Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1810 results about "Air knife" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An air knife is a tool used to blow off liquid or debris from products as they travel on conveyors. Air knives are normally used in manufacturing or as the first step in a recursive recycling process to separate lighter or smaller particles from other components for use in later or subsequent steps, post manufacturing parts drying and conveyor cleaning, part of component cleaning. The knife consists of a high-intensity, uniform sheet of laminar airflow sometimes known as streamline flow.

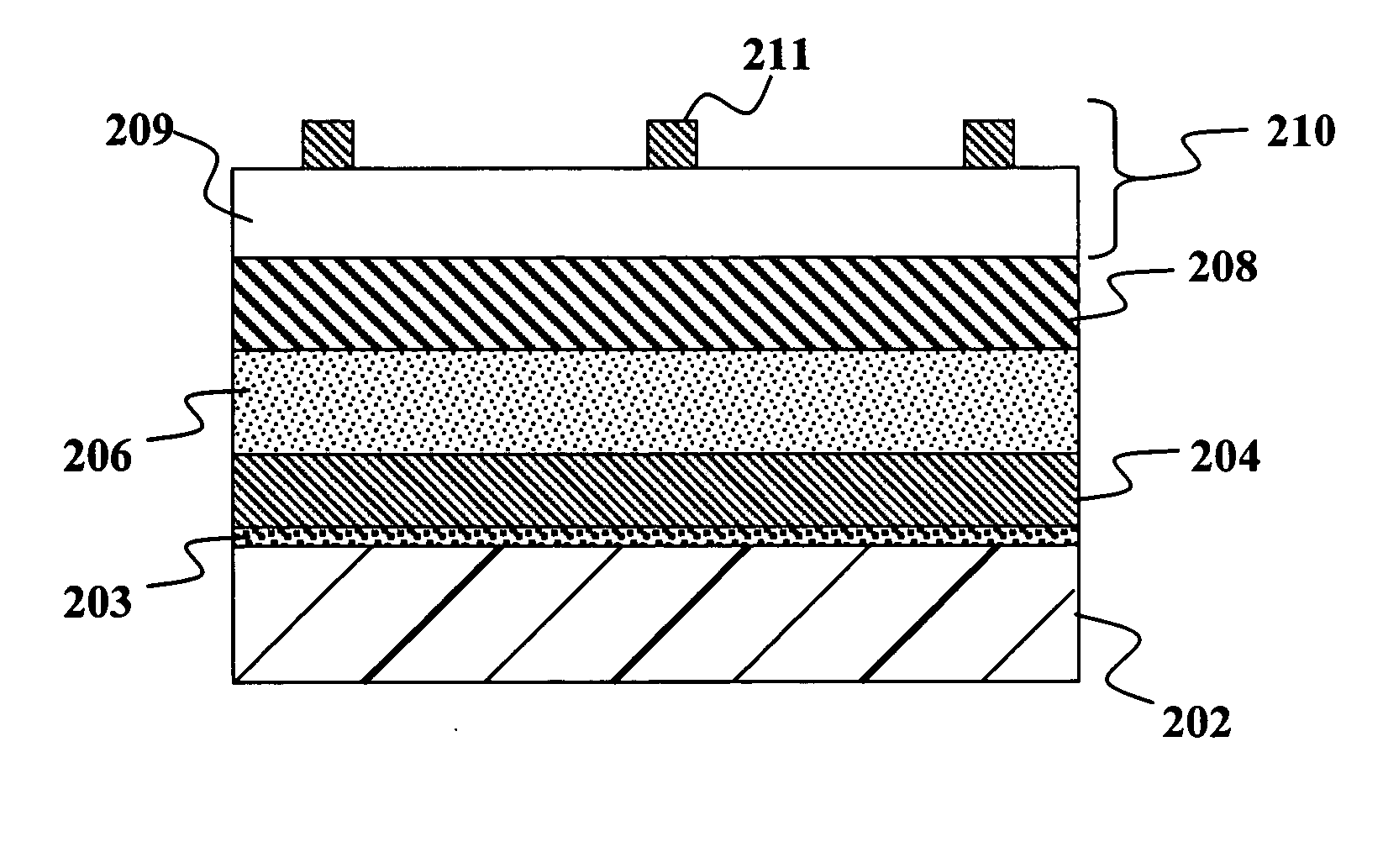

Photovoltaic thin-film cell produced from metallic blend using high-temperature printing

The metallic components of a IB-IIIA-VIA photovoltaic cell active layer may be directly coated onto a substrate by using relatively low melting point (e.g., less than about 500° C.) metals such as indium and gallium. Specifically, CI(G)S thin-film solar cells may be fabricated by blending molten group IIIA metals with solid nanoparticles of group IB and (optionally) group IIIA metals. The molten mixture may be coated onto a substrate in the molten state, e.g., using coating techniques such as hot-dipping, hot microgravure and / or air-knife coating. After coating, the substrate may be cooled and the film annealed, e.g., in a sulfur-containing or selenium-containing atmosphere.

Owner:AERIS CAPITAL SUSTAINABLE IP

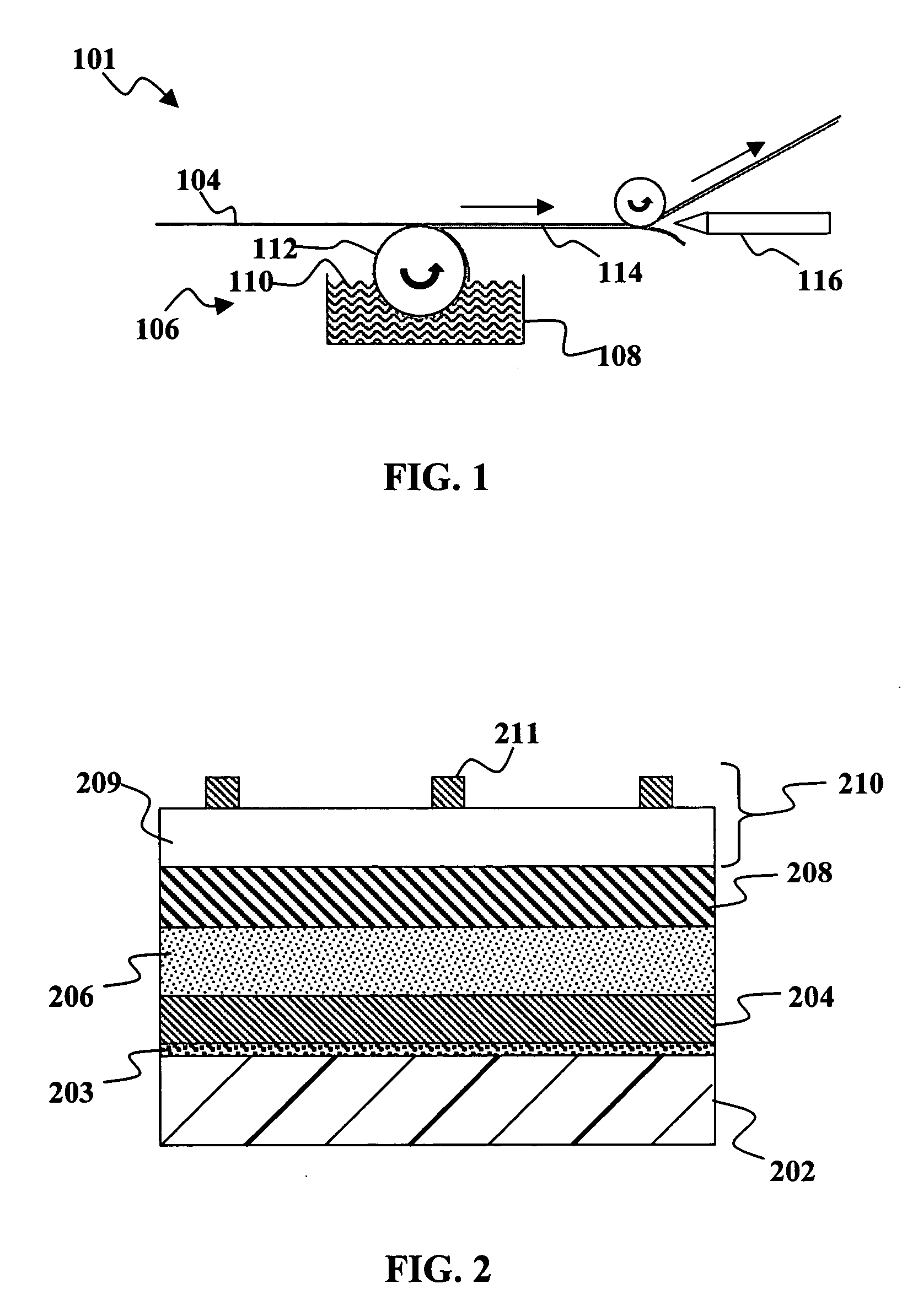

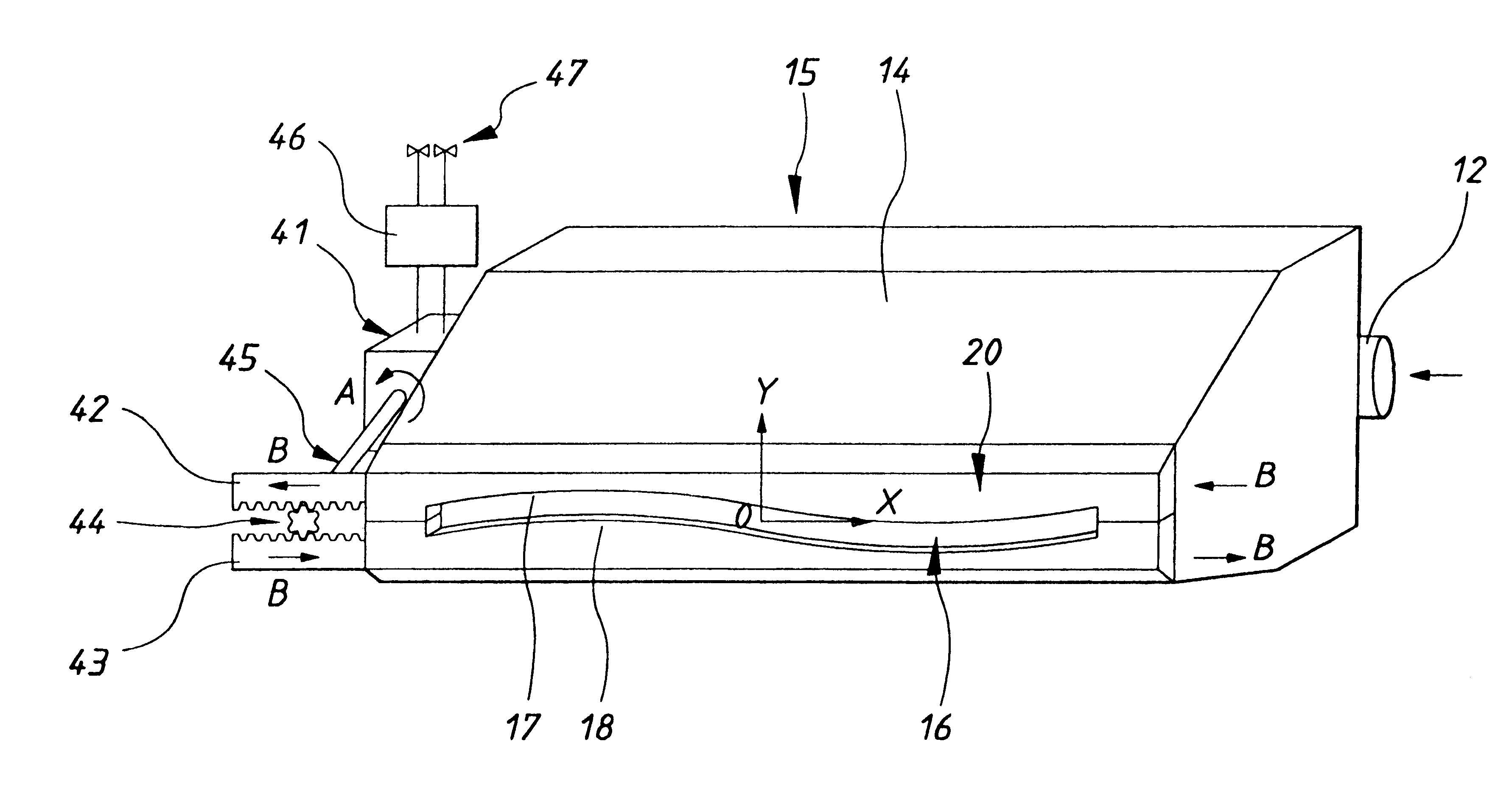

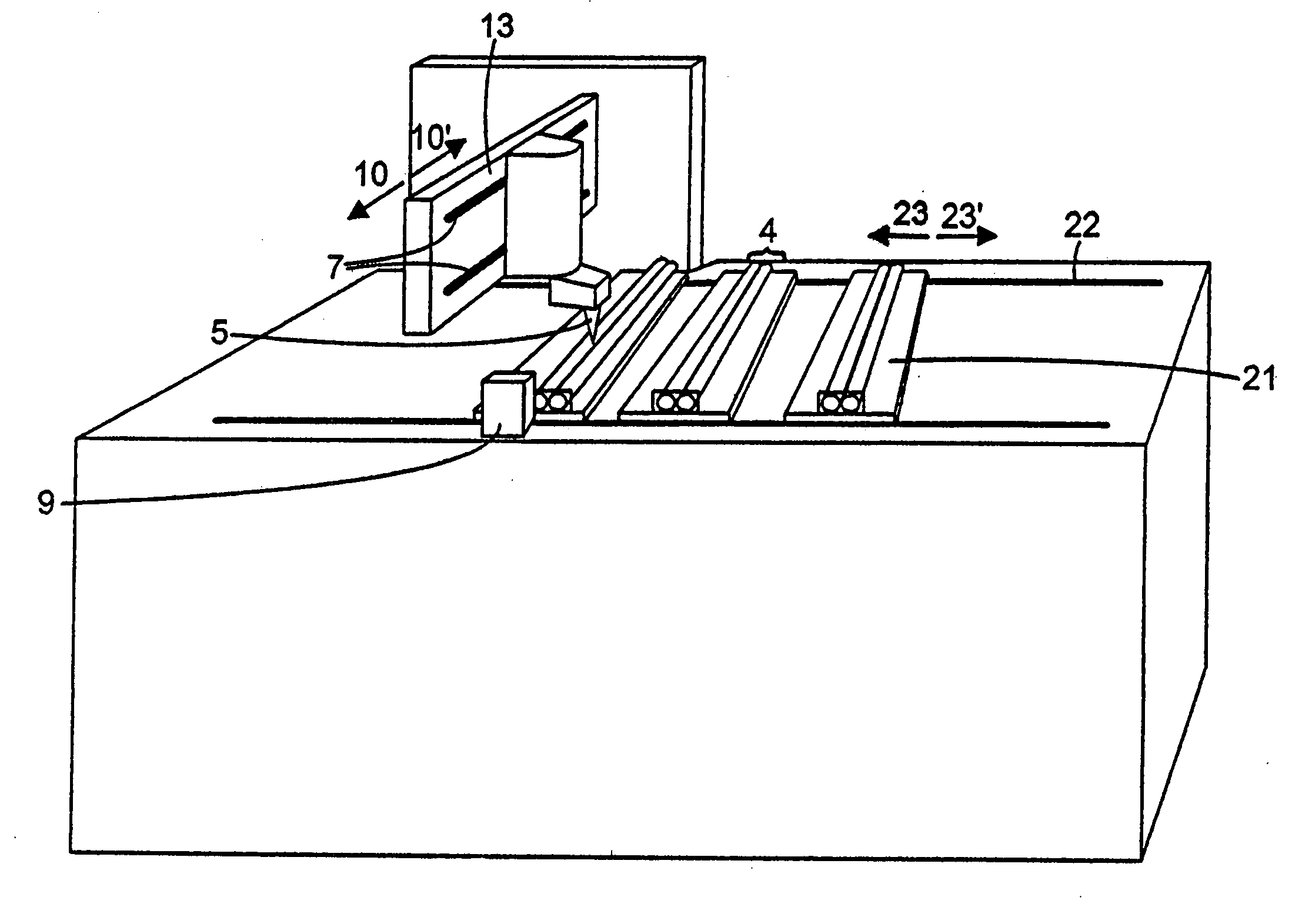

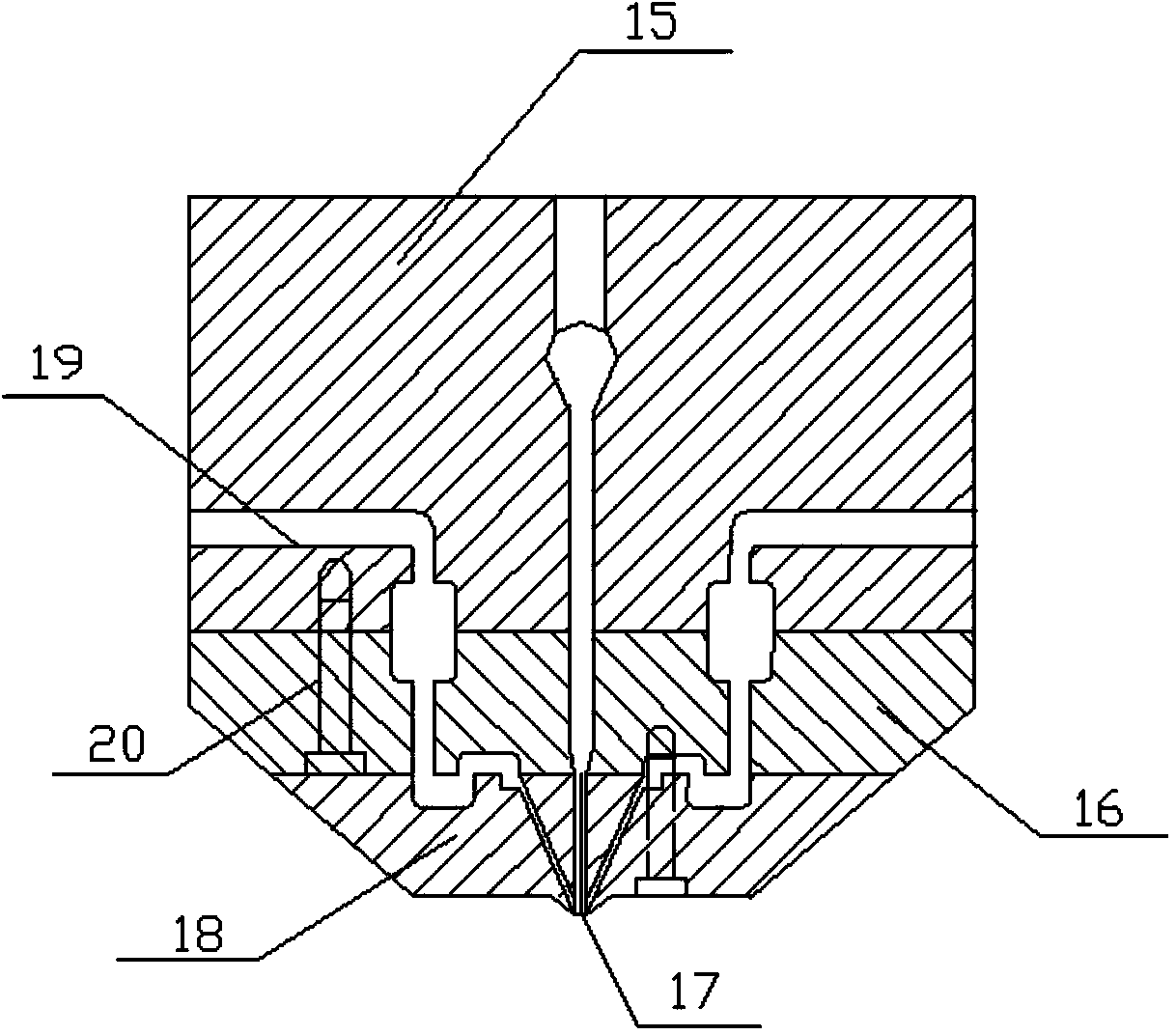

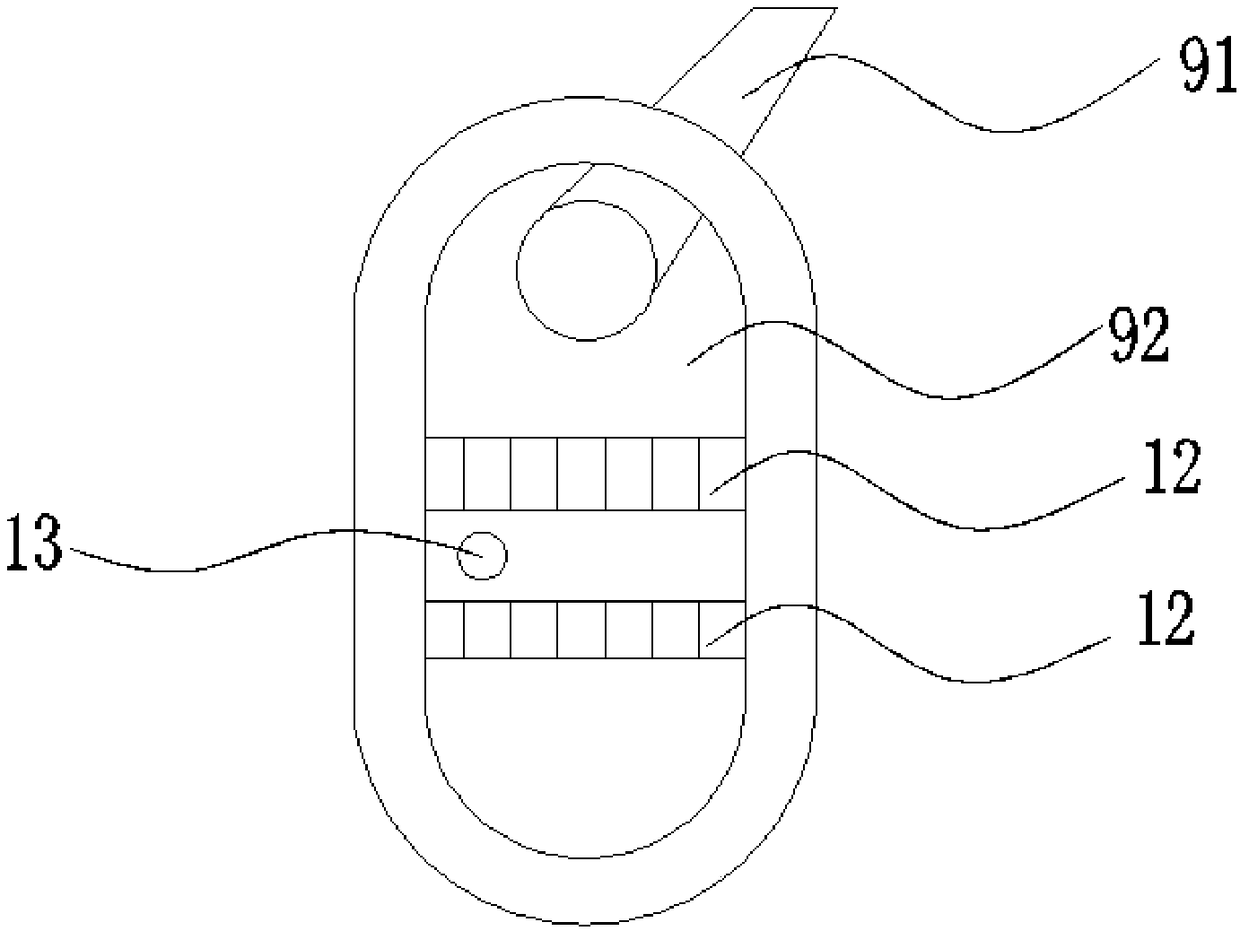

Coating thickness control

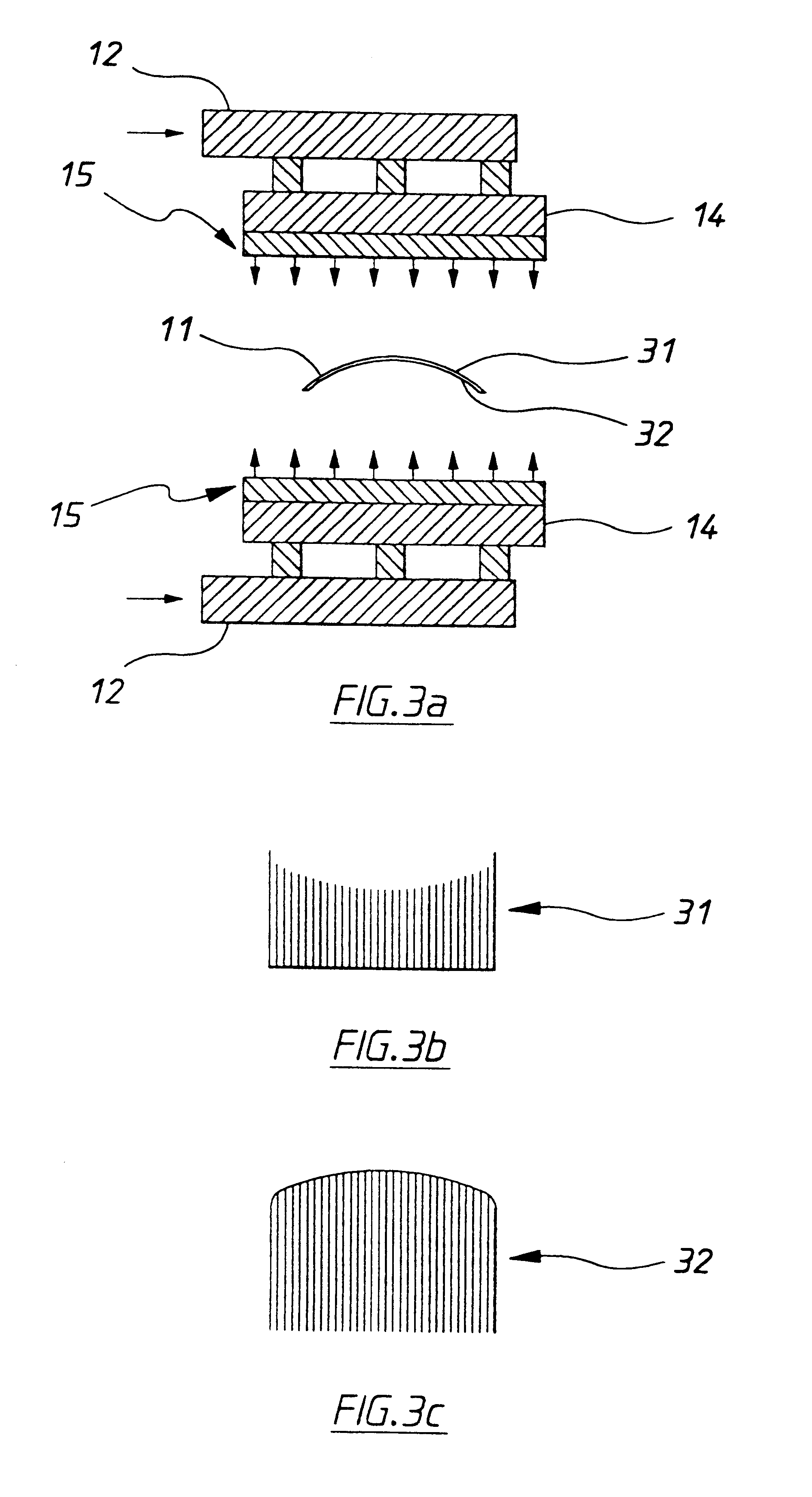

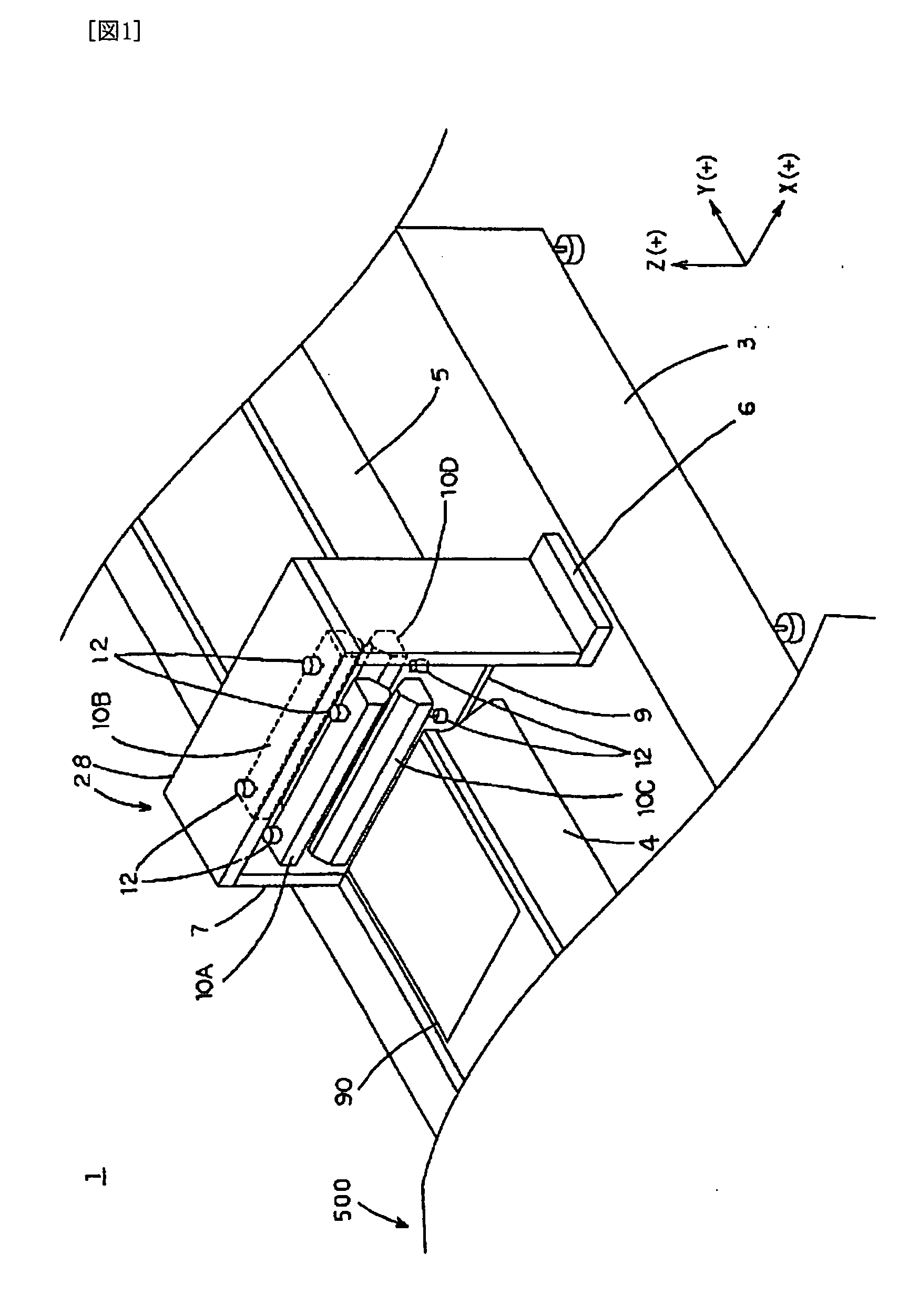

An air knife mouth arrangement for use in an air knife assembly having a laterally extending mouth through which pressurized fluid passes to operate on a coating applied to a surface of a sheet material passing the mouth in a longitudinal direction to control the thickness of the coating. In the preferred form of the invention shown the air knife mouth arrangement comprises a mouth defined by a pair of facing lips, each lip having in front elevation a curved shape along its length. The curved shapes of the two lips face each other. The lips of the air knife mouth arrangement are selectively laterally displaceable relative to each other by a moving means so as to thereby vary the separation of the lips and hence the width of the mouth along the length of the mouth. It is to be noted that the term "length" refers to the dimension of the mouth in the lateral direction (indicated by the X axis), while the term "width" refers to the dimension of the mouth in the longitudinal direction (indicated by the Y axis).

