Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

167results about How to "Shrinkage stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

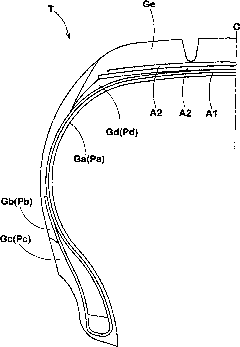

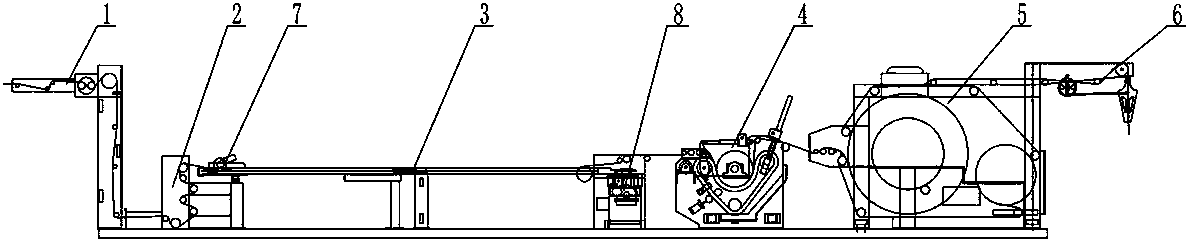

Manufacturing method of rubber component for tire and manufacturing device used therein

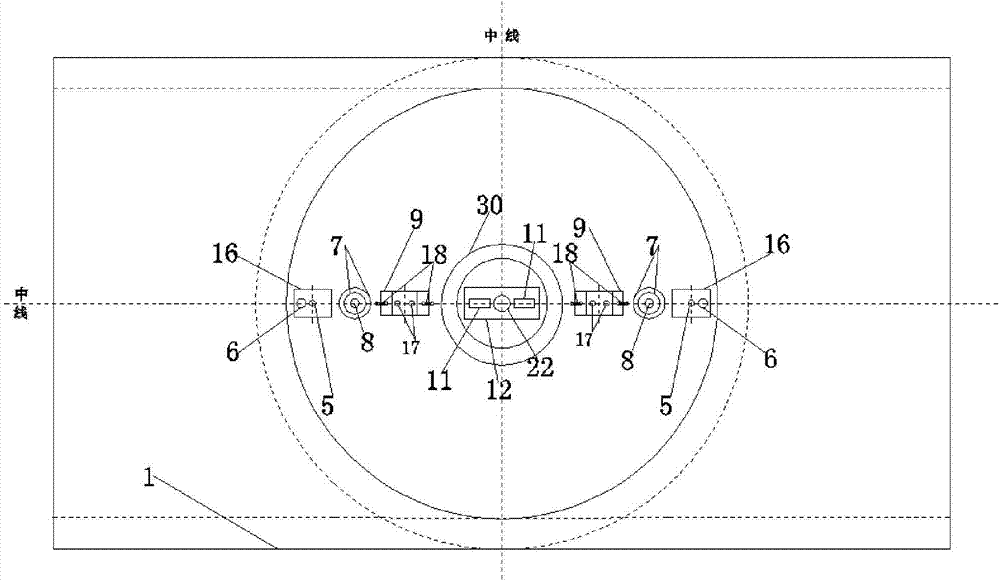

The present invention provides a manufacturing method of a rubber component for a tire and a manufacturing device used therein. A rubber strip from a rubber strip supply unit is directly wound on a forming machine with high precision. Furthermore dimension deviation of contraction reeled member after winding, which is caused by contraction, can be restrained. The manufacturing method of the rubber component for the tire comprises a winding step and a tire rubber component removing step. In the winding step, the rubber strip is conveyed from a delivery roller to the forming machine. The forming machine rotates and simultaneously moves transversely in an axial direction thereby winding the rubber strip from a set of conveying equipment on the forming machine and adhibiting to a spherical shape for furthermore forming the rubber component for the tire. In the tire rubber component removing step, an applicator ascends from a descending position to an ascending position thereby removing the rubber component for the tire, which is formed on the forming machine. At the descending position, the rubber strip is adhibited on the forming machine; and at the ascending position, the delivery roller leaves upwards from the forming machine for standby.

Owner:SUMITOMO RUBBER IND LTD

Processing method for improving easy-care performance of moist crosslinking finishing yarn-dyed fabric

ActiveCN108457082AAdequate responseGood flatness effectHeating/cooling textile fabricsWrinkle resistant fibresYarnProduct inspection

The invention belongs to the technical field of textile dyeing and finishing, and particularly relates to a processing method for improving easy-care performance of a moist crosslinking finishing yarn-dyed fabric. The processing method comprises the steps of singeing, desizing, mercerizing, liquid ammonia, pre-softening, moist crosslinking rolling, moist crosslinking, baking, primary washing, secondary washing, tentering and finished product inspection and packaging. Baking is carried out with a baker at a baking temperature of 120 to 140 DEG C for 3 to 5 minutes. According to the invention, two crosslinking is creatively adopted, the water shrinkage and heat shrinkage of a fabric are more stable, a pre-shrinking process is omitted, and thus the production cost of the fabric is reduced; the baking process is introduced into the moist crosslinking finishing process, and the time of moist crosslinking finishing piling is shortened by 6 to 12 hours, and the usage amount of resin and a catalyst is reduced by 20% to 50% compared with a traditional moist crosslinking process; the easy-care performance of the moist crosslinking finishing yarn-dyed fabric is enhanced by 0.2 to 0.5 grade, the fabric can be washed for 50 times, the easy-care degree is 4.0 or above.

Owner:LUTAI TEXTILE

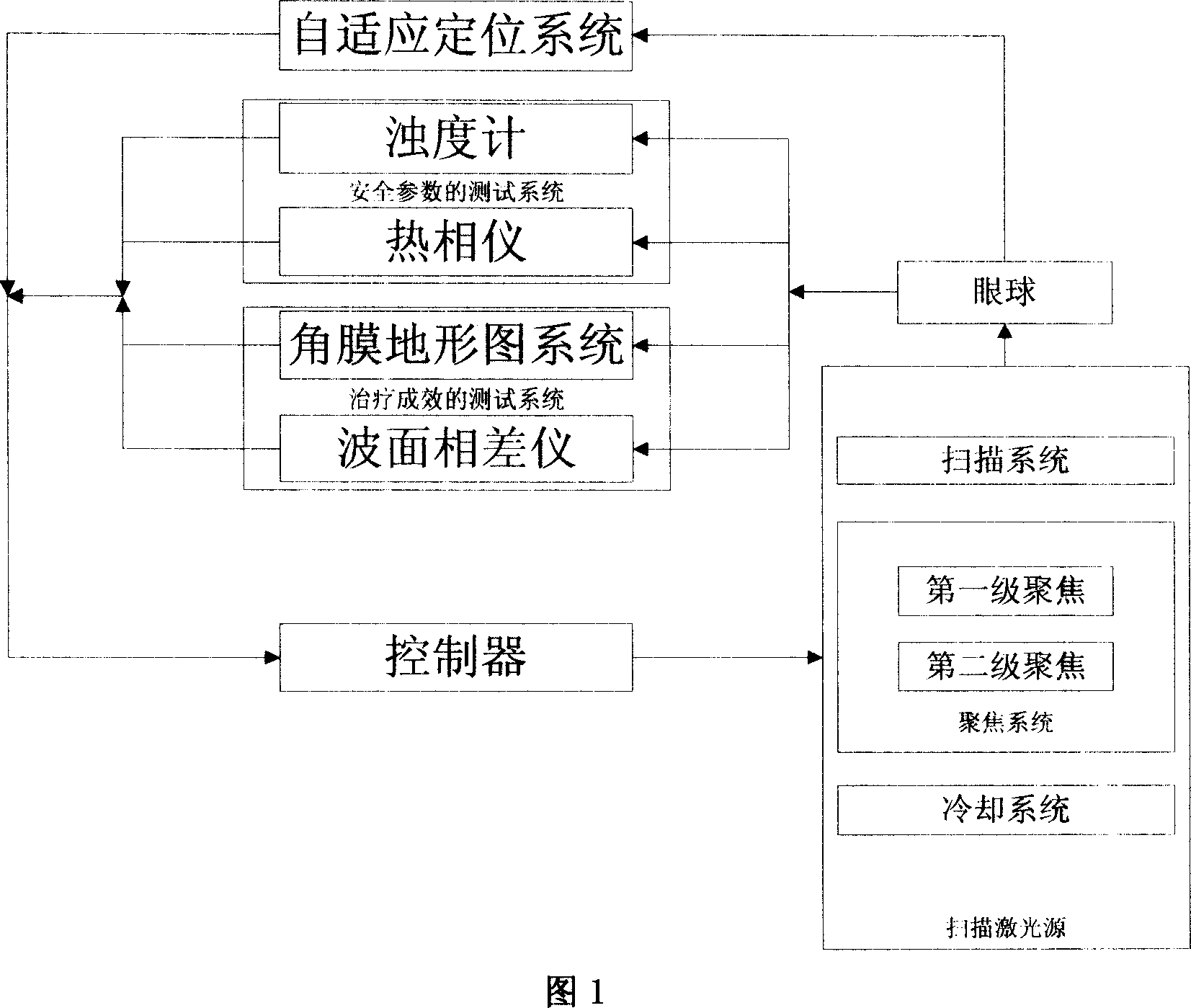

Intravital surgery system for scanning type laser operation of hot forming cornea

InactiveCN1957867AImprove stabilityImprove predictabilityLaser surgeryTherapeutic effectUnexpected therapeutic effect

A scanning laser operation system for the thermo-shaping operation of cornea on living body is composed of a scanning laser source, an adaptive locating system, a safte parameter testing system, a therapeutic effect testing system, and a controller.

Owner:SHANGHAI JIAO TONG UNIV

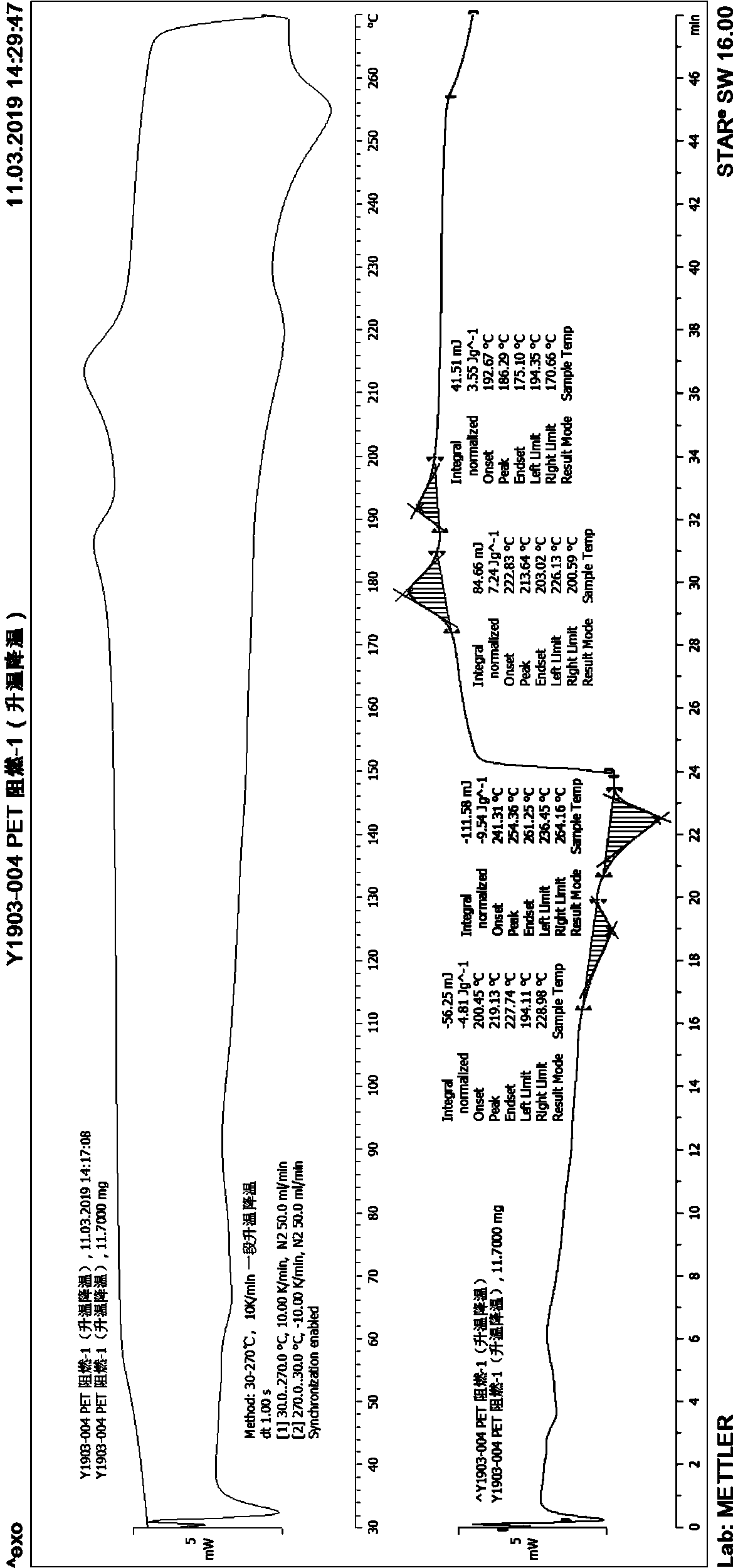

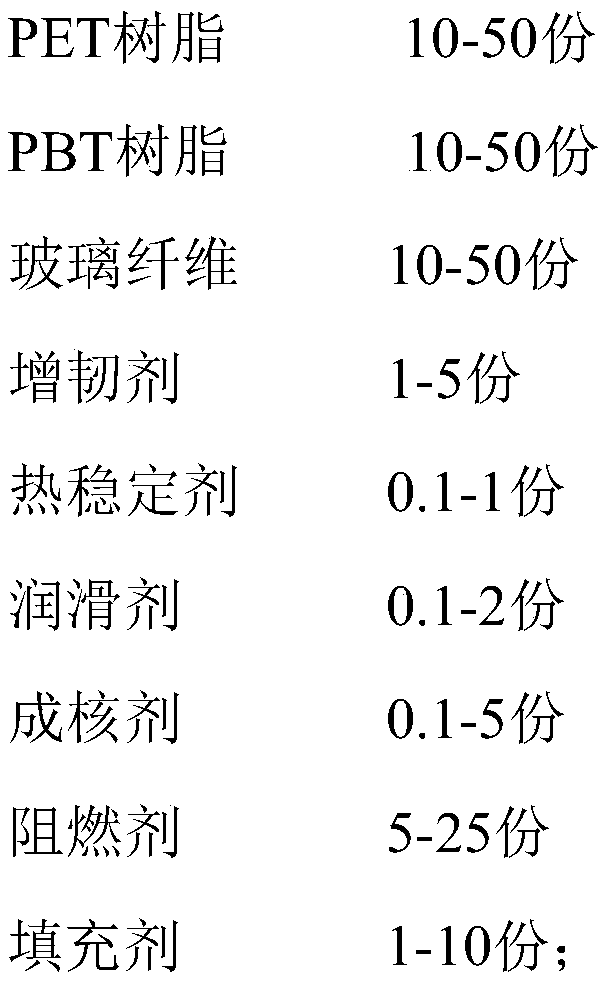

Low-warpage good-appearance high-heat resistance polyester composite material and preparation method thereof

The invention relates to the technical field of polymer material modification, in particular to a low-warpage good-appearance high-heat resistance polyester composite material and a preparation methodthereof. The polyester composite material is composed of the following raw materials: PET resin, PBT resin, glass Fiber, a toughening agent, a heat stabilizer, a lubricant, a nucleating agent, a flame retardant and filler, wherein the nucleating agent is a mixture of LCP, modified montmorillonite, silica and sodium polyacrylate. The low-warpage good-appearance high-heat resistance polyester composite material has a stable shrinkage rate and good processability of injection molding, and has a lower water absorption rate than nylon at the same time, heat aging resistance is achieved, and the composite material has toughness comparable to PA66, chemical corrosion resistance comparable to PPS, can replace expensive PA66 or PPS, has better heat resistance than PBT and PA6, good appearance andlow warpage, and is mainly applied to precision-structure appearance parts and heat-resistant parts of electronic appliances, automobiles and new energy industries.

