Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1594 results about "Flow divider" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

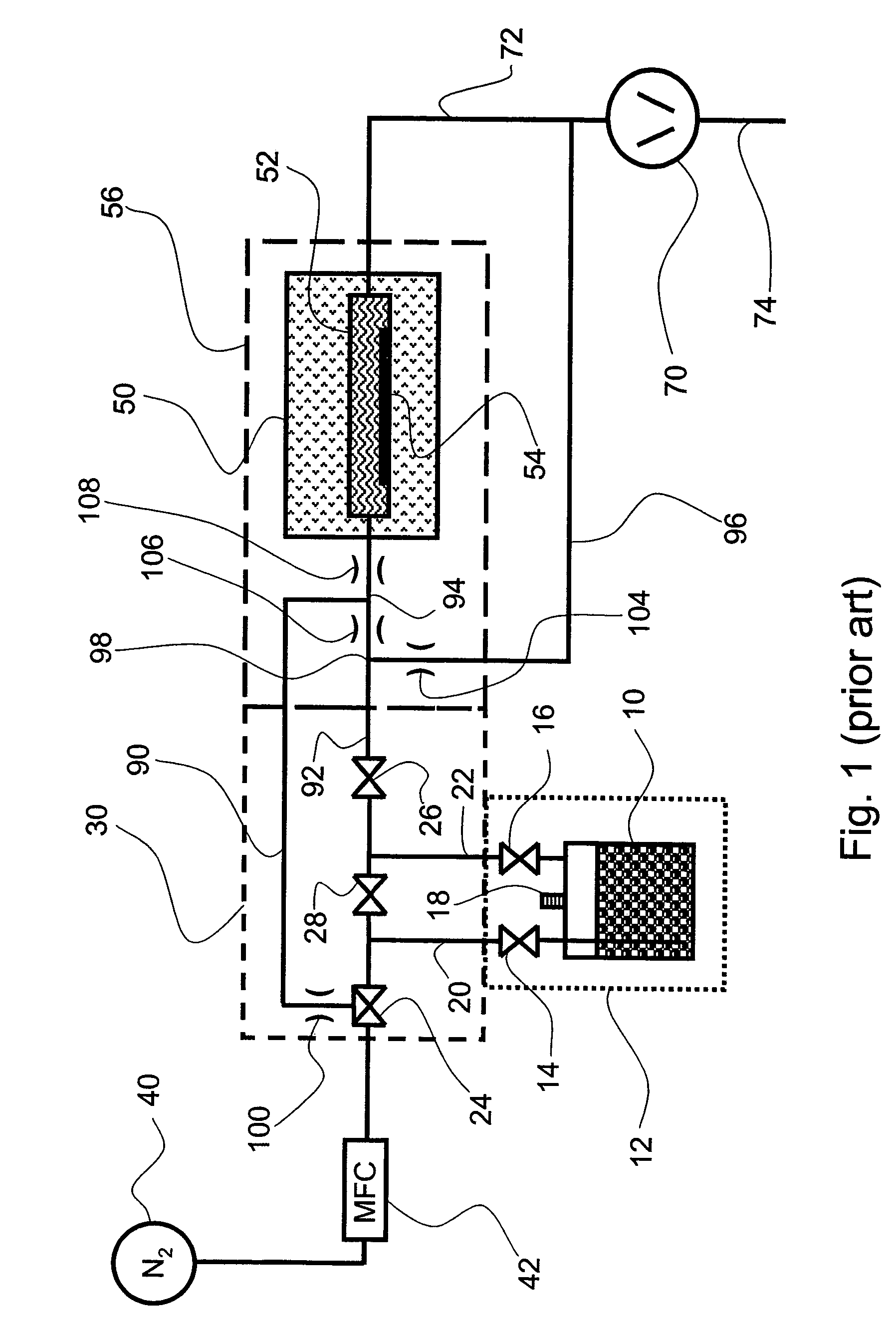

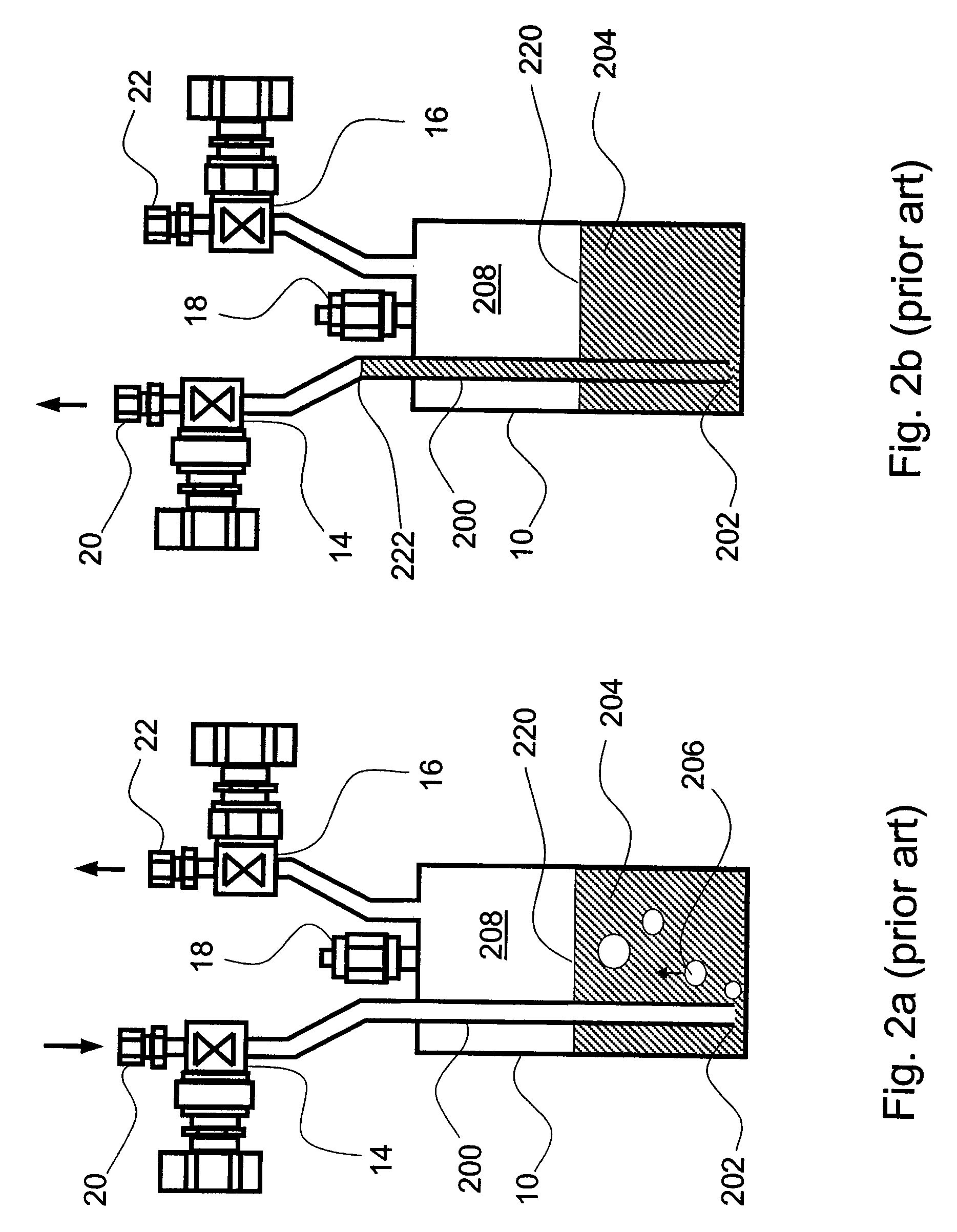

Safe liquid source containers

ActiveUS20050066893A1Excessive pressure increaseEncouraging capillary migrationCarburetting airMixing methodsPorous membraneEngineering

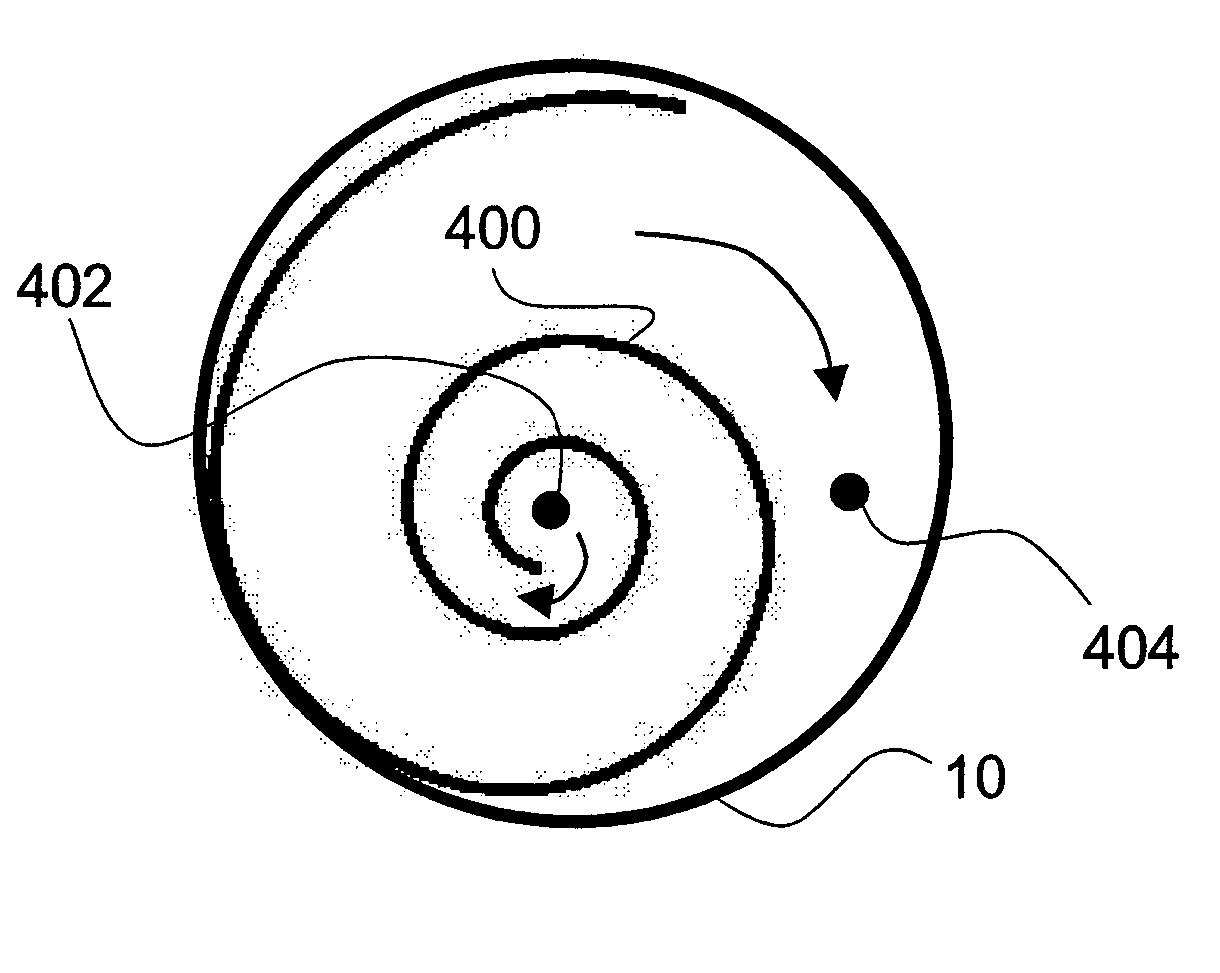

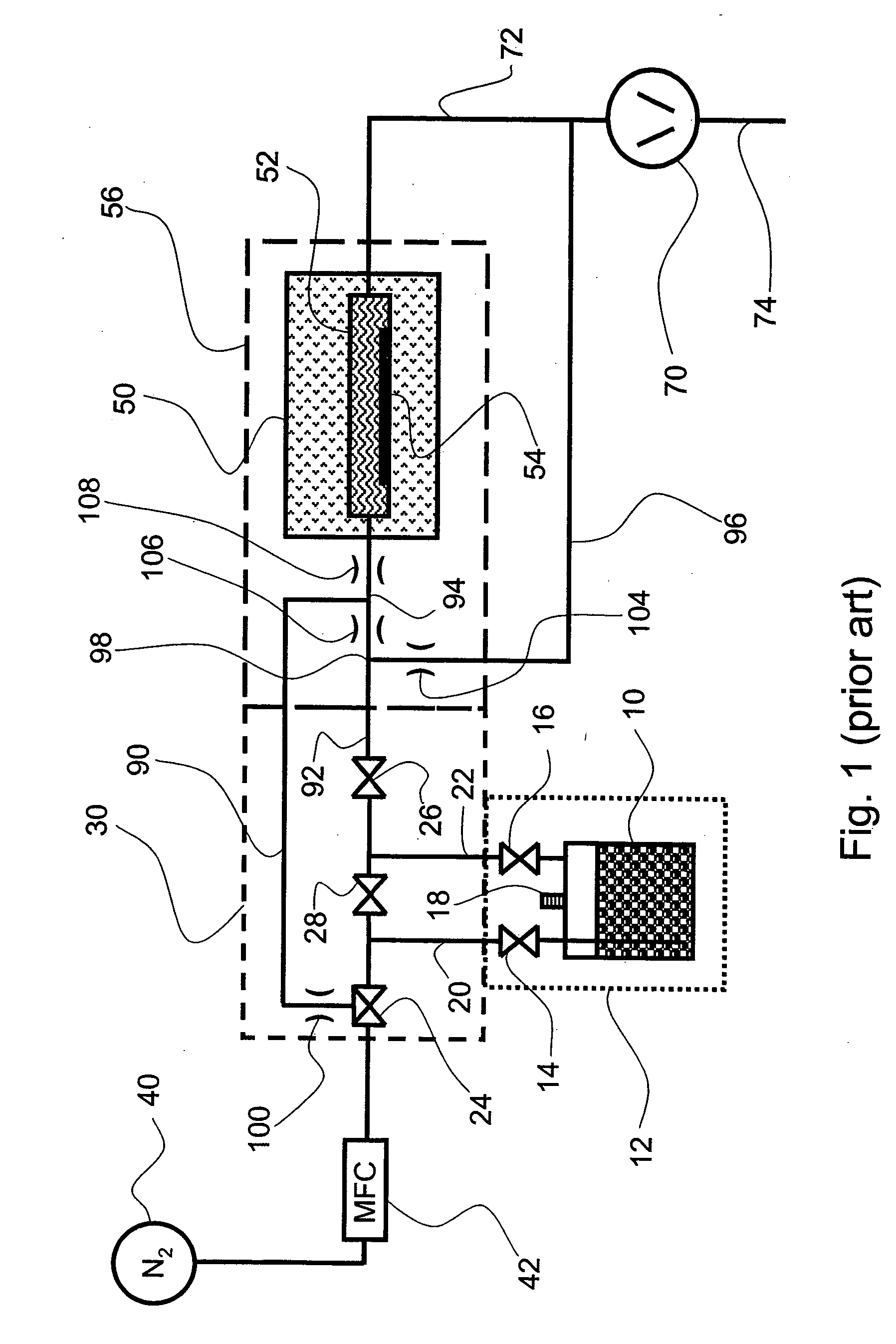

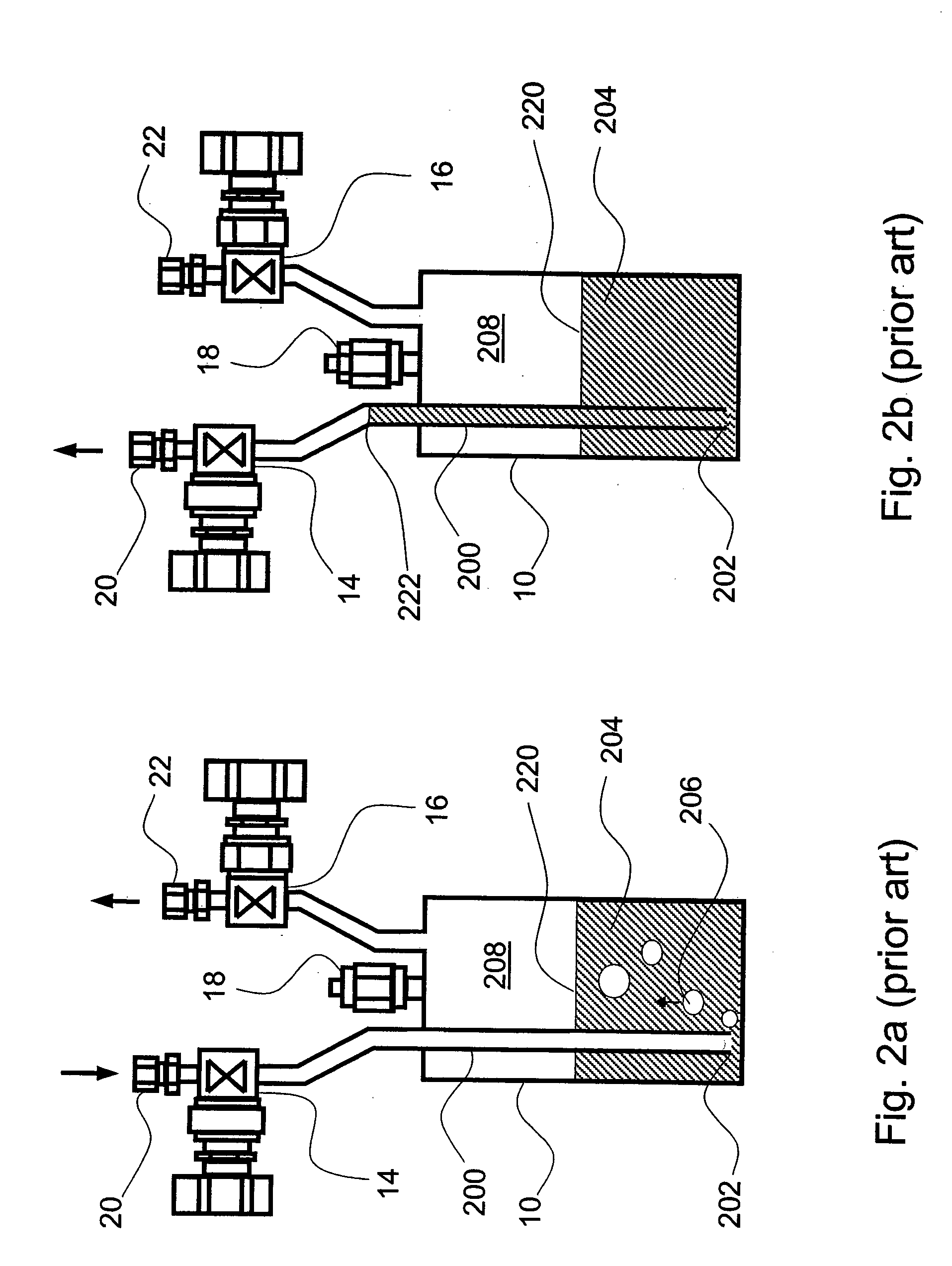

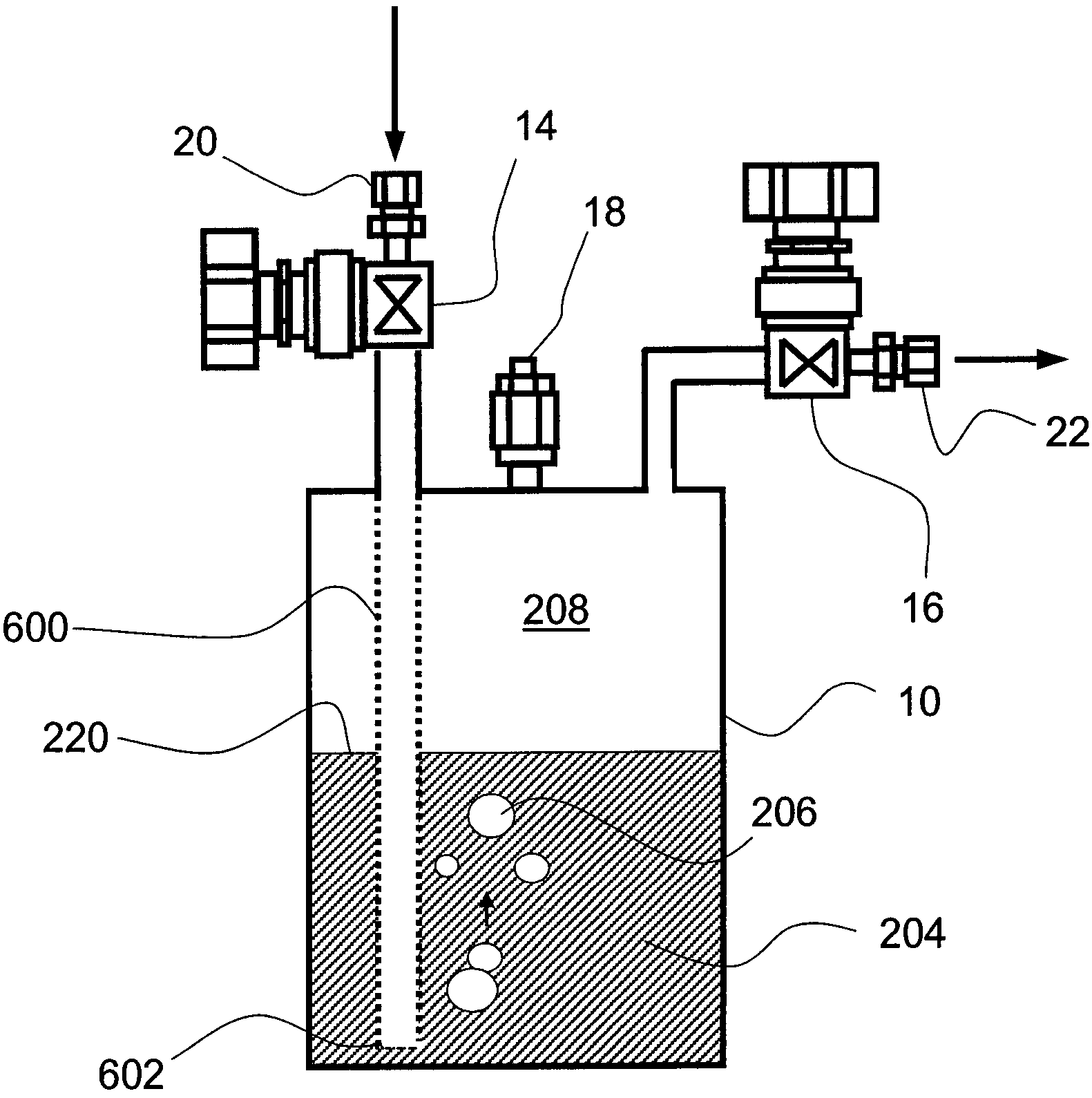

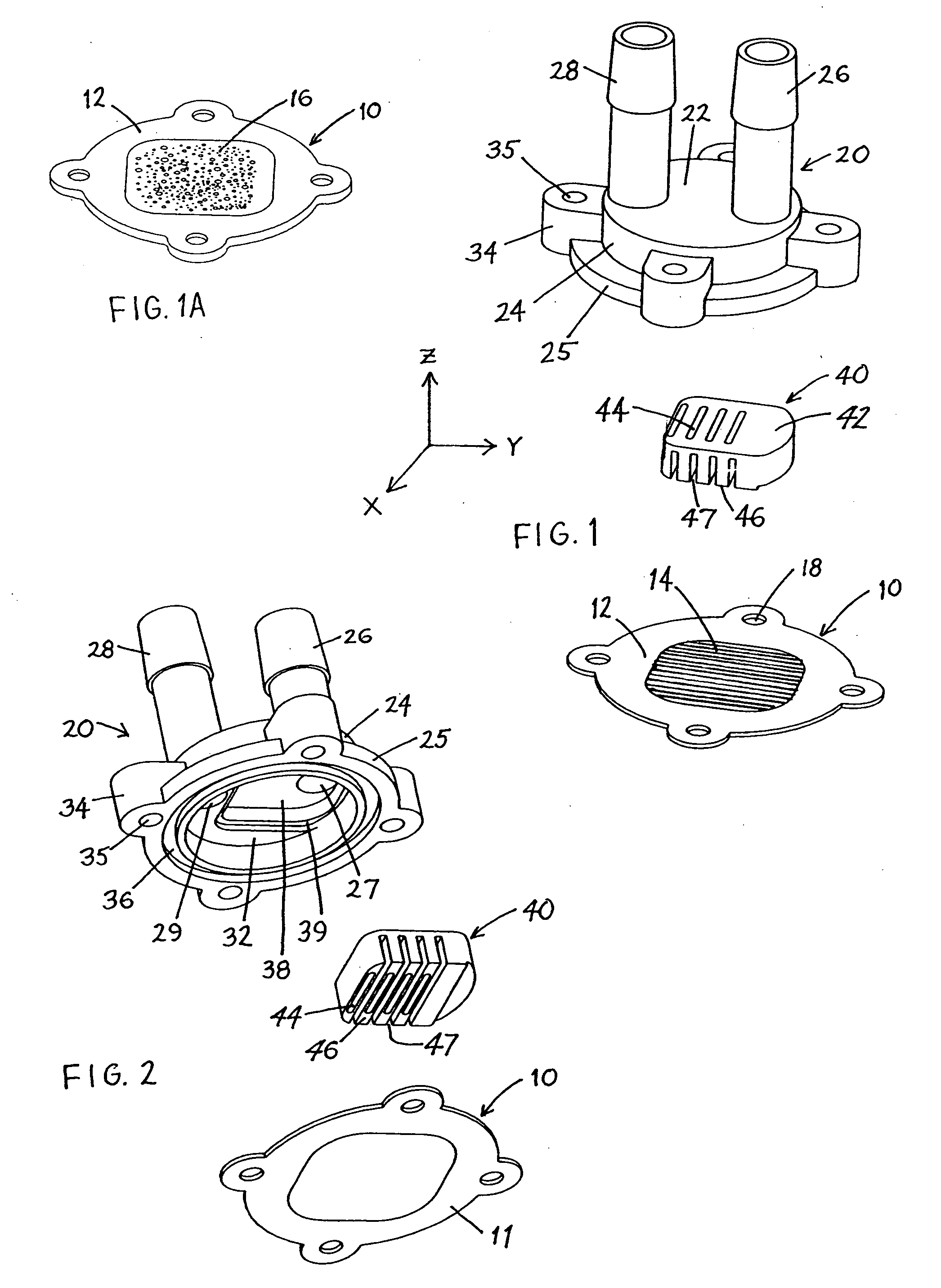

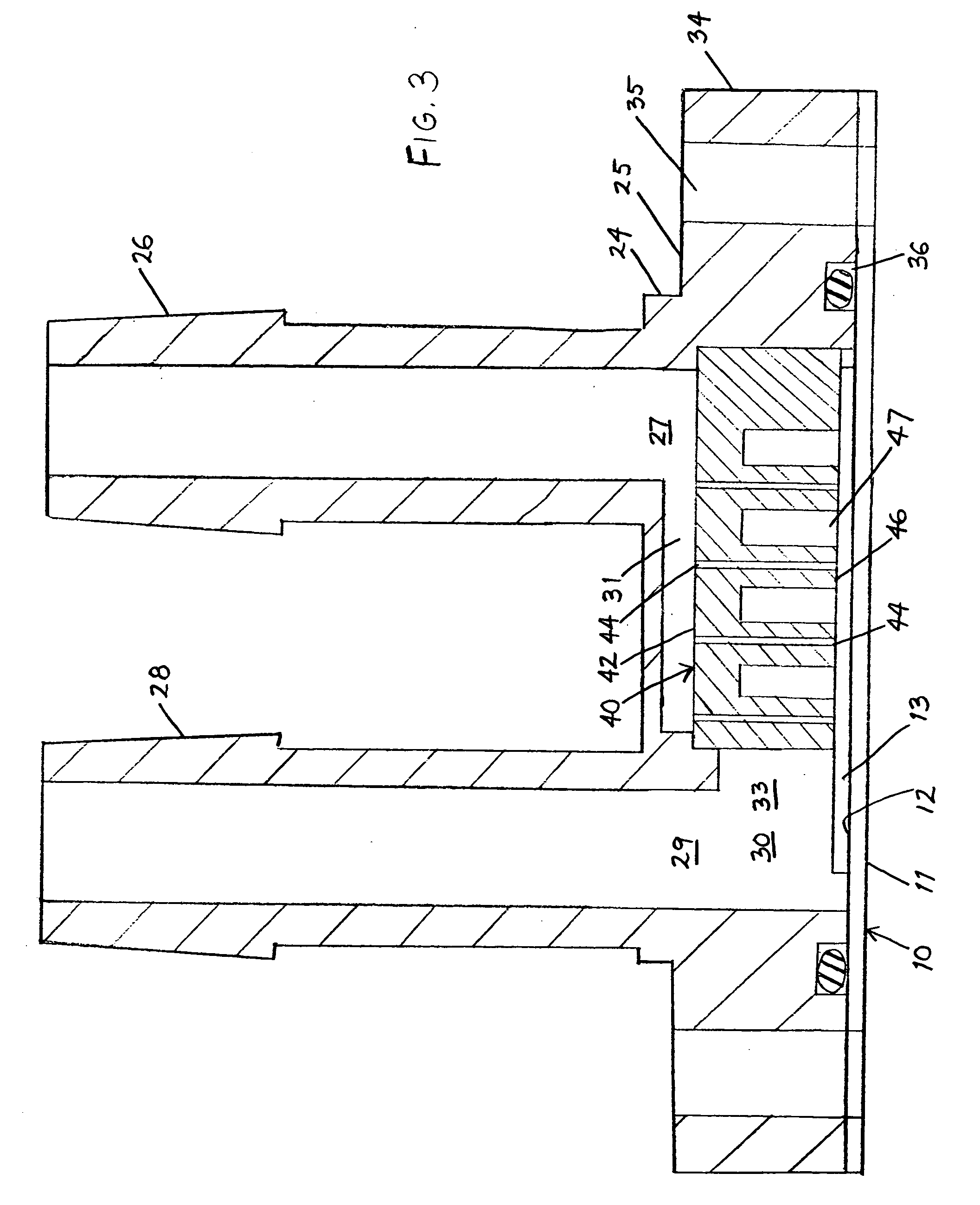

Containers for providing vapor phase reactant from liquid sources include bubbler designs and designs in which carrier gas flows over the liquid surface. Among the bubbler arrangements, a bypass conductance is provided to release excess pressure from the gas volume inside the container, or an enlarged bubbler tube is provided with a volume sufficient to accommodate all possible liquid backflow without having the liquid exit the container. Among the overflow designs, flow dividers provide a tortuous path for the gas to increase the time exposure of carrier gas packets to the evaporating liquid surface. The flow dividers can be microporous to encourage capillary action, thereby increasing the evaporating surface. The tortuous gas flow path can be separated from the liquid phase by a breathable semi-porous membrane that permits vapor phase reactant to pass through but prohibits liquid from passing in the other direction.

Owner:ASM INTERNATIONAL

Safe liquid source containers

ActiveUS7156380B2Encouraging capillary migrationFine surfaceCarburetting airMixing methodsPorous membraneProduct gas

Containers for providing vapor phase reactant from liquid sources include bubbler designs and designs in which carrier gas flows over the liquid surface. Among the bubbler arrangements, a bypass conductance is provided to release excess pressure from the gas volume inside the container, or an enlarged bubbler tube is provided with a volume sufficient to accommodate all possible liquid backflow without having the liquid exit the container. Among the overflow designs, flow dividers provide a tortuous path for the gas to increase the time exposure of carrier gas packets to the evaporating liquid surface. The flow dividers can be microporous to encourage capillary action, thereby increasing the evaporating surface. The tortuous gas flow path can be separated from the liquid phase by a breathable semi-porous membrane that permits vapor phase reactant to pass through but prohibits liquid from passing in the other direction.

