Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

122results about How to "Guaranteed drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

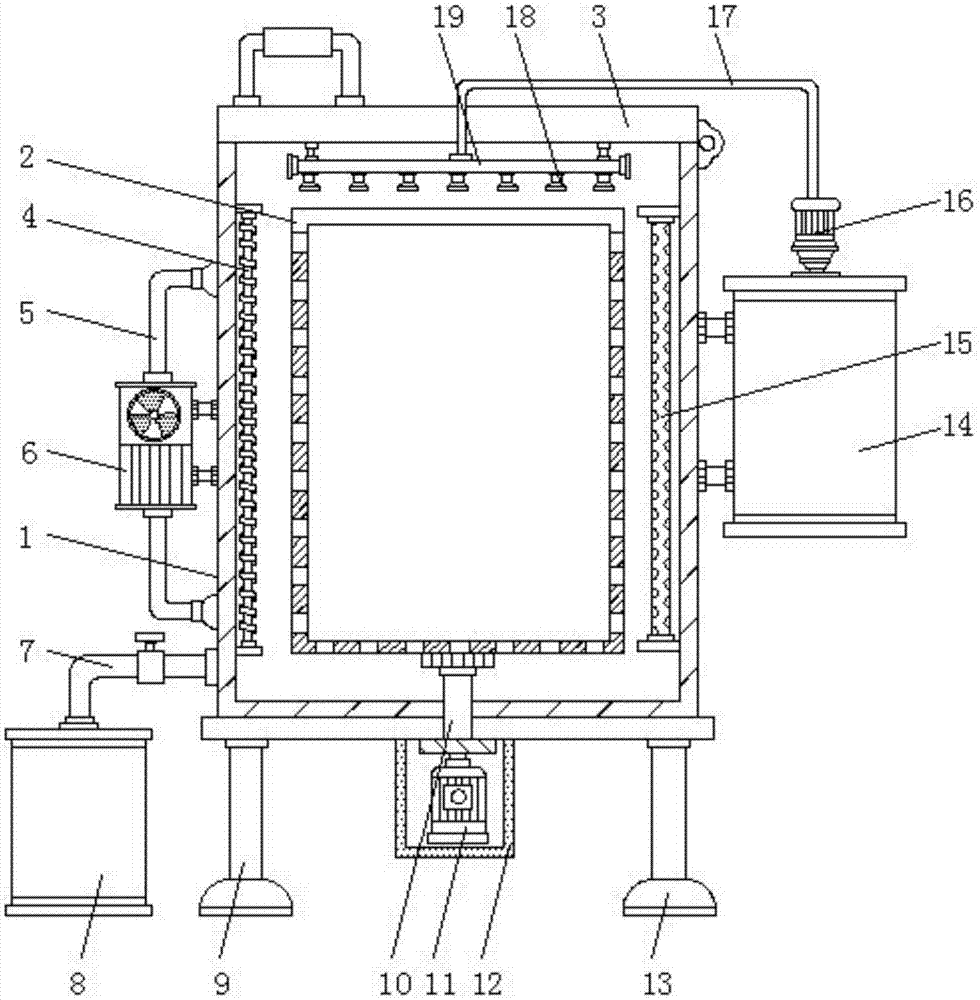

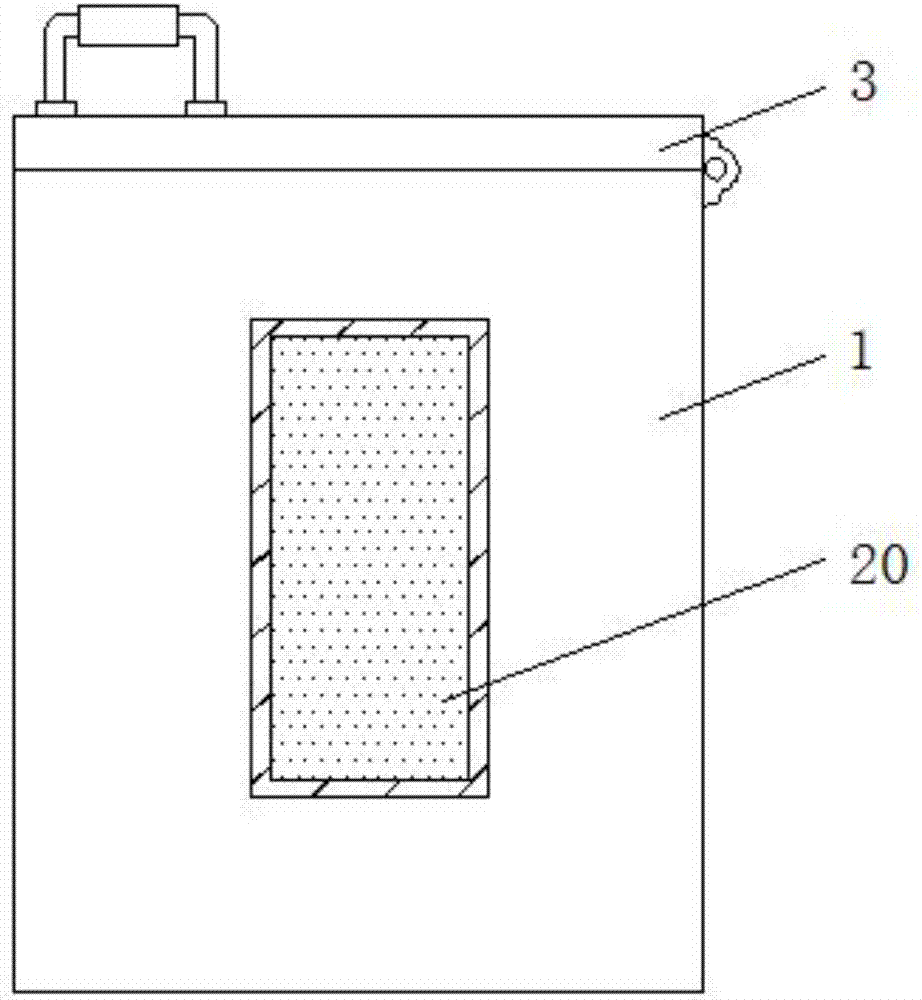

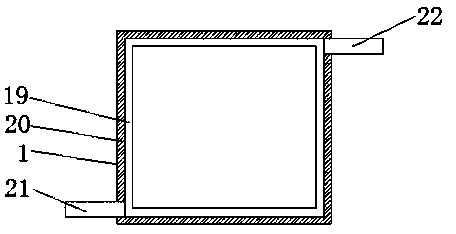

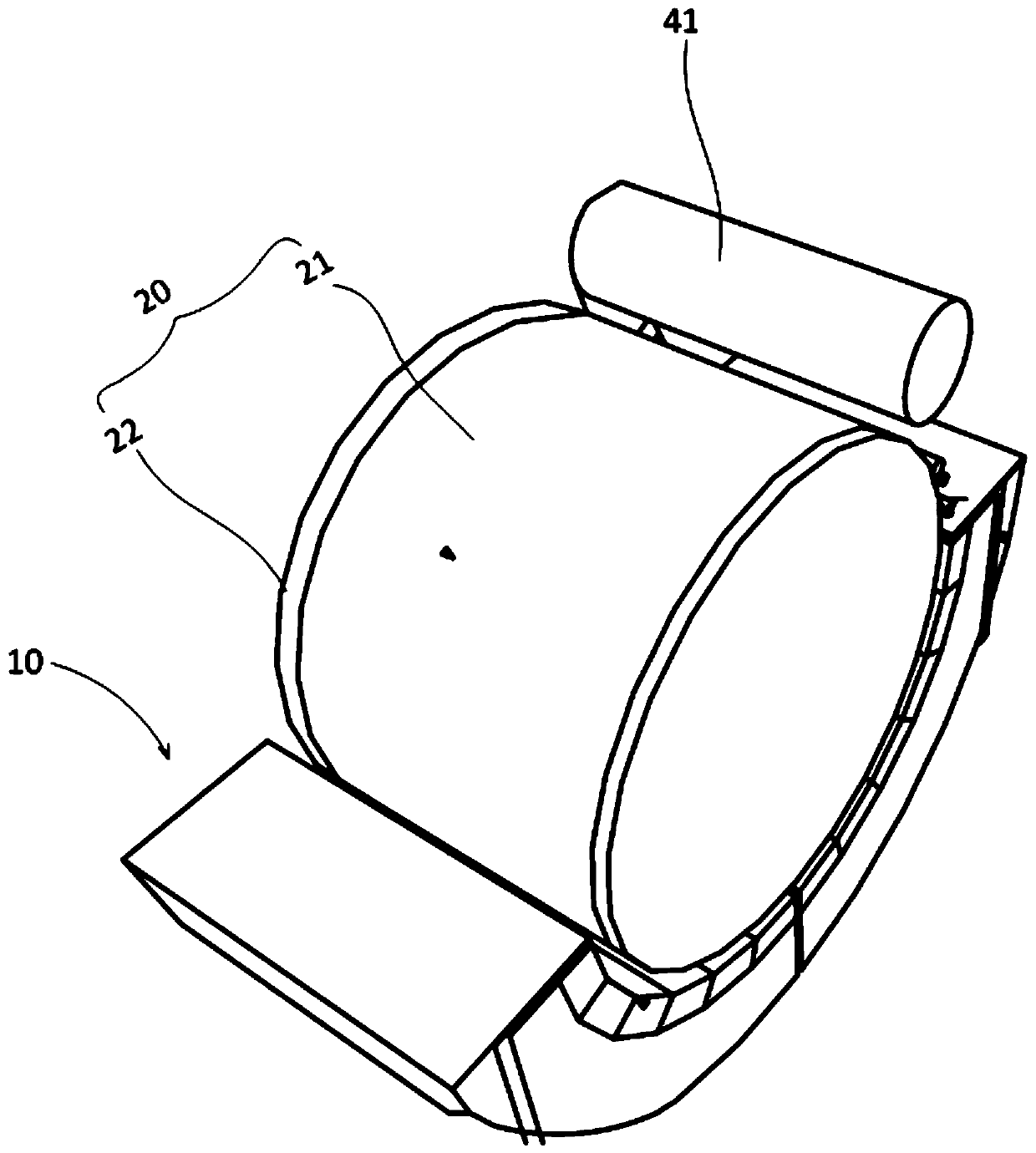

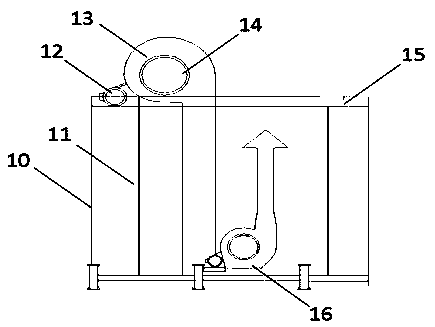

Tea cleaning and drying device

InactiveCN107965989ARealize the function of cleaning and removing impuritiesSpeed up the flowPre-extraction tea treatmentDrying gas arrangementsWater resourcesAgricultural engineering

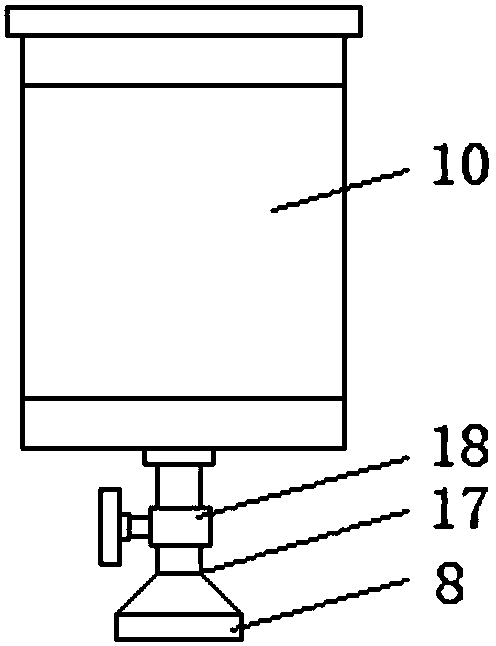

The invention discloses a tea cleaning and drying device which comprises a drying box, a rotating tube and a seal cover. The bottom of the drying box is provided with a rotating motor, the rotating motor is connected with the rotating tube through a rotating shaft, two inner walls, close to the rotating tube, of the drying box are provided with a heating pipe and an ultraviolet ray lamp pipe correspondingly, the outer wall, close to the heating pipe, of the drying box is provided with an air blower, the bottom of one side of the drying box is connected with a waste water treatment box througha pollution discharge pipe, the top of the seal cover is provided with an air exhaust fan, and the bottom of the seal cover is provided with a water spray pipe. By means of the tea cleaning and dryingdevice, before agricultural and sideline products are dried, cleaning and impurity removing functions performed on the agricultural and sideline products can be realized, and the quality of dried products is improved; by means of the arrangement of the waste water treatment box, the waste water after cleaning can be filtered and purified, and the recycling of water resources is facilitated; and the tea cleaning and drying device is simple in structure, the efficiency of drying performed on the agricultural and sideline products is high, and the drying is performed more thoroughly.

