Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

801results about How to "Good shaping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-retaining support for plants and plant body-growing water-retaining material

InactiveUS6615539B1Reduce contentSuppress Ca absorption amountAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersIon exchangePolymer

A water-retaining support for plants comprising a hydrogel-forming polymer (A) having a calcium ion absorption of 0-100 mg per 1 g of the dry weight thereof, having a chlorine ion content of 0.07-7 mmol per 1 g of the dry weight thereof and having a water absorption magnification in ion-exchanger water at 25° C. of 1.0x101 to 1.0x102; or a plant body-growing water-retaining material comprising a molded product of a mixture of such a polymer (A) and a plant body-growing support (B). The water-retaining support for plants and the plant body-growing water-retaining material are those which have an excellent water-retaining property and they substantially do not cause inhibition of root generation or inhibition of root elongation.

Owner:MEBIOL +2

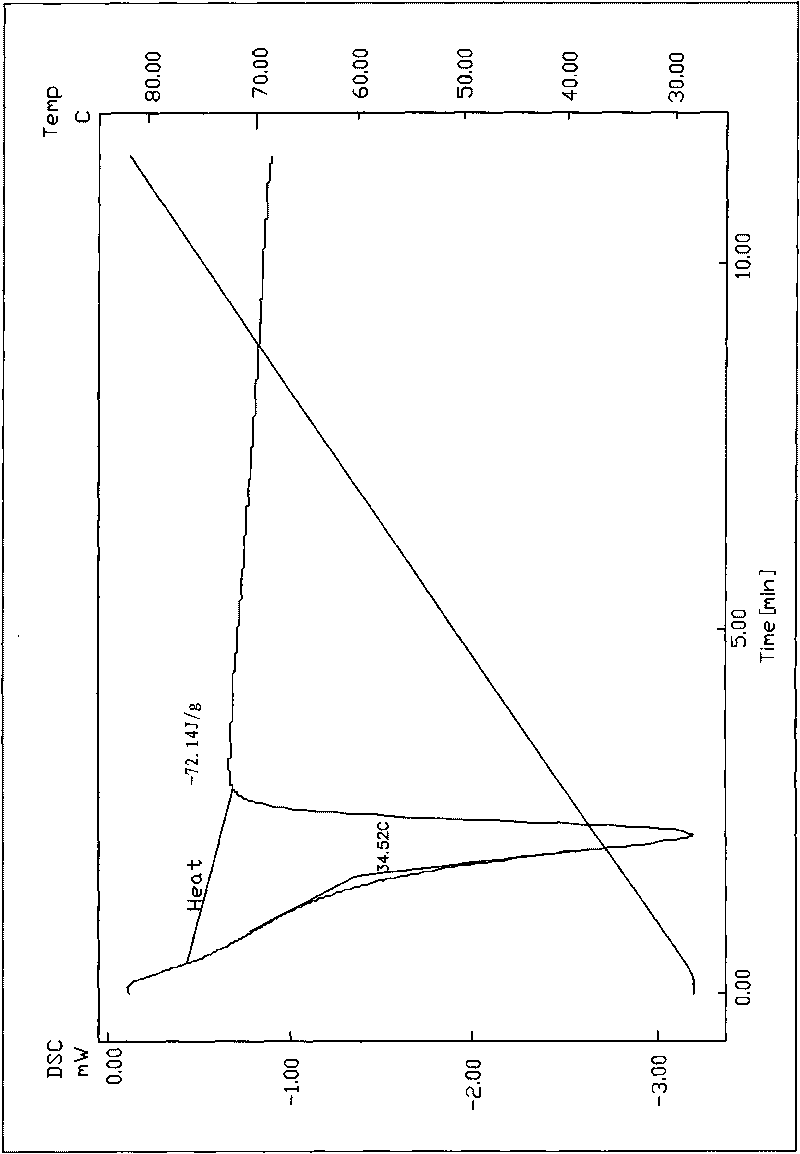

Composite phase-change thermal storage material

ActiveCN104140786AHigh freeze-thaw rateHigh thermal conductivityHeat-exchange elementsLiquid metalVolumetric Mass Density

The invention provides a composite phase-change thermal storage material. A porous material with high thermal conductivity is used as a supporting framework, and low-melting-point metal or low-melting-point metal with nano-particles is distributed in pores of the porous material, wherein melting point or solidus temperature of the low-melting-point metal is less than or equal to 80 DEG C; and thermal conductivity of the porous material is within 40-400 W / (m.K). The material provided by the invention has high equivalent thermal conductivity and high storage energy density; there is a large contact area between the liquid metal and the porous material; and the material has a wide application temperature range, has good fixability, stable physico-chemical property and good reversibility; and the problem of decreasing heat storage efficiency after multiple times of heat adsorption and release cycles is avoided.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

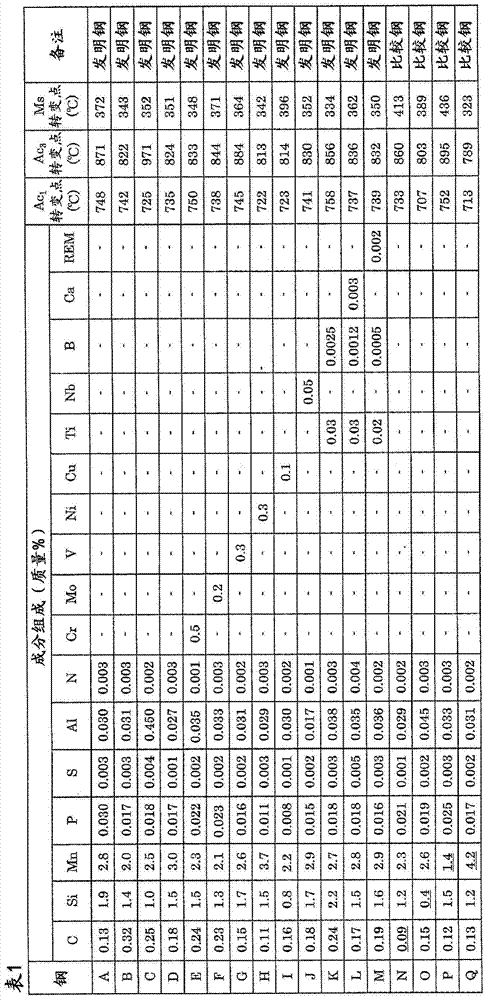

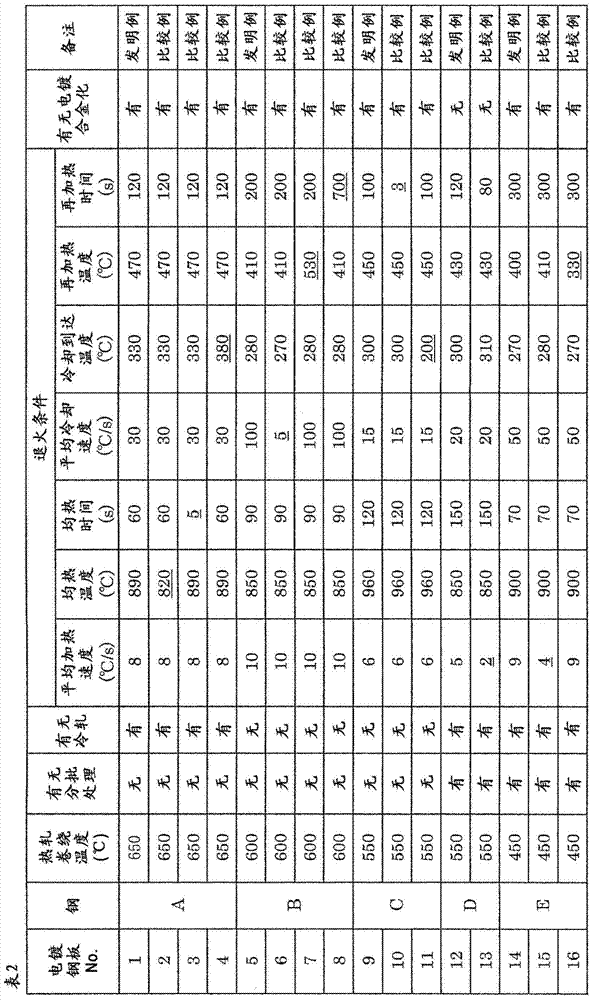

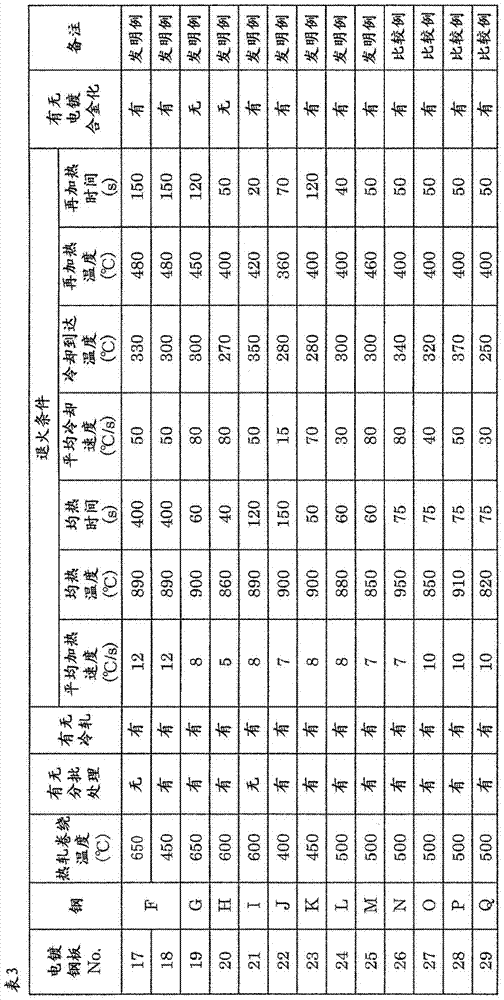

High-strength hot-dip galvanized steel sheet having excellent moldability and shape fixability, and method for manufacturing same

ActiveCN104508163AExcellent formability and settabilityGood formabilityHot-dipping/immersion processesFurnace typesSheet steelExpansion ratio

Provided is a high-strength hot-dip galvanized steel sheet having: a tensile strength (TS) no less than 1180 MPa; a total elongation (EL) no less than 14%; a hole expansion ratio (lambda) no less than 30%; and a yield ratio (YR) no greater than 70%, and having excellent moldability and shape fixability. Also provided is a method for manufacturing the high-strength hot-dip galvanized steel sheet. A high-strength hot-dip galvanized steel sheet having excellent moldability and shape fixability, characterized in having a component composition comprising, by mass, 0.10 to 0.35% of C, 0.5 to 3.0% of Si, 1.5 to 4.0% of Mn, 0.100% or less of P, 0.02% or less of S, and 0.010 to 0.5% of Al, with the remainder made up by Fe and unavoidable impurities; the microstructure containing, by area ratio, 0 to 5% of polygonal ferrite, 5% or more of bainitic ferrite, 5 to 20% of martensite, 30 to 60% of tempered martensite, and 5 to 20% of residual austenite; and the average particle diameter of prior austenite being no greater than 15 mum.

