Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Good hydrogenation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetylene hydrocarbon selective hydrogenation method

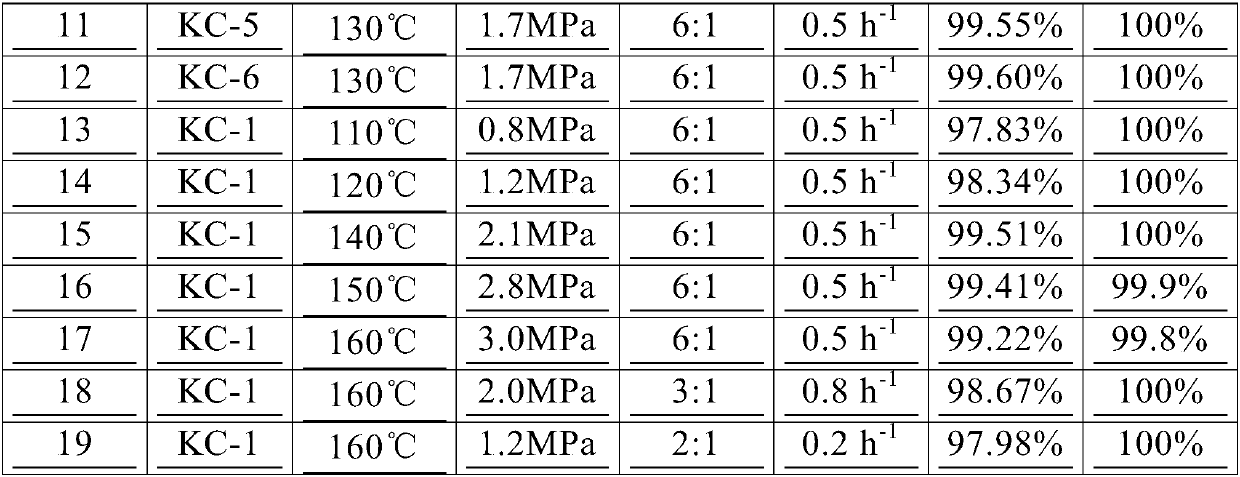

ActiveCN101434508AGood hydrogenation effectImprove hydrogenation activityHydrocarbon by hydrogenationHydrocarbon purification/separationButadiene DioxideUnsaturated hydrocarbon

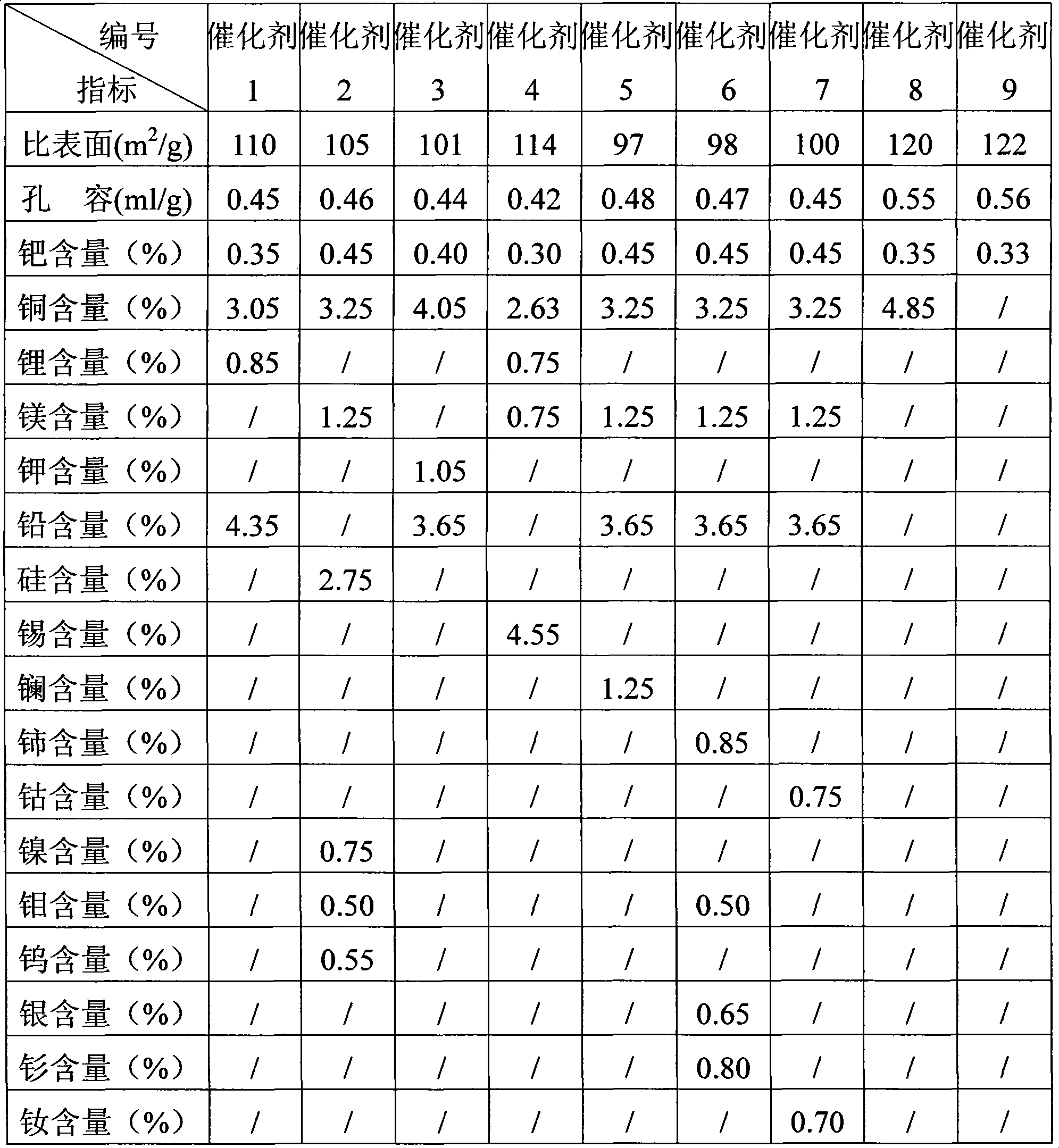

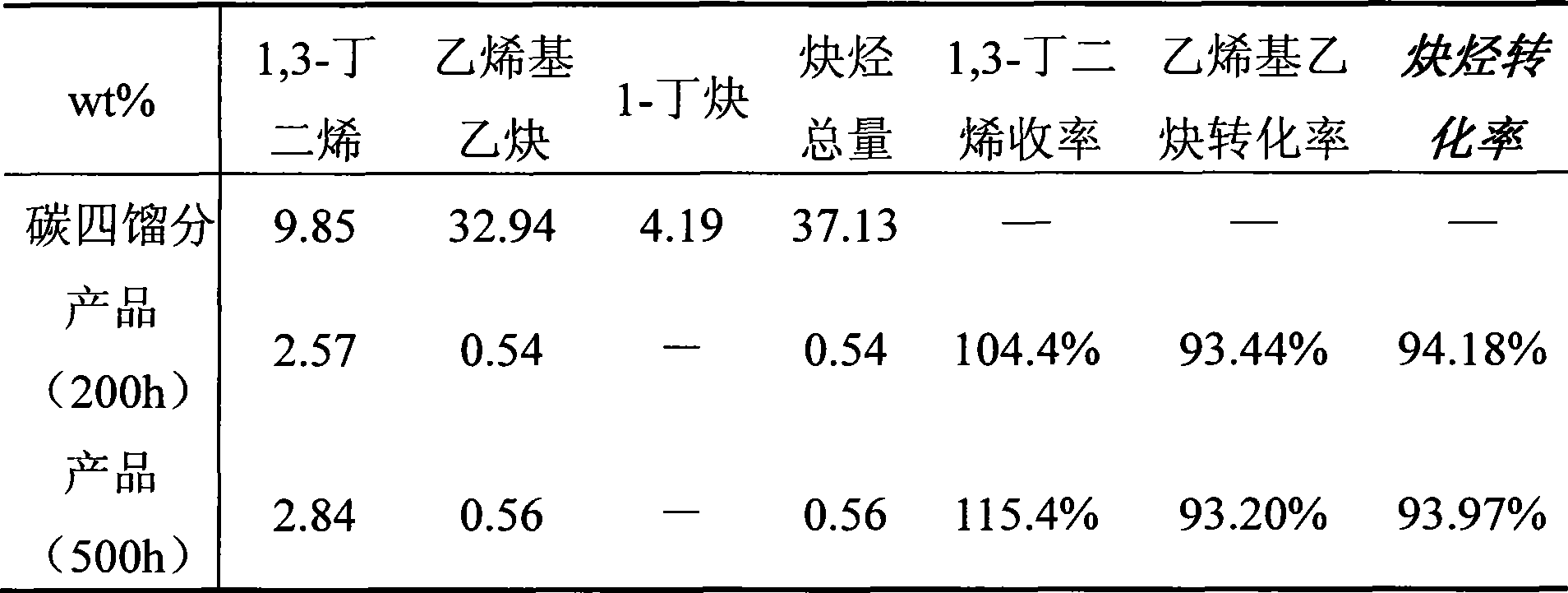

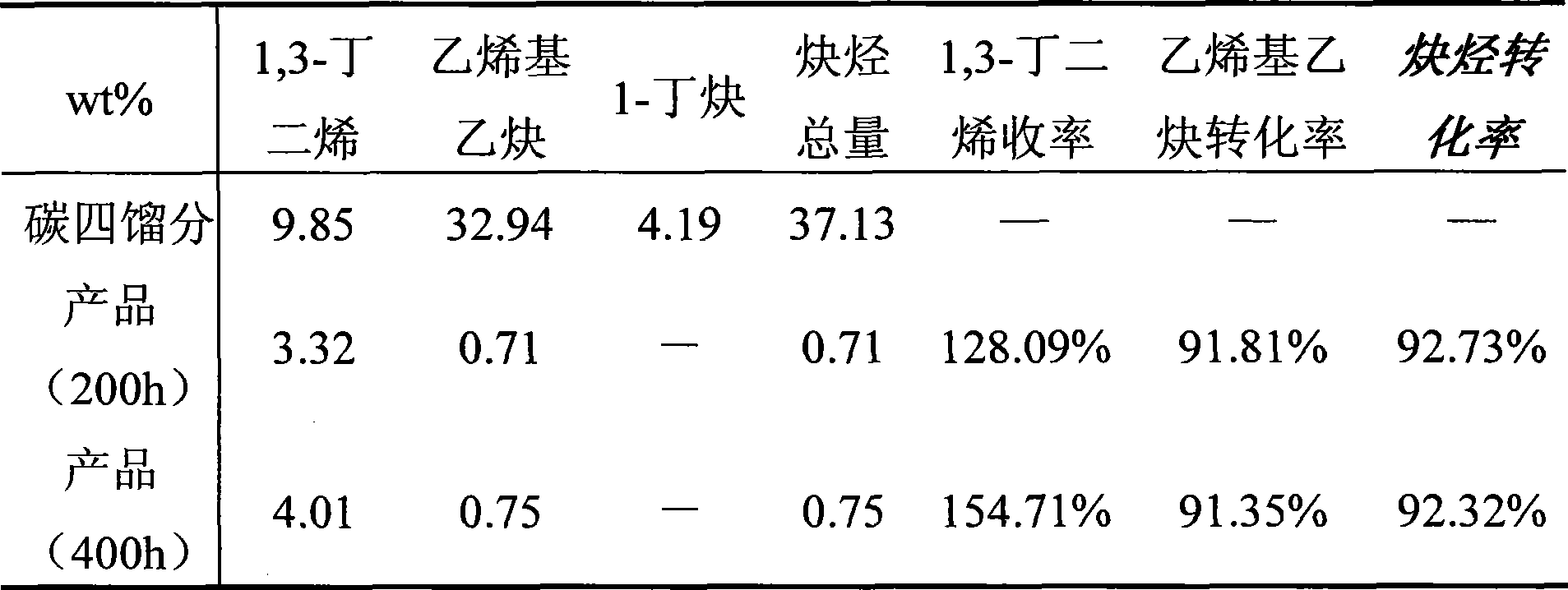

The invention relates to a selective hydrogenation method of high unsaturated hydrocarbons in C4 fractions, which is characterized in that salvage stores which are rich in acetylene hydrocarbon and prepared by extracting butadiene are used as the material, and a fixed bed reactor is adopted to obtain 1, 3-budiene by selective hydrogenation under the existence of a catalyst. The adopted process conditions are as follows: the reaction temperature is between 30 DEG C and 90 DEG C, the reaction pressure is between 1.0 MPa and 4.0 MPa and the liquid space velocity is 7 to 20h<-1>. The catalyst is preferably a palladium system catalyst with alumina as a carrier, the specific surface is 50 to 150m<2> / g and the specific pore volume is 0.25 to 1.0ml / g. The method has remarkable good effects on reducing waste of resources and improving economic benefits by effectively utilizing the salvage stores rich in acetylene hydrocarbon and prepared by extracting butadiene.

Owner:PETROCHINA CO LTD

Full-cut fraction pyrolysis gasoline diolefin selective hydrogenation method

ActiveCN101429454AGood hydrogenation effectGood hydrogenation stabilityRefining by selective hydrogenationSilicon dioxideImpurity