Owner:WUZHOU YAZHENG AGRI TECH CO LTD

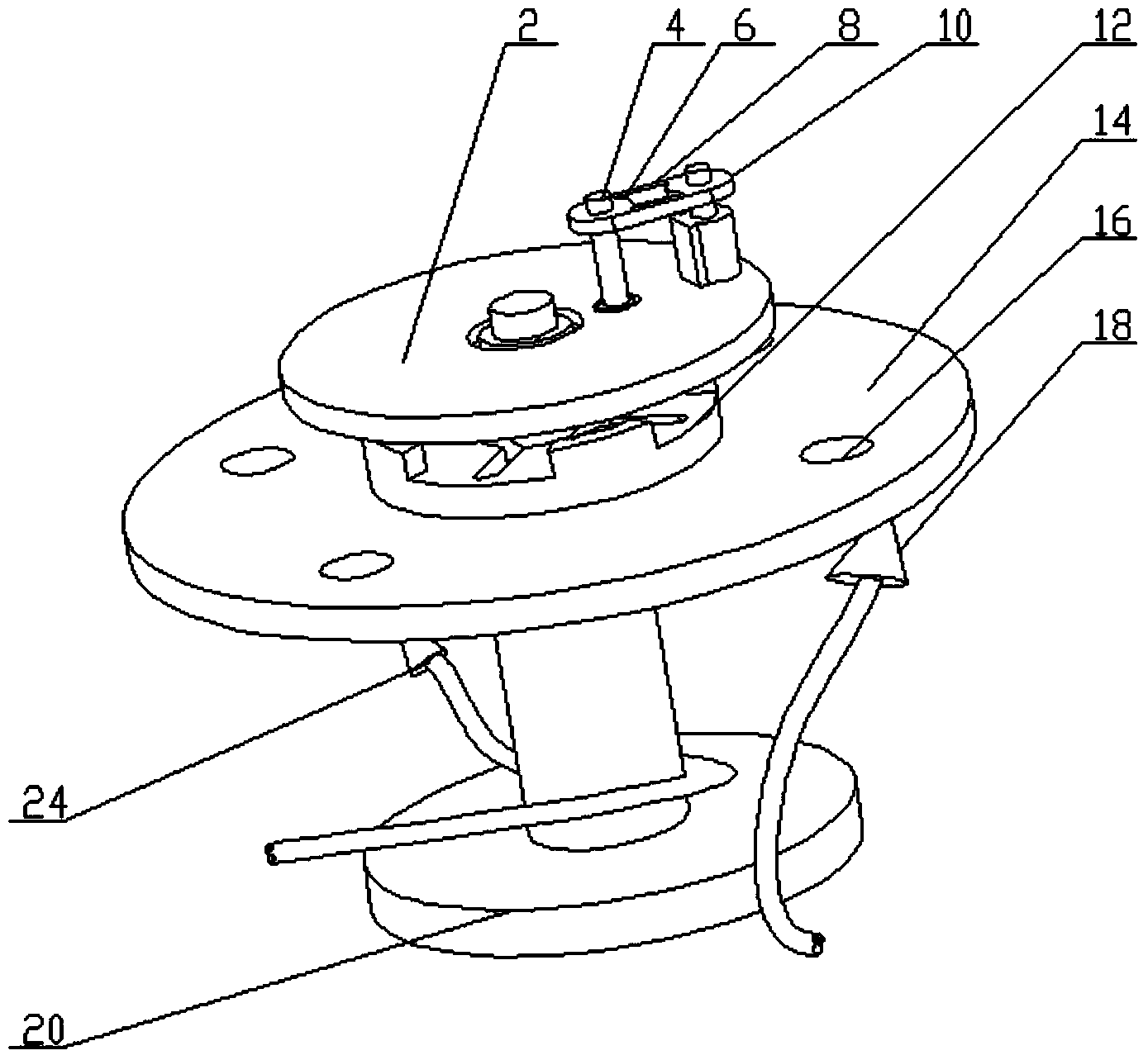

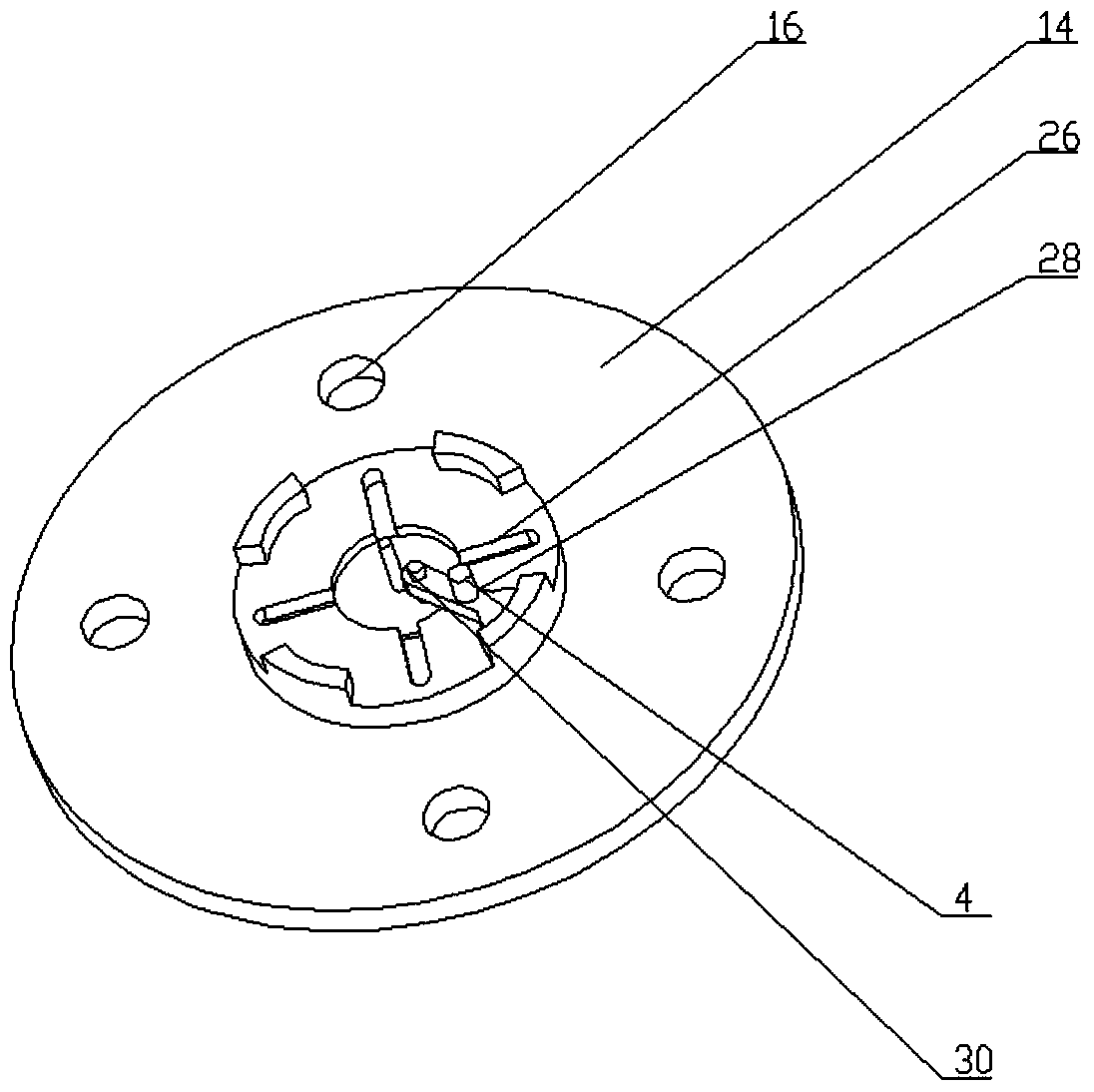

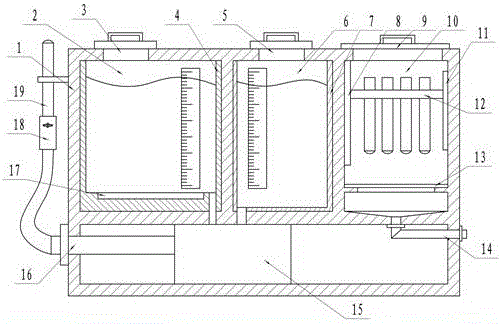

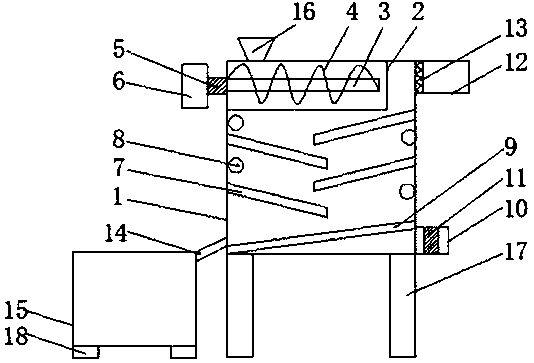

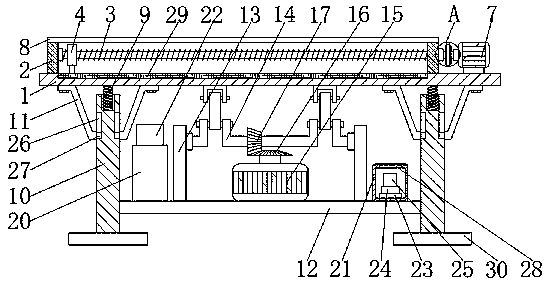

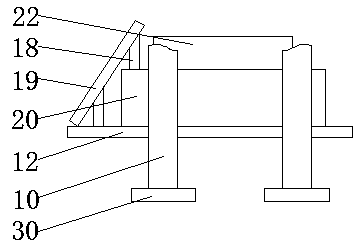

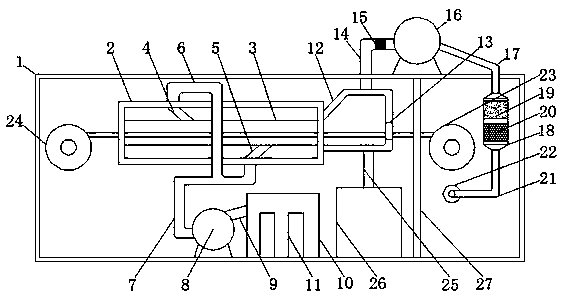

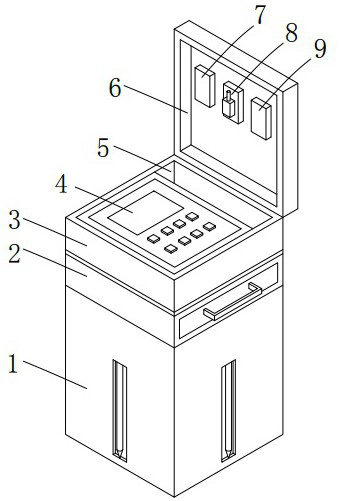

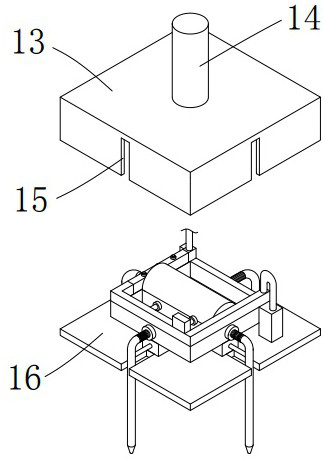

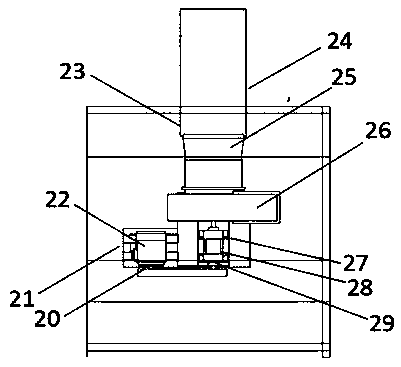

Novel beaker washing device

InactiveCN103658135AGuaranteed cleaning effectGuaranteed dryingHollow article cleaningDrying gas arrangementsIntermittent motionSufficient time

