Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

221 results about "Food level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

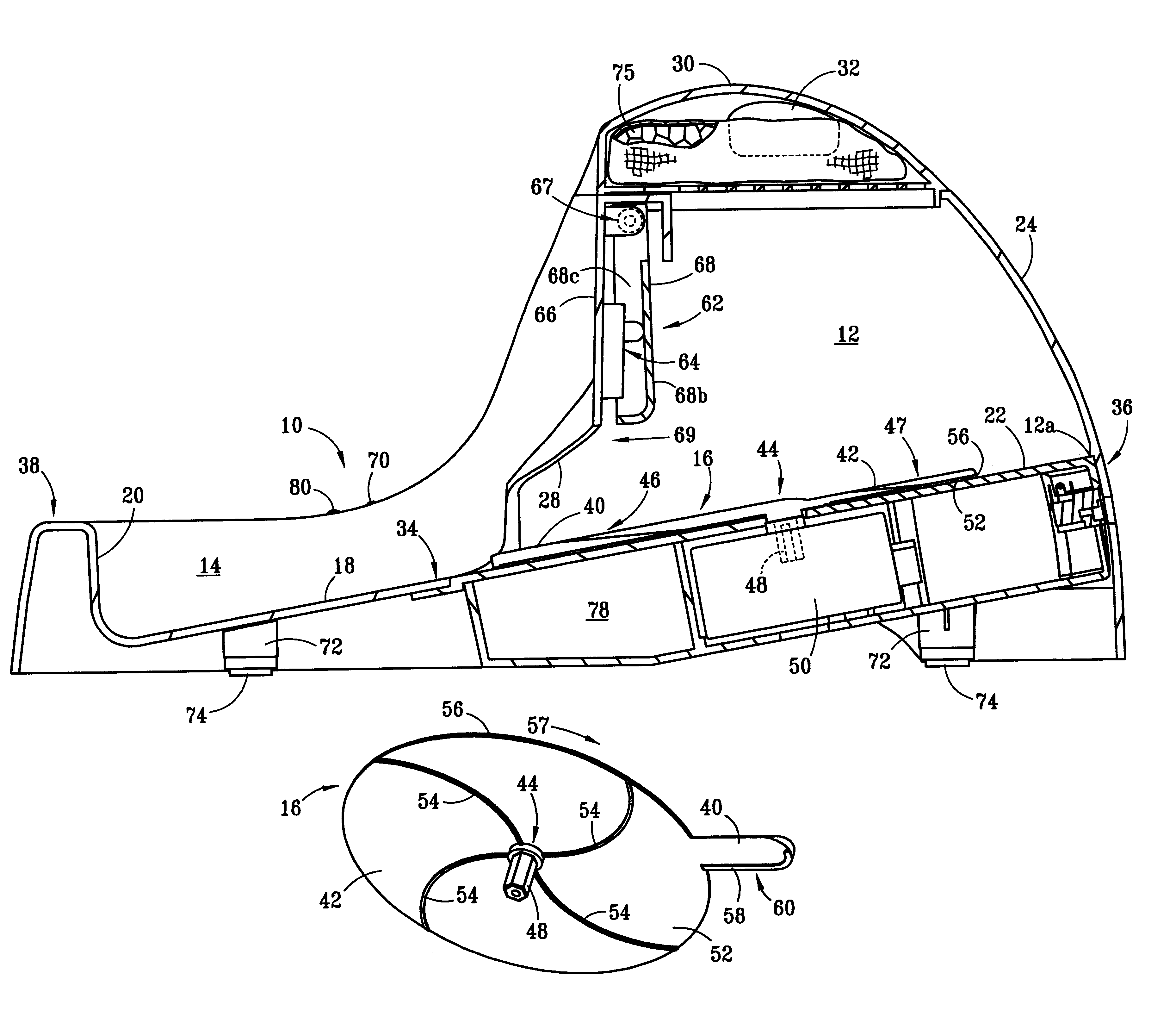

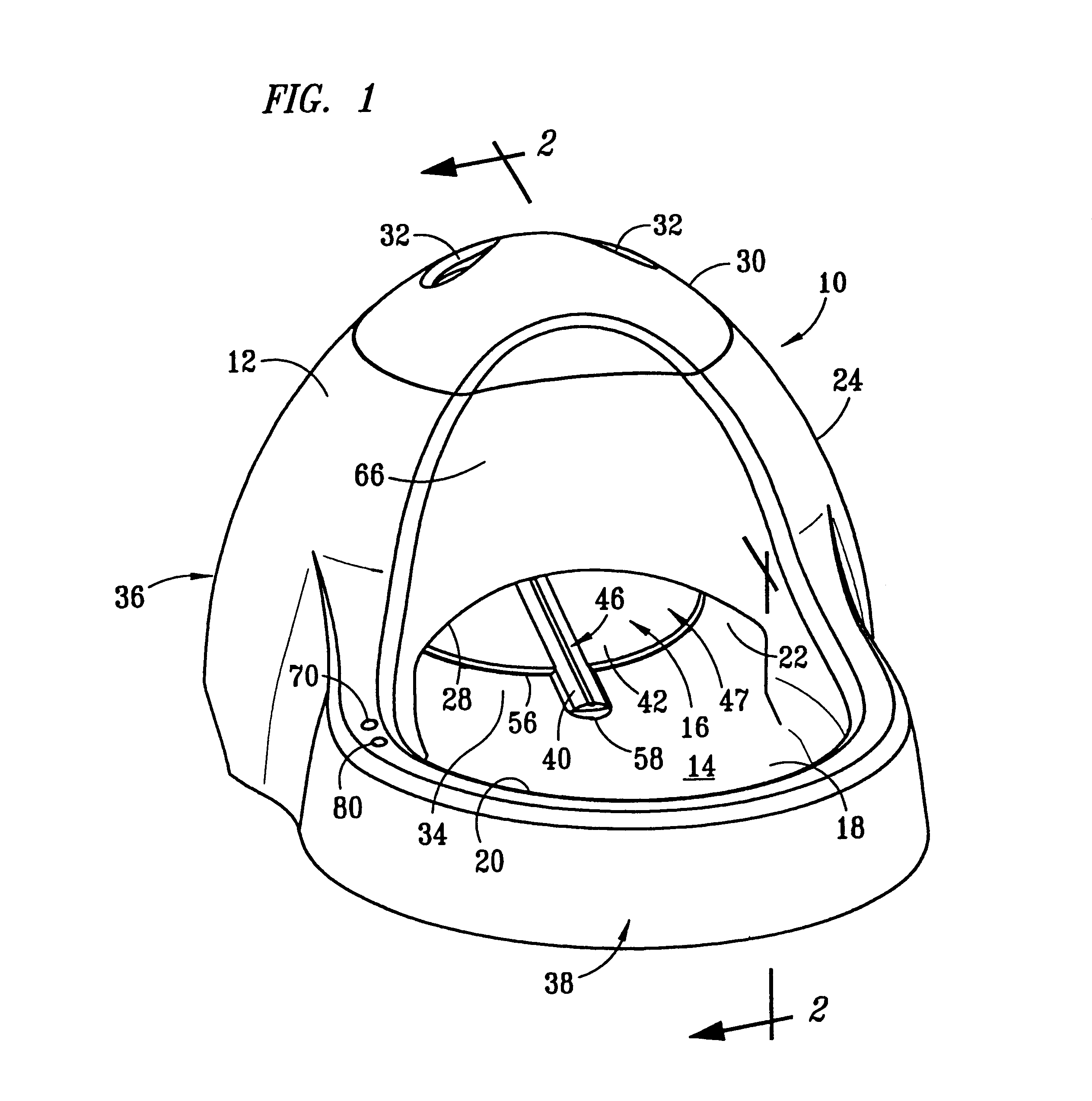

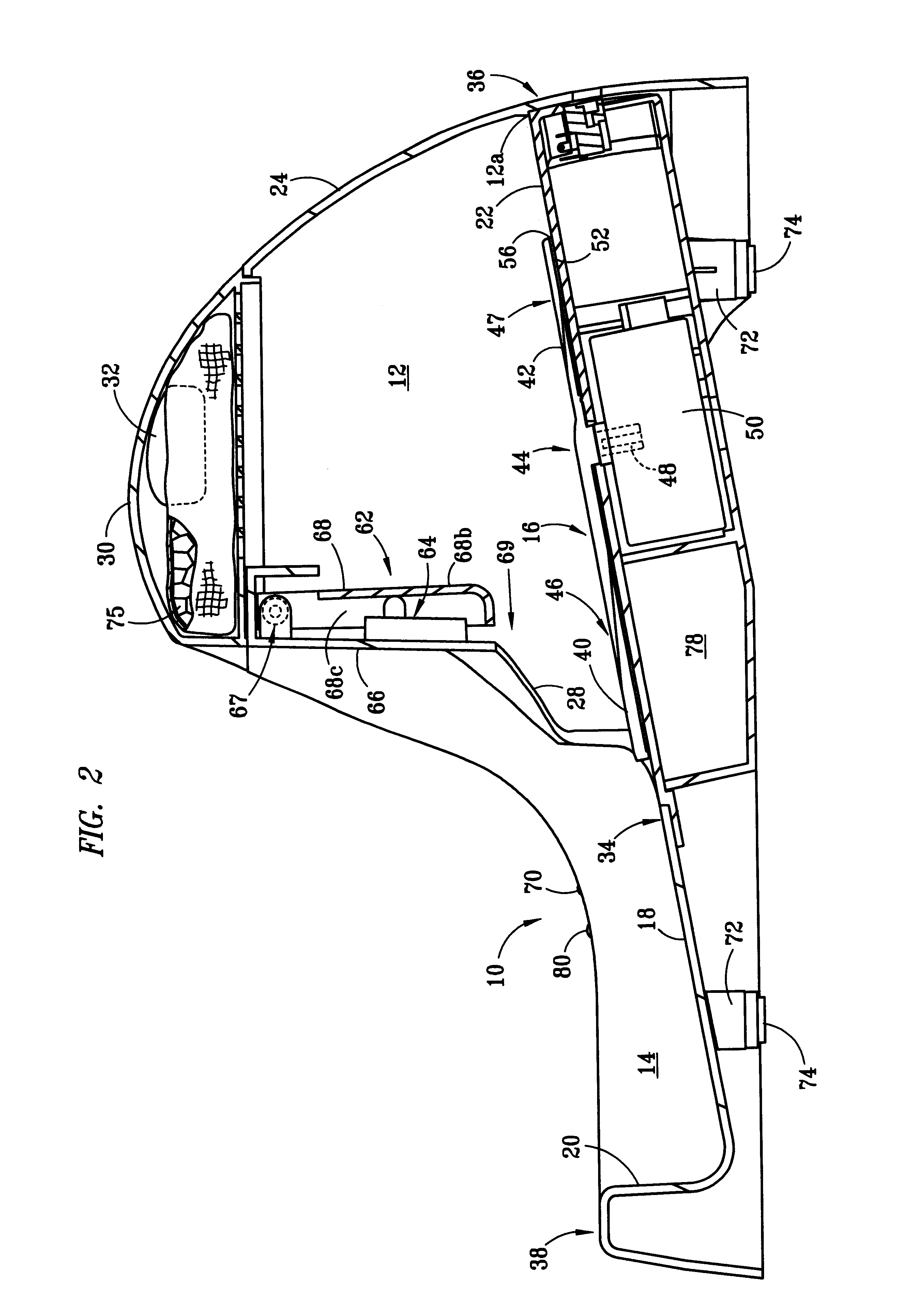

Pet feeder

InactiveUS6845735B1Minimal food stagnationEasy to identifyMovable measuring chambersAnimal feeding devicesEngineeringFood storage

A pet feeder for dispensing a supply of pet food includes a food dish and a food storage reservoir. The food storage reservoir is disposed adjacent the food dish and is adapted for holding a supply of the food. A top wall and a floor define the reservoir. The food dish is defined by a sidewall and a floor and has an open top to allow pets access to the food dish. The reservoir floor and the food dish floor form a continuous and downwardly sloping floor to gravitally direct pet food from the storage reservoir into the food dish. An agitator is disposed inside the reservoir. The agitator includes an arm secured to a disc for stirring the food to reduce food stagnation inside said reservoir. A food level sensor is further included in the reservoir to alert the user when the food level in the reservoir is empty or is approaching empty.

Owner:DOSKOCIL MFG

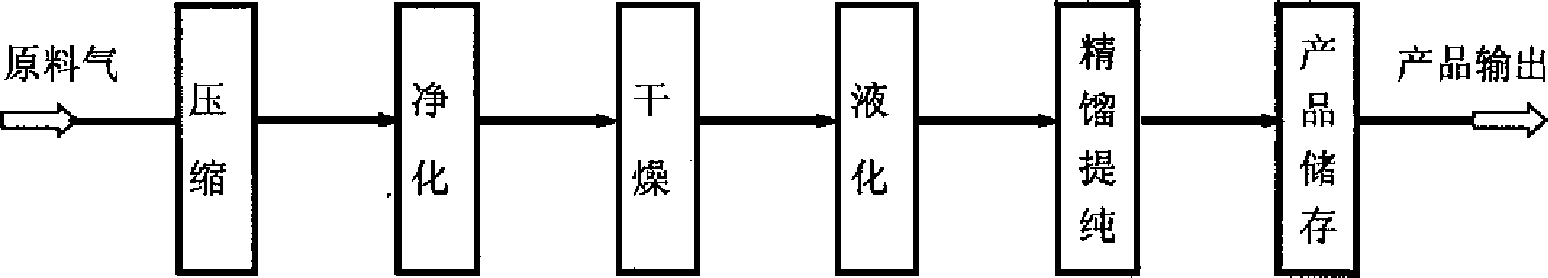

Method for producing food level liquid carbon dioxide product

ActiveCN101040674AReduce external heat sourcesImprove qualityCarbon compoundsFood preparationDistillationLiquid carbon

The invention relates to a method for producing edible liquid carbon dioxide product, characterized in that in compression step, the distribution of the third-stage outlet gas of compressor is adjusted by an adjusting valve, to supply needed thermal source to distillation via the compressed gas transmitted to a purifying tower, in the purifying step, some carbon dioxide gas and foul gas of purifying tower are discharge from tower top as splash steam to be throttled, expanded and reduced temperature via an adjusting valve A, to be feedback to a heat exchanger at the upper part of the purifying tower, to exchange heat with ascending splash steam in tube, and reduce pressure to 0.05MPa via an adjusting valve B, to be feed into purifying process to exchange heat with material gas to recycle cold as the regenerated gas of purifying or drying process. The invention uses adjusting valves A, B to control pressure discharge of purifying tower, to assure the stable pressure of purifying tower. The recycle rate of carbon dioxide of invention is at least improved 3%, while the consumption is at least reduced 5% and the carbon dioxide can reach the standard of edible carbon dioxide.