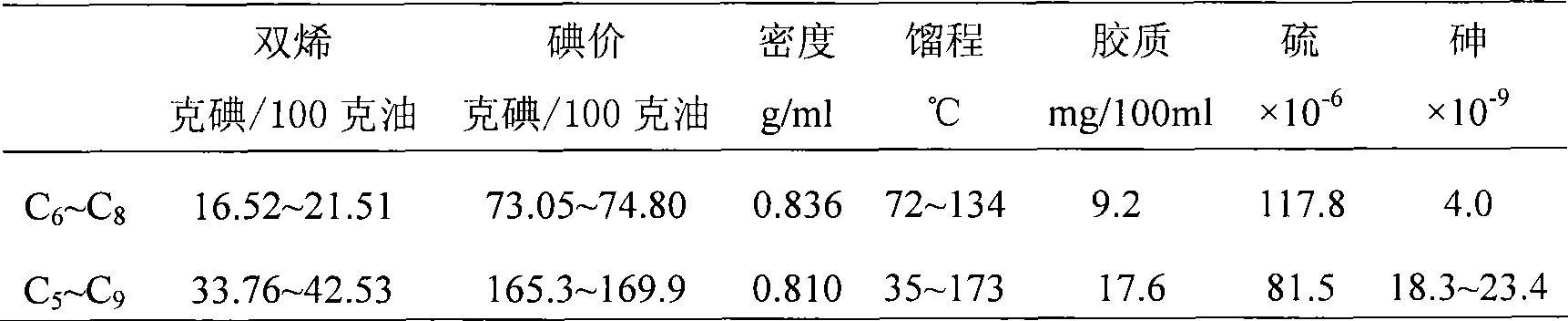

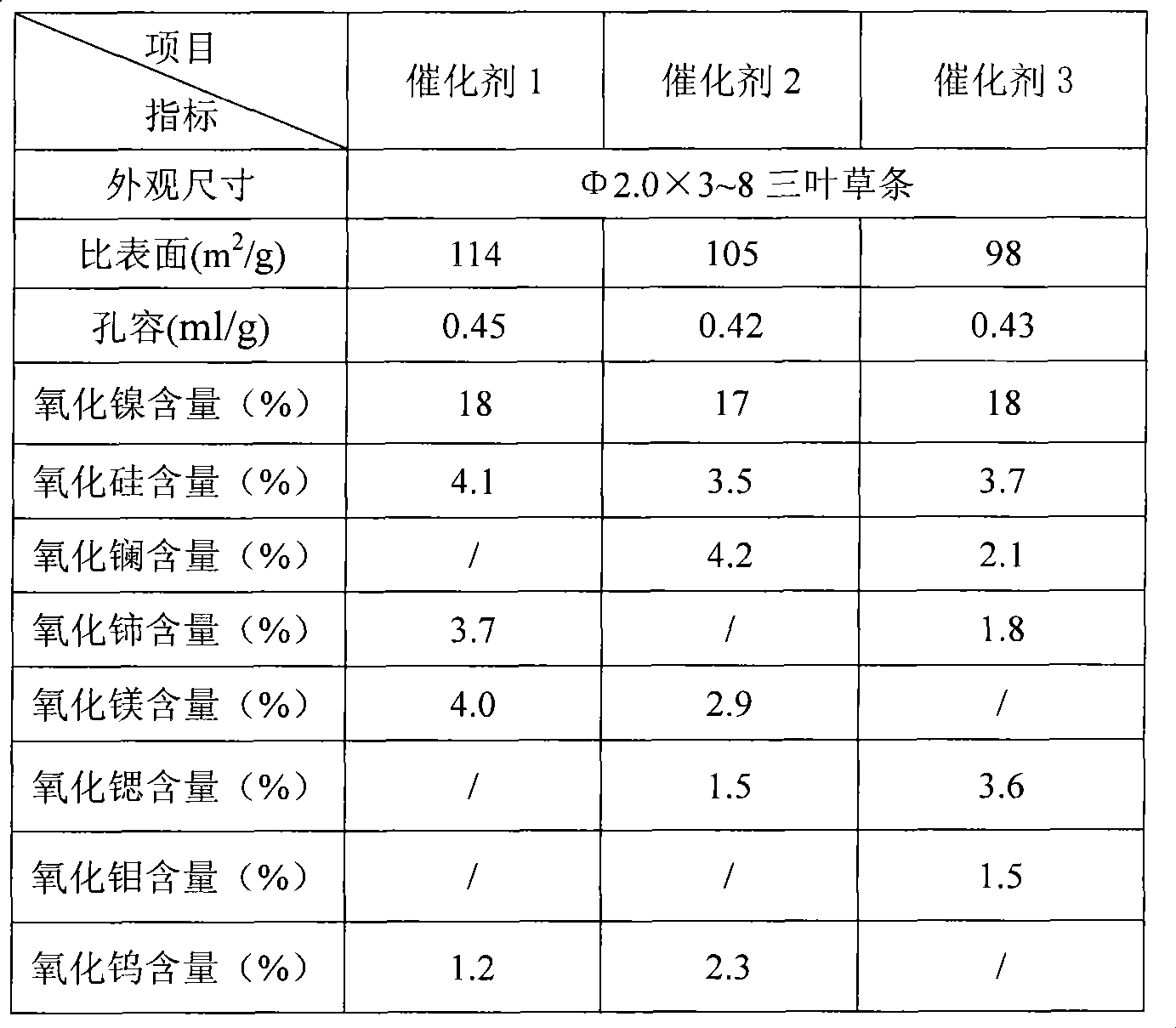

The invention provides a selectivity hydrogenation method for diolefin of full-fraction pyrolysis gasoline, which comprises reduction and passivation of catalyst and application of technological conditions. The catalyst is nickel series hydrogenation catalyst which is used after being reduced or being subjected to reduction and passivation. The selectivity hydrogenation method is characterized in that the hydrogenation technological conditions are as follows: the volume space velocity of a liquid is less than or equal to 4h<-1>, the inlet temperature of a reactor is between 40 and 130 DEG C, the reaction pressure is more than or equal to 2 MPa, and the hydrogen / oil ratio is between 100 and 500 (v / v); the nickel series catalyst takes alumina as a carrier, is prepared by the immersion method, and contains 14 to 20 percent of nickel oxide, 1 to 8 percent of lanthanum oxide and / or cerium oxide, 1 to 8 percent of 4B oxide auxiliary agent, 2 to 8 percent of silicon dioxide and 1 to 8 percent of alkaline earth oxide as calculated by 100 weight percent of the catalyst; and the specific surface of the catalyst is between 60 and 150 square meters per gram, and the pore volume of the catalyst is between 0.4 and 0.6 milliliter per gram. The invention also provides a method for performing reduction and passivation on the catalyst on a hydrogenation unit. Under the conditions of the application method and the technological conditions, the nickel catalyst has good hydrogenation performance, and particularly has strong impurity and colloid resistance and good hydrogenation stability.

Owner:PETROCHINA CO LTD

Industrial manufacture method for hydrogenated petroleum resin

ActiveCN102382259ASimplify the caustic cleaning processReduce corrosionPetroleum resinHydrogenation reaction

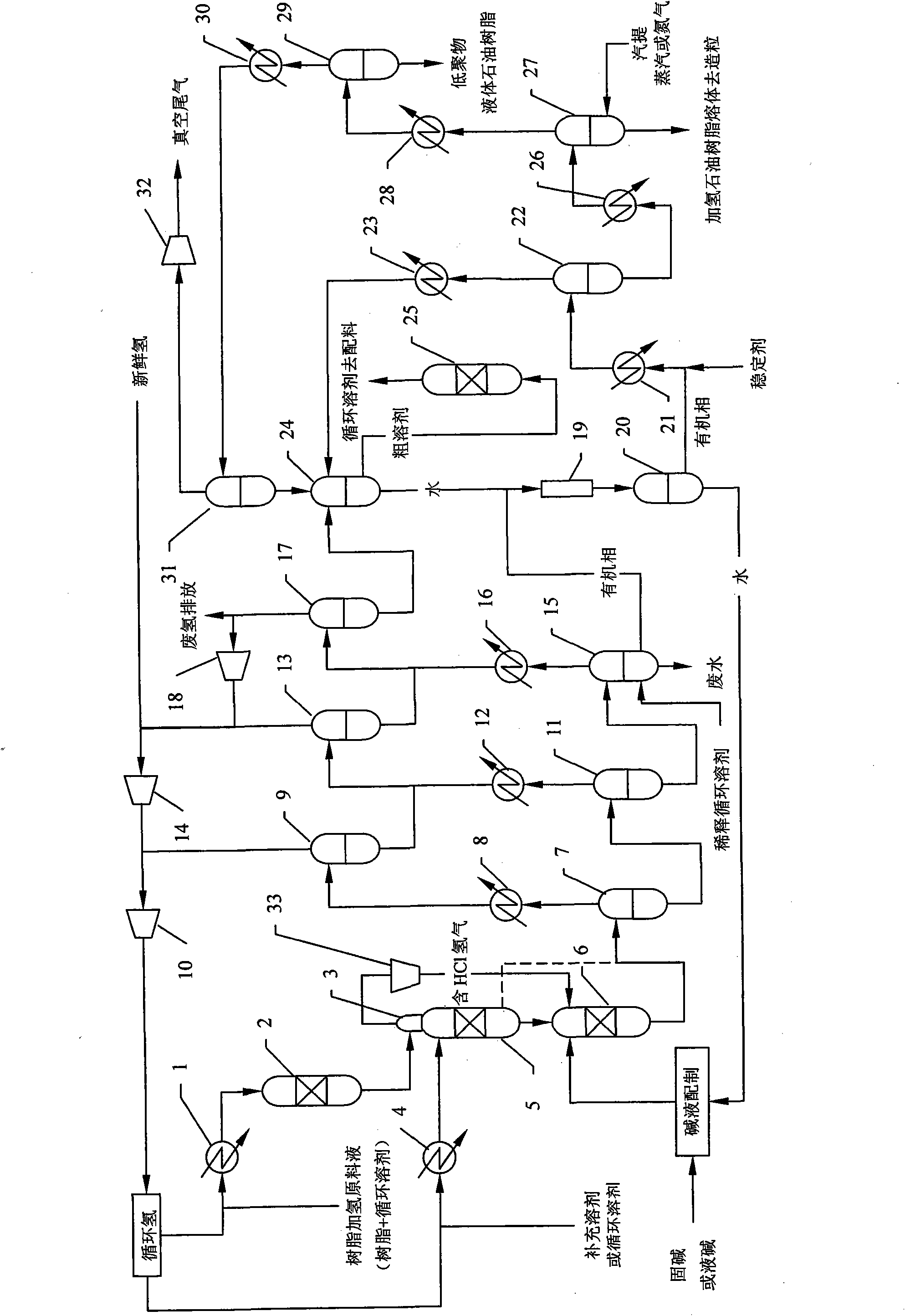

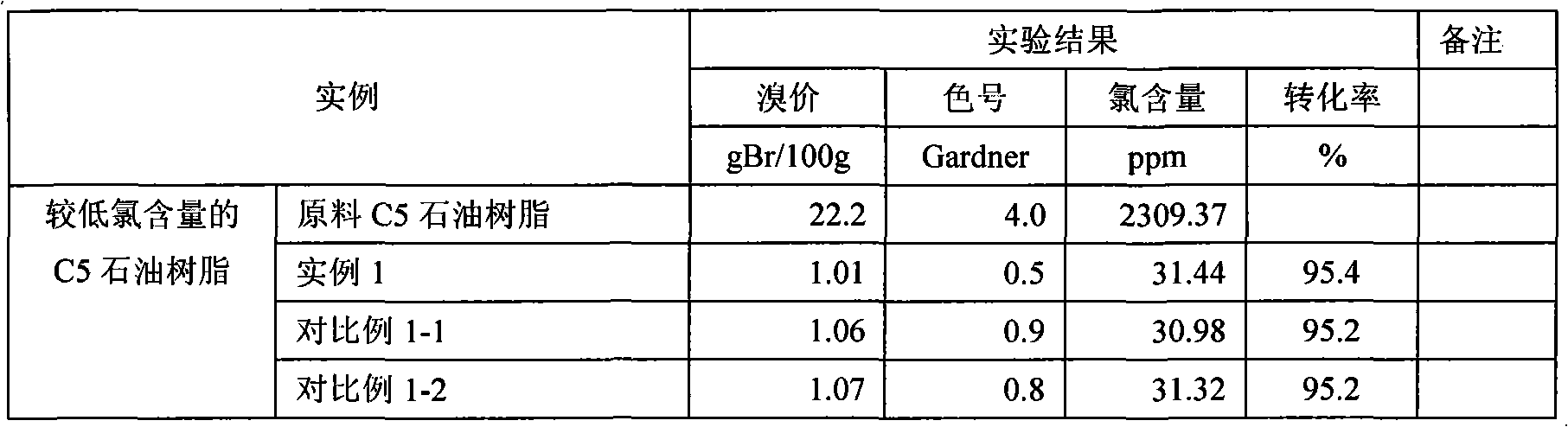

The invention relates to an industrial manufacture method for hydrogenated petroleum resin, which comprises the following steps of: generating hydrogenation reaction on petroleum resin which is obtained by polymerizing cracking C5 and C9 fractions under the proper condition of the existence of hydrogenation catalyst and solvents by adopting the processes of two-section hydrogenation and combination alkaline cleaning neutralization; hydrogenating the unsaturated component in the petroleum resin to reduce double-bond content; hydrogenating a non-ferrous perssad to fade; hydrogenating to remove chlorine retained in the polymerization process; and carrying out alkaline cleaning, water cleaning, stabilizer injection and solvent removal to obtain light or colourless hydrogenated petroleum resin. The method further simplifies the process through the organic combination of unit operation, and the industrial manufacture method for the hydrogenated petroleum resin, which has the advantages of wide adaptability on hydrogenated raw materials, less corrosion on system equipment, high product quality and high production capability is formed.

