Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

374results about How to "Easy to curl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

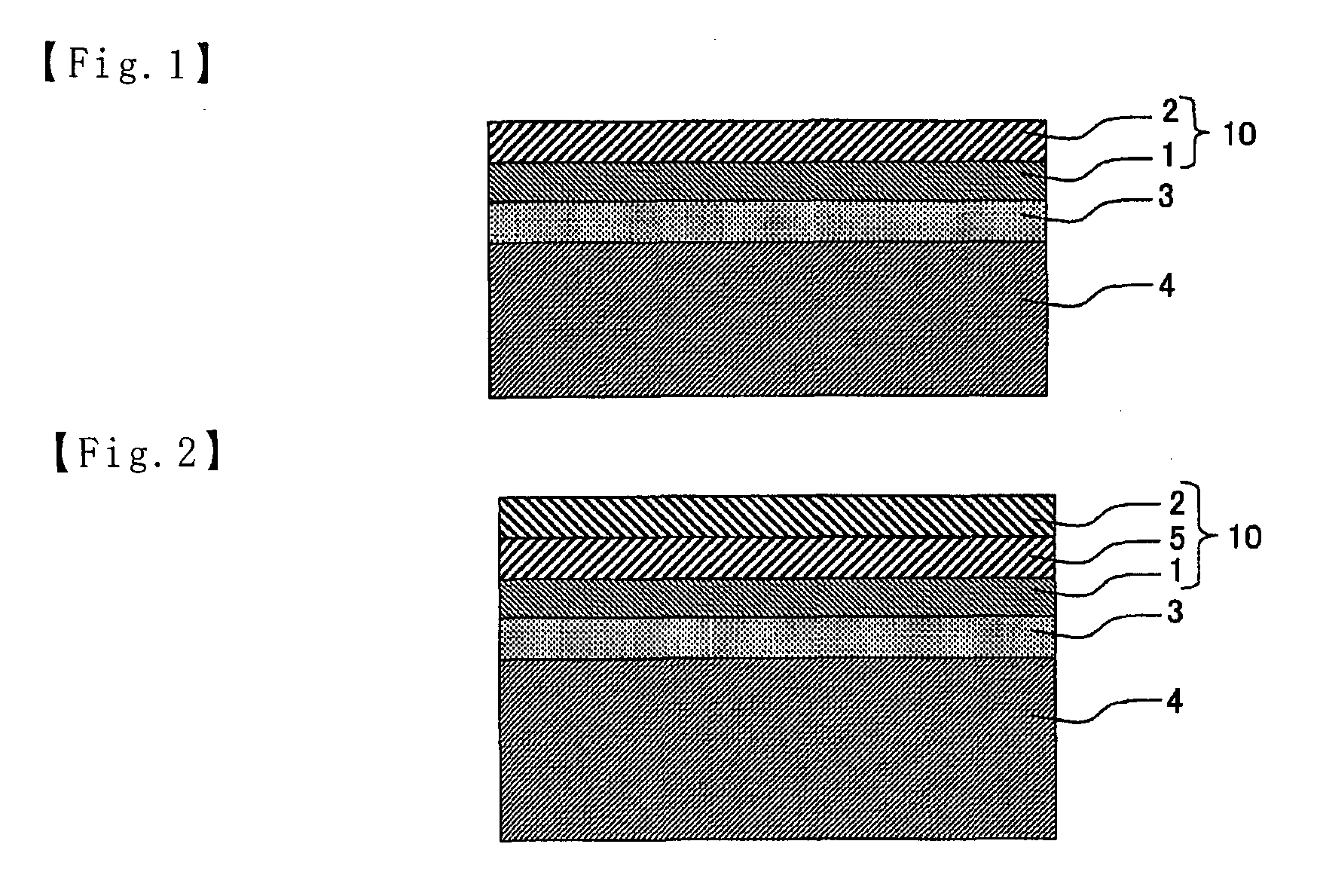

Retardation film, manufacturing method thereof, polarizing plate and liquid crystal display apparatus

ActiveUS20070046865A1Easy to curlPolarising elementsNon-linear opticsLiquid-crystal displayRefractive index

A film bonded to a polarizer of a polarizing plate, has a surface A and a surface B opposite to the surface A; and a thickness of 10 μm to 70 μm; wherein a refractive index difference between the surface A and the surface B is 5×10−4 to 5×10−3.

Owner:KONICA MINOLTA OPTO

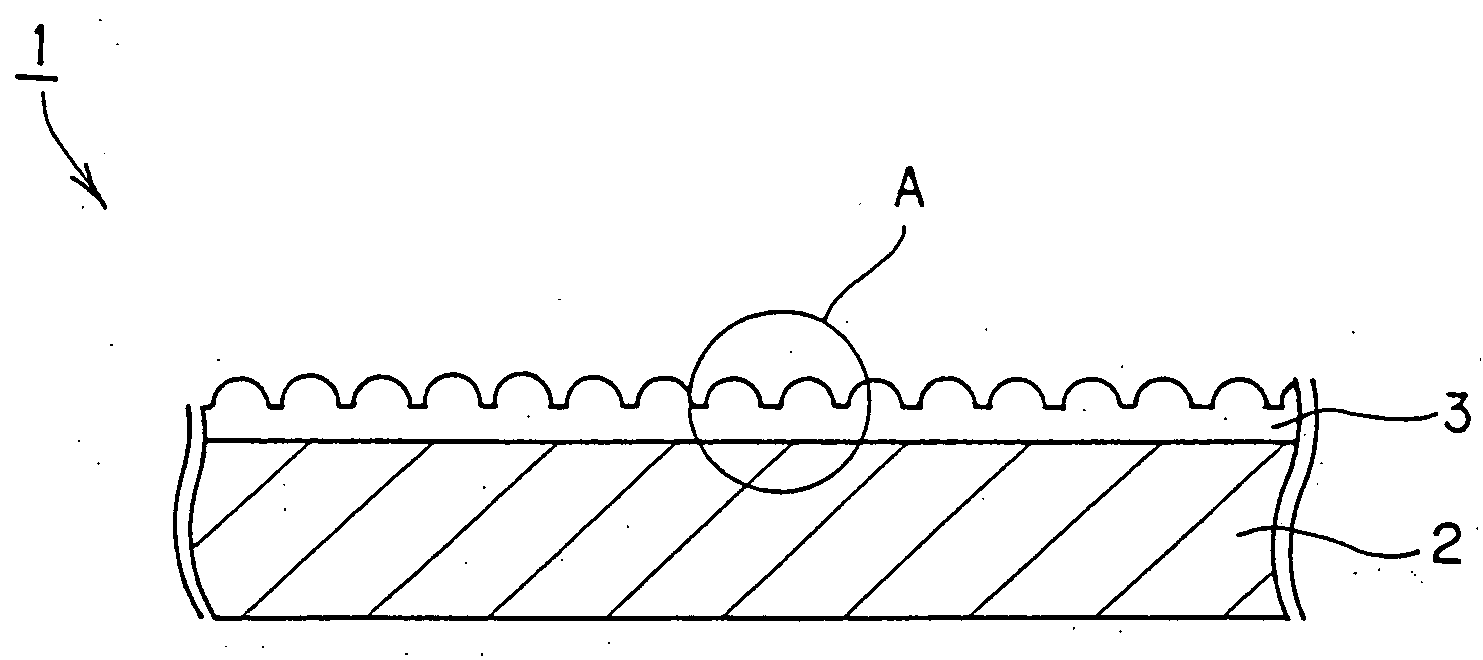

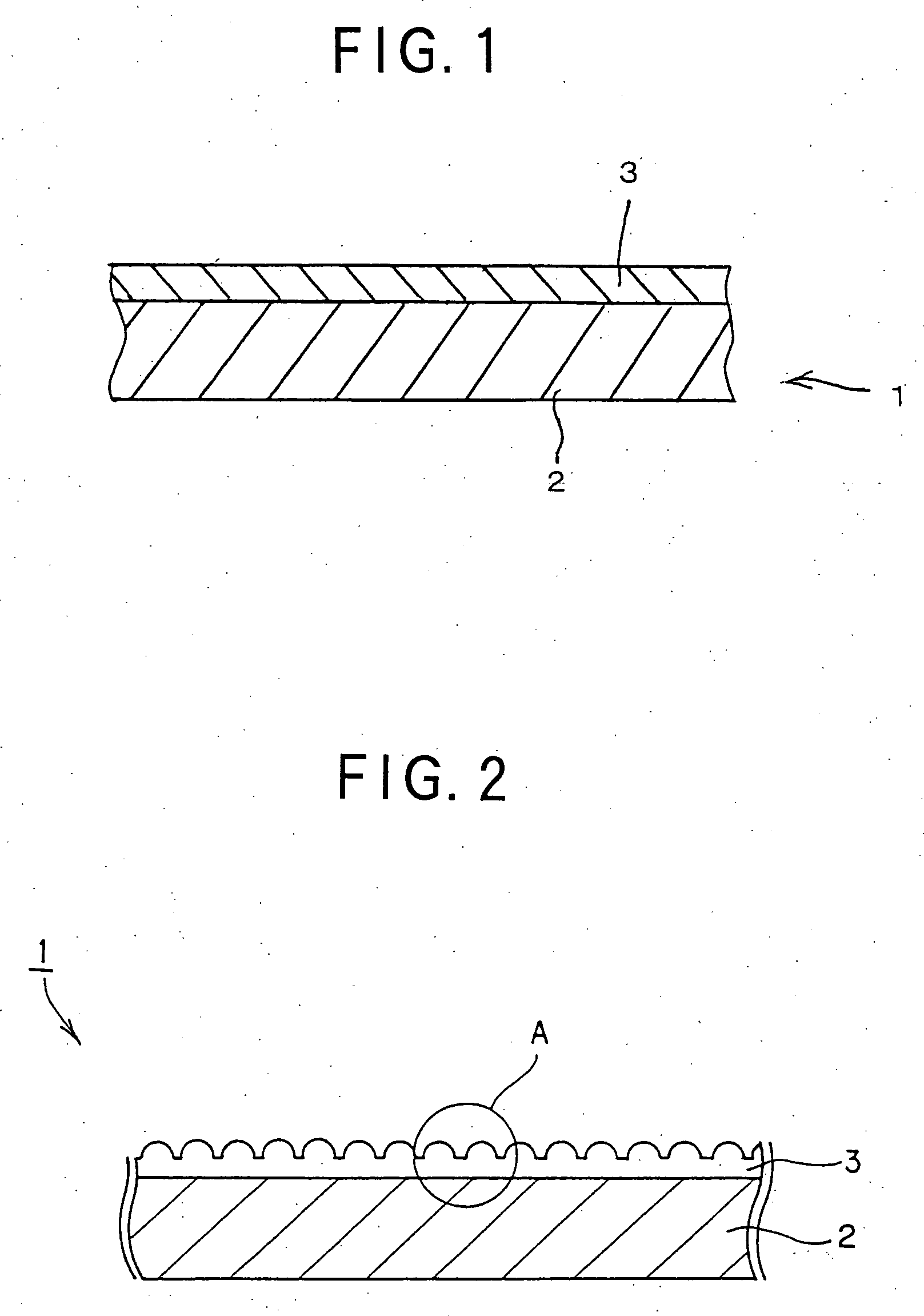

Gas barrier film

InactiveUS20050019503A1Excellent gas barrier performanceAvoid crackingSynthetic resin layered productsVacuum evaporation coatingCarbon atomSilicon oxide

The purpose of the present invention is to provide a gas barrier film having extremely excellent gas barrier property while retaining the film thickness at a predetermined thickness. A gas barrier film having a silicon oxide film formed by the plasma CVD method on the one side or both sides of a base material is provided, the silicon oxide film is characterized in that the film is comprised of the rate of components that the number of oxygen atoms is from 170 to 200 and the number of Carbon atoms is 30 or less to the number of Si atoms of 100, and that further the film has a peak position of IR absorption band based on the stretching vibration of Si—O—Si that exist between 1055 and 1065 cm−1.

Owner:KOMADA MINORU

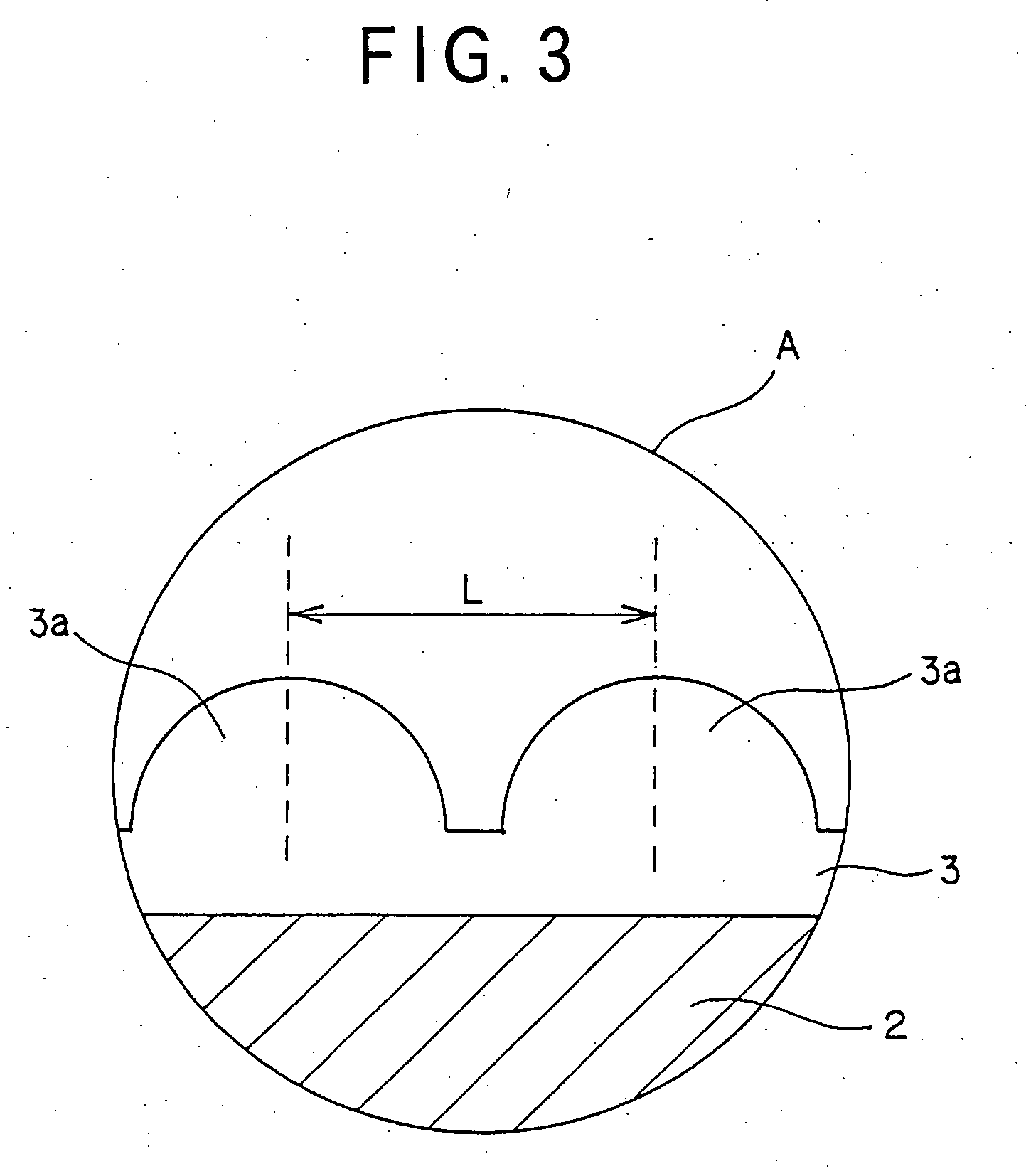

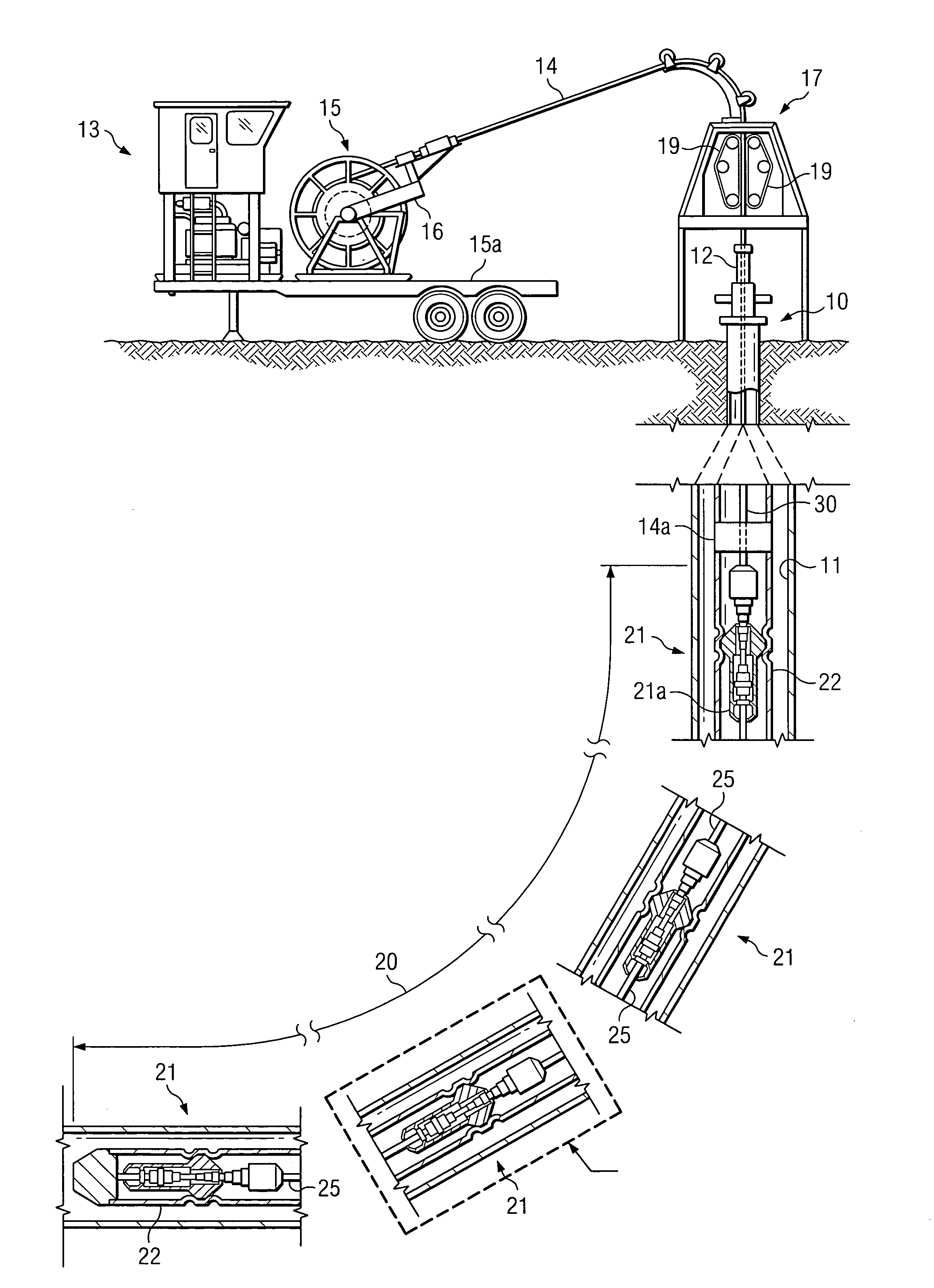

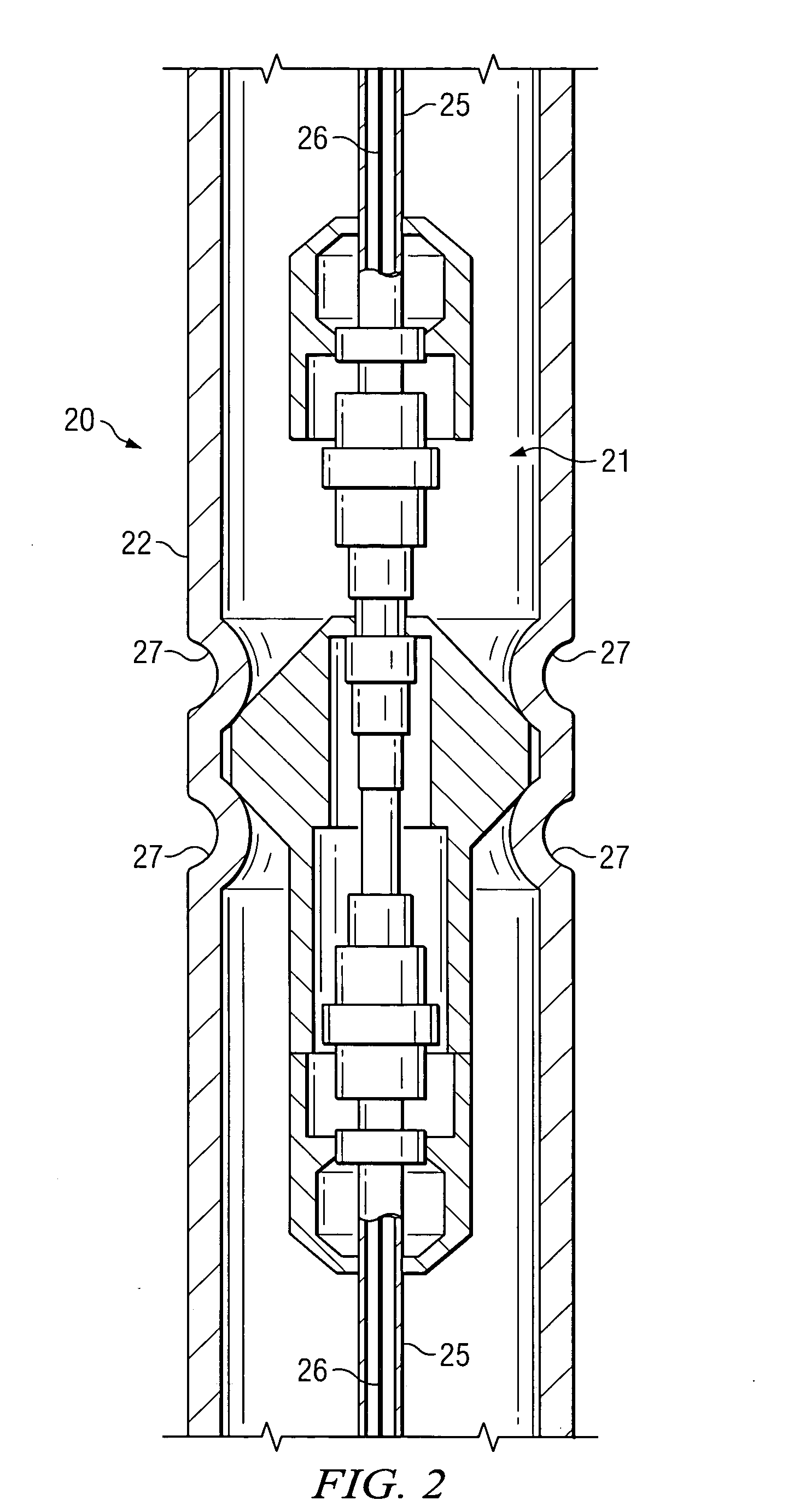

Coiled tubing well tool and method of assembly

InactiveUS20080041596A1Quick and easyWithout requiring time-consume and tedious operating stepDrilling rodsFluid removalGeophoneTube well

A long, well tool which effectively performs as an integral part of a typical coiled tubing string and accordingly can be ran continuously into a pressurized wellbore with the same deployment equipment as used with known coiled tubing. The tool is comprised of a plurality of elements (e.g. perforating charges or logging sensors such as hydrophones, geophones, gamma ray sensors, gravity sensors, etc.) fixed at spaced, known distances from each other within a flexible housing, e.g. a length of coiled tubing.

