Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3198 results about "Dibutyl phthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dibutyl phthalate (DBP) is an organic compound commonly used plasticizer. With the chemical formula C₆H₄(CO₂C₄H₉)₂, it is a colorless oil, although commercial samples are often yellow. Because of its low toxicity and wide liquid range, it is used as a plasticizer.

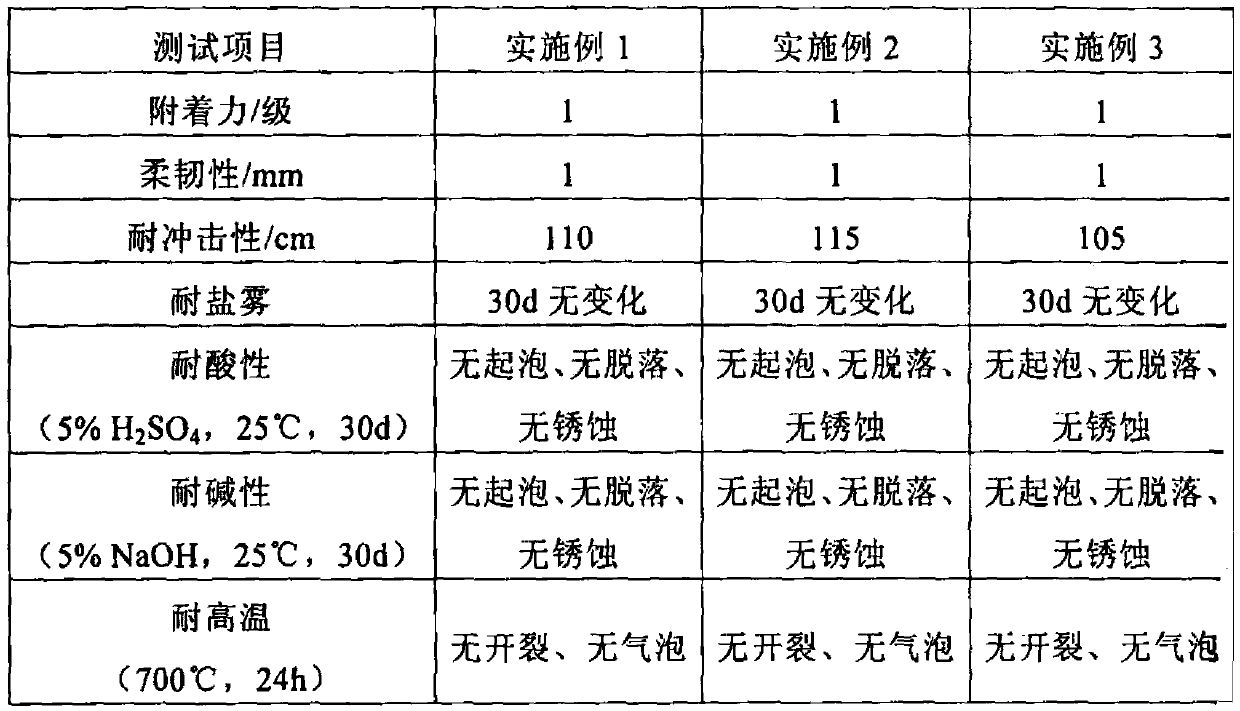

High temperature resistant anticorrosion coating based on graphene and preparation method thereof

InactiveCN103589281AImprove high temperature resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySodium Bentonite

The invention relates to a high temperature resistant anticorrosion coating based on graphene and a preparation method thereof. The high temperature anticorrosion coating comprises the following components by the mass percentage: 5-60% of epoxy resin, 3-30% of polyphenylene sulfide resin, 3-30% of amino resin, 1-10% of a pigment, 1-20% of graphene, 3-50% of n-butyl alcohol, 0.1-0.3% of a defoaming agent, 0.1-10% of polyhydroxy acid sodium salt, 0.1-5% of benzenedicarboxylic acid dibutyl ester, 0.5-1.0% of bentonite, and 0.2-0.5% of a leveling agent. Compared with the prior art, the prepared coating has the advantages of quite excellent waterproof and anticorrosion performance, high temperature resistance, weather resistance, alkali resistance, impact resistance, artificial aging resistance and the like, and the preparation method has the advantages of good controllability, simple operation, low production cost, and easy industrialized production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

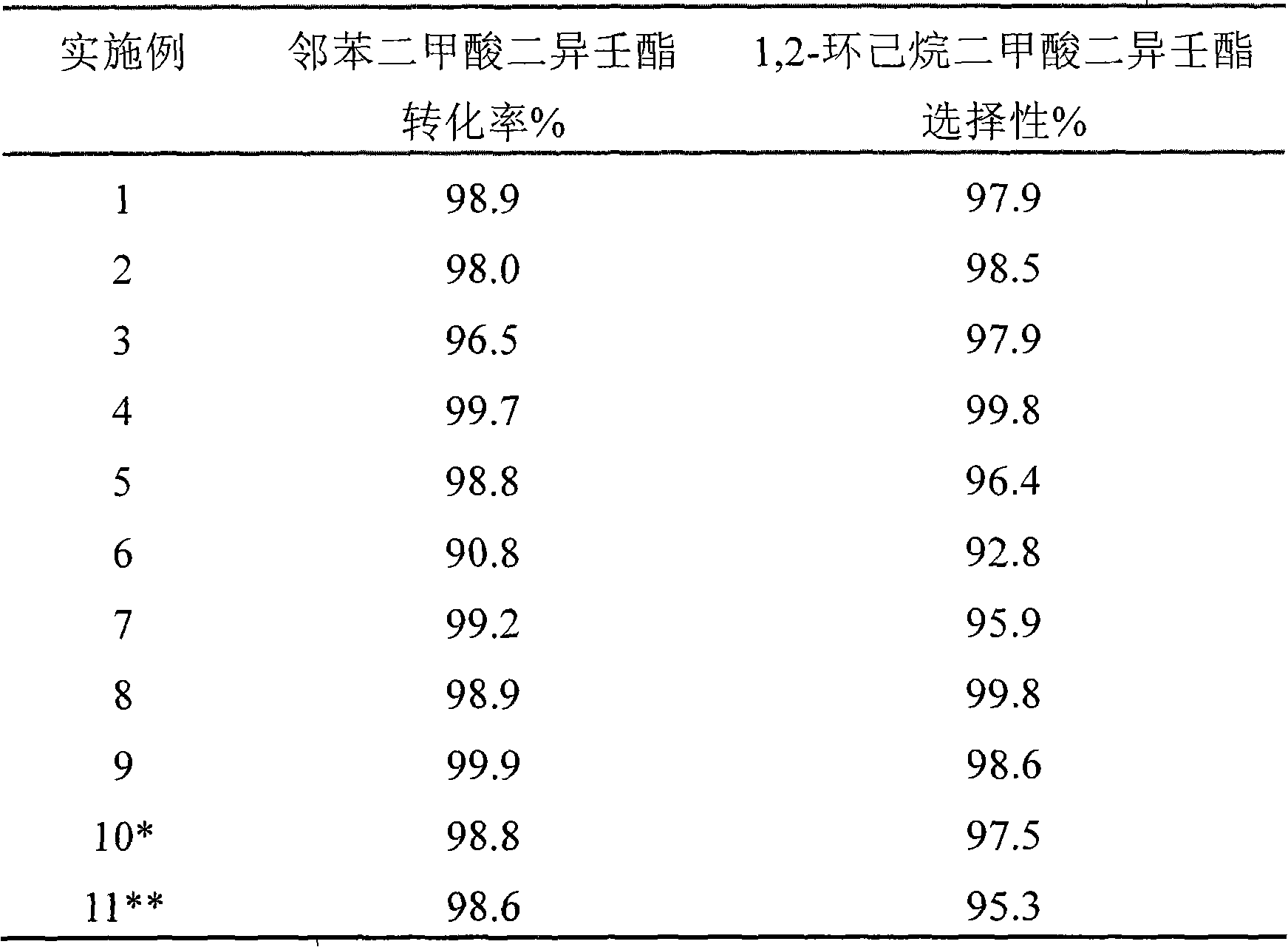

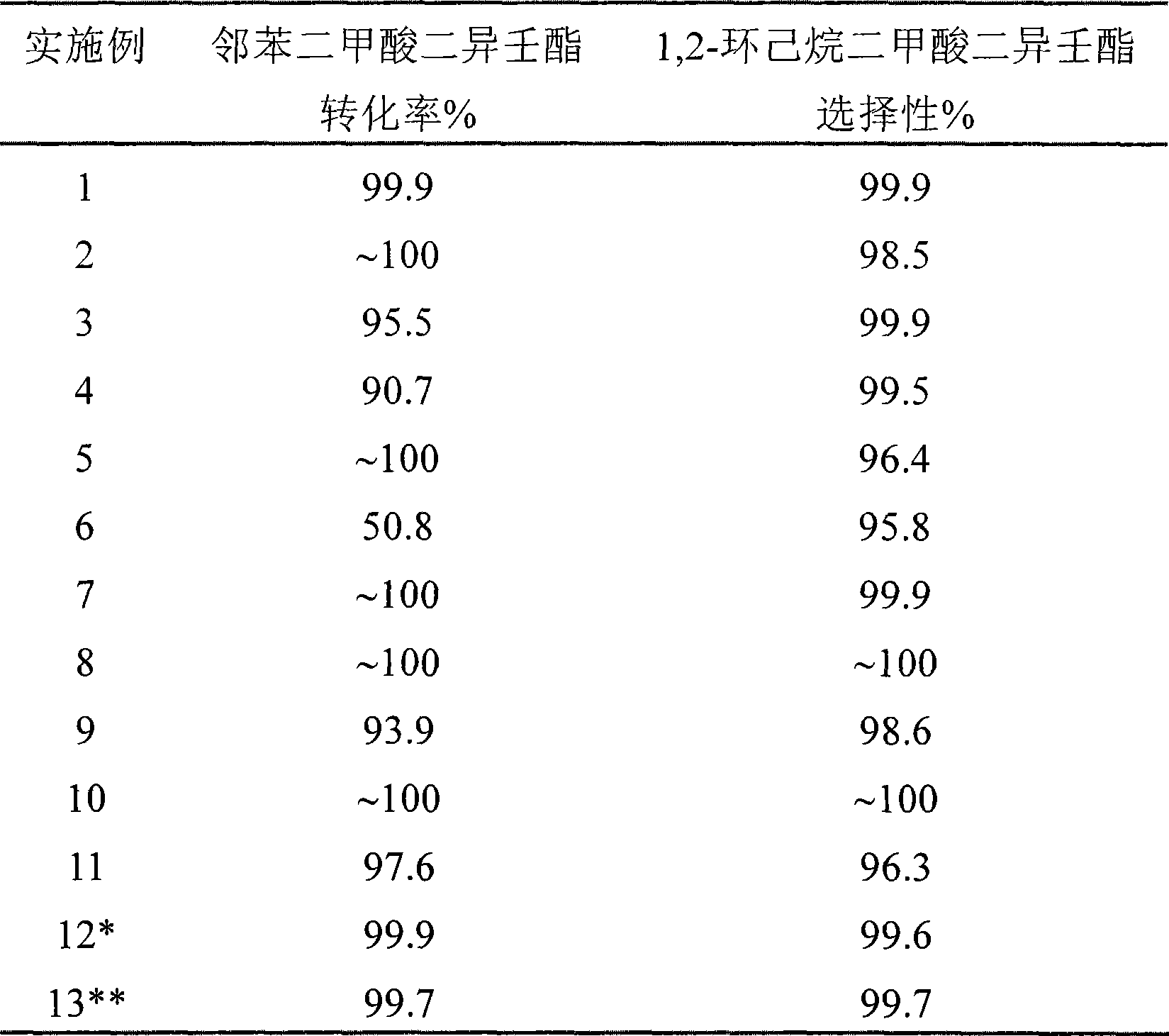

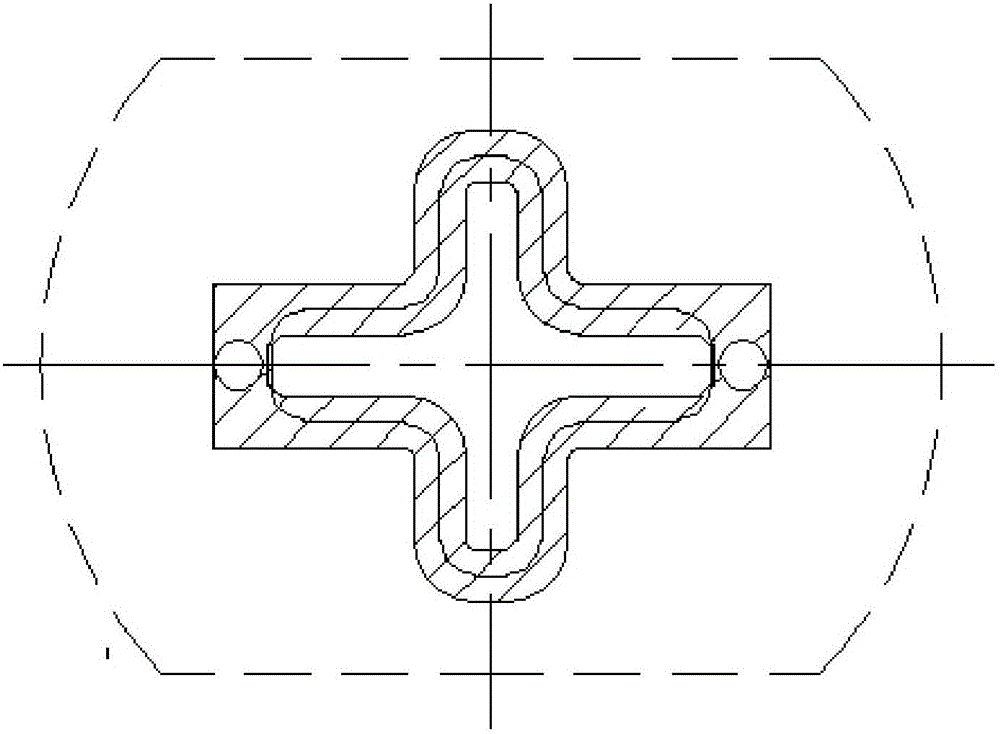

Catalyst for producing 1,2-cyclohexane dicarboxylic acid diesters

InactiveCN101406840AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationHydrogen pressureBULK ACTIVE INGREDIENT