Owner:ASM INTERNATIONAL

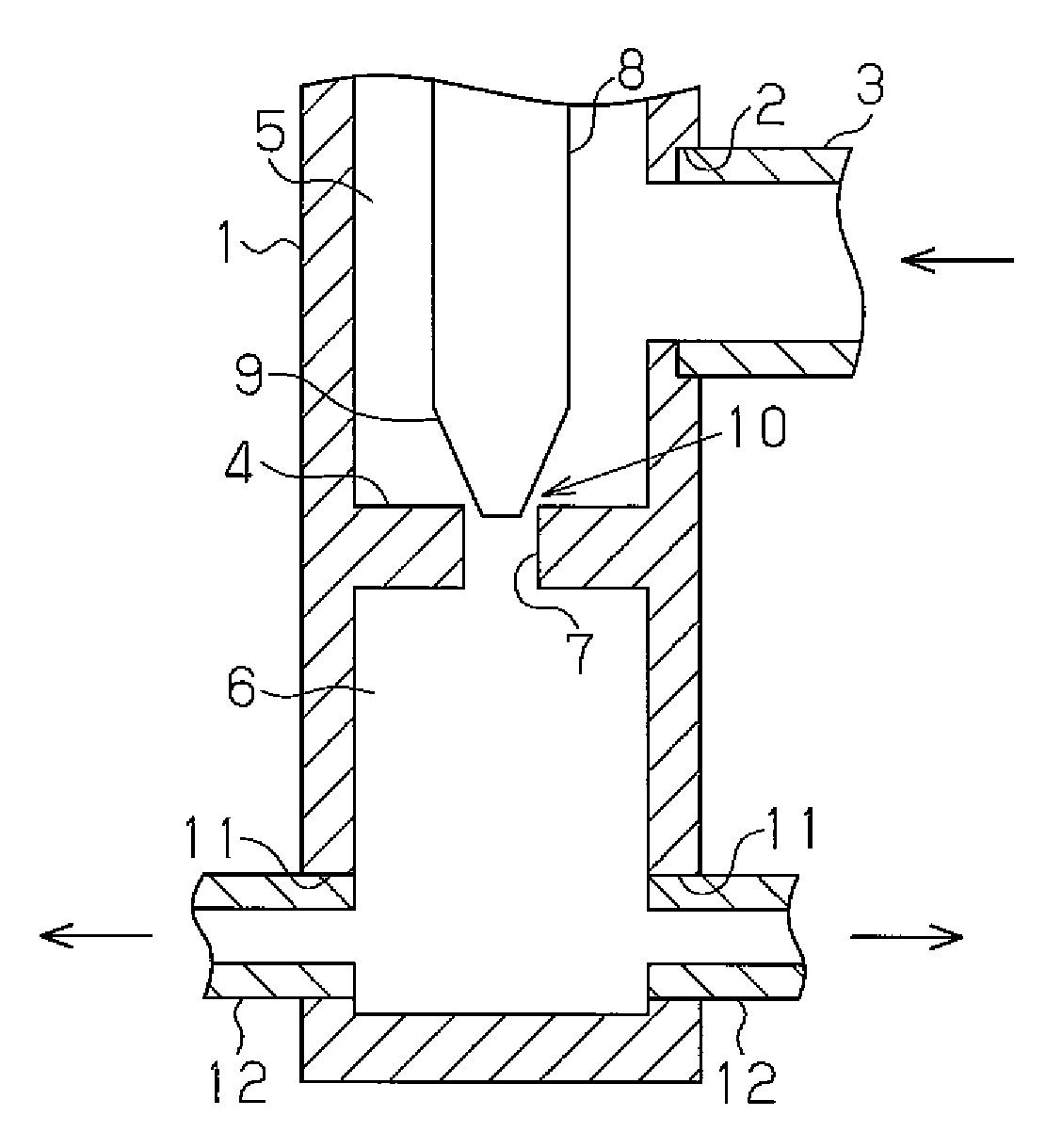

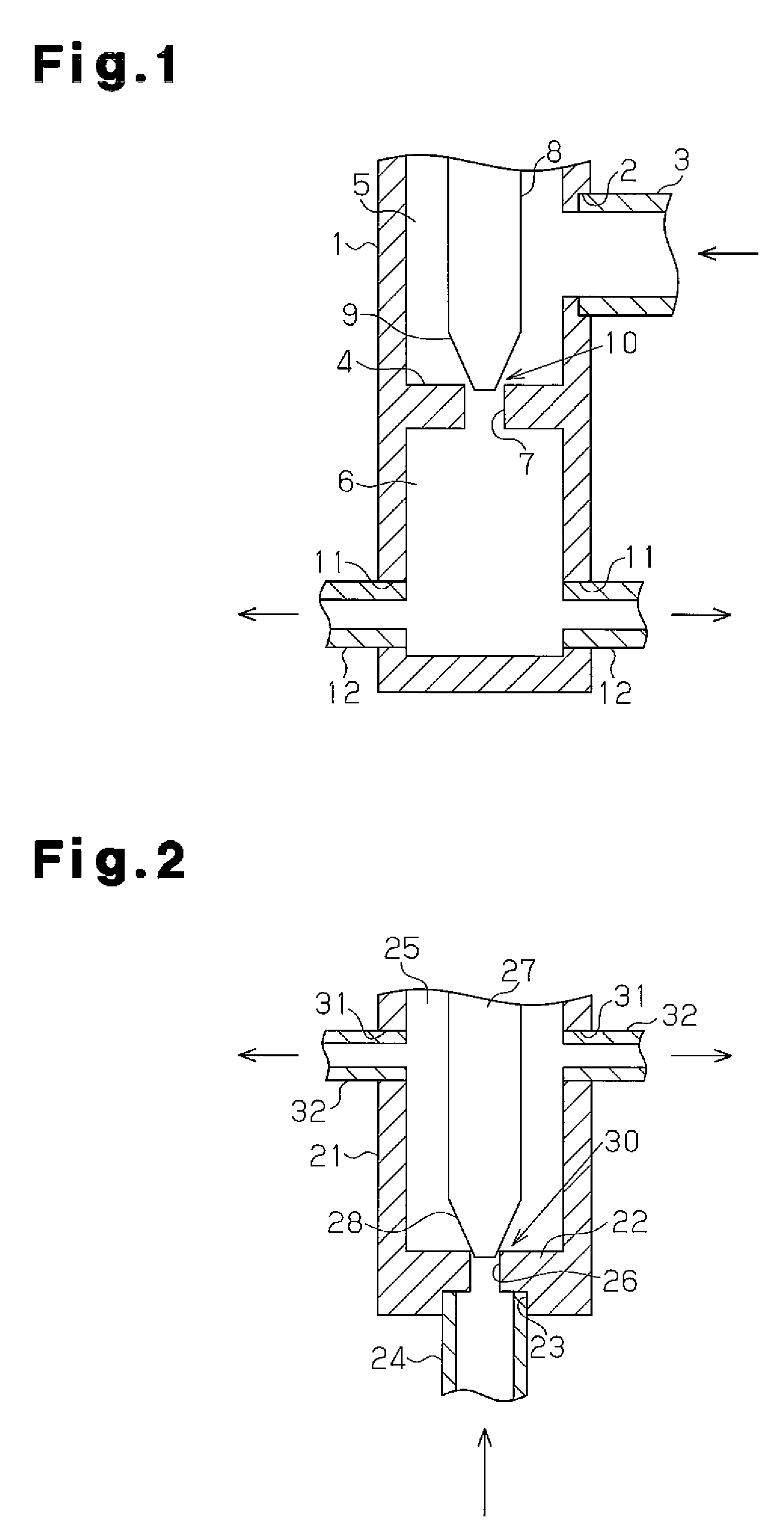

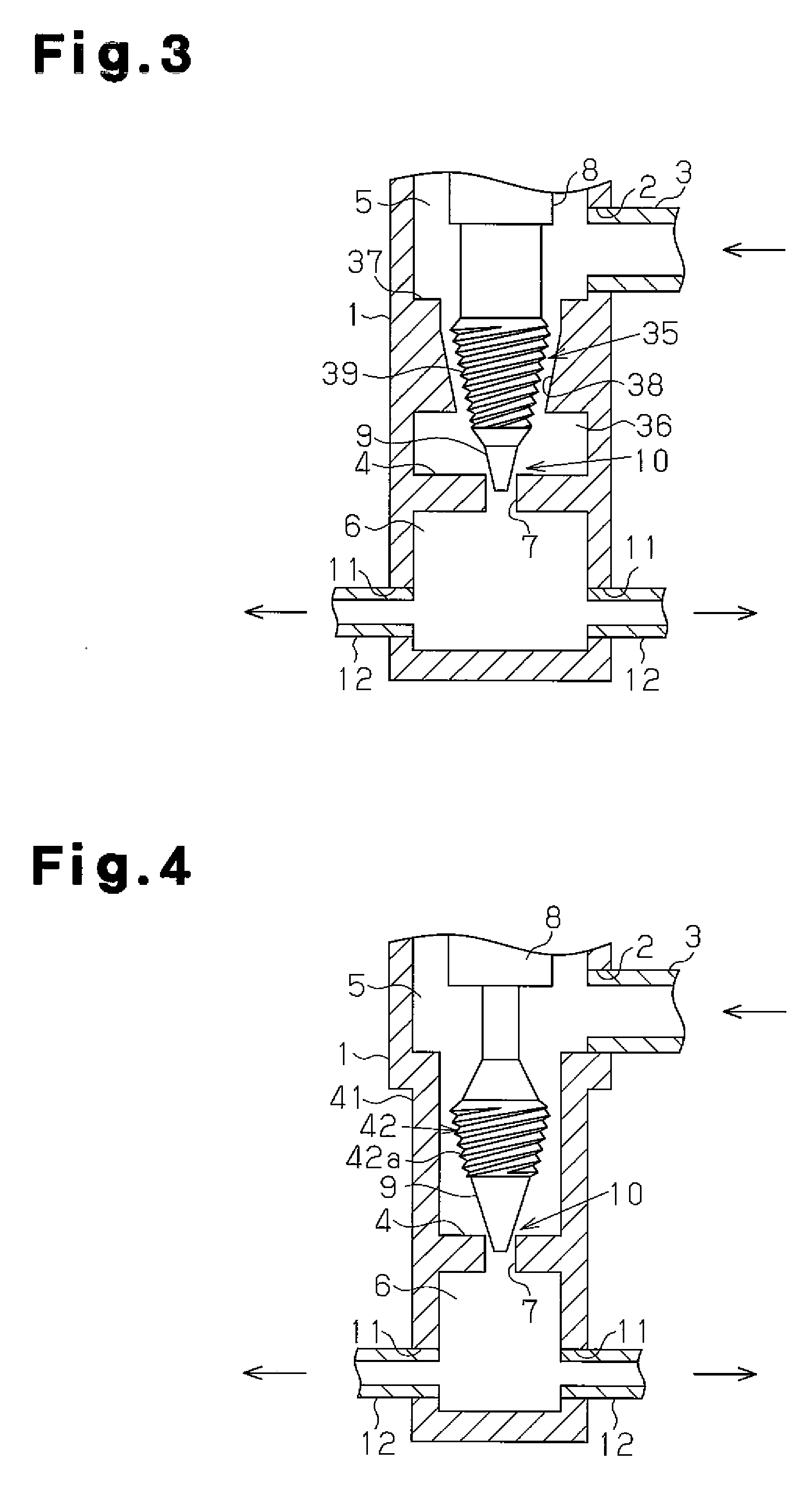

Expansion valve with refrigerant flow dividing structure and refrigeration unit utilizing the same

InactiveUS20090183520A1Reduce noiseShorten speedEvaporators/condensersValve members for absorbing fluid energyEngineeringRefrigeration

An expansion valve of the present invention has a structure which integrates a refrigerant flow divider. The expansion valve includes a refrigerant flow dividing chamber 6 on the downstream side of a first throttle 10. Flow dividing tubes 12 are connected to the refrigerant flow dividing chamber 6. In the expansion valve, refrigerant which has passed through the first throttle 10 is sprayed into the refrigerant flow dividing chamber 6, so that the flow dividing characteristic of the refrigerant is improved. Also, due to an enlargement of the passage in the refrigerant flow dividing chamber 6, the ejection energy of a flow of the refrigerant ejected from the first throttle 10 is dispersed, whereby a discontinuous refrigerant flow noise is reduced.

Owner:DAIKIN IND LTD

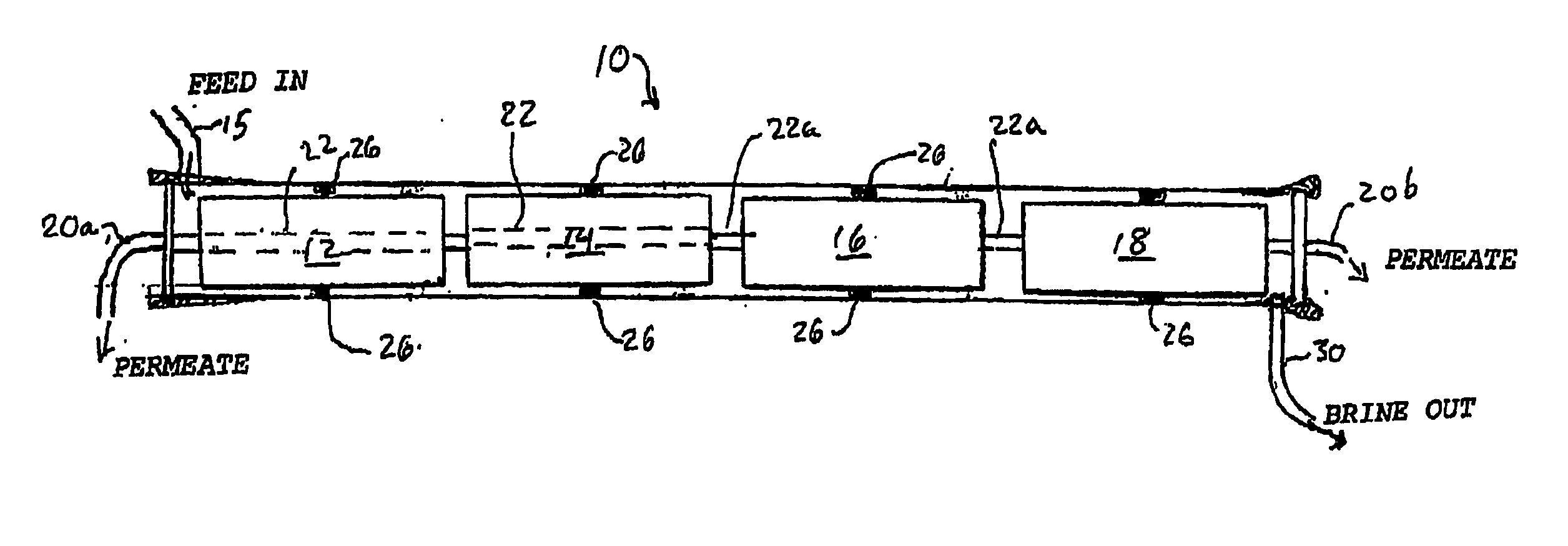

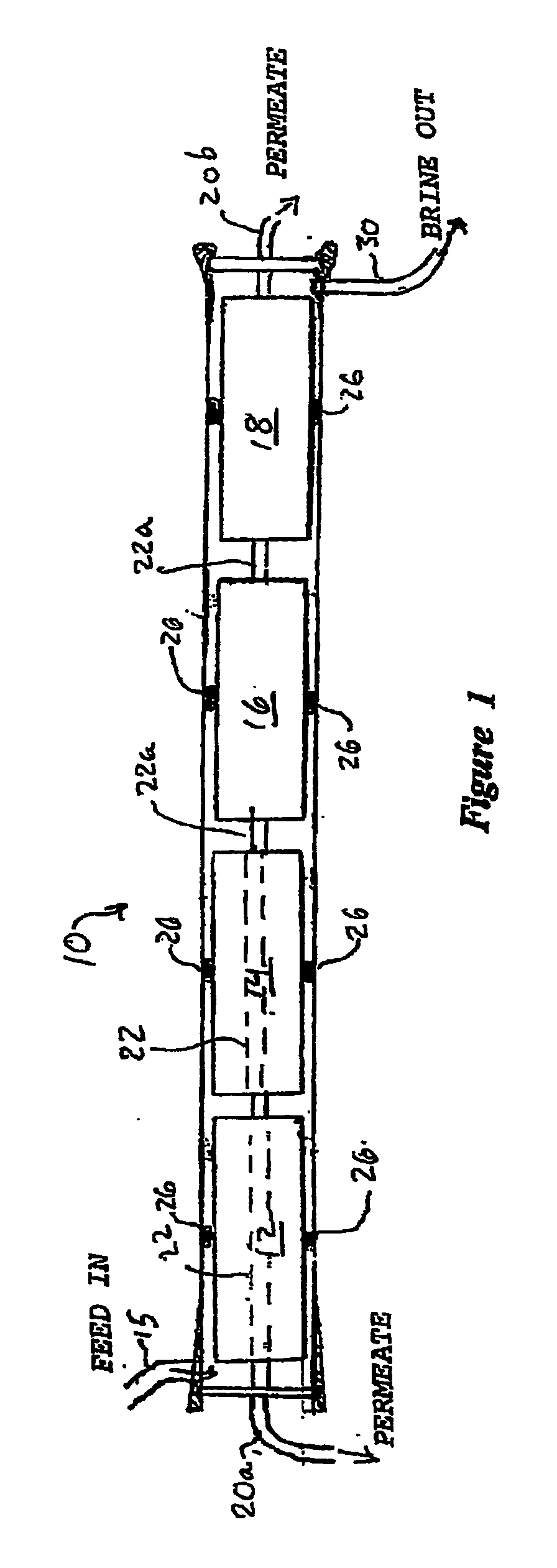

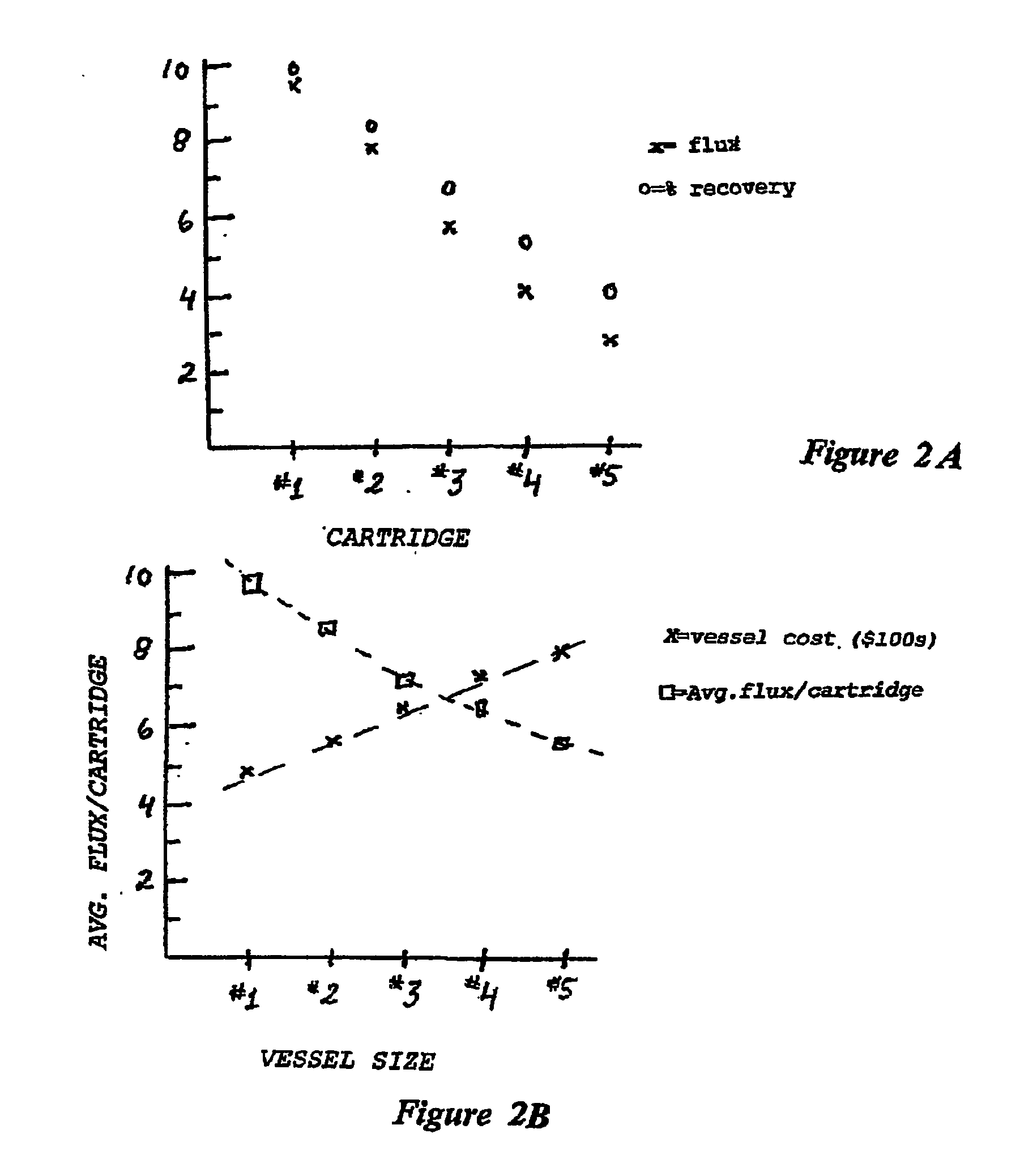

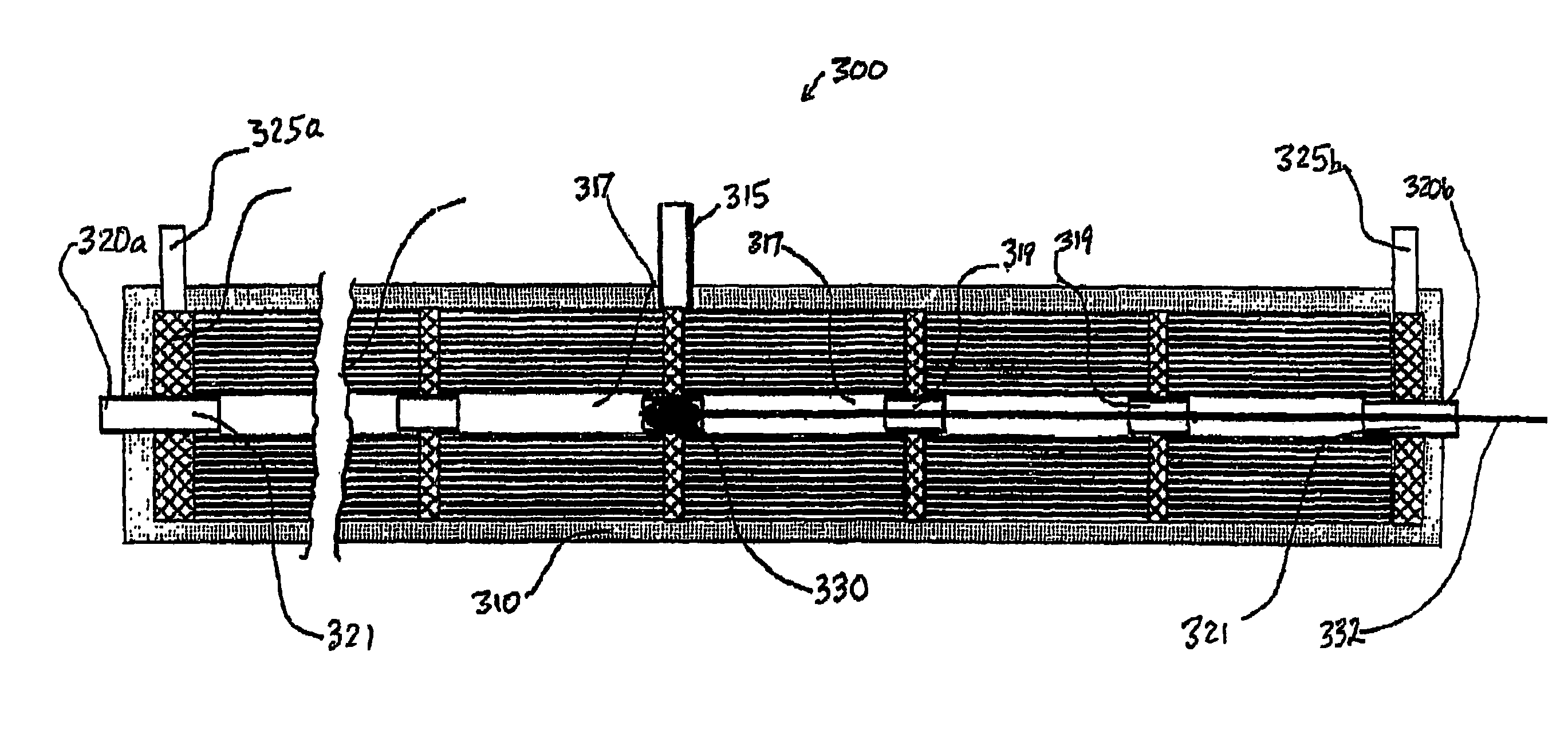

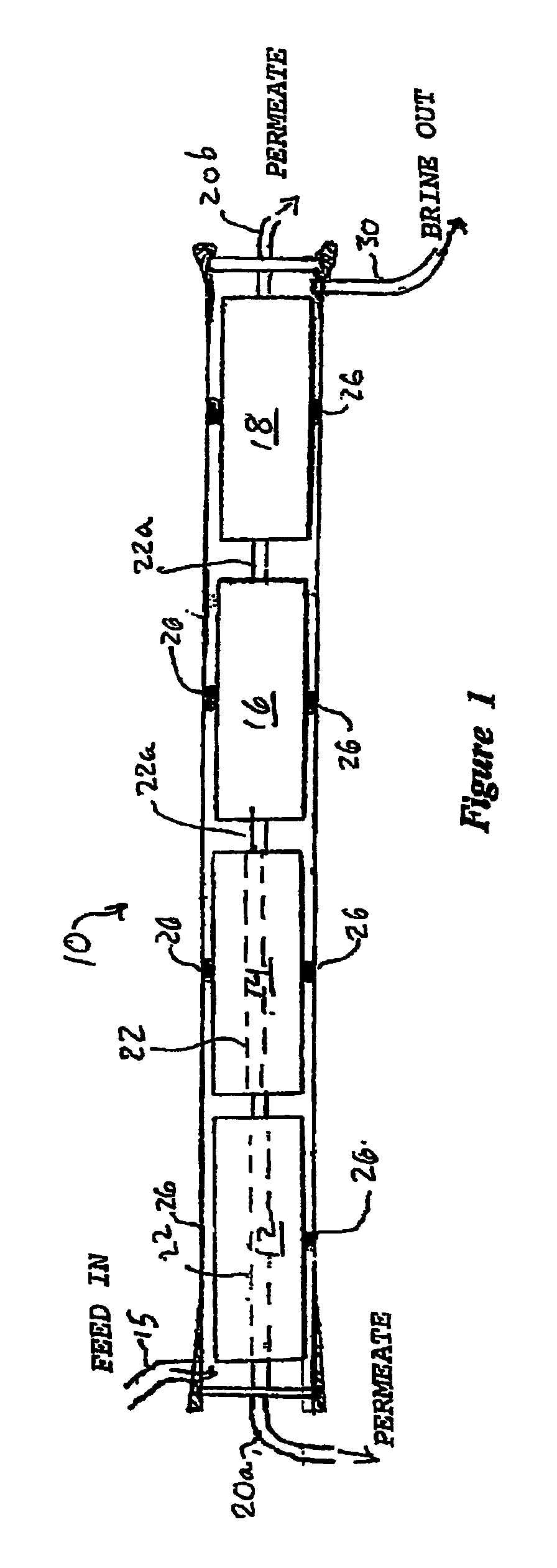

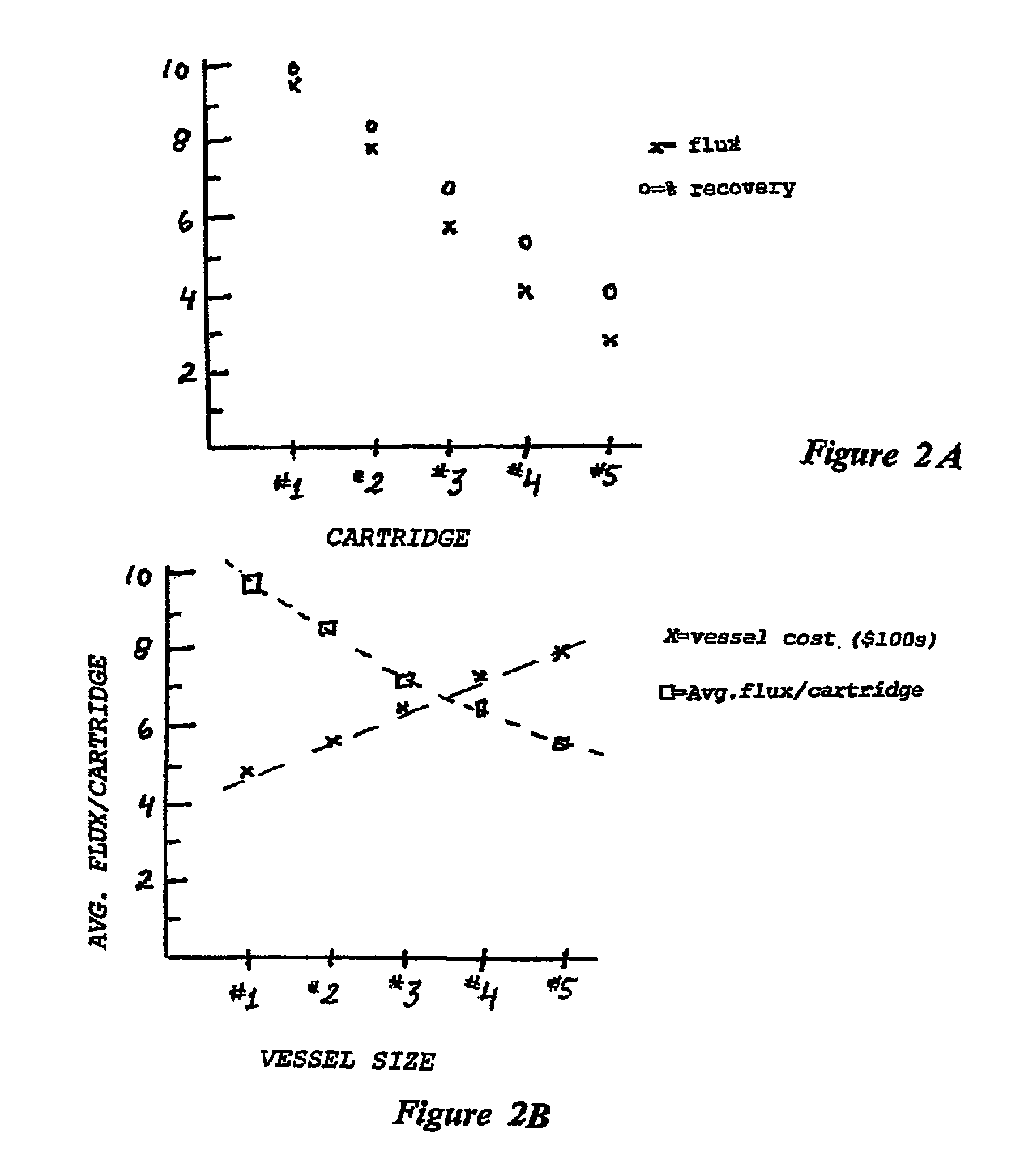

Branched flow filtraction and system

InactiveUS20050029192A1Improve operationImprove performanceMembranesWater/sewage treatment bu osmosis/dialysisReverse osmosisCross-flow filtration

A cross flow filtration apparatus for nanofiltration or reverse osmosis has pressure vessels with a plurality of filter cartridges in each vessel. A feed port is provided at an intermediate position on the side of the vessel, and two permeate flows or branches exit opposite ends of the vessel, and the first branch has a characteristically high “upstream” flux and quality, while the second is of lesser flux and / or quality. The system provides a high degree of moduarity, enhancing flux or yield at a reduced driving pressure or overall pressure drop. Centered or off-center port, and a stop or valve in the permeate stream may apportion flows between the two outlets. Staged systems may employ a first stage bypass to achieve a target quality with increased yield. A flow divider or adaptor permits the cartridges to fit and seal in the vessel and an installation tool or sleeve may facilitate installation or replacement of cartridges having a directional perimeter seal. A tool permits modules to be bi-directional installed in the pressure vessel. Other embodiments involve adapting a conventional vessel designed for end-to-end feed flow utilizing a restrictor, obstruction or valve inside the filter cartridge to bifurcate or otherwise split or apportion the permeate. RO elements may be modified to movably position an obstruction or valve along a string of the elements and vary the take-off to two or more permeate outlets, or to provide pressure relief valves that present different pressure conditions for different elements of a string. A pressure vessel may have an intermediate inlet, with symmetric or asymmetric branching of permeate flow to opposed ends of the vessel, enhancing permeate flux, permeate quality and / or energy efficiency.

