Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Secondary hole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

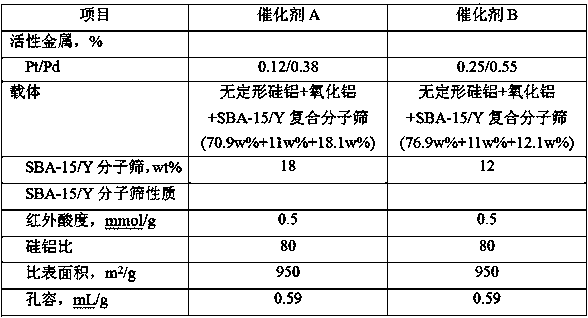

Hydrogenation dearomatization catalyst and preparation method thereof

ActiveCN104588073AHigh activityFacilitates selective loop openingMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveNaphtha

The invention discloses a hydrogenation dearomatization catalyst and a preparation method thereof. The catalyst comprises a main active component Pt, an auxiliary component Pd and a carrier prepared from a small-grain Y type molecular sieve, alumina and amorphous silicon aluminum. According to the preparation method, the small-grain Y type molecular sieve with the characteristics of great dealumination depth, good crystallinity retentivity and well-developed secondary pores is used as an acid component and cooperates with the amorphous silicon aluminum, the main active component and the auxiliary component, so the hydrogenation dearomatization catalyst has higher hydrogenation dearomatization activity and is especially applicable to hydrogenation dearomatization and decoloring of heavy aromatic-containing naphthenic high-viscosity white oil and solvent naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

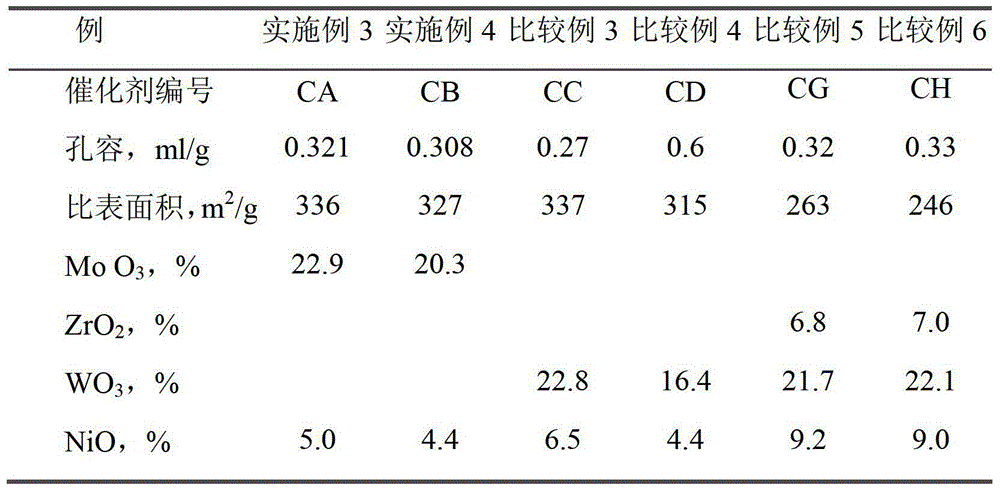

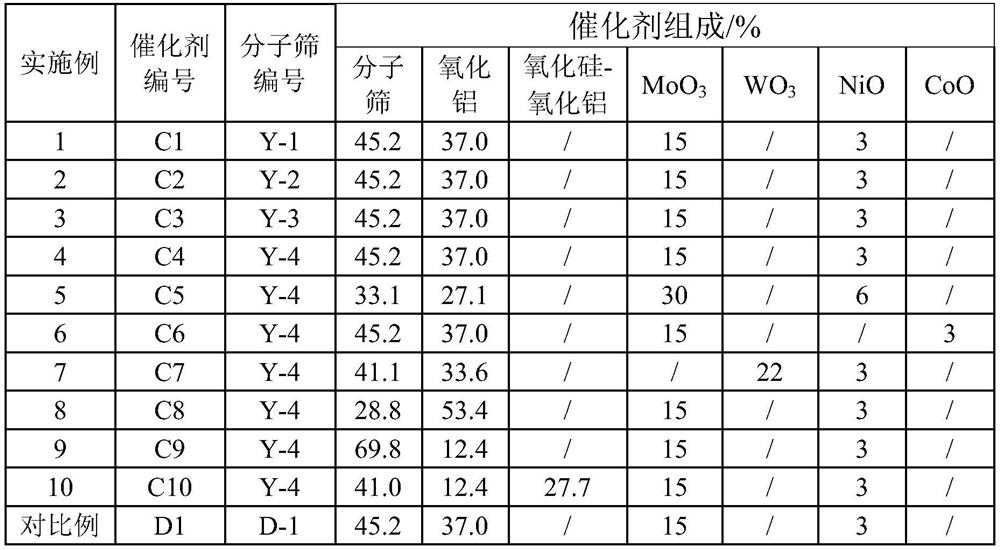

Composite molecular sieve-containing medium oil type hydrocracking catalyst, preparation method and application thereof

ActiveCN103551186BHigh crystallinityIncrease surface areaMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