Owner:CHINA PETROLEUM & CHEM CORP

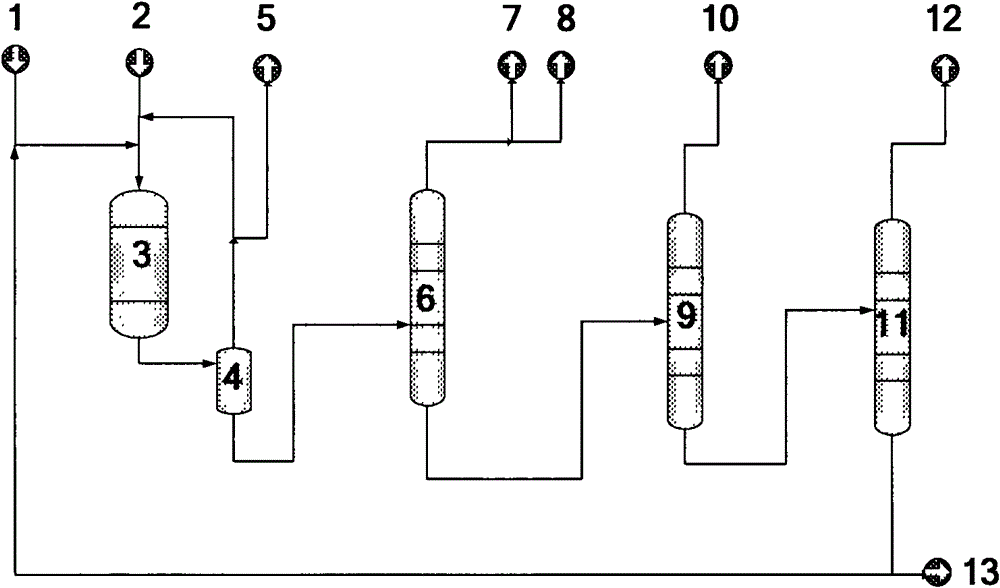

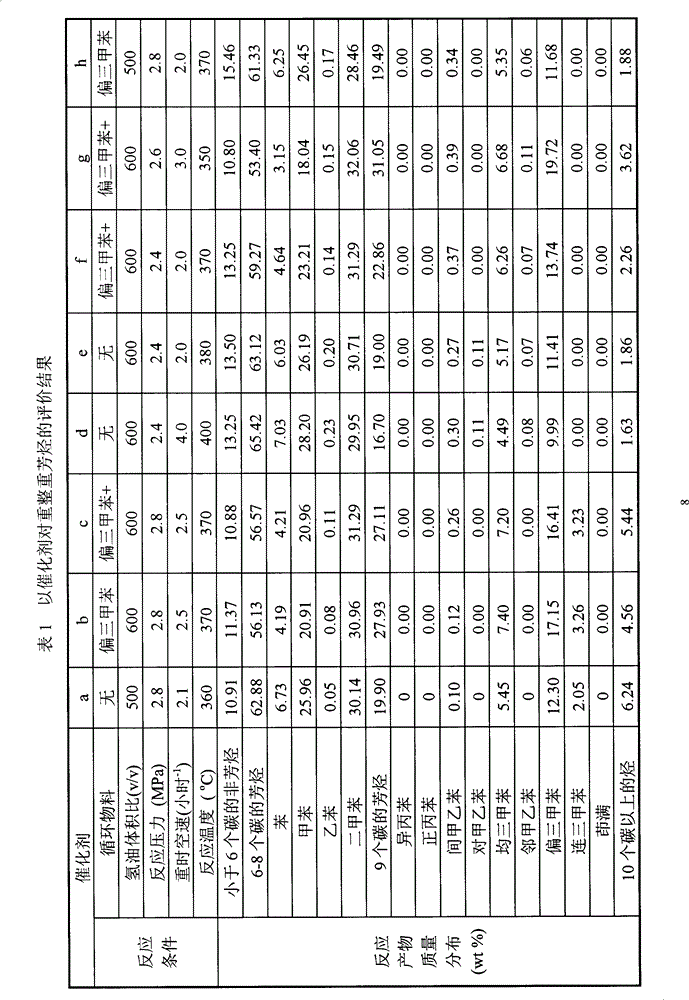

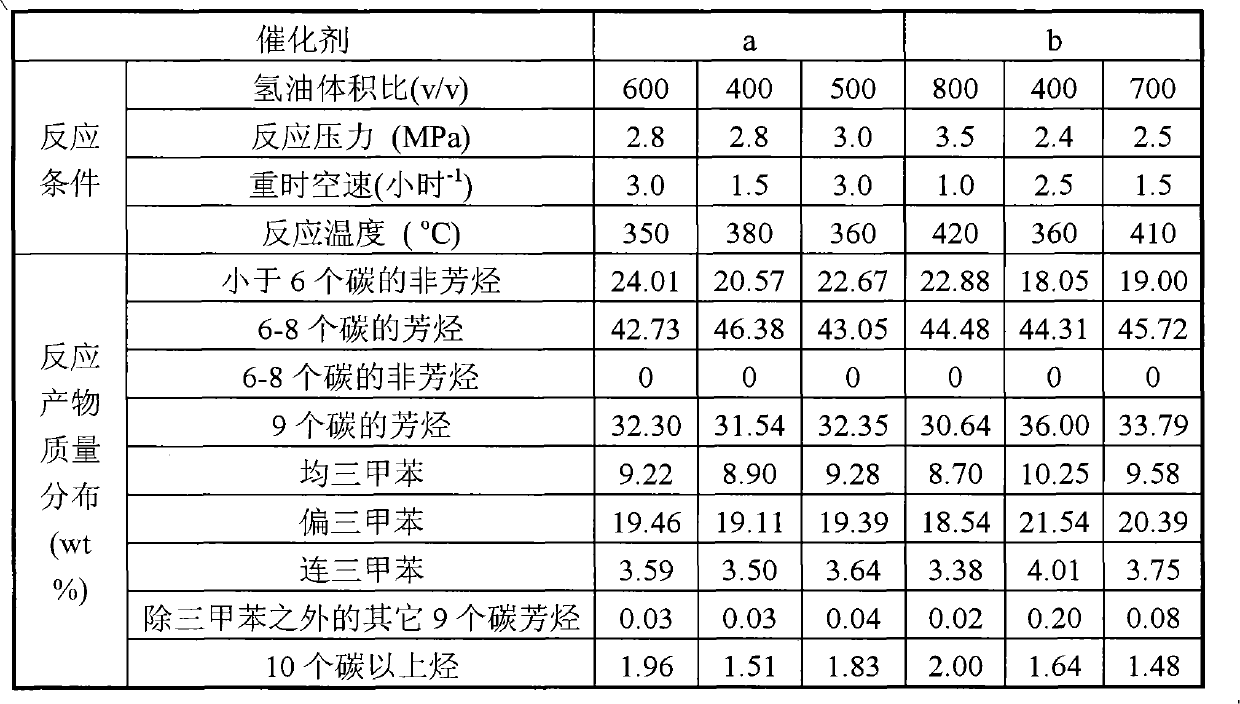

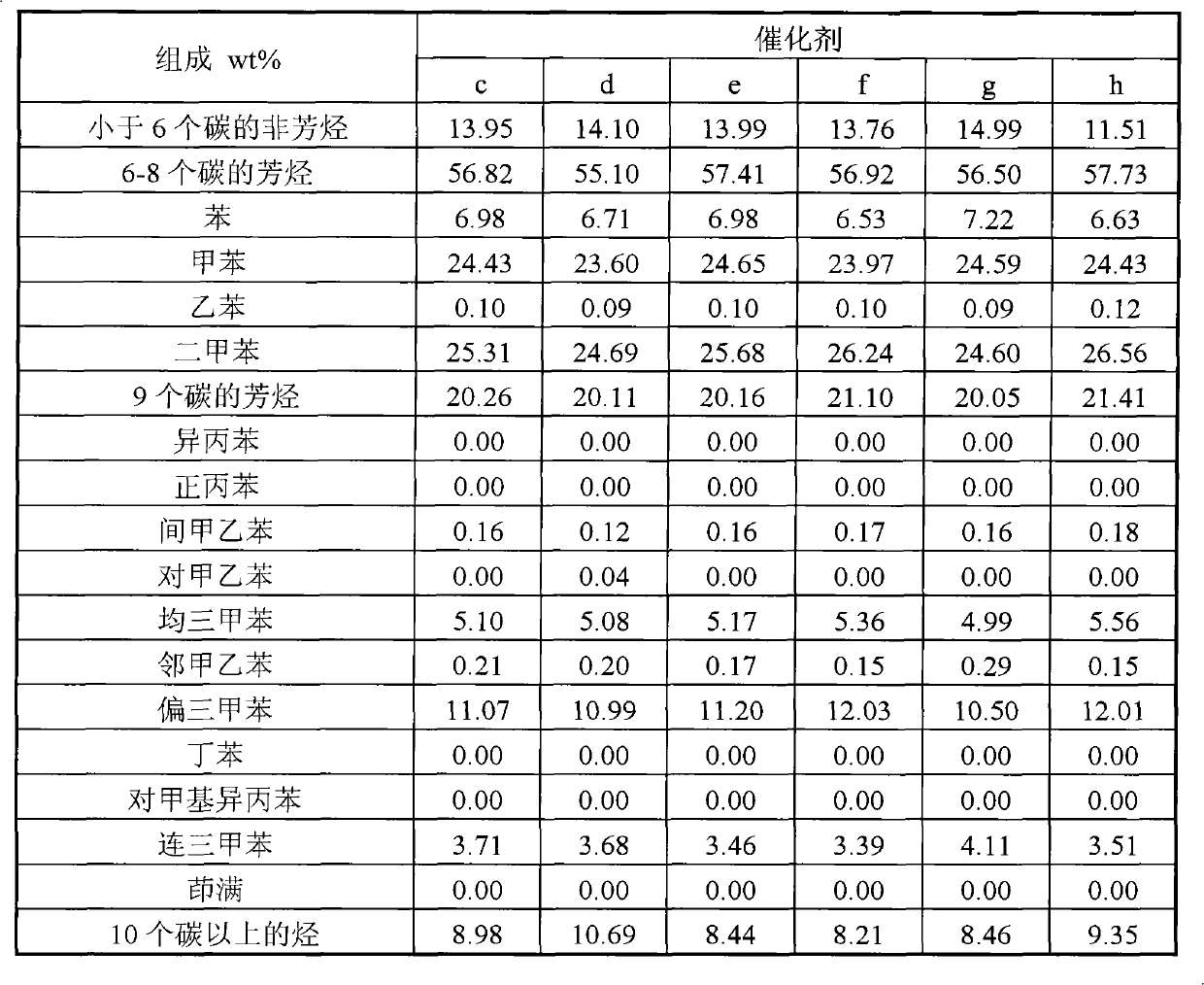

Method for separating and producing 1,3,5-trimethylbenzene through hydrocracking heavy aromatic hydrocarbons

ActiveCN102746092AEasy to removeHigh removal activityHydrocarbonsBulk chemical productionHydrogenBoiling point

The invention relates to a method for separating and producing 1,3,5-trimethylbenzene through hydrocracking heavy aromatic hydrocarbons to mainly solve technical problems of low added value of the heavy aromatic hydrocarbons, and complex flow, low product purity, low yield and the like in separation of 1,3,5-trimethylbenzene monomers from the heavy aromatic hydrocarbons. According to the method, hydrogen type binder-free ten-membered ring zeolite loading 0.005-0.5% by mass of Pt or Pd is adopted as a catalyst, hydrogen and the heavy aromatic hydrocarbons which are raw materials undergo hydrocracking treatment, and 1,2,4-trimethylbenzene and heavy aromatic hydrocarbons having boiling points greater than the boiling point of the 1,2,4-trimethylbenzene in products are returned to a reactor, so BTX aromatic hydrocarbon yield increase and 1,3,5-trimethylbenzene separation production are realized. The method well solves the problems, and can be used for the industrial production for yield increases of the BTX (benzene, toluene and xylol) aromatic hydrocarbon and the 1,3,5-trimethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for increase production of BTX (benzene, toluene and xylol) aromatic hydrocarbons and trimethylbenzene through hydrocracking heavy aromatic hydrocarbons

ActiveCN102746093AEasy to removeHigh removal activityHydrocarbonsBulk chemical productionBenzeneHydrogen

The invention relates to a method for the increase production of BTX aromatic hydrocarbons and trimethylbenzene through hydrocracking heavy aromatic hydrocarbons to mainly solve technical problems of low heavy aromatic hydrocarbon added value and high cost for separating and producing trimethylbenzene monomers in the heavy aromatic hydrocarbons containing methylethylbenzene, propylbenzene and butylbenzene. The method comprises a step that the heavy aromatic hydrocarbons are subjected to a hydrocracking reaction through adopting Pt / Pd-loaded hydrogen type binder-free ten-membered ring zeolite as a catalyst under reaction conditions comprising that the reaction temperature is 320-450DEG C, the reaction pressure is 2.0-4.0Mpa, the hydrocarbons raw material weight hourly space velocity is 1.0-4.0h<-1> and the hydrogen / hydrocarbon raw material ratio by mole is 3-10:1. The method well solves the problems through above technical scheme, and can be applied to the industrial production of the BTX aromatic hydrocarbons and the trimethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of micro low-oxygen titanium hydride powder

InactiveCN105195750AIncrease oxygen contentGood hydrogenation effectHydrogenation reactionOxygen content

The invention relates to a preparation method of micro low-oxygen titanium hydride powder, and belongs to the technical field of powder preparation in a powder metallurgy technology. Hydrogenation treatment and a ball grinding technology are combined; firstly, high-purity hydrogen is fed under a vacuum condition, so that blocky sponge titanium and the hydrogen generate hydrogenation reaction to prepare titanium hydride; then the titanium hydride is crushed by the mechanical ball grinding technology, so that the titanium hydride powder is obtained. The oxygen content of the prepared micro low-oxygen titanium hydride powder is 500 to 900ppm, and the average particle size D50 is 1 to 10 microns.

Owner:BEIJING UNIV OF TECH

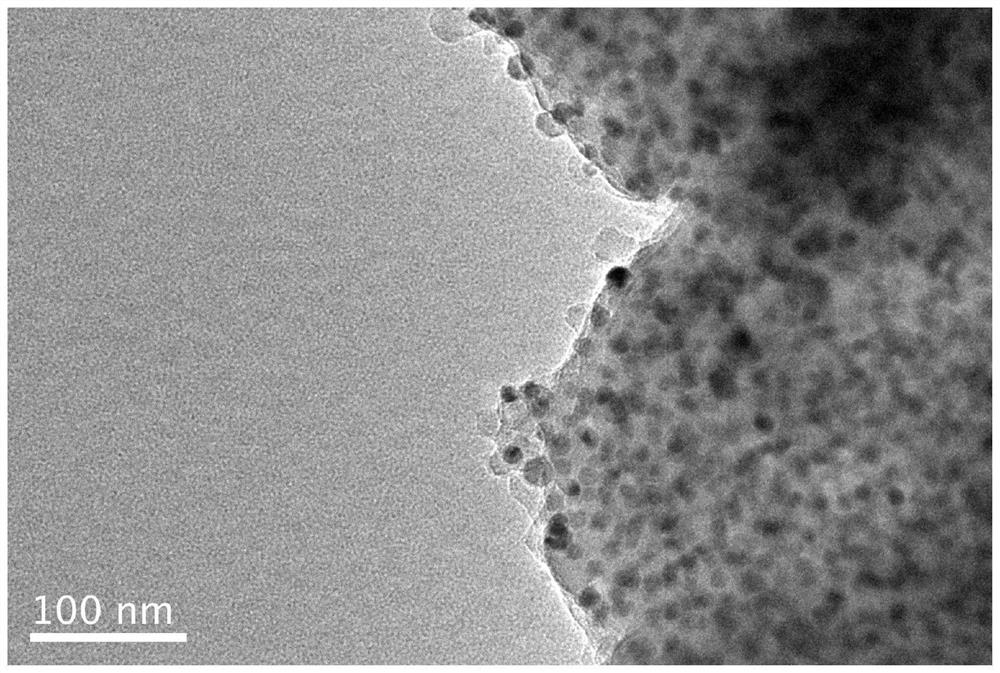

Loaded palladium catalyst and preparing method and its use

InactiveCN1748860AImprove hydrogenation activityMild reaction conditionsCatalyst carriersCatalyst activation/preparationFiberActive component

The present invention belongs to the field of the preparation of palladium catalyst, and is especially supported palladium catalyst and its preparation process and application. The supported palladium catalyst is noble metal palladium supported onto nanometer alumina fiber carrier and has the supported amount of palladium as the active component in 0.1-1 wt%. The nanometer alumina fiber carrier is gamma-alumina fiber, and the noble metal palladium is supported onto the nanometer alumina fiber carrier through equal volume soaking process. The high dispersive supported palladium catalyst is used in hydrogenating anthraquinone to prepare hydrogen peroxide solution, has high hydrogenating effect and mild reaction condition, and suitable for industrial production.

Owner:NANKAI UNIV

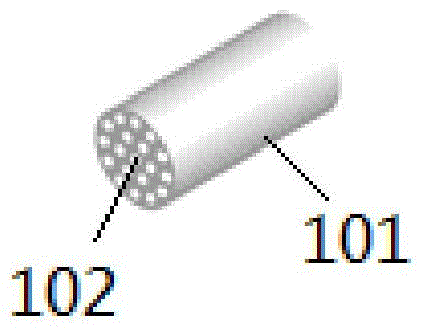

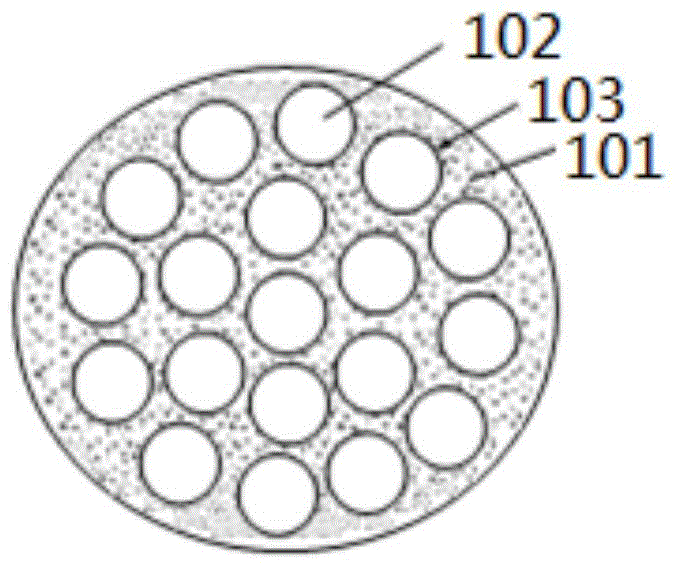

Method for purifying recycle alcohol solvent of olefin epoxidation process and olefin epoxidation method

ActiveCN104926606AProcess stabilityImprove effective utilizationOrganic compound preparationHydroxy compound preparationAlcoholHydrogenation reaction

The present invention provides a method for purifying a recycle alcohol solvent of olefin epoxidation process, and the method is as follows: hydrogen is sent into the recycle alcohol solvent by holes with the average pore size in nanoscale to obtain a hydrogen-containing recycle alcohol solvent; and the hydrogen-containing recycle alcohol solvent is sent into a tubular fixed bed reactor in the upward flowing manner for contact with a catalytic hydrogenation catalyst under the condition of liquid phase hydrogenation processing. The present invention also provides an olefin epoxidation method using the method for purifying. The method for purifying can effectively reduce the dosage of hydrogen without maintaining of recycle hydrogen in the reactor, the demand for a hydrogen recycle device is eliminated, the hydrogenation reaction process is simplified, the equipment investment and operation cost can be greatly reduced, and the operation can be performed under high space velocity. By adoption of the method for purifying of the recycle alcohol solvent, the method has good hydrogenation effect on a variety of impurities in the recycle alcohol solvent, and a high purity recycle alcohol solvent can be obtained.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Unsaturated polymer hydrogenation catalyst and preparation method thereof

InactiveCN102580774AHigh hydrogenation selectivityNot easy to residueOrganic-compounds/hydrides/coordination-complexes catalystsCobalt metalInorganic salts

The invention provides an unsaturated polymer hydrogenation catalyst and a preparation method thereof. The unsaturated polymer hydrogenation catalyst is formed by reacting metal organic compounds of IA, IIA and IIIA groups with a nickel / cobalt metal inorganic salt, wherein the metal mol ratio of organic metal to inorganic metal is (1-10): 1. The hydrogenation effect of the catalyst on a homopolymer of conjugated diene or a copolymer of the conjugated diene and vinyl arene is obvious, the hydrogenation selectivity of the catalyst is high and the catalyst is not easily remained in the polymer after a hydrogenation reaction and can be washed by water, so that the catalyst is good for improving the purity and the quality of the polymer.