Owner:深圳市高科塑化有限公司

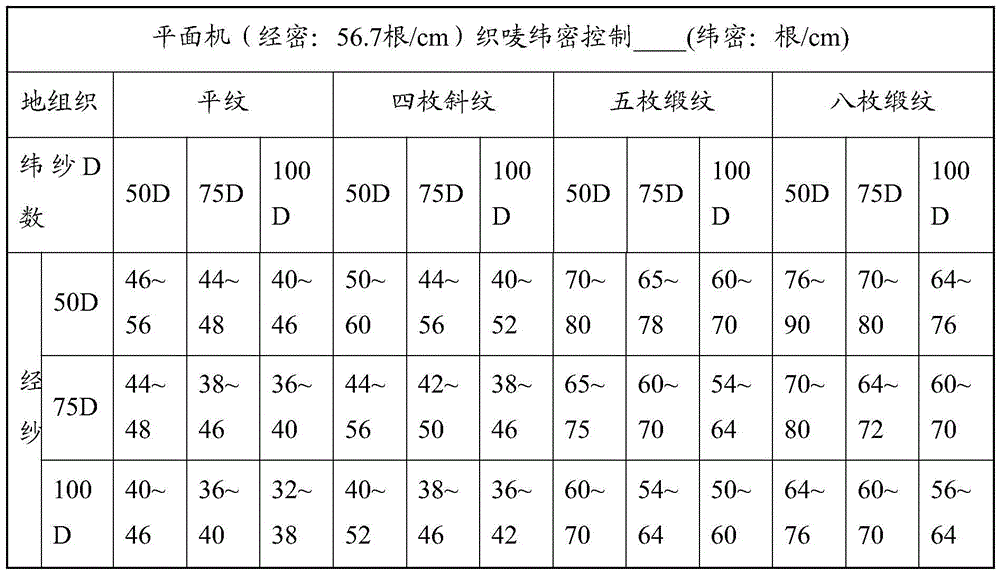

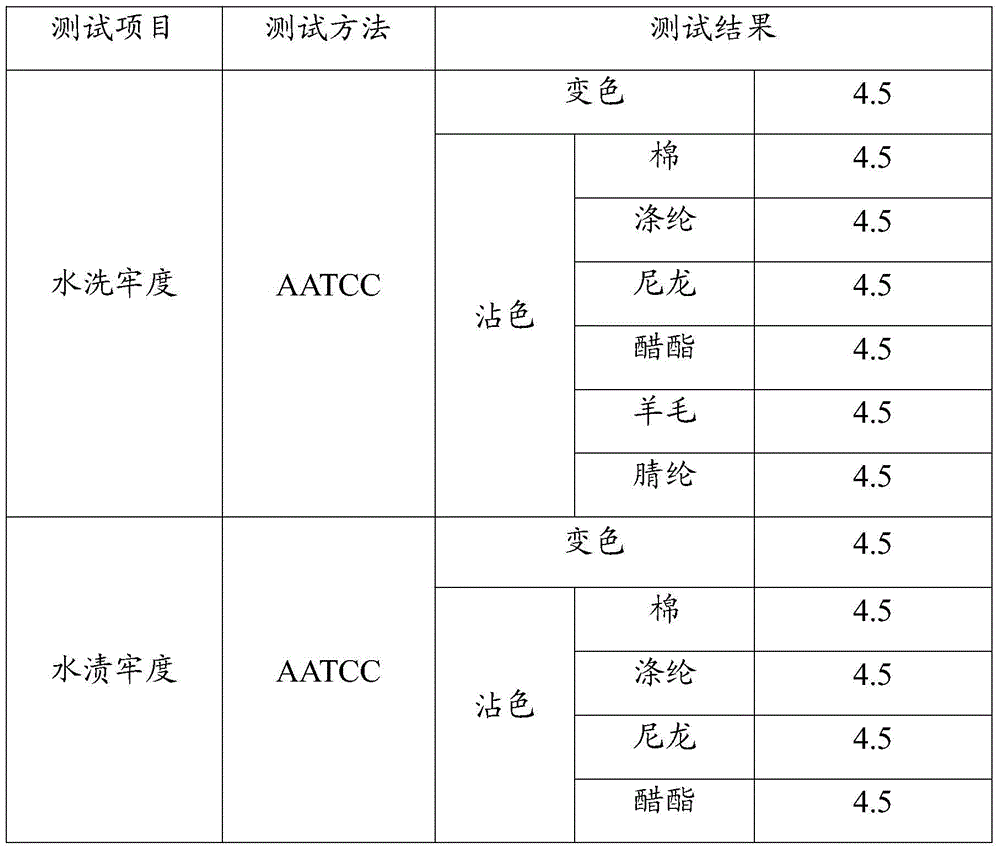

Polyester woven label and preparation method thereof

ActiveCN105525417AImprove heat shrinkageHigh fastnessSevering textilesWoven fabricsPolyesterShrinkage rate

The invention discloses a polyester woven label and a preparation method thereof. The preparation method includes following steps: (1), warp pretreatment; (2), weft selection; (3), pattern printing; (4), label weaving; (5), cutting and slitting. The polyester woven label made by the preparation method does not need to go through wash care and ironing processes, and the polyester woven label is less prone to wrinkling and contracting when being subjected to subsequent dyeing and wash care at 60-100 DEG C and press-ironing and drying at 100-160 DEG C. By using the preparation method, production period is shortened, production cost is lowered, fastness of the woven label in each aspect can be controlled at four or higher grade, and heat shrinkage rate of the woven label can be controlled below 3%.

Owner:广东康派环创科技有限公司

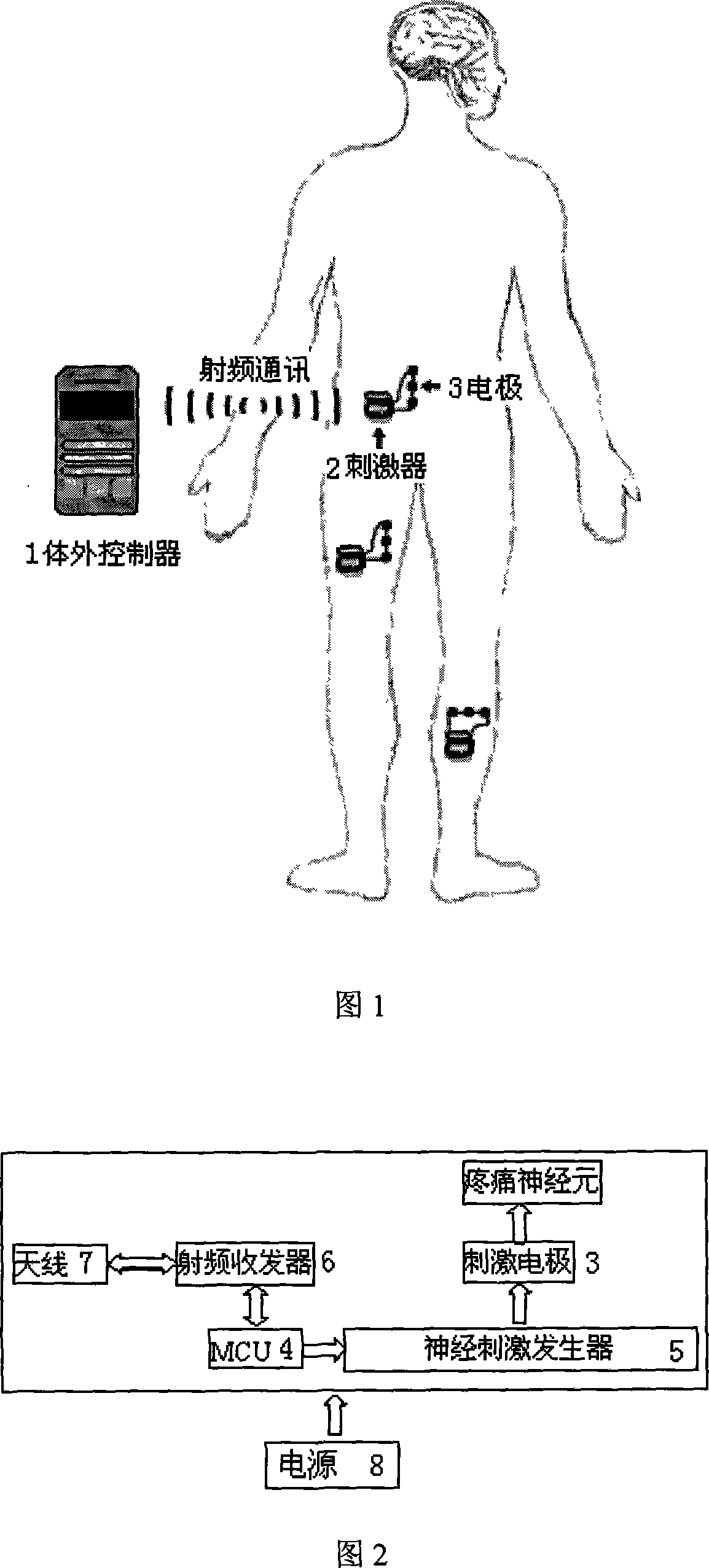

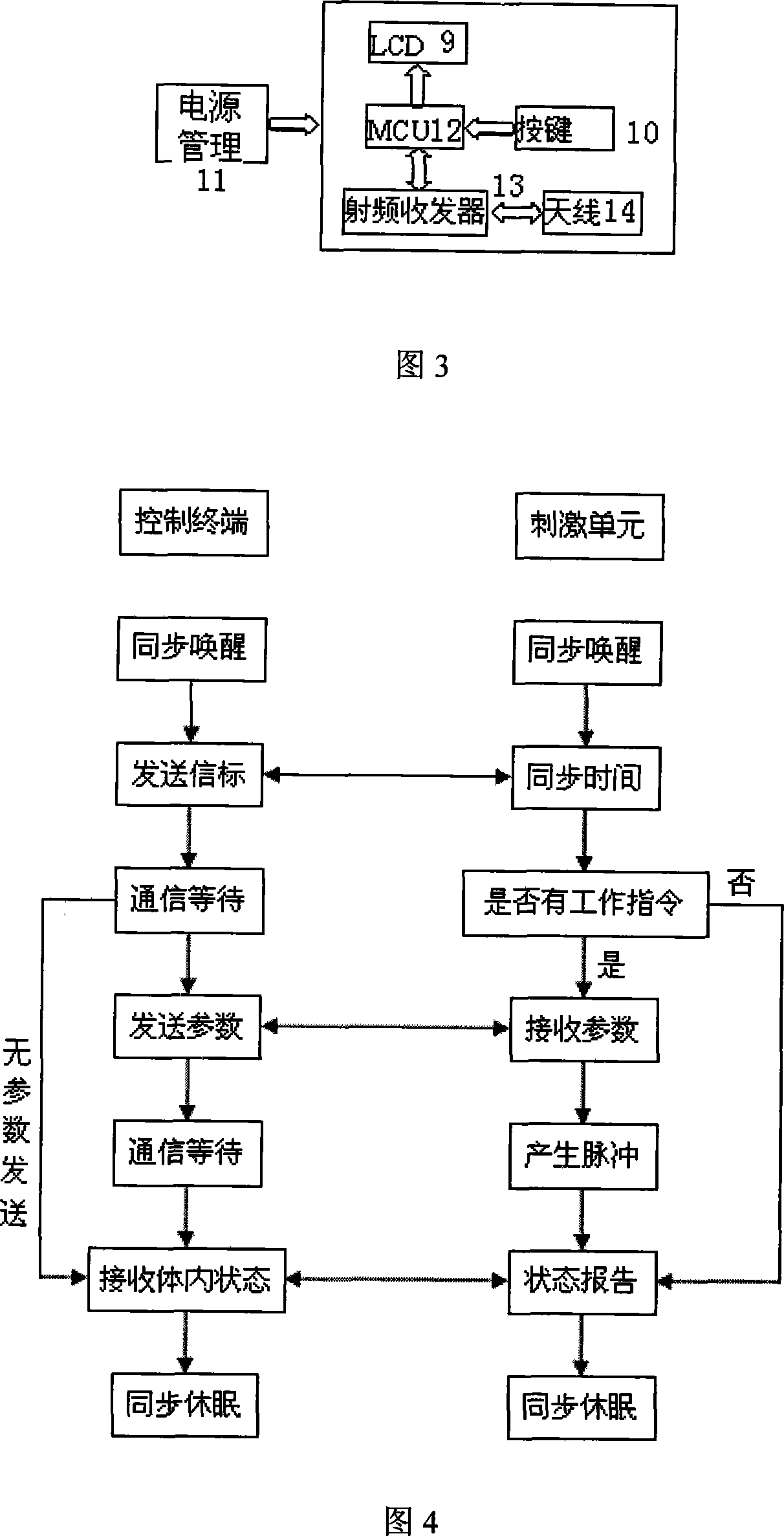

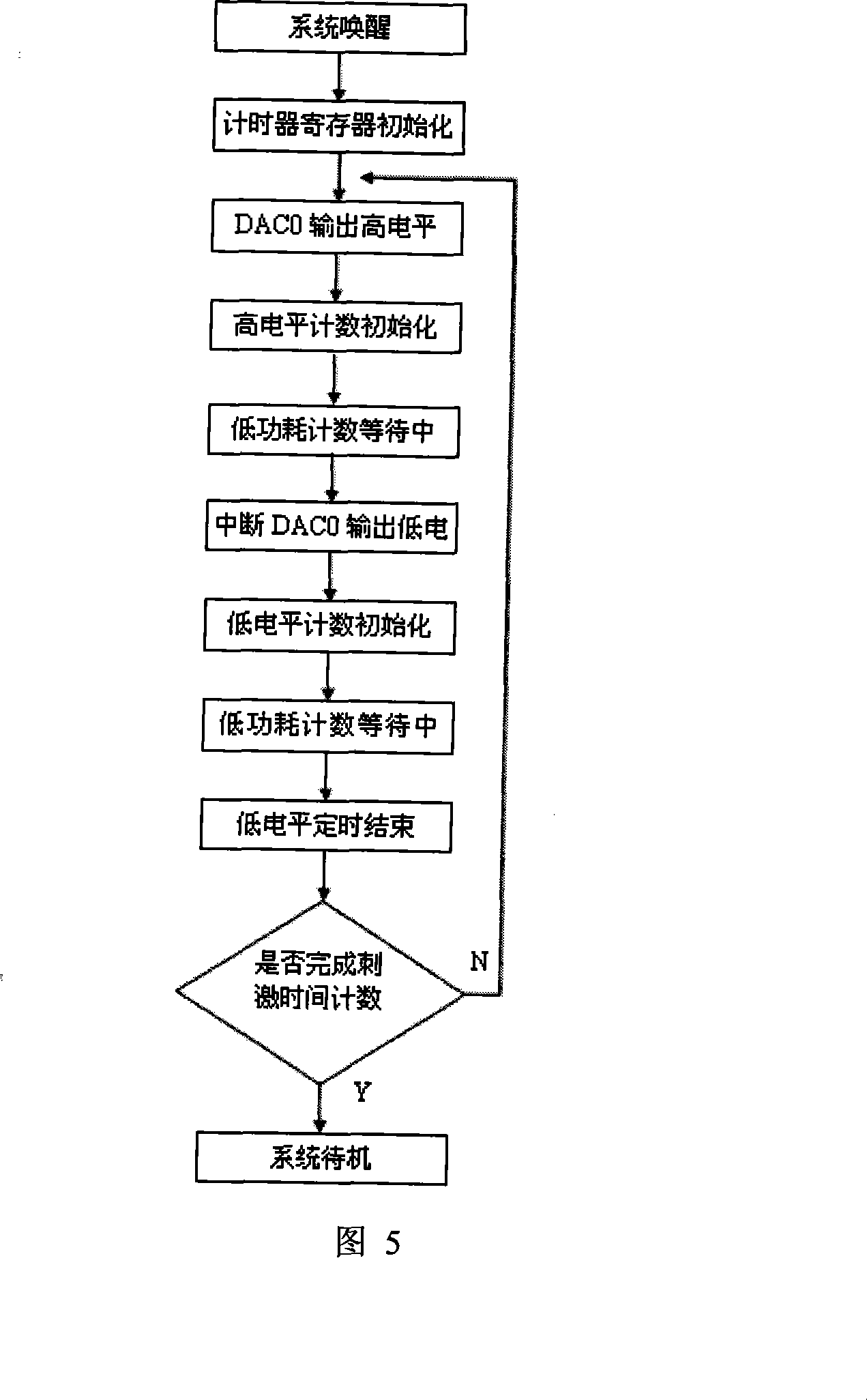

Implantation type wireless limbs sport control nerve stimulation network system and control method

InactiveCN101234227AFlexible topologyImprove scalabilityInternal electrodesExternal electrodesExtensibilityEngineering

The invention requests to protect an implantation-type nervous stimulation system of controlling wireless limb motions and a control method thereof, which relates to a technical field of human implantation-type medical devices. The system makes use of the principle of advanced wireless sensing network technology, constructs a star-type network and not limits to a wireless stimulation network of star-type network topology, and the topological structure is flexible and the extensibility is strong, and stimulation networks with different scales are constructed according to requirements of controlling of different limb motions; by adopting a wireless time synchronous protocol and the coordination work of synchronous dormancy and synchronous awaking of an external control terminal and an internal stimulation unit, the system realizes a multi-target implantation-type nerve stimulation method of wireless limb motion controlling, and the Burst working mode is low in power consumption and can prolong the service life of the internal stimulation unit greatly. The system and the control method thereof provide a novel stimulation device and a control method for the recovery treatment of nervous system diseases or patients of nervous system injury, and are beneficial to realize the controlling over more coordinate and natural limb motions in low trauma through the wireless synchronous controlling stimulation of multiple nerves and multiple muscles.

