Dish-washing machine with oxygen sensor and control method of dish-washing machine

A technology of an oxygen sensor and a control method, which is applied to the washing machine/washing machine of tableware, parts of the washing machine/rinsing and washing machine of tableware, household appliances, etc., can solve the problem of unsatisfactory detection results, affecting user experience, dishwasher Inner cavity odor and other problems, to achieve the effect of simple structure, long service life and thorough drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

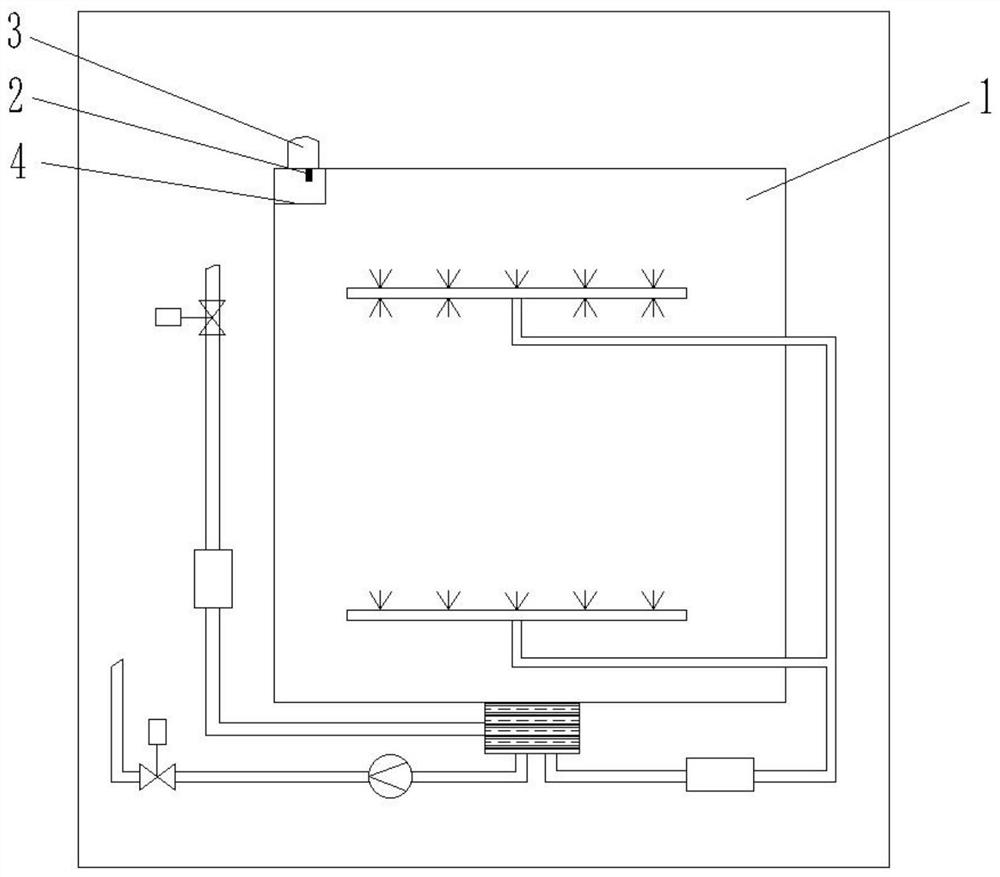

[0045] Embodiment one: if figure 1 with figure 2 As shown, this embodiment provides a dishwasher with an oxygen sensor, including a dishwasher cavity 1, an oxygen sensor 2, a controller and a drying module, and a spray arm is arranged in the dishwasher cavity 1, In addition, an exhaust channel 3 is provided on the inner cavity 1 of the dishwasher, and the oxygen sensor 2 is arranged in the inner cavity 1 of the dishwasher or in the exhaust channel 3, and the controller is electrically connected to the oxygen sensor 2 and the drying module. , the controller is used to judge whether the inner cavity 1 or the exhaust passage 3 of the dishwasher has reached the drying condition according to the data fed back by the oxygen sensor 2. The drying module includes a fan and a heating pipe. The fan is used to use the heat generated by the heating pipe to Blow to the dishwasher cavity 1 to dry the dishwasher cavity 1.

[0046] This embodiment provides a dishwasher with an oxygen sensor...