Owner:CHINA PETROCHEMICAL CORP

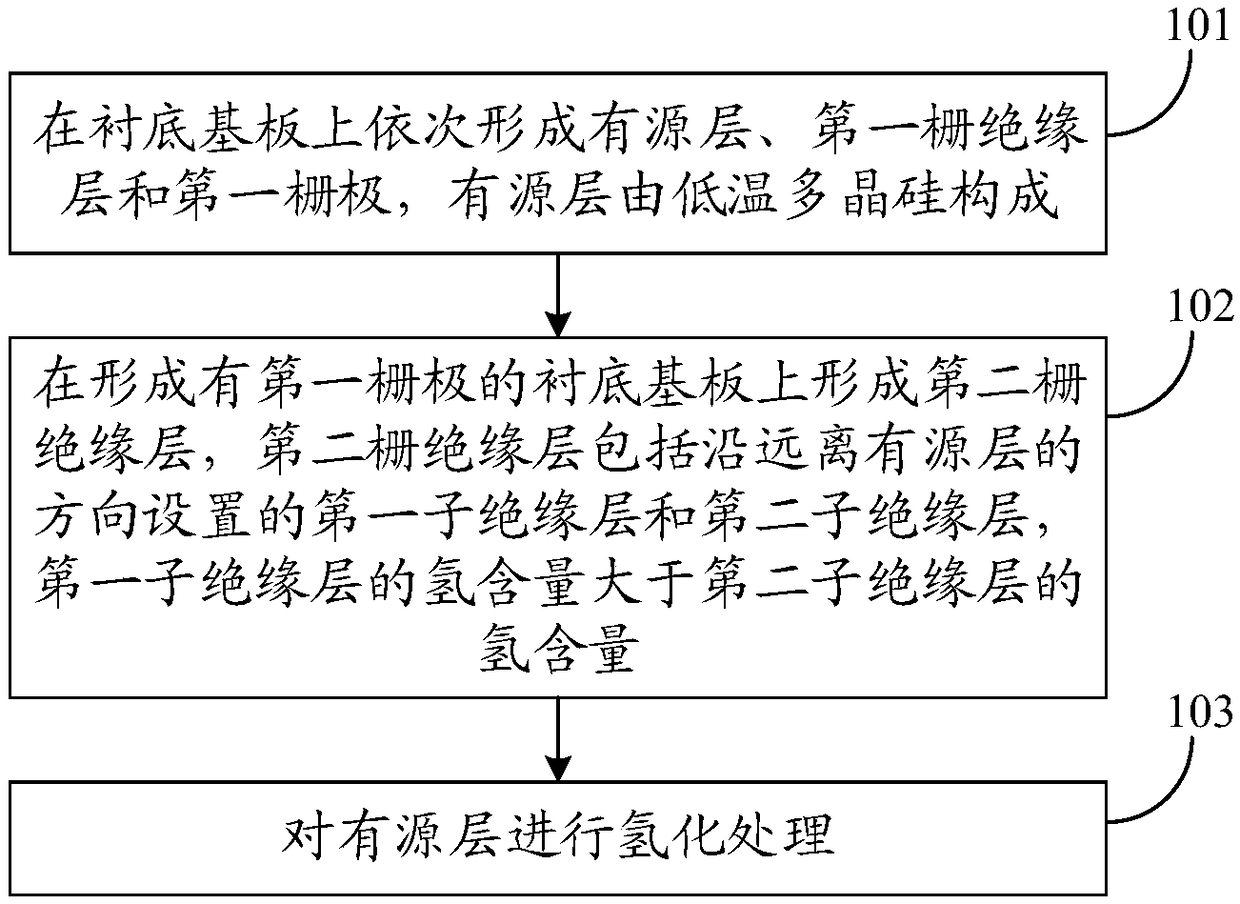

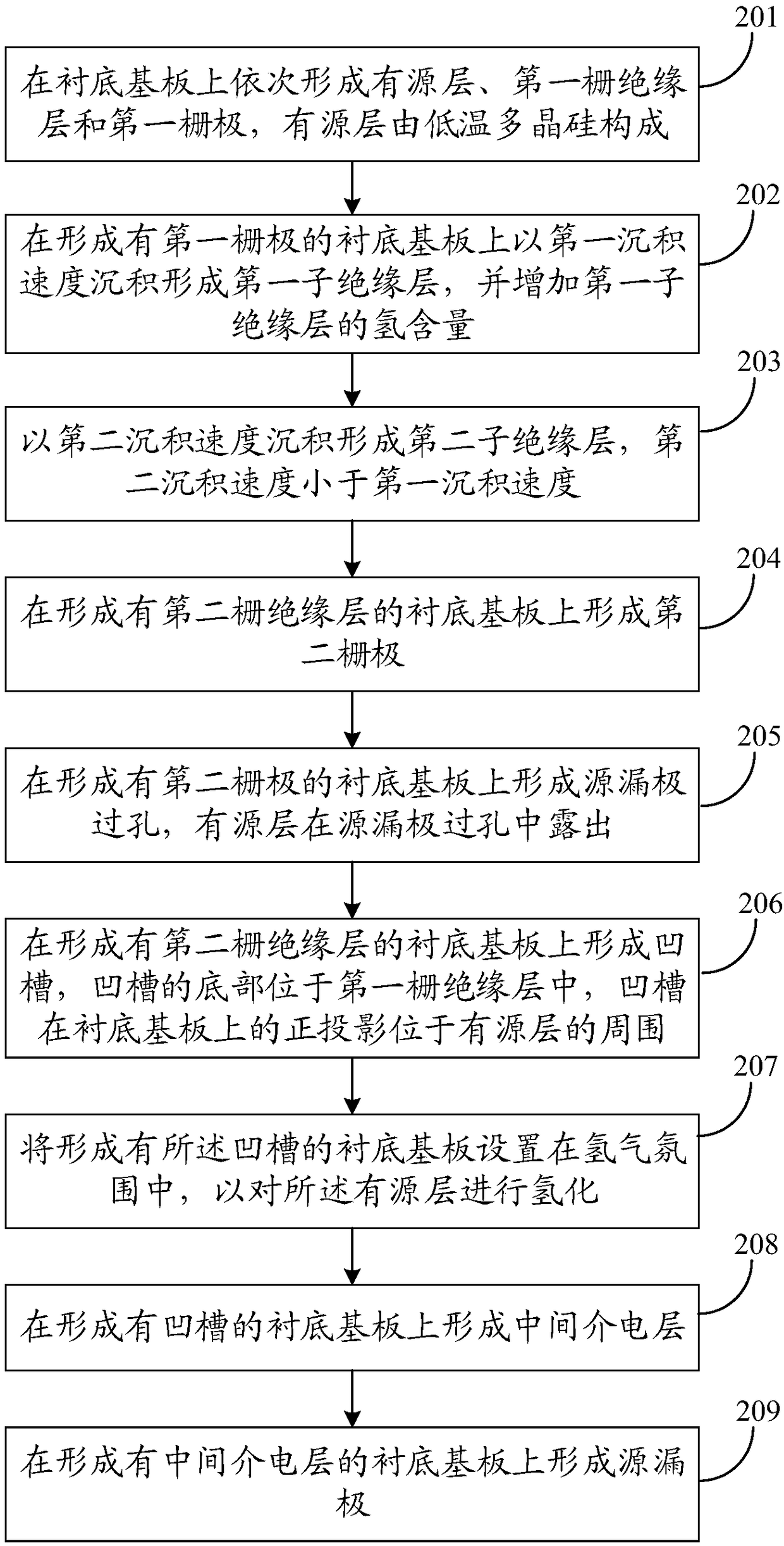

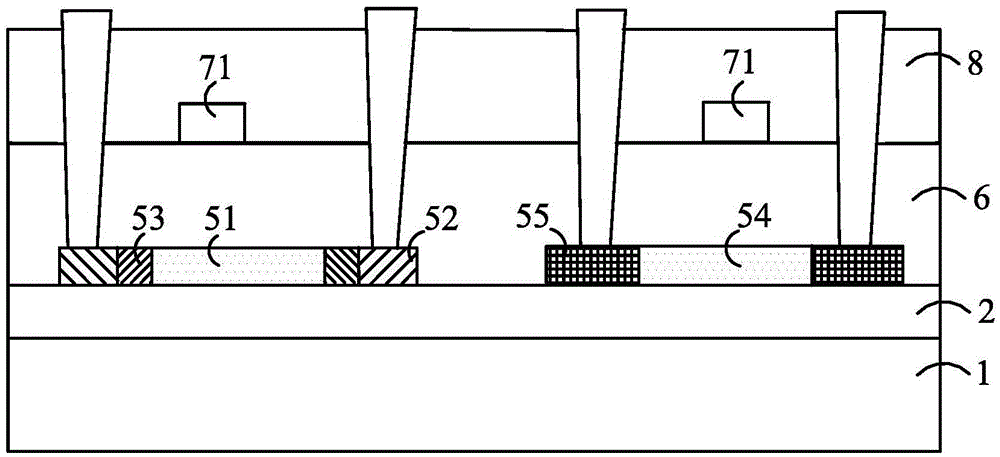

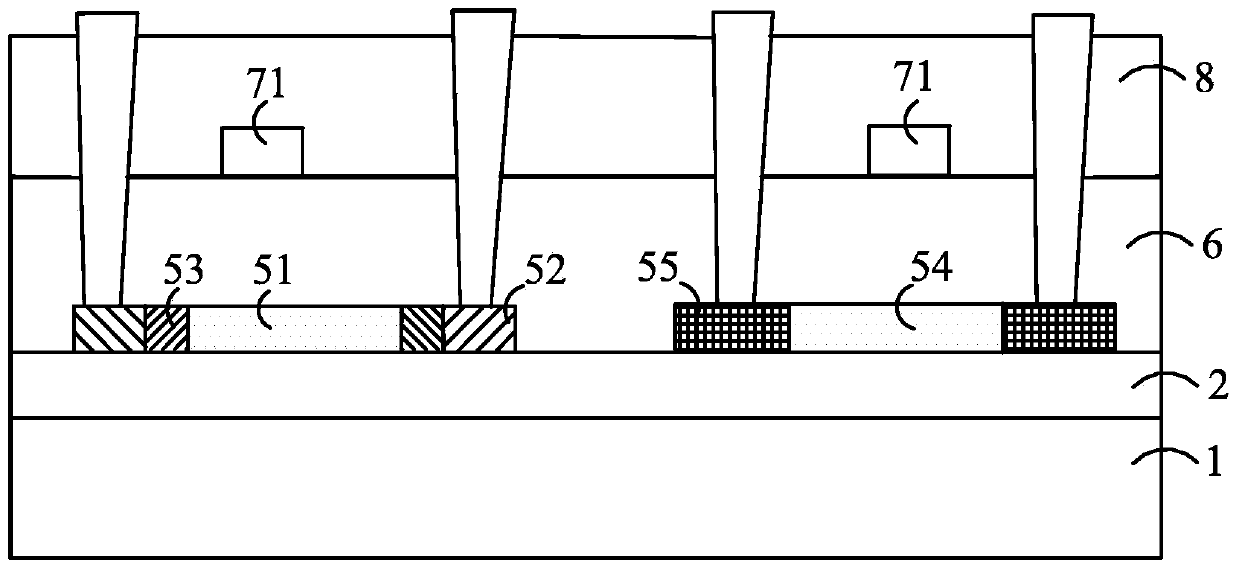

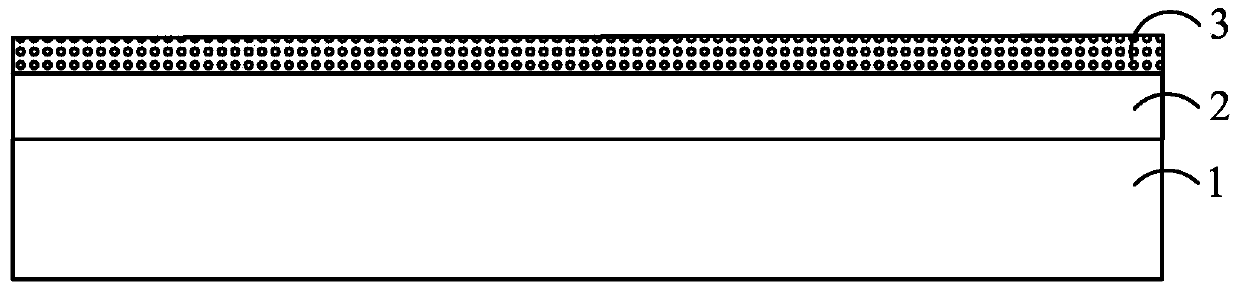

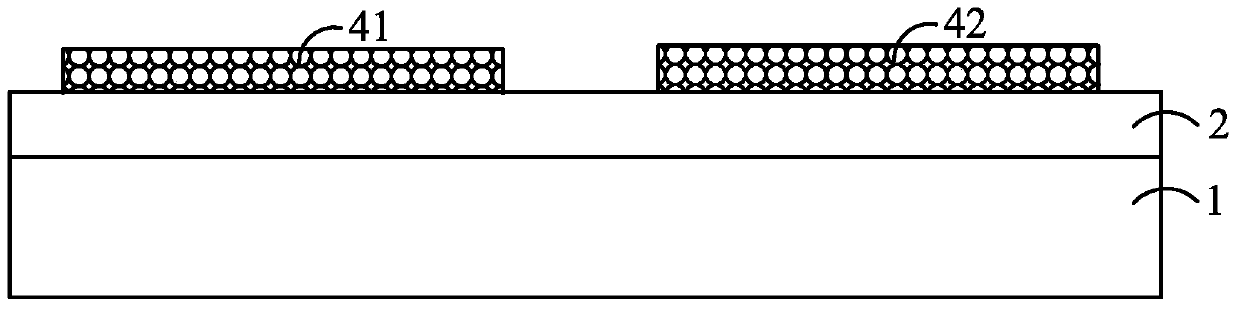

Manufacturing method of array substrate, array substrate and display panel

ActiveCN108598093AGood hydrogenation effectImprove electrical performanceSolid-state devicesSemiconductor/solid-state device manufacturingHydrogen concentrationBiochemical engineering

The invention discloses a manufacturing method of an array substrate, the array substrate and a display panel, and belongs to the technical field of display. The method comprises the following steps:sequentially forming an active layer, a first gate insulating layer and a first gate electrode on a substrate; forming a second gate insulating layer on the substrate on which the first gate electrodeis formed, wherein the second gate insulating layer includes a first sub-insulating layer and a second sub-insulating layer arranged in a direction away from the active layer, and the hydrogen content of the first sub-insulating layer is greater than the hydrogen content of the second sub-insulating layer; and carrying out hydrogenation treatment on the active layer. According to the manufacturing method of the array substrate provided by the invention, the first sub-insulating layer with relatively large hydrogen content and the second sub-insulating layer with relatively small hydrogen content are formed, so that in the hydrogenation treatment process, hydrogen can diffuse better towards the active layer, thereby improving the distribution of the hydrogen concentration gradient towardsthe direction of the active layer, and improving a hydrogenation effect on the active layer; and in addition, the problem of affecting the electrical properties of the active layer in the related technology is solved, and the effect of improving the electrical properties of the active layer is achieved.

Owner:BOE TECH GRP CO LTD

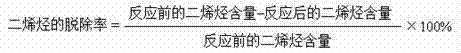

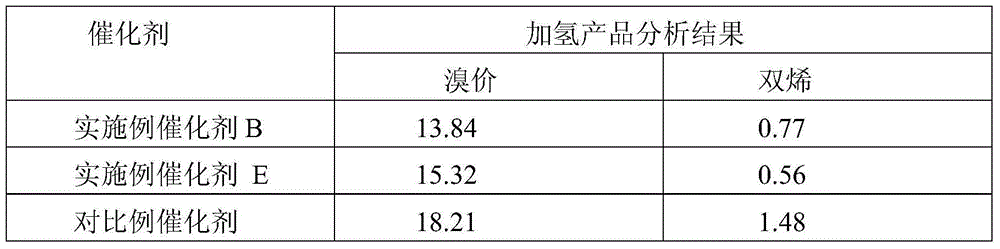

A preparing method of a mercaptan etherification catalyst

InactiveCN104511287AImprove anti-coking performanceImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationThiolActive component

A preparing method of a mercaptan etherification catalyst is disclosed. The method includes: (1) dipping an Al2O3 carrier with a potassium salt solution, drying, and calcinating at 300-600 DEG C to obtain a K2O / Al2O3 carrier; and (2) adding a molybdenum-containing compound, a nickel-containing compound and a composite auxiliary agent into deionized water to prepare a dipping solution; and (3) dipping the carrier obtained in the step (1), drying and calcinating at 200-400 DEG C to obtain a NiO-MoO3-K2O / Al2O3 catalyst. The Al2O3 carrier is modified by the K2O so as to enhance carbon deposit resistance and stability of the catalyst. The composite auxiliary agent, the molybdenum-containing compound and the nickel-containing compound form a complex, thus weakening interaction of NiO, MoO3 and the Al2O3 carrier, promoting dispersion of active components in the Al2O3 carrier, and enhancing activity of the catalyst. The catalyst is high in activity of removing mercaptan in gasoline, and has good hydrogenation effects for dienes.

