Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

159results about How to "Not easy to delaminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor chip assembly with post/base heat spreader and cavity over post

InactiveCN102456637AImprove cooling effectNot easy to delaminateSemiconductor/solid-state device detailsSolid-state devicesSignal routingElectrical conductor

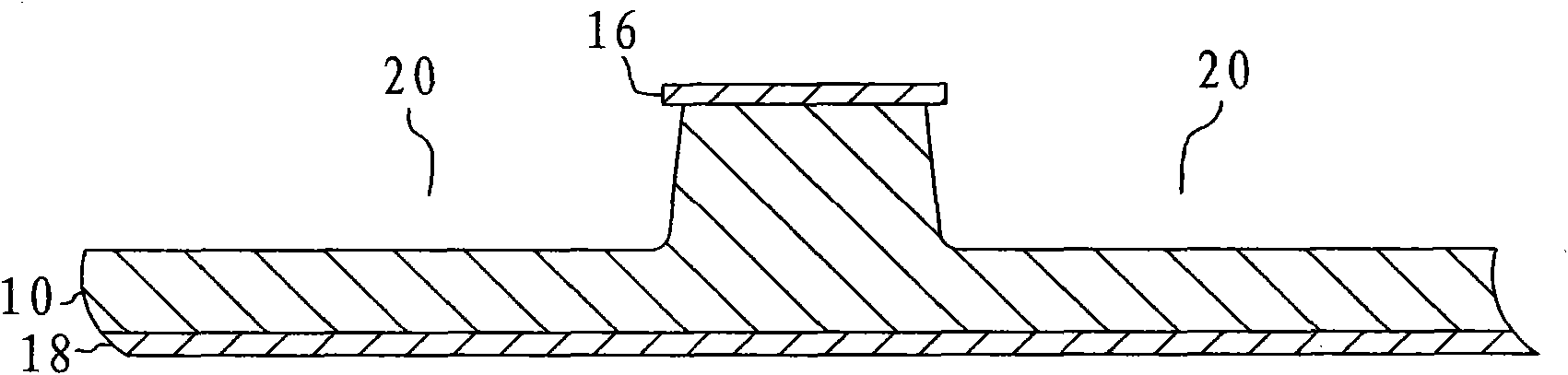

The invention relates to a semiconductor chip assembly with a post / base heat spreader and a cavity over post. The semiconductor chip assembly at least includes a semiconductor device, the heat spreader, the substrate and an adhesive. The semiconductor device is electrically connected to the substrate and thermally connected to the heat spreader. The heat spreader at least includes a post and a base. The post extends upwardly from the base into an opening in the adhesive and an aperture in the substrate, and the base extends laterally from the post. The adhesive extends between the post and the substrate and between the base and the substrate. The assembly provides signal routing between a pad and a terminal.

Owner:BRIDGE SEMICON

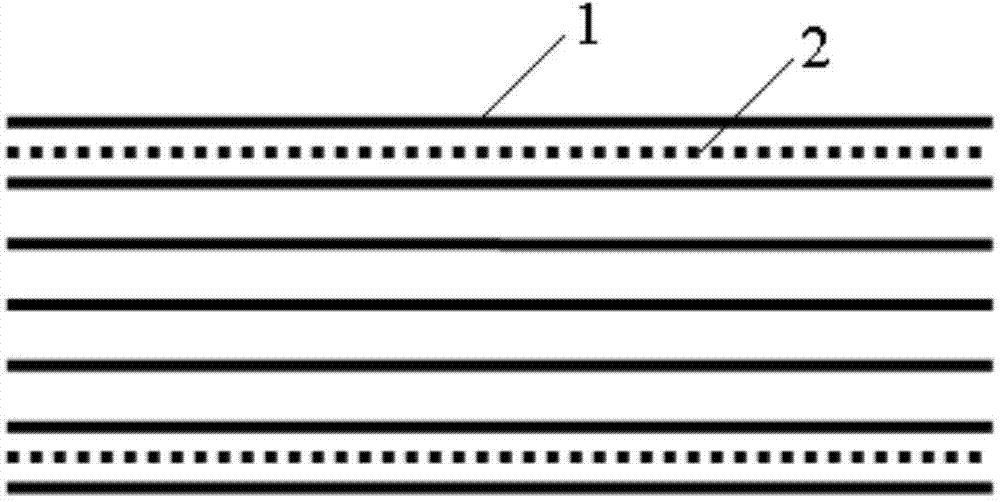

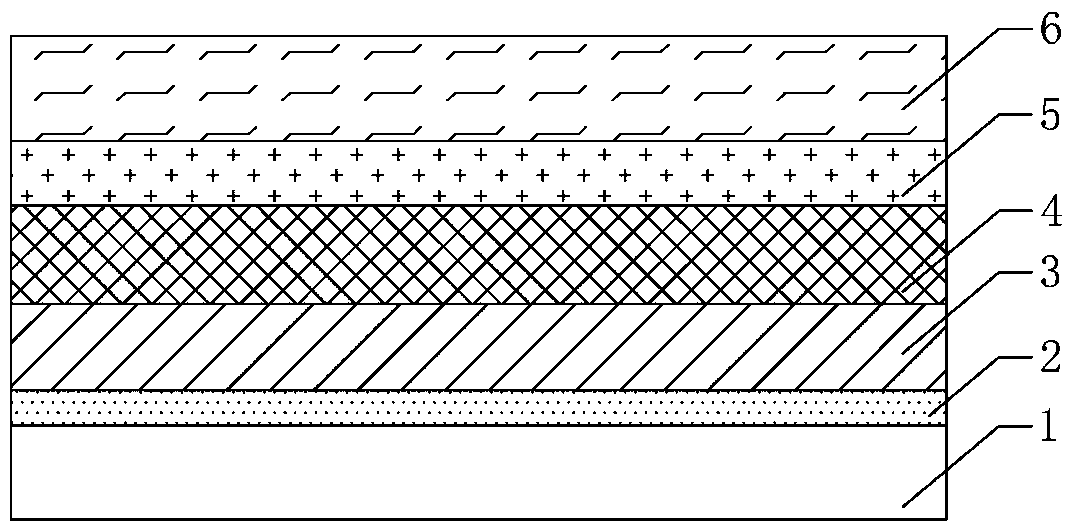

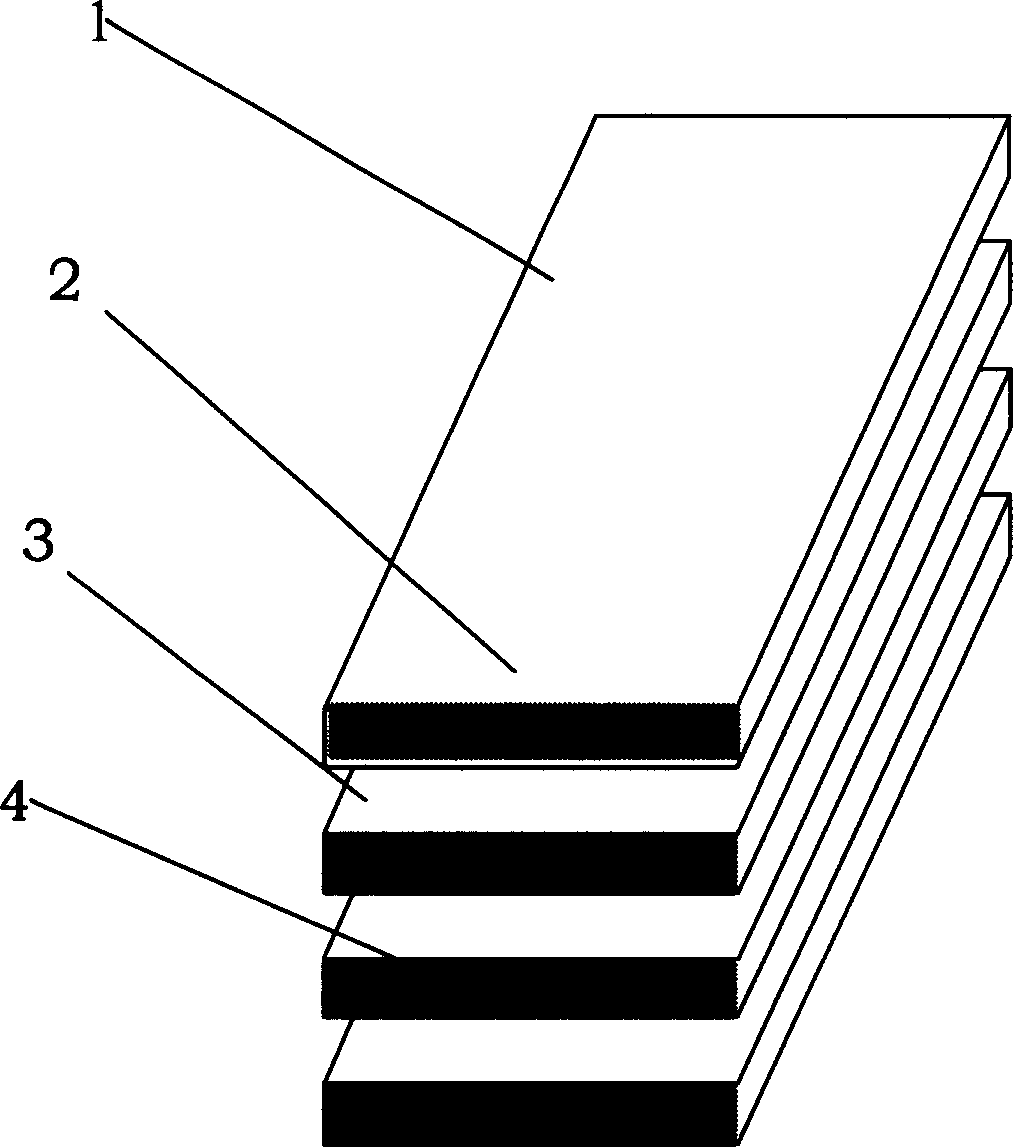

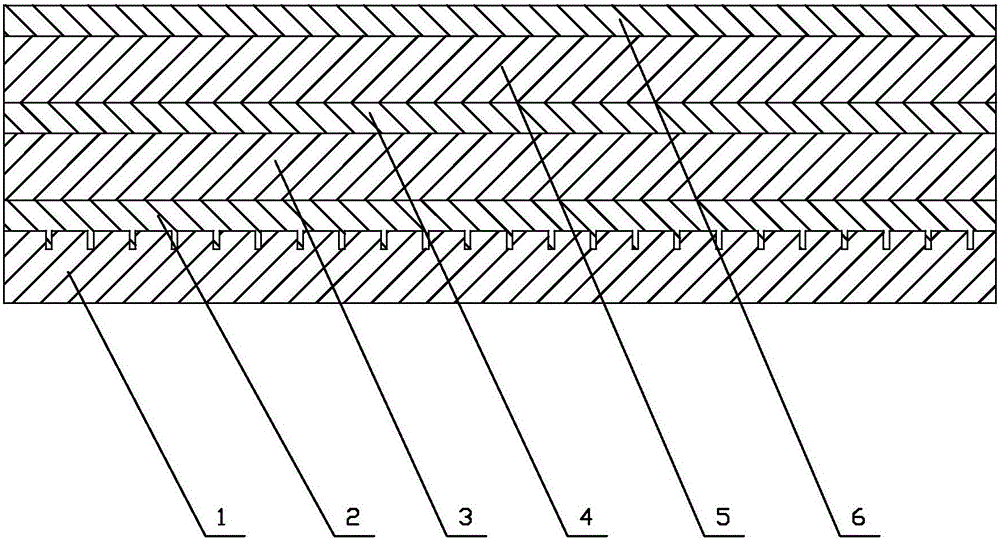

Environment-friendly wall decoration plate and preparing method of environment-friendly wall decoration plate

InactiveCN105421697AGood weather resistanceImprove stain resistanceCovering/liningsLaminationLacquerUltraviolet

The invention discloses an environment-friendly wall decoration plate and a preparing method of the environment-friendly wall decoration plate. The environment-friendly wall decoration plate comprises a substrate layer, wherein a UV (ultraviolet) back coating coats the back side of a substrate; a UV permeation bottom coats the front side of the substrate; a UV putty layer is arranged on the UV permeation bottom; a bonding layer is arranged on the UV putty layer; multicolor water paint, i.e., water-in-water or water real stone paint or UV solid color paint coats the bonding layer; a finishing paint layer coats the water water-in-water or water real stone paint or UV solid color paint; and a film covering layer is arranged on finishing paint. The environment-friendly wall decoration plate has the advantages that green and environment-friendly effects are achieved; the attaching performance, the water-resistant performance and the water-boiling-resistant performance are good; and delamination cannot easily occur. Natural vivid and colorful patterns and various stone imitating decoration effects can be provided; and the surface physical and chemical property is excellent. The preparing method comprises seven steps, and has the advantages that no solvent volatilizes in the construction process; the production efficiency is high; energy sources are saved; and the occupied area can be reduced.