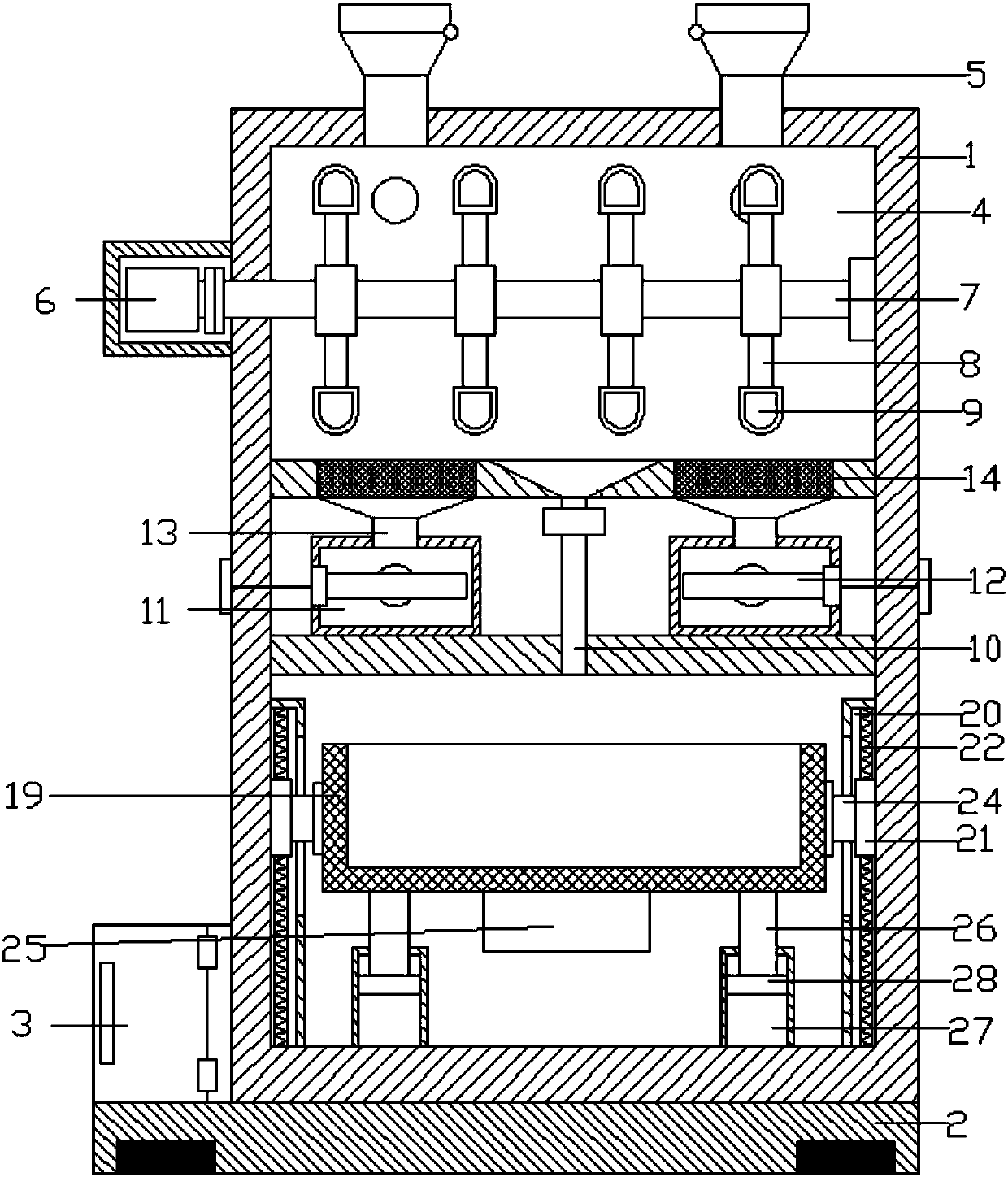

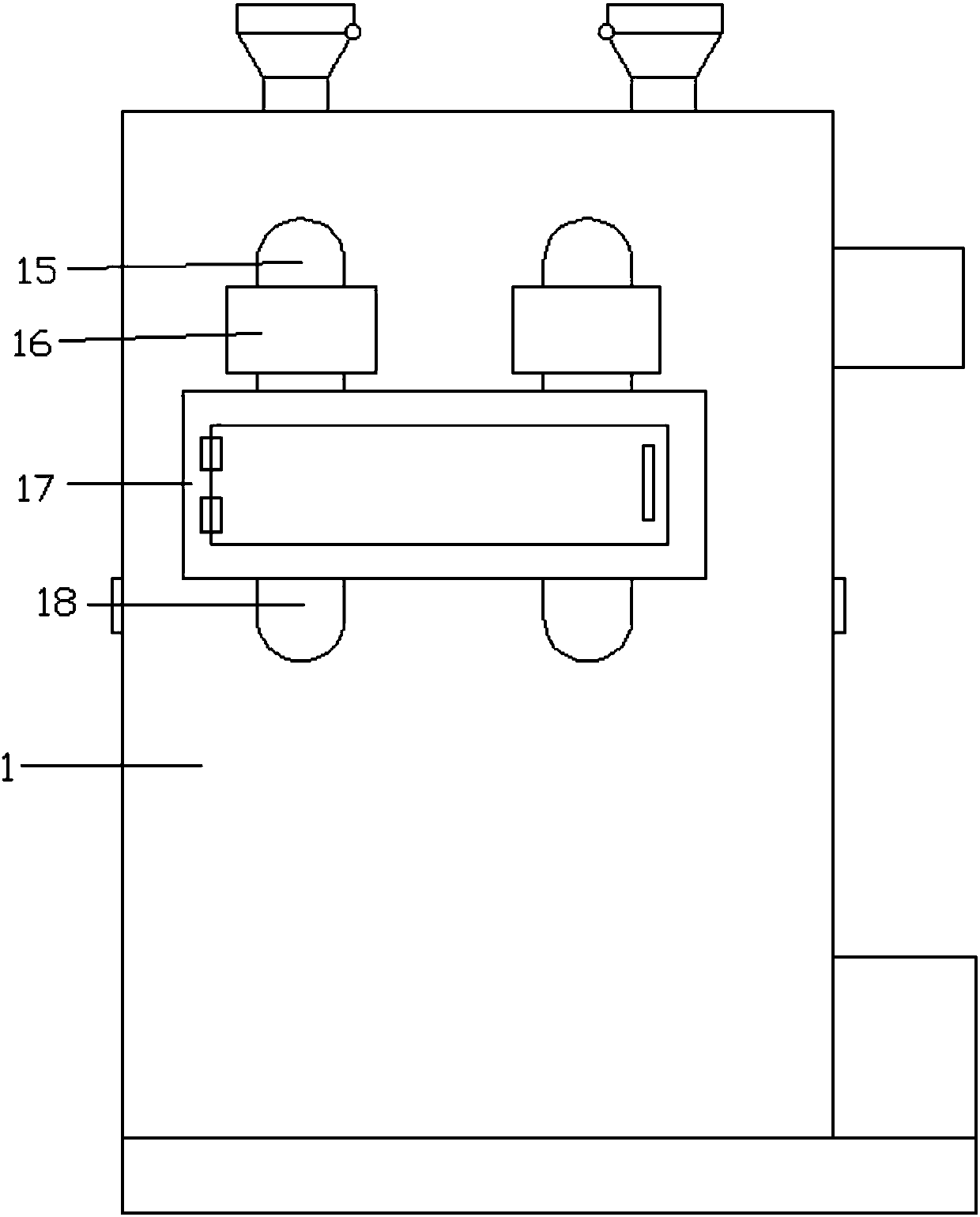

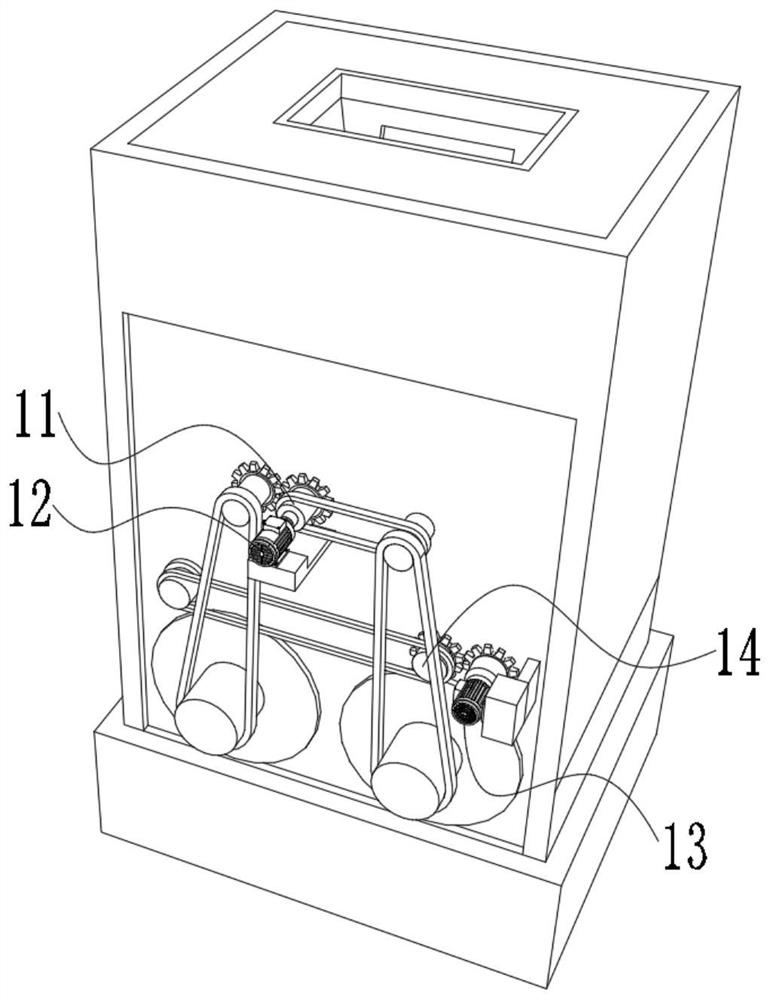

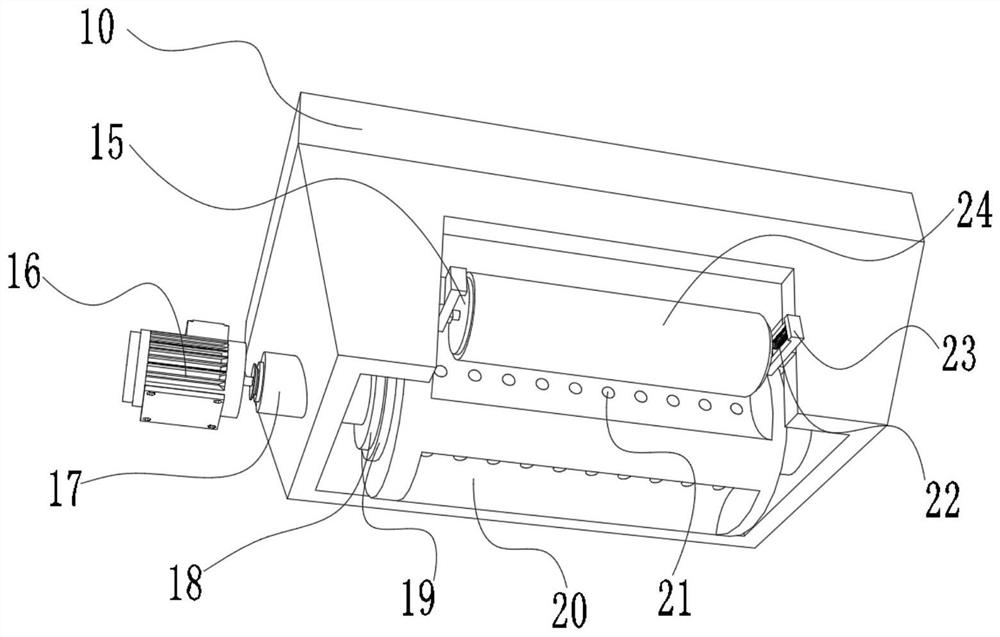

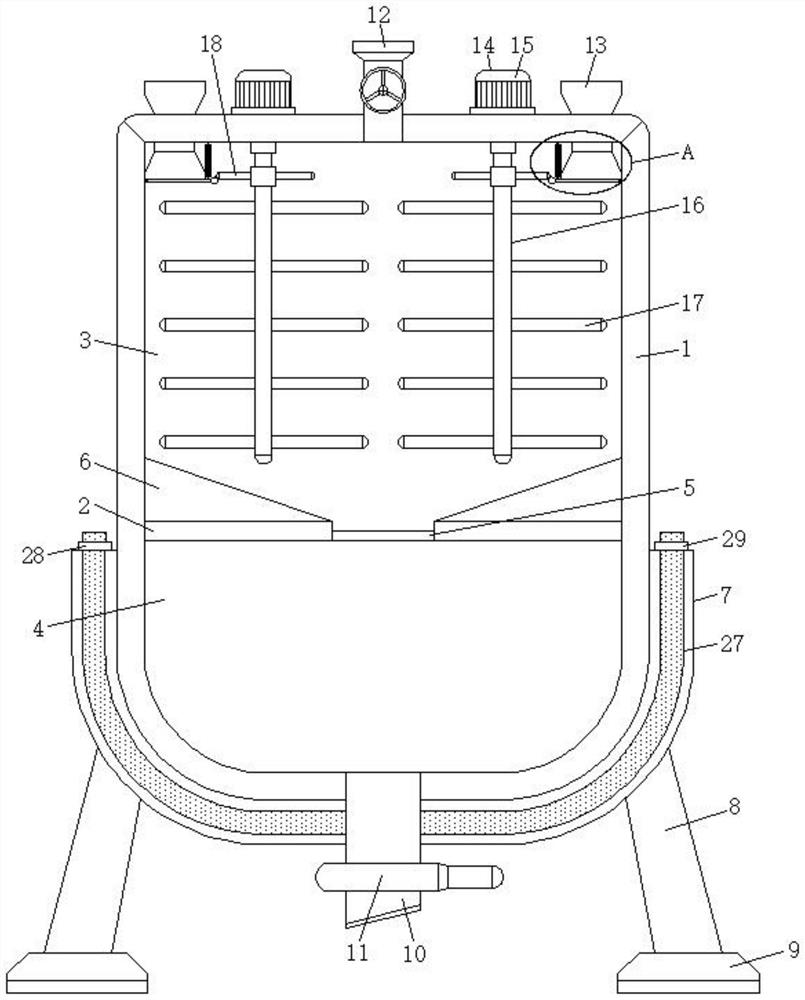

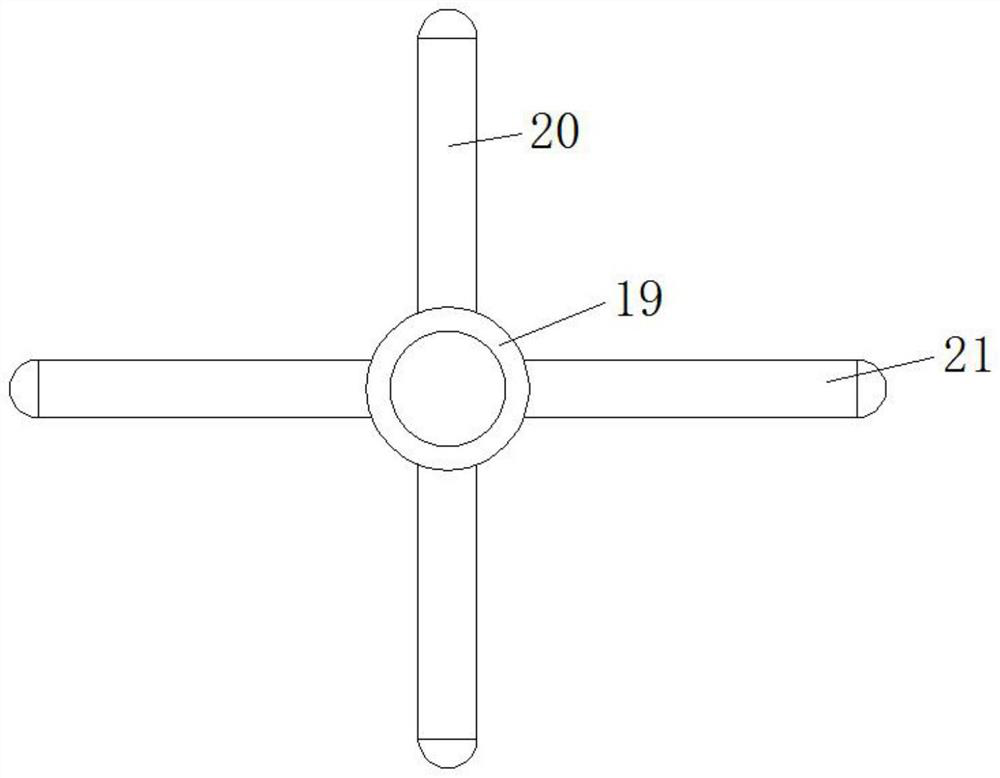

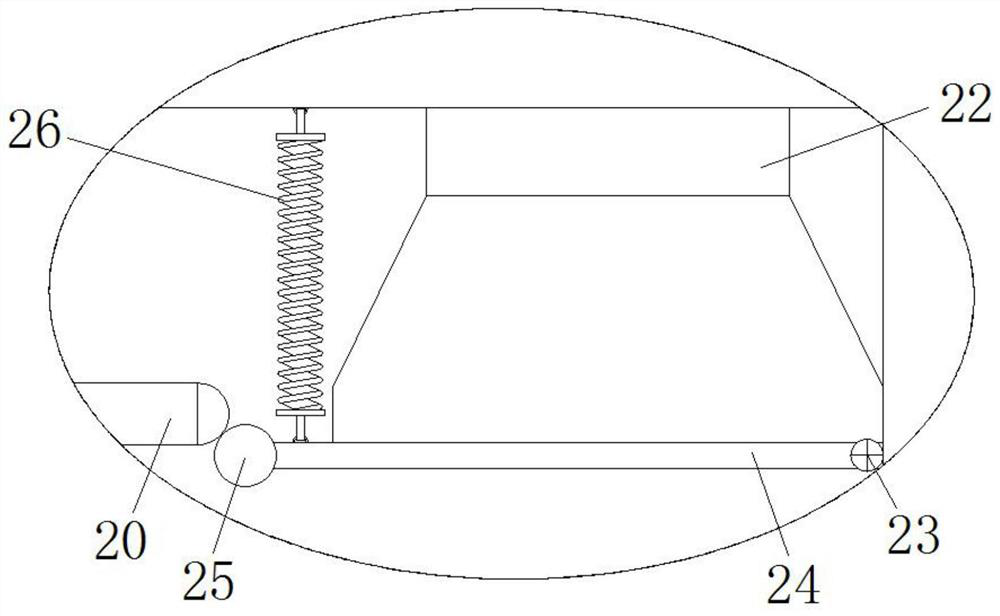

The invention discloses a novel beaker washing device which comprises a rack (2) and a working platform (14) connected to the rack (2) in a rotary mode. The novel beaker washing device is characterized in that an intermittent motion mechanism (12) is further and fixedly connected to the working platform (14), drives the working platform (14) to rotate and can control the working platform (14) to stop at least three times when being rotated for a circle, at least three beaker installation holes (16) where beakers are clamped are formed in the working platform (14), a first nozzle (24) and a second nozzle (18) are further formed below the working platform (14), the first nozzle (24) can upwards spray water, the second nozzle (18) can upwards spray hot air, and two adjacent beaker installation holes (16) are located right above the first nozzle (24) and the second nozzle (18) respectively when the working platform (14) is stopped. Installation-spraying washing-drying-taking out assembly line type operation on the beakers can be achieved through the novel beaker washing device, the intermittent motion mechanism (12) is adopted to serve as a power carrier, sufficient time is guaranteed for washing and drying the beaker, and the washing efficiency is greatly improved.

Owner:NANJING COLLEGE OF CHEM TECH

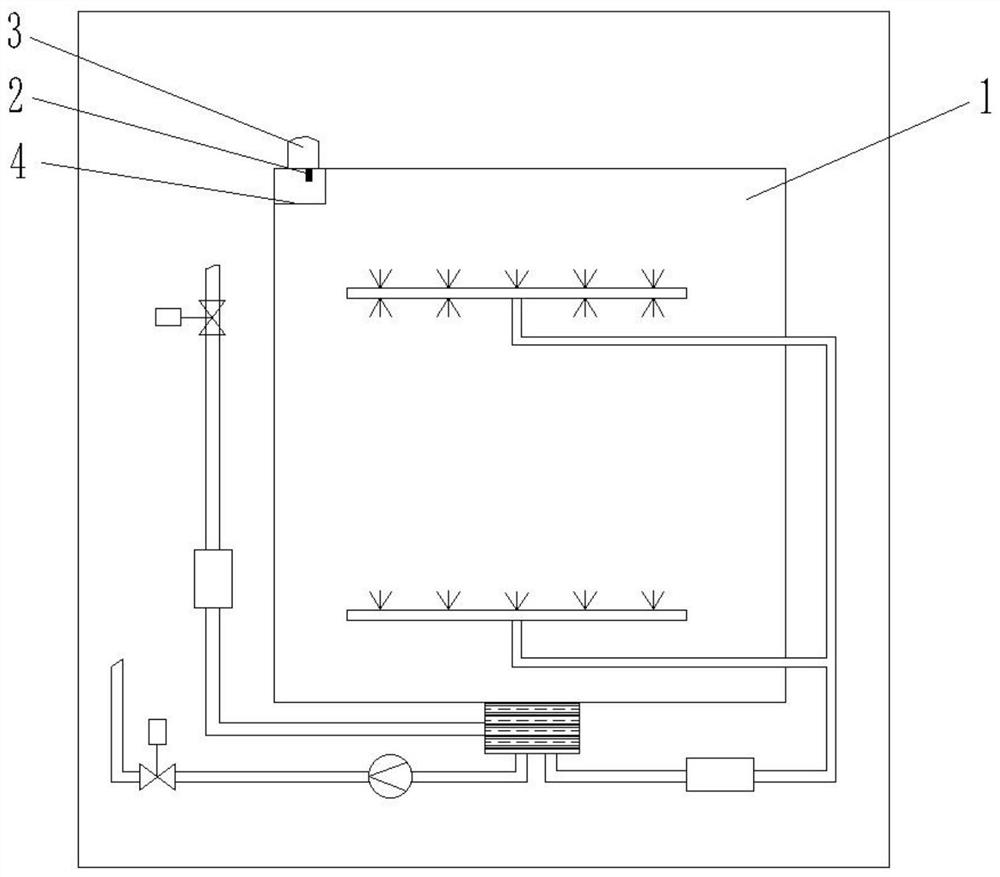

Clinical atomizing cleaning and sterilizing device suitable for gynaecological nursing

InactiveCN106421955AGuaranteed dryingGuaranteed disinfectionCannulasEnemata/irrigatorsControl switchCross infection

The invention discloses a clinical atomizing cleaning and sterilizing device suitable for gynaecological nursing. The clinical atomizing cleaning and sterilizing device comprises a shell, a saline chamber, a first upper cover, a first heat preservation layer, a second upper cover, a medicine dispensing chamber, a second heat preservation layer, a drier, a third upper cover, a drying sterilizing chamber, a sterilizing device, a fixed chuck, a filtering net, a drainage pipe, a pump body, a water outlet pipe, a heater, a control connector and atomizing cleaning spraying heads. When the clinical atomizing cleaning and sterilizing device is used, the adopted atomizing cleaning spraying head is moved to the pudendum and the vagina, then a control switch on the control connector is switched on to allow the pump body to work, and normal saline or purified water in the saline chamber and a sterilizing agent in the medicine dispensing chamber are jointly absorbed in proportion through the pump body and finally sprayed out for atomizing cleaning through the atomizing cleaning spraying head. As the drying sterilizing chamber is arranged, the multiple atomizing cleaning spraying heads can be dried and sterilized, the usage requirement of multiple patients is guaranteed accordingly, and the cross infection caused in patient usage is avoided.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

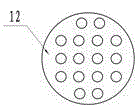

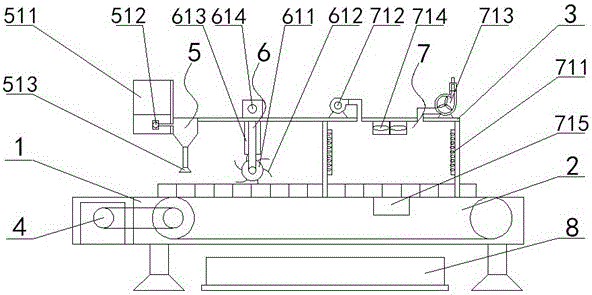

Open-width knitted fabric pre-shrinking machine and pre-shrinking process thereof

ActiveCN104018311AGuaranteed dryingMake sure to ironShrinkingTextile treatment cleaning apparatusShrinkage rateAgricultural engineering

The invention discloses an open-width knitted fabric pre-shrinking machine, comprising an open-width cloth-feeding device, a mechanical weft-straightening device, a steam conditioning and stentering device, a rubber blanket pre-shrinking device and an open-width plaiting device, wherein the front end of the steam conditioning and stentering device is provided with an overfeed pinning device; and a felt finishing device is arranged between the rubber blanket pre-shrinking device. The open-width knitted fabric pre-shrinking machine comprises the felt finishing device; and the fabric is finished by the felt finishing device after passing through the rubber blanket pre-shrinking device, thereby guaranteeing the fabric to be dried and flatten, further improving handfeel of the fabric and increasing glossiness of the fabric surface. Meanwhile, shrinkage rate of the fabric can be more stable, so that the open-width knitted fabric with flat cloth surface, good surface glossiness, good handfeel and stable shrinkage rate can be processed.

Owner:浙江瑞格机械科技有限公司

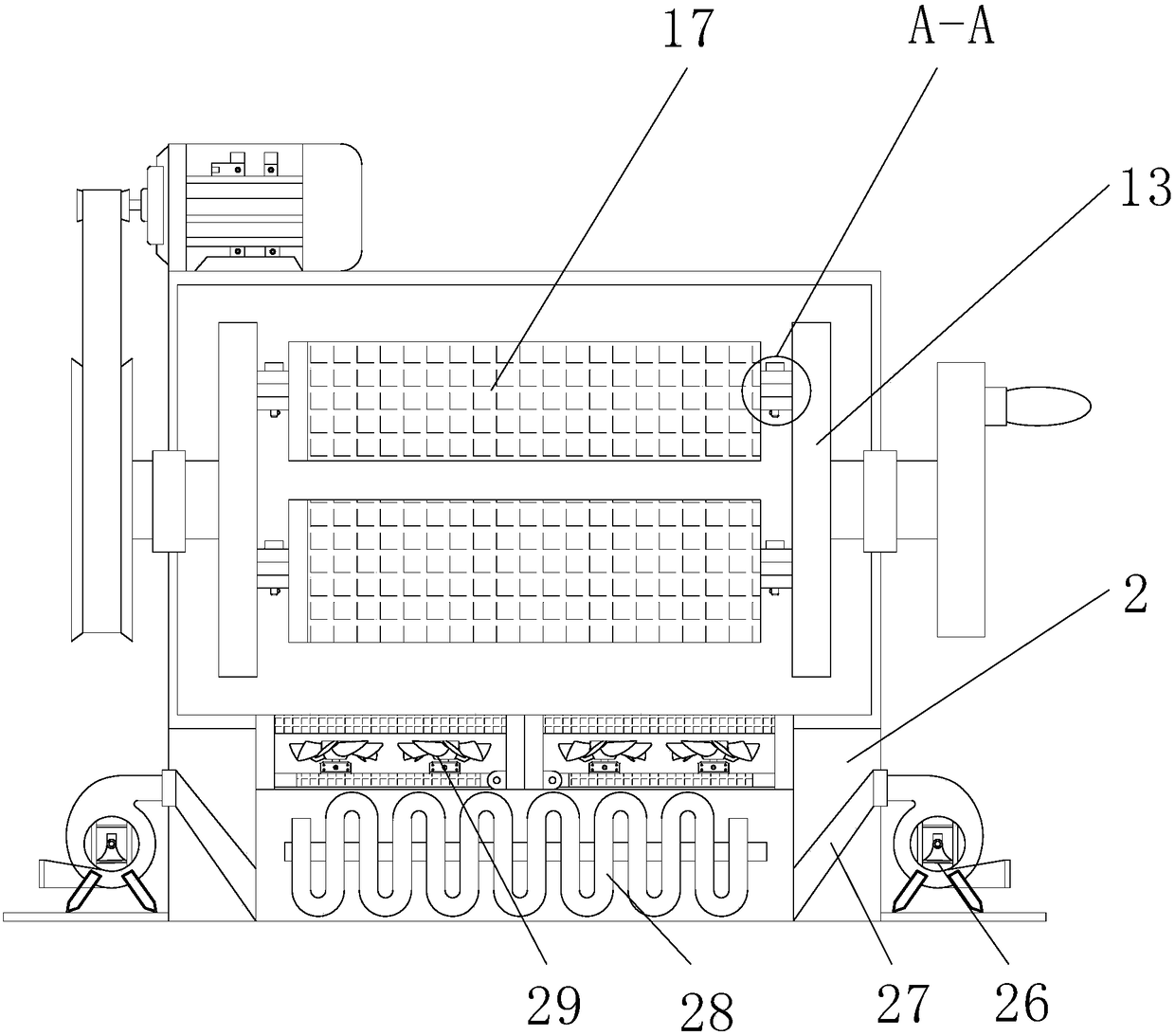

Rice seed drying and screening device

The invention discloses a rice seed drying and screening device which comprises a box body. A base plate is arranged on the lower side of the box body, an electric control box is arranged on the upperside of the left end of the base plate, a stirring and drying cavity is formed in the top end of the inside of the box body, a discharging pipe is arranged in the middle of the lower side of the stirring and drying cavity, heating cavities are formed in the left side and the right side of the discharging pipe, heating rods are arranged in the heating cavities, air outlet pipes are arranged on theupper sides of the heating cavities, air spraying nozzles are formed on the upper sides of the air outlet pipes, a screening groove is formed in the lower side of the discharging pipe, a screening door is arranged on the front side of the screening groove, a vibrator is arranged on the lower side of the screening groove, sliding grooves are formed in the left side and the right side of the screening groove, sliding blocks are arranged in the sliding grooves, springs are arranged on the upper side and the lower side of the sliding blocks, connecting rods are arranged in the sliding blocks, supporting rods are arranged at left and right points of the lower side of the screening groove, supporting pipes are arranged at the lower ends of the supporting rods, piston plates are arranged at theupper ends of the insides of the supporting pipes, and the upper sides of the piston plates are connected with the supporting rods. The rice seed drying and screening device can effectively facilitateseed drying and separation of impurities in seeds and accordingly facilitates seed processing.

Owner:殷毡毡

Traditional Chinese medicinal material grinding and drying equipment with grinding mechanism

InactiveCN112403586APrevent splashPlay a drying effectDrying solid materials without heatGrain treatmentsEngineeringMaterials processing

The invention discloses traditional Chinese medicinal material grinding and drying equipment with a grinding mechanism, relates to the field of traditional Chinese medicinal material processing, and aims to solve the problem that moisture exists in medicinal materials, powder is likely to form agglomeration, and the agglomerated powder are prone to remaining on grinding rollers. The traditional Chinese medicinal material grinding and drying equipment specifically comprises a base, a grinding chamber is welded to the outer wall of the top of the base, a feeding port is formed in the inner wallof the top of the grinding chamber, a feeding bin is clamped to the inner wall of the feeding port, a rotating rod is rotationally connected to the inner wall of the side, close to the bottom, of thefeeding bin, water absorption sponge is clamped to the outer wall of the rotating rod, a circular rod is clamped to the outer wall of the water absorption sponge, and an arc shaped groove is formed inthe outer wall of the circular rod; and vent holes are formed in the bottom inner wall of the arc-shaped groove. By arranging the feeding bin, medicinal materials are put into the arc-shaped groove,the generated heat can dry the medicinal materials, the generated moisture can be absorbed by the water absorption sponge through the vent holes, a third motor is started to drive the rotating rod torotate, and under the action of a spring, an extrusion roller can enter the arc-shaped groove to extrude the medicinal materials, so that the moisture of the medicinal materials is further removed.

Owner:李小平

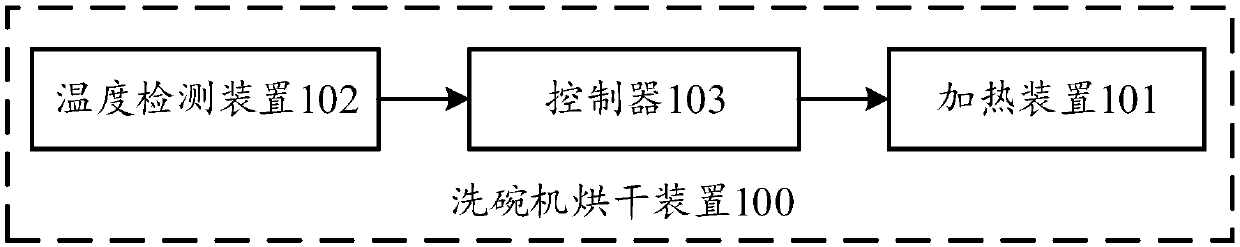

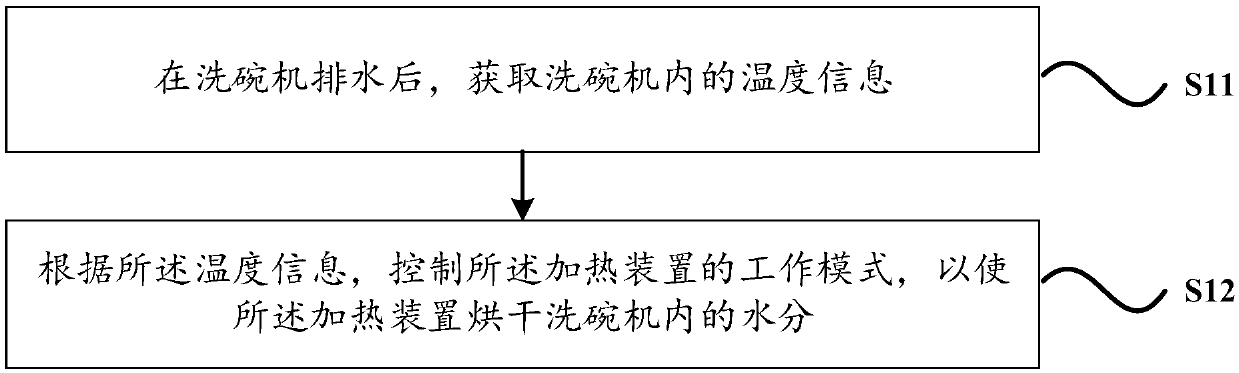

Drying method and device for dish washing machine and dish washing machine

InactiveCN109674423AGuaranteed dryingEliminate dead spots that cannot be driedTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionPulp and paper industryMoisture

The invention relates to a drying method and device for a dish washing machine and the dish washing machine. The device comprises a heating device, a temperature detection device and a controller, wherein the heating device is arranged on a base in a dish washing machine; the temperature detection device is used for detecting the temperature information in the dish washing machine; and the controller is used for controlling the working mode of the heating device according to the temperature information so as to dry the moisture in the dish washing machine. According to the technical scheme provided by the invention, the working mode of the heating device is controlled according to the temperature information in the dish washing machine after the draining of the dish washing machine so as to dry the moisture in the dish washing machine by the heating device, and the heating device is arranged on the base of the dish washing machine, so that the residual moisture at the base of the dishwashing machine can be dried, food residue and moisture at the bottom of the dish washing machine can be dried, a dead corner which cannot be dried in the dish washing machine is eliminated, a dry environment in which bacteria is unlikely to be bred can be maintained in the dish washing machine for a long time, relatively healthy guarantee is provided for a user, and the user experience is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Lignite drying/low-temperature carbonization method with function of conducting heat by steam

InactiveCN103146409AImprove securityImprove thermal conductivityDrying solid materials with heatDirect heating destructive distillationHeating timeSteam pressure

The invention discloses a lignite drying / low-temperature carbonization method with a function of conducting heat by steam. The method comprises the steps of: after putting a material to be dried into more than two drying chambers which are sequentially communicated, and sealing, introducing steam into one drying chamber, stopping feeding the steam until the drying chamber is full of steam and with a required steam pressure, and starting a heating device in the drying chamber; and when the steam temperature raises to exceed the burning point of the material, prolonging the heating time to achieve the low-temperature carbonization of the material. Overpressure steam generated in the drying chamber in the material heating process is discharged into the next sealed drying chamber in which the martial to be heated is put, and so forth, the upstream drying chamber recycles the overpressure steam discharged by the previous drying chamber to preheat and dry as shown in step two; and the generated condensate water is drained from a condensate water drain outlet. The lignite subjected to drying / low-temperature carbonization is obviously reduced in moisture, greatly reduced in size, increased in particle strength, and low in production input cost, and is simultaneously suitable for the drying process of other materials.