Owner:JFE STEEL CORP

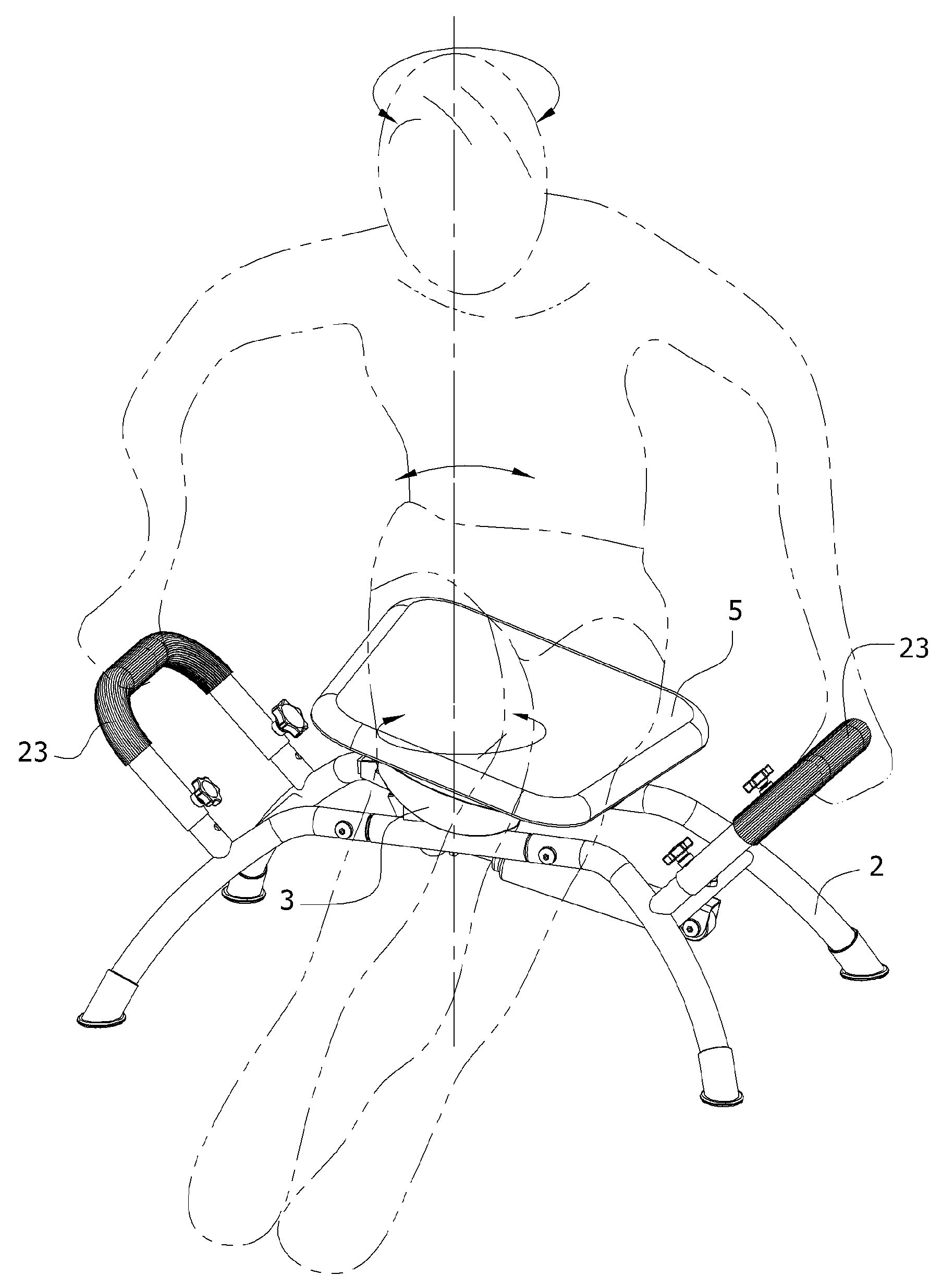

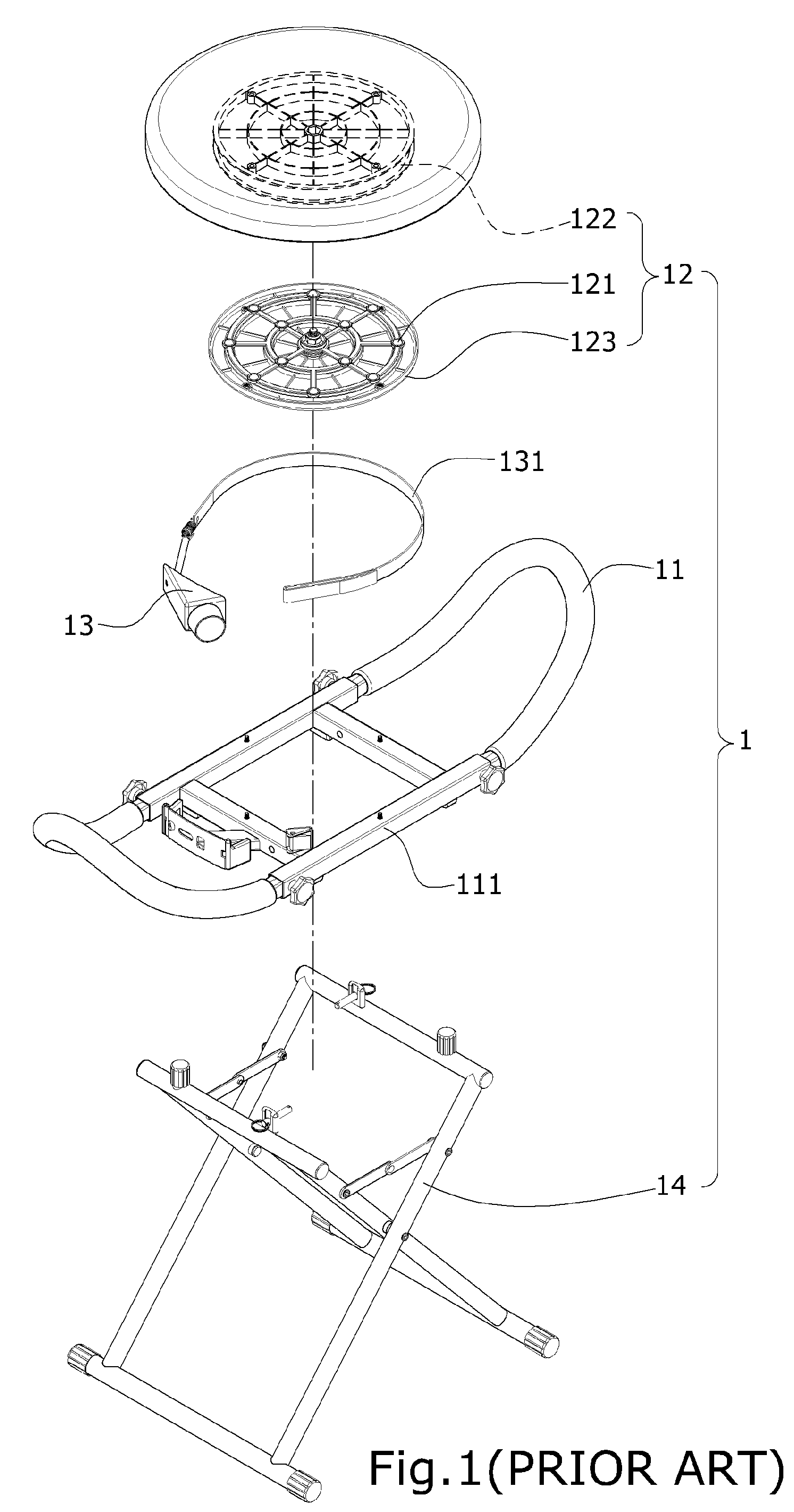

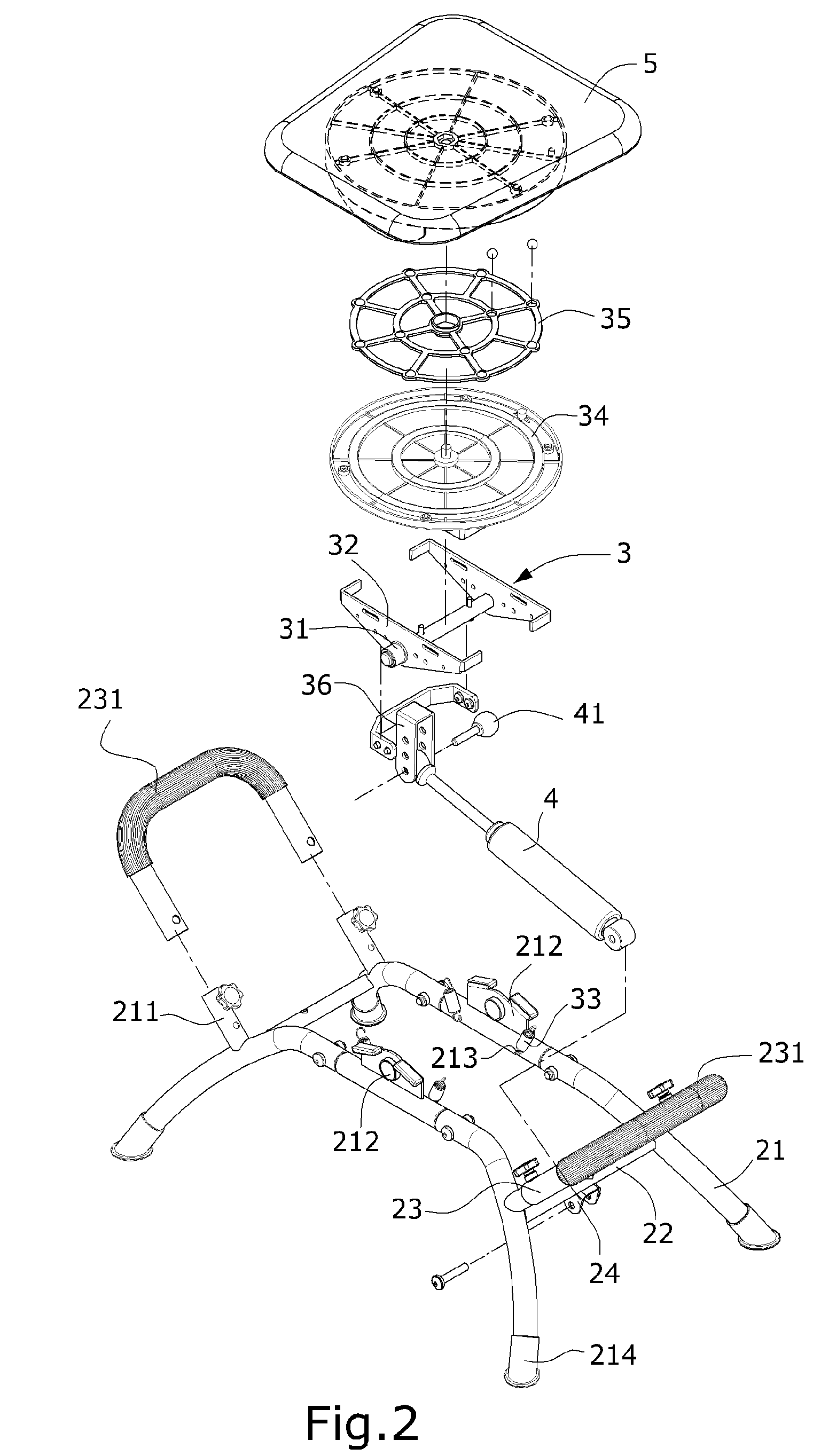

Swing rotary fitness apparatus

InactiveUS7625323B1Increase exerciseGood shaping effectResilient force resistorsSpace saving gamesEngineeringLumbar

A swing rotary fitness apparatus is described. A swing base is axially disposed at a center of a bracket having a pair of handles. A pound-force adjuster is disposed between the swing base and the bracket, and elastic elements for restoration are disposed between the swing base and the bracket. In addition, a rotatable seat is disposed on the swing base. When a user rides on the seat, the user exerts a force by lumbar muscles, so as to generate a circumferential motion of synchronous swing and rotation, which increases amplitude of twisting lumbar muscles greatly and thus improves an effect of exercising the waist.

Owner:XIAMEN KANG SOU FITNESS

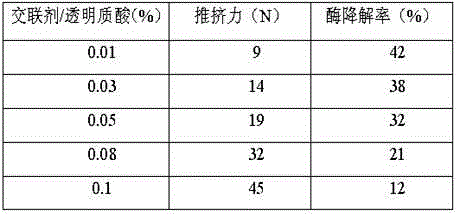

Modified sodium hyaluronate gel for injection

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

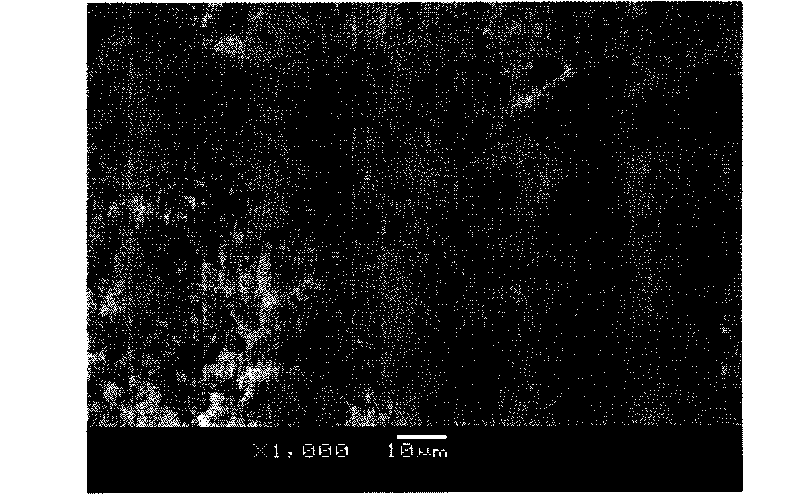

Three-dimensional gel network carrier and form-stable phase change composite material

InactiveCN101709104AReduce lossesNo lossHeat-exchange elementsPhase change enthalpyPolyethylene glycol

The invention relates to a three-dimensional gel network carrier and a form-stable phase change composite material which adopt fatty acid (hydrocarbon), polyethylene glycol and other organic phase change materials as work material and use poly-(N-hydroxymethyl)-acrylamide heat-shrinkable interpenetration network as form-stable carrier. The preparation method of the phase change composite material comprises the following steps: firstly adopting low temperature eutectic method to select multiple components composite phase change material with proper phase change temperature, high phase change enthalpy and low cost, designing and determining the preparation method of the interpenetration network carrier and the addition mode of the composite phase change material and the combination mode of the carrier, preparing the form-stable phase change composite material based on multiple actions of bonding, physical adsorption and network confinement, cooling and grinding to obtain the form-stable heat storage functional particles. The form-stable phase change composite material containing 50%-75% of material can be prepared by the method, the maximum phase change enthalpy can be up to 110J / g, and the form-stable phase change composite material prepared by the method can be directly applied in the textile field, building field, military field, etc.