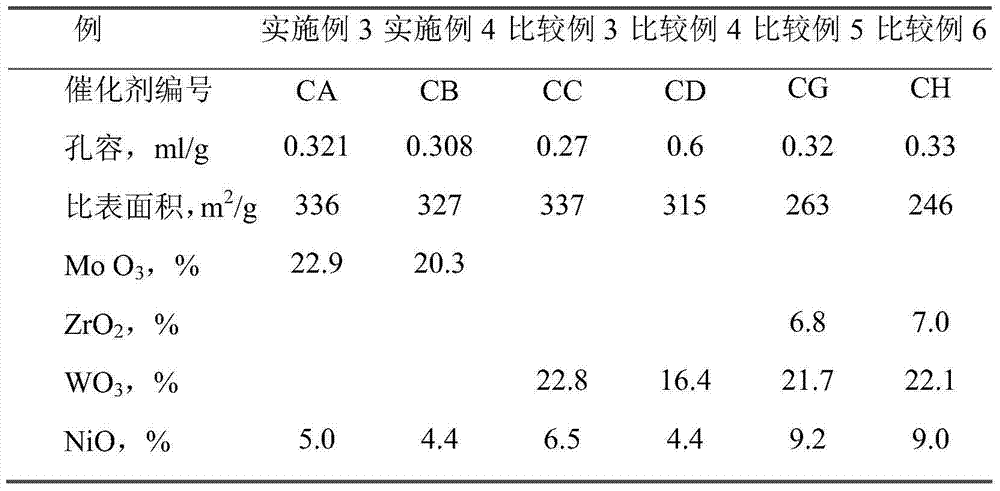

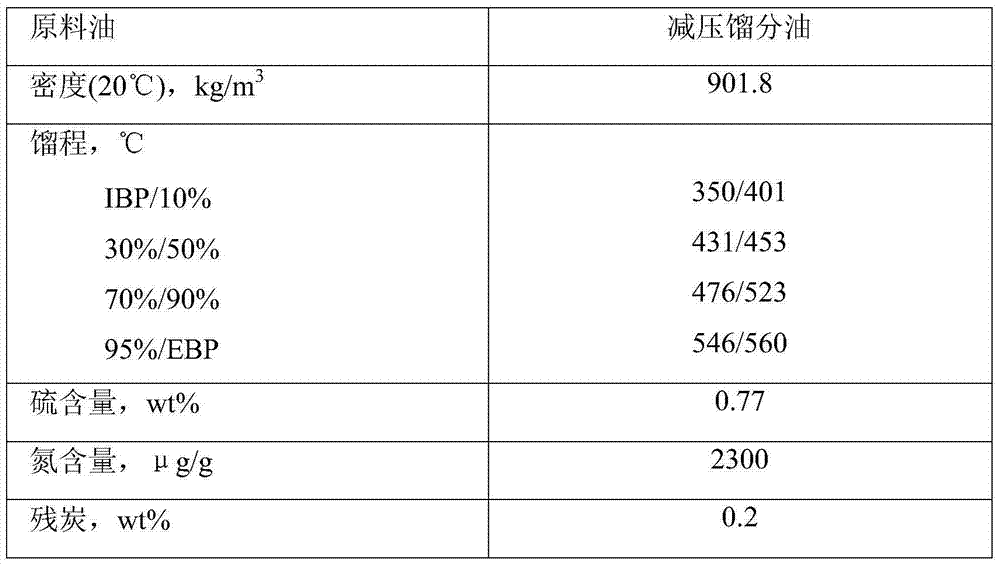

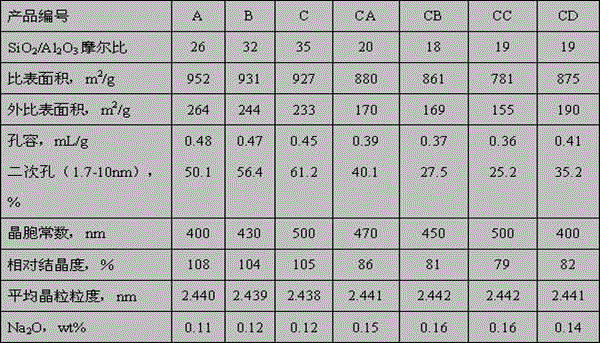

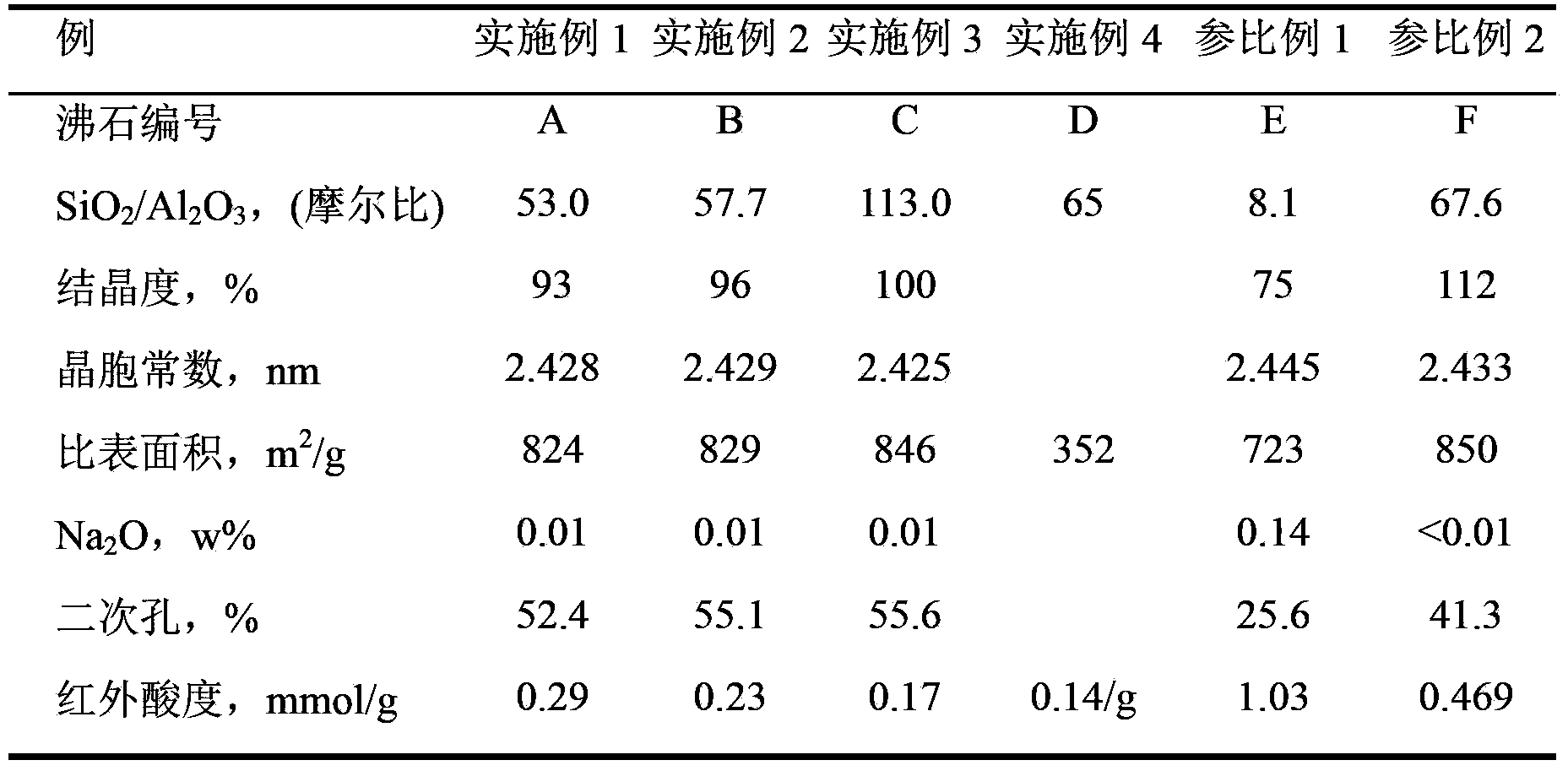

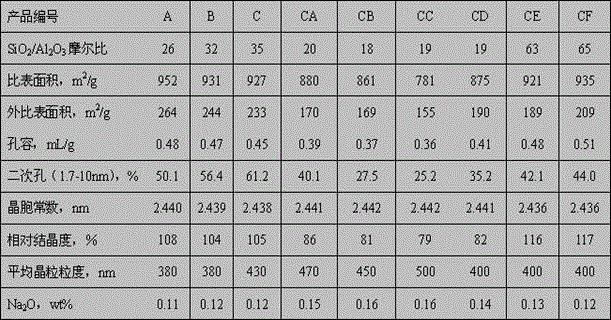

The invention relates to a composite molecular sieve-containing medium oil type hydrocracking catalyst, which comprises an active component and a binder, wherein the active component adopts amorphous SiO2-Al2O3 as a carrier, adopts a composite molecular sieve as an acid component, and adopts a group VIB metal and a group VIII metal as hydrogenation activity components, and the composite molecular sieve comprises a Y molecular sieve and a ZSM-23 molecular sieve. According to the present invention, the deep dealuminzation modified Y molecular sieve has characteristics of high crystallinity, large surface area, high silica-alumina ratio, low cell constant, rich secondary pore, low acid center density, high moderate-intensity acid center ratio, and the like; the modified ZSM-23 molecular sieve has characteristics of smooth pore channel, less acid center and outstanding isomerism performance, wherein a light naphtha component is isomerized so as to increase an octane number of naphtha; the composite molecular sieve compounded from the Y molecular sieve and the ZSM-23 molecular sieve is adopted as the acid cracking component so as to provide advantages of the Y molecular sieve and the ZSM-23 molecular sieve, and compounding is performed according to the ratio of the present invention, such that the best catalysis effect can be obtained, and the obtained catalyst is suitable for the medium oil type hydrocracking catalyst; and the catalyst prepared from the composite molecular sieve has characteristics of excellent medium oil selectivity, good activity and good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

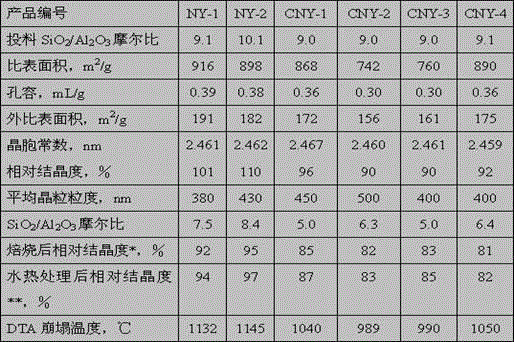

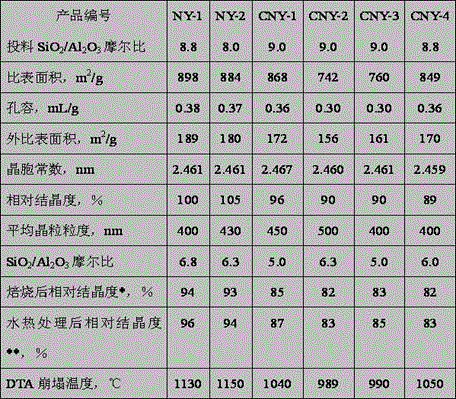

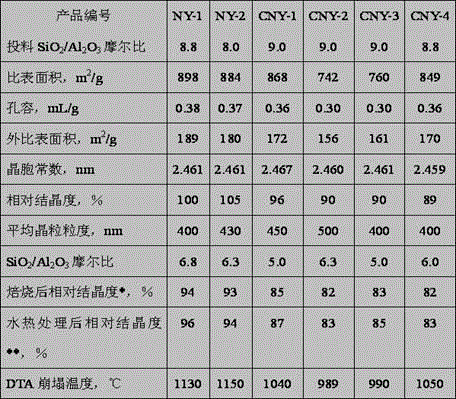

Medium oil type hydrocracking catalyst and its preparing process

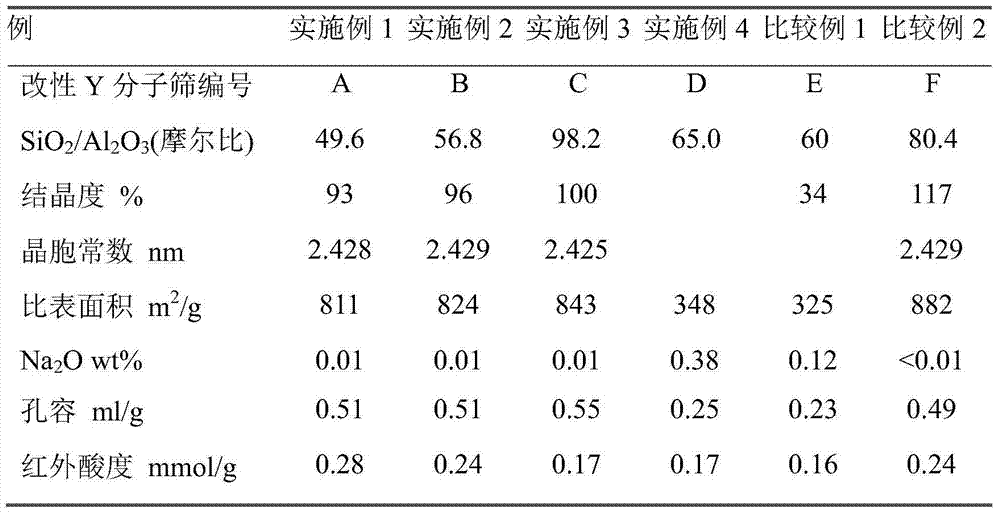

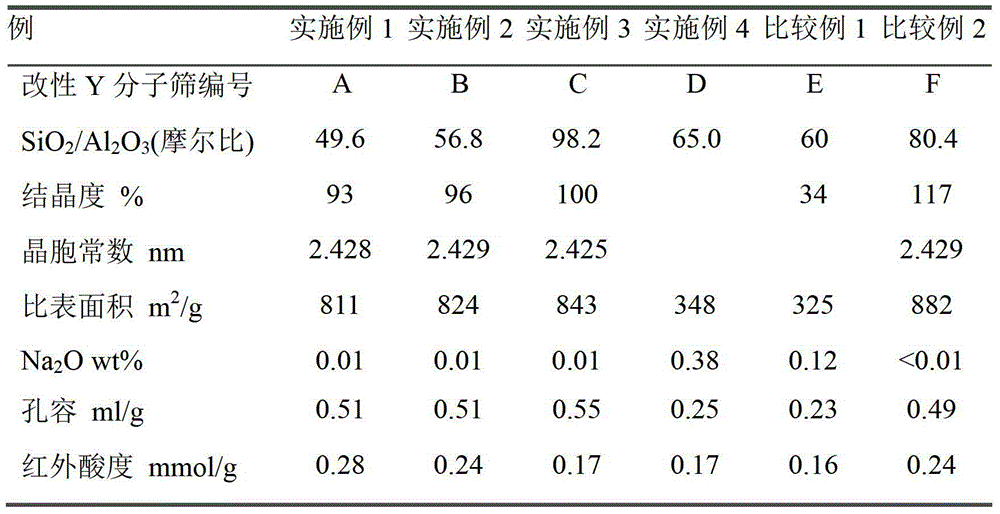

ActiveCN1566283AHigh crystallinityLow cell parametersHydrocarbon oil crackingMolecular sieveAluminium