Owner:蔡京鹏

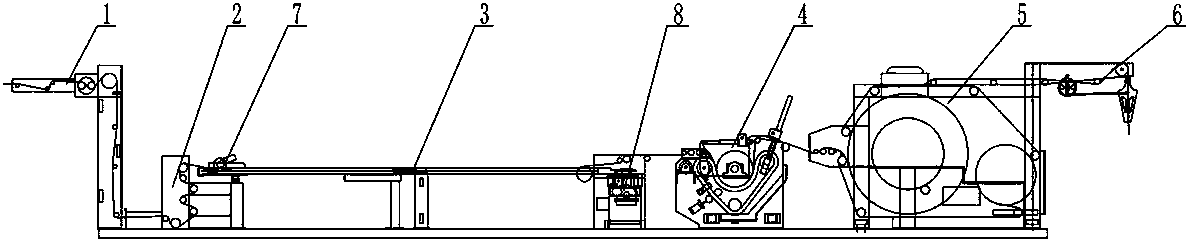

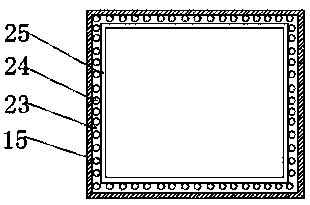

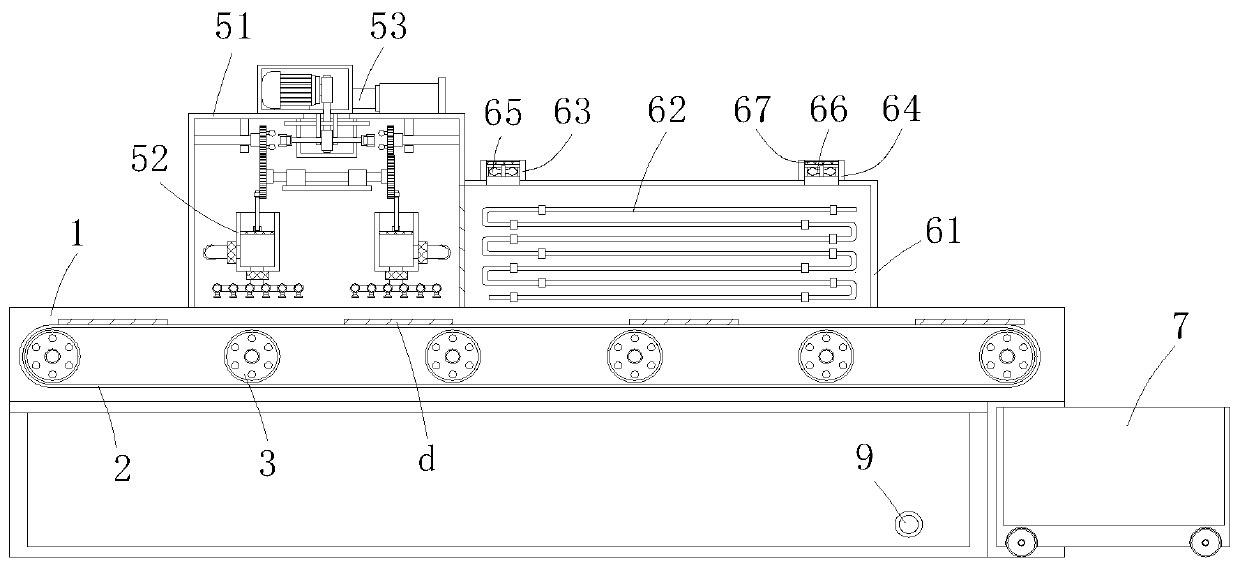

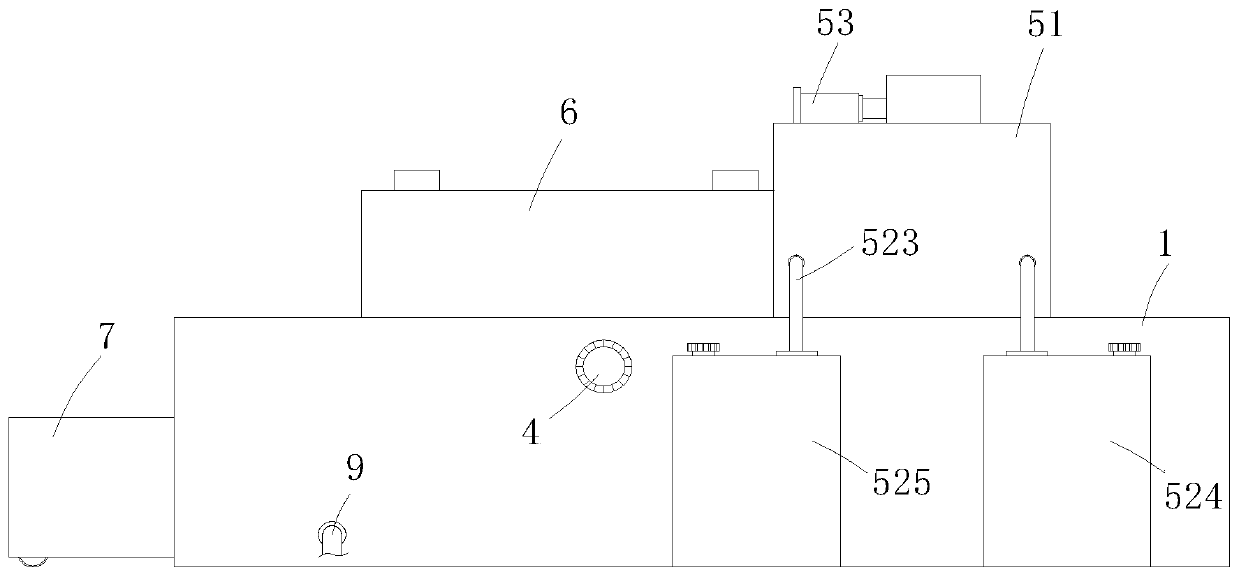

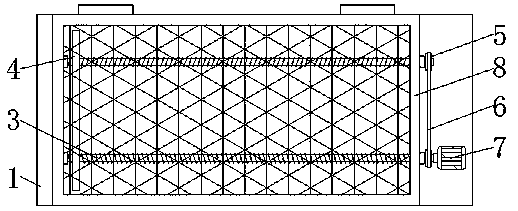

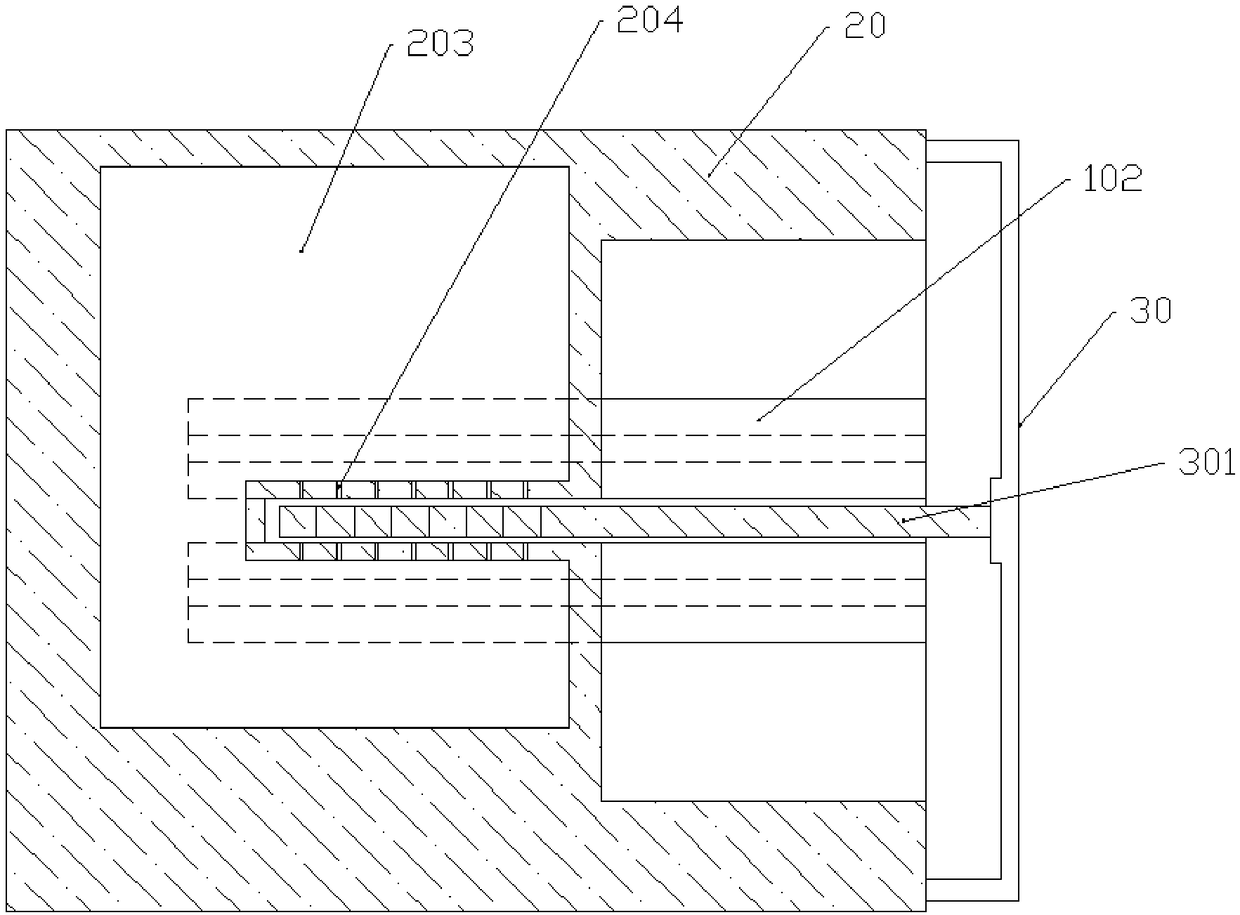

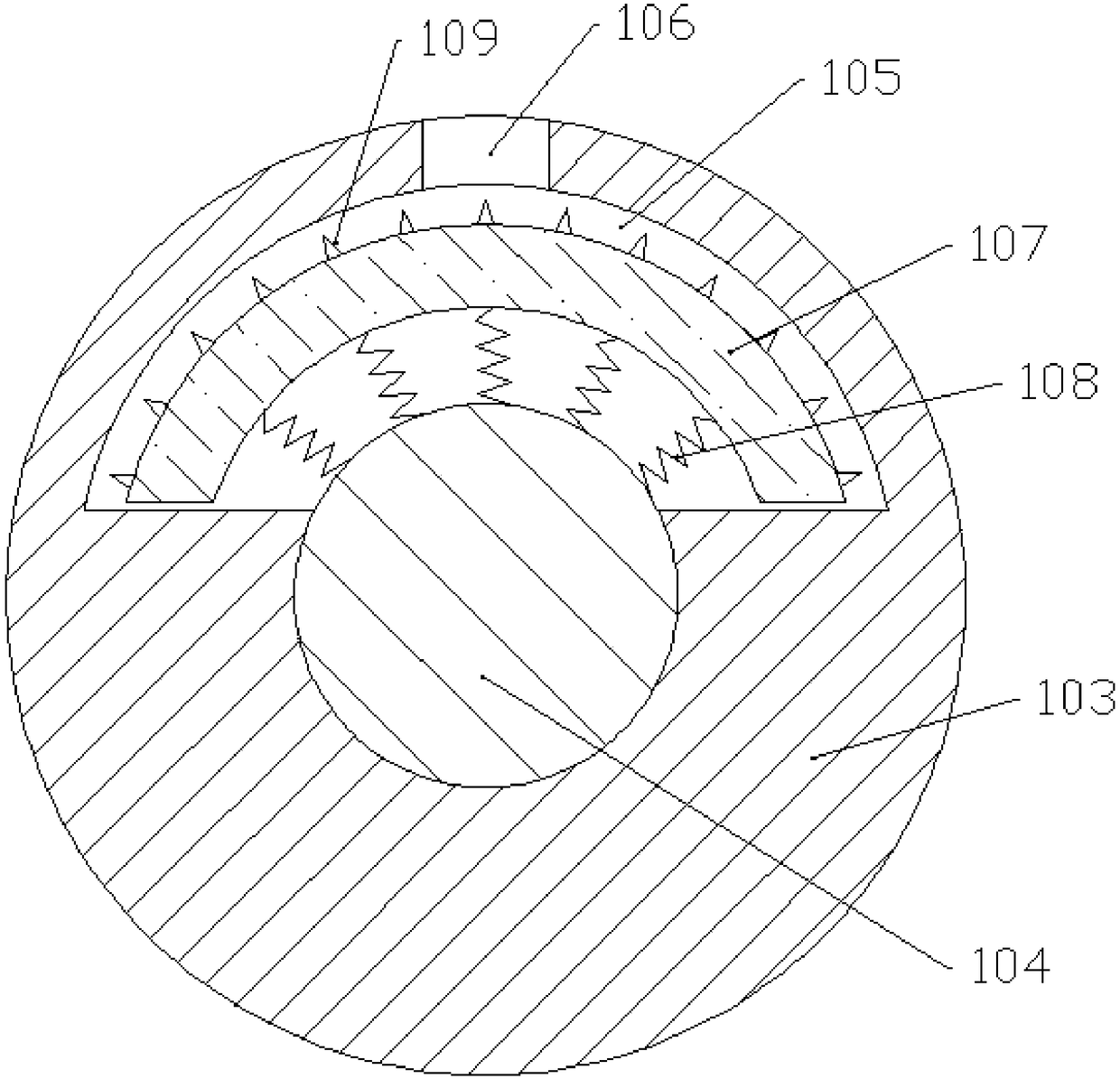

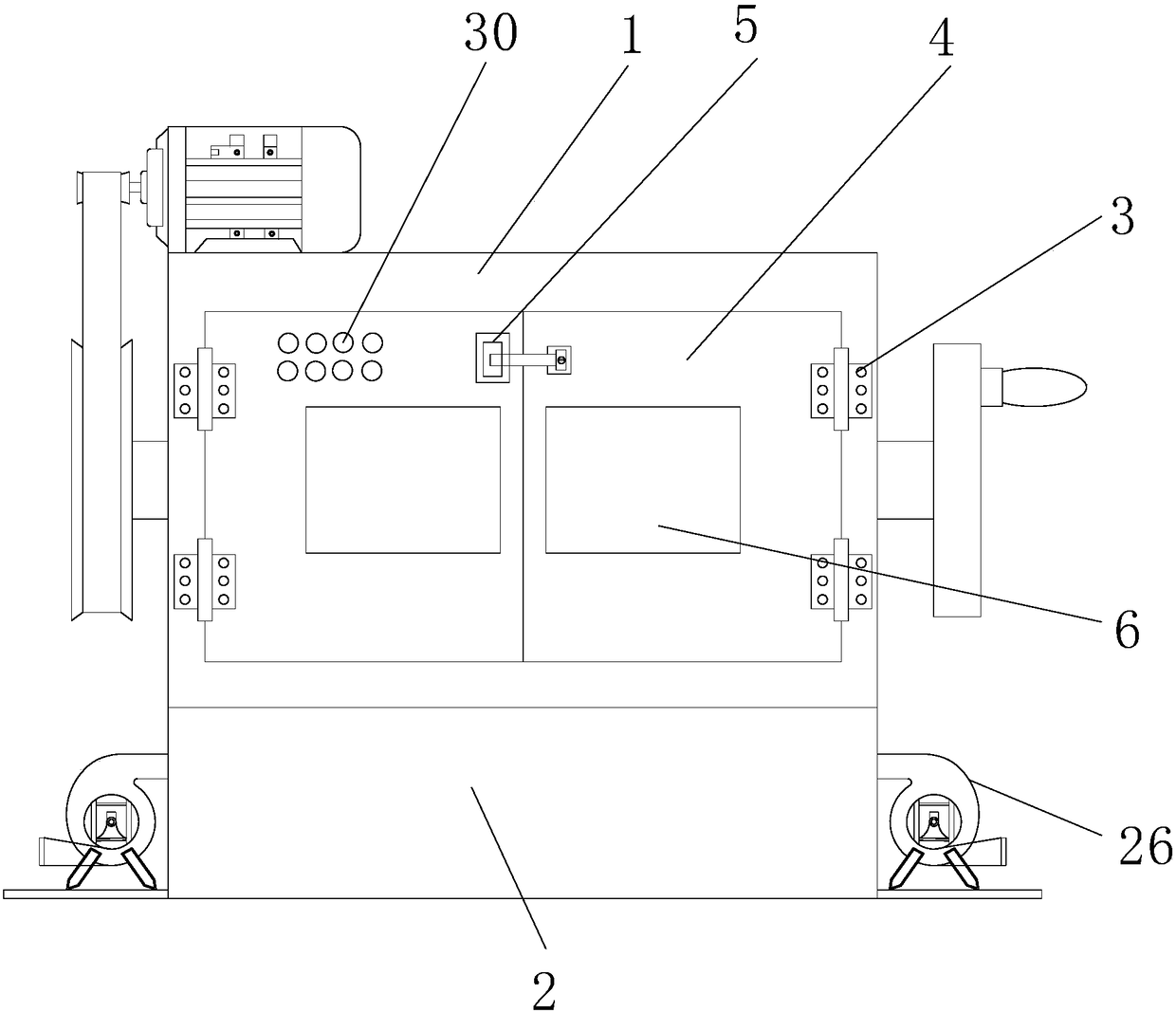

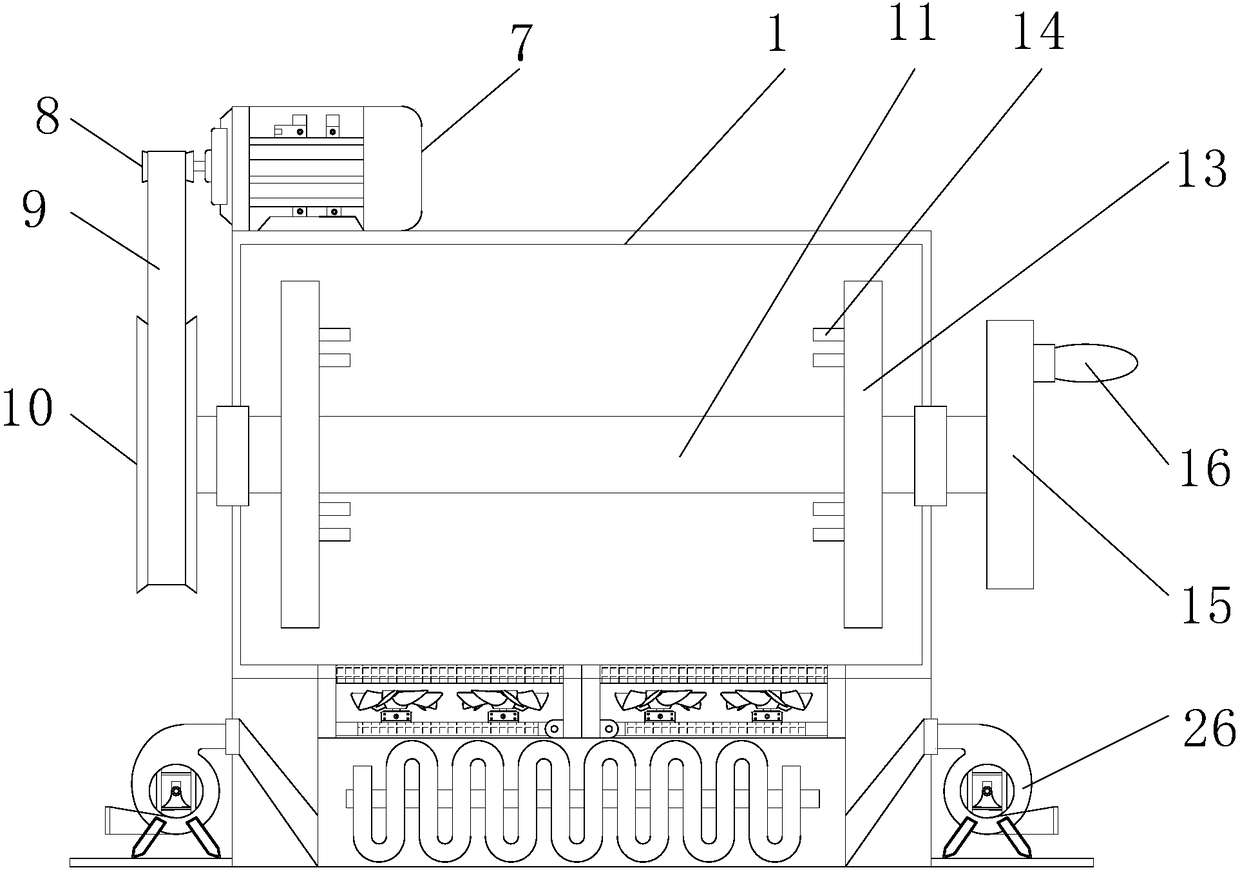

Cleaning device used for network filter shell

PendingCN105880191AEven and effective hot airGuaranteed dryingDrying gas arrangementsCleaning using toolsYarnOrganic solvent

