A silica-alumina carrier containing two modified molecular sieves and its preparation method and application

A silica-alumina carrier and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of low octane number of light naphtha, poor selectivity of medium oil, good reactivity, etc. , to achieve excellent medium oil selectivity, high proportion of medium strong acid and small unit cell constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

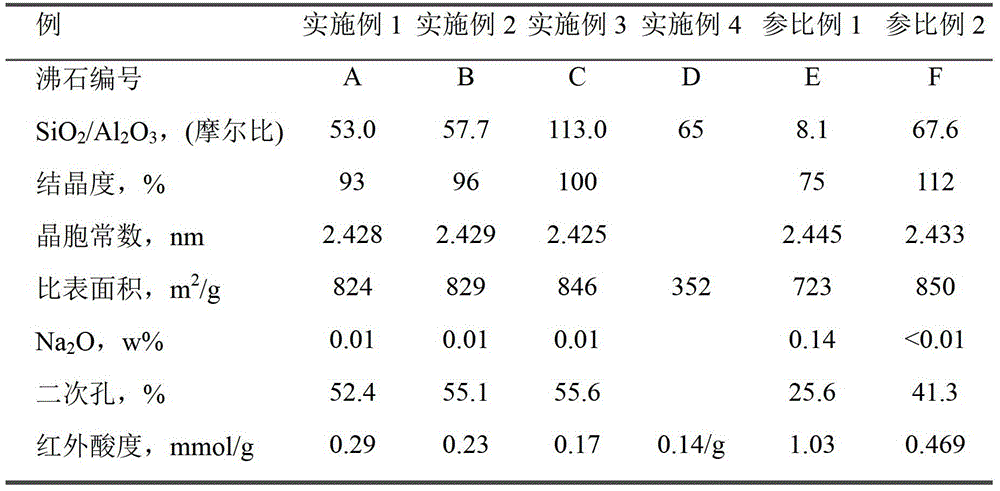

Embodiment 1

[0039] Take 250 grams of NH 4 NaY molecular sieve (produced by Wenzhou Catalyst Factory, SiO 2 / Al 2 o 3 The molar ratio is 5.1, the unit cell constant a0=2.470nm, the crystallinity is 95%, Na 2 O is 2.3w%, dry basis is 70w%. ) in a heat treatment furnace, control the heating rate of 500°C / hour, raise the temperature to 600°C, and maintain the water vapor pressure of the system at 0.15MPa, treat for 2.0 hours, cool down, and take out the sample. with NH 4 + and H + 1500ml of the solution (mixed solution of ammonium chloride and hydrochloric acid) with concentrations of 2.0mol / L and 0.2mol / L was contacted with the sample and stirred, and the temperature of the slurry was maintained at 90°C for 1.5 hours. Repeat the treatment once under the same conditions, filter Wash the cake with water; place the wet filter cake in a heat treatment furnace, raise the temperature to 650°C, control the water vapor pressure to 0.20MPa, keep the temperature constant for 3 hours, cool down,...

Embodiment 2

[0041] ① Put 2kg NH 4 NaY zeolite (the same as Example 1) is placed in a heat treatment furnace, and the temperature is raised to 630°C within 2 hours, injecting water vapor (steam rate 3.0kg / h), and maintaining the system pressure at 0.1MPa, at 650°C Keep the temperature constant for 3.5 hours, cool down, and take out the sample;

[0042] ② Add 15kg of water to the autoclave, industrial NH 4 NO 3 2.4kg, HNO 3 0.2kg and the zeolite sample after the first heat treatment, seal it, start stirring, raise the temperature to 120°C, treat at a constant temperature for 1 hour, treat the filter cake again under the same conditions, filter the mother liquor, and dry until the water content of the filter cake is ≯25 %.

[0043] ③ The sample is placed in a heat treatment furnace under the same conditions as step ① for a second hydrothermal treatment, wherein the hydrothermal treatment temperature is 650°C and the hydrothermal treatment time is 2 hours.

[0044] ④ The zeolite sample w...

Embodiment 3

[0046] ①300g NH 4 NaY zeolite (same as Example 1) was placed in a heat treatment furnace, and the temperature was raised to 560° C. in 1 hour, and the pressure was maintained at 0.1 MPa by the zeolite’s own water vapor. The temperature was kept constant for 3 hours, and the temperature was lowered, and the zeolite sample was taken out.

[0047] ② Use 200ml of a solution containing NH4+ and H+ with a concentration of 2.0mol / L and 0.15mol / L respectively (a mixed solution of ammonium nitrate and nitric acid) to contact and stir the sample, raise the temperature to 90°C and maintain it for 2 hours, repeat 2 Once, the filter cake was washed with clean water and dried.

[0048] ③The zeolite sample is placed in the heat treatment furnace, and the temperature is raised to 680°C in 1.5 hours, and 300g / h of water vapor is introduced at the same time, the pressure of the control system is at 0.1±0.02MPa, the temperature of the control system is at 680°C, and the temperature is maintained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com