The invention relates to a medium oil type hydrocracking catalyst and its preparing process, wherein the catalyst employs non-shaped silicon aluminium as carrying agent, and the particularity modified type Y molecular sieve is used as the acidic component, the molecular sieve possesses high degree of crystallization, low unit cell parameter, strong nitrogen resistant property and good destroying capability. The hydrocracking catalyst employing the molecular sieve has strong nitrogen resistant capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

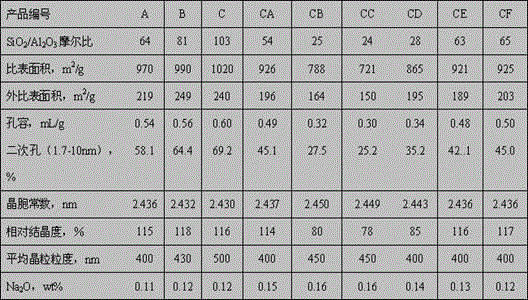

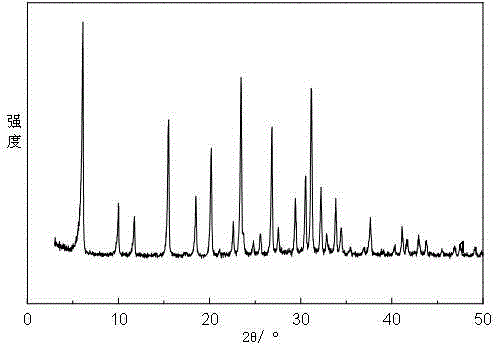

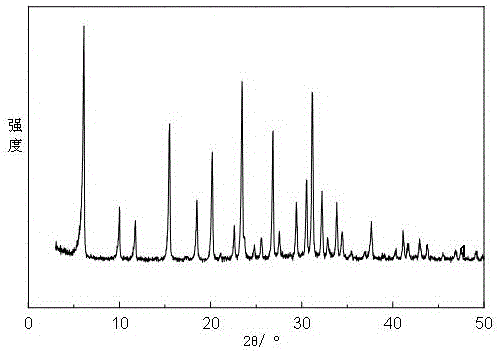

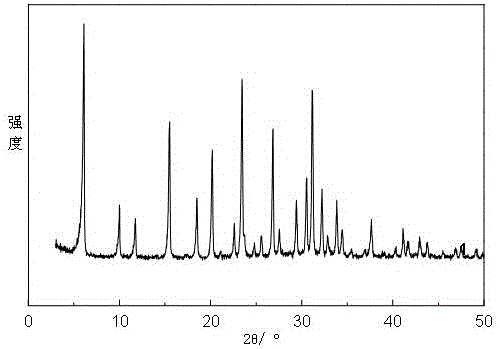

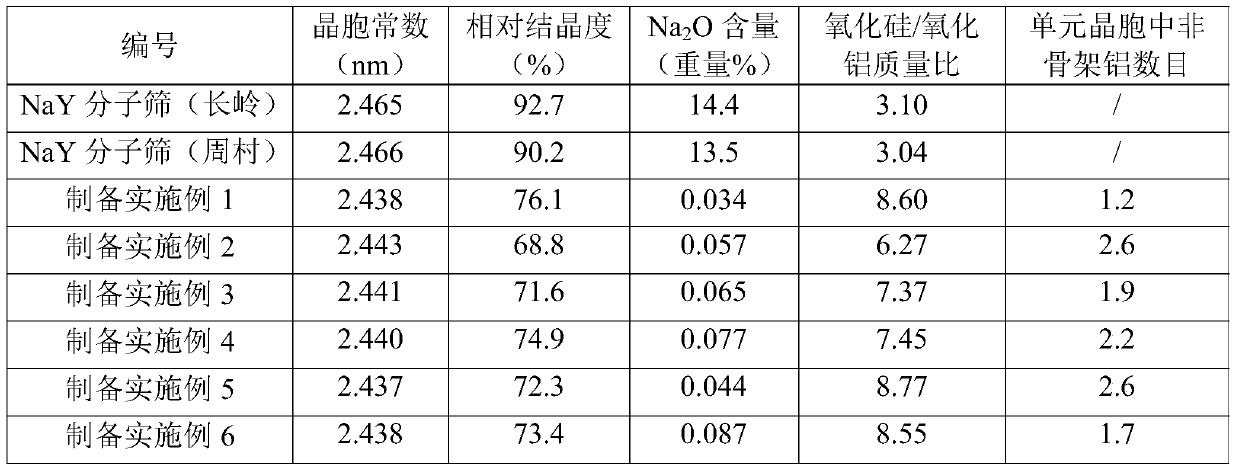

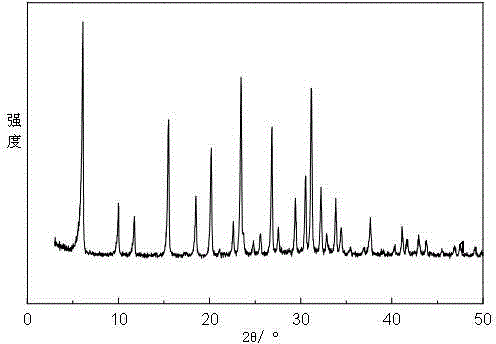

Deep sealumination modified Y zeolite preparation method

ActiveCN1951816AStable structureHigh crystallinityMolecular sieve catalystsFaujasite aluminosilicate zeoliteHigh densityCrystallinity

The invention discloses a preparing method of deep aluminium-stripping Y-zeolite, which comprises the following steps: adopting NH4NaY with the content of Na2O not more than 2.5w%; proceeding first water heat disposal; utilizing high-density H+ ammonium salt solution to exchange to strip aluminium; proceeding second water heat disposal; removing non-frame aluminium through acid solution; setting the disposing temperature of second water heat disposal higher than the first one; improving crystallinity and silicon-aluminium rate with abundant secondary hole.

Owner:CHINA PETROLEUM & CHEM CORP +1

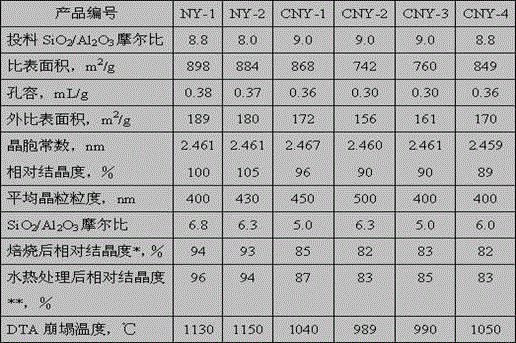

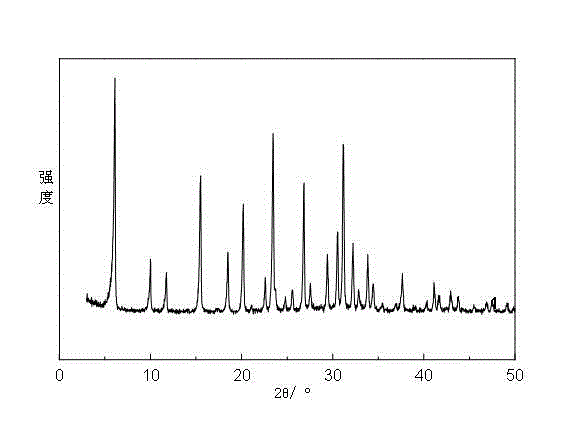

High crystallinity modified Y zeolite and its preparation method

ActiveCN1951815AEasy to useHigh crystallinityMolecular sieve catalystsFaujasite aluminosilicate zeolitePhysical chemistryCrystallinity

The invention discloses a high-crystallinity modified Y-zeolite with cell parameter at 2.425-2.435nm, relative crystallinity not less than 95% and specific surface area at 800-950m2 / g, which is characterized by the following: adopting NaY zeolite as raw material to do amino exchange through ammonium salt solution; controlling the exchanging degree not less than 80%; placing in the water heat disposing furnace under 400-700 deg.c at 0.05-0.5Mpa for 1.0-5.0h; contacting the zeolite sample and ammonium salt solution; controlling the pH value; exchanging Na+ in the zeolite further; stripping non-frame aluminium selectively; proceeding secondary water heat disposal; setting the molar rate of SiO2 / Al2O3 at 15-16; obtaining the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite molecular sieve-containing medium oil type hydrocracking catalyst, preparation method and application thereof

ActiveCN103551186AHigh crystallinityIncrease surface areaMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention relates to a composite molecular sieve-containing medium oil type hydrocracking catalyst, which comprises an active component and a binder, wherein the active component adopts amorphous SiO2-Al2O3 as a carrier, adopts a composite molecular sieve as an acid component, and adopts a group VIB metal and a group VIII metal as hydrogenation activity components, and the composite molecular sieve comprises a Y molecular sieve and a ZSM-23 molecular sieve. According to the present invention, the deep dealuminzation modified Y molecular sieve has characteristics of high crystallinity, large surface area, high silica-alumina ratio, low cell constant, rich secondary pore, low acid center density, high moderate-intensity acid center ratio, and the like; the modified ZSM-23 molecular sieve has characteristics of smooth pore channel, less acid center and outstanding isomerism performance, wherein a light naphtha component is isomerized so as to increase an octane number of naphtha; the composite molecular sieve compounded from the Y molecular sieve and the ZSM-23 molecular sieve is adopted as the acid cracking component so as to provide advantages of the Y molecular sieve and the ZSM-23 molecular sieve, and compounding is performed according to the ratio of the present invention, such that the best catalysis effect can be obtained, and the obtained catalyst is suitable for the medium oil type hydrocracking catalyst; and the catalyst prepared from the composite molecular sieve has characteristics of excellent medium oil selectivity, good activity and good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