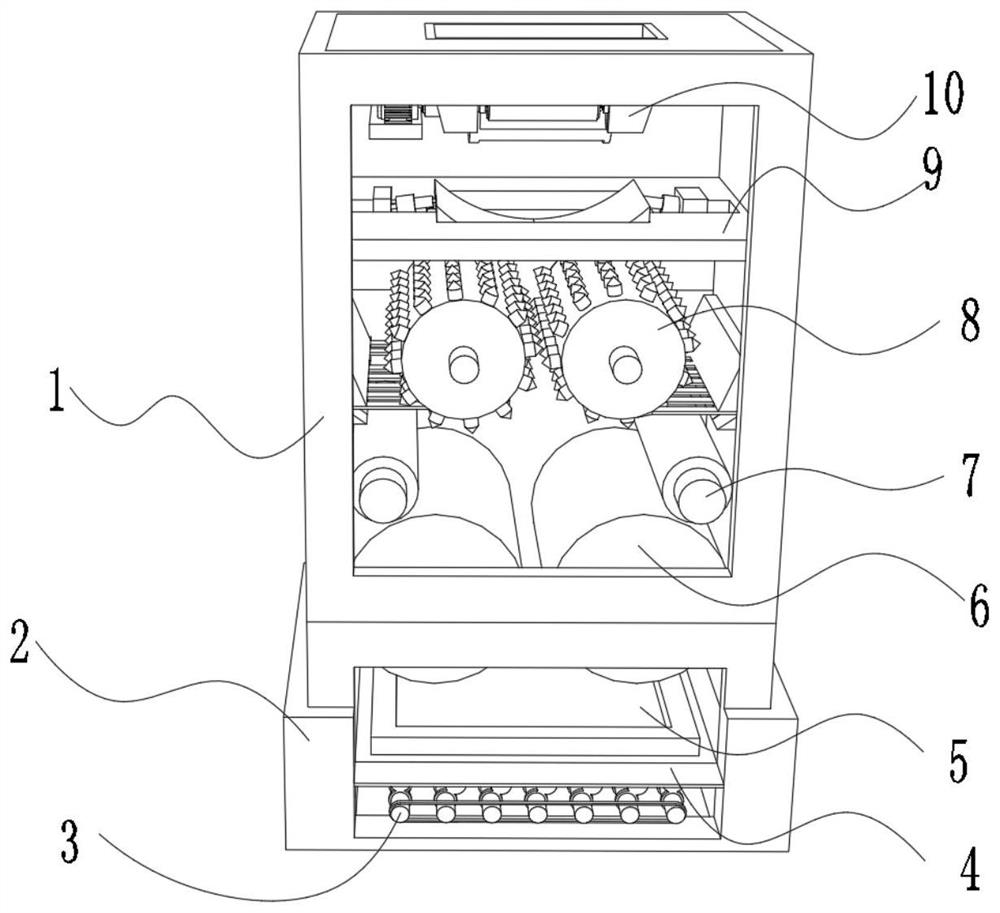

The invention provides a cleaning device used for a network filter shell and relates to the field of cleaning device technology. The cleaning device used for the network filter shell comprises a rack, a conveying belt and a supporting frame which is installed on the conveying belt. One side of the rack is provided with a motor. A solvent injection mechanism, a cleaning mechanism and a drying box are installed under the supporting frame in order, wherein the solvent injection mechanism is provided with an organic solvent box, a boosting pump which is installed below the organic solvent box and an injection nozzle which is connected with the boosting pump. The cleaning mechanism comprises a cleaning roller, cotton yarn which is arranged outside the cleaning roller in a sleeve manner, a water pouring pipe which is installed above the cleaning roller and a driving machine. The drying box comprises heating tubes which are installed on the inner wall of the drying box, a blower and a dehumidifying fan which are installed on the exterior of the drying box and communicated with the interior of the drying box, a circulating fan which is installed at the inner top and a sensor which is installed under the drying box. According to the device, the working efficiency can be improved, the filter shell can be dried completely and the residual of organic solvent can be avoided.

Owner:LEIYANG YAXIANG ELECTRONICS TECH

Kitchen garbage pathogenic bacteria high-temperature inactivation technology

ActiveCN101185768AEvenly heatedAvoid overall overheatingMedical waste disposalHeatMicroorganismUv disinfection

The invention relates to a high temperature-UV inactivation device for the harmful bacteria of kitchen garbage and a method thereof. The invention can further carry out UV disinfection even after the constant temperature and high temperature heat treatment of the kitchen garbage in a sealed spiral dryer, so as to inactivate the pathogen, conditioned pathogen and other harmful microorganisms in the kitchen garbage, and safe and sanitary renewable raw materials or feeds can be generated after the inactivation process. The inactivation device has compact structure, high sterilization rate and simple operation, so the invention is a very effective inactivation method of the harmful microorganisms of kitchen garbage.

Owner:青海洁神环境科技股份有限公司

Automatic drying device for rice processing

InactiveCN108967532AEasy to dryGuaranteed dryingDrying gas arrangementsSeed preservation by dryingDesiccantUv disinfection

The invention discloses an automatic drying device for rice processing. The automatic drying device comprises a drying box; a feeding tube is arranged on the top of the upper end of the drying box; ascrew is arranged in the feeding tube; a screw panel is arranged on the screw; a plurality of baffles are arranged in the drying box; a plurality of first heating tubes are arranged in the baffle; a plurality of ultraviolet disinfection lamps are arranged on a side wall in the drying box; a partition plate is obliquely arranged at the bottom end in the drying box; a plurality of through holes areformed in the partition plate; an air inlet tube is arranged on the lower side of the right end of the drying box; a hot air fan is installed in the air inlet tube; an air outlet tube is arranged on the upper side of the right end of the drying box; a storage box is arranged at the left end of a discharge tube; a cavity is formed in the inner wall of the storage box; a silica desiccant is installed in the cavity; a plurality of second heating tubes are uniformly installed at the bottom end of the storage box. The automatic drying device is convenient for ice drying, has good uniform drying effect and can sterilize rice.

Owner:丘莲清

Method for drying transformer

InactiveCN101710532ASolve the practical problem of low insulation resistanceMeet maintenanceTransformers/inductances coolingLow voltageAlternating current

The invention discloses a method for drying a transformer, comprising: the high voltage side of the transformer is in short circuit, and the low voltage side is applied with lower voltage, so that the current of a winding is 120-125% of rated current, and the rated current is used until the temperature of the high voltage winding reaches 65 DEG C; when the temperature of the high voltage winding reaches 75 DEG C, 85% of rated current is used for heating; when the temperature of the high voltage winding is lower than or equal to 90 DEG C, the temperature of oil surface is less than or equal to 85 DEG C; and the operation is carried out until the insulating property of the winding is qualified. The method is used for solving the problem of resorting over-low insulation of the transformer by copper loss drying, and changes the phenomenon that a drying stove is used for heating the winding of the transformer and improving the insulation degree of the transformer in the prior art; furthermore, the process is simple, and the operation is easy no matter the winding of the transformer is heated by DC or AC.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

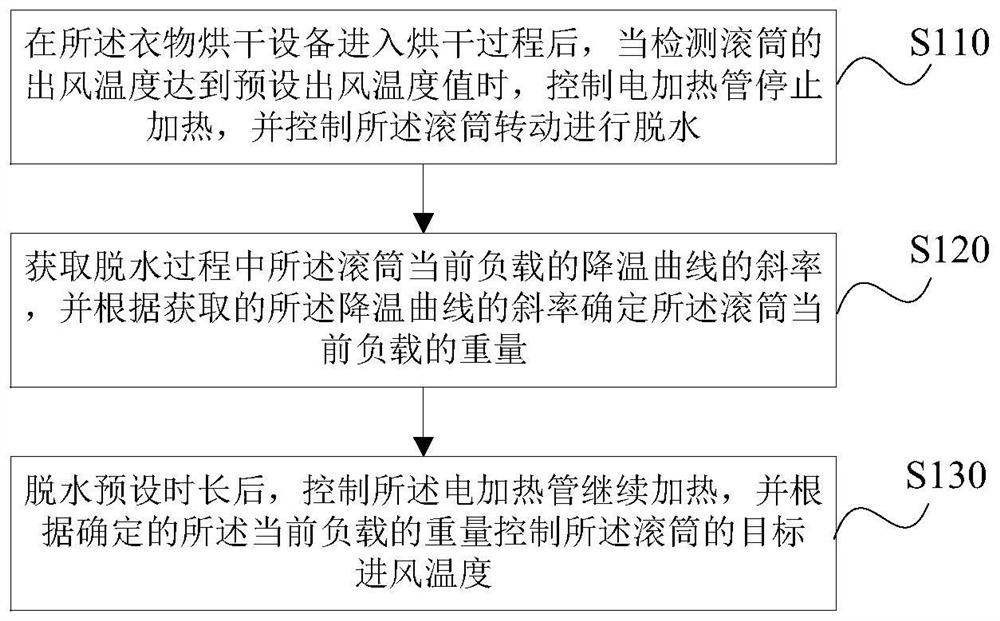

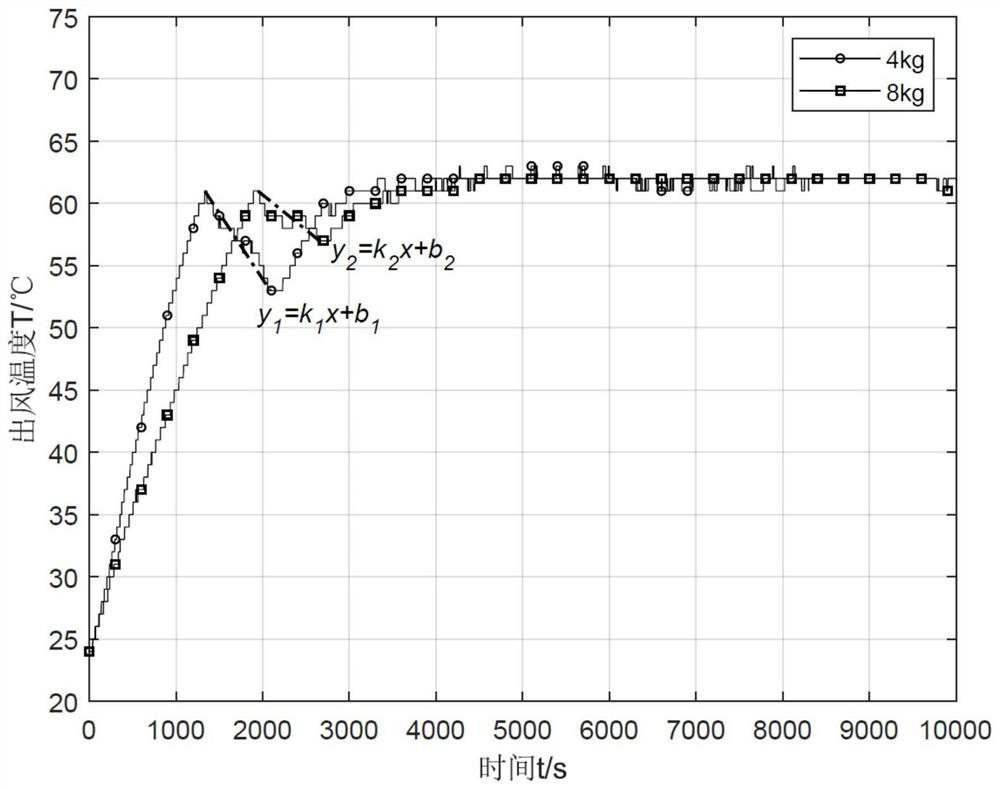

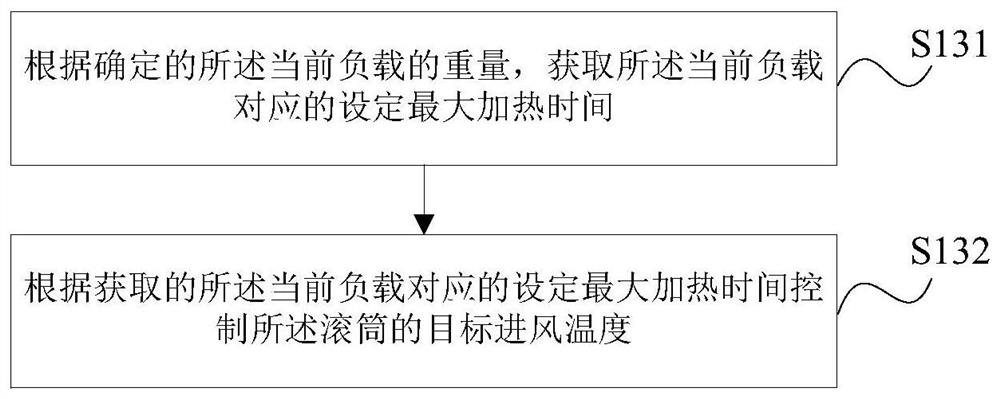

Clothes drying equipment, drying control method and device of clothes drying equipment and storage medium

ActiveCN112481977AGuaranteed dryingImprove drying efficiencyTextiles and paperLaundry driersCooling curveCurrent load

The invention provides clothes drying equipment, a drying control method and device of the clothes drying equipment and a storage medium. The method comprises the steps that after the clothes drying equipment enters a drying process, when it is detected that the air outlet temperature of a roller reaches a preset air outlet temperature value, an electric heating tube is controlled to stop heating,and the roller is controlled to rotate for dehydration; the slope of a cooling curve of the current load of the roller in the dehydration process is obtained, and the weight of the current load of the roller is determined according to the obtained slope of the cooling curve; and after dehydration is conducted for preset duration, the electric heating tube is controlled to continue to conduct heating, and the target air inlet temperature of the roller is controlled according to the determined weight of the current load. According to the scheme provided by the invention, the load weight of theclothes drying equipment can be accurately measured, and the target air inlet temperature of the roller is controlled according to the load weight.

Owner:GREE ELECTRIC APPLIANCES INC

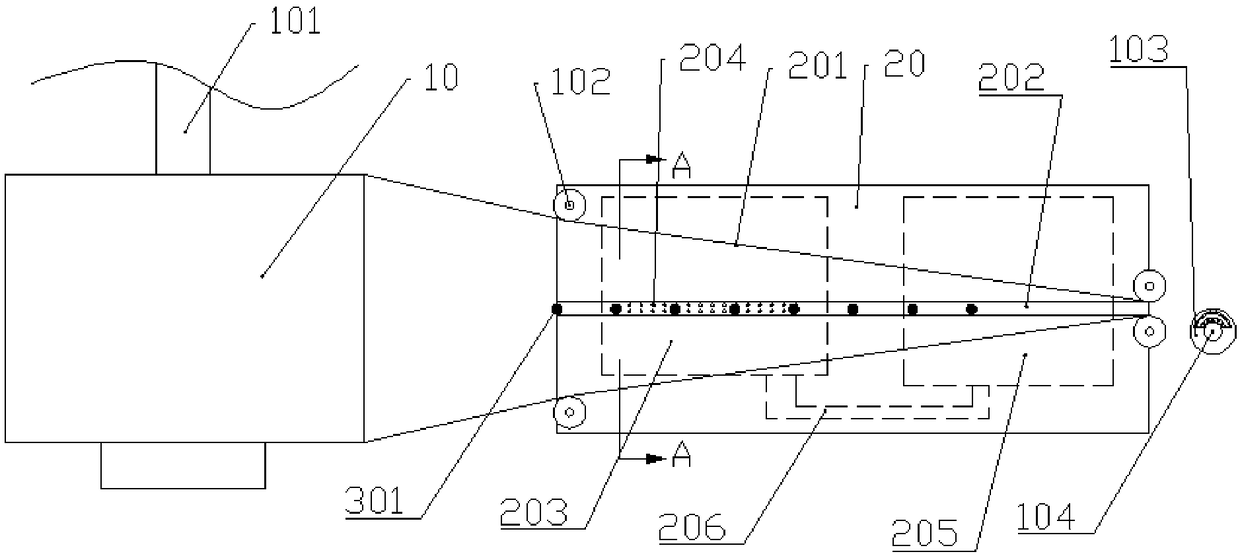

Energy-saving washing device for washing machine part processing

ActiveCN111545516ALow costReduce electricity consumptionDrying gas arrangementsDrying machines with progressive movementsLaundry washing machineMachine parts

The invention relates to the technical field of furniture processing equipment, and provides an energy-saving washing device for washing machine part processing, which aims to solve the problems thata medium-large-sized washing device introduced in an existing large-scale production plant is used for washing a workpiece, is higher in cost, is complex in structure, is high in operation energy consumption, and does not meet energy-saving proposal. The energy-saving washing device comprises a strip-shaped transmission box, upper end of which is not sealed, wherein a transmission braided strap for transmitting the workpiece is horizontally arranged in the inner cavity of the strip-shaped transmission box; a plurality of transmission wheels are rotatably arranged inside the transmission braided strap; the upper end of the strip-shaped transmission box is provided with a washing mechanism; the washing mechanism comprises a washing room arranged at the upper end of the strip-shaped transmission box, and a spraying-washing unit and a drive unit for driving the spraying-washing unit are arranged in the washing room. The energy-saving washing device is especially suitable for energy-savingefficient washing of washing machine parts, and has a higher social use value and a higher application prospect.

