Lithium-ion secondary battery and its composite positive electrode active material and preparation method

A technology for secondary batteries and composite positive electrodes, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems that limit the application of high-performance lithium-ion secondary batteries, the rate performance limitation of lithium-ion secondary batteries, and the electrochemical performance of positive electrode active materials. Poor performance and other problems, to achieve the effect of improving cycle performance and storage performance, good thermal and chemical stability, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

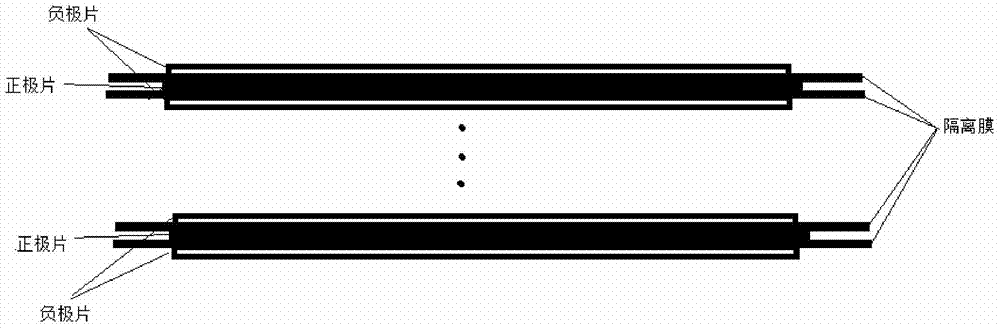

[0030] According to the preparation method of the composite positive electrode active material of the lithium ion secondary battery of the second aspect of the present invention, it is used to prepare the composite positive electrode active material of the lithium ion secondary battery of the first aspect of the present invention, comprising the steps of: (1) adding the dispersant The primary particles of deionized water and lithium manganese phosphate (LMP) are mixed and ball milled at a volume ratio of 1:1 to 3:1, and then ball milled and dispersed at a speed of 800r / min to 1000r / min for 1h to 2h to obtain lithium manganese phosphate ( Dispersion slurry of primary particles of LMP), wherein the general chemical formula of lithium manganese phosphate (LMP) is LiB y mn 1-y PO 4 , 0≤yx co 1-x o 2 , where, 0≤x<1, A is at least one of Ni, Mn, Al, Mg, Ca, Cr, Zr, Mo, Ag, Nb; (3) the primary particles of lithium manganese phosphate (LMP) Add the dispersion slurry to the dispers...

Embodiment 1

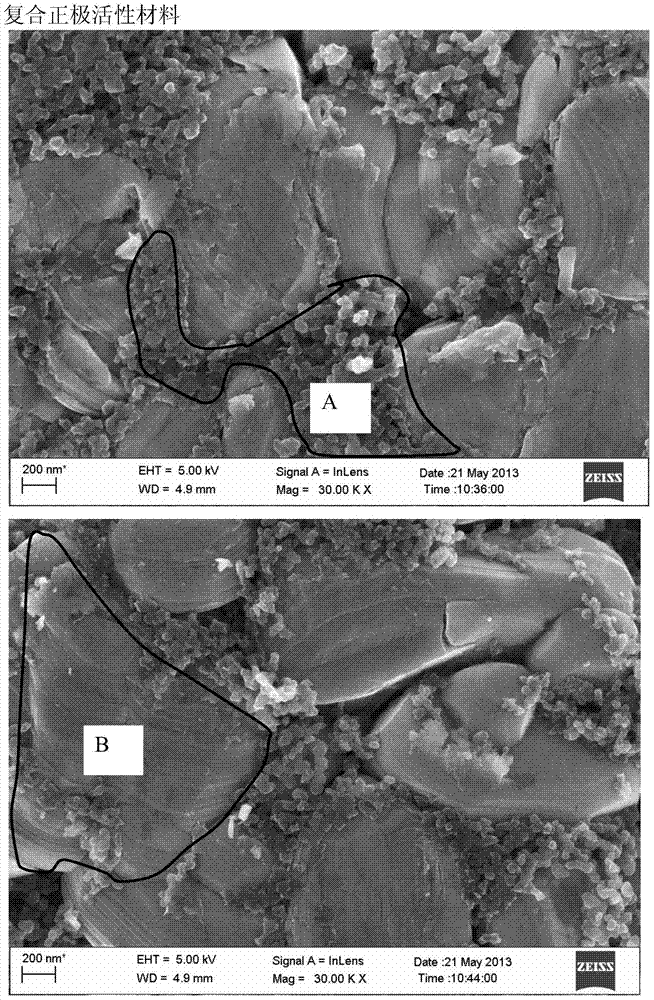

[0056] 1. Preparation of composite cathode active materials for lithium-ion secondary batteries

