Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

301results about How to "Improve temperature distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

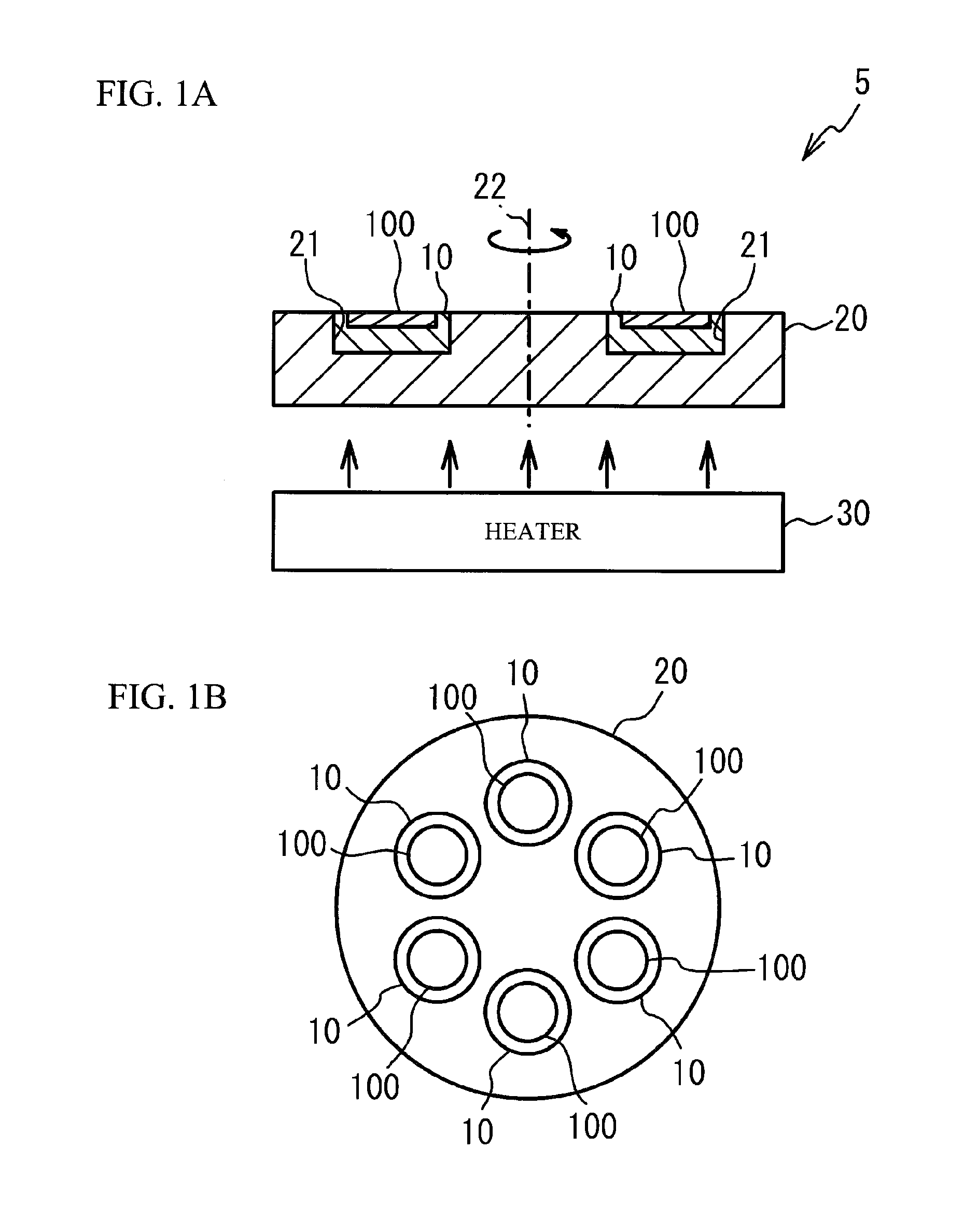

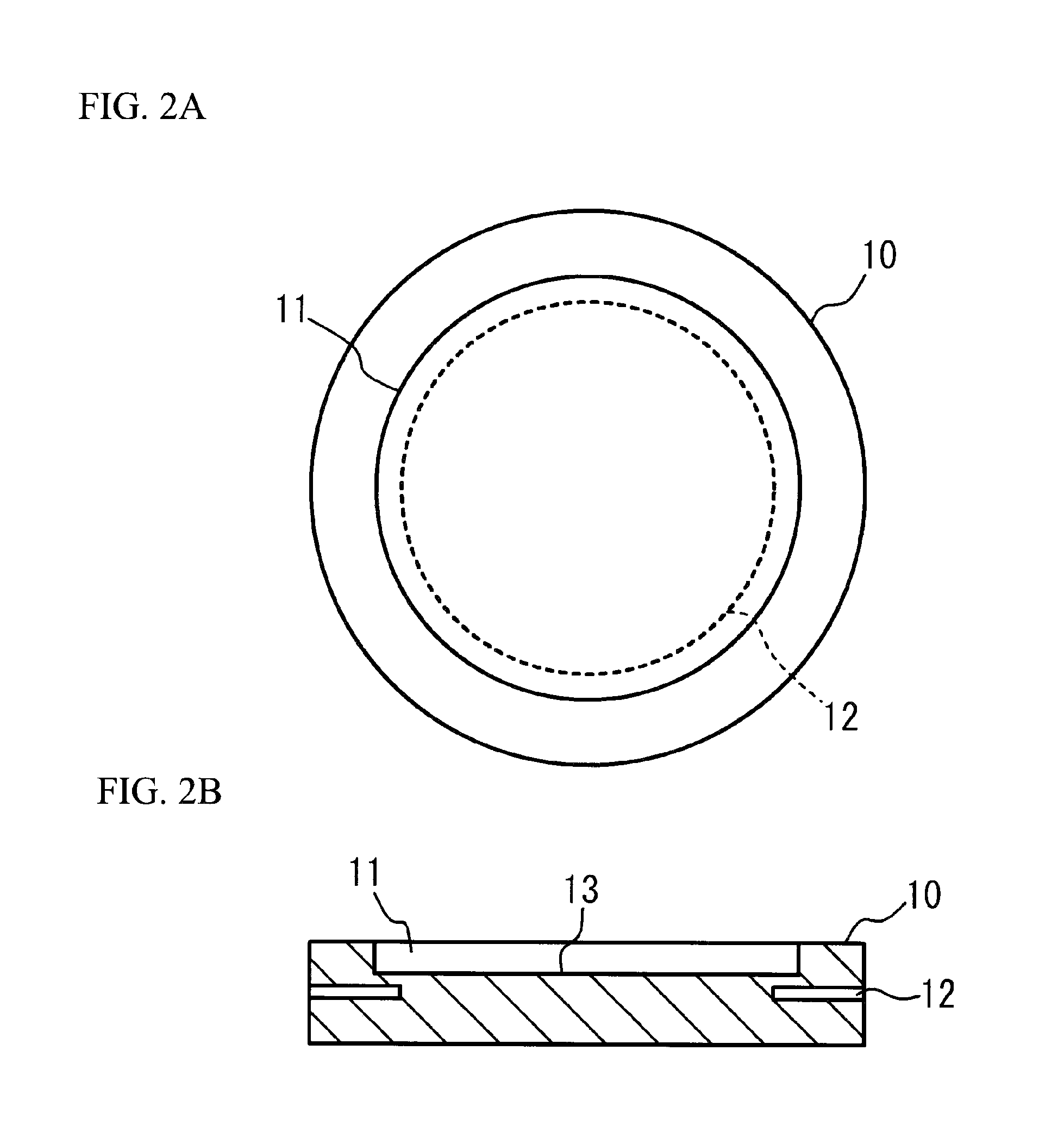

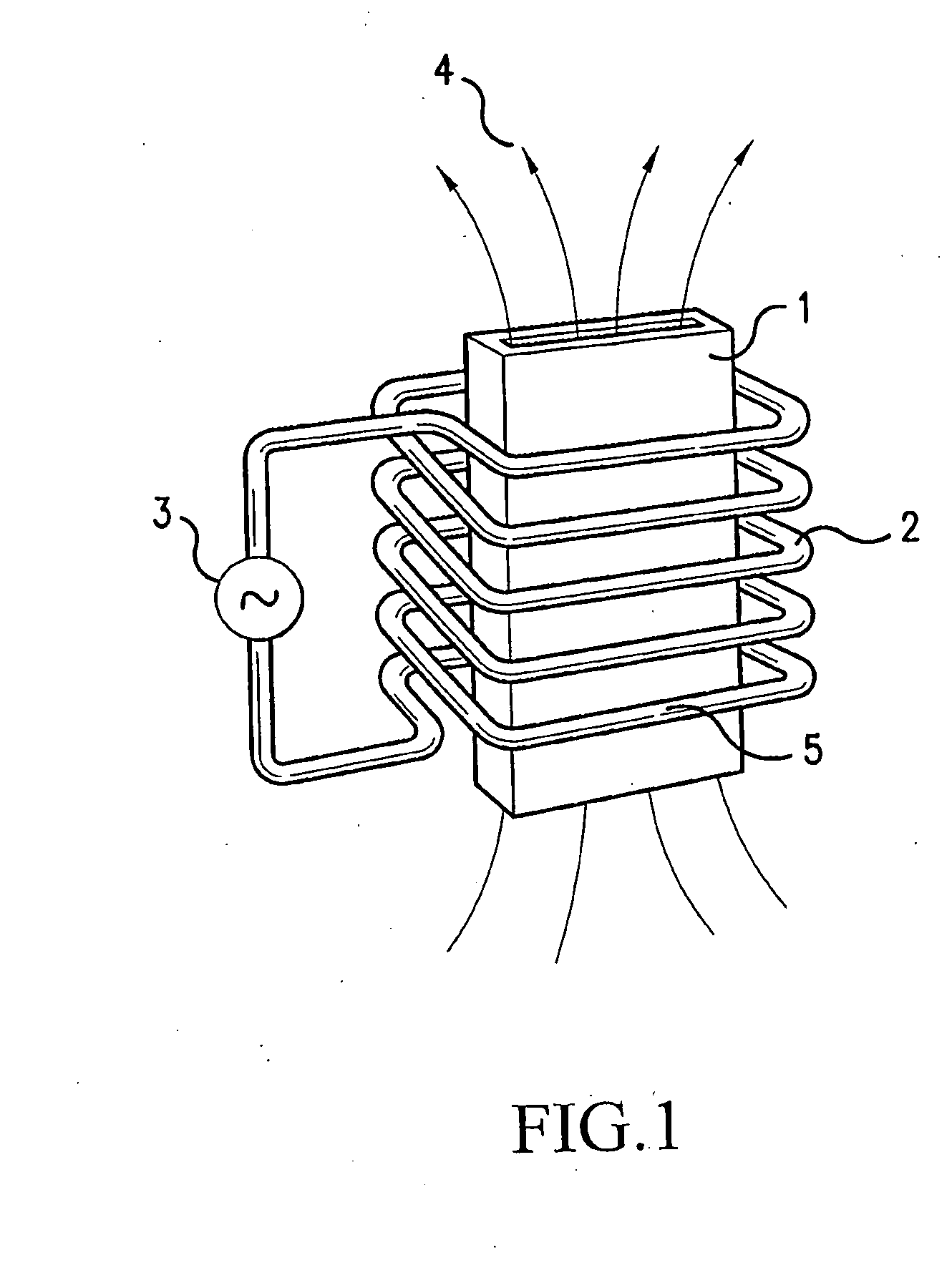

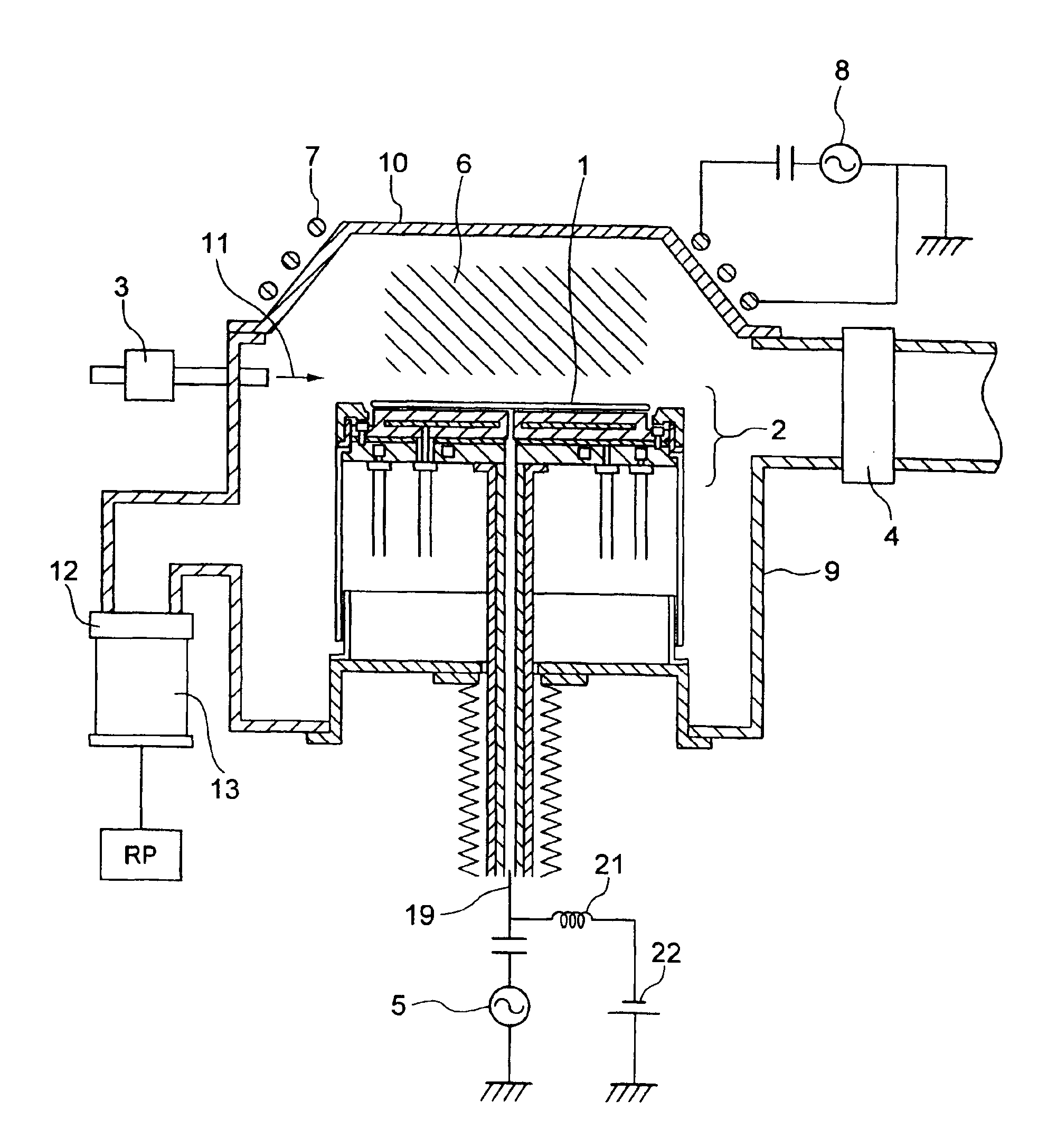

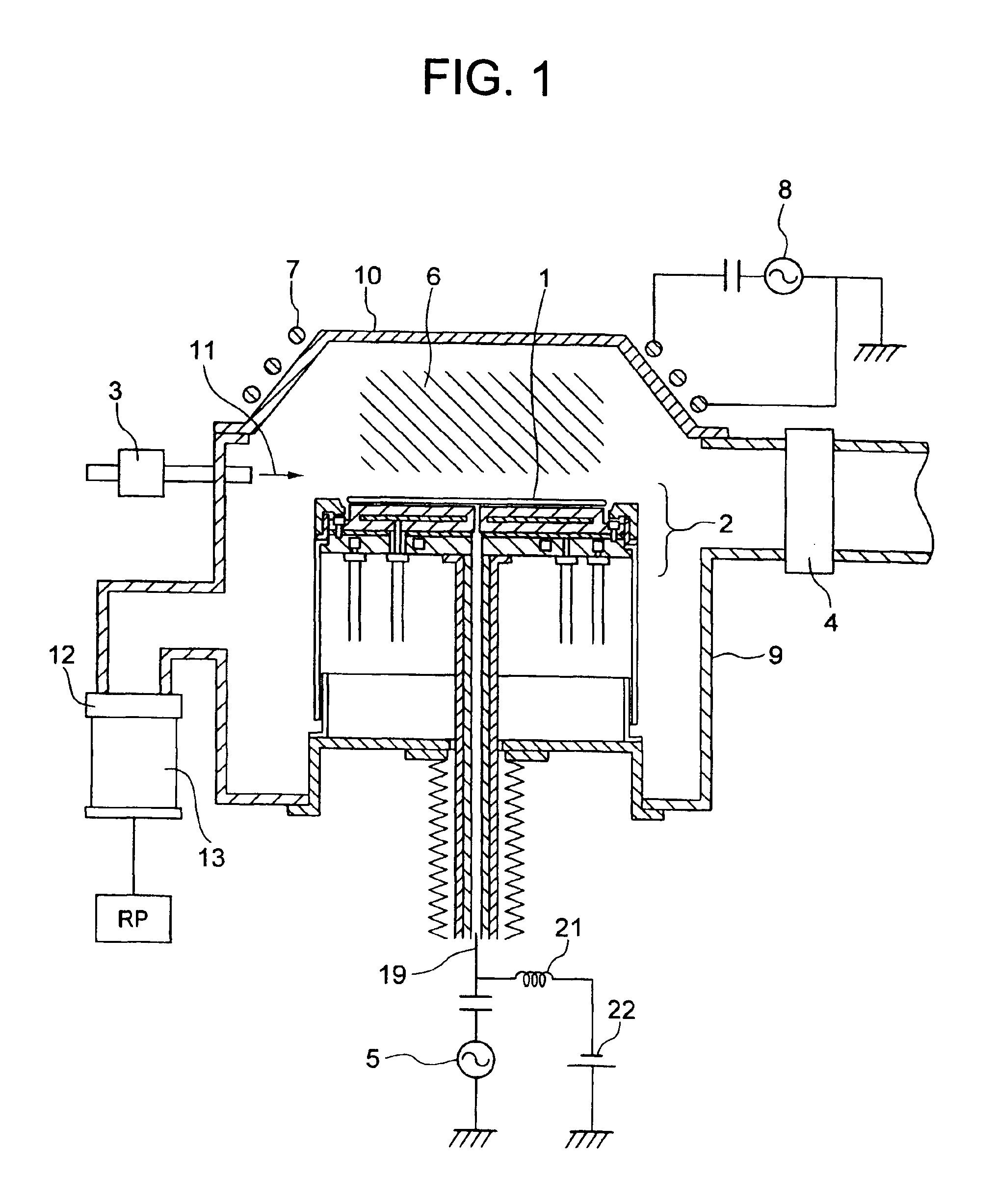

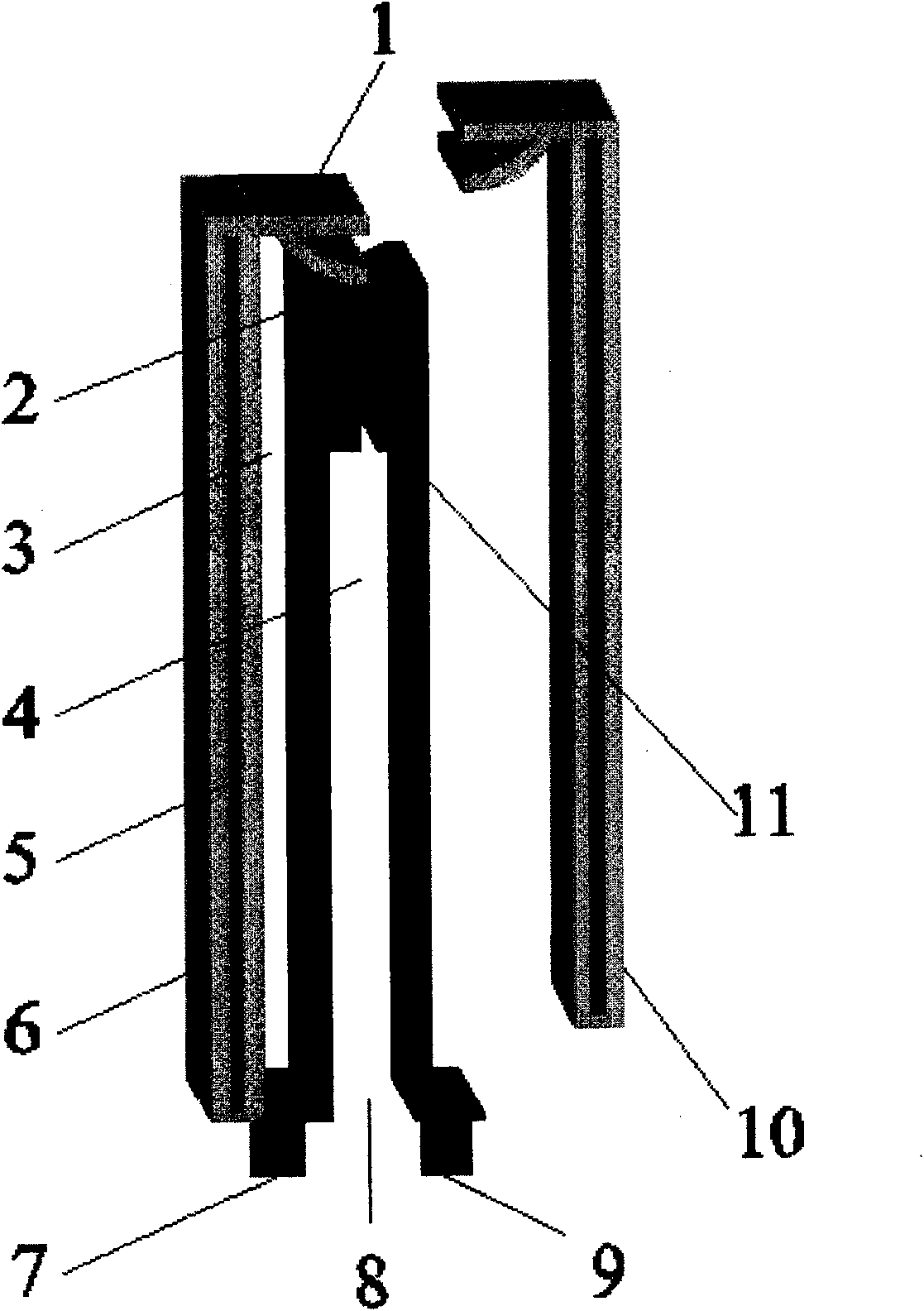

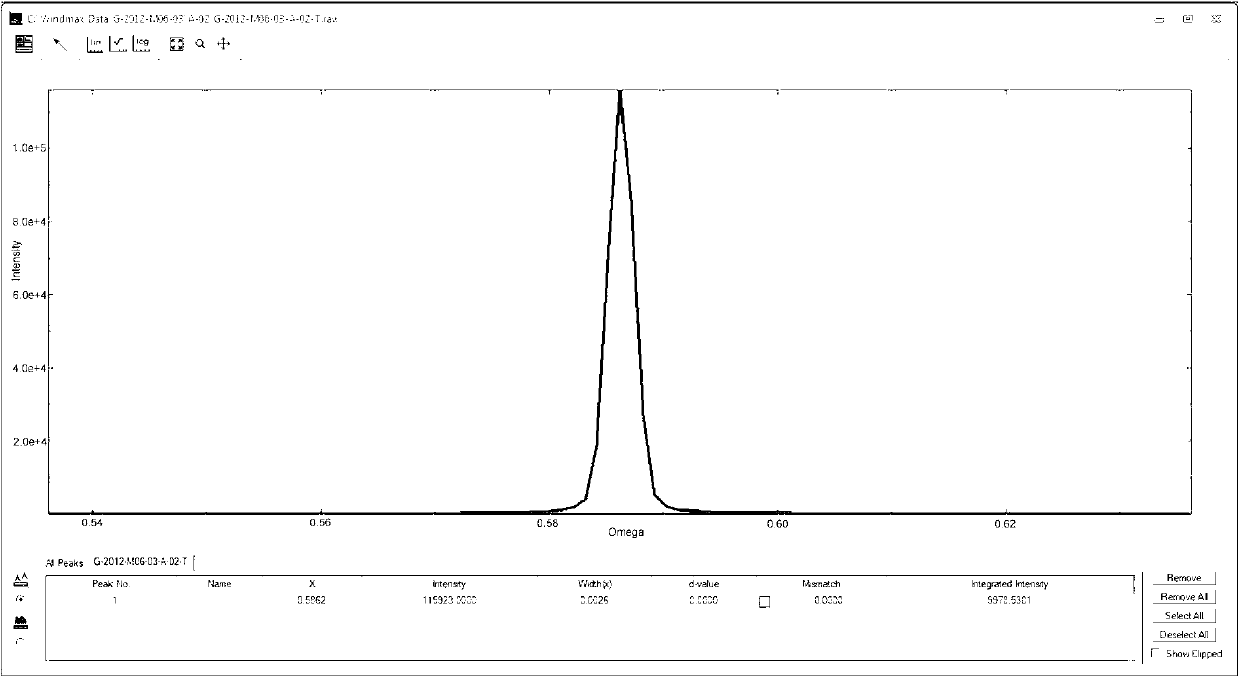

Semiconductor growing apparatus

ActiveUS20120024231A1Improve temperature distributionFrom chemically reactive gasesChemical vapor deposition coatingSusceptorEngineering

A semiconductor growing apparatus including: susceptor having a main face and a side face, the main face receiving a substrate for growing a semiconductor layer, and the side face having a groove; a heating element for heating the susceptor.