Owner:HUNAN BANFERT NEW MATERIALS TECH

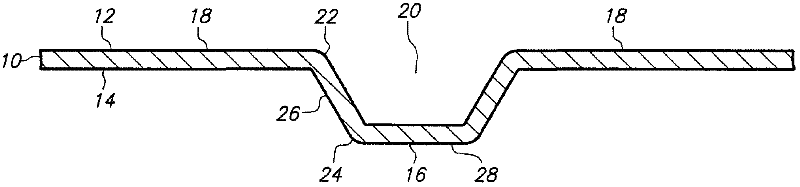

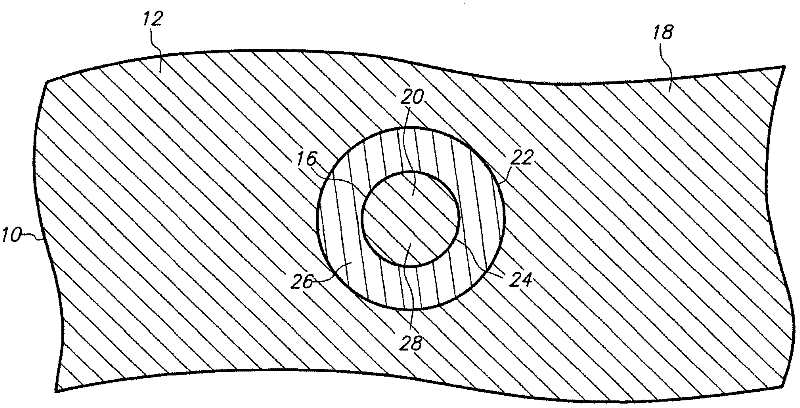

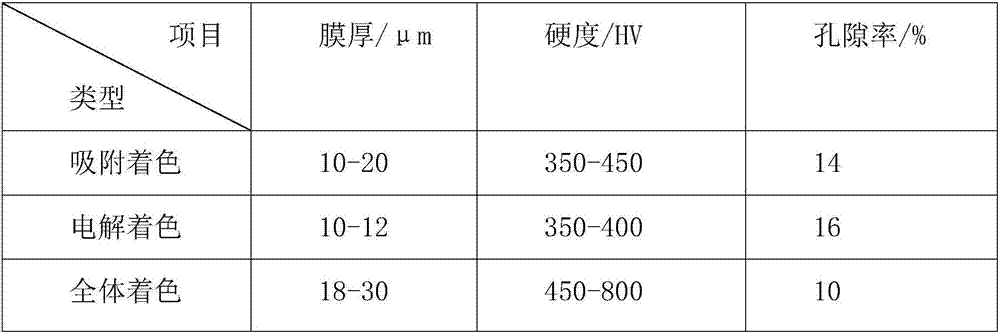

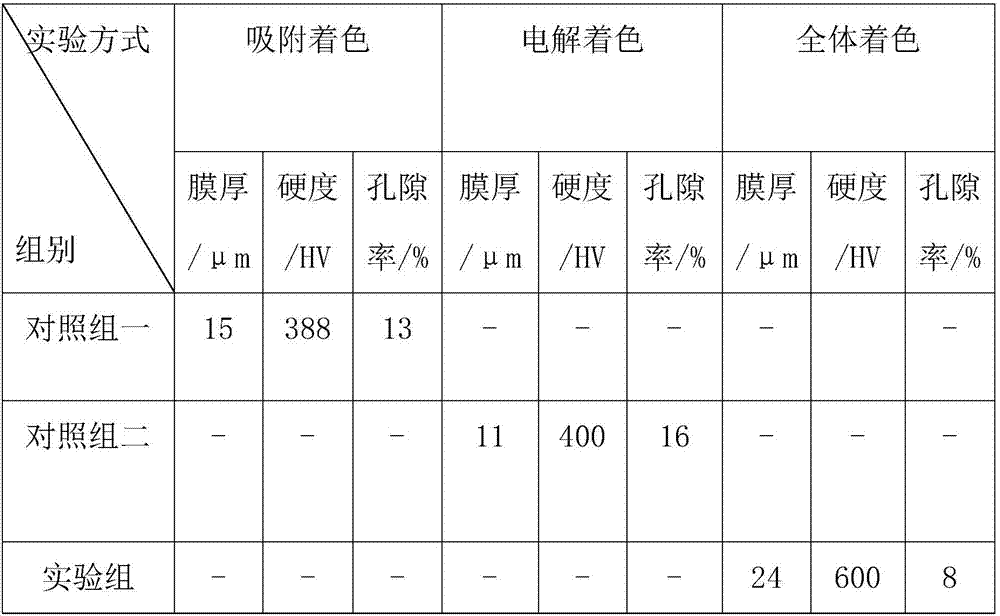

Aluminum alloy corrosion-resistant surface treatment method

ActiveCN107059091ACorrosion resistanceImprove interface adhesionSurface reaction electrolytic coatingChlorideCorrosion resistant

The invention discloses an aluminum alloy corrosion-resistant surface treatment method. An aluminum alloy plate is firstly placed into a sodium hydroxide solution to be subject to soaking and scrubbing ungreasing treatment; secondly, the remnant solution on the aluminum alloy plate is washed with ionized water, and the aluminum alloy plate is subject to alkali corrosion treatment; thirdly, an electrolyte is used for conducting anodic oxidation treatment on the aluminum alloy plate, and therefore an oxydic hard film is generated on the surface of the aluminum alloy plate; fourthly, nickel chloride acid liquor is adopted for conducting activating treatment on the hard film on the surface of the aluminum alloy plate, and the deionized water is adopted for washing the remnant solution; and finally, the aluminum alloy plate is subject to electrolytic coloring and hole sealing treatment. The aluminum alloy plate prepared through the method has the beneficial effects of being resistant to corrosion, good in interface bonding force and not prone to delaminating.

Owner:浙江春旭铝业有限公司

High sealing cold punching press shaped bubble cup plustic aluminium composite hard sheet and its production technology

A laminated hard plastics / aluminium plate with surficial PVC layer, and high sealing nature and able to be shaped by punch is prepared from at least one polyester (or polyamide) film treated by corona impact, at least one aluminium foil and one surficial PVC film through adhering them together by use of high-adhesion adhesive.

Owner:刘继福

Semiconductor chip assembly with post/base heat spreader and conductive trace

InactiveCN102074518AImprove cooling effectNot easy to delaminateSemiconductor/solid-state device detailsSolid-state devicesSignal routingElectrical conductor

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a conductive trace and an adhesive. The semiconductor device is electrically connected to the conductive trace and thermally connected to the heat spreader. The heat spreader includes a post and a base. The post extends upwardly from the base into an opening in the adhesive, and the base extends laterally from the post. The adhesive extends between the post and the conductive trace and between the base and the conductive trace. The conductive trace provides signal routing between a pad and a terminal.

Owner:BRIDGE SEMICON

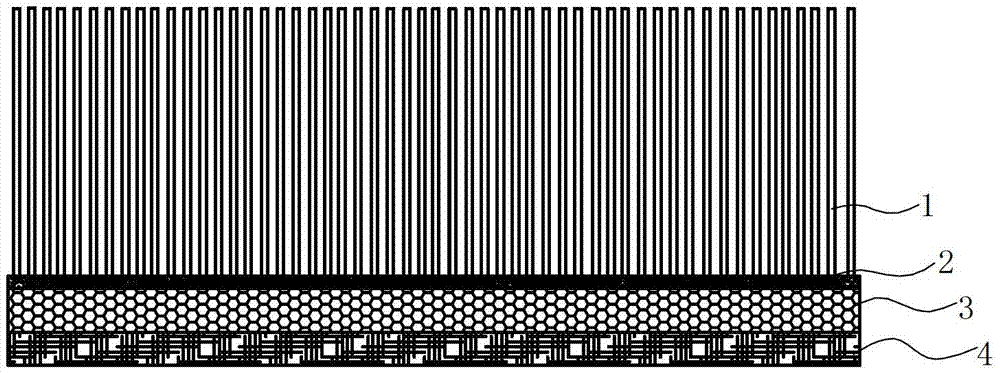

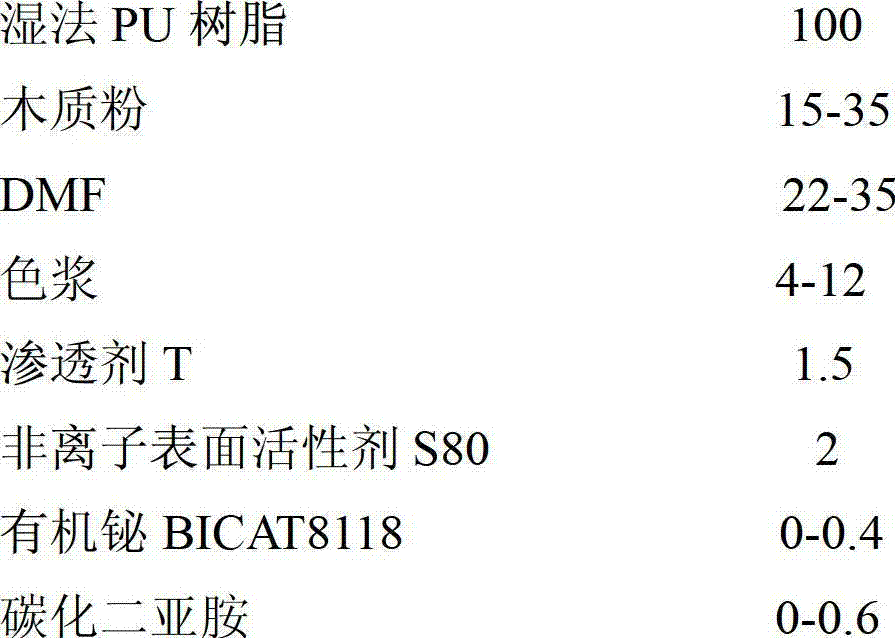

High-stimulation fur fabric and its making method

InactiveCN103085402ATightly boundNot easy to delaminateLamination ancillary operationsSynthetic resin layered productsFiberSurface layer

The invention relates to a high-stimulation fur fabric and its making method. The fabric comprises artificial wool formed by a base cloth and a wool layer, the base cloth is coated with an elastic polymer layer formed by wet PU, the elastic polymer layer is infiltrated into the artificial wool, and the surface layer of the wet PU layer is coated with a dry PU layer. Compared with high-stimulation fur fabrics in the prior art, the high-stimulation fur fabric provided by the invention allows a stimulation fur layer and the elastic polymer layer formed by the artificial wool through the wet PU to have the characteristics of tight combination, difficult layer removal and good firmness; and the elastic polymer is infiltrated into fibers of the artificial wool, and the natural elasticity of the stimulation fur is partially reserved in a zonal direction, so the high-stimulation fur fabric has a natural flesh feeling and a good stimulation effect.

Owner:苏春

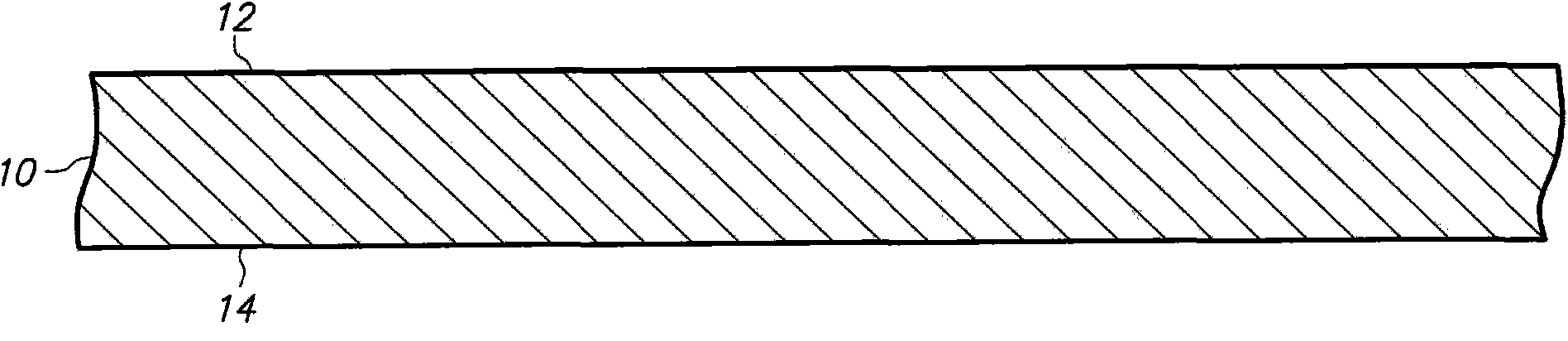

Semiconductor chip assembly with a post/base heat spreader and a signal post

InactiveCN102130084ALow thermal conductivityLow cost dielectricSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorAdhesive

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a conductive trace and an adhesive. The semiconductor device is electrically connected to the conductive trace and thermally connected to the heat spreader. The heat spreader includes a thermal post and a base. The thermal post extends upwardly from the base into a first opening in the adhesive, and the base extends laterally from the thermal post. The conductive trace includes a pad, a terminal and a signal post. The signal post extends upwardly from the terminal into a second opening in the adhesive.