Owner:DALIAN POLYTECHNIC UNIVERSITY

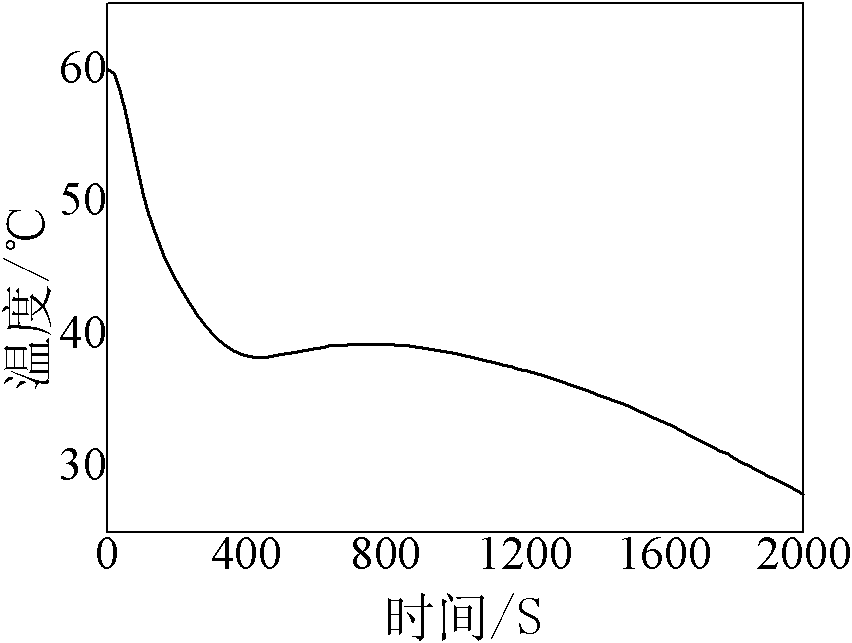

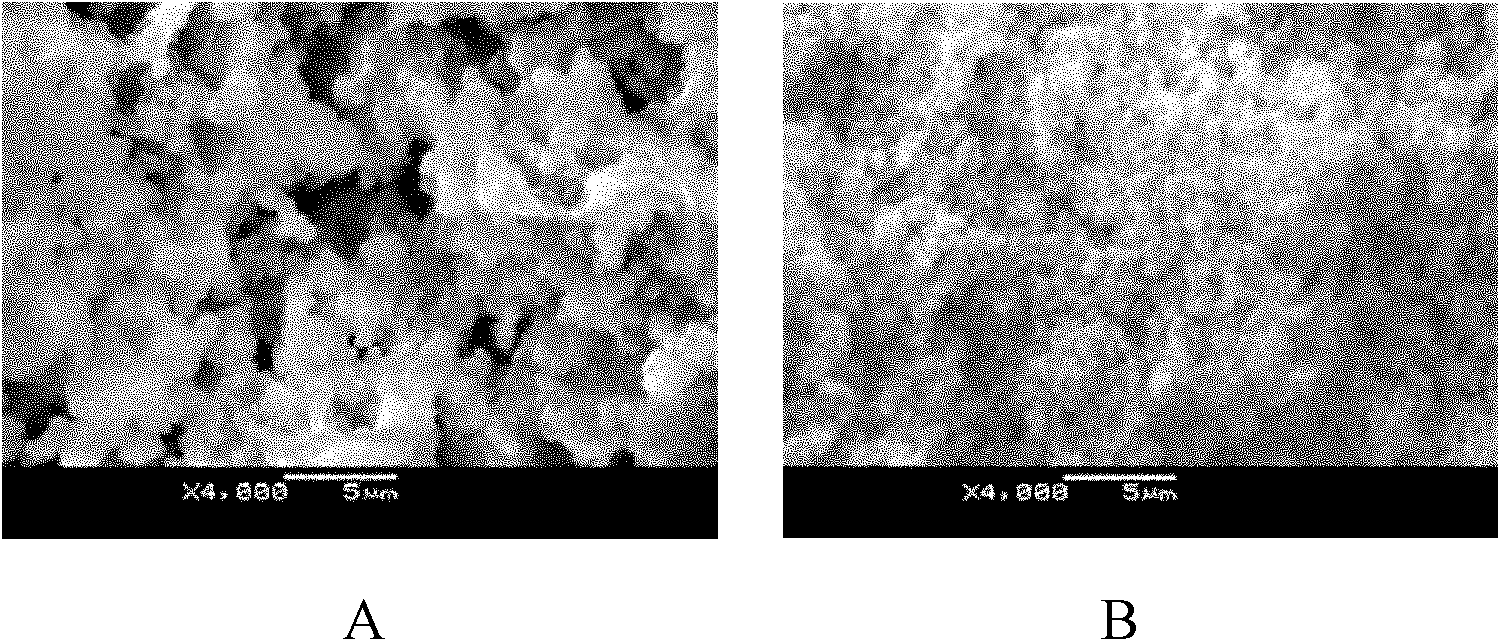

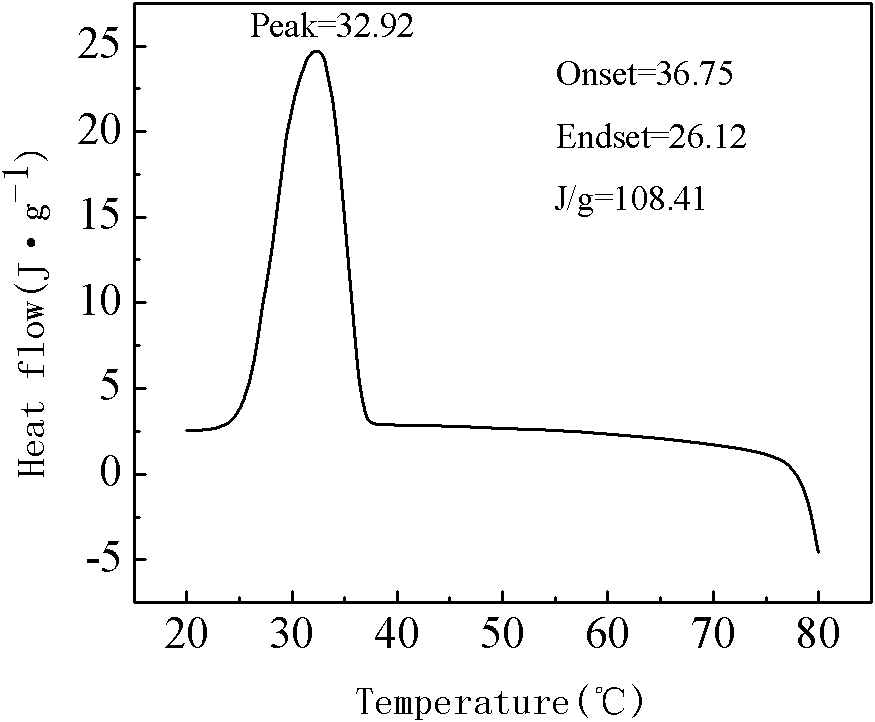

Preparation method of interpenetrating network formed phase-change material

InactiveCN102061148AGood shaping effectGood strengthHeat-exchange elementsConjugated synthetic polymer artificial filamentsTemperature resistanceMethylene bisacrylamide

The invention relates to a preparation method of an interpenetrating network formed phase-change material, comprising the following steps of: adding N-hydroxymethyl acrylamide as a network monomer, N, N-methylene-bisacrylamide as a cross linking agent, polyethylene glycol as a phase-change material and distilled water into a flask, ultrasonic-dispersing for 5 minutes after dissolving (the molar ratio of the cross linking agent to the network monomer is (1 / 7):(1 / 11), the mass ratio of the network monomer to the water is (1 / 6):(1 / 14), and the proportion of the polyethylene glycol accounts for 40-80 percent of the total mass); adding ammonium persulfate as an initiator and continuously ultrasonic-dispersing for 5 minutes, wherein the mass fraction of the initiator accounts for 1.5-3.5 percent of the network monomer; and reacting at a temperature of 70-80 DEG C for 3-4 hours to generate interpenetrating network hydrogel, and then drying to a constant weight to obtain the interpenetrating network formed phase-change material. The preparation method has a simple process and a low production cost and is friendly to environment. Moreover, the phase-change material has the advantages of high enthalpy (reaching over 108.41J / g), less loss, suitable phase-change temperature (32-42 DEG C) and good performance in high temperature resistance.

Owner:DALIAN POLYTECHNIC UNIVERSITY

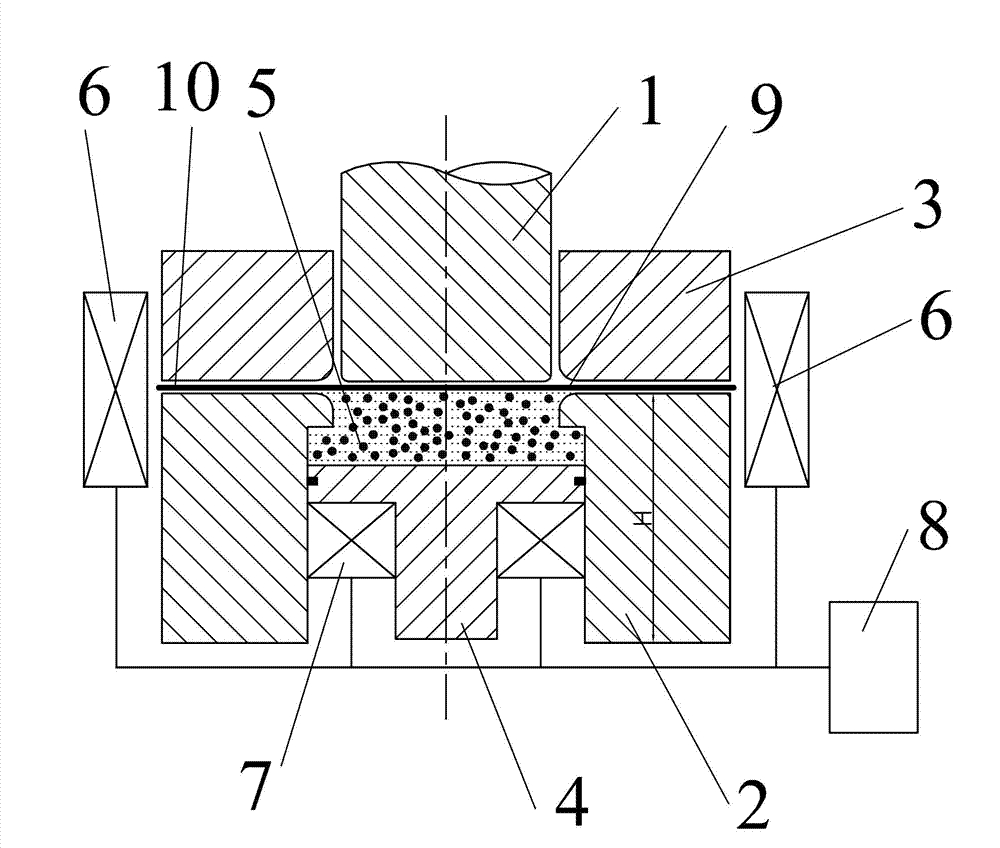

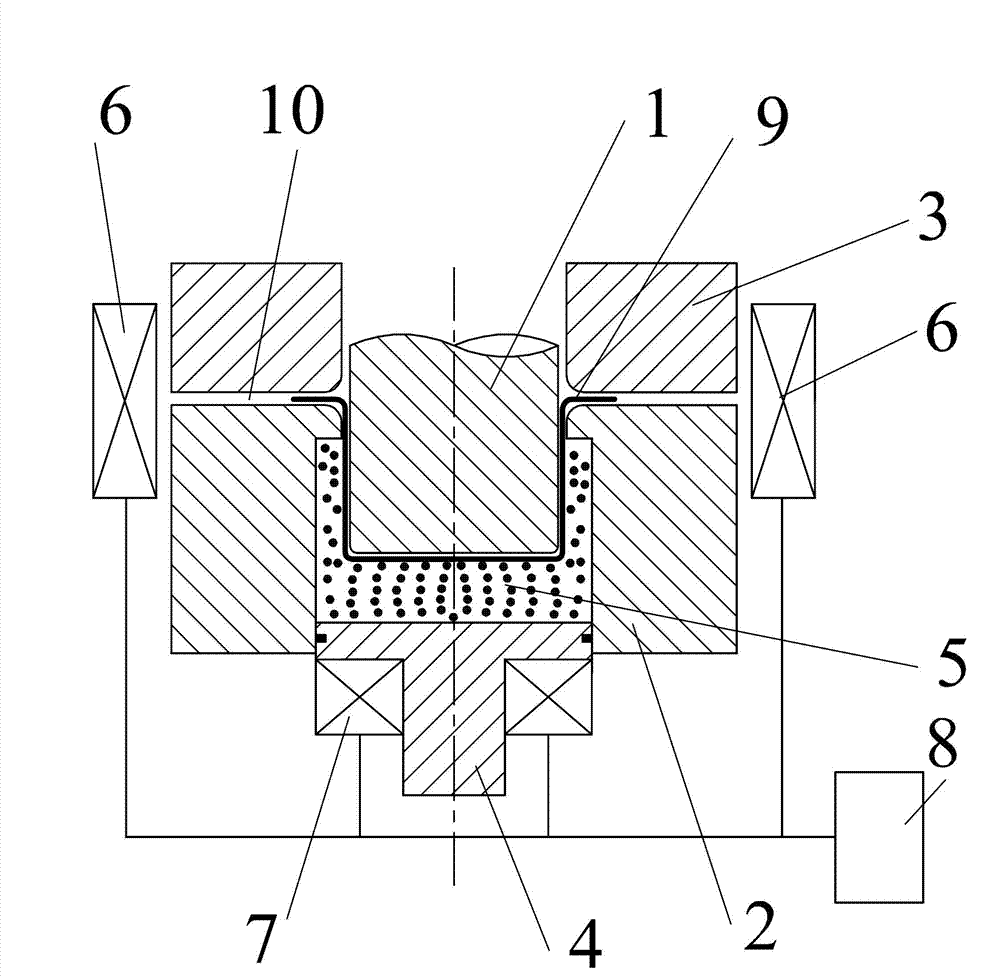

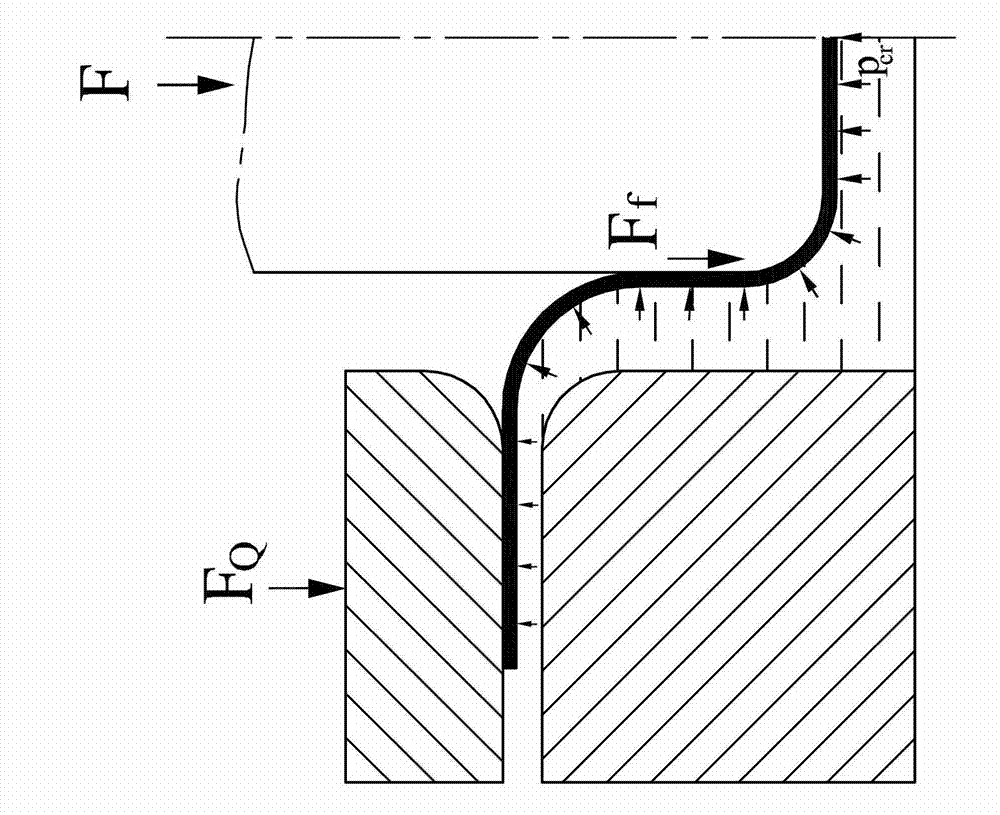

Sheet material hydro-mechanical deep drawing forming device and method using magnetic medium to pressurize

The invention provides a sheet material hydro-mechanical deep drawing forming device and a sheet material hydro-mechanical deep drawing forming method using a magnetic medium to pressurize, belongs to the technical field of hydro-mechanical deep drawing, and solves the technical problems in a traditional sheet material hydraulic forming process that wrinkles are formed, the deformation uniformity is poor and the like, caused by the reason that overflowing pressure of a flange region is reduced, when a sealing ring is not used in order to realize overflowing and lubrication. A sealed hydraulic chamber formed by a concave die and a lower plunger piston is used for containing the magnetic medium; a convex die can penetrate through an edge pressing ring to drive a plate blank to move downwards to enter the sealed hydraulic chamber formed by the concave die and the lower plunger piston; a first coil is arranged on the periphery of the outer side of the flange region formed by the concave die and the edge pressing ring; a second coil is arranged on a pull rod of the lower plunger piston; and a magnetic control unit is used for controlling the sizes of magnetic fields generated by the first coil and the second coil. Firstly, a certain amount of the magnetic medium is poured into the hydraulic chamber and the edge pressing ring is moved downwards after the plate blank is placed; the viscosity and the pressure value of the magnetic mediums on a flange and in the hydraulic chamber are respectively adjusted and controlled through the magnetic fields; and a punching head is moved downwards until a plate piece is formed. The sheet material hydro-mechanical deep drawing device and the sheet material hydro-mechanical deep drawing method using the magnetic medium to pressurize are suitable for hydro-mechanical deep drawing formation of a sheet material.