Owner:SUMITOMO ELECTRIC IND LTD

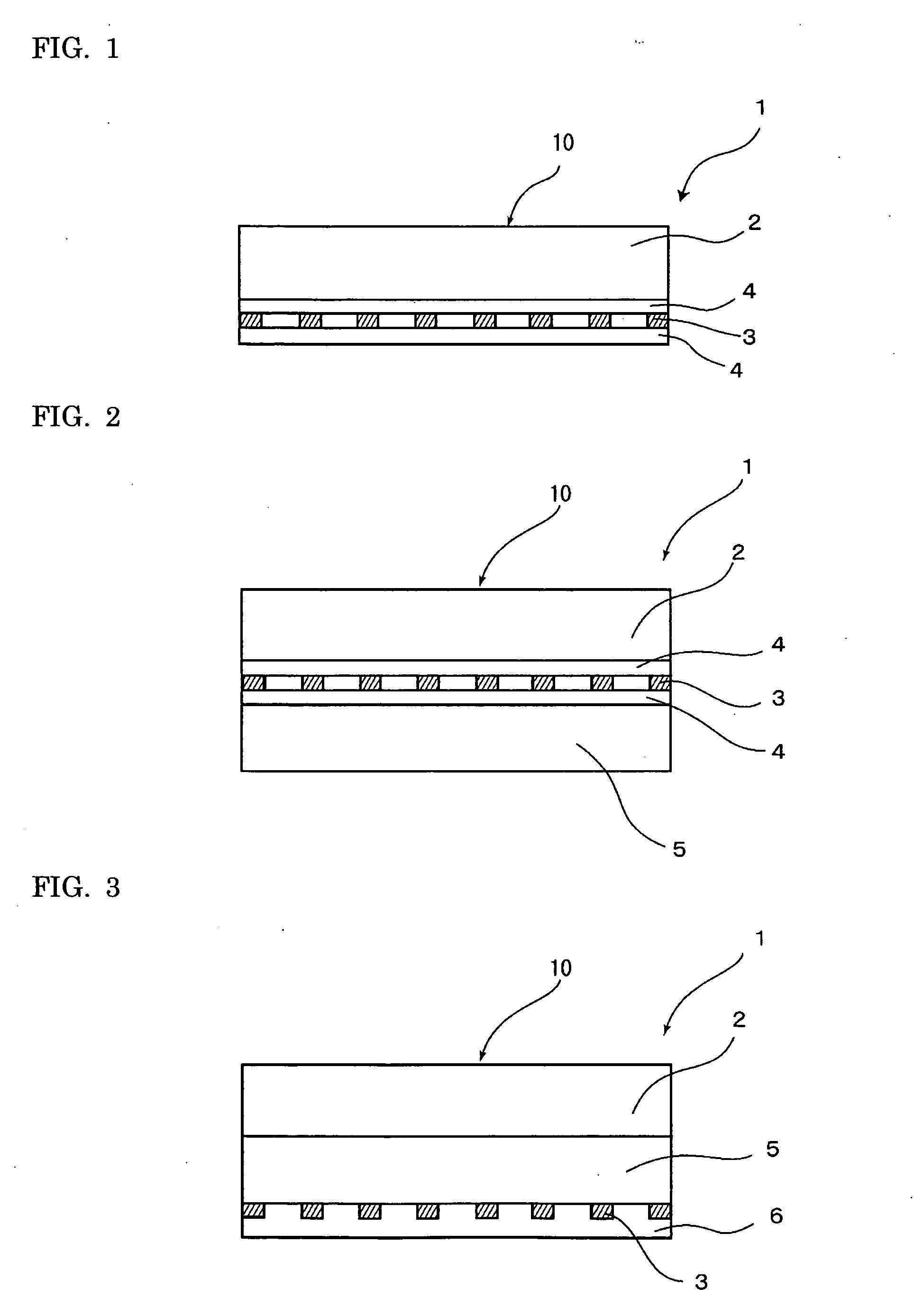

Heater for heating a wafer and method for fabricating the same

ActiveUS7361865B2Improve temperature distributionIncandescent ignitionSemiconductor/solid-state device manufacturingHeating element

Owner:KYOCERA CORP

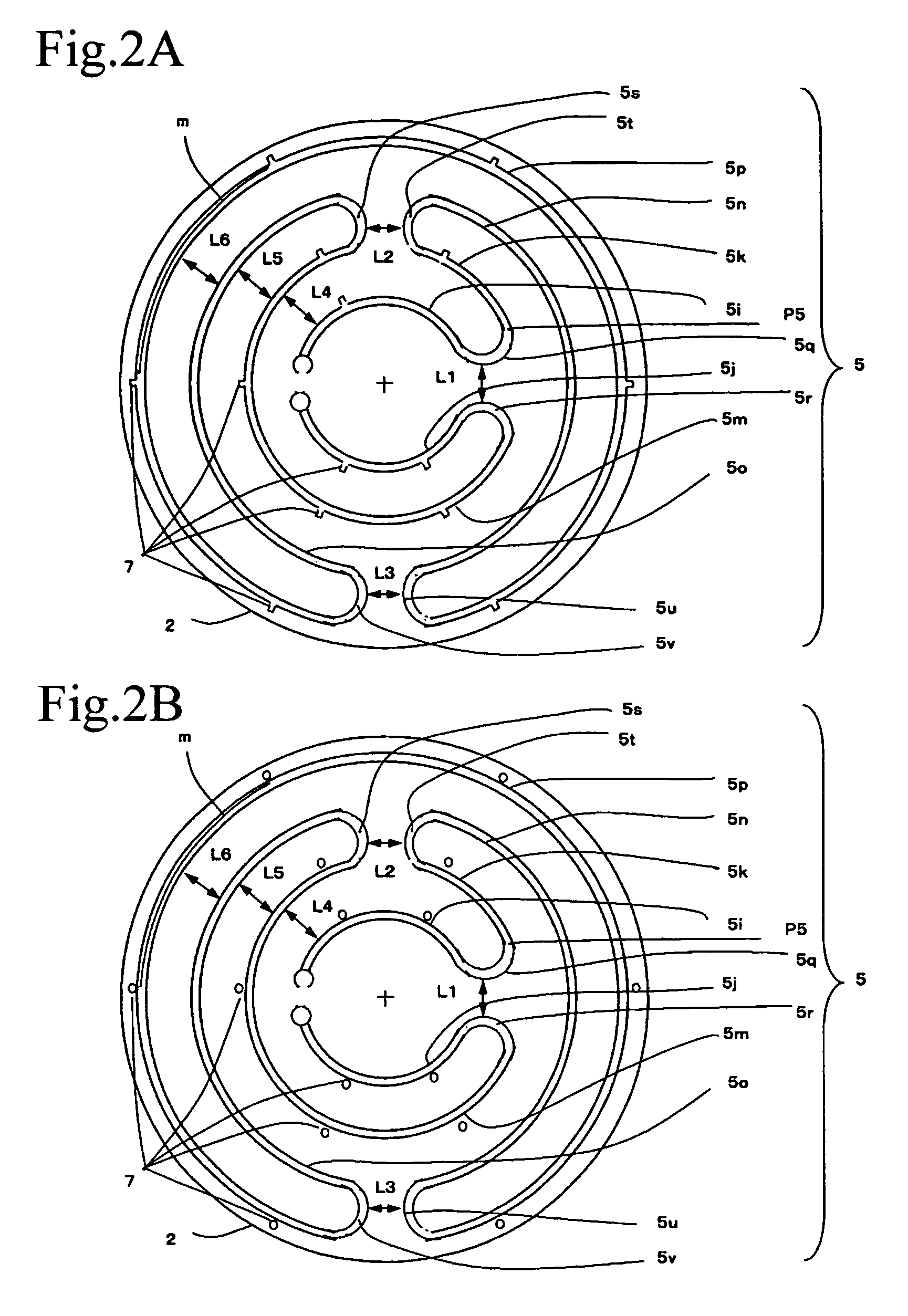

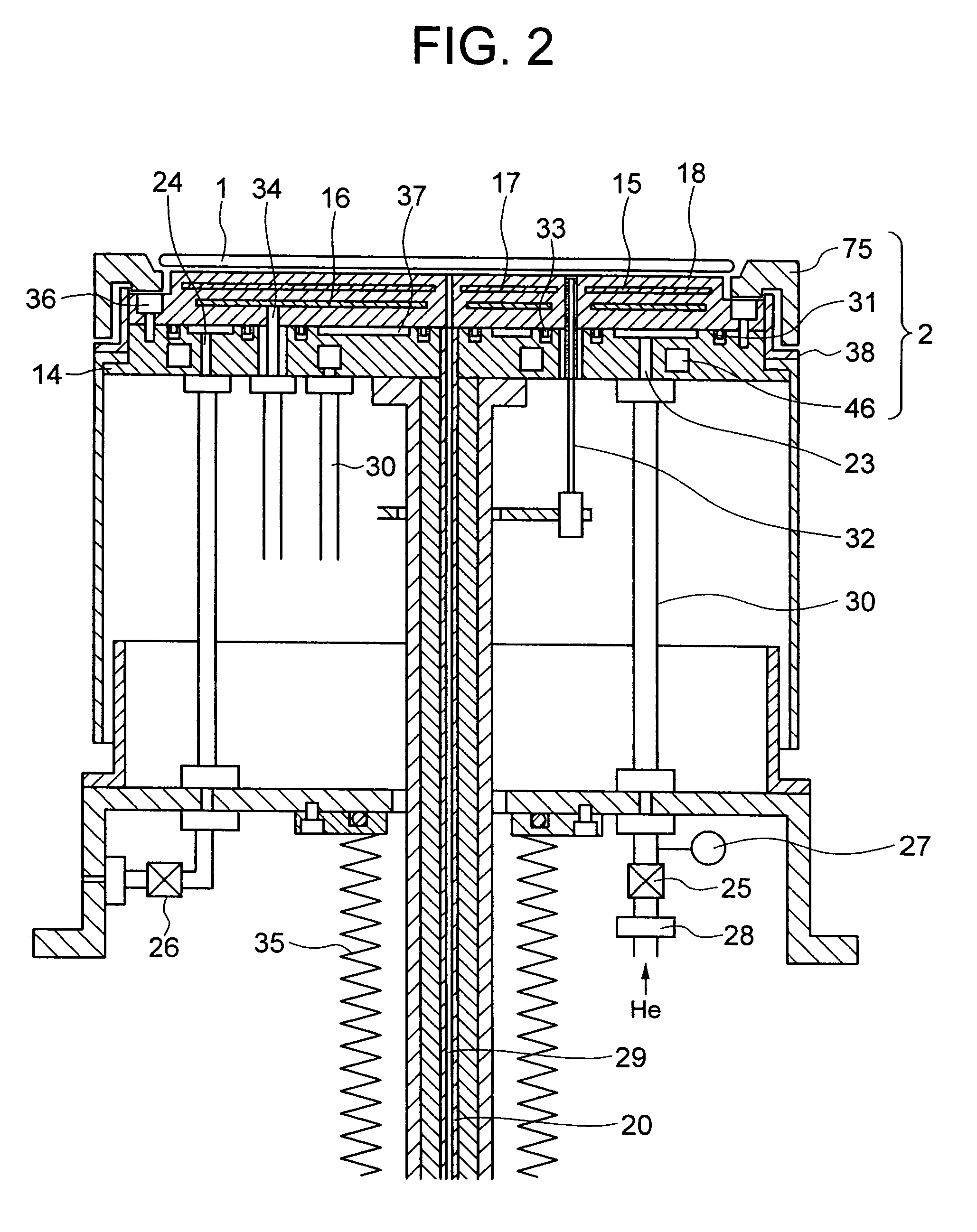

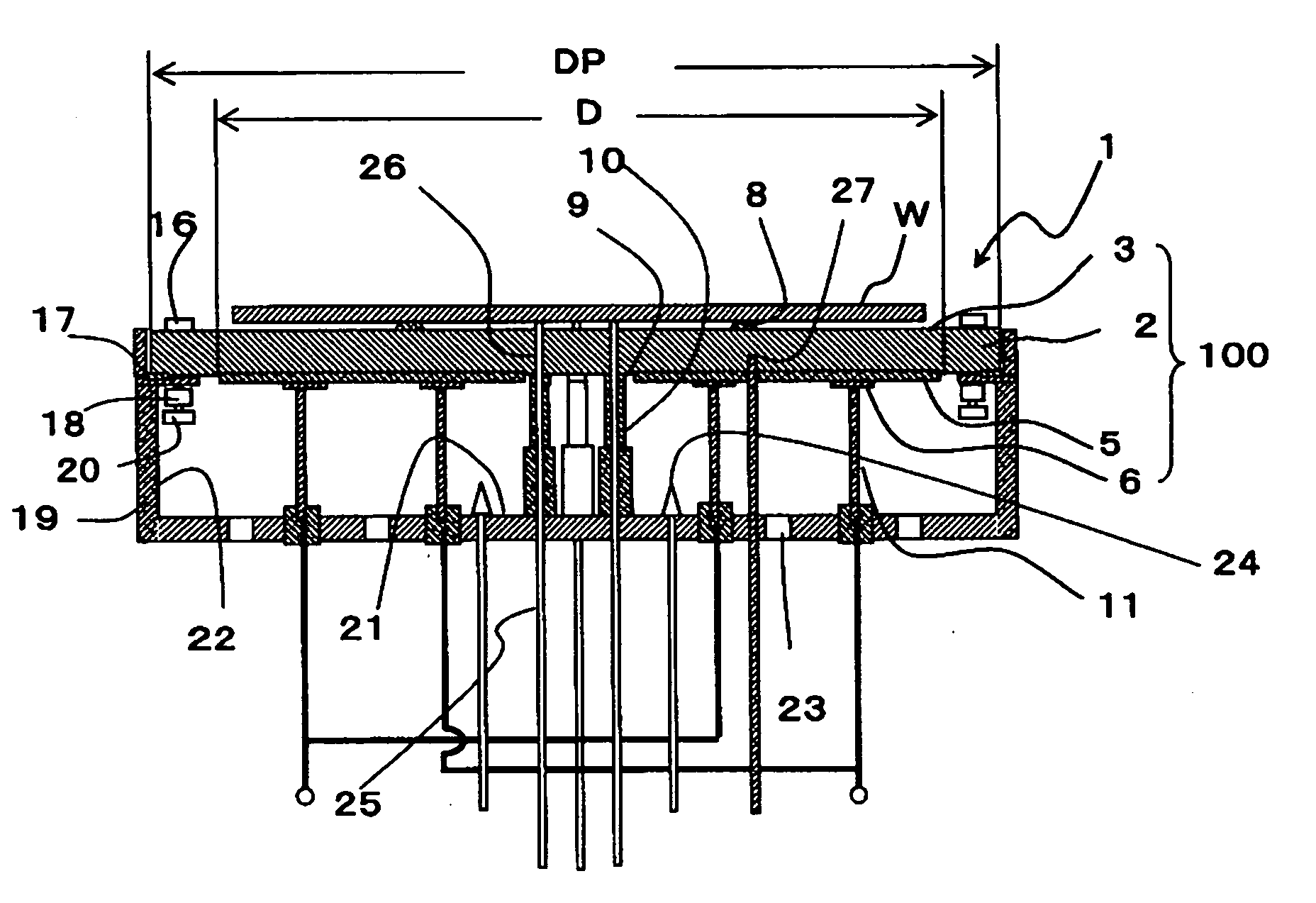

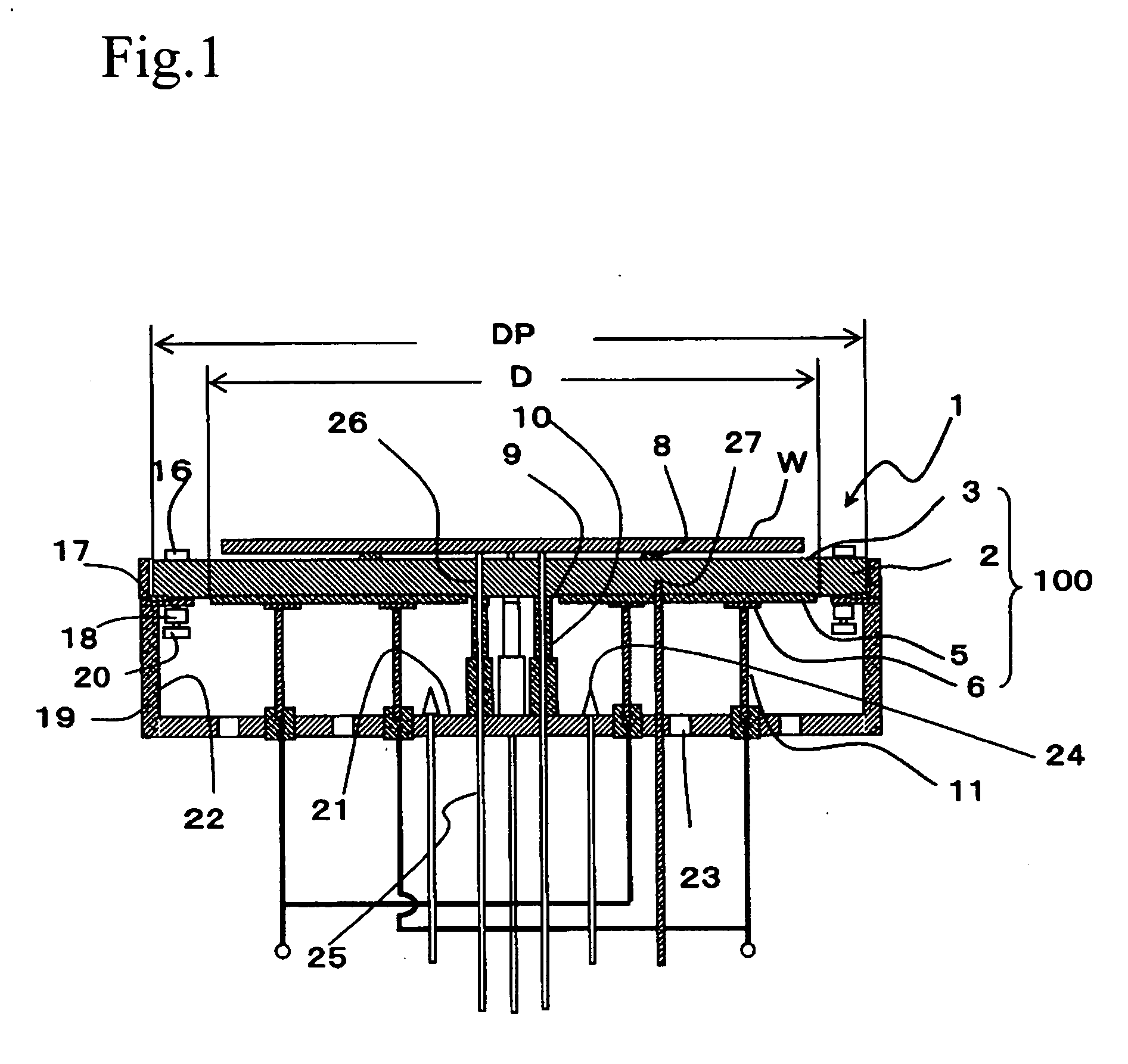

Wafer processing method

InactiveUS7138606B2Improve temperature distributionUniform temperatureDrying solid materials with heatMuffle furnacesEngineeringLiquid circulation

A wafer processing method for use with a wafer processing apparatus having a liquid cooling jacket with a built-in coolant liquid circulation path and a ceramic plate as attached onto the liquid cooling jacket and having therein a heater and an electrode for an electrostatic chuck. The method enables performance of wafer processing while letting a wafer be mounted on the ceramic plate by a wafer transport. The method includes causing the wafer transport to transport the wafer onto the ceramic plate, pre-heating the wafer while the wafer is held on the ceramic plate for a predetermined length of time, and mounting the preheated wafer on the ceramic plate.

Owner:HITACHI HIGH-TECH CORP

Semiconductor fabrication device heater and heating device equipped with the same

InactiveUS20060102613A1Improve temperature distributionSemiconductor/solid-state device manufacturingHot plates heating arrangementsElectrical resistance and conductanceSemiconductor

A heating body and a device equipped with the same provide greater uniformity in temperature distribution between the start of heating and the end of cooling. A semiconductor fabrication device heating body includes a base having a heating surface upon which an object is mounted or positioned at a fixed distance away and is heated, and a resistance heating body. All or part of the base of the heating body has a thermal capacity per unit volume of at least 2.0 J / K·cm3 and a thermal conductivity of at least 50 W / mK.

Owner:WEST VIRGINIA UNIVERSITY +1

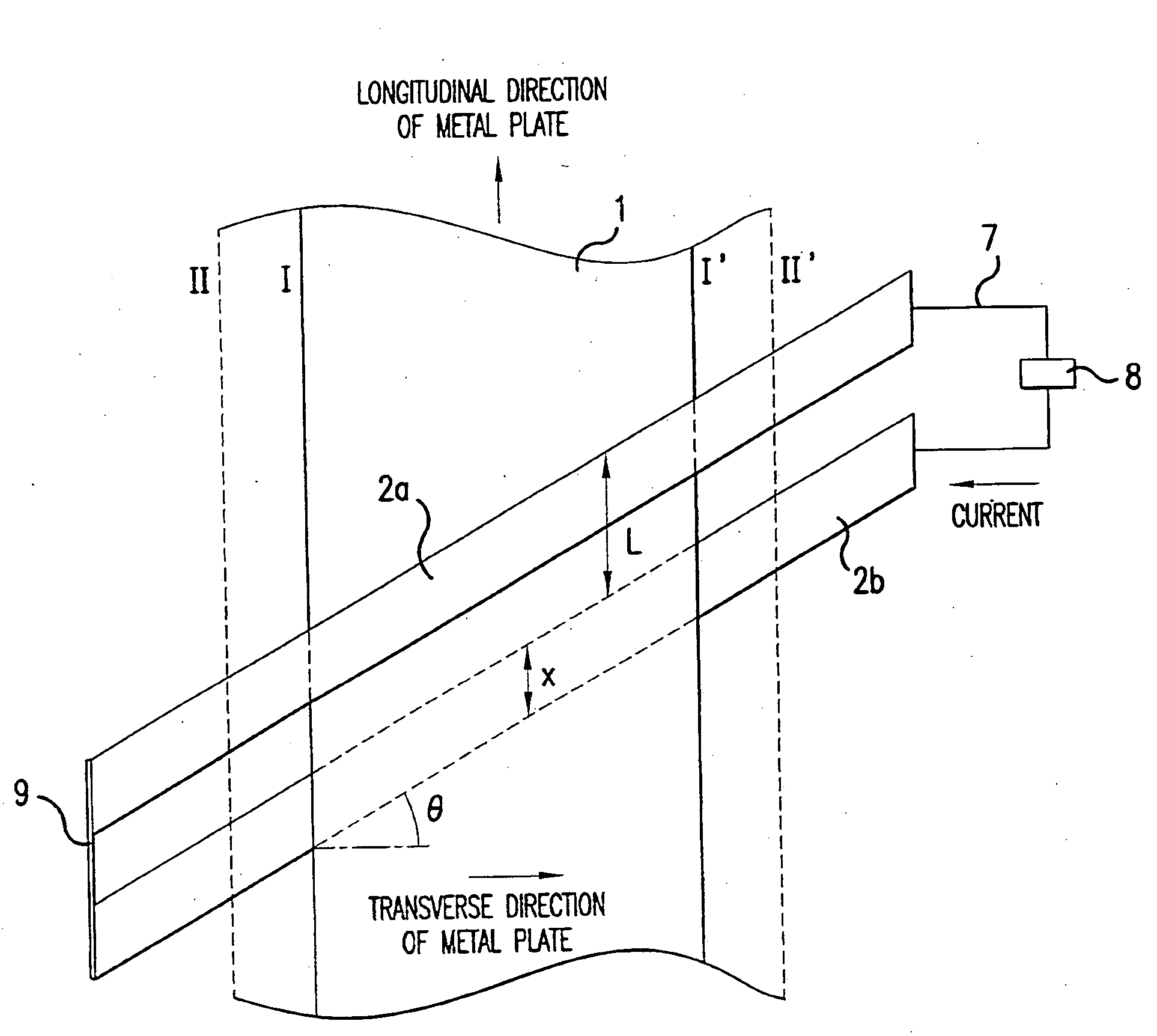

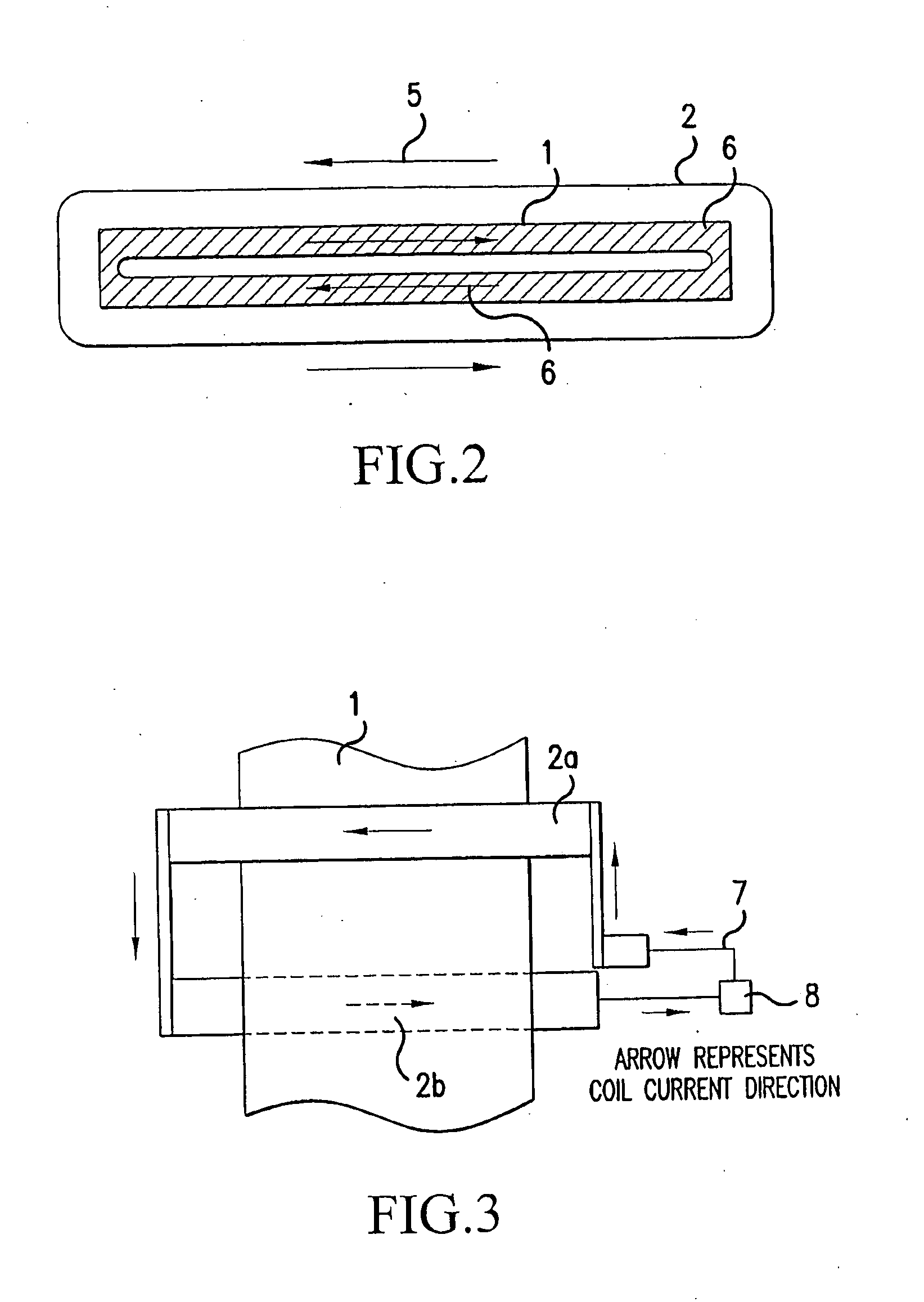

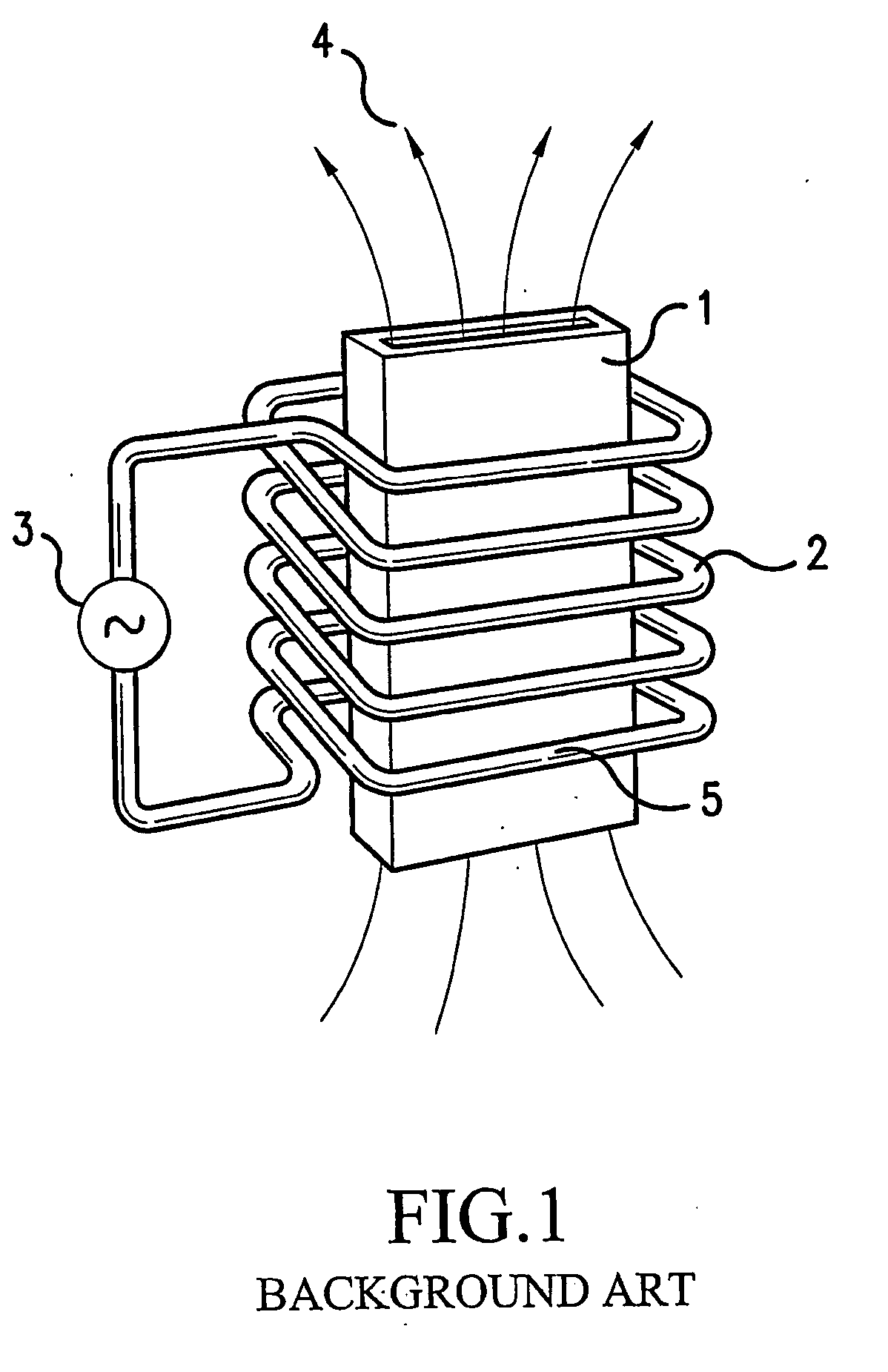

Induction Heating Device for a Metal Plate

ActiveUS20080264932A1Avoid overall overheatingEasy to realize desired temperature distributionLiquid surface applicatorsCoil arrangementsOblique angleMetal

An induction heating apparatus for heating a traveling metal plate includes an induction coil for surrounding the metal plate. The induction coil includes an upper induction coil for being located above the metal plate and a lower induction coil for being located below the metal plate. The upper and lower induction coils are spaced from each other in a longitudinal direction of the metal plate a constant distance across a transverse direction of the metal plate. Each of the upper induction coil and the lower induction coil is arranged obliquely at an edge area of the metal plate so as to form an oblique angle with the transverse direction of the metal plate.