Owner:CONOCOPHILLIPS CO

Timber softening fluid

InactiveCN103406961AFlame retardantChange hardnessWood treatment detailsWood impregnation detailsParaffin waxBoric acid

The invention discloses a timber softening fluid which is prepared from the following raw materials in parts by weight: 35 to 45 parts of semi-refined paraffin wax No.58, 15 to 25 parts of a softening agent containing multiple chemical components, 5 to 7 parts of boric acid and 35 to 45 parts of water.

Owner:安徽雪峰木业有限公司

Ink composition, ink jet recording method, and recorded matter

InactiveUS20110236649A1Easy to curlExcellent cockling propertyLayered productsDecorative surface effectsAlcoholNitrogen

An ink composition includes at least a pigment, a polyhydric alcohol monoalkyl ether having a vapor pressure of 0.1 mmHg or less at 20° C. and / or a nitrogen-containing cyclic compound, a polyhydric alcohol, an unsaturated fatty acid, an alkyl alcohol having 1 to 4 carbon atoms, a surfactant, and 10% to 60% by mass of water. An in jet recording method uses the ink composition, and a recorded matter is produced by the ink jet recording method.

Owner:SEIKO EPSON CORP

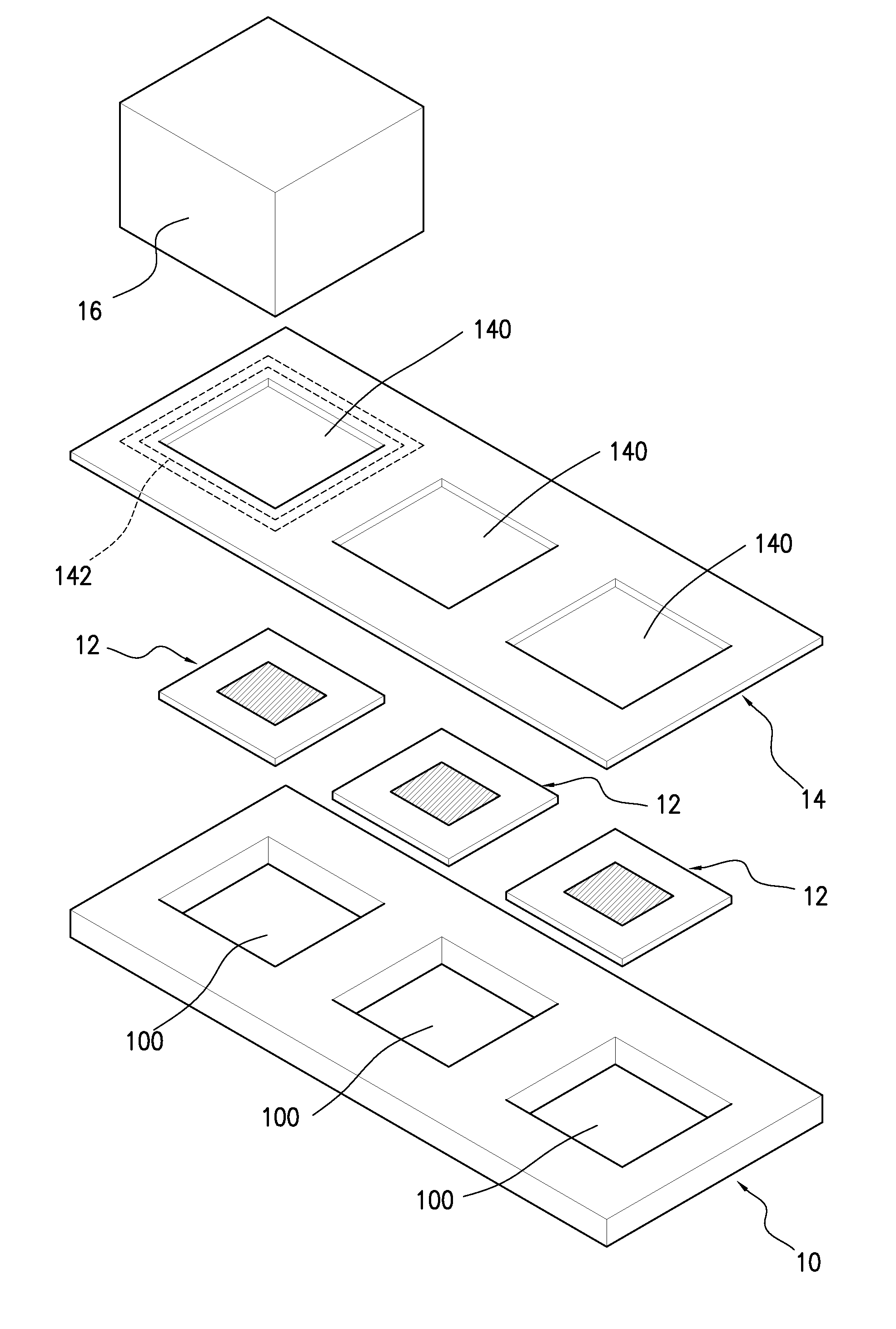

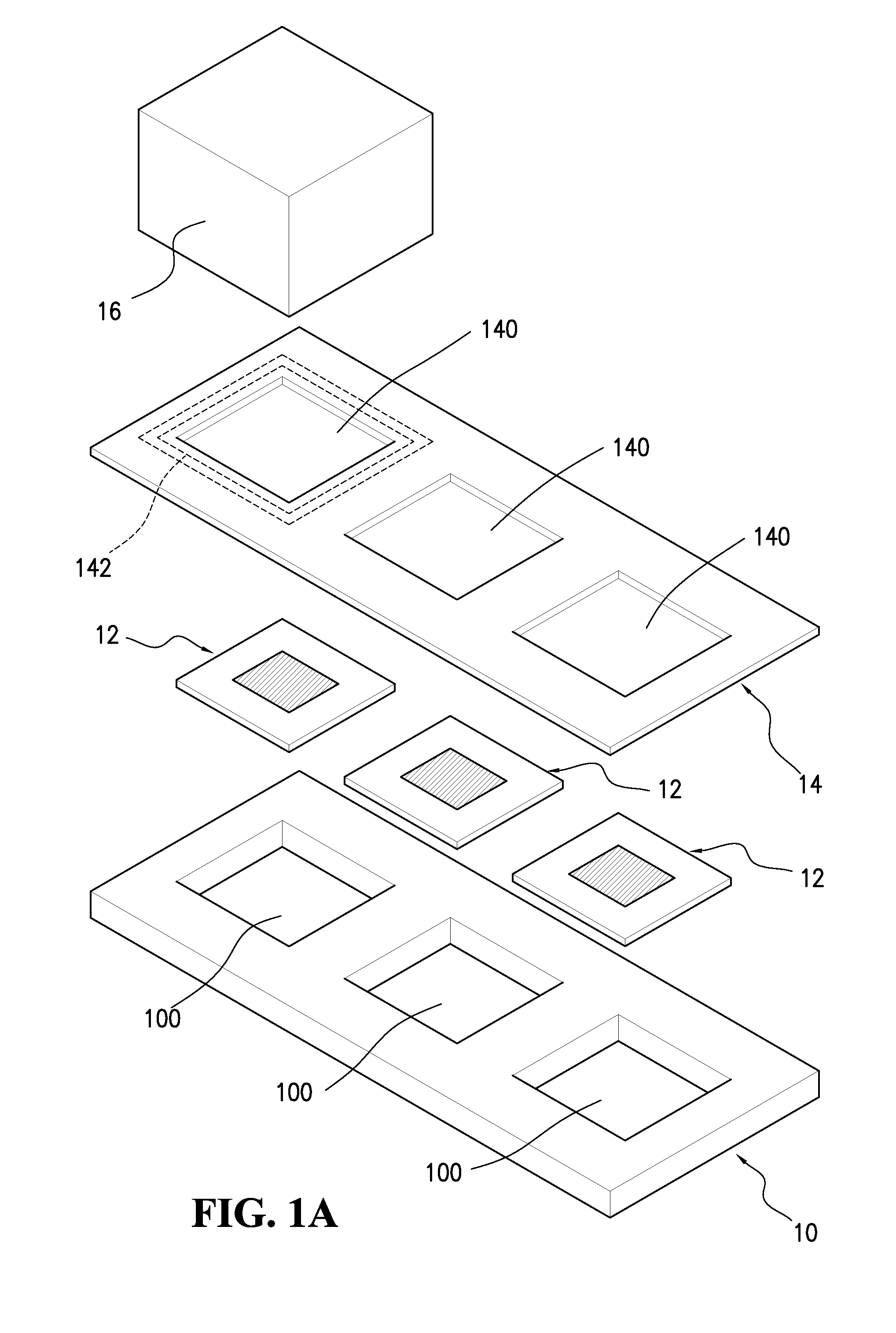

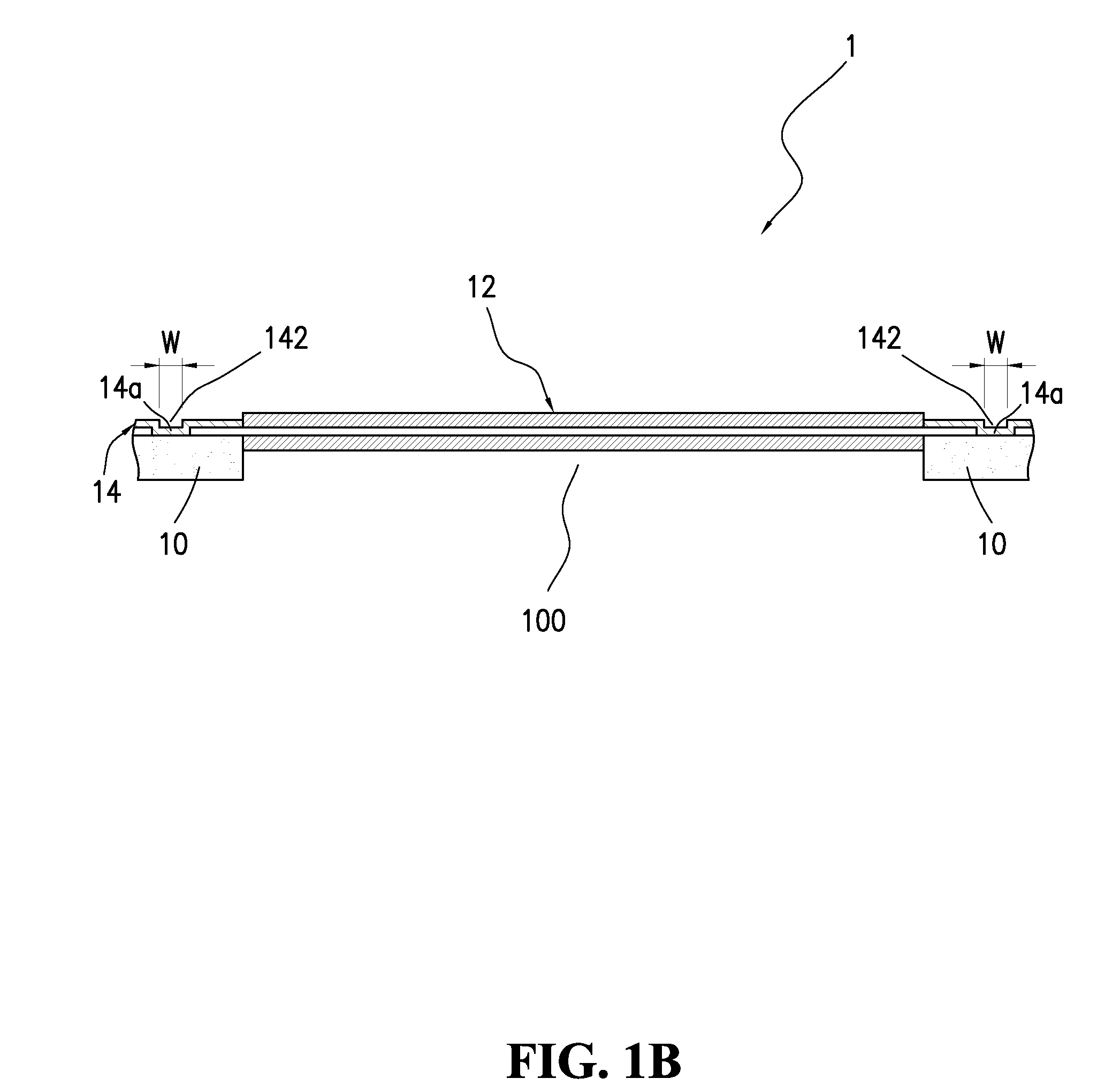

Assembly method for assembling plate-type membrane electrode assembly layer and the structure thereof

InactiveUS20070254199A1Improve assembly qualityEasy to curlFinal product manufactureCell electrodesEngineeringBiomedical engineering

The present invention discloses an assembly method for assembling plate-type membrane electrode assembly layer and the structure thereof; wherein, the assembly method includes the following steps: providing at least one membrane electrode assembly (MEA); providing a frame, in which the frame is provided with at least one first hole, and the opening area of the first hole is slightly smaller than the area of the MEA; providing a bonding sheet, in which the bonding sheet is provided with at least one second hole, and the opening area of the second hole is slightly smaller than the area of the MEA, and each second hole is corresponding to each first hole respectively; placing these MEAs into these first holes on the frame, and covering these MEAs with the bonding sheet; and, pressing the pressing areas on the bonding sheet surrounding these second holes, so the bonding sheet, these MEAs, and the frame stacked sequentially could be joined as a plate-type MEA layer, in which these pressing areas are corresponding to the outer periphery surrounding these MEAs.

Owner:SHU HSI MING +3

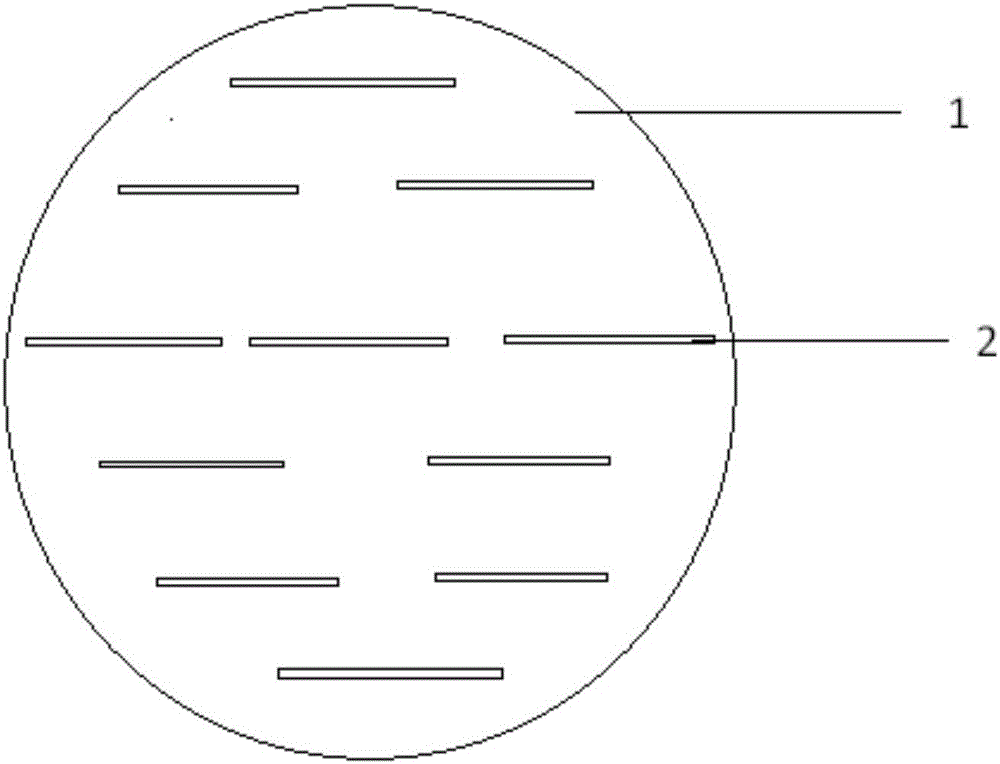

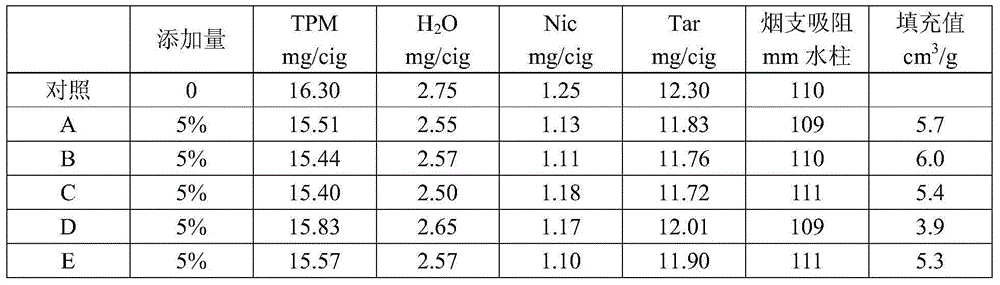

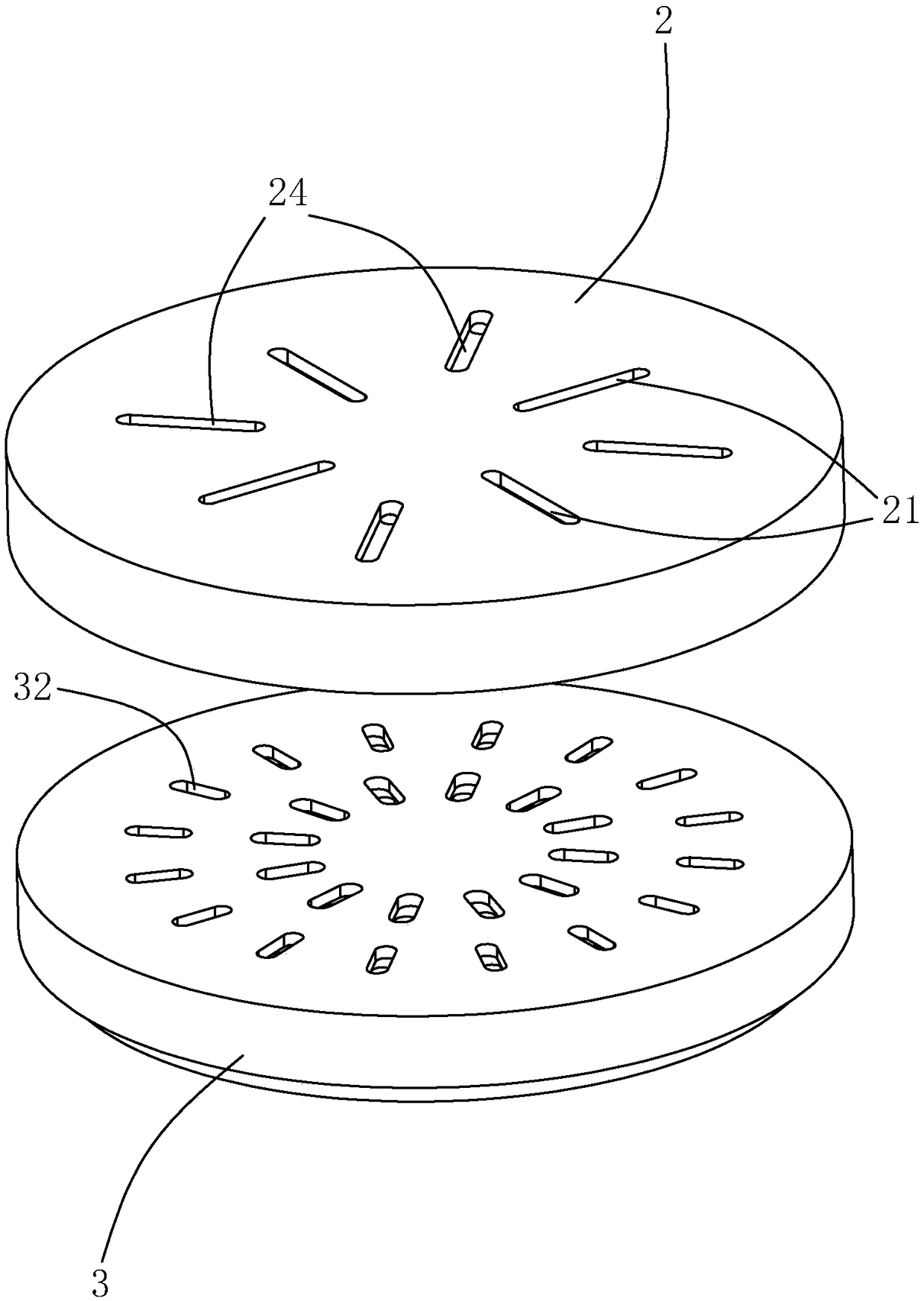

Method for preparing reconstituted cut tobacco sheets

The invention discloses a method for preparing reconstituted cut tobacco sheets. The method comprises the following steps that a, tobacco waste and binding agent powder are evenly mixed according to the mass ratio of 100-5:1, and a tobacco powder mixture is obtained; b, humectant is sprayed into the tobacco powder mixture after being dissolved into water according to the mass ratio of the tobacco waste to the humectant of 100:10-1, and even stirring is carried out to form a semihumid powder mixture; c, the semihumid powder mixture is added to a single-screw extruding machine or a double-screw extruding machine, and extrusion molding is carried out through a flat hole in an open die to obtain long and thin strip-shaped cut sheets; d, the long and thin strip-shaped cut sheets are cut off and dried, and the needed reconstituted cut tobacco sheets are obtained; The method for preparing the reconstituted cut tobacco sheets is simple, the requirement for equipment and places is low, and no additional production pollution is generated; meanwhile, the cut sheets have certain crimpness and good filling performance, and the tar content of cigarettes prepared from the cut sheets is lower.

