Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

237 results about "Vegetable material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

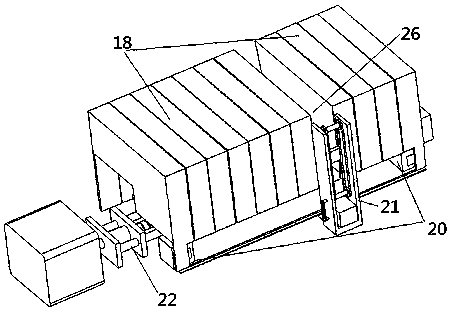

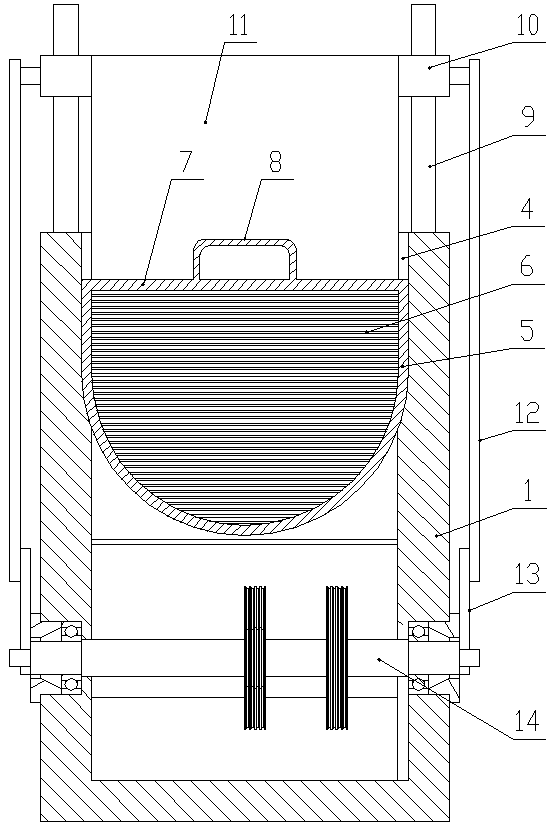

Mill for drying and pulverizing high-moisture and high-viscosity material and application method thereof

ActiveCN107694135ASolve the problem of hanging on the wallSolve the problem of dry millingEvaporator accessoriesGrain treatmentsImpellerEngineering

The invention provides a Yunjie mill. The Yunjie mill adopts a Yunjie mill main engine composed of a shell body, a rotor with a powder mill and a grading function and an inner circulating pipe, so that materials are pulverized and dried at the same time in a high-speed circulating flowing process in an inner circulating channel composed of an inner circulating pipe, a pulverizing impeller, a spacebetween the pulverizing impeller and an inner wall of a barrel body and the like; a wall remaining problem of the inner circulating channel is solved by utilizing an impact effect of a high-speed material flow; the wall remaining problem of an outer circulating channel is solved by controlling the moisture content of materials, discharged by the main engine, through a grading impeller; the defects of equipment in the inventive patent 2015110139212 are overcome and a method and a product of the inventive patent 2015110139212 are economically realized; the invention provides an application method of the Yunjie mill, so that the drying and pulverizing problem of high-moisture and high-viscosity materials including vegetable materials, meat, liquid materials and the like is solved; a solutionwith good economical efficiency is provided for processing feed and preparing a medicine which takes a volatile component as a functional component.

Owner:KUNMING TEKANG TECH CO LTD

Method for producing atmosphere heat drying and vacuum oil frying combined dewatered fruit and vegetable crisp chip

InactiveCN1554274AAvoid severe deformationKeep shapeFood preservationFood preparationFood materialEdible mushroom

The present invention belongs to the field of fruit and vegetable food producing technology. The production process of crisp fruit and vegetable chip includes the steps of: selecting fruit, vegetable material, edible mushroom and other food material; pre-treatment including washing, peeling, slicing, scalding to kill enzyme, etc; heating to dry at normal pressure; oil frying to dewater, centrifuging to eliminate oil, seasoning and packing. Owing to the combined dewatering process of normal pressure hot drying and vacuum frying, the present invention has low oil content in crisp fruit and vegetable chip, short frying time and well maintained food shape.

Owner:JIANGNAN UNIV +1

Method for preparing quickly-fermented probiotic pickle by biological method

The invention discloses a method for preparing quickly-fermented probiotic pickle by the biological method, belongs to the field of deep processing of vegetables, and particularly relates to a method for producing pickle by compound bacteria powder. The method solves the technical problem about quick production of high-quality fermented pickle and includes main steps of firstly, adding raw materials and sealing: cutting vegetables and placing cut vegetables into a container, adding compound bacteria powder containing bacillus aceticus and brewer's yeast, and auxiliaries with salt, and sealing the container; secondly, fermenting: controlling the temperature at 23-36 DEG C for early fermenting, and controlling temperature at 15-25 DEG C for later fermenting, and keeping fermenting time within 20-40 hours; and thirdly, dewatering and flavoring: dewatering the pickle after fermenting, and adding seasoning to mix uniformly. The method is applicable to pickle production in different scale and has wide application prospect in the pickle production field, production time can be obviously shortened, and pickle products are rich in nutrition and pure in taste.

Owner:李绩

Method for producing directly putting type fermented pickled vegetables

InactiveCN1615740AIncrease acidityPh value dropsFood preservationFood preparationVegetable ProductDeep processing

The present invention relates to deep processing of vegetable, is especially the process of producing pickled vegetable with compound bacteria powder, and solves the technological problem of fast producing high quality fermented pickled vegetable. The production process includes the main steps of 1) mixing cut vegetable, compound bacteria powder containing plant lactobacillus, acetobacter, cheese lactobacillus and Saccharomyces cerevisiae, and supplementary material containing salt, and sealing in the container; 2) fermentation first at the temperature of 23-36 deg.c and then at 15-25 deg.c for 20-40 hr; 3) eliminating water from the fermented pickled vegetable and mixing with seasonings. The said process has different production scales and short production period, and the pickled vegetable product has rich nutrients and pure taste.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

Method of producing fertilizer from black liquid generated during paper making by potassium hydroxide alkali method

InactiveCN1537830ALess investmentReduce energy consumptionSewage/sludge fertilisersFertiliser formsPotassium hydroxideOrganic fertilizer

A process for preparing fertilizer from the black liquid generated during making paper by KOH method features that said black liquid is used to treat vegetable material to obtain fertilizer, which can be further processed to obtain different kinds of organic fertilizer, composite inorganic-organic fertilizer and biologic organic fertilizer.