The invention provides a catalyst for converting diisononyl phthalate, diisooctyl phthalate, dibutyl phthalate and other long-chain esters into corresponding 1, 2-cyclohexane dicarboxylic acid binary ester through hydrogenation. The catalyst for converting the diisononyl phthalate, the diisooctyl phthalate, the dibutyl phthalate and other long-chain esters into corresponding the 1,2-cyclohexane dicarboxylic acid binary ester through the hydrogenation consists of main active ingredients, additives and carriers, wherein the main active ingredients are noble metal Ru and Pd; the additives are Fe, Co, Ni, Cu and other metals or oxides; and macroporous Al2O3, ZrO2, TiO2 and the like are selected as the carriers. Under certain temperature, certain hydrogen pressure and the action of the catalyst, the diisononyl phthalate, the diisooctyl phthalate, the dibutyl phthalate and other long-chain esters in a trickle bed reactor can be converted into the corresponding the 1, 2-cyclohexane dicarboxylic acid binary ester with high activity and high selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

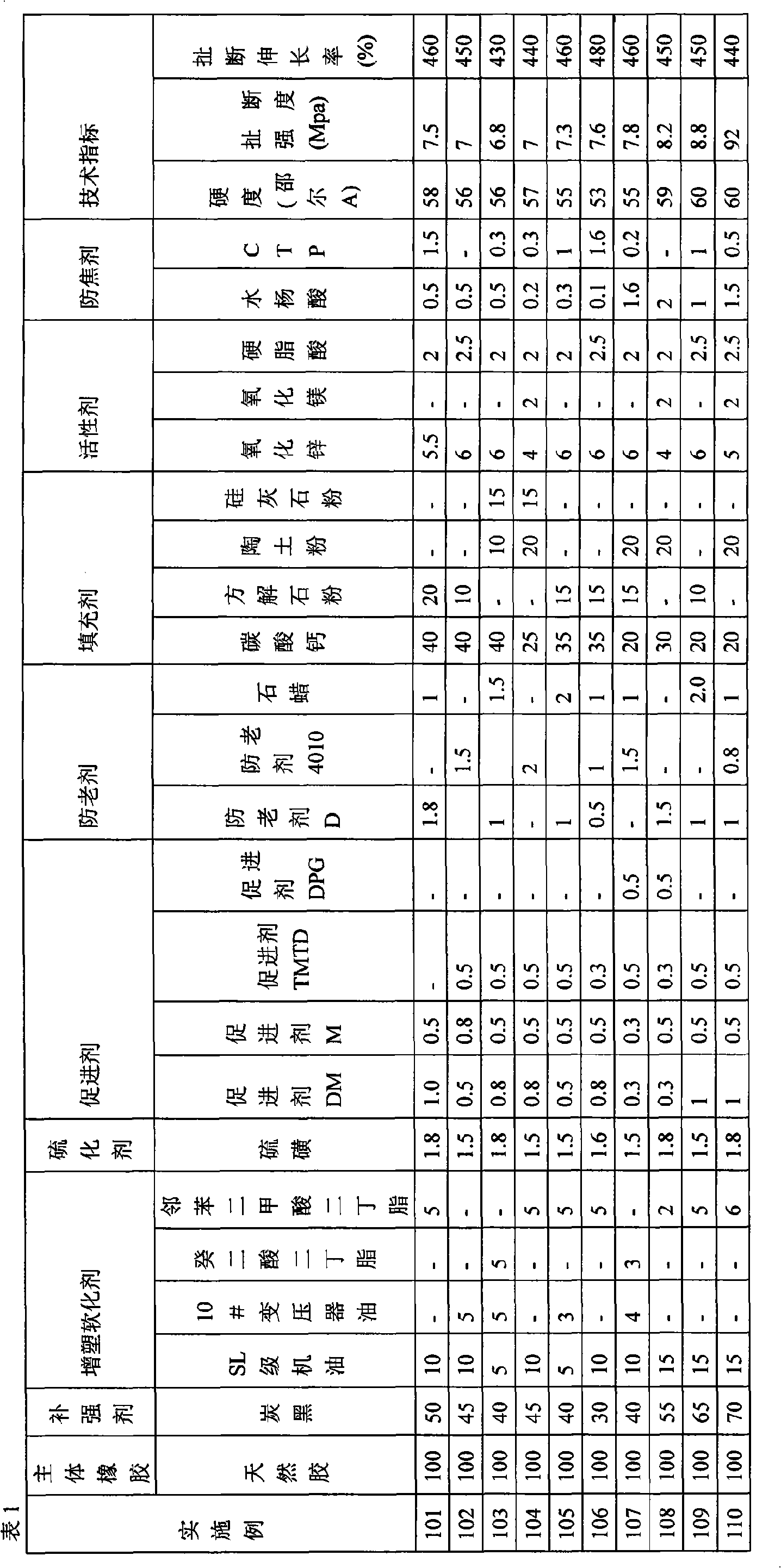

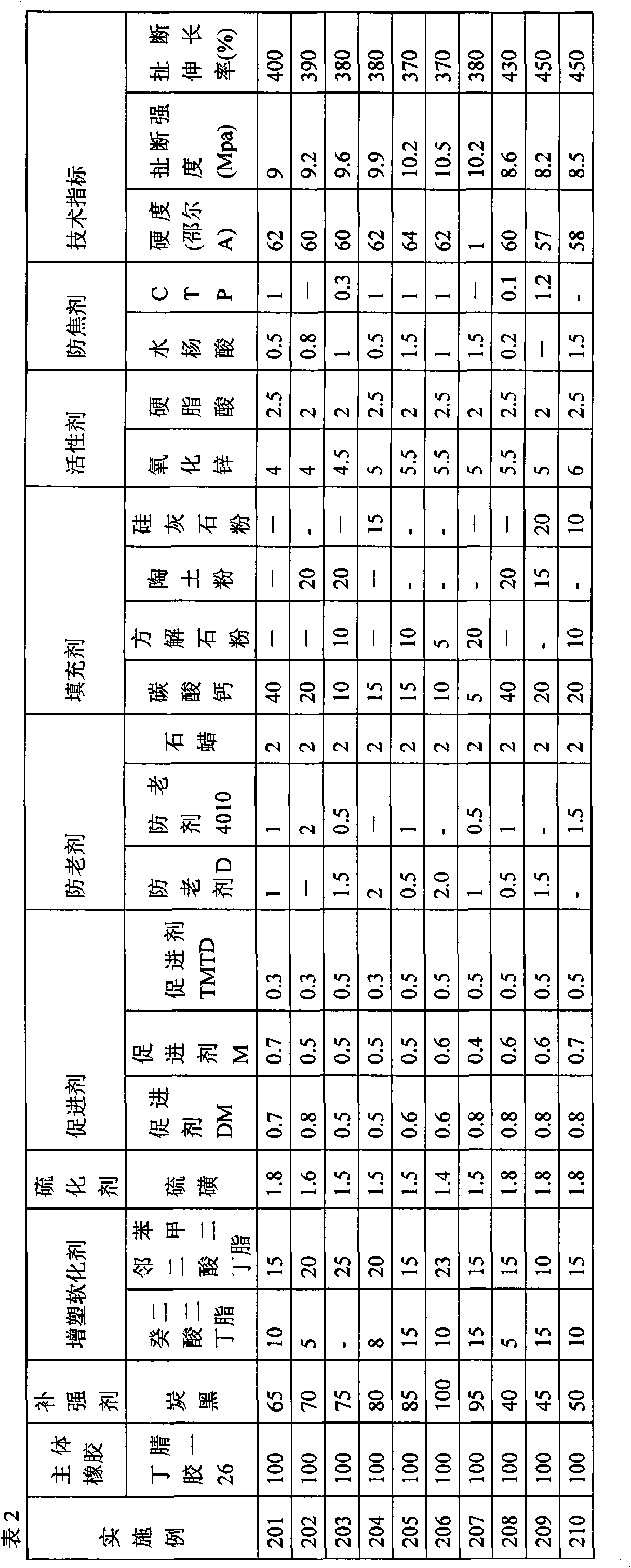

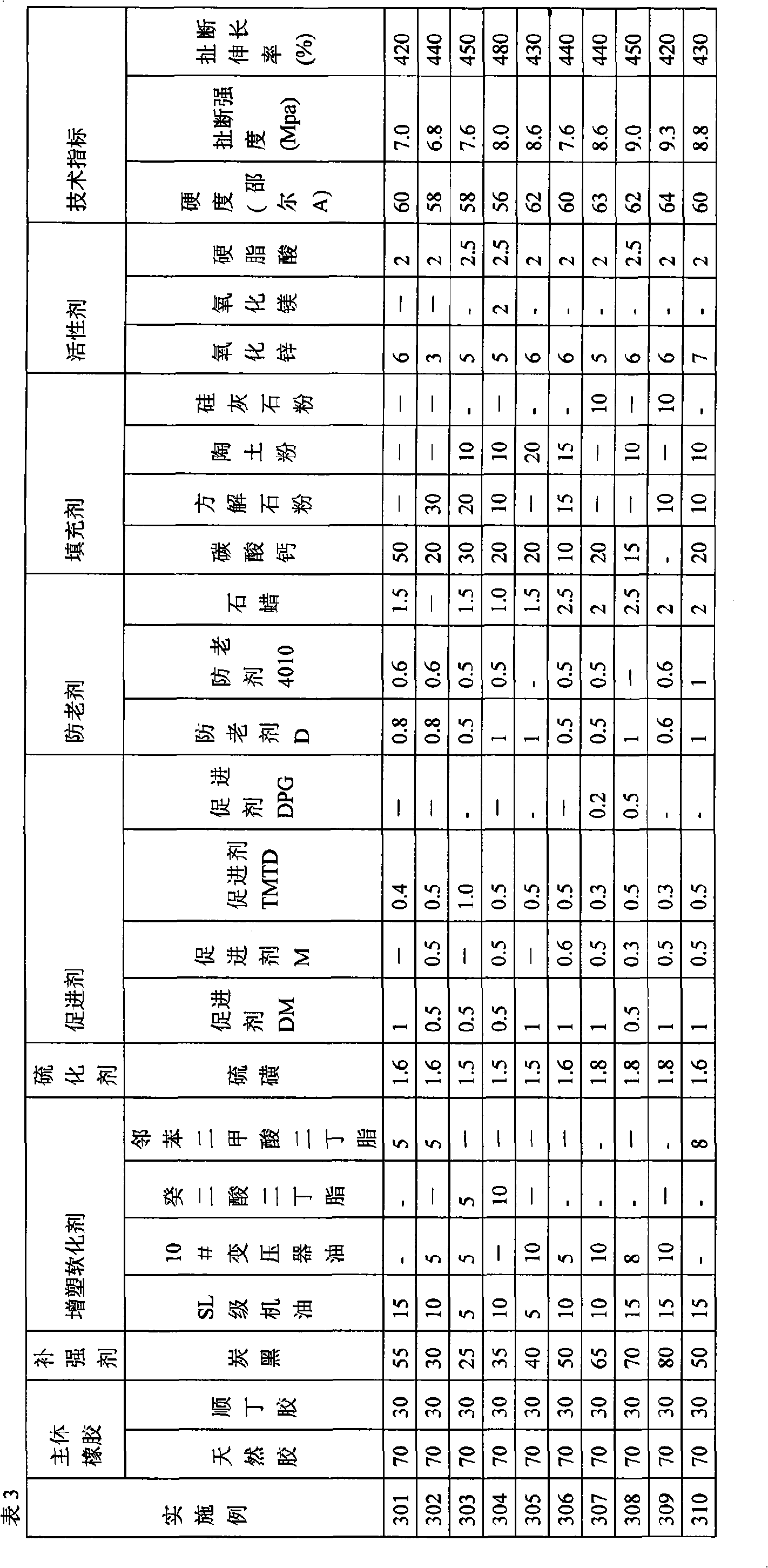

Cold resistant rubber

The invention aims at providing a low-temperature resistant rubber which can be used for a long time in low temperature and has almost the same tensile strength and elongation at break and the same hardness at low temperature as at normal temperature. The low-temperature resistant rubber contains main body rubber, strengthening agent, plasticization softener and curing ingredient, and the weight ratio of main body rubber : strengthening agent : plastifying softener : curing ingredient is 100:10-350:5-75:0.5-3; the main body rubber is natural gum, styrene-butadiene-rubber, cis-butadiene rubber, butyl rubber, ethylene propylene diene rubber, butadiene nitrile rubber or the combination of natural gum and cis-butadiene rubber; the strengthening agent is black carbon or white carbon; the plastifying softener is machine oil, transformer oil, dibutyl sebacate, dibutyl phthalate or silicon oil; the curing ingredient is 2,5-dimethyl curing ingredient or sulphur.

