Roll-to-roll hot rolling powder forming method and system for thin polymer film surface microstructure

A polymer film, hot rolling technology, used in household appliances, other household appliances, flat products, etc., can solve the problems of less than 20% light emitting efficiency, no way to process powdery raw materials, and less than 60% light utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

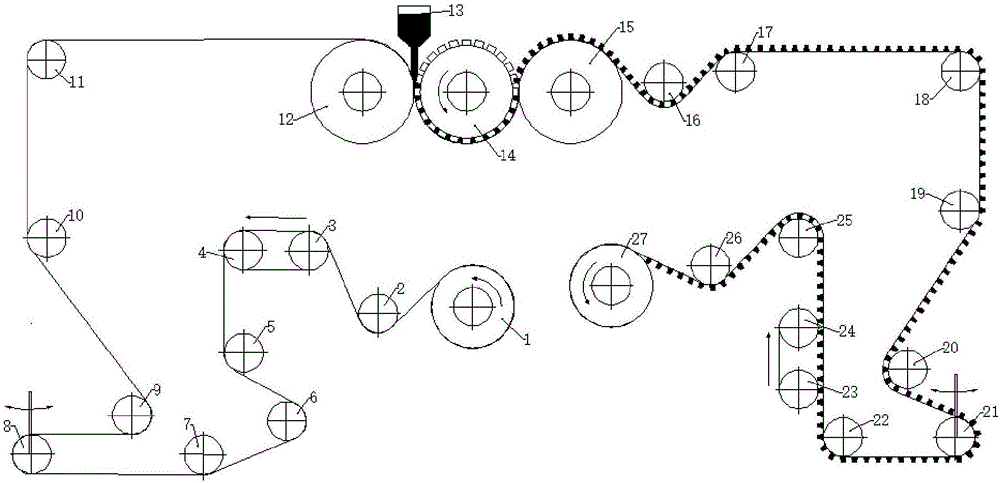

[0045] Roll-to-roll hot rolling polymer film surface microstructure powder forming system, such as figure 1 As shown, the present embodiment comprises: unwinding roller 1, the first driving roller 6, the second driving roller 11, the third driving roller 18, the fourth driving roller 20 and the fifth driving roller 25, the first transmission roller 2, the second driving roller The second conveying roller 5, the third conveying roller 7, the fourth conveying roller 9, the fifth conveying roller 10, the sixth conveying roller 16, the seventh conveying roller 17, the eighth conveying roller 19, the ninth conveying roller 22 and the tenth conveying roller Roller 26, first tension roller 8 and second tension roller 21, pressure roller 12, mold roller 14, cooling roller 15, powder supply device 13, winding roller 27, first deviation correction device 3, second deviation correction device 4 , the third deviation correcting device 23 and the fourth deviation correcting device 24 .

...

Embodiment 2

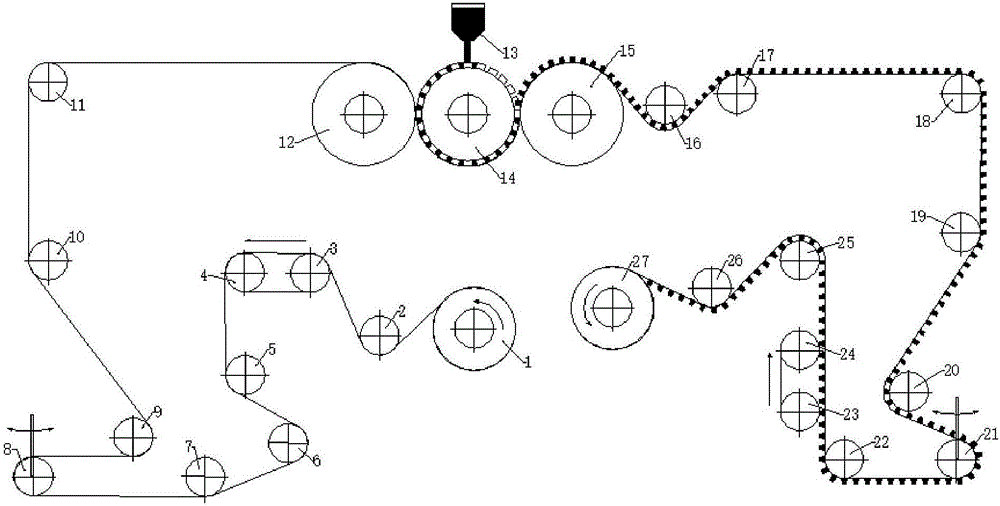

[0049] Roll-to-roll hot rolling polymer film surface microstructure powder forming system, such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the powder supply device 13 is placed directly above the mold roller 14 .

[0050] First, heat the mold roller at 14 to 140°C, set the speed at 0.1m / min, put PE polymer powder through the powder inlet, start the motor to control the stirring device to stir the powder in the powder supply device 13 at a certain speed, and adjust the powder supply device The powder supply port of 13 is directly above the mold roller 14, then open the powder supply port, and evenly spread a PE polymer powder layer with a thickness of about 200um on the surface of the mold roller 14, set the pressure of the pressure roller 12 to 700N, and press the pressure roller 12 to the mold. The movement of the roller 14 drives the PET base material to press and contact with the mold roller 14. The polymer powder is pressed to fo...

Embodiment 3

[0052] Roll-to-roll hot rolling polymer film surface microstructure powder forming system, such as image 3 As shown, the present embodiment comprises: unwinding roller 1, the first driving roller 6, the second driving roller 11, the third driving roller 18, the fourth driving roller 20 and the fifth driving roller 25, the first transmission roller 2, the second driving roller The second conveying roller 5, the third conveying roller 7, the fourth conveying roller 9, the fifth conveying roller 10, the sixth conveying roller 16, the seventh conveying roller 17, the eighth conveying roller 19, the ninth conveying roller 22 and the tenth conveying roller Roller 26, first tension roller 8 and second tension roller 21, pressure roller 12, mold roller 14, cooling roller 15, powder supply device 13, winding roller 27, first deviation correction device 3, second deviation correction device 4 , the third deviation correction device 23 and the fourth deviation correction device 24, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com