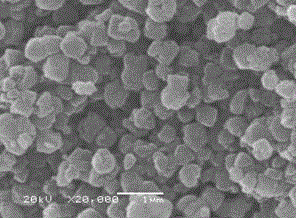

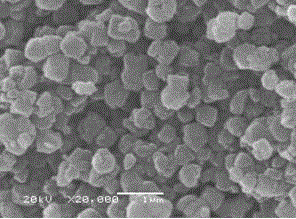

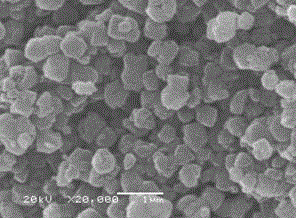

Preparation method for small-grain Y type molecular sieve

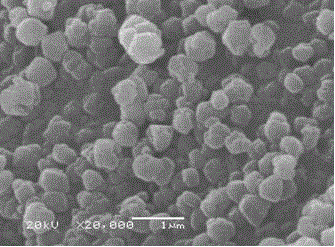

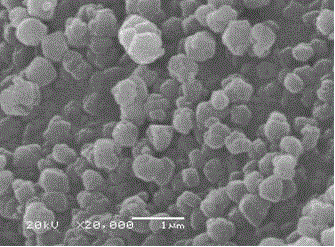

ActiveCN104828839AImprove stabilityStability is not affectedFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses a preparation method for a small-grain Y type molecular sieve. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes alkali washing, ammonium exchange, aluminum removal and silicon supplement, hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt; and the obtained small-grain Y type molecular sieve has a high SiO2 / Al2O3 mol ratio and a high proportion of secondary pores, remains the stability of a Y type molecular sieve and has a high specific surface area and a high degree of crystallization. The small-grain Y type molecular sieve prepared in the invention is applicable as a cracking component for a hydrocracking catalyst used for high and medium oil and enables the hydrocracking catalyst to have good activity, medium oil selectivity and product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

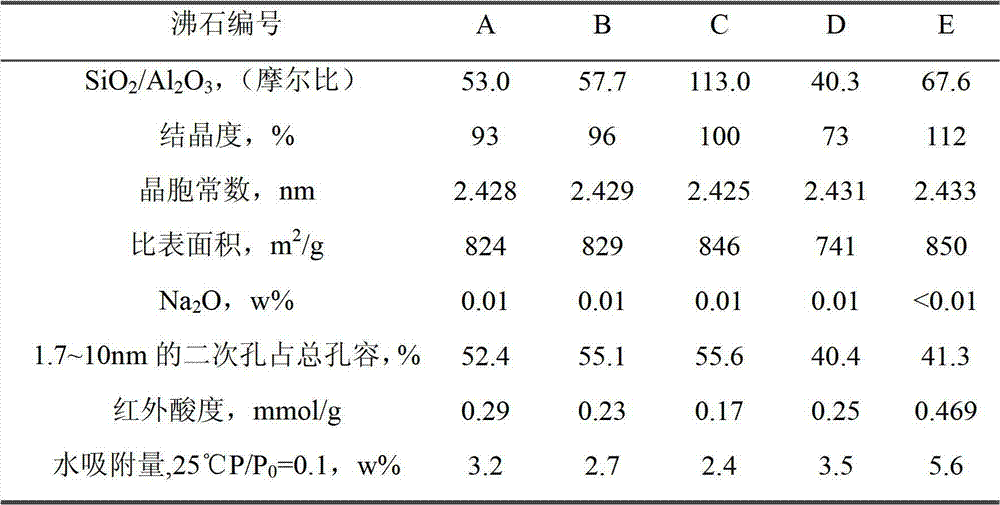

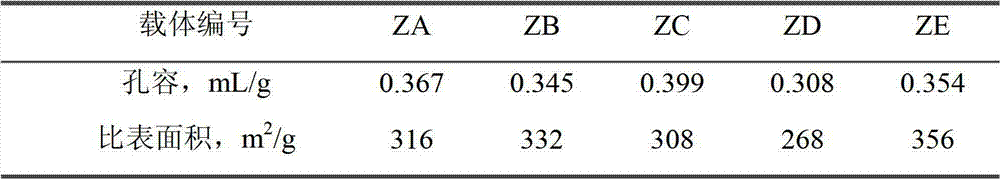

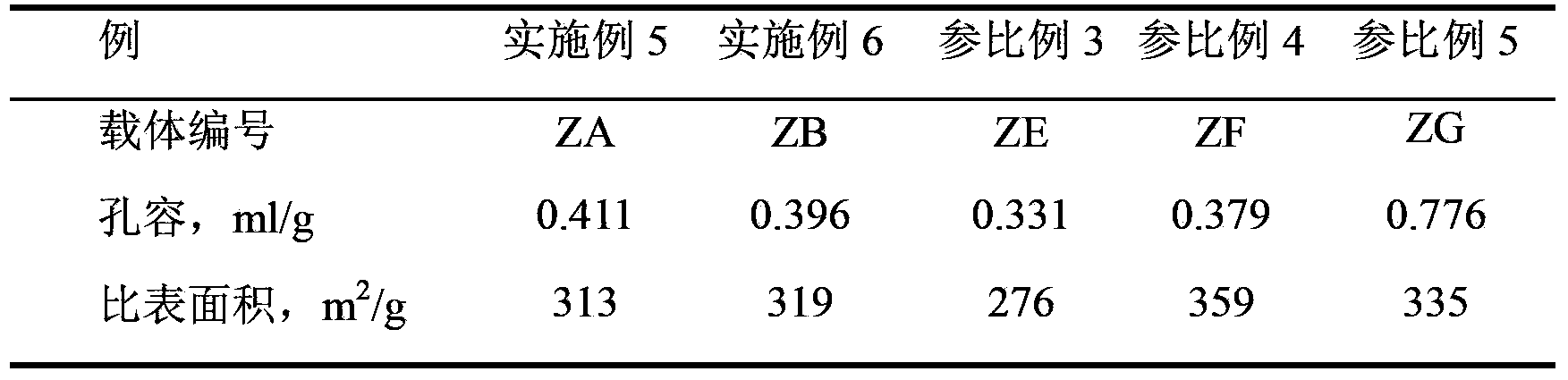

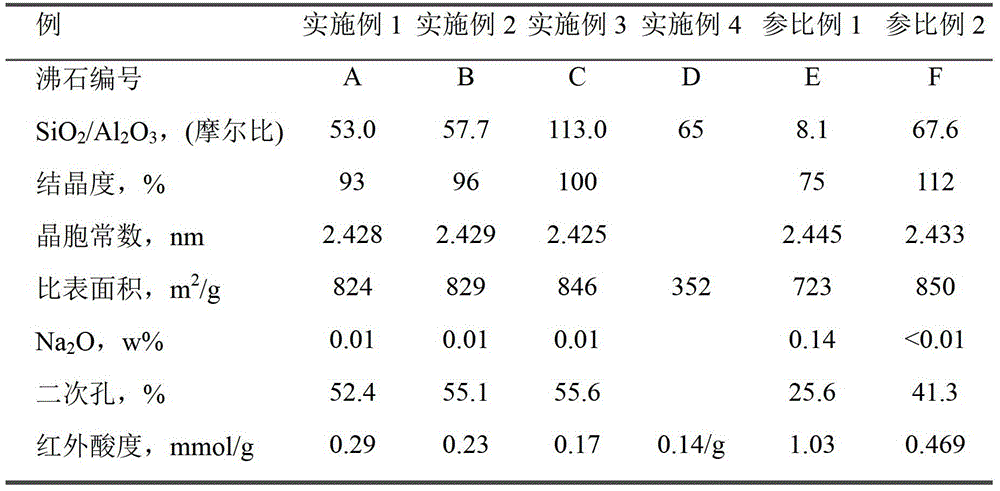

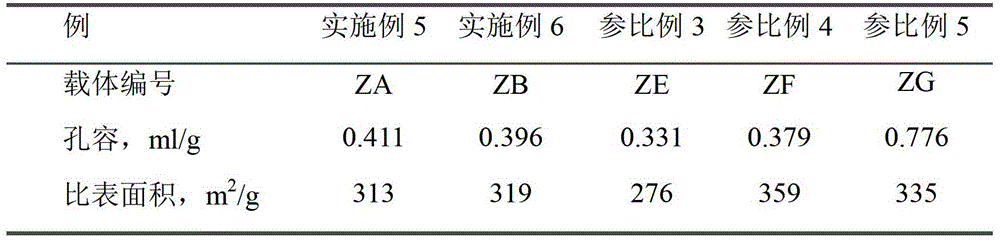

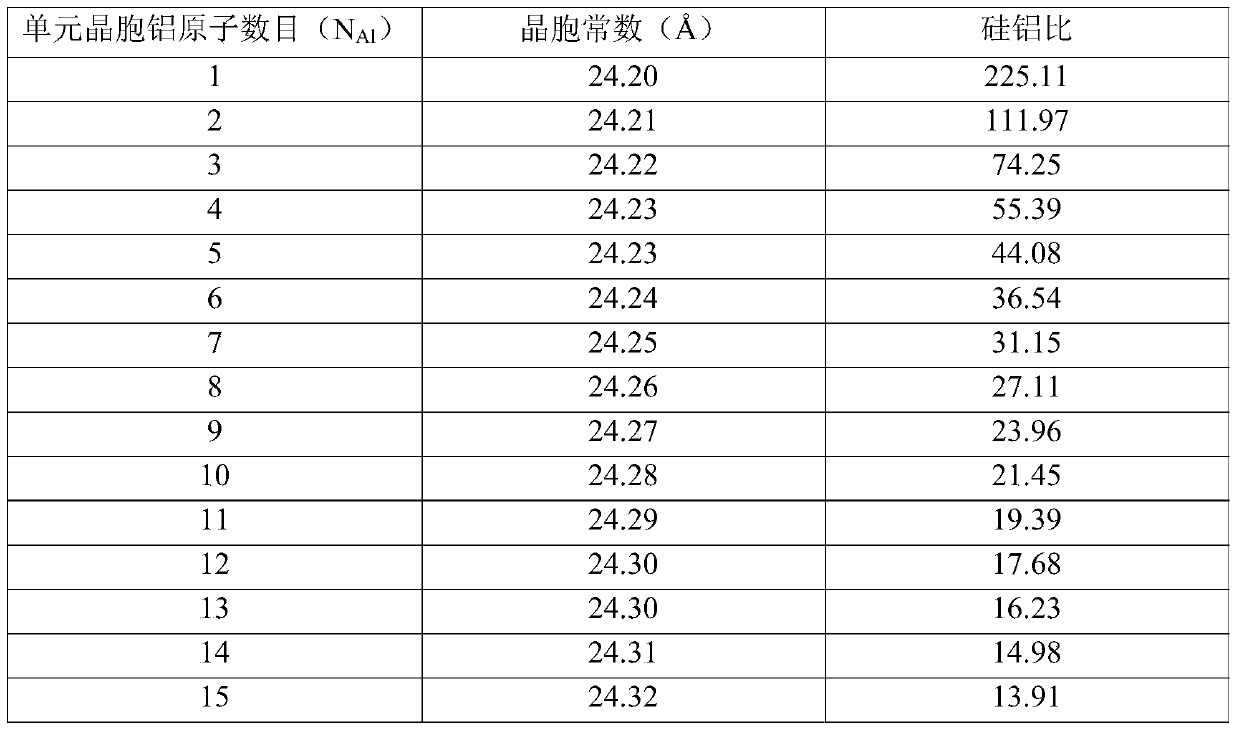

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN102786064AHigh activityImprove heat resistanceCatalyst carriersMolecular sieve catalystsIon exchangeExtrusion moulding