Owner:HUNAN KAIMEITE GASES +1

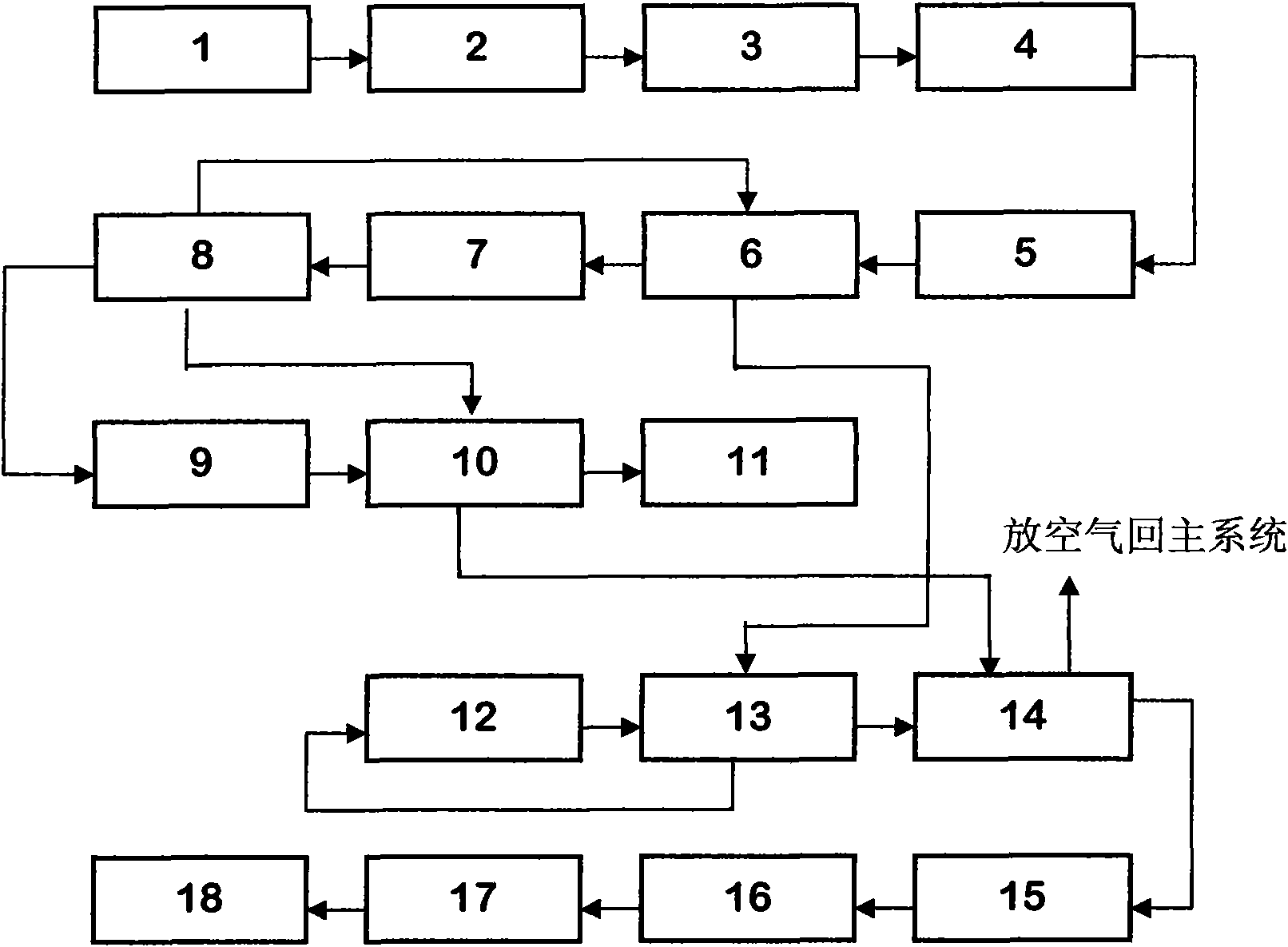

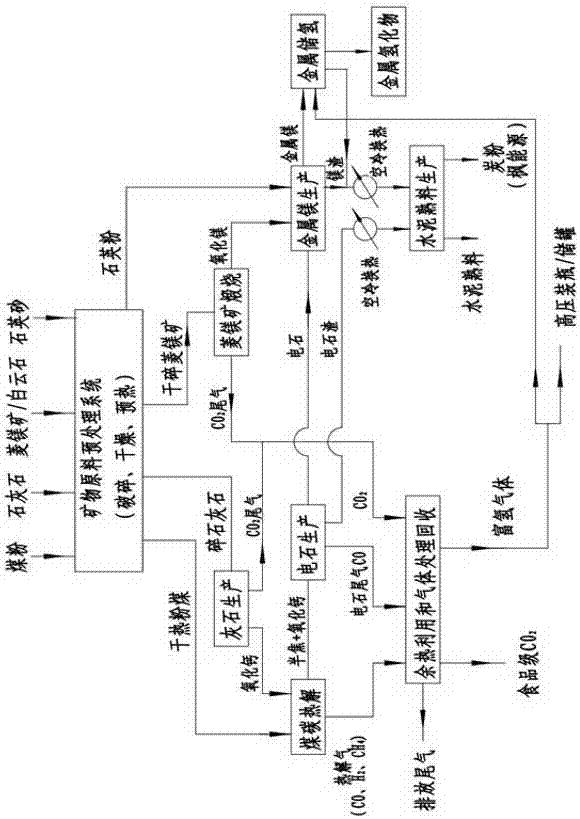

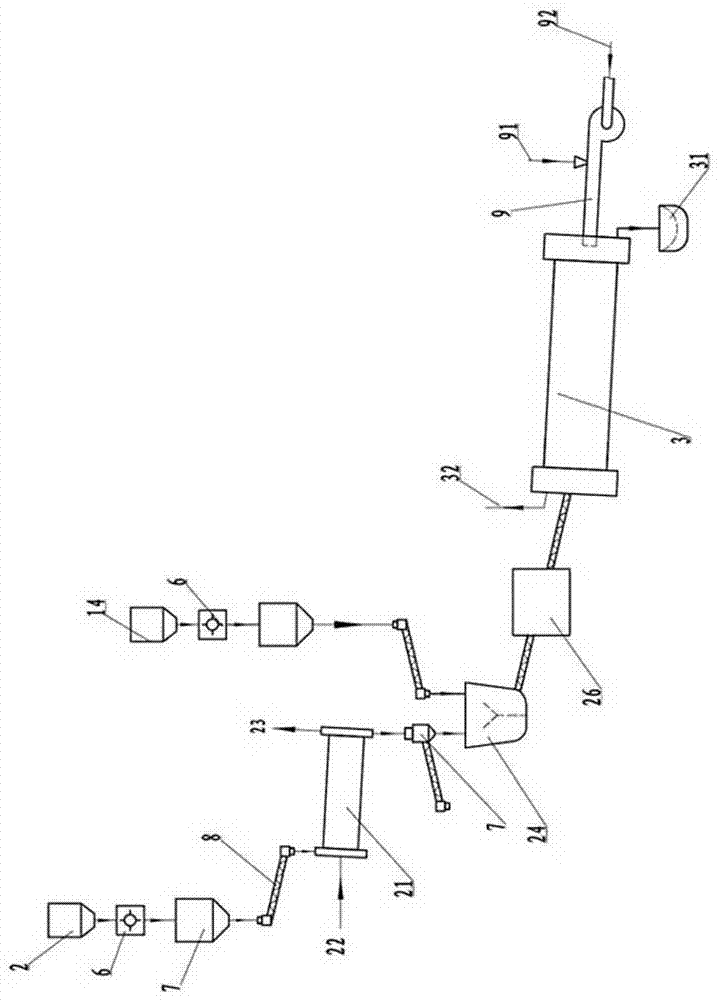

Method and device for united production of industrial level and food level liquid carbon dioxide

The invention discloses a method and a device for the united production of industrial level and food level liquid carbon dioxide, which is suitable for a concentrated occasion of carbon dioxide. The method comprises the following steps: carbon dioxide raw material gas after being pressurized is desulfurized, dewatered, dried and processed, non-condensable gas is separated after precooling and low-temperature liquefaction, and one part of liquid carbon dioxide is purified and supercooled to obtain an industrial level liquid carbon dioxide product; a food level liquid carbon dioxide product is obtained after precooling, hydrocarbon removal, purifying, cooling, drying, low-temperature liquefaction and extraction are carried out on the other part of liquid carbon dioxide. The device realizing the method comprises a pipe opening, a compressor, a devulcanizer, a dryer, a precooler, a condenser, a separator, a purifying tower, a supercooling device, a storage tank, a hydrocarbon removal tower, a heat exchanger, a cooler and the like which are sequentially communicated. The invention has the advantages of advanced process technology, full energy utilization, little energy consumption, low production cost, high production efficiency, little equipment investment, stable product quality, and the like.