Owner:INST OF FIELD OPERATION SURGERY NO 3 MILITARY MEDICL UNIV PLA

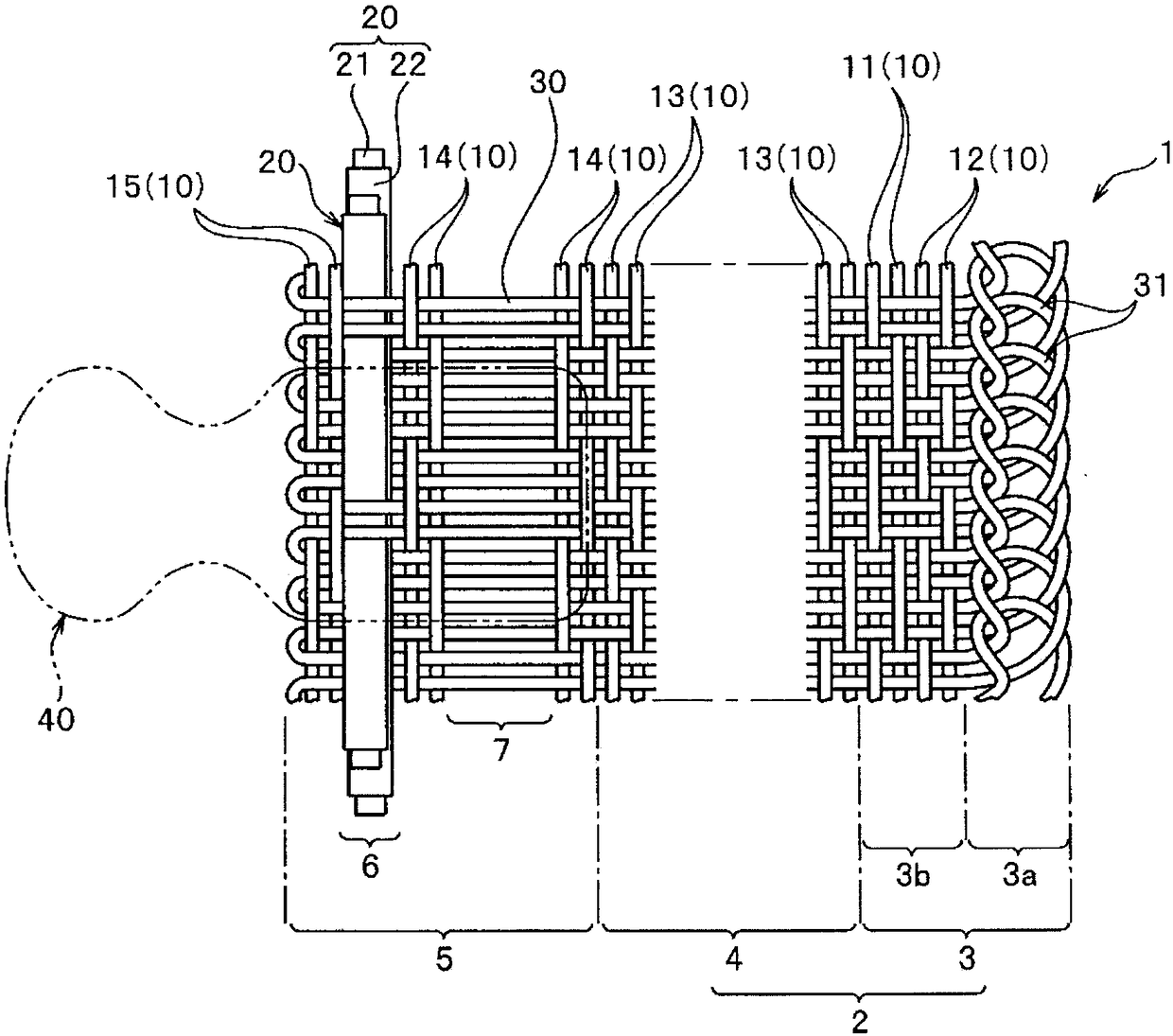

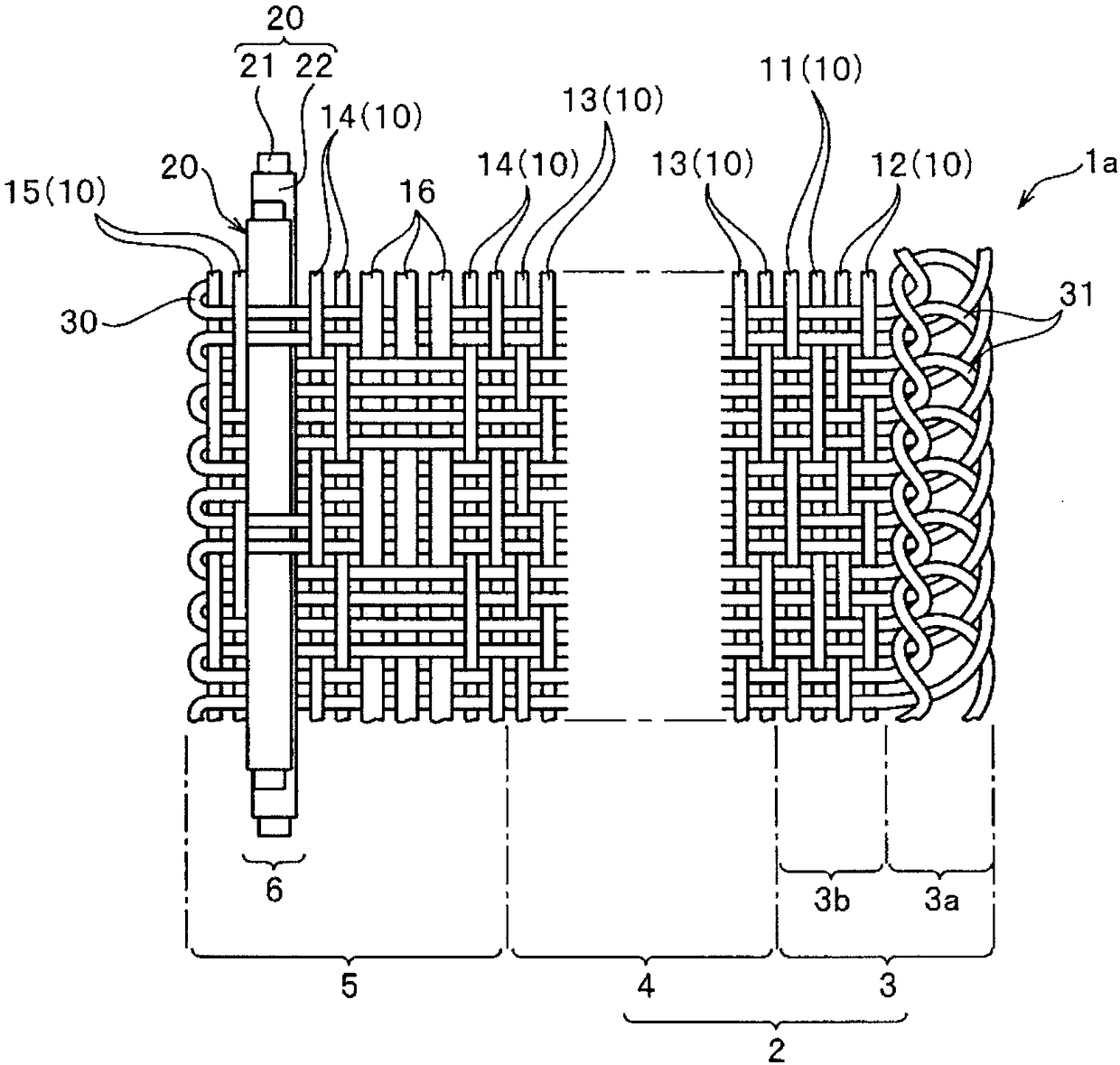

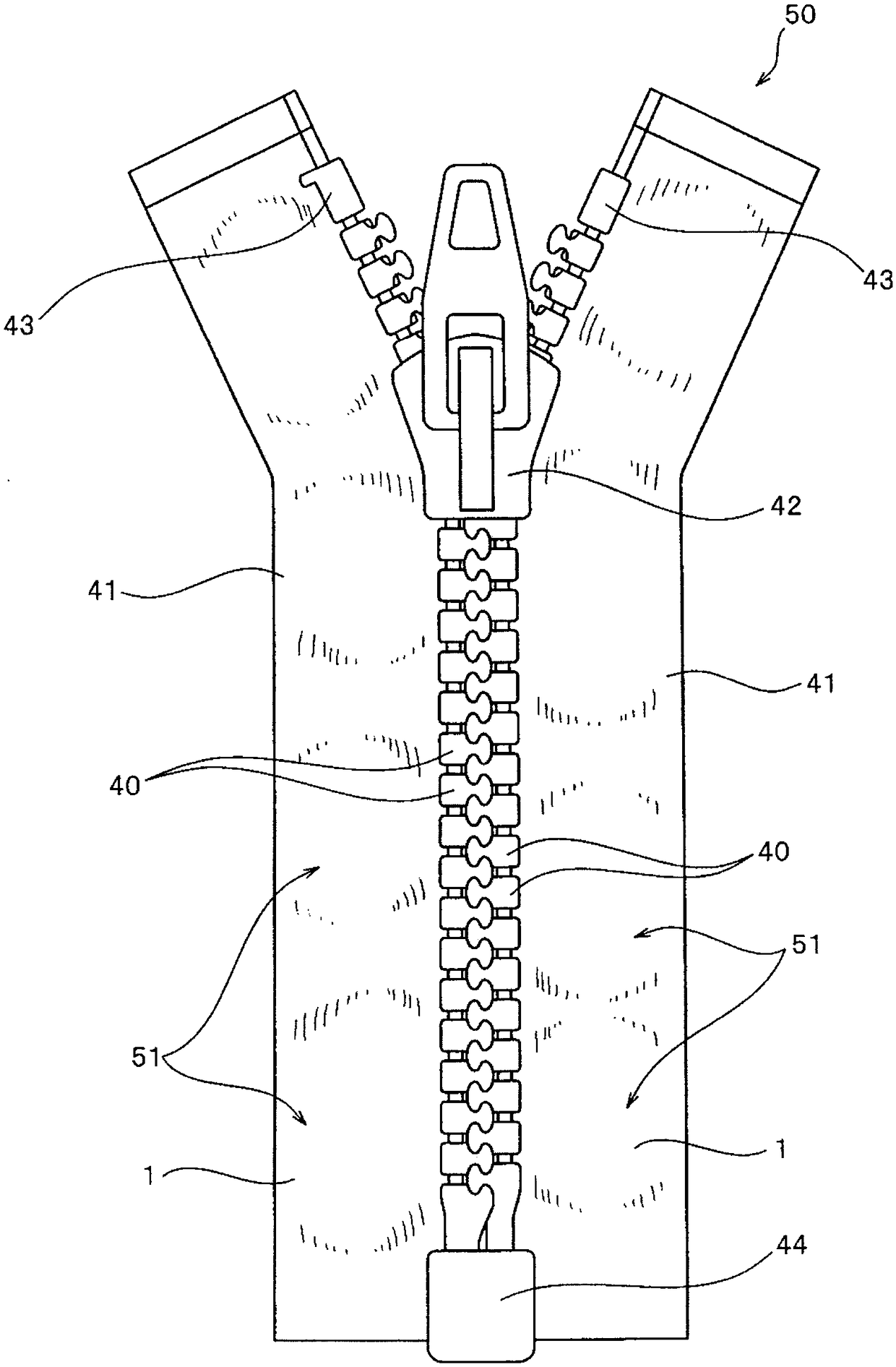

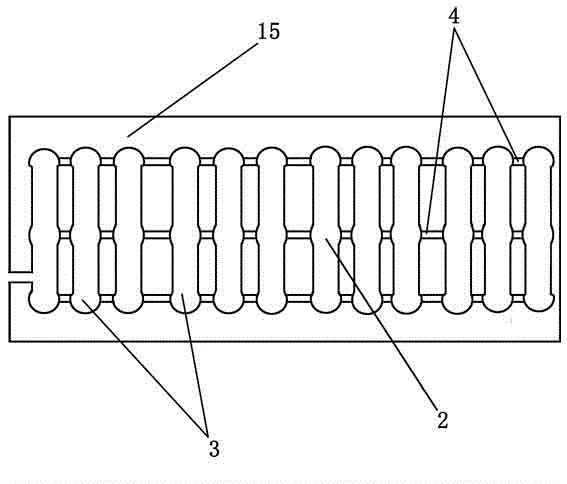

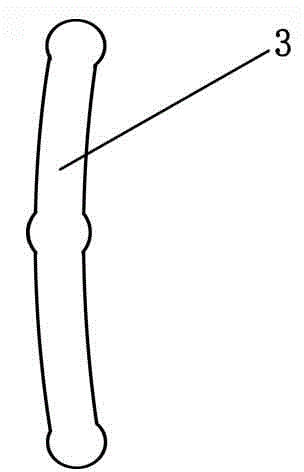

Zipper belt and zipper chain belt

The invention provides a zipper belt and a zipper chain belt, which can prevent reverse wrinkles when a zipper is woven to a product. Moreover, the problems caused by wrinkles in the zipper in the steps such as dyeing, delivering, injection moulding, and the like, are solved. The provided zipper belt (1,1b) comprises a belt main body (2) and a chain installation part (5) provided with a core rope(20). The belt main body (2) comprises an ear part (4) containing a plurality of warps (10) and a basic part (4) arranged between the ear part (3) and the chain installation part (5). The warps (10) of the basic part (4) are arranged in a more released state, compared with the at least one of the warps of the ear part (3) and the core rope (20).

Owner:YKK CORP

Epoxy resin seepy material and preparation method thereof and application

ActiveCN106277932AGood water permeability and air permeabilityUniform pore size distributionCeramicwareAbsorption rateChemistry

The invention belongs to the technical field of epoxy resin preparation and discloses an epoxy resin seepy material and a preparation method thereof and application. The epoxy resin seepy material is prepared from, by weight percentage, 5-35% of epoxy resin, 5-30% of modified self-emulsifying epoxy hardener, 0.5-3% of polyether polyamine, 0.5-3.5% of epoxy resin accelerator, 1-3.5% of epoxy resin diluent, 35-10% of water and 53-15% of inorganic filler. The modified self-emulsifying epoxy hardener is ricinoleic acid and / or fatty polyamine and / or alicyclic polyamine modified by a polymer of the ricinoleic acid. The epoxy resin seepy material has excellent seepy and breathable performances, the pore diameter of the epoxy resin seepy material is smaller than 20 [mu]m, the porosity is larger than 20%, the water absorption rate is larger than 20%, the pore diameter distribution is uniform, the surface is bright and clean, and the epoxy resin seepy material can be used for manufacturing ceramic industry slip casting dies, filter materials and air purification materials.