Owner:CHINA PETROLEUM & CHEM CORP +1

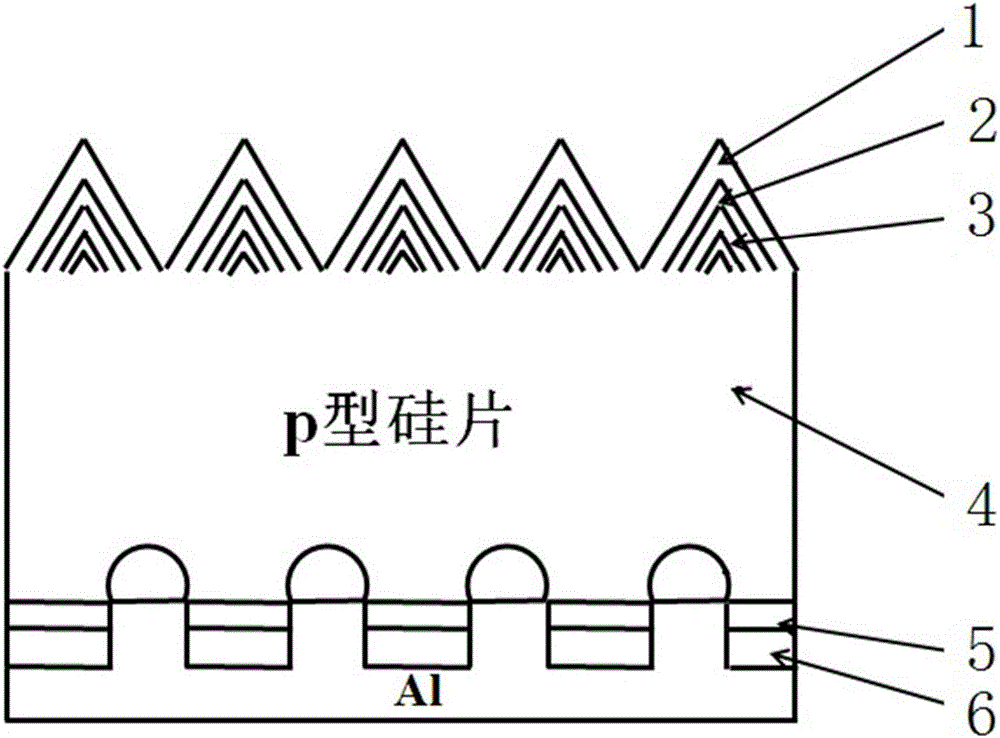

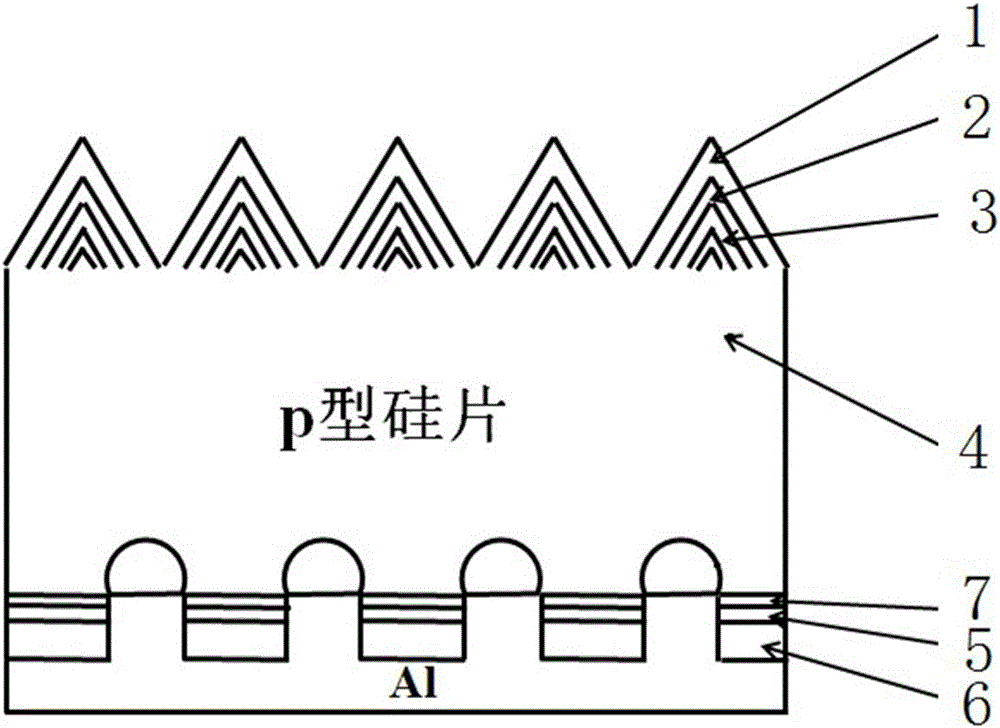

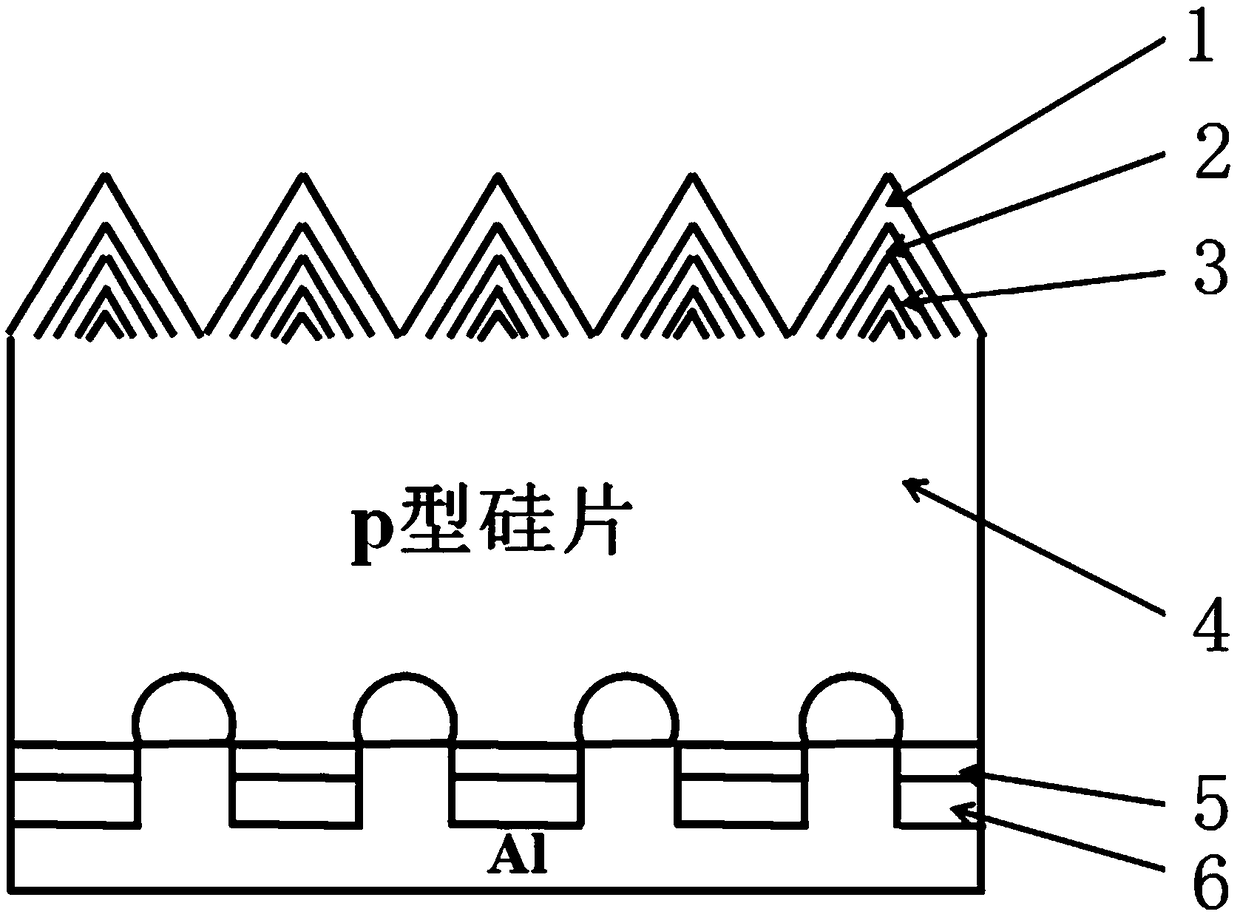

PERC solar cell structure and preparation process thereof

ActiveCN106653871AIncrease impurity concentrationImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationElectrical batteryEngineering

The invention discloses a PERC solar cell structure and a preparation process thereof. The PERC solar cell structure comprises a cell piece body. A SiO2 layer, an anti-reflection layer and an AlOx layer are successively deposited / grown on the front surface of the cell piece body. An AlOx layer and a SiNx layer are successively deposited on the back surface of the cell piece body. On the basis of a conventional PERC cell preparation process, a surface oxidation doping process is used. In addition, the PERC battery process is adjusted. A unique surface passivation layer deposition process is also used. The beneficial effect of the preparation process is that effective doping in an oxidation process improves the surface impurity concentration of the cell, improves the FF of the cell, compensate the deterioration of the FF due to the local contact on the back surface; and the adjustment of the PERC cell process solves edge electric leakage due to doping process so as to simply the process, thereby improving the conversion efficiency of the cell and providing a better hydrogenation effect for the subsequent photonic recovery process of the PERC battery so as to achieve anti-LID.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

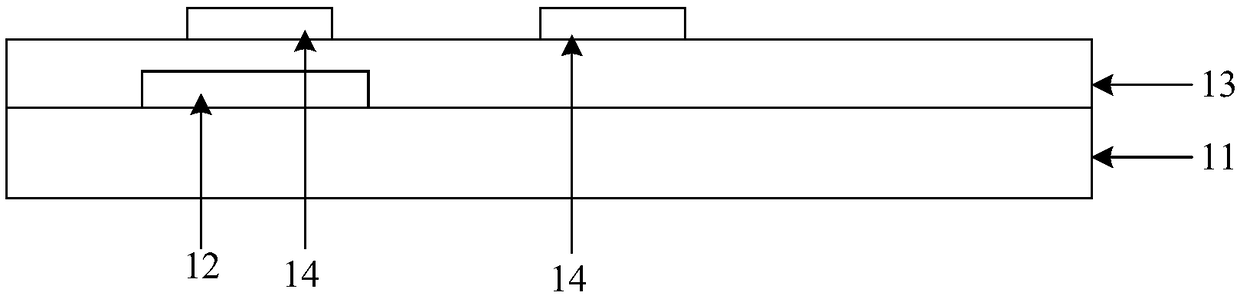

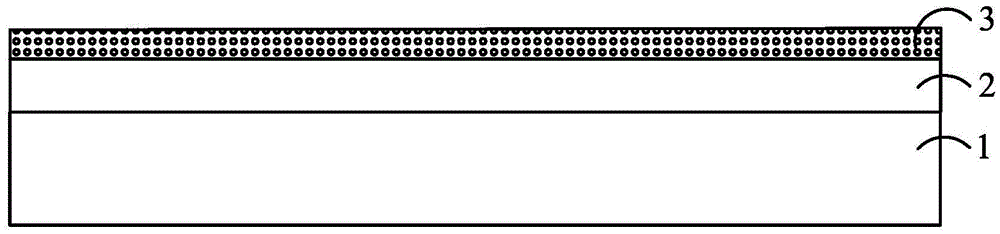

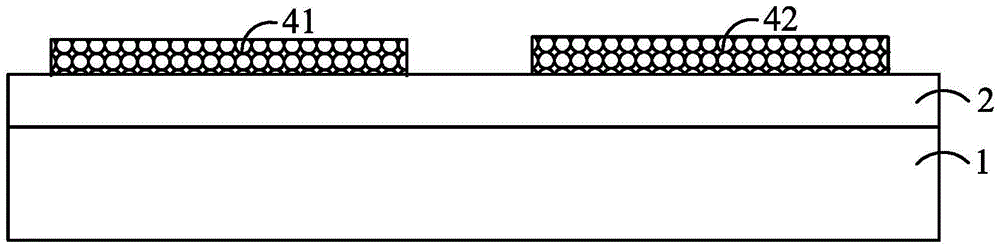

Low-temperature polycrystalline silicon thin film transistor and preparation method thereof

ActiveCN105655404AIncrease profitImprove the activation effectTransistorSemiconductor/solid-state device manufacturingCrystalline siliconRadiation

The invention relates to a low-temperature polycrystalline silicon thin film transistor and a preparation method thereof. The method comprises the following steps: providing a substrate; depositing a buffering layer and a non-crystalline silicon layer on the substrate in sequence, and performing laser radiation to change the non-crystalline silicon layer into a polycrystalline silicon layer which is an active layer; depositing a first grid insulating layer, a second grid insulating layer and a first metal layer on the buffering layer and the active layer in sequence, performing high-temperature activation, and photoetching and etching the first metal layer to form a grid; depositing dielectric layers on the grid insulating layers and the grid; depositing first contact holes and second contact holes in the dielectric layers, the first grid insulating layer and the second grid insulating layer; and respectively depositing source electrodes and drain electrodes on the first contact holes and the second contact holes. The thin film transistor prepared by the method can effectively overcome the structural defects of polycrystalline silicon, and the performance of the thin film transistor can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

A Fe-BASED HYDROGENATION CATALYST AND USE THEREOF

ActiveUS20160158733A1Good hydrogenation effectEasy to carryHeterogenous catalyst chemical elementsCatalytic naphtha reformingPotassiumZinc

The present invention relates to a Fe-based hydrogenation catalyst having Fe as a primary active metal component, and zinc and potassium as a first co-active metal component. The molar ratio of the primary active metal component to the first co-active metal component is 0.5-200:1. The Fe-based hydrogenation catalyst in present invention overcomes the problem of limiting to the active metal components as used over decades for the conventional hydrogenation catalyst, and thus has long-term values for industrial application.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Hydroprocessing method of catalytic cracking heavy cycle oil, processing method of raw materials for producing needle coke, and method for producing needle coke

ActiveCN104927899AExtended service lifeGood hydrogenation effectTreatment with hydrotreatment processesCoking carbonaceous materialsCycle oilNanometer size

The invention provides a hydroprocessing method of catalytic cracking heavy cycle oil. The hydroprocessing method comprises the following steps of: sending hydrogen into the catalytic cracking heavy cycle oil through holes of which the average hole size is in nanometer sizes so as to obtain hydrogen-containing heavy cycle oil; sending the obtained hydrogen-containing heavy cycle oil into a tubular reactor, and enabling the hydrogen-containing heavy cycle oil to be in contact with a hydrogenation catalyst filled in the tubular reactor under liquid phase hydrogenation processing conditions. The invention further provides a processing method for producing raw materials of needle coke. The invention further provides a method for producing the needle coke. According to the hydroprocessing method disclosed by the invention, even if a diluting agent and / or cycle oil are / is not used, the hydrogen can also be highly dispersed and dissolved in the catalytic cracking heavy cycle oil, enough hydrogen sources are provided for hydroprocessing, and the efficient processing quantity for a hydroprocessing device is increased. In addition, the hydroprocessing method disclosed by the invention can effectively remove metal, sulfur and asphalt substances in the catalytic cracking heavy cycle oil, so that the raw materials conforming to the needle coke for producing ultra-high power electrodes are obtained.