Owner:申屠晶

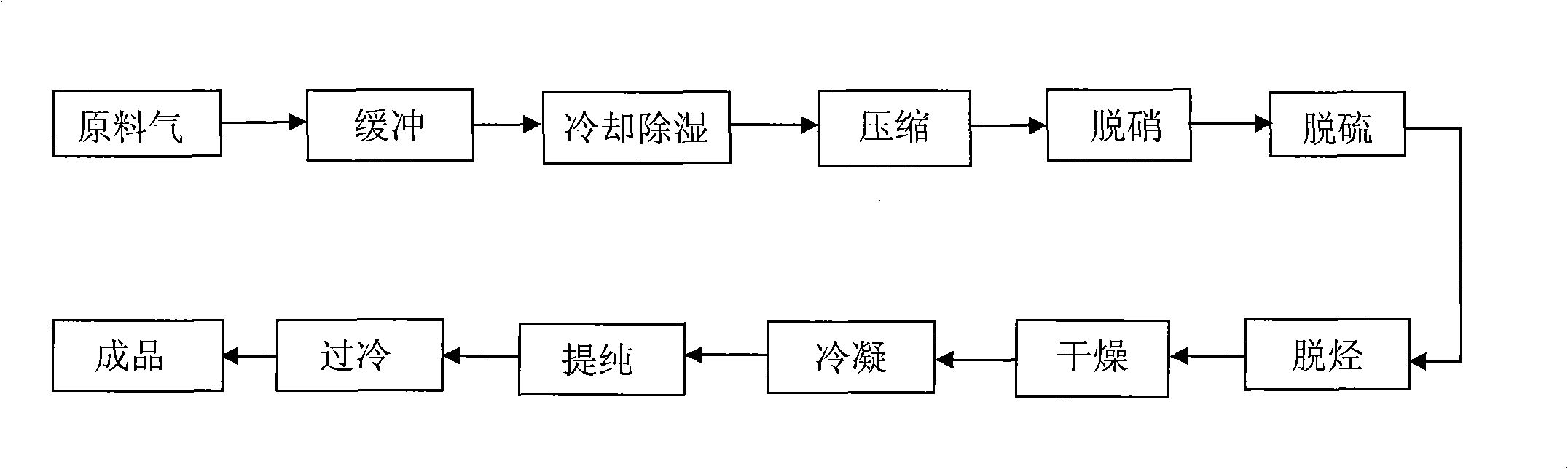

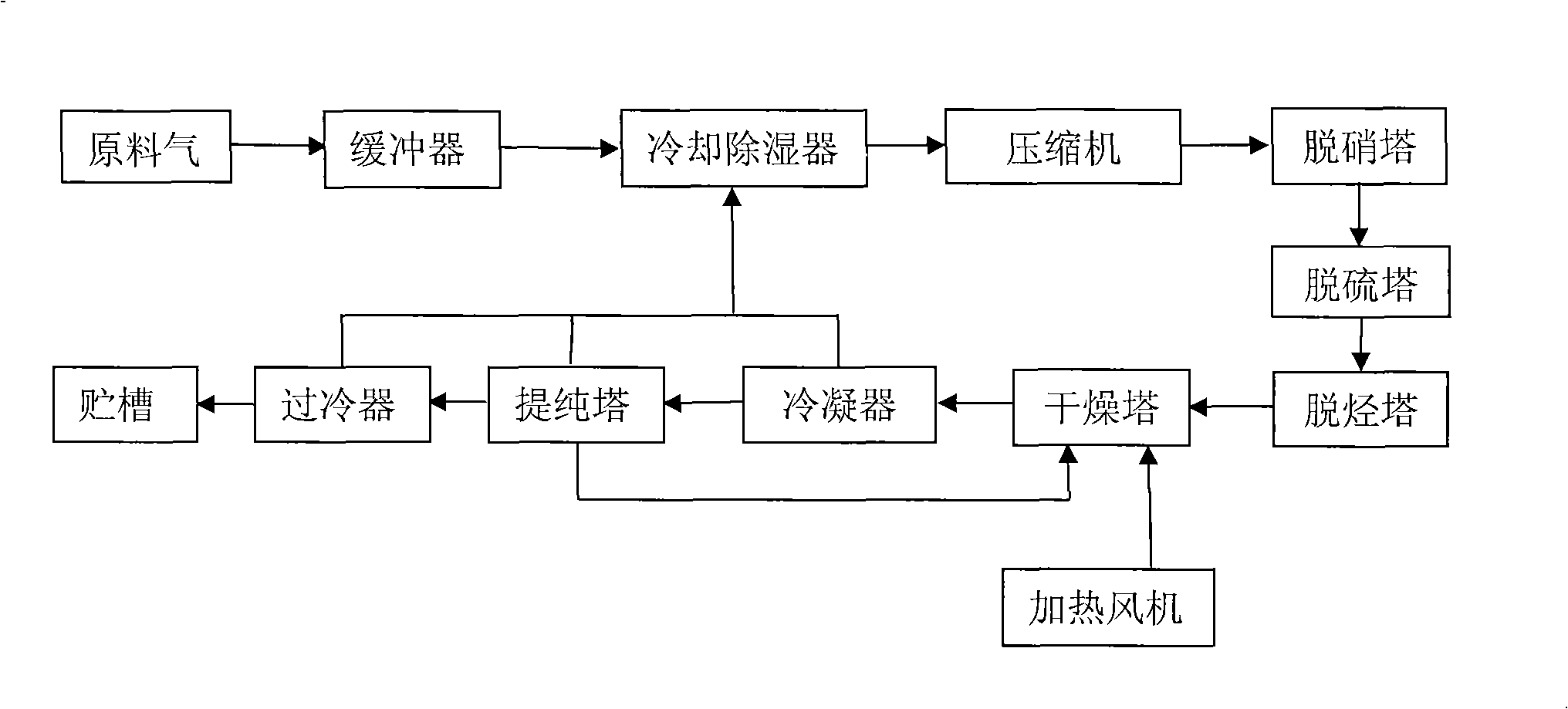

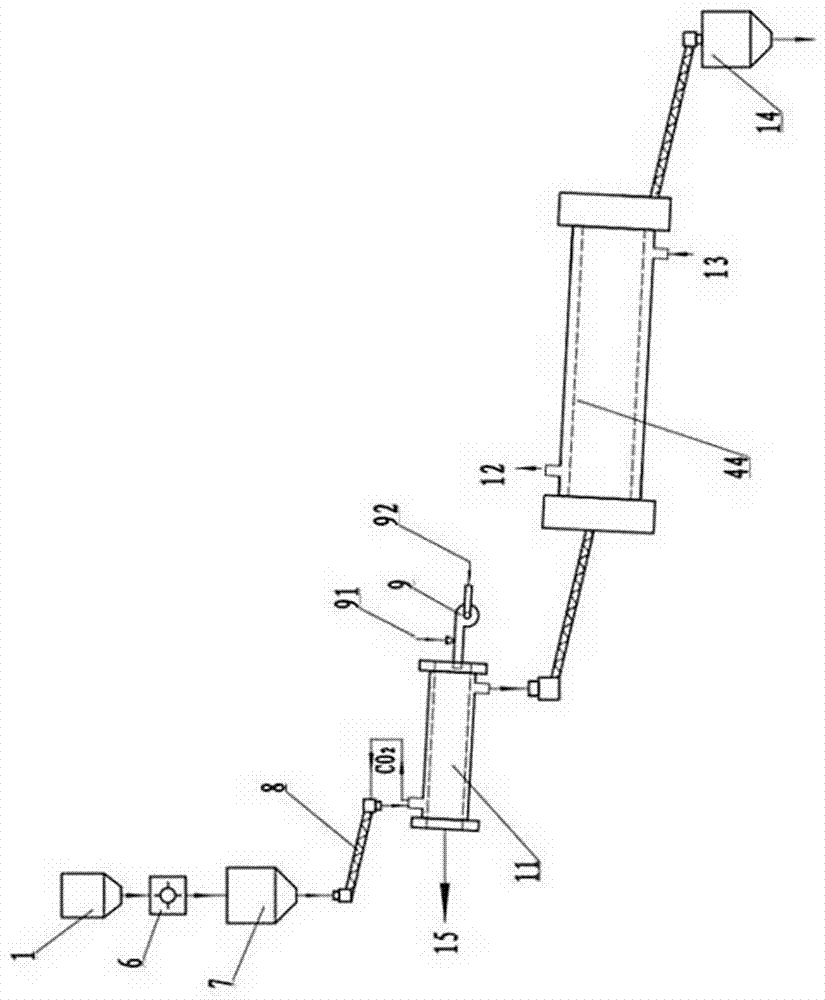

Method and apparatus for preparing food level liquid carbon dioxide with flue gas

The invention discloses a method of using flue gas to prepare food-grade liquid carbon dioxide, comprising steps that the carbon dioxide is collected and recovered as raw material to be treated by cooling, drying, compression, denitration, desulfurization and de-hydrocarbon, and is further treated by drying, purification and cooling to obtain the food-grade liquid carbon dioxide; a device to be adopted comprises a cooling dehumidifier, a compressor, a denitration tower, a desulfurization tower, a de-hydrocarbon tower, a drying tower, a condenser, a purification tower, a subcooler and a storage tank, etc., which are all connected by pipelines; the food-grade liquid carbon dioxide prepared by using the method and the device has advantages of high purity, small power consumption and low cost, etc.; the method can be widely used in the occasions of making use of the flue gas which is emitted from coal-fired power plants, cement factories, lime plants and coal-fired boilers and then collected and recovered to prepare food-grade liquid carbon dioxide.

Owner:杭州快凯高效节能新技术有限公司

A producing method of food-level concentrated soybean phospholipid

InactiveCN101006824AHigh depigmentationSpeed up filteringPhosphatide foodstuff compositionsFood preparationFood gradeFiltration technique

A method for producing food level condensed soybean phospholipids belongs to the field of soybean phospholipids. The invention comprises: taking feedstuff level soybean phospholipids as raw material, dissolving with nonpolar solvent such as N-hexane or ligarine, decolorizing with food level H2O2, removing ethylether insoluble substance influencing the product transparence with inorganic membrane filtration technique (including inorganic ceramic membrane and stainless steel membrane), and evaporating to obtain the light-colored final product with good transparence and low ethylether insoluble substance content (less than 0.2%, while 0.3% as the abroad product index). The invention establish a complete technology for producing food level condensed soybean phospholipids with high quality with feedstuff level soybean phospholipids as raw material through discolorations, filtration and de-dissolve.

Owner:JIANGNAN UNIV

Production process for manufacturing food-level polyester bottle flakes utilizing polyester recovered bottles

This invention discloses a production technology for producing the food-grade polyester bottle slices by utilizing the restored polyester bottles. According the characteristics of restored PET bottle, the restored polyester bottles were washed firstly and pulverized to slices, then the PVC bottle bodies, the volume labels, the impurities and the foreign materials were wiped off. Secondly, according the species of the residuum, the removing technology of the corresponding trace impurity was used. So the trace impurities of PVC, PP, PE and the other mechanical impurities can be removed again. The residuum of the restored PET bottle can be cut down greatly. Finally, the solid phases were condensed together so as to obtain the food-grade polyester bottle slices. Because of using the restored polyester bottles, the production cost is low, and the production technology meet the circulating economical development idea which advocated by the country nearly. The quality of the reproduction accords with the national standards of the food-grade PET bottle. The foreign exchange of the production technology is high and the economic effects as well as the social effects are obvious.

Owner:谭亦武 +1

Preparation method of teabag

The invention discloses a preparation method of a teabag, comprising the following steps of: 1. adopting refined tea leaves as materials, eliminating the coarse leaves, stems and pinaculum, removing tea dust of below 60 meshes by a tea sifting and grading machine and crushing the material of more than 20 meshes; 2. crushing the tea leaves by a tea leaf crushing machine to be more than 60 meshes, and screening out tea powder of more than 20 meshes and smaller than 60 meshes by a sizing screen; 3. selecting corresponding tea powder according to different flavor requirements, stirring for 20 to 40 minutes in a stirrer so as to lead the tea powder to be mixed evenly; 4. carrying out processing of impurity removing and processing of drying, sterilizing and increasing incense to the tea leaves meeting bag-packaged materials so as to lead the tea to achieve standard of food level materials; and 5. conveying the materials into a teabag machine special for tea to be packed into a food-level permeable strip bag and carrying out package to the finished product. As the tea is packed into the food-level permeable strip bag, the tea is applicable to be made by a bottled container with a slim outlet and has convenient package, drink and carry.