Owner:NIPPON STEEL CORP

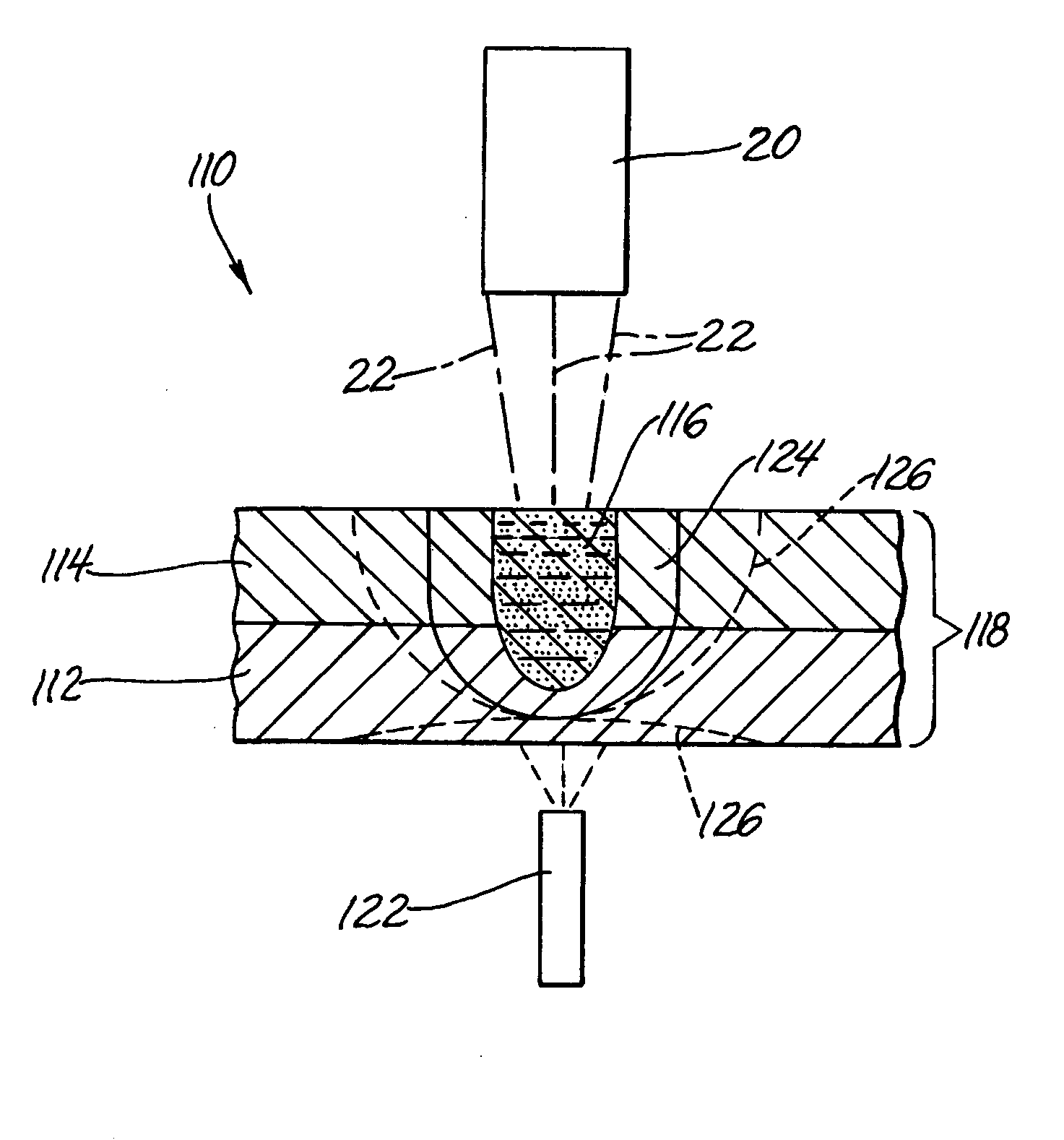

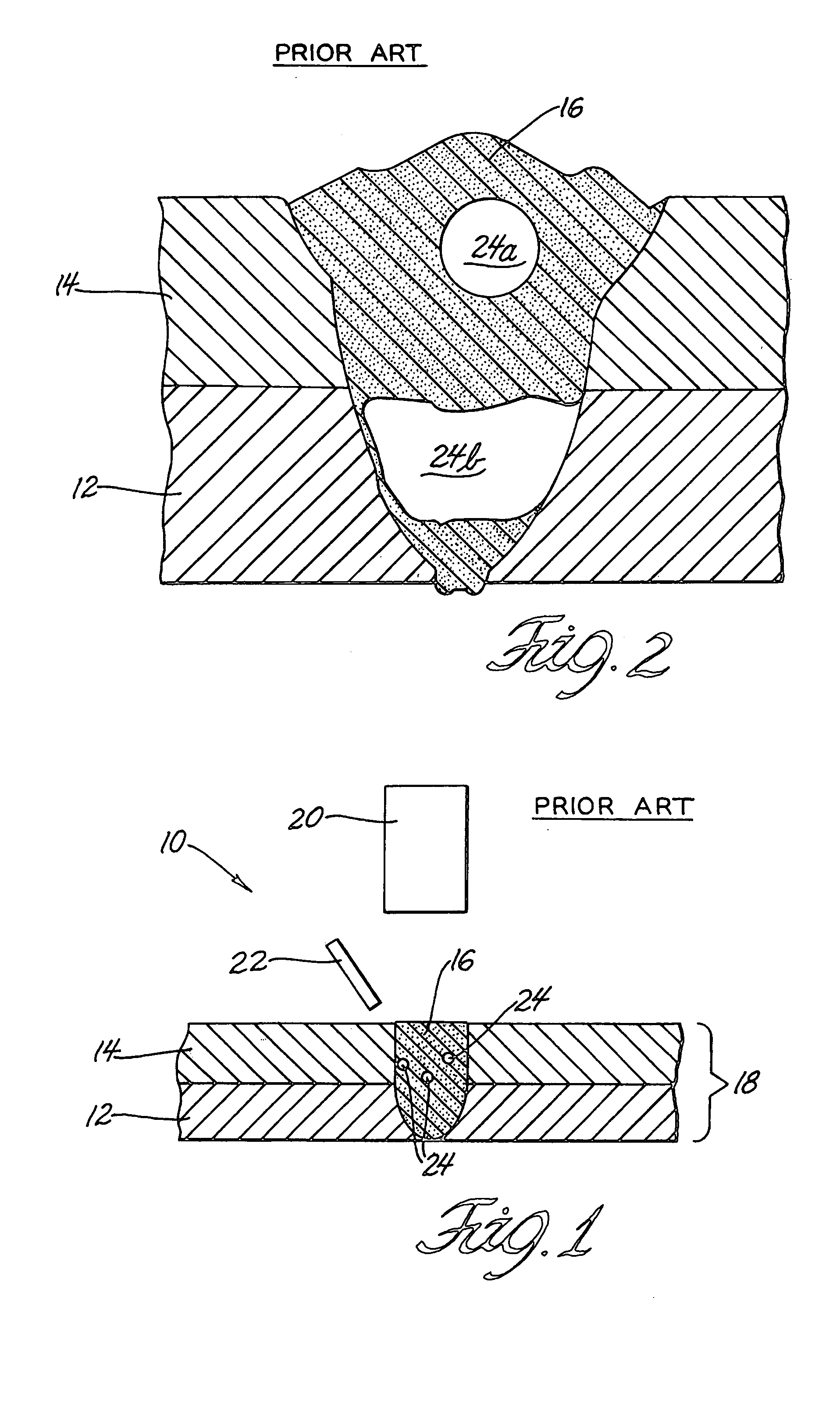

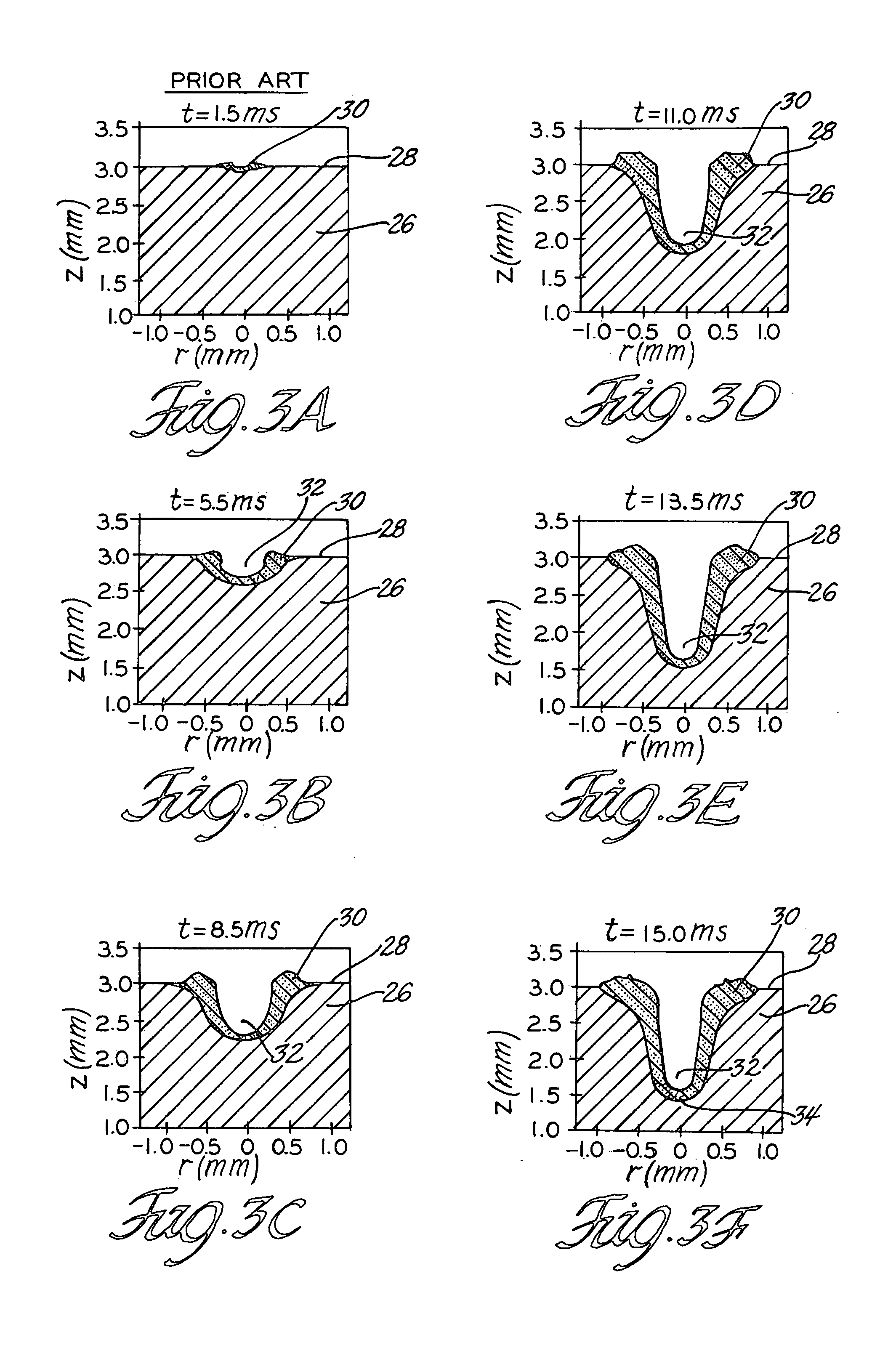

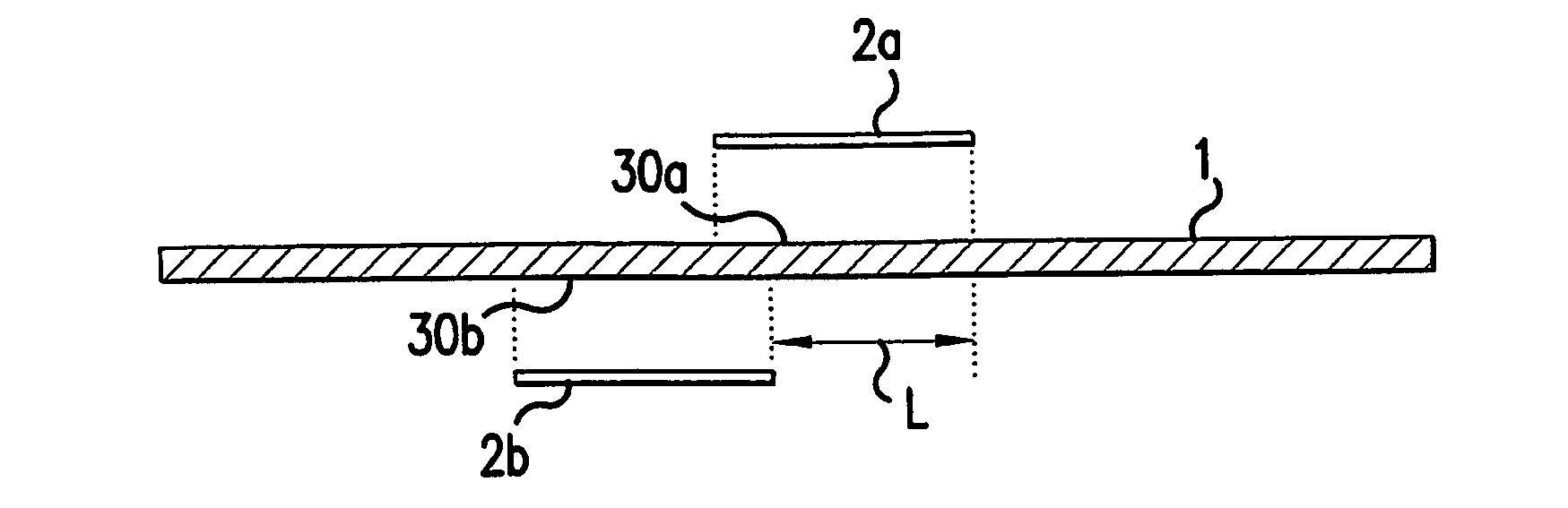

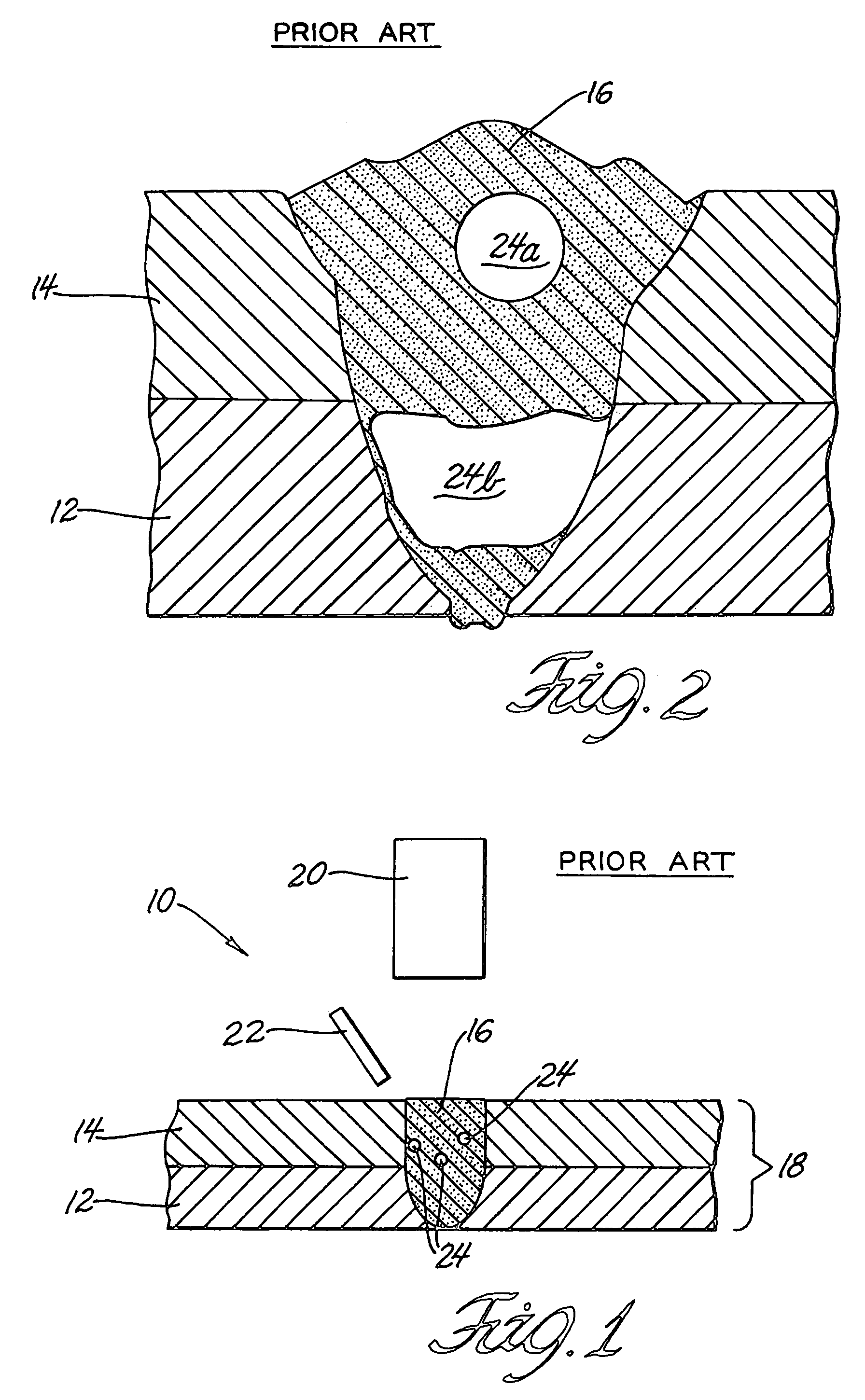

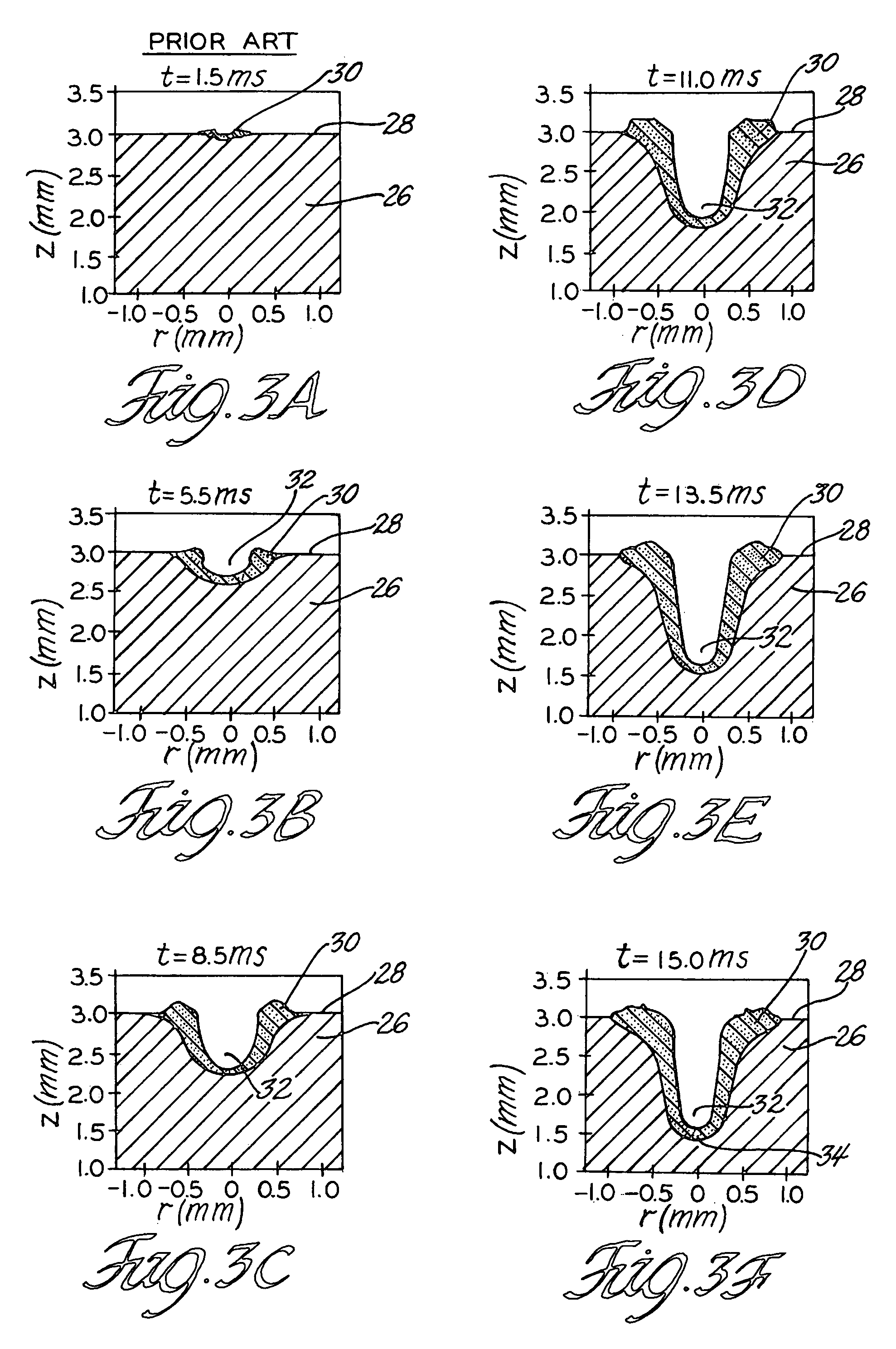

Method of improving weld quality

InactiveUS20050121426A1Improve temperature distributionReduce solidificationWelding/soldering/cutting articlesLaser beam welding apparatusIrradiationLaser beams

A method of improving weld quality between aluminum members by slowing the rate of solidification of a molten weld trough into solidified material. Upper and lower aluminum members are positioned together in contact between facing surfaces thereof to expose a first outer surface of the upper aluminum member to laser irradiation. A welding laser beam is moved in a path over the first outer surface, wherein the welding laser beam has an energy and width to progressively melt a trough of molten metal to a depth through the upper aluminum member and into the lower aluminum member. The molten metal in the trough has a void filled with gas, and the molten metal re-solidifies into re-solidified metal after the passage of the welding laser beam. An area in and around the trough is heated to slow the rate of solidification of the molten metal into the re-solidified metal, thereby preventing entrainment of the gas within the re-solidified metal.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

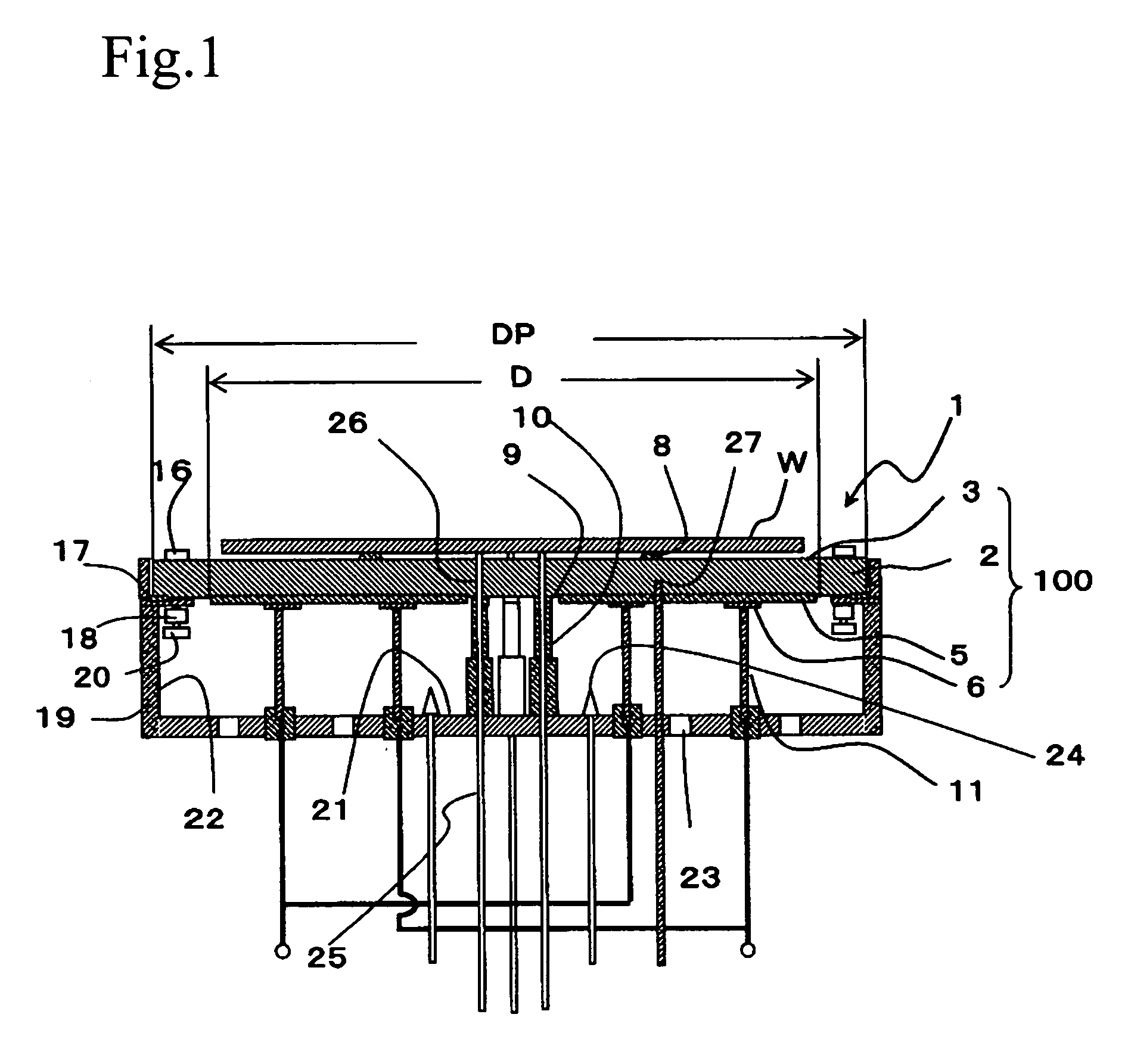

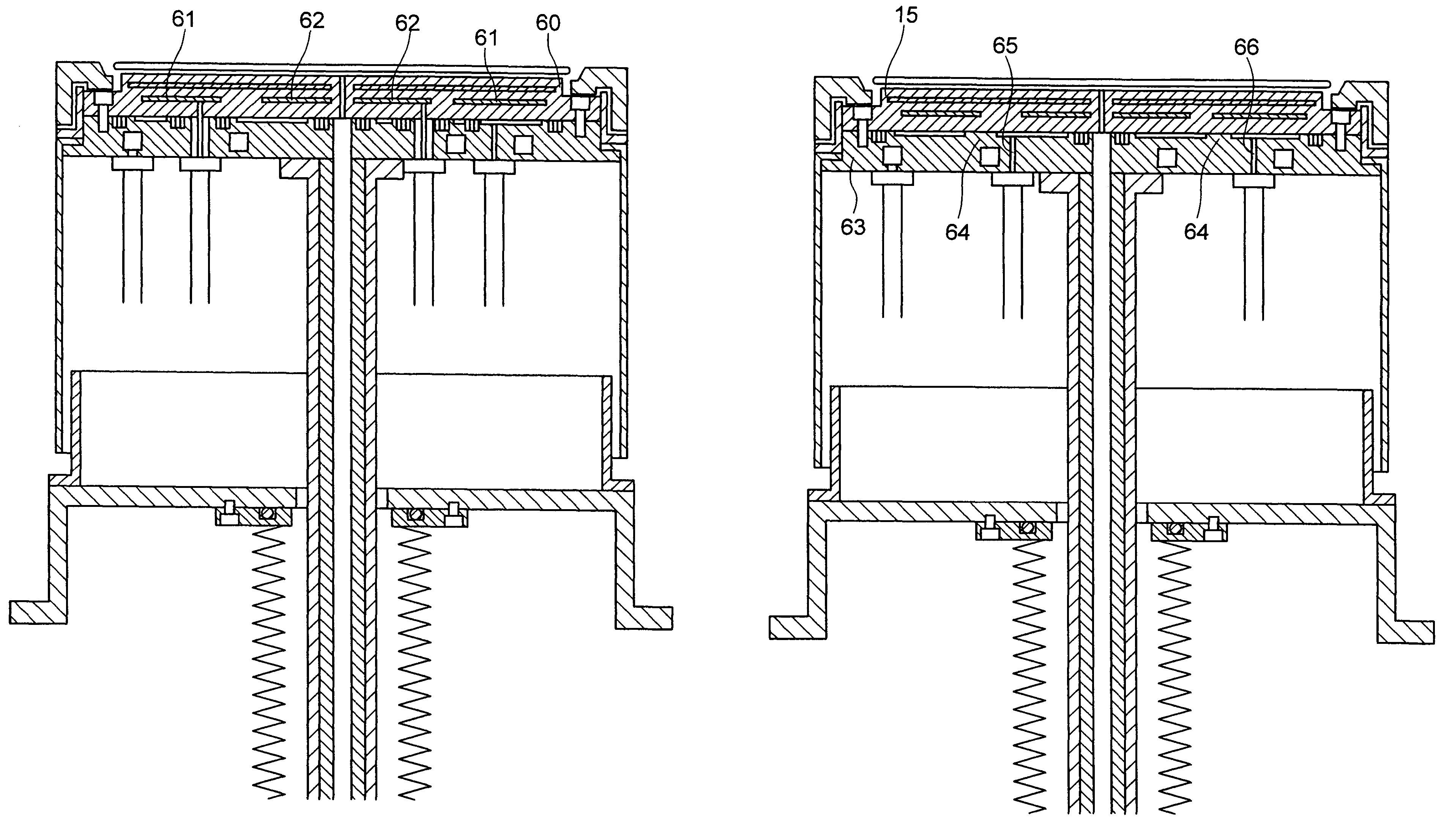

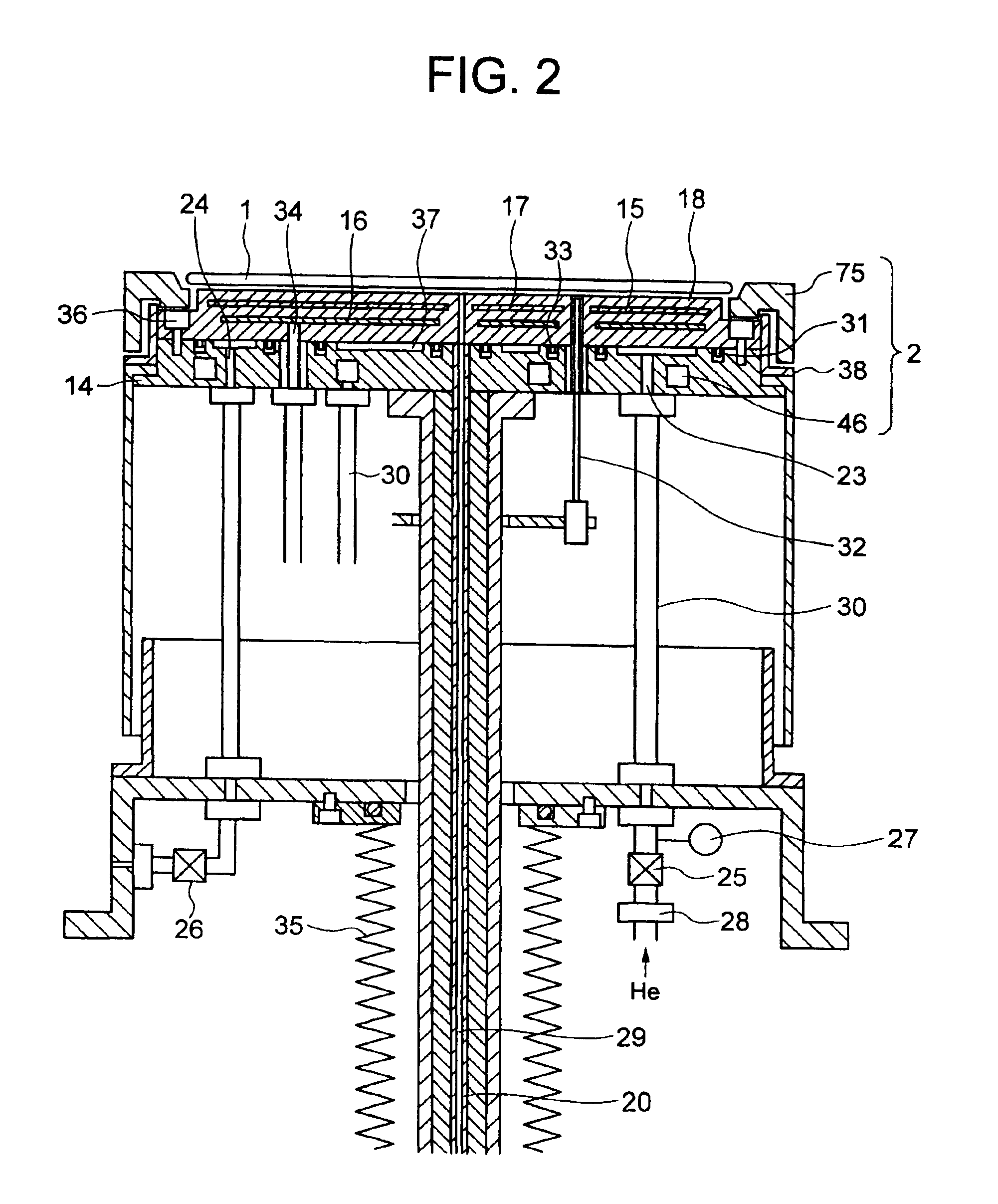

Wafer stage for wafer processing apparatus

InactiveUS6895179B2Improve temperature distributionUniform temperatureDrying solid materials with heatMuffle furnacesElastomerEngineering

A wafer stage for use in a wafer processing apparatus having a liquid cooling jacket with a built-in coolant liquid circulation path and a ceramic plate as attached onto the liquid cooling jacket and having therein a heater and an electrode for an electrostatic chuck. The wafer stage enables performance of wafer processing while letting a wafer be mounted on the ceramic plate. The liquid cooling jacket enables attachment of the ceramic plate through a gap for circulation of a coolant gas as formed over the liquid cooling jacket, and a heat resistant seal material containing therein an elastic body for sealing the coolant gas between the liquid cooling jacket and the ceramic plate.

