Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

315results about How to "Complete crystal form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

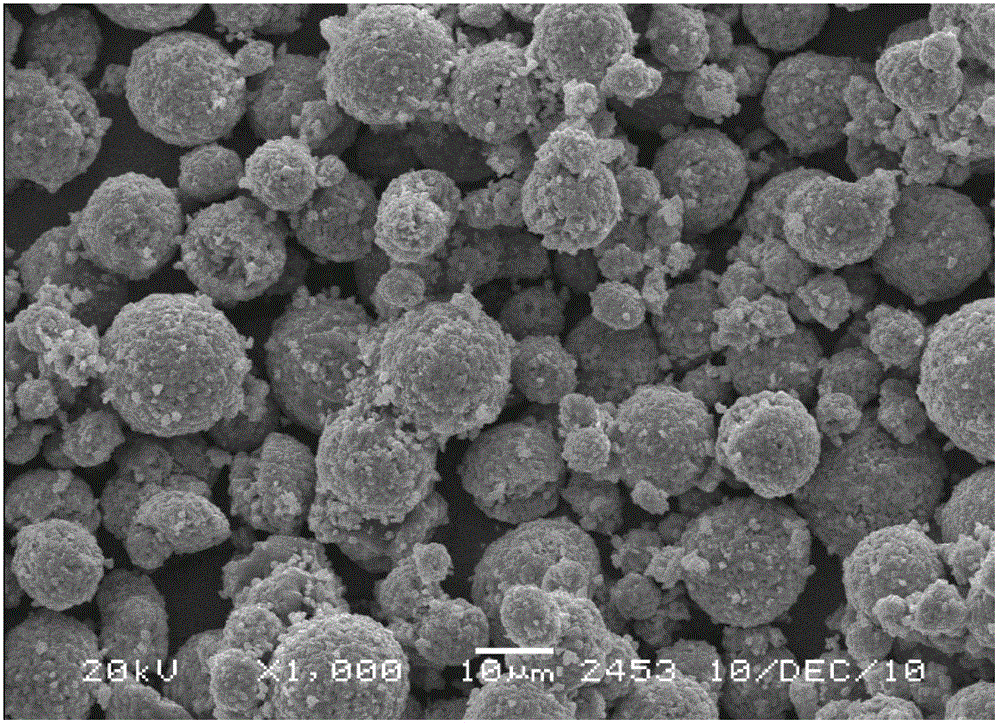

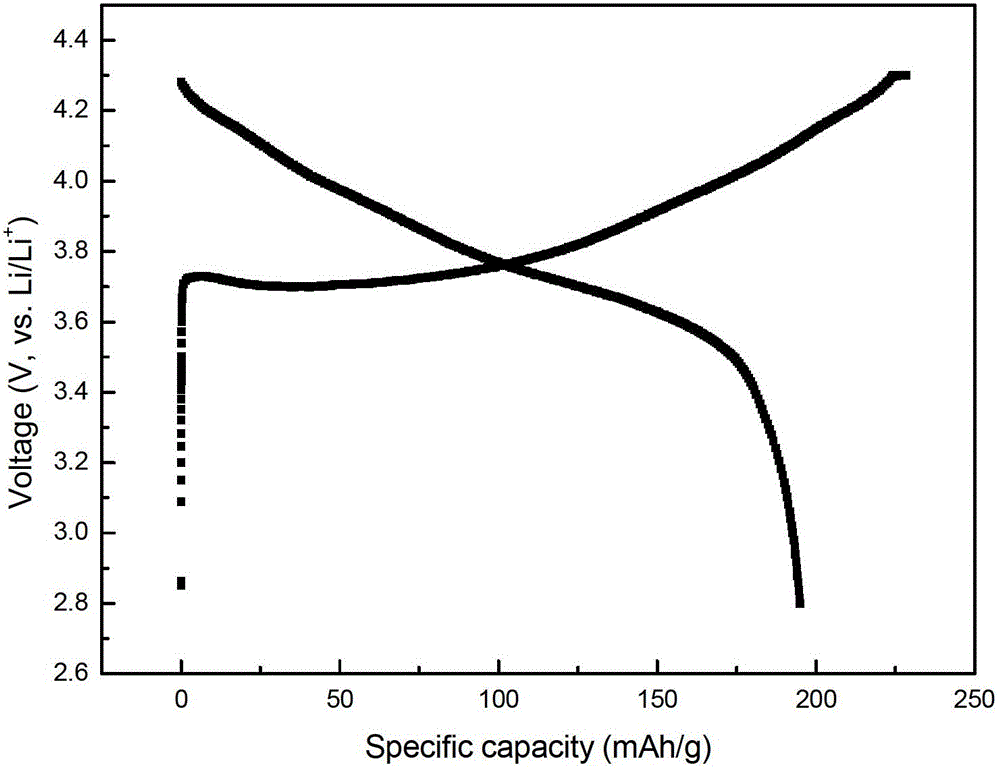

Preparation method of lithium iron phosphate cathode material for lithium ion battery

ActiveCN101966986AReduce manufacturing costEvenly distributedPhosphorus compoundsLithium iron phosphateSource material

The invention discloses a preparation method of a lithium iron phosphate cathode material for a lithium ion battery, which comprises the steps of: placing a lithium source, an iron source, a phosphorus source and a doped source material into a stirring ball mill for mixing; adding the obtained mixture into a twin-screw extruder for reaction and extrusion; placing an extruded product into an inert atmosphere furnace, calcining for several hours at a temperature of 600-800 DEG C; and cooling in the furnace to obtain a sample, i.e. the lithium iron phosphate cathode material, wherein the lithium iron phosphate cathode material has high specific capacity (more than 140mAh / g, 0.2C) and excellent circulating property. The invention has the advantages of simple process and low cost, and is suitable for massive production.

Owner:CENT SOUTH UNIV

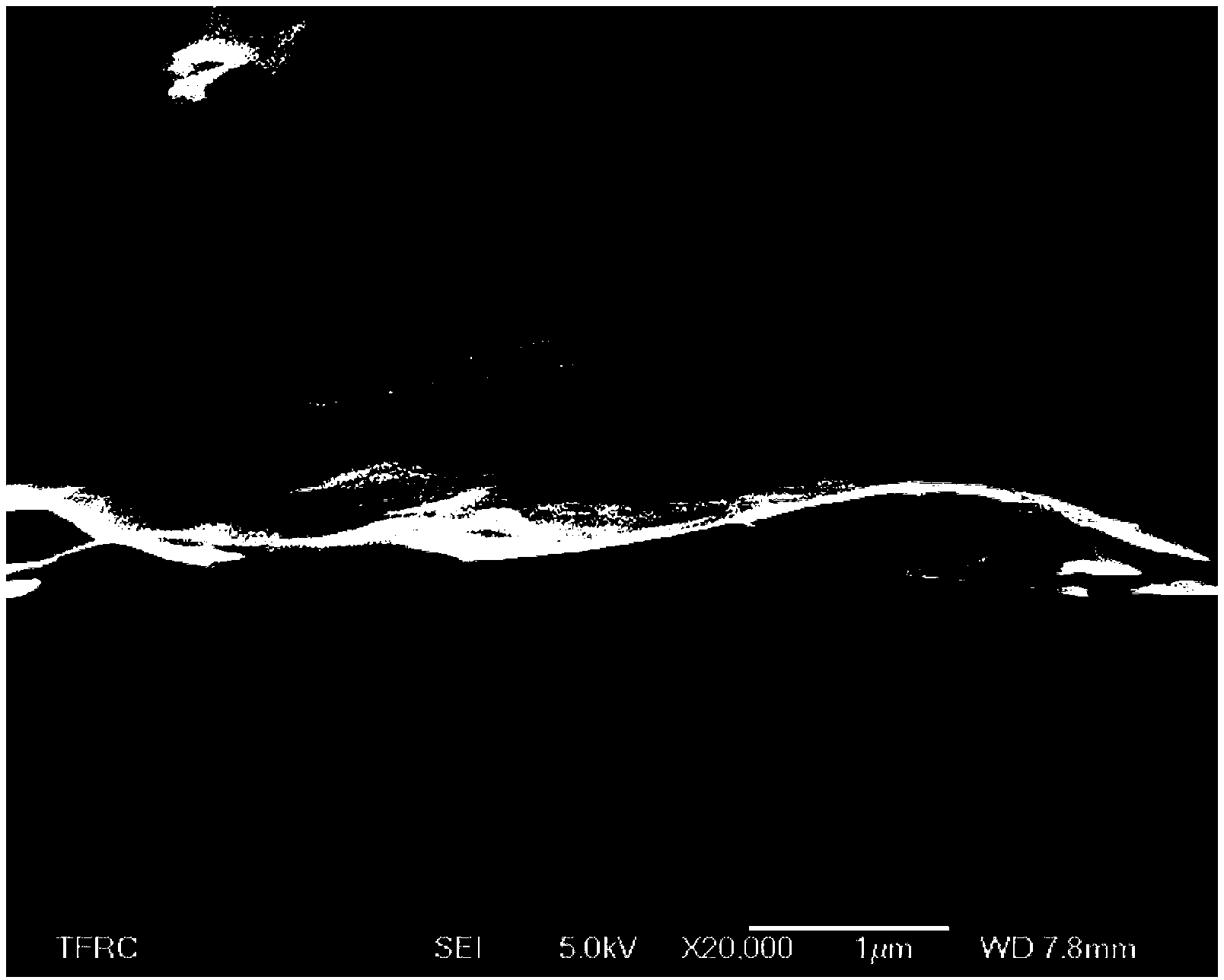

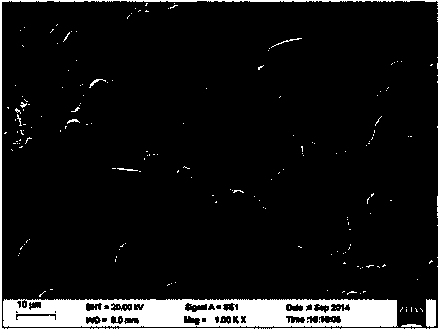

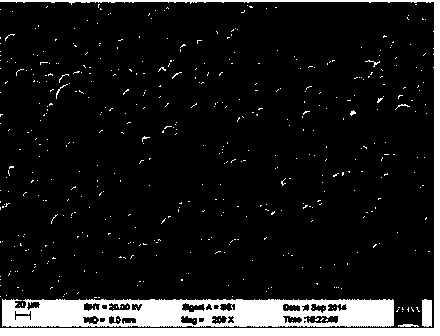

Method for preparing graphene material based on chemical deposition

InactiveCN102127750AReduce manufacturing costAchieve mass productionChemical vapor deposition coatingCvd grapheneCarbon source

The invention aims at providing a method for preparing a graphene material based on chemical deposition. The method comprises the following steps of: (1) uniformly mixing a soluble salt of a graphite catalyst, a polymer and an organic solvent; (2) adding a substrate in a reactor, heating the reactor to 450-1000 DEG C under the protection of inert gas; (3) introducing the mixture obtained by the step (1) into the reactor under the protection of inert gas to be subjected to chemical deposition; and (4) cooling and taking out the substrate, and removing catalyst particles by ultrasonic processing and acid pickling, thus the graphene material is obtained. In the invention, an organic solvent and a soluble polymer are adopted as the carbon sources, and a floating catalyst is used for cracking the carbon sources under the protective gas atmosphere, thus a single-layer or multi-layer graphene material is grown on the substrate, the graphene material is prepared in batch by chemical deposition, and the graphene material prepared by the method has the advantages of complete crystal form, low oxygen content and less defects.

Owner:HARBIN ENG UNIV

Preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries

ActiveCN103066257ASolve the problem of complete oxidationPrevent "cation mixing" phenomenonCell electrodesLithium hydroxideOxygen

The invention provides a preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries. The method comprises: step 1, using a nickel-cobalt-aluminum precursor prepared through a coprecipitation method and doped with mixed ions as raw materials, putting the raw materials into a sealed hearth of a pressure furnace, continuously introducing oxygen until a fixed pressure value is formed, then heating to a pre-burning temperature and keeping warm for a period of time, and cooling to obtain an oxidized precursor; and step 2, adding measured lithium salt or lithium hydroxide into the oxidized precursor, ball milling and uniformly mixing; heating the uniformly mixed raw materials to a certain temperature and keeping warm for a period of time, and meanwhile continuously introducing oxygen to complete a sintering process, thereby obtaining the finish product. According to the invention, through a hyperbaric oxygen atmosphere, the oxygen are enabled to fully infiltrate into particles of the raw materials which has a certain accumulation thickness, thereby preventing situations that only surface materials are oxidized under a normal pressure, and ensuring a full conversion of Ni<2+> to Ni<3+> by a full pre-oxidation.