Owner:顾小平 +1

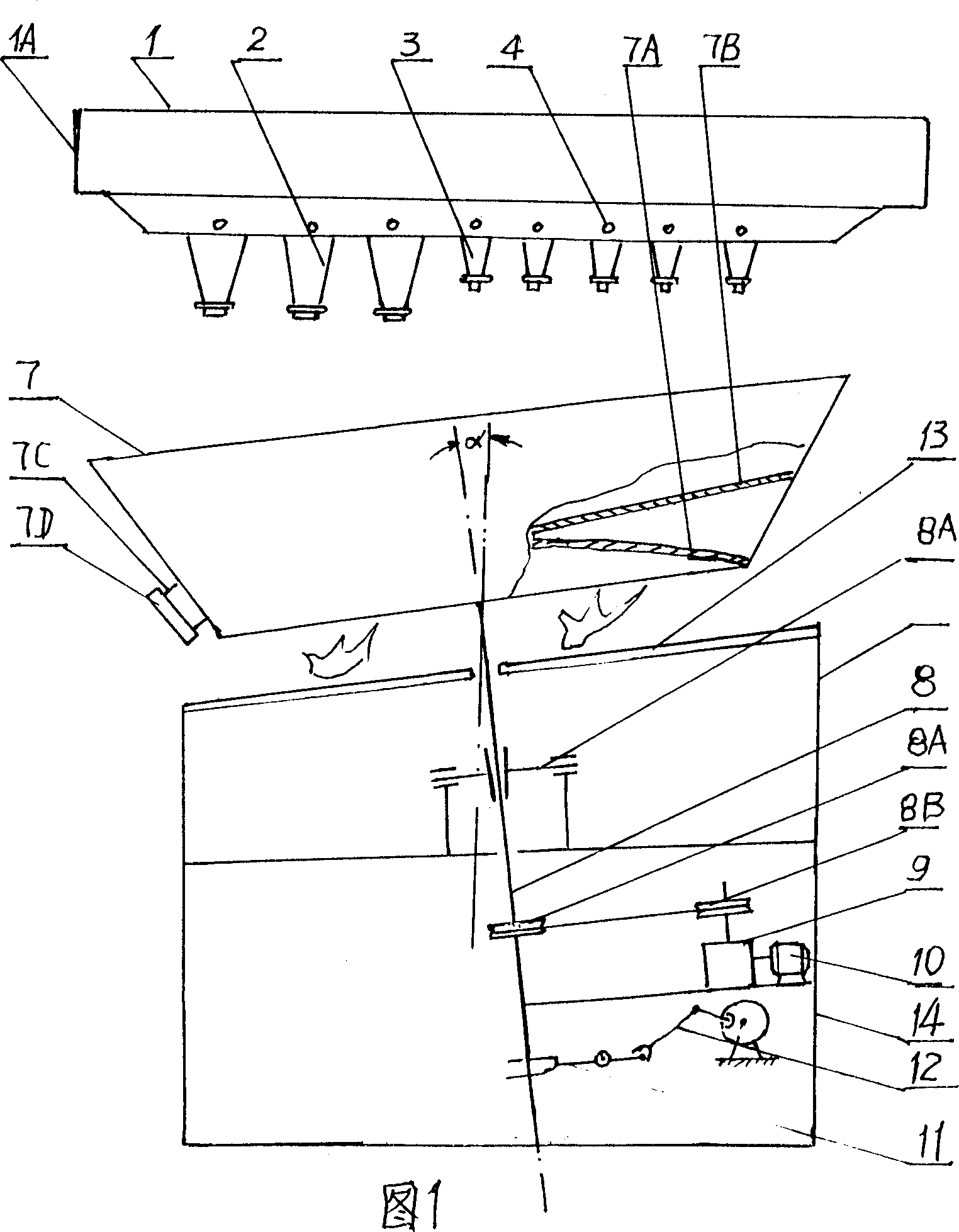

Automatic stir-frying machine

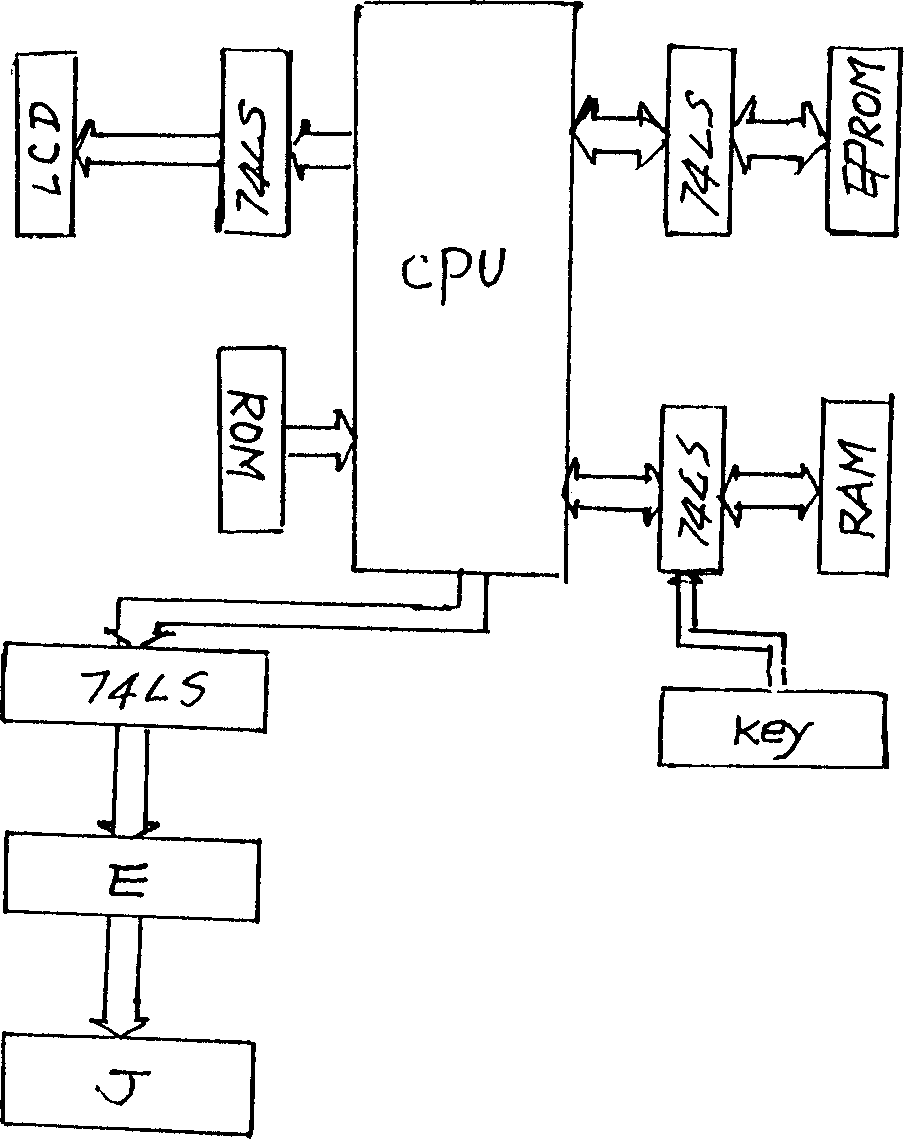

InactiveCN1399934ASave heavy physical laborGuaranteed stir-frying effectCooking vesselsMicrocomputerEngineering

The present invention relates to an automatic cooking pan for stir-frying dish, and is characterized by that a basin-shaped cooking pan with stirring blades is connected with a tilting shaft, under the action of supporting mechanism and driving system the stirring blades can be rotated along self axis and the pan can be reciprocally swinged along the tilting surface so as to ofrm a composite movement, and said composite movement can make the vegetable materials in the pan produce autoamtic rolling movement, and over the cooking pan a flavouring material automatically-adding device controlled by microcomputer is set, so that it can make all the operations of large cooking pan implement automation.

Owner:康文朝

Pets food

InactiveCN1883292AImprove adhesionIncrease appetiteFood processingAnimal feeding stuffYeastAnimal science

