Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Enhanced charcoal capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

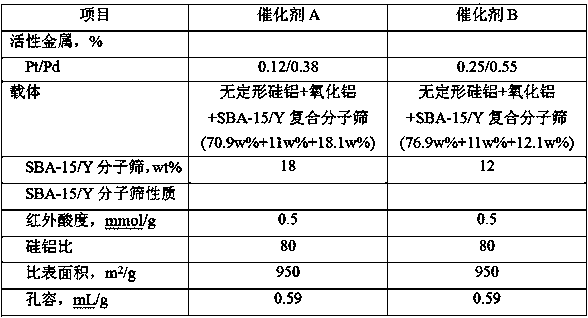

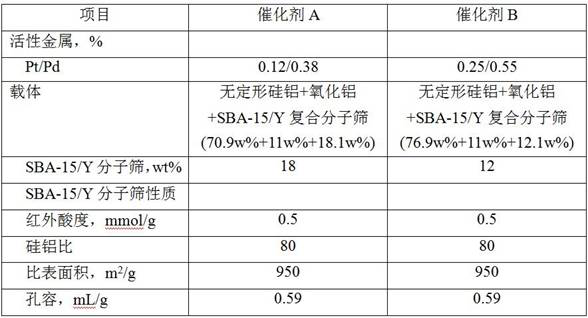

Hydrogenation dearomatization catalyst and preparation method thereof

ActiveCN104588073AHigh activityFacilitates selective loop openingMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveNaphtha

The invention discloses a hydrogenation dearomatization catalyst and a preparation method thereof. The catalyst comprises a main active component Pt, an auxiliary component Pd and a carrier prepared from a small-grain Y type molecular sieve, alumina and amorphous silicon aluminum. According to the preparation method, the small-grain Y type molecular sieve with the characteristics of great dealumination depth, good crystallinity retentivity and well-developed secondary pores is used as an acid component and cooperates with the amorphous silicon aluminum, the main active component and the auxiliary component, so the hydrogenation dearomatization catalyst has higher hydrogenation dearomatization activity and is especially applicable to hydrogenation dearomatization and decoloring of heavy aromatic-containing naphthenic high-viscosity white oil and solvent naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

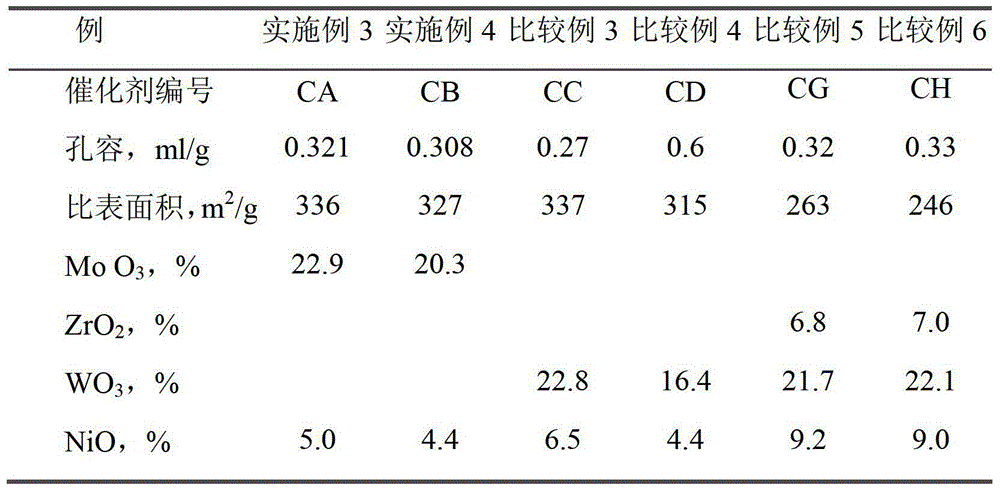

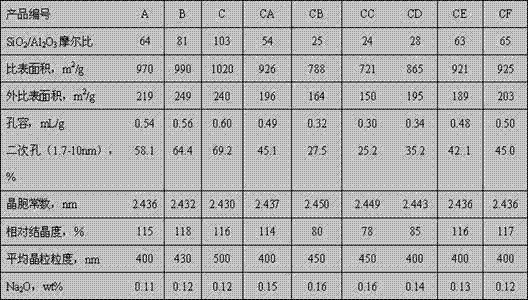

Composite molecular sieve-containing medium oil type hydrocracking catalyst, preparation method and application thereof

ActiveCN103551186BHigh crystallinityIncrease surface areaMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

