Rotary kiln and poly-generation system utilizing rotary kiln for producing metal hydride

A rotary kiln and subsystem technology, applied in the field of polygeneration systems, can solve the problems that coking, coal gasification or blue charcoal cannot be directly produced, the quality of calcined or reduced products is affected, and it is not conducive to the recovery and utilization of carbon dioxide, a by-product of limestone calcination. , to achieve the remarkable effect of reducing carbon emissions and utilizing sensible heat to save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

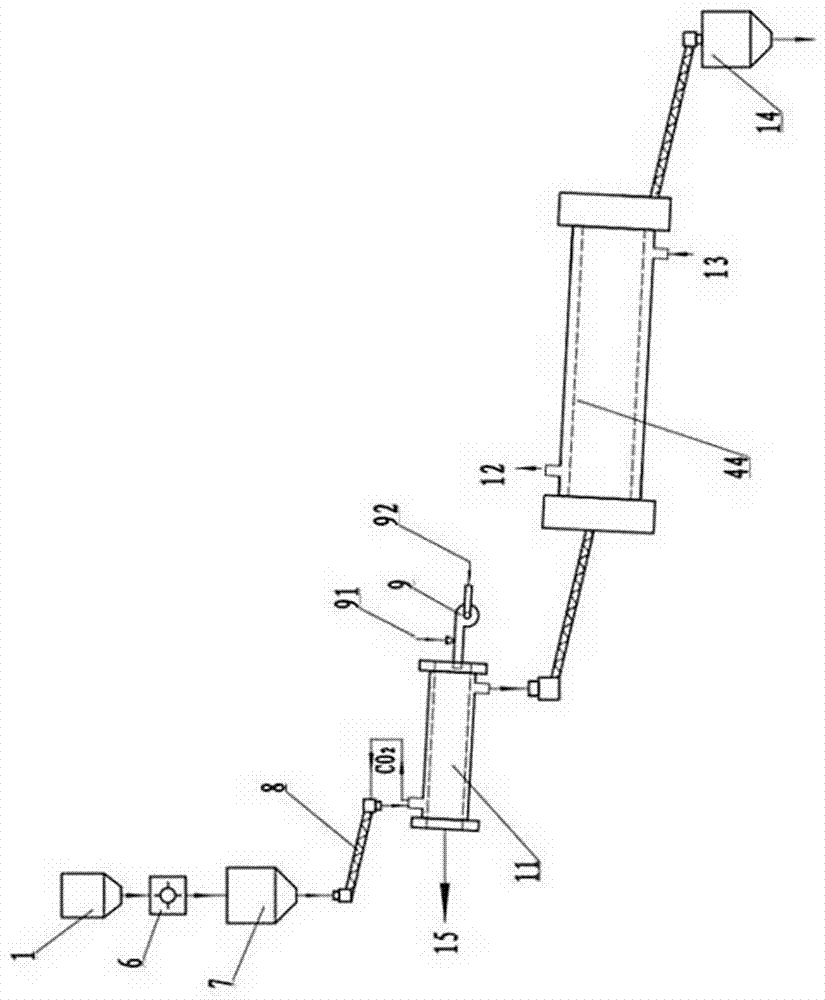

Embodiment 1

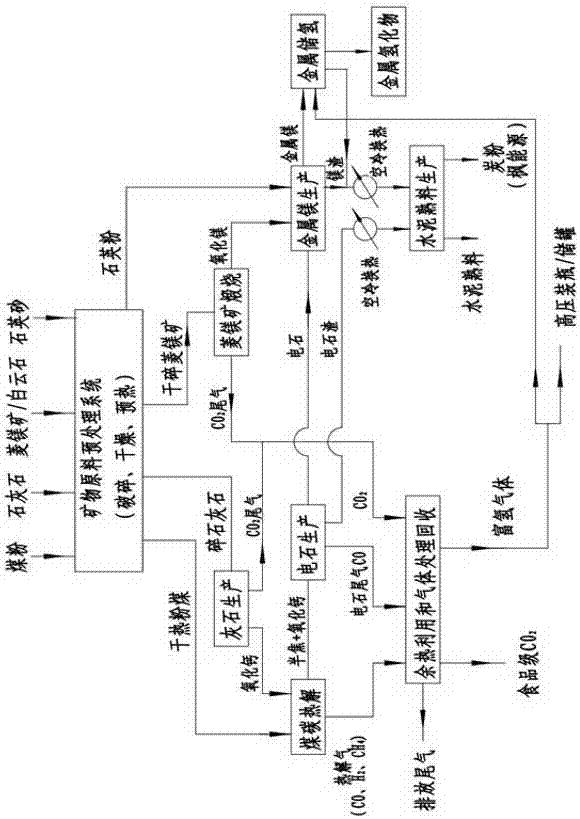

[0037] A polygeneration system for the production of metal hydrides utilizing zirconia bricks such as Figure 1-12 As shown, it includes lime production subsystem, coal powder production subsystem and calcium carbide production subsystem, metal magnesium production subsystem, waste heat utilization and gas recovery subsystem, metal hydrogen storage subsystem, and cement clinker production subsystem.