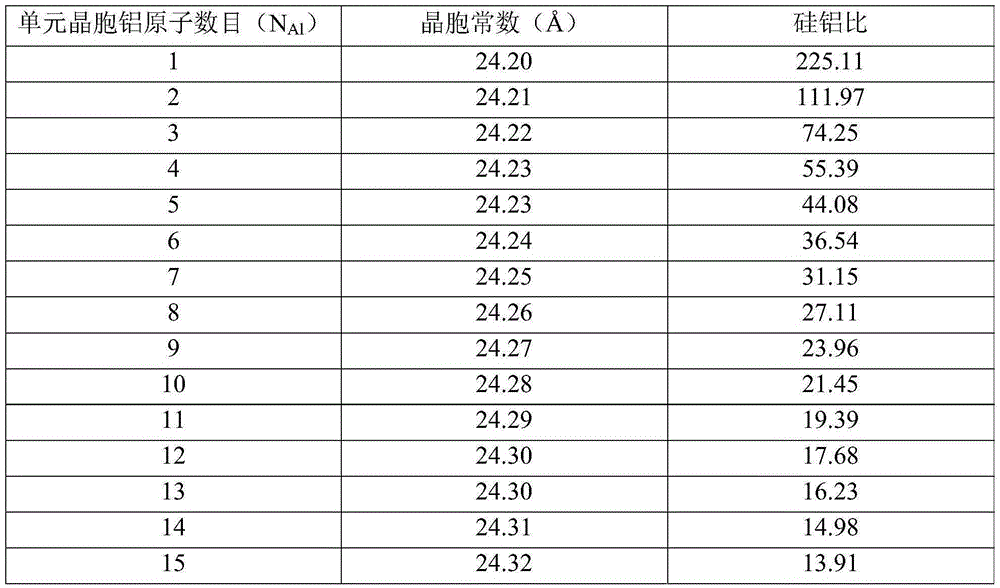

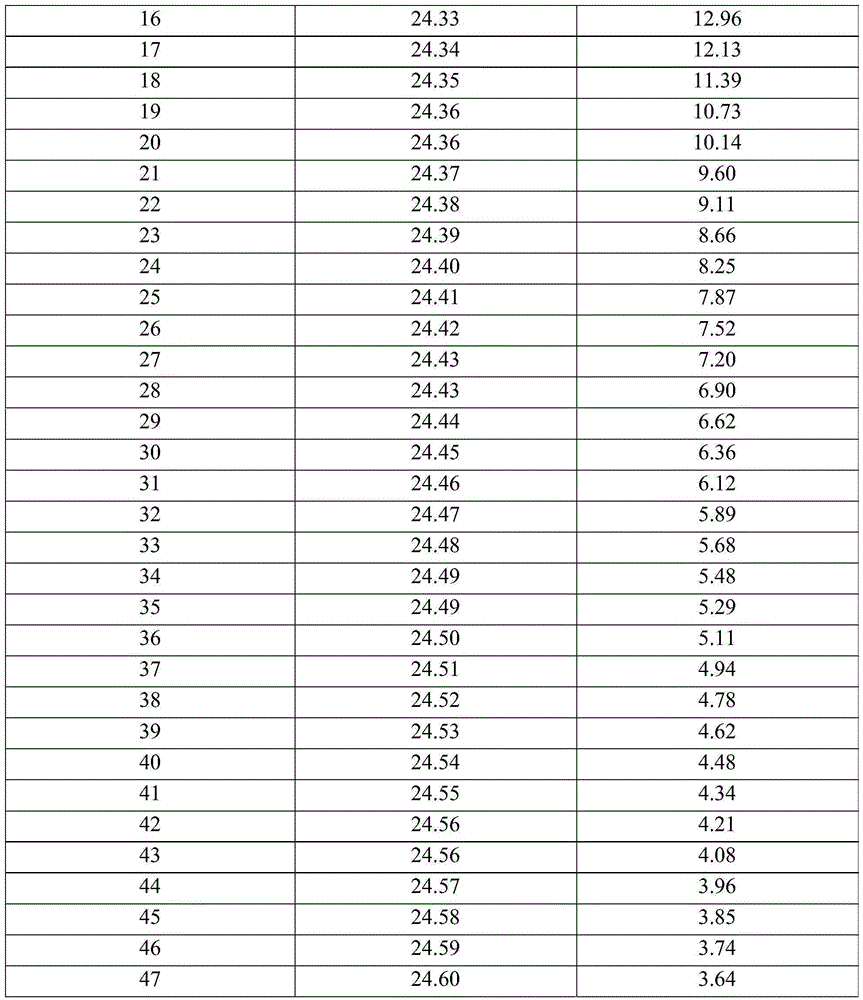

The invention discloses a hydrocracking catalyst carrier and a preparation method of the hydrocracking catalyst carrier. The hydrocracking catalyst carrier is prepared by using modified Y zeolite, aluminum oxide and amorphous silicon-aluminum. The modified Y zeolite has the following physiochemical properties: the mole ratio of SiO2 to Al2O3 is 30-120; the lattice constant is 2.420-2.435nm; the relative crystallinity is more than or equal to 90%; the specific surface area is 750-850m<2> / g; the secondary pore with 1.7-10nm accounts for more than 50% of the total pore volume; the infrared acidity is 0.10-0.50mmol / g; the ion exchange capacity is less than or equal to 0.10%; and the water adsorption quantity is less than 5.0% in percentage by weight at 25 DEG C and P / P0 of 1.0. The preparation method of the catalyst carrier provided by the invention comprises the following steps: mechanically mixing the modified Y zeolite, aluminum oxide, amorphous silicon-aluminum and adhesive, grinding, extrusion-moulding, drying and calcining to obtain the catalyst carrier. The catalyst carrier prepared by using the modified (deeply dealuminated) Y zeolite as the acidic cracking component is suitable to be used as the hydrocracking catalyst for middle distillates oil.