Owner:HARBIN UNIV OF SCI & TECH

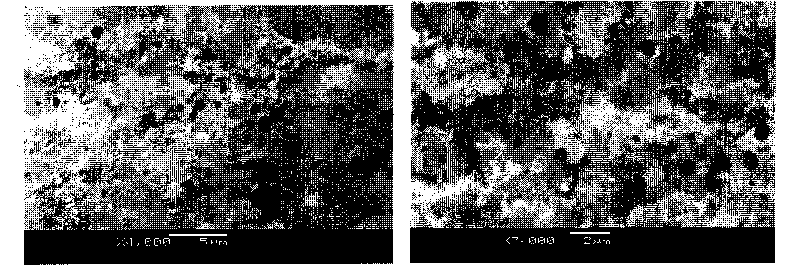

Preparation method of hydroxyapatite/sodium alginate nano composite material

The invention relates to a preparation method of a hydroxylapatite / sodium alginate nanometer composite material, which mixes calcium hydroxide and phosphoric acid water solution according to the chemical stoichiometric ratio of Ca / P in the hydroxylapatite and carries out the in-situ composite reaction with sodium alginate water gel, and a three dimensional net shaped structure similar to a natural bone is formed by adding calcium chloride to realize the intercrossing reaction with the sodium alginate. The method has the advantages that: the hydroxylapatite / sodium alginate nanometer composite material maintains the good biological compatibility, biological activity and bone conductibility of HA; the combination of the sodium alginate as an organic substrate with the HA can bestow the HA good processing and forming property, thus effectively inhabiting the moving of HA particles from the transplanting parts; and the sodium alginate has rich source and low price, and the preparation process can be operated at normal temperature and pressure, and has simple operation and low cost, and is an ideal bone repairing substitute materials of the new generation.

Owner:CHINA NAT ACAD NANOTECH & ENG

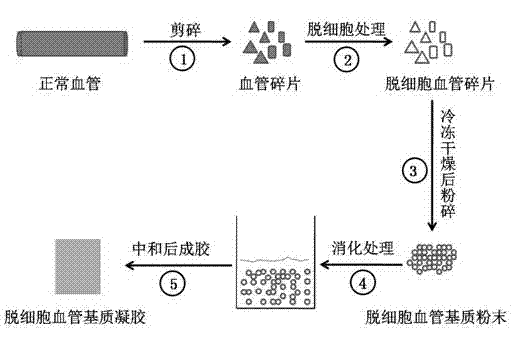

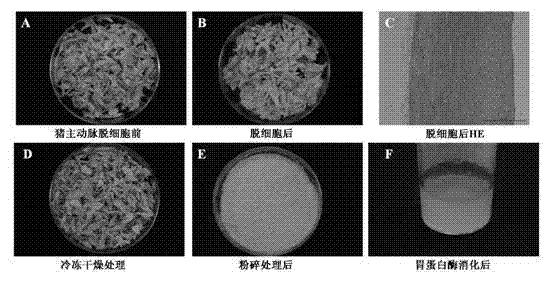

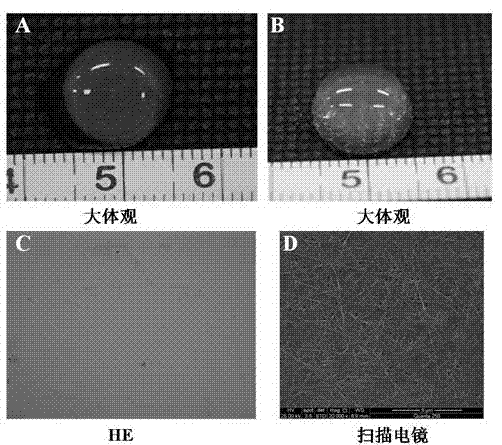

Decellularized blood vessel matrix gel, preparation method therefor and applications thereof

InactiveCN103705542AGood shaping effectGuaranteed uniformityAerosol deliveryOintment deliveryDigestionBlood vessel

The invention relates to a kind of decellularized blood vessel matrix gel, a preparation method therefor and applications thereof. The preparation method is as follows: first, after blood vessel outer membranes and anadesma are removed, the blood vessels are cut into blood vessel pieces, the blood vessel pieces are subjected to decellularized treatment in a TritonX-100 solution, then subjected to freeze drying, smashed into powder, and filtered with a 60-mesh screen, and decellularized blood vessel matrix powder is obtained; second, the decellularized blood vessel matrix powder is placed in a hydrochloric acid solution containing pepsin with a concentration of 0.09-0.11%, and subjected to digestion for 66-78h, a sodium hydroxide solution is added to neutralize hydrochloric acid, then PBS is added to balance ion concentration, finally, the gel solution is placed in an incubator with a temperature of 37 DEG C for gel forming. The decellularized blood vessel matrix gel has good molding capability and mechanical properties, the interior is loose, the gel has certain poriness, and the collagen fiber has appropriate diameters and good stability. The gel can meet requirements of preparation of medicines treating ischemic diseases, support materials of tissue engineering and / or cell culture.

Owner:SHANGHAI CHILDRENS MEDICAL CENT AFFILIATED TO SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

Method for controlling finishing elongation rate of strip steel by utilizing second flow

ActiveCN102407240AHigh yieldStable productionElongation control deviceHuman–machine interfaceLoop control

The invention provides a method for controlling a finishing elongation rate of strip steel by utilizing second flow, comprising the following steps of: respectively measuring an actual speed value and an actual tension value by using an encoder and a tension meter for measuring the speeds of an inlet and an outlet of a finishing machine; additionally arranging a second flow closed loop control system module in a programmable controller of the finishing machine, i.e., a PLC (Programmable Logic Controller); additionally arranging a second flow function option button in a human-computer interface; adopting a speed control mode for a main motor as well as a front tension roller and a back tension roller of the finishing machine; introducing an outlet tension deviation matching coefficient to a rolling force controller; and carrying out gain processing on a system function according to an input time interval. By using the method, the set value of the rolling force as well as parameters such as speed, tension and the like before and after finishing are not needed to be changed according to the material of the strip steel, the speed and the tension before and after the finishing are in astable state, the elongation rate is controlled more precisely, the steel plate pattern and the elongation rate index before and after the specification changes are effectively improved, a favorable surface quality of a product is obtained, and the yield of the strip steel is increased.

Owner:ANGANG STEEL CO LTD

Organic/inorganic hybrid phase-change energy-storage material with enhanced thermal conductivity and preparation method thereof

ActiveCN101948674AGood shaping effectHigh energy storage densityChemical industryHeat-exchange elementsHigh energyInorganic compound

The invention provides an organic / inorganic hybrid phase-change energy-storage material with enhanced thermal conductivity and a preparation method thereof, belonging to the energy storage technical field. The preparation method comprises the following steps: taking an inorganic compound with enhanced thermal conductivity connected by chemical bonds as a supporting material, and taking an organicphase-change energy-storage material as a working substance; hydrolyzing and condensing with an inorganic compound-sol precursor; and compounding and hybridizing with the organic phase-change material to obtain the organic / inorganic hybrid phase-change energy-storage material. The organic / inorganic hybrid phase-change energy-storage material has the advantages of good shaping property, high energy storage density and wide application prospect, thus being applicable to the fields such as energy-saving building materials, solar energy storage and utilization, industrial waste heat recovery and the like.

Owner:DALIAN UNIV OF TECH

Grinding unit for high speed train and preparation method of grinding unit

ActiveCN108839640AReduce wearReduce friction noiseMetal-working apparatusVehicle cleaningHot pressHigh speed train

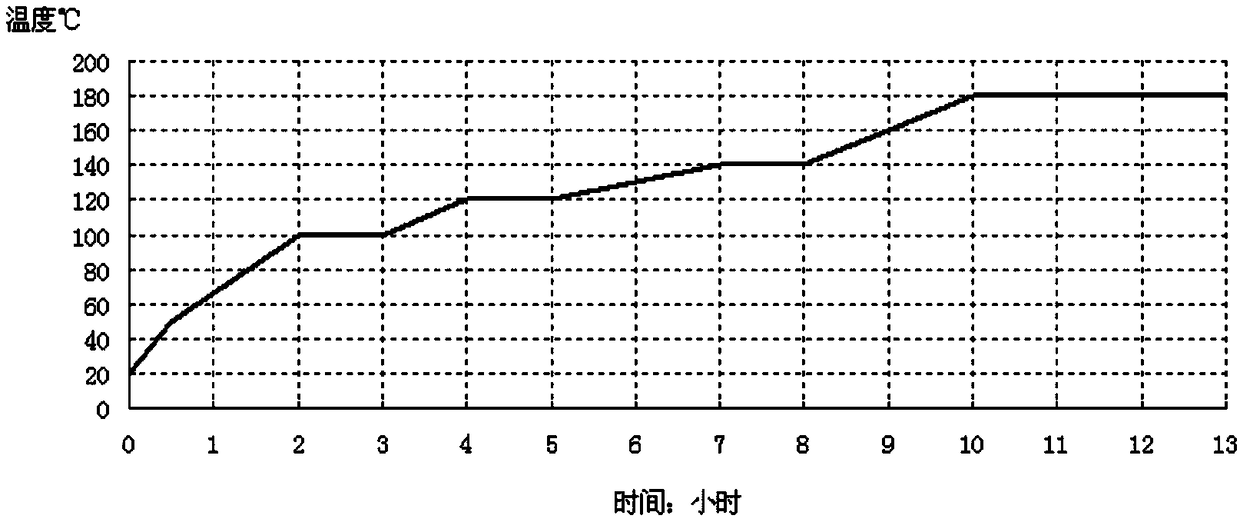

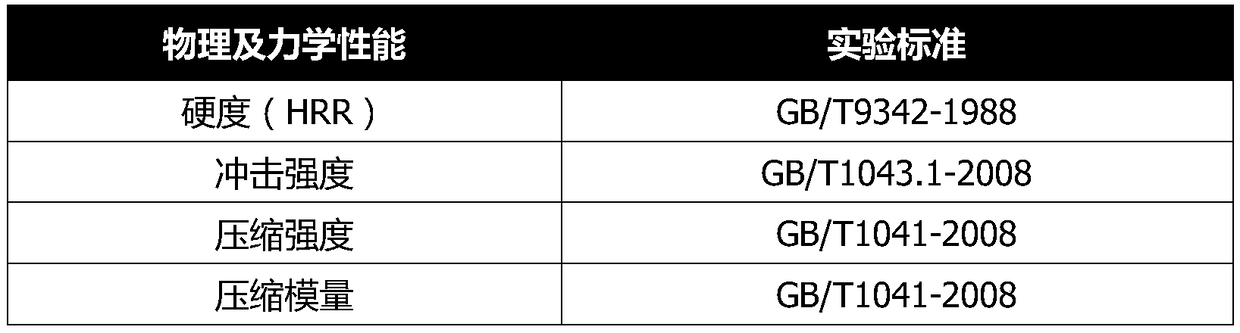

The invention provides a grinding unit for a high speed train and a preparation method of the grinding unit. The grinding unit is composed of a friction material and a steel backing, wherein the friction material is composed of phenolic resins having specific physical properties, reinforced fibers, fillers and the like; the components of the friction material need to be pretreated such as mixing and drying; the steel backing needs to be pretreated such as abrasive blasting and resin glue spraying; the pretreated friction material and steel backing are subjected to special hot press molding, heat treatment and other processes, thereby obtaining the grinding unit. According to the grinding unit disclosed by the invention, by improving the thermal stability and enhancing the shock strength, the performance of the grinding unit in aspects such as metal inlaying, crack chipping, wheel shaping, friction noise and the like are improved, damage to the wheel tread is small, the phenomena such as hot cracks and severe wave furrowed abrasion are difficultly caused, and the grinding unit has important application value and wide market prospects in the field of high-speed trains.

Owner:中申(上海)管道工程股份有限公司

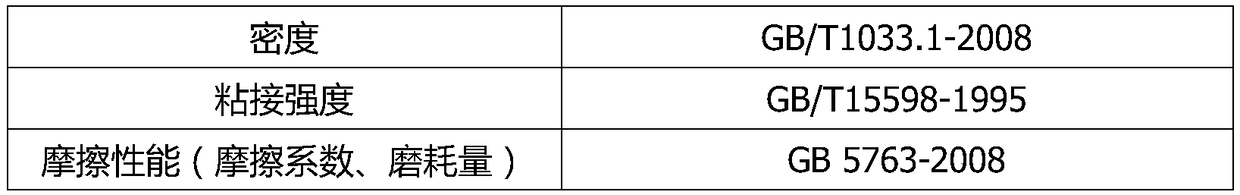

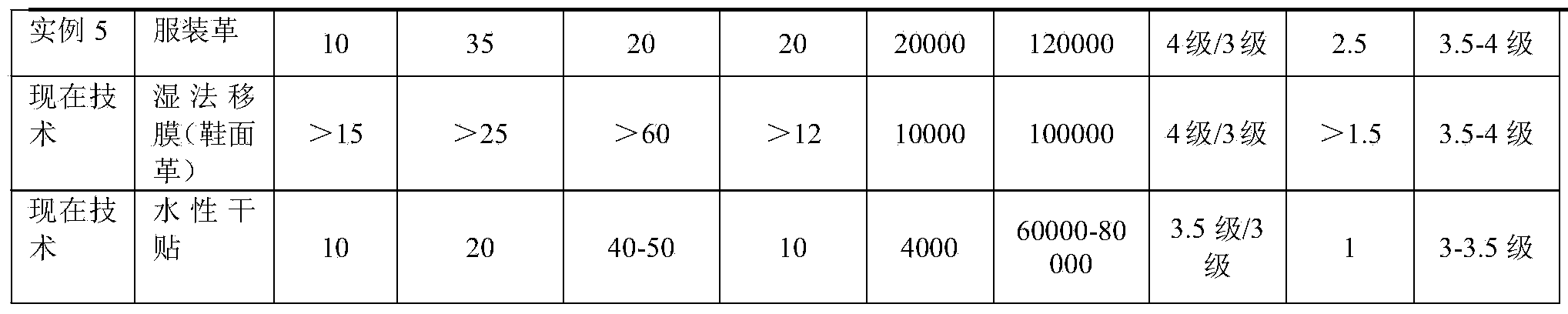

Leather coating composition and preparation method thereof

ActiveCN103709873AEasy to operateLess equipmentAntifouling/underwater paintsFibre treatmentWaxResist

The invention belongs to the field of leather coating, and particularly discloses a leather coating composition and a preparation method thereof. The leather coating composition comprises acrylic resin, wood cellulose, silica, a feeling agent, wax, a foaming agent, an antioxidant, a curing agent, a neutralization agent, a dispersant, a wetting agent, a leveling agent, a defoaming agent, a sterilizing agent, essences, hydroxyethyl cellulose and water. The preparation method comprises the following steps: adding the components in three steps under a stirring condition, uniformly mixing the components, filtering and packaging. The leather coating composition prepared by the method disclosed by the invention is a waterborne environmentally friendly material, has good physical properties such as excellent adhesive force, fillibility, settability, covering power, air bubble forming, winding resistance and scraping resistance. The leather coating composition has high combination degree with leather fibers, and after leather is ironed and pressed by a plate, a surface formed by the coating is smooth, does not become thick, resists winding and has good settability, good breathability and good handfeel; and the leather coating composition can be directly used for coating good two-layer leather blank and bad head layer leather blank.