Owner:NINGBO HAILUKONG ECO FOOD TECH

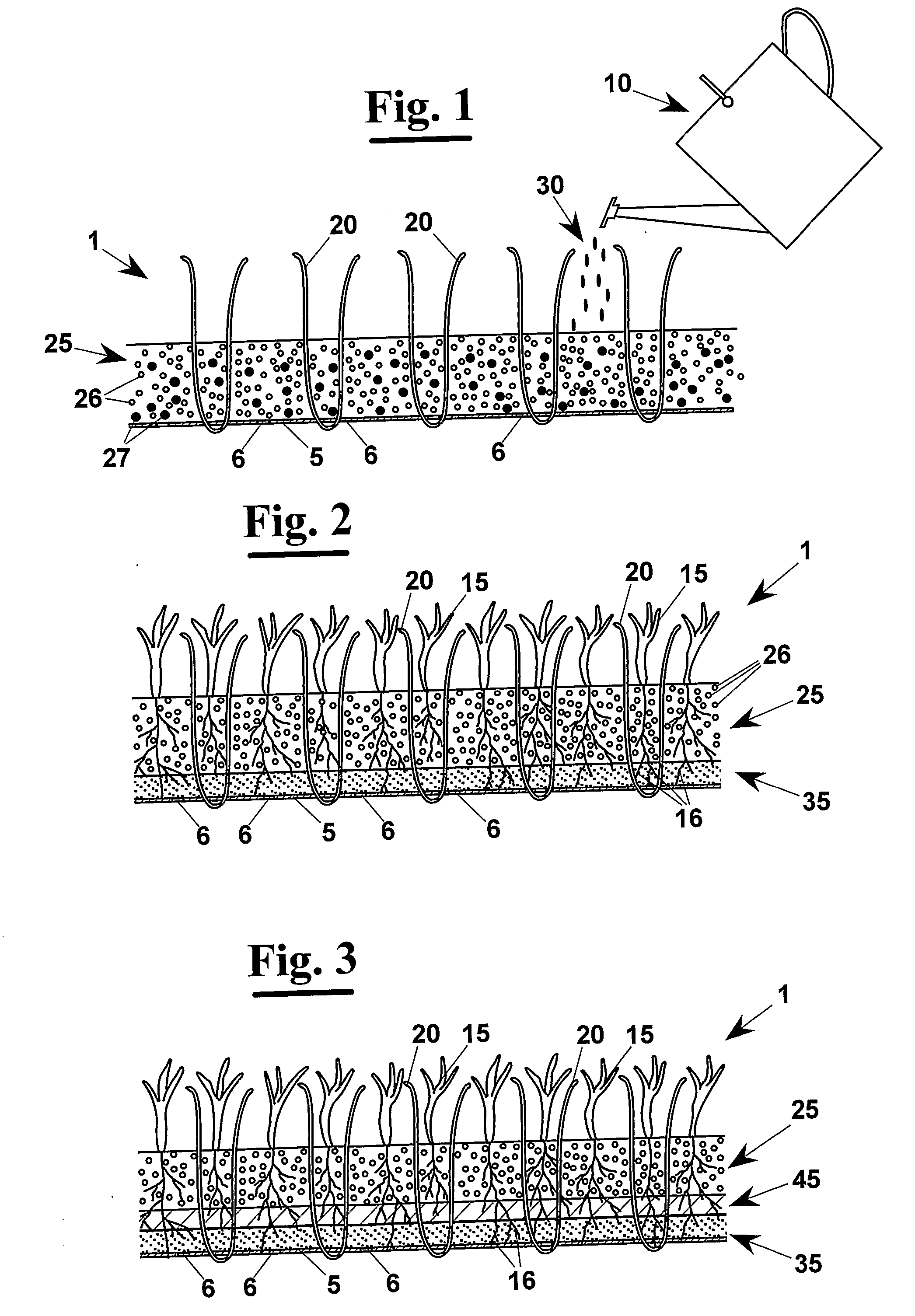

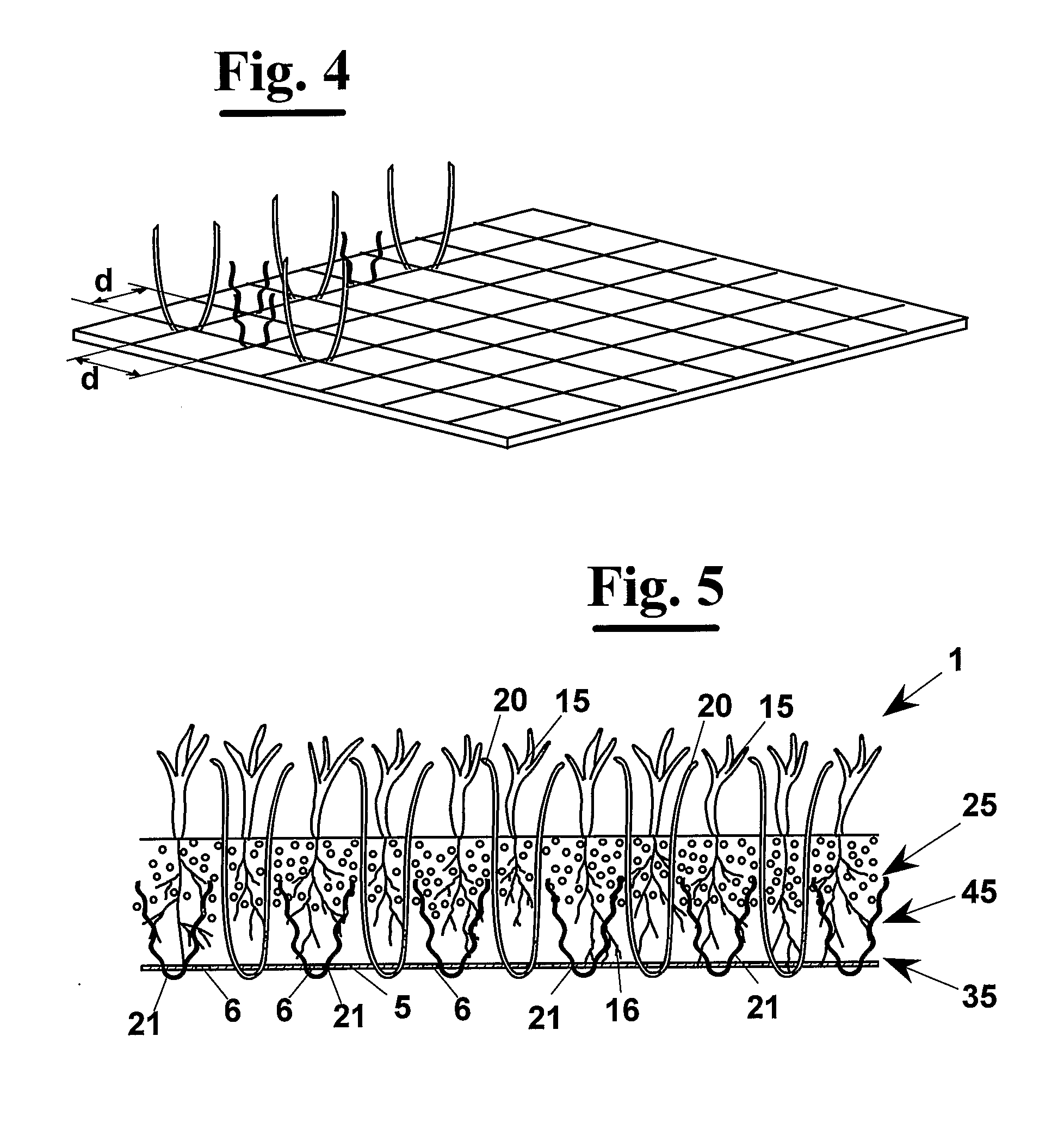

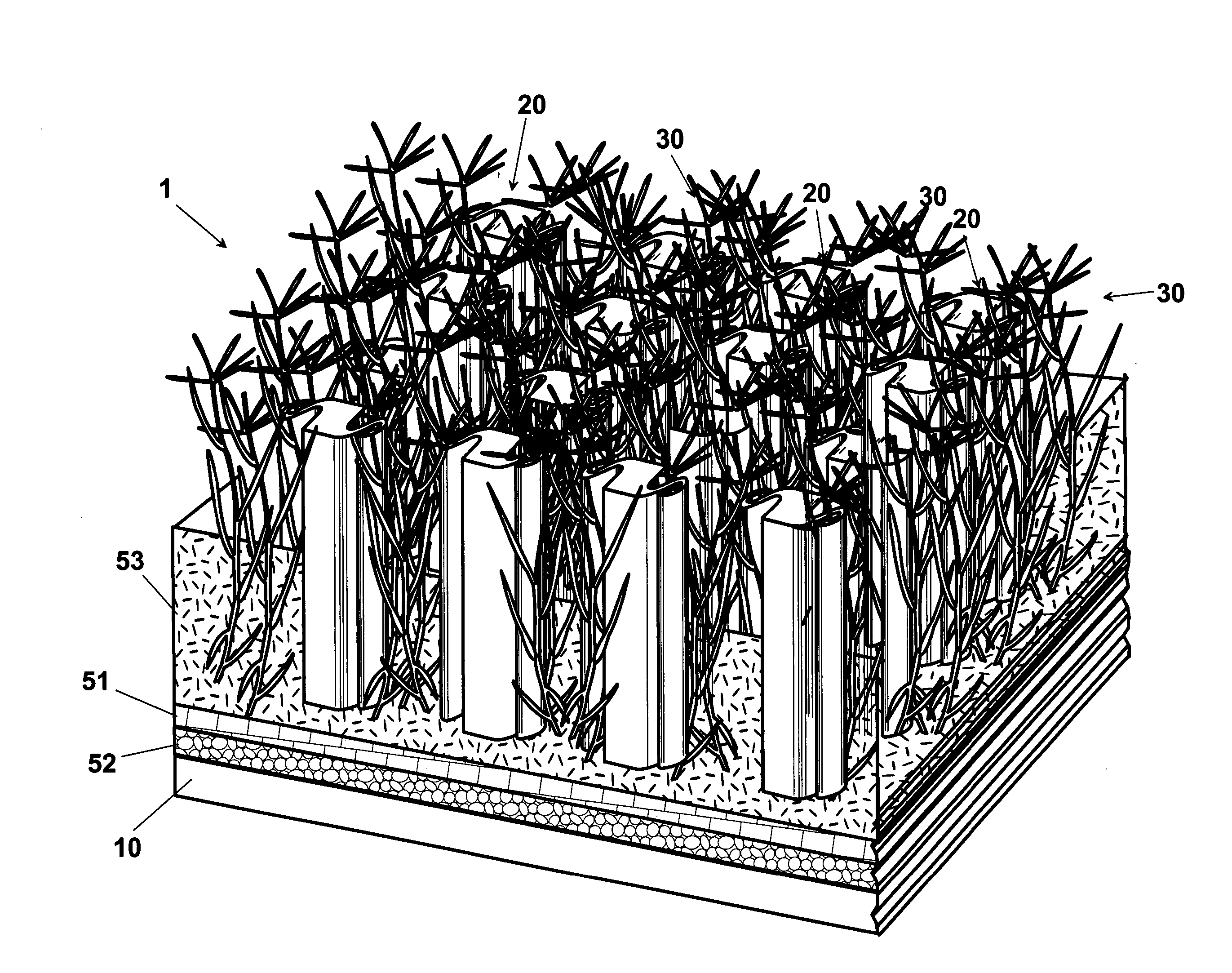

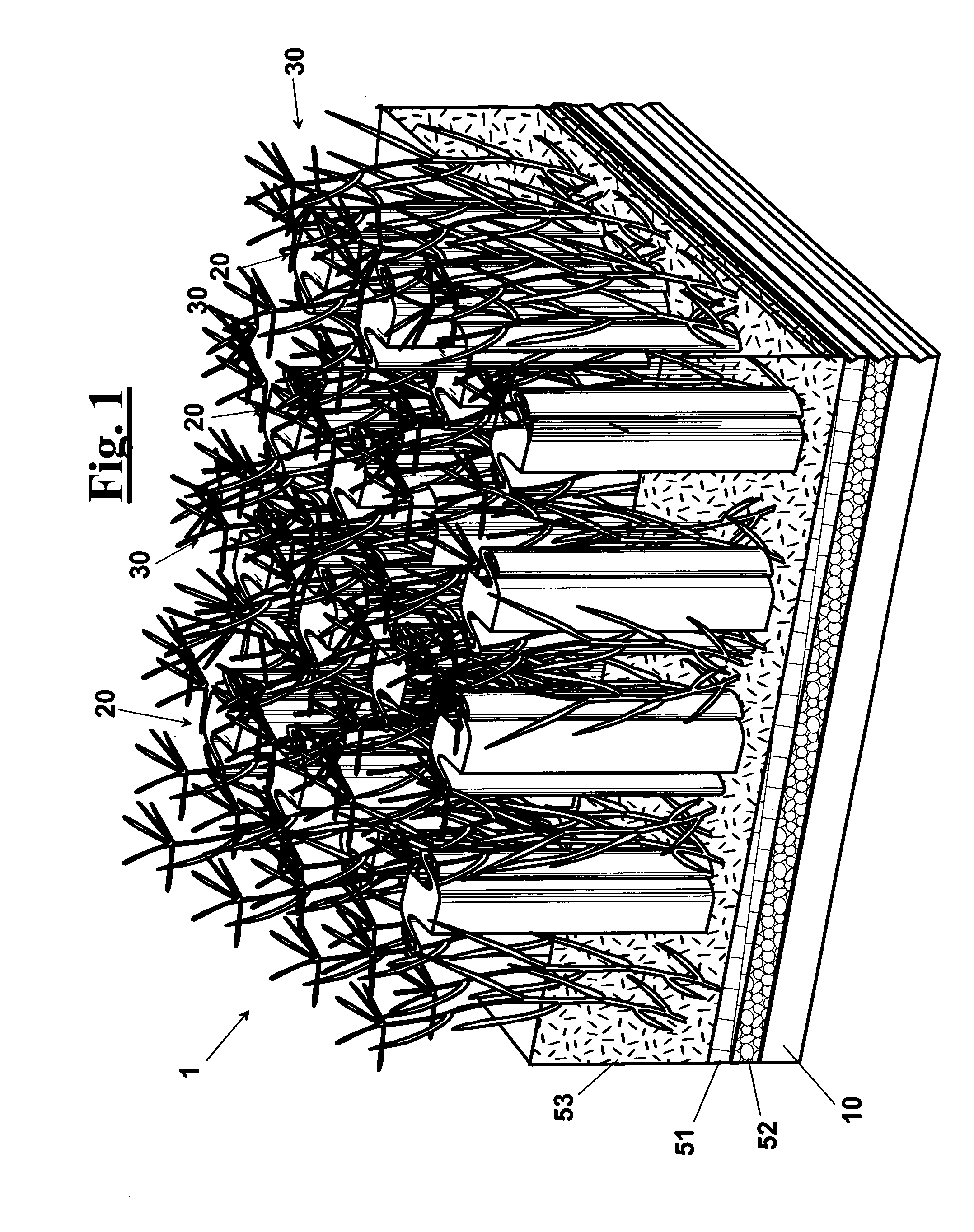

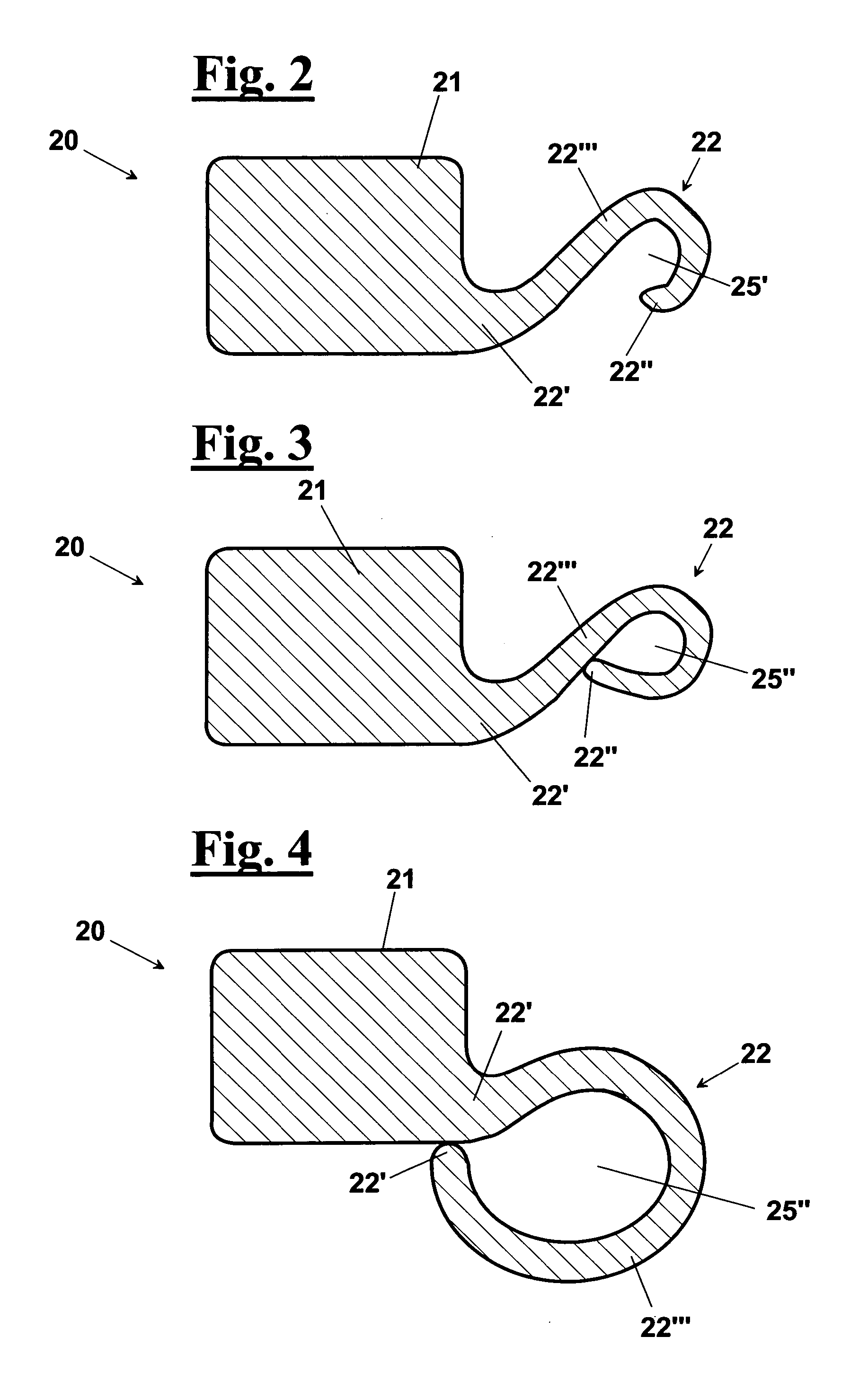

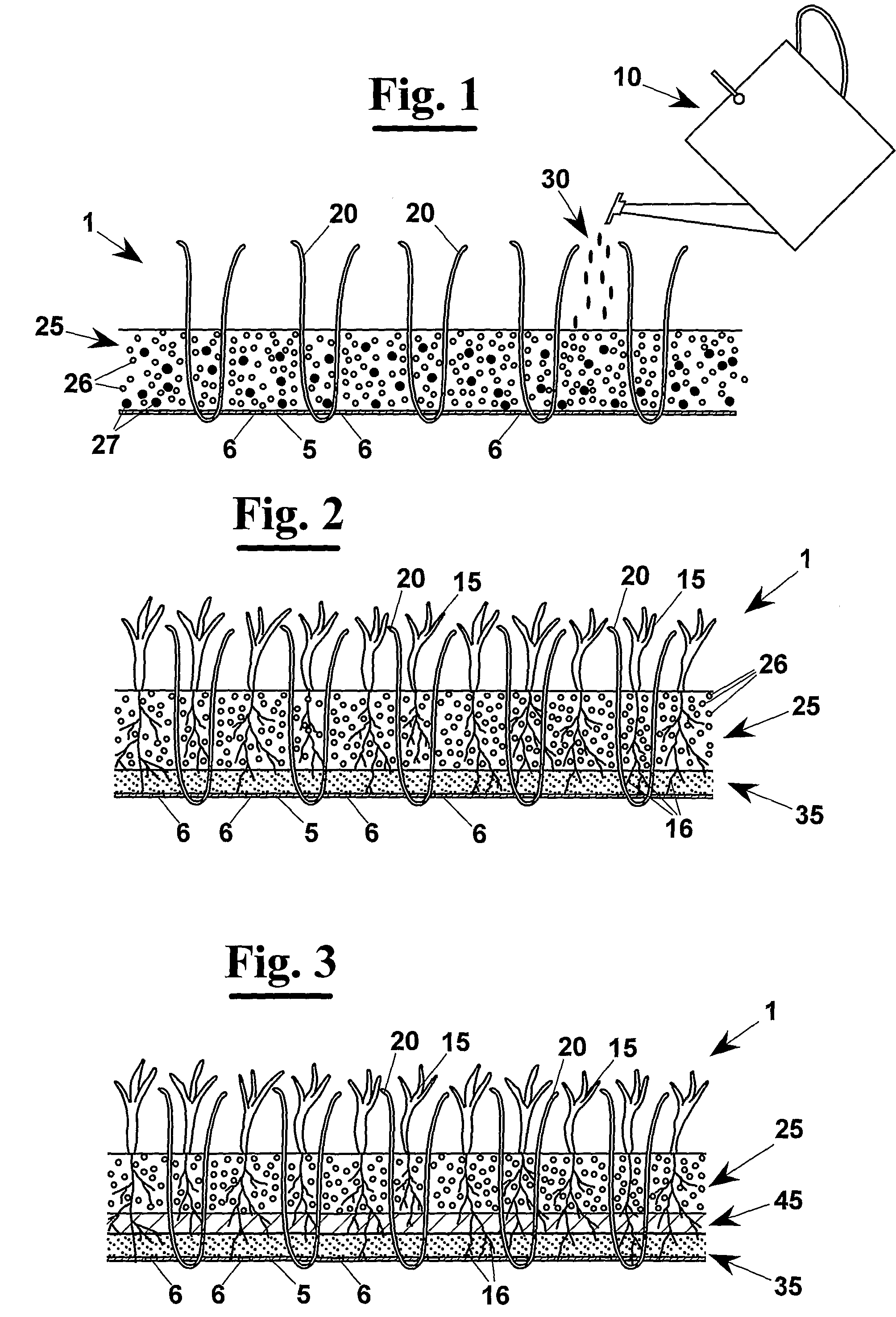

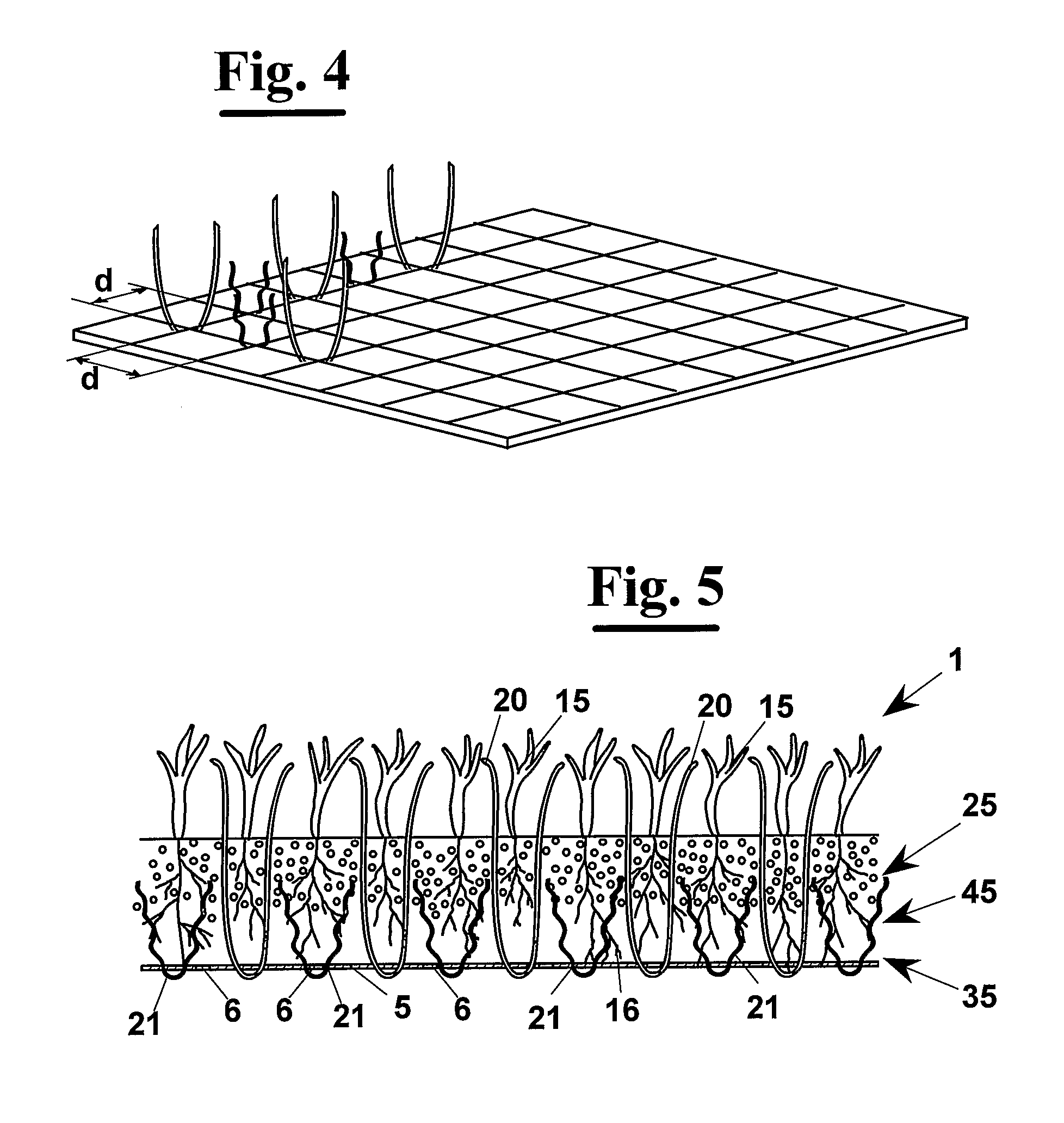

Mixed Turf and Method for its Production

ActiveUS20070248773A1Easy to carryEasy to disassembleHair accessoriesToupeesFiberArtificial materials

Turf (1) for playing sport, for recreation and / or for ornamental purpose comprising a flexible not biodegradable support (5) having a plurality of holes (6) for allowing the drainage of water through the support (5) same. To the flexible support (5) fibres (20) are connected of artificial material in order to form a turf of artificial blades extending from the upper side of the support (5). The fibres (20) are then kept substantially vertical by granular filling material (25), can be made of rubber granules (26). The turf (1) is therefore completed by living vegetable material put into the granular material by means of sowing, transplantation of portions of plants (15) or a combination thereof. Finally, the living vegetable material in the form of seeds (27), or of portions of plants (15), is watered and dressed as known in the art. The turf can be easily carried, rolled up, turned over without spreading the granular material, and laid in a desired moment on a desired support surface for immediate use.

Owner:NUSCA ROBERTO +1

Extraction of phenolic antioxidants

InactiveUS20050095332A1Increase pressureIncrease temperatureOrganic compound preparationCarboxylic acid esters preparationOff-flavourPhenolic antioxidant

Owner:STANLEY ROGER ANTHONY

Process of making frozen light pickled seasoning vegetable