Owner:CHINA TOBACCO HUNAN INDAL CORP

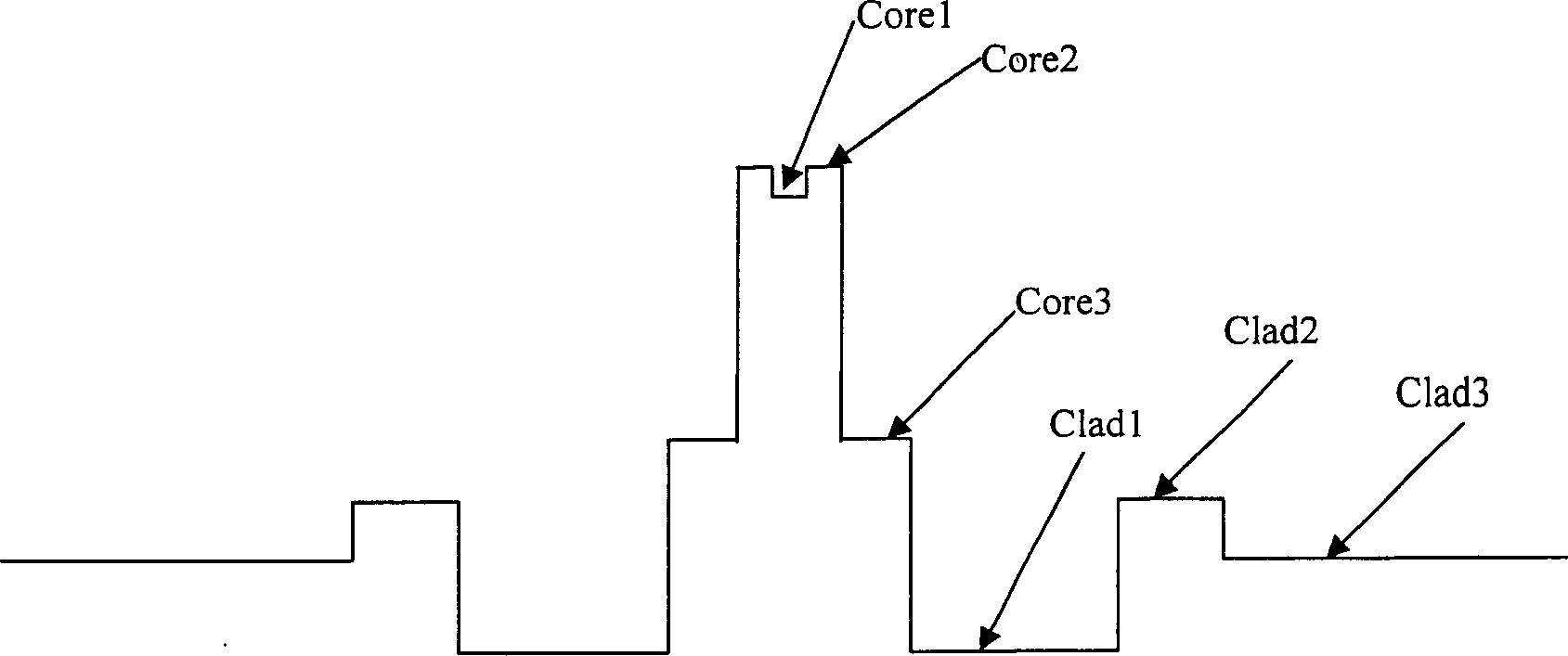

Bending non-sensitive fibre optical with moderate modulus filed diameter

ActiveCN1818728AWiring construction is convenientEasy to curlOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingMode field diameterSingle-mode optical fiber

A monomode optical fiber with suitable mode-field diameters, whcih is not sensitive to bending, is available for double windows of 1310nm and 1550nm wavelengths. It consists of three sub-layered cores and three sub-claddings with different refraction index profiles. The third layer of the sub-claddings is of pure silicon dioxide glass. It is suitable for distribution in rooms.

Owner:JIANGSU HENGTONG OPTICAL FIBER TECH +1

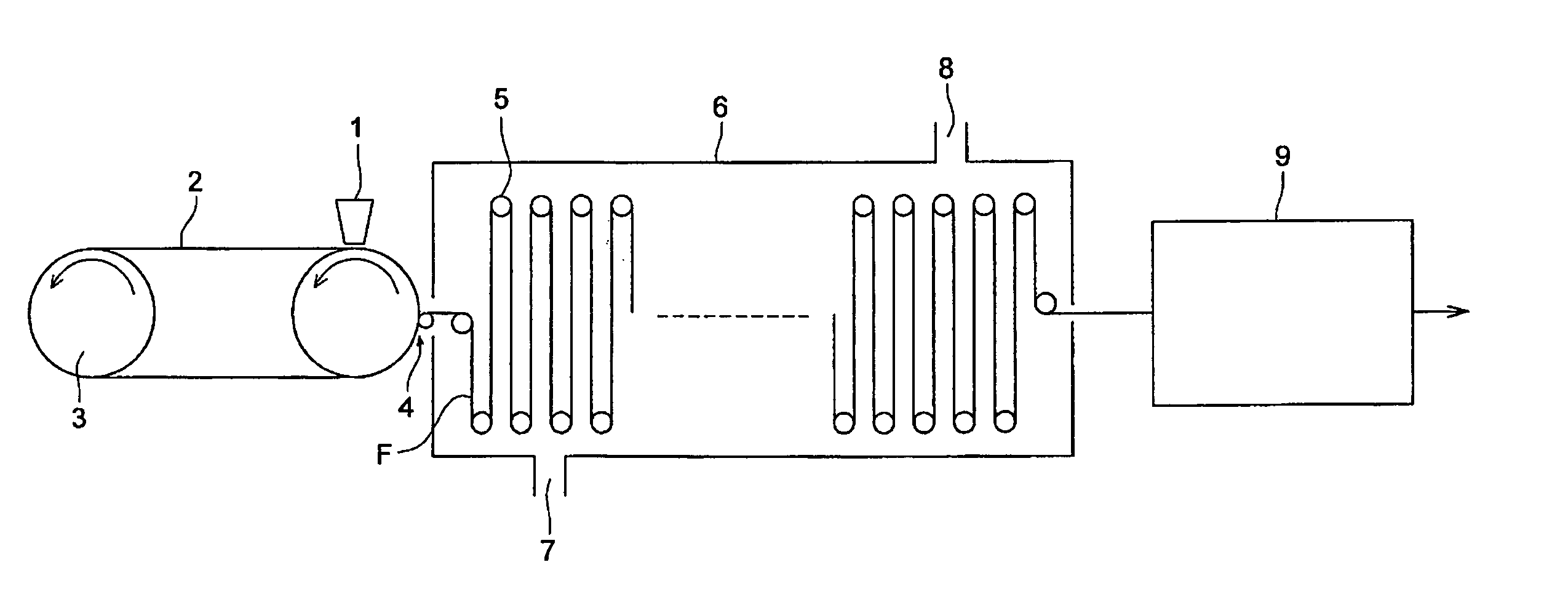

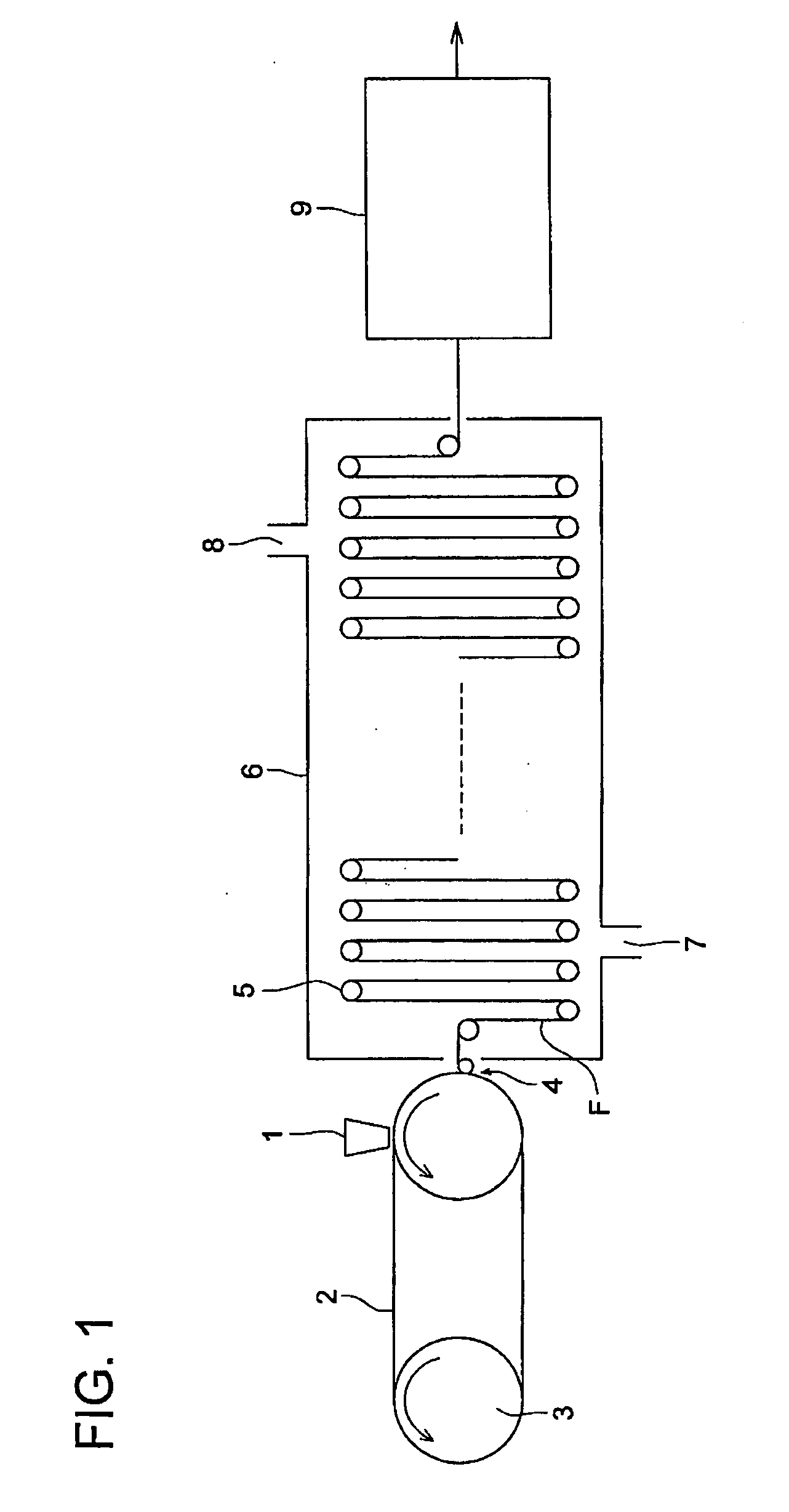

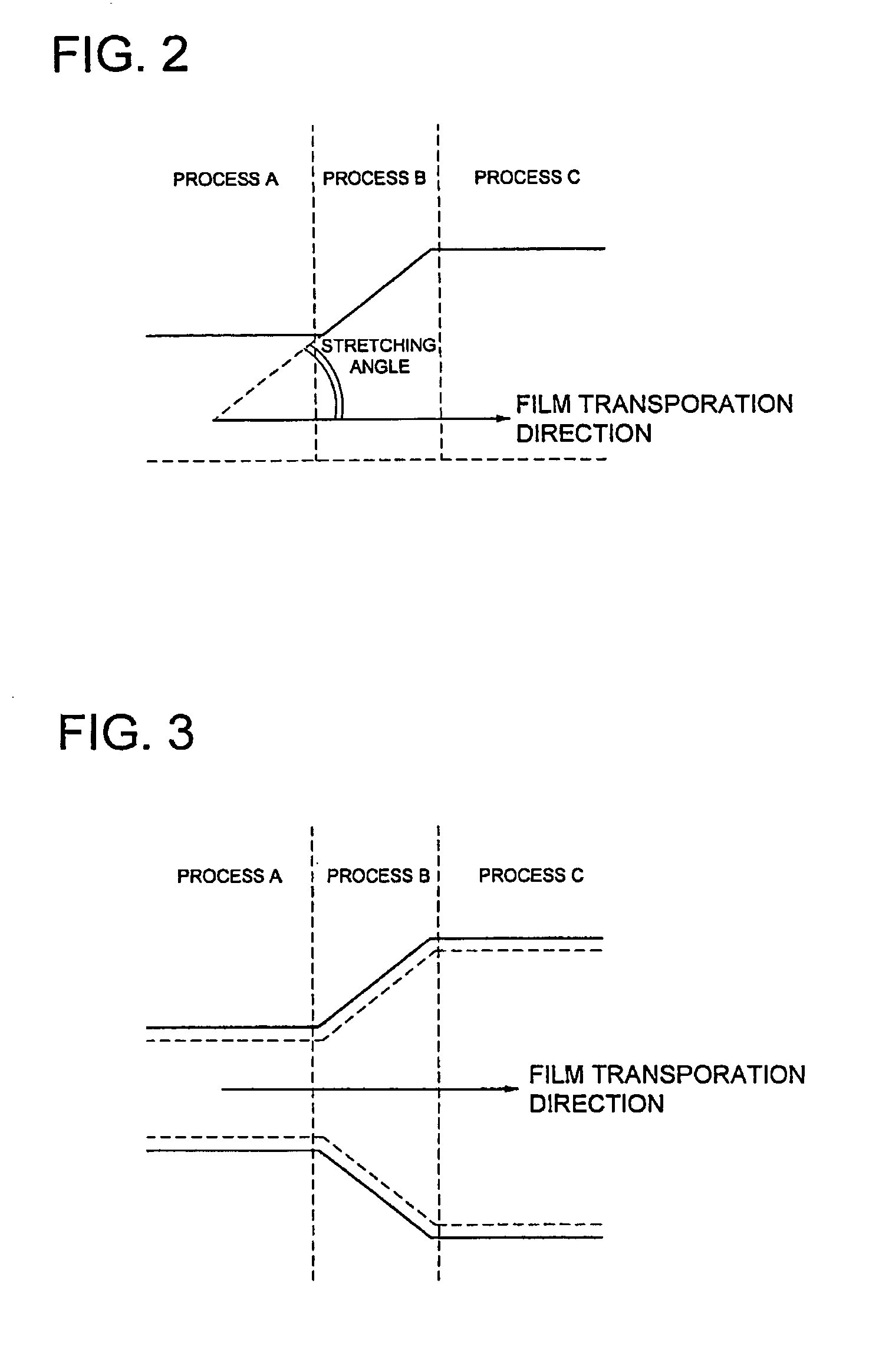

Preparation method of polyester staple fiber

InactiveCN101285218AStable supplyHigh strengthFilament/thread formingMonocomponent polyesters artificial filamentYarnPolymer science

The invention aims to provide a method for preparing polyester staple fiber. The invention is characterized in that the method adopts the process route of directly spinning melt mass to manufacture, and uses purified terephthalic acid (PTA) and ethylene glycol (EG) as raw materials and adds small quantities of mono-pentaerythritol, DEG, antimony trioxide, titanium dioxide and other catalysts, flatting agents and stabilizing agents. The method uses the process flow of five autoclaves polymerization to perform polyreaction so as to receive the melt which is finally spun into tows, and prepares the polyester staple fiber via primary drawing, secondary drawing, 18 roller tension heat setting, third drawing, crimping, relaxation heat setting and cutting. The method has the advantages of stable raw material supply, high product strength, few defects, good crimp, moderate oil applying rate and stable dry-heat shrinkage percentage; products prepared by the method have good spinnability, so that yarn spun by the product is high in each quality index, and produced textile has soft and smooth hand feeling; and the manufacturing cost is lower than chip spinning, so that the marketing competitive power of the products is stronger.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

Continuous adjustment screen printing process of water-based gloss oil

The invention belongs to the technical field of printing and particularly relates to a continuous adjustment screen printing process of water-based gloss oil. The continuous adjustment screen printing process comprises the following steps of: 1) manufacture of continuous adjustment image files; 2) manufacture of films; 3) cleaning of the films; 4) stretching of a screen; 5) gluing; 6) positioning of the films; 7) exposure; 8) development; 9) drying; and 10) screen printing. The continuous adjustment screen printing process has the advantages that 1) the wear resistance is strong, the scratching is resisted, the screen-printed surface is wear-resistant, water-repellent and oil-repellent, and no color-fading phenomenon occurs on the surface of a printed product; 2) the film forming speed is fast, and the drying is rapid; 3) the high temperature resistance and the hot-sealing performance are good; 4) the degree of planeness is good, and the winding force resistance is strong; 5) the used water-based gloss oil has better leveling property, can realize fast leveling before a coating layer is dried to form a smooth surface, so that the coating layer can have high glossiness; and 6) the water-based gloss oil adopts water as a solvent without toxicity and smell. Compared with the water-based gloss oil used for local glossing, the continuous adjustment screen printing has the advantage that the image layering can be reproduced.

Owner:浙江华人数码科技有限公司

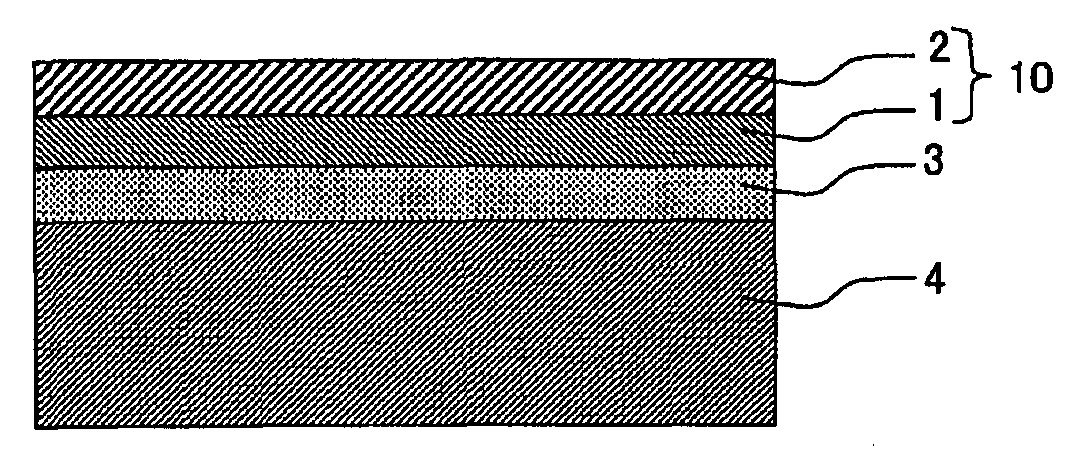

Pressure-sensitive adhesive layer-carrying transparent conductive film and method for production thereof

InactiveUS20100136276A1Easy to curlEasy to processConductive layers on insulating-supportsSynthetic resin layered productsTransparent conducting filmPlastic film

An object of the invention is to provide a transparent conductive film having good processability and to provide a method for production thereof. The pressure-sensitive adhesive layer-carrying transparent conductive film of the invention comprises: an amorphous transparent conductive laminate comprising a transparent plastic film substrate and an amorphous transparent conductive thin film provided on one side of the transparent plastic film substrate; a pressure-sensitive adhesive layer; and a release film that is provided on another side of the transparent plastic film substrate with the pressure-sensitive adhesive layer interposed therebetween and comprises at least a film substrate, wherein the release film is thicker than the amorphous transparent conductive laminate, and a value obtained by subtracting the thermal shrinkage percentage of the release film in the MD direction from the thermal shrinkage percentage of the amorphous transparent conductive laminate in the MD direction is from −0.3% to 0.45%.