Owner:HATCH LTD

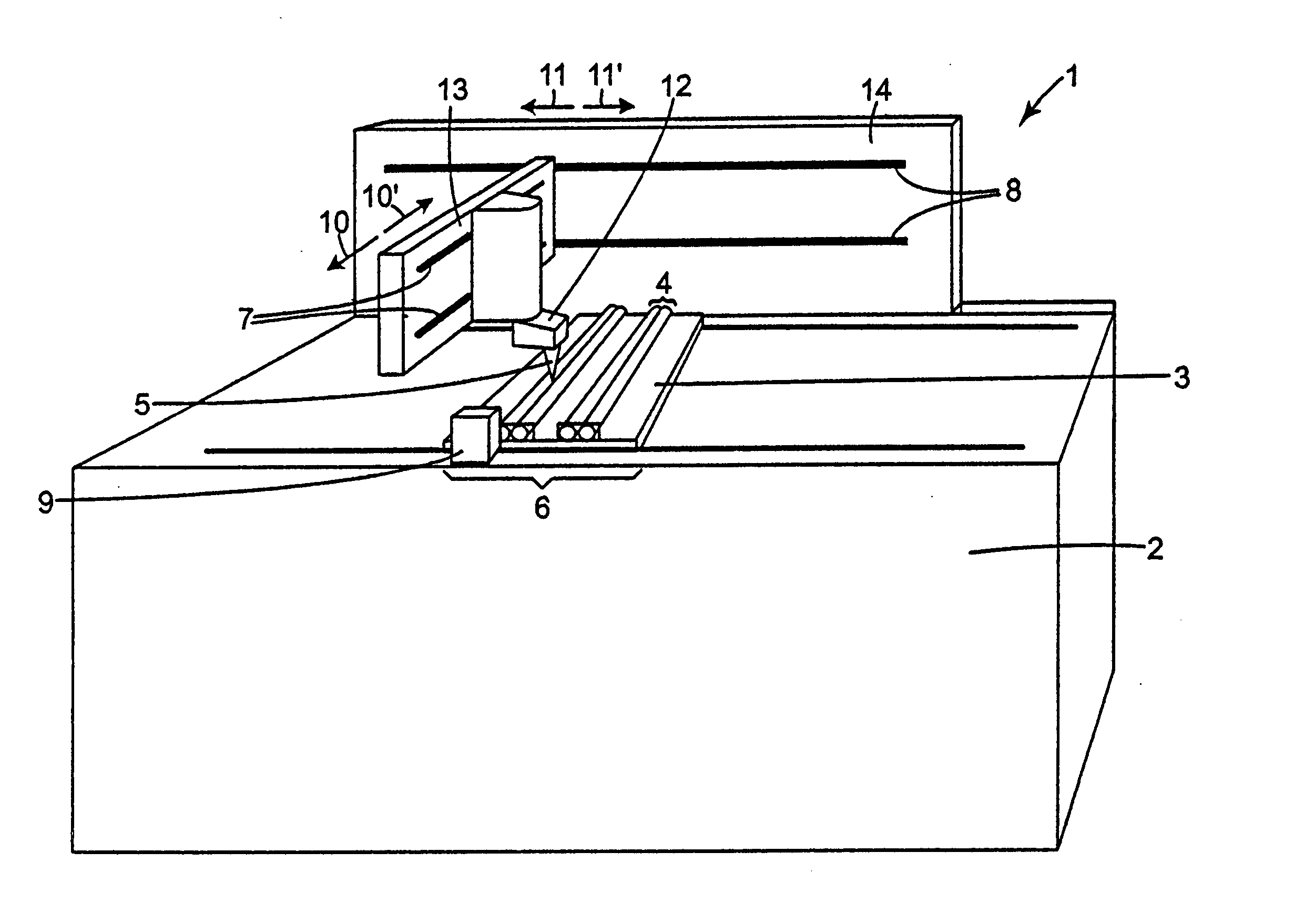

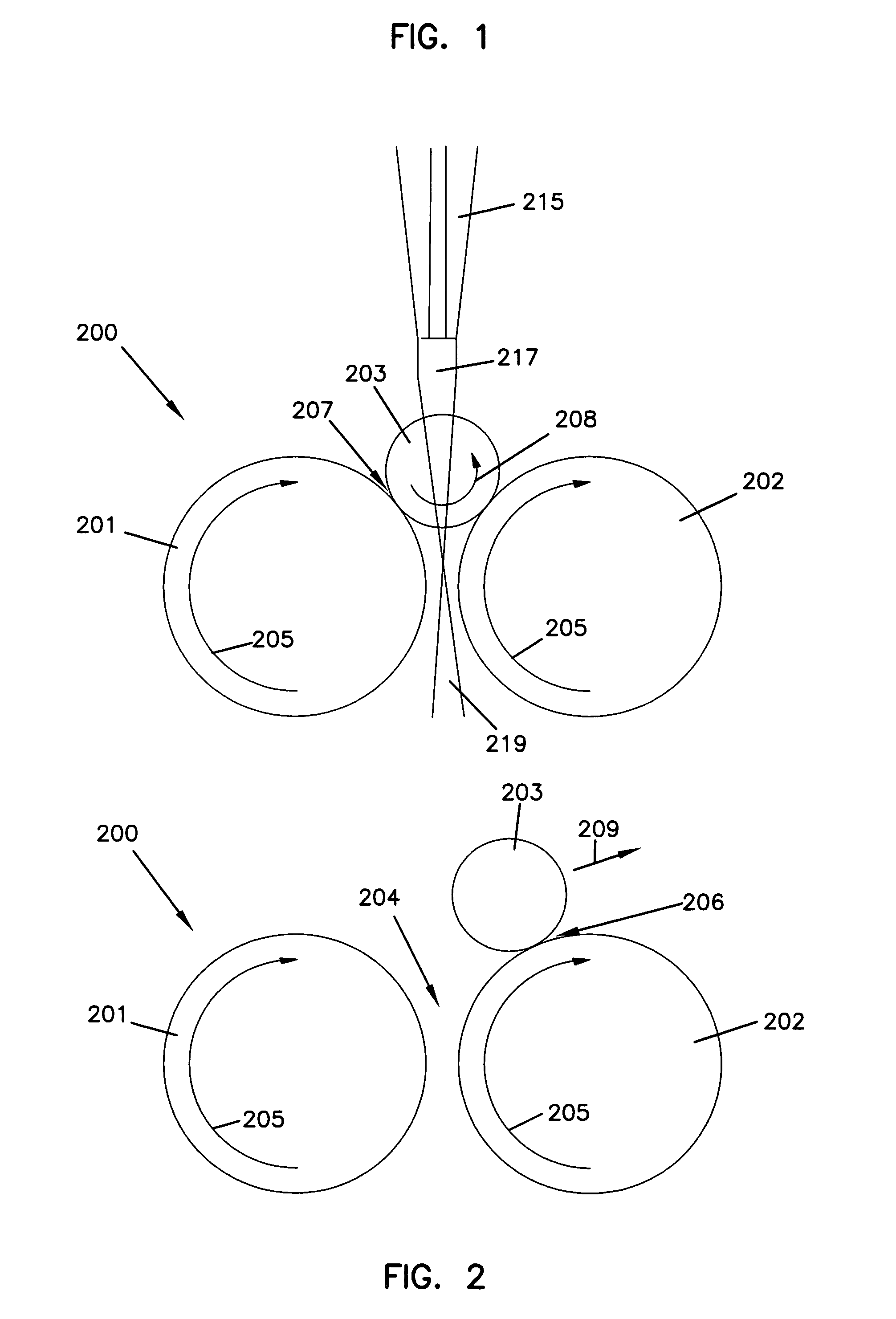

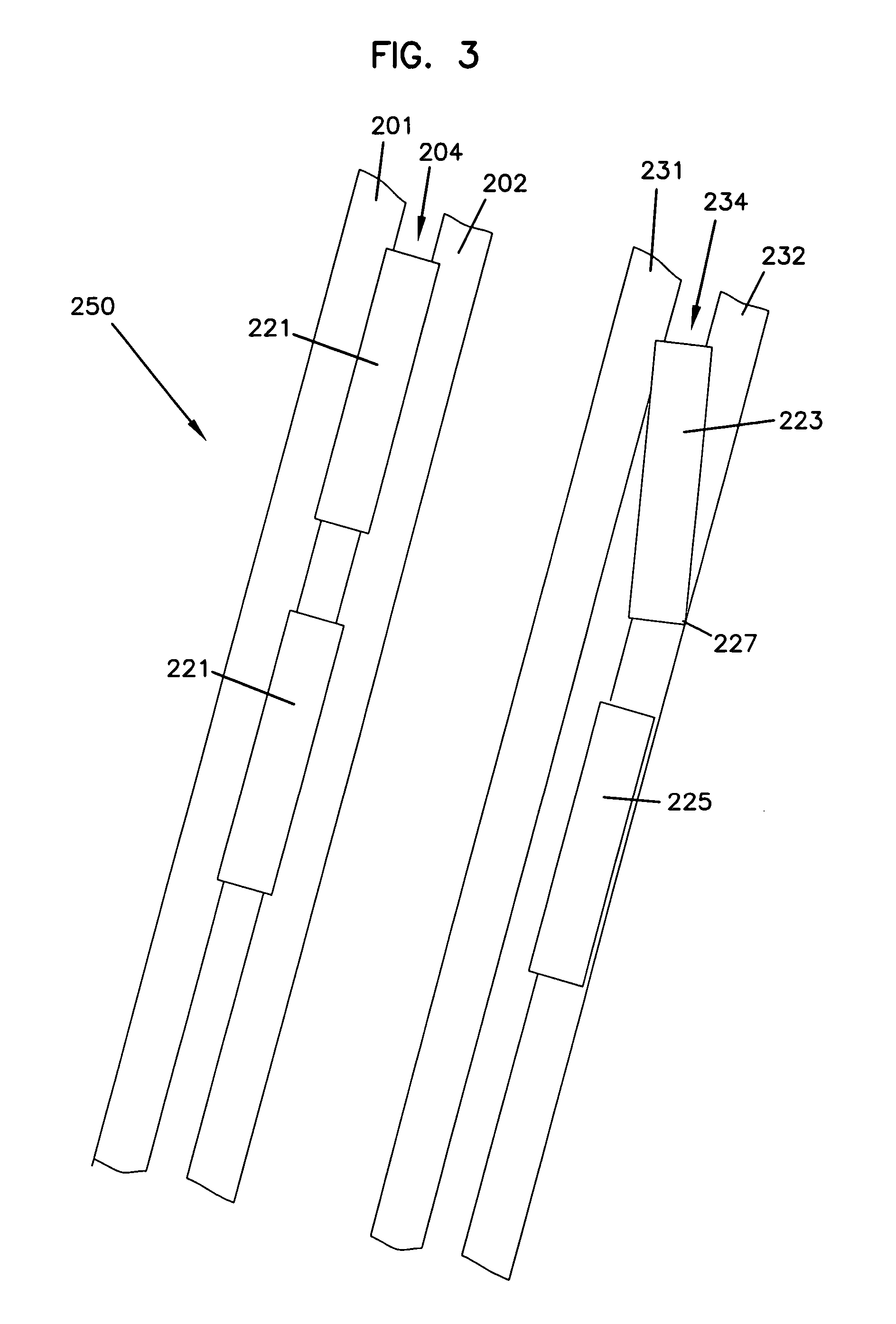

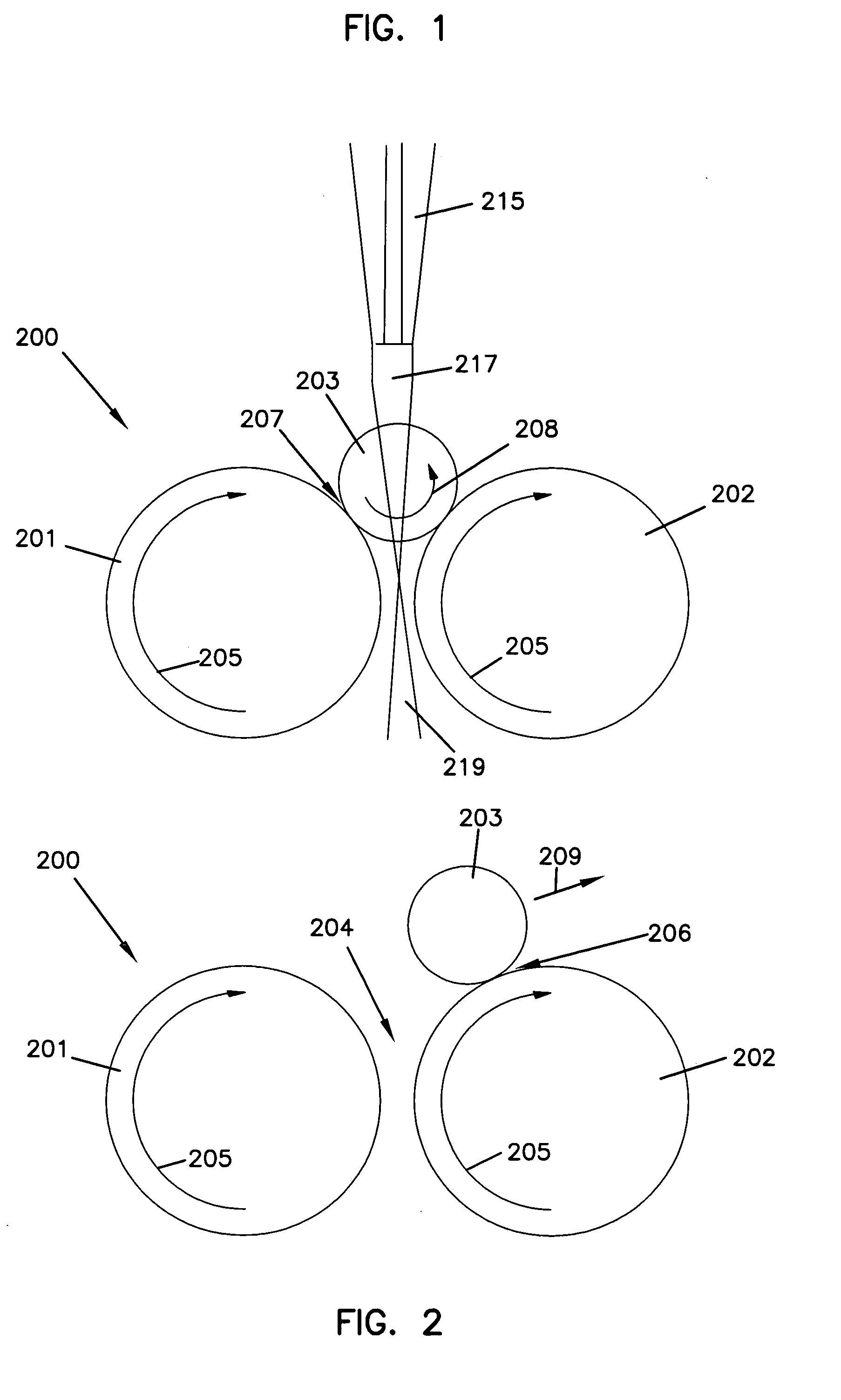

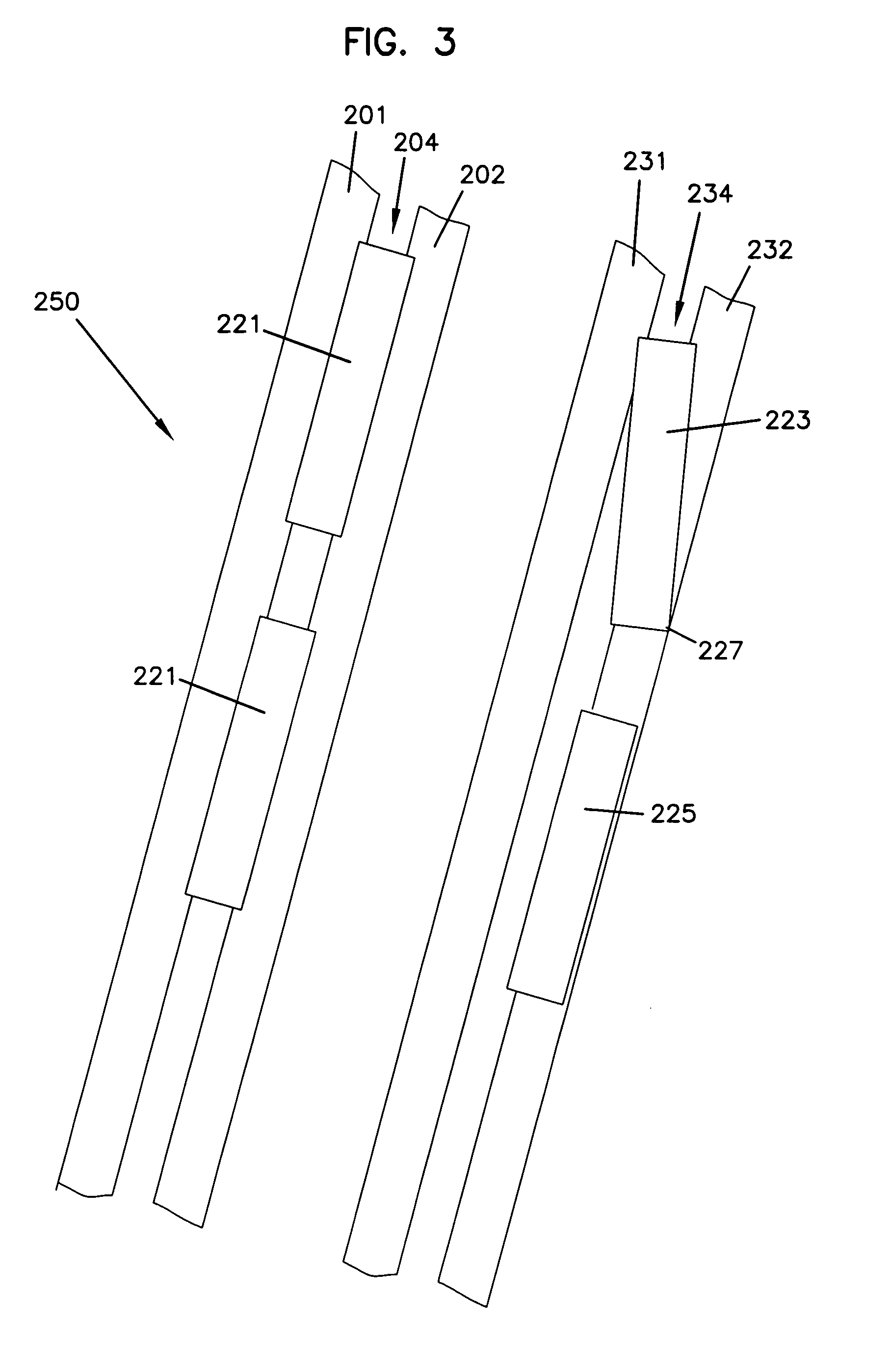

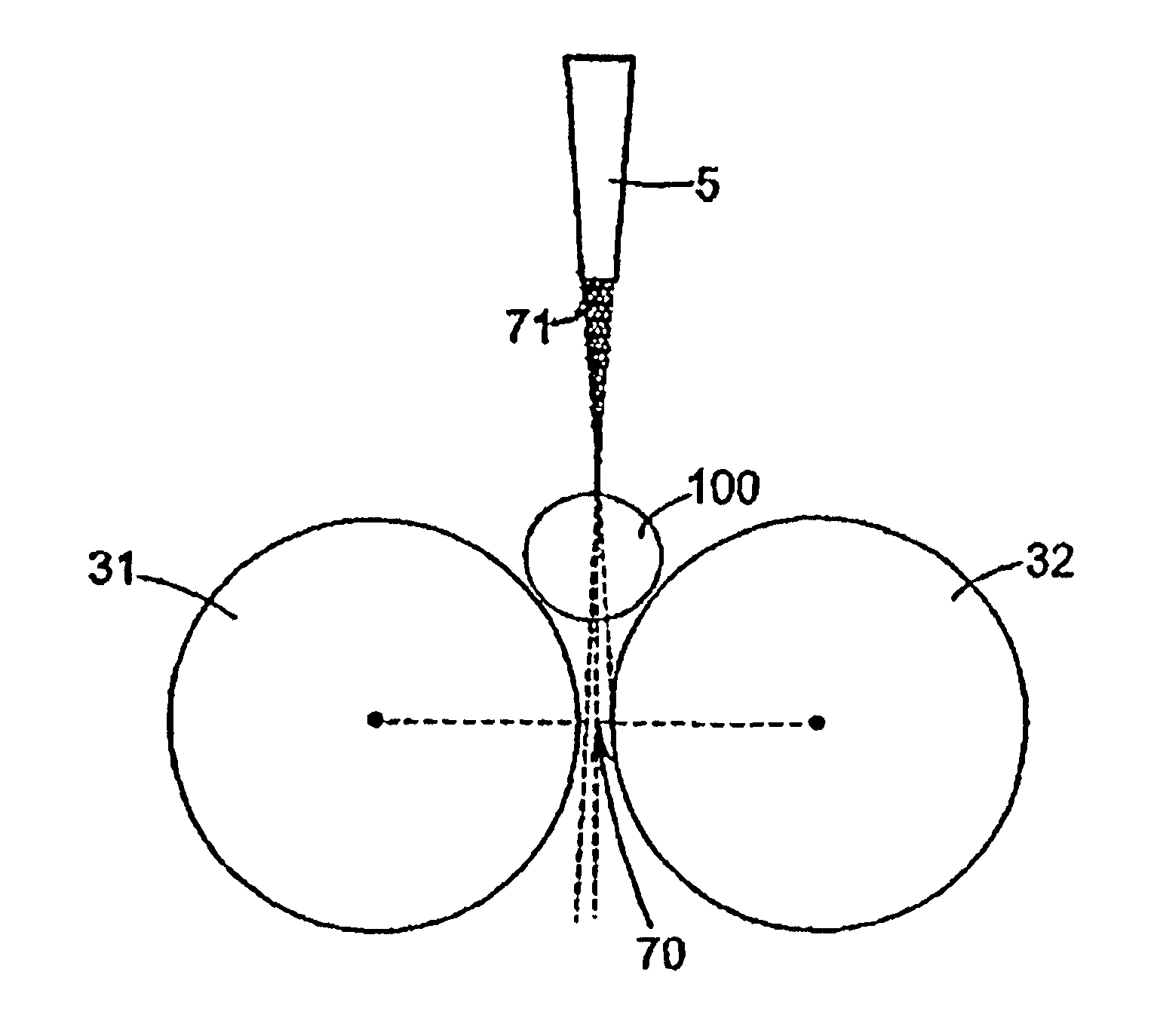

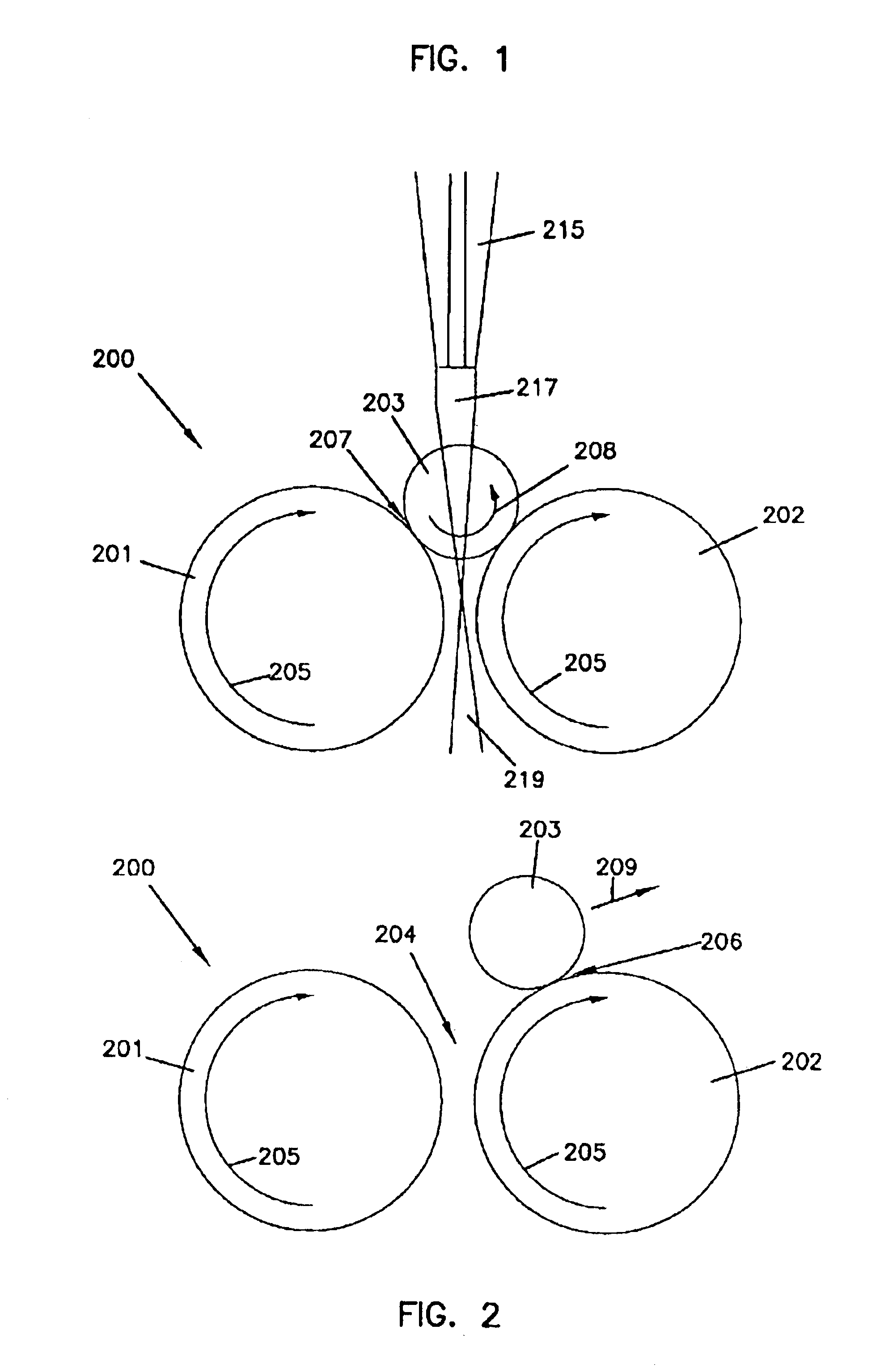

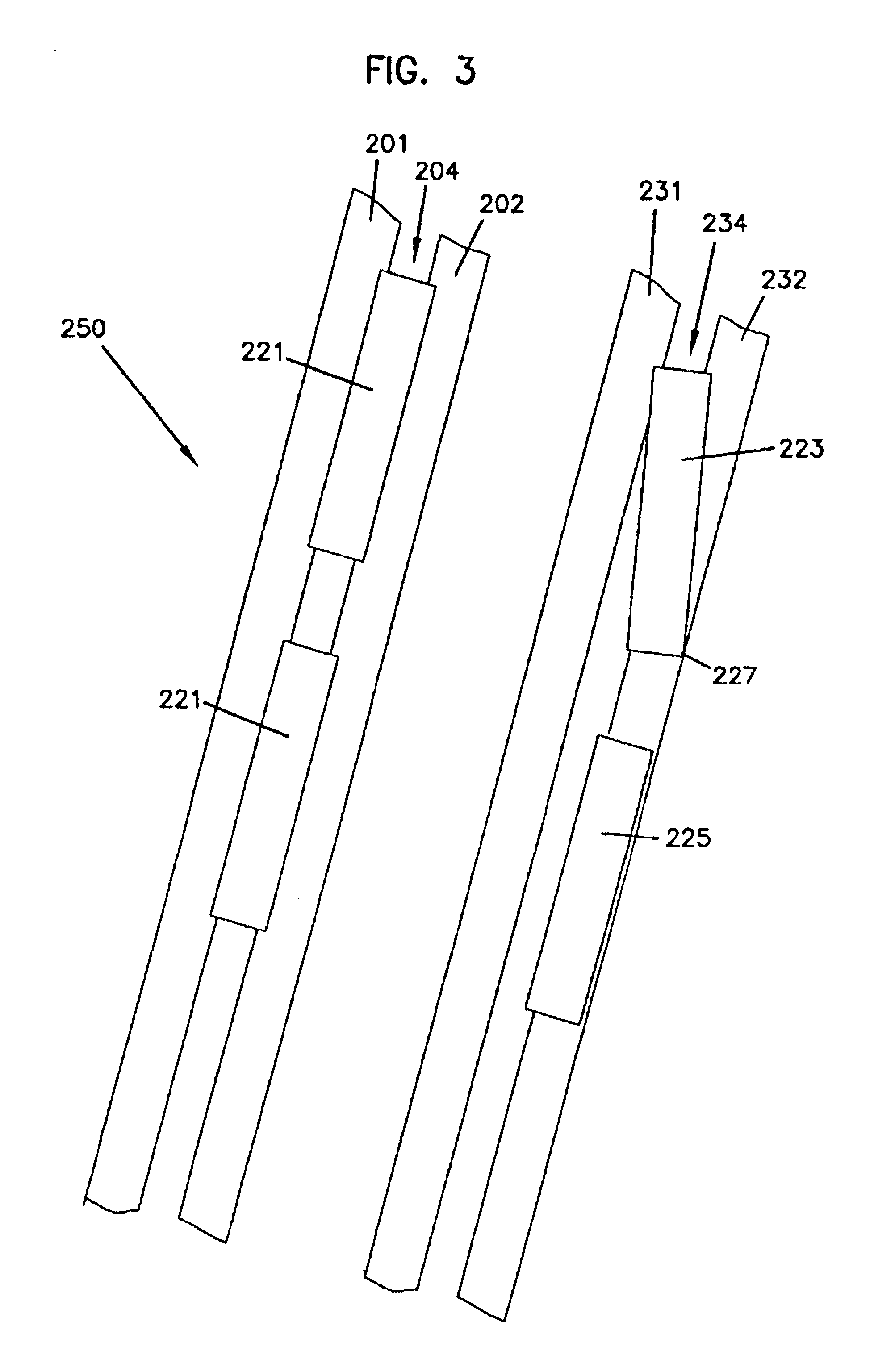

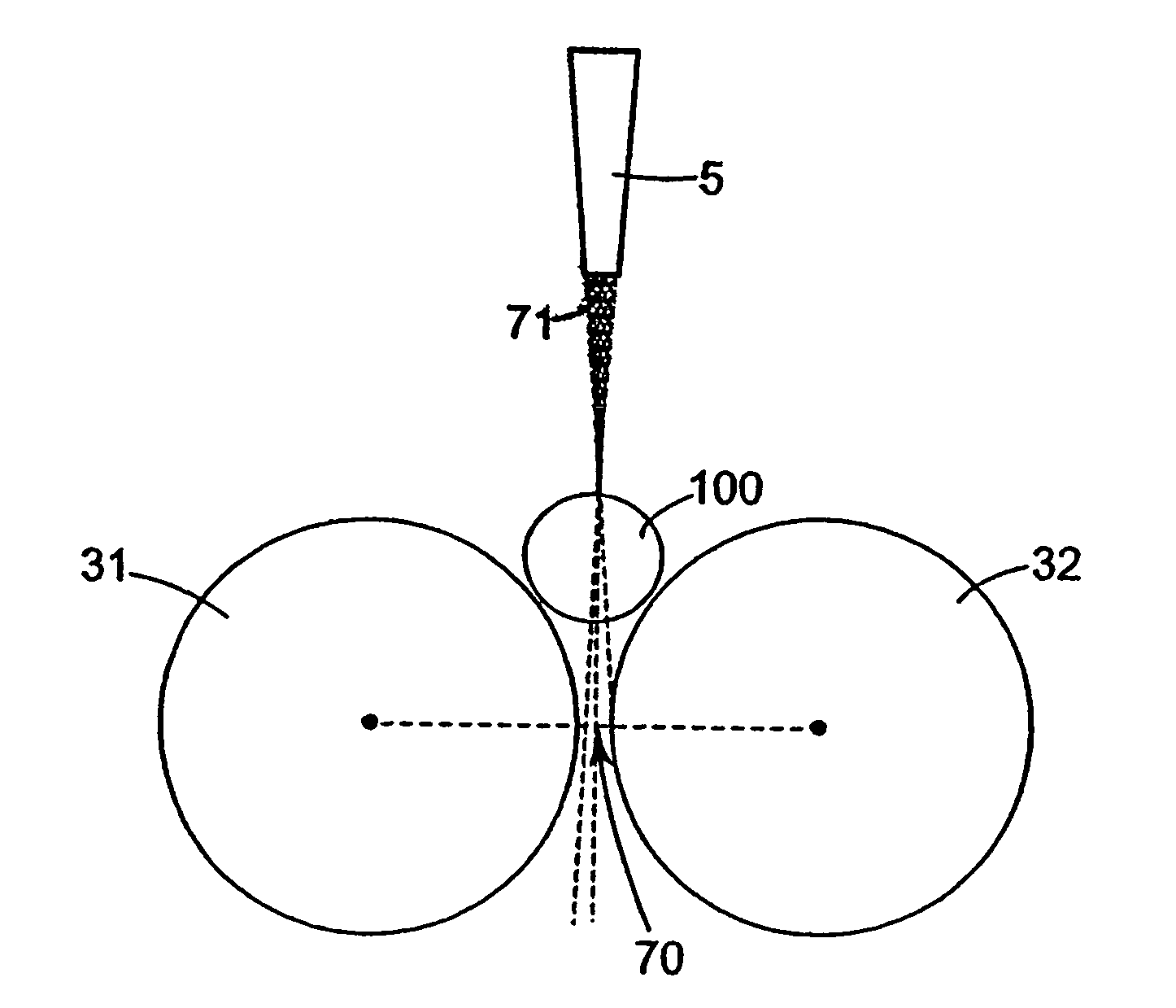

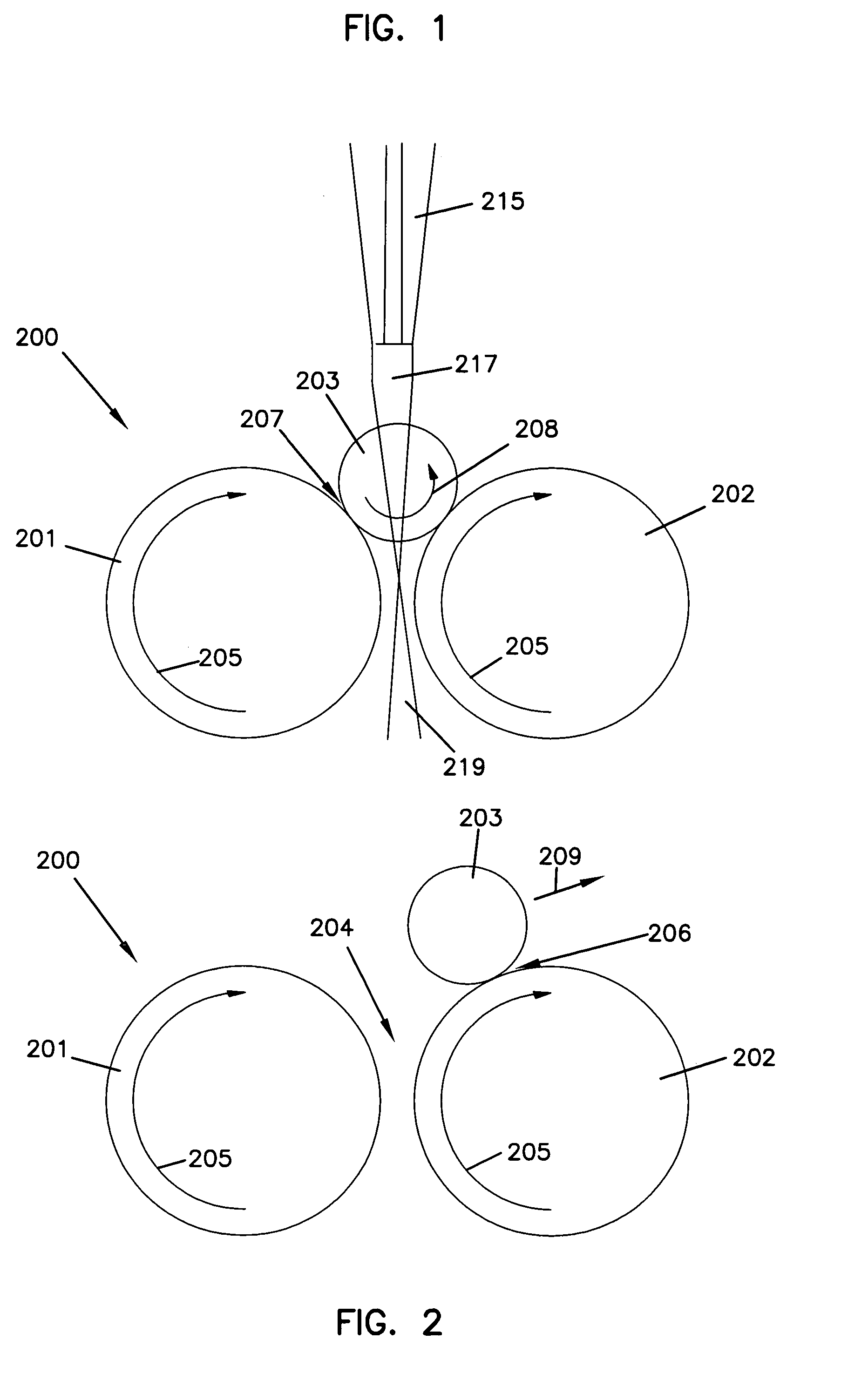

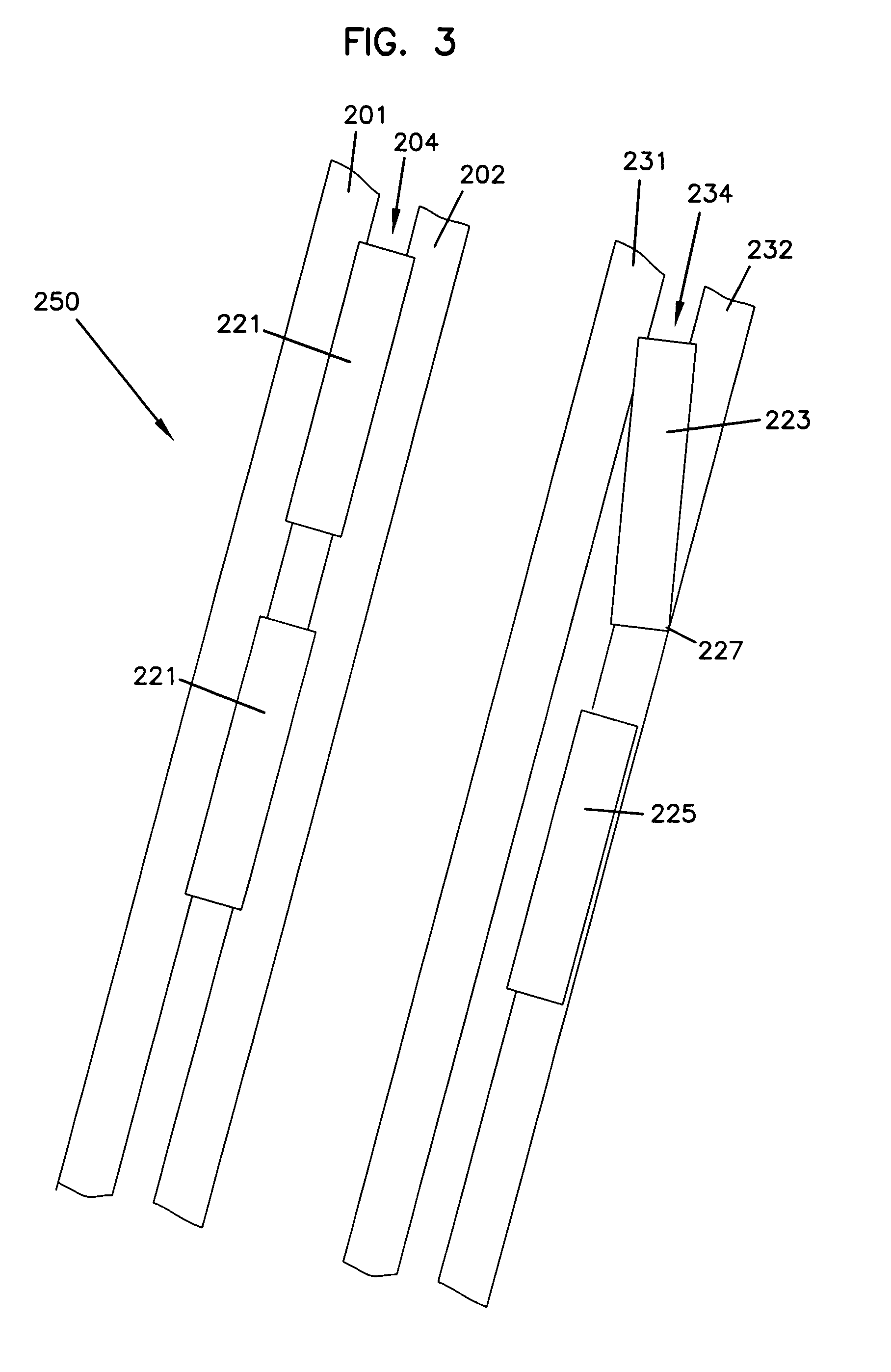

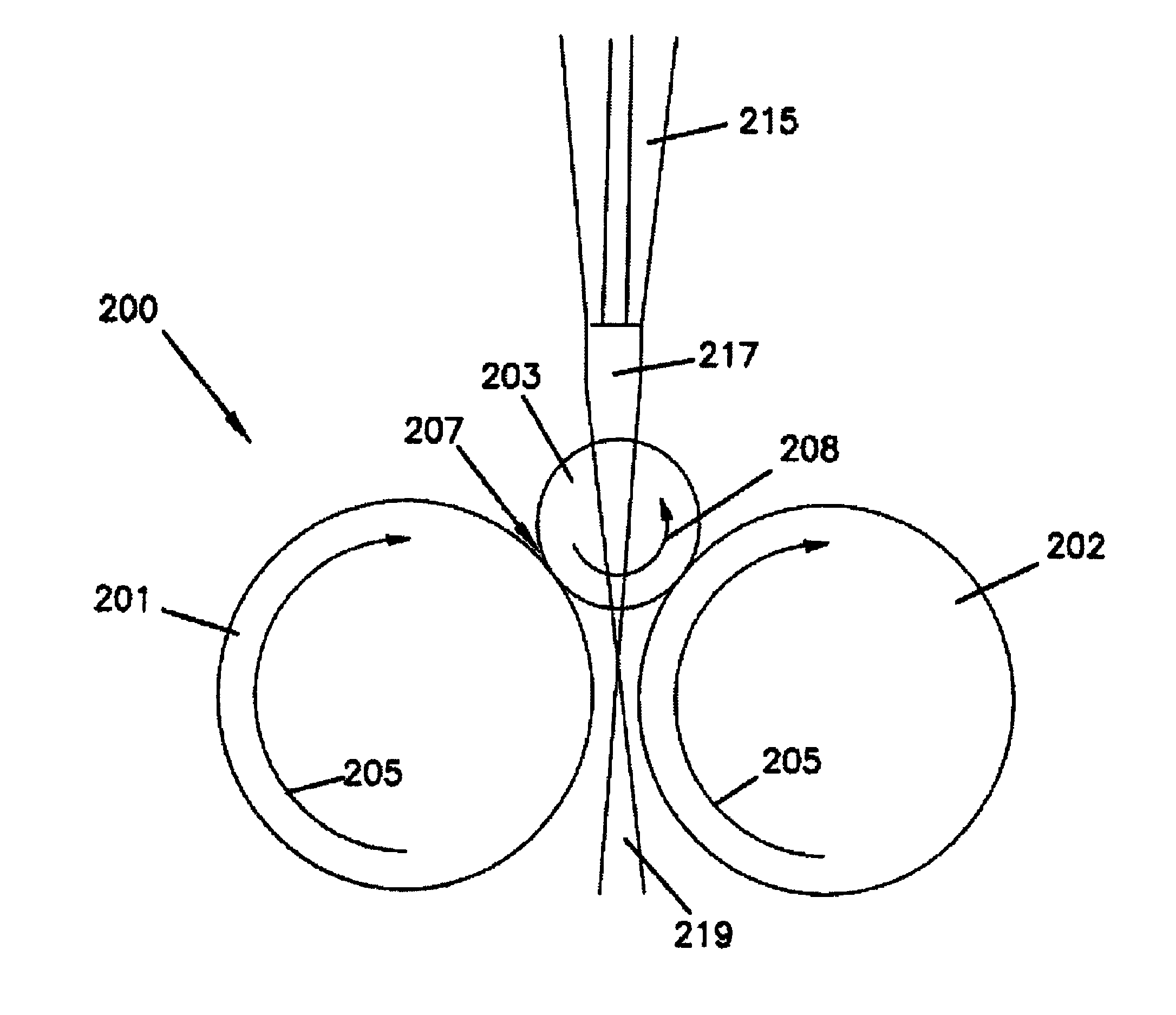

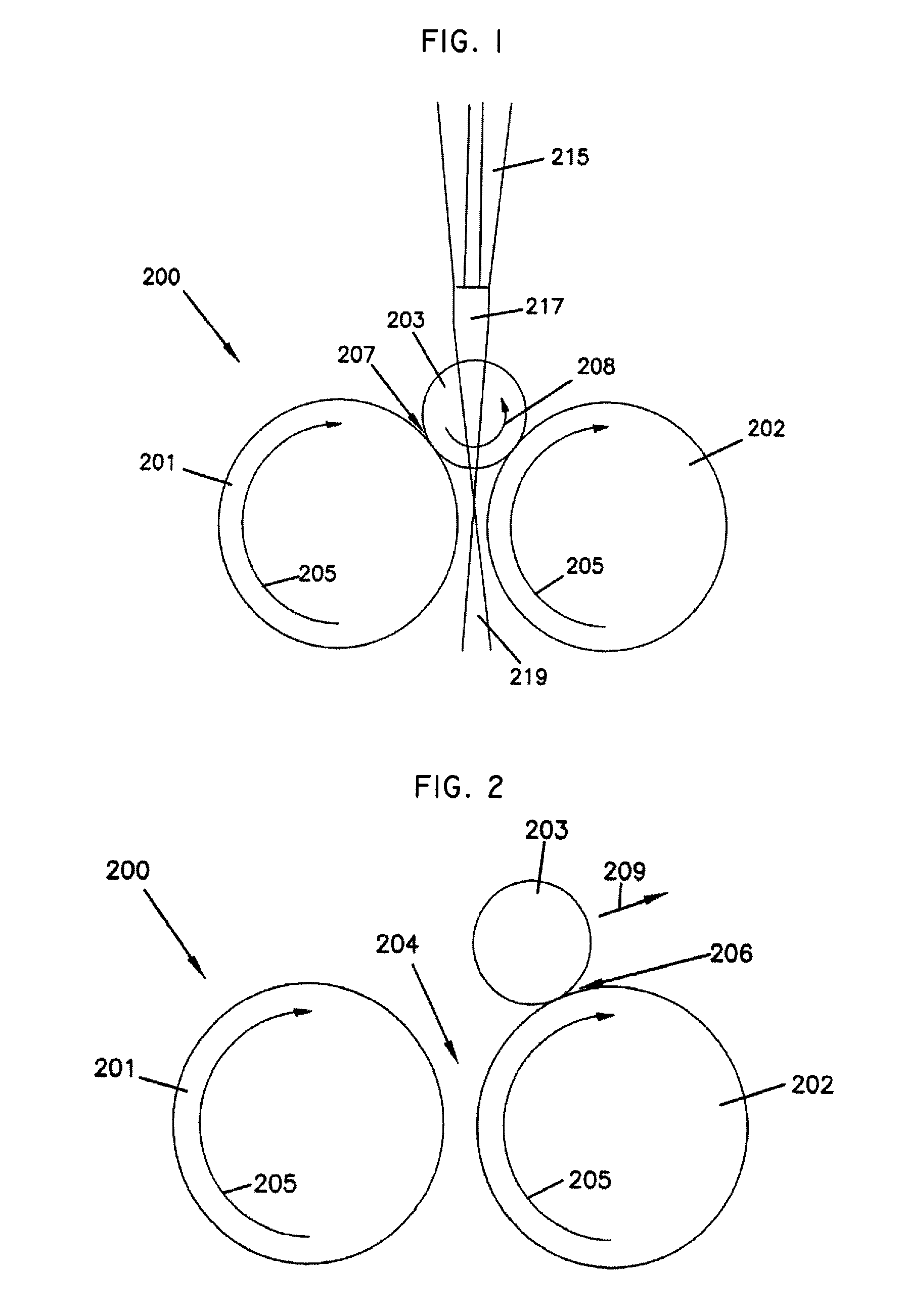

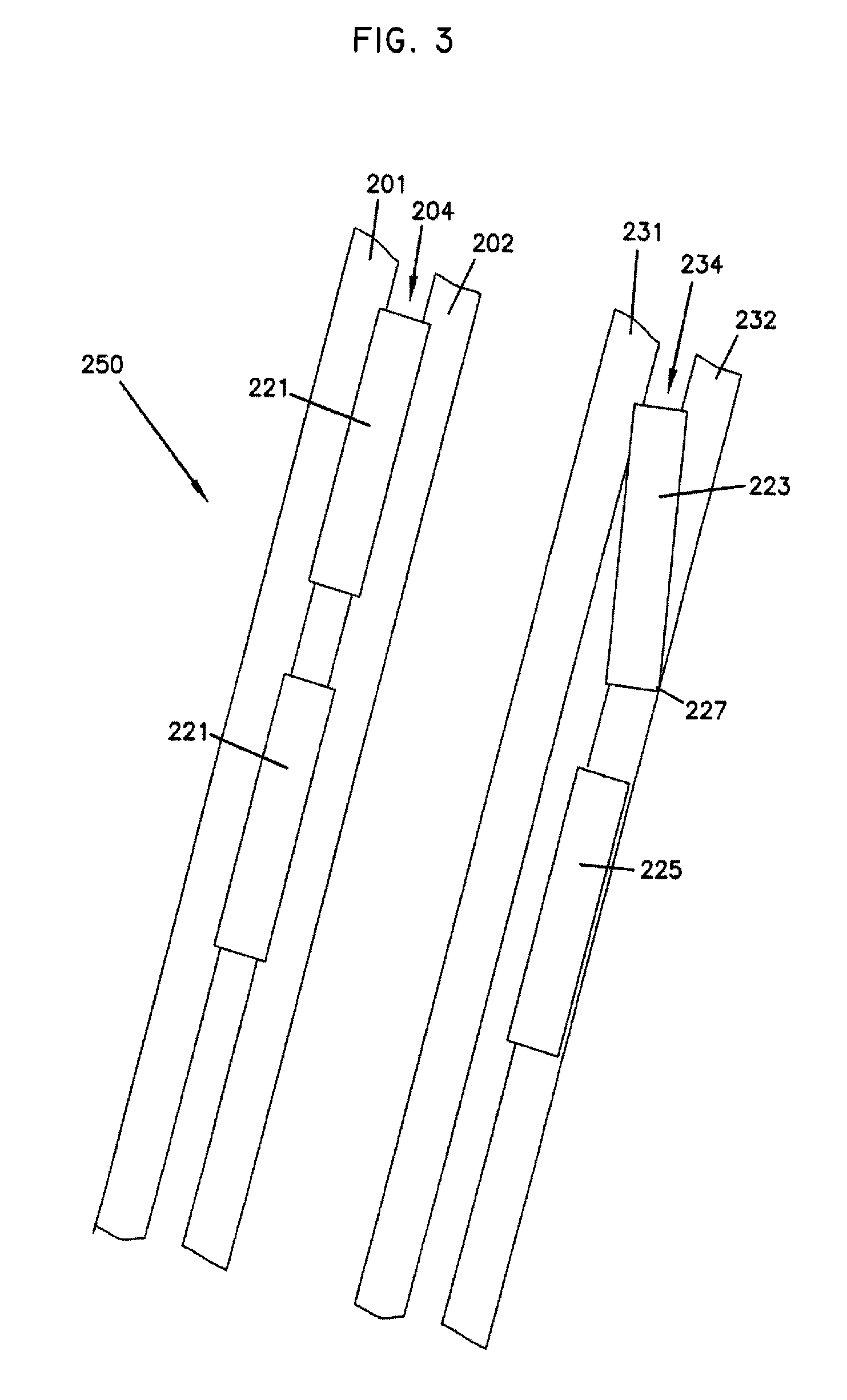

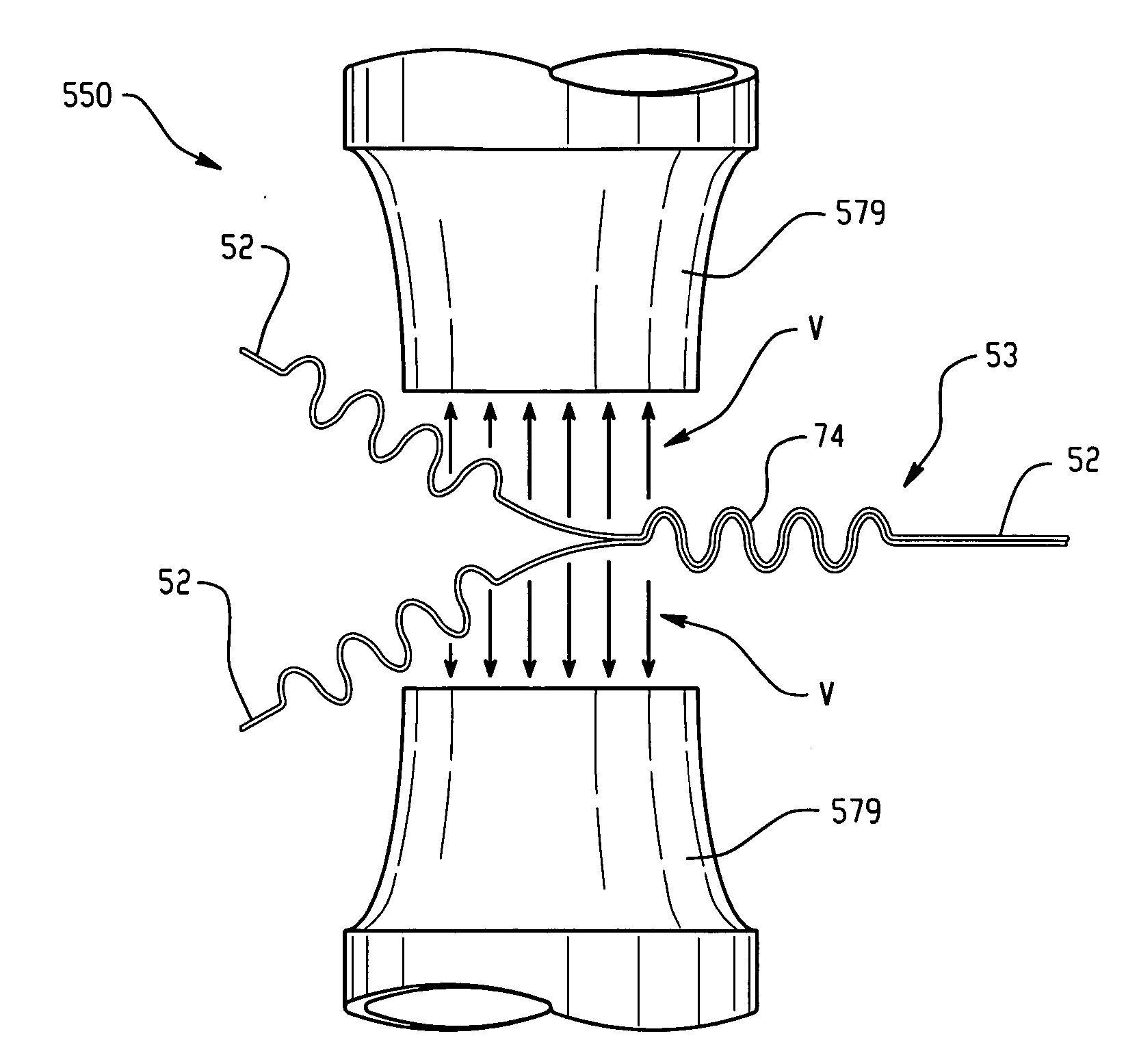

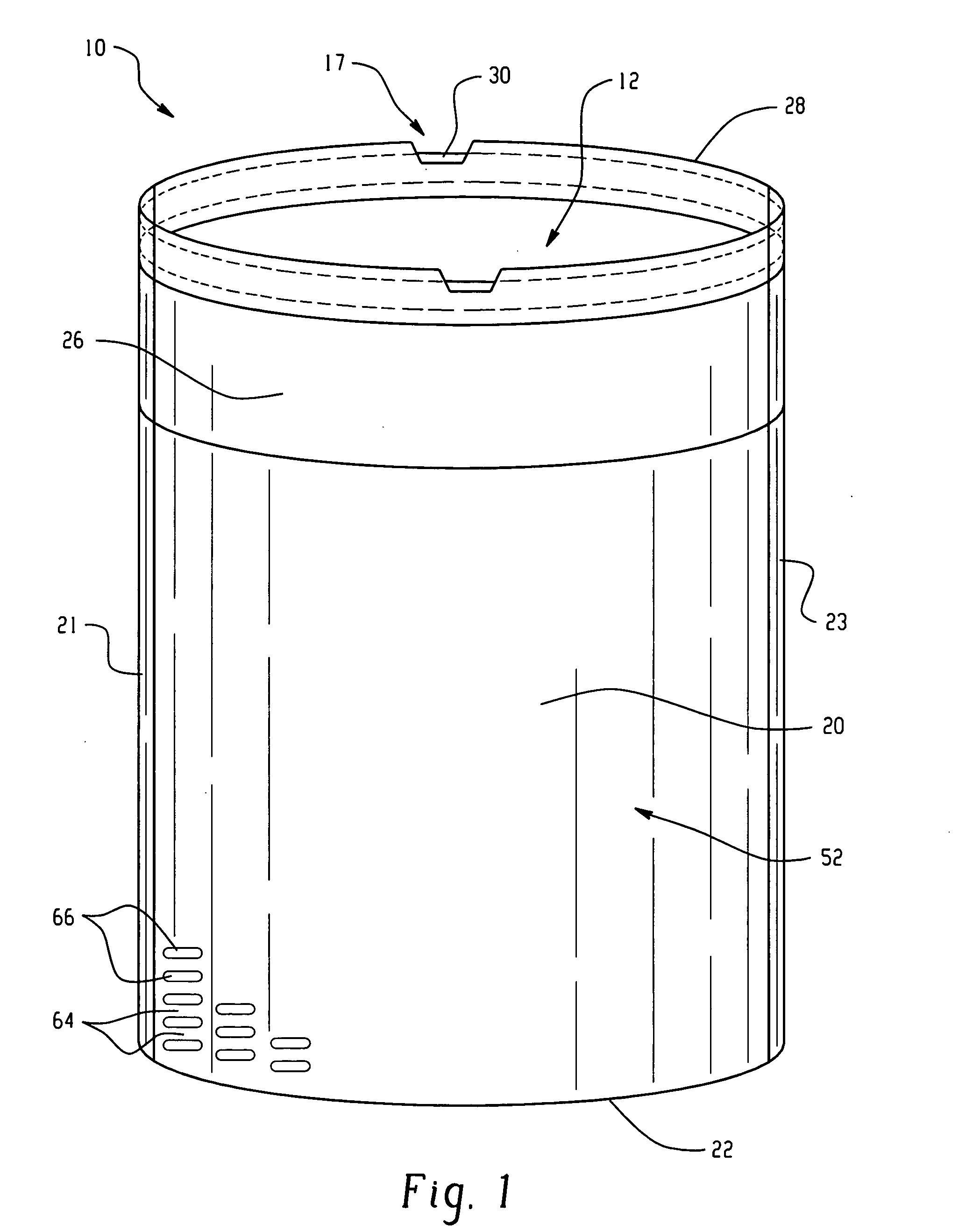

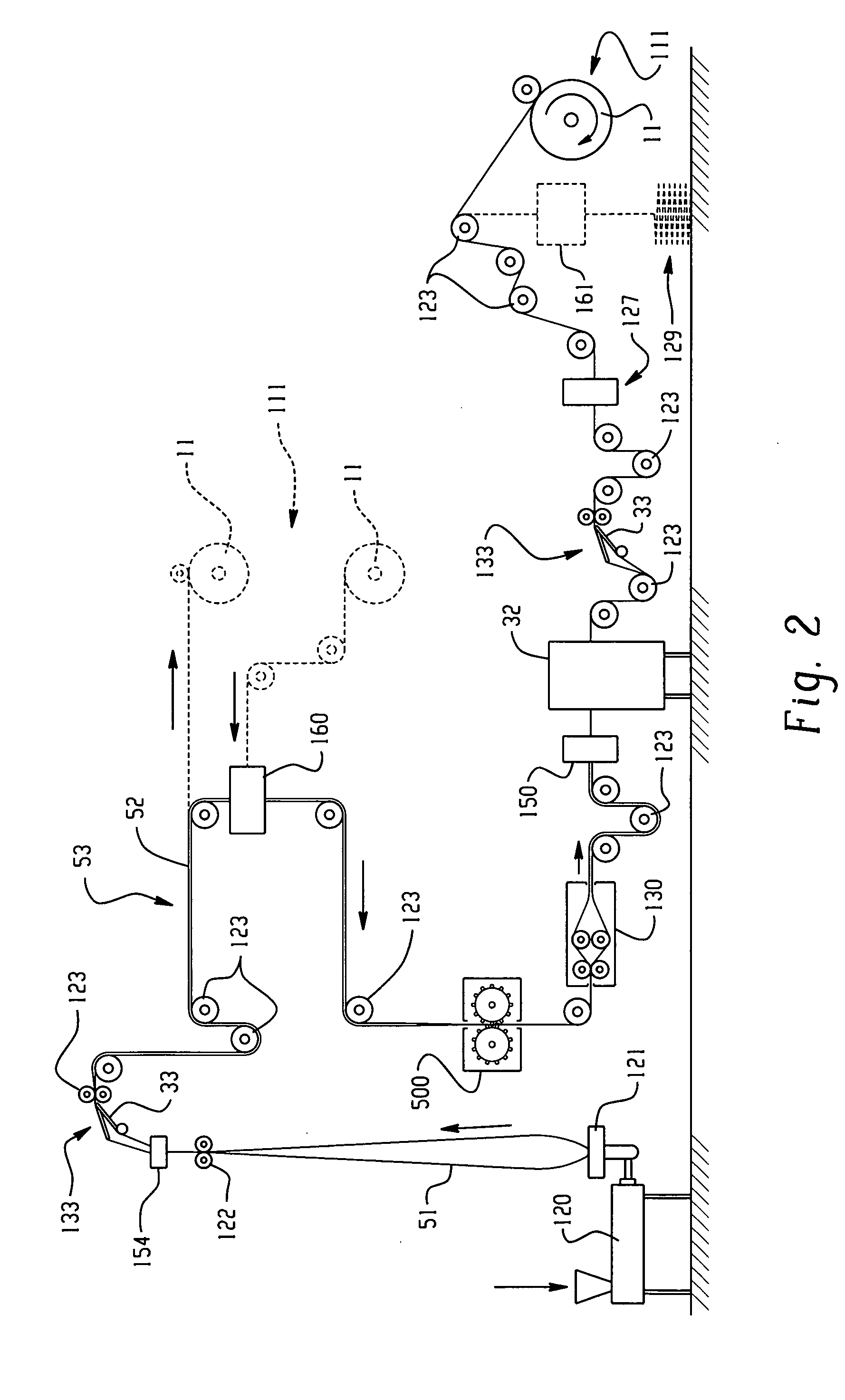

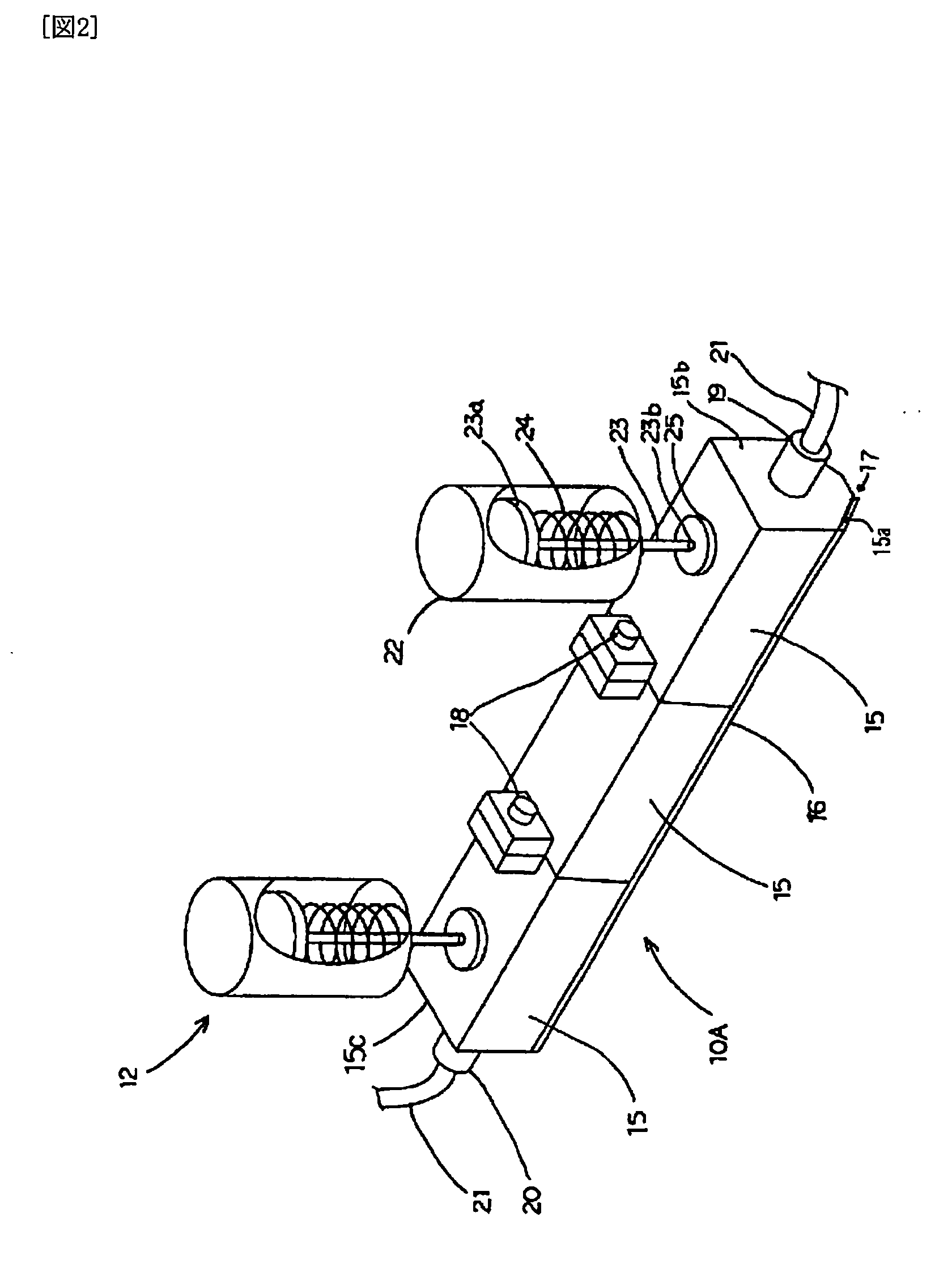

Method and apparatus for coating of substrates

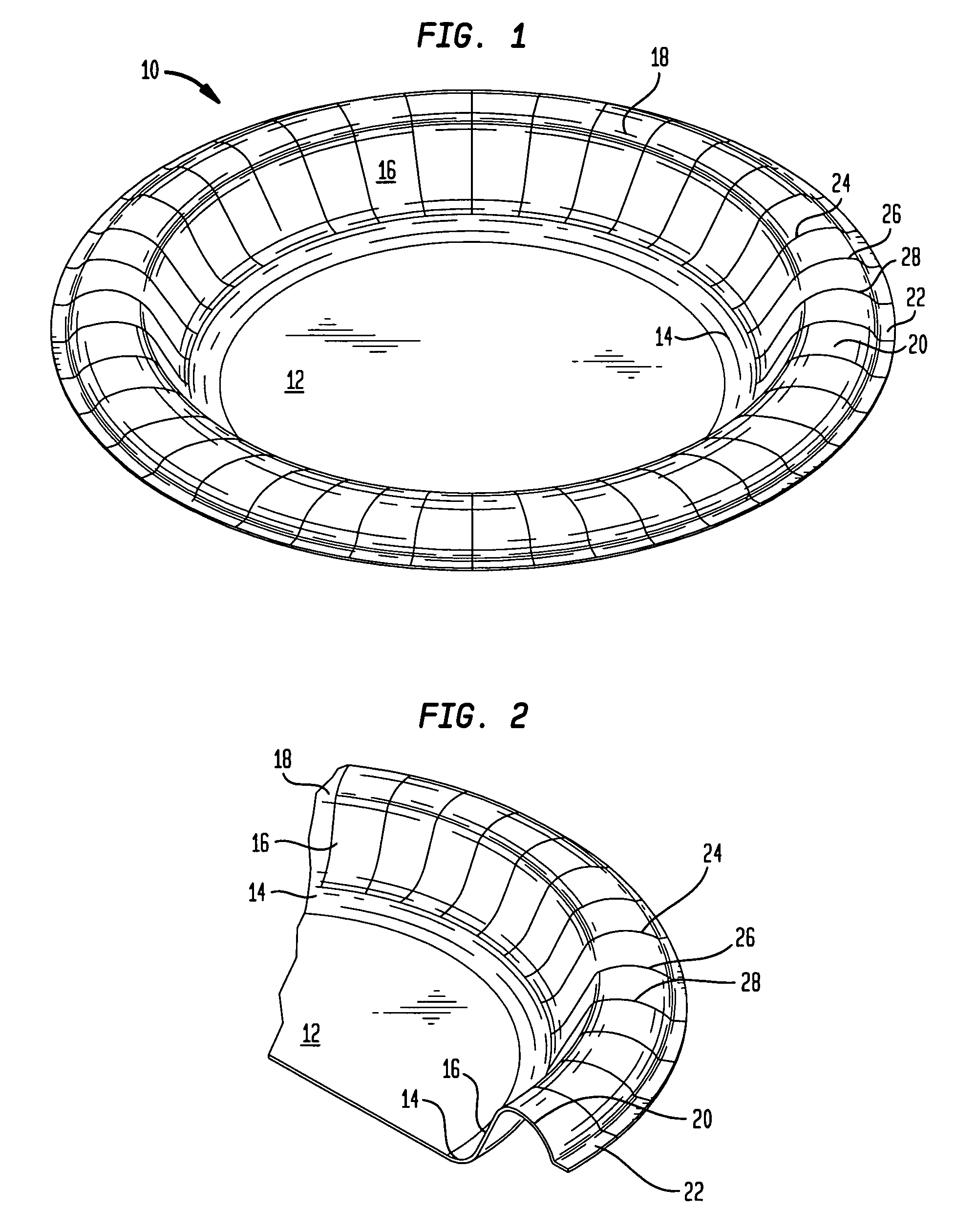

The invention relates to methods and apparatuses that reduce problems encountered during coating of a device, such as a medical device having a cylindrical shape. In an embodiment, the invention includes an apparatus including a bi-directional rotation member. In an embodiment, the invention includes a method with a bi-directional indexing movement. In an embodiment, the invention includes a coating solution supply member having a major axis oriented parallel to a gap between rollers on a coating apparatus. In an embodiment, the invention includes a device retaining member. In an embodiment, the invention includes an air nozzle or an air knife. In an embodiment, the invention includes a method including removing a static charge from a small diameter medical device.

Owner:SURMODICS INC

Method and apparatus for coating of substrates

The invention relates to methods and apparatuses that reduce problems encountered during coating of a device, such as a medical device having a cylindrical shape. In an embodiment, the invention includes an apparatus including a bi-directional rotation member. In an embodiment, the invention includes a method with a bi-directional indexing movement. In an embodiment, the invention includes a coating solution supply member having a major axis oriented parallel to a gap between rollers on a coating apparatus. In an embodiment, the invention includes a device retaining member. In an embodiment, the invention includes an air nozzle or an air knife. In an embodiment, the invention includes a method including removing a static charge from a small diameter medical device.

Owner:SURMODICS INC

Method and apparatus for coating of substrates