Owner:BRIDGE SEMICON

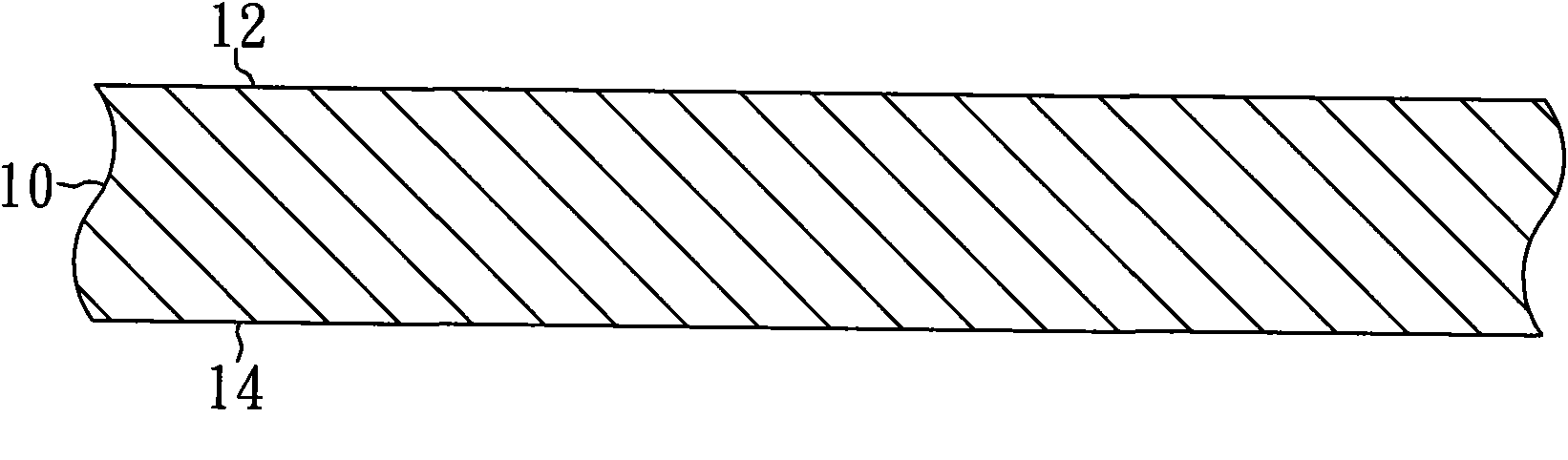

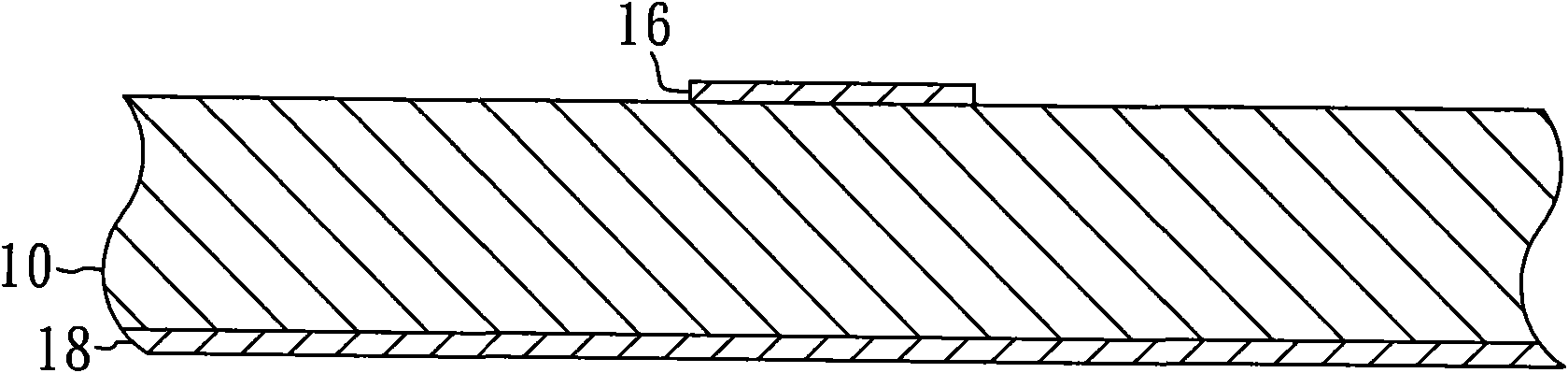

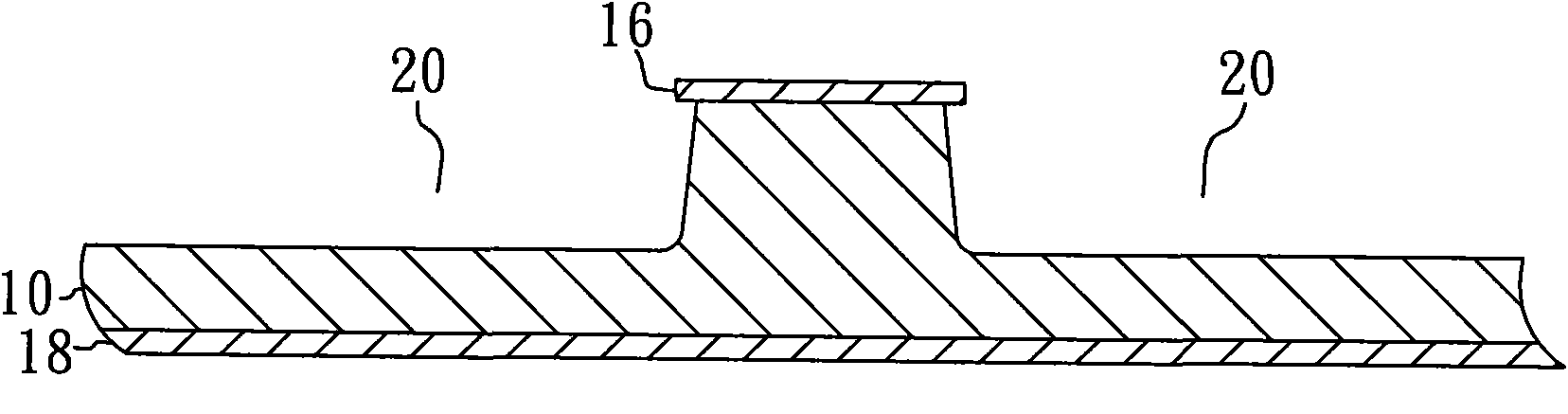

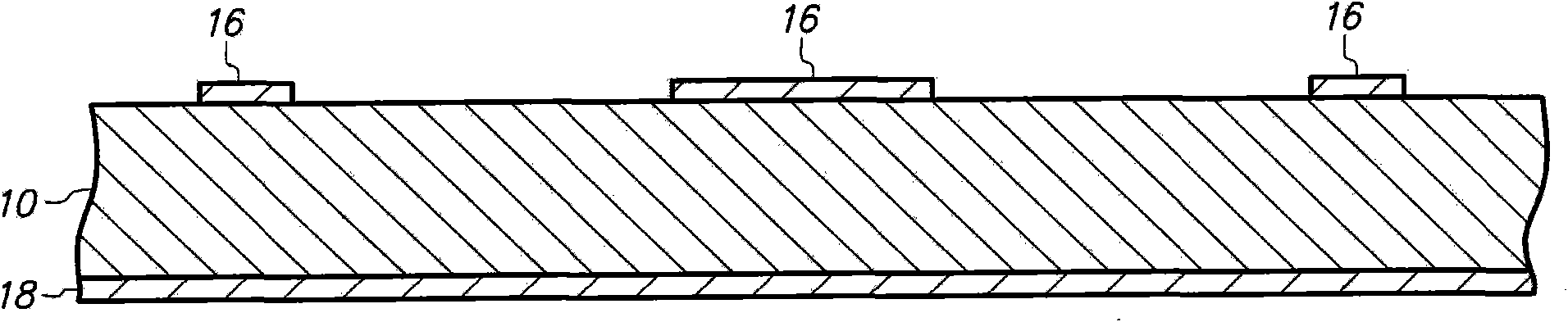

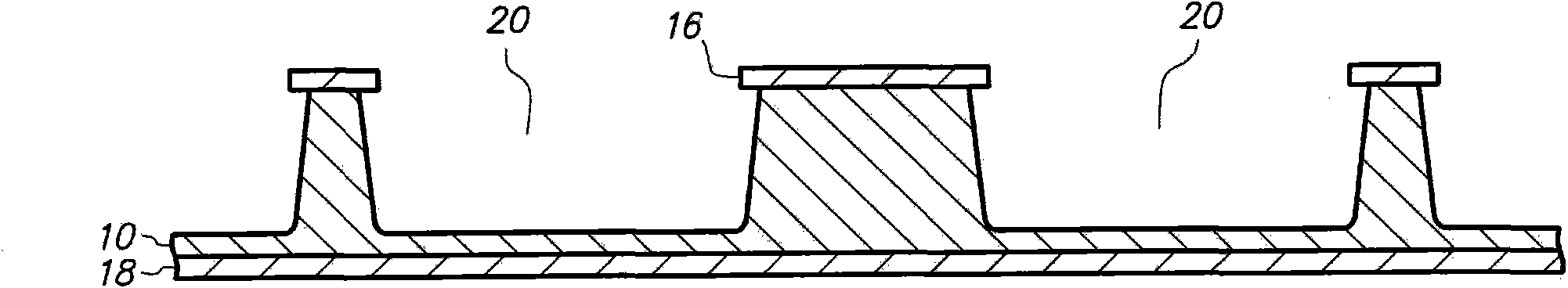

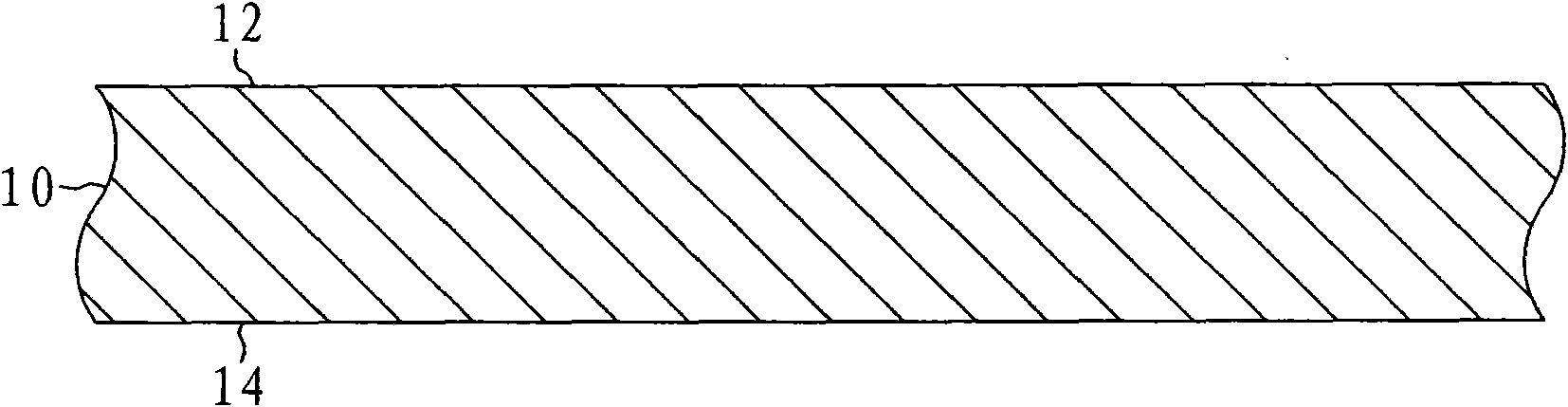

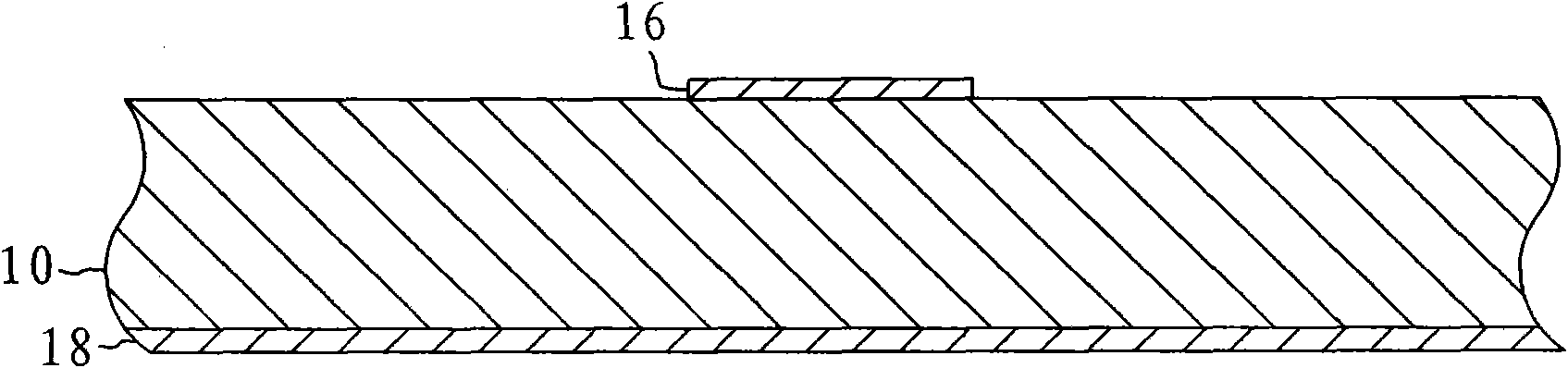

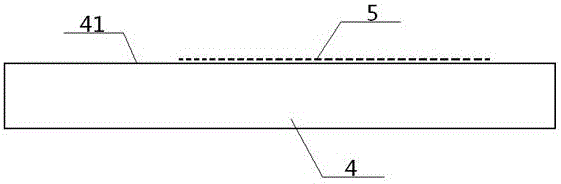

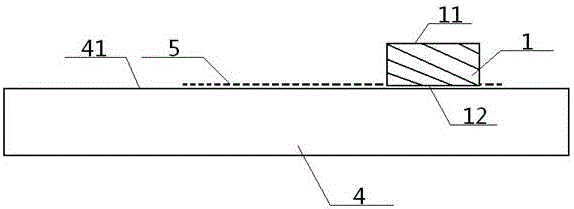

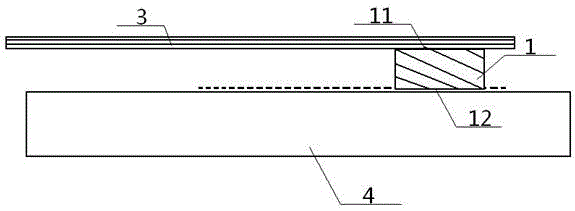

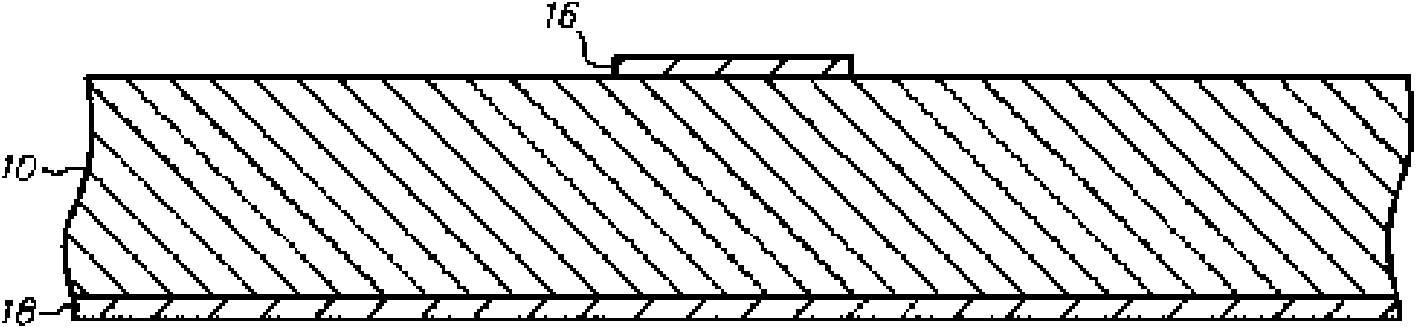

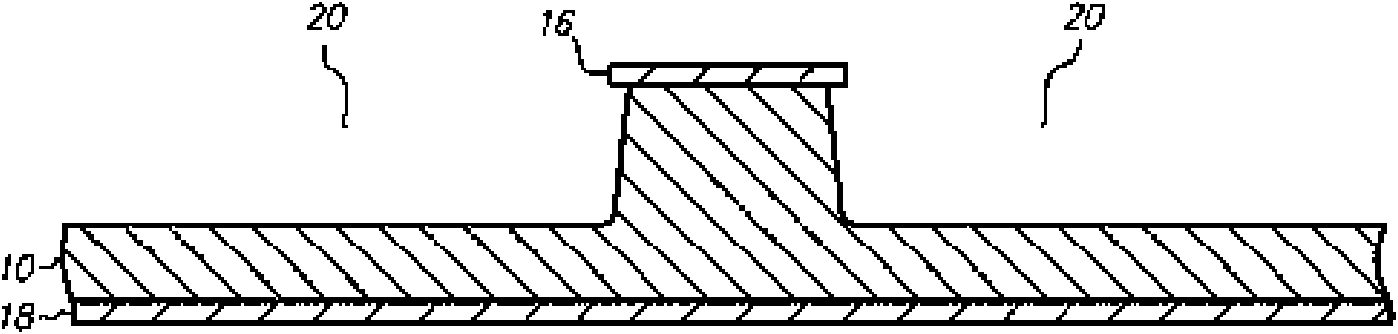

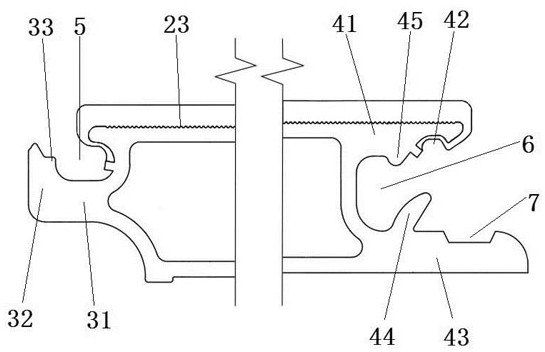

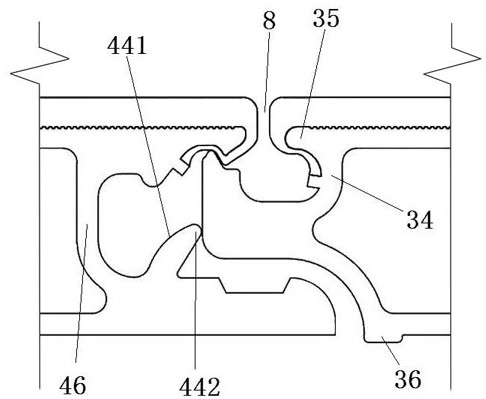

Semiconductor chip assembly with post/base heat spreader and substrate

InactiveCN102064265AImprove cooling effectLow cost dielectricSolid-state devicesSemiconductor devicesSignal routingElectrical conductor

The invention relates to a semiconductor chip assembly with a post / base heat spreader and a substrate. The semiconductor chip assembly at least includes a semiconductor device, the heat spreader, the substrate and an adhesive. The semiconductor device is electrically connected to the substrate and thermally connected to the heat spreader. The heat spreader at least includes a post and a base. Thepost extends upwardly from the base into an opening in the adhesive and an aperture in the substrate, and the base extends laterally from the post. The adhesive extends between the post and the substrate and between the base and the substrate.The assembly provides signal routing between a pad and a terminal.

Owner:BRIDGE SEMICON

Travertine-like arabesquitic vat and production technology thereof

The invention discloses a travertine-like arabesquitic vat. The forming material of the travertine-like arabesquitic vat mainly comprises a solid material, a blended solution and staple, wherein the solid material comprises the following components in percentage by weight: 30-45% of rapid-hardening sulphoaluminate cement, 45-65% of fine river sand, 1-3% of titanium dioxide, 1-3% of yellow powder and 0.01-0.15% of red powder; the blended solution comprises the following components in percentage by weight: 99-99.9% of water and 0.01-0.1% of polyacrylamide; and the staple is glass fiber of which the length is 5-10cm. The invention also discloses a production technology for the travertine-like