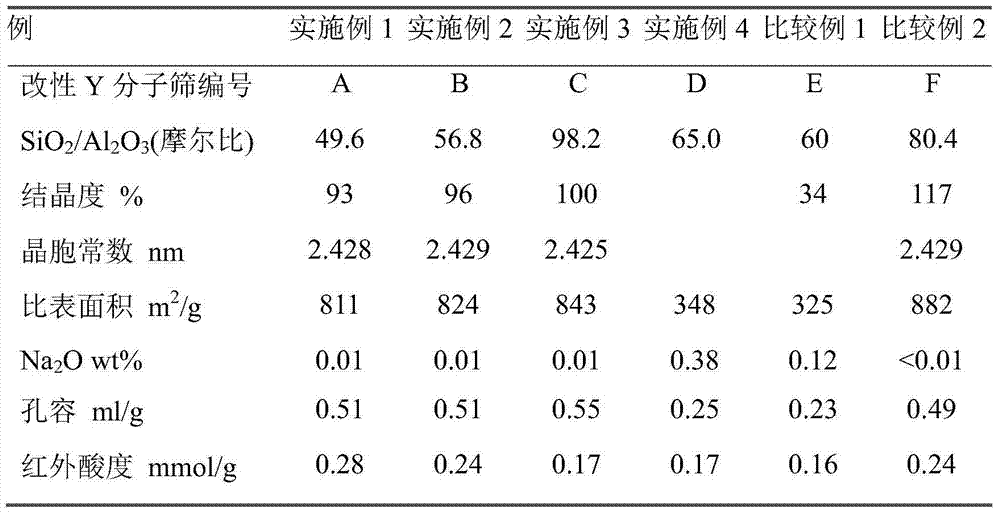

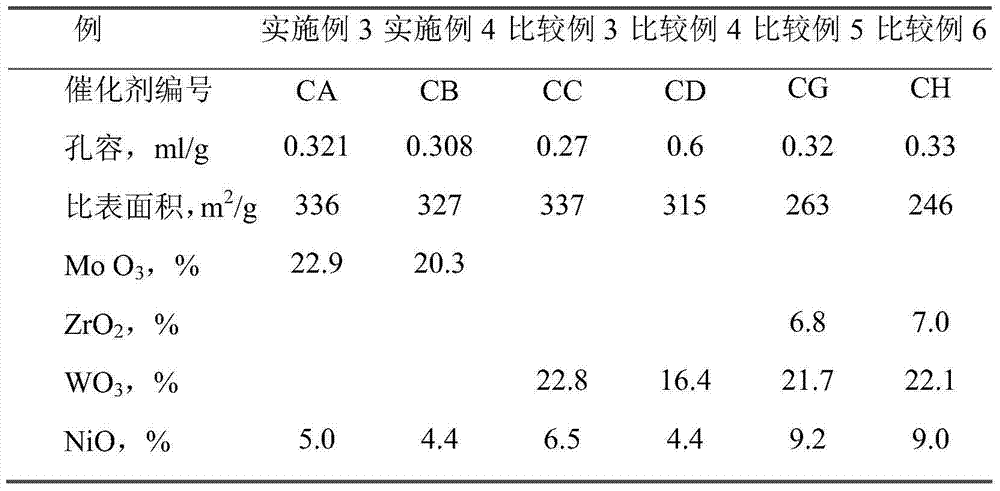

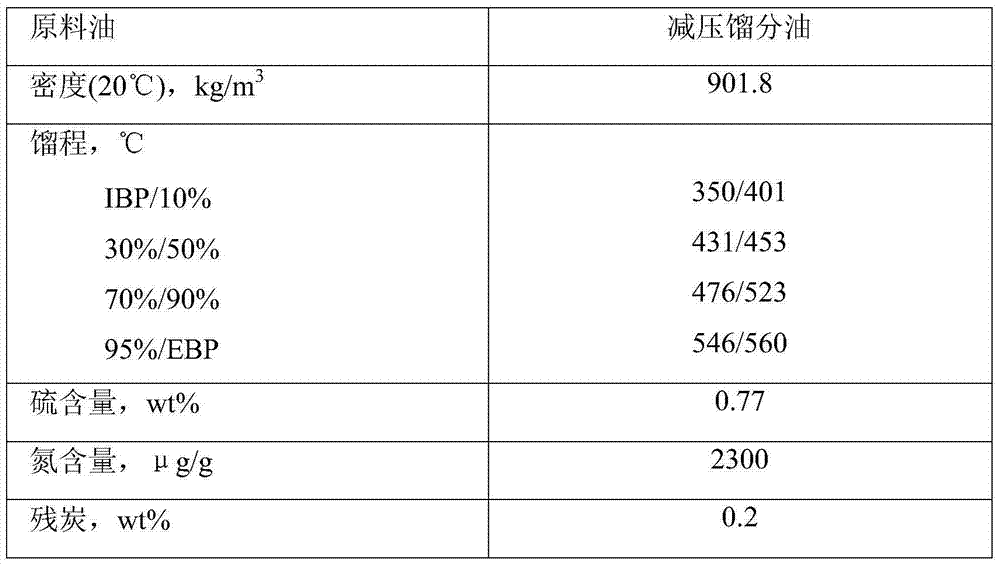

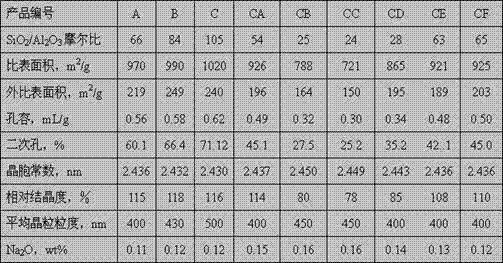

The invention relates to a composite molecular sieve-containing medium oil type hydrocracking catalyst, which comprises an active component and a binder, wherein the active component adopts amorphous SiO2-Al2O3 as a carrier, adopts a composite molecular sieve as an acid component, and adopts a group VIB metal and a group VIII metal as hydrogenation activity components, and the composite molecular sieve comprises a Y molecular sieve and a ZSM-23 molecular sieve. According to the present invention, the deep dealuminzation modified Y molecular sieve has characteristics of high crystallinity, large surface area, high silica-alumina ratio, low cell constant, rich secondary pore, low acid center density, high moderate-intensity acid center ratio, and the like; the modified ZSM-23 molecular sieve has characteristics of smooth pore channel, less acid center and outstanding isomerism performance, wherein a light naphtha component is isomerized so as to increase an octane number of naphtha; the composite molecular sieve compounded from the Y molecular sieve and the ZSM-23 molecular sieve is adopted as the acid cracking component so as to provide advantages of the Y molecular sieve and the ZSM-23 molecular sieve, and compounding is performed according to the ratio of the present invention, such that the best catalysis effect can be obtained, and the obtained catalyst is suitable for the medium oil type hydrocracking catalyst; and the catalyst prepared from the composite molecular sieve has characteristics of excellent medium oil selectivity, good activity and good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Aluminium oxide carrier containing magnesium and phosphor and preparing method

InactiveCN101069853AStrong anti-coking abilityHigh activityMetal/metal-oxides/metal-hydroxide catalystsLarge poreChemistry

The present invention discloses an aluminium oxide carrier which contains magnesium and phosphorus, also can contain potassium and its preparation method. The magnesium, phosphorus and potassium can be added in the process of preparation. Said carrier is low in acidity and has large pore volume and large specific surface area. The catalyst prepared by using said carrier has the features of strong anti-coking property and good stability.

Owner:林方 +3

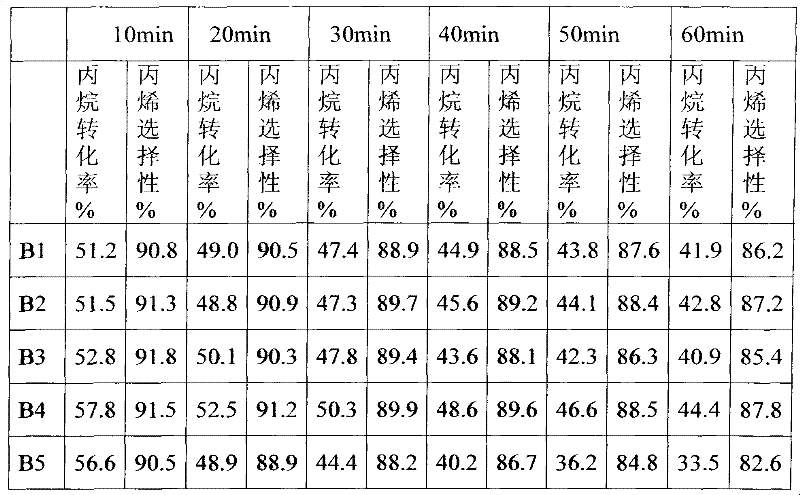

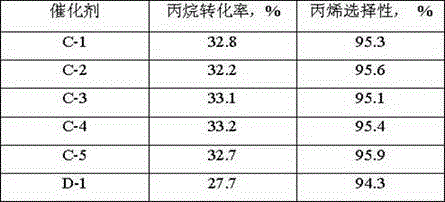

Low-carbon alkane dehydrogenation catalyst and preparation method thereof

ActiveCN101940922BEvenly distributedEnhanced charcoal capacityCatalyst activation/preparationHydrocarbonsAlkaneDehydrogenation

Owner:CHINA PETROLEUM & CHEM CORP +1

Modification treatment method and application of HZSM-5 molecular sieve catalyst

ActiveCN106215970AExtend your lifeImprove pore structureMolecular sieve catalystsMolecular sieve catalystMolecular sieveWater vapor

The invention discloses an HZSM-5 molecular sieve catalyst. The HZSM-5 molecular sieve catalyst is based on HZSM-5 molecular sieve which is commonly used in low-carbon hydrocarbon aromatization technology, and the HZSM-5 molecular sieve is subjected to a post-treatment by means of alkali / water vapor double-modification method which comprises the following steps that the HZSM-5 molecular sieve catalyst is added to the alkaline solution for a treatment, then a water vapor treatment is carried out to prepare the modification catalyst. Compared with an unmodified catalyst, the modification catalyst has the advantages that after the molecular sieve is treated by alkali, framework silicon is removed, the framework pore structure is enlarged and a portion of mesopores are formed, therefore the ability to hold carbons is improved; after the molecular sieve is treated by water vapor, framework aluminum is removed and the acidity ratio is adjusted and changed, therefore the ability to resist carbon deposition is enhanced. Accordingly, the modification catalyst is capable of enhancing effectively the stability of the catalyst, greatly prolonging the service life of the catalyst and exhibiting a better reaction performance of low-carbon hydrocarbon aromatization while increasing the aromatization activity.