The invention relates to methods and apparatuses that reduce problems encountered during coating of a device, such as a medical device having a cylindrical shape. In an embodiment, the invention includes an apparatus including a bi-directional rotation member. In an embodiment, the invention includes a method with a bi-directional indexing movement. In an embodiment, the invention includes a coating solution supply member having a major axis oriented parallel to a gap between rollers on a coating apparatus. In an embodiment, the invention includes a device retaining member. In an embodiment, the invention includes an air nozzle or an air knife. In an embodiment, the invention includes a method including removing a static charge from a small diameter medical device.

Owner:SURMODICS INC

Method and apparatus for coating of substrates

The invention relates to methods and apparatuses that reduce problems encountered during coating of a device, such as a medical device having a cylindrical shape. In an embodiment, the invention includes an apparatus including a bi-directional rotation member. In an embodiment, the invention includes a method with a bi-directional indexing movement. In an embodiment, the invention includes a coating solution supply member having a major axis oriented parallel to a gap between rollers on a coating apparatus. In an embodiment, the invention includes a device retaining member. In an embodiment, the invention includes an air nozzle or an air knife. In an embodiment, the invention includes a method including removing a static charge from a small diameter medical device.

Owner:SURMODICS INC

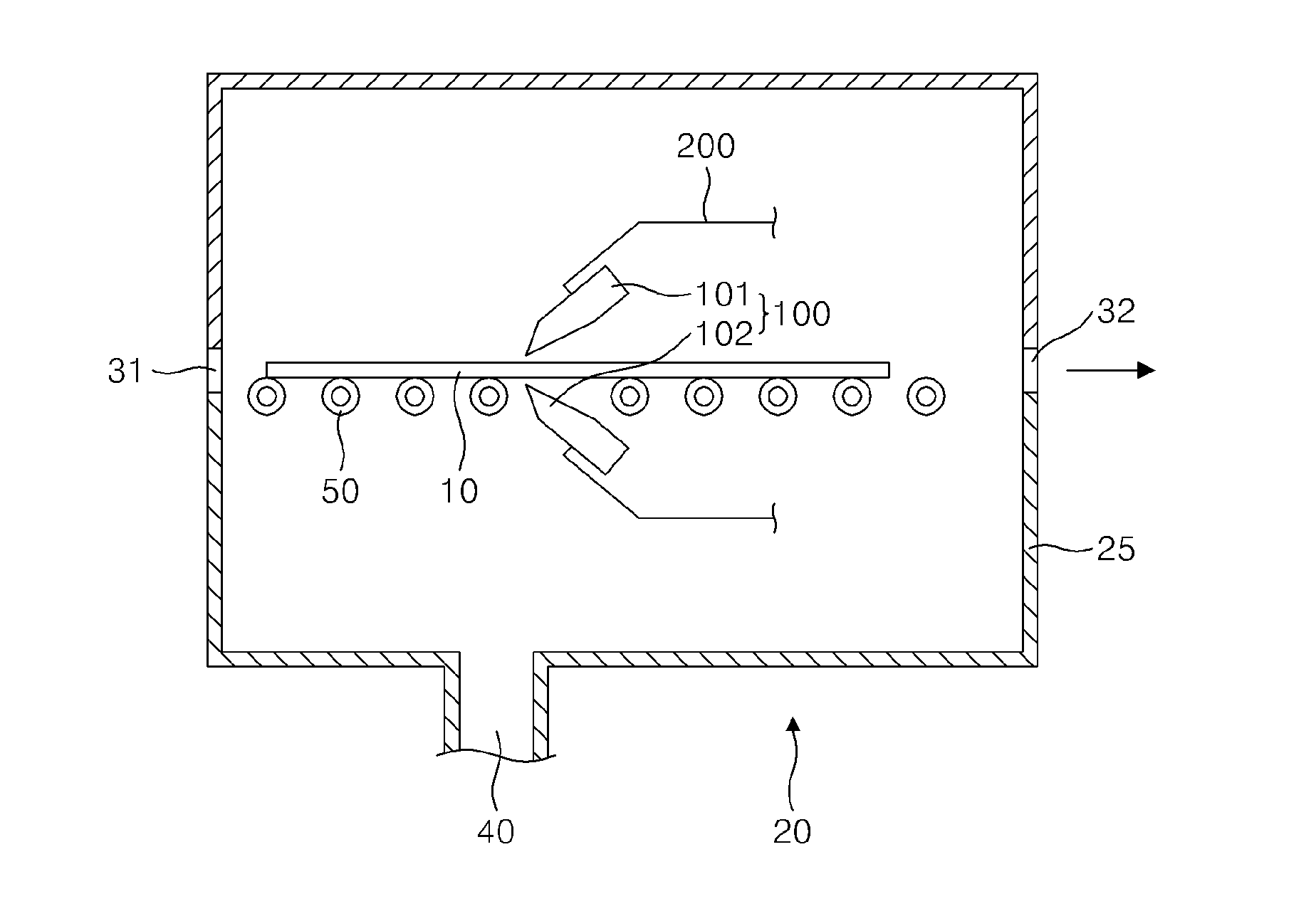

Air knife and substrate drying apparatus having the same

InactiveUS20080244925A1Avoid impuritiesDrying gas arrangementsSemiconductor/solid-state device manufacturingAir knifeReference line

An air knife capable of preventing drying defects during substrate drying processes includes an inlet through which air is supplied from an outside of the air knife, a chamber which stores the air flowing through the inlet, and an outlet which is connected to the chamber and sprays the air stored in the chamber on a substrate, and a main body having a lower end portion extending from the outlet and past at least a portion of the chamber, wherein an angle between the lower end portion of the main body and a body reference line extended from the outlet is less than 40 degrees.

Owner:SAMSUNG ELECTRONICS CO LTD

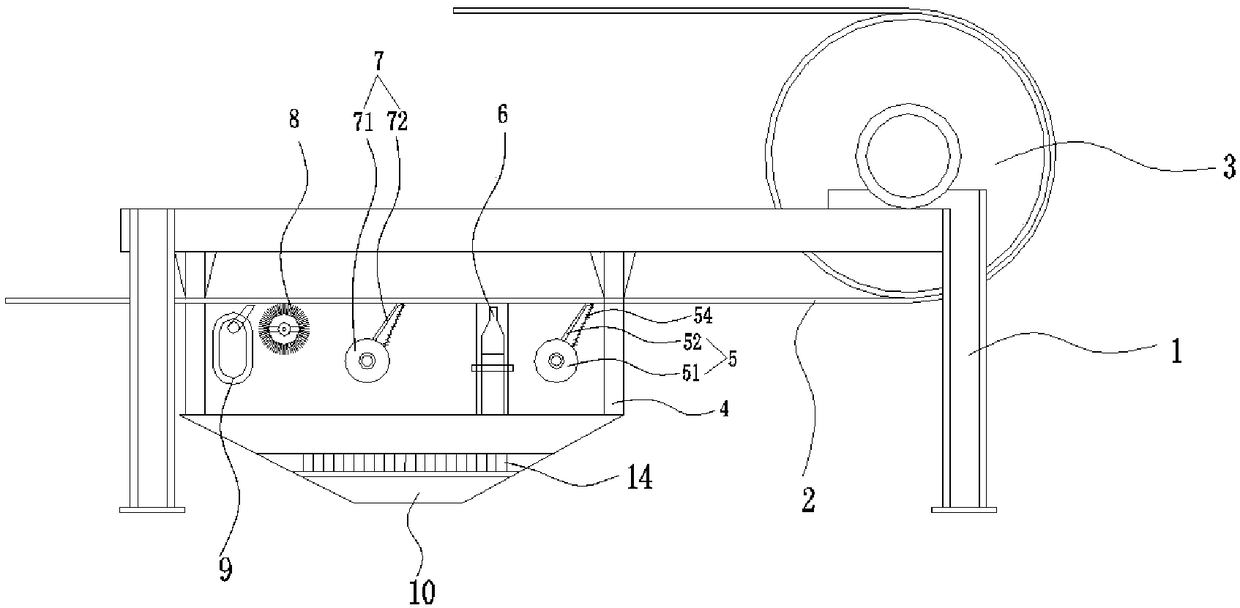

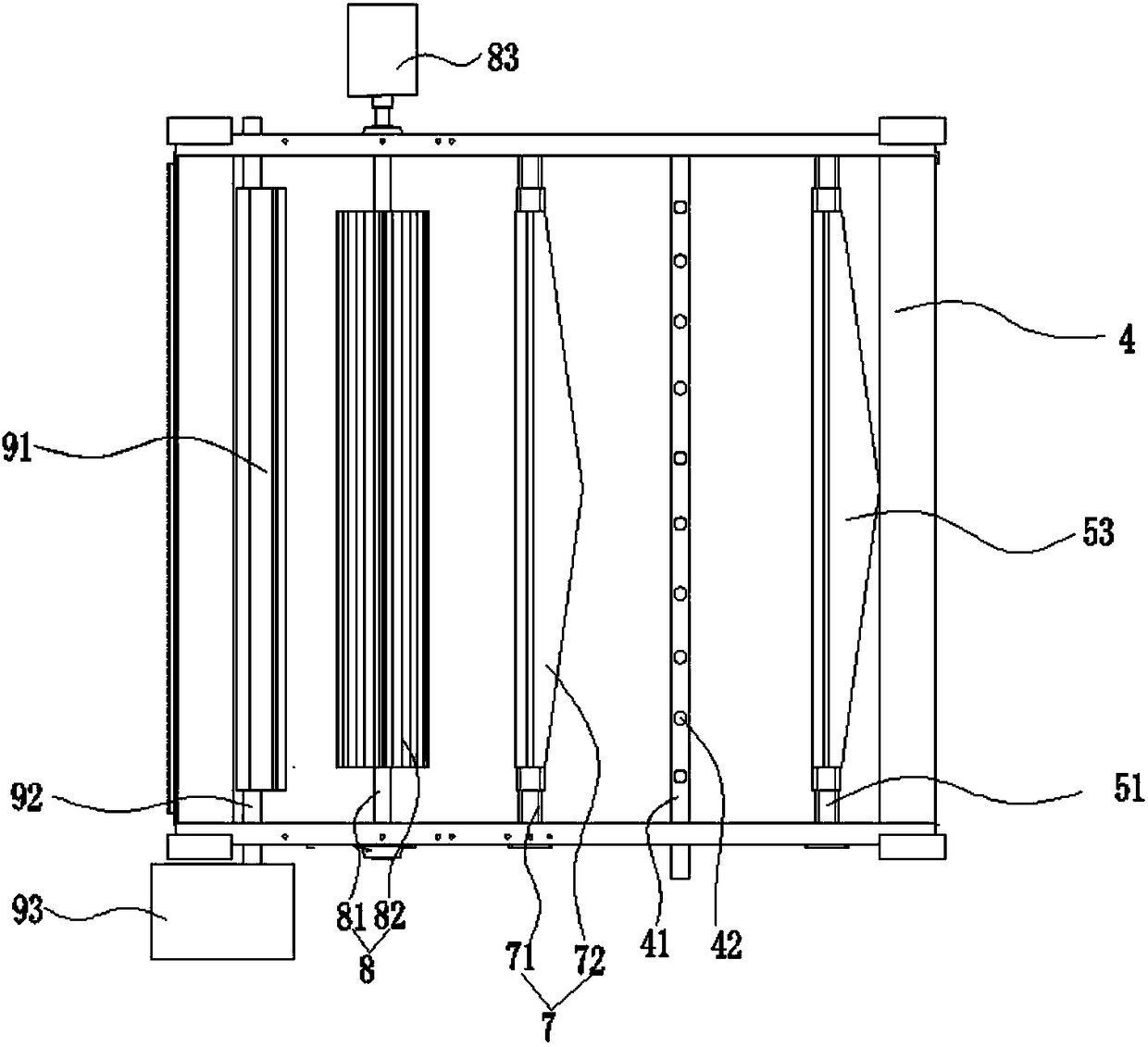

Glass-cleaning and drying device

