Lithium polyoxometallate composite diaphragm for lithium battery

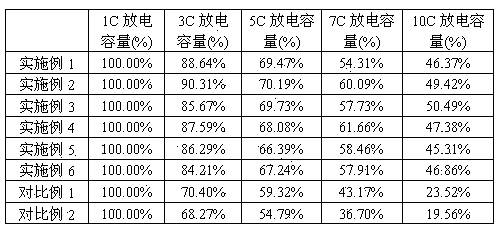

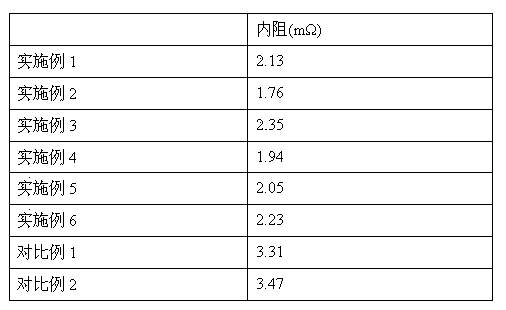

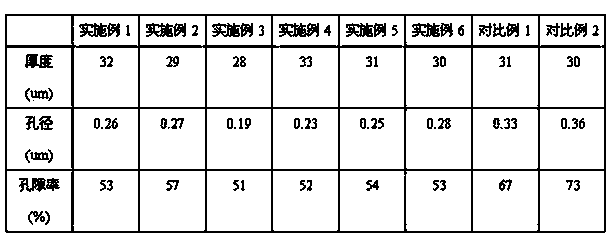

A technology of lithium polyoxometalate and composite diaphragm, which is applied to battery components, circuits, electrical components, etc., can solve the problems of inability to realize lithium ion combination and the influence of ion-conducting characteristics, and achieve good pore size and ion transmission rate , reduce the internal resistance of the battery, and improve the effect of the rate characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method is:

[0030] 1. Lithium polyoxometalate-SiO 2 Preparation of composite carrier

[0031] SiO 2 Powder in Li 3 PMo 12 O 40 After being immersed in anhydrous methanol solution for 12 hours, it is filtered out, baked at 100℃-120℃ for 2-3 hours, and baked at 500℃ for 3 hours to obtain Li 3 PMo 12 O 40 -SiO 2 Composite carrier powder.

[0032] 2. Preparation of composite diaphragm

[0033] Stir the PVDF-HFP (polyvinylidene fluoride) copolymer in acetone to obtain a viscous solution. According to PVDF-HFP copolymer and Li 3 PMo 12 O 40 -SiO 2 The composite carrier powder is added with Li in a mass ratio of 10:2 3 PMo 12 O 40 -SiO 2 The composite carrier powder is stirred again, then anhydrous ethanol is added to stir, and finally extruded, stretched, and dried into a film with a thickness of 10-40um.

[0034] The composite diaphragm of this embodiment is used in a battery for testing, and the battery used is:

[0035] Positive electrode: active material lithium ...

Embodiment 2

[0051] The preparation method is:

[0052] 1. Lithium polyoxometalate-SiO 2 Preparation of composite carrier

[0053] SiO 2 The powder was soaked in hydrochloric acid for 3 hours, washed with deionized water, and baked at 300°C for 10 hours. Lithium Phosphotungstate Li 3 PW 12 O 40 Dry at 90°C for 1 hour. SiO 2 Powder in Li 3 PW 12 O 40 Soaked in anhydrous methanol solution for 6 hours and then filtered out, baked at 60°C for 10 hours, and baked at 300°C for 10 hours to obtain Li 3 PW 12 O 40 -SiO 2 Composite carrier powder.

[0054] 2. Preparation of composite diaphragm

[0055] Stir the PVDF-HFP copolymer in acetone at a constant temperature of 50°C for 1 hour to obtain a viscous solution. According to PVDF-HFP copolymer and Li 3 PW 12 O 40 -SiO 2 The composite carrier powder is added with Li in a mass ratio of 10:3 3 PW 12 O 40 -SiO 2 The composite carrier powder was stirred for another 4 hours, anhydrous ethanol was added dropwise and stirred for 30 minutes, and then extrude...

Embodiment 3

[0058] The preparation method is:

[0059] 1. Lithium polyoxometalate-SiO 2 Preparation of composite carrier

[0060] SiO 2 The powder was soaked in hydrochloric acid for 3 hours, washed with deionized water, and baked at 600°C for 2 hours. Lithium Silicotungstate Li 4 SiW 12 O 40 Dry at 40°C for 10 hours. SiO 2 Powder in Li 4 SiW 12 O 40 After being immersed in anhydrous methanol solution for 24 hours, filtered out, baked at 200°C for 1 hour, and baked at 600°C for 2 hours to obtain Li 4 SiW 12 O 40 -SiO 2 Composite carrier powder.

[0061] 2. Preparation of composite diaphragm

[0062] Stir the PVDF-HFP copolymer in acetone at a constant temperature of 50°C for 1 hour to obtain a viscous solution. According to PVDF-HFP copolymer and Li 4 SiW 12 O 40 -SiO 2 The composite carrier powder is added with Li in a mass ratio of 10:5 4 SiW 12 O 40 -SiO 2 The composite carrier powder was stirred for another 24 hours, anhydrous ethanol was added dropwise and stirred for 2 minutes, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com