Owner:TAIYUAN UNIV OF TECH

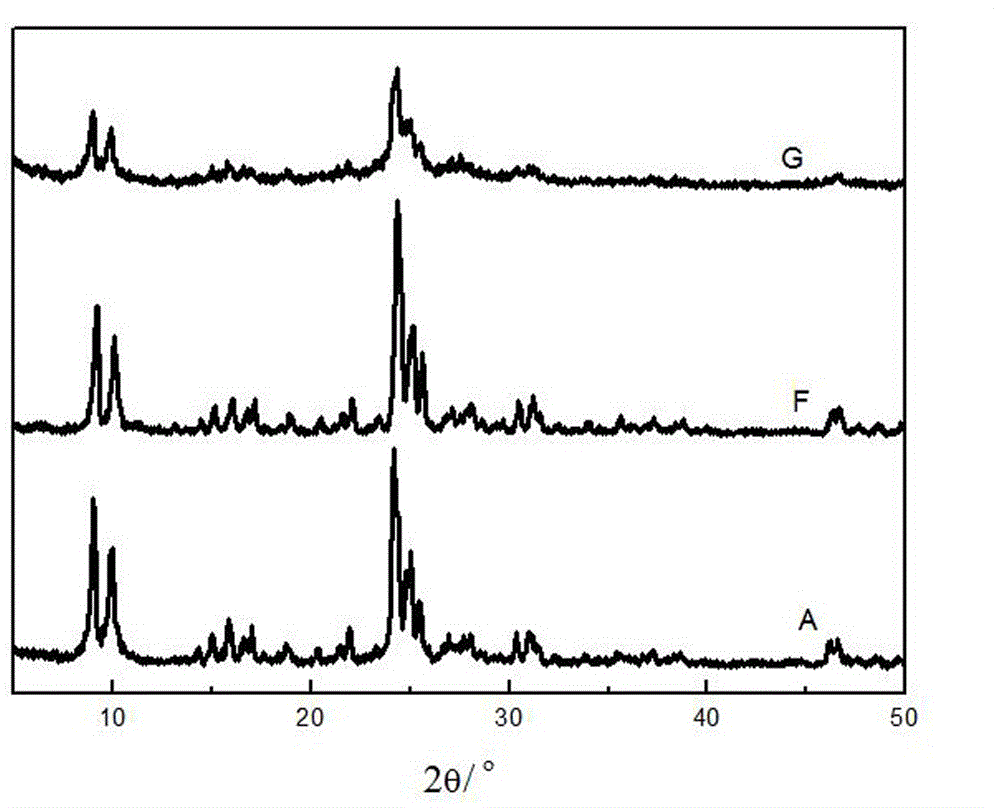

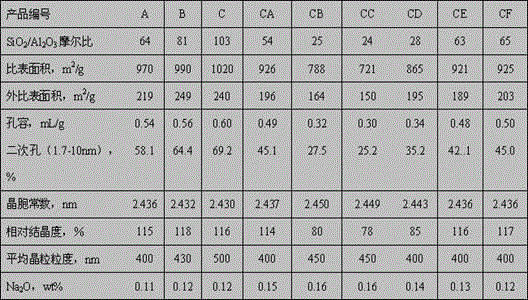

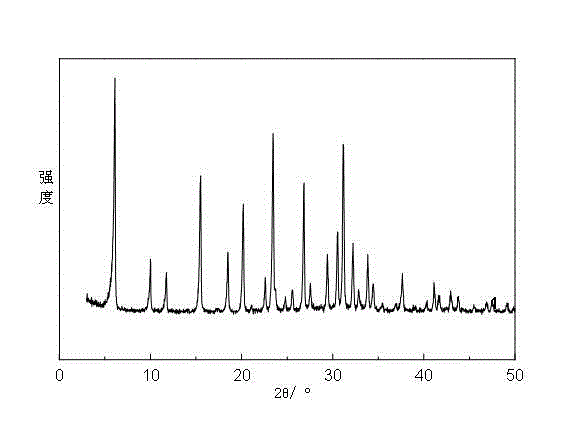

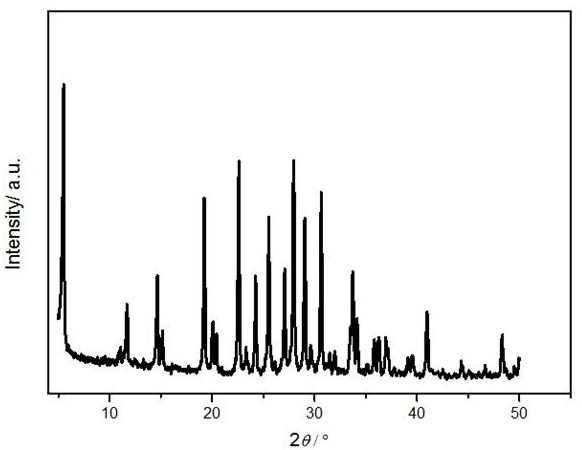

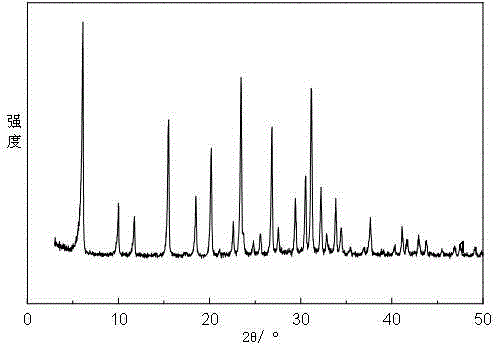

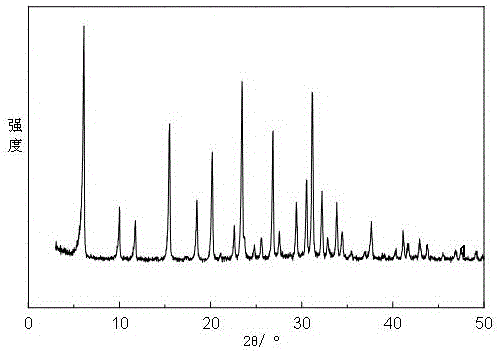

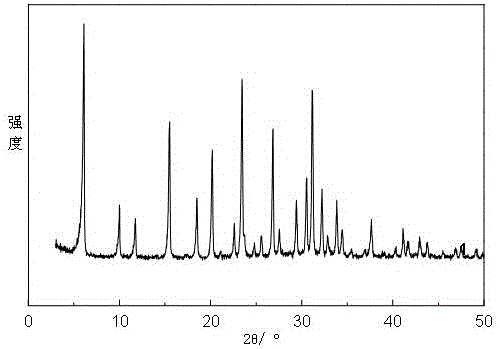

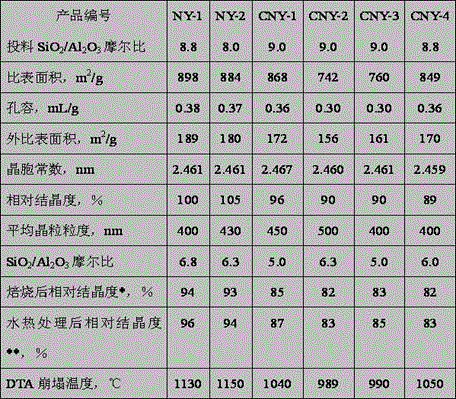

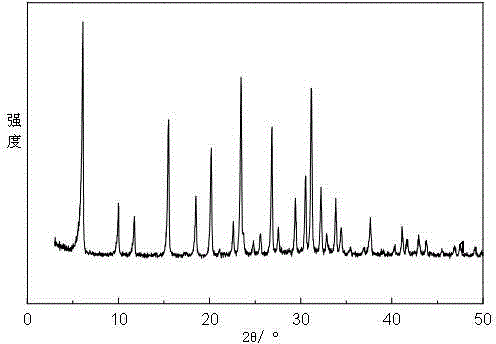

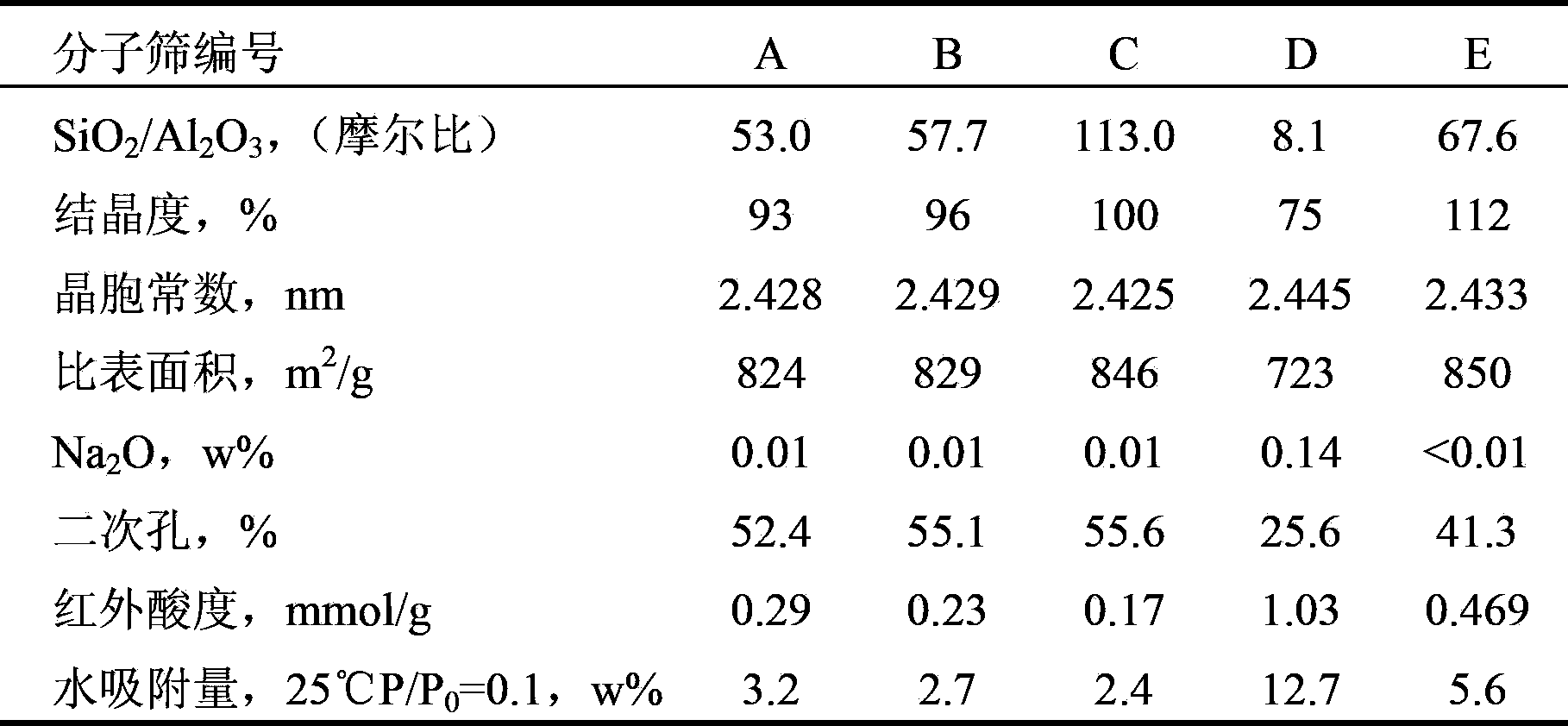

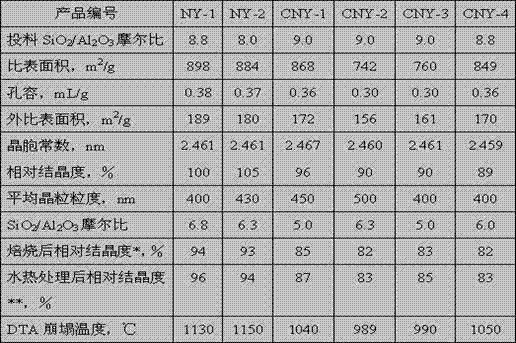

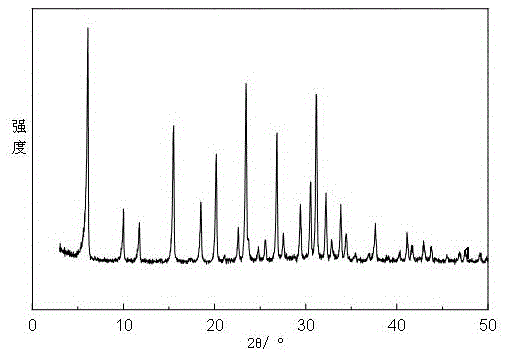

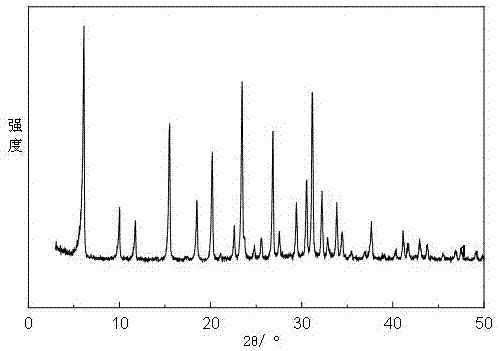

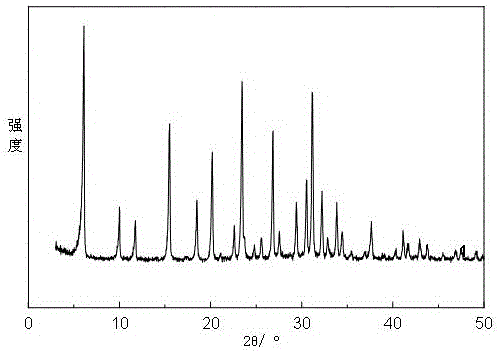

Deep sealumination modified Y zeolite preparation method

ActiveCN1951816AStable structureHigh crystallinityMolecular sieve catalystsFaujasite aluminosilicate zeoliteHigh densityCrystallinity

