Lithium supplementing method for energy storage device

A technology for replenishing lithium and devices, applied in the manufacture of electrical components, electrochemical generators, hybrid/electric double layer capacitors, etc. Lithium cost, effect from wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

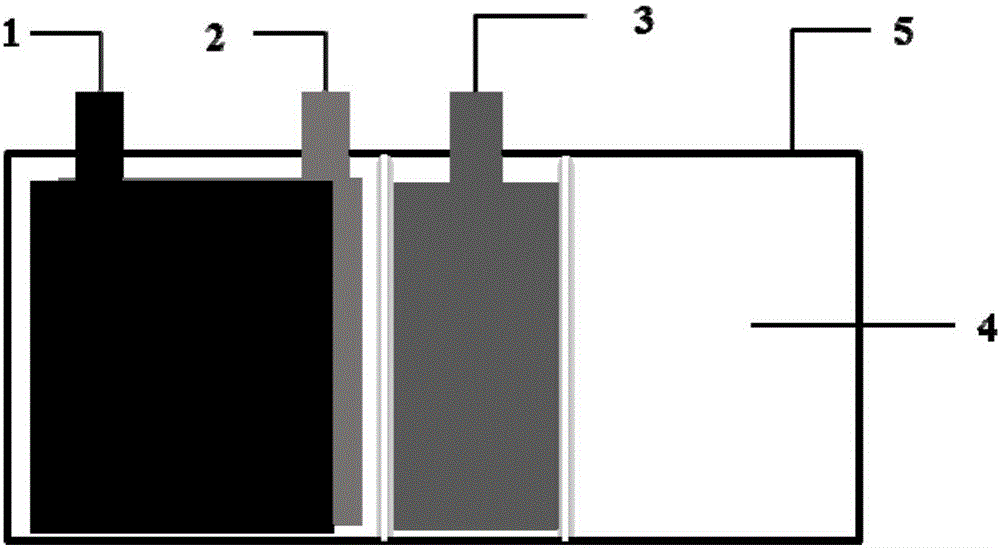

[0059] The aluminum plastic film was die-cut into a battery case with three chambers, and the LiCoO 2 The positive electrode and the graphite negative electrode are assembled into a core package, using LiCoO 2 The waste electrode sheet is a supplementary lithium electrode, and the through porosity of the positive and negative current collectors is 0%. The core pack and the lithium supplementing electrode are respectively placed in the core pack chamber and its adjacent chamber, and the airbag is adjacent to the lithium supplementing electrode. After the electrolyte is injected, the casing is encapsulated as a whole (one-time packaging), so that the chamber where the core pack and the lithium-replenishing electrode are located is rich in electrolyte. The battery structure is as follows: figure 1 shown.

[0060] After the battery core pack is formed, the lithium supplementary electrode is used as the anode, and the graphite negative electrode in the core pack is used as the ca...