InactiveCN1887114ALighten the original amountAvoid infectionFood preservationFood preparationSodium hypochlorite solutionProduct processing

The process of making frozen lightly pickled and seasoned vegetable belongs to the field of deep agricultural product processing technology. The process includes the steps of: soaking fresh vegetable material in 150-250 ppm sodium hypochlorite solution for 6-10 min to sterilize; twice low salt short period pickling; soaking inside seasoning liquid containing trehalose in 5-6 % at the temperature of -4 to 0 deg.c; vacuum packing; quick freezing and maintaining at -18 deg.c. The frozen lightly pickled and seasoned vegetable has the mouth feeling and color of natural vegetable maintained.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD

Mesona chinensis benth series drinks and preparation method thereof

InactiveCN101703293ANo incompatibilitySimple ingredientsFood preparationHigh volume manufacturingAdditive ingredient

The invention discloses mesona chinensis benth series drinks and a preparation method thereof, wherein the method takes mesona chinensis benth as main material to prepare mesona chinensis benth herbal drink, mesona chinensis benth gelatine powder, hot grass jelly electuary and immortal grass tea with milk through the processes of boiling extraction, concentration and the like. Compared with the existing mesona chinensis benth drinks, the product has the effects of cooling, lowering fire and relieving restlessness, has simple and convenient carrying, convenient drinking, and simple ingredients without incompatibility, reduces precipitation and impurities, and retains the special flavour of vegetable material as much as possible, and also has lower cost, exact efficacy, simple production process and easy operation and control, thus ensuring the product quality and being applicable to large-scale production.