Owner:IONICS INC

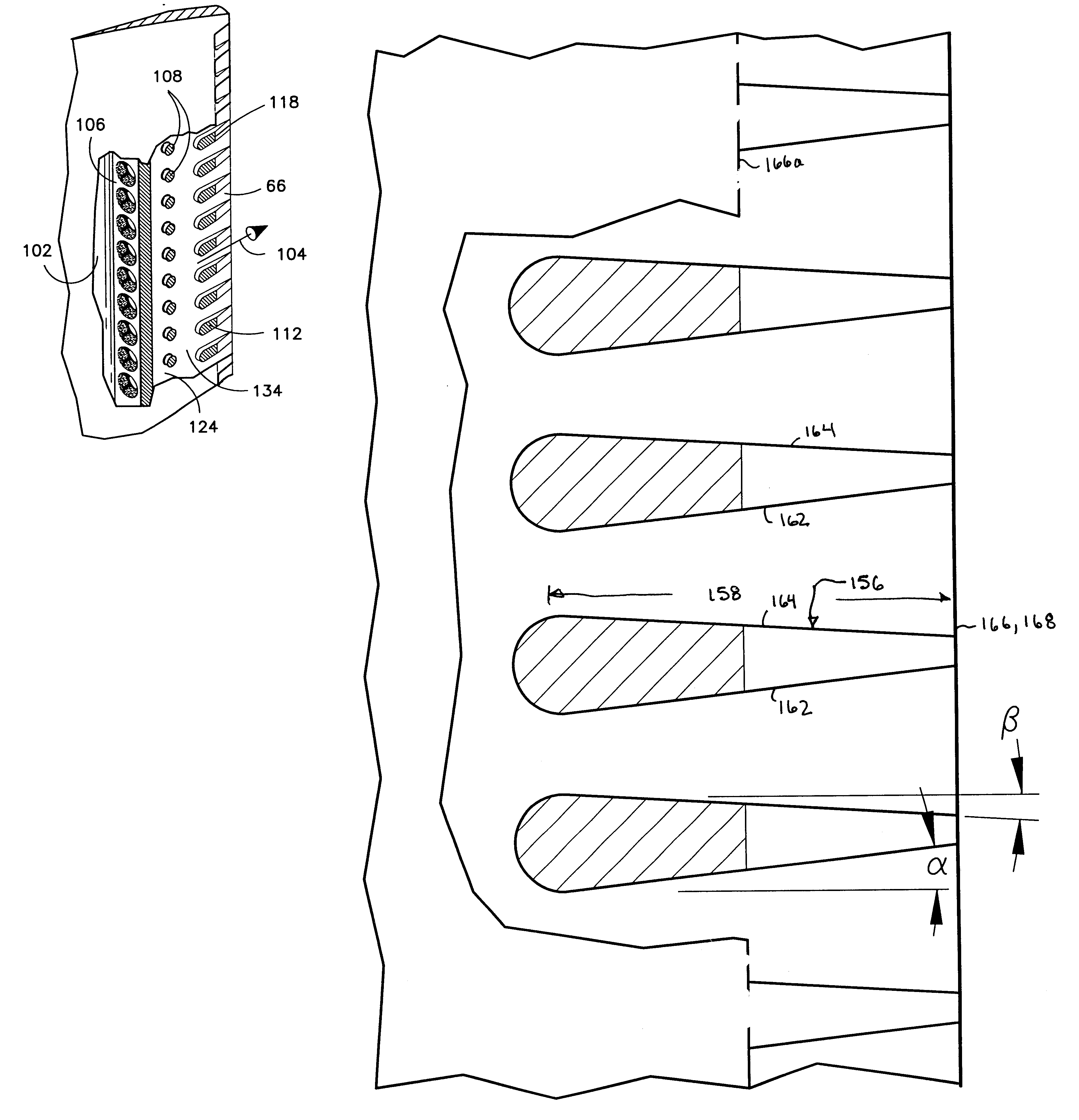

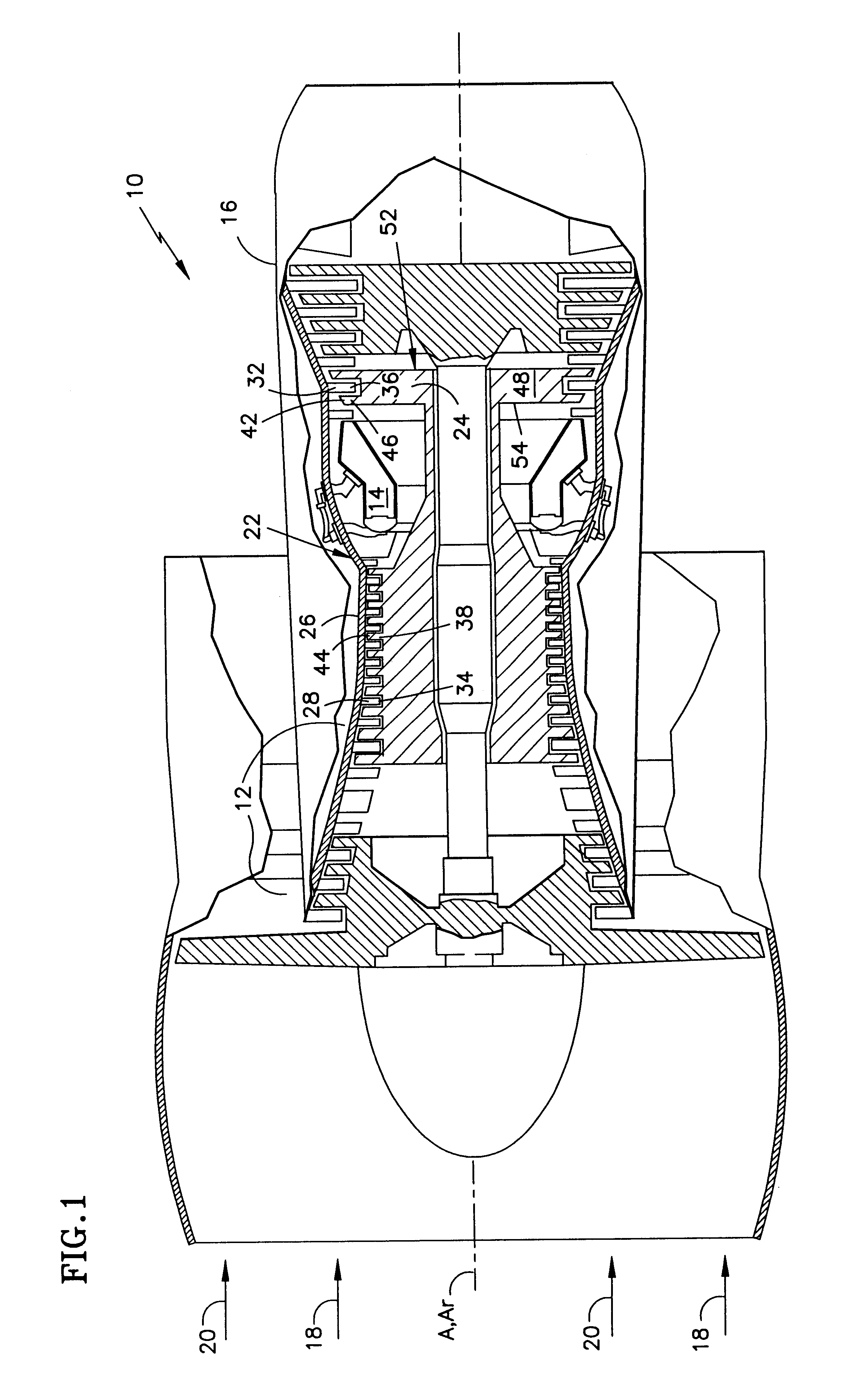

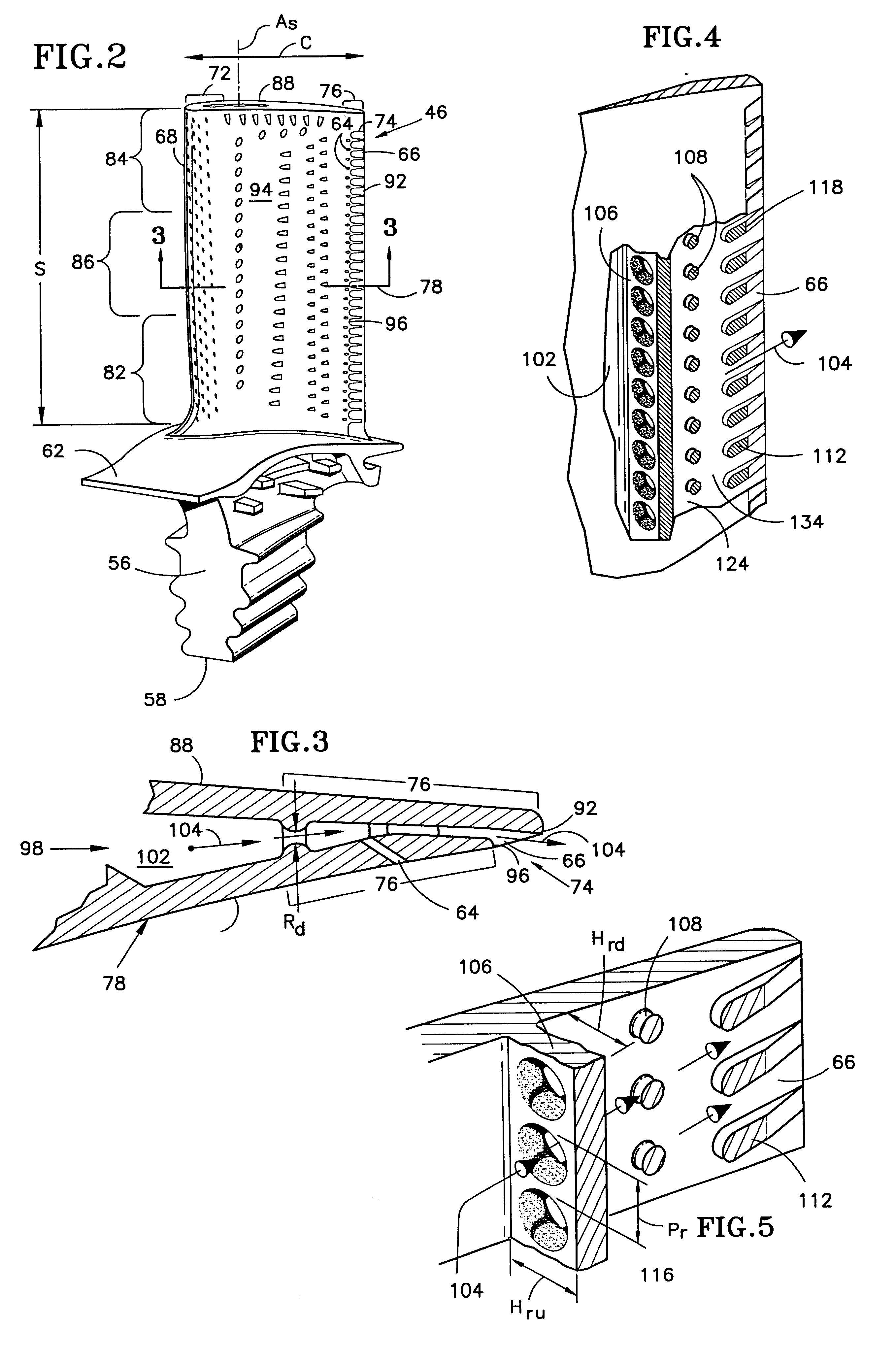

Coolable airfoil structure

InactiveUS6234754B1Durability and thermomechanical performanceIncreased durabilityPump componentsEngine fuctionsCastabilityInternal heat transfer

A coolable airfoil structure having internal heat transfer features through which cooling air is flowed under operative conditions is disclosed. Various construction details and features are developed which affect the castability and core strength during manufacture and strength and cooling effectiveness of the airfoil after manufacture. In one particular embodiment, the airfoil has a plurality of heat transfer members disposed in the rearmost section of the trailing edge region which comprises a single impingement rib, a single row of pedestals and a single row of chordwisely extending flow dividers.

Owner:UNITED TECH CORP

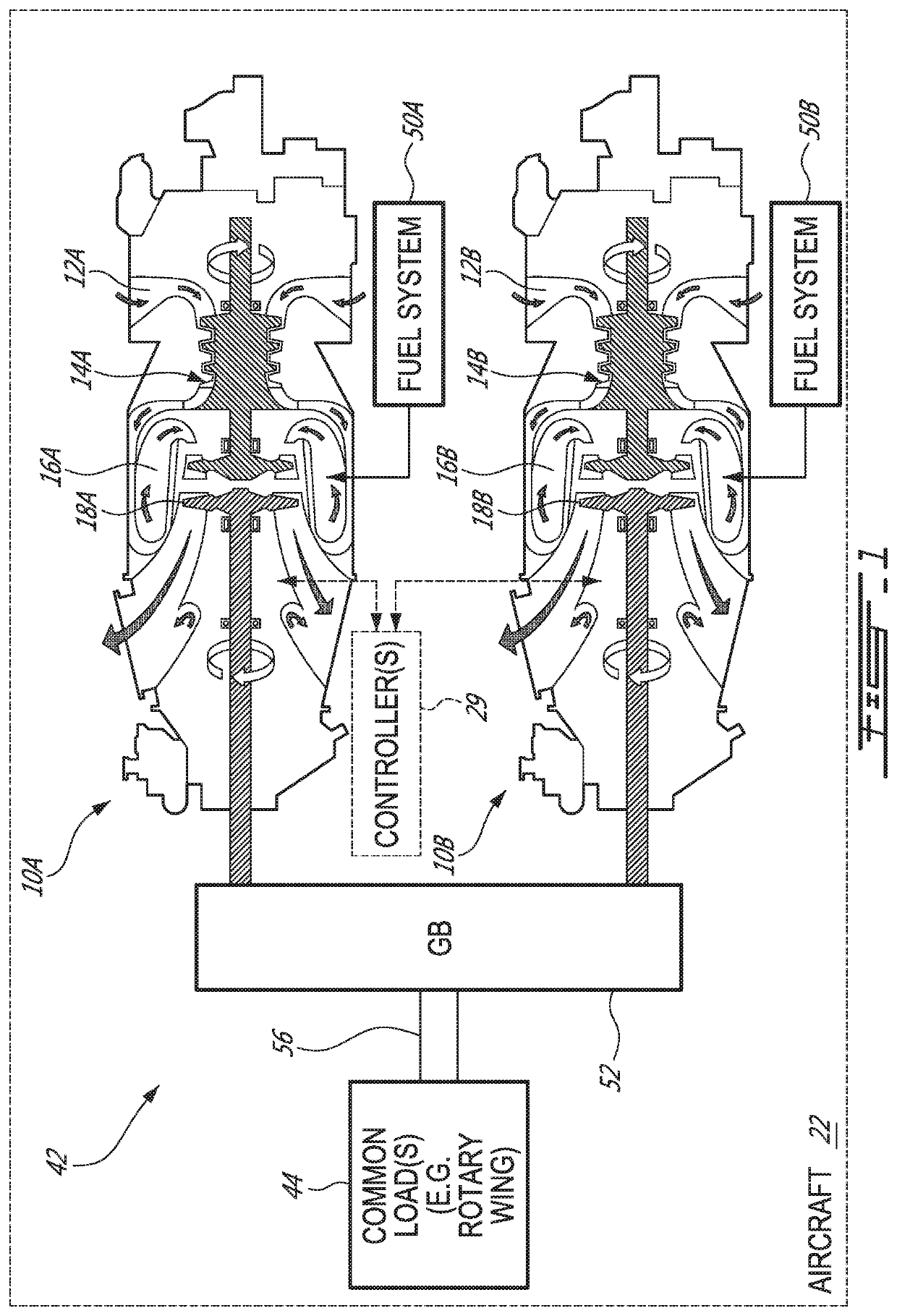

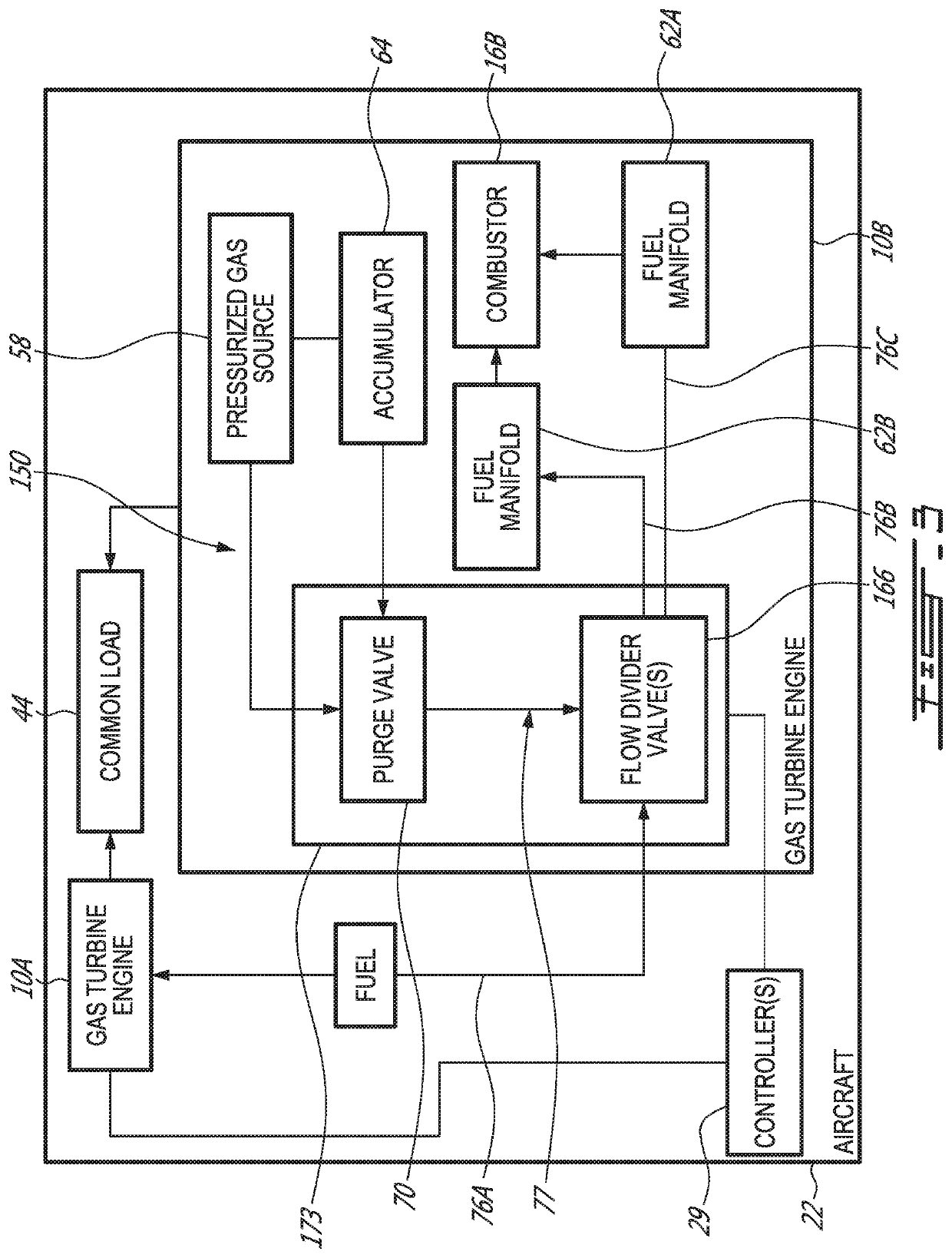

System and method for purging a fuel manifold of a gas turbine engine using a flow divider assembly

Methods and systems of operating a gas turbine engine in a low-power condition are provided. In one embodiment, the method includes supplying fuel to the combustor by supplying fuel to the first fuel manifold via a first flow divider valve and supplying fuel to the second fuel manifold via a second flow divider valve. While supplying fuel to the combustor by supplying fuel to the first fuel manifold, the method includes stopping supplying fuel to the second fuel manifold and supplying pressurized gas to the second fuel manifold via the second flow divider valve to flush fuel in the second fuel manifold into the combustor and hinder coking in the second fuel manifold and associated nozzles.

Owner:PRATT & WHITNEY CANADA CORP

Multi-functional floor-cleaning tool

In one aspect of the invention, the tool includes: a housing having a front wall, a back wall, a top wall connecting the front and back walls, an interior surface, a liquid-delivery opening, and a soil-uptake opening, the soil-uptake opening being connectable to a vacuum source; a first squeegee blade depending from the front wall; a second squeegee blade depending from the back wall; an interior space defined by the interior surface, first squeegee blade, and second squeegee blade; a diverter valve connected to the housing, the diverter valve having at least an inlet, a first outlet, a second outlet, and a diverter, the diverter capable of selectively directing the flow of a pressurized liquid from the inlet to either the first outlet or the second outlet, the diverter valve being connectable to a pressurized-liquid source; a high-pressure nozzle connected to the first outlet of the diverter valve, the high-pressure nozzle constructed and arranged to deliver a liquid into the interior space via the liquid-delivery opening; and a low-pressure nozzle connected to the second outlet of the diverter valve, the low-pressure nozzle constructed and arranged to deliver a liquid exterior to the interior space.