The invention discloses a preparing method of deep aluminium-stripping Y-zeolite, which comprises the following steps: adopting NH4NaY with the content of Na2O not more than 2.5w%; proceeding first water heat disposal; utilizing high-density H+ ammonium salt solution to exchange to strip aluminium; proceeding second water heat disposal; removing non-frame aluminium through acid solution; setting the disposing temperature of second water heat disposal higher than the first one; improving crystallinity and silicon-aluminium rate with abundant secondary hole.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite molecular sieve-containing medium oil type hydrocracking catalyst, preparation method and application thereof

ActiveCN103551186AHigh crystallinityIncrease surface areaMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention relates to a composite molecular sieve-containing medium oil type hydrocracking catalyst, which comprises an active component and a binder, wherein the active component adopts amorphous SiO2-Al2O3 as a carrier, adopts a composite molecular sieve as an acid component, and adopts a group VIB metal and a group VIII metal as hydrogenation activity components, and the composite molecular sieve comprises a Y molecular sieve and a ZSM-23 molecular sieve. According to the present invention, the deep dealuminzation modified Y molecular sieve has characteristics of high crystallinity, large surface area, high silica-alumina ratio, low cell constant, rich secondary pore, low acid center density, high moderate-intensity acid center ratio, and the like; the modified ZSM-23 molecular sieve has characteristics of smooth pore channel, less acid center and outstanding isomerism performance, wherein a light naphtha component is isomerized so as to increase an octane number of naphtha; the composite molecular sieve compounded from the Y molecular sieve and the ZSM-23 molecular sieve is adopted as the acid cracking component so as to provide advantages of the Y molecular sieve and the ZSM-23 molecular sieve, and compounding is performed according to the ratio of the present invention, such that the best catalysis effect can be obtained, and the obtained catalyst is suitable for the medium oil type hydrocracking catalyst; and the catalyst prepared from the composite molecular sieve has characteristics of excellent medium oil selectivity, good activity and good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