The invention provides a glass-cleaning and drying device suitable for cleaning and drying coated glass. The glass-cleaning and drying device comprises a stand, a conveying mechanism, a tray brush device, a brush device, a water-absorbing component, a drying device and a heat drying device. The conveying mechanism comprises a driving motor and a plurality of conveying rollers arranged in a line, wherein the driving motor drives the conveying rollers to convey coated glass; the tray brush device comprises a lifting mechanism, a plurality of tray brushes and a tray brush driving mechanism; the lifting driver of the lifting mechanism drives the tray brushes to move up and down relative to the coated glass; the tray brush driving mechanism drives the tray brushes to rotate; the clamped transmission roller group of the brush device is arranged between the tray brush device and the brush device for conveying the coated glass in a clamping mode and expelling moisture on the coated glass; the water-absorbing component comprises a water-absorbing roller group which comprises water-absorbing rollers with water absorption in vertical two-to-two correspondence; the drying device comprises air knives and a blower; and the air knives respectively face to the upper surface and the lower surface of the coated glass.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

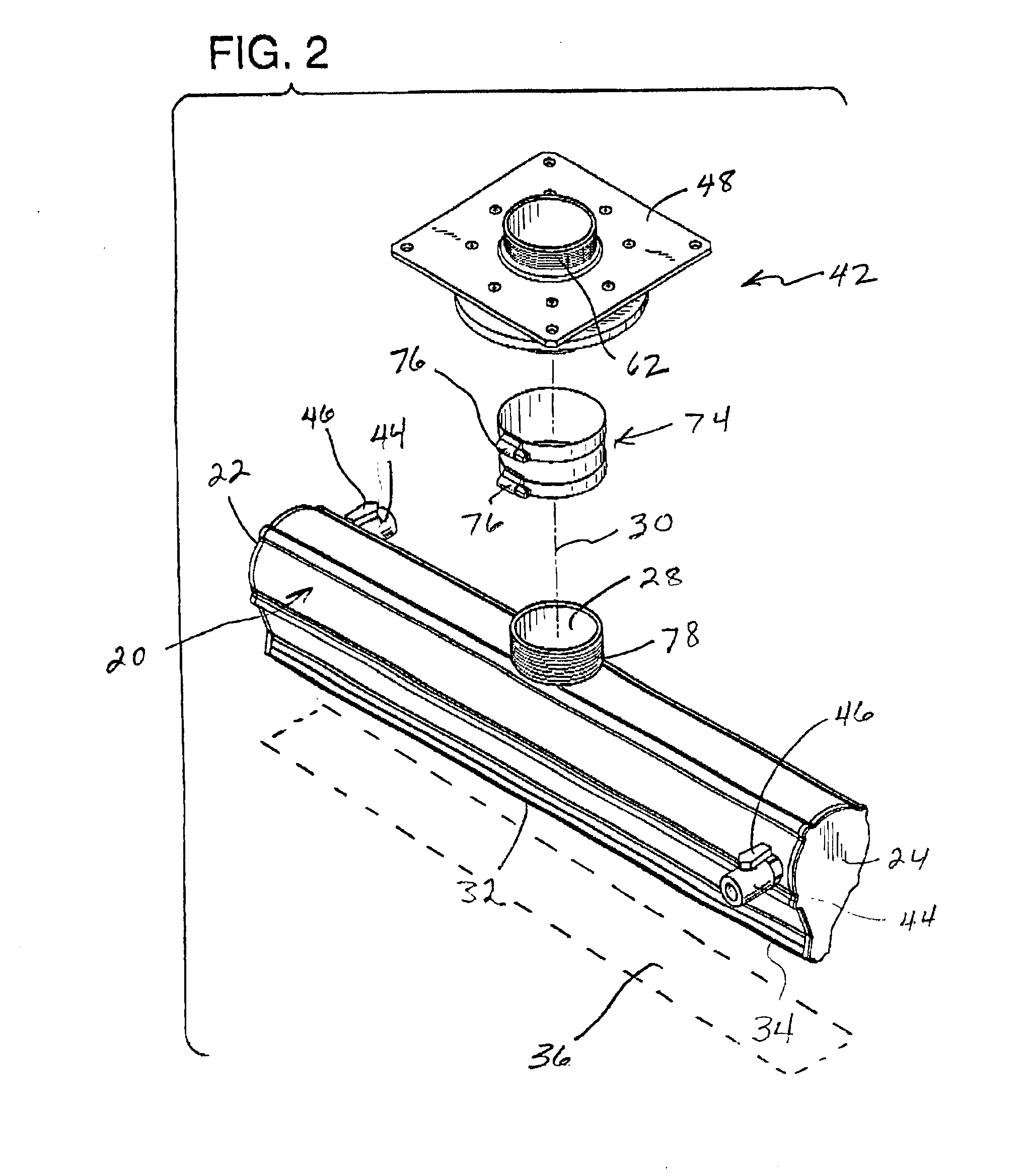

Rotatable air knife

InactiveUS6990751B2Extended stayDried or blown off more effectivelyDrying solid materials with heatDrying gas arrangementsCouplingEngineering

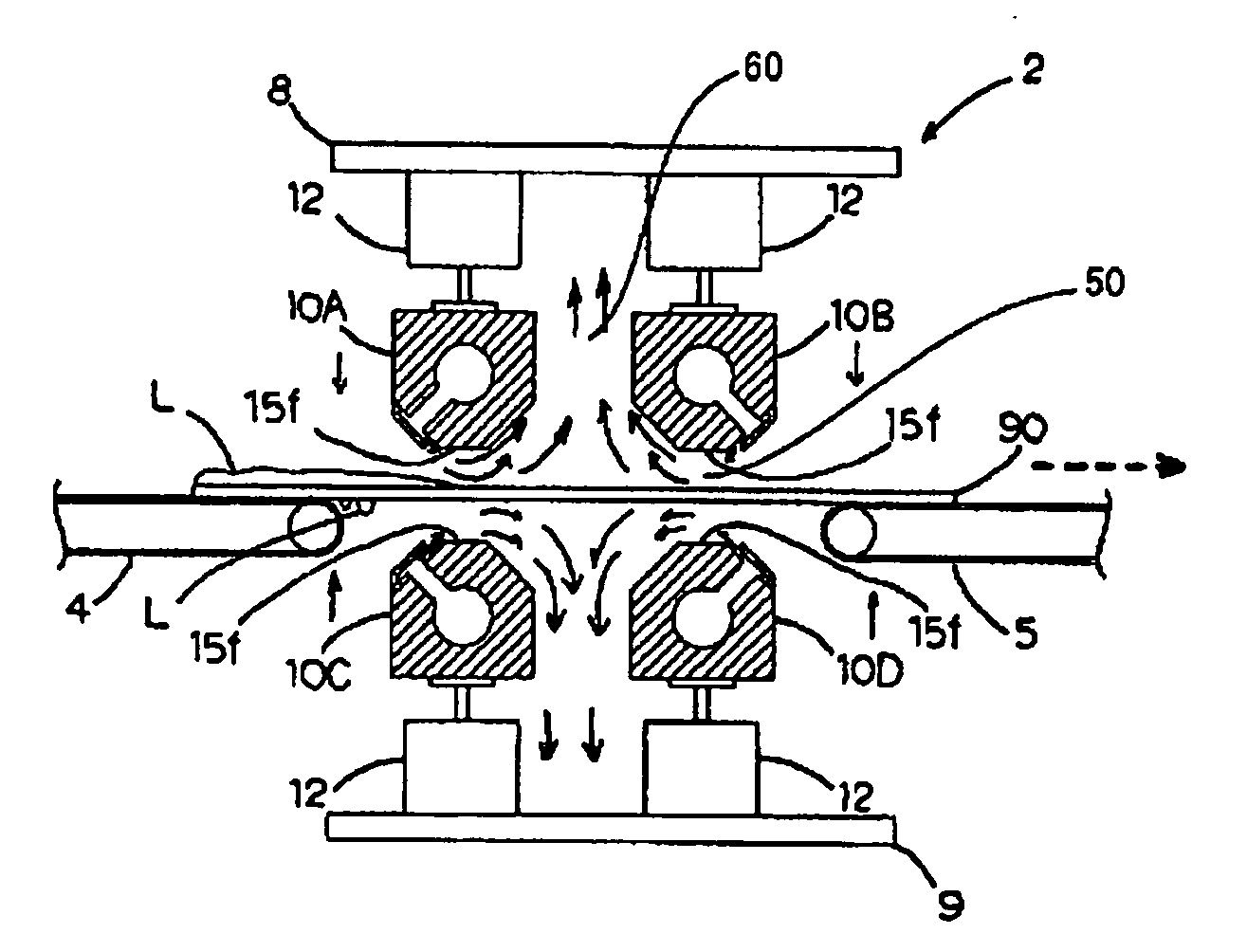

An air knife or air nozzle manifold for drying or blowing off passing articles moved by a conveyor system is provided with a coupling that permits rotation of the air knife or air nozzle manifold relative to the air inlet duct leading from a blower. The air knife or air nozzle manifold has opposing ends located equidistant from a longitudinal axis of rotation relative to a stationary element of the coupling. Thrust nozzles are provided at each of the opposing ends of the air knife or air nozzle manifold to deflect a certain portion of the air from the plenum chamber to provide thrusting jets of air that rotate the air knife or air nozzle manifold about the longitudinal axis. The flow of air emitted from the air knife or air nozzle manifold is thereby directed onto the passing articles from different directions as the articles move by. The efficiency of drying and blowing off the articles to be processed is thereby significantly improved.