Embodiment 2

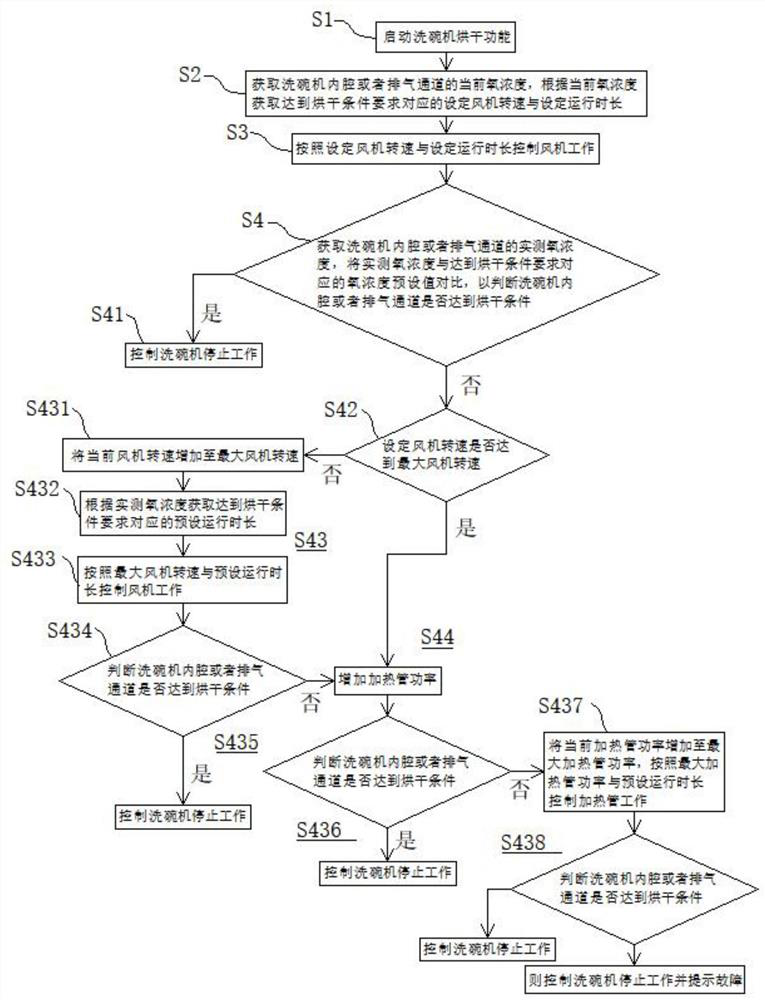

[0054] Embodiment two: if figure 1 and figure 2 As shown, this embodiment provides a control method for a dishwasher with an oxygen sensor, which is applied to a dishwasher with an oxygen sensor as described in Embodiment 1. The control method includes the following steps:

[0055] S1, start the drying function of the dishwasher;

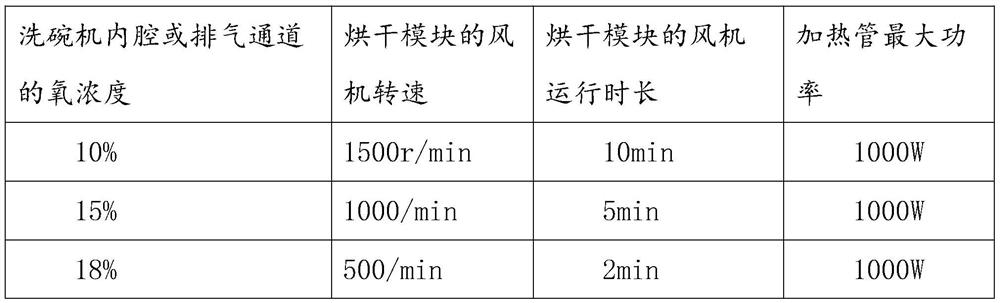

[0056] S2, obtain the current oxygen concentration of the dishwasher cavity 1 or the exhaust passage 3, and obtain the set fan speed and the set running time corresponding to the drying conditions according to the current oxygen concentration. In this embodiment, in order to improve the detection of oxygen The accuracy of the concentration, single or multiple oxygen sensors 2 can be set in the dishwasher cavity 1 or in the exhaust channel 3 to detect the multi-point oxygen concentration in the dishwasher cavity 1 or in the exhaust channel 3, And calculate the average oxygen concentration value according to the oxygen concentration of multiple point...

Embodiment 3

[0070] Embodiment three: as figure 1 and figure 2 As shown, this embodiment provides a control method for a dishwasher with an oxygen sensor, which is different from the control method for a dishwasher with an oxygen sensor provided in Embodiment 2 in that the control method for washing dishes is controlled in step S42. The actions performed by the machine that do not meet the drying conditions include:

[0071] Determine whether the set fan speed reaches the maximum fan speed. In this embodiment, the maximum fan speed of the drying module is 2000r / min;

[0072] If not, enter step S43, increase the current fan speed to the maximum fan speed, and run at the maximum fan speed until the inner cavity or the exhaust channel reaches the drying condition;

[0073] If yes, go to step S44, increase the power of the heating tube to run until the inner cavity or the exhaust channel reaches the drying condition.

[0074] The above steps are designed reasonably. If the inner cavity 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com