Owner:浙江茶乾坤食品股份有限公司

Preparation method of chicken powder seasoning

The invention discloses chicken powder seasoning which comprises the following ingredients by the mass portion: 50 portions to 60 portions of chicken extract, 23 portions to 35 portions of soybean protein hydrolysate, 10 portions to 20 portions of sodium glutamate, 8 portions to 10 portions of salt, 12 portions to 15 portions of sucrose, 13 portions to 18 portions of maltodextrin, 20 portions to 30 portions of starch, 12 portions to 15 portions of flavoring agent, 15 portions to 20 portions of plant spice, 15 portions to 20 portions of yeast extract, 5 portions to 8 portions of ginger powder, 30 portions and 34 portions of chicken oil, 20 portions to 25 portions of chicken essence, 5 portions to 10 portions of garlic powder, 10 portions to 12 portions of microcrystalline cellulose, 5 portions to 8 portions of red jujube powder, 2 portions to 5 portions of lotus nut starch, and 1 portion to 4 portions of medlar powder. A preparation method comprises the steps that (1) a chicken powder raw material is prepared; (2) the raw material is dried until the water content is less than or equal to 0.2Wt. percent; and (3) the material is screened through a sieve being 18 mesh to 20 mesh, and a target product is obtained. Through the ingredients and a processing method, the seasoning powder with uniform particle size and less water is prepared, the taste is mellow and the after taste is long-lasting. Because the food-level microcrystalline cellulose is added into the ingredients, the viscosity among the particles is reduced, and the problems that the seasoning powder is caked after being stored for a long time during the shelf life and the flavor is changed are prevented.

Owner:ZHANGJIAGANG TAOYUAN FOOD

Water-retaining method for frozen peeled shrimps

InactiveCN101919571AEasy to keepAchieve the purpose of phosphorus-free water retentionFood preservationPhosphatePercent sodium chloride

The invention discloses a water-retaining method for frozen peeled shrimps, which comprises the following steps of: removing heads and shells of shrimps, sterilizing with ozone water with the ozone concentration of 1-1.5mg / L for 1 to 5 minutes, and controlling the temperature of the ozone water below 10 DEG C; taking the peeled shrimps out, soaking in sterile water containing 0.5 to 0.45 mass percent sodium chloride, 0.25 to 0.75 mass percent food-level trehalose and 0.5 to 1.5 mass percent sodium alginate lysate for 30 to 50 minutes, controlling the water temperature at about 4-10 DEG C and the water amount 1.5 to 2 times weight of the peeled shrimps, taking the peeled shrimps out, and freezing until the core temperature is below -18 DEG C to obtain the frozen peeled shrimp products. In the method, a phosphorus-free water-retaining agent is adopted to process the peeled shrimps for the first time to fulfill the aim of retaining water; and the technology changes the traditional phosphate water-retaining process for the frozen peeled shrimps, solves the problems of water loss and color change in the freezing storage process, avoids the unpleasant metal astringency of the peeled shrimp products and unfavorable human health events caused by the conventional phosphate water-retaining agent, improves the quality appearance and price of the peeled shrimp products, and promotes the economic benefit of the peeled shrimp products.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Fermented soda biscuit and its production process

InactiveCN1973636AImproving dough propertiesShorten fermentation timeDough treatmentPre-baking dough treatmentBiotechnologyIcing sugar

The fermented soda biscuit and its production process belong to the field of food producing technology. The fermented soda biscuit is produced with flour, yeast, milk powder, sugar powder, maltose, ammonium bicarbonate, palm oil, baking soda, table salt, protease preparation and water, and through mixing the materials, fermentation and roasting. The present invention replaces enzyme preparation for food level sodium metabisulfite, and adopts low temperature roasting, laminating and short fermentation time.

