High-temperature crude synthesis gas chilling device

A crude synthesis gas and chilling technology, which is applied in the manufacture of combustible gas, climate sustainability, petroleum industry, etc., can solve the problems of high power consumption of synthesis gas cycle compression, poor chilling effect, and large chilled gas volume, etc. To achieve the effect of shortened residence time, simple structure and high chilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

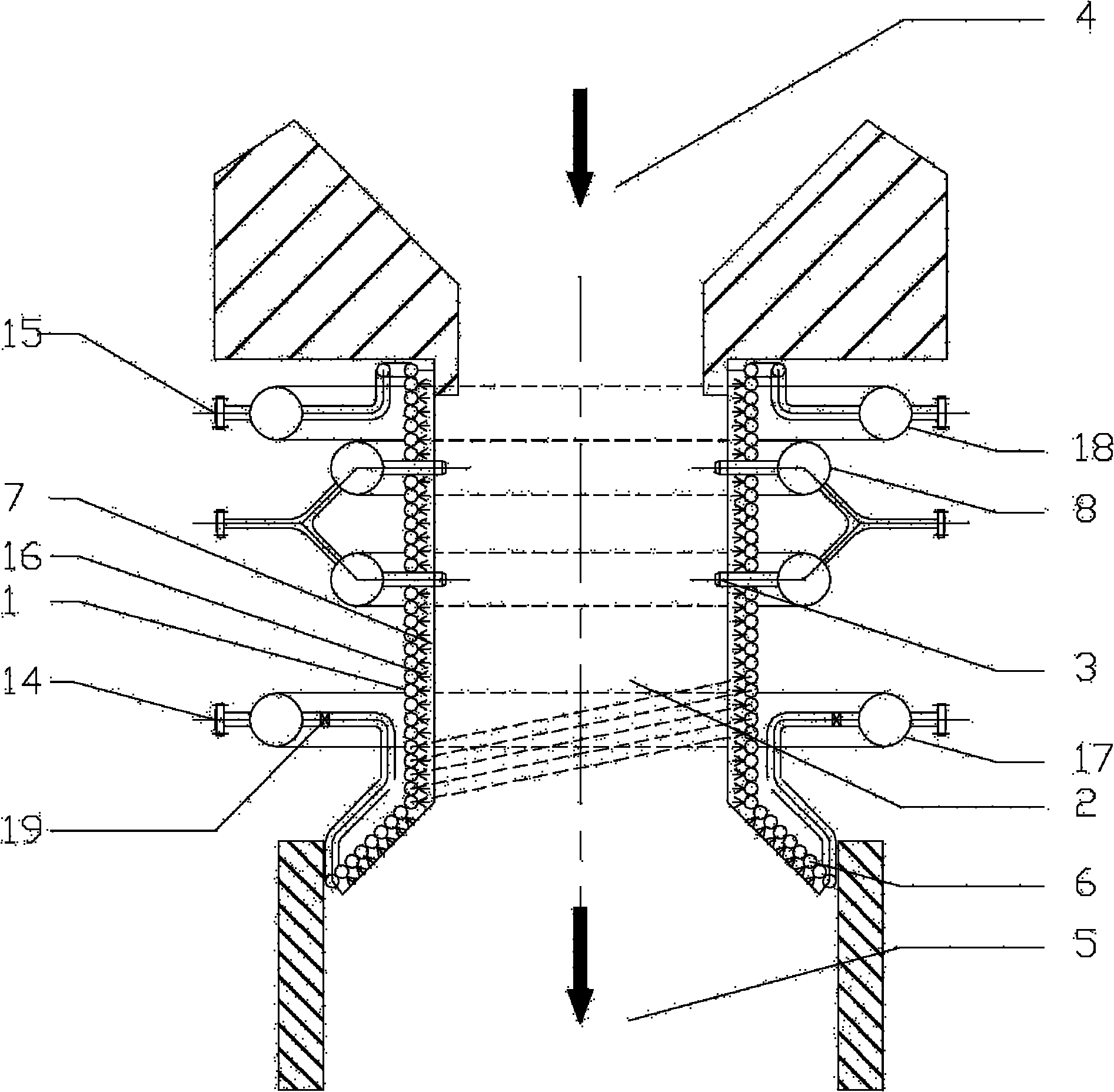

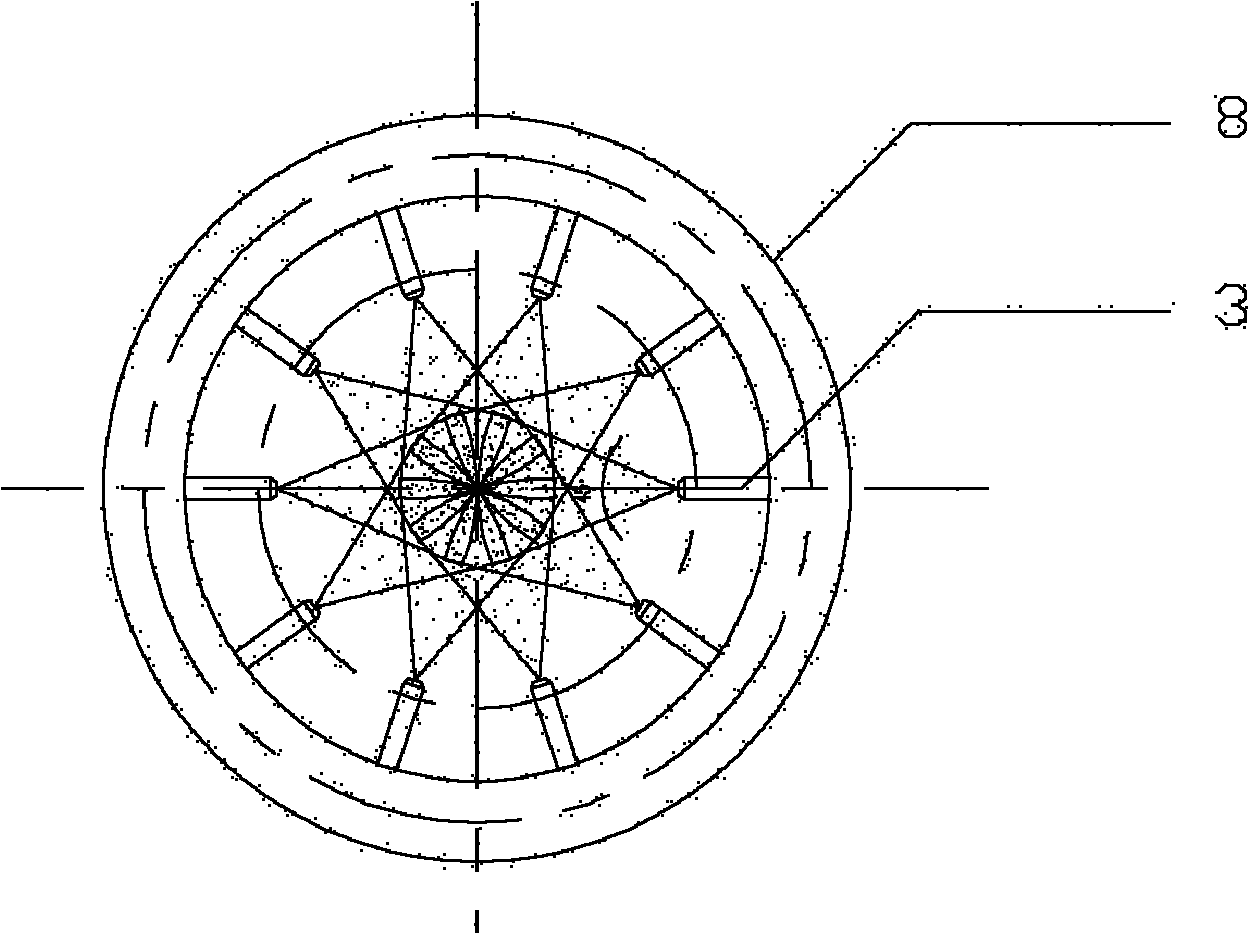

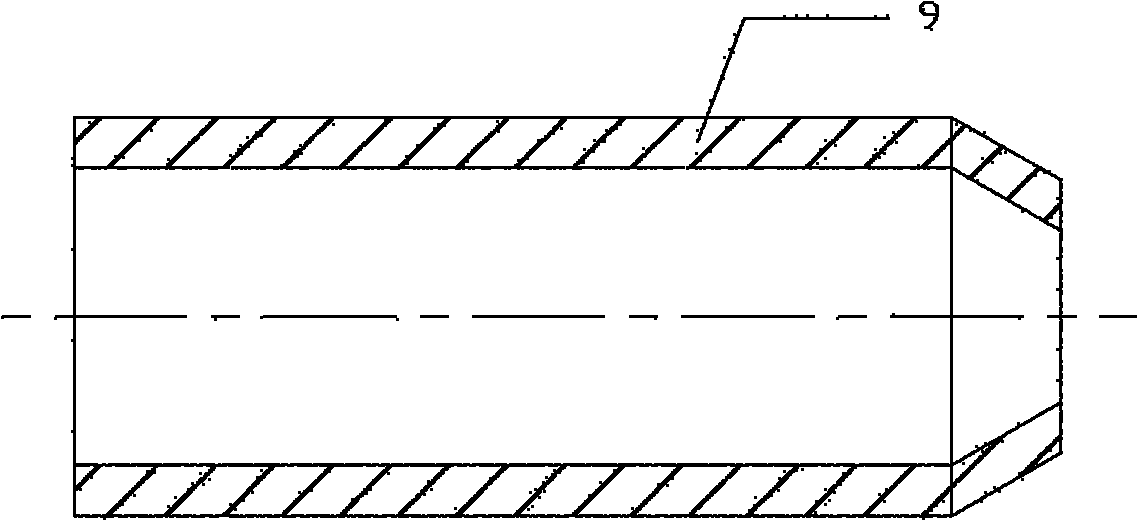

[0026] Such as figure 1 As shown, a chiller 1 for high-temperature crude syngas includes a gas flow channel 2 of the chiller 1 and an atomizing nozzle 3 installed on the side wall of the gas flow channel 2, and the gas flow channel 2 is used to connect the gasifier The reaction chamber 4 and the cooling chamber 5 provide a mixing space for the quenching medium and the high-temperature crude synthesis gas; the atomizing nozzle 3 can be a single-channel pressure