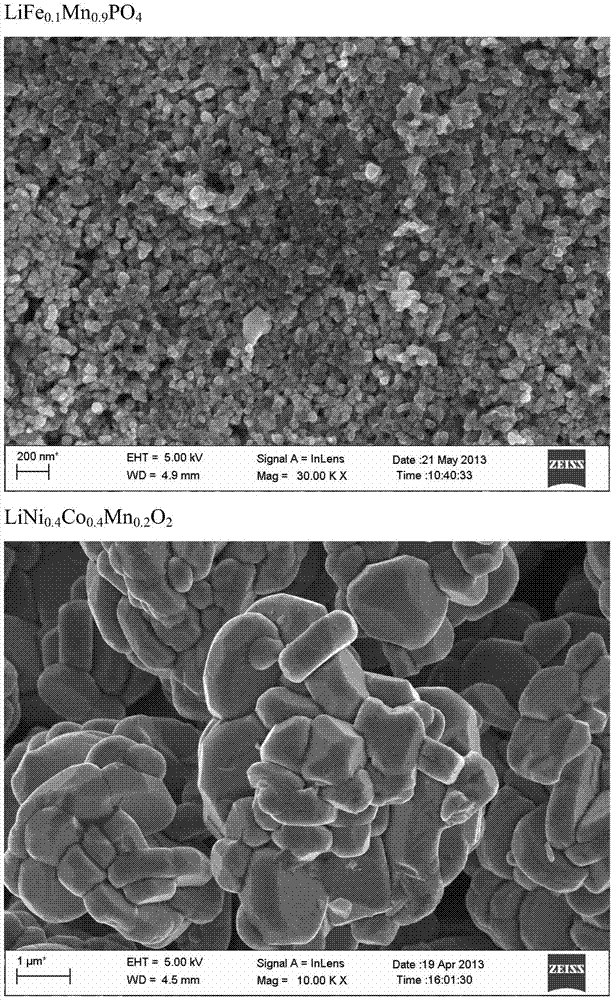

[0057] (1) The dispersant deionized water and lithium manganese phosphate (LiFe 0.1 mn 0.9 PO 4 ) of the primary particles ( figure 2 ) mixed and milled on a planetary ball mill at a volume ratio of 1:1, and then ball milled and dispersed for 1 hour at a speed of 800r / min to obtain lithium manganese phosphate (LiFe 0.1 mn 0.9 PO 4 ) of the primary particle dispersion slurry, where lithium manganese phosphate (LiFe 0.1 mn 0.9 PO 4 ) The primary particle size is 3nm ~ 10nm, BET specific surface area > 25m 2 / g;

[0058] (2) The dispersant deionized water and lithium cobalt series oxides (LiNi 0.4 co 0.4 mn 0.2 o 2 ) of the secondary particles ( figure 2 ) was mixed and milled on a planetary ball mill at a volume ratio of 1:1, and then ball milled and dispersed for 1 hour at a speed of 200r / min to obtain lithium-cobalt series oxides (LiNi 0.4 co 0.4 mn 0.2 o 2 ) d...

Embodiment 2

[0067] 1. Preparation of composite cathode active materials for lithium-ion secondary batteries

[0068] (1) The dispersant deionized water and lithium manganese phosphate (LiFe 0.3 mn 0.7 PO 4 ) primary particles in a planetary ball mill at a volume ratio of 1.5:1, and then ball milled and dispersed for 2 hours at a speed of 1000r / min to obtain lithium manganese phosphate (LiFe 0.3 mn 0.7 PO 4 ) of the primary particle dispersion slurry, where lithium manganese phosphate (LiFe 0.3 mn 0.7 PO 4 ) The primary particle size is 5nm ~ 12nm, BET specific surface area > 20m 2 / g;

[0069] (2) The dispersant deionized water and lithium cobalt series oxides (LiCoO 2 ) secondary particles were mixed and milled on a planetary ball mill at a volume ratio of 3:1, and then ball milled and dispersed for 3 hours at a speed of 400r / min to obtain lithium cobalt series oxides (LiCoO 2 ) dispersion slurry of secondary particles, in which lithium cobalt series oxides (LiCoO 2 ) The part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com