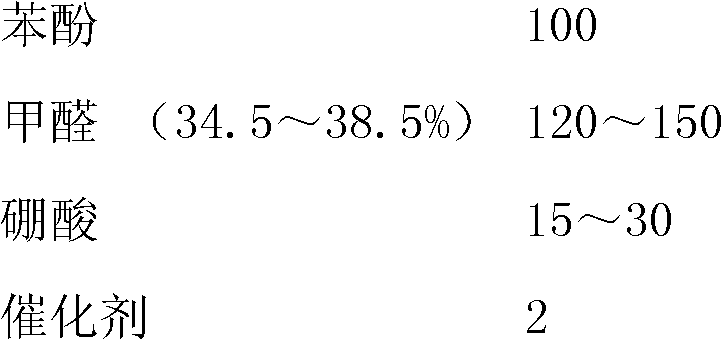

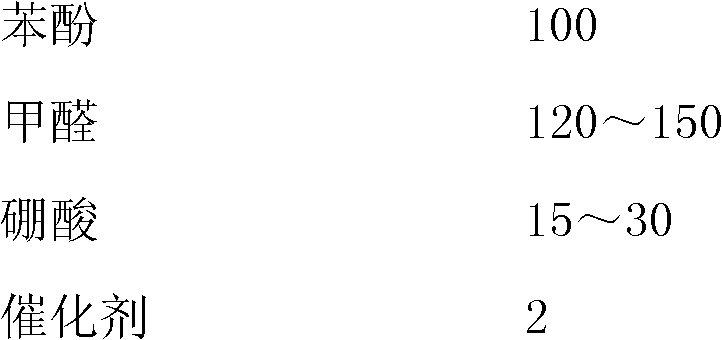

[0030] Preparation of thermosetting boron phenolic resin: first 100 grams of preheated and molten phenol, 130 grams of formaldehyde (36.5%) are sucked into the reactor by vacuum, then add 1 gram of zinc oxide and 1 gram of zinc acetate, and stir Heat up to boiling, keep warm for 2 hours, then add 18 grams of boric acid, keep the temperature at 80-90°C, react until the system becomes turbid, heat up to boiling, keep warm for 0.5 hours, and dehydrate under reduced pressure to obtain 167.0 grams of the thermosetting boron phenolic resin.

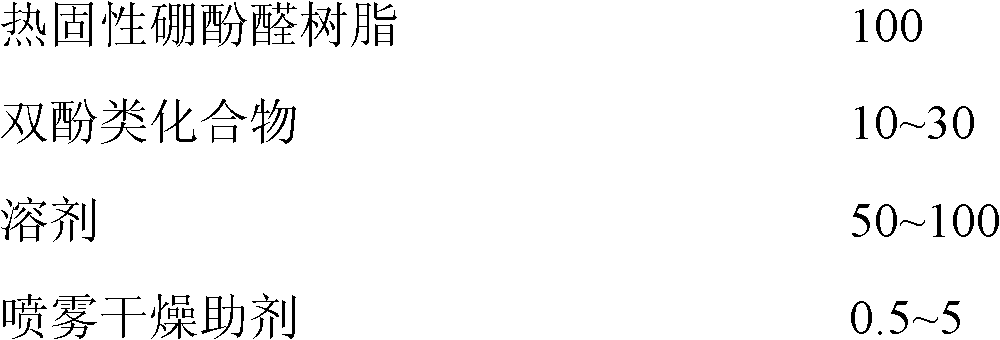

[0031] Preparation of the spray-dried composition: Take the above-mentioned 100 grams of thermosetting boron phenolic resin, 20 grams of bisphenol A, 50 grams of acetone, and 0.5 grams of OP-10 and mix them evenly to obtain 170.5 grams of the spray-dried composition with a viscosity of 1000 mPa.s / 25°C.

[0032] The above spray-dried composition was spray-dried in a spray-drying device (inlet temperature 80° C., outlet temperature 150° C.) to ...

Embodiment 2

[0034] Preparation of thermosetting boron phenolic resin: first 100 grams of preheated fused phenol, 120 grams of formaldehyde (34.5%) are sucked into the reaction kettle by vacuum, then add 1 gram of magnesium oxide and 1 gram of zinc acetate, and stir. Heat up to boiling, keep warm for 3 hours, then add 15 grams of boric acid, keep the temperature at 90-100°C, react until the system becomes turbid, heat up to boiling, keep warm for 1 hour, and dehydrate under reduced pressure to obtain 161.0 grams of the thermosetting boron phenolic resin.

[0035] Preparation of the spray-dried composition: Take the above-mentioned 100 grams of thermosetting boron phenolic resin, 10 grams of resorcinol, 100 grams of methanol, and 5 grams of Tween-20 and mix them evenly to obtain 215 grams of the spray-dried composition, which has a viscosity of 3000 mPa. s / 25°C.

[0036] The above spray-dried composition was spray-dried in a spray-drying device (inlet temperature 80° C., outlet temperature...

Embodiment 3

[0038] Preparation of thermosetting boron phenolic resin: first 100 grams of preheated and molten phenol, 120 grams of formaldehyde (38.5%) are sucked into the reactor by vacuum, then add 1 gram of zinc oxide and 1 gram of zinc acetate, and stir Heat up to boiling, keep warm for 3 hours, then add 30 grams of boric acid, keep the temperature at 80-90°C, react until the system becomes turbid, heat up to boiling, keep warm for 1 hour, and dehydrate under reduced pressure to obtain 176.0 grams of the thermosetting boron phenolic resin.

[0039] Preparation of the spray-dried composition: Take the above-mentioned 100 grams of thermosetting boron phenolic resin, 30 grams of bisphenol F, 50 grams of ethanol, and 0.5 grams of OP-7 and mix them evenly to obtain 180.5 grams of the spray-dried composition with a viscosity of 2000 mPa.s / 25°C.

[0040] The above spray-dried composition was spray-dried in a spray-drying device (inlet temperature 80° C., outlet temperature 150° C.) to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com