Owner:惠安县品创工业设计有限公司

Wheat drying device and operation method thereof

InactiveCN109405456AQuick drying jobWon't stealBatteries circuit arrangementsElectric powerScrew threadTimer

The invention discloses a wheat drying device and an operation method thereof. The wheat drying device comprises an airing plate. The top of the airing plate is fixedly connected with a baffle plate.The front end and the rear end of the two sides of the inner cavity of the baffle are fixedly connected with threaded rods through bearings, and the left side of the inner cavity of the baffle plate is in threaded connection with a material turning plate. According to the wheat drying device and the operation method thereof, the airing plate, the baffle plate, the threaded rod, a material turningplate, a belt disc, a belt, a first motor, a yarn net rack, a spring, supporting legs, a supporting rod, a bottom plate, a supporting plate, a crank connecting rod mechanism, a second motor, a drivingbevel gear, a driven bevel gear, a mounting rod, a solar panel, a storage battery, a protection box, a photovoltaic converter, a processor, a storage module and a timer are arranged and matched witheach other to use, the wheat can be quickly aired, and time and labor are saved, so that the airing efficiency is greatly improved; moreover, birds cannot be eaten and cannot be mixed with the silt,so that great convenience is brought to later collecting and assembling.

Owner:许昌泰禾农业科技发展有限公司

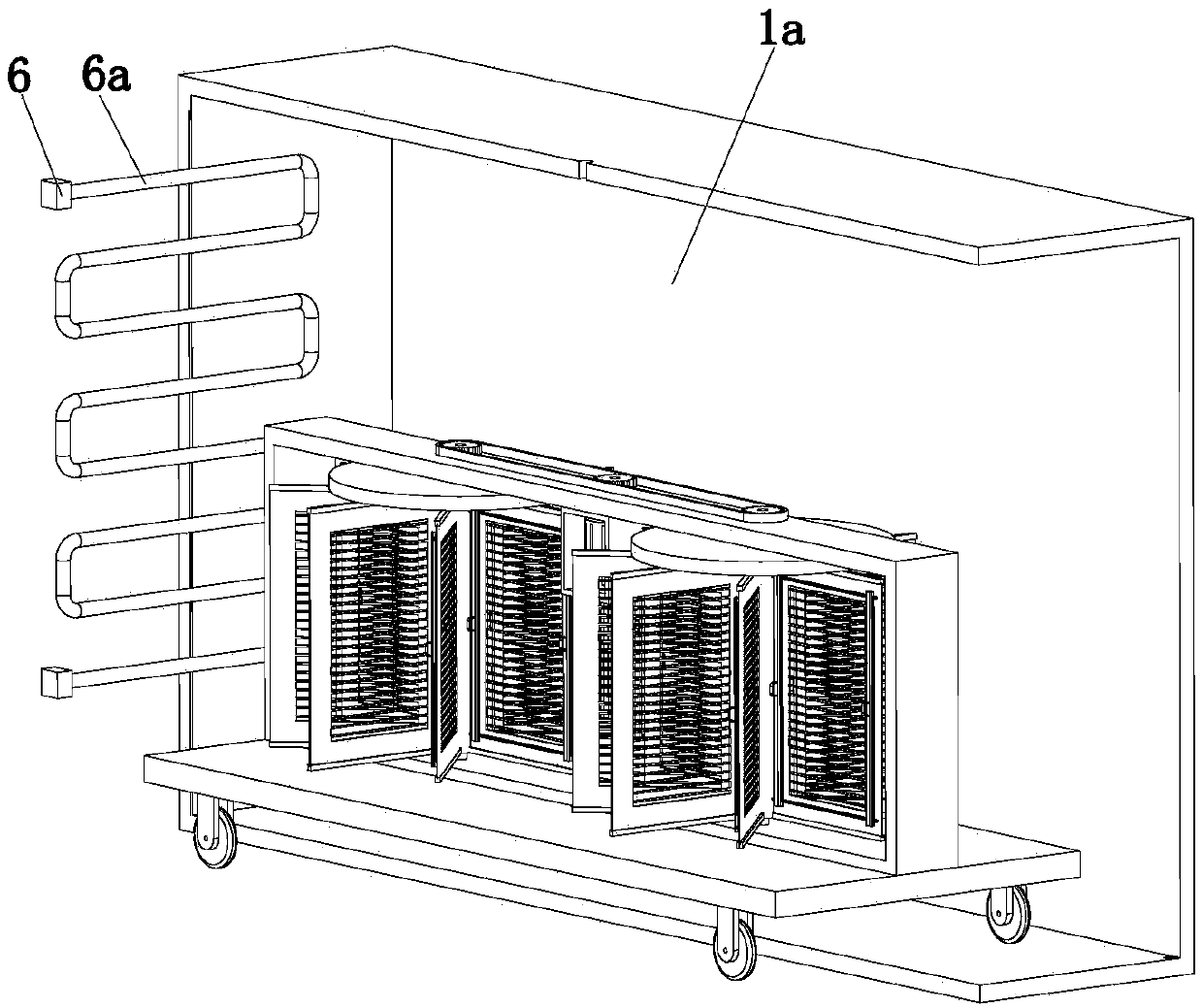

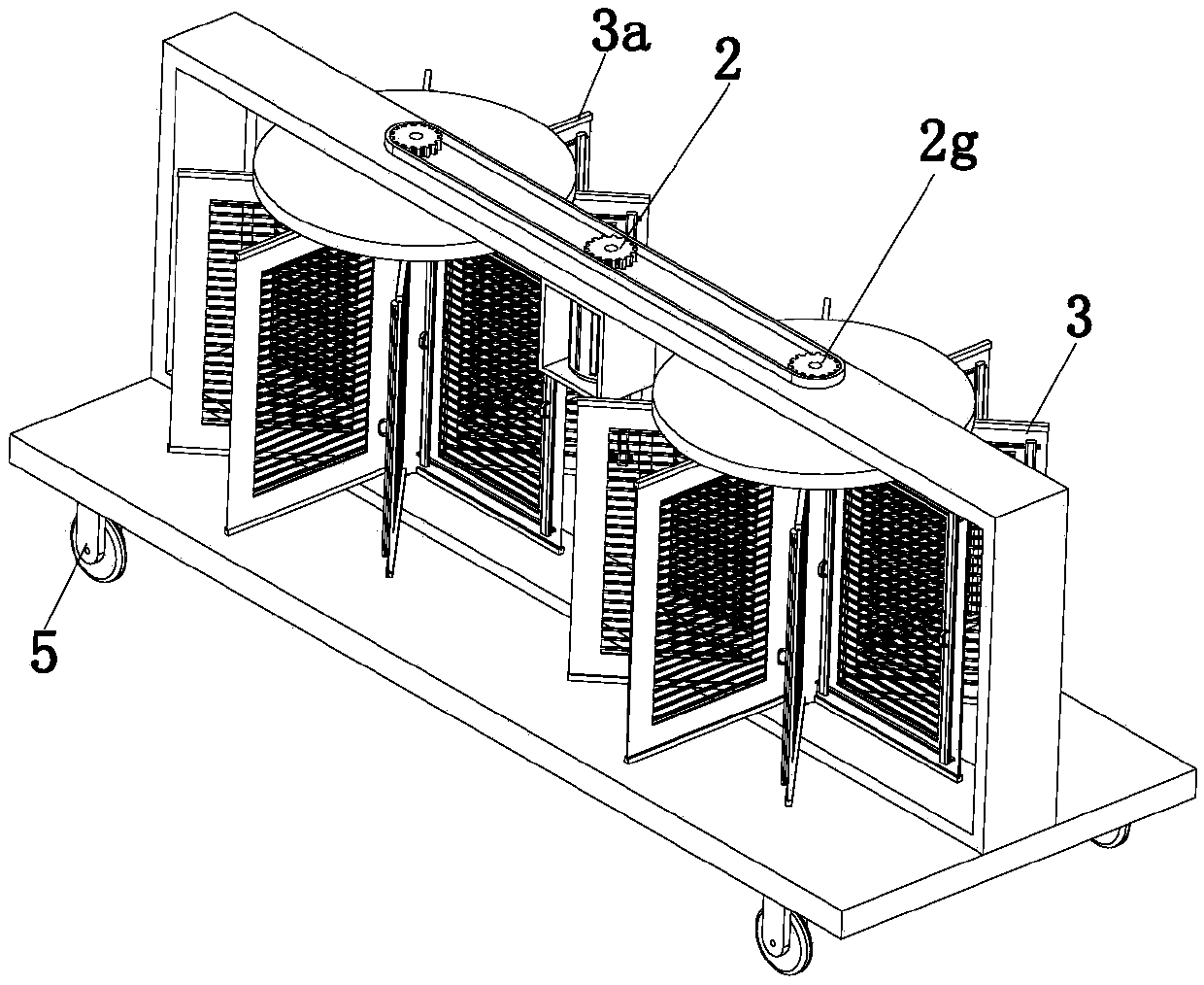

Drying control method for papermaking

The invention discloses a drying control method for papermaking and belongs to the technical field of papermaking processing equipment. The method is realized based on a drying device, which comprisesa drying box, a rotating component, a fixing component, a shaking component, a drying component and a moving component. One end of the drying box is provided with a receiving cavity which is arrangedalong the length direction of the drying box and is open outward; the rotating component is arranged on the fixing component, which is arranged on the rotating component and is rotatively connected with the rotating component; the shaking component is disposed at the top of the drying box and a moving end of the shaking component extends into the receiving chamber; and the drying component is disposed on the drying box. An oscillating motor rotates to drive a shaking fan to rotate along the axial direction of a mounting rack, and the shaking fan rotates to drive the air in the drying box to flow, thus making the air in the drying box to be circulated. And it is ensured that the temperature is consistent everywhere in the drying box. The method is helpful for drying paper to be dried in the drying box.

Owner:维达护理用品(广东)有限公司

Edge rolling method for cloths

ActiveCN108149401AEasy to foldFast folding and shapingWork-feeding meansLiquid/gas/vapor removalMiddle lineEngineering

The invention relates to the field of a cloth processing method, and particularly discloses an edge rolling method for cloths. The method includes steps of preparing distilled water, cloth to be edge-turned, an unwinding roller, a winding roller and a limiting block; placing the distilled water in a steam cavity while keeping temperature in the steam cavity at 120-150 DEG C; meanwhile, keeping temperature in the drying cavity at 200-300 DEG C; coaxially placing the cloth on the unwinding roller, pulling out the end part of the cloth, and folding along the horizontal middle line of the cloth; making the end part of the folded cloth cross through an edge-rolling through slot horizontally, and then fixing the end part of the cloth on the winding roller, wherein the winding roller drives the cloth to move at the speed of 1-5 cm / s towards the direction of the winding roller; when the cloth is moved to the steam cavity, spraying steam to the cloth, soaking and shaping the cloth; when the cloth is moved to the drying cavity, drying and shaping the cloth by the drying cavity. The plan can carry out accurate edge folding process on the cloths.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

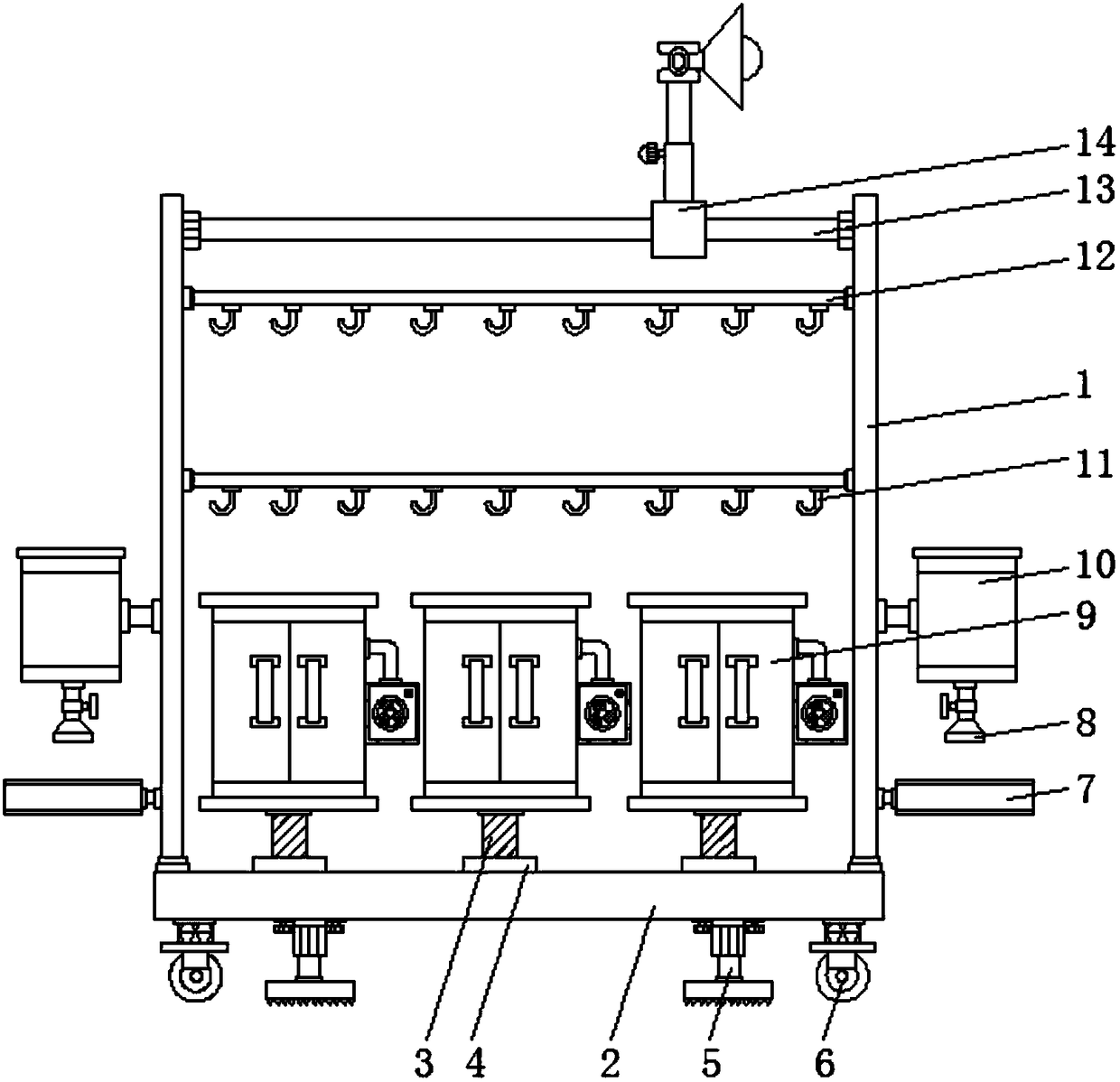

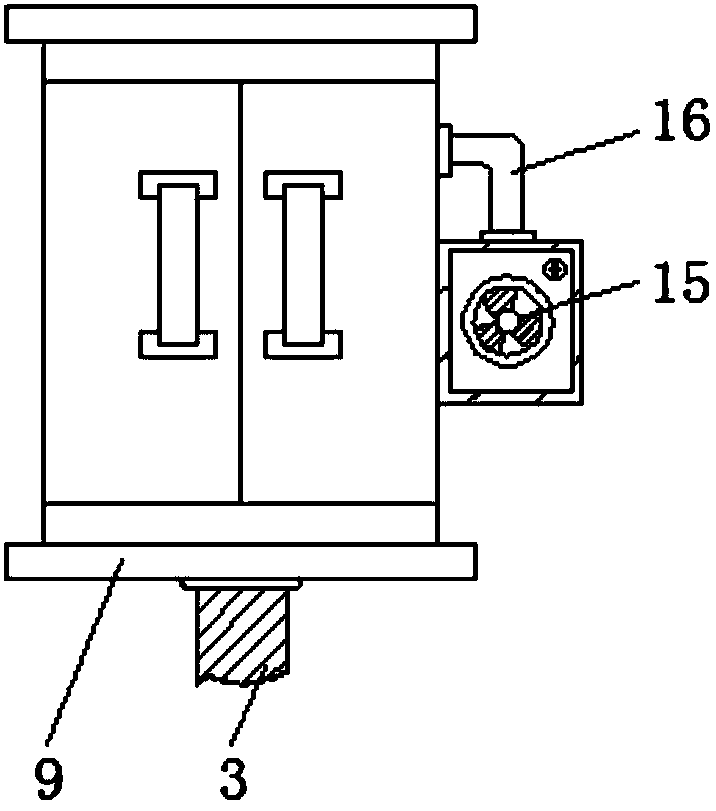

Tool rack for building construction

The invention discloses a tool rack for building construction. The tool rack comprises a supporting shelf and a base, hanging rods are distributed at the inner side of the supporting shelf at equal intervals, uniformly-distributed hanging hooks are arranged on the hanging rods, a slide rod is arranged at the inner side of the top of the supporting shelf, a slide block is slidably arranged on the slide rod, a telescopic lamp post is installed on the slide block, an illumination lamp is arranged at the top of the telescopic lamp post, cleanout fluid tanks and cleaning tables are arranged on theside walls of the supporting shelf, tool kits are connected to the top of the base through rotary shafts, and hot air blowers are arranged on the side walls of the tool kits. By means of the tool rackfor the building construction, tools are conveniently cleaned after being utilized, and cleanliness of the tools is maintained; through the hot air blowers arranged on the side walls of the tool kits, the cleaned tools can be effectively and cleanly dried, and it is prevented that the tools are rusted and damaged; meanwhile, the tool rack is simple in structure and flexible to move, the functionof rotating the tool kits can be achieved, and workers conveniently store and take the tools from different angles.

Owner:玉林市金腾建材有限公司

Tilapia mossambica abdominal cavity black membrane removing culture method and feed treatment device thereof

InactiveCN113261516AAvoid problemsWell mixedFeeding-stuffRotary stirring mixersAnimal scienceZoology

The invention discloses a tilapia mossambica abdominal cavity black membrane removing culture method which comprises the following steps: step 1, selecting tilapia mossambica fries, removing female tilapia mossambica in the tilapia mossambica fries, and reserving male tilapia mossambica; and step 2, feeding the male tilapia mossambica in selected in the step 1 with feed mixed with traditional Chinese medicines in the 2-3 month growth period. Radix glycyrrhizae preparata and microcos paniculata which are doped in the feed are arranged, so that diseases in the tilapia mossambica can be eliminated, and abdominal cavity black membranes of the tilapia mossambica can be prevented to a certain extent due to reduction of the diseases; and an arranged mixing device can fully mix the fish feed with the radix glycyrrhizae preparata and the microcos paniculata, an extrusion device can continuously push an extrusion block and a sealing cover plate to continuously rotate along with a fixed pin shaft when a rotating shaft rotates, a materials in a discharging pipe slowly descend and fall in batches, and the fish feed can be more fully mixed with the radix glycyrrhizae preparata and the microcos paniculata leaves.

