Novel conductive agent for lithium-sulfur primary battery and preparation method of novel conductive agent

A conductive agent and battery technology, applied in battery electrodes, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of battery energy density reduction and achieve high conductivity, high conductivity, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

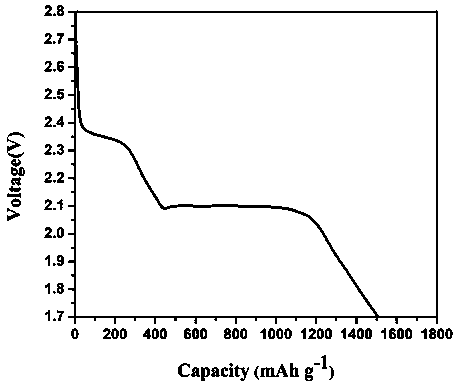

[0028] First, 1 g of 3,4-dioxyethylthiophene (EDOT) monomer was added to 50 mL of deionized water,

[0029] 3000 rpm, under the condition of stirring at room temperature, then add 0.2g conductive carbon black to obtain a mixed solution, then continue to stir, add 0.2g acetonitrile to the mixed solution after 20 minutes, then add 0.5g ammonium persulfate, ultrasonic 10 minutes, and stirred at 50°C for 10 minutes, and finally collected the black precipitate, washed three times with deionized water, and dried in an oven at 60°C as a conductive agent for lithium-sulfur primary batteries.

[0030] Then, place the sulfur electrode and the conductive agent and binder prepared in this example in a mortar in a mass ratio of 8:1:1, grind and mix to form a slurry, and evenly scrape the slurry on the carbon-containing Dry on aluminum foil at 55° C. for 24 hours, and press into thin sheets using a tablet press under a pressure of 5 MPa to obtain a positive electrode sheet. The sulfur comp...

Embodiment 2

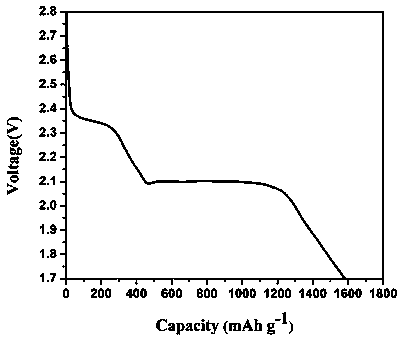

[0033] First, add 1.5g of 3,4-dioxyethylthiophene (EDOT) monomer into 100mL of deionized water, and then add 0.3g of conductive carbon black to obtain a mixed Solution, then continue to stir, after 22 minutes, add 0.3g of acetonitrile to the mixed solution, then add 0.75g of ammonium persulfate, ultrasonic for 10 minutes, and stir at 55°C for 10 minutes, finally collect the black precipitate, wash with deionized water 3 times Finally, it was dried in an oven at 60°C and used as a conductive agent for lithium-sulfur primary batteries.

[0034] Then, place the sulfur electrode and the conductive agent and binder prepared in this example in a mortar in a mass ratio of 8:1:1, grind and mix to form a slurry, and evenly scrape the slurry on the carbon-containing Dry on aluminum foil at 55° C. for 24 hours, and press into thin sheets using a tablet press under a pressure of 5 MPa to obtain a positive electrode sheet. The sulfur composite electrode or sulfur electrode is used as the ...

Embodiment 3

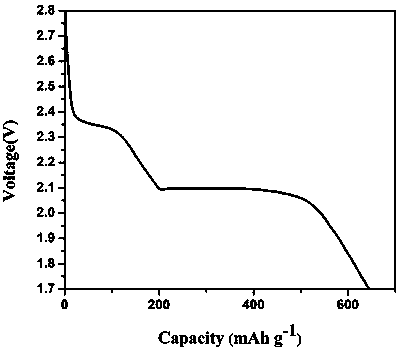

[0037] First, 2g of 3,4-dioxyethylthiophene (EDOT) monomer was added to 150mL of deionized water, and then 0.4g of conductive carbon black was added to obtain a mixed Solution, then continue to stir, after 25 minutes, add 0.4g of acetonitrile to the mixed solution, then add 1g of ammonium persulfate, ultrasonic for 10 minutes, and stir at 50°C for 10 minutes, finally collect the black precipitate, wash with deionized water 3 times , dried in an oven at 60°C, used as a conductive agent for lithium-sulfur primary batteries.

[0038] Then put the sulfur electrode and the conductive agent and binder prepared in this experiment in the mortar according to the mass ratio of 8:1:1, grind and mix to form a slurry, and evenly scrape the slurry on the carbon-containing aluminum foil, Dry at 55° C. for 24 hours, and press into a thin sheet using a tablet press under a pressure of 5 MPa to obtain a positive electrode sheet. The sulfur composite electrode or sulfur electrode is used as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com