Owner:NITTO DENKO CORP

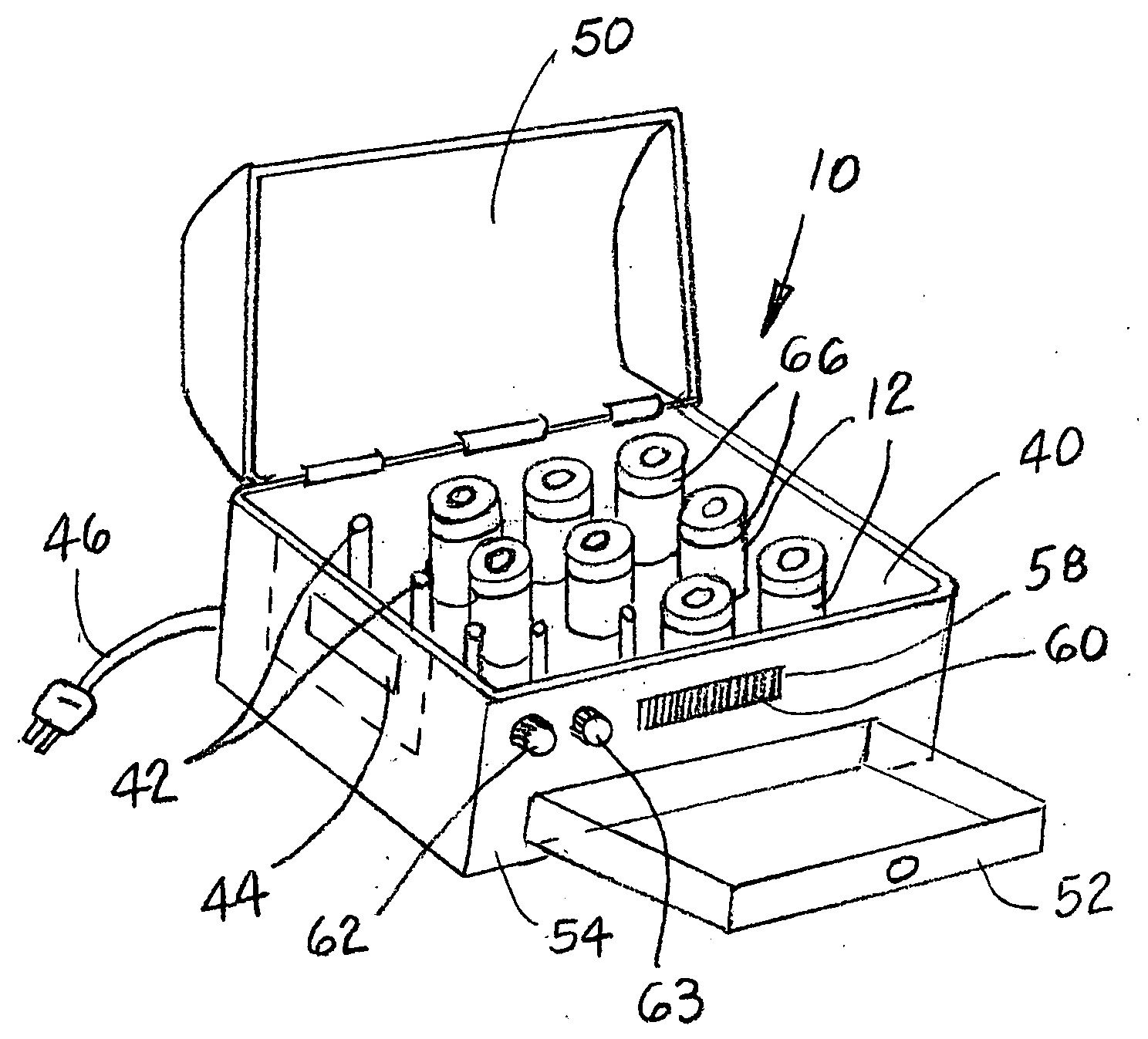

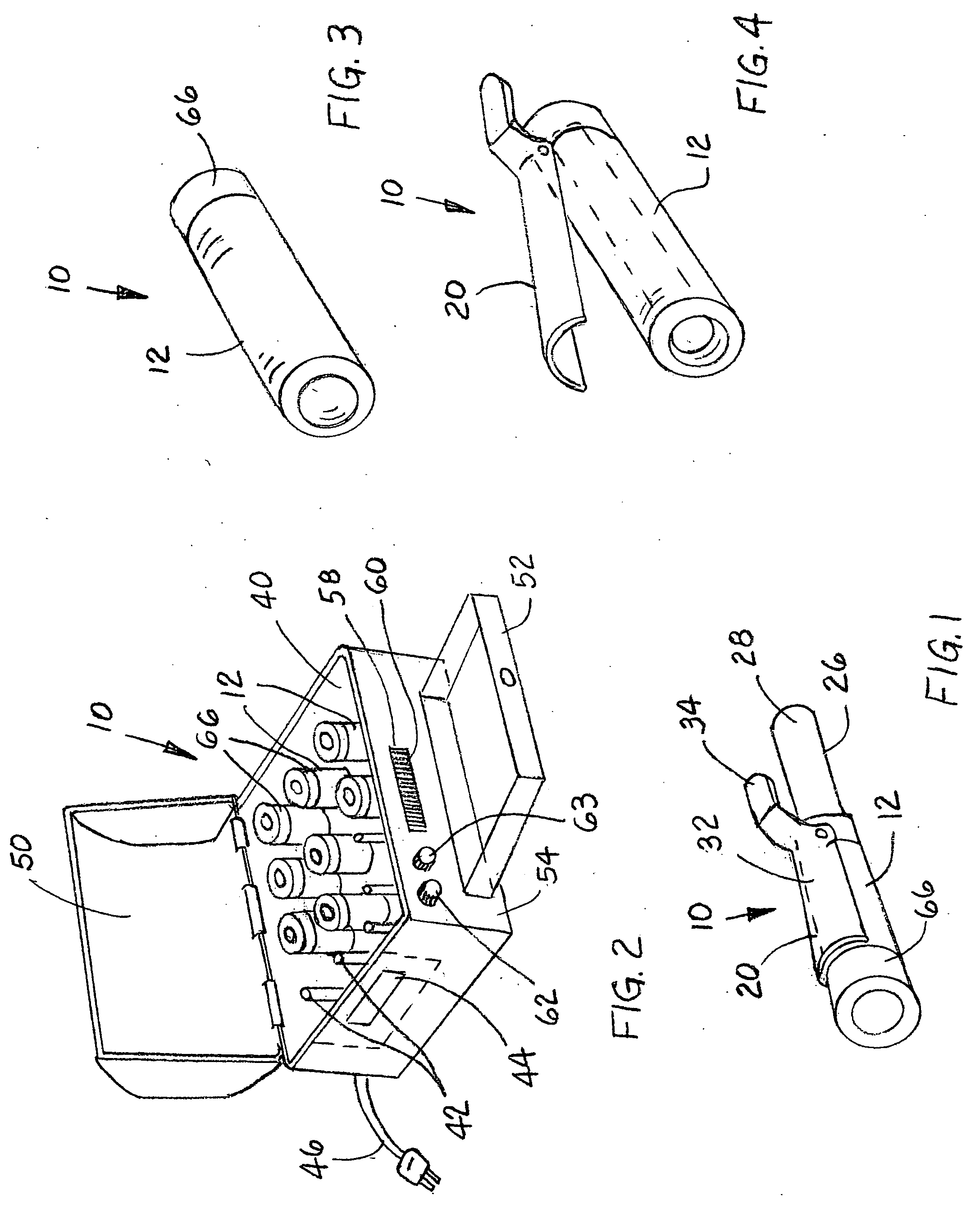

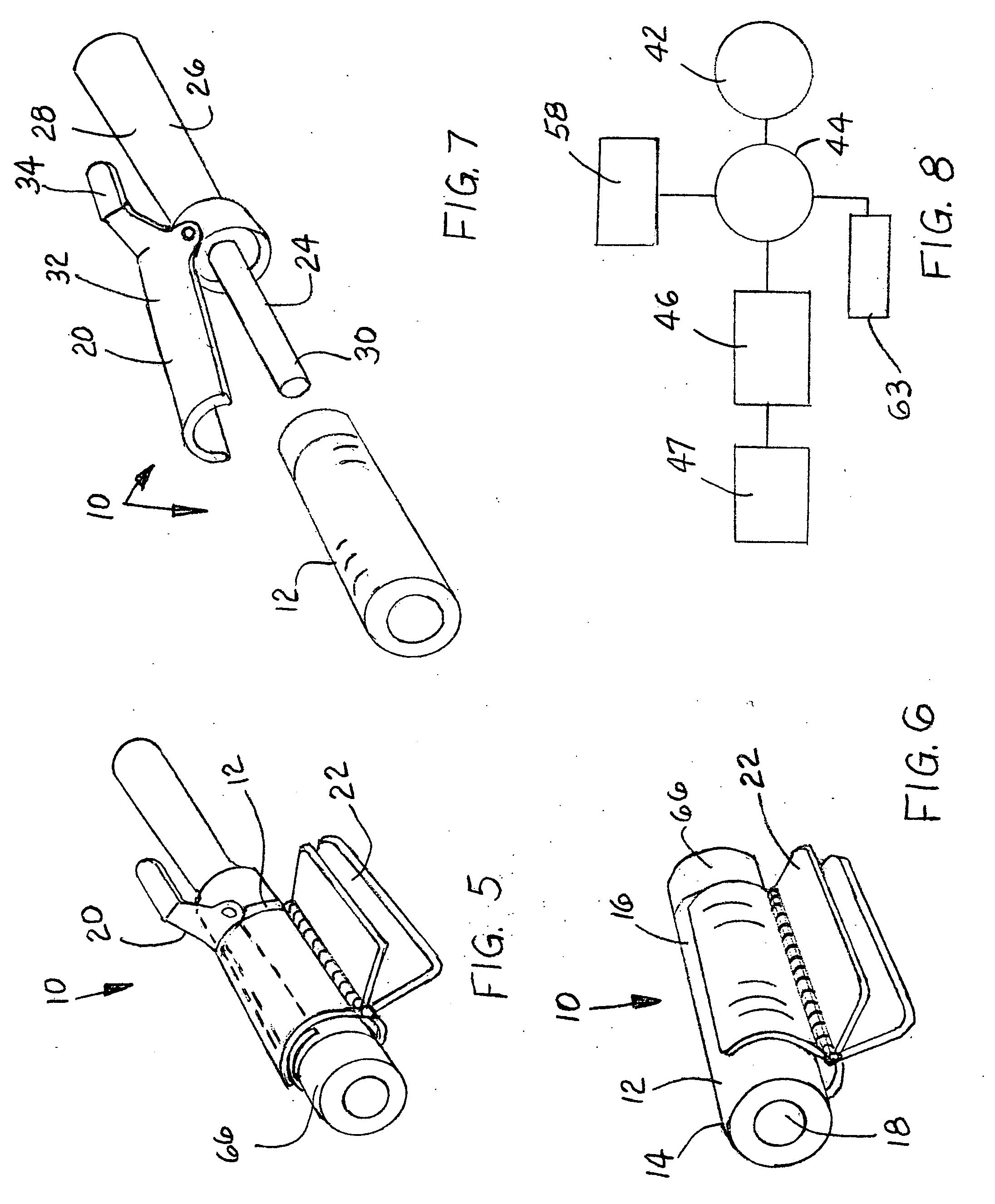

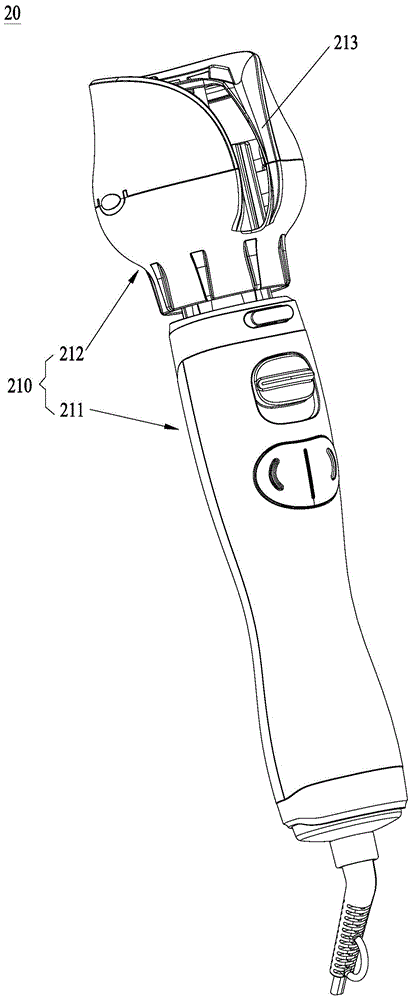

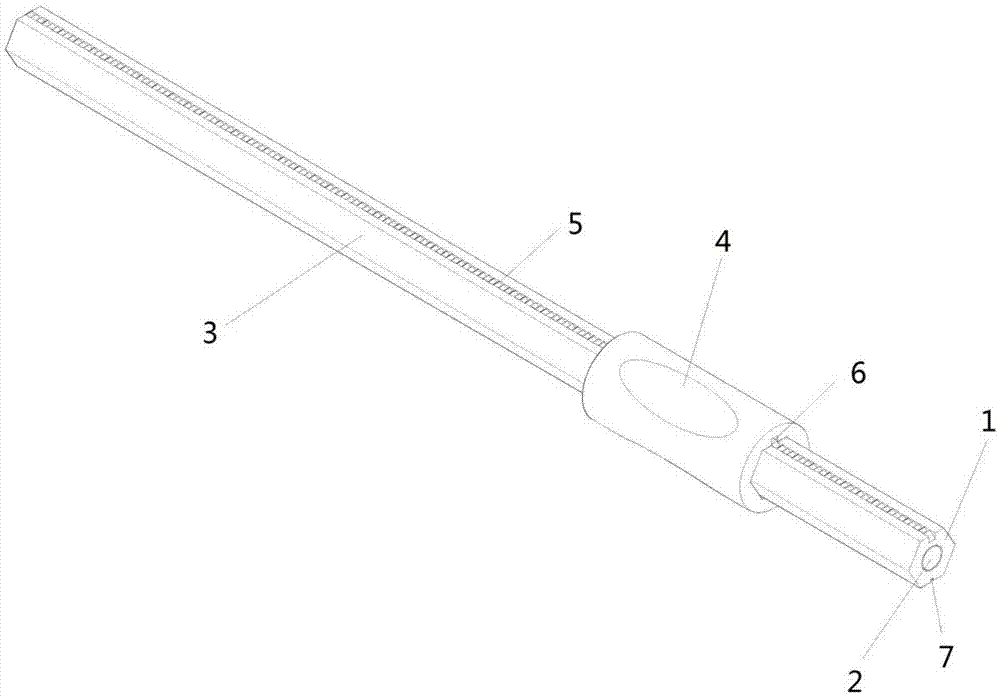

Apparatus for styling hair

InactiveUS20080210255A1Easy to useEasy to curlCurling-ironsCurling-tongsEngineeringMechanical engineering

An apparatus for styling hair including a plurality of hair curling rollers manufactured from a first predetermined material and having a first predetermined size and a first predetermined shape. Each of such rollers having a first end and a second end, a cavity formed adjacent at least one of such first end and such second end and extending along a longitudinal axis of such rollers for a predetermined distance. The cavity being of a second predetermined size and a second predetermined shape. A hair gripping device is releasably connected to such rollers at a predetermined end thereof. A securing device is releasably connected to such rollers at a predetermined location thereon for securing hair of a user rolled upon such rollers to at least one of such roller and a predetermined location on such user's head.

Owner:MOLL DAWN

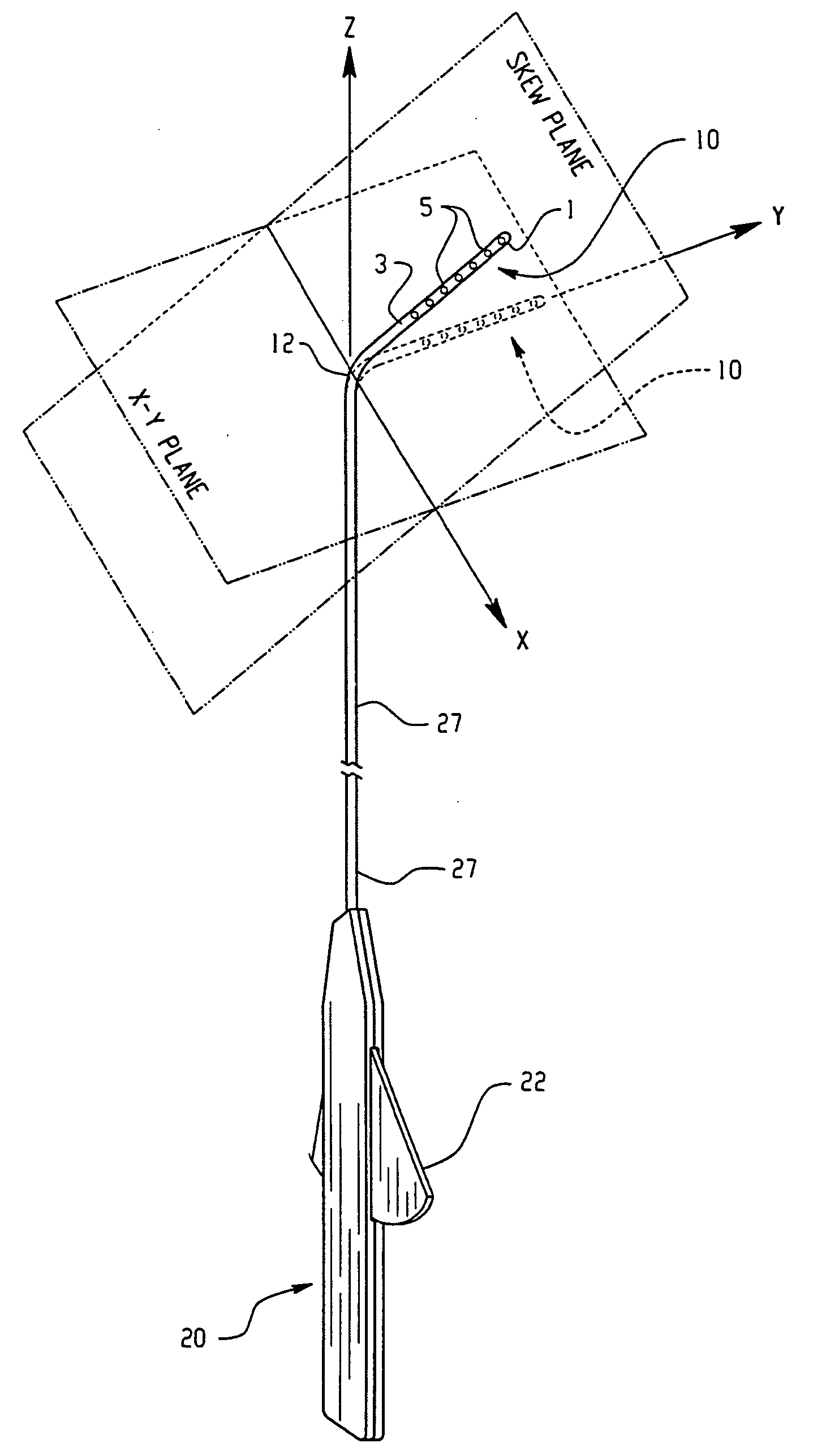

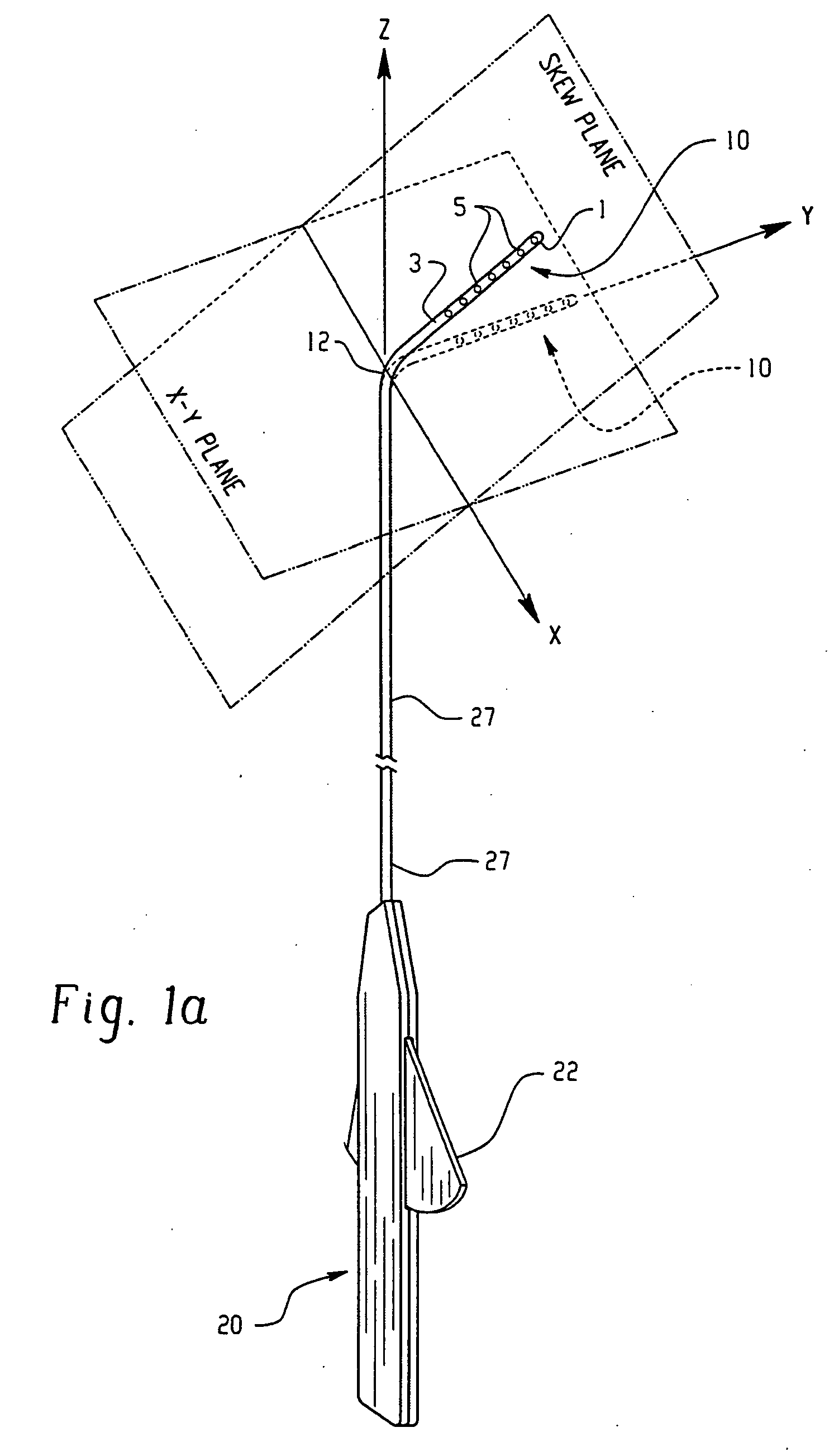

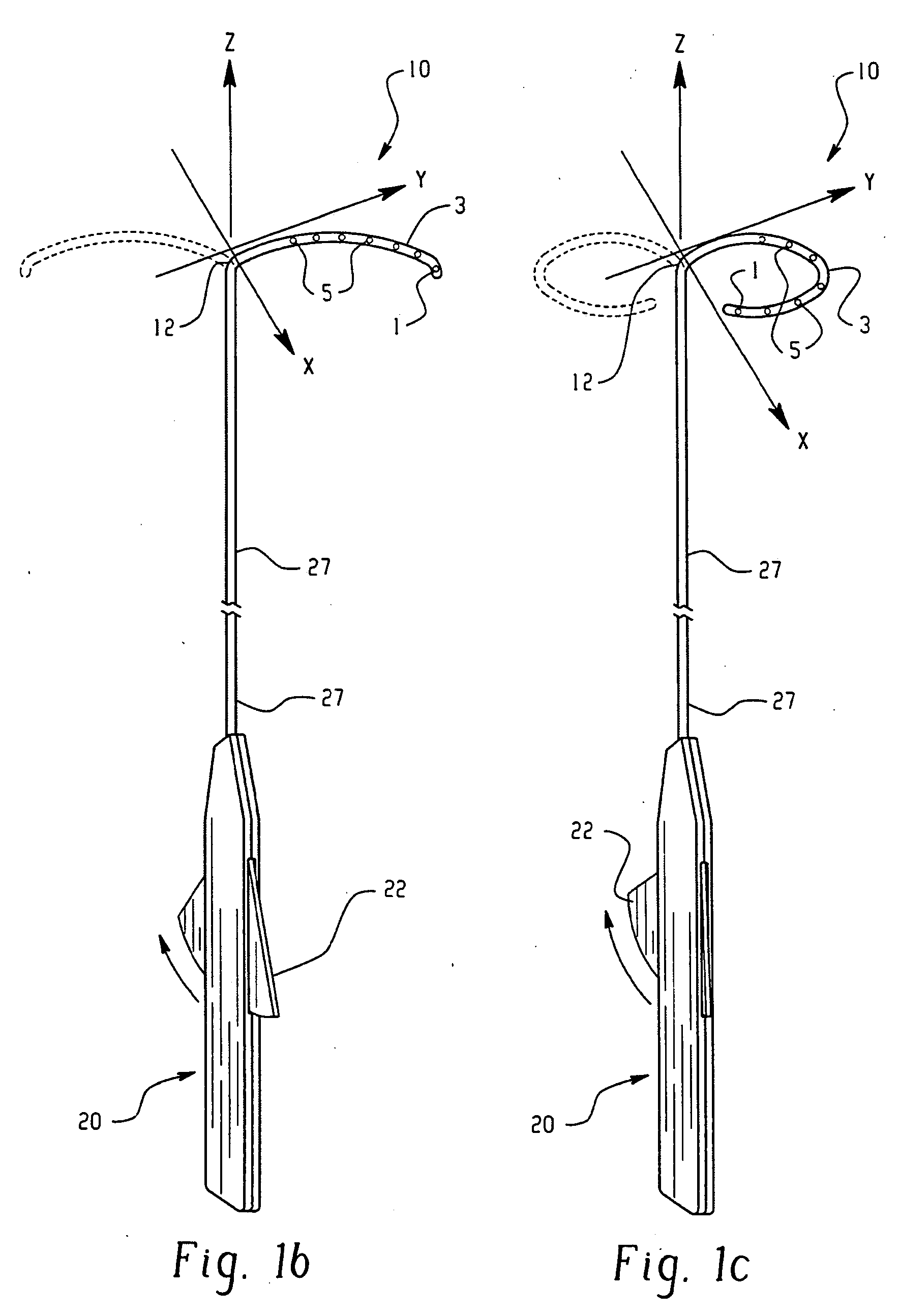

Electrophysiology/ablation catheter having lariat configuration of variable radius