Owner:GUANGZHOU LIBODE NEW MATERIAL

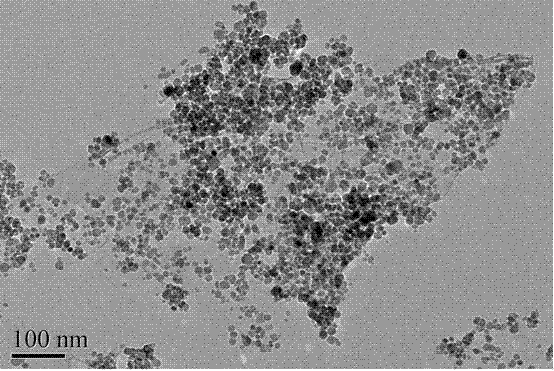

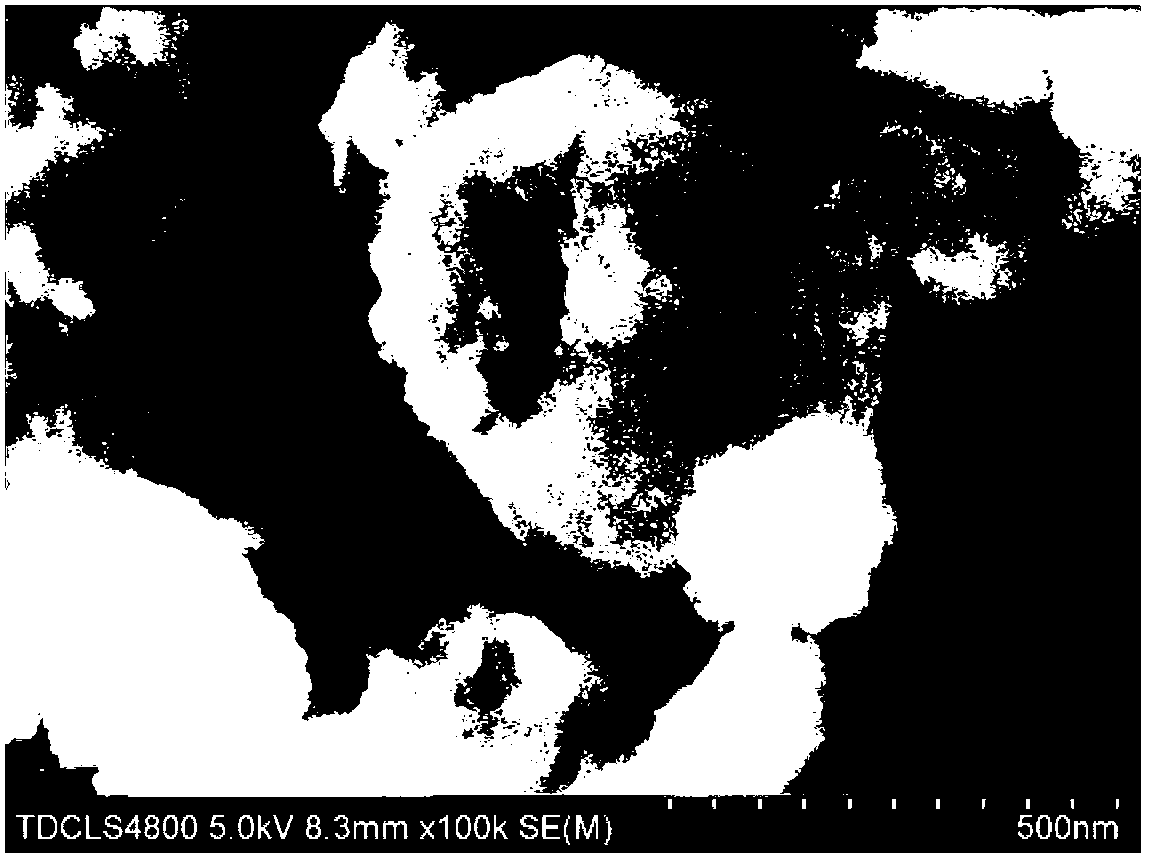

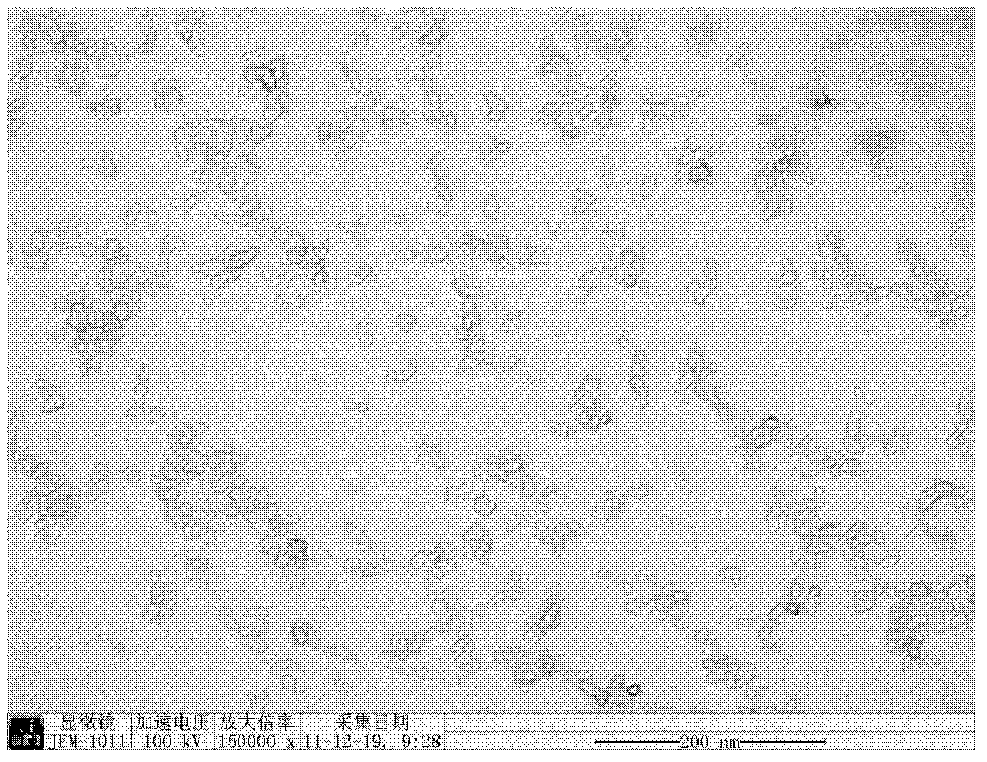

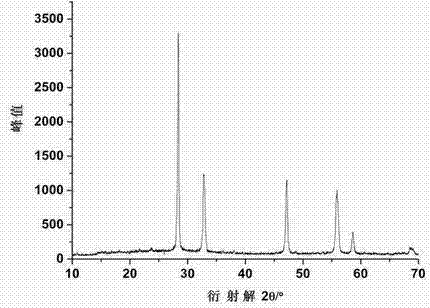

Method for preparing ferroferric oxide/graphene magnetic nano composite material by solvothermal one-step method

InactiveCN104261487AAvoid reunionEvenly dispersedMaterial nanotechnologyInorganic material magnetismSodium bicarbonateActive agent

The invention relates to a method for preparing a ferroferric oxide / graphene magnetic nano composite material by a solvothermal one-step method. The method comprises the following steps: by using ferric chloride hexahydrate and graphite oxide as raw materials, sodium bicarbonate as an alkali source, ethylene glycol and water as the solvent and polyvinylpyrrolidone as a surface active agent, dissolving graphite oxide, ferric chloride hexahydrate and polyvinylpyrrolidone into a mixed solvent of ethylene glycol and water, and carrying out ultrasonic treatment to obtain mixed solution A; dissolving sodium bicarbonate into ethylene glycol and carrying out ultrasonic treatment to prepare mixed solution B; after mixing the mixed solution A and B, reacting at 150-200 DEG C and at the pressure of less than 2.5 MPa for 4-12h, and then carrying out aftertreatment to obtain the ferroferric oxide / graphene magnetic nano composite material, wherein the ferroferric oxide particles are uniform, the distribution is narrow and the grain size is 10-30nm. The method is simple and convenient in process, environment-friendly and suitable for batch production.

Owner:NANCHANG HANGKONG UNIVERSITY

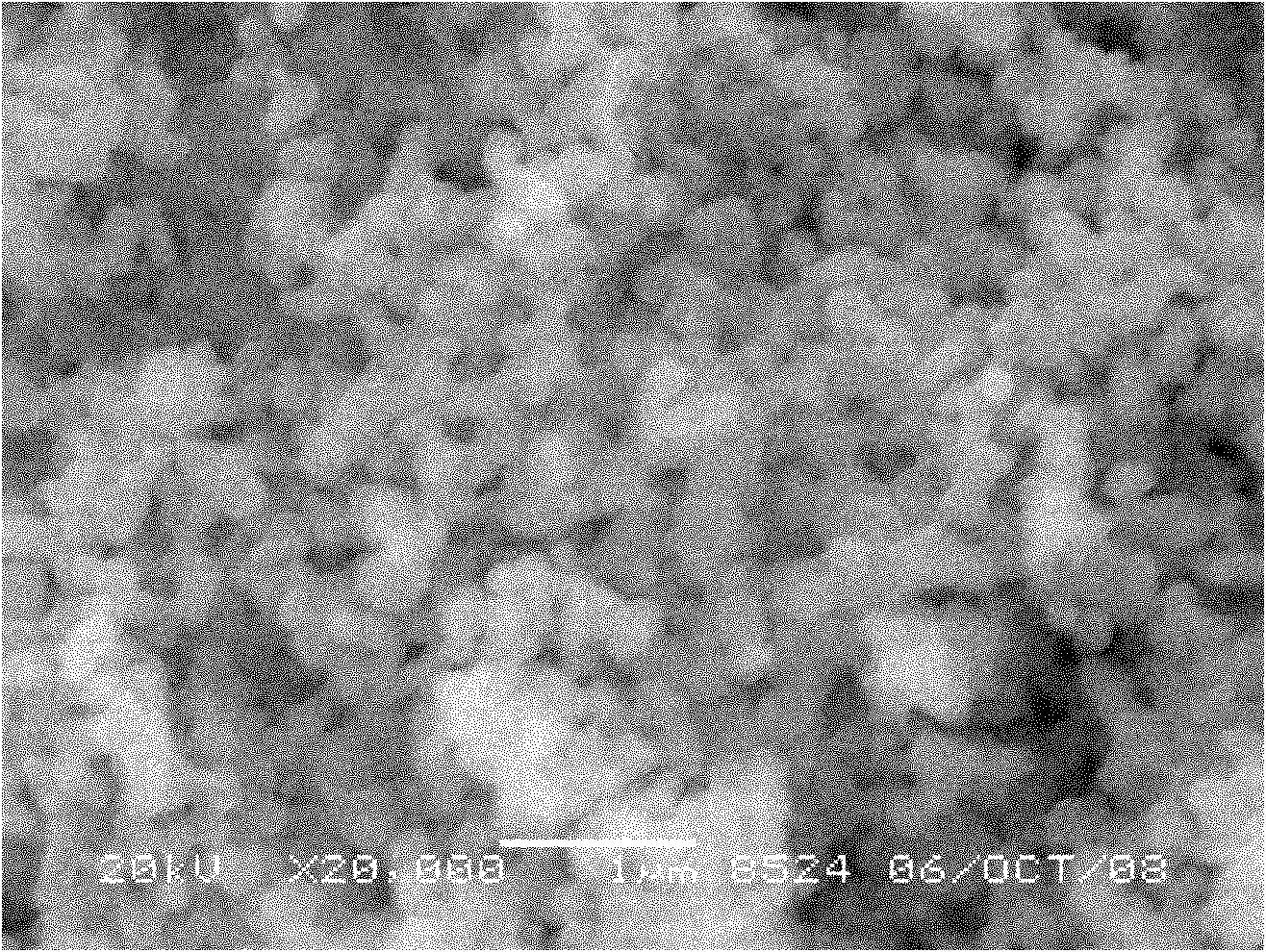

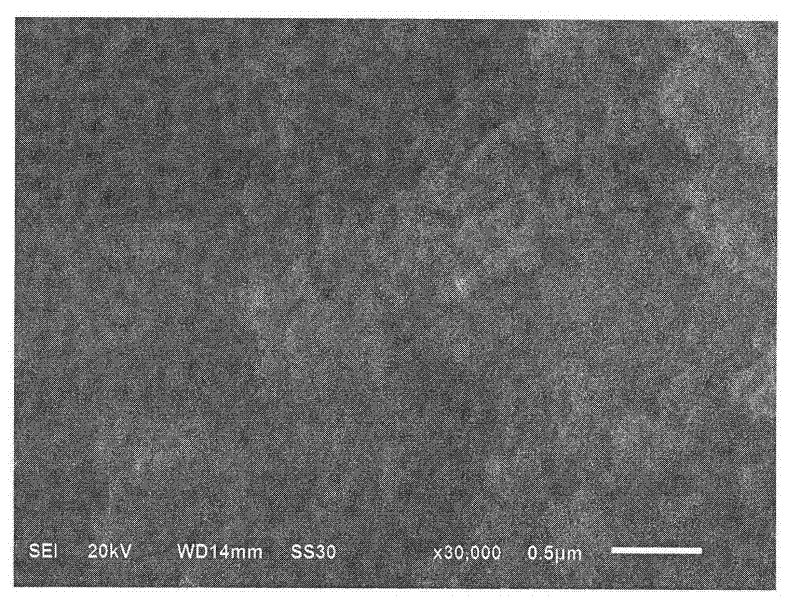

Method of preparing surface modified nano magnesium hydroxide

InactiveCN101054190AComplete crystal formThe synthesis process is simpleMagnesium hydroxideMagnesium saltRoom temperature

A method for preparing surface modified nano-scaled Mg(OH)2 comprises the steps of: preparing the soluble magnesium salt into magnesium salt solution, preparing the surface modification agent and alkali into a mixed solution, dipping the magnesium salt solution into the mixed solution at the temperature of 20-100 degree, stirring strongly for 1-10H, cooling for 2-24H at room temperature, filtering and washing with de-ionized water till PH6-7, drying in vacuum oven and hence obtaining the surface modified nano-scaled Mg(OH)2. The invention is characterized in integral crystal shape of the sample during preparation, simple processing and soft reaction conditions etc.

Owner:CHINA RES INST OF DAILY CHEM IND

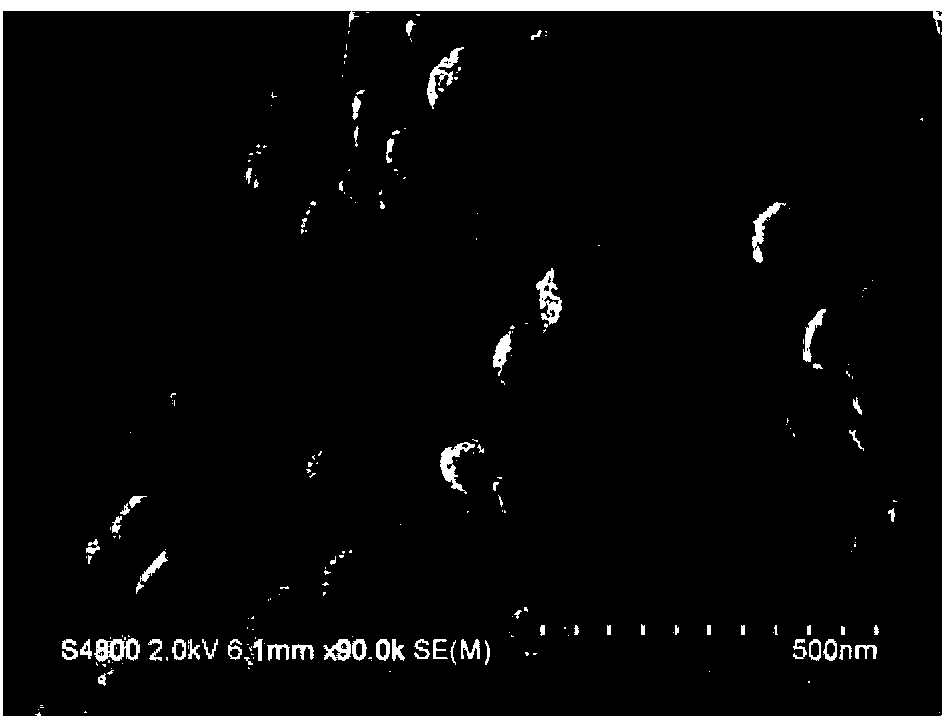

Method for preparing nano-zeolite metal-organic framework compounds by microreactor

InactiveCN102993221ALarge specific surface areaNarrow particle size distributionCopper organic compoundsZinc organic compoundsMicroreactorMetal-organic framework

The invention relates to a method for preparing nano-zeolite metal-organic framework compounds by a microreactor, and belongs to the technical field of preparation of nano-particles, which is characterized by comprising the following steps of: constructing a microreactor by a porous film; respectively dissolving a metal precursor and an organic ligand in a solvent to prepare a metal precursor solution A and an organic ligand solution B; respectively arranging the metal precursor solution A and the organic ligand solution B at two sides of the film; by a pressure difference of the two sides of the film, uniformly pressing reactants at one side of the film into reactants at the other side of the film through the pores of the film, to generate nano-particles; and centrifuging, washing and drying to obtain the target product. The method for preparing the nano-zeolite metal-organic framework compounds by the microreactor is simple in operation, strong in controllability of particle structure, and is suitable for preparation and industrial production of various nano-zeolite metal-organic framework compounds.