Owner:CHINA PETROLEUM & CHEM CORP +2

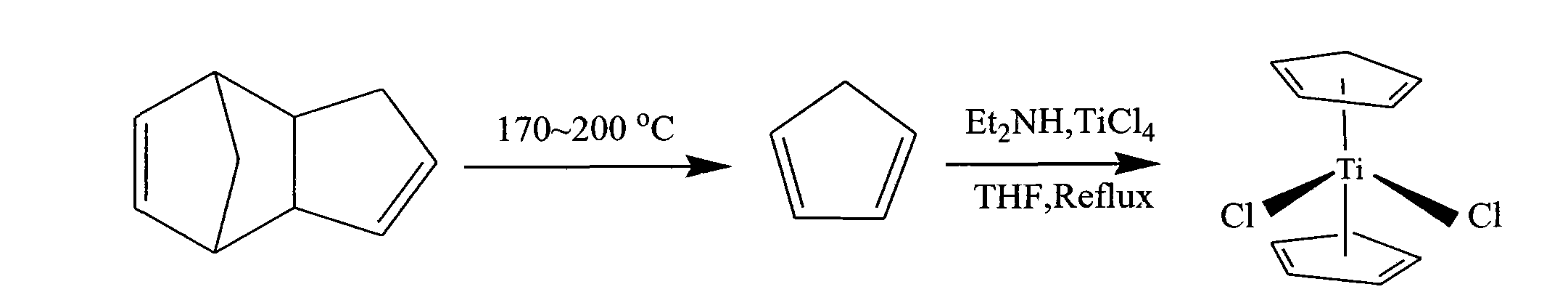

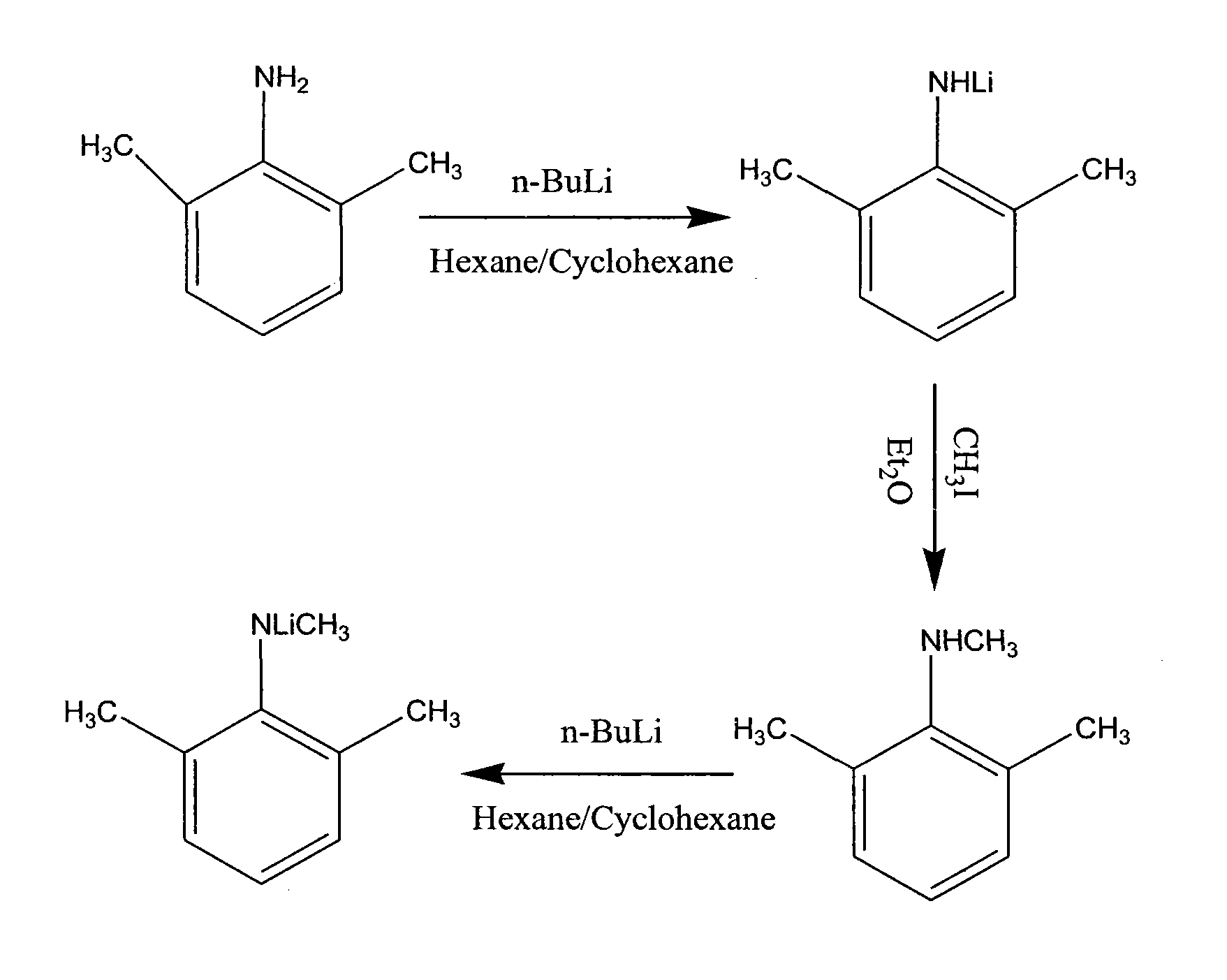

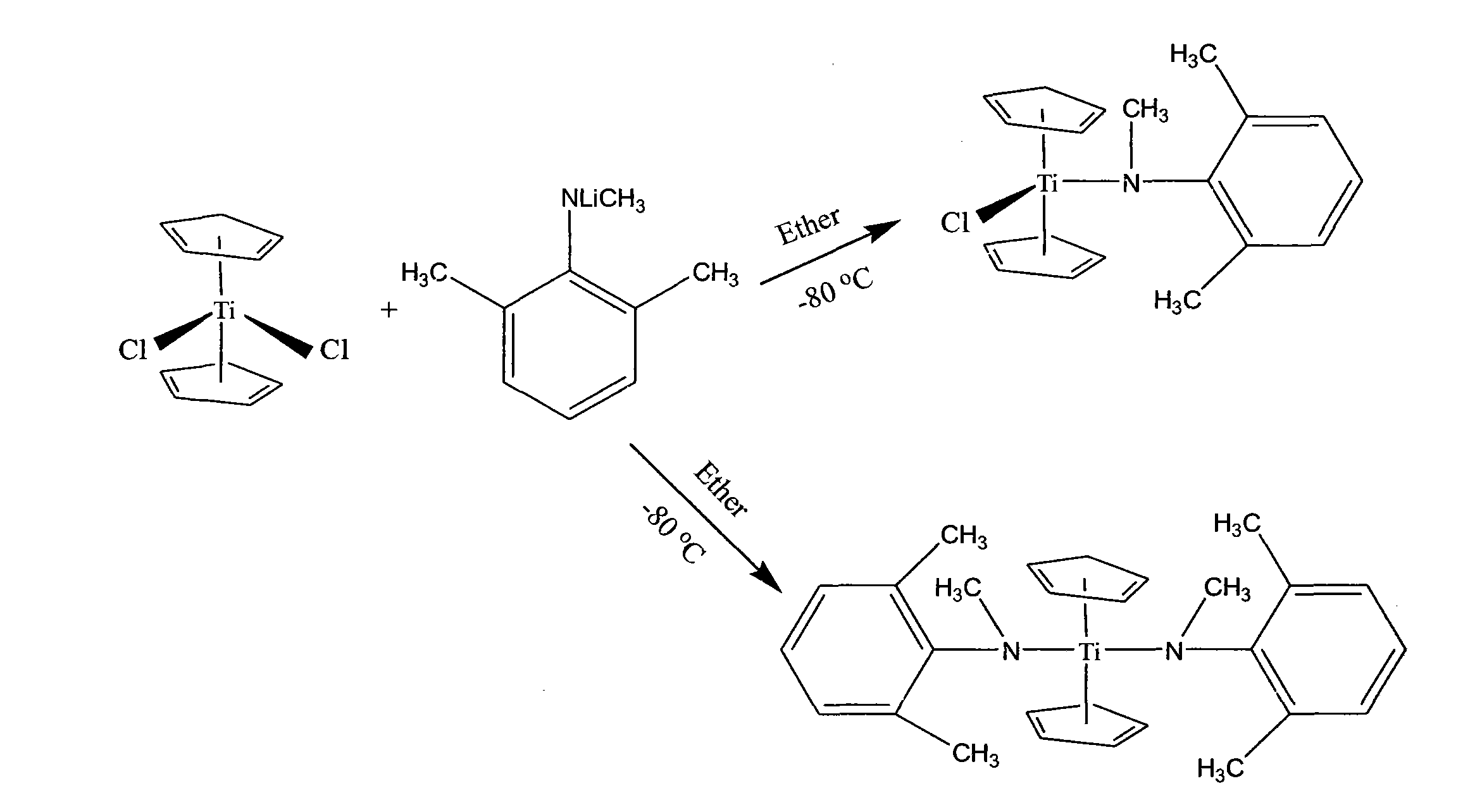

Preparation of novel hydrogenation catalyst

InactiveCN104226365AImprove catalytic performanceSimple manufacturing methodOrganic-compounds/hydrides/coordination-complexes catalystsLithiumEther

The invention relates to preparation of a novel hydrogenation catalyst. The invention is characterized in that a two-stage distillation method is employed to prepare titanocene Cp2TiCl2, then a simple method is taken to prepare the lithium salt complex LiN(2, 6-Me2C6H3)(Me), the two prepared compounds are utilized to prepare the target product Cp2TiCl[N(2, 6-Me2C6H3)(CH3)] in an ether solution. The catalyst shows excellent hydrogenation performance in SBS hydrogenation, does not need to be removed after reaction, and has no influence to the chemical properties of the product SEBS. The novel hydrogenation catalyst has wide application prospects in the field of polymer hydrogenation.

Owner:BEIJING UNIV OF CHEM TECH

Method for reducing aromatic aldehyde into aromatic alcohol through selective catalysis of tetraethylammonium fluoride at low temperature

PendingCN109516967AImprove securityGood hydrogenation effectOrganic compound preparationPreparation by oxygen reductionTetraethylammoniumAromatic alcohol

The invention discloses a mild, simple and convenient preparation method. The preparation method comprises the steps of mixing a reactant solution, silicon hydrogen and a catalyst, namely tetraethylammonium fluoride, putting the mixture into a sealed reaction container, and reacting at 25-60 DEG C for 0.5-2 hours, so as to obtain aromatic alcohol, wherein the use amount of silicon hydrogen is 2-4times of that of aromatic aldehyde, the concentration of aromatic aldehyde in the organic solvent is 2wt%-4wt%, and the content of the catalyst, namely tetraethylammonium fluoride relative to aromaticaldehyde is 5mol%-10mol%. According to the preparation method, the deficiencies of a traditional catalytic system that the dangerousness is high, the environment is polluted, the process is complex,and the content of byproducts is high can be effectively overcome.

Owner:GUIZHOU UNIV

A method of purifying recovered alcohol solvent from an olefin epoxidation reaction process and a method of olefin epoxidation

ActiveCN104926606BProcess stabilityImprove effective utilizationOrganic compound preparationHydroxy compound preparationPurification methodsAlcohol

The present invention provides a method for purifying a recycle alcohol solvent of olefin epoxidation process, and the method is as follows: hydrogen is sent into the recycle alcohol solvent by holes with the average pore size in nanoscale to obtain a hydrogen-containing recycle alcohol solvent; and the hydrogen-containing recycle alcohol solvent is sent into a tubular fixed bed reactor in the upward flowing manner for contact with a catalytic hydrogenation catalyst under the condition of liquid phase hydrogenation processing. The present invention also provides an olefin epoxidation method using the method for purifying. The method for purifying can effectively reduce the dosage of hydrogen without maintaining of recycle hydrogen in the reactor, the demand for a hydrogen recycle device is eliminated, the hydrogenation reaction process is simplified, the equipment investment and operation cost can be greatly reduced, and the operation can be performed under high space velocity. By adoption of the method for purifying of the recycle alcohol solvent, the method has good hydrogenation effect on a variety of impurities in the recycle alcohol solvent, and a high purity recycle alcohol solvent can be obtained.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

A kind of perc solar cell structure and preparation technology thereof

ActiveCN106653871BIncrease impurity concentrationImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationElectrical batteryEngineering

The invention discloses a PERC solar cell structure and a preparation process thereof. The PERC solar cell structure comprises a cell piece body. A SiO2 layer, an anti-reflection layer and an AlOx layer are successively deposited / grown on the front surface of the cell piece body. An AlOx layer and a SiNx layer are successively deposited on the back surface of the cell piece body. On the basis of a conventional PERC cell preparation process, a surface oxidation doping process is used. In addition, the PERC battery process is adjusted. A unique surface passivation layer deposition process is also used. The beneficial effect of the preparation process is that effective doping in an oxidation process improves the surface impurity concentration of the cell, improves the FF of the cell, compensate the deterioration of the FF due to the local contact on the back surface; and the adjustment of the PERC cell process solves edge electric leakage due to doping process so as to simply the process, thereby improving the conversion efficiency of the cell and providing a better hydrogenation effect for the subsequent photonic recovery process of the PERC battery so as to achieve anti-LID.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