InactiveUS20060229599A1Reduced radiusFlexure of the catheter is facilitatedDiagnostic recording/measuringSurgical instruments for heatingDistal portionCell electrophysiology

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

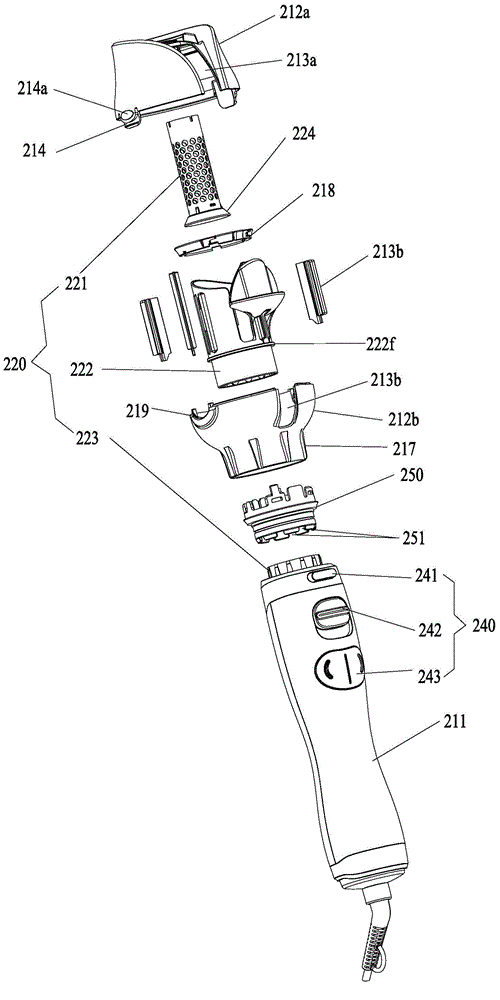

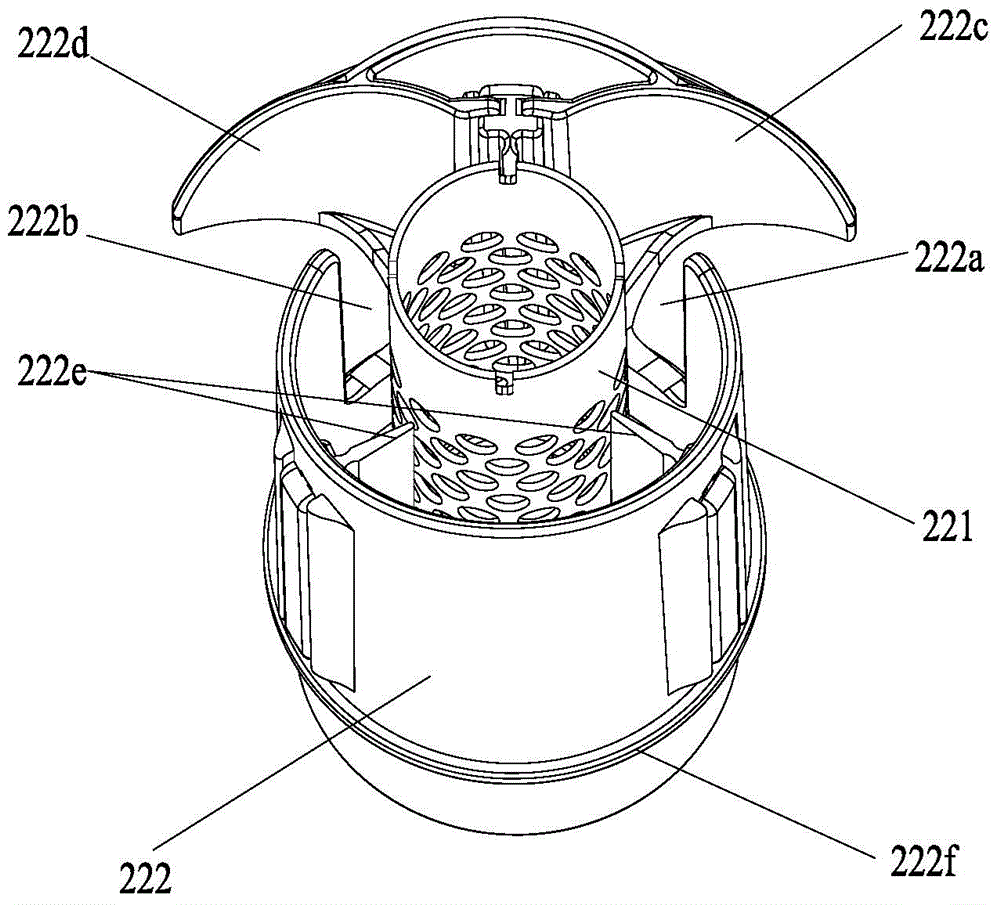

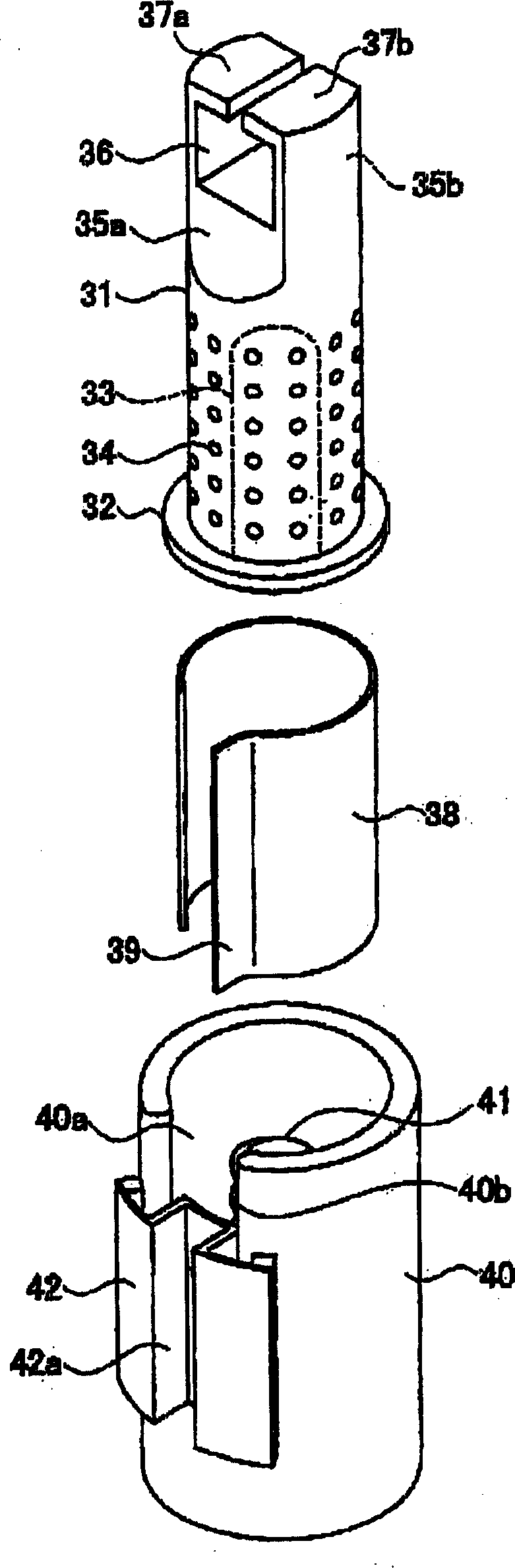

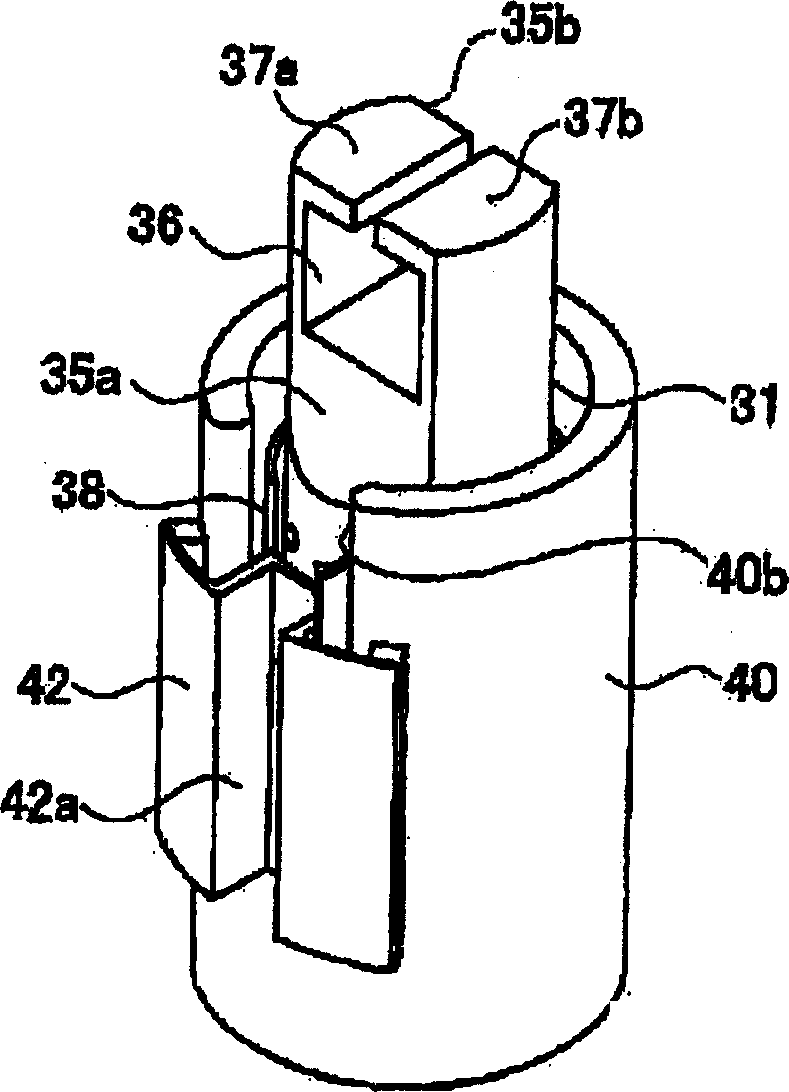

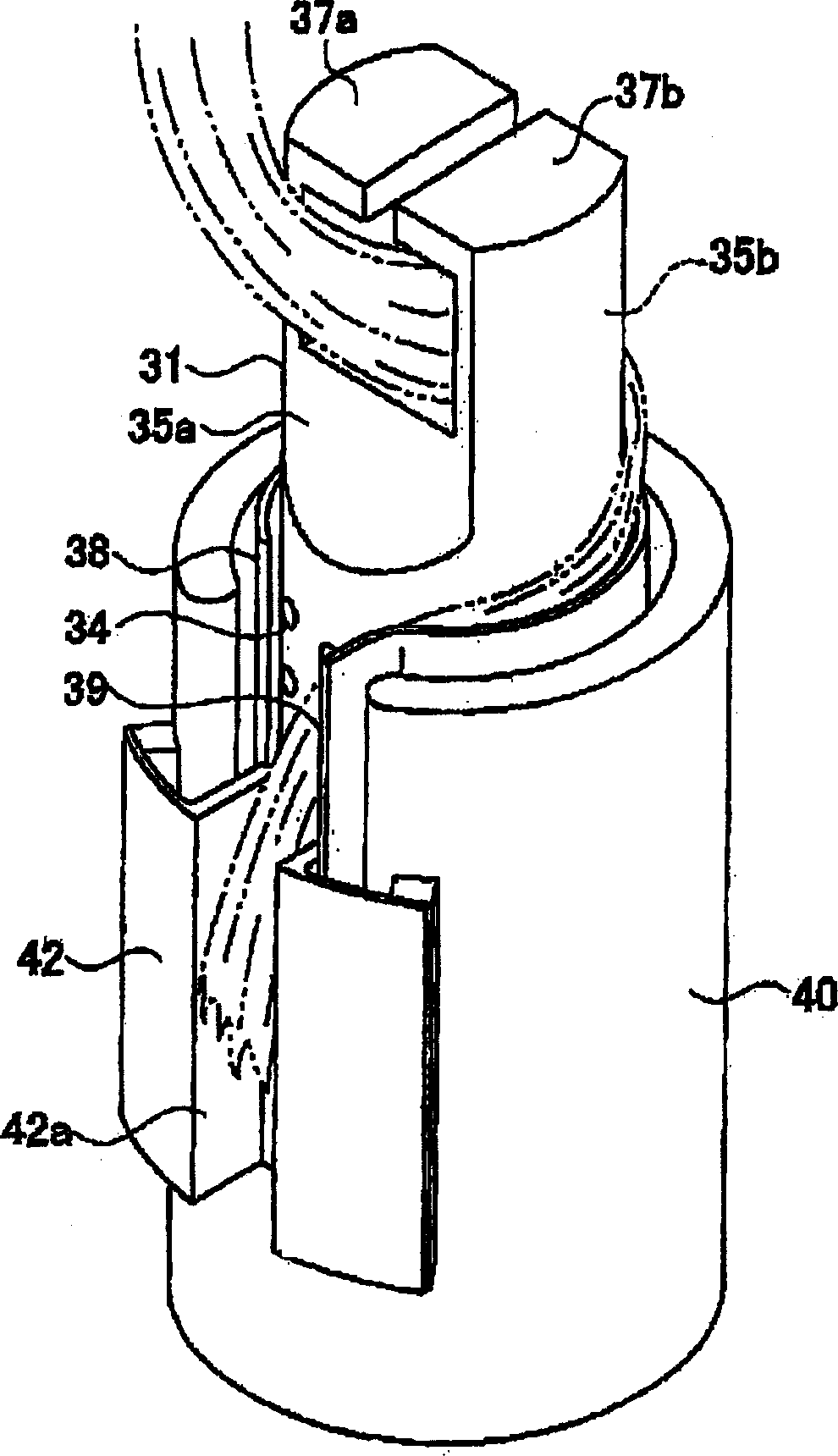

Hair curling device

The invention discloses a hair curling device which comprises a shell, a hair curling assembly, an air supply assembly and a control assembly. The hair curling assembly comprises a long narrow net barrel fixed into a top shell, a rotary barrel and a drive assembly connected with the rotary barrel, wherein the long narrow net barrel is sleeved with the rotary barrel. The drive assembly is used for driving the rotary barrel to rotate around the long narrow net barrel, so that hair entering from a hair inlet is wound around the long narrow net barrel. At least one high-temperature-resistant elastic pressing piece is arranged on the rotary barrel, the elastic pressing pieces are longitudinally arranged along the inner wall of the rotary barrel, extend in the direction close to the long narrow net barrel and are used for exerting pressure to the hair wound around the long narrow net barrel. By the adoption of the hair curling device, the hair wound around the rotary barrel is tightly attached to the long narrow net barrel through pressure of the elastic pressing pieces, the hair can well accords with the radian of the long narrow net barrel, the shaping effect is better, and the curling degree is higher.

Owner:SUN LUEN ELECTRICAL MFG

Plastic pencil and preparation method thereof

The present invention relates to a plastic pencil, which comprises a pencil rod, a pencil core and a pencil skin, wherein the components of the pencil rod comprise 30-50 wt% of polystyrene (PS), 10-30 wt% of a synthetic rubber, 2-8 wt% of a nucleating agent, 30-50 wt% of talc powder, and 5-10 wt% of calcium stearate, and are added with polyethylene (PE), the components of the pencil core comprise 20-50 wt% of polystyrene (PS), 2-10 wt% of an organosilicon polymer, 30-60 wt% of graphite powder, 2-10 wt% of hydrogenated palm oil, 2-10 wt% of oleic acid amide, and 5-10 wt% of a synthetic rubber, and the components of the pencil skin comprise 70-90 wt% of polystyrene (PS), 5-20 wt% of color master batch, and 2-10 wt% of hydrogenated palm oil. According to the present invention, the pencil rod and the pencil core are not easily broken, the pencil core has characteristics of good striking degree, good brightness and dreg falling resistance, and the manufacturing cost is low.

Owner:JIANGXI JISHUI GEMSTAR STATIONERY CO LTD

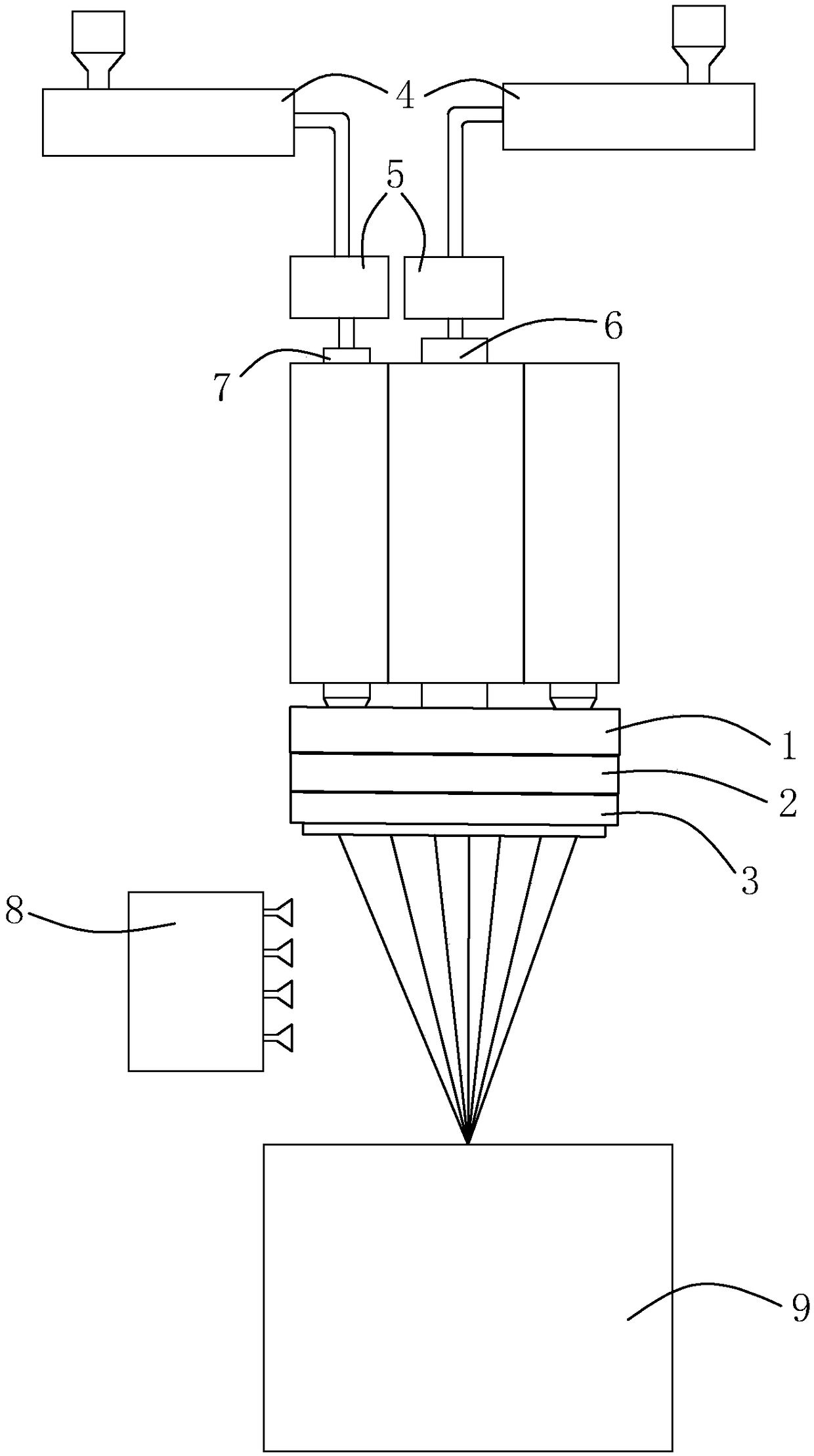

Graphene polylactic acid bicomponent composite fiber and preparation method and equipment thereof

ActiveCN109487352AConductiveBacteriostaticArtificial thread manufacturing machinesFilament/thread formingGrapheneUltimate tensile strength

The invention relates to a graphene polylactic acid bicomponent composite fiber and a preparation method and equipment thereof, and belongs to the technical field of melt-spinning fibers. The preparation method comprises the following steps: respectively drying and mixing 60-75wt% of polylactic acid slices and 25-40wt% of graphene master batches to obtain a component A; drying the polylactic acidslices as a component B; respectively melting and extruding the component A and the component B, and then spinning together. The bicomponent composite fiber prepared by the graphene polylactic acid bicomponent composite fiber and preparation method and equipment thereof has obvious crimping effect, excellent elasticity and fluffiness, and good effects of strength, wear resistance, heat preservation, bacteriostasis and conduction.