Owner:CHINA NAT OFFSHORE OIL CORP +2

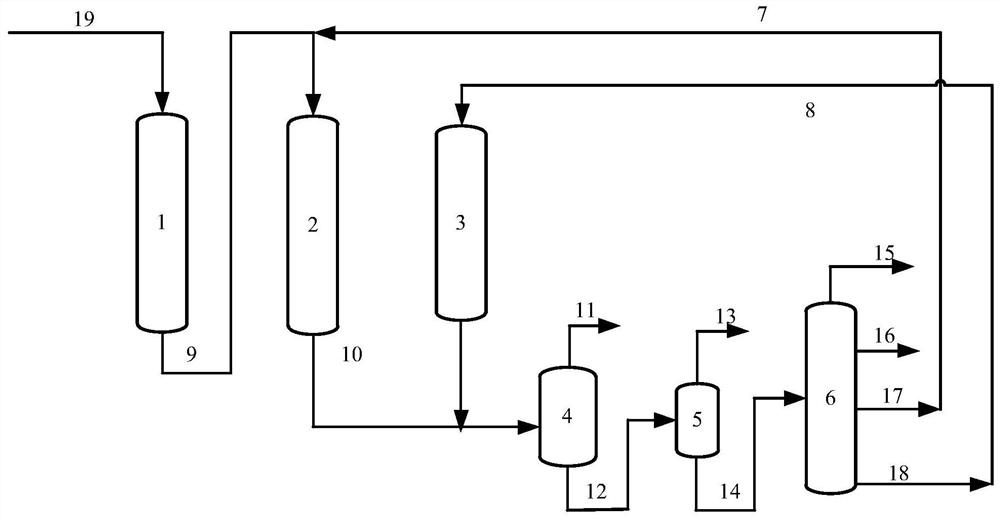

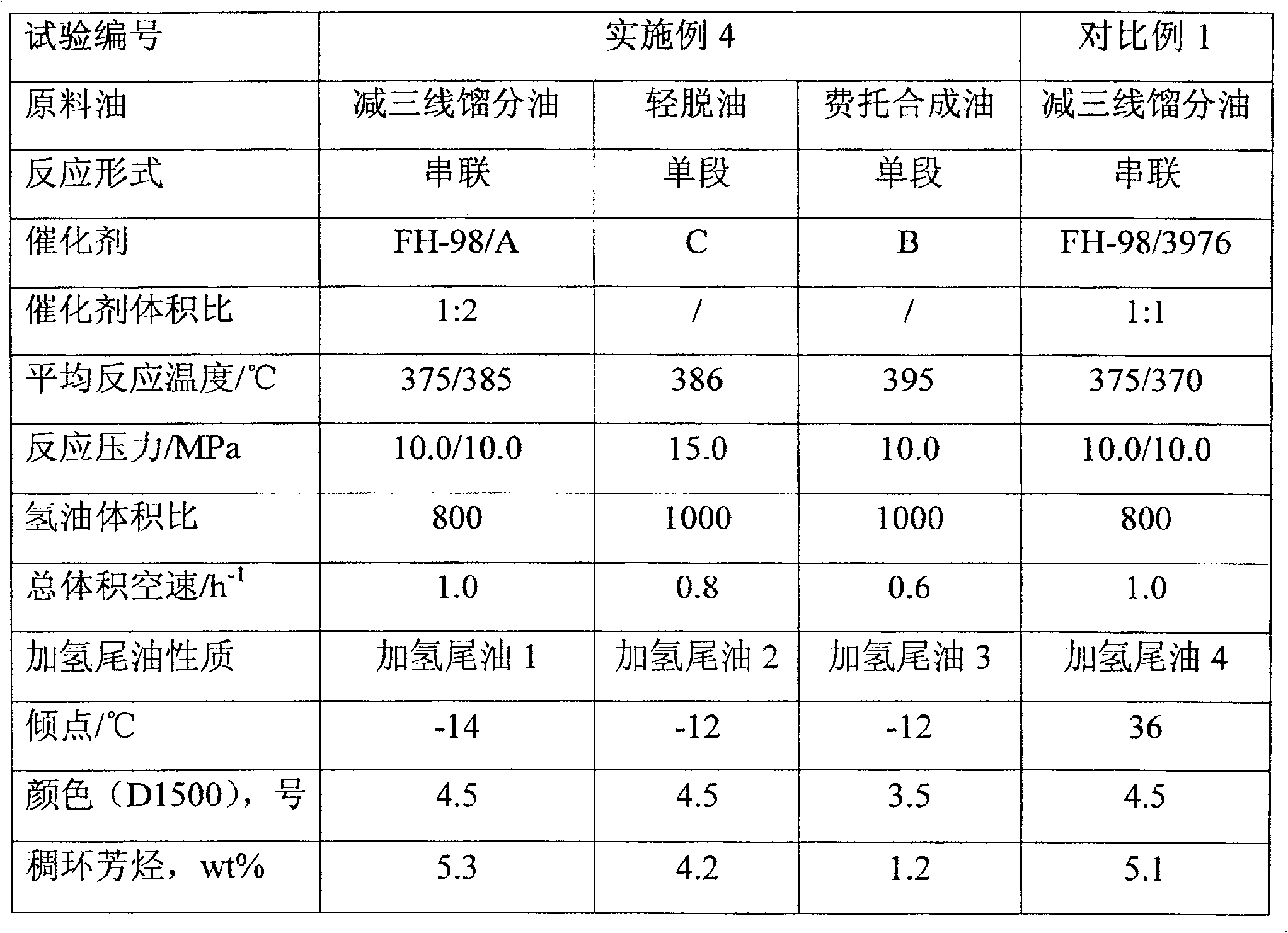

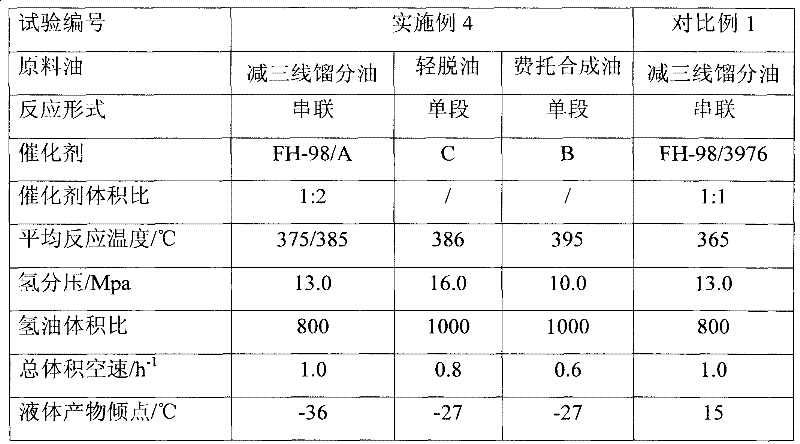

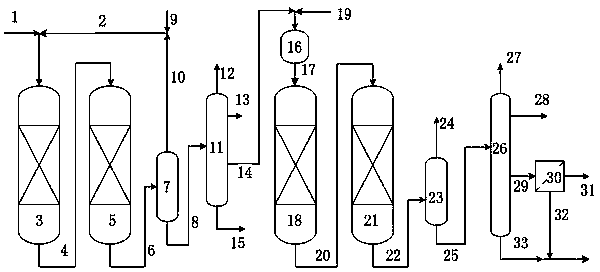

One-stage hydrogenation method for producing food-level white oil

ActiveCN101148606AHigh activityHigh selectivityTreatment with hydrotreatment processesEdible oils/fatsLiquid productMolecular sieve

The present invention provides one-section hydrogenation process for producing food level white oil. By using vacuum gas oil, deasphalted solvent oil and Fischer-Tropsch process oil as material, and hydrogenating catalyst containing modified beta-molecular sieve in 1-9 wt%, and through hydrocracking or hydrogenating, hot high pressure separating out gas and light distillate to obtain liquid product, mixing with newly formed hydrogen, and high pressure hydro-finishing in a reactor with loaded reduction type hydrogenating catalyst, food level white oil is produced. The process is simple and has high product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modification method of small-grain NaY-type molecular sieve

ActiveCN104591210AImprove stabilityStability is not affectedMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveNaphtha

The invention discloses a modification method of a small-grain NaY-type molecular sieve. According to the invention, the NaY-type molecular sieve raw material with relatively high silica-to-alumina ratio, high crystallinity and good stability is adopted. Through sequential steps of alkali wash, ammonium exchange, hydrothermal treatment, and acid and ammonium salt mixed solution treatment, the obtained small-grain Y-type molecular sieve has relatively high SiO2 / A12O3 molar ratio as well as relatively high secondary pore proportion. Also, the stability of the Y-type molecular sieve is maintained. The molecular sieve has relatively high specific surface area and relatively high crystallinity. The Y-type molecular sieve provided by the invention is suitable to be used as a cracking component of a light oil hydrocracking catalyst. With the Y-type molecular sieve, the catalyst has the advantages of good activity, good heavy naphtha selectivity and excellent product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carrier and catalyst and preparation method and application thereof and hydrocracking method

ActiveCN106622390AHigh crystallinitySecondary holeCatalyst carriersMolecular sieve catalystsMolecular sieveInorganic oxide

The invention discloses a carrier and an application thereof. The carrier contains an aluminum-removal Y-type molecular sieve and a heatproof inorganic oxide. The invention also discloses a catalyst by employing the carrier and a preparation method and an application thereof. The invention further discloses a hydrocracking method of the catalyst. According to the molecular sieve in the carrier, the molecular sieve has high crystallization degree and abundant secondary pores, and has lower non-framework aluminum content. The catalyst is prepared by VIII metallic element and VIB metallic element loaded on the carrier, the catalyst displays better catalysis performance in a hydrocracking reaction, and can obtain good balance among catalytic activity, middle distillate selectivity and tail oil BMCI value.

Owner:CHINA PETROLEUM & CHEM CORP +1

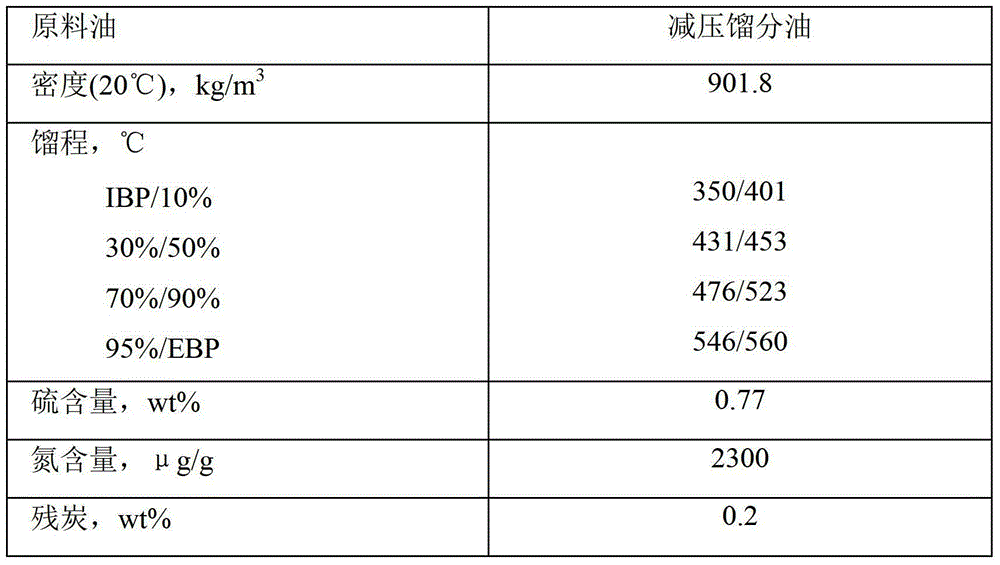

Method for hydrogenating naphthenic base distillate to produce lubricating oil basic oil

ActiveCN102311785BImprove comprehensive hydroprocessing capacityImprove stabilityTreatment with hydrotreatment processesLubricant compositionHydrogenation processBase oil

The invention relates to a method for hydrogenating naphthenic base distillate to produce lubricating oil basic oil. The naphthenic distillate is used as raw material and a one-stage in series hydrogenation process of hydrotreating-hydrodewaxing-hydrofinishing is adopted to produce the lubricating oil basic oil. Ordinary hydrotreating catalysts are filled in the upper part of a hydrotreating reaction area, and hydrotreating catalysts containing modified zeolites are filled in the lower part of the hydrotreating reaction area. The hydrodewaxing and hydrofinishing reaction areas are the same as those of the prior art, and are filled with hydrodewaxing catalysts and hydrofinishing catalysts. Compared with the prior art, the method disclosed by the invention has the advantages that system energy consumption is reduced, the pour point of a product is properly reduced, and the stability of the product is effectively improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Silicon-aluminum carrier containing two modified molecular sieves, preparation method and application thereof

ActiveCN104250010ASmall cell constantImprove stabilityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveAmorphous silicon

