Open-width knitted fabric pre-shrinking machine and pre-shrinking process thereof

A pre-shrinking machine and open-width technology, which is applied in the direction of compressing water, textiles and papermaking, and fabric surface trimming, can solve the problems of steam waste increasing factory production costs, steam waste, and wasted steam, etc., to improve hand feeling, Save steam and feel good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below by means of the accompanying drawings and examples.

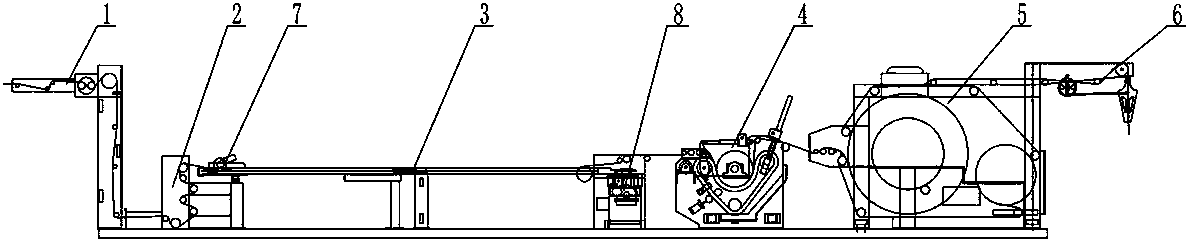

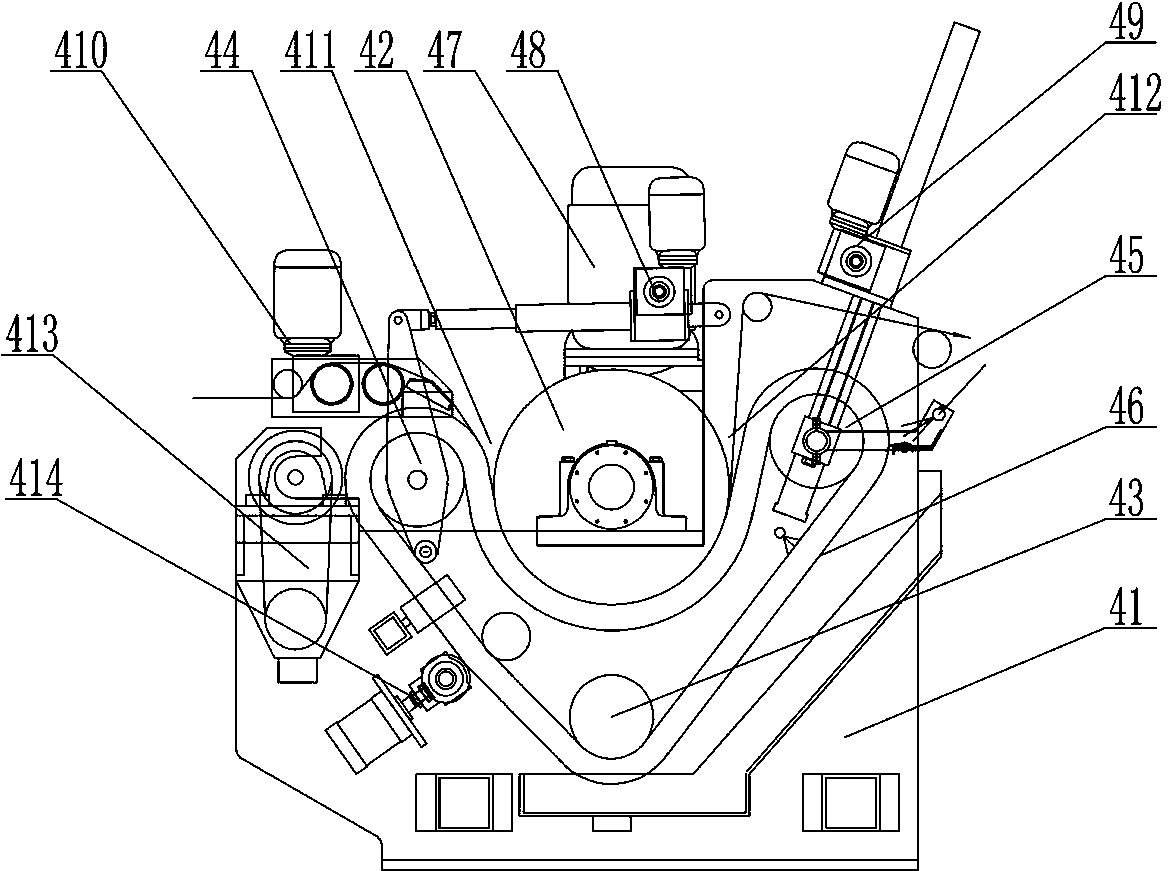

[0030] Such as figure 1 Shown: a flat-width knitting pre-shrinking machine, including a flat-width cloth feeding device 1, a mechanical weft adjustment device 2, a steam wet tenter device 3, a rubber blanket pre-shrinking device 4 and a flat-width doffing device 6 arranged in sequence, The front end of the steam feeding wet tentering device 3 is provided with an overfeeding needle device 7 , and a woolen blanket finishing device 5 is provided between the rubber blanket preshrinking device 4 and the flat width doffing device 6 .

[0031] The open-width cloth feeding device 1 is used to smoothly introduce the cloth into the machine, and it includes a walking platform bridge, several cloth guide rollers and an infrared centering expansion device arranged on the walking platform bridge. The width device selects SDC10223 sliding bar type correction infrared centering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com