Owner:SHANDONG ZHENGHANG FOODSTUFF

Tropical fruit and vegetable crisp slices and preparation method thereof

ActiveCN101077162ASolve the problem of unsatisfactory low-temperature steam puffing effectGood for healthDigestive systemFood preparationPullulanCitric acid

The present invention provides one kind of crisp tropic fruit and vegetable chip and its making process. The crisp tropic fruit and vegetable chip is made with the materials, including tropic fruit and vegetable, food level pullulan polysaccharide, mycose, fructose, table salt, citric acid, edible essence and water. The making process includes washing tropic fruit and vegetable material, peeling, stoning, slicing, deactivating enzyme, protecting color, protecting tissue, dewatering, low temperature airflow puffing and seasoning. The making process has ideal puffing effect and no-sulfide color protection, and the crisp tropic fruit and vegetable chip is favorable to health.

Owner:广东富味健康科技有限公司

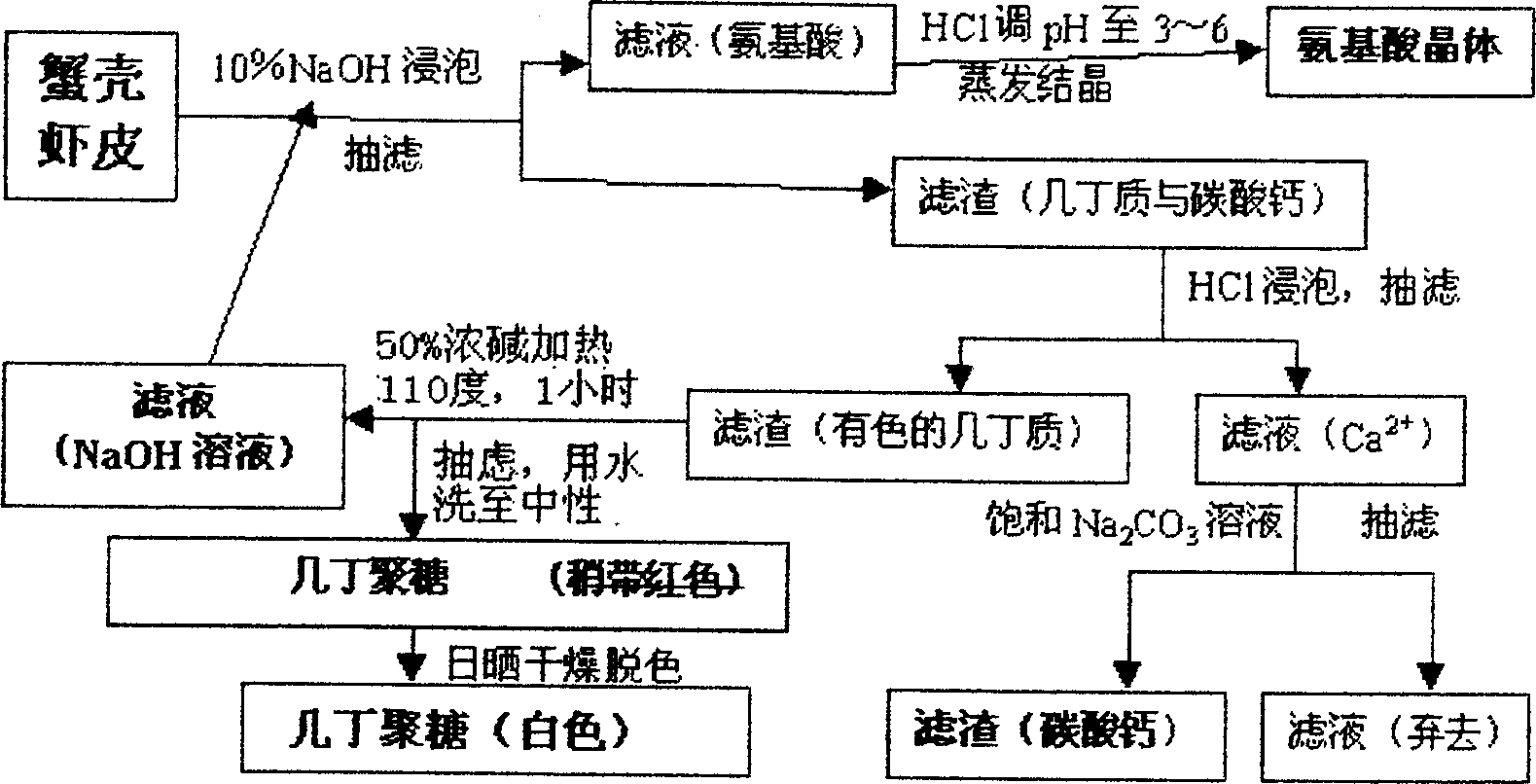

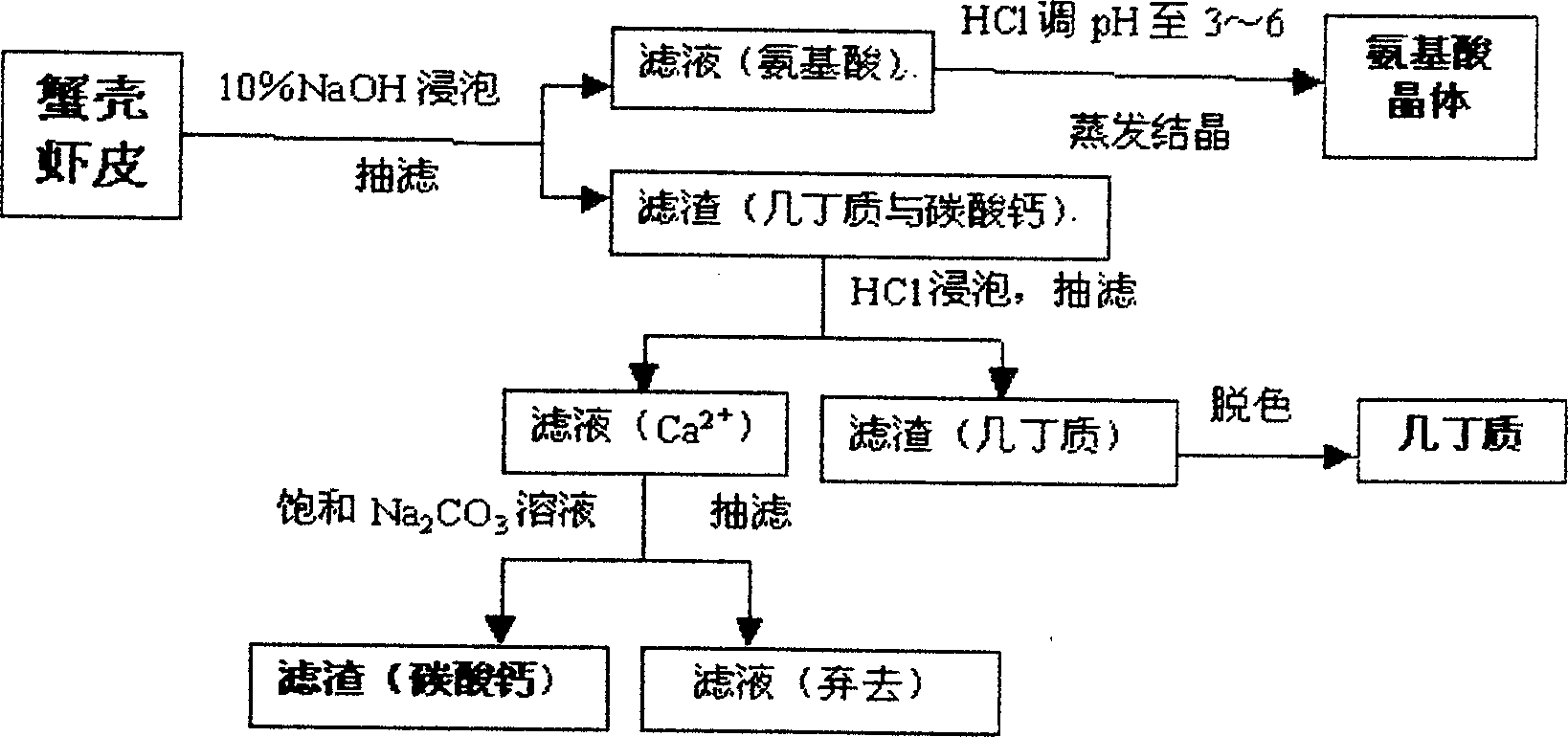

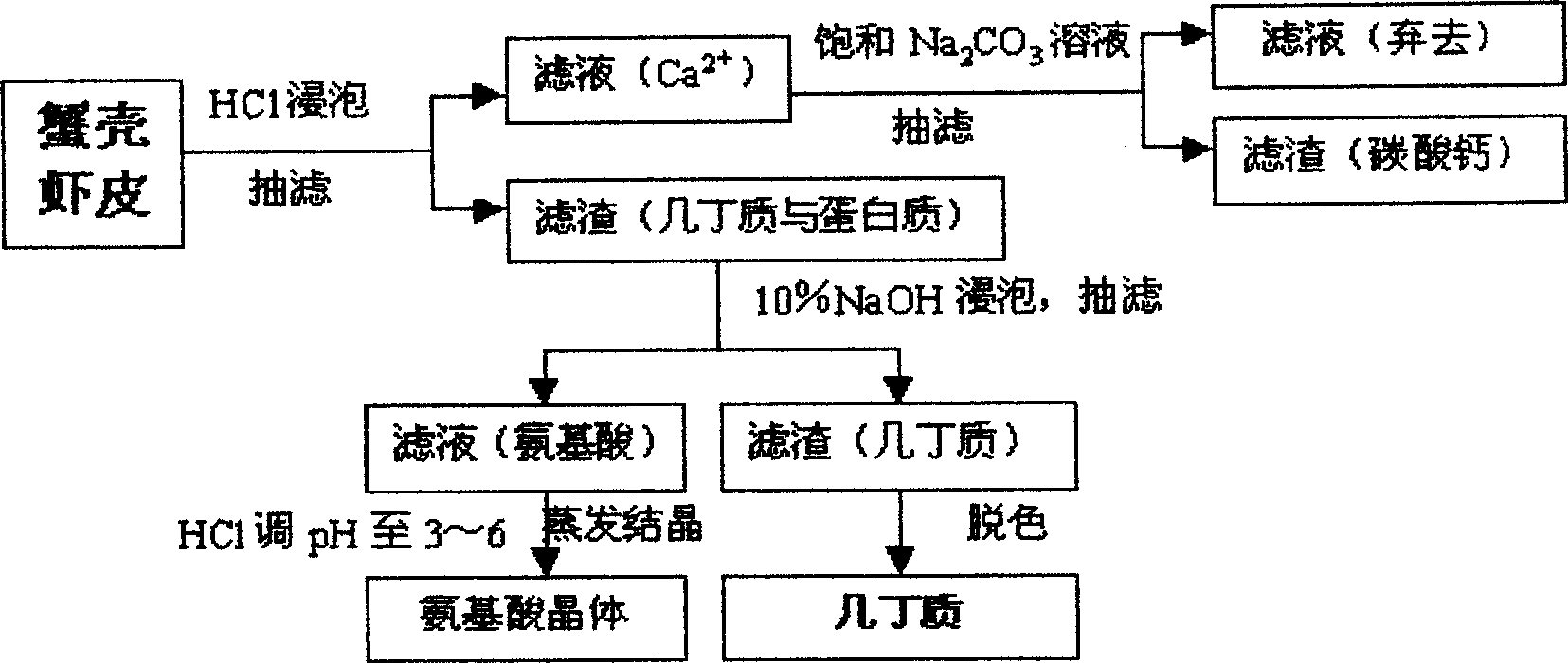

Treatment process of reusing crab and shrimp shell

InactiveCN1772769ATake advantage ofFully reflect the valueCalcium/strontium/barium carbonatesFood scienceChitin formationChloride

The treatment process of reusing crab and shrimp shell includes soaking crab and shrimp shell, eliminating calcium, filtering to obtain filtrate containing great amount of calcium chloride, adding sodium carbonate for reaction with calcium chloride to obtain calcium carbonate precipitate, filtering, water washing and drying to obtain white fine food level calcium carbonate powder; or, eliminating protein after the soaking step, filtering to obtain filtrate containing great amount of amino acids, regulating pH value of the filtrate to 3.5-6 to separate amino acids. The present invention can obtain chitin, edible calcium carbonate and protein from crab and shrimp shell in low sodium carbonate consumption. The present invention utilizes acid and base fully, has no toxic exhaust and is environment friendly.

Owner:SHANGHAI QIBAO HIGH SCHOOL

Hydrogenation process of producing food-level white oil

ActiveCN1952066ALow pour pointSuitable hydrocrackingTreatment with hydrotreatment processesEdible oils/fatsFood industryIsomerisms

The invention disclosed a second-stage hydrogenating way to produce vash oil of food class. It adopts the two-stage method of low pressure hydrogenation and refined hydrogenation. The material is first put in the low pressure hydrogenating reactor to lower the pour point. After separating the isomerism substances, put the distillate which is higher than 320 Deg C into the hydrogenation reactor to saturize the aromatic hydrocarbon to satisfy the index of vash oil of food class. The invention has many advantages such as strong material adaptability, modem operating conditions, low investment and operating cost and high quality of the products. The vash oil can be used in medicine industry, cosmetics industry and food industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

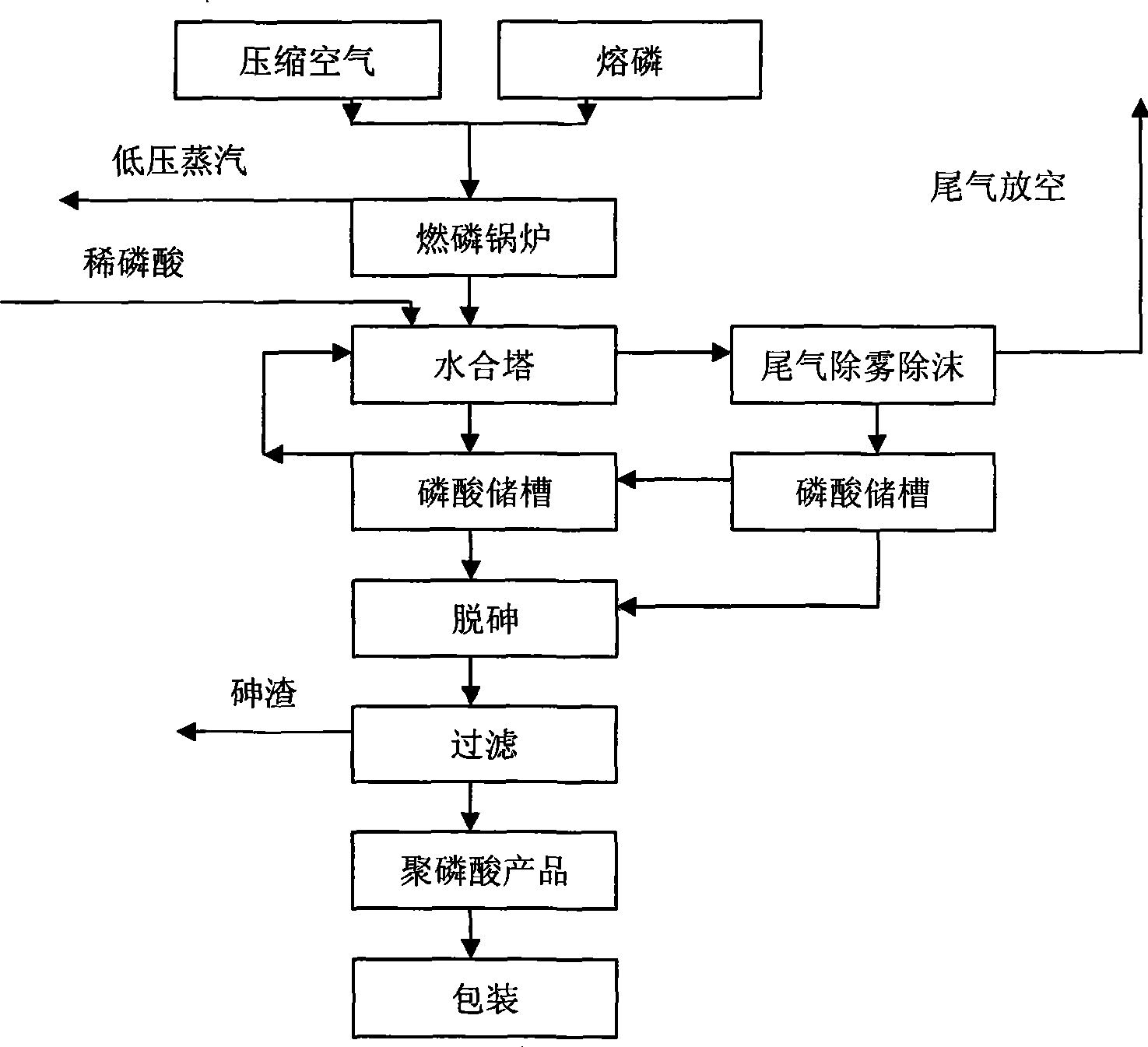

Method for using phosphoric oxide to concentrate diluted phosphoric acid to prepare polyphosphoric acid