The invention relates to a silicon-aluminum carrier containing two modified molecular sieves. The silicon-aluminum carrier includes a modified Y molecular sieve, a modified ZSM-23 molecular sieve, and amorphous silicon-aluminum. The modified Y molecular sieve adopted by the carrier is a deep dealuminated Y molecular sieve, which has the characteristics of integral crystal form, high silicon-aluminum ratio, low acid center density, high medium-strong acid proportion and abundant secondary pores, and is suitable to serve as the acidic cracking component of a medium oil type hydrocracking catalyst. The high specific surface and developed secondary pores not only promote exertion of the hydrogenation activity, but are also conducive to spread of the reaction product, the secondary pores are numerous, and the acid center density is low, so that the probability of excessive cracking and secondary cracking can be reduced. Therefore, the catalyst can have excellent medium oil selectivity, high silicon-aluminum ratio, small lattice constant and stable structure, and has very good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

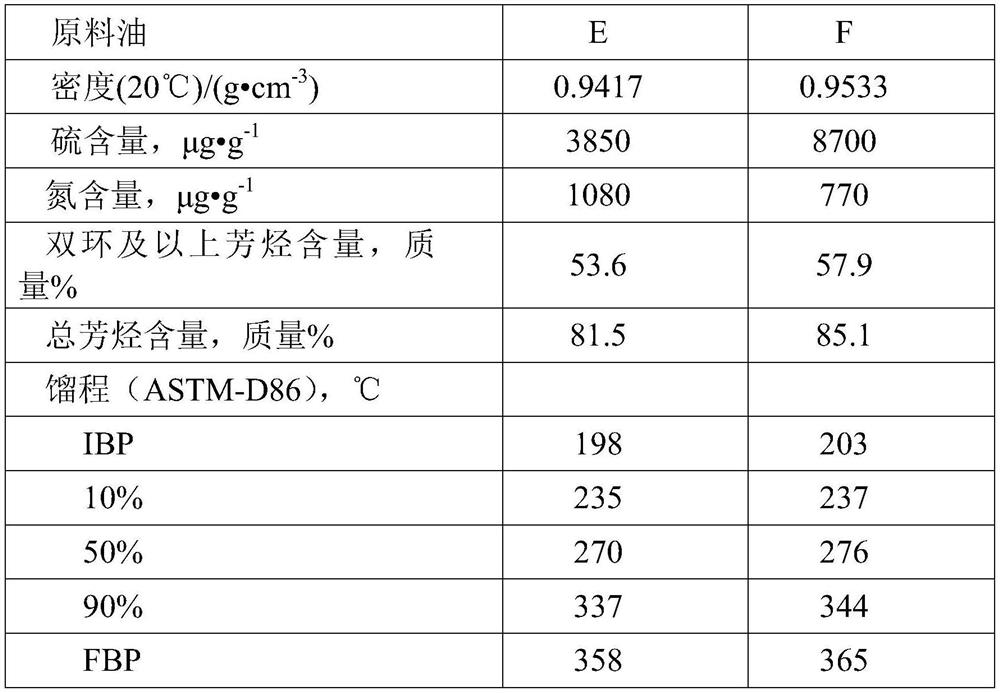

Hydro-upgrading catalyst as well as preparation method and application thereof

PendingCN112742451ASecondary holeHigh yieldMolecular sieve catalystsHydrocarbon oils treatmentPolycyclic aromatic hydrocarbonMolecular sieve

The invention provides a hydro-upgrading catalyst as well as a preparation method and an application thereof. The hydro-upgrading catalyst comprises a carrier and an active metal component loaded on the carrier, the carrier comprises a matrix and a Y molecular sieve, and the cell constant of the Y molecular sieve is 2.415-2.440 nm; the ratio of the peak area of a resonance signal with chemical shift of 0+ / -2ppm in a 27Al MAS NMR spectrum of the Y molecular sieve to the total peak area is not more than 4%; and the strong acid amount of the Y molecular sieve accounts for 70% or above of the total acid amount. According to the hydro-upgrading catalyst, the Y molecular sieve with high silica-alumina ratio, less non-framework aluminum, large specific surface area, rich secondary pores and high strong acid center proportion is used, so that the polycyclic aromatic hydrocarbon hydrogenation saturation and ring opening performance of the catalyst is enhanced, and the aromatic hydrocarbon selective hydrogenation ring opening of the catalyst is high and good in selectivity; and the cetane number of the diesel oil can be remarkably increased while the high diesel oil yield is maintained in the hydro-upgrading process of the inferior diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing food-level white oil by hydrogenation technique

ActiveCN101148610AHigh activityHigh selectivityTreatment with hydrotreatment processesHydrocarbon oils refiningMolecular sieveDistillation

The present invention provides one-section hydrogenation process for producing food level white oil. By using vacuum gas oil, deasphalted solvent oil and Fischer-Tropsch process oil as material, and hydrogenating catalyst containing modified beta-molecular sieve in 1-9 wt%, and through hydrocracking inside a hydrocracking co-current reactor to obtain reaction product, hydrorefining in a countercurrent hydrorefining reactor with flash region to exhaust gas and liquid hydrocarbon, the reverse contact reaction between the downward flowing liquid hydrocarbon and the bottom entering newly formed hydrogen in the bed layer with reduction type hydrogenating catalyst, and final gas-liquid separation and product distillation, food level white oil is produced. The process is simple and has high product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrodearomatization catalyst and preparation method thereof

ActiveCN104588073BHigh activityFacilitates selective loop openingMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveNaphtha

The invention discloses a hydrogenation dearomatization catalyst and a preparation method thereof. The catalyst comprises a main active component Pt, an auxiliary component Pd and a carrier prepared from a small-grain Y type molecular sieve, alumina and amorphous silicon aluminum. According to the preparation method, the small-grain Y type molecular sieve with the characteristics of great dealumination depth, good crystallinity retentivity and well-developed secondary pores is used as an acid component and cooperates with the amorphous silicon aluminum, the main active component and the auxiliary component, so the hydrogenation dearomatization catalyst has higher hydrogenation dearomatization activity and is especially applicable to hydrogenation dearomatization and decoloring of heavy aromatic-containing naphthenic high-viscosity white oil and solvent naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modification method for small-grain NaY type molecular sieve

ActiveCN104828840AImprove stabilityStability is not affectedFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses a modification method for a small-grain NaY type molecular sieve. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes alkali washing, ammonium exchange, aluminum removal and silicon supplement, hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt; and the obtained small-grain Y type molecular sieve has a high SiO2 / Al2O3 mol ratio and a high proportion of secondary pores, retains the stability of a Y type molecular sieve and has a high specific surface area and a high degree of crystallization. The small-grain Y type molecular sieve prepared in the invention is applicable as a cracking component for a hydrocracking catalyst used for high and medium oil and enables the hydrocracking catalyst to have good activity, medium oil selectivity and product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

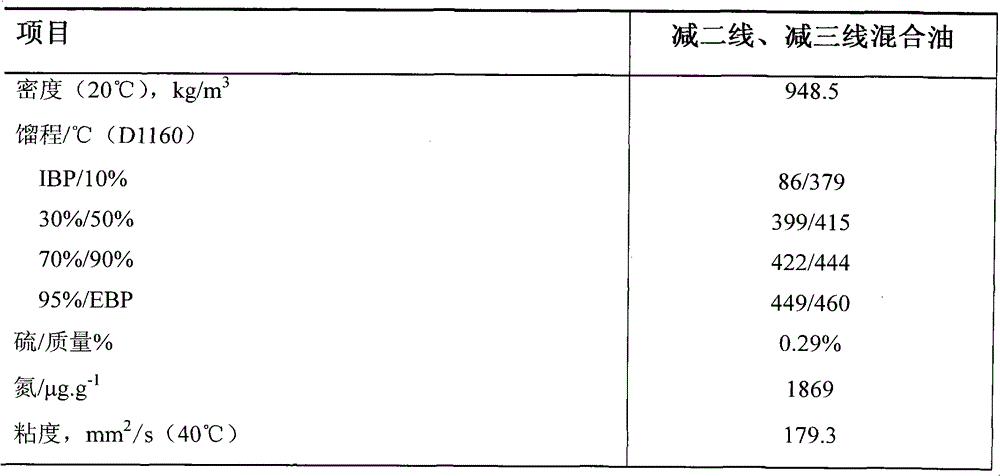

Hydrocracking method for producing high-octane gasoline

ActiveCN112745920AReduce lossesHigh activityTreatment with hydrotreatment processesHydrocarbon oils treatment productsPolycyclic aromatic hydrocarbonReaction zone

The invention relates to a hydrocracking method for producing high-octane gasoline, which comprises the following steps: reacting a diesel oil raw material in a hydrofining reaction zone and a hydrocracking reaction zone I, and separating to obtain a gasoline fraction, a middle fraction and a tail oil fraction. Wherein the middle fraction returns to the hydrocracking reaction zone I for further conversion, and the tail oil fraction enters the hydrocracking reaction zone II for further conversion. According to the method, polycyclic aromatic hydrocarbons in the middle fraction and the tail oil fraction are converted to the maximum extent, high-octane gasoline fractions are produced, the RON of the gasoline fractions can reach 93 or above, and the loss of total aromatic hydrocarbons is small.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing lubricating oil basic oil from hydrogenated tail oil

ActiveCN100549142CHigh activityHigh selectivityHydrocarbon oil crackingTreatment with hydrotreatment processesMolecular sieveDistillation

The invention relates to a method for producing lubricating oil base oil from hydrogenated tail oil. Using hydrocracking tail oil as raw material, it can directly carry out vacuum distillation, and under suitable conditions, lubricating oil base oil products can be obtained. The hydrocracking tail oil is made of vacuum distillate oil, solvent refined deasphalted oil and Fischer-Tropsch synthetic oil as raw materials, and uses a hydrocracking catalyst containing modified β molecular sieves. Modified β-molecular sieve with high silicon-aluminum ratio, high crystallinity, and certain secondary pores, through hydrocracking or hydrocracking process, the tail oil with pour point less than -10°C can be obtained. The invention can produce lubricating oil base oil products with excellent performance by selecting the hydrogenated tail oil processed by suitable hydrocracking catalysts without going through pour point depressing and refining processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst as well as preparation method and application thereof

