Device and method for continuously producing sodium methyl taurate in pipeline mode

A technology of sodium methyl taurate and its production method, which is applied in the field of pipeline continuous production of sodium methyl taurate, can solve the problems of long reaction time impurities, no operating flexibility, fast power consumption, etc., and achieve product quality Effects of stability, reduced dosage, and less reaction by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

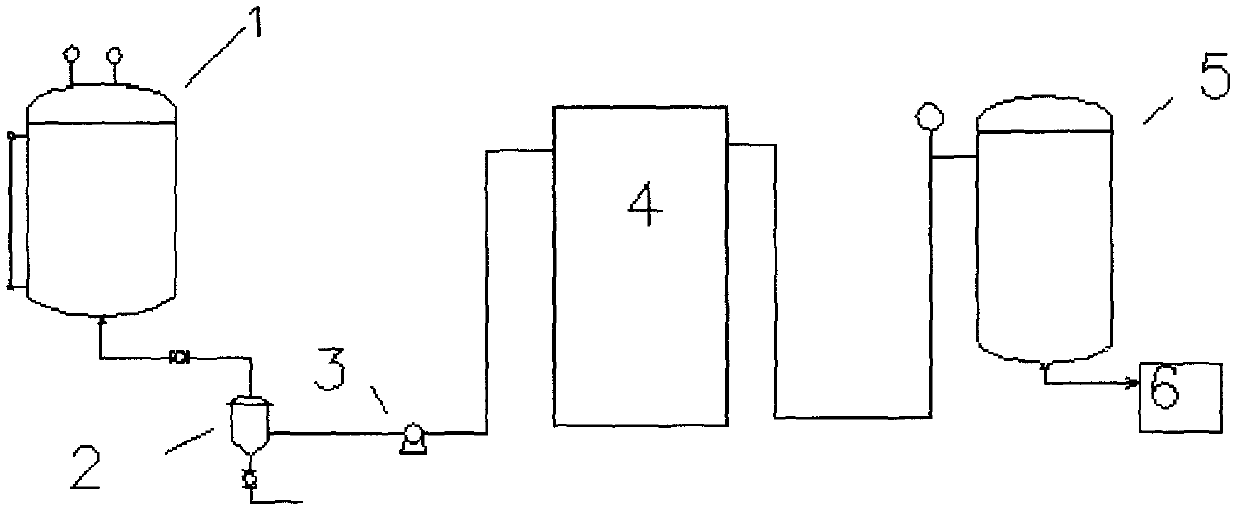

[0022] Sodium isethionate, water, methylamine, catalyst sodium hydroxide are joined in the storage tank 1, the addition of sodium hydroxide accounts for 0.3% of the total mass of the reaction solution, and the sodium isethionate and methylamine The molar ratio is controlled to be 1:8 and mixed evenly, and then the material is pumped into the continuous pipeline reactor 4 through the booster pipeline pump 3, and heated at a high temperature of 180°C by the heat transfer oil, and the booster pump increases the pressure to 18Mpa, and reacts in the pipeline The reaction time in the device 4 is 30 minutes. After the reaction, the material enters the evaporator 5 and undergoes multi-stage distillation. The decolorization and water replenishment refinement 6 is qualified sodium methyl taurate, and the yield is 90%.

Embodiment 2

[0024] Sodium isethionate, water, methylamine, catalyst potassium hydroxide are added in the storage tank 1, the addition of potassium hydroxide accounts for 0.5% of the total mass of the reaction solution, and the sodium isethionate and methylamine The molar ratio is controlled to be 1:10 and mixed evenly, then the material is pumped into the continuous pipeline reactor 4 through the booster pipeline pump 3, and heated at a high temperature of 240°C by the heat transfer oil, the booster pump increases the pressure to 19Mpa, and reacts in the pipeline The reaction time in the device 4 is 25min. After the reaction, the material enters the evaporator 5 and undergoes multi-stage distillation, and the decolorization and water replenishment refining 6 is qualified sodium methyl taurate with a yield of 93%.

Embodiment 3

[0026] Sodium isethionate, water, methylamine, catalyst sodium hydroxide are added in storage tank 1, the add-on of sodium hydroxide accounts for 1% of the total mass of reaction solution, the sodium isethionate and methylamine The molar ratio is controlled at 1:11 and mixed evenly, then the material is pumped into the continuous pipeline reactor 4 through the booster pipeline pump 3, and heated at a high temperature of 260°C by the heat transfer oil, the booster pump increases the pressure to 20Mpa, and the reaction occurs in the pipeline The reaction time in the device 4 is 40min. After the reaction, the material enters the evaporator 5 and undergoes primary and secondary distillation. The decolorization and water replenishment refining 6 is qualified sodium methyl taurate with a yield of 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com