arabesquitic vat, which comprises the following steps of: burdening, mixing, cleaning a mold, installing a material mold, installing the staple, demolding, nursing, trimming, repairing, brushing to be smooth, applying a surface coating and the like. The travertine-like arabesquitic vat disclosed by the invention has the advantages of clear and natural texture, good product intensity, light weight, hard surface layer, abrasion resistance, small possibility of delaminating and falling powder, low cost and good decoration effect, is convenient to produce on a large scale and is easy for stable control of product chromatic aberration, natural travertine in the natural world can be prevented from being mined on a large scale, and mine waste can be utilized to protect the ecological environment.

Owner:泉州市嘉利来石材工艺有限公司

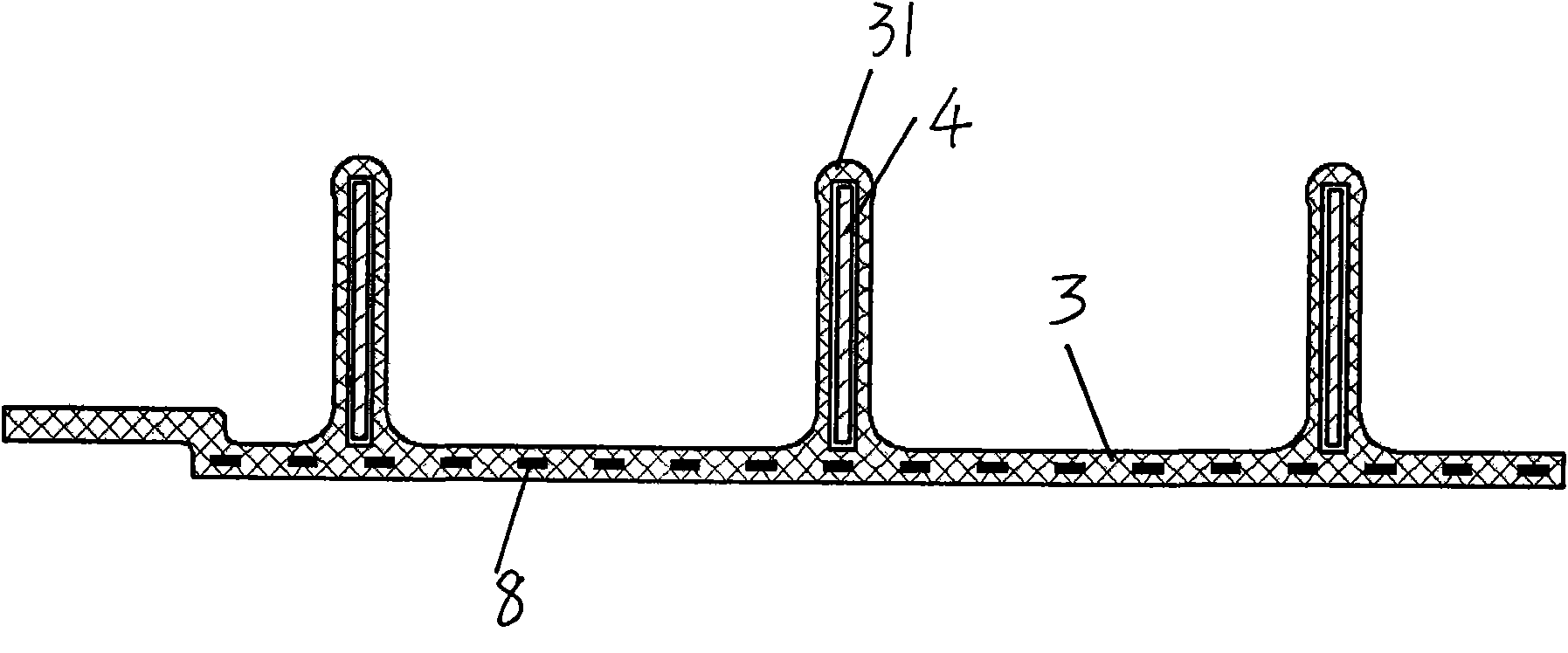

Metal reinforcement structural wall plastic pipe and manufacture method

ActiveCN101943297ANot easy to corrodeExtended service lifeRigid pipesBlocking layerHot-melt adhesive

The invention relates to a metal reinforcement structural wall plastic pipe and a manufacture method thereof. The metal reinforcement structural wall plastic pipe comprises a plastic pipe and is characterized in that at least one metal sheet reinforcement is wound along the outer wall of a plastic pipe; and the metal sheet reinforcement comprises a metal sheet as well as hot melting glue, a blocking layer, hot melting glue and plastics which are sequentially coated at the outer layer. The method for manufacturing the metal reinforcement structural wall plastic pipe is characterized by comprising the following steps of: (1) pretreating; (2) coarsening and heating; (3) coating the hot melting glue and the blocking layer; (4) manufacturing the metal reinforcement; (5) bending and moulding; (6) overlapping, jointing and heating; (7) bonding on the surface of the plastic pipe; and (9) cutting to form a finished product. Compared with the traditional steel plastic winding drainage pipe, the invention has the advantage of adding the hot melting glue between the reinforced metal sheet and the plastics so that the plastics and metal are tightly bonded into a whole. A protecting layer can prevent the metal reinforcement of the plastic pipe from damage in construction and rusting.