Owner:杭州三信实业有限公司

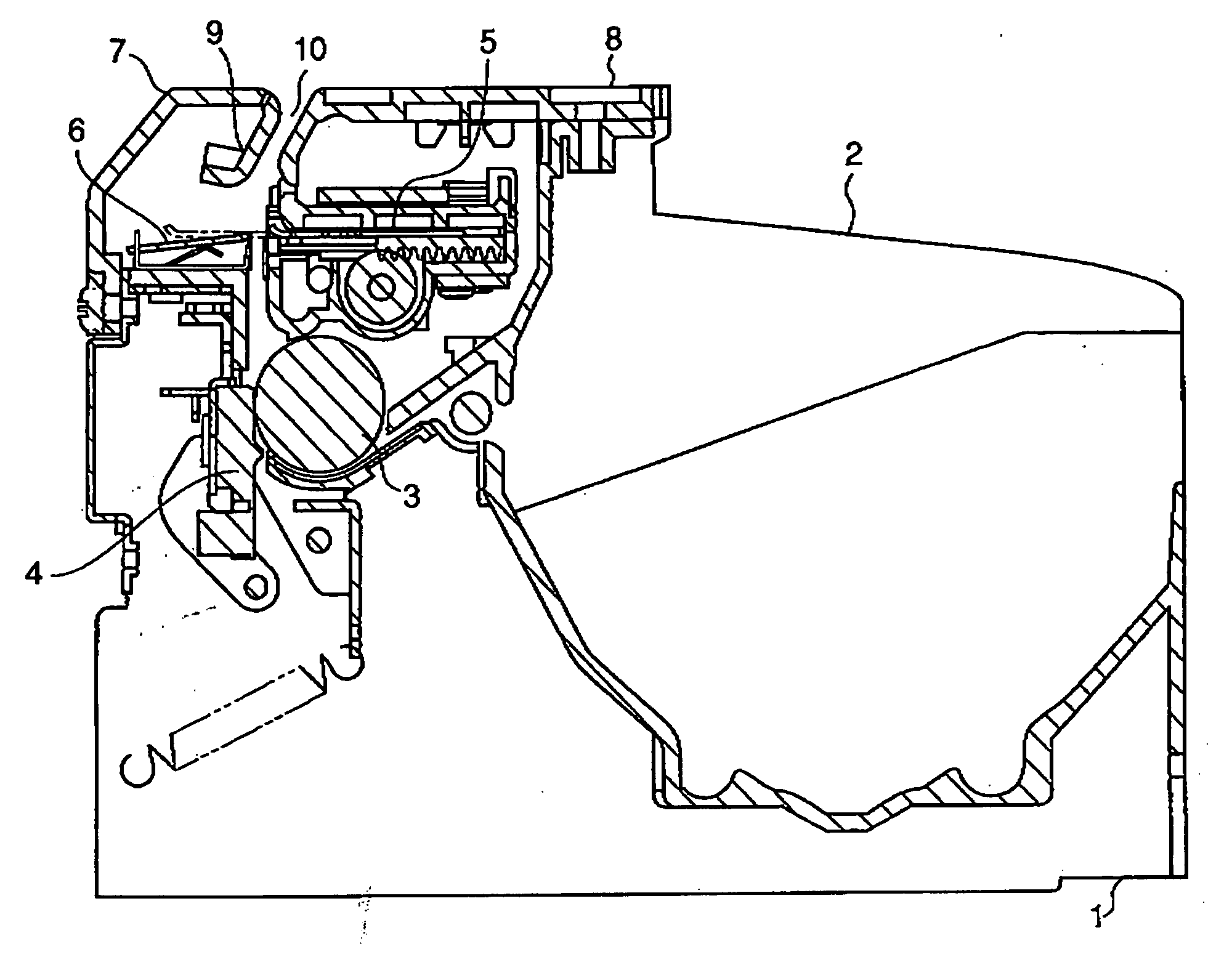

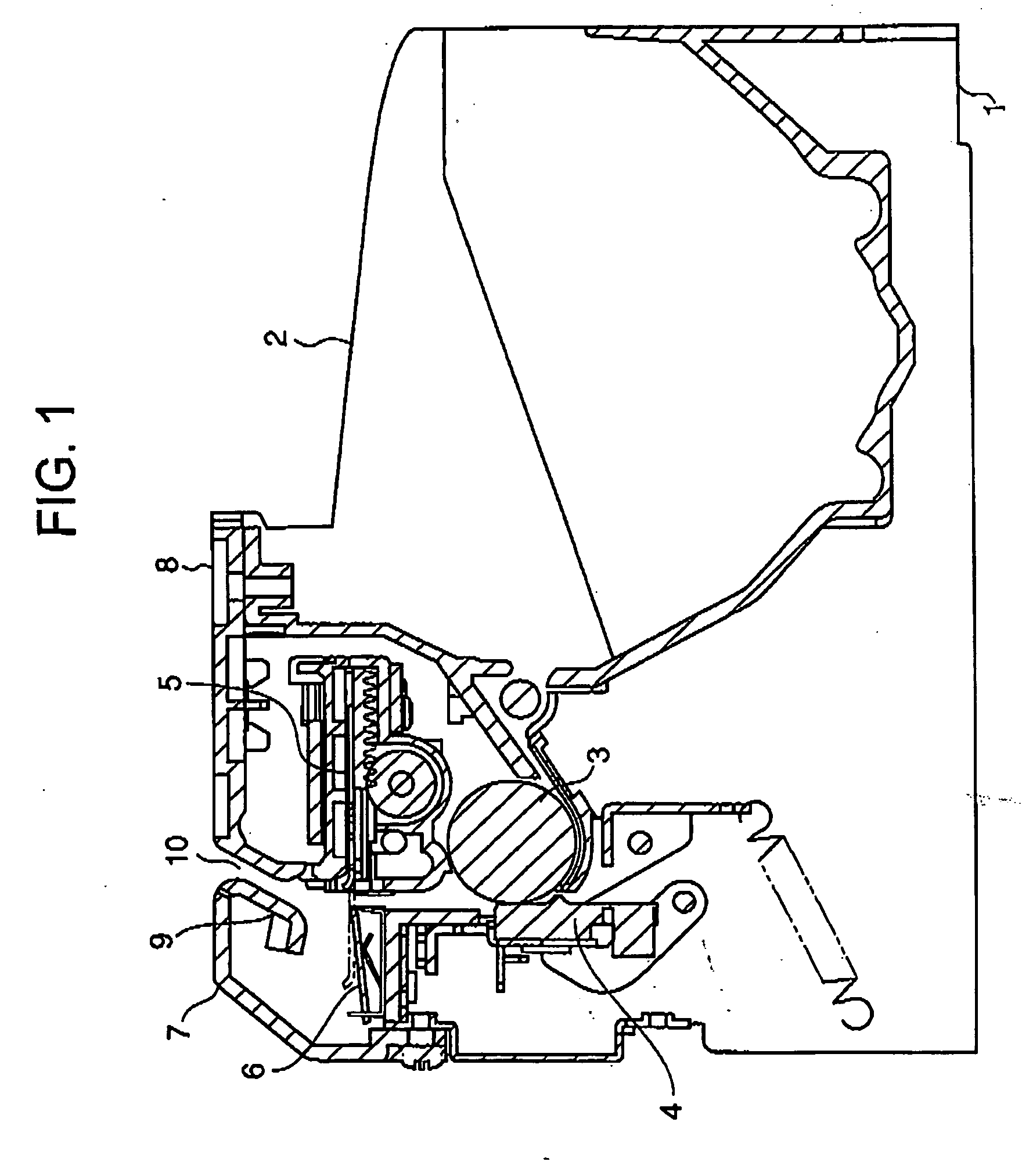

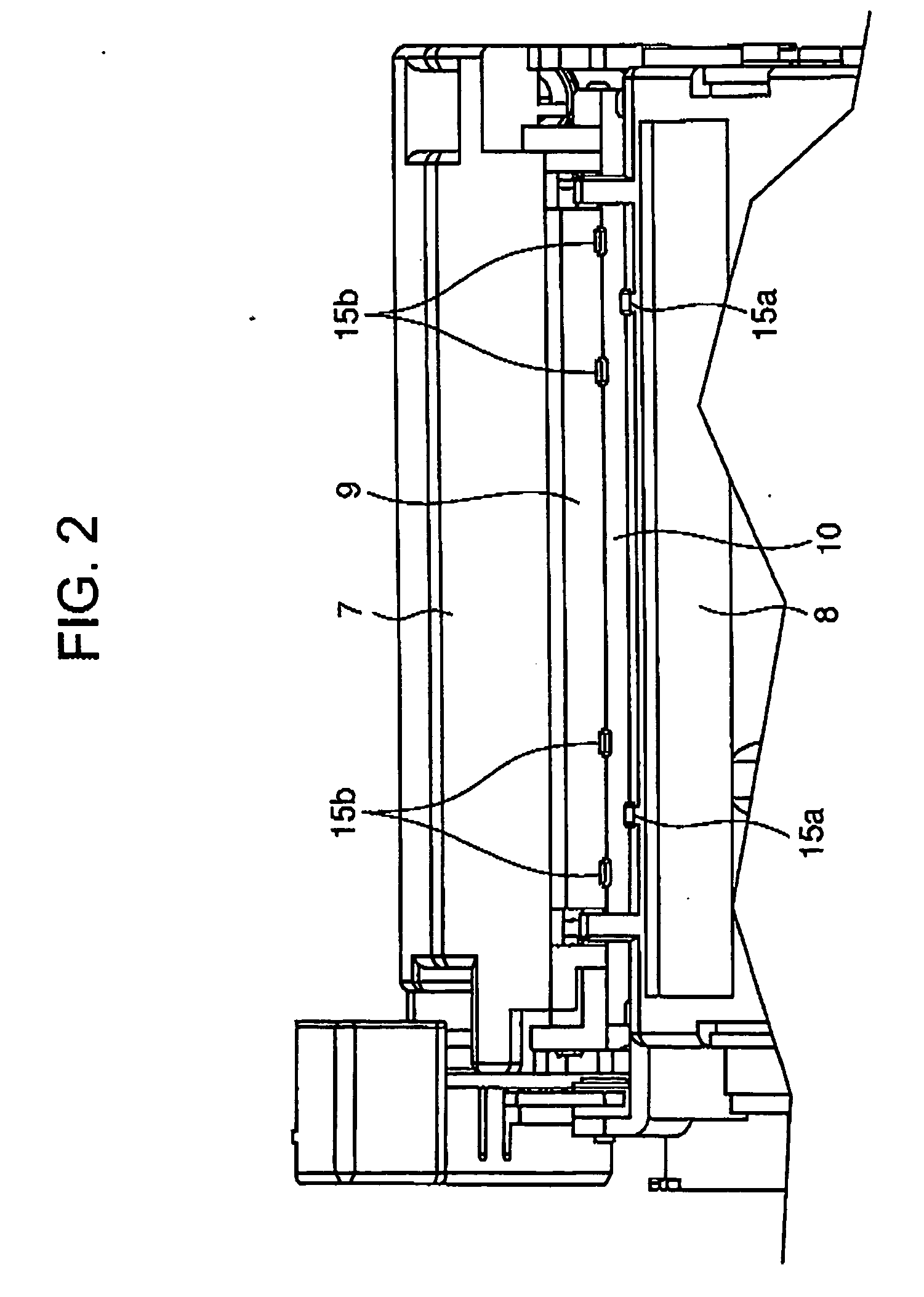

Printer, cut paper discharge mechanism used for printer, and paper jam prevention method

InactiveUS20070065217A1High degree of curlEasy to curlOther printing apparatusArticle deliveryRolling paperPulp and paper industry

A plurality of ribs are provided on a cut paper discharge guide and an upper cover which define a discharge port for discharging a cut paper. The ribs hold a cut paper in width direction. Even if a cut paper having a high degree of curl is supplied when a roll diameter of a roll paper is reduced, it is possible to prevent a paper jam such as falling or clogging of the cut paper. It is desirable that the ribs provided on the cut paper discharge guide and the upper cover are disposed in an alternate pattern along the width direction of the discharge port. This arrangement is particularly effective in a printer having an inclined paper passage.

Owner:NEC PLATFORMS LTD

DE type air purification filter material and method for processing the same

ActiveCN101219308AImprove density uniformitySimple structureFiltration separationDomestic articlesFiberPolyester

The invention adopts hollow polyester fiber, polyester short fiber and ES fiber according to mixture ratio of 1-4:1-4:2-8, including the steps of loosening-> quantitative feeding-> hot melting->cold roll forming->hot rolling->air cooling->trim cutting. The fiber of the invention is conglutinated after hot melting treatment; therefore, fiber pad has good toughness and uniform density and stable structure; the produced filtering material has large pore space, good loading capacity which is difficult to be deformed with small resistance and large dust holding performance and good filtering effect.

Owner:丹东天皓净化材料有限公司

Poplar ultrasonic chemical mechanical pulping technique

ActiveCN106120418ALarge specific surface areaHigh bonding strengthPulping with organic compoundsMultistage pulping processChemistryPre treatment

The invention relates to a poplar ultrasonic chemical mechanical pulping technique. The pulping technique includes the steps: performing ultrasonic pretreatment on steamed poplar pulp after first stage impressafining; performing xylanase pretreatment on the pulp after the ultrasonic pretreatment; soaking the pulp in soda hydrogen dioxide solution after pretreatment; performing second stage impressafining after soaking; performing second stage soaking on the pulp in the soda hydrogen dioxide solution after the second stage impressafining; performing first stage refining on the pulp with the soaking liquid; performing high concentrated storage and bleaching after the first stage refining; and performing second stage refining to obtain high-brightness high-yield high-strength chemical mechanical pulp. The poplar ultrasonic chemical mechanical pulping technique can improve the mechanical pulping performance of fast-growing poplar, enlarge the application range of poplar high-yield pulp, improve the performance of poplar paper pulp, and improve the use value of the poplar.

Owner:QILU UNIV OF TECH

Two-way warp knitted fabric

A two-way warp knitted fabric of warp knit structure prepared by cross-knitting a polytrimethylene terephthalate fiber as a front yarn and an elastomer fiber as a back yarn, which has a knitted fabric density ratio represented by the following formula (I): knitted fabric density ratio = number of course / 2.54 cm / number of wale / 2.54 cm of 1.55 to 2.35. This knitted fabric is a stretchable ground material of knitted fabric for clothes which is suppressed in curl, has a soft feeling and suffers no yellowing.

Owner:ASAHI KASEI KK

Method for preparing tows for modified cigarettes

ActiveCN102134758ALight weightSimple spinning processArtificial filament physical treatmentMelt spinning methodsFiberPolymer science

The invention relates to a method for preparing tows for blended modified polylactic acid cigarettes. Fiber grade polypropylene particles, functional master batches and polylactic acid particles are uniformly mixed according to a certain ratio, and the tows for polylactic acid cigarettes are prepared through the working procedures of spinning, oiling, drafting, wrapping and drying. The method has a simple process and high speed to form, the produced product can reduce the specific weight of polylactic acid fiber, the operational performance is increased, the surface area of the fiber is increased, grain phase particles in smoke can be effectively absorbed, and a good filtering effect is generated.

Owner:JIANGSU DAYA CIGARETTE FILTER MATERIAL CO LTD

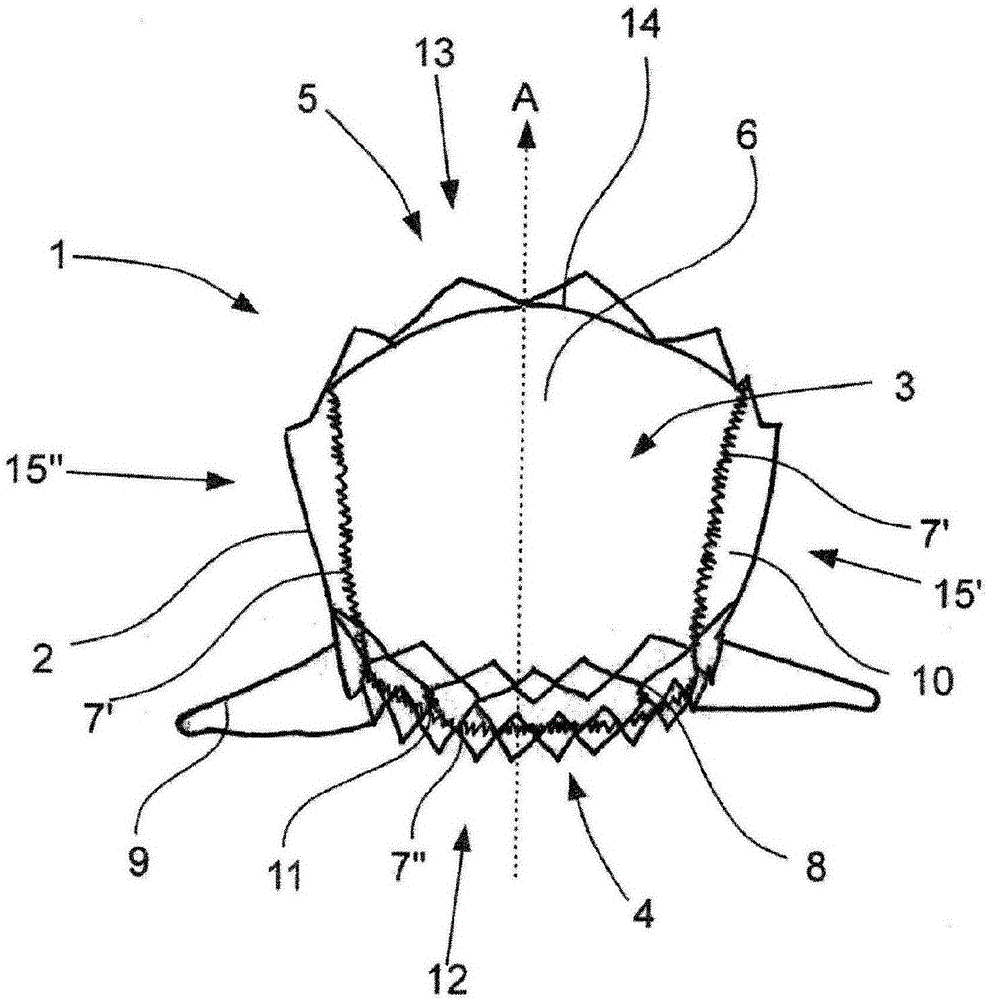

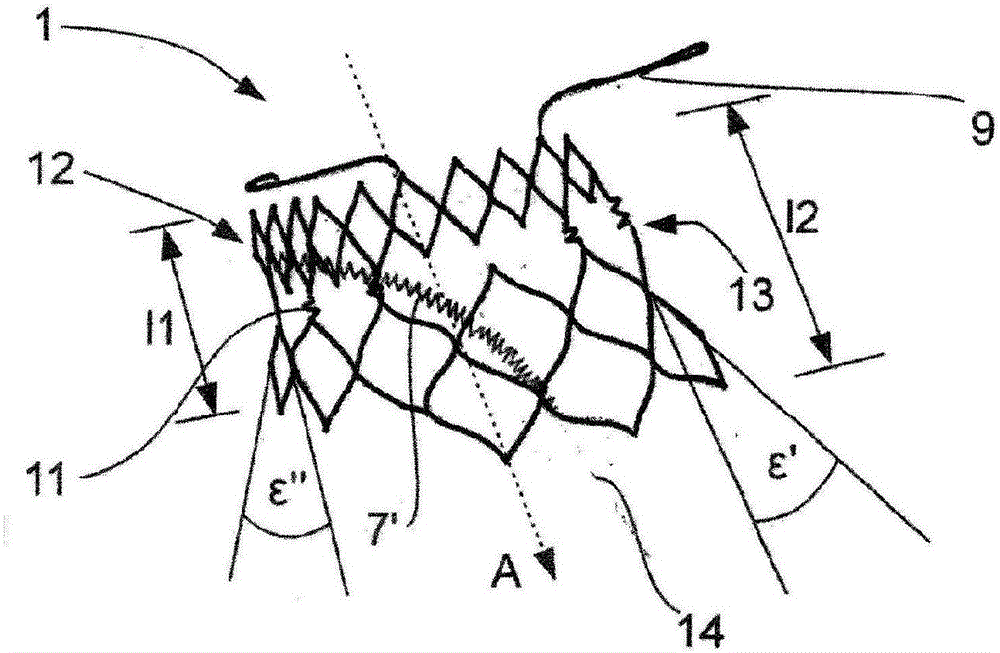

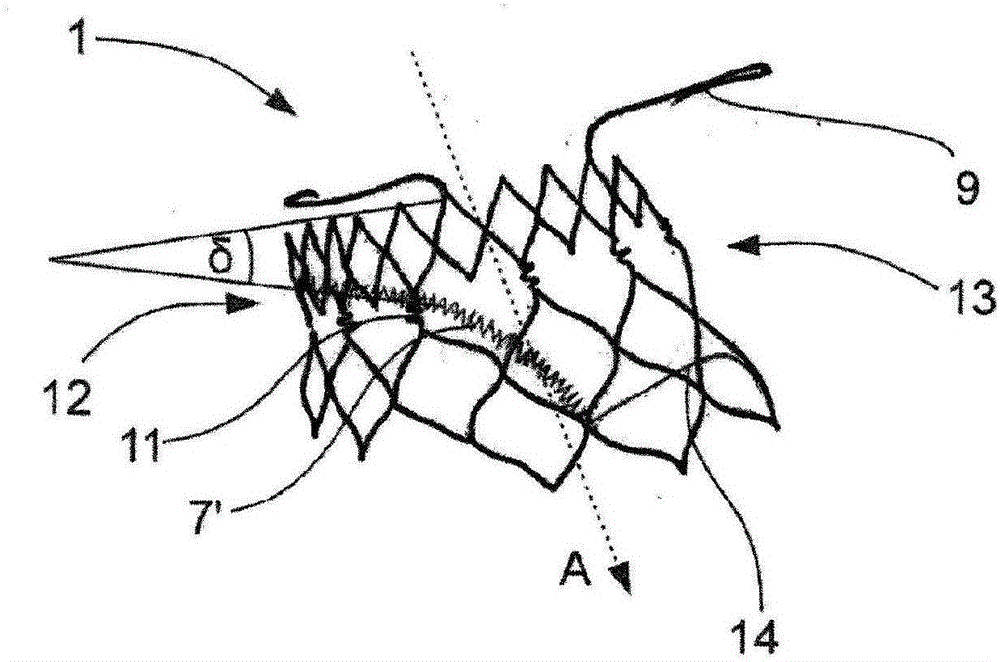

Cardiac stent-valve and delivery device for such a valve

A cardiac stent-valve (1), preferably a mitral stent-valve, comprising a stent component (2) and a valve component (3), wherein the stent component (2) comprises an inflow end (4) and an outflow end (5) and a wall between the inflow (4) and the outflow end (5), and wherein the valve component (3) is made of one single leaflet (6); the periphery of said single leaflet (6) being partially attached or attachable to the stent component (2) along at least fixation lines (7', 7''), characterized in that said two fixation lines (7') are at least partially inclined with respect to an annular plane of said valve perpendicular to a flow direction (A) through the stent-valve (1) and wherein the third fixation line (7'') runs parallel with respect to said plane.