Owner:安徽瀚沣渔业科技发展有限公司

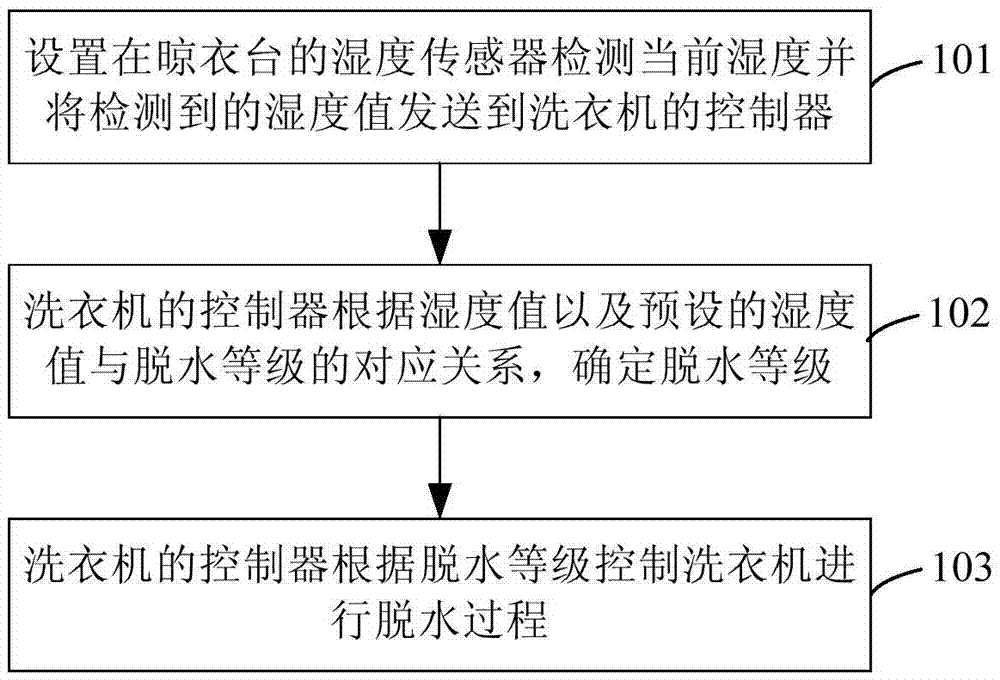

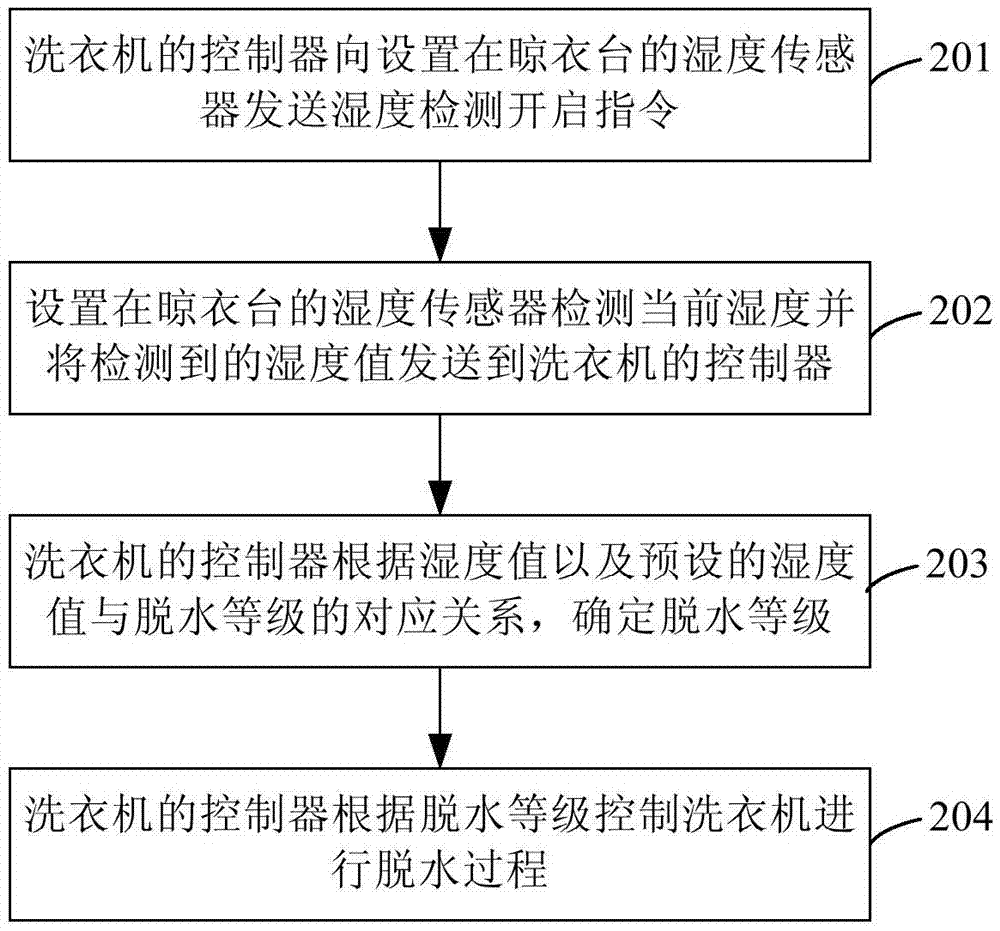

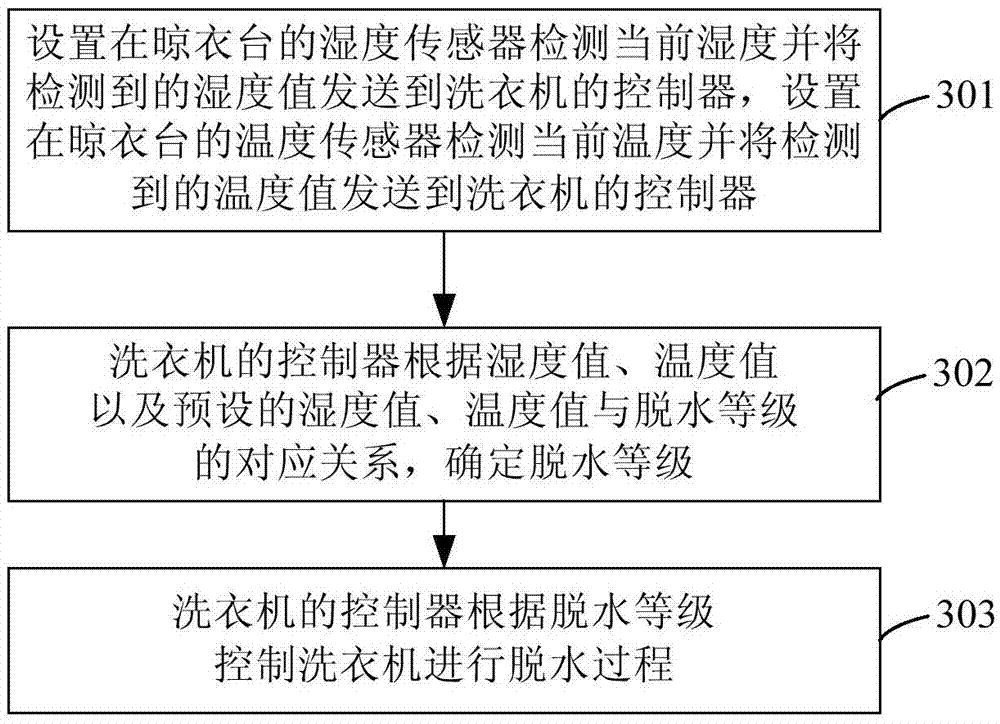

Washing machine dehydration control method and washing machine

InactiveCN106894193AReduce energy consumptionGuaranteed dryingControl devices for washing apparatusTextiles and paperMachine controlProcess engineering

The embodiment of the invention provides a washing machine dehydration control method and a washing machine. A humidity sensor arranged on a clothes stand detects current humidity and sends a detected humidity value to a controller of the washing machine; the controller of the washing machine determines the dehydration level according to the humidity value and a preset corresponding relation of the humidity value and the dehydration level; the controller of the washing machine controls the washing machine to conduct dehydration according to the dehydration level. According to the washing machine dehydration control method and the washing machine, the energy can be saved.

Owner:BEIJING QIHOO TECH CO LTD +1

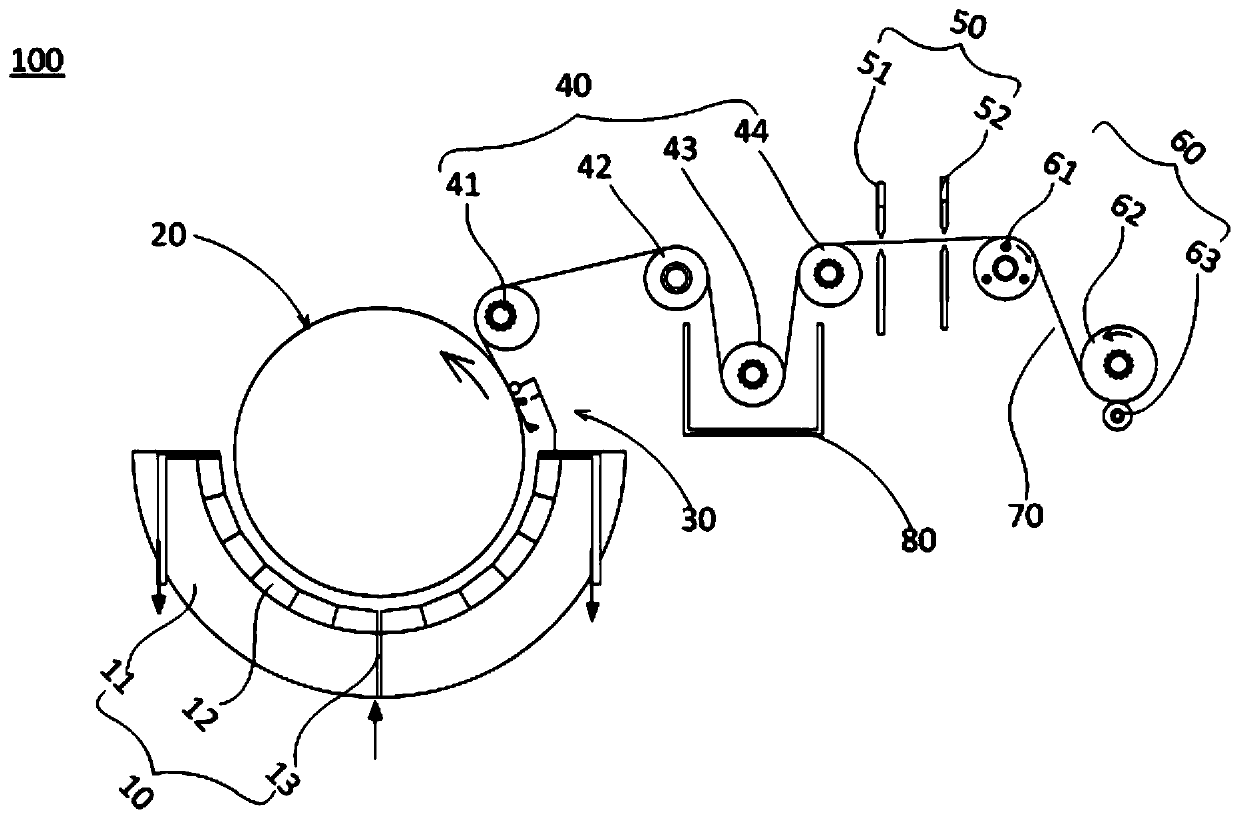

Fast drying and cooling foil production device

ActiveCN109943869AGuaranteed dryingGuaranteed cooling effectDrying gas arrangementsElectroforming processesElectricityCold air

The invention provides a fast drying and cooling foil production device. The fast drying and cooling foil production device comprises an anode unit, a cathode roller, a conveying unit, a drying and cooling unit and a rolling unit, wherein the anode unit is electrically connected with the positive pole, the cathode roller is electrically connected with the negative pole, and the conveying unit, thedrying and cooling unit and the rolling unit are arranged on one side of the cathode roller; the drying and cooling unit is arranged between a passivation tank and the rolling unit; the drying and cooling unit comprises a drying unit arranged near the conveying unit and a cooling unit arranged near the rolling unit; the drying unit comprises an upper hot air knife, a lower hot air knife and a hotair pipeline, the upper hot air knife and the lower hot air knife are symmetrically arranged, and the hot air pipeline is connected with the upper hot air knife and the lower hot air knife; and the cooling unit comprises an upper cold air knife, a lower cold air knife and a cold air pipeline, the upper cold air knife and the lower cold air knife are symmetrically arranged, and the cold air pipeline is connected with the upper cold air knife and the lower cold air knife.

Owner:FUJIAN QINGJING COPPER FOIL

Sufficient and anti-wrinkling textile drying equipment

ActiveCN111380348AFully dryEnough timeDrying machines with progressive movementsFabric finishing guides/expandersStructural engineeringMechanical engineering

The invention discloses sufficient and anti-wrinkling textile drying equipment. The equipment comprises a box body, wherein a blocking door connected with the box body in a matched mode is arranged onthe front end wall of the box body, supporting blocks are fixedly connected to the rear end wall of the blocking door in a bilateral symmetry mode, the supporting blocks are rotationally connected with a spline shaft, the spline shaft is connected with a textile product containing shaft in a matched mode, textile products are arranged on the textile product containing shaft, the left textile product and the right textile product are connected through textile cloth, the textile product containing shaft is rotationally connected with the box body, an intermittent rotating mechanism is arrangedat the rear end of the textile product containing shaft, first sliding grooves with openings facing a textile product grooves are symmetrically formed in the upper end wall and the lower end wall of the textile product groove, the first sliding grooves are internally and slidably connected with first sliding blocks, flattening mechanisms are arranged in the first sliding blocks, drying mechanismsare arranged on the right sides of the first sliding grooves, repeating mechanisms are arranged at the left ends of the first sliding blocks, the two faces of the textile fabric can be fully dried atthe same time, flattening operation is conducted in time after drying, and wrinkles are reduced.

Owner:淄博玉华纺织有限公司

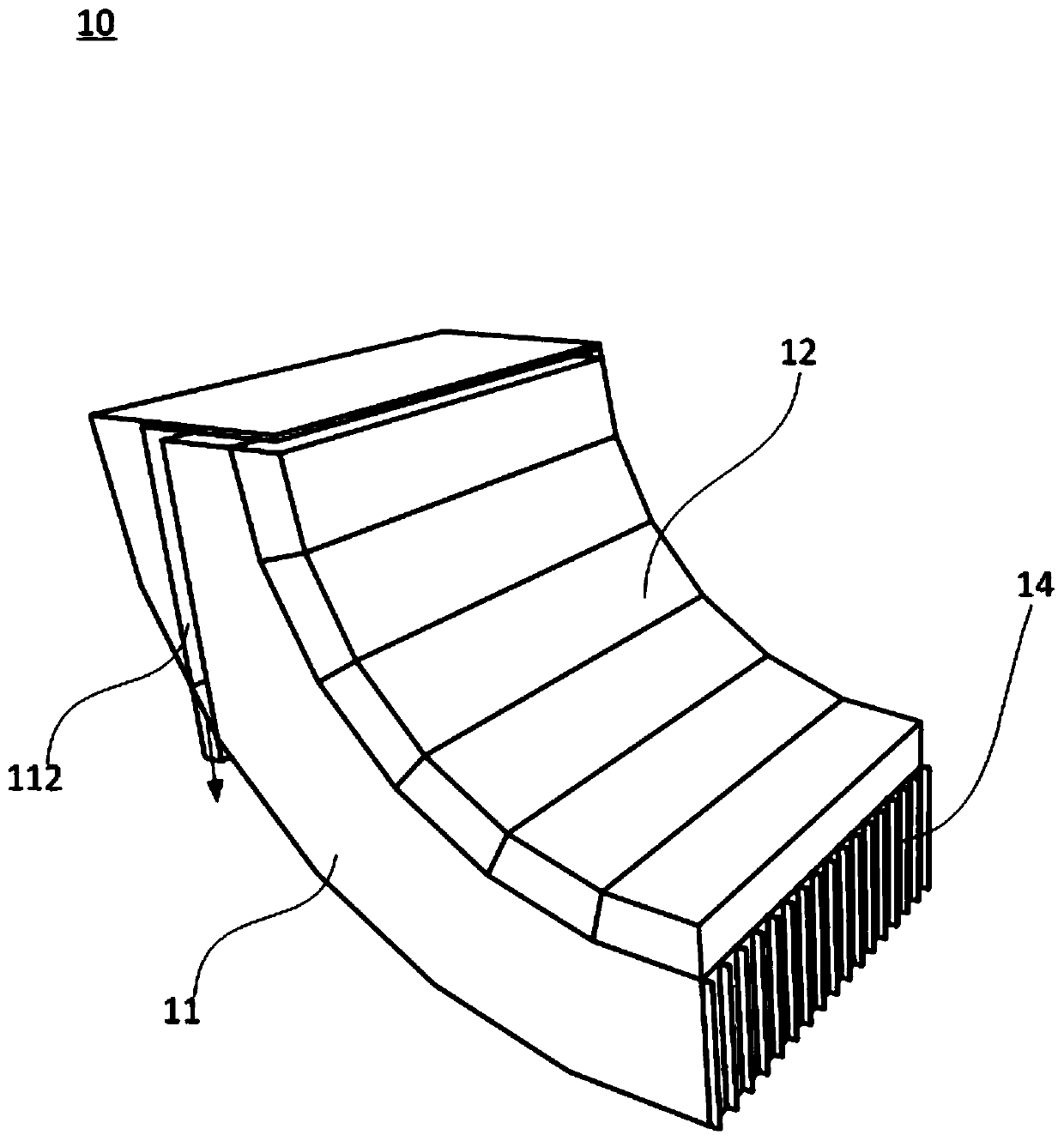

Tea leaf drying device

InactiveCN108444260AQuality assuranceImprove practicalityPre-extraction tea treatmentDrying gas arrangementsEngineeringTea leaf

The invention discloses a tea leaf drying device. The tea leaf drying device comprises a main body, wherein a drying box is fixedly connected to the bottom of the main body, one side surface of the main body is rotationally connected with a box door through hinges, and a clamping buckle lock is arranged on the box door; and a motor is fixedly connected to the top of the left side of the main body,and the output end of the motor is fixedly connected with a first rotating wheel, The invention relates to the technical field of tea processing. According to the tea leaf drying device, the motor isrotated to drive rotating discs to rotate, or the rotating discs are rotated manually, so that the practicability of the device is improved, the labor force is saved, tea leaves are driven to roll, and drying is more comprehensive, and the purpose of ensuring the quality of the tea leaves is guaranteed; screen frames are convenient to disassemble and assemble, the installation efficiency of the operation is improved, the labor force is saved, and the drying efficiency is improved; hot air is conveyed upwards through fans, so that the tea leaves are dried, the drying effect of the tea leaves is improved, all the surfaces of the tea leaves are dried, the fragrance of the tea leaves is improved, and the tea leaves are convenient to store and transport.

Owner:安吉恒盛白茶有限公司

Spinning drying device

InactiveCN107843089AImprove drying effectGuaranteed dryingDrying gas arrangementsDrying machines with progressive movementsAgricultural engineeringBellows

The invention discloses a spinning drying device. The spinning drying device comprises a frame; a drying plate is fixedly connected to the middle part between the front surface and the back surface ofan inner cavity of the frame; through grooves are formed in the middle part in the drying plate at equal intervals; a first intake groove and a second intake groove respectively communicate with theleft sides of the tops and the right sides of the bottoms of the through grooves; one end of an exhaust pipe communicates with a first fan; the right side of the first fan communicates with an air sucking pipe; the right side of the drying plate communicates with an air collecting box; one end of a first air guide pipe penetrates through a frame, and communicates with a second fan; the upper partof an inner cavity of a drying chamber is fixedly connected with a drying agent; the lower part of the inner cavity of the drying chamber is fixedly connected with water sucking sponge; and one end ofa third air guide pipe penetrates through the frame, and communicates with an air spraying plate. Through arrangement of the drying plate, the intake grooves, a through groove, the air collecting box, the second fan, the drying chamber and the air spraying plate, the spinning drying device is excellent in drying effect.