Owner:高峰

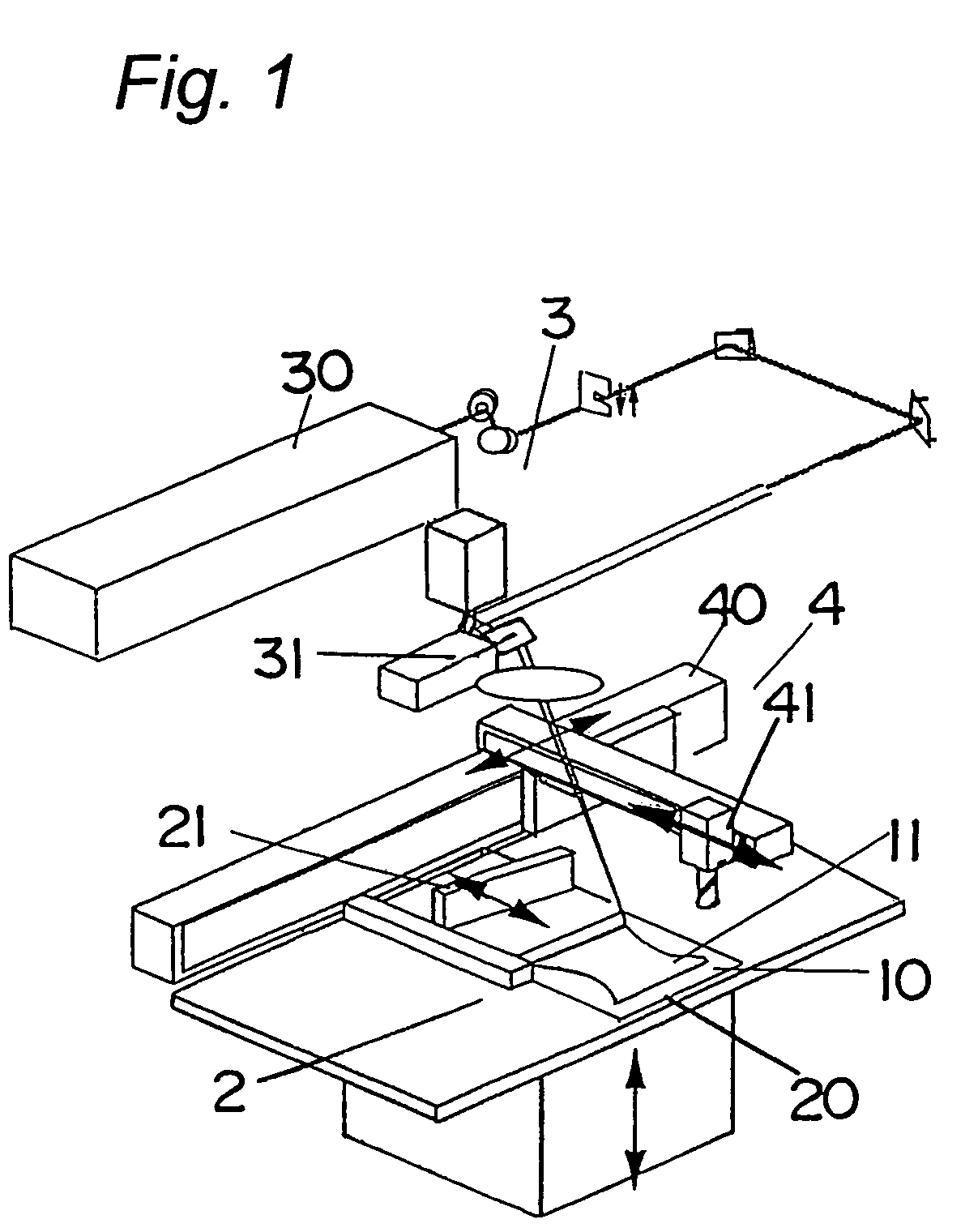

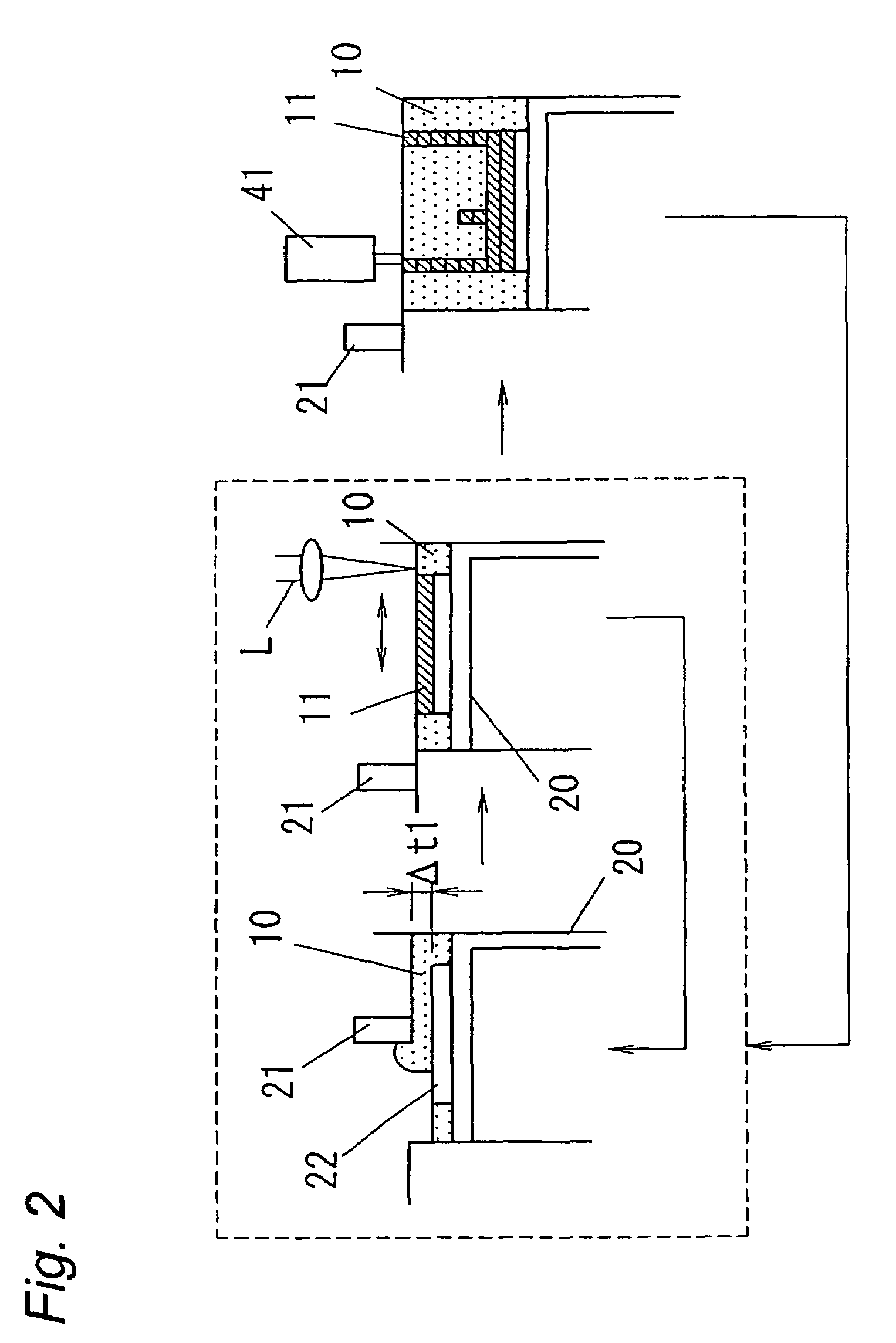

Metal powder composition for use in selective laser sintering

InactiveUS7258720B2Significant heatingEasy to separateAdditive manufacturing apparatusTransportation and packagingSelective laser sinteringGraphite

A three-dimensional object of a desired shape is made by irradiating an optical beam on a metal powder layer to form a sintered layer and by laminating such sintered layer one above another. A metal powder composition for use in making such a three-dimensional object includes an iron-based powder material, a nickel and / or nickel alloy powder material, a copper and / or copper alloy powder material, and a graphite powder material. The graphite powder material acts to enhance the wettability during melting and to reduce microcracks during solidification.

Owner:MATSUSHITA ELECTRIC WORKS LTD

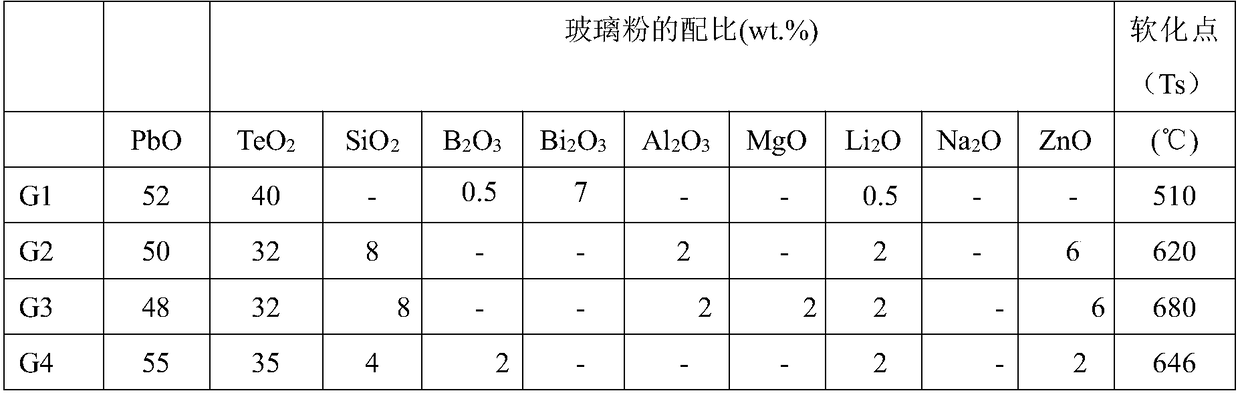

Crystalline silicon solar cell front silver paste and preparation method thereof

InactiveCN108766618AGood ink permeabilityEasy to fillNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a crystalline silicon solar cell front silver paste and a preparation method thereof. The front silver paste comprises the following components in percentage by weight: 85-90%of silver powder, 5-10% of an organic carrier, 5-10% of an organic carrier, 1.5-5% of composite glass powder, and 0.05-1% of a silver paste additive. The silver powder in different particle size distribution is cooperatively used, the slurry is good in ink permeability, and the silver powder particles in the grid line are more uniformly and tightly filled, so that the sintering density of the gridline is facilitated, the resistance of the grid lines is reduced, and the photoelectric conversion efficiency is improved. The preparation process of the glass powder is simple, the control is facilitated; the glass powder with different components is compounded and used, so that a series of particles are uniform, the softening temperature is low, and the composite glass powder has good wettability to the silver powder and the silicon substrate, a front silver paste prepared from the composite glass powder is sintered on the front surface of the cell, the silver electrode and the silicon havegood ohmic contact and welding performance, and the adhesion strength of the electrode is high.

Owner:湖南省国银新材料有限公司

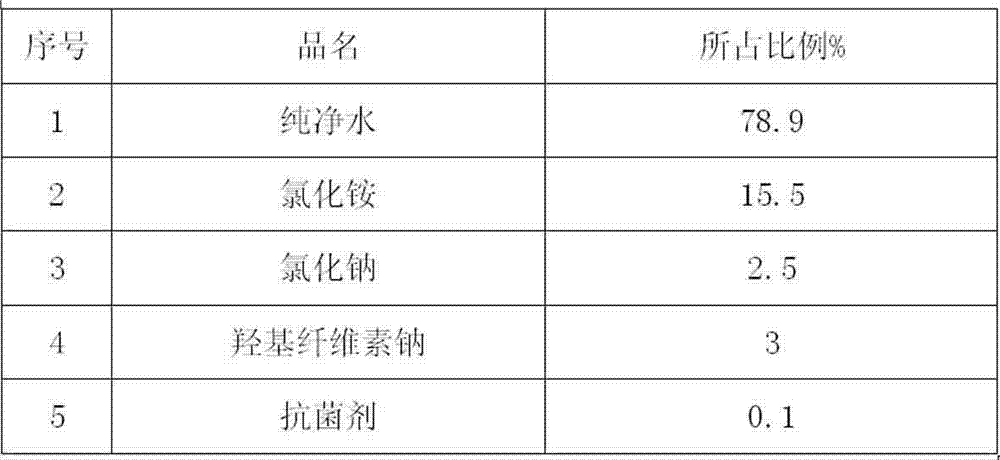

Production process of low temperature phase change cold accumulation ice box or ice bag

InactiveCN103486793AImprove cooling effectWide range of usesDomestic cooling apparatusLighting and heating apparatusCelluloseAntibacterial agent

The invention discloses a production process of a low temperature phase change cold accumulation ice box or ice bag in the field of phase change material cold accumulation containers. The production process is implemented according to six steps including box or bag manufacturing, edge cutting or trimming, internal material stirring, filling, sealing and encasement. Purified water, ammonium chloride, sodium chloride, sodium carboxymethyl cellulose and antibacterial agents are slowly added into a reaction kettle in sequence; then, internal materials are stirred sufficiently, wherein the accurate ratio of the internal materials is 78.9 to 15.5 to 2.5 to 3 to 0.1; the stirred internal materials are poured in the ice box or ice bag, sealed and encased. The production process has the advantages of being good in cold accumulation effect, wide in usage, good in shaping performance (smoothness), suitable for low temperature refrigeration and freshness preservation, environmentally friendly and safe, lowering use cost, saving energy and power, shortening cold accumulation time, reducing cold accumulation space and the like.