Owner:灵山县宇峰保健食品厂

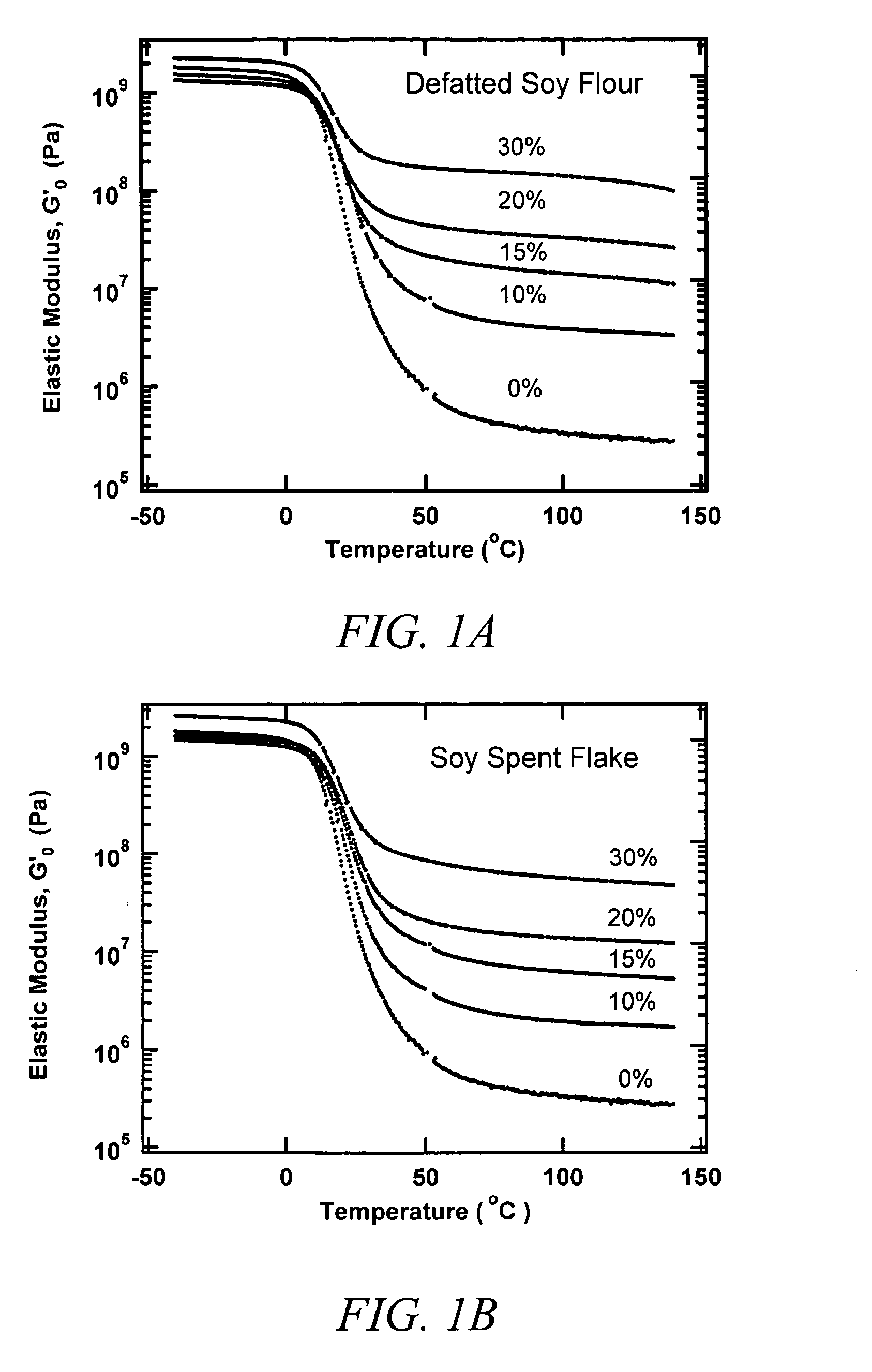

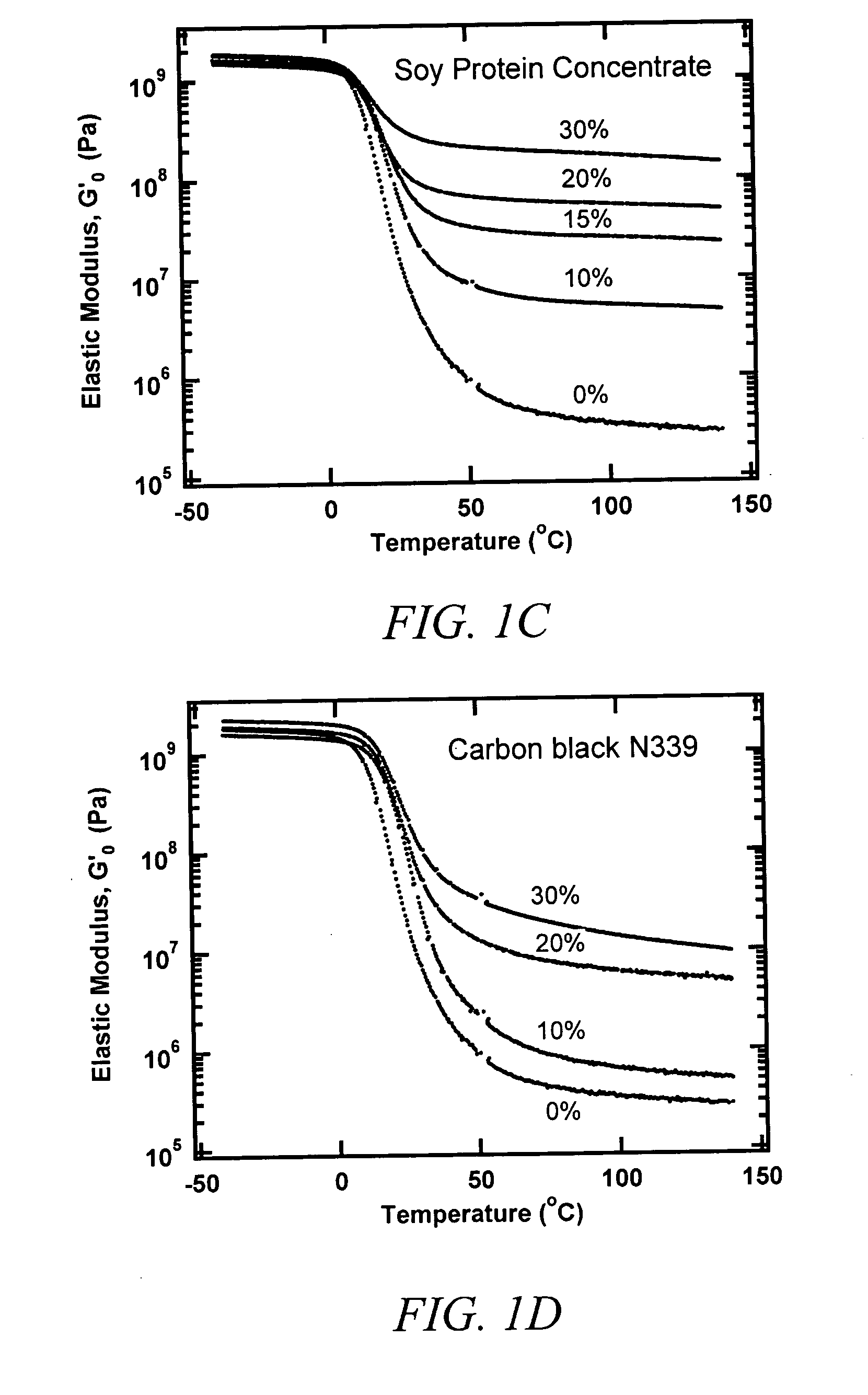

Material compositions for reinforcing ionic polymer composites

InactiveUS20060094800A1High elastic modulusImprove functional propertiesPaper coatingCoatingsPolymer sciencePolystyrene

The invention is related to the preparation of an ionic polymer composite material comprising a protein and carbohydrate-containing vegetable material component that serves as a reinforcement agent for the composite. In preferred embodiments of the invention, the vegetable seed component is selected from the group of soy spent flakes, defatted soy flour, or soy protein concentrate with ionic polymers and the ionic polymer is carboxylated poly(styrene-butadiene). The composites have a significantly higher elastic modulus when compared with base polymer.

Owner:US SEC AGRI

Method for Preparing a Proteinaceous Vegetable Flavor Enhancer

This invention includes a method of producing hydrolyzed vegetable protein from proteinaceous vegetable material using commercial enzymes and optimally also fresh baker's yeast as source of proteases and peptidases. The invention further includes a method of solubilizing and pasteurizing proteinaceous vegetable material.

Owner:SYNERGY FLAVORS INNOVA LLC

Method of improving comprehensive performance of vegetable paper

InactiveCN1887112AIncrease moisture contentImprove palatabilityFood preservationFood preparationPack materialMoisture

The method of improving comprehensive performance of vegetable paper belongs to the field of fruit and vegetable food producing technology and is for mainly production of edible packing paper and paper type vegetable product. The vegetable paper producing process includes the steps of: sorting vegetable material, peeling, washing, slicing, scalding to deactivate enzyme, color protecting, mixing with moisture reducing agent and forming agent, pulping, deairing, forming, hot blast drying, microwave drying or infrared drying to water content of 20-30 %, peeling, cutting, further drying to water content of 10-20 %, and nitrogen filling or vacuum packing of the product. Owing to the moisture reducing agent and forming agent, the vegetable paper has good taste, relatively high tensile strength and breaking strength and may be eaten and used as the food packing material.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