Owner:KAIVAC

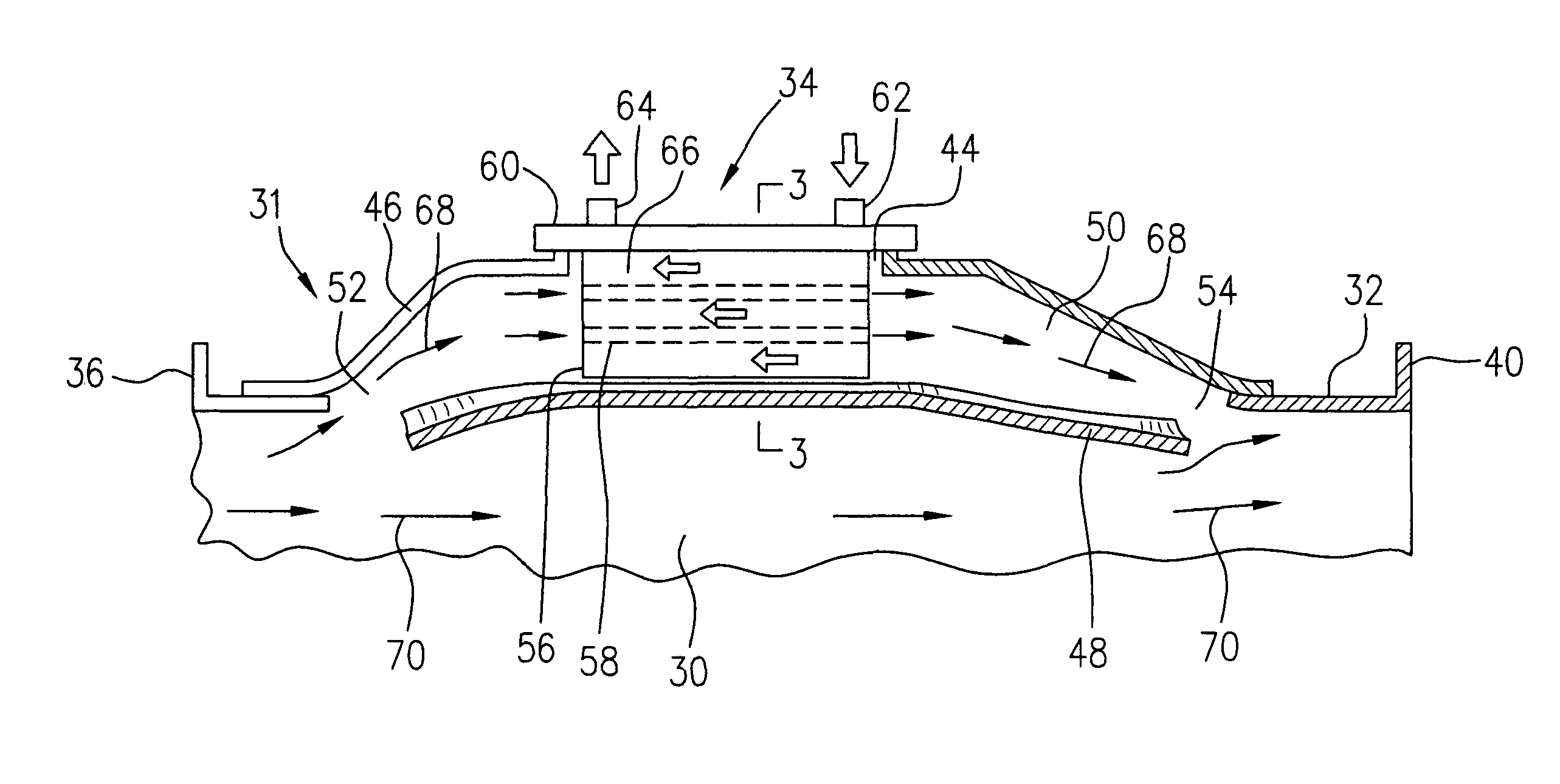

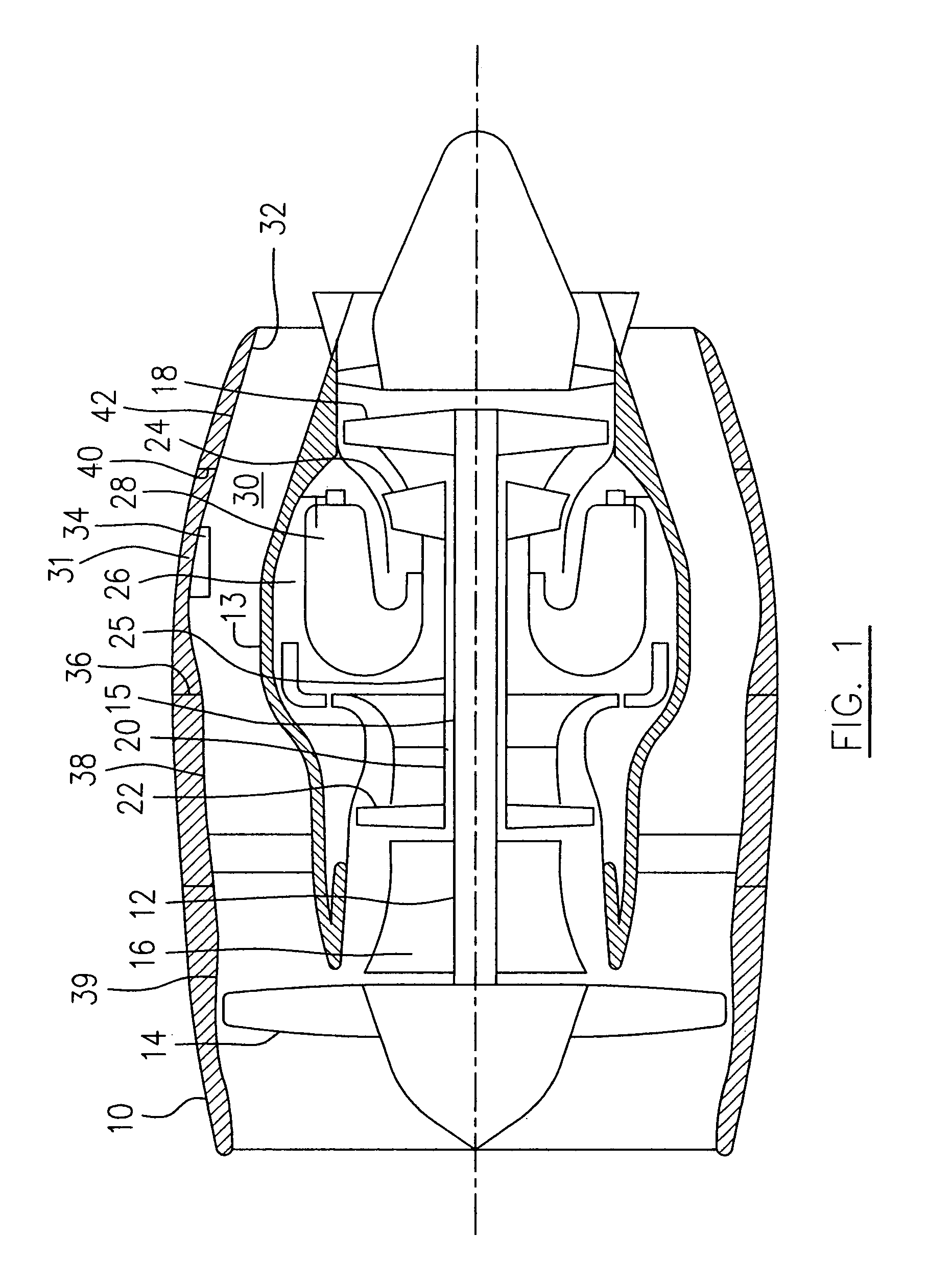

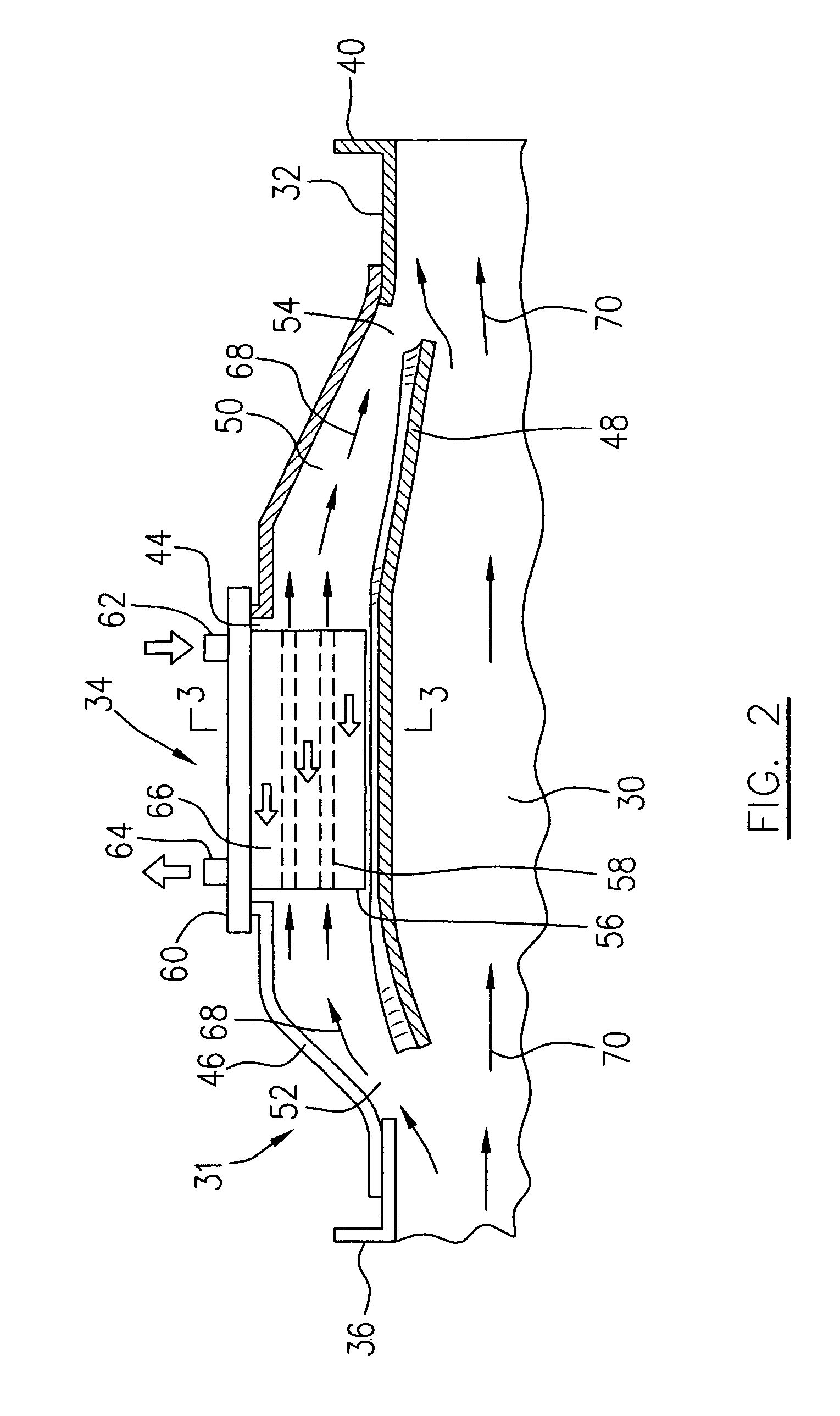

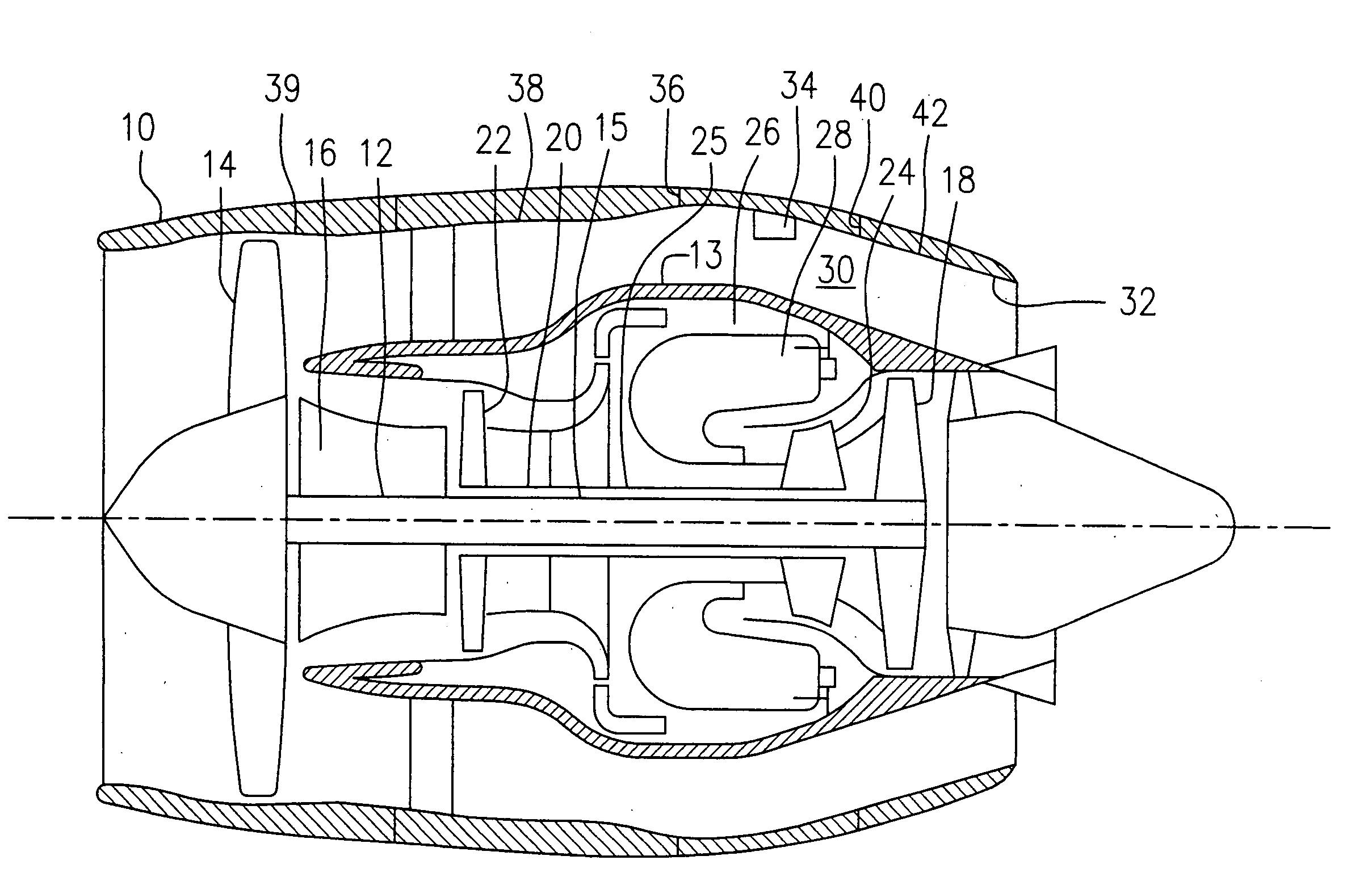

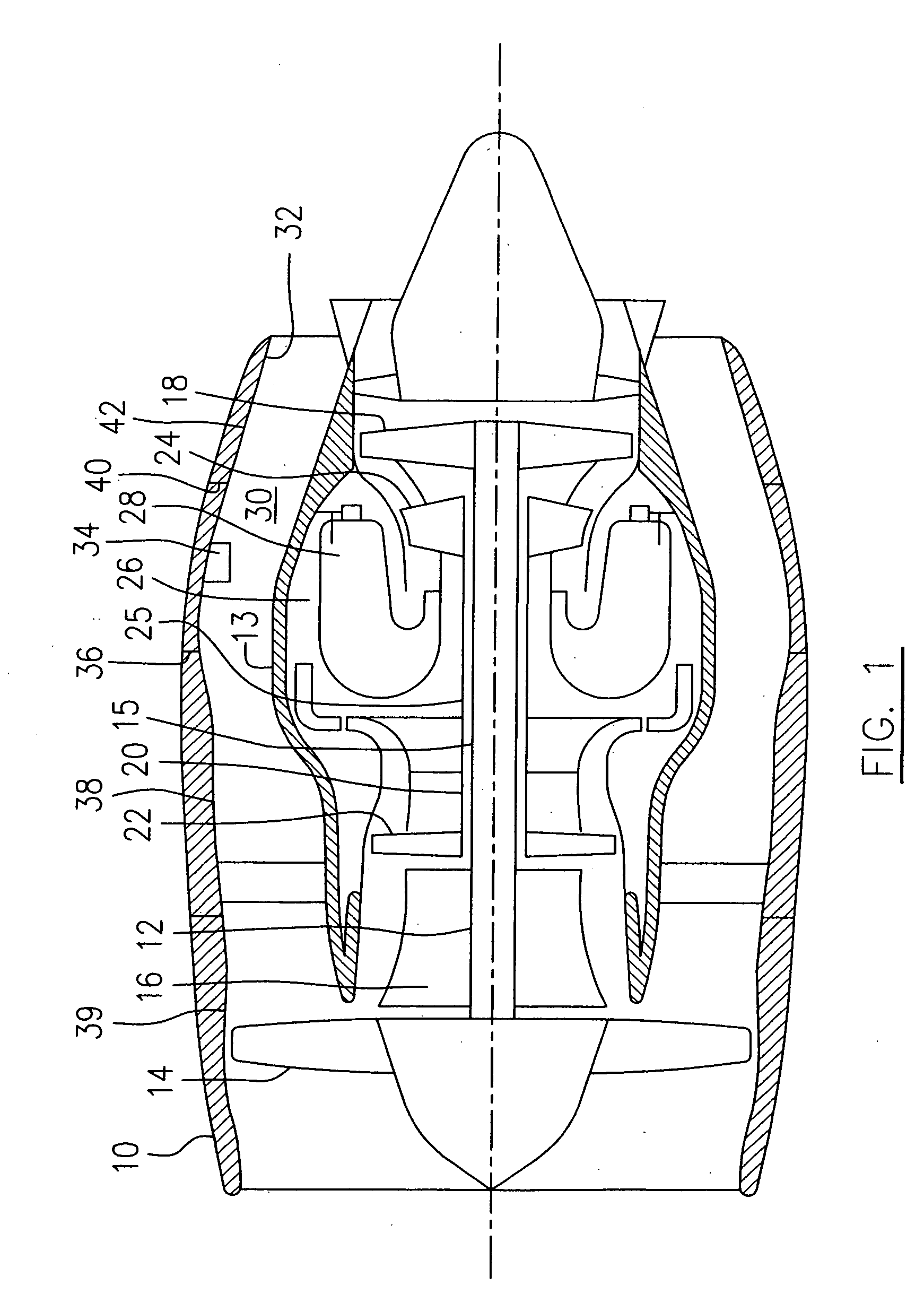

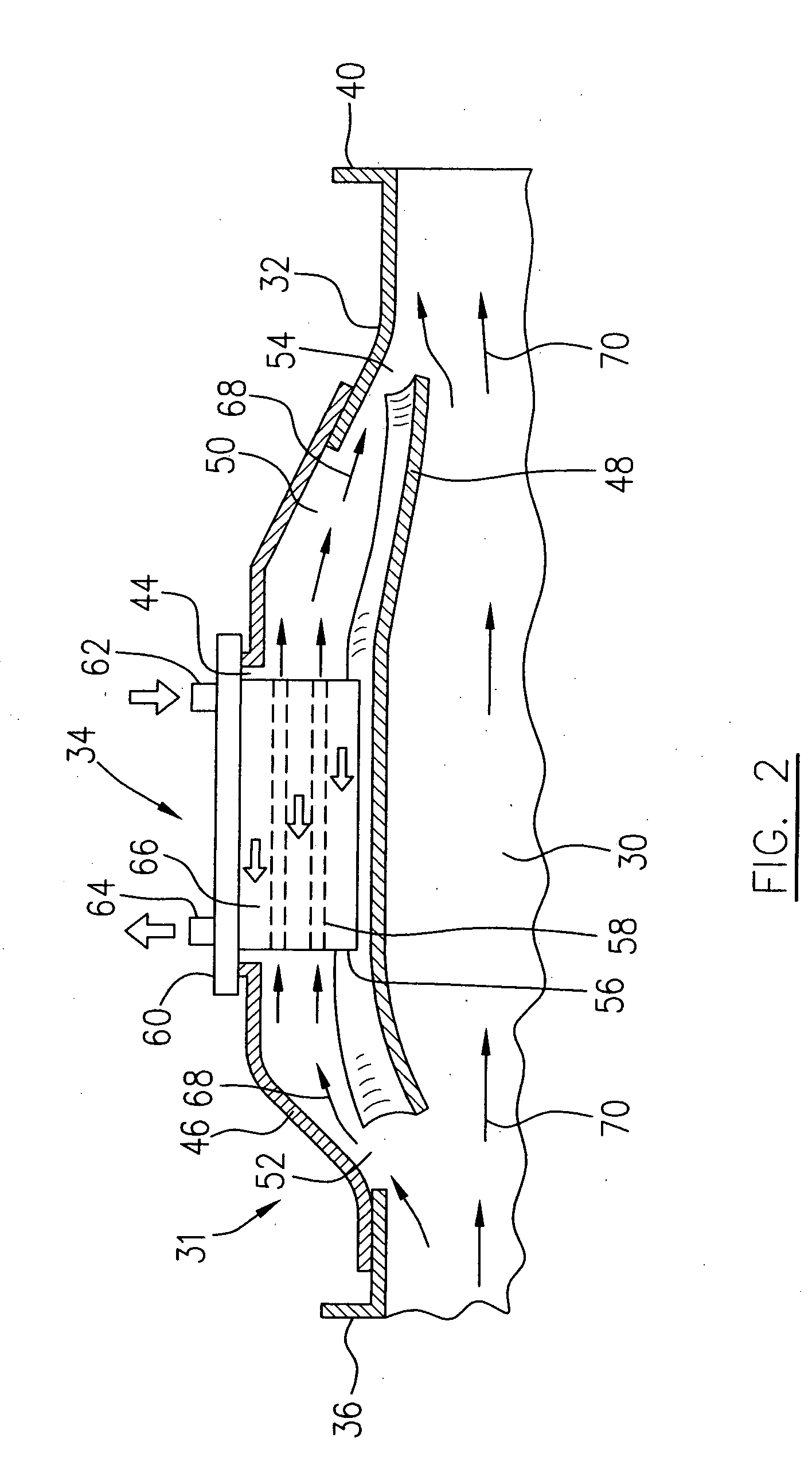

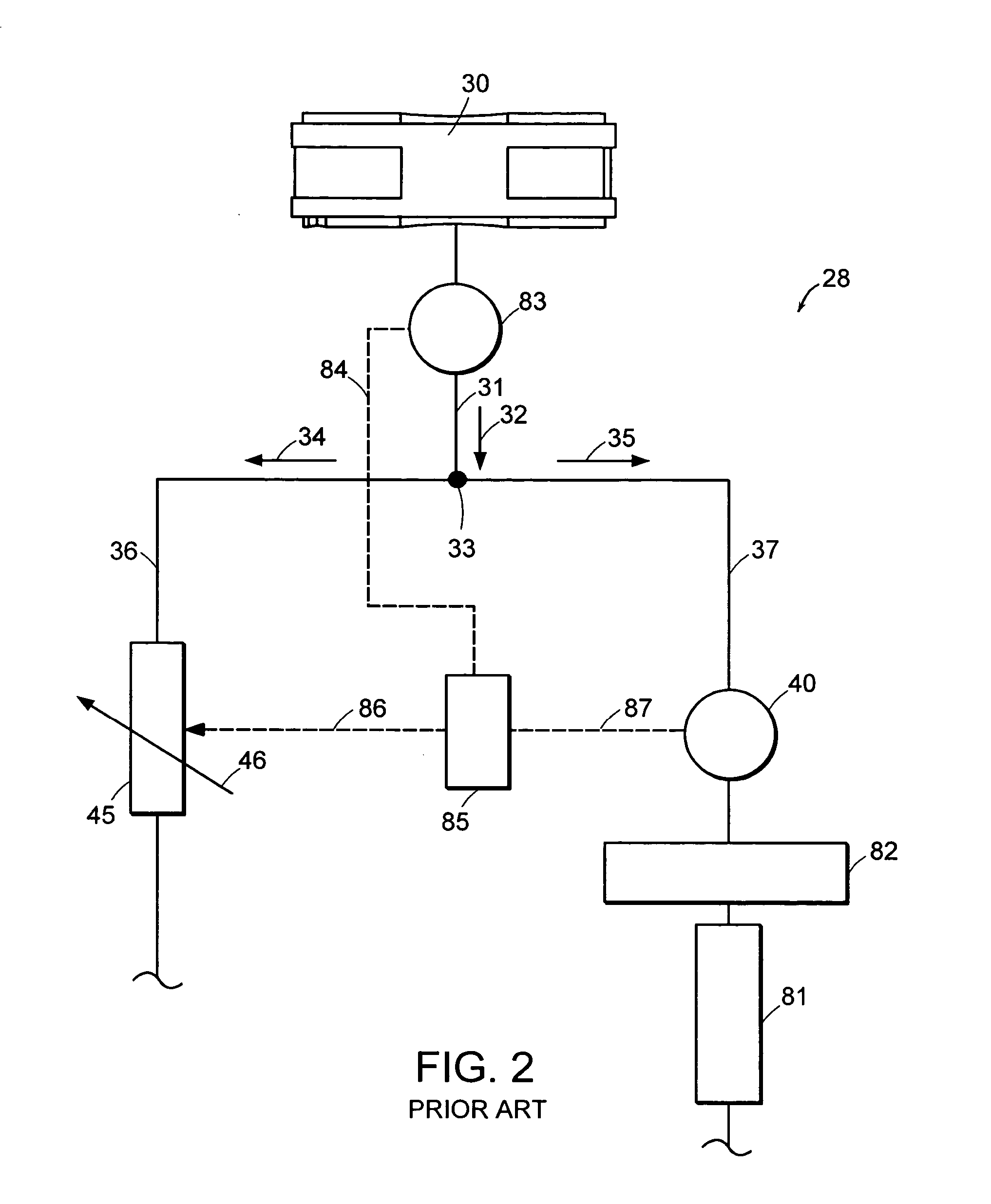

Turbofan bypass duct air cooled fluid cooler installation

ActiveUS7861512B2Facilitate heat exchangeTurbine/propulsion engine coolingEngine fuctionsCooling fluidTurbofan

A cooling apparatus for cooling a fluid in a bypass gas turbine engine comprises a heat exchanger disposed within a bypass duct and accommodated by a sub-passage defined by a flow divider affixed to an annular wall of the bypass duct. The sub-passage defines an open upstream end and an open downstream end to direct a portion of the bypass air flow to pass therethrough.

Owner:PRATT & WHITNEY CANADA CORP

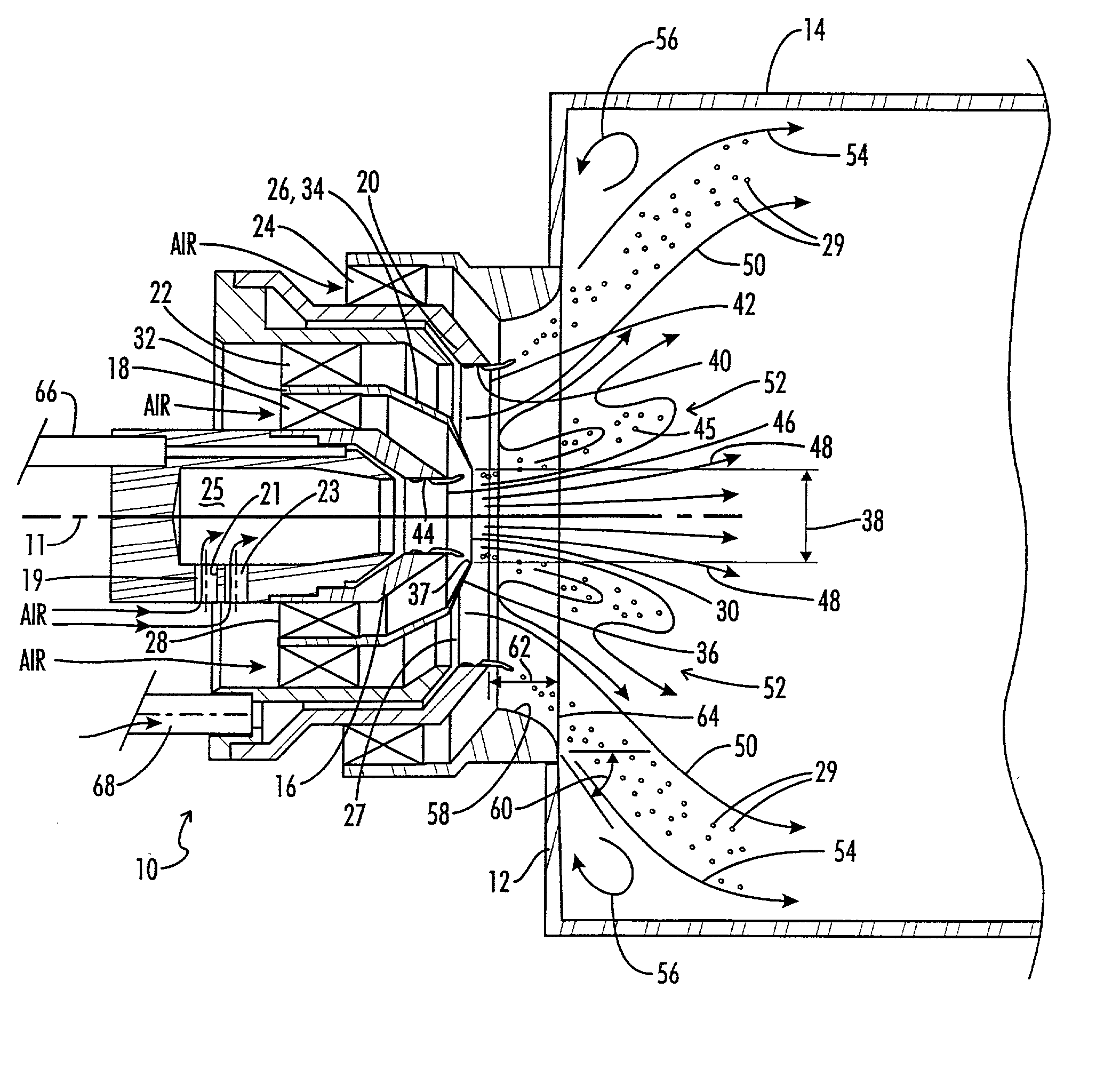

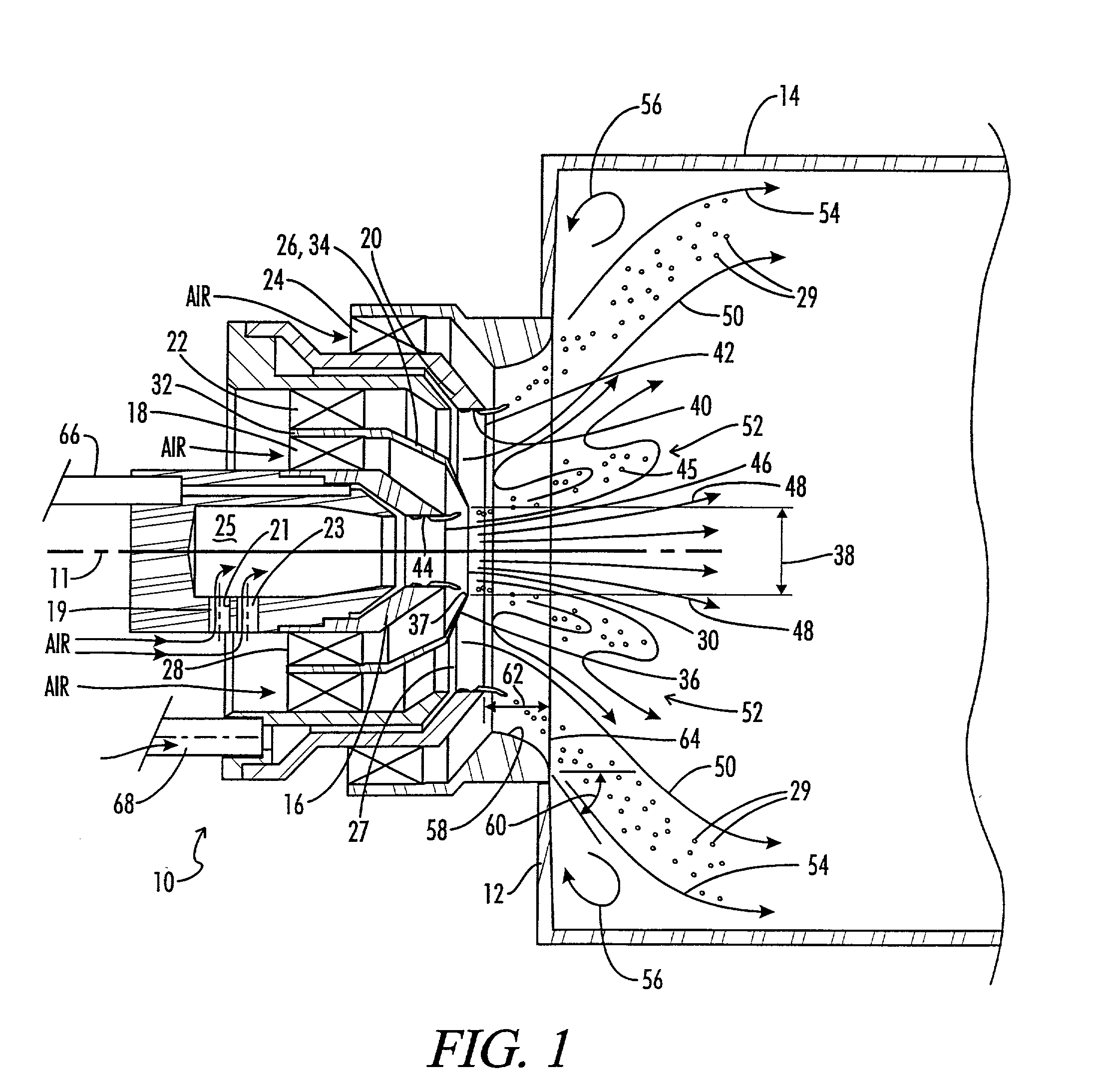

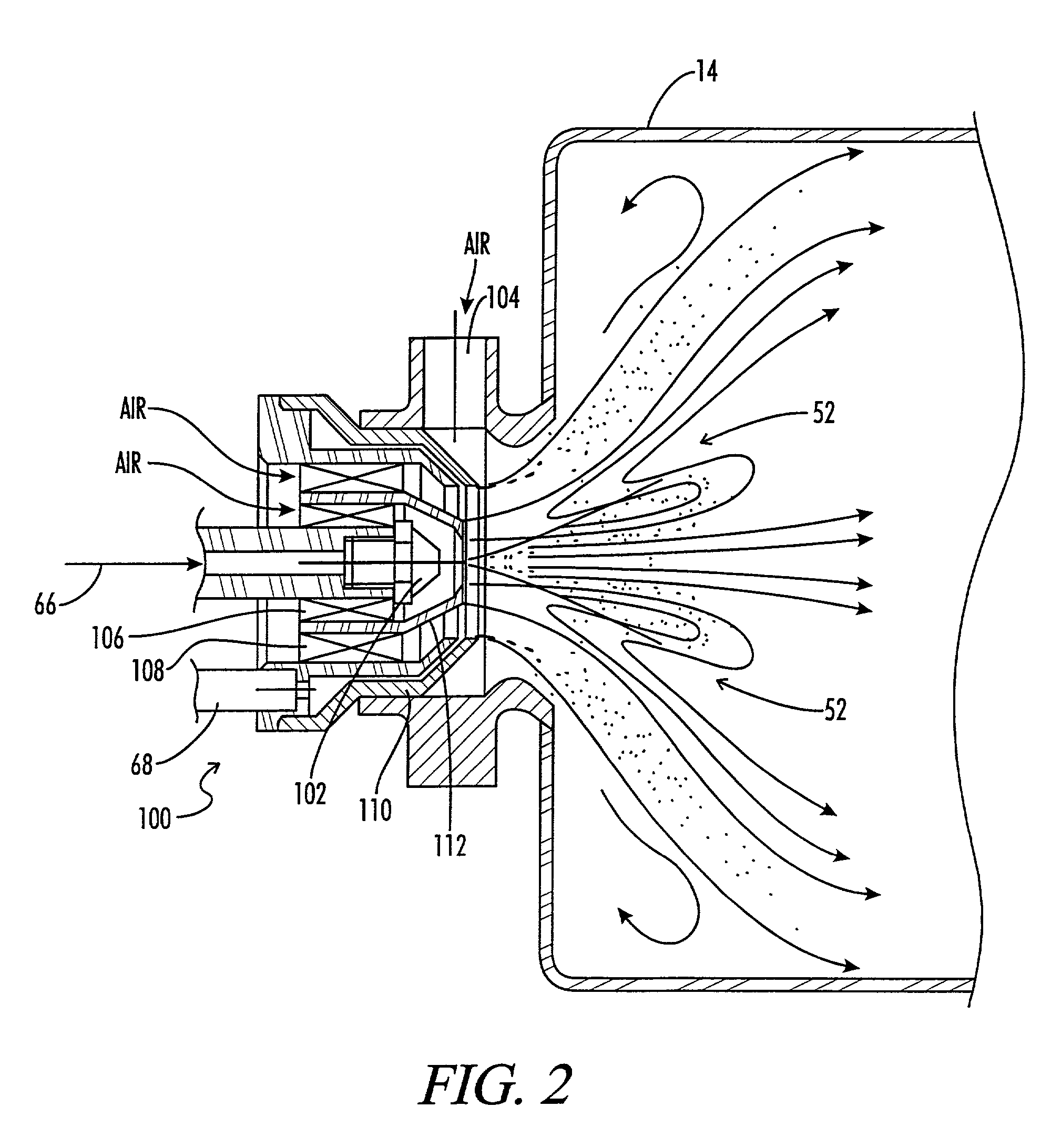

Fuel injector with bifurcated recirculation zone

InactiveUS20020011064A1Low pollutant emissionReduce nitrogen oxide emissionsBurnersTurbine/propulsion fuel supply systemsProcess engineeringNitrous oxide

A gas turbine fuel injection system of the lean direct injector type designed to reduce nitrous oxide (NOx) emissions is provided. The configuration includes a pilot fuel injector for injecting a pilot fuel stream, and a pilot swirler for providing a swirling pilot air stream to atomize and entrain the pilot fuel stream. A main airblast fuel injector is located concentrically about the pilot fuel injector, for injecting a main fuel stream concentrically about the pilot fuel stream. Inner and outer main swirlers provide a swirling main air stream to atomize and entrain the main fuel stream. An air splitter is located between the pilot swirler and the main swirler. The air splitter is so arranged and constructed as to divide the pilot air stream exiting the pilot swirler and the air splitter, from the main air stream exiting the inner main swirler, whereby a bifurcated recirculation zone is created.

Owner:CROCKER DAVID S +2

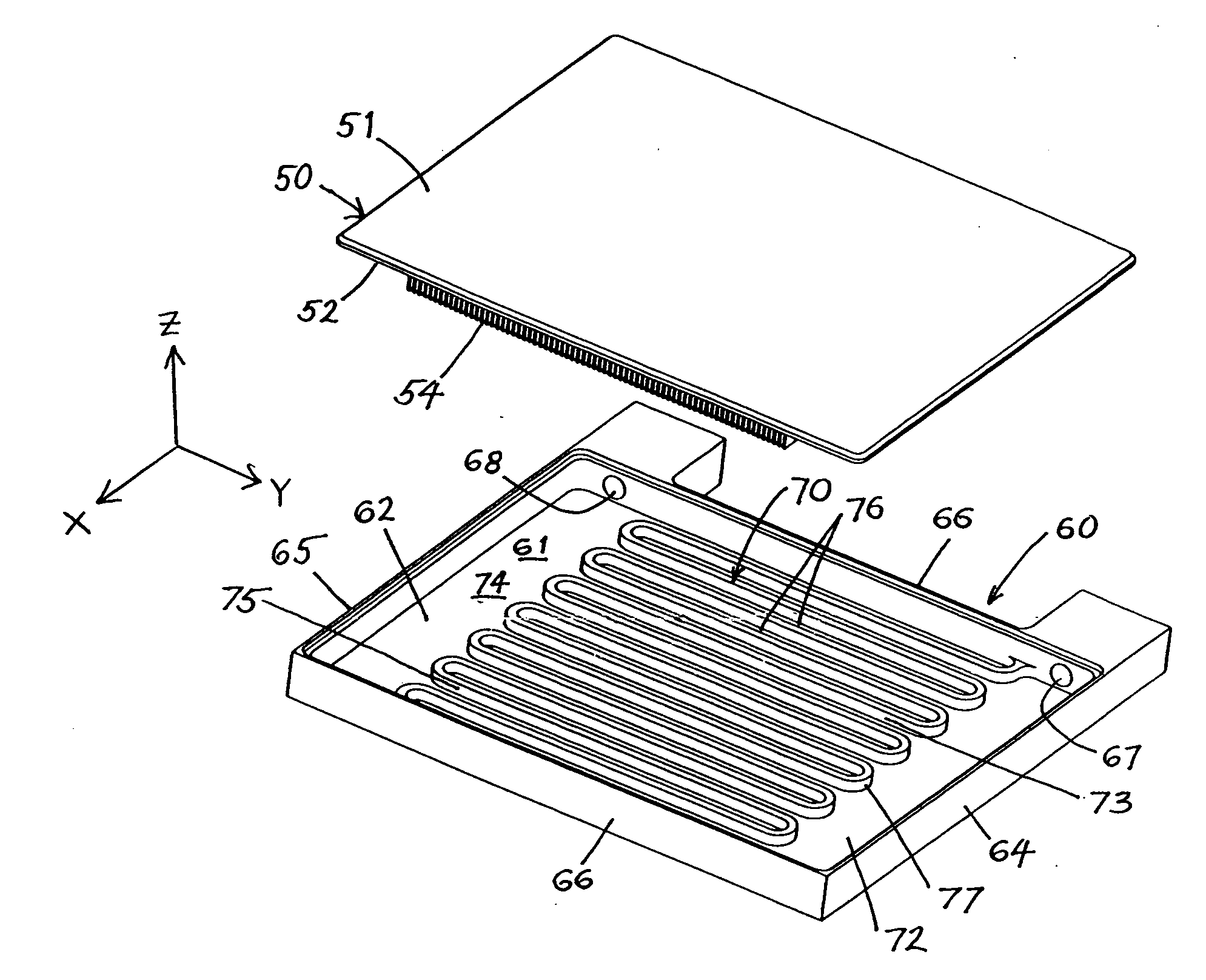

Liquid cold plate heat exchanger

InactiveUS20060096738A1Net flow rateReduce the average velocitySemiconductor/solid-state device detailsSolid-state devicesHeat transmissionCooling chamber

A heat exchanger includes a cooling plate having a heat collection surface for fixing against an object to be cooled, an opposed heat transfer surface which may be provided with fins, and a cooling chamber over the heat transfer surface, the cooling chamber having an inlet port and an outlet port for circulating a fluid through the cooling chamber via a flow path between the ports. A flow distributor in the flow path forms a plurality of inlet channels communicating with the inlet port, a plurality of outlet channels alternating with the inlet channels and communicating with the outlet port, and a plurality of flow surfaces which are spaced from the heat transfer surface by gaps. The inlet channels communicate with the gaps so that a fluid entering the inlet channels via the inlet port will flow through the gaps, into the outlet channels, and out of the chamber via the outlet port. The gaps are dimensioned to increase fluid velocity and promote mixing of the fluid, thereby improving heat transfer.