Owner:SONIC AIR SYST

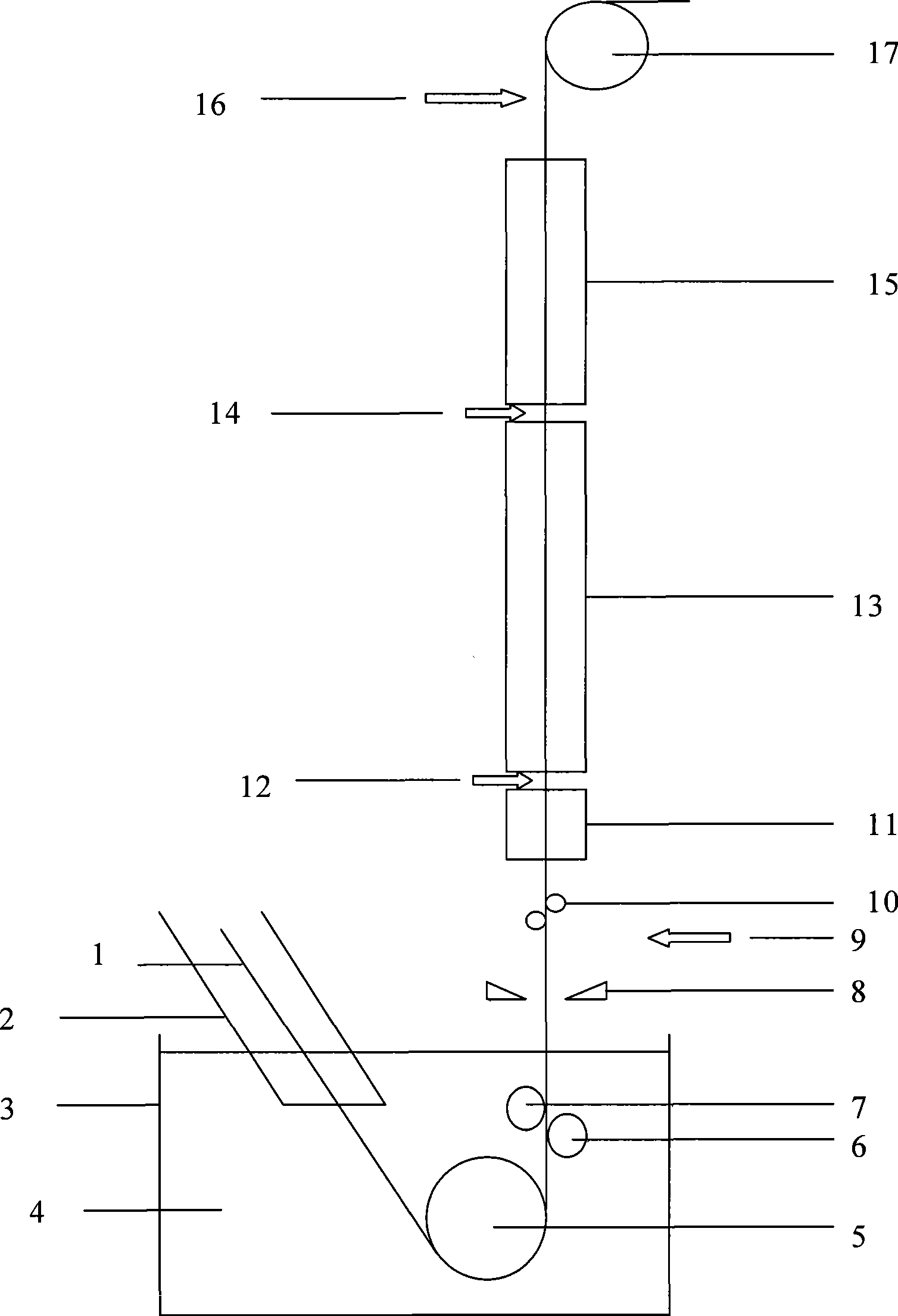

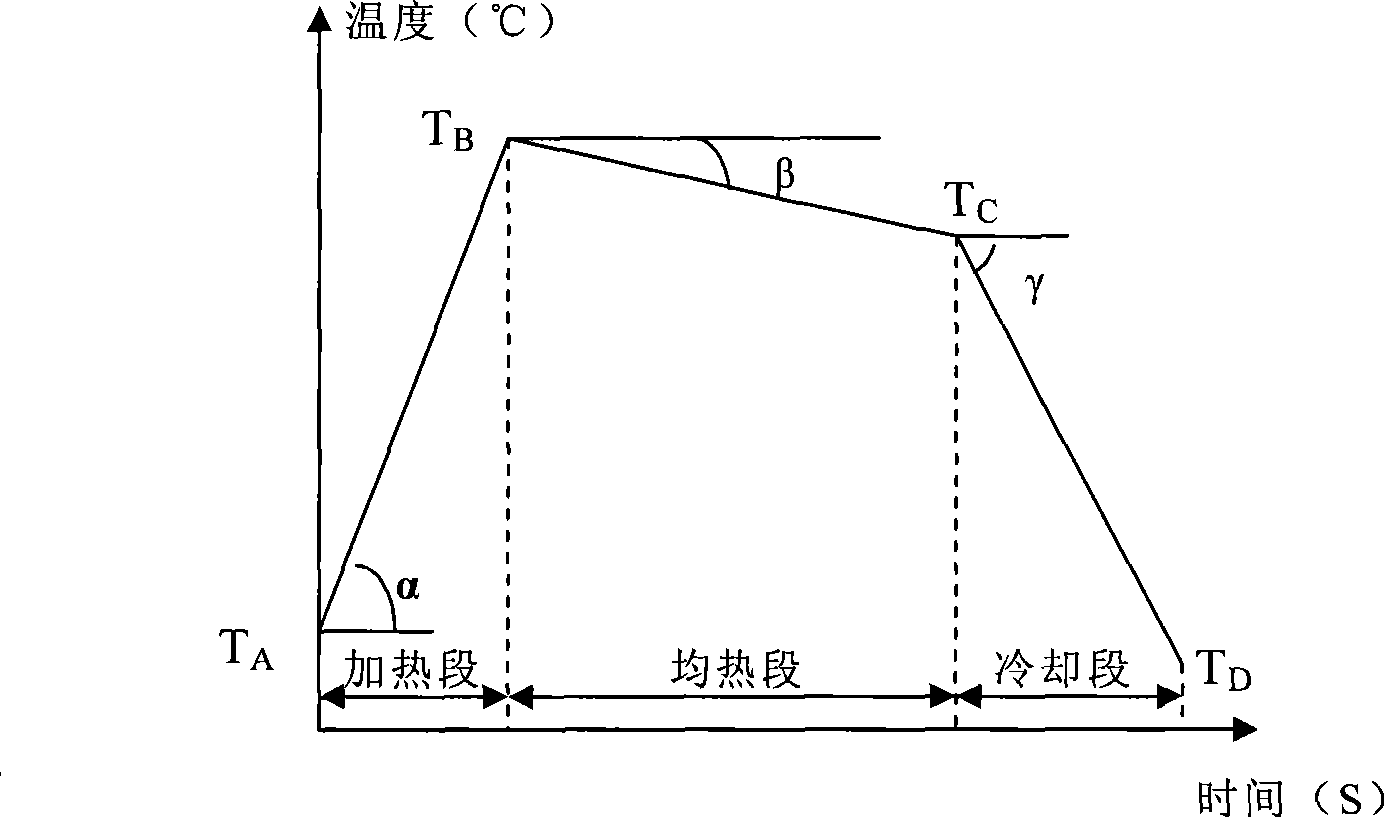

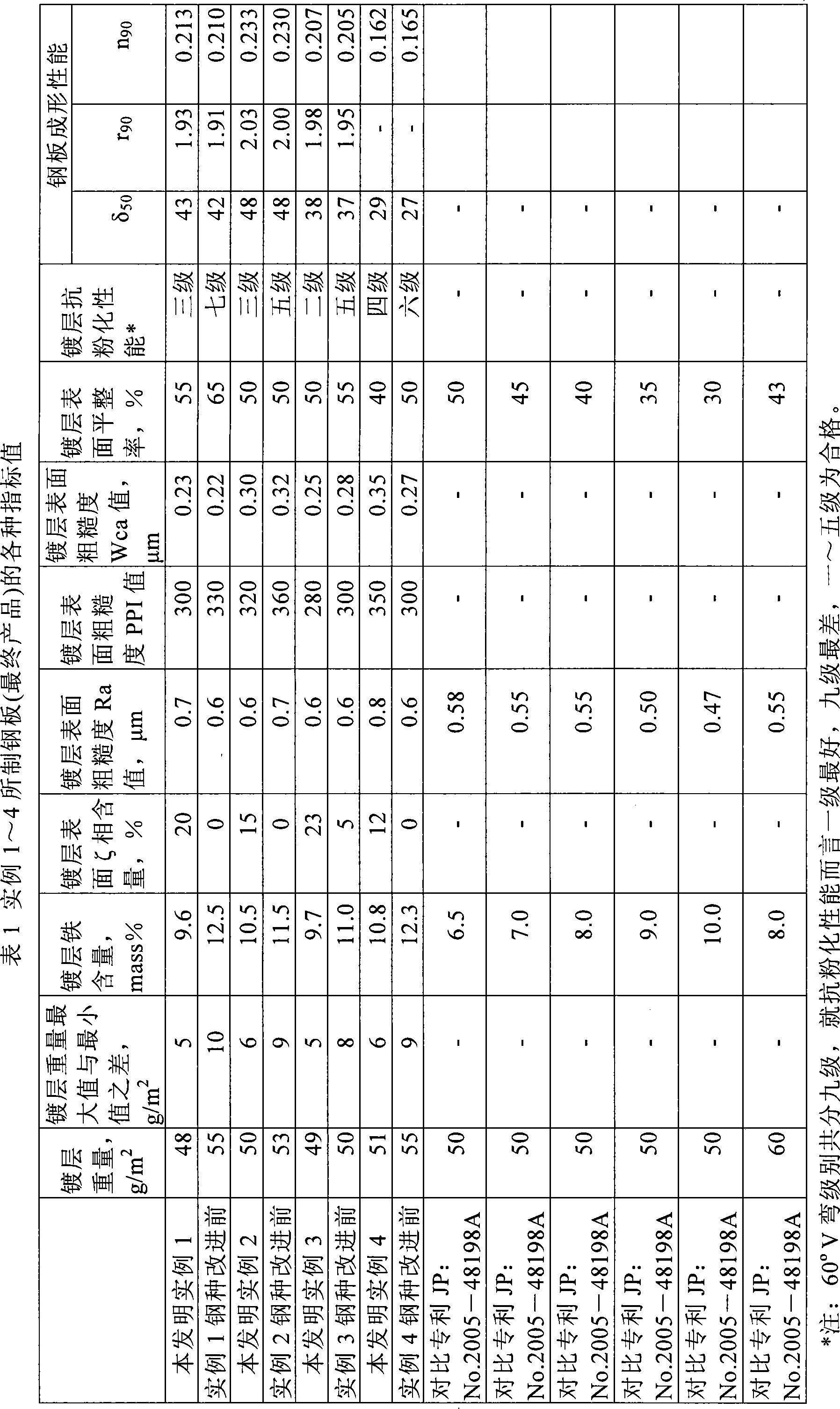

Method for controlling alloyed hot dip galvanizing steel plate coating phase structure and alloyed hot dip galvanizing steel plate

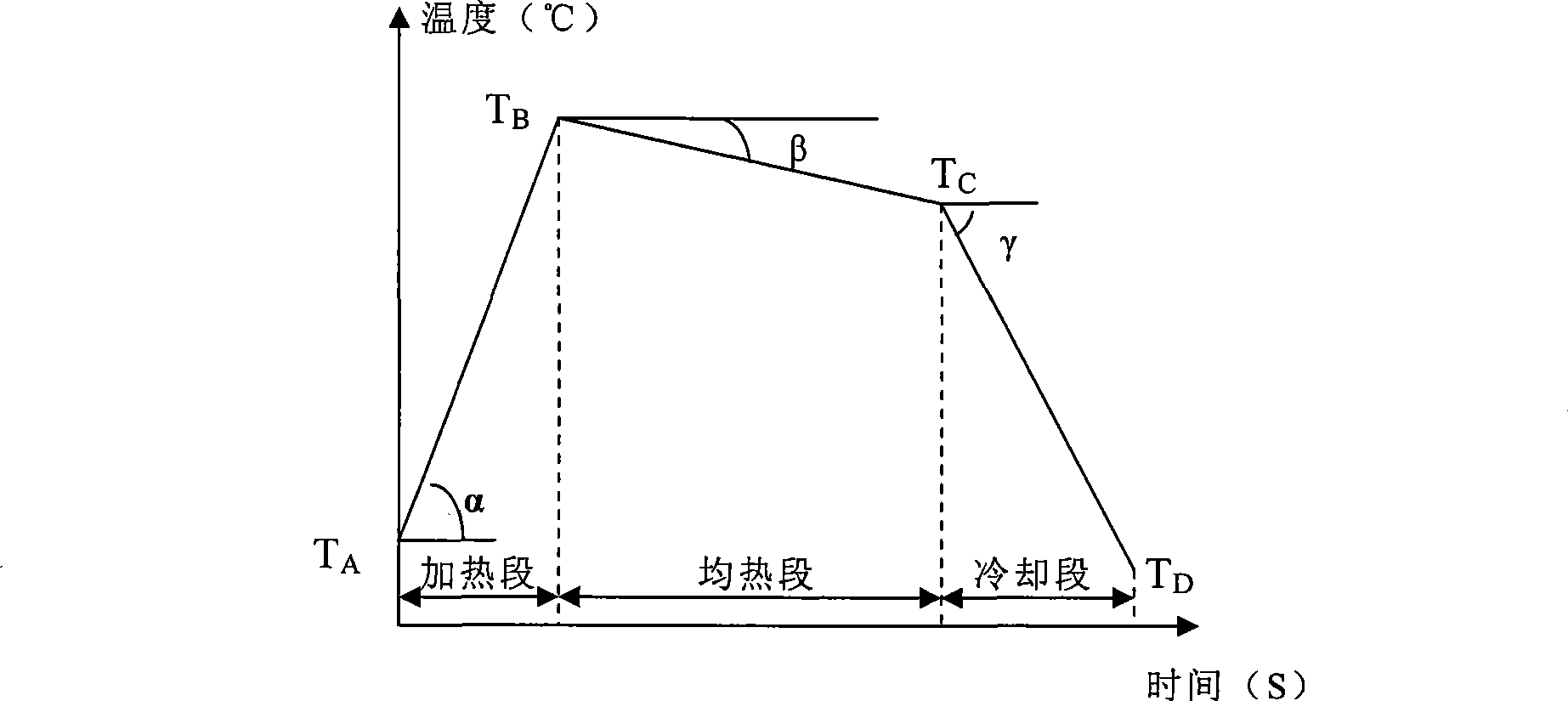

InactiveCN101376956AGood chalking resistanceGood stamping performanceHot-dipping/immersion processesFurnace typesSheet steelSurface roughness

The invention provides a method for controlling alloyed hot-dip galvanized cladding, in particular hot-dip galvanized steel sheet cladding phase structure. The method comprises the following steps: at least a set of strip steel which is provided with a steel stabilizing device and can stably control hot-dip galvanization process parameters and air knife parameters to obtain even thickness of the cladding is arranged between an air knife and a top roller; an inclined alloyed cladding heat treatment annealing curve with even temperature sections from high temperature to low temperature is selected and the strip steel is evenly alloyed, to improve the evenness of the alloying process and the alloying degree of the strip steel cladding; in addition, flat roll surface roughness and flat extensibility are selected, to control the cladding surface roughness and cladding surface flat rate and improve the shaping performance of the steel sheet. The invention also provides an alloyed hot-dip galvanized steel sheet manufactured by the method for controlling the alloyed hot-dip galvanized steel sheet cladding phase structure; the hot-dip galvanized steel sheet has excellent cladding powder resistance and shaping performance, and is very applicable to automobile internal and external plates as well as household electric appliance external plates.

Owner:BAOSHAN IRON & STEEL CO LTD

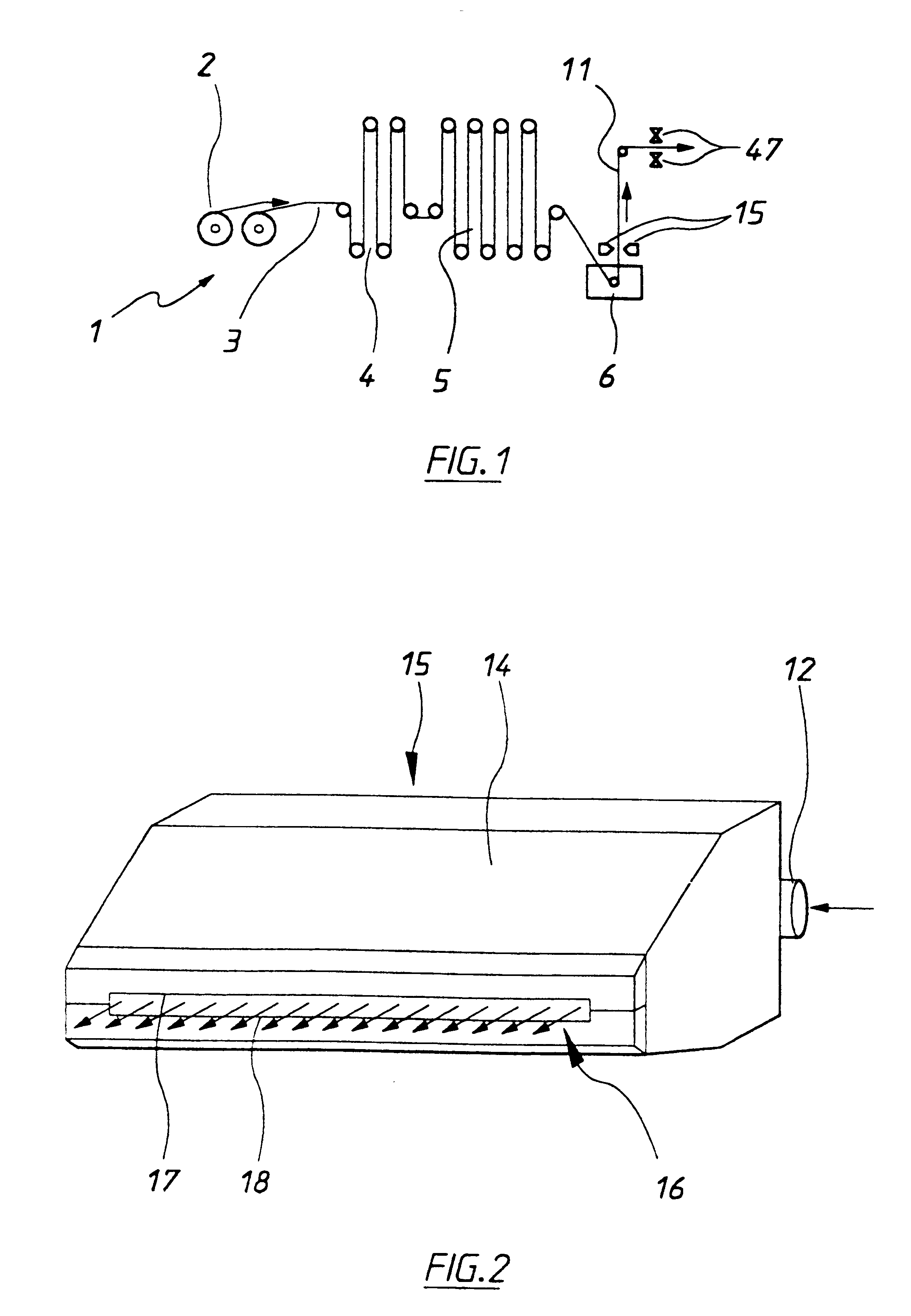

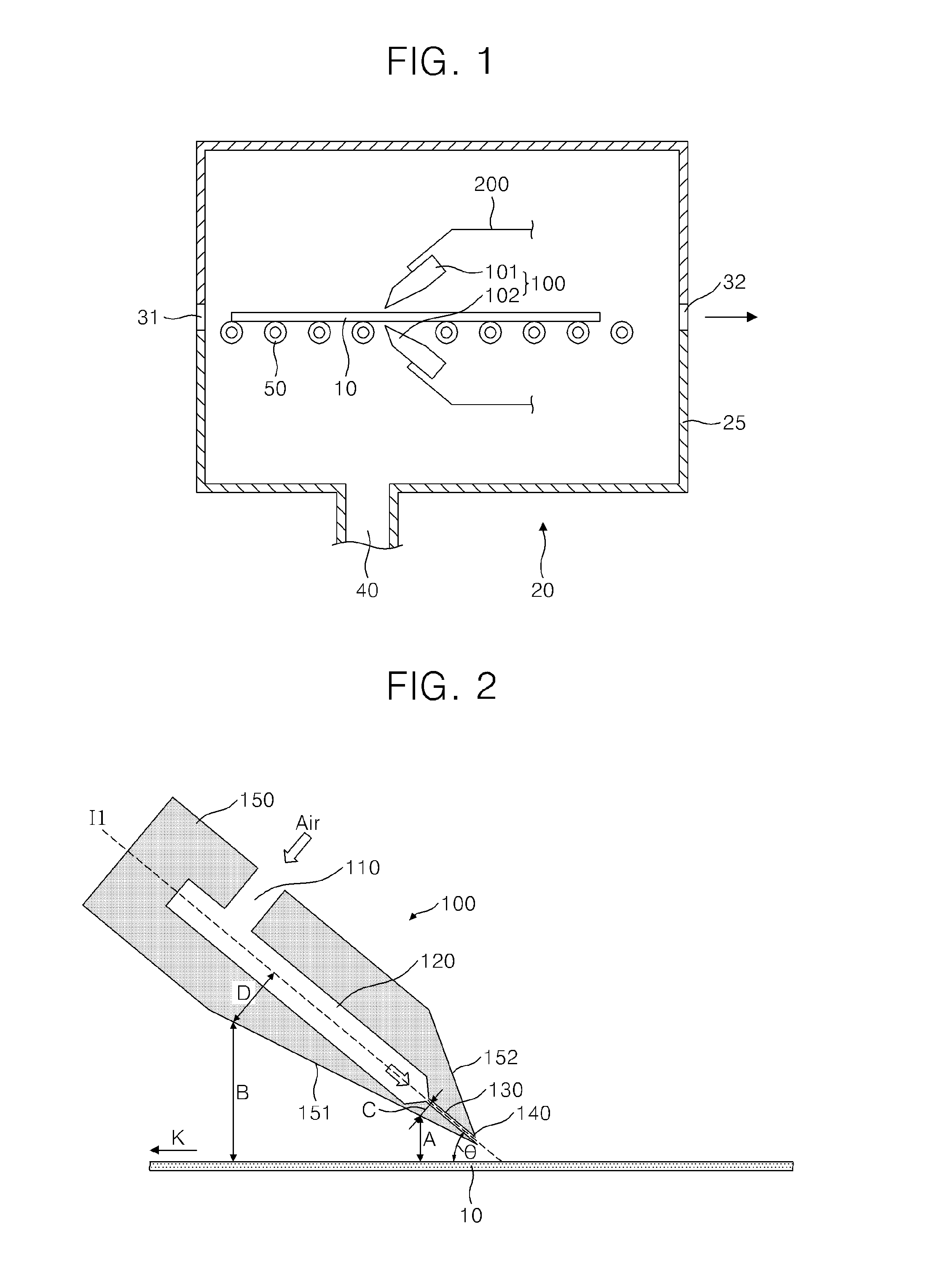

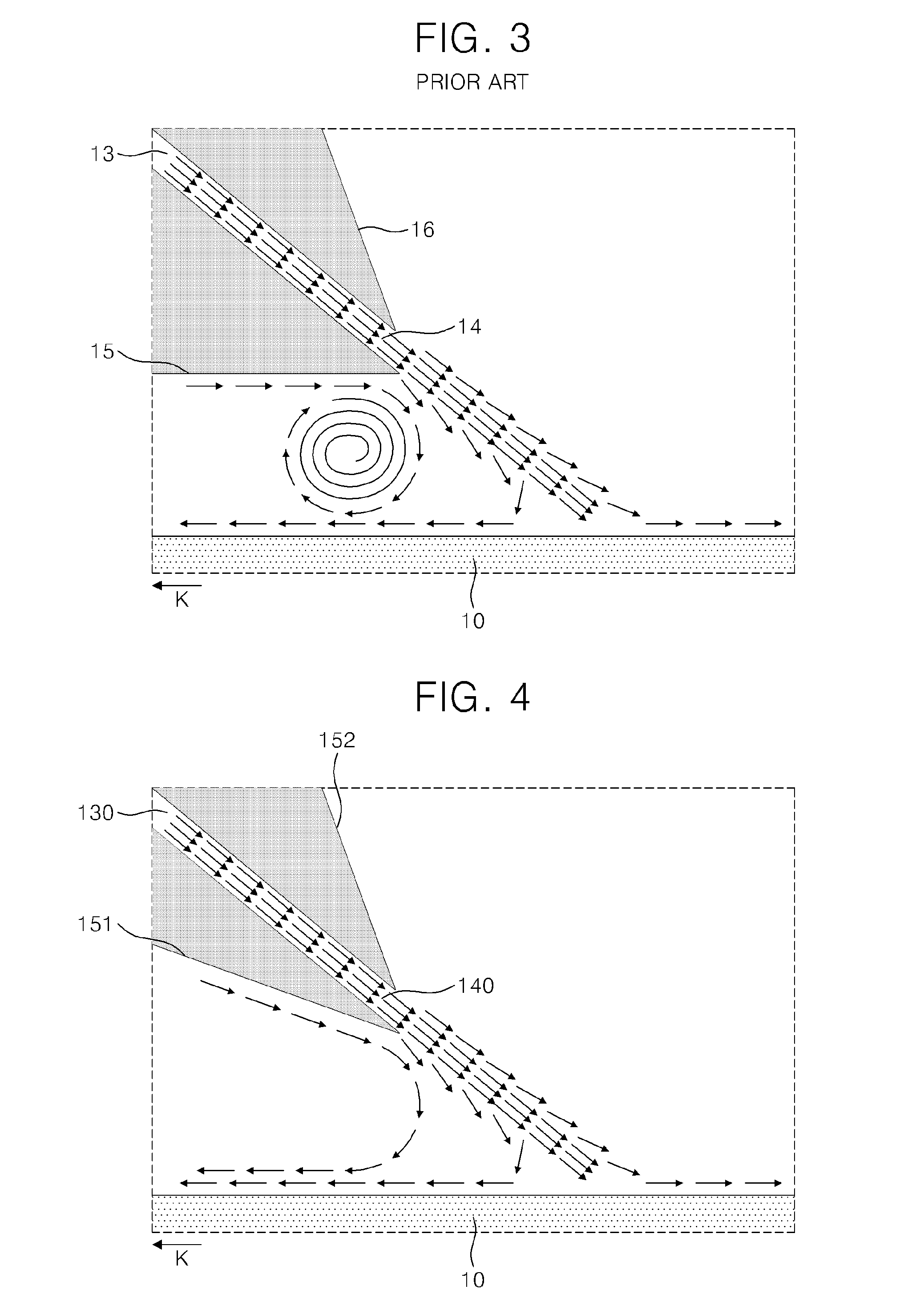

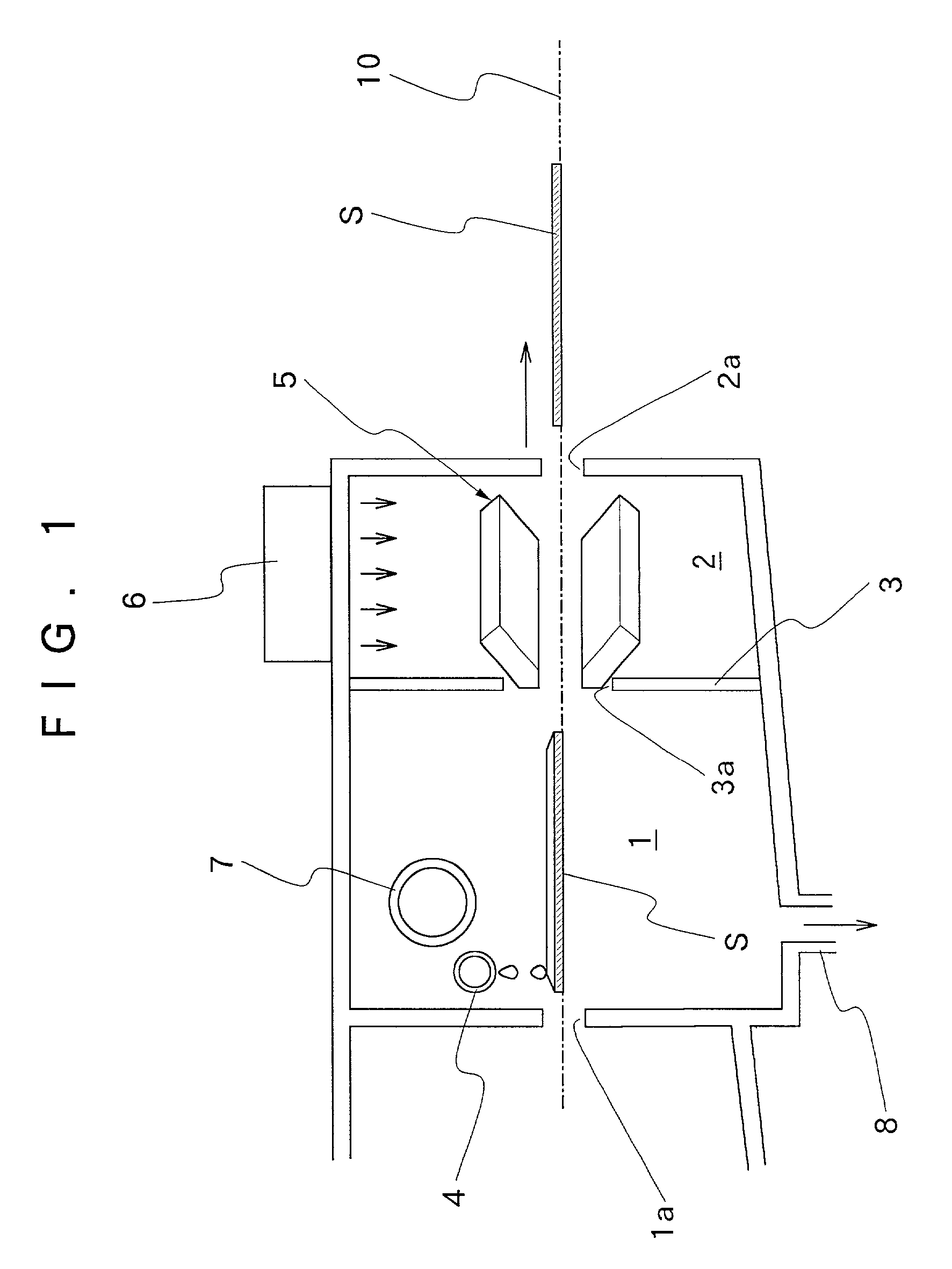

Method and apparatus for drying substrate plates

InactiveUS20010015021A1Fast dryingDrying solid materials with heatDrying solid materials without heatAngle of incidenceEngineering

While being transferred in substantially horizontal state along a predetermined path of transfer by a conveyer means, a substrate plate is dried by a jet of compressed air which is spurted out from a slit-like mouth of an air knife nozzle crosswise of the entire width of the substrate plate and at a predetermined angle of incidence with respect to a drying surface of the substrate plate to scrape off a liquid. The angle of incidence of jet air is made shallower as soon as the substrate on the conveyer means comes to a point of entry to an air blasting zone and is made deeper at latest when the substrate plate comes to a position immediately before a point of disengagement from the air blasting zone.