Owner:崔德顺

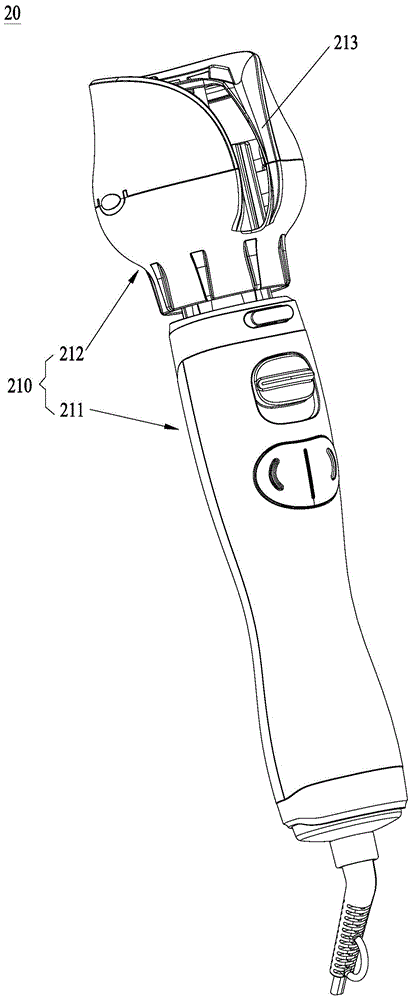

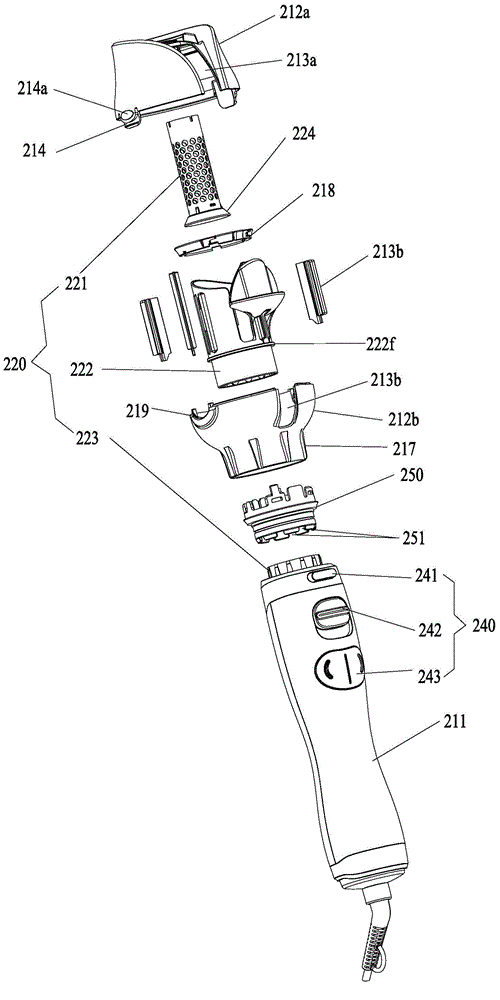

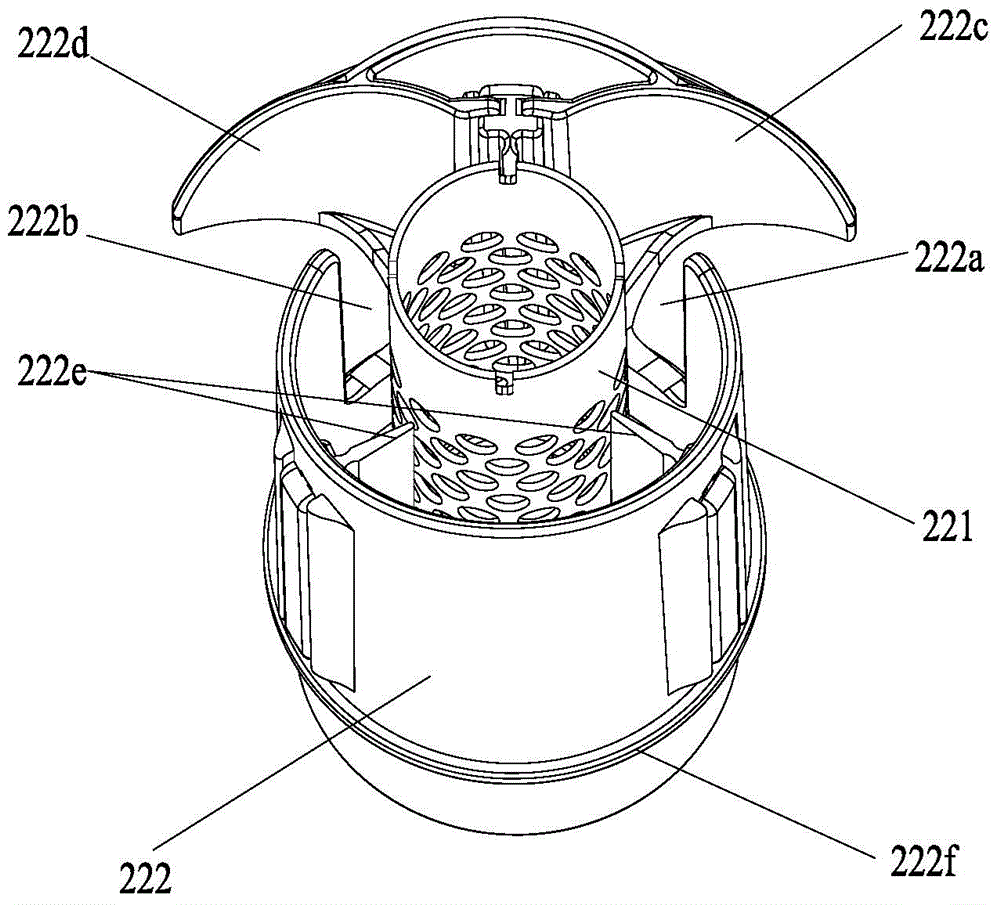

Hair curling device

The invention discloses a hair curling device which comprises a shell, a hair curling assembly, an air supply assembly and a control assembly. The hair curling assembly comprises a long narrow net barrel fixed into a top shell, a rotary barrel and a drive assembly connected with the rotary barrel, wherein the long narrow net barrel is sleeved with the rotary barrel. The drive assembly is used for driving the rotary barrel to rotate around the long narrow net barrel, so that hair entering from a hair inlet is wound around the long narrow net barrel. At least one high-temperature-resistant elastic pressing piece is arranged on the rotary barrel, the elastic pressing pieces are longitudinally arranged along the inner wall of the rotary barrel, extend in the direction close to the long narrow net barrel and are used for exerting pressure to the hair wound around the long narrow net barrel. By the adoption of the hair curling device, the hair wound around the rotary barrel is tightly attached to the long narrow net barrel through pressure of the elastic pressing pieces, the hair can well accords with the radian of the long narrow net barrel, the shaping effect is better, and the curling degree is higher.

Owner:SUN LUEN ELECTRICAL MFG

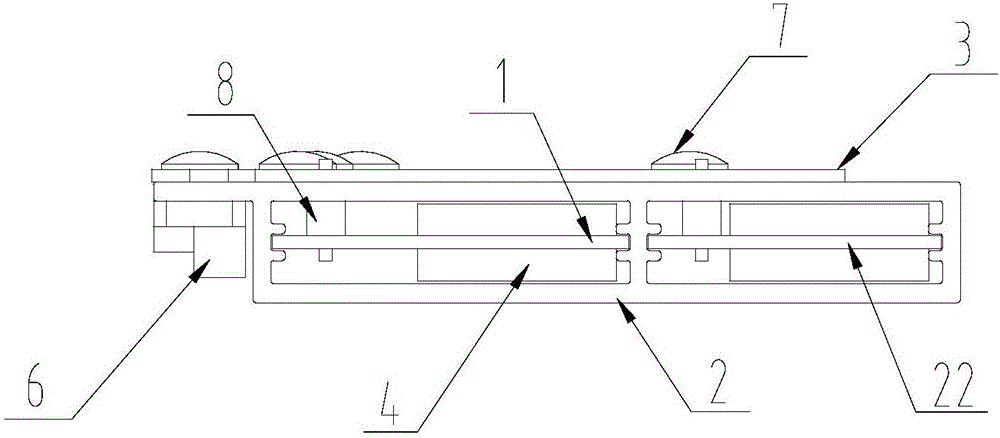

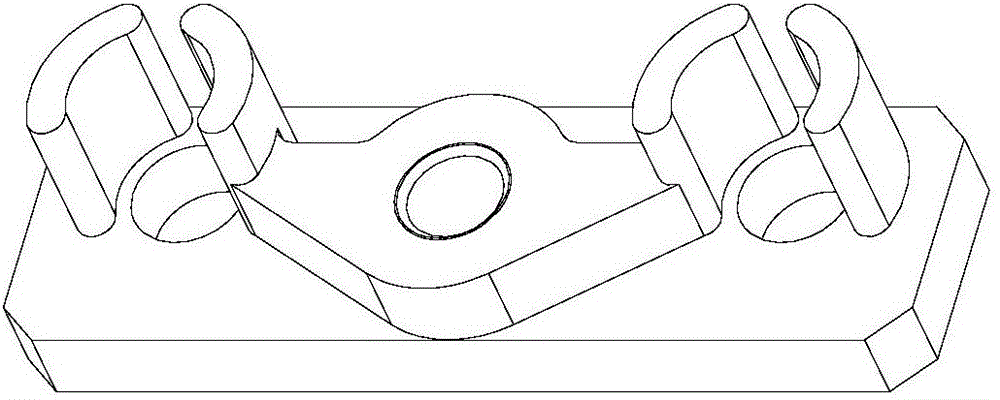

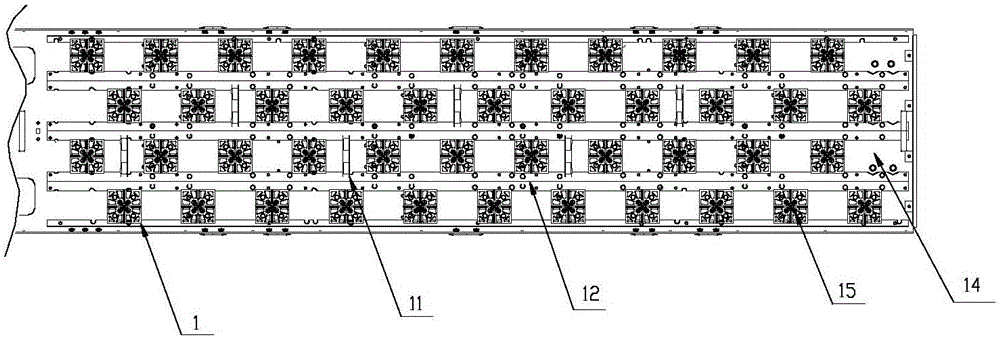

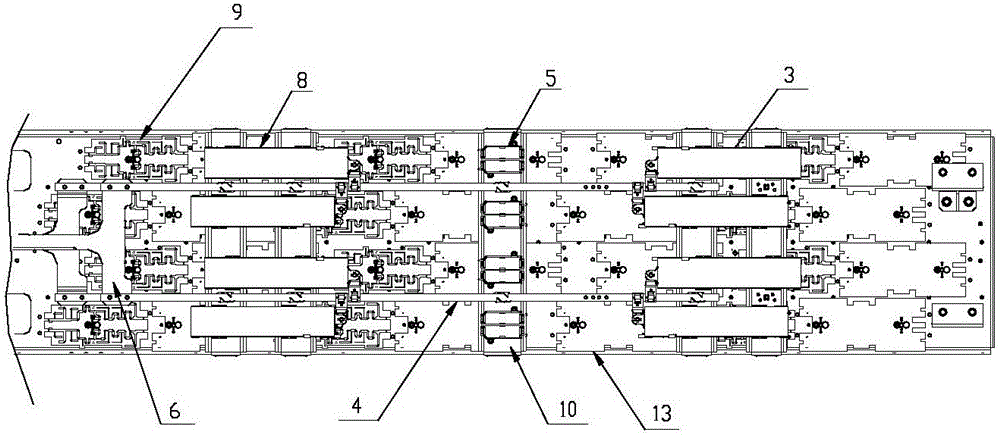

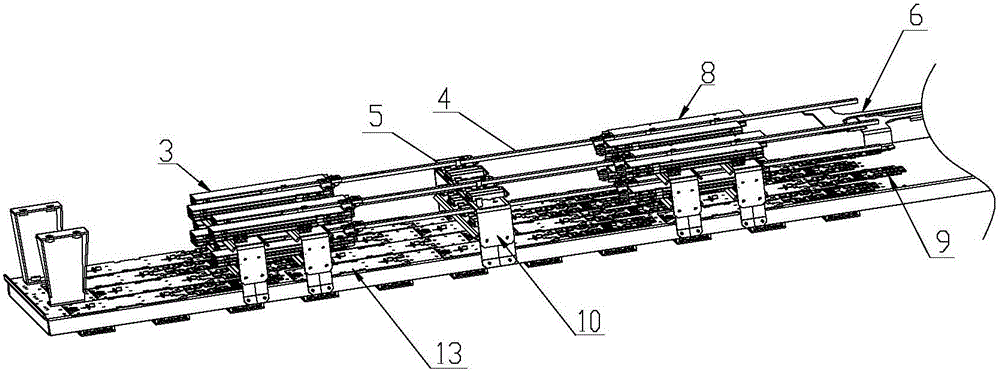

Dual-system phase shift combining module and separate electronic tilting antenna

InactiveCN106654494ASimple designGood shaping effectCoupling devicesAntennasPhase shiftedEngineering

A dual-system phase shift combining module and a separate electronic tilting antenna are disclosed. The dual-system phase shift combining module comprises a system 1 phase shifter, a system 2 phase shifter, combiner PCBs, and a main feeder PCB. The system 1 phase shifter and the system 2 phase shifter work in two separate bands respectively. The system 1 phase shifter and the system 2 phase shifter share a profile cavity. The combiner PCBs and the main feeder PCB are in the same plane. The combiner PCBs are fixed on the surface of the profile cavity, the input ends are connected with the system 1 phase shifter and the system 2 phase shifter through shorting stubs, and the output ends are connected with an output port coaxial cable. The main feeder PCB is fixed on the surface of the profile cavity, the output end is connected with the system 1 phase shifter and the system 2 phase shifter through shorting stubs, and the input end is connected with a main feeder input coaxial cable. The phase shift combining module has the advantages of low cost, convenient assembly, low weight, excellent indicators and low profile, and can realize multi-path phase shift flexibly.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

Carbon fiber sheet and method for producing the same

InactiveUS20030027471A1High bulk densityAppropriate flexibilityMaterial nanotechnologyWood working apparatusCarbon fibersPolymer science

The present invention discloses a process for producing a carbon fiber sheet, which comprises allowing, as necessary, an oxidized polyacrylonitrile fiber sheet to contain 0.2 to 5% by mass of a resin, then subjecting the resin-containing oxidized polyacrylonitrile fiber sheet to a compression treatment in the thickness direction under the conditions of 150 to 300° C. and 5 to 100 MPa (10 to 100 MPa when no resin treatment is made) to obtain a compressed, oxidized fiber sheet having a bulk density of 0.40 to 0.80 g / cm3 and a compression ratio of 40 to 75%, and thereafter subjecting the compressed, oxidized fiber sheet to a carbonizing treatment. The carbon fiber sheet has a thickness of 0.15 to 1.0 mm, a bulk density of 0.15 to 0.45 g / cm3, a carbon fiber content of 95% by mass or more, a compression deformation ratio of 10 to 35%, an electric resistance of 6 mOMEGA or less and a feeling of 5 to 70 g. Having a small electric resistance in the thickness direction, the carbon fiber sheet is suitable as an earth material and a conductive material such as battery electrode material or the like.