Owner:国科广化(南雄)新材料研究院有限公司 +1

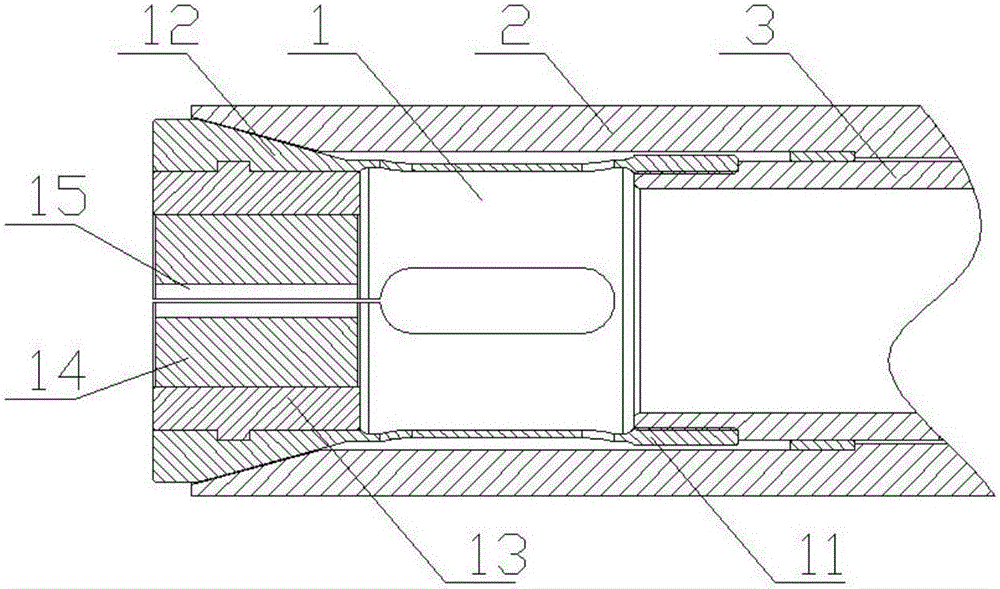

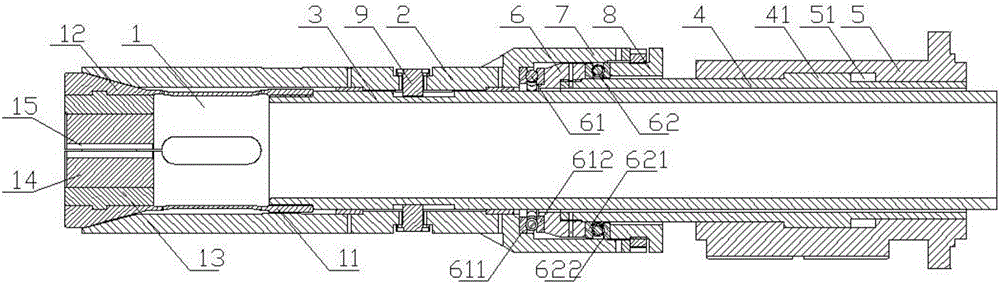

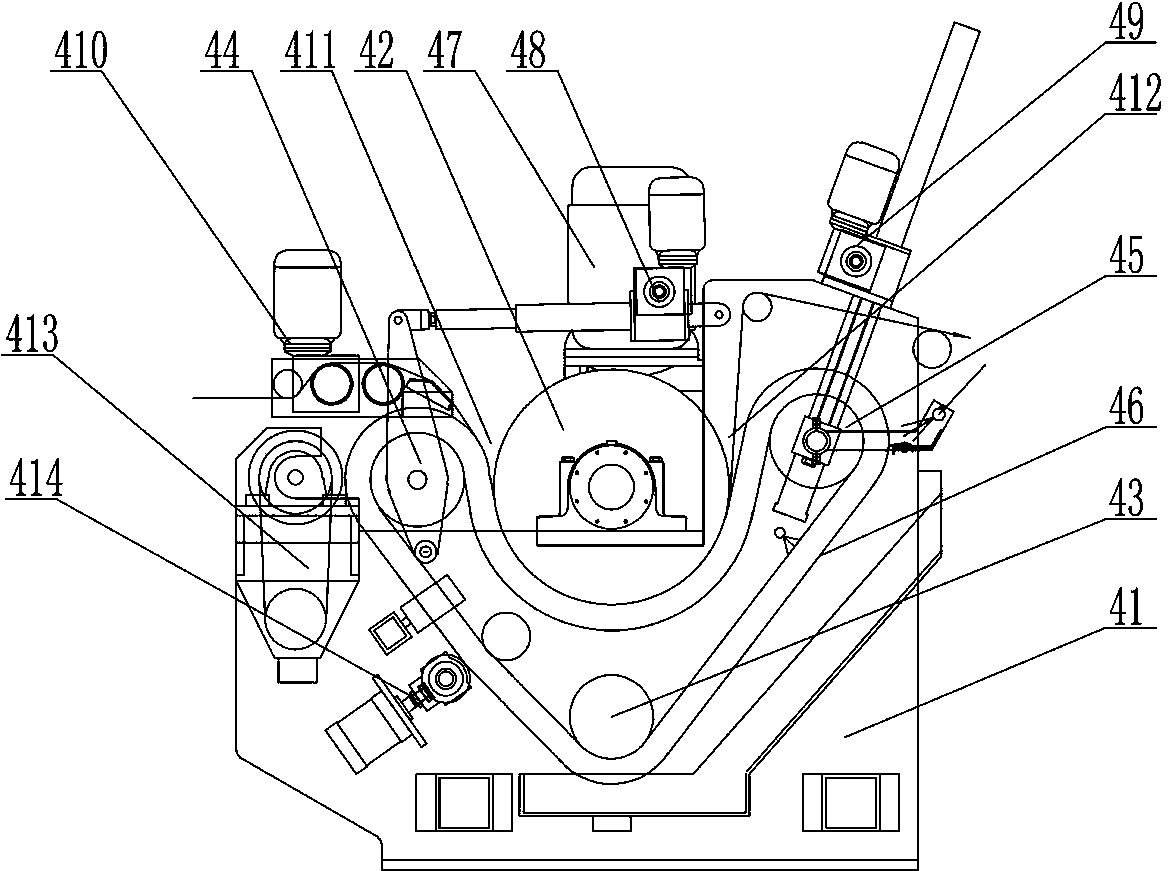

Improved inner-pushing type clamping device for numerical control tube bending machine

ActiveCN105750384AQuick putAccurate placementMetal-working feeding devicesPositioning devicesNumerical controlEngineering

The invention discloses an improved inner-pushing type clamping device for a numerical control tube bending machine and belongs to the field of numerical control tube bending machines. The improved inner-pushing type clamping device solves the problems that an oil cylinder of an existing clamping device for a numerical control tube bending machine is poor in rotation sealing in the autorotation process and is likely to leak oil, and the service life is short. The improved inner-pushing type clamping device comprises a flexible chuck, an oil cylinder and a component, wherein the flexible chuck and the oil cylinder are connected through the component. The component for connecting the flexible chuck and the oil cylinder comprises a chuck pushing bush and a rotating rod. The oil cylinder comprises a cylinder body and a piston rod arranged in the cylinder body, and the chuck pushing bush is arranged at the stretching-out end of the piston rod, is fixed relative to the piston rod in the axial direction and can relatively rotate around the axis. The rotating rod is arranged in the piston rod, and is connected with the chuck pushing bush in the connecting mode that the rotating rod and the chuck pushing bush can rotate synchronous and move relatively in the axial direction. The flexible chuck is arranged at one end of the rotating rod. By means of the improved inner-pushing type clamping device, the problem of oil leakage caused by poor rotation sealing of the oil cylinder can be solved, so that the working stability of the clamping device is improved, and the service life is prolonged.

Owner:ANHUI DEXI DHI TECH

Production process of colorful soft denim

InactiveCN105803761AShrinkage stableStable weightInspecting textilesLiquid/gas/vapor removalGramShrinkage rate

The invention discloses a production process of colorful soft denim. The production process comprises the specific steps as follows: pre-treating; feeding cloth-immersing in water and penetrating-straightening weft; and overfeeding-drying-dyeing-dehydrating-washing with ferment-washing and whitening-feeding a softening agent-sizing. By virtue of the process, the air permeability can be effectively improved, the light shading property is reduced, the perspective property of a fabric is avoided and an ultra-soft denim fabric with soft and light texture is prepared; a condition that the denim is faded can be effectively reduced, the stability of the shrinkage rate and the gram weight of the denim are guaranteed and the sizing property is good; and an optimal fabric condition is created for clothes manufacturing. Meanwhile, the problems of traditional denim that the color is single, a fabric surface style is dull and visual impact is lacked are solved, and the trend of times is adapted.

Owner:TAICANG QIDE GARMENT

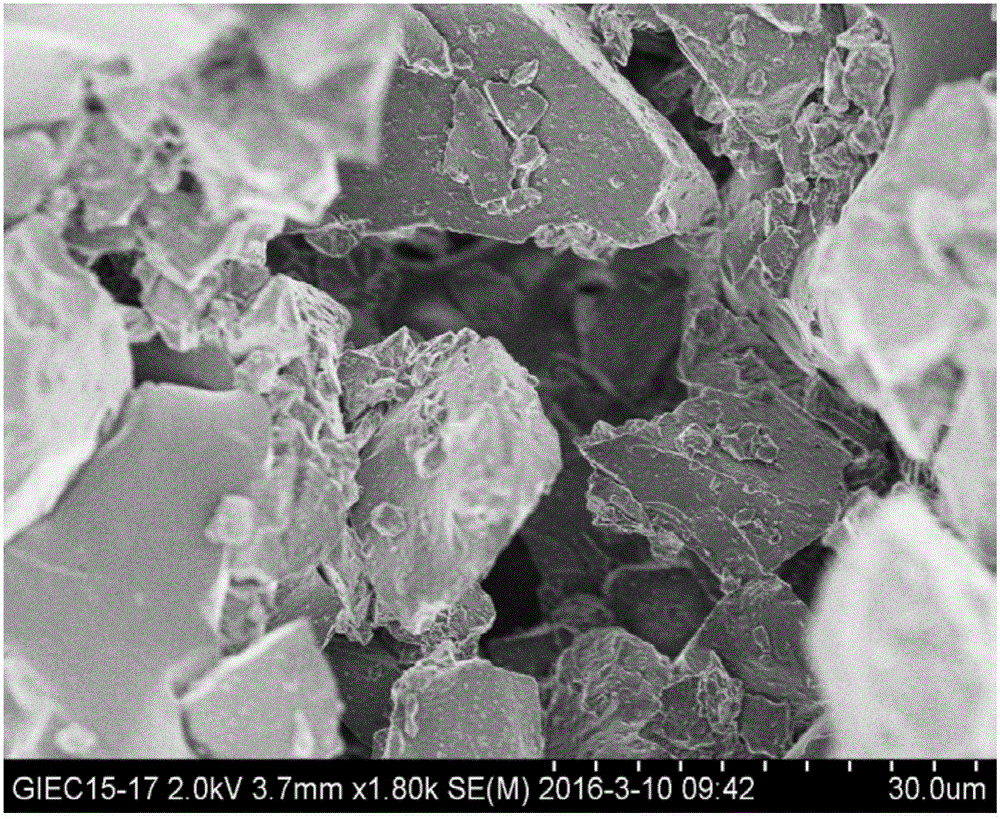

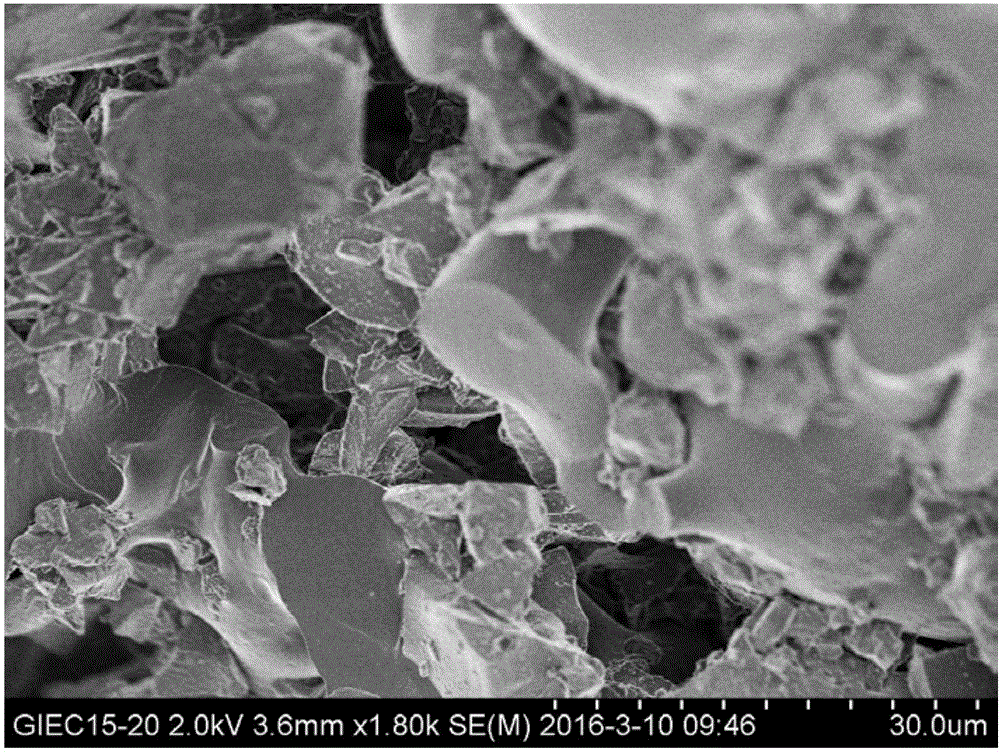

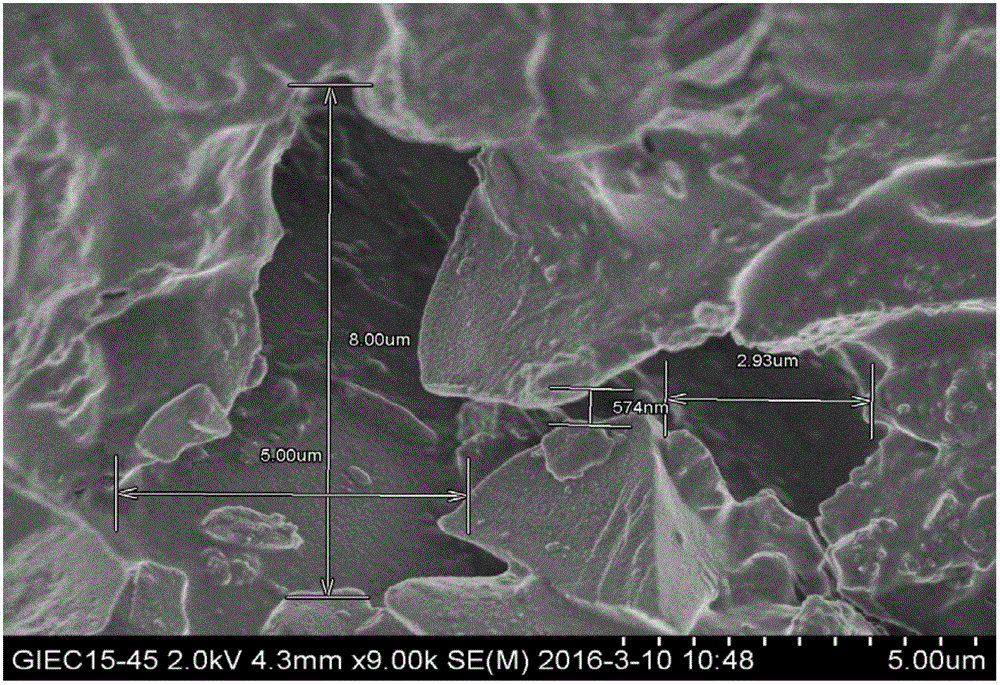

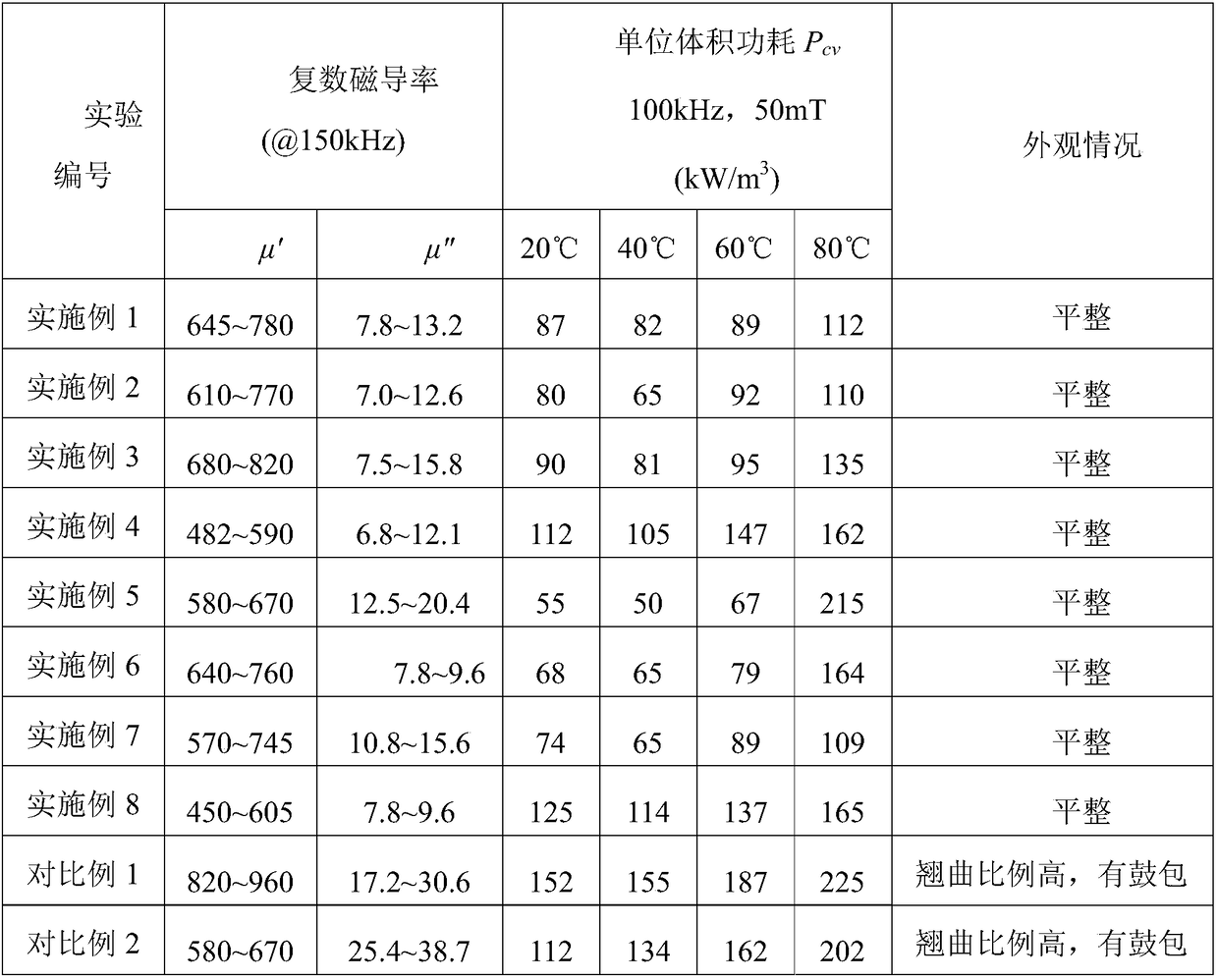

Nickel-zinc soft ferrite for wireless charging and preparation method and application thereof

ActiveCN108164260AImprove the sintering temperature rangeImprove magnetic propertiesInorganic material magnetismShrinkage rateNickel-zinc ferrite

The invention belongs to the field of soft ferrite, and discloses nickel-zinc soft ferrite for wireless charging and a preparation method and application thereof. The ferrite comprises a main component and a doping component, wherein the main component comprises Fe2O3, NiO, ZnO and CuO; the doping component at least comprises one of Nd2O3, Pr6O11, Gd2O3, Dy2O3, Tb2O3, Ho2O3 and Sm2O3; in terms ofthe weight of the main component, the Fe2O3 content of the main component is 64-67wt%, the NiO content thereof is 4-10wt%, the ZnO content thereof is 18-24wt% and the CuO content thereof is 3-9wt%; interms of the weight of the main component, the content of each doping component is 0.02-0.2wt%, and the total addition amount is smaller than or equal to 0.5wt%. Through improvement on the doping component of the nickel-zinc soft ferrite, a thin ferrite magnetic sheet product is sintered densely when T is equal to 0.05-0.2mm, the sintering temperature width is increased, the shrinkage rate is slow during sintering temperature rise, and the appearance is smooth; meanwhile, the power loss per unit volume of the magnetic sheet (power consumption) can be also effectively reduced, the working temperature rise of a wireless charging component can be reduced, and the transmission efficiency can be improved.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