Owner:HITACHI HIGH-TECH CORP

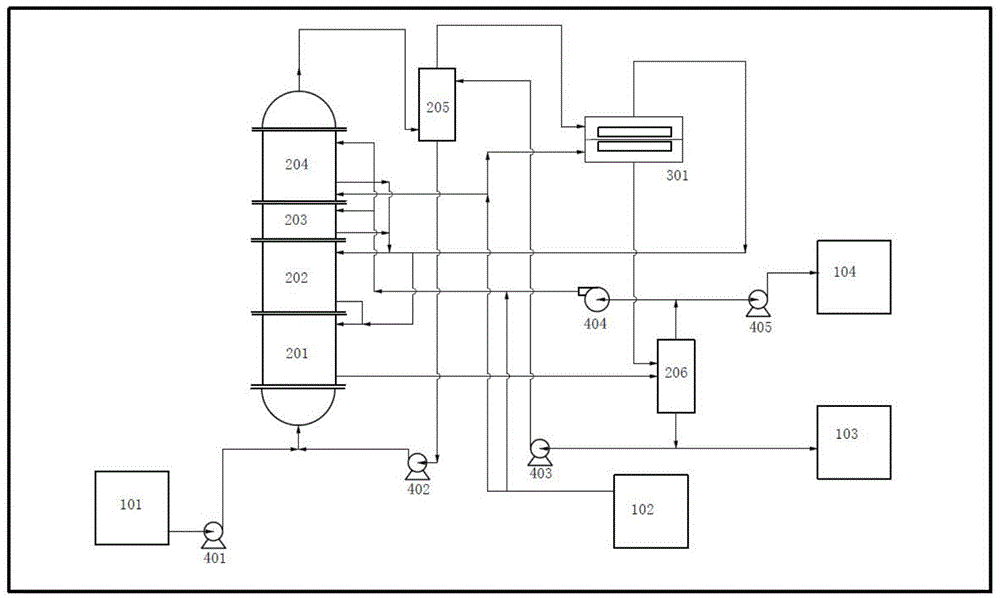

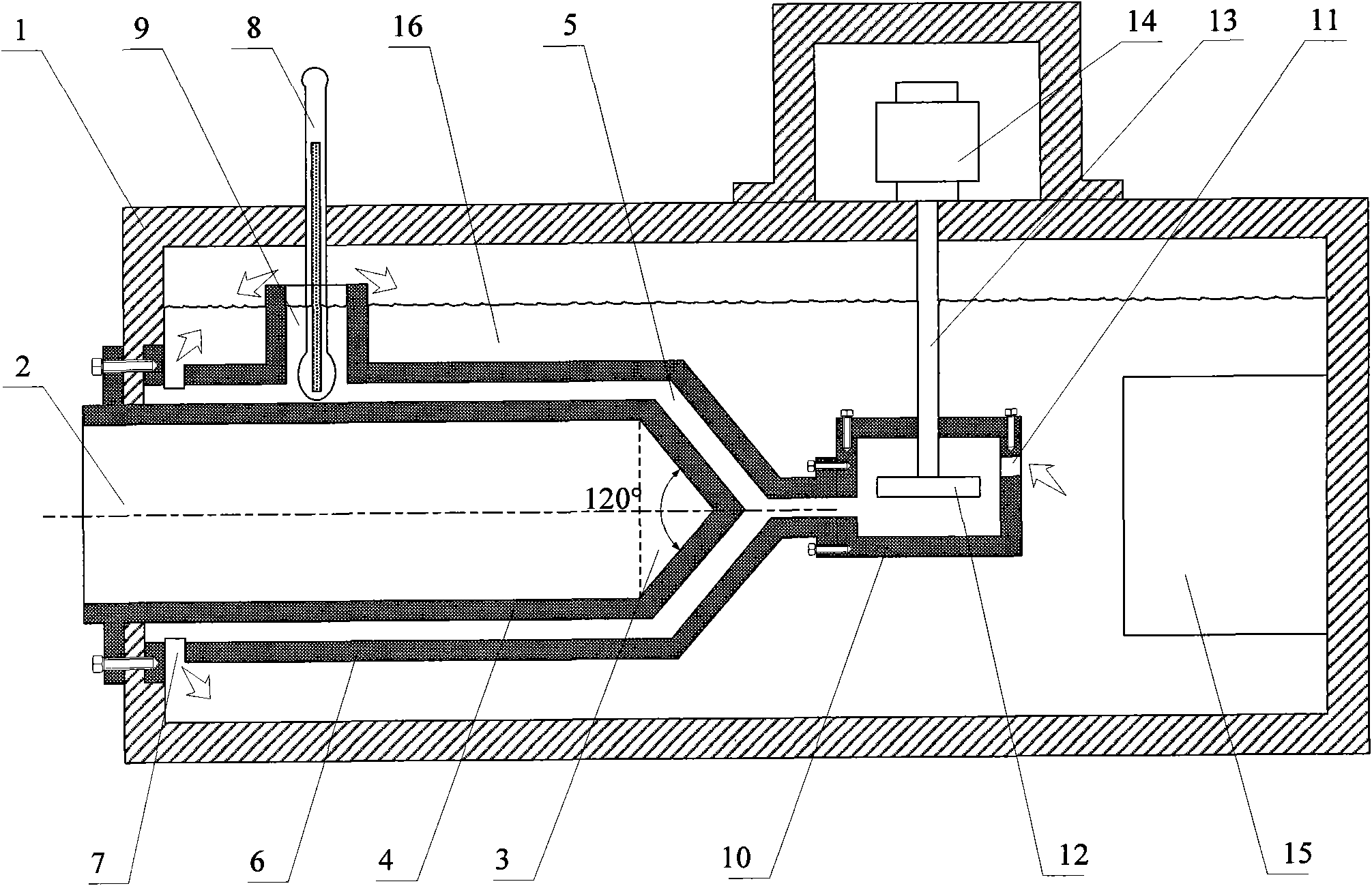

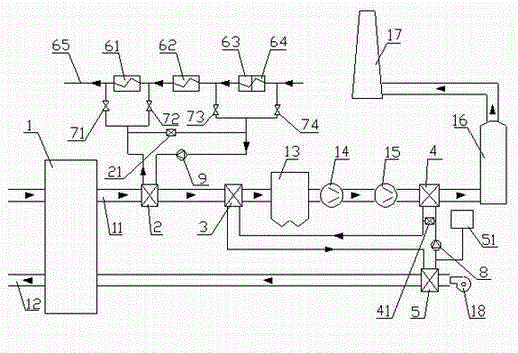

Enclosed methanol-water steam reforming fuel cell hydrogen source system and hydrogen production method

ActiveCN105655612AReduce CO2 concentrationGuaranteed uptimeHydrogenFuel cell auxillariesElectrochemical responseSteam reforming

The invention discloses an enclosed methanol-water steam reforming fuel cell hydrogen source system, which comprises a methanol supplying device, a liquid oxygen device, a carbon dioxide storage device, a water storage device, and a methanol hydrogen producing device; wherein the methanol hydrogen producing device comprises an evaporation device, a reforming device, a combustion device, a carbon monoxide selective oxidation reactor, and other auxiliary systems; and the combustion device, reforming device, evaporation device, and carbon monoxide selective oxidation reactor are integrated into a module. According to the hydrogen production method, methanol and water are gasified by the evaporation device and then react in the reforming device to obtain reformed gas; then the reformed gas is processed by the monoxide selective oxidation reactor, the concentration of carbon monoxide in reformed gas is further reduced, and finally the reformed gas is introduced into the fuel cell system to carry out electrochemical reactions. The provided system has the advantages that the system operates in an enclosed space, the operability and safety of the system are both improved; the heat exchange and reactions are well matched, and the whole reforming hydrogen production system is high efficient and compact.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

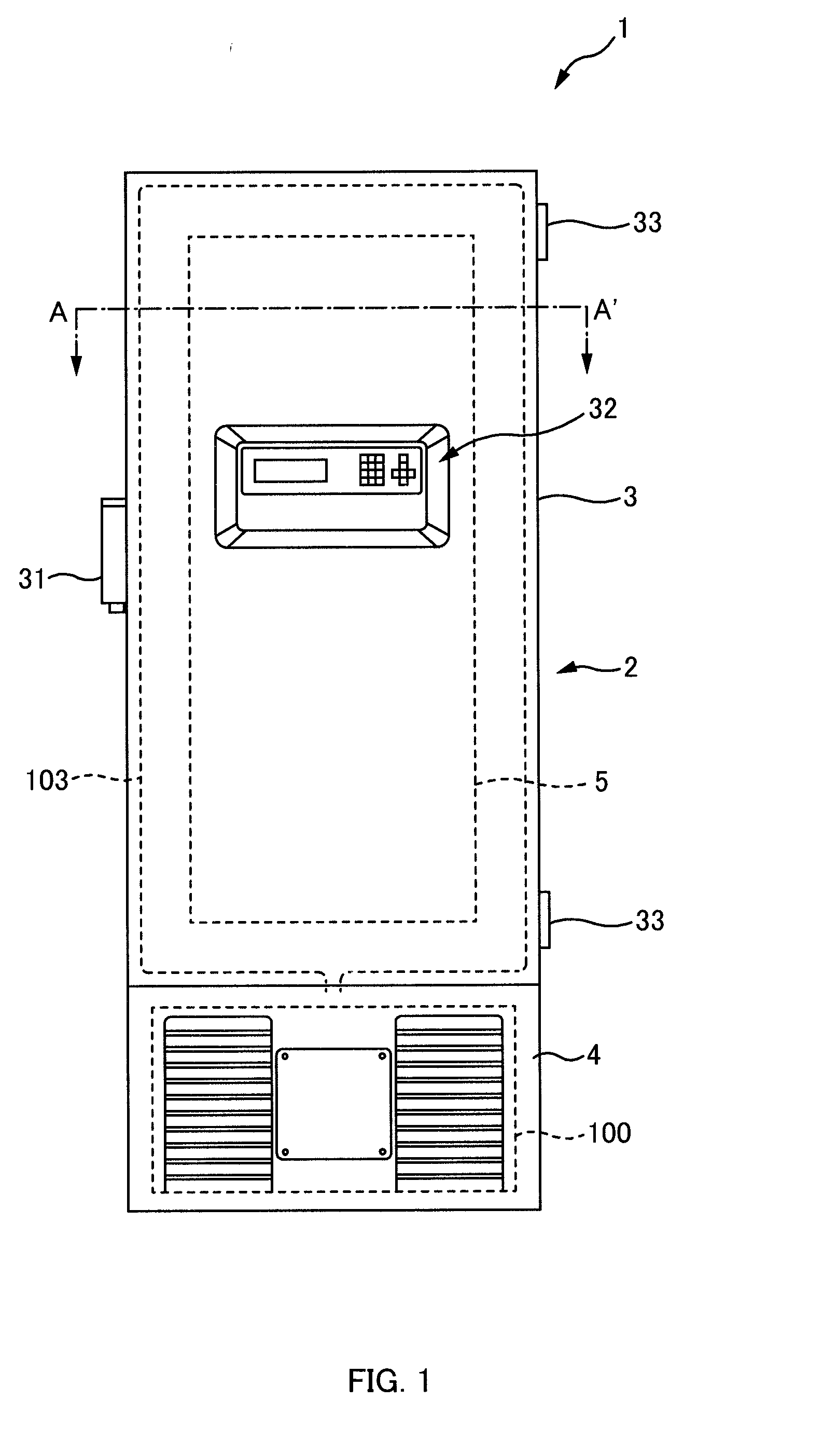

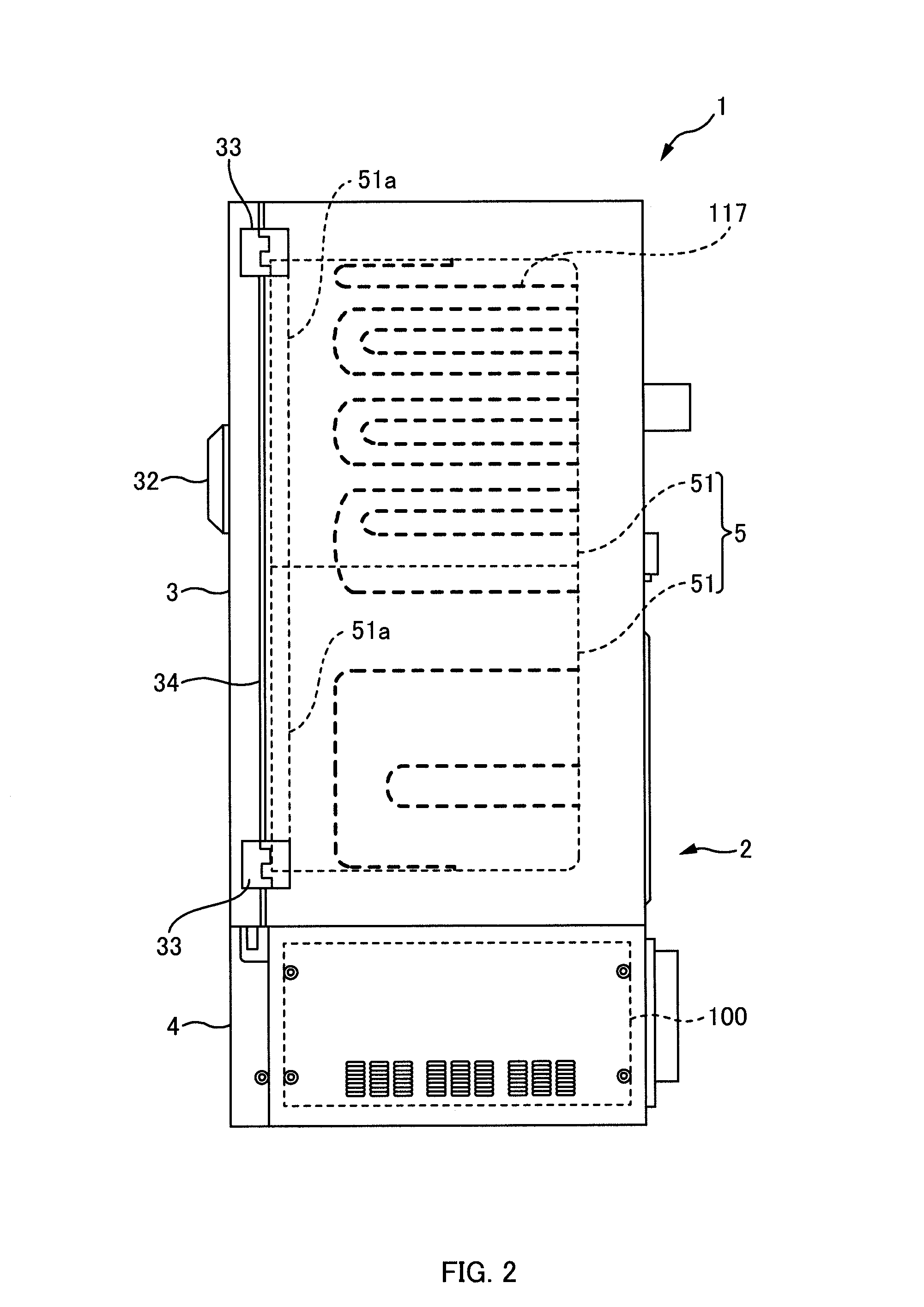

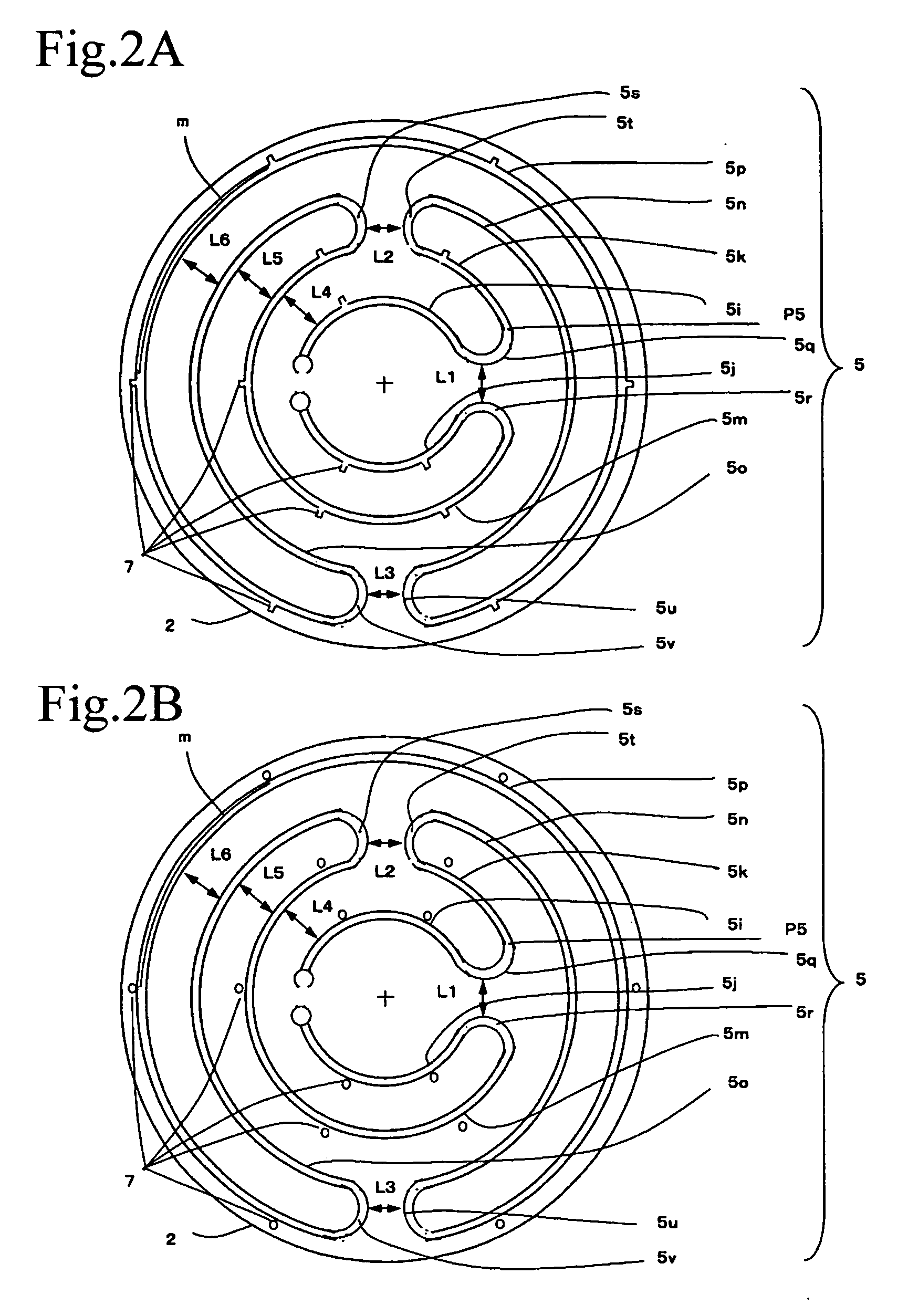

Refrigerating apparatus

InactiveUS20110023532A1Cost containmentImprove temperature distributionCompression machines with non-reversible cycleDomestic refrigeratorsPlate heat exchangerEngineering

A refrigerating apparatus includes a refrigerating cycle including a compressor, a condenser, a flow divider, a first heat exchanger, a second heat exchanger, a decompressing device, and an evaporator. The refrigerant cycle has sealed therein a mixed refrigerant obtained by mixing at least first to third refrigerants with different evaporation temperatures. The first heat exchanger and the second heat exchanger each includes a double pipe to form a first flow passage in an inner pipe of the double pipe, a second flow passage in an outer pipe of the double pipe, and an intermediate port in a piping connecting between the second flow passage of the first heat exchanger and the second flow passage of the second heat exchanger. A high-temperature and high-pressure refrigerant discharged from the compressor is cooled by the condenser to liquefy the first refrigerant having a high evaporation temperature into a liquid refrigerant.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

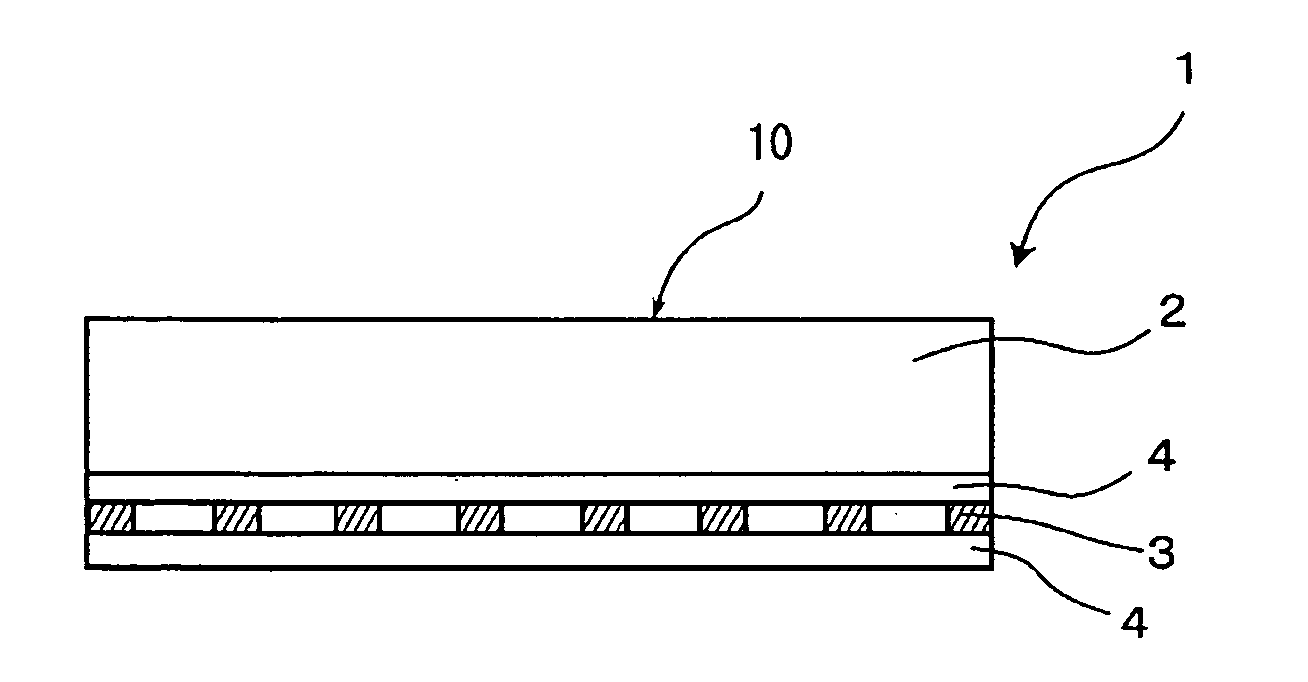

Heater for heating a wafer and method for fabricating the same

ActiveUS20050252903A1Improve production yieldEasy to mass produceIncandescent ignitionSemiconductor/solid-state device manufacturingElectrical resistance and conductanceBand shape

The invention is to provide a heater capable of having a high uniform heating characteristic and substantially equally heating a wafer etc. mounted thereon, and a wafer heating device using the same, as well as a method thereof. In order to solve the above object, the invention provides a heater which comprises a plate shaped body, a belt-like resistance heating element formed on the plate shaped body and having a channel for adjusting the resistance value, and a positioning mark formed on the plate shaped body, which serves as a reference for positioning the channel.