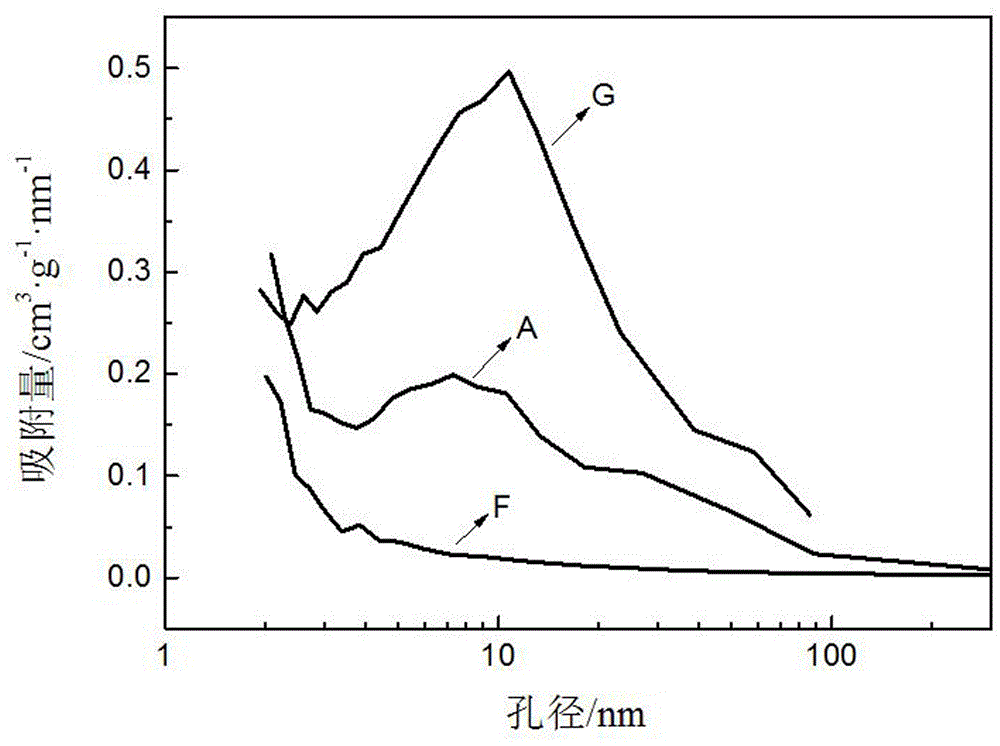

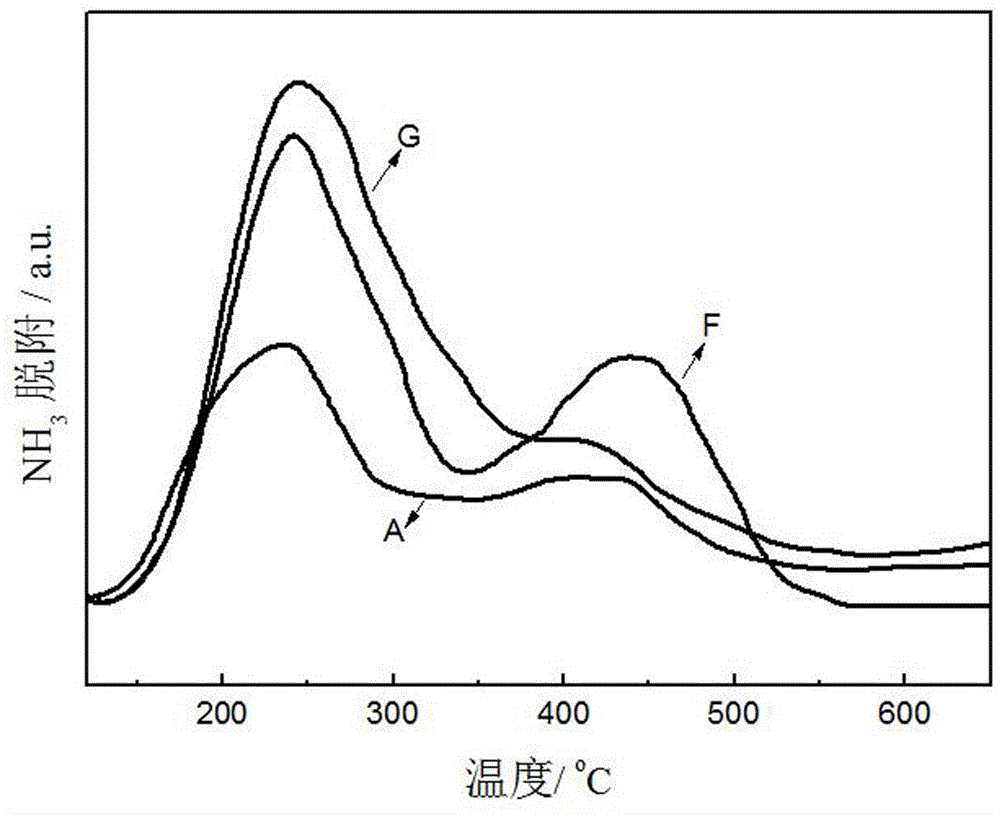

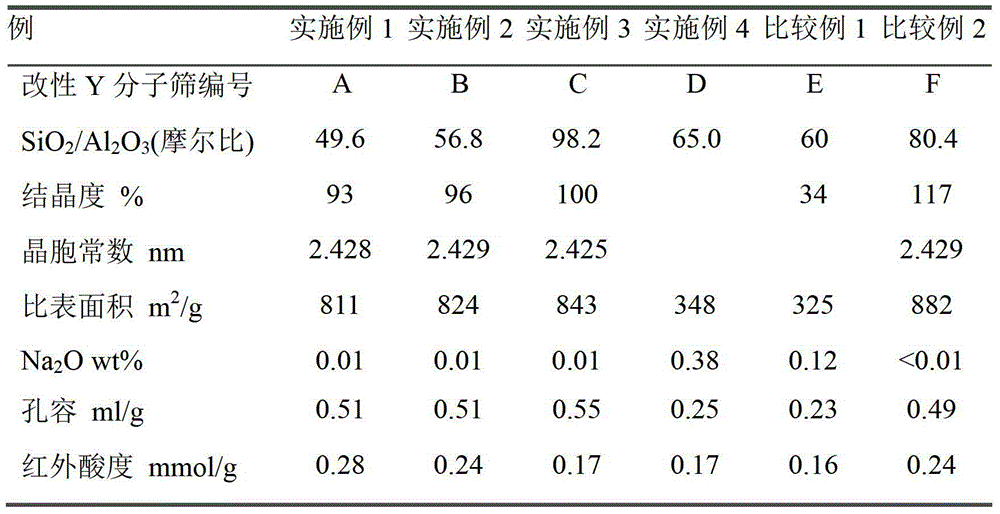

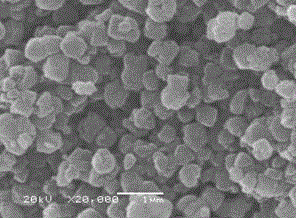

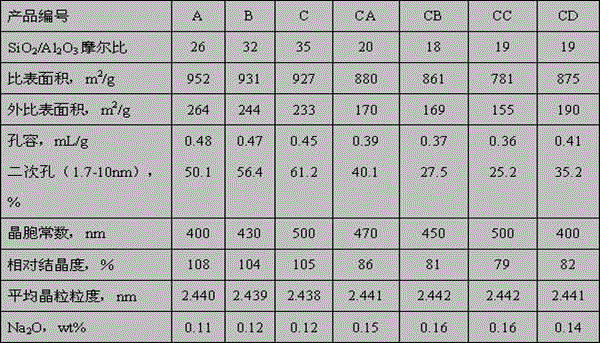

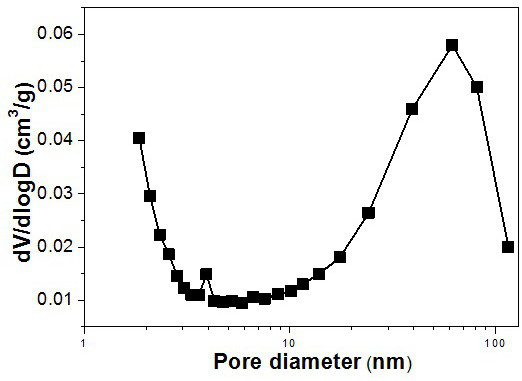

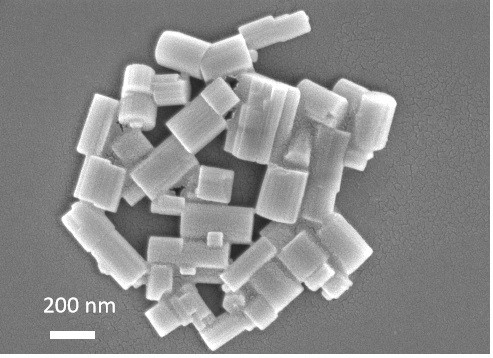

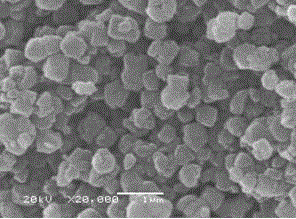

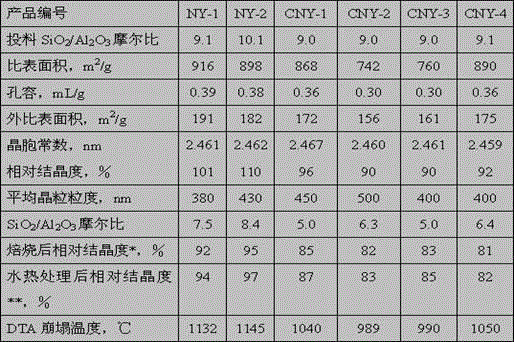

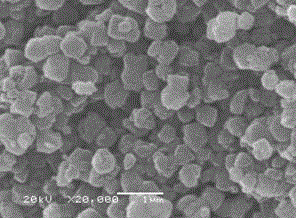

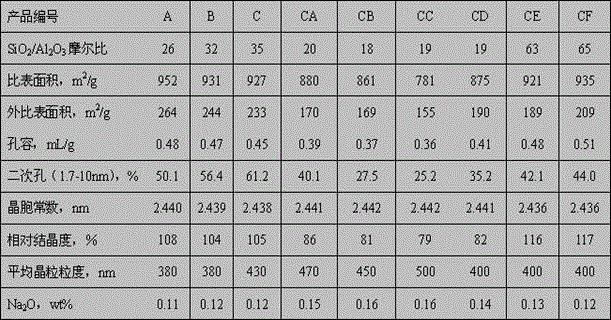

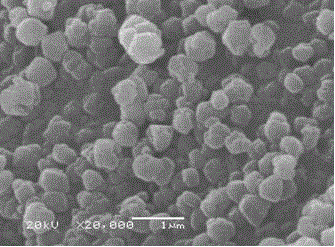

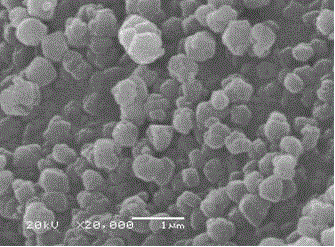

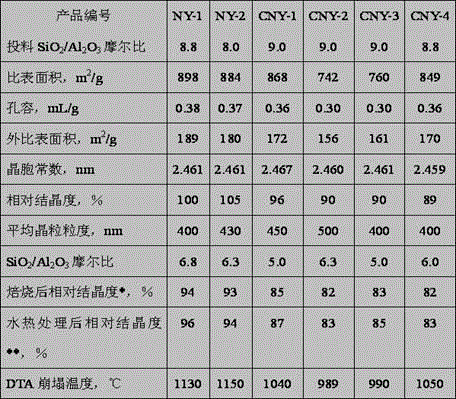

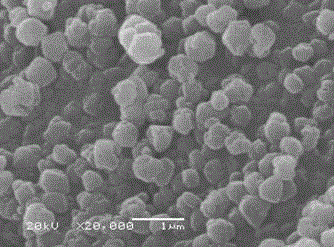

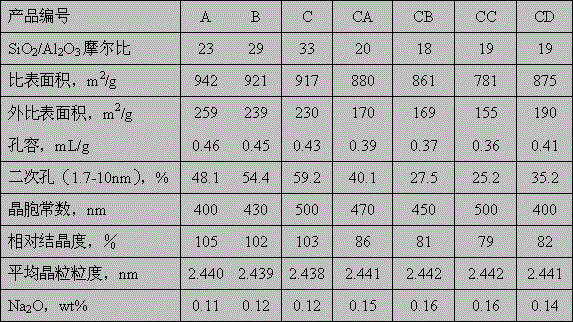

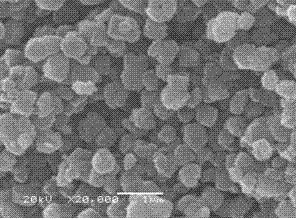

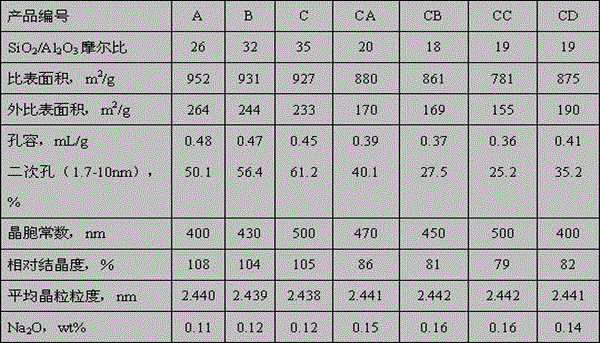

Preparation method for small-grain Y type molecular sieve

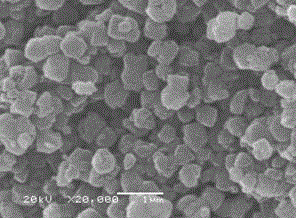

ActiveCN104828839AImprove stabilityStability is not affectedFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses a preparation method for a small-grain Y type molecular sieve. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes alkali washing, ammonium exchange, aluminum removal and silicon supplement, hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt; and the obtained small-grain Y type molecular sieve has a high SiO2 / Al2O3 mol ratio and a high proportion of secondary pores, remains the stability of a Y type molecular sieve and has a high specific surface area and a high degree of crystallization. The small-grain Y type molecular sieve prepared in the invention is applicable as a cracking component for a hydrocracking catalyst used for high and medium oil and enables the hydrocracking catalyst to have good activity, medium oil selectivity and product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