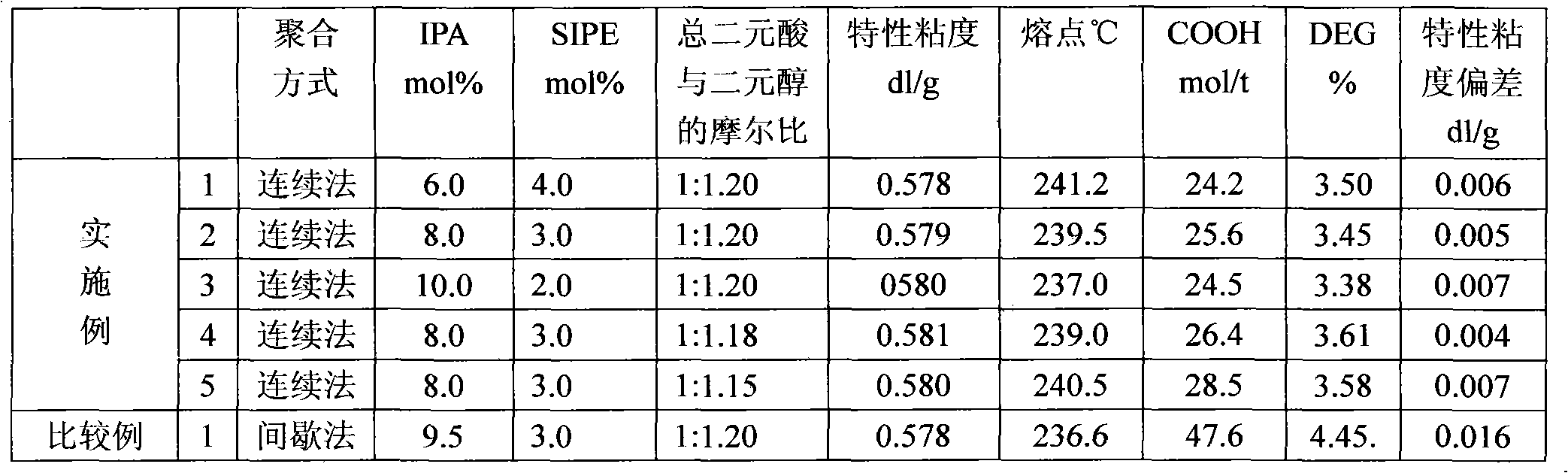

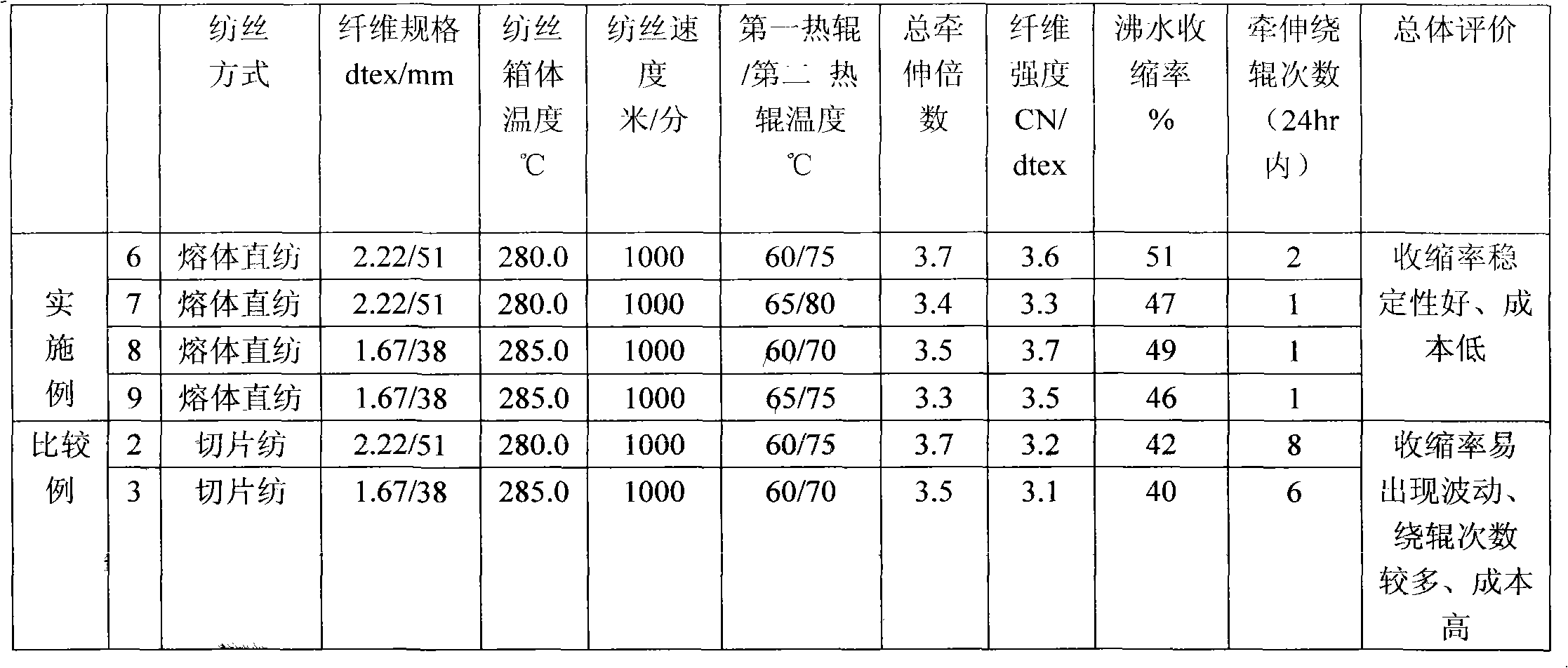

Method for preparing continuous polymerization directly-spun cation-dyeable high-shrinkage polyester staple fibers

InactiveCN101781811AShrinkage stableUniform dyeingFilament forming substance formingMonocomponent copolyesters artificial filamentFiberPolymer science

The invention discloses a method for preparing continuous polymerization directly-spun cation-dyeable high-shrinkage polyester staple fibers. A continuous polyester preparation process is adopted, and comprises a process for preparing continuous polymerization modified copolyester melt and a process for preparing directly-spun cation-dyeable high-shrinkage polyester staple fibers; in the process for preparing the continuous polymerization modified copolyester melt, purified terephthalic acid, isophthalic acid, glycol and sodium ethylene glycol isophthalate-5-sulfonate monomers are taken as raw materials to prepare the modified copolyester melt; and then the modified copolyester melt is metered, extruded, blown to be cooled, subjected to oil finish and strand integration, drawn, heat-shaped, coiled and cut to prepare the cation-dyeable high-shrinkage polyester staple fibers. The method has the advantages of short flow, less working procedures, reasonable process, stable melt quality, and good spinning performance; and the prepared high-shrinkage polyester staple fibers have the advantages of good shrinkage stability and even dyeing, and can be dyed by a cation dye, so the production cost is obviously reduced.

Owner:杭州栋华实业有限公司

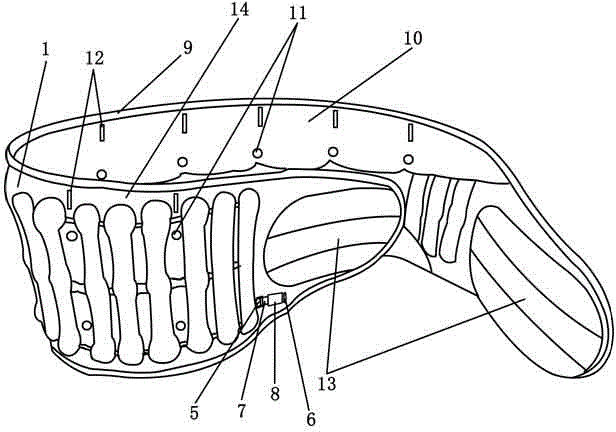

Traction fixing belt for lumbar vertebra

InactiveCN104800045AShrinkage stableMeet structural requirementsChiropractic devicesHuman bodyCotton cloth

The invention relates to the field of medical apparatuses and instruments, and particularly relates to a traction fixing belt for a lumbar vertebra. The traction fixing belt for the lumbar vertebra comprises a belt body, wherein a telescopic air bag layer is arranged in the belt body; the belt body consists of PU (polyurethane) leather, pure-cotton cloth and the telescopic air bag layer; the telescopic air bag layer is formed by using a one-step air bag molding technique; after being inflated, at joints of all transverse air passages and all longitudinal air passages of the telescopic air bag layer, all the longitudinal air passages are outwards convex; the whole air bag layer is in an inverted C shape. The structural requirements of the normal physiological curve of a human body are met much more; the belt is attached to a waist more easily; moreover, an air faucet is provided with an inflation connector; the inflation connector is of a copper structure; the conventional rotation deflation is changed through the connector; the push-pressing deflation is used; the deflation is uniform; the belt shrinks stably; the left end and the right end of the belt body are provided with a hook and loop fastener, so that the traction fixing belt for the lumbar vertebra is more convenient and quicker to use and disassemble.

Owner:王文军

Open-width knitted fabric pre-shrinking machine and pre-shrinking process thereof

ActiveCN104018311AGuaranteed dryingMake sure to ironShrinkingTextile treatment cleaning apparatusShrinkage rateAgricultural engineering

The invention discloses an open-width knitted fabric pre-shrinking machine, comprising an open-width cloth-feeding device, a mechanical weft-straightening device, a steam conditioning and stentering device, a rubber blanket pre-shrinking device and an open-width plaiting device, wherein the front end of the steam conditioning and stentering device is provided with an overfeed pinning device; and a felt finishing device is arranged between the rubber blanket pre-shrinking device. The open-width knitted fabric pre-shrinking machine comprises the felt finishing device; and the fabric is finished by the felt finishing device after passing through the rubber blanket pre-shrinking device, thereby guaranteeing the fabric to be dried and flatten, further improving handfeel of the fabric and increasing glossiness of the fabric surface. Meanwhile, shrinkage rate of the fabric can be more stable, so that the open-width knitted fabric with flat cloth surface, good surface glossiness, good handfeel and stable shrinkage rate can be processed.

Owner:浙江瑞格机械科技有限公司

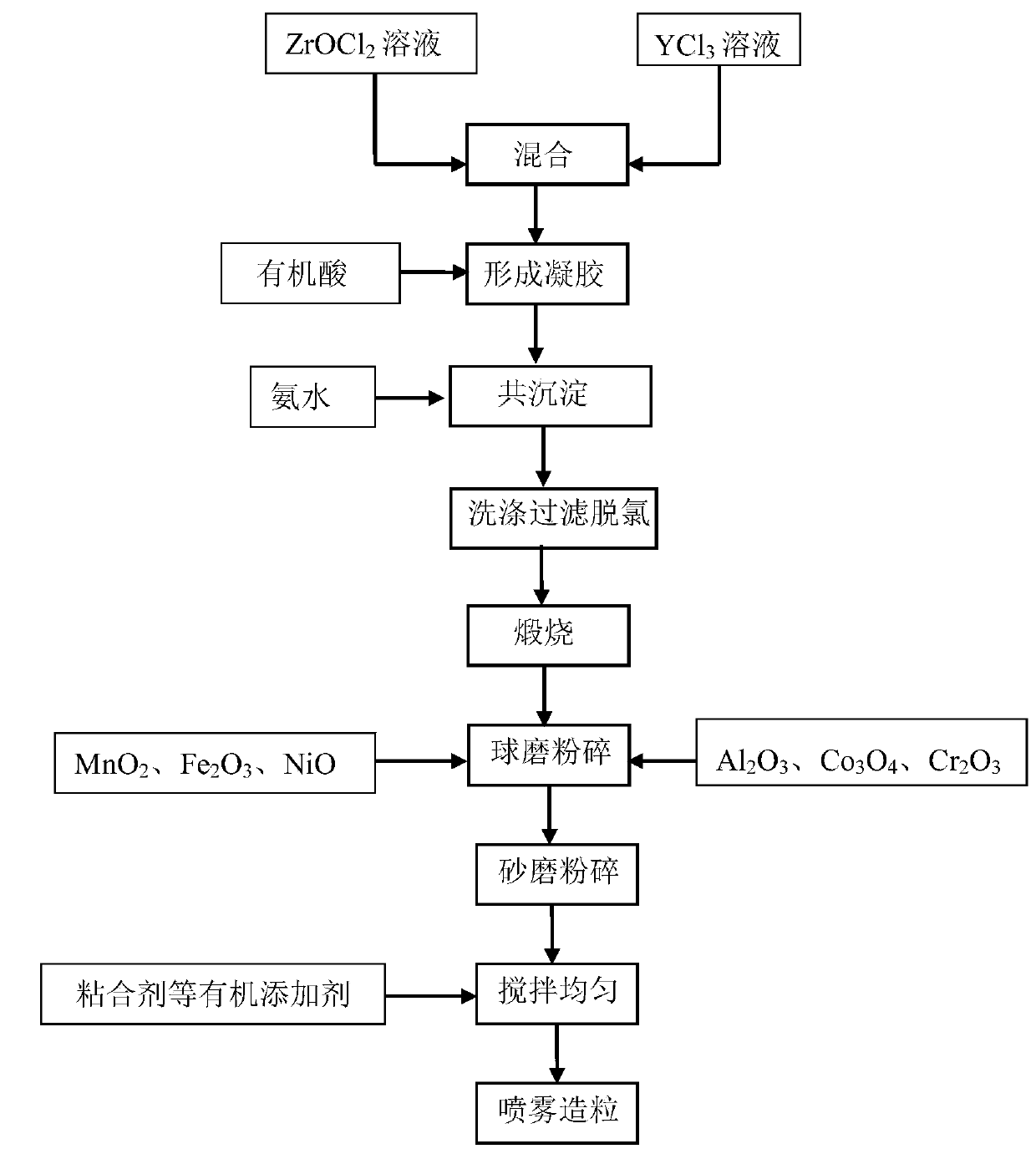

Preparation method of black yttrium-stabilized zirconium oxide powder

ActiveCN111204802AImprove stabilityUniform particle size distributionZirconium oxidesAdhesiveZirconium oxychloride

The invention belongs to the technical field of inorganic new materials, and particularly relates to a preparation method of black yttrium-stabilized zirconium oxide powder. The preparation method comprises the steps: mixing a zirconium oxychloride solution and a yttrium trichloride solution in a proportion; adding an organic acid to generate a gel, adding an ammonia water solution to neutralize and precipitate, washing, filtering and dechlorinating, calcining an obtained filter cake to obtain a precursor powder, adding a coloring agent and a binding agent, ball-milling, sanding and crushing,adding an adhesive and a release agent, uniformly mixing, spraying, granulating and drying to obtain the yttrium-stabilized zirconium oxide powder. The invention relates to the preparation method of black yttrium-stabilized zirconium oxide powder. The process is simple, the yield is high, the produced powder is good in stability, uniform in particle size distribution, good in flowability and stable in shrinkage rate; the sintering temperature is 1350 DEG C, which is 100 DEG C lower than the temperature of common zirconium oxide ceramic production, moulding is convenient, the blank strength ishigh, the processability is good, and black ceramic products prepared from the powder has the advantages of high strength, good toughness, good stability and the like.

Owner:长裕控股集团股份有限公司

1,2-propylene glycol modified terylene fully drawn yarn

InactiveCN102787383AStable fiber shrinkageUniform dyeingSpinning head liquid feederArtificial thread manufacturing machinesChemistryDyeing

The present invention relates to a preparation method for a 1,2-propylene glycol modified terylene fully drawn yarn. The method comprises preparation steps of a condensation polymerization modified polyester melt and a preparation process of a direct spinning terylene fully drawn yarn (FDY). In the preparation process of the condensation polymerization modified polyester melt, p-phthalic acid (PTA), 1,2-propylene glycol, and an ethylene glycol (EG) monomer are adopted as raw materials to prepare a modified copolyester melt; the resulting polyester melt is directly subjected to melt conveying, extruding with a metering pump and a spinning assembly, air blowing cooling and oiling, then passes through a channel, a first godet roller and a second godet, and is finally subjected to winding to prepare the modified terylene fully drawn yarn. The modified terylene fully drawn yarn prepared by the method of the present invention has characteristics of stable fiber shrinkage, uniform dyeing, and excellent spinning performance.

Owner:JIANGSU YINGXIANG FIBER

Anti-pilling and washable wool knitted trousers material and process for preparing same

InactiveCN106757714AShrinkage stablePrevent pillingWeft knittingHeating/cooling textile fabricsPolyesterPolymer science

The invention discloses an anti-pilling and washable wool knitted trousers material and a process for preparing the same. The anti-pilling and washable wool knitted trousers material is a jacquard double-faced fabric and comprises fabric faces and fabric bottoms. Cotton yarns and wool yarns are patterned to form the fabric faces; wool yarns and polyester filaments are interwoven with one another to form the fabric bottoms; Australian wool silver, acrylic fibers and viscose fibers are blended to obtain the wool yarns. The process includes carrying out dyeing, silver mixing and combing treatment and carrying out spinning by the aid of a spinning frame to obtain single yarns; carrying out automatic winding, doubling and re-twisting and yarn steaming treatment on the single yarns; weaving the wool yarns, the polyester filaments and the cotton yarns to obtain grey fabrics of the jacquard double-faced fabric; carrying out fulling and washing treatment on the grey fabrics of the jacquard double-faced fabric and then drying the grey fabrics of the jacquard double-faced fabric; carrying out water type approval and over-feed treatment, shearing technologies and decatizing on the dried grey fabrics of the jacquard double-faced fabric to obtain the anti-pilling and washable wool knitted trousers material. The anti-pilling and washable wool knitted trousers material and the process have the advantages that the anti-pilling and washable wool knitted trousers material which is a fabric is high in yarn count density, tight in weaving and good in fuzzing and pilling performance and is difficult to shrink after being washed.