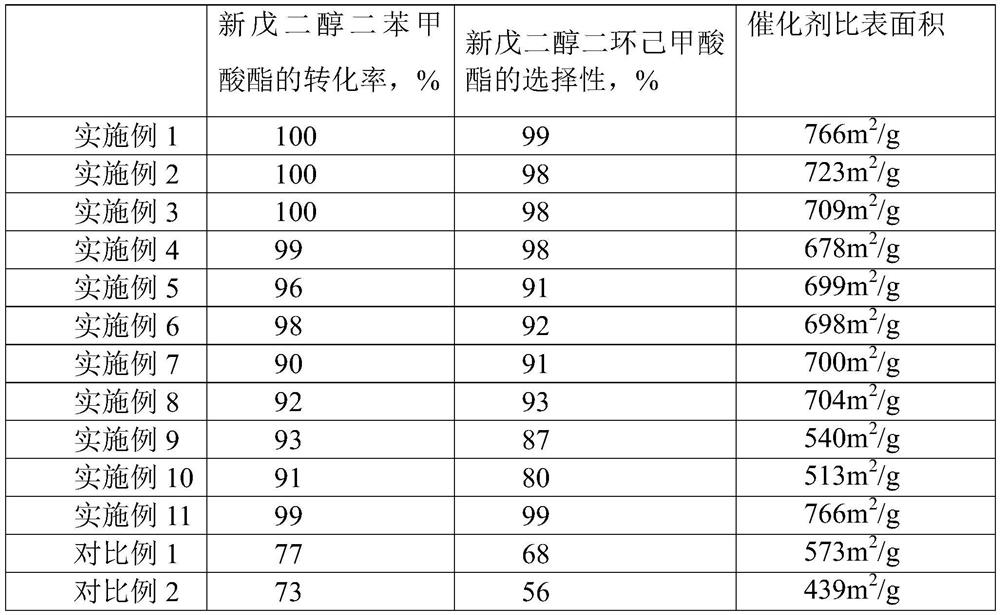

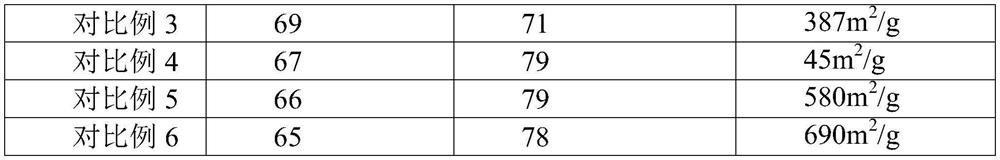

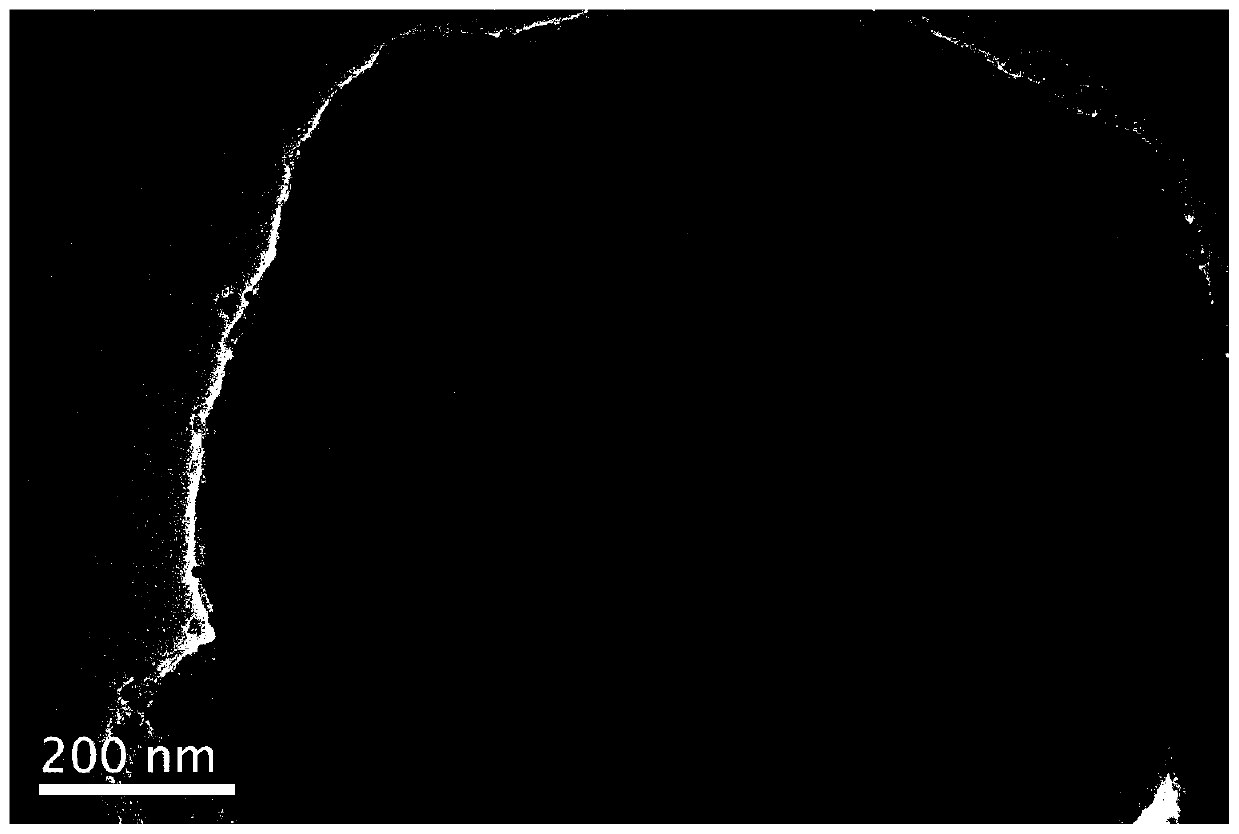

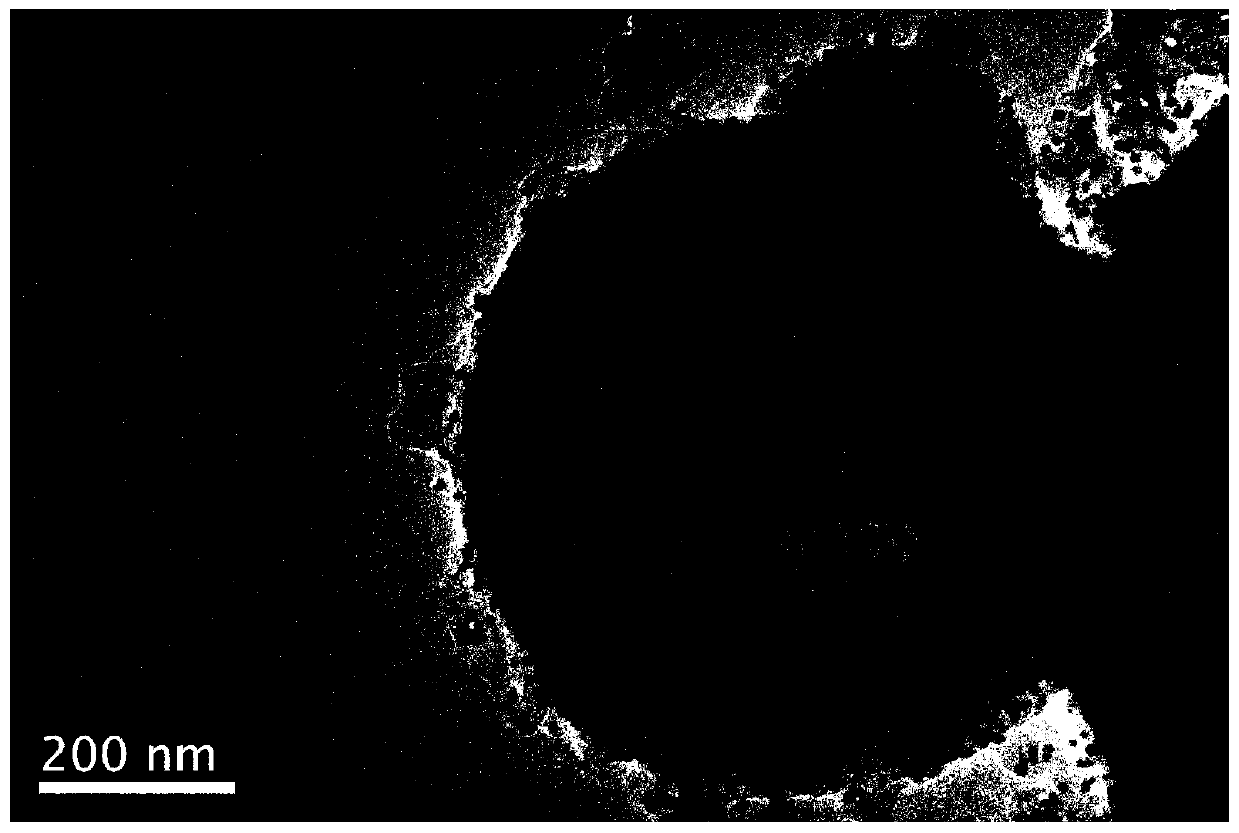

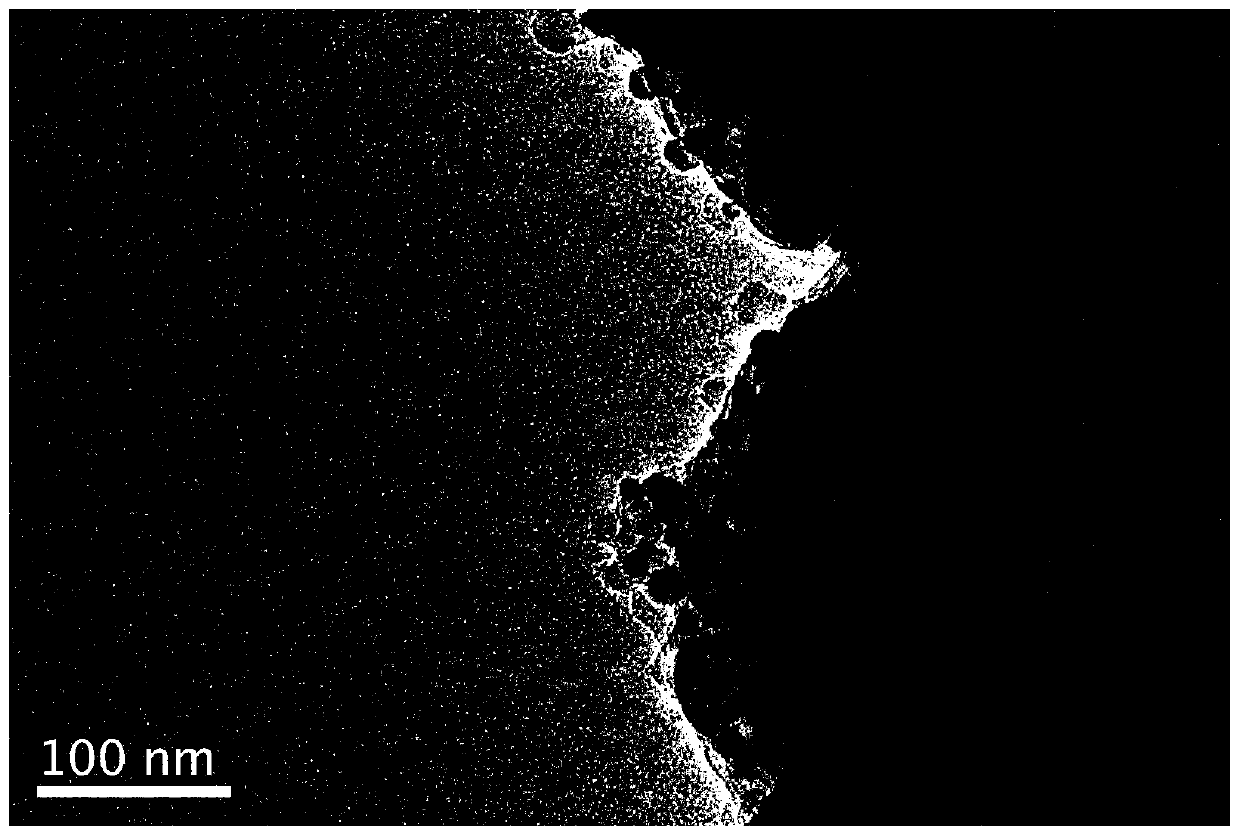

Ni@MoC/NMC catalyst for reducing biological plasticizer neopentyl glycol dibenzoate and preparation method

InactiveCN111841591AGood dispersionEvenly dispersedOrganic compound preparationCarboxylic acid esters preparationBenzoic acidPolymer science

The invention belongs to the technical field of catalysis, and particularly relates to a Ni@MoC / NMC catalyst for reducing a biological plasticizer neopentyl glycol dibenzoate and a preparation method.The Ni@MoC / NMC catalyst disclosed by the invention is synthesized by adopting a one-step method. An active center is embedded into a carrier by mainly utilizing a template under the action of a carbon-containing ligand. The catalyst prepared by the method is low in cost, high in activity and good in stability, and the Ni@MoC / NMC catalyst is large in specific surface area, high in active componentdispersity and good in reaction activity and selectivity.

Owner:RUNTAI CHEM TAIXING CO LTD

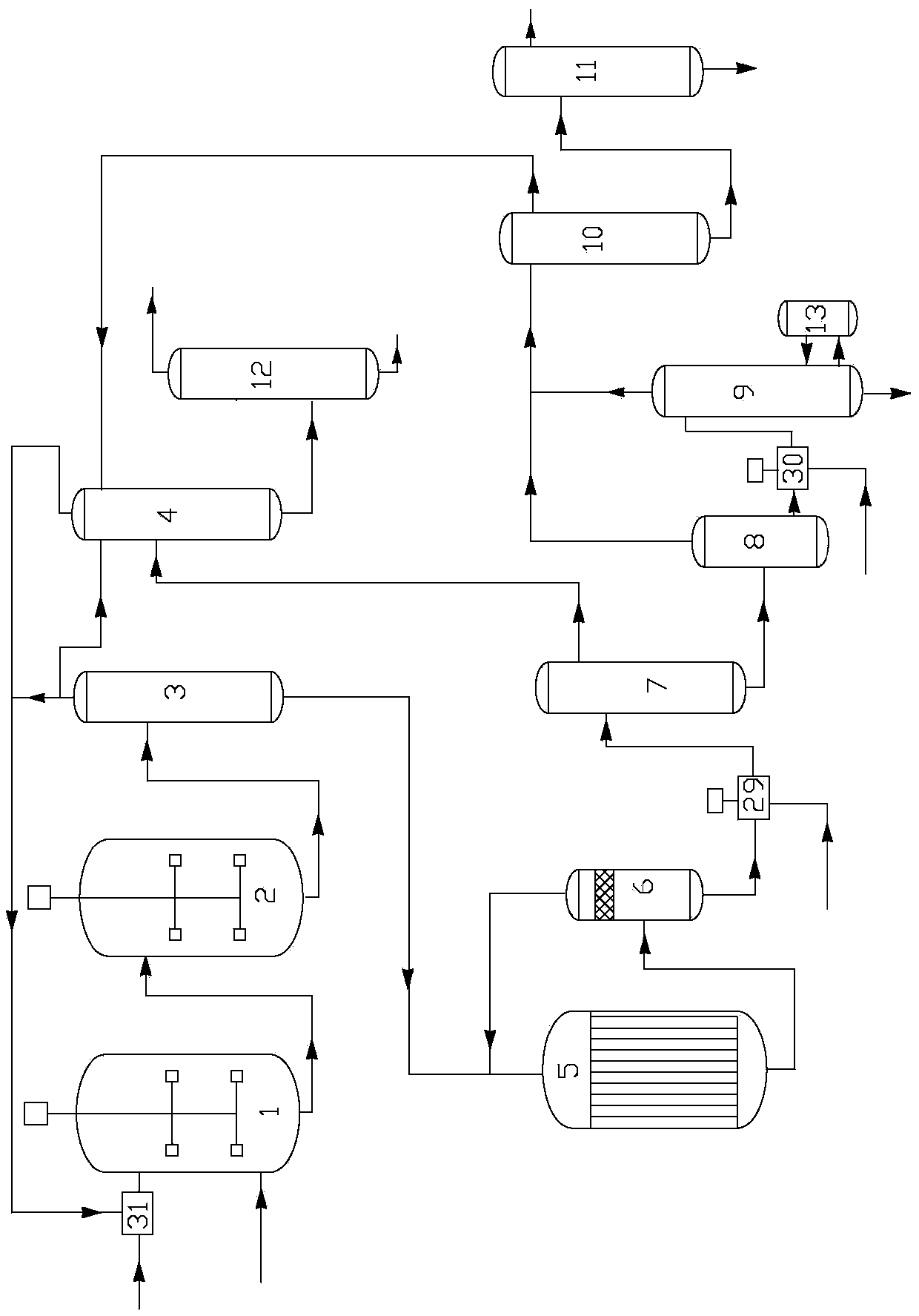

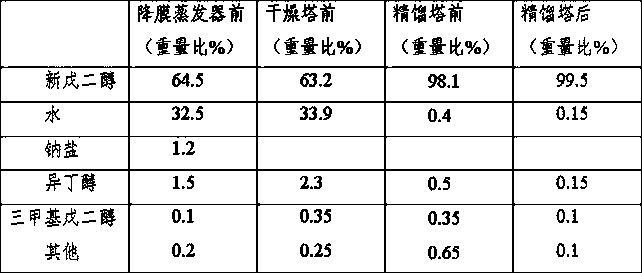

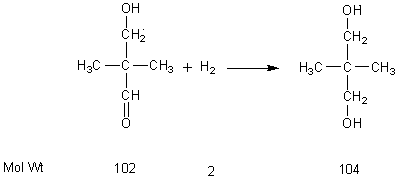

Neopentyl glycol condensation hydrogenation production process and its equipment

ActiveCN103130611BHigh yieldGood hydrogenation effectOrganic compound preparationHydroxy compound separation/purificationGas phaseSaponification

The invention discloses a neopentyl glycol condensation hydrogenation production process which comprises the following steps of: 1) condensation, that is, performing a condensation reaction of isobutyraldehyde with a methanol aqueous solution of formaldehyde, delivering the mixed condensation products into a condensation circulation tower for separation, allowing hydroxypivalaldehyde to enter a hydrogenation reactor from the condensation circulation tower, allowing a gas-phase component to flow back to a raw material mixing zone for mixing, and to enter a condensation reactor; 2) hydrogenation, that is, performing a hydrogenation reaction of the hydroxypivalaldehyde with hydrogen, delivering the products into a gas-liquid separation tank, allowing a gas-phase component to flow back to the hydrogenation reactor, allowing the liquid-phase neopentyl glycol crude product to enter a saponification reactor; 3) refining, that is, performing a saponification reaction of the neopentyl glycol crude product, allowing the product to enter a low-boiling-point substance fractionating tower, allowing a liquid-phase component at the tower bottom to enter a flash tank, allowing a liquid-phase component at the flash tank bottom to enter a pH adjusting tank, adjusting the pH to 6.5-7, allowing the product to enter a falling film evaporator, allowing a gas-phase component at the top of the falling film evaporator to enter a drying tower, then to enter a rectifying tower for refining so as to obtain neopentyl glycol. The process of the invention is high in neopentyl glycol yield, and simple and effective in separation purification process.

Owner:SHANDONG HUALU HENGSHENG CHEM IND

Ni2P/NC catalyst, and preparation method and application thereof

ActiveCN110813352AEvenly distributedLarge specific surface areaPhysical/chemical process catalystsOrganic compound preparationHydration reactionPtru catalyst

The invention relates to the technical field of catalysts, and concretely relates to a Ni2P / NC catalyst for producing 1,2-cyclohexane dioctyl phthalate, and a preparation method and an application thereof. The preparation method of the Ni2P / NC catalyst comprises the following steps: mixing water and ethanol, adding a polyoxyethylene polyoxypropylene ether block copolymer, and performing stirring and mixing; adding dopamine, performing stirring, adding nickel nitrate hexahydrate, and performing stirring; adding hydrochloric acid, and performing stirring; continuously adding mesitylene, and performing stirring; slowly dropwise adding ammonia water; and centrifugally separating the obtained solution, washing and drying the obtained reaction product, and carrying out phosphatizing reduction onthe reaection product to obtain the product. The Ni2P / NC catalyst prepared by the method has the advantages of large specific surface area, good dispersity and low production cost.