Owner:EPYGON

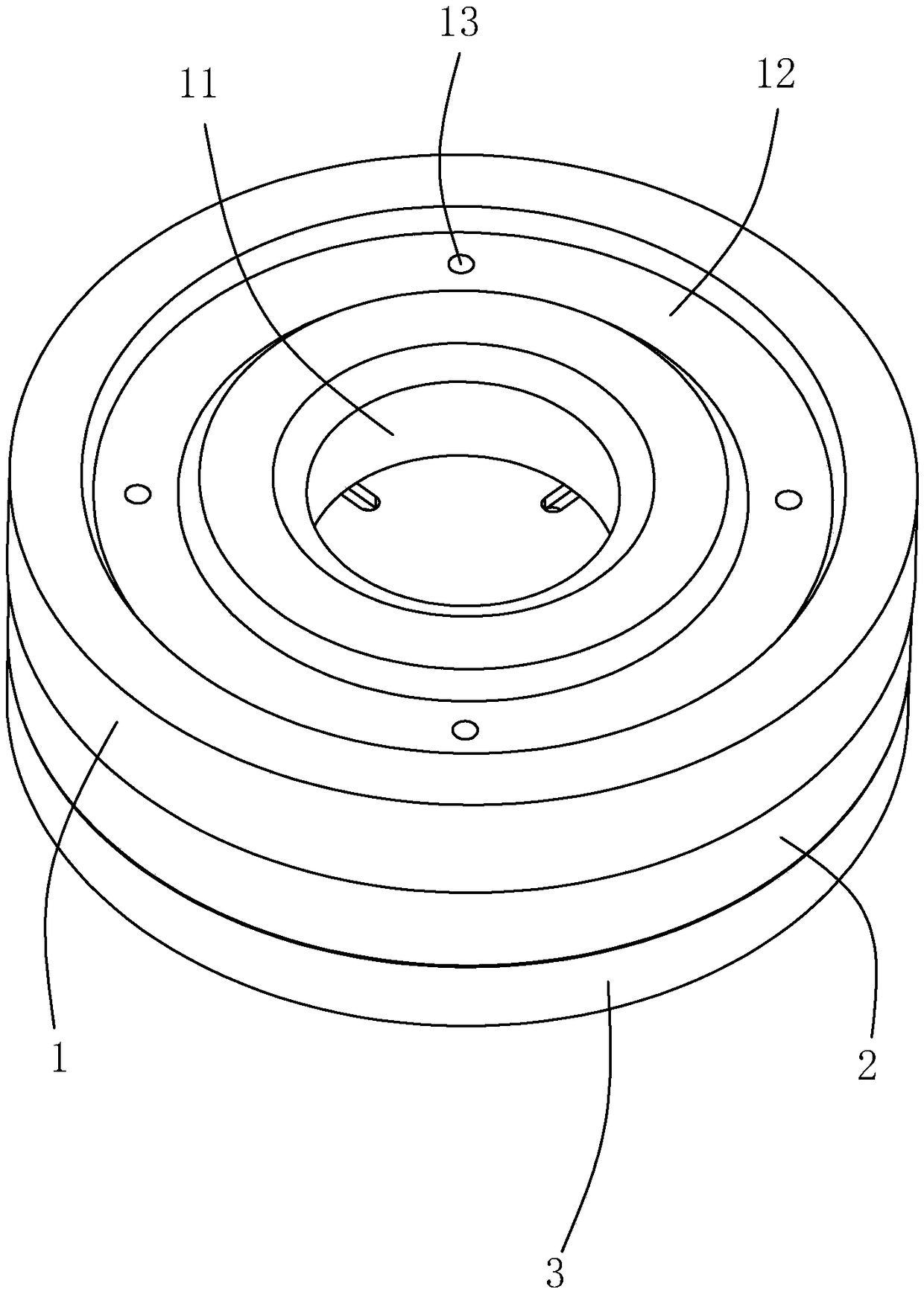

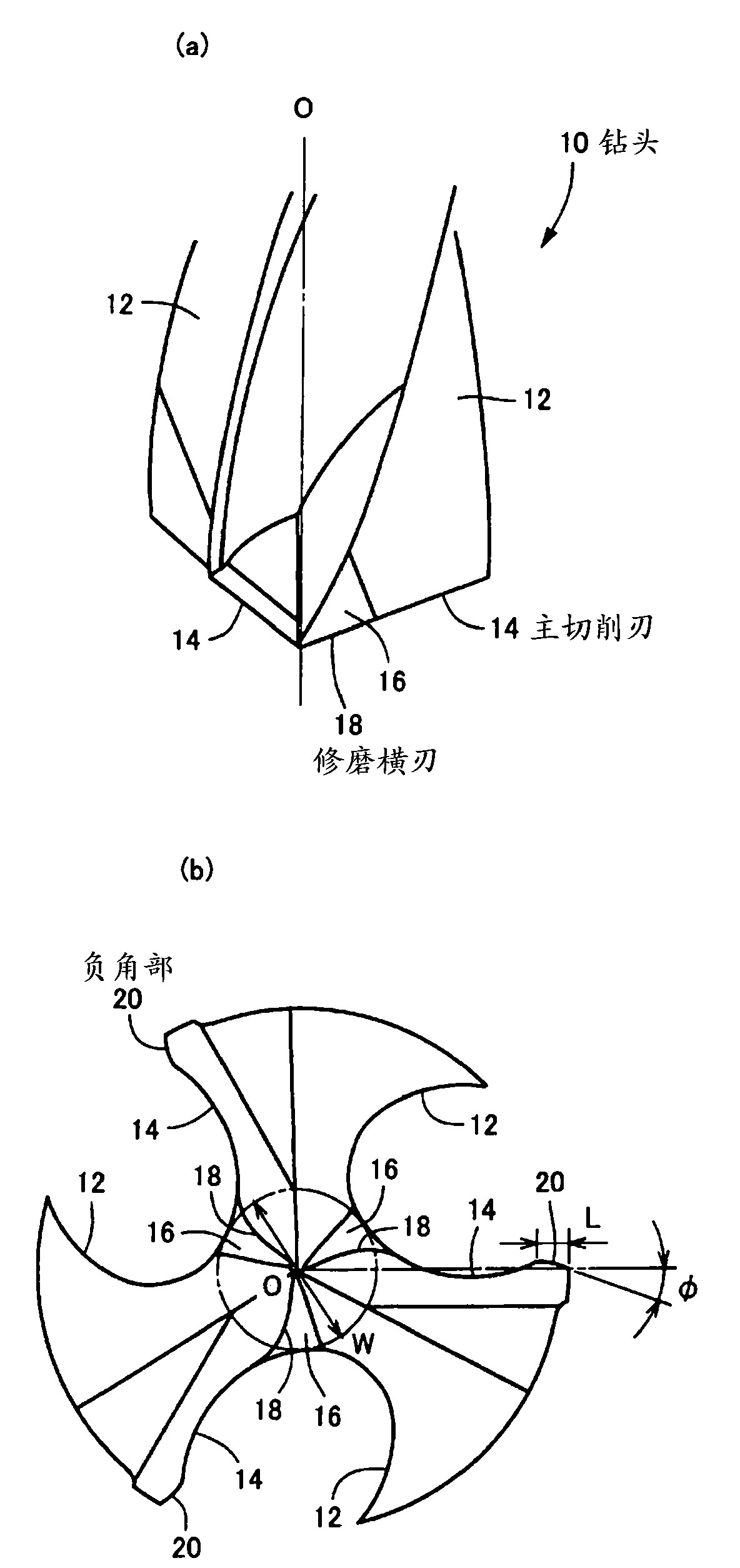

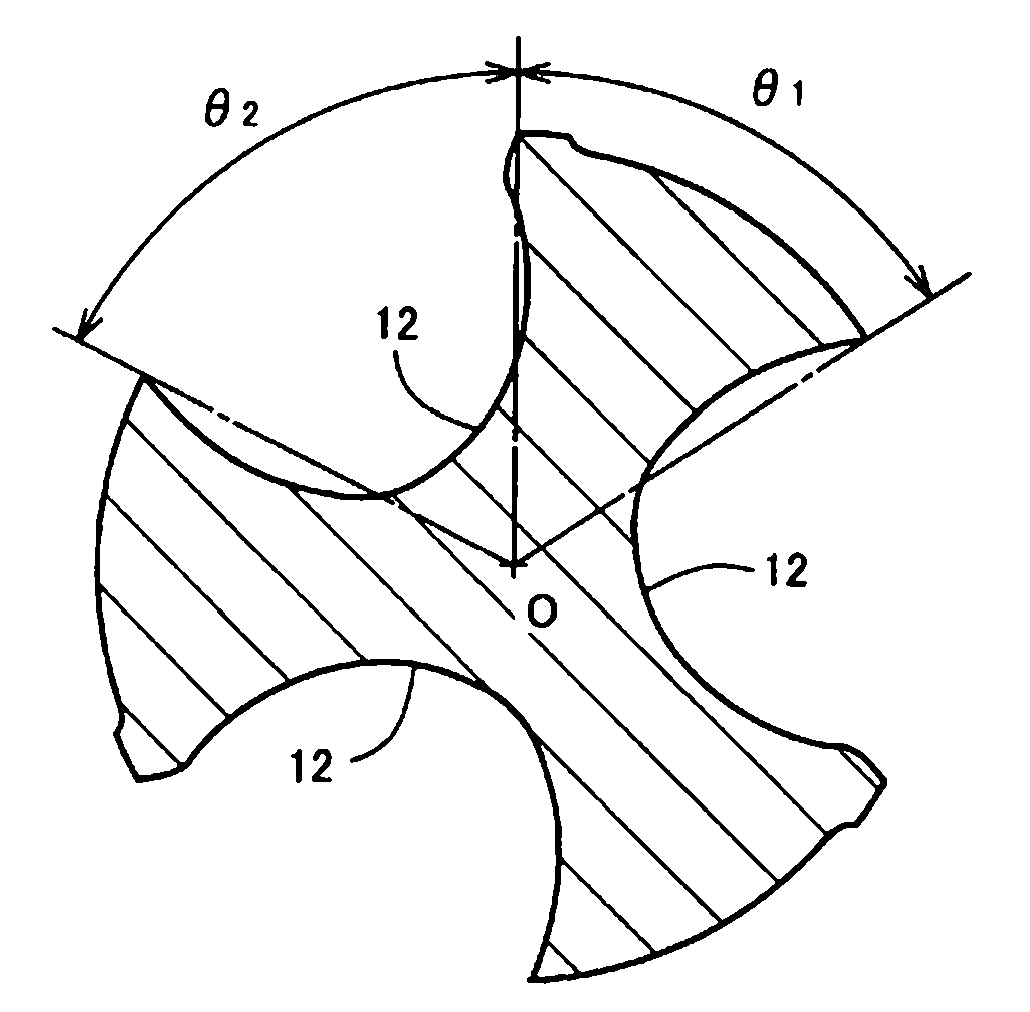

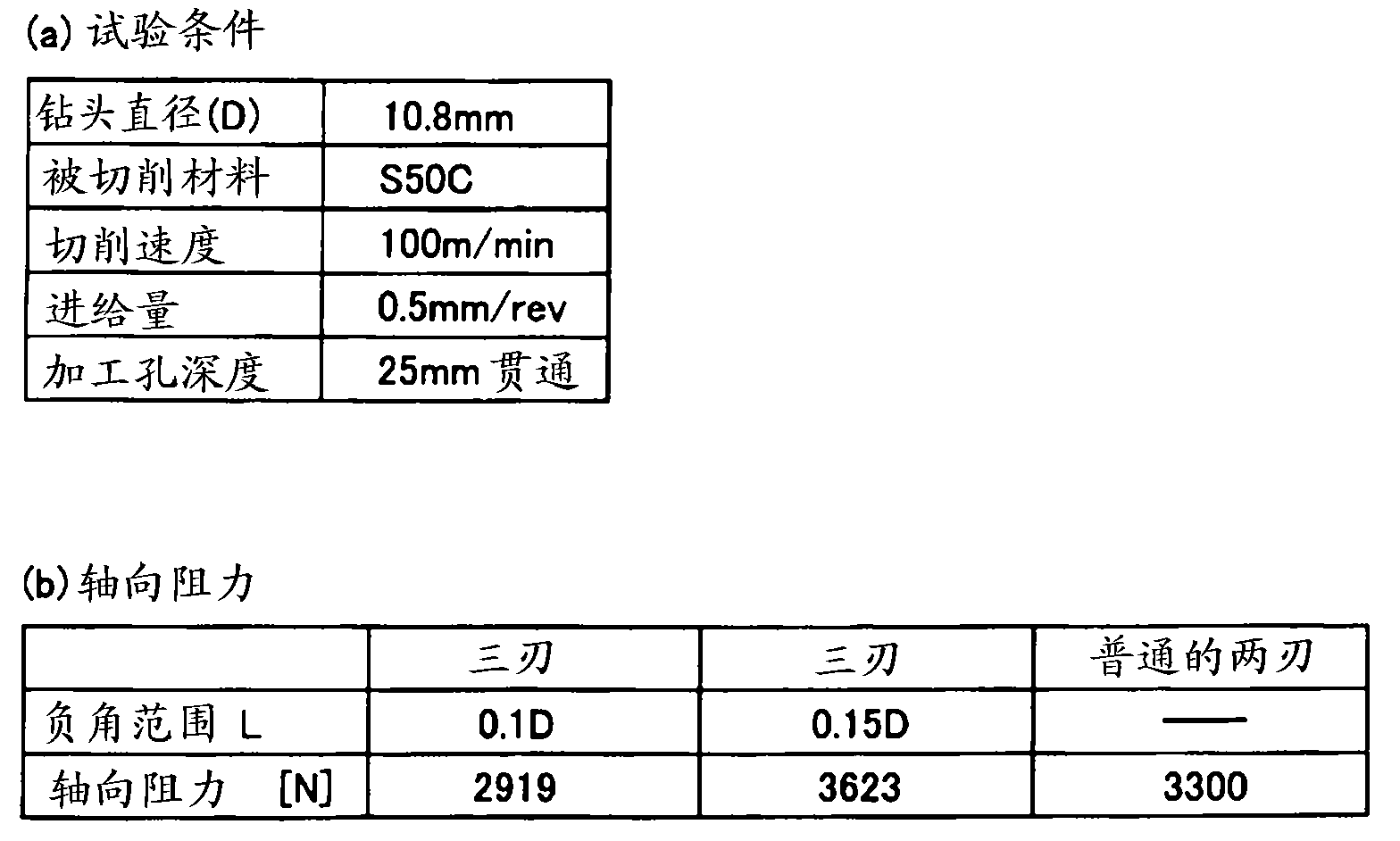

Drill

InactiveCN102170989AEasy to curlImprove discharge effectTransportation and packagingWorkpiecesEdge strengthEngineering

Owner:OSG

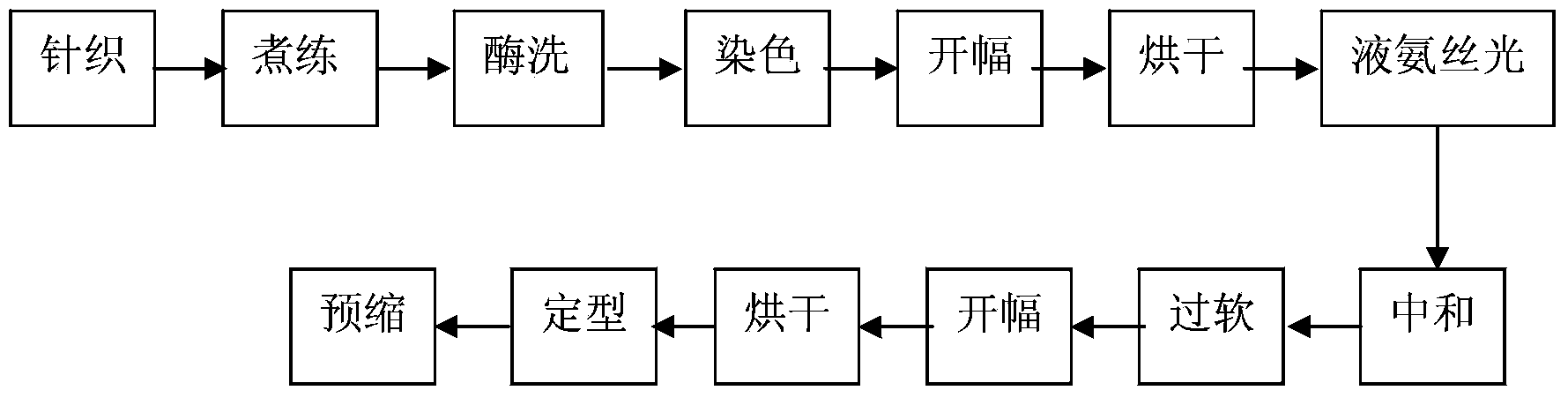

Production method of washable piece-dyed knitted fabric

ActiveCN104264447AImproved dimensional stability and wash resistanceEliminate internal stressMercerising of indefinite length fabricsBiochemical fibre treatmentLiquid ammoniaYarn

The invention provides a production method of washable piece-dyed knitted fabric. The production method comprises steps as follows: undyed yarn is knitted into gray fabric, the gray fabric is sequentially subjected to boiling-off, enzyme wash, dyeing, scotching, drying, liquid ammonia mercerization, neutralization, softening, scotching, drying, setting and preshinking, and the washable piece-dyed knitted fabric is obtained. The production method adopts steps of boiling-off, enzyme wash, dyeing and liquid ammonia mercerization sequentially, the liquid ammonia mercerization effect and the liquid ammonia recycling are facilitated, and resin treatment is combined, so that an obtained knitted product has better dimensional stability, and more durable hand feeling and color are kept; and the fabric has high flatness, touches comfortable and is soft, elastic and better in strength. By means of the production method, various properties of the knitted product are improved, the additional value and the technological content of the knitted product are increased, and recyclable liquid ammonia used for treatment is environment-friendly.

Owner:GUANGDONG ESQUEL TEXTILES

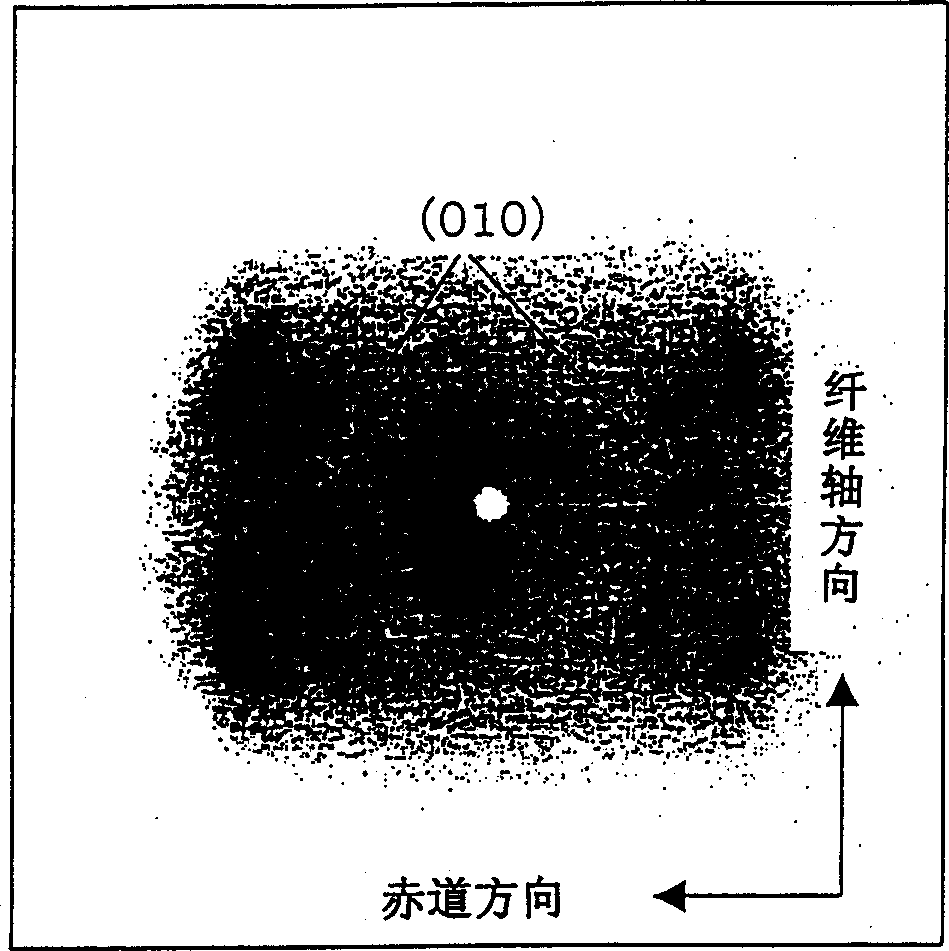

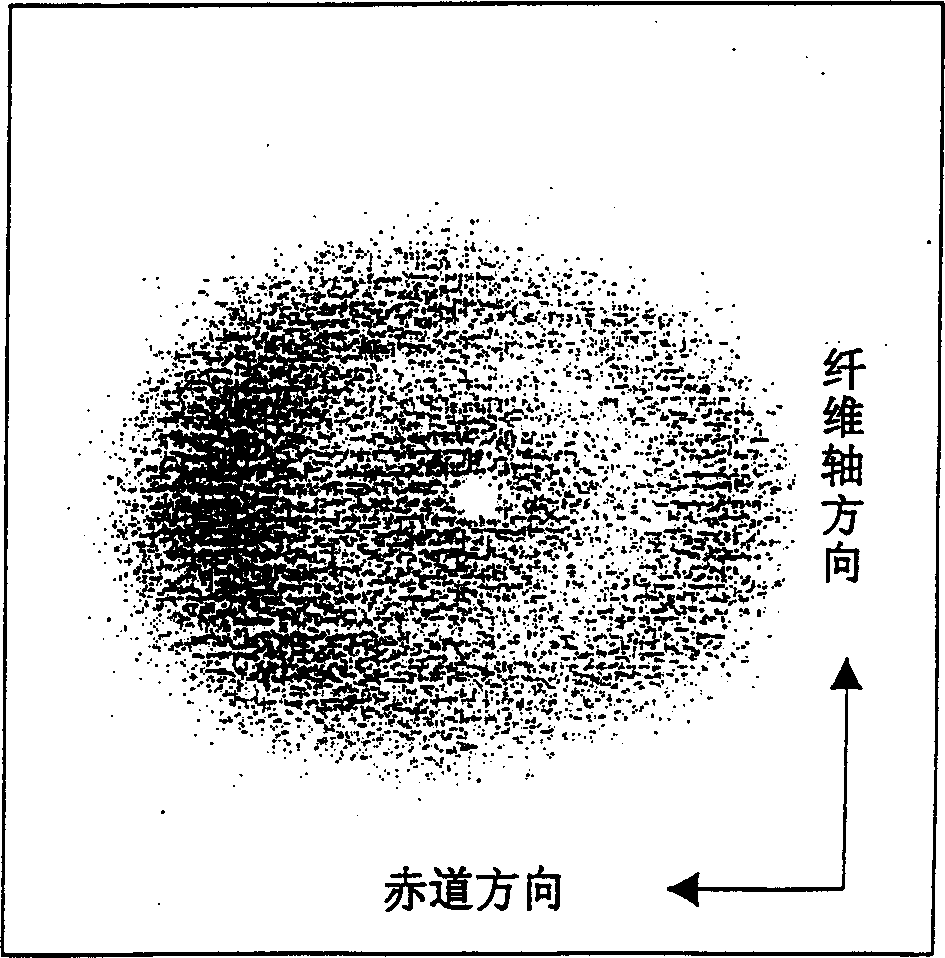

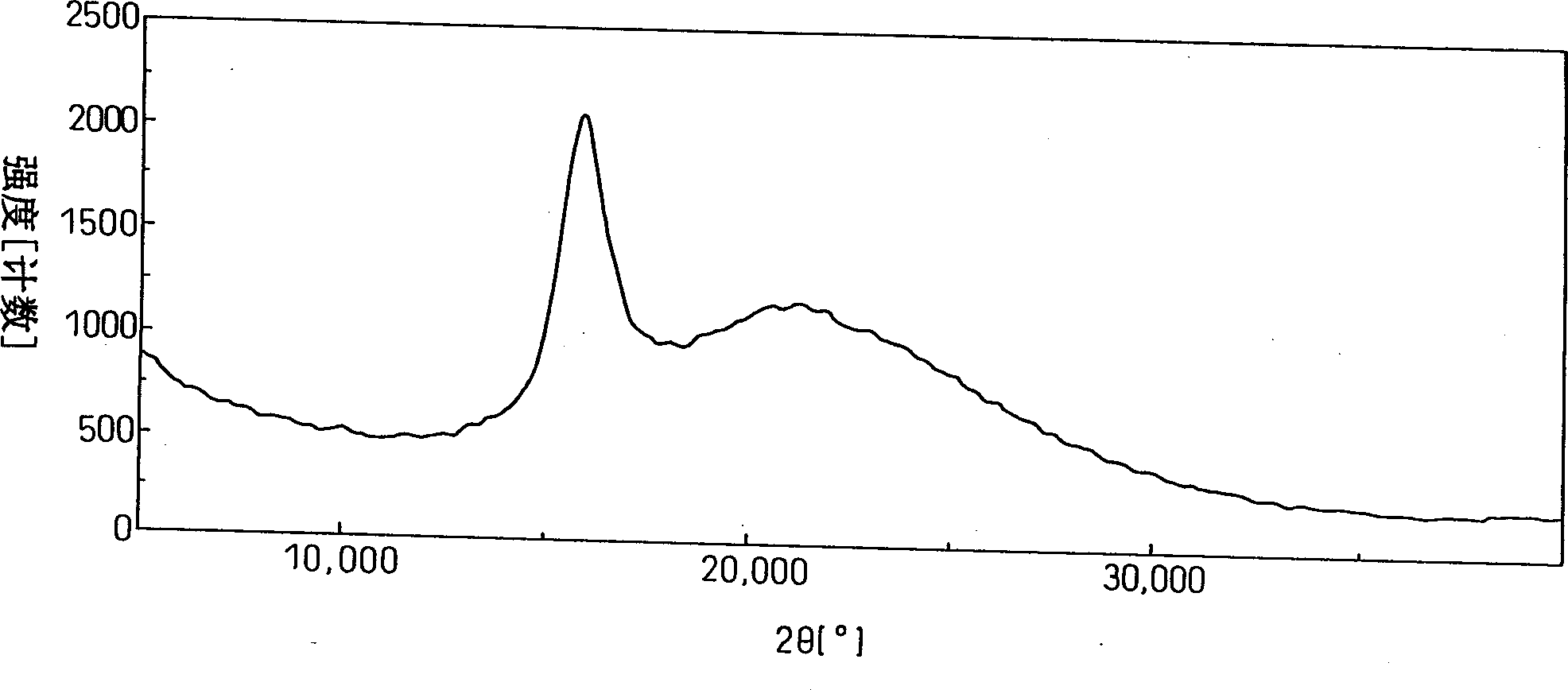

Polytrimethylene terephthalate fiber and process for producing the same

InactiveCN1358242AEasy to curlNot easy to tangleFibre treatmentWoven fabricsYarnPolyethylene terephthalate

