A preparing method of a mercaptan etherification catalyst

A catalyst, etherification technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Divided into the problems of easy loss of phosphoric acid and polyphosphoric acid, and high catalyst carbon deposition, to achieve good hydrogenation effect, improve the ability and stability of carbon deposition resistance, and weaken the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Set the specific surface area to 100 m 2 / g, the pore volume is 0.5 cm 3 / g, spherical Al with an average pore size of 50 nm 2 o 3 K 2 O / Al 2 o 3 carrier;

[0031] (2) Add ammonium molybdate, nickel nitrate, and citric acid and phosphoric acid into deionized water, stir well, and make an impregnation solution; the amount of compound additive is 0.5 times the mass of ammonium molybdate and nickel nitrate , the mass content of citric acid in the composite auxiliary agent is 60%, and the mass content of phosphoric acid is 40%;

[0032] (3) K obtained in step (1) 2 O / Al 2 o 3 The impregnating solution in the carrier impregnation step (2) was 0.5 h, dried at 100 °C for 10 h and calcined at 300 °C for 4 h to obtain NiO-MoO 3 -K 2 O / Al 2 o 3 catalyst.

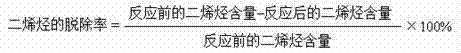

[0033] The mass content of each component in the catalyst that present embodiment obtains is: NiO is 15%, MoO 3 5%, K 2 O is 0.5%, the rest is Al 2 o 3 , the activity of the catalyst is shown in Table 1. ...

Embodiment 2

[0035] (1) Set the specific surface area to 50 m 2 / g, the pore volume is 0.3 cm 3 / g, powdered Al with an average pore size of 100 nm 2 o 3 The carrier was impregnated with potassium nitrate solution, dried at 100 °C for 10 h and calcined at 300 °C for 4 h to obtain K 2 O / Al 2 o 3 carrier;

[0036] (2) Add ammonium molybdate and nickel chloride, and composite additives composed of citric acid and phosphoric acid into deionized water, stir evenly, and make an impregnation solution; the amount of composite additives is the quality of ammonium molybdate and nickel chloride 2 times, the mass content of citric acid in the compound additive is 10%, and the mass content of phosphoric acid is 90%;

[0037] (3) K obtained in step (1) 2 O / Al 2 o 3 The impregnation solution in the carrier impregnation step (2) was 0.1 h. After the impregnation, it was dried at 100 °C for 10 h and calcined at 200 °C for 4 h to obtain NiO-MoO 3 -K 2 O / Al 2 o 3 catalyst.

[0038] The mass co...

Embodiment 3

[0040] (1) Set the specific surface area to 200 m 2 / g, the pore volume is 1.0 cm 3 / g, flake Al with an average pore size of 10 nm 2 o 3 The carrier was impregnated with potassium hydroxide solution, dried at 100 °C for 10 h and calcined at 600 °C for 4 h to obtain K 2 O / Al 2 o 3 carrier;

[0041] (2) Add molybdenum oxide, nickel sulfate, and composite additives composed of citric acid and urea into deionized water, stir evenly, and make an impregnation solution; the amount of composite additives is 0.1 times the mass of molybdenum oxide and nickel sulfate, compound The mass content of citric acid in the auxiliary agent is 90%, and the mass content of urea is 10%;

[0042] (3) K obtained in step (1) 2 O / Al 2 o 3 The impregnation solution in the carrier impregnation step (2) was used for 1 h, dried at 100 °C for 10 h and calcined at 400 °C for 4 h to obtain NiO-MoO 3 -K 2 O / Al 2 o 3 catalyst.

[0043] The mass content of each component in the catalyst that presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com