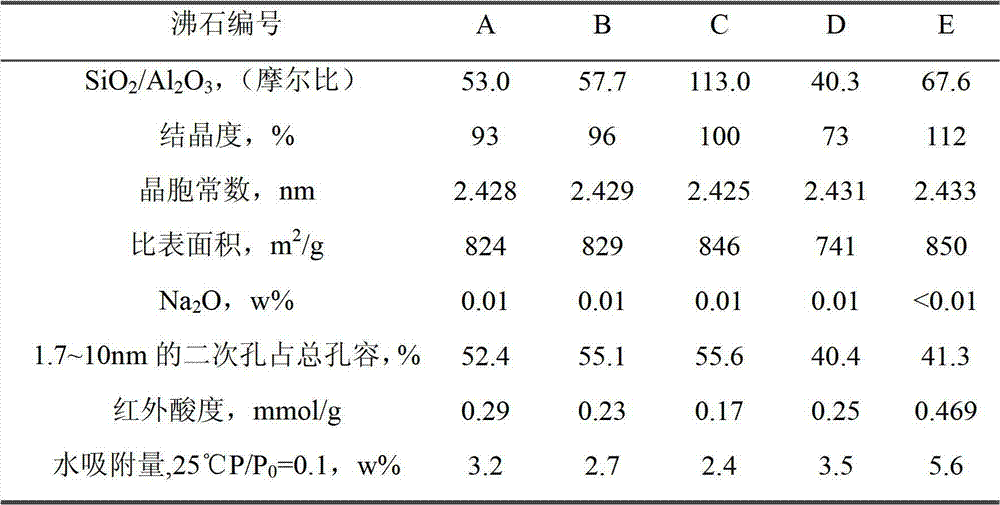

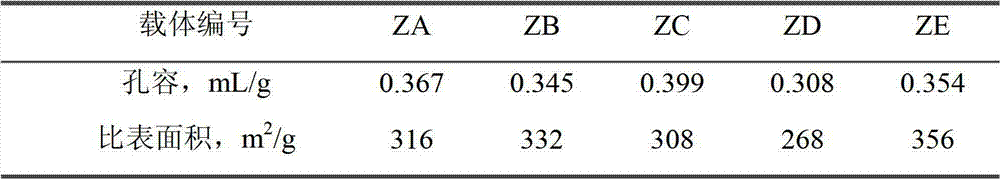

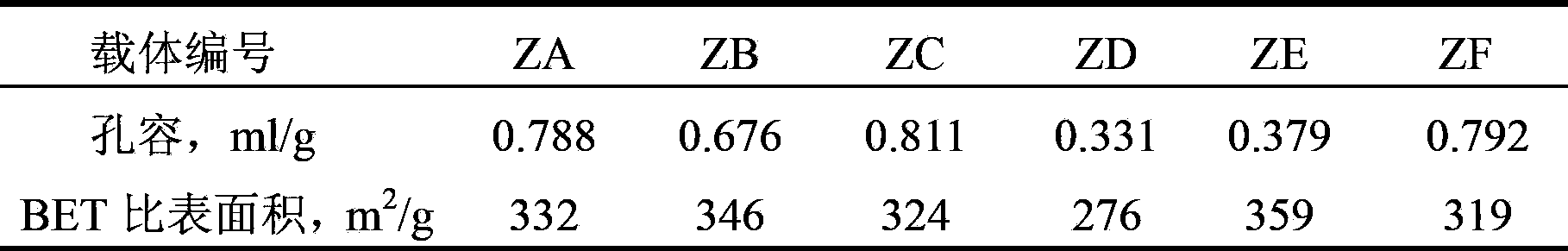

Hydrocracking catalyst carrier and preparation method thereof

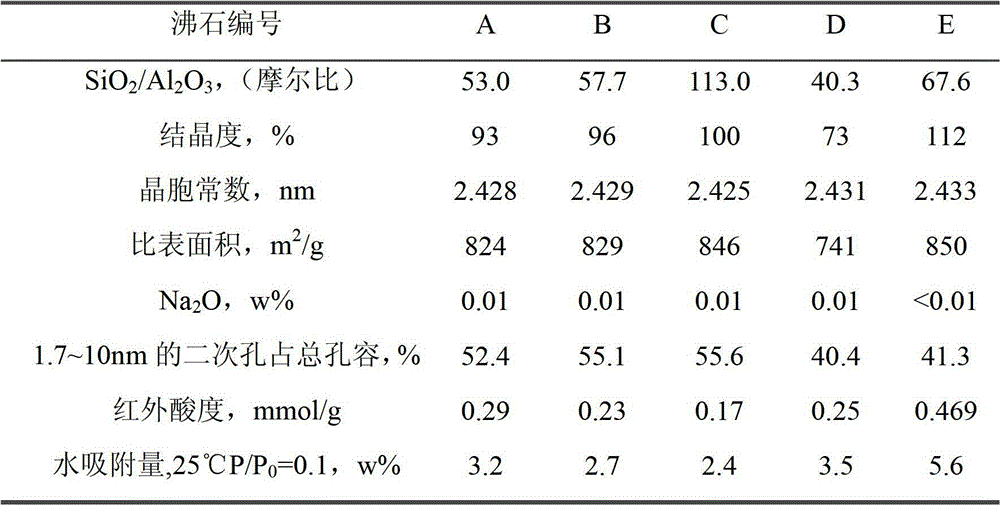

ActiveCN102786064AHigh activityImprove heat resistanceCatalyst carriersMolecular sieve catalystsIon exchangeExtrusion moulding

The invention discloses a hydrocracking catalyst carrier and a preparation method of the hydrocracking catalyst carrier. The hydrocracking catalyst carrier is prepared by using modified Y zeolite, aluminum oxide and amorphous silicon-aluminum. The modified Y zeolite has the following physiochemical properties: the mole ratio of SiO2 to Al2O3 is 30-120; the lattice constant is 2.420-2.435nm; the relative crystallinity is more than or equal to 90%; the specific surface area is 750-850m<2> / g; the secondary pore with 1.7-10nm accounts for more than 50% of the total pore volume; the infrared acidity is 0.10-0.50mmol / g; the ion exchange capacity is less than or equal to 0.10%; and the water adsorption quantity is less than 5.0% in percentage by weight at 25 DEG C and P / P0 of 1.0. The preparation method of the catalyst carrier provided by the invention comprises the following steps: mechanically mixing the modified Y zeolite, aluminum oxide, amorphous silicon-aluminum and adhesive, grinding, extrusion-moulding, drying and calcining to obtain the catalyst carrier. The catalyst carrier prepared by using the modified (deeply dealuminated) Y zeolite as the acidic cracking component is suitable to be used as the hydrocracking catalyst for middle distillates oil.

Owner:CHINA NAT OFFSHORE OIL CORP +2

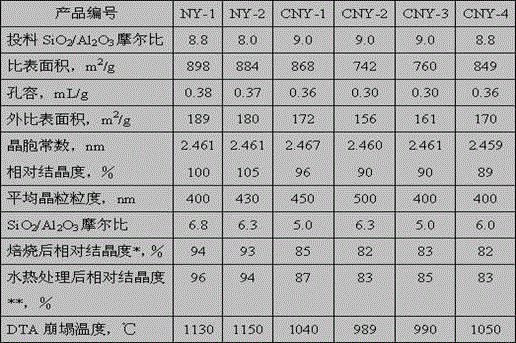

Modification method of small-grain NaY-type molecular sieve

ActiveCN104591210AImprove stabilityStability is not affectedMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveNaphtha

The invention discloses a modification method of a small-grain NaY-type molecular sieve. According to the invention, the NaY-type molecular sieve raw material with relatively high silica-to-alumina ratio, high crystallinity and good stability is adopted. Through sequential steps of alkali wash, ammonium exchange, hydrothermal treatment, and acid and ammonium salt mixed solution treatment, the obtained small-grain Y-type molecular sieve has relatively high SiO2 / A12O3 molar ratio as well as relatively high secondary pore proportion. Also, the stability of the Y-type molecular sieve is maintained. The molecular sieve has relatively high specific surface area and relatively high crystallinity. The Y-type molecular sieve provided by the invention is suitable to be used as a cracking component of a light oil hydrocracking catalyst. With the Y-type molecular sieve, the catalyst has the advantages of good activity, good heavy naphtha selectivity and excellent product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrodearomatization catalyst and preparation method thereof

ActiveCN104588073BHigh activityFacilitates selective loop openingMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveNaphtha

The invention discloses a hydrogenation dearomatization catalyst and a preparation method thereof. The catalyst comprises a main active component Pt, an auxiliary component Pd and a carrier prepared from a small-grain Y type molecular sieve, alumina and amorphous silicon aluminum. According to the preparation method, the small-grain Y type molecular sieve with the characteristics of great dealumination depth, good crystallinity retentivity and well-developed secondary pores is used as an acid component and cooperates with the amorphous silicon aluminum, the main active component and the auxiliary component, so the hydrogenation dearomatization catalyst has higher hydrogenation dearomatization activity and is especially applicable to hydrogenation dearomatization and decoloring of heavy aromatic-containing naphthenic high-viscosity white oil and solvent naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis method of nano BaKL zeolite applied to aromatization of low-carbon alkane

ActiveCN113800535AEnhanced aromatization performanceEnhanced charcoal capacityMolecular sieve catalystsAluminosilicate zeolite type-LAlkanePhysical chemistry

The invention discloses a synthesis method of nano BaKL zeolite applied to aromatization of low-carbon alkane, and belongs to the technical field of zeolite preparation. The method comprises the following steps: mixing a barium source, an alkali source, an aluminum source, a silicon source and water according to a molar ratio to prepare a sol, and performing solid-state or dynamic crystallization to obtain the nano-scale BaKL zeolite. According to the invention, the BaKL zeolite with nanoscale, high crystallinity and hierarchical pore structure can be synthesized under the conditions of low silica-alumina ratio feeding and no addition of a template agent and a structure-directing agent. When the BaKL zeolite provided by the invention is used in a low-carbon alkane aromatization reaction, the yield of aromatic hydrocarbon, especially the yield of C8 aromatic hydrocarbon, can be obviously improved. Compared with a traditional method, the method is simple in preparation process, high in raw material utilization rate, low in cost and wide in application prospect.

Owner:奥斯催化材料(大连)有限公司

Modification method for small-grain NaY type molecular sieve

ActiveCN104828840AImprove stabilityStability is not affectedFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses a modification method for a small-grain NaY type molecular sieve. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes alkali washing, ammonium exchange, aluminum removal and silicon supplement, hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt; and the obtained small-grain Y type molecular sieve has a high SiO2 / Al2O3 mol ratio and a high proportion of secondary pores, retains the stability of a Y type molecular sieve and has a high specific surface area and a high degree of crystallization. The small-grain Y type molecular sieve prepared in the invention is applicable as a cracking component for a hydrocracking catalyst used for high and medium oil and enables the hydrocracking catalyst to have good activity, medium oil selectivity and product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Saturated alkane dehydrogenation catalyst and preparation method thereof

ActiveCN104588008BImprove thermal stabilityHigh activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsIridiumDehydrogenation

The invention discloses an alkane dehydrogenation catalyst. The catalyst adopts MgAl2O4 doped by alumina and SiO2 and having a magnesium aluminate spinel structure as a carrier, an active metal component is generally selected from one or more of platinum, palladium, iridium, rhodium and osmium in the platinum family, and preferably Pt, and the catalyst comprises 0.2-0.6wt% of the active component, 1.0-3.0wt% of Sn, 30-60wt% of the MgAl2O4 structure component, and the balance of alumina. The catalyst has a good hydrothermal stability, and can inhibit the aggregation growth of Pt particles in the hydrothermal dechlorination process, so the activity and the stability of the catalyst are substantially improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Small-grain Y-type molecular sieve and preparation method thereof

ActiveCN104591209BImprove stabilityStability is not affectedFaujasite aluminosilicate zeoliteMolecular sieveNaphtha

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of small-grain Y-type molecular sieve

ActiveCN104828838BImprove stabilityStability is not affectedMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses a preparation method for a small-grain Y type molecular sieve. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes ammonium exchange, primary hydro-thermal treatment, treatment with an alkali-containing solution, secondary hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt; and the obtained small-grain Y type molecular sieve has a high SiO2 / Al2O3 mol ratio and a high proportion of secondary pores, retains the stability of a Y type molecular sieve and has a high specific surface area and a high degree of crystallization. The small-grain Y type molecular sieve prepared in the invention is applicable as a cracking component for a hydrocracking catalyst used for high and medium oil and enables the hydrocracking catalyst to have good activity, medium oil selectivity and product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN104588121AHigh ratio of silicon to aluminumHigh crystallinityCatalyst carriersMolecular sieve catalystsMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier is composed of a small-grain Y type molecular sieve, amorphous silica-alumina and alumina. According to the preparation method, the small-grain Y type molecular sieve with the characteristics of proper dealumination degree, good crystallinity retentivity and well-developed secondary pores is used as an acid component; and when the small-grain Y type molecular sieve and the amorphous silica-alumina are cooperatively used for preparing a hydrocracking catalyst, the hydrocracking catalyst has the advantages of good activity, heavy naphtha selectivity and superior product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for small-grain Y type molecular sieve