Owner:HITACHI ELECTRONICS ENG CO LTD

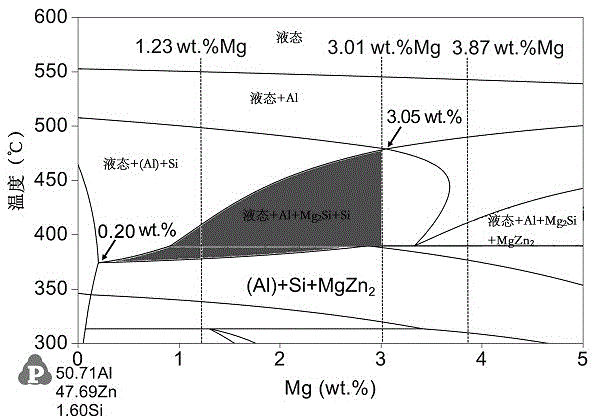

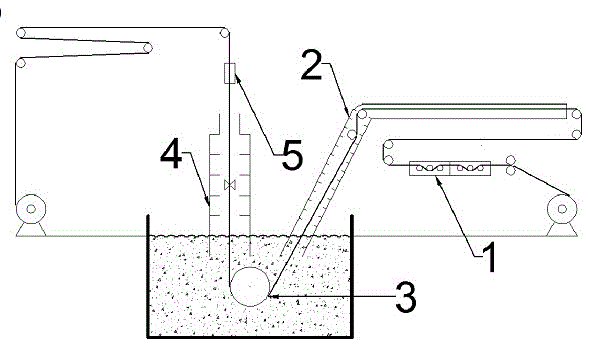

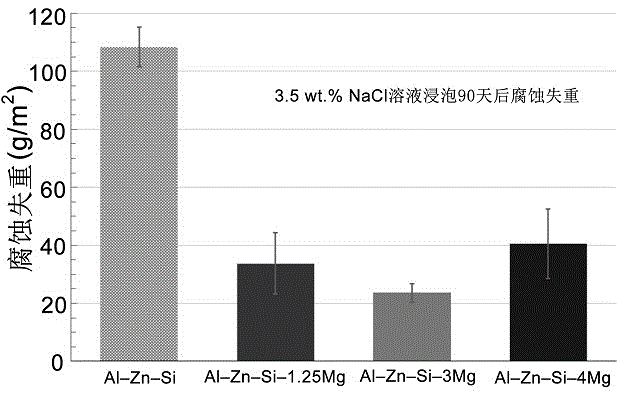

Method for plating surface of steel with Al-Zn-Mg-Si alloy plating layer in continuous hot-dipping manner

The invention relates to a method for plating the surface of steel with an Al-Zn-Mg-Si alloy plating layer in a continuous hot-dipping manner and a manufacturing process of the Al-Zn-Mg-Si alloy plating layer. The Al-Zn-Mg-Si alloy plating layer manufactured through the process comprises, by weight percentage, 48% to 55% of Al, 40% to 50% of Zn, 1% to 4% of Mg and 1% to 3% of Si. The manufacturing process of the Al-Zn-Mg-Si alloy plating layer includes the steps of firstly, surface cleaning treatment, secondly, reducing and annealing, thirdly, hot-dipping plating in plating liquid at the temperature from 550 DEG C to 700 DEG C, fourthly, the annealing process for 0.1 s to 5 s at the temperature from 400 DEG C to 700 DEG C and air cutter leveling and fifthly, cooling. The manufactured alloy plating layer contains Al-rich dendritic crystal phases, Zn-rich interdendritic phases, Mg2Si phases and a small amount of MgZn2 phases. The preferable alloy components can guarantee the even plating liquid components, floating residues are few, and the quality of the plating layer manufactured through the continuous hot-dipping process is uniform and stable. The content of the Mg2Si phases on the surface of the plating layer can be increased through the annealing process performed after dipping plating is performed, and the corrosion resistance of the plating layer is improved.

Owner:SHANGHAI UNIV

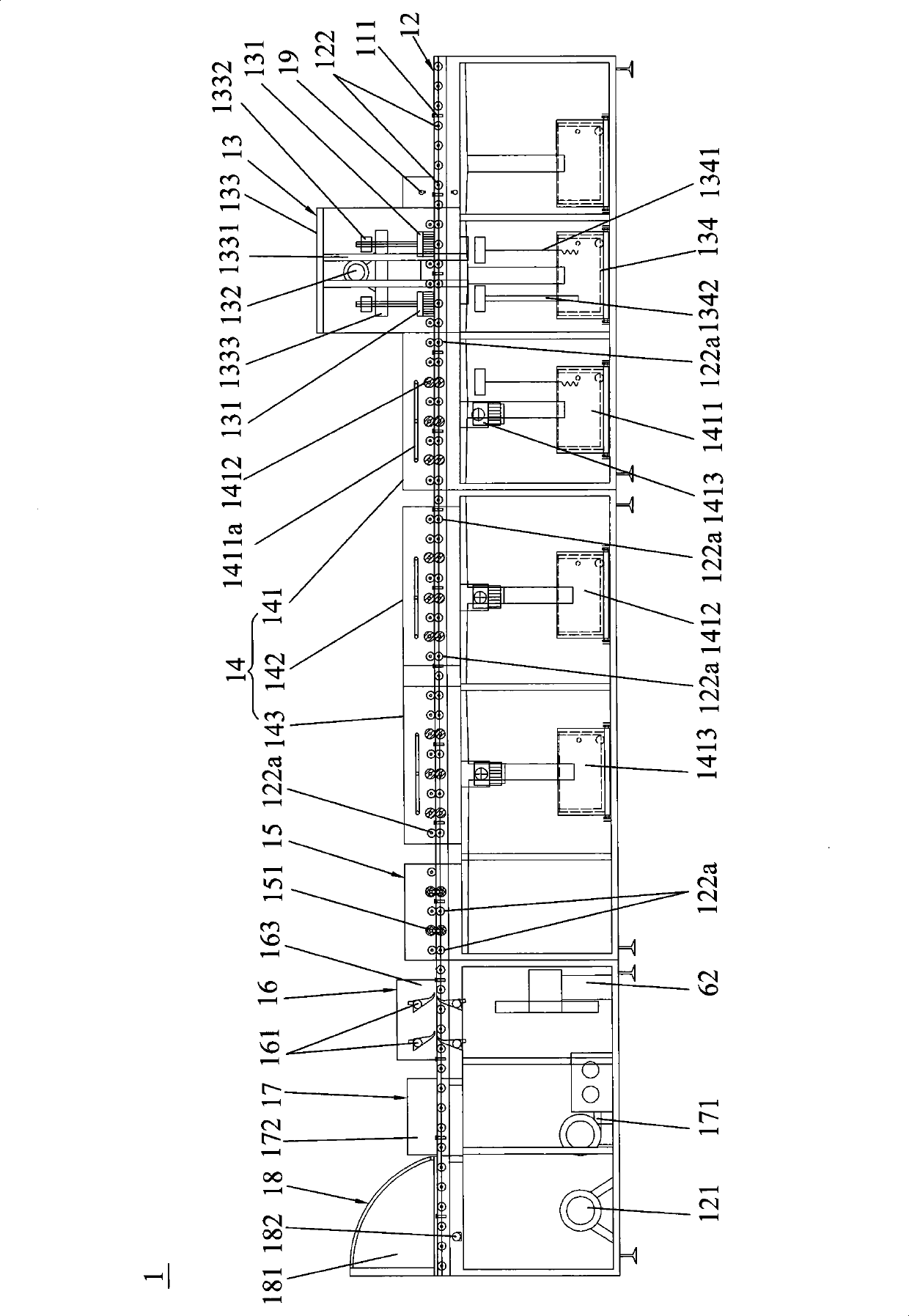

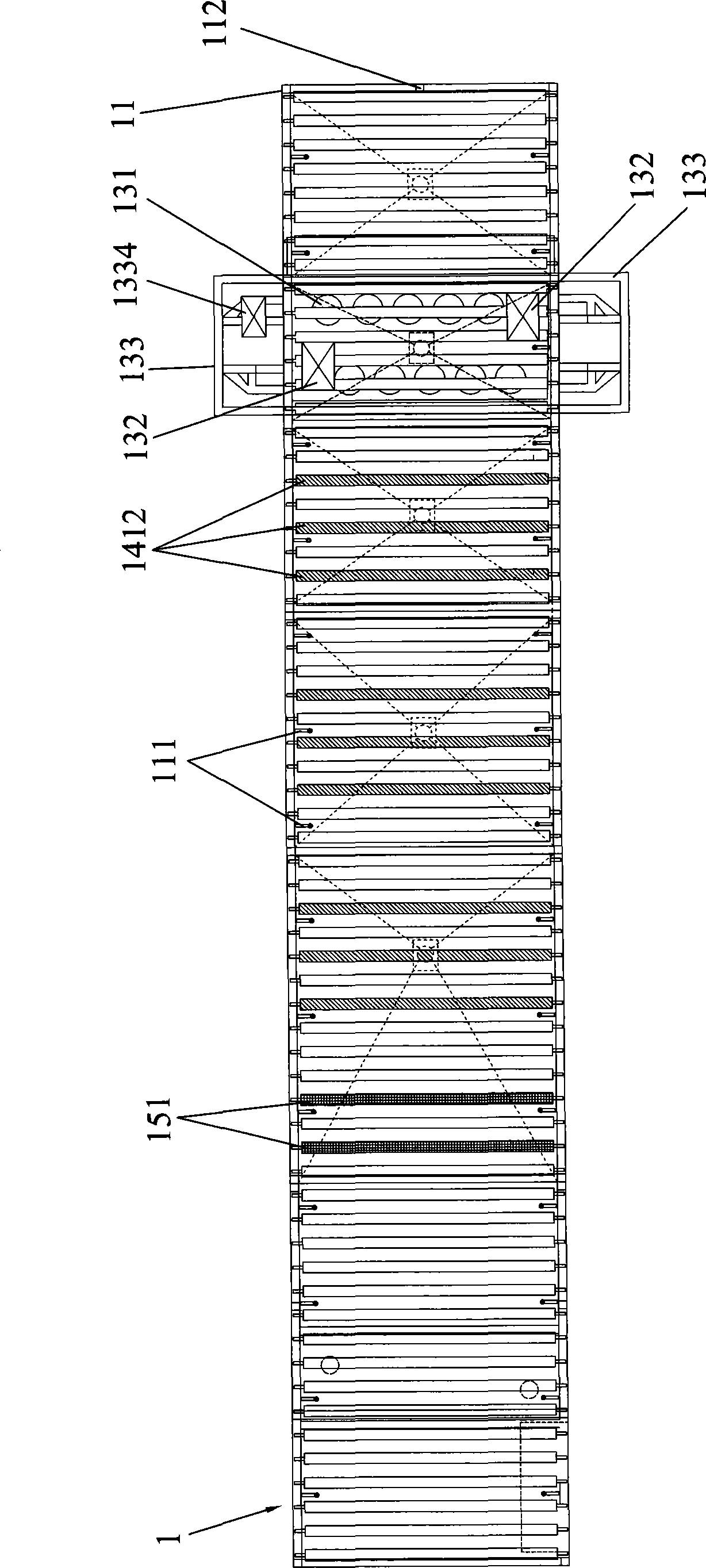

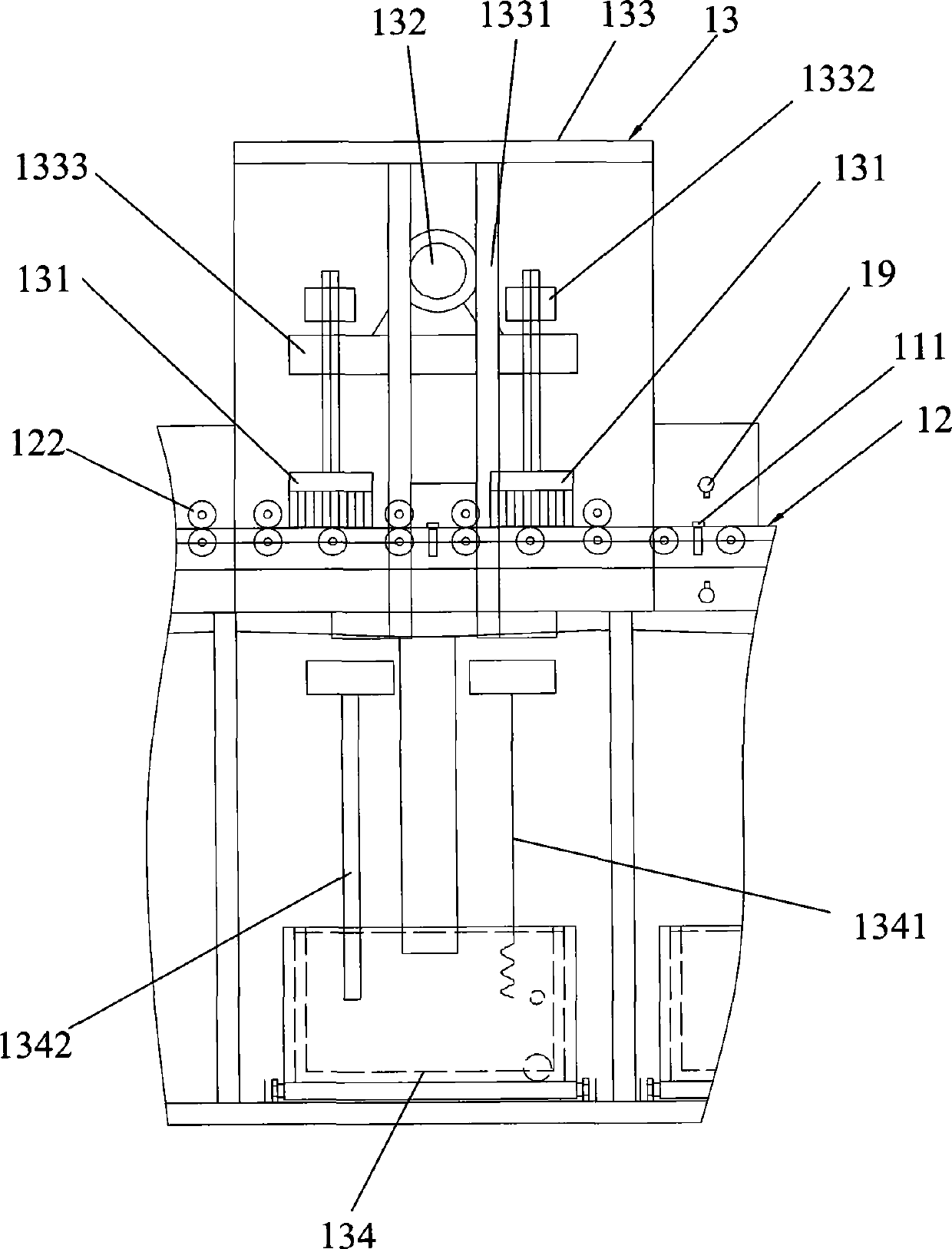

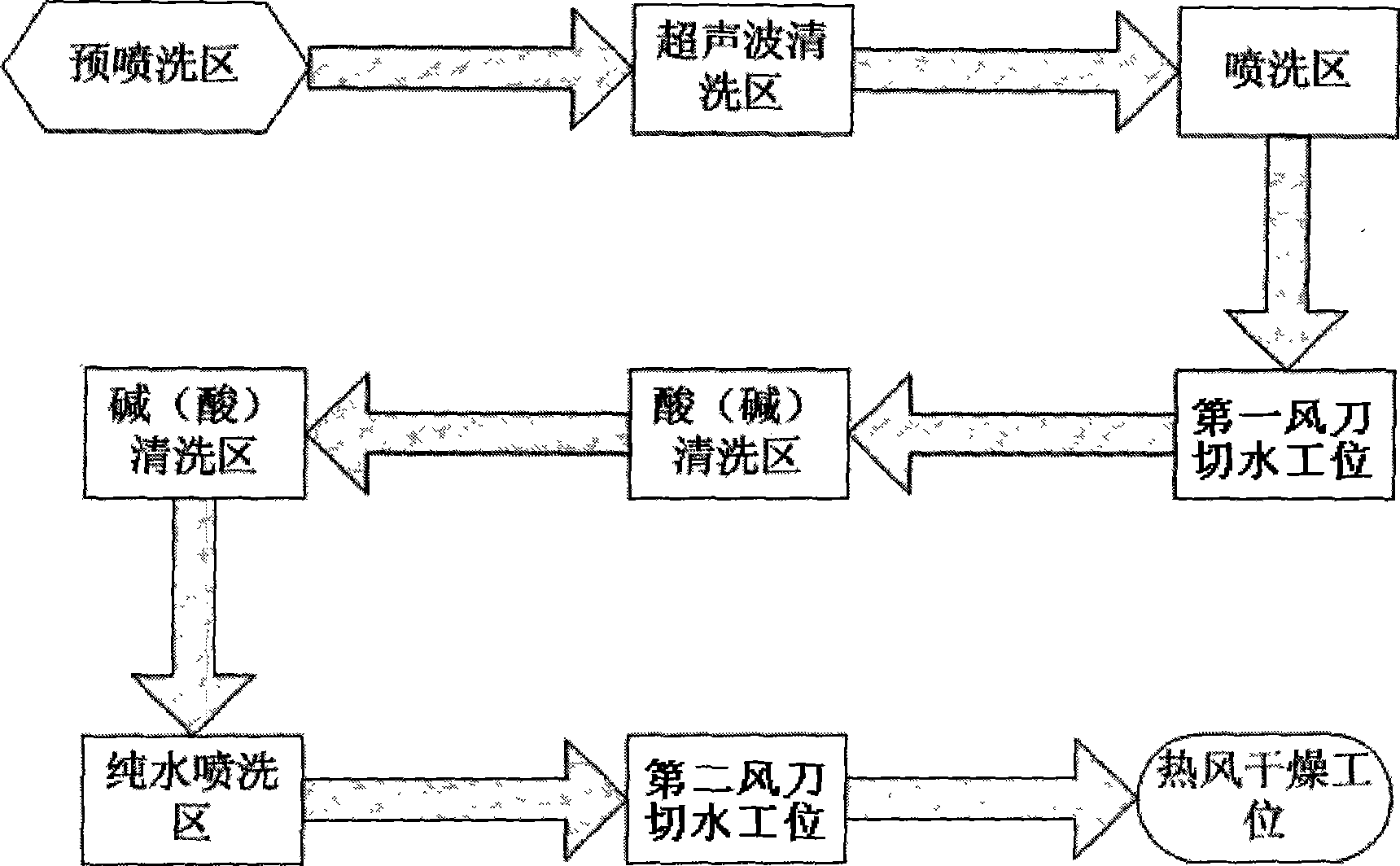

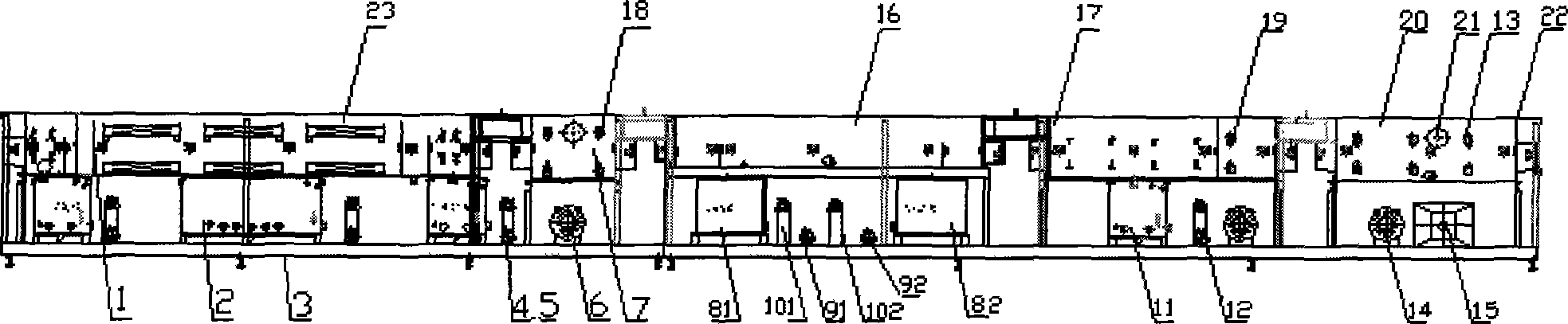

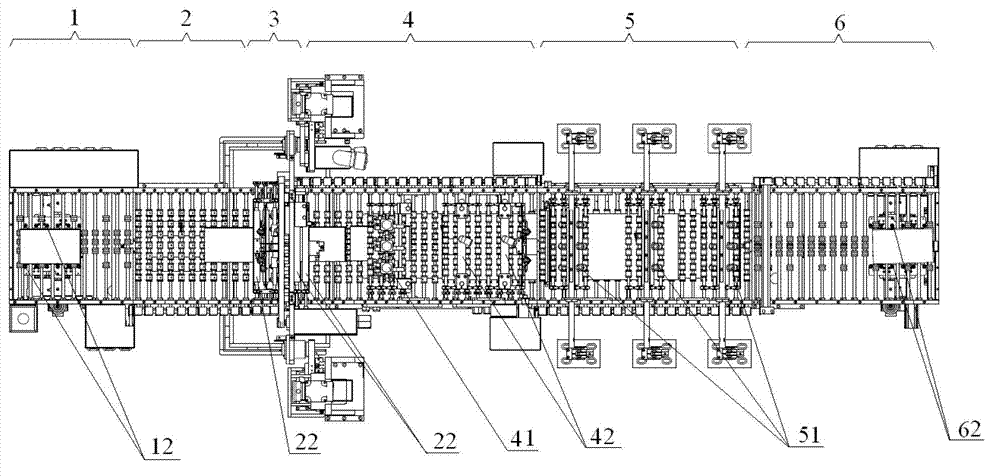

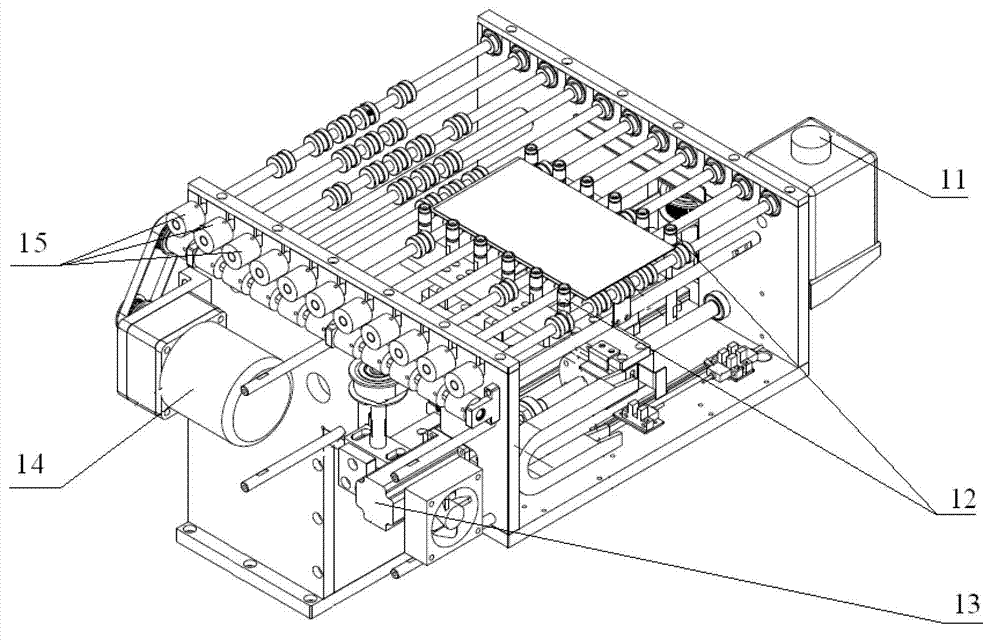

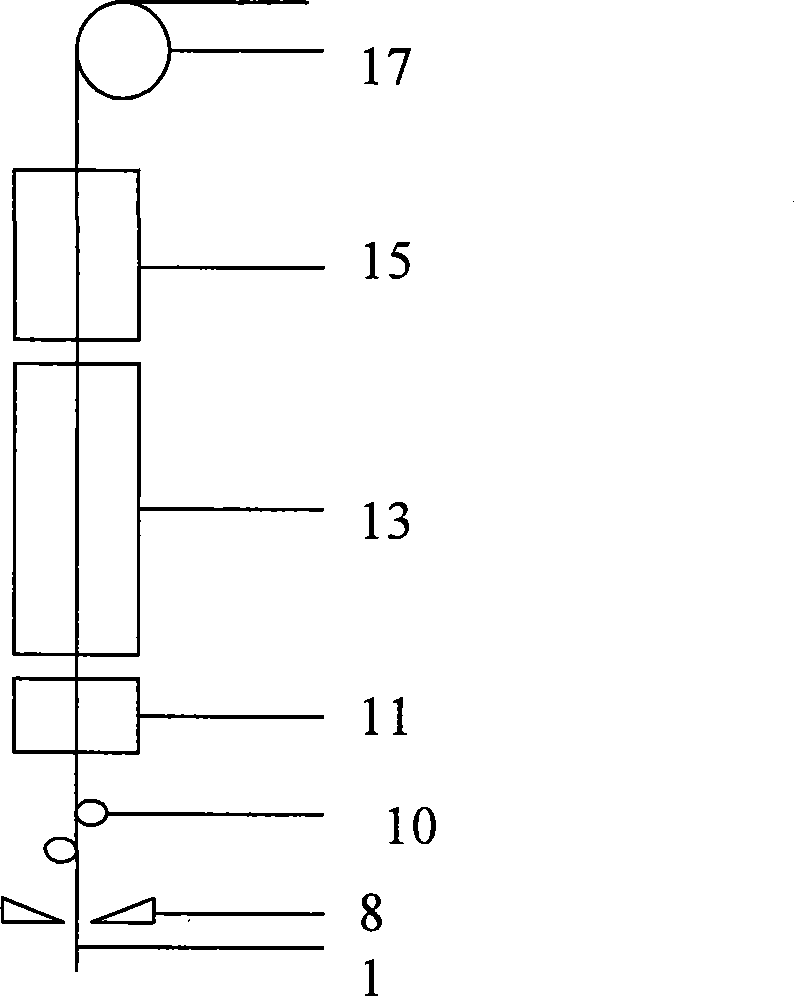

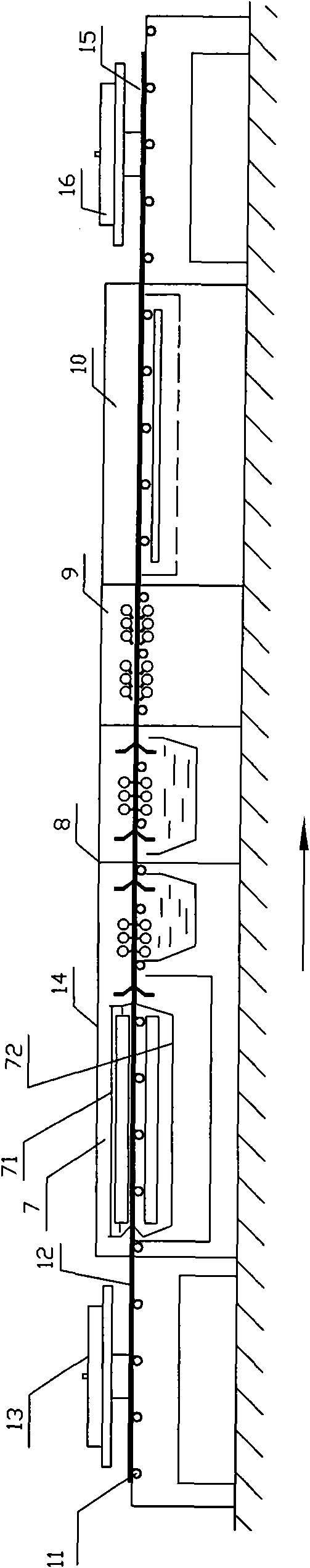

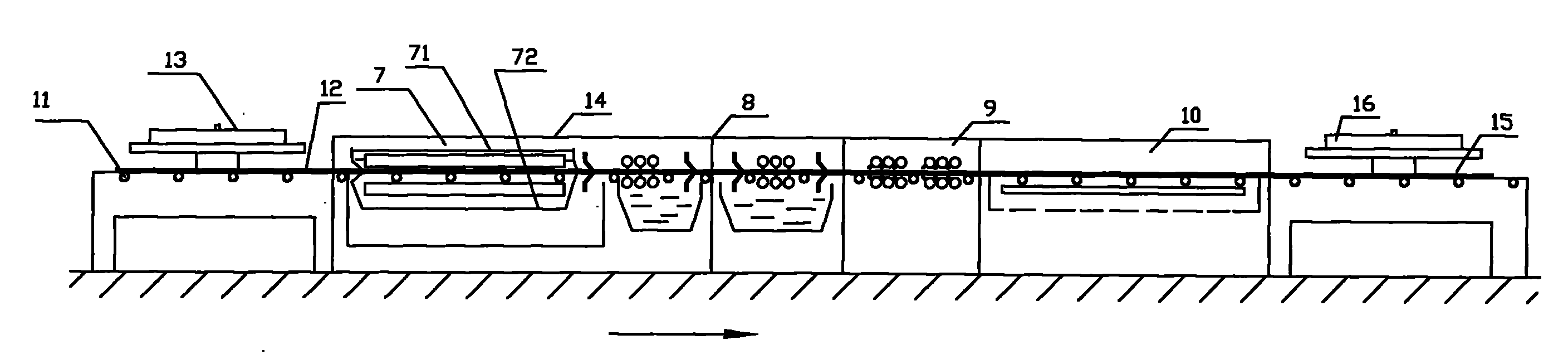

Continuous cleaning equipment system for strip

InactiveCN101474621AReduce manufacturing costMeet production requirementsDrying using combination processesDrying solid materials with heatWater savingMegasonic cleaning

The invention discloses a continuous belt material cleaning equipment system, comprising a station of a pre-spray cleaning area, a station of an ultrasonic cleaning area, a station of a spray cleaning area, a station for a first air knife water shearing, a station of an acidic or alkaline cleaning area, a station of a pure water spray cleaning area, a station for a second air knife water shearing and a station for hot air drying which are connected in turn and arranged on a frame; the stations are electrically connected with a PLC controller; the PLC controller detects and controls input of the belt material from the station of the pre-spray cleaning area; and the belt material is then output after ultrasonic cleaning, spray cleaning, air drying, acid and alkaline cleaning, pure-water cleaning and drying. The system adopts the PLC controller to automatically control and detect the production process without additional auxilians. The system has the function of removing oil and oxide on the surface of the belt material; and the secondary products meet the requirements of electronic-grade product manufacturing. Washing agent is used to carry out internal circle cleaning without discharging, thereby satisfying environment-friendly manufacturing. The system adopts a method combining rinsing and pre-rinsing, so as to reach the goal of water saving and energy saving.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Method for preparing polyolefin microporous membrane with symmetrical upper and lower surface structures

ActiveCN101724170ASymmetrical structureImprove breathabilityFlat articlesDomestic articlesPolyolefinAir knife

The invention provides a method for preparing a polyolefin microporous membrane with symmetrical upper and lower surface structures. The method comprises the following steps of: 1) mixing polyolefin resin with a diluting agent in a weight ratio of 1-6:4-9; 2) extruding the mixture by a neck ring mold in an extrusion flow-casting mode and performing cold rolling and strip casting to obtain a thick sheet; 3) preheating the thick sheet and stretching the preheated thick sheet longitudinally and transversely; 4) shaping the stretched thick sheet; 5) extracting the diluting agent and drying the thick sheet; 6) stretching the thick sheet transversely and shaping the stretched thick sheet; and 7) winding the shaped thick sheet. For the polyolefin microporous membrane prepared by the process steps, the upper and lower two surfaces of the thick sheet are particularly provided with a set of rollers with the same diameter respectively, or one side of an air knife is provided with a set of the rollers on a conventional cold roller and an air knife auxiliary patch device to obtain the thick sheet in an auxiliary cooling mode, and then, the thick sheet is stretched and extracted to finally obtain a product with symmetrical and uniform upper and lower surface microporous structures and good ventilation property. Furthermore, warping deformation phenomenon is prevented.