Owner:TOHO TAYON CO LTD

Light-emitting shoe material and preparation method thereof

The invention discloses a light-emitting shoe material and a preparation method thereof. The light-emitting shoe material comprises styrene type thermoplastic elastomer, 1,2-polybutadiene, styrene-butadiene copolymer (K adhesive), white mineral oil, a photo-thermal stabilizer, a lubricant and nano silicon dioxide. The preparation method comprises the following steps: premixing the components in a high-speed mixer, carrying out melt extrusion on the premixture at 120-130 through a double screw extruder, cooling, granulating, and finally, carrying out injection molding at 137-145 DEG C to obtain the light-emitting shoe material. The light-emitting shoe material has the characteristics of uniform light scattering, uniform brightness, soft light rays, favorable toughness, high anti-skid property, stable dimension and the like.

Owner:MAOTAI FUJIAN SOLES CO LTD

Continuous hot melting dyeing technology for polyester fiber fabric

InactiveCN103668829AReduce consumptionLow baking temperatureSucessive textile treatmentsDyeing processDisperse dyeHot melt

The invention aims at providing a continuous hot melting dyeing technology for a polyester fiber fabric. The traditional pad dyeing technology of carrying out rolling, drying and baking in sequence on the polyester fiber fabric is changed into the technology of carrying out steaming, rolling, drying and baking in sequence. Before padding, a polyester fiber is steamed through negative pressure saturation steam so that the expansion degree of the polyester fiber can be improved, the dyeing speed, the dye utilization ratio and the level dyeing degree of dyes can be improved, and the effects of shaping the polyester fiber and improving the quality of the fiber can be achieved. In the padding process, the dyeing speed and the dyeing uptake of disperse dyes are further improved by utilizing the function of a dyeing assistant, and the liquid rate and the level dyeing effect of two-immersing and two-rolling technology can be achieved by adopting the one-immersing and one-rolling technology. After pre-drying is carried out through high-frequency infrared rays, the temperature of the baking and drying is reduced to 180 DEG C to 190 DEG C from 210 DEG C to 220 DEG C by adopting the low-temperature dyeing technology. By means of the technology, dyeing and printing enterprises can greatly reduce energy consumption, and meanwhile, high quality dyed fabrics with the superior performance can be obtained.

Owner:YANCHENG INST OF IND TECH

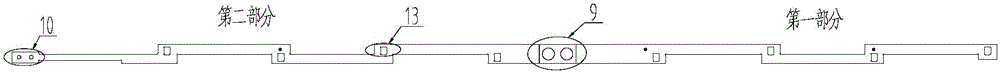

Dual system independent downward inclination angle adjustment base station electrically-controlled antenna

ActiveCN105762535ASimplify the assembly processSave layout spaceAntenna supports/mountingsAntennas earthing switches associationElectricityVertical plane

The invention discloses a dual system independent downward inclination angle adjustment base station electrically-controlled antenna, and the antenna comprises a front radiating element and a back feed network. The feed network comprises a single combiner, a power dividing combiner and an independent phase shift part, the independent phase shift part comprises two layers, and the two layers can respectively and independently adjust an electrical downward inclination angle of one system, so that a dual system independent downward inclination angle adjustment function is realized. Each system adopts an independent feed cable network to form a vertical plane directional diagram, so that forming effect of each system can be effectively improved. Upper and lower phase shift modules comprised by the independent phase shift part and a middle power divider can commonly realize a six-way phase shift function, a good vertical plane forming effect can be acquired, feeder connection can be effectively dispersed, so that the assemblability and the index consistency can be greatly improved. The dual system sharing radiating element, independent forming and independent adjusting downward inclination angle base station electrically-controlled antenna scheme saves antenna resources and can effectively improve covering effect of each system.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

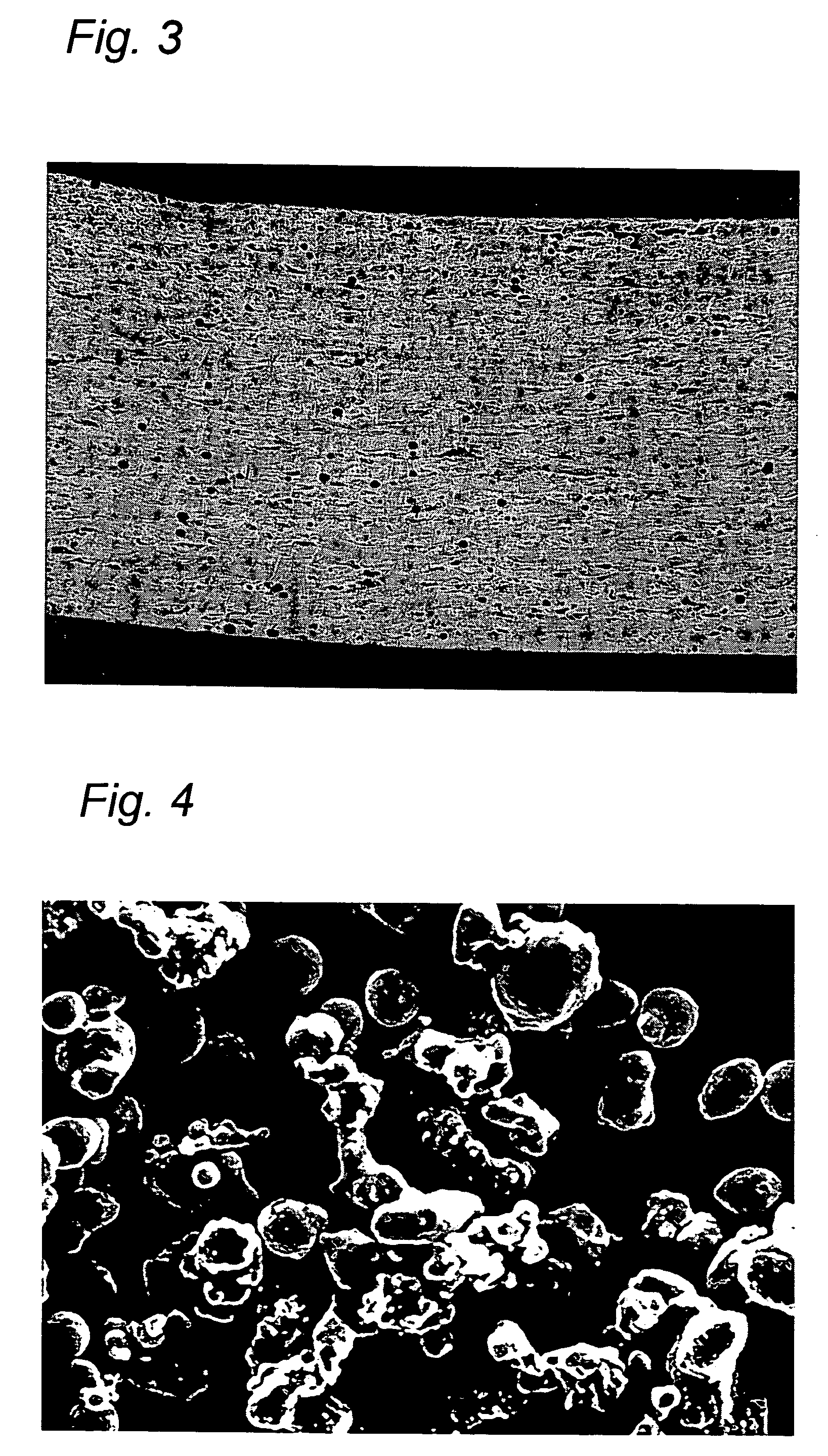

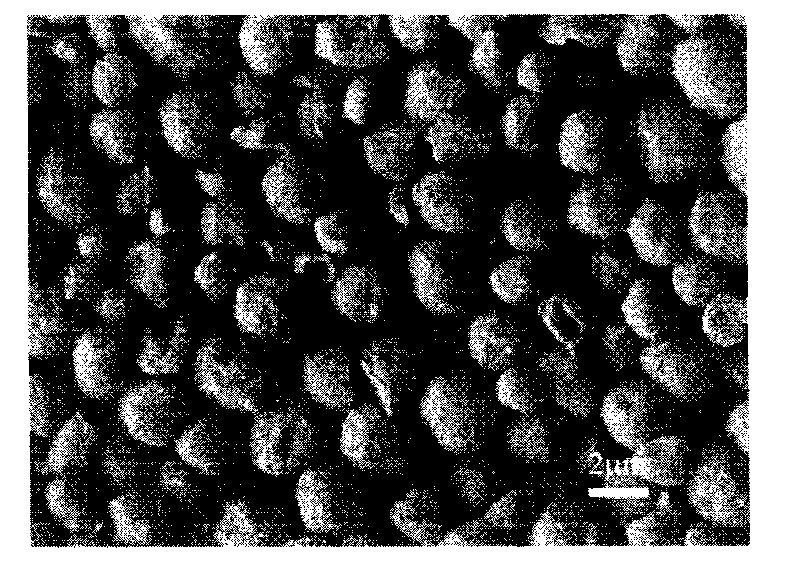

Process for preparing polymer ultra-fine particles by applying supercritical fluid

InactiveCN101693768AHigh crystallinityCrystal stableBulk chemical productionPolymer scienceUltra fine

The invention relates to a process for preparing polymer ultra-fine particles, in particular to a process for preparing polymer ultra-fine particles by applying supercritical fluid, which utilizes the supercritical fluid to process one type of polymer or a mixture of various types of polymers to prepare polymer ultra-fine particles or polymer microcapsule ultra-fine particles. As dissolubility to polymer is increased in a supercritical fluid state, polymer can be precipitated from the supercritical fluid after the supercritical fluid state is eliminated, and then polymer ultra-fine particles or polymer microcapsule ultra-fine particles with high degree of crystallinity and fine shape can be prepared after thermostatic treatment. Besides, the prepared ultra-fine particles are narrow in distribution, and shapes thereof can be controlled into regular spheres. The process is simple in technique and easy in operation without complex devices, the prepared ultra-fine particles are regular in shapes, stable in crystalline form, higher in crystallinity and higher in application value and are adoptable to industrialized production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

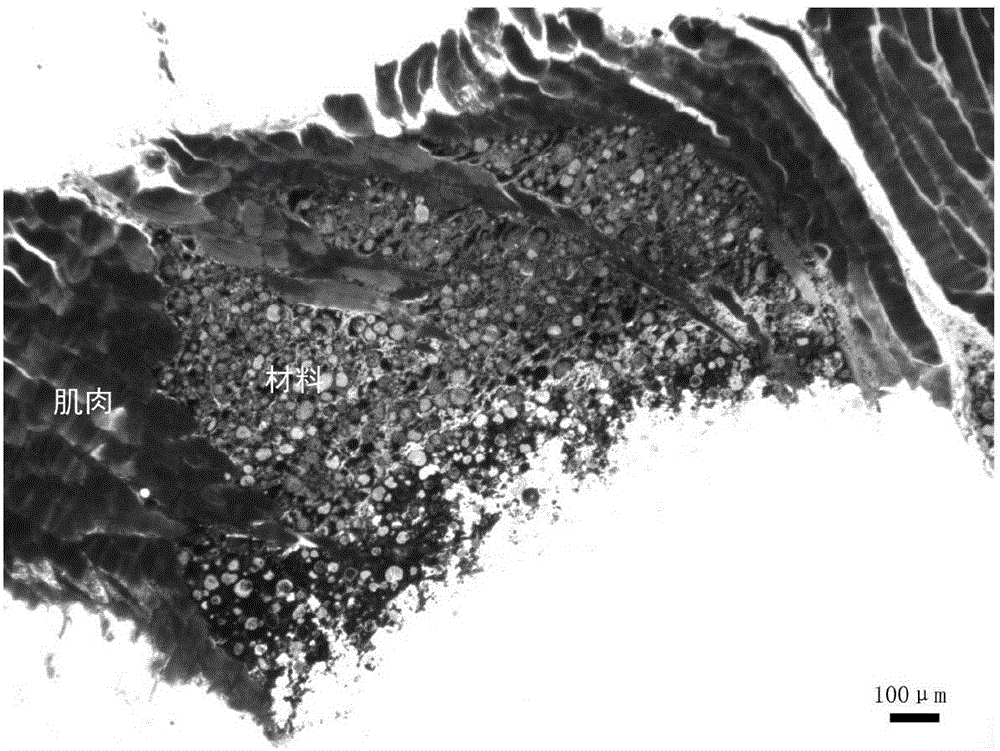

Injectable calcium phosphate/natural polymer composite material and preparation method and application thereof

ActiveCN106421929AGood shaping effectGood prospects for clinical applicationPharmaceutical delivery mechanismProsthesisSodium hyaluronateCeramic particle

The invention discloses an injectable calcium phosphate / natural polymer composite material. The injectable calcium phosphate / natural polymer composite material is an injectable paste material formed by uniformly dispersing approximately spherical calcium phosphate ceramic particles with the particle size of 20-100 microns in a natural polymer (or its derivative) solution, wherein calcium phosphate is hydroxyapatite or diphasic calcium phosphate, 0-20% of bioactive glass can be added, the natural polymer or its derivative is one or more of sodium hyaluronate, collagen, chitosan, chondroitin sulfate and the like. The invention further discloses a preparation method of an injectable calcium phosphate / natural polymer composite material and a method for performing facial mini-plastic surgery by adopting the method. After the injectable calcium phosphate / natural polymer composite material is implanted in a body by adopting the method, a natural polymer in the material is degraded and absorbed, the calcium phosphate ceramic particles are fused with an autologous bone tissue together, a lasting shaping effect can be achieved, and clinical application prospect is good.