Owner:南京固柏橡塑制品有限公司

Method for preparing 1,2-cyclohexane cyclohexanedimethanol dibasic ester

ActiveCN101417950AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationReaction temperatureDibasic ester

The invention relates to a method for preparing 1, 2-cyclohexanedicarboxylic acid ester of binary, comprising a reaction system composed by binary phthalate ester, hydrogen and a catalyst; the reaction temperature ranges from 100 to 250 DEG C; the reaction pressure ranges from 3.0 to 12.0 Mpa; the molar ratio of H2 and X ranges from 50 to 450; the liquid space velocity of binary phthalate ester ranges from 0.1 to 2.5 h<-1>; the catalyst uses Al2O3, ZrO2, TiO2 or SiO2-Al2O3 as vehicle, and load active component can be Ru, Pt, Pd, Rh, Fe, Co, Ni and Cu; the binary phthalate ester is diisonynol phthalate, diisooctyl phthalate or dibutyl phthalate; the product 1, 2-cyclohexanedicarboxylic acid ester of binary is 1, 2-cyclohexane diisononyl dimethyl ester, 1, 2-cyclohexane diisooctyl dimethyl ester or 1, 2-cyclohexane dibutyl dimethyl ester.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Anticorrossion antiwear ceramic paint

InactiveCN1325931AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGlass fiber

An anticorrosion and antiwear ceramic paint is prepared from epoxy resin (28.5-35 wt.portions), dibutyl phthalate (3.75-6), mixed solvent of xyrene and n-butyl ester (20-24), gas-phase SiO2 (0.5-1) and ceramic powder (38-45) which contains TiO2 (3-6.3), Al2O3 (11.7-20) and Si3N4 (16-20.45). The weight ratio of main component to slidifying agent is (14.5-17):1. It can be directly applied to the surfaces of metal, glass fibre, plastic, or concrete with the advantages of high antiwear performance and adhesion, and thin and compact coated layer.

Owner:BEIJING UNIV OF CHEM TECH

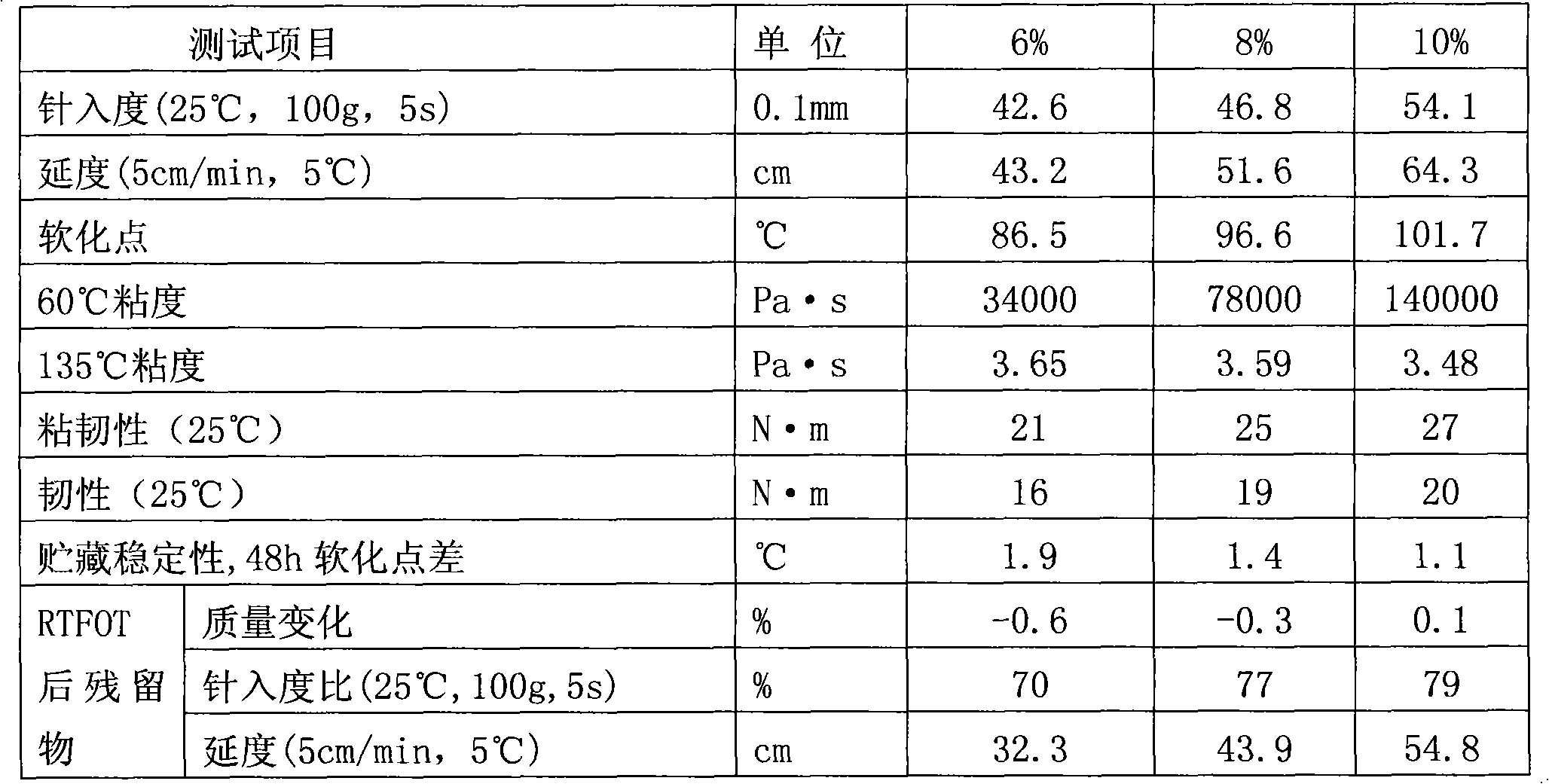

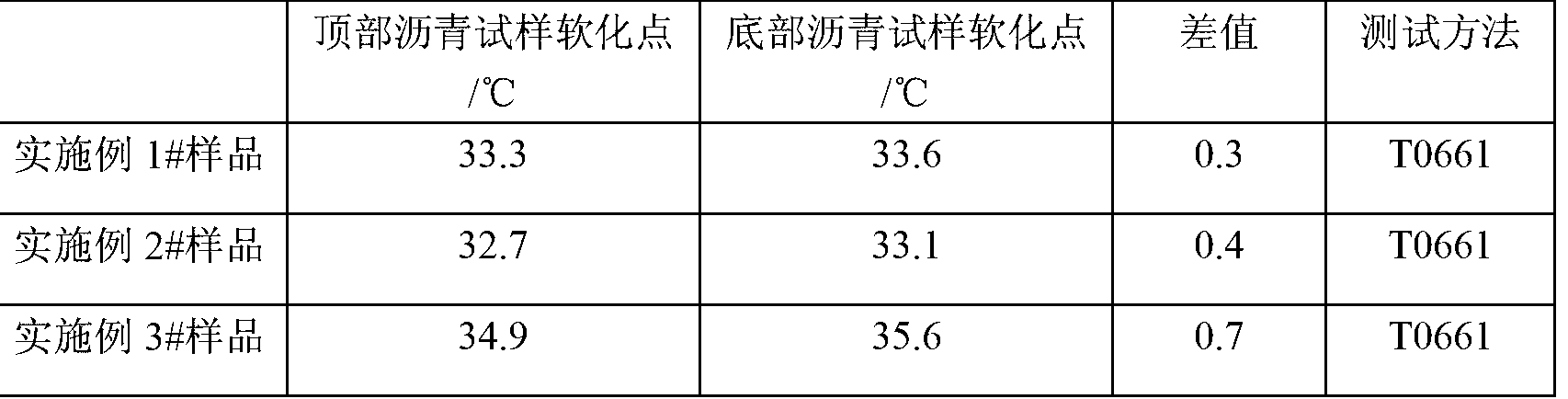

High viscosity high elasticity asphalt modifier and preparation method thereof

ActiveCN101613515AImprove adhesionImprove high temperature stabilityBuilding insulationsPolymer sciencePetroleum

The invention belongs to the technical field of asphalt modifier, in particular relates to a high viscosity high elasticity asphalt modifier and a preparation method thereof. The high viscosity high elasticity asphalt modifier is characterized in that the high viscosity high elasticity asphalt modifier is prepared by raw materials of a primary modifier, a tackifier, an anti-ageing component, a plastifying component and a stabilizer with the mass proportioning being 100:20-40:18-32:15-30:2-5 sequentially; the primary modifier is of phenylethylene-butadiene-phenylethylene segmented copolymer; the tackifier is petroresins or abietic resin; the anti-ageing component is activated rubber powder; the plastifying component is dioctyl phthalate or dibutyl phthalate; and the stabilizer is sulfur. The asphalt modifier prepared by the method can improve high temperature stability, low temperature anti-cracking performance, anti-ageing performance and elasticity restoration capability of asphalt.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Preparing technology of polyurethane modified ethoxyline resin adapted for composite wear-resistant coating material

InactiveCN101445583ASolve the problem of poor flexibilityHigh bonding strengthPolyurea/polyurethane coatingsDiphenylmethaneWear resistant

The invention discloses a preparing technology of polyurethane modified ethoxyline resin adapted for composite wear-resistant coating material. Polyether dihydroxy alcohol having a degree of functionality of 2 and an average relative molecular weight of 1200 to 2200 is reacted with toluene di-isocyanate or diphenylmethane-4,4'-diisocyanate prepared for preheating to synthetize polyether dihydroxy alcohol polyurethane performed polymer for reservation; one of bisphenol A E-44 and E-51 after pre-dehydration is selected for reservation; polyurethane modified epoxy is formed through polyaddition reaction in which a mass ratio of polyether dihydroxy alcohol polyurethane performed polymer to epoxide resin is 15 to 70: 100. The polyurethane modified epoxy obtained by the technology has high bonding strength, good flexibility and shock resistance with basal bodies of spare parts, totally without using plasticizers, such as dibutyl phthalate, dioctylphthalate, etc., without using or using less plasticizers, such as polysulfide rubber, liquid acrylonitrile butadiene rubber, etc., thereby not only solving the problem that general epoxide resin has bad flexibility but also saving the production cost.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