Owner:AAVID THERMALLOY LLV

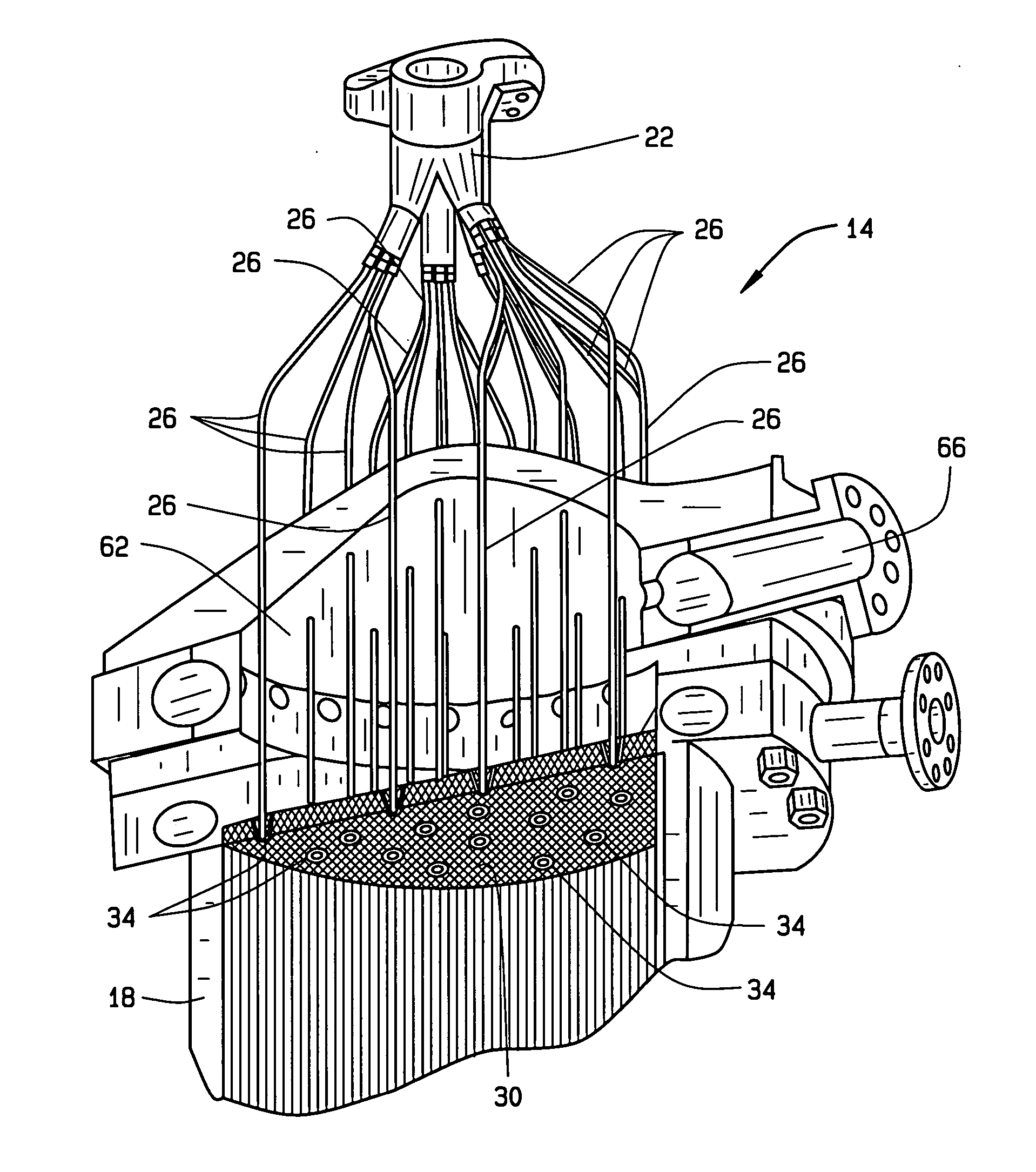

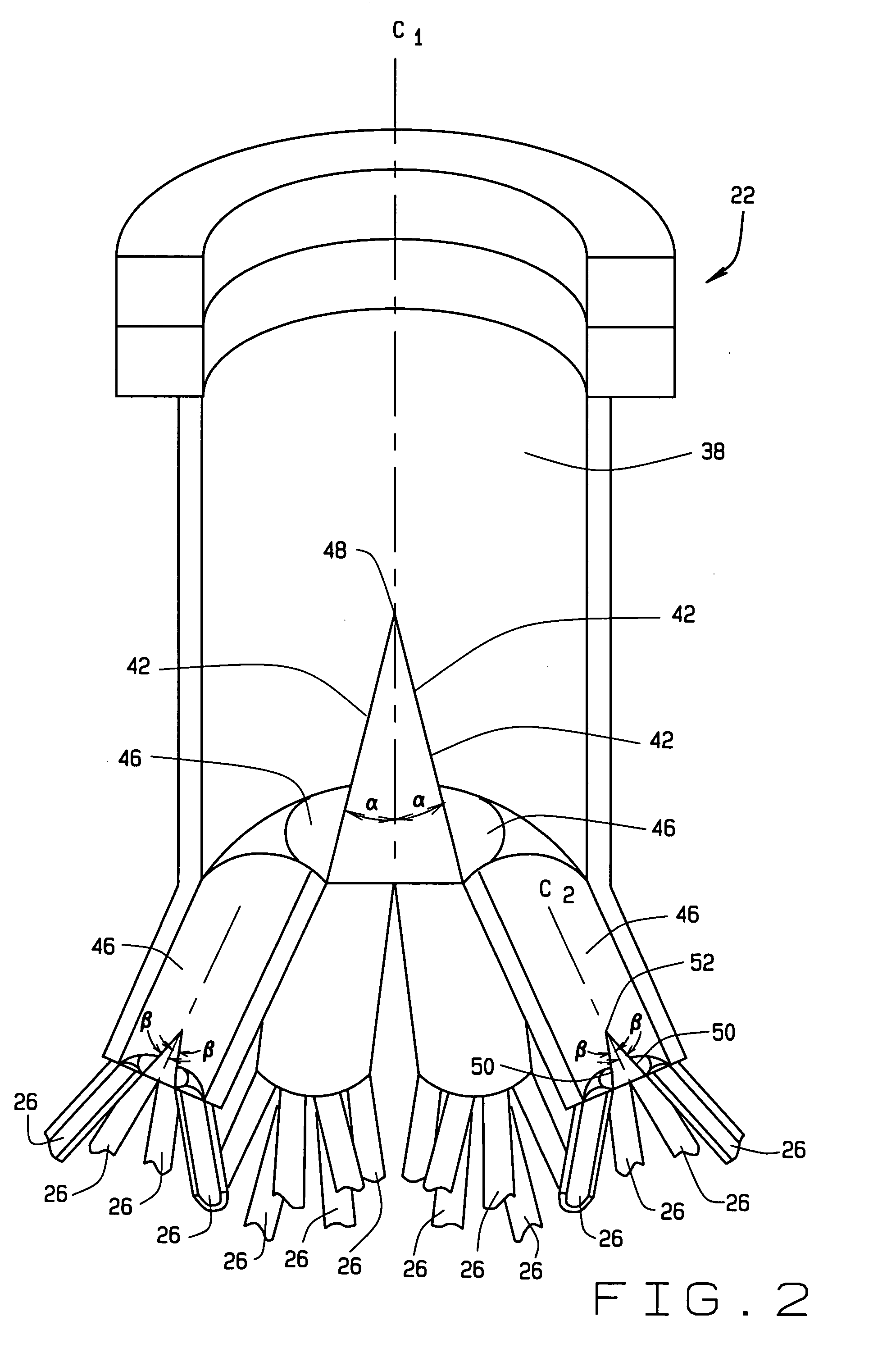

Gasifier injector

ActiveUS20060242907A1Reduce and prevent damageHigh-temperatures and abrasive matterDust removalFire preventionEngineeringHigh pressure

A gasifier injection module includes a two-stage slurry splitter and an injector face plate with a coolant system incorporated therein. The two-stage slurry splitter includes a main cavity into which a main slurry flow is provided. The main cavity includes a plurality of first stage flow dividers that divide the main slurry flow into a plurality of secondary slurry flows that flow into a plurality of secondary cavities that extend from the main cavity. Each secondary cavity includes a plurality of second stage flow dividers that divide each secondary slurry flow into a plurality of tertiary slurry flows that flow into a plurality of slurry injection tubes extending from the secondary cavities. The tertiary flows are injected as high pressure slurry streams into the gasification chamber via the slurry injection tubes. A reactant is impinged at high pressure, as an annular shaped spray, on each high pressure slurry stream via a plurality of annular impinging orifices incorporated into the injector face plate. The coolant system incorporated within the injector face plate maintains the injector face plate at a temperature sufficient to substantially reduce or prevent damage to the injector face plate by high temperatures and / or abrasive matter created by the resulting gasification reaction.

Owner:GAS TECH INST +1

Bypass lip seal

InactiveUS20080053060A1Facilitate heat exchangeTurbine/propulsion engine coolingEfficient propulsion technologiesFlow dividerLip seal

A cooling apparatus for cooling a fluid in a bypass gas turbine engine comprises a heat exchanger disposed within a bypass duct and accommodated by a sub-passage defined by a flow divider affixed to an annular wall of the bypass duct. The sub-passage defines an open upstream end and an open downstream end to direct a portion of the bypass air flow to pass therethrough. A sealing assembly for the bypass duct is also provided.

Owner:PRATT & WHITNEY CANADA CORP

Downhole surge reduction method and apparatus

A method and apparatus for use in the oil well industry for running in drilling / production liners and sub-sea casings down a borehole through drilling fluid on a drill pipe using a multifunction diverter tool with the benefits of surge pressure reduction are disclosed. In accordance with the present invention, a multi-function diverter tool includes a housing assembly with a set of flow holes formed therein and a sliding sleeve arranged within the housing assembly having two sets of flow ports formed therein at different axial locations along the sleeve. By aligning either set of flow ports of the sleeve with the flow holes of the housing, the tool is set in a "surge pressure reduction" mode. By shifting, or axially indexing, the sleeve downward, the set of flow holes becomes blocked by the sleeve thus setting the tool in a "circulation" or "cementing" mode. This shifting or indexing is accomplished using an indexing mechanism. The multi-function diverter tool of the present invention can be shifted from a first "surge pressure reduction" mode to a "circulation mode," from the "circulation mode" to a second "surge pressure reduction" mode, and finally from the second "surge pressure reduction" mode to a "cementing" mode. The indexing mechanism of the present invention includes a return spring and brake system which provides the tool with more reliable shifting functionality.

Owner:ALLAMON INTEREST

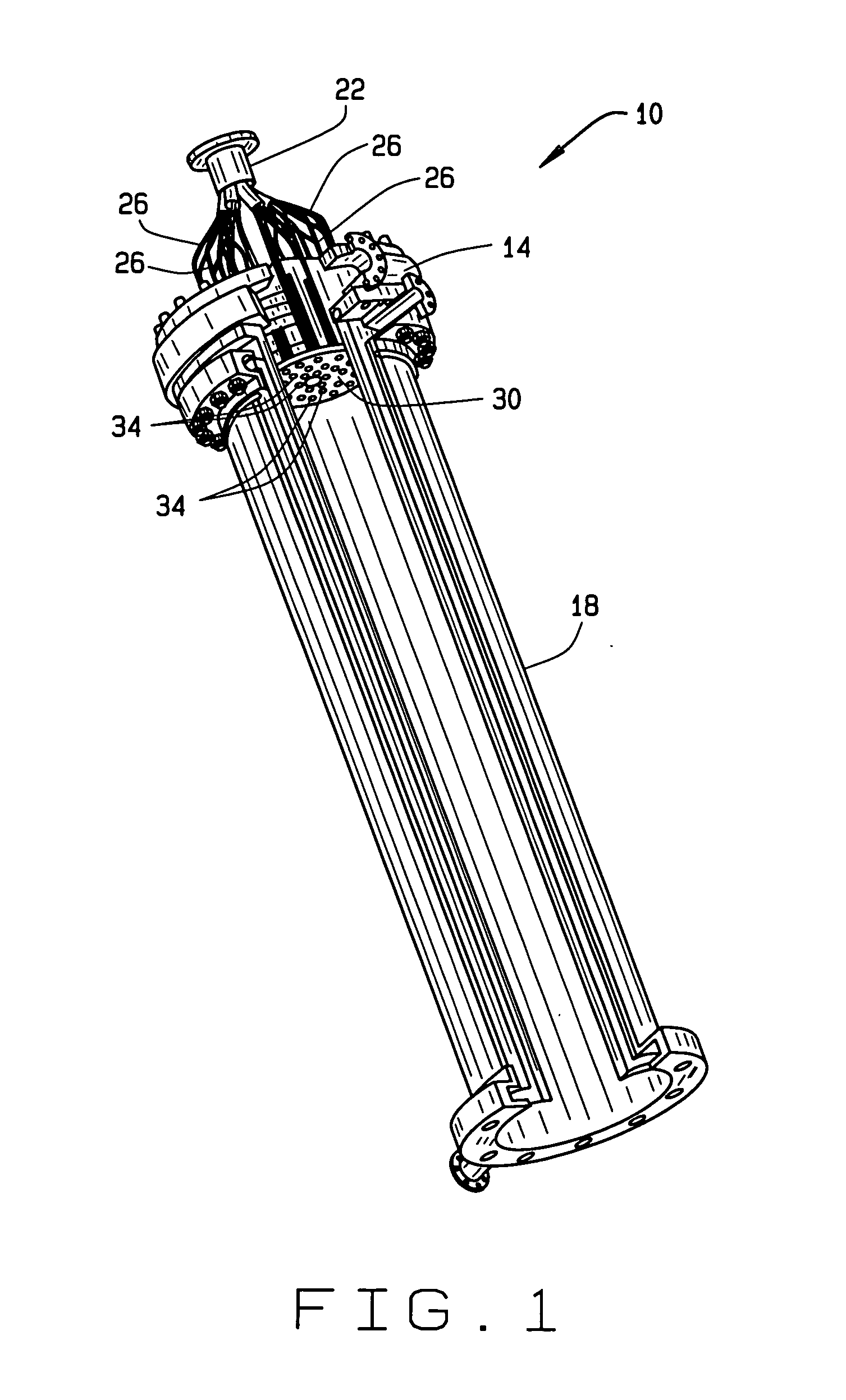

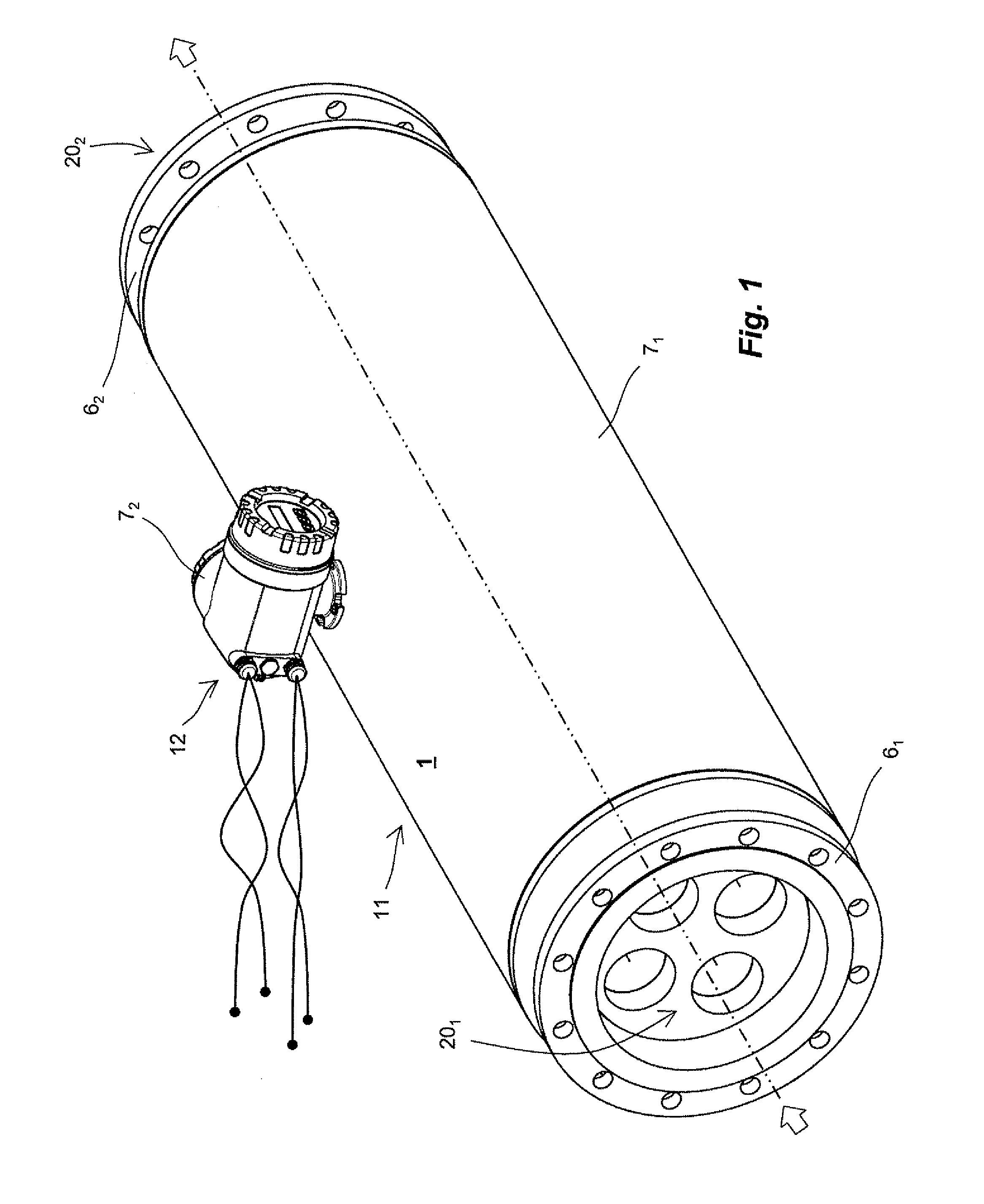

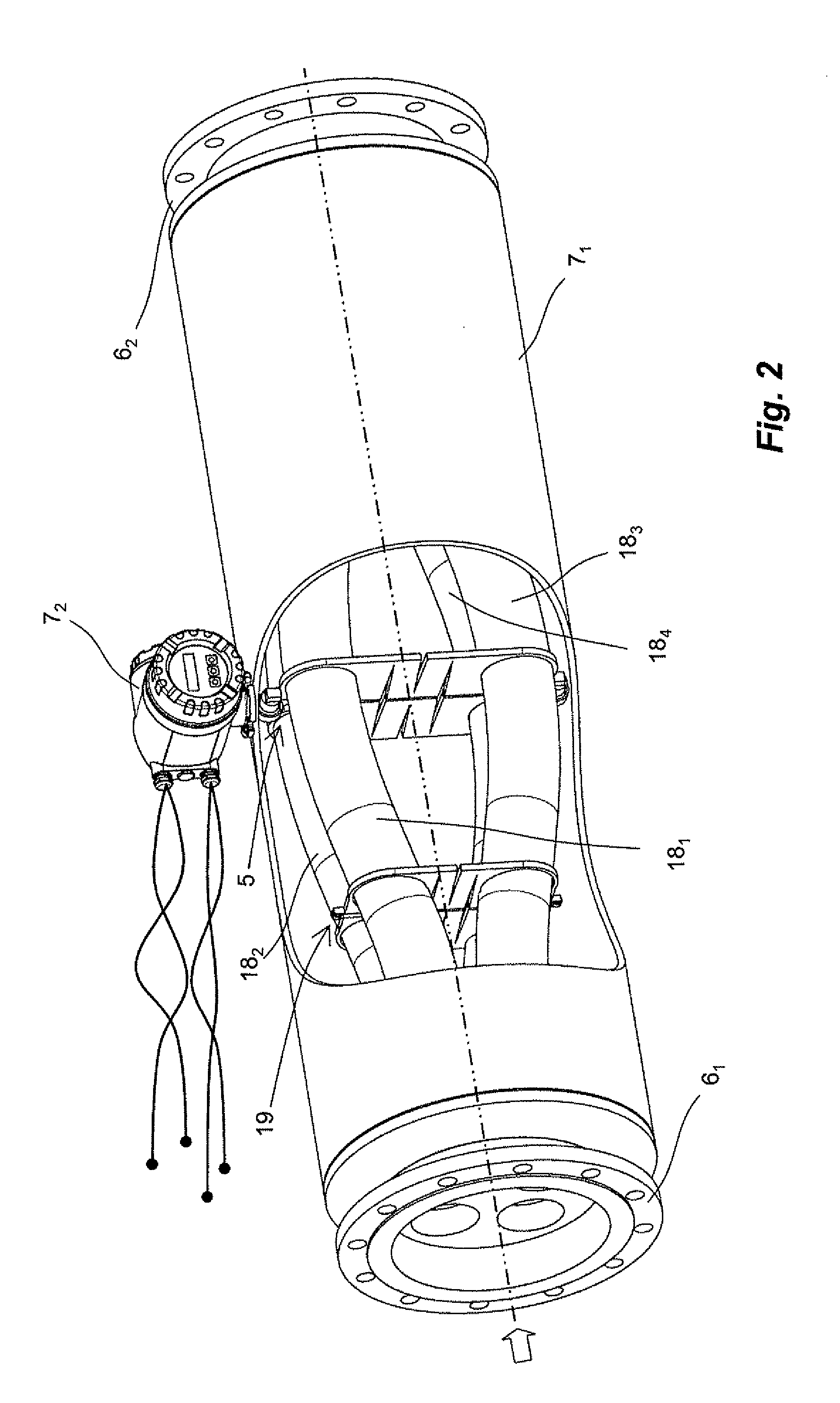

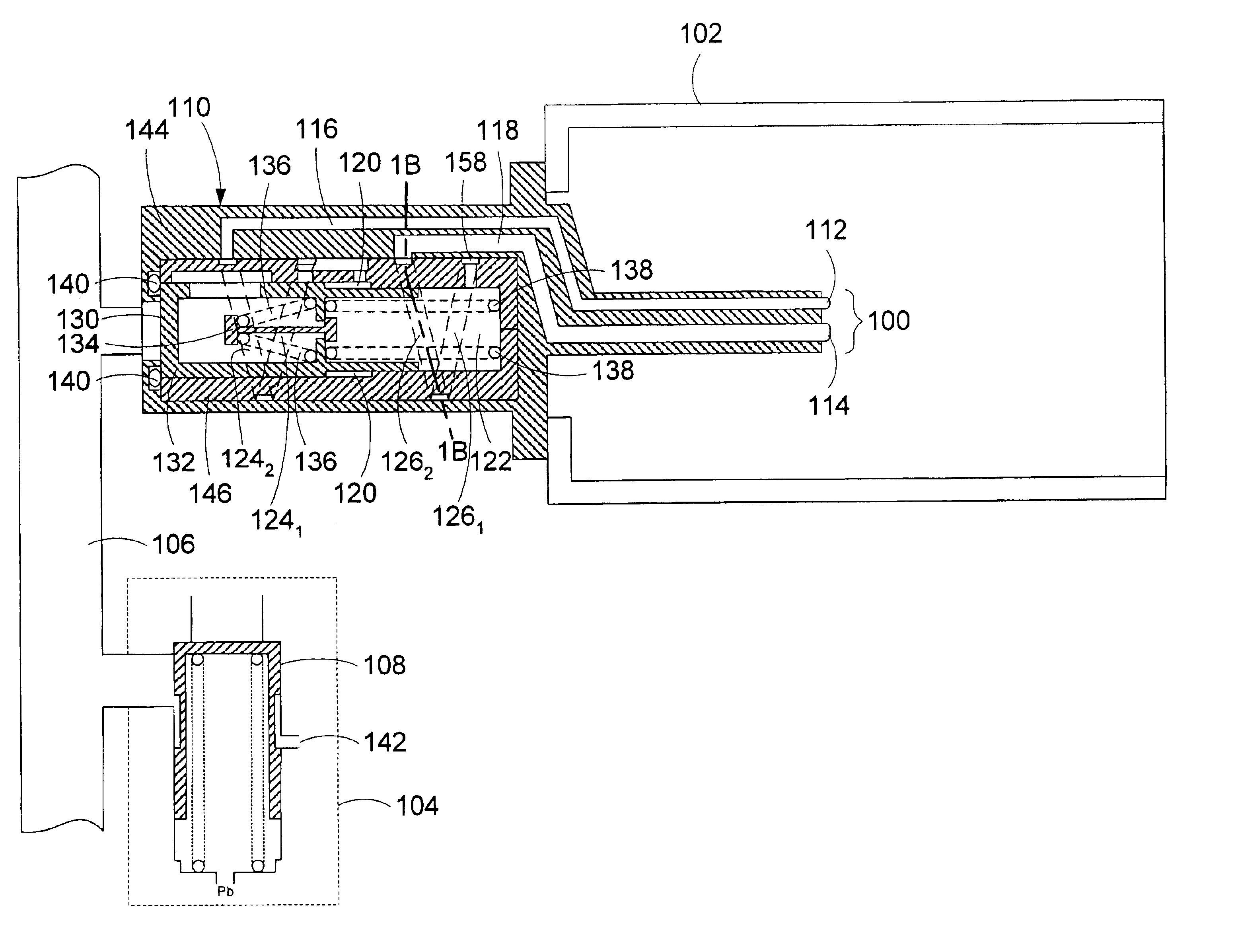

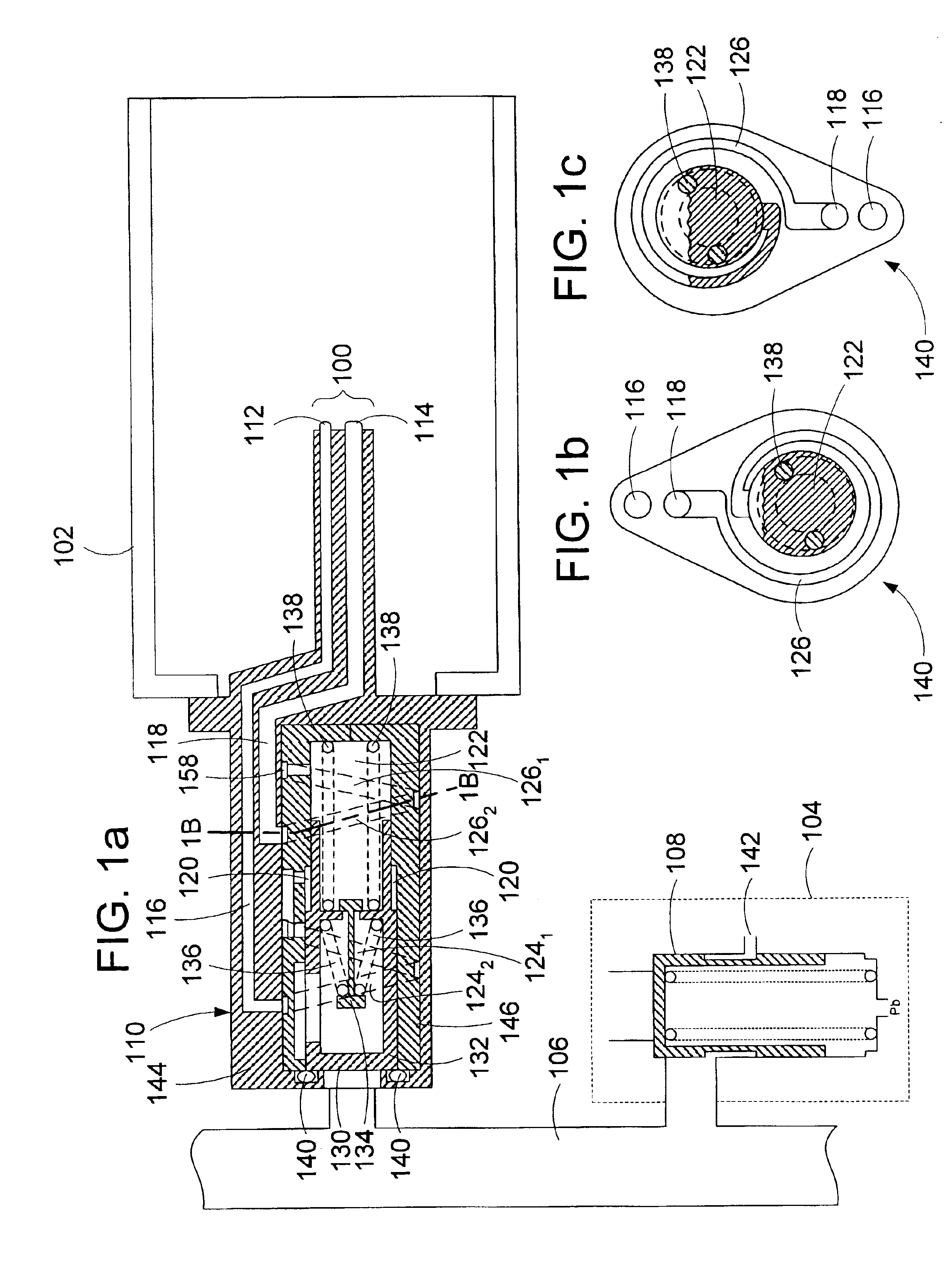

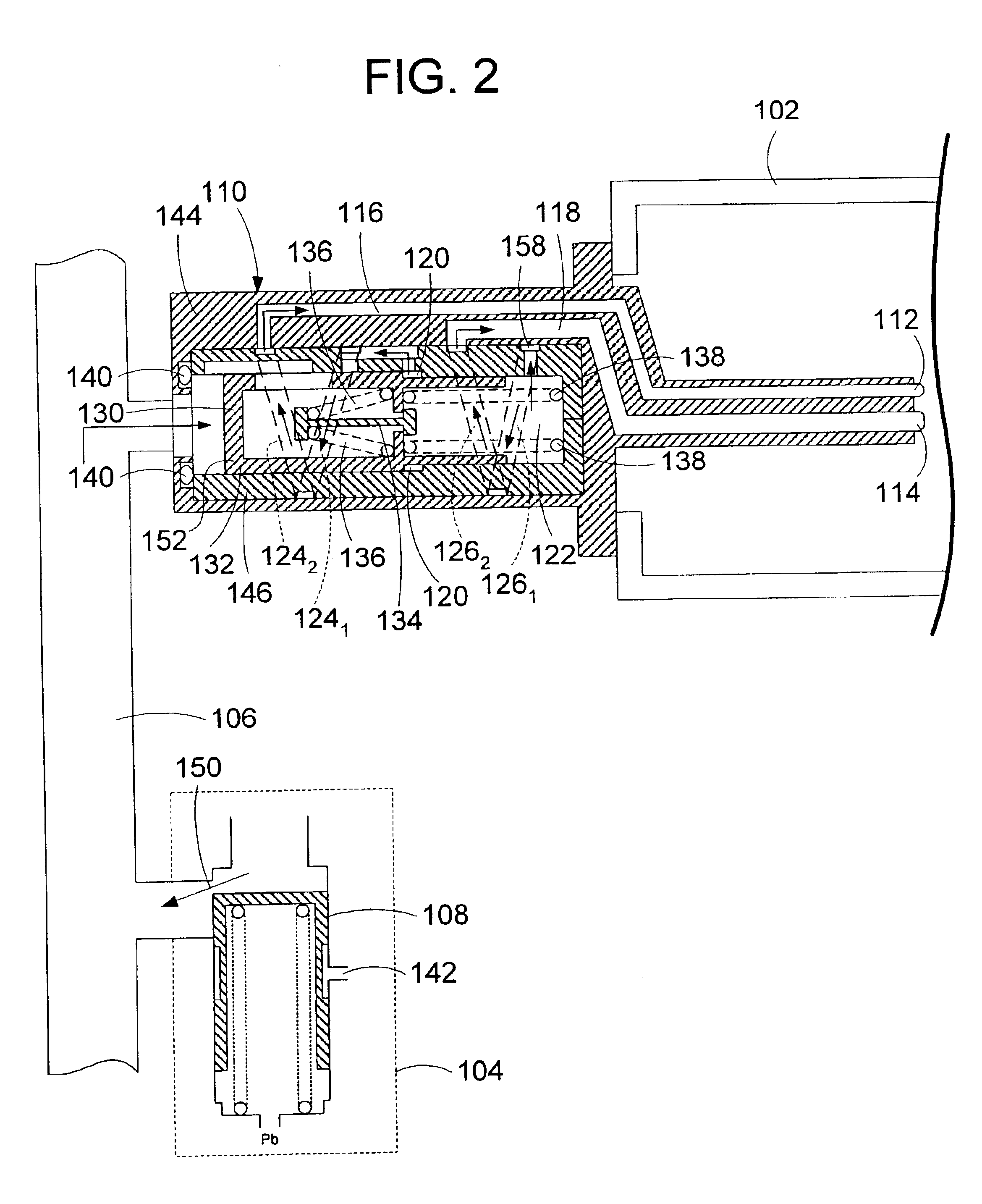

Measuring transducer of vibration-type

ActiveUS20110167907A1Impairs accuracy of measurementMeasurement accuracySpecific gravity using flow propertiesVolume variation compensation/correction apparatusSection planeTransducer

The measuring transducer comprises: a transducer housing, of which an inlet-side, housing end is formed by means of a flow divider including four flow openings spaced, and an outlet-side, formed by means of a flow divider including four flow openings spaced, from one another. A tube arrangement including four curved measuring tubes connected to the flow dividers for guiding flowing medium along flow paths connected in parallel. Each measuring tubes opens with an inlet-side, measuring tube end into one of the flow openings of the flow divider and with an outlet-side, measuring tube end into one the flow openings of the flow divider. The two flow dividers are embodied and arranged in the measuring transducer, so that the tube arrangement extends both between a first and a second of the measuring tubes and between a third and a fourth of the measuring tubes. An imaginary longitudinal-section plane, with respect to which the tube arrangement is mirror symmetric and perpendicular to the imaginary longitudinal-section plane, an imaginary longitudinal-section plane, with respect to which the tube arrangement likewise is mirror symmetric. An electromechanical exciter mechanism of the measuring transducer serves for producing and / or maintaining mechanical oscillations of the four measuring tubes.