Owner:SHANGHAI JWELL PIPE EQUIP +1

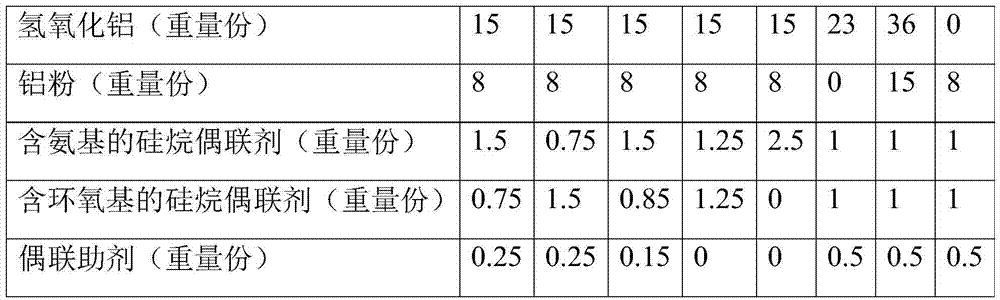

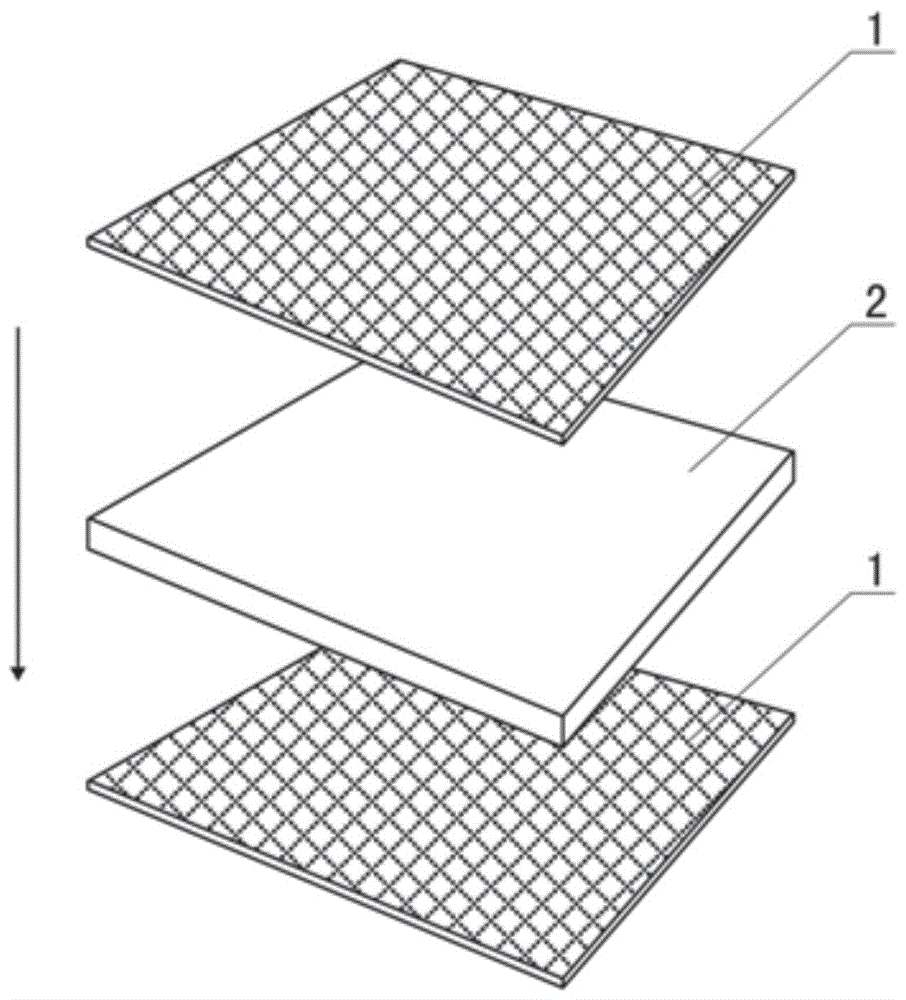

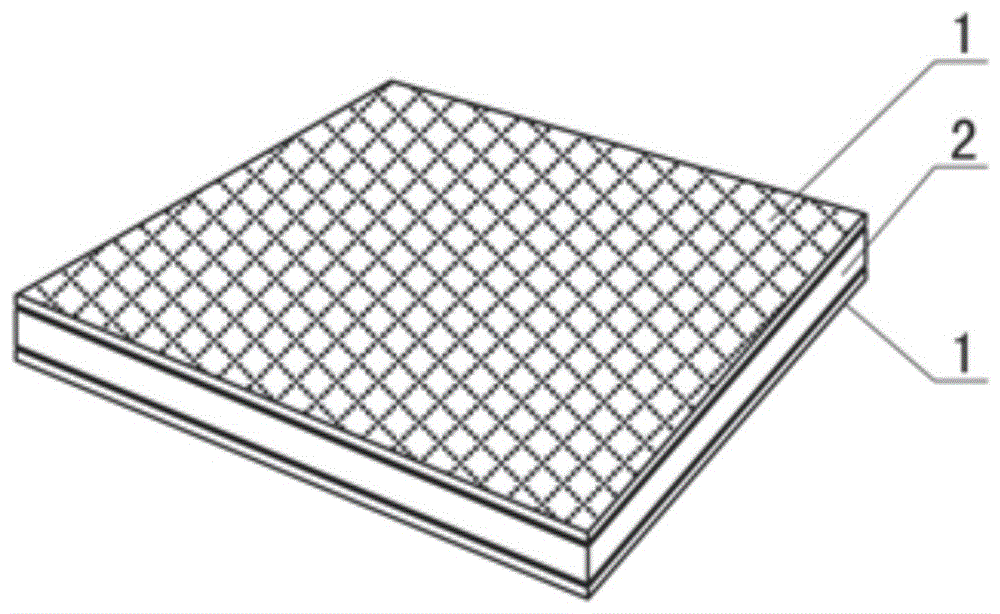

Composite honeycomb sandwich board and preparation method thereof

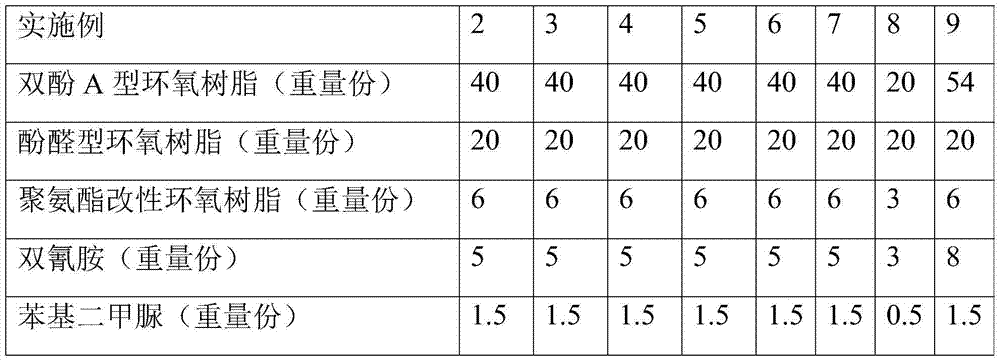

ActiveCN106926516ANot easy to delaminateThe connection structure is stableLayered product treatmentSynthetic resin layered productsEpoxySurface layer

The invention discloses a composite honeycomb sandwich board and a preparation method of the composite honeycomb sandwich board. The composite honeycomb sandwich board comprises an aluminum honeycomb sandwich and an epoxy resin reinforcing material surface layer composited on the surface of one or two sides of the aluminum honeycomb sandwich, the epoxy resin reinforcing material surface layer is a solidifying product of a hot melting type epoxy resin prepreg, the hot melting type epoxy resin prepreg comprises a reinforcing material and an epoxy resin composition, the epoxy resin composition comprises an epoxy resin, a latent solidifying agent, an accelerant, a coupling agent, optional flexibilizer and optional filler, and the coupling agent comprises a silane coupling agent containing an amino. The provided composite honeycomb sandwich board avoids using an extra solvent type adhesive, and is further environmentally friendly; meanwhile, the bonding strength between the aluminum honeycomb sandwich and the epoxy resin reinforcing material surface layer is improved, and the composite honeycomb sandwich board does not delaminate easily.

Owner:BYD CO LTD

Carbon fiber cloth reinforced poplar laminated veneer lumber and making method thereof

InactiveCN104493917AHigh strengthNot easy to delaminateLaminationLamination apparatusFiberCarbon fibers

The invention discloses a carbon fiber cloth reinforced poplar laminated veneer lumber and a making method thereof, relates to a laminated veneer lumber and a preparation method thereof, and aims to solve the problems that the mechanical strength of the conventional poplar laminated veneer lumber is low, an interface bonding capability of carbon fibers and lumber is poor, and delamination is easily caused. The carbon fiber cloth reinforced poplar laminated veneer lumber is made from seven poplar veneers and two pieces of carbon fiber cloth, and sequentially comprises a poplar veneer I, one surface-treated carbon fiber cloth, a poplar veneer II, a poplar veneer III, a poplar veneer IV, a poplar veneer V, a poplar veneer VI, the other surface-treated carbon fiber cloth and a poplar veneer VII from top to bottom. The preparation method comprises the following steps: firstly pre-treating the carbon fiber cloth, then gluing, and finally thermally-pressing to obtain the carbon fiber cloth reinforced poplar laminated veneer lumber. According to the invention, the carbon fiber cloth reinforced poplar laminated veneer lumber and the preparation method thereof can be obtained.

Owner:NORTHEAST FORESTRY UNIVERSITY

Printing and flocking process capable of improving elasticity of specific portions of cloth

InactiveCN106436348AIncrease elasticityImprove smoothnessPretreated surfacesCoatingsAdhesion forceEngineering

The invention discloses a printing and flocking process capable of improving elasticity of specific portions of cloth. The printing and flocking process includes spraying a mold release agent onto the upper surface of a clean platen, printing first glue, laying cloth on the first glue, printing second glue on the cloth, electrostatically flocking the second glue, turning over the cloth, and electrostatically flocking the first glue to obtain a flocky product. The first glue and the second glue have high elasticity and adhesion force. Stripes, patterns or characters can be printed on the first glue and the second glue. The printing and flocking process has the advantages that the elasticity of the cloth can be enhanced in any directions according to ergonomics, adhesion force is high, less proneness to delaminating is achieved, and the edge of the cloth is not loosened; flocking modes are rich, flocking quality and breathability are high, and strapping lines are avoided when a user wears clothes made from the flocky product.

Owner:刘青霞

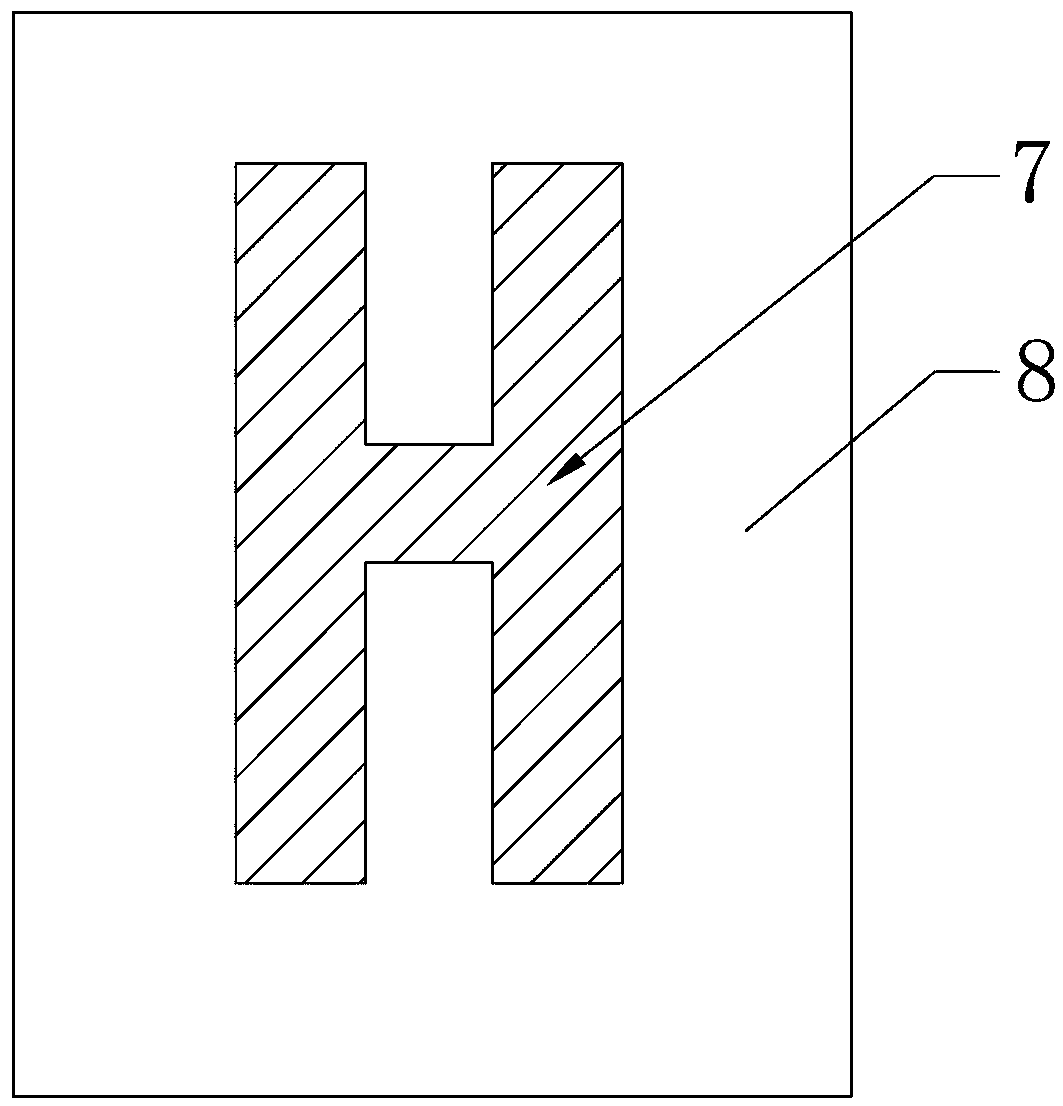

Device and process for forming double-layer brick

ActiveCN104070594AImprove molding efficiencyImprove integrityFeeding arrangmentsBrickUltimate tensile strength

The invention provides a device for forming a double-layer brick. The device comprises a conveying mechanism and a blanking mechanism. The conveying mechanism comprises a conveying belt, a first vibrating mechanism and a second vibrating mechanism. The conveying belt comprises a first steady conveying section, a first vibrating conveying section, a second steady conveying section, a second vibrating conveying section and a third steady conveying section. The blanking mechanism comprises a brick surface material blanking mechanism and a brick backing material blanking mechanism. When the device for forming the double-layer brick is in use, after a pulpy brick surface material is vibrated in a die to be evenly spread and is naturally coagulated to the setting degree and not completely coagulated, a pulpy brick backing material is poured on an upper layer and is vibrated to be evenly spread, contact surfaces of both the brick backing material and the brick surface material are in full combination, and the brick backing material and the brick surface material are simultaneously naturally coagulated to be an integrated body. The device for forming the double-layer brick is novel and reasonable in structure, forming efficiency and integration of the double-layer brick are high, the brick surface and a brick base are not subject to delamination easily, and the strength is high. The invention further provides a double-layer brick forming process matched with the device, the whole process is clear and simple, and forming efficiency is high.