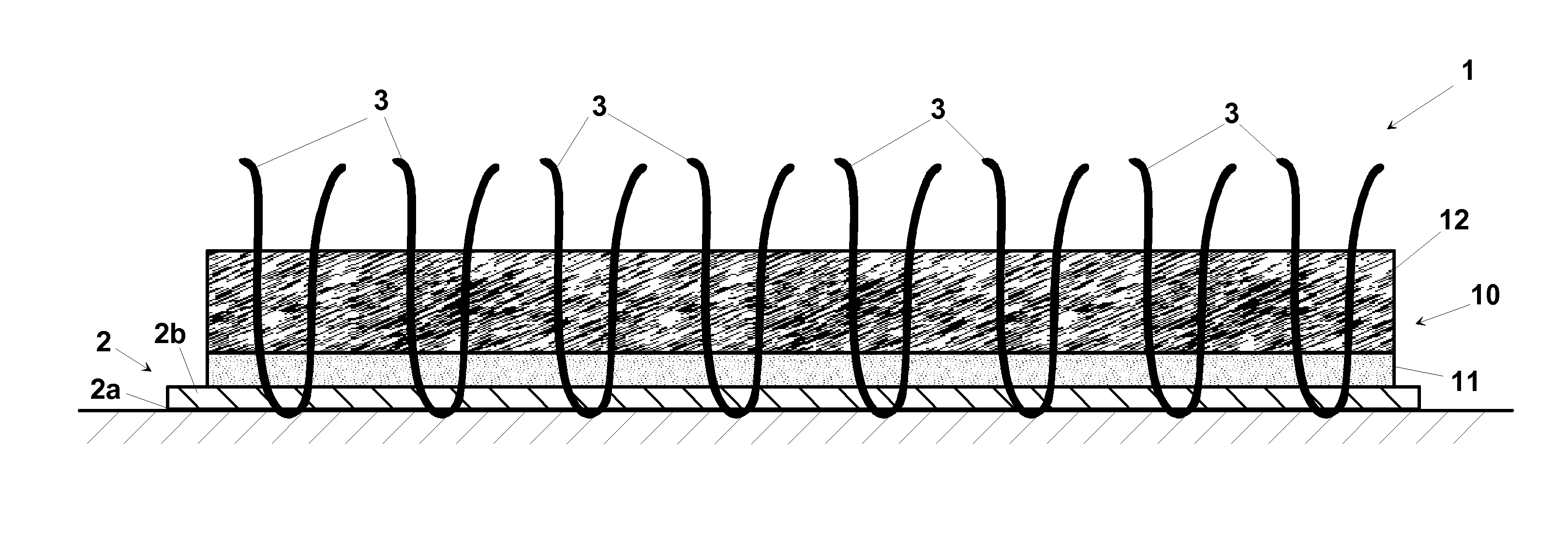

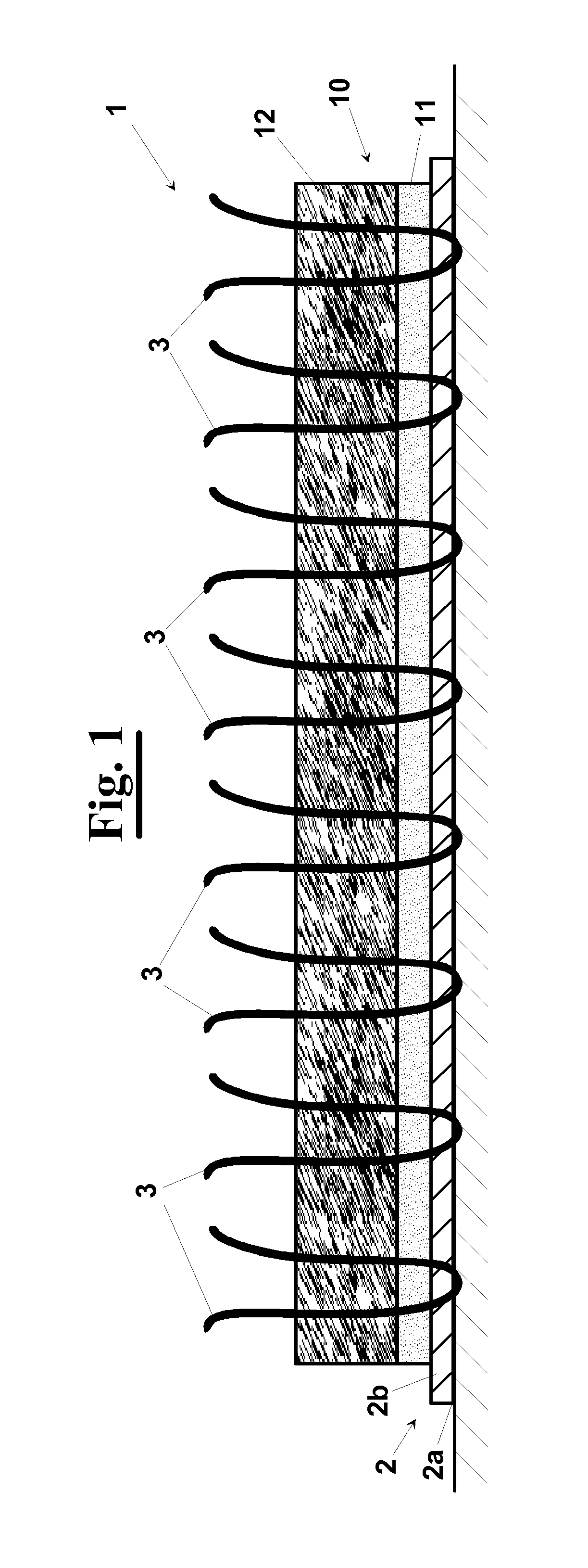

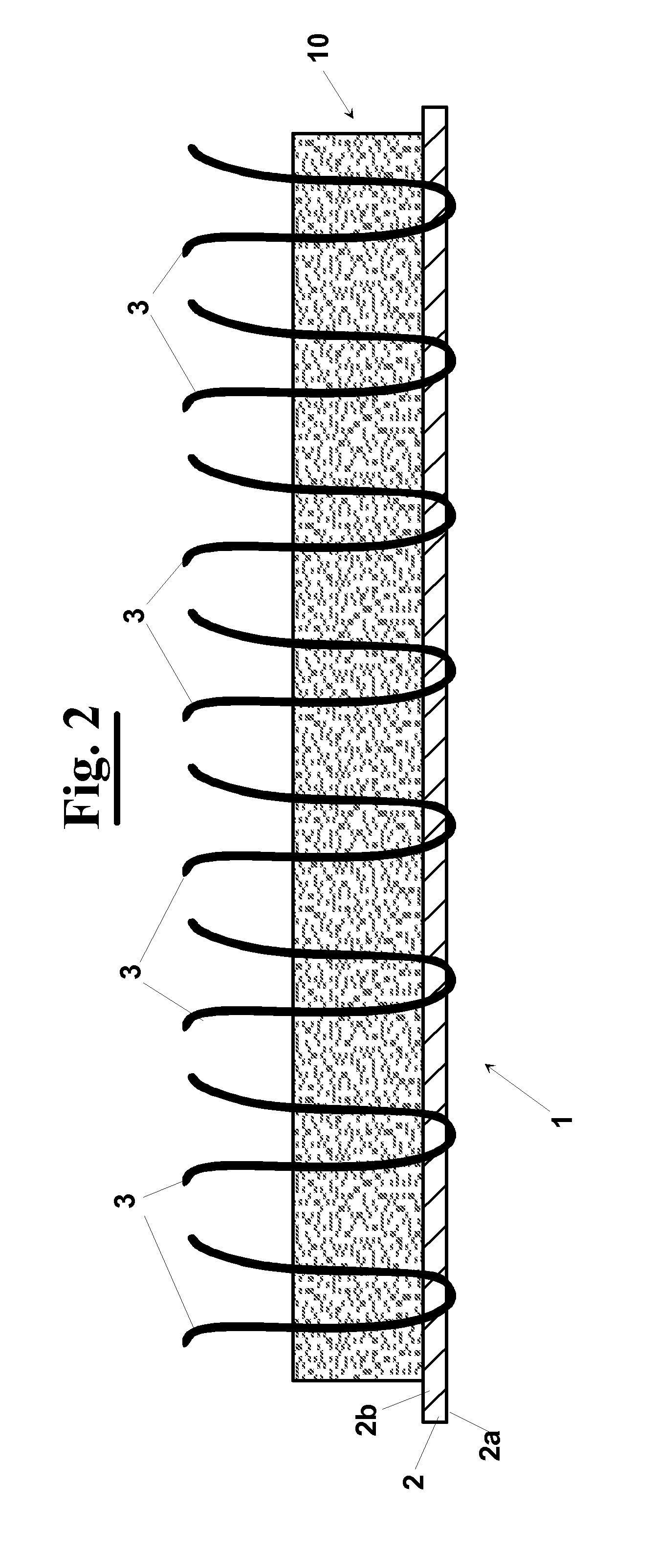

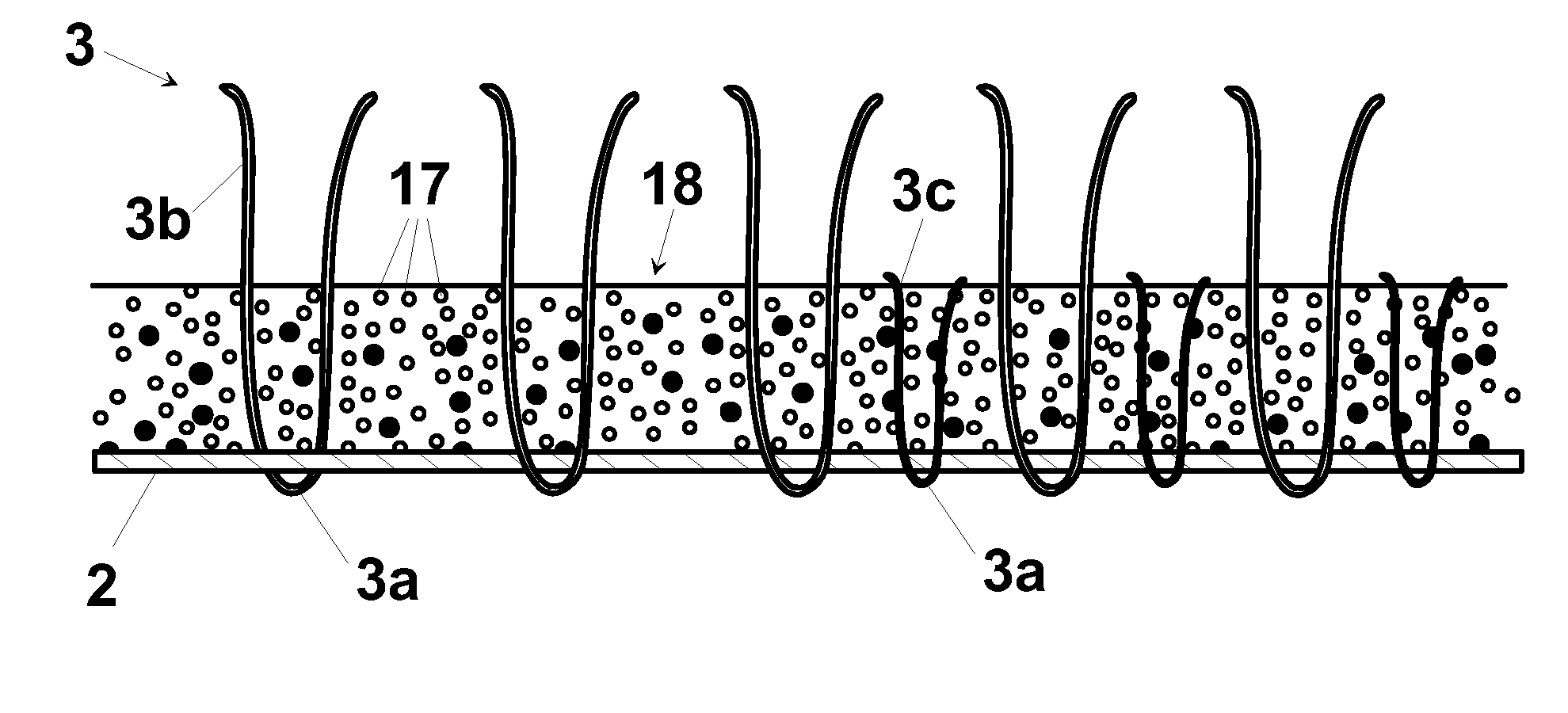

Mixed turf and method for its production

InactiveUS20120279125A1Quick and long lasting abilityAccurately developedGround pavingsCultivating equipmentsFiberInfill

Turf (1) for sports, recreactional activities and / or for ornamental purposes comprising a mat of flexible material (10) equipped with a first face (11) and a second face (12) opposite to each other. To the mat (10) a plurality of fibres (20) are connected of an artificial material in such a way that it forms an artificial turf (50) that protrudes from the first face (11). The turf (1) comprises, furthermore, a measured amount of a loose infill material (50), for example of granular type, distributed on the face (11) of the mat (10). The turf (1) comprises, furthermore, natural vegetable material, i.e.plants, belonging to one, or more plant species (30) put in the loose infill material (50) by means of sowing, traplantation of portions of plants, or a combination of the two solutions. The fibres of artificial material (20) have a profiled shape comprising a main blade (21) and at least one side wing (22). More precisely, the side wing (22) has a curved profile suitable for forming a channel (25) arranged substantially parallel to the main blade (21) in order to form a channel that is substantially parallel to said main blade, so that the profile of the channel partially or completely encircles the spaces that are occupied by water, roots and loose infill material, creating a water reserve for roots.

Owner:MAR PROJECT

Protective coating for decorative vegetable material

The present invention is directed to a composition adapted to be applied to coat a surface area of a vegetable in order to retard environmental degradation thereof. The composition comprises a film-former, a fungicide and a thickener distributed in a carrier liquid. The fungicide may be present in less than one percent (1%) by weight. The composition may include a pH buffer operative to maintain the pH of the mixture between 8.5-10.5. The film-former is operative to coalesce to form a film covering the surface area of the vegetable which is operative to retard dehydration thereof. The fungicide is entrapped throughout the film and is operative to inhibit mildew and fungus growth thereon. The present invention also provides a method of formulating a composition according to the present invention, as well as a method of protecting a decorative vegetable material using a composition according to the present invention.

Owner:PUMPKIN

Method for producing plant cultivating and seedling raising matrix by using cattle manure and use method for matrix

InactiveCN105794530AImprove cakingImprove problems such as poor rehydrationBio-organic fraction processingOrganic fertiliser preparationSurface layerPlant stalk

The invention relates to a method for producing a plant cultivating and seedling raising matrix by using cattle manure and a use method for the matrix. The cattle manure contains a large amount of organic colloidal matters, so that when a fermented material of pure cattle manure or a fermented material of a mixture of fresh cattle manure and vegetable material debris directly serves as the matrix, during planting, the material is easily bonded into lumps due to alternate change of dryness and humidity and is poor in rehydration and difficult in scattering, and water absorption property, water retention property and air permeability are required to be improved; after a large number of research trials, the production of the plant cultivating and seedling raising matrix is carried out through compounding vermiculite and / or coco coir and / or pearlite and the fermented material of the pure cattle manure or the fermented material of the mixture of the fresh cattle manure and the vegetable material debris; in view of the characteristics of the pearlite, a planting and use method which comprises the step of covering an upper layer or surface layer of the pearlite-containing compounded matrix with a pearlite-free matrix is invented; and novel ways and methods are provided for utilizing the cattle manure and plant stalks.

Owner:HANGZHOU MANTINGFANG BIOTECH +1

Methods of obtaining selected pectin fractions, such fractions and their use

InactiveUS6855363B1Enhanced functional specificitySpecific functionalityMilk preparationWhey manufactureOrganic solventPre treatment

A method of providing selected fractions of high-esterified pectin, each having different functionalities, by consecutive extraction of a vegetable material with acidic aqueous solutions to obtain successive fractions of high-esterified pectin with increasing setting time. The vegetable material is optionally prior to being extracted subjected to an acid pre-treatment by heating it in a homogeneous mixture of water and a water-miscible organic solvent. The pectin fractions obtainable by the method have improved properties when used in the preparation of food products such as preserves and acidified milk products. The pectin fractions are also useful as starting materials in a method of obtaining deesterified and optionally amidated pectin fractions having additionally improved functional characteristics.

Owner:AS DE DANSKE SUKKERFABRIKKER

Method for the treatment of a material other than the human body

InactiveCN101175556ASame favorable characteristicsGood drying trendOrganic chemistryMixing methodsCompound aHuman body

The invention relates to a surface treatment method, in which a material other than the human body, which is selected from metallic materials and fibrous materials, is brought into contact with a composition comprising at least one dianhydrohexitol ether (compound A). The dianhydrohexitol ether can be associated with a compound B which is selected from among solubilising agents, acid agents and alkaline agents. The fibrous material to undergo surface treatment is chosen from the following materials in particular, namely: wood materials, vegetable materials, paper materials and textile materials.