Owner:JIANGNAN UNIV

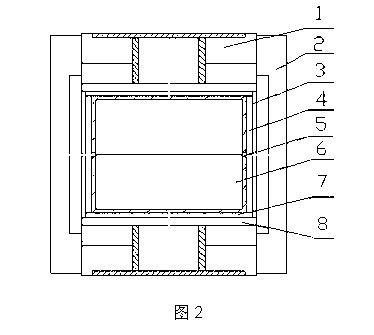

Protogenic diamond fine particle for precisio machining and production method thereof

ActiveCN102580618AGood self-sharpeningImprove processing efficiencyUltra-high pressure processesOctahedronPyrophyllite

The invention relates to a protogenic diamond fine particle for precision machining and a production method thereof. The diamond particle is 1-30 microns in size, is of the shape of hexahedron, octahedron or hexahedron-octahedron and has a nitrogen content of 200-500 ppm. The production method comprises the steps of: mixing graphite powder, a metal catalyst and a nitrogenous substance at a proportion of 0.4-1: 0.6-1.0: 0.01-0.05 for an isostatic cool pressing treatment; pressing the mixed material into a cylindrical synthesis column for vacuum sintering; then filling pyrophyllite synthetic block and performing a high-temperature and high-pressure treatment in a cubic press; the crushing the synthesis column and separating the crushed synthesis column by a swing bed to obtain the protogenic diamond fine particle for precision machining. The protogenic diamond fine particle has the advantages of being applicable for machining tools, such as fretsaws, ultra-thin saw blades and electroplated grinding wheels, being suitable for efficient precision machining of glass, monocrystalline silicon, polycrystalline silicon, sapphires and silicon carbide crystals and having high machining efficiency as well as long service life. The method, disclosed by the invention, has the advantages of being green, environment-friendly and energy-saving and having steady product performance, low cost and good application performance.

Owner:HENAN UNION ABRASIVES

Positive material for lithium ion battery, preparation method of material, and lithium ion battery

ActiveCN103258994AImprove performanceSmall particle sizeCell electrodesSecondary cellsSodium-ion batterySolvent

The invention provides a positive material for a lithium ion battery and a preparation method thereof. The method comprises the following steps of: providing nano lithium phosphate with a hollow structure; mixing the nano lithium phosphate, a soluble manganese source compound and an additive with a mixed solvent of water and polyhydric alcohol; carrying out ball milling to obtain a mixed solution; then keeping heat of the mixed solution in a closed reaction kettle filled with inert gas under the condition that the temperature is 150-230 DEG C to obtain lithium phosphate; mixing the lithium phosphate with a carbon source compound and carrying out the ball milling; and calcining to obtain the positive material for the lithium ion battery of carbon coated lithium phosphate. According to the positive material and the preparation method thereof disclosed by the invention, polyhydric alcohol-hydrothermal reaction between a solid and liquid can be carried out on the lithium phosphate and the soluble manganese source compound, so that the grain diameter of a lithium phosphate crystal is effectively reduced and a crystal form of the lithium phosphate crystal is integrally formed; and furthermore, the positive material for the lithium ion battery with high specific capacity and specific energy can be obtained and is good for popularization. The invention further provides the lithium ion battery.

Owner:TIANJIN B&M SCI & TECH

Preparation method for hexagonal sheet magnesium hydroxide

ActiveCN102502726ANo pollution in the processShape is easy to controlMagnesium hydroxideWater bathsMagnesium salt

The invention provides a preparation method for hexagonal sheet magnesium hydroxide, which includes the following steps: 1 roasting natural magnesite to obtain light-roasting magnesium oxide, 2 adding the light-roasting magnesium oxide to magnesium salt aqueous solution according to a certain proportion, 3 enabling the suspension prepared in step 2 to react for a certain period of time in constant-temperature water bath under the condition of mixing, 4 adding magnesium hydroxide seed crystal after a certain period of time of reaction in step 3, and standing the reaction product in the constant-temperature water bath, and 5 filtering, washing and drying the product of step 4 to obtain the hexagonal sheet magnesium hydroxide with regular shapes. The preparation method for the hexagonal sheet magnesium hydroxide has the advantages that raw materials can be easily obtained, a process is simple, a step of traditional hydration hydro-thermal treatment is removed, energy consumption is reduced, and the preparation method is suitable for industrial production and the like. Different sizes and thicknesses of hexagonal sheet magnesium hydroxide can be prepared by changing process conditions of magnesium salt type and concentration, hydration temperature and time, standing time and the like. The prepared magnesium hydroxide can serve as seed crystal to be recycled so that production cost is lowered.