Owner:KYOCERA CORP

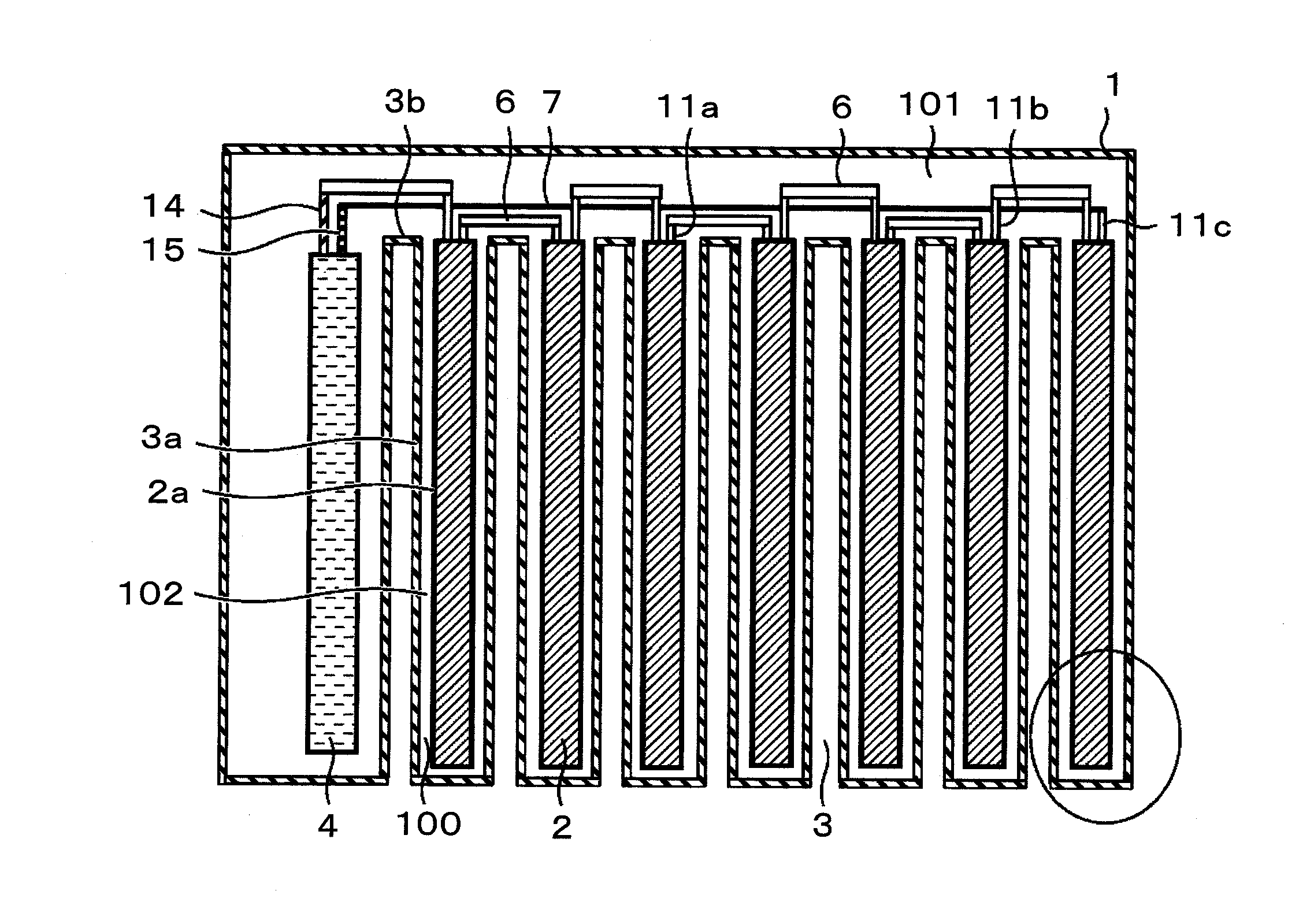

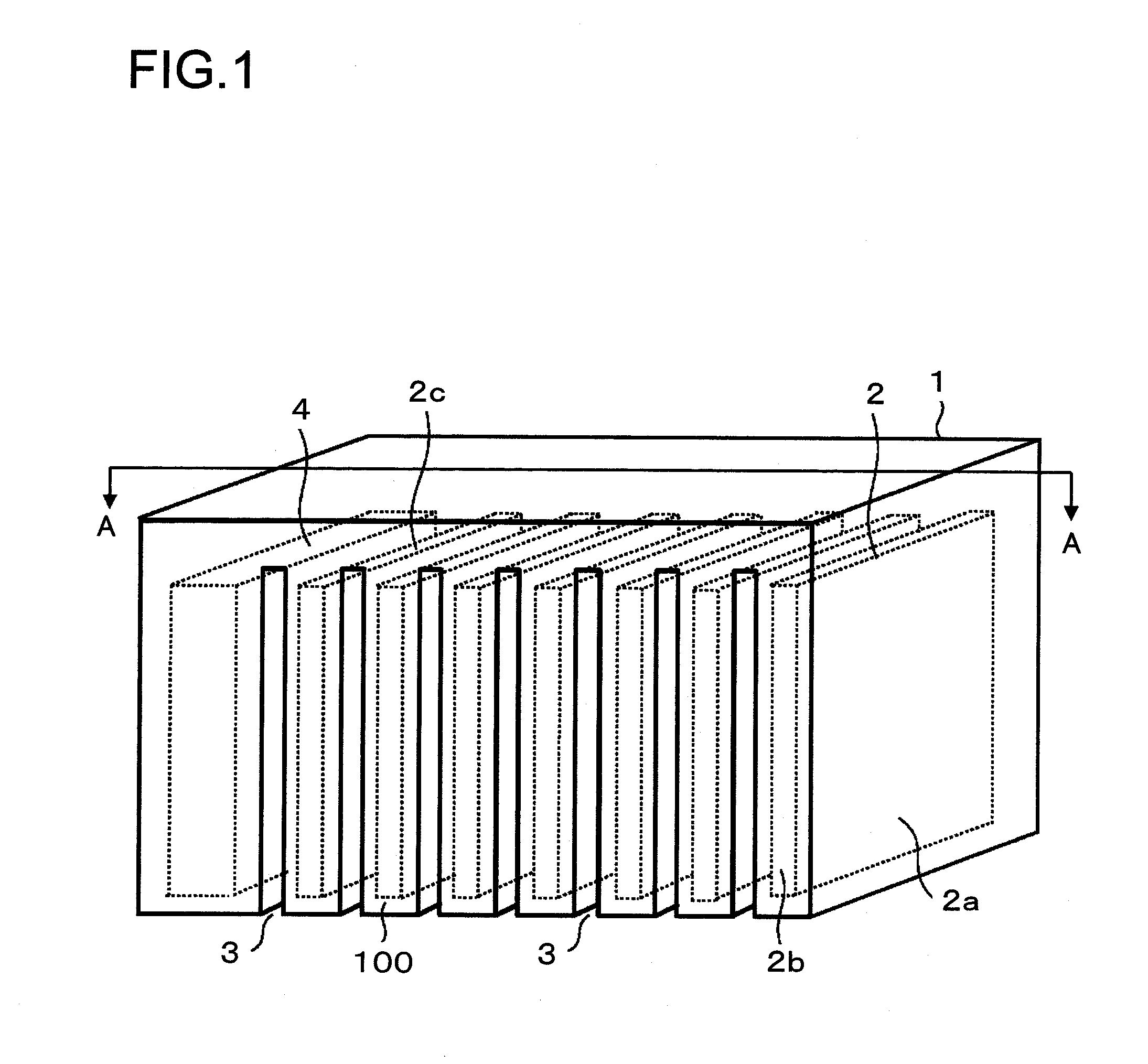

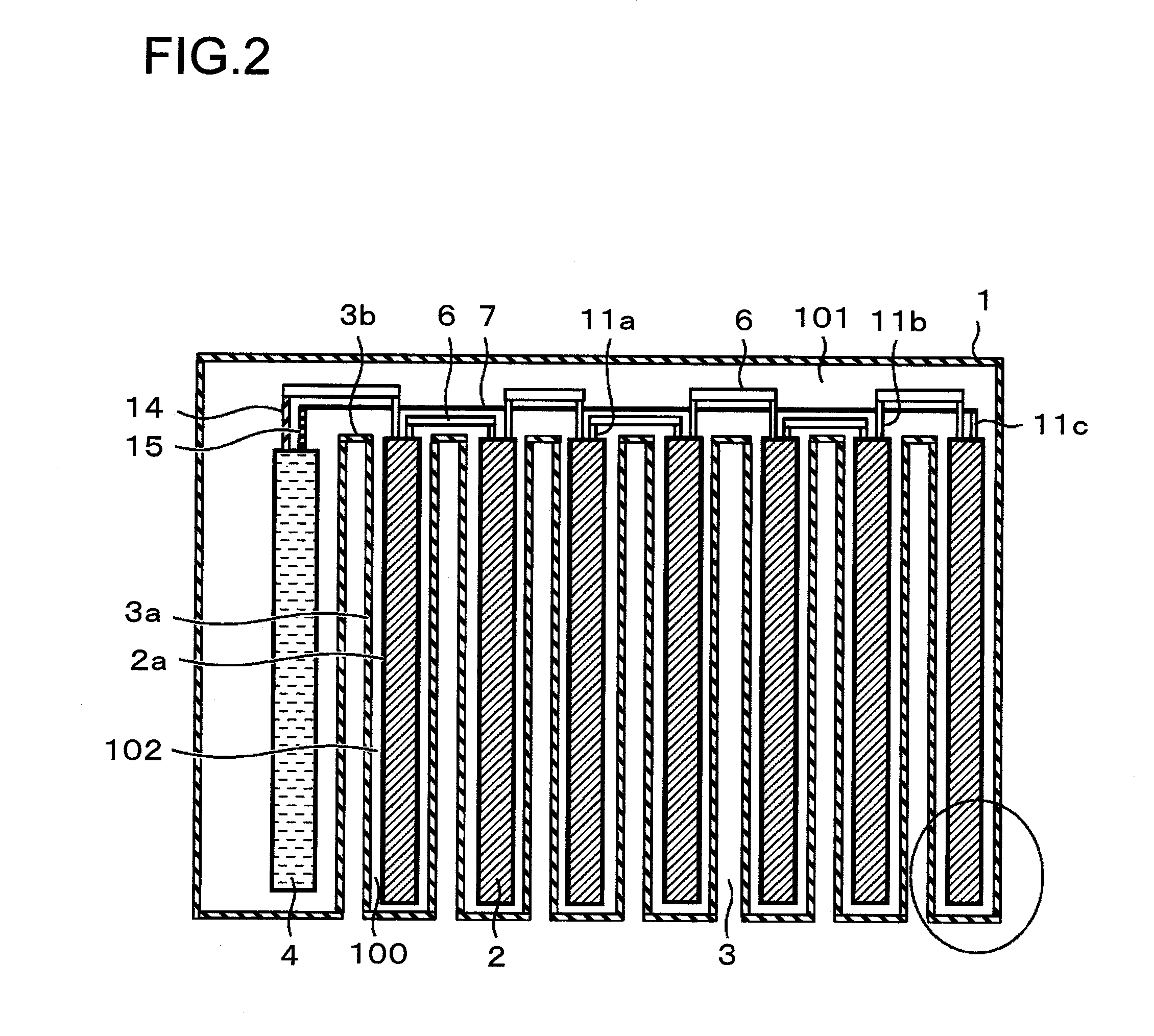

Secondary battery module and secondary battery pack

ActiveUS20120270075A1Simple and easy to exchangeImprove cooling effectPrimary cell to battery groupingSmall-sized cells cases/jacketsEngineeringDepth direction

A secondary battery module includes a plurality of plate shaped secondary cells; and a casing that is formed with a plurality of grooves extending in its depth direction, with at least one of the secondary cells being housed in a space defined between neighboring grooves, wherein: the plurality of grooves each extends from a lower portion of the casing towards an upper portion of the casing; and the plurality of secondary cells are electrically connected together in a space defined above the grooves and internal to the casing.

Owner:HITACHI LTD

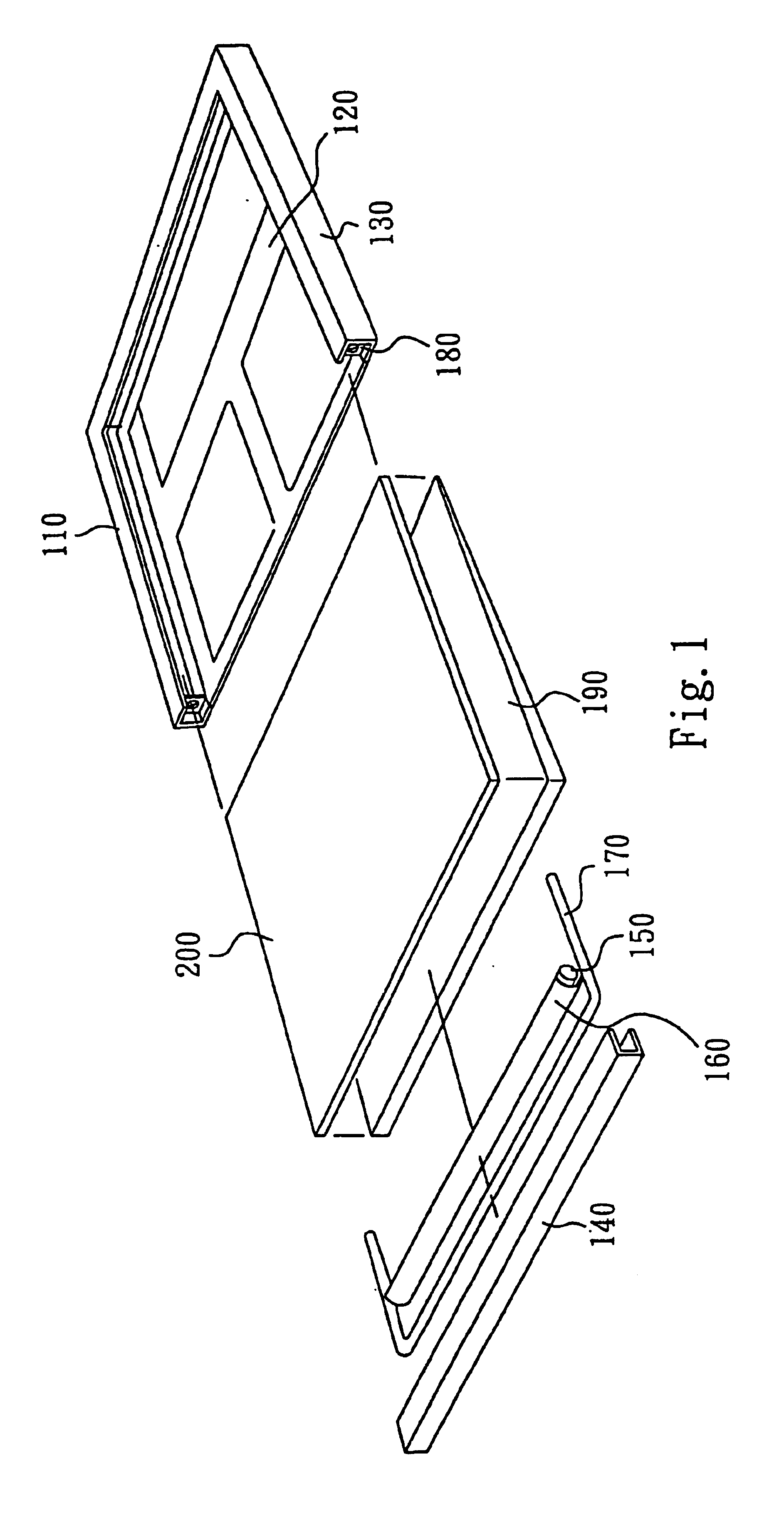

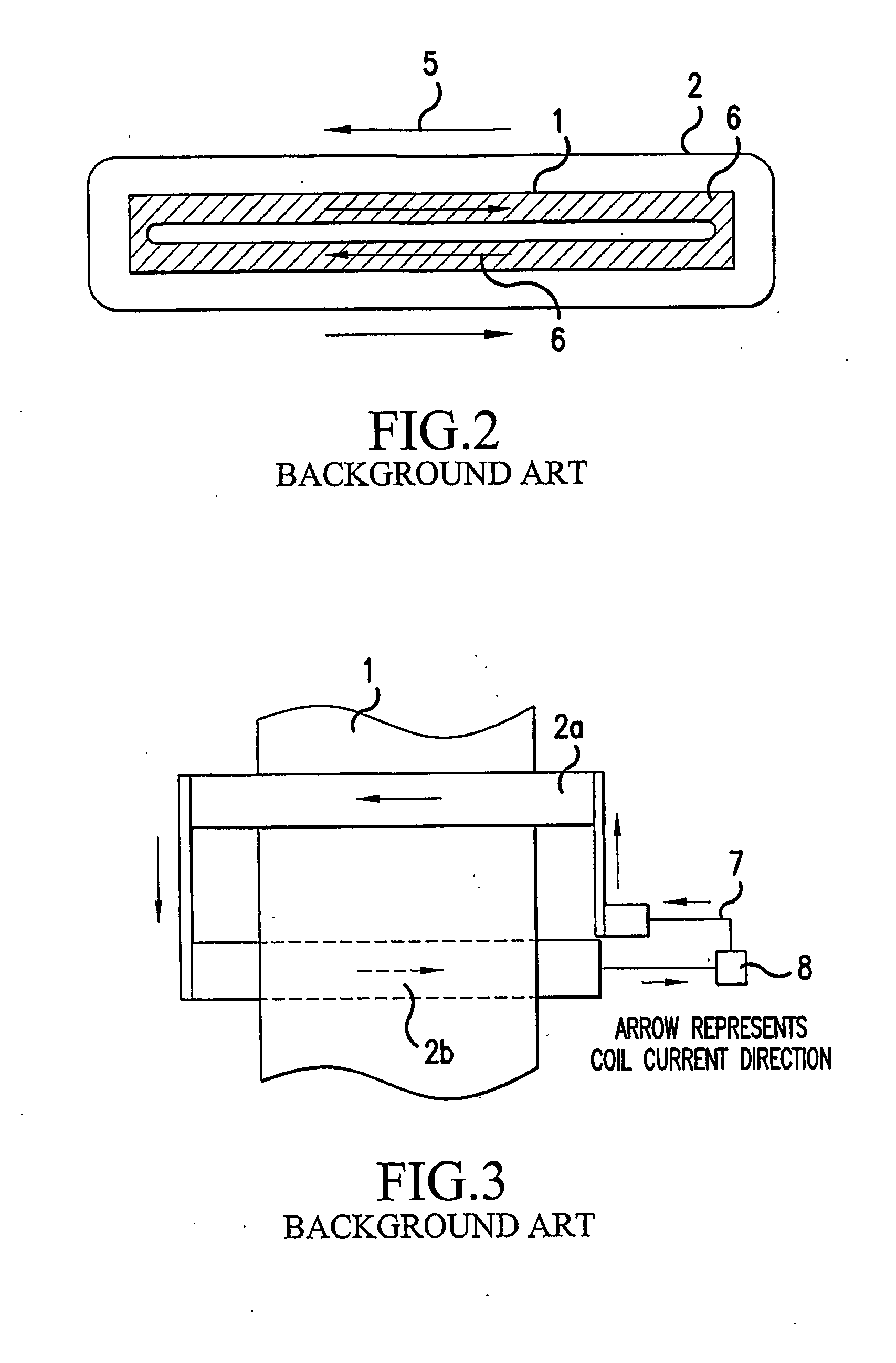

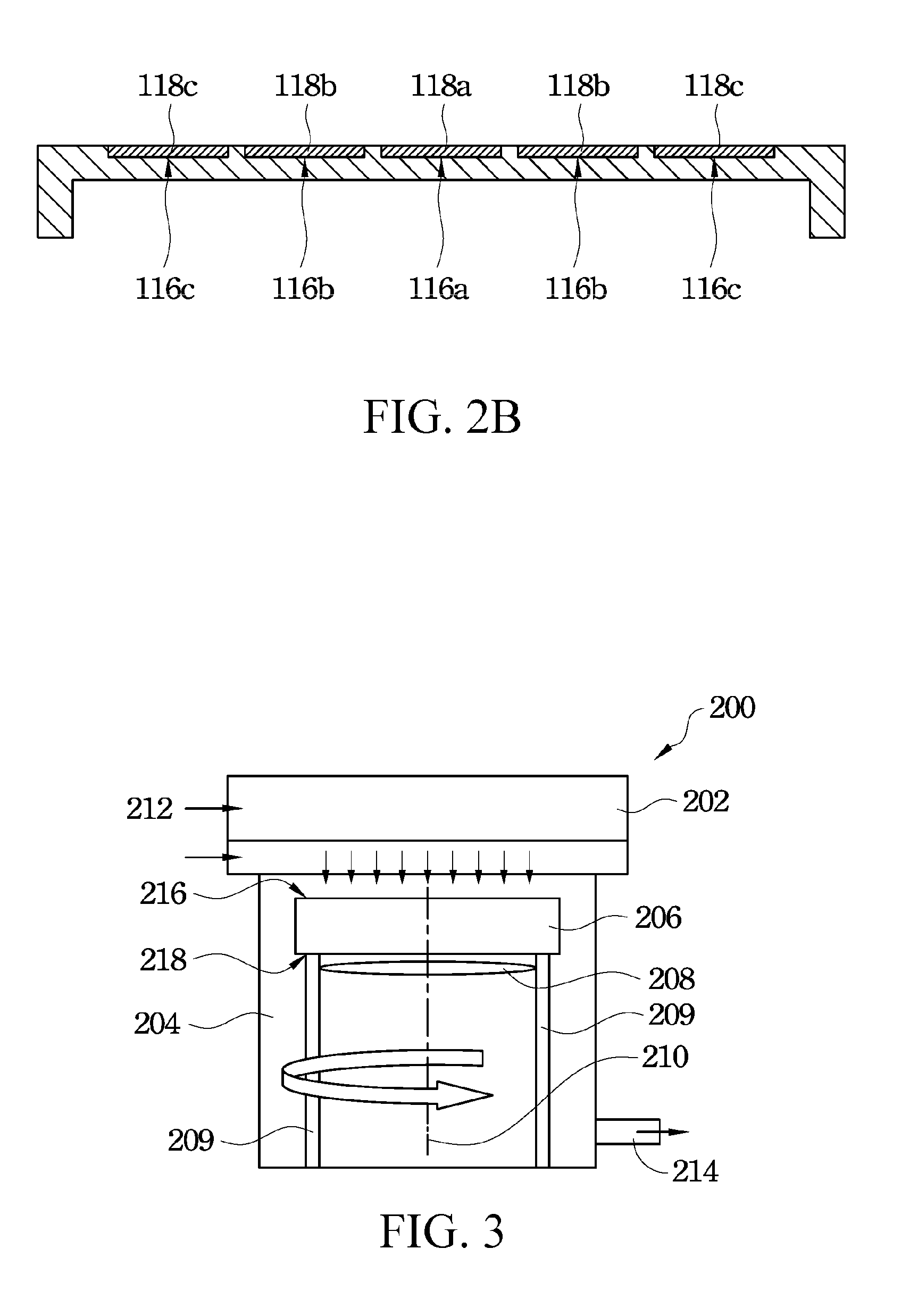

Backlight module for homogenizing the temperature of a flat panel display device

InactiveUS6954238B2Improved temperature distributionImprove temperature distributionStatic indicating devicesNon-linear opticsFlat panel displayLight source

A flat panel display or a backlight module for homogenizing temperature distribution. The backlight module utilizes a heat pipe to carry out the heat from the light source quickly and homogenizes the distribution of temperature of the light source.

Owner:AU OPTRONICS CORP

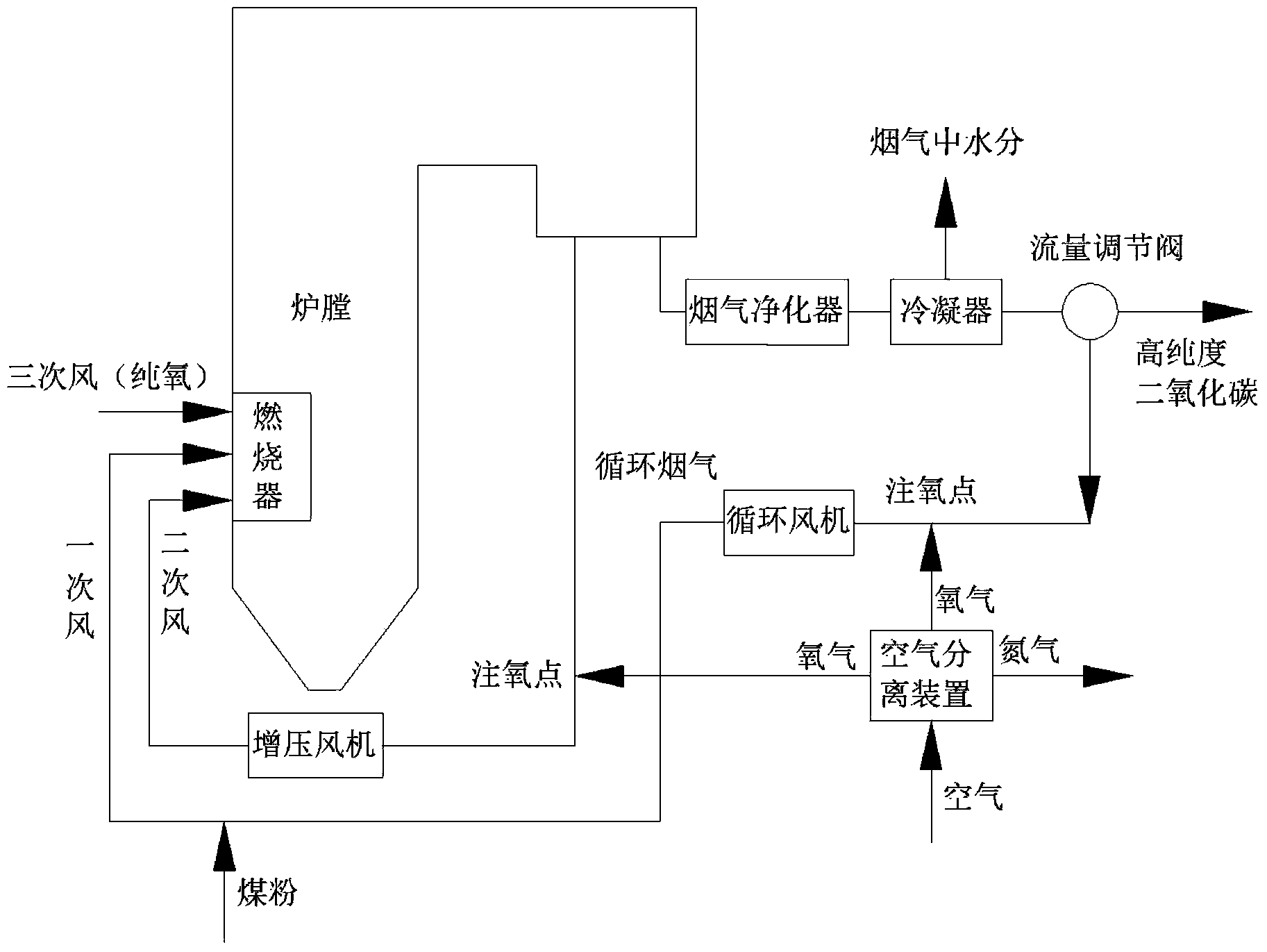

Pulverized coal oxygen-rich combustion method and system

InactiveCN103968373AEasy to captureEfficient use ofDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationCombustion systemAir volume

The invention discloses a pulverized coal oxygen-rich combustion method. According to the method, based on traditional oxygen-rich combustion CO2 enrichment, oxygen proportions in a primary air and a secondary air are adjusted to ensure that the oxygen concentration of the primary air is higher than the oxygen concentration of the secondary air, wherein the oxygen content of the primary air is about 30-50 %, the oxygen content of the secondary air is 10-25 % and a third air is pure oxygen; oxygen volume flow entering a furnace chamber takes up 25-35 % of total furnace chamber air volume flow; the pulverized coal is carried by the primary air; the proportion of the primary air to the secondary air is (5 %-25 % ) to (95 % - 75 %); the oxygen excess air coefficient is 1.0-1.2. The invention further provides a corresponding pulverized coal oxygen-rich combustion system. According to the pulverized coal oxygen-rich combustion method, the stability of combustion is improved, the temperature distribution in combustion process is changed and the NOX generation is reduced eventually; after the improvement, the thermal utilization efficiency can be increased by 5-15% and generated NOX can be reduced by 15-45 %.

Owner:HUAZHONG UNIV OF SCI & TECH

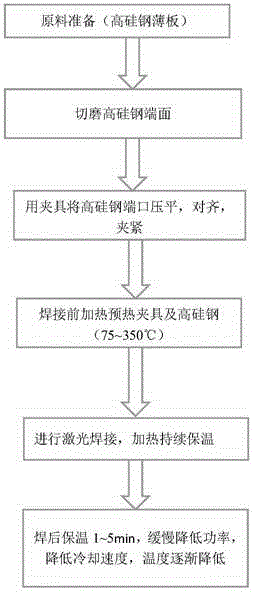

Laser welding method of high silicon steel

ActiveCN106041305ARealize welding formingImprove cooling conditionsWelding/soldering/cutting articlesLaser beam welding apparatusAlloySlow cooling

The invention belongs to the field of the metallurgy technology and material science, and aims at providing a laser welding process method of brittle high silicon steel. Quick welding of strip tension rolling in the rolling preparation process of a high silicon steel thin strip is met. According to the mass ratio, an adopted alloy is prepared from 93%-96.5% of Fe and 3.5%-7% of Si; and the thickness ranges from 0.1 mm to 3.5 mm. According to the method, laser welding and a supplementary heat source are combined, and double-face or single-face welding is adopted; preheating carried out before welding is utilized for controlling the temperature rise speed, and heat preservation during welding and heat preservation carried out after welding are utilized for slow cooling to control the temperature reduction speed; and the temperature gradient and welding stress in the weld joint cooling process are reduced, and welding forming of the brittle high silicon steel is achieved. By means of the adoption of the method, cracks generated by the too high welding stress of the brittle high silicon steel can be avoided well, and the yield and the mechanical performance of the brittle high silicon steel are increased.

Owner:UNIV OF SCI & TECH BEIJING

Induction Heating Device for a Metal Plate

ActiveUS20100155390A1Easy to realize desired temperature distributionImprove non-uniform temperature distributionInduction heating apparatusMetalMaterials science

An induction heating apparatus for heating a traveling metal plate includes an induction coil for surrounding the metal plate. The induction coil includes an upper portion for being located above the metal plate and a lower portion for being located below the metal plate. The upper and lower portions of the induction coil are spaced from each other in a longitudinal direction of the metal plate at least at one position in a transverse direction of the metal plate. The distance in the longitudinal direction of the metal plate between the upper portion and the lower portion of the induction coil varies across a transverse direction of the metal plate.