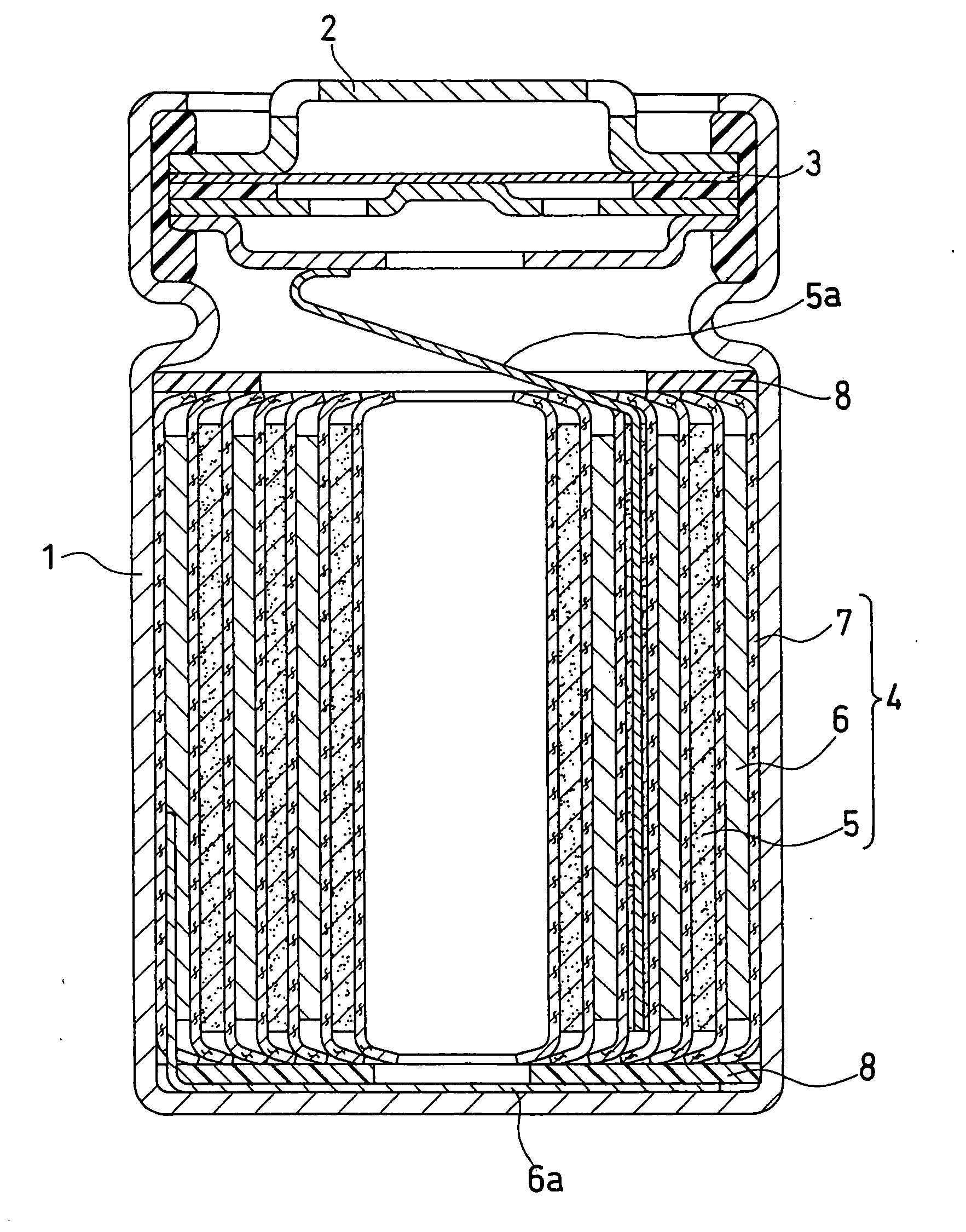

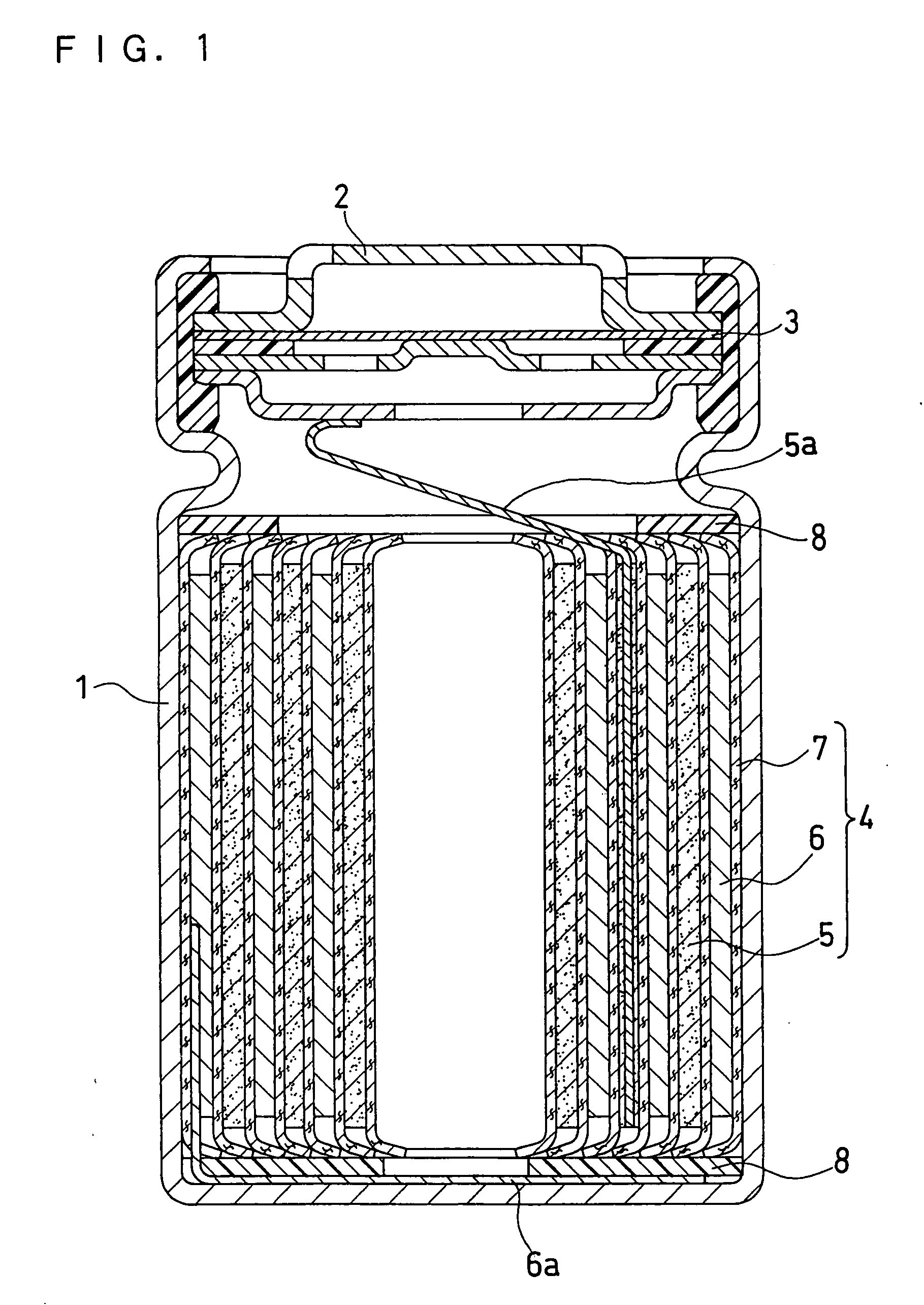

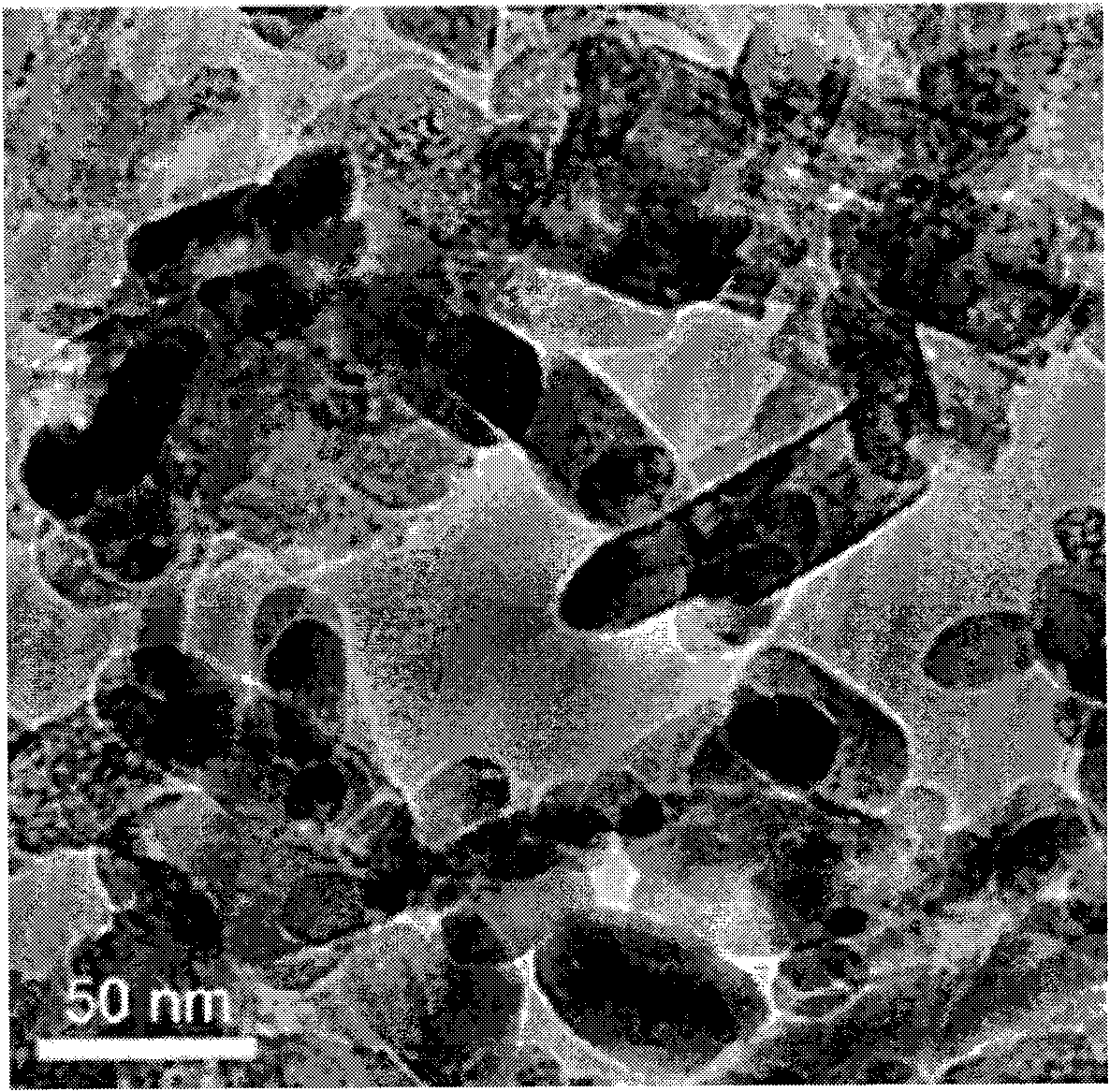

Positive electrode active material, non-aqueous electrolyte secondary battery containing the same and method for evaluating positive electrode active material

InactiveUS20050221182A1Maintain good propertiesHighly practicalOxygen/ozone/oxide/hydroxideAlkali metal oxidesABSORPTION BASEViscosity

A positive electrode active material powder for a non-aqueous electrolyte secondary battery, wherein an amount of a liquid reagent absorbed by the powder is 20 to 40 ml per 100 g of the powder when the liquid reagent is dibutyl phthalate, and the amount is 20 to 50 ml per 100 g of the powder when the liquid reagent is N-methyl-2-pyrrolidone or water, the absorption amount is a value measured using a device according to test method A or B regarding DBP absorption based on JIS K6217 (1997), and the measured value is an amount of the liquid reagent added until the viscosity of a mixture of the powder and the liquid reagent reaches a level corresponding to 70% of a maximum torque which is recorded when a change in the viscosity of a mixture of the powder and the liquid reagent is measured by a torque detecting device.

Owner:PANASONIC CORP

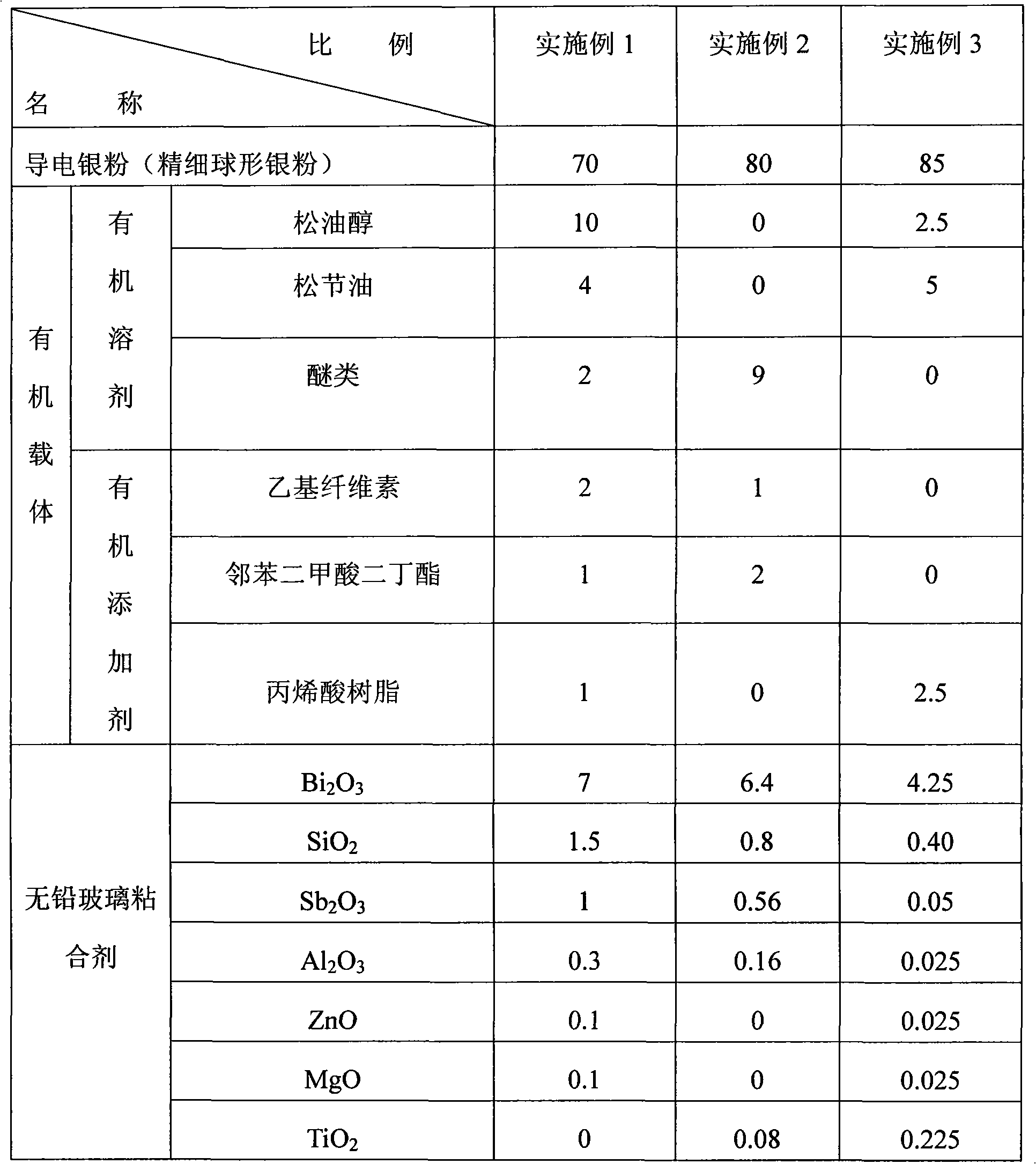

Leadless solar battery silver paste and method for producing the same

InactiveCN101271929AImprove photoelectric conversion efficiencyStrong adhesionFinal product manufactureNon-conductive material with dispersed conductive materialAcrylic resinContact resistance