Owner:SHENZHEN SENIOR TECH MATERIAL

Method and apparatus for coating of substrates

The invention relates to methods and apparatuses that reduce problems encountered during coating of a device, such as a medical device having a cylindrical shape. In an embodiment, the invention includes an apparatus including a bi-directional rotation member. In an embodiment, the invention includes a method with a bi-directional indexing movement. In an embodiment, the invention includes a coating solution supply member having a major axis oriented parallel to a gap between rollers on a coating apparatus. In an embodiment, the invention includes a device retaining member. In an embodiment, the invention includes an air nozzle or an air knife. In an embodiment, the invention includes a method including removing a static charge from a small diameter medical device.

Owner:SURMODICS INC

Method and apparatus for making flexible articles having elastic-like behavior with visually distinct regions

InactiveUS20050178493A1Envelopes/bags making machineryMechanical working/deformationEngineeringAir knife

A method of forming flexible bags from a continuous web is disclosed. The method includes introducing a continuous web of sheet material and passing it through a process whereby the flexible bag is formed having elastic-like behavior. The continuous web is processed into a continuous web having at least two regions that are visually distinct. A sheet material is introduced having one portion of the sheet material overlapping another portion of the sheet material. The sheet material is formed into a strainable network. The strainable network includes a plurality of first regions and a plurality of second regions. The first regions are substantially un-deformed and the second regions are formed into disengageable pleat elements. As the overlapped portions of the sheet material are formed they engage each other at the pleat elements. The pleat elements of each overlapped portion become engaged within each other and resist disengagement because of the frictional forces of the sheet material. The overlapped portions of the sheet material are separated using a disengaging means so that the overlapped portions become disengaged and are separated from each other while riding on the disengaging means. The disengaging means is in the form of either air knife, static opening bar, dynamic opening bar, or suction means, and any combinations thereof.

Owner:BROERING SHAUN THOMAS +2

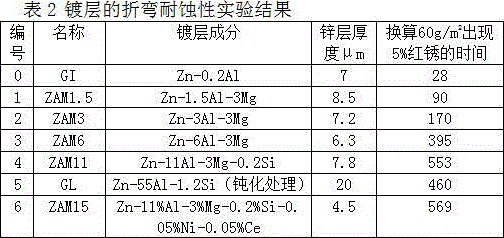

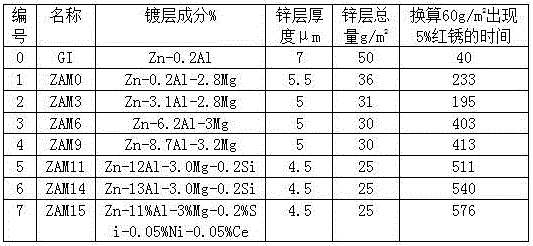

Alloyed zinc aluminum magnesium alloy coated steel plate and production method thereof

ActiveCN103507324AImprove corrosion resistanceGood formabilityHot-dipping/immersion processesMetal layered productsRare earthAir knife

The invention provides an alloyed zinc aluminum magnesium alloy coated steel plate and a production method thereof. The coating has an Fe content of not more than 5%, the coating surface contains an MgZn2 phase, which has a particle size of not greater than 5 micrometers. The coating surface is in the form of equiaxed grains, and in the coating, Mg accounts for 1.5-8wt%, aluminum accounts for 1.5-15wt%, and rare earth accounts for 0-0.2wt%. According to the production method, cold rolled strip steel is subjected to continuous annealing and hot dipping in a continuous hot dip galvanizing unit, and then alloy treatment is carried out on the hot-dip galvanized zinc aluminum magnesium steel plate. Chemically, a plating solution comprises 1.0-11wt% of Al, 0.5-5wt% of Mg, and the balance Zn and inevitable impurities. After the steel plate undergoes annealing by N2 containing 0.5%-30 vol % of H2, the steel plate is immersed in the plating solution at a temperature of 450-650DEG C, the steel plate enters a zinc pot at 420-580DEG C, and the immersion plating time of the steel plate in the plating solution is 1-10s. After air knife cooling, the zinc aluminum magnesium steel plate enters an alloying furnace to undergo alloying treatment, the alloying temperature is 450-650DEG C, the alloying time is 3-20s, and then the steel plate is cooled at a speed of 10-50DEG C / s. The steel plate provided by the invention ensures that the coating does not fall off in a complex forming process, and after forming, the zinc aluminum magnesium coating can put its excellent corrosion resistance to good use, thus prolonging the service life of components.

Owner:ANGANG STEEL CO LTD

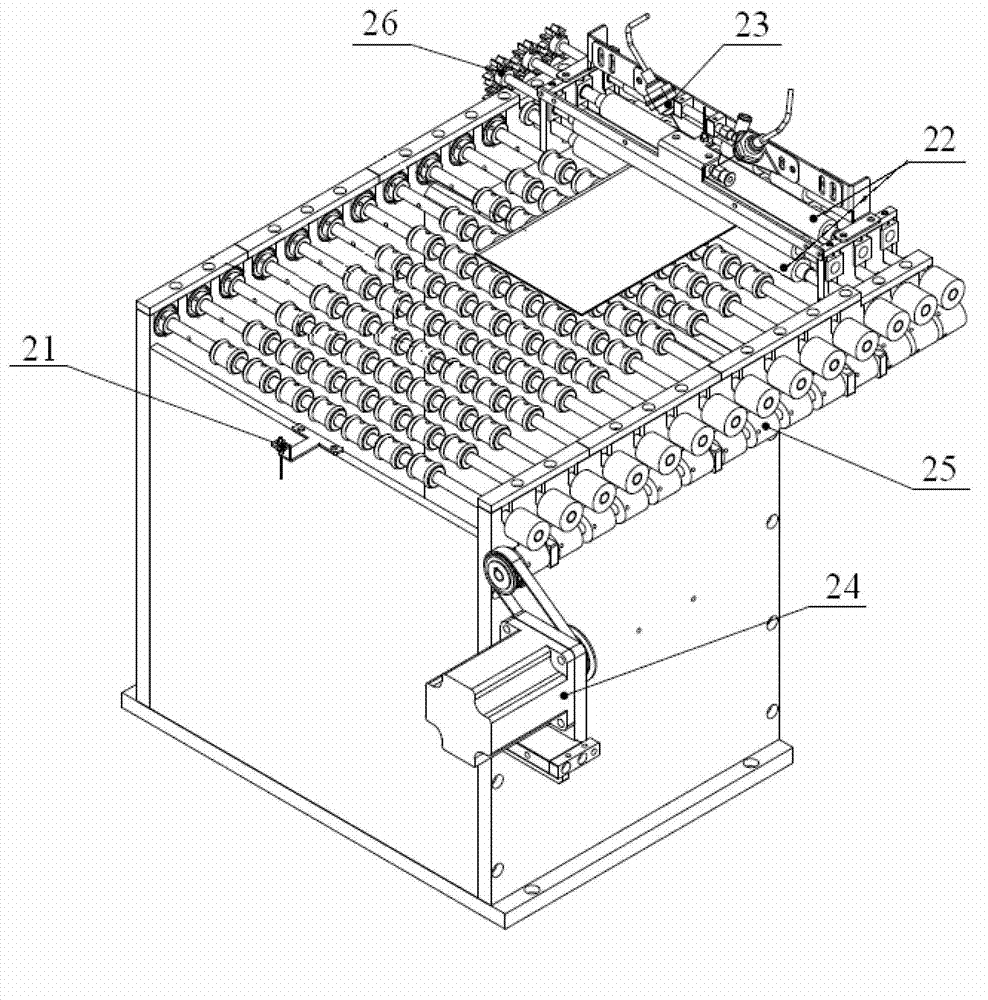

Glass cleaning device

ActiveCN103084366AAvoid secondary pollutionImprove work efficiencyFlexible article cleaningAir knifeWater spray

The invention discloses a glass cleaning device which comprise a material loading unit, a buffer unit, a grinding unit, a cleaning unit, an air-drying unit, and a feeding unit, wherein the material loading unit is provided with a first alignment device which is used for conducting alignment for the glass, the grinding unit is provided with a grinding belt which is capable of grinding and cleaning the surface of the glass, the cleaning unit is provided with a pure water spraying device which is capable of washing the glass, the air-dry unit is provided with an air knife device which is capable of drying the glass through compressed air in a blowing mode, and the feed unit is used for conveying the glass to a specified position and is provided with a second alignment device which is used for conducting the alignment for the glass. In addition, the material loading unit, the buffer unit, the grinding unit, the cleaning unit, the air-drying unit, and the feeding unit are connected in sequence and are all provided with a plurality of transfer rollers used for conveying the glass, and the transfer rollers are arranged in parallel. The glass cleaning device is capable of automatically completing the whole glass cleaning process, the work efficiency is increased, and labor cost is reduced.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

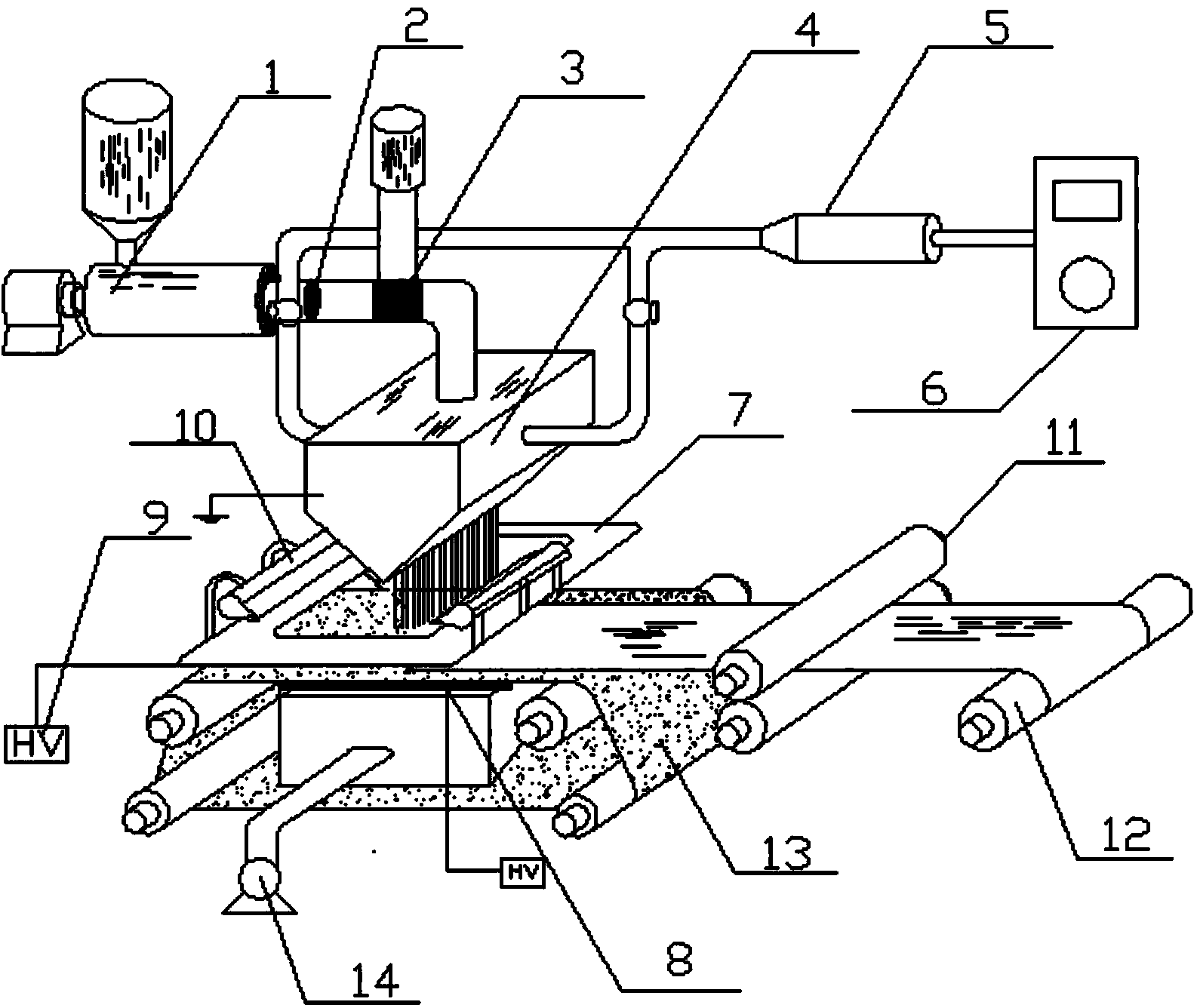

Differential melt electro-blowing spinning device and technology for preparing nanofibers in batches

ActiveCN103451754ARealize industrial productionRealize batch preparationFilament/thread formingNon-woven fabricsFiberSpinning

The invention discloses a differential melt electro-blowing spinning device and technology for preparing nanofibers in batches, and belongs to the field of electrostatic spinning. The device mainly comprises an extruder, a filter screen, a melt metering pump, a spinning manifold, an airflow heating device, an air compressor, an upper plate electrode, a lower plate electrode, a high-voltage electrostatic generator, a guide air knife, a hot rolling device, a receiving device, a screen spreading belt and an air draft system. An outlet of the extruder is connected with the filter screen, and the melt metering pump is connected between the filter screen and the spinning manifold through a flange. Airflow is divided into two portions through a flow divider to be connected to the spinning manifold; after melt is divided and guided in flow through the spinning manifold, a thin uniform-flowing melt layer is obtained at the lower end of a wavy flow guide plate; under the high-voltage electrostatic action, the melt layer forms a plurality of Taylor cones in a self-organization manner, the Taylor cones are stretched and split continuously under the conditions of high-speed airflow and high-voltage electrostatics, and superfine fibers are formed at the receiving end of the screen spreading belt by means of curing. By the aid of the device and technology, difficulties of high viscosity of polymers, low yield, complicated devices and the like are overcome, and industrial production of differential melt electro-blowing spinning can be achieved.

Owner:BEIJING UNIV OF CHEM TECH

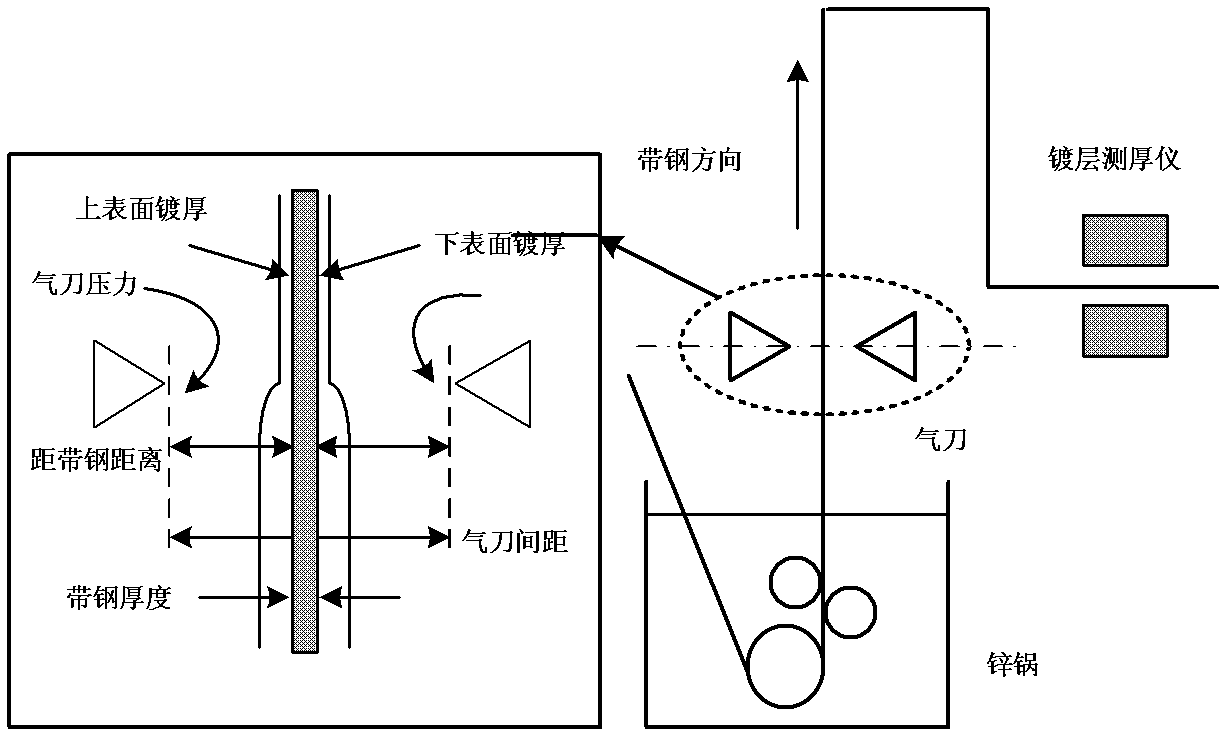

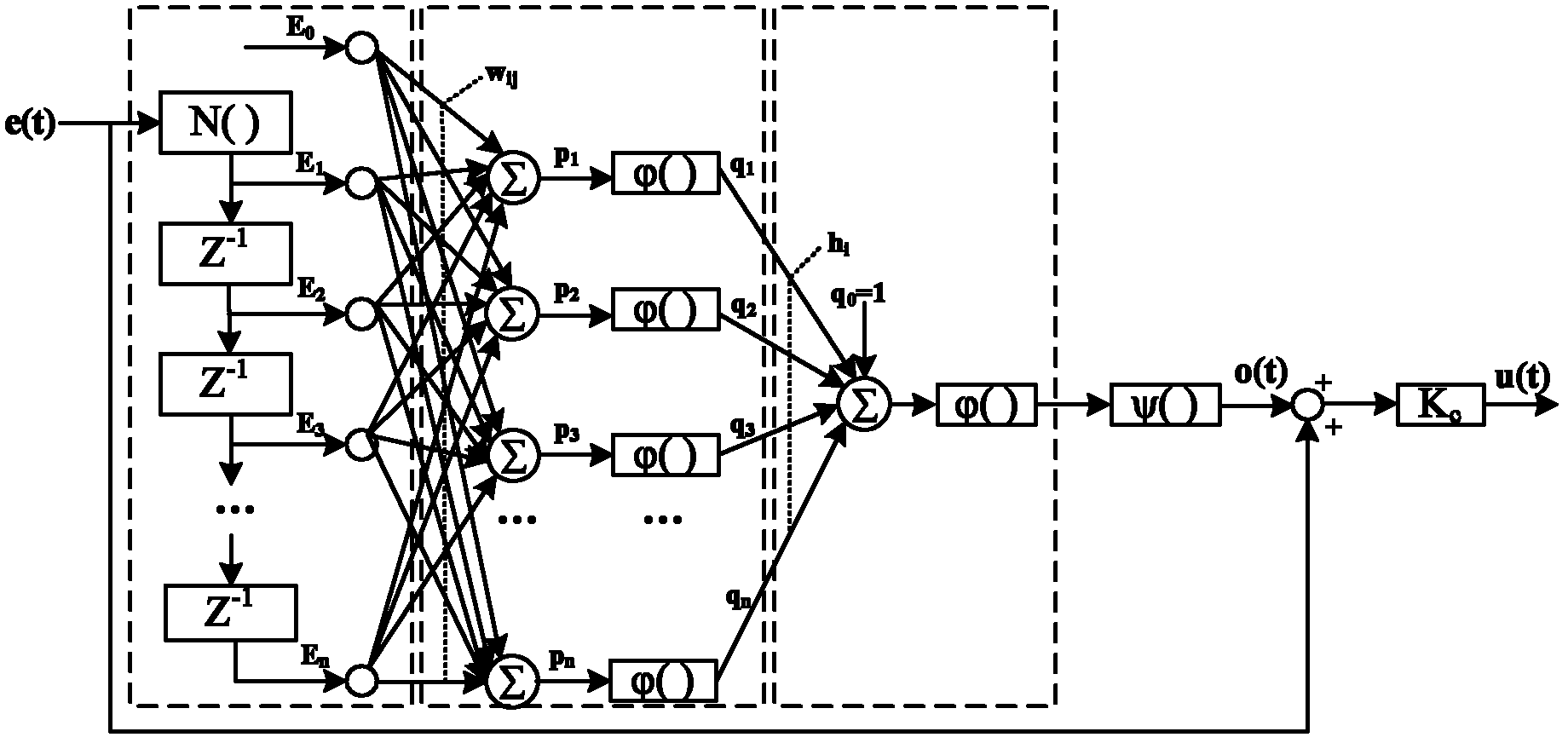

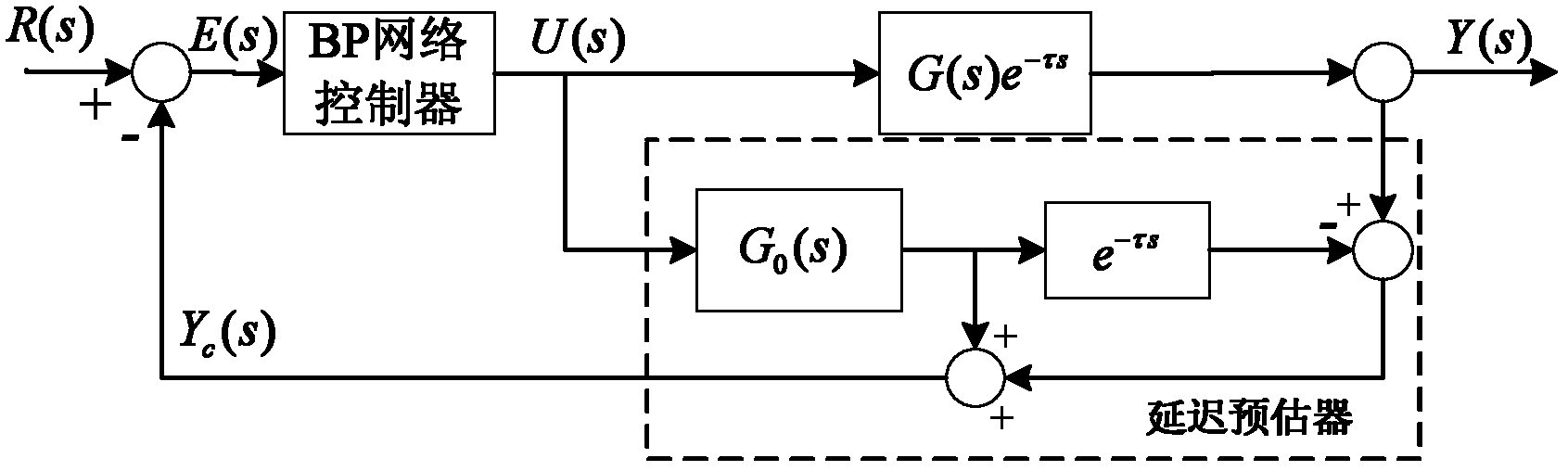

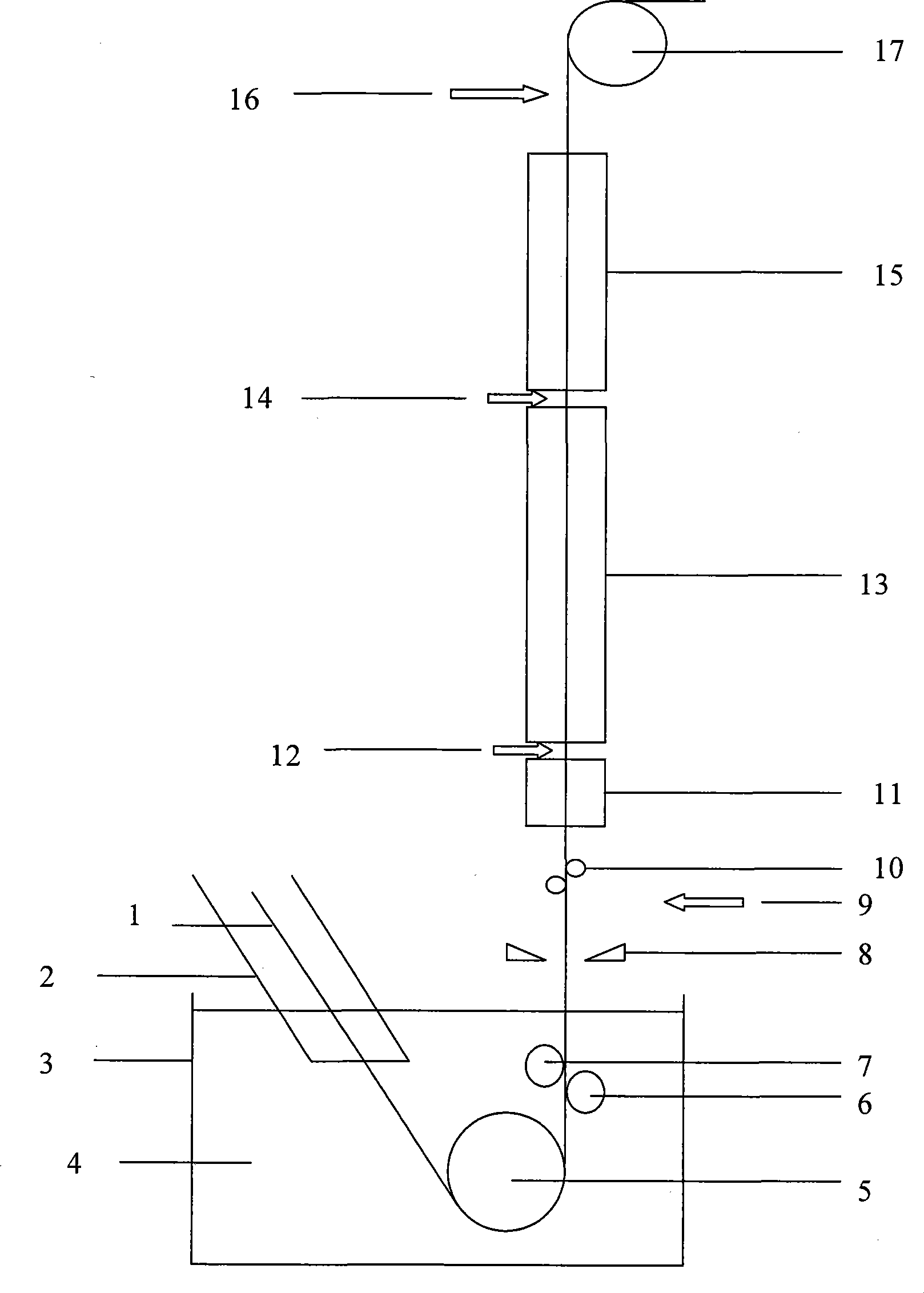

An automatic control method for zinc layer thickness in a continuous hot galvanizing zinc line

ActiveCN103205665AReduce excessive consumptionImprove surface qualityHot-dipping/immersion processesAutomatic controlClosed loop

The invention provides an automatic control method for zinc layer thickness in a continuous hot galvanizing zinc line. According to the method, a self-adaptive controller of a BP neural network structure and a delay estimation strategy are adopted to realize closed-loop precise control of a plating layer; a sampling thickness deviation of the plating layer is adopted as inputs of a self-adaptive control model of the BP neural network structure; and finally reasonable outputs are generated through data treatment of two groups of weighting factors [Delta]wij(n) and [Delta]hj(n) in the self-adaptive control model, so that air-knife pressure can be adjusted in time; and finally, the deviation between a preset value of the thickness of the plating layer and an actual sampling value becomes smaller and smaller. A learning algorithm of the weighting factors refreshes the weighting factors continuously by the smallest deviation between the preset value of the thickness of the plating layer and a measured value as a principle, and finally the results of self-adaptive adjustment of the two groups of the weighting factors make deviation between the preset value of the thickness of the plating layer and the actual sampling value tend to zero. The method can greatly reduce excessive consumption of zinc, improves surface quality of the hot galvanizing zinc plating layer, and increases added value of products.

Owner:ANGANG STEEL CO LTD

Method for controlling coating alloying homogeneity

InactiveCN101376961AImprove stabilityGuaranteed uniformityHot-dipping/immersion processesFurnace typesStrip steelAir knife

The invention provides a method for controlling the evenness of cladding alloying, which comprises the following steps: at least a set of strip steel stabilizing device is arranged between an air knife and a top roller and air knife parameters are adjusted, to improve the evenness of the strip steel cladding thickness; the strip steel temperature evenly enters into an alloying heating furnace, evenly heats and / or cools, to improve the evenness of cladding alloying. The method ensures the evenness of the strip steel surface cladding thickness by improving the stability of the strip steel at the air knife; meanwhile, improves the evenness of the strip steel temperature along the width of the strip steel before alloying heating, during the alloying heat evenness process and in the alloying cooling process, so as to evenly alloy the strip steel cladding. An alloyed hot-dip galvanized steel sheet manufactured by the method can ensure the evenness of cladding alloying, and is in particular applicable to automobile internal and external plates as well as household electric appliance external plates.

Owner:BAOSHAN IRON & STEEL CO LTD

Coal conveying belt sweeping and drying device

The invention discloses a coal conveying belt sweeping and drying device comprising a belt support, a belt, a transmission roller and a frame body. The frame body is arranged below the belt support, the belt is wound around the transmission roller, and the frame body is internally provided with a large particle scraping device, a high-pressure washing device, a small particle scraping device, a cleaning rolling brush and a drying device body in sequence from the input direction to the output direction of the belt; and a solid-liquid separating tank is formed in the lower portion of the frame body. According to the coal conveying belt sweeping and drying device, the scraping devices, the high-pressure washing device and the cleaning rolling brush are arranged in a combined mode, the clearing efficiency reaches up to 99.9%, the output end of the belt is provided with the high-efficiency drying device body, heated air is blown out through an air knife, the drying efficiency is extremely high, and residual dust on the belt can further be removed while drying, so that the double benefits are achieved.