Owner:LILANG CHINA

Production process of snow-wash jean cloth

InactiveCN105755658AShrinkage stableStable weightFabric breaking/softeningSolvent-treatmentGramReduction ratio

The invention discloses a production process of snow-wash jean cloth. The production process particularly comprises the following steps of cloth feeding, water infiltration, weft finishing, overfeeding, baking, float stone dry grinding, plate aligning and cleaning, neutralization, softening agent applying and shaping. According to the production process, the situation of fading of jean cloth can be effectively alleviated, furthermore, the stabilities of reduction ratio and gram weight of the jean cloth are guaranteed, the shaping property is good, and an optimal cloth surface condition is created for production of clothes.

Owner:TAICANG QIDE GARMENT

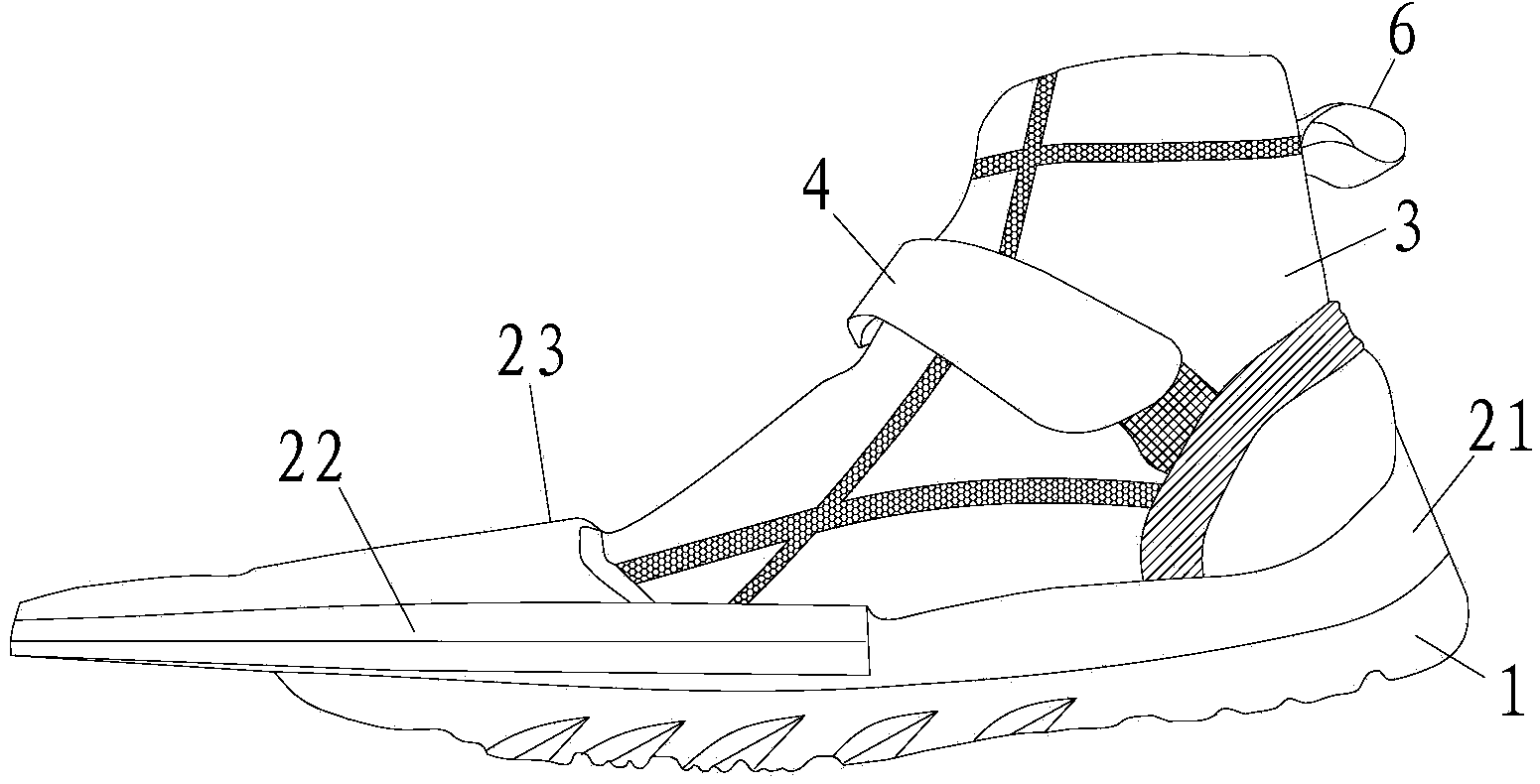

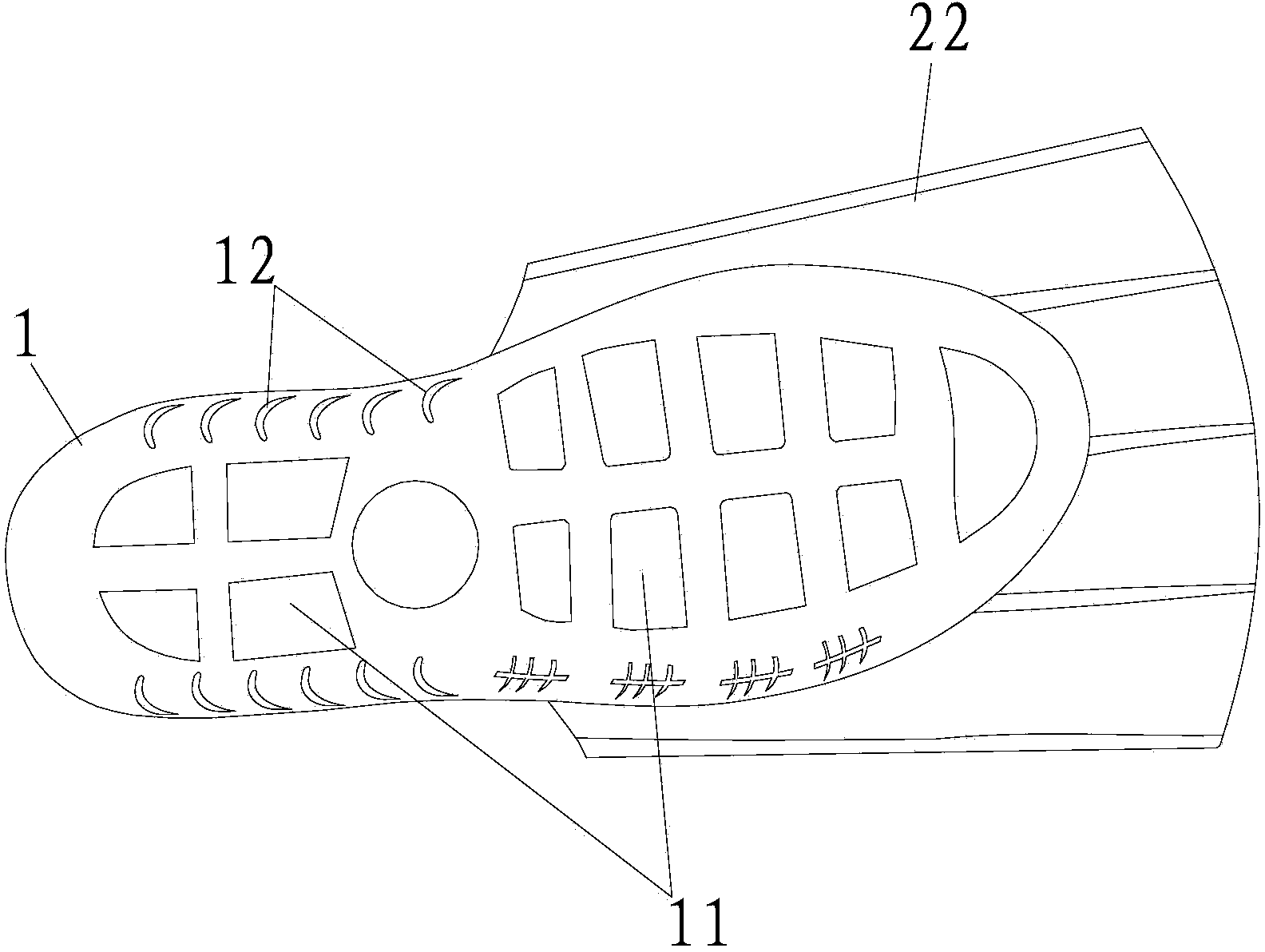

Flippers

The invention discloses a pair of flippers. Each flipper comprises an outsole, a mid-sole and a shoe vamp which are arranged in sequence from bottom to top, wherein the shape and the size of the outsole are matched with those of a foot of a human body; the outsole is a rubber outsole made of rubber; the mid-sole comprises a supporting part matched with the outsole in shape and size and a web-shaped swimming part outwards extending along the edge of the foot sole part of the supporting part; the mid-sole is a polyurethane mid-sole made of polyurethane; the shoe vamp is formed by stitching a diving suit fabric; the mid-sole is integrally formed by the polyurethane by an upper connection injection molding technology and is integrally connected with the shoe vamp and the outsole respectively in the upper connection injection molding process; a containing cavity for containing the whole foot of the human body is formed between the supporting part of the mid-sole and the shoe vamp. The invention discloses the flippers which are simple in structure and convenient to use; the flippers can be used during diving and walking on the land and have the characteristics of softness, durability, shock absorption, slippage resistant and wearing comfortability.

Owner:广州市宏来鞋业有限公司

Method for producing biaxially oriented multilayer co-extruded polyolefin shrink film by flat film process

ActiveCN102765190AAvoid compromising appearance qualityLow melting pointLow-density polyethylenePolymer science

The invention relates to a method for producing a biaxially oriented multilayer co-extruded polyolefin shrink film by a flat film process, which comprises the following steps: adding 95-97% of ternary-polymerized polypropylene (PP) and 3-5% of silicon dioxide using PP copolymer as a carrier into two surfaces of the co-extruded polyolefin shrink film, adding C6 linear low-density polyethylene (C6-LLDPE) into a core layer, sufficiently fusing and plastifying in an extruder at 220-250 DEG C, extruding by a hanger-type die, processing a thick piece into a film and then longitudinally / horizontally stretching, and then hauling and coiling. The method provided by the invention has advantages of high annual productivity and stable product shrinkage rate.

Owner:江苏恒创包装材料有限公司

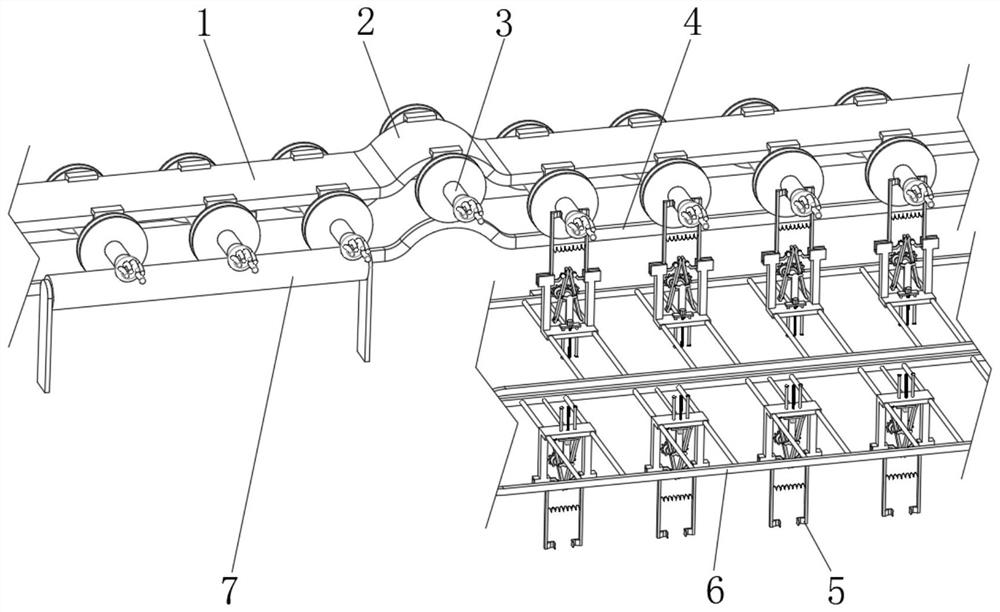

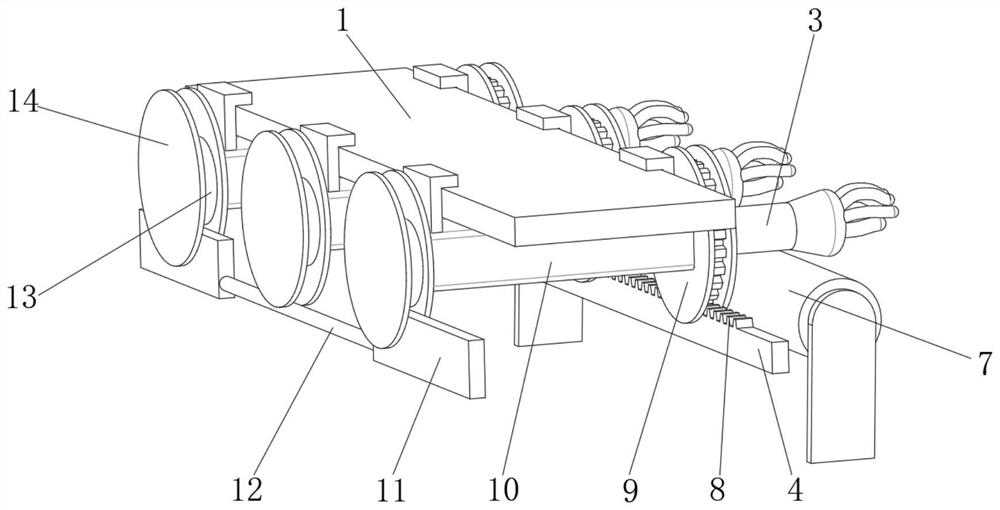

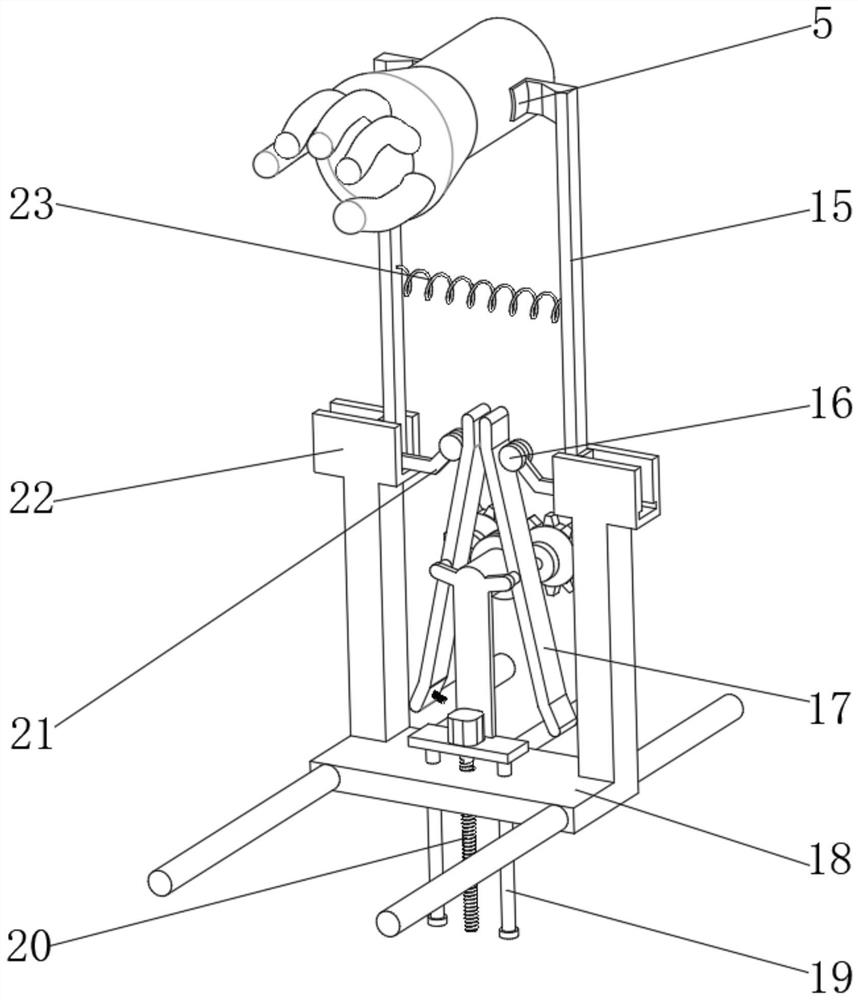

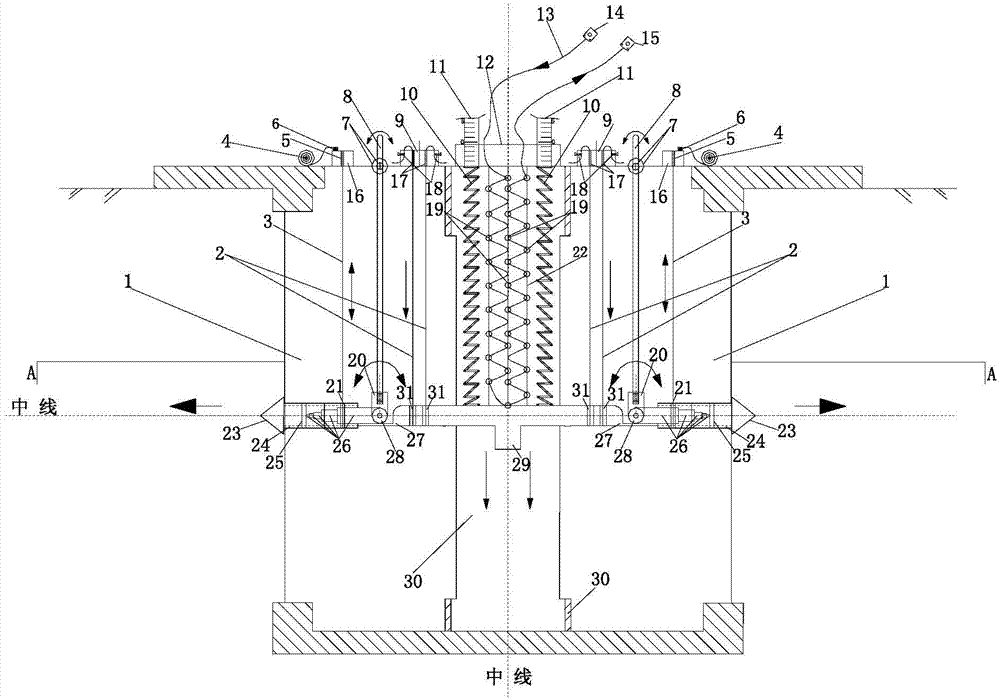

Automatic demolding machine for medical gloves

ActiveCN112476879AImprove device reliabilityImprove stabilityDomestic articlesElectric machineryEngineering