Owner:ROQUETTE FRERES SA

Preparation method for lactobacillus fermentation pickled vegetable liquor for seasoning

ActiveCN103704646AProduces high total acid contentPure flavorSugar food ingredientsFood preparationBiotechnologyMicrobiology

The invention relates to a preparation method for lactobacillus fermentation pickled vegetable liquor for seasoning, belonging to the fields of biotechnology and food. The preparation method comprises the following technique steps: washing and putting fresh vegetables into a pot, dissolving and evenly mixing glucose, compound phosphate, Paolemei lactobacillus preparation activating fluid and salt with cooled boiled water, then pouring into a fermentation tank, and evenly circulating and sealing for fermentation for 7-25 days, thus obtaining the fermentation pickled vegetable liquor product. The usage amount of the cooled boiled water is twice that of the fresh vegetables, and one the basis of the total weight of the fresh vegetables and cooled boiled water, adding amount of all auxiliary materials are respectively as follows. Compared with the traditional fermentation mode, not only is the fermentation period shortened greatly, but also large-scale production can be realized, and the prepared pickled vegetable liquor is rich in lactobacillus, mellow in acid fragrance, and palatable in mouth feeling.

Owner:四川西兴食品有限公司

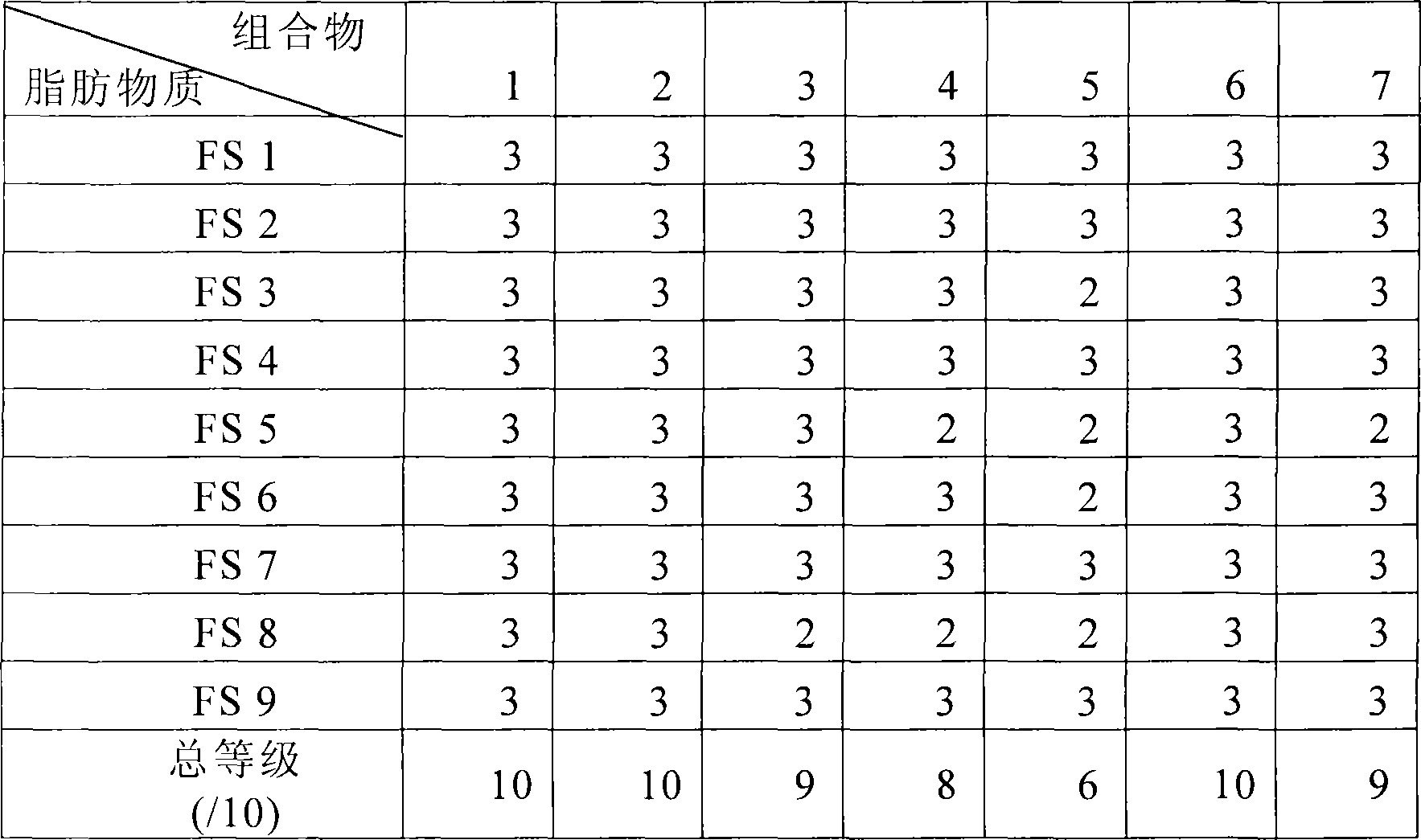

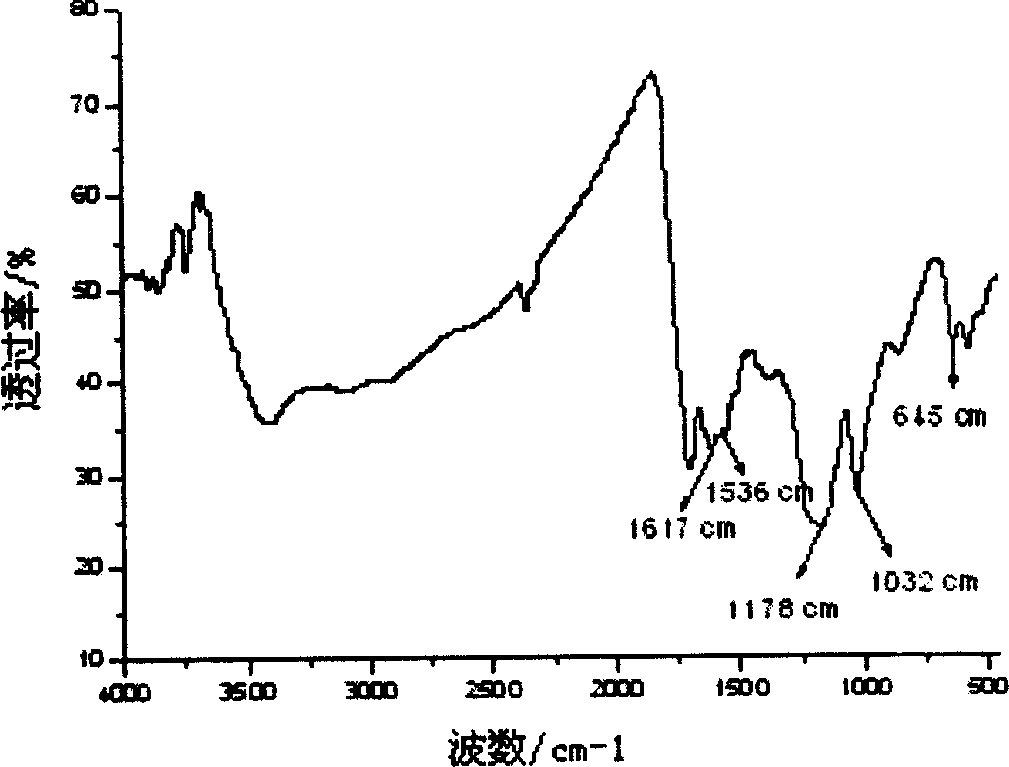

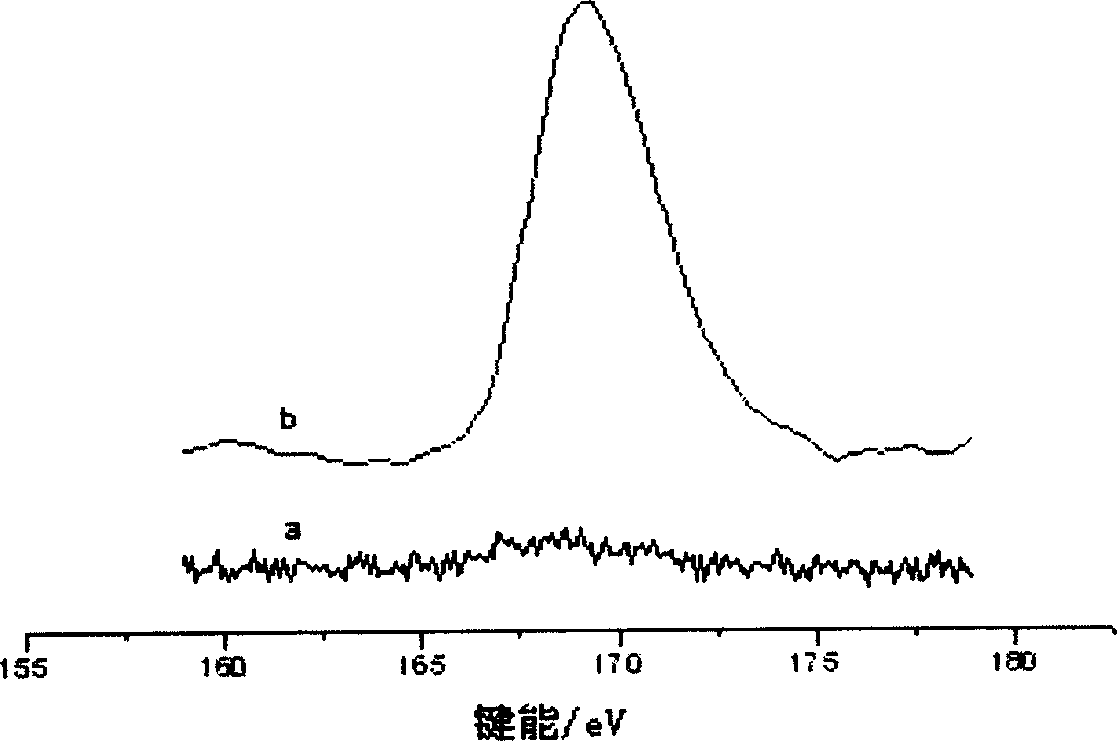

Method for preparing solid sulfonic acid from reproducible vegetable material

InactiveCN1915507AReduce wear and tearReduce energy consumptionPhysical/chemical process catalystsCelluloseResource utilization

A process for preparing solid sulfonic acid from the regeneratable vegetative raw material, such as wood bits and bamboobits, includes such steps as drying the vegetative raw material containing cellulose and lignin, breaking, proportionally mixing it with sulfuric acid, stirring at 40-200 deg.C for 1-20 hr, cooling, washing with deionized water until it becomes neutral, baking, proportionally adding sulfonating agent, sulfonating at 30-150 deg.C for 1-20 hr, cooling, washing with deionized water until it becomes neutral, testing no deposition in BaCl2 solution, and baking.