ActiveCN101531354ALower packagingReduce logistics costsChemical industryCondensed phosphoric acidsO-Phosphoric AcidEconomic benefits

A method for using phosphoric oxide to concentrate diluted phosphoric acid to prepare polyphosphoric acid, including following steps: mixing yellow phosphorus and air with the proportion of 1kg yellow phosphorus to 6.3-6.6 m3, burning, absorbing the obtained P2O5 by diluted acid; applying the obtained phosphoric acid into a phosphoric acid groove; then using acid pump to send into a condenser to remove the heat; then sending the phosphoric acid into a hydration tower to circularly spray and absorb P2O5 to increase the concentrated phosphoric acid; cycling without stop to obtain the phosphoric acid having 82%-84% P2O5. The recovery coefficient of phosphorus is more than 98%. The obtained product reaches the standard of the food-level phosphoric acid. This invention may greatly reduce the cost of package and distribution of the phosphoric acid production enterprise via using the wet-method phosphoric acid or hot-method phosphoric acid of the concentrated content of the phosphoric acid anhydride of less than 100% obtained by yellow phosphorus burning. This invention does not need to consume the extra energy, and can fully use the burning heat and the hydration heat of the yellow phosphorus; the generated steam can be recycled. So this invention has the advantages of saving energy and greatly reducing the production cost of the polyphosphoric acid, with remarkable social and economic benefits.

Owner:WENGFU (GRP) CO LTD

Nutritious plumule biscuit and its production process

InactiveCN1973634AHigh nutritional valuePromote peristalsisDough treatmentBakery productsFermentationChemistry

The nutritious plumule biscuit and its production process belong to the field of food producing technology. The nutritious plumule biscuit is produced with wheat plumule powder, flour, starch, sugar powder, ammonium bicarbonate, water, palm oil and compound enzyme preparation, and through mixing the materials, fermentation and roasting. The present invention replaces enzyme preparation for food level sodium metabisulfite, and adopts low temperature roasting, laminating and short fermentation time. The nutritious plumule biscuit has less damping, less breaking and long shelf life.

Owner:SHANDONG ZHENGHANG FOODSTUFF

Short lactobacillus producing gamma-aminobutyric acid and use thereof

InactiveCN1673351AThere are no security risksBacteriaFermentationGlutamate decarboxylaseMicroscopic observation

The present invention discloses one kind of gamma-aminobutyric acid producing lactobacillus brevis and its use. The lactobacillus brevis has preservatioin number of CGMCC No. 1306; exhibits pairs or chains; and has no motion, no spore, small colony and smooth surface. It belongs to Gram positive bacteria and facultative anaerobe, and may be used in producing gamma-aminobutyric acid. By means of biological synthesis process, the high activity glutamate decarboxylase connected in the lactobacillus brevis and sodium L-glutamate as substrate, the sodium L-glutamate is decarboxylated to produce gamma-aminobutyric acid and CO2. Thus produced gamma-aminobutyric acid is safe in food level.

