Novel beaker washing device

A cleaning device and a new type of technology, applied in the directions of cleaning hollow objects, drying gas arrangement, cleaning methods and utensils, etc., can solve the problems of low work efficiency and not suitable for mechanical clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

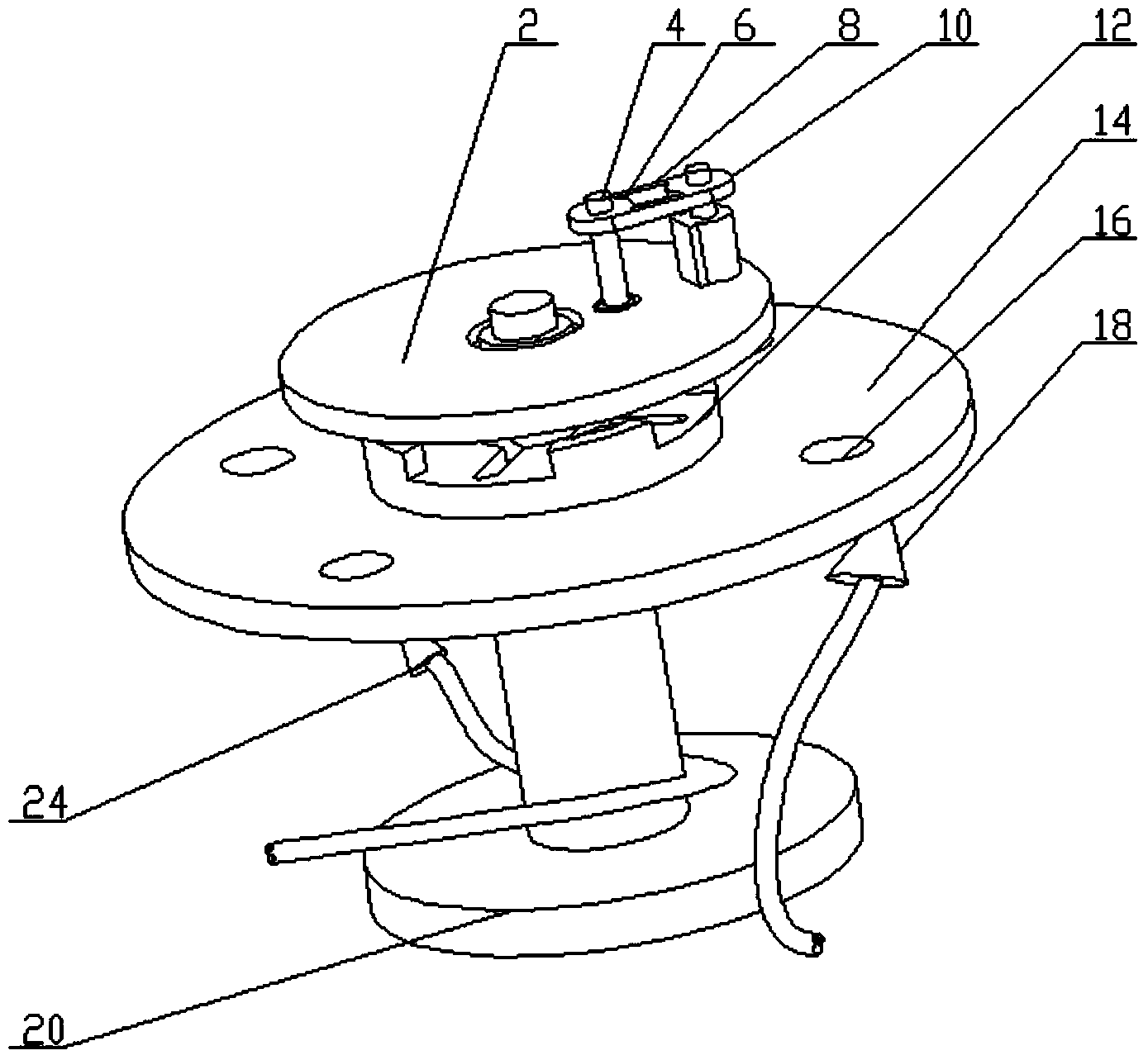

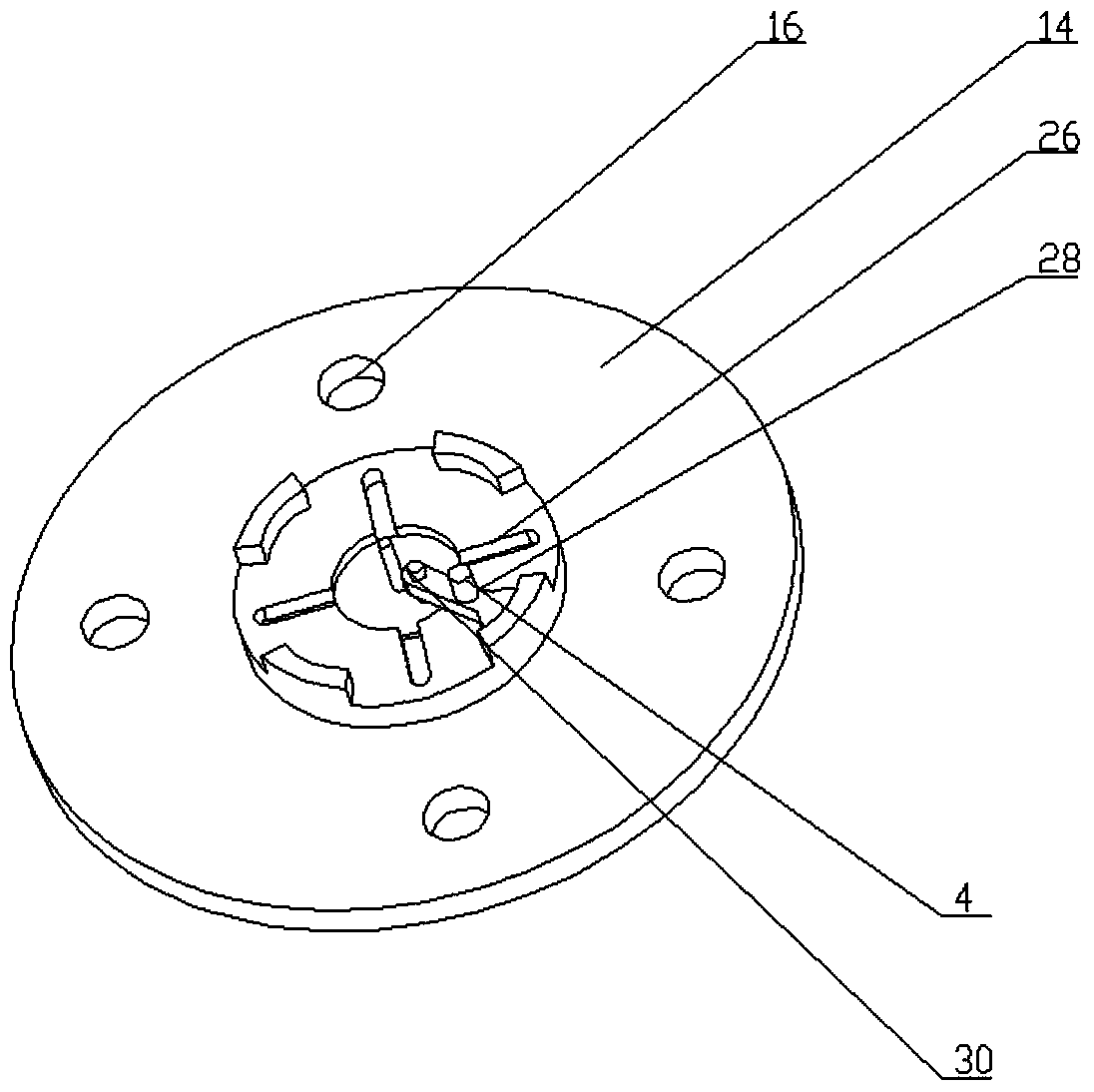

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Such as Figure 1-2 As shown, the present invention includes a frame 2 and a workbench 14 that is rotatably connected to the frame 2, and is characterized in that, the workbench 14 is also fixedly connected to drive the workbench 14 to rotate and can control the The workbench 14 is an intermittent motion mechanism 12 that stops at least three times when it rotates once. The workbench 14 is provided with at least three beaker mounting holes 16 for accommodating beakers. The first spray head 24 for spraying water and the second spray head 18 that can spray hot gas upwards. When the workbench 14 stops, the two adjacent beaker mounting holes 16 are located at the first spray head 24 and the second spray head 18 respectively. directly above the .

[0018] As a further improvement of the present invention, the intermittent motion mechanism 12 includes an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com