Owner:RUNTAI CHEM TAIXING CO LTD +1

Nickel-based catalyst and preparation method therefor

ActiveCN105080594AHigh activityStrong low temperature hydrogenation activityMolecular sieve catalystsRefining by selective hydrogenationActive componentTitanium oxide

The present invention relates to a nickel-based catalyst. The catalyst is prepared by loading metallic nickel active components on a composite carrier which consists of an aluminum oxide-titanium oxide complex and ZSM-5, wherein in the catalyst, a weight ratio of aluminum oxide and titanium oxide is 4:1; a content of nickel oxide is 12%-20% by weight; the aluminum oxide-titanium oxide takes 30%-70% of the entire composite carrier by weight, the ZSM-5 takes 30%-70% of the entire composite carrier by weight; the surface area of the catalyst is 90-260 m 2 / g; and the pore volume is 0.5-1.5 ml / g. The catalyst has characteristics of good low-temperature hydrogenation activity, strong anti-impurity ability and sol ability, a long regeneration cycle, and good stability. Applying the catalyst to a process in which diene is converted to monoolefins through selective hydrogenation can maintain a good hydrogenation effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

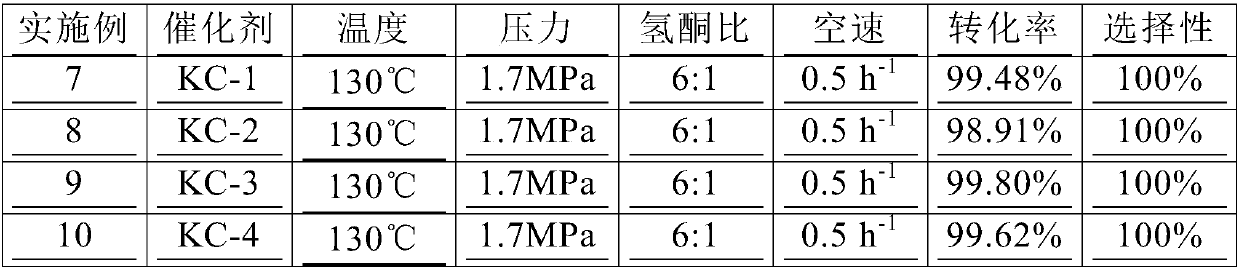

Methyl isobutyl ketone low-temperature hydrogenation catalyst, preparation method and applications thereof

ActiveCN110871080AReproducibleLarge operating windowOrganic compound preparationHydroxy compound preparationMethyl isobutyl ketonePtru catalyst

The invention discloses a methyl isobutyl ketone low-temperature hydrogenation catalyst, a preparation method and applications thereof. The catalyst is prepared from the following components in partsby weight: 10-25 parts of nickel, 0.5-3 parts of lead, and 72-89.5 parts of a lanthanum-modified aluminum oxide carrier based on 100 parts of total weight of the catalyst, wherein the content of lanthanum in the carrier is 1-5 wt%. The catalyst disclosed by the invention is good in stability, and has high activity and high selectivity at a low temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low temperature polysilicon thin film transistor and its manufacturing method

ActiveCN105655404BIncrease profitFacilitated DiffusionTransistorSemiconductor/solid-state device manufacturingDielectricBiological activation

The invention relates to a low-temperature polycrystalline silicon thin film transistor and a preparation method thereof. The method comprises the following steps: providing a substrate; depositing a buffering layer and a non-crystalline silicon layer on the substrate in sequence, and performing laser radiation to change the non-crystalline silicon layer into a polycrystalline silicon layer which is an active layer; depositing a first grid insulating layer, a second grid insulating layer and a first metal layer on the buffering layer and the active layer in sequence, performing high-temperature activation, and photoetching and etching the first metal layer to form a grid; depositing dielectric layers on the grid insulating layers and the grid; depositing first contact holes and second contact holes in the dielectric layers, the first grid insulating layer and the second grid insulating layer; and respectively depositing source electrodes and drain electrodes on the first contact holes and the second contact holes. The thin film transistor prepared by the method can effectively overcome the structural defects of polycrystalline silicon, and the performance of the thin film transistor can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

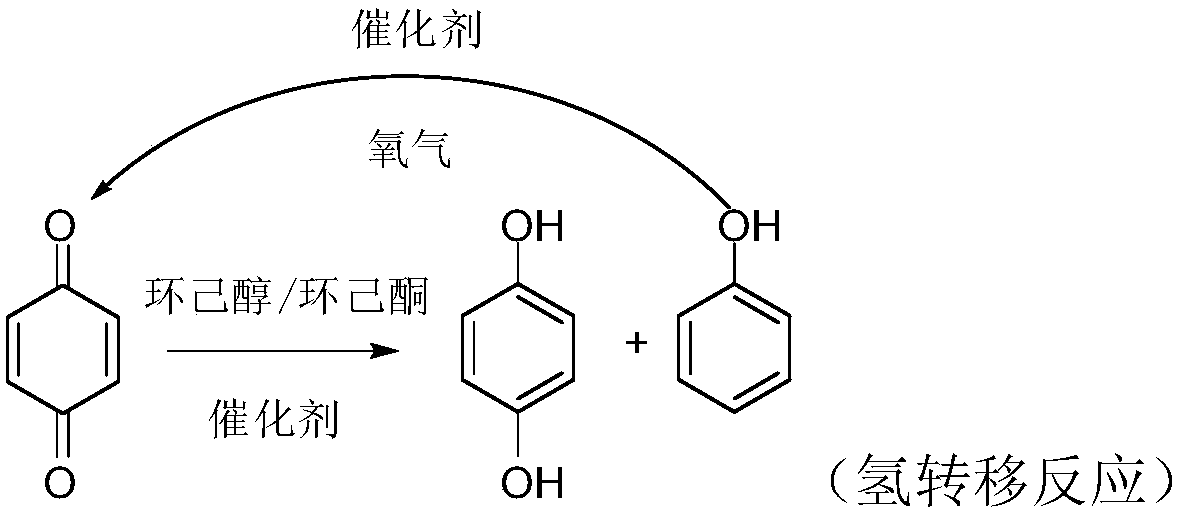

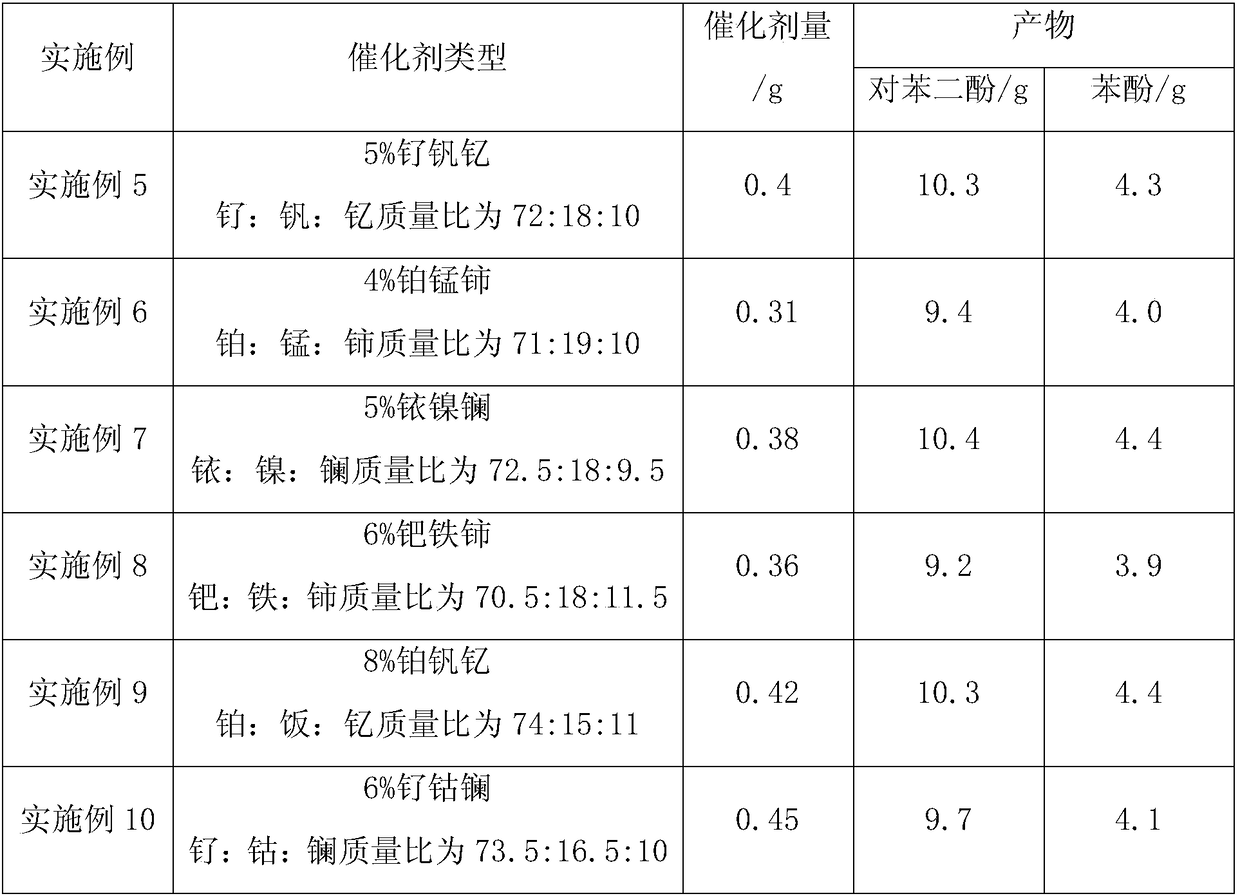

A kind of comprehensive utilization method of ketone alcohol mixture

ActiveCN106278826BGood hydrogenation effectNo security riskOrganic compound preparationQuinone preparation by oxidationCyclohexanoneAlcohol

The invention provides a method of using a cyclohexanol / cyclohexanone mixture as a raw material to prepare hydroquinone. According to the method, the cyclohexanol / cyclohexanone mixture is utilized as the raw material, the hydrogen isn't utilized as a hydrogen source, a catalyst is utilized to convert the hydrogen portion on the cyclohexanol and the cyclohexanone to benzoquinone to be synthesized into hydroquinone, the cyclohexanol and the cyclohexanone are partially converted into phenol at the same time, the separated and obtained phenol is utilized as a raw material to obtain benzoquinone through oxidation reaction, and the benzoquinone can generate hydrogen transfer reaction with the unreacted cyclohexanol and the unreacted cyclohexanone to synthesize hydroquinone. Thus, the phenol and benzoquinone circulation in the whole process is achieved, finally the comprehensive utilization of the cyclohexanol / cyclohexanone mixture is achieved, and the relative cheap cyclohexanol / cyclohexanone mixture is utilized as the raw material to prepare the hydroquinone with high added value.

Owner:YANGZHOU POLYTECHNIC INST +2

a ni 2 Preparation method of p/nc catalyst, ni2p/nc catalyst and its application

ActiveCN110813352BEvenly distributedLarge specific surface areaPhysical/chemical process catalystsOrganic compound preparationHydration reactionPtru catalyst

The invention relates to the technical field of catalysts, in particular to Ni 2 The preparation method of P / NC catalyst, Ni 2 P / NC catalyst and its application. Ni of the present invention 2 The preparation method of the P / NC catalyst comprises mixing water and ethanol, then adding polyoxyethylene polyoxypropylene ether block copolymer, stirring and mixing; adding dopamine, stirring, adding nickel nitrate hexahydrate, and stirring; then adding hydrochloric acid, and stirring; Continue to add mesitylene and stir; slowly drop ammonia water; centrifuge the above-prepared solution, wash, and finally dry and phosphate the product obtained by the above-mentioned reaction to obtain the product. Ni prepared by the present invention 2 The P / NC catalyst has large specific surface area, good dispersion and low production cost.

Owner:RUNTAI CHEM TAIXING CO LTD +1

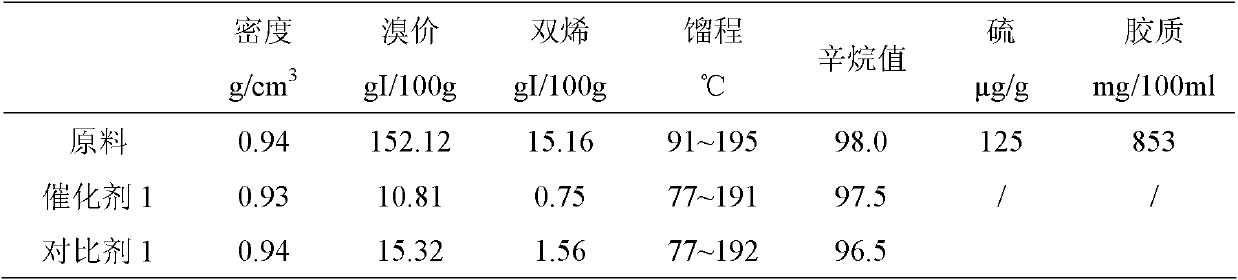

Saturation and hydrogenation method of C9 fraction through cracking by petroleum hydrocarbons

ActiveCN102994145BImprove hydrogenation activityImprove thermal stabilityCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsSulfurHydrogenation reaction

The invention relates to a saturation and hydrogenation method of C9 fraction through cracking by petroleum hydrocarbons, a catalyst is a nickel-based hydrogenation catalyst, a hydrogenation technology is characterized in that the inlet temperature of a reactor is 30-50 DEG C, the reaction pressure is 2.7-4.0MPa, the liquid volume space velocity is 2.0-4.5h<-1>, the volume ratio of hydrogen to oil is 100 to 400, and the catalyst comprises a main active ingredient Ni, an assisted active ingredient Mg, Mo, Sn, X1 and X2. The preparation method is employed to obtain the nickel-based saturation hydrogenation catalyst, the hydrogenation condition of the present invention is used for acquiring especially excellent hydrogenation effect, the hydrogenation catalyst has high hydrogenation activity, the hydrogenation reaction is carried out under low temperature, and the hydrogenation catalyst has the characteristics of good heat stability, sulfur resistance and colloid resistance, and is suitable for saturation and hydrogenation of the C9 fraction through cracking by petroleum hydrocarbons.

Owner:PETROCHINA CO LTD

Methyl isobutyl ketone high-space-velocity hydrogenation catalyst, preparation method and applications thereof

InactiveCN110871073AReproducibleLarge operating windowOrganic compound preparationHydroxy compound preparationPtru catalystSulfate radicals

The invention discloses a methyl isobutyl ketone high-space-velocity hydrogenation catalyst, a preparation method and applications thereof. The catalyst is prepared from the following components in parts by weight: 12-26 parts of cobalt and 70-88 parts of a zirconium-modified alumina carrier based on 100 parts of the total weight of the catalyst, wherein the zirconium-modified aluminum oxide is analuminum oxide carrier formed by molding pseudo-boehmite powder, the pseudo-boehmite powder is prepared by using an aluminum sulfate solution containing a soluble zirconium salt as a raw material through an aluminum sulfate-sodium metaaluminate method, the zirconium content in the aluminum oxide carrier is 1-8 wt%, and the sulfate ion content is less than 0.4 wt%. The catalyst disclosed by the invention is good in stability, and has high activity and high selectivity at a low temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

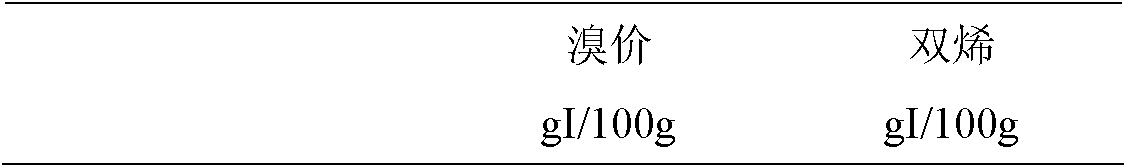

Saturation and hydrogenation method of C4 and C5 fraction through cracking by petroleum hydrocarbons

ActiveCN102994143BImprove hydrogenation activityImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentHydrogenation reactionHeat stability

The invention relates to a saturation and hydrogenation method of C4 and C5 fraction through cracking by petroleum hydrocarbons, a catalyst is a nickel-based hydrogenation catalyst, a hydrogenation technology condition is characterized in that the inlet temperature of a reactor is 30-50 DEG C, the reaction pressure is 1.0-4.0MPa, the liquid volume space velocity is 1.0-5.0h<-1>, the volume ratio of hydrogen to oil is 100 to 400, and the nickel-based hydrogenation catalyst is prepared by using a coprecipitation method. The nickel-based hydrogenation catalyst comprises a main active ingredient Ni, an assisted active ingredient Mg, Mo, Sn, X1 and X2. The catalyst has high hydrogenation activity, the hydrogenation reaction is carried out under low temperature, and the catalyst has characteristics of good heat stability, water resistance and coking resistance. The hydrogenation method can obtain especially excellent hydrogenation effect, and is suitable for saturation and hydrogenation of the C4 and C5 fraction through cracking by petroleum hydrocarbons.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com