Owner:NANJING UNIV OF TECH

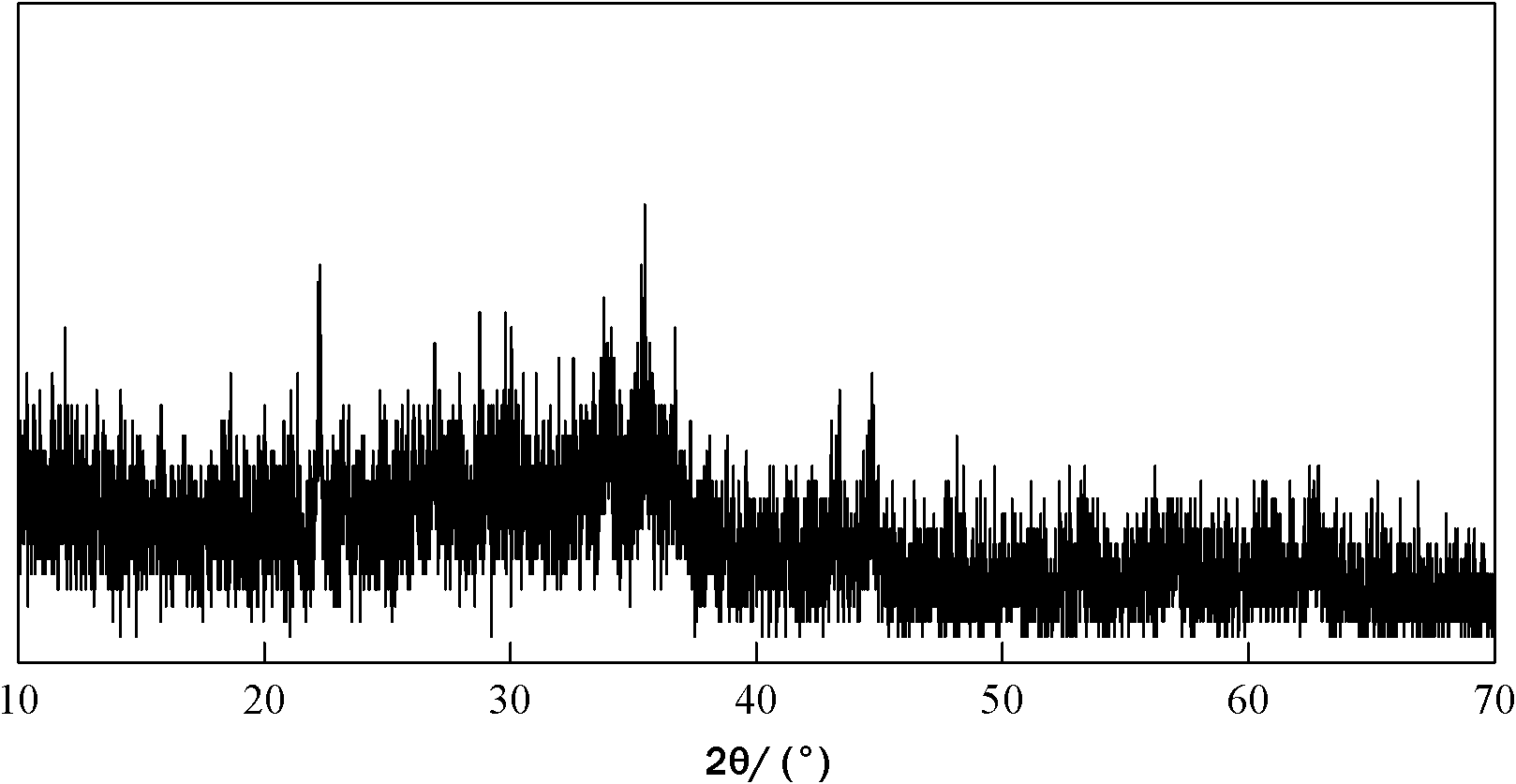

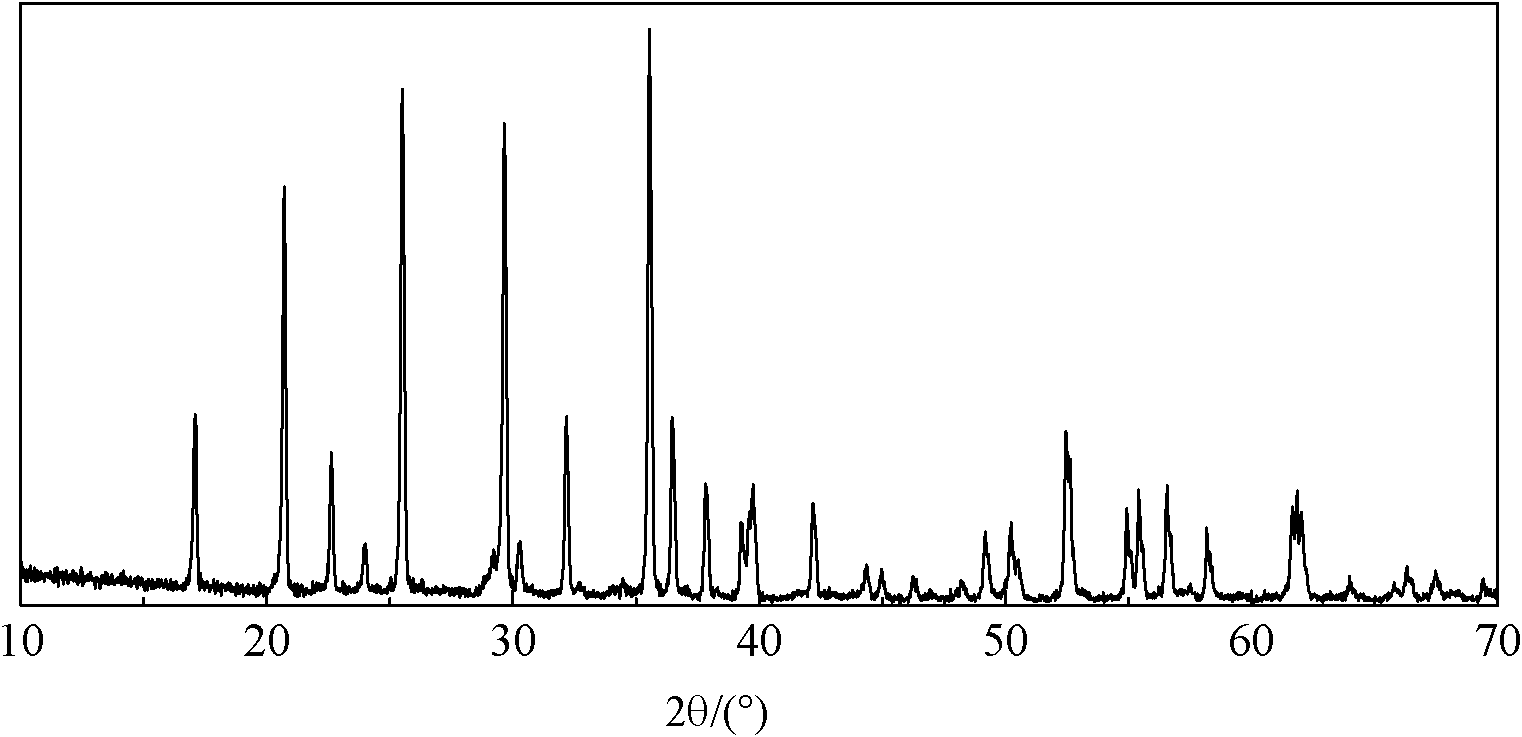

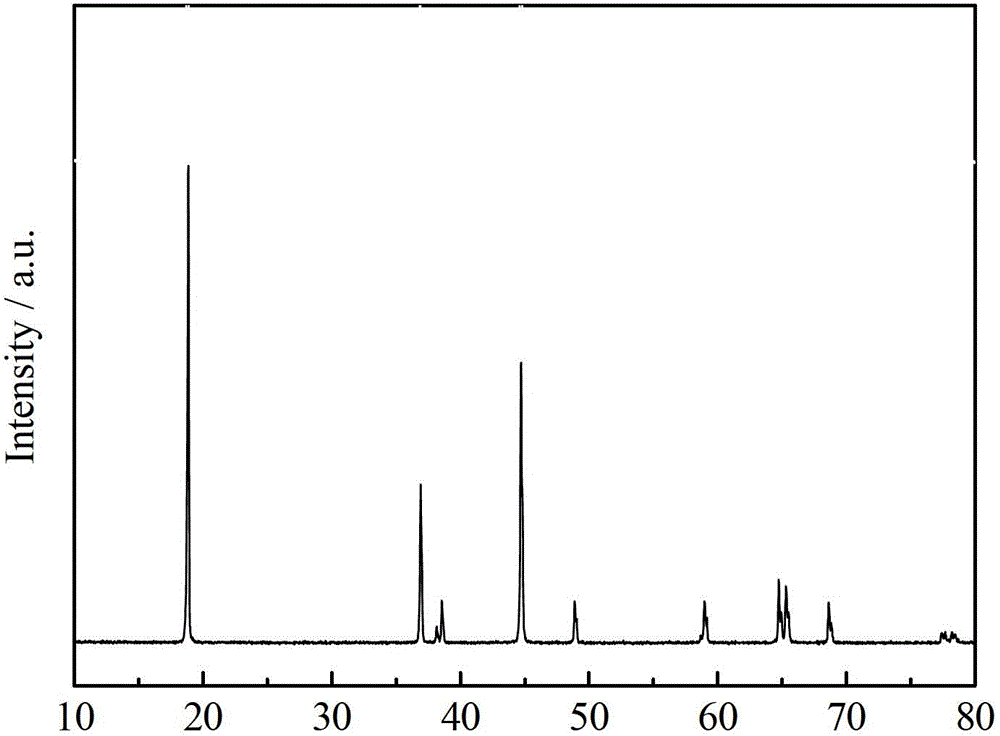

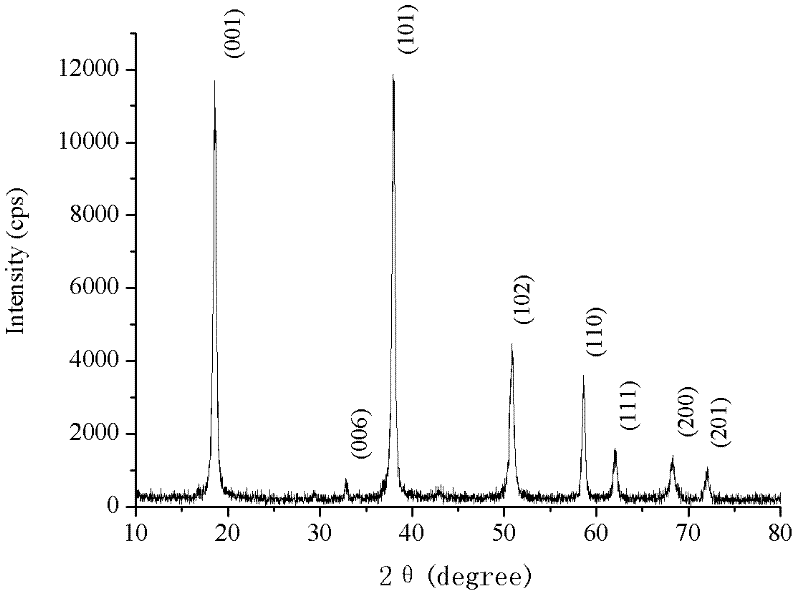

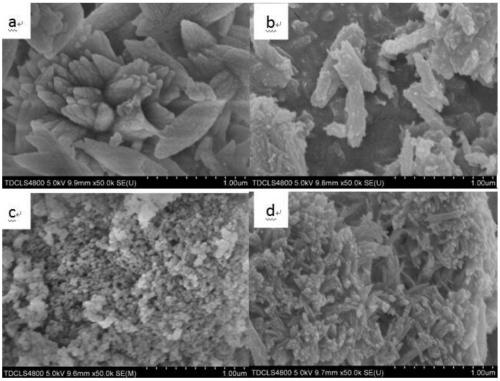

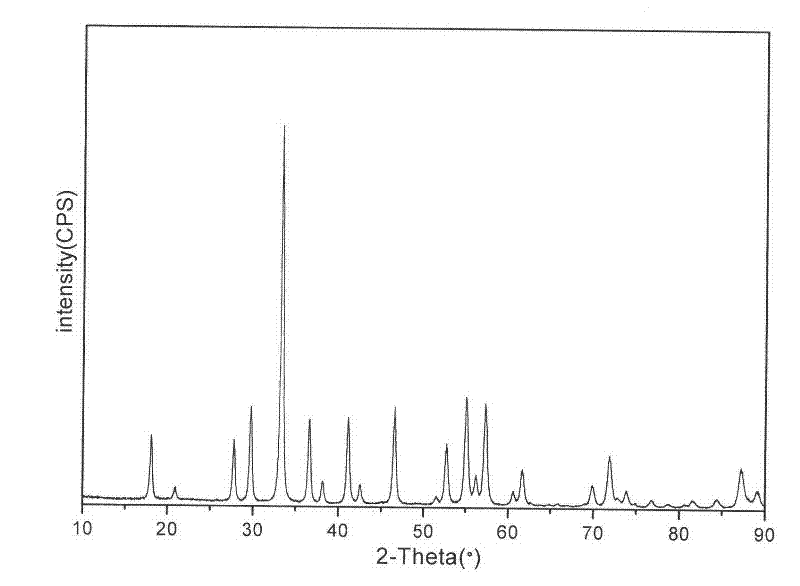

Method for preparing lithium iron phosphate cathode material by three-stage high-temperature solid phase calcination

InactiveCN101279728AWide variety of sourcesLow priceCell electrodesPhosphorus compoundsFurnace temperaturePhosphate

The invention discloses a method for preparing lithium iron phosphate anode material by three-step high temperature solid state sintering and pertains to the technique of chemical power source anode material. The process of the preparation method is that lithium salt, Fe<2+> compound, phosphate and carbon source are mixed according to certain ratio, ground and granulated; particles obtained are transferred in a rotary sintering furnace and carried out predecomposition for 3-10 hours when the temperature is increased to 300-500 DEG C under the protection of nitrogen; the temperature raises to 650-850 DEG C and the heat is preserved for 6-15 hours and then the temperature is dropped to room temperature with furnace temperature; the material obtained is added with carbon source in different amount and is carried out ball milling, the temperature raises to 650-850 DEG C and the heat is preserved for 6-15 hours and then the temperature is dropped to room temperature with furnace temperature, and the lithium iron phosphate anode material is obtained after ball milling. The method of the invention is characterized by simple process, being easy to realize industrial scale production, wide sources of raw materials, low cost, complete crystal form of anode material, regular product pattern, excellent electrochemical performance and high tap density which reaches 1.36g cm<-3>.

Owner:TIANJIN UNIV

Preparation method of nano calcium fluoride for self-lubricating tool material

InactiveCN102583486AHigh purityComplete crystal formCalcium/strontium/barium fluoridesNanotechnologyAlcoholSolvent

The invention relates to a preparation method of nano calcium fluoride for a self-lubricating tool material. According to the preparation method, an ultrasonic reduction method is adopted. The preparation method comprises the following steps of: preparing calcium nitrate and ammonium fluoride serving as raw materials into aqueous or alcohol solution respectively; adding PEG 6000-abslute ethyl alcohol composite solvent; performing ultrasonic dispersion; mixing the dispersed calcium nitrate solution and the ammonium fluoride solution under ultrasonic and stirring conditions; and reacting, aging, centrifuging, cleaning and drying to obtain nano calcium fluoride powder. The prepared nano calcium fluoride has the particle size of 15-50 nm and has high purity, complete crystal form, high crystallinity, uniform size distribution and high dispersion. The preparation method also has the advantages of simple technical process, convenience for operation and low equipment requirements.

Owner:QILU UNIV OF TECH

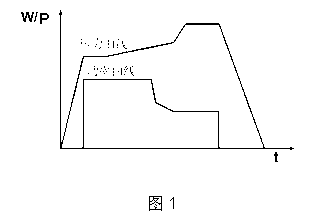

Micron-level fine particle diamond synthesis process

ActiveCN102935346AEasy to remove impuritiesLarge amount of nucleationUltra-high pressure processesPressure curveSingle crystal

The invention provides a micro-level fine particle diamond synthesis process. The micro-level fine particle diamond synthesis process comprises the steps of mixing graphite powder and Fe-based alloy catalyst powder according to the weight ratio of 8:(5-7), then carrying out isostatic pressing and vacuum process and then carrying out compression molding on the mixture in a four-column press machine, putting a core column into a diamond synthesis block, and putting the diamond synthesis block into a cubic press to carry out synthesis, wherein the practical synthesis pressure is 6.1-6.6GPa, the synthesis temperature is 1000-1100 DEG C, and the practical synthesis pressure and the synthesis temperature are finished respectively by utilizing a control pressure curve and a power curve. According to the micro-level fine particle diamond synthesis process disclosed by the invention, the synthesized micron-level fine particle diamonds have the characteristics of large nucleation amount, short growth time and the like, products conform to an artificial diamond national standard and have consistent crystal forms, smooth crystal surfaces, a few of impurities and high hot punching values, the particle granularity of 270 / 325 and 325 / 400 is a peak value, a single crystal ratio reaches to 70-80%, and the micro-level fine particle diamond synthesis process can effectively meet the field of high-grade grinding tools and the like with high requirements on particle granularity.

Owner:山东昌润钻石股份有限公司

Method for recycling lithium cobalt oxide from waste positive electrode of lithium cobalt oxide battery

ActiveCN103199319ANot very tightly boundReduce the binding forceWaste accumulators reclaimingProcess efficiency improvementLithiumMass ratio

The invention discloses a method for recycling lithium cobalt oxide from a waste positive electrode of a lithium cobalt oxide battery. The method comprises the following steps of: (1) feeding the waste positive electrode of the lithium cobalt oxide battery into a 1-2mol / L hydrochloric acid lixivium in which citric acid is dissolved, and reacting for 4-6 hours at 60-80 DEG C; (2) filtering the lixivium in the step (1) so as to separate aluminum foil and solid grains; and (3) washing and drying the solid grains; and (4) adding a lithium source into the solid grains to adjust the mass ratio of Co / Li in the solid grains, uniformly mixing, calcining and cooling so as to obtain lithium cobalt oxide. The method adopts the mixed acid of citric acid and hydrochloric acid as the lixivium so as to effectively separate a positive electrode material and the aluminum foil, the process is simple, and no toxic or harmful gases are generated. The first discharge capacity of recovered lithium cobalt oxide can still be 140mAh / g, and the discharge capacity after 40 times of charge and discharge circulation is not less than 90%.

Owner:河南省冶金研究所有限责任公司

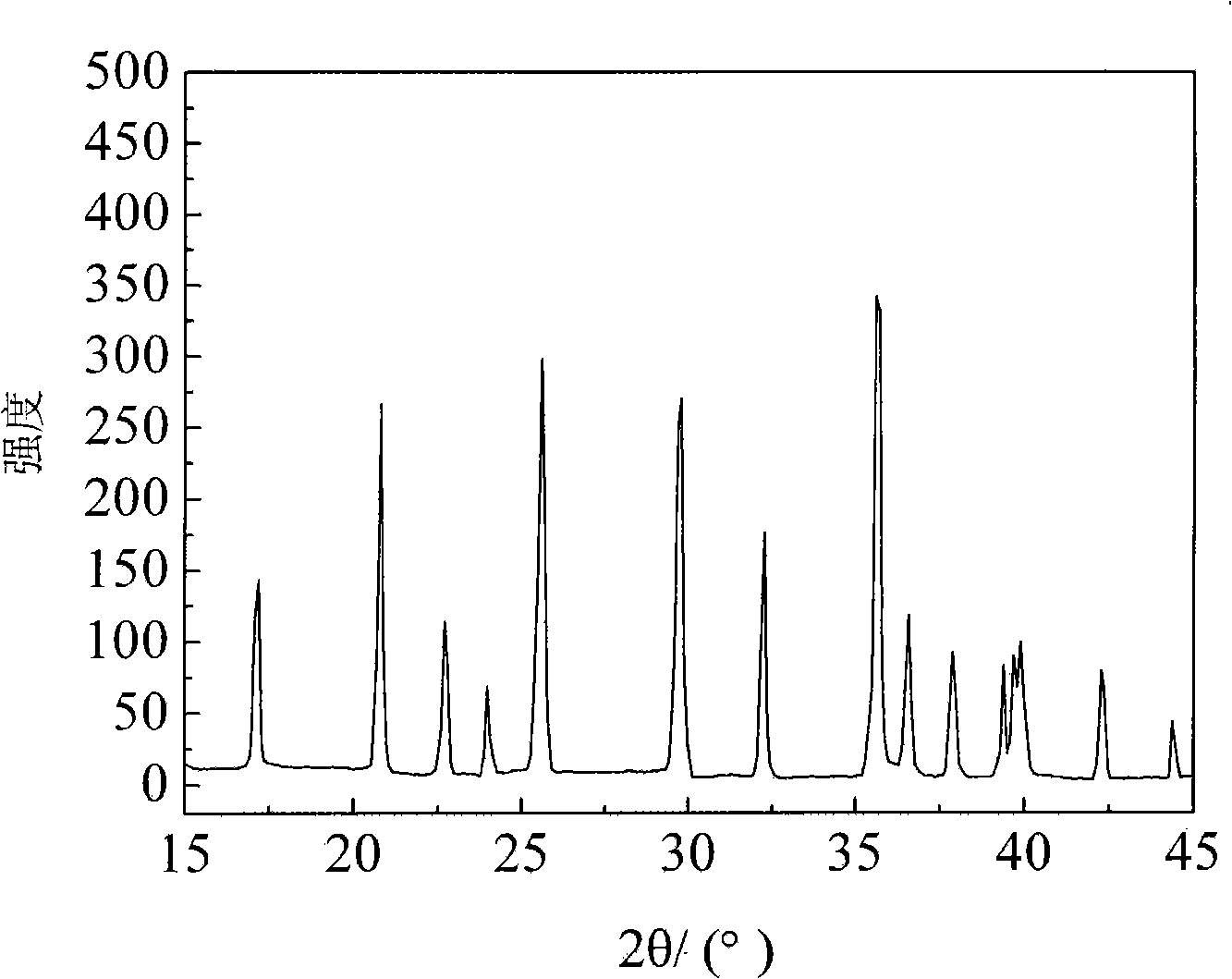

Method for regulating and controlling preparation of nano calcium carbonate by using crystal form control agent

InactiveCN111268712AWide range of raw materialsOptimization mechanismCalcium/strontium/barium carbonatesNanotechnologyPrinting inkNanostructured carbon

The invention discloses a method for regulating and controlling preparation of nano calcium carbonate by using a crystal form control agent. By using cheap and accessible limestone as a calcium sourceand low temperature as a carbonization condition, the nucleation rate is controlled by the crystal form control agent by lowering the carbonization temperature of slaked lime to obtain nano calcium carbonate powder with finer particles; the obtained product is nano calcium carbonate powder with different morphologies, the average particle size is 20-100 nm, the crystal form is complete, the particle size is uniform, the dispersity is good, and the high additional value is achieved in the industries of rubber, paint, paint, printing ink and the like.

Owner:TIANJIN UNIV

Method for preparing magnetic P-type molecular sieve by using coal gangue

InactiveCN107285341AReduce preparation and application costsShort reaction timeOther chemical processesMolecular-sieve and base-exchange compoundsMolecular sieveChemistry

The invention discloses a method for preparing a magnetic P-type molecular sieve by using coal gangue. The method comprises: 1, grinding coal gangue, and carrying out high temperature calcining activating on the grinded coal gangue by using sodium carbonate; 2, oxidizing at a low temperature, adding hydrochloric acid, soaking, and filtering; 3, preparing an iron-doped molecular sieve from the filtration residue and the filtrate obtained after the filtration; and 4, placing the iron-doped molecular sieve in a porcelain boat, placing the porcelain boat in a tubular furnace, introducing nitrogen into the tube furnace, introducing hydrogen after the air in the tubular furnace is completely discharged, heating to a temperature of 650-700 DEG C, continuously carrying out a reduction reaction for 2-3 h, introducing nitrogen after completing the reaction, and cooling to a room temperature to obtain the magnetic P-type molecular sieve. According to the present invention, the coal gangue is used as the raw material, the Fe<3+> dissolution is performed with hydrochloric acid and is complexed by adding oxalic acid, and finally high temperature reduction is performed to prepare the magnetic P-type molecular sieve; the magnetic P-type molecular sieve has characteristics of high specific surface area and strong adsorption performance; and the magnetic P-type molecular sieve is easy to separate and recover through the external magnetic field, and the problem of high cost of the molecular sieve synthesis is solved.