[0038] Such as figure 1As shown, the raw materials required by the whole system are limestone, anthracite, magnesite / dolomite, and quartz sand. The lime production subsystem uses limestone as raw material and obtains lime through calcination and crushing; the pulverized coal production subsystem crushes coal, and then mixes Coal and lime are pyrolyzed to obtain lime powder and coke powder; then, in the calcium carbide production subsystem, the rotary kiln is used as the main equipment for liquid calcium carbide production; liquid calcium carbide, magnesite / dolomite, and quartz sa...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that part of the ordinary refractory bricks is built as an indirect passage structure, which is mainly composed of refractory bricks to form an inner cylinder, an outer cylinder, and an intermediate support structure. The bricks form the inner cylinder, the refractory bricks on the outer ring and the steel structure form the outer cylinder, and refractory materials are built between the inner cylinder and the outer cylinder to form a support. The inner ring and the outer ring in the present invention may refer to one layer of refractory bricks, or multiple layers of refractory bricks, so as to ensure the stability of the overall structure. The material inlet and material outlet connected to the partition channel are set on the steel structure, and the powdery or granular material is transported into the partition channel by the carbon dioxide gas flow. The material is organic and / or inorganic, and the material is...

Embodiment 3

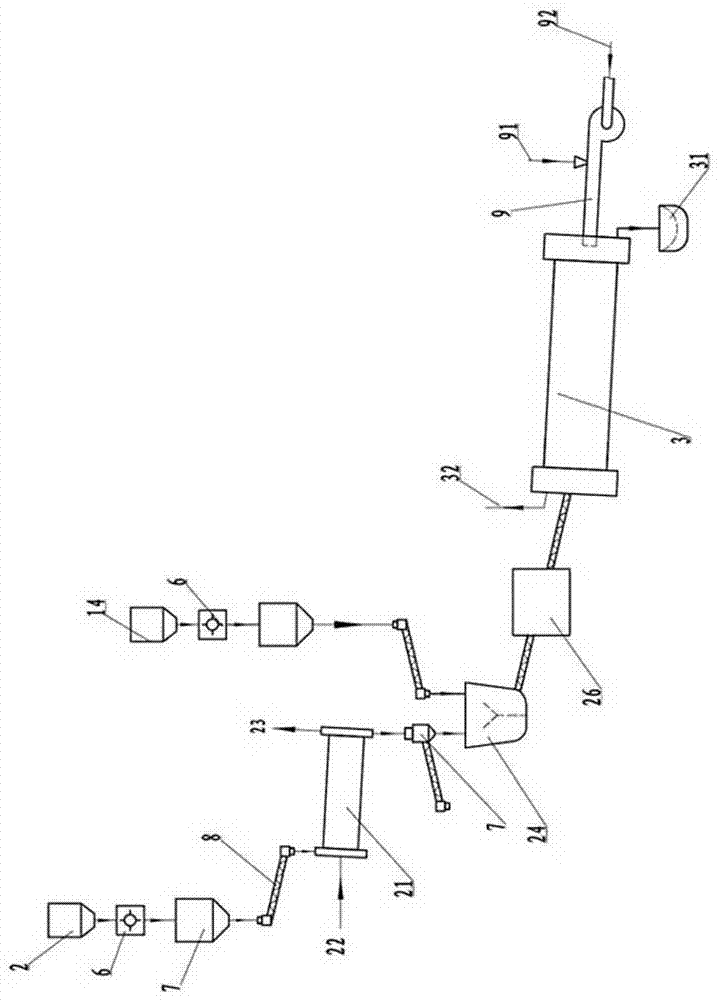

[0051] The difference between this embodiment and embodiment 1 is: as Figure 13 As shown, the lime production subsystem and the calcium carbide production subsystem are combined, and the combination of the rotary kiln 3 and the vertical kiln 38 is used to produce lime and calcium carbide. All the refractory materials of the rotary kiln 3 are built with zirconia bricks, and the length of the rotary kiln 3 is 6 meters. A vertical kiln 38 is arranged at the kiln tail of the rotary kiln 3, and a vertical preheating passage 36 is arranged in the kiln chamber in the vertical kiln 38. The preheating passage 36 is isolated from the kiln chamber, and the combustion exhaust gas at the kiln tail is drawn out through the exhaust gas outlet. From the bottom of the shaft kiln to the kiln chamber between the shaft kiln and the preheating channel. In this embodiment, two preheating channels 36 with square holes are provided. The preheating channels 36 include a wear-resistant silicon carbid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com