Degreasing-free punching cleaning oil for automobile steel plate, and preparation method thereof

A technology for automobile steel plate and cleaning oil, which is applied in chemical instruments and methods, petroleum industry, detergent compositions, etc., can solve the problems of large water body influence and water body pollution, etc., to improve economic benefits, improve adhesion, and promote removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

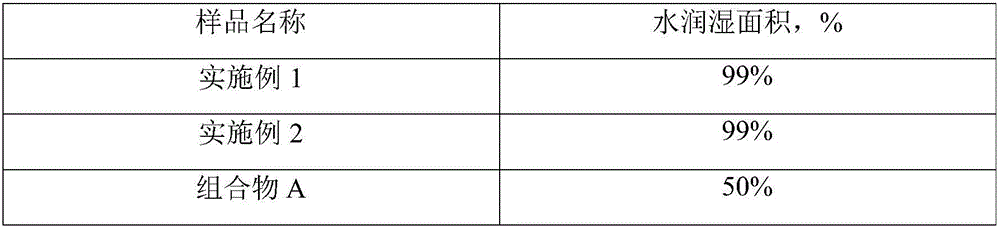

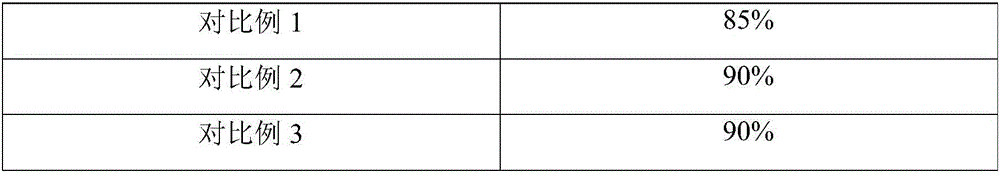

Examples

Embodiment 1

[0023] This embodiment provides a stamping cleaning oil for degreasing automobile steel sheets and a preparation method thereof. The specific substances and weight percentages of each component selected in the stamping cleaning oil are as follows:

[0024] (1) Refined mineral oils are aviation kerosene, alkane-based neutral oil, and paraffin-based neutral oil, and their mass percentages are respectively: 20%, 20%, and 30%;

[0025] (2) The extreme pressure antiwear agent is sulfurized lard, sulfurized olefin, dioleyl phosphite, and its weight percentage is 2%, 1%, 4%;

[0026] (3) antirust agent is petroleum calcium sulfonate, synthetic calcium sulfonate, imidazoline, and its percentage by weight is 3%, 4%, 2%;

[0027] (4) film forming agent is lanolin magnesium soap, oxidized wax soap, and its percentage by weight is 3%, 0.8%;

[0028] (5) emulsifying agent is sodium petroleum sulfonate, polyisobutylene succinic anhydride, and its percentage by weight is 2%, 2%;

[0029] (...

Embodiment 2

[0034] This embodiment provides a stamping cleaning oil for degreasing automobile steel sheets and a preparation method thereof. The specific substances and weight percentages of each component selected in the stamping cleaning oil are as follows:

[0035] (1) Refined mineral oils are aviation kerosene, alkane-based neutral oil, and paraffin-based neutral oil, and their mass percentages are respectively: 30%, 10%, and 17%;

[0036] (2) The extreme pressure antiwear agent is sulfurized lard, sulfurized olefin, dioleyl phosphite, and its weight percentage is 4%, 2%, 2%;

[0037] (3) antirust agent is petroleum calcium sulfonate, synthetic calcium sulfonate, imidazoline, and its percentage by weight is 3%, 4%, 3%;

[0038] (4) film-forming agent is lanolin magnesium soap, oxidized wax soap, and its percentage by weight is 3%, 4%;

[0039] (5) emulsifying agent is sodium petroleum sulfonate, polyisobutylene succinic anhydride, and its percentage by weight is 5%, 2%;

[0040] (6)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com