The invention discloses lead-free solar cell silver serum and a preparation method thereof, which consists of 70-85 percent of conducting silver powder, 5-10 percent of lead-free glass glue and 5.5-25 percent of organic carrier, wherein, the organic carrier consists of organic solvent and organic additive, the organic solvent is any kind of terpineol, terebinth and ethers or their combination; the organic additive is any kind of ethyl cellulose, dibutyl phthalate and acrylic resin or their combination; the particle size of the conducting silver powder is 0.2-2mum; and the lead-free glass glue belongs to bismuth-silicon- antimony glass system. The solar cell silver serum obtained by the method in the invention is lead-free, which complies with requirements of environmental protection, and a conducting electrode with strong adhesive force and low ohm contact resistance can be formed on the surface of the solar cell. The cell has high photoelectric conversion efficiency and is an ideal substituent of the lead silver serum.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Composite modified asphalt and preparation method thereof

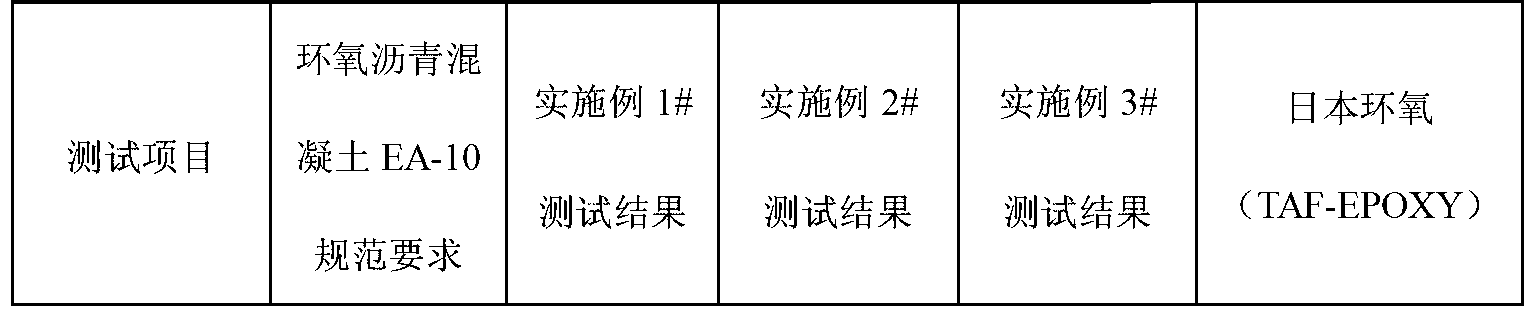

ActiveCN103232717AGood compatibilityHigh temperature and low temperature performanceBuilding insulationsEpoxyBridge deck

The invention relates to composite modified asphalt. The composite modified asphalt is prepared from the following raw materials in percentage by weight: 23.1-45.5% of polyurethane modified epoxy resin, 5-10% of compatibilizer, 5-10% of plasticizer, 5-10% of curing agent and 40-60% of road petroleum asphalt, wherein the polyurethane modified epoxy resin is terminal-amino polyurethane modified epoxy resin, terminal-isocyanato polyurethane modified epoxy resin or imidazolyl-terminal-capped polyurethane modified epoxy resin, the compatibilizer is naphthalene oil, asphalt tar or a mixture of naphthalene oil and asphalt tar, the plasticizer is dioctyl phthalate, dibutyl phthalate or a mixture of dioctyl phthalate and dibutyl phthalate, the curing agent is a modified aromatic amine curing agent, and the road petroleum asphalt is 70# petroleum asphalt, 90# petroleum asphalt or 110# petroleum asphalt. The road performance of concrete adopting the polyurethane epoxy resin composite modified asphalt further meets the requirements of technical specifications and surpasses that of the similar imported product Japan Epoxy, so that the composite modified asphalt can be widely applied to the construction of steel bridge deck pavement, and has great significance in opening a market for domestic epoxy asphalt materials.

Owner:重庆市智翔铺道技术工程有限公司

Anti-skid sole material

The invention relates to the field of a formula for a sole material, especially to an anti-skid sole material. The anti-skid sole material comprises, by mass, 30 to 40 parts of butadiene rubber, 10 to 20 parts of butadiene-acrylonitrile rubber, 5 to 8 parts of white carbon black, 1 to 2 parts of magnesium oxide, 3 to 4 parts of stearic acid, 2 to 5 parts of polyethylene glycol, 1 to 2 parts of zinc oxide, 1 to 2 parts of machine oil, 5 to 7 parts of dibutyl phthalate, 0.5 to 1.3 parts of an antioxidant and 0.8 to 2.4 parts of an activator. The anti-skid sole material has a wet antiskid coefficient of 0.8 and a wet antiskid coefficient of 0.6; and the antiskid performance of the sole material is improved, so safety in usage of the sole material is guaranteed.

Owner:TONGXIANG YIYUAN SHOES

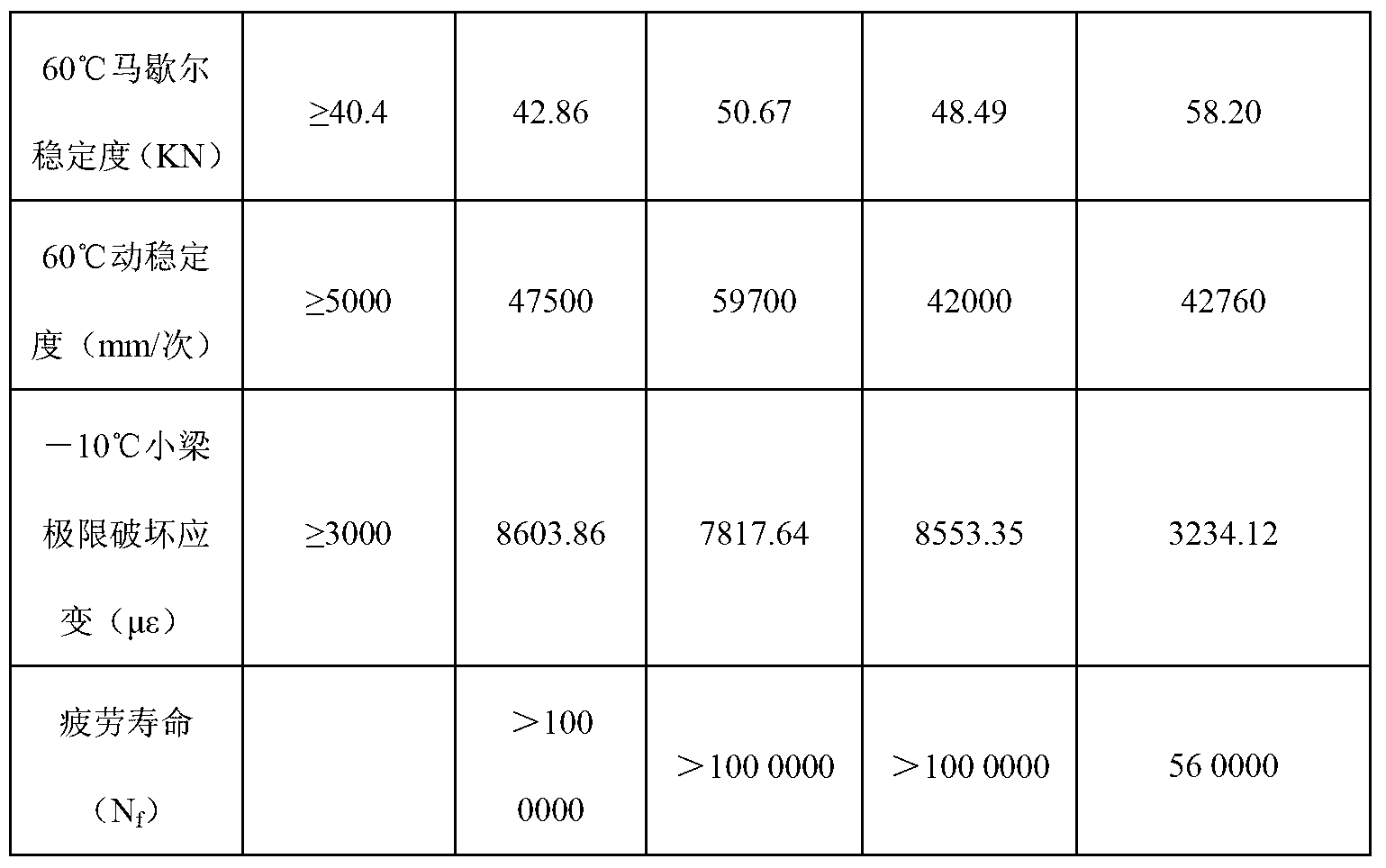

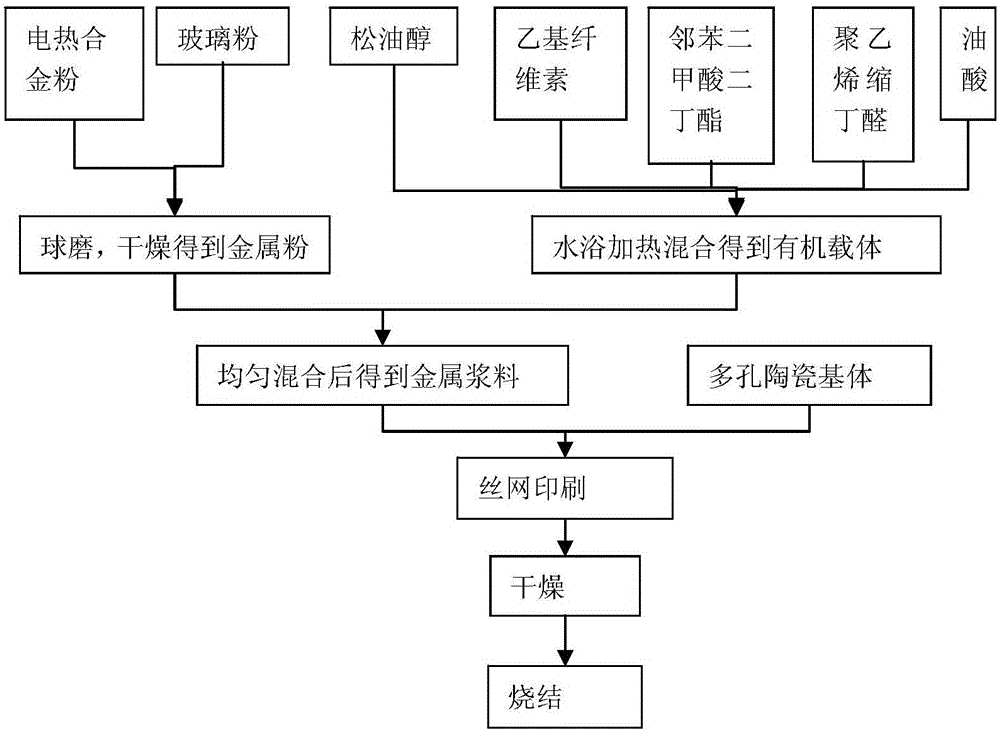

Metal-film porous ceramic heating element and application thereof

ActiveCN107182139AHigh bonding strengthSolve the problem of residual carbon prone to appear on the interfaceTobacco devicesHeating element materialsPolyvinyl butyralScreen printing

The invention relates to a metal-film porous ceramic heating element and application thereof, more particularly to a metal-film porous ceramic heating element and application thereof in an electronic cigarette atomizer. A preparation method of a metal-film porous ceramic heating element comprises: electrothermal alloy powder and glass powder are mixed uniformly to obtain a metal powder mixture; terpineol, ethyecellulose, dibutyl phthalate, polyvinyl butyral and oleic acid are mixed uniformly to obtain an organic carrier; the metal powder mixture and the organic carrier are mixed uniformly to obtain a metal paste; and the metal paste is coated on a porous ceramic substrate by screen printing, and sintering is carried out to obtain a metal-film porous ceramic heating element. The process is simple and is easy to control; and large-scale industrial application can be realized conveniently. And the prepared metal-film porous ceramic heating element is especially suitable for an electronic cigarette atomizer.

Owner:周宏明

Water-solubility printing ink washing agent

InactiveCN101638532ASimple recipeEasy to manufactureChemical paints/ink removersSolubilityAlkylphenol

A water-solubility printing ink washing agent comprises A component, B component and solvent according to weight ratio of 1: (1.5-2.5): (0.04-0.08), wherein raw materials of the A component are as follows according to weight parts: 12-15 parts of fatty alcohol-polyoxyethylene ether, 0.5-1 part of alkylphenol polyoxyethylene, 8-10 parts of aviation kerosene, 2-4 parts of dibutyl phthalate, 1-3 parts of butyl cellosolve, 1-2 parts of benzyl alcohol and 1-3 parts of butyl acetate; raw materials of the B component are as follows according to weight parts: 5-8 parts of sodium dodecyl benzene sulfonate, 1-2 parts of ethanolamine, 1-3 parts of diethanolamide, 0.5-1 part of urea, 0.5-1 part of sodium carbonate, 0.3-0.5 part of sodium silicate, and 45-55 parts of water. The preparation of the invention is simple, has simple and convenient manufacture, stable performance, safe usage, does not easily burn, does not corrode device and does not pollute the environment. The washing agent has good washing effect, is safe and non-toxic, has easily obtained and stored raw materials, has high stability, can be repeatedly used, and has wide market prospect.