Owner:XIAN UNIV OF SCI & TECH

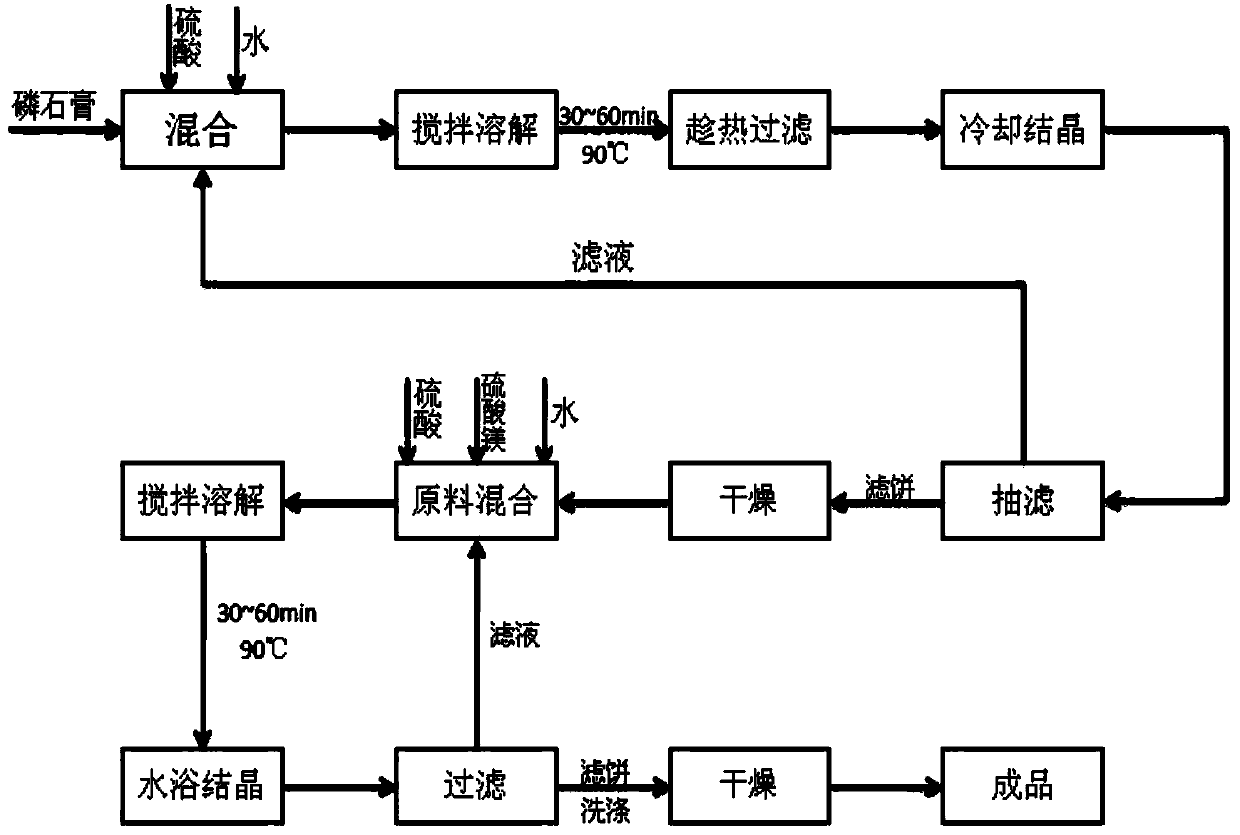

Method for preparing phosphogypsum whiskers by secondary crystallization

InactiveCN103628142AGood solid-liquid ratioSolve the problem of generating large amounts of sewagePolycrystalline material growthFrom normal temperature solutionsWater bathsMagnesium salt

The invention discloses a method for preparing phosphogypsum whiskers by secondary crystallization. The method comprises the steps of weighing dried phosphogypsum, adding a sulfuric acid solution, performing stirring reaction in a water bath, filtering when being hot, abandoning insoluble substances, cooling filtrate at room temperature for crystallization, performing suction filtration, and then retaining a filter cake; adding the sulfuric acid solution and a crystallization promoting agent, namely magnesium salt, performing stirring reaction in the water bath, naturally cooling the solution in the water bath for crystallization, performing suction filtration to obtain the whiskers, washing till neutrality and drying. The crystallization promoting agent is not used in primary crystallization in the method disclosed by the invention, the solid-liquid ratio of raw materials has a good effect, the reaction temperature and the stirring rotational speed are reasonably designed, the secondary crystallization method is created, the problems of short length-diameter ratio, low yield, difficulty in production under non-high pressure conditions and difficulty in succeeding without pretreatment of the phosphogypsum whiskers in the prior art are solved, the problems of phosphorus residue and the like can be solved by recycling a solvent, and the sustained cyclic production can be further realized. The length-diameter ratio of the whiskers produced by the method disclosed by the invention is more than 100, the whiteness is not less than 95%, and the product yield is improved by 10%-15%.

Owner:GUIZHOU KAILIN GRP CO LTD

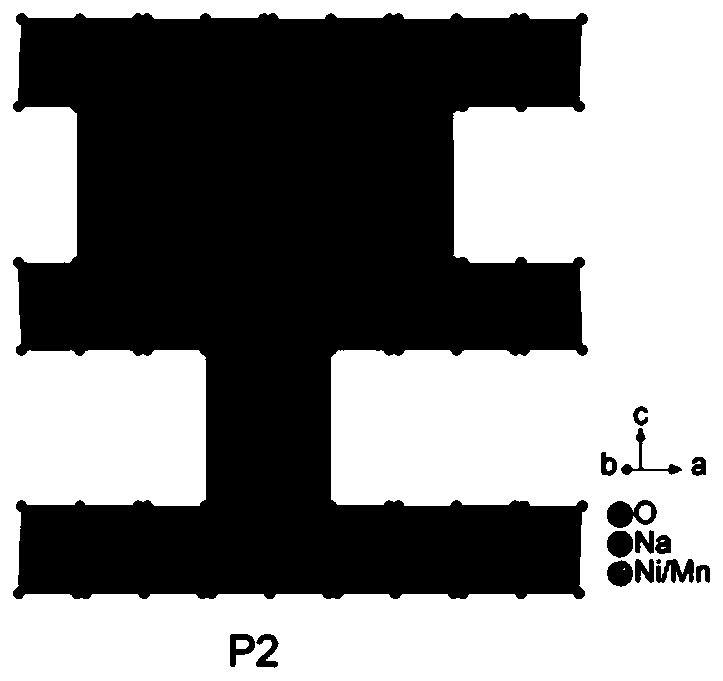

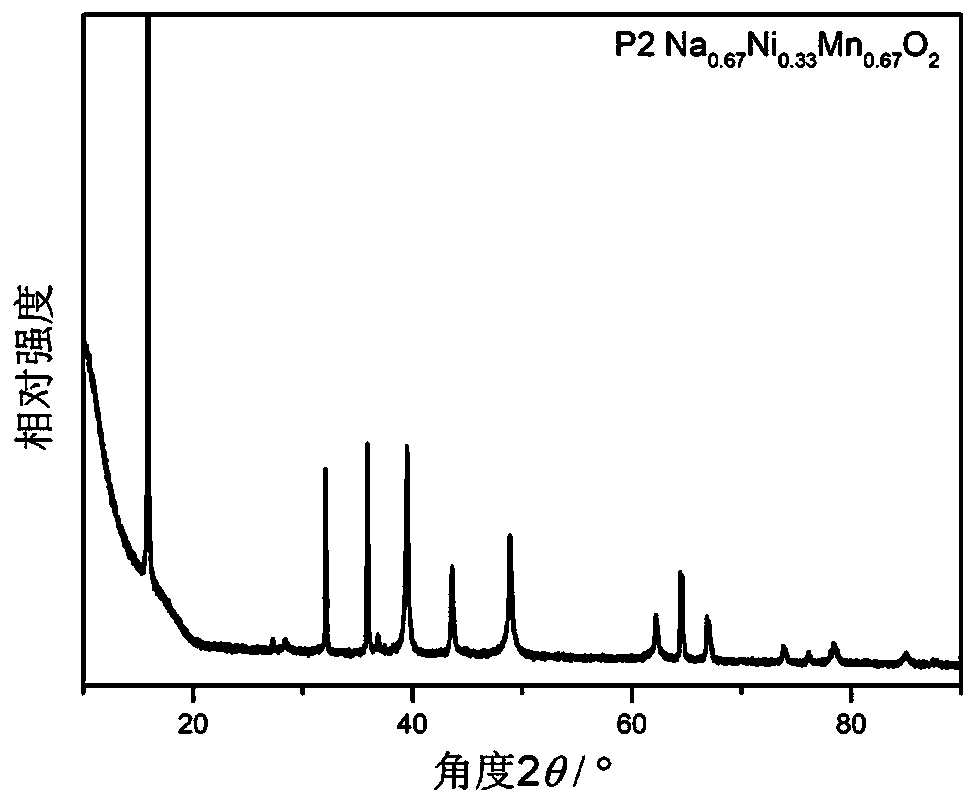

Sodium transition metal oxide with P3 structure and preparation method thereof, and sodium ion battery

ActiveCN110380024AGood de-intercalation abilityPromote application developmentSecondary cellsPositive electrodesInstabilitySodium-ion battery

The invention relates to the technical field of sodium ion batteries, and particularly provides a sodium transition metal oxide with a P3 structure and a preparation method thereof, and a sodium ion battery. The sodium transition metal oxide with the P3 structure has a general formula shown in the specification: NaxNiaMnbMcO2+d, wherein, 0.9<=x<=1.1, a>0, b>0, c>=0, a+b+c=1, d>=0, M is selected from one or more of Cu, Mg, Fe, Zn, Ti, Co and Al. The sodium transition metal oxide with the P3 structure has a stable P3 crystalline phase structure, does not have sodium defects, can solve the problems of sodium ion deintercalation, air instability and the like of the conventional sodium ion battery positive electrode material after being used as a sodium ion battery positive electrode active material to prepare a sodium ion battery, and is beneficial to the commercial application of the sodium ion battery.

Owner:钠远新材科技(无锡)有限公司

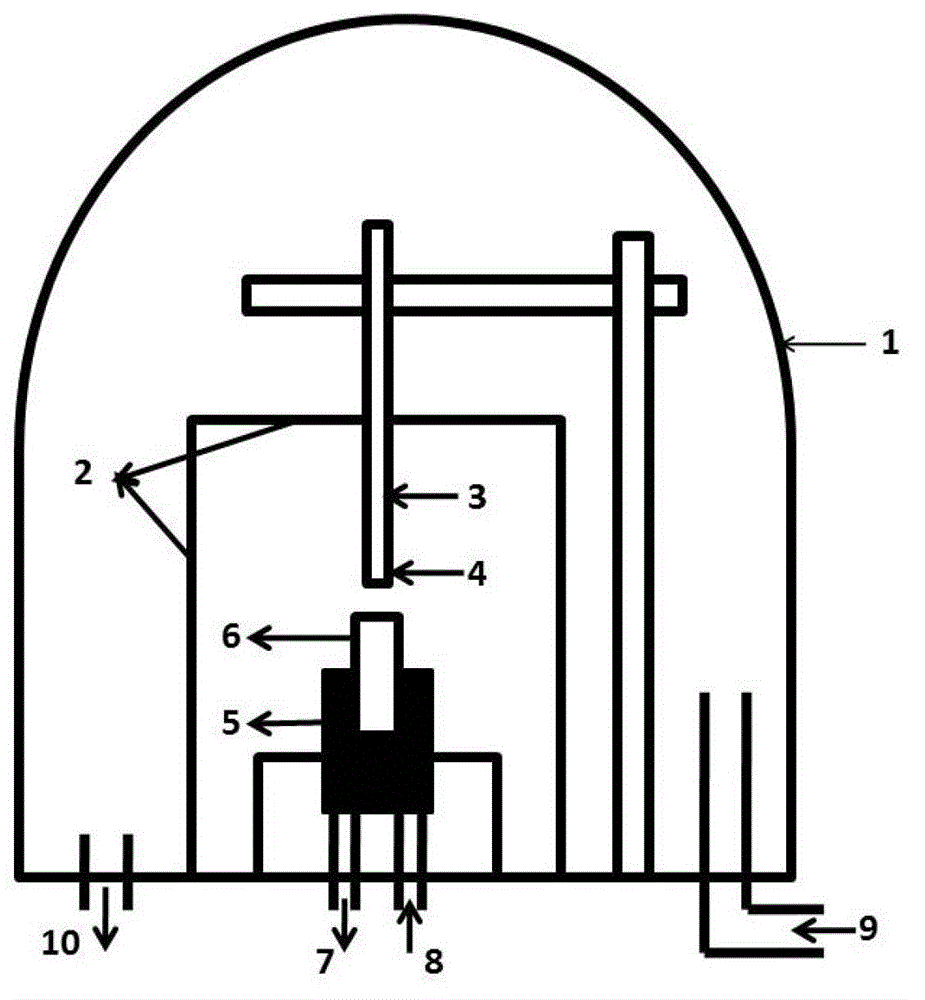

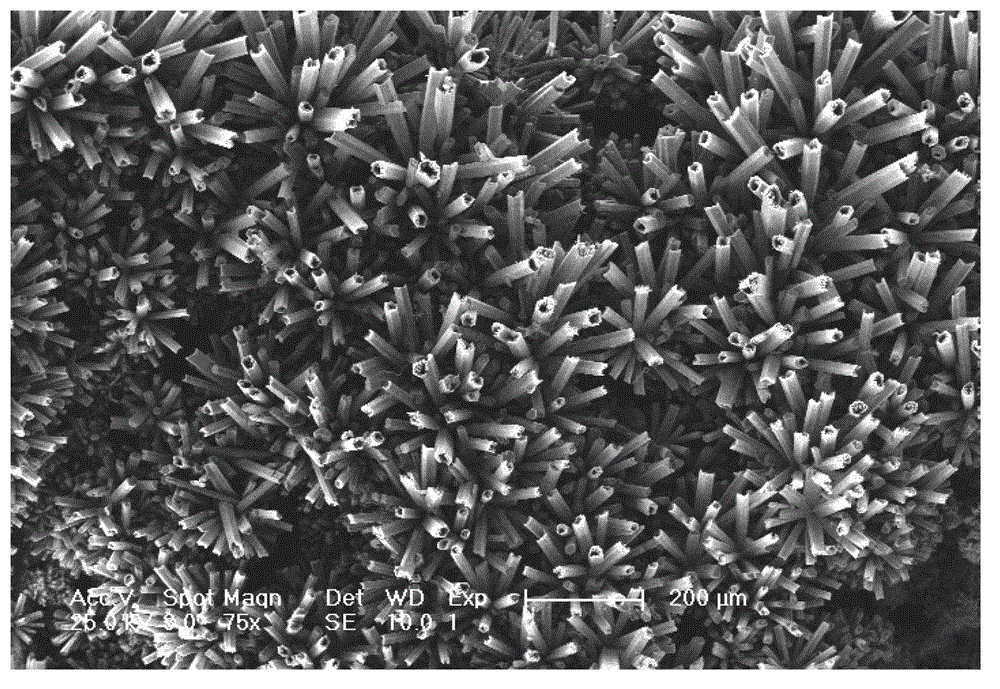

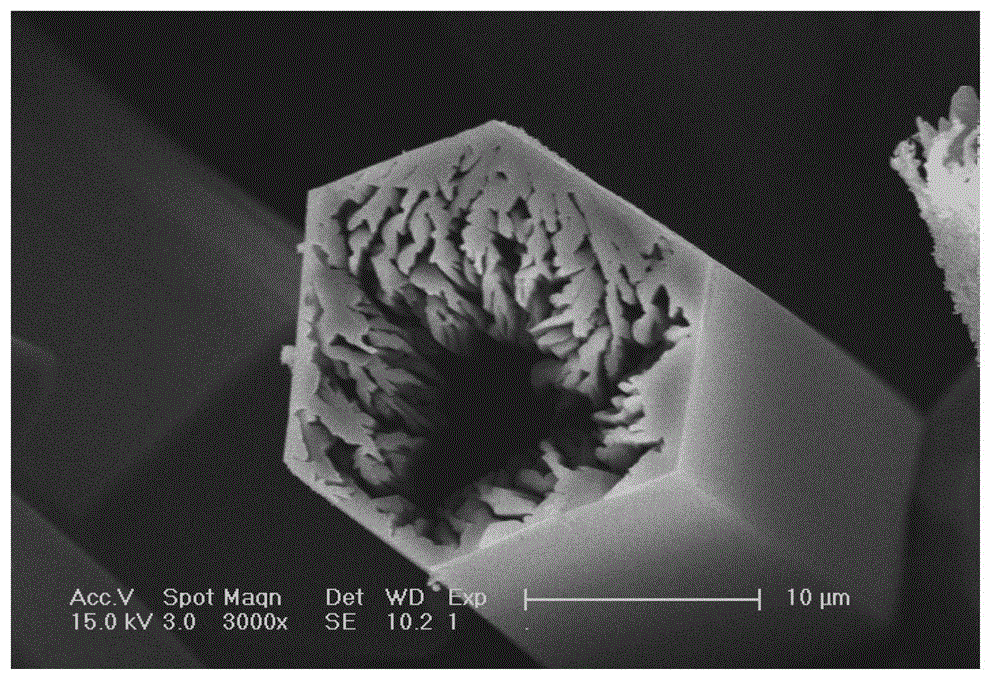

Yttrium-doped aluminum nitride diluted magnetic semiconductor quasi-array microtube and fabrication method of microtube

InactiveCN102910598AIncrease productionHigh purityNitrogen compoundsInorganic material magnetismAl powderNitrogen gas

The invention discloses an yttrium-doped aluminum nitride diluted magnetic semiconductor quasi-array microtube and a fabrication method of the microtube, which belong to the technical field of semiconductor spinning electron device materials. The yttrium-doped aluminum nitride diluted magnetic semiconductor quasi-array microtube is in a hexagon column structure, the outside surface of the microtube is smooth, and uneven folds are formed in the microtube, so that a multi-hole structure is formed. The fabrication method comprises the steps that Al powder and Y powder are taken as raw materials, nitrogen is taken as reaction gas, the fabrication is conducted in a direct-current arc plasma discharging device, a reaction chamber is vacuumed, the reaction gas is filled into the reaction chamber for discharging, the power is cut off after 3-5 minutes of the discharging reaction, and plush blocks are collected in a cathode sediment zone of a tungsten rod after standing and argon passivation. Fabricated samples are large in output, high in purity, complete in crystal form and uniform in size; the fabrication time is short; and the energy consumption and cost are low. No substrates, templates or catalyzers are needed in the fabrication process, and the fabrication method is environment-friendly and high in repeatability.