A polytrimethylene terephthalate fiber, a method for producing the same, a cheese-shaped package formed thereof, a false-twist textured yarn using the fiber and a fabric using the false-twist textured yarn are provided. The fiber is composed of 90 mol% or more of trimethylene terephthalate repeating units having a density in a range from 1.320 to 1.340 g / cm<3>, a birefringence in a range from 0.030 to 0.070, a peak value of thermal stress in a range from 0.01 to 0.12 cN / dtex, a boiling water shrinkage in a range from 3 to 40%, and an elongation at break in a range from 40 to 140%. The inventive polytrimethylene terephthalate fiber has both of proper crystallinity and orientation and is free from the package tightness due to yarn shrinkage and the bulge. The inventive fiber can be produced on an industrial scale.

Owner:ASAHI KASEI KK

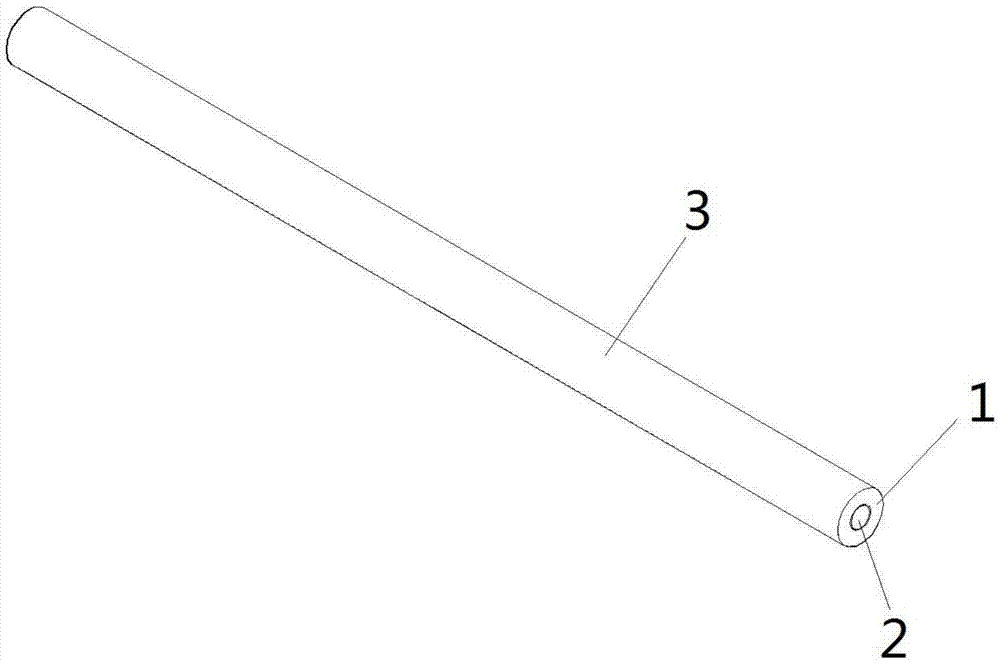

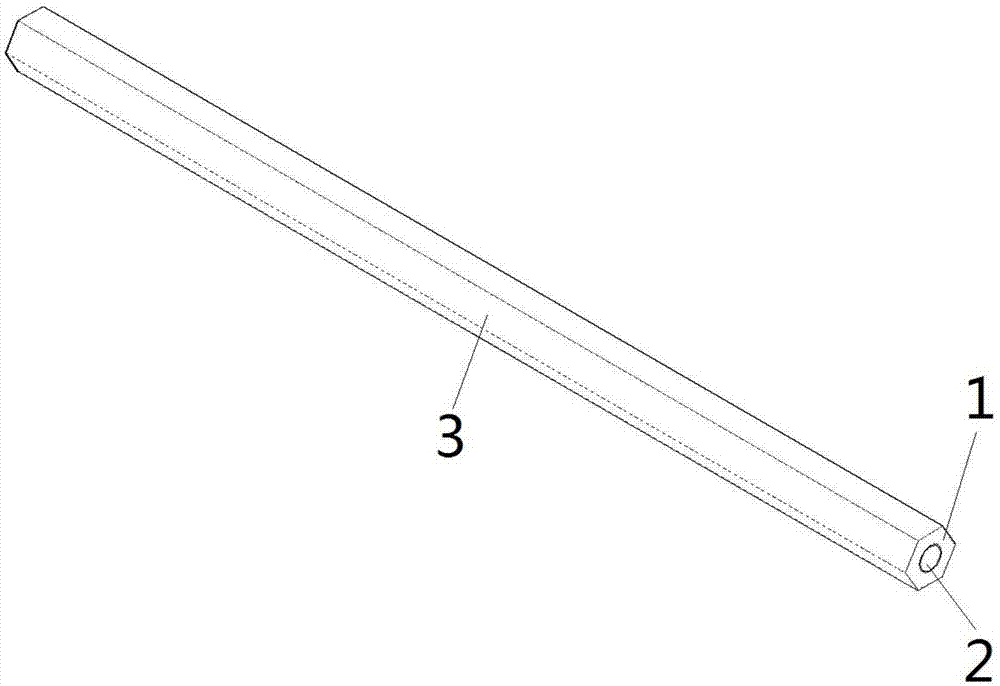

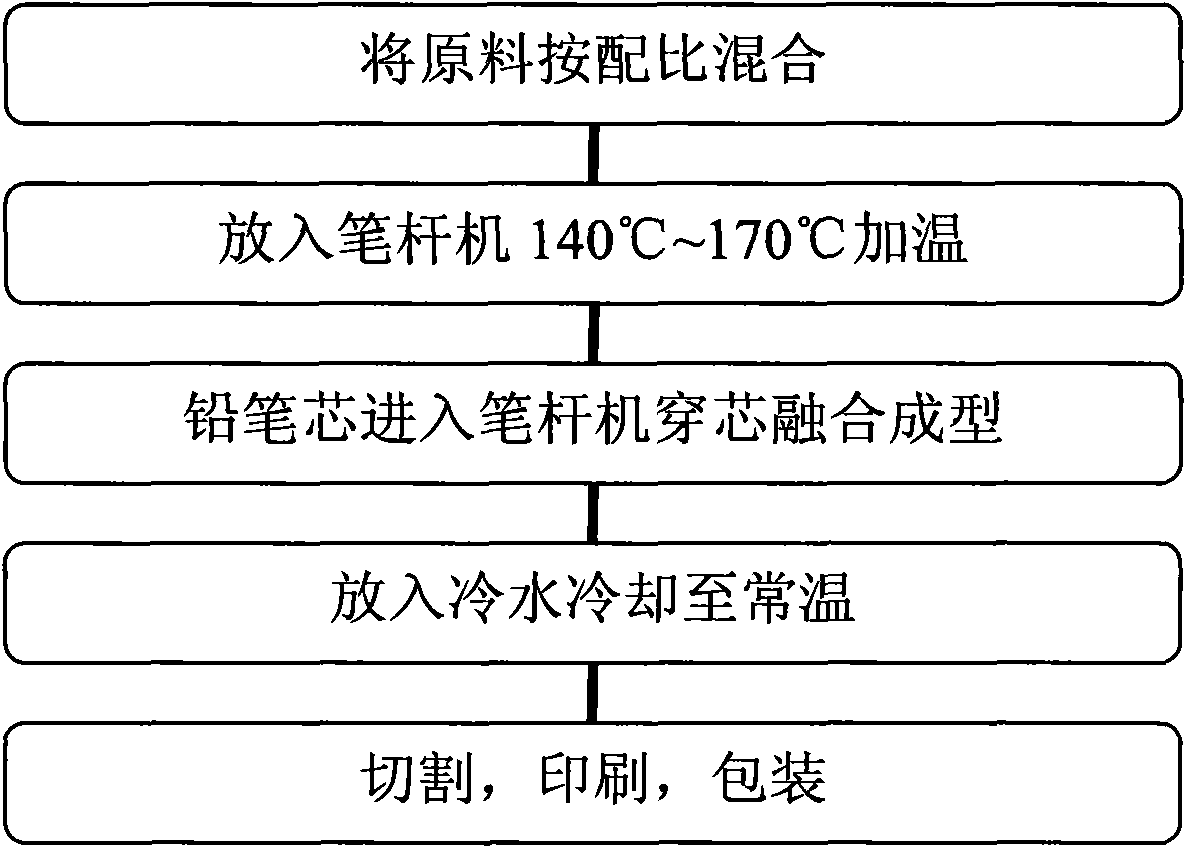

Degradable pencil holder, pencil and fabricating method thereof

ActiveCN101565537AEasy to curlReduce lead breakNon-propelling pencilsNib holdersCross linkerToxicity

The invention provides a degradable pencil holder and a pencil adopting the same, wherein the pencil holder comprises the following components by the weight percent: 40-60 of polyhydroxy fatty acid ester, 30-50 of starch, 1-10 of cross linker and 1-10 of plasticizing agent. The invention also provides a fabricating method of the pencil, which comprises the steps of mixing raw materials, heating, lead penetrating and forming. The degradable pencil holder is environmental-friendly without toxicity, and can replace a wooden pencil holder so that wood consumption can be reduced; the pencil is easy to sharpen so as to reduce the lead-breaking; and the fabricating method of the pencil has simple process, convenient fabrication, low cost and no pollution.

Owner:SHENZHEN CERTAINN TECH CO LTD

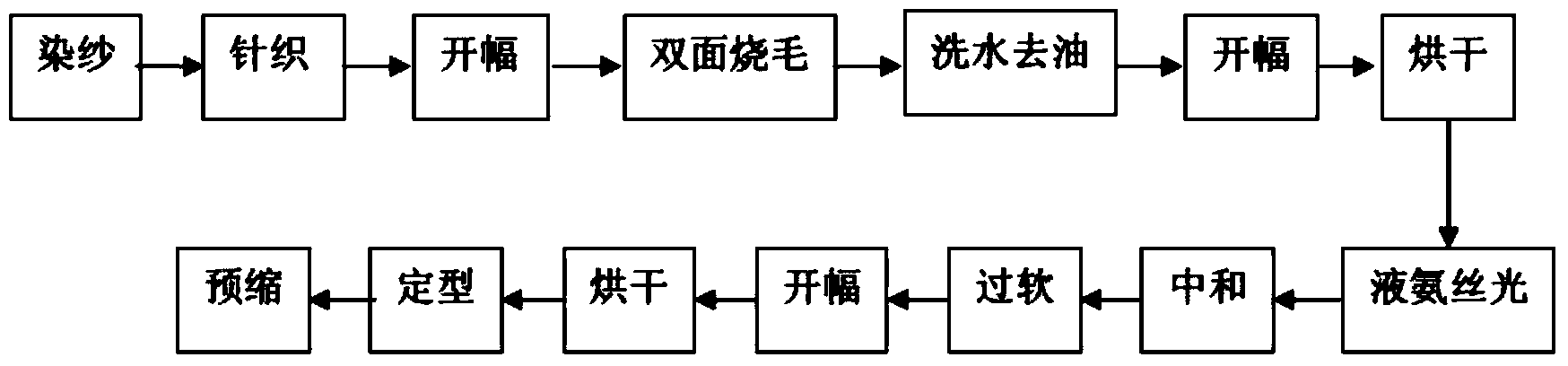

Production method of washable yarn-dyed knitted fabric

InactiveCN104264412AImprove responseImprove hydrophilicityMercerising of indefinite length fabricsFibre treatmentYarnAdditional values

The invention provides a production method of washable yarn-dyed knitted fabric. The production method comprises steps as follows: yarn is sequentially subjected to yarn dyeing, knitting, scotching, double-side singeing, washing for oil removal, scotching, drying, liquid ammonia mercerization, neutralization, softening, scotching, drying, setting and preshinking, and the washable yarn-dyed knitted fabric is obtained. The production method adopts steps of singeing, washing for oil removal and liquid ammonia mercerization sequentially, the liquid ammonia mercerization effect and the liquid ammonia recycling are facilitated, and resin treatment is combined, so that an obtained knitted product has better dimensional stability, and more durable hand feeling and color are kept; and the fabric has high flatness, touches comfortable and is soft, elastic and better in strength. By means of the production method, various properties of the knitted product are improved, the additional value and the technological content of the knitted product are increased, and recyclable liquid ammonia used for treatment is environment-friendly.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Textile fabric and yarn quick winding, coiling and uncoiling device

The invention discloses a textile fabric and yarn quick winding, coiling and uncoiling device. The textile fabric and yarn quick winding, coiling and uncoiling device comprises a first support plate,wherein first support columns are arranged at both ends of the surface of the first support plate; a vertical column is arranged between the two first support columns; a guide rod is arranged on the vertical column; a second support plate is arranged on the first support plate; a first motor is arranged in the middle part of the bottom surface of the second support plate; rotary sleeves are arranged at both sides of the first motor; a rotary rod is arranged in each rotary sleeve; coiling rolls are arranged between the second support columns; one side of each coiling roll penetrates through thesecond support columns and is connected with a coiling shaft; a second motor is arranged at the upper end of the second support column near the coiling shafts; a cleaning frame is arranged between frame rods; the interior of the cleaning frame is provided with an opening. The textile fabric and yarn quick winding, coiling and uncoiling device has the advantages that the structure is simple, and the convenience in use is realized; the fabrics and yarns can be quickly wound into coils, and the yarn columns can be conveniently stored; the working efficiency is improved, and the labor intensity is reduced.

Owner:湖州泰鑫无纺布有限公司

Hair curling apparatus and hair curling method

A curling appliance for curling hair, comprising: a shaft body for curling hair; a detachably arranged stopper with a slightly C-shaped cross-section on the outside of the shaft body; arranged on the outside of the stopper, and A screwing device screwed to the shaft body, wherein by rotating the screwing device in a state where the root side of the hair stays on the shaft body and the front side of the hair is guided to the screwing device side, The hair is curled in a helical shape by the rotation of the shaft. The present invention provides a hair curling technique that makes hair curl beautifully but has excellent workability.

Owner:木俣 年博 +1

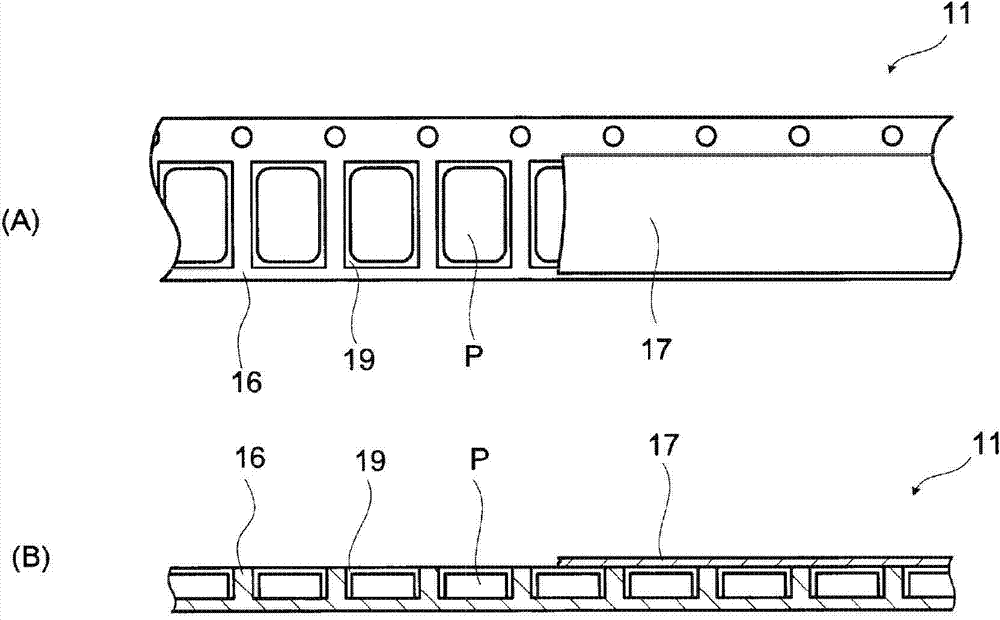

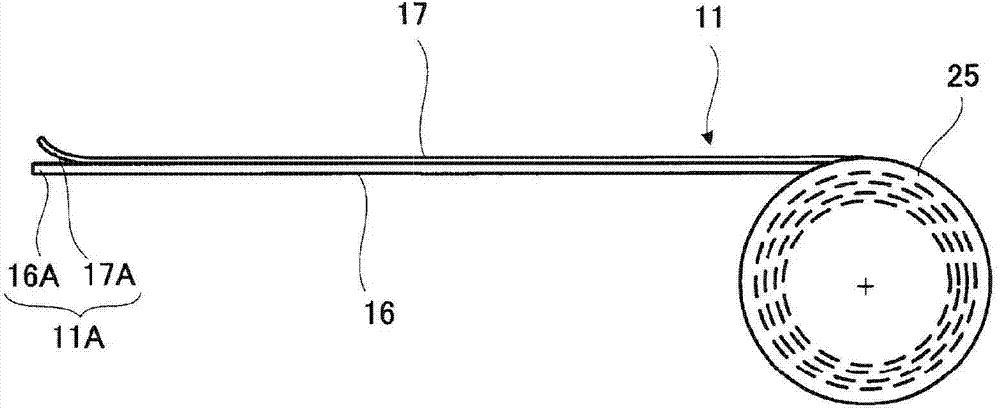

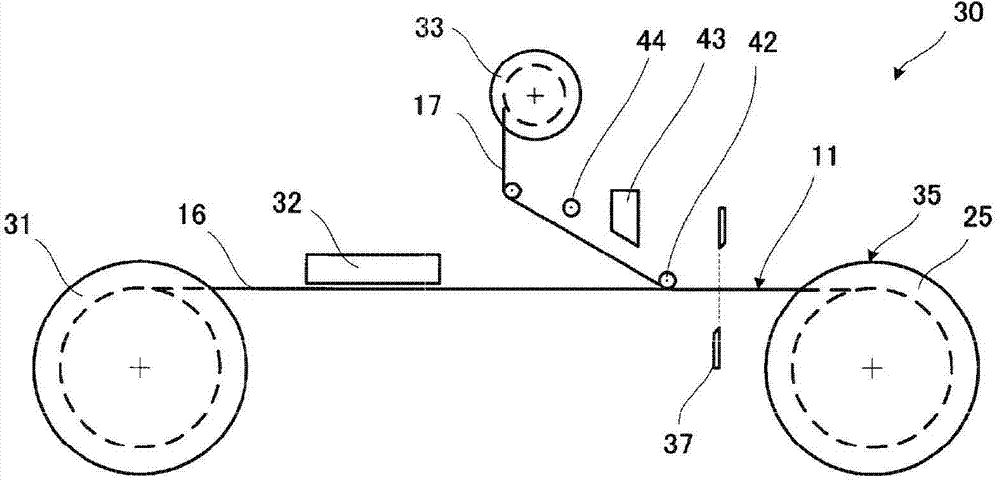

Method for manufacturing carrier tape

A method for manufacturing a carrier tape is disclosed. With the method, a carrier tape which can store more electronic components and is excellent in operability in the installation process is manufactured. A non-storage part (18A) which does not store electronic components (P) is arranged at the position of an end part (11A) of a carrier tape (11). At the non-storage part (18A), a film non-adhesive part (28A) is formed on a tape main body (16). The tape main body (16) and a cover film (17) are cut off at the film non-adhesive part (28A). As the electronic components (P) can be stored on the carrier tape (11) without cutting off the tape main body (16), the number of stored electronic components (P) is increased. In addition, by forming a rolling part (17A), the cover film (17) can be easily peeled off.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com