The invention discloses an automatic demolding machine for medical gloves, and relates to the technical field of automatic demolding machines for the gloves. Demolding is realized without participation of a blow-off mechanism. The automatic demolding machine specifically comprises a mold conveying rail used for conveying glove molds and a demolding rail with demolding mechanisms, the glove molds are installed on the mold conveying rail through a conveying fixing seat, the demolding rail is arranged below the mold conveying rail, the demolding mechanisms are evenly distributed on the demoldingrail, and the demolding mechanisms comprise demolding clamps, demolding bases and lifting motors; and a pushing mechanism for pushing the demolding mechanisms to longitudinally move relative to the glove molds is further arranged on one side of the demolding rail. By arranging a lifting stud, the lifting motors, a rotating rod and other structures, a mounting frame can be driven to perform liftingmotion, rolling wheels correspondingly slide on the outer wall of the rotating rod, the motion trails of the rolling wheels are limited through the acting force between the rotating rod and the rolling wheels, and the demolding clamps can achieve demolding without the participation of the blow-off mechanism.

Owner:苏州维凯医用器材科技有限公司

Device and method for monitoring differential settlement in portfolio for soil-stone combined region with hydraulic structure

ActiveCN104501772AEasy to disassembleFlexible liftingHeight/levelling measurementHydraulic structureRepeatability

The invention discloses a device and a method for monitoring differential settlement in portfolio for a soil-stone combined region with a hydraulic structure. The device comprises a bottom-through shaft and an inner carrying tube positioned inside the bottom-through shaft, wherein a displacement station is arranged in the inner carrying tube; drill driving devices are symmetrically arranged on two sides of the displacement station, and are connected with conical drills; the drill driving devices on two sides are respectively connected with lifting devices which are used for promoting motion of the drill driving devices; correcting devices which are used for correcting level of the displacement station are symmetrically arranged at two ends of the displacement station; the middle part of the displacement station is connected with one end of a group of symmetrically arranged springs, and the other end of each spring is hinged with a vertical measuring tape; an optical fiber hanging drum is arranged between two springs, and is filled with a corrugated loop optical fiber; and an optical fiber buckle is arranged on the corrugated loop optical fiber. The device has the advantages of use repeatability, convenience in assembly, real-time detection and maintenance and the like, and has the characteristics of distribution type, micro-macro structure, real-time performance, high adaptability to complex environment and the like.

Owner:HOHAI UNIV

Bionic robot with flying and climbing functions

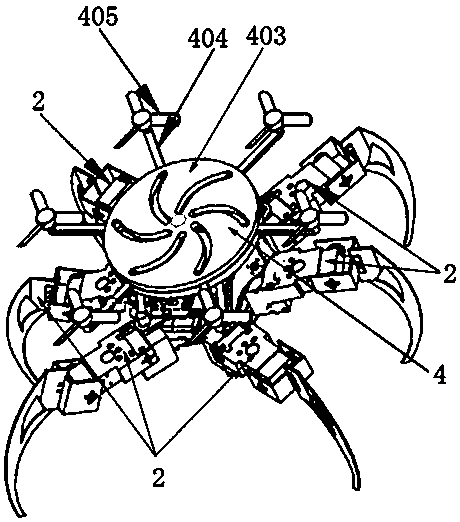

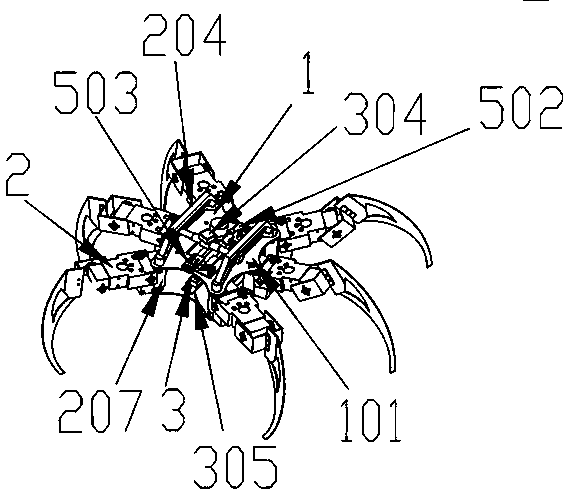

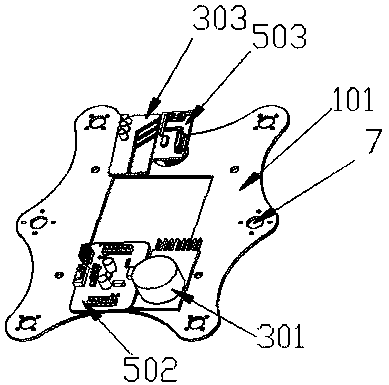

PendingCN108382487AImprove stabilityImprove the ability to adapt to various complex terrainFuselagesAir-flow influencersTerrainBionics

A bionic robot with flying and climbing functions comprises an aircraft, a base and climbing mechanisms. The base comprises an upper basal body platform and a lower basal body platform. The climbing mechanisms each comprise a hip bone member, a thigh member, a shank member, a connecting frame, a first steering engine, a second steering engine and a third steering engine. The two ends of output shafts of the first steering engines are connected with the base, and through rotation of the output shafts of the first steering engines, mutual rotation of the climbing mechanisms and the base in the horizontal direction is achieved; the hip bone members and the thigh members are connected through the second steering engines, and through rotation of output shafts of the second steering engines, mutual rotation of the hip bone members and the thigh members in the vertical direction is achieved; and the thigh members and the connecting frames are connected through the third steering engines, andthrough rotation of output shafts of the third steering engines, mutual rotation of the thigh members and the connecting frames in the vertical direction is achieved. According to the bionic robot with the flying and climbing functions, the capability that the robot adapts to various complicated terrains is improved, the bionic robot has the fly capability, the searching range is expanded, the diversity and portability of a manipulation terminal platform are promoted, and the high obstacle-crossing capability is achieved.

Owner:LUOYANG INST OF SCI & TECH

Manufacture method for producing high-shrinkage regenerated terylene short fiber with recovered polyester bottle chips

ActiveCN102864516ASolve the problem that the modified shrinkage rate is not highFix stability issuesFilament forming substance formingArtificial filament heat treatmentFiberPolyester

The invention relates to regenerated terylene short fiber production technology, in particular to a manufacture method for producing high-shrinkage regenerated terylene short fiber with recovered polyester bottle chips. The manufacture method comprises the steps as follows: drying amorphous polyester chips through a low-temperature drying method; mixing the dried amorphous polyester chips with common PET (polyethylene terephthalate) bottle chips; putting the uniformly mixed chips and the bottle chips into a spinning material bin, and then putting into a screw for extruding and smelting so as to obtain smelt; conveying the melt which meets the spinning requirement to a a filter under the effect of a melt conveying pump for filtering, and then putting into a spinning box body; spinning while metering, cooling and applying oil, pulling to feed, and falling into a barrel; finally stretching at low temperature during the post-processing of as-spun fiber. The manufacture method provided by the invention has the characteristic of being high in heat absorbing property; and the production of regenerating the high-shrinkage regenerated terylene short fiber can be achieved.

Owner:宁波大发新材料有限公司

Fabric brushing process

InactiveCN105063949AGram weight is easy to controlShrinkage stableSucessive textile treatmentsSolvent-treatmentProcess engineeringDyeing

A fabric brushing process comprises dyeing and finishing operation and is characterized in that the dyeing and finishing operation comprises the following steps: 1), loop drying of a blank; 2), scutching and rolling with a fuzzing agent; 3), brushing; 4), setting. The fabric brushing process has the following steps: in the fabric brushing process, the steps including blank loop drying, scutching and rolling with the fuzzing agent, high-temperature setting and the like are added, specific processes are optimized, so that the dyelot chromatism is basically avoided for the fabric brushing style, the gram weight is easier to control, and the shrinkage is stable.

Owner:NINGBO DAQIAN TEXTILE

Modified terylene fully drawn yarn (FDY) with good abrasion resistance performance

InactiveCN102330184AImprove wear resistanceShrinkage stableSpinning head liquid feederMelt spinning methodsYarnFiber

The invention relates to a method for preparing modified terylene fully drawn yarns (FDYs) with good abrasion resistance performance, which comprises a polycondensation modified polyester melt preparation step and a direct spinning terylene FDY preparation process, wherein in the polycondensation modified polyester melt preparation process, terephthalic acid (PTA) and ethylene glycol (EG) monomers are used as raw materials, in addition, nano silicon dioxide is added for preparation to obtain the modified copolyester melt, the modified copolyester melt is directly carried out melt conveying, and the modified terylene FDYs are prepared through metering, spinning assembly extrusion, air blowing cooling, oiling, course ways, a first yarn guide roller, a second yarn guide roller and coiling process. The modified terylene FDY fiber prepared by the method provided by the invention has good abrasion resistance performance and also has better reflecting capacity on ultraviolet rays, the prepared fiber has stable shrinkage rate, the dyeing is uniform, and the spinning performance is excellent.