Owner:MAOMING COLLEGE

Coloring agent for textile fabric

The invention discloses a coloring agent for a textile fabric. The coloring agent consists of the following ingredients in parts by weight: 1 to 2 parts of polypropylene glycol, 2 to 3 parts of tetracarboxydiphthalic ether dianhydride (ODPA), 1 to 2 parts of zinc stearate, 4 to 5 parts of trimethylolpropane, 4 to 5 parts of mica powder, 5 to 6 parts of butyl methacrylate, 4 to 5 parts of dibutyltin dilaurate, 3 to 4 parts of polyurethane, 6 to 7 parts of iron oxide red, 1 to 2 parts of dibutyl phthalate, 3 to 4 parts of ethyl acetate, 3 to 4 parts of an initiator, 5 to 6 parts of closed blocked isocyanate, 5 to 6 parts of water and 2 to 3 parts of polyvinylpyrrolidone. The coloring agent for the textile fabric is easy for coloring and unlikely to fade.

Owner:江苏金牛华尔车服饰有限公司

Diamond resin grinding wheel and preparation method thereof

ActiveCN102814759ANot easy to fall offImprove heat resistanceAbrasion apparatusGrinding devicesIron powderHeat resistance

The invention discloses a diamond resin grinding wheel and a preparation method of the diamond resin grinding wheel. The diamond corundum resin grinding wheel is prepared from the following components by weight, 50-60 parts of diamond grinding material, 10-20 parts of silicon carbide powder, 5-15 parts of phenolic resin powder, 2-6 parts of phenolic resin liquid, 1-2 parts of dibutyl phthalate, 5-10 parts of nano fluorite powder, 5-10 parts of fungacetin, 2-5 parts of black manganese ore and 2-5 parts of scrap iron powder. According to the diamond resin grinding wheel, as the ceramic material is added into padding, the adhesive property is good, the grinding materials hardly fall off, the heat resistance and hardness of the resin grinding wheel are improved, cracks formed by rigid grinding are reduced, and the use efficiency and service life of the resin grinding wheel are improved further; in addition, as the iron power is added, fast heat dissipation effect is achieved, a great deal of heat generated in the cutting process of the grinding wheel can be dissipated quickly, and the effect of lowering cutting temperature is lowered.

Owner:安徽威铭耐磨材料有限公司

Method for preparing electrolyte ceramic membrane of lithium ion battery

The invention relates to a method for preparing an electrolyte ceramic membrane of a lithium ion battery, in particular to a tape casting method for preparing the electrolyte ceramic membrane of the lithium ion battery, and belongs to the field of ion conductive ceramic materials. The invention adopts the tape casting method; ceramic powder with a chemical formula of Li1.4Al0.4(Gel-xTix)1.6(PO4)3(wherein x is equal to 0-1.0) is selected as raw material powder; triethanolamine or phosphate are selected as a dispersing agent; ethanol, propyl alcohol, butanone, triclene, or azeotropic solution prepared from any two of the ethanol, propyl alcohol, butanone and triclene is selected as a solvent; polyvinyl butyral (PVB) is selected as an adhesive; polyethylene glycol or dibutyl phthalate is selected as a plasticizer; the range of solid content of slurry is controlled between 18 and 30vol percent; the uniform slurry is prepared through ball milling, and then is prepared into a green belt bythe tape casting method, and the green belt is subjected to heat treatment to form the electrolyte ceramic membrane; and the electrolyte ceramic membrane has good strength and toughness, and can be applied to actual production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Steel structure aqueous corrosion resisting paint without need of cleaning rust and preparation thereof

InactiveCN101323726AGood acid and alkali resistanceImprove the painting environmentLiquid surface applicatorsAnti-corrosive paintsAqueous corrosionWater based

The invention relates to a water-base rusting anti-corrosion paint of a steel structure, and a manufacturing technology thereof. The water-base rusting paint comprises styrene-acrylic latex, ferric oxide, talcum powder, phosphoric acid, tannin, aluminum hydroxide, zinc oxide, zinc dihydric phosphate, potassium dichromate, a film-forming auxiliary agent, sodium hexametaphosphate, dibutyl phthalate, an antifoam agent and water which is added till 100 percent (mass). The preparation method of the paint of the invention is that a pigment filler is added into a ball mill to prepare pigment filler slurry according to a mixing ratio, the phosphoric acid, the tannin, the zinc oxide and the aluminum hydroxide are mixed and heated till the solution is clear so as to prepare transformation liquid, then the pigment filler slurry and the transformation liquid and other components are mixed and stirred, and finally a finished product is obtained after filtration. The paint of the invention is characterized by good performance and low cost, etc., can be used for hull painting with rust directly, and can be used not only as a base paint, but also as a surface paint.

Owner:HUNAN UNIV

Oil resistant rubber

The invention discloses an oil resistant rubber, which contains the following substances in part by weight: nitrile rubber, sulfur, zinc oxide, stearic acid, anti-aging agent RD, anti-aging agent 4010NA, paraffin, carbon black N660, carbon black N330, dibutyl phthalate, calcium carbonate, dibenzothiazyl disulfide, tetramethylthiuram disulfide and tetraethylthiuram disulfide. Compared with the prior art, the oil resistant rubber has the advantages that: the oil resistance of the oil resistant rubber produced by using the rubber formula is less than 8.5 percent, and the oil resistant rubber has good heat resistance and air tightness.

Owner:芜湖禾田汽车工业有限公司

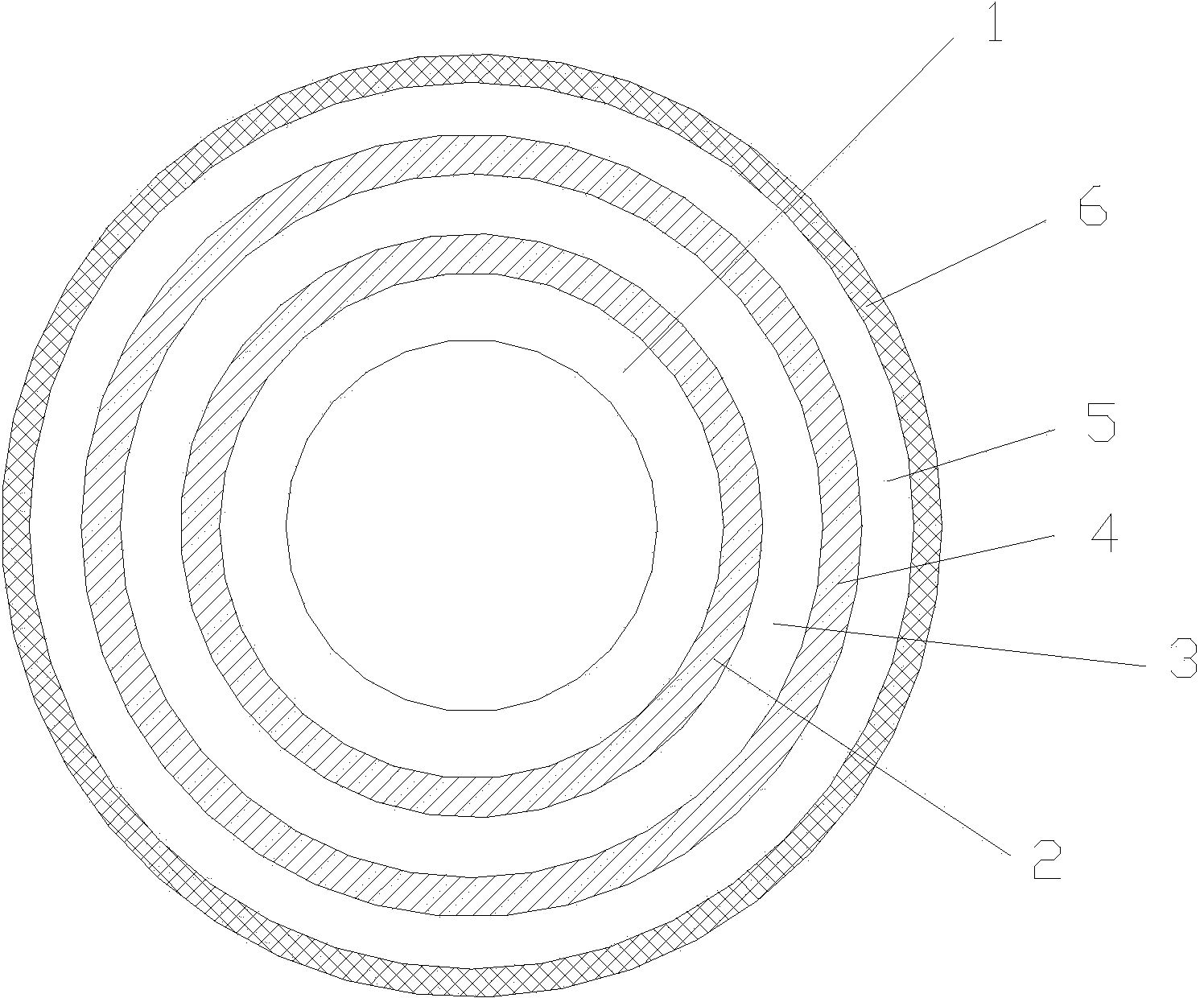

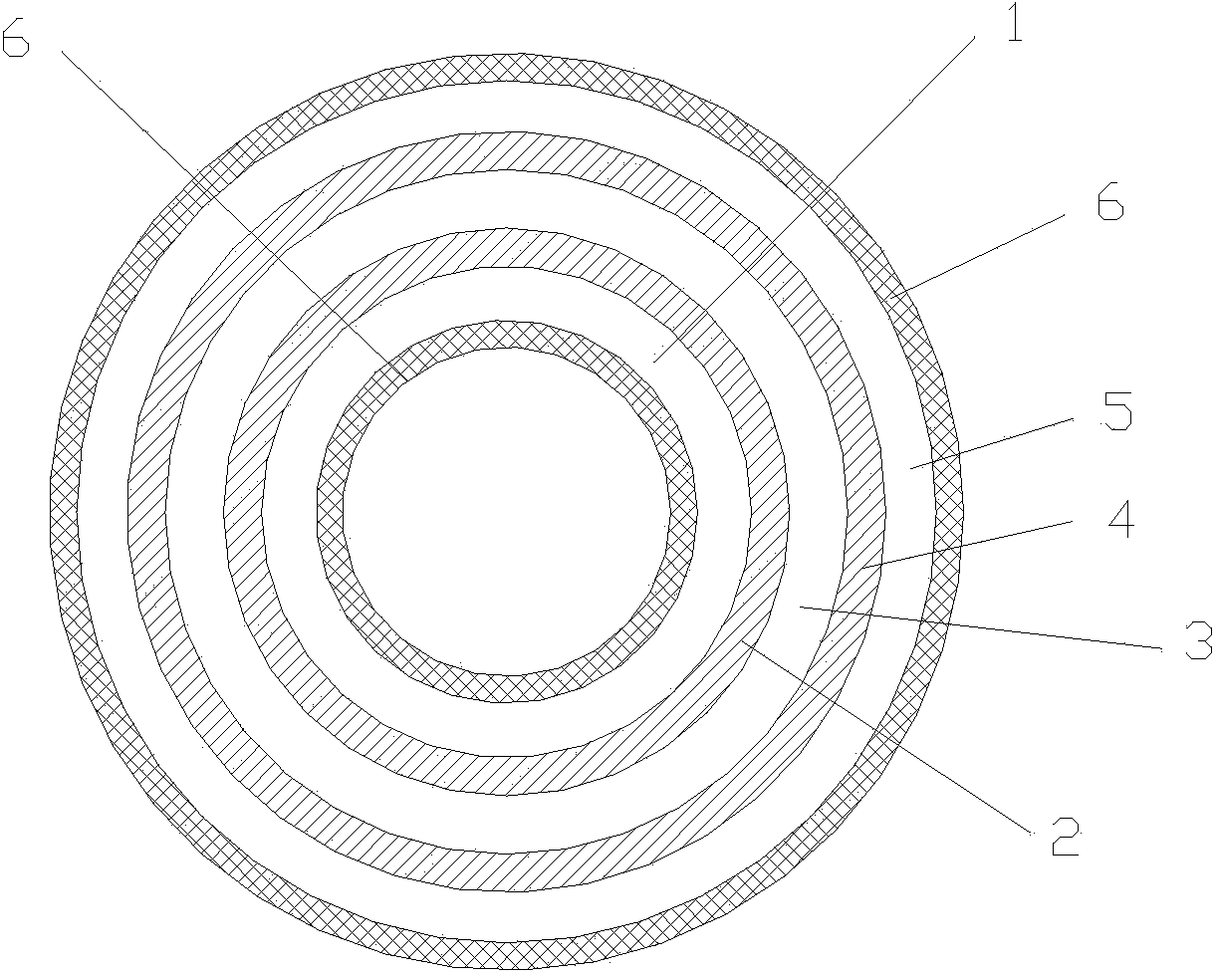

High-pressure rubber hose and production process thereof

InactiveCN103899855ANot easy to delaminateStrong impact resistanceFlexible pipesCoatingsEngineeringStearic acid

The invention relates to a high-pressure rubber hose and a production process of the high-pressure rubber hose. The high-pressure rubber hose includes an inner rubber layer, a first reinforcement layer, a middle rubber layer, a second reinforcement layer, an outer rubber layer and an ultra-high molecular weight polyethylene film from inside to outside in sequence. The outer rubber layer contains 90-110 parts of ethylene-propylene rubber, 4.5-5.2 parts of zinc oxide, 0.8-1.2 parts of stearic acid, 55-65 parts of carbon black, 20-22 parts of dibutyl phthalate, 0.48-0.55 part of dimethylaminoethyl methacrylate, 1.2-1.8 parts of accelerants and 1.2-1.8 parts of sulfur. The production process is characterized in that on the basis of an existing process, the following steps are added: the outer rubber layer is extruded and then passes through a heating cylinder, and when the temperature of the outer rubber layer reaches 120 DEG C to 150 DEG C, the outer rubber layer is coated with the ultra-high molecular weight polyethylene film; water cloth is wound around the outer rubber layer, and then sulfuration is carried out. The high-pressure rubber hose resists shock, corrosion, low temperature and adhesion, and is high in wear resistance, capable of conducting self-lubrication, long in service life, sanitary and non-toxic.