Owner:HUNAN NORMAL UNIVERSITY

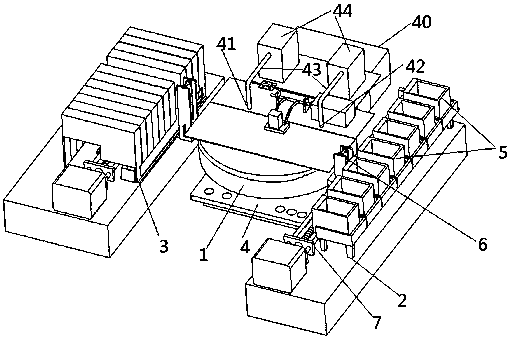

Automatic feeding cooking system

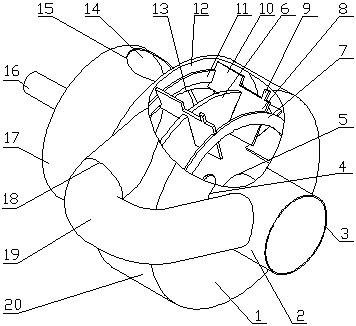

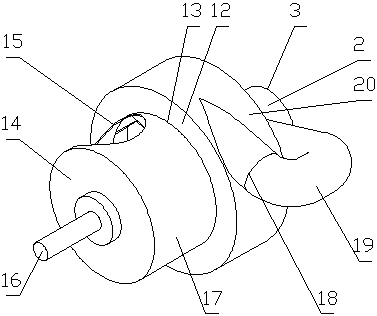

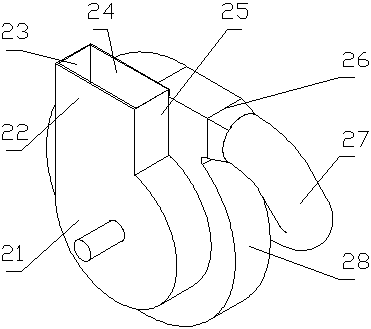

ActiveCN107928380AJoin smoothlyEfficient dischargeCooking vessel constructionsProcess engineeringIndustrial engineering

The invention discloses an automatic feeding cooking system, which comprises a pot body, a vegetable material adding device and a seasoning material adding device, wherein the vegetable material adding device comprises a vegetable material box, a first lifting and turning device and a first moving device; the first moving device drives the first lifting and turning device to move; the seasoning material adding device comprises a seasoning material box, a material collecting box, a second lifting and turning device and a second moving device; the material collecting box is used for receiving seasoning; the second moving device drives the second lifting and turning device to move; and the pot body collects vegetable materials in the vegetable material box and seasoning materials in the material collecting box. By combining the program control, the automatic addition and cooking of the vegetable materials and the seasoning materials in the pot body can be realized; the structure is simple; and the manufacturing is convenient.

Owner:王伟

Whole-grain rice enzymolysis infant milky rice powder and manufacturing method thereof

InactiveCN106136052AImprove the efficiency of surface gelatinizationConducive to the efficiency of enzymatic hydrolysis operationMilk preparationSugar food ingredientsAmylaseBiotechnology

The invention relates to the field of baby foods, in particular to whole-grain rice enzymolysis infant milky rice powder. Whole-grain rice which substitutes for polished rice is supplemented with cow milk materials to serve as raw materials of baby foods, nutrients of husks, aleurone layers and grain embryos in whole-grain rice are used completely, and comprehensive nutrition is guaranteed due to joint addition of animal and vegetable materials. By protease, lactase and amylase for enzymolysis, enzymolysis of allergenic protein, lactose and starch is realized to make the allergenic protein, the lactose and the starch easier to digest and absorb, and transitional period of baby foods can be effectively shortened for infants.

Owner:SHANTOU PEIZHI FOOD

Mixed turf and method for its production

ActiveUS7943212B2Easy to carryEasy to disassembleHair accessoriesDead plant preservationFiberArtificial materials

Owner:NUSCA ROBERTO +1

Creams, whipped products thereof, dry powders thereof and process for producing the same

It is intended mainly to provide creams not restricted in flavor which are excellent in whipping properties under acidic conditions (in particular, in a pH region shifting toward the acidic side from the isoelectric point but not being extremely acidic) and free from any problems in physical properties (i.e., capable of giving whipped products which have smooth texture and excellent shape-retention) and can fully utilize the refreshing flavor of fruit acids, etc. Secondarily, it becomes possible to provide vegetable plants obtained from vegetable materials alone, whipped products thereof or dry powders thereof. Namely, creams obtained by using acid-soluble soybean protein without resort to nonfat solid milk, acid-soluble milk whey protein or stabilizer in solidifying milk.

Owner:FUJI OIL CO LTD

Vegetable dough, a process for its production and vegetable bakery products made therewith

Vegetable-based dough that comprises softened gluten and added vegetable material. The vegetables comprise legumes and / or fruits and / or fibers. The Vegetable dough essentially consists of softened gluten in admixture with vegetable materials or of an essentially homogeneous mixture of softened gluten, to which vegetable material has been added. The vegetable dough is produced by first softening a gluten mass, and then by mixing the resulting softened gluten with a preferred vegetable, until an essentially homogeneous mass is obtained.

Owner:TIVALL 1993

Infill for synthetic and hybrid turfs and turfs so obtained

ActiveUS20150252537A1Improve performanceLiquid surface applicatorsAntifouling/underwater paintsInfillSynthetic materials

A synthetic turf having a mat with a face arranged adjacent to a surface to coat, and a face opposite the face. The turf includes a plurality of blades made of a synthetic material that are connected to the mat. Above the face of the mat, an infill material is provided that is arranged among the blades. The infill material includes a predetermined percentage by volume of a vegetable material consisting of rachis of cereal ear. The infill material also includes a predetermined percentage by volume of a ligninic and / or resinous material of vegetable origin.

Owner:MAR PROJECT +1

Method for producing synthetic turfs

ActiveUS20100166984A1Cheaply and easilyAvoid chalkingDead plant preservationArtificial flowers and garlandsInfillFilling materials

Method for making a synthetic turf comprising laying a turf (1) consisting of a mat (2) on which a plurality of blades (3, 3a, 3b, 3c) of synthetic material is woven. An infill material (18) is obtained using the granular and fibrous part (17) of a loose product based on ground coconut, alone or with addition of other material such as rubber in granules or sand or other loose vegetable material such as cork. The raw material based on coconut, having a heterogeneous granulometry set between about 500 micron and several mm, is obtained loading a loose product based on ground coconut by a hopper on a conveyor belt for being fed in a sieve, for example a rotating screen that separates the powder part from the granular and fibrous part. In particular, the powder part of the raw material, is gathered on a conveyor belt and from here sent to a storage reservoir. The granular and fibrous part of the raw material, which represents the main product of the process, is, instead, sent by a conveyor belt to a storage, reservoir from where it is taken for the process to provide infill material for a synthetic turf.

Owner:LIMONTA SPORT SPA

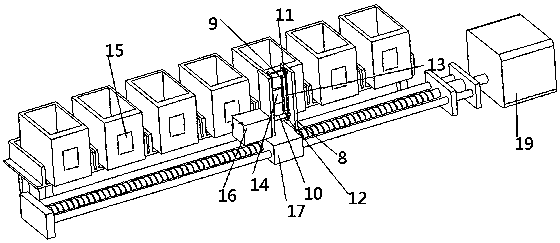

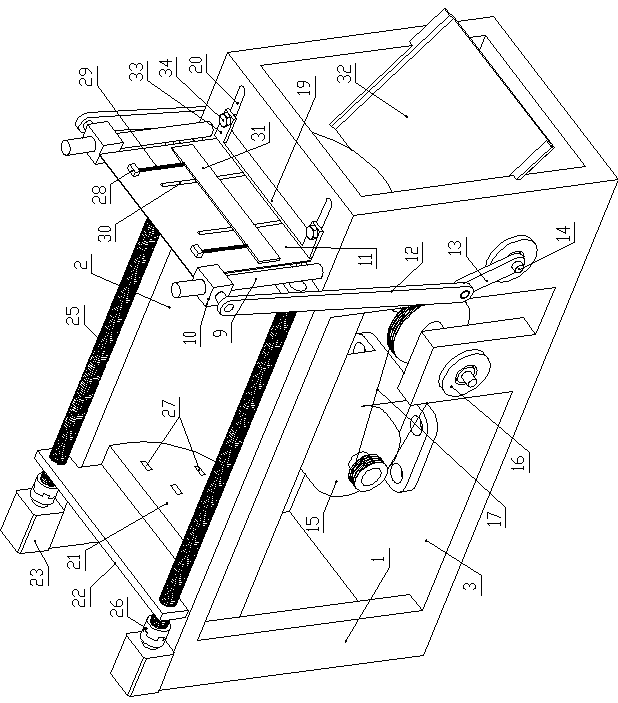

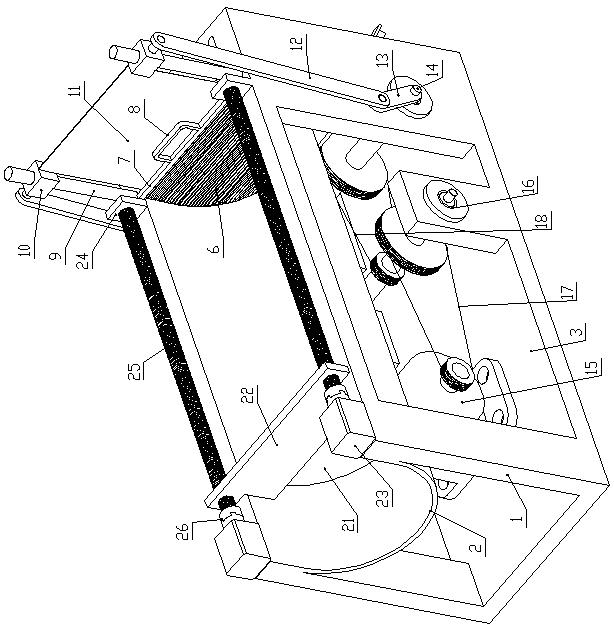

Vegetable foods slicing and slitting device and slicing and slitting method

PendingCN109732691APrinciples of ScienceCompact structureMetal working apparatusSlice thicknessEngineering

The invention discloses a vegetable foods slicing and slitting device. The vegetable foods slicing and slitting device comprises a frame which is in a cuboid shape, a material guide groove used for containing vegetable raw material is formed in the inner upper part of the frame, the material guide groove is thorough from front to rear, the top of the material guide groove is open, the inner spaceof the cross section of the material guide groove is of a U-shaped structure, the front side of the top of the frame is provided with a lifting type slicing mechanism which is positioned right above the front port of the material guide groove, a power driving mechanism is arranged in the frame, the power driving mechanism is connected with the lifting type slicing mechanism, the top of the frame is provided with a slicing thickness adjusting mechanism arranged in the front side of the lifting type slicing mechanism, a slitting tool is arranged on the rear side of the lifting type slicing mechanism and on the inner wall of the material guide groove, and a linear stepping driving mechanism used for driving the vegetable raw material to move forwards along the material guide groove is arranged at the top of the frame. During operation, workers only need to put the raw material into the device, labor intensity is greatly reduced, two functions of slicing and slitting are achieved at the same time, the slicing or slitting operation efficiency is high, the slicing thickness is consistent, and the thickness of slicing or slitting can be conveniently adjusted.

Owner:HUANGHE S & T COLLEGE

Enzyme method of extracting oils and proteins from vegetable matter in an aqueous medium

ActiveUS20120196332A1Volume of water is minimizedReduce sewagePeptide preparation methodsFermentationVegetable matterEmulsion

Method for extracting oils, proteins and fermentable sugars from vegetable material in an aqueous medium, includes:a) adding water to the vegetable material;b) adding an enzyme mixture containing at least one cellulase, at least one hemicellulase, and at least one pectinase, the ratio between the pectinase activity and the cellulase activity being at least 0.14, and the ratio between the pectinase activity and the hemicellulase activity being at least 7.10−3, the pectinase activity being less than 120 μmol / min / mL;c) incubating the vegetable material and the enzyme mixture with stirring to release oils, proteins and fermentable sugars in the reaction medium;d) separating the reaction medium to obtain free oil, an aqueous phase containing proteins and fermentable sugars, and a solid phase;e) optionally separating and recycling an emulsion of free oil or aqueous phase, to the medium;f) separating the proteins and fermentable sugars from the aqueous phase.

Owner:UNIVERSITY OF LORRAINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com