Owner:ENDRESS HAUSER FLOWTEC AG

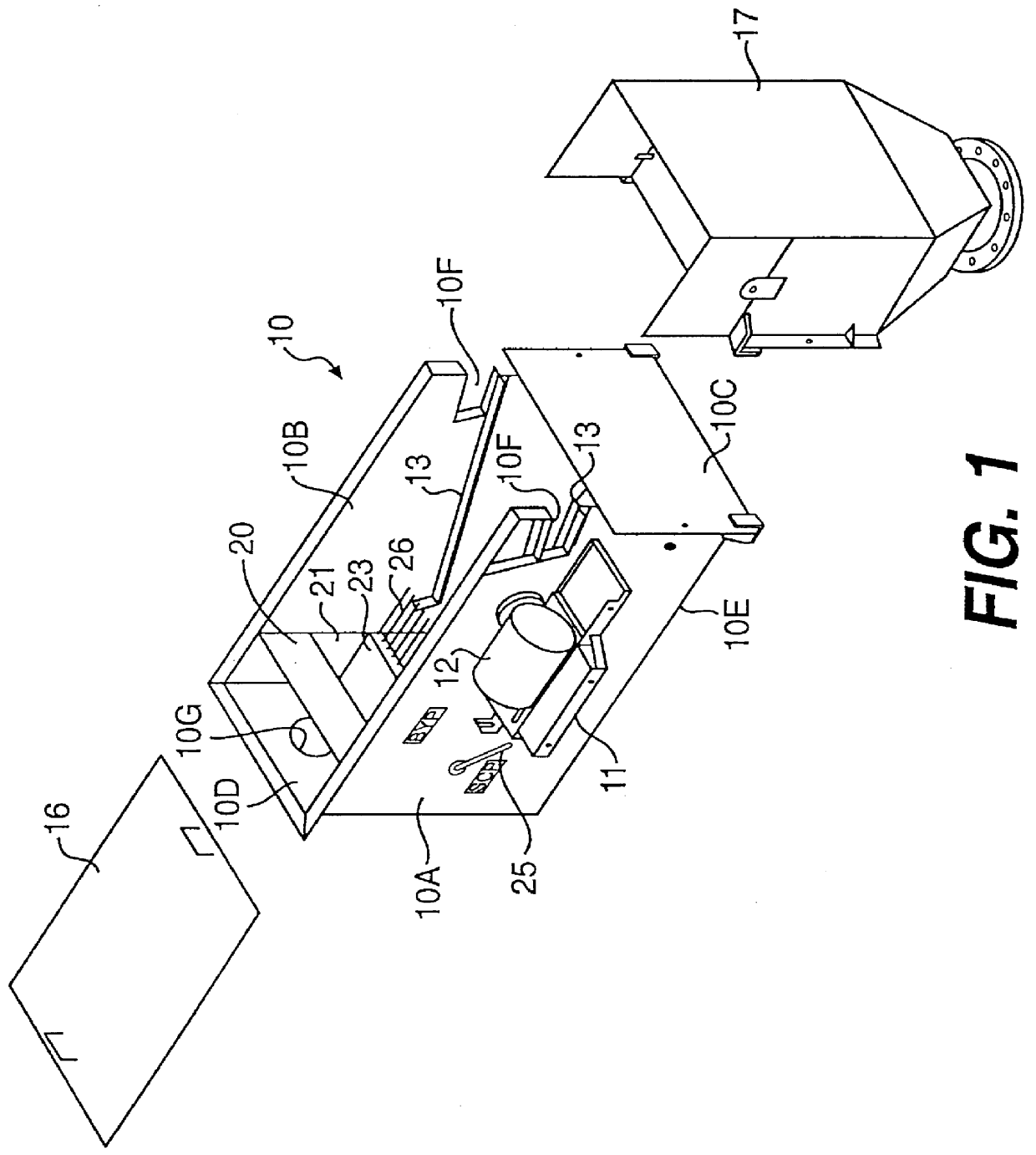

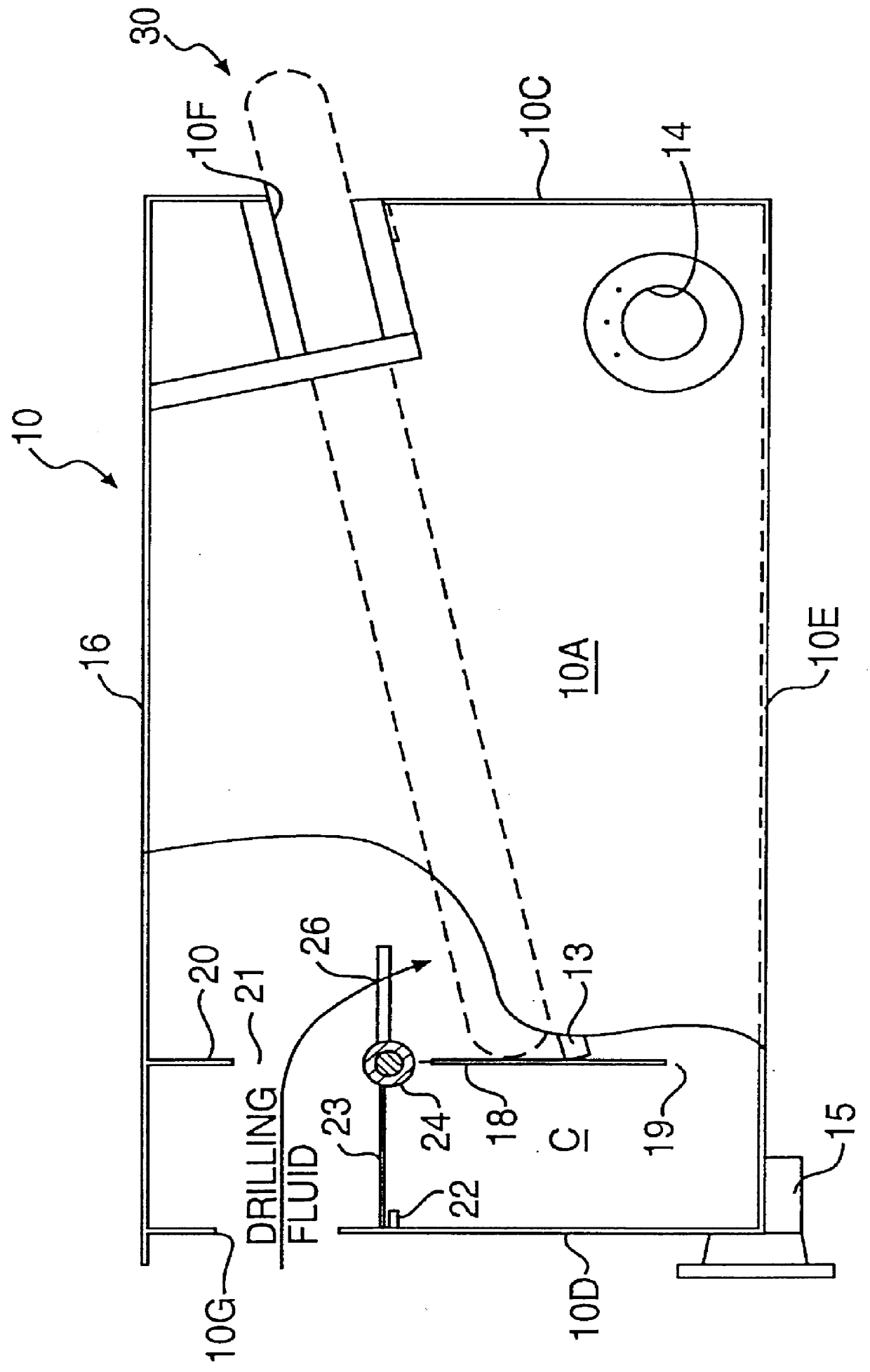

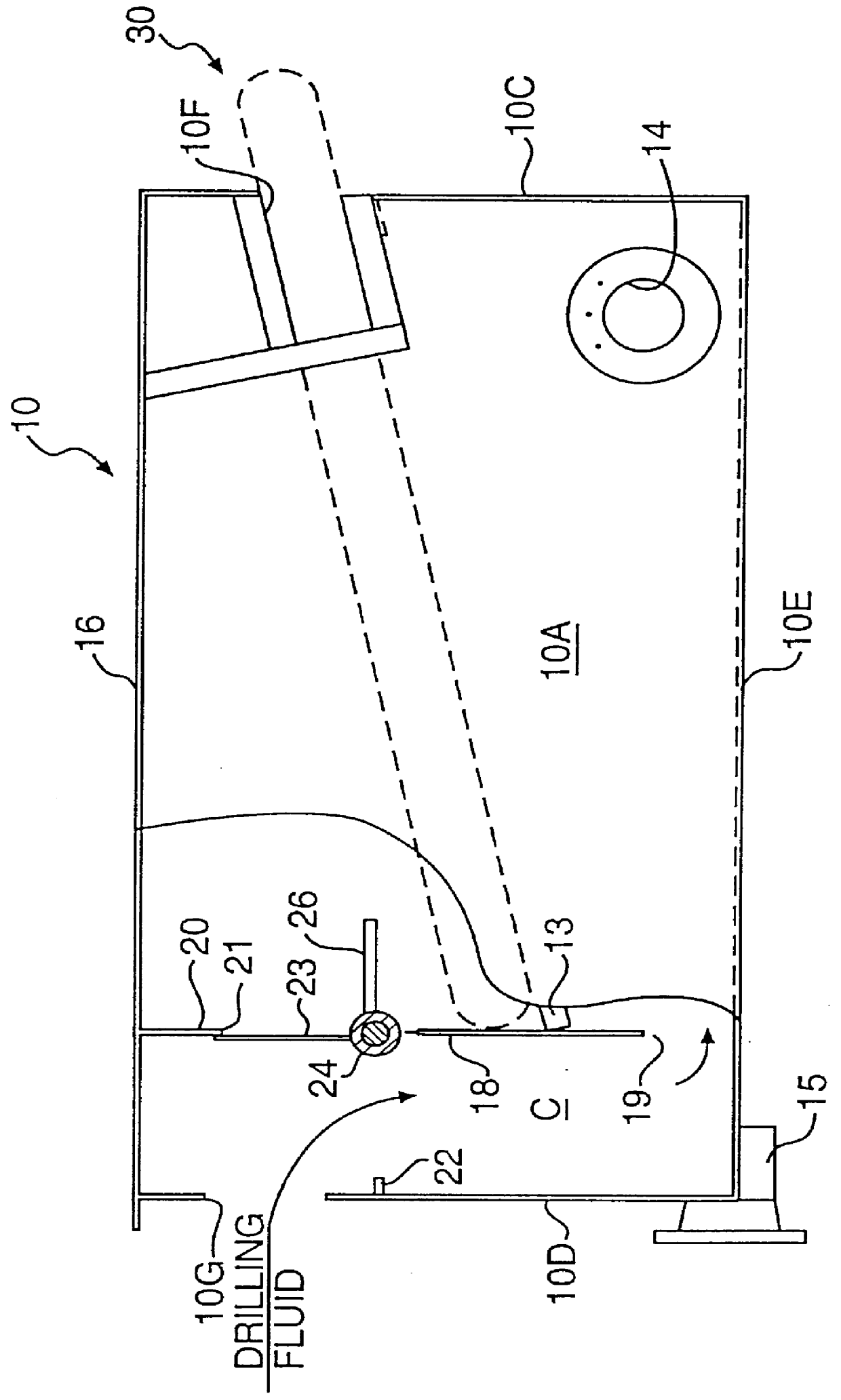

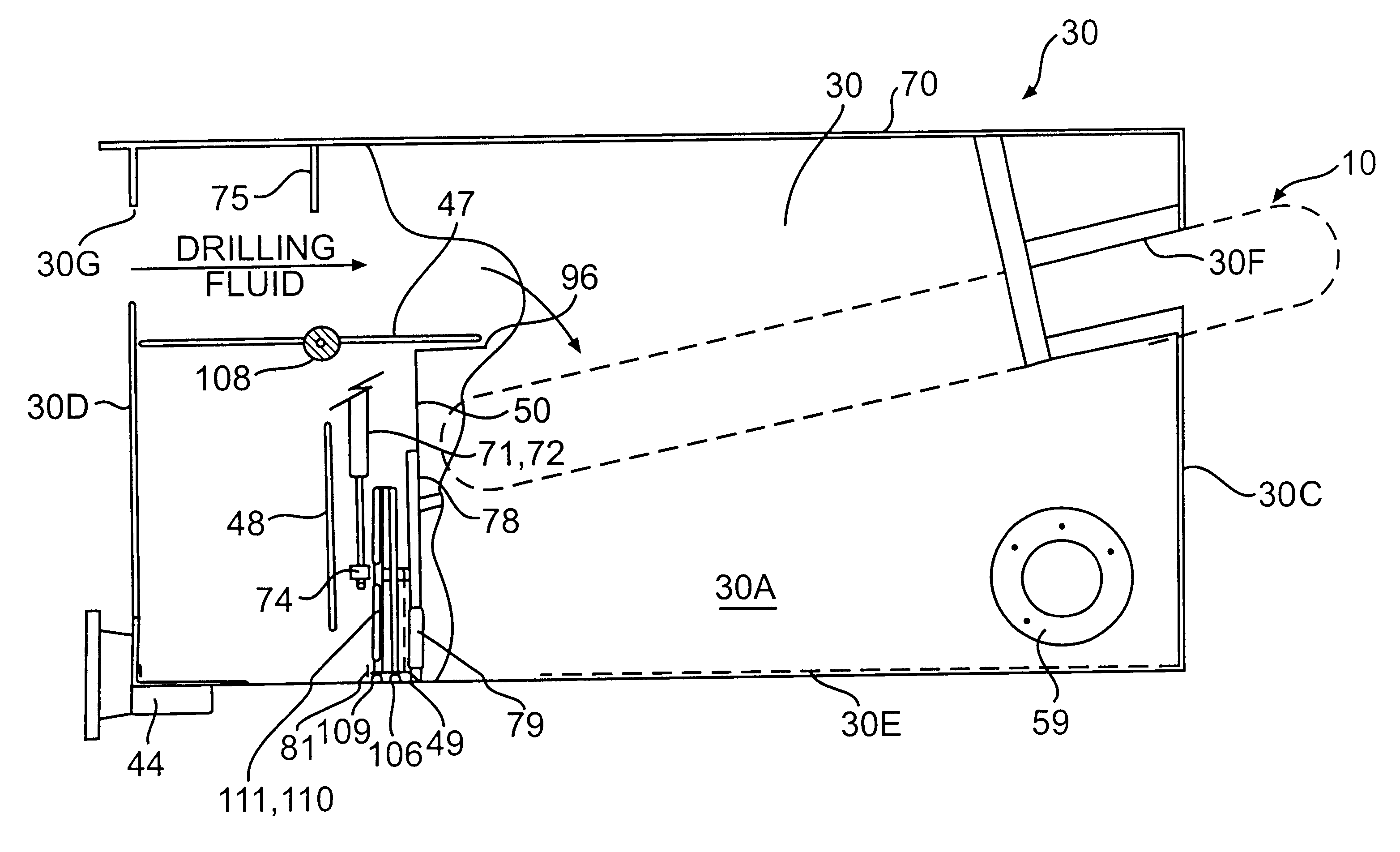

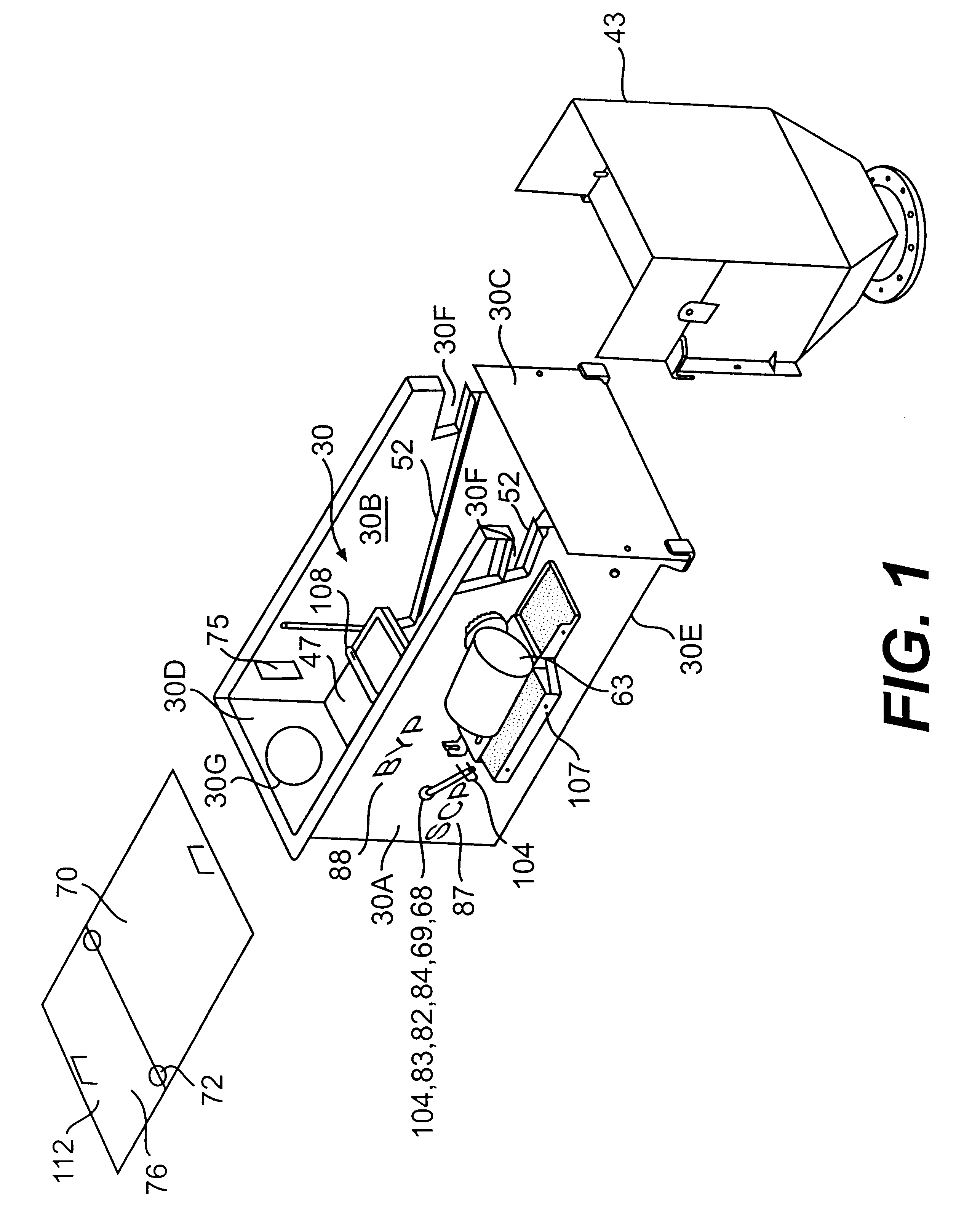

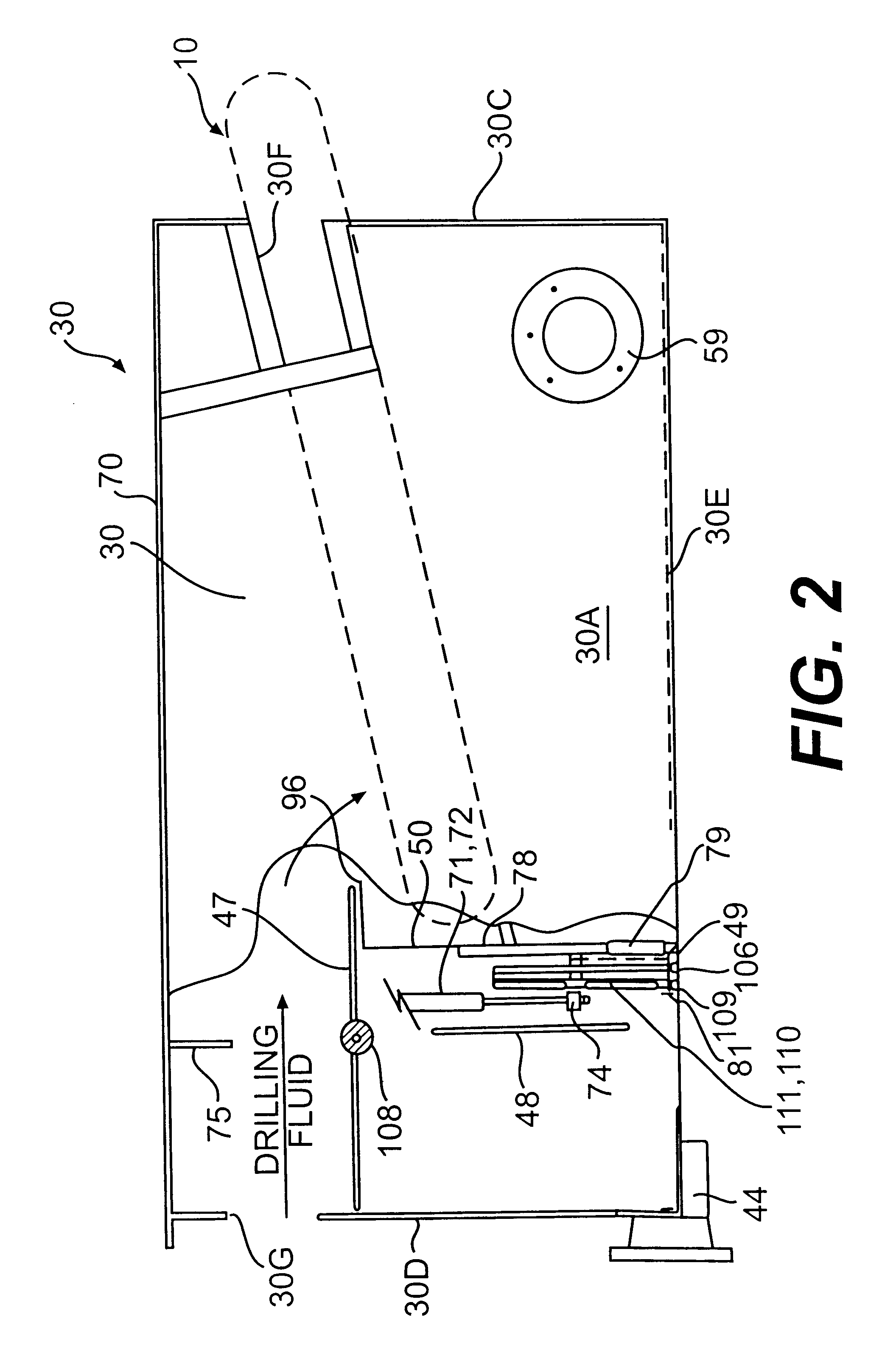

Bypass diverter box for drilling mud separation unit

A bypass diverter box disposed upstream from conventional solids control equipment of a mud system of a drilling rig contains a drilling mud separation unit having a continuous-loop scalper screen that is driven in a continuous loop to separate, convey and discharge large amounts of gumbo, heavy clays and drill solids at the end of the separation unit. The flow divider box is a box-like housing with a verter plate, upper and lower baffle plates and a grate that allows drilling fluid or drilling mud to be selectively directed to the mud separation unit to be separated prior to passing to the conventional downstream solids control equipment or allows the fluid to bypass the separation unit and flow directly to the conventional solids control equipment. The bypass diverter box baffle plates, diverter plate and grate, and selective utilization of the mud separation unit removes large amounts of gumbo, heavy clays and drill solids from the drilling mud and allows high flow rates to be easily processed by shale shakers and other conventional downstream solids control equipment of the mud system and compliments the drilling operations with respect to changes in the lithology, geological formations, or loss of returns in relation to the gallons pumped or folume of drilling fluid or drilling mud entering the bypass diverter box.

Owner:TUBOSCOPE NU TECGNT

Branched flow filtration and system

InactiveUS7410581B2Improve operationImprove performanceMembranesReverse osmosisCross-flow filtrationReverse osmosis

A cross flow filtration apparatus for nanofiltration or reverse osmosis has pressure vessels with a plurality of filter cartridges in each vessel. A feed port is provided at an intermediate position on the side of the vessel, and two permeate flows or branches exit opposite ends of the vessel, and the first branch has a characteristically high “upstream” flux and quality, while the second is of lesser flux and / or quality. The system provides a high degree of moduarity, enhancing flux or yield at a reduced driving pressure or overall pressure drop. Centered or off-center port, and a stop or valve in the permeate stream may apportion flows between the two outlets. Staged systems may employ a first stage bypass to achieve a target quality with increased yield. A flow divider or adaptor permits the cartridges to fit and seal in the vessel and an installation tool or sleeve may facilitate installation or replacement of cartridges having a directional perimeter seal. A tool permits modules to be bi-directional installed in the pressure vessel. Other embodiments involve adapting a conventional vessel designed for end-to-end feed flow utilizing a restrictor, obstruction or valve inside the filter cartridge to bifurcate or otherwise split or apportion the permeate. RO elements may be modified to movably position an obstruction or valve along a string of the elements and vary the take-off to two or more permeate outlets, or to provide pressure relief valves that present different pressure conditions for different elements of a string. A pressure vessel may have an intermediate inlet, with symmetric or asymmetric branching of permeate flow to opposed ends of the vessel, enhancing permeate flux, permeate quality and / or energy efficiency.