Owner:福建省东方水泥制品有限公司

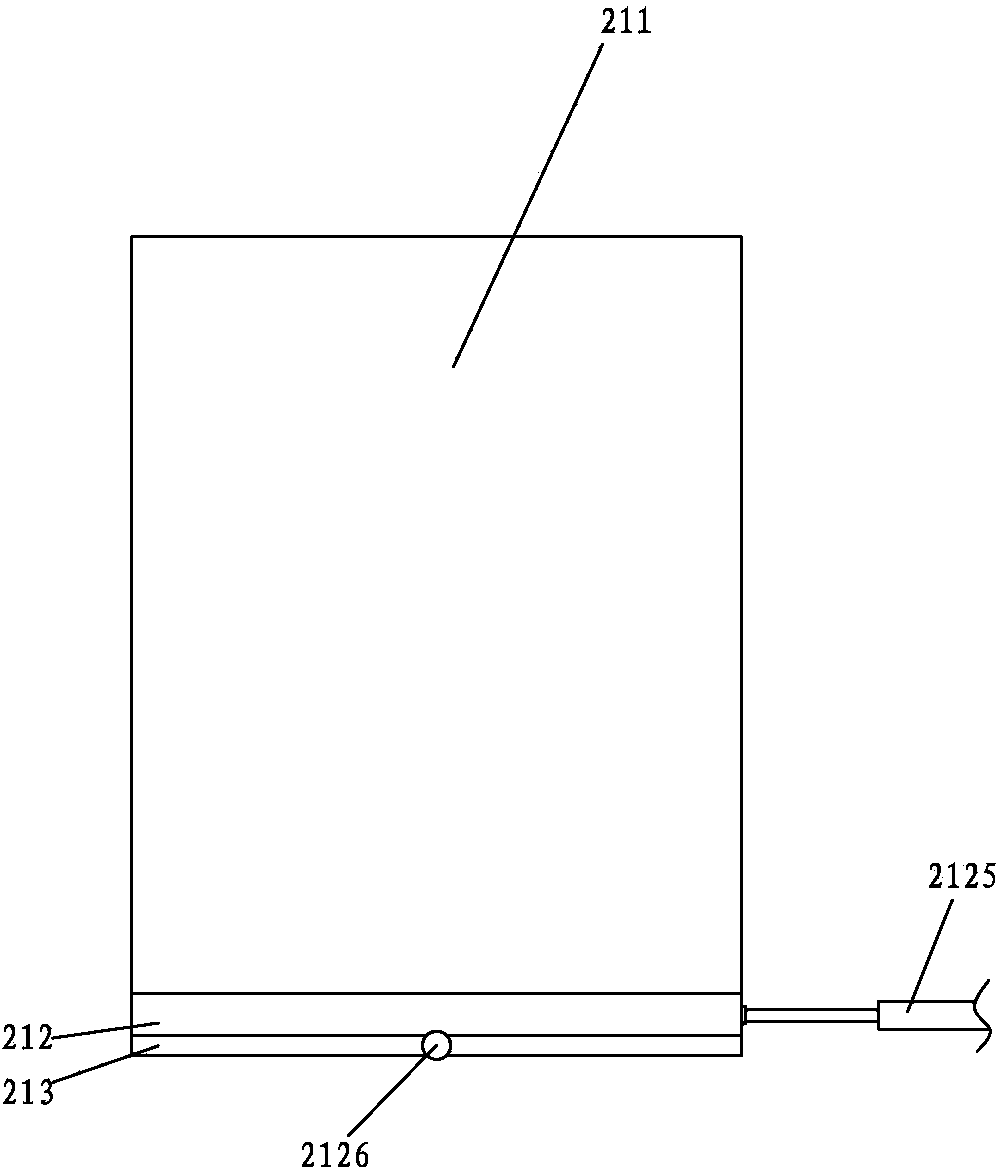

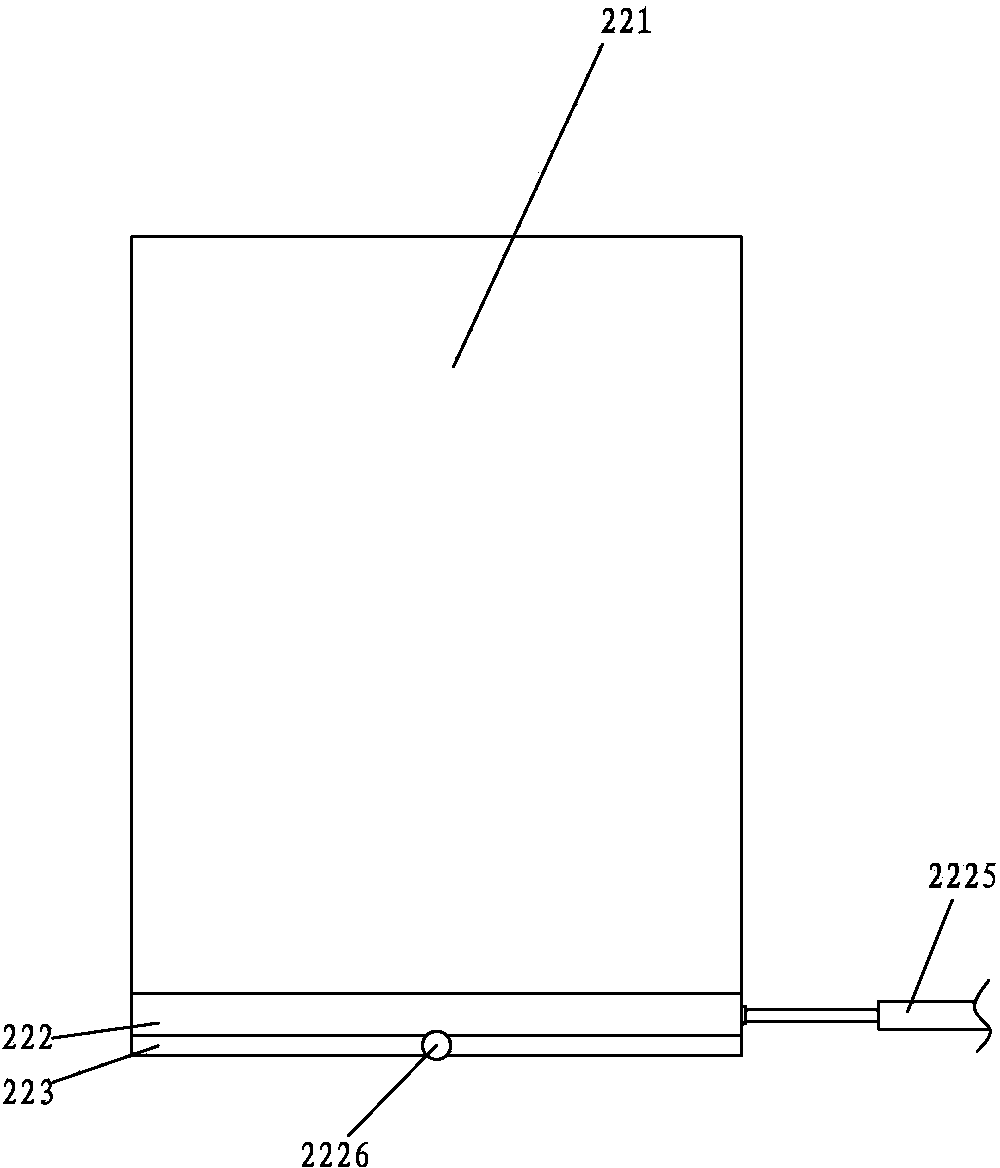

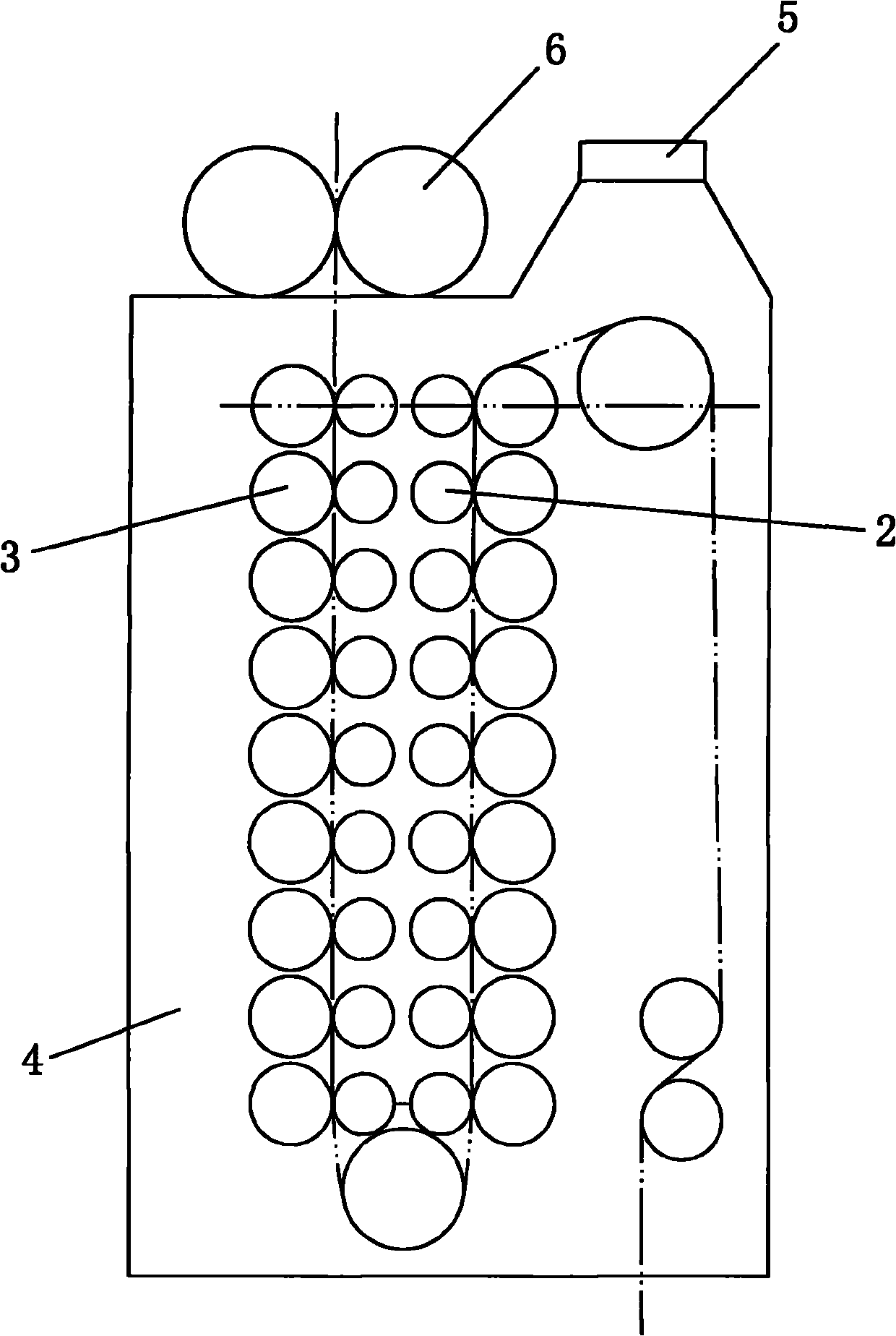

Method and device for after-finishing of various textiles and non woven fabrics through plasma treatment technology

InactiveCN102021814AChange propertiesProduce adhesionUltrasonic/sonic fibre treatmentTextile printerPlasma generator

The invention discloses a method and a device for after-finishing of various textiles and non woven fabrics through the plasma treatment technology. Various textiles and non woven fabrics are fed in through a group of fabric clamping rollers, and electro discharge treatment is carried out through a carrier roller rotating electrode fixed on a stand and a discharge channel of a plasma generator connected with an electric control box. Under the action of electric ions, the molecular characteristics of the textiles are changed, hydrophilcity, adhesiveness and proportionality of the textiles are increased, and the after-finishing process is carried out. For after-finished textiles through the plasma electro discharge treatment, the color fastness and the colorfulness of textile printing are increased. During coating, because the textiles have no dirt or dust, the adhesiveness is strong, the coating is even and is not easy to degum. The adhesion degree is increased during compounding, the textiles are not easy to degum and scale off and not easy to blister. According to the process, the quality of the textiles is greatly improved, and the economic benefit is increased. A large amount of ozone gas generated during the electro discharge treatment process of the various textiles and the non woven fabrics is absorbed through an ozone collector.

Owner:FUCHENG CHINA

Vertical carbon fiber template and production method thereof

InactiveCN105666978APrying resistanceWear-resistantNon-macromolecular adhesive additivesLayered product treatmentNonwoven fabricWear resistance

The invention discloses a vertical carbon fiber template, comprising a carbon fiber composite skin made of carbon fiber cloth, spunlace non-woven fabric, random copolymerized polypropylene and a binder, and a core board formed by splicing and curing a plurality of wooden strips , two carbon fiber composite skins are pasted and connected to the large planes on both sides of the core board. The invention discloses a production method of a vertical carbon fiber template, which comprises the following steps: processing a core board; processing a carbon fiber composite skin; applying glue to the core board and the carbon fiber composite skin; covering the skin; cold pressing; hot pressing to obtain a finished product. The present invention uses construction waste templates as the main material to make the load-bearing main material, that is, the core board, and uses carbon fiber cloth, spunlace non-woven fabric, random copolymerized polypropylene and adhesive to jointly process it into a carbon fiber composite skin, and then the carbon fiber composite skin and The core board is processed into a vertical carbon fiber template through gluing, cold pressing, and hot pressing, which has the advantages of high reuse rate, cost saving, high density, high strength, wear resistance, and corrosion resistance.