ActiveCN104828838AImprove stabilityStability is not affectedMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses a preparation method for a small-grain Y type molecular sieve. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes ammonium exchange, primary hydro-thermal treatment, treatment with an alkali-containing solution, secondary hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt; and the obtained small-grain Y type molecular sieve has a high SiO2 / Al2O3 mol ratio and a high proportion of secondary pores, retains the stability of a Y type molecular sieve and has a high specific surface area and a high degree of crystallization. The small-grain Y type molecular sieve prepared in the invention is applicable as a cracking component for a hydrocracking catalyst used for high and medium oil and enables the hydrocracking catalyst to have good activity, medium oil selectivity and product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

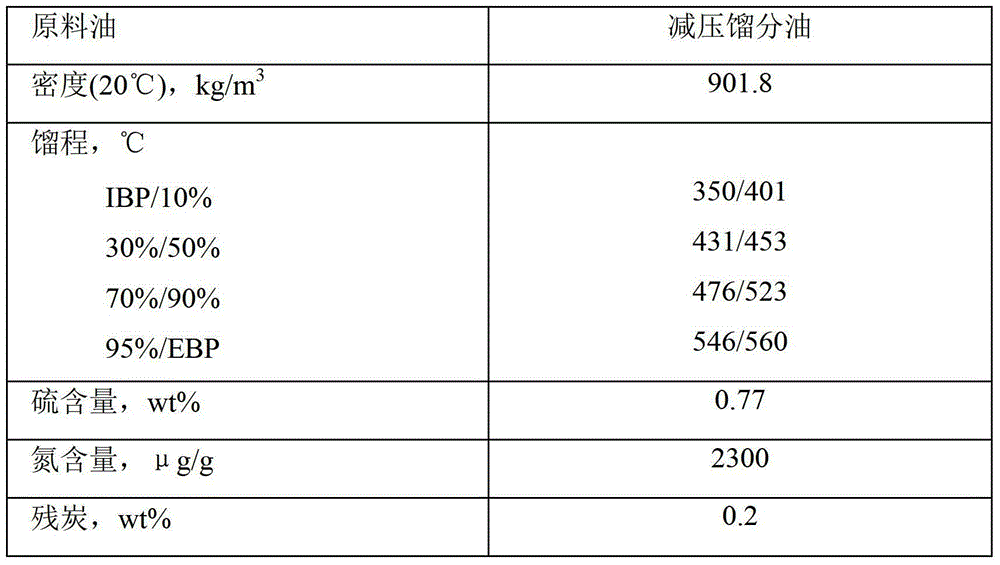

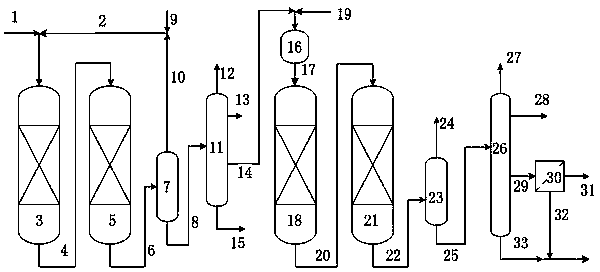

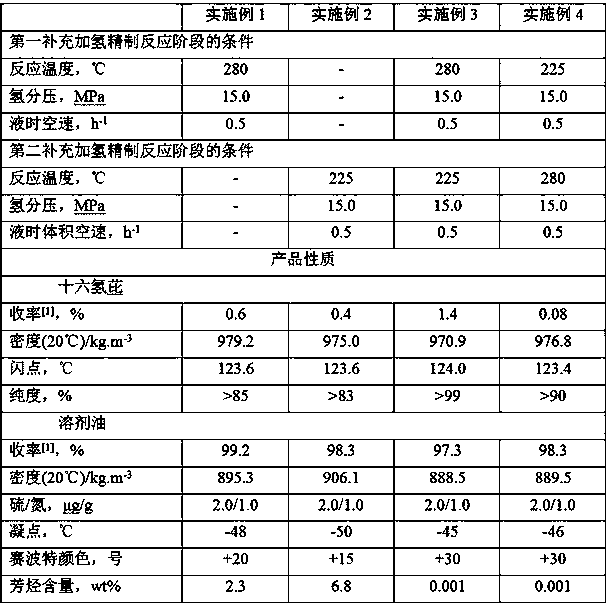

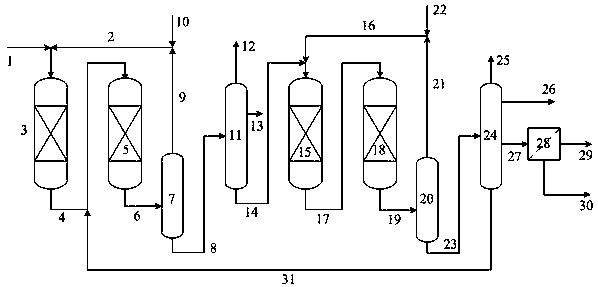

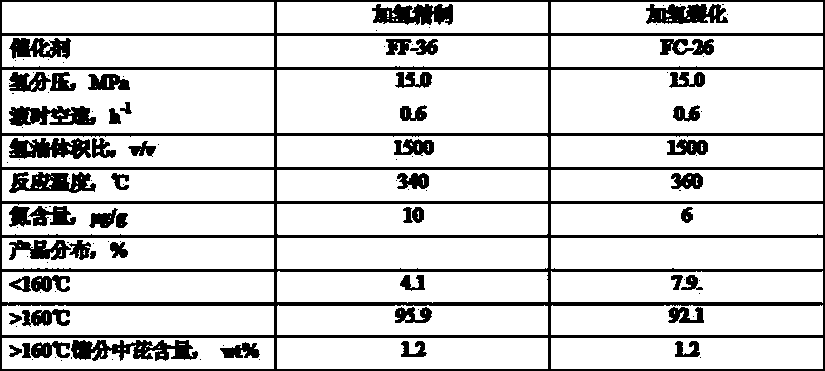

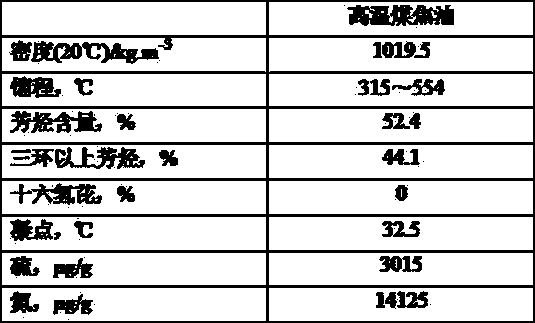

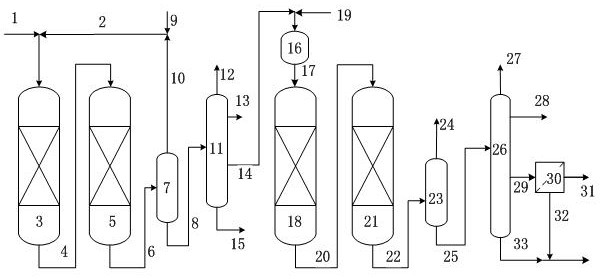

Preparation method of medical intermediate hexadecahydropyrene

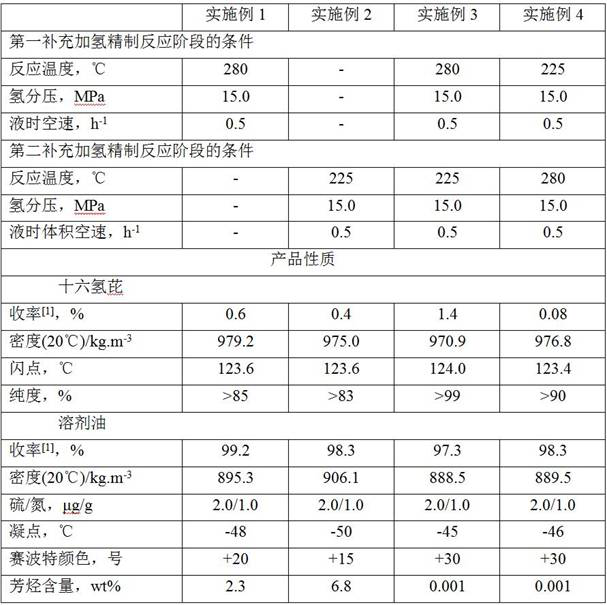

ActiveCN109851468AHigh purityImprove economyHydrocarbon by hydrogenationDistillation purification/separationHydrogenation processFuel oil

The invention discloses a preparation method of medical intermediate hexadecahydropyrene. The preparation method comprises the following steps: after coal tar raw materials are pretreated, carrying out hydrofining and hydrocracking reactions to fractionate the obtained liquid; feeding the obtained diesel oil fraction into a supplementary refining reaction area, and carrying out a hydrogenation saturation reaction under the action of a supplementary refining catalyst; and cutting the supplementary refining product, cooling the obtained fraction, and carrying out filtering to obtain high-purityhexadecahydropyrene. According to the method, the purpose of producing hexadecahydropyrene from the coal tar raw materials by using a hydrogenation process is achieved for the first time. Compared with the prior art, the method disclosed by the invention has the advantages that the high-purity hexadecahydropyrene is obtained, and meanwhile, quality of byproducts meets the requirements of clean fuel oil products and solvent oil products. The method disclosed by the invention improves economic performance of coal tar processing, and has the characteristics of simple process and low operation energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of silica-alumina carrier containing molecular sieve and preparation method thereof