Owner:成都睿漾再生医疗科技有限公司

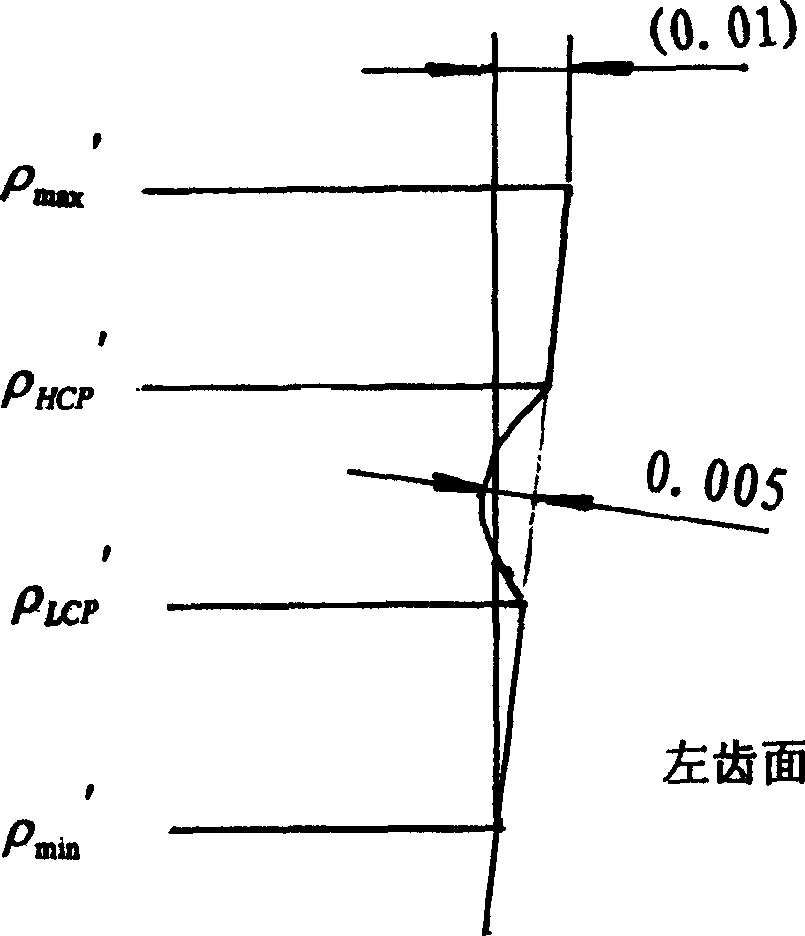

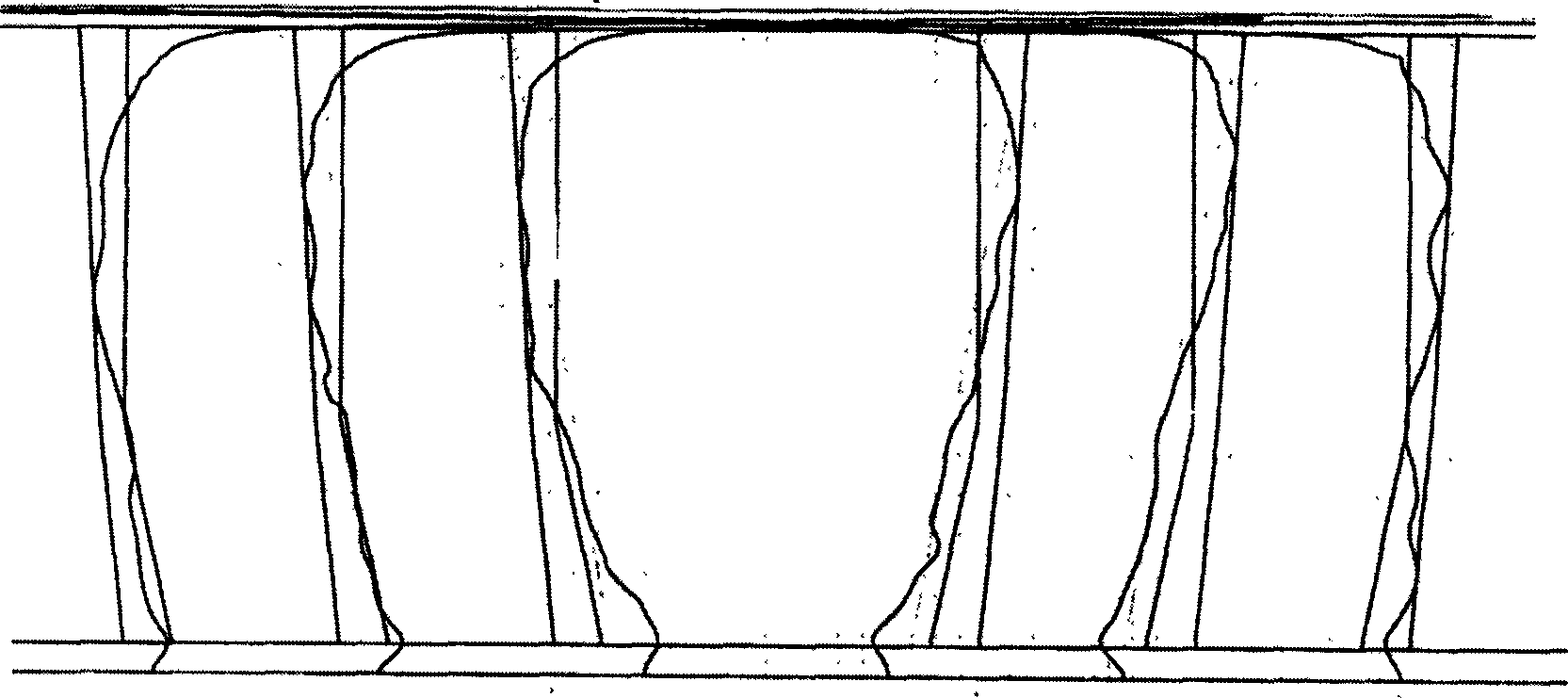

Method for shaping gear shaver

InactiveCN1781637AFew engagement pointsStrong targetingGear teeth manufacturing toolsGear teethEngineeringMechanical engineering

The method of shaping gear shaver includes calculating the curvature values of the practical engagement conversion point based on the curvature values of the machined gear, calculating the corresponding curvature values of the gear shaver in the engagement conversion point based on the no-side gap helical gear engagement formulation, and designing the shape correcting curve of the gear shaver precisely. The method can determine the reverse concave position range of gear shaver fast and accurately and has high shape correcting efficiency and low production cost.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

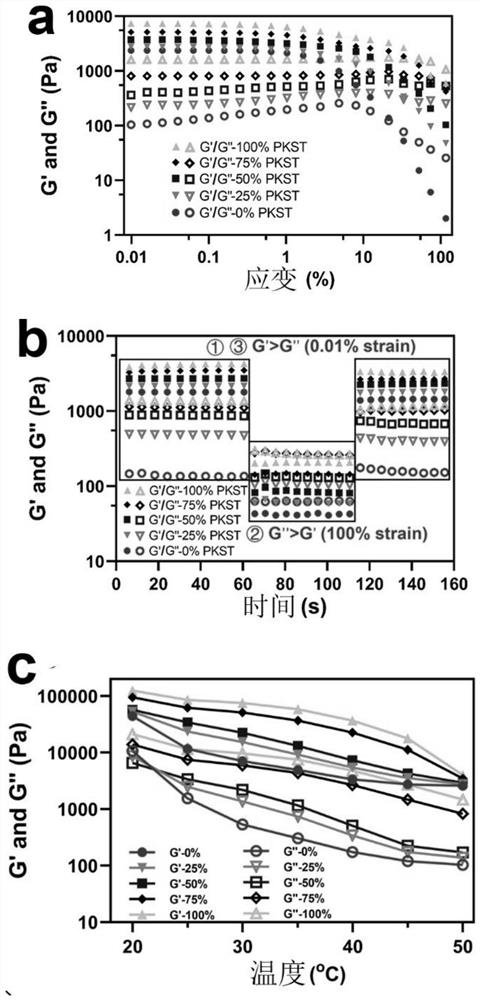

Dual-network zero-trans-fat-like emulsion gel capable of 3D/4D printing and preparation method of dual-network zero-trans-fat-like emulsion gel

ActiveCN114468062AImprove thixotropyGood shaping effectAdditive manufacturing apparatusCocoaBiotechnologyVegetable oil

The invention discloses dual-network zero-trans fat-like emulsion gel capable of 3D / 4D printing and preparation, and belongs to the technical field of healthy grease and food processing. The method for preparing the emulsion gel comprises the following steps: (1) adding a hydrophilic colloid into hot water containing emulsifier nanoparticles, and dissolving to obtain an aqueous solution; wherein the mass concentration of the nanoparticles in the aqueous solution is 0.5-15%; (2) dissolving oil-soluble small molecules in the heated vegetable fat, and uniformly mixing to obtain an oil solution; or mixing and heating a plurality of vegetable oils and fats to obtain mixed oil and fat; and (3) mixing the aqueous solution in the step (1) and the oil solution or the mixed grease in the step (2) according to a volume ratio of 1: 1-9: 1, homogenizing and emulsifying to obtain the emulsion gel. The emulsion gel provided by the invention can partially or completely replace traditional fat in chocolate, ice cream, non-dairy cream and other foods, and has the characteristics of zero trans-low saturated fatty acid nutrition and health.

Owner:JIANGNAN UNIV

Vertical bar artificial silk spinning fabric production process

InactiveCN103173912AHighly breathable drapabilityGood shaping effectWoven fabricsPolymer scienceEngineering

The invention discloses a vertical bar artificial silk spinning fabric production process. The fabric comprises warp yarn and weft yarn, 75D ultra-fine denier polyester filament yarn through weak twisting and 75D polyester black yarn are adopted in the warp yarn, and 75D ultra-fine denier polyester filament yarn through weak twisting and 75D glazed artificial filament yarn without twisting are adopted in the weft yarn. The warp yarn process includes the steps: winding, two-for-one twisting, sectional warping and drafting, and the weft yarn process includes the steps: spooling, two-for-one twisting and rewinding. According to the vertical bar artificial silk spinning fabric production process, on the basis of improvement of a device, the problems that viscose fibre is fine denier high-F fiber with low twisting degree, broken filament can be easily generated in the twisting process, and therefore unsmooth wefting insertion can happen easily in the weaving process, weft yarn is stopped and returns in a weaving machine easily, and the like are chiefly solved. Through optimization of weaving process parameters, weaving quality and efficiency are improved, and novel fabric which is like light and thin and transparent real silk is successively developed. Through the vertical bar artificial silk spinning fabric production process, textile is high in ventilation and drapability, and good in shaping effect, and particularly suitable for being used as high-range closed-fit fabric.

Owner:JIANGSU DEHUA TEXTILES

Production process of colorful soft denim

InactiveCN105803761AShrinkage stableStable weightInspecting textilesLiquid/gas/vapor removalGramShrinkage rate

The invention discloses a production process of colorful soft denim. The production process comprises the specific steps as follows: pre-treating; feeding cloth-immersing in water and penetrating-straightening weft; and overfeeding-drying-dyeing-dehydrating-washing with ferment-washing and whitening-feeding a softening agent-sizing. By virtue of the process, the air permeability can be effectively improved, the light shading property is reduced, the perspective property of a fabric is avoided and an ultra-soft denim fabric with soft and light texture is prepared; a condition that the denim is faded can be effectively reduced, the stability of the shrinkage rate and the gram weight of the denim are guaranteed and the sizing property is good; and an optimal fabric condition is created for clothes manufacturing. Meanwhile, the problems of traditional denim that the color is single, a fabric surface style is dull and visual impact is lacked are solved, and the trend of times is adapted.

Owner:TAICANG QIDE GARMENT

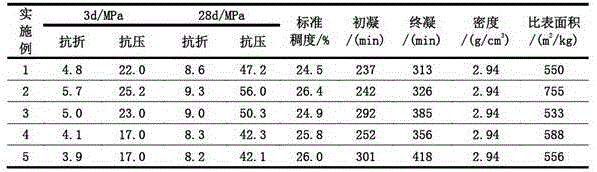

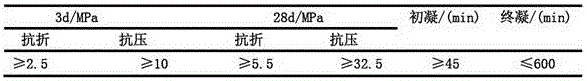

Retarded portland cement and preparation method thereof

InactiveCN105948544AProlong clotting timeIncrease late strengthCement productionSlagMaterials science

The invention relates to a retarded Portland cement and a preparation method thereof. The retarded Portland cement is prepared from the following components in percentage by weight: 52 to 58 percent of Portland cement clinkers, 22.2 to 25.5 percent of mixed slags, 14.8 to 17.5 percent of silica fume, and 5 percent of gypsum. The preparation method comprises the following steps of premixing a phosphorus slag, a vanadium-titanium bearing slag and a zinc slag according to the proportion to obtain a mixed slag a; mixing and grinding the mixed slag a, the Portland cement clinkers, the silica fume and the gypsum to prepare the retarded Portland cement. According to the retarded Portland cement provided by the invention, the usage amount of the Portland cement clinkers is reduced, so that the ingredient cost of producing the cement is effectively reduced, and the discharge of carbon dioxide is reduced; meanwhile, with the adding of the phosphorus slag and the silica fume, the problem that the long-term strength is reduced since the Portland cement clinkers are reduced is solved. The defects that the setting time is prolonged and the strength is reduced, or the strength is increased and the setting time is shorter due to the utilization of other materials in the prior art are overcome, and the obtained retarded Portland cement is remarkably prolonged in initial setting time and remarkably improved in long-term strength.

Owner:四川省宁南县白鹤滩水泥有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com