Owner:NIPPON STEEL CORP

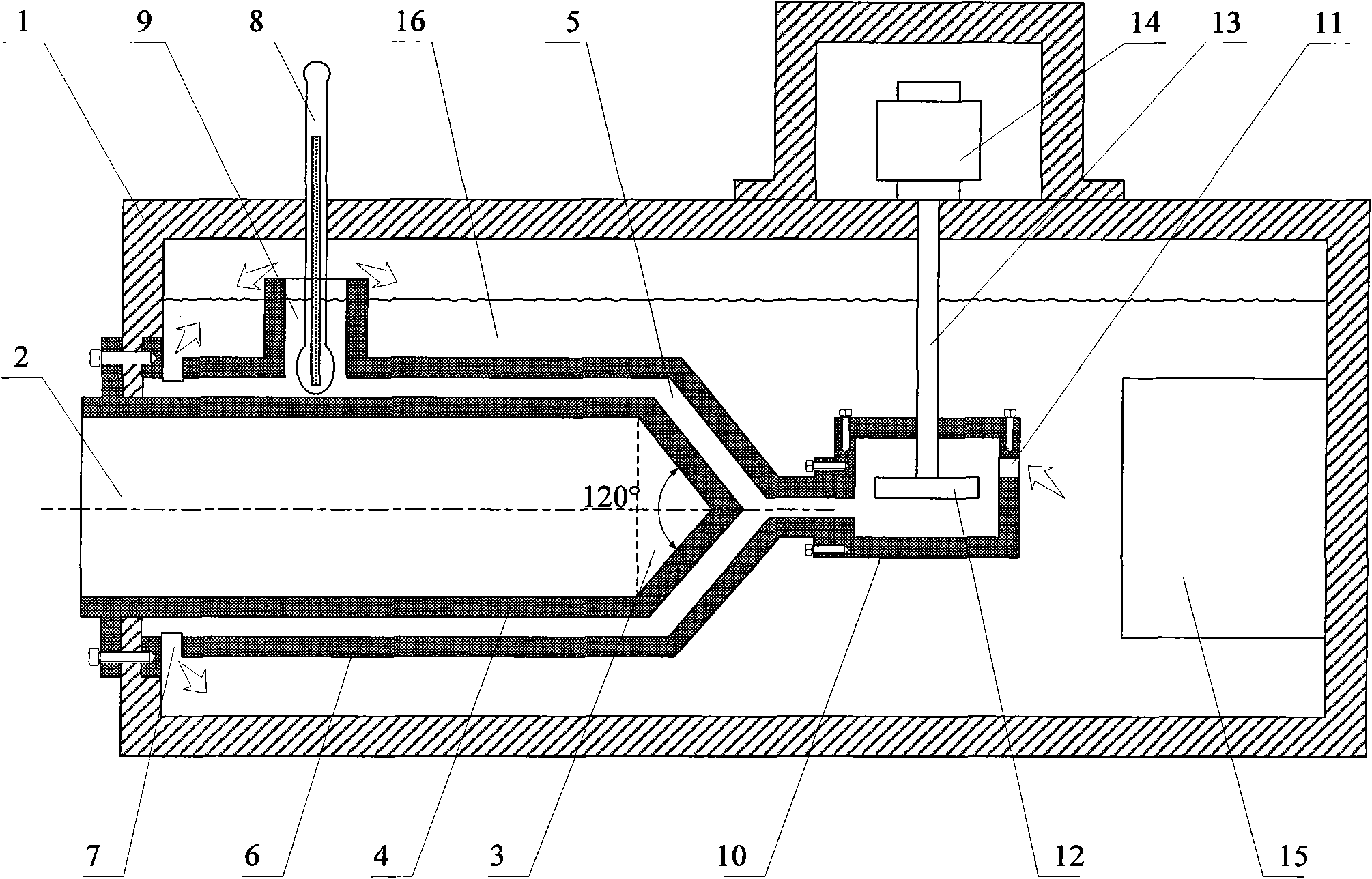

Black body cavity radiation source

InactiveCN101873728AImprove temperature distributionHigh emissivityRadiation pyrometryOhmic-resistance heating detailsImpellerLiquid medium

The invention discloses a black body cavity radiation source which comprises a liquid thermostat, a black body cavity, a temperature controller, a pump and a standard thermometer. The black body cavity and the temperature controller are installed in the liquid thermostat, the black body cavity comprises a cavity inner shell and a cavity outer shell, and the inner wall of the cavity inner shell and the inner wall of the cavity outer shell are coated with black diffuse reflection coatings. The cavity inner shell with the front end being a conical cavity and the rear end being a columniform cavity is coaxially installed in the liquid thermostat, and the cavity outer shell with the same shape as that of the cavity inner shell is installed outside the cavity inner shell to form an equally spaced hollow interlayer. The end surface of the cavity inner shell is connected with the outer wall of the liquid thermostat, a conical cavity opening of the cavity outer shell is communicated with a pump shell, the pump shell is communicated with the liquid thermostat through the opening, an impeller in the pump shell is connected with a motor through a pump shaft, the standard thermometer is arranged in the hollow interlayer, and openings are equally distributed on the cavity outer shell. In the invention, the cavity outer shell and the pump are additionally arranged to enable liquid medium in the thermostat to flow in a circulating way in the hollow interlayer, thereby improving the temperature distribution of a black body cavity, enabling the black body cavity to have the characteristic of isothermy and further enhancing the emissivity of the black body cavity.

Owner:CHINA JILIANG UNIV

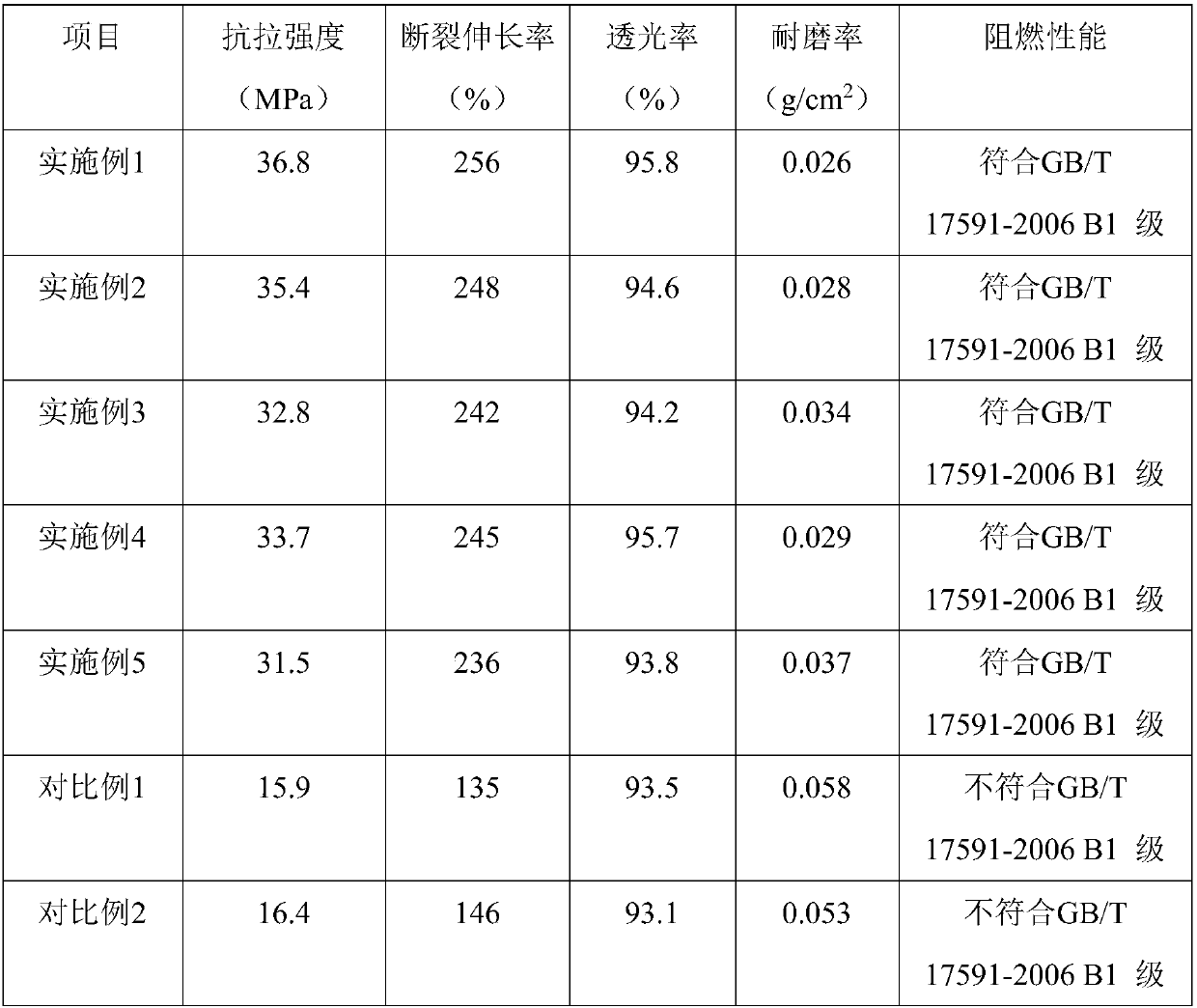

Technology for processing floor films

The invention discloses a technology for processing floor films, and relates to the field of floor film processing. The technology for processing the floor films includes steps of (1),mixing ingredients, to be more specific, weighing, by weight, PVC (polyvinyl chloride) resin powder, impact-resistant MBS (methyl methacrylate) resin, ACR (acrylamide) processing agents, di-iso-decylphthalate, internal lubricants, 3-10 parts of external lubricants and phosphate ester flame retardants, stirring the ingredients at the high speeds, and then carrying out cold stirring on the ingredients to obtain mixed materials; (2), carrying out extrusion, plasticization and calendaring molding on the mixed materials; (3), carrying out cooling and ageing treatment; (4), carrying out traction, winding and packaging. The technology has the advantages that the floor films are reasonable in composition proportion, high in light transmittance and suitable for large-scale industrial production, the technology isreasonable in design, and the toughness, the abrasion resistance, the flame retardance and the temperature resistance of the floor films can be enhanced.

Owner:安徽嘉阳新材料科技有限公司

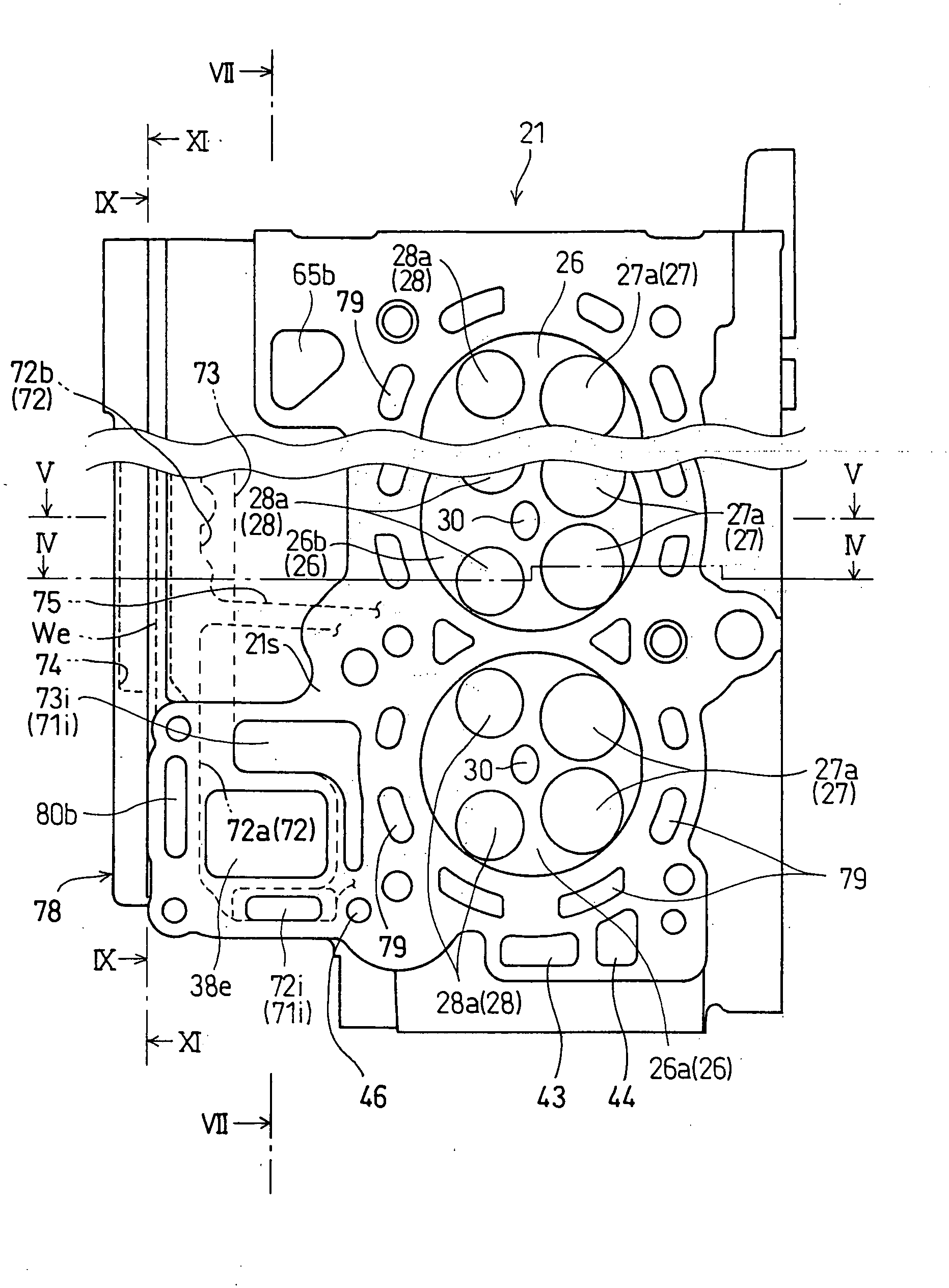

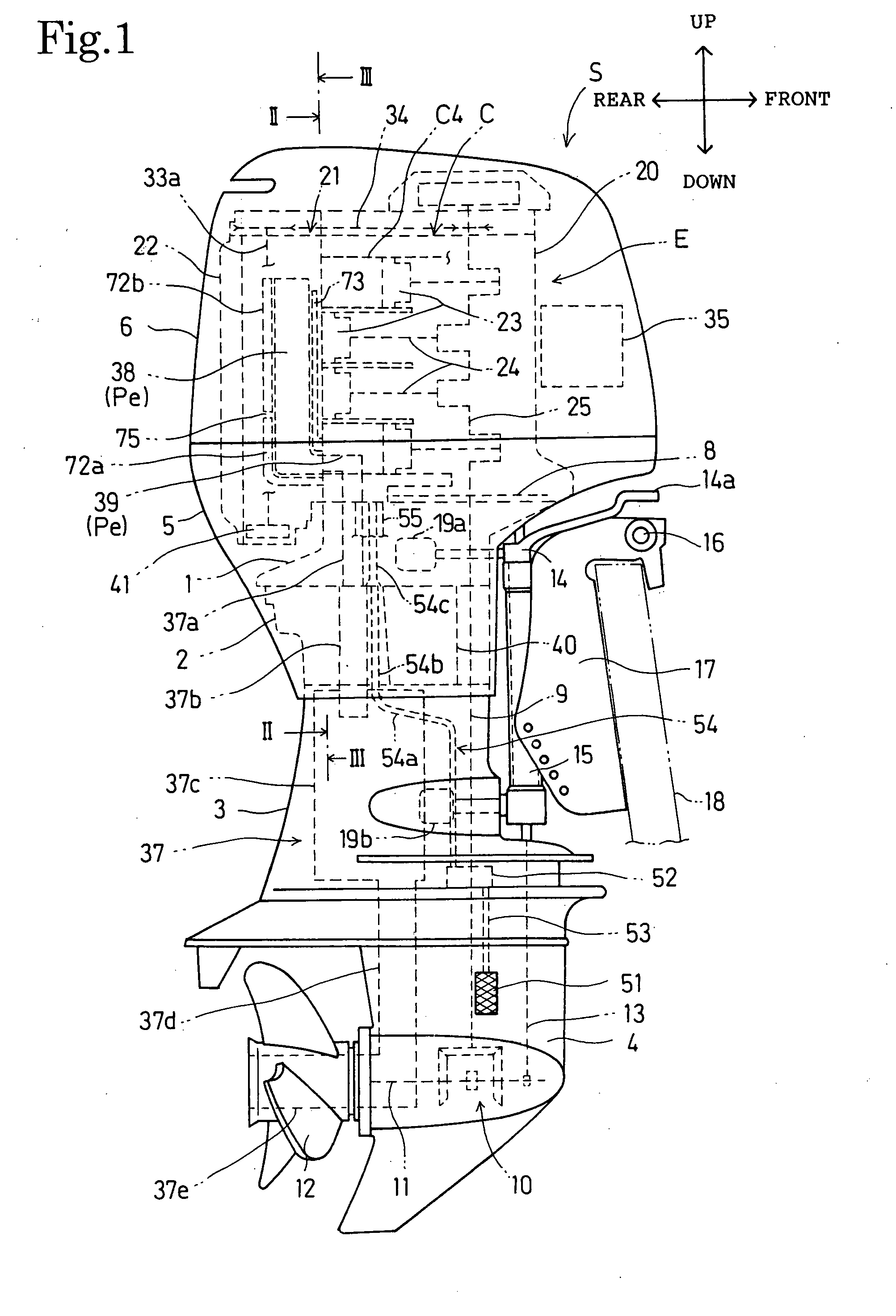

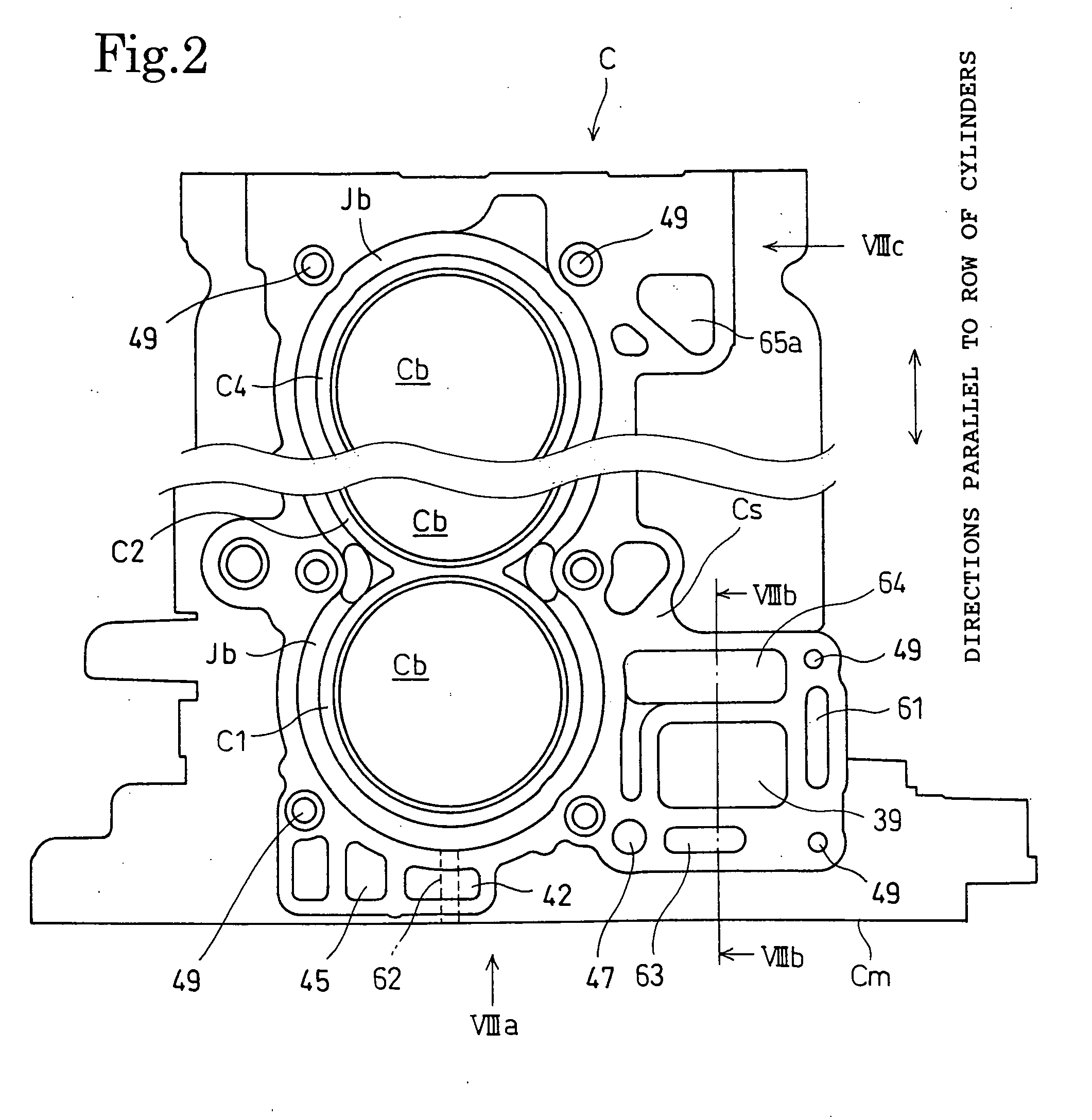

Water-cooled internal combustion engine

ActiveUS20070227473A1Improve cooling effectImprove temperature uniformityLiquid coolingAir coolingCombustion chamberCylinder head

A water-cooled internal combustion engine has a cylinder head 21 provided with a cylinder head water jacket Jh through which cooling water flows. The cylinder head water jacket Jh includes a combustion chamber water jacket 70 surrounding combustion chambers 26 and an exhaust passage water jacket 71 around an exhaust manifold passage 38. The exhaust gas discharged from the combustion chambers 26 through exhaust ports 28 flows through the exhaust manifold passage. The exhaust passage water jacket 71 is divided into an upstream water jacket 72a and a downstream water jacket 72b by a partition wall 75. The cooling water flows from both the upstream water jacket 72a and the downstream water jacket 72a into the combustion chamber water jacket 70. Equality in temperature between a combustion chamber wall and an exhaust passage wall is improved and the cylinder head 21 is heated in a uniform temperature distribution.

Owner:HONDA MOTOR CO LTD

High-temperature crude synthesis gas chilling device

ActiveCN102140372AIncrease contact areaSimple structureChemical industryCombustible gas productionWear resistantChiller

The invention relates to a high-temperature crude synthesis gas chilling device, which comprises a gas flow channel of a chiller and an atomizing nozzle arranged on the side wall of the gas flow channel, wherein the gas flow channel is connected with a reaction chamber and a cooling chamber of a gasification furnace and provides a mixing space for a chilling medium and high-temperature crude synthesis gas; the atomizing nozzle is a single-flow-channel pressure nozzle or a double-flow-channel gas-liquid two-phase nozzle, and is partitioned into 1-20 layers; each layer is uniformly distributed on the circumference and is used for uniformly spraying the chilling medium into the high-temperature crude synthesis gas and chilling the synthesis gas to be in a specific temperature range; the gas flow channel is a water cooled-wall or a fire-resistant and wear-resistant liner or the combination of the water-cooled wall and the fire-resistant and wear-resistant liner; and the gas flow channel has a cylindrical structure or a conical structure or the combination of the cylindrical structure and the conical structure. The chilling device has the advantages of high chilling efficiency, large gas-liquid contact area, high chilling rate, small dosage of the chilling medium, mature manufacturing technology, high reliability and capability of reducing the consumption and the discharge of cleaning black water, and relates to an environmentally-friendly and-energy saving technology.

Owner:WISON ENG

Micro parallel plate burner with preheating channel

InactiveCN101539293AImprove temperature distributionIncrease enthalpyGaseous fuel burnerCombustion chamberHydrogen

The invention belongs to the field of micro-power electromechanical systems (MEMS), particularly relates to a micro parallel plate burner with a preheating channel. The micro parallel plate burner with a preheating channel consists of a parallel plate burning chamber, a preheating channel and a quartz shade, which are arranged from inside to outside, wherein the upper half section of the parallel plate burner is an oxy-hydrogen premixing zone; and the quartz shade is double-layered and internally vacuumized. Fuels and oxidant can be preheated before being mixed by the preheating channel, thereby more stable burning is realized; and the double-layered vacuumized quartz shade not only can make most of photons generated on the radiation surface of the burner pass through, but also play a heat insulation role, so that the whole transformation efficiency and the working performance of micro thermophotovoltaic systems are greatly improved.

Owner:JIANGSU UNIV

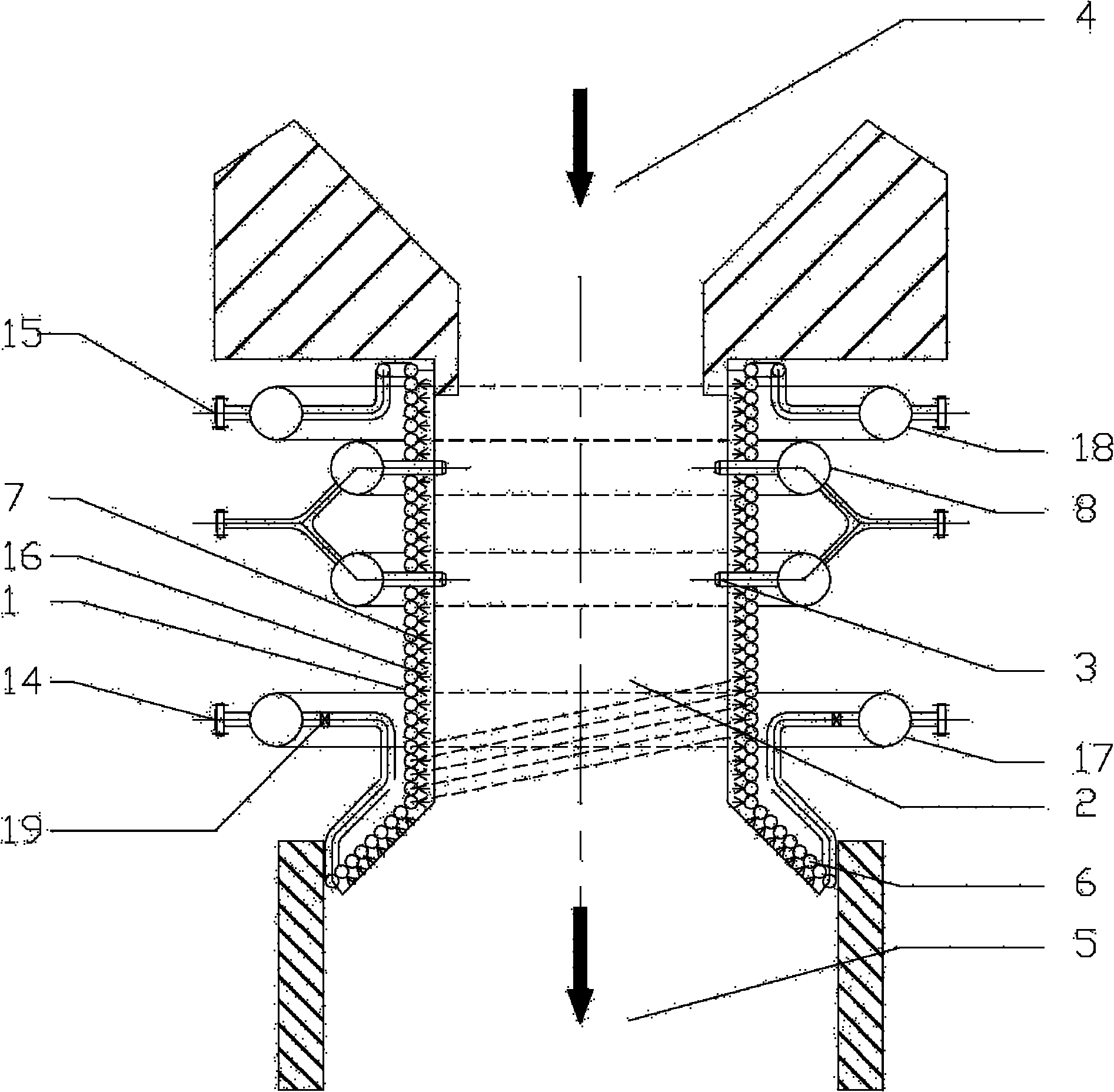

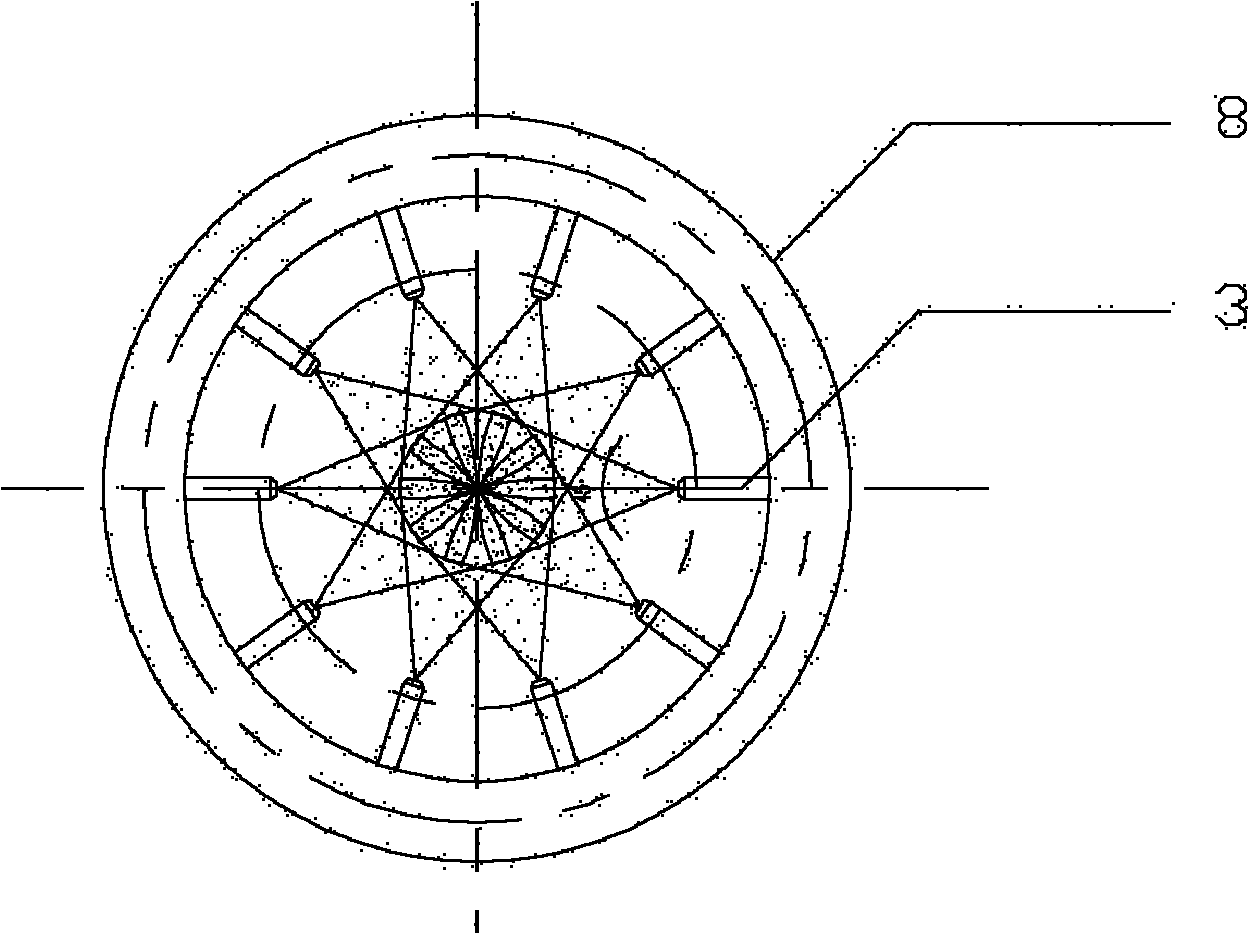

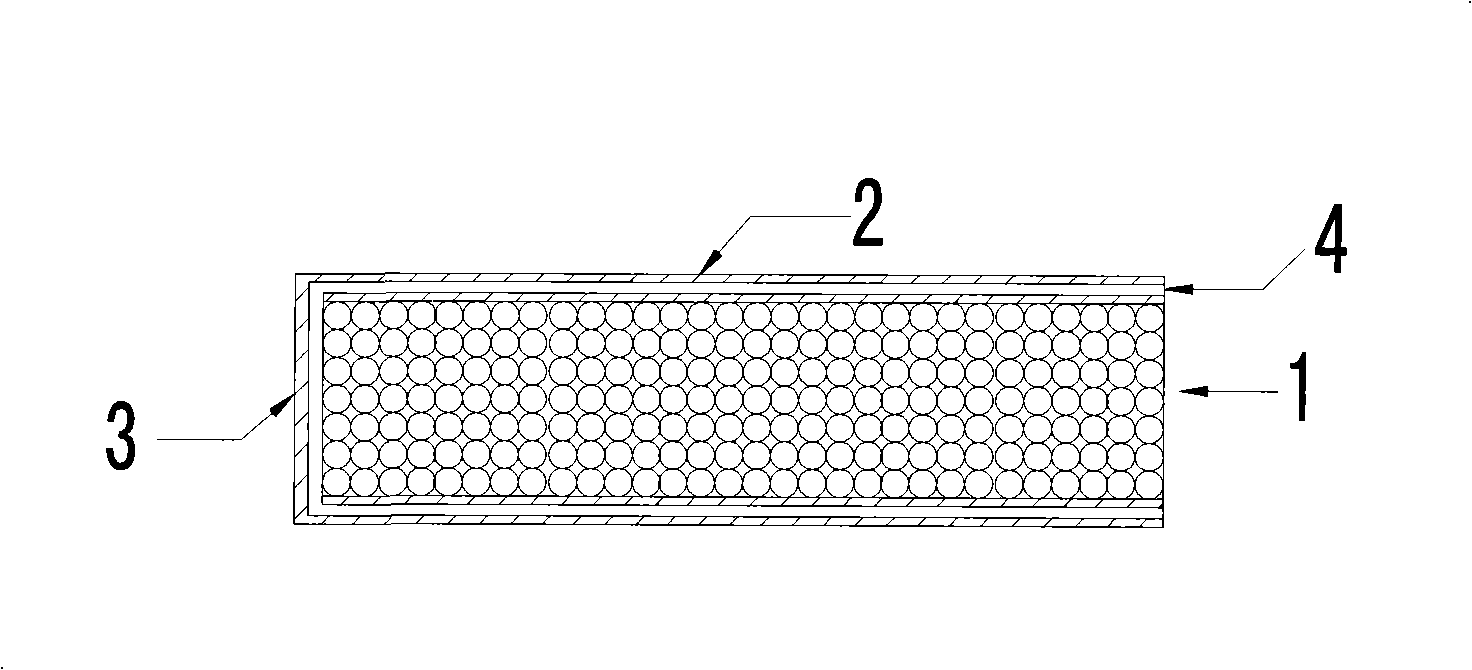

High-efficiency porous media combustor for minitype heat optoelectronic system

InactiveCN101354132AImprove temperature distributionStable and efficient workGaseous fuel burnerExhaust gasProduct gas