Owner:JILIN UNIV

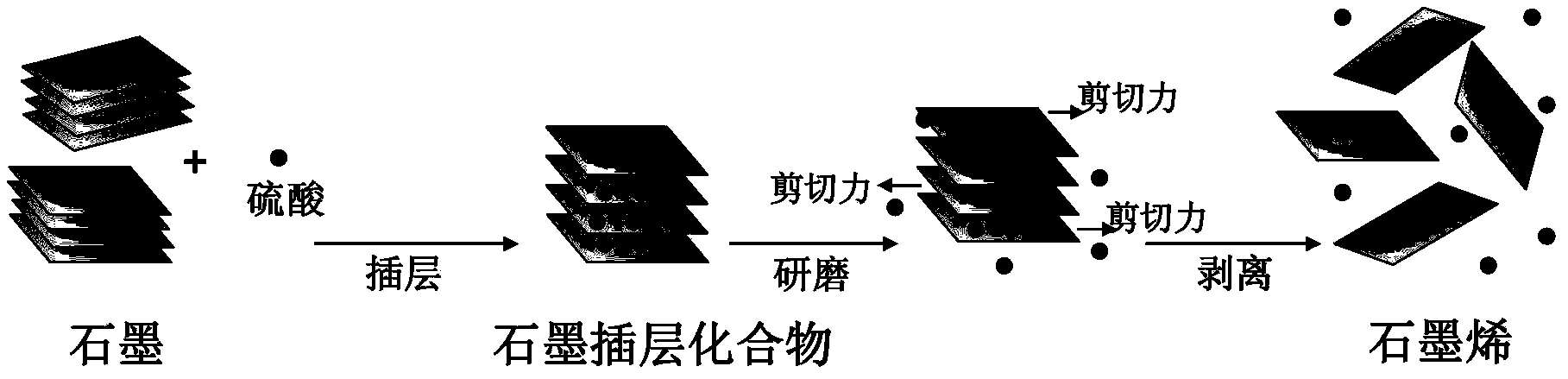

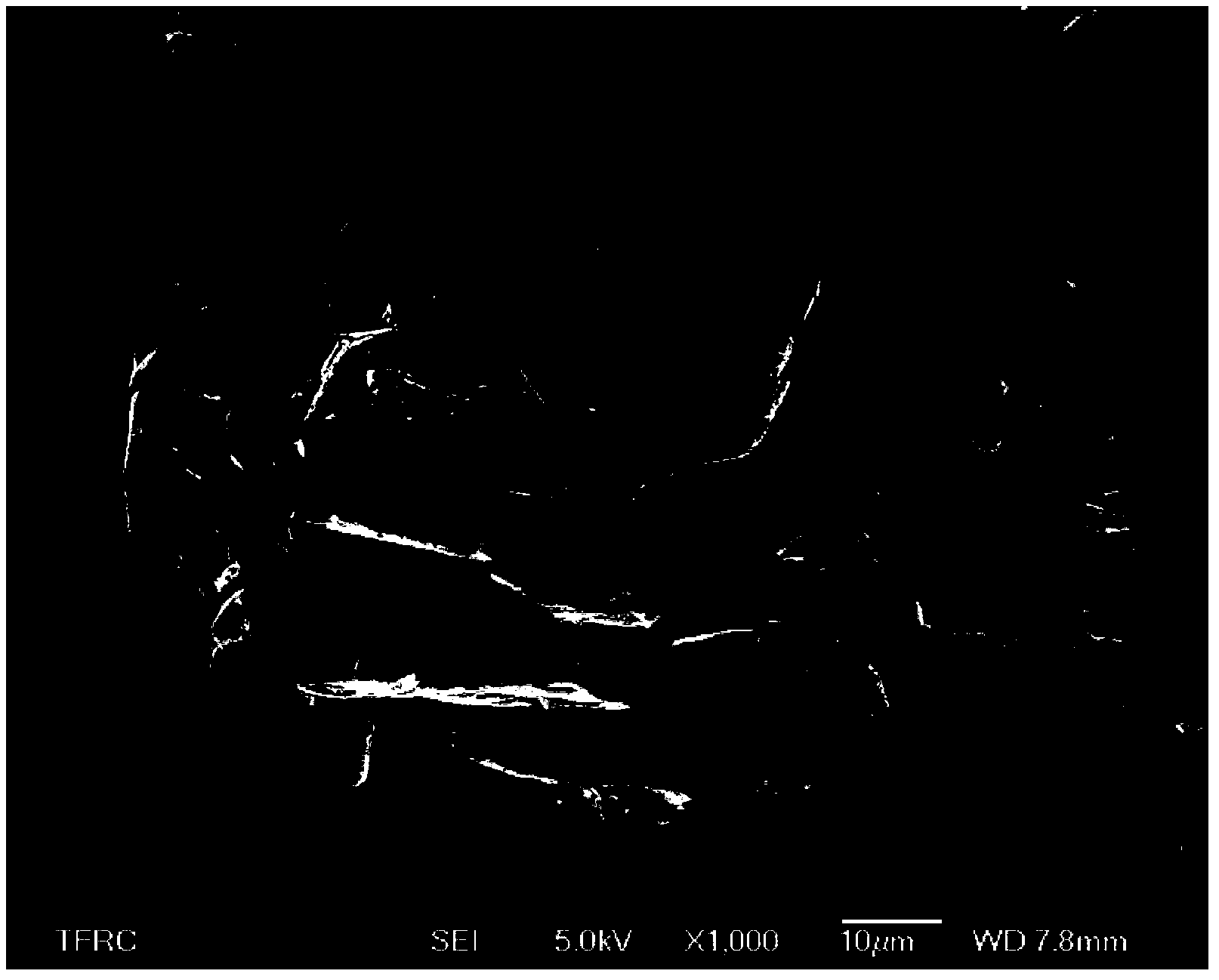

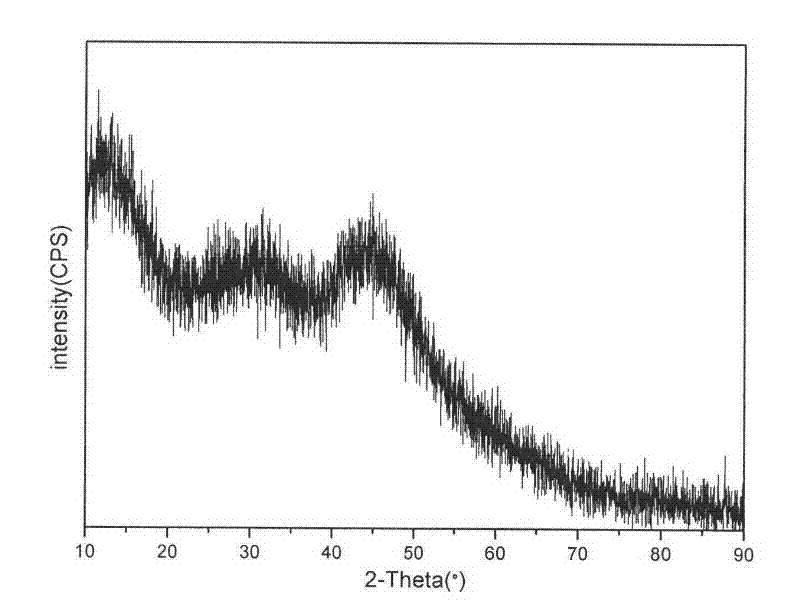

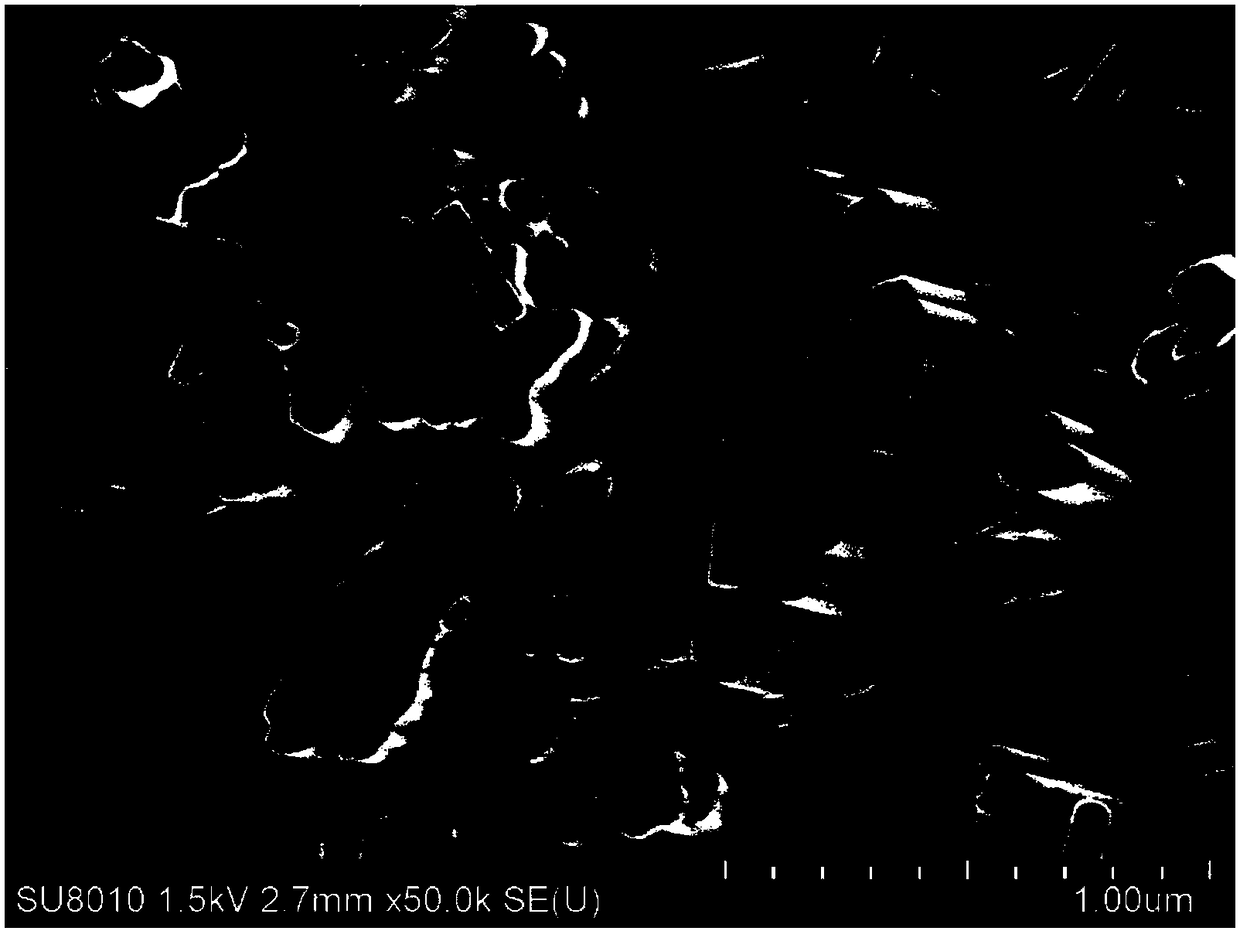

Method for preparing graphene by peeling off graphite

The invention provides a process method for preparing graphene by peeling off graphite. The method comprises the following steps: putting the graphite, a grinding material and concentrated sulfuric acid into grinding equipment, and grinding the materials to obtain a mixture; and separating the sulfuric acid and the grinding material out of the mixture, and washing and drying the remaining materials to obtain the graphene. The preparation flow of the graphene is very short, the cost is low, and the prepared graphene is complete in crystal form, has high conductivity, ad can be widely applied to a plurality of fields of battery materials, composite materials, electronic devices, energy storing materials and the like.

Owner:TORAY IND INC

Sol-gel-hydrothermal method for preparing bismuth tungstate and indium-doped bismuth tungstate

InactiveCN102765758AHigh crystallinityLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsTungsten compoundsIndiumTungstate

The invention discloses a sol-gel-hydrothermal method for preparing bismuth tungstate and indium-doped bismuth tungstate. The technical scheme point of the invention is to respectively disclose a sol-gel-hydrothermal method for preparing a bismuth tungstate catalyst and a sol-gel-hydrothermal method for preparing an indium-doped bismuth tungstate catalyst. The preparation method disclosed by the invention has the advantages of simple operation and low cost; and the prepared bismuth tungstate catalyst and the indium-doped bismuth tungstate catalyst have excellent photocatalysis performance.