Owner:姚平经

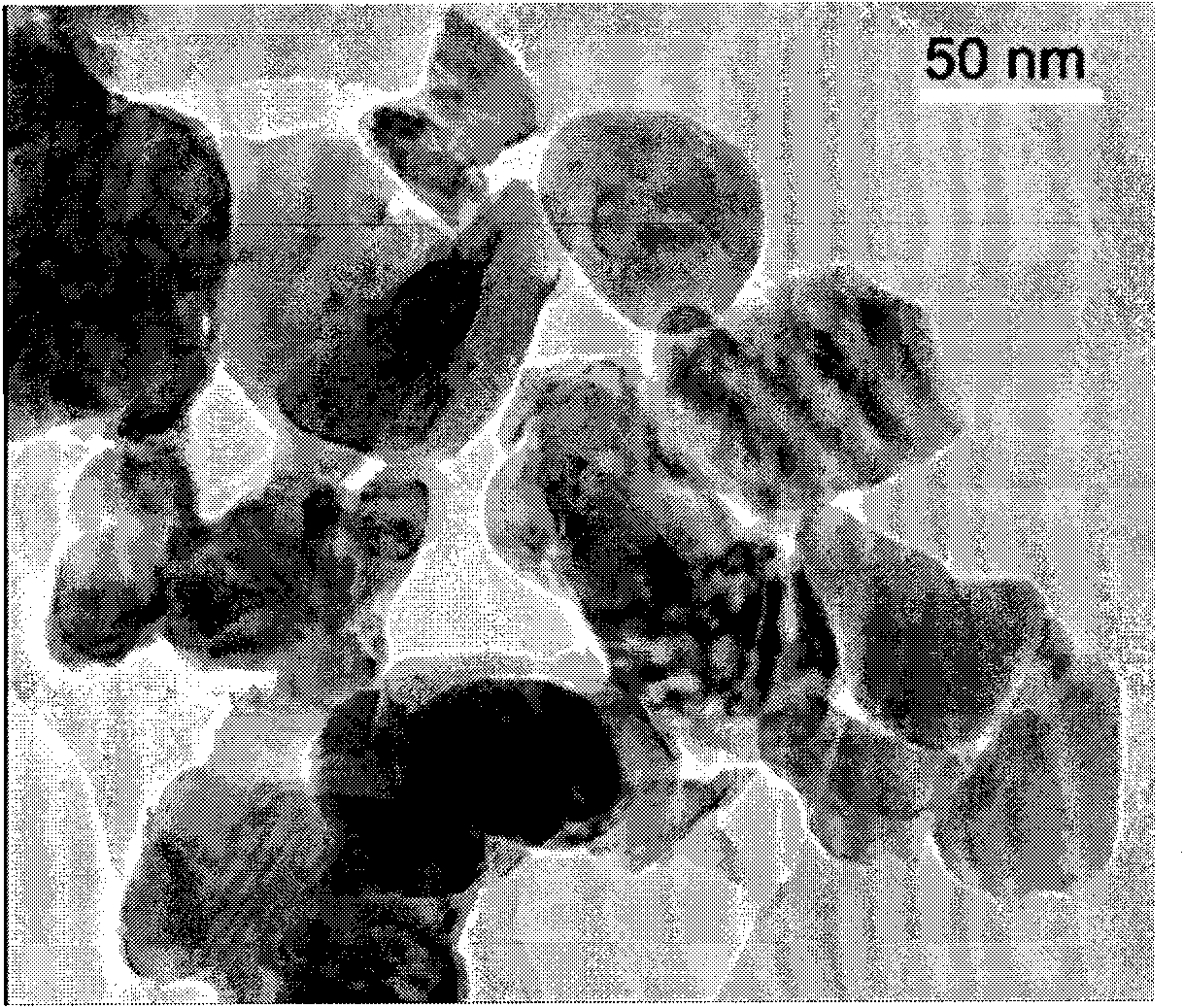

Hollow ceramic microsphere and preparation method of hollow ceramic microsphere

InactiveCN103387395AAvoid heat conductionPlay a thermal insulation effectThermal insulationMicrosphere

Owner:TIANJIN CHENGJIAN UNIV

Liquid bandage and preparation method

The invention discloses a liquid bandage and a preparation method. The liquid bandage comprises the following raw materials: polyvinyl acetal, dibutyl phthalate, methyl cellulose, glycerol, laurocapram, chitosan, 95% ethanol, securidaca inappendiculata, dragon blood, frankincense, myrrh and sanchi; the preparation method comprises the following steps: stirring and dissolving the polyvinyl acetal,the chitosan and the ethanol at a temperature of 5 DEG C, and adding the laurocapram, the glycerol, the dibutyl phthalate and the methyl cellulose to obtain film liquid; performing reflux extraction on the crushed securidaca inappendiculata, dragon blood, frankincense, myrrh and sanchi with ethanol at a temperature of 60 DEG C until the extracted liquid is colorless, filtering at a normal pressure and concentrating; and adding the concentrated solution of the securidaca inappendiculata, the dragon blood, the frankincense, the myrrh and the sanchi into the film liquid and mixing uniformly. Theliquid bandage is convenient to use and has high water resistance and air permeability, without sticking on clothes and cotton-padded mattress, causing anaphylaxis and drug resistance or being limited by the shape, size and location of the wound.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Self-repairing self-lubricating material and preparation method thereof

The invention provides a self-repairing self-lubricating material and a preparation method thereof. The self-repairing self-lubricating material comprises modified PTFE and a microcapsule containing arepairing agent, wherein the modified PTFE is a particle with a core / shell structure, and uses PTFE particles are a core and a wear-resistant polymer or a two-dimensional material as a shell; the microcapsule is composed of a capsule core and a capsule wall, the capsule wall is a high-molecular polymer such as urea-formaldehyde resin and polyvinylpyrrolidone or a two-dimensional material such asgraphene, and the capsule core is a repairing agent such as dibutyl phthalate, glycidyl methacrylate and linseed oil. The material provided by the invention improves the problems that compatibility ofPTFE with heterogeneous materials is poor, mechanical strength is low and the PTFE is extremely easy to wear; and in addition, introduction of the microcapsule enables the PTFE lubricating material to have self-repairing regulating and controlling functions, friction-reducing anti-wear properties of the material are enhanced, and the service life of the lubricating material is improved.