Owner:JIANGSU YINGXIANG FIBER

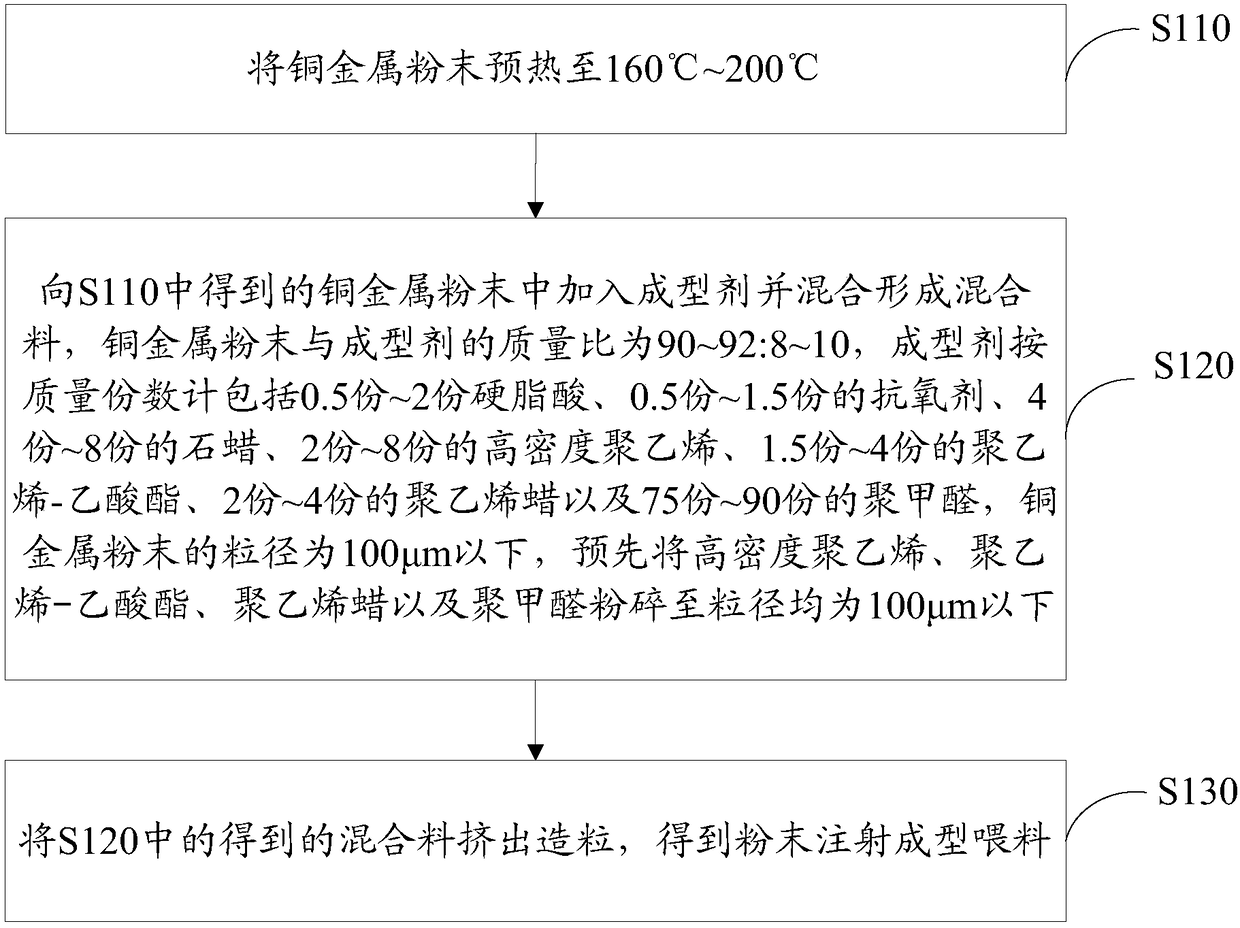

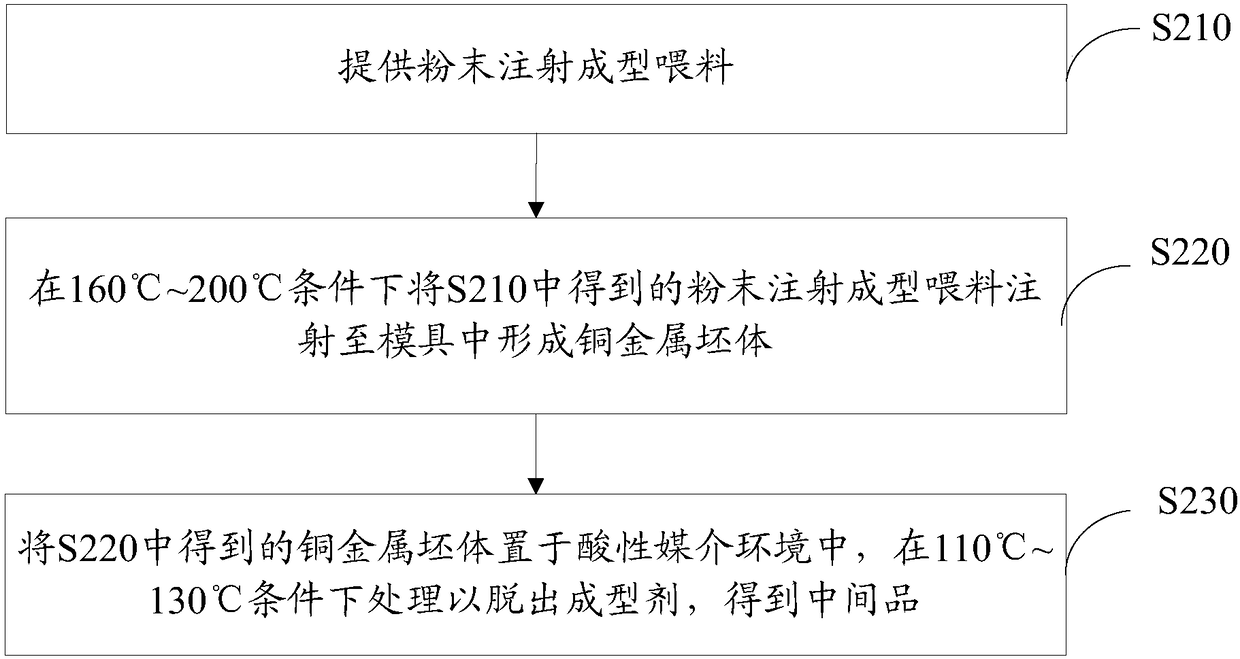

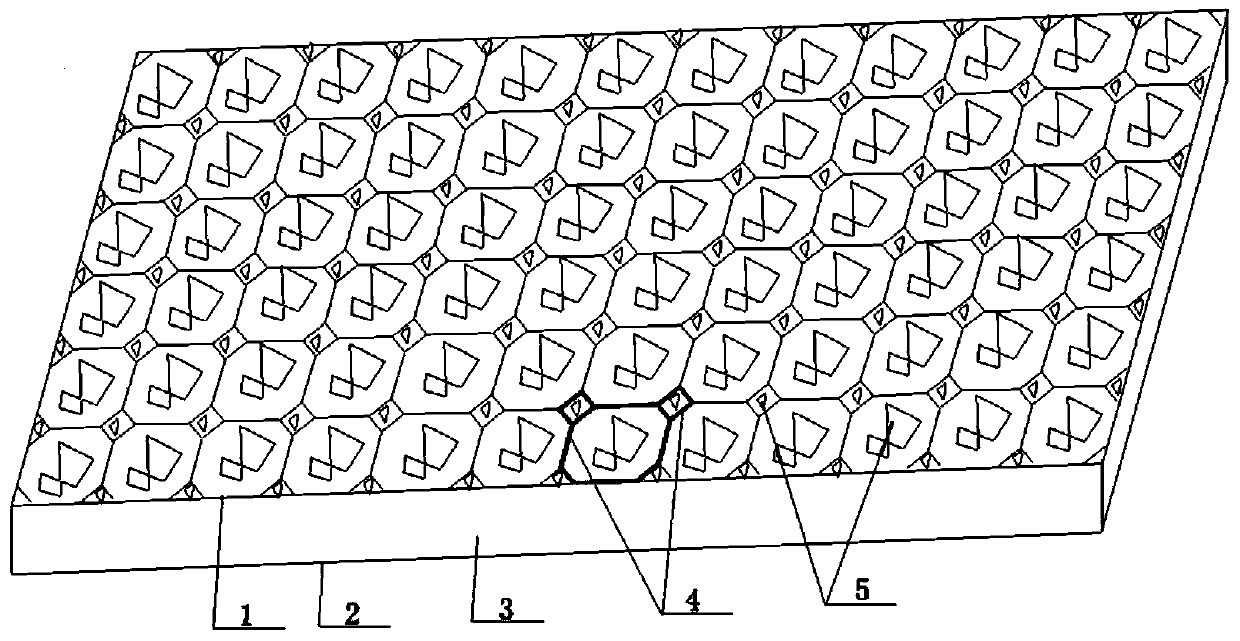

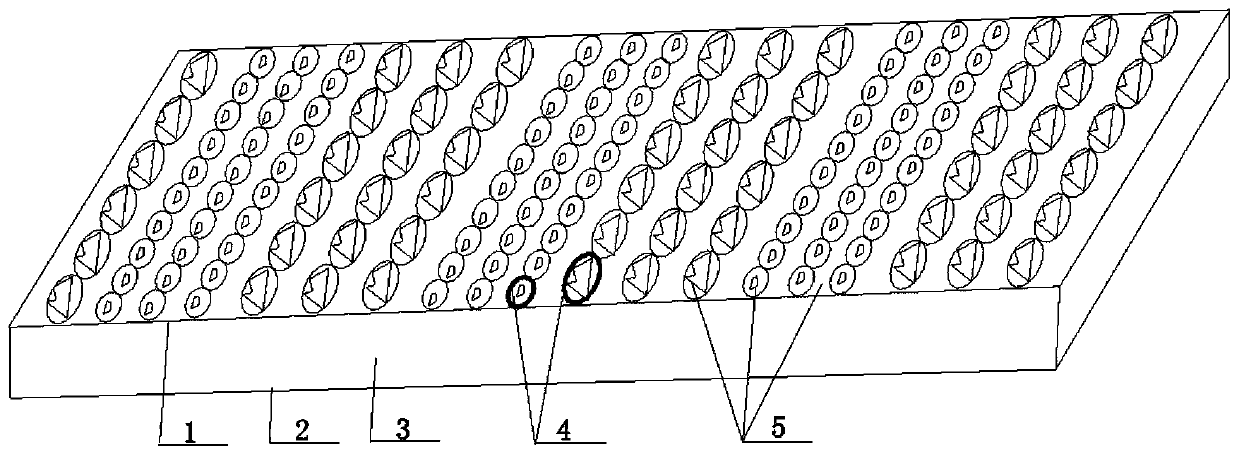

Powder injection molding feedstock, and preparation method and application thereof

ActiveCN108311689AShrinkage stableAvoid deformationTransportation and packagingMetal-working apparatusParaffin waxMass ratio

The invention discloses a powder injection molding feedstock, and a preparation method and application thereof. The powder injection molding feedstock comprises copper metal powder and a forming agent, and the mass ratio of the copper metal powder to the forming agent is (90-92):(8-10); and the forming agent comprises, by mass, 0.5-2 parts of stearic acid, 0.5-1.5 parts of antioxidants, 4-8 partsof paraffin, 2-8 parts of high density polyethylene, 1.5-4 parts of polyethylene-acetate, 2-4 parts of polyethylene wax, and 75-90 parts of polyformaldehyde. The grain size of each of the polyethylene-acetate, the polyethylene wax and the polyformaldehyde is 100 [mu]m or below and is at the same grain size level with the copper metal powder, so that the forming agent can be melted within the shorttime, the high-temperature mixing time is reduced, and ingredient volatilization is reduced. A cooper metal product prepared through the feedstock is stably shrunk and not prone to deforming after being sintered.

Owner:DONGGUAN HUAJING POWDER METALLURGY

Dyeing process of T/R cloth

The invention discloses a dyeing process of T / R cloth. The process comprises the steps of grey cloth preparation, pre-shaping, singeing, enzyme processing, washing, dispersion priming, dyeing, color fixing, post-treating, product inspecting, and packaging. According to the invention, with the added pre-shaping step, crinkle marks can hardly form during a cloth dyeing process, and unit-area mass, washing shrinkage, and the like of a fabric can be stabilized. Therefore, product stability is promoted. The process provided by the invention is simple, such that the process is suitable for industrialized productions.

Owner:TAICANG MINGLIU GARMENT

Thick warp-knitted spacer-fabric three-dimensional quilted mattress cover material and preparation method thereof

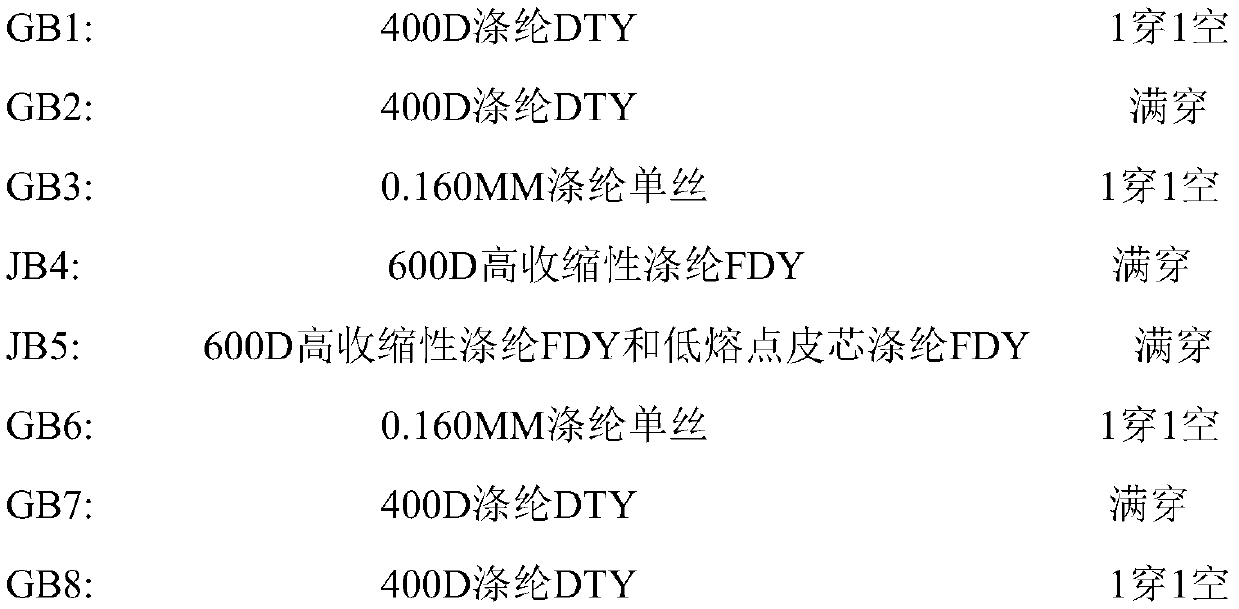

ActiveCN109898227AReduce production processShorten the production cycleWarp knittingHeating/cooling textile fabricsYarnBiomedical engineering

The invention discloses a thick wrap-knitted spacer-fabric three-dimensional quilted mattress cover material and a preparation method thereof. The cover material is provided with two jacquard combs and six floor combs, the comb bar arrangement from the front to the back of the machine is that GB1 and GB2 are only woven in the front needle bed, GB3, JB4, JB5 and GB6 are successively woven in a circle on the front and back needle beds, and GB7 and GB8 are only woven on the back needle bed; GB1 and GB2 pierce first and second system yarn, and GB7 and GB8 pierce the seventh and eighth system yarn; GB3 and GB6 pierce the third and sixth system yarn; JB4 and JB5 pierce the fourth and the fifth system yarn. The preparation method includes that the GB1 and the GB2 pierce the first and second system yarn in a full or empty manner; the GB7 and the GB8 pierce the seventh and eighth system yarn in a full or empty manner; the GB3 and the GB6 pierce the third or sixth system yarn in a full or empty manner; the JB4 pierces the fourth system yarn in a full manner, and the JB5 pierce the fifth system yarn in a full manner; woven fabric is thermally finished.

Owner:福建福联精编有限公司

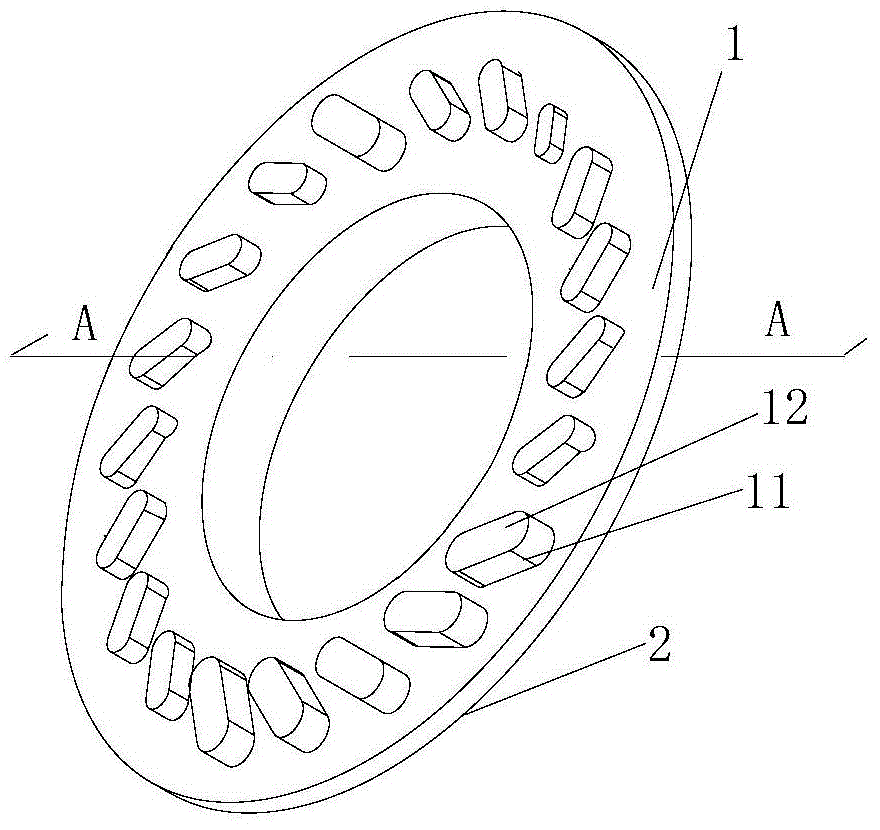

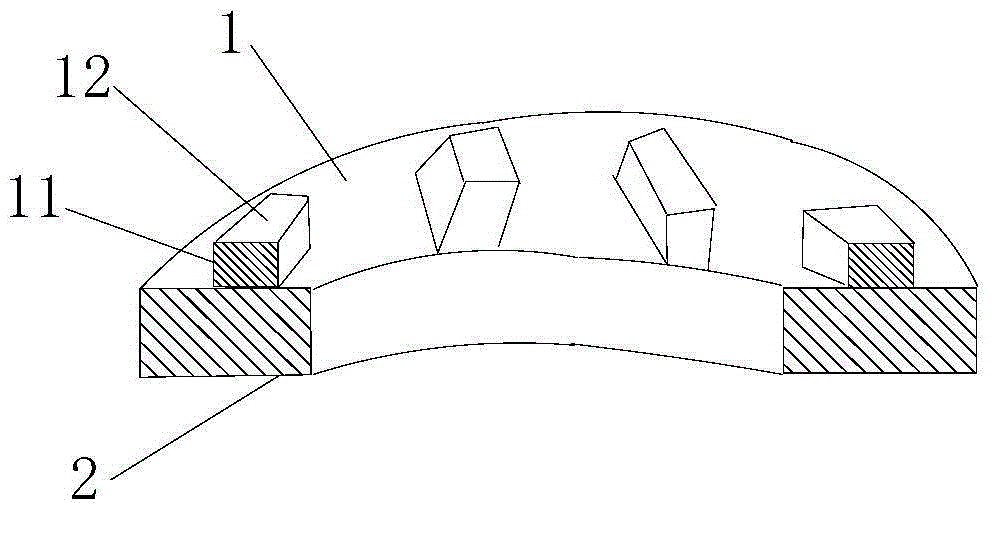

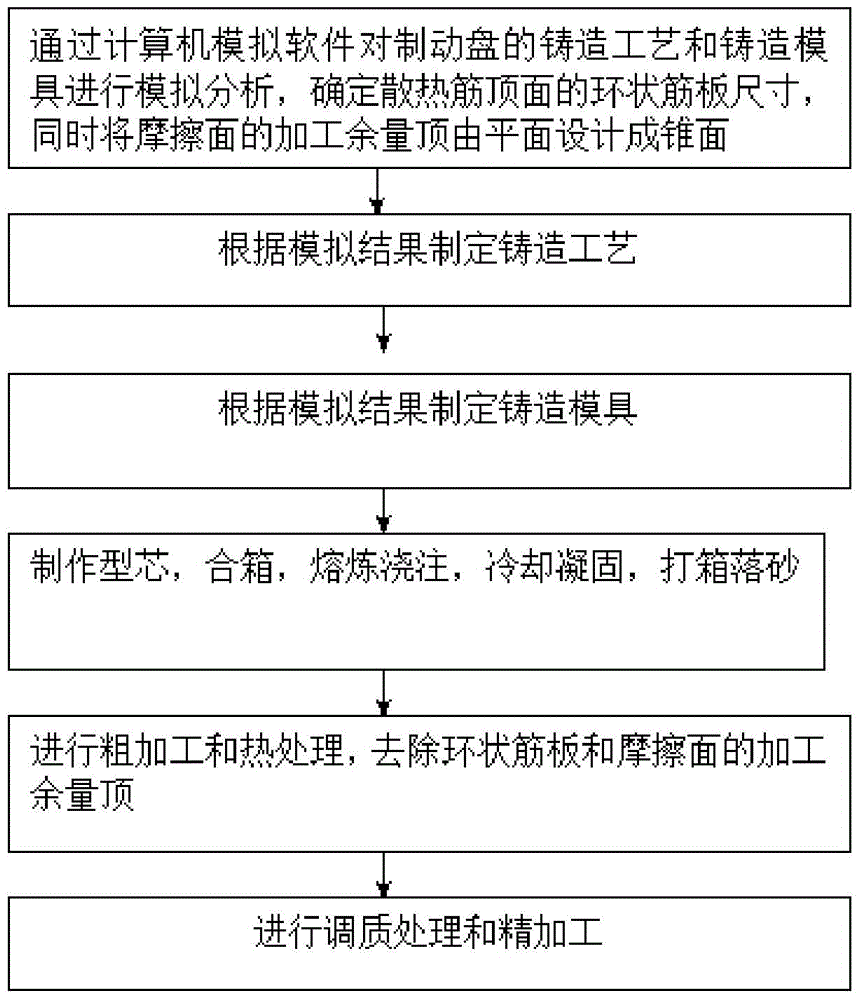

Wheel-like braking disc production method and wheel-like braking disc produced by using wheel-like braking disc production method

ActiveCN106392016ASolve warping deformationSolve defects that form wavy surfacesBraking discsFoundry mouldsDynamic balanceEngineering

The present invention relates to a wheel-like braking disc production method and a wheel-like braking disc produced by using the wheel-like braking disc production method. According to the present invention, during the wheel-like braking disc casting process, an integral and annular rib plate is additionally arranged on the heat dissipation rib top surface of the heat dissipation surface of a braking disc, the annular rib plate and the braking disc are subjected to one casting molding, and the heat dissipation rib top surfaces are connected one by one to form a stable annular frame structure with double rings arranged on the upper surface and the lower surface; during the cooling solidification process after the casting, the annular rib plate on the heat dissipation rib top surface is firstly solidified so as to fix a heat dissipation rib, such that the shrinkage is significantly uniform when the cast is cooled, and the warping deformation generated due to the asymmetric geometrical size of the cast can be avoided; the machining allowance top surface of the friction surface of the braking disc is designed into to a tapered surface so as to increase the cast deformation resistance and make the cast maintain the stabilized shrinkage; and after the cooling molding, the annular rib plate is removed through the machining and the machining allowance top surface of the friction surface is processed into the plane, such that the cast structure shape is not affected, and the product dynamic balance detection qualification rate is substantially improved.

Owner:JIANGSU DINGTAI ENG MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com