Method for using phosphoric oxide to concentrate diluted phosphoric acid to prepare polyphosphoric acid

A technology of dilute phosphoric acid and polyphosphoric acid, which is applied in the field of polyphosphoric acid production, can solve the problems of high energy consumption, achieve energy saving, reduce production costs, and achieve significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

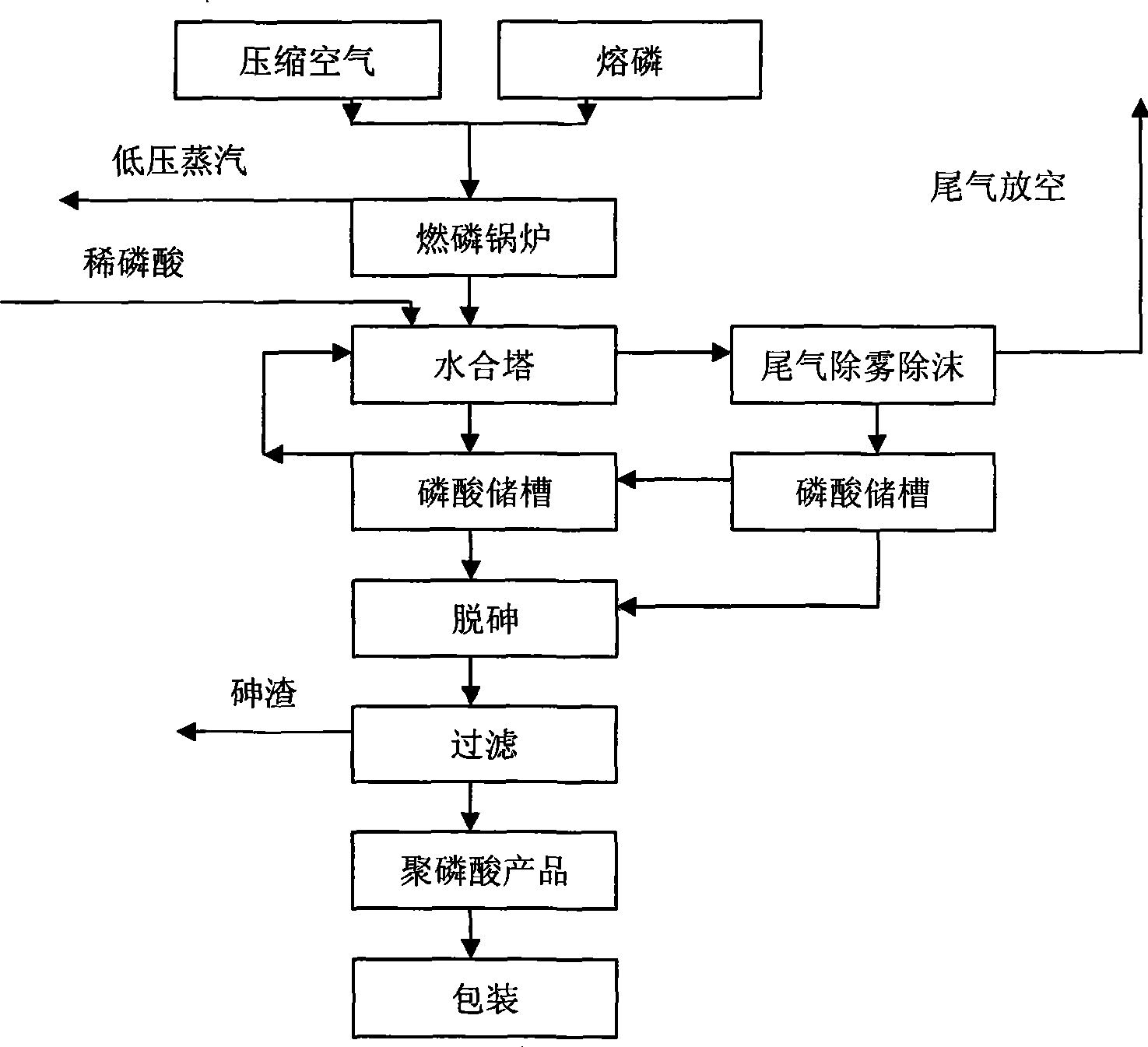

Image

Examples

Embodiment 1

[0022] Embodiment 1: the purity 99.95%, containing arsenic 152 * 10 -6 The yellow phosphorus is fully melted at 70°C, according to 1kg of yellow phosphorus and 6.3~6.6m 3 The proportion of air, pump the yellow phosphorus to the yellow phosphorus burner and mix it with 0.7MPa compressed air, spray it into the phosphorus-burning boiler, and the yellow phosphorus is atomized rapidly in the phosphorus-burning boiler and burns violently.

[0023] P produced by combustion 2 o 5 Introduced into the top of the hydration tower, the top of the tower is sprayed with deionized water first, and then sprayed with dilute acid after obtaining dilute acid. Dilute phosphoric acid is continuously sprayed from the top and evenly overflows from the inner wall to absorb P in a circular manner. 2 o 5 , giving 116% H 3 PO 4 Finally, the top of the tower is supplemented with an appropriate amount of deionized water spraying to continue spraying, and 116% phosphoric acid is sent to the arsenic rem...

Embodiment 2

[0024] Embodiment 2 the purity 99.95%, arsenic content is 10 * 10 -6 The yellow phosphorus is fully melted at 70°C, according to 1kg of yellow phosphorus and 6.3~6.6m 3 The proportion of air, pump the yellow phosphorus to the yellow phosphorus burner and mix it with 0.7MPa compressed air, spray it into the phosphorus-burning boiler, and the yellow phosphorus is atomized rapidly in the phosphorus-burning boiler and burns violently.

[0025] P produced by combustion 2 o 5 Introduced into the top of the hydration tower, the top of the tower starts to be sprayed with 85% phosphoric acid, and evenly overflows from the inner wall to absorb P in a cycle 2 o 5 , giving 116% H 3 PO 4 Finally, add 85% phosphoric acid to the top of the tower in an appropriate amount, and continue to circulate and absorb to obtain P 2 o 5 The content is 72.42% polyphosphoric acid.

Embodiment 3

[0026] Embodiment 3: the purity 99.95%, arsenic content is 10 * 10 -6 The yellow phosphorus is fully melted at 70°C, according to 1kg of yellow phosphorus and 6.3~6.6m 3 The proportion of air, pump the yellow phosphorus to the yellow phosphorus burner and mix it with 0.8MPa compressed air, spray it into the phosphorus-burning boiler, and the yellow phosphorus is atomized rapidly in the phosphorus-burning boiler and burns violently.

[0027] P produced by combustion 2 o 5 Introduced into the top of the hydration tower, the top of the tower is sprayed with 85% purified wet-process phosphoric acid, and part of it overflows evenly from the inner wall to absorb P in a circular manner. 2 o 5 , giving 116% H 3 PO 4 Finally, add an appropriate amount of purified phosphoric acid to the top of the tower to continue spraying, and send 116% phosphoric acid to the arsenic removal device, add 0.5% phosphorus pentasulfide of the total weight of phosphoric acid, filter at a temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com