Owner:四川省中鑫威格节能科技股份有限公司

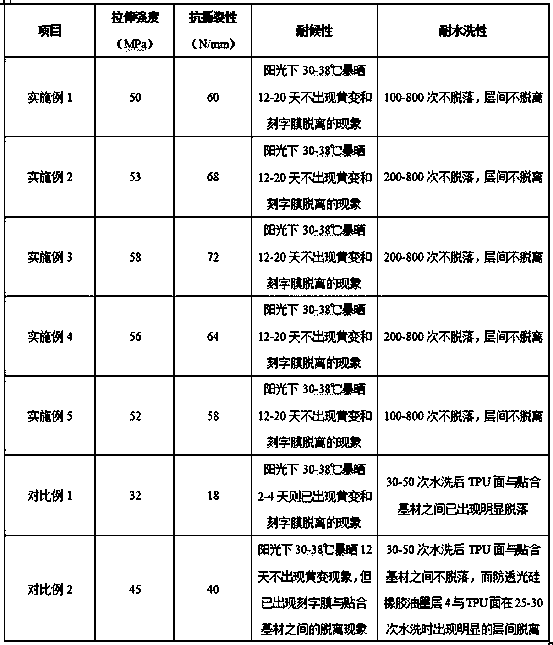

High-elasticity silicone rubber lettering film and preparation method and application method thereof

ActiveCN108610997AIncrease elasticityAvoid deformationPolyureas/polyurethane adhesivesInksRubber materialPolymer science

The invention relates to the technical field of thermal transfer printing lettering film, and in particular, relates to a high-elasticity silicone rubber lettering film and a preparation method and anapplication method thereof. The high-elasticity silicone rubber lettering film comprises a load-bearing substrate, a release layer, a surface layer silicone rubber ink layer, an anti-photopermeable silicone rubber ink layer, an adhesive interfacial agent layer and a TPU hot melt adhesive film which are connected from bottom to top successively; the adhesive interfacial agent layer is prepared from an adhesive interfacial agent, and the adhesive interfacial agent is an adhesive interfacial agent containing dual-resin components. The silicone rubber lettering film has the advantages of both thesilicone rubber material and the TPU material, has good elasticity, tearing strength, weatherability, yellowing resistance, water washing resistance and other comprehensive properties, has layers noteasy to separate, is not easy to discolor or fade by sunlight exposure, and has the water-washing fading rate not less than 0.5%, is not easy to dye when being mixed and washed with materials with other colors, and is high in stability, easy to bond with a variety of materials, high in bonding strength, not easy to peel off, good in stability, delicate in hand feeling, good in aesthetic degree, and long in service life.

Owner:卢汉军

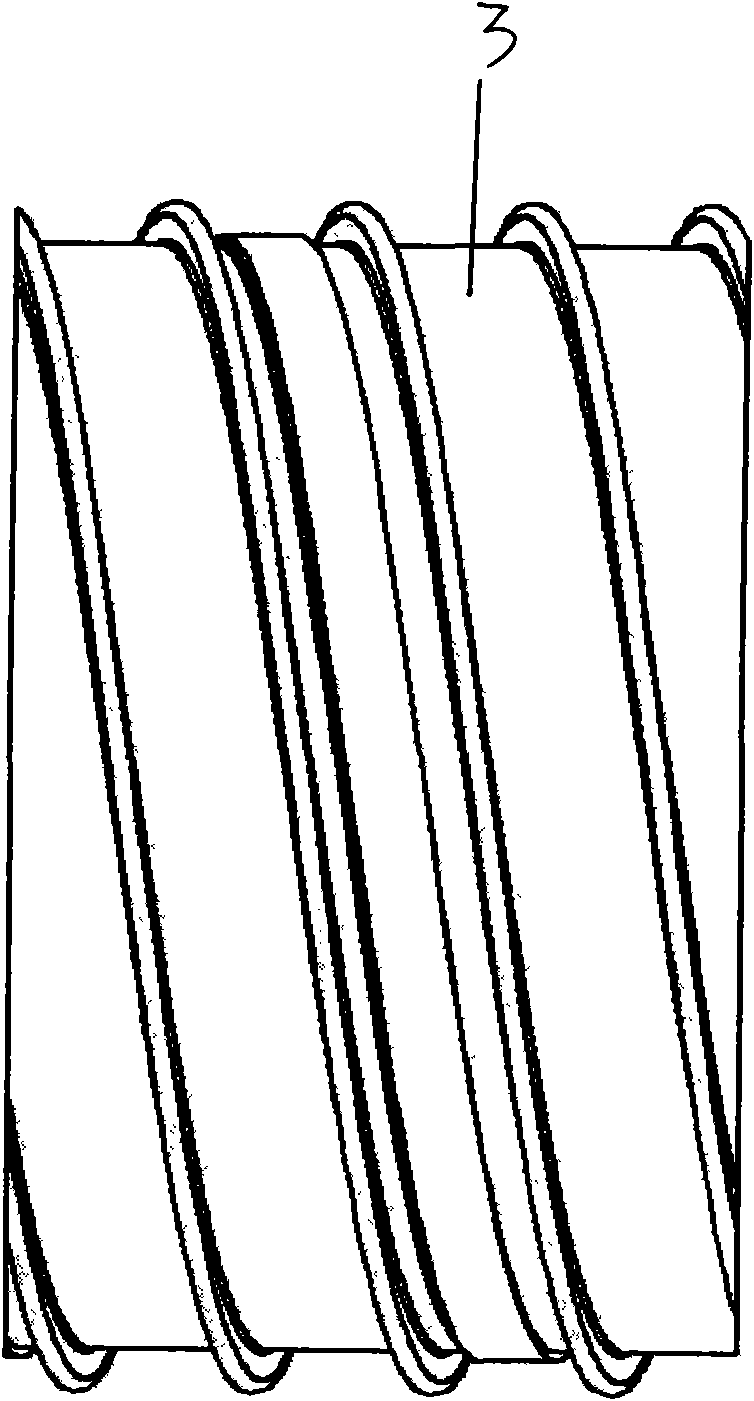

Production method of high-curliness canvas for rubber conveyer

InactiveCN103753931AEasy to curlEven by forceLamination ancillary operationsFibre typesPolyesterTear resistance

The invention discloses a production method of a high-curliness canvas for a rubber conveyer. The production method comprises the following steps: selecting high-strength polyester and nylon industry long filament as materials of products; selecting a structure with coordinated weft and warp match and using a broken twill texture structure with proper weft and warp-density; subjecting the gray fabric to gum dipping, so as to produce the framework material. The framework material produced by the method is used for producing the canvas for the rubber conveyer, and the canvas has advantages of uniform stress, high curliness, impact resistance, not easy delamination and corrugation, tear resistance, stable bonding with the rubber and high strength, so that the canvas is the ideal framework material for producing the rubber conveyer, and the rubber conveyer produced by the framework material can be used in production equipment with relatively small roller diameter or improve the warp-direction curliness in the production process of a high-layer thick rubber belt. The rubber conveyer is prevented from bending and corrugating, or being broken during the using process, and the service life of the rubber conveyer is prolonged.

Owner:SHANDONG TIANHENG CHEM FIBER

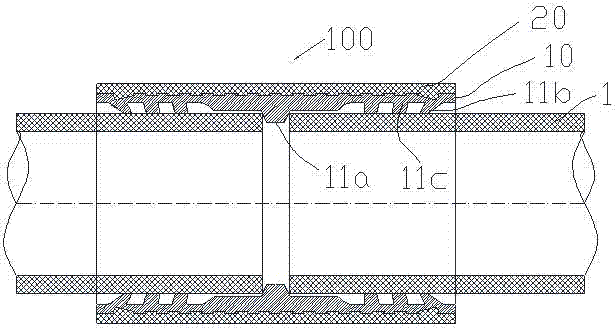

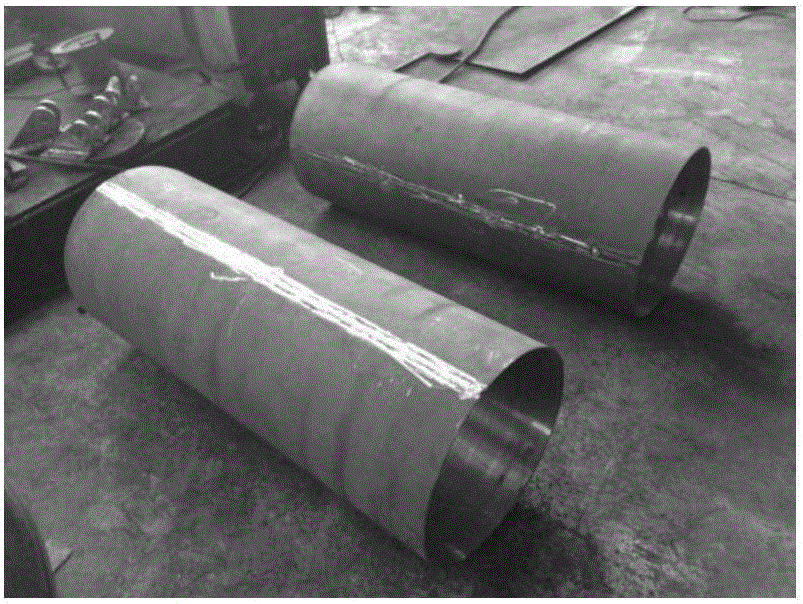

Composite sleeve joint and manufacturing method thereof

The invention discloses a composite sleeve joint which takes the shape of a drum with the two ends open. The composite sleeve joint comprises an inner drum layer and an outer drum layer which is tightly attached on the outer circumference of the inner drum layer. The inner drum layer is made of rubber and the outer drum layer is made of glass fiber reinforced plastic. According to the invention, the outer layer of the composite sleeve joint is a glass fiber reinforced plastic layer and the inner layer is a rubber sealing layer; the glass fiber reinforced plastic layer and the rubber sealing layer are of good integrality, and the layers are not easy to peel; when the sleeve joint is used to connect pipes, the connection joint is stable and reliable in quality and the phenomenon of displacement of the rubber cannot happen; so the sleeve joint overcomes the problem that when a flexible socket O-shaped rubber seal ring is used for connection, the rubber seal ring is easy to twist and displace, which affects the sealing effect of the joint. In addition, the invention further provides a manufacturing method of the composite sleeve joint.

Owner:SHENZHEN KANGQIANG CONSTR NEW TECH ENG

Semiconductor chip set

InactiveCN102104102AImprove cooling effectLow thermal conductivitySolid-state devicesSemiconductor devicesPower semiconductor deviceSemiconductor chip

The invention relates to a semiconductor chip set at least comprising a semiconductor assembly, a heat-radiating seat, a base plate and an adhering layer, wherein the semiconductor assembly is electrically connected with the base plate and thermally connected with the heat-radiating seat; the heat-radiating seat at least comprises a protruding column and a base, wherein the protruding column upwards extends to pass through an opening of the adhering layer and enter a through hole of the base plate, and the base extends out of the side direction of the protruding column; the adhering layer extends between the protruding column and the base plate and between the base and the base plate; and the base plate at least comprises a first conducting layer, a second conducting layer and a dielectric layer and supplies a horizontal signal route between a weld pad positioned on the first conducting layer and a terminal, wherein the dielectric layer is positioned between the first conducting layerand the second conducting layer. The semiconductor chip set has high reliability and moderate price and is greatly suitable for quantity production and especially suitable for a high-power semiconductor chip set which is easy to generate high heat and needs excellent heat-radiating effect.

Owner:BRIDGE SEMICON

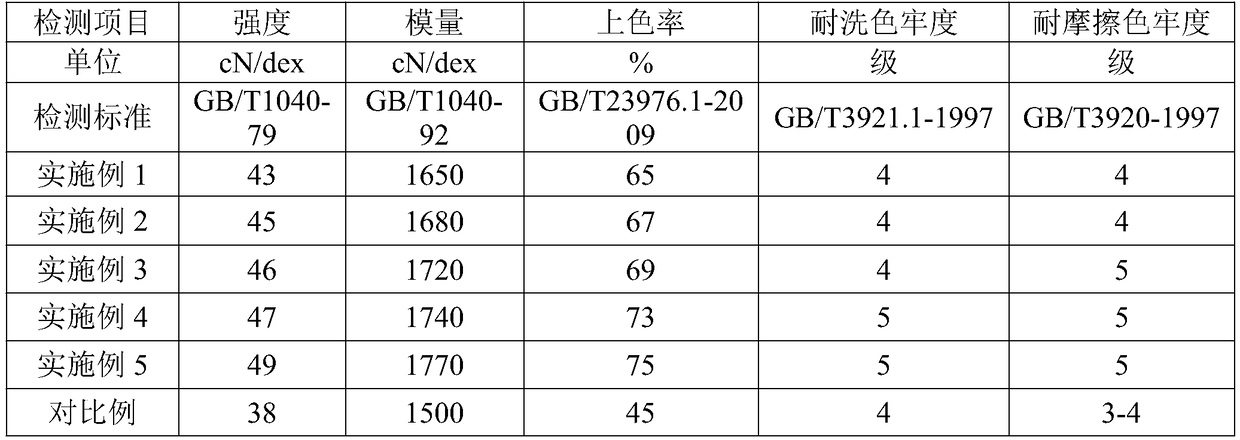

Colored high-strength polyethylene fibers and preparation method thereof

ActiveCN109322006ARaw materials are easy to getLow priceFilament/thread formingConjugated synthetic polymer artificial filamentsFiberWeather resistance

The invention discloses a preparation method of colored high-strength polyethylene fibers. The preparation method comprises the following steps: (I) preparing a spinning solution A; (II) preparing a spinning solution B; (III) preparing high-strength polyethylene fibers; (IV) spraying and modifying the high-strength polyethylene fibers; and (V) performing ultraviolet treatment. The invention further discloses colored high-strength polyethylene fibers prepared according to the preparation method of the colored high-strength polyethylene fibers. The colored high-strength polyethylene fibers disclosed by the invention not only reserve the excellent comprehensive performance of the traditional high-strength polyethylene fibers, but also can improve the weather resistance, surface hardness, heatresistance, creep resistance and oxidation resistance, and are simple and easy in dyeing, high in color fastness and uniform in dyeing.