Owner:ZHEJIANG UNIV

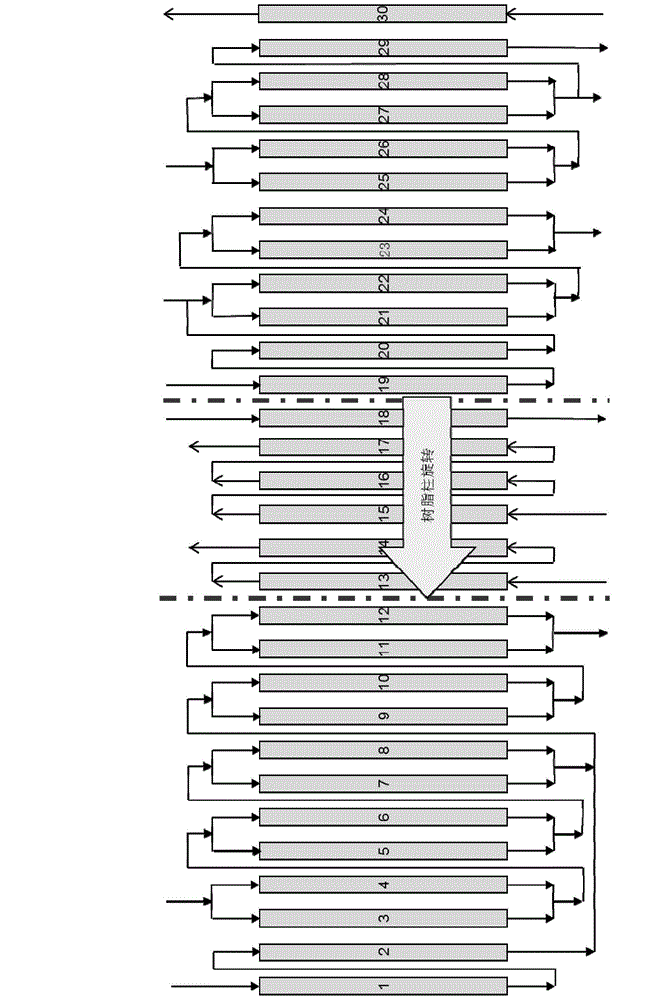

Separation and purification method of valine

ActiveCN104592047AReduce sewageImprove energy savingOrganic compound preparationAmino-carboxyl compound preparationPurification methodsRight-to-left

The invention discloses a separation and purification method of valine. The separation and purification method comprises the following steps: (1) performing frame filtering on valine fermentation liquid to obtain filtered solutions, and feeding the filtered solutions into a cation exchange resin column, which rotates from right to left, of a continuous moving bed; (2) sequentially dividing the cation exchange resin column of the continuous moving bed into a feeding area, a material washing area, a back-washing area, a product water ejection area, a first analyzing area, a second analyzing area, an analyzing solution recovery area, an acid regeneration area and a washing acid area from right to left, and collecting the analyzing solutions of the first analyzing area and the second analyzing area and applying the analyzing solutions to production of medicine-level valine products and food-level valine products. The yield of the valine obtained by using the method can reach about 98 percent.

Owner:SANDA FILM SCI & TECH XIAMEN +1

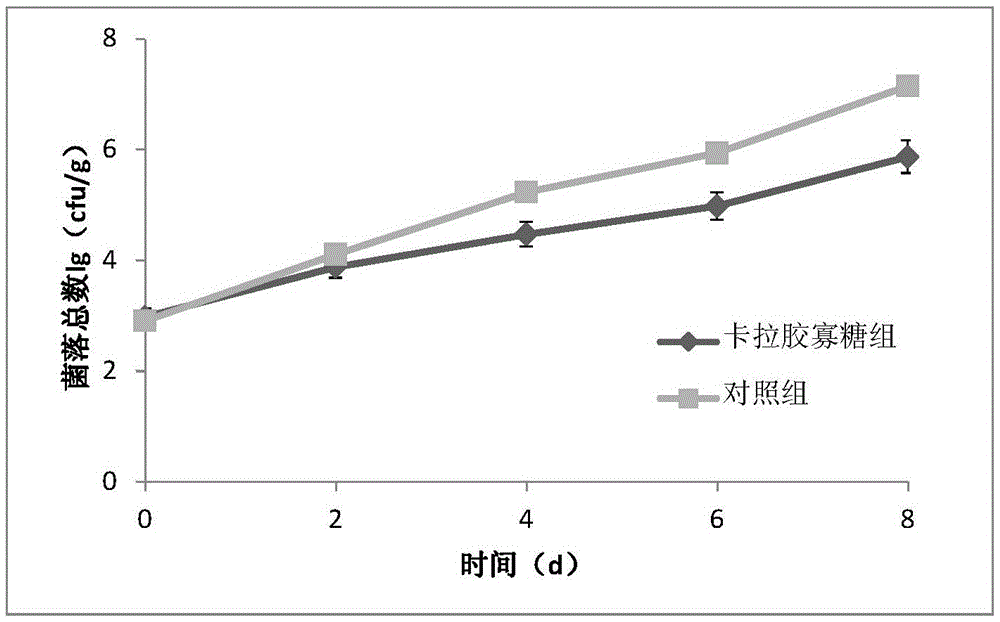

Seafood preservative and preparation and application thereof

InactiveCN105613708APrevent corruptionExtended shelf lifeMeat/fish preservation using chemicalsHydrolysisPolyphenol oxidase

The invention relates to seafood preservative and preparation and application thereof and belongs to the field of food preservation and fresh-keeping. The seafood preservative is prepared from carrageenan oligosaccharides and water, and the concentration of carrageenan oligosaccharides is 10-25 g / L. A preparation method includes the steps that firstly, the carrageenan oligosaccharides are prepared from carrageenan through an enzyme hydrolysis method, then the carrageenan oligosaccharides are used for preparing the preservation, specifically, the carrageenan oligosaccharides are dissolved in water, and the concentration of the carrageenan oligosaccharides in a solution is 10-25 g / L. The seafood preservative has the advantages that seafood can be effectively prevented from decaying, the total number of bacterial colonies of shrimps, the total volatile basic nitrogen (TVB-N), the Ph value, the activity of polyphenol oxidase, sensory indexes and other physiological and biochemical indexes are effectively improved, the shelf life of seafood is prolonged, and the preservative is in the food level and is safe and free of toxin.

Owner:DALIAN UNIV

One-stage medium-pressure hydrogenation method for producing food-level white oil

ActiveCN101265419AWide variety of sourcesSimple processRefining to eliminate hetero atomsWhite oilMedium pressure

The invention relates to a method for producing food-grade white oil through a medium pressure hydrogenation. After raw oil and hydrogen gas are mixed, the hydrogenation reaction is performed, under the reaction conditions as follows: the temperature is 180 to 320 DEG C, the hydrogen partial pressure is 4.0 to 1.0 Mpa, the volume space velocity is 0.1 to 1.0h<-1>, and the hydrogen and oil volume ratio is (200-1000):1; the catalyst pore volume is 0.4 to 1.0ml.g<-1>, and the specific surface area is 150 to 280m<2>.g<-1>; the content of active component metal Ni is 1 to 55 percent of the total weight of the catalyst, the carrier adopts the mixture of macropore aluminium oxide and microbore aluminium oxide, the weight ratio of the both is (2-4):1, silicon or / and phosphor is (are) added in the carrier as the additive, the content of the silicon in aluminium oxide is 1 to 20 percent, the content of the phosphor is 1 to 10 percent, or the content of the silicon and the phosphor is 1 to 10 percent. The method has the advantages that the process is simple, the operation is convenient, the investment and the operation costs are low, the raw material source is wide, and the method is applied to the production of the food-grade white oil.

Owner:PETROCHINA CO LTD

Method of extracting rosemary as matural antioxidant

InactiveCN1441030AHigh yieldReduce heating effectBulk chemical productionChemical inhibitorsOrganic solventFreeze-drying

The present invention relates to method of extracting rosemary natural antioxidant from rosemary plant. The extraction process incldues distilling fresh rosemary plant to obtain resemary oil and material containing resemary antioxidant; crushing the material and adding food level organic solvent in a diffuser to extract rosemary leaching liquid; concentrating the resemary leaching liquid, supercritical extracting and high pressure separation to obtain extractive liquid; recovering solvent; spray or freeze drying to obtain yellowish antioxidant product. The said process obtains rosemary oil and antioxidant separately and has high yield and quality of antioxidant product.

Owner:马文彬

Manufacturing technique for extracting silkworm chrysalis oil

This invention discloses a kind of production technique about the extraction of silkworm chrysalis oil, which is proceeded through such steps: (1) Disintegrate dried silkworm chrysalis powder and put it into a extraction kettle; (2) pressurize food-level carbon dioxide with compressor and deliver it to the extraction kettle by a pressure-stable tank; (3)After the setted pressur 15MPa-30MP and setted temperature 30deg C-50deg C are obtained, open control flap of the separating pot to make carbon dioxide, which has extracted silkworm chrysalis oil, enter into the extraction kettle. Then lower the pressure to 4MPa- 6Mpa, here the extracted substance separates from carbon dioxide gas, thereby the manufactured goods are resolved and carbon dioxide gas can be used cyclely. The product made through this production technique remains no organic solvent, and the biological active compounds in it won't be destroyed, at the same time, the recovery ratio of the product is high.

Owner:国化低碳科技有限责任公司 +1

Food-grade polypropylene composite material and preparation method and application thereof

The invention relates to a food-grade polypropylene composite material, a preparation method and an application thereof. The composite material is composed of the following components in mass percentage: 48-78wt% of polypropylene, 20-50wt% of food-grade additive calcium carbonate; 0.5-2wt% of food-grade processing aid and 0-1.0wt% of food-grade coloring agent, wherein the food-level standard is as follows: the content is 98.0-100% calculated by dry basis, the loss on drying is less than or equal to 2.0%, the content of acid insoluble matter is less than or equal to 0.2%, the content of fluoride is less than or equal to 0.005%, the content of alkali metals and magnesium salt is less than or equal to 1.0%, the content of arsenic metals is less than or equal to 3.0mg / kg, and the content of lead metals is less than or equal to 3.0mg / kg. The food-grade polypropylene composite material and the prepared tableware in the invention have favorable mechanical property and lower cost; and compared with the traditional tableware, the tableware filled with food-grade additive calcium carbonate are more in accordance with the hygienic standard and are easily degraded.