Owner:IONICS INC

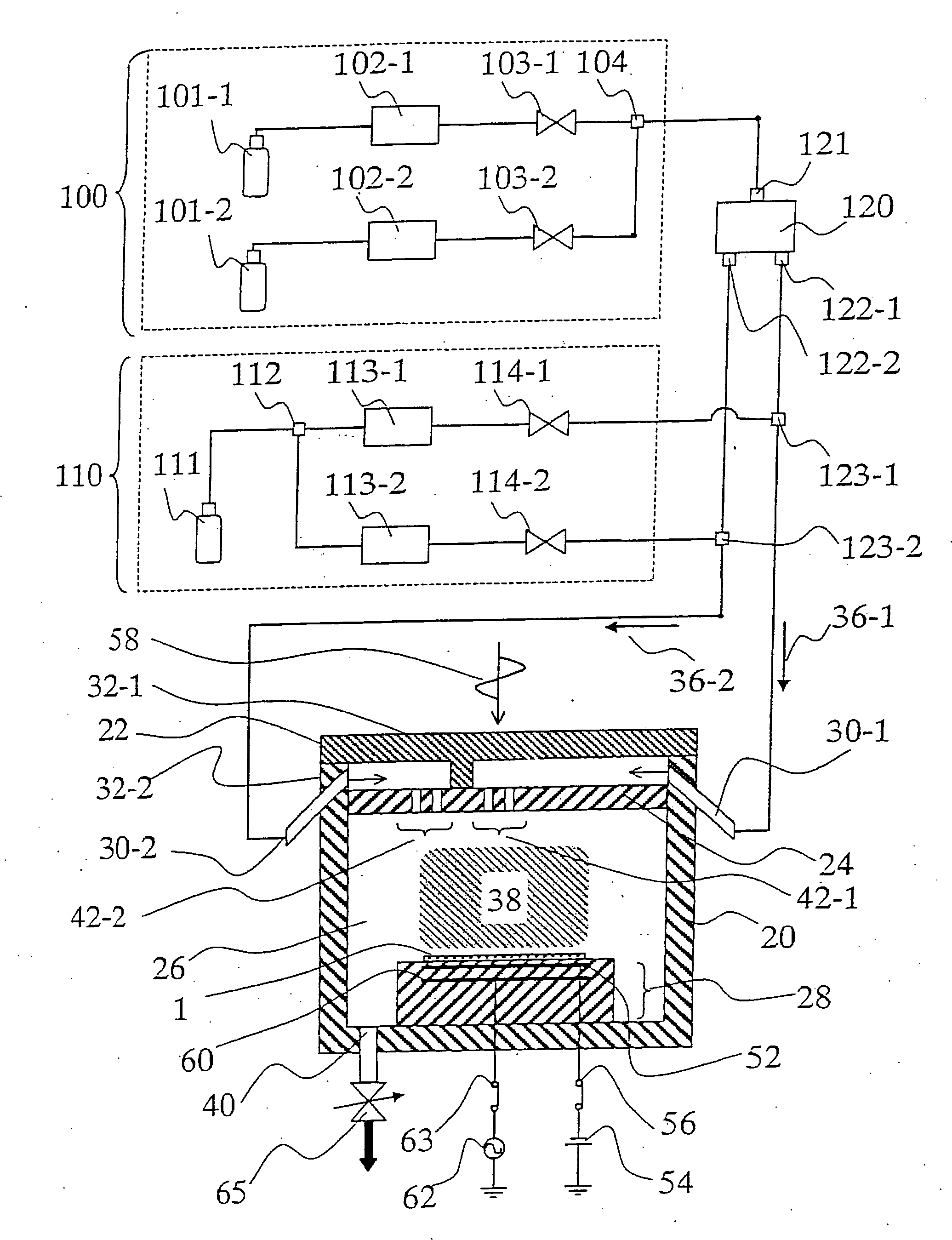

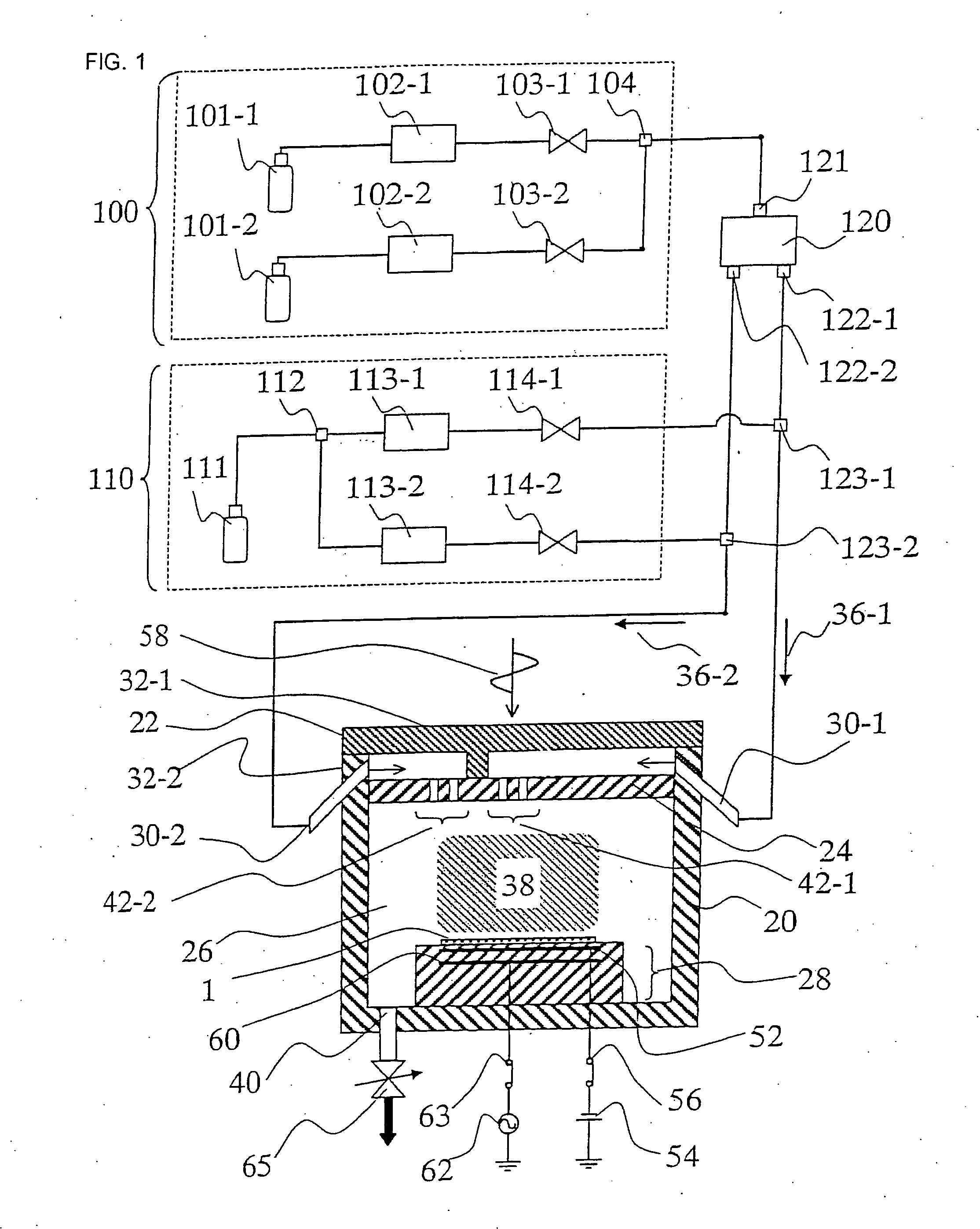

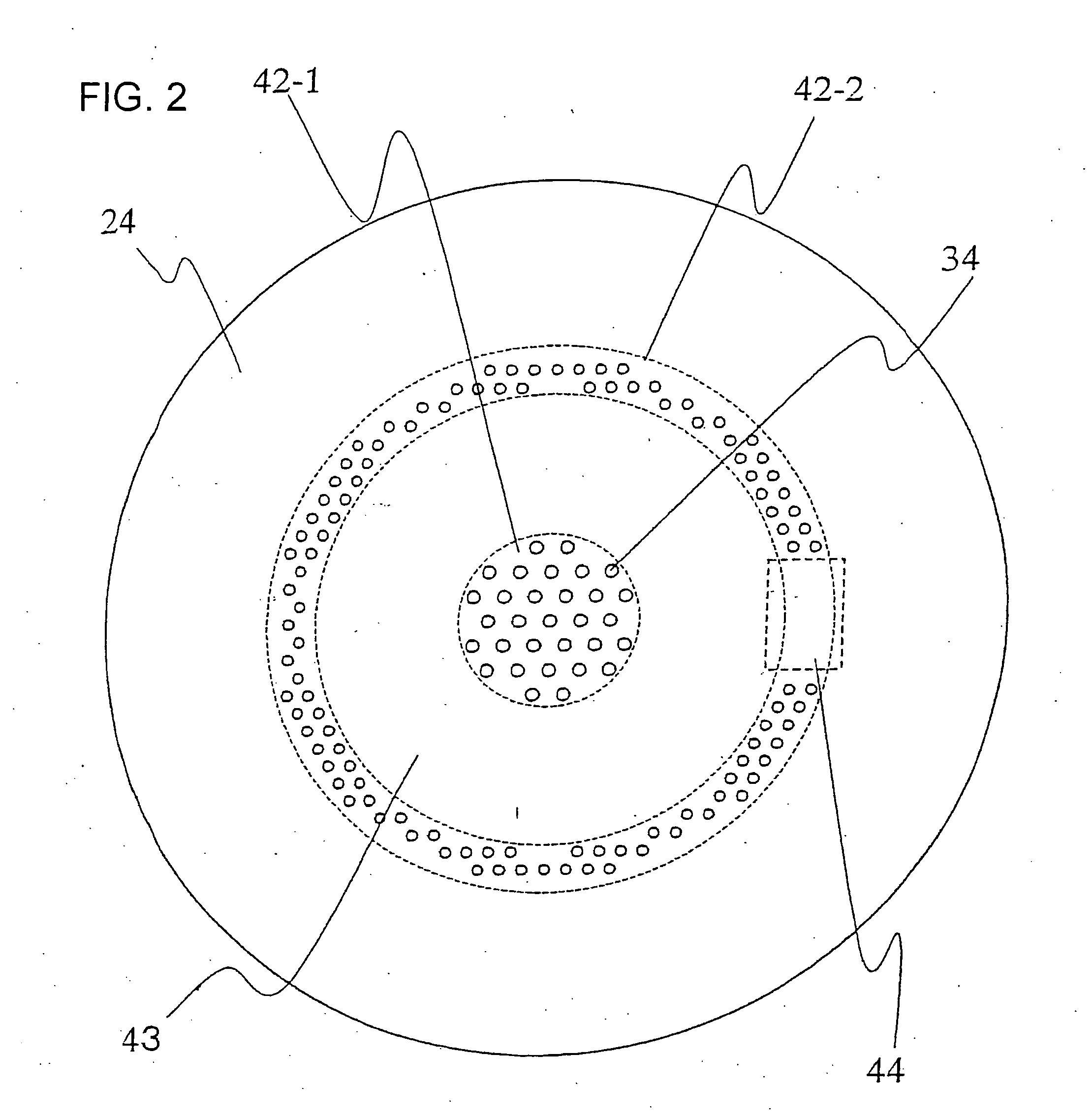

Plasma etching apparatus and plasma etching method

InactiveUS20060169671A1High in-plane uniformityImprove in-plane uniformityElectric discharge tubesDecorative surface effectsIn planeProcess engineering

To provide a plasma etching apparatus that achieves a high in-plane uniformity of the CD shift. A plasma etching apparatus includes: a process chamber 26 in which a plasma etching process is performed on a process target object 1; A first gas supply source 100 for supplying a first process gas; a second gas supply source 110 for supplying a second process gas; a first gas introduction area 42-1 having a first gas introduction port for introducing the first process gas into the process chamber 26; a second gas introduction area 42-2 having a second gas introduction port 3 for introducing the second process gas into the process chamber 26; flow controllers 102, 113 for adjusting the flow rates of the process gasses; and a gas flow divider 120 for dividing the process gas into a plurality of gas flows, in which the first gas introduction port and the second gas introduction port are provided substantially in the same plane, and the first gas introduction area 42-1 and the second gas introduction area 42-2 are separated from each other.

Owner:HITACHI LTD +1

Base unit for breathing gas heating and humidification system

A base unit for use in a breathing gas heating and humidification apparatus includes a gas source configured to generate an initial gas flow, the gas source having a gas source outlet and a flow divider in fluid communication with the gas source outlet. The flow divider is configured to divide the initial gas flow into a first flow of gas and a second flow of gas. The flow divider includes a first compartment including a first gas flow path for the first flow of gas and a second compartment including a second gas flow path for the second flow of gas. A heater is disposed in the second compartment. A method for use in generating breathing gas and insulating gas from a gas source is also disclosed.

Owner:VAPOTHERM INC

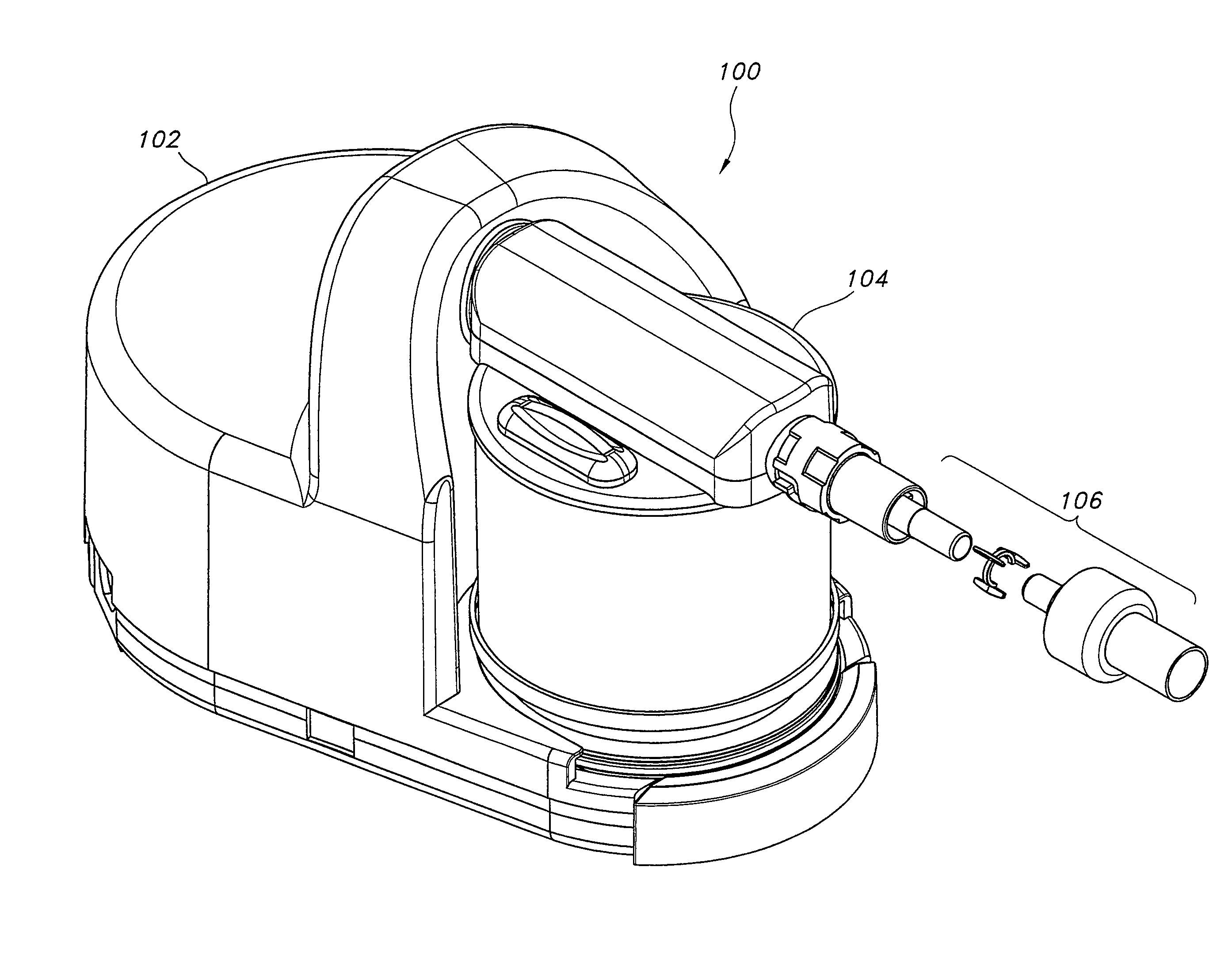

Humidifier for breathable gas apparatus

A humidifier for use with a breathable gas supply apparatus includes a hollow body adapted for partial filling with water to a predetermined maximum water level, a gas inlet to the body above the maximum water level and a gas outlet from the body above the maximum water level. The humidifier further includes a temperature heating element for heating the water and / or an adjustable flow divider adapted to divide the interior of the body above the maximum water level into a relatively dry gas region and a relatively wet gas region. The position of the divider is variable so as to vary the relative proportion of the gas flowing from the inlet to the outlet that passes through the relatively dry and relatively wet gas regions to thereby vary the amount of humidification thereof.

Owner:RESMED LTD

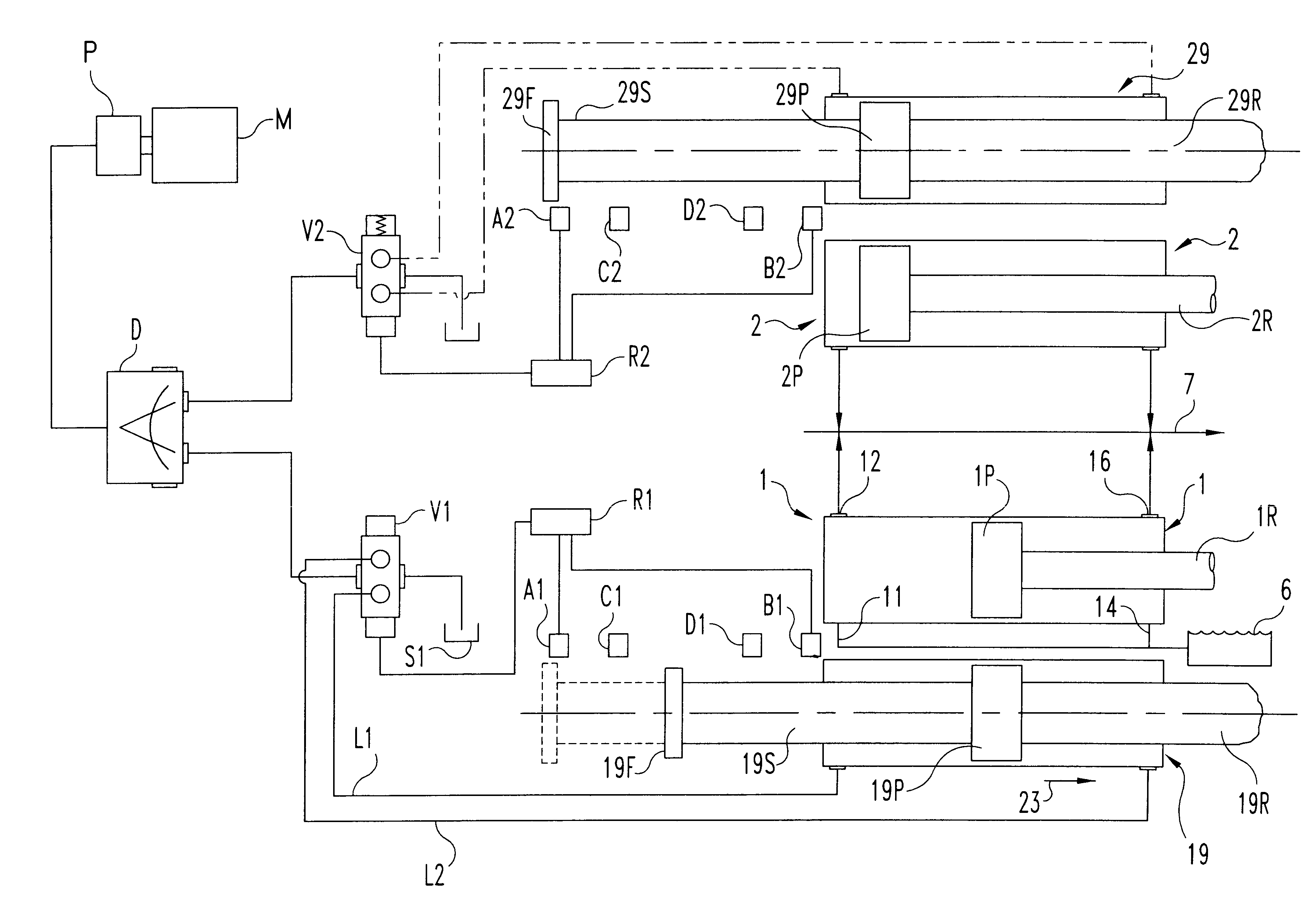

Hydraulic cylinder powered double acting duplex piston pump

A mud pump is provided with two cylinders for pumping mud in connection with water well drilling, and two sets of hydraulic oil cylinders with pistons connected to and driving the pistons of the mud pump by piston rod connecting plates. A flow divider located downstream from a hydraulic oil power supply pump applies hydraulic power evenly to two sets of mud pump driving cylinders, but the flow divider accommodates re-routing of hydraulic oil to one driving cylinder during a directional valve shift for the other driving cylinder. Rod position sensing switches coupled to an electro-hydraulic control system coordinates the action of the sets of pump driving cylinders and thereby of the mud pumping cylinders, to control and phase the mud driving pistons produce a steady mud pump output simulating the effect of constant velocity pistons.

Owner:LAIBE CORP

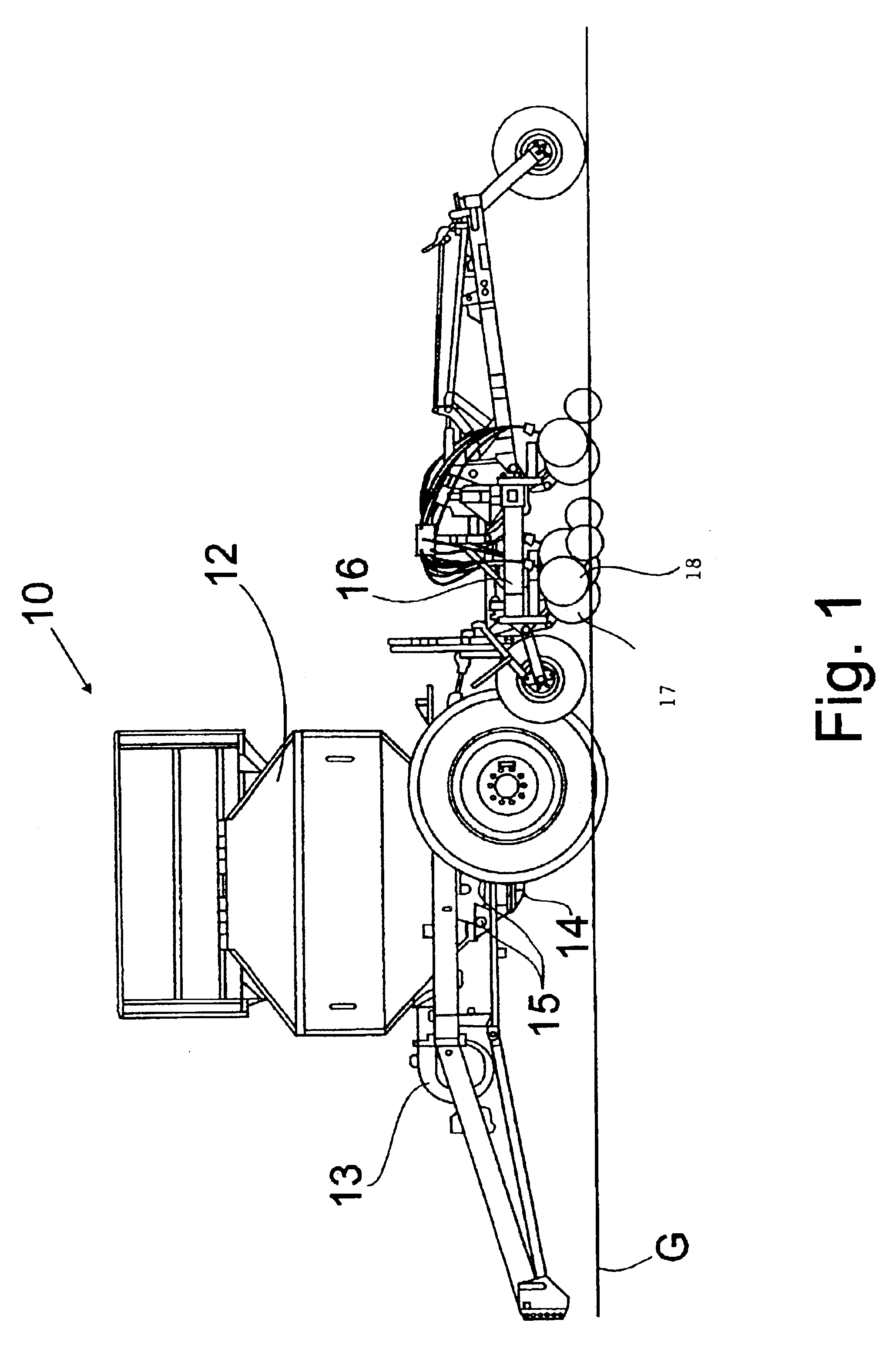

Variable rate meter drive system

InactiveUS6851377B2Efficiently usReduce manufacturing costServomotorsServometer circuitsHydraulic fluidControl theory

A hydraulic drive system provides a priority flow of hydraulic fluid to a variable rate drive system for powering the operation of the metering mechanisms before hydraulic fluid is supplied to a secondary drive mechanism for powering the operation of secondary devices, such as the fan mechanism or the loading auger. The hydraulic drive system includes a priority flow divider valve that diverts a predetermined flow rate to the variable rate drive system. The variable rate drive system includes a drive mechanism arranged in series for a plurality of metering mechanisms. The secondary drive system includes a selector valve that permits a selection between the alternative secondary devices. An alternative embodiment of the hydraulic drive system includes a counter balance valve that operates to provide a priority flow to the variable rate drive system.

Owner:CNH IND CANADA

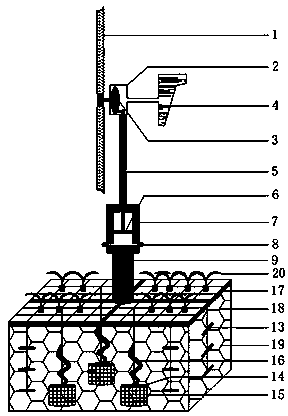

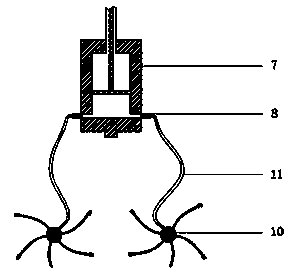

Wind and light coupled oxygen-enriched nanometer matrix composite ecological floating bed

InactiveCN103359834AHigh efficiency in removing pollutantsImprove efficiencyTreatment with aerobic and anaerobic processesEnergy based wastewater treatmentEmergent plantFlywheel

Owner:HOHAI UNIV

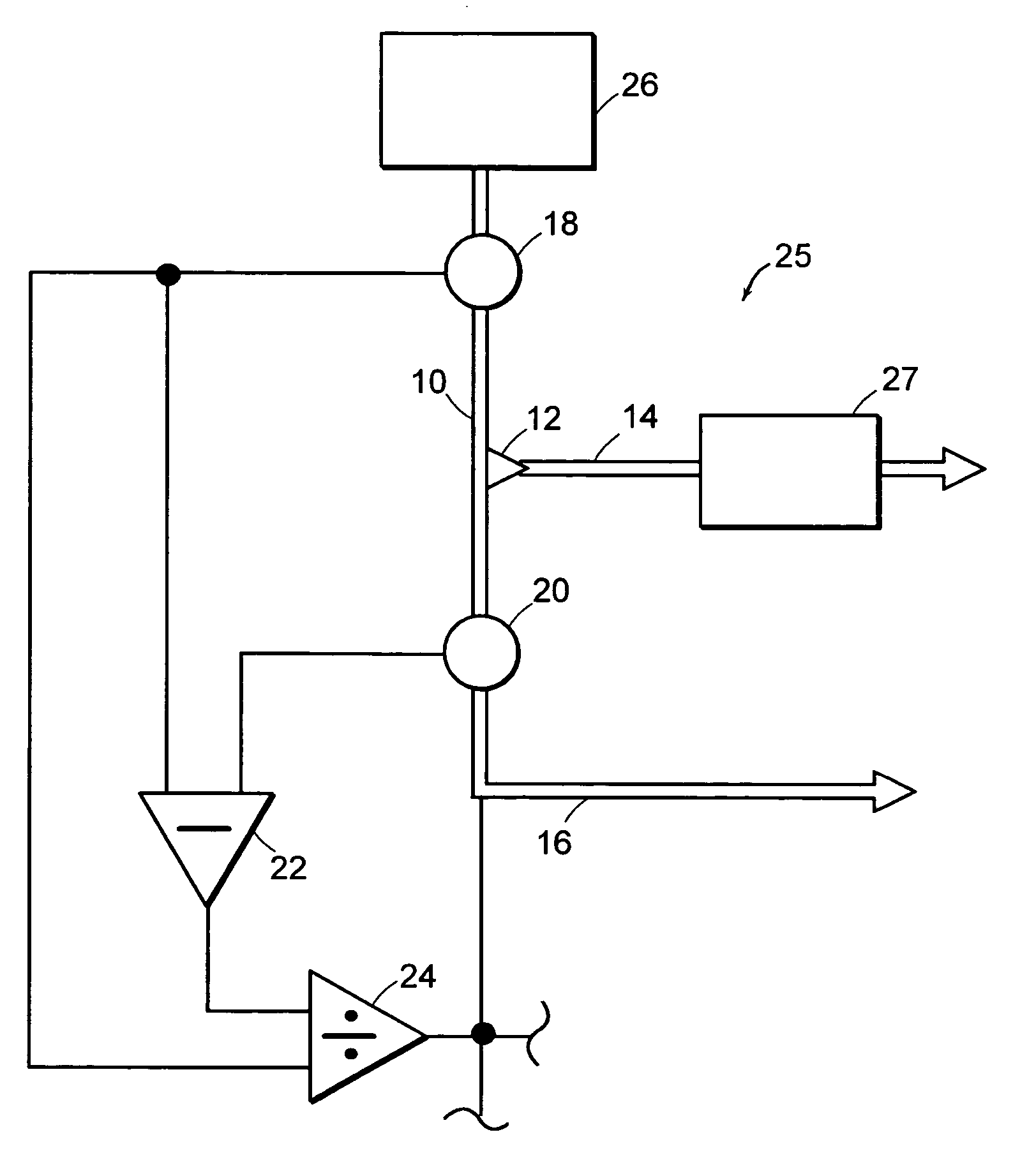

Flow sensing apparatus

ActiveUS20050109698A1Improve accuracyGood precisionComponent separationIon-exchanger regenerationFlow transducerStream flow

A method and apparatus for monitoring and controlling the nano-scale flow rate of fluid in the operating flow path of a HPLC system. A first flow sensor is disposed in a first flow path between a first flow-divider and a fluidic tee. A second flow sensor is disposed in a second flow path between a second flow-divider and the fluidic tee. A first recycle flow restrictor is disposed in the first recycle flow path in fluid communication with the first flow-divider. A second recycle flow restrictor is disposed in the second The permeability of each recycle flow restrictor can be selected to produce a desired flow rate with each respective flow path. The output signals of the first and second flow sensors to control output of a pump within each flow path.

Owner:WATERS TECH CORP

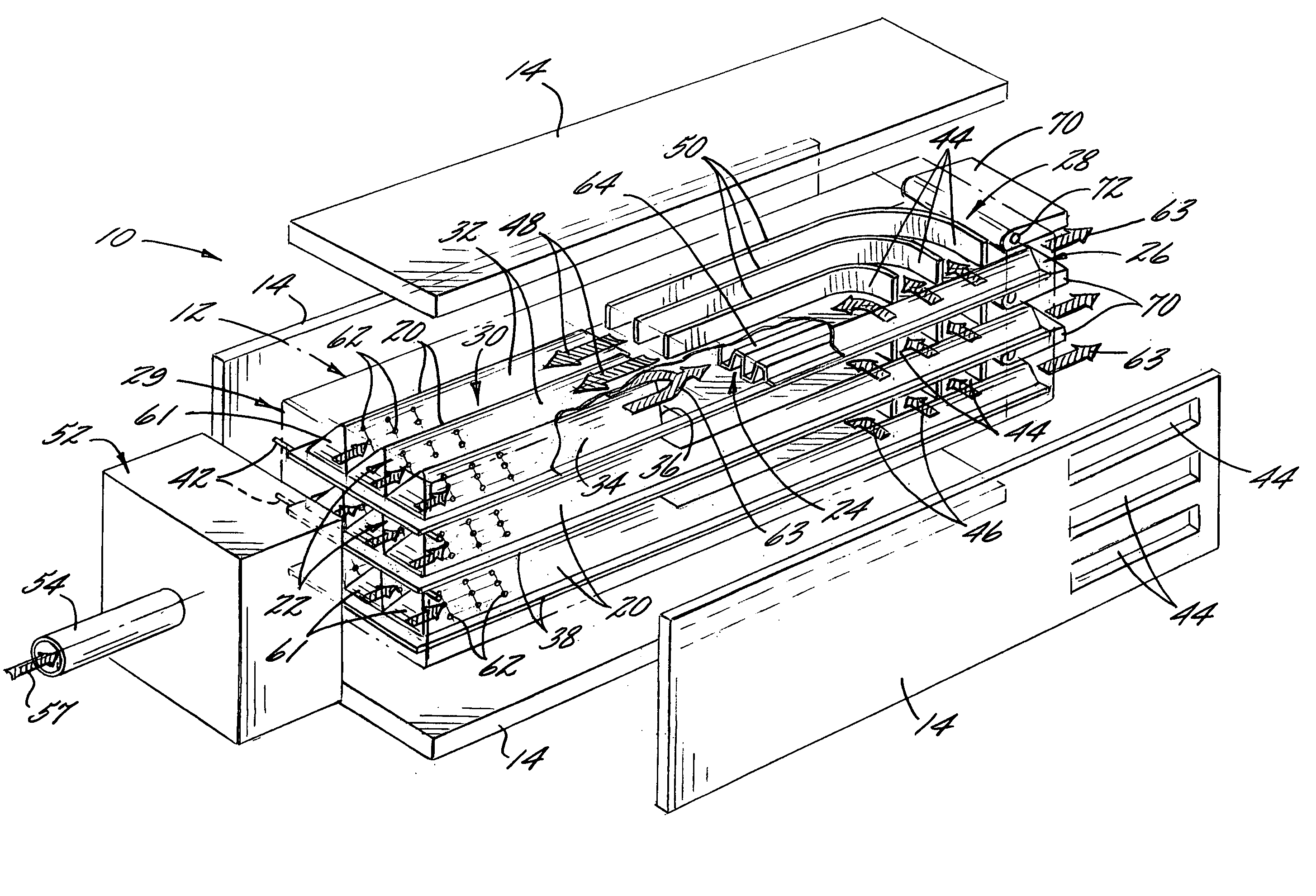

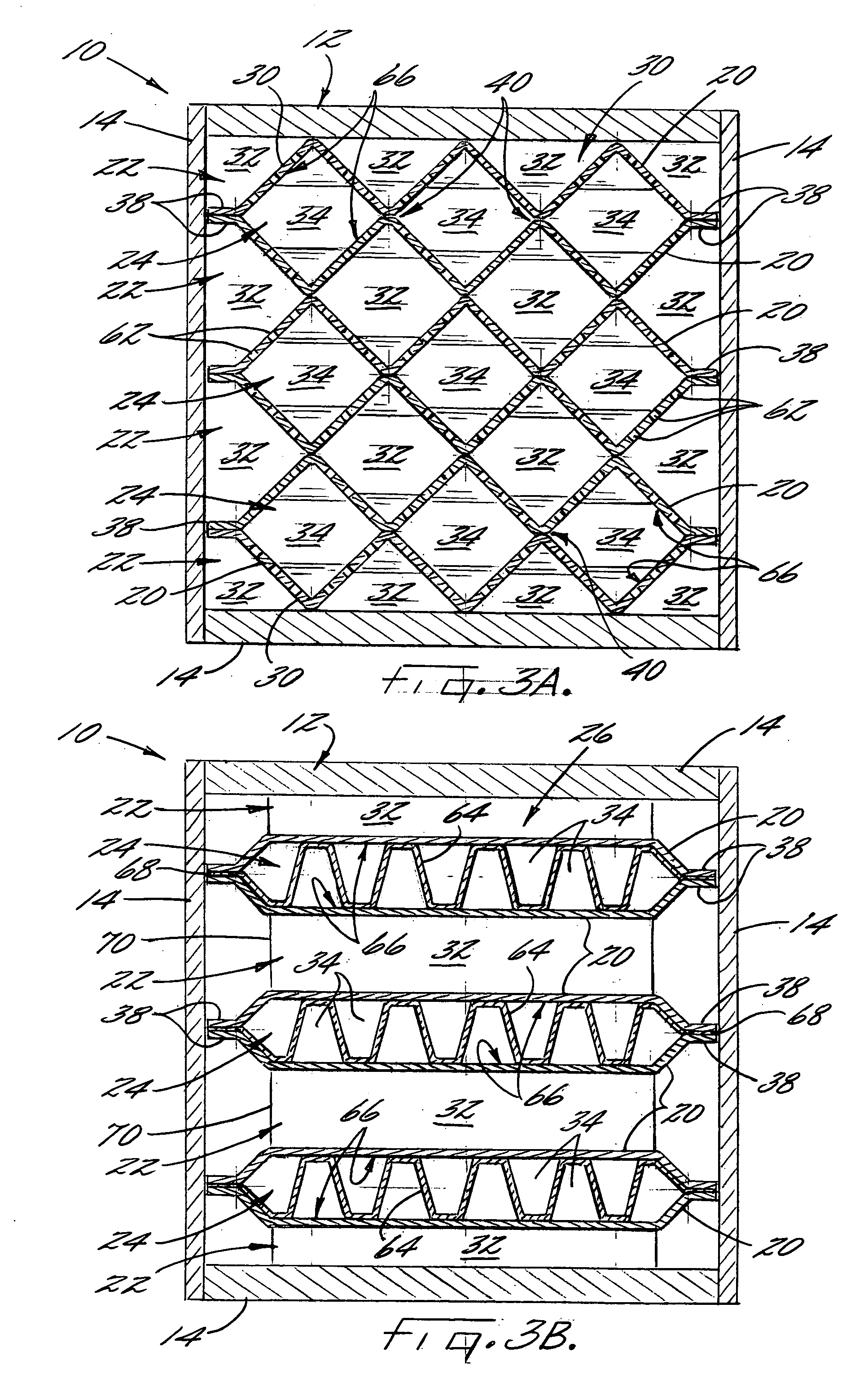

Formed sheet heat exchanger

InactiveUS20050189097A1Improve thermal efficiencyEfficient heat exchangeCombustion processIndirect carbon-dioxide mitigationThermal energyPlate heat exchanger

A formed sheet heat exchanger is provided for exchanging heat between fluids is provided. The apparatus includes flow divider sheets that are positioned in a stacked configuration and extend in a longitudinal direction so that adjacent pairs of the sheets define flow passages therebetween for receiving first and second fluids. Each of the sheets is nonuniform in the longitudinal direction, having a manifold portion and a corrugated portion. The corrugated portions of each adjacent pair of sheets define a plurality of fluid channels therebetween that are connected to the portion of the flow passage defined between the manifold portions. The fluid channels are configured to receive the first or second fluids and transfer thermal energy therebetween through the flow divider sheets.