The invention provides a high-efficiency porous medium burner used in a micro thermo photovoltaic system, relating to the technical field of combined combustion of a two-phrase gas. SiC ceramic spherules with diameter of 0.3mm to 0.35mm are filled in a shell of the burner in the form of oblique parallelepiped and then sintered with the shell to form a porous medium structure with porosity epsilon equal to 26 percent to 27 percent and a tail gas discharging channel is arranged on the external wall of the burner. The shell of the burner is processed first and then a bottom cover (3) of the burner is processed and sintered with the shell, and finally, in the interior of which the screened SiC ceramic spherules with diameter of 0.34mm are filled, after sintering, the porous medium structure is formed and the tail gas discharging channel is arranged in the interior of the shell (2) of the burner. The porous medium burner reduces the heat loss brought by increase of surface to volume ratio due to microscale, greatly improves the temperature distribution on the external wall of the burner, promotes combustion efficiency and combustion stability, lowers gas discharging temperature and heightens the temperature of the external wall, thus greatly advancing the efficiency of the whole micro thermo photovoltaic system.

Owner:JIANGSU UNIV

Phase change heat storage device

ActiveCN105115338AGood thermal conductivityLarge specific surface areaHeat storage plantsHeat exchanger casingsLatent heat storagePorous channel

The invention discloses a phase change heat storage device. The phase change heat storage device comprises a heat accumulator shell, heat exchange pipelines and phase change materials, wherein the heat exchange pipelines and the phase change materials are arranged in the heat accumulator shell. The phase change heat storage device is characterized in that a porous metal framework is arranged in the heat accumulator shell, porous channel arrays are arranged on the porous metal framework in parallel in the axial direction, and the phase change materials are located in all porous channels of the porous channel arrays; the heat exchange pipelines are arranged in the porous channel arrays in the axial direction of the porous metal framework at intervals; each heat exchange pipeline is surrounded by at least one circle of pore channels; a flow dividing device is arranged at inlets of the heat exchange pipelines, and a flow collecting device is arranged at outlets of the heat exchange pipelines; three-dimensional crossed flow guide type chaos turbulators are further arranged in the heat exchange pipelines. According to the phase change heat storage device, due to the fact that the three-dimensional crossed flow guide type chaos turbulators are arranged in the heat exchange pipelines, flow guide blocks which are arrayed periodically and alternately can induce fluid to generate chaos convection, heat exchange between the fluid and pipe walls can be enhanced obviously, and the heat storage device can achieve excellent heat storage and heat exchange capability.

Owner:SOUTHEAST UNIV

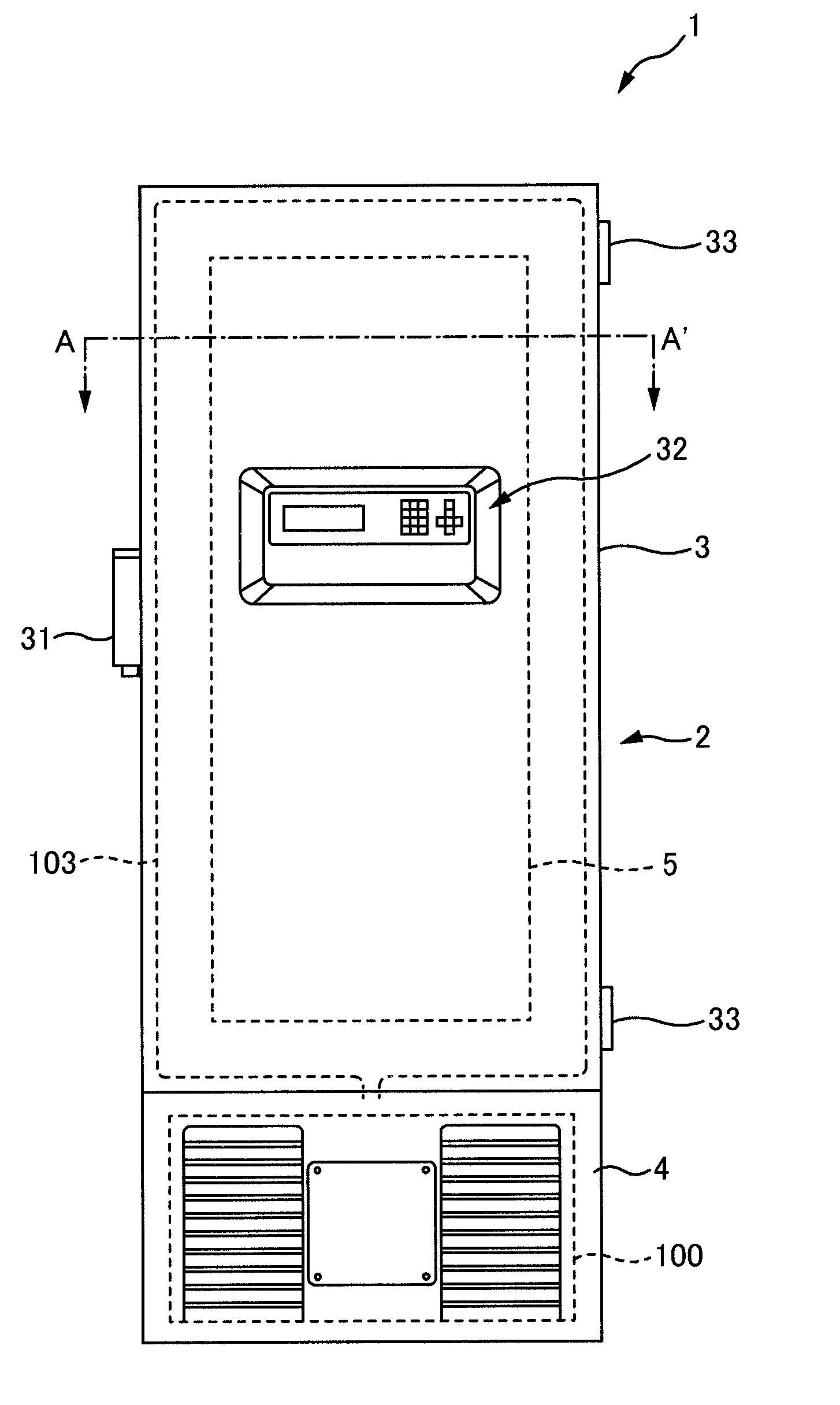

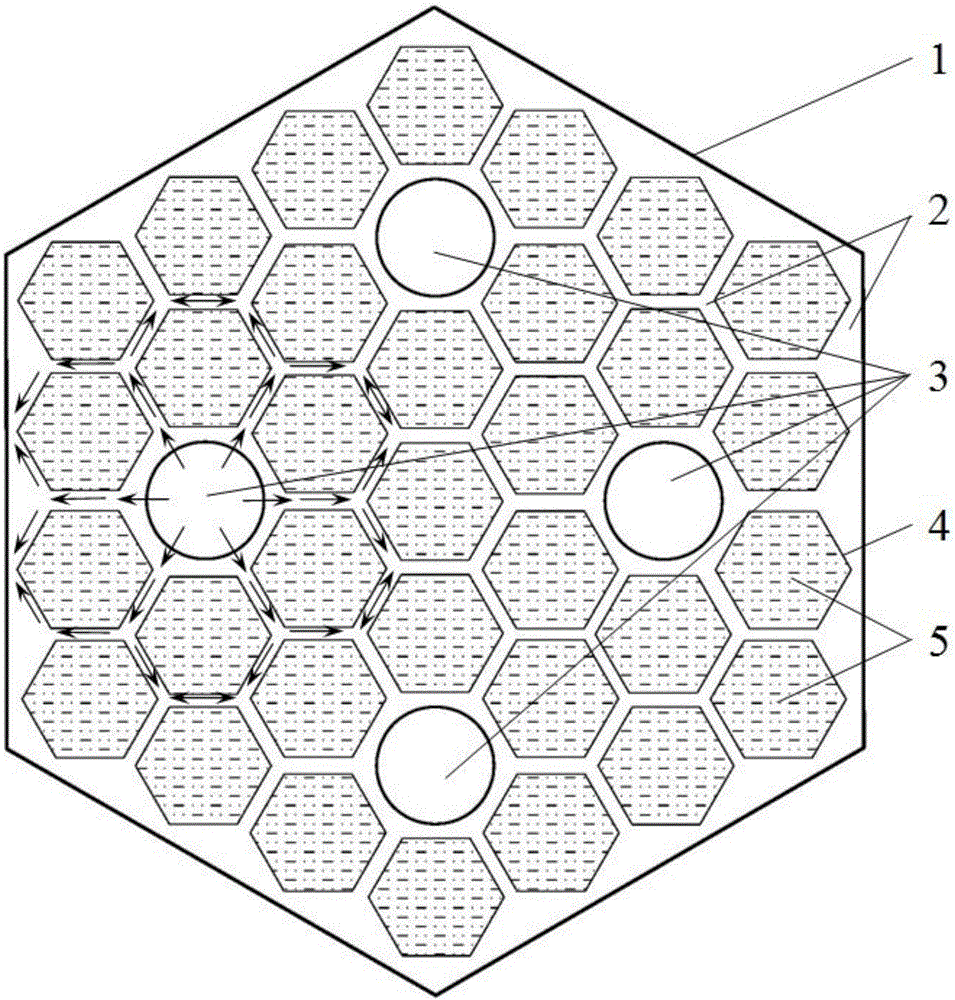

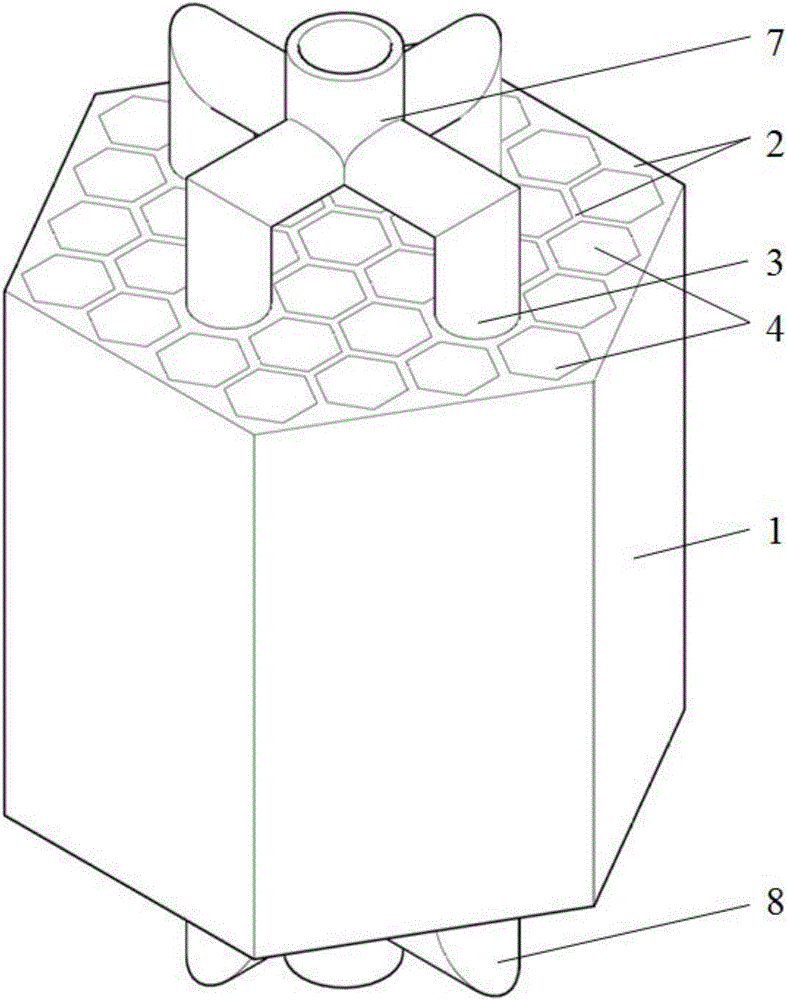

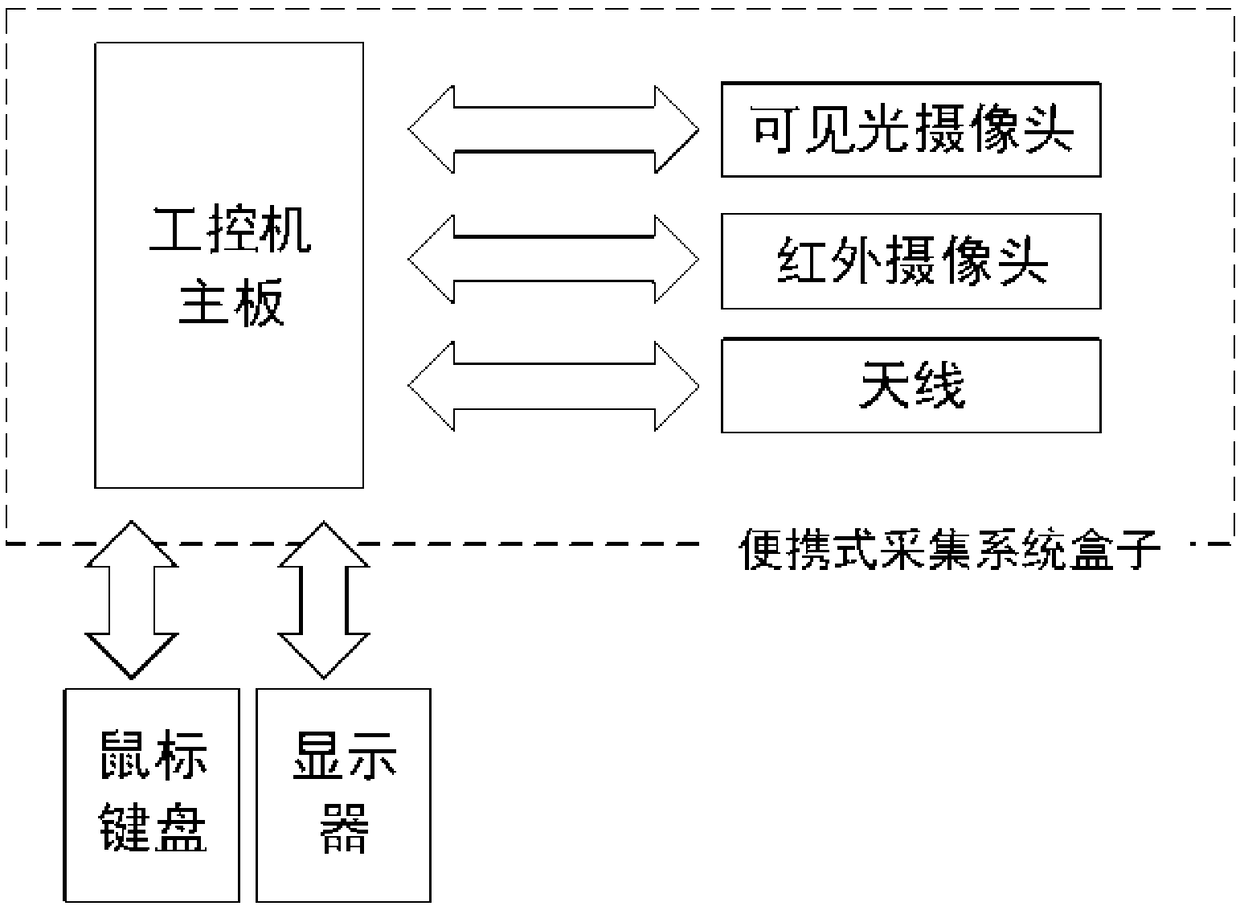

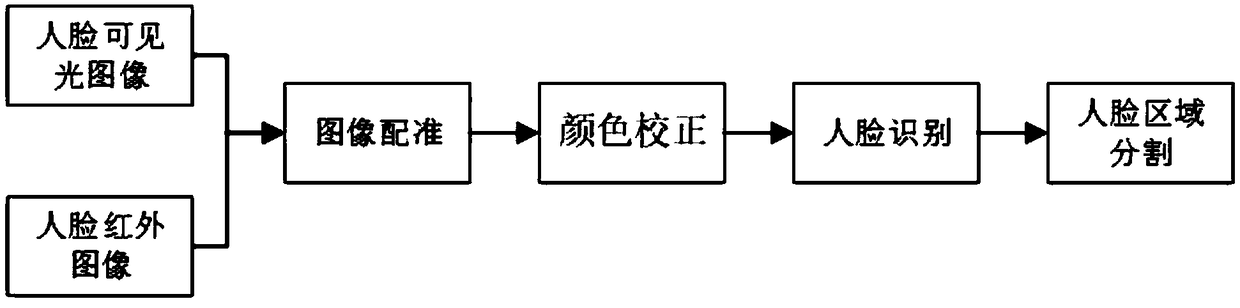

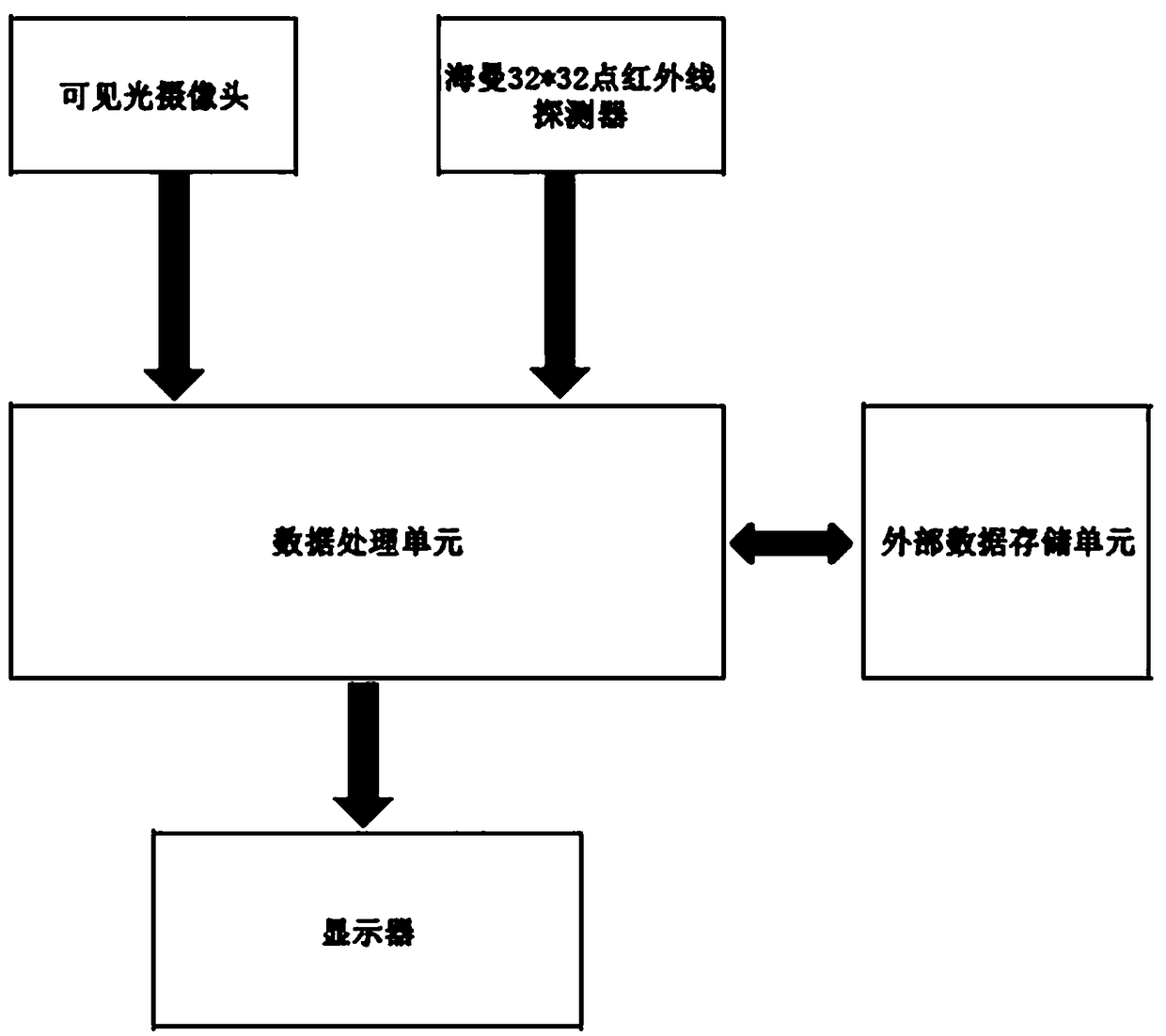

Face multimodal image acquisition and processing device and method

InactiveCN109192302AAchieve matchingPrecise registrationHealth-index calculationCharacter and pattern recognitionColor correctionPersonal computer

The invention discloses a face multimodal image acquisition and processing device and method. The face multimodal image acquisition and processing device comprises a box body; an industrial personal computer main board for processing face images, as well as a visible light camera and an infrared camera which are used for collecting the face images and are electrically connected with the industrialpersonal computer main board are installed in the box body; the visible light camera and the infrared camera are arranged side by side; through holes corresponding to the visible light camera and theinfrared camera are formed in the box body; the industrial personal computer main board comprises a control module; the control module is connected with an image registration module for aligning visible light images collected by the visible light camera with infrared images collected by the infrared camera, a color correction module for normalizing the colors of the collected face images, a faceidentification module for precisely positioning a face region, and a face region segmentation module used for segmenting the face region so as to put the temperature of each area into statistics.

Owner:杭州体光医学科技有限公司

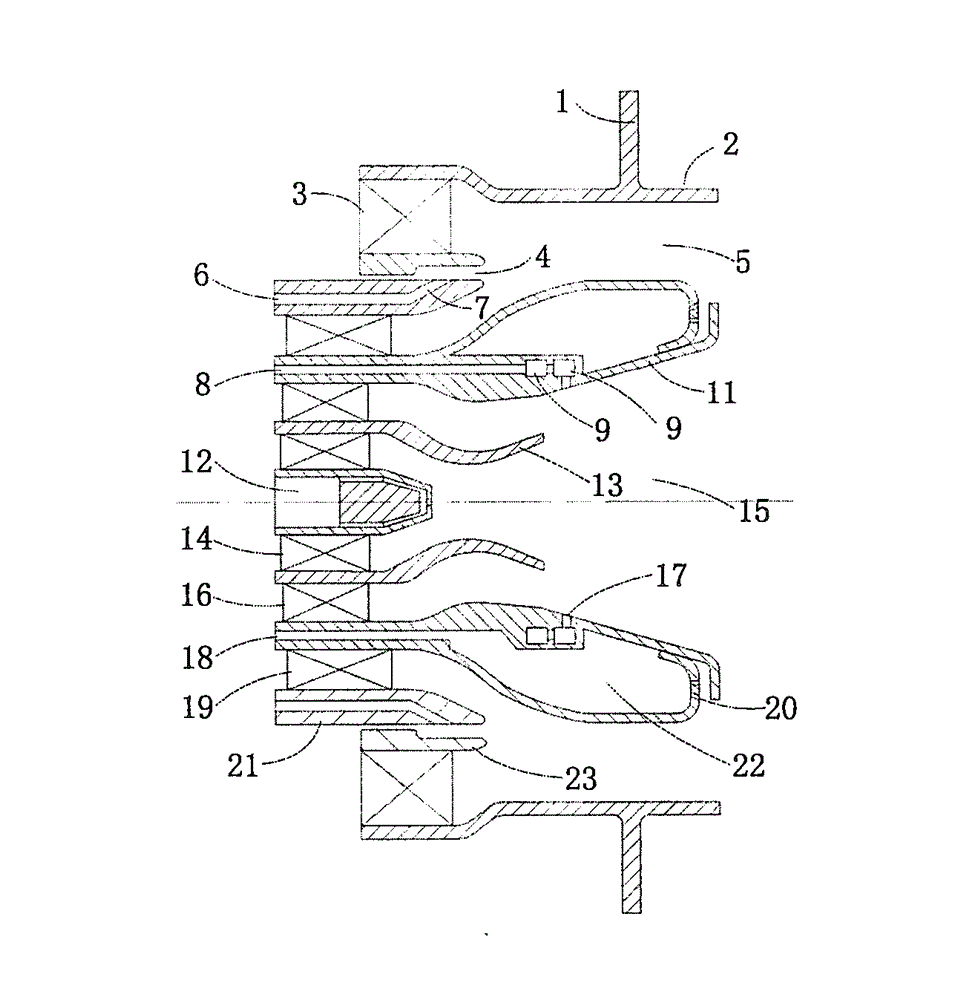

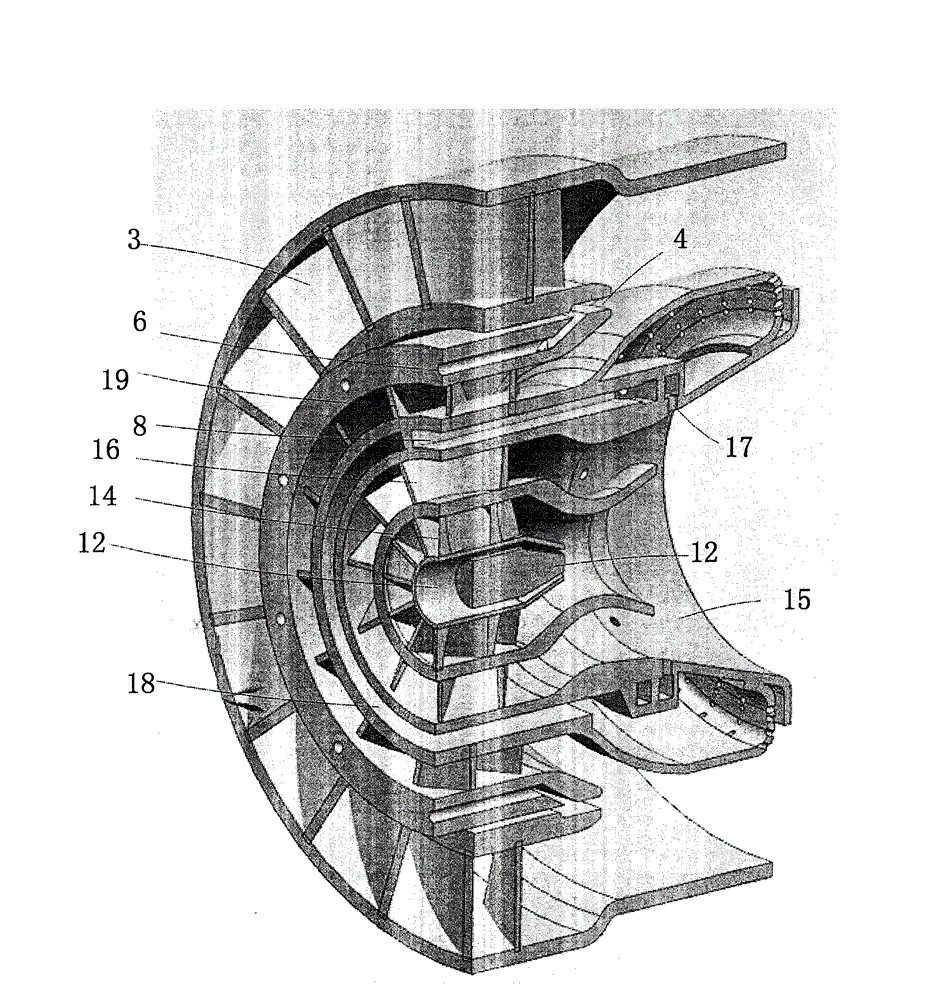

Combustor fuel injection and mixing device

ActiveCN103062798AImprove blending uniformityImprove temperature distributionContinuous combustion chamberCombustion chamberCombustor