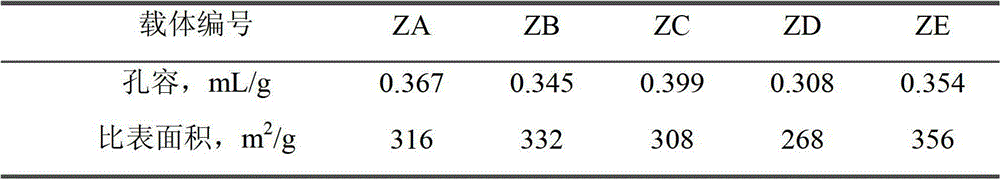

ActiveCN103011192BPrevent sinteringHigh catalytic efficiencyMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sievePhysical chemistry

The invention discloses a silicon-aluminium carrier comprising a molecular sieve and a preparation method thereof. The silicon-aluminium carrier is prepared from 5 weight percent to 50 weight percent of a modified Y molecular sieve and 50 weight percent to 95 weight percent of amorphous silicon-aluminium; and the silicon-aluminium carrier has a BET specific surface area of 260 to 400m<2> / g and a pore volume of 0.50 to 0.95ml / g. The preparation method of the silicon-aluminium carrier comprises the following steps of: (1) mixing a silicon source and an aluminium source which are used for preparing the amorphous silicon-aluminium, and then adding a precipitating agent under the stirring condition to obtain a gelatinous mixture; (2) adding the modified Y molecular sieve into the gelatinous mixture to carry out aging; (3) filtering aged slurry to obtain a filter cake and carrying out drying, lamination and extrusion forming on the filter cake; and (4) sequentially carrying out washing, steam processing, drying and roasting on the product obtained after extrusion forming so as to obtain the silicon-aluminium carrier.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Preparation method of hydrodearomatization catalyst

ActiveCN104826647BHigh activityFacilitates selective loop openingMolecular sieve catalystsRefining by aromatic hydrocarbon hydrogenationSolventWhite oil

The invention discloses a preparation method for a hydrogenation dearomatization catalyst. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes ammonium exchange, primary hydro-thermal treatment, treatment with an alkali-containing solution, secondary hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt, so a small-grain Y type molecular sieve is obtained. The small-grain Y type molecular sieve is used as an acidic component and cooperates with amorphous silicon-aluminum, active components and auxiliary components; and the obtained hydrogenation dearomatization catalyst has higher hydrogenation dearomatization activity and is especially applicable to hydrogenation dearomatization and decoloring of high-viscosity cycloalkyl white oil and solvent naphtha containing heavy aromatics.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing small-grain Y-type molecular sieve

ActiveCN104828839BImprove stabilityStability is not affectedMolecular sieve catalystsMolecular sieveCrystallinity

The invention discloses a preparation method of a small-grain Y-type molecular sieve. The method adopts NaY type molecular sieve raw material with high silicon-aluminum ratio, high crystallinity and good stability, and sequentially undergoes alkali washing, ammonium exchange, dealumination of silicon, hydrothermal treatment, and treatment with a mixed solution of acid and ammonium salt to obtain The small-grain Y-type molecular sieves obtained higher SiO 2 / A1 2 o 3 While the molar ratio is high, the proportion of secondary pores is high, and the stability of the Y-type molecular sieve is maintained. The molecular sieve has a high specific surface area and a high crystallinity. The Y-type molecular sieve obtained by the invention is suitable as a cracking component of a hydrocracking catalyst for medium oil, and can make the catalyst have good activity, medium oil selectivity and excellent product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modification method of small grain nay type molecular sieve

ActiveCN104591211BImprove stabilityStability is not affectedFaujasite aluminosilicate zeoliteMolecular sieveNaphtha

The invention discloses a modification method for a small-grain NaY molecular sieve. According to the method, an NaY molecular sieve with a high Si / Al ratio, high crystallinity and good stability is used as a raw material, caustic washing, ammonium exchange, hydrothermal treatment and treatment with a mixed solution of acid and ammonium salt are successively carried out, so the obtained small-grain NaY molecular sieve has a higher SiO2 / Al2O3 molar ratio and higher proportion of secondary pores, maintains the stability of the NaY molecular sieve, and has a great specific surface area and higher crystallinity. The small-grain NaY molecular sieve prepared in the invention is applicable as a cracking component of a light oil type hydrocracking catalyst and enables the catalyst to have good activity, heavy naphtha selectivity and excellent product nature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel production process of coal-based chemical

ActiveCN108130128ARaise the potentialImprove economyHydrocarbon by hydrogenationTreatment with hydrotreatment processesAdditive ingredientFractionation

The invention discloses a novel production process of a coal-based chemical. A coal tar raw material is subjected to pretreatment; hydrofining and hydrocracking reaction are performed; the obtained liquid is subjected to fractionation; diesel fractions are obtained and enter a supplementation refining reaction region; under the effect of supplementation refining catalysts, hydrogenation saturationreaction is performed; supplementation refining products are cut; the obtained distillates are subjected to cooling temperature lowering and filtering to obtain high-purity hexadecahydropyrene; the rest heavy distillates return to a hydrocracking reactor for continuous cracking reaction so as to obtain more hexadecahydropyrene ingredients. The goal of producing the hexadecahydropyrene by using coal tar as raw materials through a hydrogenization process is firstly realized. Compared with the prior art, the method provided by the invention has the advantages that the high-purity hexadecahydropyrene is obtained; meanwhile, byproducts of clean fuel oil products and solvent oil products with the quality meeting the requirements can be obtained. The method changes the situation that the hexadecahydropyrene completely relies on the import; the coal tar processing economical performance is improved; the characteristics of simple process and low operation energy consumption are realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for modifying small-grain nay-type molecular sieves

ActiveCN104828840BImprove stabilityStability is not affectedMolecular sieve catalystsMolecular sieveCrystallinity

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN102786064BHigh activityImprove heat resistanceCatalyst carriersMolecular sieve catalystsPtru catalystIon exchange

The invention discloses a hydrocracking catalyst carrier and a preparation method of the hydrocracking catalyst carrier. The hydrocracking catalyst carrier is prepared by using modified Y zeolite, aluminum oxide and amorphous silicon-aluminum. The modified Y zeolite has the following physiochemical properties: the mole ratio of SiO2 to Al2O3 is 30-120; the lattice constant is 2.420-2.435nm; the relative crystallinity is more than or equal to 90%; the specific surface area is 750-850m<2> / g; the secondary pore with 1.7-10nm accounts for more than 50% of the total pore volume; the infrared acidity is 0.10-0.50mmol / g; the ion exchange capacity is less than or equal to 0.10%; and the water adsorption quantity is less than 5.0% in percentage by weight at 25 DEG C and P / P0 of 1.0. The preparation method of the catalyst carrier provided by the invention comprises the following steps: mechanically mixing the modified Y zeolite, aluminum oxide, amorphous silicon-aluminum and adhesive, grinding, extrusion-moulding, drying and calcining to obtain the catalyst carrier. The catalyst carrier prepared by using the modified (deeply dealuminated) Y zeolite as the acidic cracking component is suitable to be used as the hydrocracking catalyst for middle distillates oil.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN104588121BImprove stabilityPromote productionCatalyst carriersMolecular sieve catalystsMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier is composed of a small-grain Y type molecular sieve, amorphous silica-alumina and alumina. According to the preparation method, the small-grain Y type molecular sieve with the characteristics of proper dealumination degree, good crystallinity retentivity and well-developed secondary pores is used as an acid component; and when the small-grain Y type molecular sieve and the amorphous silica-alumina are cooperatively used for preparing a hydrocracking catalyst, the hydrocracking catalyst has the advantages of good activity, heavy naphtha selectivity and superior product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of modification method of small grain nay type molecular sieve

ActiveCN104591210BImprove stabilityStability is not affectedMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveNaphtha

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of hydrocracking catalyst carrier

ActiveCN104826646BImprove stabilityGuaranteed stabilityCatalyst carriersMolecular sieve catalystsChemistryRaw material

The invention discloses a preparation method for a hydrocracking catalyst carrier. The method comprises the following steps: subjecting a small-grain Y type molecular sieve, amorphous silicon-aluminum and a binder prepared from alumina to mixing and extrusion molding and then carrying out drying and roasting so as to prepare the carrier. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes ammonium exchange, primary hydro-thermal treatment, treatment with an alkali-containing solution, secondary hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt; and the obtained small-grain Y type molecular sieve has a high SiO2 / Al2O3 mol ratio and a high proportion of secondary pores, retains the stability of the molecular sieve and has a high specific surface area and a high degree of crystallization. The hydrocracking catalyst carrier provided by the invention is applicable to a hydrocracking catalyst for high and medium oil and enables the hydrocracking catalyst to have good activity, medium oil selectivity and product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of pharmaceutical intermediate hexahydropyrene

ActiveCN109851468BImprove economyImprove performanceHydrocarbon by hydrogenationDistillation purification/separationPtru catalystHydrogenation process

The invention discloses a preparation method of a pharmaceutical intermediate hexahydropyrene. After the coal tar raw material is pretreated, it undergoes hydrofining and hydrocracking reactions, and the resulting liquid is subjected to fractional distillation; the obtained diesel fraction enters the supplementary refining reaction zone, and undergoes hydrogenation saturation reaction under the action of supplementary refining catalyst; the supplementary refined product is cut , the resulting fractions were cooled and filtered to obtain high-purity hexadecahydropyrene. The present invention realizes for the first time the purpose of producing hexahydropyrene by using coal tar raw material through a hydrogenation process. Compared with the prior art, the method of the present invention obtains high-purity hexadecahydropyrene, and at the same time produces clean fuel oil and solvent oil products whose quality meets the requirements. The method of the invention improves the economical efficiency of coal tar processing, and has the characteristics of simple process and low operation energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com