Owner:江苏智芯新能源装备制造有限公司

Building decoration plate with heat insulation and reflection functions and preparation method

InactiveCN105863201AImprove protectionGood for healthCovering/liningsFlooringPhysical healthThermal insulation

The invention relates to a building decoration plate with heat insulation and reflection functions and a preparation method. The building decoration plate with the heat insulation and reflection functions comprises a basic material layer, a bottom coating and a surface coating. The basic material layer is any one of an inorganic board, a PVC board and a galvanized board. The preparation method includes the steps that the basic material layer is coated with the bottom coating and the surface coating in sequence, wherein coating of the bottom coating is coating of one or more of a UV penetrating bottom, UV filling putty, UV roller-painting sanded bottom, a UV roller-painting spray front roller, a UV covering white bottom, a UV adhesion bottom, a UV covering white bottom and a self-drying white bottom; coating of the surface coating sequentially includes coating of UV heat-insulating and reflecting colored paint and coating of UV heat-insulating and reflecting varnish; the total coating amount of the UV heat-insulating and reflecting coating is 40-100 g / m<2>; and a curing light source is an LED / UV light source or a UV light source formed by combining one to two gallium lamps with 0-2 mercury lamps. The building decoration plate with the heat insulation and reflection functions has strong cooling and heat insulating functions, no solvent release occurs in the coating process, and the building decoration plate is beneficial for the physical health of construction persons accordingly.

Owner:HUNAN BANFERT NEW MATERIALS TECH

Production method for durable plastic surface waterproof building template

InactiveCN102877641AAvoid pollutionImprove bindingSynthetic resin layered productsLaminationCoated surfaceHot melt

The invention relates to a production method for a durable plastic surface waterproof building template and belongs to the technical field of plastic wood composite building templates. The method comprises the steps of rolling holes on a base plate, preheating and dehumidifying, extruding and coating plastic, rolling and compounding, cooling and solidifying, and cutting and forming. After the base plate is subjected to hole rolling and preheating, hot-melt plastic is directly extruded onto the surface of the base plate by an extruding machine, the plastic coated surface is subjected to rolling and compounding by a pressing roller, and the plastic surface and the base plate are formed through rolling at one step, so that the production process is simple and high in efficiency. The surface and the base plate are intersected transversely and longitudinally and connected firmly, so that delamination and cracking are avoided, the service life is long and the quality of the template is high.

Owner:WEIFANG LAIPUDE PLASTIC & WOOD TECH

Punching press shaped high sealing tropical type plastic aluminium composite hard sheet and production technology

Owner:刘继福

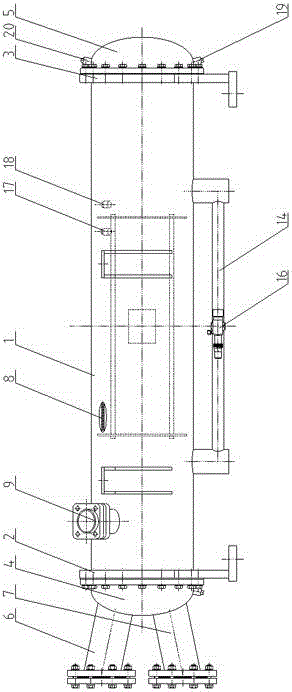

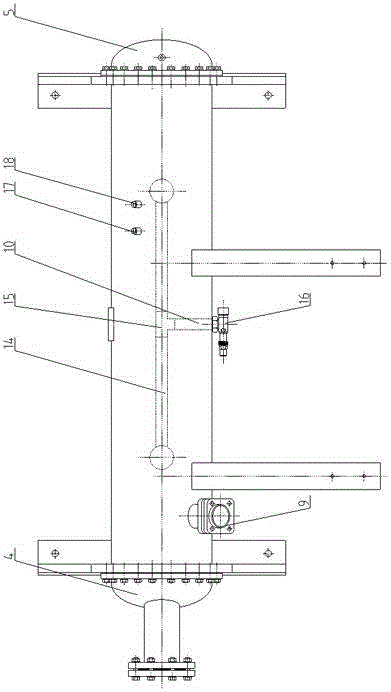

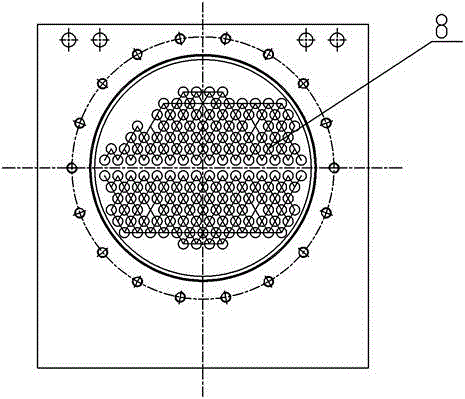

Marine condenser with carbon steel and polyethylene hot-melted combined pipe box

InactiveCN102914207AImprove bindingNot easy to delaminateEvaporators/condensersCorrosion preventionEngineeringHot melt

The invention relates to the field of refrigeration and especially relates to a marine condenser with a carbon steel and polyethylene hot-melted combined pipe box. The marine condenser is mainly used for solving the technical problems of the prior art that a zinc block is corroded when the zinc block is adopted by the condenser for protecting a pipe box, the pipe box is detached and overhauled, a gasket is manufactured again, the operation is troublesome, the position and the construction of the zinc block are specially designed, the parts of the pipe box are increased, the structure of the equipment is more complex, and the like. The marine condenser comprises a cylinder, wherein a front pipe plate and a rear pipe plate are respectively arranged at front and rear two ends of the cylinder; a front pipe box and a rear pipe box are respectively connected with the front and rear pipe plates; a water inlet and a water outlet are arranged on the front pipe box; a plurality of heat exchange pipes are arranged in the cylinder; a refrigerant inlet and a refrigerant outlet are connected with the exterior of the cylinder; plastic lining layers are arranged inside the front pipe box and the rear pipe box; and the plastic lining layers are plastic and steel substrate hot-melted combined layers.

Owner:HANGZHOU SAFETY EQUIP

Nontoxic environment-friendly plastic ground for kindergarten and construction method

ActiveCN105908596AGuaranteed CompatibilityNot easy to change colorGround pavingsToxic gasEnvironmental resistance

The invention provides a nontoxic environment-friendly plastic ground for a kindergarten and a construction method. The nontoxic environment-friendly plastic ground comprises a base layer. A waterproof bonding layer is arranged on the base layer and partially permeates into the base layer. The waterproof bonding layer is sequentially provided with a bottom layer, a second bonding layer and a surface layer from bottom to top. The nontoxic environment-friendly plastic ground for the kindergarten has the advantages that only MID glue is used for bonding, and thus the bonding effect is good; due to the fact that the viscidity of the glue before solidification is small, construction is easier and more convenient compared with TDI, and smearing is easier and more uniform; the compatibility of the MDI glue contained in different layers can be guaranteed, and thus delamination is unlikely to occur; compared with a TDI glue system, the harm of the MDI glue to the human body is extremely small, so that pollution is avoided in the use process, and the softness and safety are good; the surface layer has ultraviolet ray blocking and toxic gas sealing functions to a certain extent, and thus the color of EPDM is unlikely to change in the use process, and pollution is smaller; and since the MDI glue content of each layer is high, compared with an ordinary plastic ground with the same thickness, the nontoxic environment-friendly plastic ground is good in elasticity and long in service life.

Owner:张健

Waterproof panel and manufacturing method thereof

InactiveCN104929333ALight in massComfortable feetCovering/liningsSynthetic resin layered productsWater immersionVolumetric Mass Density

The invention discloses a waterproof panel and a manufacturing method of the waterproof panel, and belongs to the technical field of a floor, a wall slab and other panels. The waterproof panel includes a waterproof layer, a wear-resisting layer, a bottom layer, and a flute and a tenon which are respectively arranged at both sides of the panel; the wear-resisting layer is adhered on the waterproof layer, and the waterproof layer is adhered on the bottom layer; the waterproof layer is formed by performing extrusion molding on extrusion molding raw materials containing resin and main bamboo wood components; the density of the waterproof layer is 0.60 kg / cm3-0.95 kg / cm3. The waterproof panel is high in intensity, strong in tensile strength, and not easy to rupture; the waterproof panel is strong in stability, not easy to deform for the temperature change or water immersion, light in quality, and more comfortable in touch; moreover, materials and transportation cost are reduced.

Owner:ANHUI SENTAI WPC TECH FLOOR CO LTD

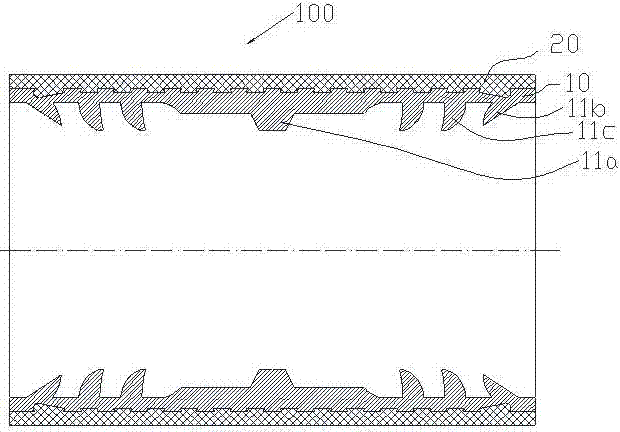

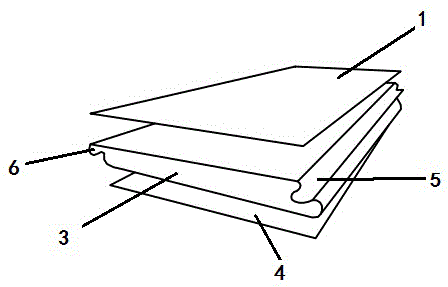

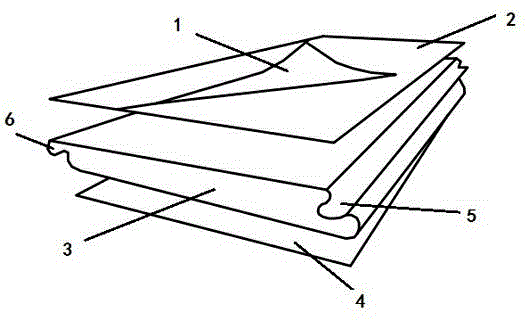

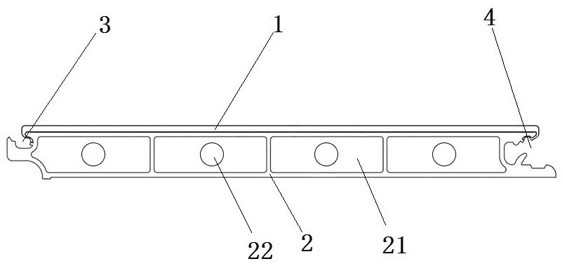

Aluminum-plastic composite floor with water accumulation prevention and snow melting functions

InactiveCN111946010AStrong chemical adhesionHigh bonding strengthCovering/liningsResiliently-mounted floorsSnowpackSnow melting

The invention provides an aluminum-plastic composite floor with water accumulation prevention and snow melting functions. The floor comprises a base layer made of aluminum alloy and an elastic surfacelayer which is attached to the base layer and mainly formed by resin, two side ends of the base layer are provided with a male splicing end with a male tenon structure and a female splicing end witha female groove structure respectively, during paving, any two adjacent floors in the length direction of the floors are connected in a matched mode through the male tenon structures and the female groove structures, a gap is formed between the upper surfaces of any two adjacent floors to form a water inlet, each of the male tenon structure and the female tenon structure is provided with a plurality of drainage grooves, one or more cavities are formed inside the base layer, and heating sources are arranged in the cavities or allowed to be arranged in the cavities. According to the aluminum-plastic composite floor with the water accumulation prevention and snow melting functions, through the design of the water inlet and the multiple drainage grooves, it is guaranteed that rainwater cannotpermeate into the lower portion of the floor and is drained as soon as possible; and when accumulated snow is generated on the surface of the floor, the accumulated snow can be quickly melted throughthe heating sources arranged in the cavities of the base layer.

Owner:ANHUI SENTAI WPC GRP CO LTD

Welding forming method of highly corrosion-resistant stainless steel composite tube

InactiveCN105945525ANot prone to delaminationImprove mechanical propertiesArc welding apparatusWelding/soldering/cutting articlesStainless steel electrodeComposite plate

The invention provides a welding forming method of a highly corrosion-resistant stainless steel composite tube. The method comprises the following steps: (1) cutting a stainless steel composite plate into panels in required sizes; (2) symmetrically processing long sides of the panels of the stainless steel composite tubes into X-shaped grooves; (3) bending the stainless steel composite tubes into stainless steel composite tubes, wherein the outer diameter is a required diameter; (4) performing preweld cleaning; (5) performing electric-arc welding on a cladding metal by using a welding rod, wherein the welding rod is a stainless steel welding rod; (6) performing electric-arc welding on a base metal by using a welding rod, wherein the welding rod is a stainless steel welding rod or a carbon steel welding rod; and (7) grinding and straightening the welded stainless steel composite tubes. According to the method provided by the invention, various welding steps such as sealing, transition welding and overlay welding are reduced, the welding efficiency is extremely improved and the production cost is extremely lowered. Furthermore, the method is relatively simple, and a relatively strong metallurgical bonding interface prevents occurrence of delamination cracks.

Owner:HEBEI UNIV OF TECH

Reinforced skateboard and production thereof

A reinforced slide board for sliding on snow, grass and sand is composed of a core board made of at least one foamed board, the top and bottom surface boards with a pattern printed film and a foamed upper liner layer adhered by a ultralow-density adhering metallocene film, a solid board with low friction coefficient, and a reinforcing high-density edge clad. Its advantages are high bending strength, low weight and high adhesion.

Owner:张广基

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com