PendingCN112742450AReduce the ratioRaise the ratioMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention provides a hydrocracking catalyst as well as a preparation method and an application thereof. The hydrocracking catalyst comprises a carrier and an active metal component loaded on the carrier, the carrier comprises a matrix and a Y molecular sieve, and the hydrocracking catalyst comprises 1-10 wt% of a group VIII metal component and 2-40 wt% of a group VIB metal component in terms of oxide on the basis of the hydrocracking catalyst; the content of the Y molecular sieve in the carrier is 30-90 wt%, and the content of the matrix is 10-70 wt%; wherein the unit cell constant of the Y molecular sieve is 2.415 to 2.440 nm; the ratio of the peak area of a resonance signal with chemical shift of 0+ / -2ppm in a 27Al MAS NMR spectrum of the Y molecular sieve to the total peak area is not more than 4%; and the strong acid amount of the Y molecular sieve accounts for 70% or above of the total acid amount. The hydrocracking catalyst is used for catalyzing diesel hydrocracking to produce gasoline or light aromatic hydrocarbon, and has the characteristics of high yield, good selectivity, high gasoline octane number and the like of ideal products such as gasoline or light aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Small-grain Y-type molecular sieve and preparation method thereof

ActiveCN104591209BImprove stabilityStability is not affectedFaujasite aluminosilicate zeoliteMolecular sieveNaphtha

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of small-grain Y-type molecular sieve

ActiveCN104828838BImprove stabilityStability is not affectedMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses a preparation method for a small-grain Y type molecular sieve. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes ammonium exchange, primary hydro-thermal treatment, treatment with an alkali-containing solution, secondary hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt; and the obtained small-grain Y type molecular sieve has a high SiO2 / Al2O3 mol ratio and a high proportion of secondary pores, retains the stability of a Y type molecular sieve and has a high specific surface area and a high degree of crystallization. The small-grain Y type molecular sieve prepared in the invention is applicable as a cracking component for a hydrocracking catalyst used for high and medium oil and enables the hydrocracking catalyst to have good activity, medium oil selectivity and product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

A silica-alumina carrier containing two modified molecular sieves and its preparation method and application

ActiveCN104250010BSmall cell constantImprove stabilityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveHydrogen

A silica-alumina carrier containing two kinds of modified molecular sieves, including modified Y molecular sieve, modified ZSM-23 molecular sieve and amorphous silica-alumina, the modified Y molecular sieve used in the inventive carrier is deeply dealuminated Y molecular sieve with complete crystal form, High silicon-aluminum ratio, low acid center density, high proportion of medium-strong acid, abundant secondary pores, suitable for use as acidic cracking component of medium oil hydrocracking catalyst, high specific surface area and developed secondary pores of molecular sieves not only facilitate the process of hydrocracking The hydrogen activity is exerted, and it is beneficial to the diffusion of reaction products. The secondary pores are many, and the acid center density is low, which reduces the probability of excessive cracking and secondary cracking, so that the catalyst has excellent medium oil selectivity and high silicon-aluminum ratio. , the unit cell constant is small and the structure is stable, so the catalyst has good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

High crystallinity modified Y zeolite and its preparation method

ActiveCN100408477CEasy to useHigh crystallinityMolecular sieve catalystsFaujasite aluminosilicate zeolitePhysical chemistryCrystallinity

The invention discloses a high-crystallinity modified Y-zeolite with cell parameter at 2.425-2.435nm, relative crystallinity not less than 95% and specific surface area at 800-950m2 / g, which is characterized by the following: adopting NaY zeolite as raw material to do amino exchange through ammonium salt solution; controlling the exchanging degree not less than 80%; placing in the water heat disposing furnace under 400-700 deg.c at 0.05-0.5Mpa for 1.0-5.0h; contacting the zeolite sample and ammonium salt solution; controlling the pH value; exchanging Na+ in the zeolite further; stripping non-frame aluminium selectively; proceeding secondary water heat disposal; setting the molar rate of SiO2 / Al2O3 at 15-16; obtaining the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing food-level white oil by hydrogenation technique

ActiveCN101148610BHigh activityHigh selectivityTreatment with hydrotreatment processesHydrocarbon oils refiningMolecular sieveDistillation

The present invention provides one-section hydrogenation process for producing food level white oil. By using vacuum gas oil, deasphalted solvent oil and Fischer-Tropsch process oil as material, and hydrogenating catalyst containing modified beta-molecular sieve in 1-9 wt%, and through hydrocracking inside a hydrocracking co-current reactor to obtain reaction product, hydrorefining in a countercurrent hydrorefining reactor with flash region to exhaust gas and liquid hydrocarbon, the reverse contact reaction between the downward flowing liquid hydrocarbon and the bottom entering newly formed hydrogen in the bed layer with reduction type hydrogenating catalyst, and final gas-liquid separation and product distillation, food level white oil is produced. The process is simple and has high product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN104588121AHigh ratio of silicon to aluminumHigh crystallinityCatalyst carriersMolecular sieve catalystsMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier is composed of a small-grain Y type molecular sieve, amorphous silica-alumina and alumina. According to the preparation method, the small-grain Y type molecular sieve with the characteristics of proper dealumination degree, good crystallinity retentivity and well-developed secondary pores is used as an acid component; and when the small-grain Y type molecular sieve and the amorphous silica-alumina are cooperatively used for preparing a hydrocracking catalyst, the hydrocracking catalyst has the advantages of good activity, heavy naphtha selectivity and superior product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

A carrier and its application, a catalyst, its preparation method and application, and a hydrocracking method

ActiveCN106622390BHigh crystallinitySecondary holeCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a carrier and an application thereof. The carrier contains an aluminum-removal Y-type molecular sieve and a heatproof inorganic oxide. The invention also discloses a catalyst by employing the carrier and a preparation method and an application thereof. The invention further discloses a hydrocracking method of the catalyst. According to the molecular sieve in the carrier, the molecular sieve has high crystallization degree and abundant secondary pores, and has lower non-framework aluminum content. The catalyst is prepared by VIII metallic element and VIB metallic element loaded on the carrier, the catalyst displays better catalysis performance in a hydrocracking reaction, and can obtain good balance among catalytic activity, middle distillate selectivity and tail oil BMCI value.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for small-grain Y type molecular sieve

ActiveCN104828838AImprove stabilityStability is not affectedMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses a preparation method for a small-grain Y type molecular sieve. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes ammonium exchange, primary hydro-thermal treatment, treatment with an alkali-containing solution, secondary hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt; and the obtained small-grain Y type molecular sieve has a high SiO2 / Al2O3 mol ratio and a high proportion of secondary pores, retains the stability of a Y type molecular sieve and has a high specific surface area and a high degree of crystallization. The small-grain Y type molecular sieve prepared in the invention is applicable as a cracking component for a hydrocracking catalyst used for high and medium oil and enables the hydrocracking catalyst to have good activity, medium oil selectivity and product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

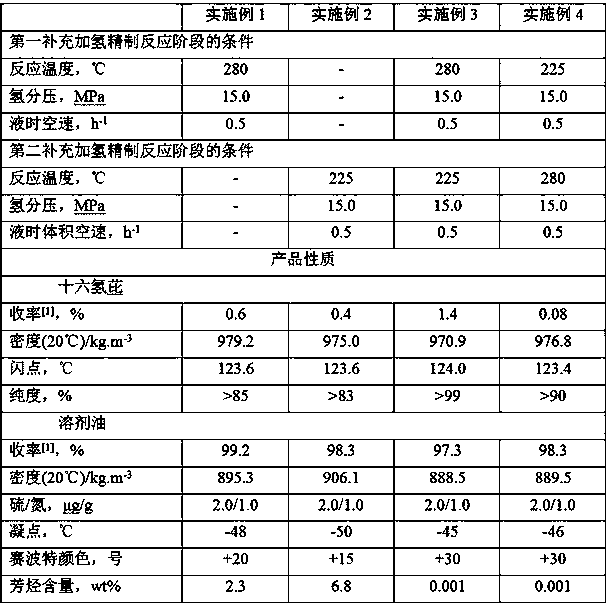

Preparation method of medical intermediate hexadecahydropyrene

ActiveCN109851468AHigh purityImprove economyHydrocarbon by hydrogenationDistillation purification/separationHydrogenation processFuel oil

The invention discloses a preparation method of medical intermediate hexadecahydropyrene. The preparation method comprises the following steps: after coal tar raw materials are pretreated, carrying out hydrofining and hydrocracking reactions to fractionate the obtained liquid; feeding the obtained diesel oil fraction into a supplementary refining reaction area, and carrying out a hydrogenation saturation reaction under the action of a supplementary refining catalyst; and cutting the supplementary refining product, cooling the obtained fraction, and carrying out filtering to obtain high-purityhexadecahydropyrene. According to the method, the purpose of producing hexadecahydropyrene from the coal tar raw materials by using a hydrogenation process is achieved for the first time. Compared with the prior art, the method disclosed by the invention has the advantages that the high-purity hexadecahydropyrene is obtained, and meanwhile, quality of byproducts meets the requirements of clean fuel oil products and solvent oil products. The method disclosed by the invention improves economic performance of coal tar processing, and has the characteristics of simple process and low operation energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrocracking method for producing high-octane gasoline

ActiveCN112745920BReduce lossesHigh activityTreatment with hydrotreatment processesHydrocarbon oils treatment productsPolycyclic aromatic hydrocarbonProcess engineering

The invention relates to a hydrocracking method for producing high-octane gasoline. The method comprises the steps of: reacting diesel raw materials in a hydrorefining reaction zone and a hydrocracking reaction zone I, and then separating and obtaining gasoline fractions, middle fractions and tail oil fractions . Among them, the middle distillate is returned to the hydrocracking reaction zone I for further conversion, and the tail oil fraction enters the hydrocracking reaction zone II for further conversion. The invention maximizes the conversion of polycyclic aromatic hydrocarbons in middle distillates and tail oil fractions, produces more high-octane gasoline fractions, the RON of the gasoline fractions can reach more than 93, and the loss of total aromatics is small.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com