Disclosed is a combustor fuel injection and mixing device. A main combustion level, a middle combustion level, and a pre-combustion level are sequentially arranged from outside to inside of the combustor fuel injection and mixing device. Fuel respectively flows into oil pipelines of the main combustion level, the middle combustion level and a pre-combustion level through a main combustion level oil inlet hole, a middle combustion level oil inlet hole and a pre-combustion level oil inlet hole. The fuel in the oil pipelines are injected into a main combustion level channel, a middle combustion level channel and a pre-combustion level channel through a main combustion level nozzle, a middle combustion level nozzle and a pre-combustion level nozzle. The main combustion level nozzle is a pre-film type nozzle. Wall surface of two sides of the main combustion level nozzle is an assembling surface for assembling. The main combustion level oil pipe after a curve section is gradually expanded into a slit to enable the fuel in the main combustion level oil pipeline to form a layer of oil film behind the outer side wall of the main combustion level nozzle. Swirler components capable of shearing and atomizing the fuel injected into the main combustion level channel under the act of swirling are arranged around the main combustion level nozzle. The combustor fuel injection and mixing device is capable of improving mixture evenness of fuel and gas in the main combustion level and further improving temperature distribution of the outlet of the combustor.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

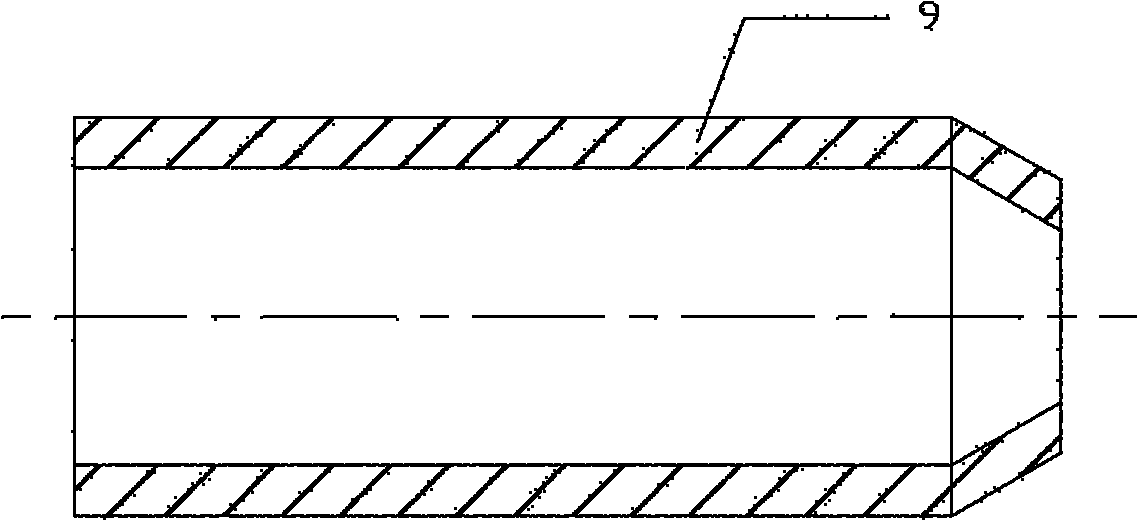

Manufacturing method of large-size C-oriented sapphire crystals

ActiveCN103103604AImprove temperature distributionAvoid or reduce air bubblesPolycrystalline material growthBy pulling from meltCrucibleSeed crystal

The invention relates to a manufacturing method of large-size C-oriented sapphire crystals. According to the method, an alumina raw material with the high purity of 99.999 wt% is adopted and is heated to be molten and subjected to crystal seeding and crystal growing. A main heater and an assistant heater are adopted, wherein a tungsten rod cylinder-shaped heating body is arranged around a crucible and is used as the main heater; another tungsten disc-shaped heating body is arranged at the bottom of the crucible and is be used as the assistant heater; the power ratio of the main heater to the assistant heater is (20 to 80 KW): (10 to 60 KW). In addition, a tungsten tube is mounted at the top of the crucible, and argon is introduced into the tungsten tube to regulate the temperature of the seed crystal and a liquid surface. As the method is used, the temperature distribution of a longitudinal temperature field in the crucible is improved, so that air bubbles, cracks and other defects are avoided or reduced, i.e., the seed crystal is prevented from being molten at overhigh temperature during the crystal seeding process. Therefore, the generation of a C-oriented long crystal boundary with a small angle is controlled effectively. As a result, the growing C-oriented crystals with the diameter of 14 inches are good in position staggering density and single crystal performance. Consequently, the method provided by the invention reaches the international advanced level.

Owner:TDG HLDG CO LTD

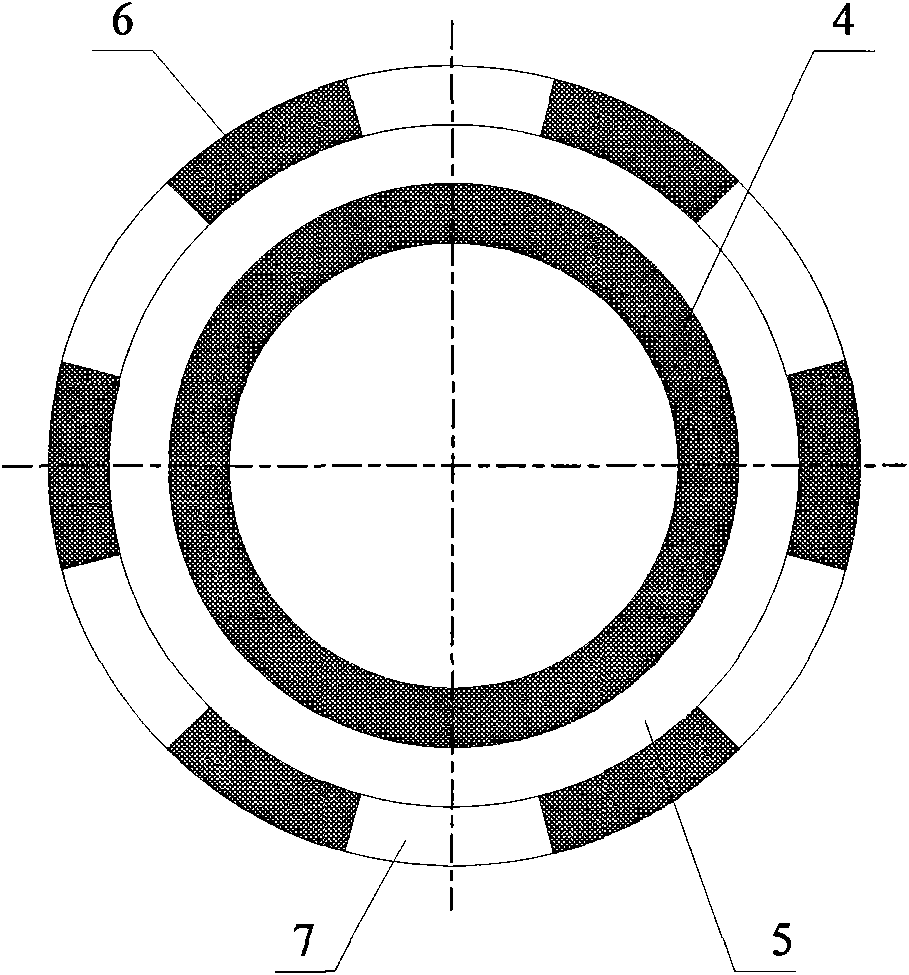

Equipment and method for simultaneously preparing multiple round aluminum alloy ingots

The invention belongs to the field of aluminum alloy casting, and in particular relates to equipment and a method for simultaneously preparing multiple round aluminum alloy ingots. The equipment mainly comprises a crystallizer, a water tank, a magnet exciting coil, a magnet exciting power supply, a porous graphite ring, a lubricating oil supply system and a casting machine. The method comprises the following steps of: starting the lubricating oil supply system, introducing molten aluminum into a cavity which is formed by ingot butts, the porous graphite ring and a heat preservation cap, starting the casing machine for casting, starting the magnet exciting power supply, dynamically crystallizing aluminum melt under the stirring action of an induced magnetic field, and thus obtaining a fineand uniform metallurgical structure and the good surface quality of the ingots. By the equipment and the method, the semi-continuous casting of round aluminum alloy cast rods under the combined action of electromagnetic stirring and oil lubrication is realized, and the internal metallurgical quality and the surface quality of the ingots can be improved.

Owner:沈阳东铝特材科技有限公司

Power station boiler smoke waste heat deep recycling and emission reducing system

ActiveCN104006401AReduce the temperatureImprove temperature distributionCombustion processIndirect carbon-dioxide mitigationAir preheaterPower station

The invention discloses a power station boiler smoke waste heat deep recycling and emission reducing system. A first low-temperature heat exchanger is arranged between an air pre-heater and a dust remover, a second low-temperature heat exchanger is arranged between a pressurizing fan and a desulfurizing tower, an air heat exchanger is arranged between a secondary fan and the air pre-heater, a heat exchanging medium output end of the air heat exchanger is connected with a heat exchanging medium input end of the second low-temperature heat exchanger through a first water pump, a heat exchanging medium output end of the second low-temperature heat exchanger is connected with a heat exchanging medium input end of the first low-temperature heat exchanger, and a heat exchanging medium output end of the first low-temperature heat exchanger is connected with a heat exchanging medium input end of the air heat exchanger. According to the power station boiler smoke waste heat deep recycling and emission reducing system, the defect existing in waste heat recycle of traditional low-temperature economizers is overcome, smoke temperatures can be deeply reduced, smoke temperature distribution is optimized, and the purposes of deeply recycling smoke waste heat and reducing dust discharge concentration are achieved.

Owner:CHENGXIN GREEN INTEGRATION

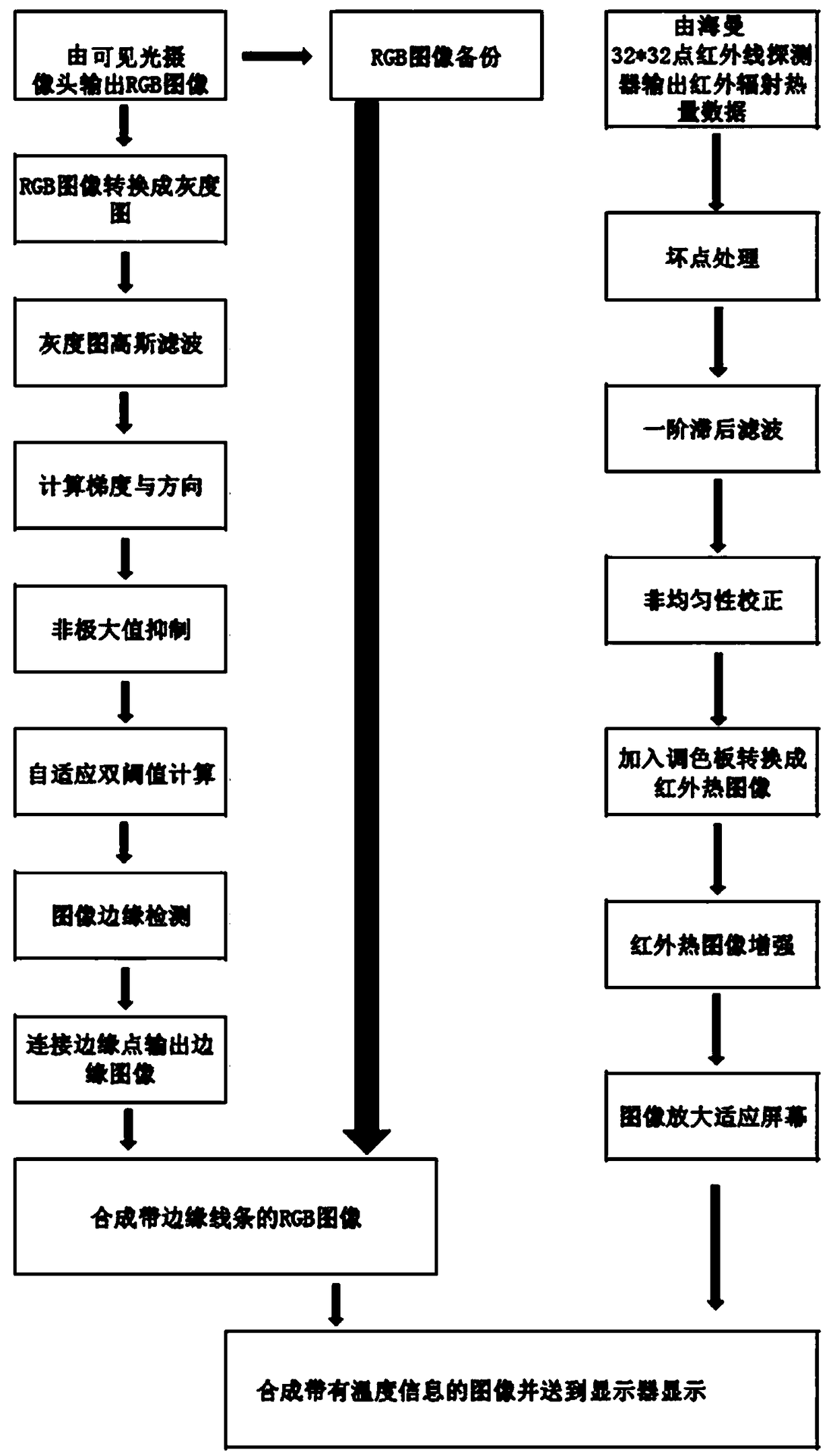

Thermal imaging fusion visible light image processing method, system and storage medium

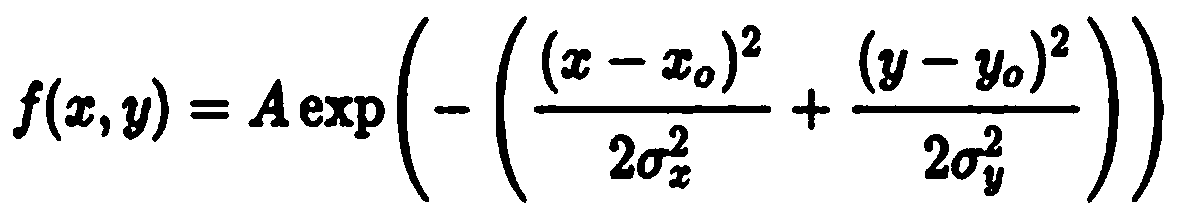

ActiveCN109377469AImprove temperature distributionObserve the temperature distributionImage enhancementImage analysisHysteresisRgb image

The invention relates to a thermal imaging fusion visible light image processing method, system and storage medium, comprising the following steps: 1, a camera collects visible light data and outputsan RGB image; 2, an infrared detector collects infrared radiation data and outputs that data; 3, RGB image backup; 4, convert that RGB image into a grayscale image; 5, Gaussian filtering of grayscaleimage; 6, calculate that gradient and the direction; 7, non-maximum suppression; 8, adaptive double threshold calculation; 9, image edge detection; 10, connecting edge points to output edge image; 11,synthesize an RGB image with edge lines; 12, bad point treatment; 13, first-order hysteresis filter; 14, non-uniformity correction; 15, adde a color palette to convert that color palette into an infrared thermal image; 16, infrared thermal image enhancement. 17, an image enlarge adaptive screen; 18, image display. The invention fuses visible light images by infrared thermal imaging, so that humaneyes can better observe the temperature distribution of the measured scene from the thermal imager.

Owner:YONGZHOU NUOFANGZHOU ELECTRONIC TECH CO LTD

Method of improving weld quality

InactiveUS7154064B2Reduce solidificationReduce porosityWelding/soldering/cutting articlesLaser beam welding apparatusIrradiationLaser beams

A method of improving weld quality between aluminum members by slowing the rate of solidification of a molten weld trough into solidified material. Upper and lower aluminum members are positioned together in contact between facing surfaces thereof to expose a first outer surface of the upper aluminum member to laser irradiation. A welding laser beam is moved in a path over the first outer surface, wherein the welding laser beam has an energy and width to progressively melt a trough of molten metal to a depth through the upper aluminum member and into the lower aluminum member. The molten metal in the trough has a void filled with gas, and the molten metal re-solidifies into re-solidified metal after the passage of the welding laser beam. An area in and around the trough is heated to slow the rate of solidification of the molten metal into the re-solidified metal, thereby preventing entrainment of the gas within the re-solidified metal.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

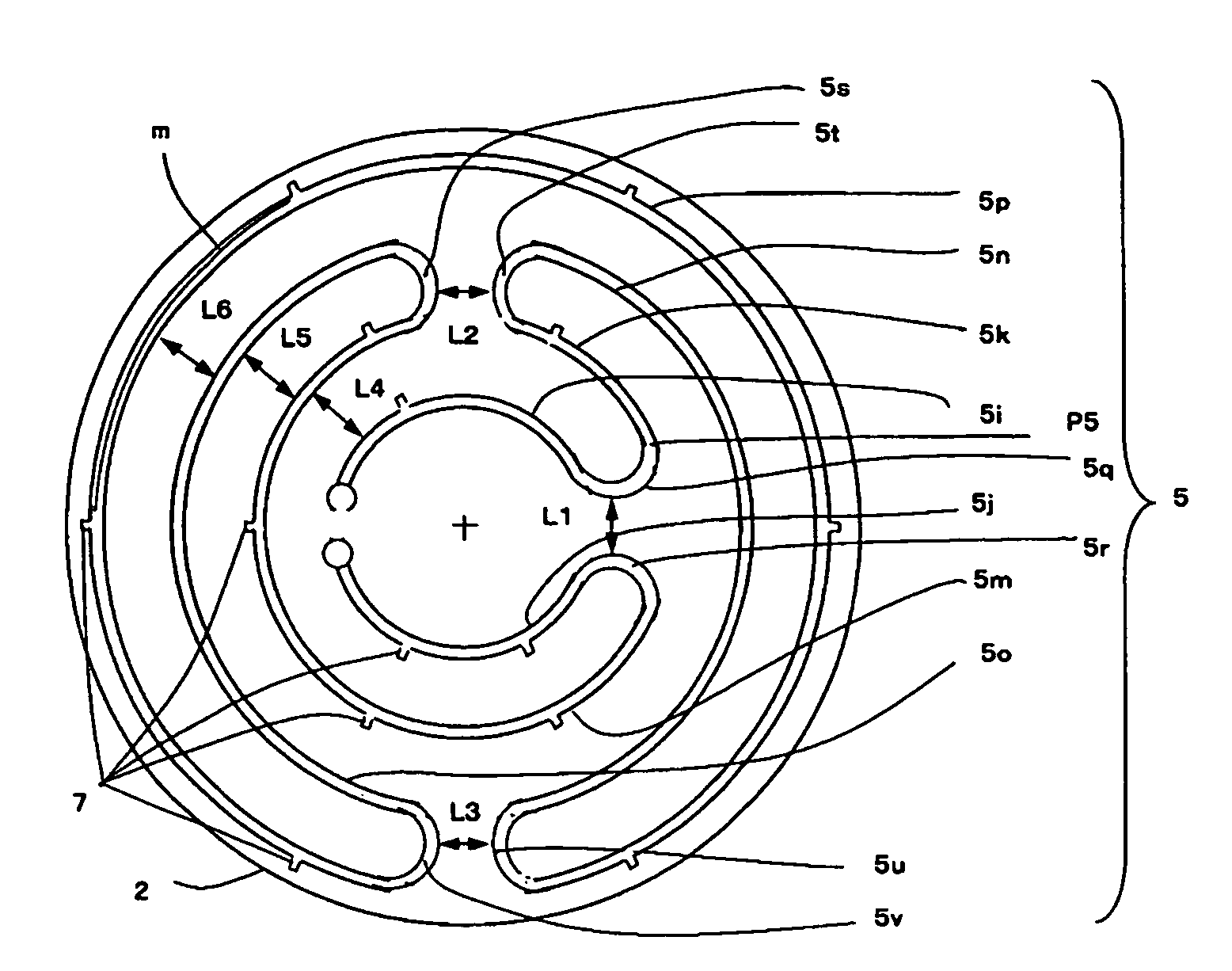

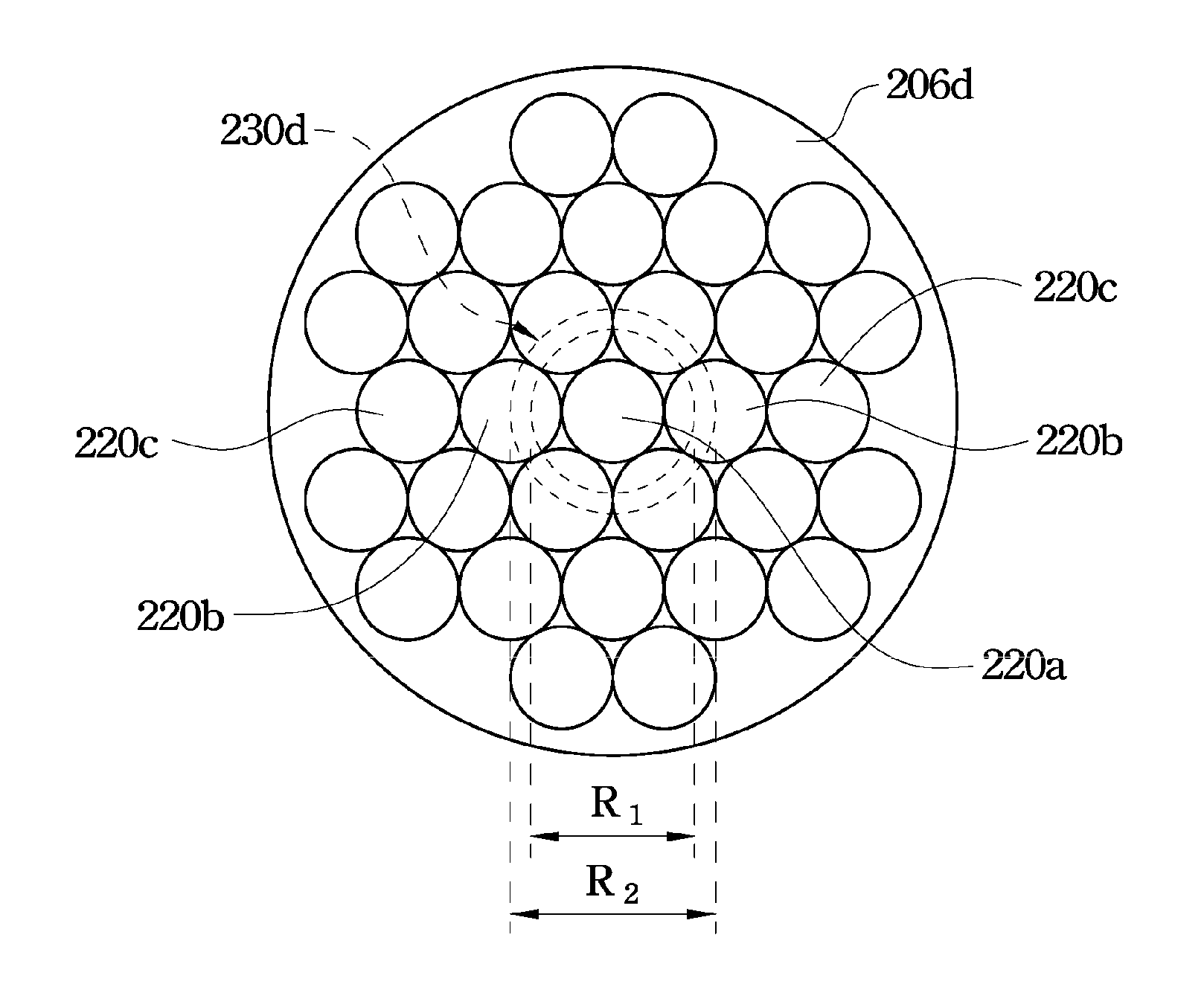

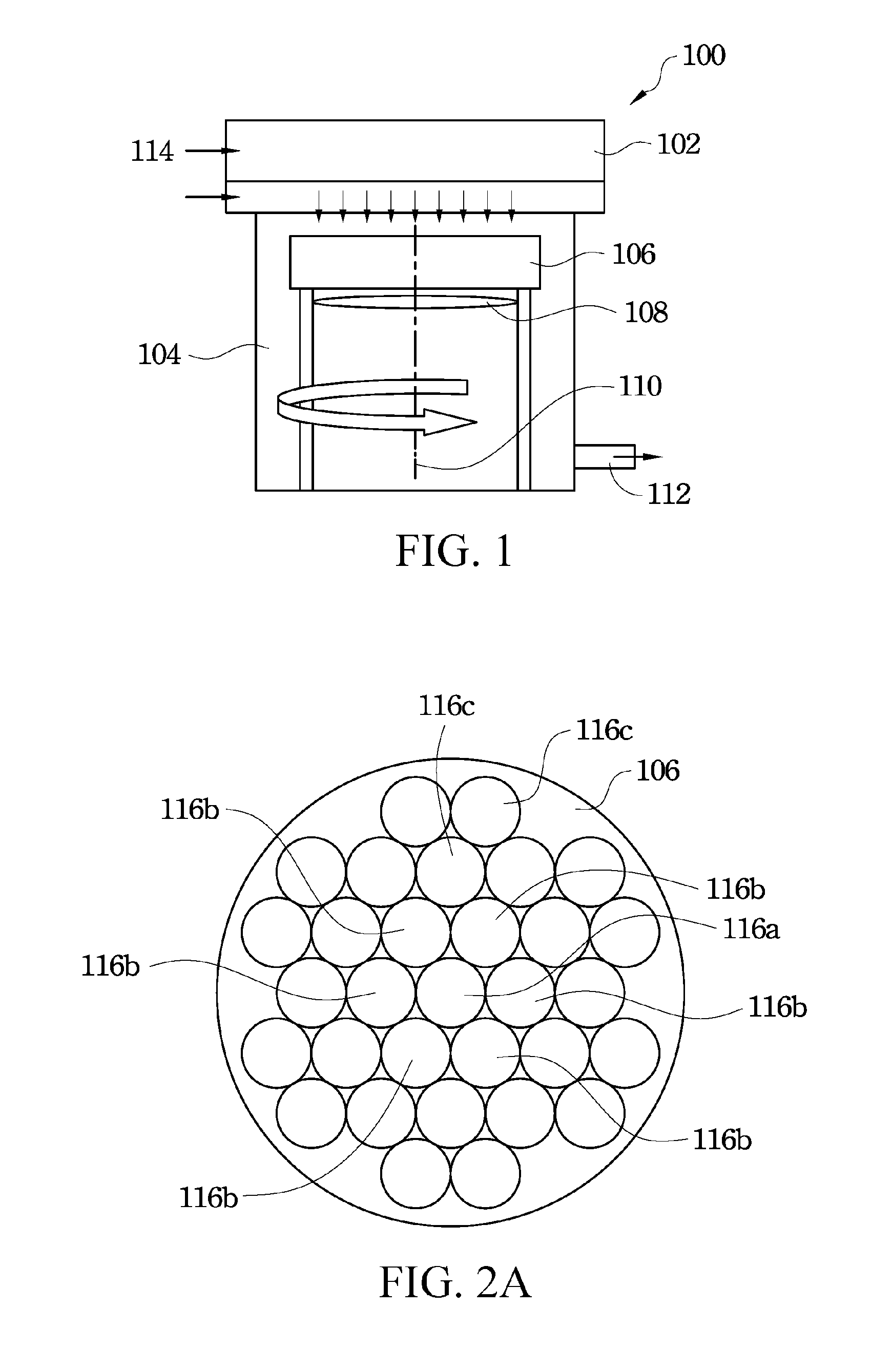

Wafer susceptor and chemical vapor deposition apparatus

InactiveUS20120240859A1Improve consistencyUneven temperatureLiquid surface applicatorsSemiconductor/solid-state device manufacturingProcess engineeringGas supply

A wafer susceptor and a chemical vapor deposition apparatus. In one embodiment, the chemical vapor deposition apparatus includes a chamber, a susceptor, a heater and a gas supply system. The susceptor is disposed within the chamber and is rotatable around a rotation axis, wherein an upper surface of the susceptor is suitable for carrying a plurality of wafers, and a middle region of a lower surface of the susceptor is set with a first cavity. The heater is disposed under the susceptor and is used to heat the wafers on the susceptor. The gas supply system is used to introduce a reactive gas into the chamber.

Owner:CHI MEI LIGHTING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com