Lithium ion battery, negative electrode material, negative electrode filler and preparation process thereof

A negative electrode material and filler technology, applied in secondary batteries, battery pack parts, battery boxes/jackets, etc., can solve the problem of increased polarization of lithium-ion batteries, ensure rate performance, and reduce the generation of hydrofluoric acid , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

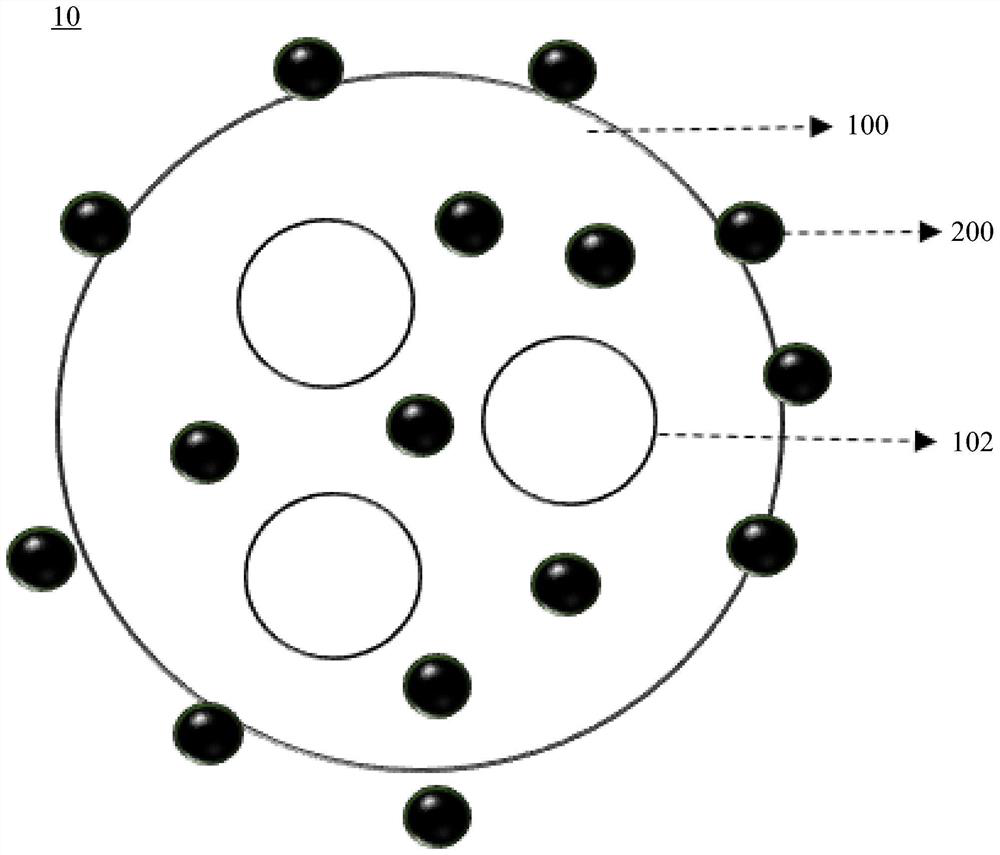

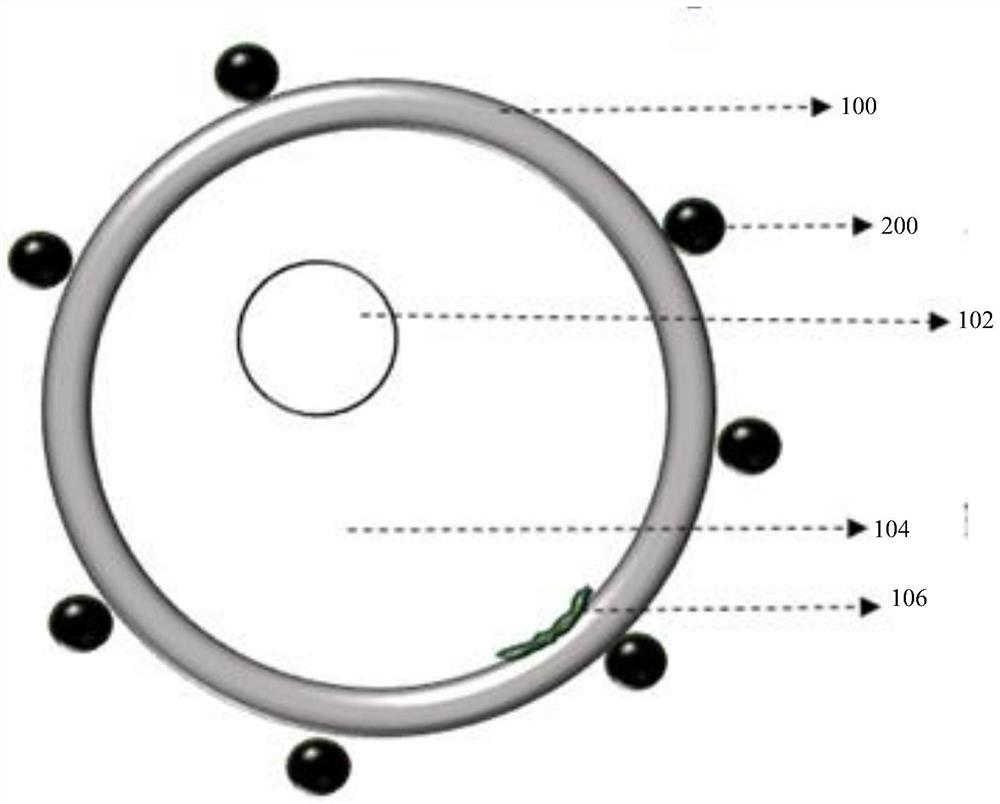

[0054] In the above-mentioned preparation process of the negative electrode filler 10 of the negative electrode material, since the outer surface of the elastic casing film 100 is formed with a porous body 102, and the elastic casing film 100 is formed with a hollow cavity 104, when the lithium ion battery expands, The elastic shell film 100 of the negative electrode filler 10 is squeezed and shrunk, and the hollow cavity 104 of the elastic shell film 100 provides a buffer space for the expansion of the pole piece, so as to avoid affecting the overall thickness expansion of the pole piece, thereby ensuring the pole piece. The conductive network and bonding network of the sheet are not damaged, which improves the overall stability of the pole piece, and improves the stability, cycle performance, and service life of the lithium ion battery. Because the hole body 102 is connected with the hollow cavity 104, the electrolyte solution is It can enter the interior of the elastic shell...

Embodiment 1

[0065] The negative electrode filler 10 of 1% wt negative electrode material was added to the graphite negative electrode slurry to make a soft pack battery; cycle performance: 1000 retention rate was 80%, increased to 1000 retention rate of 90%, and the thickness expansion of the pole piece was reduced from 15% to 8%; high temperature performance: after 28 days of storage at 60°C, the remaining capacity retention rate increased from 88% to 93%.

Embodiment 2

[0067] The negative electrode filler 10 of 5% wt negative electrode material was added to the silicon carbon negative electrode slurry to make a soft pack battery; cycle performance: after 500 cycles of charge and discharge, the battery capacity was increased from 80% to 88%, extremely Sheet thickness expansion was reduced from 40% to 12%; high temperature performance: after 28 days of storage at 60°C, the residual capacity retention rate was increased from 81% to 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com