Owner:富岭科技股份有限公司

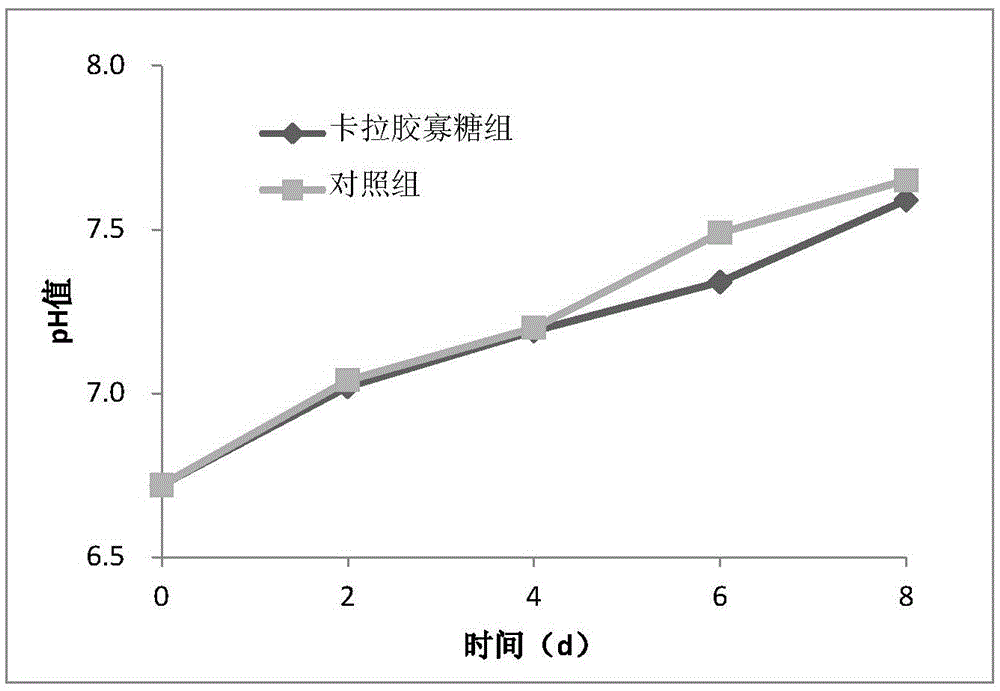

Rotary kiln and poly-generation system utilizing rotary kiln for producing metal hydride

InactiveCN107091569ARealize continuous productionNo emissionsFurnace componentsAlkali/alkaline-earth/beryllium/magnesium hydridesHigh concentrationBrick

The invention discloses a rotary kiln and a poly-generation system utilizing the rotary kiln for producing metal hydride. The poly-generation system comprises a lime production sub-system, a pulverized coal production sub-system, a calcium carbide production sub-system, a magnesium metal production sub-system, a waste heat utilizing and gas recycling sub-system, a metal hydrogen storage sub-system and a cement clinker production subsystem. Limestone, magnesite / dolomite, quartz sand and coal serve as raw materials, and the limestone is roasted into lime; in a lime kiln built through zirconia bricks, the lime and the coke powder are subjected to the high-temperature reaction so that liquid calcium carbide can be obtained; the magnesite / dolomite is roasted into magnesium oxide, and the calcium carbide, the magnesium oxide and the quartz sand are mixed to generate magnesium; high-concentration carbon dioxide, coal pyrolysis gas and calcium carbide tail gas obtained through decomposing of the limestone and the magnesite are recycled and processed, and hydrogen and food-level carbon dioxide are obtained; magnesium hydride is generated through union of hydrogen and magnesium; and carbide slag and magnesium slag are processed, and cement clinker and carbon powder are obtained. According to the poly-generation system, emission of solid waste is avoided, and carbon emission is greatly reduced.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Environmentally-friendly indoor air purification, disinfection, humidification and dehumidification device

InactiveCN103191632AAchieve humidification effectReduce humidityGas treatmentMechanical apparatusParticulatesChemical adsorption

The invention discloses an environmentally-friendly indoor air purification, disinfection, humidification and dehumidification device. Various common pollutants, such as nitride, sulfide, cigarette tar, organic gas, inorganic gas, particles (containing PM2.5) and microorganisms such as germs and viruses, can be irreversibly removed from air by adopting chemical adsorption liquid; the raw material of the chemical adsorption liquid is in a food level, so secondary pollution is avoided. An adsorption process is irreversible; the purification is complete; and the device is environmentally-friendly.

Owner:河北安多翔科技有限公司

Catching and refining device of carbon dioxide gas

ActiveCN102442667AReduce energy consumptionGuaranteed uptimeCarbon compoundsProduct systemAgricultural engineering

The invention discloses a catching and refining device of a carbon dioxide gas, which is composed of a blower, a compressor, an enrichment system, a desulphurization system, a de-hydrocarbon system, a purification system, a refrigeration system, a rectification system and a product system. The front end of the enrichment system is connected with the blower while the rear end thereof is connected with the desulphurization system; the rear end of the desulphurization system is connected with the de-hydrocarbon system; the rear end of the de-hydrocarbon system is connected with the purification system; the rear end of the purification system is connected with the refrigeration system; the rear end of the refrigeration system is connected with the rectification system; and the rear end of therectification system is connected with the product system. Raw gas containing carbon dioxide is led to the enrichment system through the blower, then pressurized by the compressor and then enters into a desulphurizer and a de-hydrocarbon device for desulphurization and de-hydrocarbon; the purified carbon dioxide then enters in the refrigeration system; then the purified carbon dioxide after beingliquefied enters into the rectification system and sent to a food-level carbon dioxide storage tank for storage. The liquid carbon dioxide products can be en-trucked or bottled for sale and also can be further made into solid dry ice through a dry ice machine.

Owner:白洪亮

Method for preparing food-level titanium dioxide

The invention relates to a method for preparing food-level titanium dioxide, which is characterized by comprising the following steps of: uniformly mixing titanium white and deionized water in a weight part ratio of 3-8:1, adding 0.0048 to 0.064 weight part of hydrogen peroxide, 0.0024 to 0.32 weight part of formic acid, 0.0012 to 0.128 weight part of ammonium acetate and 0.12 to 0.64 weight part of nitric acid, performing reaction, standing for a period of time, adding 23 to 63 weight parts of deionized water, performing suction filtration and drying treatment, and crushing to obtain the food-level titanium dioxide product. Impurities in the industry titanium dioxide can be removed easily by the method; and the prepared product is the food-level titanium dioxide, and has the advantages of high yield and guaranteed quality.

Owner:JIANGSU HONGYUAN PHARMA

Lutein extracting process from marigold flower

The lutein extracting process from marigold flower include the steps of: conveying marigold flower and solvent in certain ratio with conveyer to rotary leaching device, leaching, three stage filtering, washing, depositing, degluing, desugaring, evaporating concentration to obtain extractum, compounding in food level refining tank and refining. The present invention has the advantages of large production scale, high lutein yield, low solvent consumption, high lutein content in product, high product quality and low production cost.

Owner:DAQING JINTUDI BIOLOGICAL SCI TECH

Method of producing glossy ganoderma polypeptide product

InactiveCN101108196ASmall molecular weightPromote absorptionMetabolism disorderSolution deliveryEnzyme digestionAdditive ingredient

The invention belongs to an enzyme complex extraction method in ganodermataceae and degreased silkworm pupa, which is characterized in that: mix the ganodermataceae and degreased silkworm pupa; add water; add food level cellulose and trypsinase and conduct the enzyme digestion under certain temperature; then filter, concentrate and dry the ingredients to get ganodermataceae polypeptide product which has the active ingredients of ganodermataceae, polypeptide and aminophenol and ensures double effects of ganodermataceae and polypeptide. Therefore, the invention has outstanding health-improving effect.

Owner:江苏江南生物科技有限公司

Compound effervescent tablets for water purification and disinfection and preparation method thereof

InactiveCN105906005AUnique methodSimple processWater treatment parameter controlSpecific water treatment objectivesAluminium chlorideEffervescent tablet

The invention provides compound effervescent tablets for water purification and disinfection and a preparation method thereof. The compound effervescent tablets for water purification and disinfection comprise the components of a disinfector, food level polyaluminium chloride, food level chitosan and auxiliary materials of effervescent tablets, wherein the disinfector is stable chlorine dioxide powder or potassium monopersulfate disinfecting powder, the content of the food level polyaluminium chloride is 10-15mg, the content of the food level chitosan is 1-2mg and the balance is the auxiliary materials of effervescent tablets. The purifying agent has the advantages of simple preparation process, low cost and good purifying effect, and is suitable for disinfection for military personnel, field operation personnel, tourists and residents in regions without tap water as well as for disinfection of industrial drinking water.

Owner:SHANDONG JIANZHU UNIV

Method for manufacturing paper cup material

ActiveCN103085443ADoes not affect print qualityDoes not affect the sensory effectLamination ancillary operationsSynthetic resin layered productsCardboardPolyethylene terephthalate

The invention discloses a method for manufacturing a paper cup material. The method comprises the following steps of: 1, taking food-level white cardboard for food package as a base material; 2, sticking a polyethylene terephthalate (PET) aluminum coating film on the front surface of the food-level white cardboard by high-temperature-resistant environmentally-friendly glue; 3, printing patterns on the PET aluminum coating film by high-temperature-resistant composite ink at a temperature being more than 150 DEG C; 4, sticking a PET coverage film on the PET aluminum coating film printed by the ink by adopting transparent composite glue; 5, coating a first layer of polyethylene (PE) spraying film on the back surface of the food-level white cardboard; 6, sticking aluminum foil material paper on the first layer of PE spraying film; and 7, sticking a second layer of PE spraying film on the aluminum foil material paper. A paper cup made of the material has a good printing effect and high quality; and the sense of metal is strong.

Owner:罗明亮 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com