Owner:宿迁至诚纺织品股份有限公司

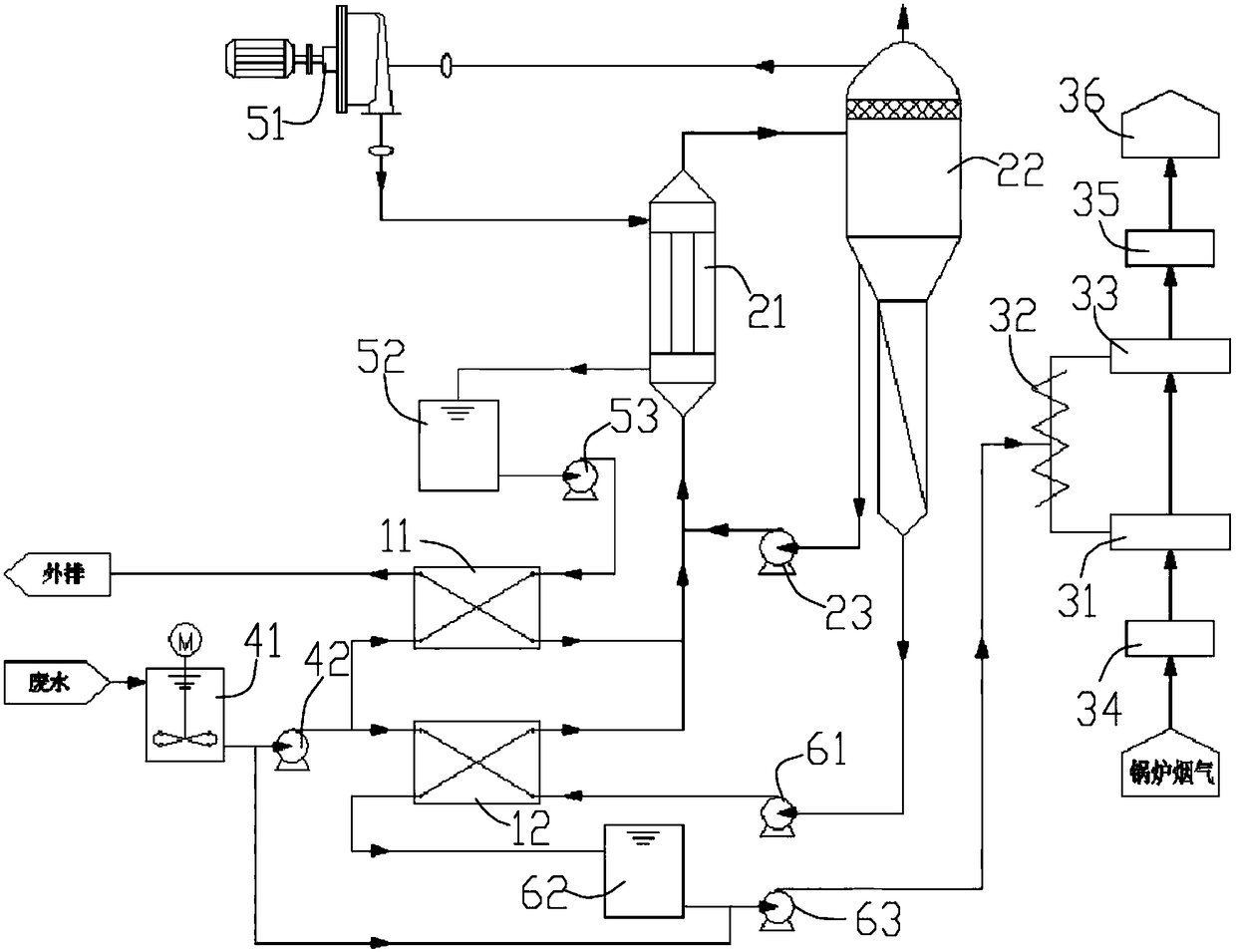

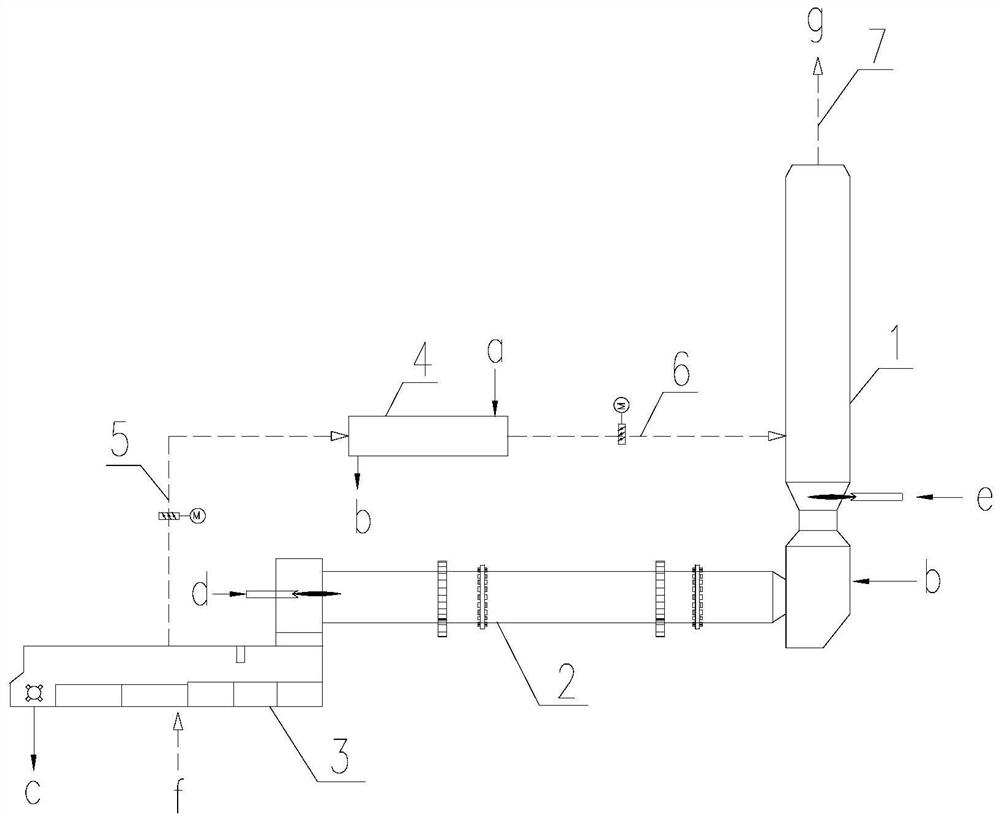

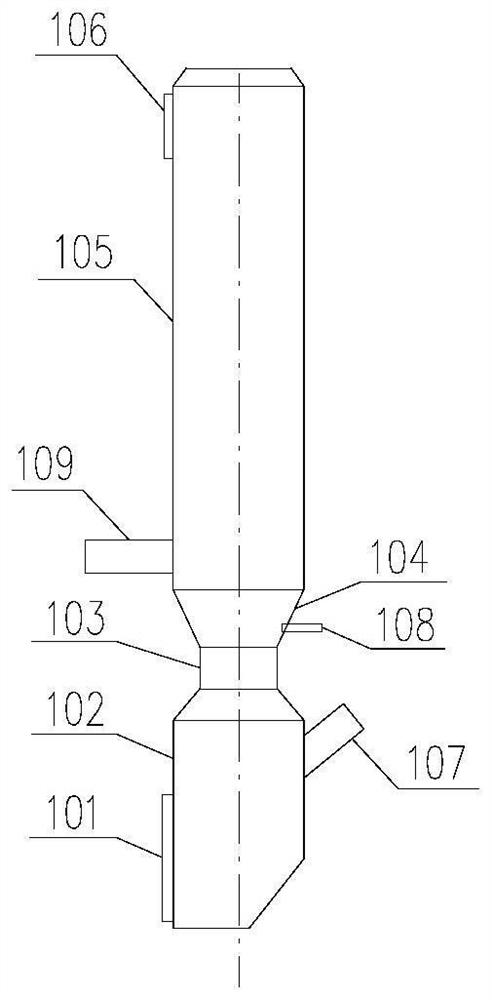

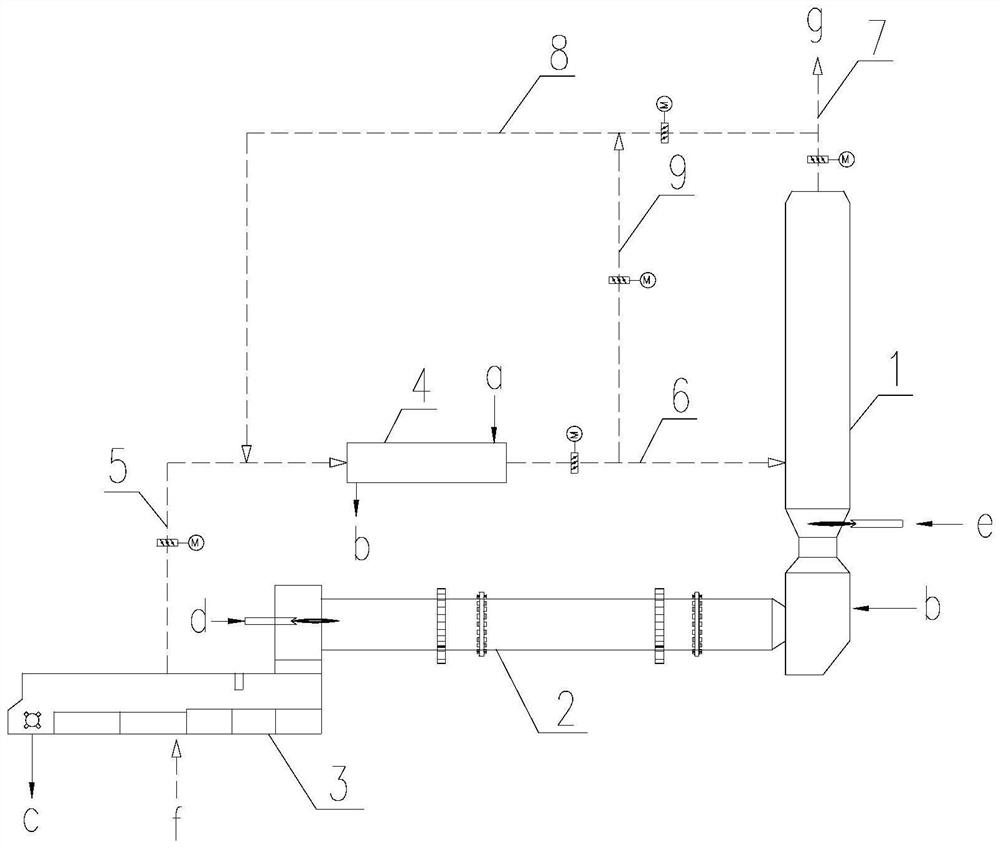

MVR concentration and swirling-flow atomization cooperated processing process and system

PendingCN108383313AReduce doseNo processing issuesMultistage water/sewage treatmentWater/sewage treatment by heatingAir preheaterFlue gas

The invention discloses an MVR concentration and swirling-flow atomization cooperated processing process and system. The process combines the MVR evaporation technology and a bypass flue swirling-flowatomization evaporation drying method to treat desulfurization waste water, the desulfurization waste water is subjected to preprocessing and heat exchanging and is concentrated in an MVR evaporationsystem, the concentrated desulfurization waste water is atomized by the swirling-flow atomization method and then enters a boiler bypass flue at the rear of an air preheater, boiler hot flue gas is used to evaporate and dry the wastewater, salt in the dried wastewater forms a powdered product, and the dried product enters an electrostatic precipitator along with the flue gas and is processed therein. The MVR concentration and swirling-flow atomization cooperated processing process and system can effectively lower energy consumption and can solve the salt treatment problem in desulfurization waste water zero emission.

Owner:GUANGDONG DEGA POWER ENVIRONMENTAL PROTECTION TECH CO LTD

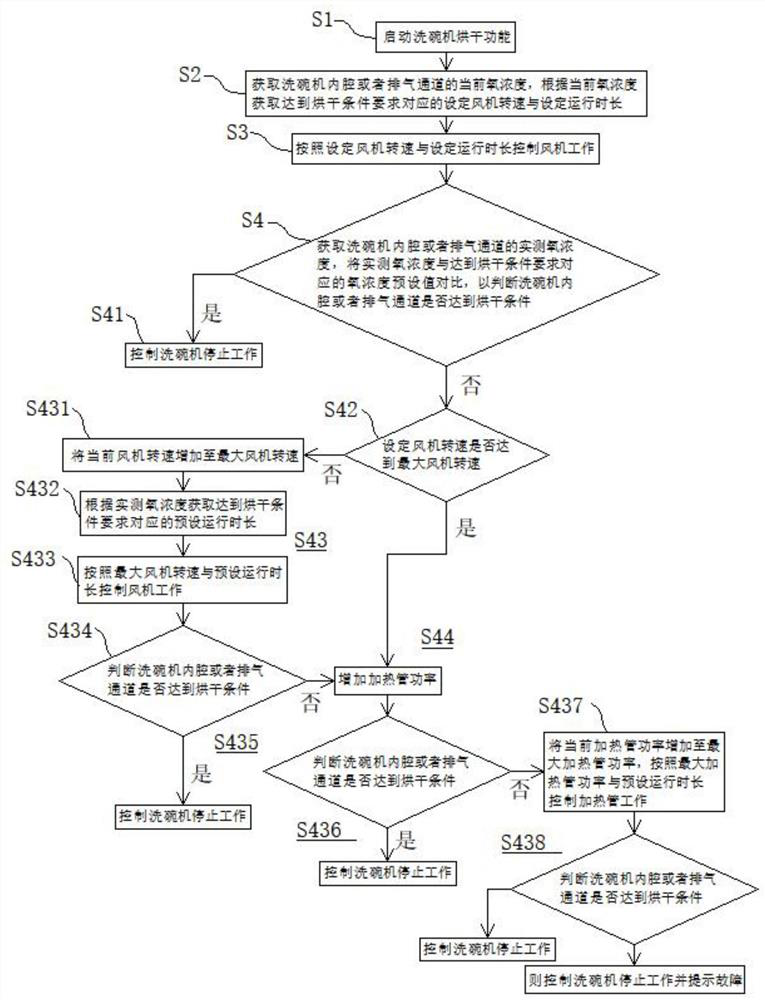

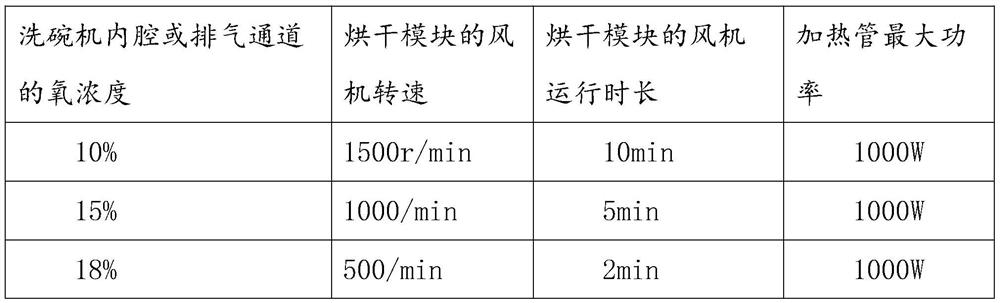

Dish-washing machine with oxygen sensor and control method of dish-washing machine

PendingCN112137543AEffective detection of drying degreeExtended service lifeTableware washing/rinsing machine detailsOxygen sensorControl engineering

The invention discloses a dish-washing machine with an oxygen sensor and a control method of the dish-washing machine. The dish-washing machine comprises a dish-washing machine inner cavity, an oxygensensor and a controller, an exhaust channel is formed in the dish-washing machine inner cavity, the oxygen sensor is arranged in the dish-washing machine inner cavity or in the exhaust channel, the controller is electrically connected with the oxygen sensor, and the controller is used for judging whether the dish-washing machine inner cavity or the exhaust channel meets a drying condition or notaccording to data fed back by the oxygen sensor, and can effectively detect the drying degree of the dish-washing machine inner cavity.

Owner:VATTI CORP LTD

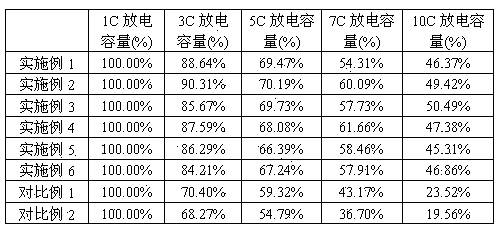

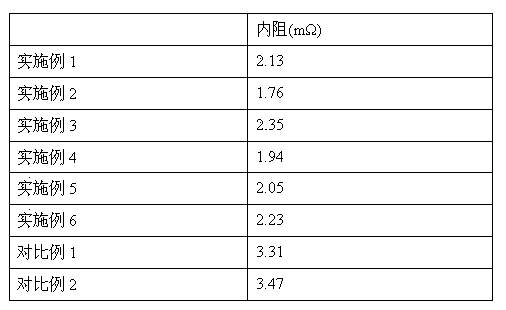

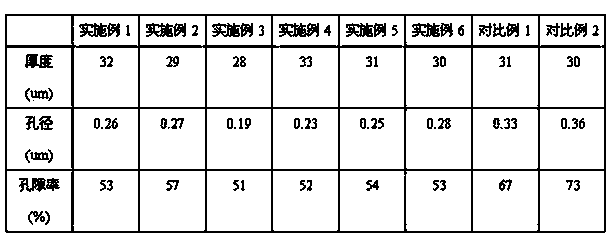

Lithium polyoxometallate composite diaphragm for lithium battery

ActiveCN104051694AGuaranteed ionic conductivityLower battery internal resistanceCell component detailsBattery chargeElectrolyte

The invention discloses a lithium polyoxometallate composite diaphragm for a lithium battery and a preparation method of the diaphragm. The composite diaphragm comprises a PVDF-HFP copolymer, SiO2 and lithium polyoxometallate, wherein the lithium polyoxometallate has a three-dimensional skeleton structure, and lithium ions are combined with anions of lithium polyoxometallate; in the battery charging / discharging process, the lithium ions of the lithium polyoxometallate can be continuously exchanged with the lithium ions in electrolyte, the combination of the diaphragm material with the lithium ions in the electrolyte is realized, the internal resistance of the battery is reduced, and the rate characteristic of the battery is improved.

Owner:DONGFANG ELECTRIC CORP LTD

Soil heavy metal content detection device and detection method

ActiveCN114414283ATo achieve the purpose of synchronous samplingImprove detection efficiencyWithdrawing sample devicesPreparing sample for investigationSoil scienceSoil heavy metals

The invention belongs to the technical field of environment detection equipment, and particularly relates to a soil heavy metal content detection device and method. The first shell assembly comprises a first shell; through the sampling mechanism, the distribution mechanism and the air drying mechanism in the first shell assembly, four groups of ground inserting steel pipes on the sampling mechanism are expanded outwards and then are distributed in four directions of the first shell assembly, so that the purpose of synchronously sampling soil layers at four different positions of a detection area is achieved; the sampled soil in the four groups of ground inserting steel pipes is sequentially sucked for air-drying treatment, conditions are provided for accurate detection of the soil, then the air-dried soil is conveyed to the second shell assembly by the air-drying mechanism for classified storage of the soil, and the effect of unified detection is achieved after batch sampling of detection personnel in different soil areas is facilitated; the soil heavy metal detection efficiency is also improved.

Owner:深圳市宗兴环保科技有限公司

Efficient and stable integrated solidification and drying system

InactiveCN108870935ASave human and material resourcesUniform temperatureDrying gas arrangementsDrying machines with progressive movementsAuto regulationFiber

The invention discloses an efficient and stable integrated solidification and drying system. A trend mode of an external furnace mesh belt is adopted, a working speed is 130m / min. The solidification and drying system is composed of a drying and solidification furnace body, a mesh belt conveying part and a drying and solidification furnace hot air circulation and a control system which integrate with solidification, drying, conveying and circulation into a integrate structure in a compact join cooperation mode, and the integrate structure provides a necessary precondition for fully-automatic integrated solidification and drying; the drying and solidification furnace body is provided with a plurality of sections of solidification zones, so that the solidification effect is good; a circulating air duct and a dehumidifying air duct are arranged at the same time, so that the drying of a product is guaranteed; superfine ceramic fiber cotton is adopted as a core material for a heat preservation board, so that heat insulation is realized; the mesh belt conveying part is provided with a tensioning and deviation correcting device, a photoelectric electric automatic correcting system is adopted for deviating correction, automatic control is carried out, so that the tension of a conveying belt in the product conveying process is guaranteed, and the process is stable; a plurality of circulating fans are arranged in the hot air circulation and the control system, redundant hot air is recycled, so that resources are saved; and a feedback device is arranged on the control system, so that automatic adjustment is achieved, time and labor are saved.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

Low-energy-consumption system and process for preparing ceramsite from solid waste

PendingCN114370759AReduce exhaust gas treatment costsReduce system power consumptionRotary drum furnacesHandling discharged materialVolatile organic compoundProcess engineering

The invention belongs to the technical field of environmental protection engineering, and particularly relates to a low-energy-consumption system and process for preparing ceramsite through solid waste, the low-energy-consumption system for preparing ceramsite through solid waste comprises a reburning furnace, a material ball drying machine and a cooling machine, the cooling machine is connected with an air inlet of the material ball drying machine through the front section of a tertiary air pipe, and the rear section of the tertiary air pipe is connected with a secondary air pipe; and an air outlet of the pellet dryer is connected with the reburning furnace through the rear section of the tertiary air pipe. While ceramsite is prepared, waste heat in a calcining system is fully utilized for combustion supporting, pellet drying and the like, the heat efficiency of the system is improved, and the energy consumption of the system is reduced; the problems of treatment and emission of harmful substances such as volatile organic compounds and malodorous gases generated in the flue gas when the solid wastes are digested are solved, and the low-energy-consumption system and process for preparing the ceramsite by utilizing the solid wastes are realized in low-carbon green production.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com