Owner:扬州益洋科技发展有限公司

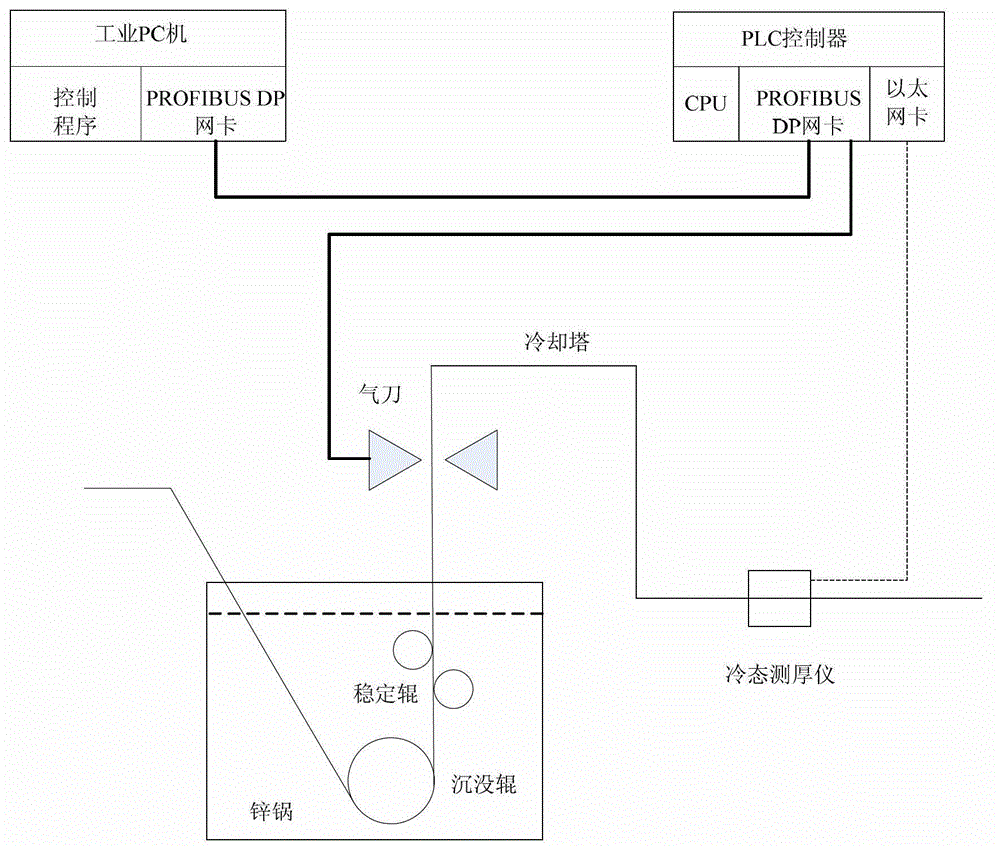

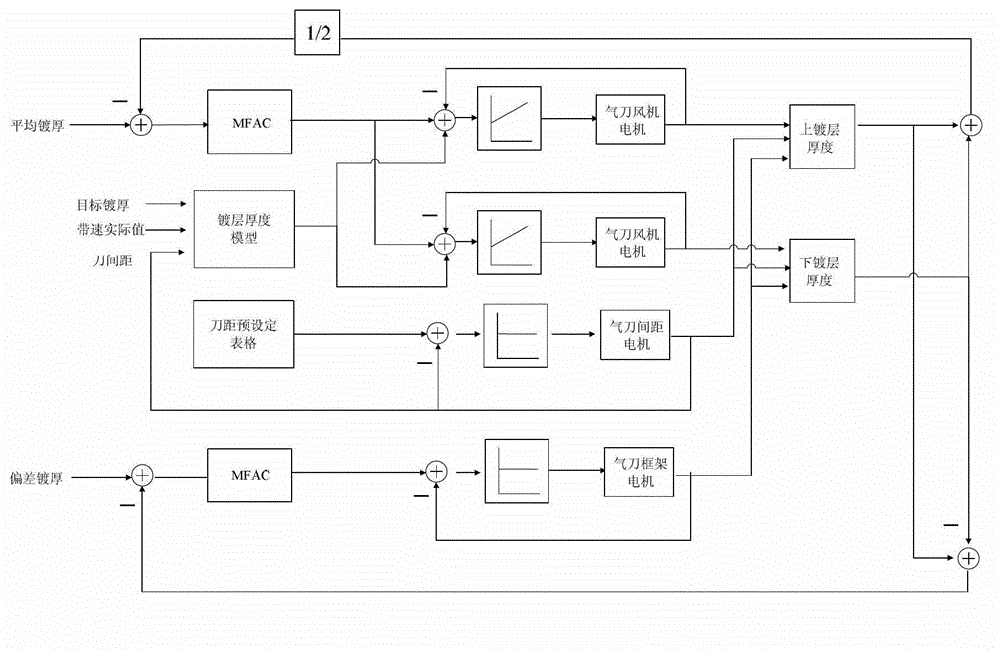

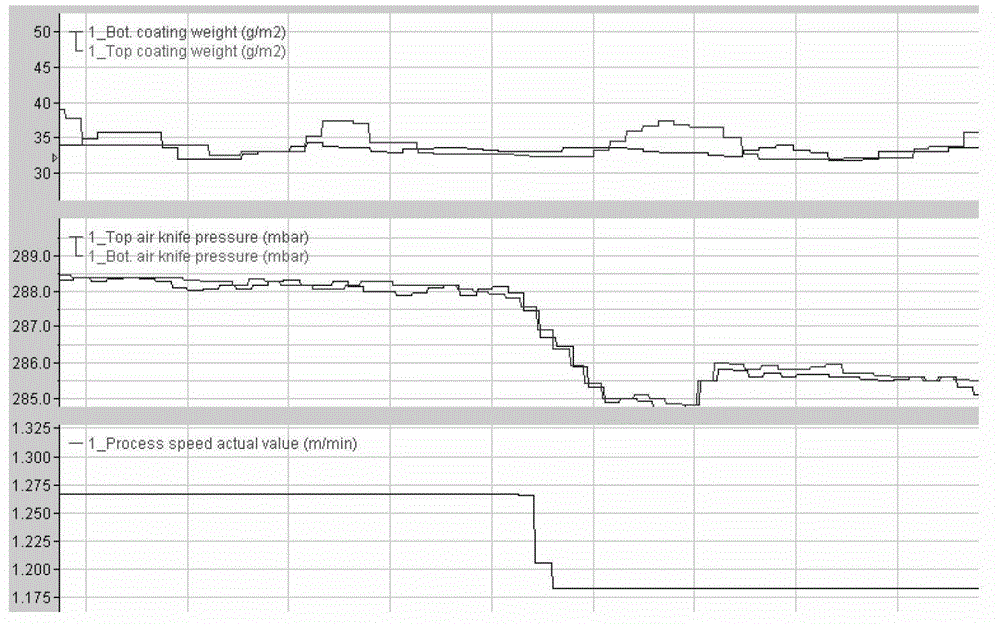

Automatic control system for plating thickness of hot galvanizing line

ActiveCN102912275AEliminate thickness errorsEliminate thickness deviationHot-dipping/immersion processesAutomatic controlAutomatic train control

The invention provides an automatic control system for plating thickness of cold rolling hot galvanizing line, which comprises an air knife, a thickness gauge, an industrial PC (Personal Computer), a PLC (Programmable logic Controller) and a plating thickness control program, wherein the control program is run in the industrial PC; the industrial PC and the PLC controller are connected by using a PROFIBUS (Process Field Bus) DP field bus; the PLC controller acquires the actual value of plating thickness and data in production process and sends into the industrial PC; the control program adopts cascade control method; a minor loop is designed into a servo system by utilizing the advantages of conventional PID (Proportion Integration Differentiation) dense sampling; the sampling period of a major loop is 50-100 times of that of the minor loop; the control program calculates the setting values of air knife pressure, distance and frame position in real time according to the actual value of plating thickness and the data in production process and sends into the PLC controller so as to realize the adjustments of the air knife pressure, distance and frame position; and simultaneously, the controls for undisturbed switching and plating variable specification switching in manual / automatic mode are further designed. According to the automatic control system, the deviation of plating thickness can be quickly eliminated, and the system has good control effect on variable specification in the processes of accelerating and decelerating.

Owner:ANGANG STEEL CO LTD

Hot-dip zinc aluminum magnesium silicon rare earth coated steel strips taking air as air source of air knife during production

InactiveCN101812653AEvenly distributedUniform tissue structureHot-dipping/immersion processesCeriumAir knife

The invention relates to hot-dip zinc aluminum magnesium silicon rare earth coated steel strips taking air as an air source of an air knife during production. The coating material on the surface of the steel strips comprises the following components in percentage by weight: 9.9 to 12.1 percent of Al, 1.0 to 1.8 percent of Mg, 0.18 to 0.22 percent of Si, 0.01 to 0.3 percent of rare earth (RE), and the balance of Zn. Based on a quaternary component Zn-Al-Mg-Si in Nippon Steel, the rare earth (RE) comprising lanthanum and cerium is added into the coating material so as to become a quintuple component Zn-Al-Mg-Si-RE, and the content of the magnesium is reduced. Because of the addition of the trace RE, the component distribution of the coating can become more uniform, the organizational structure is more uniform, and the corrosion resistance is further improved based on the original corrosion resistance; and because the content of the magnesium is reduced properly, the coating can bear the blowing of the air knife and cannot be oxidized and discolored on the premise of ensuring high corrosion resistance, and meets the requirements of the corrosion resistance and apparent mass.

Owner:梁士臣

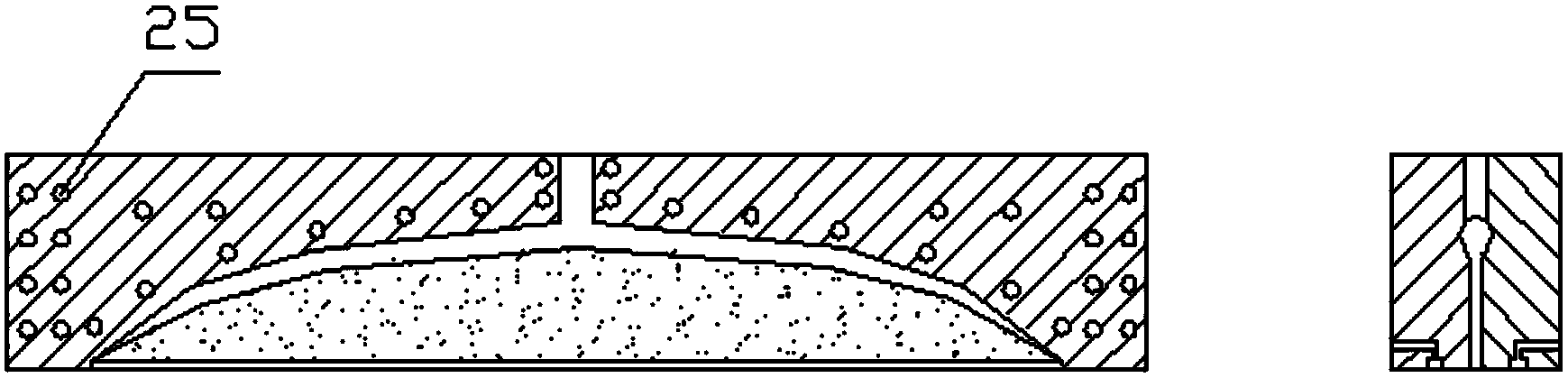

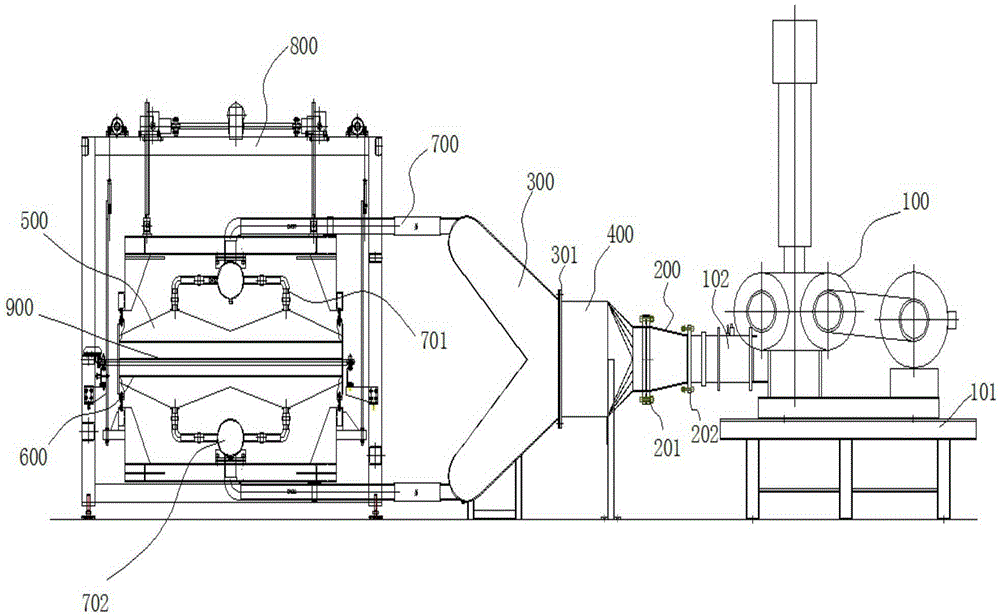

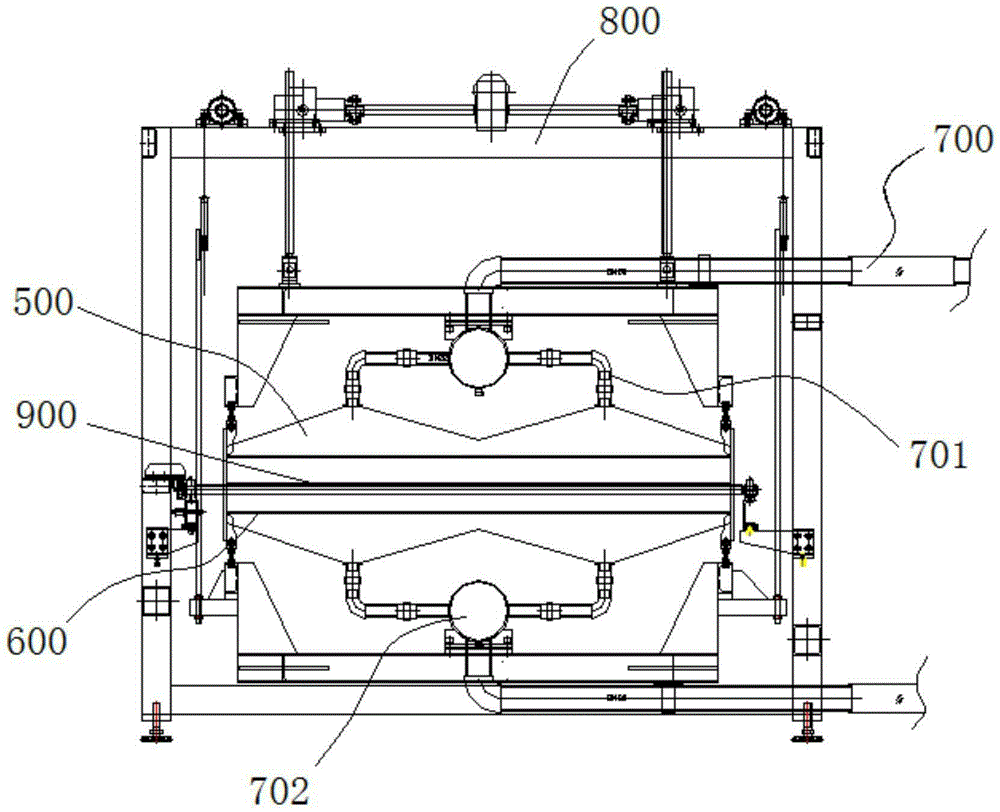

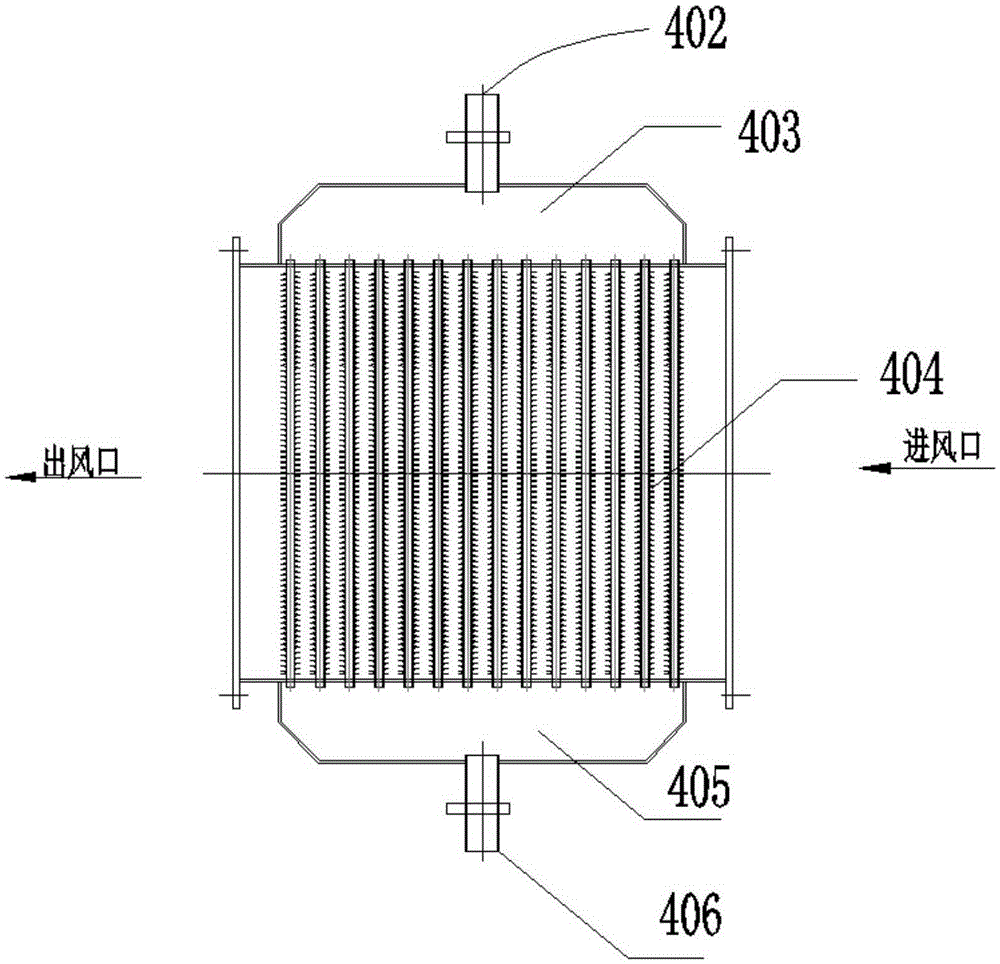

Cooling system for tempered glass and cooling method thereof

The invention discloses a cooling system used for tempered glass and a cooling method thereof. The cooling system comprises a Roots blower for producing cooing airflow, an air shunting bellows for shunting of cooling airflow and a glass cooling mechanism. An air cooling device for cooling the cooling airflow is arranged between the Roots blower and the air shunting bellows. The glass cooling mechanism comprises a rollgang for conveying glass and a cooling assembly. The cooling assembly comprises a cooling air-knife and a wind grating. The Roots blower is adopted as a gas source. A cooled gas source can cool the gas source temperature by 15-20 DEG C. the cooling system can completely meet tempering requirements. Costs are saved, noise is reduced, and energy is saved by 50% and above in comparison with a system of using a traditional centrifugal high pressure fan or an air compressor as a gas source.

Owner:ZHEJIANG HANNENG TECH CO LTD

Automatic cleaning method and device for aluminium alloy composite boards

InactiveCN101966524AImprove efficiencyLess investmentDrying using combination processesCleaning using liquidsMegasonic cleaningEconomic benefits

The invention relates to an automatic cleaning method and a device for aluminium alloy composite boards. The method comprises the following steps: putting composite boards on a feeding platform; and orderly transporting the composite boards to an ultrasonic cleaning region, a spraying and rinsing region and an airing and drying region by using a transport mechanism, wherein after the composite boards are transported to the ultrasonic washing region, an ultrasonic cleaning mechanism carries out ultrasonic washing on two sides of each composite board to remove pollutants and part of oxides on the board surface, and a spraying and rinsing mechanism is arranged at the back end of the ultrasonic washing region and used for removing the cleaning solution and impurities, thereby preventing the cleaning solution from being taken into the drying region. The device comprises the ultrasonic cleaning mechanism, the spraying and rinsing mechanism, an air knife dewatering mechanism and a hot air drying mechanism, wherein the transport mechanism is arranged among the ultrasonic cleaning mechanism, the spraying and rinsing mechanism, the air knife dewatering mechanism and the hot air drying mechanism to connect the mechanisms; and the transport mechanism is provided with the feeding platform on which composite boards are put. Compared with the traditional cleaning method, the invention saves the fixed investment by about **yuan, enhances the efficiency by more than 80%, and has high economic benefit.

Owner:HANGZHOU HANGYANG

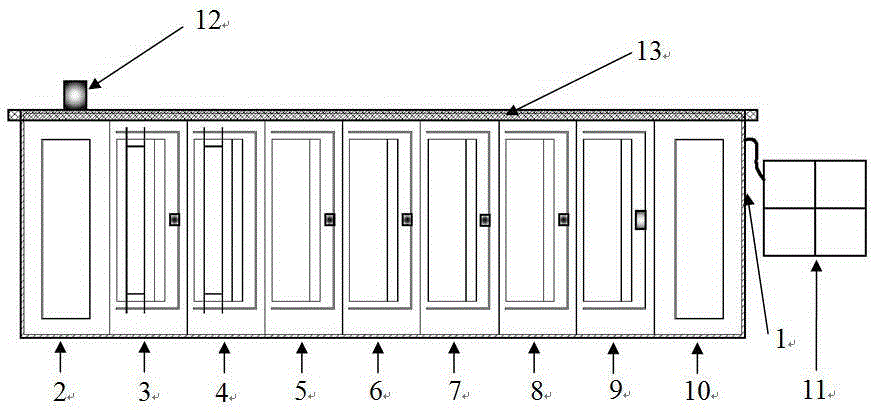

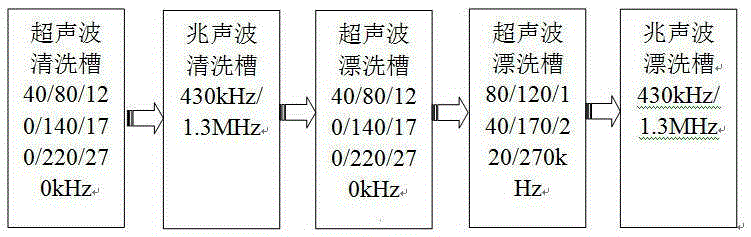

Fully-automatic optical element cleaning device with ultrasonic-megasonic composite frequency

InactiveCN105195465AInhibition retentionMeet cleaning and removal needsFlexible article cleaningCleaning using liquidsMicron scaleFiltration

The invention discloses a fully-automatic optical element cleaning device with an ultrasonic-megasonic composite frequency. The ultrasonic-megasonic composite frequency covers low / intermediate / high ultrasonic frequencies and low / intermediate / high megasonic frequencies. Particularly, an appropriate program and process parameters are selected to aim at super-clean washing requirements for an optical element, and pollutants from a micron scale to a nanometer scale on the surface of the optical element can be effectively removed. The fully-automatic optical element cleaning device with the ultrasonic-megasonic composite frequency has the main characteristics that an ultrasonic solution soaking cleaning tank, a megasonic cleaning tank and a spraying tank are designed; different frequency ultrasonic and megasonic waves are adopted, and cleaning requirements from a micron size to a nanometer size are covered; a workpiece is driven by a cylinder to reciprocate up and down in a tank body, a wave node of a standing wave field is prevented from being generated in a fixed area of the surface of the workpiece by virtue of a frequency sweeping function of an ultrasonic-megasonic generator, and the surface damage is avoided; the tank body adopts overflow cycle heating filtration; the total length of an overflow front edge is increased by using a trapezoidal saw-tooth type overflow edge design to obtain uniform and stable overflow; an inclined workpiece clamping device cooperates with an air knife and a slow lifting mechanism to dry the workpiece.

Owner:TONGJI UNIV +1

Method for Removing Deposit from Substrate and Method for Drying Substrate, as Well as Apparatus for Removing Deposit from Substrate and Apparatus for Drying Substrate Using These Methods

InactiveUS20070281094A1Easy to disassembleStable maintenanceMechanical cleaningPressure cleaningEngineeringAir knife

In a method for removing deposit that has attached to a main surface of a substrate from the main surface of the substrate using air knife units where a slit portion is formed so that a fluid can be discharged in band form, a fluid introduction path having an approximately uniform form in the direction perpendicular to the direction in which a number of air knife units move relative to the substrate is formed between the air knife units and the main surface of the substrate while the air knife units move relative to the substrate, a fluid is discharged toward the fluid introduction path from a slit that is formed in the rear portion of the above described air knife units, and then, passes through the fluid introduction path so as to be led to a wall surface that is formed so as to face the front portion of the air knife units or the fluid which has the appearance of a wall surface, and furthermore, deposit on the substrate that has attached to the substrate is led away from the main surface of the substrate, together with said fluid, via a fluid lead-out path of which the cross sectional area of the low path is greater than that of the fluid introduction path, and which is formed between the air knife units and the wall surface.

Owner:MITSUBOSHI DIAMOND IND CO LTD

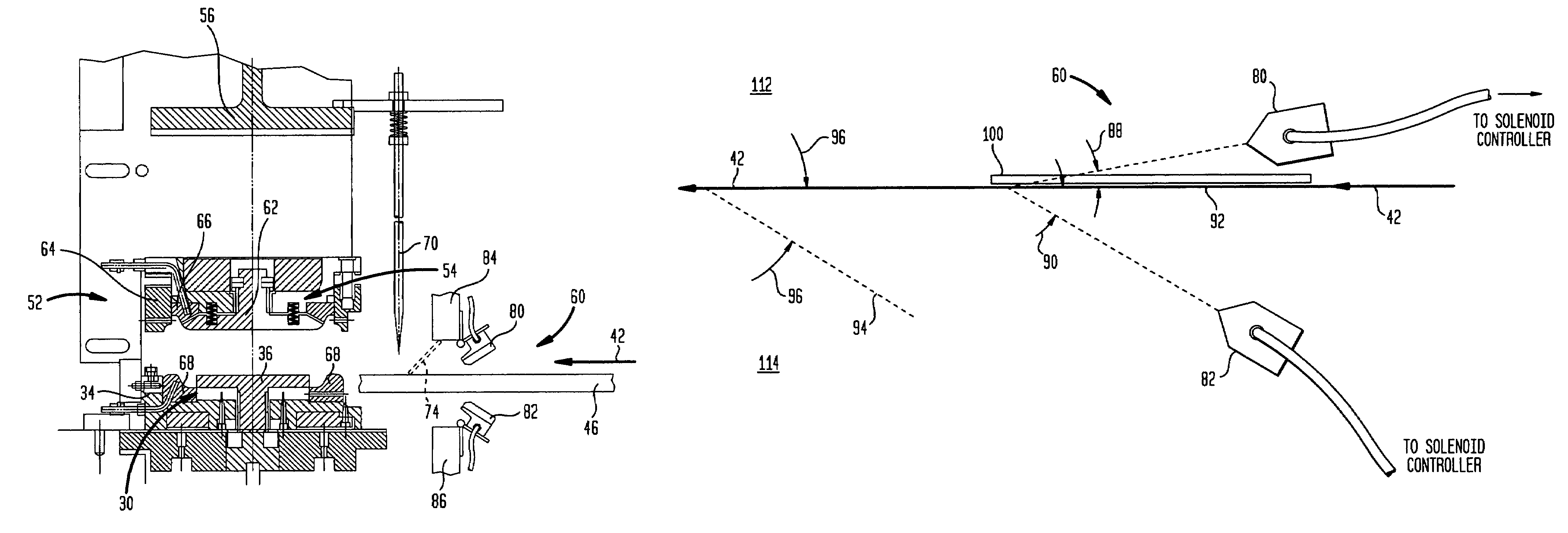

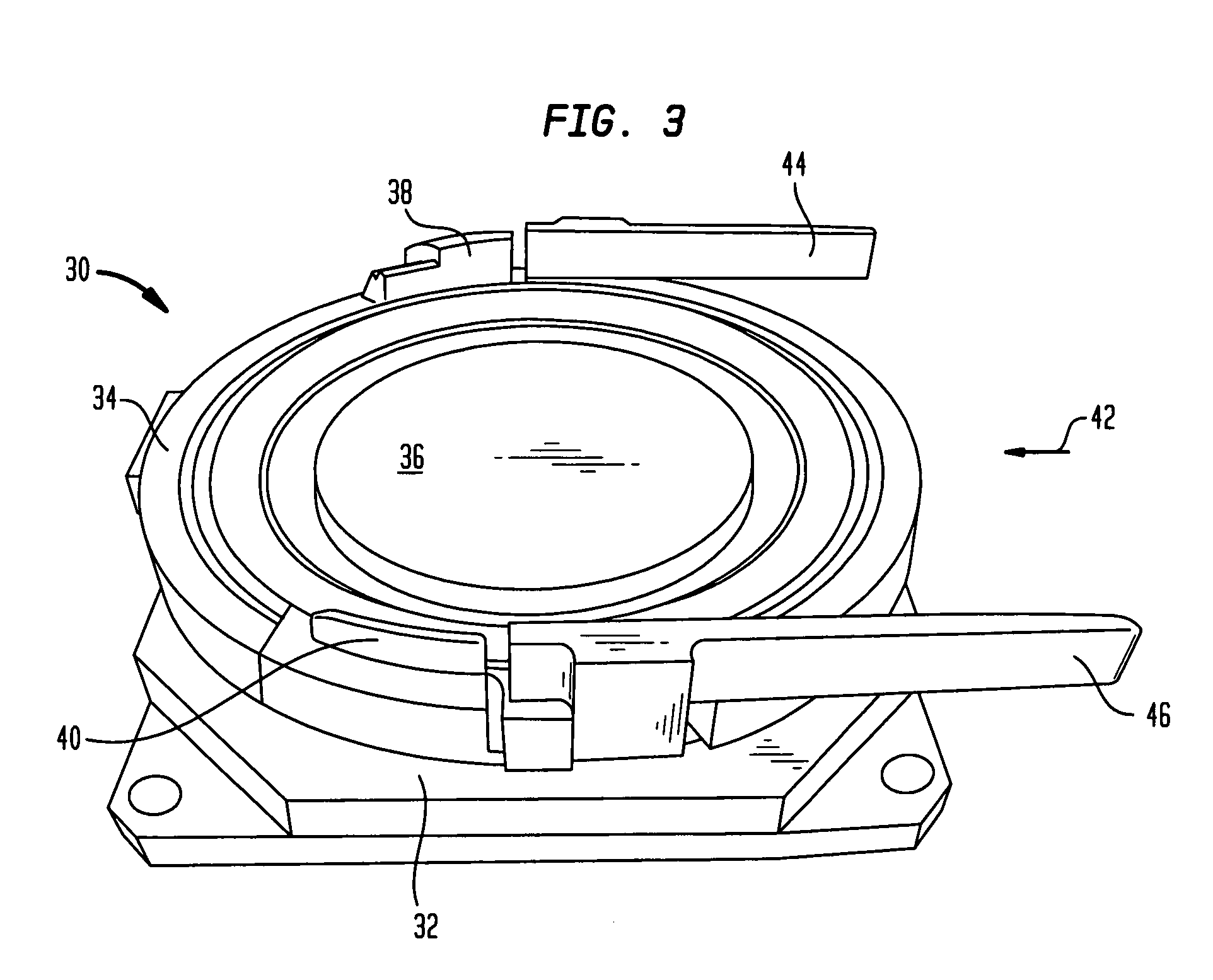

Pressware die set with pneumatic blank feed

An improved apparatus for making disposable pressware features a pneumatic feeding system which accelerates a paperboard blank into a forming die. In a typical embodiment, a pair of adjustable air knives propel a paperboard blank into the forming cavity.

Owner:GPCP IP HLDG LLC

High-corrosion-resistance hot galvanizing aluminum-magnesium-nickel rare earth alloy coated steel plate and production method thereof

InactiveCN106222593AImprove organizationGood adhesionHot-dipping/immersion processesRare-earth elementElectrolysis

The invention relates to a high-corrosion-resistance hot galvanizing aluminum-magnesium-nickel rare earth alloy coated steel plate and a production technology of the steel plate. According to the steel plate, a base plate is made of low-carbon steel, alloy components of a coating include 5-25% of Al, 1-5% of Mg, 0.1-0.3% of Si, 0.01-0.1% of Ni, 0.01-0.1 of Ce and Zn. The production technology includes the steps of conducting cold rolling on a raw material plate, conducting electrolysis and degreasing, heating a vertical annealing furnace through full-radiation tubes for annealing, conducting plating on an inductive heating type zinc pot, using a pure nitrogen air knife, conducting cooling after plating, conducting finishing and tension leveling, conducting passivation, conducting drying, conducting electrostatic oiling, and conducting inspection, packaging and storage. Magnesium nickel enrichment is formed on the surface of the coating, surface oxidation resistance of the coating of the steel plate is effectively improved, and accordingly blackening resistance and corrosion resistance of the coating of the steel plate are improved. A trace amount of rare earth elements are added in the coating to be matched with a proper amount of Al and Zn, the structure of the coating is refined, and adhesiveness, welding performance and machinability of the coating are improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com