Owner:TSINGHUA UNIV

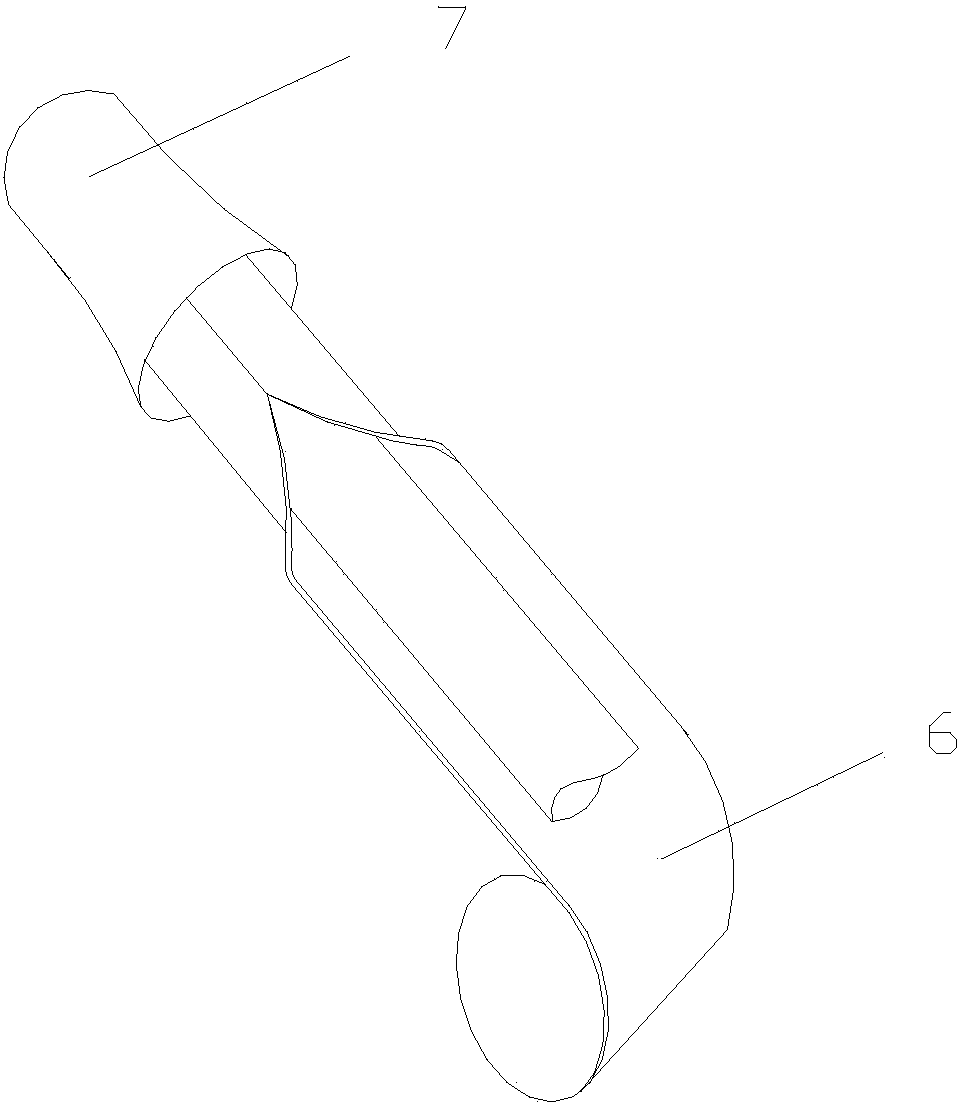

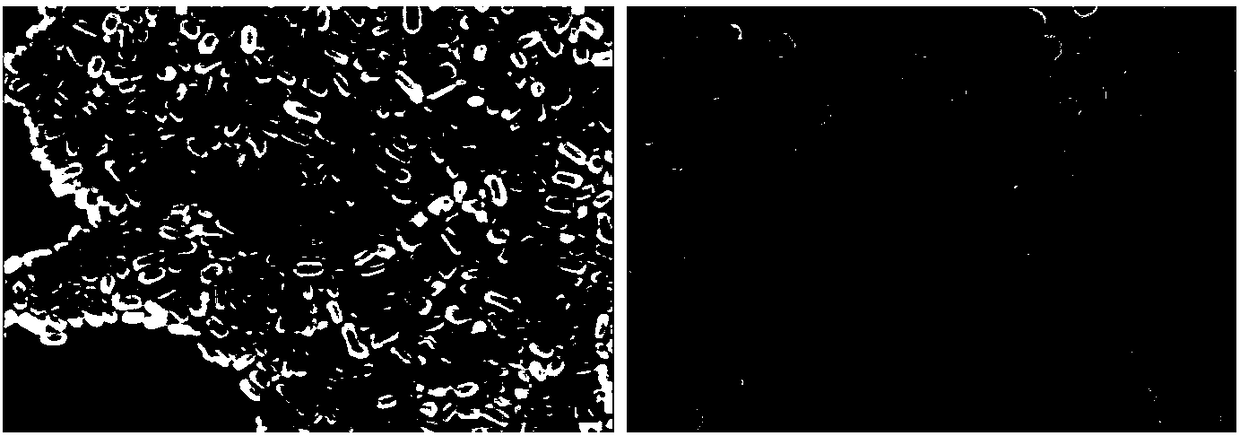

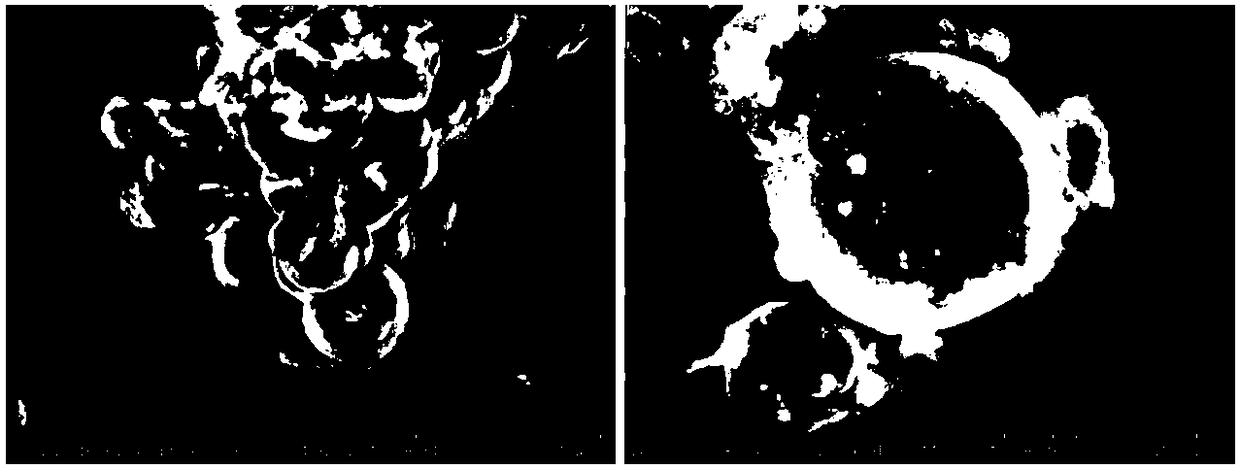

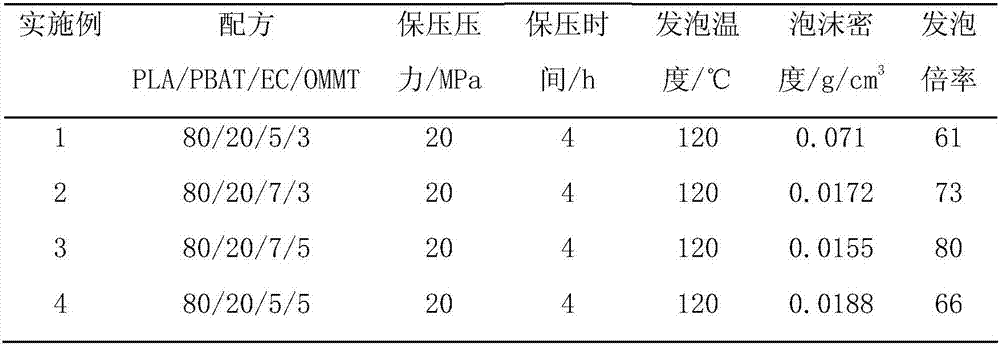

Preparation method of high magnification full biodegradable foaming material

InactiveCN106967280AImprove toughnessGuaranteed to be fully biodegradableEnvironmental resistanceFoaming agent

The invention discloses a preparation method of a high magnification full biodegradable foaming material, a blend of full biodegradable material polylactic acid (PLA) and full biodegradable material poly (butyleneadipate-co-terephthalate) (PBAT) / dibutyl phthalate is prepared by an internal mixer, at the same time, an epoxy chain extender is added as a reaction compatilizer EC, an organic modification montmorillonoid (OMMT) is added as a nucleating agent, then the prepared material is placed into a high pressure foaming kettle, supercritical CO2 is injected as a foaming agent, and rapid depressurization is performed to obtain the product with high foaming ratio after long-time high pressure maintaining. With the preparation method, the polylactic acid foaming material with the foam density of 0.0155-0.0205 g / cm3 and the foaming ratio of 60-80 times can be obtained. The prepared polylactic acid foaming material is high in foaming ratio, full biodegradable, green and environment-friendly and capable of replacing most packaging undegradable foamed plastic in a wide range.

Owner:启迪再生资源科技发展有限公司

Capacitor thin film with homo-polypropylene as substrate and preparation method thereof

InactiveCN103102587AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethyleneEpoxy

The invention discloses a capacitor thin film with homo-polypropylene as a substrate and a preparation method of the capacitor thin film. The composition raw materials of the thin film in parts by weight are as follows: 20-30 parts of LDPE (Low Density Polyethylene), 30-40 parts of homo-polypropylene, 3-5 parts of epoxy linseed oil, 2-3 parts of polyvinyl alcohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutene, 8-12 parts of diatomite, 1-2 parts of dicyclopentadienyl iron, 0.9-1.1 parts of poly-4-methyl-1-pentene, 0.5-0.7 part of permanent white, 9-11 parts of nano-clay, 2.0-2.5 parts of catechol, 1.2-1.6 parts of di(ethylene glycol) benzoate, 1.3-1.8 parts of dibutyl phthalate, 4-6 parts of calcium stearate, 1.5-2.0 parts of vinyl triethoxy silane, and 2.5-3.0 parts of modified tree ash. The thin film provided by the invention is manufactured by taking the homo-polypropylene as a main raw material and the low density polyethylene as an auxiliary raw material, and enabling a plurality of auxiliary additives and the homo-polypropylene as well as the low density polyethylene to be subjected to mixed extrusion, film blowing sizing, and cutting; the preparation method is simple; simultaneously, the diatomite, the nano-clay and the modified tree ash are added into the raw materials to enhance barrier property and air tightness of the thin film; and the thin film has the characteristics of good pressure resistance, good impact resistance, heat seal strength, and good heat seal performance.

Owner:TONGLING YIHENGDA ELECTRONICS

Preparation method of low shrink air dry vinyl ester heavy-duty anti-corrosive paint

InactiveCN101760115AStrong resistance to media penetrationImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsGas phaseSilicon dioxide

The invention discloses a preparation method of low shrink air dry vinyl ester heavy-duty anti-corrosive paint. The anti-corrosive paint comprises a first component of the dry vinyl ester heavy-duty anti-corrosive paint and a second component of the dry vinyl ester heavy-duty anti-corrosive paint, wherein the first component of the dry vinyl ester heavy-duty anti-corrosive pain t comprises vinyl ester resin, titanium pigment, French chalk, mica powder, gas phase silicon dioxide, styrene, BYK-410, BYK-555, glass scales and like, the second component of the dry vinyl ester heavy-duty anti-corrosive paint comprises dibutyl phthalate, methylethyl ketone peroxide and cobalt naphthenate. The defects of low air dry capability and high cure shrinkage of the traditional vinyl ester glass scale heavy-duty anti-corrosive paint are solved by introducing the air dry addition product group to synthesize low shrink air dry resin, and the paint has the advantages of high media penetrability resistance, abrasive resistance and the like. The low shrink air dry vinyl ester heavy-duty anti-corrosive paint has the characteristics of simple preparation process, abundant raw materials and stable performance, and is suitable for large-scale industrial production.

Owner:中昊北方涂料工业研究设计院有限公司

Making process of Chinese cypress paper with wide-spectrum antiseptic function for cygarette

InactiveCN1417413ABroad spectrum antibacterialAvoid infectionPaper/cardboardPolyvinyl alcoholAntiseptic solutions

In the present invention, China cypress paper is painted with the ink and rolled, so that wide-spectrum antiseptic ink with inorganic antiseptic, organic antiseptic and Chinese medicinal antiseptic is painted on the surface to produce wide-spectrum antiseptic China cypress paper. The present invention features the ink, which consists of modified rosin, PVA, dibutyl phthalate, butyl aldehyde condensate, anatase type titania, medical alcohol, ferrite yellow calcium carbonate and talcum powder; has silver ion, copper ion, Ampicillin sodium and Eight Health Restoring Medicine mixture; and is produced through reaction, grinding, and dispersion.

Owner:YUNNAN YUXI TIPPING PAPER FACTORY +1

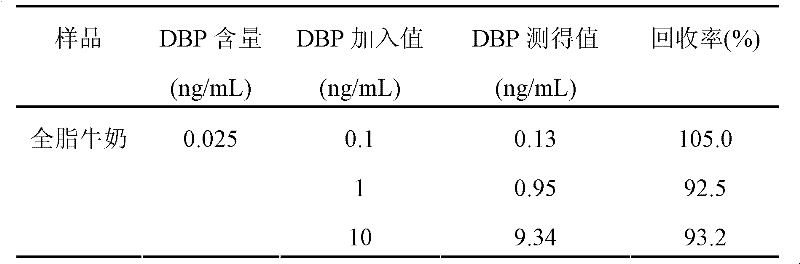

Method for quickly detecting dibutyl phthalate in food

InactiveCN102520153AStrong specificityReduce the impactFluorescence/phosphorescenceBiologyPhthalic acid ester

The invention discloses a method for quickly detecting dibutyl phthalate, which comprises the following steps of: a, constructing an inhibitory curve; and b, sample detection. Compared with the prior art, the method is high in sensitivity, quick and high in specificity, adopts simple method and consumes less time, is applicable to the quick analysis of environment pollutant DBP (Dibutyl Phthalate) and is also significant for the determination of phthalate.

Owner:ANHUI NORMAL UNIV

Water-resistant white latex

ActiveCN101705065AImprove water resistanceIncrease crosslink densityMonocarboxylic acid ester polymer adhesivesMacromolecular adhesive additivesAdhesive1-Propanol

The invention discloses water-resistant white latex, which comprises the following main components: vinyl acetate, butyl acrylate, diacetone acrylamide, N-hydroxymethyl acrylamide, polyvinyl formal water agent, dibutyl phthalate, deionized water, initiator, defoamer, glycol alcohol, emulsifier, 2-amino-2-methyl-1-propanol. The white latex has the following advantages that: 1, polyvinyl formal is used as protective colloid to improve the water resistance of adhesive; 2, the diacetone acrylamide and the N-hydroxymethyl acrylamide are added as modification-polymerization monomer so as to increase crosslinking density and improve bonding strength; and 3, the butyl acrylate is added as the modification-polymerization monomer, and the copolymerization of the butyl acrylate and the vinyl acetate can reduce the glass transition temperature and minimum film-forming temperature of the white latex, improve the low-temperature film-forming performance of emulsion and play a role in internal plasticization so as to increase the flexibility of the white latex.

Owner:GUANGDONG SANVO CHEM IND TECH

Polymer cement based composite waterproof coating material for construction and its preparation

InactiveCN1472259AMake up for lack of flexibilityCompensation for re-swelling of polymer emulsion filmAntifouling/underwater paintsPaints with biocidesPliabilityPropanediol

A composite water-proof cement-base polymer paint for building is composed of the organic liquid (component A) prepared from acrylate emulsion, siloxane emulsion, dibutyl phthalate, propanediol, sodium tripolyphosphate, and tributyl phosphate, and the inorganic powder (component B) prepared from silicate cement, talk powder and pigment. Said two components are proportionally mixing before it is used. Its advantages are better elasticity and flexibility, high adhesion, and no environmental pollution.

Owner:TONGJI UNIV

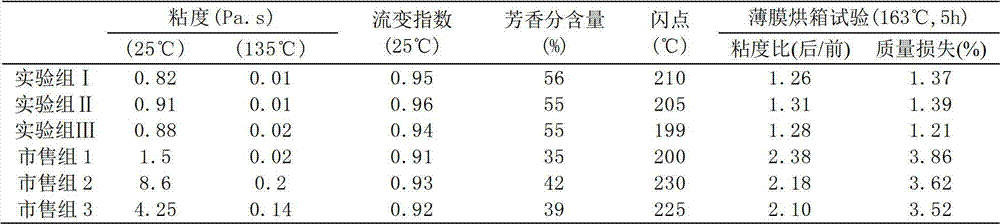

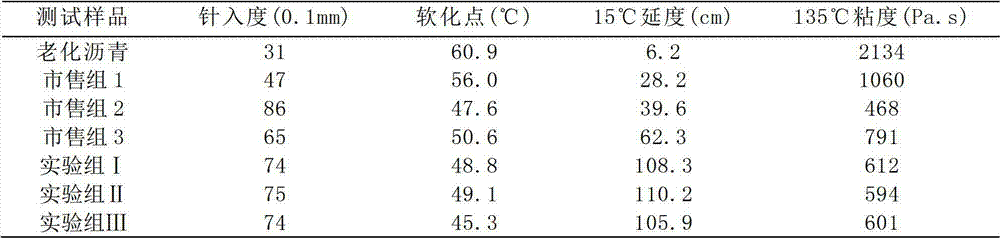

Waste and old asphalt thermal circulation recycling regenerating agent and preparation method thereof

ActiveCN102786806AImprove the safety of useReduce volatilityBuilding insulationsPetroleum resinPlasticizer

The invention provides a waste and old asphalt thermal circulation recycling regenerating agent which has a prescription comprising extract oil from fourth side line of a vacuum tower, epoxidized soybean oil, turpentine and petroleum resin, wherein the epoxidized soybean oil serves as a plasticizer and softener. The waste and old asphalt thermal circulation recycling regenerating agent has various physicochemical indexes obviously higher than those of commercially available waste and old asphalt regenerating agent, and meets the national recommended standard; more important, the epoxidized soybean oil is adopted as the plasticizer and the softener instead of dibutyl phthalate DBP and dioctyl phthalate DOP, so that the quantity of violated harmful substance is lower, and the safety of the regenerating agent in use is improved.

Owner:CHONGQING ZONJO RENEWABLE RESOURCES DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com