Owner:HENAN NORMAL UNIV

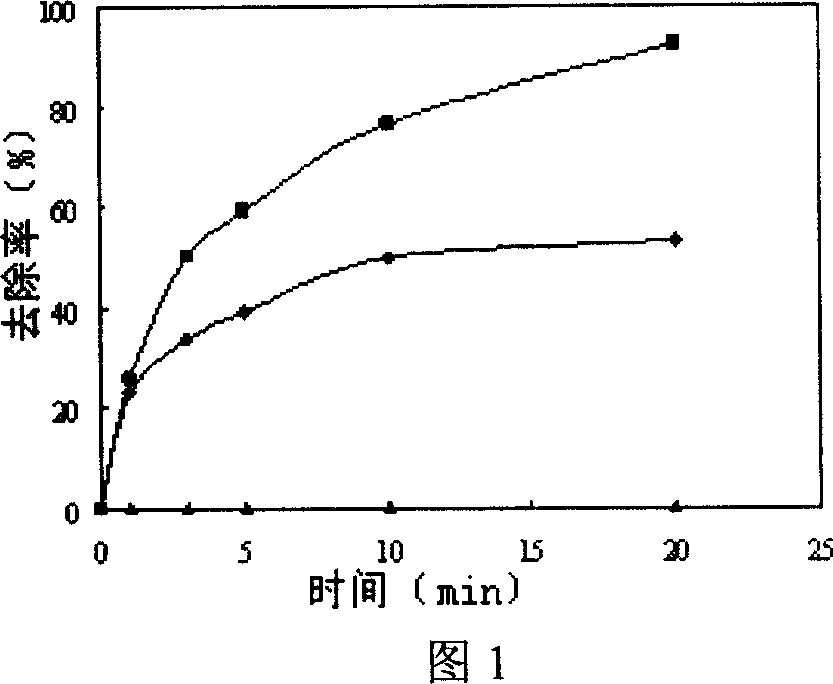

Preparation method of hydroxylation cobalt and its application in water treatment

ActiveCN100999337AComplete crystal formUniform and dense particle size distributionCobalt oxides/hydroxidesChemistryEnvironmental chemistry

This invention discloses a preparation method of hydroxylated cobalt and its application in water treatment. It relates to a preparation method of mixture and its application in water treatment. It is first time to disclose a preparation method of hydroxylated cobalt and its application in water treatment. Prepare hydroxylated cobalt: 1. add alkaline solution into divalence cobalt salt solution until no sediment emerging; 2. adjust suspension PH more than 12, activate; 3. filter, wash sediment to neutrality with distilled water, dry, and get hydroxylated cobalt. Hydroxylated cobalt is used as ozone catalytic agent for water treatment technology. This hydroxylated cobalt is of integrated and uniform particle crystal form, and uniform grain size. This invention avoids impurity precipitating. Hydroxylated cobalt purity reaches more than 99%. Hydroxylated cobalt can promote ozone to transform into hydroxy group free radicle, increase production rate and quantity of free radicle that is in water body. Ability of ozone removing organic contaminant that is in water can be raised 35-42%.

Owner:江苏哈宜环保研究院有限公司

Method of recovering copper and nickel from plastic plated parts

ActiveCN105200238ANo discoloration etc.Increase contentProcess efficiency improvementCycloneClosed loop

The invention belongs to the field of metallurgy and relates to a method of recovering copper and nickel from plastic plated parts. The method is mainly characterized in that by means of sulfuric acid leaching and using hydrogen peroxide and air or oxygen as oxidizing agents, a micro-bubble generator is used to blow the air or oxygen into a reactor in a micro-bubble form, leached solution is treated by cyclone electrowinning to produce cathode copper, anode liquor is frozen and crystallized to produce crude nickel sulfate, and the crude nickel sulfate is subjected to the steps such as dissolving, impurity removal by extracting, evaporation concentration, and cooling crystallization to produce high-purity nickel sulfate. The method has the advantages that reaction speed is high, no other impurities are introduced, metal recovery rate is high, solution circulates in a closed loop, no wastewater or waste residue is produced, few auxiliaries are used, energy consumption is low, and low carbon, energy conservation and emission reduction can be achieved.

Owner:广西银亿再生资源有限公司 +1

Method for preparing nano nickel borate whiskers

ActiveCN101845668AUniform size distributionHigh purityPolycrystalline material growthSingle crystal growth detailsAir atmosphereNickel salt

The invention relates to a method for preparing nano nickel borate whiskers. The nano nickel borate whiskers are prepared by a sol-gel method, and the method comprises the following steps of: (1) adding water into inorganic nickel salt, boric acid and citric acid in an amount-of-substance ratio of 1:1-10:1-10 to prepare aqueous solution, controlling the concentration of the inorganic nickel salt in the aqueous solution to between 0.1 and 2.0mol / L, stirring at room temperature for 2 to 72 hours, and drying at the temperature of between 40 and 300 DEG C to obtain coffee dried gel; (2) sintering the dried gel obtained by the step (1) at the temperature of between 500 and 1,500 DEG C for 2 to 72 hours in air atmosphere to obtain green powder; and (3) post-treating the green powder obtained by the step (2) to prepare the nano nickel borate whiskers shown as Ni3B2O6. Compared with the traditional molten salt growth method, the method has the advantages of simple formula, easy operation, high yield, low sintering temperature and the like, and is favorable for industrialization.

Owner:海宁市黄湾镇资产经营有限公司

Preparation method of nano yttrium aluminum garnet fluorescent powder

InactiveCN102391871ANarrow particle size distributionNo reunionLuminescent compositionsRare-earth elementDispersity

The invention discloses a preparation method of a nano yttrium aluminum garnet fluorescent powder, comprising the following steps of: preparing raw materials such as aluminium nitrate, yttrium nitrate and nitrate of the rare earth elements into mother liquor of which the total cation concentration is 0.1-1.0mol / L according to the proportion of 5: (3-X): X, wherein X is 0-0.1, reacting the evenly-mixed mother liquor in a depositing way by the means that weak base alcohol water solution or ammonia is added into an ultra-gravity field, and controlling the pH value at 7.0-8.0 so as to obtain turbid liquid; performing aging, extraction filtering, and microwave drying on the turbid liquid so as to obtain a precursor body; and putting the precursor body in a microwave field, and calcinating the precursor body so as to obtain a yttrium aluminum garnet fluorescent powder which is good in dispersity and has the particle size of 20-100 nanometers. Compared with the prior art, the preparation method has the advantages that the product has the mean grain size of about 20-100 nanometers, and the product is narrow in particle size distribution, free of conglobation, good in dispersity, high in crystallization degree, and free of transient phase. Furthermore, the preparation method is simple in technology, and can be used for quickly producing the nano yttrium aluminum garnet fluorescent powder in batches.

Owner:XIANGTAN UNIV

Powder catalyst for synthesizing ultrafine granular diamond

ActiveCN104226355AImprove crystal qualityLower melting temperaturePhysical/chemical process catalystsUltra-high pressure processesSingle crystalMaterials science

The invention discloses a powder catalyst for synthesizing ultrafine granular diamond. The powder catalyst is mainly prepared from the following alloying components by weight percent: 20% to 25% of Fe, 3% to 5% of Co, 0.5% to 2% of Ce, 3% to 5% of Mn, 0.5% to 1% of SiC, 0.5% to 1% of Mo and the balance being Ni. By utilizing the technical scheme of the powder catalyst, the high-purity ultrafine-particle spherical or approximately spherical powder catalyst can be prepared, and the granularity of the obtained powder catalyst is 600 to 1000 meshes. When the powder catalyst is applied to synthesis of ultrafine diamond single crystal, single-crystal diamonds within 400 meshes can be produced.

Owner:HENAN POWER NEW MATERIAL

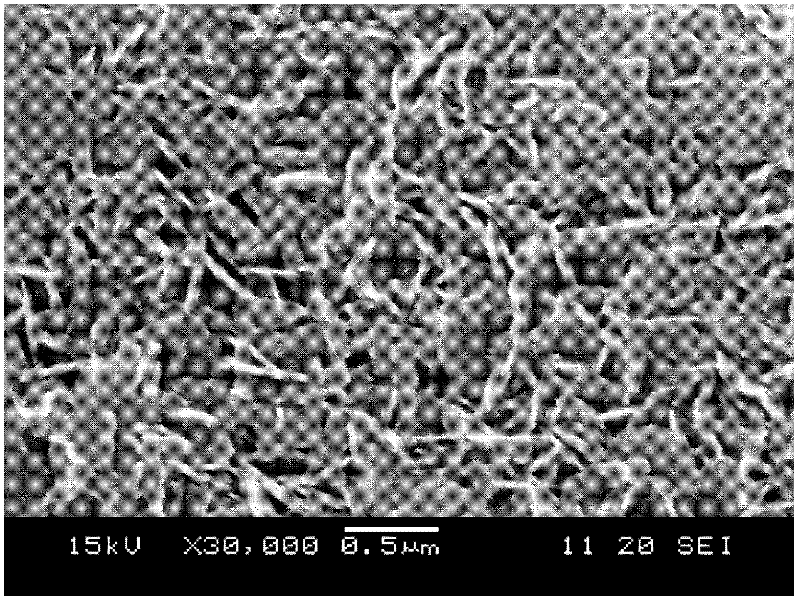

Copper-based ternary hydrotalcite thin film and preparation method thereof

ActiveCN102677029AComplete crystal formUniform and dense crystal formSolid/suspension decomposition chemical coatingReaction temperatureZinc nitrate

The invention relates to a copper-based ternary hydrotalcite thin film and a preparation method thereof, wherein a copper-zinc-alumium composite oxide thin film material complete, even and compact in crystal form is synthesized on a copper substrate by an in-situ growth method, and the thin film is high in adhesion and not easy to fall off. The method for preparing the thin film provided in the invention comprises the following steps of: putting a copper sheet in the mixed solution of boehmite sol and zinc nitrate, and growing CuZnAl-LDHs hydrotalcite thin film in situ on the copper sheet by controlling the reaction conditions such as pH, reaction temperature and time. The copper source of the copper-based ternary hydrotalcite thin film comes from the surface of the substrate; and compared with a hydrotalcite thin film formed through simple deposition on the substrate, the prepared thin film is better in adhesion to the substrate. Besides, the material has good corrosion resistance and is capable of protecting copper.

Owner:BEIJING UNIV OF CHEM TECH

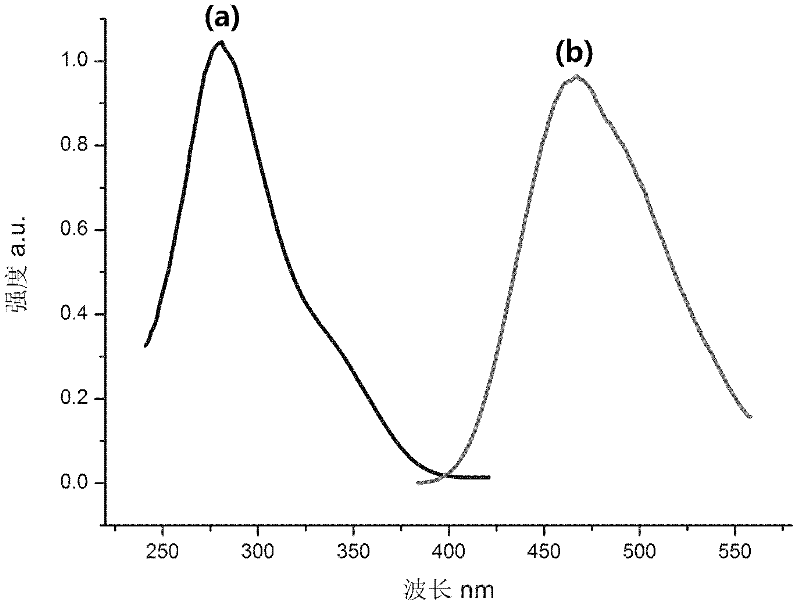

Single-substrate fluorescent powder for ultraviolet excitation white-light LED (Light-Emitting Diode) as well as preparation and application methods thereof

InactiveCN102391864AUniform particle sizeComplete crystal formGas discharge lamp usageLuminescent compositionsDispersityLuminous intensity

The invention provides single-substrate fluorescent powder for an ultraviolet excitation white-light LED (Light-Emitting Diode) as well as preparation and application methods thereof. The chemical molecular formula of the fluorescent powder is Sr2-x-yAyCeO4:xB<3+>, wherein A is selected from one of Li, Na and Mg, B is selected from one of Eu, Pr, Cr and Sm, x is not less than 0 and not more than 0.02, and y is not less than 0 and not more than 0.02. The single-substrate fluorescent powder is prepared through a hydrothermal method and a posttreatment incineration method. In the invention, according to the characteristic that the substrate Sr2CeO4 can give out broad-peak blue and green lights under the excitation of ultraviolet light and can give out red light with the doping of ion B, the purpose of compounding the blue and green lights and the red light to white light by regulating the proportion of x and changing the intensity of the red light is achieved. The doped ion A is used as a charge extender in the whole structure. The single-substrate fluorescent powder has the characteristics of high luminous intensity, even granularity, good dispersity, simple components, good chemical stability and the like.

Owner:CENT SOUTH UNIV

High-temperature dechlorinating agent and preparing method thereof

ActiveCN101274211AImprove thermal stabilityImprove stabilityDispersed particle separationCatalytic reformingCalcium hydroxide

The invention relates to a high-temperature dechlorination agent, which consists of 0 to 42 wt percent of CaOH, 18 to 70 wt percent of CaO, 20 to 40 wt percent of hydrotalcite, 7 to 17 wt percent of clay and 0 to 7 wt percent of adhesive. Based on the high-temperature dechlorination agent, the invention further discloses a preparation method of the high-temperature dechlorination agent. The high-temperature dechlorination agent prepared by the preparation method can be applied to a coal gasification fuel cell (MCFC) system, a coal gasification combination circulation power generation (IGCC) system and catalytic reforming regeneration gas so as to remove the HCl; furthermore, the dechlorination agent has high chlorine content and good dechlorination effect.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

