Hydrocracking catalyst carrier and preparation method thereof

A technology of catalyst carrier and alumina, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, molecular sieve catalyst, etc., and can solve the problems of high reactivity, environmental pollution, unfavorable environmental protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

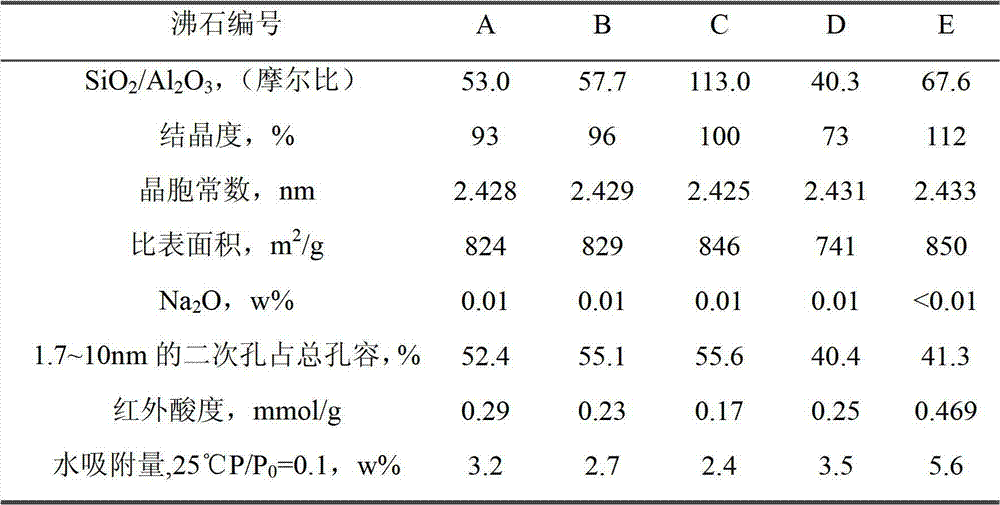

[0037] Embodiment 1, the preparation of deep dealumination Y zeolite A

[0038] ①Take 250 grams of NH 4 NaY zeolite (produced by Wenzhou Catalyst Factory, SiO 2 / Al 2 o 3 Molar ratio is 5.1, unit cell constant a 0 =2.470nm, crystallinity is 95%, Na 2 O is 2.3w%, dry basis is 70w%) placed in a heat treatment furnace, control the heating rate of 500 ℃ / hour, raise the temperature to 600 ℃, while maintaining the water vapor pressure of the system at 0.15MPa, treat for 2.0 hours, cool down , take out the sample.

[0039] ② with NH 4 + and H + 1500mL of solutions (mixed aqueous solution of ammonium chloride and hydrochloric acid) with a concentration of 2.0mol / L and 0.2mol / L were contacted with the sample and stirred to maintain the temperature of the slurry at 90°C for 1.5 hours. Repeat the treatment once under the same conditions, filter wash the cake with water;

[0040] ③Place the wet filter cake in a heat treatment furnace, raise the temperature to 650°C, control th...

Embodiment 2

[0042] Embodiment 2, the preparation of deep dealumination Y zeolite B

[0043] ① Put 2kg NH 4 NaY zeolite (physical and chemical parameters are the same as in Example 1) is placed in a heat treatment furnace, the temperature is raised to 630 °C within 2 hours, water vapor is injected (the steam rate is 3.0kg / h), and the system pressure is kept at 0.1MPa. Keep the temperature at ℃ for 3.5 hours, cool down, and take out the sample;

[0044] ② Add 15kg of water to the autoclave, industrial NH 4 NO 3 2.4kg, HNO 3 0.2kg and the zeolite sample after the first heat treatment (in the mixed solution, NH 4 + and H + The concentrations are 1.2mol / L and 0.25mol / L respectively), sealed, started stirring, raised the temperature to 120°C, treated at constant temperature for 1 hour, treated the filter cake once more under the same conditions, filtered off the mother liquor, and dried until the filter cake contained Water volume≯25%.

[0045] ③ The sample is placed in a heat treatment...

Embodiment 3

[0047] Embodiment 3, the preparation of deep dealumination Y zeolite C

[0048] ①300g NH 4 NaY zeolite (physical and chemical parameters are the same as in Example 1) was placed in a heat treatment furnace, and the temperature was raised to 560°C in 1 hour, the pressure was maintained at 0.1 MPa by the zeolite's own water vapor, the temperature was kept constant for 3 hours, the temperature was lowered, and the zeolite sample was taken out.

[0049] ② with NH 4 + and H + The concentration of 2.0mol / L and 0.15mol / L solution (ammonium nitrate and nitric acid mixed solution) 200mL contacted with the sample and stirred, the temperature was raised to 90 ℃, and maintained for 2 hours, repeated twice, the filter cake was cleaned Wash with water and dry.

[0050] ③The zeolite sample is placed in the heat treatment furnace, and the temperature is raised to 680°C in 1.5 hours, and 300g / h of water vapor is introduced at the same time, the pressure of the control system is at 0.1±0.02...

PUM

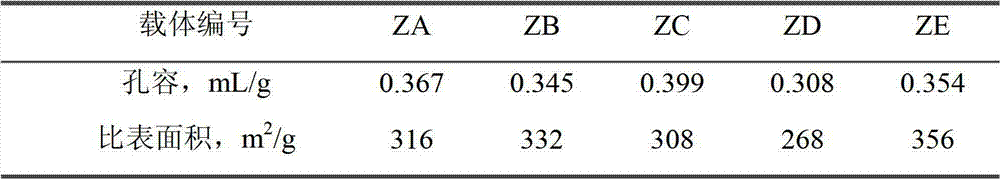

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com