Owner:THE BOEING CO

Weir box for drilling mud separation unit

InactiveUS6244362B1Settling tanks feed/dischargeLoose filtering material filtersLithologyShale shakers

A weir box disposed upstream from conventional solids control equipment of a mud system of a drilling rig contains a drilling mud separation unit having a continuous-loop scalper screen that is driven in a continuous loop to separate, convey and discharge large amounts of gumbo, heavy clays and drill solids at the end of the separation unit. The flow divider box is a box-like housing with a diverter plate, weir baffle plates and a sliding gate that allows drilling fluid or drilling mud to be selectively directed to the mud separation unit to be separated prior to passing to the conventional downstream solids control equipment or allows the fluid to bypass the separation unit and flow directly to the conventional solids control equipment. The sliding gate is adjustable to selectively control or meter the flow rate and to create a hydrostatic head upstream from the conventional solids control equipment. The weir box baffle plates, sliding gate, and selective utilization of the mud separation unit allows the operator to produce an increased hydrostatic head, which enables high flow rates to be easily processed by shale shakers and other conventional downstream solids control equipment of the mud system and to compliment the drilling operation with respect to changes in the lithology, geological formations, or loss of returns in relation to the gallons pumped or volume of drilling fluid or drilling mud entering the weir box.

Owner:WILLIAMS J TERRELL

Device for forming tight radius curbs and gutters with a paving machine

InactiveUS6890123B2Improve mobilityTighter radiusPaving gutters/kerbsRoads maintainenceHydraulic circuitEngineering

A system and method to allow a paving machine to form tight radii in continuous extrusions such as curbs and gutters is disclosed. A shift cylinder is used with the steering mechanism of a typical paving machine to allow sharp radius turns. The steering cylinder is used to pivot the track of the paving machine about its leg and the steering cylinder is used to pivot the leg relative to the frame of the paving machine. A hydraulic circuit is operator activated to allow fluid flow through a flow divider to ensure each cylinder operates in concert.

Owner:N PICCOLI CONSTR

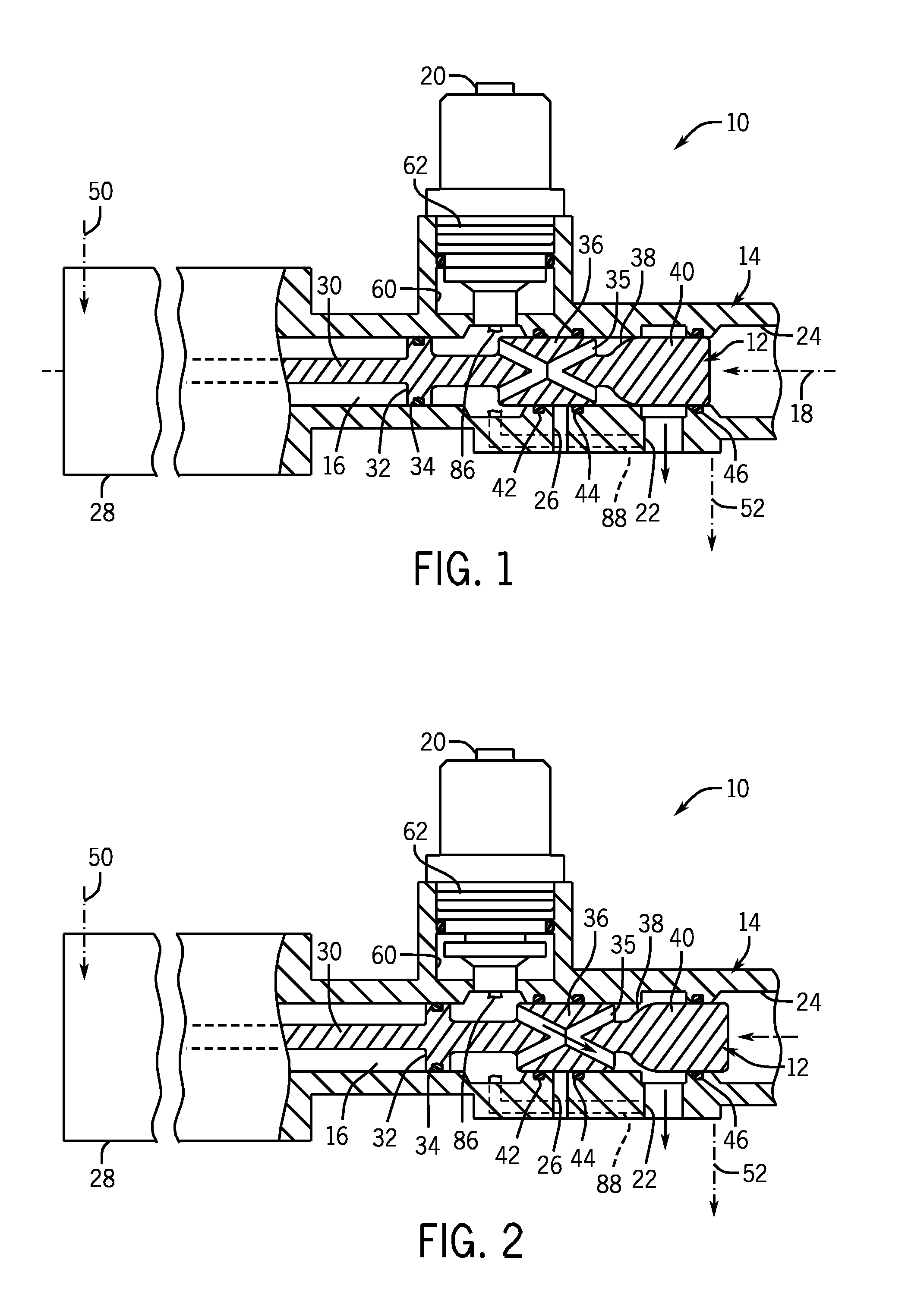

Nozzle assembly with flow divider and ecology valve

InactiveUS6877306B2Prevent drainageSpraying apparatusTurbine/propulsion fuel valvesEngineeringFlow divider

A fuel system having an ecology valve controlling liquid flow through a retention passage when pressurized liquid is passed through the valve is presented. The retention passage winds between the valve outlet and a cavity such that no matter which way the valve is oriented gravity alone is unable to drain liquid from the cavity to the outlet. The ecology valve serves to suction fuel from fuel nozzle passages upon engine shutdown. Fuel is temporarily stored in the cavity and the retention passage. The ecology valve also provides a fuel splitting function for providing a port geometry determined split between fuel nozzles in the fuel system.

Owner:WOODWARD GOVERNOR CO

Fuel control system with metering purge valve for dual fuel turbine

ActiveUS8104258B1Reduce sensitivityPlug valvesLiquid fuel feeder/distributionCrossbar switchSpool valve

The fuel system of a dual fuel turbine includes a flow control valve having a metering purge valve that in one state directly meters fuel to injectors of the turbine, in another state closes of fuel flow and passes purge air to the injectors and in another state positively closes of flow of both fuel and purge air. The metering purge valve is a pressure compensated spool valve that has a unique cross-ported interchange that passes fuel from the inlet through the spool to the metering edge. The direct metering of the valve to the injectors eliminates the need for additional shut off valves, and if used with a combining valve having an integral distributor section metering fuel to multiple injectors, the need for a separate flow divider is also eliminated. The valve can be actively cooled by dedicated coolant lines or lines shared with other flow control components such as additional metering valves for either the primary or secondary fuel.

Owner:JANSENS AIRCRAFT SYST CONTROLS

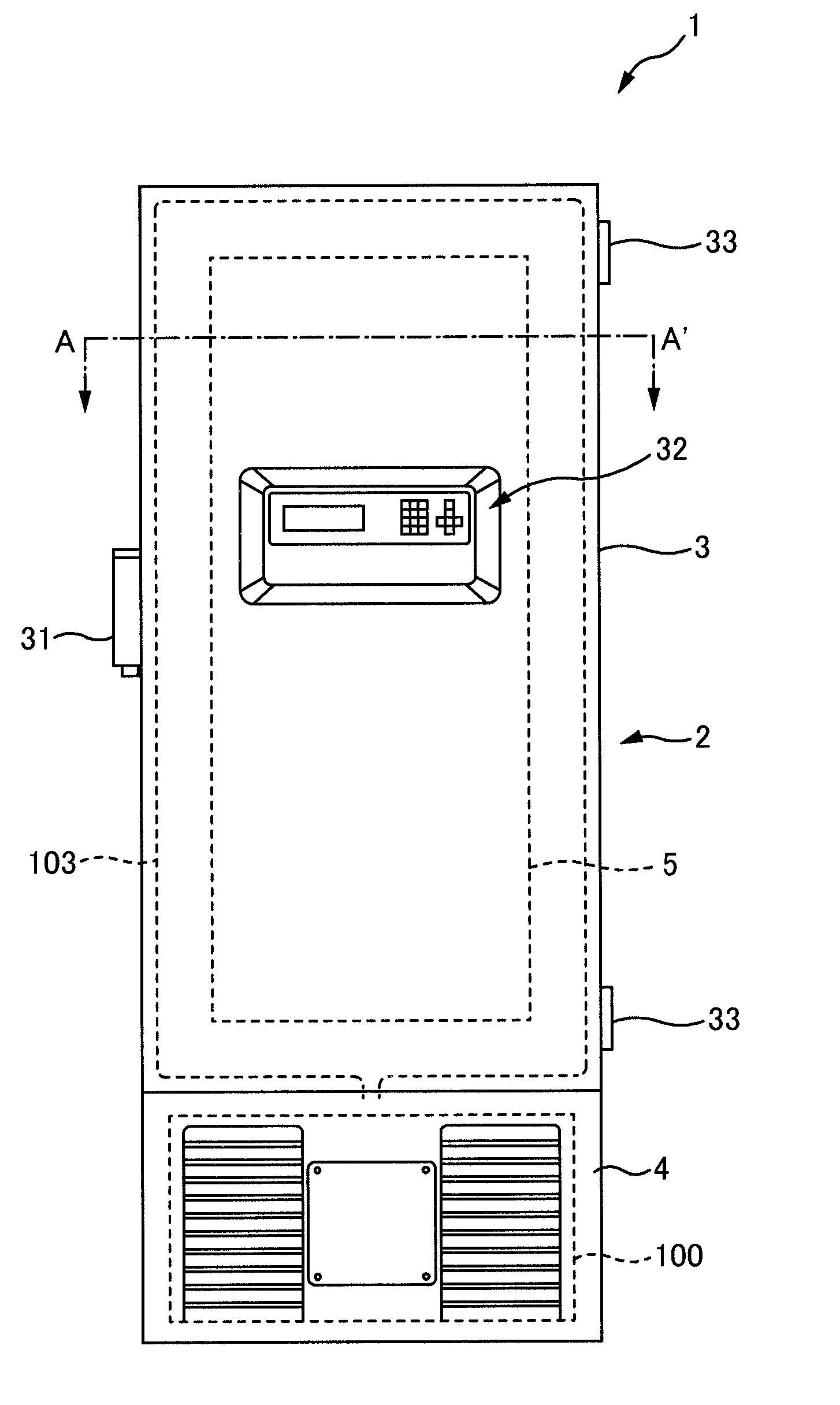

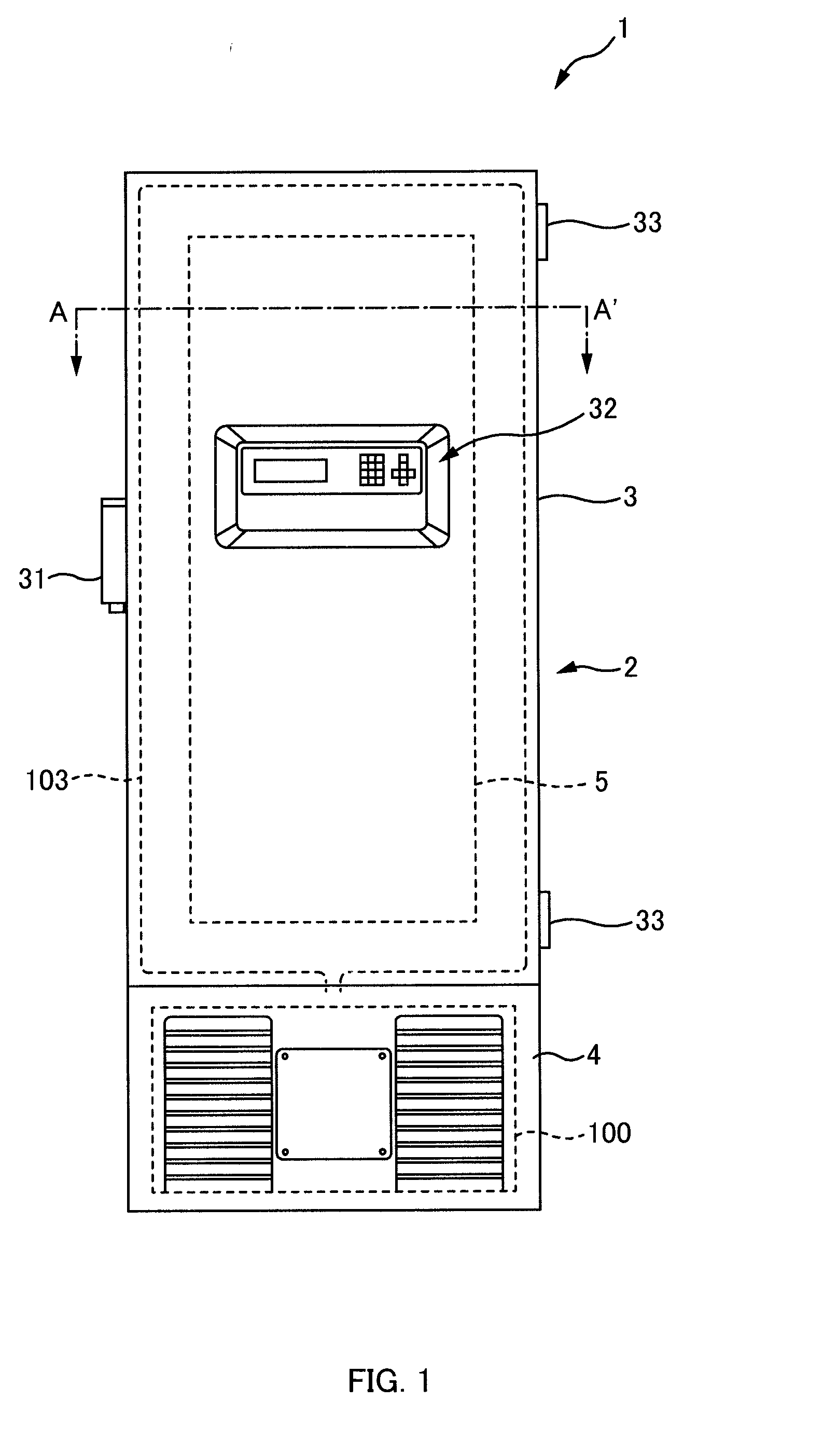

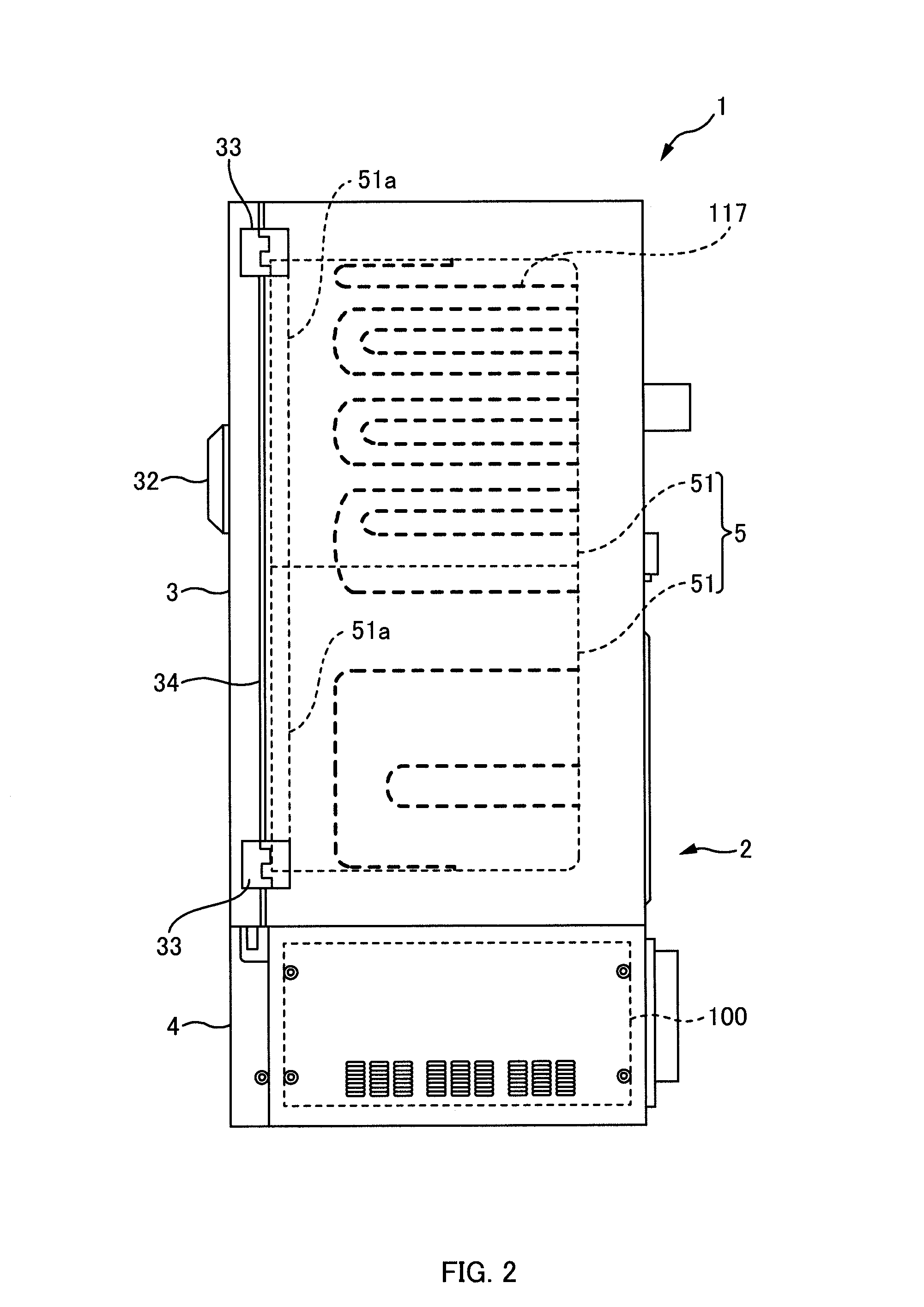

Refrigerating apparatus

InactiveUS20110023532A1Cost containmentImprove temperature distributionCompression machines with non-reversible cycleDomestic refrigeratorsPlate heat exchangerEngineering

A refrigerating apparatus includes a refrigerating cycle including a compressor, a condenser, a flow divider, a first heat exchanger, a second heat exchanger, a decompressing device, and an evaporator. The refrigerant cycle has sealed therein a mixed refrigerant obtained by mixing at least first to third refrigerants with different evaporation temperatures. The first heat exchanger and the second heat exchanger each includes a double pipe to form a first flow passage in an inner pipe of the double pipe, a second flow passage in an outer pipe of the double pipe, and an intermediate port in a piping connecting between the second flow passage of the first heat exchanger and the second flow passage of the second heat exchanger. A high-temperature and high-pressure refrigerant discharged from the compressor is cooled by the condenser to liquefy the first refrigerant having a high evaporation temperature into a liquid refrigerant.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

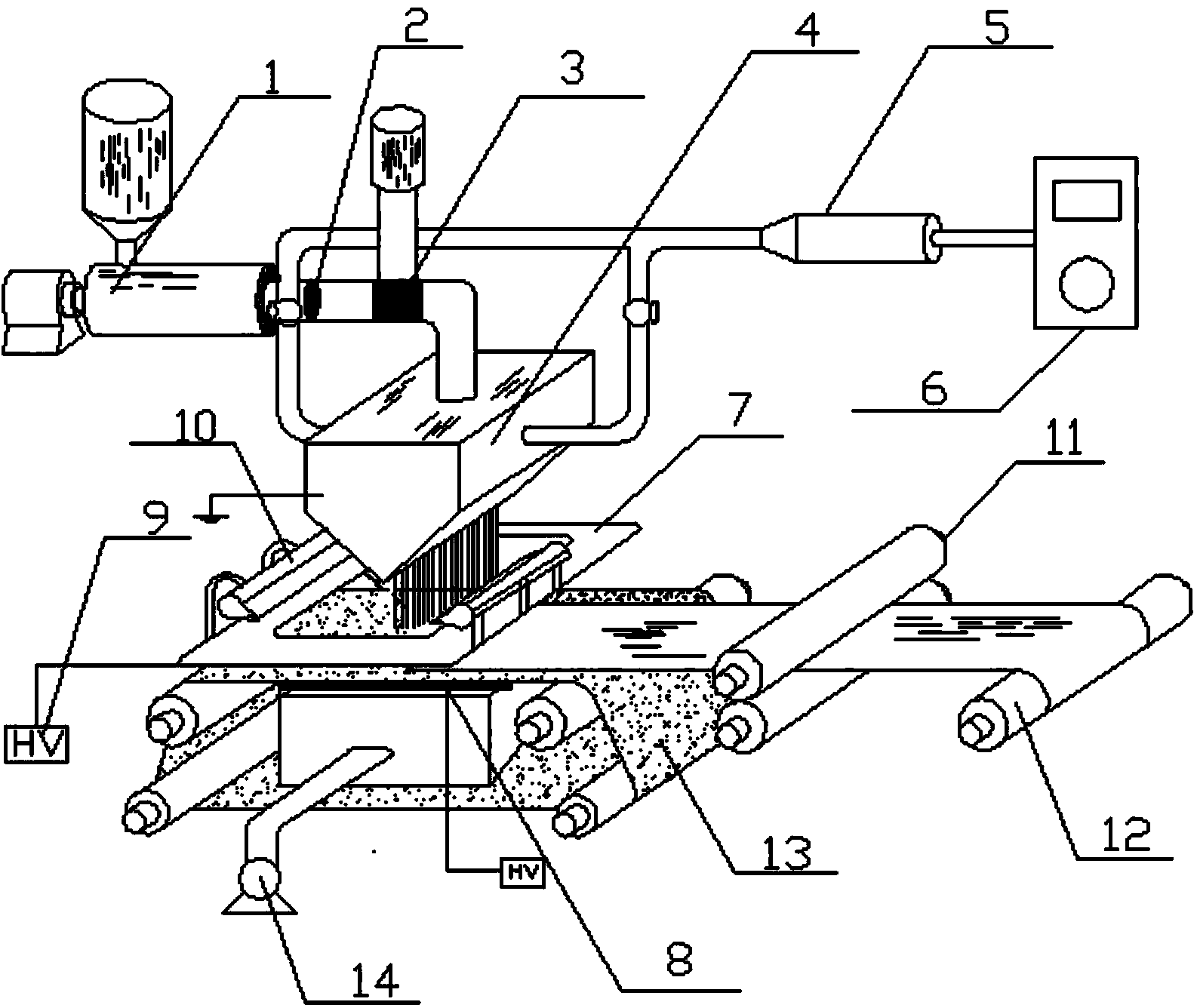

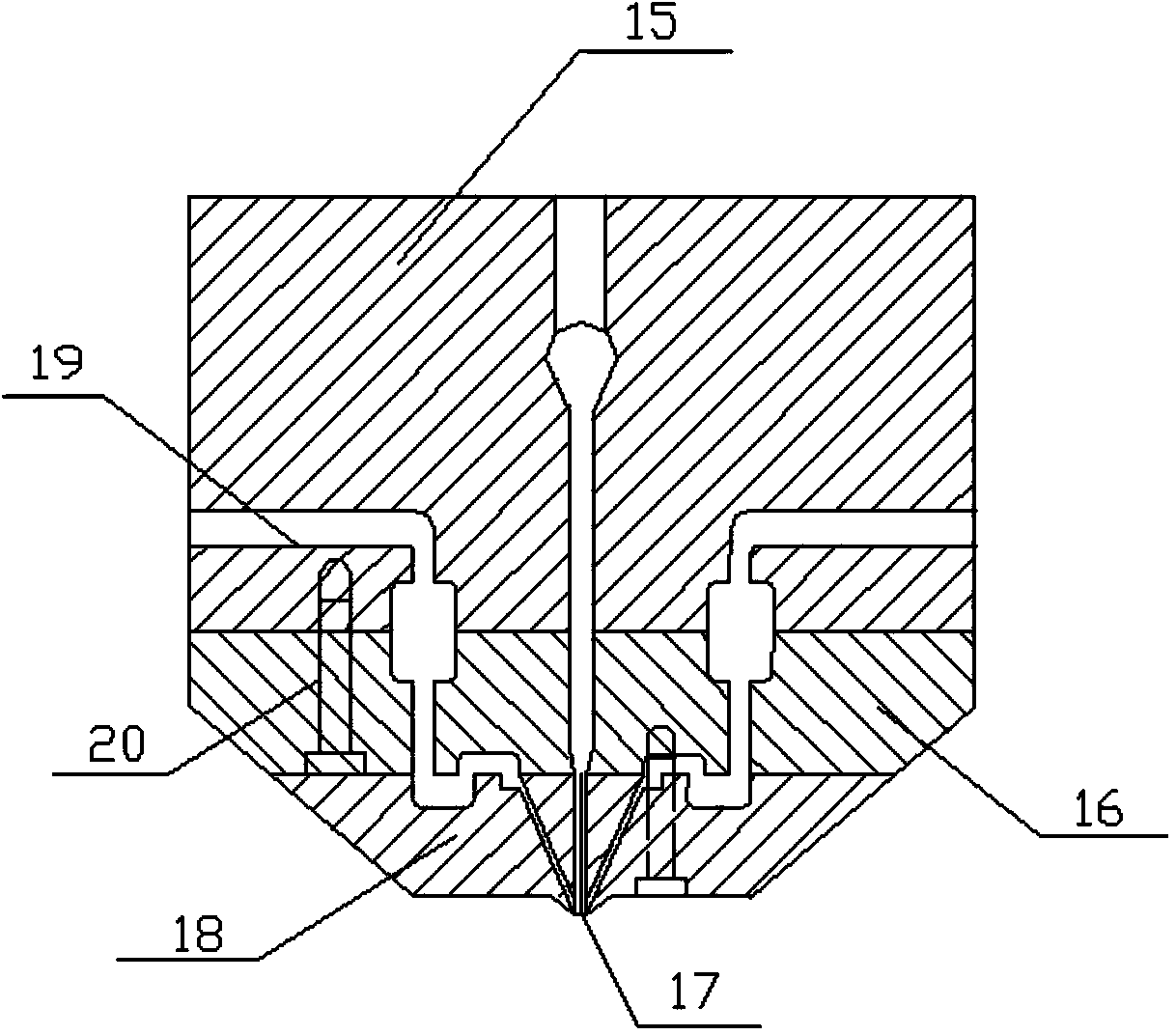

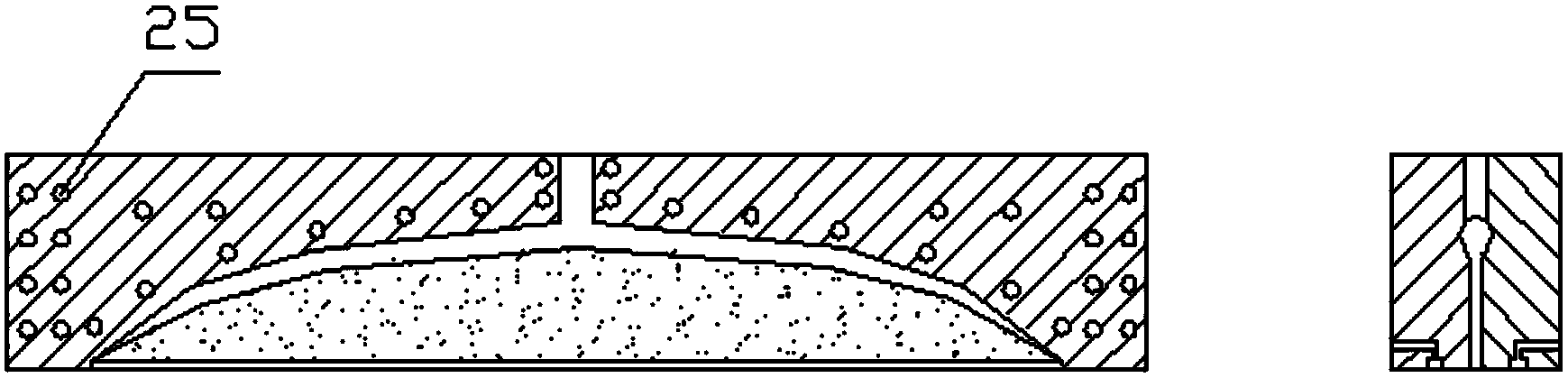

Differential melt electro-blowing spinning device and technology for preparing nanofibers in batches

ActiveCN103451754ARealize industrial productionRealize batch preparationFilament/thread formingNon-woven fabricsFiberSpinning

The invention discloses a differential melt electro-blowing spinning device and technology for preparing nanofibers in batches, and belongs to the field of electrostatic spinning. The device mainly comprises an extruder, a filter screen, a melt metering pump, a spinning manifold, an airflow heating device, an air compressor, an upper plate electrode, a lower plate electrode, a high-voltage electrostatic generator, a guide air knife, a hot rolling device, a receiving device, a screen spreading belt and an air draft system. An outlet of the extruder is connected with the filter screen, and the melt metering pump is connected between the filter screen and the spinning manifold through a flange. Airflow is divided into two portions through a flow divider to be connected to the spinning manifold; after melt is divided and guided in flow through the spinning manifold, a thin uniform-flowing melt layer is obtained at the lower end of a wavy flow guide plate; under the high-voltage electrostatic action, the melt layer forms a plurality of Taylor cones in a self-organization manner, the Taylor cones are stretched and split continuously under the conditions of high-speed airflow and high-voltage electrostatics, and superfine fibers are formed at the receiving end of the screen spreading belt by means of curing. By the aid of the device and technology, difficulties of high viscosity of polymers, low yield, complicated devices and the like are overcome, and industrial production of differential melt electro-blowing spinning can be achieved.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com