Embodiment 2

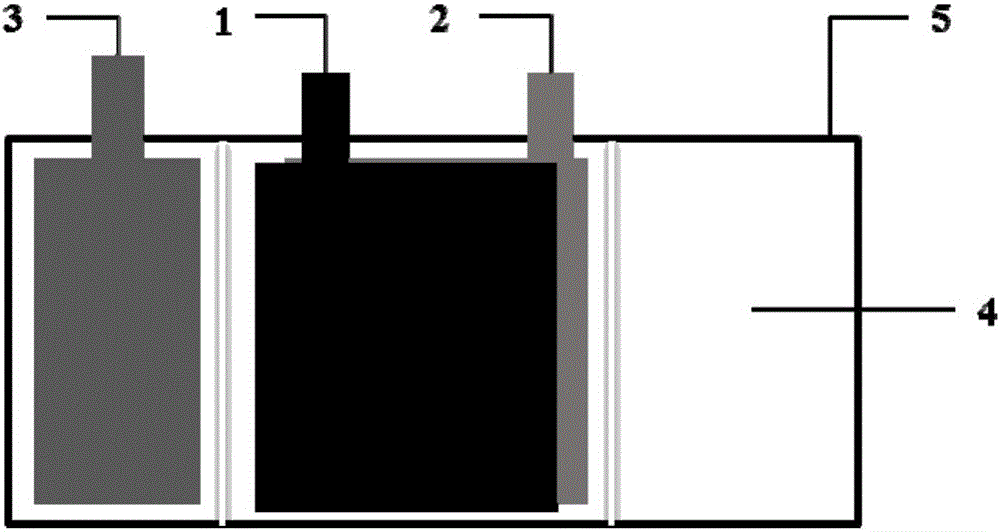

[0062] The aluminum plastic film was punched into a battery case with three chambers, and the LiNi 0.6 Mn 0.2 Co 0.2 O 2 The positive electrode and the Si / C negative electrode are assembled into a core package, using LiNi 0.5 Mn 0.3 Co 0.2 O 2 The waste electrode sheet is a supplementary lithium electrode, and the through porosity of the positive and negative current collectors is 15%. The core pack and the lithium supplementing electrode are respectively placed in the core pack chamber and its adjacent chamber, and the airbag is adjacent to the core pack chamber. After the electrolyte is injected, the casing is encapsulated as a whole (one-time packaging), so that the chamber where the core pack and the lithium-replenishing electrode are located is rich in electrolyte. The battery structure is as follows: figure 2 shown.

[0063] After the battery core pack is formed, the lithium supplement electrode is used as the anode, and the Si / C composite negative electrode in ...

Embodiment 3

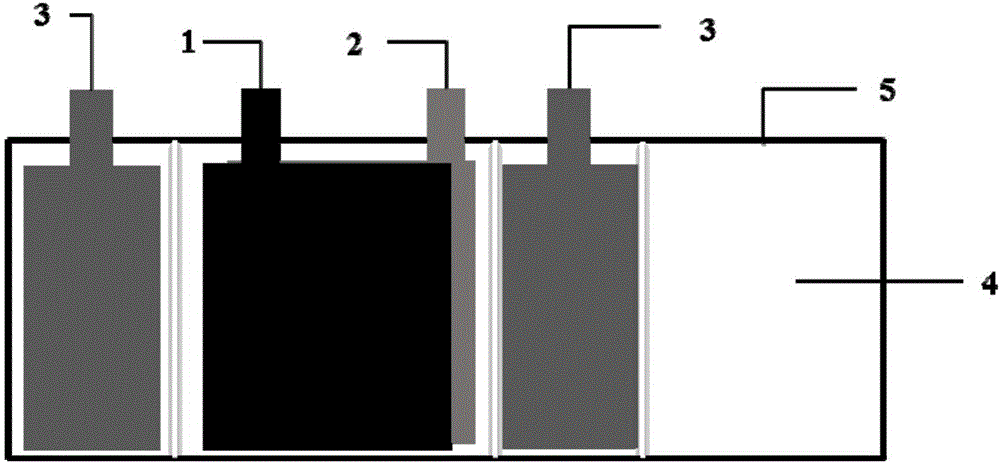

[0065] The aluminum plastic film was punched into a battery case with 4 chambers, and the LiNi 0.8 Mn 0.1 Co 0.1 O 2 The positive electrode and the Si / C composite negative electrode are assembled into a core package with LiMnO 4 with LiNi 0.6 Mn 0.2 Co 0.2 O 2 The mixed negative electrode sheet is a lithium supplementing electrode, and the number of lithium supplementing electrodes is 2, and the through porosity of the positive and negative current collectors is 30%. The core pack is placed in the core pack chamber, and the two lithium-replenishing electrodes are placed in the chambers on both sides of the core pack. Rich in electrolyte, battery structure such as image 3 shown.

[0066]After the battery core pack is formed, the lithium supplementary electrode is used as the anode, and the Si / C composite negative electrode in the core pack is used as the cathode. The amount is about 30% of the designed capacity of the Si / C composite anode. After the lithium suppleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com