nozzle 9 or a double-channel gas-liquid two-phase nozzle 10, and the single-channel pressure type The structures of the nozzle 9 or the two-channel gas-liquid two-phase nozzle 10 are respectively as follows image 3 , Figure 4 As shown, what is used in this embodiment is a single-channel pressure nozzle 9, which is evenly distributed on the side wall of the gas flow channel 2. The gas flow channel 2 can be a water wall 6 or a refractory and wear-resistant lining 7 or both. Combination forms, the shape is cylindrical o...

Embodiment 2

[0028] The atomizing nozzle 3 in the embodiment 1 adopts the dual-channel gas-liquid two-phase nozzle 10, the chilled water inlet main pipe 8 increases the gas-phase channel, the gas-phase channel uses the compressed synthesis gas, and the central channel of the gas-liquid two-phase nozzle 10 uses the compressed synthesis gas, The annulus is quenched water, the quenched water is sheared and broken by high-speed airflow, atomized and sprayed into the gas flow channel 2, and the rest of the structure is the same as that of embodiment 1.

Embodiment 3

[0030] A quenching device for high-temperature crude syngas, the quenching device is provided with a gas flow channel, an atomizing nozzle installed on the side wall of the gas flow channel, the gas flow channel is used to connect the reaction chamber and the cooling chamber of the gasification furnace and provide an excitation The mixing space of cold medium and high-temperature crude synthesis gas, the atomizing nozzle is a double-channel gas-liquid two-phase nozzle, one channel is a liquid phase channel, and the other channel is a gas phase channel, the liquid phase is water, and the gas phase can be water vapor, Syngas or inert gas. The atomizing nozzles are evenly distributed on the side wall of the gas flow channel, which is used to spray the quenching medium evenly into the high-temperature raw syngas to quench the high-temperature raw syngas to a specific temperature range. The gas flow channel is composed of a water-cooled wall and a refractory The combination form of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com