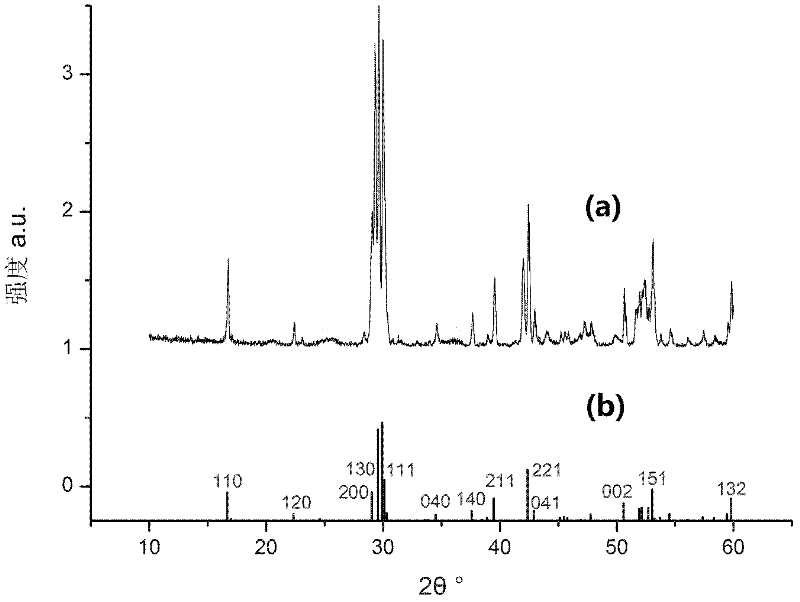

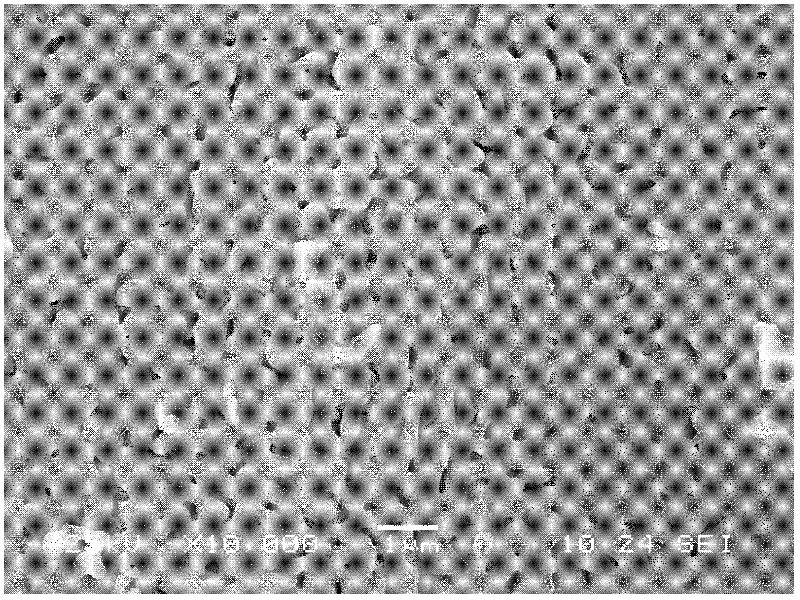

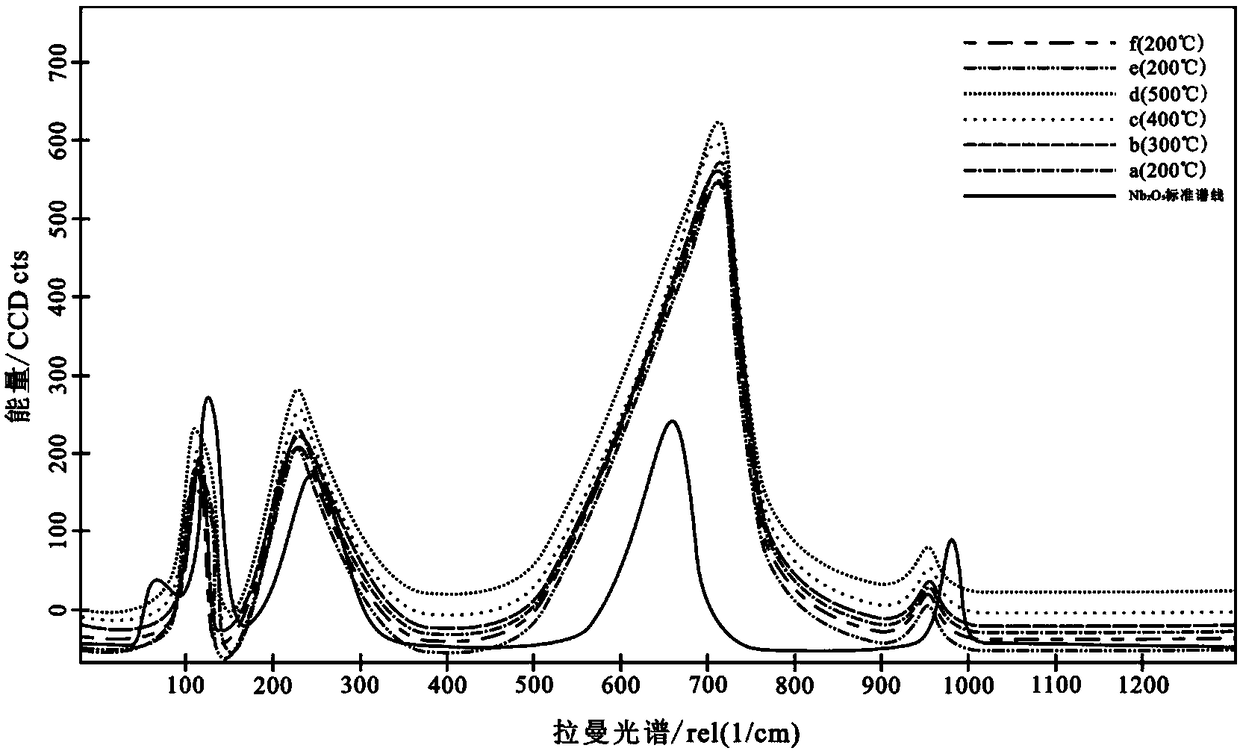

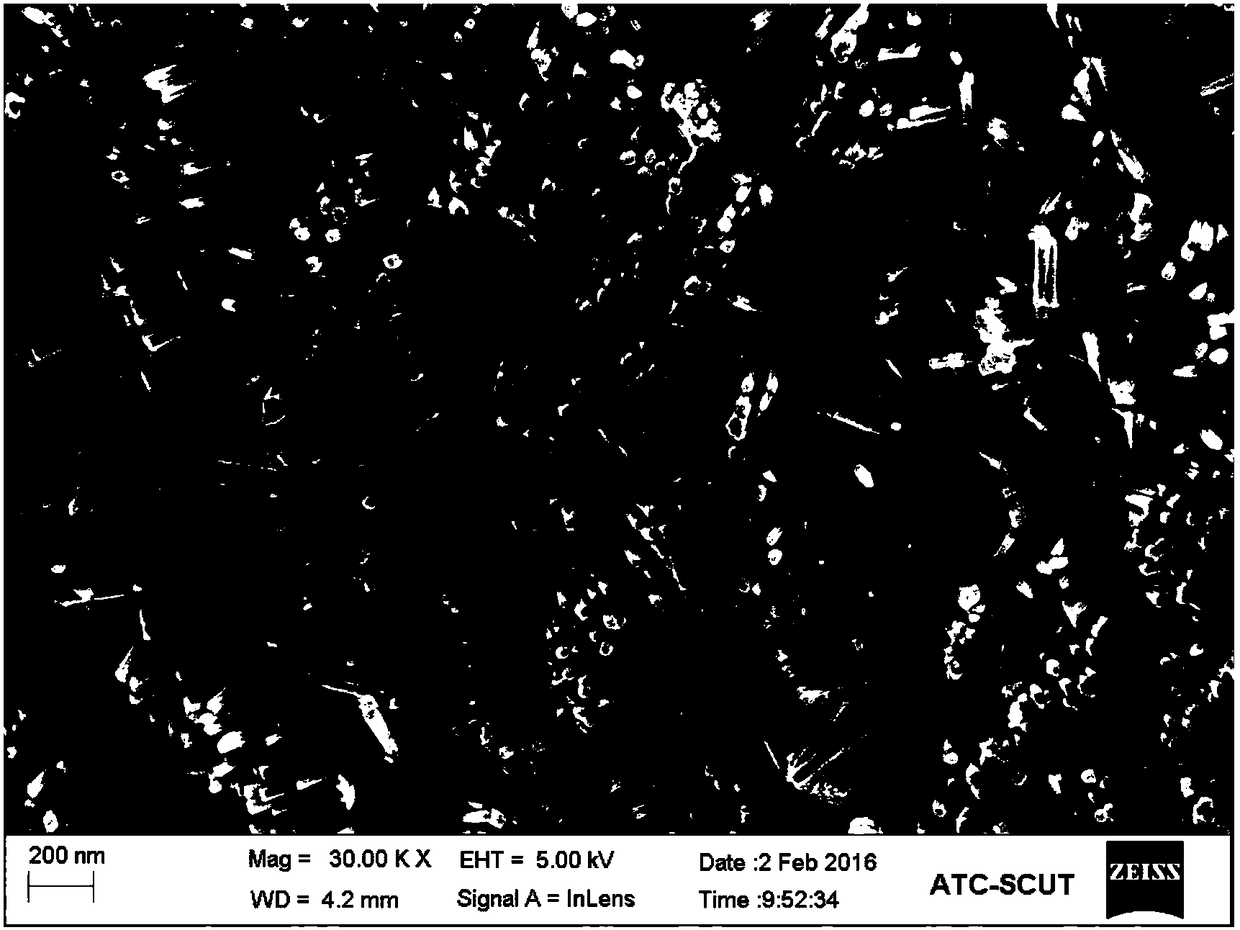

Method for preparing orientation arrangement Nb2O5 nanorod through single-reagent self reaction

ActiveCN108264087AAvoid process problemsSimple processMaterial nanotechnologyNiobium compoundsPotassiumRoom temperature

The invention discloses a method for preparing an orientation arrangement Nb2O5 nanorod through single-reagent self reaction. The method comprises the following steps that (1) potassium fluoniobate powder is selected and dissolved in deionized water; a potassium fluoniobate dilute solution is put into a pretreated noble metal tube; sealing is performed; (2) the noble metal tube is put into a hydrothermal reaction kettle for sealing; the temperature in the hydrothermal reaction kettle is regulated to 200 to 500 DEG C; inert gas or deionized water is used for regulating the pressure in the hydrothermal reaction kettle to be 50 to 200MPa; hydrolysis reaction is performed for 12 to 24h; after the reaction is finished, the reaction kettle is subjected to temperature reduction to room temperature; (3) the hydrothermal reaction kettle is opened; the noble metal tube after the reaction is taken out and opened; residual solution is recovered; samples are collected; the orientation arrangement Nb2O5 nanorod is obtained. The method has the advantages that the single reagent is used as a synthetic raw material; the raw materials are simple and can be easily obtained; the cost is low; the energy consumption is low; the Nb2O5 nanorod obtained through preparation has good crystal form; the directionality is obvious.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

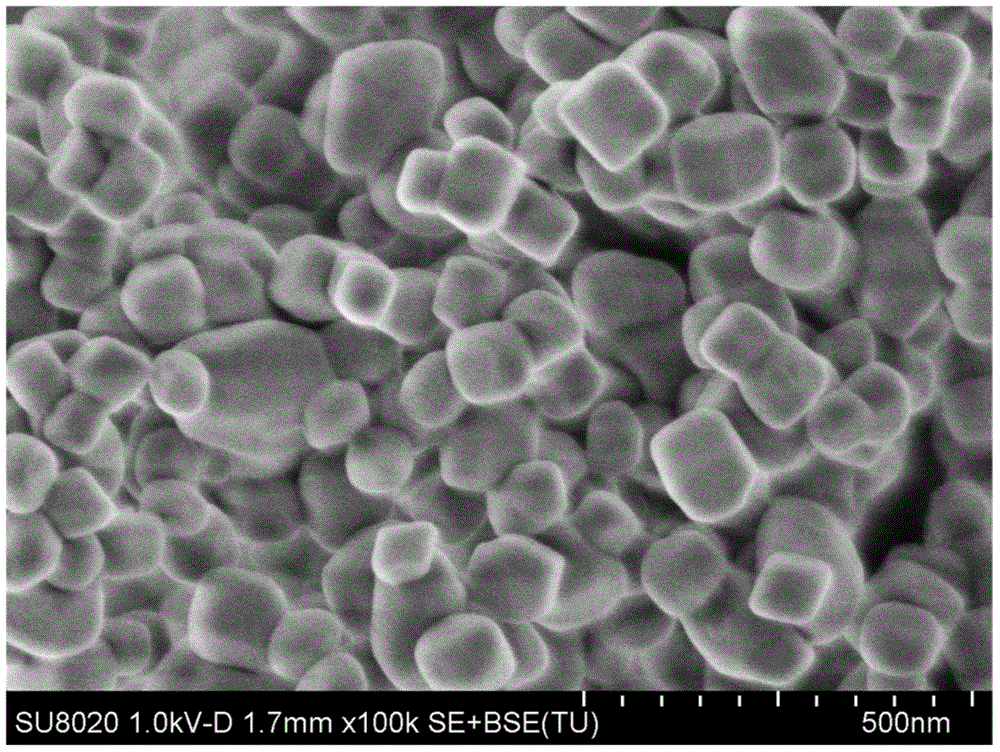

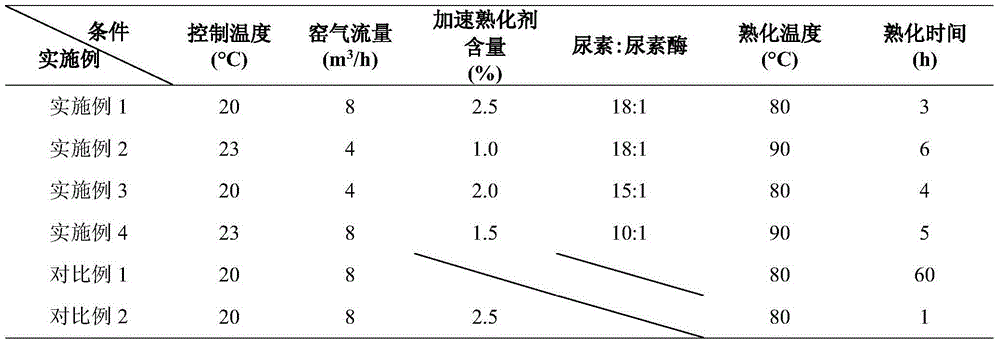

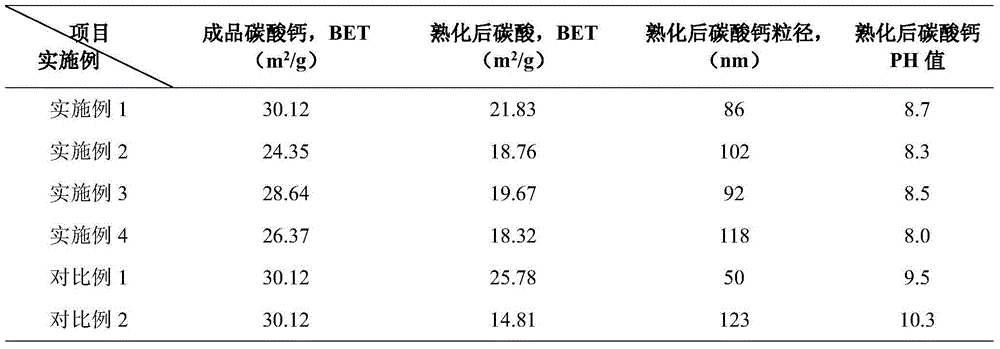

Preparation method for cubic precipitated calcium carbonate

ActiveCN104609453AInhibition of dissolutionImprove solubilityCalcium/strontium/barium carbonatesPresent methodPrecipitated calcium carbonate

The present invention discloses a preparation method for cubic precipitated calcium carbonate. The method comprises the following processes: transporting refined and aged lime cream into a carbonation bubbling reactor with stirring, injecting purified and cooled limekiln gas to carry out carbonation reaction, when pH of the reaction mixture drops to 7.0, stopping the carbonation reaction, and controlling specific surface area (BET) of the finished calcium carbonate between 20-35 m<2> / g. Adding accelerating curing agent, heating to performing curing, maintaining the temperature between 60-90 DEG C for 2-15 hours, adding a surface treating agent, stirring the materials for 60 minutes to obtain a slurry of calcium carbonate, and subjecting the slurry to pressure filtration for dewatering, drying and pulverizing to obtain the calcium carbonate product. Compared with traditional heating curing methods, the present method has a higher curing efficiency, and obtains large cubic precipitated calcium carbonate particles in short time; size control and pH value control are more effective and more stable; the processed are simple and feasible, the costs are low, and economic effectiveness is good.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com